LM5010A

High Voltage 1A Step Down Switching Regulator

LM5010A High Voltage 1A Step Down Switching Regulator

January 25, 2008

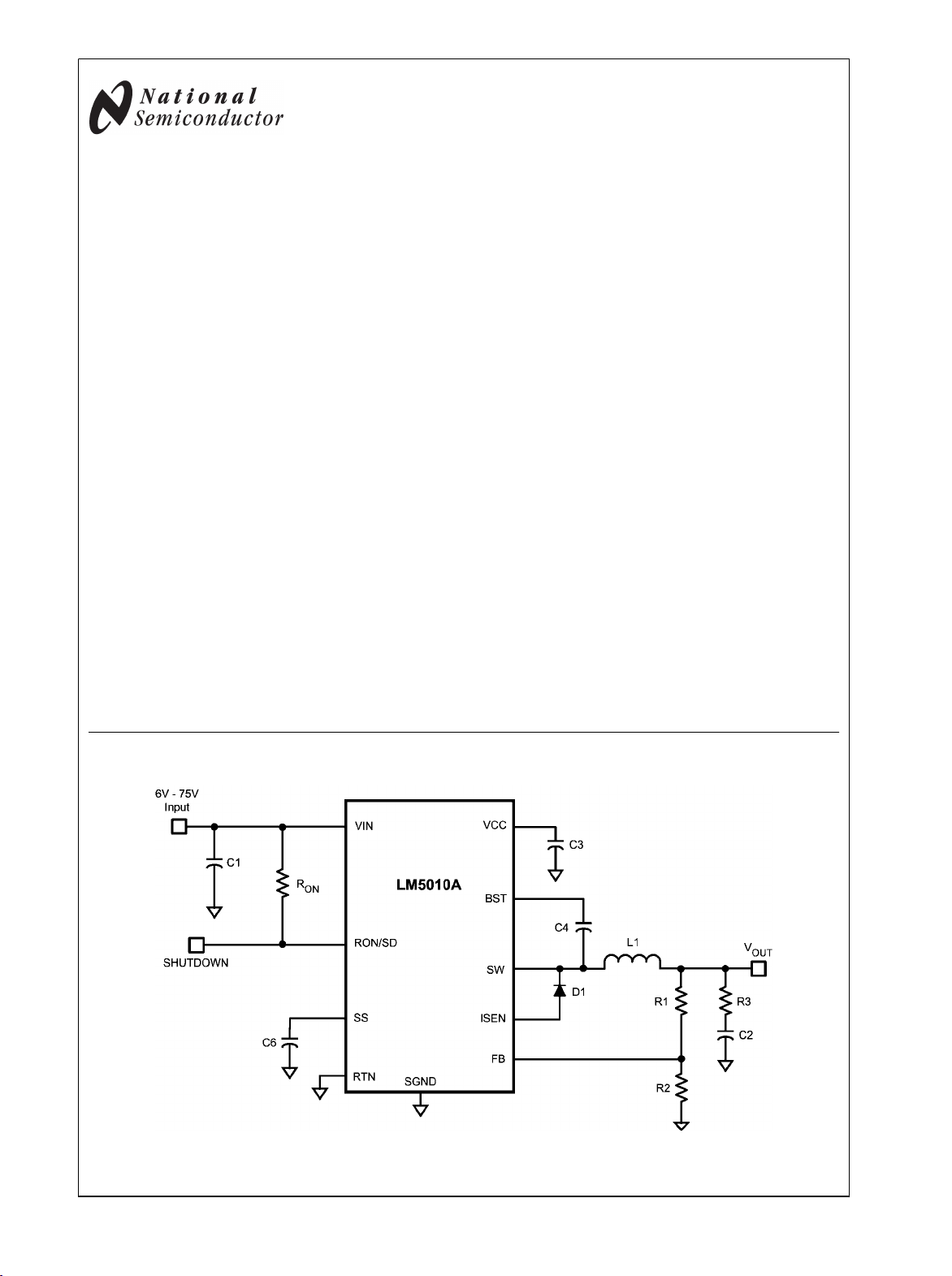

General Description

The LM5010A Step Down Switching Regulator is an enhanced version of the LM5010 with the input operating range

extended to 6V minimum. The LM5010A features all the functions needed to implement a low cost, efficient, buck regulator

capable of supplying in excess of 1A load current. This high

voltage regulator integrates an N-Channel Buck Switch, and

is available in thermally enhanced LLP-10 and TSSOP-14EP

packages. The constant on-time regulation scheme requires

no loop compensation resulting in fast load transient response and simplified circuit implementation. The operating

frequency remains constant with line and load variations due

to the inverse relationship between the input voltage and the

on-time. The valley current limit detection is set at 1.25A. Additional features include: VCC under-voltage lock-out, thermal

shutdown, gate drive under-voltage lock-out, and maximum

duty cycle limiter.

Features

Wide 6V to 75V Input Voltage Range

■

Valley Current Limiting At 1.25A

■

Programmable Switching Frequency Up To 1 MHz

■

Integrated 80V N-Channel Buck Switch

■

Integrated High Voltage Bias Regulator

■

No Loop Compensation Required

■

Ultra-Fast Transient Response

■

Nearly Constant Operating Frequency With Line and Load

■

Variations

Adjustable Output Voltage

■

2.5V, ±2% Feedback Reference

■

Programmable Soft-Start

■

Thermal shutdown

■

Typical Applications

Non-Isolated Telecommunications Regulator

■

Secondary Side Post Regulator

■

Power Supply for Automotive Electronics

■

Package

LLP-10 (4 mm x 4 mm)

■

TSSOP-14EP

■

Both Packages Have Exposed Thermal Pad For Improved

■

Heat Dissipation

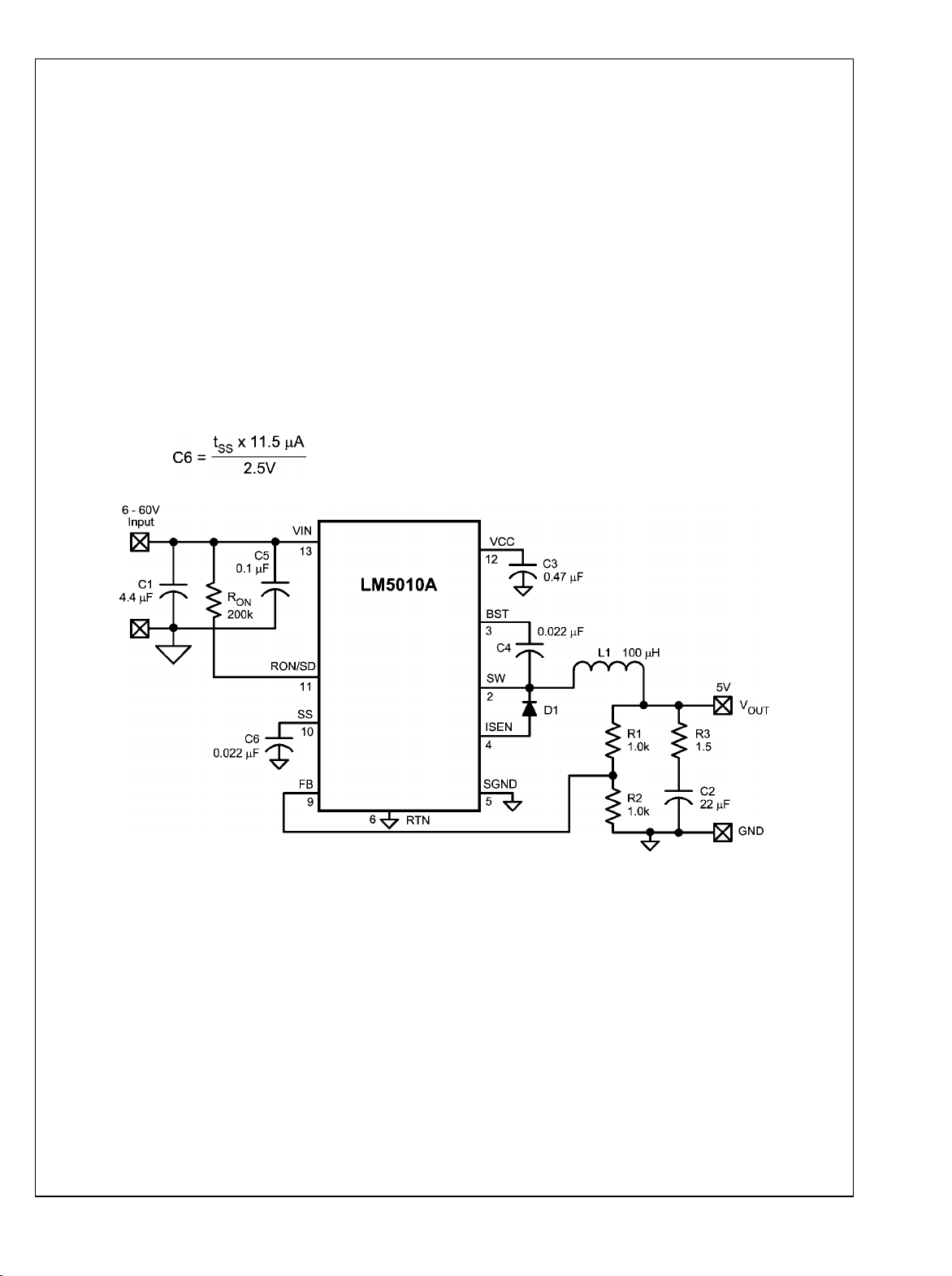

Basic Step Down Regulator

20153843

© 2008 National Semiconductor Corporation 201538 www.national.com

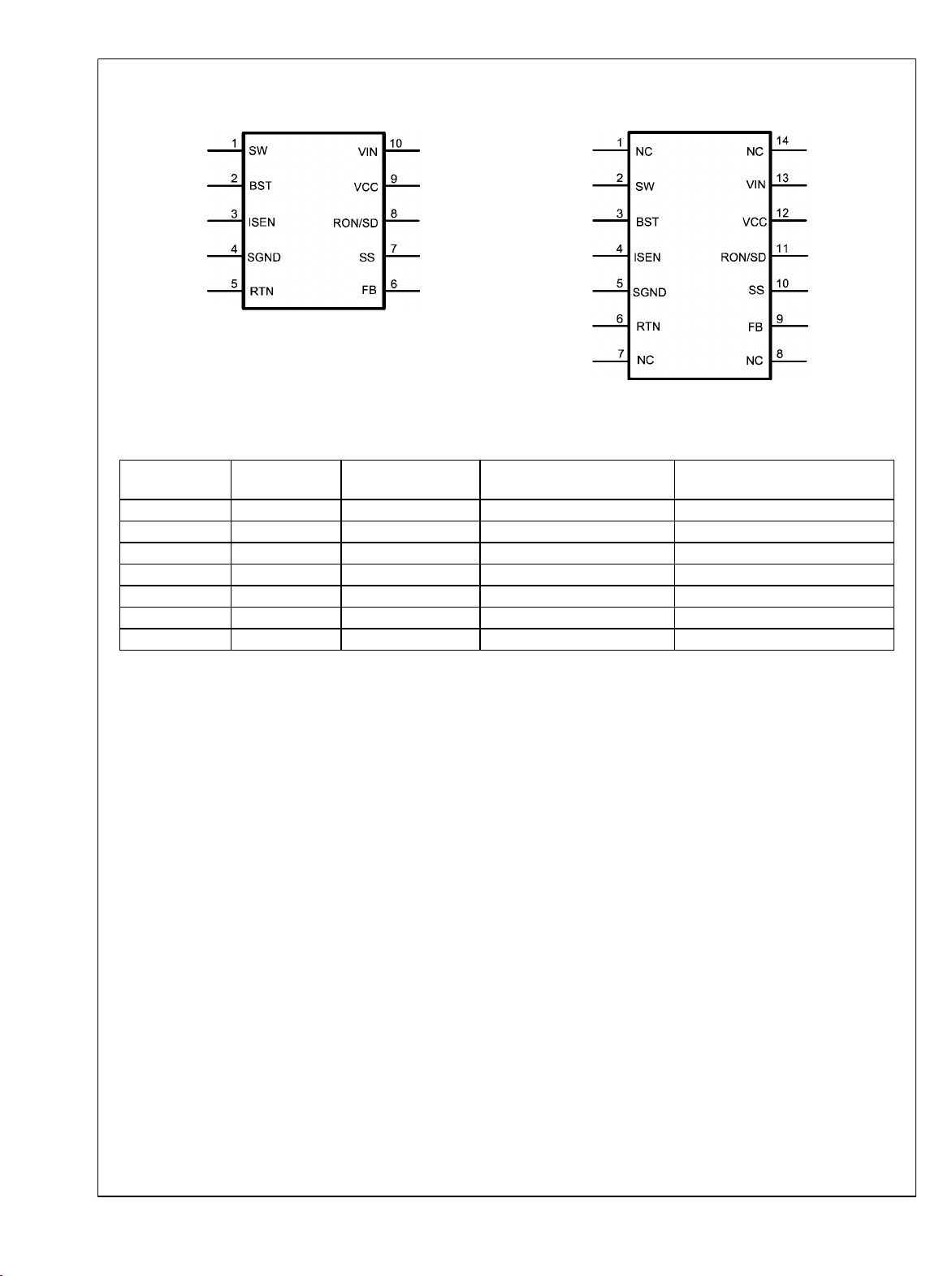

Connection Diagrams

LM5010A

Ordering Information

20153802

20153803

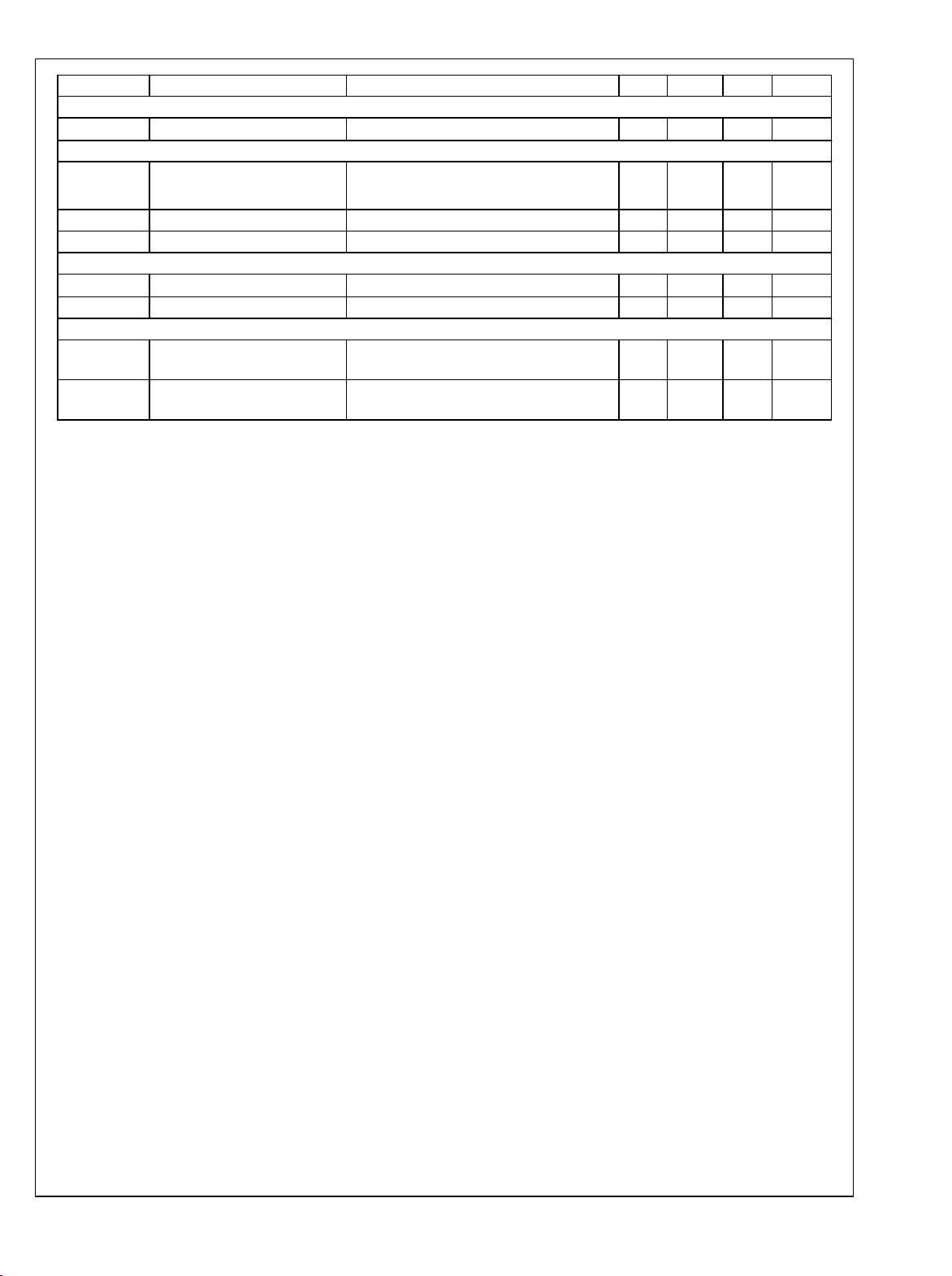

Order Number Package Type NSC Package

Drawing

LM5010ASD LLP-10 (4x4) SDC10A −40°C to + 125°C 1000 Units on Tape and Reel

LM5010ASDX LLP-10 (4x4) SDC10A −40°C to + 125°C 4500 Units on Tape and Reel

LM5010AMH TSSOP-14EP MXA14A −40°C to + 125°C 94 Units in Rail

LM5010AMHE TSSOP-14EP MXA14A −40°C to + 125°C 250 Units on Tape and Reel

LM5010AMHX TSSOP-14EP MXA14A −40°C to + 125°C 2500 Units on Tape and Reel

LM5010AHMH TSSOP-14EP MXA14A −40°C to + 150°C Available Soon

LM5010AHMHX TSSOP-14EP MXA14A −40°C to + 150°C Available Soon

Junction Temperature Range Supplied As

www.national.com 2

Pin Descriptions

Pin Number Name Description Application Information

LLP-10 TSSOP-14

1 2 SW Switching Node Internally connected to the buck switch source.

Connect to the inductor, free-wheeling diode, and

bootstrap capacitor.

2 3 BST Boost pin for bootstrap capacitor Connect a capacitor from SW to the BST pin. The

capacitor is charged from VCC via an internal diode

during the buck switch off-time.

3 4 ISEN Current sense During the buck switch off-time, the inductor current

flows through the internal sense resistor, and out of

the ISEN pin to the free-wheeling diode. The current

limit comparator keeps the buck switch off if the ISEN

current exceeds 1.25A (typical).

4 5 SGND Current Sense Ground Re-circulating current flows into this pin to the current

sense resistor.

5 6 RTN Circuit Ground Ground return for all internal circuitry other than the

current sense resistor.

6 9 FB Voltage feedback input from the

regulated output

7 10 SS Softstart An internal 11.5 µA current source charges the SS pin

8 11 RON/SD On-time control and shutdown An external resistor from VIN to the RON/SD pin sets

9 12 VCC Output of the bias regulator The voltage at VCC is nominally equal to VIN for V

10 13 VIN Input supply voltage Nominal input range is 6V to 75V. Input bypass

1,7,8,14 NC No connection. No internal connection. Can be connected to ground

EP Exposed Pad Exposed metal pad on the underside of the device. It

Input to both the regulation and over-voltage

comparators. The FB pin regulation level is 2.5V.

capacitor to 2.5V to soft-start the reference input of

the regulation comparator.

the buck switch on-time. Grounding this pin shuts

down the regulator.

< 8.9V, and regulated at 7V for VIN > 8.9V. Connect

a 0.47 µF, or larger capacitor from VCC to ground, as

close as possible to the pins. An external voltage can

be applied to this pin to reduce internal dissipation if

VIN is greater than 8.9V. MOSFET body diodes clamp

VCC to VIN if VCC > VIN.

capacitors should be located as close as possible to

the VIN pin and RTN pins.

plane to improve heat dissipation.

is recommended to connect this pad to the PC board

ground plane to aid in heat dissipation.

LM5010A

IN

3 www.national.com

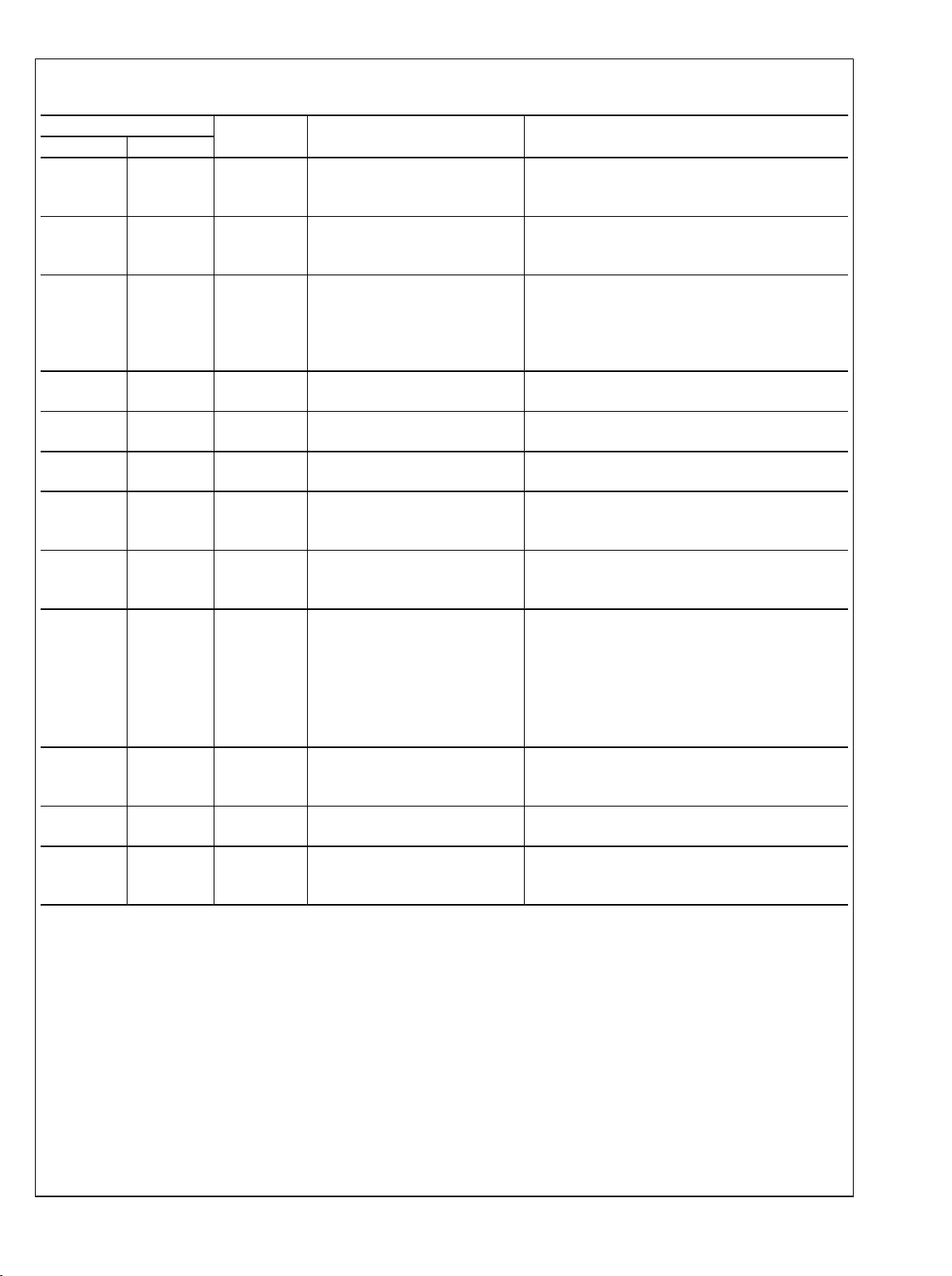

Absolute Maximum Ratings (Note 1)

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales Office/

LM5010A

Distributors for availability and specifications.

VIN to RTN -0.3V to 76V

BST to RTN -0.3V to 90V

SW to RTN (Steady State) -1.5V

BST to VCC 76V

BST to SW 14V

VCC to RTN -0.3V to 14V

SGND to RTN -0.3V to +0.3V

SS to RTN -0.3V to 4V

VIN to SW 76V

All Other Inputs to RTN -0.3V to 7V

ESD Rating (Note 2)

Human Body Model 2kV

Storage Temperature Range -65°C to +150°C

Lead Temperature (Soldering 4 sec) (Note 4) 260°C

Operating Ratings (Note 1)

VIN Voltage 6.0V to 75V

Junction Temperature

LM5010A −40°C to + 125°C

LM5010AH −40°C to + 150°C

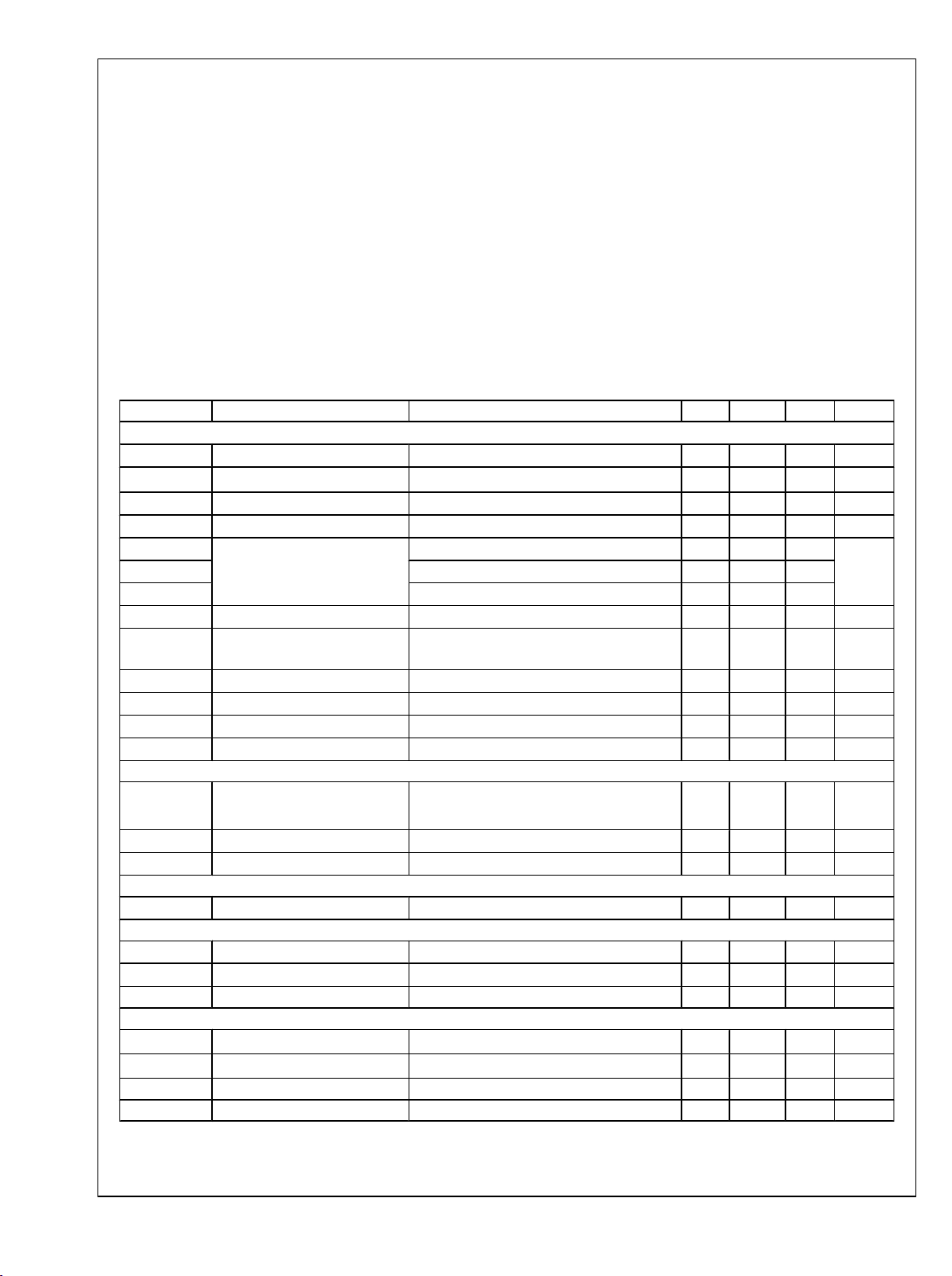

Electrical Charateristics Specifications with standard type are for T

= 25°C only; limits in boldface type apply

J

over the full Operating Junction Temperature (TJ) range. Minimum and Maximum limits are guaranteed through test, design, or

statistical correlation. Typical values represent the most likely parametric norm at TJ = 25°C, and are provided for reference

purposes only. Unless otherwise stated the following conditions apply: VIN = 48V, RON = 200kΩ. See (Note 5).

Symbol Parameter Conditions Min Typ Max Units

VCC Regulator

VCCReg VCC regulated output 6.6 7 7.4 Volts

VIN - V

CC

ICC = 0 mA, FS < 200 kHz, 6.0V ≤ VIN ≤ 8.5V

100 mV

VCC Bypass Threshold VIN Increasing 8.9 V

VCC Bypass Hysteresis VIN Decreasing 260 mV

VCC output impedance

VIN = 8.0V 50

(0 mA ≤ ICC ≤ 5 mA)

VIN = 6.0V 55

Ω

VIN = 48V 0.21

VCC current limit (Note 3) VIN = 48V, VCC = 0V 15 mA

UVLOVcc VCC under-voltage lock-out

VCC Increasing 5.25 V

threshold

UVLO

UVLO

hysteresis VCC Decreasing 180 mV

VCC

filter delay 100 mV overdrive 3 µs

VCC

IIN operating current Non-switching, FB = 3V 675 950 µA

IIN shutdown current RON/SD = 0V 100 200 µA

Switch Characteristics

R

DS(on)

UVLO

Buck Switch R

DS(on)

200 mA

Gate Drive UVLO V

GD

@ ISW =

TJ ≤ 125°C

TJ ≤ 150°C

- VSW Increasing 1.7 3.0 4.0 V

BST

0.35 0.80

0.85

Ω

UVLOGD hysteresis 400 mV

SOFT-START Pin

I

SS

Internal current source 8.0 11.5 15 µA

Current Limit

I

LIM

Resistance from ISEN to SGND 130

Threshold Current out of I

SEN

1 1.25 1.5 A

mΩ

Response time 150 ns

On Timer, RON/SD Pin

tON - 1 On-time

tON - 2 On-time

VIN = 10V, RON = 200 kΩ

VIN = 75V, RON = 200 kΩ

2.1 2.75 3.4 µs

290 390 496 ns

Shutdown threshold Voltage at RON/SD rising 0.30 0.7 1.05 V

Threshold hysteresis 40 mV

www.national.com 4

Symbol Parameter Conditions Min Typ Max Units

Off Timer

t

OFF

Minimum Off-time 260 ns

Regulation and Over-Voltage Comparators (FB Pin)

V

REF

FB regulation threshold

TJ ≤ 125°C

TJ ≤ 150°C

2.445

2.435

2.50 2.550 V

FB over-voltage threshold 2.9 V

FB bias current 1 nA

Thermal Shutdown

T

SD

Thermal shutdown temperature 175 °C

Thermal shutdown hysteresis 20 °C

Thermal Resistance

θ

JA

Junction to Ambient, 0 LFPM Air

Flow

θ

JC

Note 1: Absolute Maximum Ratings are limits beyond which damage to the device may occur. Operating Ratings are conditions under which operation of the

device is intended to be functional. For guaranteed specifications and test conditions, see the Electrical Characteristics.

Note 2: The human body model is a 100pF capacitor discharged through a 1.5kΩ resistor into each pin.

Note 3: VCC provides bias for the internal gate drive and control circuits. Device thermal limitations limit external loading.

Note 4: For detailed information on soldering plastic TSSOP and LLP packages refer to the Packaging Data Book available from National Semiconductor

Corporation.

Note 5: Typical specifications represent the most likely parametric norm at 25°C operation.

Junction to Case SDC Package

SDC Package

MXA Package

MXA Package

40

40

5.2

5.2

°C/W

°C/W

LM5010A

5 www.national.com

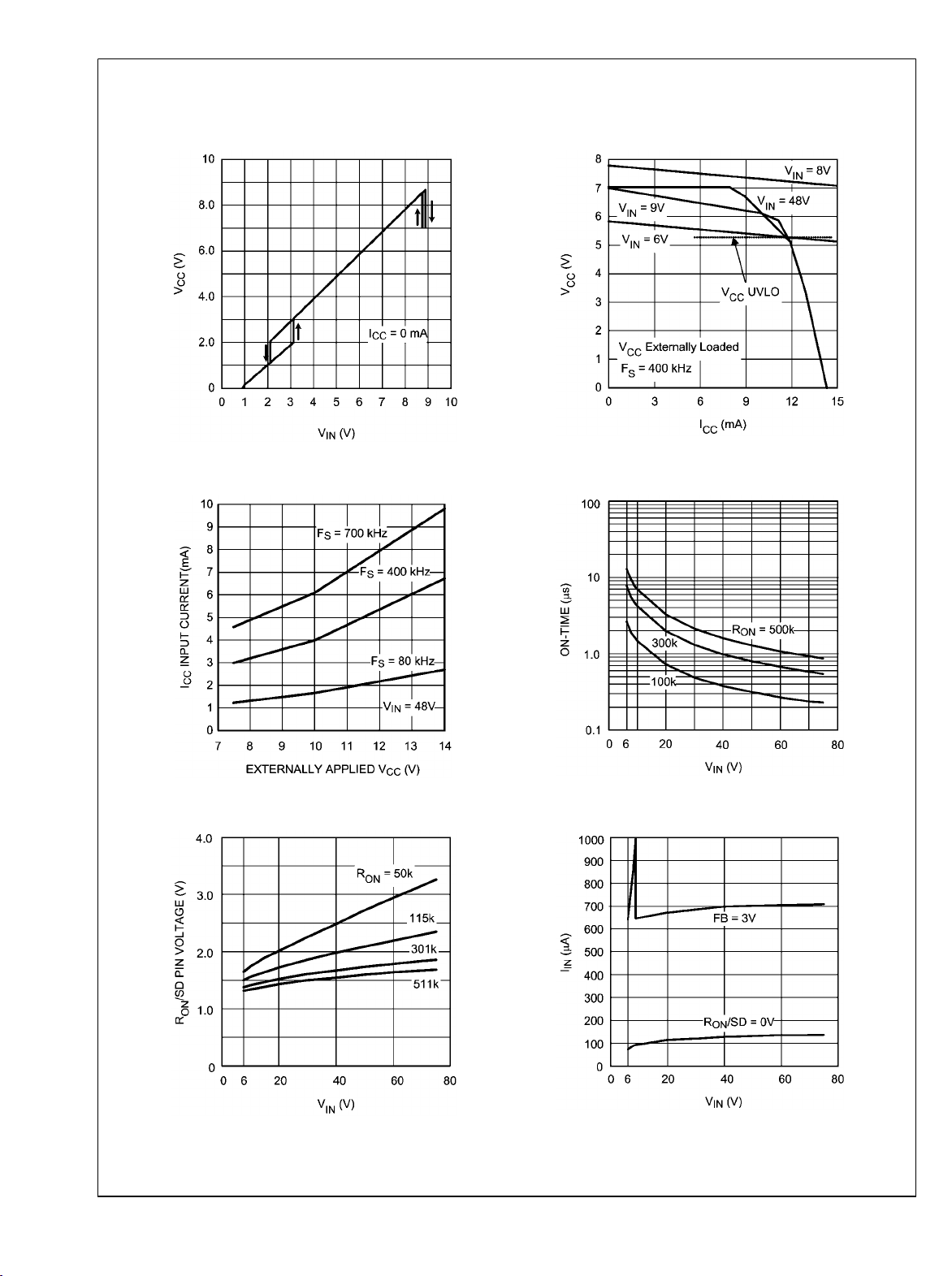

Typical Performance Characteristics

LM5010A

VCC vs V

IN

ICC vs Externally Applied V

CC

20153804

VCC vs I

CC

On-Time vs VIN and R

20153805

ON

20153806

Voltage at RON/SD Pin

20153808

www.national.com 6

IIN vs V

20153807

IN

20153810

Block Diagram

LM5010A

20153844

7 www.national.com

LM5010A

FIGURE 1. Startup Sequence

Functional Description

The LM5010A Step Down Switching Regulator features all

the functions needed to implement a low cost, efficient buck

DC-DC converter capable of supplying in excess of 1A to the

load. This high voltage regulator integrates an 80V N-Channel

buck switch, with an easy to implement constant on-time controller. It is available in the thermally enhanced LLP-10 and

TSSOP-14EP packages. The regulator compares the feedback voltage to a 2.5V reference to control the buck switch,

and provides a switch on-time which varies inversely with VIN.

This feature results in the operating frequency remaining relatively constant with load and input voltage variations. The

switching frequency can range from less than 100 kHz to 1.0

MHz. The regulator requires no loop compensation resulting

in very fast load transient response. The valley current limit

circuit holds the buck switch off until the free-wheeling inductor current falls below the current limit threshold, nominally set

at 1.25A.

The LM5010A can be applied in numerous applications to efficiently step down higher DC voltages. This regulator is well

www.national.com 8

20153811

suited for 48V telecom applications, as well as the 42V automotive power bus. Features include: Thermal shutdown, VCC

under-voltage lock-out, gate drive under-voltage lock-out, and

maximum duty cycle limit.

Control Circuit Overview

The LM5010A employs a control scheme based on a comparator and a one-shot on-timer, with the output voltage feedback (FB) compared to an internal reference (2.5V). If the FB

voltage is below the reference the buck switch is turned on for

a time period determined by the input voltage and a programming resistor (RON). Following the on-time the switch remains

off for a fixed 260 ns off-time, or until the FB voltage falls below

the reference, whichever is longer. The buck switch then turns

on for another on-time period. Referring to the Block Diagram,

the output voltage is set by R1 and R2. The regulated output

voltage is calculated as follows:

V

= 2.5V x (R1 + R2) / R2 (1)

OUT

The LM5010A requires a minimum of 25 mV of ripple voltage

at the FB pin for stable fixed-frequency operation. If the output

LM5010A

capacitor’s ESR is insufficient additional series resistance

may be required (R3 in the Block Diagram).

The LM5010A operates in continuous conduction mode at

heavy load currents, and discontinuous conduction mode at

light load currents. In continuous conduction mode current always flows through the inductor, never decaying to zero

during the off-time. In this mode the operating frequency remains relatively constant with load and line variations. The

minimum load current for continuous conduction mode is onehalf the inductor’s ripple current amplitude. The operating

frequency in the continuous conduction mode is calculated as

follows:

(2)

The buck switch duty cycle is equal to:

(3)

Under light load conditions, the LM5010A operates in discontinuous conduction mode, with zero current flowing through

the inductor for a portion of the off-time. The operating frequency is always lower than that of the continuous conduction

mode, and the switching frequency varies with load current.

Conversion efficiency is maintained at a relatively high level

at light loads since the switching losses diminish as the power

delivered to the load is reduced. The discontinuous mode operating frequency is approximately:

(4)

where RL = the load resistance.

Start-Up Bias Regulator (VCC)

A high voltage bias regulator is integrated within the

LM5010A. The input pin (VIN) can be connected directly to

line voltages between 6V and 75V. Referring to the block diagram and the graph of VCC vs. VIN, when VIN is between 6V

and the bypass threshold (nominally 8.9V), the bypass switch

(Q2) is on, and VCC tracks VIN within 100 mV to 150 mV. The

bypass switch on-resistance is approximately 50Ω, with inherent current limiting at approximately 100 mA. When VIN is

above the bypass threshold, Q2 is turned off, and VCC is regulated at 7V. The VCC regulator output current is limited at

approximately 15 mA. When the LM5010A is shutdown using

the RON/SD pin, the VCC bypass switch is shut off, regardless

of the voltage at VIN.

When VIN exceeds the bypass threshold, the time required for

Q2 to shut off is approximately 2 - 3 µs. The capacitor at VCC

(C3) must be a minimum of 0.47 µF to prevent the voltage at

VCC from rising above its absolute maximum rating in response to a step input applied at VIN. C3 must be located as

close as possible to the LM5010A pins.

In applications with a relatively high input voltage, power dissipation in the bias regulator is a concern. An auxiliary voltage

of between 7.5V and 14V can be diode connected to the VCC

pin (D2 in Figure 2) to shut off the VCC regulator, reducing

internal power dissipation. The current required into the VCC

pin is shown in the Typical Performance Characteristics. Internally a diode connects VCC to VIN requiring that the auxiliary voltage be less than VIN.

The turn-on sequence is shown in Figure 1. When VCC exceeds the under-voltage lock-out threshold (UVLO) of 5.25V

(t1 in Figure 1), the buck switch is enabled, and the SS pin is

released to allow the soft-start capacitor (C6) to charge up.

The output voltage V

increases to the desired value as the soft-start voltage increases (t2 in Figure 1).

is regulated at a reduced level which

OUT

FIGURE 2. Self Biased Configuration

Regulation Comparator

The feedback voltage at the FB pin is compared to the voltage

at the SS pin (2.5V, ±2%). In normal operation an on-time

period is initiated when the voltage at FB falls below 2.5V. The

buck switch conducts for the on-time programmed by RON,

causing the FB voltage to rise above 2.5V. After the on-time

period the buck switch remains off until the FB voltage falls

20153816

below 2.5V. Input bias current at the FB pin is less than 5 nA

over temperature.

Over-Voltage Comparator

The feedback voltage at FB is compared to an internal 2.9V

reference. If the voltage at FB rises above 2.9V the on-time

is immediately terminated. This condition can occur if the in-

9 www.national.com

put voltage, or the output load, changes suddenly. The buck

switch remains off until the voltage at FB falls below 2.5V.

LM5010A

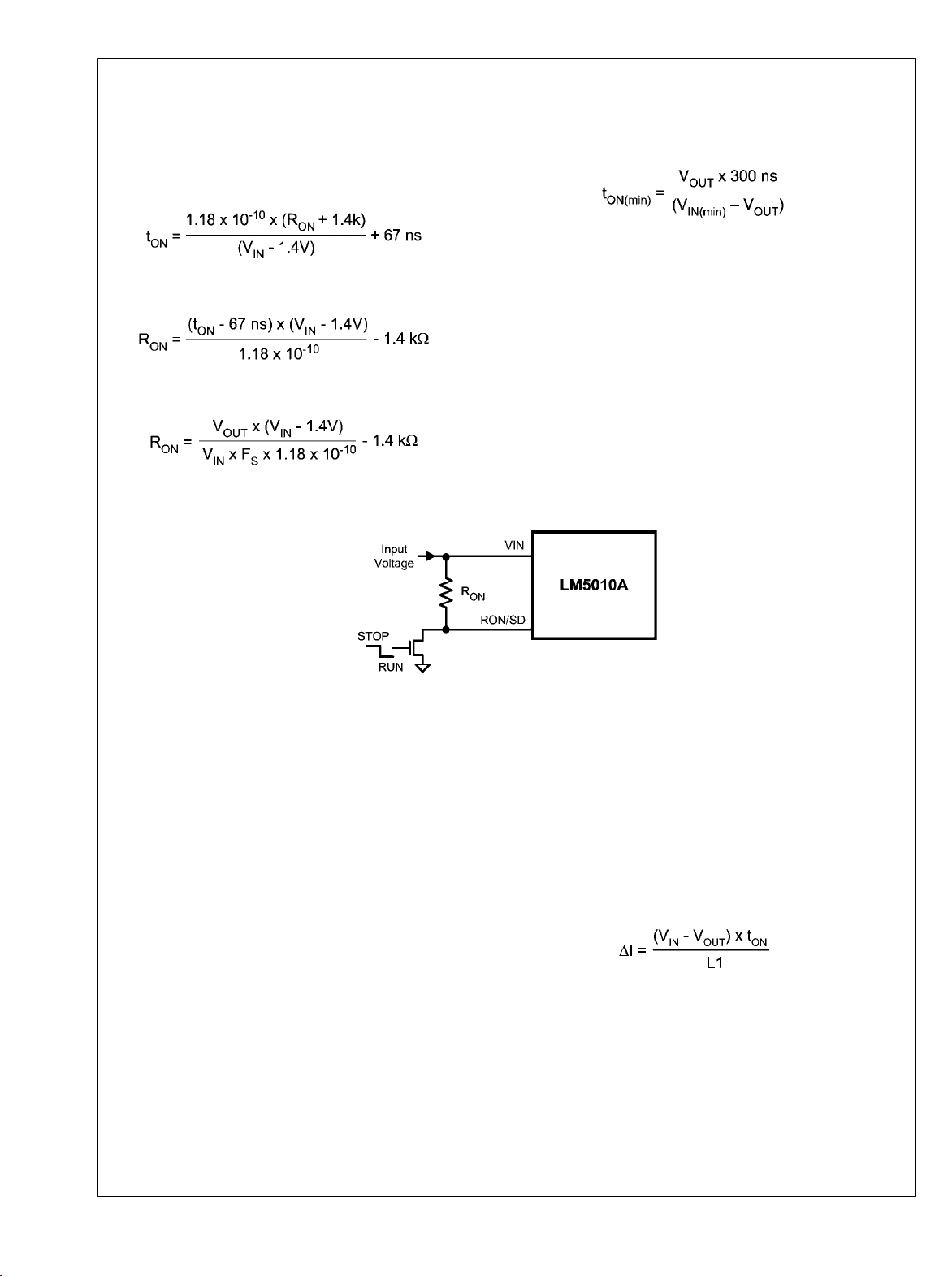

ON-Time Control

The on-time of the internal buck switch is determined by the

RON resistor and the input voltage (VIN), and is calculated as

follows:

the minimum off-time of the LM5010A (260 ns, ±15%). The

fixed off-time limits the maximum duty cycle achievable with

a low voltage at VIN. The minimum allowed on-time to regulate the desired V

the following:

at the minimum VIN is determined from

OUT

(8)

(5)

The RON resistor can be determined from the desired on-time

by re-arranging Equation 5 to the following:

(6)

To set a specific continuous conduction mode switching frequency (Fs), the RON resistor is determined from the following:

(7)

In high frequency applications the minimum value for tON is

limited by the maximum duty cycle required for regulation and

FIGURE 3. Shutdown Implementation

Shutdown

The LM5010A can be remotely shut down by forcing the RON/

SD pin below 0.7V with a switch or open drain device. See

Figure 3. In the shutdown mode the SS pin is internally

grounded, the on-time one-shot is disabled, the input current

at VIN is reduced, and the VCC bypass switch is turned off.

The VCC regulator is not disabled in the shutdown mode. Releasing the RON/SD pin allows normal operation to resume.

The nominal voltage at RON/SD is shown in the Typical Performance Characteristics. When switching the RON/SD pin,

the transition time should be faster than one to two cycles of

the regulator’s nominal switching frequency.

20153818

Current Limit

Current limit detection occurs during the off-time by monitoring the recirculating current through the internal current sense

resistor (R

Referring to the Block Diagram, if the current into SGND during the off-time exceeds the threshold level the current limit

comparator delays the start of the next on-time period. The

next on-time starts when the current into SGND is below the

threshold and the voltage at FB is below 2.5V. Figure 4 illustrates the inductor current waveform during normal operation

and during current limit. The output current IO is the average

of the inductor ripple current waveform. The Low Load Current waveform illustrates continuous conduction mode operation with peak and valley inductor currents below the current

limit threshold. When the load current is increased (High Load

Current), the ripple waveform maintains the same amplitude

and frequency since the current falls below the current limit

threshold at the valley of the ripple waveform. Note the average current in the High Load Current portion of Figure 4 is

above the current limit threshold. Since the current reduces

below the threshold in the normal off-time each cycle, the start

www.national.com 10

). The detection threshold is 1.25A, ±0.25A.

SENSE

of each on-time is not delayed, and the circuit’s output voltage

is regulated at the correct value. When the load current is further increased such that the lower peak would be above the

threshold, the off-time is lengthened to allow the current to

decrease to the threshold before the next on-time begins

(Current Limited portion of Figure 4). Both V

switching frequency are reduced as the circuit operates in a

constant current mode. The load current (I

current limit threshold plus half the ripple current (ΔI/2). The

ripple amplitude (ΔI) is calculated from:

The current limit threshold can be increased by connecting an

external resistor (RCL) between SGND and ISEN. RCL typically is less than 1Ω, and the calculation of its value is explained in the Applications Information section. If the current

limit threshold is increased by adding RCL, the maximum continuous load current should not exceed 1.5A, and the peak

current out of the SW pin should not exceed 2A.

OCL

and the

OUT

) is equal to the

(9)

FIGURE 4. Inductor Current - Current Limit Operation

LM5010A

20153820

N - Channel Buck Switch and Driver

The LM5010A integrates an N-Channel buck switch and associated floating high voltage gate driver. The peak current

through the buck switch should not exceed 2A, and the load

current should not exceed 1.5A. The gate driver circuit is

powered by the external bootstrap capacitor between BST

and SW (C4), which is recharged each off-time from V

through the internal high voltage diode. The minimum offtime, nominally 260 ns, ensures sufficient time during each

cycle to recharge the bootstrap capacitor. A 0.022 µF ceramic

capacitor is recommended for C4.

CC

Soft-start

The soft-start feature allows the regulator to gradually reach

a steady state operating point, thereby reducing startup

stresses and current surges. At turn-on, while VCC is below

the under-voltage threshold (t1 in Figure 1), the SS pin is internally grounded, and V

the under-voltage threshold (UVLO) an internal 11.5 µA current source charges the external capacitor (C6) at the SS pin

to 2.5V (t2 in Figure 1). The increasing SS voltage at the noninverting input of the regulation comparator gradually increases the output voltage from zero to the desired value. The softstart feature keeps the load inductor current from reaching the

current limit threshold during start-up, thereby reducing inrush

currents.

An internal switch grounds the SS pin if VCC is below the under-voltage lock-out threshold, if a thermal shutdown occurs,

or if the circuit is shutdown using the RON/SD pin.

is held at 0V. When VCC exceeds

OUT

Applications Information

EXTERNAL COMPONENTS

The procedure for calculating the external components is illustrated with a design example. Referring to the Block Diagram, the circuit is to be configured for the following

specifications:

•

V

= 5V

OUT

•

VIN = 6V to 60V

•

FS = 175 kHz

•

Minimum load current = 200 mA

•

Maximum load current = 1.0A

•

Softstart time = 5 ms.

R1 and R2: These resistors set the output voltage, and their

ratio is calculated from:

R1/R2 = (V

R1/R2 calculates to 1.0. The resistors should be chosen from

standard value resistors in the range of 1.0 kΩ - 10 kΩ. A value

of 1.0 kΩ will be used for R1 and for R2.

RON, FS: RON can be chosen using Equation 7 to set the nom-

inal frequency, or from Equation 6 if the on-time at a particular

VIN is important. A higher frequency generally means a smaller inductor and capacitors (value, size and cost), but higher

switching losses. A lower frequency means a higher efficiency, but with larger components. Generally, if PC board space

is tight, a higher frequency is better. The resulting on-time and

frequency have a ±25% tolerance. Using equation 7 at a

nominal VIN of 8V,

/2.5V) - 1 (10)

OUT

Thermal Shutdown

The LM5010A should be operated below the Maximum Operating Junction Temperature rating. If the junction temperature increases during a fault or abnormal operating condition,

the internal Thermal Shutdown circuit activates typically at

175°C. The Thermal Shutdown circuit reduces power dissipation by disabling the buck switch and the on-timer, and

grounding the SS pin. This feature helps prevent catastrophic

failures from accidental device overheating. When the junction temperature reduces below approximately 155°C (20°C

typical hysteresis), the SS pin is released and normal operation resumes.

A value of 200 kΩ will be used for RON, yielding a nominal

frequency of 161 kHz at VIN = 6V, and 205 kHz at VIN = 60V.

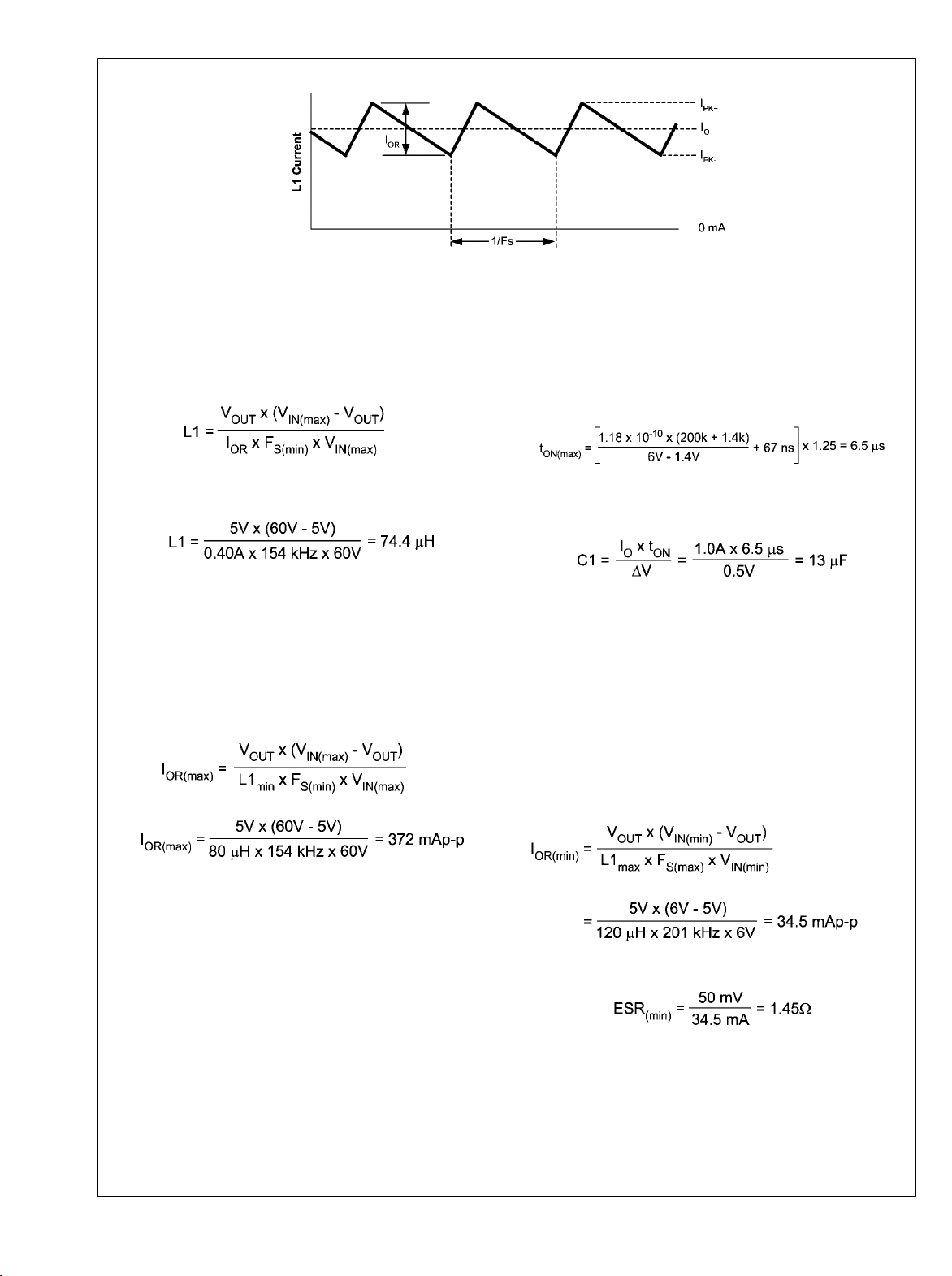

L1: The guideline for choosing the inductor value in this example is that it must keep the circuit’s operation in continuous

conduction mode at minimum load current. This is not a strict

requirement since the LM5010A regulates correctly when in

discontinuous conduction mode, although at a lower frequency. However, to provide an initial value for L1 the above

guideline will be used.

11 www.national.com

LM5010A

20153822

FIGURE 5. Inductor Current

To keep the circuit in continuous conduction mode, the maximum allowed ripple current is twice the minimum load current, or 400 mAp-p. Using this value of ripple current, the

inductor (L1) is calculated using the following:

(11)

where F

- 25%) at V

is the minimum frequency of 154 kHz (205 kHz

S(min)

IN(max)

.

This provides a minimum value for L1 - the next higher standard value (100 µH) will be used. To prevent saturation, and

possible destructive current levels, L1 must be rated for the

peak current which occurs if the current limit and maximum

ripple current are reached simultaneously (IPK in Figure 4).

The maximum ripple amplitude is calculated by re-arranging

Equation 11 using V

value, based on the manufacturer’s tolerance. Assume, for

IN(max)

, F

, and the minimum inductor

S(min)

this exercise, the inductor’s tolerance is ±20%.

(12)

ue (I

), then drops to zero at turn-off. The average current

PK+

into VIN during this on-time is the load current. For a worst

case calculation, C1 must supply this average current during

the maximum on-time. The maximum on-time is calculated at

VIN = 6V using Equation 5, with a 25% tolerance added:

The voltage at VIN should not be allowed to drop below 5.5V

in order to maintain VCC above its UVLO.

Normally a lower value can be used for C1 since the above

calculation is a worst case calculation which assumes the

power source has a high source impedance. A quality ceramic

capacitor with a low ESR should be used for C1.

C2 and R3: Since the LM5010A requires a minimum of 25

mVp-p of ripple at the FB pin for proper operation, the required

ripple at V

is increased by R1 and R2, and is equal to:

OUT

V

= 25 mVp-p x (R1 + R2)/R2 = 50 mVp-p

RIPPLE

This necessary ripple voltage is created by the inductor ripple

current acting on C2’s ESR + R3. First, the minimum ripple

current, which occurs at minimum VIN, maximum inductor

value, and maximum frequency, is determined.

IPK = I

where I

LIM

At the nominal maximum load current of 1.0A, the peak in-

LIM

+ I

= 1.5A + 0.372A = 1.872A

OR(max)

is the maximum guaranteed current limit threshold.

ductor current is 1.186A.

RCL: Since it is obvious that the lower peak of the inductor

current waveform does not exceed 1.0A at maximum load

current (see Figure 5), it is not necessary to increase the current limit threshold. Therefore RCL is not needed for this

exercise. For applications where the lower peak exceeds

1.0A, see the section entitled Increasing The Current Limit

Threshold.

C1: This capacitor limits the ripple voltage at VIN resulting

from the source impedance of the supply feeding this circuit,

and the on/off nature of the switch current into VIN. At maximum load current, when the buck switch turns on, the current

into VIN steps up from zero to the lower peak of the inductor

current waveform (I

www.national.com 12

in Figure 5), ramps up to the peak val-

PK-

(13)

The minimum ESR for C2 is then equal to:

If the capacitor used for C2 does not have sufficient ESR, R3

is added in series as shown in the Block Diagram. The value

chosen for C2 is application dependent, and it is recommended that it be no smaller than 3.3 µF. C2 affects the ripple at

V

, and transient response. Experimentation is usually nec-

OUT

essary to determine the optimum value for C2.

LM5010A

C3: The capacitor at the VCC pin provides noise filtering and

stability, prevents false triggering of the VCC UVLO at the buck

switch on/off transitions, and limits the peak voltage at V

when a high voltage with a short rise time is initially applied

CC

at VIN. C3 should be no smaller than 0.47 µF, and should be

a good quality, low ESR, ceramic capacitor, physically close

to the IC pins.

C4: The recommended value for C4 is 0.022 µF. A high quality

ceramic capacitor with low ESR is recommended as C4 supplies the surge current to charge the buck switch gate at each

turn-on. A low ESR also ensures a complete recharge during

each off-time.

C5: This capacitor suppresses transients and ringing due to

lead inductance at VIN. A low ESR, 0.1 µF ceramic chip capacitor is recommended, located physically close to the

LM5010A.

C6: The capacitor at the SS pin determines the soft-start time,

i.e. the time for the reference voltage at the regulation comparator, and the output voltage, to reach their final value. The

capacitor value is determined from the following:

For a 5 ms softstart time, C6 calculates to 0.022 µF.

D1: A Schottky diode is recommended. Ultra-fast recovery

diodes are not recommended as the high speed transitions at

the SW pin may inadvertently affect the IC’s operation through

external or internal EMI. The diode should be rated for the

maximum VIN (60V), the maximum load current (1A), and the

peak current which occurs when current limit and maximum

ripple current are reached simultaneously (IPK in Figure 4),

previously calculated to be 1.87A. The diode’s forward voltage drop affects efficiency due to the power dissipated during

the off-time. The average power dissipation in D1 is calculated from:

PD1 = VF x IO x (1 - D)

where IO is the load current, and D is the duty cycle.

FINAL CIRCUIT

The final circuit is shown in Figure 6, and its performance is

shown in Figures 7 & 8. Current limit measured approximately

1.3A.

FIGURE 6. Example Circuit

13 www.national.com

20153833

LM5010A

Item Description Value

C1 Ceramic Capacitor (2) 2.2 µF, 100V

C2 Ceramic Capacitor 22 µF, 16V

C3 Ceramic Capacitor 0.47 µF, 16V

C4, C6 Ceramic Capacitor 0.022 µF, 16V

C5 Ceramic Capacitor 0.1 µF, 100V

D1 Schottky Diode 100V, 6A

L1 Inductor 100 µH

R1 Resistor

R2 Resistor

R3 Resistor

R

ON

Resistor

1.0 kΩ

1.0 kΩ

1.5 Ω

200 kΩ

U1 National Semi LM5010A

will either shutdown, or cycle on and off at a low frequency. If

the load current is expected to drop below 500 µA in the application, R1 and R2 should be chosen low enough in value

so they provide the minimum required current at nominal

V

.

OUT

LOW OUTPUT RIPPLE CONFIGURATIONS

For applications where low output voltage ripple is required

the output can be taken directly from the low ESR output capacitor (C2) as shown in Figure 9. However, R3 slightly

degrades the load regulation. The specific component values,

and the application determine if this is suitable.

20153835

FIGURE 7. Efficiency vs Load Current and V

Circuit of Figure 6

FIGURE 8. Frequency vs V

Circuit of Figure 6

IN

IN

20153837

MINIMUM LOAD CURRENT

The LM5010A requires a minimum load current of 500 µA. If

the load current falls below that level, the bootstrap capacitor

(C4) may discharge during the long off-time, and the circuit

20153815

FIGURE 9. Low Ripple Output

Where the circuit of Figure 9 is not suitable, the circuits of

Figure 10 or Figure 11 can be used.

20153848

FIGURE 10. Low Output Ripple Using a Feedforward

Capacitor

In Figure 10, Cff is added across R1 to AC-couple the ripple

at V

directly to the FB pin. This allows the ripple at V

OUT

to be reduced, in some cases considerably, by reducing R3.

In the circuit of Figure 6, the ripple at V

mVp-p at VIN = 6V to 320 mVp-p at VIN = 60V. By adding a

ranged from 50

OUT

OUT

www.national.com 14

LM5010A

1000 pF capacitor at Cff and reducing R3 to 0.75Ω, the

V

ripple was reduced by 50%, ranging from 25 mVp-p to

OUT

160 mVp-p.

20153849

FIGURE 11. Low Output Ripple Using Ripple Injection

To reduce V

used. R3 has been removed, and the output ripple amplitude

ripple further, the circuit of Figure 11 can be

OUT

is determined by C2’s ESR and the inductor ripple current. RA

and CA are chosen to generate a 40-50 mVp-p sawtooth at

their junction, and that voltage is AC-coupled to the FB pin via

CB. In selecting RA and CA, V

ground as the SW pin switches between VIN and -1V. Since

is considered a virtual

OUT

the on-time at SW varies inversely with VIN, the waveform

amplitude at the RA/CA junction is relatively constant. R1 and

R2 must typically be increased to more than 10k each to not

significantly attenuate the signal provided to FB through CB.

Typical values for the additional components are RA = 200k,

CA = 680 pF, and CB = 0.01 µF.

INCREASING THE CURRENT LIMIT THRESHOLD

The current limit threshold is nominally 1.25A, with a minimum

guaranteed value of 1.0A. If, at maximum load current, the

lower peak of the inductor current (I

1.0A, resistor RCL must be added between S

increase the current limit threshold to equal or exceed that

in Figure 5) exceeds

PK-

GND

and I

SEN

to

lower peak current. This resistor diverts some of the recirculating current from the internal sense resistor so that a higher

current level is needed to switch the internal current limit comparator. I

is calculated from:

PK-

(14)

where I

minimum ripple current calculated using Equation 13. RCL is

is the maximum load current, and I

O(max)

OR(min)

is the

calculated from:

(15)

where 0.11Ω is the minimum value of the internal resistance

from SGND to ISEN. The next smaller standard value resistor

should be used for RCL. With the addition of RCL, and when

the circuit is in current limit, the upper peak current out of the

SW pin (IPK in Figure 4) can be as high as:

where I

L1 and diode D1 must be rated for this current. If IPK exceeds

is calculated using Equation 12. The inductor

OR(max)

2A , the inductor value must be increased to reduce the ripple

amplitude. This will necessitate recalculation of I

and RCL.

OR(min)

, I

PK-

Increasing the circuit’s current limit will increase power dissipation and the junction temperature within the LM5010A. See

the next section for guidelines on this issue.

PC BOARD LAYOUT and THERMAL CONSIDERATIONS

The LM5010A regulation, over-voltage, and current limit comparators are very fast, and will respond to short duration noise

pulses. Layout considerations are therefore critical for optimum performance. The layout must be as neat and compact

as possible, and all the components must be as close as possible to their associated pins. The two major current loops

have currents which switch very fast, and so the loops should

be as small as possible to minimize conducted and radiated

EMI. The first loop is that formed by C1, through the VIN to

SW pins, L1, C2, and back to C1. The second loop is that

formed by D1, L1, C2, and the SGND and ISEN pins. The

ground connection from C2 to C1 should be as short and direct as possible, preferably without going through vias. Directly connect the SGND and RTN pin to each other, and they

should be connected as directly as possible to the C1/C2

ground line without going through vias. The power dissipation

within the IC can be approximated by determining the total

conversion loss (PIN - P

losses in the free-wheeling diode and the inductor. The power

), and then subtracting the power

OUT

loss in the diode is approximately:

PD1 = IO x VF x (1-D)

where Io is the load current, VF is the diode’s forward voltage

drop, and D is the duty cycle. The power loss in the inductor

is approximately:

2

PL1 = I

x RL x 1.1

O

where RL is the inductor’s DC resistance, and the 1.1 factor

is an approximation for the AC losses. If it is expected that the

internal dissipation of the LM5010A will produce high junction

temperatures during normal operation, good use of the PC

board’s ground plane can help considerably to dissipate heat.

The exposed pad on the IC package bottom should be soldered to a ground plane, and that plane should both extend

from beneath the IC, and be connected to exposed ground

plane on the board’s other side using as many vias as possible. The exposed pad is internally connected to the IC substrate. The use of wide PC board traces at the pins, where

possible, can help conduct heat away from the IC. The four

No Connect pins on the TSSOP package are not electrically

connected to any part of the IC, and may be connected to

ground plane to help dissipate heat from the package. Judicious positioning of the PC board within the end product,

along with the use of any available air flow (forced or natural

convection) can help reduce the junction temperature.

,

15 www.national.com

Physical Dimensions inches (millimeters) unless otherwise noted

LM5010A

14-Lead TSSOP Package

NS Package Number MXA14A

10-Lead LLP Package

NS Package Number SDC10A

www.national.com 16

Notes

LM5010A

17 www.national.com

Notes

For more National Semiconductor product information and proven design tools, visit the following Web sites at:

Products Design Support

Amplifiers www.national.com/amplifiers WEBENCH www.national.com/webench

Audio www.national.com/audio Analog University www.national.com/AU

Clock Conditioners www.national.com/timing App Notes www.national.com/appnotes

Data Converters www.national.com/adc Distributors www.national.com/contacts

Displays www.national.com/displays Green Compliance www.national.com/quality/green

Ethernet www.national.com/ethernet Packaging www.national.com/packaging

Interface www.national.com/interface Quality and Reliability www.national.com/quality

LVDS www.national.com/lvds Reference Designs www.national.com/refdesigns

Power Management www.national.com/power Feedback www.national.com/feedback

Switching Regulators www.national.com/switchers

LDOs www.national.com/ldo

LED Lighting www.national.com/led

PowerWise www.national.com/powerwise

Serial Digital Interface (SDI) www.national.com/sdi

Temperature Sensors www.national.com/tempsensors

Wireless (PLL/VCO) www.national.com/wireless

THE CONTENTS OF THIS DOCUMENT ARE PROVIDED IN CONNECTION WITH NATIONAL SEMICONDUCTOR CORPORATION

(“NATIONAL”) PRODUCTS. NATIONAL MAKES NO REPRESENTATIONS OR WARRANTIES WITH RESPECT TO THE ACCURACY

OR COMPLETENESS OF THE CONTENTS OF THIS PUBLICATION AND RESERVES THE RIGHT TO MAKE CHANGES TO

SPECIFICATIONS AND PRODUCT DESCRIPTIONS AT ANY TIME WITHOUT NOTICE. NO LICENSE, WHETHER EXPRESS,

IMPLIED, ARISING BY ESTOPPEL OR OTHERWISE, TO ANY INTELLECTUAL PROPERTY RIGHTS IS GRANTED BY THIS

DOCUMENT.

TESTING AND OTHER QUALITY CONTROLS ARE USED TO THE EXTENT NATIONAL DEEMS NECESSARY TO SUPPORT

NATIONAL’S PRODUCT WARRANTY. EXCEPT WHERE MANDATED BY GOVERNMENT REQUIREMENTS, TESTING OF ALL

PARAMETERS OF EACH PRODUCT IS NOT NECESSARILY PERFORMED. NATIONAL ASSUMES NO LIABILITY FOR

APPLICATIONS ASSISTANCE OR BUYER PRODUCT DESIGN. BUYERS ARE RESPONSIBLE FOR THEIR PRODUCTS AND

LM5010A High Voltage 1A Step Down Switching Regulator

APPLICATIONS USING NATIONAL COMPONENTS. PRIOR TO USING OR DISTRIBUTING ANY PRODUCTS THAT INCLUDE

NATIONAL COMPONENTS, BUYERS SHOULD PROVIDE ADEQUATE DESIGN, TESTING AND OPERATING SAFEGUARDS.

EXCEPT AS PROVIDED IN NATIONAL’S TERMS AND CONDITIONS OF SALE FOR SUCH PRODUCTS, NATIONAL ASSUMES NO

LIABILITY WHATSOEVER, AND NATIONAL DISCLAIMS ANY EXPRESS OR IMPLIED WARRANTY RELATING TO THE SALE

AND/OR USE OF NATIONAL PRODUCTS INCLUDING LIABILITY OR WARRANTIES RELATING TO FITNESS FOR A PARTICULAR

PURPOSE, MERCHANTABILITY, OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY

RIGHT.

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT DEVICES OR

SYSTEMS WITHOUT THE EXPRESS PRIOR WRITTEN APPROVAL OF THE CHIEF EXECUTIVE OFFICER AND GENERAL

COUNSEL OF NATIONAL SEMICONDUCTOR CORPORATION. As used herein:

Life support devices or systems are devices which (a) are intended for surgical implant into the body, or (b) support or sustain life and

whose failure to perform when properly used in accordance with instructions for use provided in the labeling can be reasonably expected

to result in a significant injury to the user. A critical component is any component in a life support device or system whose failure to perform

can be reasonably expected to cause the failure of the life support device or system or to affect its safety or effectiveness.

National Semiconductor and the National Semiconductor logo are registered trademarks of National Semiconductor Corporation. All other

brand or product names may be trademarks or registered trademarks of their respective holders.

Copyright© 2008 National Semiconductor Corporation

For the most current product information visit us at www.national.com

www.national.com

National Semiconductor

Americas Technical

Support Center

Email:

new.feedback@nsc.com

Tel: 1-800-272-9959

National Semiconductor Europe

Technical Support Center

Email: europe.support@nsc.com

German Tel: +49 (0) 180 5010 771

English Tel: +44 (0) 870 850 4288

National Semiconductor Asia

Pacific Technical Support Center

Email: ap.support@nsc.com

National Semiconductor Japan

Technical Support Center

Email: jpn.feedback@nsc.com

Loading...

Loading...