Page 1

USER MANUAL

NI 9755

NI Powertrain Controls CompactRIO NOx Sensor Module Kit

Contents

Introduction .............................................................................................................................. 1

System Diagram ....................................................................................................................... 2

Hardware .................................................................................................................................. 2

Powering the Hardware ............................................................................................................ 3

Wiring Harness ......................................................................................................................... 5

Introduction

The National Instruments 9755 CompactRIO NOx Sensor Module Kit interfaces with NOx and

exhaust gas sensors.

O

2

Features

• Configurable from one to four channels

• Measures NOx (ppm) and O2 (%) concentrations

• Sensor controller supply voltage of 12 V to 16 V (24 V version available)

• Reverse battery protection on sensor controller module

• Sensor controller module harness

• LabVIEW FPGA and RT VIs for quick integration with application

• Integration with existing PXI or CompactRIO chassis hardware

Page 2

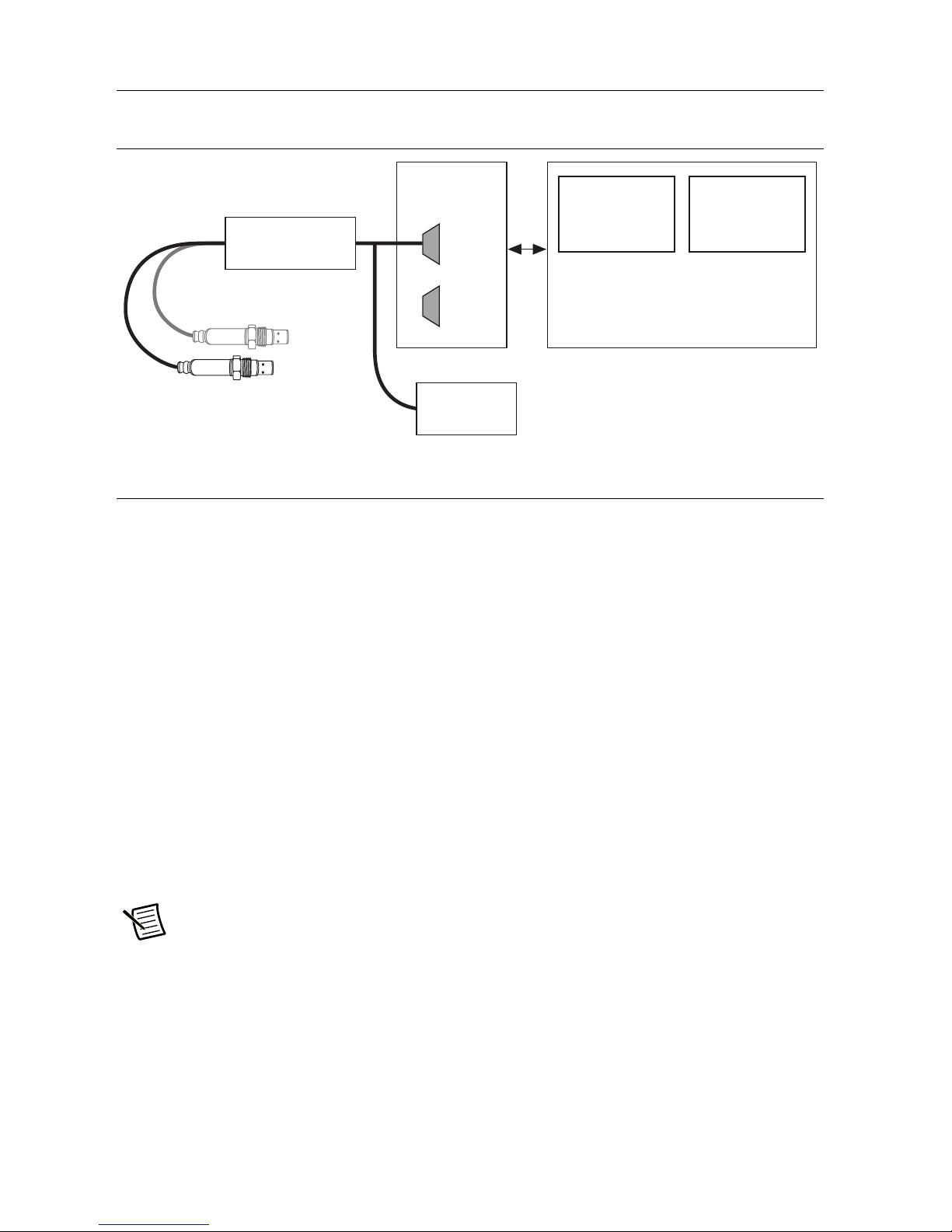

System Diagram

NI USB-9853

CompactRIO

Optional Second Sensor

CAN 1

CAN 2

LabVIEW FPGA

Interface to

NI 9853

LabVIEW RT

Interface to

LabVIEW FPGA

National Instruments Software Support

Provides NOx and O2 Data to

User Application

Sensor

Control Module(s)

DC Power

Supply 12V

Figure 1. NI 9755 System

Hardware

The NI 9755 includes the following hardware:

• Continental UniNOx Smart NOx Sensor with integrated sensor controller module

• Sensor bung

• Wiring harness

• NI-9853 CompactRIO High-Speed CAN module

The wiring harness in the NI 9755 connects to the NOx Sensor Control Module and splits into

two cables for the NI-9853 module and an external power supply. The first cable connects to the

NI-9853 with a female DB-9 connector. A terminating resistor of approximately 120 Ω is located

inside this cable near the NOx Sensor Control Module and between the CAN High and CAN

Low wires. The second cable provides three non-terminated leads for connecting to a power

supply, which requires two leads, and for address selection of the NOx Sensor Module, which

requires one lead. If the cable is to be extended, follow CAN network wiring guidelines.

Refer to the NI 9853 CAN Module Operating Instructions and Specifications for more

information on cabling requirements.

Note You must use the sensor included in the NI 9755 kit. NI does not support other

sensors.

2 | ni.com | NI 9755 User Manual

Page 3

Powering the Hardware

The NI 9755 requires power from a range of 12 V to 16 V with a continuous current of 1.5 A

and a peak current of 16 A. The maximum power requirement is 20 W, which typically occurs

when the heating element is being turned on from a cold state. If you are using two sensors,

double the capacity of the power supply.

Refer to the NI 9853 Operating Instructions and Specifications for more information on power

requirements.

Contact National Instruments for more information about sensor specifications.

NOx Sensor Light-Off Times

Conditions

Air T ......................................................... 25 ±5 °C

Batt V........................................................ 14 V

Heater........................................................ ON

................................................................... < 100 s

NO

x

O2...................................................................... < 80 s

NOx Sensor Preheating Function

When power is supplied to the sensor, the sensor enters preheating mode automatically until the

Sensor Enable Boolean is set to TRUE within the supporting software. The Sensor Enable

Boolean turns the internal sensor heater to its ON state. If the Sensor Enable Boolean is set to

FALSE, the sensor returns to preheating mode. The preheating mode protects the sensor from

mechanical cracks caused by water splash.

NOx Sensor Operating Temperature Ranges

Sensor module controller temperature.............. -40 °C to 105 °C

(105 °C to 115 °C for a maximum of 10 minutes)

Storage temperature range ................................ -40 °C to 120 °C

Maximum storage time ..................................... 2 years

Maximum exhaust gas temperature.................. 800 °C (950 °C for a maximum of 100 hours)

Maximum sensor hexagon screw temperature ...620 °C (650 °C for a maximum of 100 hours)

Maximum sensor grommet temperature........... 200 °C (230 °C for a maximum of 100 hours)

Preheating sensor temperature.......................... 80 °C to 120 °C

Lifespan approved by life cycle pattern ........... 2,000 hours or 120 K miles

NI 9755 User Manual | © National Instruments | 3

Page 4

NOx Sensor Electrical Characteristics

NOx Sensor Supply Voltage

Minimum supply voltage ..................................12 V

Maximum supply voltage ................................. 16 V

NOx Sensor Supply Current

Average supply current ..................................... 1.5 A

Peak supply current at switch on ......................16 A

Supply Power

Maximum supply power ................................... 20 W

NOx Sensor Miscellaneous

Thread Torque................................................... 50 N · m (36.88 lb · ft)

Lubrication........................................................ Anti-seize compound

Figure 2. Installation Position

To p

0°

+80°

Exhaust Gas Pipe

Figure 3. Tilt Angle in Gas Flow Direction

90°

–10° +10°

–80°

D/E

4 | ni.com | NI 9755 User Manual

Page 5

NOx Sensor Controller Module Connector

Type of connector .............................................Hirschmann MLK 872-860-501

Number of pins .................................................5

Connector pin assignment

Pin 1 .......................................................... Battery [red]

Pin 2 .......................................................... Ground [black]

Pin 3 .......................................................... CAN Low [blue]

Pin 4 .......................................................... CAN High [orange]

Pin 5 .......................................................... Address Switch [purple]

Pulling Pin 5 to ground changes the CAN transmit ID of the NOx sensor control module so that

two NOx sensor control modules can be added to the same network. Sensor Control Modules

with Pin 5 floating are Ch. 1 and Sensor Control Modules with Pin 5 grounded are Ch. 2.

Wiring Harness

Sensor 1

Sensor 2

Sensor

Control Module

Sensor

Control Module

Figure 4. 2-Sensor Harness

1. Batt

2. Gnd

3. CAN-Low

4. CAN-High

1. Batt

2. Gnd

3. CAN-Low

4. CAN-High

5. Add. Sw

• Each leg from the junction is 4 ft

• Batt, Gnd, and CAN wires are 20 AWG

• 120 Ω resistors across CAN-Low and CAN-High near sensor 1 and 2

• NI-CAN devices connect to the harness through a female DB-9 connector

• CAN-Ground is connected to Ground near junction

• Add. Sw should be connected to ground at the power supply

1

CAN-Low .2

CAN-High .7

CAN-Gnd .6

Batt .9

Batt

Gnd

Add. Sw

1

Power Supply

NI-CAN

Device

12 V DC

1

Batt and GND wires manufactured in 2018 or earlier use 18 AWG wires.

Refer to the NI Trademarks and Logo Guidelines at ni.com/trademarks for more information on National Instruments trademarks. Other

product and company names mentioned herein are trademarks or trade names of their respective companies. For patents covering National

Instruments products/technology, refer to the appropriate location: Help»Patents in your software, the patents.txt file on your media, or

the National Instruments Patents Notice at ni.com/patents. You can find information about end-user license agreements (EULAs) and

third-party legal notices in the readme file for your NI product. Refer to the Export Compliance Information at

ni.com/legal/export-compliance for the National Instruments global trade compliance policy and how to obtain relevant HTS

© 2013–2019 National Instruments. All rights reserved.

376104B-01 Apr19

Loading...

Loading...