Page 1

AMUX-64T

User Manual

Analog Multiplexer with Temperature Sensor

November 1994 Edition

Part Number 320253B-01

© Copyright 1989, 1994 National Instruments Corporation.

All Rights Reserved.

Page 2

National Instruments Corporate Headquarters

6504 Bridge Point Parkway

Austin, TX 78730-5039

(512) 794-0100

Technical support fax: (800) 328-2203

(512) 794-5678

Branch Offices:

Australia (03) 879 9422, Austria (0662) 435986, Belgium 02/757.00.20, Canada (Ontario) (519) 622-9310,

Canada (Québec) (514) 694-8521, Denmark 45 76 26 00, Finland (90) 527 2321, France (1) 48 14 24 24,

Germany 089/741 31 30, Italy 02/48301892, Japan (03) 3788-1921, Mexico 95 800 010 0793,

Netherlands 03480-33466, Norway 32-84 84 00, Singapore 2265886, Spain (91) 640 0085, Sweden 08-730 49 70,

Switzerland 056/20 51 51, Taiwan 02 377 1200, U.K. 0635 523545

Page 3

Limited Warranty

The AMUX-64T is warranted against defects in materials and workmanship for a period of one year from the date of

shipment, as evidenced by receipts or other documentation. National Instruments will, at its option, repair or replace

equipment that proves to be defective during the warranty period. This warranty includes parts and labor.

The media on which you receive National Instruments software are warranted not to fail to execute programming

instructions, due to defects in materials and workmanship, for a period of 90 days from date of shipment, as

evidenced by receipts or other documentation. National Instruments will, at its option, repair or replace software

media that do not execute programming instructions if National Instruments receives notice of such defects during

the warranty period. National Instruments does not warrant that the operation of the software shall be uninterrupted

or error free.

A Return Material Authorization (RMA) number must be obtained from the factory and clearly marked on the

outside of the package before any equipment will be accepted for warranty work. National Instruments will pay the

shipping costs of returning to the owner parts which are covered by warranty.

National Instruments believes that the information in this manual is accurate. The document has been carefully

reviewed for technical accuracy. In the event that technical or typographical errors exist, National Instruments

reserves the right to make changes to subsequent editions of this document without prior notice to holders of this

edition. The reader should consult National Instruments if errors are suspected. In no event shall National

Instruments be liable for any damages arising out of or related to this document or the information contained in it.

EXCEPT AS SPECIFIED HEREIN, NATIONAL INSTRUMENTS MAKES NO WARRANTIES, EXPRESS OR IMPLIED,

AND SPECIFICALLY DISCLAIMS ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE

OF

NATIONAL INSTRUMENTS WILL NOT BE LIABLE FOR DAMAGES RESULTING FROM LOSS OF DATA, PROFITS,

USE OF PRODUCTS, OR INCIDENTAL OR CONSEQUENTIAL DAMAGES, EVEN IF ADVISED OF THE POSSIBILITY

THEREOF

whether in contract or tort, including negligence. Any action against National Instruments must be brought within

one year after the cause of action accrues. National Instruments shall not be liable for any delay in performance due

to causes beyond its reasonable control. The warranty provided herein does not cover damages, defects,

malfunctions, or service failures caused by owner's failure to follow the National Instruments installation, operation,

or maintenance instructions; owner's modification of the product; owner's abuse, misuse, or negligent acts; and

power failure or surges, fire, flood, accident, actions of third parties, or other events outside reasonable control.

. CUSTOMER'S RIGHT TO RECOVER DAMAGES CAUSED BY FAULT OR NEGLIGENCE ON THE PART

NATIONAL INSTRUMENTS SHALL BE LIMITED TO THE AMOUNT THERETOFORE PAID BY THE CUSTOMER.

. This limitation of the liability of National Instruments will apply regardless of the form of action,

Copyright

Under the copyright laws, this publication may not be reproduced or transmitted in any form, electronic or

mechanical, including photocopying, recording, storing in an information retrieval system, or translating, in whole

or in part, without the prior written consent of National Instruments Corporation.

Trademarks

LabVIEW®, NI-DAQ®, and RTSI® are trademarks of National Instruments Corporation.

Product names and company names listed are trademarks or trade names of their respective companies.

Page 4

WARNING REGARDING MEDICAL AND CLINICAL USE

OF NATIONAL INSTRUMENTS PRODUCTS

National Instruments products are not designed with components and testing intended to ensure a level of reliability

suitable for use in treatment and diagnosis of humans. Applications of National Instruments products involving

medical or clinical treatment can create a potential for accidental injury caused by product failure, or by errors on

the part of the user or application designer. Any use or application of National Instruments products for or involving

medical or clinical treatment must be performed by properly trained and qualified medical personnel, and all

traditional medical safeguards, equipment, and procedures that are appropriate in the particular situation to prevent

serious injury or death should always continue to be used when National Instruments products are being used.

National Instruments products are NOT intended to be a substitute for any form of established process, procedure, or

equipment used to monitor or safeguard human health and safety in medical or clinical treatment.

Page 5

Contents

About This Manual.............................................................................................................ix

Organization of This Manual.........................................................................................ix

Conventions Used in This Manual.................................................................................x

Chapter 1

Introduction

About the AMUX-64T...................................................................................................1-1

What You Need to Get Started ......................................................................................1-1

Optional Equipment.......................................................................................................1-5

Unpacking......................................................................................................................1-6

Chapter 2

Configuration and Installation

Board Configuration ......................................................................................................2-1

Single-Board and Multiple-Board Configurations.........................................................2-7

Installation......................................................................................................................2-10

Power-On Sequence.......................................................................................................2-11

..........................................................................................................................1-1

Software Programming Choices........................................................................1-2

LabVIEW and LabWindows Application Software..........................................1-2

NI-DAQ Driver Software...................................................................................1-2

Register-Level Programming.............................................................................1-5

.......................................................................................2-1

Power, Tempeture Sensor, and Shield Configuration........................................2-1

Supplementary Configuration Information........................................................2-4

Power Supply Selection.........................................................................2-4

Temperature Sensor...............................................................................2-5

Shield Selection......................................................................................2-5

Single-Board Configuration...............................................................................2-9

Two-Board Configuration..................................................................................2-9

Four-Board Configuration..................................................................................2-9

Chapter 3

Signal Connections

I/O Connector.................................................................................................................3-2

Differential Connections................................................................................................3-4

Using the AMUX-64T for Thermocouple Measurements.............................................3-4

Selecting the Gain and Input Ranges.................................................................3-4

Linearizing the Data...........................................................................................3-5

Differential Measurements.................................................................................3-6

An Example of Using Thermocouples (Differential) ........................................3-7

Single-Ended Measurement...............................................................................3-9

Using More Than One AMUX-64T...................................................................3-9

Sources of Error.................................................................................................3-9

Thermocouple Measurement Accuracies...........................................................3-10

Other Connection Considerations..................................................................................3-10

© National Instruments Corporation v AMUX-64T User Manual

.............................................................................................................3-1

Procedure 1 ............................................................................................3-7

Procedure 2 ............................................................................................3-8

Comments..............................................................................................3-8

Page 6

Contents

Chapter 4

Signal Conditioning

Analog Input ..................................................................................................................4-1

Application Notes ..........................................................................................................4-3

Soldering and Desoldering on the AMUX-64T Board......................................4-3

Channel Configurations.....................................................................................4-3

Connecting Nonreferenced or Floating Signal Sources.....................................4-4

Connecting Ground-Referenced Signal Sources................................................4-5

Building Lowpass Filters...................................................................................4-6

Building Highpass Filters...................................................................................4-7

Building Attenuators (Voltage Dividers)...........................................................4-9

............................................................................................................4-1

Differential Inputs..................................................................................4-4

Single-Ended Inputs...............................................................................4-5

Differential Inputs..................................................................................4-5

Single-Ended Inputs...............................................................................4-5

Chapter 5

Theory of Operation and Register-Level Programming

Functional Overview......................................................................................................5-1

How to Address AMUX-64T Analog Input Channels...................................................5-3

A/D Conversions on a Single AMUX-64T Analog Input Channel...................5-3

Automatic Channel Scanning with the AMUX-64T......................................................5-6

Scanning Order ..............................................................................................................5-9

Programming Channel Scanning with the AMUX-64T ................................................5-10

Initialize the AMUX-64T Scanning Counter.....................................................5-10

Configure Counter 1 to Control the MIO Scanning Clock................................5-10

Set the SCAN DIV Bit in MIO Command Register 1.......................................5-11

......................................5-1

Appendix A

Specifications

........................................................................................................................A-1

Appendix B

Customer Communication

...............................................................................................B-1

Glossary......................................................................................................................Glossary-1

Index..................................................................................................................................Index-1

AMUX-64T User Manual vi © National Instruments Corporation

Page 7

Contents

Figures

Figure 1-1. The Relationship between the Programming Environment,

NI-DAQ, and Your Hardware ...............................................................................1-4

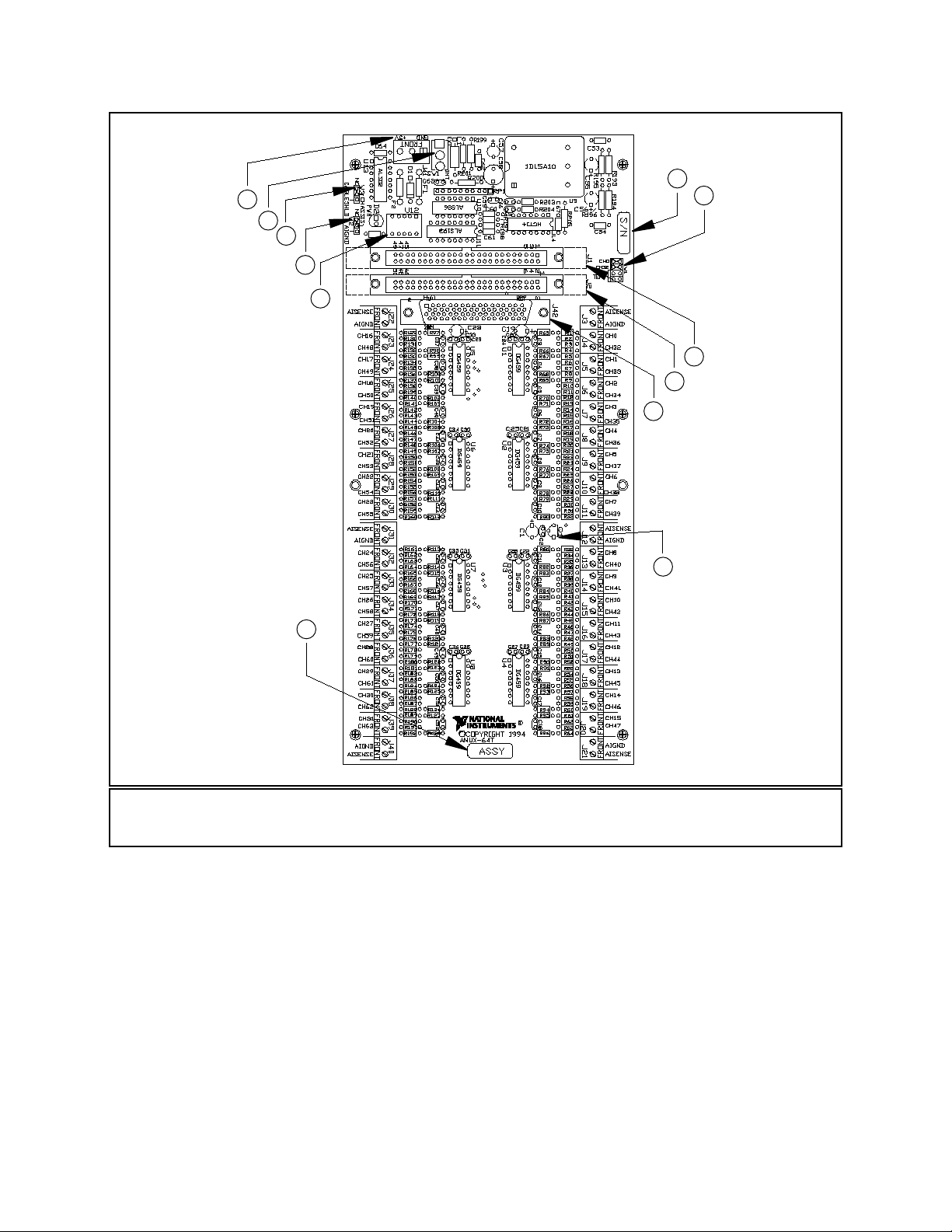

Figure 2-1. AMUX-64T Parts Locator Diagram ......................................................................2-2

Figure 2-2. Daisy-Chaining Multiple AMUX-64T Boards ......................................................2-8

Figure 2-3. Cable Positioning for the AMUX-64T...................................................................2-10

Figure 3-1. AMUX-64T Signal Routing...................................................................................3-3

Figure 4-1. Onboard Equivalent Circuit ...................................................................................4-1

Figure 4-2. Bias Return Resistor for DC-Coupled Floating Source on Channel 1...................4-4

Figure 4-3. Normalized Frequency Response of Lowpass Filter..............................................4-6

Figure 4-4. Lowpass Filter on Differential Channel 1..............................................................4-7

Figure 4-5. Normalized Frequency Response of Highpass Filter.............................................4-8

Figure 4-6. Highpass Filter on Differential Channel 1.............................................................4-9

Figure 4-7. Attenuator for Use with Differential Inputs...........................................................4-10

Figure 5-1. AMUX-64T Block Diagram..................................................................................5-2

Figure 5-2. Scanning Counter Control Bits ..............................................................................5-3

Figure 5-3. AMUX-64T Channel Address Mapping................................................................5-5

Figure 5-4. Two-Level Multiplexer Arrangement Showing Channel 9 Selected.....................5-7

Figure 5-5. Scanning Order for Different AMUX-64T Board Configurations.........................5-8

Tables

Table 2-1. Power Supply Selection...........................................................................................2-3

Table 2-2. Temperature Sensor Selection.................................................................................2-3

Table 2-3. Shield Selection.......................................................................................................2-4

Table 2-4. MIO Board Power Budget.......................................................................................2-5

Table 2-5. Single- and Multiple- Board Configuration.............................................................2-7

Table 2-6. Channel Ranges for Multiple AMUX-64T Boards.................................................2-8

Table 2-7. U12 Switch Settings for Two-Board Configuration................................................2-9

Table 2-8. U12 Switch Settings for Four-Board Configuration................................................2-10

Table 3-1. Pin Mapping for I/O Connectors J1, J2, and J42.....................................................3-2

Table 3-2. Thermocouple Voltage Output Extremes (mV)......................................................3-5

Table 3-3. NBS Polynomial Coefficients .................................................................................3-6

Table 3-4. Thermocouple Measurement Accuracies................................................................3-10

Table 4-1. Component Positions in Each Channel ...................................................................4-2

Table 5-1. AMUX-64T Channel Selection...............................................................................5-4

Table 5-2. Multiple AMUX-64T Board Addressing ................................................................5-5

Table 5-3. AMUX-64T Scanning Order for Each MIO Board Input Channel.........................5-9

© National Instruments Corporation vii AMUX-64T User Manual

Page 8

About This Manual

This manual describes the mechanical and electrical aspects of the AMUX64T and contains information about configuring, operating, and

programming the AMUX-64T.

multiplexer that quadruples the number of analog input signals that can be

digitized with a National Instruments MIO board (except the AT-MIO-64).

The AMUX-64T also has an integrated circuit temperature sensor that can

be connected as a differential input to two of the 64 input channels

(jumper-selectable) for low-cost thermocouple cold junction compensation.

The AMUX-64T also has signal conditioning positions available for all 64

input channels.

Organization of This Manual

The AMUX-64T User Manual is organized as follows:

The AMUX-64T is a front-end analog

• Chapter 1, Introduction, describes the AMUX-64T; lists what you need

to get started with your AMUX-64T; describes the software

programming choices and optional equipment; and explains how to

unpack your AMUX-64T.

• Chapter 2, Configuration and Installation, describes the configuration

and installation of your AMUX-64T. The topics discussed include switch

and jumper configuration, connection of the AMUX-64T board to the

MIO board, power, and signal connections.

• Chapter 3, Signal Connections, describes the AMUX-64T signal

connections and has specifications and connection instructions for the

AMUX-64T connector signals.

• Chapter 4, Signal Conditioning, discusses signal conditioning and

describes how to build systems such as filters and attenuators for

passive analog input signal conditioning.

• Chapter 5, Theory of Operation and Register-Level Programming,

contains a functional overview of the AMUX-64T and explains the

operation of each functional unit making up the AMUX-64T. This

© National Instruments Corporation ix AMUX-64T User Manual

Page 9

About This Manual

chapter also contains register-level programming information for the

MIO board.

• Appendix A, Specifications, lists the specifications for the AMUX-64T.

• Appendix B, Customer Communication, contains forms you can use to

request help from National Instruments or to comment on our products

and manuals.

• The Glossary contains an alphabetical list and description of terms used

in this manual, including abbreviations, acronyms, metric prefixes,

mnemonics, and symbols.

• The Index contains an alphabetical list of key terms and topics in this

manual, including the page where you can find each one.

AMUX-64T User Manual x © National Instruments Corporation

Page 10

About This Manual

Conventions Used in This Manual

The following conventions are used in this manual:

bold italic Bold italic text denotes a note, caution, or warning.

italic Italic text denotes emphasis, a cross reference, or an

introduction to a key concept.

E Series E Series refers to the AT-MIO-16E-2, AT-MIO-16E-10,

AT-MIO-16DE-10, AT-MIO-16XE-10, and NEC-MIO-16E-4

boards.

MC MC refers to the Micro Channel Series computers.

MIO board MIO board refers to the AT-MIO-16, AT-MIO-16D,

AT-MIO-16DE-10, AT-MIO-16E-2, AT-MIO-16E-10, ATMIO-16F-5, AT-MIO-16X, AT-MIO-16XE-10, MC-MIO-16,

NB-MIO-16, NB-MIO-16X, NEC-MIO-16E-4, and SB-MIO16E-4 boards.

monospace Text in this font denotes text or characters that are to be

literally input from the keyboard, sections of code,

programming examples, and syntax examples. This font

is also used for the proper names of disk drives, paths,

directories, programs, subprograms, subroutines, device

names, functions, variables, filenames, and extensions,

and for statements and comments taken from program

code.

NB NB refers to the NuBus series computers.

PC PC refers to the IBM PC/XT, the IBM PC AT, and

compatible computers.

Abbreviations, acronyms, metric prefixes, mnemonics, symbols, and terms

are listed in the Glossary.

© National Instruments Corporation xi AMUX-64T User Manual

Page 11

About This Manual

National Instruments Documentation

The AMUX-64T User Manual is one piece of the documentation set for your

system. You could have any of several types of manuals, depending on the

hardware and software in your system. Use the different types of manuals

you have as follows:

• Your DAQ hardware user manuals—These manuals have detailed

information about the DAQ hardware that plugs into or is connected to

your computer. Use these manuals for hardware installation and

configuration instructions, specification information about your DAQ

hardware, and application hints.

• Software manuals—Examples of software manuals you may have are the

®

LabVIEW and LabWindows

After you set up your hardware system, use either the application

software (LabVIEW or LabWindows) manuals or the

NI-DAQ manuals to help you write your application. If you have a large

and complicated system, it is worthwhile to look through the software

manuals before you configure your hardware.

manual sets and the NI-DAQ manuals.

• Accessory installation guides or manuals—If you are using accessory

products, read the terminal block and cable assembly installation guides

or accessory board user manuals. They explain how to physically

connect the relevant pieces of the system. Consult these guides when

you are making your connections.

Related Documentation

The following manuals contain information you may find helpful as you

read this manual:

• NIST Monograph 175: Temperature-Electromotive Force Reference

Functions and Tables for the Letter-Designated Thermocouple Types

Based on the ITS-90, National Institute of Standards and Technology,

1993

The following document contains information you may find helpful as you

read this manual and is available from National Instruments upon request:

• Application Note 043, Measuring Temperature with Thermocouples

AMUX-64T User Manual xii © National Instruments Corporation

Page 12

About This Manual

In addition, the National Instruments DAQ board user manuals contain

information you may find helpful as you read this manual.

Customer Communication

National Instruments wants to receive your comments on our products and manuals. We are

interested in the applications you develop with our products, and we want to help if you have

problems with them. To make it easy for you to contact us, this manual contains comment and

configuration forms for you to complete. These forms are in Appendix B, Customer

Communication, at the end of this manual.

© National Instruments Corporation xiii AMUX-64T User Manual

Page 13

Chapter 1 Introduction

This chapter describes the AMUX-64T; lists what you need to get started with your AMUX-64T;

describes the software programming choices and optional equipment; and explains how to

unpack your AMUX-64T.

About the AMUX-64T

The AMUX-64T is a front-end analog multiplexer that quadruples the number of analog input

signals that can be digitized with a National Instruments MIO board (except the AT-MIO-64).

The AMUX-64T has 16 separate four-to-one analog multiplexer circuits. Four AMUX-64T

boards can be cascaded to digitize up to 256 single-ended or 128 differential signals by one

MIO board.

The AMUX-64T has an integrated circuit temperature sensor that can be connected as a

differential input to two of the 64 input channels (jumper-selectable) for low-cost thermocouple

cold-junction compensation. Cold-junction compensation is achieved by adding the temperature

reading of the sensor to the temperature readings of thermocouples at the remaining 62

AMUX-64T input channels. You can cascade up to four AMUX-64T boards to increase the

number of thermocouple inputs with cold-junction compensation to 248 in single-ended mode or

124 in differential mode.

The AMUX-64T also has open component positions on all 64 input channels. These positions

are for building signal conditioning devices such as filters and attenuators.

Note: When an MIO board is referred to without an AT, MC, NB, NEC, or SB prefix, the

reference applies to the AT, MC, NB, NEC, and SB versions of that board.

The AMUX-64T is a circuitboard assembly that is placed on a workbench or mounted in a 19-in.

rack. You can configure the AMUX-64T to draw power from the MIO board or from an external

+5 V supply. A red LED indicates when the board is powered on. Input signal leads are

attached at screw terminals.

What You Need to Get Started

To set up and use your AMUX-64T, you will need the following:

AMUX-64T board

AMUX-64T User Manual

0.2, 0.5, 1.0, or 2.0 m cable

MIO board

Detailed specifications of the AMUX-64T are listed in Appendix A, Specifications.

© National Instruments Corporation 1-1 AMUX-64T User Manual

Page 14

Introduction Chapter 1

Software Programming Choices

There are four options to choose from when programming your National Instruments DAQ and

SCXI hardware. You can use LabVIEW, LabWindows, NI-DAQ, or register-level programming

software.

Your accessory hardware kit does not include software. The AMUX-64T works with LabVIEW

for Windows, LabVIEW for Macintosh, LabWindows for DOS, and LabWindows/CVI for

Windows, NI-DAQ for PC compatibles, and NI-DAQ for Macintosh.

LabVIEW and LabWindows Application Software

LabVIEW and LabWindows are innovative program development software packages for data

acquisition and control applications. LabVIEW uses graphical programming, whereas

LabWindows enhances traditional programming languages. Both packages include extensive

libraries for data acquisition, instrument control, data analysis, and graphical data presentation.

LabVIEW currently runs on four different platforms—AT/MC/EISA computers running

Microsoft Windows, NEC computers running Windows, the Macintosh platform, and the Sun

SPARCstation platform. LabVIEW features interactive graphics, a state-of-the-art user

interface, and a powerful graphical programming language. The LabVIEW Data Acquisition VI

Library, a series of VIs for using LabVIEW with National Instruments DAQ hardware, is

included with LabVIEW. The LabVIEW Data Acquisition VI Libraries are functionally

equivalent to the NI-DAQ software, except that the SCXI functions are not included in the

LabVIEW software for Sun.

LabWindows has two versions—LabWindows for DOS is for use on PCs running DOS, and

LabWindows/CVI is for use on PCs running Windows and for Sun SPARCstations.

LabWindows/CVI features interactive graphics, a state-of-the-art user interface, and uses the

ANSI standard C programming language. The LabWindows Data Acquisition Library, a series

of functions for using LabWindows with National Instruments DAQ hardware, is included with

the NI-DAQ software kit. The LabWindows Data Acquisition libraries are functionally

equivalent to the NI-DAQ software except that the SCXI functions are not included in the

LabWindows/CVI software for Sun.

Using LabVIEW or LabWindows software will greatly reduce the development time for your

data acquisition and control application.

NI-DAQ Driver Software

The NI-DAQ driver software is included at no charge with all National Instruments DAQ

hardware. NI-DAQ is not packaged with SCXI or accessory products, except for the

SCXI-1200. NI-DAQ has an extensive library of functions that you can call from your

application programming environment. These functions include routines for analog input

(A/D conversion), buffered data acquisition (high-speed A/D conversion), analog output

(D/A conversion), waveform generation, digital I/O, counter/timer operations, SCXI, RTSI,

self calibration, messaging, and acquiring data to extended memory.

AMUX-64T User Manual 1-2 © National Instruments Corporation

Page 15

Chapter 1 Introduction

NI-DAQ has both high-level DAQ I/O functions for maximum ease of use and low-level data

acquisition I/O functions for maximum flexibility and performance. Examples of high-level

functions are streaming data to disk or acquiring a certain number of data points. An example of

a low-level function is writing directly to registers on the data acquisition device. NI-DAQ does

not sacrifice the performance of National Instruments data acquisition devices because it lets

multiple devices operate at their peak performance—up to 500 kS/s on ISA computers and up to

1 MS/s on EISA computers.

NI-DAQ includes a Buffer and Data Manager that uses sophisticated techniques for handling

and managing data acquisition buffers so that you can simultaneously acquire and process data.

NI-DAQ functions for the DAQCard-DIO-24 can transfer data using interrupts or software

polling.

With the NI-DAQ Resource Manager, you can simultaneously use several functions and several

DAQ devices. The Resource Manager prevents multiple-device contention over DMA channels,

interrupt levels, and RTSI channels.

NI-DAQ can send event-driven messages to DOS, Windows, or Windows NT applications

whenever a user-specified event occurs. Thus, polling is eliminated and you can develop eventdriven data acquisition applications. An example of an NI-DAQ user event is when a specified

digital I/O pattern is matched.

NI-DAQ also internally addresses many of the complex issues between the computer and the

DAQ hardware such as programming the PC interrupt and DMA controllers. NI-DAQ maintains

a consistent software interface among its different versions so that you can change platforms

with minimal modifications to your code.

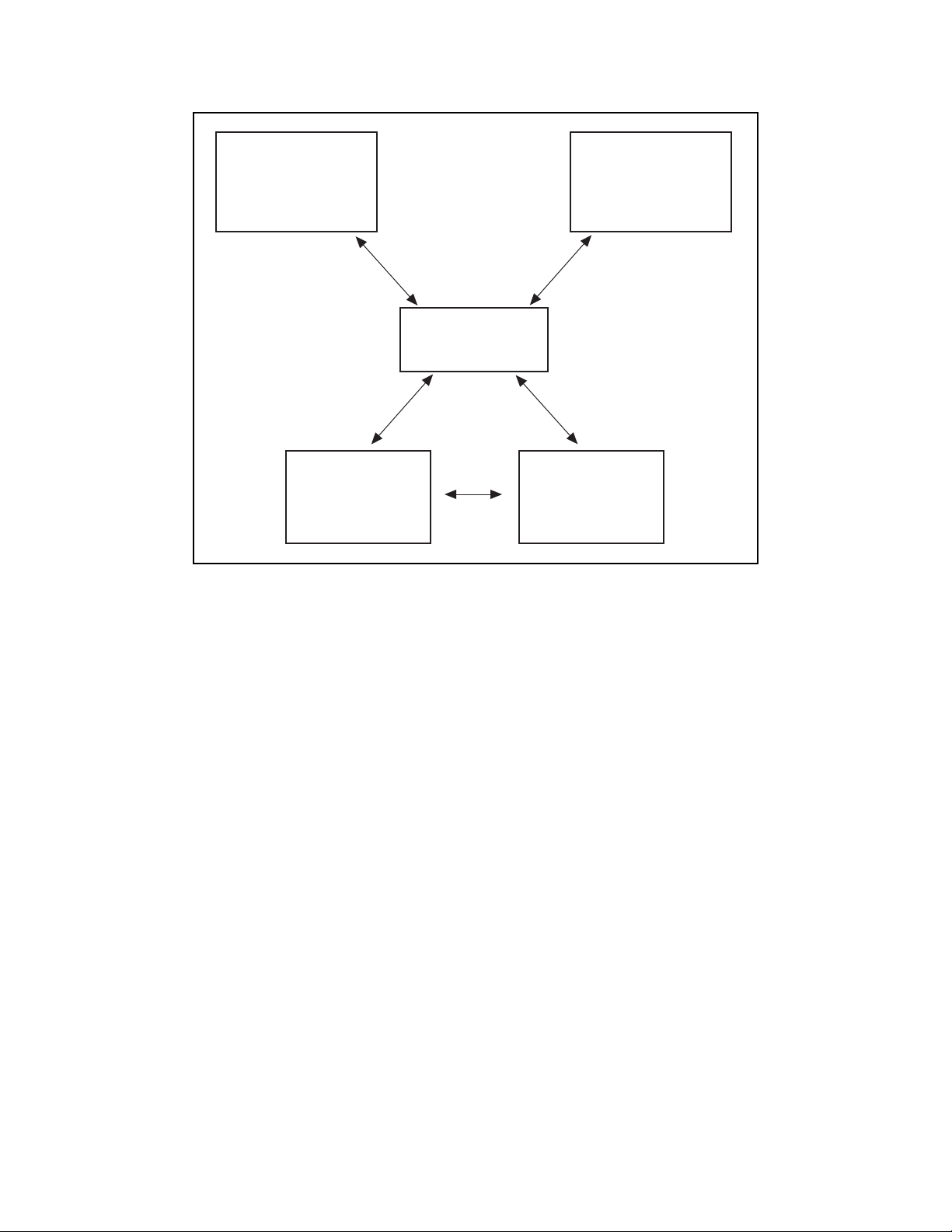

Figure 1-1 illustrates the relationship between NI-DAQ and LabVIEW and LabWindows. You

can see that the data acquisition parts of LabVIEW and LabWindows are functionally equivalent

to the NI-DAQ software.

© National Instruments Corporation 1-3 AMUX-64T User Manual

Page 16

Introduction Chapter 1

Conventional

Programming

Environment

(PC, Macintosh, or

Sun SPARCstation)

NI-DAQ

Driver Software

LabVIEW

(PC, Macintosh, or

Sun SPARCstation)

DAQ or

SCXI Hardware

Personal

Computer

or

Workstation

Figure 1-1. The Relationship between the Programming Environment,

NI-DAQ, and Your Hardware

The National Instruments PC, AT, MC, DAQCard, and DAQPad Series DAQ hardware is

packaged with NI-DAQ software for PC compatibles. NI-DAQ software for PC compatibles

comes with language interfaces for Professional BASIC, QuickBASIC, Visual Basic, Borland

Turbo Pascal, Turbo C++, Borland C++, Microsoft Visual C++, and Microsoft C for DOS; and

Visual Basic, Turbo Pascal, Microsoft C with SDK, and Borland C++ for Windows and

Microsoft Visual C++ for Windows NT. You can use your AMUX-64T, together with other PC,

AT, MC, EISA, DAQCard, and DAQPad Series DAQ and SCXI hardware, with NI-DAQ

software for PC compatibles.

The National Instruments NB Series DAQ boards are packaged with NI-DAQ software for

Macintosh. NI-DAQ software for Macintosh comes with language interfaces for MPW C,

THINK C, Pascal, and Microsoft QuickBASIC. Any language that uses Device Manager

Toolbox calls can access NI-DAQ software for Macintosh. You can use NB Series DAQ boards

and SCXI hardware with NI-DAQ software for Macintosh.

The National Instruments SB Series DAQ boards are packaged with NI-DAQ software for Sun,

which comes with a language interface for ANSI C.

AMUX-64T User Manual 1-4 © National Instruments Corporation

Page 17

Chapter 1 Introduction

Register-Level Programming

The final option for programming any National Instruments DAQ hardware is to write registerlevel software. Writing register-level programming software can be very time-consuming and

inefficient, and is not recommended for most users. The only users who should consider writing

register-level software should meet at least one of the following criteria:

• National Instruments does not support your operating system or programming language.

• You are an experienced register-level programmer who is more comfortable writing your

own register-level software.

Even if you are an experienced register-level programmer, always consider using NI-DAQ,

LabVIEW, or LabWindows to program your National Instruments DAQ hardware. Using the

NI-DAQ, LabVIEW, or LabWindows software is easier than, and as flexible as, register-level

programming, and can save you weeks of development time.

The AMUX-64T User Manual and your software manuals contain complete instructions for

programming your AMUX-64T with NI-DAQ, LabVIEW, or LabWindows. For register-level

programming information, see Chapter 5, Theory of Operation and Register-Level

Programming. If you are using NI-DAQ with LabWindows, use this manual and your

LabWindows software manual. If you are using LabVIEW, use your LabVIEW manual. If you

are using NI-DAQ, LabVIEW, or LabWindows to control your board, you should not need the

programming information in Chapter 5, Theory of Operation and Register-Level Programming.

Chapter 5, Theory of Operation and Register-Level Programming, contains low-level

programming details, such as register maps, bit descriptions, and register programming hints,

that you will need only for register-level programming.

Optional Equipment

Contact National Instruments to order any of the following optional equipment:

• CB-50 I/O connector (50-screw terminals) with 0.5 or 1.0 m cable

• SCB-68 I/O connector (68-screw terminals) with 0.5 or 1.0 m cable

• SH6868 shielded cable assembly with 1, 2, 5, or 10 m cable

• SH6850 shielded cable assembly with 1, 2, 5, or 10 m cable

• R6868 1 m ribbon cable assembly

• R6850 1 m ribbon cable assembly

• Rack-mount kit with acrylic plastic cover (single- or double-height)

• Rack-mount kit with metal wraparound cover (single- or double-height)

© National Instruments Corporation 1-5 AMUX-64T User Manual

Page 18

Introduction Chapter 1

For more information about optional equipment available from National Instruments, refer to

your National Instruments catalog or call the office nearest you.

Unpacking

Your AMUX-64T board is shipped in an antistatic package to prevent electrostatic damage to the

board. Electrostatic discharge can damage several components on the board. To avoid such

damage in handling the board, take the following precautions:

• Ground yourself via a grounding strap or by holding a grounded objects.

• Touch the antistatic package to a metal part of your computer chassis before removing the

board from the package.

• Remove the board from the package and inspect the board for loose components or any other

sign of damage. Notify National Instruments if the board appears damaged in any way. Do

not install or connect a damaged board in your computer or to your MIO board.

• Never touch the exposed pins of connectors.

AMUX-64T User Manual 1-6 © National Instruments Corporation

Page 19

Chapter 2 Configuration and Installation

This chapter describes the configuration and installation of your AMUX-64T. The topics

discussed include switch and jumper configuration, connection of the AMUX-64T to the MIO

board, power, and signal connections.

Board Configuration

The AMUX-64T contains two sets of switches and three jumpers to change the multiplexer

settings and power connection configurations of the board. These jumpers and switches are

shown in Figure 2-1.

The five-position switch at U12 configures the AMUX-64T for single-board or multiple-board

operation. Switch SW1 selects either the internal +5 V power from the MIO board or an external

+5 V power source for the AMUX-64T. Jumper W1 optionally connects the onboard

temperature sensor to Channels 0 and 32 of the AMUX-64T. Jumper W2 connects the

AMUX-64T analog ground to the shield of a rack-mounted chassis. Jumper W3 connects the

AMUX-64T 68-pin connector shield to the shield of a rack-mounted chassis.

Power, Temperature Sensor, and Shield Configuration

To configure the AMUX-64T board, use the three user-configurable jumpers (W1–W3) shown in

the parts locator diagram, Figure 2-1. Tables 2-1 to 2-3 list the description and configuration of

the user-configurable jumpers.

© National Instruments Corporation 2-1 AMUX-64T User Manual

Page 20

Configuration and Installation Chapter 2

7

1

2

3

4

5

11

8

9

10

12

6

1 J41 5 U12 9 J1

2 SW1 6 Product Name and Assembly Number 10 J2

3 W3 7 Serial Number 11 J42

4 W2 8 W1 12 Temperature Sensor

Figure 2-1. AMUX-64T Parts Locator Diagram

AMUX-64T User Manual 2-2 © National Instruments Corporation

Page 21

Chapter 2 Configuration and Installation

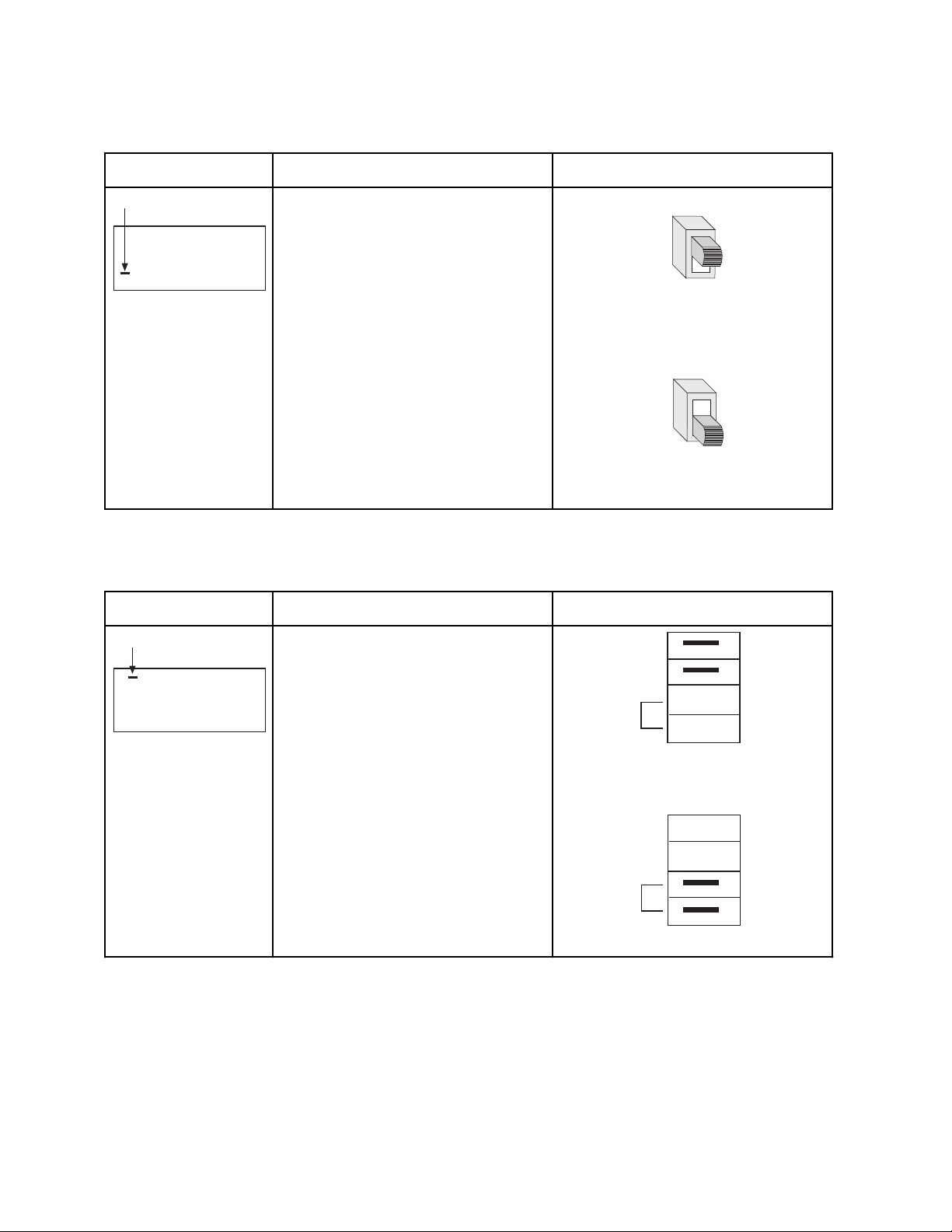

Table 2-1. Power Supply Selection

Switch Description Configuration

SW1

INT position—Use this setting to

configure the AMUX-64T to

INT

draw +5 V power through the

MIO board. (factory setting)

EXT

Internal Power

EXT position—Use this setting to

draw +5 V power from an

external supply connected to

connector J41.

INT

EXT

External Power

Table 2-2. Temperature Sensor Selection

Jumper Description Configuration

W1

CH0 and CH32 position—Use

this setting to select CH0 and

CH32. (factory setting)

CH0

CH32

Temp

SW1

Selected

SW1

Selected

W1

• •

• •

Channel 0 and 32 Selected

(Factory Setting)

Temp position—Use this setting

to select the temperature sensor.

© National Instruments Corporation 2-3 AMUX-64T User Manual

CH0

CH32

Temp

Temperature Sensor Selected

• •

• •

W1

Page 22

Configuration and Installation Chapter 2

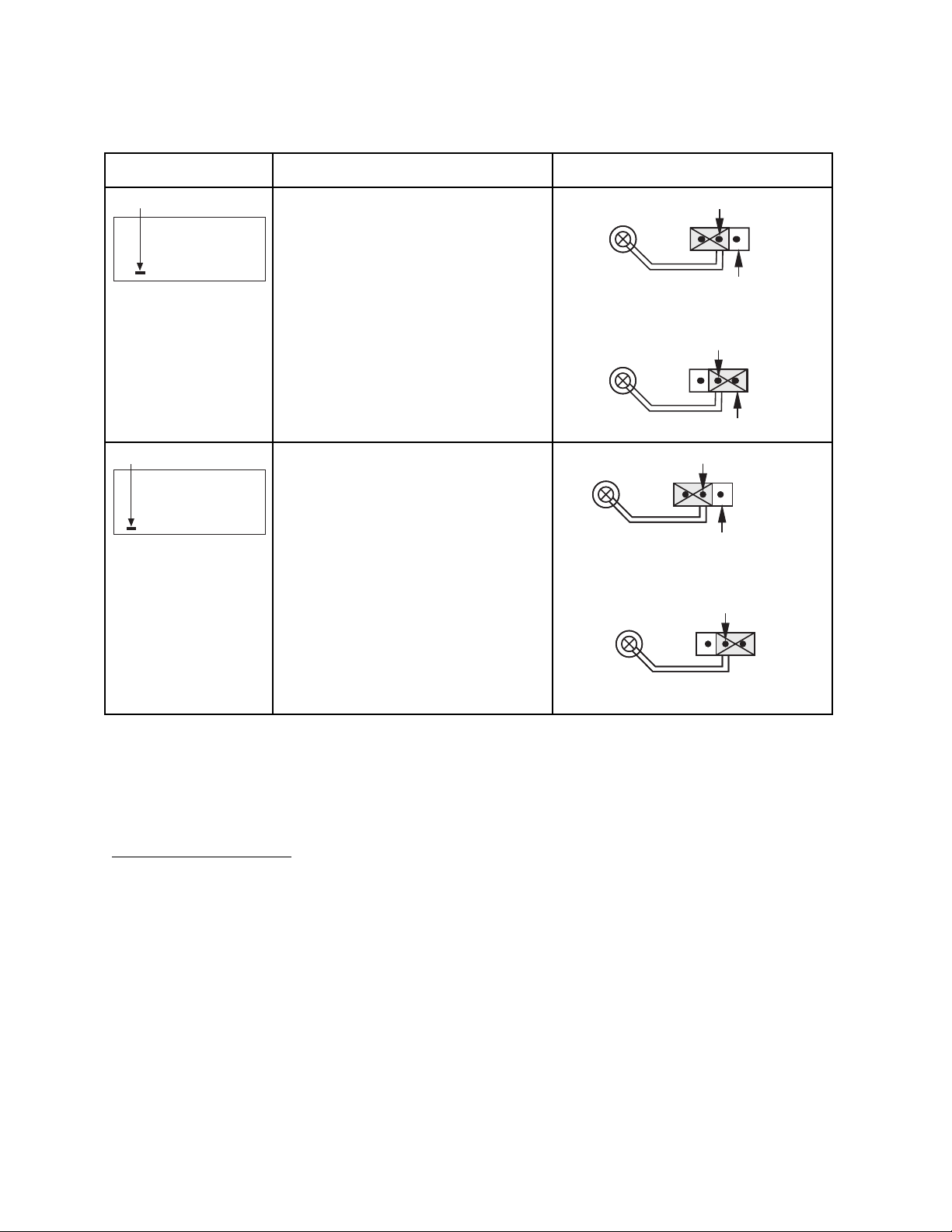

Table 2-3. Shield Selection

Jumper Description Configuration

W3

W2

No Connect position—Use this

setting to disconnect the

AMUX-64T analog ground from

the shield of a rack-mounted

chassis. (factory setting)

AIGND position—Use this

setting to connect the

AMUX-64T analog ground to the

shield of a rack-mounted chassis.

No Connect position—Use this

setting to disconnect the

AMUX-64T 68-pin connector

shield from the shield of a rackmounted chassis. (factory setting)

CABLE SHLD position—Use

this setting to connect the

AMUX-64T 68-pin connector

shield to the shield of a rackmounted chassis.

NC

NC

CHASSIS

W3

NC

Shield

Disconnected

NC

Shield

Connected

CHASSIS

W2

AIGND

CHASSIS

W2

AIGND

CABLE SHLD

CHASSIS

W3

Note: The shaded area indicates the position of the jumper.

Supplementary Configuration Information

Power Supply Selection

Switch SW1 selects internal or external +5 V power for the AMUX-64T. Set SW1 to the INT

position to power the AMUX-64T by drawing power through the MIO board. Set SW1 to the

EXT position to draw power from an external +5 V source connected to J41.

With the exception of the MC-MIO-16, all MIO boards are capable of powering up to four

AMUX-64T boards. The MC-MIO-16 has enough remaining power to start up to two

AMUX-64T boards. Each AMUX-64T board typically draws 78 mA. Table 2-4 shows the

amount of power the MIO boards can supply to the AMUX-64T.

AMUX-64T User Manual 2-4 © National Instruments Corporation

Page 23

Chapter 2 Configuration and Installation

Table 2-4. MIO Board Power Budget

Board Power Allotted Power

Used

AT-MIO-16 no restriction* 1.5 A 1.0 A

AT-MIO-16D no restriction* 1.75 A 1.0 A

AT-MIO-16F-5 no restriction* 1.6 A 1.0 A

AT-MIO-16X no restriction* 1.6 A 1.0 A

E Series no restriction* 1.0 A 1.0 A

MC-MIO-16 1.6 A 1.4 A 0.2 A 2

NB-MIO-16 2.0 A 1.5 A 0.5 A 4

NB-MIO-16X 2.0 A 1.4 A 0.6 A 4

SB-MIO-16E-4 2.0 A 1.5 A 0.5 A 4

* This value depends on the computer model and configuration of other boards in the system.

Power Remaining Total Number of AMUX-64Ts That

Can Be Powered through MIO

Board

(limited by a fuse)

(limited by a fuse)

(limited by a fuse)

(limited by a fuse)

(limited by a fuse)

Temperature Sensor

4

4

4

4

4

Table 2-2 shows the positions for jumper W1.

The AMUX-64T is equipped with an onboard temperature sensor for use with thermocouple

cold-junction compensation. This sensor is a National Semiconductor LM-35CZ that provides a

voltage output of 10 m V/°C, with an accuracy of ±1° C. The sensor is jumper-selected on

differential input channel 0.

Configure the host MIO board for differential inputs if you plan to use this temperature sensor.

Use jumper W1 to select either the temperature sensor or the external screw terminals as the

input source for differential channel 0. The AMUX-64T is shipped from the factory with the

jumpers set so that CH0 and CH32 are connected to the terminal block (the temperature sensor is

not selected).

Shield Selection

The AMUX-64T is shipped from the factory with the jumpers set so that AIGND and

CABLE SHLD are disconnected from CHASSIS. Table 2-3 shows the jumper W2 and

jumper W3 settings.

The AMUX-64T has two optional connections that are relevant when using a rack-mount kit to

mount the AMUX-64T, jumpers W2 and W3. Jumper W2 connects the analog input ground

(AIGND) to the rack-mount kit. Setting this jumper to the AIGND position connects the

AIGND signal to the metal standoff in the lower left corner of the board. Setting this jumper to

the NC position keeps the AMUX-64T AIGND isolated from the rack.

© National Instruments Corporation 2-5 AMUX-64T User Manual

Page 24

Configuration and Installation Chapter 2

Jumper W3 connects the shield of the 68-position connector to the rack-mount kit. Setting this

jumper to the CABLE SHLD position connects the shield of the 68-position connector to the

metal standoff in the lower left corner of the board. Setting this jumper to the NC position keeps

the computer chassis isolated from the rack.

Both jumpers’ ground configurations may or may not be desired for your application.

For most applications, you should not connect the grounds together with these jumpers.

Connecting jumper W3 may cause ground currents to flow between the computer chassis and the

rack-mount chassis. These currents are likely to couple noise into the analog signals in the

cabling. Connecting jumper W2 may cause ground currents to flow between the MIO board

AIGND signal (measurement ground) and the rack-mount chassis. These currents directly

interfere with measurements made with the analog signals, especially when the MIO board is in

RSE mode.

If the rack-mount chassis is floating (that is, not earth-grounded) then you should ground it.

Ground the rack should via a ground strap or other recommended ways. You may ground it

using jumper W3. In general, you will get the best results if all grounds and shields have exactly

one conduction path to earth ground.

AMUX-64T User Manual 2-6 © National Instruments Corporation

Page 25

Chapter 2 Configuration and Installation

Single-Board and Multiple-Board Configurations

The AMUX-64T is designed so that up to four AMUX-64T boards can be daisy-chained and

connected to a single MIO board, as shown in Figure 2-2. You can configure the five-position

switch labeled U12 according to the number of boards daisy-chained together. This switch is

also used to assign distinct channel addresses to different AMUX-64T boards. Table 2-5 lists the

description and configuration of the switches.

Note: In all of the following dual in-line package (DIP) switch illustrations, the dark-

shaded end of the switch is the end that you press down.

Table 2-5. Single- and Multiple-Board Configuration

Switch Description Configuration

SW1

SW2

SW3

SW4

OFF

SW5

OFF

U12

U12—Set for

single-board

configuration.

(factory setting).

U12

OFO

N

F

OFF

OFF

OFF

4231

5

U12—Set for twoboard configuration.

U12—Set for fourboard configuration.

U12

OFFON

Board A

13245

U12

OFFON

Board A

U12

OFFON

Board B

13245

1324

5

U12

OFFON

Board B

U12

OFFON

Board C

1324

5

13245

U12

OFFON

Board D

13245

© National Instruments Corporation 2-7 AMUX-64T User Manual

Page 26

Configuration and Installation Chapter 2

Mounting holes for

standoffs or for

mounting in a

50-Pin Ribbon Cable

Daisy-Chaining Cable

MIO Board

16 single-ended

(8 differential)

analog input channels.

Total of 64 single-

ended per board.

AISENSE

rack-mount kit or

anywhere elseExternal +5 V

Cascade up to four AMUX-64T boards for a total of 256

single-ended (128 differential) analog input channels

Figure 2-2. Daisy-Chaining Multiple AMUX-64T Boards

Table 2-6 lists the valid multiple-board configurations for both single-ended and differential

modes.

Table 2-6. Channel Ranges for Multiple AMUX-64T Boards

Number of External

Multiplexer Boards

Channel Range

Single-Ended

Channel Range

Differential

16432

2 128 64

4 256 128

When you connect two or more AMUX-64T boards together, the multiplexers on different

boards must be enabled at different times. Therefore, each board is assigned a different channel

address range determined by the configuration of switch U12. The switch settings for each board

configuration are given in the following sections.

AMUX-64T User Manual 2-8 © National Instruments Corporation

Page 27

Chapter 2 Configuration and Installation

Single-Board Configuration

The AMUX-64T is shipped from the factory with U12 set for single-board configuration as

shown in Table 2-5.

Two-Board Configuration

For the two-board single-ended configuration, assign one board channel addresses from 0 to 63,

and assign the other board channel addresses from 64 to 127. For differential operation, assign

one board channel addresses 0 through 31 and assign the other board channel addresses 32

through 63. The board that you assign addresses 0 through 63 (or 0 through 31) is referred to as

board A, and the board that you assign addresses 64 through 127 (or 32 through 63) is referred to

as board B. You can configure any board as board A or board B, as shown in Table 2-7.

Table 2-7. U12 Switch Settings for Two-Board Configuration

Board Channel Address Range Switches

Single-Ended Differential SW1 SW2 SW3 SW4 SW5

Board A 0–63 0–31 ON OFF ON OFF OFF

Board B 64–127 64–95 OFF OFF ON OFF OFF

The switch settings for board A and board B in a two-board configuration are shown in

Table 2-5.

Four-Board Configuration

For the four-board configuration, each board has a different switch setting. You assign the first

board channel addresses from 0 to 63, the second board channel addresses from 64 to 127, the

third board channel addresses from 128 to 191, and the fourth board channel addresses from 192

to 255. For differential operation, assign the first board channel addresses 0 through 31, the

second board channel addresses 32 through 63, the third board channel addresses 64 through 95,

and the fourth board channel addresses 96 through 127. The board that you assign addresses 0

through 63 (or 0 through 31) is referred to as board A; the board that you assign addresses 64

through 127 (or 32 through 63) is referred to as board B; the board that you assign addresses 128

to 191 (or 64 through 95) is referred to as board C; and the board that you assign addresses 192

through 255 (or 96 through 127) is referred to as board D. You can configure any board as

board A, board B, board C, or board D, as shown in Table 2-8.

© National Instruments Corporation 2-9 AMUX-64T User Manual

Page 28

Configuration and Installation Chapter 2

Table 2-8. U12 Switch Settings for Four-Board Configuration

Board Channel Address Range Switches

Single-Ended Differential SW1 SW2 SW3 SW4 SW5

Board A 0–63 0–31 ON ON ON ON OFF

Board B 64–127 64–95 OFF ON ON ON OFF

Board C 128–191 128–159 ON OFF ON ON OFF

Board D 192–255 192–223 OFF OFF ON ON OFF

The switch settings for boards A, B, C, and D in a four-board configuration are shown in

Table 2-5.

Installation

Warning: Power off all units connected to your computer before you install the AMUX-64T.

If you have a 50-pin MIO board, connect a 50-pin ribbon cable from the 50-pin MIO board I/O

connector to either connector J1 or J2 on the AMUX-64T. If you have a 68-pin MIO board,

connect a 68-pin shielded or ribbon cable from the 68-pin MIO board I/O connector to J42 on the

AMUX-64T.

If you use more than one AMUX-64T, you can daisy-chain the boards by connecting J1 or J2 on

one AMUX-64T to J1 or J2 on another AMUX-64T, and so on (see Figure 2-2).

You can install the AMUX-64T into a 19-in. rack-mount kit as shown in Figure 2-3. If you use a

round 68-pin shielded cable, route the cable as shown, leaving passage for the ribbon cable (if

you use it for daisy-chaining) in the other direction.

Figure 2-3. Cable Positioning for the AMUX-64T

AMUX-64T User Manual 2-10 © National Instruments Corporation

Page 29

Chapter 2 Configuration and Installation

Power-On Sequence

If the AMUX-64T is powered by an external power source, you must turn on power to the

AMUX-64T before turning on the computer. Similarly, you must turn off power to the

AMUX-64T after turning off the computer. The red LED, labeled D2, indicates when power is

applied to the board.

© National Instruments Corporation 2-11 AMUX-64T User Manual

Page 30

Chapter 3 Signal Connections

This chapter describes the AMUX-64T signal connections and has specifications and connection

instructions for the AMUX-64T connector signals.

The following warnings contain important safety information concerning hazardous voltages.

Warning: Connections that exceed any of the maximum ratings of input signals on the

AMUX-64T board can damage the AMUX-64T, the MIO board, or the

computer. This includes connecting any power signals to ground and vice

versa. Maximum input ratings are given in Appendix A, Specifications.

National Instruments is

connections that exceed these ratings.

DO NOT OPERATE DAMAGED EQUIPMENT. The safety-protection features built

into this board can become impaired if the board becomes damaged in any way.

If it is damaged, disconnect power and do not use the board until servicetrained personnel can check its safety. If necessary, return the board to

National Instruments for service and repair to ensure that its safety is not

compromised.

NOT liable for any damages resulting from signal

D

O NOT SUBSTITUTE PARTS OR MODIFY EQUIPMENT. Because of the danger of

introducing additional hazards, do not install unauthorized parts or modify the

board. Return the board to National Instruments for service and repair to

ensure that its safety features are not compromised.

Caution: N

EVER connect a signal to screw terminals CH0–CH63 that violates their

overvoltage protection limits. When the AMUX-64T is powered on, the screw

terminals CH0–CH63 overvoltage protection is

powered off, overvoltage protection is

±

20 V.

±

35 V; when the AMUX-64T is

I/O Connector

Connectors J1 and J2 are connected together pin by pin and have exactly the same pinout as the

50-pin MIO board I/O connector. J42 has the exact same pinout as the 68-pin MIO board I/O

connector. Table 3-1 shows the pin mapping between J1, J2, and J42.

© National Instruments Corporation 3-1 AMUX-64T User Manual

Page 31

Signal Connections Chapter 3

Table 3-1. Pin Mapping for I/O Connectors J1, J2, and J42

50-Pin Connector

(J1 and J2)

Pin Numbers

1, 2 24, 27, 29, 32, 56, 59,

368

434

533

666

765

831

930

10 63

11 28

12 61

13 60

14 26

15 25

16 58

17 57

18 23

19 62

20 22

21 21

22 20

23 54, 55

24, 33 4, 7, 9, 12, 13, 15, 18,

25 52

26 19

27 17

28 51

29 49

30 16

31 47

32 48

34, 35 8, 14

36 46

37 45

38 11

39 10

40 43

41 42

42 41

43 40

44 6

45 5

46 38

47 37

48 3

49 2

50 1

68-Pin Connector (J42)

Pin Numbers

35, 36, 39, 44, 50, 53

64, 67

AMUX-64T User Manual 3-2 © National Instruments Corporation

Page 32

Chapter 3 Signal Connections

The signals from the AMUX-64T input connector screw terminals are connected to the MIO

board via J1, J2, or J42 as shown in Figure 3-1. Observe that AISENSE is connected directly to

the MIO board AISENSE pin and that AIGND on the AMUX-64T is connected to the AIGND

signal of the MIO board.

AMUX-64T

Input Signals

AIGND

CH0

CH1

CH2

CH3

CH4

CH5

CH6

CH7

CH28

CH29

CH30

CH31

CH32

CH33

CH34

CH35

CH36

CH37

CH38

CH39

CH60

CH61

CH62

CH63

Signal Conditioning Area

Jumper W1

IC Temperature Sensor

Jumper W1

.

.

.

.

GND

AMUX-64T

Signals Sent to

MIO Board

AIGND

ACH0

ACH1

.

.

.

.

.

.

.

.

.

.

.

ACH7

ACH8

ACH9

.

.

.

.

.

.

.

.

.

.

ACH15

AISENSE

Screw

Terminals

on AMUX-64T

AISENSE

J1, J2, and J42

Connectors

on AMUX-64T

Figure 3-1. AMUX-64T Signal Routing

© National Instruments Corporation 3-3 AMUX-64T User Manual

Page 33

Signal Connections Chapter 3

Differential Connections

On the AMUX-64T, channels 0 through 31 are connected to channels 0 through 7 of the

MIO board. AMUX-64T channels 32 through 63 are connected to channels 8 through 15 of the

MIO board. If the MIO board is configured for differential mode, the AMUX-64T input

channels are automatically used in differential mode. The input screw terminals on the

AMUX-64T are grouped together such that for differential mode, all input signals (SIG+) and

the corresponding signal return path (SIG-) input appear directly next to each other. For

example, signal return path for channel 0 is channel 32, and the signal return path for channel 31

is channel 63.

Using the AMUX-64T for Thermocouple Measurements

The AMUX-64T is equipped with a temperature sensor for thermocouple cold-junction

compensation. Because thermocouple output voltages are typically a few millivolts, you must

use a high-gain board (any speed) for best resolution. Thermocouples may be measured in either

differential or single-ended configurations. Differential connection tends to yield the best

results, but single-ended connection allows twice as many thermocouples to be used on each

AMUX-64T.

The cold-junction compensation is accurate only if the temperature sensor reading is close to the

temperature of the screw terminals. Therefore, when thermocouples are being read, you should

keep the AMUX-64T away from drafts or other temperature gradients such as those caused by

heaters, radiators, fans, very warm equipment, and so on.

Selecting the Gain and Input Ranges

Since thermocouple output voltages are very low, a gain of 500 or 100 is usually necessary for

best resolution. You should set the input range on the MIO board to ±5 V to improve resolution.

You can use these settings in all but a few cases, such as a fairly high-output thermocouple type

that is being used at elevated temperatures. Table 3-2 lists the voltage extremes from several

popular thermocouple types. Use it as a guide for determining the best gain and input range

settings to use. If you are using the thermocouples in a known temperature range, consult a book

of thermocouple tables to determine the approximate millivolt output and the best gain and input

range settings.

Caution: N

EVER connect a signal to screw terminals CH0–CH63 that violates their

overvoltage protection limits. When the AMUX-64T is powered on, the screw

terminals CH0–CH63 overvoltage protection is

powered off, overvoltage protection is

±

20 V.

±

35 V; when the AMUX-64T is

AMUX-64T User Manual 3-4 © National Instruments Corporation

Page 34

Chapter 3 Signal Connections

Table 3-2. Thermocouple Voltage Output Extremes (mV)

1

Thermocouple Low High

J

-8.095 at -210° C

2

69.553 at 1,200° C

2

K -6.458 at -270° C 54.886 at 1,372° C

E -9.835 at -270° C 76.373 at 1,000° C

T -6.258 at -270° C 20.872 at 400° C

S -0.236 at -50° C 18.693 at 1,768° C

R -0.226 at -50° C 21.101 at 1,768° C

B -0.000 at 0° C 13.820 at 1,820° C

1

Source of information is NIST Monograph 175: Temperature-Electromotive Force Reference Functions and

Tables for the Letter-Designated Thermocouple Types Based on the ITS-90, National Institute of Standards and

Technology, 1993.

2

All temperatures are the difference between the measuring end and the cold junction, or AMUX-64T screw

terminals in this case.

Linearizing the Data

Thermocouple output voltages are highly nonlinear. The Seebeck coefficient, or voltage change

per degree of temperature change, can vary by a factor of three or more over the operating

temperature range of some thermocouples. For this reason, the temperature from thermocouple

voltages must either be approximated by often complex polynomials or matched against a lookup table. The polynomial approach is easier to use, but it trades measurement time for memory

usage. The polynomials are in the following form:

T = a

+ a1x + a2x2 + ... + anx

0

n

where x is the thermocouple voltage in volts, T is the temperature difference between the

measuring end and the AMUX-64T screw terminals in degrees Celsius, and a

through an are

0

coefficients that are specific to each thermocouple type. To speed computation time, a

polynomial should be computed in nested form. Consider the following fourth order polynomial:

T = a0 + a1x + a2x2 + a3x3 + a4x

4

If this polynomial is evaluated as it is written, then several extra multiplications will be

performed to raise x to the various powers. If the polynomial is instead written as follows:

T = a0 + x(a

+ x(a

1

+ x(a3 + xa4)))

2

and evaluated this way, then no powers are computed, and execution proceeds much faster.

Table 3-3 lists the National Institute of Standards and Technology (NIST) polynomial

coefficients for several popular thermocouples.

© National Instruments Corporation 3-5 AMUX-64T User Manual

Page 35

Signal Connections Chapter 3

Table 3-3. NIST Polynomial Coefficients

Type

Temp.

Range

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

10

EEJJTT

-200° C to 0° C

0.03°

C to -0.01° C

0

1

2

3

4

5

6

7

8

9

0.0000000 0.0000000 0.000000 0.000000 0.0000000 0.000000

1.6977288E - 2 1.7057035E - 2 1.9528268E - 2 1.978425E - 2 2.5949192E - 2 2.592800E - 2

-4.3514970E - 7 -2.3301759E - 7 -1.2286185E - 6 -2.001204E - 7 -2.1316967E - 7 -7.602961E - 7

-1.5859697E - 10 6.5435585E -1 2 -1.0752178E - 9 1.036969E - 11 7.9018692E -1 0 4.637791E - 11

-9.2502871E - 14 -7.3562749E - 17 -59086933E - 13 -2.549687E - 16 4.2527777E - 13 -2.165394E - 15

-2.6084314E - 17 -1.7896001E - 21 -1.7256713E - 16 3.585153E - 21 1.3304473E - 16 6.048144E - 20

-4.1360199E - 21 8.4036165E - 26 -2.8131513E - 20 -5.344285E - 26 2.0241446E - 20 -7.293422E - 25

-3.4034030E - 25 -1.3735879E - 30 -2.3963370E - 24 5.099890E - 31 1.2668171E - 24

-1.1564890E - 29 1.0629823E - 35 -8.3823321E - 29

0° C to 1,000° C

± 0.02° C

-3.2447087E - 41

-210° C to 0° C

0.0.3° C to -0.05° C

0° C to 760° C

± 0.04° C

-200° C to 0° C

0.04° C to -0.02° C

0° C to 400° C

RRSSKK

-50° C to 250° C

± 0.02° C

0

1

2

3

4

5

6

7

8

9

0.0000000 1.334584505E + 1 0.00000000 1.291507177E + 1 0.000000 0.000000

1.8891380E - 1 1.472644573E - 1 1.84949460E - 1 1.466298863E - 1 2.5173462E - 2 2.508355E - 2

-9.3835290E - 5 -1.844024844E - 5 -8.00504062E - 5 -1.534713402E - 5 -1.1662878E - 6 7.860106E - 8

1.3068619E - 7 4.031129726E - 9 1.02237430E - 7 3.145945973E - 9 -1.0833638E - 9 -2.503131E - 10

-2.2703580E - 10 -6.249428360E - 13 -1.52248592E - 10 -4.163257839E - 13 -8.9773540E -1 3 8.315270E - 14

3.5145659E - 13 6.468412046E - 17 1.88821343E - 13 3.187963771E - 17 -3.7342377E - 16 -1.228034E - 17

-3.8953900E - 16 -4.458750426E - 21 -1.59085941E - 16 -1.291637500E - 21 -8.6632643E - 20 9.804036E - 22

2.8239471E - 19 1.994710149E - 25 8.23027880E - 20 2.183475087E - 26 -1.0450598E - 23 -4.413030E - 26

-1.2607281E - 22 -5.313401790E - 30 -2.34181944E - 23 -1.447379511E - 31 -5.1920577E - 28 1.057734E - 30

3.1353611E - 26 6.481976217E - 35 2.79786260E - 27 8.211272125E - 36 -1.052755E - 35

-3.3187769E - 30

250° C to 1,200° C

± 0.005° C

-50° C to 250° C

± 0.02° C

250° C to 1,200° C

± 0.01° C

-200° C to 0° C

0.04° C to -0.02° C

0° C to 500° C

0.04° C to -0.05° C

± 0.03° C

These polynomials are accurate only within the temperature ranges specified. Also, all terms

must be included to achieve the specified accuracy.

To avoid the long computation time required for these high-order polynomials, the operating

range of a thermocouple can be subdivided into several smaller ranges. Each of the smaller

ranges can then be approximated by a much lower order polynomial (i.e., third or fourth degree).

Further examples of polynomials, including lower order polynomials for subdivided temperature

ranges, can be found in NIST Monograph 175: Temperature-Electromotive Force Reference

Functions and Tables for the Letter-Designated Thermocouple Types Based on the ITS-90.

Differential Measurements

Connect the temperature sensor to channel 0 and channel 32 (differential channel 0) by

configuring jumper W1 as shown in Table 2-2. Connect the thermocouples to the appropriate

pairs of input channel screw terminals (for example, CH1 and CH33, CH2 and CH34, and so on).

Notice that some thermocouples, such as those from Omega Engineering, have red insulation on

the negative terminal. Check with the vendor to determine the output polarity of any particular

AMUX-64T User Manual 3-6 © National Instruments Corporation

Page 36

Chapter 3 Signal Connections

thermocouple. Since thermocouples are floating signal sources, you must attach a bias return

resistor between the negative channel and ground, which is connected to the MIO board AIGND

(analog input ground) pin. The signal path of each channel has component locations for such

resistors. Refer to the Connecting Nonreferenced or Floating Signal Sources section of

Chapter 4, Signal Conditioning, for the resistor component locations. For more information

about signal sources and their connections, see the configuration chapter of the user manual that

came with your MIO board.

An Example of Using Thermocouples (Differential or Single-Ended)

For this example, assume that a J-type thermocouple is connected to differential channel 1 and is

being used to measure a high-pressure boiler system. The maximum temperature that can be

reached is 300° C. Before taking readings, it is necessary that you configure the MIO board for

the maximum resolution possible. A thermocouple table shows that the output voltage will never

exceed 16 to 17 mV (recall that the exact voltage measured is a function of the AMUX-64T

temperature as well as the temperature being measured). Therefore, you could select either a

±5 V input range with a gain of 100 (±50 mV maximum signal) or a ±10 V input range with a

gain of 500 (±20 mV maximum signal). In this case, the ±10 V input range with a gain of 500

gives the best resolution. Set the jumpers on the MIO board for differential input, ±10 V input

range.

Note: Set jumper W1 on the AMUX-64T to select the temperature sensor, and connect the

thermocouple to CH1 and CH33. Connect a resistor between CH33 and GND for the

bias current return path.

Set the jumpers on the MIO board for single-ended input,

±

10 V input range. Set

jumper W1 on the AMUX-64T to select the temperature sensor, and connect the

thermocouple to CH1.

Two software compensation procedures for this example follow. Procedure 1 is more accurate,

but procedure 2 is faster and requires less computation.

Procedure 1

1. Read the voltage from the temperature sensor (channel 0). If you are using NI-DAQ, you can

use the AI_Read and AI_Scale functions to do the reading. This voltage is 10 mV/°C, so

the gain should be either 1 or 10 (10 for the best resolution). Multiply the voltage by 100 to

get the AMUX-64T temperature in degrees Celsius. For example, if the reading is 0.25 V,

then the AMUX-64T is at 25° C.

© National Instruments Corporation 3-7 AMUX-64T User Manual

Page 37

Signal Connections Chapter 3

2. Translate the reading into the voltage for a J-type thermocouple at that temperature using

either a look-up table or an NIST polynomial. Notice that the polynomials required here are

the inverses of those given in Table 3-3. For your reading of 25° C, you would have

1.277 mV.

3. Read the voltages on any thermocouple channels. If you are using NI-DAQ, you can use the

AI_Read and AI_Scale functions to read each channel. For the example given, assume

that you get a reading of 9.39 mV on channel 1.

4. Add the voltage from step 2 to the voltage measured in step 3. You then have:

1.277 + 9.39= 10.667 mV

5. Translate the result into a temperature using either a look-up table or a polynomial such as

one from Table 3-3. For example, assume that the reading from the J-type thermocouple is

10.667 mV. By applying the third formula in the Linearizing the Data section and using the

coefficients from Table 3-3, you can calculate that the temperature is 198° C.

Procedure 2

1. Read the voltage from the temperature sensor (channel 0). If you are using NI-DAQ, you can

use the AI_Read and AI_Scale functions to do the reading. This voltage is 10 mV/°C, so

the gain should be either 1 or 10 (10 for the best resolution). Multiply the voltage by 100 to

get the AMUX-64T temperature in degrees Celsius. For example, if the reading is 0.25 V,

then the AMUX-64T is at 25° C.

2. Read the voltages on any thermocouple channels. If you are using NI-DAQ, you can use the

AI_Read and AI_Scale functions to read each channel, or you can use the SCAN

functions to scan all the channels at once. If you use the SCAN functions, use a sample

interval of 100 µs between channels. For the example given, the gain is at 500 for channel 1.

Other thermocouple types may require other gains.

3. Translate the reading into a temperature using either a look-up table or a polynomial such as

one from Table 3-3. For example, when reading 9.39 mV from a type J thermocouple, the

temperature is 175° C.

4. Add the cold-junction temperature from step 1 to the temperature obtained in the previous

step. This result is the temperature at the measuring end of the thermocouple. For the

example given, the temperature is 175° C + 25° C = 200° C.

Comments

Procedure 1 is more accurate, but it requires two temperature-voltage conversions. Procedure 2

is faster, but introduces an error of 2° C. To determine if the error from procedure 2 is

acceptable or not in your application, you can work through some examples both ways. Use a

thermocouple reference table and consider voltages and temperatures close to those in your

application.

AMUX-64T User Manual 3-8 © National Instruments Corporation

Page 38

Chapter 3 Signal Connections

Single-Ended Measurement

Connect the temperature sensor to channels 0 and 32 by configuring jumper W1 as shown in

Table 2-2. Connect the positive leads of the thermocouples to any AMUX-64T input channels

except CH0 and CH32. Connect the negative leads to GND. Notice that some thermocouples,

such as those from Omega Engineering, have red insulation on the negative terminal. Check

with the vendor to determine the output polarity of any particular thermocouple. Configure the

MIO board for ground-referenced, single-ended inputs. For more information about signal

sources and their connections, see the Signal Connections chapter of the user manual that came

with your MIO board.

Using More Than One AMUX-64T

Two cold-junction compensation options are possible when thermocouples are being used with

two or more AMUX-64T boards connected to one MIO board. If all AMUX-64T boards are at

approximately the same temperature, then only one needs to have the temperature sensor

connected to channels 0 and 32. These two channels on the other boards are then free for more

thermocouples. If the AMUX-64T boards are not at approximately the same temperature, then

you should use the temperature sensor on each AMUX-64T. Using the temperature sensors on

each board reduces the chance of cold-junction compensation error, but it does increase software

overhead and reduce the number of channels available for general use.

If you use two AMUX-64T boards, the sensors will appear at channel 0 for board A and

channel 64 for board B. If you use four AMUX-64T boards, the sensors will appear at channel 0

for board A, channel 64 for board B, channel 128 for board C, and channel 192 for board D (see

the Single-Board and Multiple-Board Configurations section earlier in this chapter).

Sources of Error

There are several major sources of error when making thermocouple measurements with the

AMUX-64T and an MIO board. These sources of error are compensation, linearization,

measurement, and thermocouple wire errors.

Compensation error can arise from two sources, inaccuracy of the temperature sensor and

temperature differences between the sensor and the screw terminals. The sensor on the

AMUX-64T is specified to be accurate to ±1° C. You can minimize temperature differences

between the sensor and the screw terminals by keeping the AMUX-64T away from drafts,

heaters, warm equipment, and so on. Linearization error is a consequence of the fact that the

polynomials are by nature approximations of the true thermocouple output. The linearization

error is dependent on the degree of polynomial used. Table 3-3 lists the linearization errors for

the NIST polynomials.

© National Instruments Corporation 3-9 AMUX-64T User Manual

Page 39

Signal Connections Chapter 3

Measurement error is the result of inaccuracies in the MIO board. These include gain and offset

errors. If the board is properly calibrated, the offset error should be zeroed out. The only

remaining error is a gain error of ±0.08% of full range (see the MIO board specifications). If the

input range is ±10 V and the gain is 500, then gain error will contribute 0.0008 x 20 mV, or

16 µV of error. If the Seebeck coefficient of a thermocouple is 32 µV/°C, then this measurement

error will add 0.5° C of uncertainty to the measurement. For best results, use a well-calibrated

MIO board so that you can ignore offsets.

You can eliminate offset error, however, by grounding one channel on the AMUX-64T and

measuring it. This value is the offset of the MIO board, and it can then be subtracted in software

from all other readings. For the best results, you should use an average of many readings (about

100 or so). When you take these measures, typical accuracies are about ±2° C.

Finally, thermocouple wire error is caused by inhomogeneities in the thermocouple

manufacturing process. These errors vary widely depending on the thermocouple type and even

the gauge of wire used, but a value of ±2° C is typical. For more information on thermocouple

wire errors and more specific data, see Application Note 043, Measuring Temperature with

Thermocouples.

Thermocouple Measurement Accuracies

Table 3-4 lists the expected thermocouple accuracies in degrees Celsius, subject to the following

conditions:

• The MIO board must be correctly calibrated.

• The temperature of the screw terminals equals the temperature of the board (no gradients on

the board).

The uncertainties listed apply at either 0° C (Type J, K, E, T) or 600° C (Type S, R). The

linearization errors of the NIST polynomials in Table 3-2, measurement error of a calibrated

MIO board, and the ±1° C cold-junction sensor error are included. Thermocouple wire error is

neglected because of dependence on several factors as listed above. Finally, these uncertainties

are for the gains listed with a ±10 V input range.