Page 1

National Semiconductor

Evaluation Board User’s Guide

ADC10DV200, 10-Bit, 200 Msps A/D Converter

ADC11DV200, 11-Bit, 200 Msps A/D Converter

June 2009

Rev 0.9

1 http://www.national.com

© 2009 National Semiconductor Corporation.

Page 2

Table of Contents

1.0 Introduction......................................................................................................................................... 3

2.0 Board Assembly .................................................................................................................................. 3

3.0 Quick Start........................................................................................................................................... 4

4.0 Functional Description ........................................................................................................................ 4

4.1 Analog Input ......................................................................................................................... 4

4.2 ADC reference circuitry........................................................................................................5

4.3 ADC clock circuit ................................................................................................................. 5

4.4 Digital Data Output...............................................................................................................5

4.5 Data Format/ Duty Cycle Stabilizer..................................................................................... 5

4.6 Power Supply Connections ................................................................................................... 5

5.0 Installing the ADC10DV200 Evaluation Board..................................................................................5

6.0 Hardware Schematic............................................................................................................................ 6

7.0 Evaluation Board Layout..................................................................................................................... 12

8.0 Evaluation Board Bill of Materials...................................................................................................... 15

A1.0 Operating in the Computer Mode..................................................................................................... 17

A2.0 Summary Tables of Test Points, Connectors, and Jumper Settings................................................. 17

A2.1 Test Points.......................................................................................................................... 17

A2.2 Connectors.......................................................................................................................... 17

A2.3 Jumper settings................................................................................................................... 17

A2.4 Clock Circuit Solder Jumper settings................................................................................. 18

2 http://www.national.com

Page 3

1.0 Introduction

This Evaluation Board may be used to evaluate the

ADC10DV200, or ADC11DV200. The ADC is one of a

family of 10 and 11 bit converters that provides data at

rates of up to 200MHz. Further reference in this manual

to the ADC10DV200 is meant to also include the other

frequency domain plot, shows dynamic performance in

the form of SNR, SINAD, THD and SFDR. The latest

WaveVision hardware and software is available through

the National Semiconductor website:

http://www.national.com/store/view_item/index.html?nsid=

WAVEVSN+BRD+5.1

listed parts unless otherwise specified

The evaluation board is designed to be used with the

WaveVision5™ Data Capture Board which is connected

to a personal computer through a USB port and running

WaveVision5™ software, operating under Microsoft

Windows. The software can perform an FFT on the

captured data upon command and, in addition to a

JR507

+5V

J301

Channel B

Input

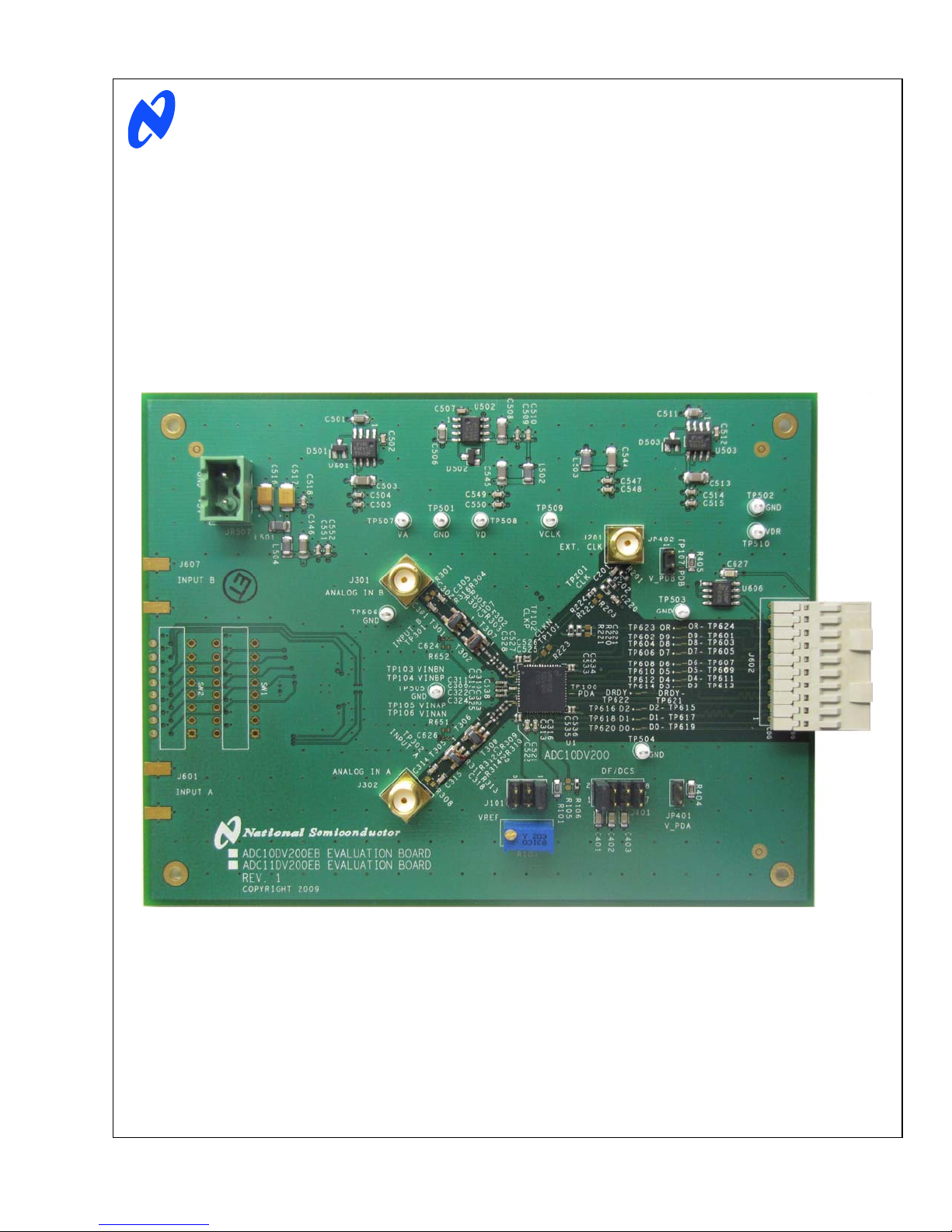

2.0 Board Assembly

The ADC10DV200 Evaluation Board comes preassembled. Refer to the Bill of Materials in Section 8 for a

description of components, to Figure 1 for major

component placement and to Section 6 for the Evaluation

Board schematic.

ADC10DV200

or

ADC11DV200

J201

CLK

JP401

PDA

WV5

Connector

3 http://www.national.com

J302

Channel A

Input

J101

VREF

J401

DF/DCS

JP401

PDA

Figure 1. Major Component and Jumper Locations

Page 4

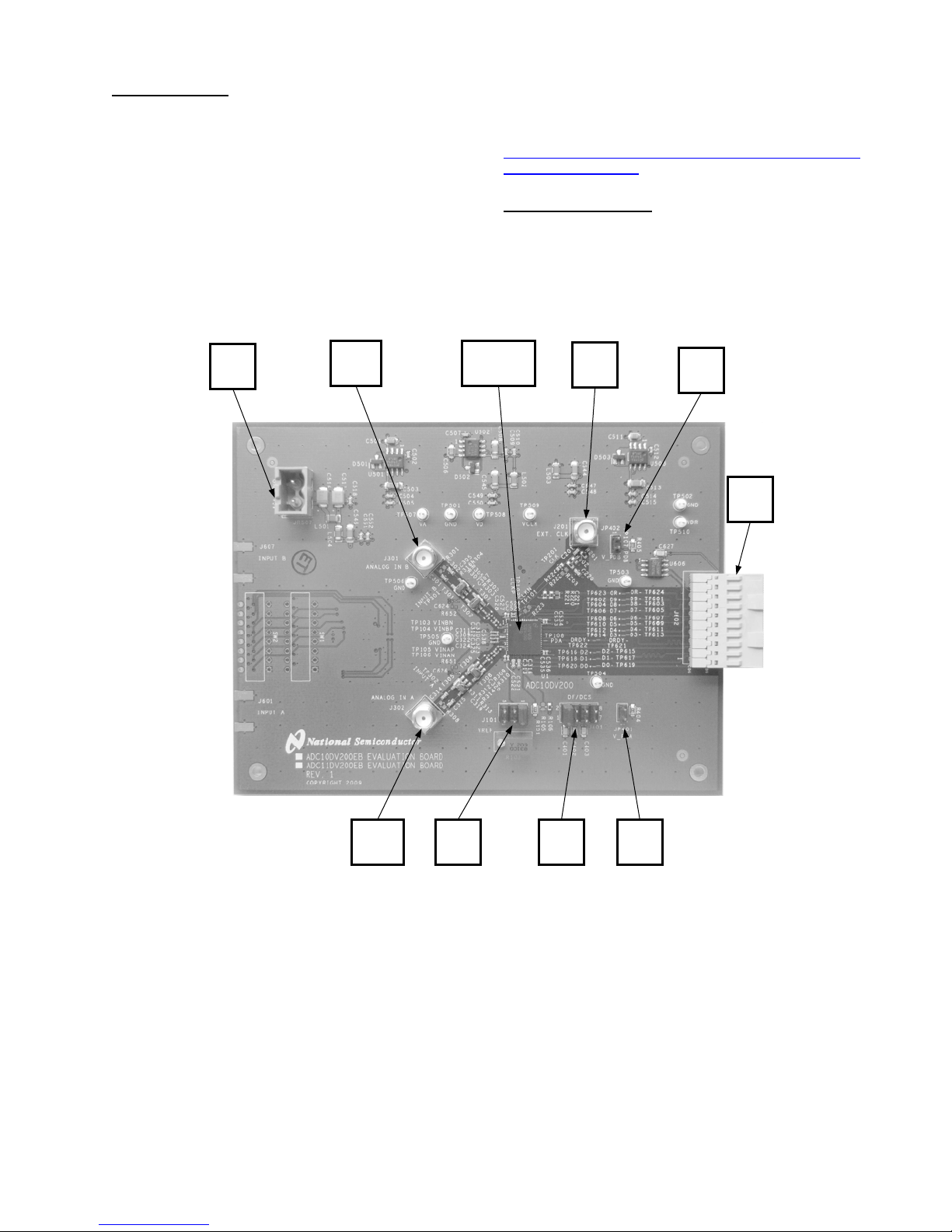

Figure 2. Test Set up

3.0 Quick Start

Refer to Figure 1 for locations of jumpers, test points and

major components. Refer to Figure 2 for the test set up.

The board is configured by default to use a external clock

source and internal reference. Refer to Section 4.0 and

the Appendix for more information on jumper settings.

The input network of this board is configured for input

frequencies greater than 70MHz. Refer to Section 4.1 for

more information about input networks.

You must have version 5.0 or later of the WaveVision™

software to properly test this board. You can download

the latest version from:

http://www.national.com/analog/adc/wavevision5

1. Apply power to the WaveVision5™ board and

connect it to the computer using a USB cable. See

the WaveVision5™ Board Manual for operation of

that board. Connect the evaluation board to the

WaveVision™ Digital Interface Board.

2. Connect a clean +5V power supply to pin 2 of Power

Connector JR507. Pin 1 is ground.

3. Connect a signal from a 50-Ohm source to

connector J301 or J302. Be sure to use a bandpass

filter before the Evaluation Board.

4. Adjust the input signal amplitude as needed to

ensure that the signal does not over-range by

examinining a histogram of the output data with the

WaveVision5™ software.

4.0 Functional Description

The ADC10DV200 Evaluation Board schematic is shown

in Section 6. A list of test points and jumper settings can

be found in the Appendix.

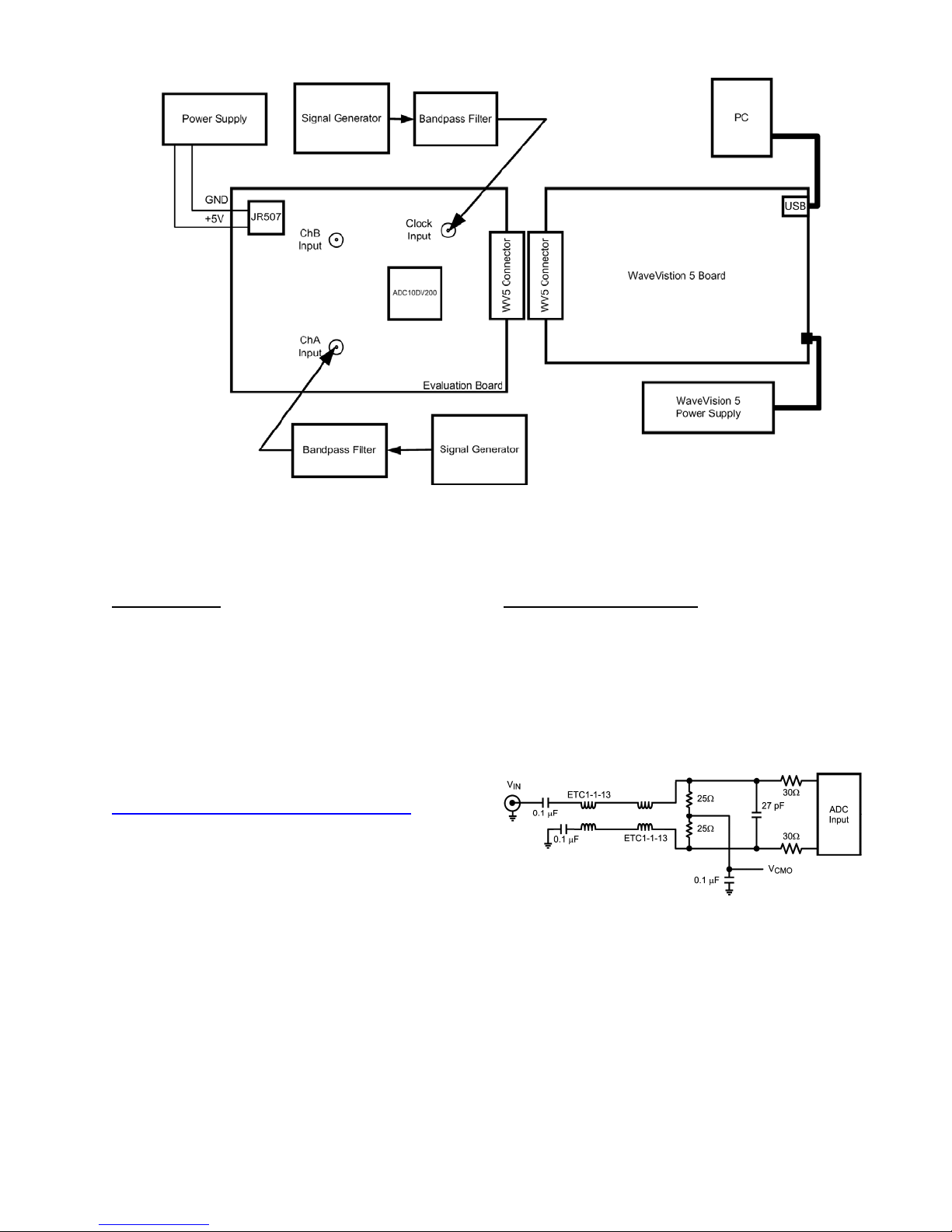

4.1 Analog Input

To obtain the best distortion results the analog input

network must be optimized for the signal frequency being

applied. The ADC10DV200 Evaluation Board comes

configured as seen in Figure 3.

Figure 3. Analog Input Network for FIN > 70MHz

The input network is intended to accept a low-noise sine

wave and will perform well over a wide input frequency

range. To accurately evaluate the dynamic performance

of this converter, the input test signal will have to be

passed through a high-quality bandpass filter.

4 http://www.national.com

Page 5

Input signals can also be amplified using an onboard

LMH6517 DVGA (U601). To use the DVGA, some

components must be installed and some removed. The

following components must be installed: R651-R656. The

following components must be removed: R302, R303,

R309, and R310. Then connect signals from a 50-Ohm

source to connectors J601 and J607.

4.2 ADC reference circuitry

The ADC10DV200 can use an internal or external voltage

reference. The internal reference is selectable between a

0.75V or 0.5V reference. External references can be set

from 0.2V to 1.4V. This Evaluation Board is configured to

use the internal 0.75V reference.

4.3 ADC clock circuit

Components can be installed or removed to select the

path of the clock to the ADC. While not as convenient as

pin-type jumpers, these introduce less distortion into the

clock signal.

Care must be taken to provide a high quality low jitter

clock source. A single ended input clock can be buffered

by U203 (NC7SV125) and applied to the ADC’s clock

input pin. Or U203 can be bypassed and the input clock

pin driven directly.

A differential clock can also be applied to the ADC’s clock

input pins through U201 (ETC-1-13).

Refer to Appendix A to configure the clock for your

application. The Evaluation Board is configured by default

to use a single ended clock to drive the input pins directly.

should be connected to the Signal Input SMA connectors

J301 or J302. When evaluating dynamic performance, an

appropriate signal generator (such as the HP8644B or the

R&S SME-03) with 50 Ohm source impedance should be

connected to the Analog Input connector through an

appropriate bandpass filter as even the best signal

generator available can not produce a signal pure enough

to evaluate the dynamic performance of an ADC.

If this board is used in conjunction with the

WaveVision5™ Data Capture Board and WaveVision5™

software, a USB must be connected between the Data

Capture Board Board and the host. See the

WaveVision5™ Data Capture Board manual for details.

4.4 Digital Data Output

The LVDS digital output data is available for probing at

test points TP601 through TP624. The signals are also

available at the WaveVision™ (WV5) connector J602.

4.5 Data Format/ Duty Cycle Stabilizer

Output data format and the duty cycle stabilizer (DCS)

are controlled by jumper J401.

Shorting pins 1-2 of J401 sets the output format to offset

binary with DCS On. This is the default setting.

Shorting pins 3-4 of J401 sets the output format to 2’s

complement with DCS Off.

Shorting pins 5-6 of J401 sets the output format to offset

binary with DCS Off.

Shorting pins 7-8 of J401 sets the output format to 2’s

complement with DCS On.

4.6 Power Supply Connections

Power to this board is supplied through power connector

J507. The only supply needed is +5V at pin 2 plus ground

at pin 1.

Voltage and current requirements for the ADC10DV200

Evaluation Board are:

+5.0V at 500 mA

5.0 Installing the ADC10DV200 Evaluation Board

The evaluation board requires power supplies as

described in Section 4.6. An appropriate signal source

5 http://www.national.com

Page 6

6 http://www.national.com

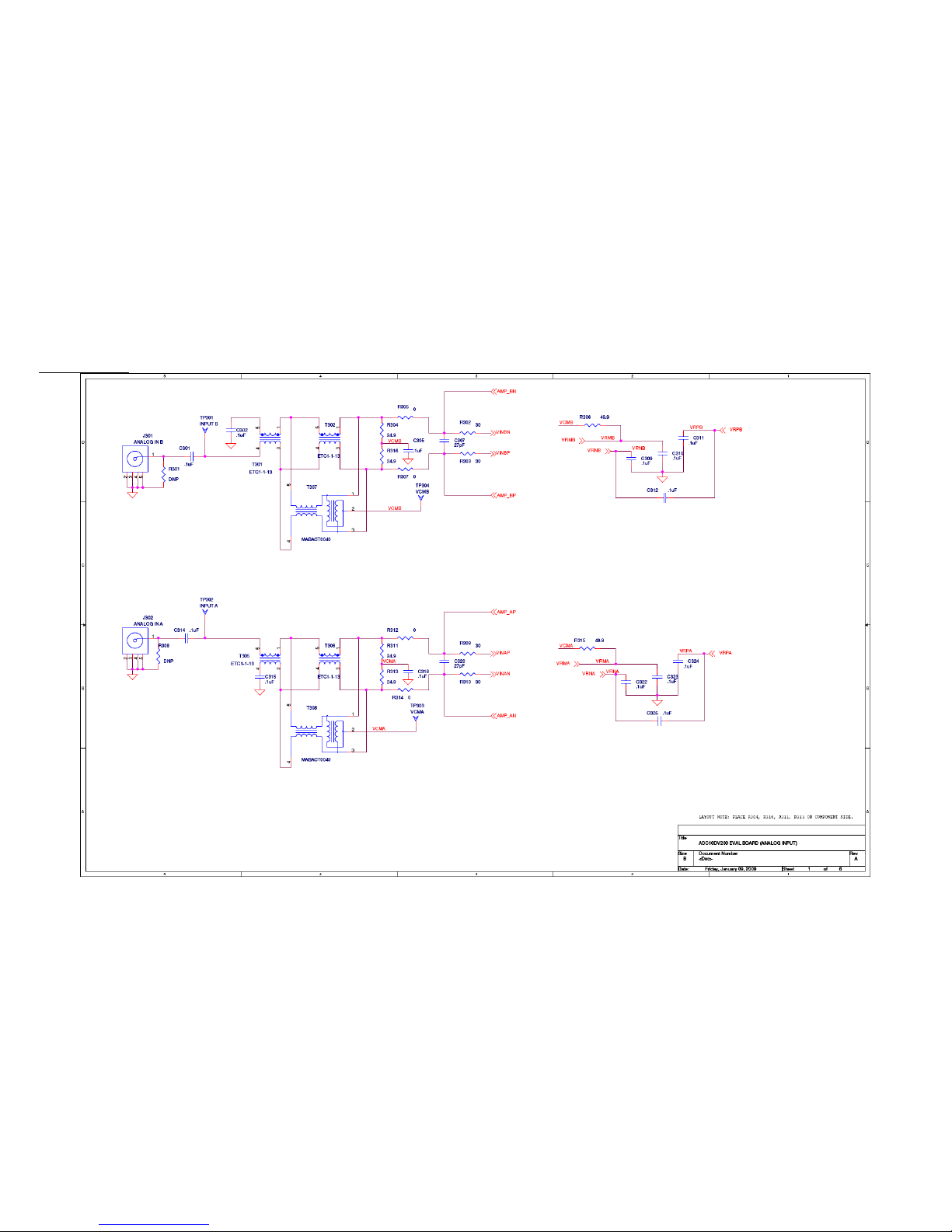

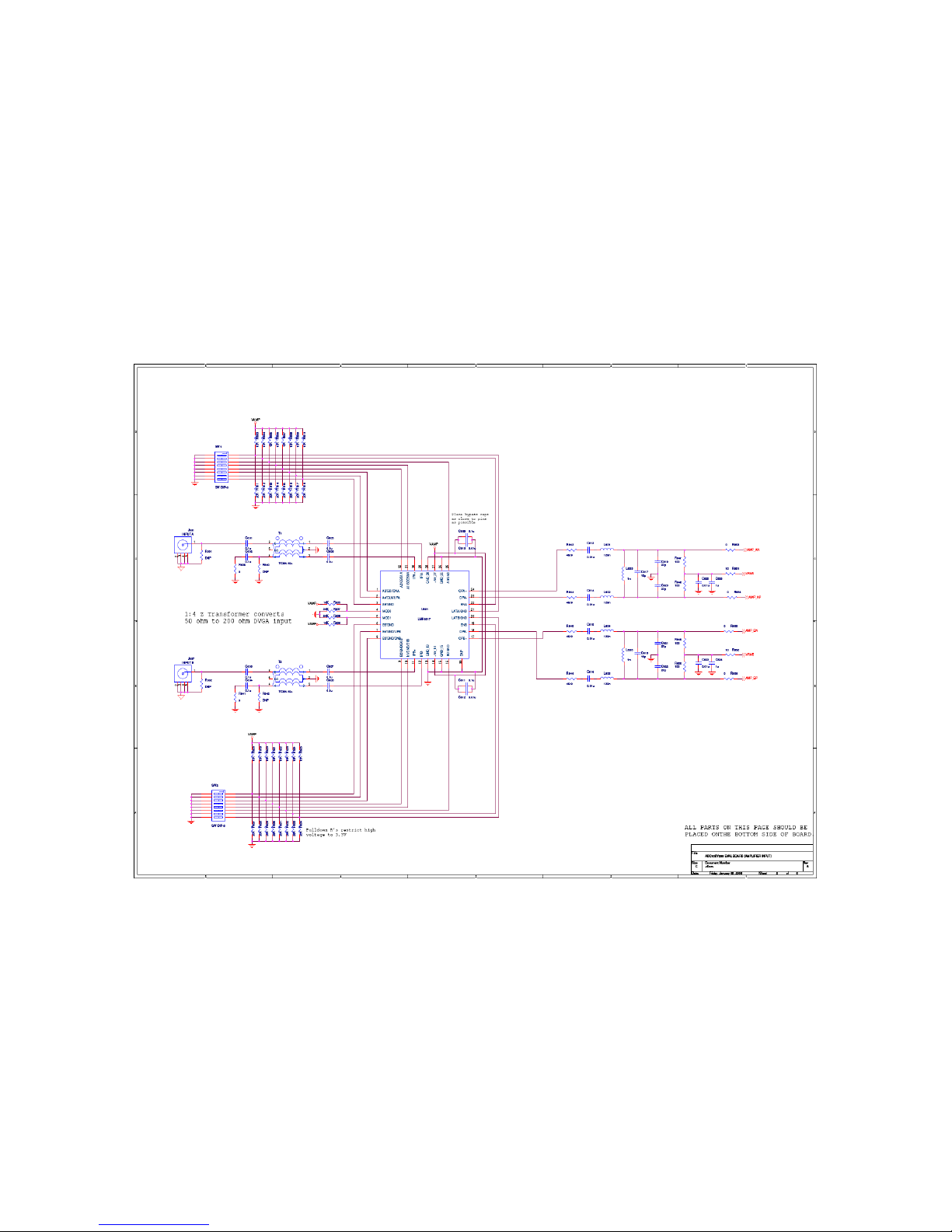

6.0 Hardware Schematic

Page 7

7 http://www.national.com

Page 8

8 http://www.national.com

Page 9

9 http://www.national.com

Page 10

10 http://www.national.com

Page 11

11 http://www.national.com

Page 12

7.0 Evaluation Board Layout

Layer 1 : Component Side

12 http://www.national.com

Layer 2 : Ground

Page 13

Layer 3 : Ground

13 http://www.national.com

Layer 4 : Power

Page 14

Layer 5 : Ground

14 http://www.national.com

Layer 6 : Circuit Side

Page 15

8.0 Evaluation Board Bill of Materials

Item Qty Reference Part Part Number Vendor

______________________________________________

1 15 C201,C220, .1uF PCC1762CT Digi-Key

C301,C302,C313,C314,

C315,C316,C504,C509,C514,

C518,C547,C549,C551

3 8 C305,C309,C311, .1uF 490-1318-1 Digi-Key

C312,C318,C322,C324,C325,

4 10 C218,C502,C505,C507,C510, .01uF PCC1784CT Digi-Key

C512,C515,C548,C550,C552

5 1 C219 1uF PCC2224CT Digi-Key

6 2 C307,C320 27pF PCC270CQCT Digi-Key

7 2 C310,C323 .1uF PCC2336CT Digi-Key

8 4 C401,C402,C403,C627 .1uF PCC1828CT Digi-Key

9 3 C501,C506,C511 4.7uF PCC1842CT Digi-Key

10 6 C503,C508,C513,C544,C545, 10uF PCC1894CT Digi-Key

C546

11 1 C516 22uF 399-3717-1 Digi-Key

12 1 C517 10uF 399-3705-1 Digi-Key

13 9 C520,C522,C524,C526,C528, .1uF PCC2146CT Digi-Key

C530,C532,C534,C536

14 10 C521,C523,C525,C527,C529, .01uF PCC2270CT Digi-Key

C531,C533,C535,C537,C538

______________________________________________

18 3 D501,D502,D503 BAT54 BAT54-FDICT Digi-Key

______________________________________________

19 1 JP204 HEADER 2 N/A

20 1 JP401 V_PDA S1011E-2

21 1 JP402 V_PDB S1011E-2

22 1 JR507 +5V 277-1150 Digi-Key

23 1 J101 VREF S2011E-3

24 1 J201 EXT. CLK ARFX1231 Digi-Key

25 1 J301 ANALOG IN B ARFX1231

26 1 J302 ANALOG IN A ARFX1231

27 1 J401 DF/DCS S2011E-4

29 1 J602 CONN 60 PIN HMZD 6469028-1 Digi-Key

31 4 L501,L502,L503,L504 10UH 490-1055-1 Digi-Key

______________________________________________

34 1 R101 3.3K 311-3.3KARCT Digi-Key

35 1 R103 20K 3296y-203LF Digi-Key

37 1 R106 10K 311-10KGRCT Digi-Key

38 1 R201 49.9 P49.9HCT Digi-Key

39 2 R202,R203 1K P1.00KHCT Digi-Key

40 6 R218,R219,R304,R311,R313, 24.9 P24.9LCT Digi-Key

R316

41 2 R220,R221 10K P10.0KHCT Digi-Key

42 2 R224,R225 0 311-0.0GRCT Digi-Key

43 4 R302,R303,R309,R310 30 311-30JRCT Digi-Key

44 4 R305,R307,R312,R314 0 311-0.0JRCT Digi-Key

45 2 R306,R315 49.9 311-49.9HRCT Digi-Key

15 http://www.national.com

Page 16

46 3 R401,R404,R405 10K 311-10KARCT Digi-Key

47 2 R402,R403 5.1K 311-5.1KARCT Digi-Key

70 6 TP501,TP502,TP503,TP504, GND 5002K Digi-Key

TP505,TP506

71 1 TP507 VA 5002K Digi-Key

72 1 TP508 VD 5002K Digi-Key

73 1 TP509 VCLK 5002K Digi-Key

74 1 TP510 VDR 5002K Digi-Key

100 4 T301,T305,T302,T306 ETC1-1-13 ETC1-1-13 Richardson

102 1 U1

104 1 U203 NC7SV125 NC7SV125P5X Mouser

105 3 U501,U502,U503 LP2989LV-1.8 LP2989AIM-1.8 Digi-Keys

107 1 U606 24C02/SO8 511-M24C02-WMN6P Mouser

DO NOT POPULATE

100 1 U201 ETC1-1-13 ETC1-1-13 Richardson

101 2 T307,T308 MABACT0040 MABACT0040 Richardson

36 3 R105,R301,R308 DNP

42 2 R222,R223 0 311-0.0GRCT Digi-Key

2 3 C213,C214,C215 DNP

3 2 C216,C217 .1uF 490-1318-1 Digi-Key

1 4 C210,C211,C212,C221 .1uF PCC1762CT Digi-Key

106 1 U601 LMH6517 LMH6517SQ National

28 1 J601 INPUT A WM5534 Digi-Key

30 1 J607 INPUT B WM5534 Digi-Key

48 4 R601,R602,R640,R642 DNP

56 2 SW1,SW2 SW DIP-8 GH7176 Digi-Key

99 2 T1,T2 TCM4-19+ TCM4-19+ Mini-Circuits

50 18 R611,R612,R613,R614,R615, 20K P20.0KLCT Digi-Key

R616,R617,R618,R627,R628,

R629,R630,R631,R632,R633,

R634,R637,R638

49 16 R603,R604,R605,R606,R607, 10K 311-10KJRCT Digi-Key

R608,R609,R610,R619,R620,

R621,R622,R623,R624,R625,

R626

51 2 R635,R636 10K 311-10.0KLCT Digi-Key

32 4 L601,L602,L604,L605 129nH 495-3433-1 Digi-Key

33 2 L603,L606 1nH

44 4 R653,R654,R655,R656 0 311-0.0JRCT Digi-Key

52 2 R639,R641 0 311-0.0JRCT Digi-Key

53 4 R643,R644,R645,R646 49.9 311-49.9LCT Digi-Key

54 4 R647,R648,R649,R650 100 311-100JCT Digi-Key

55 2 R651,R652 10 311-10JRCT Digi-Key

3 10 C601,C602,C603,C604,C605, .1uF 490-1318-1 Digi-Key

C606,C607,C608,C609,C611

15 8 C610,C612,C613,C614,C615, 0.01uF PCC103BQCT Digi-Key

C616,C623,C625

16 2 C617,C618 15pF PCC150CQCT Digi-Key

17 2 C624,C626 1uF PCC2364CT Digi-Key

6 4 C619,C620,C621,C622 27pF PCC270CQCT Digi-Key

ADC10DV200 (or

ADC11DV200)

ADC10DV200CISQ or

ADC11DV200CISQ

16 http://www.national.com

Page 17

APPENDIX

A1.0 Operating in the Computer Mode

The ADC10DV200 Evaluation Board is compatible with the WaveVision5™ Data Capture Board and WaveVision5™

software. You can download the latest version from: http://www.national.com/analog/adc/wavevision5

When connected to the WaveVision5™ Board, data capture is easily controlled from a personal computer operating in

the Windows environment. The data samples that are captured can be observed on the PC video monitor in the time and

frequency domains. The FFT analysis of the captured data yields insight into system noise and distortion sources and

estimates of ADC dynamic performance such as SINAD, SNR and THD.

A2.0 Summary Tables of Test Points, Connectors, and Jumper Settings

A2.1 Test Points

Test Points on the ADC10DV200 Evaluation Board

Voltage Signal Name Measure at Nominal Voltage (V) Voltage Limits (V)

VA TP507 1.8 1.7 to 1.9

VD TP508 1.8 1.7 to 1.9

VDR TP510 1.8 1.7 to 1.9

VCLK TP509 1.8 1.7 to 1.9

A2.2 Connectors

JR507 Connector - Power Supply Connections

1 GND Power Supply Ground

2 +5V +5V Power Supply

A2.3 Jumper settings

Note: Default settings are in bold

JP401 : Power Down Chan nel A

Connect 1-2 Channel A is in power down mode

1-2 OPEN Channel A is in normal operation

JP402 : Power Down Channel B

Connect 1-2 Channel B is in power down mode

1-2 OPEN Channel B is in normal operation

J401 : Output Data Format and Duty Cycle Stabilizer

Connect 1-2

Connect 3-4

Connect 5-6

Connect 7-8

Output format is offset binary, DCS is On

Output format is 2’s complement, DCS is Off

Output format is offset binary, DCS is Off

Output format is 2’s complement, DCS is On

17 http://www.national.com

Page 18

A2.4 Clock Circuit Solder Jumper settings

Components can be installed or removed to select the path of the clock to the ADC. While not as convenient as pin-type

jumpers, these introduce less distortion into the clock signal.

Termination A: Differential Sinusoid Install C210, C216, and C217

Remove R223, R224, R225, and JP204

Termination B: Single Ended Sinusoid Install R222 and R223

Remove C210, C216, C217, R224, R225 and JP204

Termination C: Single Ended Square Install R223, R224, R225, and JP204

Remove C210, C216, C217, and R222

18 http://www.national.com

Page 19

BY USING THIS PRODUCT, YOU ARE AGREEING TO BE BOUND BY THE TERMS AND CONDITIONS OF NATIONAL

SEMICONDUCTOR'S END USER LICENSE AGREEMENT. DO NOT USE THIS PRODUCT UNTIL YOU HAVE READ AND AGREED

TO THE TERMS AND CONDITIONS OF THAT AGREEMENT. IF YOU DO NOT AGREE WITH THEM, CONTACT THE VENDOR

WITHIN TEN (10) DAYS OF RECEIPT FOR INSTRUCTIONS ON RETURN OF THE UNUSED PRODUCT FOR A REFUND OF THE

PURCHASE PRICE PAID, IF ANY.

The ADC10DV200 Evaluation Boards are intended for product evaluation purposes only and are not intended for resale to end

consumers, is not authorized for such use and is not designed for compliance with European EMC Directive 89/336/EEC, or for

compliance with any other electromagnetic compatibility requirements.

National Semiconductor Corporation does not assume any responsibility for use of any circuitry or software supplied or described. No

circuit patent licenses are implied.

LIFE SUPPORT POLICY

NATIONAL'S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT DEVICES OR

SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT OF NATIONAL SEMICONDUCTOR

CORPORATION. As used herein:

1. Life support devices or systems are devices or systems

which, (a) are intended for surgical implant into the body,

or (b) support or sustain life, and whose failure to perform,

when properly used in accordance with instructions for use

provided in the labeling, can be reasonably expected to

result in a significant injury to the user.

National Semiconductor Corporation

Americas

Tel: 1-800-272-9959

Fax: 1-800-737-7018

Email: support@nsc.com

www.national.com

National does not assume any responsibility for any circuitry described, no circuit patent licenses are implied and National reserves the right at any time

without notice to change said circuitry and specifications.

19 http://www.national.com

National Semiconductor Europe

Fax: +49 (0) 1 80-530 85 86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 699508 6208

English Tel: +49 (0) 870 24 0 2171

Français Tel: +49 (0) 141 91 8790

2. A critical component is any component in a life support

device or system whose failure to perform can be

reasonably expected to cause the failure of the life support

device or system, or to affect its safety or effectiveness.

National Semiconductor

Asia Pacific Customer

Response Group

Tel: 65-2544466

Fax: 65-2504466

Email:sea.support@nsc.com

National Semiconductor

Japan Ltd.

Tel: 81-3-5639-7560

Fax: 81-3-5639-7507

Page 20

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, modifications, enhancements, improvements,

and other changes to its products and services at any time and to discontinue any product or service without notice. Customers should

obtain the latest relevant information before placing orders and should verify that such information is current and complete. All products are

sold subject to TI’s terms and conditions of sale supplied at the time of order acknowledgment.

TI warrants performance of its hardware products to the specifications applicable at the time of sale in accordance with TI’s standard

warranty. Testing and other quality control techniques are used to the extent TI deems necessary to support this warranty. Except where

mandated by government requirements, testing of all parameters of each product is not necessarily performed.

TI assumes no liability for applications assistance or customer product design. Customers are responsible for their products and

applications using TI components. To minimize the risks associated with customer products and applications, customers should provide

adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any TI patent right, copyright, mask work right,

or other TI intellectual property right relating to any combination, machine, or process in which TI products or services are used. Information

published by TI regarding third-party products or services does not constitute a license from TI to use such products or services or a

warranty or endorsement thereof. Use of such information may require a license from a third party under the patents or other intellectual

property of the third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of TI information in TI data books or data sheets is permissible only if reproduction is without alteration and is accompanied

by all associated warranties, conditions, limitations, and notices. Reproduction of this information with alteration is an unfair and deceptive

business practice. TI is not responsible or liable for such altered documentation. Information of third parties may be subject to additional

restrictions.

Resale of TI products or services with statements different from or beyond the parameters stated by TI for that product or service voids all

express and any implied warranties for the associated TI product or service and is an unfair and deceptive business practice. TI is not

responsible or liable for any such statements.

TI products are not authorized for use in safety-critical applications (such as life support) where a failure of the TI product would reasonably

be expected to cause severe personal injury or death, unless officers of the parties have executed an agreement specifically governing

such use. Buyers represent that they have all necessary expertise in the safety and regulatory ramifications of their applications, and

acknowledge and agree that they are solely responsible for all legal, regulatory and safety-related requirements concerning their products

and any use of TI products in such safety-critical applications, notwithstanding any applications-related information or support that may be

provided by TI. Further, Buyers must fully indemnify TI and its representatives against any damages arising out of the use of TI products in

such safety-critical applications.

TI products are neither designed nor intended for use in military/aerospace applications or environments unless the TI products are

specifically designated by TI as military-grade or "enhanced plastic." Only products designated by TI as military-grade meet military

specifications. Buyers acknowledge and agree that any such use of TI products which TI has not designated as military-grade is solely at

the Buyer's risk, and that they are solely responsible for compliance with all legal and regulatory requirements in connection with such use.

TI products are neither designed nor intended for use in automotive applications or environments unless the specific TI products are

designated by TI as compliant with ISO/TS 16949 requirements. Buyers acknowledge and agree that, if they use any non-designated

products in automotive applications, TI will not be responsible for any failure to meet such requirements.

Following are URLs where you can obtain information on other Texas Instruments products and application solutions:

Products Applications

Audio www.ti.com/audio Automotive and Transportation www.ti.com/automotive

Amplifiers amplifier.ti.com Communications and Telecom www.ti.com/communications

Data Converters dataconverter.ti.com Computers and Peripherals www.ti.com/computers

DLP® Products www.dlp.com Consumer Electronics www.ti.com/consumer-apps

DSP dsp.ti.com Energy and Lighting www.ti.com/energy

Clocks and Timers www.ti.com/clocks Industrial www.ti.com/industrial

Interface interface.ti.com Medical www.ti.com/medical

Logic logic.ti.com Security www.ti.com/security

Power Mgmt power.ti.com Space, Avionics and Defense www.ti.com/space-avionics-defense

Microcontrollers microcontroller.ti.com Video and Imaging www.ti.com/video

RFID www.ti-rfid.com

OMAP Mobile Processors www.ti.com/omap

Wireless Connectivity www.ti.com/wirelessconnectivity

TI E2E Community Home Page e2e.ti.com

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2012, Texas Instruments Incorporated

Page 21

Mouser Electronics

Authorized Distributor

Click to View Pricing, Inventory, Delivery & Lifecycle Information:

Texas Instruments:

ADC10DV200EB/NOPB

Loading...

Loading...