Page 1

FIELDPOINT OPERATING INSTRUCTIONS AND SPECIFICATIONS

cFP-2200/2210/2220

Intelligent Real-Time Controllers for Compact FieldPoint

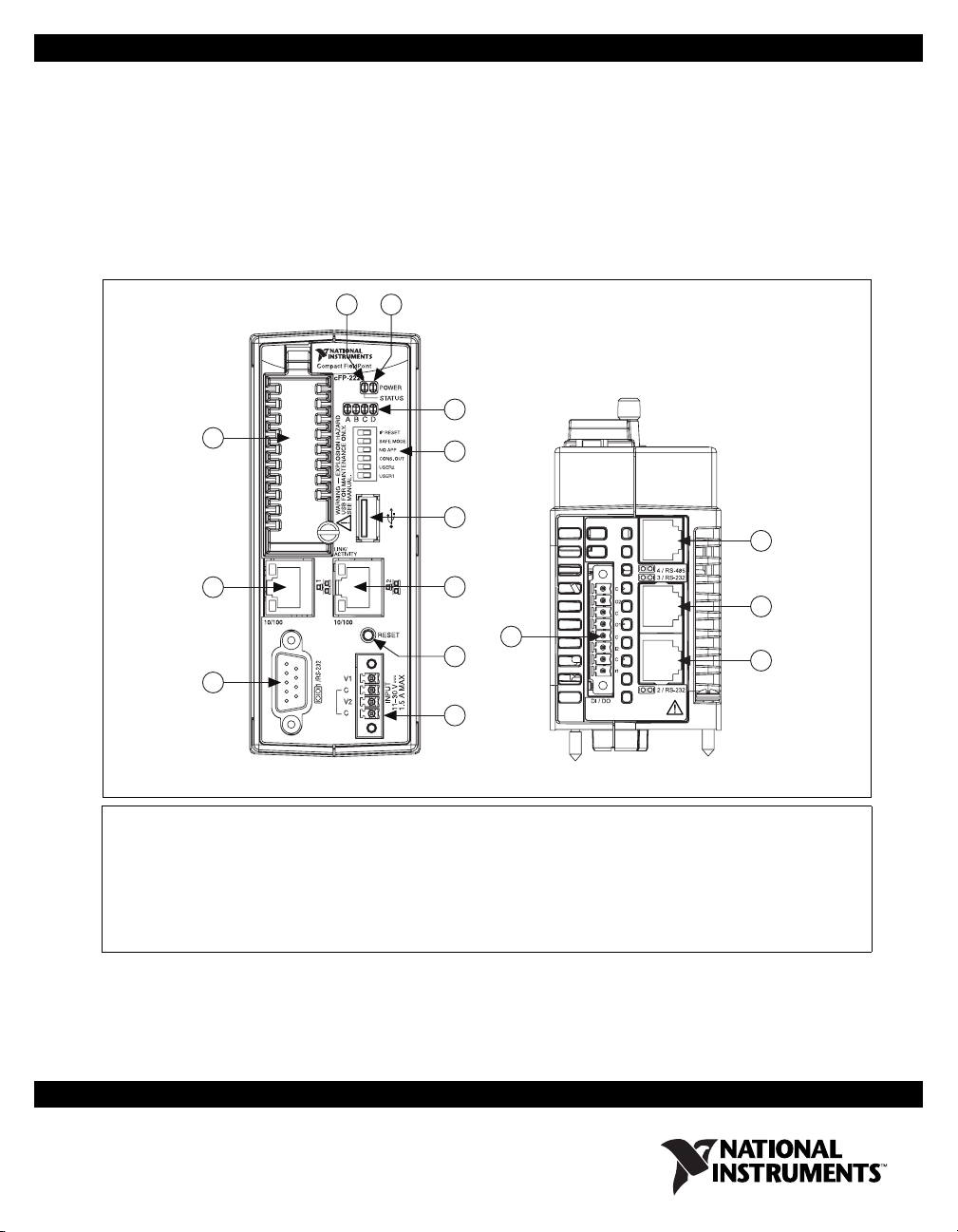

4

5

6

3

7

8

13

2

1

Front

1 RS-232 Serial Port

2 RJ-45 Ethernet Port 1

3 Removable Compact Flash (cFP-2220 Only)

4 Status LED

5 Power LED

6 User-Configurable LEDs

7 DIP Switches

8 USB Port (cFP-2220 Only)

9

12

10

11

BottomBottom

9 RJ-45 Ethernet Port 2 (cFP-2220 Only)

10 Reset Button

11 Power Connector

12 Digital Input/Output Terminals (cFP-2220 Only)

13 RS-485 Serial Port (cFP-2220 Only)

14 RS-232 Serial Port (cFP-2220 Only)

15 RS-232 Serial Port (cFP-2210 and cFP-2220 Only)

Figure 1. cFP-22xx, Front and Bottom Views

14

15

Page 2

This document describes how to mount the cFP-2200/2210/2220

controllers, how to connect the controllers to networks, and how to use

the features of the controllers. This document also contains specifications

for the controllers. In this document, the cFP-2200/2210/2220 controllers

are referred to inclusively as the cFP-22xx.

What You Need to Install the cFP-22xx

❑ cFP-22xx intelligent real-time controller

❑ cFP-BP-4 or cFP-BP-8 Compact FieldPoint backplane

❑ Compact FieldPoint I/O modules

❑ Compact FieldPoint connector blocks and/or cables

❑ Ethernet cable

❑ Mounting hardware (DIN rail, panel-mount, or rack-mount accessory)

❑ Two M4 or number 10 panhead screws (for panel mounting only)

❑ Number 2 Phillips screwdriver

❑ 14 AWG (1.6 mm) wire with ring lug to fit #8 screw

❑ 11–30 VDC Power supply

❑ PC running Windows

❑ FieldPoint software 6.0.1 or later

❑ LabVIEW Real-Time Module 8.5.1 or later

Mounting the Compact FieldPoint Backplane

You can mount the cFP-BP-x backplane on a 35 mm DIN rail, on a panel,

or in a standard 19 in. rack. NI recommends DIN rail mounting for the

cFP-BP-4 only. Use panel mounting or rack mounting for the cFP-BP-8.

Use the panel mounting method for high shock and vibration applications.

Before using any mounting method, record the serial number from the back

of the backplane. You will be unable to read the serial number after you

have mounted the backplane.

Each set of mounting instructions in this document includes an instruction

to connect the protective earth (PE) ground terminal on the cFP-BP-x

backplane to the system safety ground. The backplane PE ground terminal

cFP-2200/2210/2220 2 ni.com

Page 3

has the following symbol stamped beside it: . Connect the backplane PE

ground terminal to safety ground using 14 AWG (1.6 mm) wire with a ring

lug. Use the 5/16 in. panhead screw shipped with the backplane to secure

the ring lug to the backplane PE ground terminal.

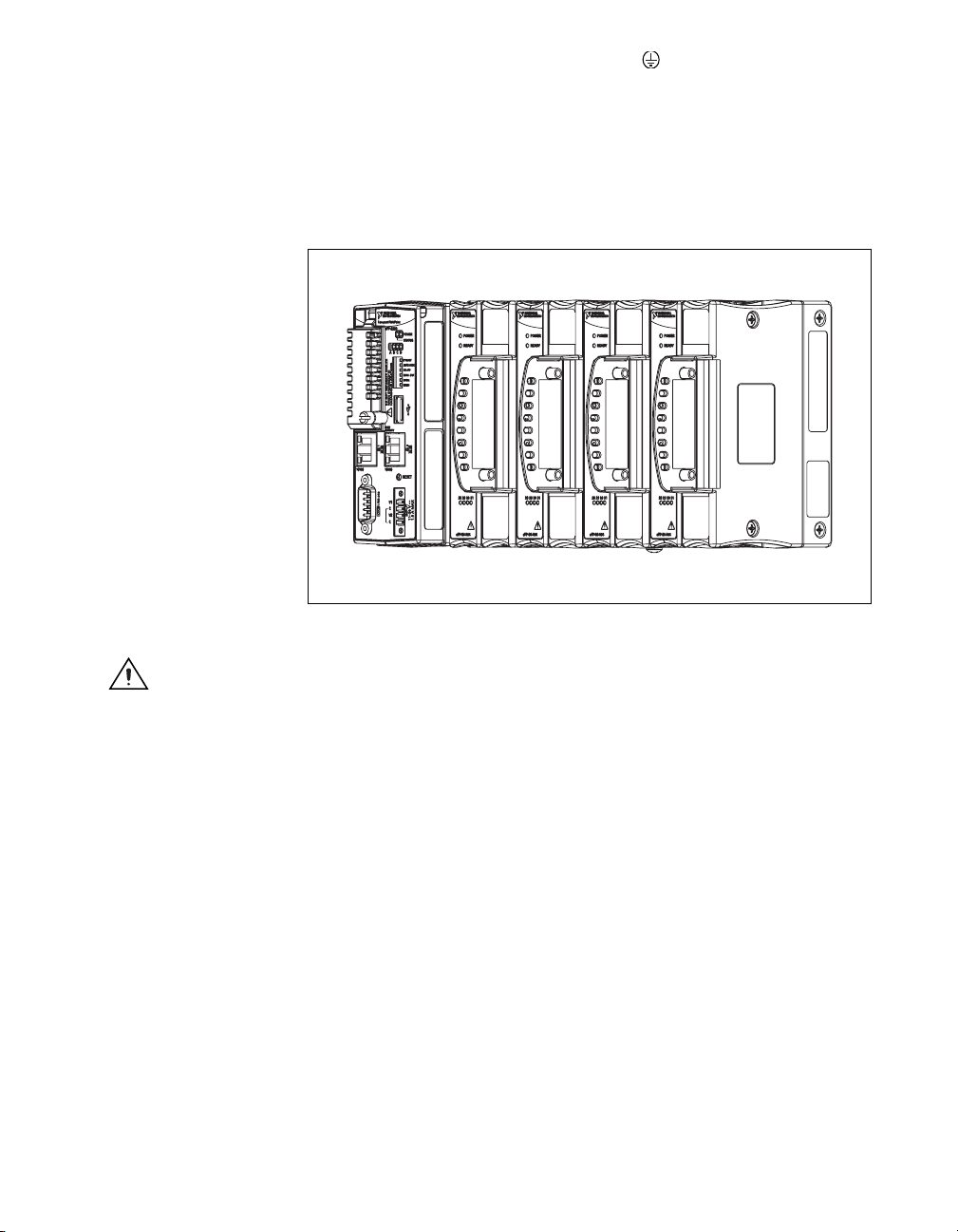

To ensure maximum cooling efficiency, mount the Compact FieldPoint so

that the I/O module vents are at the top and bottom, as shown in the

following figure:

Figure 2. cFP-22xx Installed on cFP-BP-4 Mounted Upright

Caution

Your installation must meet the following requirements for space and cabling

clearance:

• Allow at least 51 mm (2 in.) all around the backplane for air circulation.

• Allow 38 mm (1.5 in.) below and 51 mm (2 in.) above the controller.

© National Instruments Corporation 3 cFP-2200/2210/2220

Page 4

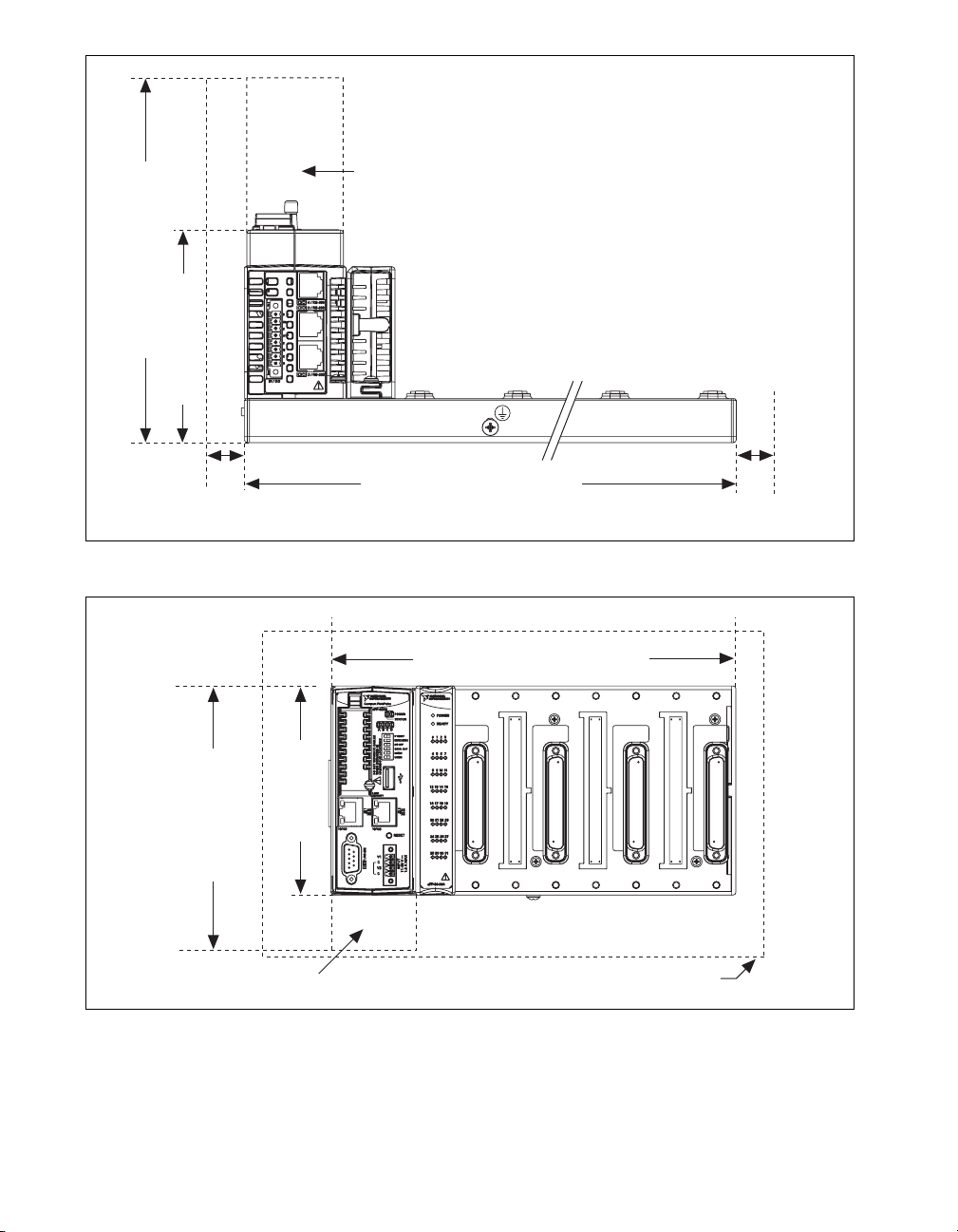

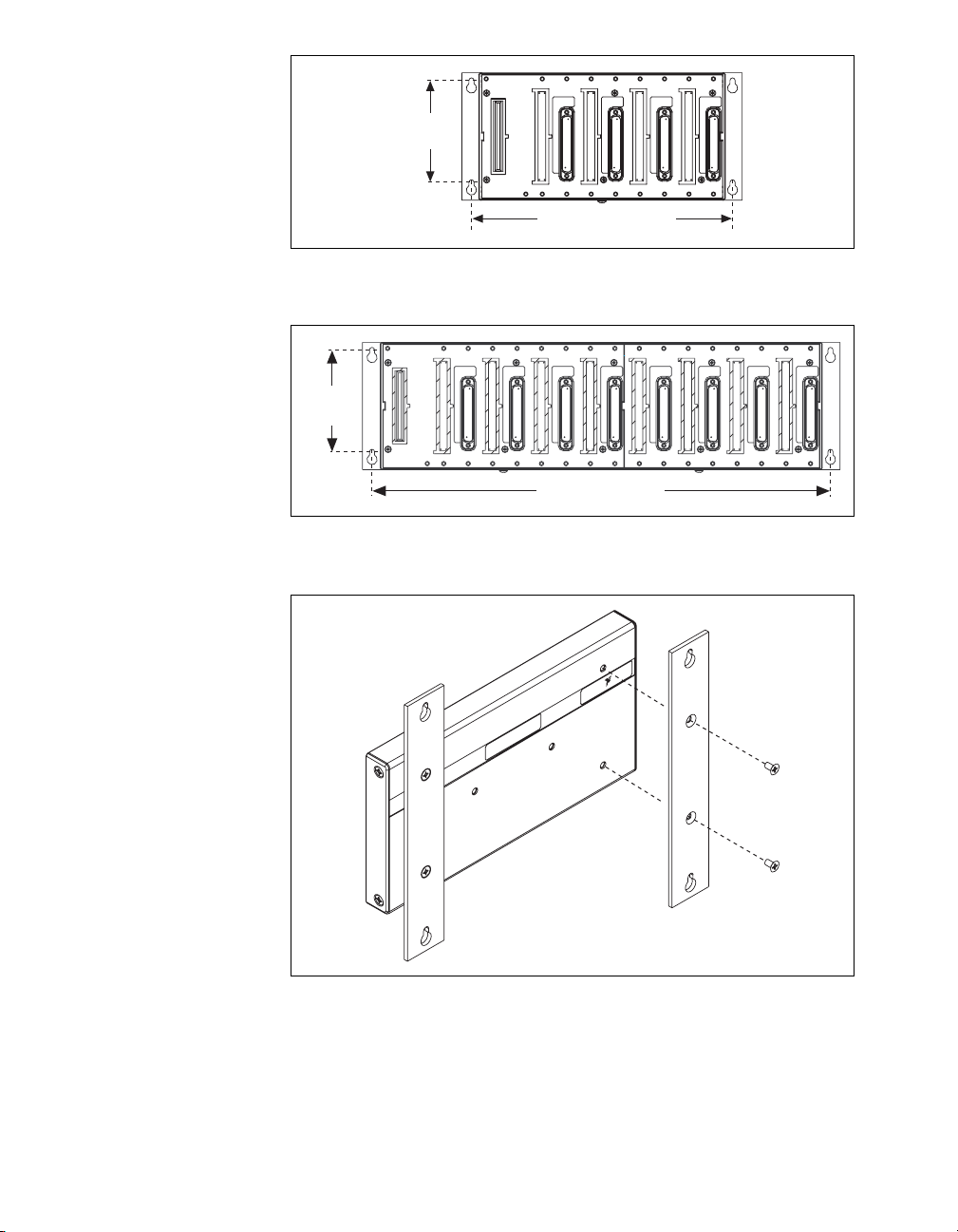

Cabling

Clearance

Min. 182 mm (7.18 in.)

106 mm (4.18 in.)

4 slots = 246 mm (9.68 in.)

8 slots = 441 mm (17.4 in.)

Cooling Outline 51 mm (2 in.) Cooling Outline 51 mm (2 in.)

Figure 3. cFP-22xx Installed on cFP-BP-x, Bottom View with Dimensions

4 slots = 246 mm (9.68 in.)

8 slots = 441 mm (17.4 in.)

127 mm

(5.00 in.)

(6.50 in.)

Min. 165 mm

Cabling Clearance Cooling Outline 51 mm (2 in.) All Around

Figure 4. cFP-22xx Installed on cFP-BP-4, Front View with Dimensions

cFP-2200/2210/2220 4 ni.com

Page 5

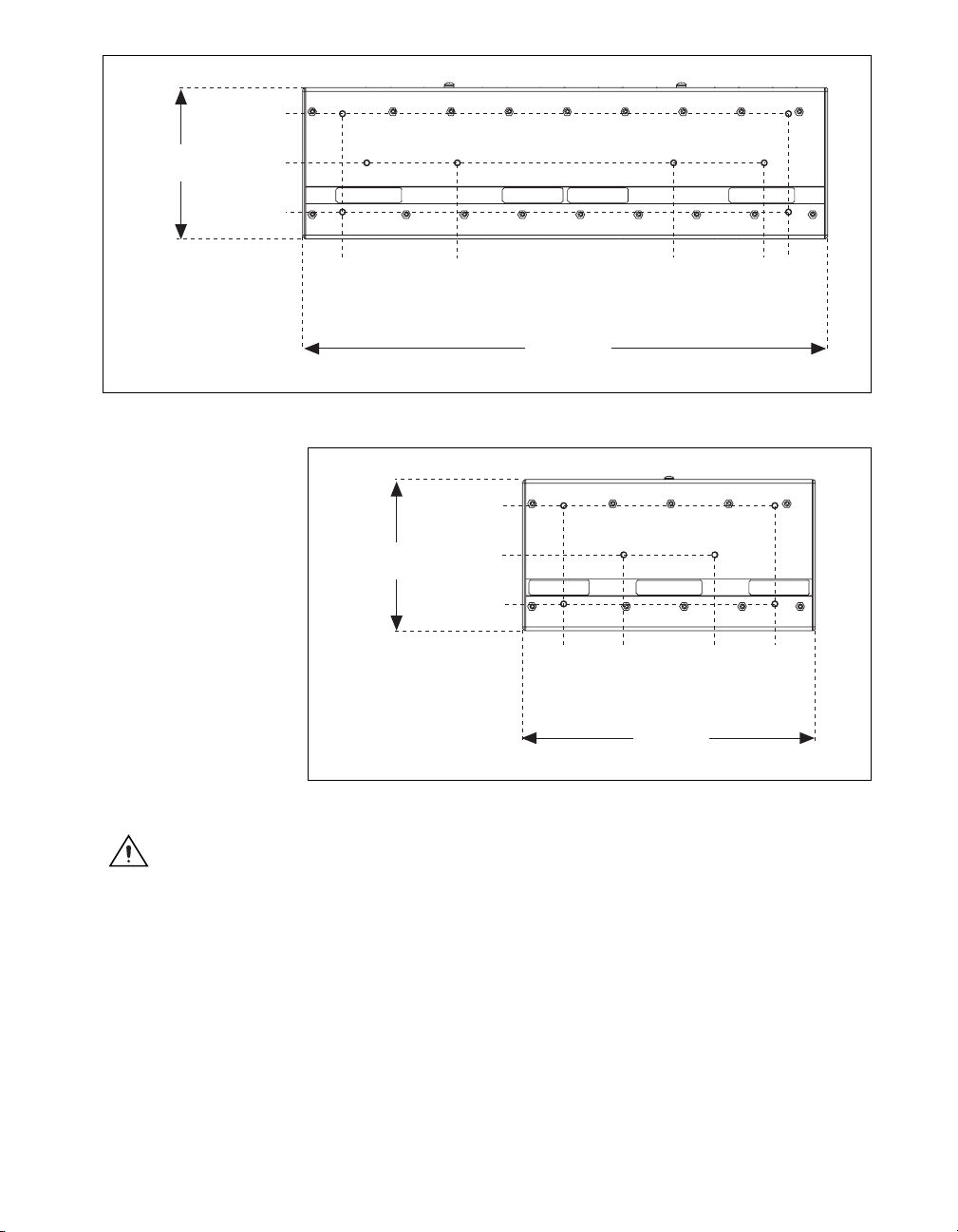

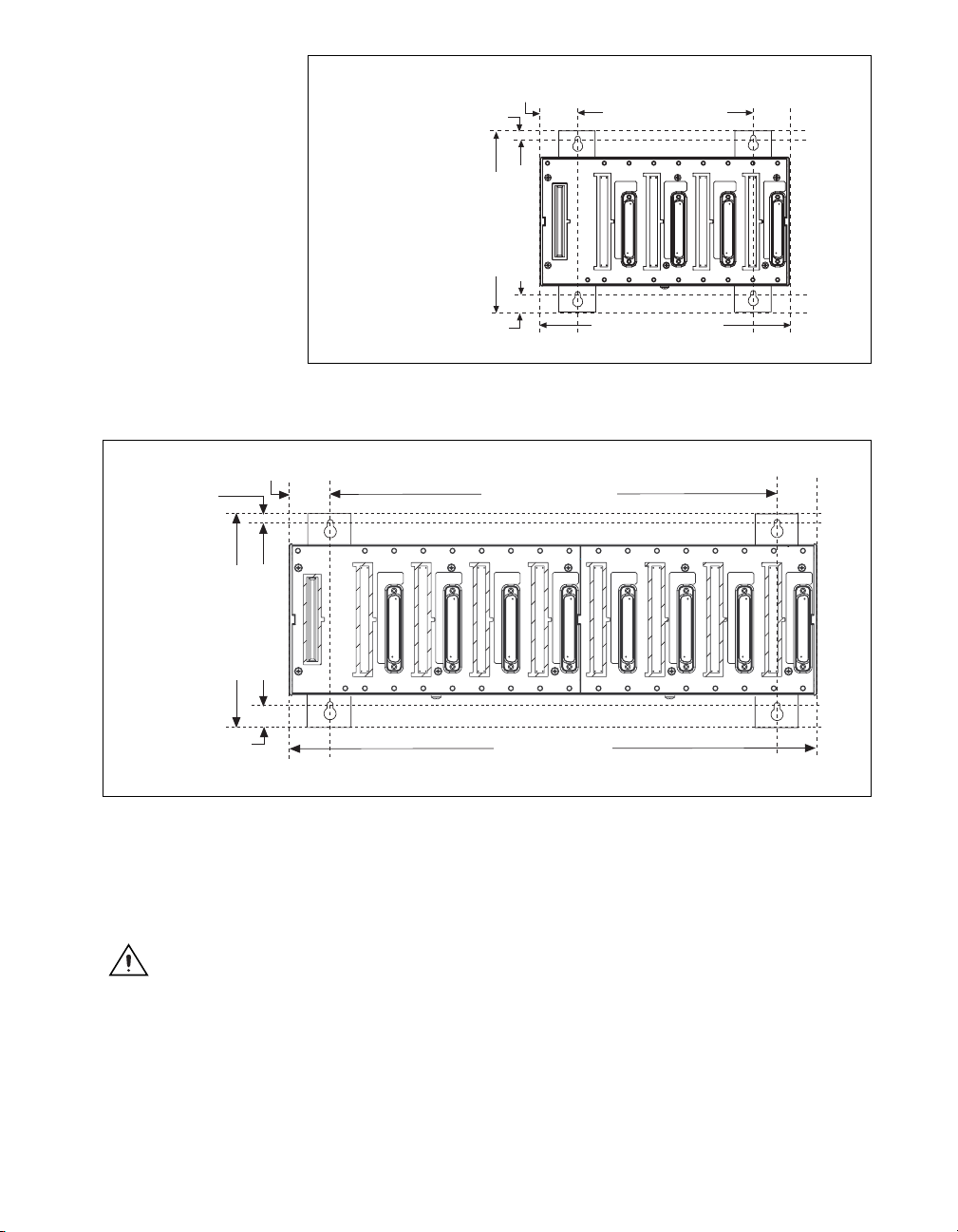

127.00 mm

(5.0 in.)

104.78 mm

(4.1 in.)

63.50 mm

(2.5 in.)

22.23 mm

(0.9 in.)

Caution

(1.3 in.)

33.15 mm

(5.1 in.)

129.54 mm

440.94 mm

(17.4 in.)

(12.3 in.)

311.40 mm

(15.3 in.)

387.60 mm

Figure 5. cFP-BP-8, Back View with Dimensions

104.74 mm

(4.1 in.)

127.00 mm

(5.0 in.)

63.46 mm

(2.5 in.)

22.19 mm

(0.9 in.)

(1.3 in.)

34.04 mm

(3.3 in.)

84.84 mm

245.87 mm

(9.6 in.)

(6.3 in.)

161.04 mm

(8.3 in.)

211.84 mm

Figure 6. cFP-BP-4, Back View with Dimensions

Make sure that no I/O modules are in the backplane before mounting it.

(16.1 in.)

407.80 mm

© National Instruments Corporation 5 cFP-2200/2210/2220

Page 6

Mounting the Backplane on a DIN Rail

The DIN rail mounting kit is NI part number 778614-01. You need one kit

to mount the cFP-BP-4 on a standard 35 mm DIN rail. Complete the

following steps to mount the backplane on a DIN rail.

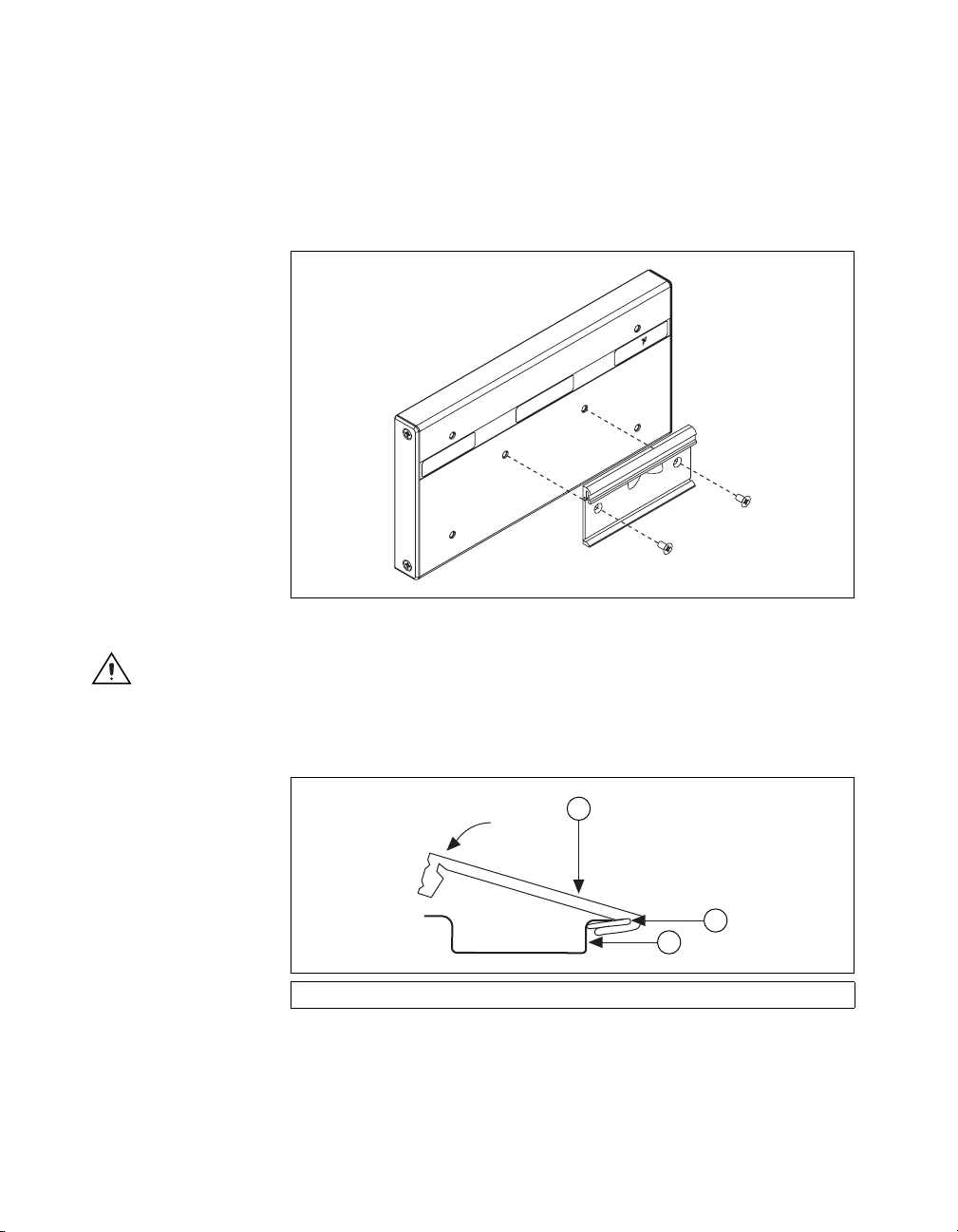

1. Fasten the DIN rail clip to the cFP-BP-4 using a number 2 Phillips

screwdriver and the 8-32 × 5/16 in. countersink screws shipped with

the mounting kit.

L

S

A

T

N

N

E

IO

T

M

A

U

R

N

T

S

IN

Figure 7. Installing the DIN Rail Clip on the cFP-BP-4

Caution

Do not use screws longer than 5/16 in. to fasten the DIN rail clip to the backplane.

2. Insert one edge of the DIN rail into the deeper opening of the DIN rail

clip, as shown in Figure 8.

1

2

3

1 DIN Rail Clip 2 DIN Rail Spring 3 DIN Rail

Figure 8. One Edge of DIN Rail Inserted in Clip

cFP-2200/2210/2220 6 ni.com

Page 7

3. Press down firmly on the backplane to compress the spring until the

clip locks in place on the DIN rail.

4. Connect the PE ground terminal on the backplane to safety ground.

Caution Disconnect power and make sure that no I/O modules are in the backplane before

removing it from the DIN rail.

Mounting the Backplane on a Panel

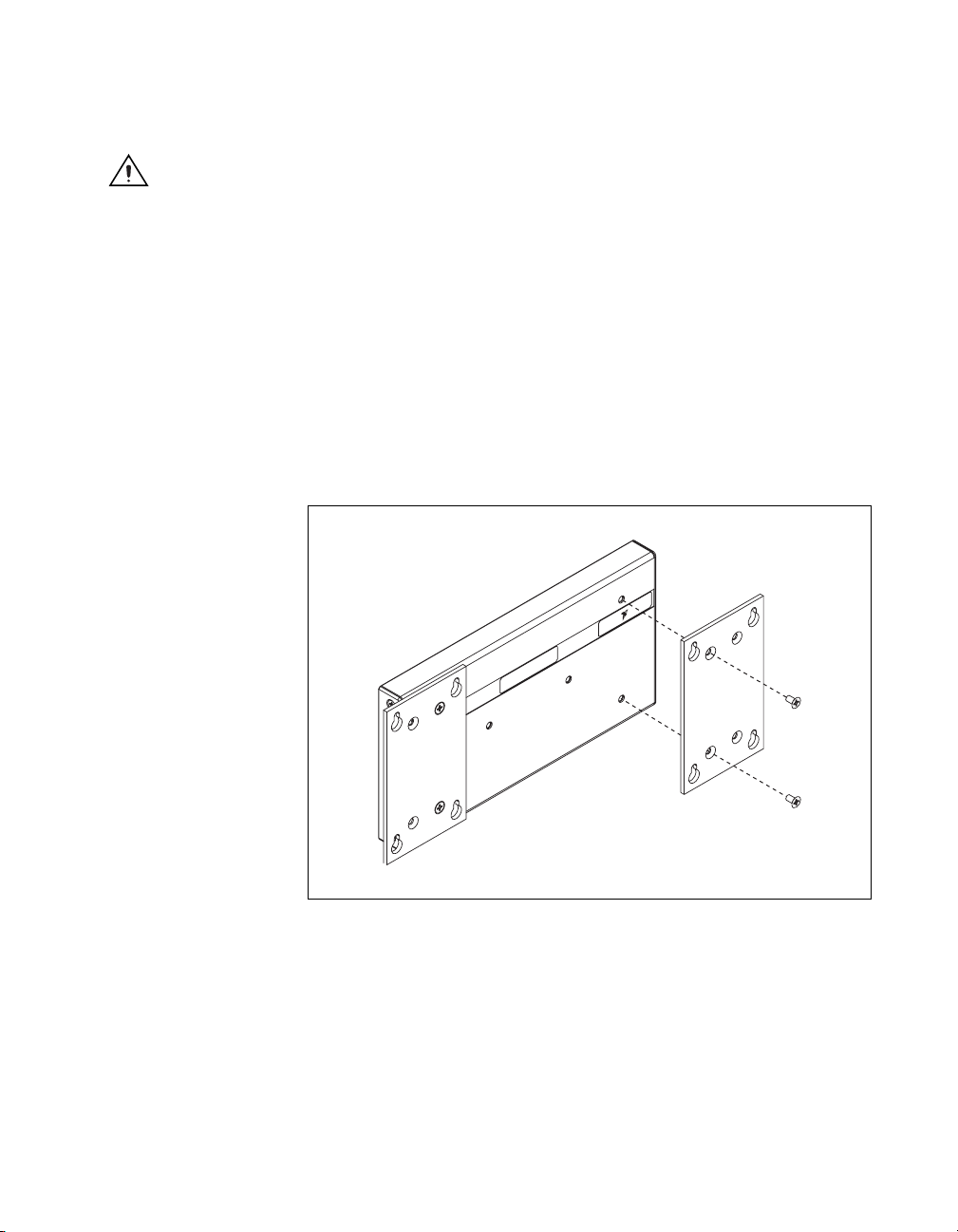

The horizontal panel-mount kit has mounting holes on the sides of the

backplane and is NI part number 778616-01. The vertical panel-mount kit

has mounting holes on the top and bottom of the backplane and is NI part

number 778688-01. Complete the following steps to mount the system on

a flat surface.

1. Fasten the panel-mount plates to the back of the cFP-BP-x using a

number 2 Phillips screwdriver and the 8-32 × 5/16 in. countersink

screws shipped with the kit. You must use these screws because they

are the correct depth and thread for the plates and backplane.

AL

NATION

INSTRUMENTS

Figure 9. Installing the Horizontal Panel-Mount Kit on the cFP-BP-4

© National Instruments Corporation 7 cFP-2200/2210/2220

Page 8

102 mm

(4 in.)

260 mm (10.25 in.)

Figure 10. cFP-BP-4 with Horizontal Panel Mount Kit Installed,

Front View with Dimensions

102 mm

(4 in.)

457 mm (18 in.)

Figure 11. cFP-BP-8 with Horizontal Panel-Mount Kit Installed,

Front View with Dimensions

L

S

A

T

N

N

E

IO

T

M

A

RU

N

ST

IN

Figure 12. Installing the Vertical Panel-Mount Kit on the cFP-BP-4

cFP-2200/2210/2220 8 ni.com

Page 9

34.0 mm (1.34 in.)

7.6 mm (0.30 in.)

152 mm (6 in.)

178 mm (7 in.)

178 mm (7.0 in.)

7.6 mm

(0.30 in.)

17.8 mm

(0.70 in.)

33.1 mm (1.31 in.)

152 mm (6 in.)

178 mm (7 in.)

17.8 mm (0.70 in.)

246 mm (9.7 in.)

Figure 13. cFP-BP-4 with Vertical Panel-Mount Kit Installed,

Front View with Dimensions

374 mm (14.7 in.)

457 mm (18 in.)

Figure 14. cFP-BP-8 with Vertical Panel-Mount Kit Installed,

Front View with Dimensions

2. Bolt or screw the plates to a panel.

3. Connect the PE ground terminal on the cFP-BP-x to safety ground.

Caution Disconnect power and make sure that no I/O modules are in the backplane before

removing it from the panel.

© National Instruments Corporation 9 cFP-2200/2210/2220

Page 10

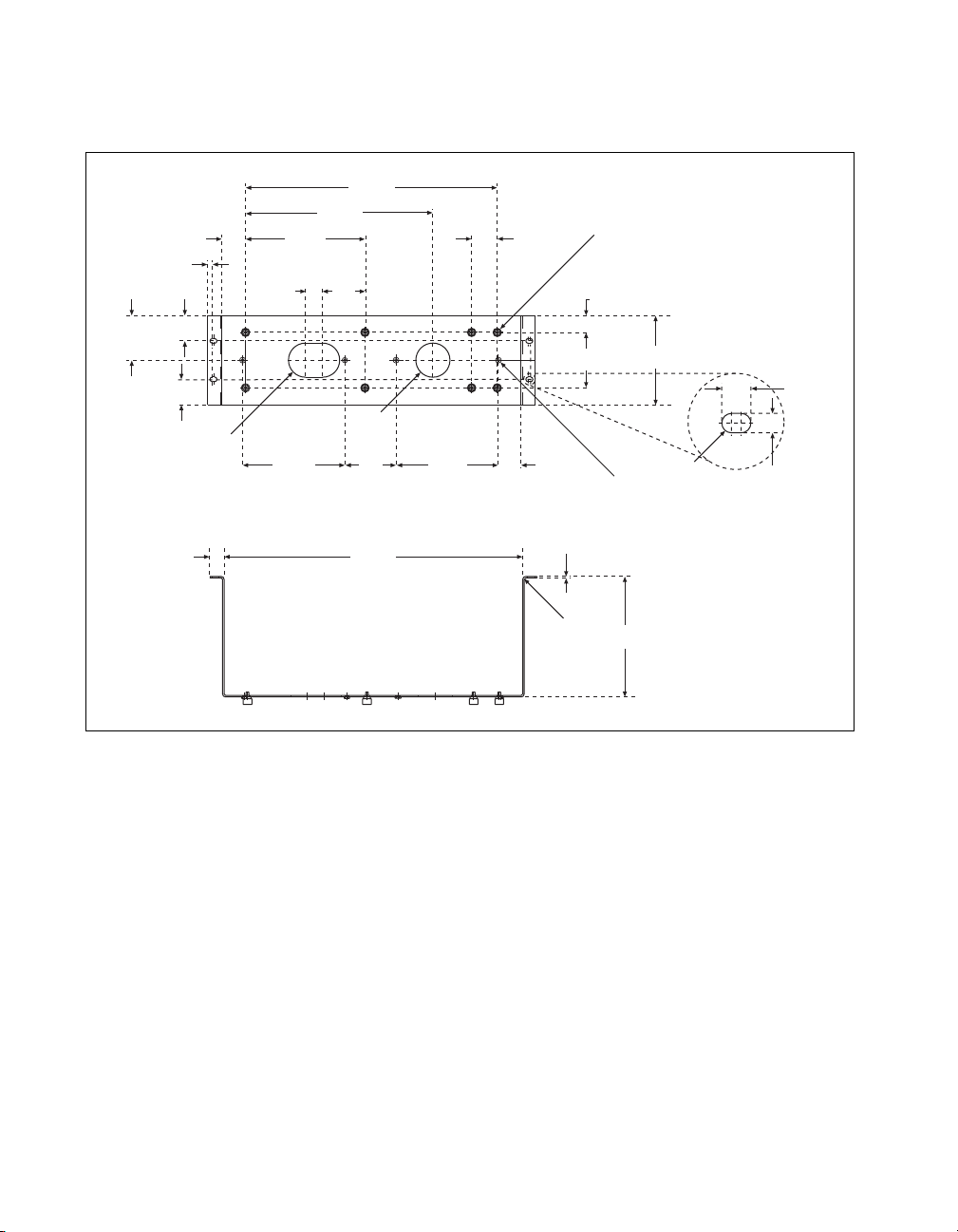

Mounting the Backplane in a Standard 19 in. Rack

The rack-mount kit for Compact FieldPoint is NI part number 778615-01.

The following figure shows the dimensions of the rack-mount kit.

374.65 mm

(14.750 in.)

278.89 mm

177.8 mm

(7.000 in.)

152.15 mm

(5.990 in.)

(10.980 in.)

63.07 mm

(2.483 in.)

Diameter

50.8 mm

(2.00 in.)

76.2 mm

(3.000 in.)

444.5 mm

(17.500 in.)

152.4 mm

(6.000 in.)

38.1 mm

(1.500 in.)

8× Diameter

7.92 mm

0.312 in.

()

25.02 mm (0.985 in.)

82.52 mm

(3.249 in.)

33.15 mm

(1.305 in.)

Diameter

6.35 mm

0.250 in.

()

2.29 mm

(0.090 in.)

66.29 mm

(2.610 in.)

34.93 mm

(1.375 in.)

2×

6.91 mm

(0.272 in.)

37.69 mm

(1.484 in.)

37.72 mm

(1.485 in.)

2×

21.34 mm

(0.840 in.)

2×

2× Radius

25.4 mm

(1.000 in.)

25.4 mm

(1.000 in.)

+0.07 mm

0 mm

+0.003 in.

–0.000 in.

132.56 mm

(5.219 in.)

+0.07 mm

–0.02 mm

+0.003 in.

–0.001 in.

Full Radius

4×

7.06 mm

(0.278 in.)

10.59 mm

(0.417 in.)

4× Radius

179.32 mm

2.29 mm

(0.090 in.)

(7.060 in.)

Figure 15. Dimensions of Rack-Mount Kit

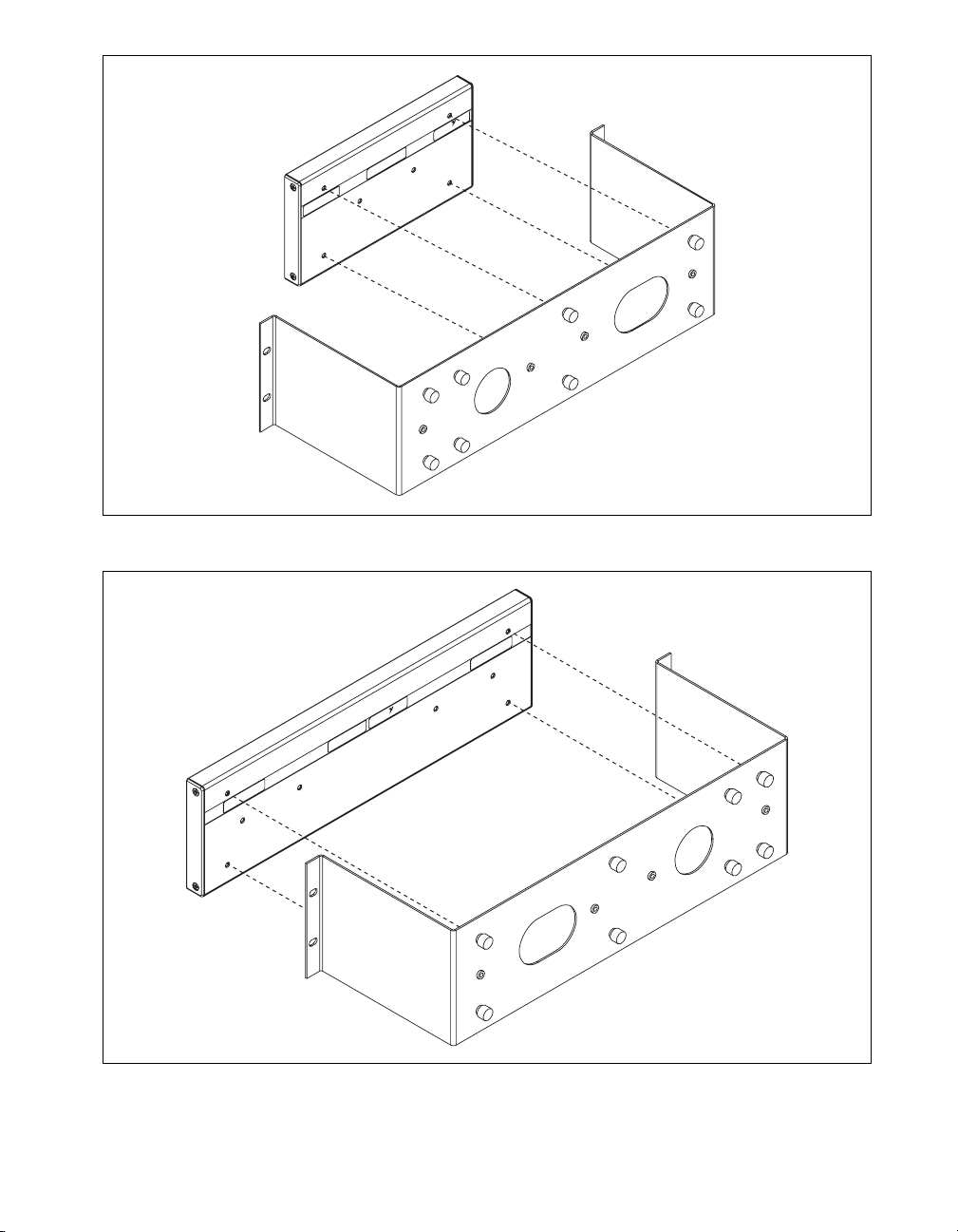

Complete the following steps to mount the system in a rack.

1. Fasten the rack-mount bracket to the back of the cFP-BP-x using the

captive screws on the bracket.

cFP-2200/2210/2220 10 ni.com

Page 11

AL

TS

ION

UMEN

NAT

INSTR

Figure 16. Installing the Rack-Mount Bracket on the cFP-BP-4

L

NA

NATIO

INSTRUMENTS

Figure 17. Installing the Rack-Mount Bracket on the cFP-BP-8

© National Instruments Corporation 11 cFP-2200/2210/2220

Page 12

2. Bolt the rack-mount bracket to a standard 19 in. rack.

3. Connect the PE ground terminal on the cFP-BP-x to safety ground.

Caution Disconnect power and make sure that no I/O modules are in the backplane before

removing it from the rack.

You can install an 8 in. DIN rail in the rack-mount kit to mount a power

supply such as the PS-5. The captive #10-32 nuts on the rack-mount kit

make it easy to attach a DIN rail. Use two #10-32 screws of 3/8 in. length

as shown in Figure 18. If you want to install flat washers under the screw

heads, use a slightly longer screw, up to 1/2 in. length. If you need more

DIN rail space, you can install an 18 in. rail in a second rack-mount kit

using four #10-32 screws.

1

2

3

4

1 cFP-BP-4 Backplane

2 Captive #10-32 Nuts

Figure 18. Installing an 8 in. DIN Rail in the Rack-Mount Kit

cFP-2200/2210/2220 12 ni.com

3 8 in. DIN Rail

4 #10-32 Screws, 3/8–1/2 in.

Page 13

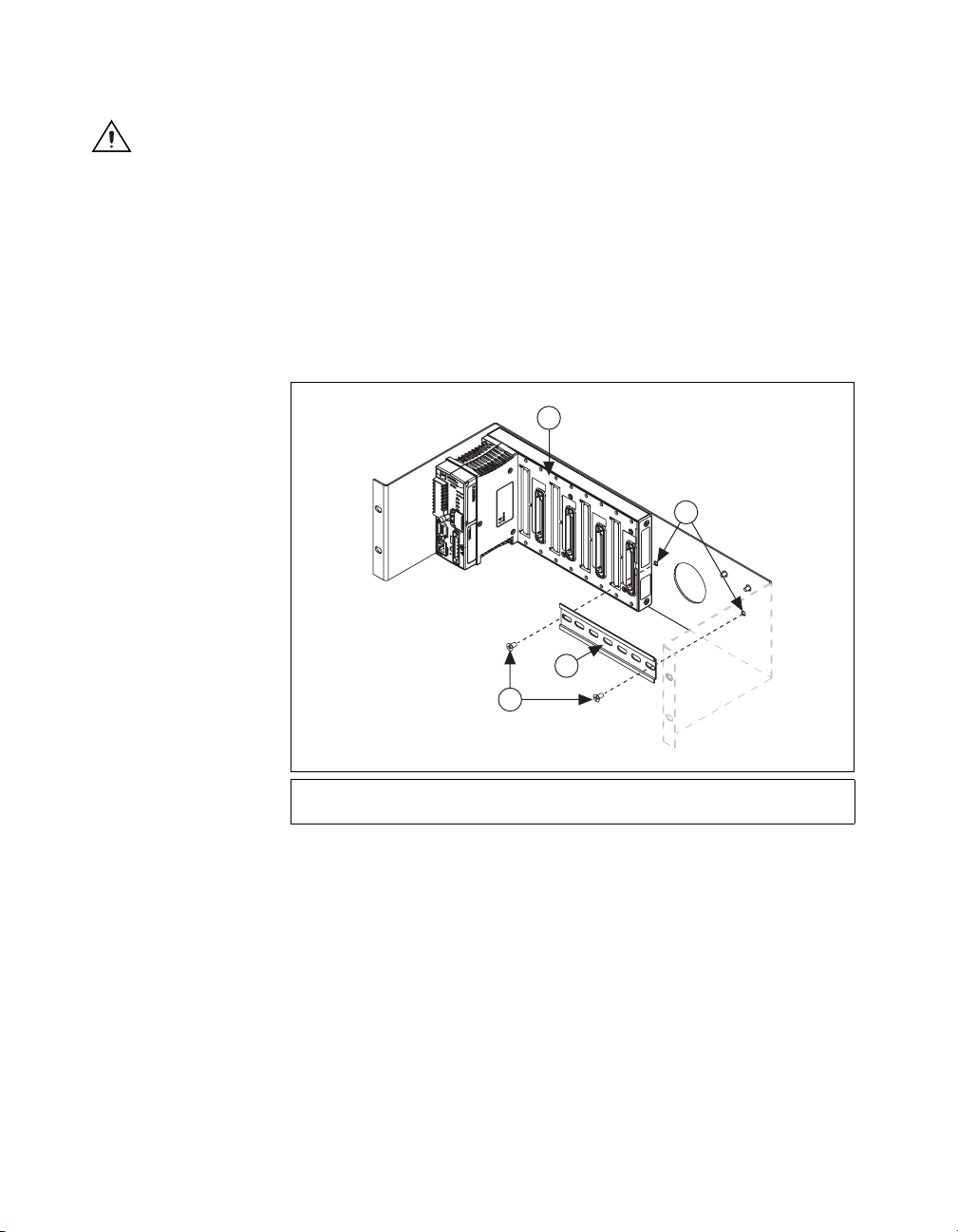

Installing the cFP-22xx on the Backplane

1. Make sure that no power is connected to the controller.

2. Make sure that the controller is right side up with the NI logo at the top,

and align the captive screws on the controller with the holes on the

backplane.

3. Seat the card edge at the back of the controller in the card-edge

connector on the backplane.

4. Press the controller firmly to seat it on the backplane.

Figure 19. Installing the Controller on the Backplane

5. Using a number 2 Phillips screwdriver with a shank of at least 64 mm

(2.5 in.) length, tighten the captive screws to 1.1 N · m (10 lb · in.) of

torque.

© National Instruments Corporation 13 cFP-2200/2210/2220

Page 14

Installing I/O Modules on the Backplane

1. Align the captive screws on the I/O module with the holes on the

backplane.

2. Press firmly to seat the I/O module on the backplane.

3. Using a number 2 Phillips screwdriver with a shank of at least 64 mm

(2.5 in.) length, tighten the captive screws to 1.1 N · m (10 lb · in.) of

torque.

4. Repeat this procedure to install additional I/O modules on the

backplane.

Figure 20. Installing an I/O Module on the Backplane

cFP-2200/2210/2220 14 ni.com

Page 15

Installing Connector Blocks on the Backplane

In order to connect I/O modules to input signals or loads, you need to install

a cFP-CB-x connector block or other connectibility accessory for each I/O

module on the backplane. Use the connector socket to the right of each I/O

module socket.

Caution Do not insert or remove connector blocks or other connectivity accessories while

power is applied to them.

1. Wire signals or loads as described in the I/O module and connector

block operating instructions.

Caution Hazardous voltage wiring should be performed by qualified personnel and in

accordance with local electrical standards.

2. Align the captive screws on the connector block with the holes on the

backplane.

3. Press firmly to seat the connector block on the backplane.

© National Instruments Corporation 15 cFP-2200/2210/2220

Page 16

Figure 21. Installing a Connector Block on the Backplane

4. Using a number 2 Phillips screwdriver with a shank of at least 64 mm

(2.5 in.) length, tighten the captive screws to 1.1 N · m (10 lb · in.) of

torque.

5. Repeat this procedure to install additional connector blocks on the

backplane.

cFP-2200/2210/2220 16 ni.com

Page 17

Connecting the cFP-22xx to a Network

Connect the cFP-22xx to an Ethernet network using RJ-45 Ethernet port 1

on the controller front panel. Use a standard Category 5 (CAT-5) or better

Ethernet cable to connect the controller to an Ethernet hub, or use an

Ethernet crossover cable to connect the controller directly to a computer.

Caution To prevent data loss and to maintain the integrity of your Ethernet installation,

do not use a cable longer than 100 m. If you are using 100 Mbps Ethernet, National

Instruments recommends using a CAT-5 or better shielded twisted-pair Ethernet cable.

If you need to build your own cable, refer to the Cabling section for more

information about Ethernet cable wiring connections.

The host computer communicates with the controller over a standard

Ethernet connection. If the host computer is on a network, you must

configure the controller on the same subnet as the host computer. If neither

the host computer nor the controller is connected to a network, you can

connect the two directly using a crossover cable.

If you want to use the controller on a subnet other than the one the host

computer is on, first connect the controller on the same subnet as the host

computer. Use DHCP to assign an IP address or reassign a static IP address

for the subnet where you want to use the controller and physically move it

to the other subnet. The first time you configure the controller, you may

also have to install software on it. Refer to the Measurement & Automation

Explorer Help for more information about installing software on and

configuring the controller in Measurement & Automation Explorer

(MAX). Contact your network administrator if you need assistance

configuring the host computer and controller on the same subnet.

Using Ethernet Port 2 to Connect the cFP-2220 to Other FieldPoint Systems on the Network

You can use Ethernet port 2 to connect the cFP-2220 to another system on

a private network. You must first configure the second system with a static

IP address in MAX. For information about using Ethernet port 2, go to

ni.com/info and enter the infocode dualenet.

© National Instruments Corporation 17 cFP-2200/2210/2220

Page 18

Wiring Power to the cFP-22xx

The cFP-22xx requires an external power supply that meets the

specifications in the Power Requirements section. The cFP-22xx filters and

regulates the supplied power and provides power for all of the I/O modules.

You must connect a power supply to at least one pair of V and C terminals.

Optionally, you can connect a power supply to the other pair of V and

C terminals. The controller draws power from the power supply with the

higher voltage. The controller has one layer of reverse-voltage protection.

Caution In order to comply with standards and laws governing electromagnetic emissions

and compatibility, you must install the ferrite shipped with the controller. If you decide to

connect an optional second power supply, you must install a second, similar ferrite. You

can order the ferrite from

Complete the following steps to connect power supplies to the controller.

1. Install the ferrite 2–3 in. from the ends of the power wires. Wrap the

ni.com. The ferrite is NI part number 711849-01.

wires around one side of the ferrite so that they pass through the ferrite

twice, as shown in Figure 22.

Figure 22. Wrapping the Power Wires around the Ferrite

Figure 23. Closed Ferrite

cFP-2200/2210/2220 18 ni.com

Page 19

2. Install a tie wrap or other device on the power wires to secure the ferrite

in place near the controller power connector, as shown in Figure 24.

Figure 24. Ferrite Installed with Tie Wrap

3. Connect the positive lead of the power supply to the V1 terminal of the

COMBICON connector shipped with the cFP-22xx.

4. Connect the negative lead of the power supply to one of the C terminals

of the COMBICON connector.

5. Optionally, connect the positive lead of another power supply to the

V2 terminal and the negative lead to one of the C terminals of the

COMBICON connector.

6. Install the COMBICON connector on the front panel of the cFP-22xx.

Note The controller draws power from either V1 or V2 depending on which terminal has

a higher voltage. It does not draw power from both terminals. The controller switches

between V1 and V2 without affecting operation. If the output voltages of the two power

supplies are within 0.1–0.6 V of each other, the cFP-22xx can use either supply.

© National Instruments Corporation 19 cFP-2200/2210/2220

Page 20

Note The controller indicates which terminal it is using on the channel called Power

Source in software. A value of 0 indicates V2, and a value of 1 indicates V1. This behavior

is different from that of older Compact FieldPoint controllers. If your application uses

input from the Power Source channel, you must change your application to reflect the

change in channel behavior. You can either make the change in software or connect the

primary power supply to V2 and a backup power supply to V1.

Caution The C terminals are internally connected to each other. If you use two power

supplies, make sure that they share a common ground.

Caution The C terminals are internally connected to the controller chassis to prevent a

faulty ground connection from causing the chassis ground to float. If you reverse the input

voltage, the positive input voltage is connected directly to the chassis. The controller

has built-in reverse-voltage protection, but reversed voltage can damage connected

peripherals if the chassis ground is not reliably connected to earth ground.

Caution Do not tighten or loosen the terminal screws on the power connector while the

power connector is plugged into the controller or while the power supply is on.

Powering On the cFP-22xx

When you apply power to the cFP-22xx, the controller runs a power-on

self test (POST). During the POST, the Power and Status LEDs turn on.

The Status LED turns off, indicating that the POST is complete. If the

LEDs do not behave in this way when the system powers on, refer to the

Understanding LED Indications section.

You can configure the cFP-22xx to launch an embedded stand-alone

LabVIEW RT application each time you boot the controller. Refer to the

Running a Stand-Alone Real-Time Application (RT Module) topic of the

LabVIEW Help for more information.

Connecting Serial Devices to the cFP-22xx

You can connect devices such as displays or input devices to the serial ports

of the cFP-22xx. Use the Serial VIs to read from and write to the serial ports

from a LabVIEW RT application. If your application is not embedded on

the controller, you must target the cFP-22xx to access the serial ports. Refer

to the LabVIEW Help for information about the Serial VIs and about

targeting the cFP-22xx. Refer to Figure 1 for the locations of the serial

ports.

cFP-2200/2210/2220 20 ni.com

Page 21

COM 1

COM 1 is an RS-232 DTE serial port with a standard DB-9 connector.

The Serial VIs access COM 1 as port 0. The following figure shows the

locations of the DB-9 connector pins and Table 1 lists the signals on

the pins.

Pin 5

Pin 1

Figure 25. Controller Serial Port

Table 1. DB-9 Pin Descriptions

Pin Signal

1 DCD

2 RXD

3 TXD

4 DTR

5 GND

6 DSR

7 RTS

8 CTS

9 RI

Pin 9

Pin 6

COM 2 (cFP-2210 and cFP-2220 Only)

COM 2 is an RS-232 DTE serial port with a 10-position modular jack. The

Serial VIs access COM 2 as port 1. Refer to Figure 26 and Table 2 for pin

locations and signal descriptions.

COM 3 (cFP-2220 Only)

COM 3 is an RS-232 DTE serial port with a 10-position modular jack. The

Serial VIs access COM 3 as port 2. Refer to Figure 26 and Table 2 for pin

locations and signal descriptions.

© National Instruments Corporation 21 cFP-2200/2210/2220

Page 22

COM 4 (cFP-2220 Only)

COM 4 is an RS-485 serial port with a 10-position modular jack. The Serial

VIs access COM 4 as port 3. COM 4 has 100 V

Use an external RS-485 isolator if your application requires more isolation.

Refer to Figure 26 and Table 2 for pin locations and signal descriptions.

of operational isolation.

rms

Pin 1

Figure 26. 10-Position Modular Jack Pin Locations

Table 2. 10-Position Modular Jack Pin Descriptions

10-Position

Modular Jack Pin

10 DCD GND

9 RXD CTS+ (HSI+)

8 TXD RTS+ (HSO+)

7 DTR RXD+

6 GND RXD–

5 DSR CTS– (HSI–)

4 RTS RTS– (HSO–)

3 CTS TXD+

Pin 10

RS-232 Signal RS-485 Signal

2 RI TXD–

1 No Connect No Connect

cFP-2200/2210/2220 22 ni.com

Page 23

Figure 27 shows how to wire several FP-1001 banks in an RS-485 network

controlled by the cFP-2220. Only two FP-1001 banks are shown, but the

cFP-2220 can control up to 24 FP-1001 banks. Install 120 Ω termination

resistors at each end of the network as shown in Figure 27.

cFP-2220 COM 4 FP-1001 FP-1001

RX–

RXD– RXD+ TXD– TXD+

120 Ω 120 Ω120 Ω120 Ω

Figure 27. Wiring for an RS-485 Network Controlled by the cFP-2220

RX+ TX– TX+ RX– RX+ TX– TX+

COM 4 is designed to operate in four-wire mode as shown in Figure 27.

You can use COM 4 in two-wire mode, but you must design your

application so that it filters out the writes that echo back over the read

channels. NI does not recommend this method.

NI offers a DIN rail–mountable screw terminal adapter that you can use

to connect termination resistors to COM 4. The adapter is part number

778674-01.

Cable adapters for the 10-position modular jacks are available from NI.

Part numbers 182845-01, -02, and -03 are 1, 2, and 3 m cable adapters for

connecting the 10-position modular jack to a 9-position D-SUB plug.

External Digital Inputs and Outputs (cFP 2220 Only)

The cFP-2220 has two digital inputs and two digital outputs that you can

use to connect a simple operator interface to the controller. Refer to

Figure 1 for the location of the input and output terminals. The inputs and

outputs appear in software as Input 1, Input 2, Output 1, and Output 2.

Logic high for the DIO ports is +5 V. Logic low is 0 V. The DIO ports are

not isolated and are not intended for field connections. Use them only for

simple VI controls and indicators.

© National Instruments Corporation 23 cFP-2200/2210/2220

Page 24

You can use the two digital inputs to control the cFP system from

LabVIEW. For example, one input could be a START/STOP switch, and

the other could determine which of two VIs should run at startup. NI

recommends connecting a single-pole single-throw (SPST) switch between

the input terminal and one of the C terminals. The inputs have a value of 1

when the switch is closed and 0 when the switch is open.

C

R2

O2

C

R1

O1

C

I2

C

I1

Figure 28. Wiring the cFP-2220 External Input and Output Terminals

LED B

LED A

Switch 2

Switch 1

Connecting USB Mass-Storage Devices to the cFP-2220

The cFP-2220 supports common USB mass-storage devices such as USB

Flash drives. You can connect USB mass-storage devices to the cFP-2220

while the controller is operating. USB devices are mapped to the

in LabVIEW. The cFP-2220 does not support other types of USB devices.

Refer to the LabVIEW Real-Time Module Help for more information.

Caution Do not hotswap USB devices while the Compact FieldPoint system is in a

hazardous location or connected to high voltages.

Using the Internal Real-Time Clock

The system clock of the cFP-22xx gets the date and time from the internal

high-precision real-time clock at startup. This synchronization provides

timestamp data to the controller. You can also use the internal real-time

clock to correct drift of the system clock. Please contact National

Instruments for more information.

U: drive

cFP-2200/2210/2220 24 ni.com

Page 25

Configuring DIP Switches

All of the DIP switches are in the OFF position when the controller is

shipped from National Instruments.

IP RESET Switch

Push the IP RESET switch to the ON position and reboot the controller to

reset the IP address to

the IP RESET switch is in the ON position, the controller appears in MAX

with IP address

controller in MAX. Refer to the Resetting the Network Configuration of the

cFP-22xx section for more information about resetting the IP address. You

also can push this switch to the ON position to unlock a controller that was

previously locked in MAX.

0.0.0.0. You can configure a new IP address for the

IP RESET

SAFE MODE

NO APP

CONS. OUT

USER2

USER1

Figure 29. DIP Switches

0.0.0.0. If the controller is on your local subnet and

SAFE MODE Switch

The position of the SAFE MODE switch determines whether the embedded

LabVIEW Real-Time engine launches at startup. If the switch is in the OFF

position, the LabVIEW Real-Time engine launches. Keep this switch in the

OFF position during normal operation. If the switch is in the ON position

at startup, the cFP-22xx launches only the essential services required

for updating its configuration and installing software. The LabVIEW

Real-Time engine does not launch.

Push the SAFE MODE switch to the ON position if the software on the

controller is corrupted. Even if the switch is not in the ON position, the

controller automatically boots into safe mode if there is no software

installed on it. The SAFE MODE switch must be in the ON position to

reformat the drive on the controller. Refer to the Measurement &

Automation Explorer Help for more about installing software and

reformatting the drive.

© National Instruments Corporation 25 cFP-2200/2210/2220

Page 26

NO APP Switch

CONS OUT Switch

Push the NO APP switch to the ON position to prevent a LabVIEW RT

startup application from running at startup. If you want to permanently

disable a LabVIEW RT application from running at startup, you must

disable it in LabVIEW. To run an application at startup, push the NO APP

switch to the OFF position, create an application using the LabVIEW

Application Builder, and configure the application in LabVIEW to launch

at startup. If you already have an application configured to launch at startup

and you push the NO APP switch from ON to OFF, the startup application

is automatically enabled. For more information about automatically

launching VIs at startup and disabling VIs from launching at startup, refer

to the Running a Stand-Alone Real-Time Application (RT Module) topic of

the LabVIEW Help.

With a serial-port terminal program, you can use the CONS OUT switch

to read the IP address and firmware version of the controller. Use a

null-modem cable to connect the serial port to a computer. Push the switch

to the ON position. Make sure that the serial-port terminal program is

configured to the following settings:

• 9,600 bits per second

• Eight data bits

• No parity

• One stop bit

• No flow control

The serial-port terminal program displays the IP address and firmware

version of the controller, and alerts you when you connect an unsupported

USB device to the cFP-2220. Keep this switch in the OFF position during

normal operation.

USER2 and USER1 Switches

You can define the USER2 and USER1 switches for your application.

To define the switches in an embedded application, use the RT Read

Switch VI in a LabVIEW RT embedded VI. You can use the FieldPoint

ReadVI to read defined switches in embedded or unembedded applications.

For more information about the RT Read Switch VI and the FieldPoint

Read VI, refer to the LabVIEW Help.

cFP-2200/2210/2220 26 ni.com

Page 27

Using the Reset Button

Pressing the Reset button resets the processor in the same manner as

cycling power.

Understanding LED Indications

Figure 30. LEDs

STATUS LED

The STATUS LED is off during normal operation. The cFP-22xx indicates

specific error conditions by flashing the STATUS LED a certain number of

times as shown in Table 3.

Table 3. Status LED Indications

Number of Flashes Indication

1 The controller is unconfigured. Refer to the Measurement & Automation

Explorer Help for information about configuring the controller in MAX.

2 The controller has detected an error in its software. This can occur

when an attempt to upgrade the software is interrupted. Refer to the

Measurement & Automation Explorer Help for information about

reinstalling software on the controller.

3 The controller is in safe mode. Refer to the Configuring DIP Switches

section for information about the Safe Mode DIP switch.

4 The software has crashed twice without rebooting or cycling power

between crashes. This usually occurs when the controller runs out of

memory. Review your RT VI and check the memory usage. Modify

the VI as necessary to solve the memory usage issue.

Solid The controller has detected an unrecoverable error. Please contact

National Instruments.

© National Instruments Corporation 27 cFP-2200/2210/2220

Page 28

POWER LED

The POWER LED is lit while the cFP-22xx is powered on. This LED

indicates that the power supply connected to the controller is adequate. The

POWER LED lights green when the controller is using the primary power

supply and amber when the controller is using the secondary power supply.

User-Configurable LEDs

You can use the FieldPoint Write VI to write values to LEDs A, B, C, and

D. The LEDs can have any of three values: 0 is OFF, 1 is green, and 2 is

amber.

Removable CompactFlash (cFP-2220 Only)

You can use CompactFlash for removable data storage with the cFP-2220.

The controller takes Type I and Type II CompactFlash up to 512 MB. With

the power off, open the CompactFlash cover and plug a CompactFlash into

the slot, then power up the controller. You can access the removable

CompactFlash by using LabVIEW file I/O VIs running embedded on the

controller. To read from or write to the removable CompactFlash, point the

VI to the

Caution You must power down the controller before installing or removing a

CompactFlash. Removing the CompactFlash without powering down the controller can

cause data corruption. In order to get data from the CompactFlash while the controller is

operating, use an FTP client to download the data from the

D: drive on the controller.

D: drive on the controller.

File Transfer Capability

When running on a cFP-22xx, the Real-Time Engine has a File Transfer

Protocol (FTP) server. The FTP server gives you the ability to use any

standard FTP utility for transferring files to and from the hard drive of the

cFP-22xx. You must provide the correct password when opening a

connection to the cFP-22xx if the configuration is locked in MAX.

For programmatic file transfer control in LabVIEW or LabVIEW

Real-Time, use the Internet Developers Toolkit, included in the LabVIEW

Enterprise Connectivity Toolset. Refer to

about the LabVIEW Enterprise Connectivity Toolset.

Note Contact NI to determine whether the version of the toolkit you are using can be

downloaded onto the cFP-22xx.

cFP-2200/2210/2220 28 ni.com

ni.com for more information

Page 29

Remote Front Panels

You may need to monitor and control an embedded VI remotely. The

cFP-22xx supports multiple remote front panels for embedded VIs. Users

can view the remote front panel using either LabVIEW or a Web browser.

Users accessing the remote front panels with a Web browser need to have

either Internet Explorer 5.5 Service Pack 2 or later, or Netscape 4.7 or later.

If you plan to use remote front panels to control the VI, keep the front panel

simple and do not use property nodes. Complex front panels can cause

slight control latency when users operate them remotely. Users cannot

programmatically change the value of a control remotely.

Resetting the Network Configuration of the cFP-22xx

If the cFP-22xx is not able to communicate with the network, you can use

the IP RESET switch to manually restore the controller to the factory

network settings. When you restore the controller to the factory network

settings, the IP address, subnet mask, DNS address, gateway, and Time

Server IP are set to

VIs are unaffected.

Complete the following steps to reset the network configuration.

1. Move the IP RESET DIP switch to the ON position.

2. Push the RESET button to cycle power to the controller. The STATUS

LED flashes once, indicating that the IP address is unconfigured.

3. Move the IP RESET switch to the OFF position.

0.0.0.0. Power-on defaults, watchdog settings, and

The network settings are restored. You can reconfigure the settings in MAX

from a computer on the same subnet. Refer to the Measurement &

Automation Explorer Help for more information about configuring the

controller.

Note If the controller is restored to the factory network settings, the LabVIEW run-time

engine does not load. You must reconfigure the network settings and restart the controller

for the LabVIEW run-time engine to load.

© National Instruments Corporation 29 cFP-2200/2210/2220

Page 30

Troubleshooting

This section contains troubleshooting instructions for the cFP-22xx and

FieldPoint software. For more troubleshooting information, refer to the

Measurement & Automation Explorer Help for FieldPoint and the

Measurement & Automation Explorer Remote Systems Help.

Runaway Startup Application

If a runaway startup application causes the cFP-22xx to become

unresponsive, you must power down the cFP-22xx, then reboot it with

either the NO APP switch or the SAFE MODE switch in the ON position.

Rebooting the controller with the NO APP switch ON prevents any VIs

from running at startup. Rebooting with the SAFE MODE switch ON starts

the cFP-22xx in safe mode, and the embedded LabVIEW Real-Time engine

is not launched. Refer to the Configuring DIP Switches section for more

information.

Other Indications of Trouble with the Controller

• Amber status LED stays lit when controller is in normal mode

• Cannot detect controller in MAX unless it is in safe mode

• After you set the IP address, the controller reboots unconfigured or

with the old IP address

• Green status LED error code greater than 3

• Green status LED error code 2 during normal operation

• Controller incorrectly reports that the disk is full

• I/O module ready LEDs off in normal mode but on in safe mode

• Unusual file or folder names when you FTP to the controller

First, use MAX to reinstall software on the controller. If that does not solve

the problem, you may have to reformat the internal memory of the

controller.

Reformatting the Internal Memory

1. Reboot the controller into safe mode by moving the SAFE MODE DIP

switch to the ON position and cycling the power.

2. Open MAX and expand Remote Systems to find the FieldPoint bank.

3. Right-click the FieldPoint bank and select Format Disk.

After formatting, you must reconfigure network settings and reinstall

software. Remember to install LabVIEW Real-Time 8.5.1 or later on the

controller, because previous versions do not work with the controller.

cFP-2200/2210/2220 30 ni.com

Page 31

Specifications

Network

Memory

The following specifications are typical for the –40 to 70 °C operating

temperature range unless otherwise noted.

Network interface................................... 10BaseT and 100BaseTX

Ethernet

Compatibility ......................................... IEEE 802.3

Communication rates ............................. 10 Mbps, 100 Mbps,

auto-negotiated

Maximum cabling distance .................... 100 m/segment

cFP-2200 ................................................ 128 MB nonvolatile;

128 MB DRAM

cFP-2210 ................................................ 128 MB nonvolatile;

256 MB DRAM

cFP-2220 ................................................ 256 MB nonvolatile;

256 MB DRAM

Memory lifetime (nonvolatile)............... 100,000 writes per block

For information about the amount of memory used by the LabVIEW

Real-Time Module and the operating system, go to

enter

rdfpec.

ni.com/info and

Serial Ports

cFP-2200 ................................................ One RS-232 serial port

cFP-2210 ................................................ Two RS-232 serial ports

cFP-2220 ................................................ Three RS-232 serial ports;

one RS-485 serial port

© National Instruments Corporation 31 cFP-2200/2210/2220

Page 32

RS-232 (DTE) serial ports

Maximum baud rate.........................115,200 bps

Data bits...........................................5, 6, 7, 8

Stop bits...........................................1, 1.5, 2

Parity................................................Odd, Even, Mark, Space

Flow control.....................................RTS/CTS, XON/XOFF,

RS-485 (DTE) serial port

Baud rate..........................................9,600 to 115,200 bps

Data bits...........................................5, 6, 7, 8

Stop bits...........................................1, 1.5, 2

Parity................................................Odd, Even, Mark, Space

Flow control.....................................XON/XOFF

Wire mode .......................................4-wire

Isolation voltage, port to earth ground

USB Port (cFP-2220 Only)

Maximum data rate.................................12 Mb/s

DTR/DSR

Continuous ...............................100 V

Dielectric withstand..................740 V

rms

, verified by 5 s test

rms

Maximum current ...................................500 mA

Power Requirements

Caution You must use a National Electric Code (NEC) UL Listed Class 2 power supply

with the cFP-22xx.

Power supply input voltage range ..........11 to 30 VDC

Recommended minimum power

cFP-BP-4 system .............................15 W

cFP-BP-8 system .............................20 W

Power consumption ................................6.1 W + 1.1(I/O module power

requirements)

cFP-2200/2210/2220 32 ni.com

Page 33

Physical Characteristics

If you need to clean the controller, wipe it with a dry towel.

Screw-terminal wiring............................ Use copper conductor wire with

External digital I/O terminals ......... 16 to 28 AWG

Power supply terminals................... 14 to 30 AWG

Torque for screw terminals .................... 0.5 to 0.6 N · m

Weight.................................................... 278 g (9.8 oz)

Safety Voltages

Connect only voltages that are within these limits.

V terminal to C terminal ........................35 V max, Measurement

Measurement Category I is for measurements performed on circuits not

directly connected to the electrical distribution system referred to as

MAINS voltage. MAINS is a hazardous live electrical supply system that

powers equipment. This category is for measurements of voltages from

specially protected secondary circuits. Such voltage measurements include

signal levels, special equipment, limited-energy parts of equipment,

circuits powered by regulated low-voltage sources, and electronics.

10 mm (0.39 in.) of insulation

from the ends.

(4.4 to 5.3 lb · in.)

Category I

Caution Do not connect the system to signals or use for measurements within

Measurement Categories II, III, or IV.

Safety Standards

This product is designed to meet the requirements of the following

standards of safety for electrical equipment for measurement, control,

and laboratory use:

• IEC 61010-1, EN 61010-1

• UL 61010-1, CSA 61010-1

Note For UL and other safety certifications, refer to the product label or visit ni.com/

certification

in the Certification column.

© National Instruments Corporation 33 cFP-2200/2210/2220

, search by model number or product line, and click the appropriate link

Page 34

Electromagnetic Compatibility

⬉ᄤֵᙃѻક∵ᶧࠊㅵ⧚ࡲ⊩ ˄Ё

˅

Ёᅶ᠋

This product is designed to meet the requirements of the following

standards of EMC for electrical equipment for measurement, control,

and laboratory use:

• EN 61326 EMC requirements; Industrial Immunity

• EN 55011 Emissions; Group 1, Class A

• CE, C-Tick, ICES, and FCC Part 15 Emissions; Class A

Note For EMC compliance, operate this device according to product documentation.

CE Compliance

This product meets the essential requirements of applicable European

Directives, as amended for CE marking, as follows:

• 2006/95/EC; Low-Voltage Directive (safety)

• 2004/108/EC; Electromagnetic Compatibility Directive (EMC)

Note Refer to the Declaration of Conformity (DoC) for this product for any additional

regulatory compliance information. To obtain the DoC for this product, visit

certification

in the Certification column.

, search by model number or product line, and click the appropriate link

ni.com/

Environmental Management

National Instruments is committed to designing and manufacturing

products in an environmentally responsible manner. NI recognizes that

eliminating certain hazardous substances from our products is beneficial

not only to the environment but also to NI customers.

For additional environmental information, refer to the NI and the

Environment Web page at

ni.com/environment. This page contains the

environmental regulations and directives with which NI complies, as well

as other environmental information not included in this document.

Waste Electrical and Electronic Equipment (WEEE)

EU Customers At the end of their life cycle, all products must be sent to a WEEE recycling

center. For more information about WEEE recycling centers and National Instruments

WEEE initiatives, visit

ni.com/environment/weee.htm.

RoHS

National Instruments

݇Ѣ

National InstrumentsЁRoHS

(For information about China RoHS compliance, go to

cFP-2200/2210/2220 34 ni.com

ヺড়Ё⬉ᄤֵᙃѻકЁ䰤ࠊՓ⫼ᶤѯ᳝ᆇ⠽䋼ᣛҸ

ড়㾘ᗻֵᙃˈ䇋ⱏᔩ

ni.com/environment/rohs_china

ni.com/environment/rohs_china

(RoHS)

DŽ

DŽ

.)

Page 35

Environmental

Note To meet this operating temperature range, follow the guidelines in the installation

instructions for your Compact FieldPoint system.

The cFP-22xx is intended for indoor use only, but it may be used outdoors

if mounted in a suitably rated enclosure.

Operating temperature

(IEC 60068-2-1, IEC 60068-2-2)........... –40 to 70 °C

Storage temperature

(IEC 60068-2-1, IEC 60068-2-2)........... –55 to 85 °C

Ingress protection................................... IP 20

Operating humidity

(IEC 60068-2-56)................................... 10 to 90% RH, noncondensing

Storage humidity

(IEC 60068-2-56)................................... 5 to 95% RH, noncondensing

Maximum altitude .................................. 2,000 m

Pollution Degree (IEC 60664) ............... 2

Shock and Vibration

To meet these specifications, you must panel mount the Compact

FieldPoint system and affix ferrules to the ends of the power terminal wires.

Operating shock

(IEC 60068-2-27)................................... 30 g, 11 ms half sine;

50 g, 3 ms half sine;

18 shocks at 6 orientations

Operating vibration,

random (IEC 60068-2-64)...................... 5 g

Operating vibration,

sinusoidal (IEC 60068-2-6).................... 5 g, 10 to 500 Hz

, 10 to 500 Hz

rms

Special Conditions for Marine Applications

Some products are Lloyd’s Register (LR) Type Approved for marine

applications. To verify Lloyd’s Register certification, visit

certification

Register mark on the product.

© National Instruments Corporation 35 cFP-2200/2210/2220

and search for the LR certificate, or look for the Lloyd’s

ni.com/

Page 36

Cabling

Table 4 shows the standard Ethernet cable wiring connections for both

normal and crossover cables.

Table 4. Ethernet Cable Wiring Connections

Connector 2

Pin Connector 1

(Normal)

1 white/orange white/orange white/green

2 orange orange green

3 white/green white/green white/orange

4 blue blue blue

5 white/blue white/blue white/blue

6 green green orange

7 white/brown white/brown white/brown

8 brown brown brown

Connector 1 Connector 2

Pin 1

Pin 1 Pin 8Pin 8

Connector 2

(Crossover)

Figure 31. Ethernet Connector Pinout

cFP-2200/2210/2220 36 ni.com

Page 37

Where to Go for Support

The National Instruments Web site is your complete resource for technical

support. At

troubleshooting and application development self-help resources to email

and phone assistance from NI Application Engineers.

National Instruments corporate headquarters is located at

11500 North Mopac Expressway, Austin, Texas, 78759-3504.

National Instruments also has offices located around the world to help

address your support needs. For telephone support in the United States,

create your service request at

instructions or dial 512 795 8248. For telephone support outside the United

States, contact your local branch office:

Australia 1800 300 800, Austria 43 662 457990-0,

Belgium 32 (0) 2 757 0020, Brazil 55 11 3262 3599,

Canada 800 433 3488, China 86 21 5050 9800,

Czech Republic 420 224 235 774, Denmark 45 45 76 26 00,

Finland 358 (0) 9 725 72511, France 01 57 66 24 24,

Germany 49 89 7413130, India 91 80 41190000, Israel 972 3 6393737,

Italy 39 02 41309277, Japan 0120-527196, Korea 82 02 3451 3400,

Lebanon 961 (0) 1 33 28 28, Malaysia 1800 887710,

Mexico 01 800 010 0793, Netherlands 31 (0) 348 433 466,

New Zealand 0800 553 322, Norway 47 (0) 66 90 76 60,

Poland 48 22 3390150 , Portugal 351 210 311 210, Russia 7 495 783 6851,

Singapore 1800 226 5886, Slovenia 386 3 425 42 00,

South Africa 27 0 11 805 8197, Spain 34 91 640 0085,

Sweden 46 (0) 8 587 895 00, Switzerland 41 56 2005151,

Taiwan 886 02 2377 2222, Thailand 662 278 6777,

Turkey 90 212 279 3031, United Kingdom 44 (0) 1635 523545

ni.com/support you have access to everything from

ni.com/support and follow the calling

© National Instruments Corporation 37 cFP-2200/2210/2220

Page 38

National Instruments, NI, ni.com, and LabVIEW are trademarks of National Instruments Corporation.

Refer to the Terms of Use section on ni.com/legal for more information about National

Instruments trademarks. Other product and company names mentioned herein are trademarks or trad e

names of their respective companies. For patents covering National Instruments products, refer to the

appropriate location: Help»Patents in your software, the patents.txt file on your CD, or

ni.com/patents.

© 2008 National Instruments Corporation. All rights reserved.

374708A-01 Mar08

Loading...

Loading...