February 2002

DS92LV16

16-Bit Bus LVDS Serializer/Deserializer - 25 - 80 MHz

DS92LV1616-Bit Bus LVDS Serializer/Deserializer - 25 - 80 MHz

General Description

The DS92LV16Serializer/Deserializer(SERDES)pairtransparently translates a 16–bit parallel bus into a BLVDS serial

stream with embedded clock information. This single serial

stream simplifies transferring a 16-bit, or less bus over PCB

traces andcablesby eliminating the skew problems between

parallel data and clock paths. It saves system cost by narrowing data paths that in turn reduce PCB layers, cable

width, and connector size and pins.

This SERDES pair includes built-in system and device test

capability. The line loopback and local loopback features

provide the following functionality: the local loopback enables the user to check the integrity of the transceiver from

the local parallel-bus side and the system can check the

integrity of the data transmission line by enabling the line

loopback.

The DS92LV16 incorporates BLVDS signaling on the highspeed I/O. BLVDS provides a low power and low noise

environment for reliably transferring data over a serial transmission path. The equal and opposite currents through the

differential data path control EMI by coupling the resulting

fringing fields together.

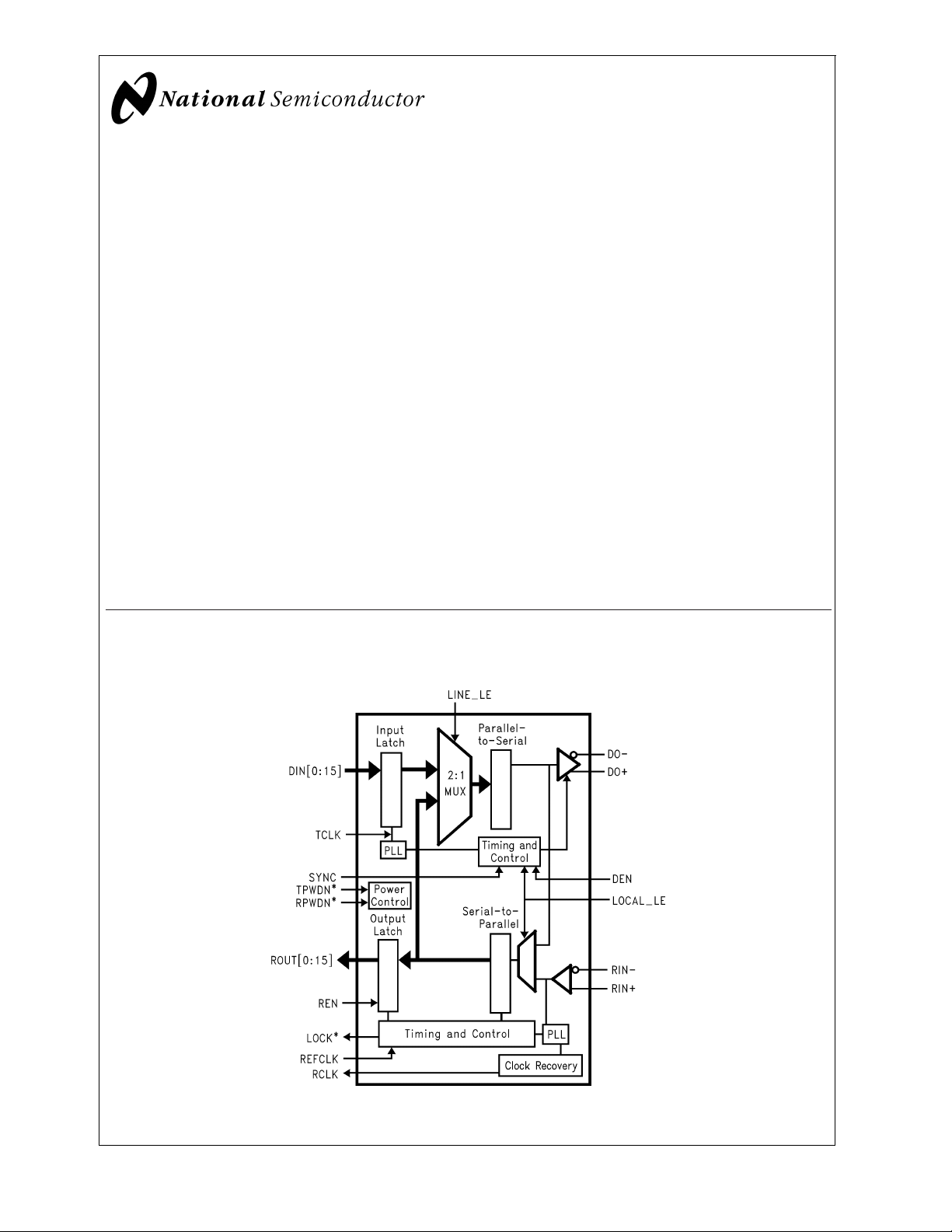

Block Diagram

DS92LV16

Features

n 25–80 MHz 16:1/1:16 serializer/deserializer (2.56Gbps

full duplex throughput)

n Independent transmitter and receiver operation with

separate clock, enable, power down pins

n Hot plug protection (power up high impedance) and

synchronization (receiver locks to random data)

n Wide +/−5% reference clock frequency tolerance for

easy system design using locally-generated clocks

n Line and local loopback modes

n Robust BLVDS serial transmission across backplanes

and cables for low EMI

n No external coding required

n Internal PLL, no external PLL components required

n Single +3.3V power supply

n Low power: 104mA (typ) transmitter, 119mA (typ)

receiver at 80MHz

±

n

100mV receiver input threshold

n Loss of lock detection and reporting pin

n Industrial −40 to +85˚C temperature range

>

n

2.5kV HBM ESD

n Compact, standard 80-pin PQFP package

20014301

© 2002 National Semiconductor Corporation DS200143 www.national.com

Absolute Maximum Ratings (Note 1)

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales Office/

DS92LV16

Distributors for availability and specifications.

Supply Voltage (V

LVCMOS/LVTTL Input

Voltage −0.3V to (V

) −0.3V to +4V

CC

CC

+0.3V)

Maximum Package Power Dissipation Capacity

Package Derating:

23.2 mW/˚C above

80L PQFP

θ

JA

θ

JC

ESD Rating (HBM)

+25˚C

43˚C/W

11.1˚C/W

>

LVCMOS/LVTTL Output

Voltage −0.3V to (V

Bus LVDS Receiver Input

Voltage −0.3V to +3.9V

Bus LVDS Driver Output

Voltage −0.3V to +3.9V

Bus LVDS Output Short

Circuit Duration 10ms

Junction Temperature +150˚C

Storage Temperature −65˚C to +150˚C

CC

+0.3V)

Recommended Operating Conditions

Min Nom Max Units

Supply Voltage (V

Operating Free Air

Temperature (T

Clock Rate 25 80 MHz

) 3.15 3.3 3.45 V

CC

)

A

−40 +25 +85 ˚C

Lead Temperature

(Soldering, 4 seconds) +260˚C

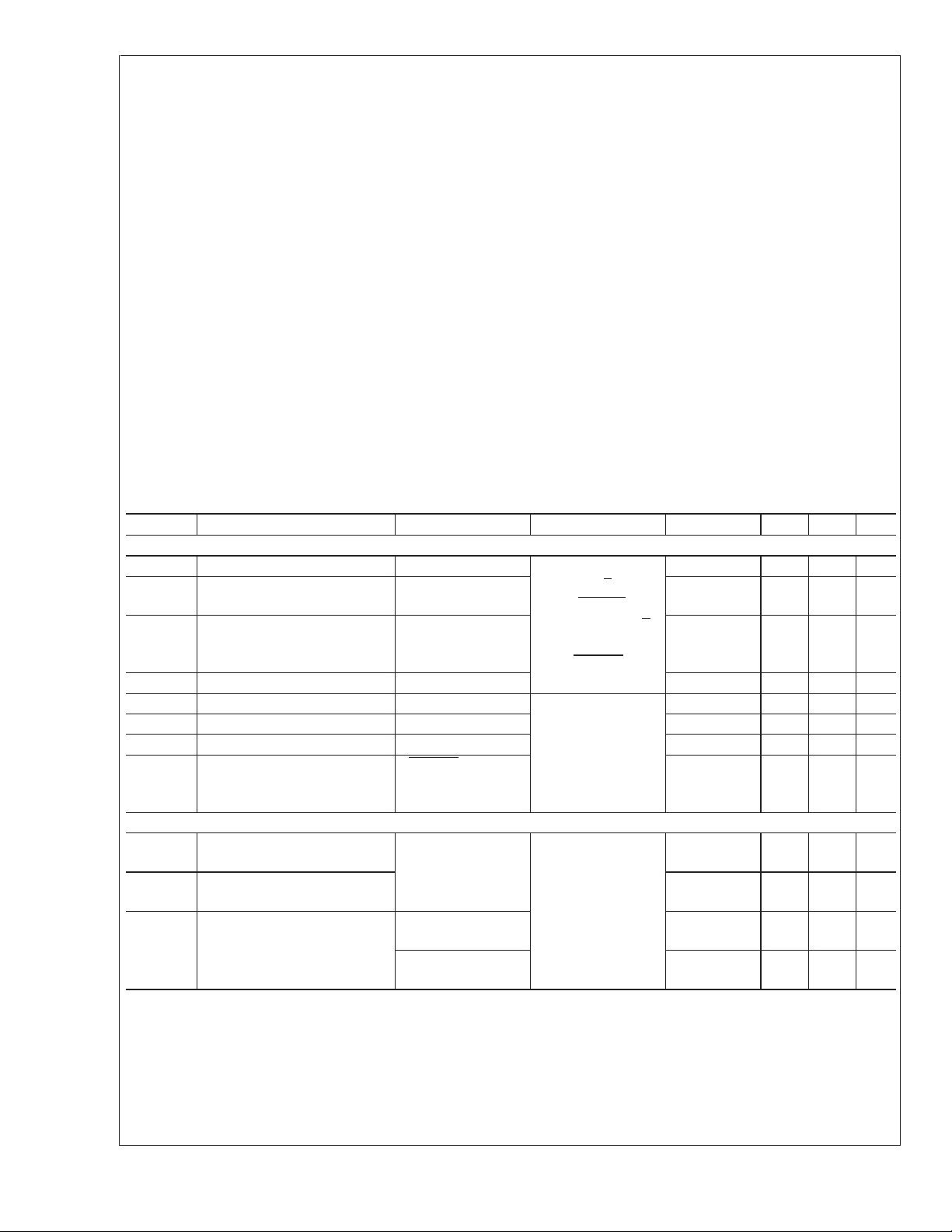

Electrical Characteristics

Over recommended operating supply and temperature ranges unless otherwise specified.

Symbol Parameter Conditions Pin/Freq. Min Typ Max Units

LVCMOS/LVTTL DC Specifications

V

IH

V

IL

V

CL

I

IN

V

OH

V

OL

I

OS

I

OZ

Bus LVDS DC specifications

VTH

VTL

I

IN

High Level Input Voltage 2.0 V

Low Level Input Voltage

TCLK_R/F,DEN,

TCLK, TPWDN, DIN,

GND 0.8 V

SYNC, RCLK_R/F,

Input Clamp Voltage ICL= −18 mA

REN, REFCLK,

-0.7 −1.5 V

PWRDN

Input Current VIN= 0V or 3.6V −10

±

2 +10 µA

High Level Output Voltage IOH= −9 mA 2.3 3.0 V

Low Level Output Voltage IOL=9mA R

, RCLK, LOCK GND 0.33 0.5 V

OUT

Output Short Circuit Current VOUT = 0V −15 −48 −85 mA

PWRDN or REN =

TRI-STATE Output Current

0.8V, V

OUT

=0Vor

R

, RCLK, −10

OUT

±

0.4 +10 µA

VCC

Differential Threshold High

Voltage

Differential Threshold Low

Voltage

Input Current

VCM = +1.1V +100 mV

RI+, RI- −100 mV

= +2.4V, VCC=

V

IN

3.6V or 0V

= 0V, VCC= 3.6V

V

IN

or 0V

−10

−10

±

5 +10 µA

±

5 +10 µA

2.5kV

CC

CC

V

V

www.national.com 2

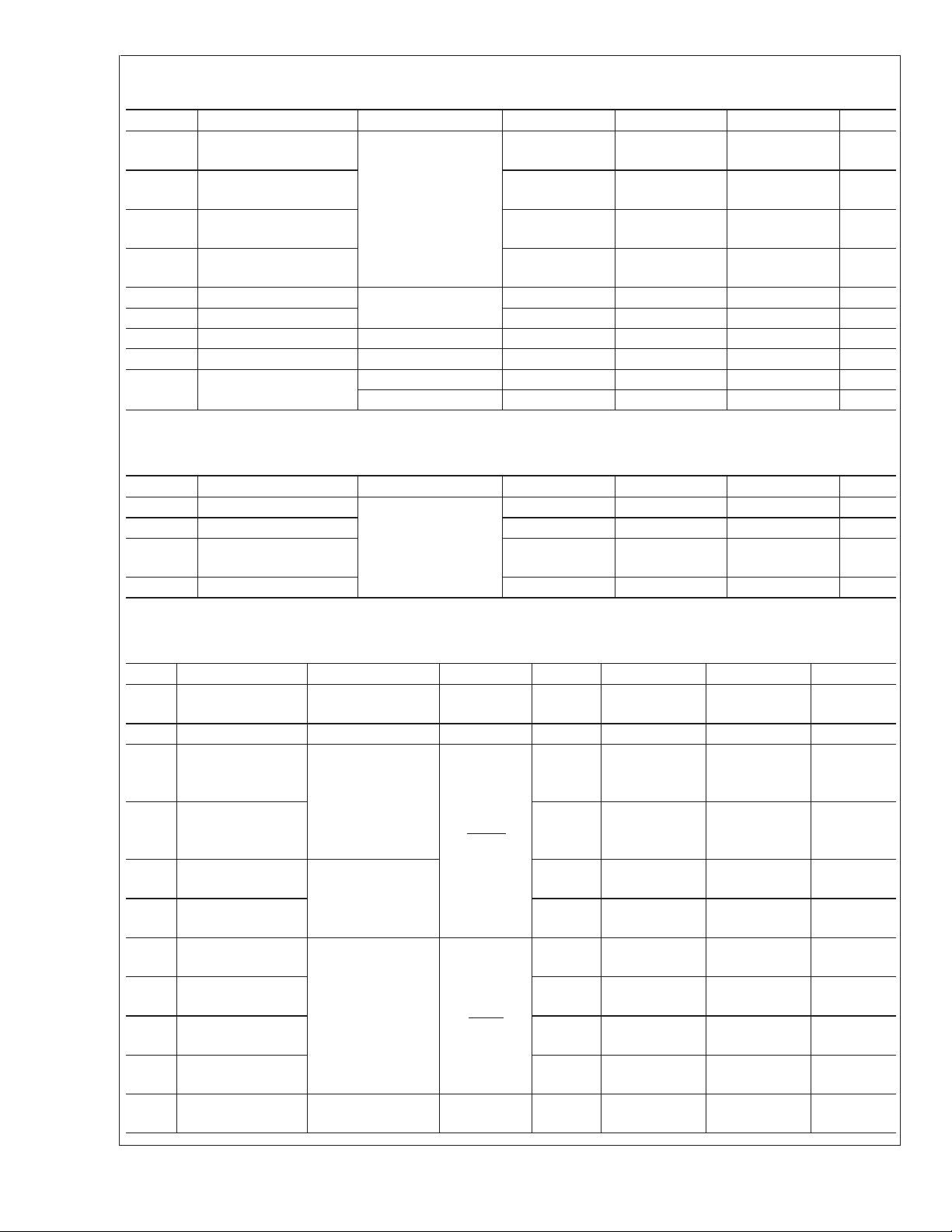

Electrical Characteristics (Continued)

Over recommended operating supply and temperature ranges unless otherwise specified.

Symbol Parameter Conditions Pin/Freq. Min Typ Max Units

V

OD

∆V

OD

V

OS

∆V

OS

I

OS

I

OZ

I

OX

SER/DES SUPPLY CURRENT (DVDD, PVDD and AVDD pins)

I

CCT

I

CCX

Output Differential Voltage

(DO+) - (DO-)

Output Differential Voltage

Unbalance

RL = 100Ω,

Figure 17

350 500 550 mV

215mV

Offset Voltage 1.05 1.2 1.25 V

Offset Voltage Unbalance 2.7 15 mV

Output Short Circuit Current

DO = 0V, Din = H,

TXPWDN and DEN =

DO+, DO-

-35 -50 -70 mA

2.4V

TXPWDN or DEN =

Tri-State Output Current

0.8V, DO = 0V OR

-10

±

110µA

VDD

Power-Off Output Current

Total Supply Current (includes

load current)

VDD = 0V, DO = 0V

or 3.6V

= 15 pF, RL= 100Ωf = 80 MHz, PRBS15

C

L

pattern

f = 80 MHz, Worse

= 15 pF, RL= 100

C

L

Ω

case pattern

(Checker-board

-10

±

110µA

209 mA

225 320 mA

pattern)

Supply Current Powerdown

PWRDN = 0.8V,

REN = 0.8V

0.35 1.0 mA

DS92LV16

Serializer Timing Requirements for TCLK

Over recommended operating supply and temperature ranges unless otherwise specified.

Symbol Parameter Conditions Min Typ Max Units

t

TCP

t

TCIH

t

TCIL

t

CLKT

t

JIT

Transmit Clock Period 12.5 T 40 ns

Transmit Clock High Time 0.4T 0.5T 0.6T ns

Transmit Clock Low Time 0.4T 0.5T 0.6T ns

TCLK Input Transition

Time

TCLK Input Jitter 80

36ns

ps

(RMS)

Serializer Switching Characteristics

Over recommended operating supply and temperature ranges unless otherwise specified.

Symbol Parameter Conditions Min Typ Max Units

t

LLHT

t

LHLT

t

t

DIS

DIH

Bus LVDS Low-to-High

Transition Time

Bus LVDS High-to-Low

Transition Time

DIN (0-15) Setup to TCLK

DIN (0-15) Hold from

TCLK

= 100Ω

R

L

Figure 3

CL=10pF to GND

Figure 6

RL= 100Ω,

=10pF to GND

C

L

2.4 ns

0ns

0.2 0.4 ns

0.2 0.4 ns

www.national.com3

Serializer Switching Characteristics (Continued)

Over recommended operating supply and temperature ranges unless otherwise specified.

Symbol Parameter Conditions Min Typ Max Units

DS92LV16

t

t

t

t

t

t

t

t

HZD

LZD

ZHD

ZLD

SPW

PLD

t

SD

RJIT

DJIT

DO±HIGH to

TRI-STATE Delay

DO±LOW to

TRI-STATE Delay

DO±TRI-STATE to

HIGH Delay

Figure 7

C

(Note 4)

= 100Ω,

R

L

=10pF to GND

L

DO±TRI-STATE to

LOW Delay

SYNC Pulse Width

Serializer PLL Lock Time 510*t

Serializer Delay

Figure 8

RL= 100Ω

Figure 9

RL= 100Ω t

5*t

TCP

TCP

TCP

+ 1.0 t

2.3 10 ns

1.9 10 ns

1.0 10 ns

1.0 10 ns

6*t

TCP

513*t

TCP

+ 2.0 t

TCP

+ 4.0 ns

TCP

Random Jitter 10 ps(rms)

Deterministic Jitter

Figure 15

35 MHz -240 140 ps

80 MHz -75 100 ps

Deserializer Timing Requirements for REFCLK

Over recommended operating supply and temperature ranges unless otherwise specified.

Symbol Parameter Conditions Min Typ Max Units

t

RFCP

t

RFDC

t

RFCP

t

t

RFTT

/

TCP

REFCLK Period 12.5 T 40 ns

REFCLK Duty Cycle 40 50 60 %

Ratio of REFCLK to

TCLK

0.95 1.05

REFCLK Transition Time 6ns

ns

ns

Deserializer Switching Characteristics

Over recommended operating supply and temperature ranges unless otherwise specified.

Symbol Parameter Conditions Pin/Freq. Min Typ Max Units

t

t

Receiver out Clock

RCP

RDC

RCLK Duty Cycle RCLK 45 50 55 %

Period

CMOS/TTL

t

CLH

Low-to-High

Transition Time

CMOS/TTL

t

CHL

High-to-Low

Transition Time

t

t

t

t

t

t

ROUT (0-9) Setup

ROS

ROH

HZR

LZR

ZHR

ZLR

t

DD

Data to RCLK

ROUT (0-9) Hold

Data to RCLK

HIGH to TRI-STATE

Delay

LOW to TRI-STATE

Delay

TRI-STATE to HIGH

Delay

TRI-STATE to LOW

Delay

Deserializer Delay RCLK

Figure 9

t

RCP=tTCP

CL=15pF

Figure 4

Figure 11

Figure 12

RCLK 12.5 40 ns

24ns

Rout(0-9),

LOCK,

24ns

RCLK

0.35*t

−0.35*t

RCP

RCP

0.5*t

−0.5*t

RCP

RCP

2.2 10 ns

Rout(0-9),

LOCK

2.2 10 ns

2.3 10 ns

2.9 10 ns

1.75*t

+2

RCP

1.75*t

+ 5 1.75*t

RCP

+7 ns

RCP

ns

ns

www.national.com 4

Deserializer Switching Characteristics (Continued)

Over recommended operating supply and temperature ranges unless otherwise specified.

Symbol Parameter Conditions Pin/Freq. Min Typ Max Units

Deserializer PLL

t

DSR1

Lock Time from

PWRDWN (with

SYNCPAT)

(Note 7)

Deserializer PLL

t

DSR2

Lock time from

SYNCPAT

t

RNMI-R

t

RNMI-L

Note 1: “Absolute Maximum Ratings” are those values beyond which the safety of the device cannot be guaranteed. They are not meant to imply that the devices

should be operated at these limits. The table of “Electrical Characteristics” specifies conditions of device operation.

Note 2: Typical values are given for V

Note 3: Current into device pins is defined as positive. Current out of device pins is defined as negative. Voltages are referenced to ground except VOD, ∆VOD,

VTH and VTL which are differential voltages.

Note 4: Due to TRI-STATE of the Serializer, the Deserializer will lose PLL lock and have to resynchronize before data transfer.

Note 5: For the purpose of specifying deserializer PLL performance tDSR1 and tDSR2 are specified with the REFCLK running and stable, and specific conditions

of the incoming data stream (SYNCPATs). It is recommended that the derserializer be initialized using either tDSR1 timing or tDSR2 timing. tDSR1 is the time

required for the deserializer to indicate lock upon power-up or when leaving the power-down mode. Synchronization patterns should be sent to the device before

initiating either condition. tDSR2 is the time required to indicate lock for the powered-up and enabled deserializer when the input (RI+ and RI-) conditions change

from not receiving data to receiving synchronization patterns (SYNCPATs).

Note 6: tRNMI is a measure of how much phase noise (jitter) the deserializer can tolerate in the incoming data stream before bit errors occur. It is a measurement

in reference with the ideal bit position, please see National’s AN-1217 for detail.

Note 7: Sync pattern is a fixed pattern with 8-bit of data high followed by 8-bit of data low.

Ideal Deserializer

Noise Margin Right

Ideal Deserializer

Noise Margin Left

Figure 16

(Note 6)

Figure 16

(Note 6)

= 3.3V and TA= +25˚C.

CC

35MHz 3.7 10 µs

80 MHz 1.9 4 µs

35MHz 1.5 5 µs

80 MHz 0.9 2 µs

35 MHz +630 ps

80 MHz +230 ps

35 MHz −630 ps

80 MHz −230 ps

DS92LV16

www.national.com5

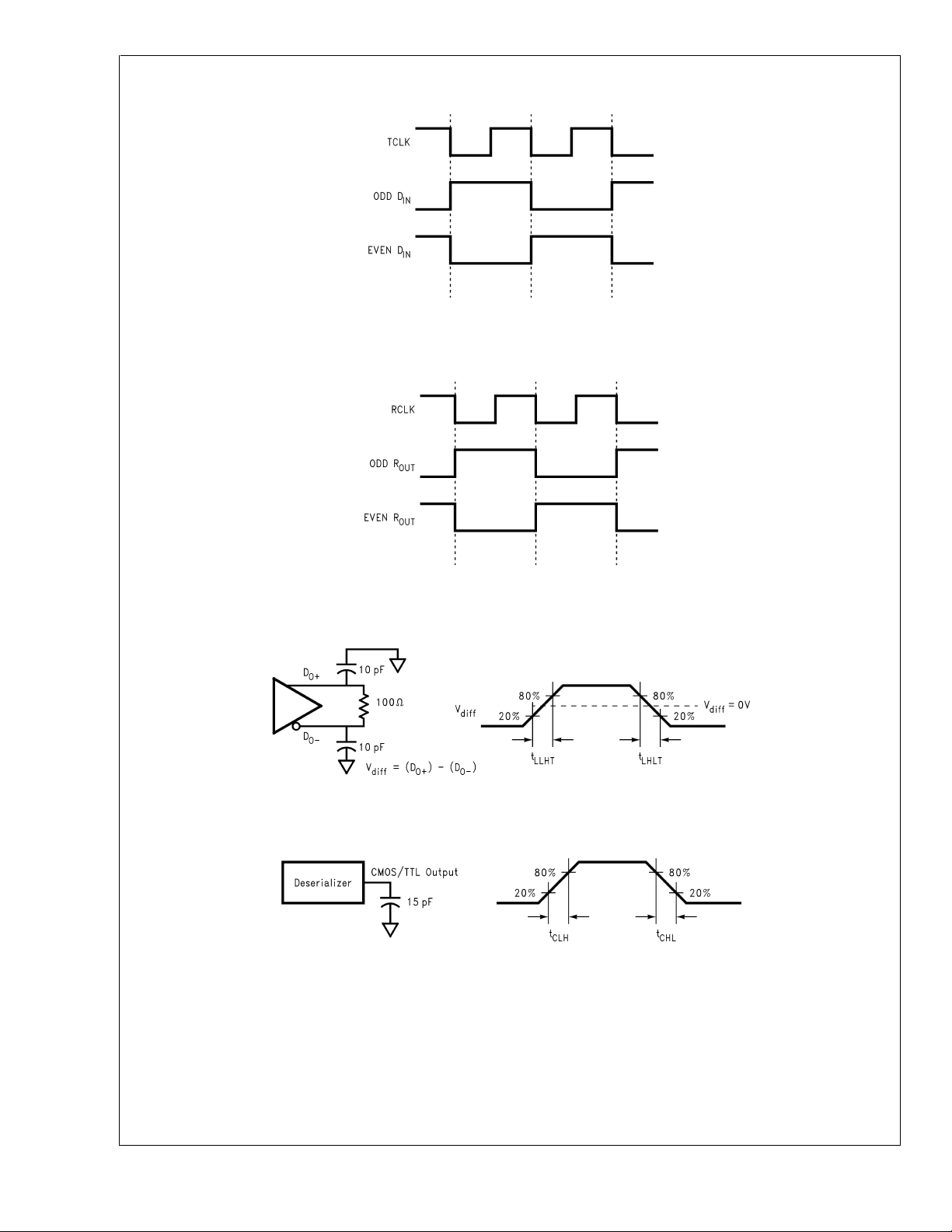

AC Timing Diagrams and Test Circuits

DS92LV16

FIGURE 1. “Worst Case” Serializer ICC Test Pattern

20014303

20014304

FIGURE 2. “Worst Case” Deserializer ICC Test Pattern

FIGURE 3. Serializer Bus LVDS Output Load and Transition Times

20014306

FIGURE 4. Deserializer CMOS/TTL Output Load and Transition Times

20014305

www.national.com 6

AC Timing Diagrams and Test Circuits (Continued)

FIGURE 5. Serializer Input Clock Transition Time

DS92LV16

20014307

20014308

FIGURE 6. Serializer Setup/Hold Times

20014309

FIGURE 7. Serializer TRI-STATE Test Circuit and Timing

www.national.com7

AC Timing Diagrams and Test Circuits (Continued)

DS92LV16

FIGURE 8. Serializer PLL Lock Time, SYNC Timing and PWRDN TRI-STATE Delays

20014310

FIGURE 9. Serializer Delay

FIGURE 10. Deserializer Delay

20014311

20014312

FIGURE 11. Deserializer Setup and Hold Times

www.national.com 8

20014313

AC Timing Diagrams and Test Circuits (Continued)

DS92LV16

FIGURE 12. Deserializer TRI-STATE Test Circuit and Timing

20014314

FIGURE 13. Deserializer PLL Lock Times and PWRDN TRI-STATE Delays

20014315

www.national.com9

AC Timing Diagrams and Test Circuits (Continued)

DS92LV16

FIGURE 14. Deserializer PLL Lock Time from SyncPAT

FIGURE 15. Deterministic Jitter and Ideal Bit Position

20014322

20014329

www.national.com 10

AC Timing Diagrams and Test Circuits (Continued)

DS92LV16

t

is the noise margin on the left of the above figure. It is a negative value to indicate early with respect to ideal.

RNMI-L

t

is the noise margin on the right of the above figure. It is a positive value to indicate late with respect to ideal.

RNMI-R

FIGURE 16. Deserializer Noise Margin (t

VOD= (DO+)–(DO−).

Differential output signal is shown as (DO+)–(DO−), device in Data Transfer mode.

) and Sampling window

RNMI

20014316

FIGURE 17. VODDiagram

20014332

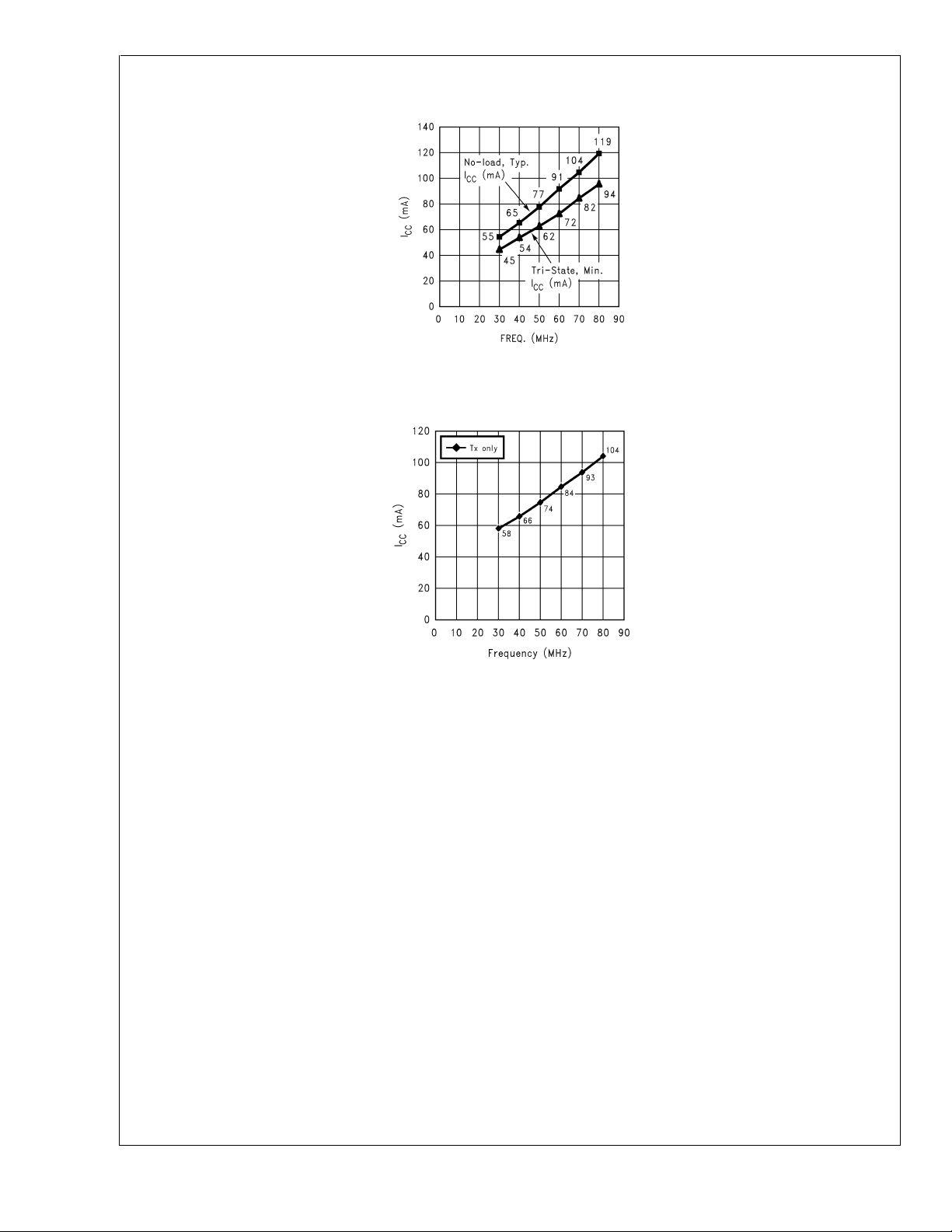

FIGURE 18. Icc vs Freq

20014323

www.national.com11

AC Timing Diagrams and Test Circuits (Continued)

DS92LV16

FIGURE 19. Icc vs Freq (Rx only)

20014324

20014325

FIGURE 20. Icc vs Freq (Tx only)

www.national.com 12

Functional Description

The DS92LV16 combines a serializer and deserializer onto a

single chip. The serializer accepts a 16-bit LVCMOS or

LVTTL data bus and transforms it into a BLVDS serial data

stream with embedded clock information. The deserializer

then recovers the clock and data to deliver the resulting

16-bit wide words to the output.

The device has a separate Transmitblock and Receive block

that can operate independent of each other. Each has a

power down control to enable efficient operation in various

applications. For example, the transceiver can operate as a

standby in a redundant data path but still conserve power.

The part can be configured as a Serializer, Deserializer, or

as a Full Duplex SER/DES.

The DS92LV16 serializer and deserializer blocks each has

three operating states. They are the Initialization, Data

Transfer, and Resynchronization states. In addition, there

are two passive states: Powerdown and TRI-STATE.

The following sections describe each operation mode and

passive state.

Initialization

Before the DS92LV16 sends or receives data, it must initialize the links to and from another DS92LV16. Initialization

refers to synchronizing the Serializer’s and Deserializer’s

PLL’s to local clocks. The local clocks must be the same

frequency or within a specified range if from different

sources. After the Serializers synchronizes to the local

clocks, the Deserializers synchronize to the Serializers as

the second and final initialization step.

Step 1: When V

rializer, the respective outputs are held in TRI-STATE and

internal circuitry is disabled by on-chip power-on circuitry.

When V

begins locking to a local clock. For the Serializer, the local

clock is the transmit clock, TCLK. For the Deserializer, the

local clock is applied to the REFCLK pin. A local on-board

oscillator or other source provides the specified clock input

to the TCLK and REFCLK pin.

The Serializer outputs are held in TRI-STATE while the PLL

locks to the TCLK. After locking to TCLK, the Serializer block

is now ready to send data or synchronization patterns. If the

SYNC pin is high, then the Serializer block generates and

sends the synchronization patterns (sync-pattern).

The Deserializer output will remain TRI-STATE while its PLL

locks to the REFCLK.Also, the Deserializer LOCK output will

remain high until its PLL locks to an incoming data or syncpattern on the RIN pins.

Step 2: The Deserializer PLL must synchronize to the Serializer to complete the initialization. The Serializer that is

generating the stream to the Deserializer must send random

(non-repetitive) data patterns or sync-patterns during this

step of the Initialization State. The Deserializer will lock onto

sync-patterns within a specified amount of time. The lock to

random data depends on the data patterns and therefore,

the lock time is unspecified.

In order to lock to the incoming LVDS data stream, the

Deserializer identifies the rising clock edge in a sync-pattern

and after 150 clock cycles will synchronize. If the Deserializer is locking to a random data stream from the Serializer,

then it performs a series of operations to identify the rising

clock edge and locks to it. Because this locking procedure

depends on the data pattern, it is not possible to specify how

long it will take. At the point where the Deserializer’s PLL

CC

is applied to both Serializer and/or Dese-

CC

reaches VCCOK (2.2V) the PLL in each device

DS92LV16

locks to the embedded clock, the LOCK pin goes low and

valid data appears on the output. Note that the LOCK signal

is synchronous to valid data appearing on the outputs.

The user’s application determines whether sync-pattern or

lock to random data is the preferred method for synchronization. If sync-patterns are preferred, the associated deserializers LOCK pin is a convenient way to provide control of

the SYNC pin.

Data Transfer

After initialization, the DS92LV16 Serializer isable to transfer

data to the Deserializer. The serial data stream includes a

start bit and stop bit appended by the serializer,which frame

the sixteen data bits. The start bit is always high and the stop

bit is always low. The start and stop bits also function as

clock bits embedded in the serial stream.

The Serializer block accepts data from the DIN0-DIN15 parallel inputs. The TCLK signal latches the incoming data on

the rising edge. If the SYNC input is high for 6 TCLK cycles,

the DS92LV16 does not latch data on the DIN0-DIN15.

The Serializer transmits the data and clock bits (16+2 bits) at

18 times the TCLK frequency. For example, if TCLK is 60

MHz, the serial rate is 60 X 18 = 1080 Mbps. Since only 16

bits are from input data, the serial ’payload’ rate is 16 times

the TCLK frequency. For instance, if TCLK = 60 MHz, the

payload data rate is 60 X 16 = 960 Mbps. TCLK is provided

by the data source and must be in the range of 25 MHz to 80

MHz.

When the Deserializer channel synchronizes to the input

from a Serializer, it drives its LOCK pin low and synchronously delivers valid data on the output. The Deserializer

locks to the embedded clock, uses it to generate multiple

internal data strobes, and then drives the recovered clock on

the RCLK pin. The RCLK is synchronous to the data on the

ROUT[0:15] pins. While LOCK is low, data on ROUT[0:15] is

valid. Otherwise, ROUT[0:15] is invalid.

ROUT[0:15], LOCK, and RCLK signals will drive a minimum

of three CMOS input gates (15pF total load) at a 80 MHz

clock rate. This drive capacity allows bussing outputs of

multiple Deserializers and multiple destination ASIC inputs.

REN controls TRI-STATE of the all outputs.

The Deserializer input pins are high impedance during Receiver Powerdown (RPWDN* low) and power-off (VCC =

0V).

Resynchronization

Whenever the Deserializer loses lock, it will automatically try

to resynchronize. For example, if the embedded clock edge

is not detected two times in succession, the PLL loses lock

and the LOCK pin is driven high. The Deserializer then

enters the operating mode where it tries to lock to random a

data stream. It looks for the embedded clock edge, identifies

it and then proceeds through the synchronization process.

The logic state of the LOCK signal indicates whether the

data on ROUT is valid; when it is low, the data is valid. The

system must monitor the LOCK pin to determine whether

data on the ROUT is valid. Because there is a short delay in

the LOCK signals response to the PLL losing synchronization to the incoming data stream, the system must determine

the validity of data for the cycles before the LOCK signal

goes high.

www.national.com13

Resynchronization (Continued)

The user can choose to resynchronize to the random data

stream or to force fast synchronization by pulsing the Seri-

DS92LV16

alizer SYNC pin. Since lock time varies due to data stream

characteristics, we cannot possibly predict exact lock time.

The primary constraint on the ’random’ lock time is the initial

phase relation between the incoming data and the REFCLK

when the Deserializer powers up. An advantage of using the

SYNC pattern to force synchronization is the ability for user

to predict the delay for PLL to regain lock. This scheme is left

up to the user discretion. One recommendation is to provide

a feedback loop using the LOCK pin itself to control the sync

request of the Serializer, which is the SYNC pin.

If a specific pattern is repetitive, the Deserializer’s PLL will

not lock in order to prevent the Deserializer to lock to the

data pattern rather than the clock. We refer to such pattern

as a repetitive multi-transition, RMT. This occurs when more

than one Low-High transition takes places in a clock cycle

over multiple cycles. This occurs when any bit, except DIN

15, is held at a low state and the adjacent bit is held high,

creating a 0-1 transition. The internal circuitry accomplishes

this by detecting more than one potential position for clocking bits. Upon detection, the circuitry will prevent the LOCK

output from becoming active until the RMT pattern changes.

Once the RMT pattern changes and the internal circuitry

recognized the clock bits in the serial data stream, the PLLof

the Deserializer will lock, which will drive the LOCK output to

low and the output data ROUT will become valid.

Powerdown

The Powerdown state is a low power sleep mode that the

Serializer and Deserializer will occupy while waiting for initialization. You can also use TPWDN* and RPWDN* to reduce power when there are no pending data transfers. The

Deserializer enters Powerdown when RPWDN* is driven

low. In Powerdown, the PLL stops and the outputs go into

TRI-STATE, which reduces supply current to the µA range.

To bring the Deserializer block out of the Powerdown state,

the system drives RPWDN* high. When the Deserializer

exits Powerdown, it automatically enters the Initialization

state. The system must then allow time for Initialization

before data transfer can begin.

The TPWDN* driven to a low condition forces the Serializer

block into low power consumption where the supply current

is in the µA range. The Serializer PLL stops and the output

goes into a TRI-STATE condition.

To bring the Serializer block out of the Powerdown state, the

system drives TPWDN* high. When the Serializer exits Powerdown, its PLL must lock the TCLK before it is ready for the

Initialization state. The system must then allow time for

Initialization before data transfer can begin.

TRI-STATE

When the system drives the REN pin low, the Deserializer

output enter TRI-STATE. This will TRI-STATE the receiver

output pins (ROUT[0:15]) and RCLK. When the system

drives REN high, the Deserilaizer will return to the previous

state as long as all other control pins remain static (RPWDN*).

When the system drives the DEN pin low, the Serializer

output enters TRI-STATE. This will TRI-STATE the LVDS

output. When the system drives the DEN signal high, the

Serializer output will return to the previous state as long as

all other control and data input pins remain in the same

condition as when the DEN was driven low.

Loopback Test Operation

The DS92LV16 includes two Loopback modes for testing the

device functionality and the transmission line continuity. Asserting the Line Loopback control signal connects the serial

data input (RIN+/−) to the serial data output (DO+/−) and to

the parallel data output (ROUT[0:15]). The serial data goes

through deserializer and serializer blocks.

Asserting the Local Loopback control signal connects the

parallel data input (DIN[0:15]) back to the parallel data output (ROUT[0:15]). The connection route includes all the

functional blocks of the SER/DES Pair. The serial data output (DO+/−) is automatically disabled during the Local Loopback operating mode.

Application Information

Using the DS92LV16

The DS92LV16 combines a Serializer and a Deserializer into

a single chip that sends 16 bits of parallel TTL data over a

serial Bus LVDS link up to 1.28 Gbps. Serialization of the

input data is accomplished using an onboard PLL at the

Serializer which embeds two clock bits with the data. The

Deserializer uses a separate reference clock (REFCLK) and

an onboard PLL to extract the clock information from the

incoming data stream and deserialize the data. The Deserializer monitors the incoming clock information to determine

lock status and will indicate loss of lock by raising the LOCK

output.

Power Considerations

All CMOS design of the Serializer and Deserializer makes

them inherently low power devices.Additionally,the constant

current source nature of the LVDS outputs minimize the

slope of the speed vs. I

Powering Up the Deserializer

The REFCLK input can be running before the Deserializer is

powered up and it must be running in order for the Deserializer to lock to incoming data. The Deserializer outputs will

remain in TRI-STATE until the Deserializer detects data

transmission at its inputs and locks to the incoming stream.

Noise Margin

The Deserializer noise margin is the amount of input jitter

(phase noise) that the Deserializer can tolerate and still

reliably receive data. Various environmental and systematic

factors include:

Serializer: TCLK jitter, V

out-of-band noise)

Media: ISI, V

Deserializer: V

For typical receiver noise margin, please see

Recovering from LOCK Loss

In the case where the Serializer loses lock during data

transmission up to 5 cycles of data that was previously

received can be invalid. This is due to the delay in the lock

detection circuit. The lock detect circuit requires that invalid

clock information be received 2 times in a row to indicate

loss of lock. Since clock information has been lost it is

possible that data was also lost during these cycles. When

the Deserializer LOCK pin goes low, data from at least the

previous 5 cycles should be resent upon regaining lock.

CM

noise

CC

curve of CMOS designs.

CC

noise (noise bandwidth and

CC

noise

Figure 16

.

www.national.com 14

Application Information (Continued)

Lock can be regained at the Deserializer by causing the

Serializer to resend SYNC patterns as described above or

by random lock which can take more time depending upon

the data patterns being received.

Input Failsafe

In the event that the Deserializer is disconnected from the

Serializer, the failsafe circuitry is designed to reject certain

amount of noise from being interpreted as data or clock. The

outputs will be tri-stated and the Deserializer will lose lock.

Hot Insertion

All the LVDS devices are hot pluggable if you follow a few

rules. When inserting, ensure the Ground pin(s) makes contact first, then the VCC pin(s), then the I/O pins. When

removing, the I/O pins should be unplugged first, then the

VCC, then the Ground.

PCB Layout and Power System Considerations

Circuit board layout and stack-up for the BLVDS devices

should be designed to provide low-noise power feed to the

device. Good layout practice will also separate highfrequency or high-level inputs and outputs to minimize unwanted stray noise pickup, feedback and interference.

Power system performance may be greatly improved by

using thin dielectrics (2 to 4 mils) for power / ground sandwiches. This arrangement provides plane capacitance for

the PCB power system with low-inductance parasitic, especially proven effective at high frequencies above approx

50MHz, and makes the value and placement of external

bypass capacitors less critical. External bypass capacitors

should include both RF ceramic and tantalum electrolytic

types. RF capacitors may use values in the range of 0.01 uF

to 0.1 uF. Tantalum capacitors may be in the 2.2 uF to 10 uF

range. Voltagerating of the tantalum capacitors should be at

least 5X the power supply voltage being used.

It is a recommended practice to use two vias at each power

pin as well as at all RF bypass capacitor terminals. Dual vias

reduce the interconnect inductance by up to half, thereby

reducing interconnect inductance and extending the effective frequency range of the bypass components. Locate RF

capacitors as close as possible to the supply pins, and use

wide low impedance traces (not 50 Ohm traces). Surface

mount capacitors are recommended due to their smaller

parasitics. When using multiple capacitors per supply pin,

locate the smaller value closer to the pin. A large bulk

capacitor is recommend at the point of power entry. This is

typically in the 50uF to 100uF range and will smooth low

frequency switching noise. It is recommended to connect

power and ground pin straight to the power and ground

plane, with the bypass capacitors connected to the plane

with via on both ends of the capacitor. Connecting power or

ground pin to an external bypass capacitor will increase the

inductance of the path.

A small body size X7R chip capacitor, such as 0603, is

recommended for external bypass. Its small body size reduces the parasitic inductance of the capacitor. User must

pay attention to the resonance frequency of these external

bypass capacitors, usually in the range of 20-30MHz range.

To provide effective bypassing, very often, multiple capacitors are used to achieve low impedance between the supply

rails over the frequency of interest. At high frequency, it is

also a common practice to use two via from power and

ground pins to the planes, reducing the impedance at high

frequency.

DS92LV16

Some devices provide separate power and ground pins for

different portions of the circuit. This is done to isolate switching noise effects between different sections of the circuit.

Separate planes on the PCB are typically not required. Pin

Description tables typically provide guidance on which circuit

blocks are connected to which power pin pairs. In some

cases, an external filter many be used to provide clean

power to sensitive circuits such as PLLs.

Use at least a four layer board with a power and ground

plane. Locate CMOS (TTL) swings away from the LVDS

lines to prevent coupling from the CMOS lines to the LVDS

lines. Closely-coupled differential lines of 100 Ohms are

typically recommended for LVDS interconnect. The closelycoupled lines help to ensure that coupled noise will appear

as common-mode and thus is rejected by the receivers.Also

the tight coupled lines will radiate less.

Termination of the LVDS interconnect is required. For pointto-point applications termination should be located at the

load end. Nominal value is 100 Ohms to match the line’s

differential impedance. Place the resistor as close to the

receiver inputs as possible to minimize the resulting stub

between the termination resistor and receiver.

Additional general guidance can be found in the LVDSOwner’s Manual - available in PDF format from the national web

site at: www.national.com/lvds

Specific guidance for this device is provided next:

DS92LV16 BLVDS SER/DES PAIR

General device specific guidance is given below. Exact guidance can not be given as it is dictated by other board level

/system level criteria. This includes the density of the board,

power rails, power supply,and other integrated circuit power

supply needs.

DVDD = Digital section power supply

These pins supply the digital portion of the device and also

receiver output buffers. TheTX DVDD is less critical. The RX

DVDD requires more bypass to power the outputs under

synchronous switching conditions. The receiver DVDD pins

power 4 outputs from each DVDD pin. An estimate of local

capacitance required indicates a minimum of 22nF is required. This is calculated by taking 4 times the maximum

short current (4 X 70 = 280mA) multiplying by the rise time of

the part (4ns) and dividing by the maximum allowed droop in

VDD (assume 50mV) yields 22.4nF. Rounding up to a standard value, 0.1uF is selected for each DVDD pin.

PVDD = PLL section power supply

The PVDD pin supplies the PLL circuit. Note that the

DS92LV16 has two separate PLLs and supply pins. The

PLL(s) require clean power for the minimization of Jitter. A

supply noise frequency in the 300kHZ to 1MHz range can

cause increased output jitter. Certain power supplies may

have switching frequencies or high harmonic content in this

range. If this is the case, filtering of this noise spectrum may

be required. A notch filter response is best to provide a stable

VDD, suppression of the noise band, and good highfrequency response (clock fundamental). This may be accomplished with a pie filter (CRC or CLC). If employed, a

separate pie filter is recommended for each PLL to minimize

drop in potential due to the series resistance. The pie filter

should be located close to the PVDD power pin. Separate

power planes for the PVDD pins is typically not required.

AVDD = LVDS section power supply

The AVDD pin supplies the LVDS portion of the circuit. The

DS92LV16 has four AVDD pins. Due to the nature of the

design, current draw is not excessive on these pins. A0.1uF

www.national.com15

Application Information (Continued)

capacitor is sufficient for these pins. If space is available it

0.01uF may be used in parallel with the 0.1uF capacitor for

DS92LV16

additional high frequency filtering.

GROUNDs

TheAGND pin should be connected to the signal common in

the cable for the return path of any common-mode current.

Most of the LVDS current will be odd-mode and return within

the interconnect pair. A small amount of current may be

even-mode due to coupled noise, and driver imbalances.

This current should return via a low impedance known path.

Asolid ground plane is recommended for both DVDD, PVDD

or AVDD. Using a split plane may have potential problem of

ground loops, or difference in ground potential at various

ground pins of the device.

www.national.com 16

Pin Diagram

DS92LV16

DS92LV16TVHG

Top VIew

20014302

www.national.com17

Pin Descriptions

DS92LV16

Pin # Pin Name I/O Description

1 RPWDN* CMOS, I RPWDN* = Low will put the Receiver in low power, stand-by,

mode. Note: The Receiver PLL will lose lock.(Note 8)

2 REN CMOS, I REN = Low will disable the Receiver outputs. Receiver PLL

remains locked. (See LOCK pin description)(Note 8)

3 CONFIG1 Configuration pin - strap or tie this pin to High with pull-up resistor.

No-connect or Low reserved for future use.

4 REFCLK CMOS, I Frequency reference clock input for the receiver.

5, 10, 11, 15 AVDD Analog Voltage Supply

6,9,12,16 AGND Analog Ground

7 RIN+ LVDS, I Receiver LVDS True Input

8 RIN- LVDS, I Receiver LVDS Inverting Input

13 DO+ LVDS, O Transmitter LVDS True Output

14 DO- LVDS, O Transmitter LVDS Inverting Output

17 TCLK CMOS, I Transmitter reference clock. Used to strobe data at the DIN Inputs

and to drive the transmitter PLL. See TCLK Timing Requirements.

18 CONFIG2 Configuration pin - strap or tie this pin to High with pull-up resistor.

No-connect or Low reserved for future use.

19 DEN CMOS, I DEN = Low will disable the Transmitter outputs. The transmitter

PLL will remain locked.(Note 8)

20 SYNC CMOS, I SYNC = High will cause the transmitter to ignore the data inputs

and send SYNC patterns to provide a locking reference to

receiver(s). See Functional Description.(Note 8)

21, 22, 23, 24, 25, 26,

27, 28, 33, 34, 35, 36,

37, 38, 39, 40

29,32 PGND PLL Ground.

30,31 PVDD PLL Voltage supply.

41, 44, 51, 52, 59, 60,

61, 68, 80

42 TPWDN* CMOS, I TPWDN* = Low will put the Transmitter in low power, stand-by

43, 50, 53, 58, 62, 69 DVDD Digital Voltage Supplies.

45, 46, 47, 48, 54, 55,

56, 57, 64, 65, 66, 67,

70, 71, 72, 73

49 RCLK CMOS, O Recovered Clock. Parallel data rate clock recovered from

63 LOCK* CMOS, O LOCK* indicates the status of the receiver PLL. LOCK=H-

74,76 PGND PLL Grounds.

75,77 PVDD PLL Voltage Supplies.

78 LINE_LE CMOS, I LINE_LE = High enables the receiver loopback mode. Data

79 LOCAL_LE CMOS, I LOCAL_LE = High enables the transmitter loopback mode. Date

Note 8: Input defaults to ’low’ state when left open due to internal pull-device.

DIN (0:15) CMOS, I Transmitter data inputs.(Note 8)

DGND Digital Ground.

mode. Note: The transmitter PLL will lose lock.(Note 8)

ROUT (0:15) CMOS, O Receiver Outputs.

embedded clock. Used to strobe ROUT (0:15). LVCMOS Level

output.

receiver PLL is unlocked, LOCK=L-receiver PLL is locked.

received at the RIN+/- inputs is fed back through the DO+/outputs.(Note 8)

received at the DIN inputs is fed back through the ROUT

outputs.(Note 8)

www.national.com 18

Physical Dimensions inches (millimeters)

unless otherwise noted

DS92LV1616-Bit Bus LVDS Serializer/Deserializer - 25 - 80 MHz

Dimensions shown in millimeters only

Order Number DS92LV16TVHG

NS Package Number VHG80A

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT

DEVICES OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT AND GENERAL

COUNSEL OF NATIONAL SEMICONDUCTOR CORPORATION. As used herein:

1. Life support devices or systems are devices or

systems which, (a) are intended for surgical implant

into the body, or (b) support or sustain life, and

whose failure to perform when properly used in

accordance with instructions for use provided in the

2. A critical component is any component of a life

support device or system whose failure to perform

can be reasonably expected to cause the failure of

the life support device or system, or to affect its

safety or effectiveness.

labeling, can be reasonably expected to result in a

significant injury to the user.

National Semiconductor

Corporation

Americas

Email: support@nsc.com

www.national.com

National does not assume any responsibility for use of any circuitry described, no circuit patent licenses are implied and National reserves the right at any time without notice to change said circuitry and specifications.

National Semiconductor

Europe

Fax: +49 (0) 180-530 85 86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 69 9508 6208

English Tel: +44 (0) 870 24 0 2171

Français Tel: +33 (0) 1 41 91 8790

National Semiconductor

Asia Pacific Customer

Response Group

Tel: 65-2544466

Fax: 65-2504466

Email: ap.support@nsc.com

National Semiconductor

Japan Ltd.

Tel: 81-3-5639-7560

Fax: 81-3-5639-7507

Loading...

Loading...