Page 1

Jupiter 30 / 20

GPS receiver module

Integrator’s Manual

Related documents

•Jupiter Series Development kit guide

LA000645

• Navman NMEA reference manual

MN000315

• SiRF Binary Protocol reference manual

LA000577C © 2006 N avman New Zealand. All rights reserved. Proprietar y information and speci cations subj ect to change wit hout not ice.

Page 2

Contents

1.0 Introduction .......................................................................................................4

2.0 Hardware application information................................................................... 4

2.1 Electrical connections (SMT pad interface) .................................................................. 4

2.2 Physical dimensions

2.3 Manufacturing process recommendations ................................................................... 6

2.3.1 Reow recommendations ..................................................................................... 6

2.3.2 Connection pad material ...................................................................................... 6

2.3.3 Solder paste mask size ........................................................................................ 7

2.3.4 Solder paste type ................................................................................................. 7

2.3.5 Coating ................................................................................................................. 7

2.3.6 Post reow washing ............................................................................................. 7

2.3.7 Pre-baking ............................................................................................................ 7

2.3.8 Rework ................................................................................................................. 7

2.4 Typical application circuit ............................................................................................. 7

2.4.1 Power for receiver and active antenna

2.4.2 Grounding ............................................................................................................ 7

2.4.3 Decoupling ........................................................................................................... 8

2.4.4 Serial RS232 data level shifter ............................................................................. 9

2.4.5 External RF lter .................................................................................................. 9

2.5 PCB design recommendations ..................................................................................... 9

2.5.1 Recommended PCB pad layout ........................................................................... 9

2.5.2 General recommendations ................................................................................... 9

2.6 Antenna system design choices

2.6.1 Antenna types

2.6.2 Active antenna ....................................................................................................12

2.6.3 Passive antenna ..................................................................................................13

2.6.4 Jupiter module used as a GPS sensor................................................................13

2.6.5 DC supply protection for an active antenna ........................................................14

2.7 Jupiter adapter printed circuit board ............................................................................16

..................................................................................................... 6

................................................................. 7

..................................................................................12

.....................................................................................................12

3.0 Software application information .................................................................. 17

3.1 Normal mode operation ...............................................................................................17

3.2 Power management

3.2.1 Adaptive TricklePower mode ...............................................................................18

3.2.2 Push-to-Fix mode ...............................................................................................18

3.3 Serial I/O .....................................................................................................................18

3.3.1 Default settings ....................................................................................................18

3.3.2 NMEA input commands ......................................................................................18

3.3.3 Altitude output .....................................................................................................19

3.4 Navman proprietary NMEA low power mode messages

3.4.1 Low power conguration ..................................................................................... 20

3.4.2 Low power acquisition conguration .................................................................. 20

3.5 Control of GPIO connections via serial commands (Jupiter 20) ................................ 20

3.5.1 Congure port directions .....................................................................................21

3.5.2 Set outputs ..........................................................................................................21

3.5.3 Clear outputs .......................................................................................................21

3.5.4 Read inputs .........................................................................................................21

3.6 GPS x output .............................................................................................................21

3.7 Antenna power monitor messages

3.8 Custom application software ...................................................................................... 22

....................................................................................................17

........................................... 20

............................................................................. 22

4.0 Glossary and acronyms .................................................................................23

LA000577C © 2006 N avman New Zealand. All rights reserved. Proprietar y information and speci cations subj ect to change wit hout not ice.

Page 3

Figures

Figure 2-1: Lead-free and tin/lead reow prole recommendation ..................................... 6

Figure 2-2: Sample application circuit ................................................................................ 8

Figure 2-3: Recommended application layout dimensions................................................. 9

Figure 2-4: Typical module layout .....................................................................................10

Figure 2-5: Example PCB layout for external active antenna ............................................10

Figure 2-6: PCB microstrip dimensions .............................................................................11

Figure 2-7: Arrangement of active antenna and application board....................................12

Figure 2-8: Cross section of application board with passive patch antenna .....................13

Figure 2-9: Simple current limiter circuit ............................................................................14

Figure 2-10: Active current limit using an IC ......................................................................14

Figure 2-11: Antenna short/open circuit sensor circuit (3.3 V supply only)

........................15

Tables

Table 2-1: Jupiter 30 and Jupiter 20 Module pin functions ................................................. 5

Table 2-2: Summary of pin multi-functionality .................................................................... 6

Table 2-3: Decoupling recommendations ........................................................................... 8

Table 2-4: PCB substrate thicknesses v track width .........................................................11

Table 2-5: Passive and active antenna features ................................................................12

Table 2-6: Recommended antenna characteristics ...........................................................13

Table 2-7: Antenna sense and control functions ...............................................................15

Table 2-8: Connector conguration ...................................................................................17

Table 3-1: Low power modes message values ................................................................ 20

Table 3-2: Low power acquisition input values ................................................................. 20

Table 3-3: Pin conguration of the GPIO lines ..................................................................21

Table 3-4: Antenna status output message values .......................................................... 22

LA000577C © 2006 N avman New Zealand. All rights reserved. Proprietar y information and speci cations subj ect to change wit hout not ice.

Page 4

1.0 Introduction

The Navman Jupiter 30 and Jupiter 20 series of GPS receiver modules are complete GPS

receivers designed for surface mount assembly (SMT) integration. The modules provide a

simple, cost effective GPS solution for application designers. Application integration will vary

primarily with respect to antenna system design and EMI protective circuitry.

The Jupiter 30 is the successor to the established Jupiter 20, sharing the same form factor

(25.4 x 25.4 mm) and electrical compatibility. This provides a low risk migration path for existing

users, offering greater sensitivity, lower power consumption and a faster x.

Fundamental operation requires a 3.3 VDC power supply, approximate current of 80 mA

(Jupiter 30) or 100 mA (Jupiter 20), GPS antenna system interface, relevant EMI protection, and

the design and layout of a custom PCB.

This document outlines the following design considerations and provides recommended

solutions:

Hardware application information

This section introduces the system interface and provides the following physical specications:

a. electrical connections (SMT pad interface)

b. mounting (PCB pad layout dimensions)

c. manufacturing recommendations

d. application circuit interface

It also discusses the fundamental considerations when designing for RF, and presents the

antenna system design overview. This covers the following topics:

a. PCB layout

b. antenna system design choices

Software application information

This section provides answers to some common questions that may not have been covered in

the above topics.

A sample solution is presented and discussed for example purposes only. Due to the nature and

complexity of GPS signals, it is recommended that application integrators adhere to the design

considerations and criteria described in this document.

2.0 Hardware application information

The modules provide 30 Surface Mount pads for electrical connections. The sections that follow

introduce the physical and relative functional specications for application integration.

Note: The electrical connections can carry very low level GPS signals at 1.57542 GHz. The

layout must be designed appropriately with consideration of the frequencies involved.

2.1 Electrical connections (SMT pad interface)

Details of the module connector conguration are shown in Table 2-1.

LA000577C © 2006 N avman New Zealand. All rights reserved. Proprietar y information and speci cations subj ect to change wit hout not ice.

4

Page 5

Pin

No.

Name Type Description

1 PWRIN P main power input (3.3 V)

2 GND P ground

3 BOOT I

serial boot (high for serial boot, low or open circuit

for normal operation)

4 RXA I CMOS level asynchronous input for UART A

5 TXA O CMOS level asynchronous output for UART A

6 TXB O CMOS level asynchronous output for UART B

7 RXB I CMOS level asynchronous input for UART B

8 pin 8 multi-functional (see table 2-2)

9 RF_ON O

output to indicate whether the RF section is

enabled (active high)

10 GND P ground

11 GND P ground

12 GND P ground

13 GND P ground

14 GND P ground

15 GND P ground

16 GND P ground

17

RF_IN I RF input

18 GND P ground

19 ACTIVE_PWR P

active power input, 70 mA current limit supply to

this pin

20 VCC_RF O RF Power (+2.85 V) supply output

21 V_BATT P backup battery input

22 NRESET I

external reset (active low), voltage on PIN 22

NRESET must not exceed PWRIN at all times

23 GPS_FIX O GPS x indication (active low)

24

25

pins 24-28 multi-functional (see table 2-2)

26

27

28

29 1PPS O 1 pulse per second output

30 GND P ground

Table 2-1: Jupiter 30 and Jupiter 20 Module pin functions

LA000577C © 2006 N avman New Zealand. All rights reserved. Proprietar y information and speci cations subj ect to change wit hout not ice.

5

Page 6

Jupiter 30 Jupiter 20

Pin

GPIO Name and Description GPIO

24 13 reserved 6 GPIO (SDO) not connected

25 4 reserved 5 GPIO (SDI) ADC DOut

26 –

27 15

28 1

8 14

push-to-x wakeup (active on +ve edge)

antenna open circuit sensor input (active

active antenna control output

antenna short circuit sensor input (active

WAKEUP

ANT_OC

high)

ANT_CTRL

NANT_SC

low)

7 GPIO (SCK) ADC Clk

15 ANT_OC

1 ANT_CTRL

3 NANT_SC

Standard &

XTrac name

DR function

FWD/REV

fwd/rev input

(low=forward,

high=reverse)

WHEEL_TICKS

wheel tick input

GYRO_IN

gyro input

(analogue 0–5 V)

Table 2-2: Summary of pin multi-functionality

GPIO

Note that the Jupiter 20 D (Dead Reckoning) does not support the active antenna supervisory

functionality and associated proprietary NMEA status messaging (see section 3.7).

SPI (Jupiter 20 only)

The Jupiter 20 (GSW2) and Jupiter 20 S (XTrac) do not support the SPI. These pins function

only as user GPIOs.

The SPI on the Jupiter 20 D is used to control an internal ADC, which interfaces to an

external gyro.

Implementation of the SPI for any other alternative function requires an SDK (Software

Development Kit) from SiRF.

2.2 Physical dimensions

The physical dimensions of the Jupiter 30 and Jupiter 20 modules are identical:

length: 25.4 mm ± 0.1 mm

width: 25.4 mm ± 0.1 mm

thickness: 3.0 mm max

weight: 4.0 g max

2.3 Manufacturing process recommendations

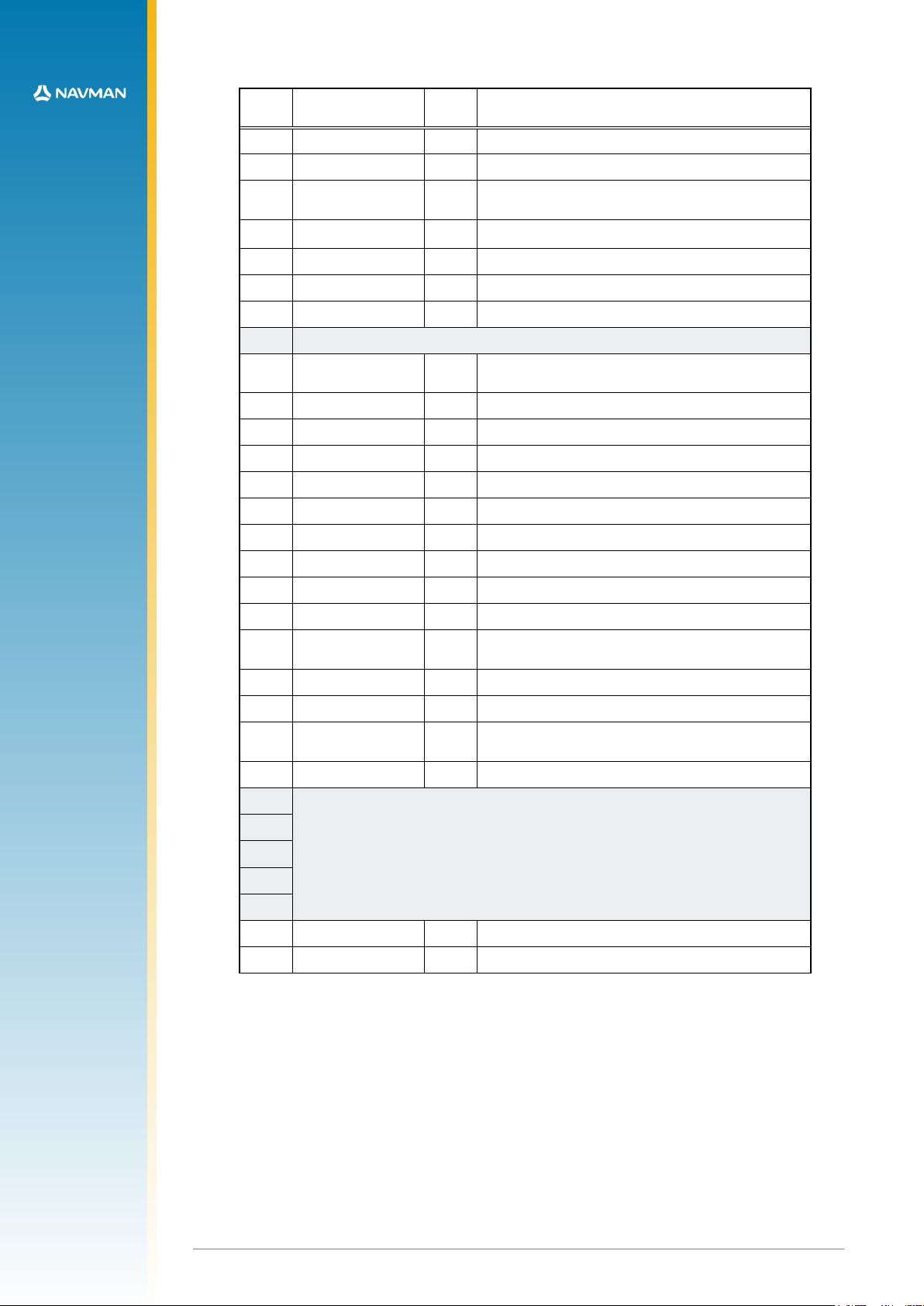

2.3.1 Reow recommendations

For lead based solder pastes, the maximum reow temperature is 225 °C for 10 seconds. For

lead-free solder pastes, the maximum reow temperature is 265 °C for 10 seconds. Refer to

Figure 2-1.

Figure 2-1: Lead-free and tin/lead reow prole recommendation

2.3.2 Connection pad material

The 30 surface mount connection pads have a base metal of copper with a gold ash nish.

This is suitable for a lead free manufacturing process.

LA000577C © 2006 N avman New Zealand. All rights reserved. Proprietar y information and speci cations subj ect to change wit hout not ice.

6

Page 7

2.3.3 Solder paste mask size

This should be adjusted by experimentation according to the customer’s production process

requirements. A 1:1 (paste mask:pad size) ratio has been found to be successful.

2.3.4 Solder paste type

The module accepts all commonly used solder pastes. The solder paste can be lead based

or lead-free. If a lead-free process is introduced, factors such as circuit board thickness,

fabrication complexity, assembly process compatibility, and surface nish should be taken

into consideration.

2.3.5 Coating

The nal PCB may be selectively coated with an acrylic resin, air/oven cured conformal

coating, clear lacquer or corresponding method, which gives electrical insulation and

sufcient resistance to corrosion.

2.3.6 Post reow washing

It is recommended that a low residue solder paste is used to prevent the need for post reow

washing. If a washing process is used, an aqueous wash is not recommended due to the

long drying time required and danger of contaminating the ne pitch internal components.

2.3.7 Pre-baking

The modules are delivered on a tape and reel package sealed in an airtight bag. The MSR

(Moisture Sensitivity Rating) is 3, therefore they should be loaded and reowed within

168 hours. If the modules are in ambient humidity for longer than this, a pre-baking/drying

process will be required.

2.3.8 Rework

Navman recommends that rework and repair is carried out in accordance with the following

guidelines:

• IPC-7711 Rework of Electronic Assemblies

• IPC-7721 Repair and Modication of Printed Boards and Electronic Assemblies

Note: Jupiter 30 and Jupiter 20 modules are covered by a 12-month warranty.

2.4 Typical application circuit

The schematic in Figure 2-2 represents a very basic application circuit, with simple interfaces to

the module. It is subject to variations depending on application requirements.

Note: Refer to the Jupiter 20 Dead Reckoning Application Note (LA000433) for the Jupiter 20 D

reference design.

2.4.1 Power for receiver and active antenna

The receiver power connection requires a clean 3.3 VDC. Noise on this line may affect the

performance of the GPS receiver.

When an active antenna is used, the DC power is fed to it through the antenna coax. This

requires the user to apply the antenna DC voltage to pad 19 of the module. A 2.7 V 25 mA

supply is made available on pad 20 if the chosen antenna can accept that voltage. This

supply is under the command of the TricklePower energy control.

2.4.2 Grounding

Separate AGND (Analogue Ground) and DGND (Digital Ground) grounds are shown

in Figure 2-2. If this grounding method is used, the ground planes can be connected

underneath the module. In some applications with very small ground planes, separate ground

planes may not be required. This should be determined by the application integrator. See

Section 2.5.2 for ground plane recommendations and design considerations involving the

antenna input and the 50 Ω microstrip connection.

LA000577C © 2006 N avman New Zealand. All rights reserved. Proprietar y information and speci cations subj ect to change wit hout not ice.

7

Page 8

2.4.3 Decoupling

The schematic in Figure 2-2 illustrates a suggested method of decoupling. These are

capacitors C1 to C7. This level of decoupling may not be required in a particular application,

in which case these capacitors could be omitted. Only the signal lines used in the application

require decoupling.

All capacitors are highly recommended if the module will experience substantial

electromagnetic interference (EMI). All low value capacitors should be as close as possible

to the module pad with a short connection to the ground plane. Any data lines that have not

been properly shielded are susceptible to data corruption. Refer to Table 2-3 for suggested

values of decoupling relative to the function desired.

J1 coaxia l connec tor

MCX, SM A or MMCX

I/P

GND

3 V RTC lithium

backup batter y

1PPS

1

2

C4

27pF

C7

1nF

GND

C3

1nF

16

GND

17

RF_IN

18

GND

19

V_ANT

20

VCC_RF

21

V_BATT

22

RESET

23

GPIO/G PS_ FIX

24

GPIO

25

GPIO

26

GPIO/ WAKE _UP

27

GPIO/ANT_OC

28

GPIO/ANT_CTRL

29

GPIO/1PPS

30

GND

Jupiter 3 0 or Jupi ter 20 GPS Module

RF

Digital

GND

GND

GND

GND

GND

GND

RF_ON

GPIO/NANT_SC

RXB

TXB

TXA

RX A

BOOT

GND

PWRIN

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

C5

27pF

AGND

TPO

TPI

C1

1µF

serial d ata por ts

to applic ation p roces sor

or RS232 level conver ter

10K

R2

R1

10K

C6

27pF

C2

10nF

SDO

SDI

TP

POWER

Figure 2-2: Sample application circuit

Function Pad Decoupling

PWRIN 1 1 µF||1 nF

BOOT 3 27 pF

RXA 4 27 pF

TXA 5 27 pF

TXB 6 27 pF

RXB 7 27 pF

NANT_SC 8 27 pF

RF_ON 9 27 pF

ACTIVE_PWR 19 1 nF

VCC_RF 20 1 nF

V_BATT 21 1 µF||1 nF

NRESET 22 27 pF

GPS_FIX 23 27 pF

GPIO13 24 27 pF

GPIO4 25 27 pF

WAKEUP 26 27 pF

ANT_OC 27 27 pF

ANT_CTRL 28 27 pF

1PPS 29 27 pF

Note: ‘||’ represents a parallel connection

DGND

Table 2-3: Decoupling recommendations

LA000577C © 2006 N avman New Zealand. All rights reserved. Proprietar y information and speci cations subj ect to change wit hout not ice.

8

Page 9

2.4.4 Serial RS232 data level shifter

To connect the module to a PC comm. port, the serial data signals must be level shifted to

RS232 levels. This has not been shown in the reference design, but many single chip RS232

level shifters are available, such as MAX3232.

Note: It is highly recommended to provide test points on the serial data lines and ‘Boot’

signal (pad 3), even if the application circuit does not use these signals. This will allow the

user to connect to these signals if a rmware upload or new conguration is required. These

test points can take the form of an untted ‘through-hole’ connector. Refer to Figure 2-2

showing test points TPO, TPI & TP.

2.4.5 External RF lter

If there is a high potential for interference (EMI) though the antenna system, an external

bandpass SAW lter may be added to the antenna input connection (pad 17) which will

attenuate interfering frequencies. (Many commercial active antennas have a lter so it would

not be necessary to add another).

When using an active antenna, the lter will not pass DC through to the antenna, so an

alternate power source would be required if an active antenna is used. Alternatively a

parallel RF choke across the lter will allow the antenna power to pass through, but choice

of components is important, for example using a choke of sufciently high self-resonant

frequency. Care should also be taken not to exceed the lter maximum DC voltage.

2.5 PCB design recommendations

The modules are surface mounted devices, hence the layout of the application PCB plays an

integral part in the overall performance of the nished system.

It is not difcult to design such a PCB, despite the presence of high frequency, low level radio

signals. The following recommendations have been offered to allow the designer to create a

design that will meet the requirements of this product.

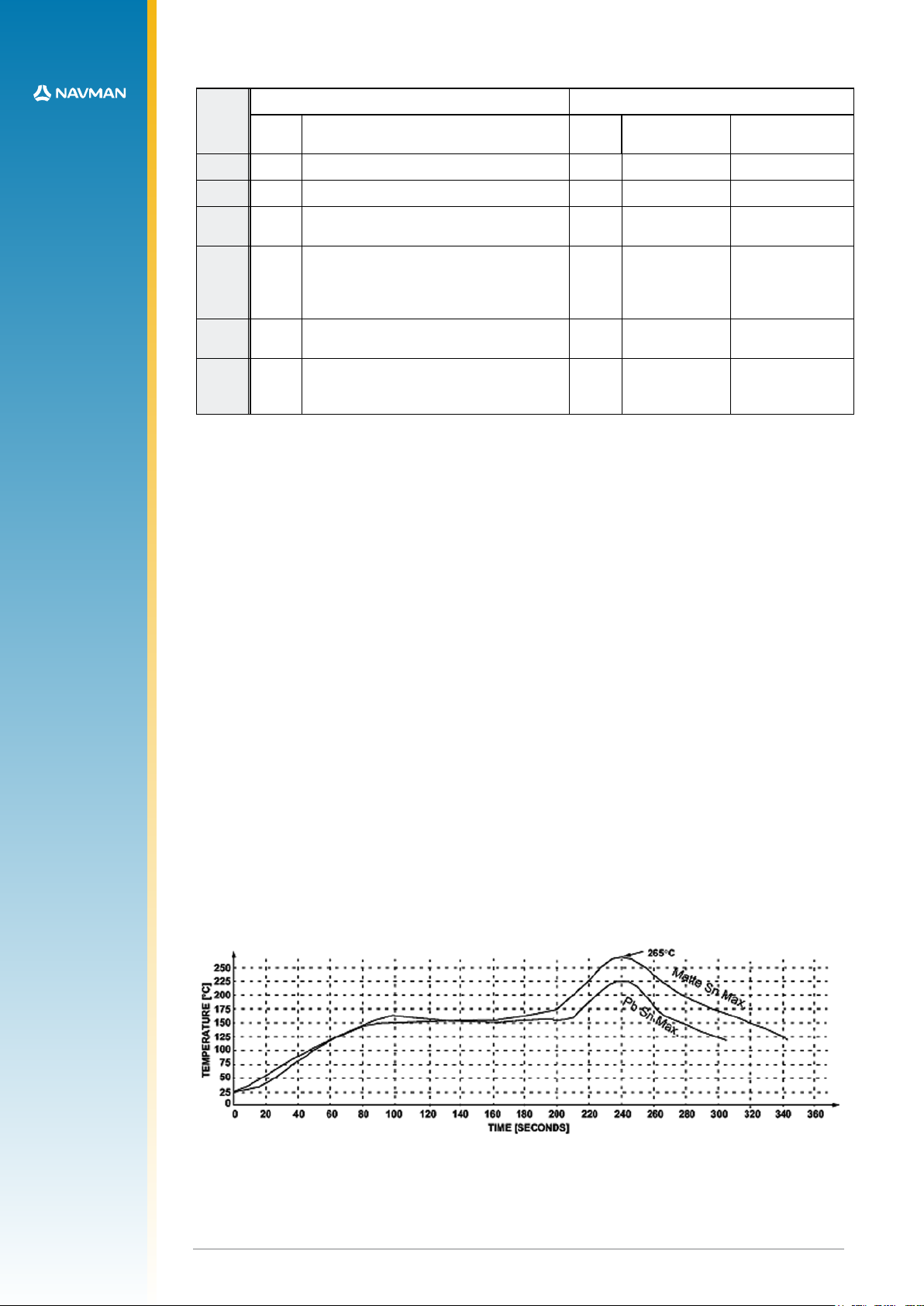

2.5.1 Recommended PCB pad layout

The layout in Figure 2-3 shows the recommended copper pad dimensions. The solder paste

mask needs to be adjusted to suit the application’s reow process, however a 1:1 (paste

mask:pad size) ratio is the recommended starting point.

1.0

16

1.9

2.8

21

25.4 ±0.1

top view

of pad layout

(all measur ements i n mm)

25.4 ±0.1

2.0

15

10

0.8

1.277

130

1.5

Figure 2-3: Recommended application layout dimensions

2.5.2 General recommendations

Choice of PCB stack up

In general, a two layer PCB substrate can be used, with all the RF signals on one side.

Multi-layer boards can also be used. These design recommendations here only address the

microstrip style of RF connection. Stripline designs can also be accommodated. However,

long lengths of stripline can cause excessive signal loss and vias in the signal track should

be avoided.

LA000577C © 2006 N avman New Zealand. All rights reserved. Proprietar y information and speci cations subj ect to change wit hout not ice.

9

Page 10

Ground plane design

Through holes (vias)

Jupiter 30 / 20 outline

We reccomend a complete ground plane is used under the PCB with signal tracks on the

same layer as the module. We also recommend having a ground plane on both sides of the

PCB underneath the module.

If the ground planes are very small, separate analogue and digital ground planes may not be

required. The ground return for any signal should have a clear path back to its source and

should not mix with other ground return signal paths. Hence the return path, which is the

ground underneath the microstrip antenna connection, should not be shared with any digital

signal or power supply return paths. Pads 16 and 18 are the RF signal Ground connections.

Decoupling components

The recommended values for power and signal decoupling are listed in Table 2-3. The

placement of these components must ensure that the low value capacitors have very

short tracks to the module pad, and very close vias connecting them to the ground plane.

(Figure 2-4 shows a typical layout).

Figure 2-4: Typical module layout

Antenna connection

The PCB layout design of the antenna input connection requires appropriate selection of

PCB track width, substrate material and careful attention to the layout geometry. If this overall

system is not implemented correctly, the module will receive poor GPS signals and therefore

provide inferior navigation data.

Figure 2-5 illustrates an example of a PCB design integrating an external active antenna

connected via an MCX or SMA coaxial connector.

(Top)

(Bottom)

Figure 2-5: Example PCB layout for external active antenna

The modules can be used with a passive patch antenna if the connection to the antenna

input is very short. It is possible to mount the patch antenna on the same PCB as the module,

but to reduce the possibility of digital noise, it is recommended that the antenna be mounted

on the opposite side of the board to the module.

LA000577C © 2006 N avman New Zealand. All rights reserved. Proprietar y information and speci cations subj ect to change wit hout not ice.

10

Page 11

Design of 50 ohm microstrip antenna connection

When designing the signal track from the antenna connection to the antenna input on the

module, a controlled impedance microstrip with a characteristic impedance of 50 ohms must

be used.

The PCB parameters that affect impedance are as follows:

1. Track width (W)

2. PCB substrate thickness (H)

3. PCB substrate permittivity (εr)

4. To a lesser extent, PCB copper thickness (T) and proximity of same layer ground plane.

Figure 2-6 shows a representation of the PCB microstrip and its parameters.

Figure 2-6: PCB microstrip dimensions

Table 2-4 shows typical track widths for an FR4 material PCB substrate (permittivity εr of 4.3

at 1.5 GHz) and different PCB thickness. The effect of track thickness (T) can be ignored for

the short track lengths associated with this design.

Substrate

material

FR4 4.3

Permittivity

ε

r

Substrate

thickness H

(mm)

1.6 2.0

1.2 1.8

1.0 1.6

0.8 1.4

0.6 1.2

0.4 0.7

0.2 0.4

Track width

W (mm)

Table 2-4: PCB substrate thicknesses v track width

Notes:

1. If a multi-layer PCB is used, the thickness is the distance from signal track to nearest

ground plane.

2. If the antenna connection is routed under the module, the track width should be

approximately halved for that section only.

It is recommended that the antenna connection PCB track should be routed around the

outside of the module outline, kept on a single layer and have no bends greater than

45 degrees. It is not recommended, for production reasons, to route the track under the

module.

However, if the track has to route under the module, it should have a modied track width and

solder mask to avoid short circuits to the underside of the module.

To minimise signal loss and reduce the requirement for vias, it is not recommended to place

the signal track on an inner layer of a multi-layer PCB.

The PCB track connection to the RF antenna input must:

• have a characteristic impedance of 50 ohm

• be as short as possible

LA000577C © 2006 N avman New Zealand. All rights reserved. Proprietar y information and speci cations subj ect to change wit hout not ice.

11

Page 12

• be interfaced to a coaxial connector if an external antenna is used

• have maximum clearance to ground on the same layer, or at least be half the substrate

thickness

• be routed away from noise sources such as: switching power supplies, digital signals,

oscillators and transmitters

The PCB track connection to the RF antenna input must NOT have:

• vias

• sharp bends

• components overlaying the track

2.6 Antenna system design choices

2.6.1 Antenna types

There are two major types of GPS antenna: passive and active. The active antenna has a

built in LNA (Low Noise Amplier) to increase the strength of the signal, and to compensate

for the signal loss in a long cable connection.

The features of each type of antenna are shown in Table 2-5, comparing an externally

mounted active antenna with a passive patch antenna mounted on the same PCB as the

module.

Feature Passive antenna Active antenna

requires short cable between antenna and receiver yes no

consumes power no yes

can be mounted remote from receiver no yes

gives good performance in poor signal situations no yes

has built in additional ltering no yes

low cost

requires a coaxial connector no yes

yes no

Table 2-5: Passive and active antenna features

2.6.2 Active antenna

An active antenna is a passive antenna with a built in LNA that requires a power supply.

Active antennas are used when the antenna input is connected to the receiver through a

coaxial cable (usually longer than 3 m) or any high loss transmission path. The GPS signals

experience loss in the transmission path from the antenna. The loss is overcome by the

antenna’s LNA, which amplies the signal before it enters the transmission path.

The amplication is also used to enhance the signal in areas of low signal. If the coaxial

cable is shorter than 3 m it may experience too much gain at the receiver and degrade the

performance. There are some variations as to how the antenna will receive its power but it

is usually supplied through the coaxial cable via the antenna input as shown in Figure 2-7.

(Refer to Table 2-6 for the recommended active antenna characteristics.)

Active GPS

antenna

Application PCB

connec ting c oax carryi ng

GPS signals and DC

power for amplication

Jupiter

module

coaxial conn ector

tted to applic ation

PCB

Figure 2-7: Arrangement of active antenna and application board

LA000577C © 2006 N avman New Zealand. All rights reserved. Proprietar y information and speci cations subj ect to change wit hout not ice.

12

Page 13

2.6.3 Passive antenna

A passive antenna does not require any power because it has no amplier. This is not the

best choice if signal strength is a concern, however, it may be sufcient if the signal path is

kept to a minimum (usually below 300 mm). An advantage to using a passive antenna is the

ability to mount directly onto the application. For best performance, a passive patch antenna

should have a metal ground plane (about 80 mm in diameter) placed directly under the

antenna, and it is advisable to screen the module and application circuits from the antenna.

For this reason the antenna and module should not be mounted on the same side of the PCB

(see Figure 2-8).

FR4 breglass PCB

ground plane ground via

Jupiter module

50 ohm microstrip

passive patch antenna

Figure 2-8: Cross section of application board with passive patch antenna

Any cover close to the antenna (called the superstrate) will cause the resonant frequency and

efciency of the antenna to drop. It is therefore recommended to keep any distance to the

superstrate to a minimum of 3 mm from the top surface of the patch.

See Table 2-6 for recommended characteristics of both passive patch and active antennas

for use with the Jupiter receiver.

Characteristic Active antenna Passive antenna

Polarisation

Receive frequency

Power supply 3 V –

DC current < 10mA at 3 VDC –

Antenna gain

Total gain (includes

antenna gain, LNA

gain and cable loss)

Axial ratio < 3 dB < 3 dB

Output VSWR

right-hand circular polarised right-hand circular polarised

1.57542 GHz

+/- 1.023 MHz

–

≤ 26 dBi (Jupiter 20)

≤18 dBi (Jupiter 30)

< 2.5

+2 to 5 dBi with 1 dB loss (max)

1.57542 GHz

> +/- 1.023 MHz

in connections

–

–

Table 2-6: Recommended antenna characteristics

Note: GPS active and passive antenna selection must include practical TTFF tests

in weak and strong outdoor environments – noting peak and average signal strength

measurements. This must be done in comparison with the antenna supplied in the

Development kit. Performance results and signal strength measurements must be

comparable to the reference antenna supplied. Passive antenna signal strength

measurements will be lower than an active antenna, but time to x should be comparable.

2.6.4 Jupiter module used as a GPS sensor

The adapter board reference design shows how a Jupiter GPS receiver module can be used

with an external active antenna via a coax connector. The same design can be used with

a passive patch antenna on the same PCB. It follows the general arrangement described

in Section 2.6.3. The module is placed such that the connection between the antenna and

the antenna input pad is as short as possible. Also note the PCB should have a complete

ground plane on the patch side of the board. This serves as the ground plane required by the

antenna.

The serial data from the module must be connected to a local host processor, and care

should be taken such that noise from these devices cannot enter the signal path or GPS

antenna. It is recommended that all digital devices are placed on the opposite side of the

board to that of the antenna.

LA000577C © 2006 N avman New Zealand. All rights reserved. Proprietar y information and speci cations subj ect to change wit hout not ice.

13

Page 14

2.6.5 DC supply protection for an active antenna

Antenna DC supply current limit

When the Jupiter receiver is used with an external active antenna, the DC supply in the coax

cable is vulnerable to over-current if a fault occurs in the antenna or its cable gets crushed,

for example in a car door.

WARNING

It is important to note that the module antenna power feed does not have internal current

limiting. Damage can occur if unlimited current is permitted to ow through the module

antenna power feed components.

The circuit shown in Figure 2-9 will provide over-current protection.

70 mA Antenna supply current limit

L3

120R / 100 MHz

C8

100nF

GND GND

C7

18pF

ANTEN NA _SUPPLY

(V_A NT)

SUPPLY_INPUT

3-5 VDC

C9

100nF

GND

R1

200 mW

10R

Q2

BC857B

BC857B

Q1

R10

1K

GND

Figure 2-9: Simple current limiter circuit

Transistor Q1 serves as a series pass transistor. Q2 is used to sense the current in the

antenna circuit, turning off Q1 if the voltage across the current sense resistor R1 exceeds

0.6 V. This circuit does not turn off the supply to the antenna, but merely limits it to a safe

value. With the components shown the supply will be limited to approximately 70 mA.

Other options are available to provide this function. MAXIM can supply a current trip IC

that will turn off the load if a preset supply current is exceeded. The part number for this is

MAX4785. The circuit is shown in Figure 2-10.

Antenna current limit using an IC

antenna sh ort circuit sense signal

C5

100 nF

GND

4

U3

5

MAX4785EX K–T

IN

FLAG

ON

OUT

GND

2

GND

antenna power enable

3

1

L2

120R / 100 MHz

C4

100 nF

C6

18 pF

GND

GND

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

Jupiter G PS Module

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

PWR_IN

Figure 2-10: Active current limit using an IC

Electro-resistive fuses can be used to protect the supply over-current. These are available

from Bourns, Vitromon and other manufacturers.

LA000577C © 2006 N avman New Zealand. All rights reserved. Proprietar y information and speci cations subj ect to change wit hout not ice.

14

Page 15

Antenna short/open sense inputs and control output

The Jupiter receiver has a digital input to provide signalling when an antenna fault has

occurred. These functions are shared with the Jupiter 30 GPIO pads as shown in Table 2-7.

Antenna sense

functions

Jupiter GPIO function

ANT_CTRL GPIO1 (ON=High)

ANT_OC GPIO15 (Active High)

NANT_SC GPIO3 (Active Low)

Table 2-7: Antenna sense and control functions

The reference design shown in gure 2-11 is indicative of an open-circuit switchover

threshold of approximately 3 mA. This maybe too high for some low-power antennae and

can be adjusted by changing the following resistor values – R7 to 12Ω and R3 to 2K2Ω. This

results in an open-circuit switchover threshold of approximately 2 mA.

The over current circuit consisting of Q1 and Q2 is the same as the simple current limit circuit

shown in Figure 2-9, providing a 70 mA current limit.

In addition, this design has the following features:

1. Q4-A and Q4-B form a low current sensor, thus providing a signal to indicate when the

antenna has become disconnected or open circuit. It is not mandatory to use a matched

pair of transistors, as shown in this design, but it will provide consistent results over a wide

temperature range.

2. Q3 provides a method for the receiver to turn off the active antenna supply in the event of

a fault occurring. This is a latched condition in the software and can be restored by issuing

a reset or power down.

3. Short circuit sensing is achieved by feeding the antenna supply into the NANT_SC input.

When a short circuit occurs, this line will go low.

This design provides the lowest cost solution for this function. Other designs can be created

giving higher stability over a wide temperature range, using operational ampliers.

Discrete antenna current monitor

SUPPLY_IN

C2

100 nF

Q4- A

BC857BS

GND

R7

56R

Q3

BC847B

R4

Q1

R3

1K

GND

10K

R1

R6

10R

200 mW

R5

5K6

R8

5K6

GND

BC857B

Q2

BC857B

Q4- B

BC857BS

120R / 100 MHz

C1

100 nF

GND

10K

R2

10K

L1

V_ANT

C3

18 pF

GND

NANT_SC

ANT_CTR L

ANT_OC

Figure 2-11: Antenna short/open circuit sensor circuit (3.3 V supply only)

LA000577C © 2006 N avman New Zealand. All rights reserved. Proprietar y information and speci cations subj ect to change wit hout not ice.

15

Page 16

2.7 Jupiter adapter printed circuit board

The module supplied in the Development kit is mounted on a carrier PCB in a method typical

of a customer application. This carrier PCB illustrates and implements many of the design

considerations discussed in this document.

The module is interfaced through two separate 20-pin data connectors with different header

pitches. This is for development purposes and provides a simple way to evaluate the surface

mount module.

The RTC (Real-Time Clock) backup supply voltage can be provided by an onboard lithium cell,

or from the development unit backup supply. The adapter board carries the antenna DC supply

over-current protection circuits (as shown in Figure 2-11), and a switch de-bounce IC to provide

reliable reset action from the development unit.

Figure 2-12 shows the adapter board with the positions of the connectors and indicators.

J1

J2 (not normally tted)

GPS x LED

power LED

RTC backup battery

(not normally tted)

Jupiter module

antenna

Figure 2-12: Adapter printed circuit board

LA000577C © 2006 N avman New Zealand. All rights reserved. Proprietar y information and speci cations subj ect to change wit hout not ice.

16

Page 17

Refer to Table 2-8 for a description of the connector interfaces.

Jupiter

function

V_ANT 1 1

VCC_RF 2 –

V_BATT 3 3

VDD 4 4

M_RST 5 5

GPIO/GYRO IN 6 6

GPIO/FR 7 7

BOOT 8 8

GPIO/W TICKS 9 9

RFON 10 –

GND – 10

TXA 11 11

RXA 12 12

GPIO/SDI 13 –

GND – 13

TXB 14 14

RXB 15 15

GPIO/SCK 16* –

GND 17 16

GPIO/SDO 18 –

GND – 17

GND – 18

1PPS 19 19

GPS_FIX/GPIO 20 –

*Note: J2 Pin 16 on the adapter card is the wake-up line for

push to x mode on the Jupiter 30

J2 (2.54 mm

pitch header)

pin no.

J1 (2 mm pitch

header) pin no.

Table 2-8: Connector conguration

3.0 Software application information

3.1 Normal mode operation

In normal mode of operation, the baseband processor software runs continuously, providing

a navigation solution at the maximum rate of once per second. No power saving functions are

applied.

If the power to the module is disrupted, the restart time can be shortened to a warm or hot start

by keeping the RTC and SRAM contents valid with a backup battery on the VBATT input.

If the module has been turned off for greater than 2 hours, the unit will revert to a warm or cold

start. This is caused by the stored ephemeris data becoming invalid after 4 hours.

3.2 Power management

The TricklePower mode of operation can be enabled to reduce the average power consumption.

The main power is supplied to the module continuously. An internal timer wakes the processor

from sleep mode. The module computes a navigation position x, after which the processor

reverts to sleep mode. The duty cycle is controlled by a user-congurable parameter.

If ephemeris data becomes outdated, the TricklePower mode will attempt to refresh the data set

within every 30 minute period, or for every new satellite that comes into view.

With TricklePower set to a 20% duty cycle, a power saving of 50% can easily be achieved with

minimal degradation in navigation performance.

LA000577C © 2006 N avman New Zealand. All rights reserved. Proprietar y information and speci cations subj ect to change wit hout not ice.

17

Page 18

3.2.1 Adaptive TricklePower mode

In Adaptive TricklePower mode, the processor automatically returns to full power when signal

levels are below the level at which they can be tracked in TricklePower mode. This is the

default behaviour when TricklePower is active. Adaptive TricklePower is always enabled on

the Jupiter 30 and Jupiter 20 S (XTrac), and selectable on the Jupiter 20 standard module.

3.2.2 Push-to-Fix mode

Unlike TricklePower, the operation in this mode is not cyclic. This mode always forces the

GPS software to revert to a continuous sleep mode after a navigation position x. It will

stay in sleep mode until woken by activation of the reset input (Jupiter 20) or wakeup input

(Jupiter 30), and compute a fresh position.

If the ephemeris data becomes invalid or new satellites come into view, the RTC has the

ability to self activate and refresh the data, thus keeping the restart TTFF very short.

This mode yields the lowest power consumption of the module, and is ideal where a battery

powered application requires very few position xes.

For further information on the TricklePower and Push-To-Fix modes refer to the Low Power

Operating Modes application note (LA000513).

3.3 Serial I/O

The module can output serial data in the NMEA format or SiRF Binary format. The serial I/O

protocols are dened in the Navman NMEA reference manual (MN000315) and the SiRF Binary

Protocol reference manual. These describe the format of the serial data from the module, as well

as the structure of the commands. Navman has provided additional functionality to the NMEA

protocol as detailed in the following sections.

3.3.1 Default settings

The default protocol is NMEA, at a baud rate of 9600bps. The frame format is 8 data bits, no

parity bit and 1 stop bit.

The following messages are output by default, at a rate of once per second each:

$GPGGA, $GPGLL, $GPGSA, $GPGSV, $GPRMC, $GPVTG, $GPZDA

All output messages have checksums by default.

Note: message $GPZDA is not available for Jupiter 20 S, or Jupiter 20 D.

3.3.2 NMEA input commands

All NMEA input commands are in the form:

$PSRFxxx,…[*CS] <CR> <LF>

where xxx is a decimal number between 100 and 255 (inclusive).

Note: In each case, CS represents an NMEA checksum, <CR> is carraige return, <LF> is line

feed. These details are covered in the Navman NMEA reference manual MN000315.

Acknowledgements

All input commands other than the standard SiRF commands will be acknowledged with a

sentence of the form:

$PTTK,…*CS

Where the arguments provided to a command are invalid, the response will be the message:

$PTTK,NACK*CS

Checksums

All input commands are accepted whether or not they include a checksum, however if a

checksum is included it must be correct in order for the message to be accepted.

Incorrect checksums will result in the response:

$PTTK,CHECKSUM*CS

LA000577C © 2006 N avman New Zealand. All rights reserved. Proprietar y information and speci cations subj ect to change wit hout not ice.

18

Page 19

Unused messages

Input messages where the message ID is not between 100 and 255, or where the message

ID does not correspond to a specied function, result in the response:

$PTTK,INVALID*CS

Errors

Errors in message receipt (other than checksum errors) result in the response:

$PTTK,ERROR,xx*CS

where xx is a hexadecimal error code.

Magnetic Variation (Declination)

The Jupiter 20 module calculates the magnetic variation (the Jupiter 30 does not).

Magnetic Variation elds in $GPRMC

The last two elds in the message $GPRMC are the magnetic variation. An Easterly variation

should be subtracted from, or a Westerly variation added to, the true heading to give the

magnetic heading (the heading given by a magnetic compass).

For example, the output might be:

$GPRMC,220137.250,A,4331.9077,S,17238.2308,E,0.075949,168.82,071004,23.1,E*4C

Standard SiRF output:

$GPRMC,220137.250,A,4331.9077,S,17238.2308,E,0.075949,168.82,071004,,*17

Magnetic Heading eld in $GPVTG

The third eld in the message $GPVTG is the magnetic heading (denoted by the ‘M’ in the

following eld). This is the heading that would be reported by a magnetic compass.

For example, the output might be:

$GPVTG,168.82,T,145.70,M,0.08,N,0.14,K*41

The standard SiRF output:

$GPVTG,168.82,T,,M,0.08,N,0.14,K*58

3.3.3 Altitude output

The module outputs the correct altitude and geoid separation in the $GPGGA NMEA

message. Most SiRFstar-based modules output the height above the current datum (usually

WGS84) ellipsoid as the altitude, contrary to the NMEA specication, and older modules

omit the geoid separation. The Jupiter receiver outputs the height above mean sea level, as

required by the NMEA specication.

For example, the output might be:

$GPGGA,220137.869,4331.9077,S,17238.2308,E,1,06,1.6,61.7,M,11.3,M,0.0,0000*55

Standard SiRF output (v2.3 and earlier):

$GPGGA,220137.869,4331.9077,S,17238.2308,E,1,06,1.6,72.0,M,,M,0.0,0000*6D

Or (v2.3.1 and 2.3.2):

$GPGGA,220137.869,4331.9077,S,17238.2308,E,1,06,1.6,72.0,M,11.3,M,0.0,0000*50

LA000577C © 2006 N avman New Zealand. All rights reserved. Proprietar y information and speci cations subj ect to change wit hout not ice.

19

Page 20

3.4 Navman proprietary NMEA low power mode messages

Navman has added a number of proprietary NMEA input messages to congure the

TricklePower and Push-To-Fix modes.

3.4.1 Low power conguration

The following message sets the receiver to low power mode:

$PSRF151,a,bbbb,cccc[*CS] <CR> <LF>

where:

Field Description

a Push-To-Fix* (1=on, 0=off)

b

c TricklePower on time (milliseconds)

*Note that Push-To-Fix

so they may be left blank

Table 3-1: Low power modes message values

This message is the NMEA equivalent of the SiRF Binary input message ID 151.

System response:

$PTTK,LPSET,a,bbbb,cccc*CS

TricklePower duty cycle (parts per

thousand)

TM

does not require elds b and c

The updated values returned by the system are as described in Table 3-1.

3.4.2 Low power acquisition conguration

The following message sets the acquisition parameters of the low power mode:

$PSRF167,aaaaaa,bbbbbb,cccc,d[*CS] <CR> <LF>

where:

Field Description

a maximum off time (milliseconds)

b maximum search time (milliseconds)

c Push-To-Fix period (seconds)

d adaptive TricklePower (1=on, 0=off)

Table 3-2: Low power acquisition input values

This message is the NMEA equivalent of the SiRF Binary input message ID 167.

System response:

$PTTK,LPACQ,aaaaaa,bbbbbb,cccc,d*CS

The updated values returned by the system are as described in Table 3-2.

3.5 Control of GPIO connections via serial commands (Jupiter 20)

Note: The information in this section does not apply to the Jupiter 30 module.

The Jupiter 20 receiver has many unused GPIO (user programmable input output) signal pads.

These can be utilised in the application by introducing custom software written with the SiRF

SDK (Software Development Kit) tools.

Alternatively, the receiver has an NMEA default instruction protocol that can control these IO

ports through the standard serial communication ports using proprietary NMEA commands.

The GPIO lines are treated as a single 8-bit register, with the pins occupying the positions

shown in Table 3-3.

LA000577C © 2006 N avman New Zealand. All rights reserved. Proprietar y information and speci cations subj ect to change wit hout not ice.

20

Page 21

Bit Pad function Pin

(LSB) 0 GPIO15/Fwd-Rev 27

1 GPIO1/Wheel Tick 28

2 GPIO3/Gyro In 8

3 GPIO5/SDI 25

4 GPIO6/SDO 24

5 GPIO7/SCLK 26

6 GPIO9/1PPS 29

(MSB) 7 GPIO10/GPS Fix 23

Table 3-3: Pin conguration of the GPIO lines

On the Jupiter 20 D, there is no control of GPIO15, GPIO1, GPIO3, GPIO5, GPIO6 or GPIO7,

and all references to these pins are ignored.

In each of the messages described in the following sections, x represents a hexadecimal digit.

3.5.1 Congure port directions

$PSRF225,xx,xx[*CS] <CR> <LF>

Sets the direction of the GPIO pins. The rst octet is the mask (which ports to override), the

second the new direction. A zero represents an input, and a one an output. This command

must be sent before attempting to manipulate or read any the specied GPIO. It also has the

effect of suspending the normal port functions on the pins specied. Normal operation will

resume following a hardware reset (including any use of the reset line in Push-to-Fix mode).

Response:

$PTTK,GPIO,DIR,xx,xx*CS

3.5.2 Set outputs

$PSRF226,xx[*CS] <CR> <LF>

Changes the specied outputs to high. Other outputs are not affected. There are no

changes to any pins that are congured as inputs.

Response:

$PTTK,GPIO,SET,xx*CS

3.5.3 Clear outputs

$PSRF227,xx[*CS] <CR> <LF>

Changes the specied outputs to low. Other outputs are not affected. There are no changes

to any pins that are congured as inputs.

Response:

$PTTK,GPIO,CLEAR,xx*CS

3.5.4 Read inputs

$PSRF228[*CS] <CR> <LF>

Returns the values on the input pins. Pins congured as outputs read as zero.

Response:

$PTTK,GPIO,READ,xx*CS

This message is sometimes output automatically.

3.6 GPS x output

The GPS x output is an active low output on pin 23 of the module. Whenever the unit has

either a 2D or a 3D x, this output will be low. When the unit has no x, the output will be high.

This function can be overridden and the pin used as GPIO10 using the commands described in

Section 3.5. The GPS x output function returns after a reset.

LA000577C © 2006 N avman New Zealand. All rights reserved. Proprietar y information and speci cations subj ect to change wit hout not ice.

21

Page 22

3.7 Antenna power monitor messages

The Jupiter software includes antenna monitor messages driven by the state of the antenna

monitor inputs. The inputs NANT_SC (short circuit detect – active low) and ANT_OC (open

circuit detect – active high) are congured as inputs, and ANT_CTRL (active antenna control) is

congured as an output.

If the function of any of these pins is overridden using the procedure described in Section 3.6,

then this feature is disabled. However if an antenna short circuit has occurred before any pins

are overridden in this manner, the status will continue to be reported as ‘short circuit’ until such

time as the active antenna control output is overridden.

In normal operation, the active antenna control output is high. If the short circuit detect pin goes

low, the active antenna control signal will go low. This condition is latched until the user resets

the module.

The active antenna control pin output is low when the receiver enters a low power mode due to

TricklePower, Push-to-Fix or APM, and returns to its previous state when the receiver starts up

again. No checking of the antenna current is performed while the output is low for this reason.

The antenna status output message is an NMEA message in the form:

$PTTK,ANT,d*CS

Where

d represents any of the following numbers:

d Description

0 normal antenna operation

1 antenna open circuit

2 antenna short circuit - antenna disabled

-1

antenna sensing disabled (due to GPIO

override)

Table 3-4: Antenna status output message values

The antenna status message is output automatically in the event of a short circuit or open circuit

being detected, or an open circuit condition coming to an end.

In addition, this message is output on the receipt of the NMEA input message:

$PSRF199[*CS]

The antenna status is also output as the SiRF binary message with message ID 99. It contains

one byte of data, being the appropriate value from Table 3-4. This gives a payload length of

2 bytes, since the message ID is considered part of the payload.

The antenna status message is output automatically in the event of a short circuit, or open circuit

being detected, or an open circuit condition coming to an end.

In addition, this message is output on the receipt of the SiRF binary message with message ID

199. The output rate of this message is also under the normal control of the SiRF Binary Query/

Rate Control input message, however this message is not output at a regular rate by default.

3.8 Custom application software

The module provides custom modication of the rmware to use available CPU processing

capacities and I/O capabilities. The custom application software can be invoked internally or

externally, providing the ability to dedicate the module as the host application or an external

processor as the host. The module also provides the ability to communicate externally with

standard or customer specic communication protocols.

The custom application software has access to the ash memory, navigation data from the GPS

Navigation software, and access to various I/O lines used on the module.

This can be developed using the SiRF SDK. The SDK provides all the tools and resources

necessary for custom software development. Refer to http://www.sirf.com for more information

about the SDK.

LA000577C © 2006 N avman New Zealand. All rights reserved. Proprietar y information and speci cations subj ect to change wit hout not ice.

22

Page 23

4.0 Glossary and acronyms

EMI: Electromagnetic Interference

FR4 substrate: Flame Retardant type 4

The usual base material from which plated-through-hole and multi-layer printed circuit boards

are constructed. The type ‘4’ indicates woven glass reinforced epoxy resin.

GPS: Global Positioning System

A space-based radio positioning system that provides accurate position, velocity, and time data.

NMEA: National Marine Electronics Association

RF: Radio Frequency

SRAM: Static Random Access Memory

TTFF: Time-To-First-Fix

The actual time required by a GPS receiver to achieve a position solution. This specication

will vary with the operating state of the receiver, the length of time since the last position x, the

location of the last position x, and the specic receiver design.

© 2006 Navman New Zealand. All Rights Reserved.

SiRF and SiRF logo are registered trademarks of SiRF Technology, Inc. SiRFstar, SiRFLoc, Push-to-Fix, and TricklePower are trademarks of SiRF Technology, Inc. All other trademarks mentioned in this document are property of their

respective owners.

Information in this document is provided in connection with Navman New Zealand (‘Navman’) products. These materials

are provided by Navman as a service to its customers and may be used for informational purposes only. Navman

assumes no responsibility for errors or omissions in these materials. Navman may make changes to specications and

product descriptions at any time, without notice. Navman makes no commitment to update the information and shall have

no responsibility whatsoever for conicts or incompatibilities arising from future changes to its specications and product

descriptions. No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted by

this document. Except as provided in Navman’s Terms and Conditions of Sale for such products, Navman assumes no

liability whatsoever.

THESE MATERIALS ARE PROVIDED ‘AS IS’ WITHOUT WARRANTY OF ANY KIND, EITHER EXPRESSED OR

IMPLIED, RELATING TO SALE AND/OR USE OF NAVMAN PRODUCTS INCLUDING LIABILITY OR WARRANTIES

RELATING TO FITNESS FOR A PARTICULAR PURPOSE, CONSEQUENTIAL OR INCIDENTAL DAMAGES,

MERCHANTABILITY, OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY

RIGHT. NAVMAN FURTHER DOES NOT WARRANT THE ACCURACY OR COMPLETENESS OF THE INFORMATION,

TEXT, GRAPHICS OR OTHER ITEMS CONTAINED WITHIN THESE MATERIALS. NAVMAN SHALL NOT BE

LIABLE FOR ANY SPECIAL, INDIRECT, INCIDENTAL, OR CONSEQUENTIAL DAMAGES, INCLUDING WITHOUT

LIMITATION, LOST REVENUES OR LOST PROFITS, WHICH MAY RESULT FROM THE USE OF THESE MATERIALS.

Navman products are not intended for use in medical, lifesaving or life sustaining applications. Navman customers using

or selling Navman products for use in such applications do so at their own risk and agree to fully indemnify Navman

for any damages resulting from such improper use or sale. Product names or services listed in this publication are for

identication purposes only, and may be trademarks of third parties. Third-party brands and names are the property

of their respective owners. Additional information, posted at www.navman.com, is incorporated by reference. Reader

response: Navman strives to produce quality documentation and welcomes your feedback. Please send comments

and suggestions to tech.pubs@navman.com. For technical questions, contact your local Navman sales ofce or eld

applications engineer.

LA000577C © 2006 N avman New Zealand. All rights reserved. Proprietar y information and speci cations subj ect to change wit hout not ice.

23

Loading...

Loading...