查询5962-8962501HA供应商

LM6165/LM6265/LM6365

High Speed Operational Amplifier

General Description

The LM6165 family of high-speed amplifiers exhibits an excellent speed-power product in delivering 300 V/µs and

725 MHz GBW (stable for gains as low as +25) with only

5 mA of supply current. Further power savings and application convenience are possible by taking advantage of the

wide dynamic range in operating supply voltage which extends all the way down to +5V.

These amplifiers are built with National’s VIP

tegrated PNP) process which produces fast PNP transistors

that are true complements to the already fast NPN devices.

This advanced junction-isolated process delivers high speed

performance without the need for complex and expensive dielectric isolation.

™

(VerticallyIn-

n High GBW product: 725 MHz

n Low supply current: 5 mA

n Fast settling: 80 ns to 0.1

n Low differential gain:

n Low differential phase:

n Wide supply range: 4.75V to 32V

n Stable with unlimited capacitive load

%

<

%

0.1

<

0.1˚

Applications

n Video amplifier

n Wide-bandwidth signal conditioning

n Radar

n Sonar

LM6165/LM6265/LM6365 High Speed Operational Amplifier

May 1999

Features

n High slew rate: 300 V/µs

Connection Diagrams

10-Lead Flatpak

Top View

Order Number LM6165W/883

See NS Package Number W10A

DS009152-14

DS009152-8

Order Number LM6165J/883

See NS Package Number J08A

Order Number LM6365M

See NS Package Number M08A

Order Number LM6265N or LM6365N

See NS Package Number N08E

VIP™is a trademark of National SemiconductorCorporation.

© 1999 National Semiconductor Corporation DS009152 www.national.com

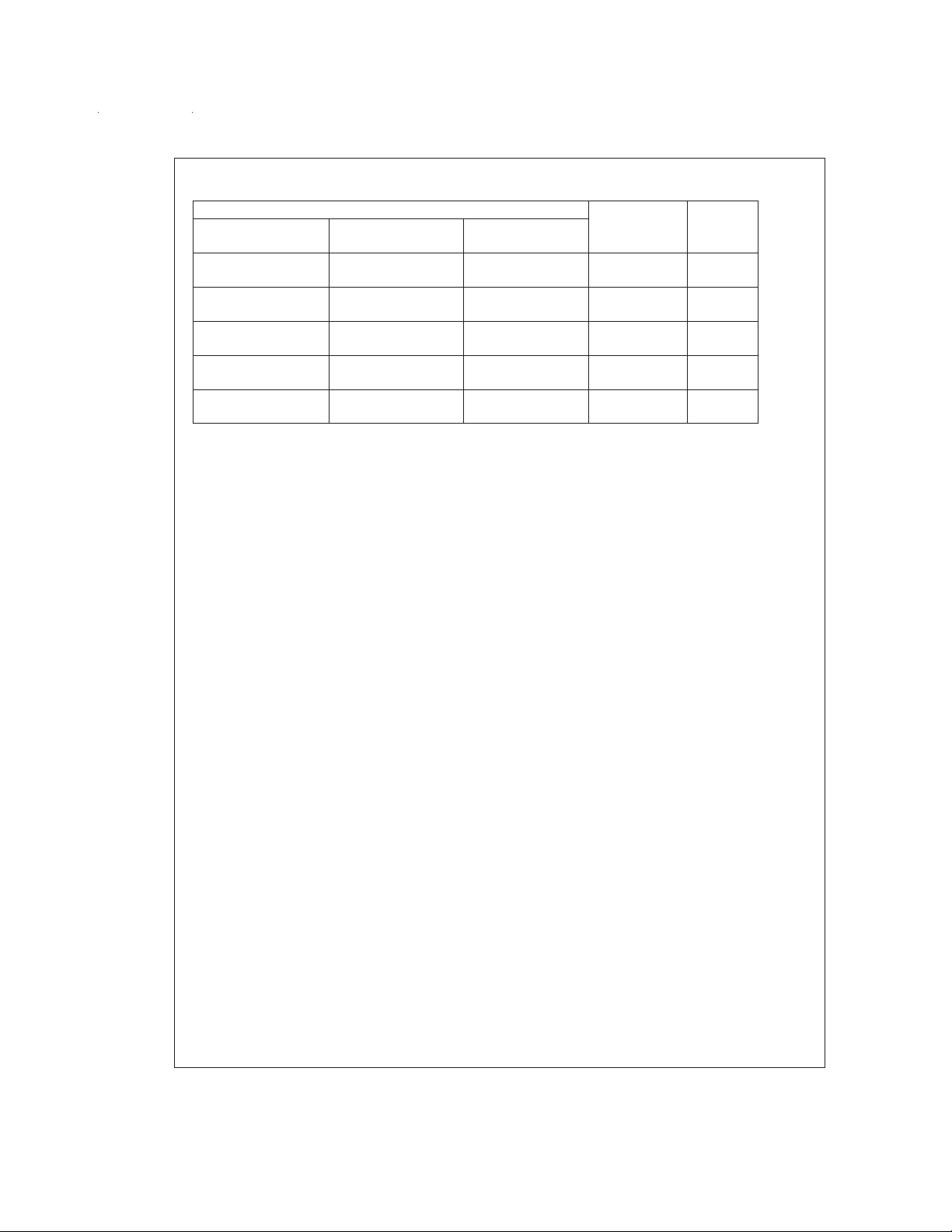

Connection Diagrams (Continued)

Temperature Range Package NSC

Military Industrial Commercial

−55˚C ≤ T

LM6165J/883 8-Pin J08A

5962-8962501PA Ceramic DIP

LM6165WG/883 10-Lead WG10A

5962-8962501XA Ceramic SOIC

LM6165W883 10-Pin W10A

5962-8962501HA Ceramic Flatpak

≤ +125˚C −25˚C ≤ TA≤ +85˚C 0˚C ≤ TA≤ +70˚C

A

LM6265N LM6365N 8-Pin N08E

LM6365M 8-Pin Molded M08A

Molded DIP

Surface Mt.

Drawing

www.national.com 2

Absolute Maximum Ratings (Note 1)

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

Supply Voltage (V

Differential Input Voltage

(Note 7)

Common-Mode Voltage

Range (Note 11) (V

Output Short Circuit to GND

(Note 2) Continuous

Soldering Information

Dual-In-Line Package (N, J)

Soldering (10 sec.) 260˚C

Small Outline Package (M)

Vapor Phase (60 sec.)

Infrared (15 sec.)

+−V−

) 36V

+

− 0.7V) to (V−+ 0.7V)

±

215˚C

220˚C

See AN-450 “Surface Mounting Methods and Their Effect

on Product Reliability” for other methods of soldering

surface mount devices.

Storage Temp Range −65˚C to +150˚C

Max Junction Temperature

(Note 3) 150˚C

ESD Tolerance (Notes 7, 8)

8V

Operating Ratings

Temperature Range (Note 3)

LM6165, LM6165J/883 −55˚C ≤ T

LM6265 −25˚C ≤ T

LM6365 0˚C ≤ T

Supply Voltage Range 4.75V to 32V

±

≤ +125˚C

J

≤ +85˚C

J

≤ +70˚C

J

700V

DC Electrical Characteristics

=

The following specifications apply for Supply Voltage

Boldface limits apply for T

=

=

T

A

to T

T

J

MIN

MAX

±

15V, V

; all other limits T

Symbol Parameter Conditions Typ LM6165 LM6265 LM6365 Units

V

V

Input Offset Voltage 1 3 3 6 mV

OS

Input Offset Voltage 3 µV/˚C

OS

Drift Average Drift

I

b

I

OS

I

OS

Input Bias Current 2.5 3 3 5 µA

Input Offset Current 150 350 350 1500 nA

Input Offset Current 0.3 nA/˚C

Drift Average Drift

R

C

A

V

Input Resistance Differential 20 kΩ

IN

Input Capacitance 6.0 pF

IN

Large Signal V

VOL

Voltage Gain R

(Note 10) R

Input Common-Mode Supply

CM

=

±

10V, 10.5 7.5 7.5 5.5 V/mV

OUT

=

2kΩ 5.0 6.0 5.0

L

=

10 kΩ 38

L

=

±

15V +14.0 +13.9 +13.9 +13.8 V

Voltage Range +13.8 +13.8 +13.7 Min

Supply=+5V 4.0 3.9 3.9 3.8 V

(Note 5) 3.8 3.8 3.7 Min

CMRR Common-Mode −10V ≤ V

≤ +10V 102 88 88 80 dB

CM

Rejection Ratio 82 84 78 Min

PSRR Power Supply

±

10V ≤ V±≤±16V 104 88 88 80 dB

Rejection Ratio 82 84 78 Min

=

≥ 100 kΩ and R

0, R

CM

L

=

=

T

25˚C.

A

J

=

50Ω unless otherwise noted.

S

Limit Limit Limit

(Notes 4, 12) (Note 4) (Note 4)

447Max

656Max

800 600 1900 Max

−13.6 −13.4 −13.4 −13.3 V

−13.2 −13.2 −13.2 Min

1.4 1.6 1.6 1.7 V

1.8 1.8 1.8 Max

Min

www.national.com3

DC Electrical Characteristics (Continued)

=

The following specifications apply for Supply Voltage

Boldface limits apply for T

=

=

T

A

to T

T

J

MIN

MAX

±

15V, V

; all other limits T

Symbol Parameter Conditions Typ LM6165 LM6265 LM6365 Units

=

V

Output Voltage Supply

O

Swing R

±

15V, +14.2 +13.5 +13.5 +13.4 V

=

2kΩ +13.3 +13.3 +13.3 Min

L

Supply=+5V 4.2 3.5 3.5 3.4 V

=

R

2kΩ(Note 5) 3.3 3.3 3.3 Min

L

Output Short Source 65 30 30 30 mA

Circuit Current 20 25 25 Min

Sink 65 30 30 30 mA

I

S

Supply Current 5.0 6.5 6.5 6.8 mA

=

≥ 100 kΩ and R

0, R

CM

L

=

=

T

25˚C.

A

J

=

50Ω unless otherwise noted.

S

Limit Limit Limit

(Notes 4, 12) (Note 4) (Note 4)

−13.4 −13.0 −13.0 −12.9 V

−12.7 −12.8 −12.8 Min

1.3 1.7 1.7 1.8 V

2.0 1.9 1.9 Max

20 25 25 Min

6.8 6.7 6.9 Max

AC Electrical Characteristics

=

The following specifications apply for Supply Voltage

Boldface limits apply for T

=

=

T

A

to T

T

J

MIN

MAX

±

15V, V

; all other limits T

Symbol Parameter Conditions Typ LM6165 LM6265 LM6365 Units

GBW Gain Bandwidth F=20 MHz 725 575 575 500 MHz

=

±

Product Supply

SR Slew Rate A

PBW Power Bandwidth V

V

Supply

OUT

5V 500

=

+25 (Note 9) 300 200 200 200 V/µs

=

±

5V 200

=

20 V

PP

Product

t

S

φ

m

A

φ

D

e

np-p

i

np-p

Note 1: “Absolute Maximum Ratings” indicate limits beyond which damage to the device may occur. Operating Ratings indicate conditions for which the device is

functional, but do not guarantee specific performance limits.

Note 2: Continuous short-circuit operation at elevated ambient temperature can result in exceeding the maximum allowed junction temperature of 150˚C.

Note 3: The typical junction-to-ambient thermal resistance of the molded plastic DIP (N) is 105˚C/Watt, and the molded plastic SO (M) package is 155˚C/Watt, and

the cerdip (J) package is 125˚C/Watt. All numbers apply for packages soldered directly into a printed circuit board.

Note 4: All limits guaranteed by testing or correlation.

Note 5: For single supply operation, the following conditions apply: V+=5V, V−=0V, V

to Pin 4 (V−) to realize maximum output swing. This connection will degrade V

Note 6: C

Note 7: In order to achieve optimum AC performance, the input stage was designed without protective clamps. Exeeding the maximum differential input voltage re-

sults in reverse breakdown of the base-emitter junction of one of the input transistors and probable degradation of the input parameters (especially V

Noise).

Settling Time 10V Step to 0.1

=

A

−25, R

V

Phase Margin A

Differential Gain NTSC, A

D

=

+25 45 Deg

V

Differential Phase NTSC, A

Input Noise Voltage F=10 kHz 5

Input Noise Current F=10 kHz 1.5

≤ 5pF.

L

%

=

2kΩ

L

=

+25

V

=

+25

V

=

≥ 100 kΩ and R

0, R

CM

=

A

L

=

T

25˚C. (Note 6)

J

=

50Ω unless otherwise noted.

S

Limit Limit Limit

(Notes 4, 12) (Note 4) (Note 4)

350

180

4.5 MHz

80 ns

<

0.1

<

0.1 Deg

=

2.5C, V

CM

.

OS

=

2.5V. Pin1&Pin8(V

OUT

Adjust) are each connected

OS

OS,IOS

Min

Min

%

, and

www.national.com 4

AC Electrical Characteristics (Continued)

Note 8: The average voltage that the weakest pin combinations (those involving Pin 2 or Pin 3) can withstand and still conform to the datasheet limits. The test circuit

used consists of the human body model of 100 pF in series with 1500Ω.

Note 9: V

Note 10: Voltage Gain is the total output swing (20V) divided by the input signal required to produce that swing.

Note 11: The voltage between V

Note 12: A military RETS electrical test specification is available on request. At the time of printing, the LM6165J/883 RETS spec complied with the Boldface limits

in this column. The LM6165J/883 may also be procured as Standard Military Drawing

=

0.8V step. For supply

IN

=

=

±

5V, V

0.2V step.

IN

+

and either input pin must not exceed 36V.

#

5962-8962501PA.

Typical PerformanceCharacteristics R

Supply Current vs

Supply Voltage

DS009152-16

Gain-Bandwidth

Product

DS009152-19

Common-Mode

Rejection Ratio

Propagation Delay,

Rise and Fall Times

=10kΩ,TA= 25˚C unless otherwise specified

L

Power Supply

Rejection Ratio

DS009152-17

Gain-Bandwidth Product vs

Load Capacitance

DS009152-20

DS009152-18

DS009152-21

Slew Rate vs

Load Capacitance

DS009152-22

Overshoot vs

Capacitive Load

DS009152-23

Slew Rate

DS009152-24

www.national.com5

Typical Performance Characteristics R

=10kΩ,TA= 25˚C unless otherwise specified (Continued)

L

Output Impedance

Gain vs Supply Voltage

(Open-Loop)

DS009152-25

Differential Gain (Note 13)

DS009152-6

Note 13: Differential gain and differential phase measured for four series LM6365 op amps configured with gain of +25 (each output attenuated by 96%), in series

with an LM6321 buffer. Error added by LM6321 is negligible. Test performed using Tektronix Type 520 NTSC test system.

Differential Phase (Note 13)

DS009152-26

DS009152-7

Step Response; Av=+25

Input (0.2v/div) Output (5v/div)

TIME (50 (ns/div)

www.national.com 6

DS009152-1

Typical Performance Characteristics R

=10kΩ,TA= 25˚C unless otherwise specified (Continued)

L

Input Noise Voltage

Open-Loop

Frequency Response

Common-Mode Input

Saturation Voltage

DS009152-27

DS009152-30

Input Noise Current

Open-Loop

Frequency Response

Output Saturation Voltage

DS009152-28

DS009152-31

Power Bandwidth

DS009152-29

Voltage Gain vs

Load Resistance

DS009152-32

Bias Current vs

Common-Mode Voltage

DS009152-33

DS009152-34

DS009152-35

www.national.com7

Simplified Schematic

Application Tips

The LM6365 is stable for gains of 25 or greater. The LM6361

and LM6364, specified in separate datasheets, are compensated versions of the LM6365. The LM6361 is unity-gain

stable, while the LM6364 is stable for gains as low as 5. The

LM6361, and LM6364 have the same high slew rate as the

LM6365, typically 300 V/µs.

To use the LM6365 for gains less than 25, a series

resistor-capacitor network should be added between the input pins (as shown in the Typical Applications, Noise Gain

Compensation) so that the high-frequency noise gain rises

to at least 25.

Power supply bypassing will improve stability and transient

response of the LM6365, and is recommended for every design. 0.01 µF to 0.1 µF ceramic capacitors should be used

Typical Applications

DS009152-3

(from each supply “rail” to ground); an additional 2.2 µF to

10 µF (tantalum) may be required for extra noise reduction.

Keep all leads short to reduce stray capacitance and lead inductance, and make sure ground paths are low-impedance,

especially where heavier currents will be flowing. Stray capacitance in the circuit layout can cause signal coupling between adjacent nodes, and can cause circuit gain to unintentionally vary with frequency.

Breadboarded circuits will work best if they are built using

generic PC boards with a good ground plane. If the op amps

are used with sockets, as opposed to being soldered into the

circuit, the additional input capacitance may degrade circuit

performance.

Offset Voltage Adjustment

DS009152-11

www.national.com 8

Noise-Gain Compensation

RXCX≥ 1/(2π•25 MHz)

(1 + R1/R2)]=25 R

[R1+R

F

DS009152-12

X

Typical Applications (Continued)

All diodes 1N914

1 MHz Voltage-to-Frequency Converter

(f

OUT

=

1 MHz for V

=

10V)

IN

DS009152-13

www.national.com9

Physical Dimensions inches (millimeters) unless otherwise noted

Ceramic Dual-In-Line Package (J)

Order Number LM6165J/883

NS Package Number J08A

Molded Package SO (M)

Order Number LM6365M

NS Package Number M08A

www.national.com 10

Physical Dimensions inches (millimeters) unless otherwise noted (Continued)

Molded Dual-In-Line Package (N)

Order Number LM6265N or LM6365N

NS Package Number N08E

10-Pin Ceramic Flatpak

Order Number LM6165W/883

NS Package Number W10A

www.national.com11

Notes

LM6165/LM6265/LM6365 High Speed Operational Amplifier

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT

DEVICES OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT AND GENERAL

COUNSEL OF NATIONAL SEMICONDUCTOR CORPORATION. As used herein:

1. Life support devices or systems are devices or

systems which, (a) are intended for surgical implant

into the body, or (b) support or sustain life, and

whose failure to perform when properly used in

accordance with instructions for use provided in the

labeling, can be reasonably expected to result in a

significant injury to the user.

National Semiconductor

Corporation

Americas

Tel: 1-800-272-9959

Fax: 1-800-737-7018

Email: support@nsc.com

www.national.com

National does not assume any responsibility for use of any circuitry described, no circuit patent licenses are implied and National reserves the right at any time without notice to change said circuitry and specifications.

National Semiconductor

Europe

Fax: +49 (0) 1 80-530 85 86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 1 80-530 85 85

English Tel: +49 (0) 1 80-532 78 32

Français Tel: +49 (0) 1 80-532 93 58

Italiano Tel: +49 (0) 1 80-534 16 80

2. A critical component is any component of a life

support device or system whose failure to perform

can be reasonably expected to cause the failure of

the life support device or system, or to affect its

safety or effectiveness.

National Semiconductor

Asia Pacific Customer

Response Group

Tel: 65-2544466

Fax: 65-2504466

Email: sea.support@nsc.com

National Semiconductor

Japan Ltd.

Tel: 81-3-5639-7560

Fax: 81-3-5639-7507

Loading...

Loading...