Page 1

NCR RealPOSTM Presentation Scanner

(7893)

Release 1.0

User Guide

B005-0000-1917

Issue A

27355

Page 2

The product described in this book is a licensed product of NCR Corporation.

NCR is a registered trademark of NCR Corporation.

NCR RealPOS is either a registered trademark or a trademark of NCR Corporation in the United States and/or other countries.

It is the policy of NCR Corporation (NCR) to improve products as new technology, components, software, and firmware become available.

NCR, therefore, reserves the right to change specifications without prior notice.

All features, functions, and operations described herein may not be marketed by NCR in all parts of the world. In some instances,

photographs are of equipment prototypes. Therefore, before using this document, consult with your NCR representative or NCR office for

information that is applicable and current.

To maintain the quality of our publications, we need your comments on the accuracy, clarity, organization, and value of this book.

Address correspondence to:

Manager, Information Products

NCR Corporation

Discovery Centre, 3 Fulton Road

Dundee, DD2 4SW

Scotland

Or send feedback:

http://www.info.ncr.com/eFeedback.cfm

Copyright © 2009-2012

By NCR Corporation

Duluth, GA U.S.A.

All Rights Reserved

Page 3

i

Preface

Audience

This book is written for hardware installer/service personnel, system integrators, and field

engineers.

Notice: This document is NCR proprietary information and is not to be disclosed or

reproduced without consent.

Page 4

ii

References

NCR RealPOSTM Presentation Scanner (7893)Hardware Service Guide

(B005-0000-1918)

NCR RealPOS Scanner Tool Suite Guide

(B005-0000-1883)

NCR RealPOS

(B005-0000-1699)

TM

Scanners Safety and Regulatory Information

Page 5

iii

Table of Contents

Chapter 1: Introduction

Using the Scanner......................................................................................................1-1

Chapter 2: Product Information

Physical Considerations ............................................................................................2-1

Environmental Considerations ..................................................................................2-2

Power Considerations................................................................................................ 2-2

Features and Options................................................................................................. 2-3

Scanning Performance ........................................................................................2-3

Communications Protocol...................................................................................2-3

Autodiscrimination .............................................................................................2-4

USB Peripheral Port and Main (POS) Communication Port ..............................2-5

Operator Interface ............................................................................................... 2-6

Voice Messages.............................................................................................. 2-6

LED Status Indicator ......................................................................................2-6

Motion Detector .............................................................................................2-6

Not–On–File .......................................................................................................2-7

Power Supply......................................................................................................2-7

Parameter Programming .....................................................................................2-8

Scan Doctor Diagnostics..................................................................................... 2-8

Power–On Wellness Check ............................................................................2-8

Ongoing Wellness Check ...............................................................................2-9

Service Diagnostics ......................................................................................2-10

Soft Power Down/Power Up.............................................................................2-10

Chapter 3: Installation

Preparing for Installation........................................................................................... 3-1

Unpack the Unit.................................................................................................. 3-1

Inspect the Unit for Damage...............................................................................3-1

Verify Correct Cables .........................................................................................3-2

Identifying Available Kits ..................................................................................3-2

Determine Scanner Location ..............................................................................3-3

Installing the 7893.....................................................................................................3-4

USB Keyboard Wedge Communication.............................................................3-5

Programmables............................................................................................... 3-5

Tag Message Format ......................................................................................3-5

Connecting Power .....................................................................................................3-6

Modifying the Scanner Program ...............................................................................3-7

Page 6

iv

Communications Protocol .........................................................................................3-7

IBM RS-485........................................................................................................3-7

RS-232 ................................................................................................................3-7

IBM USB ............................................................................................................3-7

NCR (RS-232) USB............................................................................................3-7

Wedge ................................................................................................................. 3-7

Chapter 4: Operating the Scanner

Scanner Components.................................................................................................4-1

Pass-by Scanning.......................................................................................................4-2

Presentation Scanning ...............................................................................................4-2

Hand Scanning ..........................................................................................................4-4

Label Orientation.......................................................................................................4-4

Scan Pattern Location .........................................................................................4-4

Label Rotation ....................................................................................................4-5

Distance from Scanner........................................................................................4-6

Bar Code Quality....................................................................................................... 4-6

PACESETTER ..........................................................................................................4-7

PACESETTER Plus ...........................................................................................4-7

Mode 1–Inquiry.............................................................................................. 4-7

Mode 2–Demonstration Mode........................................................................ 4-7

Mode 3–Operations ........................................................................................4-7

PACESETTER III...............................................................................................4-8

Read Indicators.......................................................................................................... 4-8

LED Status Indicator ..........................................................................................4-8

Audible Indicator ................................................................................................4-8

Speech Functionality .................................................................................................4-8

Programming Speech..........................................................................................4-9

Speech Enable/Disable toggle ........................................................................4-9

Speech in Foreign Languages ............................................................................. 4-9

Setting Speech to a Foreign Language ...........................................................4-9

Setting Speech to English (Default) ...............................................................4-9

Taking Care of Your Scanner.................................................................................. 4-10

Chapter 5: Programming

Programming Mode ............................................................................................5-1

Preparing for Your Program ...............................................................................5-1

Completing the Worksheets................................................................................5-1

Entering Your Program....................................................................................... 5-2

Requirements ......................................................................................................5-2

Help.....................................................................................................................5-2

Page 7

v

Suggestion...........................................................................................................5-2

Programming Considerations .................................................................................... 5-3

Programming Tags..............................................................................................5-3

Using the Programming Worksheets ..................................................................5-4

Programming Description .........................................................................................5-6

Creating the Program .......................................................................................... 5-6

Write the Program ..........................................................................................5-6

Enter the Program........................................................................................... 5-6

Save the Program............................................................................................5-6

Programming Tags..............................................................................................5-7

ABORT ..........................................................................................................5-7

DEFAULT......................................................................................................5-8

END................................................................................................................5-8

HEX 0–HEX F ...............................................................................................5-9

PROGRAM MODE .......................................................................................5-9

SAVE AND RESET....................................................................................... 5-9

Speak Bar Codes Currently Enabled ............................................................5-10

Indication......................................................................................................5-10

Speak Scanner Serial Number ......................................................................5-10

Indication......................................................................................................5-10

Program Entry Procedure..................................................................................5-10

Enter All Parameters.....................................................................................5-10

Enter Specific Parameters (Shortcut Method) .............................................. 5-12

Parameter Defaults............................................................................................5-14

Programming Tips ............................................................................................5-19

Program Parameter Descriptions.............................................................................5-20

Communications Protocol.................................................................................5-20

IBM Slot Scanner .........................................................................................5-20

IBM USB...................................................................................................... 5-20

NCR (RS-232 USB) .....................................................................................5-20

RS-232..........................................................................................................5-21

Good Read Tone ...............................................................................................5-21

Tone On/Off .................................................................................................5-21

Tone Frequency (Hertz) ...............................................................................5-22

Tone Length (Milliseconds) .........................................................................5-22

Tone Volume................................................................................................5-22

Not-On-File Volume ....................................................................................5-22

Timers ............................................................................................................... 5-23

Lockout Time ...............................................................................................5-23

Restart Lockout Timer..................................................................................5-24

Active Time..................................................................................................5-24

Page 8

vi

900ms Lockout Timer Restart Limit ............................................................5-24

Bar Codes–1......................................................................................................5-25

UPC/EAN..................................................................................................... 5-25

Extend UPC–A to EAN–13..........................................................................5-26

Extend UPC–E to UPC–A............................................................................5-26

Add-On Bar Codes .......................................................................................5-26

Add-On Code Length ...................................................................................5-26

Send Data .....................................................................................................5-26

Set 2 Tag Label.............................................................................................5-26

Bar Codes–2......................................................................................................5-27

Code 39.........................................................................................................5-27

Minimum Characters.................................................................................... 5-28

Full ASCII ....................................................................................................5-28

Check Digit Present......................................................................................5-28

Transmit Check Digit ...................................................................................5-28

Allow 1- or 2-Character Tags.......................................................................5-28

Code 39 Tone ...............................................................................................5-28

Tone Length .................................................................................................5-28

Tone Frequency............................................................................................ 5-29

Code 39 Halves Enable ................................................................................5-29

Code 39 Stitch Enable ..................................................................................5-29

Code 39 Stitch Check Digit..........................................................................5-29

Check Digit Length1 and Length2 ...............................................................5-29

Scans Required .............................................................................................5-30

Overlap Characters .......................................................................................5-30

Minimum Segment Size ...............................................................................5-30

Bar Codes–3......................................................................................................5-31

Interleaved 2 of 5.......................................................................................... 5-31

Bar Code Length ..........................................................................................5-32

Value 1 and 2................................................................................................ 5-32

Check Digit Present......................................................................................5-32

Transmit Check Digit ...................................................................................5-32

Interleaved 2 of 5 Tone.................................................................................5-32

Tone Length .................................................................................................5-33

Tone Frequency............................................................................................ 5-33

Interleaved 2 of 5 Check Digit Length1 .......................................................5-33

Interleaved 2 of 5 Check Digit Length2 .......................................................5-33

Enable Interleaved 2 of 5 Stitching ..............................................................5-33

Scans Required .............................................................................................5-34

Overlap Characters .......................................................................................5-34

Minimum Segment Size ...............................................................................5-34

Page 9

vii

Bar Codes–4......................................................................................................5-34

Code 128.......................................................................................................5-35

Code 128 Tone .............................................................................................5-35

Tone Length .................................................................................................5-35

Tone Frequency............................................................................................ 5-35

Code 128 Stitch Enable ................................................................................5-35

Scans Required .............................................................................................5-36

Overlap Characters .......................................................................................5-36

Minimum Segment Size ...............................................................................5-36

Bar Codes–5......................................................................................................5-36

GS1 DataBar Enable.....................................................................................5-37

Scans Required on GS1 DataBar–14............................................................ 5-37

Scans Required on GS1 DataBar–E .............................................................5-37

UCC–128 Emulation Mode..........................................................................5-37

GS1 DataBar Expanded Application Identifier Programming Options .......5-38

Bar Codes–6......................................................................................................5-40

Codabar Check Digit ....................................................................................5-40

Codabar Check Digit Transmission..............................................................5-40

Codabar Tone Length................................................................................... 5-41

Codabar Tone Frequency .............................................................................5-41

Codabar Tone ...............................................................................................5-41

Codabar Halves ............................................................................................5-41

Codabar Stitch ..............................................................................................5-41

Number of Codabar Scans Required ............................................................5-41

Bar Codes–7......................................................................................................5-42

Pharmacode Check Digit Transmission .......................................................5-42

Label Identifiers................................................................................................5-43

Identifier Type.............................................................................................. 5-43

Common Byte 1 and Common Byte 2..........................................................5-44

Bar Code Type..............................................................................................5-45

Common Byte...............................................................................................5-45

Unique Identifier ..........................................................................................5-45

RS-232 Parameters 1 ........................................................................................5-46

Baud Rate .....................................................................................................5-46

Parity ............................................................................................................5-46

Stop Bits and Character Length.................................................................... 5-47

Handshake ....................................................................................................5-47

RS-232 Parameters 2 ........................................................................................5-48

BCC Options ................................................................................................5-48

Interface Control...........................................................................................5-49

Check Digit...................................................................................................5-49

Page 10

viii

RS-232 Prefix Byte...........................................................................................5-49

Prefix Byte.................................................................................................... 5-50

ASCII Code ..................................................................................................5-50

RS-232 Terminator Byte................................................................................... 5-50

Terminator Byte ...........................................................................................5-51

ASCII Code ..................................................................................................5-51

RS-232 Communications Options ....................................................................5-51

Message Delay .............................................................................................5-51

Scanner/Scale Format...................................................................................5-52

Miscellaneous Parameters.................................................................................5-53

Host Tone Control ........................................................................................5-53

Enable/Disable Voice Messages................................................................... 5-53

IBM–485 / IBM–USB Tag Data Format......................................................5-54

Number System Character Parameter...............................................................5-54

Programming Worksheets .......................................................................................5-55

Communications Protocol.................................................................................5-55

Good Read Tone ...............................................................................................5-56

Timers ............................................................................................................... 5-57

Bar Codes–1......................................................................................................5-58

Bar Codes–2......................................................................................................5-59

Bar Codes–3......................................................................................................5-60

Bar Codes–4......................................................................................................5-61

Bar Codes–5......................................................................................................5-62

Bar Codes–6......................................................................................................5-63

Bar Codes–7......................................................................................................5-63

Label Identifiers................................................................................................5-64

Number System Character ................................................................................ 5-65

RS-232 Parameters 1 ........................................................................................5-65

RS-232 Parameters 2 ........................................................................................5-66

RS-232 Prefix Byte...........................................................................................5-67

RS-232 Terminator Byte................................................................................... 5-67

RS-232 Communications Options ....................................................................5-68

Miscellaneous Options...................................................................................... 5-68

Miscellaneous Parameters ............................................................................5-68

Code 128 Tone Length .................................................................................5-69

Code 128 Tone Frequency............................................................................5-69

Code 128 Tone .............................................................................................5-69

Code 128 Minimum and Maximum Tag Length.......................................... 5-70

Code 128 Stitch ............................................................................................5-70

Code 39 Tone Length ...................................................................................5-70

Code 39 Tone Frequency..............................................................................5-71

Page 11

ix

Code 39 Tone ...............................................................................................5-71

Code 39 Quiet Zone......................................................................................5-71

Code 39 InterCharacter Gap Check.............................................................. 5-71

Code 39 Halves ............................................................................................5-71

Code 39 Stitch ..............................................................................................5-72

Code 39 CD Length1.................................................................................... 5-72

Code 39 CD Length2.................................................................................... 5-72

Code 39 Minimum and Maximum Length...................................................5-72

Interleaved 2 of 5 Tone Length ....................................................................5-73

Interleaved 2 of 5 Tone Frequency............................................................... 5-73

Interleaved 2 of 5 Tone.................................................................................5-73

Interleaved 2 of 5 CD Length1.....................................................................5-74

Interleaved 2 of 5 CD Length2.....................................................................5-74

Interleaved 2 of 5 Scans Required................................................................5-74

Interleaved 2 of 5 Overlap............................................................................5-75

Interleaved 2 of 5 Minimum Segment Size.................................................. 5-75

Enable/Disable Interleaved 2 of 5 Partials ...................................................5-75

GS1 DataBar Tone Length ...........................................................................5-76

GS1 DataBar Tone Frequency......................................................................5-76

GS1 DataBar Tone .......................................................................................5-76

GS1 DataBar–E AI 93 to Code 39 Tag Data Conversion ............................5-77

GS1 DataBar–E AI 94 to UCC–128 Tag Data Conversion..........................5-77

GS1 DataBar–E AI 94 to Code–128 Tag Data Conversion .........................5-77

GS1 DataBar–E AI 95 to Interleaved 2 of 5 Tag Data Conversion..............5-77

Codabar Tone Length................................................................................... 5-78

Codabar Tone Frequency .............................................................................5-78

Codabar Tone ...............................................................................................5-78

Codabar Halves ............................................................................................5-79

Codabar Stitch ..............................................................................................5-79

Codabar Require Start/Stop Match............................................................... 5-79

Codabar Require Quiet Zones ......................................................................5-79

Codabar Start/Stop Transmission .................................................................5-79

Codabar Hard Correlation ............................................................................5-80

Number of Codabar Overlaps Required .......................................................5-80

Number of Codabar Scans Required ............................................................5-80

Number of Coupon Scans Required .............................................................5-80

Number of UPC/EAN Scans Required.........................................................5-81

Number of Code 39 Scans Required ............................................................5-81

Number of Code 128 Scans Required ..........................................................5-81

Number of Code 39 Overlaps Required .......................................................5-81

Number of Minimum Code 39 Characters in Code 39 Partial .....................5-82

Page 12

x

Number of Code 128 Overlaps Required .....................................................5-82

Number of Minimum Interleaved 2 of 5 Characters in Interleaved 2 of 5

Partial............................................................................................................5-82

Number of Minimum Code 128 Characters in Code 128 Partial .................5-82

Command–type Disable ...............................................................................5-83

Ignore RS-232 Commands from Host Terminal ..........................................5-83

Enable UPC NS5 Coupon ............................................................................5-83

GS1 DataBar AI 8110 coupons ....................................................................5-83

EAN–13 98 coupons.....................................................................................5-83

EAN–13 99 coupons.....................................................................................5-84

Expand E to EAN–13 Directly ..................................................................... 5-84

Scanner Power-On State...............................................................................5-84

ASCII Code Chart.............................................................................................5-84

USB Programming ..................................................................................................5-85

NCR USB Communications .............................................................................5-85

IBM USB ..........................................................................................................5-85

Chapter 6: Special Programming

Changing Program Defaults to Current Parameters ..................................................6-1

Set Current Parameters to Default Values ..........................................................6-1

Enable Soft Defaults....................................................................................... 6-1

Disable Soft Defaults...................................................................................... 6-1

Convert UPC–E Tags to EAN–13 Tags..............................................................6-2

Check Digits on Price Fields ..............................................................................6-2

Mandatory 4 Digit Price Check......................................................................6-2

Mandatory 5 Digit Price Check......................................................................6-2

Enable/Disable Code 128 Partials.......................................................................6-3

Code 128 Overlap Characters .............................................................................6-3

EAN/JAN/UPC Multi-Symbol Scanning Parameters ...............................................6-3

Label Construction..............................................................................................6-3

Single Label Restriction......................................................................................6-3

Transmitting Label Data .....................................................................................6-4

Programming Multi-Symbol Scanning............................................................... 6-4

Scanning UPC/EAN/JAN Tags without a Center Band .....................................6-5

Good Read Tone........................................................................................................6-5

GS1 DataBar .............................................................................................................6-6

Enable GS1 DataBar...........................................................................................6-6

GS1 DataBar-14..................................................................................................6-6

GS1 DataBar-14 Stacked .................................................................................... 6-6

GS1 DataBar Expanded...................................................................................... 6-6

GS1 DataBar Expanded Stacked ........................................................................6-7

Page 13

xi

Send GS1 DataBar14 as EAN13 Tag Data.........................................................6-7

Terminal Coupon Interface Parameters..................................................................... 6-7

Terminal Coupon Select 1 Parameters................................................................6-7

Terminal Coupon Select 2 Parameters................................................................6-8

Voice Volume ...........................................................................................................6-9

Volume Levels....................................................................................................6-9

Single Volume Adjust Bar Code ........................................................................6-9

Firmware Flashing.....................................................................................................6-9

Obtaining the Tools and New Firmware.............................................................6-9

Acquiring and Installing the RealPOS Scanner Flash Tool for Windows....6-10

Acquiring Firmware .....................................................................................6-11

Identifying Firmware Version ..........................................................................6-11

Firmware Flashing Procedure...........................................................................6-12

Flash Utility Notes............................................................................................ 6-15

Checking 7893 Scanner Firmware Level .....................................................6-15

NCR RealPOS Scanner Flash Drive Support..........................................................6-17

NCR RealPOS Scanner Flash Drive Prep Tool ................................................6-18

Scanner Cloning using Programming Tags.................................................. 6-18

Chapter 7: Troubleshooting

Scanner Operation Summary.....................................................................................7-1

Scan the Bar Code Label ....................................................................................7-1

Pass-by Scanning............................................................................................ 7-1

Presentation Scanning ....................................................................................7-1

Hand Scanning ...............................................................................................7-1

Observe the Read Indication...............................................................................7-1

Good Read Indication..................................................................................... 7-1

No Read Indication......................................................................................... 7-1

Tones and Status Indicators ................................................................................7-2

Scanner Replacement ................................................................................................7-3

Inspect the Unit for Damage...............................................................................7-3

Prepare Scanner for Replacement.......................................................................7-3

Appendix A: PS/2 Keyboard Wedge

Operational Overview........................................................................................ A-1

Wedge-In State ..............................................................................................A-1

Wedge-Out State ...........................................................................................A-1

PS/2 Keyboard Emulation .............................................................................A-2

Programmables.............................................................................................. A-3

Tag Translation Scan Code Table .................................................................A-4

Start/Stop Sentinel Table............................................................................... A-5

Page 14

xii

Tag Message Format .....................................................................................A-7

Installation Details......................................................................................... A-7

Appendix B: NCR Scanner Programming Tags

Appendix C: Service Diagnostics

Scanner Service Diagnostics .................................................................................... C-1

Appendix D: Checkpoint

Operation.................................................................................................................. D-1

Non Interlock Mode........................................................................................... D-1

Appendix E: Additional Information Products

Appendix F: Technical Support

Appendix G: User Feedback

Page 15

xiii

Revision Record

Issue Date Remarks

A May 29, 2009 First issue

Sept 14, 2010 Added “Scanner Cloning using Programming

tags” section

Page 16

Page 17

1

Chapter 1: Introduction

The new NCR RealPOS Presentation Scanner (7893) represents the latest technology in laser

scanning. It features bi-optic electronics, including dual video, flash download technology, and

flash programmability. It is a small, compact unit that weighs about 14 ounces. Being a

presentation scanner, it permits you to present the bar code label to the scanner or pass it by for

bar code reading.

Power for the 7893 is provided either by a powered USB cable or powered RS-232 cable, if

available from the host terminal, or through a +12Vdc wall adapter Power Module. The input

voltage to the NCR 7893 must be +12Vdc.

Using the Scanner

Although the 7893 is very simple to use, it is quite a complex electronic device. It contains a

laser module that generates a low-level laser light. The laser light passes through a series of

mirrors to generate a scan pattern. Reflected light from the bar code is collected and decoded to

determine the bar code data. The scanner then sends the information to the host terminal or

personal computer (PC).

The 7893 produces an omni-directional scan pattern that makes scanning easier. The pattern

looks like several lines are scanning simultaneously, but is actually just a single beam reflected

through several mirrors. It is this pattern that enables the scanner to read bar codes from most

orientations.

This scanner meets the flexible mounting and use requirements for both hands-free and handheld scanning. The 20 line scan pattern is designed to handle the aspect ratio tags commonly

found in the general merchandise environment, with no orientation required. The large area

covered by the pattern makes presentation scanning easy. The scan pattern is designed such

that all lines expand in length and separation equally through space. The versatility of the scan

pattern results in effective presentation and pass-by scanning. The scan pattern consists of 5

angular sets of 4 scan lines.

There may be times when the merchandise is too large to be presented to the scanner. In these

cases, you can pick up the scanner and move it to the merchandise. Because the scanner is very

light, you can maneuver it easily in these circumstances.

The 7893 does not have an On/Off switch. If you present a label to the scanner when it is idle,

it detects the label and turns on. This occurs with minimal delay in reading the label. After

several minutes of not detecting a valid bar code, the laser (programmable 5-30 minutes) shuts

off.

Page 18

Page 19

2

Chapter 2: Product Information

The 7893 is designed to operate within a wide environmental range. Being a small peripheral

unit, it does not require any special wiring or mounting. Normally, its requirements are within

those of the host terminal or PC.

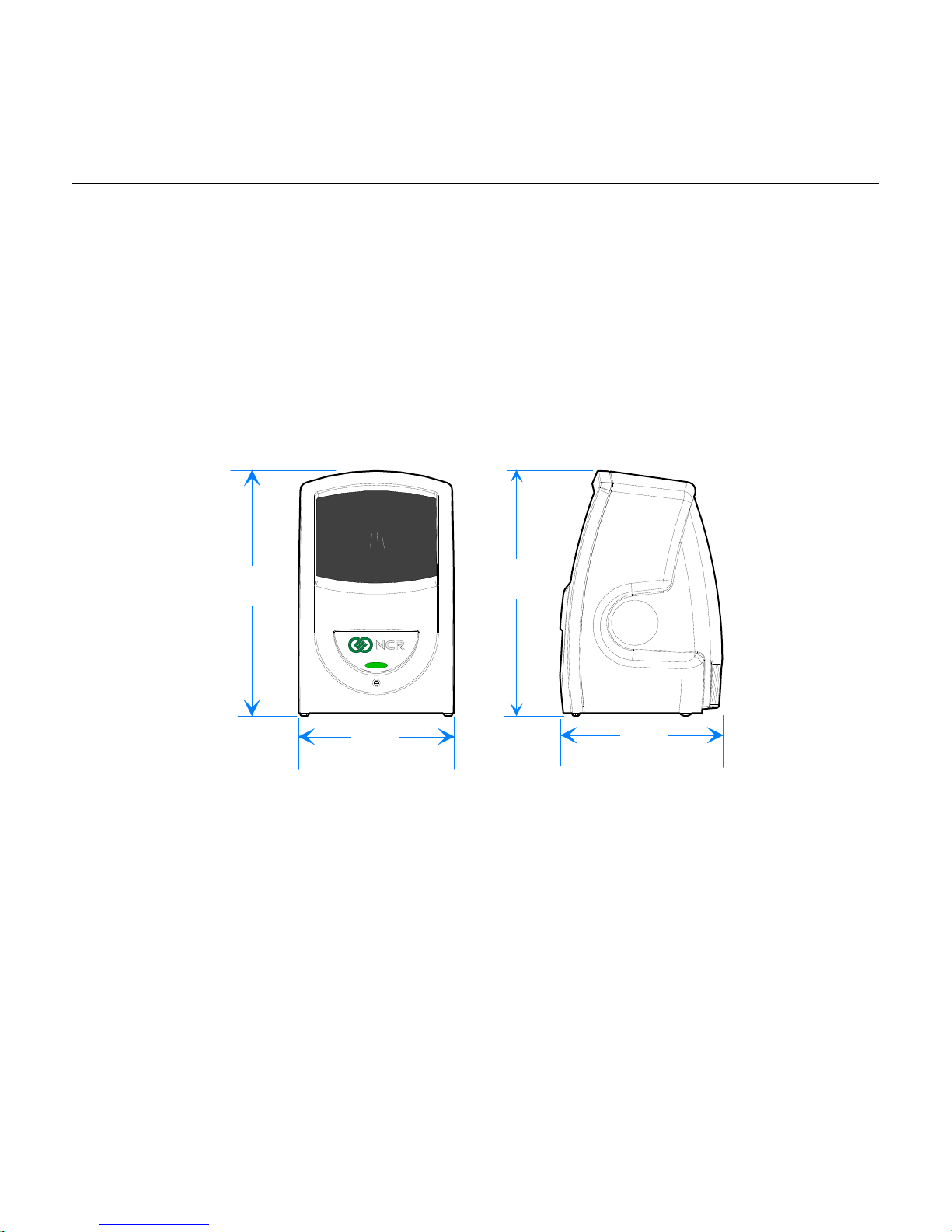

Physical Considerations

The 7893 is a lightweight unit with design consideration given to handling by store personnel.

Weighing about 14 ounces, it is remarkably easy to pick up when necessary. The 7893 requires

minimal counter space as shown below:

140 mm

(5.5 in.)

89 mm

(3.5 in.)

140 mm

(5.5 in.)

91 mm

(3.6 in.)

27356

Page 20

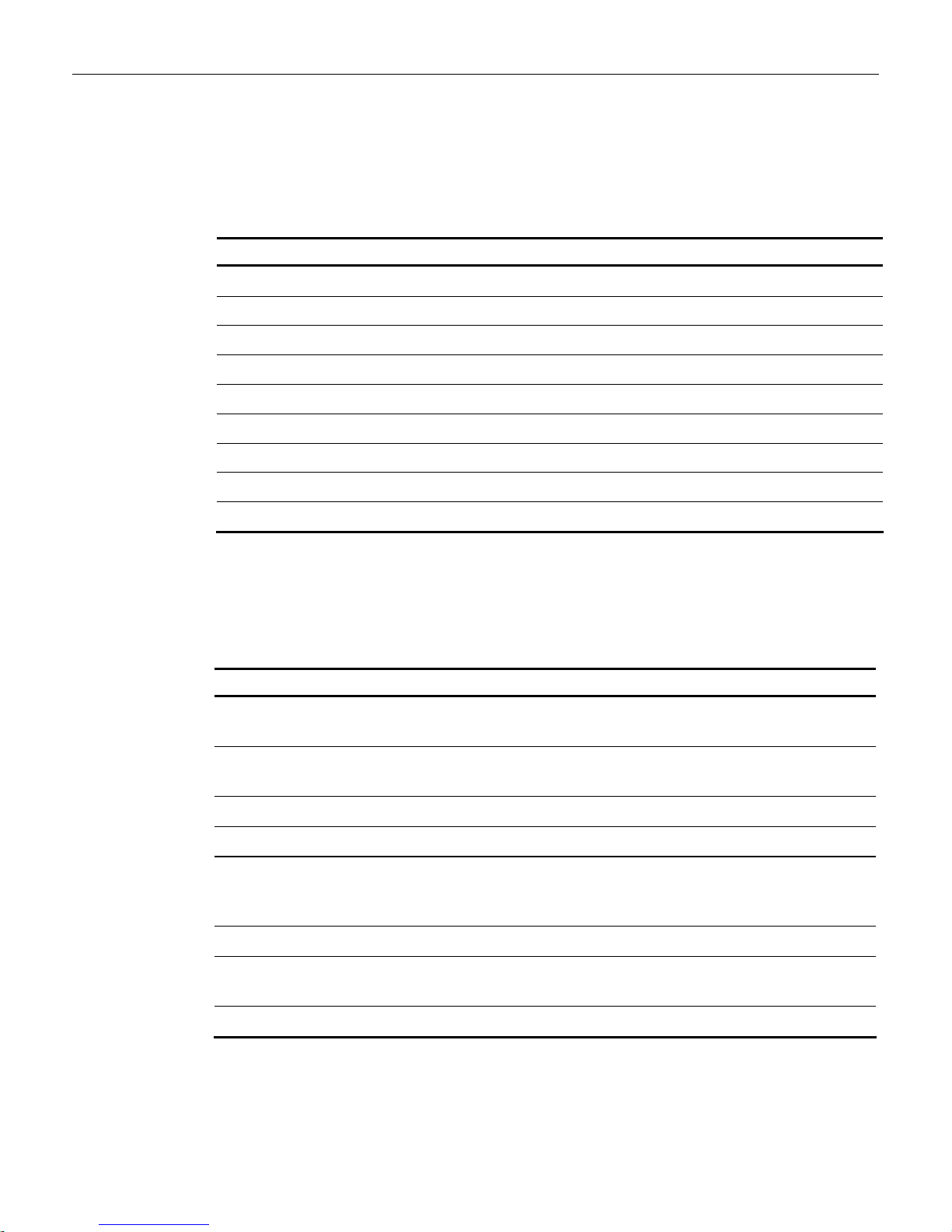

2-2 Chapter 2: Product Information

Environmental Considerations

The 7893 operates in all standard-working environments. Temperature and humidity ranges

permitted are greater when the 7893 is in storage or transit. The following table gives the

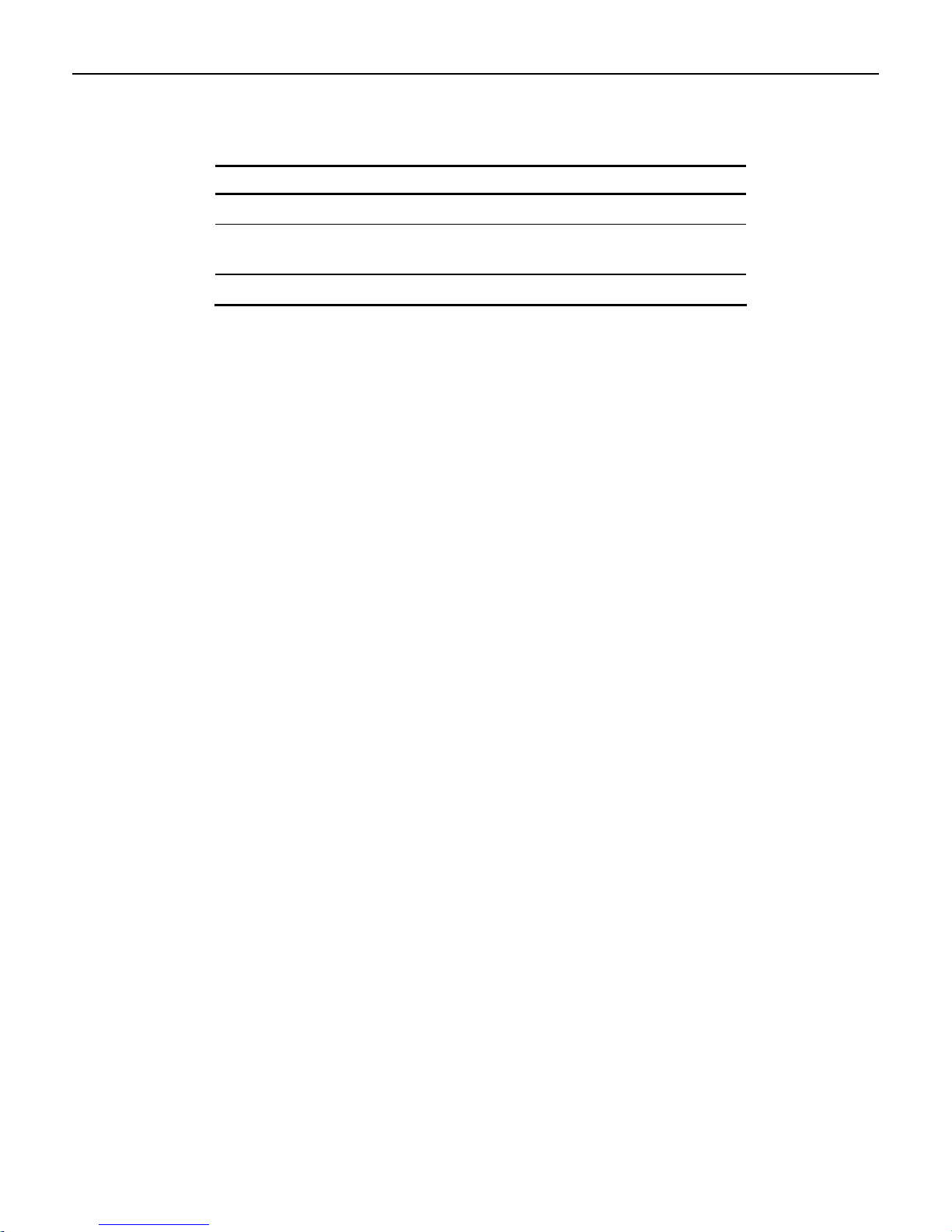

various environmental requirements.

Temperature Temperature Change Humidity Range

Operating Environment

(Working Range)

Extreme Power-on Range

Storage Range

Transit Range

Operating

Transit

10°C to 40°C

(50°F to104°F)

-15°C to 45°C

(5°F to 113°F)

-15°C to 50°C

(5°F to 120°F)

-40°C to 60°C

(-40°F to 140°F)

Barometric Pressure Equivalent Altitude (Reference Only)

(105 - 79.5) × 103 Pascal (Pa)

(105 - 74) × 103 Pascal (Pa)

10°C (18°F) / Hour

20°C (36°F) / Hour

20°C (36°F) / Hour

20°C (36°F) / Hour

Up to 2,000 meters (6560 feet)

Up to 2,500 meters (8200 feet)

5% - 95%

(No Condensation)

5% - 95%

(No Condensation)

5% - 95%

(No Condensation)

5% - 95%

(No Condensation)

Power Considerations

An external power supply provides power to the scanner through the interface cable. Due to

power limitations, the 7893 will not be capable of operating solely from 5VDC USB power.

The scanner shall operate with a 12 VDC supply with a peak current draw of less than 1 A.

The power supply input can be 90-264 VAC at 50-60 Hz. A universal power supply comes

with the scanner, depending on the requirements you specify.

Page 21

Chapter 2: Product Information 2-3

Features and Options

The 7893 is rich in features and options. This section details the features and options that are

available.

Scanning Performance

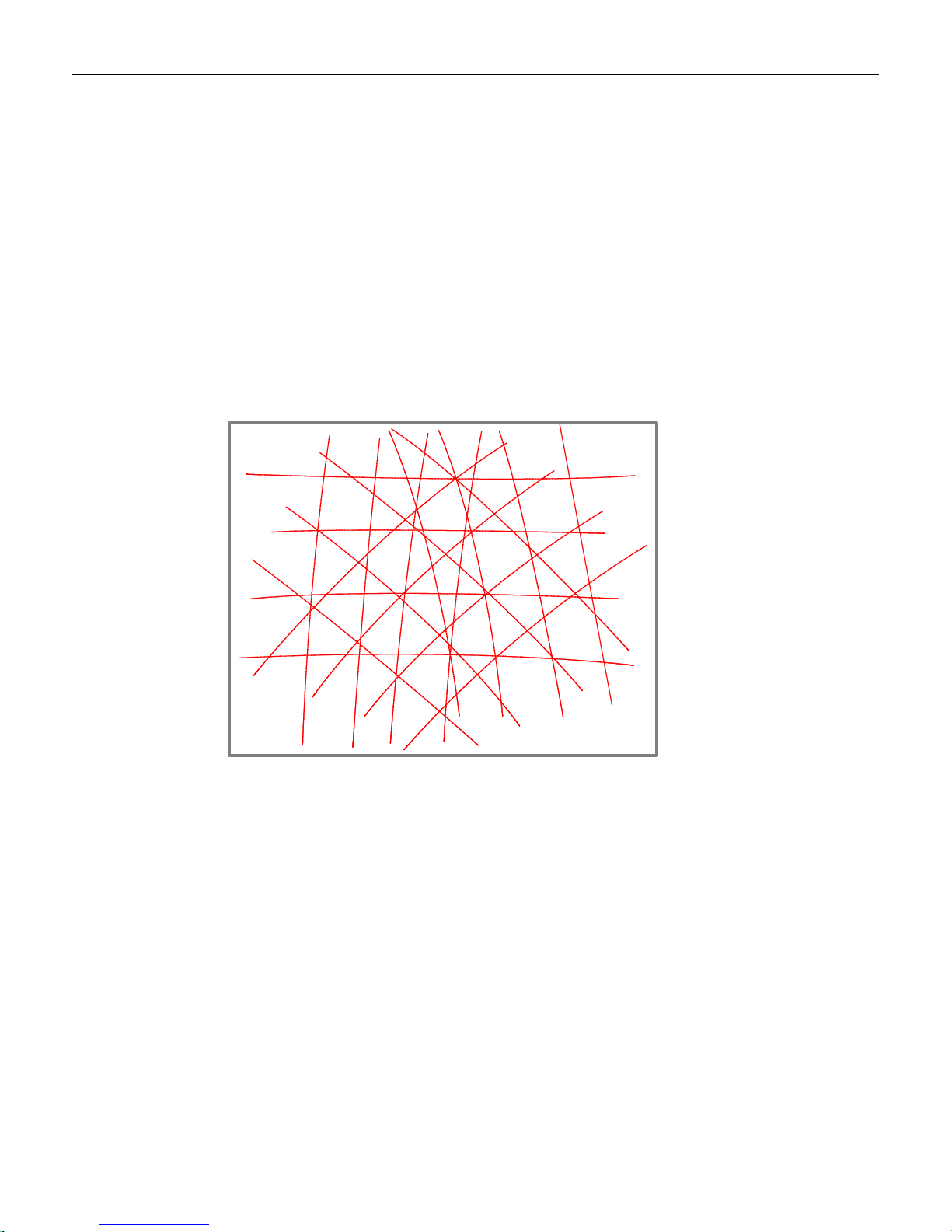

The NCR 7893 uses laser light to create a pattern of 20 scan lines. As a bar code passes

through these scan lines, the 7893 scanner uses the reflected light to identify the location of

each bar in the bar code.

The following illustration displays the scan pattern. Item scanning maybe done from left to

right or vice versa.

The image below shows the 7893 scan pattern.

Communications Protocol

The 7893 communicates with the host terminal through the following:

RS-232

USB (IBM, NCR)

PS/2 Keyboard Wedge

USB Keyboard Wedge

IBM RS–485

27483

Page 22

2-4 Chapter 2: Product Information

Autodiscrimination

The 7893 can decode a variety of barcodes. The ability to differentiate the various barcode

types is a standard feature of the 7893. The following is a list of the different barcode types:

UPC–A and UPC–E

UPC–A and UPC–E with two-digit Add-on Symbols

UPC–A and UPC–E with five-digit Add-on Symbols

GS1–128 Coupon Extended Code

Code 128 Markdown Code

EAN–8 and EAN–13

EAN–13 with two-digit Add-on Symbols

EAN–13 with five-digit Add-on Symbols

GS1 DataBar, formerly Reduced Space Symbology (RSS)

GS1 DataBar–14

GS1 DataBar–14 Stacked Omni–directional

GS1 DataBar Expanded

GS1 DataBar Expanded Stacked

Interleaved 2 of 5

Code 39

Code 39 Full ASCII

Code 128 (including GS1–128)

Multi–Stage Dual for Japan

Codabar

Pharmacode

Page 23

Chapter 2: Product Information 2-5

USB Peripheral Port and Main (POS) Communication Port

The 7893 includes a USB Peripheral ports and a Main (POS) Communication Port. This port is

included to permit an easy connection for peripherals and to improve its capabilities by

permitting the devices to be hot–swappable (connecting or disconnecting devices without

restarting the unit).

The USB peripheral port is located at the underside the unit. The purpose of the single USB

peripheral port is to permit the use of a USB thumb drive.

Note: The total combined 5V current for the USB peripheral port must be limited to 500mA.

USB Peripheral Port

The Main (POS) Communication port is used to connect to the host terminal.

Main (POS) Communication Port

27484

27480

Page 24

2-6 Chapter 2: Product Information

Operator Interface

Interface between the operator and the 7893 is very minimal. Messages are sent from the 7893

to the operator through LED status indicator, audio tones, and voice messages.

Voice Messages

If the 7893 has voice enabled, certain mode changes and error conditions are alerted by

synthesized voice messages. These messages give either the changed mode or the error

message with the suggested corrective action. Voice is enabled and disabled in the

Miscellaneous Parameter program.

Note: By default, Voice is ON.

LED Status Indicator

The LED Status Indicator is an intuitive feature of the 7893. It provides visual confirmation for

scanning items using different colors— which is especially ideal for hearing–impaired cashiers

and enables a quieter front end.

The LED Status Indicator is also useful in diagnosing problems with the 7893. Using a color

coded LED, the user may quickly identify problems – thus effectively decreasing downtime

and enhancing productivity.

LED Status Indicator

27485

Motion Detector

The Motion Detector feature prolongs the life of the 7893. This is located inside the scanner

window; it turns off components of the 7893 after an extended period of non–activity. The

default non–active time is fifteen (15) minutes, but can be changed by programming. An item

passing in front of the Motion Detector causes the 7893 to turn on. This movement is the

normal item scanning movement.

Page 25

Chapter 2: Product Information 2-7

Not–On–File

The 7893 has a Not-On-File feature that locks the scanner and causes the LED Status Indicator

to flash when a bar code is read that is not on file in the store system. This feature prevents the

checker from moving beyond a product not recognized by the system. The Not-On-File feature

is enabled and disabled through programming.

Note: The in-store processor and host terminal must have the host terminal software capable

of supporting Not-On-File determination.

The 7893 is disabled from reading additional tags until the error is cleared. To clear, select the

host terminal’s CLEAR key and manually enter the item and price.

Power Supply

Power Cord (U.S.)

Power Supply

23756

The Power Supply provides the required DC voltage of the NCR 7893 The Power Cord plugs

into an electrical outlet and connects to the Power Supply. A low voltage Power Cable

connects the Power Supply to the 7893. Several power cords are available depending on the

country of installation. The scanner shall operate with a 12 VDC supply with a peak current

draw of less than 1 A. The power supply input can be 90-264 VAC at 50-60 Hz.

In addition, some host terminal interface types can power the 7893 without the use of this

power supply. Please contact your NCR sales representative for details.

Page 26

2-8 Chapter 2: Product Information

Parameter Programming

The NCR 7893 may need to be configured to meet specific installation needs. The 7893 uses

special programming tags to modify the various programming parameters (refer to Chapter 5).

This can be done through the following:

scan using special tags

sent from a PC with the NCR RealPOS Scanner Tool Suite

remotely through the host terminal using the NCR RealPOS Scanner Tool Suite

Note: NCR does not control or specify the NCR scanner configuration required to support

specific host terminal software unless you are using NCR host terminal software. You should

consult with your host terminal software vendor or reseller to determine the correct

configuration for your NCR scanner.

Scan Doctor Diagnostics

Scan Doctor is the state–of–the–art diagnostic software included in every 7893. It continually

monitors the unit to identify components that are not functioning correctly. It also provides

inquiry capability for the host terminal to access specific diagnostic data. Scan Doctor

diagnoses the 7893 each time power is applied and continues all throughout operation. When a

problem is found, it notifies the operator through a color-coded LED on the LED Status

Indicator, and a voice message. It lists the most probable causes first.

Many Scan Doctor statuses are available from the scanner using the NCR Scanner Tool Suite

sold separately.

Power–On Wellness Check

When power is applied to the 7893, Scan Doctor performs a series of diagnostic tests after

Power–On. These diagnostic tests include the following:

RAM (read/write test).

Spinner Motor Speed Test.

Non-volatile Memory Test.

IBM RS-485 TERMPWR Test

Laser Diode Test.

Program Code (ROM sum-check) Test.

FPGA Load Test

If Scan Doctor finds a problem that hinders operation of the 7893 it disables the unit; otherwise

the problem is identified and operation continues.

Page 27

Chapter 2: Product Information 2-9

Ongoing Wellness Check

Scan Doctor runs continuously the moment 7893 is turned on. It constantly performs on-going

diagnostic tests while the unit is running. These diagnostic tests include the following:

Spinner Motor Speed Test.

IBM RS-485 TERMPWR Test

Laser Diode Test.

If a scanner malfunction is discovered during the power-on or on-going diagnostic tests, an

error code will flash on the indicator LED with a unique color sequence. The speech that

accompanies the indicator LED error sequence will suggest corrective action. The following

table lists the supported error codes:

Error Code Problem Suspect Component

0 No power (LED off) Power supply or PCB assembly

2 RAM test failed PCB assembly

5 Motor too slow Motor

6 Bad non-volatile memory (EEPROM) PCB assembly

9 IBM RS485 – no TERMPWR signal IBM host terminal; cable

11 Laser not turned on PCB assembly

12 Program (ROM sum-check) test failed PCB assembly

13 FPGA failed to program PCB assembly

The following table lists the LED color sequences for each error code. The 7893 does not

support all the available color sequences but they are included here for completeness and

future additions:

Error Code Sequence

0 RED ORANGE (PAUSE)

1 RED ORANGE ORANGE (PAUSE)

2 RED ORANGE ORANGE ORANGE (PAUSE)

3 RED ORANGE ORANGE ORANGE ORANGE (PAUSE)

4 RED BLUE (PAUSE)

5 RED BLUE BLUE (PAUSE)

6 RED BLUE BLUE BLUE (PAUSE)

7 RED BLUE BLUE BLUE BLUE (PAUSE)

8 RED GREEN (PAUSE)

9 RED GREEN GREEN (PAUSE)

10 RED GREEN GREEN GREEN (PAUSE)

Page 28

2-10 Chapter 2: Product Information

Error Code Sequence

11 RED GREEN GREEN GREEN GREEN (PAUSE)

12 RED RED (PAUSE)

13 RED RED RED (PAUSE)

14 RED RED RED RED (PAUSE)

15 RED RED RED RED RED (PAUSE)

Note: The 7893 will flash sequences of changing colors that match the Scan Advisor (5-LED

light bar) color sequences used on other PXA scanners like the 7884. Except that the 7893

must flash the colors in sequence instead of displaying them all at once.

Service Diagnostics

Scan Doctor includes service diagnostics for the trained service technician. These go beyond

the wellness checks and are accessed through the use of special programming tags. Refer to

Appendix C for more information on the Scanner Service Diagnostics Tests.

Soft Power Down/Power Up

The 7893 can sense periods of scanner inactivity. The scanner's soft power down feature

extends the life of the 7893 by disabling major portions of the unit, which includes the laser

diode, spinner motor, and associated electronics. The length of the inactive period prior to the

soft power down is user-selected and programmed remotely or through tags.

Scanner power up occurs when the 7893 motion detector detects movement. This detector is

located inside the scan window. The 7893 can also be powered up when the checker signs on

the host terminal. This capability assumes appropriate host terminal software.

Page 29

3

Chapter 3: Installation

Preparing for Installation

There are several things you should do when preparing to install a 7893. Each of these is

discussed in the following sections.

Unpack the Unit

Unpack the unit according to the instructions printed on the box. After everything is out of the

box, take inventory to ensure that you have received all components. The following list

identifies the package contents.

7893 scanner

Power Supply

Scanner Cable

Documentation (also available from the NCR Web site (www.ncr.com

Inspect the Unit for Damage

Inspect the unit for physical damage: broken or scratched scan window, broken or scratched

cabinet, and so forth. If the scanner has been damaged due to shipping, notify the shipping

carrier and the NCR representative. If other damages are found, notify NCR or the other

supplier if not purchased directly from NCR. Out of Box failures are handled through the NCR

customer Satisfaction Hot line.

)

Page 30

3-2 Chapter 3: Installation

Verify Correct Cables

The following table identifies the most common interface cables required for the different host

connections that can be made with the 7893. See your NCR representative for additional

cables.

Cable Number Description

1432-C899-0040 Cable – USB, Latching, 7892SA, black

1432-C679-0040 Cable – PS/2 Keyboard Wedge, SuperASIC, black, coiled

1432-C897-0040 Cable – USB, non-latching

1432-C038-0030 Cable – Powered RS-232, Checkpoint, (coiled), black

1432-C967-0030 Cable – RS-232 Powered-Straight (black), coiled section

1416-C971-0030 Cable – RS-232 Scanner-Coiled (black)

1416-C807-0030 Verifone Ruby Powered Cable

1416-C547-0030 468X-9B

1416-C768-0040 Cable – Scanner, Gilbarco-coiled w/ RJ-45

Identifying Available Kits

A Power Brick for the electrical requirements you specified must be ordered with the 7893 if

host terminal power is not used.

The following table identifies the kit number for all available kits.

Kit Number Kit Description

7892-K125-V003

7892-K111-V003

7892-K129-V002 Kit – US Power Supply with Twist Lock Power Cord

7892-K120-V002 Kit – Universal Input, +12v output Power Supply

7892-K119-V002

7892-K128-V001 Kit – SEV Power Supply and Swiss Cordset

7892-K118-V003

7892-K901-V001 Kit – Stand NCR-CG1

Universal Input, +12v output Power Supply w/ Australian Cable with

Straight 'BM' Power

Kit – Universal Input, +12v output Power Supply, North American &

Japanese

Universal Input, +12v output Power Supply, UK Plug with Straight

'BM' Power, RoHS

(7892-K119-V002)

Universal Input, +12v output Power Supply, European w/ Cord-Power

(Intl)

Page 31

Chapter 3: Installation 3-3

Determine Scanner Location

When identifying a location for the 7893 scanner, consider the length of the connecting cables.

The electrical outlet used for the Power Module can be approximately 74 in. (188 cm) from the

host terminal. Depending on the Scanner Module Cable, the scanner can be approximately 9 ft.

(274 cm), 6.6 feet (2 meters) or 13.1 feet (4 meters) from the host terminal or PC. These

distances are normally shorter depending on how you route the connecting cables. Be sure that

the Scanner Module Cable is long enough to permit the scanner to be picked up when required

for large packages.

Like any electronic device, the 7893 should not be located in direct sunlight. Temperatures

above 104 degrees Fahrenheit (40 degrees Celsius) can occur when sunlight falls on objects

through windows or on an outdoor checkstand.

Page 32

3-4 Chapter 3: Installation

Installing the 7893

The 7893 can be connected to the host terminal through a PS/2 keyboard connector. Scan data

is input into the PS/2 keyboard port. When connected in this configuration the 7893 cannot

receive commands from the host terminal.

Note: For the 7893 there is only a single transmit message buffer. Also, the transmission of

the data can be significantly longer than other communication protocols; the time depends on

the length of the intercharacter delay.

Note: The PS/2 Keyboard Wedge cable connects both the scanner and the keyboard to the

host terminal through the PS/2 keyboard port. This cable has two PS/2 connectors. If the host

terminal system has an AT keyboard connector, two adapters are required: an AT to PS/2 and a

PS/2 to AT. These adapters are available locally at most computer stores. For more

information about PS/2 Keyboard Wedge, see Appendix A.

Belkin F2N017—AT to PS/2

Belkin F2N018—PS/2 to AT

Keyboard Wedge Cable

1416-C636-0030

Keyboard

Scanner Cable

Host Terminal

Power Cable

AC Power Cord

7893 Scanner

Power

Supply

27473

Page 33

Chapter 3: Installation 3-5

USB Keyboard Wedge Communication

The 7893 can emulate a USB keyboard device by enumerating itself as an HID keyboard. By

doing so, it passes barcodes directly to the host’s keyboard driver. This eliminates the need of

installing a third party driver since the operating system’s native keyboard input driver will be

used.

Programmables

1. Enable USB keyboard Communications Interface

Programming Mode + 1 + 0 + E + 3

2. Inter Character Delay

4 ms: Programming Mode + 2 + 8 + D + 0

8 ms: Programming Mode + 2 + 8 + D + 1

16 ms: Programming Mode + 2 + 8 + D + 2

32 ms: Programming Mode + 2 + 8 + D + 3

64 ms: Programming Mode + 2 + 8 + D + 4

1 ms: Programming Mode + 2 + 8 + D + 5 (New for this release, new default value)

3. Start and Stop Sentinel, maximum of 9 bytes each

Disable: Programming Mode + 2 + 9 + 0 (zeros all start/stop entries)

Start Sentinel: Programming Mode + 2 + 9 + 1 + DATA + End

Stop Sentinel: Programming Mode + 2 + 9 + 2 + DATA + End

DATA Input: Enter each byte as 2 nibbles

Example: Start Sentinel = 0x31, 0x21, 0x2D (0x31 will be transmitted first)

DATA Tag Sequence = 3 + 1 + 2 + 1 + 2 + D

Tag Message Format

The Tag Message will consist of the following:

Start Sentinel – 0 to 9 bytes

Tag Identifier – 1 byte

Tag Data – Variable, depending on the scanned tag

Stop Sentinel – 0 to 9 bytes

Page 34

3-6 Chapter 3: Installation

Connecting Power

1. Verify that you have the correct Power Module for your electrical outlet.

2. Connect the power connector to the Interface Cable. Depending on the installation, this

may be a connector on the cable or a box on the end of the cable.

3. Plug the Power Module into an electrical outlet. When the 7893 receives power, the

diagnostics checks various hardware components. If the scanner passes the diagnostic

tests, it gives a "ready" indication (four flashes of the LED Status Indicator). A green flash

followed by a red flash is normal and indicates the scanner serial number is stored in the

scanner’s EEPROM.

Note: If the 7893 is receiving power from the host terminal, do not connect the Power

Module.

Host Terminal

Interface Box

Dongle Adapter Cable

7893 Scanner

Scanner Cable

27474

Warning: When the host terminal powers the 7893, do not plug the unit in live. This can

cause the Power Supply in the host terminal to shut down and may also blow an internal

fuse in the host terminal. Be sure to turn off the power to the host terminal before

connecting the 7893.

Page 35

Chapter 3: Installation 3-7

Modifying the Scanner Program

The 7893 comes from the factory with all programming parameters set to default values. For

changes on any values that do not match the system requirements, refer to Chapter 5,

Programming.

Communications Protocol

The Communications Protocol programming mode selects the protocol that the 7893 uses to

communicate with the host terminal.

Note: The factory sets the Communications Protocol according to the specifications on your

order. Since there is no default Communications Protocol; the Default tag does not change this

parameter.

IBM RS-485

The 7893 supports the IBM 468x/9x format and use the same protocol found on IBM host

terminals.

RS-232

RS-232 is used to connect the 7893 to almost any RS-232 type of communications device. This

protocol uses 7-bit ASCII to send tag to the device.

IBM USB

The 7893 can communicate to the host terminal through a USB cable. This parameter enables

the IBM-USB format.

NCR (RS-232) USB

The 7893 can communicate with the host terminal through a USB cable. This parameter

enables the NCR (RS-232) format.

Note: Two programming tags must be scanned to enable this parameter: Hex E followed by

Hex 0.

Wedge

The 7893 can communicate to the host terminal through a Wedge cable.

Page 36

Page 37

4

Chapter 4: Operating the Scanner

Scanner Components

Before using the 7893, the user needs to be familiar with some of its components. The figure

below shows the scanner and identifies some of the parts and features.

Scan Window

Scanner Module Cable

Status Indicator

Speaker

27475

Page 38

4-2 Chapter 4: Operating the Scanner

Pass-by Scanning

This type of scanning is the familiar style used at checkout stands, such as in supermarkets.

The item is moved across the front of the scanner window with the barcode label oriented to

face the scanner window, as shown.

When the label is read the LED Status Indicator turns GREEN. If enabled, a Good Read Tone

also sounds.

Scan Window

27476

Presentation Scanning

Presentation scanning is much different from that used at checkout stands, such as in grocery

stores. In the checkout stand environment, normally large quantities of items must be scanned

in a short amount of time. Therefore, you pass the items over the scanner, moving them from

one side of the checkstand to another. The scanner reads the label while the items are moving

by.

With presentation scanning, you simply present the label to the scanner and then remove it. Do

not move the label past the scanner, but to the scanner. Presentation scanning is particularly

useful in a retail environment where the number of items associated with each transaction is

normally small. There are three simple steps to presentation scanning.

1. Move the bar code label to the scanner as shown.

Scan Window

27477

Page 39

Chapter 4: Operating the Scanner 4-3

2. Position the bar code label completely within the red Laser Scan Pattern as indicated

below. Normally the bar code should be three to four inches from the scanner. When the

label is read the LED Status Indicator turns green. If enabled, a Good Read Tone also

sounds.

Laser Scan

Pattern

27478

3. Move the bar code label away from the scanner as shown. The scanner is now ready to

read another bar code label. To read another bar code, simply perform these three steps

again.

27479

Page 40

4-4 Chapter 4: Operating the Scanner

Hand Scanning

Occasionally you have merchandise that cannot be picked-up and presented to the scanner. The

package may be too heavy or too awkward to hold while trying to position the bar code label.

In these circumstances you can pick up the scanner and take it to the merchandise. The 7893 is

designed so that you can easily pick the scanner up and hold it. Being light-weight, you can

present the scanner to the merchandise with little effort.

Careful

Label Orientation

Because the 7893 produces a dense, omni-directional scan pattern, labels can be read from

many different angles.

Scan Pattern Location

In order for the scanner to read a label, the center 90% of one scan line must cross the bar

code. To successfully read Code 39 and Interleaved 2 of 5 labels, the scan line must cross the

entire label, not missing any of the bars or spaces. UPC and Code 128 labels can be read by

piecing together two reads of slightly more than half of each side of the bar code. Therefore,

these labels are much easier to read and do not require as much accuracy when presenting the

label to the scanner.

17269

Because of the large scan pattern, you do not have to be very precise when you position the

label. However, the concentration of scan lines is greater in the center of the scan pattern.

Because of this, fewer rejects occur if you try to position the merchandise so that the label is

presented toward the center of the scan pattern.

Page 41

Chapter 4: Operating the Scanner 4-5

Label Rotation

The 7893 can read labels that are presented in many different positions. You can present labels

that are rotated left or right 30 degrees from center, up or down 30 degrees from center, and

360 degrees around center.

30

30

30

360

30

27481

Page 42

4-6 Chapter 4: Operating the Scanner

Distance from Scanner

For optimum reading, the distance you must place the label from the 7893 depends on the

density and height of the bar code. You can relate this to focusing a camera, where you change

the focus setting based on how far away the object is.

Depending on the label, reading can range from zero to six inches. Therefore, when you use

your scanner, move the label toward the scanner to a comfortable distance in front of the scan

window (approximately three to four inches) and hold the item momentarily. Normally the

"Good Read" indication occurs within one fourth of a second. If this does not happen, try

moving the label a little closer to the scanner.

Bar Code Quality

The ability of your 7893 to read bar code labels depends greatly on the quality of the label.

Although the 7893 can often read bar codes that appear to be bad, it cannot read bar codes that

are obstructed, defective, or damaged. If the scanner cannot read the bar code, you must key in

the merchandise information at the host terminal and go on to the next item. Be sure to tell

your supervisor if many bar code labels are defective. The figure below shows some examples

of bad bar codes. These are only examples and are not all-inclusive.

06

06

06

01 23 4 67 85 9

Bar Code Scratched Bar Code Folded Bar Code Truncated

06

0 1 23 4 67 85 9

Bar Code Torn Poor Color Contrast Red Bar Code On

0 1 23 4 67 85 9

06

01 23 4 67 85 9

01234 67859

0 1 234 67 85 9

06

Red Background

R0026

The readability of a label depends on variables such as sizing, placement, color, paper type, ink

viscosity, and package coatings. The middle of a printing run can yield erroneous labels due to

the many variants involved. In particular, poor color contrast and marginal print quality can

make a label hard to read.

A label should be considered readable if it meets or exceeds the requirements set forth in the

EAN UCC General Specification 1/2000.

Page 43

Chapter 4: Operating the Scanner 4-7

PACESETTER

NCR has continually improved its PACESETTER technology used on NCR scanner products.

Starting out as PACESETTER, it progressed to PACESETTER Plus, and then to

PACESETTER III. Vendors and printers regularly supply products with overprinted,

underprinted, or truncated bar codes to the market. Some labels have missing margins. Others

may be printed around the corner of packages or on media that wrinkles when picked up.

PACESETTER addresses the problems caused by these unreadable labels. PACESETTER III

is standard on all NCR scanner products.

PACESETTER Plus

PACESETTER Plus determines what is wrong with a bar code label, fixes the data, and then

transfers the information to the host terminal. It provides information on possible bar code

printer problems but is not a bar code specification conformity verifier.

The three modes of PACESETTER Plus operation are summarized in the following

paragraphs.

Mode 1–Inquiry

PACESETTER Plus can be used as a management tool by store personnel and chain

management to monitor and report the status of label readability. Tally counters are kept for

the following.

Good reads

No read due to lack of full label (missing bars or folded label)

Good reads with overprinted bars

Good reads with underprinted bars

Missing margins

Missing print lines

Mode 2–Demonstration Mode

In Mode 2, the scanner is offline. Each subsequent scan of a bar code causes the scanner to

indicate the status of label readability. The scanner recognizes missing bars in labels, highly

overprinted or underprinted labels, missing margins, or a “no read” condition.

Mode 3–Operations

Mode 3 is the normal operating mode. The scanner can be programmed to add PACESETTER

Plus information to the decoded UPC/EAN data. This information describes the label

readability. However, the host terminal software must be capable of receiving the extra data.

The host terminal software should enable this at a regular interval (for example, Cashier Sign

On) and check for the presence of the data if enabled.

Page 44

4-8 Chapter 4: Operating the Scanner

PACESETTER III

The PACESETTER III feature of the 7893 scanner performs many functions that improve the

efficiency of the scanner. It determines what is wrong with a bar code and then fixes it. It also

keeps track of problems found.

PACESETTER III also detects, corrects, and reports errors discovered in UPC Number System

Two and Number System Four labels. These two label types are printed in the store and

account for a significant number of unreadable labels due to failures of the in–store printing

mechanism. PACESETTER III looks for errors in these labels and learns from each attempted

scan. After seeing a particular printing error a number of times, PACESETTER III may

determine that an error is present in the label and that the error may be correctable. If the

correction capability of PACESETTER III is enabled, the scanner attempts an error–free

correction of the label and passes the results to the host terminal. Whenever an error–free

correction is not possible, PACESETTER III does not pass label data to the host terminal.

Read Indicators

The 7893 provides two methods of indicating valid reads: LED Status Indicator (visual) and

Audible Tone (audio). The LED Status Indicator is always enabled; however, you can disable

the Audible Tone.

LED Status Indicator

The LED Status Indicator light is located above the speaker. When the 7893 detects bar code