Page 1

User Manual

BridgeVIEW User Manual

May 1998 Edition

Part Number 321294C-01

Page 2

Internet Support

E-mail: support@natinst.com

FTP Site: ftp.natinst.com

Web Address: http://www.natinst.com

Bulletin Board Support

BBS United States: 512 794 5422

BBS United Kingdom: 01635 551422

BBS France: 01 48 65 15 59

Fax-on-Demand Support

512 418 1111

Telephone Support (USA)

Tel: 512 795 8248

Fax: 512 794 5678

International Offices

Australia 03 9879 5166, Austria 0662 45 79 90 0, Belgium 02 757 00 20, Brazil 011 288 3336,

Canada (Ontario) 905 785 0085, Canada (Québec) 514 694 8521, Denmark 45 76 26 00,

Finland 09 725 725 11, France 01 48 14 24 24, Germany 089 741 31 30, Hong Kong 2645 3186,

Israel 03 6120092, Italy 02 413091, Japan 03 5472 2970, Korea 02 596 7456, Mexico 5 520 2635,

Netherlands 0348 433466, Norway 32 84 84 00, Singapore 2265886, Spain 91 640 0085, Sweden 08 730 49 70,

Switzerland 056 200 51 51, Taiwan 02 377 1200, United Kingdom 01635 523545

National Instruments Corporate Headquarters

6504 Bridge Point Parkway Austin, Texas 78730-5039 USA Tel: 512 794 0100

© Copyright 1996, 1998 National Instruments Corporation. All rights reserved.

Page 3

Important Information

Warranty

The media on which you receive National Instruments software are warranted not to fail to execute programming

instructions, due to defects in materials and work man ship, for a peri od of 90 d ays from da te o f sh ipm ent, as evi denced

by receipts or other documentation. National Instruments will, at its option, repair or replace software media that do not

execute programming instructions if National Instruments receives noti ce of su ch defect s d uring th e warranty perio d.

National Instruments does not warrant that the op eration of t he soft ware shall b e uni nterrup ted or erro r free.

A Return Material Authorization (RMA) number must b e ob tain ed fro m th e facto ry an d clearl y mark ed on t he outsi de

of the package before any equipment will be a ccepted for warranty work. National Instruments will pay the shipping c osts

of returning to the owner parts which are covered by warran ty.

National Instruments believes that the information in this manual is accurate. The document has been c arefully reviewed

for technical accuracy. In the event that technical or typographical errors exist, National Instruments reserves the right to

make changes to subsequent editions of th is do cume nt with ou t p rio r no ti ce to hold ers o f thi s ed itio n. The read er sh ou ld

consult National Instruments if errors are suspected. In no event shall National Instruments be liable for any damages

arising out of or related to this docume nt o r th e in form ati on con tai ned in i t.

XCEPT AS SPECIFIED HEREIN

E

SPECIFICALLY DISCLAIMS ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE

RIGHT TO RECOVER DAMAGES CAUSED BY FAULT OR NEGLIGENCE ON THE PART OF NATIONAL INSTRUMENTS SHALL BE

LIMITED TO THE AMOUNT THERETOFORE PAID BY THE CUSTOMER

DAMAGES RESULTING FROM LOSS OF DATA, PROFITS, USE OF PRODUCTS, OR INCIDENTAL OR CONSEQUENTIAL DAMAGES

EVEN IF ADVISED OF THE POSSIBILITY THEREOF

regardless of the form of action, whether in contract or tort , incl udin g n egli gen ce. An y action against National

Instruments must be brought within one year after the cause of action accrues. National Instruments shall not be liable for

any delay in performance due to causes beyond its reason able control . T he wa rranty pro vided herein does n ot cove r

damages, defects, malfunctions, or service failures caused by own er’s fai lure to fol low the Nati onal In st rume nts

installation, operation, or maintenan ce in structi on s; ow ner’s modi ficat io n o f th e pro du ct; ow ner’s ab use, m isus e , o r

negligent acts; and power failure or surges, fire, flood, accident, actions of third pa rties, or other events outside reasonable

control.

ATIONAL INSTRUMENTS MAKES NO WARRANTIES, EXPRESS OR IMPLIED, AND

, N

. This limitation of the liability of Nati onal In st rum ent s will appl y

Copyright

Under the copyright laws, this publication may not be reproduced or transmitted in any form, electronic or mechanical,

including photocopying, recording, storing in an information retrieval system, or translating, in whole or in part, without

the prior written consent of National Instruments Corporation.

USTOMER’S

. C

ATIONAL INSTRUMENTS WILL NOT BE LIABLE FOR

. N

,

Trademarks

BridgeVIEW™, LabVIEW™, National Instruments™, natinst.com™, and NI-DAQ™ are trademarks of National

Instruments Corporation.

Product and company names listed are trademarks or trade names of their respective companies.

WARNING REGARDING MEDICAL AND CLINICAL USE OF NATIONAL INSTRUMENTS PRODUCTS

National Instruments products are not designed with com ponent s and tes ting inten ded to ensure a l evel of reliab ilit y

suitable for use in treatment and diagnosis of humans. Applications of National Instruments products invol ving m edical

or clinical treatment can create a potential for accidental injury caused by product failure, or by errors on the part of the

user or application designer. Any use or application of National Instruments products for or involving medical or clinical

treatment must be performed by properly trained and qualified medical personnel, and all traditional medical safeguards,

equipment, and procedures that are appropriate in the particular situation to prevent serious injury or death should always

continue to be used when National Instruments products are being used . National Instrum ents product s are NOT intended

to be a substitute for any form of established process, procedure, or equipment used to monitor or safeguard human health

and safety in medical or clinical treatment.

Page 4

Contents

About This Manual

Organization of This Manual...............................................................................................xix

BridgeVIEW Concepts..........................................................................................xix

G Tutorial ...............................................................................................................xx

Appendices, Glossary, and Index..........................................................................xxi

Conventions Used in This Manual......................................................................................xxii

Related Documentation........................................... ...........................................................xxiii

Customer Communication.................................................................................................xxiii

Chapter 1

Introduction

Welcome to BridgeVIEW....................................................................................................1-1

Required System Configuration............................................................................1-2

Installation............................ .................................................................................1-2

What Is BridgeVIEW?.........................................................................................................1-3

How Does BridgeVIEW Work? ..........................................................................................1-3

G Programming.....................................................................................................1-4

Tag Configuration .................................................................................................1-5

Alarms ...................................................................................................................1-6

Events....................................................................................................................1-7

Historical Data Logging and Extraction................................................................1-7

Security..................................................................................................................1-7

What Is the BridgeVIEW System Architecture?.................................................................1-8

User HMI Application...........................................................................................1-8

BridgeVIEW Engine .............................................................................................1-9

Device Servers.......................................................................................................1-9

Where Should I Start?........................................................................................................1-10

P

I

ART

BridgeVIEW Concepts

Data Type................................................................................................1-5

General....................................................................................................1-5

Connection.............................................................................................. 1-6

Scaling.....................................................................................................1-6

Operations...............................................................................................1-6

© National Instruments Corporation v BridgeVIEW User Manual

Page 5

Contents

Chapter 2

BridgeVIEW Environment

What Is G?...........................................................................................................................2-1

How Does G Work? ........................................................... .................................................2-1

Virtual Instruments ...............................................................................................2-2

Front Panel.............................................................................................. 2-2

Block Diagram........................................................................................2-3

Icon/Connector .......................................................................................2-3

Tools Palette..........................................................................................................2-4

Controls Palette.....................................................................................................2-5

Functions Palette...................................................................................................2-5

Controls and Indicators.........................................................................................2-6

Numeric ..................................................................................................2-6

Boolean...................................................................................................2-7

String ......................................................................................................2-7

Tag..........................................................................................................2-8

BridgeVIEW Environment Project Menu.........................................................................2-10

What Is the BridgeVIEW Engine Manager?.....................................................................2-12

What Are System Errors and Events?............................................................................... 2-15

What Is the Tag Browser?................................................................................................. 2-16

What Is the Tag Monitor?.................................................................................................. 2-18

How Do You Access Online Help?...................................................................................2-23

Simple/Complex Help View...............................................................................2-23

Links to Online Help Files..................................................................................2-24

Chapter 3

Tag Configuration

What Is a Tag?.....................................................................................................................3-1

Tag Attributes .......................................................................................................3-1

General Attributes................................................................................... 3-2

Connection Attributes............................................................................. 3-2

Operation Attributes ...............................................................................3-2

Scaling Attributes ...................................................... .............................3-2

Alarm Attributes.....................................................................................3-3

Static vs. Dynamic Attributes ...............................................................................3-3

BridgeVIEW User Manual vi © National Instruments Corporation

Page 6

Contents

What Is the Tag Configuration Editor?................................................................................3-3

How Do You Create a Tag? ..................................................................................3-5

How Do You Edit a Tag?......................................................................................3-5

How Do You Delete a Tag? ..................................................................................3-5

What are Network Tags?.......................................................................................3-6

How Do You Add Network Tags?........................................................................3-7

How Do You Set Default Values for Tag Configuration Fields? .........................3-7

How Do You Use Spreadsheet Files for Tag Configuration?...............................3-8

How Do You Configure Tags?..........................................................................................3-10

Data Type ............................................................................................................3-10

Analog Tags..........................................................................................3-10

Discrete Tags.........................................................................................3-10

Bit Array Tags.......................................................................................3-10

String Tags............................................................................................3-11

General ................................................................................................................3-11

Connection...........................................................................................................3-12

I/O Group Configuration.......................................................................3-14

I/O Group Configuration Options...........................................3-15

Server Configuration Options.................................................3-16

Item Configuration................................................................................3-18

Item Configuration Options—Configuring

Item Names..........................................................................3-18

Item Configuration Options—Configuring

Item Resources.....................................................................3-18

What Is a Memory Tag?........................................................................3-19

When Should You Use a Memory Tag?.................................3-19

How Do You Automatically Generate Tags

from Server Information? ..................................................................3-20

How Do You Connect a Tag to an OPC Server?..................................3-21

How Do You Connect a Tag to a DDE Server? ...................................3-21

How Do You Define a Group of Tags for Alarming? ..........................3-21

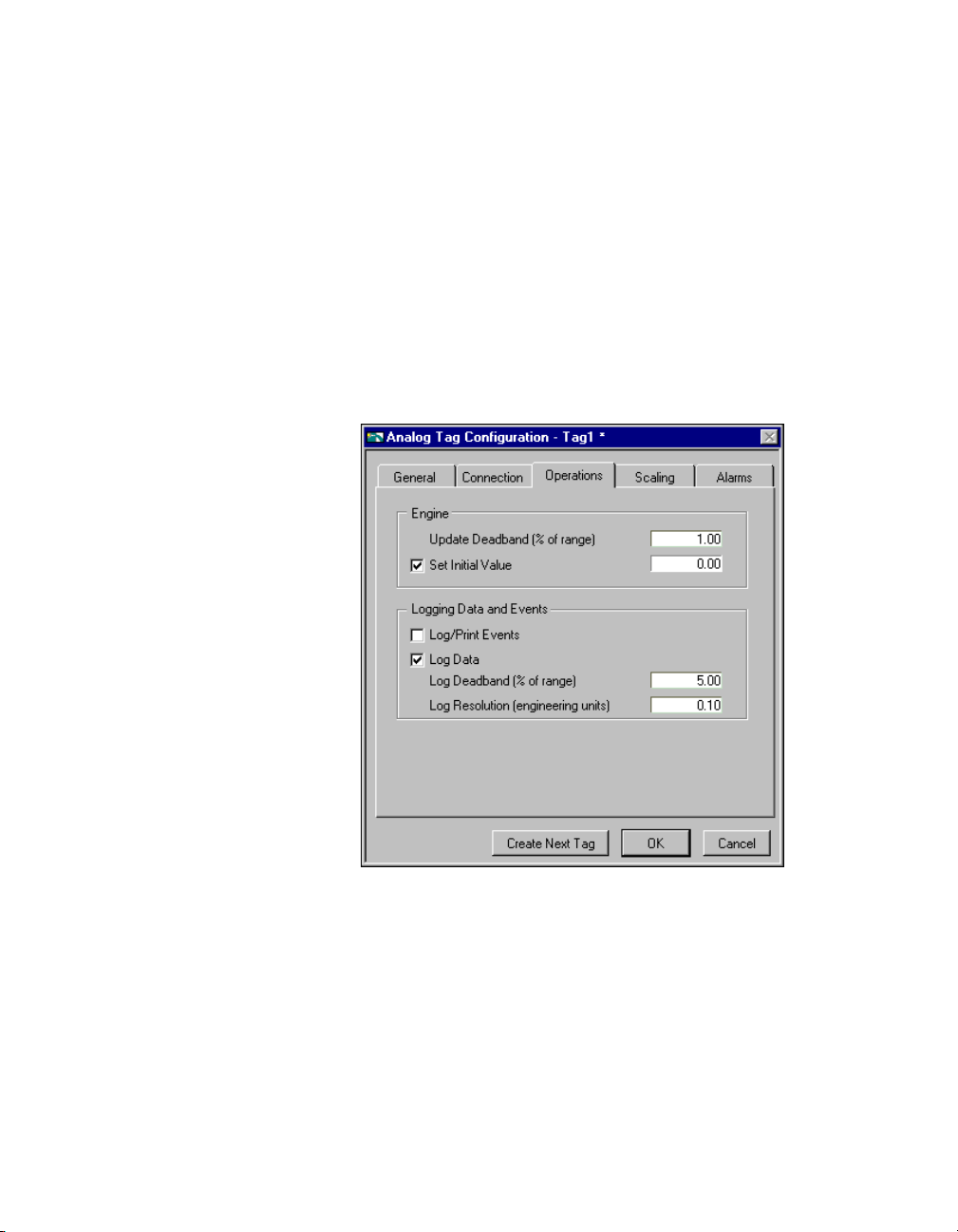

Operations............................................................................................................3-22

What Is Deadband?...............................................................................3-24

How Do You Use Deadband to Increase Engine Throughput? ............3-2 4

How Do You Configure a Tag to Log Its Data or Events?...................3-25

How Do You Set Initial Tag Value at Startup? ....................................3-25

Scaling................................................................................................................. 3-25

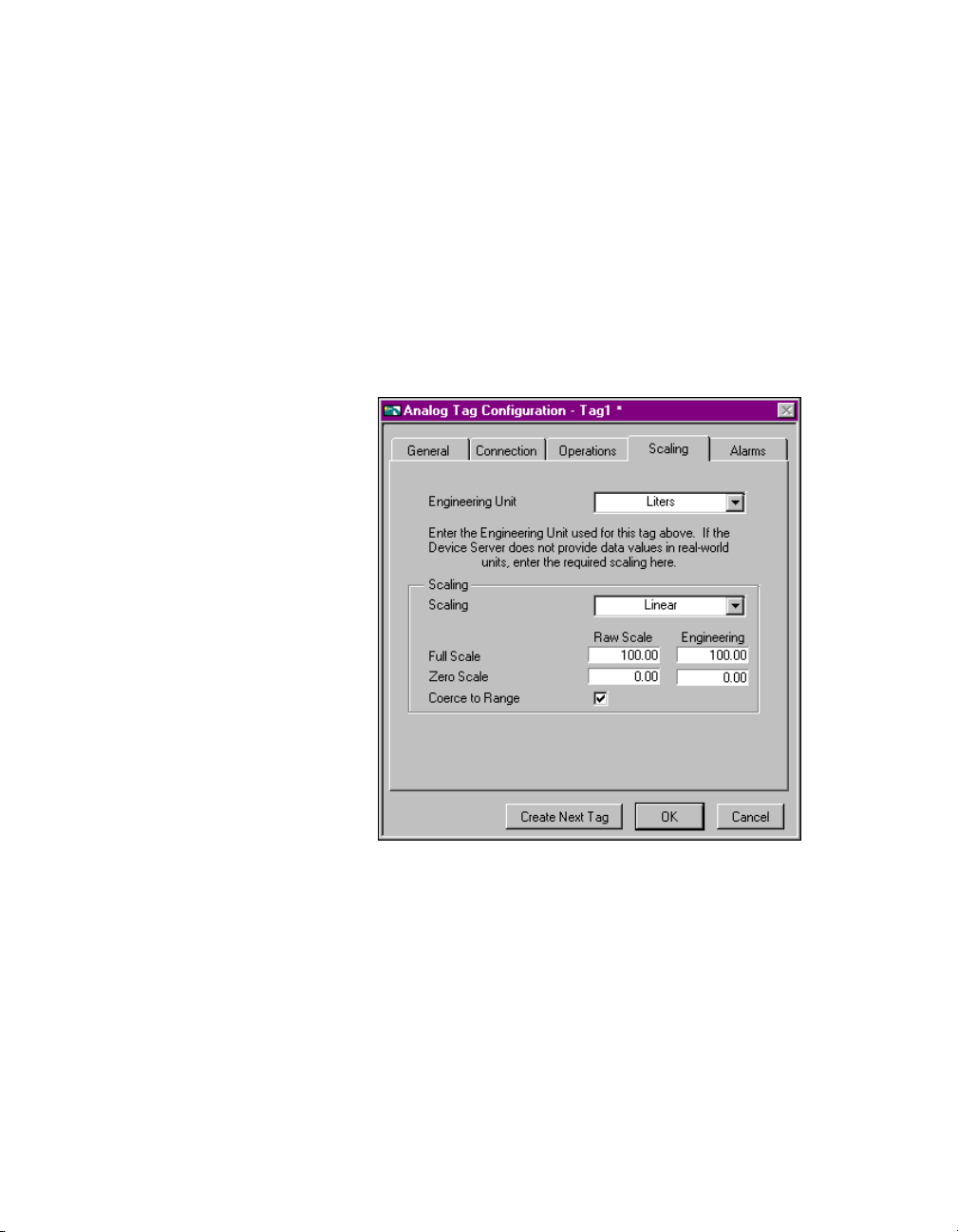

Analog Tags..........................................................................................3-27

Example—Linear Scaling......................................................3-27

Example—Square Root Scaling ............................................3-28

How Do You Assign Units to an Analog Tag?.....................................3-28

Discrete Tags.........................................................................................3-28

Bit Array Tags.......................................................................................3-29

© National Instruments Corporation vii BridgeVIEW User Manual

Page 7

Contents

Alarms.................................................................................................................3-31

How Do You Configure Alarms for a Tag?.........................................3-34

What Is Alarm Deadband on Analog Tags?......................................... 3-36

How Do You Keep an Alarm Unacknowledged

after the Alarm Returns to Normal? ..................................................3-37

How Do You Configure Other Engine Parameters? ......................................................... 3-44

How Do You Turn on Historical and Event Logging at Startup?....................... 3-44

How Do You Set the File Paths for Historical and Events Files?.......................3-44

How Do You Configure Shifts?..........................................................................3-44

How Do You Configure Engine Parameters?.....................................................3-44

How Do You Launch Server Configuration Utilities

from the Tag Configuration Editor?.................................................................3-46

How Do You Access or Change Tag Configuration Information

in Your Application?......................................................................................................3-46

Chapter 4

Human Machine Interface

What Is an HMI?.................................................................................................................4-1

How Do You Build an HMI? ..............................................................................................4-2

Front Panel Objects...............................................................................................4-3

HMI G Wizard ......................................................................................................4-3

Generate the Block Diagram ..................................................................4-8

Front Panel Object and Wizard Subdiagram Association ...................... 4-8

How Do You Customize Front Panel Objects? ..................................................4-12

Control Editor.......................................................................................4-12

Importing Graphics............................................................................... 4-13

How Do You Configure Front Panel

Objects Programmatically?............................................................ .... 4-15

How Do You Monitor and Control Tags?.........................................................................4-16

Tag Data Type.....................................................................................................4-17

Tags VIs and Alarms and Events VIs................................................................. 4-20

How Do the Tags, and Alarms and Events VIs

Affect Startup/Shutdown?..................................................................4-24

Analog Tags ...........................................................................3-34

Discrete Tags..........................................................................3-35

Bit Array Tags........................................................................3-35

String Tags .............................................................................3-36

Auto Ack on Normal..............................................................3-37

User Must Ack .......................................................................3-38

BridgeVIEW User Manual viii © National Instruments Corporation

Page 8

General Principles of G HMI Programming......................................................................4-25

How Do You Implement Event-Driven Programming in G?..............................4-25

How Do You Implement Polled Programming in G?.........................................4-27

How Do You Initialize and Shut Down Multiple-Loop Applications?...............4-28

How Do You Display Real-Time Trends?..........................................................4-29

How Can You Use Tag Attributes to Configure HMI Indicator

Attributes Programmatically? ..........................................................................4-31

Chapter 5

Alarms and Events

What are Alarms and Events?.............................................................................................. 5-1

Alarm States ..........................................................................................................5-1

Alarm Limit...........................................................................................................5-1

Alarm Priority........................................................................................................5-2

Alarm Summary ....................................................................................................5-2

Event History.........................................................................................................5-2

How Do You Display Alarm Summary Information?......................................................... 5-2

How Do You Display Event History Information?.............................................................5-6

How Do You Acknowledge Alarms? .................................................................................5-6

How Do You Configure Logging and Printing of Alarms and Events?............................5-10

How Do You Log Alarms and Events?...............................................................5-12

How Do You Print Alarms and Events?..............................................................5-13

How Do You View Alarms and Events?.............................................................5-14

Contents

Chapter 6

Historical Data Logging and Extraction

What Is a Trend?..................................................................................................................6-1

Real-Time Trend ...................................................................................................6-1

Historical Trend.............................................................. .......................................6-1

What Is Citadel?........................................... ........................................................................6-1

How Do You Log Historical Data? .....................................................................................6-2

How Do You Configure Historical Logging?.......................................................6-3

How Do You Extract and View Data from Historical Log Files?.......................................6-4

Historical Data VIs................................................................................................6-4

Historical Trend Viewer (HTV)............................................................................6-9

How Do You Select the Tags to Display? ............................................6-10

How Do You Change the Time Axis?..................................................6-10

Panning Buttons......................................................................6-11

Manual Changes ................................................. ... .................6-11

How Do You Change the Timespan of Data Displayed? .....................6-12

How Do You View the Value of a Tag at

a Specific Point in Time? ...................................................................6-12

© National Instruments Corporation ix BridgeVIEW User Manual

Page 9

Contents

How Do You Change the Y Axis? .......................................................6-12

How Do You Change the Plot Colors and Style in the Trend? ............ 6-13

How Do You Zoom In on the Trend?...................................................6-13

How Do You Export Data to a Spreadsheet?.......................................6-13

How Do You Get Online Help for the HTV?.......................................6-13

How Do You Set Tag, Time, and Color Preferences?..........................6-13

How Do You View New Data Automatically After

It Has Been Logged to Citadel?......................................................... 6-14

How Do You Incorporate the HTV into Your HMI Application? ....... 6-14

Chapter 7

Advanced Application Topics

How Do You Build an HMI with Multiple Panels?............................................................ 7-1

Front Panel Buttons...............................................................................................7-1

Panel G Wizard.....................................................................................................7-1

How Do You Use the Panel G Wizard? .................................................7-2

How Do You Configure Security with the Panel G Wizard?................. 7-3

How Do You Configure When a Button Will Be Polled?......................7-3

VI Server Functions..............................................................................................7-5

How Do You Control Panel Size?..........................................................7-6

How Do You Control Panel Visibility?.................................................. 7-7

BridgeVIEW System Control.............................................................................................. 7-7

System VIs............................................................................................................ 7-7

How Do You Start or Stop the BridgeVIEW Engine

from Your Application?........................................................ ...............7-8

How Do You Start or Stop Historical Logging from

Your Application?................................................................................7-8

How Do You Start or Stop Event Logging

from Your Application?.......................................................................7-8

How Do You Start or Stop Event Printing

from Your Application?.......................................................................7-8

Tag Attributes VIs............................... ................................................................................7-9

BridgeVIEW Security ....................................................................................................... 7-13

Environment Security ....................................... ..................................................7-13

How Do You Log In and Out? ............................................................. 7-15

How Do You Find Your Access Level?...............................................7-15

How Do You Find Your Environment Privileges? ..............................7-15

How Do You Change Your Password?................................................7-16

How Do You Check a User’s Privileges?.............................................7-16

How Do You Prompt the Operator to Log In

to Your Application? .........................................................................7-16

BridgeVIEW User Manual x © National Instruments Corporation

Page 10

Chapter 8

Servers

What Are BridgeVIEW Device Servers? ............................................................................8-1

How Do You Install and Configure a Device Server?......................................................... 8-2

How Do You Use OPC Servers with BridgeVIEW?...........................................................8-5

How Do You Use DDE Servers with BridgeVIEW? ..........................................................8-9

How Do You View BridgeVIEW Server Configuration?...................................................8-9

How Do You Develop an IA Device Server?....................................................................8-12

Contents

How Do You Programmatically Log an Operator In

to Your Application?..........................................................................7-17

How Do You Programmatically Log an Operator Out

of Your Application?..................................... ... ..................................7-17

How Do You Identify the Current Operator? .......................................7-17

How Do You Restrict Access to the BridgeVIEW Environment? .......7-17

How Do You Create and Modify User Accounts? ...............................7-17

How Do You Modify the List of Available User

Access Levels?...................................................................................7-19

How Do You Export a List of Users to a File?.....................................7-19

How Do You Export Users to Another Computer

on the Network? .................................................................................7-20

How Do You Import a List of Users from a File?................................7-20

How Do You Import Users from Another Computer

on the Network? .................................................................................7-21

How Do You Modify a User’s BridgeVIEW

Environment Privileges?..................................... ...............................7-22

Operator Interface Security .................................................................................7-22

How Do You Limit User Access to HMI Objects? ..............................7-23

Installing and Configuring the NI-DAQ OPC Server ...........................................8-3

Installing and Configuring Device Servers from

the BridgeVIEW Device Servers CD.................................................................8-4

Registering Simulation Servers.............................................................................8-4

Using Remote OPC Servers ..................................................................................8-7

Registered Server Device and Item Parameters ..................................................8-11

© National Instruments Corporation xi BridgeVIEW User Manual

Page 11

Contents

Chapter 9

Creating VIs

What is a Virtual Instrument?.............................................................................................. 9-1

How Do You Build a VI?....................................................................................................9-1

What is a SubVI?...............................................................................................................9-12

How Do You Debug a VI?................................................................................................ 9-21

P

II

ART

G Tutorial

VI Hierarchy ....................................... ..................................................................9-1

Controls, Constants, and Indicators ......................................................................9-2

Terminals .............................................................................................................. 9-3

Wires.....................................................................................................................9-3

Tip Strips ................................................................................................9-4

Wire Stretching................................... ....................................................9-5

Selecting and Deleting Wires ................................................................. 9-5

Bad Wires ...............................................................................................9-6

VI Documentation.................................. ...............................................................9-9

Hierarchy Window..............................................................................................9-12

Search Hierarchy ..................................................................................9-14

Icon and Connector.............................................................................................9-14

Opening, Operating, and Changing SubVIs........................................................9-19

Chapter 10

Customizing VIs

Set Window Options...........................................................................................10-1

SubVI Node Setup ..............................................................................................10-1

Chapter 11

Loops and Charts

What is a Structure?...........................................................................................................11-1

Charts.................................................................................................................................11-2

Chart Modes........................................................................................................11-2

Faster Chart Updates...........................................................................................11-3

Overlaid Versus Stacked Plots............................................................................ 11-3

While Loops ......................................................................................................................11-4

Mechanical Action of Boolean Switches............................................................11-7

Timing................................................................................................................. 11-9

Preventing Code Execution in the First Iteration..............................................11-10

BridgeVIEW User Manual xii © National Instruments Corporation

Page 12

Shift Registers..................................................................................................................11-11

Using Uninitialized Shift Registers...................................................................11-15

For Loops.........................................................................................................................11-20

Numeric Conversion............................................... ...........................................11-21

Chapter 12

Case and Sequence Structures and the Formula Node

Case Structure....................................................................................................................12-2

Sequence Structures...........................................................................................................12-5

Formula Node ..................................................................................................................12-11

Artificial Data Dependency .............................................................................................12-15

Chapter 13

Front Panel Object Attributes

Chapter 14

Arrays, Clusters, and Graphs

Arrays.................................................................................................................................14-1

How Do You Create and Initialize Arrays? ........................................................14-1

Array Controls, Constants, and Indicators............................................14-2

Auto-Indexing......................................................................................................14-2

Using Array Functions ........................................................................................14-9

Build Array ...........................................................................................14-9

Initialize Array.................................................................................... 1 4-10

Array Size ...........................................................................................14-11

Array Subset........................................................................................14-12

Index Array .........................................................................................14-13

Efficient Memory Usage: Minimizing Data Copies..........................................14-16

What is Polymorphism?...................................................................................................14-17

Clusters ............................................................................................................................14-17

Graphs..............................................................................................................................14-18

Customizing Graphs..........................................................................................14-18

Graph Cursors.....................................................................................14-19

Graph Axes .........................................................................................1 4-20

Data Acquisition Arrays....................................................................................14-20

Intensity Plots ..................................................................................................................14-23

Contents

Chapter 15

Application Control

What is the VI Server? ........................................................................................15-2

© National Instruments Corporation xiii BridgeVIEW User Manual

Page 13

Contents

Chapter 16

Program Design

Use Top-Down Design......................................................................................................16-1

Make a List of User Requirements .....................................................................16-1

Design the VI Hierarchy..................................................................................... 16-1

Create the Program..............................................................................................16-3

Plan Ahead with Connector Panes ....................................................................................16-3

SubVIs with Required Inputs.............................................................................. 16-4

Good Diagram Style..........................................................................................................16-4

Watch for Common Operations..........................................................................16-4

Use Left-to-Right Layouts.................................................................................. 16-5

Check for Errors..................................................................................................16-5

Watch Out for Missing Dependencies................................................................16-7

Avoid Overuse of Sequence Structures ..............................................................16-8

Study the Examples.............................................................................................16-8

Appendix A

HMI Function Reference

Appendix B

Citadel and Open Database Connectivity

Appendix C

Customer Communication

Glossary

Index

Figures

Figure 1-1. BridgeVIEW Architecture ..........................................................................1-8

Figure 2-1. Engine Manager Display........................................................................... 2-12

Figure 2-2. Engine Manager with System Events Displayed......................................2-14

Figure 2-3. Tag Browser Utility ..................................................................................2-16

Figure 2-4. Tag Monitor Utility ...................................................................................2-19

Figure 2-5. Status Details Dialog Box.........................................................................2-21

BridgeVIEW User Manual xiv © National Instruments Corporation

Page 14

Contents

Figure 2-6. Select Tags to Monitor Dialog Box...........................................................2-22

Figure 2-7. Write to Tag dialog box.............................................................................2-22

Figure 2-8. Tag Monitor Preferences Dialog Box .......................................................2-23

Figure 3-1. Tag Configuration Editor ............................................................................3-4

Figure 3-2. Flowchart of Server/Client Interaction........................................................3-6

Figure 3-3. Select Tags for Network Import Dialog Box ..............................................3-7

Figure 3-4. General Attributes Dialog Box..................................................................3-12

Figure 3-5. Tag Connection Dialog Box......................................................................3-14

Figure 3-6. I/O Group Configuration Dialog Box ....................................................... 3-17

Figure 3-7. Tag Operations Dialog Box.......................................................................3-24

Figure 3-8. Analog Tag Scaling Dialog Box ...............................................................3-29

Figure 3-9. Scaling for Discrete Tag Configuration ....................................................3-30

Figure 3-10. Scaling for Bit Array Tag Configuration ..................................................3-31

Figure 3-11. Alarms for Analog Tag Configuration......................................................3-36

Figure 3-12. Alarms for Discrete Tag Configuration.....................................................3-37

Figure 3-13. Alarms for Bit Array Tag Configuration...................................................3-38

Figure 4-1. HMI G Wizard Dialog Box......................................................... ... .............4-6

Figure 4-2. Control Dialog Box...................................................................................4-11

Figure 4-3. Monitor Tag Value and Alarm VI.............................................................4-26

Figure 4-4. Process View Display VI ..........................................................................4-28

Figure 4-5. Two Trend Display VI ..............................................................................4-30

Figure 4-6. Initializing the Waveform Chart Indicator

for a Real-Time Trend Display .................................................................4-30

Figure 4-7. Using the Tag Attributes VIs to Initialize

Front Panel Indicators, Frame 0 ................................................................4-32

Figure 4-8. Using the Tag Attributes VIs to Initialize

Front Panel Indicators, Frame 1 ................................................................4-33

Figure 5-1. Event Configuration Dialog Box...............................................................5-10

Figure 6-1. Historical Logging Configuration Dialog Box............................................6-3

Figure 6-2. Historical Trend Viewer..............................................................................6-9

Figure 6-3. Select Tags Dialog Box.............................................................................6-10

Figure 7-1. Panel G Wizard ...........................................................................................7-2

Figure 7-2. Access Levels Dialog Box ........................................................................7-14

Figure 7-3. Privileges Dialog Box ...............................................................................7-15

Figure 7-4. Edit User Accounts Dialog Box ................................................................7-17

Figure 7-5. Add a User Account..................................................................................7-17

Figure 7-6. Using the Security Monitor VI to Control Visibility ................................7-22

© National Instruments Corporation xv BridgeVIEW User Manual

Page 15

Contents

Tables

Figure 8-1. Server Browser............................................................................................8-6

Figure 8-2. View Server Information Dialog Box.........................................................8-7

Figure 8-3. Browse OPC Servers on Network Dialog Box...........................................8-8

Figure 8-4. Server Browser..........................................................................................8-11

Figure 8-5. View Server Information Dialog Box.......................................................8-12

Table 2-1. BridgeVIEW Project Menu Items ............................................................2-10

Table 2-2. Engine Manager Field Descriptions .........................................................2-13

Table 2-3. Tag Browser Field Descriptions ..............................................................2-17

Table 2-4. Tag Monitor Utility Field Descriptions ...................................................2-20

Table 3-1. General Configuration Attributes ............................................................ 3-12

Table 3-2. Connection Configuration Attributes .......................................................3-15

Table 3-3. I/O Group Configuration Attributes .........................................................3-17

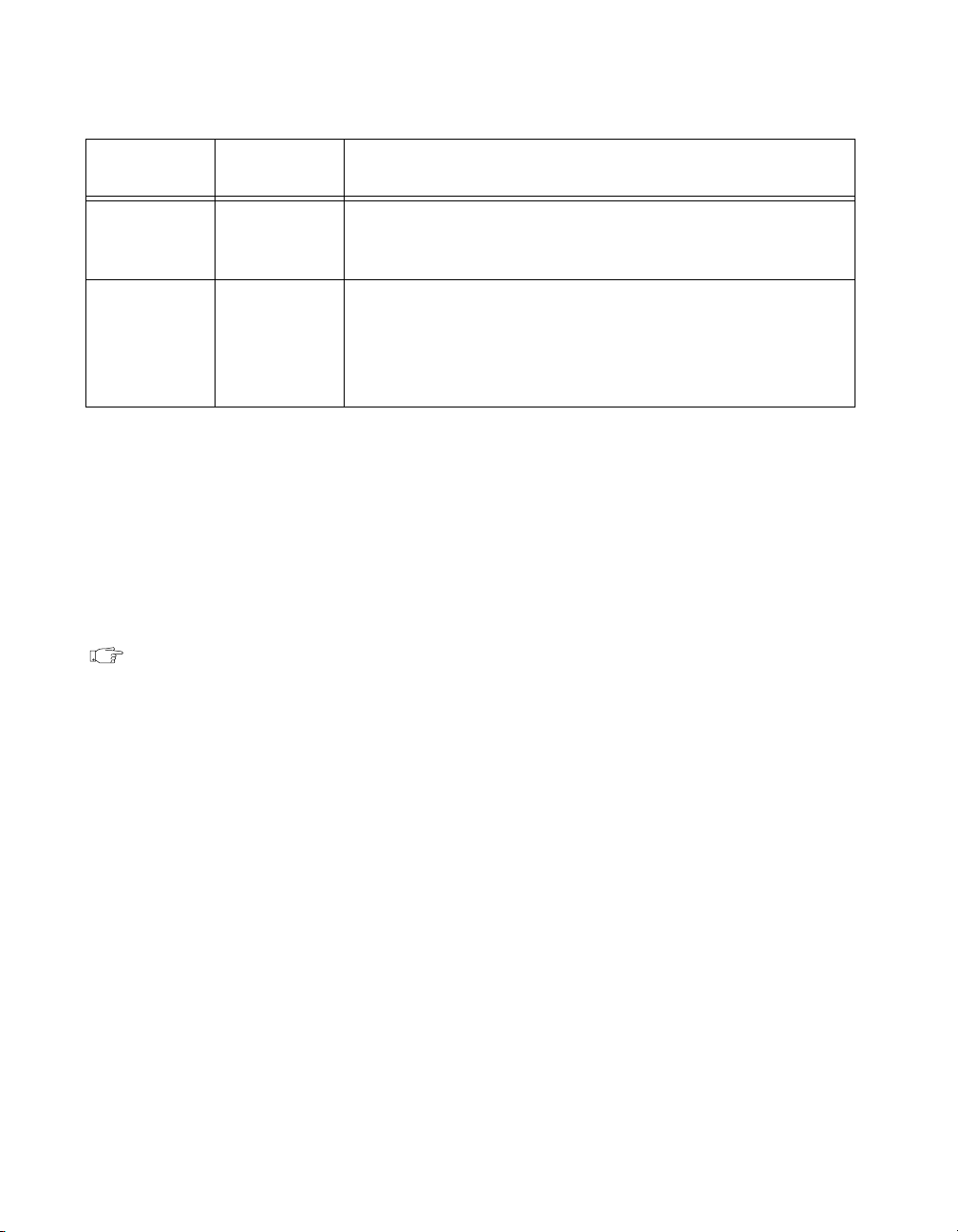

Table 3-4. Operations Configuration Attributes ........................................................3-25

Table 3-5. Scaling Configuration Attributes .............................................................3-27

Table 3-6. Bit Array Scaling Examples...................................................................... 3-32

Table 3-7. Alarms Configuration Attributes ............................................................3-33

Table 3-8. Events with Alarm Deadband = 0.0% ......................................................3-38

Table 3-9. Events with Alarm Deadband = 1.0% ......................................................3-39

Table 3-10. Configuration Settings for Activity 3-1 ................................................... 3-42

Table 3-11. Configuration Modifications for Activity 3-1...........................................3-43

Table 3-12. Configurable Memory Allocation Parameters ......................................... 3-47

Table 4-1. HMI G Wizard Operations .........................................................................4-4

Table 5-1. Tag Configuration Editor Event Configuration Selections ......................5-10

Table 5-2. Event Configuration, Log, and Print Format Selections ..........................5-12

Table 6-1. Parameters You Can Configure for Historical Logging ............................ 6-3

Table 6-2. Panning Button Functions.........................................................................6-11

Table 7-1. BridgeVIEW Environment Privileges ....................................................7-12

Table 7-2. Abbreviations Used to Enable Privileges for a User ...............................7-19

Table B-1. Data Transform Commands .......................................................................B-5

BridgeVIEW User Manual xvi © National Instruments Corporation

Page 16

Activities

Activity 2-1. Open and Run a VI......................................................................................2-8

Activity 3-1. Configure a Tag, and View the Tag Configuration

Activity 4-1. Use the HMI G Wizard ...............................................................................4-8

Activity 4-2. Import a Graphic Image into BridgeVIEW...............................................4-13

Activity 4-3. Read a Tag .................................................................................................4-20

Activity 5-1. Build an Alarm Summary Display..............................................................5-3

Activity 5-2. Acknowledge Alarms in the Alarm Summary Display...............................5-7

Activity 6-1. Use the Historical Data VIs.........................................................................6-6

Activity 6-2. Use the Historical Trend Viewer...............................................................6-15

Activity 7-1. Use the Panel G Wizard ..............................................................................7-3

Activity 7-2. Use Tag Attributes.....................................................................................7-10

Activity 7-3. Apply Security to the Alarm Summary Display .......................................7-23

Activity 9-1. Create a VI...................................................................................................9-6

Activity 9-2. Document a VI ..........................................................................................9-10

Activity 9-3. Create an Icon and Connector...................................................................9-16

Activity 9-4. Call a SubVI..............................................................................................9-19

Activity 9-5. Debug a VI in BridgeVIEW......................................................................9-21

Contents

Parameters and Tag Values.......................................................................3-40

Activity 10-1. Use Setup Options for a SubVI .................................................................10-2

Activity 11-1. Experiment with Chart Modes .................................................................11-3

Activity 11-2. Use a While Loop and a Chart .................................................................11-4

Activity 11-3. Change the Mechanical Action of a Boolean Switch...............................11-8

Activity 11-4. Control Loop Timing................................................................................11-9

Activity 11-5. Use a Shift Register................................................................................11-13

Activity 11-6. Create a Multiplot Chart and Customize Your Trends...........................11-17

Activity 11-7. Use a For Loop.......................................................................................11-22

Activity 12-1. Use the Case Structure .............................................................................12-2

Activity 12-2. Use a Sequence Structure.........................................................................12-5

Activity 12-3. Use the Formula Node............................................................................12-13

Activity 14-1. Create an Array with Auto-Indexing........................................................14-3

Activity 14-2. Use Auto-Indexing on Input Arrays.........................................................14-7

Activity 14-3. Use the Build Array Function ................................................................14-15

Activity 14-4. Use the Graph and Analysis VIs ............................................................14-20

© National Instruments Corporation xvii BridgeVIEW User Manual

Page 17

About This Manual

The BridgeVIEW User Manual contains the information you need to get

started with the BridgeVIEW software package. This manual explains the

BridgeVIEW environment, tag configuration, human machine interfaces,

alarms and events, and historical data logging and extraction. This manual

also reviews the concepts of G programming.

Throughout both sections of this manual, there are activities that teach

you what you need to know to build your own virtual instruments, and

ultimately, your own SCADA system. This manual assumes that you

know how to operate your computer and that you are familiar with its

operating system.

Organization of This Manual

This manual is divided into two parts. Part I, BridgeVIEW Concepts,

introduces you to the basic BridgeVIEW concepts, and includes Chapters 1

through 8. Part II, G Tutorial, describes the G programming language, and

how it works within BridgeVIEW, and includes Chapters 9 through 15.

We encourage you to work through all the activities in this manual before

you begin building your applications. You should save all of the VIs you

create with the BridgeVIEW activities in the

directory. To view the VI(s) for an activity that you have not completed

yourself, see the

solutions to the activities from the BridgeVIEW Concepts section of this

manual, and the

solutions to the activities in the G Tutorial section of this manual.

BridgeVIEW\Activity\Solutions

BridgeVIEW\Activity\Solution

BridgeVIEW\Activity

directory for the

directory for the

BridgeVIEW Concepts

Part I, BridgeVIEW Concepts, contains the following chapters.

• Chapter 1, Introduction, describes the unique BridgeVIEW approach

to Human Machine Interface (HMI) and Supervisory Control and

Data Acquisition (SCADA). It also contains system configuration,

installation instructions and basic information that explains how

to start using BridgeVIEW to develop industrial automation

applications.

• Chapter 2, BridgeVIEW Environment, describes the BridgeVIEW

environment. It explains the basic concepts behind G, the

© National Instruments Corporation xix BridgeVIEW User Manual

Page 18

About This Manual

programming language upon which BridgeVIEW is built, the

BridgeVIEW Engine Manager, system errors and events, the Tag

Monitor utility, and the Tag Browser utility. This chapter also explains

how to access online help for BridgeVIEW and provides an activity

that illustrates how to examine the front panel and block diagram of a

virtual instrument (VI).

• Chapter 3, Tag Configuration, explains tags, the Tag Configuration

Editor, and how you edit tags within the BridgeVIEW system.

• Chapter 4, Human Machine Interface, explains what a Human

Machine Interface (HMI) is and how you can monitor and control tags

from your HMI.

• Chapter 5, Alarms and Events, introduces the basic concepts of alarms

and events, and explains how to view, acknowledge, and configure

them within the BridgeVIEW system.

• Chapter 6, Historical Data Logging and Extraction, explains the

concept of a trend, how to log and extract historical data, and how to

use the Historical Trend V iewer (HTV), a utility that displays historical

data that has been logged to disk with BridgeVIEW.

• Chapter 7, Advanced Application Topics, explains the advanced topics

you need to understand to make optimum use of BridgeVIEW for

developing applications. The advanced topics covered in this chapter

are the Panel G Wizard, BridgeVIEW System Control, Tag Attributes

VIs, and BridgeVIEW Security.

• Chapter 8, Servers, explains how to use servers with BridgeVIEW.

BridgeVIEW supports several types of servers including OPC Serv ers,

DDE Servers, and IA Device Servers.

G Tutorial

Part II, G Tutorial, contains the following chapters.

• Chapter 9, Creating VIs, introduces the basic concepts of virtual

instruments and provides activities that explain how to create the icon

and connector, how to use a VI as a subVI, ho w to use the VI Setup…

option, and how to use the SubVI Node Setup… option.

• Chapter 10, Customizing VIs , introduces the basic concepts used for

customizing VIs.

• Chapter 11, Loops and Charts, introduces structures and explains

the basic concepts of charts, the While Loop, and the For Loop.

BridgeVIEW User Manual xx © National Instruments Corporation

Page 19

• Chapter 12, Case and Sequence Structures and the Formula Node,

introduces the basic concepts of Case and Sequence structures, and

provides activities that explain how to use the Case structure, how

to use the Sequence structure, and what sequence locals are and

how to use them.

• Chapter 13, Front Panel Object Attributes, describes objects called

attribute nodes, which are special block diagram nodes that control the

appearance and functional characteristics of controls and indicators.

• Chapter 14, Arrays, Clusters, and Graphs, introduces the basic

concepts of polymorphism, arrays, clusters, and graphs and provides

activities that explain auto-indexing and the Graph and Analysis VIs.

• Chapter 15, Application Control, introduces the VI Server and

provides an activity that explains how to use it within BridgeVIEW.

The VI Server allows you to control when a VI is loaded into memory,

run, and unloaded from memory.

• Chapter 16, Program Design, suggests some techniques to use when

creating programs and offers programming style recommendations.

Appendices, Glossary, and Index

• Appendix A, HMI Function Reference, describes error handling

for BridgeVIEW VIs and contains an explanation of the VIs in the

BridgeVIEW VI library. In this appendix, the VIs are arranged

alphabetically, first by VI Library name (Alarms and Events,

Historical Data, System, Tags, and Tag Attributes), then by VI name.

• Appendix B, Citadel and Open Datab ase Connectivity, describes the

Citadel database and the Open Database Connectivity (ODBC) driver ,

and includes several examples of how to use it.

• Appendix C, Customer Communication, contains forms to help

you gather the information necessary to help us solve your

technical problems, and a form you can use to comment on

the product documentation.

• The Glossary contains an alphabetical list of terms used in this

manual, including abbreviations, acronyms, metric prefixes,

mnemonics, and symbols.

• The Index contains an alphabetical list of key terms and topics in

this manual, including the page where you can find each one.

About This Manual

© National Instruments Corporation xxi BridgeVIEW User Manual

Page 20

About This Manual

Conventions Used in This Manual

The following conventions are used in this manual:

bold Bold text denotes a parameter, menu name, palette name, menu item,

return value, function panel item, or dialog box button or option.

italic Italic text denotes mathematical variables, emphasis, a cross reference,

or an introduction to a key concept.

bold italic Bold italic text denotes an activity objective, note, caution, or warning.

monospace

monospace bold

monospace italic

<> Angle brackets enclose the name of a key on the keyboard—for example,

- A hyphen between two or more key names enclosed in angle brackets

<Control> Key names are capitalized.

» The » symbol leads you through nested menu items and dialog box options

Text in this font denotes text or characters that you should literally enter

from the keyboard. Sections of code, programming examples, and syntax

examples also appear in this font. This font also is used for the proper

names of disk drives, paths, directories, programs, subprograms,

subroutines, device names, variables, filenames, and extensions, and

for statements and comments taken from program code.

Bold text in this font denotes the messages and responses that the computer

automatically prints to the screen. This font also emphasizes lines of code

that are different from the other examples.

Italic text in this font denotes that you must enter the appropriate words or

values in the place of these items.

<PageDown>.

denotes that you should simultaneously press the named keys—for

example, <Control-Alt-Delete>.

to a final action. The sequence File»Page Setup»Options»Substitute

Fonts directs you to pull down the File menu, select the Page Setup item,

select Options, and finally select the Substi tute Fonts option from the last

dialog box.

paths Paths in this manual are denoted with backslashes (\) to separate drive

names, directories, and files, as in

BridgeVIEW User Manual xxii © National Instruments Corporation

C:\dir1name\dir2name\filename

.

Page 21

This icon to the left of bold text denotes the beginning of an activity, which

contains step-by-step instructions you can follow to learn more about

BridgeVIEW.

This icon to the left of bold text denotes the end of an activity, which

contains step-by-step instructions you can follow to learn more about

BridgeVIEW.

This icon to the left of bold italicized text denotes a note, which alerts you

to important information.

Abbreviations, acron yms, metric pref ixes, mnemonics , symbols, and terms

are listed in the Glossary.

Related Documentation

The following documents contains information that you might find helpful

as you read this manual:

• G Programming Reference Manual

• BridgeVIEW Online Reference, available online by selecting

Help»Online Reference

About This Manual

Customer Communication

National Instruments wants to receive your comments on our products

and manuals. We are interested in the applications you develop with our

products, and we want to help if you have problems with them. To make it

easy for you to contact us, this manual contains comment and configuration

forms for you to complete. These forms are in Appendix C, Customer

Communication, at the end of this manual.

© National Instruments Corporation xxiii BridgeVIEW User Manual

Page 22

BridgeVIEW Concepts

This section contains information about the BridgeVIEW environment, tag

configuration, Human Machine Interface, alarms and events, historical data

logging and extraction, servers, and advanced application topics such as

system control and security.

Part I, BridgeVIEW Concepts, contains the following chapters.

• Chapter 1, Introduction, describes the unique BridgeVIEW approach

to Human Machine Interface (HMI) and Supervisory Control and

Data Acquisition (SCADA). It also contains system configuration,

installation instructions and basic information that explains how

to usestart using BridgeVIEW to develop industrial automation

applications.

• Chapter 2, BridgeVIEW Environment, describes the BridgeVIEW

environment. It explains the basic concepts behind G, the

programming language upon which BridgeVIEW is built, the

BridgeVIEW Engine Manager, system errors and even ts, th e Tag

Monitor utility, and the Tag Browser utility. This chapter also explains

how to access online help for BridgeVIEW and provides an activity

that illustrates how to examine the front panel and block diagram of a

virtual instrument (VI).

• Chapter 3, Tag Configuration, explains tags, the Tag Configuration

Editor, and how you edit tags within the BridgeVIEW system. Before

you can run a BridgeVIEW application, you must specify a tag

configuration.

• Chapter 4, Human Machine Interface, explains what a Human

Machine Interface (HMI) is and how you can monitor and control tags

from your HMI.

• Chapter 5, Alarms and Events, introduces the basic concepts of alarms

and events, and explains how to view, acknowledge, and configure

them within the BridgeVIEW system.

Part I

Page 23

Part I BridgeVIEW Concepts

• Chapter 6, Historical Data Logging and Extraction, explains the

concept of a trend, how to log and extract historical data, and how to

use the Historical Trend V iewer (HTV), a utility that displays historical

data that has been logged to disk with BridgeVIEW.

• Chapter 7, Advanced Application Topics, explains BridgeVIEW

Environment Securitythe advanced topics you need to understand to

make optimum use of BridgeVIEW for developing applications. The

advanced topics covered in this chapter are the Panel G Wizard,

BridgeVIEW System Control, Tag Attributes VIs, and BridgeVIEW

Security.

• Chapter 8, Servers, explains how to use servers with BridgeVIEW.

BridgeVIEW supports several types of servers including OPC Serv ers,

DDE Servers, and IA Device Servers.

BridgeVIEW User Manual I-2 © National Instruments Corporation

Page 24

Introduction

This chapter describes the unique BridgeVIEW approach to

Human Machine Interface (HMI) and Supervisory Control and Data

Acquisition (SCADA). It also contains system configuration, installation

instructions, and basic information that explains how to start using

BridgeVIEW to develop industrial automation applications. This chapter

refers you to other chapters or manuals for more information.

Welcome to BridgeVIEW

BridgeVIEW adds real-time process monitoring, historical trending, alarm

and event reporting, online configuration tools and PLC connectivity to a

premiere graphical development environment, G.

BridgeVIEW makes use of an intuitive graphical user interface combined

with a powerful graphical programming language, G, that enables you to

perform data acquisition and analysis, create an operator interface or

Human Machine Interface (HMI), and develop adv anced supervisory

control applications.

1

BridgeVIEW provides the following features for the development of your

Industrial Automation applications.

• Graphical human-machine interface (HMI)

• Easy-to-use, fill in the blank configuration utilities

• Graphical programming tools

• Real-Time Database (RTDB)

• Historical data collection and trending (Citadel)

• Alarm and event reporting and logging

• Security

• Connectivity to PLC and industrial device networks

• OPC Server Support

© National Instruments Corporation 1-1 BridgeVIEW User Manual

Page 25

Chapter 1 Introduction

Required System Configuration

BridgeVIEW is distributed on a CD-ROM that includes the complete

BridgeVIEW 2.0 release.

The Windows 95/NT version of BridgeVIEW runs on any system that

supports Windows 95 or W indows NT 4.0. A minimum of 24 MB of RAM

is required for this version to run effectively. We recommend 32 MB of

RAM and at least 30 MB of swap space available on your system.

Note

Installation

The standard BridgeVIEW installation requires approximately 110 MB of disk

space. A full installation requires approximately 150 MB. If you plan to install the

NI-DAQ Server as well, an additional 30 MB of disk space is required.

Complete the following steps to install BridgeVIEW.

1. Insert the CD in your CD-ROM drive.

2. Run the BridgeVIEW installer.

a. If you have Windows 95 or Windows NT 4.0 and your system

uses the AutoPlay feature, the Welcome to BridgeVIEW screen

appears a short time after you insert the CD.

b. If you have a system not using AutoPlay, run the following

program:

X

:\bvsetup.exe

X

where

is the letter of your CD-ROM drive.

3. Choose an installation. The installer offers several installation types:

Standard, Full, Minimum, and Custom. The Standard installation

requires approximately 110 MB. The Full installation, which also

includes Data Acquisition, GPIB, and VISA libraries and examples,

requires approximately 150 MB of disk space. The Standard

installation is recommended.

4. After selecting an installation, follow the instructions that appear on

your screen.

Note

If you plan to use National Instruments Data Acquisition (DAQ) devices, VISA, or

GPIB instrumentation, you can perform either the Full installation, which installs

all necessary drivers and example programs, or the Custom installation, in which

you select the items to install.

After you have installed BridgeVIEW completely, it is ready to run.

You migh t need to re-boo t your machine after installation so that updated

system, DAQ, VISA, or GPIB drivers can be loaded properly.

BridgeVIEW User Manual 1-2 © National Instruments Corporation

Page 26

What Is BridgeVIEW?

BridgeVIEW is a software package specifically targeted at industrial

automation applications. BridgeVIEW provides configurable solutions for

common HMI and SCADA functions while leveraging the flexibility of

graphical programming. BridgeVIEW is built around the Gprogramming

language, created by National Instruments Corporation.

With BridgeVIEW, you can acquire data and control one or more

distributed devices in an overall facility. BridgeVIEW can change set points

or send control instructions to the individual devices while monitoring the

entire system. It also can gather information like alarms and measurement

points from these devices.

Common devices used for data acquisition include Programmable Logic

Controllers (PLCs), plug-in Data Acquisition boards, and other distributed

Input/Output (I/O) modules. BridgeVIEW device servers communicate

with these non-plug-in devices through RS-232, RS-485, TCP/IP, DDE,

netDDE, direct I/O, or other proprietary interfaces. BridgeVIEW device

servers provide the necessary protocol software to communicate with

thesedevices. BridgeVIEW also operates directly with OPC servers.

Chapter 1 Introduction

How Does BridgeVIEW Work?

BridgeVIEW uses a combination of tags, events, and data. A tag is a

connection to a real-world I/O point, while an event is anything that

happens to a tag or to the BridgeVIEW Engine in general. The

BridgeVIEW Engine communicates with device servers on one end,

andwith your HMI application at the other end. The BridgeVIEW

Enginemaintains a Real-Time Database (RTDB) of tag information and

logs historical data and events. You can build your HMI to interface with

the BridgeVIEW Engine using virtual instruments (VIs) to read and write

tag values, view alarm information and trend data. A virtual instrument is

a BridgeVIEW function, written in the graphical programming language G.

For more information about G, see any of the chapters in the G Tutorial

section of this manual.

Start by configuring all the tags in your system with the Tag Configuration

Editor. Then, you can launch the BridgeVIEW Engine, which reads your

configuration file and starts monitoring tags, logging data and events. You

can create your HMI application to display tag values, trends, and alarms.

You also can acknowledge alarms and control output tags. You can build

the HMI using BridgeVIEW VIs to read and write tag values, view alarm

© National Instruments Corporation 1-3 BridgeVIEW User Manual

Page 27

Chapter 1 Introduction

G Programming

information, acknowledge alarms, view real-time trends and retrieve

historical data. For more information about how to get started with

BridgeVIEW, see the Where Should I Start? section at the end of this

chapter.

G is the easy-to-use graphical data flow programming language

BridgeVIEW is based upon. G simplifies scientific computation,

processmonitoring and control, test and measurement, and a wide

varietyof other applications.

G was first introduced by National Instruments as the programming

language behind LabVIEW, the program development application used

commonly for test and measurement purposes. BridgeVIEW has taken all

the functionality of G and enhanced it for your industrial automation needs.

The G Tutorial section of this manual covers the functionality of G that you

need to get started with most BridgeVIEW applications. For a more

extensive explanation of BridgeVIEW functionality, see the

GProgramming Reference Manual.

The basic concepts of G that are covered in this manual are as follows:

• VIs—Virtual instruments (VIs) have three main parts: the front panel,

the block diagram, and the icon/connector. The front panel specifies

the user interface of the VI. The block diagram consists of the

executable code that you create using nodes, terminals, and wires.

With the icon/connector, you can use a VI as a subVI in the block

diagram of another VI. For more information about VIs, refer to

Chapter9, CreatingVIs, and Chapter10, Customizing VIs.

• Loops and Charts—G has two structures to repeat execution of a

sub-diagram—the While Loop and the For Loop. Both structures are

resizable boxes. You place the subdiagram to be repeated inside the

border of the loop structure. The While Loop executes as long as the

value at the conditional terminal is TRUE. The For Loop executes a set

number of times. Charts are used to display real-time trend information

to the operator. For more information about loops and charts, refer to

Chapter11, Loops and Charts.

• Case and Sequence Structures—The Case structure is a conditional

branching control structure, which executes a subdiagram based on

certain input. sequence structure is a program control structure that

executes its subdiagrams in numeric order. For more information about

Case or Sequence structures, refer to Chapter12, Case and Sequence

Structures and the Formula Node.

BridgeVIEW User Manual 1-4 © National Instruments Corporation

Page 28

Tag Configuration

Chapter 1 Introduction

• Attribute Nodes—Attribute nodes are special block diagram nodes that

you can use to control the appearance and functional characteristics of

controls and indicators. For more information about attribute nodes,

refer to Chapter13, Front Panel Object Attributes.

• Arrays, Clusters and Graphs—An array is a resizable collection of

data elements of the same type. A cluster is a statically sized collection

of data elements of the same or different types. Graphs commonly are

used to display data. For more information about arrays, clusters, and

graphs, refer to Chapter14, Arrays, Clusters, and Graphs.

• VI Server—The VI Server allows you to control when a VI is loaded

into memory, run, and unloaded from memory. For more information

about VI Control VIs, refer to Chapter15, Application Control.

A tag value is acquired and/or controlled by a device server that

communicates with the BridgeVIEW Engine and can be read or set by

aVIin your HMI application. Tags can be of the following types: input,

output, Input/Output, or memory. You can configure tags through the

TagConfiguration Editor. A tag configuration consists of its data type,

connection, scaling, operations, and alarms settings. For more information

about this topic, refer to Chapter3, Tag Configuration.

Data Type

A tag datatype can be analog, discrete, bit array, or string. Analog tags

have continuous values with a specified range (such as 0.0 to 100.0).

Discrete tags have values that are either ON (1) or OFF (0). Bit array tags

are comprised of up to 32 bits, each of which can have an ON (1) or OFF(0)

state. String tags consist of ASCII characters or binary data and can be of

any length.

General

General includes the following tag attributes:

•Tag name

• Tag description

• Tag group

• Length (for bit array and string tags)

© National Instruments Corporation 1-5 BridgeVIEW User Manual

Page 29

Chapter 1 Introduction

Connection

Connection includes the following tag attributes:

• Access rights (input only, output only, Input/Output, or memory)

•Server name

• I/O group name

• Item name

• Access path (for OPC servers)

Scaling