Page 1

imnenb_LR3.0

LTE

Installation Manual

eNB

MB-14310050-001(E)-01

March, 2012

1

Page 2

Copyright © 2012 by NEC Corporation

This document describes the current planned product and feature description and release. However, the

specifications, configuration and the release plan contained in this document are subject to change without any

notice due to NEC's continuing design improvement.

All rights reserved. No part of this publication may be reproduced, transmitted, transcribed, stored in a retrieval

system, or translated in any form for by any means without the written permission of NEC Corporation.

All designations used in this document can be trademarks, the use of which by third parties for their own

purposes violates the rights of their owners.

Printed in Japan

2

Page 3

Revision History

Revision History

Issue Date Revision Description Author Approval Remarks

1.0 March 30, 2012 1st release T.Araki K. Yoshida

3

Page 4

Preface

Preface

Purpose of This Manual

This manual describes the required knowledge and procedure to install the LTE system (eNodeB, hereafter referred to as

eNB).

G This manual targets the 700MHz All-in-one Type eNB.

Target Reader

This manual is intended for the LTE system installation personnel and operation and maintenance personnel of a network

operator.

Manual Structure

• Section 1 Overview

Describes the system structure, equipment names and the main specification of the equipment.

• Section 2 Equipment Appearance

Shows the appearance of eNB equipment and its dimensions.

• Section 3 Equipment Installation Conditions

Shows the required space to install eNB equipment.

• Section 4 Interface Conditions

Shows the cable connection system diagram and eNB equipment interface.

• Section 5 Installation

Describes the cautions when carrying the equipment and the procedure to install eNB equipment.

• Section 6 Cable Work

Describes the procedure to work on various types of cables.

• Section 7 Voltage Check

Describes the procedure to check the voltage of the eNB equipment.

Symbols Used in This Manual

In this manual, the following symbol is used to show notes. When reference to a note is required, it is expressed as "Refer to

[i]."

G CCC...CCC (CCC...CCC : note text)

4

Page 5

Precautions

!

!

!

Precautions

The alert labels in this manual and attached to the eNB equipment body indicates the items you must follow to prevent

potential injury and safety hazard to you and other people, and perform the operation safely. Please read this manual

thoroughly before starting any operations.

Also, this manual must be kept in a safe place, so that you can read it whenever required.

When alert labels are directly attached to the equipment, always read the content.

This manual is intended for the LTE system installation personnel and operation and maintenance personnel of a network

operator.

Safety Instructions

The "Safety Instructions" provides safety instructions for the LTE system installation operations. For other items, read the

equipment manuals.

Definitions of Alert Categories

The following symbols categorize the dangers and level of damage that occurs when the content is ignored or wrong

procedure was performed.

DANGER:

This symbol indicates that there is explicit life-threatening danger that may cause death or

serious injuries if this item is ignored and the equipment is handled wrongly.

WARNING:

This symbol indicates that it may cause death or serious injuries if this item is ignored and the

equipment is handled wrongly.

CAUTION:

This symbol indicates that it may cause injuries and physical damage if this item is ignored and

the equipment is handled wrongly.

5

Page 6

Precautions

Alert Labels

The following shows the alert labels attached to the equipment. If an alert label is attached, always follow the instruction

written on the label.

Federal Communications Commission

Changes or modifications not expressly approved by NEC Corporation could void the userʼ s authority to operate the

equipment. (Section 15.21)

Section 15.105 (a) Class A Warning Label

NOTE: This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to part 15

of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the

equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency energy

and, if not installed and used in accordance with the instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is likely to cause harmful interference in which case the

user will be required to correct the interference at his own expense.

About the Safety Instructions

When you find a safety instruction in this manual, be sure to read the instruction before starting the work.

The following safety instructions, especially regarding items that may cause death or injury to you and other people in this

manual are listed by their alert categories.

6

Page 7

Alert Category: CAUTION

!

Precautions

CAUTION:

About the Work in General

• Before starting the work, check the area of evacuation at the time of disaster.

• Do not work wearing slippers. They may cause injury by falling, etc.

• Be careful not to stumble over cables, parts and tools while working. It may cause

injuries and accidents.

• Be careful not to get the sleeves and hems of the working clothes caught. It may

cause injuries and accidents.

• Do not place liquid such as water into the equipment, and do not touch the

equipment with wet hands. Moisture in the equipment may cause electrocution

and equipment failure. In case liquid gets into the equipment, turn off the

equipment power and request repair.

• Do not dismantle or alter the equipment. It may cause electrocution, fire and

equipment failure.

• When installing or removing the equipment, cure the floor surface of the installed

location to prevent damage by dropping parts.

About Handling the eNB Equipment and SFP

• When handling eNB equipment itself and SFP, wear globes (thin cotton gloves).

Working with bare hands may cause burns, injury and accidents.

• Use correctly the parts for testing such as SFP, tester and cable referring to their

user manuals.

• When handling the eNB equipment and the SFP, wear a wrist band as an antistatic

measure. If you do not take any antistatic measures, the static electricity may

damage the equipment and the SFP.

About Handling High Voltage/ High Current

• Only the installation worker can touch the eNB equipment . Inside eNB

equipment, there are high voltage/ high currents flows, and they may cause

accidents.

• Always perform ground connection. Not following this instruction would cause

system failure by lightening and electrocution.

• When measuring voltage/ current, take appropriate insulating measures such as

covering the measurement terminal and the unused tool parts with insulating

tapes. Contact of measurement terminal and other terminals, or short-circuit by

tools may cause electrocution and accidents.

7

Page 8

Precautions

Notes on Running the System

In "Notes on Running the System", the notes to protect the equipment from failure are described. To run the system normally,

follow the notes to operate.

Environment Conditions on Running the System

The following shows the usage conditions of eNB equipment. To run the system normally, consider the following items

during installation operation.

Category Details

Installation Install in a limited access area.

Temperature and

humidity

Liquid - Do not place liquid such as water and oil near eNodeB.

Vibration eNodeB is a precision instrument, so do not expose to vibration of

Heat dissipation - Natural cooling of eNB satisfies all the environmental conditions.

- Do not ventilate outside air.

- Refer to the following and check that the temperature and humidity

are appropriate. Also, check that there is no condensation.

Vertical Setup

-33ºC to +50ºC (No sunlight)

-33ºC to +45ºC (With sunlight)

Horizontal setup

-33ºC to +45ºC (No sunlight)

-33ºC to +40ºC (With sunlight)

The above temperature limits of operation environment drops by

2.5ºC for every 1km of altitude rise.

standard level (Telcordia NEBS GR-63-CORE Zone4) or more.

- To gain the expected heat dissipation, eNB has a radiator for natural

cooling on its surface. Natural cooling radiator, for its physical

characteristic, must be set up so that the fin part is vertical or

horizontal.

- No cooling method such as cooling by fans is used for eNodeB.

- There is no periodic replacement parts such as air filters.

- No always-driving part such as a fan is used for eNodeB.

8

Page 9

Precautions

Notes on Running the System in General

• Before installing the equipment, remove all connector caps attached to the equipment side external interface connectors

to which external cables are planned to be connected.

Removing the connector caps, etc. in a high place may result in the connector caps dropping.

- If external cables are not connected right after equipment installation, place outdoor weather resistant tapes on the

temporary connector caps as waterproof treatment.

• In case you touch the equipment for maintenance, there may be places on the equipment reaching high temperature.

Wear protection such as gloves when handling the equipment.

• Do not allow foreign objects such as screws, wire rods and metal scraps inside the eNB Equipment. They may cause eNB

equipment failure by equipment damage and short-circuit.

• Wear antistatic shoes while working.

• When working after rain, wipe the water drops on the equipment before opening the maintenance window.

9

Page 10

Precautions

Notes on Handling the eNB Equipment and SFP

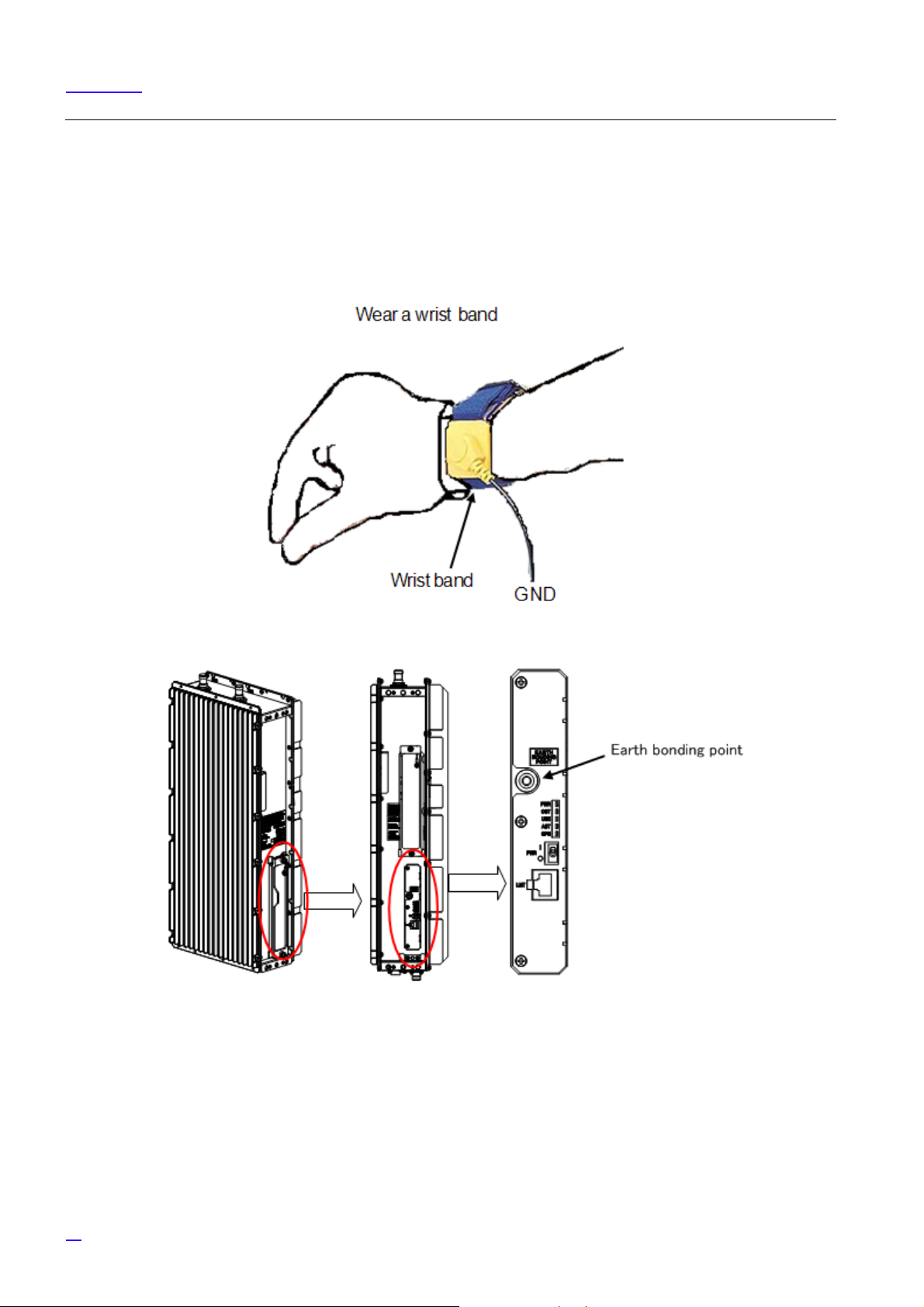

• To prevent static electricity, always wear globes (thin cotton gloves) and a wrist band as antistatic measures when

working on the eNB equipment, inserting or removing SFP into/from the equipment.

By static electricity the electrical parts of the equipment or the SFP may be damaged. The grounding terminal of the wrist

band is connected to the earth bonding point in the maintenance window of the equipment.

10

Page 11

Precautions

Notes on Handling the Power

• Do not turn the power ON/ OFF unless required.

Notes on Handling the Cables and Connectors

• Do not swing or bend the cable with force. It may cause the cable to break or damage the connector.

• Do not remove the optical connector cap unless connecting the connector. If the optical connector is damaged or gets

dust on it, it may cause communication failure.

• Use the tools and parts such as cables correctly, referring to their user manuals.

• Tie the external cables without putting stress, meaning without twisting and pulling on the equipment connector part.

• When removing the connector or the waterproof cap to mate again, clean the mating parts.

• Depending on the environment condition, the FullAXS connector surface may become rough, and touching it by bare

hands may cause the plastic toughening agent to irritate the skin. If the toughening agent gets on to your skin, wash it

thoroughly.

11

Page 12

Table of Content

Table of Content

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1.1 System Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

1.2 Equipment Names . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

1.3 Main Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2 Equipment Appearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3 Equipment Installation Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4 Interface Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

4.1 Cable Connection System Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.2 External Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.2.1 Bottom Face External Interface Locations/ Names and Interface Details. . . . . . . . . . . . . . . . 22

4.2.2 Top Face External Interface Locations/ Names and Details. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.2.3 Maintenance Window Interface Locations/ Names and Details . . . . . . . . . . . . . . . . . . . . . . . . 24

5 Equipment Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.1 Cautions on Carrying the Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.1.1 Temporary Placement of Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.1.2 Carrying the Equipment by the Handles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.1.3 Carrying Equipment by Hoisting Up/ Down. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

5.2 Equipment Installation Forms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

5.2.1 Installation Examples of Ladder/ Wall/ Pole/ Cross arm/ Suspension Mount . . . . . . . . . . . .29

5.3 Ladder/ Wall/ Pole/ Cross Arm/ Suspension Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5.3.1 Dedicated Mounting Hardware for Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

5.3.2 Installation Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

5.3.3 Installation Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

5.3.4 C-COVER (Connector Cover) Installation Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

5.3.5 F-COVER (Front Cover) Installation Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

5.4 List of Attachments and Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

6 Cable Work . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

6.1 List of Used Cables and Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

6.2 Power Cable Connection (-48V DC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

6.2.1 Power Cable Connection Composition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

6.2.2 Power Cable Connection Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

6.2.2.1 Floating Type Cable Connection Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

6.2.2.2 Fixed Type Cable Connection Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

6.3 Backhaul Cable Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

6.3.1 Metal Type Backhaul Cable Connection (BH(E)) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

6.3.1.1 Backhaul Cable Connection Procedure (Electrical) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

6.3.2 Optical Type Backhaul Cable Connection (BH(O)) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

6.3.2.1 Backhaul Cable Connection Procedure (Optical) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

6.3.3 Notes on Handling Optical Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

12

Page 13

Table of Content

6.4 GPS Cable Connection (GPS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

6.4.1 GPS Cable Connection Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

6.5 External Alarm Interface Cable Connection (EXT ALM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

6.5.1 External Alarm Interface Cable Connection Procedure (EXT ALM) . . . . . . . . . . . . . . . . . . . . . 64

6.6 FG Cable Connection (FG) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

6.6.1 FG Cable Connection Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

6.7 Antenna Tilt Control Cable Connection (RET) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

6.7.1 Antenna Tilt Control (RET) Cable Connection Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

6.8 Antenna Cable Connection (ANT0/ANT1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

6.8.1 Antenna Cable Connection Procedure (ANT0/ANT1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

6.9 Connector Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

6.9.1 Power Connector Pin Allocation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

6.9.2 Antenna Tilt Control Connector (IEC60130-9) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

6.9.3 External Alarm Interface (EXT ALM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

7 Voltage Check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

7.1 Cable Side Power Connector Pin Location Polarity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

7.2 Voltage Check Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

13

Page 14

Overview

1Overview

This manual describes the installation of eNodeB (hereafter called eNB) NL Rel 3.0.

G This manual is created as a standard version.

1.1 System Structure

The installation target in this manual, All-in-one Type eNB is a micro-miniature base station equipment which can be

installed out of doors. Its micro-miniaturization was accomplished by unification of the parts: the interface part to upper level

lines, call processing control part, monitor control part, Baseband processing part (BB part), TRXBB part, radio amplifier part

and radio function part. By this, the space required for installation, installation man-hours, installation parts and maintenance

man-hours are all reduced and the degree of freedom in selecting the installation location and direction is increased.

Figure 1

shows the installation image of All-in-one Type eNB.

14

Figure 1 All-in-one Type eNB Installation Image

Page 15

1.2 Equipment Names

Table 1 shows the equipment type and displayed code applicable to this manual.

Table 1 Equipment List

No. Equipment Type Display Code Note

1 Band 13: 700MHz MB4300-n313 Power source: DC -48V

Transmission output: 5w x 2ports

1.3 Main Specifications

Table 2 shows the main specifications of All-in-one Type eNB.

Table 2 Main Specifications of All-in-one Type eNB

No. Item Performance/ Characteristic/ Applied Method

Overview

1

2

3

4

5

6

7

Transmission/ Reception

Frequency

Dimensions

Mass

Power Specification DC-48 [V]: -43.2V to -57.0V

Rated current

Maximum Power

Consumption

Operation Environment

Temperatures

[DL] 746 - 756MHz

[UL] 777 - 787MHz

251.0 ± 2.5[mm](W)

562.0 ± 4.0[mm](H)

149.0 ± 2.5[mm](D)

(Excluding protrusions)

17.0[kg]

Excluding mounting hardware, F-COVER (Front Cover) and CCOVER (Connector Cover).

7[A]

Including AISG consumption:

206.6[W]

Excluding AISG consumption:

198.6[W]

Vertical setup

-33ºC to +50ºC (No sunlight)

-33ºC to +45ºC (With sunlight)

Horizontal setup

-33ºC to +45ºC (No sunlight)

-33ºC to +40ºC (With sunlight)

The above temperature limits of operation environment drops

by 2.5ºC for every 1km of altitude rise.

8

Relative Humidity 5% - 95%

15

Page 16

Overview

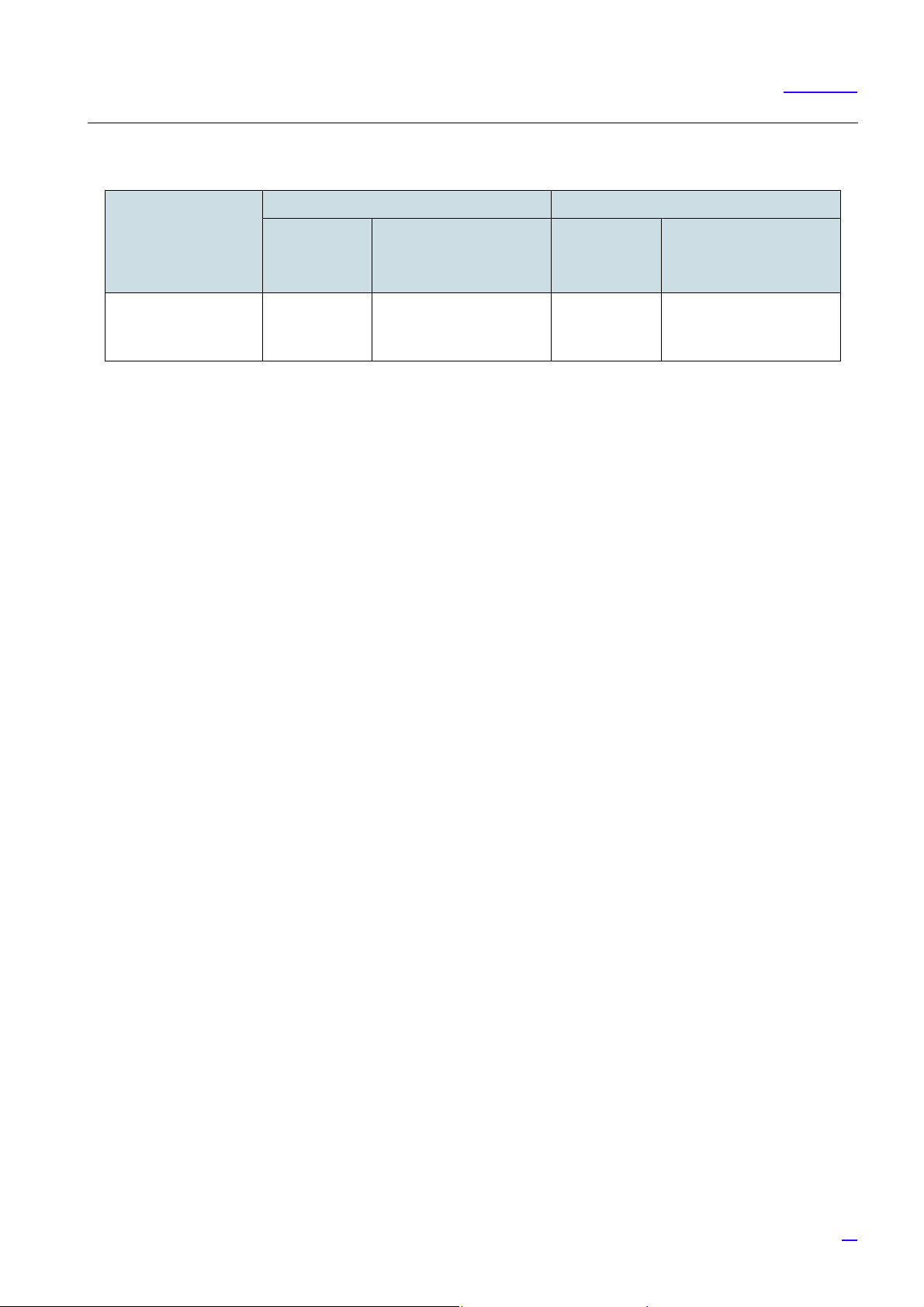

Table 2 Main Specifications of All-in-one Type eNB

No. Item Performance/ Characteristic/ Applied Method

9 Quake Resistance - Telcordia NEBS GR-63-CORE Zone 4

- IEC 60721-2-6: Zone 4

10

11

12

13

EMC Standard FCC Part15 Subpart B Class A

Waterproof/Dustproof IP65 (IP66 with cover)

Surge Limit - Power voltage (outdoors)

Conforms to CE marking

L-E 1.2/50μs, ± 0.5kV 8/20μs

L-L 1.2/50μs, ± 0.5kV 8/20μs

- External alarm interface

Conforms to CE marking

L-E 1.2/50μs, ± 1kV 8/20μs

- Backhaul interface

Conforms to CE marking

L-E 1.2/50μs, ± 1kV 8/20μs

- Lightening SURGE

L-E 1.2/50μs, 10kV 8/20μs, 5kA

L-L 1.2/50μs, 2.5kV 8/20μs, 1.25kA

Safety Standards CSA 60950-1, 60950-22

16

Page 17

Equipment Appearance

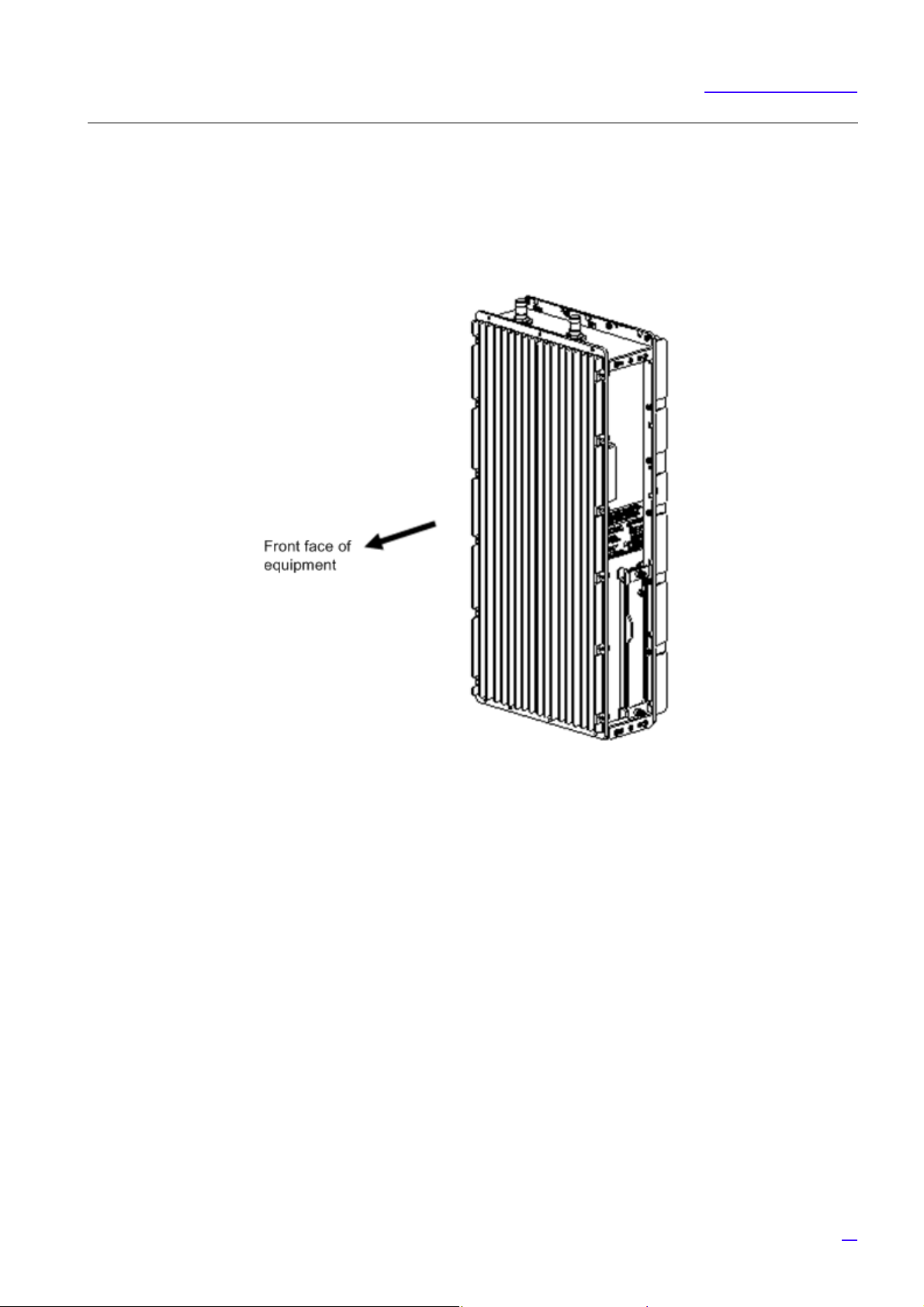

2 Equipment Appearance

The following shows the equipment appearance and equipment flat surface appearance of All-in-one Type eNB.

1 Equipment Appearance

Figure 2 Equipment Appearance

17

Page 18

Equipment Appearance

2 Equipment Flat Face Appearance

18

Figure 3 Equipment Flat Face Appearance

Page 19

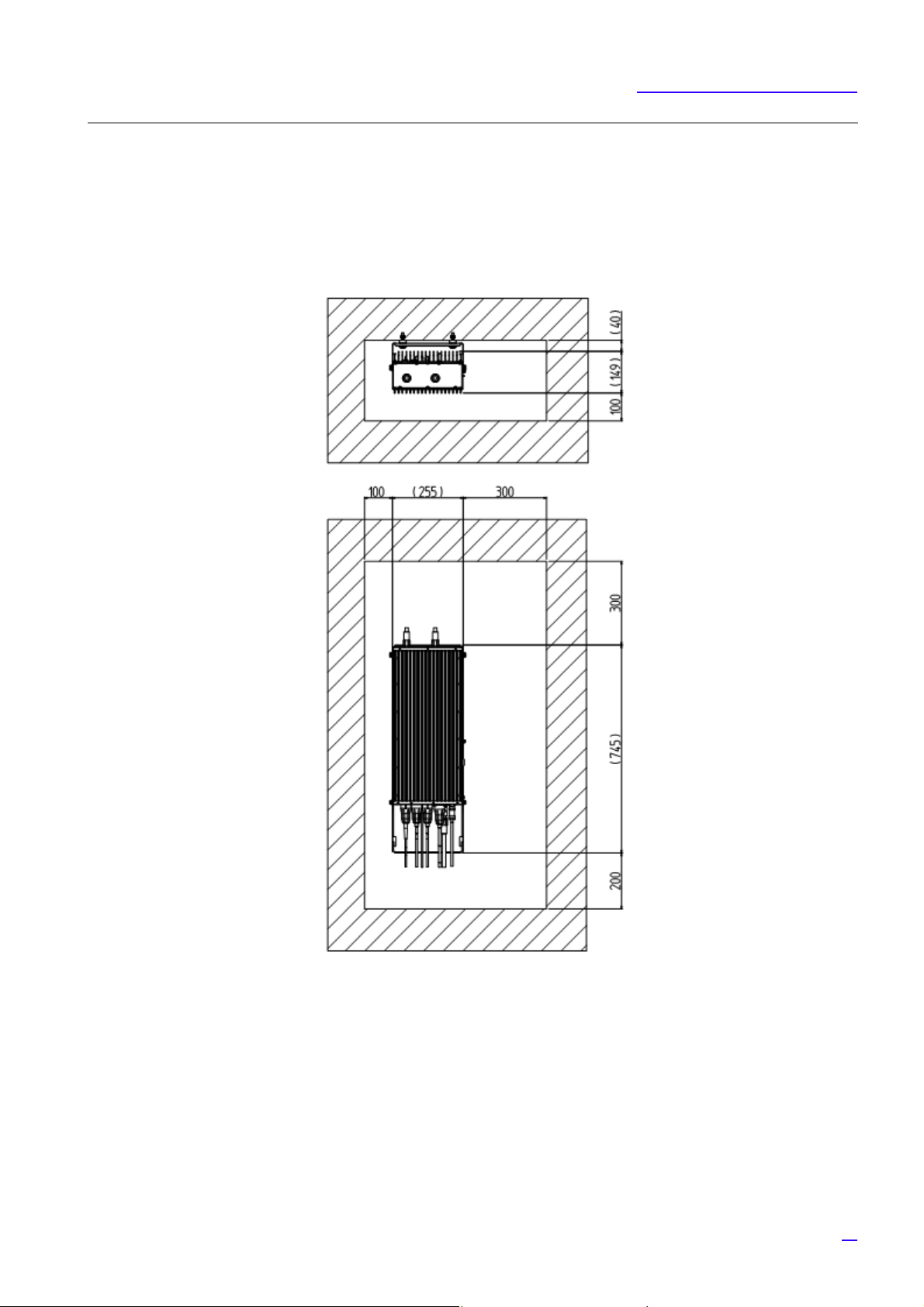

Equipment Installation Conditions

3 Equipment Installation Conditions

The following shows the clearance condition for single installation of All-in-one Type eNB. (In case of "Ladder mount/ wall

mount/ pole mount/ cross arm mount or suspension mount” .)

Figure 4 Single Installation Clearance

G

1 Make sure the temperature is 50ºC or lower at all the front, back, left and right sides.

2 Make sure air ventilation is possible through the top face.

19

Page 20

Interface Conditions

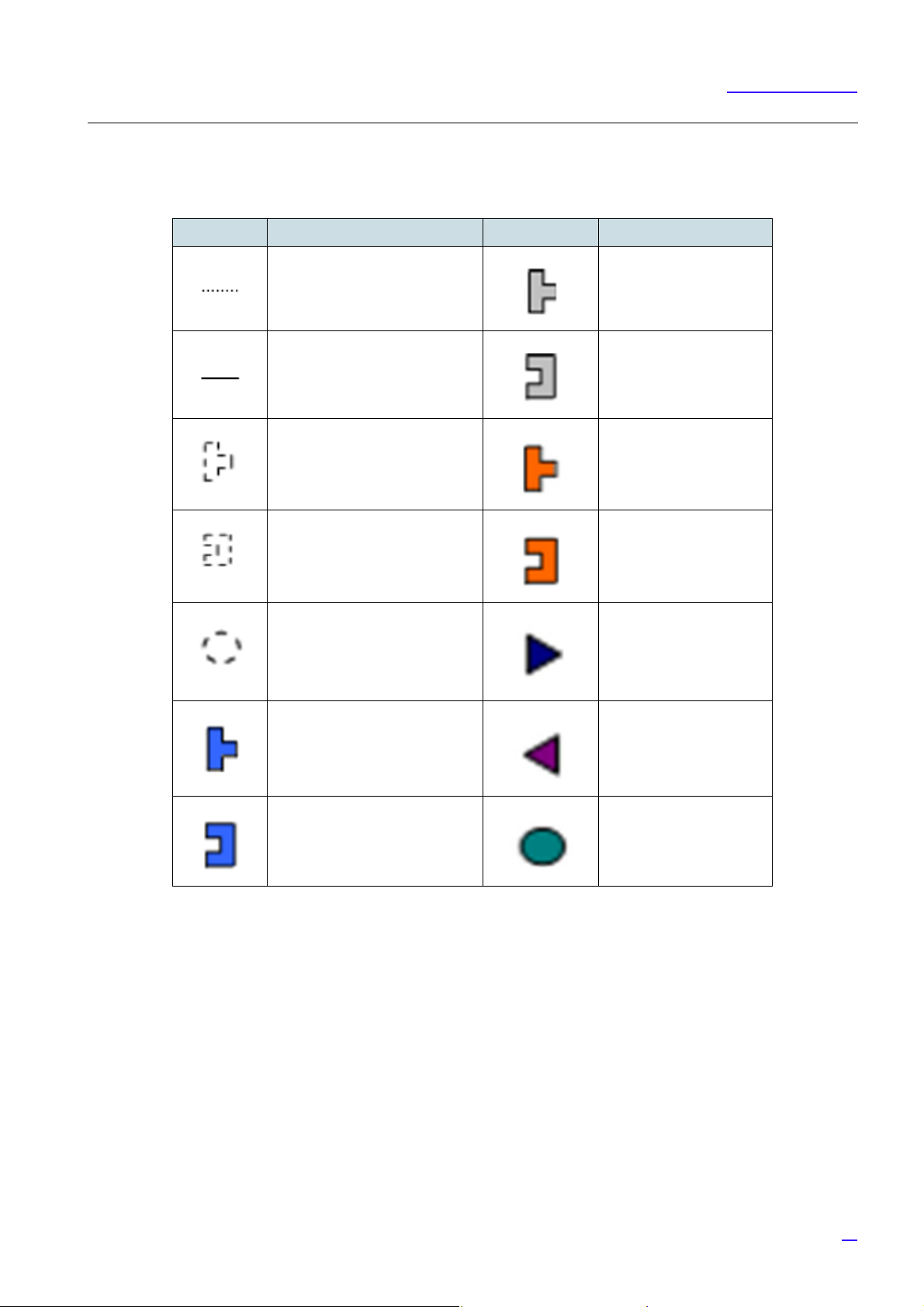

4 Interface Conditions

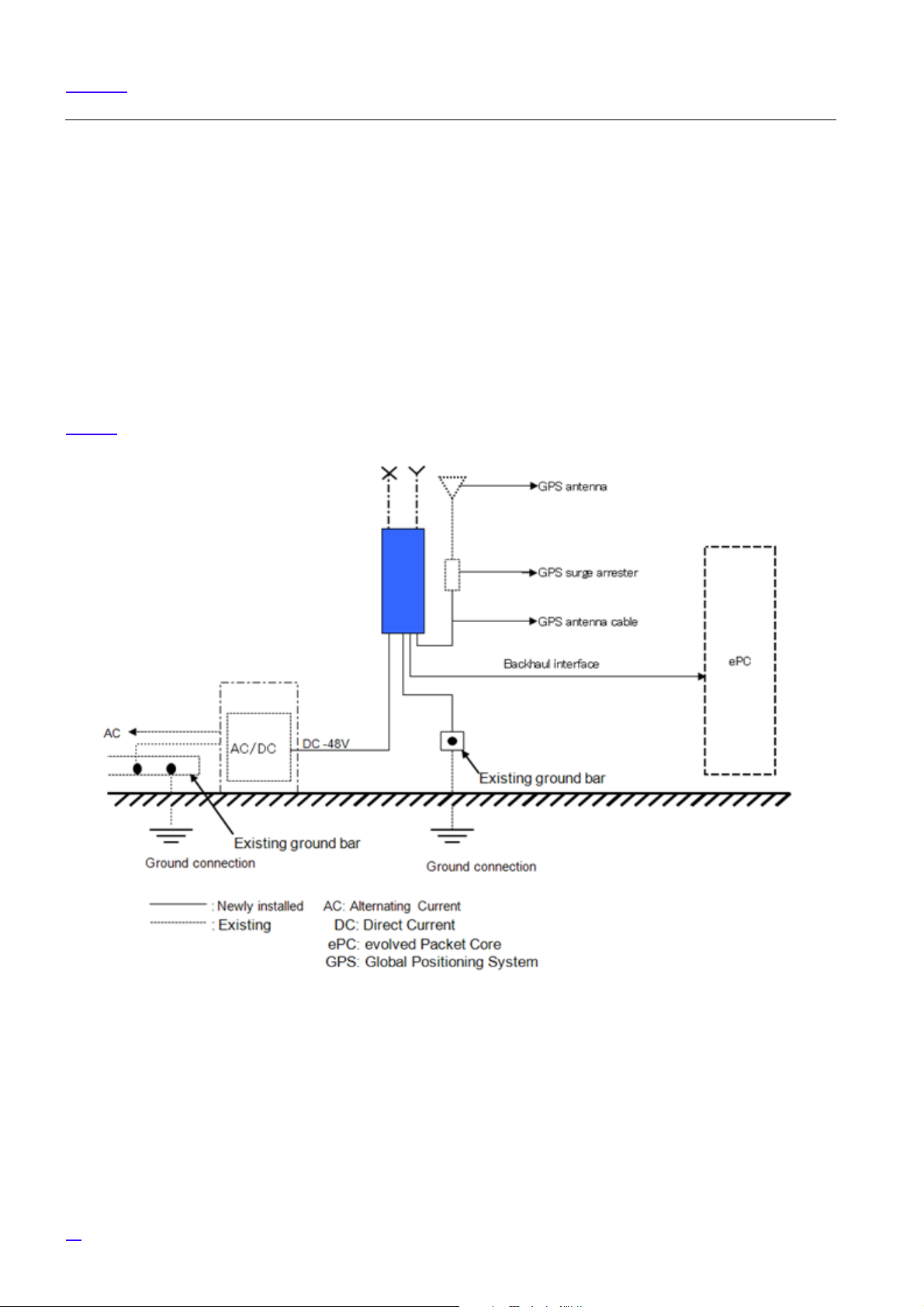

4.1 Cable Connection System Diagram

Figure 5 shows the cable connection system diagram for All-in-one Type eNB. Table 3 shows the list of connectors and

legends.

Figure 5 Cable Connection System Diagram

G

1 Install dedicated power supply cable and breaker to the eNB equipment from the power source facility (DCPD).

Breaker would work as the equipment's breaker.

2 Connector type on the backhaul network side depends on the remote equipment.

3 Figure 5

4 Broken line in Figure 5

omits ACPDB master, ACPDB, storage battery, UPS equipment, etc.

may change depending on installation contract, scope of work and installation design.

20

Page 21

Table 3 Connector List/ Legend

Symbol Details Symbol Detail

Out of preparation range Round waterproof (P)

IEC60130-9

Interface Conditions

Attachment to equipment main

body/ installation cables

N type waterproof (P) Optical 2-core waterproof

N type waterproof (J) Optical 2-core waterproof

Out of preparation range, or

parts different by office

condition or design

RJ-45+waterproof boots (P) Square waterproof boots

Round waterproof (J)

IEC60130-9

boots (P)

boots (J)

Square waterproof boots

(P)

(J)

RJ-45+ waterproof boots (J) M6 crimping terminal

21

Page 22

Interface Conditions

4.2 External Interface

The following shows the interface locations, names and details on bottom face, top face and maintenance window of All-inone Type eNB.

4.2.1 Bottom Face External Interface Locations/ Names and Interface Details

1 Bottom Face External Interface Locations and Names

Figure 6 External Interface Locations and Names (Bottom Face)

2 Interface Details

No. in Fig External Interface Label External Interface Name

(1) BH (O)

(2) BH (E)

(3) EXT ALM

(4) -48V DC

(5) RET

(6 FG Frame ground

(7) GPS

Table 4 External Interface Details (Bottom Face)

Backhaul interface (Optical)

Backhaul interface (Electrical)

External alarm interface

Power input interface

Antenna tilt control interface

L1 GPS interface

22

Page 23

4.2.2 Top Face External Interface Locations/ Names and Details

1 Top Face External Interface Locations and Names

Interface Conditions

Figure 7 External Interface Locations and Names (Top Face)

2 Interface Details

Table 5 External Interface (Top Face)

No. in Fig External Interface Label External Interface Name

(1) ANT 0

(2) ANT 1

RF antenna interface 0

RF antenna interface 1

23

Page 24

Interface Conditions

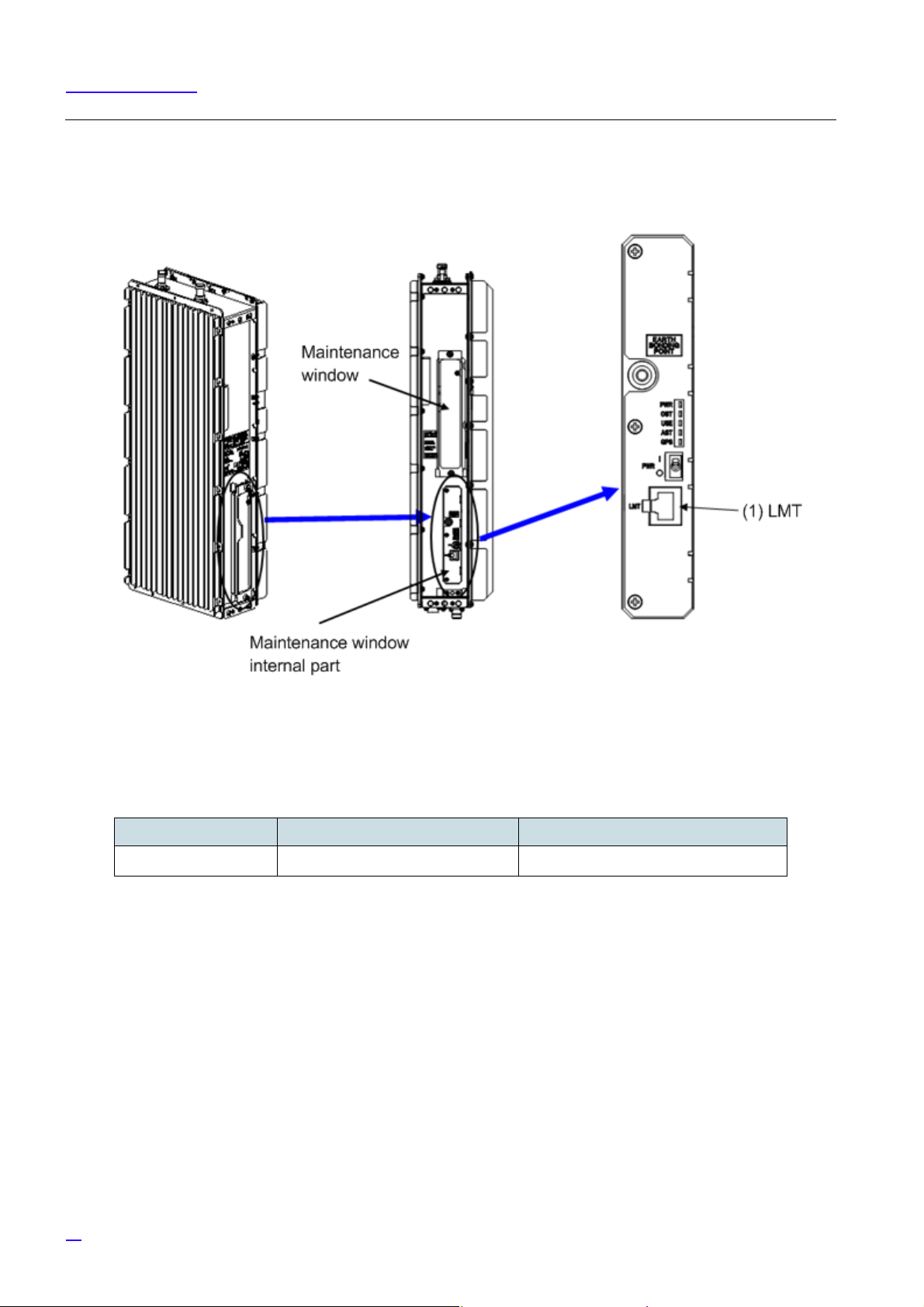

4.2.3 Maintenance Window Interface Locations/ Names and Details

1 Maintenance Window Interface Locations and Names

Figure 8 Maintenance Window Image

2 Interface Details

No. in Fig External Interface Label External Interface Name

(1) LMT

Table 6 Maintenance Window Interface Details

LMT interface

24

Page 25

5 Equipment Installation

This section shows the installation procedure of All-in-one Type eNB.

G

1 Before installing the equipment, remove all connector caps attached to the equipment side external interface

connectors to which external cables are planned to be connected.

Removing the connector caps, etc. in a high place may result in the connector caps dropping.

2 If external cables are not connected right after equipment installation, place outdoor weather resistant tapes on

the temporary connector caps as waterproof treatment.

5.1 Cautions on Carrying the Equipment

The following shows the cautions on when carrying the All-in-one Type eNB.

G

1 Carrier of All-in-one Type eNB must wear working gloves and shoes.

2 When carrying the equipment into the premise, perform required curing on the route.

Equipment Installation

3 Carry the equipment in its package box to prevent damage while carrying.

4 When the equipment goes through the inspection door, cure the opening to prevent damage to the building

and equipment.

5.1.1 Temporary Placement of Equipment

If temporarily placing All-in-one Type eNB on the floor, place it carefully as shown in Figure 9 to prevent damage to

connectors and protrusions.

Figure 9 Temporary Placement Image

25

Page 26

Equipment Installation

5.1.2 Carrying the Equipment by the Handles

When carrying All-in-one Type eNB, the flange part (shaded part) on both sides of the main body can be used as handles.

Refer to Figure 10

.

Figure 10 Handling Parts Used for Carrying

G When handling the equipment, be careful not to damage the connectors on the bottom face of equipment.

If you place the equipment vertically on the floor, it may damage the connectors on the bottom face.

26

Page 27

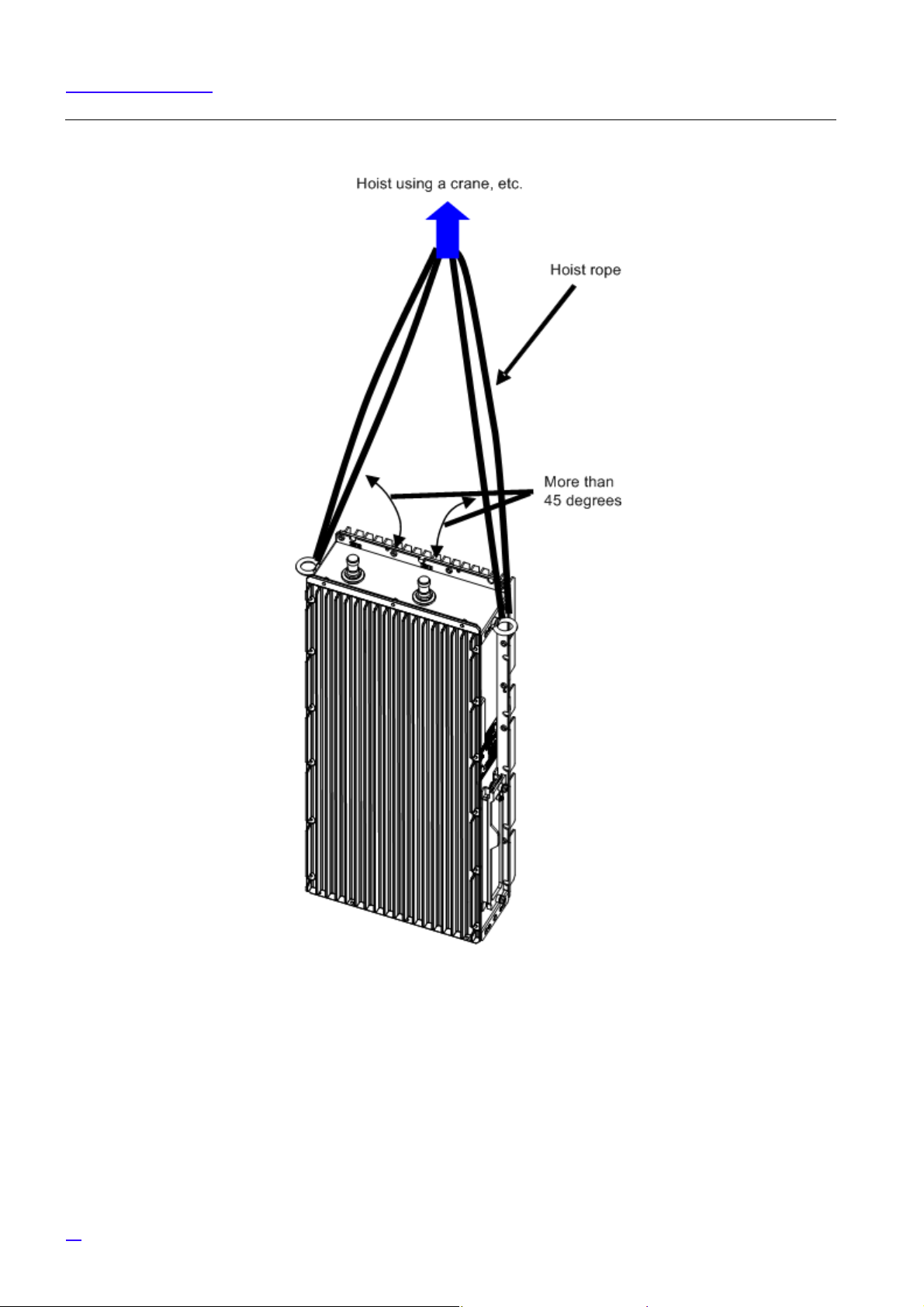

5.1.3 Carrying Equipment by Hoisting Up/ Down

When hoisting the equipment up/ down, use eye-bolts and follow the procedure below.

Equipment Installation

1 Insert eye-bolts into the screw holes on the sides of the equipment as shown in Figure 11

.

Figure 11 Attaching eye-bolts

2 Hoist the equipment using a crane, etc. up to a higher place or down to a lower place by placing ropes in the eye-

bolts as shown in Figure 12

3 After carrying the equipment, remove the eye-bolts.

.

27

Page 28

Equipment Installation

28

Figure 12 Hoist up/down Image

Page 29

Equipment Installation

5.2 Equipment Installation Forms

All-in-one Type eNB has the following installation forms considering the ease of installation.

• Ladder mount/ Wall mount/ Pole mount

Vertical setup

• Cross arm mount/Suspension mount

Horizontal setup

5.2.1 Installation Examples of Ladder/ Wall/ Pole/ Cross arm/ Suspension Mount

The following shows the images of ladder/ wall/ pole/ cross arm/ suspension mount of All-in-one Type eNB.

1 Ladder mount/ Wall mount/ Pole mount

Figure 13 Installation Images Part 1

29

Page 30

Equipment Installation

2 Cross Arm Mount/ Suspension Mount

Figure 14 Installation Images Part 2

G When setting up the equipment horizontally, set it so that the mounting hardware is on the top face.

30

Page 31

Equipment Installation

5.3 Ladder/ Wall/ Pole/ Cross Arm/ Suspension Installation

5.3.1 Dedicated Mounting Hardware for Installation

All-in-one Type eNB (ladder/ wall/ pole/ cross arm/ suspension mount) is installed using the dedicated mounting hardware

which is the standard installation method. For details on the dedicated mounting hardware, refer to the following figure.

Figure 15 Dedicated Mounting Hardware

31

Page 32

Equipment Installation

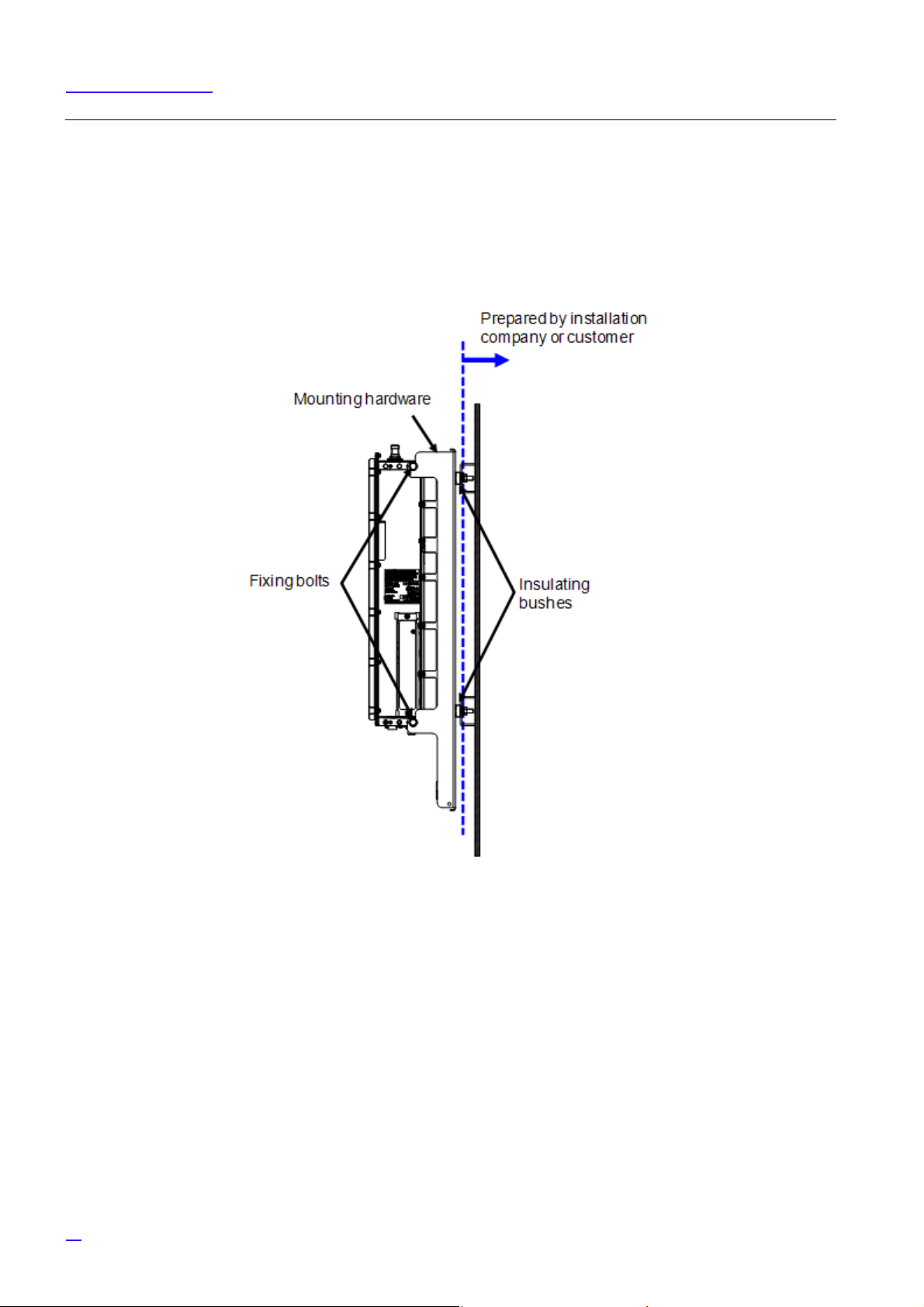

5.3.2 Installation Method

The following shows the method to install All-in-one Type eNB (ladder/ wall/ pole/ cross arm/ suspension mount).

The following shows the image to mount the dedicated mounting hardware on the installation surface.

1 Wall/ Ladder Mount

32

Figure 16 Wall/ Ladder Mount Installation Image

Page 33

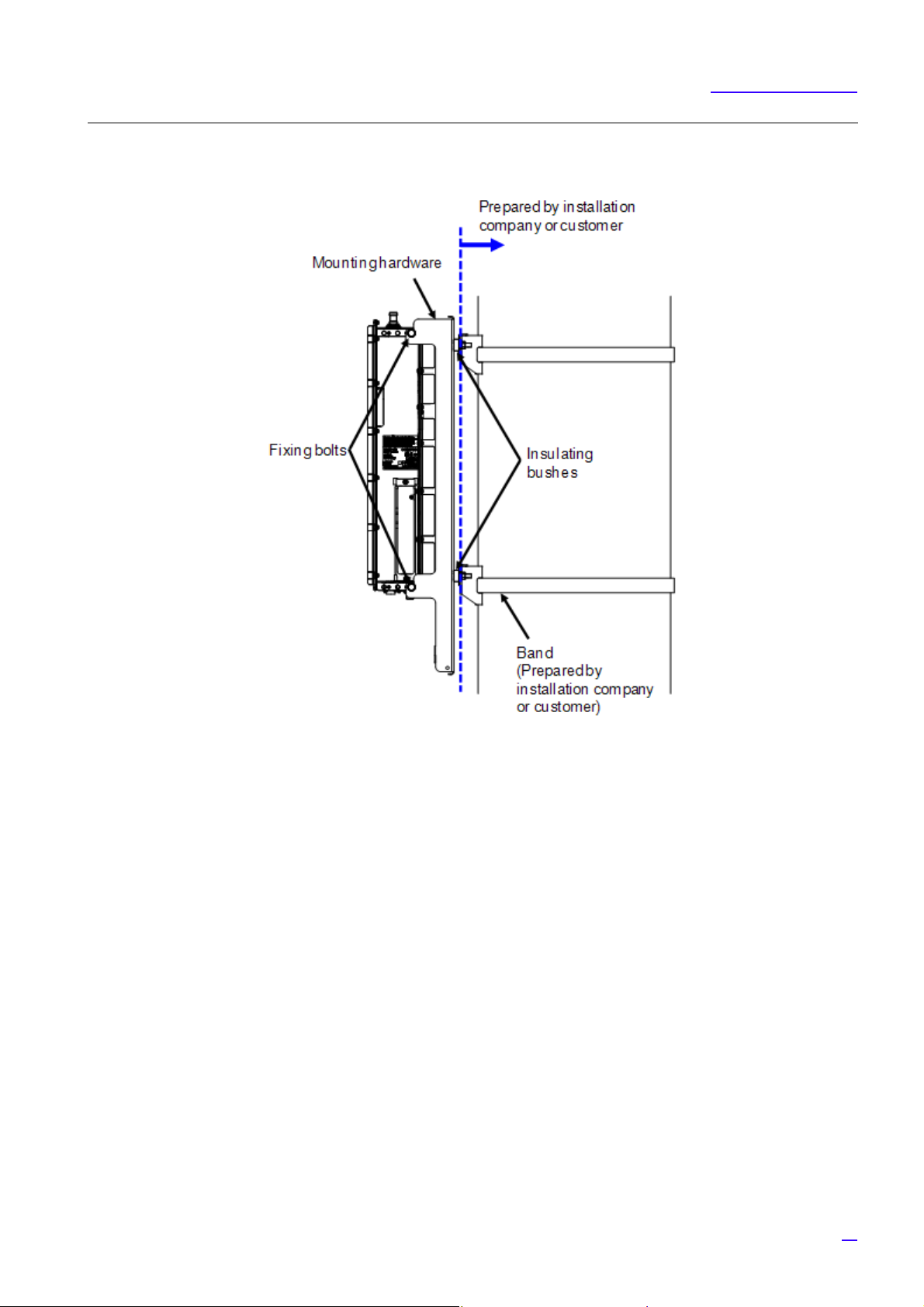

2 Pole Mount

Equipment Installation

Figure 17 Pole Mount Installation Image

G The bands and any ledge to put on the mounting hardware must be prepared by the installation company or

the customer.

33

Page 34

Equipment Installation

3 Cross Arm/ Suspension Mount

Figure 18 Cross Arm/ Suspension Mount Installation Image

G Cross Arms, suspension parts and cross arm fixing bolts on the power source column, etc., suspension part

mounting bolts, wires between poles must be prepared by the installation company or the customer.

34

Page 35

Equipment Installation

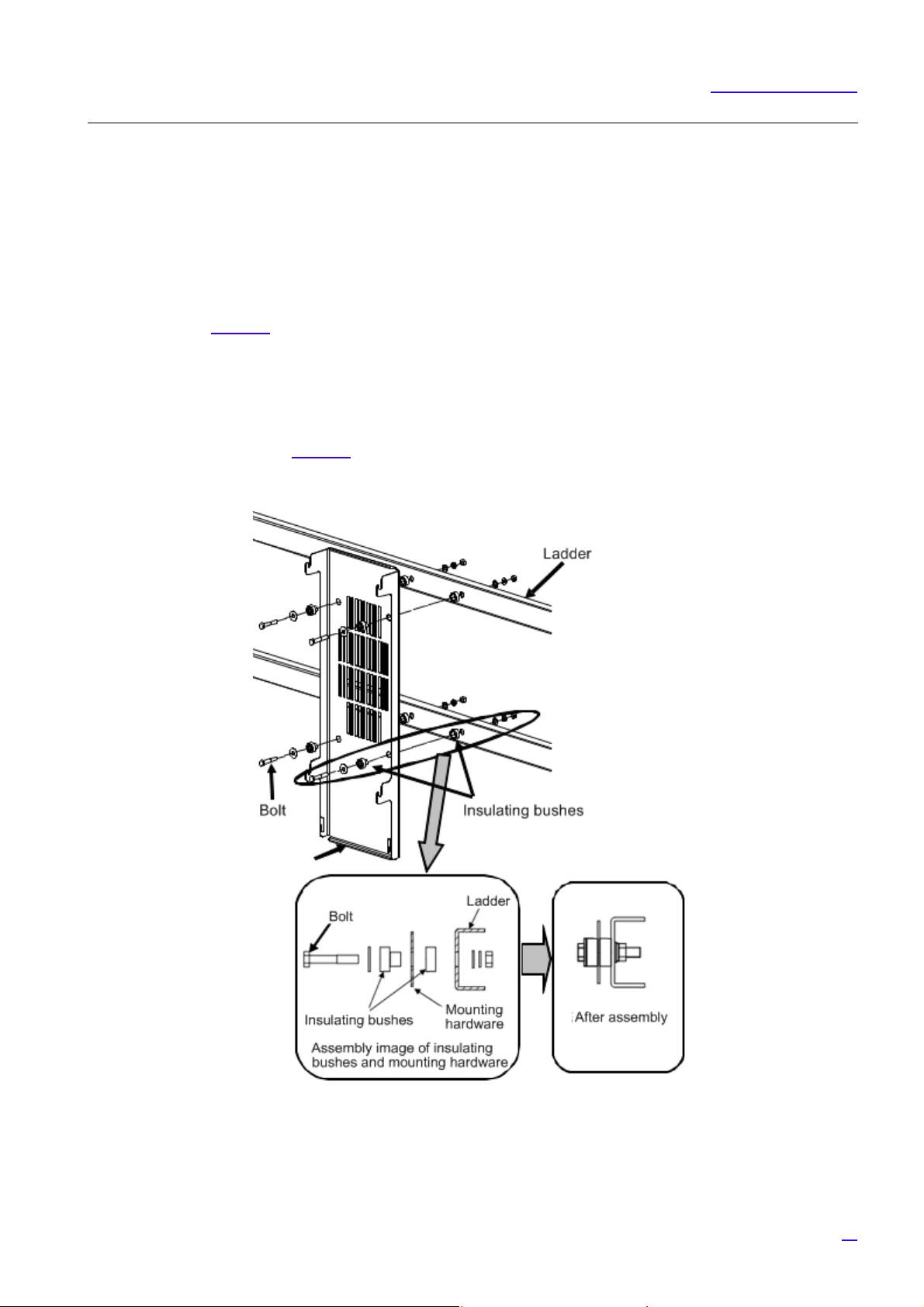

5.3.3 Installation Procedure

The following shows the procedure to install All-in-one Type eNB (ladder/ wall/ pole/ cross arm/ suspension mount).

Installing the dedicated mounting hardware (ladder/ wall/ pole/ cross arm/ suspension)

G This equipment requires electrical insulation with the installed surface, so when fixing by M8 bolts, insulating bushes

are used.

1 Refer to Figure 19

If there is no male screw, fix with M8 nut, etc.

2 Finally, tighten the bolts again, and mark the bolts. (M8: torque 17 ± 1 N• m)

G If there is no hole to install the equipment on the installed surface (ladder/ wall/ pole/ electrical pole/

suspension parts), perform drilling referring to the dedicated mounting hardware installation hole

dimensions (Figure 15

Be careful not to deform the mounting hardware when fixing the equipment.

, and fix using M8 bolt with the bushes in the correct order.

).

Figure 19 Dedicated Mounting Hardware Installation

35

Page 36

Equipment Installation

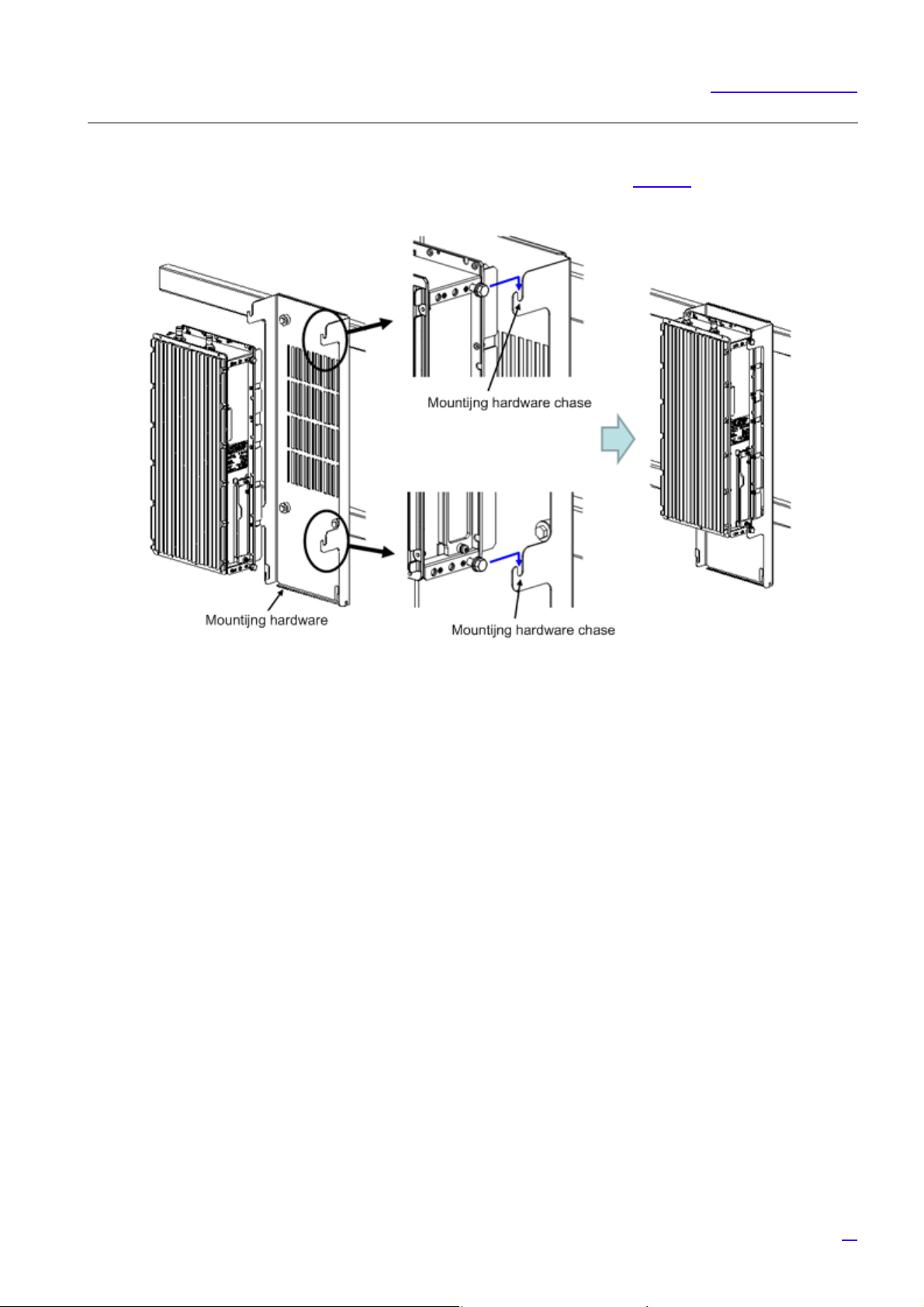

Installing the Equipment to Dedicated Mounting Hardware

1 Insert the 4 fixing bolts into the screw holes on the top, bottom, left and right side of equipment (the back side hole

out of the 3 screw holes in a row) for about the half of their length and temporarily fix them. Refer to Figure 20

installation of fixing bolts

for

36

Figure 20 Fixing Bolts Installation

Page 37

Equipment Installation

2 Hang the equipment by the four M8 bolts (attached to equipment) temporarily fixed in step (1) onto the chases

on top/ bottom/ left and right of the dedicated mounting hardware. Refer to Figure 20

mounting hardware.

for installation onto the

Figure 21 Installing the Equipment onto the Mounting Hardware

37

Page 38

Equipment Installation

3 Tighten the four M8 bolts temporarily fixed in step (1). Lastly, tighten the bolts further and mark the bolts, and

the installation is complete (torque value M8: 17 ± 1 N• m).

38

Figure 22 Tightening the Fixing Bolts

Page 39

5.3.4 C-COVER (Connector Cover) Installation Procedure

G C-COVER is an optional part.

1 Check the screw holes (the center of the 3 screw holes) on the left and right sides of eNB equipment.

Equipment Installation

Figure 23 Right Side Fixing Bolt Installation Location (Reference)

2 Insert the two fixing bolts into the screw holes on the left and right sides of the equipment bottom part (the center

of the 3 screw holes) for half of its length and fix temporarily.

Figure 24 Installing Fixing Bolts

39

Page 40

Equipment Installation

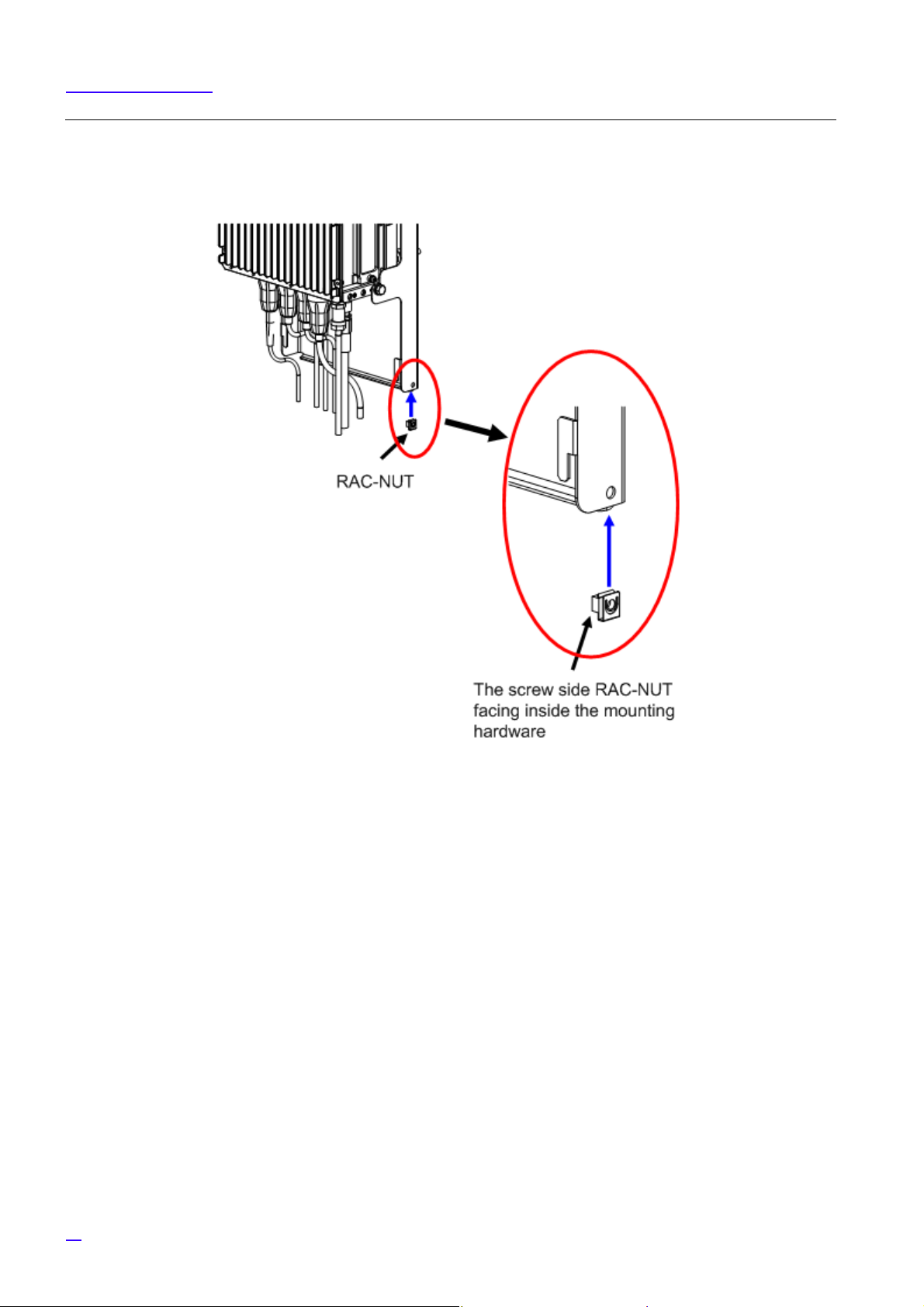

3 Set a RAC-NUT into the round hole on the mounting hardware, with the screw side facing inward.

Figure 25 Installing RAC-NUT

40

Page 41

Equipment Installation

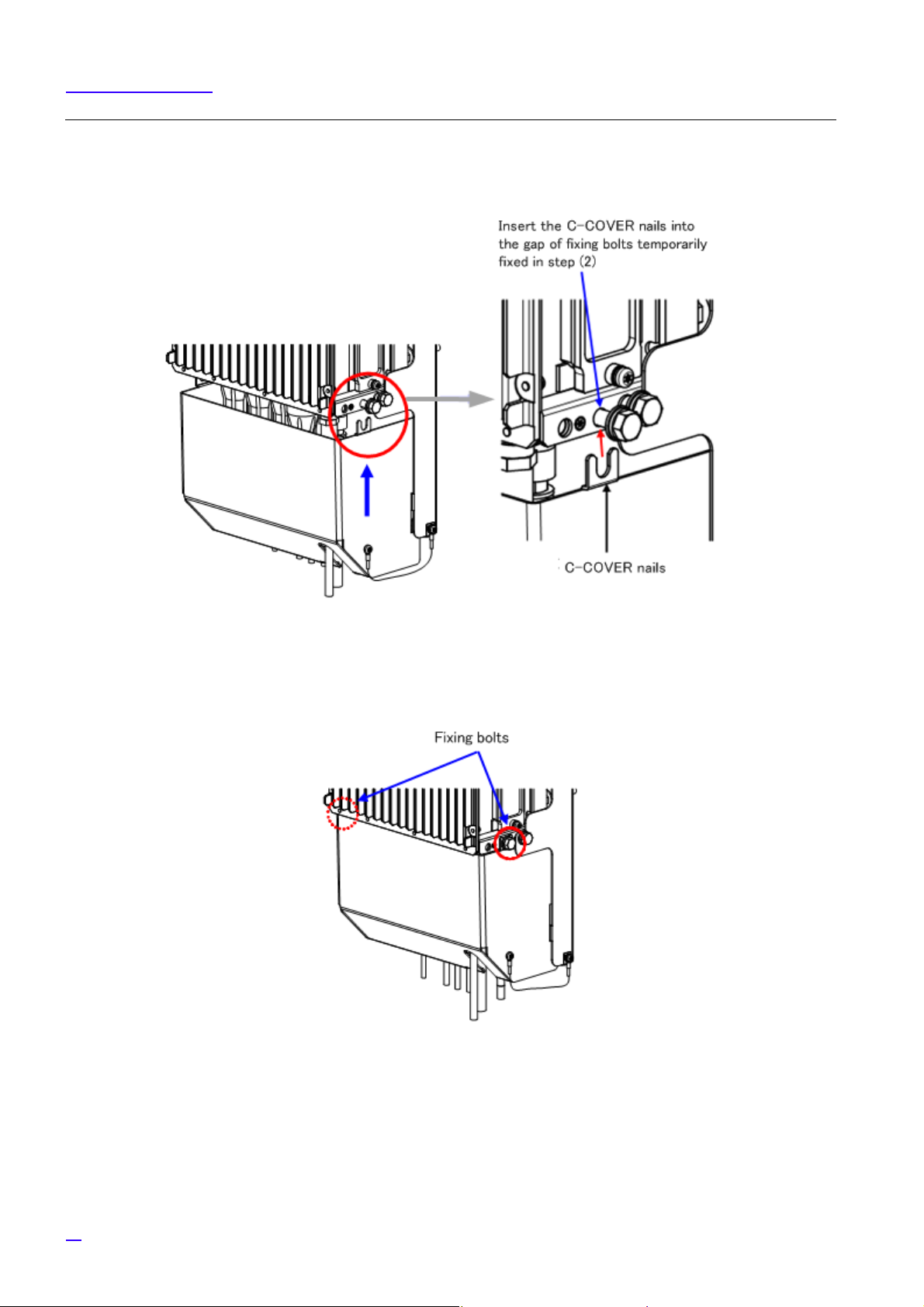

4 Set the C-COVER chase to the protruding parts on the left and right of dedicated mounting hardware, and pull

the C-COVER a little downwards to hang the C-COVER on the mounting hardware.

Figure 26 Temporarily Installing the C-COVER

5 Fix the drop-proof wire of the C-COVER using a TORX screw (M5) onto the dedicated mounting hardware

(torque value M5: 4 ± 0.5 N• m).

Figure 27 Installing the Drop-Proof Wire

G Pulling the drop-proof wire of the C-COVER strongly may cut it off. If the wire is cut, there is a risk of the

C-COVER dropping when trying to remove it.

41

Page 42

Equipment Installation

6 Lift the C-COVER upwards (in direction indicated by the blue arrow), and insert (red arrow) the C-COVER nails

into the gaps of two fixing bolts of the left and right side, which were temporarily fixed in step (2).

Figure 28 Temporarily Installing the C-COVER

7 Tighten the fixing bolts which were temporarily fixed in step (2). Finally, tighten the bolts again and mark the

bolts, and the installation procedure is complete (torque value M8: 17 ± 1 N•m).

Figure 29 Tightening the Fixing Bolts

42

Page 43

Equipment Installation

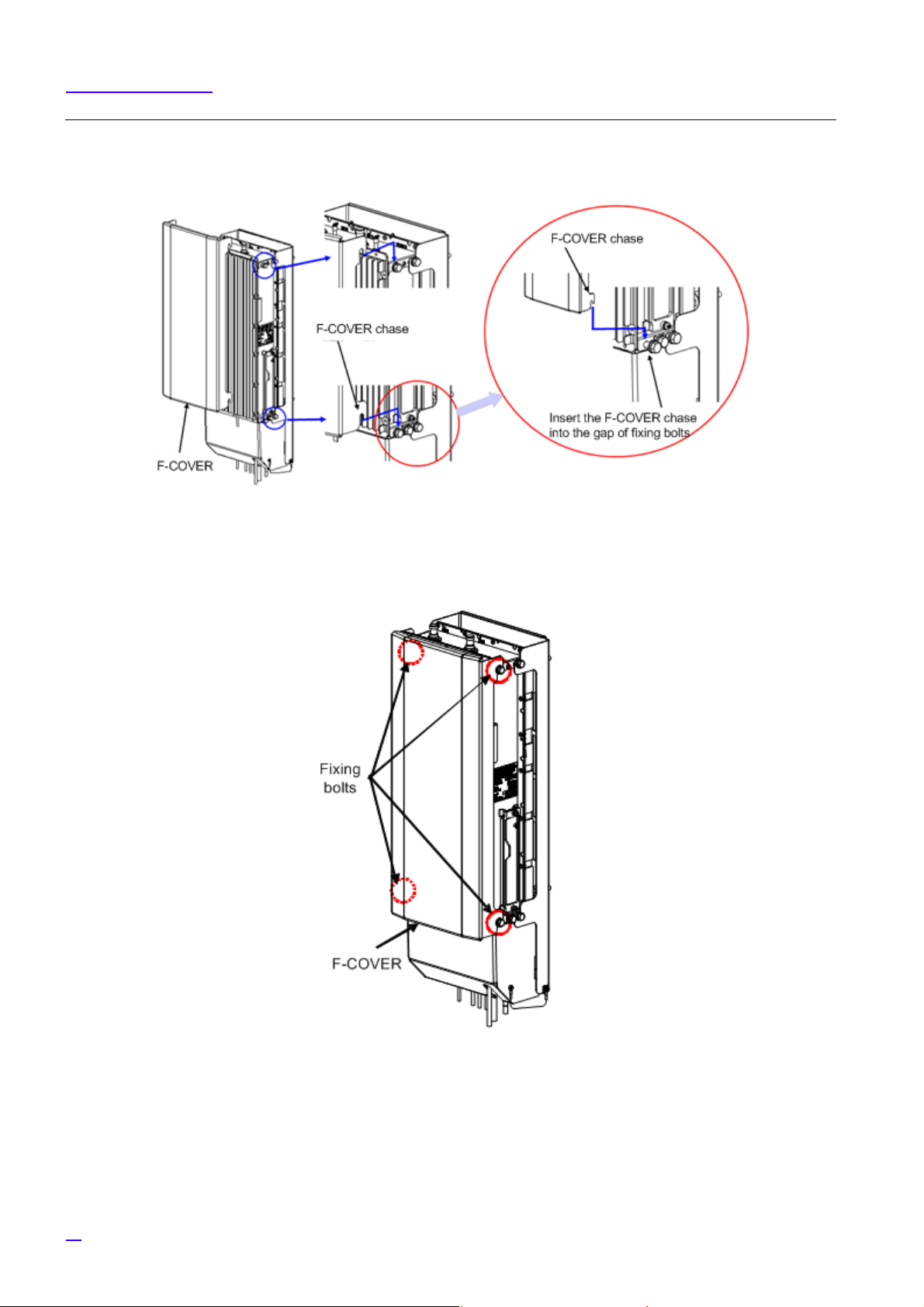

5.3.5 F-COVER (Front Cover) Installation Procedure

G F-COVER is an optional part.

1 Check the screw holes (front side hole out of the three screw holes) on the top, bottom, left and right to set the

fixing bolts.

Figure 30 Installation Location of Fixing Bolts on the Right Side Top and Bottom (Reference)

2 Insert the four fixing bolts (attached parts) into the screw holes (front side hole out of the three screw holes) on

the top, bottom, left and right of equipment for half of their length and fix temporarily.

Figure 31 Installing Fixing Bolts

43

Page 44

Equipment Installation

3 Insert the F-COVER chase into the gap of fixing bolts temporarily fixed in step (2).

Figure 32 Installing the F-COVER

4 Tighten the four fixing bolts on top, bottom, left and right which were temporarily fixed in step (2). Finally, tighten

the bolts again and mark the bolts, and the installation procedure is complete (torque value M8: 17 ± 1 N•m).

44

Figure 33 Tightening the Fixing Bolts

Page 45

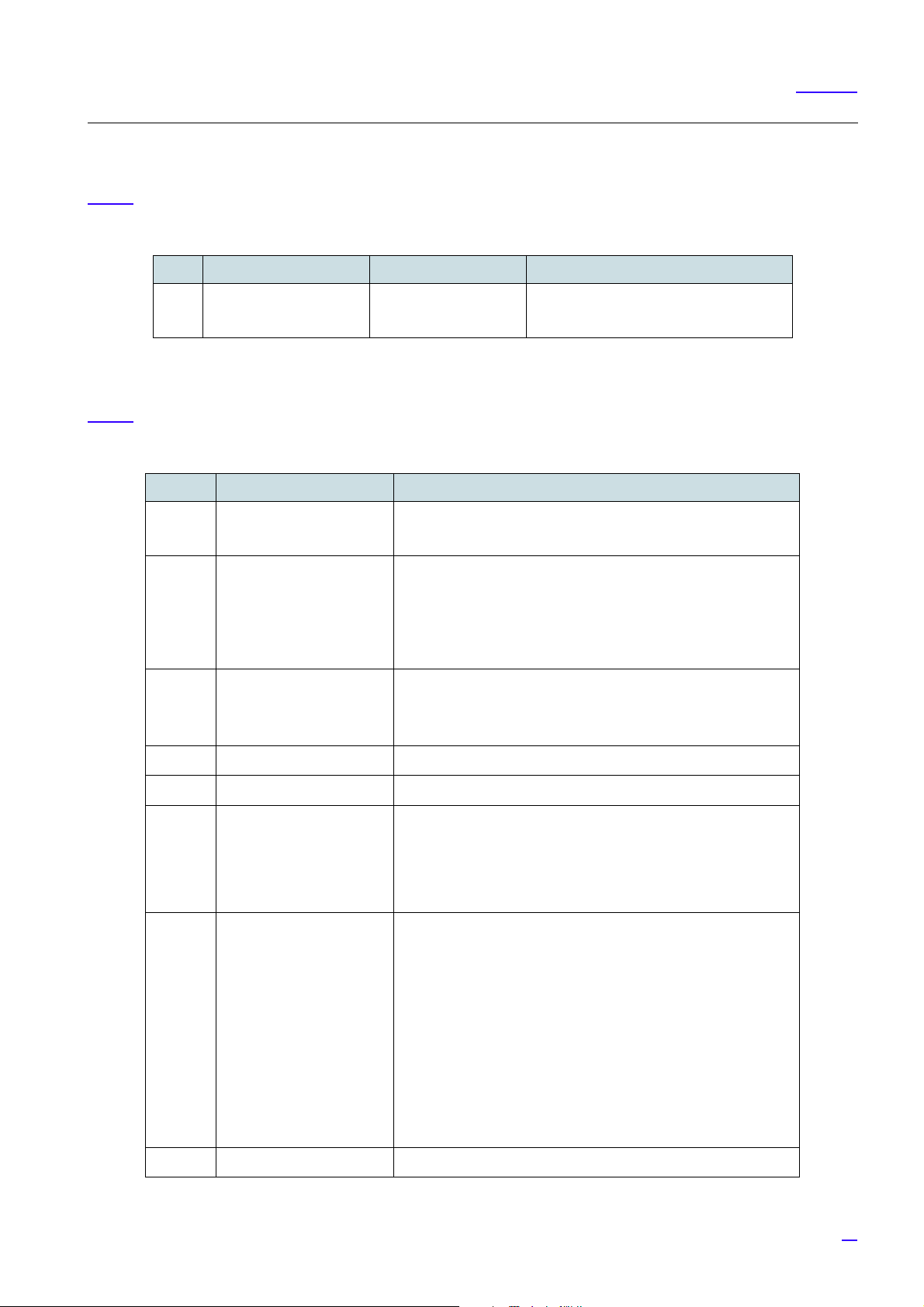

5.4 List of Attachments and Tools

The following lists the attachments and tools required for equipment installation.

Table 7 Attachment List

Item Name Quantity Note

For FG (M6 + pan head screw) 1 Mount on equipment

Connector caps 1 set Mount on equipment

Dedicated mounting hardware 1 set Including installation parts

F-COVER 1 set Optional, including installation parts

C-COVER 1 set Optional, including installation parts

Table 8 Tool List

Item Name Used for Note

Equipment Installation

M6 + Standard driver FG

TORX T25 size screw driver C-COVER drop-proof wire fixing screw

and maintenance window

Hexagonal spanner (For M8) Dedicated mounting hardware, C-COVER

and F-COVER

With tamper-resistant pin

45

Page 46

Cable Work

6 Cable Work

6.1 List of Used Cables and Connectors

Table 9 shows the cables and connectors used for this equipment.

Table 9 Used Cables and Connectors

External Interface/

Name

Power source input

interface -48V DC

GPS interface / GPS N type

External alarm

interface / EXT ALM

Optical BH interface /

BH(O)

Connectors on Equipment Connectors on Cable

Connector

type

Square bipolar TE

waterproof (J)

RJ-45 TE

LC 2-core

(MMF core

radius 50 μm)

1st line: Vender name

2nd line: Vender model

name

FOAC FullAXS

BULKHEAD HOUSING +

square bipolar

DDK

N-SR-J-1.5D

FOAC FullAXS

BULKHEAD HOUSING +

RJ45

TE

FOAC FullAXS

BULKHEAD HOUSING +

LC 2-core

Connector

type

FullAXS TE

N type

waterproof

RJ-45 TE

LC 2-core TE

1st line: Vender name

2nd line: Vender model

name

FullAXS POWER

FLOATING or FullAXS

POWER FIXED

General-purpose

connector. No vender/

model name specified.

FullAXS SIGNAL

FLOATING

FOMM50 LEAD4.8mm

FullAXS LC/DPXLC/DPX

Metal BH interface /

BH(E)

Antenna tilt control

input interface / RET

46

LC 2-core

(MMF core

radius 62.5

μm)

LC 2-core

(SMF)

RJ-45 TE

Round

waterproof (J)

IEC60130-9

TE

FOAC FullAXS

BULKHEAD HOUSING +

LC 2-core

TE

FOAC FullAXS

BULKHEAD HOUSING +

LC 2-core

FOAC FullAXS

BULKHEAD HOUSING +

RJ45

Amphenol

AISG-RECE-CONNESOCKET-TYPE01

LC 2-core TE

FOMM62.5 LEAD4.8mm

FullAXS LC/DPXLC/DPX (Model name not

fixed: in discussion with

TE)

LC 2-core TE

FOSM LEAD4.8mm

FullAXS LC/DPXLC/DPX

RJ-45 TE

FullAXS SIGNAL

FLOATING

Round

waterproof (P)

IEC60130-9

AISG general-purpose

Page 47

Table 9 Used Cables and Connectors

Cable Work

External Interface/

Name

RF antenna interface /

ANT0, ANT1

Connectors on Equipment Connectors on Cable

Connector

type

N type

waterproof (J)

1st line: Vender name

2nd line: Vender model

name

N(F)4H BULKHEEAD

18.0-7.0

Connector

type

N type

waterproof (P)

1st line: Vender name

2nd line: Vender model

name

General-purpose

connector. No vender/

model name specified.

47

Page 48

Cable Work

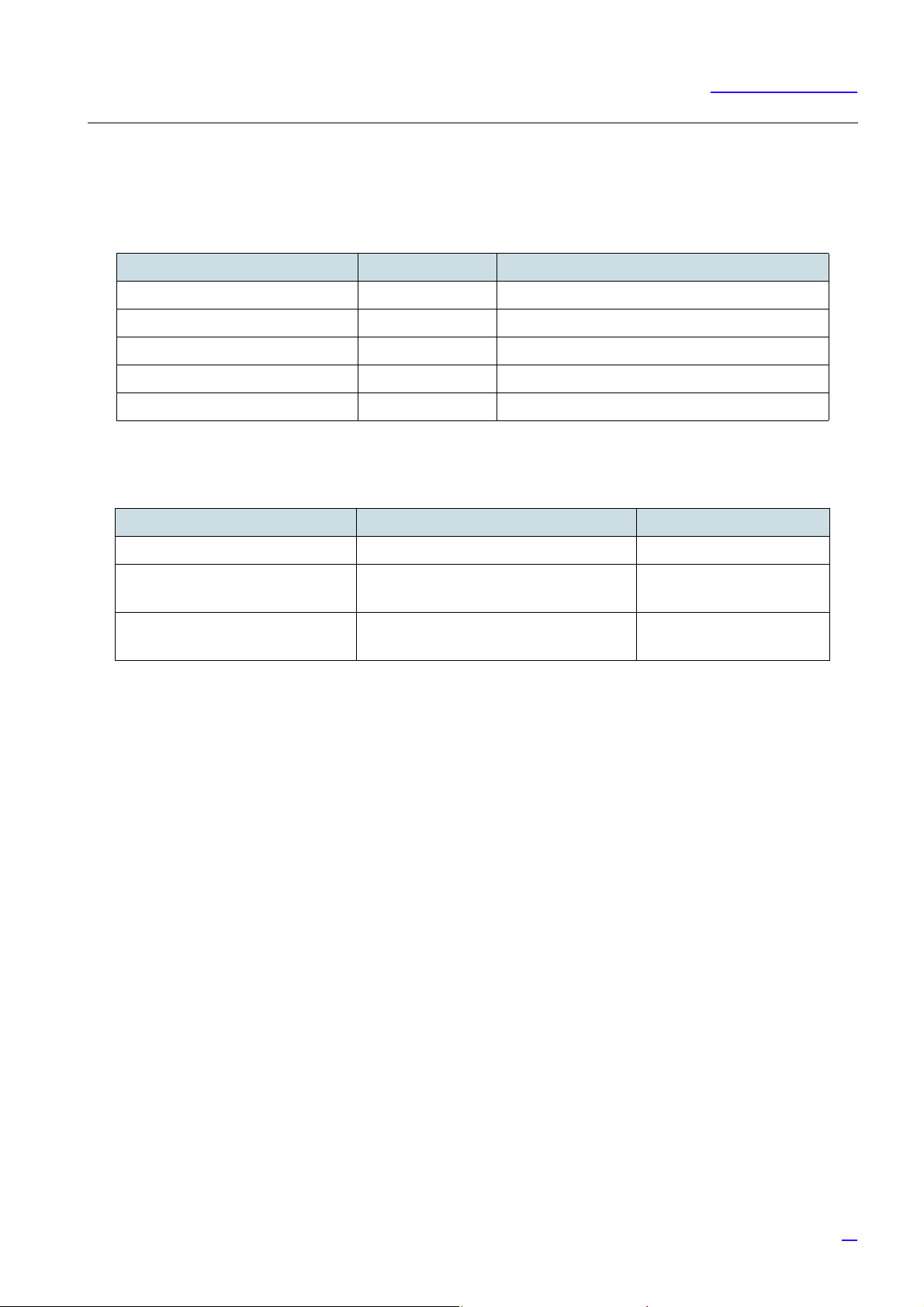

6.2 Power Cable Connection (-48V DC)

Figure 34 shows the position of the connector used to connect the power cable.

Figure 34 Bottom Face Cable Connection Position (Power Connector)

48

Page 49

Cable Work

6.2.1 Power Cable Connection Composition

The following shows the connection composition of the power cable. There are two types of power cable: the Floating type

and the Fixed type.

Figure 35 Power Connection Cable Composition

49

Page 50

Cable Work

6.2.2 Power Cable Connection Procedure

The following shows the procedure to connect the power cable.

G

1 Check that the corresponding breaker is OFF when mating the power connector.

2 Move the Inner and Outer straight to the insertion direction. Inserting them at an angle or twisting them may

damage the connector.

3 Perform the connection while holding the cables close to the equipment, so that the connectors do not drop out

by the cable weight, etc.

4 The Outer, Inner and the connectors are made out of plastic. Stepping on them or banging them may damage

them, so handle them with care.

5 Even if the Outer is fixed, twisting the cable may place load to the internal connector and damage it. When

laying cables, be careful not to twist them.

6 After mating, discard the waterproof cap attached to the cable. The wind, etc. may break the cord, and the cap

may drop.

7 When disconnecting the power cable, turn the power off from the power source.

8 When laying cables, always keep the bend radius to 66 mm or more.

50

Page 51

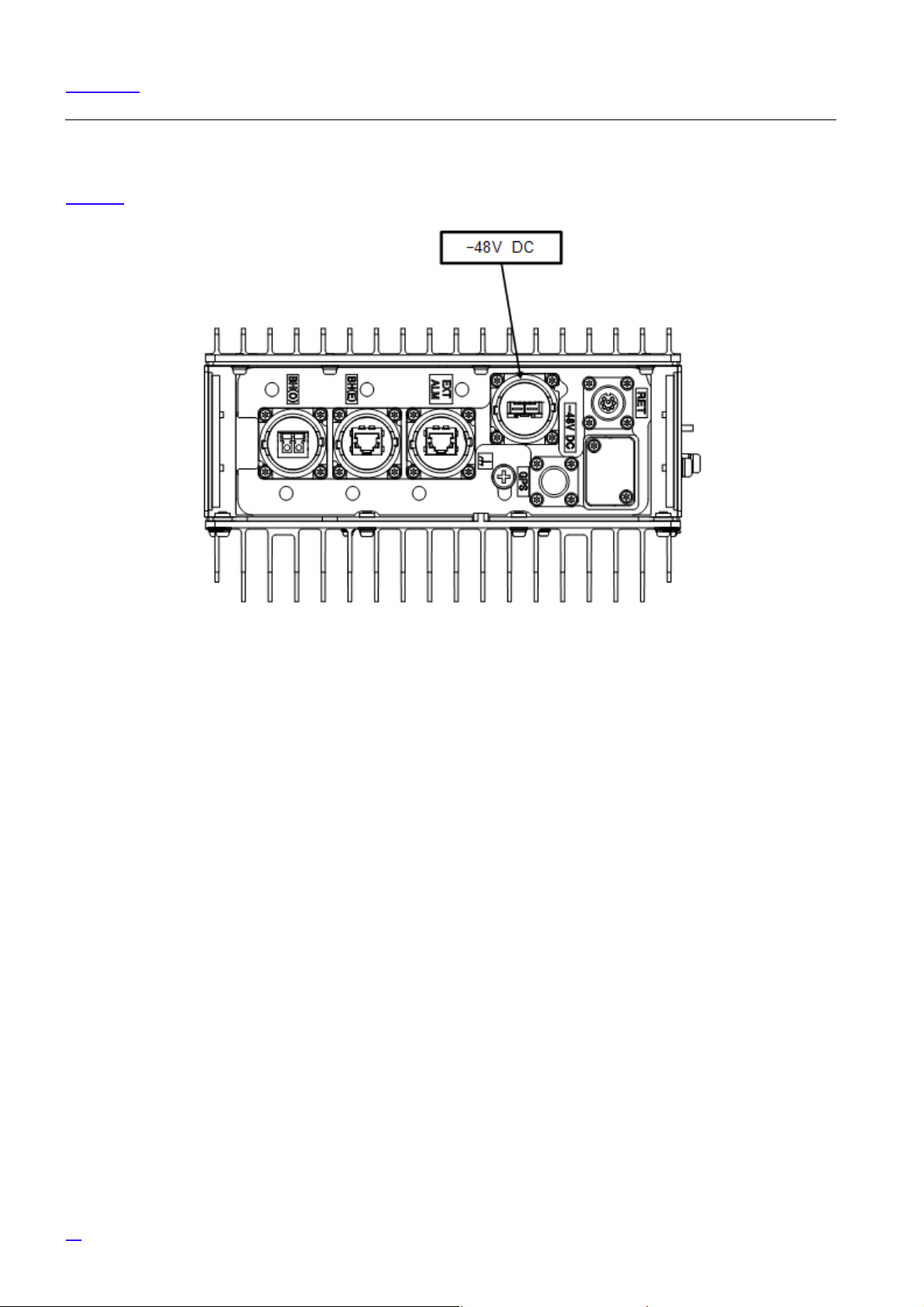

6.2.2.1 Floating Type Cable Connection Procedure

The following shows the procedure to connect the Floating type cable.

1 Insert the connector part of the power cable to the equipment side connector.

(1) Connect the connector latch of the power cable towards the mounting hardware side of eNB equipment.

Cable Work

51

Page 52

Cable Work

(2) Push in the connector of the power cable in until the latch mates.

G Pushing in by force holding the mold part may damage the connector part. Make sure to hold the

connector part when connecting.

2 Insert the power cable Inner straight into the connector on the equipment.

G When inserting the power cable Inner, there would be friction between the inner cable and the Inner, so

hold the cable with your hand while inserting.

After inserting the power cable Inner, pull the cable while still holding the cable with your hand, to closely

fit the mold part and the Inner.

52

Page 53

3 Rotate the power cable Outer clockwise to fix it in place.

Cable Work

53

Page 54

Cable Work

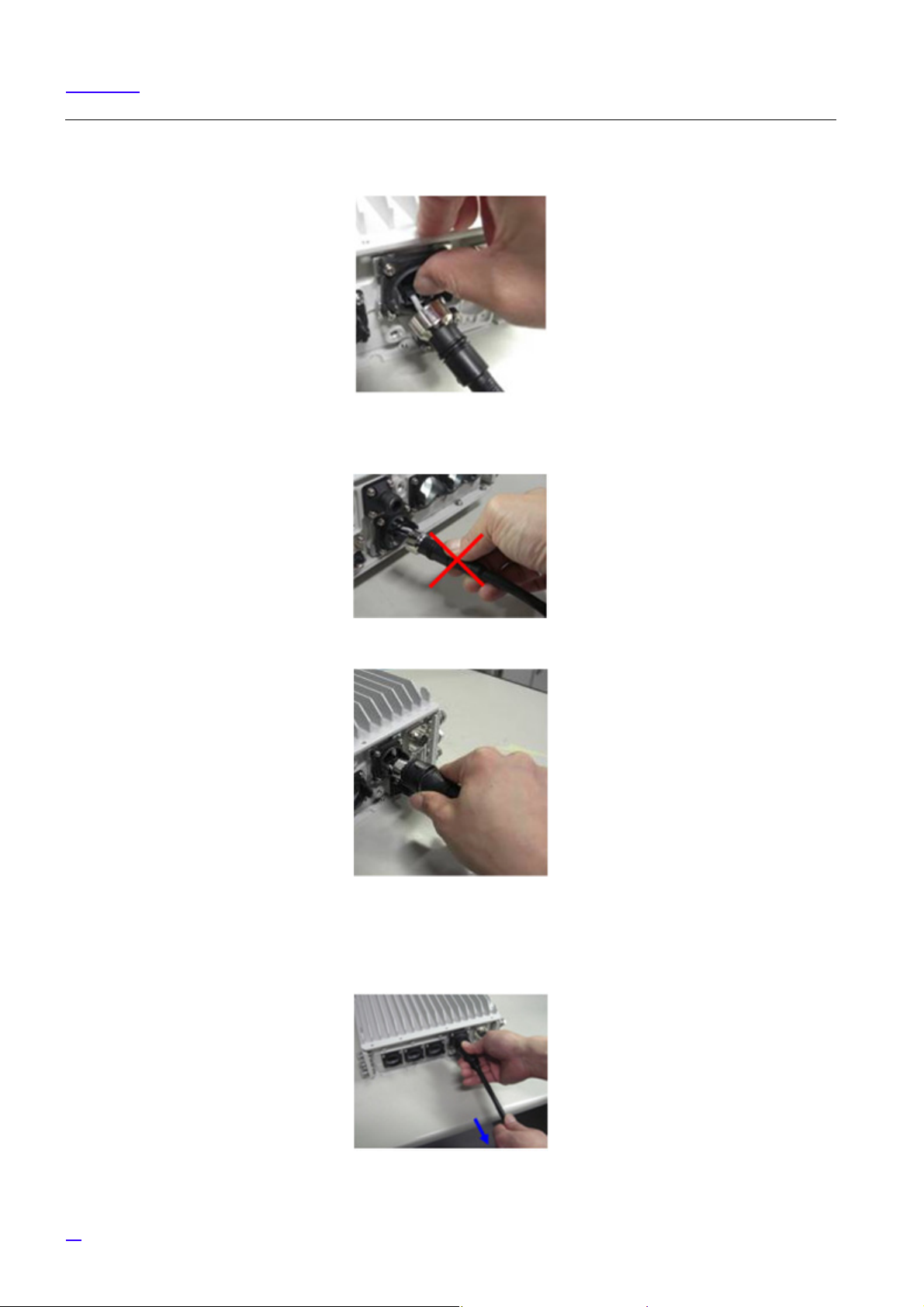

6.2.2.2 Fixed Type Cable Connection Procedure

The following shows the procedure to connect the Fixed type cable.

G Inserting the power cable by force at a wrong connector position or with the connector facing upside down may

damage the connector and the printed circuit board inside the equipment. Do not insert the cable by force, and check

the direction of the power cable connector again.

1 Positioning with the white marking, insert the power cable into the equipment connector until the Inner is beside

the guide on the equipment side connector.

2 Pushing the power cable Outer, rotate it clockwise to fix it.

54

Page 55

6.3 Backhaul Cable Connection

6.3.1 Metal Type Backhaul Cable Connection (BH(E))

Figure 36 shows the location of the connector to connect the backhaul (Electrical) cable.

Cable Work

Figure 36 eNB Bottom Face Cable Connection Position (Backhaul interface (Electrical))

The following shows the composition of the backhaul connection cable (Electrical).

Figure 37 Backhaul Connection Cable (Electrical) Composition

55

Page 56

Cable Work

6.3.1.1 Backhaul Cable Connection Procedure (Electrical)

The following shows the procedure to connect the backhaul cable (Electrical).

G

1 Move the Inner and Outer straight to the insertion direction. Inserting them at an angle or twisting them may

damage the connector.

2 Perform the connection while holding the cables close to the equipment, so that the connectors do not drop out

by the cable weight, etc.

3 The Outer, Inner and the connectors are made out of plastic. Stepping on them or banging them may damage

them, so handle them with care.

4 Even if the Outer is fixed, twisting the cable may place load to the internal connector and damage it. When

laying cables, be careful not to twist them.

5 After mating, discard the waterproof cap attached to the cable. The wind, etc. may break the cord, and the cap

may drop.

6 When laying cables, always keep the bend radius to 22 mm or more.

1 Insert the RJ45 connector part to the equipment connector, until the latch mates.

56

Page 57

2 Insert the Inner straight into the equipment connector.

G When inserting the Inner, there would be friction between the inner cable and the Inner, so hold the cable

with your hand while inserting.

Cable Work

3 Rotate the Outer clockwise to fix it in place.

57

Page 58

Cable Work

6.3.2 Optical Type Backhaul Cable Connection (BH(O))

Figure 38 shows the position of the connector to connect the backhaul (Optical) cable.

G For notes on handling the optical cable, refer to section 6.3.3.

Figure 38 eNB Bottom Face Cable Connection Position (Backhaul Interface (Optical))

The following shows the backhaul connection cable (Optical) composition.

Figure 39 Backhaul Connection Cable (Optical) Composition

58

Page 59

6.3.2.1 Backhaul Cable Connection Procedure (Optical)

The following shows the procedure to connect the backhaul cable (Optical).

G

1 When connecting cable to BH(O), remove the waterproof cap on BH(O) and put it on BH(E).

2 Move the Inner and Outer straight to the insertion direction. Inserting them at an angle or twisting them may

damage the connector.

3 Perform the connection while holding the cables close to the equipment, so that the connectors do not drop out

by the cable weight, etc.

4 The Outer, Inner and the connectors are made out of plastic. Stepping on them or banging them may damage

them, so handle them with care.

5 Even if the Outer is fixed, twisting the cable may place load to the internal connector and damage it. When

laying cables, be careful not to twist them.

6 After mating, discard the waterproof cap attached to the cable. The wind, etc. may break the cord, and the cap

may drop.

Cable Work

7 When laying cables, always keep the bend radius to 30 mm or more.

1 Insert the LC 2-core connector part into the equipment SFP, until the latch mates.

59

Page 60

Cable Work

2 Insert the Inner straight into the equipment SFP.

G When inserting the Inner, there would be friction between the inner cable and the Inner, so hold the cable

with your hand while inserting.

3 Rotate the Outer clockwise to fix it in place.

60

Page 61

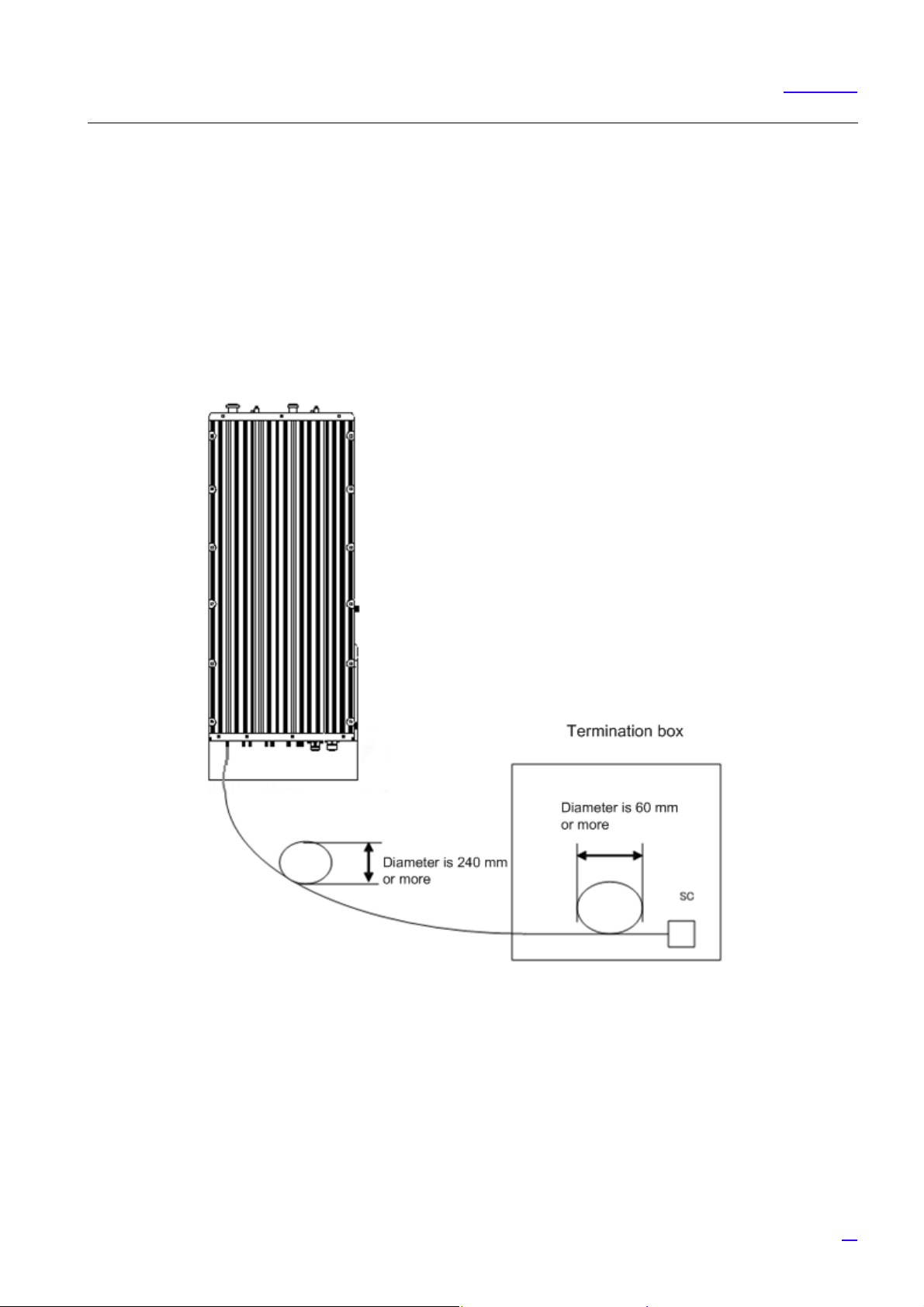

6.3.3 Notes on Handling Optical Cables

The following shows the notes on handling the optical cables.

G

1 When applying surplus treatment to the optical cable connecting the BH(O) connector of this equipment and

the termination box, keep the outdoor armored cable bend radius to 120 mm (240 mm in diameter) or more.

2 When applying surplus treatment inside the termination box, keep the able bend radius to 30 mm (60 mm in

diameter) or more for the parts without outdoor armored cable.

3 Applying too much force on the optical cable may damage it. Connect the optical cable so that it is not twisted.

4 When fixing the optical cable, tie the optical cable so that it is not twisted.

Cable Work

Figure 40 Surplus Treatment of Optical Cable

• Cleaning Equipment SFP and Optical Cable LC Connector

Use the cleaning utensil (stick type) (for φ 1.25) to wash the ferrule (pin-shaped) end-face and side-face of the contact

terminal on the SFP and optical cable LC connector mating part. (Alcohol cannot be used together)

G Do not reuse the cleaning utensil already used once. Invisible dust is attached on the used utensil so reusing it

may damage or contaminate the optical cable.

61

Page 62

Cable Work

6.4 GPS Cable Connection (GPS)

Figure 41 shows the position of the connector to connect the GPS cable.

Figure 41 Bottom Face Cable Connection Position (GPS connector)

6.4.1 GPS Cable Connection Procedure

The following shows the procedure to connect the GPS cable.

1 Insert the GPS connector into the GPS connector on the eNB equipment.

2 After holding the ring on the GPS cable against the GPS connector on the eNB equipment, tighten until the male

screw ridges of the GPS connector on the eNB equipment are invisible.

Recommended tightening torque is 0.7 N•m to 1.1 N•m.

62

Page 63

Cable Work

Figure 42 GPS Cable Connection

3 To prevent the mating part loosening, it is recommended to protect the connector on the eNB equipment up to

the cable (so that the cable side connector is completely covered) with outdoor weather-proof tape.

Figure 43 GPS Cable Connector Protection Example

Figure 44 GPS Cable (with Waterproof Cap)

63

Page 64

Cable Work

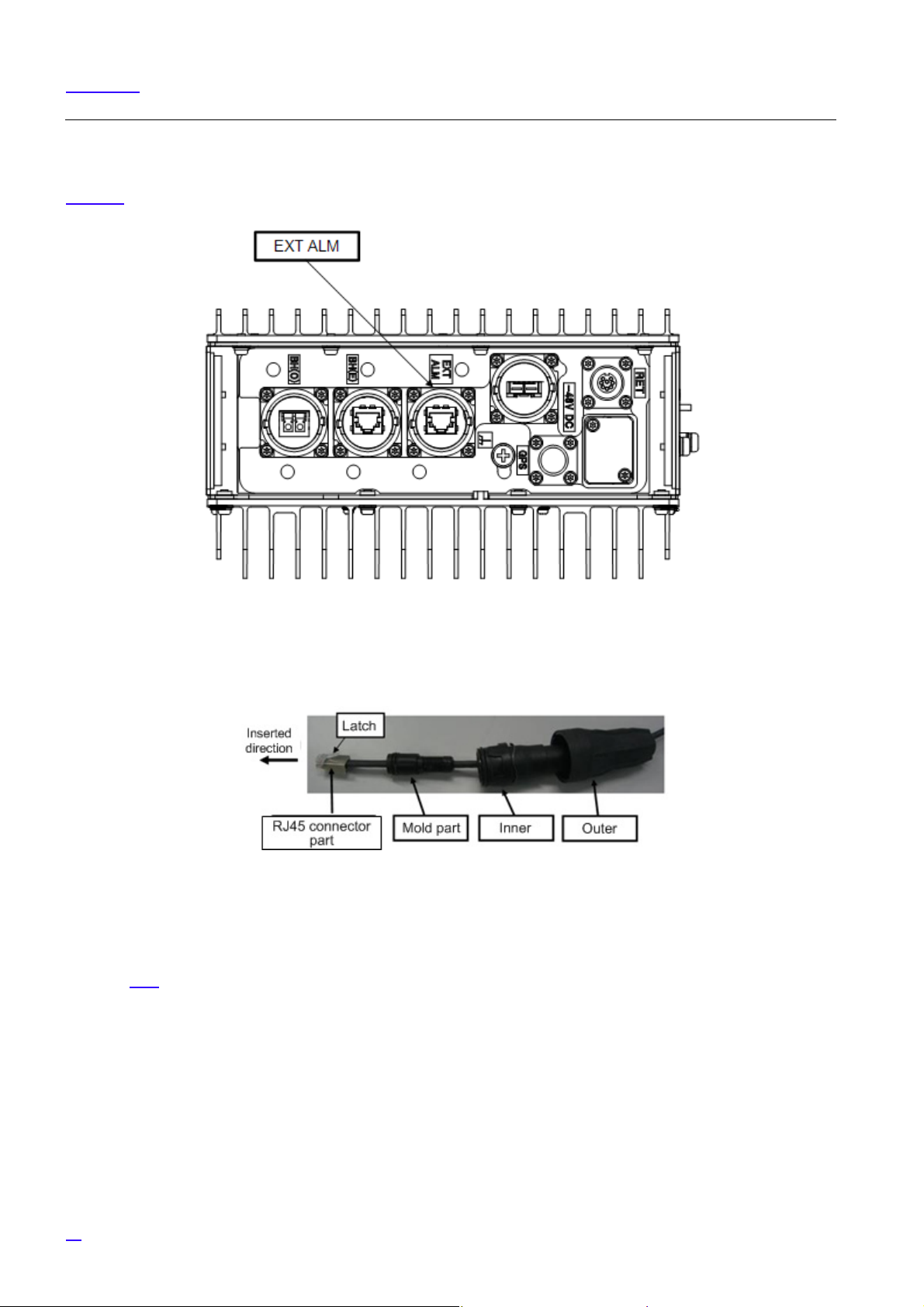

6.5 External Alarm Interface Cable Connection (EXT ALM)

Figure 45 shows the position of the connector to connect the external alarm interface cable.

Figure 45 Bottom Face Cable Connection Position (External Alarm Interface (EXT ALM))

The following shows the external alarm interface connection cable composition.

Figure 46 External Alarm Interface Connection Cable Composition

6.5.1 External Alarm Interface Cable Connection Procedure (EXT ALM)

The connection procedure of the external alarm interface cable is the same as that of the metal type backhaul cable, so refer

to section 6.3.1

.

64

Page 65

6.6 FG Cable Connection (FG)

Figure 47 shows the position of the Frame Ground (FG) connector screw to connect the FG cable.

Cable Work

Figure 47 Bottom Face Cable Connection Position (FG)

6.6.1 FG Cable Connection Procedure

The following shows the procedure to connect the FG line.

1 Use the M6 + pan head screw installed on the FG terminal to connect the FG cable to the equipment.

Figure 48 FG Terminal Connection Part

65

Page 66

Cable Work

G

1 The recommended tightening torque is 4 N•m.

2 When connecting the FG cable, connect it so that it would take the shortest way to the ground point

in the office.

2 To prevent loosening, it is recommended to protect the connector on the eNB equipment + pan-head screw to the

FG line (so that the FG line side crimping terminal is completely covered) with outdoor weather-proof tape.

G Apply protection after checking the voltage referring to section 7. If protection is applied before checking

the voltage, some voltage check procedure cannot be performed.

Figure 49 Crimping Terminal Mounting Screw Protection Example

66

Page 67

6.7 Antenna Tilt Control Cable Connection (RET)

Figure 50 shows the position of the connector to connect the antenna tilt control cable.

Cable Work

Figure 50 Bottom Face Cable Connection Position (RET)

6.7.1 Antenna Tilt Control (RET) Cable Connection Procedure

The following show the procedure to connect the antenna tilt control (RET) cable.

1 Insert the antenna tilt control cable connector into the antenna tilt control connector on the eNB equipment.

2 Holding the ring of the antenna tilt control cable against the antenna tilt connector on the eNB equipment, use

your hand to tighten the ring on the cable clockwise.

Recommended tightening torque is 1.0 N•m to 1.2 N•m.

67

Page 68

Cable Work

Figure 51 Antenna Tilt Control Connector Connection

3 To prevent the mating part loosening, it is recommended to protect the connector on the eNB equipment up to

the cable (so that the cable side connector is completely covered) with outdoor weather-proof tape.

Figure 52 Connector Protection Example (RET)

68

Figure 53 Waterproof Cap Protection Example

Page 69

6.8 Antenna Cable Connection (ANT0/ANT1)

Figure 54 shows the positions of the connectors to connect the antenna cable.

Cable Work

Figure 54 Top Face Cable Connection Position (Antenna Cable)

6.8.1 Antenna Cable Connection Procedure (ANT0/ANT1)

The following shows the procedure to connect the antenna cable.

1 Insert the antenna cable connector into the RF connector on the eNB equipment.

2 Holding the ring on the antenna cable against the RF connector on the equipment, tighten the ring of the antenna

cable until the male screw ridges of the RF connector on the equipment are invisible.

Recommended tightening torque is 0.7 N•m to 1.1 N•m.

69

Page 70

Cable Work

Figure 55 Antenna Cable Connection

3 To prevent the mating part loosening, it is recommended to protect the connector on the eNB equipment up to

the cable (so that the cable side connector is completely covered) with outdoor weather-proof tape.

Figure 56 Connector Protection Example (ANT)

70

Page 71

6.9 Connector Details

6.9.1 Power Connector Pin Allocation

The following shows the pin allocations on the power connector installed on the eNB equipment.

Table 10 Terminal Number and Signal Names

Pin No. Signal name

Cable Work

1

2

-48V DC

0V

Figure 57 Power Connector Pin Allocations

71

Page 72

Cable Work

6.9.2 Antenna Tilt Control Connector (IEC60130-9)

The following shows the pin allocations for the antenna tilt control connector on the eNB equipment.

Table 11 Terminal Number and Signal Names

Pin No. Signal name AISG Requirement

1

2

3

4

5 RS485 A

6

7

8

+12V DC nominal Not supported

-48V DC nominal Not supported

RS485 B Would be supported

RS485 GND For eNB, it is supported. Whether it is used or note depends on RET

10V -30V DC Would be supported

DC return Would be supported

N/C Reserved for future extension.

support situation.

Would be supported

72

Figure 58 Pin Allocations for Antenna Tilt Control Connector

Page 73

6.9.3 External Alarm Interface (EXT ALM)

The following shows the pin allocations of the external alarm interface (EXT ALM) on the eNB equipment.

Table 12 Pin Number and Signal Name

Pin No. Signal name

1Output 1 (Make)

2Output 1 (Break)

Cable Work

3

4

5Input 1

6

7

8

Output 1 (Common)

Input 1-G

-

Input 2-G

Input 2

Figure 59 Pin Allocation for External Alarm Interface (EXT ALM) Connector

73

Page 74

Voltage Check

7 Voltage Check

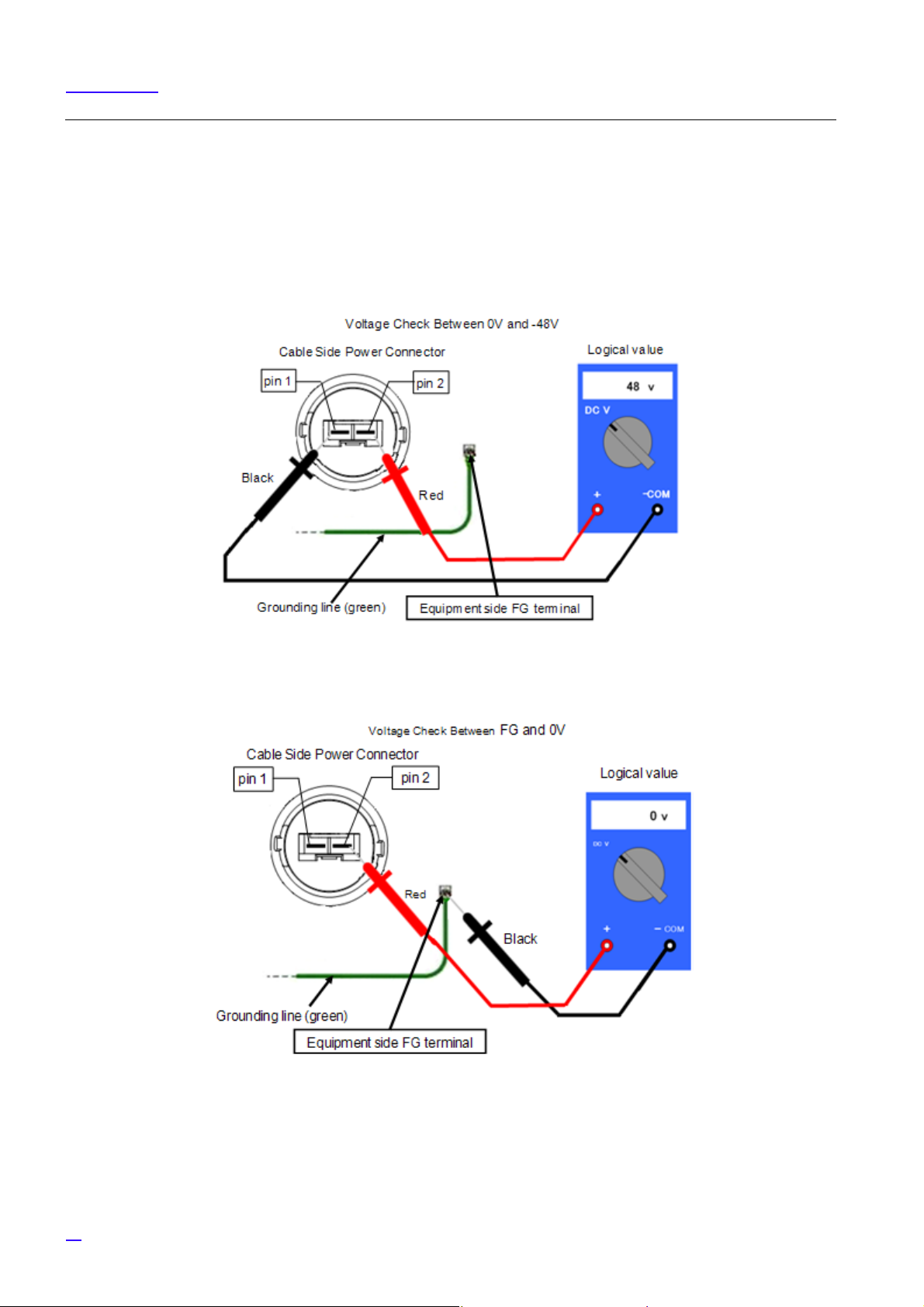

7.1 Cable Side Power Connector Pin Location Polarity

The following shows the pin location polarity image and details of the cable side power connected to the Power Distribution

Board (PDB) side breaker.

Figure 60 Cable Side Power Connector Pin Location Polarity

74

Page 75

7.2 Voltage Check Procedure

The following show the procedure to check the voltage.

1 Prepare the tester in advance. Check that the tester operates normally before starting the test.

2 Check the target location by sight and by reading out.

3 Insulate and cure the necessary parts of the cable side power connector, DC power distribution board and DC

breaker to prevent short-circuit accidents.

4 No voltage check of the breaker

Check that the target breaker on the power distribution board side is turned OFF by sight, and perform no voltage

check on the power distribution board side using the tester.

1 Check that the red lead bar is connected to the + on the tester, and black lead bar to the –COM on the tester.

2 Change the tester range to VDC range. For a tester with the Ampere range, check with two people or more

that the measurement is not performed in Ampere range and that the test bar insertion positions to the tester

are correct.

3 Connect the red lead bar of the tester to the plus (+) pole of the target power distribution board breaker, and

the black lead bar to its minus (-) pole.

4 Check that the value displayed on the tester is 0V (no voltage, logical value).

5 Disconnect both the lead bars of the tester from the breaker terminals.

Voltage Check

5 Cable Side Power Connecter Voltage Check

Check that the target power distribution side breaker is turned OFF by sight, and perform no voltage check of the

cable side power connecter using the tester.

1 Connect the red lead bar of the tester to the 0V terminal (pin 2) on the cable side power connector, and the

black lead bar to its -48V terminal (pin 1).

2 Check that the value displayed on the tester is 0V (no voltage, logical value).

75

Page 76

Voltage Check

6 Keep each lead bar (red and black) of the tester connected as is, and instruct another worker to turn ON the target

breaker.

G After the worker checks the position of the target breaker by the drawing, the target device name displayed

on the power distribution and the destination plate attached to the power cable, the worker turns ON the

target breaker. Moreover, the supervisor would always be present and checks on the work.

7 Check that the breaker switch is turned ON, and 48V (logical value) is displayed on the tester.

8 Keeping the red lead bar connected to the 0V terminal (pin 2) of the cable side power connector, slowly move the

black lead bar to the grounding terminal (E or FG) and connect to it. Upon connection, check that the voltage

changes from 48V to 0V (logical value).

76

Page 77

Voltage Check

9 Keep the black lead bar connected to the grounding terminal (E or FG), slowly move the red lead bar from the 0V

te rmi nal ( pin 2 ) of the c able side con nect or to the -48V terminal (pin 1), and connect to it. Upon connection, check

that the voltage changes from 0V to -48V.

10 Check that the polarities of the logical value and the actual measurement value are the same, the voltage value is

almost the same as the above logical value, in a range allowed by the device characteristics, or is an appropriate

voltage specified by the rectifier.

11 When the voltage check is complete, check the target breaker again and turn the breaker OFF (upon turning OFF,

check again that the cable side power connector is in 0V (no voltage)).

12 Remove the cure materials, and attach the power distribution board breaker terminal protection cover (fix by

screws and check the tightening).

13 Connect the cable side power connecter to the power connector on the equipment side.

14 Clean up the site.

77

Loading...

Loading...