LM2734

Thin SOT23 1A Load Step-Down DC-DC Regulator

LM2734 Thin SOT23 1A Load Step-Down DC-DC Regulator

June 4, 2008

General Description

The LM2734 regulator is a monolithic, high frequency, PWM

step-down DC/DC converter in a 6-pin Thin SOT23 package.

It provides all the active functions to provide local DC/DC

conversion with fast transient response and accurate regulation in the smallest possible PCB area.

With a minimum of external components and online design

support through WEBENCH®™, the LM2734 is easy to use.

The ability to drive 1A loads with an internal 300mΩ NMOS

switch using state-of-the-art 0.5µm BiCMOS technology results in the best power density available. The world class

control circuitry allows for on-times as low as 13ns, thus supporting exceptionally high frequency conversion over the entire 3V to 20V input operating range down to the minimum

output voltage of 0.8V. Switching frequency is internally set

to 550kHz (LM2734Y) or 1.6MHz (LM2734X), allowing the

use of extremely small surface mount inductors and chip capacitors. Even though the operating frequencies are very

high, efficiencies up to 90% are easy to achieve. External

shutdown is included, featuring an ultra-low stand-by current

of 30nA. The LM2734 utilizes current-mode control and internal compensation to provide high-performance regulation

over a wide range of operating conditions. Additional features

include internal soft-start circuitry to reduce inrush current,

pulse-by-pulse current limit, thermal shutdown, and output

over-voltage protection.

Features

Thin SOT23-6 package

■

3.0V to 20V input voltage range

■

0.8V to 18V output voltage range

■

1A output current

■

550kHz (LM2734Y) and 1.6MHz (LM2734X)

■

switching frequencies

300mΩ NMOS switch

■

30nA shutdown current

■

0.8V, 2% internal voltage reference

■

Internal soft-start

■

Current-Mode, PWM operation

■

WEBENCH® online design tool

■

Thermal shutdown

■

LM2734XQ/LM2734YQ are AEC-Q100 Grade 1 qualified

■

and are manufactured on an Automotive Grade Flow

Applications

Local Point of Load Regulation

■

Core Power in HDDs

■

Set-Top Boxes

■

Battery Powered Devices

■

USB Powered Devices

■

DSL Modems

■

Notebook Computers

■

Automotive

■

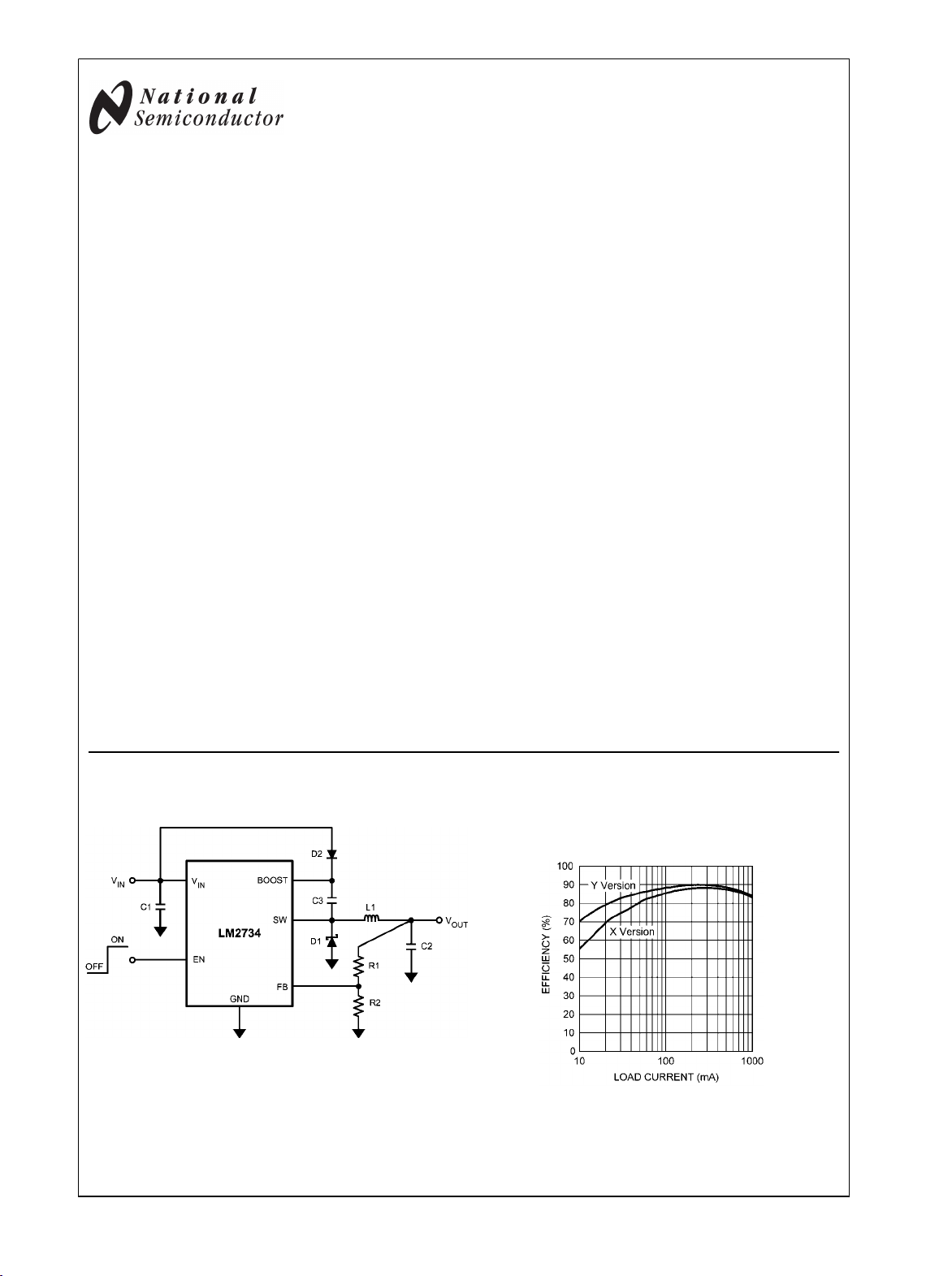

Typical Application Circuit

Efficiency vs Load Current

VIN = 5V, V

20102301

WEBENCH™ is a trademark of Transim.

© 2008 National Semiconductor Corporation 201023 www.national.com

OUT

= 3.3V

20102345

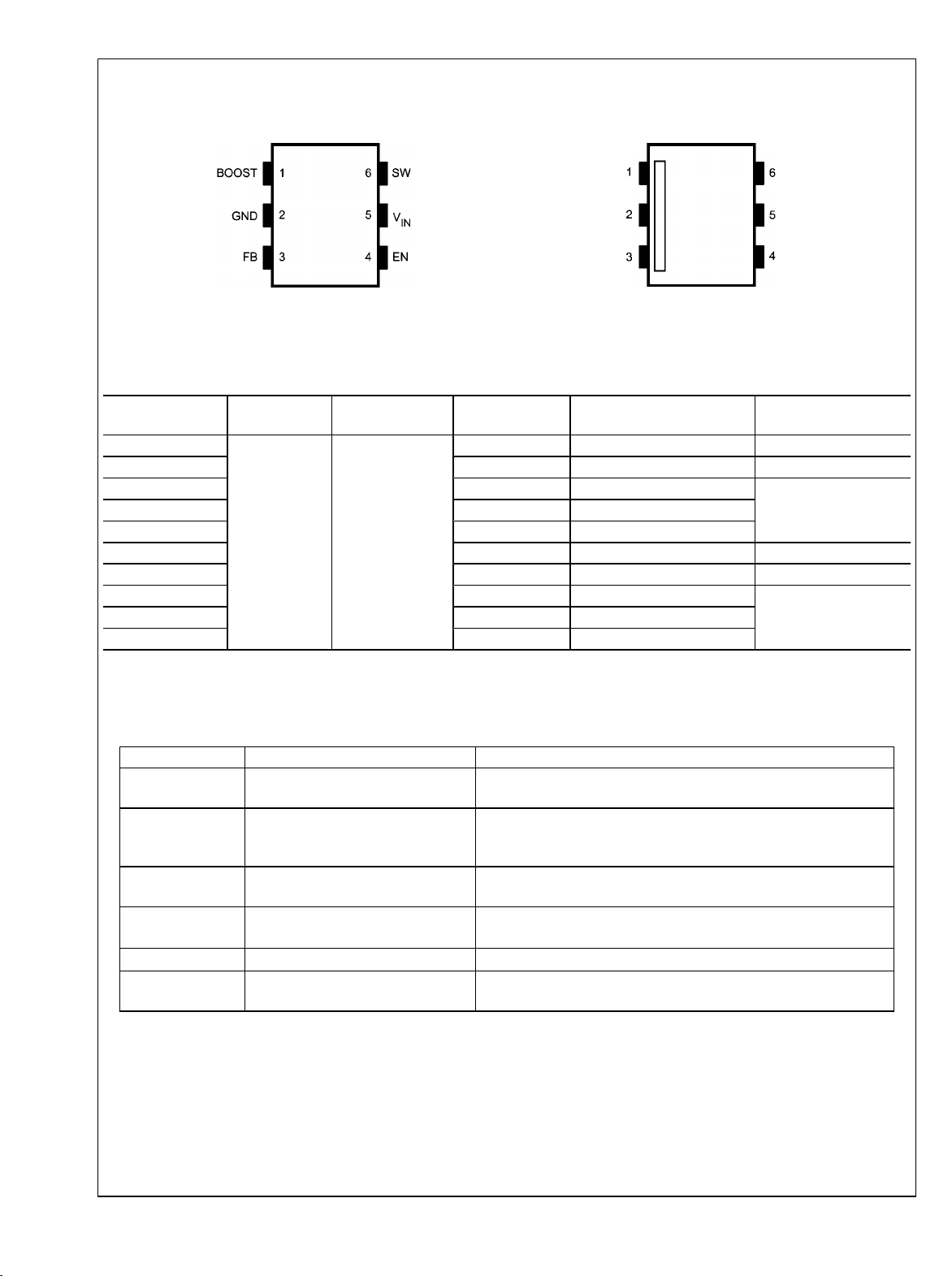

Connection Diagrams

LM2734

6-Lead TSOT

20102305

Pin 1 Indentification

20102360

NS Package Number MK06A

Ordering Information

Order Number Package Type NSC Package

Drawing

LM2734XMK

LM2734XMKX SFDB 3000 Units on Tape and Reel

LM2734XQMKE SUKB 250 Units on Tape and Reel AEC-Q100 Grade 1

LM2734XQMK SUKB 1000 Units on Tape and Reel

LM2734XQMKX SUKB 3000 Units on Tape and Reel

LM2734YMK SFEB 1000 Units on Tape and Reel

TSOT-6 MK06A

LM2734YMKX SFEB 3000 Units on Tape and Reel

LM2734YQMKE SVCB 250 Units on Tape and Reel AEC-Q10-0 Grade 1

LM2734YQMK SVCB 1000 Units on Tape and Reel

LM2734YQMKX SVCB 3000 Units on Tape and Reel

*Automotive Grade (Q) product incorporates enhanced manufacturing and support processes for the automotive market, including defect detection methodologies.

Reliability qualification is compliant with the requirements and temperature grades defined in the AEC-Q100 standard. Automotive grade products are identified

with the letter Q. For more information go to http://www.national.com/automotive.

Package

Supplied As Features

Marking

SFDB 1000 Units on Tape and Reel

Qualified. Automotive

Grade Production Flow*

Qualified. Automotive

Grade Production Flow*

Pin Descriptions

Pin Name Function

1 BOOST Boost voltage that drives the internal NMOS control switch. A

bootstrap capacitor is connected between the BOOST and SW pins.

2 GND Signal and Power ground pin. Place the bottom resistor of the

feedback network as close as possible to this pin for accurate

regulation.

3 FB Feedback pin. Connect FB to the external resistor divider to set output

voltage.

4 EN Enable control input. Logic high enables operation. Do not allow this

pin to float or be greater than V

5 V

IN

Input supply voltage. Connect a bypass capacitor to this pin.

6 SW Output switch. Connects to the inductor, catch diode, and bootstrap

capacitor.

+ 0.3V.

IN

www.national.com 2

LM2734

Absolute Maximum Ratings (Note 1)

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

V

IN

SW Voltage -0.5V to 24V

Boost Voltage -0.5V to 30V

Boost to SW Voltage -0.5V to 6.0V

FB Voltage -0.5V to 3.0V

EN Voltage -0.5V to (VIN + 0.3V)

Junction Temperature 150°C

ESD Susceptibility (Note 2) 2kV

-0.5V to 24V

Storage Temp. Range -65°C to 150°C

Soldering Information

Infrared/Convection Reflow (15sec) 220°C

Wave Soldering Lead Temp. (10sec) 260°C

Operating Ratings (Note 1)

V

IN

SW Voltage -0.5V to 20V

Boost Voltage -0.5V to 25V

Boost to SW Voltage 1.6V to 5.5V

Junction Temperature Range −40°C to +125°C

Thermal Resistance θJA (Note 3)

3V to 20V

118°C/W

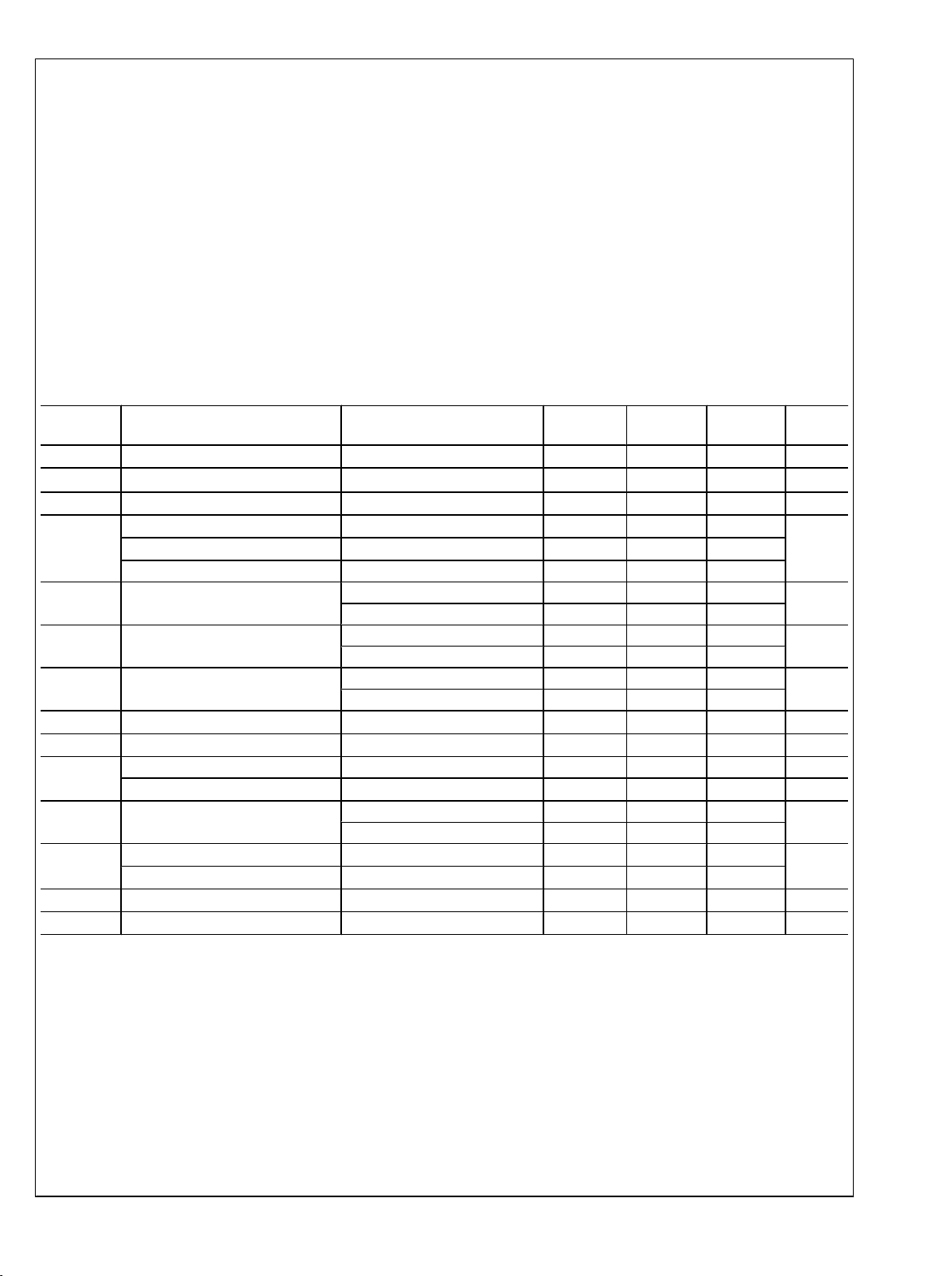

Electrical Characteristics

Specifications with standard typeface are for TJ = 25°C, and those in boldface type apply over the full Operating Temperature

Range (TJ = -40°C to 125°C). VIN = 5V, V

guaranteed by design, test, or statistical analysis.

Symbol Parameter Conditions

V

ΔVFB/ΔV

I

FB

Feedback Voltage

FB

Feedback Voltage Line Regulation

IN

Feedback Input Bias Current

Undervoltage Lockout

UVLO

Undervoltage Lockout

UVLO Hysteresis 0.30 0.44 0.62

F

D

D

R

DS(ON)

SW

MAX

MIN

I

CL

I

Switching Frequency

Maximum Duty Cycle

Minimum Duty Cycle

Switch ON Resistance V

Switch Current Limit V

Quiescent Current Switching 1.5 2.5 mA

Q

Quiescent Current (shutdown) VEN = 0V

I

BOOST

V

EN_TH

I

EN

I

SW

Note 1: Absolute Maximum Ratings indicate limits beyond which damage to the device may occur. Operating Ratings indicate conditions for which the device is

intended to be functional, but specific performance is not guaranteed. For guaranteed specifications and the test conditions, see Electrical Characteristics.

Note 2: Human body model, 1.5kΩ in series with 100pF.

Note 3: Thermal shutdown will occur if the junction temperature exceeds 165°C. The maximum power dissipation is a function of T

maximum allowable power dissipation at any ambient temperature is PD = (T

board with 2oz. copper on 4 layers in still air. For a 2 layer board using 1 oz. copper in still air, θJA = 204°C/W.

Note 4: Guaranteed to National’s Average Outgoing Quality Level (AOQL).

Note 5: Typicals represent the most likely parametric norm.

Boost Pin Current

Shutdown Threshold Voltage VEN Falling

Enable Threshold Voltage VEN Rising 1.8

Enable Pin Current Sink/Source

Switch Leakage

- VSW = 5V unless otherwise specified. Datasheet min/max specification limits are

BOOST

VIN = 3V to 20V

Sink/Source

VIN Rising

VIN Falling

Min

(Note 4)

0.784 0.800 0.816 V

0.01 % / V

10 250 nA

2.74 2.90

2.0 2.3

Typ

(Note 5)

Max

(Note 4)

LM2734X 1.2 1.6 1.9

LM2734Y 0.40 0.55 0.66

LM2734X 85 92

LM2734Y 90 96

LM2734X 2

LM2734Y 1

- VSW = 3V 300 600

BOOST

- VSW = 3V 1.2 1.7 2.5 A

BOOST

30

LM2734X (50% Duty Cycle) 2.5 3.5

LM2734Y (50% Duty Cycle) 1.0 1.8

0.4

– TA)/θJA . All numbers apply for packages soldered directly onto a 3” x 3” PC

J(MAX)

10

40

, θJA and TA . The

J(MAX)

Units

V

MHz

%

%

mΩ

nA

mA

V

nA

nA

3 www.national.com

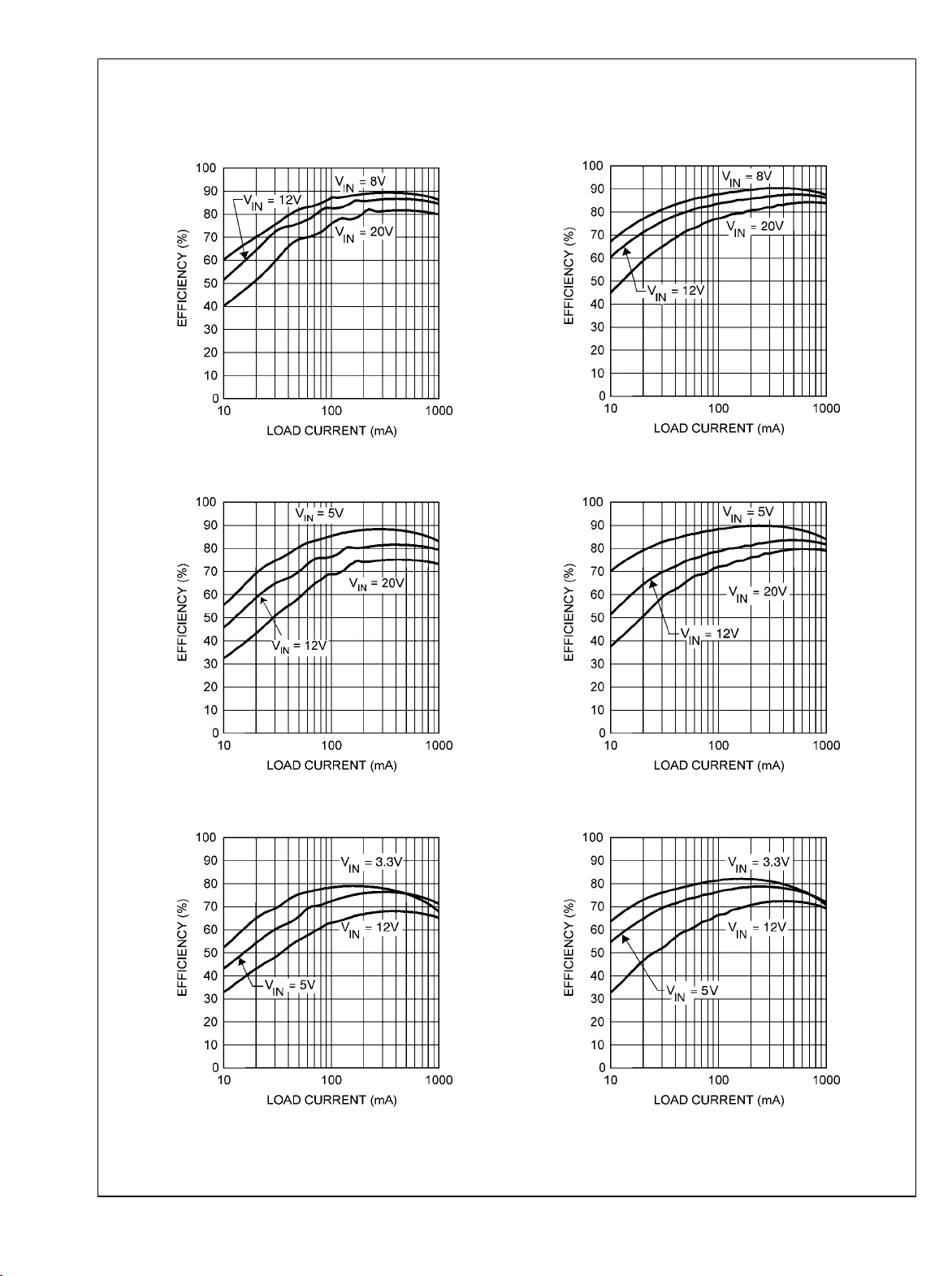

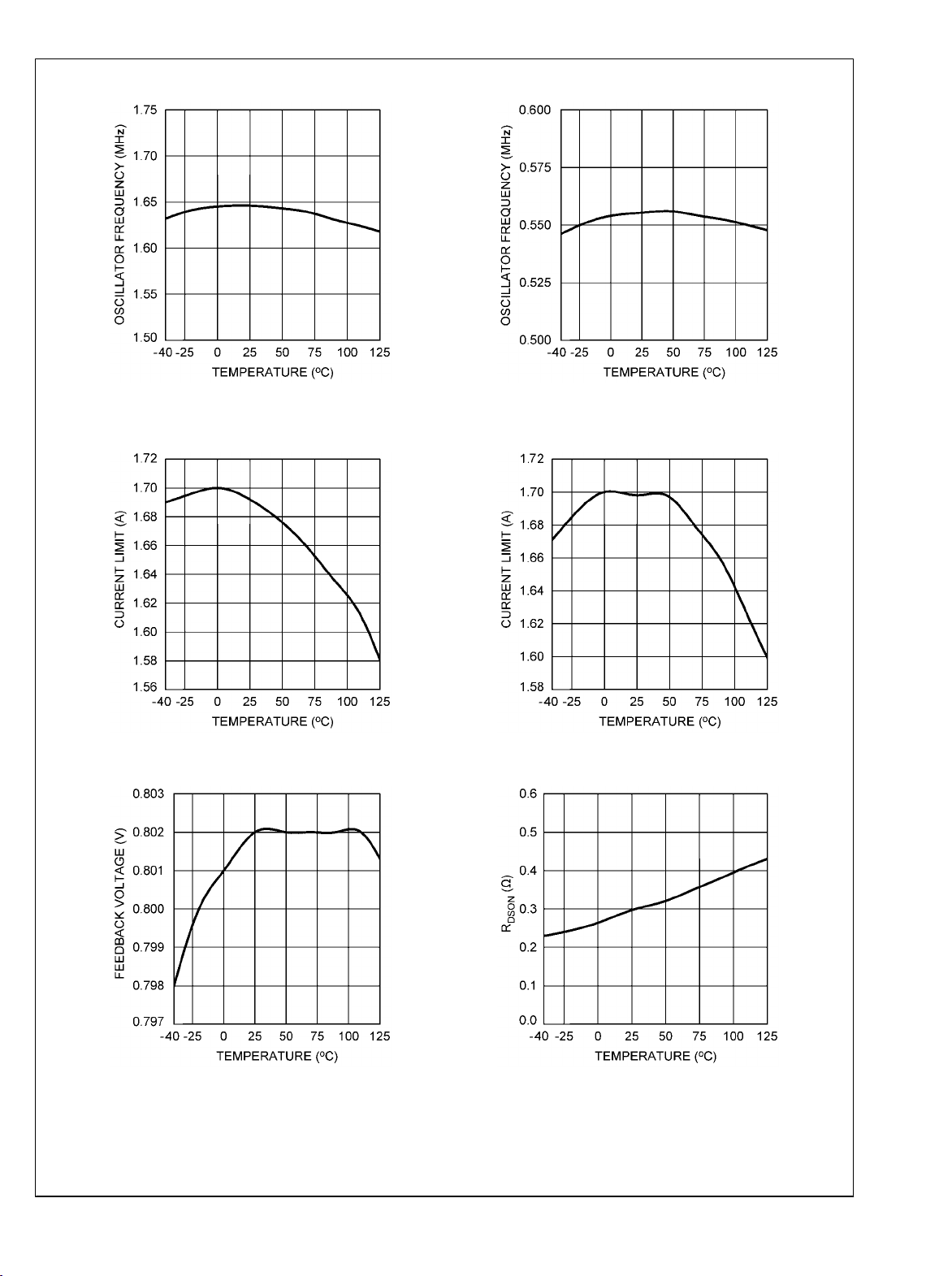

Typical Performance Characteristics All curves taken at V

L1 = 10 µH ("Y"), and TA = 25°C, unless specified otherwise.

LM2734

Efficiency vs Load Current - "X" V

OUT

= 5V

= 5V, V

IN

- VSW = 5V, L1 = 4.7 µH ("X"),

BOOST

Efficiency vs Load Current - "Y" V

OUT

= 5V

Efficiency vs Load Current - "X" V

Efficiency vs Load Current - "X" V

OUT

OUT

20102336

= 3.3V

20102351

= 1.5V

Efficiency vs Load Current - "Y" V

Efficiency vs Load Current - "Y" V

OUT

OUT

20102334

= 3.3V

20102352

= 1.5V

20102337

www.national.com 4

20102335

LM2734

Oscillator Frequency vs Temperature - "X"

20102327

Current Limit vs Temperature

VIN = 5V

Oscillator Frequency vs Temperature - "Y"

20102328

Current Limit vs Temperature

VIN = 20V

VFB vs Temperature

20102329

20102333

20102347

R

vs Temperature

DSON

20102330

5 www.national.com

LM2734

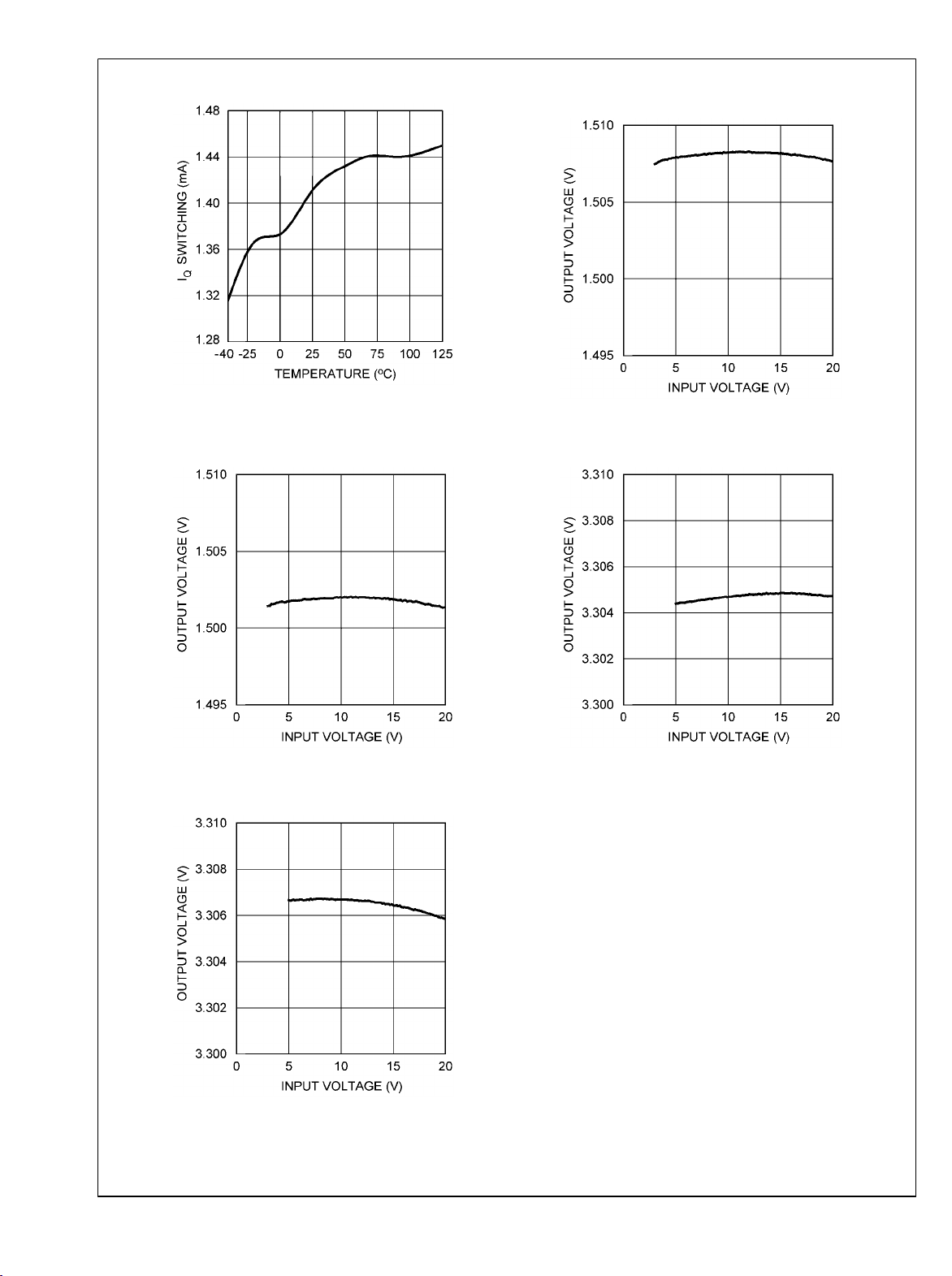

IQ Switching vs Temperature

Line Regulation - "X"

V

OUT

= 1.5V, I

= 500mA

OUT

Line Regulation - "Y"

V

OUT

= 1.5V, I

= 500mA

OUT

Line Regulation - "Y"

V

OUT

= 3.3V, I

= 500mA

OUT

20102346

20102354

Line Regulation - "X"

V

OUT

= 3.3V, I

= 500mA

OUT

20102356

20102355

20102353

www.national.com 6

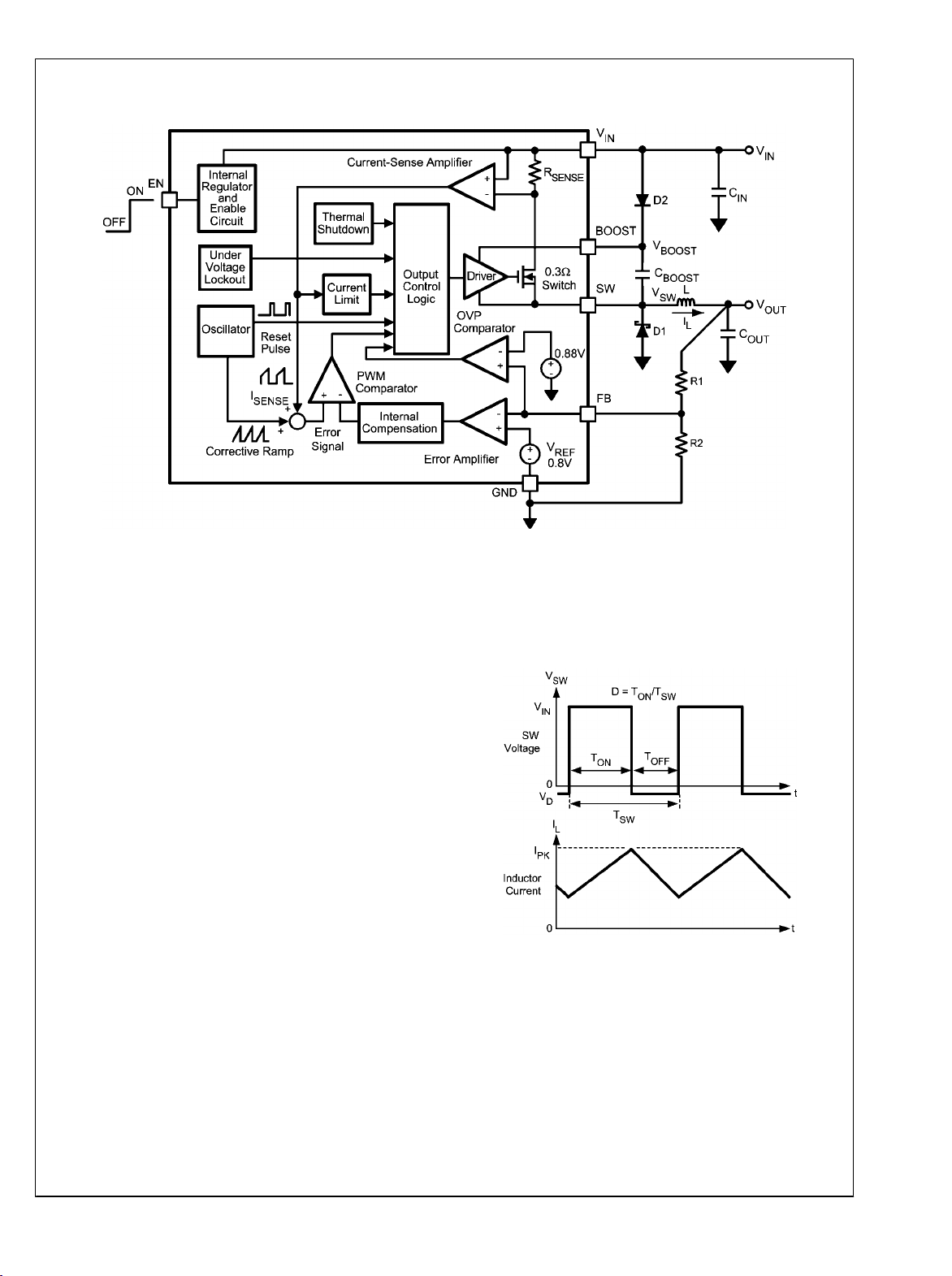

Block Diagram

LM2734

Application Information

THEORY OF OPERATION

The LM2734 is a constant frequency PWM buck regulator IC

that delivers a 1A load current. The regulator has a preset

switching frequency of either 550kHz (LM2734Y) or 1.6MHz

(LM2734X). These high frequencies allow the LM2734 to operate with small surface mount capacitors and inductors,

resulting in DC/DC converters that require a minimum amount

of board space. The LM2734 is internally compensated, so it

is simple to use, and requires few external components. The

LM2734 uses current-mode control to regulate the output

voltage.

The following operating description of the LM2734 will refer

to the Simplified Block Diagram (Figure 1) and to the waveforms in Figure 2. The LM2734 supplies a regulated output

voltage by switching the internal NMOS control switch at constant frequency and variable duty cycle. A switching cycle

begins at the falling edge of the reset pulse generated by the

internal oscillator. When this pulse goes low, the output control logic turns on the internal NMOS control switch. During

this on-time, the SW pin voltage (VSW) swings up to approximately VIN, and the inductor current (IL) increases with a linear

slope. IL is measured by the current-sense amplifier, which

generates an output proportional to the switch current. The

sense signal is summed with the regulator’s corrective ramp

and compared to the error amplifier’s output, which is proportional to the difference between the feedback voltage and

V

. When the PWM comparator output goes high, the out-

REF

put switch turns off until the next switching cycle begins.

During the switch off-time, inductor current discharges

through Schottky diode D1, which forces the SW pin to swing

below ground by the forward voltage (VD) of the catch diode.

FIGURE 1.

20102306

The regulator loop adjusts the duty cycle (D) to maintain a

constant output voltage.

20102307

FIGURE 2. LM2734 Waveforms of SW Pin Voltage and

Inductor Current

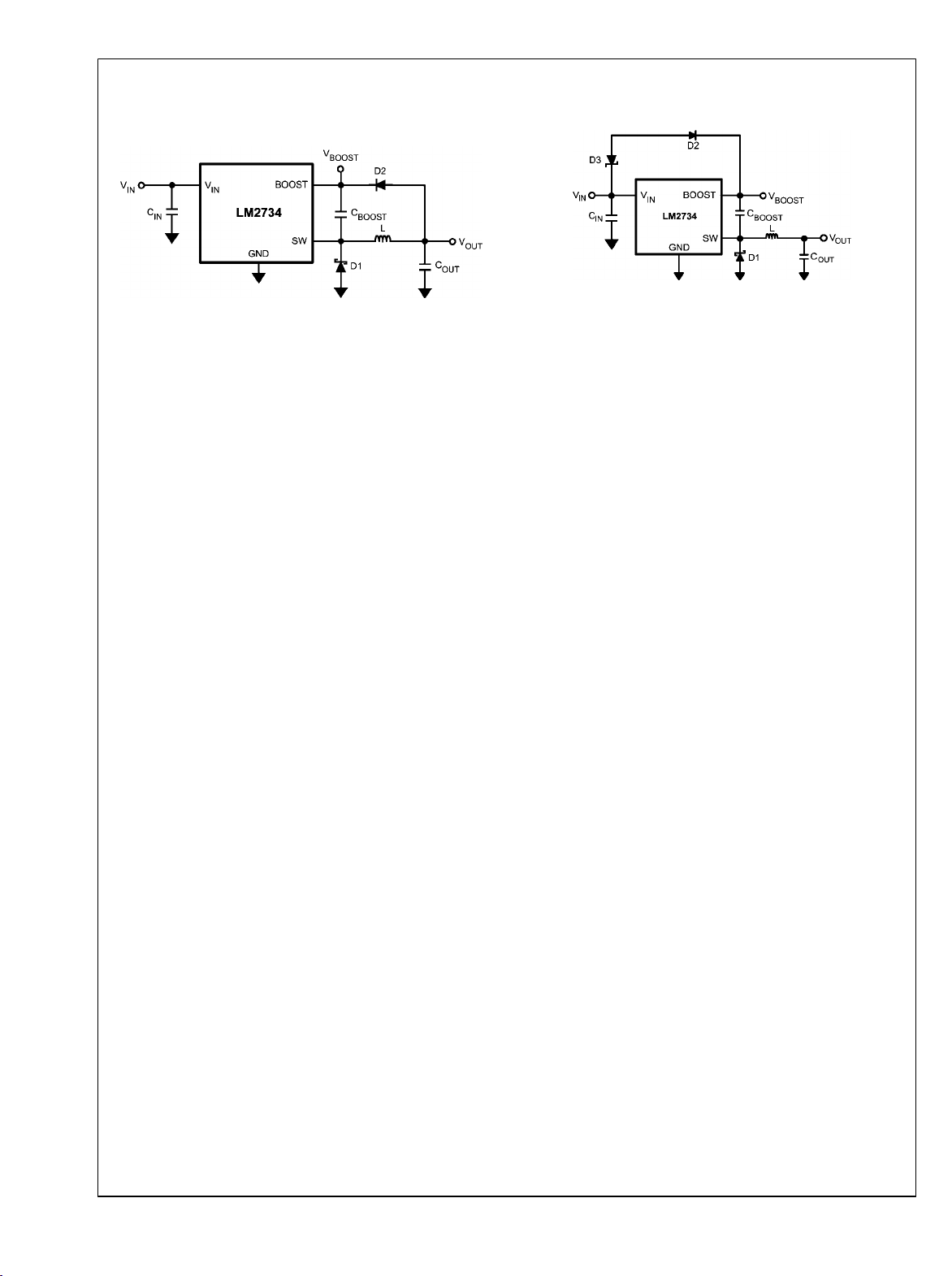

BOOST FUNCTION

Capacitor C

erate a voltage V

to the internal NMOS control switch. To properly drive the internal NMOS switch during its on-time, V

least 1.6V greater than VSW. Although the LM2734 will oper-

and diode D2 in Figure 3 are used to gen-

BOOST

BOOST

. V

- VSW is the gate drive voltage

BOOST

needs to be at

BOOST

ate with this minimum voltage, it may not have sufficient gate

drive to supply large values of output current. Therefore, it is

recommended that V

be greater than 2.5V above V

BOOST

SW

7 www.national.com

for best efficiency. V

imum operating limit of 5.5V.

LM2734

5.5V > V

– VSW > 2.5V for best performance.

BOOST

FIGURE 3. V

– VSW should not exceed the max-

BOOST

Charges C

OUT

BOOST

When the LM2734 starts up, internal circuitry from the

BOOST pin supplies a maximum of 20mA to C

current charges C

switch on. The BOOST pin will continue to source current to

C

until the voltage at the feedback pin is greater than

BOOST

0.76V.

There are various methods to derive V

1.

From the input voltage (VIN)

2.

From the output voltage (V

3.

From an external distributed voltage rail (V

4.

From a shunt or series zener diode

to a voltage sufficient to turn the

BOOST

:

BOOST

)

OUT

In the Simplifed Block Diagram of Figure 1, capacitor

C

and diode D2 supply the gate-drive current for the

BOOST

NMOS switch. Capacitor C

VIN. During a normal switching cycle, when the internal NMOS

control switch is off (T

VIN minus the forward voltage of D2 (V

OFF

current in the inductor (L) forward biases the Schottky diode

D1 (V

). Therefore the voltage stored across C

FD1

V

- VSW = VIN - V

BOOST

is charged via diode D2 by

BOOST

) (refer to Figure 2), V

), during which the

FD2

+ V

FD2

FD1

When the NMOS switch turns on (TON), the switch pin rises

to

forcing V

V

BOOST

VSW = VIN – (R

to rise thus reverse biasing D2. The voltage at

BOOST

is then

V

= 2VIN – (R

BOOST

DSON

x IL),

DSON

x IL) – V

FD2

+ V

which is approximately

2VIN - 0.4V

for many applications. Thus the gate-drive voltage of the

NMOS switch is approximately

VIN - 0.2V

An alternate method for charging C

the output as shown in Figure 3. The output voltage should

is to connect D2 to

BOOST

be between 2.5V and 5.5V, so that proper gate voltage will be

applied to the internal switch. In this circuit, C

a gate drive voltage that is slightly less than V

In applications where both VIN and V

5.5V, or less than 3V, C

these voltages. If VIN and V

C

can be charged from VIN or V

BOOST

age by placing a zener diode D3 in series with D2, as shown

cannot be charged directly from

BOOST

are greater than 5.5V,

OUT

OUT

BOOST

OUT

are greater than

OUT

minus a zener volt-

in Figure 4. When using a series zener diode from the input,

ensure that the regulation of the input supply doesn’t create

a voltage that falls outside the recommended V

BOOST

BOOST

)

EXT

BOOST

BOOST

FD1

.

20102308

. This

equals

is

provides

voltage.

(V

– VD3) < 5.5V

INMAX

(V

– VD3) > 1.6V

INMIN

20102309

FIGURE 4. Zener Reduces Boost Voltage from V

IN

An alternative method is to place the zener diode D3 in a

shunt configuration as shown in Figure 5. A small 350mW to

500mW 5.1V zener in a SOT-23 or SOD package can be used

for this purpose. A small ceramic capacitor such as a 6.3V,

0.1µF capacitor (C4) should be placed in parallel with the

zener diode. When the internal NMOS switch turns on, a pulse

of current is drawn to charge the internal NMOS gate capacitance. The 0.1 µF parallel shunt capacitor ensures that the

V

voltage is maintained during this time.

BOOST

Resistor R3 should be chosen to provide enough RMS current

to the zener diode (D3) and to the BOOST pin. A recommended choice for the zener current (I

current I

of the NMOS control switch and varies typically according to

into the BOOST pin supplies the gate current

BOOST

) is 1 mA. The

ZENER

the following formula for the X version:

I

= 0.56 x (D + 0.54) x (V

BOOST

I

can be calculated for the Y version using the following:

BOOST

I

= 0.22 x (D + 0.54) x (V

BOOST

where D is the duty cycle, V

I

is in milliamps. V

BOOST

anode of the boost diode (D2), and VD2 is the average forward

ZENER

and VD2 are in volts, and

ZENER

is the voltage applied to the

voltage across D2. Note that this formula for I

ical current. For the worst case I

by 40%. In that case, the worst case boost current will be

I

BOOST-MAX

BOOST

= 1.4 x I

– VD2) mA

ZENER

- VD2) µA

ZENER

gives typ-

BOOST

, increase the current

BOOST

R3 will then be given by

R3 = (VIN - V

For example, using the X-version let VIN = 10V, V

VD2 = 0.7V, I

I

BOOST

= 1mA, and duty cycle D = 50%. Then

ZENER

= 0.56 x (0.5 + 0.54) x (5 - 0.7) mA = 2.5mA

ZENER

) / (1.4 x I

BOOST

+ I

ZENER

ZENER

)

= 5V,

R3 = (10V - 5V) / (1.4 x 2.5mA + 1mA) = 1.11kΩ

www.national.com 8

doesn’t turn on until the junction temperature drops to approximately 150°C.

Design Guide

INDUCTOR SELECTION

The Duty Cycle (D) can be approximated quickly using the

ratio of output voltage (VO) to input voltage (VIN):

LM2734

20102348

FIGURE 5. Boost Voltage Supplied from the Shunt Zener

on V

IN

ENABLE PIN / SHUTDOWN MODE

The LM2734 has a shutdown mode that is controlled by the

enable pin (EN). When a logic low voltage is applied to EN,

the part is in shutdown mode and its quiescent current drops

to typically 30nA. Switch leakage adds another 40nA from the

input supply. The voltage at this pin should never exceed

VIN + 0.3V.

SOFT-START

This function forces V

ing start up. During soft-start, the error amplifier’s reference

to increase at a controlled rate dur-

OUT

voltage ramps from 0V to its nominal value of 0.8V in approximately 200µs. This forces the regulator output to ramp up in

a more linear and controlled fashion, which helps reduce inrush current. Under some circumstances at start-up, an output voltage overshoot may still be observed. This may be due

to a large output load applied during start up. Large amounts

of output external capacitance can also increase output voltage overshoot. A simple solution is to add a feed forward

capacitor with a value between 470pf and 1000pf across the

top feedback resistor (R1). See Figure 7 for further detail.

OUTPUT OVERVOLTAGE PROTECTION

The overvoltage comparator compares the FB pin voltage to

a voltage that is 10% higher than the internal reference Vref.

Once the FB pin voltage goes 10% above the internal reference, the internal NMOS control switch is turned off, which

allows the output voltage to decrease toward regulation.

UNDERVOLTAGE LOCKOUT

Undervoltage lockout (UVLO) prevents the LM2734 from operating until the input voltage exceeds 2.74V(typ).

The UVLO threshold has approximately 440mV of hysteresis,

so the part will operate until VIN drops below 2.3V(typ). Hysteresis prevents the part from turning off during power up if

VIN is non-monotonic.

CURRENT LIMIT

The LM2734 uses cycle-by-cycle current limiting to protect

the output switch. During each switching cycle, a current limit

comparator detects if the output switch current exceeds 1.7A

(typ), and turns off the switch until the next switching cycle

begins.

THERMAL SHUTDOWN

Thermal shutdown limits total power dissipation by turning off

the output switch when the IC junction temperature exceeds

165°C. After thermal shutdown occurs, the output switch

The catch diode (D1) forward voltage drop and the voltage

drop across the internal NMOS must be included to calculate

a more accurate duty cycle. Calculate D by using the following

formula:

VSW can be approximated by:

VSW = IO x R

DS(ON)

The diode forward drop (VD) can range from 0.3V to 0.7V depending on the quality of the diode. The lower VD is, the higher

the operating efficiency of the converter.

The inductor value determines the output ripple current. Lower inductor values decrease the size of the inductor, but

increase the output ripple current. An increase in the inductor

value will decrease the output ripple current. The ratio of ripple

current (ΔiL) to output current (IO) is optimized when it is set

between 0.3 and 0.4 at 1A. The ratio r is defined as:

One must also ensure that the minimum current limit (1.2A)

is not exceeded, so the peak current in the inductor must be

calculated. The peak current (I

by:

I

LPK

) in the inductor is calculated

LPK

= IO + ΔIL/2

If r = 0.5 at an output of 1A, the peak current in the inductor

will be 1.25A. The minimum guaranteed current limit over all

operating conditions is 1.2A. One can either reduce r to 0.4

resulting in a 1.2A peak current, or make the engineering

judgement that 50mA over will be safe enough with a 1.7A

typical current limit and 6 sigma limits. When the designed

maximum output current is reduced, the ratio r can be increased. At a current of 0.1A, r can be made as high as 0.9.

The ripple ratio can be increased at lighter loads because the

net ripple is actually quite low, and if r remains constant the

inductor value can be made quite large. An equation empirically developed for the maximum ripple ratio at any current

below 2A is:

r = 0.387 x I

OUT

-0.3667

Note that this is just a guideline.

The LM2734 operates at frequencies allowing the use of ce-

ramic output capacitors without compromising transient response. Ceramic capacitors allow higher inductor ripple

without significantly increasing output ripple. See the output

9 www.national.com

capacitor section for more details on calculating output voltage ripple.

LM2734

Now that the ripple current or ripple ratio is determined, the

inductance is calculated by:

OUTPUT CAPACITOR

The output capacitor is selected based upon the desired output ripple and transient response. The initial current of a load

transient is provided mainly by the output capacitor. The output ripple of the converter is:

where fs is the switching frequency and IO is the output current. When selecting an inductor, make sure that it is capable

of supporting the peak output current without saturating. Inductor saturation will result in a sudden reduction in inductance and prevent the regulator from operating correctly.

Because of the speed of the internal current limit, the peak

current of the inductor need only be specified for the required

maximum output current. For example, if the designed maximum output current is 0.5A and the peak current is 0.7A, then

the inductor should be specified with a saturation current limit

of >0.7A. There is no need to specify the saturation or peak

current of the inductor at the 1.7A typical switch current limit.

The difference in inductor size is a factor of 5. Because of the

operating frequency of the LM2734, ferrite based inductors

are preferred to minimize core losses. This presents little restriction since the variety of ferrite based inductors is huge.

Lastly, inductors with lower series resistance (DCR) will provide better operating efficiency. For recommended inductors

see Example Circuits.

INPUT CAPACITOR

An input capacitor is necessary to ensure that VIN does not

drop excessively during switching transients. The primary

specifications of the input capacitor are capacitance, voltage,

RMS current rating, and ESL (Equivalent Series Inductance).

The recommended input capacitance is 10µF, although 4.7µF

works well for input voltages below 6V. The input voltage rating is specifically stated by the capacitor manufacturer. Make

sure to check any recommended deratings and also verify if

there is any significant change in capacitance at the operating

input voltage and the operating temperature. The input capacitor maximum RMS input current rating (I

greater than:

RMS-IN

) must be

It can be shown from the above equation that maximum RMS

capacitor current occurs when D = 0.5. Always calculate the

RMS at the point where the duty cycle, D, is closest to 0.5.

The ESL of an input capacitor is usually determined by the

effective cross sectional area of the current path. A large

leaded capacitor will have high ESL and a 0805 ceramic chip

capacitor will have very low ESL. At the operating frequencies

of the LM2734, certain capacitors may have an ESL so large

that the resulting impedance (2πfL) will be higher than that

required to provide stable operation. As a result, surface

mount capacitors are strongly recommended. Sanyo

POSCAP, Tantalum or Niobium, Panasonic SP or Cornell

Dubilier ESR, and multilayer ceramic capacitors (MLCC) are

all good choices for both input and output capacitors and have

very low ESL. For MLCCs it is recommended to use X7R or

X5R dielectrics. Consult capacitor manufacturer datasheet to

see how rated capacitance varies over operating conditions.

When using MLCCs, the ESR is typically so low that the capacitive ripple may dominate. When this occurs, the output

ripple will be approximately sinusoidal and 90° phase shifted

from the switching action. Given the availability and quality of

MLCCs and the expected output voltage of designs using the

LM2734, there is really no need to review any other capacitor

technologies. Another benefit of ceramic capacitors is their

ability to bypass high frequency noise. A certain amount of

switching edge noise will couple through parasitic capacitances in the inductor to the output. A ceramic capacitor will

bypass this noise while a tantalum will not. Since the output

capacitor is one of the two external components that control

the stability of the regulator control loop, most applications will

require a minimum at 10 µF of output capacitance. Capacitance can be increased significantly with little detriment to the

regulator stability. Like the input capacitor, recommended

multilayer ceramic capacitors are X7R or X5R. Again, verify

actual capacitance at the desired operating voltage and temperature.

Check the RMS current rating of the capacitor. The RMS current rating of the capacitor chosen must also meet the following condition:

CATCH DIODE

The catch diode (D1) conducts during the switch off-time. A

Schottky diode is recommended for its fast switching times

and low forward voltage drop. The catch diode should be

chosen so that its current rating is greater than:

ID1 = IO x (1-D)

The reverse breakdown rating of the diode must be at least

the maximum input voltage plus appropriate margin. To improve efficiency choose a Schottky diode with a low forward

voltage drop.

BOOST DIODE

A standard diode such as the 1N4148 type is recommended.

For V

small-signal Schottky diode is recommended for greater effi-

circuits derived from voltages less than 3.3V, a

BOOST

ciency. A good choice is the BAT54 small signal diode.

BOOST CAPACITOR

A ceramic 0.01µF capacitor with a voltage rating of at least

6.3V is sufficient. The X7R and X5R MLCCs provide the best

performance.

OUTPUT VOLTAGE

The output voltage is set using the following equation where

R2 is connected between the FB pin and GND, and R1 is

connected between VO and the FB pin. A good value for R2

is 10kΩ.

www.national.com 10

PCB Layout Considerations

When planning layout there are a few things to consider when

trying to achieve a clean, regulated output. The most important consideration when completing the layout is the close

coupling of the GND connections of the CIN capacitor and the

catch diode D1. These ground ends should be close to one

another and be connected to the GND plane with at least two

through-holes. Place these components as close to the IC as

possible. Next in importance is the location of the GND connection of the C

connections of CIN and D1.

There should be a continuous ground plane on the bottom

layer of a two-layer board except under the switching node

island.

capacitor, which should be near the GND

OUT

The FB pin is a high impedance node and care should be

taken to make the FB trace short to avoid noise pickup and

inaccurate regulation. The feedback resistors should be

placed as close as possible to the IC, with the GND of R2

placed as close as possible to the GND of the IC. The V

trace to R1 should be routed away from the inductor and any

OUT

other traces that are switching.

High AC currents flow through the VIN, SW and V

so they should be as short and wide as possible. However,

OUT

traces,

making the traces wide increases radiated noise, so the designer must make this trade-off. Radiated noise can be decreased by choosing a shielded inductor.

The remaining components should also be placed as close

as possible to the IC. Please see Application Note AN-1229

for further considerations and the LM2734 demo board as an

example of a four-layer layout.

LM2734

11 www.national.com

LM2734X Circuit Examples

LM2734

FIGURE 6. LM2734X (1.6MHz)

V

Derived from V

BOOST

5V to 1.5V/1A

IN

Bill of Materials for Figure 6

20102342

Part ID Part Value Part Number Manufacturer

U1 1A Buck Regulator LM2734X National Semiconductor

C1, Input Cap 10µF, 6.3V, X5R C3216X5ROJ106M TDK

C2, Output Cap 10µF, 6.3V, X5R C3216X5ROJ106M TDK

C3, Boost Cap 0.01uF, 16V, X7R C1005X7R1C103K TDK

D1, Catch Diode 0.3VF Schottky 1A, 10VR MBRM110L ON Semi

D2, Boost Diode 1VF @ 50mA Diode 1N4148W Diodes, Inc.

L1 4.7µH, 1.7A, VLCF4020T- 4R7N1R2 TDK

R1

R2

R3

8.87kΩ, 1%

10.2kΩ, 1%

100kΩ, 1%

CRCW06038871F Vishay

CRCW06031022F Vishay

CRCW06031003F Vishay

www.national.com 12

20102343

FIGURE 7. LM2734X (1.6MHz)

V

Derived from V

BOOST

12V to 3.3V/1A

OUT

Bill of Materials for Figure 7

Part ID Part Value Part Number Manufacturer

U1 1A Buck Regulator NSC LM2734X

C1, Input Cap 10µF, 25V, X7R C3225X7R1E106M TDK

C2, Output Cap 22µF, 6.3V, X5R C3216X5ROJ226M TDK

C3, Boost Cap 0.01µF, 16V, X7R C1005X7R1C103K TDK

CFF 1000pF 25V C0603X5R1E102K TDK

D1, Catch Diode 0.34VF Schottky 1A, 30VR SS1P3L Vishay

D2, Boost Diode 1VF @ 50mA Diode 1N4148W Diodes, Inc.

L1 4.7µH, 1.7A VLCF4020T- 4R7N1R2 TDK

R1

R2

R3

31.6kΩ, 1%

10kΩ, 1%

100kΩ, 1%

CRCW06033162F Vishay

CRCW06031002F Vishay

CRCW06031003F Vishay

LM2734

13 www.national.com

LM2734

20102344

FIGURE 8. LM2734X (1.6MHz)

V

Derived from V

BOOST

18V to 1.5V/1A

Bill of Materials for Figure 8

Part ID Part Value Part Number Manufacturer

U1 1A Buck Regulator LM2734X National Semiconductor

C1, Input Cap 10µF, 25V, X7R C3225X7R1E106M TDK

C2, Output Cap 22µF, 6.3V, X5R C3216X5ROJ226M TDK

C3, Boost Cap 0.01µF, 16V, X7R C1005X7R1C103K TDK

C4, Shunt Cap 0.1µF, 6.3V, X5R C1005X5R0J104K TDK

D1, Catch Diode 0.4VF Schottky 1A, 30VR SS1P3L Vishay

D2, Boost Diode 1VF @ 50mA Diode 1N4148W Diodes, Inc.

D3, Zener Diode 5.1V 250Mw SOT-23 BZX84C5V1 Vishay

L1 6.8µH, 1.6A, SLF7032T-6R8M1R6 TDK

R1

R2

R3

R4

8.87kΩ, 1%

10.2kΩ, 1%

100kΩ, 1%

4.12kΩ, 1%

CRCW06038871F Vishay

CRCW06031022F Vishay

CRCW06031003F Vishay

CRCW06034121F Vishay

SHUNT

www.national.com 14

20102349

LM2734

V

Derived from Series Zener Diode (VIN)

BOOST

15V to 1.5V/1A

Bill of Materials for Figure 9

Part ID Part Value Part Number Manufacturer

U1 1A Buck Regulator LM2734X National Semiconductor

C1, Input Cap 10µF, 25V, X7R C3225X7R1E106M TDK

C2, Output Cap 22µF, 6.3V, X5R C3216X5ROJ226M TDK

C3, Boost Cap 0.01µF, 16V, X7R C1005X7R1C103K TDK

D1, Catch Diode 0.4VF Schottky 1A, 30VR SS1P3L Vishay

D2, Boost Diode 1VF @ 50mA Diode 1N4148W Diodes, Inc.

D3, Zener Diode 11V 350Mw SOT-23 BZX84C11T Diodes, Inc.

L1 6.8µH, 1.6A, SLF7032T-6R8M1R6 TDK

FIGURE 9. LM2734X (1.6MHz)

R1

R2

R3

8.87kΩ, 1%

10.2kΩ, 1%

100kΩ, 1%

CRCW06038871F Vishay

CRCW06031022F Vishay

CRCW06031003F Vishay

15 www.national.com

LM2734

20102350

V

Derived from Series Zener Diode (V

BOOST

15V to 9V/1A

OUT

)

Bill of Materials for Figure 10

Part ID Part Value Part Number Manufacturer

U1 1A Buck Regulator LM2734X National Semiconductor

C1, Input Cap 10µF, 25V, X7R C3225X7R1E106M TDK

C2, Output Cap 22µF, 16V, X5R C3216X5R1C226M TDK

C3, Boost Cap 0.01µF, 16V, X7R C1005X7R1C103K TDK

D1, Catch Diode 0.4VF Schottky 1A, 30VR SS1P3L Vishay

D2, Boost Diode 1VF @ 50mA Diode 1N4148W Diodes, Inc.

D3, Zener Diode 4.3V 350mw SOT-23 BZX84C4V3 Diodes, Inc.

L1 6.8µH, 1.6A, SLF7032T-6R8M1R6 TDK

FIGURE 10. LM2734X (1.6MHz)

R1

R2

R3

102kΩ, 1%

10.2kΩ, 1%

100kΩ, 1%

CRCW06031023F Vishay

CRCW06031022F Vishay

CRCW06031003F Vishay

www.national.com 16

LM2734Y Circuit Examples

FIGURE 11. LM2734Y (550kHz)

V

Derived from V

BOOST

5V to 1.5V/1A

IN

LM2734

20102342

Bill of Materials for Figure 11

Part ID Part Value Part Number Manufacturer

U1 1A Buck Regulator LM2734Y National Semiconductor

C1, Input Cap 10µF, 6.3V, X5R C3216X5ROJ106M TDK

C2, Output Cap 22µF, 6.3V, X5R C3216X5ROJ226M TDK

C3, Boost Cap 0.01µF, 16V, X7R C1005X7R1C103K TDK

D1, Catch Diode 0.3VF Schottky 1A, 10VR MBRM110L ON Semi

D2, Boost Diode 1VF @ 50mA Diode 1N4148W Diodes, Inc.

L1 10µH, 1.6A, SLF7032T-100M1R4 TDK

R1

R2

R3

8.87kΩ, 1%

10.2kΩ, 1%

100kΩ, 1%

CRCW06038871F Vishay

CRCW06031022F Vishay

CRCW06031003F Vishay

17 www.national.com

LM2734

20102343

FIGURE 12. LM2734Y (550kHz)

V

Derived from V

BOOST

12V to 3.3V/1A

Bill of Materials for Figure 12

Part ID Part Value Part Number Manufacturer

U1 1A Buck Regulator LM2734Y National Semiconductor

C1, Input Cap 10µF, 25V, X7R C3225X7R1E106M TDK

C2, Output Cap 22µF, 6.3V, X5R C3216X5ROJ226M TDK

C3, Boost Cap 0.01µF, 16V, X7R C1005X7R1C103K TDK

D1, Catch Diode 0.34VF Schottky 1A, 30VR SS1P3L Vishay

D2, Boost Diode 0.6VF @ 30mA Diode BAT17 Vishay

L1 10µH, 1.6A, SLF7032T-100M1R4 TDK

R1

R2

R3

31.6kΩ, 1%

10.0 kΩ, 1%

100kΩ, 1%

CRCW06033162F Vishay

CRCW06031002F Vishay

CRCW06031003F Vishay

OUT

www.national.com 18

FIGURE 13. LM2734Y (550kHz)

V

Derived from V

BOOST

18V to 1.5V/1A

SHUNT

LM2734

20102344

Bill of Materials for Figure 13

Part ID Part Value Part Number Manufacturer

U1 1A Buck Regulator LM2734Y National Semiconductor

C1, Input Cap 10µF, 25V, X7R C3225X7R1E106M TDK

C2, Output Cap 22µF, 6.3V, X5R C3216X5ROJ226M TDK

C3, Boost Cap 0.01µF, 16V, X7R C1005X7R1C103K TDK

C4, Shunt Cap 0.1µF, 6.3V, X5R C1005X5R0J104K TDK

D1, Catch Diode 0.4VF Schottky 1A, 30VR SS1P3L Vishay

D2, Boost Diode 1VF @ 50mA Diode 1N4148W Diodes, Inc.

D3, Zener Diode 5.1V 250Mw SOT-23 BZX84C5V1 Vishay

L1 15µH, 1.5A SLF7045T-150M1R5 TDK

R1

R2

R3

R4

8.87kΩ, 1%

10.2kΩ, 1%

100kΩ, 1%

4.12kΩ, 1%

CRCW06038871F Vishay

CRCW06031022F Vishay

CRCW06031003F Vishay

CRCW06034121F Vishay

19 www.national.com

LM2734

20102349

FIGURE 14. LM2734Y (550kHz)

V

Derived from Series Zener Diode (VIN)

BOOST

Part ID Part Value Part Number Manufacturer

U1 1A Buck Regulator LM2734Y National Semiconductor

C1, Input Cap 10µF, 25V, X7R C3225X7R1E106M TDK

C2, Output Cap 22µF, 6.3V, X5R C3216X5ROJ226M TDK

C3, Boost Cap 0.01µF, 16V, X7R C1005X7R1C103K TDK

D1, Catch Diode 0.4VF Schottky 1A, 30VR SS1P3L Vishay

D2, Boost Diode 1VF @ 50mA Diode 1N4148W Diodes, Inc.

D3, Zener Diode 11V 350Mw SOT-23 BZX84C11T Diodes, Inc.

L1 15µH, 1.5A, SLF7045T-150M1R5 TDK

R1

R2

R3

8.87kΩ, 1%

10.2kΩ, 1%

100kΩ, 1%

15V to 1.5V/1A

Bill of Materials for Figure 14

CRCW06038871F Vishay

CRCW06031022F Vishay

CRCW06031003F Vishay

www.national.com 20

20102350

LM2734

V

Derived from Series Zener Diode (V

BOOST

15V to 9V/1A

OUT

)

Bill of Materials for Figure 15

Part ID Part Value Part Number Manufacturer

U1 1A Buck Regulator LM2734Y National Semiconductor

C1, Input Cap 10µF, 25V, X7R C3225X7R1E106M TDK

C2, Output Cap 22µF, 16V, X5R C3216X5R1C226M TDK

C3, Boost Cap 0.01µF, 16V, X7R C1005X7R1C103K TDK

D1, Catch Diode 0.4VF Schottky 1A, 30VR SS1P3L Vishay

D2, Boost Diode 1VF @ 50mA Diode 1N4148W Diodes, Inc.

D3, Zener Diode 4.3V 350mw SOT-23 BZX84C4V3 Diodes, Inc.

L1 22µH, 1.4A, SLF7045T-220M1R3-1PF TDK

FIGURE 15. LM2734Y (550kHz)

R1

R2

R3

102kΩ, 1%

10.2kΩ, 1%

100kΩ, 1%

CRCW06031023F Vishay

CRCW06031022F Vishay

CRCW06031003F Vishay

21 www.national.com

Physical Dimensions inches (millimeters) unless otherwise noted

LM2734

6-Lead TSOT Package

NS Package Number MK06A

www.national.com 22

Notes

LM2734

23 www.national.com

Notes

For more National Semiconductor product information and proven design tools, visit the following Web sites at:

Products Design Support

Amplifiers www.national.com/amplifiers WEBENCH www.national.com/webench

Audio www.national.com/audio Analog University www.national.com/AU

Clock Conditioners www.national.com/timing App Notes www.national.com/appnotes

Data Converters www.national.com/adc Distributors www.national.com/contacts

Displays www.national.com/displays Green Compliance www.national.com/quality/green

Ethernet www.national.com/ethernet Packaging www.national.com/packaging

Interface www.national.com/interface Quality and Reliability www.national.com/quality

LVDS www.national.com/lvds Reference Designs www.national.com/refdesigns

Power Management www.national.com/power Feedback www.national.com/feedback

Switching Regulators www.national.com/switchers

LDOs www.national.com/ldo

LED Lighting www.national.com/led

PowerWise www.national.com/powerwise

Serial Digital Interface (SDI) www.national.com/sdi

Temperature Sensors www.national.com/tempsensors

Wireless (PLL/VCO) www.national.com/wireless

THE CONTENTS OF THIS DOCUMENT ARE PROVIDED IN CONNECTION WITH NATIONAL SEMICONDUCTOR CORPORATION

(“NATIONAL”) PRODUCTS. NATIONAL MAKES NO REPRESENTATIONS OR WARRANTIES WITH RESPECT TO THE ACCURACY

OR COMPLETENESS OF THE CONTENTS OF THIS PUBLICATION AND RESERVES THE RIGHT TO MAKE CHANGES TO

SPECIFICATIONS AND PRODUCT DESCRIPTIONS AT ANY TIME WITHOUT NOTICE. NO LICENSE, WHETHER EXPRESS,

IMPLIED, ARISING BY ESTOPPEL OR OTHERWISE, TO ANY INTELLECTUAL PROPERTY RIGHTS IS GRANTED BY THIS

DOCUMENT.

TESTING AND OTHER QUALITY CONTROLS ARE USED TO THE EXTENT NATIONAL DEEMS NECESSARY TO SUPPORT

NATIONAL’S PRODUCT WARRANTY. EXCEPT WHERE MANDATED BY GOVERNMENT REQUIREMENTS, TESTING OF ALL

PARAMETERS OF EACH PRODUCT IS NOT NECESSARILY PERFORMED. NATIONAL ASSUMES NO LIABILITY FOR

LM2734 Thin SOT23 1A Load Step-Down DC-DC Regulator

APPLICATIONS ASSISTANCE OR BUYER PRODUCT DESIGN. BUYERS ARE RESPONSIBLE FOR THEIR PRODUCTS AND

APPLICATIONS USING NATIONAL COMPONENTS. PRIOR TO USING OR DISTRIBUTING ANY PRODUCTS THAT INCLUDE

NATIONAL COMPONENTS, BUYERS SHOULD PROVIDE ADEQUATE DESIGN, TESTING AND OPERATING SAFEGUARDS.

EXCEPT AS PROVIDED IN NATIONAL’S TERMS AND CONDITIONS OF SALE FOR SUCH PRODUCTS, NATIONAL ASSUMES NO

LIABILITY WHATSOEVER, AND NATIONAL DISCLAIMS ANY EXPRESS OR IMPLIED WARRANTY RELATING TO THE SALE

AND/OR USE OF NATIONAL PRODUCTS INCLUDING LIABILITY OR WARRANTIES RELATING TO FITNESS FOR A PARTICULAR

PURPOSE, MERCHANTABILITY, OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY

RIGHT.

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT DEVICES OR

SYSTEMS WITHOUT THE EXPRESS PRIOR WRITTEN APPROVAL OF THE CHIEF EXECUTIVE OFFICER AND GENERAL

COUNSEL OF NATIONAL SEMICONDUCTOR CORPORATION. As used herein:

Life support devices or systems are devices which (a) are intended for surgical implant into the body, or (b) support or sustain life and

whose failure to perform when properly used in accordance with instructions for use provided in the labeling can be reasonably expected

to result in a significant injury to the user. A critical component is any component in a life support device or system whose failure to perform

can be reasonably expected to cause the failure of the life support device or system or to affect its safety or effectiveness.

National Semiconductor and the National Semiconductor logo are registered trademarks of National Semiconductor Corporation. All other

brand or product names may be trademarks or registered trademarks of their respective holders.

Copyright© 2008 National Semiconductor Corporation

For the most current product information visit us at www.national.com

www.national.com

National Semiconductor

Americas Technical

Support Center

Email: support@nsc.com

Tel: 1-800-272-9959

National Semiconductor Europe

Technical Support Center

Email: europe.support@nsc.com

German Tel: +49 (0) 180 5010 771

English Tel: +44 (0) 870 850 4288

National Semiconductor Asia

Pacific Technical Support Center

Email: ap.support@nsc.com

National Semiconductor Japan

Technical Support Center

Email: jpn.feedback@nsc.com

Loading...

Loading...