Page 1

INSTALLER: LEAVE THIS MANUAL WITH THE APPLIANCE.

CONSUMER: RETAIN THIS MANUAL FOR FUTURE REFERENCE.

NEVER LEAVE CHILDREN OR OTHER AT RISK INDIVIDUALS ALONE WITH THE APPLIANCE.

INSTALLATION AND

OPERATING INSTRUCTIONS

CERTIFIED UNDER AMERICAN NATIONAL STANDARDS: ANSI Z21.11.2B, VOLUME II FOR UNVENTED ROOM HEATERS.

GVFS20P

PROPANE

1

CERTIFIED FOR THE UNITED STATES USING ANSI METHODS.

SAFETY INFORMATION

!

WARNING

If the information in these instructions are

not followed exactly, a fi re or explosion

may result causing property damage,

personal injury or loss of life.

- Do not store or use gasoline or other fl ammable

vapors and liquids in the vicinity of this or any

other appliance.

- WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use

any phone in your building.

• Immediately call your gas supplier from a

neighbour’s phone. Follow the gas supplier’s

instructions.

• If you cannot reach your gas supplier, call the

fi re department.

- Installation and service must be performed by a

qualifi ed installer, service agency or the supplier.

- This is an unvented gas-fi red heater that

uses air (oxygen) from the room in which it is

installed. Provisions for adequate combustion

and ventilation air must be provided. Refer to

section “ COMBUSTION AND VENTILATION AIR

PROVISIONS”.

This appliance may be installed in an aftermarket,

permanently located, manufactured (mobile) home,

where not prohibited by local codes.

This appliance is only for use with the type of gas

indicated on the rating plate. This appliance is not

convertible for use with other gases.

GVFS20N

NATURAL GAS

UNVENTED MILLIVOLT

SYSTEM

$10.00

Wolf Steel Ltd., 24 Napoleon Rd., Barrie, ON, L4M 0G8 Canada /

103 Miller Drive, Crittenden, Kentucky, USA, 41030

Phone (705)721-1212 • Fax (705)722-6031 • www.napoleonfi replaces.com • ask@napoleonproducts.com

1.23B

W415-0559 / D / 05.09.12

Page 2

2

TABLE OF CONTENTS

1.0 INSTALLATION OVERVIEW 3

2.0 INTRODUCTION 4

2.1 DIMENSIONS 5

2.2 GENERAL INSTRUCTIONS 5

2.3 GENERAL INFORMATION 6

2.4 RATING PLATE INFORMATION 7

3.0 INSTALLATION 8

3.1 COMBUSTION AND VENTILATION AIR PROVISIONS 8

3.2 DETERMINING CONFINED OR UNCONFINED SPACE 9

3.3 GAS INSTALLATION 10

3.4 OPTIONAL WALL SWITCH / THERMOSTAT 11

3.5 MOBILE HOME INSTALLATION 11

4.0 FINISHING 12

4.1 CAST FRONT INSTALLATION AND REMOVAL 12

4.2 SCREEN INSTALLATION AND REMOVAL 12

4.3 LOGO PLACEMENT 12

4.4 LOG PLACEMENT 13

5.0 OPTIONAL BLOWER INSTALLATION 14

5.1 BLOWER INSTALLATION AND CONNECTION 14

5.2 SWITCH CONNECTIONS 14

6.0 OPERATION 15

7.0 ADJUSTMENT 16

7.1 VENTURI ADJUSTMENT 16

7.2 FLAME CHARACTERISTICS 16

8.0 MAINTENANCE 17

8.1 OXYGEN DEPLETION SENSOR PILOT CLEANING 17

8.3 PILOT INDICATOR LIGHT BATTERY REPLACEMENT 18

8.2 ORIFICE REPLACEMENT 18

9.0 REPLACEMENTS 19

10.0 TROUBLE SHOOTING 21

11.0 WARRANTY 24

12.0 SERVICE HISTORY 25

NOTE: Changes, other than editorial, are denoted by a vertical line in the margin.

W415-0559 / D / 05.09.12

Page 3

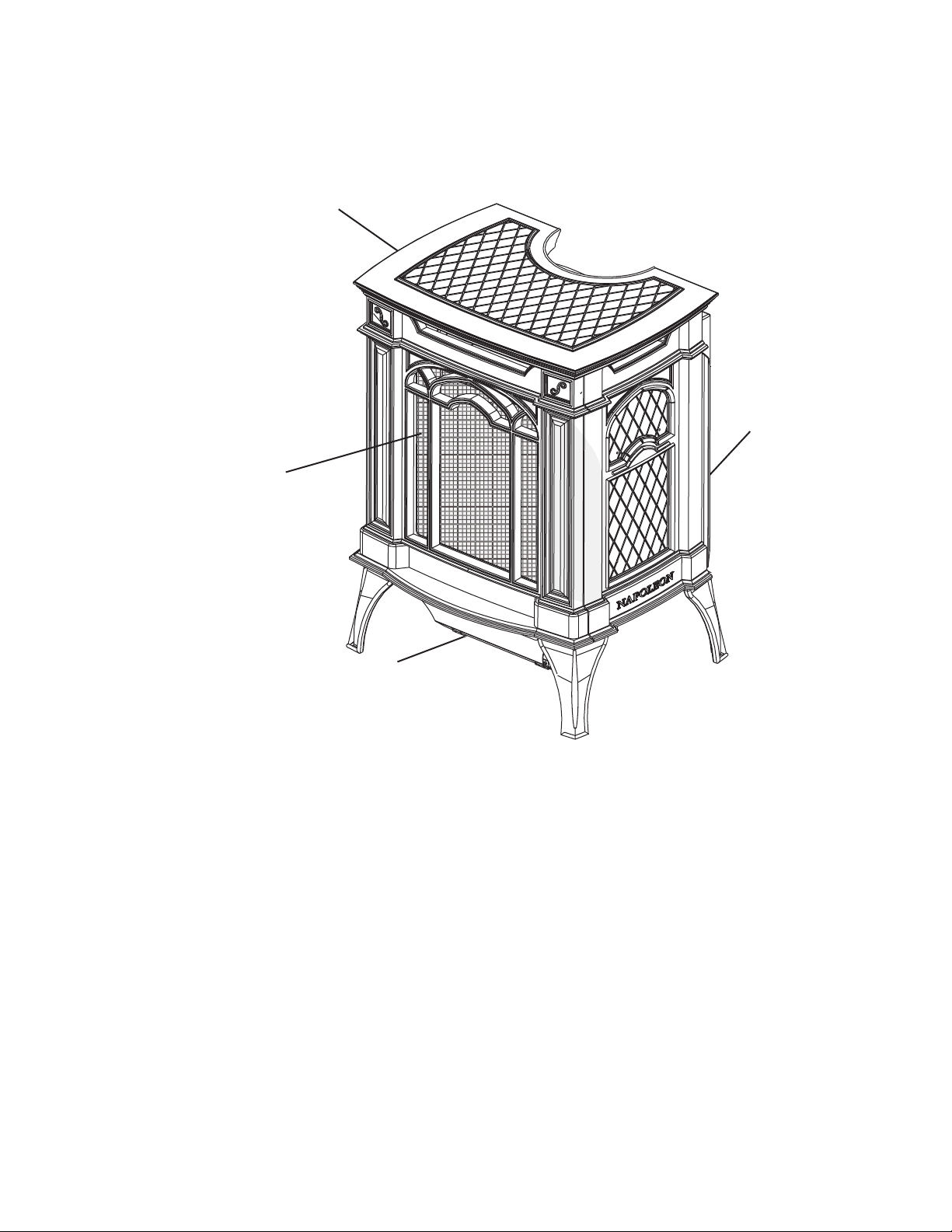

1.0 INSTALLATION OVERVIEW

Cast top, see “FINISHING - CAST

FRONT INSTALLATION AND

REMOVAL” section.

Door, see “FINISHING

- SCREEN

INST ALLA TION AND

REMOVAL” section.

3

Blower, see “OPTIONAL

BLOWER

INSTALLATION” section.

Rating Plate, see

“RATING PLATE

INFORMATION”

section.

W415-0559 / D / 05.09.12

Page 4

4

2.0 INTRODUCTION

• THIS APPLIANCE IS HOT WHEN OPERATED AND CAN CAUSE SEVERE BURNS IF CONTACTED.

• ANY CHANGES TO THIS APPLIANCE OR ITS CONTROLS CAN BE DANGEROUS AND IS PROHIBITED.

• Under no circumstances should this appliance be modifi ed.

• Do not operate appliance before reading and understanding operating instructions. Failure to operate

appliance according to operating instructions could cause fi re or injury.

• Risk of burns. The appliance should be turned off and cooled before servicing.

• Do not install damaged, incomplete or substitute components.

• Risk of cuts and abrasions. Wear protective gloves and safety glasses during installation. Sheet metal edges

may be sharp.

• Provide adequate ventilation and combustion air. Provide adequate accessibility clearance for servicing and

operating the appliance. Never obstruct the front opening of the appliance.

• If the appliance shuts off, do not re-light until you provide fresh air. If appliance keeps shutting off, have it

serviced. Keep burner and control compartment clean.

• Do not burn wood or other materials in this appliance.

• Children and adults should be alerted to the hazards of high surface temperature and should stay away to

avoid burns or clothing ignition.

• Young children should be carefully supervised when they are in the same room as the appliance. Toddlers,

young children and others may be susceptible to accidental contact burns. A physical barrier is recommended

if there are at risk individuals in the house. To restrict access to an appliance, install an adjustable safety gate

to keep toddlers, young children and other at risk individuals out of the room and away from hot surfaces.

• Due to high temperatures, the appliance should be located out of traffi c and away from furniture and

draperies.

• Ensure you have incorporated adequate safety measures to protect infants/toddlers from touching hot

surfaces.

• Clothing or other fl ammable material should not be placed on or near the appliance.

• Check with your local hearth specialty dealer for safety screens and hearth guards to protect children from

hot surfaces. These screens and guards must be fastened to the fl oor.

• Any safety screen or guard removed for servicing must be replaced prior to operating the appliance.

• It is imperative that the control compartments, burners and circulating blower and its passageway in the

appliance are kept clean. The appliance should be inspected before use and at least annually by a qualifi ed

service person. More frequent cleaning may be required due to excessive lint from carpeting, bedding

material, etc. The appliance area must be kept clear and free from combustible materials, gasoline and other

fl ammable vapours and liquids.

• Furniture or other objects must be kept a minimum of 4 feet away from the front of the appliance.

• Do not use this appliance if any part has been under water. Immediately call a qualifi ed service technician

to inspect the appliance and to replace any part of the control system and any gas control which has been

under water.

• Do not allow fans to blow directly into the appliance. Avoid any drafts that alter burner fl ame patterns.

• Do not use a blower insert, heat exchanger insert or other accessory not approved for use with this appliance.

• Carbon or soot should not occur in a vent free appliance as it can distribute into the living area of your home.

If you notice any signs of carbon or soot, immediately turn off your appliance and arrange to have it serviced

by a qualifi ed technician before operating it again.

• Keep the packaging material out of reach of children and dispose of the material in a safe manner. As with all

plastic bags, these are not toys and should be kept away from children and infants.

• As with any combustion appliance, we recommend having your appliance regularly inspected and serviced as

well as having a Carbon Monoxide Detector installed in the same area to defend you and your family against

Carbon Monoxide.

• If equipped, the screen must be in place (closed) when the appliance is in operation.

• Ensure clearances to combustibles are maintained when building a mantel or shelves above the appliance.

Elevated temperatures on the wall or in the air above the appliance can cause melting, discolouration or

damage to decorations, a T.V. or other electronic components.

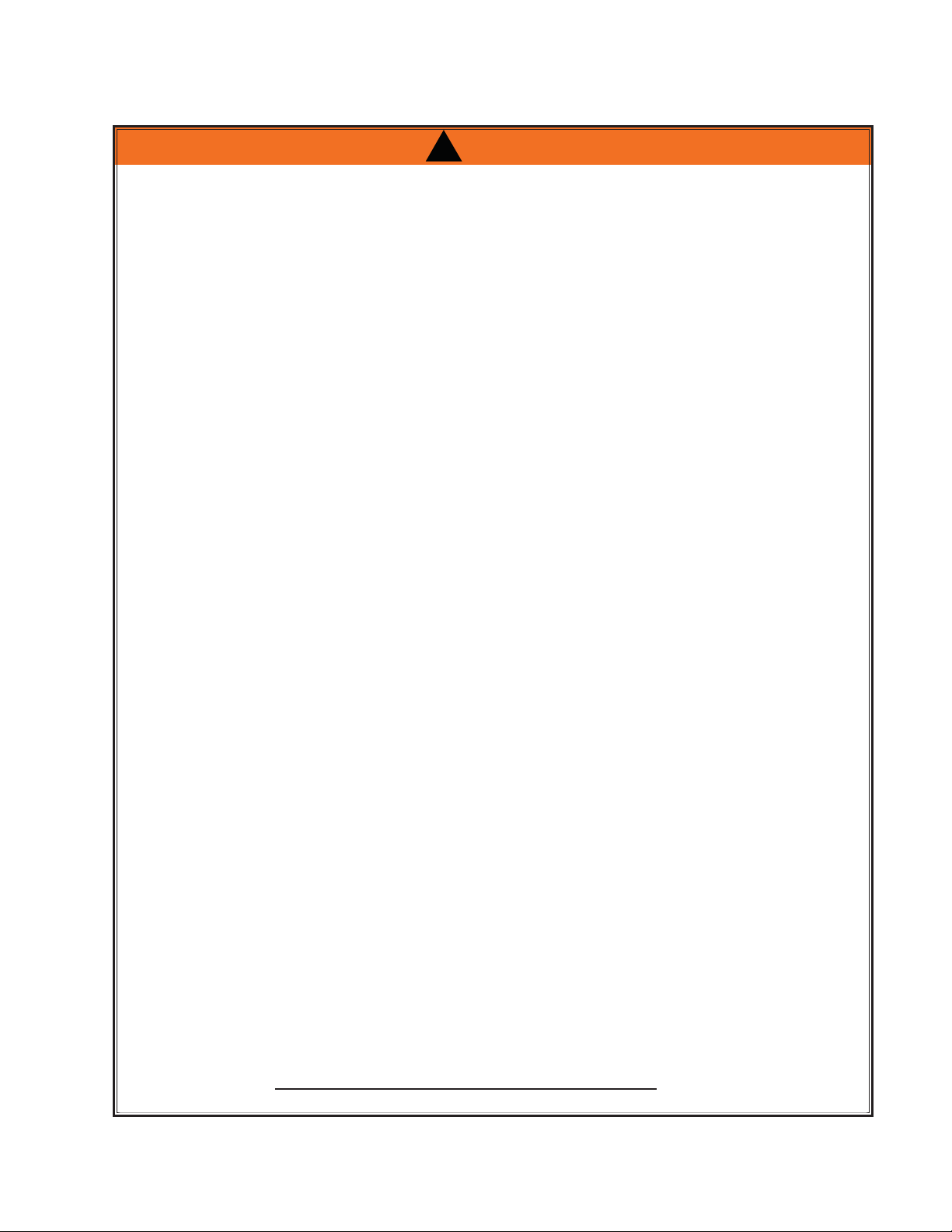

!

WARNING

3.4B

W415-0559 / D / 05.09.12

Page 5

2.1 DIMENSIONS

19 1/4"

9

5

/8"

25 3/8"

15 3/4"

2.2 GENERAL INSTRUCTIONS

* CARBON MONOXIDE POISONING MAY LEAD TO DEATH

EARLY SIGNS OF CARBON MONOXIDE POISONING RESEMBLE THE FLU, WITH HEADACHE,

DIZZINESS AND/OR NAUSEA. IF YOU HAVE THESE SIGNS, THE HEATER MAY NOT BE WORKING

PROPERLY. GET FRESH AIR AT ONCE! HAVE HEATER SERVICED.

SOME PEOPLE---PREGNANT WOMEN, PERSONS WITH HEART OR LUNG DISEASE, ANEMIA,

THOSE UNDER THE INFLUENCE OF ALCOHOL, THOSE AT HIGH ALTITUDES--- ARE MORE

AFFECTED BY CARBON MONOXIDE THAN OTHERS.

!

WARNING

5

IT IS RECOMMENDED THAT PERSONS WITH RESPIRATORY PROBLEMS NOT USE VENT FREE

THE APPLIANCE IS ONLY FOR USE WITH THE TYPE OF GAS INDICATED ON THE RATING PLATE.

OBJECTS PLACED IN FRONT OF THE HEATER SHOULD BE KEPT A MINIMUM OF 48” AWAY FROM

USE ONLY WOLF STEEL APPROVED OPTIONAL ACCESSORIES AND REPLACEMENT PARTS WITH

THIS APPLIANCE. USING NON-LISTED ACCESSORIES AND REPLACEMENT PARTS (BLOWERS,

LOUVRES, TRIMS, GAS COMPONENTS, VENT COMPONENTS, ETC.) COULD RESULT IN A SAFETY

NOT DESIGNED FOR USE WITH A GLASS DOOR. SCREEN MUST BE CLOSED WHEN APPLIANCE IS

This gas appliance should be installed and serviced by a qualifi ed installer to conform with local codes.

Installation practices vary from region to region and it is important to know the specifi cs that apply to your

area, for example: in Massachusetts State:

• The appliance off valve must be a “T” handle gas cock.

• The fl exible connector must not be longer than 36“.

• The appliance is not approved for installation in a bedroom or bathroom unless the appliance is a direct

vent sealed combustion product.

• A carbon monoxide detector is required in all rooms containing gas fi red appliances.

• WARNING: This product must be installed by a licensed plumber or gas fi tter when installed within the

commonwealth of Massachusetts.

• Un-vented room appliance shall be installed in accordance with 527 CMR 30.00 and 248 CMR 3.00

through 7.00.

• Sellers of un-vented propane or natural gas-fi red space / room appliances shall provide to each purchaser

a copy of 527 CMR 30.00 upon the sale of the appliance from http://www.napoleonfi replaces.com/

Webshare/installation_manuals/mass_requirements.pdf

THIS APPLIANCE IS NOT CONVERTIBLE FOR USE WITH OTHER GASES.

THE FRONT FACE OF THE APPLIANCE.

HAZARD AND WILL VOID THE LIMITED LIFETIME WARRANTY.

THIS APPLIANCE MUST NOT BE INSTALLED IN A BEDROOM OR BATHROOM.

APPLIANCES

IN OPERATION.

W415-0559 / D / 05.09.12

Page 6

6

In absence of local codes, install the appliance to the current National Fuel Gas Code, ANSI Z223.1

Installation Code which can be obtained from:

American National Standards Institute Inc. or National Fire Protection Association Inc.

1430 Broadway Batterymarch Park

New York, NY 10018 Quincy, MA 02269

The appliance and its individual shutoff valve must be disconnected from the gas supply piping system during

any pressure testing of that system at test pressures in excess of 1/2 psig (3.5 kPa). The appliance must be

isolated from the gas supply piping system by closing its individual manual shutoff valve during any pressure

testing of the gas supply piping system at test pressures equal to or less than 1/2 psig (3.5 kPa). When

installed with a blower the junction box must be electrically connected and grounded in accordance with local

codes. In the absence of local codes, use the current ANSI / NFPA 70 National Electric Code. In the case

where the blower is equipped with a power cord it must be connected into a properly grounded receptacle.

The grounding prong must not be removed from the cord plug.

We suggest that our gas

As long as the required clearance to combustibles is maintained,

the most desirable and benefi cial location for the appliance is in

the center of a building, thereby allowing the most effi cient use of

the heat created. The location of windows, doors and the traffi c

fl ow in the room where the appliance is to be located should be

considered.

www.ncertied.org

hearth products be installed

and serviced by professionals

who are certied in the U.S.

by the National Fireplace

Institute

Specialists

®

(NFI) as NFI Gas

If the appliance is installed directly on carpeting, vinyl tile or other

combustible material other than wood fl ooring, the appliance shall be installed on a metal or wood panel

extending the full width and depth. NOTE: This does not apply to stoves.

* Air shortage caused by an inadequate air supply, improper log positions, the addition of foreign or

unapproved materials or the failure to properly maintain the appliance, may result in incomplete combustion of

the fuel. Incomplete combustion results in soot being deposited inside the fi rebox as well as surfaces outside

the appliance. If any soot deposits are observed, shut off the appliance immediately and arrange for it to be

serviced by a qualifi ed technician.

2.3 GENERAL INFORMATION

FOR YOUR SA TISFACTION, THIS APPLIANCE HAS BEEN TEST -FIRED T O ASSURE ITS OPERATION AND

QUALITY!

Altitude (FT) 0-2,000 0-2,000

Max. Input (BTU/HR) 23,000 23,000

Min. Inlet Gas Supply Pressure 4.5" Water Column 11" Water Column

Max. Inlet Gas Supply Pressure 7" Water Column 13" Water Column

Manifold Pressure (Under Flow Conditions) 3.5" Water Column 10" Water Column

When the appliance is installed at elevations above 2,000ft, and in the absence of specifi c recommendations from

the local authority having jurisdiction, the certifi ed high altitude input rating shall be reduced at the rate of 4% for each

additional 1,000ft. Expansion / contraction noises during heating up and cooling down cycles are normal and to be

expected.

4.2D

GVFS20

NG LP

No external electricity (1 10 volts or 24volts) is required for the gas system operation.

This appliance is equipped with a pilot light safety system referred to as an oxygen depletion sensor and is designed to

turn off the appliance if not enough fresh air is available.

W415-0559 / D / 05.09.12

Page 7

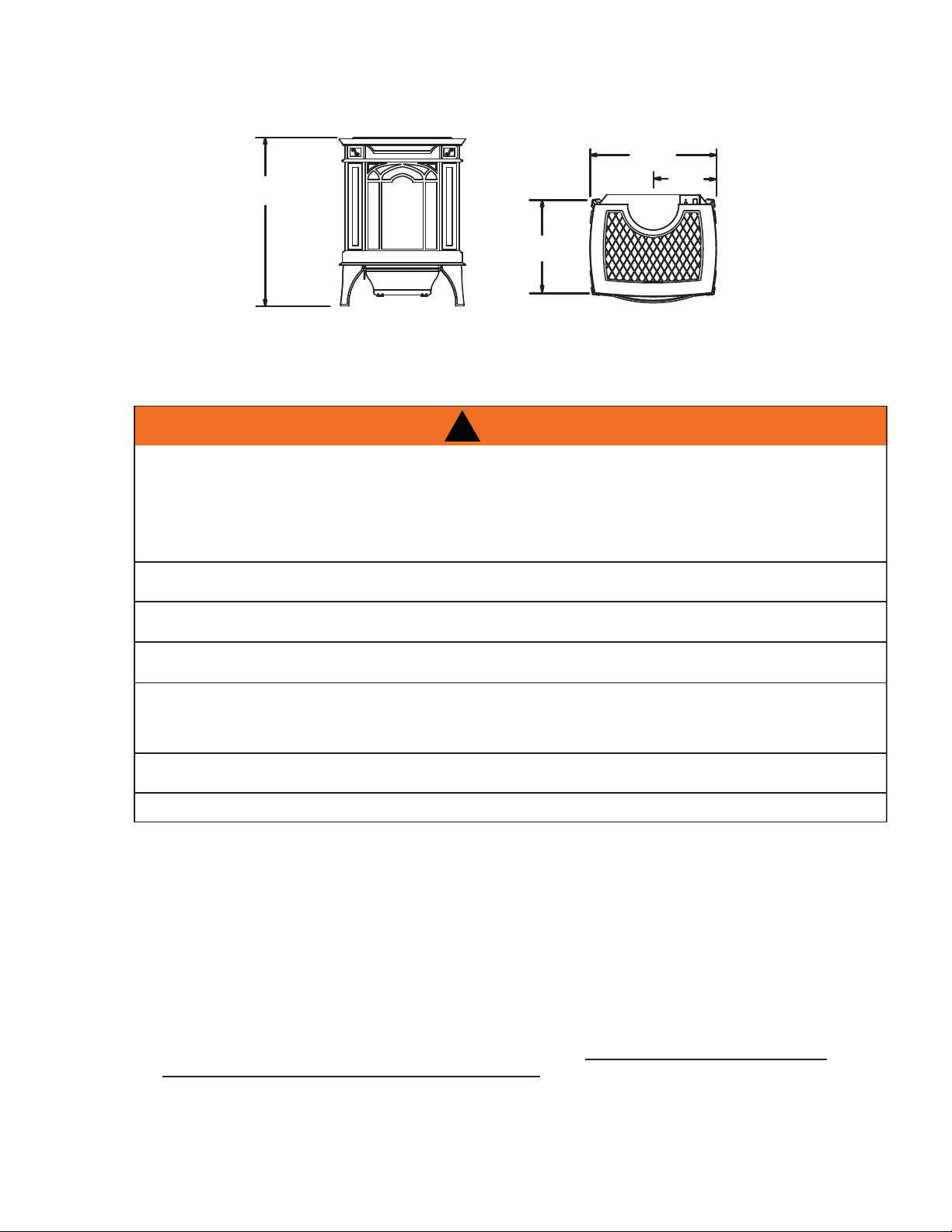

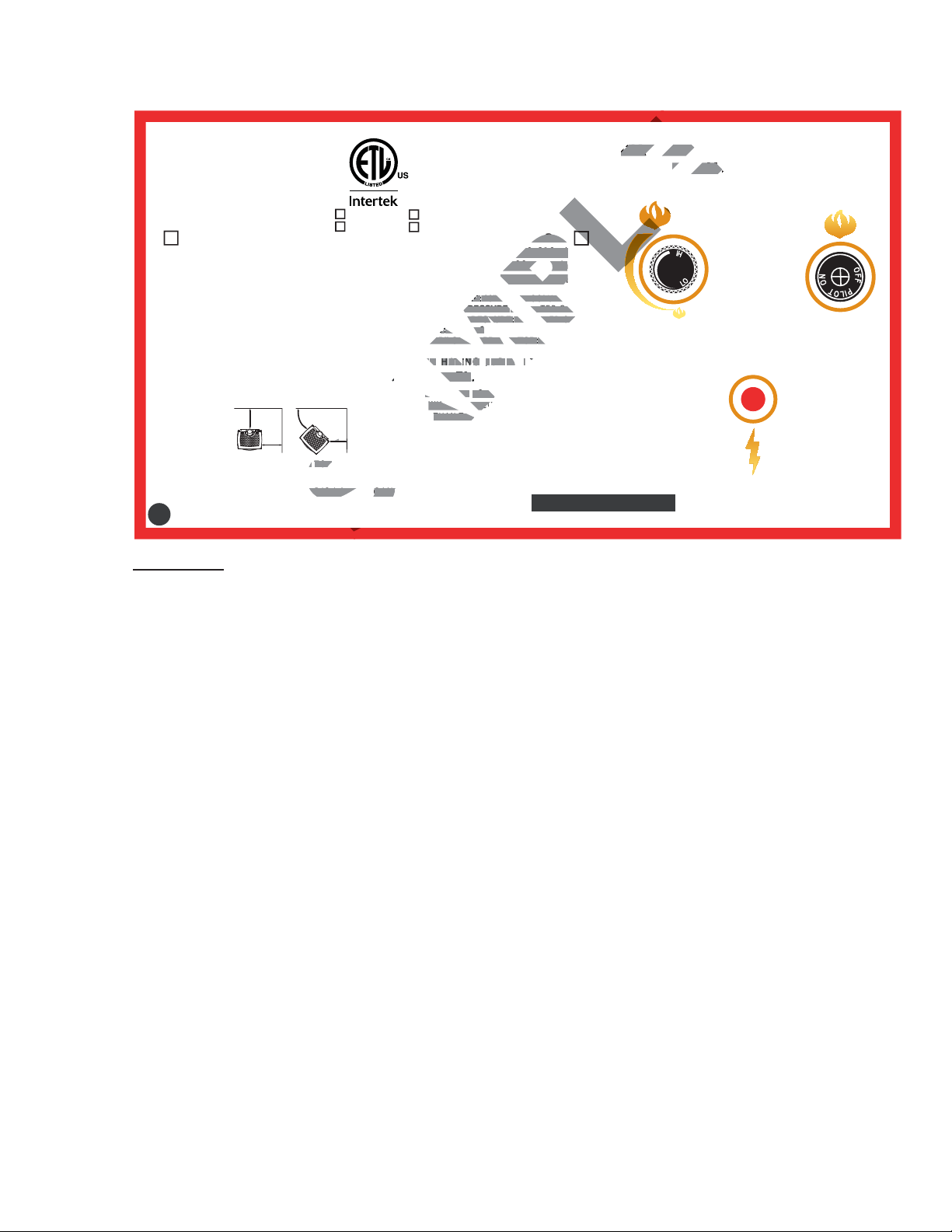

2.4 RATING PLATE INFORMATION

YAAVV

SIS

CC

ETO

ARIO L4M 0G8 CANA

/h18,000 BTU/h

N 10" WATER COLUMN

11" WATER COLUM 11" WATER COL

13" WATER COL 13" WATER CO

636 # 820.636

# 84 #

WARNING:

CONFORMS TO: ANSI Z21.11.2b-2009, UNVENTED GAS FIRED ROOM HEATER

THIS IS A GAS-FIRED UNVENTED

ROO M HEATER THAT REQUIRES

ADEQUATE COMBUSTION AND

VENT ILATIO N AI R.THIS APPLIANCE

IS NOT FIELD CONVERTIBLE FOR

USE WITH OTHER FUELS.

9700539 (WSL) 4001657 (NGZ)

4001658 (NAC) 4001659 (WUSA)

GVFS20-N MODEL GVFS20-P

**0-2000FT (0-610m) ALTITUDE **0-2000FT (0-610m)

23,000 BTU/h INPUT 23,000 BTU/h

18,000 BTU/h REDUCED INPUT 18,000 BTU/h

MANIFOLD PRESSURE: 3.5" WATER COLUMN MANIFOLD PRESSURE: 10" WATER COLUMN

MINIMUM SUPPLY PRESSURE: 4.5" WATER COLUMN MINIMUM SUPPLY PRESSURE: 11" WATER COLUMN

MAXIMUM SUPPLY PRESSURE: 7.0" WATER COLUMN MAXIMUM SUPPLY PRESSURE: 13" WATER COLUMN

SIT CONTROL: # 820.638 SIT CONTROL: # 820.636

OPERATING PILOT OXYPROTECTOR: # 8214 OPERATING PILOT OXYPROTECTOR: # 8436

**ABOVE 2,000FT, CONSULT LOCAL AUTHORITY HAVING JURISDICTION

NOT FOR USE WITH SOLID FUEL.

MINIMUM CLEARANCE TO COMBUSTIBLE MATERIALS

A 4”

B 2"

C 2"

48” MIN I M U M TO CEILING FROM STOVE TOP

WOLF STEEL LTD.

24 NAPOLEON ROAD. BARRIE, ONTARIO L4M 0G8 CANADA

B

o

45

A

C

P

THIS UNIT IS NOT APPROVED FOR

BEDROOM, BATHROOM AND

BED-SITTING ROOM INSTALLATION.

ITTY

WARNING: DO NOT ADD ANY MATERIAL TO THE APPLIANCE,

WARNING:

DIAGRAM TO AID THE OPERATION

OF THIS FIREPLACE

18,000 BTU

10" WATER COLUM

# 820.

FLAME

I

D

FUEL

WHICH WILL COME IN CONTACT WITH THE FLAMES, OTHER

THAN THAT SUPPLIED BY THE MANUFACTURER WITH THE

SCREEN MUST BE IN PLACE WHILE THE APPLIANCE IS IN

ELECTRICAL RATING: 115V 0.82AMP, 60HZ

SERIAL NUMBER

OPTIONAL FAN KIT: GS-64KT

GVFS20

ADJUSTMENT

APPLIANCE.

OPERATION.

7

ON / OFF

CONTROL

IGNITOR

W385-0337 / K

INSTALLER: It is your responsibility to check off the appropriate box on the rating plate according to

the model, venting and gas type of the appliance.

For rating plate location, see “INSTALLATION OVERVIEW” section.

This illustration is for reference only. Refer to the rating plate on the appliance for accurate information.

W415-0559 / D / 05.09.12

Page 8

8

3.0 INSTALLATION

THIS GAS HEATER SHOULD BE INSTALLED AND SERVICED BY A QUALIFIED INSTALLER to conform

with local codes. Installation practices vary from region to region and it is important to know the specifi cs that

apply to your area.

Provide adequate ventilation and combustion air. Provide adequate accessibility clearance for servicing

and operating the heater. Never obstruct the front opening of the heater.

As long as clearances to combustibles is kept within the required distances, the most desirable and benefi cial

location for a heater is in the centre of a building, thereby allowing the most effi cient use of the heat created.

The location of windows, doors and the traffi c fl ow in the room where the heater is to be located should be

considered.

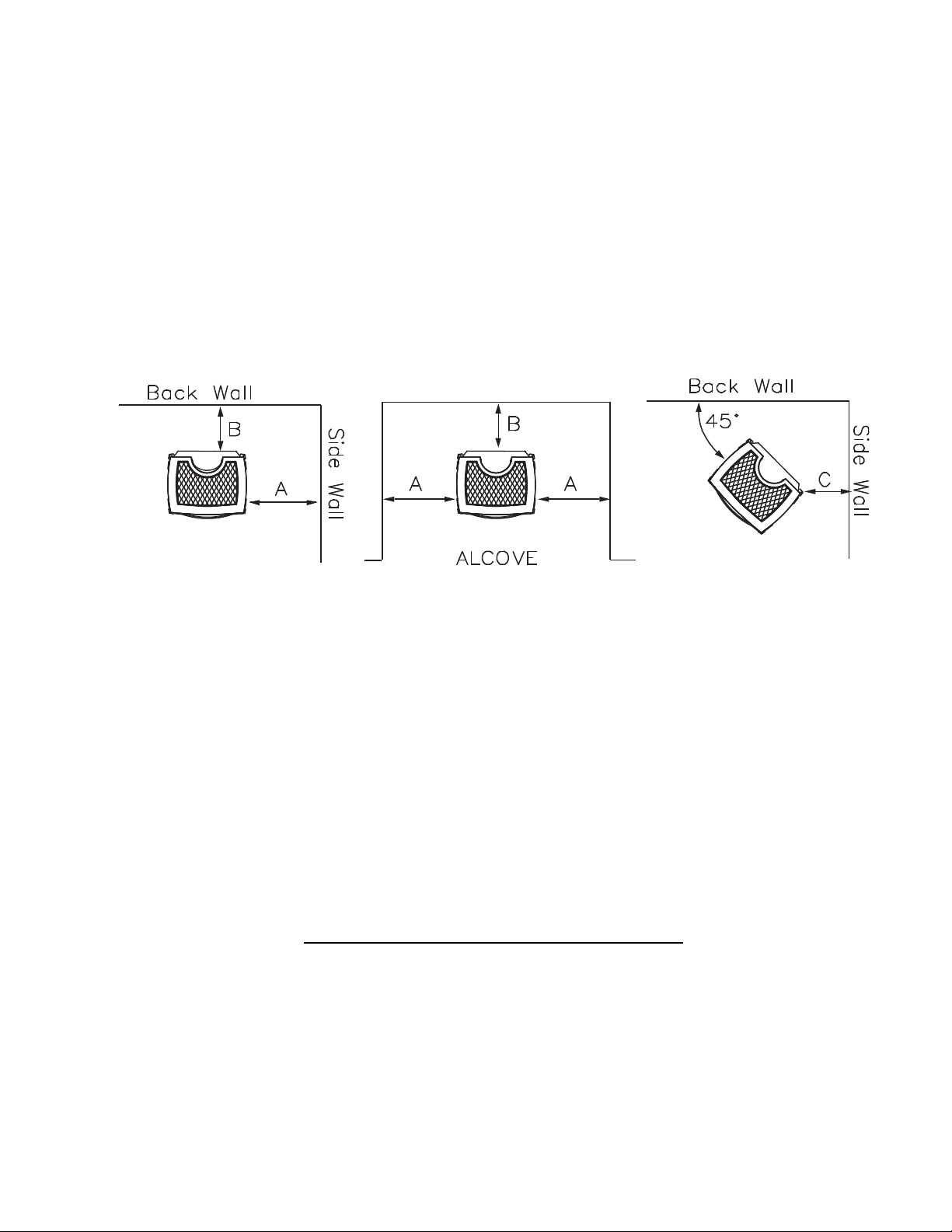

MAINTAIN THESE MINIMUM CLEARANCES TO COMBUSTIBLES:

A. 4" B. 2"* C. 2"

Heater should not be installed directly on carpeting.

Minimum 48" from top to ceiling.

* If less than 5" clearance is maintained between the back of the heater and the back wall, it will be necessary

to disconnect the gas pipe to move the heater out for installation or service of the blower.

3.1 COMBUSTION AND VENTILATION AIR PROVISIONS

This appliance shall not be installed in a confi ned space or unusually tight construction unless provisions are

provided for adequate combustion and ventilation air.

The National Fuel Gas Code, ANSI Z223.1 / NFPA 54 defi nes a confi ned space as a space whose volume is

less than 50 cubic feet per 1,000 Btu per hour (4.8 m3 per kw) of the aggregate input rating of all appliances

installed in that space and an unconfi ned space as a space whose volume is not less than 50 cubic feet per

1,000 Btu per hour (4.8 m3 per kw) of the aggregate input rating of all appliances installed in that space.

Rooms communicating directly with the space in which the appliances are installed, through openings not

furnished with doors are considered a part of the unconfi ned space.

The GVFS20 is rated at 23,000 BTU's per hour for natural gas and propane gas and therefore requires a

minimum unconfined space of 1,150 cubic feet.

17.1A

W415-0559 / D / 05.09.12

Page 9

3.2 DETERMINING CONFINED OR UNCONFINED SPACE

A

A

LENGTH

HEIGHT

ROOM 2

ROOM 1

WIDTH

To determine the volume of the room where the appliance is to be installed, multiply the width x the length x

the ceiling height of that room measured in feet. If any adjoining rooms are connected by grilles or openings

such as kitchen pass-throughs, etc., the volume of those rooms may be added to the total.

Multiply the room volume by 1000 and divide this amount by 50 to determine the maximum BTU/hr that the

space can support with adequate combustion and ventilation air.

dd the Btu/hr of all fuel burning appliances located within the space such as gas furnace, gas water

appliance, etc. Do not include direct vent gas appliances which draw their input and output air from and to the

outdoors.

9

IF THE AREA IN WHICH THE APPLIANCE MAY BE OPERATED IS SMALLER THAN THAT DEFINED AS

AN UNCONFINED SP ACE OR IF THE BUILDING IS OF UNUSUALLY TIGHT CONSTRUCTION, PROVIDE

ADEQUA TE COMBUSTION AND VENTILATION AIR BY ONE OF THE METHODS DESCRIBED IN THE

NA TIONAL FUEL GAS CODE ANSI Z223.1/ NFPA 54 , AIR FOR COMBUSTION AND VENTILATION, OR THE

APPLICABLE LOCAL CODE.

IF THE AREA IN WHICH THE APPLIANCE MAY BE OPERATED DOES NOT MEET THE REQUIRED VOLUME

FOR INDOOR COMBUSTION AIR, COMBUSTION AND VENTILATION AIR SHALL BE PROVIDED BY ONE

OF THE METHODS DESCRIBED IN THE ANSI Z223.1 / NFPA 54, THE INTERNATIONAL FUEL GAS CODE,

OR APPLICABLE LOCAL CODES.

Unusually tight construction is defi ned as construction where:

A) Walls and ceilings exposed to the outside atmosphere have a continuous water vapour retarder with a

rating of 1 perm (6 x 10-11 kg per pa-sec-m2) or less with openings gasketed or sealed, and

B) Weather stripping has been added on openable windows and doors, and

C) Caulking or sealants are applied to areas such as joints around window and door frames, between sole

plates and fl oors, between wall-ceiling joints, between wall panels, at penetrations for plumbing, electrical,

and gas lines, and at other openings.

n unvented room appliance is recommended for use as a secondary heat source rather than as a primary

source. Gas combustion produces water vapour which could occur at the rate of approximately one ounce of

water for every 1,000 BTU/hr of gas input. During the cold weather season, indoor humidity levels tend to be

low. Consequently, this water vapour can enhance the living space. However if a problem should occur:

A) Ensure suffi cient combustion and circulation air

B) Use a dehumidifi er

C) Do not use the unvented room appliance as a primary heat source

Without suffi cient fresh air for proper operation, poor fuel combustion can result. Carbon Monoxide is a result

of poor combustion.

If additional fresh air is required, use one of the methods described in the National Fuel Gas Code, ANSI

Z223.1 / NFPA54 or the applicable local code.

Room Volume = Length x Width x Height

Max BTU/hr = Room Volume x 1000 / 50

!

WARNING

If for example:

The length of the rooms is 10 feet,

The width of Room 1 is 10 feet,

The width of Room 2 is 15 feet,

The height of the rooms is 8 feet.

The volume of Room 1: 10x10x8 = 800 cubic feet

The volume of Room 2: 10x15x8 = 1200 cubic feet

19.1B

W415-0559 / D / 05.09.12

Page 10

10

EXAMPLE 1:

In this example, because there is no door to the adjoining room, the volume of the adjoining room may be

added to the volume of the room with the heater to get a total unconfi ned space.

The total unconfi ned space: 800 + 1200 = 2000 cubic feet.

Maximum BTU/h: 2000x1000 = 40,000 BTU/h

50

If there are no more fuel burning appliances within this space then the 23,000 BTU/h input of the heater is

suitable to be installed. This also assumes that the construction of this space is not unusually tight.

EXAMPLE 2:

If in this example a solid door separates Room 1 from Room 2, the volume of Room 2 could not be used. In

this case the maximum BTU/h would be:

Maximum BTU/h: 800x1000 = 16,000 BTU/h

50

This would be considered a confi ned space since it can not support the 23,000 BTU/h input of the heater and it

would be necessary to provide adequate combustion and ventilation air to Room 1.

3.3 GAS INSTALLATION

19.2

19.3

!

WARNING

RISK OF FIRE, EXPLOSION OR ASPHYXIATION. ENSURE THERE ARE NO IGNITION SOURCES SUCH

AS SPARKS OR OPEN FLAMES.

SUPPORT GAS CONTROL WHEN ATTACHING GAS SUPPLY PIPE TO PREVENT DAMAGING GAS LINE.

ALWAYS LIGHT THE PILOT WHETHER FOR THE FIRST TIME OR IF THE GAS SUPPLY HAS RUN OUT

WITH THE GLASS DOOR OPENED OR REMOVED. PURGING OF THE GAS SUPPLY LINE SHOULD BE

PERFORMED BY A QUALIFIED SERVICE TECHNICIAN. ASSURE THAT A CONTINUOUS GAS FLOW IS AT

THE BURNER BEFORE CLOSING THE DOOR. ENSURE ADEQUATE VENTILATION. FOR GAS AND

ELECTRICAL LOCATIONS, SEE “DIMENSION” SECTION.

HIGH PRESSURE WILL DAMAGE VALVE. DISCONNECT GAS SUPPLY PIPING BEFORE TESTING GAS

LINE AT TEST PRESSURES ABOVE 1/2 PSIG.

VALVE SETTINGS HAVE BEEN FACTORY SET, DO NOT CHANGE.

Installation and servicing to be done by a qualifi ed installer. Do not use open fl ame.

A. Move the appliance into position and secure.

B. If equipped with a fl ex connector the appliance is designed to accept a 1/2” gas supply. Without the

connector it is designed to accept a 3/8” gas supply. The appliance is equipped with a manual shut off

valve to turn off the gas supply to the appliance.

C. Connect the gas supply in accordance to local codes. In the absence of local codes, install to the

current CAN/CSA-B149.1 Installation Code in Canada or to the current National Fuel Gas Code, ANSI

Z223.1 / NFPA 54 in the United States.

D. When fl exing any gas line, support the gas valve so that the lines are not bent or kinked.

E. Check for gas leaks by brushing on a soap and water solution.

W415-0559 / D / 05.09.12

30.2

Page 11

3.4 OPTIONAL WALL SWITCH / THERMOSTAT

S

!

WARNING

DO NOT CONNECT EITHER THE WALL SWITCH, THERMOSTAT OR GAS VALVE DIRECTLY TO 110

VOLT ELECTRICITY.

For ease of accessibility, an optional remote wall switch or millivolt thermostat may be installed in a convenient

location. Route a 2 strand, solid core millivolt wire from the valve to the wall switch or millivolt thermostat. The

recommended maximum lead length depends on wire size:

WIRE SIZE MAX. LENGTH

14 gauge 100 feet

16 gauge 60 feet

18 gauge 40 feet

Disconnect the existing wires from terminals 1 and 3 (from the

ON/OFF switch) and replace with the leads from the wall switch / millivolt thermostat.

3.5 MOBILE HOME INSTALLATION

uitable for mobile home installation where the mobile home has been permanently placed on its site.

This appliance may be installed in an aftermarket permanently located, manufactured (mobile) home, where

not prohibited by local codes.

For mobile home installations, the appliance must be fastened in place. It is recommended that the appliance

be secured in all installations. See “REPLACEMENTS” section for the levelling / securing kit specifi c to your

appliance.

11

3

2

1

50.1

29.2

W415-0559 / D / 05.09.12

Page 12

12

3

SCREWS

BRACKET

FRONT

2

4.0 FINISHING

4.1 CAST FRONT INSTALLATION AND REMOVAL

!

WARNING

SCREENS MUST BE CLOSED WHILE THE APPLIANCE IS IN OPERATION.

A. Lift the top cast piece off of the heater.

B. Detach the front cast piece from the side pieces by removing

the screws from the brackets located in the upper inside

corners.

C. Slide the front straight up to remove.

Follow the above steps in reverse in order to reinstall

the cast front. Ensure that the tabs on the underside of

the front fi t behind the front legs.

4.2 SCREEN INSTALLATION AND REMOVAL

A. Unscrew the four screws (one in each corner) securing the screen

to the heater face.

B. Remove screen from heater.

Follow the above steps in reverse in order to reinstall the screen.

4.3 LOGO PLACEMENT

Remove the backing of the logo supplied and centre over the logo installation holes, as indicated.

FRONT

TAB

FRONT

LEGS

Four

Screws

W415-0559 / D / 05.09.12

LOGO

Page 13

4.4 LOG PLACEMENT

LOGS MUST BE PLACED IN THEIR EXACT LOCATION IN THE APPLIANCE. DO NOT MODIFY THE

PROPER LOG POSITIONS, SINCE APPLIANCE MAY NOT FUNCTION PROPERLY. DELAYED IGNITION

AND CARBON / SOOT DISTRIBUTION THROUGHOUT THE LIVING AREA MAY OCCUR.

THE LOGS ARE FRAGILE AND SHOULD BE HANDLED WITH CARE.

DO NOT PLACE CHARCOAL EMBERS, VERMICULITE OR CHARCOAL LUMPS ON THIS BURNER.

ALL PREVIOUSLY APPLIED LOOSE MATERIAL (GLOWING EMBERS) MUST BE REMOVED PRIOR TO

DO NOT CHANGE OR SUBSTITUTE THE GLOWING EMBER MATERIAL PROVIDED WITH THE

APPLIANCE. IF REPLACING, USE ONLY REPLACEMENT GLOWING EMBERS AVAILABLE FROM

FAILURE TO FOLLOW THESE INSTRUCTIONS WILL ADVERSELY EFFECT THE APPLIANCE’S

PERFORMANCE AND MAY RESULT IN CARBON / SOOT DEPOSITS INSIDE THE APPLIANCE AND ON

In order to assemble the log set, the screen and cast front must be removed, see Cast Front / Screen Removal

in the Finishing section of this manual.

!

WARNING

REAPPLICATION.

YOUR LOCAL AUTHORIZED DEALER / DISTRIBUTOR.

SURROUNDING SURFACES.

13

76.2B

A. Place the rear log, as shown, onto the rear log support brackets. Bend the bracket on the right side to

help retain the rear log against the back of the fi rebox.

B. Place the hole in the underside of log #2 onto

the locating screw, on the left side of the

burner. The fi bre burner is formed to cradle

the centre of the log.

POSITIONING THE LOGS IMPROPERLY WILL CAUSE FLAME IMPINGEMENT AND CARBONING.

C. Place the hole in the underside of log #3 onto

the locating screw, on the right side of the

burner. The bottom branch of log #3 sits in

front of, and against, the right end of log #2.

D. Reinstall the screen & front.

W415-0559 / D / 05.09.12

Page 14

14

2

3

4

4

5

1

7

7

8

9

5.0 OPTIONAL BLOWER INSTALLATION

5.1 BLOWER INSTALLATION AND CONNECTION

(SEE LOCATION AND CLEARANCES IN INSTRUCTION MANUAL)

A. Cut and remove the tie securing the blower switch wires to

the heat shield.

B. Connect the white wire coming from below the heater to the

terminal on the blower.

C. Connect the black blower wire to the black wire coming from

below the heater.

D. Insert the clips on the blower housing into the cutouts in the

rear shield. Push down to lock the clips into position.

E. Secure the blower using the screw and lock washer supplied.

NOTE: Ensure that all the wires are tucked into the blower switch

housing.

This heater comes equipped with a pilot indicator light that blinks

every few seconds when the pilot is on. For more information see step A,

section 5.2

5.2 SWITCH CONNECTIONS

A. Open the switch housing by removing the top screw.

B. With the 2 screws and extension bracket supplied in the heater baggie,

fasten extension bracket to the thermal disc bracket. Install bracket

assembly as shown, using 2 of the screws supplied. Connect the fl agged

leads to the terminals of the thermal disc 7 .

C. Remove the knock out from the switch housing label 8 . Install the

variable speed switch (rheostat) into the housing with the wires facing

up. Secure the switch to the housing using the pal nut and the knob

D. Connect the male connector on the switc to the

E. Pilot Indicator Light: Install the batteries as shown.

F. Tuck all of the wires into the switch housing and

supplied.

female connector coming from the heater 9 .

Replace the batteries annually.

NOTE: If replacing the pilot indicator light ,

ensure that the red wire lead connects to the

red lead of the thermopile and black to white.

close. Secure using the screw removed in step A.

THERMAL DISC

BRACKET

THERMAL DISC

EXTENSION

BRACKET

7

7

9

8

W415-0559 / D / 05.09.12

Page 15

6.0 OPERATION

,)<28'2127)2//2:7+(6(,16758&7,216(;$&7/<$),5(25(;3/26,210$<5(68/7

&$86,1*3523(57<'$0$*(3(5621$/,1-85<25/2662)/,)(

,)$33/,&$%/($/:$<6/,*+77+(3,/27:+(7+(5)257+(),5677,0(25,)7+(*$66833/<+$6

,IDSSOLDQFHVKXWVRIIGRQRWUHOLJKWXQWLO\RXSURYLGHIUHVKDLU,IDSSOLDQFHNHHSVVKXWWLQJRIIKDYHLWVHUYLFHG.HHSEXUQHU

DQGFRQWUROFRPSDUWPHQWFOHDQ

When lit for the first time, the appliance will emit a slight odour for a few hours. This is a normal temporary condition caused by the curing

of the logs and the “burn-in” of internal paints and lubricants used in the manufacturing process and will not occur again. After extended

periods of non-operation such as following a vacation or a warm weather season, the appliance may emit a slight odour for a few hours.

This is caused by dust particles burning off. In both cases, open a window to sufficiently ventilate the room.

FOR YOUR SAFETY READ BEFORE LIGHTING:

Ɣ This appliance is equipped with a pilot which must be lit by hand while following these instructions exactly.

Ɣ

Before operating smell all around the appliance area for gas and next to the floor because some gas is heavier than air and will settle on the floor.

Ɣ Use only your hand to push in and turn the gas control knob. Never use tools. If the knob will not push in and turn by hand, do not try

to repair it. Call a qualified service technician. Force or attempted repair may result in a fire or explosion.

Ɣ Do not use this appliance if any part has been under water. Immediately call a qualified service technician to inspect the appliance

and replace any part of the control system and any gas control which has been under water.

ƔDo not try to light any appliance.

ƔDo not touch any electric switch; do not use any phone in your building.

Ɣ Immediately call your gas supplier from a neighbour’s phone. Follow the gas supplier’s instructions.

Ɣ If you cannot reach your gas supplier, call the fire department.

!

WARNING

581287:,7+7+(*/$66'22523(1('255(029('

WHAT TO DO IF YOU SMELL GAS:

15

LIGHTING INSTRUCTIONS:

When lighting and re-lighting, the gas knob cannot be turned from pilot to off unless the knob is depressed.

$ STOP! Read the above safety information on this label.

% Set the thermostat to lowest setting.

& Turn off all electric power to the appliance.

' Open the control door. Turn the gas knob clockwise to off.

( Wait five (5) minutes to clear out any gas. If you smell gas including near the floor, STOP! Follow “B” in the above safety information

on this label. If you don’t smell gas go to the next step.

) Find pilot located in front of the back log.

G. Turn gas knob counter-clockwise to pilot.

H. Depress and hold gas knob while lighting the pilot with the push button ignitor. Keep knob fully depressed for one minute, then

release. If pilot does not continue to burn repeat steps 3 through 7.

, With pilot lit, turn gas knob counter-clockwise to on. When the pilot has been turned off,

ignition of the main burner may be delayed from 1-2 minutes. When the pilot has been left

burning, ignition of the main burner should occur almost immediatley.

- If equipped with remote on-off switch, main burner may not come on when you turn the valve to on. Remote switch must be in

the on position to ignite burner.

K. Turn on all electric power to the appliance.

TO TURN OFF GAS

A. Turn off all electric power to the appliance if service is to be performed.

%Push in gas control knob slightly and turn clockwise to off. Do not force.

47.1

W415-0559 / D / 05.09.12

Page 16

16

7.0 ADJUSTMENT

7.1 VENTURI ADJUSTMENT

CARBON CAN BE DISTRIBUTED IN SURROUNDING LIVING AREA IF THE AIR SHUTTER IS

This appliance has an air shutter that has been factory set open according

to the chart below:

Regardless of venturi orientation, closing the air shutter will cause a more

yellow flame, but can lead to carboning. Opening the air shutter will cause a

more blue flame, but can cause flame lifting from the burner ports. The

flame may not appear yellow immediately; allow 15 to 30 minutes for the

final flame colour to be established.

AIR SHUTTER ADJUSTMENT MUST ONLY BE DONE BY A QUALIFIED

INSTALLER!

!

WARNING

IMPROPERL Y ADJUSTED.

49.5

VENTURI

BURNER

AIR

SHUTTER

OPENING

ORIFICE

49.1

7.2 FLAME CHARACTERISTICS

It’s important to periodically perform a visual check of the pilot and burner fl ames. Compare them to the illustra-

tions provided. If any fl ames appear abnormal call a service person.

AIR SHUTTER OPENINGS

NG 1/16”

LP 7/16”

54.5

W415-0559 / D / 05.09.12

Page 17

8.0 MAINTENANCE

17

MAINTENANCE

MAINTENANCE

MAINTENANCE

TURN OFF THE GAS AND ELECTRICAL POWER BEFORE SERVICING THE APPLIANCE.

APPLIANCE MAY BE HOT, DO NOT SERVICE UNTIL APPLIANCE HAS COOLED.

DO NOT USE ABRASIVE CLEANERS.

CAUTION: Label all wires prior to disconnection when servicing controls. Wiring errors can cause improper

and dangerous operation. Verify proper operation after servicing. This appliance and its venting system

should be inspected before use and at least annually by a qualifi ed service person. The appliance area must

be kept clear and free of combustible materials, gasoline or other fl ammable vapors and liquids. The fl ow of

combustion and ventilation air must not be obstructed.

1. In order to properly clean the burner and pilot assembly, remove the logs, rocks and/or glass to

expose both assemblies.

2. Keep the control compartment, media, burner, air shutter opening and the area surrounding the logs

clean by vacuuming or brushing, at least once a year.

3. Check to see that all burner ports are burning. Clean out any of the ports which may not be burning or

are not burning properly.

4. Check to see that the pilot fl ame is large enough to engulf the fl ame sensor and/or thermocouple /

thermopile as well as reaches the burner.

5. Replace the cleaned logs, rocks or glass. Failure to properly position the media may cause carboning

which can be distributed in the surrounding living area.

6. Check to see that the main burner ignites completely on all openings when turned on. A 5 to 10

second total light-up period is satisfactory. If ignition takes longer, consult your local authorized dealer /

distributor.

!

WARNING

8.1 OXYGEN DEPLETION SENSOR PILOT CLEANING

40.16

This procedure must be performed by a

qualified service person!

Inspect the pilot for any visible

contamination or debris (usually lint, pet

hair, spider webs, carpet fibre, etc.) and remove.

Disconnect the pilot from the pilot tubing line,

using a 7/16” wrench. Blow out the housing in

the same direction as the gas flow. Re-install

the pilot tube, turn on the gas and check

for leaks.

If this does not improve the performance,

replace the ODS with an exact replacement. The

device is tamper resistant with no field serviceable

parts.

CORRECT PILOT FLAME

(Clean, stable, pronounced

blue flame).

INCORRECT PILOT FLAME

(Flame lifts upwards,

becomes unstable with more

of an orange tip).

46.1

W415-0559 / D / 05.09.12

Page 18

18

SCREW

LOCATIONS

ORIFICE

LOCATION

BURNER

ASSEMBLY

+

+

+

+

-

-

-

-

8.3 PILOT INDICATOR LIGHT BATTERY REPLACEMENT

If the pilot indicator light no longer fl ashes and the pilot is burning,

the batteries may require replacing.

Four "AA" batteries are required and should be replaced annually.

A. Open the switch housing by removing the top screw, then

pivoting the box open.

B. Remove the 4 "AA" batteries and replace using the new

ones.

C. Pivot the box closed and re-secure using the screw

removed in step A.

8.2 ORIFICE REPLACEMENT

A. Remove the cast front and the screen, see "CAST FRONT INSTALLATION AND

REMOVAL" and "SCREEN INSTALLATION AND REMOVAL" section in the

FINISHING segment of this manual.

B. Remove the 2 securing screws indicated and remove the burner assembly.

C. The orifi ce is located on the left hand side.

D. Reinstall the burner ensuring that the venturi tube fi ts over the orifi ce and replace the

screws.Care should be taken not to damage the gas pipe. When removing and

replacing the orifi ce, using a 9/16" socket wrench, a 7/8" back-up wrench must be

used on the manifold, located below the housing, to ensure that the aluminium tubing

does not twist or kink.

W415-0559 / D / 05.09.12

Page 19

9.0 REPLACEMENTS

Contact your dealer or the factory for questions concerning prices and policies on replacement parts. Normally

all parts can be ordered through your Authorized dealer / distributor.

FOR WARRANTY REPLACEMENT PARTS, A PHOTOCOPY OF THE ORIGINAL INVOICE WILL BE

REQUIRED TO HONOUR THE CLAIM.

When ordering replacement parts always give the following information:

• Model & Serial Number of appliance

• Installation date of appliance

• Part number

• Description of part

• Finish

* IDENTIFIES ITEMS WHICH ARE NOT ILLUSTRATED. FOR

FURTHER INFORMA TION, CONTACT YOUR AUTHORIZED DEALER.

REF PART NO. DESCRIPTION

1

2

3

4

5

5

6

7

7

8

8

9

10

11*

12*

13*

14

15*

16

17

18

19

20

21*

22

23*

W135-0254 LOG #1- REAR

W135-0249 LOG #2 - LEFT

W135-0250 LOG #3 - RIGHT

GL-651 LOG SET

W725-0050 SIT VALVE - NG

W725-0031 SIT VALVE - LP

W100-0094 FIBRE BURNER

W456-0043 #43 BURNER ORIFICE - NG

W456-0055 #55 BURNER ORIFICE - LP

W662-0001 NG OXYGEN DEPLETION SENSOR SYSTEM

W662-0005 LP OXYGEN DEPLETION SENSOR SYSTEM

W080-0756 PILOT BRACKET

W357-0001 PIEZO IGNITOR

W385-0334 NAPOLEON® LOGO

W660-0009 ON/OFF SWITCH

W690-0002 THERMAL DISC

KB-35 VARIABLE SPEED SWITCH

GZ552 REPLACEMENT BLOWER

W135-0233** FRONT CASTING

W135-0232** SIDE (LEFT OR RIGHT) CASTING

W135-0231** TOP CASTING

W080-0757 BRACKET, COLLECTOR

W565-0087 SCREEN

W430-0013 CONTROL DOOR MAGNET

W010-1307 CONTROL COVER

W750-0149 PILOT LIGHT ASSEMBLY

COMPONENTS

19

!

WARNING

FAILURE TO POSITION THE PARTS

IN ACCORDANCE WITH THIS

MANUAL OR FAILURE TO USE ONLY

PARTS SPECIFICALLY APPROVED

WITH THIS APPLIANCE MAY

RESULT IN PROPERTY DAMAGE OR

PERSONAL INJURY.

41.1

**FOR OTHER AVAILABLE COLOURS, ADD THESE LETTERS TO THE BASE PART NUMBER:

COLOR LETTER FINISH

MAJOLICA BROWN N PORCELAIN

W415-0559 / D / 05.09.12

Page 20

20

25

17

10

18

5

6

17

14

4

19

16

22

1

2

3

21

7

8

20

9

REF PART NO. DESCRIPTION

24*

24*

24* F50DR

24* F50DY

24* F50DK

25

26*

27*

28*

29*

30*

F40 REMOTE CONTROL

F50 THERMOSTATIC REMOTE CONTROL

THERMOSTATIC REMOTE CONTROL

THERMOSTATIC REMOTE CONTROL

THERMOSTATIC REMOTE CONTROL

GS-65KT BLOWER KIT

GDSLL-KT LEG LEVELLING KIT

GS-331S STOVE TOP INSET - SOAPSTONE

GS-331F STOVE TOP INSET - GRANITE - GREEN

GS-331N STOVE TOP INSET - GRANITE - BROWN

W660-0026 PROGRAMMABLE TIMER

ACCESSORIES

W415-0559 / D / 05.09.12

Page 21

10.0 TROUBLESHOOTING

!

WARNING

ALWAYS LIGHT THE PILOT WHETHER FOR THE FIRST TIME OR IF THE GAS SUPPLY HAS RAN OUT,

TURN OFF THE GAS AND ELECTRICAL POWER BEFORE SERVICING THE APPLIANCE.

APPLIANCE MAY BE HOT, DO NOT SERVICE UNTIL APPLIANCE HAS COOLED.

SYMPTOM PROBLEM TEST SOLUTION

Main burner goes

out; pilot stays on.

Main burner goes

out; pilot goes out.

Pilot goes out

when the gas knob

is released.

The gas valve has

an interlock device

which will not allow

the pilot burner

to be lit until the

thermocouple

has cooled. Allow

approximately 60

seconds for the

thermocouple to

cool.

WITH THE GLASS DOOR OPEN OR REMOVED.

DO NOT USE ABRASIVE CLEANERS.

Pilot fl ame is not large

enough or not engulfi ng

the thermopile.

Thermopile shorting /

loose connection.

Remote wall switch wire

is too long; too much

resistance in the system.

Faulty thermostat or

switch.

Insuffi cient air supply. - Open window or door. (Use one of the methods

Out of propane gas. - Fill the tank.

Pilot fl ame is not large

enough. (Supply pressure

too low.)

System is not correctly

purged.

Out of propane gas. - Fill the tank.

Pilot fl ame is not large

enough. (Supply pressure

too low.)

Thermocouple shorting /

faulty.

Faulty valve / high low

knob does not depress

smoothly.

- Ensure adequate supply pressure.

- Replace pilot assembly.

- Clean thermopile connection to the valve.

- Replace thermopile / valve.

- Shorten wire to connect length or wire gauge.

- Replace.

- Have room checked for adequate air exchange.

- See “COMBUSTION AND VENTILATION AIR

- Service or replace Oxygen Depletion Sensor

- Correct piping and / or regulator to provide correct

- Ensure adequate supply pressure.

- Purge the gas line.

- Service or replace Oxygen Depletion Sensor

- Loosen and tighten thermocouple.

- Clean thermocouple and valve connection.

- Replace Oxygen Depletion Sensor System.

- Test and replace valve.

- Replace.

21

Reconnect.

described in ANSI Z223.1 / NFPA54 or the

applicable local code.)

PROVISIONS” section to ensure adequate air supply .

System.

pressure.

System.

42.4_A

W415-0559 / D / 05.09.12

Page 22

22

SYMPTOM PROBLEM TEST SOLUTION

Pilot burning;

no gas to main

burner; gas

knob is on ‘HI’;

wall switch /

thermostat is on.

Pilot will not light. Out of propane gas. - Fill the tank.

THERMOCOUPLE

THERMOPILE

PILOT

ELECTRODE

BURNER

Pilot goes out

while standing;

Main burner is in

‘OFF’ position.

Main burner will

not light; or is slow

to light, noisy pilot.

Carbon is being

deposited on

glass, logs,

rocks, media

or combustion

chamber.

Thermostat or switch is

defective.

- Connect a jumper wire across the wall switch

terminals; if main burner lights, replace switch /

thermostat.

Wall switch wiring is

defective.

- Disconnect wires from valve. Connect a jumper wire

across terminals 1 & 3; if the main burner lights,

check the wires for defects and / or replace wires.

Main burner orifi ce is

- Remove stoppage in orifi ce.

plugged.

Faulty valve. - Replace.

No spark at pilot burner. - Check if pilot can be lit by a match.

- Check that the wire is connected to the push button

ignitor.

- Check if the push button ignitor needs tightening.

- Replace the wire if the wire insulation is broken or

frayed.

- Replace the electrode if the ceramic insulator is

cracked or broken.

- Replace the push button ignitor.

No gas at the pilot burner. - Check that the manual valve is turned on.

- Check the pilot orifi ce for blockage.

- Replace the valve / Oxygen Depletion Sensor

System.

- Call the gas distributor.

Gas piping is undersized. - Turn on all gas appliances and see if pilot fl ame

fl utters, diminishes or extinguishes, especially

when main burner ignites. Monitor appliance supply

working pressure.

- Check if supply piping size is to code. Correct all

undersized piping.

Pilot fl ame is not large

- ODS Burner requires checking.

enough.

Inlet pressure too high. - Adjust inlet pressure to ensure maximum 7.0” W.C.

Pilot fl ame blowing off,

missing thermopile.

Air shutter has become

blocked.

Flame is impinging on the

glass, logs, rocks, media

or combustion chamber.

at gas valve for natural gas and 13.0” W.C. for

propane.

- Ensure air shutter opening is free of lint or other

obstructions.

- Check that the logs are correctly positioned.

- Check for ceiling or oscillating fans that may be

infl uencing the fl ame.

- Open air shutter to increase the primary air. See

“VENTURI ADJUSTMENT” section.

- Check the input rate: check the manifold pressure

and ori

fi ce size as specifi ed by the rating plate.

42.4_2_A

W415-0559 / D / 05.09.12

Page 23

SYMPTOM PROBLEM TEST SOLUTION

Flames are

consistently too

large or too small.

Carboning occurs.

L

O

T

PILOT SCREW

Exhaust fumes

smelled in room,

headaches.

Remote wall

switch is in “off”

position; main

burner comes on

when gas knob

is turned to “ON”

position.

If optional catalytic

door is used,

White / grey fi lm

forms on the

glass.

Unit is over-fi red or under-

fi red.

- Check pressure readings:

- Inlet pressure can be checked by turning screw (A)

counter-clockwise 2 or 3 turns and then placing

pressure gauge tubing over the test point. Check

B

A

with burner operating on “HI”. Gauge should read 7”

(minimum 4.5”) water column for natural gas or 13”

(11” minimum) water column for propane.

L

O

F

O

I

H

P

I

F

N

O

P

L

T

I

O

- Outlet pressure can be checked the same as above

using screw (B). Check with burner operating on

“HI”. Gauge should read 3.5” water column for

natural gas or 10” water column for propane.

- AFTER TAKING PRESSURE READINGS, BE

SURE TO TURN SCREWS CLOCKWISE FIRMLY

TO RESEAL. DO NOT OVER TORQUE.

- Leak test with a soap and water solution.

Air shutter improperly

adjusted.

Not enough combustion

air.

- Return air shutter to specifi ed opening, see

“VENTURI ADJUSTMENT” section.

- Increase fresh air supply. (Use one of the methods

described in ANSI Z223.1 / NFPA 54 or the

applicable local code.)

Not enough ventilation air. - Increase fresh air supply. (Use one of the methods

described in ANSI Z223.1 / NFPA 54 or the

applicable local code.)

Flame is impinging on

the logs or combustion

chamber.

- Check that the logs are correctly positioned.

- Open air shutter to increase the primary air. See

“VENTURI ADJUSTMENT” section.

- Check the input rate: check the manifold pressure

and orifi ce size as specifi ed by the rating plate

values.

Wall switch is mounted

- Reverse.

upside down.

Remote wall switch is

- Replace.

grounding.

Remote wall switch wire is

grounding.

- Check for ground (short); repair ground or replace

wire.

Faulty valve. - Replace.

Sulphur from fuel is being

deposited on the glass,

logs, rocks, media or

combustion surfaces.

- Clean glass with recommended gas appliance glass

cleaner. DO NOT CLEAN GLASS WHEN HOT!

- If deposits are not cleaned off regularly, the glass

may become permanently market.

23

42.4_3_A

W415-0559 / D / 05.09.12

Page 24

24

11.0 WARRANTY

NAPOLEON® products are manufactured under the strict Standard of the world recognized ISO 9001 : 2008 Quality Assurance

NAPOLEON® products are designed with superior components and materials assembled by trained craftsmen who take great

pride in their work. The burner and valve assembly are leak and test-fi red at a quality test station. The complete appliance is

again thoroughly inspected by a qualifi ed technician before packaging to ensure that you, the customer, receives the quality

NAPOLEON® GAS APPLIANCE PRESIDENT’S LIFETIME LIMITED WARRANTY

The following materials and workmanship in your new NAPOLEON® gas appliance are warranted against defects for as long as

you own the appliance. This covers: combustion chamber, heat exchanger, stainless steel burner, phazer™ logs and embers, rocks,

ceramic glass (thermal breakage only), gold plated parts against tarnishing, porcelainized enameled components and aluminum

extrusion trims.*

Electrical (110V and millivolt) components and wearable parts such as blowers, gas valves, thermal switch, switches, wiring, remote

controls, ignitor, gasketing, and pilot assembly are covered and NAPOLEON® will provide replacement parts free of charge during

the fi rst year of the limited warranty.*

Labour related to warranty repair is covered free of charge during the fi rst year. Repair work, however, requires the prior approval of

an authorized company offi cial. Labour costs to the account of NAPOLEON® are based on a predetermined rate schedule and any

repair work must be done through an authorized NAPOLEON® dealer.

* Construction of models vary. Warranty applies only to components included with your specifi c appliance.

NAPOLEON® warrants its products against manufacturing defects to the original purchaser only. Registering your warranty is not necessary. Simply

provide your proof of purchase along with the model and serial number to make a warranty claim. NAPOLEON® reserves the right to have its

representative inspect any product or part thereof prior to honouring any warranty claim. Provided that the purchase was made through an authorized

NAPOLEON® dealer your appliance is subject to the following conditions and limitations:

Warranty coverage begins on the date of original installation.

This factory warranty is non-transferable and may not be extended whatsoever by any of our representatives.

The gas appliance must be installed by a licensed, authorized service technician or contractor. Installation must be done in accordance with the installation

instructions included with the product and all local and national building and fi re codes.

This limited warranty does not cover damages caused by misuse, lack of maintenance, accident, alterations, abuse or neglect and parts installed from

other manufacturers will nullify this warranty.

This limited warranty further does not cover any scratches, dents, corrosion or discoloring caused by excessive heat, abrasive and chemical cleaners nor

chipping on porcelain enamel parts, mechanical breakage of PHAZER™ logs and embers.

This warranty extends to the repair or replacement of warranted parts which are defective in material or workmanship provided that the product has been

operated in accordance with the operation instructions and under normal conditions.

After the fi rst year, with respect to this President’s Lifetime Limited Warranty, NAPOLEON® may, at its discretion, fully discharge all obligations with

respect to this warranty by refunding to the original warranted purchaser the wholesale price of any warranted but defective part(s).

NAPOLEON® will not be responsible for installation, labour or any other expenses related to the reinstallation of a warranted part and such expenses are

not covered by this warranty.

Notwithstanding any provisions contained in the President’s Lifetime Limited Warranty, NAPOLEON’S responsibility under this warranty is defi ned as

above and it shall not in any event extend to any incidental, consequential or indirect damages.

This warranty defi nes the obligations and liability of NAPOLEON® with respect to the NAPOLEON® gas appliance and any other warranties expressed or

implied with respect to this product, its components or accessories are excluded.

NAPOLEON® neither assumes, nor authorizes any third party to assume, on its behalf, any other liabilities with respect to the sale of this product.

NAPOLEON® will not be responsible for: over-fi ring, downdrafts, spillage caused by environmental conditions such as rooftops, buildings, nearby trees,

hills, mountains, inadequate vents or ventilation, excessive venting confi gurations, insuffi cient makeup air, or negative air pressures which may or may not

be caused by mechanical systems such as exhaust fans, furnaces, clothes dryers, etc.

Any damages to the appliance, combustion chamber, heat exchanger, plated trim or other components due to water, weather damage, long periods of

dampness, condensation, damaging chemicals or cleaners will not be the responsibility of NAPOLEON®.

All parts replaced under the President’s Limited Lifetime Warranty Policy are subject to a single claim.

During the fi rst 10 years NAPOLEON® will replace or repair the defective parts covered by the lifetime warranty at our discretion free of charge. From 10

years to life, NAPOLEON® will provide replacement parts at 50% of the current retail price.

All parts replaced under the warranty will be covered for a period of 90 days from the date of their installation.

The manufacturer may require that defective parts or products be returned or that digital pictures be provided to support the claim. Returned products are

to be shipped prepaid to the manufacturer for investigation. If a product is found to be defective, the manufacturer will repair or replace such defect.

Before shipping your appliance or defective components, your dealer must obtain an authorization number. Any merchandise shipped without

authorization will be refused and returned to sender.

Shipping costs are not covered under this warranty.

Additional service fees may apply if you are seeking warranty service from a dealer.

Warranty labour allowance is only for the replacement of the warranted part. Travel, diagnostic tests, shipping and other related charges are not covered

by this warranty.

Certifi cate.

product that you expect from NAPOLEON®.

CONDITIONS AND LIMITATIONS

ALL SPECIFICATIONS AND DESIGNS ARE SUBJECT TO CHANGE WITHOUT PRIOR NOTICE DUE TO ON-GOING PRODUCT

W415-0559 / D / 05.09.12

IMPROVEMENTS. NAPOLEON® IS A REGISTERED TRADEMARK OF WOLF STEEL LTD.

2.1B

Page 25

12.0 SERVICE HISTORY

25

W415-0559 / D / 05.09.12

Page 26

26

W415-0559 / D / 05.09.12

Loading...

Loading...