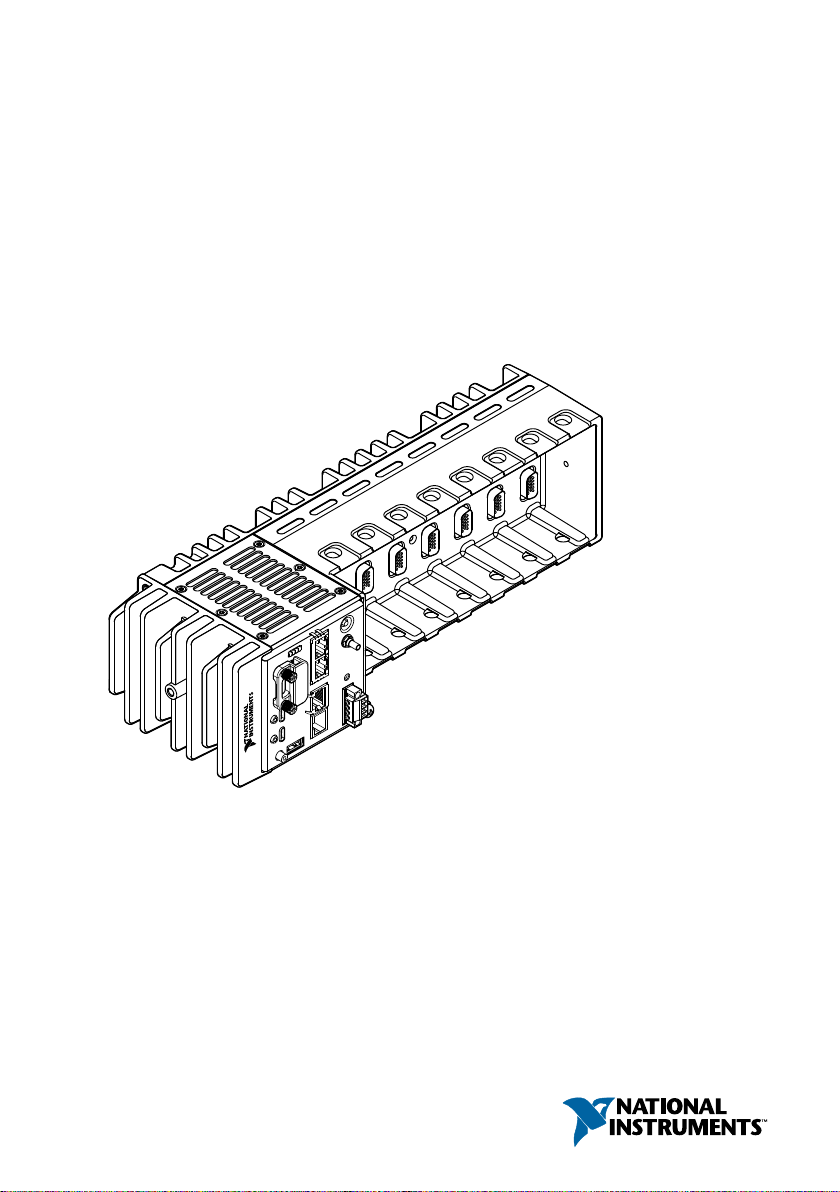

Page 1

USER MANUAL

cRIO-904x

Embedded CompactRIO Controller with Real-Time Processor and

Reconfigurable FPGA

This document describes the features of the cRIO-904x and contains information about

mounting and operating the device.

In this document, the cRIO-9040, cRIO-9041, cRIO-9042, cRIO-9043, cRIO-9045,

cRIO-9046, cRIO-9047, cRIO-9048, and cRIO-9049 are referred to collectively as cRIO-904x.

Page 2

Contents

Configuring the cRIO-904x...................................................................................................... 3

Connecting the cRIO-904x to the Host Computer Using USB........................................ 3

Connecting the cRIO-904x to the Host Computer or Network Using Ethernet............... 4

Configuring Startup Options.............................................................................................4

cRIO-904x Features.................................................................................................................. 6

Ports and Connectors........................................................................................................ 6

Buttons............................................................................................................................ 12

LEDs............................................................................................................................... 14

Chassis Grounding Screw............................................................................................... 18

Internal Real-Time Clock................................................................................................18

Digital Routing................................................................................................................19

Clock Routing................................................................................................................. 19

Synchronization Across a Network.................................................................................20

CMOS Battery.................................................................................................................22

Installing the Module Immobilization Accessory...................................................................22

Module Immobilization Accessory Dimensions.............................................................24

Mounting the Controller..........................................................................................................25

Alternate Mounting Configurations................................................................................ 27

Mounting Requirements for the cRIO-904x................................................................... 27

Dimensions......................................................................................................................28

Mounting on a Flat Surface.............................................................................................29

Mounting on a Panel ...................................................................................................... 32

Mounting on a DIN Rail ................................................................................................ 34

Mounting on a Rack........................................................................................................37

Mounting on a Desktop ..................................................................................................37

BIOS Configuration................................................................................................................ 40

Resetting the System CMOS and BIOS Settings............................................................40

Power-On Self Test Warning Messages.......................................................................... 40

BIOS Setup Utility.......................................................................................................... 41

Main Setup Menu............................................................................................................42

Advanced Setup Menu.................................................................................................... 42

Boot Setup Menu............................................................................................................ 44

Save & Exit Menu...........................................................................................................45

Choosing Your Programming Mode....................................................................................... 46

Analog Input with NI-DAQmx....................................................................................... 47

Analog Output with NI-DAQmx.................................................................................... 54

Digital Input/Output with NI-DAQmx........................................................................... 59

PFI with NI-DAQmx...................................................................................................... 71

Counters with NI-DAQmx..............................................................................................73

Counter Input Applications.............................................................................................77

Counter Output Applications.......................................................................................... 97

Counter Timing Signals................................................................................................ 105

Worldwide Support and Services.......................................................................................... 110

2 | ni.com | cRIO-904x User Manual

Page 3

Configuring the cRIO-904x

You can connect the cRIO-904x to a host computer or network and configure the startup

options using the Dual Role USB C port or the RJ-45 Gigabit Ethernet port 0 or port 1.

Tip Refer to the cRIO-904x Getting Started Guide for basic configuration

instructions and information about connecting to a host computer using the Dual

Role USB C port. NI recommends using the Dual Role USB C port for

configuration, debug, and maintenance.

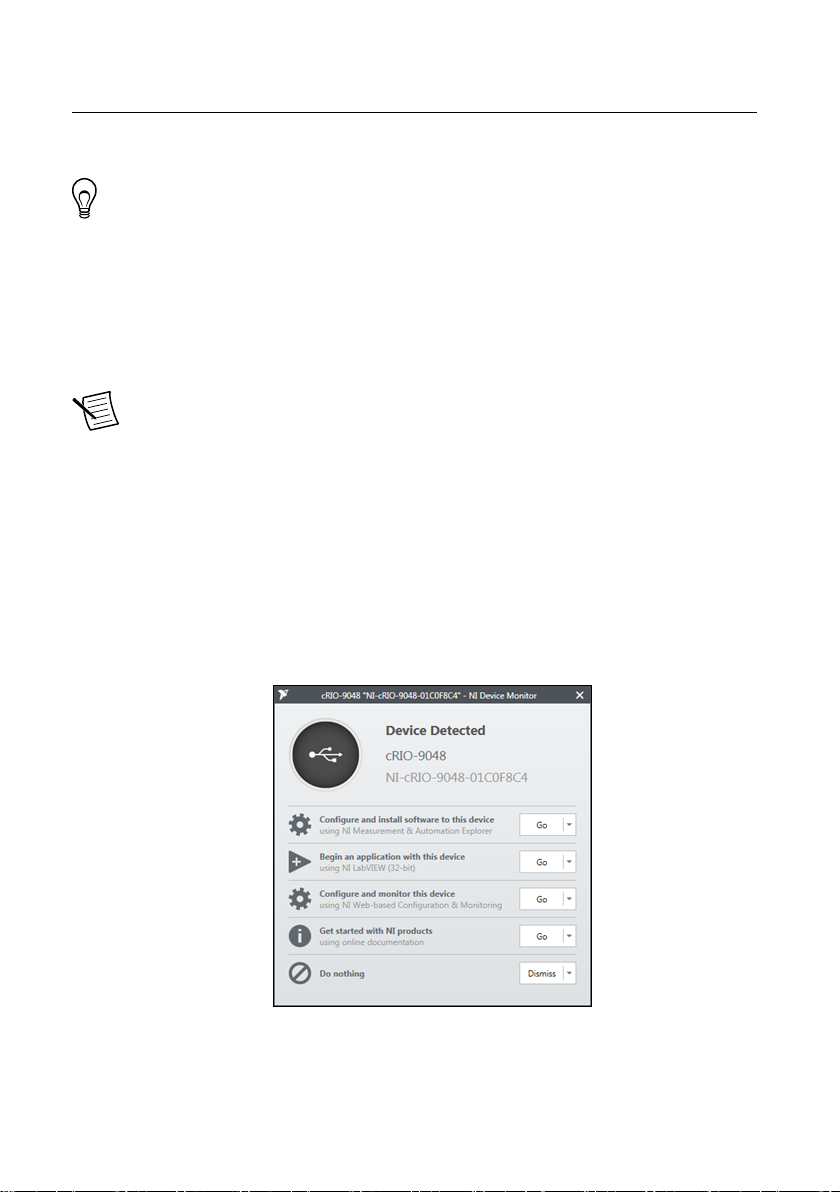

Connecting the cRIO-904x to the Host Computer Using USB

Connect your cRIO-904x to your host computer.

Note Refer to Ports and Connectors for connector and port locations.

Complete the following steps to connect the cRIO-904x to the host computer using the Dual

Role USB C Port.

1. Power on the host computer.

2. Connect the cRIO-904x to the host computer using the USB-to-Type-A cable (included in

kit), inserting the USB Type-C connector into the Dual Role USB Type-C port. Connect

the other end of the USB cable (Type-A) to the host computer.

The device driver software automatically detects the cRIO-904x. Select Configure and

install software to this device.

If the device driver software does not detect the cRIO-904x, verify that you installed the

appropriate NI software in the correct order on the host computer as described in

"Installing Software on the Host Computer" in the cRIO-904x Getting Started Guide.

cRIO-904x User Manual | © National Instruments | 3

Page 4

Connecting the cRIO-904x to the Host Computer or Network Using Ethernet

Complete the following steps to connect the cRIO-904x to a host computer or Ethernet

network using the RJ-45 Gigabit Ethernet port 0. NI recommends using the RJ-45 Gigabit

Ethernet port 0 for communication with deployed systems.

Note You can configure the RJ-45 Gigabit Ethernet port 1 in Measurement &

Automation Explorer (MAX) under the Network Settings tab.

1. Power on the host computer or Ethernet hub.

2. Connect the RJ-45 Gigabit Ethernet port 0 on the cRIO-904x to the host computer or

Ethernet hub using a standard Category 5 (CAT-5) or better shielded, twisted-pair

Ethernet cable.

Notice To prevent data loss and to maintain the integrity of your Ethernet

installation, do not use a cable longer than 100 m (328 ft).

The cRIO-904x attempts to initiate a DHCP network connection the first time you

connect using Ethernet. The cRIO-904x connects to the network with a link-local IP

address with the form 169.254.x.x if it is unable to initiate a DHCP connection.

Finding the cRIO-904x on the Network (DHCP)

Complete the following steps to find the cRIO-904x on a network using DHCP.

1. Disable secondary network interfaces on the host computer, such as a wireless access

card on a laptop.

2. Ensure that any anti-virus and firewall software running on the host computer allows

connections to the host computer.

Note MAX uses UDP on port 44525. Refer to the documentation of your

firewall software for information about configuring the firewall to allow

communication through this port.

3. Launch MAX on the host computer.

4. Expand Remote Systems in the configuration tree and locate your system.

Tip MAX lists the system under the model number followed by the serial

number, such as NI-cRIO-904x-1856AAA.

Tip If you do not see the cRIO-904x under Remote Systems, use the

Troubleshoot Remote System Discovery utility to walk through

troubleshooting steps.

Configuring Startup Options

Complete the following steps to configure the cRIO-904x startup options in MAX.

1. In MAX, expand your system under Remote Systems.

2. Select the Startup Settings tab to configure the startup settings.

4 | ni.com | cRIO-904x User Manual

Page 5

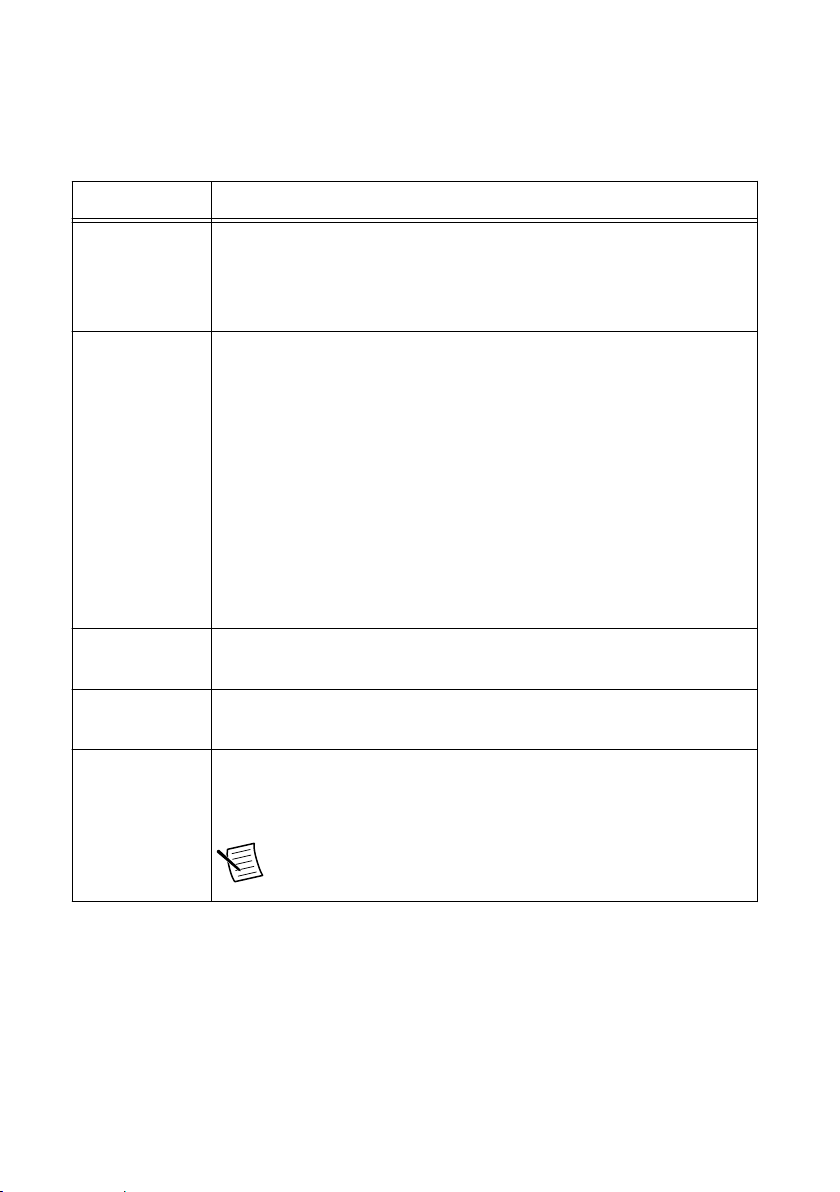

cRIO-904x Startup Options

You can configure the following cRIO-904x startup options.

Table 1. cRIO-904x Startup Options

Startup Option Description

Force Safe Mode Rebooting the cRIO-904x with this setting on starts the cRIO-904x

without launching LabVIEW Real-Time or any startup applications. In

safe mode, the cRIO-904x launches only the services necessary for

updating configuration and installing software.

Enable Console

Out

Disable RT

Startup App

Disable FPGA

Startup App

Enable Secure

Shell (SSH)

Logins

Rebooting the cRIO-904x with this setting on redirects the console output

to the RS-232 serial port. You can use a serial-port terminal program to

read the IP address and firmware version of the cRIO-904x. Use a nullmodem cable to connect the RS-232 serial port to a computer. Make sure

that the serial-port terminal program is configured to the following

settings:

• 115,200 bits per second

• Eight data bits

• No parity

• One stop bit

• No flow control

Rebooting the cRIO-904x with this setting on prevents any LabVIEW

startup applications from running.

Rebooting the cRIO-904x with this setting on prevents autoloading of any

FPGA application.

Rebooting the cRIO-904x with this setting on starts sshd on the

cRIO-904x. Starting sshd enables logins over SSH, an encrypted

communication protocol.

Note Visit ni.com/info and enter the Info Code openssh for

more information about SSH.

cRIO-904x User Manual | © National Instruments | 5

Page 6

Table 1. cRIO-904x Startup Options (Continued)

Startup Option Description

LabVIEW

Project Access

Enable

Embedded UI

Rebooting the cRIO-904x with this setting on enables you to add the

target to a LabVIEW project.

Rebooting the cRIO-904x with this setting on enables the embedded UI,

which allows you to interact with the front panels of VIs running on the

cRIO-904x using input and display devices connected directly to the

cRIO-904x. You can also browse and edit files on the cRIO-904x within a

graphical working environment. For more information, refer to the Using

the Embedded UI to Access RT Target VIs topic in the LabVIEW Help.

cRIO-904x Features

The cRIO-904x provides the following features.

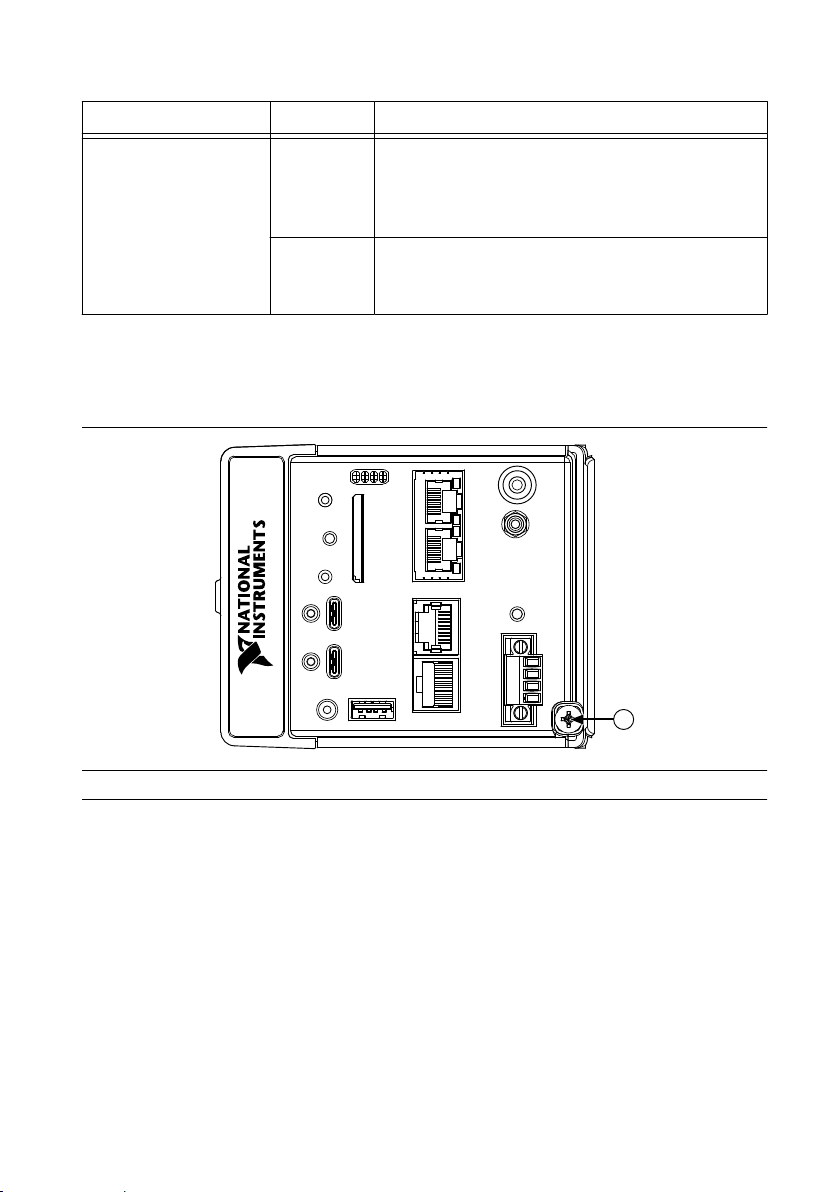

Ports and Connectors

The cRIO-904x provides the following ports and connectors.

6 | ni.com | cRIO-904x User Manual

Page 7

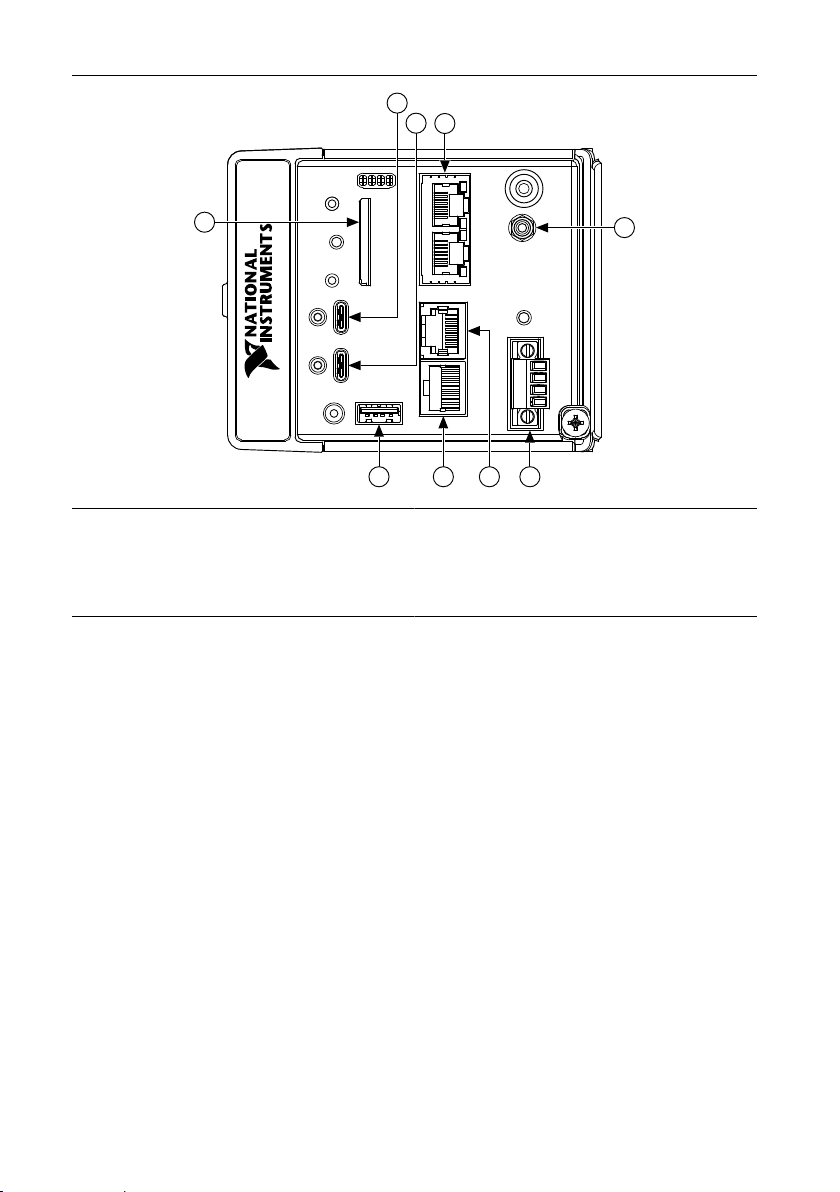

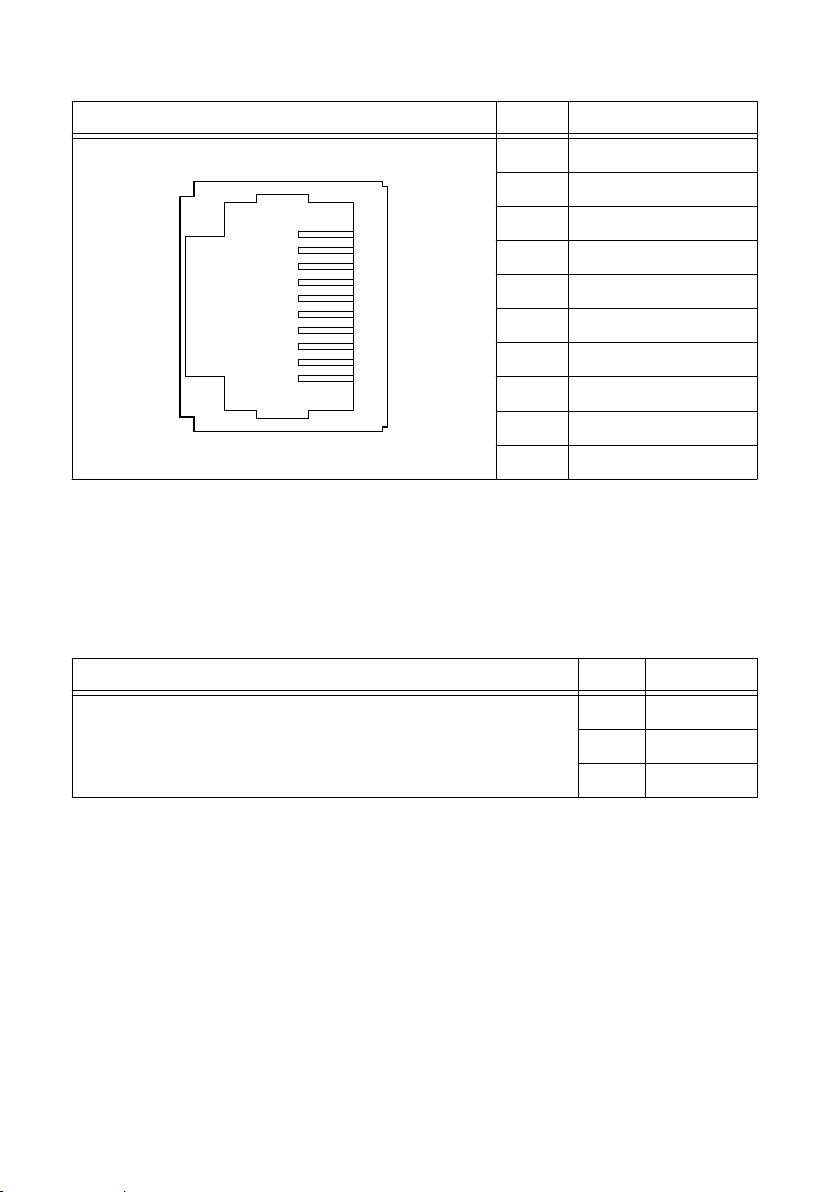

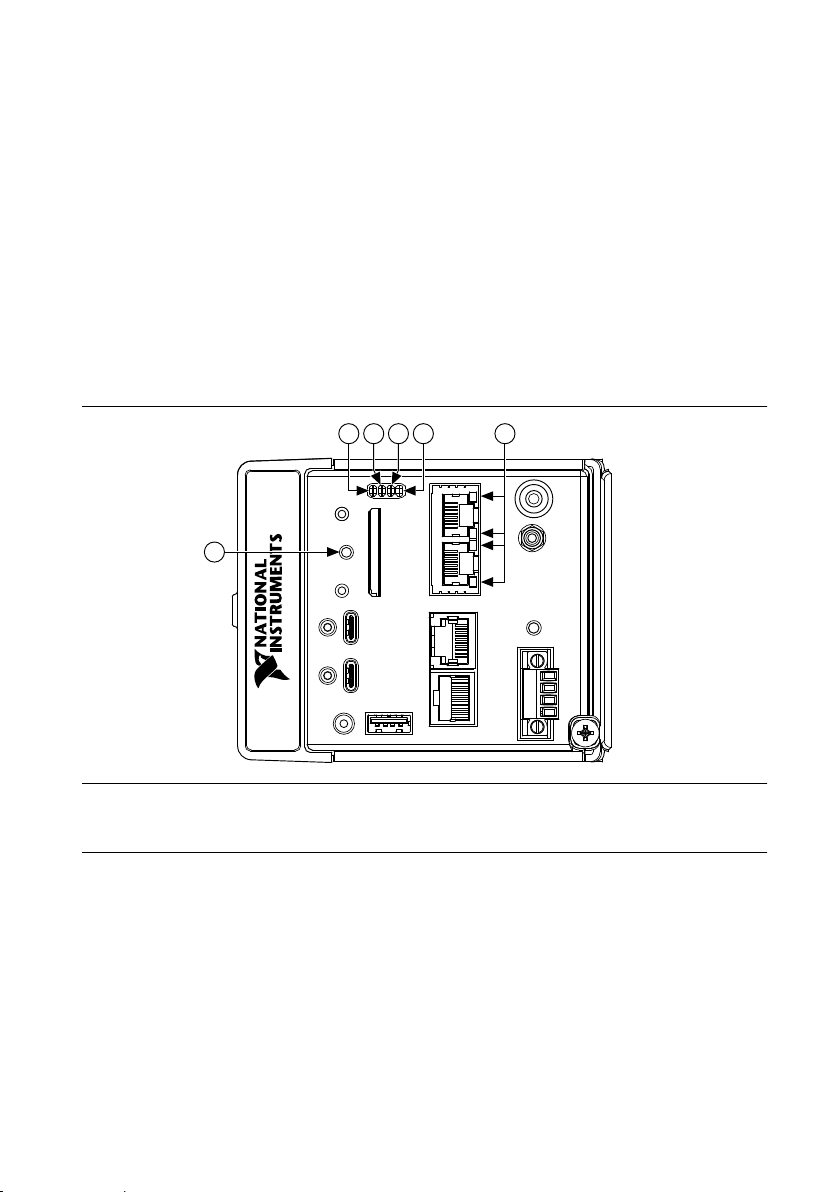

Figure 1. cRIO-904x Ports and Connectors

9

1

2

3

4

5

6

7

8

1. USB 3.1 Type-C Dual Role

2. USB 3.1 Type-C with DisplayPort Alt Mode

3. RJ-45 Gigabit Ethernet Ports

4. PFI 0

5. Power Connector

6. RS-232 Serial Port

7. RS-485 Serial Port

8. USB 2.0 Type-A

9. SD Card Removable Storage

USB 3.1 Type-C Dual Role

The USB 3.1 Type-C Dual Role port implements dual role functionality and is capable of

functioning as either a USB 3.1 Gen1 host or device. When operating as a host, the port

supports common USB devices such as mass-storage devices, keyboards, mice, and USB

cameras. When operating a device, use this port to connect the cRIO-904x to a host PC. The

USB device functionality provides an alternate method to connect the cRIO-904x to a host PC

and is intended for configuration, application deployment, debugging, and maintenance. The

role of the port is determined automatically based on the cable inserted into the port. For

example, the port will automatically function as a device when the cRIO-904x is connected to

a host PC using the NI USB Type-C male to Type-A male cable provided in the kit.

USB 3.1 Type-C with DisplayPort Alt Mode

The USB 3.1 Type-C with DisplayPort Alt Mode port implements both a USB 3.1 Gen1 host

and a DisplayPort 1.2 source using the USB Type-C DisplayPort alternate mode. Use a USB

Type-C video adapter or monitor supporting the DisplayPort alternate mode to use this port as

a display output. Alternatively, this port may be used as a standard USB host port and supports

common USB devices such as mass-storage devices, keyboards, mice, and USB cameras. Use

a USB Type-C male to USB Type-A female adapter to use this port with USB devices

cRIO-904x User Manual | © National Instruments | 7

Page 8

implementing a type-A male connector. Use a USB Type-C multiport adapter to

simultaneously use this port as a display output and a USB host port.

The following NI USB Type-C adapters are available for the cRIO-904x.

Table 2. NI USB Type-C Adapters for cRIO-904x

Adapter Length Part Number

USB to DVI Adapter with Retention, USB Type-C Male to DVI-D

0.5 m 143558-0R5

Female

USB to VGA Adapter with Retention, USB Type-C Male to VGA

0.5 m 143557-0R5

Female

USB Cable with Retention, Type-C Male to Type-A Female, USB

0.5 m 143555-0R5

3.1, 3A

The following NI USB Type-C cables with retention are available for the cRIO-904x.

Table 3. NI USB Type-C Cables for cRIO-904x

Cable Length Part Number

USB Cable with Retention, Type-C Male to Type-C Male, USB 3.1,3A0.3 m 143556-0R3

1 m 143556-01

1 m 143556-02

PFI 0

The Programmable Function Interface (PFI) terminal is a SMB connector.

Table 4. Signal Descriptions

Signal Reference Description

PFI 0 — Programmable Function Interface—You can configure the PFI terminal

as a timing input or timing output signal for AI, AO, DI, DO, or

counter/timer functions.

Note The PFI 0 terminal can only be programmed with NI-DAQmx.

Power Connector

The cRIO-904x has a power connector to which you can connect a primary and secondary

power supply. The following table shows the pinout for the power connector.

8 | ni.com | cRIO-904x User Manual

Page 9

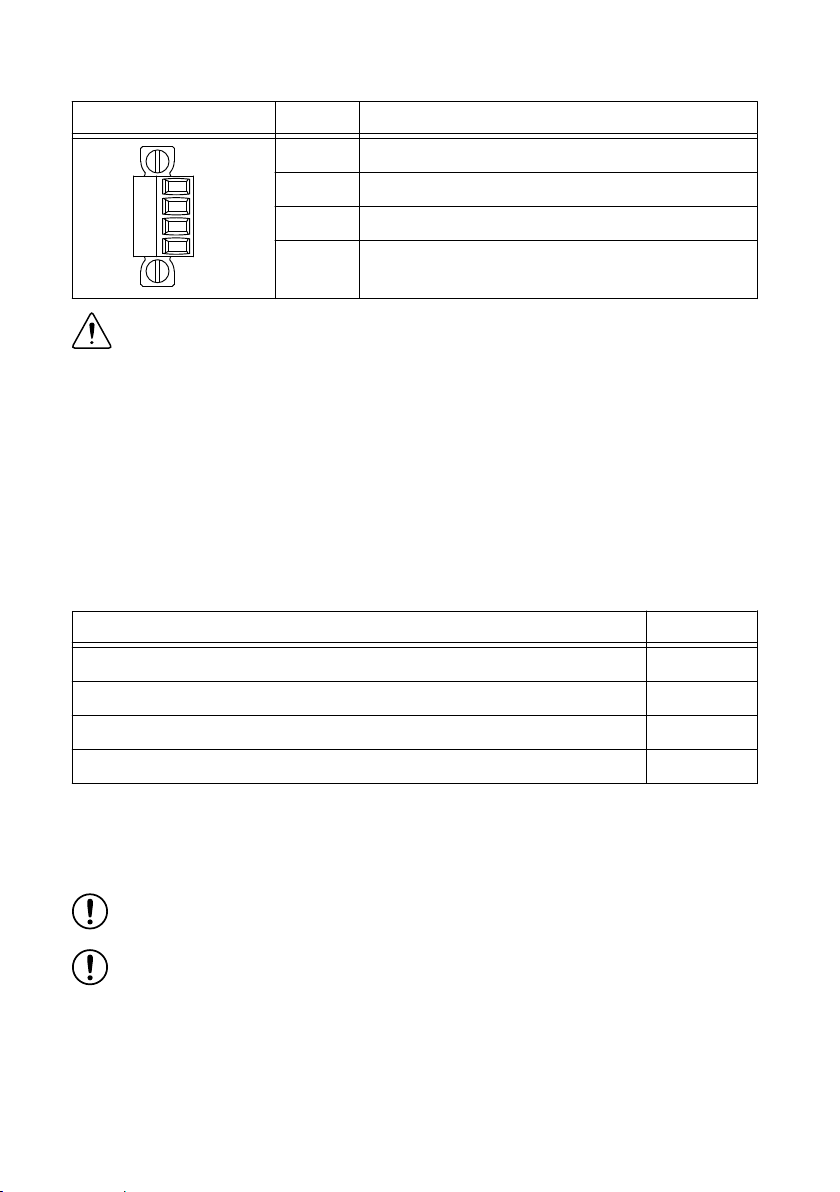

Table 5. Power Connector Pinout

V1

C

V2

C

Pinout Pin Description

V1 Primary power input

C Common

V2 Secondary power input

C Common

Caution The C terminals are internally connected to each other, but are

functionally isolated from chassis ground. This isolation is intended to prevent

ground loops, but does not meet IEC 61010-1 for safety isolation. You can connect

the C terminals to chassis ground externally. Refer to the specifications on ni.com/

manuals for information about the power supply input range and maximum voltage

from terminal to chassis ground.

If you apply power to both the V1 and V2 inputs, the cRIO-904

x operates from the V1 input.

If the input voltage to V1 is insufficient, the cRIO-904x operates from the V2 input.

The cRIO-904x has reverse-voltage protection.

The following NI power supplies and accessories are available for the cRIO-904x.

Table 6. Power Accessories

Accessory Part Number

NI PS-15 Power Supply, 24 VDC, 5 A, 100-120/200-240 VAC Input 781093-01

NI PS-10 Desktop Power Supply, 24 VDC, 5 A, 100-120/200-240 VAC Input 782698-01

4-Position Gold Power Supply Plugs (Quantity 5) 783529-01

NI 9979 Strain Relief for 4-Position Power Connector 196939-01

SD Card Removable Storage

The cRIO-904x provides an SD card slot that can read from and write to SD cards. The slot

supports SD card interface speeds up to UHS-I DDR50.

Notice Using SD cards that are not approved by NI might invalidate specifications

and result in unreliable performance.

Notice Full and high-speed SD cards are prohibited for use with the cRIO-904x.

The following accessories are available from the SD card slot.

cRIO-904x User Manual | © National Instruments | 9

Page 10

Table 7. cRIO-904x SD Storage Accessories

SD Card Capacity Part Number

Industrial SD Card, -40 to 85 °C, UHS-I 16 GB 786362-01

32 GB 786363-01

SD Door (x3) - 786218-01

SD Card Slot Cover

You must use the SD card slot cover to protect the SD card in hazardous locations. Do not

remove an SD card while either LED is flashing or lit because file corruption may result.

Note Screw the slot cover closed completely. Tighten the captive screws to a

maximum torque of 0.75 N · m (6.7 lb · in.) using a #1 Phillips screwdriver. Do not

overtighten.

RS-232 Serial Port

The cRIO-904x has an RS-232 serial port that is implemented with an RJ-50, 10-position

modular jack to which you can connect devices such as displays or input devices. Use the

Serial VIs to read from and write to the serial port. Refer to the LabVIEW Help for information

about the Serial VIs.

Find examples on how to use NI-Serial or NI-VISA to perform serial communication in the

NI Example Finder. The NI Example Finder is located on the Help menu in the LabVIEW

Help.

Note The RS-232 serial port cannot be accessed by the user application when the

Console Out startup option is enabled.

The following table shows the pinout for the RS-232 serial port.

10 | ni.com | cRIO-904x User Manual

Page 11

Table 8. RS-232 Serial Port Pinout

3

4

5

6

7

8

9

10

1

2

Pinout Pin Signal

1 No Connect

2 RI

3 CTS

4 RTS

5 DSR

6 GND

7 DTR

8 TXD

9 RXD

10 DCD

You can use the Ring Indicator (RI) on pin 2 to wake the controller from a low-power state.

You can drive RI with a logic level high to wake the cRIO-904x. Refer to the specifications on

ni.com/manuals for the RI wake voltage.

The following accessories are available to connect the RS-232 serial port to a 9-pin DSUB

plug.

Table 9. RS-232 Serial Port Accessories

Accessory Length Part Number

RS-232, S8 Serial Cable, 10-Position Modular Plug to 9-Pin DSUB 1 m 182845-01

2 m 182845-02

3 m 182845-03

RS-485 Serial Port

The cRIO-904x has an RS-485 serial port that is implemented with an RJ-50, 10-position

modular jack. The RJ-50 connector is isolated from the cRIO-904x. For more information

about the electrical isolation of the RS-485 port, refer to the specifications on ni.com/manuals.

Find examples on how to use NI-Serial or NI-VISA to perform serial communication in the

NI Example Finder. The NI Example Finder is located on the Help menu in the LabVIEW

Help.

The following table shows the pinout for the RS-485 serial port.

cRIO-904x User Manual | © National Instruments | 11

Page 12

Table 10. RS-485 Serial Port Pinout

3

4

5

6

7

8

9

10

1

2

Pinout Pin Signal

1 No Connect

2 TXD-

3 TXD+

4 No Connect

5 No Connect

6 RXD-

7 RXD+

8 No Connect

9 No Connect

10 Isolated GND

The following accessory is available to connect the RS-485 serial port to a 9-pin DSUB plug.

Notice To ensure the specified EMC performance, you must use an isolated cable

with the RS-485 serial port. The following accessory meets this requirement.

Table 11. RS-485 Serial Port Accessory

Accessory Length Part Number

RS-485, S8 Serial Cable, 10-Position Modular Plug to 9-Pin DSUB

1 m 184428-01

(Isolated)

USB 2.0 Type-A

The USB 2.0 Type-A port implements a USB 2.0 Type-A host and supports common USB

devices such as mass-storage, devices, keyboards, mice, and USB cameras.

The following NI cables with retention are available for the cRIO-904x.

Table 12. NI Cables with Retention for cRIO-904x

Cable Length Part Number

USB Extension with Retention, Type-A Male to Type-A Female,

USB 2.0

Buttons

The cRIO-904x provides the following buttons.

12 | ni.com | cRIO-904x User Manual

0.5 m 152166-0R5

2 m 152166-02

Page 13

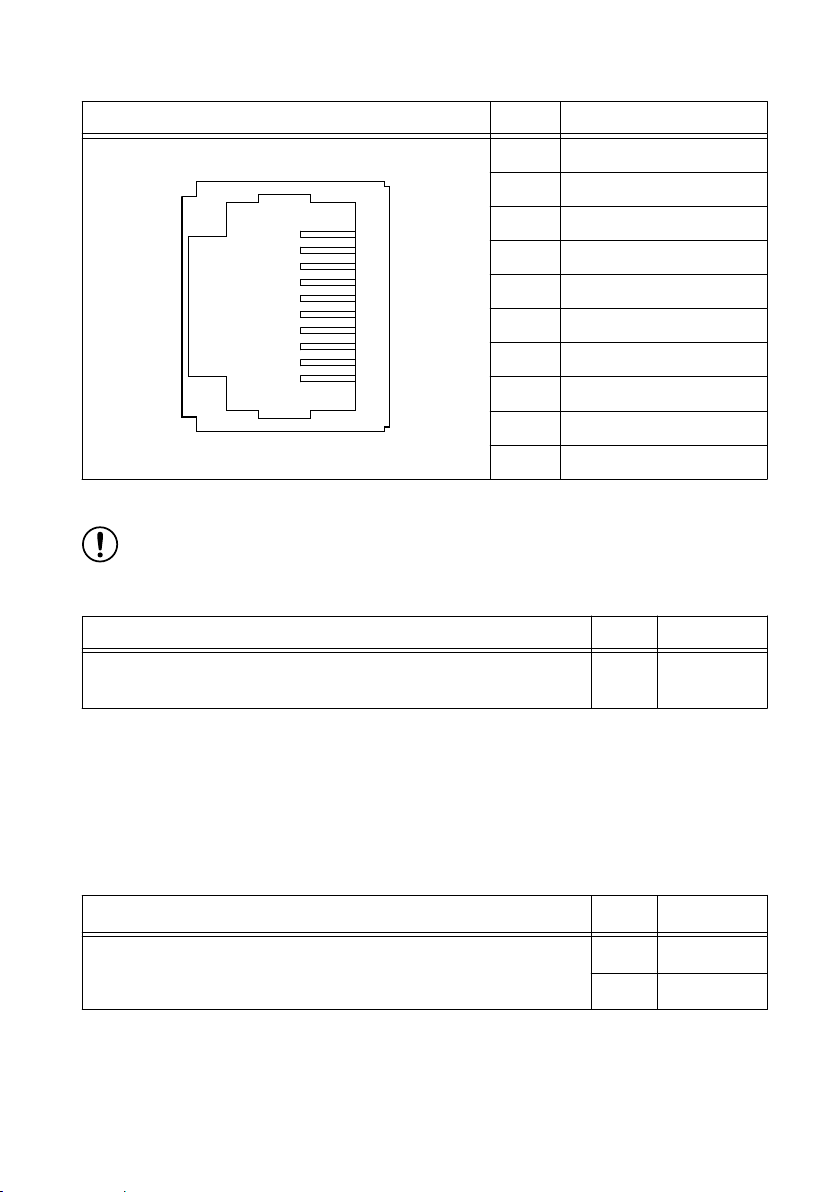

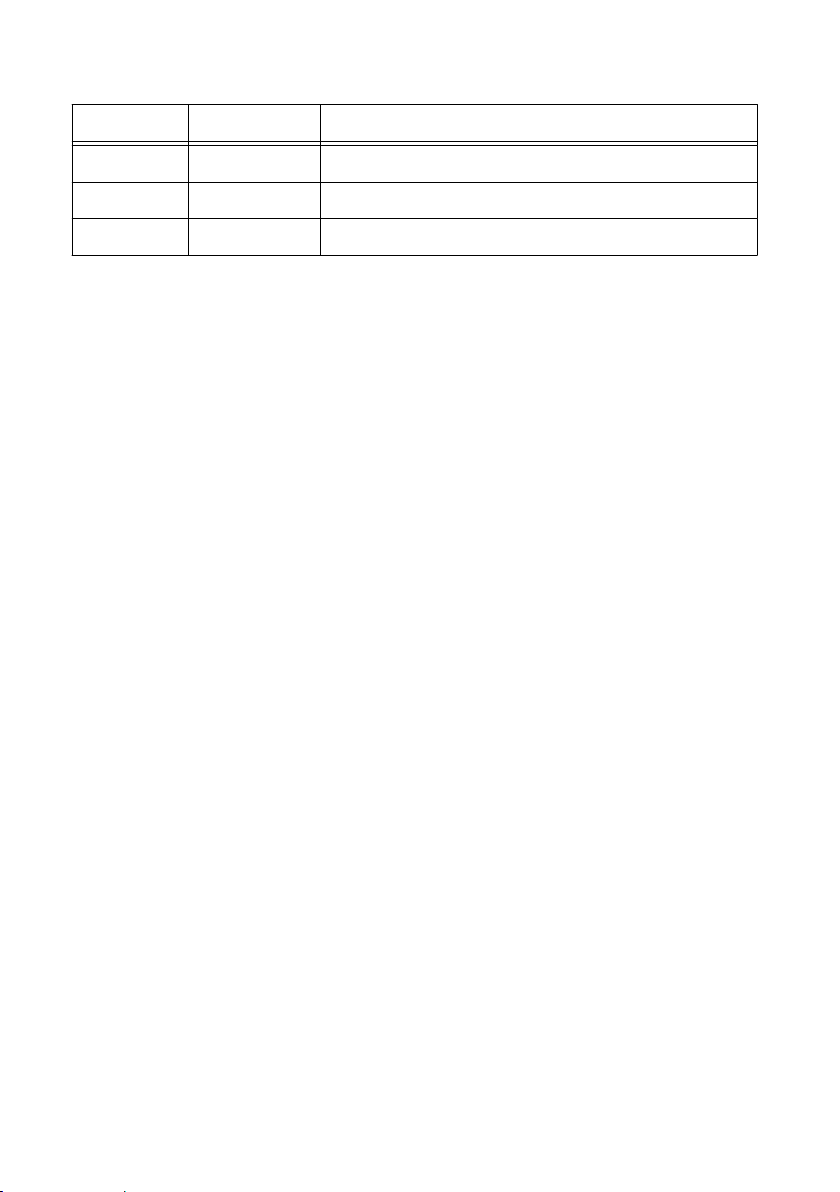

Figure 2. cRIO-904x Buttons

10/100

USER1

1: POWER

2: STATUS

3:

1 2 3 4

4:USER

FPGA1

/1000

ACT/

SYNC

PUSH TO EJECT

SD

IN USE

DUAL ROLEHOST

RS-232

RESET

PFI 0

USER1

INPUT

9–30 V

V1

V1

C

C

V2

V2

C

DO NOT SEPARATE CONNECTORS WHEN

ENERGIZED IN HAZARDOUS LOCATIONS

60 W MAX

RS-485

1

0

LINK

10/100

/1000

ACT/

LINK

DP

1

32

Press and hold RESET button for ≥ 5 s

Press and hold RESET button for < 5 s

Run Mode

Safe Mode

Press and hold RESET button for < 5 s

Press and hold RESET button for ≥ 5 s

Press and hold

RESET button for ≥ 5 s

Press and hold

RESET button for < 5 s

• Console Out enabled

• Network settings reset

• RT Startup App disabled

• FPGA Startup App disabled

• Console Out enabled

• RT Startup App disabled

• FPGA Startup App disabled

Safe Mode

1. USER1 Button

2. RESET Button

3. CMOS Reset Button

USER1 Button

The cRIO-904x has a general-purpose USER1 button that is user-defined. You can read the

state of the USER1 button from your LabVIEW FPGA application.

RESET Button

Press the RESET button to reset the processor in the same manner as cycling power.

The following figure shows the reset behavior of the cRIO-904x.

Figure 3. Reset Button Behavior

For more information about using the RESET button for network troubleshooting, see

Troubleshooting Network Connectivity.

cRIO-904x User Manual | © National Instruments | 13

Page 14

Troubleshooting Network Connectivity

6

1

2

3

4

5

You can use the RESET button to troubleshoot network connectivity.

Complete the following steps to reset the network adapters to default settings.

1. Hold the RESET button for 5 seconds, and then release it to boot the controller in safe

mode and enable Console Out.

2. Hold the RESET button again for 5 seconds to boot the controller into safe mode, enable

Console Out, and reset network adapters to default settings.

CMOS Reset Button

The cRIO-904x has a CMOS reset button that you can use to reset the CMOS and the BIOS.

LEDs

Learn more about the LEDs for your cRIO-904x.

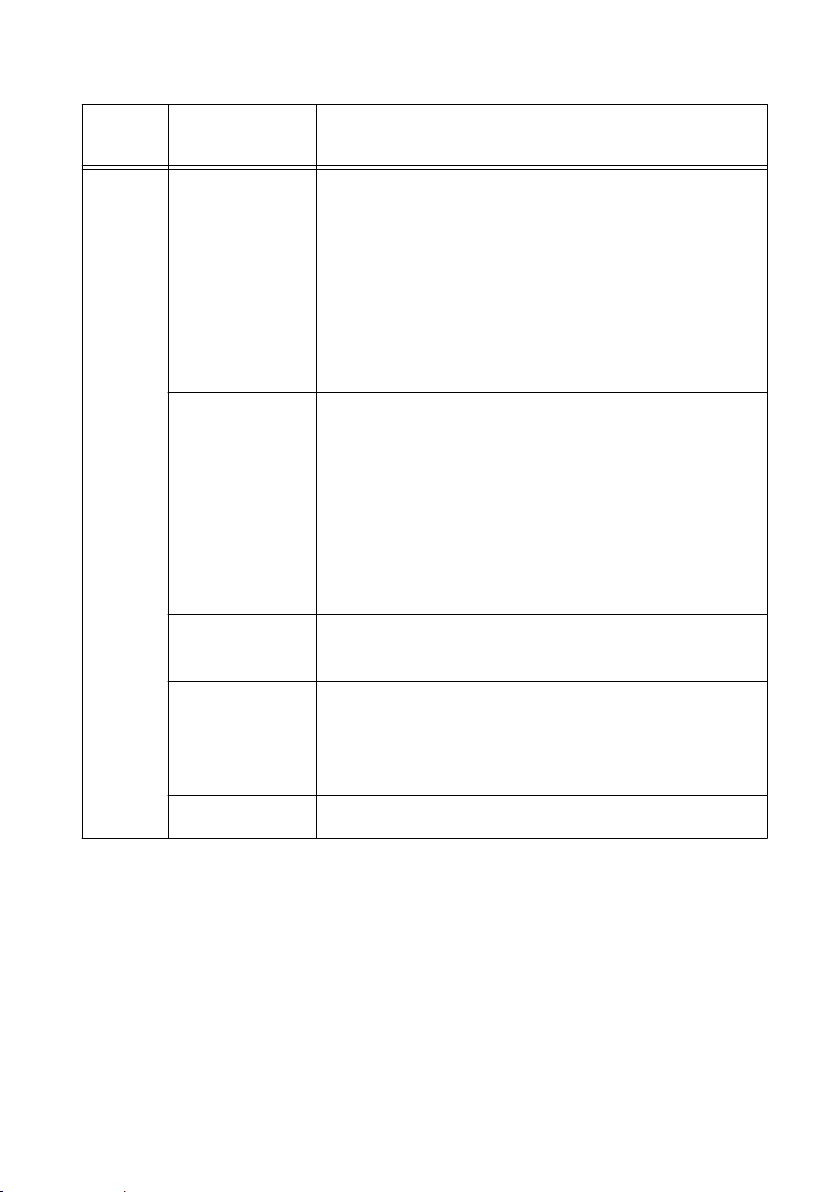

Figure 4. cRIO-904x Front Panel LEDs

1. POWER LED

2. STATUS LED

3. USER1 LED

4. USER FPGA1 LED

5. Gigabit Ethernet LEDs

6. SD In Use LED

POWER LED Indicators

The POWER LED on the cRIO-904x indicates which power input is in use, as shown in the

following table.

14 | ni.com | cRIO-904x User Manual

Page 15

Table 13. POWER LED Indicators

LED Color LED Pattern Indication

Green Solid The cRIO-904x is powered from the V1 input.

Yellow Solid The cRIO-904x is powered from the V2 input.

— Off The cRIO-904x is powered off.

For more information about connecting the cRIO-904x to power, refer to "Connecting the

Controller to Power" in the cRIO-904x Getting Started Guide .

STATUS LED Indicators

The following table describes the STATUS LED indicators.

cRIO-904x User Manual | © National Instruments | 15

Page 16

LED

Color

Table 14. STATUS LED Indicators

LED Pattern Indication

Yellow Blinks twice and

pauses

Blinks three times

and pauses

Blinks four times

and pauses

Continuously

blinks

The cRIO-904x is in safe mode. Software is not installed,

which is the factory default state, or software has been

improperly installed on the cRIO-904x.

An error can occur when an attempt to upgrade the software

is interrupted. Reinstall software on the cRIO-904x. Refer to

"Installing Software on the Controller" in the cRIO-904x

Getting Started Guide for information about installing

software on the cRIO-904x.

The cRIO-904x is in user-directed safe mode, or the

cRIO-904x is in install mode to indicate that software is

currently being installed.

This pattern may also indicate that the user has forced the

cRIO-904x to boot into safe mode by pressing the reset

button for longer than five seconds or by enabling safe mode

in MAX. Refer to the RESET Button for information about

safe mode.

The cRIO-904x is in safe mode. The software has crashed

twice without rebooting or cycling power between crashes.

The cRIO-904x has not booted into NI Linux Real-Time.

The cRIO-904x either booted into an unsupported operating

system, was interrupted during the boot process, or detected

an unrecoverable software error.

On momentarily The cRIO-904x is booting. No action required.

16 | ni.com | cRIO-904x User Manual

Page 17

LED

Color

Table 14. STATUS LED Indicators (Continued)

LED Pattern Indication

Red Continuously

blinks

This indicates a hardware error. An internal power supply

has failed. Check front-panel I/O and C Series module

connections for shorts. Remove any shorts and cycle power

the cRIO-904x. If the problem persists, contact NI.

Solid The cRIO-904x internal temperature has exceeded a critical

threshold. Ensure the ambient operating temperature does

not exceed the specified operating temperature. If the

problem persists, contact NI.

— Off The cRIO-904x is in run mode. Software is installed and the

operating system is running.

Ethernet LED Indicators

The following table lists the Ethernet LED indicators.

Table 15. Ethernet LED Indicators

LED LED Color LED Pattern Indication

ACT/LINK - Off LAN link not established

Green Solid LAN link established

Flashing Activity on LAN

10/100/1000 Yellow Solid 1,000 Mbit/s data rate selected

Green Solid 100 Mbit/s data rate selected

- Off 10 Mbit/s data rate selected

SD In Use LED Indicator

The cRIO-904x has a SD In Use LED to indicate the card drive mount status. The following

table lists details of the SD In Use LED indicator.

cRIO-904x User Manual | © National Instruments | 17

Page 18

Table 16. SD In Use LED Indicator

1

LED LED Color LED Pattern Indication

SD IN USE Green Off There is no SD card present in the slot or the

cRIO-904x has unmounted the SD card from the

operating system. It is safe to remove the SD card

from the slot.

Solid The SD card in the slot is mounted in the operating

system. Do not remove the SD card while this LED

is lit.

Chassis Grounding Screw

The cRIO-904x provides a chassis grounding screw.

Figure 5. cRIO-904x Chassis Grounding Screw

1. Chassis Grounding Screw

For information about grounding the cRIO-904

cRIO-904x Getting Started Guide.

For more information about ground connections, visit ni.com/info and enter the Info Code

emcground.

x, see "Grounding the Controller" in the

Internal Real-Time Clock

The cRIO-904x contains an internal real-time clock that maintains system time when the

cRIO-904x is powered off. The system clock of the cRIO-904x is synchronized with the

internal real-time clock at startup. You can set the real-time clock using the BIOS setup utility

or MAX, or you can set the real-time clock programmatically using LabVIEW.

18 | ni.com | cRIO-904x User Manual

Page 19

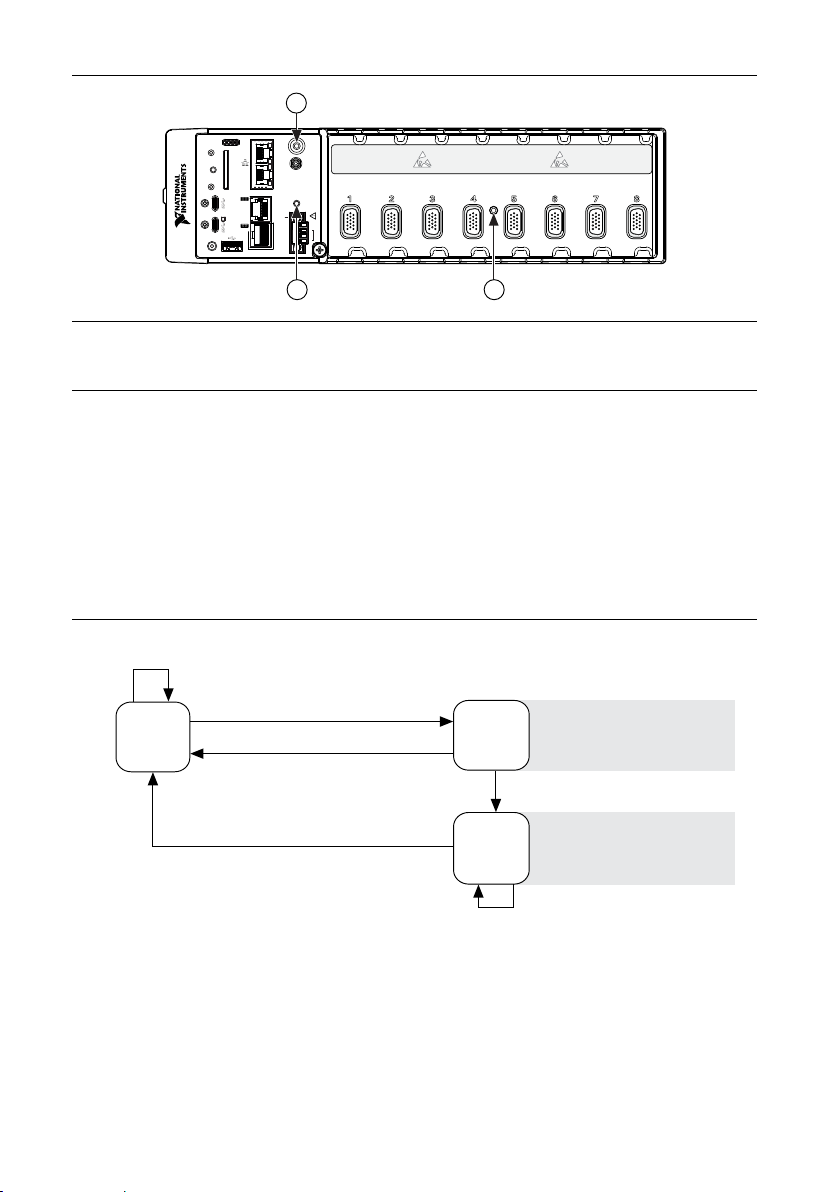

Refer to the model specifications on ni.com/manuals for the real-time clock accuracy

Onboard

100 MHz

Oscillator

Clock

Generator

DAQ ASIC

RIO FPGA

cRIO Trigger Bus

80 MHz Timebase

20 MHz Timebase

100 kHz Timebase

13.1072 MHz Timebase

12.8 MHz Timebase

10 MHz Timebase

40 MHz Onboard Clock

÷200

13.1072 MHz Carrier Clock

12.8 MHz Carrier Clock

10 MHz Carrier Clock

÷2

÷4

specifications.

Digital Routing

The digital routing circuitry of the cRIO-904x manages the flow of data between the bus

interface and the acquisition and generation sub-systems when programming C Series modules

in Real-Time (NI-DAQmx) mode. The subsystems include analog input, analog output, digital

I/O, and counters. The digital routing circuitry uses FIFOs (if present) in each sub-system to

ensure efficient data movement.

Note When programming C Series modules in FPGA mode, the flow of data

between the modules and the bus interface is programmed using LabVIEW FPGA.

The digital routing circuitry also routes timing and control signals. The acquisition and

generation sub-systems use these signals to manage and synchronize acquisitions and

generations. These signals can come from the following sources:

• C Series modules programmed in Real-Time (NI-DAQmx) mode

• User input through the PFI terminals using parallel digital C Series modules or the

cRIO-904x PFI 0 terminal

• FPGA or DAQ ASIC using the cRIO trigger bus to share hardware triggers and signals

between the LabVIEW FPGA and DAQmx applications

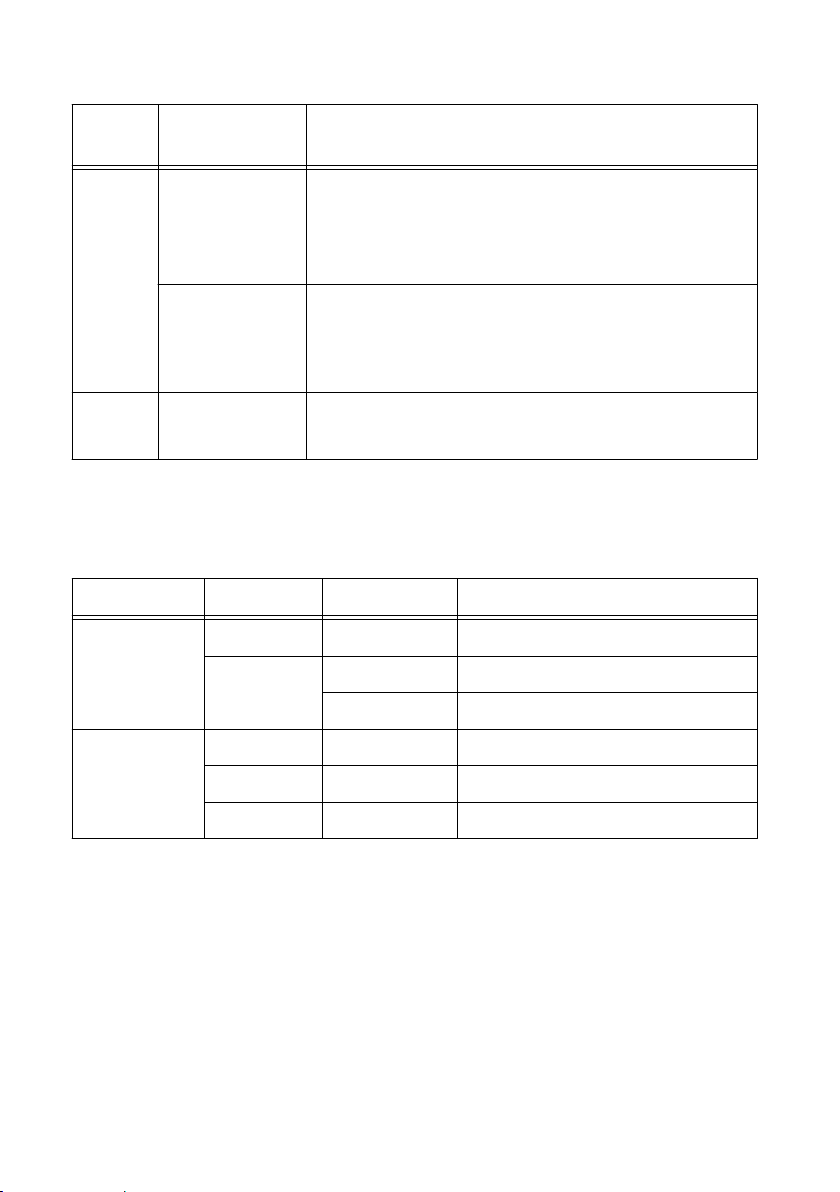

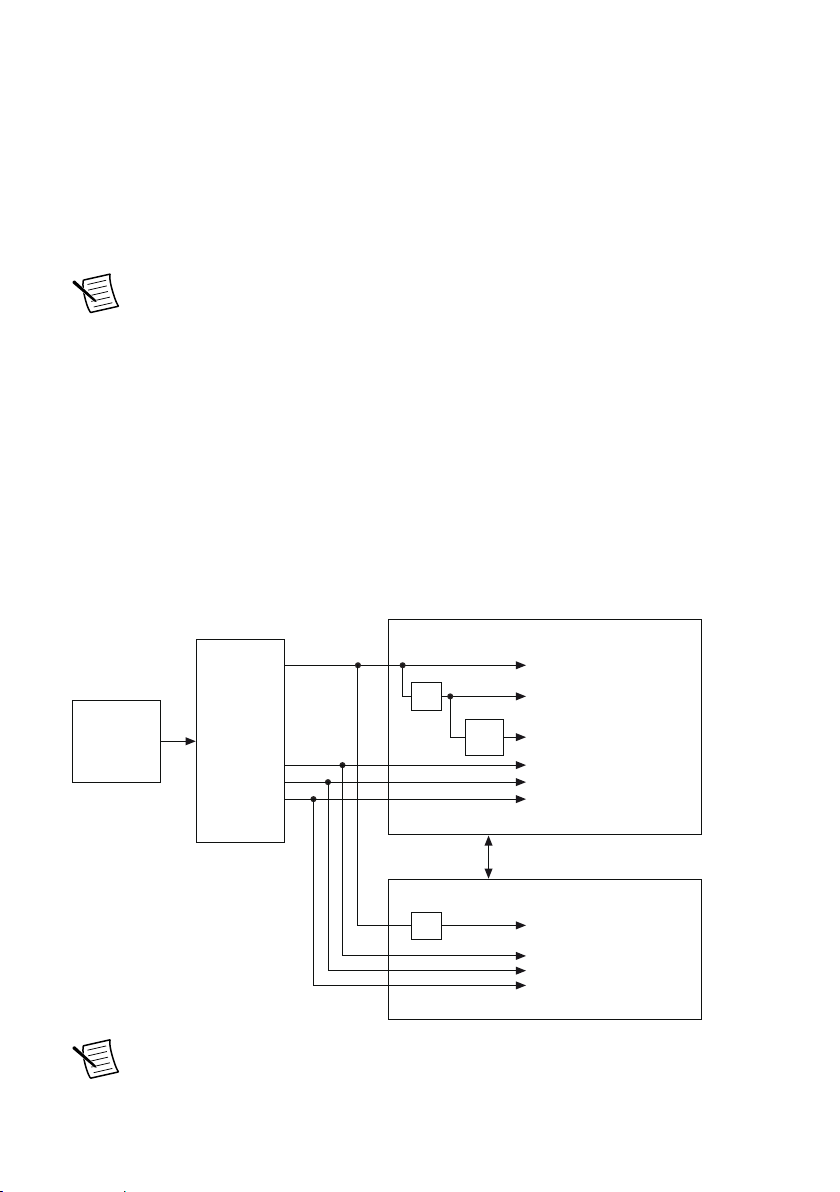

Clock Routing

The following figure shows the clock routing circuitry of the cRIO-904x.

Figure 6. Clock Routing Circuitry of the cRIO-904x

Note When switching between programming modes, you may notice the terms

timebase and clock used interchangeably. This is due to the DAQ ASIC and the RIO

cRIO-904x User Manual | © National Instruments | 19

Page 20

FPGA using different terminology for timing and clock mechanisms. The

documentation will use the term based on the programming mode discussed.

80 MHz Timebase

When programming C Series modules in Real-Time (NI-DAQmx) mode, the 80 MHz

timebase can function as the source input to the 32-bit general-purpose counter/timers. The

80 MHz timebase is generated from the onboard oscillator.

20 MHz and 100 kHz Timebases

When programming C Series modules in Real-Time (NI-DAQmx) mode, the 20 MHz and

100 kHz timebases can be used to generate many of the analog input and analog output timing

signals. These timebases can also function as the source input to the 32-bit general-purpose

counter/timers. The 20 MHz and 100 kHz timebases are generated by dividing down the

80 MHz timebase, as shown in the previous figure.

40 MHz Onboard Clock

When programming C Series modules in FPGA mode, the 40 MHz onboard clock is used as

the top-level clock for your LabVIEW FPGA application and C Series module IO nodes. The

40 MHz onboard clock can be used to clock single-cycle timed loops. Derived clocks of

varying frequency can be generated from the 40 MHz onboard clock. The 40 MHz onboard

clock is phase aligned with the incoming 80 MHz clock.

13.1072 MHz, 12.8 MHz, and 10 MHz Timebases and Carrier Clocks

When programming C Series modules in Real-Time (NI-DAQmx) mode, the 13.1072 MHz,

12.8 MHz, and 10 MHz timebases can be used to generate many of the analog input and

analog output timing signals. These timebases can also function as the source input to the 32bit general-purpose counter/timers. The 13.1072 MHz, 12.8 MHz, and 10 MHz timebases are

generated directly from the onboard clock generator.

When programming C Series modules in FPGA mode, the 13.1072 MHz, 12.8 MHz, and

10 MHz carrier clocks can be used as the master clock for C Series analog input and analog

output modules. The 13.1072 MHz, 12.8 MHz, and 10 MHz carrier clocks are available as IO

Nodes in LabVIEW FPGA applications and can be used to correlate the onboard clocks with

self-timed C Series modules containing free-running clocks.

Synchronization Across a Network

Internal Timebase

The onboard 100 MHz oscillator automatically synchronizes to other network-synchronized

devices that are part of the local IEEE 802.1AS or IEEE 1588-2008 subnet, depending on the

active time reference that is being used on the controller.

The 80 MHz, 40 MHz, 20 MHz, 100 kHz, 13.1072 MHz, 12.8 MHz, and 10 MHz timebases

are derived from the onboard oscillator and are synchronized to it. Therefore, the timebases are

also synchronized to other network-synchronized timebases on the IEEE 802.1AS or

20 | ni.com | cRIO-904x User Manual

Page 21

IEEE 1588-2008 subnet. This enables analog input, analog output, digital I/O, and counter/

timers to be synchronized to other chassis across a distributed network.

When programming C Series modules in FPGA mode, the Time Synchronization IO Nodes

can be used to synchronize the LabVIEW FPGA application to other network-synchronized

devices.

Network-based Synchronization

IEEE 1588, also known as the precision time protocol (PTP), is an Ethernet-based

synchronization method designed for cabled, local networks. The PTP protocol provides a

fault tolerant method of synchronizing all participating clocks to the highest quality clock in

the network. This method of synchronization between networked devices uses packet-based

communication and is possible over the long distances allowed for each Ethernet link, without

signal propagation impact. IEEE 1588 has many different profiles, such as

IEEE 802.1AS-2011, each of which use different features. Because the profiles are not

interoperable with each other, make sure it is known which profile is implemented on the

device. For devices on the network to synchronize with each other using IEEE 1588, all

devices must be compatible with the desired IEEE 1588 profile and must all be connected

within the selected IEEE 1588 profile-compliant network infrastructure.

The cRIO-904x controllers are compatible with both the IEEE 802.1AS-2011 profile and the

IEEE 1588-2008 (1588v2) Delay Request-Response profile. However, each network port must

be configured individually to the specific profile required for the network.

Differences Between IEEE 802.1AS-2011 and IEEE 1588-2008

IEEE 802.1AS-2011, also known as the generalized precision time protocol (gPTP), is a

profile of IEEE 1588. A cRIO-904x controller can be configured to use either the

IEEE 802.1AS-2011 profile or the IEEE 1588-2008 profile by configuring the port’s time

reference. If a user does not explicitly specify which time reference to use a cRIO-904x

controller will default to use the IEEE 802.1AS-2011 profile. There are some differences

between the IEEE 802.1AS-2011 profile and the IEEE 1588-2008 profile which are called out

below:

• IEEE 802.1AS-2011 assumes all communication between devices is done on the OSI

layer 2, while IEEE 1588-2008 can support various layer 2 and layer 3-4 communication

methods. The IEEE 1588-2008 profile National Instruments implements on the

cRIO-904x only supports layer 3-4 communication methods. Operating on the layer 2

yields better performance for the IEEE 802.1AS-2011.

• IEEE 802.1AS-2011 only communicates gPTP information directly with other

IEEE 802.1AS devices within a system. Therefore, there must be IEEE 802.1AS-2011

support along the entire path from one IEEE 802.1AS-2011 device to another. With

IEEE 1588-2008, it is possible to use non-IEEE 1588-2008 switches between two

IEEE 1588-2008 devices. The benefit of having IEEE 802.1AS-2011 support along the

entire path is a faster performance and lower jitter compared to IEEE 1588-2008.

• With IEEE 802.1AS-2011 there are only two types of time-aware systems: time-aware

end stations and time-aware bridges. Whereas with IEEE 1588-2008, there are the

following: ordinary clock, boundary clock, end-to-end transparent clock and a time-aware

bridges. Based on these factors, IEEE 802.1AS-2011 can reduce complexity and

cRIO-904x User Manual | © National Instruments | 21

Page 22

configuration challenges compared to IEEE 1588-2008. A cRIO-904x controller acts as a

time-aware end station for both protocols.

IEEE 1588 External Switch Requirements

To take advantage of the network synchronization features of the cRIO-904x controllers,

ensure that your network infrastructure meets certain requirements depending on which

IEEE 1588 profile is implemented for your application:

• IEEE 802.1AS-2011 support—Automatically enables timebase synchronization and

enables the use of time-based triggers and timestamping between devices across the

network. Synchronization performance will meet NI product specifications.

• IEEE 1588-2008 support—Enables timebase synchronization and enables the use of timebased triggers and timestamping between devices across the network. Synchronization

performance will vary and may not meet NI product specifications. As a default

configuration for IEEE 1588-2008, NI supports the IEEE 1588 Delay Request-Response

profile, using the UDP over IP transport (layer 3-4).

CMOS Battery

The cRIO-904x contains a CMOS battery. The CMOS battery is a lithium cell battery that

stores the system clock information when the cRIO-904x is powered off. There is only a slight

drain on the CMOS battery when power is applied to the cRIO-904x power connector. The rate

at which the CMOS battery drains when power is disconnected depends on the ambient

storage temperature. For longer battery life, store the cRIO-904x at a cooler temperature and

apply power to the power connector. Refer to the specifications for your model on ni.com/

manuals for the expected battery lifetime.

The CMOS BATTERY IS DEAD warning appears onscreen during the power-on self test if the

battery is dead. The cRIO-904x still starts, but the system clock is reset to the date and time of

the BIOS release. The battery is not user-replaceable. If you need to replace the CMOS

battery, contact NI. Refer to the specifications for your model on ni.com/manuals for

information about battery disposal.

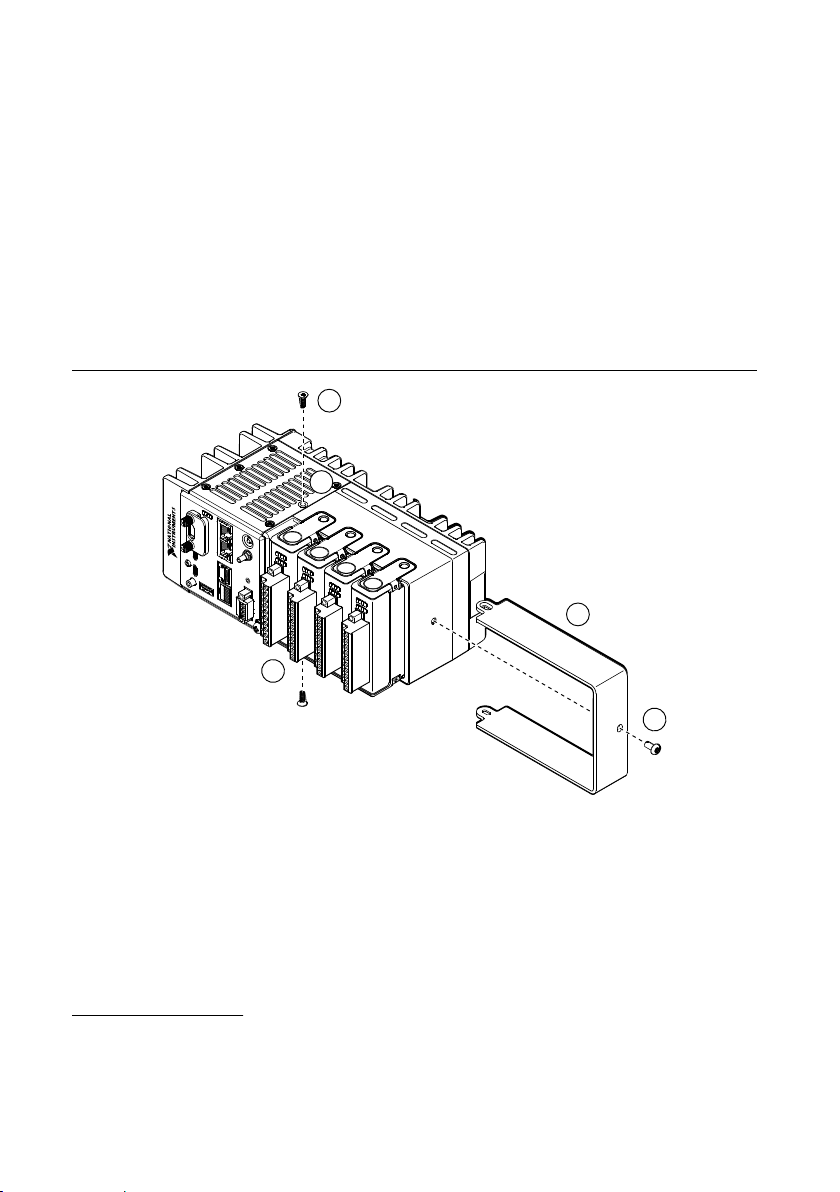

Installing the Module Immobilization Accessory

The Module Immobilization accessory ensures that the C Series module latches cannot be

retracted and modules cannot be removed from a system. The Module Immobilization

accessory provides extra system assurance and security when shipping and installing systems,

and prevents accidental removal from a system during operation.

When using the Module Immobilization accessory, NI recommends installing the accessory

prior to mounting the system in any enclosure because the accessory requires tool access to the

top, right, and bottom of the cRIO-904x.

What to Use

• cRIO-904x

• C Series modules

22 | ni.com | cRIO-904x User Manual

Page 23

• Module Immobilization accessory kit: 158533-01 for 8-slot models, 158534-01 for 4-slot

5

1

3

4

2

models

– Module immobilization bracket

– Installation screws

1

• M4 x 0.7 button-head screw, 8 mm

• M3 x 0.5 flat-head screws (x2), 10 mm

• Torx T10/T10H driver

• Torx T20/T20H driver

What to Do

Complete the following steps to install the Module Immobilization accessory.

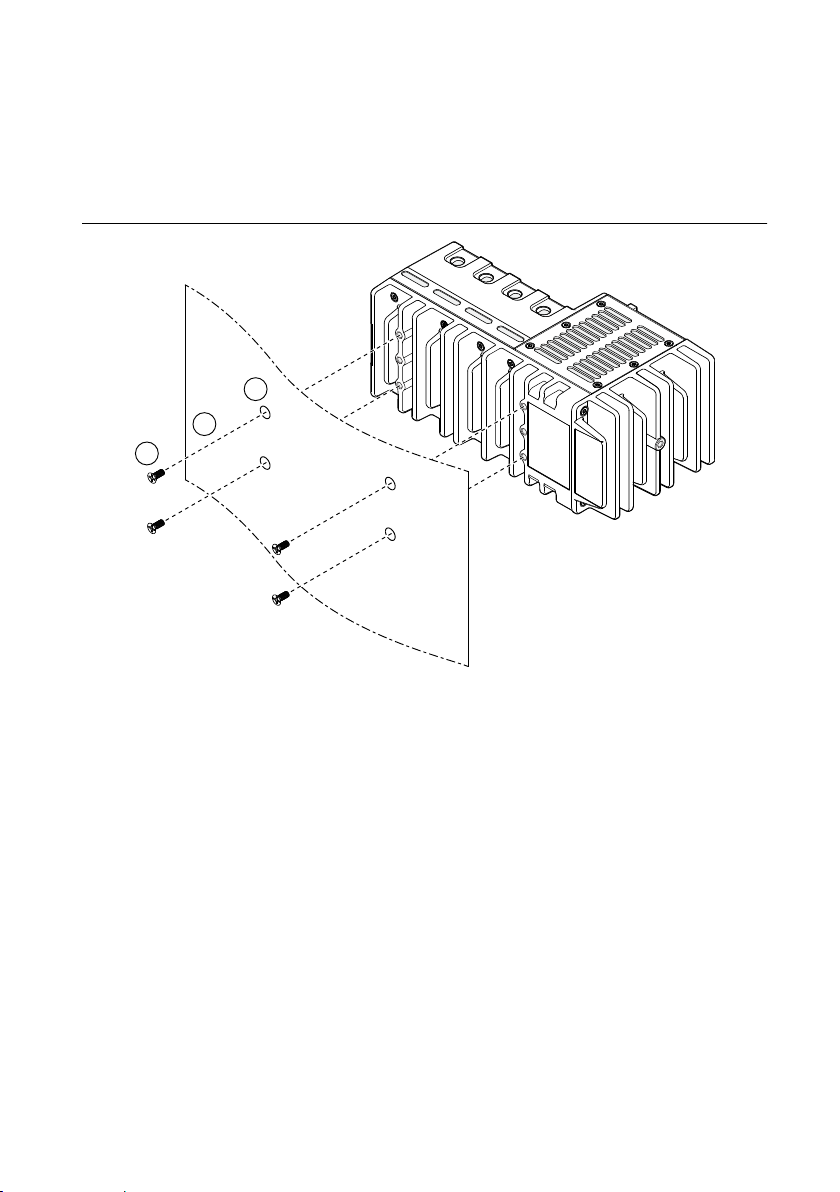

Figure 7. 4-slot cRIO-904x Module Immobilization Accessory Installation

1

The Module Immobilization accessory kit includes two sets of screws. One set is a standard set of

screws that require a standard driver type, Torx T10 and T20. The other set is a tamper-resistant set

of screws that require a security driver type, Torx T10H and T20H. Use the tamper-resistant set to

help prevent unintended modification of the system.

cRIO-904x User Manual | © National Instruments | 23

Page 24

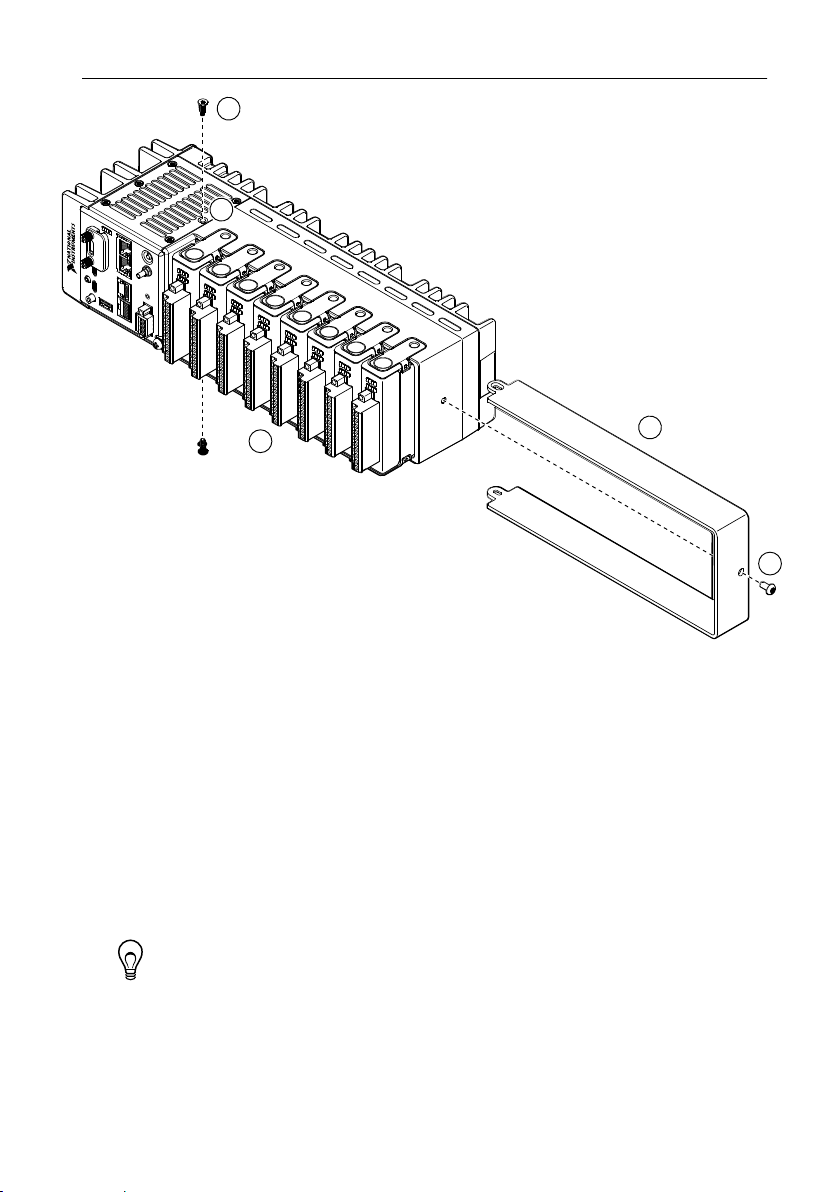

Figure 8. 8-slot cRIO-904x Module Immobilization Accessory Installation

2

5

1

3

4

1. Ensure that all the C Series modules are installed in the cRIO-904x and the latches are

locked in place.

2. Remove the center right panel screw from the top and bottom of the cRIO-904x using the

Torx T10 driver.

3. Slide the bracket into place, aligning the three clearance screw holes.

4. Install the M4 x 0.7 button-head screw in the right end of the cRIO-904x using the

appropriate Torx T20 driver. Tighten the screw to a maximum torque of 1.3 N · m

(11.5 lb · in.).

5. Install the two M3 x 0.5 flat-head screws from the accessory kit in the top and bottom of

the cRIO-904x using the appropriate Torx T10 driver. Tighten the screws to a maximum

torque of 1.3 N · m (11.5 lb · in.).

Tip NI recommends using a liquid thread locker for all fasteners if the system

is expected to experience vibration for an extended amount or time.

Module Immobilization Accessory Dimensions

The following figure shows the Module Immobilization accessory dimensions for the

cRIO-904x.

24 | ni.com | cRIO-904x User Manual

Page 25

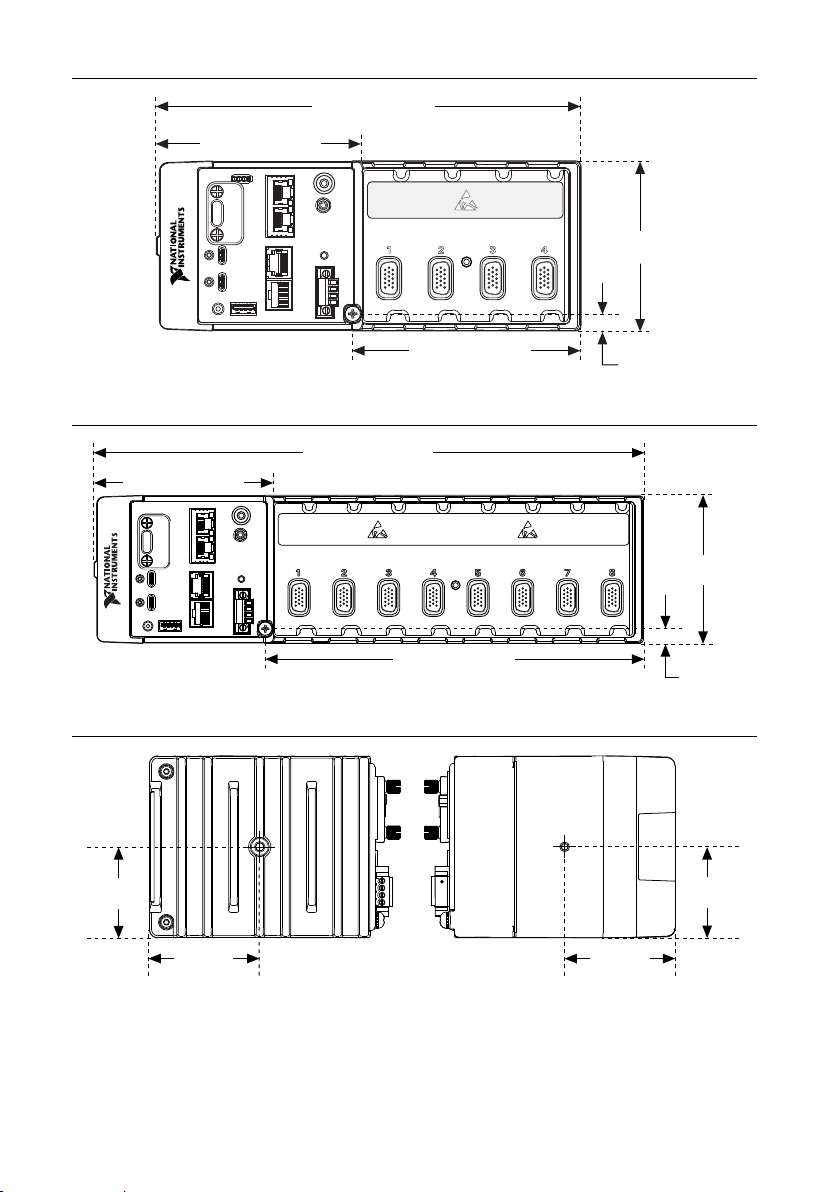

Figure 9. 4-slot cRIO-904x Module Immobilization Accessory Dimensions

94.2 mm

(3.71 in.)

1.6 mm

(0.06 in.)

1.6 mm

(0.06 in.)

220.4 mm (8.68 in.)

329.7 mm (12.98 in.)

1.6 mm

(0.06 in.)

94.2 mm

(3.71 in.)

Figure 10. 8-slot cRIO-904x Module Immobilization Accessory Dimensions

Mounting the Controller

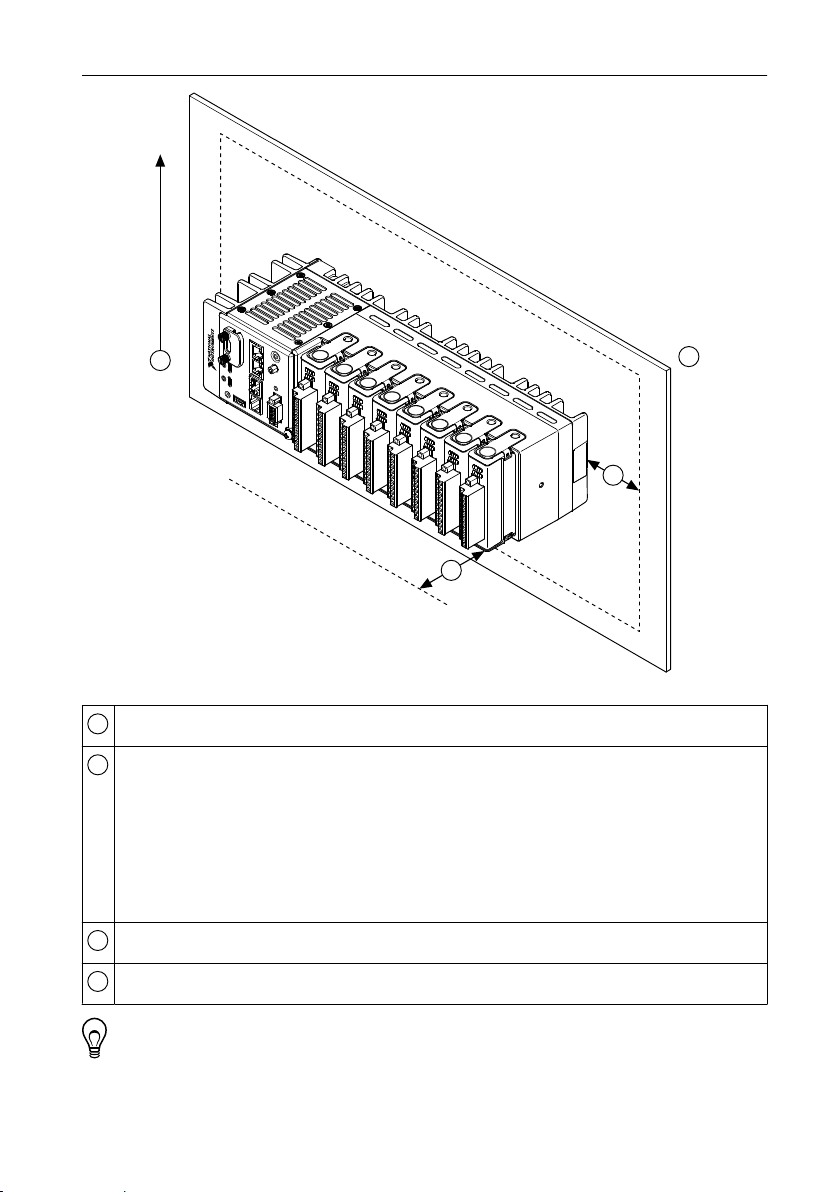

To obtain the maximum ambient temperature, you must mount the cRIO-904x in the reference

mounting configuration shown in the following image. Mounting the cRIO-904x in the

reference mounting configuration ensures that your system will operate correctly across the

full operating temperature range and provide optimal C Series module accuracy. Observe the

following guidelines to mount the cRIO-904x in the reference mounting configuration.

cRIO-904x User Manual | © National Instruments | 25

Page 26

Figure 11. cRIO-904x Reference Mounting Configuration

3

4

1

Up

2

1

2

3

4

Horizontal mounting orientation.

Mounting substrate options:

• Mount the cRIO-904x directly to a metallic surface that is at least 1.6 mm

(0.062 in.) thick and extends a minimum of 101.6 mm (4 in.) beyond all edges of

the device.

• Use the NI Panel Mounting Kit to mount the cRIO-904x to a metallic surface that is

at least 1.6 mm (0.062 in.) thick and extends a minimum of 101.6 mm (4 in.)

beyond all edges of the device.

Observe the cooling dimensions in the Mounting Requirements section.

Allow space for cabling clearance according to the Mounting Requirements section.

Tip Before using any of these mounting methods, record the serial number from

the back of the cRIO-904x so that you can identify the cRIO-904x in MAX. You will

be unable to read the serial number after you mount the cRIO-904x.

26 | ni.com | cRIO-904x User Manual

Page 27

Alternate Mounting Configurations

25.4 mm (1.00 in.)

All Around

Cooling Dimensions

The maximum operating temperature may be reduced for any mounting configuration other

than the reference mounting configuration. A 10 °C (18 °F) reduction in maximum operating

temperature is sufficient for most alternate mounting configurations. Follow the guidelines

above for all mounting configurations.

The published accuracy specifications, although not guaranteed for alternate mounting

configurations, may be met depending on the system power and the thermal performance of

the alternate mounting configuration.

Contact NI for further details regarding the impact of common alternate mounting

configurations on maximum operating temperature and module accuracy.

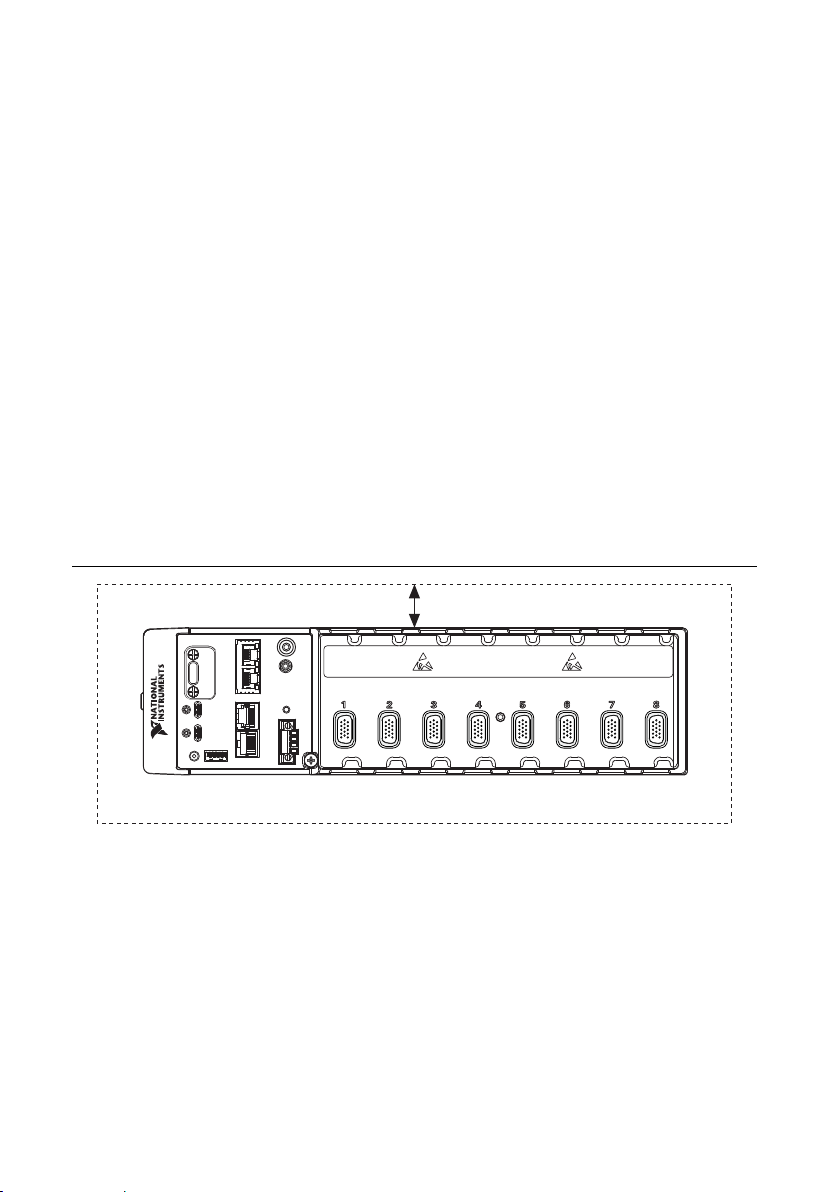

Mounting Requirements for the cRIO-904x

Use the following to ensure you meet the cooling and cabling clearance requirements for

mounting cRIO-904x models.

Your installation must meet the following requirements for cooling and cabling clearance for

all cRIO-904x models.

Allow 25.4 mm (1.00 in.) on all sides of the cRIO-904x for air circulation, as shown in the

following figure.

Figure 12. cRIO-904x Cooling Dimensions

Allow the appropriate space in front of C Series modules for cabling clearance, as shown in

the following figure. The different connector types on C Series modules require different

cabling clearances. For a complete list of cabling clearances for C Series modules, visit

ni.com/info and enter the Info Code crioconn.

cRIO-904x User Manual | © National Instruments | 27

Page 28

Figure 13. cRIO-904x Cabling Clearance

29.1 mm

(1.14 in.)

Cabling

Clearance

38.1 mm

(1.50 in.)

63.5 mm

(2.50 in.)

1

63.5 mm

(2.50 in.)

1

38.1 mm

(1.50 in.)

63.5 mm

(2.50 in.)

1

63.5 mm

(2.50 in.)

1

Measure the ambient temperature at each side of the cRIO-904x, 63.5 mm (2.50 in.) from the

side and 38.1 mm (1.50 in.) forward from the rear of the cRIO-904x, as shown in the following

figure.

Figure 14. Ambient Temperature Location

1. Measure the ambient temperature here.

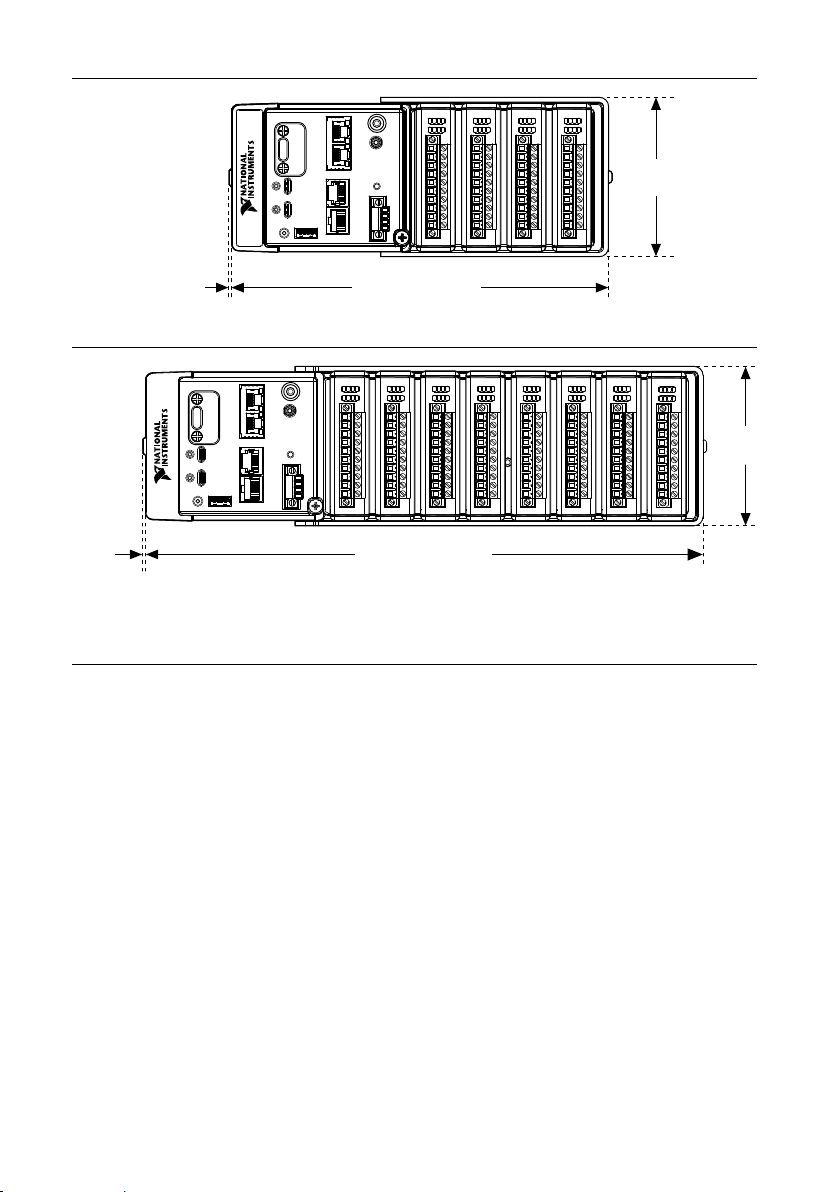

Dimensions

The following figures show the front and side dimensions of the cRIO-904x. For detailed

dimensional drawings and 3D models, visit ni.com/dimensions and search for the model

number.

28 | ni.com | cRIO-904x User Manual

Page 29

Figure 15. cRIO-904x 4-slot Controller Front Dimensions

107.0 mm (4.21 in.)

219.5 mm (8.64 in.)

117.2 mm (4.61 in.)

8.6 mm

(0.34 in.)

88.1 mm

(3.47 in.)

107.0 mm (4.21 in.)

226.6 mm (8.92 in.)

8.6 mm

(0.34 in.)

88.1 mm

(3.47 in.)

328.8 mm (12.95 in.)

44.0 mm

(1.73 in.)

44.0 mm

(1.73 in.)

44.0 mm

(1.73 in.)

44.0 mm

(1.73 in.)

53.4 mm

(2.10 in.)

53.4 mm

(2.10 in.)

53.4 mm

(2.10 in.)

53.4 mm

(2.10 in.)

Figure 16. cRIO-904x 8-slot Controller Front Dimensions

Mounting on a Flat Surface

For environments with high shock and vibration, NI recommends mounting the cRIO-904x

directly on a flat, rigid surface using the mounting holes in the cRIO-904x.

Figure 17. cRIO-904x Side Dimensions

cRIO-904x User Manual | © National Instruments | 29

Page 30

What to Use

1

2

3

• cRIO-904x

• M4 screws, user provided, which must not exceed 8 mm of insertion into the cRIO-904x

– x4 for 4-slot models

– x6 for 8-slot models

Figure 18. Mounting the 4-slot cRIO-904x Directly on a Flat Surface

30 | ni.com | cRIO-904x User Manual

Page 31

Figure 19. Mounting the 8-slot cRIO-904x Directly on a Flat Surface

1

2

3

1. Prepare the surface for mounting the cRIO-904x using the Surface Mounting

Dimensions .

2. Align the cRIO-904x on the surface.

3. Fasten the cRIO-904x to the surface using the M4 screws appropriate for the surface.

Screws must not exceed 8 mm of insertion into the cRIO-904x. Tighten the screws to a

maximum torque of 1.3 N · m (11.5 lb · in.).

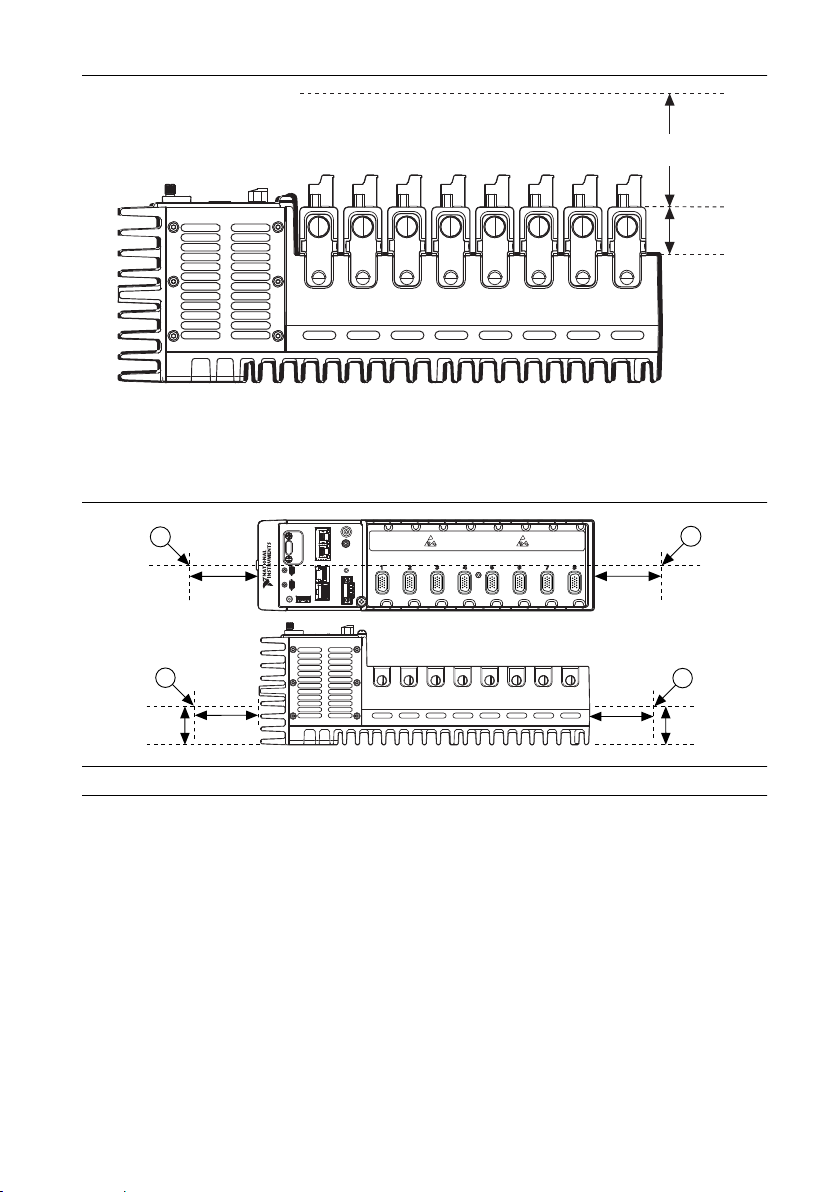

Surface Mounting Dimensions

The following figures show the surface mounting dimensions for the 4-slot and 8-slot

cRIO-904x models.

cRIO-904x User Manual | © National Instruments | 31

Page 32

Figure 20. 4-slot cRIO-904x Surface Mounting Dimensions

2×

23.7 mm (0.94 in.)

2×

20.3 mm (0.80 in.)

2×

20.3 mm (0.80 in.)

6× ISO M4 × 0.7 Thread

8 mm Maximum Insertion Depth

116.5 mm (4.59 in.)

29.0 mm (1.14 in.)

3×

23.7 mm (0.94 in.)

3×

20.3 mm (0.80 in.)

3×

20.3 mm (0.80 in.)

120 mm (4.72 in.)

9× ISO M4 × 0.7 Thread

8 mm Maximum Insertion Depth

120 mm (4.72 in.)

14.8 mm (0.59 in.)

Figure 21. 8-slot cRIO-904x Surface Mounting Dimensions

Mounting on a Panel

You can use the NI panel mounting kit to mount the cRIO-904x on a panel.

What to use

• cRIO-904x

• Screwdriver, Phillips #2

• NI panel mounting kit

– 4-slot models - 157253-01

• Panel mounting plate

• M4 x 10 screws (x4)

– 8-slot models - 157267-01

• Panel mounting plate

• M4 x 10 screws (x6)

32 | ni.com | cRIO-904x User Manual

Page 33

Figure 22. Mounting the 4-slot cRIO-904x on a Panel

1

3

2

1

2

Figure 23. Mounting the 8-slot cRIO-904x on a Panel

1. Align the cRIO-904x and the panel mounting plate.

2. Fasten the panel mounting plate to the cRIO-904x using the screwdriver and M4 x 10

screws. Tighten the screws to a maximum torque of 1.3 N · m (11.5 lb · in.).

You must use the screws provided with the NI panel mounting kit because they are the

correct depth and thread for the panel mounting plate.

cRIO-904x User Manual | © National Instruments | 33

Page 34

3. Fasten the panel mounting plate to the surface using the screwdriver and screws that are

108.8 mm (4.26 in.)

217.7 mm (8.57 in.)

199.4 mm (7.85 in.)

1.6 mm (0.06 in.)

11.1 mm (0.44 in.)

138.9 mm

(5.47 in.)

114.3 mm

(4.50 in.)

7.2 mm

(0.29 in.)

25.4 mm

(1.00 in.)

89.9 mm (3.54 in.)

147.3 mm (5.80 in.)

327 mm (12.88 in.)

152.4 mm (6.00 in.)

1.6 mm (0.06 in.)

11.1 mm (0.44 in.)

152.4 mm (6.00 in.)

138.9 mm

(5.47 in.)

114.3 mm

(4.50 in.)

7.2 mm

(0.29 in.)

25.4 mm

(1.00 in.)

appropriate for the surface. The maximum screw size is M5 or number 10.

Panel Mounting Dimensions

The following figures show the panel mounting dimensions for the 4-slot and 8-slot

cRIO-904x models.

Figure 24. 4-slot cRIO-904x Panel Mounting Dimensions

Figure 25. 8-slot cRIO-904x Panel Mounting Dimensions

Mounting on a DIN Rail

You can use the NI DIN rail mounting kit to mount the cRIO-904x on a standard 35-mm DIN

rail.

34 | ni.com | cRIO-904x User Manual

Page 35

What to use

1

2

• cRIO-904x

• Screwdriver, Phillips #2

• NI DIN rail mounting kit

– 4-slot models - 157254-01

• DIN rail clip

• M4 x 10 screws (x2)

– 8-slot models - 157268-01

• DIN rail clip

• M4 x 10 screws (x3)

Figure 26. Mounting the 4-slot cRIO-904x on a DIN Rail

cRIO-904x User Manual | © National Instruments | 35

Page 36

Figure 27. Mounting the 8-slot cRIO-904x on a DIN Rail

1

2

1

2

1. Align the cRIO-904x and the DIN rail clip.

2. Fasten the DIN rail clip to the cRIO-904x using the screwdriver and M4 x 10 screws.

Tighten the screws to a maximum torque of 1.3 N · m (11.5 lb · in.).

You must use the screws provided with the NI DIN rail kit because they are the correct

depth and thread for the DIN rail clip.

Clipping the Controller on a DIN Rail

Complete the following steps to clip the controller on a DIN rail.

Figure 28. Clipping the Controller on a DIN Rail

1. Insert one edge of the DIN rail into the deeper opening of the DIN rail clip.

2. Press down firmly to compress the spring until the clip locks in place on the DIN rail.

36 | ni.com | cRIO-904x User Manual

Notice Ensure that no C Series modules are in the controller before removing it

from the DIN rail.

Page 37

Mounting on a Rack

1

2

1

2

You can use the following rack mount kits to mount the controller and other DIN railmountable equipment on a standard 482.6 mm (19 in.) rack.

• Industrial Rack Mount Kit, 786411-01

• NI Rack-Mounting Kit, 781989-01

Note You must use the appropriate NI DIN rail mounting kit for your model in

addition to a rack-mounting kit.

Mounting on a Desktop

You can use the NI desktop mounting kit to mount the cRIO-904x on a desktop.

What to use

• cRIO-904x

• Screwdriver, Phillips #2

• NI desktop mounting kit, 779473-01

– Desktop mounting brackets (x2)

Figure 29. Mounting the 4-slot cRIO-904x on a Desktop

cRIO-904x User Manual | © National Instruments | 37

Page 38

Figure 30. Mounting the 8-slot cRIO-904x on a Desktop

1

1

2

2

1. Align the brackets with the mounting holes on the ends of the cRIO-904x.

2. Use the screwdriver to tighten the captive screws on the end of the brackets.

Desktop Mounting Dimensions

The following figures show the desktop mounting dimensions for the 4-slot and 8-slot

cRIO-904x models.

38 | ni.com | cRIO-904x User Manual

Page 39

Figure 31. 4-slot cRIO-904x Desktop Mounting Dimensions

2×

17.2 mm (0.68 in.)

39.1 mm

(1.54 in.)

253.9 mm (10.00 in.)

2×

17.2 mm (0.68 in.)

361.7 mm (14.24 in.)

39.1 mm

(1.54 in.)

Figure 32. 8-slot cRIO-904x Desktop Mounting Dimensions

cRIO-904x User Manual | © National Instruments | 39

Page 40

Figure 33. cRIO-904x Desktop Mounting Side Dimensions

132.8 mm (5.23 in.)

127.2 mm

(5.01 in.)

BIOS Configuration

Resetting the System CMOS and BIOS Settings

The cRIO-904x BIOS configuration information is stored in a nonvolatile memory location

that does not require a battery to preserve the settings. Additionally, the BIOS optimizes boot

time by saving specific system information to memory backed up by a battery (CMOS).

Complete the following steps to reset the CMOS and reset the BIOS settings to factory default

values.

1. Disconnect power from the cRIO-904x.

2. Press the CMOS reset button and hold it for 1 second.

3. Reconnect power to the cRIO-904x.

The BIOS Reset Detected warning message appears onscreen.

Note If the CMOS battery is dead, the CMOS reset button will not work.

Power-On Self Test Warning Messages

The cRIO-904x POST displays warning messages for specific issues onscreen. You can use

MAX to enable Console Out to send these warning messages through the RS-232 serial port.

The POST can display the following warning messages:

• BIOS Reset Detected—This warning is displayed when the CMOS Reset button has been

pushed. This warning indicates that the BIOS settings have the default values.

• CMOS Battery Is Dead—This warning is displayed when the CMOS battery is dead and

must be replaced. The BIOS settings are preserved even when the CMOS battery is dead,

but the system will boot very slowly because the BIOS cannot optimize boot time by

saving specific system information to CMOS.

40 | ni.com | cRIO-904x User Manual

Page 41

BIOS Setup Utility

Use the BIOS setup utility to change configuration settings and to enable special functions.

The cRIO-904x ships with configuration settings that work for most applications, but you can

use the BIOS setup utility to change configuration settings to meet the needs of your

application.

Changing BIOS settings can cause incorrect behavior, including failure to boot. In general, do

not change a setting unless you are sure what the setting does. Reset the BIOS settings to

restoring the default configuration settings.

Launching the BIOS Setup Utility

Complete the following steps to launch the BIOS setup utility.

1. Connect a video monitor to the USB 3.1 Type-C DisplayPort connector on the

cRIO-904x.

Note In order to connect the monitor to the USB 3.1 Type-C DisplayPort

connector, you may need to use a VGA-to-Type-C or DVI-to-Type-C adapter.

2. Connect a USB keyboard to the USB 2.0 host port on the cRIO-904x.

3. Power on or reboot the cRIO-904x.

4. Hold down either the <F10> key or the <Del> key until Please select boot

device: appears onscreen.

5. Use the Down Arrow key to select Enter Setup and press <Enter>. The setup utility

loads after a short delay.

The Main setup menu is displayed when you first enter the BIOS setup utility.

BIOS Setup Utility Keyboard Navigation

Use the following keys to navigate through the BIOS setup utility:

Table 17. Navigation Keys

Key(s) Function(s)

Left Arrow, Right

Arrow

Up Arrow, Down

Arrow

<Enter> Enter a submenu or display all available settings for a highlighted

<Esc> Return to the parent menu of a submenu. At the top-level menus, this

Move between the different setup menus. If you are in a submenu,

these keys have no effect, and you must press <Esc> to leave the

submenu first.

Move between the options within a setup menu.

configuration option.

key serves as a shortcut to the Exit menu.

cRIO-904x User Manual | © National Instruments | 41

Page 42

Table 17. Navigation Keys (Continued)

Key(s) Function(s)

<+>, <-> Cycle between all available settings for a selected configuration option.

<F8> Load the previous values for all BIOS configuration settings.

<F9> Load the optimal default values for all BIOS configuration settings.

The optimal default values are the same as the shipping configuration

default values.

<F10> Save settings and exits the BIOS setup utility.

Main Setup Menu

The Main setup menu reports the following configuration information:

• BIOS Version— This value indicates the version of the controller BIOS.

• Build Date—This value indicates the date and time on which the BIOS was built.

• Embedded Firmware Version—This value identifies the built-in hardware capabilities.

• Access Level— This value indicates the level of access the current user has on the

controller BIOS.

• Processor Type, Speed, and Active Processor Cores—These values indicate the type of

processor used in the controller, the speed of the processor, and the number of active

processor cores.

• Total Memory—This value indicates the size of system RAM detected by the BIOS.

The Main setup menu also includes the following settings:

• System Date—This setting controls the date, which is stored in a battery-backed real-time

clock. Most operating systems also include a way to change this setting. Use <+> and <->

in conjunction with <Enter> and <Tab> to change these values.

• System Time—This setting controls the time of day, which is stored in a battery-backed

real-time clock. Most operating systems also include a way to change this setting. Use

<+> and <-> in conjunction with <Enter> and <Tab> to change these values.

Advanced Setup Menu

The Advanced setup menu contains BIOS settings that do not require modification for normal

operation of the cRIO-904x. If you have specific problems, such as unbootable disks or

resource conflicts, you may need to examine the settings in this menu.

Notice Changing settings in the Advanced setup menu may result in an unstable or

unbootable controller. If this happens, restore BIOS settings to the factory defaults.

The Advanced setup menu includes the following submenus:

• Power/Wake Configuration Submenu

• SATA Drives Submenu

42 | ni.com | cRIO-904x User Manual

Page 43

• CPU Configuration Submenu

• USB Configuration Submenu

Power/Wake Configuration Submenu

The Power/Wake configuration submenu contains the power and wake settings for the chipset

and cRIO-904x. The factory default settings provide the most compatible and optimal

configuration.

• Ring Indicator Wake—This setting enables or disables the ability to wake a powered-off

system using the Ring Indicator pin of the RS-232 serial port. The default value is

Disabled.

• Wake on Trigger— This setting enables or disables the ability to wake a powered-off

system using a trigger programmed in software. The default value is Disabled.

SATA Drives Submenu

The SATA drives submenu contains the hard disk drive (HDD) interfaces settings. The factory

default settings provide the most compatible and optimal configuration.

• Chipset SATA—This setting enables or disables the Chipset SATA controller. The default

value is Enabled.

• Onboard Storage—This item displays the onboard drive detected in the system.

CPU Configuration Submenu

The CPU configuration submenu contains the CPU settings for the cRIO-904x. The factory

default settings provide the most compatible and optimal configuration.

CPU Power Management

The CPU Power Management submenu contains CPU power management configuration

options. The factory default settings provide the most compatible and optimal configuration.

• Burst Mode—This setting allows the processor to operate at frequencies higher than the

base processor frequency. Valid options are Enabled and Disabled. The default value is

Disabled. If enabled, the processor will run at the burst frequency if the maximum power

and temperature specifications of the processor are not exceeded. If disabled, the

processor with run at the base operating frequency. Enabling burst may increase

application jitter. As a result, NI recommends disabling burst for real time applications.

USB Configuration Submenu

The USB configuration submenu contains the USB host ports settings. The factory default

settings provide the most compatible and optimal configuration.

• Dual Role Type-C Port FW Ver— This item shows the firmware version for the dual role

USB type-C port.

• Display Port Type-C FW Ver— This items shows the firmware version for the

DisplayPort USB type-C port.

• USB Devices—This item lists the total number of devices detected in the system,

categorized by device type.

cRIO-904x User Manual | © National Instruments | 43

Page 44

• Legacy USB Support—This setting specifies whether legacy USB support is enabled.

Legacy USB support refers to the ability to use a USB keyboard and mouse during

system boot or in a legacy operating system such as DOS. Valid options are Enabled,

Disabled, and Auto. The default value is Disabled.

• Overcurrent Reporting—This setting allows the BIOS to notify the operating system

about any USB ports that source too much current. The default value is Enabled.

Hardware overcurrent protection is always active and cannot be disabled.

• USB Transfer Timeout—This setting specifies the timeout value for Control, Bulk, and

Interrupt USB transfers. The default value is 20 seconds.

• Device Reset Timeout—This setting specifies the number of seconds the POST waits for

a USB mass storage device to start. The default value is 20 seconds.

• Device Power-Up Delay—This setting specifies the maximum time a device takes before

enumerating. Valid options are Auto and Manual. The default value is Auto. When set to

Auto, a root port is granted 100 ms, and the delay value of a hub port is assigned from the

hub descriptor.

Boot Setup Menu

The Boot Setup menu contains setting related to the boot process and the boot device priority.

• Boot Settings Configuration Submenu—This item accesses the Boot Settings

Configuration submenu.

• Boot Option Priorities—These settings specify the order in which the BIOS checks for

bootable devices, including the local hard disk drive, removable devices such as USB

flash disk drives or USB CD-ROM drives, or the PXE network boot agent. The BIOS

first attempts to boot from the device associated with 1st Boot Device, followed by 2nd

Boot Device and 3rd Boot Device. If multiple boot devices are not present, the BIOS

setup utility does not display all of these configuration options. To select a boot device,

press <Enter> on the desired configuration option and select a boot device from the

resulting menu. You can also disable certain boot devices by selecting Disabled.

Note Only one device of a given type is shown in this list. If more than one

device of the same type exists, use the appropriate device BBS priorities

submenu to re-order the priority of devices of the same type.

Boot Settings Configuration Submenu

The Boot Settings Configuration submenu applies alternate configurations to boot settings.

The factory default settings provide the most compatible and optimal configuration.

• Setup Prompt Timeout—This setting specifies the number of seconds the system waits

for a BIOS Setup menu keypress (the <Delete> key). The default value is 10 seconds.

• Bootup NumLock State—This setting specifies the power-on state of the keyboard

NumLock setting. The default value is On.

44 | ni.com | cRIO-904x User Manual

Page 45

Save & Exit Menu

The Save & Exit setup menu contains all available options for exiting, saving, and loading the

BIOS default configuration. As an alternative to this menu, press <F9> to load optimal BIOS

default settings and <F10> to save changes and exit setup.

The Save & Exit setup menu includes the following settings:

• Save Changes and Reset—This setup utility then exits and reboots the cRIO-904x. Any

changes made to BIOS settings are stored in NVRAM. The <F10> key also selects this

option.

• Discard Changes and Reset—Any changes made to BIOS settings during this session of

the BIOS setup utility are discarded. The setup utility then exits and reboots the

controller. The <Esc> key can also be used to select this option.

• Save Changes—Changes made to BIOS settings during this session are committed to

NVRAM. The setup utility remains active, allowing further changes.

• Discard Changes—Any changes made to BIOS settings during this session of the BIOS

setup utility are discarded. The BIOS setup continues to be active.

• Restore Defaults—This option restores all BIOS settings to the factory default. This

option is useful if the controller exhibits unpredictable behavior due to an incorrect or

inappropriate BIOS setting. Notice that any nondefault settings such as boot order,

passwords, and so on are also restored to their factory defaults. The <F9> key also selects

this option.

• Save As User Defaults—This option saves a copy of the current BIOS settings as the

User Defaults. This option is useful for preserving custom BIOS setup configurations.

• Restore User Defaults—This option restores all BIOS settings to the user defaults. This

option is useful for restoring previously preserved custom BIOS setup configurations.

• Boot Override—This option lists all possible bootable devices and allows the user to

override the Boot Option Priorities list for the current boot. If no changes have been made

to the BIOS setup options, the system will continue booting to the selected device without

first rebooting. If BIOS setup options have been changed and saved, a reboot will be

required and the boot override selection will not be valid.

cRIO-904x User Manual | © National Instruments | 45

Page 46

Choosing Your Programming Mode

The cRIO-904x supports three programming modes. The programming modes are set per slot

on a chassis.

Real-Time Enables you to use C Series modules directly from LabVIEW Real-

Time, using NI DAQmx.

C Series modules appear under the Real-Time Resources item in the

MAX Project Explorer window and I/O channels appear as I/O

variables under the modules. To use I/O variables, you drag and drop

them from the Project Explorer window to LabVIEW Real-Time VIs.

Use this mode to make the C Series module behave like it is in a

CompactDAQ controller, using the Real-Time NI-DAQmx and NIXNET drivers to communicate, and access the four counter/timers and

the PFI trigger connector on the controller.

Real-Time

Scan (IO

Variables)

Enables you to use C Series modules directly from LabVIEW RealTime, using I/O variables.

C Series modules that you use in Scan Interface mode appear under

the Real-Time Scan Resources item in the MAX Project Explorer

window and I/O channels appear as I/O variables under the modules.

To use I/O variables, you drag and drop them from the Project

Explorer window to LabVIEW Real-Time VIs.

In this mode, you do not need to do any LabVIEW FPGA

development. LabVIEW programs the FPGA for you with a fixed

FPGA bitfile that communicates with all the C Series modules that RT

Scan mode supports. LabVIEW also sends C Series data to the RealTime host to be displayed in I/O variables. Real-Time Scan mode also

enables you to dynamically detect which types of C Series modules

are plugged into chassis slots.

46 | ni.com | cRIO-904x User Manual

Page 47

LabVIEW

FPGA

Enables you to use C Series modules from LabVIEW FPGA VIs.

C Series modules appear directly under the FPGA Target item in the

MAX Project Explorer window and I/O channels appear as FPGA I/O

items under the FPGA Target. To access the I/O channels, you either

configure FPGA I/O Nodes in a LabVIEW FPGA VI or drag and drop

the I/O channels from the Project Explorer window to a LabVIEW

FPGA VI block diagram.

Use this mode to add more flexibility, customization, timing, and

synchronization to your applications. To use the CompactRIO system

in FPGA mode, you must either have the LabVIEW FPGA Module

installed on the host computer, or have access to a compiled bitfile

that you can download to the FPGA. In either case, you use the Open

FPGA VI Reference function in a LabVIEW Real-Time VI to access

the FPGA VI or bitfile.

Use the following table to assist you in choosing a supported programming mode for your

task.

Table 18. Supported Programming Modes for Popular Tasks

Task Real-Time Real-Time Scan (IO

Variables)

LabVIEW FPGA

Control rates up to 1 kHz ■ ■

Control rates between 1 kHz and

■ ■

5 kHz (application dependent)

Control rates over 5 kHz ■

High-speed waveform acquisition ■ ■

Note Some C Series modules can only be used in certain programming modes. For

module-specific software support information, visit ni.com/info and enter the Info

Code swsupport.

To learn more about using the cRIO-904x in Real-Time mode, refer to the following sections:

• Analog Input with NI-DAQmx

• Analog Output with NI-DAQmx

• Digital Input/Output with NI-DAQmx

• PFI with NI-DAQmx

• Counters with NI-DAQmx

Analog Input with NI-DAQmx

To perform analog input measurements, install a supported analog input C Series module into

any slot on the cRIO controller and set the programming mode to Real-Time (NI-DAQmx)

mode. The measurement specifications, such as number of channels, channel configuration,

sample rate, and gain, are determined by the type of C Series module used. For more

cRIO-904x User Manual | © National Instruments | 47

Page 48

information and wiring diagrams, refer to the documentation included with your C Series

modules.

The cRIO controller has eight input timing engines, which means that up to eight hardwaretimed analog input tasks can be running at a time on the controller. An analog input task can

include channels from multiple analog input modules. However, channels from a single

module cannot be used in multiple tasks.

Multiple timing engines allow the cRIO controller to run up to eight analog input tasks

simultaneously, each using independent timing and triggering configurations. The eight timing

engines are it0, it1,…it7.

Analog Input Triggering Signal

A trigger is a signal that causes an action, such as starting or stopping the acquisition of data.

When you configure a trigger, you must decide how you want to produce the trigger and the

action you want the trigger to cause. The cRIO controller supports internal software triggering,

external digital triggering, analog triggering, and internal time triggering.

Three triggers are available: Start Trigger, Reference Trigger, and Pause Trigger. An analog or

digital signal can initiate these three trigger actions. C Series Parallel digital input modules and

the controller’s integrated PFI trigger line can be used in any controller slot to supply a digital

trigger. To find your module triggering options, refer to the documentation included with your

C Series modules. For more information about using digital modules for triggering, refer to the

Digital Input/Output with NI-DAQmx section.

Refer to the AI Start Trigger Signal, AI Reference Trigger Signal, and AI Pause Trigger Signal

sections for more information about the analog input trigger signals.

Hardware-Timed Single Point (HWTSP) Mode

In HWTSP mode, samples are acquired or generated continuously using hardware timing and

no buffer. You must use the sample clock or change detection timing types. No other timing

types are supported.

Use HWTSP mode if you need to know if a loop executes in a given amount of time, such as

in a control application. Because there is no buffer, if you use HWTSP mode, ensure that reads

or writes execute fast enough to keep up with hardware timing. If a read or write executes late,

it returns a warning.

Note DSA modules do not support HWTSP mode.

Analog Input Timing Signals

The cRIO controller features the following analog input timing signals:

• AI Sample Clock Signal*

• AI Sample Clock Timebase Signal

• AI Start Trigger Signal*

48 | ni.com | cRIO-904x User Manual

Page 49

• AI Reference Trigger Signal*

Programmable

Clock

Divider

Sample Clock

Timebase

PFI

Analog Comparison Event

Ctr n Internal Output

AI Sample

Clock

Sigma-Delta Module Internal Output

Analog Comparison

Event

80 MHz Timebase

20 MHz Timebase

PFI

13.1072 MHz Timebase

12.8 MHz Timebase

10 MHz Timebase

100 kHz Timebase

• AI Pause Trigger Signal*

Signals with an * support digital filtering. Refer to the PFI Filters section for more

information.

Refer to the AI Convert Clock Signal Behavior For Analog Input Modules section for more

information about AI Convert Clock signals and the cRIO controller.

AI Sample Clock Signal

A sample consists of one reading from each channel in the AI task. Sample Clock signals the

start of a sample of all analog input channels in the task. The sample clock can be generated

from external or internal sources as shown in the figure below.

Figure 34. AI Sample Clock Timing Options

Routing the Sample Clock to an Output Terminal

You can route Sample Clock to any output PFI terminal. Sample Clock is an active high pulse

by default.

AI Sample Clock Timebase Signal

The AI Sample Clock Timebase signal is divided down to provide a source for Sample Clock.

AI Sample Clock Timebase can be generated from external or internal sources. AI Sample

Clock Timebase is not available as an output from the controller.

cRIO-904x User Manual | © National Instruments | 49

Page 50

AI Start Trigger Signal

Use the Start Trigger signal to begin a measurement acquisition which consists of one or more