Page 1

User Guide

RealPOS X-Series Displays (5968/5985)

B005-0000-2337

Issue B

Page 2

The product described in this document is a licensed product of NCR Corporation.

NCR is a registered trademark of NCR Corporation. NCR RealPOS is a trademark of NCR Corporation in

the United States and/or other countries. Other product names mentioned in this publication may be

trademarks or registered trademarks of their respective companies and are hereby acknowledged.

The terms HDMI and HDMI High-Definition Multimedia Interface, and the HDMI Logo are trademarks

or registered trademarks of HDMI Licensing LLC in the United States and other countries.

Where creation of derivative works, modifications or copies of this NCR copyrighted documentation is

permitted under the terms and conditions of an agreement you have with NCR, NCR's copyright notice

must be included.

It is the policy of NCR Corporation (NCR) to improve products as new technology, components,

software, and firmware become available. NCR, therefore, reserves the right to change specifications

without prior notice.

All features, functions, and operations described herein may not be marketed by NCR in all parts of the

world. In some instances, photographs are of equipment prototypes. Therefore, before using this

document, consult with your NCR representative or NCR office for information that is applicable and

current.

To maintain the quality of our publications, we need your comments on the accuracy, clarity,

organization, and value of this book. Please use the link below to send your comments.

Email: FD230036@ncr.com

Copyright © 2014–2019

By NCR Corporation

Global Headquarters

864 Spring St NW

Atlanta, GA 30308

U.S.A.

All Rights Reserved

Page 3

Preface

Audience

This book is written for hardware installer/service personnel, system integrators, and

field engineers.

Notice: This document is NCR proprietary information and is not to be disclosed or

reproduced without consent.

Safety Requirements

The NCR RealPOS X-Series Displays conforms to all applicable legal requirements. To

view the compliance statements see the NCR RealPOS Peripherals Safety and Regulatory

Statements (B005-0000-1701).

Caution: The on/off switch is a logic switch only. The AC line voltage primaries are live

at all times when the power cord is connected. Therefore, disconnect the AC power

cord before opening the unit to install features or service this terminal.

iii

Lithium Battery Warning

Warning: Danger of explosion if battery is incorrectly replaced. Replace only with

the same or equivalent type as recommended by the manufacturer. Discard used

batteries according to the manufacturer's instructions.

Attention: Il y a danger d'explosion s'il y a remplacement incorrect de la batterie.

Remplacer uniquement avec une batterie du même type ou d'un type recommandé

par le constructeur. Mettre au rébut les batteries usagées conformément aux

instructions du fabricant.

Battery Disposal (Switzerland)

Refer to Annex 4.10 of SR814.013 for battery disposal.

IT Power System

This product is suitable for connection to an IT power system with a phase-to-phase

voltage not exceeding 240 V.

Peripheral Usage

This terminal should only be used with peripheral devices that are certified by the

appropriate safety agency for the country of installation (UL, CSA, TUV, VDE) or those

which are recommended by NCR Corporation.

Warning: DO NOT connect or disconnect the transaction printer while the terminal

is connected to AC power. This can result in system or printer damage.

Warning: DO NOT connect or disconnect any serial peripherals while the terminal

is connected to AC power. This can result in system or printer damage.

Page 4

iv

Grounding Instructions

In the event of a malfunction or breakdown, grounding provides a path of least

resistance for electric current to reduce the risk of electric shock. This product is

equipped with an electric cord having an equipment-grounding conductor and a

grounding plug. The plug must be plugged into a matching outlet that is properly

installed and grounded in accordance with all local codes and ordinances. Do not

modify the plug provided – if it will not fit the outlet, have the proper outlet installed by

a qualified electrician. Improper connection of the equipment-grounding conductor can

result in a risk of electric shock.

The conductor with insulation having an outer surface that is green with or without

yellow stripes is the equipment-grounding conductor.

If repair or replacement of the electric cord or plug is necessary, do not connect the

equipment-grounding conductor to a live terminal. Check with a qualified electrician or

service personnel if the grounding instructions are not completely understood, or if you

are in doubt as to whether the product is properly grounded.

Use only 3-wire extension cords that have 3-prong grounding plugs and 3-pole

receptacles that accept the product’s plug. Repair or replace damaged or worn cords

immediately.

Page 5

Out of Box Failure (OBF)

If you experience an out of box failure (OBF) during installation or staging related to a

missing, wrong or defective unit or item, simply provide NCR with a detailed

description of the issue and the item will be replaced free of charge. For assistance with

this process send an email to CustomerSat.Retail@ncr.com with the following details:

• NCR Sales Order # (Sales Order # are located on the box)

• Date of Product Installation

• Product Model #

• Unit Serial #

• NCR part # of defective/missing/wrong component

• Description of Failure (please be specific. For example: “display will not power on”)

• Customer/Requestor’s contact name, phone number and/or e-mail address

• Address to ship replacement part(s)

v

Warranty

Transport the product in its original packaging to prevent impact damages.

If you do not have access to a computer, you may leave a voice message at: 1-800-5288658 (USA), or (International) +1-770-623-7400. When leaving a message, please provide a

phone number and/or an email address so NCR can contact you if additional details are

needed.

Note: Used equipment that experiences a failure does not qualify as an OBF and should

go through the NCR warranty process.

Warranty terms vary by region and country.

All parts of this product that are subject to normal wear and tear are not included in the

warranty. In general, damages due to the following are not covered by the warranty.

• Improper or insufficient maintenance

• Improper use or unauthorized modifications of the product.

• Inadequate location or surroundings. Site installation must conform to guidelines

listed in the RealPOS X-Series Displays (5968/5985)Site Preparation Guide (BCC5-0000-

5292) and the NCR Workstation and Peripheral AC Wiring Guide (BST0-2115-53).

For detailed warranty arrangements please consult your contract documents.

Page 6

vi

Returning Defective Hardware for Service

Use the following procedure to report/return defective hardware.

Call the NCR Customer Care Center at 1-800-262-7782 and have the following information

available when you place the call.

• Class/Model number of the defective equipment

• Serial Number of the defective equipment

• Equipment location in the store

• Description of the problem, including any system error codes, error condition, or

guidance to the area of failure.

The NCR Agent will provide you with a work order number, which serves as your

Return Material Authorization (RMA). Please provide the RMA on the outside of the

shipping box.

Note: A work order must be opened for each device that is shipped for repair.

Page 7

Table of Contents

Chapter 1: Product Overview

Introduction 1

Product IDs 2

Standard Features 3

Optional Features 3

Compatibility 4

Supported Resolutions 4

Configurations 5

Display 5

Biometrics and MSR (Encrypted 3-track or JIS) 6

vii

Capacitive Biometric Reader (5968 15" and 18.5" Displays

Only) 6

Imager 7

Keypad (5968 15" Display Only) 7

Display Mounts 8

X-Series Table Top Stand (5968-F031/K031, 5985-F031) 8

XL Series Table Top Stand (5968-F033, 5915-K033) 8

XR Series Table Top Stand with Power Brick (7702-K031) 9

Integration Tray Mount (5968-K024) 9

Checkstand Mount (5968-K039) 9

Wall Mount (7702-K320) 10

VESAMount Spacer (7702-K321, For 10.4" and 15" Displays

Only) 10

X-Series Display Extension Arm Mount (7702-K453, For 10.4"

and 15" Displays Only) 11

Pole Mount (For 5985 10.4" Display Only) 11

12" Pole and Table Top Mount (5934-K020) and Pole Mount

Head for 10.4" Non-Touch Display (5985-F300) 11

Page 8

viii

Power Indicator 12

Label Locations 13

Chapter 2: Hardware Installation

Installation Restrictions 15

Ergonomic Workplace 16

Installing the Display 17

Connecting the Host Terminal Cables 18

Connecting to a POS 19

Data and Power Connections 19

Powered USBCable 19

External Power Cables 20

Video and Audio Connections 21

DisplayPort Cable 21

HDMI Cable 22

DVI to HDMICable 23

VGA Cable 24

Cable Routing 25

Routing Cables for Strain Relief 25

X-Series Table Top Stand (5968-F031/K031, 5985-F031) 28

XRSeries Table Top Stand (7702-K031) 29

Third-Party Mounts 31

VESAMount Spacer 31

Mounting Screw Length 32

Chapter 3: Operation and Cleaning

Touch Screens 35

Projected Capacitive Touch Screen 35

Using the PCap Touch Screen 35

Resistive Touch Screen 36

Using the Resistive Touch Screen 36

Touch Screen Cleaning Procedures 36

Magnetic Stripe Reader 37

Page 9

Using the MSR 37

Care of Cards 37

Card Thickness 37

Biometrics Fingerprint Reader 38

Sensor Cleaning Procedures 38

Daily Cleaning 38

Using the Biometrics Reader 38

Software Drivers 39

Cabinet Cleaning Procedures 40

Chapter 4: NCR Software OSD Utility

Introduction 41

Supported Features 41

ix

Installing the Utility 42

Running the Utility (GUI Version) 43

Main Menu 43

Monitors Detected Panel 43

Center Panel 43

Control Buttons 44

Display Adjustment Procedures 46

Resetting Factory Defaults 47

Running the Utility (Console Version) 48

Appendix A: Touch Screen Calibration

Proper Touch Screen Methods 49

Calibrating the Touch Screen 50

Resistive Touch Screen Calibration 50

PCap Touch Screen Calibration 51

Page 10

x

Revision Record

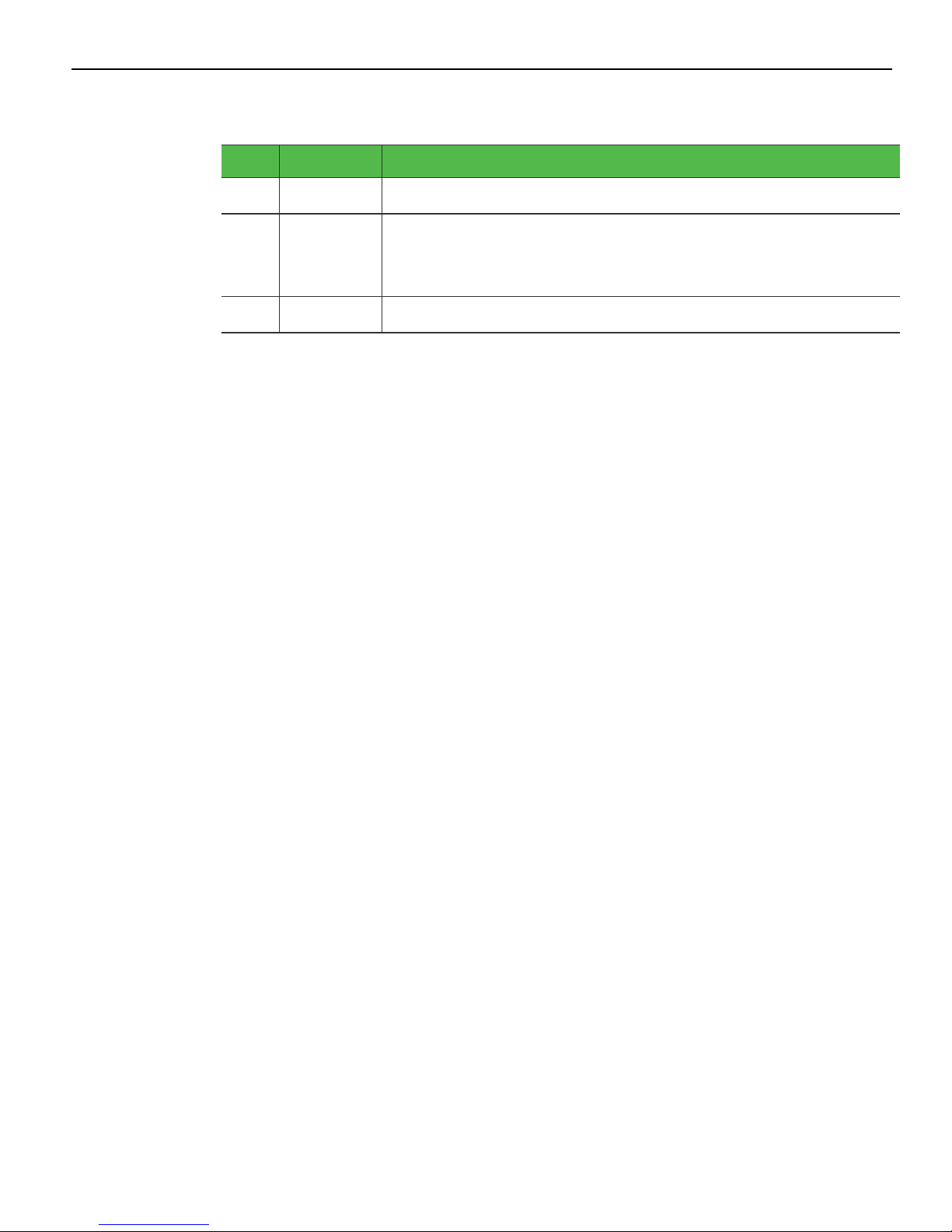

Issue Date Remarks

A

B

Aug 2014 First Issue

Jan 2019 Added Release 2 of 5968/5985 10.4" Display (with Port B)

Added Imager, Keypad, Capacitive Biometric Reader

Added 5968 18.5" Display (XT18)

Page 11

Chapter 1: Product Overview

Introduction

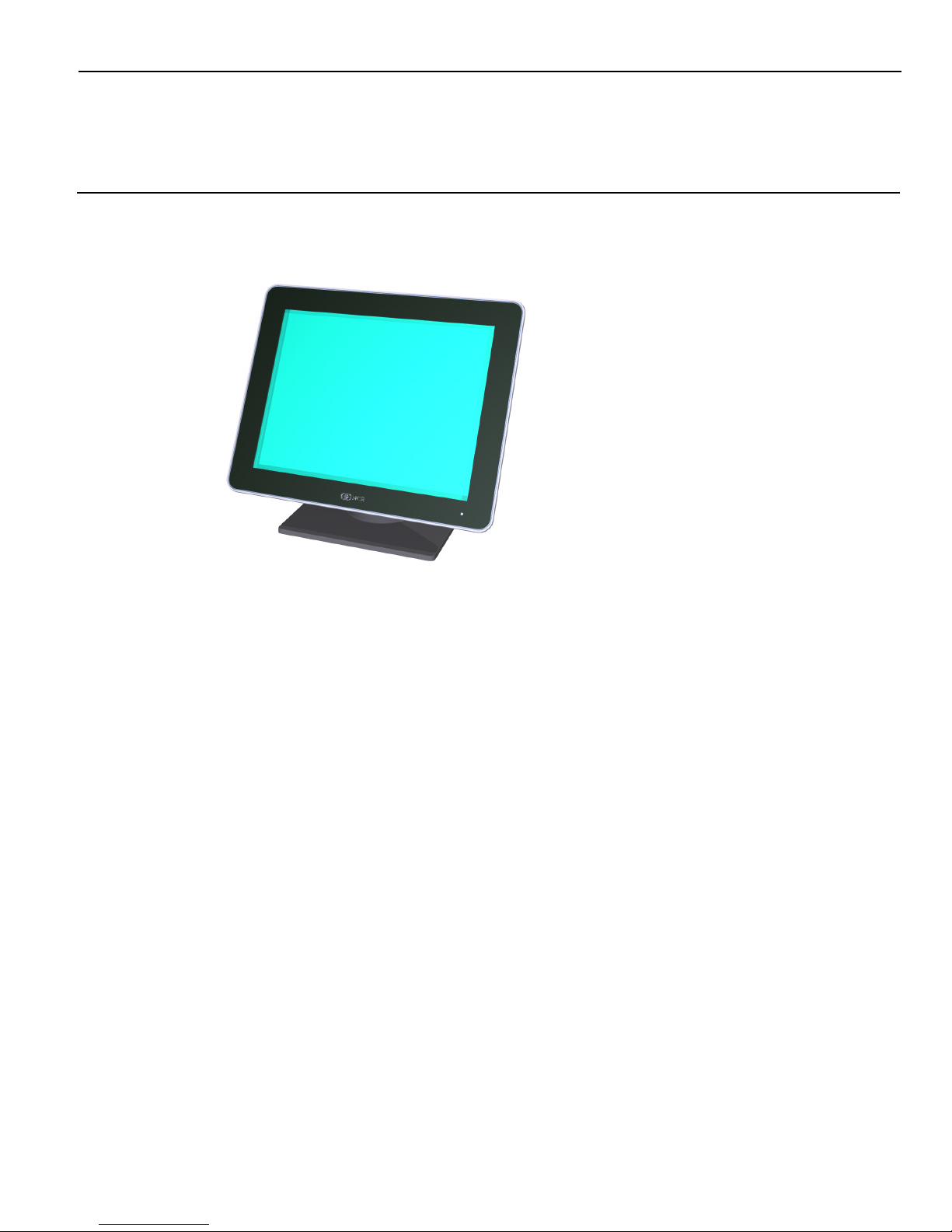

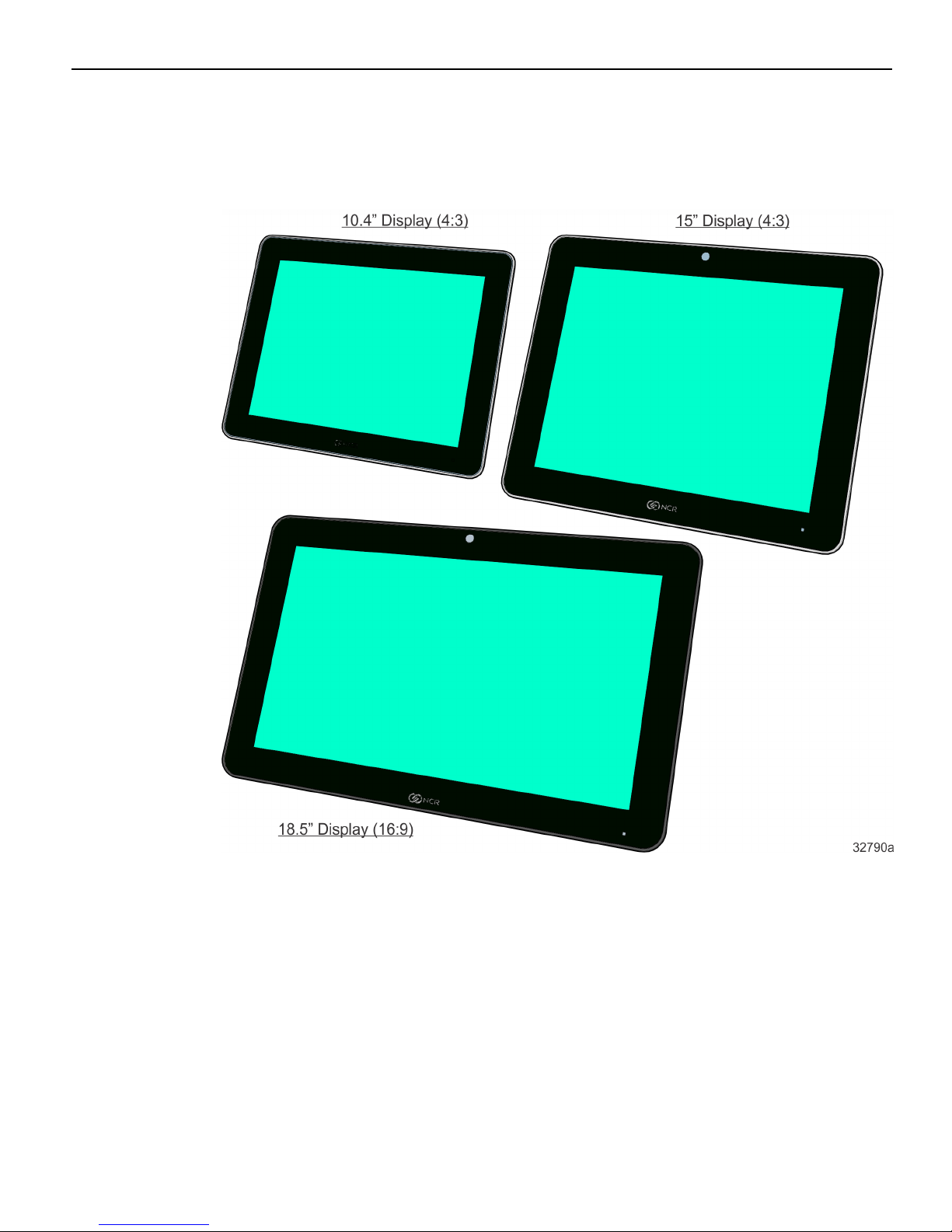

The NCR RealPOS X-Series Displays (also known as NCR 5968 and NCR 5985) offer an

innovative design, multi-touch capability, ruggedized packaging, and more. The Xseries displays are an ideal complement to any point-of-sale (POS) terminal.

The NCR RealPOS X-Series Displays are available in both touch and non-touch models.

• NCR RealPOS 5968 XT (Touch)

• NCR RealPOS 5985 XD (Non-Touch)

The NCR RealPOS X-Series Displays are available with a 10.4" (4:3), 15” (4:3), or 18.5”

(16:9) display. Place it on a tabletop, or hang it on a wall or a pole. You can also

customize your solution with integrated options including an encrypted magnetic

stripe reader (MSR), biometric fingerprint reader, or camera.

Page 12

1-2 Product Overview

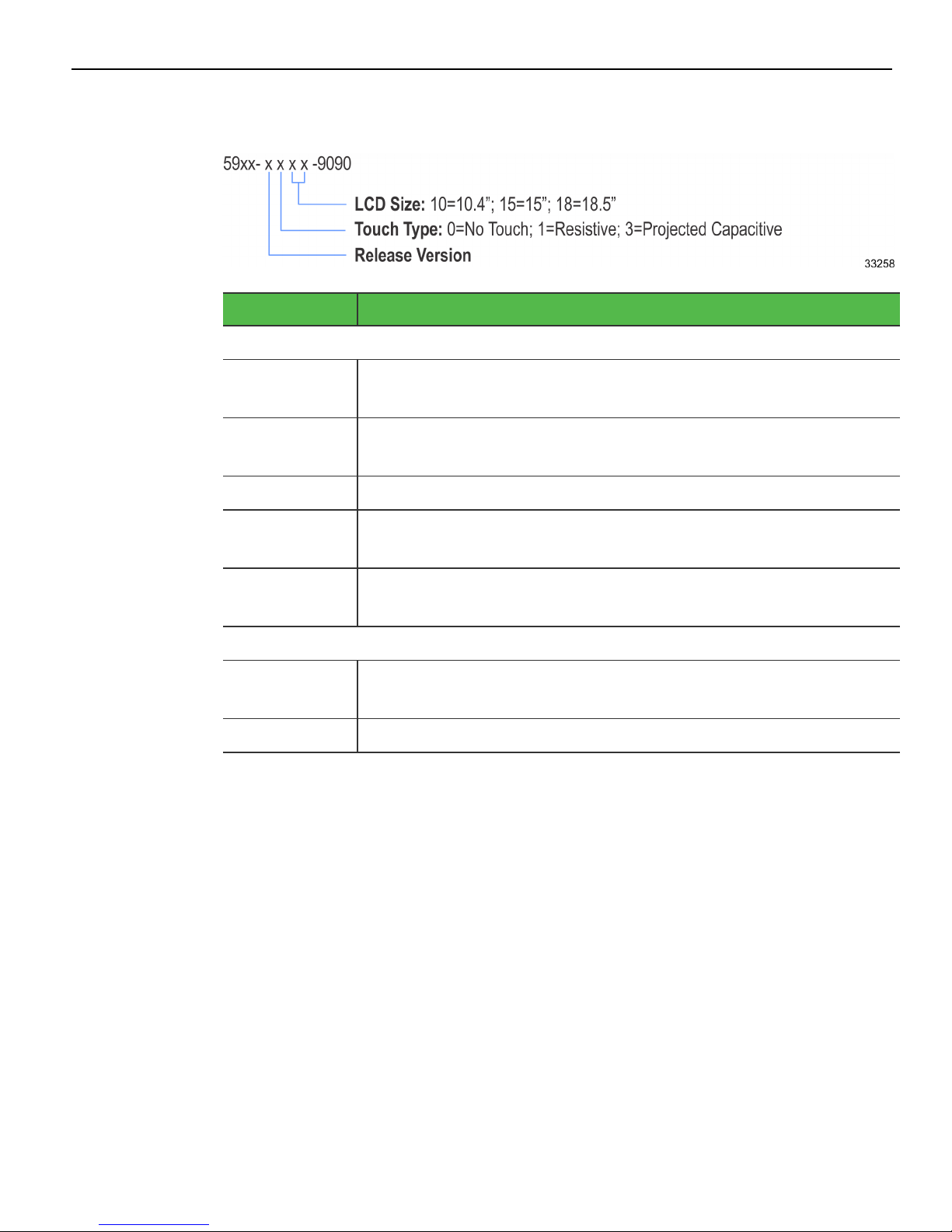

Product IDs

Major Model Description

5968

5968-2110-9090 RealPOS XT10: 10.4" Resistive Touch Display with Port B, No Mount,

No MSR

5968-1310-9090 RealPOS XT10: 10.4" Projected Capacitive Touch Display, No Mount,

No MSR

5968-1115-9090 RealPOS XT15: 15" Resistive Touch Display, No Mount, No MSR

5968-1315-9090 RealPOS XT15: 15" Projected Capacitive Touch Display, No Mount,

No MSR

5968-1318-9090 RealPOS XT18: 18.5" Projected Capacitive Touch Display, No Mount,

No MSR

5985

5985-2010-9090 RealPOS XD10: 10.4" LEDBacklight Display with Port B, No Mount,

No MSR

5985-1015-9090 RealPOS XD15: 15" LEDBacklight Display, No Mount, No MSR

Page 13

Product Overview 1-3

Standard Features

• Display

• Display Size: 10.4" (4:3 aspect ratio), 15" (4:3 aspect ratio), 18.5" (16:9 aspect ratio)

• LCD Technology: TFT; Pixel Configuration: RGB

• LCD LED Backlit Technology

• Viewing Direction: 12 o'clock

• Minimum Backlight ½ Life at Rated Luminance: 50,000 hours

• LCD LED Backlight: Controllable using the Software OSD Application

• Touch Sensor (5968): Resistive/Projected Capacitive

• Touch Interface: USB

• Video Interface: DisplayPort, HDMI, VGA, DVI through HDMI

• Physical Mounting Interface: NCRcustom and VESA 75mm/100mm mounting

compliance

• Flexible Cable Length Options (compatibility with NCR 1m and 4m external cables)

• Clean (Hidden) Cable Management

• Retail Hardened Display

• Integrated Enclosure

• Optional MSR/Biometric Reader/Imager Mounting Locations

• Rigid Mounting Attachments

• Latching/Strain-relieved Cables used where possible

• Spill-proof (front) and dust-proof (front)

• Integrated Amplified Speakers

Optional Features

• Table Top Stands

• Magnetic Stripe Reader (Encrypted 3-track or JIS)

• Biometric Fingerprint Reader (15" and 18.5" Displays only)

• Capacitive Biometric Reader (5968 15" and 18.5" Displays only)

• Imager

• Keypad (5968 15" Display only)

• Integrated Camera (5968 15" and 18.5" Displays only)

• Terminal Power Option (USB PlusPower)

Page 14

1-4 Product Overview

Compatibility

The NCRX-Series Display is designed as an optional input/output device for the

following host terminals:

• NCR RealPOS 30 (7446) POS Terminal

• NCR RealPOS 40 (7600) POS Terminal

• NCR RealPOS 60 (7601) POS Terminal

• NCR RealPOS 70 (7402) POS Terminal

• NCR RealPOS 70XRT (7403) POS Terminal

• NCRRealPOS 72XRT (7616) POSTerminal

• NCR RealPOS 80c (7457) POS Terminal

• NCR RealPOS 80 (7458) POS Terminal

• NCR RealPOS 80XRT (7459) POS Terminal

• NCR RealPOS 82XRT (7606) POS Terminal

• NCR RealPOS XR7 (7702) POS Terminal (10.4" and 15" Only)

Supported Resolutions

Display Resolution

5968

10.4" Resistive Touch 640x480, 800x600 (native)

10.4" Projected Capacitive Touch 640x480, 800x600 (native), 1024x768

15" Resistive Touch 640x480, 800x600, 1024x768 (native)

15" Projected Capacitive Touch 640x480, 800x600, 1024x768 (native), 1280x1024

18.5" Projected Capacitive Touch 640x480, 800x600, 1024x768, 1280x1024,

5985

10.4" Non-Touch 640x480, 800x600 (native)

1366x768 (native)

15" Non-Touch 640x480, 800x600, 1024x768 (native)

Page 15

Product Overview 1-5

Configurations

Display

Page 16

1-6 Product Overview

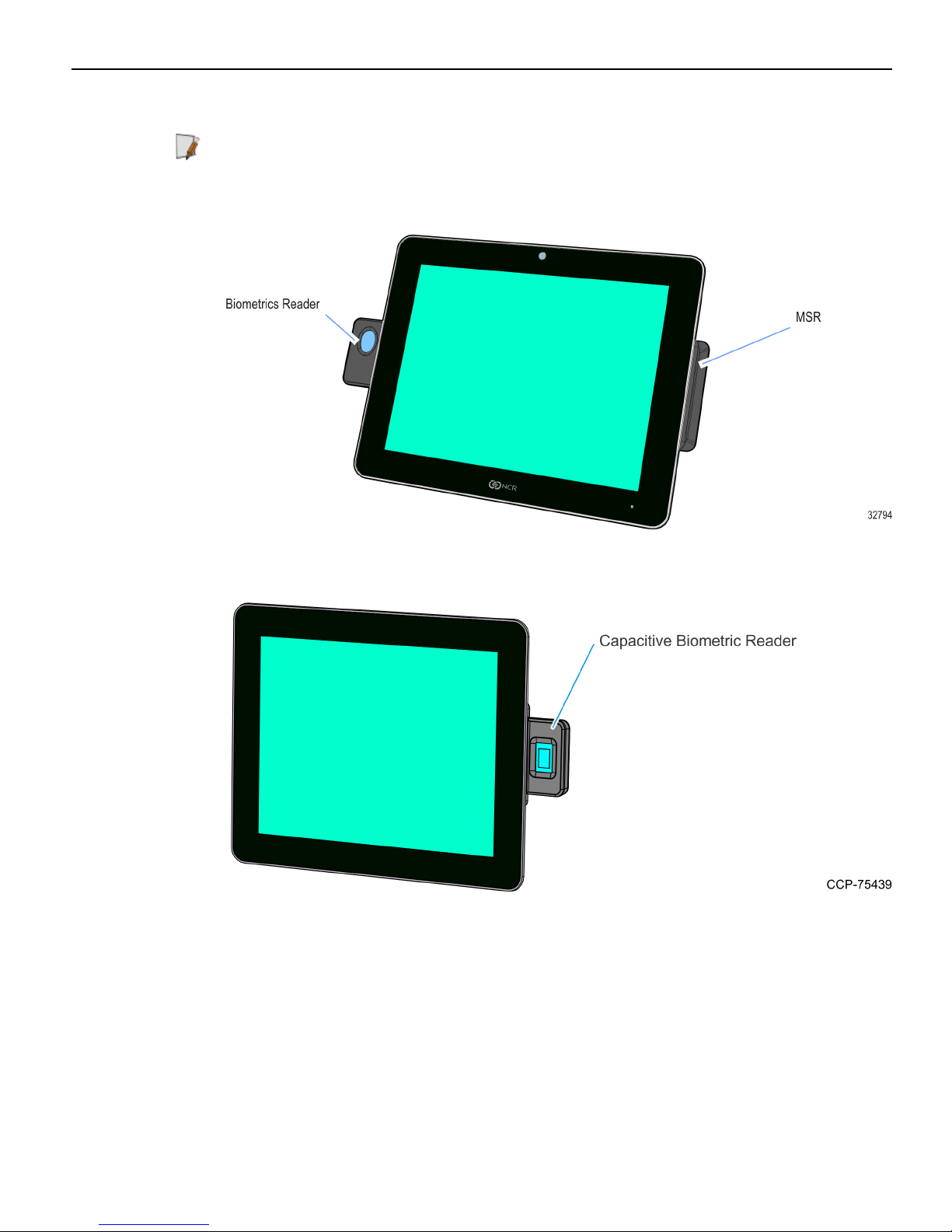

Biometrics and MSR (Encrypted 3-track or JIS)

Note: Biometrics available on 15" and 18.5" displays only. JISMSR available on 10.4" and

15" displays only.

Capacitive Biometric Reader (5968 15" and 18.5" Displays Only)

Page 17

Product Overview 1-7

Imager

Keypad (5968 15" Display Only)

Page 18

1-8 Product Overview

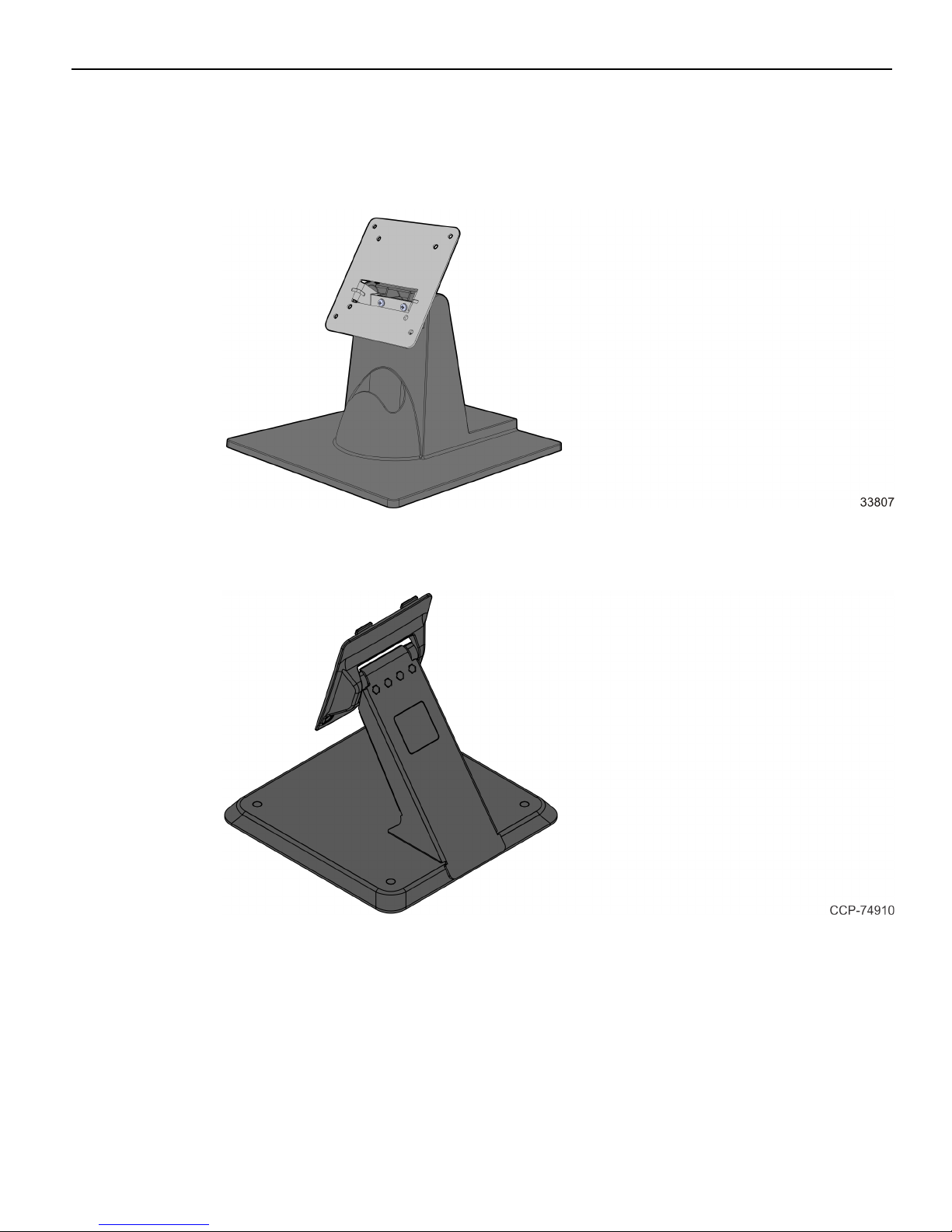

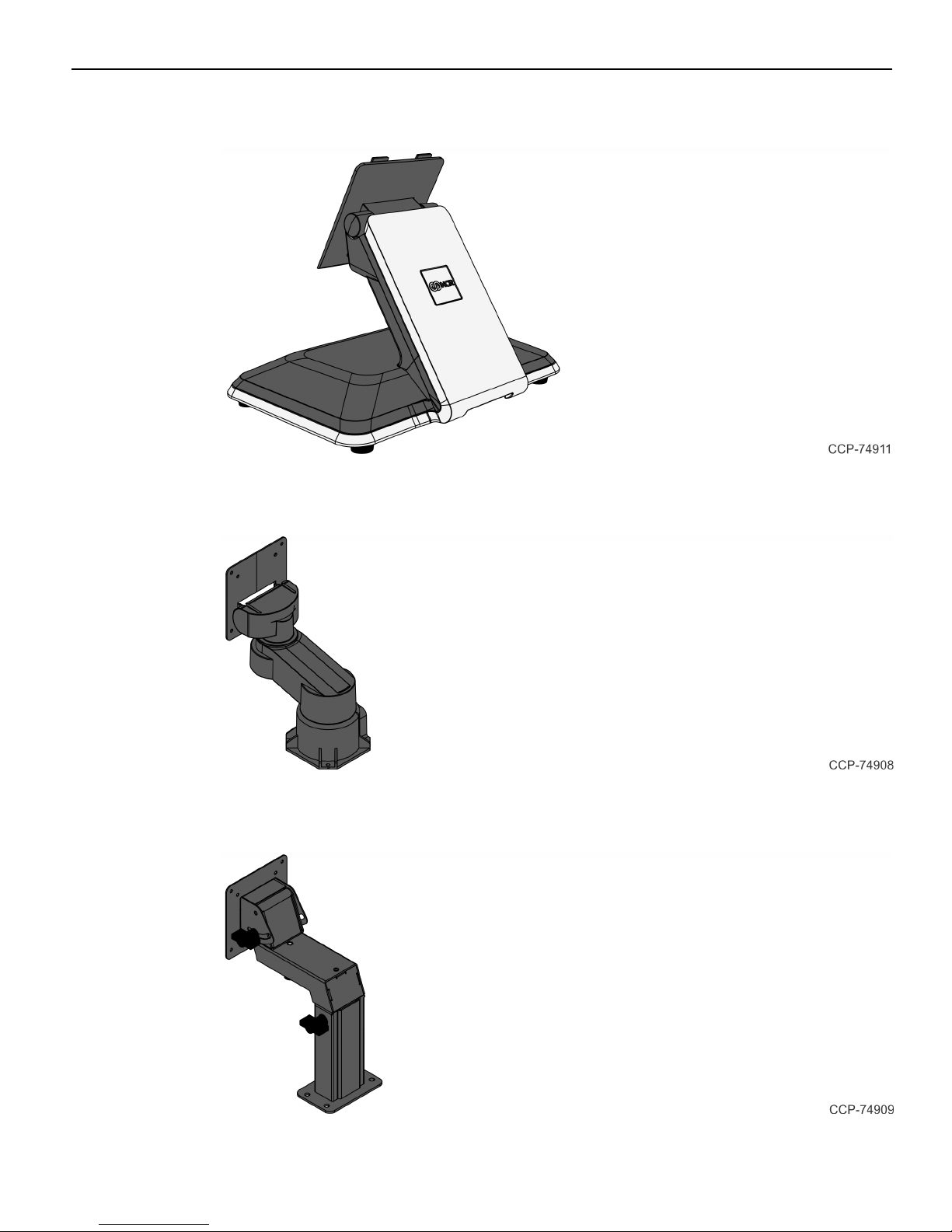

Display Mounts

X-Series Table Top Stand (5968-F031/K031, 5985-F031)

XL Series Table Top Stand (5968-F033, 5915-K033)

Page 19

Product Overview 1-9

XR Series Table Top Stand with Power Brick (7702-K031)

Integration Tray Mount (5968-K024)

Checkstand Mount (5968-K039)

Page 20

1-10 Product Overview

Wall Mount (7702-K320)

VESAMount Spacer (7702-K321, For 10.4" and 15" Displays Only)

The Rear Cover has a VESA Pattern to accommodate Third-Party Mounts. A VESA

Mount Spacer (7702-K321) is available for when the VESA mount is larger than the inset

in the Rear Cover, which provides a flat surface for the mount.

Page 21

Product Overview 1-11

X-Series Display Extension Arm Mount (7702-K453, For 10.4" and 15"

Displays Only)

This mount (7702-K453) is used to add an X-Series Display as a second display on an

XRSeries Stand (7702-K031). The second display is mounted on an Extension Arm

connected to the bottom of the Stand. The XRSeries Stand and the interface cables to

the host terminal are not included and must be ordered separately.

Pole Mount (For 5985 10.4" Display Only)

12" Pole and Table Top Mount (5934-K020) and Pole Mount Head

for 10.4" Non-Touch Display (5985-F300)

Must order both 5934-K020 and 5985-F300.

Page 22

1-12 Product Overview

Power Indicator

The Front Panel Power LED has multiple functions as defined below.

Color Description

Black System OFF or No power

Blue System ON

Green (1 sec.) Searching for an active video signal

Note: The display does not have an ON/OFF power switch.

Page 23

Product Overview 1-13

Label Locations

Page 24

1-14

Page 25

Chapter 2: Hardware Installation

Installation Restrictions

• Before installing the NCR RealPOS X-Series Display, read and follow the guidelines

in the RealPOS X-Series Displays (5968/5985) Site PreparationGuide (BCC5-0000-5292)

and the NCR Workstation and Peripheral AC Wiring Guide (BST0-2115-53).

• Install the display near an electrical outlet that is easily accessible. Use the power

cord as a power disconnect device.

• Do not permit any object to rest on the power cord. Do not locate the display

where the power cord can be walked on.

• Use a grounding strap or touch a grounded metal object to discharge any static

electricity from your body before servicing the display.

Caution: This unit contains hazardous voltages and should only be serviced by

qualified service personnel.

Caution: This device should only be powered by a power supply source which meets

Safety Extra Low Voltage (SELV) and LPS (Limited Power Source) requirements per

UL1950, IEC 950, and EN 60 950. The power source must be certified by the appropriate

safety agency for the country of installation.

Caution: Use a grounding strap when installing this feature.

Page 26

2-16 Hardware Installation

Ergonomic Workplace

The display has a high brightness LCD but for best results please observe the following

when considering the terminal workplace.

• Avoid direct–glaring and reflective–glaring light. Locate the terminal in a controlled

luminance surrounding. When installed next to windows position the terminal so it

does not reflect the outside light.

• If possible, avoid reflective glaring caused by electric light sources.

• Position the terminal for ideal viewing angles.

Page 27

Hardware Installation 2-17

Installing the Display

The display can be mounted using a variety of mounts.

• X-Series Table Top Stand (5968-F031/K031, 5985-F031)

• XL Series Table Top Stand (5968-F033, 5915-K033)

• XRSeries Table Top Stand (7702-K031)

• Integration Tray Mount (5968-K024)

• Checkstand Mount (5968-K039)

• Wall Mount (7702-K320)

• X-Series Display Extension Arm (7702-K453, For 10.4" and 15" Displays only)

• Pole Mount (5985-F300 with 5934-K020, For 5985 10.4" Display only)

• Third-Party VESA Mounts

This chapter explains how to perform an "Out-of-box" installation of a display

configured with the X-Series Table Top Stand (5968-F031/K031, 5985-F031) and how to

connect cables. The display comes fully assembled and ready to use. All that is required

to install is connect the AC Power Cord and host terminal cables.

For installation procedures for the other mounting options see their associated kit

instructions.

Page 28

2-18 Hardware Installation

Connecting the Host Terminal Cables

1. Unpack the display in the desired location.

2. Pivot the display toward the back.

Page 29

Hardware Installation 2-19

Connecting to a POS

The following illustrations show the host terminal cable connections. The required

cables vary depending on the available video connectors on the host terminal.

Data and Power Connections

Powered USBCable

The Powered USBCable provides both USB and power to the display.

1. Connect the Powered USB Cable to the display Power connector.

2. Connect the Powered USBCable to one of the 12V Powered USB connectors on the

host terminal.

Page 30

2-20 Hardware Installation

External Power Cables

An External Power Cable provides both USB and power to the display when the host

terminal does not have a USB 12V port available, but does have an available standard

USB port.

1. Connect the External Power Cable to the display Power connector.

2. Connect the other end of the External Power Cable to the USB connector on the host

terminal.

3. Connect the Power Brick DC Cable to the External Power Cable (middle of the

cable).

4. Connect the AC Power Cord to the Power Brick and an AC outlet.

Page 31

Hardware Installation 2-21

Video and Audio Connections

DisplayPort Cable

The DisplayPort Cable provides both video and audio to the display.

• Connect the DisplayPort Cable to the DisplayPort connectors on both the display and

the host terminal.

Page 32

2-22 Hardware Installation

HDMI Cable

The HDMI Cable provides both video and audio to the display.

• Connect the HDMI Cable to the HDMI connectors on both the display and the host

terminal.

Page 33

Hardware Installation 2-23

DVI to HDMICable

If the host terminal does not have an HDMI port you can use the DVI to HDMI Cable

for video to the display. A separate Audio Cable is required for audio.

1. Connect the DVI end of the cable to the DVI connector on the host terminal.

2. Connect the HDMI end of the cable to the HDMI connector on the display.

3. Optional: Connect an Audio Cable to the Audio connectors on both the display and

host terminal.

Page 34

2-24 Hardware Installation

VGA Cable

For host terminals that only have VGAfor video, a VGA Cable can be used to provide

video to the display. A separate Audio Cable is required for audio.

1. Connect the VGA Cable to the VGA connectors on both the display and host

terminal.

2. Optional: Connect an Audio Cable to the Audio connectors on both the display and

host terminal.

Note: The display has an internal audio amplifier. In order to obtain high quality

speaker output the connection from the host terminal should be driven with a Line

level signal and NOT by an Amplified or Speaker level signal. If an Amplified or Speaker

level signal is the only connection option, the volume on the terminal should be

reduced to eliminate audio distortion.

Page 35

Hardware Installation 2-25

Cable Routing

Routing Cables for Strain Relief

The display features a zip tie attachment to prevent cable strain on the cable connectors.

Cables are zip tied together at the display head and routed into the mount or stand. An

extended latch is featured on the reusable zip tie to aid with quick removal without

cutting the tie or damaging the wires.

Caution: Do not cut the zip tie.

1. Route the cables up though the mount or stand.

2. Insert the cables into their respective sockets.

3. Open the zip tie by disengaging the zip tie latch from the "teeth." Use fingernail or

small screw driver to gently disengage the latch.

Page 36

2-26 Hardware Installation

4. Bend the cables at a right angle so they cross horizontally into the open zip tie.

Note: Allow enough slack in the cables prior to closing the reusable zip tie.

5. Tighten the zip tie firmly to keep the cables in place.

6. To remove the cables, use fingernail or small screw driver to gently disengage the zip

tie latch and loosen the zip tie.

Caution: Do not cut the zip tie.

Page 37

Hardware Installation 2-27

Note: The cable management location differs slightly depending on the screen size. The

10.4" display has an added plastic zip tie mount and the 15" display has a molded zip tie

mount. Both are located at the bottom and back of the display.

Page 38

2-28 Hardware Installation

X-Series Table Top Stand (5968-F031/K031, 5985-F031)

The X-Series Table Top Stand includes a hook and loop cable management wrap to

properly route the cables though the bottom of the stand.

1. Complete the steps for cable management on the display head.

2. Adjust the display head so it is rotated as far as possible to access the connectors.

This ensures a large enough service loop to minimize strain.

3. Secure the cables with the hook and loop wrap.

Page 39

Hardware Installation 2-29

XRSeries Table Top Stand (7702-K031)

Cables are routed out the opening in the Cable Cover and down through the Stand.

1. Complete the steps for cable management on the display head.

2. Adjust the display head so it is rotated as far as possible to access the connectors.

This ensures a large enough service loop to minimize strain.

3. Remove the Upper Stand Cover by pivoting it away from the stand. The cover has a

simple snap fit connection at the top.

4. Open the Base Cable Cover (captive thumb screw).

Page 40

2-30 Hardware Installation

5. Route the cables down through the opening in the Stand Base.

6. Close the Base Stand Cover and secure it with the Captive Thumb Screw.

7. Replace the Upper Stand Cover.

Page 41

Hardware Installation 2-31

Third-Party Mounts

VESAMount Spacer

The Rear Cover has a VESA Pattern to accommodate third-party mounts. A VESA

Mount Spacer (7702-K321) is available for when the VESA mount is larger than the inset

in the Rear Cover, which provides a flat surface for the mount.

Page 42

2-32 Hardware Installation

Mounting Screw Length

Mount the VESAMount Spacer (7702-K321) and the third-party mounting plate on the

back of the display. The required screw length depends on the thickness of the thirdparty mounting plate.

Note: For 10.4" RealPOSX-Series Displays, use the 75 mm pattern on the VESA Mount

Spacer. For 15" RealPOSX-Series Displays, use the 75 mm or 100 mm pattern.

Page 43

Hardware Installation 2-33

Use the below table to determine the proper screw to use.

Mounting Plate Thickness Screw Size Screw Description

0.5mm – 2mm M4 x 14 Steel Pan Head with SEMS Washer

2mm – 4mm M4 x 16 Steel Pan Head with SEMS Washer

4mm – 6mm M4 x 18 Steel Pan Head with SEMS Washer

6mm – 8mm M4 x 20 Steel Pan Head with SEMS Washer

8mm – 10mm M4 x 22 Steel Pan Head with SEMS Washer

10mm – 12mm M4 x 24 Steel Pan Head with SEMS Washer

Page 44

2-34

Page 45

Chapter 3: Operation and Cleaning

Touch Screens

There are two types of touch screens for the RealPOS X-Series Display (5968):

• Projected Capacitive (PCap) Touch Screen

• Resistive Touch Screen

Projected Capacitive Touch Screen

PCap touch screens have all the benefits of normal capacitive touch screens and more.

• Fast processing of tough information

• High sensitivity (use conductive pencils, with hands, and with thin gloves.

• Multi-touch capability (10-finger)

• High resolution

• Improved legibility and display brightness due to optimal light transmission

• Anti-glare surface

In addition, the technology of PCap touch screens is characterized by significantly

higher robustness and stability than common capacitive touch screens because the

active touch surface is located on the back side of the touch screen. instead of the front

side. Therefore, the active surface is not directly touched and does not wear off by

normal use.

Since most surface contamination do not cause interference to the touch screen the

RealPOS X-Series Display can be used in public or severe environmental conditions.

Using the PCap Touch Screen

The PCap touch screen responds to the lightest touches. Touching with a single finger

resembles the left mouse button. Two fingers are used to zoom IN (fingers brought

together) or zoom OUT (fingers pulled apart). Circular motion can be used to rotate an

element on the screen. This function must be supported by either the Operating System

or the application.

Page 46

3-36 Operation and Cleaning

Resistive Touch Screen

The resistive TFT touch screen is constructed of a hard-coated polyester top sheet that is

overlaid on a conductive-coated glass layer. Voltage is applied to the top sheet. As a user

touches the screen, the top sheet compresses and comes into contact with the glass

layer, causing current to flow to the four corners in proportion to the distance from the

edge. Ths controller then calculates the position of the finger, based on the current flow.

Because the controller derives both the "X" and "Y" touch coordinates from the stable

glass layer, ther accuracy and operation of the touch screen is unaffected by any damage

that may have occured to the top sheet.

Using the Resistive Touch Screen

The resistive touch screen functions as traditional single-touch screens.

Touch Screen Cleaning Procedures

1. Using a soft cloth dampened with isopropyl alcohol or a mild non-abrasive soap &

water solution, gently wipe the touch screen clean.

2. Wipe the screen and edges dry.

3. Make sure the glass and screen edges dry completely before using the unit.

4. Do not use sharp objects to clean around the edges of the touch screen.

Page 47

Operation and Cleaning 3-37

Magnetic Stripe Reader

There are two types of Magnetic Stripe Readers (MSR) for the display.

• ISO 3-Track (Encrypted)

• JIS

The card reading is bi-directional and can be mounted on the right side of the display.

Using the MSR

Swipe the card through the slot in the MSR in a quick and steady movement. The

magnetic stripe must be facing up and with the stripe in the slot.

Care of Cards

• Cards should never come in contact with liquids.

• Cards should never be bent or folded in any way.

• Cards should never come in close proximity of a magnetic field.

Card Thickness

The MSR module accepts standard cards within the thickness range of 0.68 – 0.84 mm.

Page 48

3-38 Operation and Cleaning

Biometrics Fingerprint Reader

High quality fingerprint templates are imperative for the security of the biometric

security system. Low quality fingerprint templates can impact future read rates.

Therefore, using the Biometrics Module should be done very carefully. In case of

inexperienced users who are using the module for the first time, the process should be

assisted (guided) by an administrator or experienced user.

Sensor Cleaning Procedures

Daily Cleaning

Before each authentication, it is recommended that the user first clean the sensor. Place

adhesive tape onto the sensor and then pull it off. This assures that residue from

previous usage is removed.

Caution: Do not use abrasive materials to clean the sensor, including paper products.

Only adhesive tape should be used.

Using the Biometrics Reader

Place your thumb/finger flat and straight on the sensor. If this is not possible, try to

place your thumb/finger on the sensor in the same angle every time.

Page 49

Operation and Cleaning 3-39

Under normal usage conditions dirt, residue, oils, and other materials can collect on

users’ fingers. This can possibly cause poor collection of fingerprint data, which can

cause performance degradation. For best results it is recommended that the user keep

their fingers relatively clean and free of residue that may alter the sensor performance.

Adhesive tape can be used to clean fingers. Adhere the tape to the finger and then pull

it off.

Software Drivers

The RealPOS Biometrics Readers use the following modules:

Feature/Kit

Number

5985-F151

5968-F151

Description Module For Display

Biometric Reader (Port B) DigitalPersona

U.are.U 4500 Module

5985 (15")

5968 (15" or 18.5")

7702-K151

5968-F154

5968-K154

Capacitive Biometric

Reader (Port A)

TouchChip TCET

Silicon Module

5968 (18.5")

utilizing sensor

TCETD1FG022

Please visit the Crossmatch website for drivers and application developer tools.

https://www.crossmatch.com/company/support/request/

Page 50

3-40 Operation and Cleaning

Cabinet Cleaning Procedures

1. Disconnect the unit from the power outlet before cleaning.

2. Use a cloth lightly dampened with a mild detergent.

3. Do not use alcohol (methyl, ethyl, or isopropyl) or any strong dis-solvent. Do not use

thinner or benzene, abrasive cleaners, or compressed air.

Warning: Do not use any other types of cleaners such as vinegar, solvents,

degreasers, or ammonia-based cleaners. These can damage the unit.

4. Avoid getting liquids inside the unit. If liquid does get inside, have a qualified

service technician check it before you power it on again.

Page 51

Chapter 4: NCR Software OSD Utility

Introduction

The NCR Software OSD is an application that is used to adjust display parameters, such

as brightness, contrast, and Color. It also provides monitor identification information,

such as the name, serial number, and manufacturer.

Supported Features

Note: Not all features are supported on every monitor. The button is inactive and

grayed out when the feature is not supported

• Brightness

• Contrast

• V Position

• H Position

• Phase

• Clock

• Red/Green/Blue Video Gain

• Color Temperature

• Auto Setup

• Restore Default Settings

• V Moire

• H Moire

• V Size

• H Size

Page 52

4-42 NCR Software OSD Utility

Installing the Utility

1. Download the OSD Utility from the NCR website: http://www.ncr.com

a.

At this site, select the Support tab.

b.

Select Drivers and Patches → Retail Support Files→ NCR RealPOS and

Peripherals→ Displays→ 5968.

c. Download the application.

There are several versions to choose from. There are GUI versions that are used to

run locally on each system or Console versions for customers who want to run the

application from a Command Line to many systems concurrently.

Windows

• NCR_Software_OSD_GUI_x86 - (32-Bit)

• NCR_Software_OSD_Console_x86 - (32-Bit)

• NCR_Software_OSD_GUI_x64 - (64-Bit)

• NCR_Software_OSD_Console_x64 - (64-Bit)

Linux

• NCR_Software_OSD_GUI_x86 - (32-Bit)

• NCR_Software_OSD_Console_x86 - (32-Bit)

2. Click on the version of choice and Save it on your local system.

3. Unzip the application to a folder of your choice on the target system.

4. In the unzipped folder, navigate to the OSD executable.

Example: (32-Bit GUI version)

NCR_Software_OSD_GUI_x86_V2.1.7.1 >> x86

5. Run the *.exe file.

NCR_Software_OSD_GUI_x86.exe >> [Enter]

6.

Answer Yes at the Security warning.

Page 53

NCR Software OSD Utility 4-43

Running the Utility (GUI Version)

1. Unzip the application to a folder of your choice on the target system.

2. In the unzipped folder, navigate to the OSD executable.

Example: (32-Bit version)

NCR_Software_OSD_GUI_x86_V2.1.6.3>> x86

3.

Execute the NCR_Software_OSD_GUI_x86.exe file to start the application.

4.

Answer Yes at the Security warning.

Main Menu

Monitors Detected Panel

This panel lists all the monitors connected to the system. If more than one monitor is

connected, the first monitor is selected by default.

Center Panel

The Center Panel displays information pertaining the selected control.

Page 54

4-44 NCR Software OSD Utility

Control Buttons

The Control Buttons show the available features that can be modified. Unavailable

features are grayed out.

Refresh Button

Refreshes data in the Monitors Detected panel (OSD does not auto detect). Use this

button after connecting a new monitor to refresh the data.

About Button

Displays a brief description of the utility.

Help Button

Opens the Help File.

Close Button

Closes the OSD application.

Information

Provides information about the selected monitor. Information includes:

• Device manufacturer

• Date manufactured

• EDID version

• Input type

• Dimensions

• Monitor name

• Monitor serial number

• Preferred timing

• Controller type

• Firmware level

• Firmware version (for Dynamo display only)

• Display mode (for Dynamo display only)

• Timing Report

• Horizontal frequency

• Vertical frequency

• Timing status

• Raw EDID

• Raw capabilities string (CAPS)

Page 55

NCR Software OSD Utility 4-45

Brightness

Provides tools for adjusting Display brightness settings.

Contrast

Provides tools for adjusting Display contrast settings.

Positioning

Provides tools for gradually moving the image on the Display to a specific region

(either left, right, up, or down).

Size

Provides tools for increasing or decreasing the height and width of the image on the

Display.

Phase

Provides tools for increasing or decreasing the phase shift of the sampling clock.

Clock

Provides tools for increasing or decreasing the video sampling clock frequency.

Colour

Provides tools for adjusting Display color settings.

Sharpness

Provides tools for increasing or decreasing the sharpness settings of the Display.

Restore

Provides the following functions:

• Auto Setup - sets horizontal position, vertical position, clock and phase.

• Auto Color - sets red/green/blue gain.

• Factory Defaults - restores all factory defaults including brightness, contrast, and

color.

• Brightness/Contrast - restores factory defaults for brightness and contrast.

• Geometry Settings - restores factory defaults for geometry settings such as

horizontal position and vertical position.

• Colour Settings - restores factory defaults for colour settings.

Degauss

Provides tools for CRT display to perform a degauss cycle.

Moire

Provides tools for increasing or decreasing the vertical or horizontal moiré picture

cancellation.

Page 56

4-46 NCR Software OSD Utility

Language

Provides listing of the supported languages and permits changing the OSD

language.

Display Adjustment Procedures

The adjustment procedures are similar for most features. The color adjustment shown

below is an example.

1.

Select the Colour button.

2. The default Colour Settings menu has the 6500K radio button selected. To activate

the color slides select User1 .

3. Drag the slider to the right to increase the value of the property or to the left to

decrease it. Alternatively, you can click on the "+" and "-" buttons.

Page 57

NCR Software OSD Utility 4-47

Resetting Factory Defaults

Should the need arise the display settings can be reset to the factory defaults.

1.

Select the Restore button.

2. All settings or just specific groups can be reset. Select the button of choice in the

Restore window.

• Auto Setup - re-positions the window in the center of the display

• Factory Defaults - resets everything to the factory defaults

• Brightness/Contrast - resets the brightness and contrasts settings only

• Color Settings - resets the color settings only

Page 58

4-48 NCR Software OSD Utility

Running the Utility (Console Version)

1. Unzip the downloaded application to a folder of your choice on the target system.

2. In the unzipped folder, navigate to the OSD executable.

Example: (32-Bit version)

NCR_Software_OSD_Console_x86_V2.1.7.1 >> x86

3. Open a Command Line dialog window.

4. From the Command Line dialog, navigate to the OSD executable (*.exe) file.

5. Execute the file to start the application.

NCR_Software_OSD_Console_x86.exe >> [Enter]

A list of the available script command options are displayed, followed by several

example scripts. If you need further assistance with creating scripts please contact

your NCR representative for help.

Page 59

Appendix A: Touch Screen Calibration

Note: Only units with resistive touch screens need to be calibrated. PCap displays do

not require calibration.

Proper Touch Screen Methods

Before performing the calibration procedure please observe the following guidelines for

proper/improper methods of touching the screen.

• Face the monitor directly.

• Perform the calibration in the position (sitting or standing) that you normally expect

to use the touch screen.

• Touch the calibration target firmly and precisely with your fingertip. During

calibration, be careful to keep your fingernails and other fingers away from the

touch screen as you touch each target.

• The hand and calibration finger should be perpendicular (straight up) from the

touch screen during touch down and removal of the calibration finger. Keep the

other fingers closed and away from the touch screen.

• Do NOT touch the bezel with your other fingers.

Page 60

A-50 Proper Touch Screen Methods

Calibrating the Touch Screen

Resistive Touch Screen Calibration

1. Run the calibration program.

a. Open Windows Explorer.

b. Navigate to the calibration program.

C: >> Install >> Touch >> Drivers >> Resistive Touch Calibartion

2. Touch the center of the cross-hair target. When the target is touched, it disappears

and another target appears.

3. Repeat the procedure for each target as they appear.

Page 61

Proper Touch Screen Methods A-51

PCap Touch Screen Calibration

PCap touch displays rarely need to be re-calibrated. However, if the need should arise

use the following procedure.

1. Run the calibration program.

Start >> Programs >> UPDD >> Calibrate

2. Touch the center of the cross-hair target. When the target is touched, it switches to a

green check mark.

3. Repeat the prodedure for each target as they appear.

Page 62

Loading...

Loading...