Page 1

NCR RealPOS Value Touch Display

(5966 15-Inch)

Release 1.0

User Guide

B005-0000-1770

Issue D

Page 2

The product described in this book is a licensed product of NCR Corporation.

NCR is a registered trademark of NCR Corporation.

It is the policy of NCR Corporation (NCR) to improve products as new technology, components, software, and firmware become available.

NCR, therefore, reserves the right to change specifications without prior notice.

All features, functions, and operations described herein may not be marketed by NCR in all parts of the world. In some instances,

photographs are of equipment prototypes. Therefore, before using this document, consult with your NCR representative or NCR office for

information that is applicable and current.

To maintain the quality of our publications, we need your comments on the accuracy, clarity, organization, and value of this book.

Address correspondence to:

Manager, Information Products

NCR Corporation

2651 Satellite Blvd.

Duluth, GA 30096

Or send feedback:

http://www.info.ncr.com/eFeedback.cfm

Copyright © 2007

By NCR Corporation

Dayton, Ohio U.S.A.

All Rights Reserved

Page 3

i

Table of Contents

Chapter 1: Overview

Model Numbers ................................................................................ 1-1

Chapter 2: Site Preparation

Electrical Requirements .......................................................................... 2-1

5966 Electrical Requirements........................................................... 2-1

Store AC Wiring Requirements........................................................ 2-1

Environmental Requirements.................................................................. 2-2

Barometric Pressure.......................................................................... 2-2

Temperature...................................................................................... 2-2

Humidity ........................................................................................... 2-2

Weight ..................................................................................................... 2-2

Dimensions.............................................................................................. 2-3

5966 with Table Top Mount ............................................................. 2-3

5966 with 5964-K032 Table Top Mount.......................................... 2-3

System Cables ......................................................................................... 2-4

VGA Cable ....................................................................................... 2-4

12.1-Inch LCD Aux Power Cable..................................................... 2-4

Power Cords...................................................................................... 2-4

Chapter 3: Hardware Installation

Installing the 5966................................................................................... 3-1

Connector Panel Access.................................................................... 3-1

Mounting Options............................................................................. 3-2

Cable Routing ................................................................................... 3-2

Standard Integration Tray Display Mount (5964-K022/K023) .... 3-2

Standard Remote Table Top Mount (5964-K030/K031).............. 3-3

Connecting to a POS......................................................................... 3-4

Video Cable Connections ............................................................. 3-4

Data Cable Connections ............................................................... 3-5

Power Cable Connections............................................................. 3-6

Installing a 5964-K030/K031 Table Top Mount..................................... 3-7

Installation Procedures...................................................................... 3-7

Display Controls...................................................................................... 3-9

Power Indicator................................................................................. 3-9

On Screen Display (OSD)............................................................... 3-10

Menu Button............................................................................... 3-10

Select Button .............................................................................. 3-10

Page 4

ii

Navigate Up................................................................................ 3-10

Navigate Down........................................................................... 3-10

Power Button.............................................................................. 3-10

Screen Adjustment Operation Procedure........................................ 3-11

Chapter 4: OSD Adjustment

Main Menu .............................................................................................. 4-1

OSD Adjusting and Controls................................................................... 4-2

Chapter 5: Touch Screen Calibration - Windows

Installing and Calibrating the Touch Screen ........................................... 5-1

Installing the Driver and Utility........................................................ 5-1

4-Point Calibration Procedure .......................................................... 5-2

9-Point Linearization Procedure ....................................................... 5-5

Chapter 6: Touch Screen Calibration - Linux

Calibration Procedures ............................................................................ 6-1

4-Point Calibration Procedure .......................................................... 6-4

25-Point Linearization Procedure ..................................................... 6-8

Chapter 7: Auto Config Adjustment

Chapter 8: MSR Driver

Chapter 9: Maintenance

Cabinet and Touch Screen Cleaning Procedures..................................... 9-1

MSR Cleaning Procedures ...................................................................... 9-2

Appendix A: Technical Data

Display Timing........................................................................................A-2

Page 5

iii

Revision Record

Issue Date Remarks

A Feb 2007 First issue

B July 2007 Added Calibration Chapter

C Jan 2008 Added MSR Driver Chapter

D Mar 2009 Added Site Preparation Chapter; updated Hardware

Installation Chapter

Audience

This book is written for hardware installer/service personnel, system integrators, and field

engineers.

Note: This document is NCR proprietary information and is not to be disclosed or

reproduced without consent.

Safety Requirements

The NCR RealPOS 5966 conforms to all applicable legal requirements. To view the

compliance statements see the NCR RealPOS Peripherals Safety and Regulatory Statements

(B005-0000-1701).

Page 6

Page 7

1

Chapter 1: Overview

NCR’s RealPOS 5966 value touch display is designed and developed to provide a costeffective touch solution for retailers who want to maximize store productivity and extend the

life span of the touch display. The NCR 5966 is a 15-inch low cost XGA (1024x768) Liquid

Crystal Display with a 5-wire resistive touch screen for operator input.

It has the following features:

• 15’ LCD XGA (1024x768) Native Resolution, 160 nit Brightness

• Dual Bulb TFT LCD (also supports VGA, SVGA Resolutions)

• 5-Wire Resistive Touch, USB Interface

Model Numbers

• Video - VGA, Standard 15-Pin Female

• Integrated Stereo Speakers

• Power Supplied via AC Line Input or 12 DC Power Brick

• VGA, Touch, Speaker and Power Cables

• Remote Table Top Mount

• Optional MSR- Field Installable, USB Interface

• VESA standard 75mm mounting pattern on the back of the enclosure

• Uses NCR’s industry standard OPOS and JavaPOS drivers, supporting most applications

and standard NCR supported retail Windows and Linux operating systems.

Major Model Description

5966-1011 15” Value Resistive Touch Monitor, 350 nit, Remote Mount, Cables (G11)

5966-1012 15” Value Resistive Touch Monitor, 350 nit, Remote Mount, Cables (CG1)

Page 8

1-2 Chapter 1: Overview

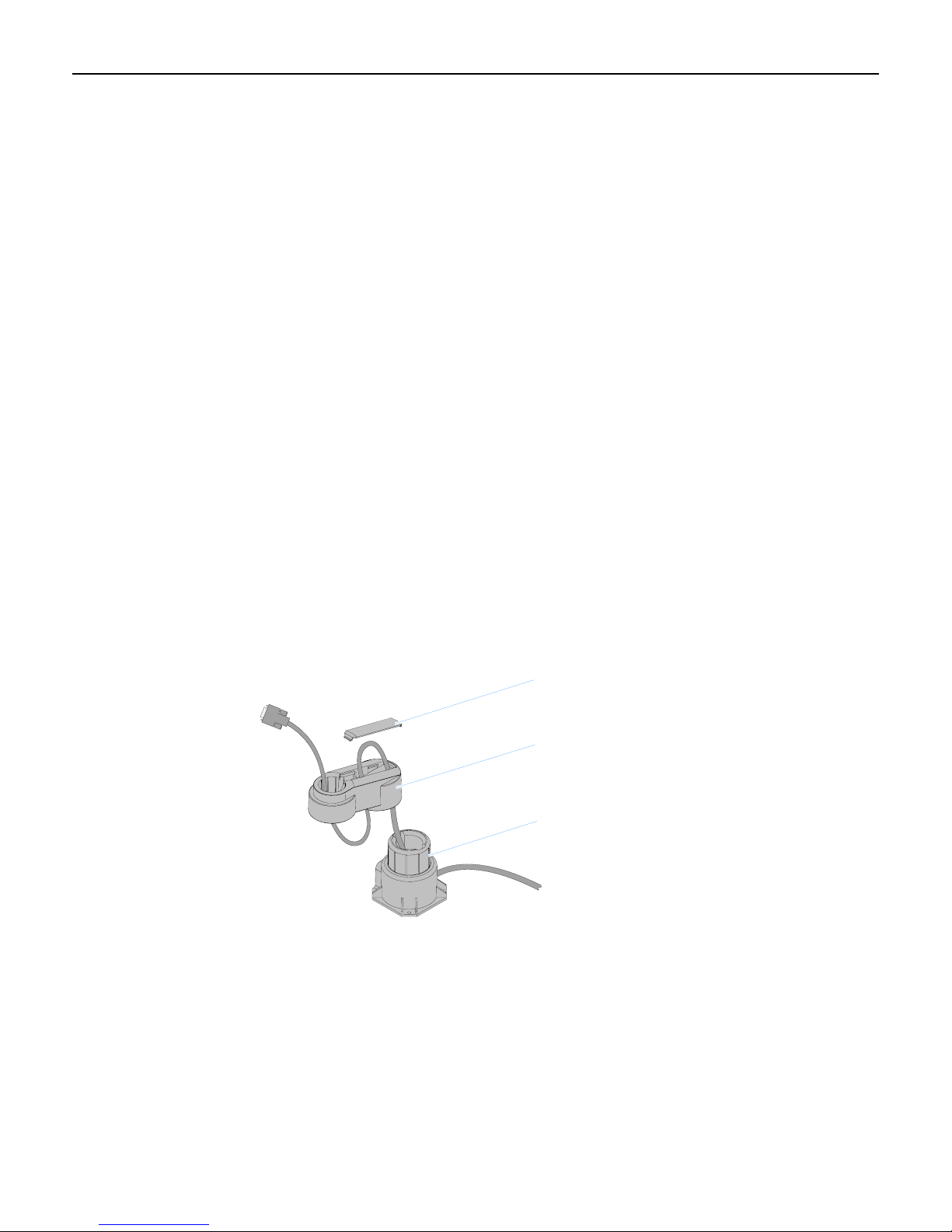

Product Components

The 5966 is shipped with a Standard Table Top Mount. This mount can be replaced with an

NCR 5964-K030 (Beige) or NCR 5964-K031 (Charcoal) Table Top Mount if desired.

Note: When using the alternate mount the Vesa Adapter Plate is required (included with the

unit).

Also included with the unit:

• VGA cable for video

• USB cable for data

• Power Brick is included for when USB power is not available on the host terminal.

Note: The USB Power Cable is ordered separately.

• Audio cable (optional) - Connects to the Audio Connector on the 5966 and the Audio Out

port on the host computer.

5966 w/Propietary Mount Vesa Adapter Plate

VGA Cable

USB Cable

Audio Cable

DC Power Brick

AC Power Cord (U.S)

5966 w/5964-K030/K031 Mount

- 5964-K030 (Beige)

- 5964-K031 (Charcoal)

27331

Page 9

2

Chapter 2: Site Preparation

Electrical Requirements

5966 Electrical Requirements

The monitor's power cord plugs into a three-wire, single-phase, 120 or 240 VAC receptacle on

the monitor. The available power cords are described in the System Cables section.

120 volt 240 volt

Voltage Ranges 100 - 127 VAC 200 - 240 VAC

Frequency 50/60 Hz 50/60 Hz

Current (A) (Max.) 0.9 0.3

Store AC Wiring Requirements

The customer must provide suitable AC power for the monitor. A dedicated unswitched power

line dedicated to the NCR equipment installation is recommended. Refer to the NCR

Workstation and Peripherals AC Wiring Guide (BSTO-2115-53) for store AC wiring

requirements. The AC outlet must be installed near the monitor and easily accessible to the

operator.

Page 10

2-2 Chapter 2: Site Preparation

Environmental Requirements

Barometric Pressure

The terminal operates within the following barometric pressure conditions:

• Maximum operating altitude: 2,750 m (9,843 ft.)

• Operating range of pressure: 105 to 72.4 kPa (15.2 to 10.5 lb./in.)

Temperature

The terminal operates over the temperature ranges shown below. Continuous operation must

be avoided at or near the indicated temperature extremes or in locations where the temperature

changes beyond the restrictions.

Temperature Parameter Restriction

Operating

Storage

Humidity

The terminal operates within the humidity ranges shown below. Continuous operation must be

avoided at or near the indicated humidity extremes or in locations where the humidity changes

beyond the restrictions. Never expose the terminal to condensation.

0°C to 40°C (32°F to 104°F), dry bulb

-20°C to 60°C (-4°F to 140°F), three months

Weight

Humidity Type Restriction

Relative 15% to 85%

Storage 15% to 85%

Shipping 15% to 85%

5.4 kg (11.9 lbs.)

Page 11

Chapter 2: Site Preparation 2-3

Dimensions

5966 with Table Top Mount

400 mm

(15.7 in.)

220 mm

(8.7 in.)

358 mm

(14.1 in.)

394 mm

(15.5 in.)

5966 with 5964-K032 Table Top Mount

180 mm

(7.1 in.)

220 mm

(8.7 in.)

27328

400 mm

(15.7 in.)

230 mm

(9.0 in.)

358 mm

(14.1 in.)

394 mm

(15.5 in.)

254 mm

(10.0 in.)

220 mm

(8.7 in.)

27327

Page 12

2-4 Chapter 2: Site Preparation

System Cables

VGA Cable

Sub Miniature D-Shell

15-Pin Plug

12.1-Inch LCD Aux Power Cable

Power

497-0464066 - 1.8 m

(1432-C321-0018)

497-0428512 - 4 m (Black)

1416-C851-0040

Sub Miniature D-Shell

15-Pin Receptacle

Powered USB

27315

Power Cords

23226

Terminal/CRT

1416-C325-0030 006-1009037 - U.S.

The following power cables (not shown)

also have an IEC connection of 45 mm:

1416-C320-0030

1416-C321-0030

1416-C322-0030

1416-C323-0030

1416-C391-0030

1416-C393-0030

006-8601011 - SEV

006-8601012 - U.K.

006-8601019 - Australia

006-8601010 - International

006-8605488 - China

006-8601001 - Japan Twist-Lock

27304

Page 13

3

Chapter 3: Hardware Installation

Installing the 5966

Caution: This device should only be powered by a power supply source which meets Safety

Extra Low Voltage (SELV) and LPS (Limited Power Source) requirements per UL1950, IEC

950, and EN 60 950. The power source must be certified by the appropriate safety agency for

the country of installation.

Caution: Use a grounding strap when installing this feature.

Connector Panel Access

The 5966 peripheral cable connectors are located on the bottom of the assembly.

VGA AC PowerUSBAudio In DC Power

27320

Page 14

3-2 Chapter 3: Hardware Installation

Mounting Options

The 5966 is shipped with a unique 5966 table top mount. However it has a VESA standard

75mm mounting pattern on the back of the enclosure, which supports the following NCR

mounts.

• Integration Tray Mount, Beige (5964-K022)

• Integration Tray Mount, Charcoal (5964-K023)

• Table Top Mount, Beige (5964-K030)

• Table Top Mount, Charcoal (5964-K031)

• Checkstand Mount, Beige (5964-K038)

• Checkstand Mount, Charcoal (5964-K039)

The additional mounts are sold as kits and are ordered separately.

Note: There is a Vesa Adapter Plate included with the 5966 that must be used with the NCR

5964-K030/K031 mount.

Cable Routing

Standard Integration Tray Display Mount (5964-K022/K023)

• 5964-K022 (Beige)

• 5964-K023 (Charcoal)

Display Cover

Display Arm

Display Base

21202b

Page 15

Chapter 3: Hardware Installation 3-3

Standard Remote Table Top Mount (5964-K030/K031)

5966 w/Propietary Mount

5966 w/5964-K030/K031 Mount

- 5964-K030 (Beige)

- 5964-K031 (Charcoal)

27330

Page 16

3-4 Chapter 3: Hardware Installation

Connecting to a POS

The following illustrations show the cable connections for the 5966 and a host terminal. There

are two cables required.

• VGA cable for video

• USB cable for data

• Powered Universal Serial Bus (USB) for power

Note: Optional Power Brick is included for when USB power is not available on the host

terminal.

• Audio cable (optional) - Connects to the Audio Connector on the 5966 and the Audio Out

port on the host computer.

Video Cable Connections

Connect the VGA Cable to the VGA connectors on both the 5966 Touch LCD and host terminal.

RS232/C RS232/D

12V

USB/C

Mouse

RS232/B

Keybd. VGA DVI

RS232/A

USB/D

12V

12V

USB/H

USB/I

12V

12V

12V

24V

USB/F

Parallel

USB/G

VGA

Cash Drw

LAN

Line Out

Speaker

Mic

USB

VGA

USB/E

497-0435044 - 1m

(1416-C972-0009)

497-0435045 - 4m

(1416-C972-0040)

27319

Page 17

Chapter 3: Hardware Installation 3-5

Data Cable Connections

Connect the included USB Cable to the USB connector on the 5966 and to a USB connector on

the host terminal.

RS232/C RS232/D

12V

12V

USB/C

USB/D

Mouse

RS232/B

Keybd. VGA DVI

RS232/A

USB/E

12V

12V

USB/H

USB/I

12V

12V

24V

Cash Drw

USB/F

USB/G

LAN

Parallel

Line Out

Speaker

Mic

USB

USB

USB

27322

Page 18

3-6 Chapter 3: Hardware Installation

Power Cable Connections

There are three methods that can be used to supply power to the 5966.

• Powered USB Cable from the host terminal

• DC Power Brick (Included with the 5966)

• AC – A U.S. Power Cord is supplied with the 5966. International cords must be ordered

separately (See the System Cables section on Chapter 1).

RS232/C RS232/D

12V

12V

USB/C

USB/D

Mouse

RS232/B

Keybd. VGA DVI

RS232/A

USB/E

12V

12V

USB/F

Parallel

12V

12V

USB/H

USB/I

24V

Cash Drw

USB/G

12V USB

LAN

Line Out

Speaker

Mic

USB

or or

DC Power

497-0445076 - 1 m

(1432-C156-0010)

497-0445077 - 4 m

(1432-C156-0040)

AC Power Cord

(Country Specific)

AC

27321

Page 19

Chapter 3: Hardware Installation 3-7

Installing a 5964-K030/K031 Table Top Mount

The 5964-K030/K031 Table Top Mount can be used with the 5966 Display Head in place of

the Standard Mount shipped with the unit. There are two versions:

• 5964-K030 (Beige)

• 5964-K031 (Charcoal)

Installation Procedures

1. Lay the 5966 face down on a flat surface.

2. Remove the Standard Mount (4 screws) from the display.

Note: Discard these screws. The 5964 mount requires longer screws.

27338

Page 20

3-8 Chapter 3: Hardware Installation

3. Place the Vesa Adapter Plate in the recess in the back of the display.

4. Install the 5964 mount using the screws included with the mount.

5964-K030/K031 Mount

Vesa Plate

27329

Page 21

Chapter 3: Hardware Installation 3-9

Display Controls

Power Indicator

The LED is green color while in the normal ON state and orange while in the Power Save

mode.

Power Indicator

24316

Page 22

3-10 Chapter 3: Hardware Installation

On Screen Display (OSD)

The OSD is accessed through five pushbuttons on the rear of the display. These buttons

provide a way to adjust display parameters of the unit.

Menu Select

1

1

Navigate

Up

2

Navigate

Down

2

Power

24317

Menu Button

Used to enter the OSD menu. This button is also used to return to the previous menu. The

changed data is not saved in memory.

Select Button

Used to confirm the current selection. It also used for go back to the previous menu. The

changed data is saved in memory.

Navigate Up

Used to scroll up in sub menus or to increase the value of the selected item. Pressing this

button when a menu is not active adjusts the Brightness.

Navigate Down

Used to scroll down in sub menus or to decrease the value of the selected item. When the OSD

menu is not active this button is a shortcut key for the Auto Config function.

Power Button

Used to turn the monitor on/off.

Page 23

Chapter 3: Hardware Installation 3-11

Screen Adjustment Operation Procedure

1) Entering the screen adjustment

The setting switches are normally at stand-by. Push the [1] button once to display the main

menu of the screen adjustment. The adjustable items will be displayed in the main menu.

2) Entering the settings

Use the Adjust ▲ and Adjust ▼ buttons to select the desired setting icon and push the

SELECT button to enter sub-menu.

3) Change the settings

After the sub-menu appears, use the Adjust ▲ and Adjust ▼ buttons to change the setting

values.

4) Save

After finishing the adjustment, push the [2] button to memorize the setting.

5) Return & Exit the main menu

To go back to the previous menu, push the MEMU button.

Page 24

3-12 Chapter 3: Hardware Installation

Page 25

4

Chapter 4: OSD Adjustment

Main Menu

The On Screen Display (OSD) main menu is displayed when the [1] key is pressed. The menu

is a combination of graphics and text. The column inside the OSD menu shows input image

information. The column beneath the menu indicates the item selected.

The ▲ and ▼ keys are used to scroll through items within the menu. The selected item is

highlighted as you scroll. The [2] key is used to activate the highlighted item.

Page 26

4-2 Chapter 4: OSD Adjustment

OSD Adjusting and Controls

BRIGHTNESS

Setup the brightness of the panel.

CONTRAST

The Contrast menu item is used to adjust image contrast.

AUTO CONFIG

There are two items: AUTO ADJUST and AUTO COLOR . Use the Adjust ▲ and ▼ key to

scroll up and down in menu, then press the [2] key to start this function. If the MENU key is

pressed, the main menu is re-displayed and nothing is changed.

AUTO ADJUST: Used to perform automatic configuration of the phase, clock, vertical, and

horizontal positioning.

AUTO COLOR: It is used to adjust the gain and offset of the Red, Green and Blue channels

on the ADC automatically.

H-POSITION

H-Position is used to adjust the horizontal image position manually. A slider with current value

is displayed.

V-POSITION

V-Position is used to adjust the vertical image position manually. A slider with current value is

displayed.

CLOCK

Reduce vertical stripes in the screen image.

PHASE

Reduce horizontal stripes in the screen image.

SHARPNESS

This can adjust the video quality to be sharp or blur (special for text mode).

INFORMATION

The “INFORMATION” menu provides the user with detailed information regarding the

current input format and version (include resolution, horizontal/vertical frequency, and

firmware version).

Page 27

Chapter 4: OSD Adjustment 4-3

COLOR

Configure the image color. There are three items : 9300K、6500K、USER MODE.

9300K: The item “9300K” is used to default 9300K color temperature.

6500K: The item “6500K” is used to default 6500K color temperature.

USER MODE

RGB ADJUST :

• RED: The item “RED” is used to adjust the gain of red channel in ADC.

• GREEN: The item “GREEN” is used to adjust the gain of green channel in ADC.

• BLUE: The item “BLUE” is used to adjust the gain of blue channel in ADC.

OSD MENU

There are five items: LANGUAGE, OSD H POSITION, OSD V POSITION, , OSD TIME

OUT and OSD BLENDING.

• OSD H POSITION : The item "OSD H Position” is used to setup the OSD menu H

position.

• OSD V POSITION : The item "OSD V Position” is used to setup the OSD menu H

position.

• OSD BLENDING : To adjust the blending of the OSD MENU.

• OSD TIME OUT : “OSD Time out” is used to set the timeout of the OSD menu. There are

three options for the automatic timeout: 20, 40 and 60 seconds.

MISC MENU

There are two items: audio and reset.

• AUDIO: This is used to adjust the sound volume.

• RESET : Press “Reset” to return the monitor to its factory default settings.

Page 28

4-4 Chapter 4: OSD Adjustment

Page 29

5

Chapter 5: Touch Screen Calibration - Windows

Installing and Calibrating the Touch Screen

The Touch Screen Calibration Utility is included when you install the TouchKit Driver. This

driver can be downloaded from the NCR Web Site.

http://www.ncr.com

1. At this site, select Support → Drivers and Patches → Retail Support Files →

Retail Platform Software → 5966.

2. Download the Touch Driver: 5966_touch_driver_4.3.6.2817 (or later).

Installing the Driver and Utility

1. Extract the driver installation files into to a working directory on the host terminal.

2. Locate the folder containing the operating system you are using and run the setup program.

The name of the setup program varies from OS to OS. Follow the instructions to install the

software

Page 30

5-2 Chapter 5: Touch Screen Calibration - Windows

4-Point Calibration Procedure

Note: The 9-Point Linearization procedure should be performed first if either the Touch

Screen Sensor or the Controller Board is replaced.

1. From the Windows Start button, select

Settings → Programs → TouchKit → Configure Utility

2. From the TouchKit:USB Controller screen, select the Tools tab.

Page 31

Chapter 5: Touch Screen Calibration - Windows 5-3

3. Select 4-Points Calibration to begin calibration.

Page 32

5-4 Chapter 5: Touch Screen Calibration - Windows

4. Place a stylus in the center of the flashing target in the lower left-hand corner of the screen

and hold it until it stops blinking.

Note: For best results, a stylus should be used to calibrate the screen rather than your

finger. Not all operators use the same touching techniques and can result in poor

calibration on terminals that have multiple operators.

5. Repeat this procedure for the other three targets

6. Select OK to continue.

7. Test the calibration by moving the stylus around on the screen and verifying that the cursor

follows it. Also, touch all 4 Corners and verify that the cursor moves deeply into the

corners.

8. If you are satisfied with the calibration results select OK to exit the TouchKit Utility.

Page 33

Chapter 5: Touch Screen Calibration - Windows 5-5

9-Point Linearization Procedure

The 9-Point Linearization procedure should be performed if either the Touch Screen Sensor or

the Controller Board is replaced.

Note: On new terminals the display is pre-linearized from the factory and performing the

linearization procedure can result in loss of the factory settings and reduced performance

1. Select the Linearization button to begin the linearization process.

Page 34

5-6 Chapter 5: Touch Screen Calibration - Windows

2. Place a stylus in the center of the flashing target in the lower left-hand corner of the screen

and hold it until it stops blinking.

Note: As with the Calibration Procedure for best results a stylus should be used rather

than your finger.

3. Repeat this procedure for the other eight targets.

4. Select OK to continue.

5. Perform the 4-Point Calibration procedure.

Page 35

6

Chapter 6: Touch Screen Calibration - Linux

Calibration Procedures

The Touch Screen Calibration Utility is included in the NCR Linux Terminal Configurator,

which gets installed when you install the NLPOS Linux software.

For more information about the Terminal Configurator, see the NCR Linux Terminal

Configurator User's Guide, B005-0000-1743.

1. Start the Terminal Configurator Utility. At the prompt enter:

TerminalConfig

2. At the Main Menu, select: 2) Video.

Page 36

6-2 Chapter 6: Touch Screen Calibration - Linux

3. Select: 1) Adapter.

4. Select: 9) Calibrate Touch.

Page 37

Chapter 6: Touch Screen Calibration - Linux 6-3

5. Press any key to continue.

Page 38

6-4 Chapter 6: Touch Screen Calibration - Linux

4-Point Calibration Procedure

Note: The 25-Point Linearization procedure should be performed first if either the Touch

Screen Sensor or the Controller Board is replaced.

1. From the TouchKit window, select the Tool tab.

Page 39

Chapter 6: Touch Screen Calibration - Linux 6-5

2. Select 4-Pts Cal to start the calibration.

Page 40

6-6 Chapter 6: Touch Screen Calibration - Linux

3. Place a stylus in the center of the flashing target in the lower left-hand corner of the screen

and hold it until it beeps.

Note: For best results, a stylus should be used to calibrate the screen rather than your

finger. Not all operators use the same touching techniques and can result in poor

calibration on terminals that have multiple operators.

Please Touch The Calibration Symbol (ESC to Abort)

Toolkit Calibration

4. Repeat this procedure for the other three targets.

5. Select OK to continue.

24913

6. Test the calibration by moving the stylus around on the screen and verifying that the cursor

follows it. Also, touch all 4 Corners and verify that the cursor moves deeply into the

corners.

7. If you are satisfied with the calibration results select OK to exit the TouchKit Utility.

Page 41

Chapter 6: Touch Screen Calibration - Linux 6-7

8. Select OK to continue.

Page 42

6-8 Chapter 6: Touch Screen Calibration - Linux

25-Point Linearization Procedure

The 25-Point Linearization procedure should be performed if either the Touch Screen Sensor

or the Controller Board is replaced.

Note: On new terminals the display is pre-linearized from the factory and performing the

linearization procedure can result in loss of the factory settings and reduced performance

1. Select the 25 Pts Linz button to begin the linearization process.

Page 43

Chapter 6: Touch Screen Calibration - Linux 6-9

2. Place a stylus in the center of the flashing target in the lower left-hand corner of the screen

and hold it until it beeps.

Note: As with the Calibration Procedure for best results a stylus should be used rather

than your finger.

Please Touch The Calibration Symbol (ESC to Abort)

Toolkit Calibration

3. Repeat this procedure for the other 24 targets.

4. Select OK to continue.

5. Perform the 4-Point Calibration procedure.

24913

Page 44

6-10 Chapter 6: Touch Screen Calibration - Linux

Page 45

7

Chapter 7: Auto Config Adjustment

How to Use the Auto Config Adjustment

This function can tune the parameters of PHASE, CLOCK, H-POSITION, and VPOSITION.

Suggesting Adjustment Steps:

1. Enter the “Windows” Shut-down frame.

Note: The Wallpaper color CAN NOT be black.)

2. Inactive OSD menu, then press knob ▼ key. The Picture will auto-adjust by itself. After 4

seconds, you can exit OSD and Shut-down frame.

Notes:

• If you do not like the effect of the AUTO CONFIG adjustment, you can adjust the PHASE

and CLOCK items using the OSD.

• The AUTO CONFIG adjustment can be used in Windows except with a black background

frame. The best effect is in the SHUT DOWN frame.

Page 46

7-2 Chapter 7: Auto Config Adjustment

Page 47

8

Chapter 8: MSR Driver

The 5966 MSR is a USB device with unique drivers that need to be loaded to enable it.

The drivers are contained within Retail Platform Software (2.4.3.0 or 2.5.0.0) in the directory

C:\Program Files\NCR\Retail Controls\Drivers, or can be downloaded from the

NCR Web Site.

http://www.ncr.com

1. At this site, select Support → Drivers and Patches → Retail Support Files →

Retail Platform Software.

2. In the Peripherals section select 5966.

3. Download the 5966MSRDrivers.ZIP file.

4. Copy the file to a working directory on the target retail terminal and extract the files.

5. Right-click on the *.inf file to begin the installation process.

The device is from XAC and should appear as Vendor ID 2182 Product ID 8000. UPOS

support is provided for this device.

Page 48

8-2 Chapter 8: MSR Driver

Page 49

9

Chapter 9: Maintenance

Cabinet and Screen Cleaning Procedures

NCR touch screen terminals are designed for general retail applications. These products are

resistant to spills and dust. However, these products are not spill proof or dust proof.

To maintain proper operation, users should prevent water, beverages, or cleaning agents from

being introduced into the unit during storage, operation, or cleaning.

To clean your terminal, use the following procedures:

1. Disconnect the unit from the power outlet before cleaning.

2. Use a soft cloth dampened lightly with a mild non-abrasive soap & water solution or 70%

Isopropy

l Alcohol.

3. Gently wipe the subject area clean.

4. Wipe the damp areas dry. Make sure the glass and touch screen edges are completely dry

before using th

5. Avoid getting any liquids inside the unit. If liqui

technician check it before you power it on again.

e unit.

Cleaners/Solvents to Use

Use the following cleaner/solvents to clean the unit.

Mild Non-Abrasive Soap and Water Solution

or

70% Isopropyl Alcohol

Cleaners/Solvents to NOT Use

Do NOT use any of the following to clean the unit. They can damage the unit.

Methyl Alcohol

Degreasers

Ethyl Alcohol

Ammonia-based Cleaners such as glass cleaners (Windex)

Abrasive Cleaners

Vinegar Cleaners

Any Strong Dissolvent

Thinner

Benzene

Compressed Air.

Solvents

Bleach

d doe

s get inside, have a qualified service

Page 50

9-2 Chapter 9: Maintenance

Cleaning the Glass

1. Spray an ammonia-based glass cleaner on a soft cloth and gently wipe the glass screen

clean.

Warning: Do not use any other types of cleaners such as vinegar, solvents, or

degreasers. These can damage the screen.

2. Wipe the screen and edges dry.

3. Allow the glass and screen edges to completely dry before using the unit.

4. When cleaning has been completed, plug in the keyboard cable and power on the

workstation.

MSR Cleaning Procedures

MSR Cleaning and Treatment Cards

Part Part Number

MSR Cleaning Card, Dry 998-0052929

MSR Cleaning Card, Wet 603-9014730 (box of 50)

MSR Treatment Card 497-0453056 (box of 20)

MSR Treatment Card

The MSR Treatment Card is used to assist in protecting Magnetic Stripe Readers from

Electrostatic Discharge (ESD), which can cause failures when swiping cards that have metallic

hologram stripes.

Swipe the card through the MSR in a smooth motion. Only swipe it down ONCE and up

ONCE. Allow the device to dry for 5 minutes before swiping any other cards.

Note: Each long side of the card may be used twice. Each short side of the card may be used

only once. Thus, a single card can treat 6 MSR devices with one UP and one DOWN swipe per

MSR device. These limits should not be exceeded due to the possibility of spreading

contaminants from machine to machine and/or reducing ESD protection.

Page 51

Chapter 9: Maintenance 9-3

Note: If all six up/down swipes are not used on a fresh card it should be placed in a sealed

(Ziploc) bag for future use.

Cleaning/Treatment Frequency

New MSR:

Prior to placing in operation, the MSR device should be swiped with the MSR Treatment Card.

Existing MSR:

An existing MSR should be cleaned using an MSR Cleaning Card before treating it with a

MSR Treatment Card. For low use retail establishments, the cleaning and treatment procedures

should be followed at least once per month. In areas of extremely high traffic (in excess of 500

swipes per day) or an operating environment that is high in contaminants, such as found in the

food service industry, a weekly cleaning and treatment should be performed.

MSR Cleaning Cards and MSR Treatment Cards may be purchased from NCR or KIC

Products. For details, see

http://www.ncr-direct.com or http://www.kicproducts.com.

Page 52

9-4 Chapter 9: Maintenance

Page 53

A

Appendix A: Technical Data

Video Input Pin Assignment

This section describes the pin assignment of the LCD’s video connector. It is called 15 Pin

Mini D-sub Connector.

Pin NO. Signal Connector

1

2

3

4

5

6

7

8

9

10

11

12

13

14

Red Video Signal

Green Video Signal

Blue Video Signal

N.C.

Ground

Ground for red video signal

Ground for green video signal

Ground for blue video signal

VGA +5 V

PC detection

N.C.

DDC data

Horizontal sync signal

Vertical sync signal

15

DDC clock

Page 54

A-2 Appendix A: Technical Data

z

z

Display Timing

The following table lists the better display quality modes that the LCD monitor provides. If the

other video modes are input, the monitor will stop working or display unsatisfactory picture

quality.

VESA MODES

Horizontal Vertical VCLK

Mode Resolution Total Nominal

Frequency

+/- 0.5KHz

DOS 720*400@70Hz 900*449 31.469 70.087 28.322

VGA

SVGA

XGA

640*480@60Hz 800*525 31.469 59.940 25.175

640*480@72Hz 832*520 37.861 72.809 31.500

640*480@75Hz 840*500 37.500 75.000 31.500

800*600@56Hz 1024*625 35.156 56.250 36.000

800*600@60Hz 1056*628 37.879 60.017 40.000

800*600@72Hz 1040*666 48.077 72.188 50.000

800*600@75Hz 1056*625 46.875 75.000 49.500

1024*768@60Hz1344*804 48.363 60.004 65.000

1024*768@70Hz1328*806 56.476 70.069 75.000

1024*768@75H

1312*800 60.023 75.029 78.750

Nominal

Frequency

+/- 1 Hz

Nominal

Pixel Clock

(MHz)

IBM MODES

DOS 720*400@70Hz 900*449 31.469 70.087 28.322

VGA 640*480@60Hz 800*525 31.469 59.940 25.175

MAC MODES

640*480@60Hz 800*525 31.469 59.940 25.175

VGA

SVGA 832*624@75Hz 1152*667 49.725 74.551 57.283

XGA

640*480@75Hz 864*525 35.000 66.667 30.240

1024*768@60Hz1312*813 48.780

1024*768@75H

1328*804 60.241 74.927 80.000

60.001 64.000

Loading...

Loading...