Page 1

NCR 7870 Scanner/Scale

Release 1.0

User's Guide

BST0-2121-90

Issue G

Page 2

The product described in this book is a licensed product of NCR Corporation.

Trademark Information

It is the policy of NCR Corporation (NCR) to improve products as new technology, components, software,

and firmware become available. NCR, therefore, reserves the right to change specifications without prior

notice.

All features, functions, and operations described herein may not be marketed by NCR in all parts of the

world. In some instances, photographs are of equipment prototypes. Therefore, before using this document,

consult with your NCR representati ve or NCR office for information that is appl icab l e and current.

To maintain the quality of our publications, we need your comments on the accuracy, clarity, organization,

and value of this book.

Address correspondence to:

Retail Solutions Group−Atlanta

NCR Corporation

2651 Satellite Blvd.

Duluth, GA 30096

Copyright © 1999

By NCR Corporati on

Dayton, Ohio U.S.A.

All Rights Reserved

Page 3

Table of Contents

Chapter 1: Introduction

About the NCR 7870 Scanner/Scale............................1-2

Models.....................................................................1-2

Reading the Product Number ...............................1-3

Common Fe a ture s..................................................1-3

7870-1000-9090........................................................1-4

7870-2000-9090........................................................1-4

7870-3000-9090........................................................1-4

7870-4000-9090........................................................1-4

7870-4500-9090........................................................1-4

Chapter 2: Features, Functions, and Kits

User's Gui de i

General Features and Functions..................................2-1

Bar Code Recognition.............................................2-1

Bi-Optic Scanning...................................................2-2

Decode Features .....................................................2-2

PACESETTER

Displays...................................................................2-3

NCR 7825 Remote Display................................2-3

Integr a t e d Displa y..............................................2-4

No Display ..........................................................2-5

Interface Types .......................................................2-5

Laser Scanner..........................................................2-5

Power Supply .........................................................2-5

Programming the 7870...........................................2-6

Scale Certifications .................................................2-7

Scan Zone................................................................2-8

Plus

.............................................2-2

Page 4

ii User's Guide

Scanner Power Requirements................................2-8

Soft Power Down....................................................2-8

Top Plates and Scan Windows..............................2-9

Top Plates............................................................2-9

Slot Scanner Window.........................................2-9

Side Scanner Window ...................................... 2-10

Scale Features and Functions .....................................2-11

Scale Functions and Features...............................2-11

Kits...............................................................................2-12

Chapter 3: Site Preparation

Getting Started..............................................................3-2

About Site Preparation.................................................3-4

Custom e r Responsibilities............................................3-6

Environmental Requirements......................................3-7

Operating Range ................................................3-7

Extreme Operating Range .................................3-7

Storage Range.....................................................3-8

Transit Range......................................................3-8

Checkstand Power and Wiring Considerations.........3-9

Power Considerations ............................................3-9

Power Applications............................................3-9

Power Transients Protection..............................3-9

Wiring Considerations ......................................... 3-10

U.S., Canadian, and Japanese Checkstand

Wiring ...............................................................3-10

European Checkstand Wiring.........................3-11

International Checkstand Wiring....................3-12

Wiring Instructions ..............................................3-13

Running Feeder Lines from Main Service

Panel.................................................................. 3-13

Circuit A............................................................3-13

Page 5

Circuit B............................................................3-14

Circuit C............................................................3-14

Checkstand Considerations.......................................3-15

Ventilation Requirements.................................... 3-15

Service Clearance..................................................3-16

Display Clear a n c e.................................................3-17

Item Diverter.........................................................3-17

Checkstand Hole..................................................3-18

Checkstand Hole - Models 1000 & 2000 .........3-19

Checkstand Hole - Models 3000, 4000, & 45003-20

Cable Lengths and Hole Sizes ...................................3-21

Cable Hole Diameters..........................................3-21

DC Power Cable – Power Supply to 7870...........3-21

AC Power Cords – Outlet to Power Supply.......3-22

Remote Display Cables........................................3-22

Interface Cables - NCR Host Terminals..............3-23

Interface Cables – NCR Host Terminals (cont.) .3-24

Interface Cables – NCR Host Terminals (cont.) .3-25

Interface Cables - Casio Host Terminals.............3-25

Interface Cables – Data Checker Host Terminals3-26

Interface Cables – Epson Host Terminals...........3-26

Interface Cables – Gilbarco Host Terminals.......3-26

Interface Cables – IBM Host Terminals ..............3-27

Interface Cables – ICL Host Terminals...............3-27

Interface Cables – ICL Host Terminals (cont.)....3-28

Interface Cables – Microbilt Host Terminals......3-28

Interface Cables – NEC Host Terminals .............3-28

Interface Cables – SASI Host Terminals.............3-29

NCR 7870 Dimensions................................................3-30

NCR 7870-1000 & 2000 Models ...........................3-30

NCR 7870-3000 Model..........................................3-31

User's Guide iii

Page 6

iv User's Guide

NCR 7870-4000 & 4500 Models ...........................3-32

Chapter 4: Installatio n

Getting Started..............................................................4-1

Reporting a Damaged Unit....................................4-1

What’s in the Box....................................................4-1

Cable Verification...................................................4-2

Checkstand Verification.........................................4-2

Installin g Unit in Che cks t and ......................................4-3

Instructions .............................................................4-3

Install Cables.......................................................4-3

Determining if the Unit is Operational.......................4-8

NCR 7870-1000 and 3000 Scanners........................4-8

NCR 7875-2000, 4000, and 4500 Scanner/Scales..4-8

If the NCR 7870 Does Not Pass Level O

Diagnostics ..............................................................4-8

Checkout Reading Operation................................4-9

Programming..........................................................4-9

Determi n i ng Com mun i catio n s Protoc o l...................4-10

Scale Address for IBM................................................ 4-11

Chapter 5: Calibration

General ..........................................................................5-1

Calibration Procedure..................................................5-3

Section 1: Exercising the Scale..............................5-3

Section 2: Accessing the Calibration Switch........5-4

Section 3: Conn e ct in g t h e Fi eld Se rv ice

Calibration Display ................................................5-7

Section 4: Performing the Calibration..................5-9

Verifying Calibration..................................................5-11

Procedure 1: Increasing Load Test.....................5-12

Procedure 2: Over-Capacity Test........................5-13

Page 7

Procedure 3: Decreasing Load Test .................... 5-14

Instructions.......................................................5-14

Procedure 4: Shift Test ........................................5-15

Securing the Calibration Switch ................................5-16

Chapter 6: Operation

About Using the Operator Controls ............................6-2

Scan Windows ........................................................6-2

Status Indicators.....................................................6-2

Motion De t e ctor......................................................6-3

Reset / Scale Zero Button......................................6-3

Audible Tone..........................................................6-3

Voice Messages.......................................................6-3

About Using the Scanner .............................................6-4

Proper Label Orientation.......................................6-4

Active Scan Zone....................................................6-5

Multiple Read s........................................................6-5

Bar Code Quality....................................................6-6

Operating Instructions .................................................6-7

Power Up ................................................................6-7

Scanner Only Models .........................................6-7

Scanner/Scale Models .......................................6-7

Scanning Procedure................................................6-8

Instructions.........................................................6-8

Not-On-File Error...................................................6-8

Weighting Procedure.............................................6-9

Instructions.........................................................6-9

Changing the Good Read Tone...........................6-10

Instructions.......................................................6-10

Routine Ma inte na n c e..................................................6-11

Instructions.......................................................6-11

User's Gui de v

Page 8

vi User's Guide

Chapter 7: Programming

General ..........................................................................7-1

How to Program the NCR 7870...................................7-3

Creating the Program.............................................7-3

Step 1. Writing the Program.............................7-3

Step 2. Entering the Program............................7-3

Step 3. Save the Program..................................7-4

Programming Mode...............................................7-5

Programming Tags.................................................7-6

Abort...................................................................7-6

Default.................................................................7-7

End ......................................................................7-7

Hex 0 – Hex F......................................................7-7

Programming Mode...........................................7-8

Save and Reset....................................................7-8

Program Entry Example.........................................7-9

Programming Tips ............................................... 7-12

Program Parameter Descriptions..............................7-13

Communications Protocol...................................7-13

Defaults............................................................. 7-13

Specific Program Parameters...........................7-13

Programming Example.................................... 7-17

Good Read Tone...................................................7-18

Defaults............................................................. 7-18

Specific Program Parameters...........................7-18

Program Example.............................................7-19

Timers....................................................................7-20

Defaults............................................................. 7-20

Specific Program Parameters...........................7-20

Program Example.............................................7-21

Bar Codes – 1 ........................................................7-22

Page 9

Defaults............................................................. 7-22

Specific Program Parameters...........................7-22

Program Example.............................................7-24

Bar Codes – 2 ........................................................7-25

Defaults............................................................. 7-25

Specific Program Parameters...........................7-25

Program Example.............................................7-27

Bar Codes – 3 ........................................................7-28

Defaults............................................................. 7-28

Specific Program Parameters...........................7-28

Program Example.............................................7-30

Bar Codes – 4 ........................................................7-31

Defaults............................................................. 7-31

Specific Program Parameters...........................7-31

Program Example.............................................7-32

Label Identifiers....................................................7-33

Defaults............................................................. 7-33

Specific Program Parameters...........................7-34

Program Example.............................................7-37

RS-232 Parameters – 1..........................................7-39

Defaults............................................................. 7-39

Specific Program Parameters...........................7-39

Program Example.............................................7-41

RS-232 Parameters – 2..........................................7-42

Defaults............................................................. 7-42

Specific Program Parameters...........................7-42

Program Example.............................................7-44

RS-232 Prefix Byte ................................................7-45

Defaults............................................................. 7-45

Specific Program Parameters...........................7-45

Program Example.............................................7-46

User's Guide vii

Page 10

viii User's Guide

RS-232 Terminator Byte ....................................... 7-47

Defaults............................................................. 7-47

Specific Program Parameters...........................7-47

Program Example.............................................7-48

RS-232 Communications Options .......................7-49

Defaults............................................................. 7-49

Specific Program Parameters...........................7-49

Program Example.............................................7-52

Scale Parameters...................................................7-53

Defaults............................................................. 7-53

Specific Program Parameters...........................7-53

Program Example.............................................7-54

Miscellaneous Parameters ................................... 7-55

Defaults............................................................. 7-55

Specific Program Parameters...........................7-55

Program Example.............................................7-57

PACESETTER

Plus

Informatio n................................7-59

Mode 1 - Inquiry...................................................7-59

Mode 2 - Real Time...............................................7-60

Mode 3 – Normal..................................................7-62

Host Access t o Tallies........................................... 7-64

Examples o f Host Access to Tallies................. 7-64

Host Reset of Tallies.........................................7-67

Special Programming.................................................7-68

Delay Weight Data to IBM Host Terminal .........7-68

EAN/JAN/UPC Multi-Symbol Scanni ng

Parameters ............................................................7-69

Label Construction...........................................7-69

Single Label Restriction....................................7-69

Transmitting Label Data.................................. 7-69

Early Beep Disable................................................7-72

Good Read Tone Presets......................................7-73

Page 11

Good Weigh Tone When Transmitting Data......7-74

Terminal Coupon Interface Parameters..............7-75

ASCII Cod e Chart.......................................................7-77

Chapter 8: Troubleshooting

Fault Ide n t ific a t ion .......................................................8-1

Scanner Troubleshooting Chart...................................8-2

Scale Troubleshooting Chart........................................8-3

Voice Messages Troubleshooting Chart...................... 8-5

Appendix A: Programming Worksheets

General .........................................................................A-1

Purpose...................................................................A-1

Format.................................................................... A-1

Shortcuts.................................................................A-1

Defaults..................................................................A-2

Hex Characters ......................................................A-2

Program Entry.......................................................A-2

Programming Parameter Defaults .............................A-3

Worksheets...................................................................A-6

User's Gui de ix

Page 12

x User's Guide

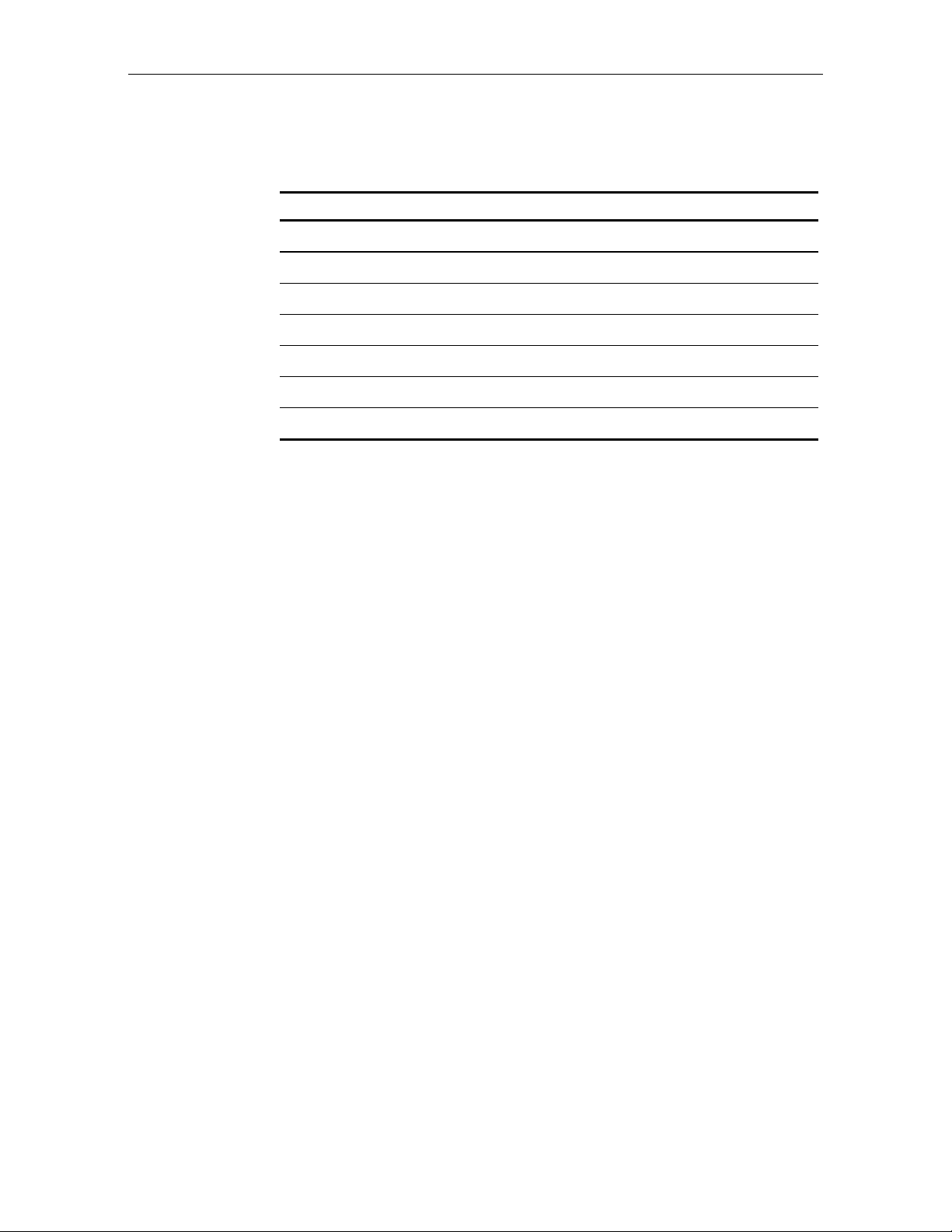

Revision Record

Issue Date Remarks

A Oct 92 First Issue

B Dec 92 Miscellaneous Changes

C Feb 93 Miscellaneous Changes

D Jan 94 Miscellaneous Changes

E Oct 94 M iscellaneous Changes

FFeb 99 Complete Revision

G Nov 99 Miscellaneous Changes

Page 13

Radio Frequency Interference Statements

Federal Communications Commission (FCC)

Information to User

This equipment has been tested and found to comply with the limits for a Class A

digital device, pursuant to Part 15 of FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in

a commercial environment. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with the instruction

manual, may cause harmful interference to radio communications. Operation of this

equipment in a residential area is likely to cause interference in which case the user

will be required to correct the interference at his own expense.

NCR is not responsible for any radio or television interference caused by unauthorized

modification of this equipment or the substitution or attachment of connecting cables

and equipment other than those specified by NCR. The correction of interference

caused by such unauthorized modification, substitution or attachment will be the

responsibility of the user. The user is cautioned that changes or modifications not

expressly approved by NCR may void the user’s authority to operate the equipment.

User's Gui de xi

Canadian Department of Co mmunications

This digital apparatus does not exceed the Class A limits for radio noise emissions

from digital apparatus set out in the Radio Interference Regulations of the Canadian

Department of Co m muni cat ion s .

Le présent appareil numérique n’émet pas de bruits radioélectriques dépassant les

limites applicables aux appareils numériques de la classe A prescrites dans le

Règlement sur le brouillage radioélectriques édicté par le ministrère des

Communications du Canada.

Voluntary Control Council For Interference (VCCI)

Page 14

xii User's Guide

C E Mark Applicability

This product co n fo rms to European Union (EU ) Direct iv es:

Council Directive 90/384/EEC

Non-Automatic Weighing Instruments

Scale Regulator y

Notificatio n o f co u n t r y, s t a t e, an d lo ca l re gu la t o ry agencies of

weighing d evice in stallation is re qu ired . Failure to comply wit h can

result in crimin a l p r osecution and jeopa r diz e the a bility to conduct

normal business. The NCR 7870 Scanner/Scale has been certified in

many countries. Contact the NCR Office of Weights & Measures and

Laser Safety for specific country approvals.

NCR Office of Weights & Measures and Laser Safety

Dennis A. Krueger

2651 Satellite Boulevard

Duluth, GA 30096-5810

Phone: 770-623-7743

Fax: 770-623-7827

E-Mail: Dennis.Krueger@AtlantaGA.NCR.COM

Web Site: http://gedwards.AtlantaGA.NCR.Com/kruegd

Page 15

Declar at ion of Conf ormi t y

Manufacturer’s Name

Manufacturer’s Ad dr ess

User's Guide xiii

NCR Corporation

NCR Corporation

Retail Solutions Group – Atlanta

2651 Satellite Boulevard

Duluth, GA 30096-5810

Type of Equipment

Model Number

Informat ion Techno l ogy Equipment – Bar Code

Scanner

Class NCR 7870-1000, NCR 7870-2000, NCR 7870-3000,

NCR 7870-4000, NCR 7870-4500

NCR Corporation, 1700 South Patterson Boulevard, Dayton, OH 45459,

USA, declares that the equipment specified conforms to the referenced

EU Directives and Harmonized Standards.

EU Directive Harmonized Standard(s)

89/336/EEC (EMC) EN 55022: 1987 (CISPR 22)

EN 50082-1, Part 1: 1992

IEC 801-2: 1984

IEC 801-3: 1984

IEC 801-4: 1988

*90/384/EEC

(Weights & Measures)

EN45501

This Directive is not applicable to NCR 7870-1000 or NCR 7870-3000

Director of Quality Assuranc e

NCR Corporation

Retail Solutions Group — Atlanta

2651 Satellite Boulevard

Duluth, GA 30096-5810

European Contact:

International IP Counsel

915 High Road, North Findlex

London N12 8QJ

United Kingdom

Page 16

xiv User's Guide

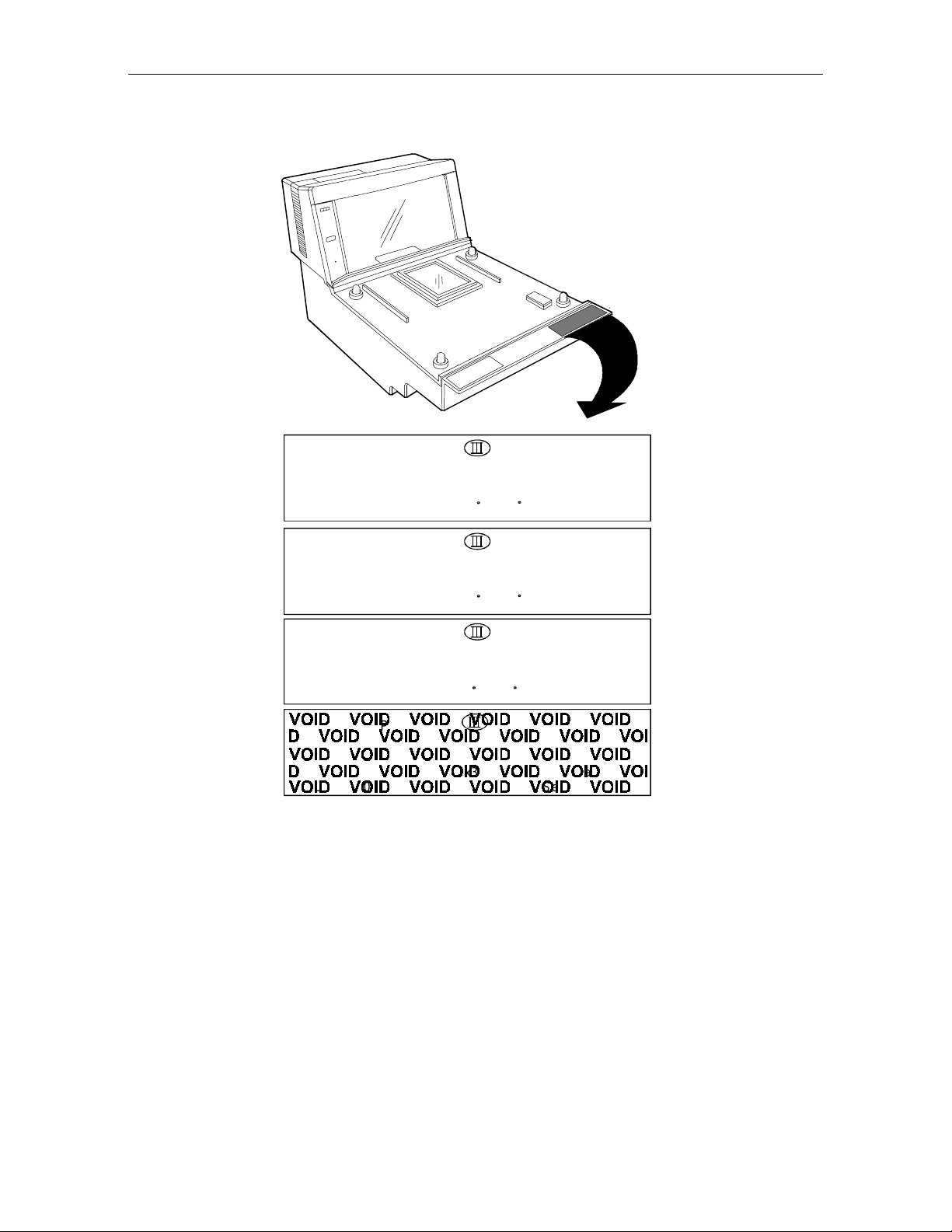

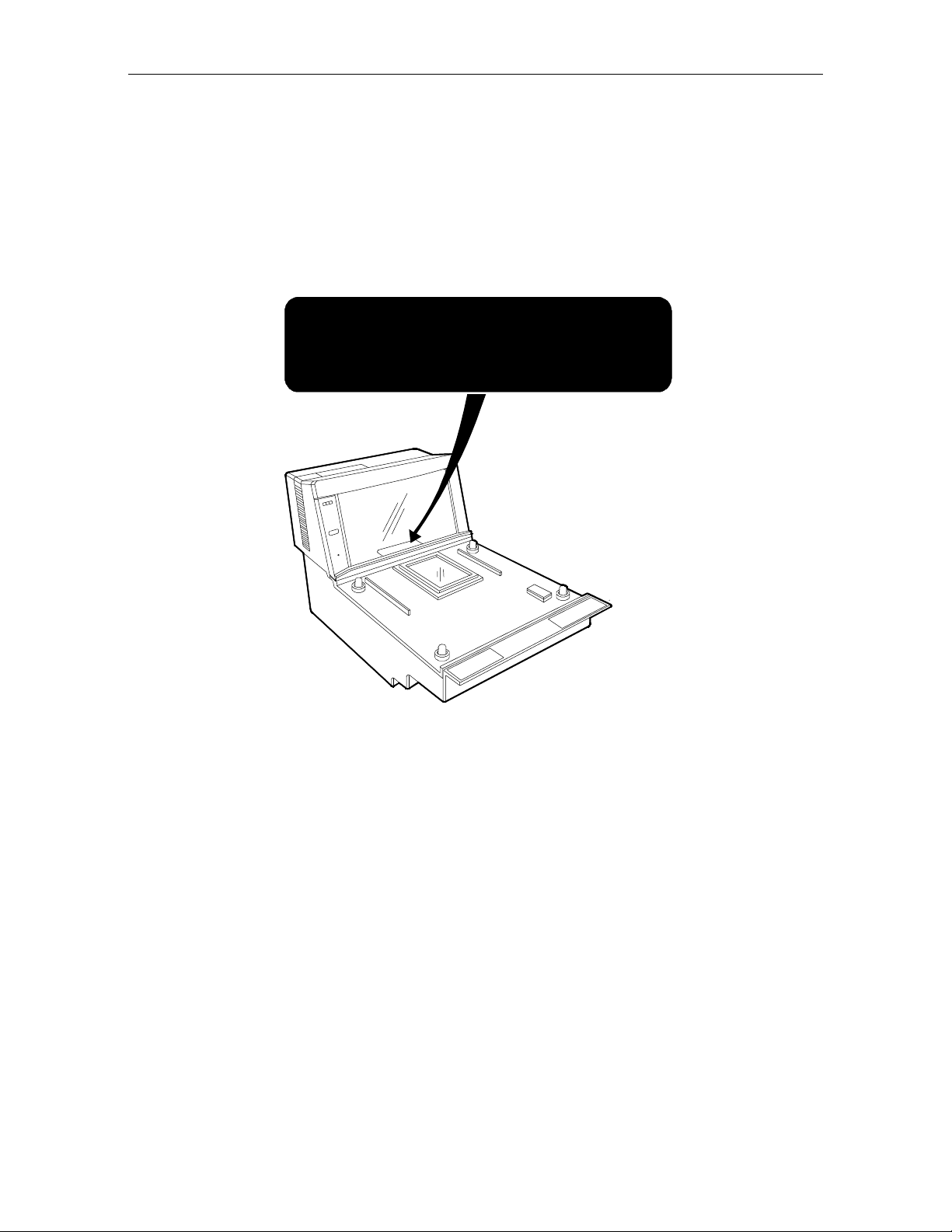

Scale Identi fication Lab el

NCR CORPORATION

Model 7875-2000

Max 13.995 kg Min 0.1 Kg ID

e = d = 0.005 kg Approval

Lim 19.990 kg +10 C /+40 C Serial No

13.995 Kilogram (kg) Label

NCR CORPORATION

Model 7875-2000

Max 9.995 kg Min 0.1 Kg ID

e = d = 0.005 kg Approval

Lim 19.990 kg +10 C /+40 C Serial No

NCR CORPORATION

Model 7875-2000

Max 30.00 Ib Min 0.2 lb ID

e = d = 0.01 lb Nmax3000 Approval

Lim 44.00 lb +10 C /+40 C Serial No

NCR CORPORATION

Model 7875-2000

Max 30.00 Ib Min 0.2 lb ID

e = d = 0.01 lb Nmax3000 Approval

Lim 44.00 lb +10 C /+40 C Serial No

Note: e = scale interval; d = scale division;

Max 30.00 lb = maximum weight permitted on scale

Min 0.2 lb = minimum weight that should be measured on scale

Nmax3000 = maximum scale divisions

9.995 Kilogram (kg) Label

Pound (lb) Label

Removing Label causes

VOID Indication

16884

Page 17

Laser Safety

The NCR 7870 Scanner is not intended for long-term viewing of the

direct laser lig ht. However, the unit is sa fe if us e d as it was in t e n ded.

Laser Saf et y Label

Class IIa Laser Product. Avoid Long-Term Viewing of Direct Laser Light.

Appareil á laser de classe IIa Dviter toute exposition

prolongée de la vue á la lumiére laser directe.

Clase IIa Producto Laser. Traté de no ver directamente él Rayo

Laser por mucho tiempó.

(IEC CLASS 1 LASER PRODUCT)

User's Gui de xv

R0130

Page 18

xvi User's Guide

Country Language Specific IEC Class 1 Laser Labels

CLASS 1 LASER

PRODUCT (IEC 825)

APPAREIL A LASER

LASER KLASS 1

Zeitbasis 1000 s

DE CLASS 1

PRODUCTO LASER

CLASE 1

LUOKAN 1

LASERELAITE

KLASS 1

LASER APPARAT

R0130B

Page 19

Laser M odule Label

User's Guide xvii

Laser Power

This laser module

does not comply

with 21CFR1040.

USE ONLY AS A

COMPONENT.

R0132A

The NCR 7870 Scanner meets the following laser power requirements.

• Class IIa CDRH (Center for Devices and Radiological Health)

• Class 1 EN60-825 (Europäische Norm)

• Class 1 IEC 825-1 1993 (International Electrotechnical

Commission)

Page 20

xviii User's Guide

Following is the radiant energ y of the las er light as applied to each of

the specified requirements.

Maximum Average Radian t Power (CDRH Cal cu lation)

Accessible Emi ssion Lim it (CDRH Calculation)

Maximum Radiant Power (EN60825-1 / IEC 825-1 Calculation)

Accessible Emission Limit (EN60825-1 / IEC 825-1 Calcul ation)

0.87 microwatts

3.9 microwatts

0.45 milliwatts

0.59 milliwatts

Caution: Use of controls or adjustments or performance of procedures

other than specified herein may result in hazardous radiation

exposure.

Page 21

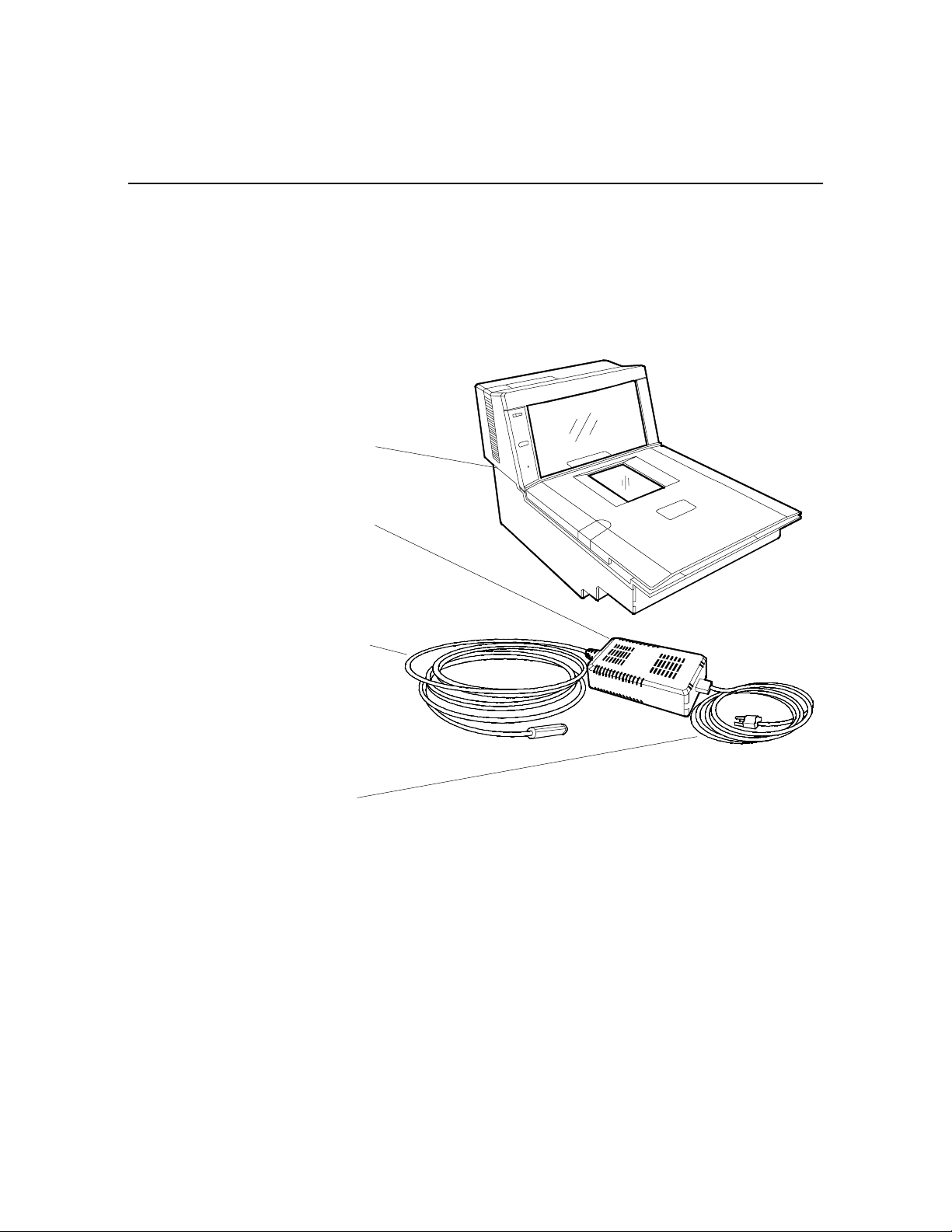

Chapter 1: Introduction

This chapter describes the models, features, and kits available for the

7870 line of scanner/scales. To familiarize you with the 7870, there is a

general overview on the unit, the models, and major components.

NCR 7870

Scanner/Scale

Power Supply

Power Cable

Power Cord

R0122

Page 22

1-2 Chapter 1: Introduction

About the NCR 7870 Scanner/Scale

The NCR 7870 is used in high-performance scanning applications in

food distribution, mass merchandise, warehouse clubs, and large drug

store chains. It is a bi-optic scanner/scale that combines the

characteristics of a slot (horizontal) scanner and a side (vertical)

scanner into a single cabinet.

Bi-optical sca n n in g crea t es a larger, four-side d scan zone which allows

the 7870 to read bar codes faster and with less orientation effort from

the checker. Scan line speeds of 2,400 lines per second permit

continuous item speeds of 2 meters per second. A good checker

operates in the range of 0.8 to 1.0 meters per second.

Models

The PACESETTER

Standard Decode feature, analyses and corrects information from

defective labels. PACESETTER

you can iden t ify p r od u cts and man ufacturers wit h poo r label q uality.

The scale will we ight items less fiv e po un ds (2 . 2 7 kg ) in 0.9 seconds.

The weight plate is offset toward the checker, allowing the checker to

do what is natu ra l wh en lift in g heavy object s – pull the we ight closer to

the body. This less e ns ope ra to r lo wer ba ck strain.

The overall resu lt o f these and many other design qua lit ies is an

ergonomic scanner/scale with a very high first-pass read rate.

The NCR 7870 is av a ilable in fiv e mode ls:

• 7870 - 1000 - 9090 – scanner only, standard length

• 7870 - 2000 – 9090 - scanner and scale, standard length

• 7870 - 3000 – 9090 - compact scanner only

• 7870 - 4000 – 9090 - compact scanner/scale (third party scale,

Plus

technology, available as an upgrade over the

Plus

also keeps track of bad labels so

European market)

• 7870 - 4500 – 9090 - compact scanner/scale (NCR scale)

Page 23

Reading the Product Number

Class 7870

Major Model:

10 = Scanner (Standard Size)

20 = Scanner/Scale (Standard Size)

30 = Scanner (Compact)

40 = Scanner/Scale (Mid-Size, European Scale)

45 = Scanner/Scale (Mid-Size)

Sub-Model: none

Power: 90 = No Characteristics

Language: 90 = No Characteristics

Common Fe atures

Chapter 1: Introduction 1-3

7870 XX00 90 90

14943

• Standard Decode or PACESETTER

Plus

and Standard Decode

• Interfaces for popular host terminals

• Large select io n o f p o we r cords t o meet cus t om a n d reg io n a l

needs while providing fle x ible co n figuration s wit h t h e

universal power supply

• Data cables ordered separate or as part of a kit

• For Scanner/Scale models -- NCR 7825 Remote Display

(standard for curren t mode ls ), In t egrated Display, or No Display

• Print or on-lin e d ocumentation

• Choice of Stainless Steel Top Plate equipped with either

Sapphire or Diamond-Coated Glass Scan Window

• Custom labels fo r t h e scann e r and scale t o mee t local

requireme n ts for las e r safe ty a n d/or weights and measur es

Page 24

1-4 Chapter 1: Introduction

7870-1000-9090

7870-2000-9090

7870-3000-9090

This is the st anda rd bi-o p t ic scanner only model. It is full-sized,

designed to fit in a 20+ inch (51+ cm) wide checkstand. It can be

configured with a variety of top plates and glass options. The 78701000 will fit into the counter hole for the NCR 7820.

This is the st anda rd bi-o p t ic scanner/scale m od el. It is ide n t ical t o the

7870-1000 with the addition of a scale unit. The 7870-2000 can be

ordered with the post-mounted NCR 7825 Remote Display (standard),

an integrated display, or no display. The 7870-2000 will fit into the

counter hole for the NCR 7820.

This is the com p a ct, bi-optic, scanner only mode l. With the sca le be d

removed, the length is reduced to 34.3 cm (13.5 in.) to fit in European

checkstands where space is tight and the checker is often seated.

7870-4000-9090

7870-4500-9090

This is the subco m pact scann e r/s ca le mod e l. With a lengt h o f 43 cm

(17 in.), the 7870-4000 has a footprint between that of the full-sized

1000/2000 models and the compact 3000 model.

The 4000 model uses a price-computing scale to meet European

requirements. This scale uses info rm a tio n obtained from the host

terminal and the measured weig h t to ca lcu la te the price in t e rn ally. The

price computing function makes the 4000 model different from all

other 7870 model scales which measure item weight and transmit the

data to the host term inal for price calculatio n .

The 4500 model is identical to the 4000 model except the scale has no

internal p rice -co m puting function a n d is manufactured by NCR .

Page 25

Chapter 2: Features, Functions, and Kits

This chapter describes the features, functions, and kits. Specification

and performance data on the 7870 unit and its major components is

also provided.

General Features and Functions

Bar Code Recognition

The 7870 can recognize and read a number of bar codes including:

• UPC-A • Code 39 (Code 3 of 9)

• UPC-E • Code 128

• UPC-D (limited s e t ) • Interleaved 2 of 5

• EAN-8/13 • Add-On Codes

• JAN-8/13

It is possible that in some situations, the 7870 may be able to read more

types of bar codes than the host terminal’s application program. In

such a case, either the application program must be upgraded to read

these bar codes or the 7870 must be told, using the Programming Tags

(BST0-2121-74), to ignore the particular bar code type.

Page 26

2-2 Chapter 2: Features, Functions, and Kits

Bi-Opti c Sca nni ng

The NCR 7870 combines horizontal and vertical scan patterns. Having

two active scan windows allows the checker to bring a product into the

scan zone without having to orient it to a single scan window. Portions

of the bar code are read by each scanner, assembled into a complete

code by the digital board and sent to the host terminal.

Decode Features

Standard Decode and PACESETTER

label decoding. Standard Decode is the standard feature and

PACESETTER

Plus

upgrade includes the Standard Decode.

PACESETTER

Bar code labels in a ret ail env iron ment are occasiona lly un rea d able .

Labels can be overprinted, underprinted, or truncated. Others may

have missing margins or be placed around corners. PACESETTER

determine s wh a t is wro ng wit h a la be l, compensat es and fix es the d ata,

and transfers the information to the host terminal. Voice messages can

be used to describe what is wrong with a label.

There are three modes of operation in PACESETTER

• Mode 1 – Inqui r y Mode

• Mode 2 – Real-T ime Mode

• Mode 3 – Oper ati ons M ode

Mode 1 – Inquiry Mode

Inquiry mod e kee ps a t a lly cou nt of label readabilit y . Labels are

judged as:

Plus

is the upgrade. Please note that the PACESETTER

Plus

Plus

are available for bar code

Plus

Plus

.

Good reads No reads (incomplete labels)

Good reads with overprinted bars Missing margins

Good reads with underprinted bars

Page 27

Displays

Chapter 2: Features, Functi ons, and Kits 2-3

In Mode 1 the t a lly counts are disp layed on the int eg ra t e d dis play or

the NCR 7825 remote display. The percentage of each error type to the

good reads t a lly is als o d isp la yed. All the tally counts can be reset to

zero.

Mode 2 – Real-Time Mode

In Mode 2 the scanner is off-line and the scale is disabled. The scanner

reads bar codes and in d ica te s la bel re a da bilit y , whethe r labels a r e

missing bars, overprinted, underprinted, missing margins, or are “no

read.”

Mode 3 – Operations Mode

Mode 3 is the norm a l ope ra t ing mode . While in t h is mod e, the scanner

can be programm e d to add traile r in fo rm a tio n a bou t label re a da bilit y

to the UPC/EAN data. The host terminal must be capable of receiving

the trailer and configured appropriately.

A display separate from the host terminal is useful and sometimes

required for use with NCR 7870 Scanner/Scales -- the 2000, 4000, and

4500. These models are available with a remote post-mounted display,

an integr at e d d isp la y, or no display .

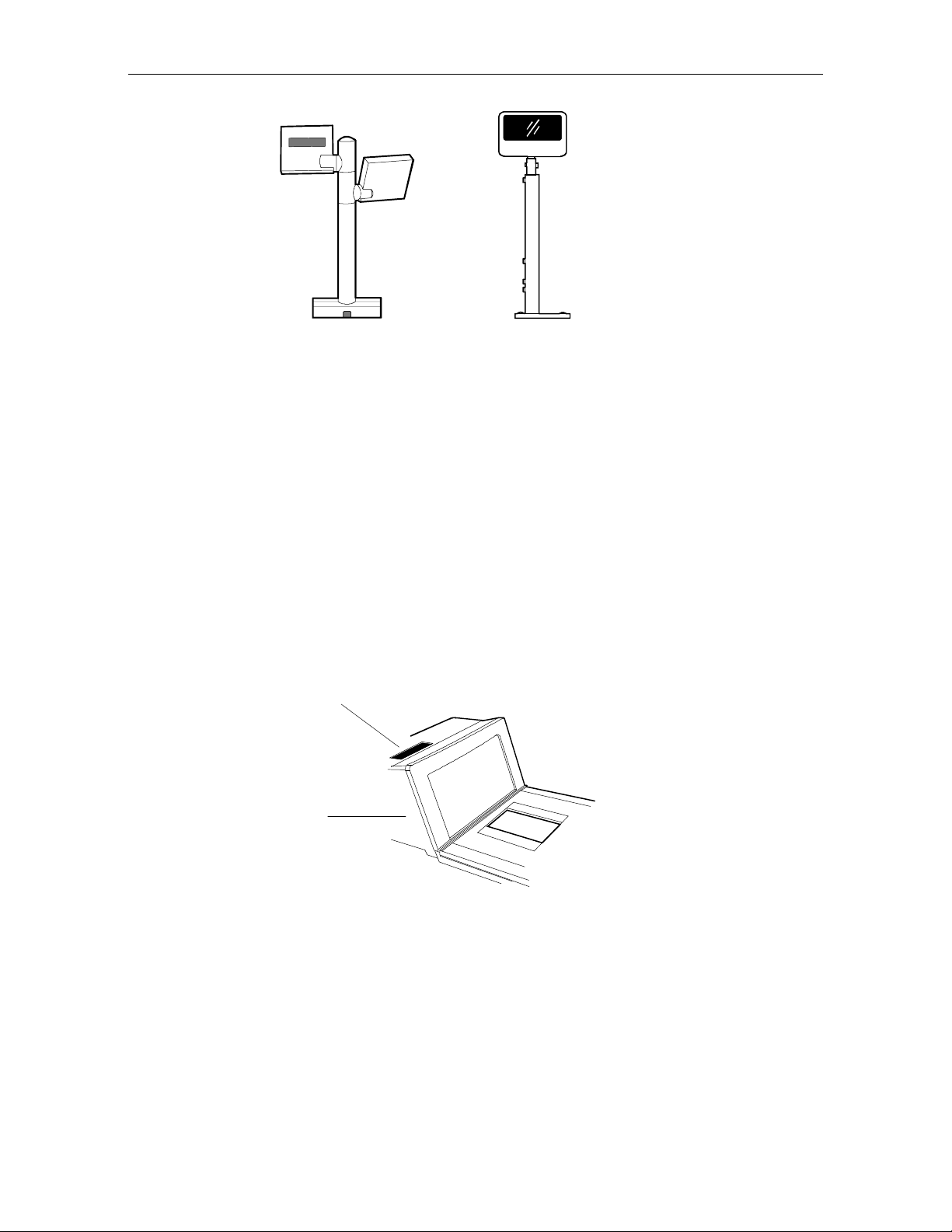

NCR 7825 Remote Di sp l a y

The post-mounted NCR 7825 is the standard display and is available as

a user-inst a lla ble kit to upgrade older u n its in th e field. Early v ersio n s

of the NCR 7825 Remote Display are mounted on a post that attaches

to the checkstand. The current NCR 7825 is a compact design available

with a single or dual display, one for the customer and one for the

checker. The following illustrat ion shows the curren t mod el wit h du al

displays a n d the earlie r m o de l.

Page 28

2-4 Chapter 2: Features, Functions, and Kits

NCR 7825 Remote

Compact Display

NCR 7825 Remote

Post Display

16345

Depending on the checkstand construction, a keyboard may be

mounte d above the 7 870, wh ich will o bs t ru ct the v ie w of the int egrated

display. In this case, it may be advantageous to install an NCR 7825

Post Mounted Display, which can be used with or without an

integra t e d display.

Integrated Display

The integrated displa y is an inset, LCD locate d o n th e top su rfa ce of t h e

tower. Depending on the checkstand design, the integrated design

may or may not be appropriate.

Integrated Display

Tower

16819

Page 29

Interf ace Ty pe s

Laser Scan n er

Chapter 2: Features, Functi ons, and Kits 2-5

No Display

If the 7870 is ordered with no display, the scale information is usually

displayed on the host terminal display. Please note, the host terminal

must be approved to perform a live/gross scale weight. This

arrangement is not available in all host terminals and some Weight and

Measures au thorit ies do not permit this arrang ement.

The NCR 7870 communicates with the host terminal through various

types of interfaces. The 7870 Scanner always uses one interface cable.

However, some host terminals require dual cables for and NCR 7870

Scanner/Scale. See the

Preparation for available interface cables.

The 7870 operates with the performance of two scanners yet the bioptic scan pattern is created by a single laser and spinner motor. A 24 line convergent scan pattern (1 2 lines per scan window) is gen e ra ted by

the laser diode. A 3-Phase, DC, brushless motor spins a tetrahedral

mirror at 6000 RPMs. The laser beam is reflected onto the stationary

mirrors in the Optics Assembly and then out the Scan Windows. The

Spinner Motor provides a scan speed of 2400 scan lines (100 scan

frames) per second. This enables the 7870 to read at a continuous item

speed of 2.0 meters per second. An experienced checker scans at a rate

of 0.8 to 1.0 meters per second, so the 7870 is able to keep up with high

volumes and fast checkers.

Interface Cables

section in Chapter 3: Site

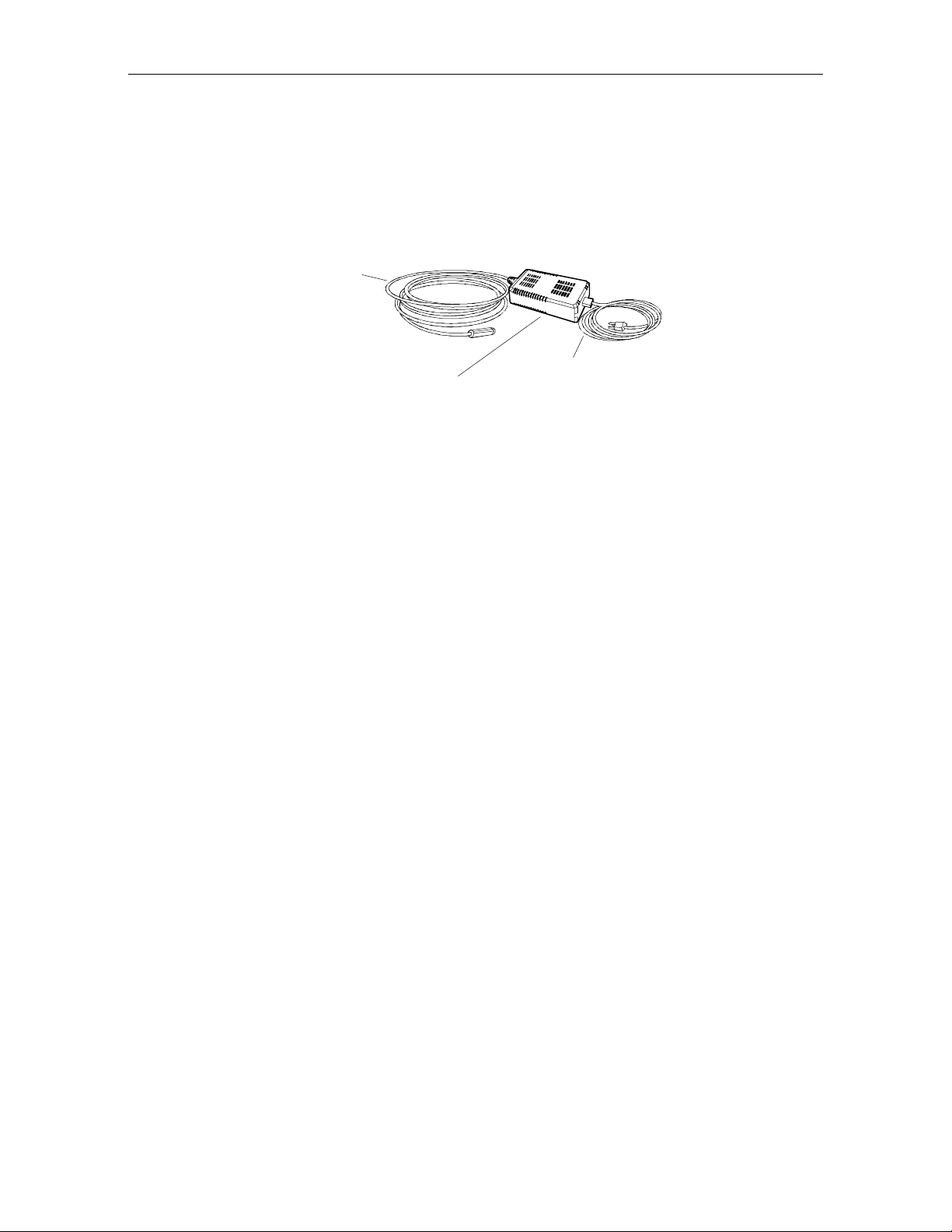

Power Supply

A univers al, switching P o we r Supp ly is us e d to prov id e DC volt a g e. It

has a replaceable, 3 m (10 foot) cord for connection to the power outlet

or source . A low volta ge power cable conn e ct s the Power Supp ly to

the unit. The Power Supply can be fixed to the unit’s chassis on or

located on the floor or checkstand in the NCR 7870-1000 and 2000. For

other mod e ls, th e Po wer Supp ly must be insta lle d in th e che ckstand.

Page 30

2-6 Chapter 2: Features, Functions, and Kits

An outboard power supply permits the 7870 to operate without

checkst a n d ve n t ilat io n . The Power S up p ly a cce p t s in pu t lin e vo lta ges

from 90 to 260 VAC at a frequency range of 47 to 63 Hz.

For a list of Power Cables and Cords, see the

Sizes

section in Chapter 3: Site Prepar a tio n.

Power Cable

(To AC)

Outboard Power Supply

Programming the 7870

The NCR 7870 is featurized to fit a customer’s needs by using

programm ing tags which alt e r the un it ’s operating parameters.

Following are some of the more common parameters which may be

adjusted:

• Communications Protocol • Code 39

Power Cord (To Unit)

Cables Lengths and Hole

16822

• Good Read Tone • Code 128

• Not-On-File Tone Volume • RS-232

• Timers • Interleaved 2 of 5

• UPC/EAN • PACESETTER

Plus

• Add-On Code • Label Identifiers

Page 31

Scale Cert if icat i on s

Scale certifications are available for these markets:

Market 9.95 kg 13.995 kg 30 lb.

Chapter 2: Features, Functi ons, and Kits 2-7

Argentina

Australia

Brazil

California

Canada

Czech Republic

Europe

Hong Kong

Indonesia

International

Mexico

New Zealand

People’s Republic of China

Russia Fede r a tion

United Kingdom

•

••

•

•

•••

•

•

••

•

•

•

••

•

•

•

U.S.

Venezuela

Vietnam

•

•

•

Page 32

2-8 Chapter 2: Features, Functions, and Kits

Scan Zone

The scan lines are dispersed in a forward and backward direction from

both windows. This allows the scanner to read a) on four sides, b)

from left-to-right or right-to-left, and c) inverted labels. If the scan

zone is thought of as a cube resting on the horizontal scan window, the

scanner is able to read the le ad ing, t ra ilin g, bottom, and fa r surfa ce s.

Another way of describing the scan zone is – if the checker can’t see the

bar code label, then the scanner can. The scan zone extends to 20.3 cm

(8 in.) high off the horizontal window. Bi-optical scanning makes the

scan zone large enough to allow a labe l to be read off o f a tall sou p ca n

even when upside-down

Scanner Power Requirements

The laser diode occupies little space, draws low current, and produces

little heat. The light produced by the scanners in current models has

been shifted toward the edge of the visual spectrum so it is not possible

to see the scan pattern in normal lighting. When active, the laser uses

22 watts. A soft power down feature allows major portions of the 7870

to shut down when no motion is detected. While in sleep mode, the

scanner’s power requirements drop to 10 watts, a 65% reduction. A

more valuable advantage of the soft power down feature is the run

time reduct ion o f critical com ponents wh ich t ranslates directly into

extending the life of the scanner. The scanner automatically powers up

after detecting motion in approximately two seconds.

Soft Power Down

During periods of inactivity, components of the scanner and scale shut

down to conserve power, reduce wear, and extend product life. A

motion sensor detects activity and signals the unit to power up from

sleep mode. The power up takes less than two seconds.

Page 33

Top Plates and Scan Wi ndows

Top Plates

A Top Plate provides a snag-free place to scan items and protects the

internal components from con t a m inat ion and liquid sp ills . It has an

inset Lift Ta b (o lde r un its may have two) which permit the Top Plate to

be quickly removed or replaced with no tools. The scan window inset

in the Top Plate is either diamond-coated (replaceable) or sapphire

glass (permanent). When a unit has a scale, the Top Plate becomes a

part of the scale system – the scale must be recalibrated when the Top

Plate or any of its components, such as the scan window, are replaced.

The current line of 7870 Scanners and Scanner/Scales have been

upgraded to come with the Stainless Steel Top Plate as a standard

feature. Older 7870 units may have the painted steel Top Plate which

is no longe r availa ble .

Chapter 2: Features, Functi ons, and Kits 2-9

Slot (Horizontal) Scan

Window

Top Plate

Lift Tab

Slot Scanner Window

The (horizon t al) scan window is mounted in the Top Plate . Th e

window (if diamond-coated) is replaced by removing the Top Plate,

snapping out the old window, and snapping the new window in place.

The slot scanner window is available as diamond-coated glass or

sapphire glass. Diamond-coated glass was formerly known as

“scratch-resistant” glass. Sapphire glass is the upgrade and was

formerly known as “scratch-proof” glass. Other glass options such as

“hardened” and “armor” glass have been discontinued.

Page 34

2-10 Chapter 2: Features, Functi ons, and Kits

Side Scanner Window

The NCR 7870 vertical scan window is mounted in a tower that rises

above the checkstand surface. The scan window can be removed from

the unit for cleaning. The upper console containing the scan window is

designed to withstand occasional impacts.

Side (Vertical) Scan Window

Slot (Horizontal) Scan Window

16821

Page 35

Scale Features and Functions

The scale is used in the 2000, 4000, and 4500 models. It can be

manufactured by NCR or by a vendor for a specialized market such as

the price-computing scale in the 4500 model to meet European

standards.

Scale Funct i on s and Fe atures

Load Cell

The NCR 7870 uses a sing le loa d ce ll rat h e r than four, which is more

typical, t o increa se reliability. Th e sca le has a se tt lin g t ime of 0.9

seconds fo r ite ms weighing less than 2.3 kg (5 lbs.) It is sealed to avoid

damage from spills aroun d the unit. There are three basic ty pes of load

cells:

• For weigh ing in pounds. Capacity: 30 lbs.

• For weigh ing in k ilo g r ams. Capacity: 9. 9 9 5 kg

Chapter 2: Features, Functi ons, and Kits 2-11

• For weigh ing in k ilo g r ams. Capacity: 1 3. 9 95 kg

Reset / Scale Zero

A front-mounted Scale Reset button is located on the front bezel, to the

left of the ve rtica l scan window. This flush m embrane switch will res et

the scale due to fluctuation from extreme temperature drift, impact, or

scale tare up to:

1. 0.3 kg (0.6 lbs.) relative to the zero established during the most

recent power-on sequence

or

2. 0.6 kg (1.2 lbs.) relative to the calibrat io n ze ro , wh ich ev e r is less.

The scale res et function is comple t e d in less than a second.

Auto-Zero

Scale electronics automatically tracks out stable shifts due to

temperature changes and compensates in 3 g (0.006 lb.) increments up

to a maximum of 0.3 kg (0.6 lbs.).

Page 36

2-12 Chapter 2: Features, Functi ons, and Kits

Kits

Kit Name Kit Type A v a ilable for

Enhanced Scratch Resistant

Window

7870-K002-V001

Upper Windows (Qty: 5)

7870-K003-V001

Stainless Steel Top Plate

7870-K005-V002

Scale Shell Model

7870-K007-V001

Digital Board Upgrade (Board,

Firmware)

7870-K100-V001

Requirements: For units with S/Ns below 50-28901727, adds Speech

and Coupon Add-On Code.

Hardware 7870-1000

7870-2000

Hardware All

Hardware 7870-1000

7870-2000

Hardware N/A

Hardware,

Firmware

All

PACESETTER

(OCIA/IBM)

7870-K401-V001, -V002

Requirements: V001 supports

units with S/Ns 50-28901727

or lower. V002 supports units

with S/Ns 50-00000000 and

higher.

Plus

Upgrade

Firmware All

Page 37

Chapter 2: Features, Functi ons, and Kits 2-13

Kit Name Kit Type A v a ilable for

PACESETTER

Plus

Upgrade

Firmware All

(RS-232/Datachecker)

7870-K402-V003, –V002, -V003

Requirements: V001 supports units with S/Ns 50-28901727 or lower.

V002 supports units with S/Ns 50-00000000 and higher. V003 has a

PACESETTER

Multi-Sy m bo l Upgrade

Plus

trailer fix.

Firmware All

7870-K404-V002

Requirements: For units with S/Ns 50-28901727 and higher. If

upgrading a unit with a lower S/N, install kit 7870-K100.

13.995 kg Upgrade

7870-K440-V001

Firmware,

Hardware

7870-2000

Requirements: For upgrade from 9.995 kg to 13.995 kg on units with

S/Ns 50-28901727 and higher. To upgrade a unit with a lower S/N,

install kit 7870-K100.

OCIA/IBM Inter face – Single

Cable

Hardware,

Firmware

All

7870-K450-V001, -V002

Requirements: V001 supports units with S/Ns 50-28901727 or lower.

V002 supports units with S/Ns 50-00000000 and higher.

OCIA/Interface – Dual Cable

7870-K451-V001, -V002

Hardware,

Firmware

7870-2000

Requirements: V001 supports units with S/Ns 50-28901727 or lower.

V002 supports units with S/Ns 50-00000000 and higher.

Page 38

2-14 Chapter 2: Features, Functi ons, and Kits

Kit Name Kit Type A v a ilable for

RS-232 Interface (Board,

Firmware)

Hardware,

Firmware

All

7870-K452-V003

Requirements: V001 supports units with S/Ns 50-28901727 or lower.

V002 supports units with S/Ns 50-00000000 and higher. V003

enhances the old digital board firmware.

Datachecker, 2170, ICL MDL,

ICL 9518/9535, SASI Interface

Hardware,

Firmware

All

7870-K455-V001, -V002, -V003

Requirements: Kit is for interfacing with these host terminals: NCR

2170 (RS-232, Weightronix Emulation), Avery Emulation (RS-232),

Datachecker (RS-422), ICL MDL, ICL 9518, ICL 9535 (ICL Team POS

5000), SASI.

V001 supports only ICL T2001, V002 supports units with S/Ns 50-

28901727 or lower. V003 supports units with S/Ns 50-00000000 and

higher.

Non NCR OCIA

7870-K457-V002

Hardware,

Firmware

All

Requirements: V001 supports units with S/Ns 50-28901727 or lower.

V002 supports units with S/Ns 50-00000000 and higher.

Casio and TEC Scale Interface

7870-K458-V003

Hardware,

Firmware

7870-2000

Requirements: V001 supports units with S/Ns 50-28901727 or lower.

V002 supports units with S/Ns 50-00000000 and higher. V003

supports the same as V002 plus TEC.

Page 39

Chapter 2: Features, Functi ons, and Kits 2-15

Kit Name Kit Type A v a ilable for

IBM 4682/4693/4694 Standard

Interface and IBM 4682-4B Full

Hardware,

Firmware

All

ASCII Inte r face

7870-K459-V002

Requirements: V001 supports units with S/Ns 50-28901727 or lower.

V002 supports units with S/Ns 50-00000000 and higher.

Datachecker 2000 Interface

Hardware All

7870-K463-V001

Requirements: 7870 must be configured for Single-Cable, OCIA.

Dual Cable RS-232 Interface for

I/F 1

Hardware,

Firmware

7870-2000

7870-K465-V001

Requirements: 7870 must be configured for OCIA or IBM

communications. Avery Emulation (RS-232), Weightronix Emulation

(RS-232) for scanners with an I/F 1 Interface Board.

Australia with I/F 1 Interface

to 2126 Dual Cable 13.995 kg

Hardware,

Firmware

7870-2000,

kg units only

(Coles)

7870-K466-V001

Requirements: For upgrading units with a) S/Ns 50-28901727 and

higher and b) I/F 1 Interface Board from 9.995 kg to 13.995 kg. To

upgrade units with lower S/Ns, kit 7870-K100 must also be installed.

If the unit has an I/F 2 Interface Board, kit 7870-K450 must also be

installed.

Integra t e d Displa y

Hardware All

7870-K480-V001

Page 40

2-16 Chapter 2: Features, Functi ons, and Kits

Kit Name Kit Type A v a ilable for

Top Plate with Scratch-Proof

Window (Standard size)

Hardware 7870-1000

7870-2000

7870-K601-V001

Top Plate with Scratch-Proof

Hardware 7870-3000

Window (Compact)

7870-K605-V001

WalMart/Argentina Upgrade

7870-K846-V001

Hardware,

Firmware

7870-2000

Requirements: To upgrade a 9.995 kg scanner/scale to Argentina

requirements, unit must have a) S/N 50-28901727 or higher and b) an

NCR 7825 Remote Display.

Coupon Add-On Code

Firmware All

Upgrade

7870-K850-V001

Requirements: For units with S/Ns between 50-28901727 and 50-

31148616. For units with S/Ns 50-2891727, use kit 7870-K100. For

units with S/Ns 50-31148616 and larger, no kit is needed – enabl e

feature through programming options.

Checkpoint Scanner Bezel

7870-K896-V001

Hardware 7870-1000

7870-3000

Requirements: A Checkpoint representative must make the final

connection from the 7870 to the Checkpoint equipment after kit

installation.

Page 41

Chapter 2: Features, Functi ons, and Kits 2-17

Kit Name Kit Type A v a ilable for

Checkpoint Scanner/Scale

Hardware

Bezel

7870-K898-V002, -V003

Requirements: Kit is mandatory for upgrading to Checkpoint on units

with S/N 50-32573274 or lower. For units with higher S/Ns, may use

this kit or kit 7870-K899-V001. V002 is for use in U.S. and Mexico

only. A Checkpoint representative must make the final connection

from the 7870 to the Checkpoint equipment after kit installation.

Checkpoint Scanner/Scale

Hardware

Bezel

7870-K899-V001

Requirements: For units with a S/N 50-32573274 and higher. For

units with a lower S/N, install kit 7870-KK898-V003. A Checkpoint

representative must make the final connection from the 7870 to the

Checkpoint equipment after kit installation.

Page 42

2-18 Chapter 2: Features, Functi ons, and Kits

Page 43

Chapter 3: Site Preparation

For the NCR 7870 to operate efficiently and safely, the selected

installation site must meet certain requirements. Ensuring that these

conditions are met and maintained will protect the 7870 from

unnecessary wear and pot e n t ia l dam a g e as we ll as e as in g in st a lla t ion.

This chapte r cov e rs

• Getting Started

• About Site Preparation

• Custom e r Responsibilities

• Environmental Requirements

• Checkstand Power and Wiring Considerations

• Checkstand Considerations

• Cable Lengths and Hole Sizes

• 7870 Dimensions

Page 44

3-2 Chapter 3: Site Preparation

Getting Started

The first step to preparing the selected site is to read the following two

secti o ns – About Sit e Prepar ation and C u sto mer Resp onsibilities.

These sections provide imp ort ant in fo rm a t ion abou t NCR’s and your

responsibilities to keep the NCR 7870 safe and in good working order.

The next step is to ev a luat e the ch ose n s it e for its s uitability. As a

minimum, these conditions need to be accessed:

• Is the environment controlled within the 7870’s operational range

• Will other ele ctr onics be pla ced in ch eckstand which co u ld

• Will the power circuit to supply the 7870 be

for temperature, temperature change, relative humidity, barometric

pressure , ambie n t light, acoust ic n oise, vibration, and shock?

necessitate use of forced air to regulate the temperature?

• dedicated to NCR equipment only and so labeled,

• equipped with an isolated, insulated ground,

• providing the re quire d in pu t to th e Power Supp ly,

• equipped with a recessed, 15-amp circuit breaker convenient to

the checker, and

• equipped with protection against voltage transients?

• Is the checkstand

• able to securely support the weight of the 7870 and

• properly ventilated?

• Has the plan for the checkstand design considered

• use of a diverter or an adjustable plate,

• clearance needed for service and customer viewing of display,

• location and size of hole for cable rout in g, and

• providing enough slack in cables so 7870 may be removed from

checkstand for service without disconnection?

Page 45

Chapter 3: Site Preparation 3-3

The following sections contain the NCR 7870’s requirements. These

specificatio n s will a llo w y o u t o evalu a t e the s ite for in s t a lla tio n .

The l ast step is t o i mpl ement th e necess ary changes b efor e beginn i ng

the installa t ion process describe d in Chapter 4: Installation .

Page 46

3-4 Chapter 3: Site Preparation

About Site Preparation

This chapter co n t ains the in forma t ion necessary for the pre p a ration o f a

site conforming to NCR specifications. It is very important that the site

complies wit h th e requ ire m ent s in this do cu ment because, on ce the

equipment has been installed, deficiencies in site preparation or the

problems ca us e d by the se deficiencies a re mu ch mo re difficu lt t o d et e ct

or correct. Further, failure to comply with these requirements or to

take proper steps to protect equipment against risks identified in this

document may cause serious damage to the equipment and to the

customer’s business.

In addition to the need to comply with the requirements specified,

electrical wiring and mechanical systems must also comply with all

relevant cod e s, la ws, and regulation s.

It is important that the site be prepared by a customer or a customer

agent who is fully conversant with the special requirements of

electronic eq u ipment. The respons ibilit y o f e n su rin g t h a t the s ite is

prepared in compliance with this document remains with the

customer.

For informa t ion an d guid a n ce pu rposes only, a lis t is prov id ed , in

general terms, of these matters for which the customer is responsible.

This list is not in t ende d to be comprehensive , a n d in no way mod ifies,

alters, or limit s the responsibilit y of the custom e r for all asp e cts o f

adequate site preparation.

NCR staff is available to answer questions relating to the contents of

this docum e n t, bu t ex ce p t whe re:

a) the customer has been notified that a full or partial consultancy

service is availa ble and/or that NCR is willin g to undertake a

prelimina ry or final site surve y an d

b) the customer shall have entered into a formal contract with

NCR for provis ion of the same.

Page 47

Chapter 3: Site Preparation 3-5

No comment, suggestion, or advice offered or not offered about

preparation of the site nor any inspection of the site whether before or

after preparation is to be taken as approval of the location of the site

and equipment or of its prepa ra t ion , a n d NCR is n o t liable in re spect of

any comment, suggestion, or advice given by its staff or in respect of

any failure to give advice.

Finally , only the cust ome r can kn o w t h e full e x t ent o f dam ag e which

may be caused to his business by reason of failure of the equipment

which is to be in st alle d . Fo r this re a son, it is the cus tom er ’s

respons ibility to ascerta in t h e ex t ent o f any su ch possible damag e to h is

existin g or plan ned business, and to effect full insurance in respect of it.

Page 48

3-6 Chapter 3: Site Preparation

Customer Responsibilities

The customer must do or provide the following.

• When required by NCR, provide the NCR Customer Services

Representative with appropriate drawings that indicate

• location of equipment,

• site wiring (power and signal, paths, and lengths),

• Location of other equipment capable of generating large

amounts of electrical noise, electromagnetic interference,

heat, and so on.

• Provide floor coverings and environmental systems that

prevent static electricity build-up and discharge.

• Provide an d install necessary power dist ribu t ion box e s,

conduits, grounds, lightening arrestors, and associated

hardware.

• Make sure clear space and environmental requirements of the

unit are met.

• Make all buildin g alterations nece ssary to meet wiring a n d

other site requirements.

• Make sure all applicable codes , regulations, and laws

(including , but not limited t o, e le ct rica l, building , safety, and

health) are met.

• Provide and install all co mmunicatio n ca ble s, wa ll jacks, spe cial

connectors, and associated hardware.

• Provide and install auxiliary power or other equipm ent as

required.

Page 49

Environmental Requirements

Operating Range

Condition Range

Temperature

Chapter 3: Site Preparation 3-7

10° C – 40° C(50° F – 104° F)

Temperature Change

Relative Humidity 5% to 95%, Non-Condensing

Barometric Pressure 79.5 x 103 Pa to 105 x 103 Pa

Ambient Light 200 Foot-candles max (2152 Lux)

Acoustica l No is e 55 dBa or less

Vibration and Shock 1 to 10 Hz with a double amplitude of

10° C per hour (18° F per hour)

on both scanner windows

0.127 cm (0.05 in.)

10 to 300 Hz with a maximum of 0.25 gee

Extreme Operating Range

Condition Range

Temperature

Temperature Change

-15° C to 45° C (5° F to 113° F)

one hour max

20° C per hour (36° F per hour)

Relative Humidity 5% to 95%, Non-Condensing

Page 50

3-8 Chapter 3: Site Preparation

Storage Range

Condition Range

Temperature

-15° C to 50° C(5° F to 120° F)

Temperature Change

20° C per hour (36° F per hour)

Relative Humidity 5% to 95%, Non-Condensing

Transit Range

Condition Range

Temperature

Temperature Change

Relative Humidity 5% to 95%, Non-Condensing

Barometric Pressure 74 x 103 Pa to 105 x 103 Pa

-40° C to 60° C (-40° F to 140 F)

20° C per hour (36° F per hour)

Page 51

Chapter 3: Site Preparation 3-9

Checkstand Power and Wiring Considerations

Power C onsiderations

In the 1000 and 2000 models, the 7870 receives power from an external

supply which is normally moun t e d to the ext e rior su rfa ce o f t h e unit’s

chassis. The power supply may be mounted near the 7870 rather than

on it, if adva n t age o us .

In the 3000, 4000, and 4500 models, the power supply is mounted on

the checkstand.

It is a 40-watt swit ch in g power supply with th e followin g inputs.

Voltage Frequency Input Power

90 to 260 Vac 47 to 63 Hz 55 Watts

Power Applications

The 7870 has no ON/OFF switch. A recessed, 15 amp circuit breaker

must be wired in the checkstand. This circuit breaker must be

accessible to the operator so the unit may be powered off and on. It

will also be nee d ed to reset the unit durin g pro g ra mming.

Power Transients Protection

Voltage transients -- surges, sags, impulses, and spikes – may be

experien ce d ro u t in e ly or spo ra d ically. When such conditions exis t , th e

use of protective devices may be required to ensure proper operation.

Page 52

3-10 Chapter 3: Site Preparation

Wiring Consi derati ons

U.S., Canadian, and Japanese Checkstand Wiring

Input

Voltage

Neutral and

Ground Bus

Isolated/Insulated

Ground Bus

Neutral

Bus

Main Service

L2

Distribution Panel

Panel

L1

L3

Belt Control

N

G

Conduit

Circuit A: Checkstand

Note:

The electrical wiring must meet all

electrical codes, laws, and regulations.

Feeder wiring and insulated ground from

main service panel to distribution panel

to be run in metal conduit.

Circuit Breakers

NCR circuits should be run in

separate metal Conduits.

Note:

NCR circuits must be dedicated to

NCR equipment or other logically

connected electronic equipment

(modems, DAA, bridges, etc.)

Circuit B: Terminal

Circuit C: Scanner/Scale

Receptacle should be easily

accessible and near the

Scanner/Scale

Isolated Ground Receptacles

Lighting

Misc. Equip.

Belt

Motor

Checkstand

Frame

Installation Type

U.S., Canada, &

Japan

International

European

Input Voltage L1, L2 Circuit Breakers

100Vac to 120Vac

220Vac to 240Vac

220Vac

100Vac to 120Vac

220Vac to 240Vac

220Vac

Standard single-pole; value

determined by type of device

branch and by electrical code.

European double-pole.

R0121

Page 53

Chapter 3: Site Preparation 3-11

European Checkstand Wiring

Use this diagram when line voltage to the Service Panel is 220 Vac and

European double-pole circuit breakers are used in the Distribution

Panel.

220Vac

Neutral and

Ground Bus

Isolated/

Insulated

Ground Bus.

Store

Load Center

L3

N

L2 L1

Circuit A

Belt Control

N

G

Lighting

Misc. Equip.

Conduit

Feeder wiring and insulated ground from main

service panel to distribution panel to be run in

metal conduit.

The electrical wiring must meet state

and local electrical codes, laws, and

regulations.

European double-pole circuit breakers.

NCR circuits should be run

in seprate metal Conduits.

Circuit B

Terminal

Checkstand

Frame

Belt

Motor

Neutral Bus

Distribution Panel

220 Vac

Circuit C

Scanner/Scale

Isolated Ground

Receptacles

Note :

NCR circuits must be dedicated to

NCR equipment or other logically

connected electronic equipment

(modems, DAA, bridges, etc.)

R0133

Page 54

3-12 Chapter 3: Site Preparation

International Checkstand Wiri ng

Use this diagram when the line voltage to the Service Panel is 220 or

240 Vac and standard single pole circuit breakers are used in the

Distribution Panel.

220

Vac

240

Neutral and

Ground Bus

Isolated/

Insulated

Ground Bus.

Main Service

Panel

L3

N

220

230

240

L2 L1

Vac

Circuit A

Belt Control

N

G

Lighting

Misc. Equip.

Conduit

Feeder wiring and insulated ground from main

service panel to distribution panel to be run in

metal conduit.

The electrical wiring must meet state

and local electrical codes, laws, and

regulations.

Standard single-pole circuit breakers.

NCR circuits should be run

in seprate metal Conduits.

Circuit B

Terminal

Checkstand

Frame

Belt

Motor

Neutral Bus

Distribution Panel

Circuit C

Scanner/Scale

Isolated Ground

Receptacles

Note :

NCR circuits must be dedicated to

NCR equipment or other logically

connected electronic equipment

(modems, DAA, bridges, etc.)

R0134

Page 55

Wiring Instructions

Running Feeder Lines from Main Service Panel

1. Select the most appropriate wiring diagram as a guide.

2. Run two separa te feed er lin e s in co n duit fro m th e Main S e rvice

Circuit A

3. Electrically connect the grounding conductor in Circuit A to Store

Chapter 3: Site Preparation 3-13

Panel in the checkstand to the customer equipment and to the NCR

Distribution Panel.

• Line 1 services Circuit A which is for customer equipment such

as checkstand belt moto r, co u n t e r ligh t in g, and cooling fa n s.

• Line 2 is dedicated to service the NCR equipment, typically

Circuit B and Circuit C.

Ground.

4. Electrically connect conduit and checkstand junction box to the

frame of the checkstand, if conductive, or to a common tie point if

not conductive.

5. Connect to the grounding conductor in Circuit A (which is Store

Ground) any

• conduit,

• metal parts,

• store ground devices

• counter belt motor ground, and

• other counter equipment grounds.

Page 56

3-14 Chapter 3: Site Preparation

Circuit B

The ground conductor in Circuit B (to the host terminal) is an isolated,

insulated ground – it must be isolated from the outlet box for the host

terminal. The circuit breaker in the power conductor of Circuit B is

optional. If used, it should be near the operator and recessed.

Circuit C

The power conductor in Circuit C (to the NCR 7870) should include a

15 Amp circuit breaker located near the operator. The circuit breaker

should be recessed to prevent be in g a ccide n t a lly switched on o r off.

Note:

insulated from the ground conductor, convenient to the equipment,

readily acces sible, and labe led a s ex clus iv ely for use with NCR

equipment.

The outlet boxes for the NCR equipment must be isolated and

Page 57

Checkstand Considerations

Careful planning of how the checkstand and 7870 work together can

improve flow and ergonomics. An evaluation of the checkstand

should tak e int o co ns ide r at io n :

• weight of the 7870,

• ventilation,

• service clearance to the 7870,

• display clearance,

• power on and off,

• secure fit and mounting in the cutout for the 7870,

• item diverter (op t ional),

• adjustable plate (optional),

Chapter 3: Site Preparation 3-15

Ventilation Requirements

The NCR 7870 Scanner/Scale does not need an exhaust fan in the

checkstand provided

• there is adequate convection air flow,

• no other equipment in the checkstand raises the temperature in the

checkstand to more than 7° C (12.6° F) above the ambient

temperature, and

• the temperature inside the checkstand does not exceed 40° F.

If the checkstand contains other heat producing equipment, forced air

may be needed to keep the temperature within the 7870’s operating

range. If forced air is used, air coming into or leaving the checkstand

MUST NOT enter or exit past the 7870.

Page 58

3-16 Chapter 3: Site Preparation

Service Clearance

The 7870 is designed to allow servicing without removal from the

checkstand. This includes component removal and replacement, scale

calibration , and installat ion o f t h e Weights and Measu res sea l. To take

advantage of this design feature, an area for service clearance must be

provided.

Note:

Access to the Power Supply may require removal of the 7870

from the checkstand.

Mounting surface for keyboard must

be removable for servicing and

vertical window replacement.

B

A

= 20.3 cm (8.0 in.) minimum if checkstand structure is not removable for servicing.

A

2.5 cm (1.0 in.) minimum if checkstand structure is removable for servicing.

= 33.0 cm (13.0 in.) minimum if checkstand structure is not removable for servicing.

B

17.8 cm (7.0 in.) minimum if checkstand structure is removable for servicing.

= 13.0 cm (5.1 in.) minimum clearance to closest checkstand panel. The 7870-1000

C

or 2000 must not be supported by this panel.

A

Item Flow Area

C

R0117

Page 59

Display Clearance

If the 7870 Scanner/Scale has an integrated display, there must be

adequate clearance for viewing by the customer. In the U.S. , this is a

Weights and Measurements req u ire m ent . Intern a tio n a l cou ntr ies

should check with their appropriate local or government agency. If the

checkstand design restricts viewing, the NCR 7825 Remote Display

may be used to mee t visibilit y requirements.

Chapter 3: Site Preparation 3-17

Item Div erter

50

30

Item Diverter

(Must be removable

to service

Scanner/Scale in

Checkstand)

This area must be clear

for viewing integrated display.

60

60

R0118

7.25 in. (18.4 cm)

R0131

Page 60

3-18 Chapter 3: Site Preparation

Check sta nd Hol e

When cutting the checkstand hole, also called a cutout, take care to

maintain the sp e cified d im e ns ion s. While this is essen t ia l fo r all

models, it is crit ical fo r u n it s wit h a s cale .

• For all mod els, t h e lea din g e d g e of t he Top P la t e mus t be flu sh o r

• For proper scale operation, the clearance between leading and

• For European installations, a 5.1 cm (2 in.) border must be provided

no more than 15 cm (0.06 in.) below the top of the checkstand. The

trailing ed g e of th e Top Pla te must be flu sh with the top of the

checkstand.

trailing e d g es o f the Top Plat e a n d th e che ckstand mus t be

maintained.

around the le a ding e dg e, t r a ilin g e dg e, a nd operator s ide of t h e

scanner scale. This border must contain the words “NO WEIGH

AREA.”

An NCR 7870-1000 may be placed in an existing cutout for an NCR

7820 and an NCR 7870-2000 may go into a cutout for the NCR 7824.

Before utilizin g an existing cut out, you MUST ensure th a t the cut out

has the correct dimensions before installing the 7870.

99999

Page 61

Checkstand Hole - Models 1000 & 2000

Chapter 3: Site Preparation 3-19

C

D

Note: Spacers are to

position scale in hole.

They should be below

the Checkstand top.

H

DD

C

E

B

No electronics under NCR 7870

NCR 7870-1000 Scanner

ABCDEFGH

29.51 cm

11 5/8 in.

50.95 cm

20 1/16 in.

3.49 cm

1 3/8 in.

0.95 cm

3/8 in.

C

43.97 cm

17 5/16 in.

F

Recommended shelf to catch

NCR 7870 if dropped during

installation. The 7870 must

not be supported by this shelf.

3.49 cm

1 3/8 in.

B

E

A

13.0 cm

5 1/8 in.

A

F

15.88 cm

6 1/4 in.

C

G

NCR 7870-2000 Scanner/Scale

ABCDEFGH

30.48 cm

12 in.

50.95 cm

20 1/16 in.

3.49 cm

1 3/8 in.

1.27 cm

1/2 in.

43.97 cm

17 5/16 in.

3.49 cm

1 3/8 in.

13.0 cm

5 1/8 in.

15.88 cm

6 1/4 in.

R0119

Page 62

3-20 Chapter 3: Site Preparation

Checkstand Hole - Models 3000, 4000, & 4500

B

C

Note: Spacers are to

position scale in hole.

They should be below

the Checkstand top.

D

C

B

No electronics under the 7870

NCR 7870 - 3000 Scanner

A

29.51 cm

29.51 cm

11 5/8 in. 13 5/8 in. 3/8 in. 6 1/4 in. 4 15/16 in.

NCR 7870 - 4000 & 4500 Scanner/Scale

A

29.51 cm

30.48 cm

12 .00 in.

BCDE

34.50 cm 0.95 cm 15.88 cm 12.54 cm

BCDE

43.97 cm 1.27 cm 15.88 cm 12.54 cm

17 3/8 in.

1/2 in. 6 1/4 in. 4 15/16 in.

A

E

A

The 7870-3000, 4000, and 4500 must sit on a shelf below the checkstand surface.

Note:

It cannot be suspended like the other units. Also, the shelf should be open at the

front and back.

16631

Page 63

Cable Lengths and Hole Sizes

When select ing a cable, take care to choos e one wit h en ough length for

easy routing to the NCR 7870. Also, include enough slack to allow the

unit to be lifted fro m the cu t out wit h o u t dis conn e ctin g the cables. This

will be beneficia l wh ile s e rv icin g the unit.

Minimum hole size data is provided for ma k ing ope n ings t o pass

cables through the checks t and. E nsure after drilling that the re ar e no

sharp edges which may damage the cable.

The following charts provid e cable le n g t h an d hole size da t a for AC

Power Cords, DC Power Cables, Interface Cables, and Remote Display

Cables. The NCR 7870 can connect to any NCR Retail Terminal as well

as many comp et it iv e host terminals so a com prehensive lis t of inte rfa ce

cables has been provided.

Cable Hol e Diam et er s

Chapter 3: Site Preparation 3-21

Cable Minimum Hole Size

Power Cord – Outlet to Power Supply 3.18 cm (1.25 in.)

Power Cable – Power Supply to 7870 1.52 cm (0.60 in.)

Interface Cable 1.90 cm (0.75 in.)

Remote Display Cable 1.90 cm (0.75 in.)

DC Power Cable – Power Supply to 7870

Minimum Hole Diam e ter: 1.52 cm (0.60 in.)

Cable Cable Length

DC Power Cable 1.22 Meters (4 Feet)

Note:

mounted on the chassis of the 7870 (Models 1000 and 2000 only).

DC Power Cable len gth is not a factor if the Power S upply is

Page 64

3-22 Chapter 3: Site Preparation

AC Power Cords – Outlet to Power Supply

Minimum Hole Diam e ter: 3.18 cm (1.25 in.)

Cable Cable Length

US Standard 3.05 Meters (10 Feet)

US Twist-Lock 3.05 Meters (10 Feet)

International Pig-Tail 3.05 Meters (10 Feet)