Page 1

INSTALLER: THESE INSTRUCTIONS MUST BE CONVEYED TO AND REMAIN WITH THE HOMEOWNER.

CERTIFIED UNDER CANADIAN AND AMERICAN NATIONAL STANDARDS, CSA 2.33, ANSI Z21.88

INSTALLATION AND OPERATION INSTRUCTIONS FOR:

VENTED GAS FIREPLACE HEATER

1

NATURAL GAS MODELS GDS 28-N and GS 28-N

PROPANE GAS MODELS GDS 28-P and GS 28-P

Model GS28 is made up of Model GDS28 and B-Vent Adapter Kit GS-150KT

WARNING: If the information in these instructions is not followed exactly, a fire or

explosion may result causing property damage, personal injury or death.

FOR YOUR SAFETY

Do not store or use gasoline or other flammable vapours and liquids in the vicinity of

this or any other appliance.

WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electrical switch.

• Do not use any phone in your building.

• Immediately call your gas supplier from

a neighbour's phone. Follow the gas supplier's instructions.

• If you cannot reach your gas supplier,

call the fire department.

Installation and service must be performed by a qualified installer, service

agency or the gas supplier .

Wolf Steel Ltd., 24 Napoleon Rd.,

Barrie, ON., Canada L4M 4Y8 (705)721-1212

Fax: (705)722-6031 Email: ask@napoleon.on.ca

Web: www.napoleonfireplaces.com

R-2000

W415-0153 / A / 10.29.01

Page 2

2

Pg

2-4 INTRODUCTION

5 LOCATION & CLEARANCES

5-10 DIRECT VENT SPECIFICS

MODEL GDS28

11-12 B-VENT SPECIFICS

MODEL GS28

TABLE OF CONTENTS

Warranty

General Instructions

General Information

Care of Glass & Plated Parts

Vent Lengths

Special Installation Example

Offset Installation Example

Air Terminal Locations

Wall & Ceiling Protection

Horizontal Venting Installation

Vertical Venting Installation

Stove Vent Connection

Mobile Home Installation

Chimney Installation

'B' Vent Adaptations

'B' Vent Installation

Combustion Air

Adding Vent Sections

Flashing and Storm Collar Installation

Pg

13 GAS INSTALLATION

Remote Wall Switch / Thermostat

14 FINISHING

Door Closing & Opening

Log Placement

15-1 6 OPERATION / MAINTENANCE

Spill Switch

Venting Action Check

Operating Instructions

Maintenance

17 REPLACEMENT BLOWER

18 ADJUSTMENTS

Pilot Burner Adjustment

Venturi Adjustments

19-20 REPLACEMENTS

Ordering Replacement Parts

Termination Kits

Burner Kit

Replacement Parts

Accessories

21-22 TROUBLE SHOOTING GUIDE

PLEASE RETAIN THIS MANUAL FOR FUTURE REFERENCE

WARNING

• The stove is a vented gas-fired heater. Do not burn wood or other materials in this sto ve.

• Adults and especially children should be alerted to the hazards of high surface temperatures and should

stay away to avoid burns or clothing ignition. Supervise young children when they are in the same room as

the stove.

• Due to high temperatures , the sto ve should be loca ted out of traffic and aw ay from furniture and draperies.

• Clothing or other flammable material should not be placed on or near the sto ve.

• Any safety screen or guard removed for servicing must be replaced prior to operating the stove.

• It is imperative that the control compartments, burners and circulating blower and its passageway in the

stove and venting system are kept clean. The stove and its venting system should be inspected before use

and at least annually by a qualified service person. More frequent cleaning may be required due to excessive lint from carpeting, bedding material, etc. The stove area must be kept clear and free from combustible materials, gasoline and other flammable vapours and liquids.

• Under no circumstances should this stove be modified.

• This stove must not be connected to a chimney flue pipe serving a separate solid fuel burning appliance.

• Do not use this stove if any part has been under water. Immediately call a qualified service technician to

inspect the stove and to replace any part of the control system and any gas control which has been under

water.

• Do not operate the stove with the glass door opened, cracked or broken. Replacement of the glass should

be done by a licensed or qualified service person.

• Do not strike or slam shut the stove glass door.

W415-0153 / A / 10.29.01

Page 3

NAPOLEON gas fireplaces are manufactured under the strict Standard of the world recognized

ISO9002 Quality Assurance Certificate.

NAPOLEON products are designed with superior components and materials, assembled by trained craftsmen who

take great pride in their work. The burner and valve assembly are leak and test-fired at a quality test station. The

complete fireplace is thoroughly inspected by a qualified technician before packaging to ensure that you, the

customer, receives the quality product that you expect from NAPOLEON.

NAPOLEON GAS FIREPLACE PRESIDENT'S LIFETIME LIMITED WARRANTY

3

The following materials and workmanship in your new The following materials and workmanship in your new

The following materials and workmanship in your new

The following materials and workmanship in your new The following materials and workmanship in your new

ranted against defects for as long as you own the fireplace. This covers: combustion chamber,ranted against defects for as long as you own the fireplace. This covers: combustion chamber,

ranted against defects for as long as you own the fireplace. This covers: combustion chamber,

ranted against defects for as long as you own the fireplace. This covers: combustion chamber,ranted against defects for as long as you own the fireplace. This covers: combustion chamber,

heat exchanger, stainless steel burner, phazer™ logs and embers, ceramic glass (thermal break-heat exchanger, stainless steel burner, phazer™ logs and embers, ceramic glass (thermal break-

heat exchanger, stainless steel burner, phazer™ logs and embers, ceramic glass (thermal break-

heat exchanger, stainless steel burner, phazer™ logs and embers, ceramic glass (thermal break-heat exchanger, stainless steel burner, phazer™ logs and embers, ceramic glass (thermal breakage only), gold plated parts against tarnishing, porcelainized enamelled components and aluminumage only), gold plated parts against tarnishing, porcelainized enamelled components and aluminum

age only), gold plated parts against tarnishing, porcelainized enamelled components and aluminum

age only), gold plated parts against tarnishing, porcelainized enamelled components and aluminumage only), gold plated parts against tarnishing, porcelainized enamelled components and aluminum

extrusion trims.extrusion trims.

extrusion trims.

extrusion trims.extrusion trims.

Electrical (110V and millivolt) components and wearable parts such as blowers, gas valves,Electrical (110V and millivolt) components and wearable parts such as blowers, gas valves,

Electrical (110V and millivolt) components and wearable parts such as blowers, gas valves,

Electrical (110V and millivolt) components and wearable parts such as blowers, gas valves,Electrical (110V and millivolt) components and wearable parts such as blowers, gas valves,

thermal switch, switches, wiring, remote controls, ignitor, gasketing, and pilot assembly arethermal switch, switches, wiring, remote controls, ignitor, gasketing, and pilot assembly are

thermal switch, switches, wiring, remote controls, ignitor, gasketing, and pilot assembly are

thermal switch, switches, wiring, remote controls, ignitor, gasketing, and pilot assembly arethermal switch, switches, wiring, remote controls, ignitor, gasketing, and pilot assembly are

covered and covered and

covered and

covered and covered and

the limited warranty.the limited warranty.

the limited warranty.

the limited warranty.the limited warranty.

Labour related to warranty repair is covered free of charge during the first year. Repair work,Labour related to warranty repair is covered free of charge during the first year. Repair work,

Labour related to warranty repair is covered free of charge during the first year. Repair work,

Labour related to warranty repair is covered free of charge during the first year. Repair work,Labour related to warranty repair is covered free of charge during the first year. Repair work,

however, requires the prior approval of an authorized company official. Labour costs to thehowever, requires the prior approval of an authorized company official. Labour costs to the

however, requires the prior approval of an authorized company official. Labour costs to the

however, requires the prior approval of an authorized company official. Labour costs to thehowever, requires the prior approval of an authorized company official. Labour costs to the

account of account of

account of

account of account of

be done through an authorized be done through an authorized

be done through an authorized

be done through an authorized be done through an authorized

NAPOLEONNAPOLEON

NAPOLEON

NAPOLEONNAPOLEON

NAPOLEONNAPOLEON

NAPOLEON

NAPOLEONNAPOLEON

will provide replacement parts free of charge during the first year ofwill provide replacement parts free of charge during the first year of

will provide replacement parts free of charge during the first year of

will provide replacement parts free of charge during the first year ofwill provide replacement parts free of charge during the first year of

are based on a predetermined rate schedule and any repair work must are based on a predetermined rate schedule and any repair work must

are based on a predetermined rate schedule and any repair work must

are based on a predetermined rate schedule and any repair work must are based on a predetermined rate schedule and any repair work must

NAPOLEONNAPOLEON

NAPOLEON

NAPOLEONNAPOLEON

dealer. dealer.

dealer.

dealer. dealer.

NAPOLEONNAPOLEON

NAPOLEON

NAPOLEONNAPOLEON

gas fireplace are war- gas fireplace are war-

gas fireplace are war-

gas fireplace are war- gas fireplace are war-

CONDITIONS AND LIMITATIONS

NAPOLEON warrants its products against manufacturing defects to the original purchaser only -- i.e., the individual or legal entity (registered customer) whose name appears on the

warranty registration card filed with NAPOLEON -- provided that the purchase was made through an authorized NAPOLEON dealer and is subject to the following conditions and limitations:

This factory warranty is nontransferable and may not be extended whatsoever by any of our representatives.

The gas fireplace must be installed by a licenced, authorized service technician or contractor. Installation must be done in accordance with the installation instructions included with the

product and all local and national building and fire codes.

This limited warranty does not cover damages caused by misuse, lack of maintenance, accident, alterations, abuse or neglect and parts installed from other manufacturers will nullify this

warranty.

This limited warranty further does not cover any scratches, dents, corrosion or discolouring caused by excessive heat, abrasive and chemical cleaners nor chipping on porcelain enamel

parts, mechanical breakage of PHAZER™ logs and embers, nor any venting components used in the installation of the fireplace.

NAPOLEON warrants its stainless steel burners against defects in workmanship and material for life, subject to the following conditions: During the first 10 years NAPOLEON will replace

or repair the defective parts at our option free of charge. From 10 years to life, NAPOLEON will provide replacement burners at 50% of the current retail price.

In the first year only, this warranty extends to the repair or replacement of warranted parts which are defective in material or workmanship provided that the product has been operated in

accordance with the operation instructions and under normal conditions.

After the first year, with respect to this President's Limited Lifetime Warranty , NAPOLEON ma y , at its discretion, fully discharge all obligations with respect to this warranty by refunding

to the original warranted purchaser the wholesale price of any warranted but defective part(s).

After the first year, NAPOLEON will not be responsible for installation, labour or any other costs or expenses related to the reinstallation of a warranted part, and such expenses are not

covered by this warranty.

Notwithstanding any provisions contained in this President's Limited Lifetime Warranty , NAPOLEON’S responsibility under this warranty is defined as above and it shall not in any event

extend to any incidental, consequential or indirect damages.

This warranty defines the obligations and liability of NAPOLEON with respect to the NAPOLEON gas fireplace and any other warranties expressed or implied with respect to this product,

its components or accessories are excluded.

NAPOLEON neither assumes, nor authorizes any third party to assume, on its behalf, any other liabilities with respect to the sale of this product. NAPOLEON will not be responsible for:

over-firing, downdrafts, spillage caused by environmental conditions such as rooftops, buildings, nearby trees, hills, mountains, inadequate vents or ventilation, excessive venting configurations, insufficient makeup air, or negative air pressures which may or may not be caused by mechanical systems such as exhaust fans, furnaces, clothes dryers, etc.

Any damages to fireplace, combustion chamber, heat exchanger, brass trim or other component due to water, weather damage, long periods of dampness, condensation, damaging

chemicals or cleaners will not be the responsibility of NAPOLEON.

The bill of sale or copy will be required together with a serial number and a model number when making any warranty claims from your authorized dealer. The warranty registration card

must be returned within fourteen days to register the warranty.

NAPOLEON reserves the right to have its representative inspect any product or part thereof prior to honouring any warranty claim.

ALL SPECIFICATIONS AND DESIGNS ARE SUBJECT TO CHANGE WITHOUT PRIOR NOTICE DUE T O ON-GOING PRODUCT IMPROVEMENTS. NAPOLEON® IS A REGISTERED

TRADEMARK OF WOLF STEEL LTD. PA TENTS U.S. 5.303.693.801, DES. 417,497 - CAN. 2.073.41 1, 2.082.915. © WOLF STEEL L TD.

W415-0153 / A / 10.29.01

Page 4

GENERAL INSTRUCTIONS

4

THIS GAS STOVE SHOULD BE INSTALLED AND SERVICED BY A QUALIFIED INSTALLER to conform with local

codes. Installation practices vary from region to region and

it is important to know the specifics that apply to your

area, ie: in Massachusetts State:

• The fireplace damper must be removed or welded in

the open position prior to installation of a fireplace

insert.

• The appliance off valve must be a “T” handle gas cock.

• The flexible connector must not be longer than 36

inches.

• The appliance is not approved for installation in a

bedroom or bathroom unless the unit is a direct-vent.

In absence of local codes, install to the current CAN1B149 Installation Code in Canada or to the National Fuel

Gas Code, ANSI Z223.1-1988, and NFPA 54-1988 in the

United States. Mobile home installation must conform

with local codes or in the absence of local codes, install

to the current standard for gas equipped mobile housing

CAN/CSA Z240 MH Series in Canada or ANSI Z223.11988 and NFPA 54-1988 in the United States.

Purge all gas lines with the glass door of the stove

opened. Assure that a continuous gas flow is at the

burner before c losing the door.

Under extreme vent configurations, allow several minutes (5-15) for the flame to stabilize after ignition.

For optimum performance, it is recommended that all

horizontal runs have a ¼ inch rise per foot.

Objects placed in front of the fireplace must be kept a

minimum of 48" away from the front face of the unit.

The stove and its individual shutoff valve must be disconnected from the gas supply piping system during any pressure testing of that system at test pressures in excess of

½ psig (3.5 kPa). The stove must be isolated from the gas

supply piping system by closing its individual manual shutoff valve during any pressure testing of the gas supply piping system at test pressures equal to or less than ½ psig

(3.5 kPa)

The stove, when installed with a blower, must be electrically connected and grounded in accordance with local

codes. In the absence of local codes, use the current CSA

C22.1 CANADIAN ELECTRICAL CODE in Canada or the

ANSI/NFPA 70-1996 NA TIONAL ELECTRICAL CODE in the

United States. The blower power cord must be connected

into a properly grounded receptacle. The grounding prong

must not be removed from the cord plug.

GENERAL INFORMATION

For your satisfaction, this stove has been test-fired

to assure its operation and quality!

Minimum inlet gas supply pressure is 4.5 inches water

column for natural gas and 11 inches water column for

propane. Maximum inlet gas pressure is 7 inches water

column for natural gas and 13 inches water column for

propane. When the valve is set to "HI", the manifold pressure under flow conditions is 3.5 inches water column for

natural gas and 10 inches water column for propane. When

the fireplace is installed at elevations above 4,500 ft., and

in the absence of specific recommendations from the local authority having jurisdiction, the certified high altitude

input rating shall be reduced at the rate of 4% for each

additional 1,000 ft.

Change in flame appearance from "HI" to "LO" is more

evident in natural gas than in propane. Expansion / contraction noises during heating up and cooling down cycles

are normal and to be expected.

GDS28: Maximum input is 30,000 BTU/hr for natural

gas and 26,000 BTU/hr for propane. Maximum output for

natural gas is 25,500 BTU/hr at an efficiency of 85% with

the fan on and 75% with the fan off. Maximum output for

propane is 22,360 BTU/hr at an efficiency of 86% with the

fan on and 76% with the fan off. Maximum A.F.U.E. (annual

fuel utilization efficiency) rating is 76% for natural gas and

77% for propane. This stove is not approved for closet or

recessed installations. It is approved for bathroom, bedroom and bed-sitting room installations.

This stove may be installed in an aftermarket permanently

located, manufactured mobile home, where not prohibited

by local codes.

This appliance is only for use with the type of gas indicated

on the rating plate. This appliance is not convertible for

use with other gases, unless a certified kit is used.

GS28: Maximum input is 30,000 BTU/hr for natural

gas and 26,000 BTU/hr for propane. Maximum

output for natural gas is 24,600 BTU/hr at an

efficiency of 82% with the fan on and 80% with

the fan off; and 21,600 BTU/hr for propane at an

efficiency of 83% with the fan on and 80% with

the fan off. This stove is approved for bedroom

and bed-sitting room installations.

CARE OF GLASS, AND PLATED PARTS

Do not use abrasive cleaners to clean these parts. Buff

lightly with a clean dry cloth.

The glass is 3/16" ceramic glass available from your Napoleon / Wolf Steel Ltd. dealer.

Do not substitute materials.

Clean the glass after the first 10 hours of operation with a

recommended gas fireplace glass cleaner. Thereafter

clean as required.

Do not clean glass when hot!

If the glass is not kept clean permanent discolouration

and / or blemishes may result.

W415-0153 / A / 10.29.01

Page 5

LOCATION AND CLEARANCES

5

Provide adequa te ventilation and combustion air.

Provide adequate accessibility clearance for servicing

and operating the stove.

Never obstruct the fr ont opening of the stove.

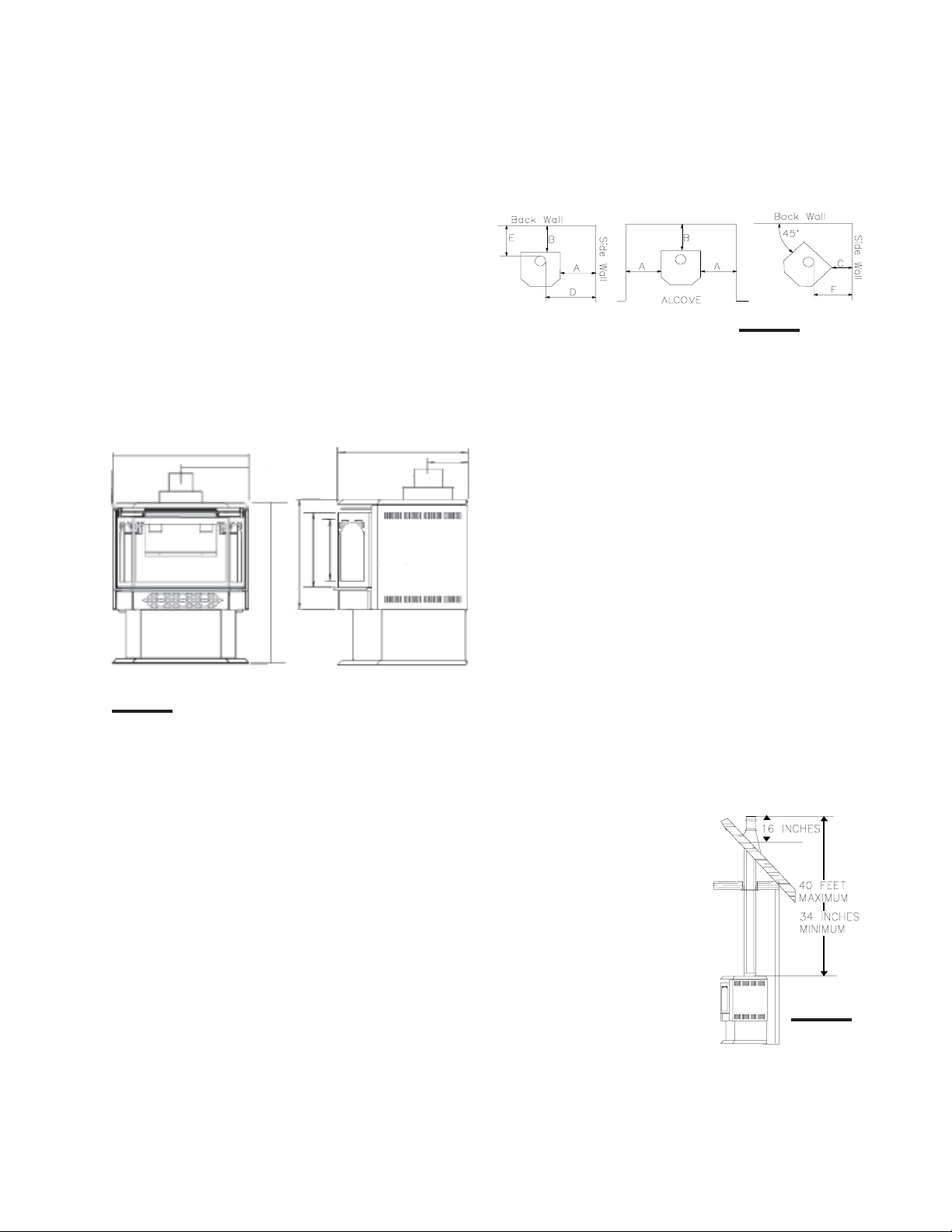

GDS28 AND GS28:

As long as clearance to combustibles is kept within the

required distances, the most desirable and beneficial location for a Napoleon stove is in the centre of a building,

thereby allowing the most efficient use of the heat created.

The location of windows, doors and the traffic flow in the

room where the stove is to be located should be considered. If possible, you should choose a location where the

vent will pass through the house without cutting a floor or

roof joist.

22½"

7"ø AIR

INTAKE

WINDOW OPENING

FIGURE 1

11¼"

15"

"

4

/

3

10"

12"

"

17

4

/

3

26

GAS LINE ACCESS HOLE

LOCATED IN PEDESTAL

BASE

4"ø

FLUE

18½"

5½"

MAINT AIN THESE MINIMUM CLEARANCES TO

COMBUSTIBLES:

FIGURE 2

A. 7" D. 143/4"

B. 2" E. 4"

C. 1"

* F. 9½"

NO ADDITIONAL FLOOR PROTECTION IS REQUIRED

MINIMUM

20" FROM STOVE TOP TO CEILING

*AT A DISTANCE OF 1" FROM THE WALL, ACCESS TO THE BLOWER

SWITCH

, ON-OFF SWITCH OR THE BLOWER POWER CORD MAY

BE PRACTICAL.

NOT

A terminal shall not terminate directly above a sidewalk

or paved driveway which is located between two single family dwellings and serves both dwellings. Local

codes or regulations may r equir e different clearances .

Do not allow the inside liner to bunch up on horizontal or

vertical runs and elbows. Keep it pulled tight. A 1-1/4" air

gap all around between the inner liner and outer stove pipe

is required for safe operation.

Use a firestop when penetrating interior walls, floor or ceiling.

DIRECT VENT SPECIFICS - GDS28

VENTING LENGTHS AND AIR TERMINAL LOCATIONS

Use only Wolf Steel or Simpson Dura-Vent Model DV-GS

venting components. Minimum and maximum vent lengths,

for both horizontal and vertical installations, and air terminal locations for either system are set out in this manual

and must be adhered to. For Simpson Dura-Vent, follow

the installation procedure provided with the venting components. Both Wolf Steel and Simpson Dura-Vent venting

components may have a 0" rise per foot on horizontal runs.

When using Wolf Steel venting components, use only the

following vent kits: WALL TERMINAL KIT GD175 (7-1/2' of

venting included), or 1/12 TO 7/12 PITCH ROOF TERMINAL

KIT GD110, 8/12 TO 12/12 ROOF TERMINAL KIT GD111,

FLAT ROOF TERMINAL KIT GD1 12 or STOVE PERISCOPE

KIT GD180 (for wall penetration below grade) in conjunc-

tion with the appropriate venting components.

For optimum performance, it is recommended that all

horizontal runs have a minimum ¼ inch rise per foot.

These vent kits allow for either

horizontal or vertical venting of

the stove. FIGURES 3, 4, & 5.

The maximum number of 4"

flexible connections is two horizontally or three vertically (excluding the stove and the air

terminal connections).

When terminating vertically , the

minimum vertical rise is

34 inches above the stove and

the maximum vertical rise is

40 feet.

FIGURE 3

Deviation from the minimum vertical vent length can

create difficulty in burner start-up and/or carboning.

Use an adjustable pipe as the final length of rigid piping to the stove for ease of installation.

W415-0153 / A / 10.29.01

Page 6

For optimum flame appearance and stove performance,

C

B

A

6

keep the vent length and number of elbows to a minimum.

The air terminal must remain unobstructed at all times.

Examine the air terminal at least once a year to verify that it

is unobstructed and undamaged.

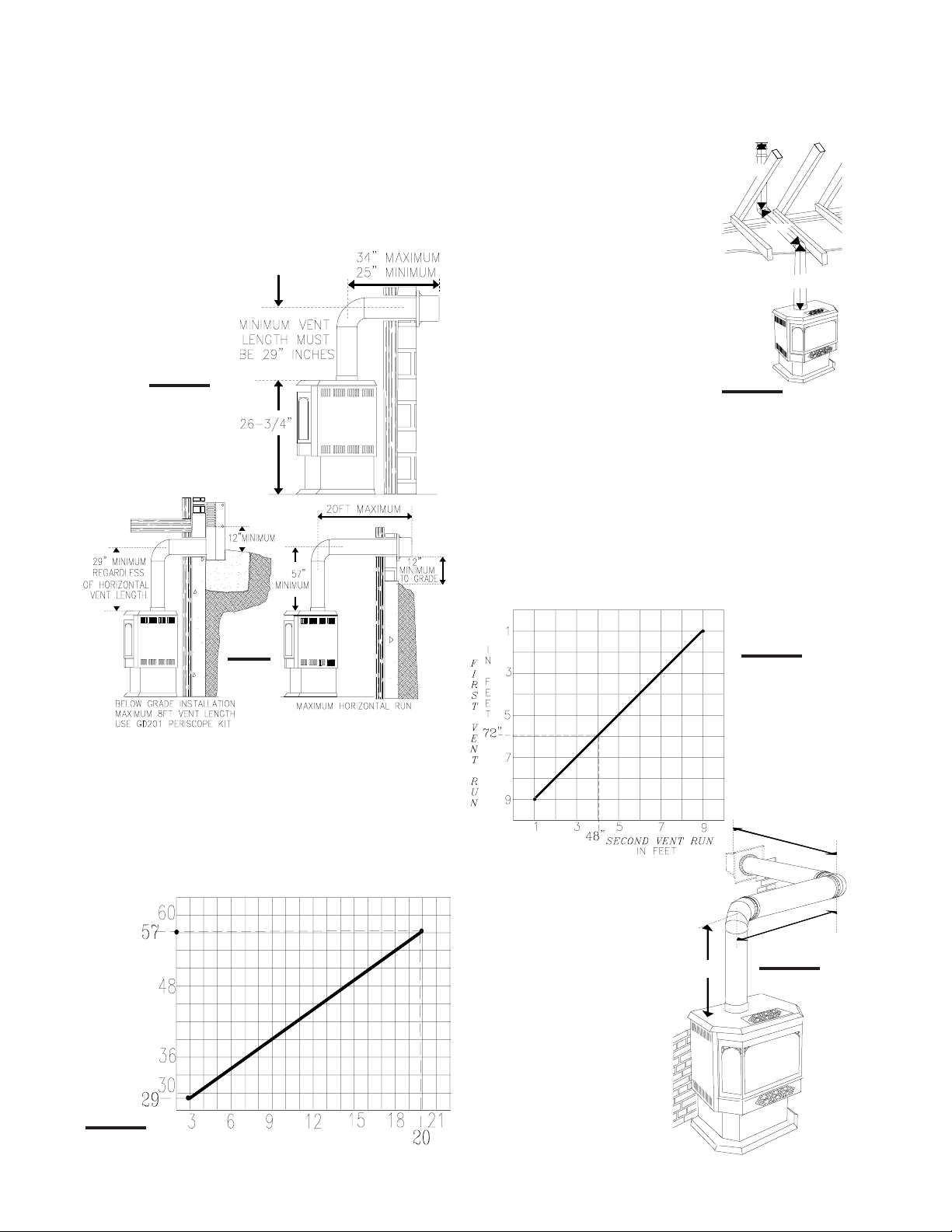

The maximum horizontal run is 34 inches with a 90° elbow

located 29" above the stove. FIGURE 4.

The maximum horizontal run with a 57 inch vertical rise

immediately above the stove is 20 feet . Figures 5.

FIGURE 4

SPECIAL INSTALLATION EXAMPLE

When a horizontal offset is required in a through-the-roof

installation, the following procedure for vent length calculations must be followed:

In an installation as shown in FIGURE 7,

lengths A and C are known based on

room height and roof requirements.

Length C must never be less than 29

inches. Any 90° and 45° elbows must

be calculated as 5 feet of venting

each.

The allowable horizontal run can be calculated using these parameters. In this

example, the total vertical height is 20

feet (length "A" is required to be 11 feet

while length "C" needs to be 9 feet). The

maximum vertical length is 40 feet and

all runs and elbows must be subtracted

from this maximum vertical length.

The maximum allowable horizontal run that "B" can be is:

40 ft. (maximum vertical run length)

-11 ft. (through the roof vertical rise "A")

-10 ft. (2 - 90° elbow)

- 9 ft. (vertical run "C")

10 ft. (maximum allowable horizontal length for "B")

The length of "B" must never be greater than the length

of "A" and "C" combined.

FIGURE 7

FIGS 5

HORIZONTAL RUN NOT TO EXCEED VERTICAL RISE

If vertical rises greater than 57 inches are necessary,

the increased rise must be deducted from the maximum horizontal run.

Use chart, Figure 6, to calculate horizontal runs for vertical

rises between 29 and 57 inches.

When calculating maximum run lengths, include 10 feet

for each 90° elbow or 5 feet for each 45° elbow.

Do not include the first elbow directly off the unit.

REQUIRED

VERTICAL

RISE FROM

FIREPLACE

TO FIRST ELBOW IN

INCHES

OFFSET INSTALLATION EXAMPLE

FIGURE 8

48"

second run

If a first run of 72 inches is required, using the "First Vent Run"

on the chart shows that a maxi-

mum second run of 48 inches

is allowable.

IF NECESSARY, THE FIRST

RUN AND THE SECOND

RUN MA Y BE REVERSED .

57"

first run

72"

FIGURE 9

FIGURE 6

W415-0153 / A / 10.29.01

CALCULATED HORIZONTAL VENT RUN IN FEET

Page 7

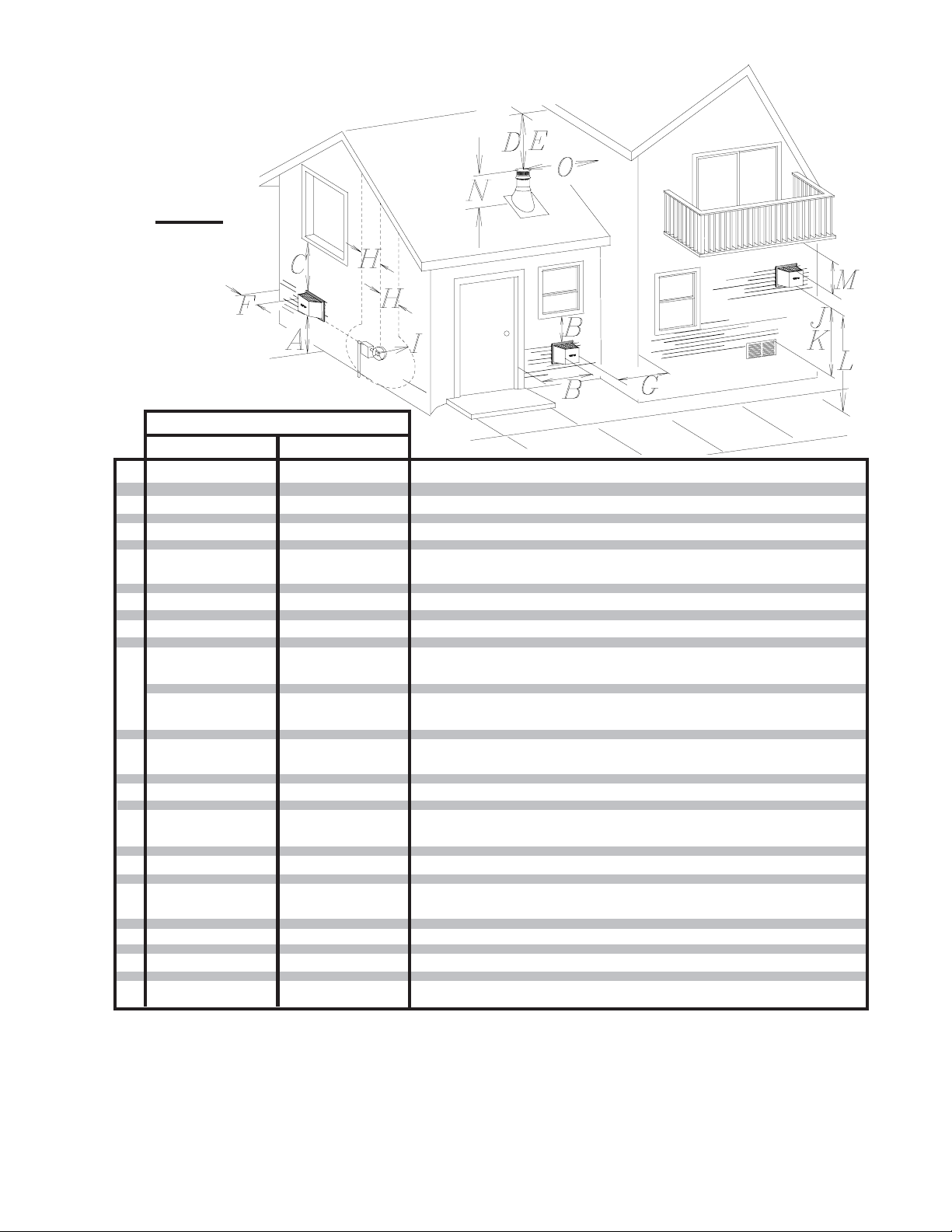

AIR AIR

AIR

AIR AIR

A

TERMINTERMIN

TERMIN

TERMINTERMIN

FIGURE 10

INSTALLATIONS

AL INSTAL INST

AL INST

AL INSTAL INST

CANADIAN U.S.A.

12 INCHES

12 INCHES

ALLAALLA

ALLA

ALLAALLA

TIONS:TIONS:

TIONS:

TIONS:TIONS:

Clearance above grade, veranda porch, deck or balcony .

7

B

C

D

E

12 INCHES

12 INCHES*

18 INCHES**

12 INCHES**

F

0 INCHES***

0 INCHES

9 INCHES

12 INCHES*

18 INCHES**

12 INCHES**

0 INCHES

0 INCHES***

G

2 INCHES***

H

I

J

K

L

M

N

O

**

* Recommended to prevent condensation on windows and thermal breakage

**

****

** It is recommended to use a heat shield and to maximize the distance to vinyl clad sof fits.

****

******

*** The periscope GD-201 requires a minimum 18 inches clearance from an inside corner.

******

********

**** This is a recommended distance. For additional requirements check local codes.

********

††

† Three feet above if within 10 feet horizontally.

††

‡‡

‡ A vent shall not terminate directly above a sidewalk or paved driveway that is located between two single family

‡‡

††††

† † Permitted only if the veranda, porch, deck or balcony is fully open on a minimum of two sides beneath the floor.

††††

†*†*

†* Recommenced to prevent recirculation of exhaust products. For additional requirements check local codes.

†*†*

3 FEET

6 FEET

12 INCHES

6 FEET

7 FEET‡

12 INCHES††

16 INCHES

2 FEET†*

dwellings and serves both dwellings.

2 INCHES***

3 FEET****

3 FEET****

9 INCHES

3 FEET†

7 FEET****

12 INCHES****

16 INCHES

2 FEET†*

Clearance to windows or doors that open.

Clearance to permanently closed windows.

Vertical clearance to ventilated soffit located above the terminal within

a horizontal distance of 2 feet from the centerline of the terminal.

Clearance to unventilated soffit.

Clearance to an outside corner wall.

Clearance to an inside non-combustible corner wall or protruding

non-combustible obstructions (chimney , etc.).

Clearance to an inside combustible corner wall or protruding com-

bustible obstructions ( vent chase, etc.).

Clearance to each side of the centerline extended above the meter

/ regulator assembly .

Clearance to a service regulator vent outlet.

Clearance to a non-mechanical air supply inlet to the building or a

combustion air inlet to any other appliance.

Clearance to a mechanical air supply inlet.

Clearance above a paved sidewalk or paved driveway located on

public property unless fitted with a heat shield kit GD-301.

Clearance under a veranda, porch, deck or balcony .

Clearance above the roof.

Clearance from an adjacent wall including neighbouring buildings.

W415-0153 / A / 10.29.01

Page 8

8

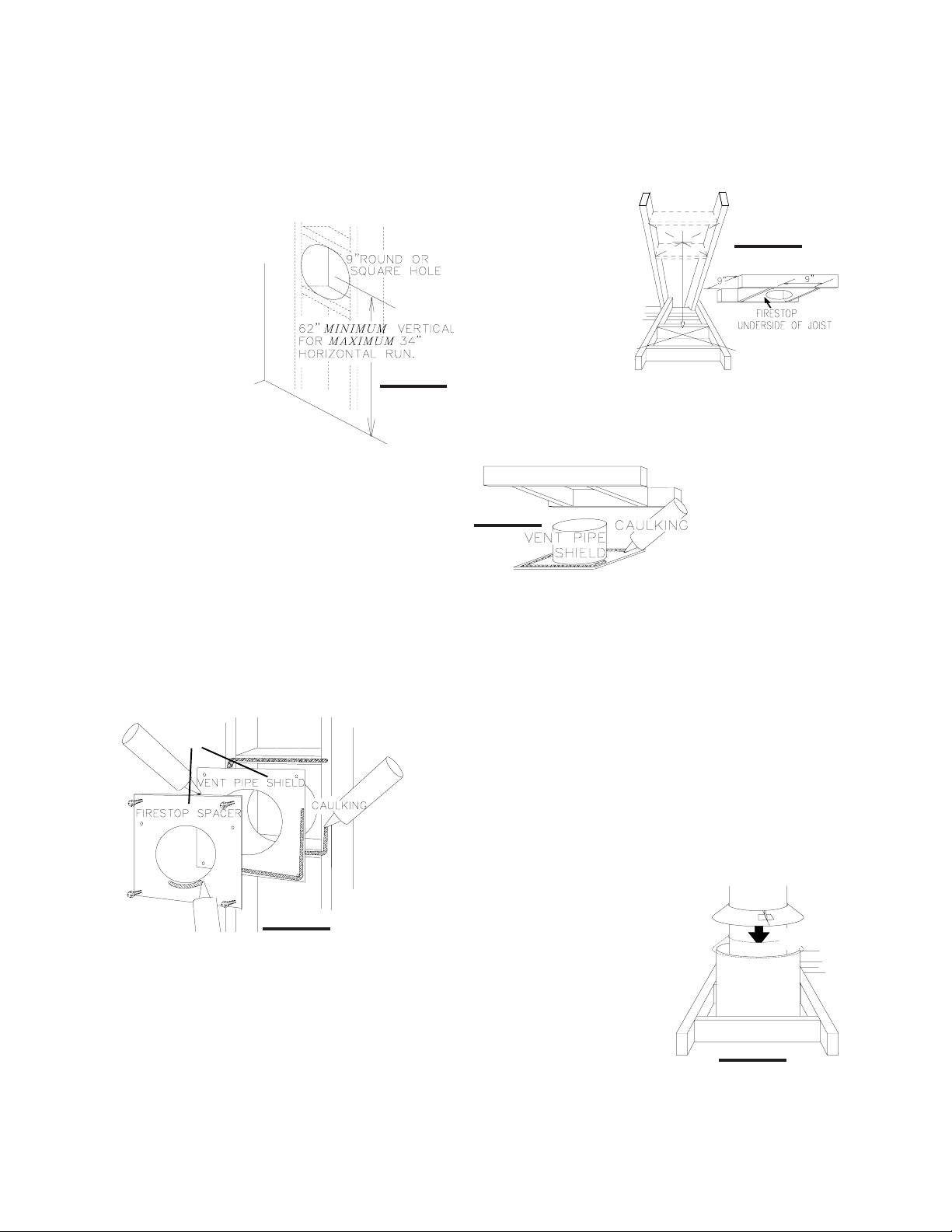

WALL AND CEILING PROTECTION

For safe and proper operation of the stove, follow

the venting instructions exactly.

HORIZONTAL INSTALLATION: This application occurs

when venting through an

exterior wall. FIGURES

4, 5, & 11. Having determined the air terminal location, cut and frame a hole

in an exterior wall with a

minimum square or round

opening of 9". (As an alternative to framing, a vent

pipe shield may be installed, ensuring a 1" clearance to combustibles.

See Figure 12.)

For optimum performance, the stove pipe should rise

¼" per foot of run.

1. Mark and cut the vent pipe shield to the determined

depth of the combustible wall. Apply a bead of caulking (not

supplied) to the framework or to the shield plate (in the

case of a finished wall) and secure the shield through the

opening to the interior wall.

pipe shield should maintain the required clearance to

the 7" vent pipe. Do not fill this cavity with any type of

material.

firestop spacer over the vent shield to restrict cold air from

being drawn into the room or around the stove. Ensure that

both spacer and shield maintain the required clearance to

combustibles. Once the vent pipe is installed in its final

position, apply sealant between the pipe and the firestop

spacer.

Apply a bead of caulking all around and place a

The final location of the vent

FIGURE 11

OR

FIGURE 12

VERTICAL INSTALLATION: This application occurs when

venting through a roof. FIGURE 3.

Installation kits for various roof pitches are

available from your Napoleon dealer. See Accessories to order the

specific kit required.

1. Determine the air terminal location and move the stove

into position. Cut and frame 9 inch openings in the ceiling

and the roof to provide the minimum 1 inch clearance between the stove pipe and any combustible material. Try to

FIGURE 14

DO NOT FILL THIS SPACE WITH ANY TYPE OF MA TERIAL.

A vent pipe shield will prevent any materials such as insu-

lation, from filling up the 1" air space around the pipe.

FIGURE 15. Nail headers between the joist for extra support.

2. Apply a bead of caulking (not supplied) to the framework or to the Wolf Steel vent pipe shield plate or equivalent (in the case of a finished ceiling), and secure over the

opening in the ceiling. FIGURE 14. A firestop must be placed

on the bottom of each framed opening in a roof or ceiling

that the venting system passes through. FIGURE 13. Apply

a bead of caulking all around and place a firestop spacer

over the vent shield to restrict cold air from being drawn

into the room or around the stove. Ensure that both spacer

and shield maintain the required clearance to

combustibles. Once the vent pipe is installed in its final

position, apply sealant between the pipe and the firestop

spacer.

3. In the attic, after the pipe

has been installed, slide the

vent pipe collar down to cover

up the open end of the shield

and tighten. This will prevent any

materials, such as insulation,

from filling up the 1" air space

around the pipe.

FIGURE 13

center the exhaust

pipe location midway

between two joist to

prevent having to cut

them. Use a plumb

bob to line up the

center of the openings.

VENT

PIPE

COLLAR

VENT PIPE

SHIELD

FIGURE 15

W415-0153 / A / 10.29.01

Page 9

HORIZONTAL VENTING INSTALLATION

For safe and proper operation of the stove, follow the

venting instructions exactly.

For horizontal runs, both Wolf Steel and Simpson Duravent venting components may have a 0" rise per foot.

For optimum performance it is recommended that all

horizontal runs have a minimum ¼ inch rise per foot.

1. Stretch the 4" diameter aluminium flexible liner to the

required length taking into account the additional length

needed for the finished wall surface.

Spacers are attached to the 4" inner flex liner at predetermined intervals to maintain a 1-1/4" air gap to the 7" outer

stove pipe. These spacers must not be removed.

Slip a 4" diameter length of aluminium flexible liner a minimum of 2" over the inner sleeve of the air terminal. Secure

to the sleeve using 3 screws. Seal the joint and screw

heads using the high temperature sealant provided.

2. Slip the first section of 7" diameter stove pipe a minimum of 2" over the outer sleeve of the air terminal. Secure

to the sleeve using 3 screws. Seal the joint and screw

heads using high temperature sealant.

3. Insert the liners through the firestop / vent pipe shield.

Holding the air terminal (lettering in an upright, readable

position), secure to the exterior wall. Make weather tight by

sealing with caulking (not supplied). The air terminal mounting plate may be recessed (up to

exterior wall or siding.

FIGURE 16

4. If more than one length of liner needs to be used to

reach the stove, couple them together as illustrated in

FIGURE 17. Seal the joints using the same procedure as

described above.

The vent system must be supported approximately every

10 feet along a horizontal run. Use supports or equivalent

non-combustible strapping to maintain the 1" clearance

from combustibles.

3

/4" maximum) into the

FIGURE 17

VERTICAL VENTING INSTALLATION

1. Fasten the roof

support to the roof using the screws provided. The roof support

is optional. In this case

the venting is to be adequately supported

using either an alternate method suitable

to the authority having

jurisdiction or the optional roof support.

2. Slip a 4" diameter length of aluminium flexible liner a

minimum of 2" over the inner sleeve of the air terminal.

Secure to the sleeve using 3 screws

FIGURE 19

and flat washers. Seal the joint and

screw heads using high temperature

sealant. Repeat using a 7" diameter

length of rigid piping.

If the attic space is tight, we recommend adding sufficient lengths

of 7" rigid piping, secured and

sealed as necessary.

3. Thread the air terminal pipe assembly down through

the roof support and attach, ensuring that a minimum 16"

of air terminal will penetrate the roof when fastened. The

air terminal must be located vertically and plumb.

4. Remove nails from the shingles, above and to the

sides of the chimney. Place the flashing over the air terminal and slide it underneath the sides and upper edge of

the shingles. Ensure that the air terminal is properly

centered

within the

flashing, giving a 3/4"

margin all

around. Fasten to the roof.

Do NOT nail

through the

lower portion

of the flashing. Make weather-tight by sealing with caulking. Where

possible, cover the sides and top edges of the flashing

with roofing material.

5. Apply a heavy bead of waterproof caulking 2 inches

above the flashing. Slide the storm collar around the air

terminal and down to the caulking. Tighten to ensure that a

weather-tight seal between the air terminal and the collar

is achieved. Attach the other storm collar centered between

the air intake and air exhaust slots onto the air terminal.

Tighten securely.

6. Attach the vertical rain cap.

7. In the attic, slide the vent pipe collar down to cover up

the open end of the shield and tighten. This will prevent any

materials, such as insulation, from filling up the 1" air space

around the pipe. Figure 15.

FIGURE 20

FIGURE 18

9

W415-0153 / A / 10.29.01

Page 10

10

STOVE VENT CONNECTION

1. Attach the adjustable pipe to the last section of rigid

piping. Secure with screws and seal.

2. Install the 4" aluminium flexible liner to the stove. Secure with 3 screws and flat washers. Seal the joint and

screw holes using the high temperature sealant provided.

3. Run a bead of high temperature sealant around the

inside of the air intake collar. Pull the adjustable pipe a

minimum 2" into the air intake collar.

FIGURE 21

#8x1/2"

SCREWS

HI-TEMP

VARIABLE

2" OVERLAP

ON/OFF

SWITCH

COMBUSTION AIR

COVER PLATES

& GASKETS

SELF DRILLING

SEALANT

SPEED SWITCH

Ensure that the sealant is not visible on the exterior pipes once installation is completed. An optional decorative brass band is available for this

use. (Standard with a GD175 kit). In the event that

the venting must be disassembled, care must be

taken to reseal the venting.

MOBILE HOME INSTALLATION

In Canada, mobile home installation may be vented horizontally or vertically. In the United States, it may only be

installed vertically. See "Vertical Venting" or "Horizontal Air

Terminal Installation" for installation.

The fireplace is equipped with two 5/16" diameter holes

located near each corner of the base. For mobile home

installations, the fireplace must be fastened in place. Use

#10 screws, inserted through the holes in the base to secure. It is recommended that the fireplace be secured in all

installations.

8"

11½"

Continue with "Gas Installation" Page 13

W415-0153 / A / 10.29.01

Page 11

B-VENT SPECIFICS - MODEL GS28

11

CHIMNEY INSTALLATION

THREE TYPES OF

CHIMNEY SYSTEMS

MAY BE USED WITH

THIS STOVE:

FIGURES 22

'B' VENT ADAPTATIONS

1. Remove and discard the two combustion air cover plates

and gaskets located on the rear panel of the unit. SEE FIG-

URE 23.

2. Replace the four screws per side to secure the rear

panel to the unit.

INSTINST

INST

INSTINST

Follow the instructions for "Wall and Ceiling Protection".

ALLING 'B' ALLING 'B'

ALLING 'B'

ALLING 'B' ALLING 'B'

FIGURE 24

SPILL

SWITCH

VENTVENT

VENT

VENTVENT

ADAPTER

::

:

::

ADAPTER INSTALLA TION FIGURE 24

1. Remove the spill switch bracket from the rear of the

adapter.

2. Gently pull the two wire terminals (located inside the 7"

flue collar at the top of the stove) out approximately 8 inches.

3. Bring the wires through the lower hole in the adapter and

out the spill switch opening.

the hole more easily , temporarily ta pe the two terminals

together.

4. With the spill switch opening aligned to the back of the

stove, push the crimped edge of the adapter into the stove

flue collar.

5. Connect the wire terminals to the spill switch and resecure the bracket.

6. Secure the terminal block into place as shown with the

screw supplied.

7. Unscrew the wire access cover plate from the rear right

hand side of the firebox. Remove and discard the gasket.

SEE FIGURE 25. Remove the knockout from the cover plate

and insert the protective bushing. Pull both spill switch wires

through the bushing taking up any slack. Replace the cover

plate. Connect one wire end to the terminal block and the

other end to terminal 1 of the gas valve. FIGURE 31. Connect the two wires running down the left side of the unit

from the on-off switch to the remaining tab on the terminal

block and to terminal 3 on the gas valve.

To pass the wires through

FIG. 23

COMBUSTION AIR COVER

PLATES & GASKETS

TERMINAL BLOCK

TERMINAL BLOCK

WIRE ACCESSWIRE ACCESS

WIRE ACCESS

WIRE ACCESSWIRE ACCESS

COCO

VER PLAVER PLA

CO

VER PLA

COCO

VER PLAVER PLA

FIGURE 25

W415-0153 / A / 10.29.01

TETE

TE

TETE

Page 12

12

For aesthetics, the adapter has been designed to accept

a standard matte black 7" stove pipe and the Napoleon

decorative brass band (standard with the GS-150KT). Both

are available from your Napoleon dealer.

B-VENT MODEL GS28 ONLY:

Attach the B-Vent label, shown below, in the control

area of the appliance.

ATTACH THIS LABEL IN THE CONTROL AREA OF THE FIREPLACE.

THIS FIREPLACE HAS BEEN CONVERTED TO A ‘B’VENT MODEL.

ATTACHEZ CET ETIQUETTE DANS LA REGION DE CONTROLE DU FOYER.

CE FOYER A ETE CONVERTI A UN MODELE A SYSTEME D’EVACUATION ‘B’.

COMBUSTION AIR

A chimney venting this stove shall not vent any solid

fuel burning appliance .

For optimum performance it is recommended that all

horizontal runs have a minimum ¼ inch rise per foot.

Any stove needs air for safe operation and must be

installed in such a way that adequate combustion air is

available.

ADDING VENT SECTIONS: For ease of assem-

bly, a 7" telescoping stove

pipe may be installed over the

4" vent connection of the

adapter. Add vent sections,

twist locking (clockwise) securely, to the required height.

The vent should extend, at

least, 3 feet above its point of

contact with the roof and, at

least, 2 feet higher than any

wall, roof or building within 10

feet. FIGURE 26. (This is a

guideline only; local venting

codes should be followed

which may differ in height and

clearance requirements.)

FIGURE 26

INSTALLING FLASHING AND STORM

COLLAR

Remove nails

from the shingles

above and to the

sides of the chimney. Place the

flashing over the

vent pipe and

slide it underneath the sides

and upper edge

of the shingles.

Ensure that the

vent pipe is properly centered within the flashing, giving a

3/4" margin all around. Fasten to the roof on the top and

sides. DO NOT NAIL through the lower portion of the flashing. Make weather-tight by sealing with caulking. Where

possible, cover the sides and top edges of the flashing

with roofing material.

Apply waterproof caulking around the vent, 1" above the

top of the flashing and push the storm collar down into the

caulking. FIGURE 27. Attach a rain cap to the top of the last

vent section.

FIGURE 27

Continue with "Gas Installation" Page 13

W415-0153 / A / 10.29.01

Page 13

GAS INSTALLATION

13

Read the section on opening the door in "Finishing" prior

to proceeding to prevent damaging the unit.

Bring the gas line to the stove through either the opening

in the pedestal back or through the floor directly beneath

the pedestal base.

Install rigid black pipe, or 1/2" type L copper tubing with a

shutoff valve to the stove.

Seal and tighten the gas line securely to the flex connector

supplied.

DO NOT KINK FLEXIBLE CONNECTOR.

FIGURE 28

MODEL GDS28 ONL Y: Attach the two leads from the on/

off switch to terminals 1 and 3 located on the gas valve.

L

O

FIGURE 29

P

I

L

T

O

Do not connect either the wall switch, thermostat or

gas valve to electricity (110 volts).

F

I

H

O

F

N

O

P

T

L

I

O

Mark the appropriate boxes on the rating plate label to indicate the model type depending on the installation (direct

vent or B-vent).

CERTIFIED UNDER : CSA 2.33A-M98, ANSI Z21.88A-1998 VENTED GAS FIREPLACE HEATER. APPLIANCE MUST BE INSTALLED USING

BURNER

KIT: GDS28BN-KT, OR GDS28BP-KT.

HOMOLOGUE SELON LES NORMES: CSA 2.33A-M98, ANSI Z21.88A-1998 FOYER DE CHAUFFAGE AU GAZ AVEC EVACUA-

TION. CET APPAREIL DOIT ETRE INSTALLE EN UTILISANT UN ENSEMBLE DU BRULEUR: GDS28BN-KT, OU GDS28BP-KT.

0-4500ft (0-1370m)

30,000 BTU/h

18,000 BTU/h

22,500 BTU/h

24,000 BTU/h

CDVS280-N

CS280-N

MANIFOLD PRESSURE: 3.5 INCHES W.C. (NG) / 10 INCHES

W.C.(LP)

PRESSION AU COLLECTEUR: 3.5" D'UNE COLONNE

D'EAU(GN)

MIN SUPPLY PRESSURE: 4.5" W.C.(NG) / 11" W.C. (LP)

PRESSION D'ALIMENTATION MIN: 4.5" D'UNE COLONNE D'EAU

(GN)

MAX. SUPPLY PRESSURE: 7" W.C. (NG) / 13" W.C. (LP)

PRESSION D'ALIMENTATION MAX: 7" D'UNE COLONNE D'EAU

(GN)

FOR USE WITH GLASS DOORS CERTIFIED WITH THIS UNIT

ONLY.

UTILISER AVEC LES PORTES VITREES HOMOLOGUEES

SEULEMENT AVEC CETTE UNITE.

WARNING: DO NOT ADD ANY MATERIAL TO THE APPLIANCE,

WHICH WILL COME IN CONTACT WITH THE FLAMES, OTHER

THAN THAT SUPPLIED BY THE MANUFACTURER WITH THE APPLIANCE.

AVERTISSEMENT: N'AJOUTEZ PAS A CET APPAREIL

AUCUN MATERIAU DEVANT ENTRER EN CONTACT

AVEC LES FLAMMES AUTRE QUE CELUI QUI EST FOURNI

AVEC CET APPAREIL PAR LE FABRICANT.

MINIMUM CLEARANCE TO COMBUSTIBLE MATERIAL /

DEGAGEMENTS MINIMAUX DES MATERIAUX COMBUSTIBLES:

A 7" D 17½"

B 2" E 6¼"

C 1" F 9½"

20" TO CEILING FROM STOVE TOP

20" ENTRE LE DESSUS DU FOYER ET LE PLAFOND

ELECTRICAL RATING / CLASS.: 115V 1.5AMP 60HZ

MODEL CS280/GS28 APPROVED FOR BEDROOM, &

BEDSITTING ROOM INSTALLATION. HOMOLOGUE POUR INSTALLATION DANS UNE CHAMBRE A COUCHER, & UN

STUDIO.

STEADY STATE EFFICIENCY (NG): 80% FAN OFF / 82%

FAN ON

STEADY STATE EFFICIENCY (LP): 80% FAN OFF / 83%

FAN ON

EFFICACITE CONSTANTE (GN): 80% VENT. ARRETE

EFFICACITE CONSTANTE (GP): 80% VENTILATEUR ARRETE

STEADY STATE EFFICIENCY APPLIES TO CANADA ONLY /

L'EFFICACITE CONSTANTE S'APPLIQUENT SEULEMENT AU

CANADA.

AFUE (NG/LP) (GN/GP): 66% / 68%

THIS APPLIANCE MUST BE INSTALLED USING AN ADAPTER

KIT GS-150KT. CET APPAREIL DOIT ETRE INSTALLE EN UTILISANT UN ENSEMBLE ADAPTATEUR GS-150KT.

UN COMBUSTIBLE SOLIDE NE DOIT PAS ETRE UTILISE

#37

10" D'UNE COLONNE D'EAU (PG)

11" D'UNE COLONNE D'EAU (PG)

13" D'UNE COLONNE D'EAU (PG)

82% VENT. FONCTIONNE

83% VENTILATEUR FONCTIONNE

NOT FOR USE WITH SOLID FUEL

AVEC CET APPAREIL

ALTITUDE / ELEVATION

INPUT / ALIMENTATION

REDUCED INPUT / ALIMENTATION REDUITE

OUTPUT (CDVS280/GDS28) RENDEMENT

OUTPUT (CS280/GS28) RENDEMENT

ORIFICE / INJECTEUR

DIRECT VENT MODEL

GDS28-N

GS28-N

‘B’ VENT MODEL

MODEL CDVS280/GDS28 APPROVED FOR BEDROOM, BATHROOM & BEDSITTING ROOM INSTALLATION. SUITABLE FOR

MOBILE HOME INSTALLATION IF INSTALLED IN ACCORDANCE

WITH THE CURRENT STANDARD CAN/CSA Z240MH SERIES

GAS EQUIPPED MOBILE HOMES, IN CANADA OR IN THE

UNITED STATES THE MANUFACTURED HOME

CONTRUCTION AND SAFETY STANDARD, TITLE 24 CFR,

PART 3280. WHEN THIS US STANDARD IS NOT APPLICABLE

USE THE STANDARD FOR FIRE SAFETY CRITERIA FOR MANUFACTURED HOME INSTALLATIONS, SITES AND COMMUNITIES, ANSI / NFPA 501A.

HOMOLOGUE POUR INSTALLATION DANS UNE CHAMBRE A

COUCHER, UNE SALLE DE BAIN ET UN STUDIO. APPROPRIE

POUR INSTALLATION DANS UNE MAISON MOBILE SI SON INSTALLATION CONFORME AUX EXIGENCES DE LA NORME

CAN/CSA Z240MH SERIE DE MAISONS MOBILES EQUIPEES AU

GAZ, EN VIGUEUR AU CANADA OU AUX ETATS-UNIS DE LA

NORME DE SECURITE ET DE CONSTRUCTION DE MAISONS

MANUFACTUREES, TITRE 24 CFR, SECTION 3280. DANS LE

CAS OU CETTE NORME D'ETATS-UNIS NE PEUT ETRE

APPLIQUEE, SE REFERER A LA NORME RELATIVE AU CRITERE

DE MESURES DE SECURITE CONTRE L'INCENDIE POUR LES

INSTALLATIONS DANS LES MAISONS MANUFACTURES, LES

SITES ET LES COMMUNAUTES, ANSI/NFPA 501A

STEADY STATE EFFICIENCY (NG): 75% FAN OFF / 78% FAN ON

STEADY STATE EFFICIENCY (LP): 75% FAN OFF / 79% FAN ON

EFFICACITE CONSTANTE (GN): 75% VENT. ARRETE

EFFICACITE CONSTANTE (GP): 75% VENTILATEUR ARRETE

STEADY STATE EFFICIENCY APPLIES TO CANADA ONLY /

L'EFFICACITE CONSTANTE S'APPLIQUENT SEULEMENT AU

CANADA.

AFUE (NG/LP) (GN/GP): 64% / 65%

MINIMUM AND MAXIMUM HORIZONTAL VENT LENGTHS ARE

25 INCHES AND 20 FEET RESPECTIVELY. LES LONGUEURS

HORIZONTALES MINIMALE ET MAXIMALE SONT 25 POUCES

ET 20 PIEDS RESPECTIVEMENT.

THE APPLIANCE MUST BE VENTED USING THE APPROPRIATE NAPOLEON VENT KITS. SEE OWNERS INSTALLATION

MANUAL FOR VENTING SPECIFICS. PROPER REINSTALLATION AND RESEALING IS NECESSARY AFTER SERVICING THE

VENT-AIR INTAKE SYSTEM.

L'APPAREIL DOIT EVACUER SES GAZ EN UTILISANT

L'ENSEMBLE D'EVACUATION PROPRE A NAPOLEON.

REFERER AU MANUEL D'INSTALLATION DE PROPRIETAIRE

POUR L'EVACUATION PRECISE. IL EST IMPORTANT DE BIEN

REINSTALLER ET RESCELLER L'EVENT APRES AVOIR ASSURE LE MAINTIEN DU SYSTEME DE PRISE D'AIR.

0-4500ft (0-1370m)

26,000 BTU/h

15,000 BTU/h

19,500 BTU/h

20,800 BTU/h

#53

GDS28-P

GS28-P

WOLF STEEL LTD

BARRIE, ONTARIO CANADA

MADE IN CANADA / FABRIQUE AU CANADA

SERIAL NUMBER

NO. DE SERIE

CDVS280-P

CS28-P

.

78% VENT. FONCTIONNE

79% VENTILATEUR FONCTIONNE

GDS28

WS-385-165

Check for gas leaks by brushing on a soap and water solution.

DO NOT USE OPEN FLAME.

For ease of accessibility , an optional remote wall switch

or millivolt thermostat may be installed in a convenient

location. Route a double strand of solid core millivolt

wire from the gas stove to the wall switch / millivolt thermostat. The recommended maximum lead length depends on the wire size: WIRE SIZE

MAX. LENGTH

14 gauge 100 feet

16 gauge 60 feet

18 gauge 40 feet

DIRECT VENT MODEL GDS28: Disconnect the existing wires from terminals 1 and 3 (from the on/off switch)

and replace with the leads from the wall switch/millivolt

thermostat.

B-VENT MODEL GS28: Disconnect the on/off switch wire

from terminal 3 on the valve and the second switch wire

from the terminal block. Replace each connection using

the wires from the wall switch/millivolt thermostat.

W415-0153 / A / 10.29.01

Page 14

14

FINISHING

DOOR CLOSING AND OPENING

When installing the fire viewing door, a simple procedure

must be followed in order to not damage the door. First

open both side doors fully. Insert the pins on the door left

side into the hinge bushings. Swing the door closed and

engage the latches into the catch slots. Push the latch handles backwards to secure the closed door. It may be necessary to lift the door when securing it to ensure that it is in

a horizontal position.

To open the door, repeat in reverse order.

HINGE

PIN

BUSHING

FIGURES 30

CATCH

SLOT

DOOR

LATCH

LOG PLACEMENT INSTRUCTIONS

PHAZERTM logs, glowing embers and charcoal embers ex-

clusive to Napoleon Fireplaces, glow when exposed to direct flame and provide a unique and realistic glowing effect

that is different in every installation. Use only certified

PHAZERTM logs, glowing embers and charcoal embers

available from your Napoleon / Wolf Steel Ltd. dealer.

Positioning the logs improperly will cause flame

impingement and carboning.

Place the back log into the firebox pushing it as close to the

firebox wall as possible and centered onto the log support

pan.

FRONT LOG

STUDS

FIGURES 31

Place the front log on the ember screen lining up the studs

with the holes on the bottom of the log.

3

Set the two crossover logs into the pockets provided on

both the front and rear logs., as shown.

FRONT LOG

RIGHT LOG

4

Tear the glowing embers into pieces and place onto the

screen beneath the front log. Care should be taken to shred

the embers into thin, small irregular pieces as only the

exposed edges of the fibre hairs will glow when exposed

to direct flame; however care should be taken to not block

the burner ports. Blocked ports can cause an incorrect flame

pattern, carbon deposits and delayed ignition.

GLOWING

EMBERS

5

Randomly place the charcoal embers along the front of the

support pan and some onto the screen in a realistic manner. Fine dust found in the bottom of the bag should not

be used. Do not place any embers on the burner.

1

SCREEN

2

W415-0153 / A / 10.29.01

REAR LOG

LEFT LOG

6

CHARCOAL EMBERS

Log colours may vary. During the initial use of the fireplace,

the colours will become more uniform as colour pigments

burn in during the heat activated curing process.

Page 15

OPERATION / MAINTENANCE

15

Purge all gas lines with the glass door open. Assure that a continuous gas flow is at the burner

before closing the door. Allow several minutes

(5-15) for the flame to stabilize after ignition.

MODEL GS28 ONLY: SPILL SWITCH

This is a thermally activated switch, attached to the back

of the chimney adapter, which senses the change in

temperature and shuts down the gas valve in the event

of a severe downdraft of air or a blocked or disconnected

vent. It acts as a safety shutoff to prevent a build up of

carbon monoxide or an explosion of unburnt gases during start up. If the flue is blocked or has no "draw", the spill

switch will automatically shut off the supply of gas within

about 5-10 minutes.

TAMPERING WITH THE SWITCH CAN RESULT IN CARBON MONOXIDE (CO) POISONING AND POSSIBLE

DEATH.

MODEL GS28 ONLY: VENTING ACTION

CHECK

A check for correct venting action must be made

before the installed stove is left with the customer.

Test in the following manner:

1. Close all doors and windows in the room / start

exhaust fans in the home / turn fireplace blower off (if equipped).

2. Set controls to "high" and light

the unit.

3. Wait 5 minutes. Light a match

and extend it 1" into the hole located

above the spill switch bracket on the

adapter.

4. Venting action is satisfactory if

the flame stays lit. Venting action is

unsatisfactory if the flame extinguishes.

5. If venting action is unsatisfactory, turn the unit off,

wait 10 minutes and try again. If the match does not stay

lit, turn the unit off and check for vent blockage or restriction. If necessary, consult with a qualified inspector.

FIGURE 32

OPERATING INSTRUCTIONS

The on-off switch is located on the back of the unit at the top left corner on models GDS28 and GS28.

When lit for the first time, the fir eplace will emit a slight odour for a f ew hours . This is a normal tempor ary condition

caused by the curing of the logs and the "burn-in" of internal paints and lubricants used in the manufacturing

process and will not occur again. Simply open a window to sufficiently ventilate the room. After extended periods

of non-operation such as following a vacation or a warm weather season, the fireplace may emit a slight odour for

a few hours. This is caused by dust particles in the heat exchanger burning of f. Open a window to sufficiently

ventilate the room.

OPERATING INSTRUCTIONS

FOR YOUR SAFETY READ BEFORE OPERATING

WARNING: If you do not follow these instructions ex-

actly , a fir e or explosion may r esult causing property

damage, personal injury or loss of life.

A. This fireplace is equipped with a pilot which must be

lit by hand while following these instructions exactly.

B. Before operating smell all around the fireplace area

for gas and next to the floor because some gas is

heavier than air and will settle on the floor.

C. Use only your hand to turn the gas control knob / manual

shutoff knob. Never use tools. If the knob will not turn by

hand, do not try to repair it. Call a qualified service technician. Force or attempted repair may result in a fire or

explosion.

D. Do not use this fireplace if any part has been under

water. Immediately call a qualified service technician to

inspect the fireplace and replace any part of the control

system and any gas control which has been under water.

WHAT T O DO IF YOU SMELL GAS:

• Turn off all gas to the fireplace.

• Open windows.

• Do not try to light any appliance.

• Do not touch any electric switch; do not use any phone

in your building.

• Immediately call your gas supplier from a neighbour's

phone. Follow the gas supplier's instructions.

• If you cannot reach your gas supplier, call the fire department.

W415-0153 / A / 10.29.01

Page 16

16

LIGHTING INSTRUCTIONS

WARNING:WARNING:

WARNING: The gas valve has an interlock device which will not allow the pilot burner to be lit until the thermo-

WARNING:WARNING:

couple has cooled. Allow approximately 60 seconds for the thermocouple to cool.

When lighting and relighting, the gas knob cannot be turner from PILOT to OFF unless the knob is depressed.

1. STOP! Read the safety information on the operating

label.

2. Turn off all electric power to the fireplace.

3. Turn the gas knob clockwise

to off.

4. Wait five (5) minutes to clear out any gas. If you smell

gas including near the floor, STOP! Follow "B" on the operating label. If you don't smell gas go to the next step.

5. Find pilot located in front of the back log.

O

F

F

N

O

P

T

L

I

O

GAS KNOB AT OFF

L

O

I

H

P

I

L

T

O

THERMOPILE

PILOT

BURNER

THERMOCOUPLE

6. Turn gas knob counter-clockwise

7. Depress and hold the gas knob while lighting the pilot

with the push button igniter. Keep knob fully depressed

for one minute, then release. If the pilot does not continue to burn, repeat steps 3 through 6.

8. With the pilot lit, turn the gas knob counter-clockwise

to on.

9. If equipped with a remote ON-OFF switch, main burner

may not come on when you turn the valve to ON. The

remote switch must be in the ON position to ignite the

burner.

10. Turn on all electric power to the fireplace.

to pilot.

TO TURN OFF GAS

1. Turn off all electric power to the fireplace if service is to

be performed.

2. Push in gas control knob slightly and turn clockwise to off. Do not force.

MAINTENANCE INSTRUCTIONS

Turn off the gas and unplug electrical

power before servicing the stove!

CAUTION: Label all wires prior to disconnection when servicing controls. Wiring errors can cause improper and dangerous operation. Verify proper operation after servicing.

This stove and its venting system should be inspected

before use and at least annually by a qualified service person. The fireplace area must be kept clear and free of combustible materials, gasoline or other flammable vapours

and liquids. The flow of combustion and ventilation air must

not be obstructed.

1. In order to properly clean the burner and pilot assem-

bly, remove the logs exposing both assemblies.

2. Keep the control compartment, logs, burner, air shutter opening and the area surrounding the logs clean by

vacuuming or brushing, at least once a year.

3. Check to see that all burner ports are burning. Clean

out any of the ports which may not be burning or are not

burning properly.

4. Check to see that the pilot flames are large enough to

engulf the thermocouple and the thermopile on one leg

and reaches toward the burner on the other leg.

5. Replace the cleaned logs.

6. Check to see that the main burner ignites completely

on all openings when the gas knob for the burner is turned

on. A 5-10 second total light-up period is satisfactory. If

ignition takes longer, consult your Napoleon dealer/distributor.

7. Check that the door gasketing is not broken or missing. Replace if necessary.

8. Lift the door from its hinges to clean hinge pins and

lubricate using high-temp dry graphite if necessary. Replace.

NOTE:

Due to the high temperatures that the hinges experience, wet lubricants such as oil and WD40 will cause

the hinge to seize and are ther efor e not suitable.

W415-0153 / A / 10.29.01

Page 17

REPLACEMENT BLOWER

17

Blower replacement may be done through either the

firebox or from the rear of the unit. Using the rear panel

is recommended.

1. Turn off the electrical power and the gas supply to the

stove.

FIGURE 33

INSTALLATION THROUGH THE REAR

PANEL:

FOR MODEL GDS28

2. Remove the two combustion air covers and gaskets

held on with 4 screws each. Remove the rear panel held

in place with 6 screws.

3. Remove the 2 screws holding the blower to its mounting plate. Disconnect the two blower wires.

4. Replace the blower and reconnect the two wires. When

replacing the rear panel, ensure that the wires are neither

pinched nor interfere with the blower operation. Ensure

that the combustion air cover plates and gaskets are properly installed and sealed.

FOR MODEL GS28

2. Remove the 8 screws securing the air intake manifolds

to the rear panel. Remove the rear panel held in place with

6 screws.

3. Remove the 2 screws holding the blower to its mounting plate. Disconnect the two blower wires.

4. Replace the blower and reconnect the two wires. When

replacing the rear panel, ensure that the wires are neither

pinched nor interfere with the blower operation. Re-secure the air intake manifolds.

INSTALLATION THROUGH THE FIREBOX:

Replacement blower access gasket is required.

2. Open the lower control door, the two side doors, and the

fire viewing door. Remove the logs.

3. Remove the blower access plate held on with 6 screws.

4. Disconnect the two blower wires. Remove the blower

bracket held on with 2 screws.

5. Replace the blower using the existing bracket. Replace

the bracket/blower assembly on the unit.

6. Reconnect the two wires. Hold the replacement gasket

in place and reattach the blower access plate. Replace the

logs. Close all doors.

FIGURE 35 - INSTALLATION FROM THE FRONT

Turn the gas supply and electricity back on.

Because the blower is thermally activated, when turned

on, it will automatically start approximately 15-30 minutes after lighting the stove and will run for approximately

30-45 minutes after the stove has been turned off. Use

of the fan increases the output of heat.

Drywall dust will penetrate into the blower bearings causing irreparable damage and must be prevented from

coming into contact with the blower or its compartment.

Any damage resulting from this condition is not covered by the warranty policy .

SCREWS

BLOWER

AIR INTAKE MANIFOLDS

FIGURE 34 - INSTALLA TION FROM THE REAR

W415-0153 / A / 10.29.01

Page 18

18

ADJUSTMENTS

INLET PRESSURE

TAP

MANIFOLD TAP

L

O

F

O

I

H

P

I

L

T

O

F

N

O

P

T

L

I

O

FIGURE 36

PILOT SCREW

PILOT BURNER ADJUSTMENT

Adjust the pilot screw to provide properly sized flame. Turn

in a clockwise direction to reduce the gas flow.

THERMOPILE

THERMO-

FLAME MUST ENVELOP

COUPLE

UPPER 3/8" TO 1/2" OF

THERMOCOUPLE &

THERMOPILE

FIGURE 37

VENTURI ADJUSTMENT

Remove the 2 screws securing the control panel plate. To

access the venturi, remove the air housing cover plate, held

on with 2 screws. Take care not to damage the gasket.

Natural gas and propane models have air shutters set fully

open. Closing the air shutter will cause a more yellow flame,

but can lead to carboning. The flame may not appear yellow immediately; allow 15 to 30 minutes for the final flame

colour to be established. After making adjustments replace the gasket and cover plate. Re-secure the control

panel plate.

CONTROL PANEL PLATE

FIGURE 38 a

AIR HOUSING

COVER PLA TE

W415-0153 / A / 10.29.01

FIGURE 38 b

FIGURE 39

Air shutter adjustment must only be

done by a qualified gas installer!

Page 19

REPLACEMENTS

ORDERING REPLACEMENT PARTS

Contact your dealer or the factory for questions concerning prices and policies on replacement parts. Normally all parts

can be ordered through your Napoleon dealer or distributor. When ordering replacement parts always give the following

information: 1. M ODEL & SERIAL NUMBER OF FIREPLACE 3. PART NUMBER 5. FINISH

2. INSTALLATION DATE OF FIREPLACE 4. DESCRIPTION OF PART

REPLACEMENT PARTS

For warranty replacement parts, a photocopy of the original invoice

will be required to honour the claim.

GDS28 / GS28 TERMINATION KITS ALL KIT

ITEMS MAY BE PURCHASED SEPARATELY

PART # DESCRIPTION

GD175 - WALL TERMINAL KIT

BM6790 90° ELBOW - 7" DIAMETER

GD222 TERMINAL ASSEMBLY

BM67ADJ 30" TO 53" ADJUSTABLE PIPE - 7" DIA

W500-0077 FIRESTOP / WALL PLA TE

W020-0032 HARDWARE

BRTC7 BRASS TRIM COLLAR

BM6724 24" STOVE PIPE - 7" DIAMETER

W010-0300 10' ALUMINIUM FLEX LINER C/W SPACERS - 4" DIA

W025-0001 DECORATIVE BRASS BAND

GD180 - PERISCOPE TERMINAL KIT

BM6790 90° ELBOW - 7" DIAMETER

GD201 PERISCOPE

BM67ADJ 30" TO 53" ADJUSTABLE PIPE - 7" DIA

W500-0077 FIRESTOP / WALL PLA TE

W020-0032 HARDWARE

BRTC7 BRASS TRIM COLLAR

BM6724 24" STOVE PIPE - 7" DIAMETER

W010-0300 10' ALUMINIUM FLEX LINER C/W SPACERS - 4" DIA

W025-0001 DECORATIVE BRASS BAND

GD110 - ROOF TERMINAL KIT - 1/12 TO 7/12 PITCH

W010-0569 AIR TERMINAL

W120-0036 VERTICAL CAP

W010-0567 ROOF SUPPORT

W170-0063 STORM COLLAR

W263-0054 ROOF FLASHING

GD111 - ROOF TERMINAL KIT - 8/12 TO 12/12 PITCH

W010-0569 AIR TERMINAL

W120-0036 VERTICAL CAP

W010-0567 ROOF SUPPORT

W170-0063 STORM COLLAR

W263-0055 ROOF FLASHING

GD112 - ROOF TERMINAL KIT - FLAT ROOF

W010-0569 AIR TERMINAL

W010-0567 ROOF SUPPORT

W120-0036 VERTICAL CAP

W263-0056 ROOF FLASHING

W170-0063 STORM COLLAR

19

included with GD175

included

with

GD180

W415-0153 / A / 10.29.01

Page 20

20

PART # DESCRIPTION

W100-056

REPLACEMENT PARTS:

GDS28/GS28

W725-0035 SIT VALVE - NG

W725-0034 SIT VALVE - LP

W100-0056 BURNER

W455-0026 #38 BURNER ORIFICE - NG

W455-0003 #54 BURNER ORIFICE - LP

W010-0575 PILOT ASSEMBLY - LP

W010-0636 PILOT ASSEMBLY - NG

W455-0052 PILOT ORIFICE - LP

W455-0053 PILOT ORIFICE - NG

W680-0008 THERMOCOUPLE

W680-0004 THERMOPILE

W290-0029 PILOT GASKET

W010-0865 EMBER SCREEN ASSEMBLY

W357-0001 PIEZO IGNITER

W425-0235 CONTROL PANEL

GL-620 4pc LOG ASSEMBLY C/W EMBERS

W135-0058 FRONT LOG

W135-0059 BACK LOG

W135-0060 LEFT LOG

W135-0061 RIGHT LOG

W361-0016 GLOWING EMBERS

W550-0001 CHARCOAL EMBERS

W573-0008 HIGH TEMPERATURE SEALANT

W715-0195 PEDESTAL TRIM

W290-0043 BURNER GASKET

W385-0045 NAPOLEON LOGO

W290-0045 BLOWER ACCESS GASKET

W430-0002 MAGNETIC CLOSURE

W390-0002 LATCH

W660-0009 ON/OFF SWITCH

W690-0002 THERMODISC

W380-0002 VARIABLE SPEED SWITCH KNOB

WKB-13 VARIABLE SPEED SWITCH

GZ-552 REPLACEMENT BLOWER

W030-0022 ACCENT BAR

W200-0077 BLACK TRIVET

W455-0026

W455-0003

P

I

L

T

O

W725-0035

W725-0034

GS328-K

GS328-G

W010-0865

L

O

O

F

I

F

H

N

O

P

T

L

I

O

W425-0235

W390-0002

W200-0077

GS200-G

GS28

W010-0459 ADAPTOR C/W SPILL SWITCH

W660-0006 SPILL SWITCH

ACCESSORIES / OPTIONS

GDS28 / GS28:

W690-0001 MILLIVOL T THERMOSTA T

W690-0002 HAND-HELD REMOTE

W690-0010 REMOTE CONTROL - ADVANTAGE

W690-0011 REMOTE CONTROL - ADVANTAGE PLUS

GS328-K BLACK DOOR KIT

GS328-G GOLD DOOR KIT

W300-0038 FRONT WINDOW GLASS

W300-0037 SIDE WINDOW GLASS

W562-0022 GLASS GASKET

GS200-G GOLD TRIVET

GS14R-KT RED ENAMELLED EURO KIT

GS14F-KT GREEN ENAMELLED EURO KIT

GS14S-KT ALMOND ENAMELLED EURO KIT

GS14K-KT BLACK ENAMELLED EURO KIT

GS14-KT METALLIC BLACK EURO KIT

GS14SS-KT STAINLESS STEEL EURO KIT

W175-0124 CONVERSION KIT - NG TO LP

GDS28:

BM6745 45° ELBOW

GD-301 HEAT GUARD

W175-0001 4" COUPLER

GD-303 VINYL SIDING SHIELD

GD-201 PERISCOPE

GS28:

GS-150KT ADAPTOR KIT

W025-0001 DECORA TIVE BRASS BAND

W415-0153 / A / 10.29.01

W430-0002

W135-0059

W135-0061

W135-0060

W135-0058

GZ-552

W361-0016

W550-0001

Page 21

TROUBLE SHOOTING GUIDE

BEFORE ATTEMPTING TO TROUBLESHOOT, PURGE YOUR UNIT AND INITIALLY LIGHT THE PILOT AND THE MAIN BURNER WITH THE GLASS DOOR REMOVED.

PROBLEM TEST SOLUTIONSYMPTOM

21

Pilot will not light.

THERMOPILE

Pilot goes out when

the gas knob is released.

PILOT

BURNER

ELECTRODE

THERMOCOUPLE

No spark at pilot burner

Spark gap is incorrect

No gas at the pilot burner

Out of propane gas.

System is not correctly purged.

Out of propane gas

Pilot flame is not large enough

Pilot flame is not engulfing the

thermocouple.

Thermocouple shorting.

- check if pilot can be lit by a match

- check that the wire is connected to the push button ignitor.

- check if the push button ignitor needs tightening.

- replace the wire if the wire insulation is broken or frayed.

-

replace the electrode if the ceramic insulator is cracked or broken.

- replace the push button ignitor.

- spark gap should be 0.150" to 0.175" (5/32" to 1 1/64" approx.)

from the electrode tip and the pilot burner. To ensure proper

electrode location, tighten securing nut (finger tight plus 1/4

turn).

- check that the manual valve is turned on.

- check the pilot orifice for blockage.

- replace the valve.

- call the gas distributor.

- fill the tank.

- purge the gas line with the glass door open.

- fill the tank.

- turn up the pilot flame.

- turn up pilot flame.

- replace pilot assembly.

- loosen and tighten thermocouple.

- clean thermocouple and valve connection.

- replace thermocouple.

- replace valve.

Pilot burning; no gas

to main burner; gas

knob is on 'HI'; wall

switch / thermostat is

on.

Pilot goes out while

standing; Main burner

is in 'OFF' position.

Main burner goes out;

pilot stays on.

Faultly thermocouple.

Faulty valve.

Main burner orifice is plugged.

Faulty thermopile.

Faulty themostat or switch.

Faulty valve.

Gas piping is undersized.

Pilot flame is not large enough

or not engulfing the thermopile.

Thermopile shorting

Remote wall switch wire is too

long, too much resistance in

the system

Faulty thermostat or switch - replace

MODEL GS28 ONL Y:

Venting is spilling

- replace.

- replace.

- remove stoppage in orifice.

- replace.

- connect a jumper wire across the wall switch terminals; if

main burner lights, replace thermostat.

- disconnect the switch wires & connect a jumper wire across

terminals 1 & 3; if the main burner lights, check the wires for

defects and / or replace wires.

- replace.

- turn on all gas appliances and see if pilot flame flutters,

diminishes or extinguishes, especially when main burner ignites. Monitor supply pressure.

- check if supply piping size is to code. Correct all undersized

piping.

- turn up pilot flame.

- replace pilot assembly.

- clean thermopile and thermopile connection to valve.

- shorten wire to correct length or wire gauge.

- test with spill switch bypassed. Replace if defective.

- check for vent blockage.

W415-0153 / A / 10.29.01

Page 22

22

Main burner goes out;

pilot goes out.

PROBLEM TEST SOLUTIONSYMPTOM

REFER TO "MAIN BURNER GOES OUT ; PILOT ST A YS ON"

Vent re-circulating

(MODEL GDS28 ONL Y)

Thermocouple shorting or

faulty.

- check joint seals and installation.

- loosen and tighten thermocouple

- clean thermocouple and valve connection.

- replace thermocouple.

- replace valve.

Exhaust fumes

smelled in room,

headaches.

Carbon is being deposited on glass,

logs or combustion

chamber surfaces.

Door sticking.

MODEL GDS28 ONLY :

Main burner flame is

a blue, lazy , transparent flame.

Fireplace is spilling.

Air shutter has become

blocked

Flame is impinging on the

logs or combustion chamber.

Dirt / dust adheres to the

hinges; is heated and burns

causing sticking.

Blockage in vent. - remove blockage. In really cold conditions, ice buildup may

Incorrect installation.

- check all seals.

- ensure air shutter opening is free of lint or other obstructions.

- check that the logs are correctly positioned.

- open air shutter to increase the primary air.

- check the input rate: check the manifold pressure and orifice

size as specified by the rating plate values.

- check that the door gasketing is not broken or missing and

that the seal is tight.

- check that both vent liners are free of holes and well sealed at

all joints.

- check that minimum rise per foot has been adhered to for any

horizontal venting.

- when heating with propane, ensure that the screen frame is

secured as far to the back of the fireplace as possible.

- lift door from its hinges. Lubricate with high-temp dry graph-

ite only. Replace.

NOTE: Due to the high temperatures that the hinges experience, wet lubricants such as oil and WD40 will cause the hinge

to seize and are therefore not suitable.

occur on the terminal and should be removed as required.

- refer to Figure 20 to ensure correct location of storm collars

White / grey film

forms.

W415-0153 / A / 10.29.01

Sulphur from fuel is being deposited on glass, logs or combustion chamber surfaces.

- clean the glass with a recommended gas fireplace glass

cleaner. DO NOT CLEAN GLASS WHEN HOT.

If deposits are not cleaned off regularly, the glass may become permanently marked.

Page 23

Wolf Steel Fireplace Service Histor y

This fireplace must be serviced annually depending on usage.

Date

Service T echnician