Page 1

ONLY QUALIFIED SERVICE TECHNICIANS SHOULD SERVICE AND REPAIR THIS APPLIANCE

SERVICE MANUAL

CERTIFIED UNDER CANADIAN AND AMERICAN NATIONAL STANDARDS: CSA C22.2 No-46 / UL 2021

ALLURE / ALLURE PHANTOM

ELECTRIC FIREPLACE

ENGLISH

SAFETY INFORMATION

WARNING

!

If the information in these instructions

are not followed exactly, fi re or electrical

shock may result causing property

damage, personal injury or loss of life.

Do not store or use gasoline or other fl ammable

vapors and liquids in the vicinity of this or any

other appliance.

Wolf Steel Ltd., 24 Napoleon Rd., Barrie, ON, L4M 0G8 Canada / 103 Miller Drive, Crittenden, Kentucky, USA, 41030

Phone (705)721-1212 • Fax (705)722-6031 • www.napoleonfi replaces.com • hearth@napoleonproducts.com

$10.00

ALLURE

NEFL32FH, NEFL42FH, NEFL50FH,

NEFL60FH, NEFL72FH, NEFL100FH

ALLURE PHANTOM

NEFL42FH-MT, NEFL50FH-MT, NEFL60FH-MT

W415-1698 / 12.20.16

Page 2

TABLE OF CONTENTS

1.0 OPERATING INSTRUCTIONS 3

1.1 OPERATING TOUCH DISPLAY PANEL AND REMOTE CONTROL 3

2.0 REPLACEMENT PARTS 4

3.0 WIRING DIAGRAM 6

4.0 TROUBLESHOOTING 9

4.1 FLAME LED TESTING 10

4.1.1 LED TESTING 10

4.1.2 MOTOR TESTING 12

4.2 HEATER/BLOWER TESTING 14

4.2.1 BLOWER TESTING 14

4.2.2 HEATER TESTING 16

4.3 HIGH LIMIT SWITCH TESTING 18

5.0 SERVICE PREPARATION 20

6.0 REPLACING COMPONENTS 24

6.1 MOTOR AND ROTISSERIE REPLACEMENT 24

6.2 CONTROL BOARD REPLACEMENT 24

6.3 CONTROL PANEL REPLACEMENT 25

6.4 LED REPLACEMENT 25

6.5 REMOTE RECEIVER / THERMOSTAT REPLACEMENT 26

6.6 HEATER, BLOWER, AND HIGH LIMIT SWITCH ASSEMBLY REPLACEMENT 27

6.7 WIRE HARNESS REPLACEMENT 28

6.8 REMOTE BATTERY INSTALLATION 28

7.0 NOTES 29

NOTE: Changes, other than editorial, are denoted by a vertical line in the margin.

EN

W415-1698 / 12.20.16

Batteries must be disposed of according to the local laws and regulations. Some batteries may be

recycled, and may be accepted for disposal at your local recycling center. Check with your municipality

for recycling instructions.

2

Page 3

1.0 OPERATING INSTRUCTIONS

!

WARNING

WHILE THE APPLIANCE IS OPERATING DO NOT REMOVE THE GLASS PANEL. THIS WILL CAUSE

THE REMOTE CONTROL AND TOUCH PANEL TO DISFUNCTION.

Once the appliance has been plugged into a grounded electrical outlet, it is ready to operate.

NOTE: Ensure the house circuit breakers for the power supply are turned on. In the event of a power

failure, the appliance will lose its memory function and will reset to factory mode when the power

returns.

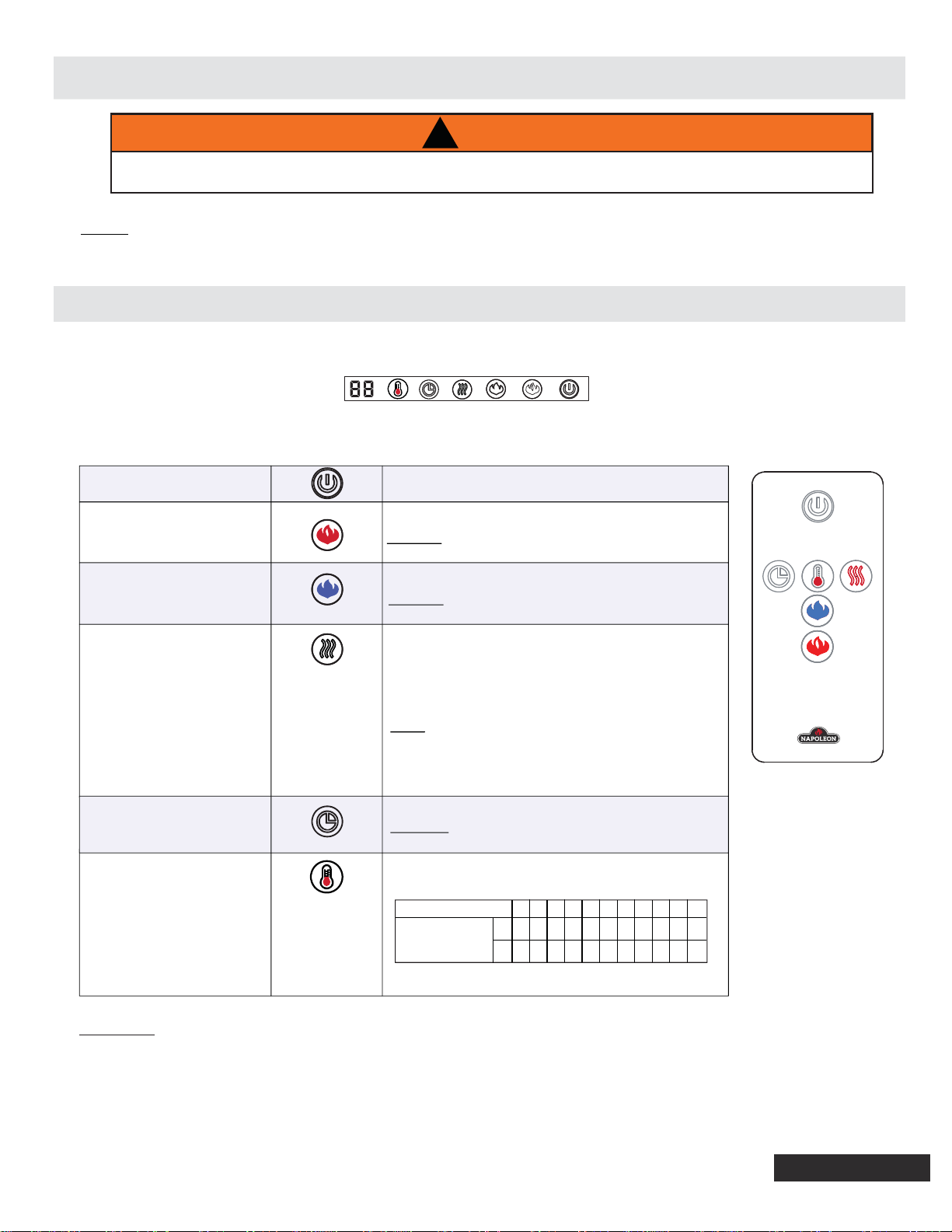

1.1 OPERATING TOUCH DISPLAY PANEL AND REMOTE CONTROL

The main power button is located on the front bottom right side of the appliance.

The touch display panel is shown by LED's on the front bottom right of the appliance. The LED's will

disappear after 10 seconds of no function change. The Main Power button will be dim.

POWER

FLAME - ORANGE

FLAME - BLUE

HEATER

TIMER

TEMPERATURE

Turns the appliance ON/OFF.

Controls Orange Flame brightness.

6 Settings: ( F5-F4-F3-F2-F1-F0 ) Flame dims from F5 to F1.

F5 is the brightest setting and F0 is off.

Controls Blue Flame brightness.

6 Settings: ( F5-F4-F3-F2-F1-F0 ) Flame dims from F5 to F1.

F5 is the brightest setting and F0 is off..

Controls the Heater.

Press button to initiate the heater.

(H0) no heater or blower.

(BL) blower only.

(H1), heater blows warm air (750W)

(H2), heater blows hot air (1500W)

NOTE: Heater functions cycle from H0-BL-H1-H2, Press

and hold the heater button for 5s, the heater and

temperature setting will be locked onto the selected

setting. Hold the button for 5s again, the heater will be

unlocked.

Controls the Timer.

9 Settings: (0.5h, 1h, 2h, 3h, 4h, 5h, 6h, 7h, 8h) Press button

until reach desired setting.

1. Press once: Touch panel indicator becomes active.

2. Press again until desired setting is reached. Digital display

shows setting circles as below.

Display Value

Temperature

NOTE: Press the button for 5 seconds, the temperature

setting will switch from °C to °F. Same way from °F to °C.

0123456789N

°

C

18 19

20 21 22 23 24 25 26 27

64 66

°

F

68 70 72 74 76 78 80 82

ON

ON

WARNING: Do not move or remove the front panel, when the appliance is plugged in and operating.

This will cause the remote control and touch panel to no longer function.

EN

3

W415-1698 / 12.20.16

Page 4

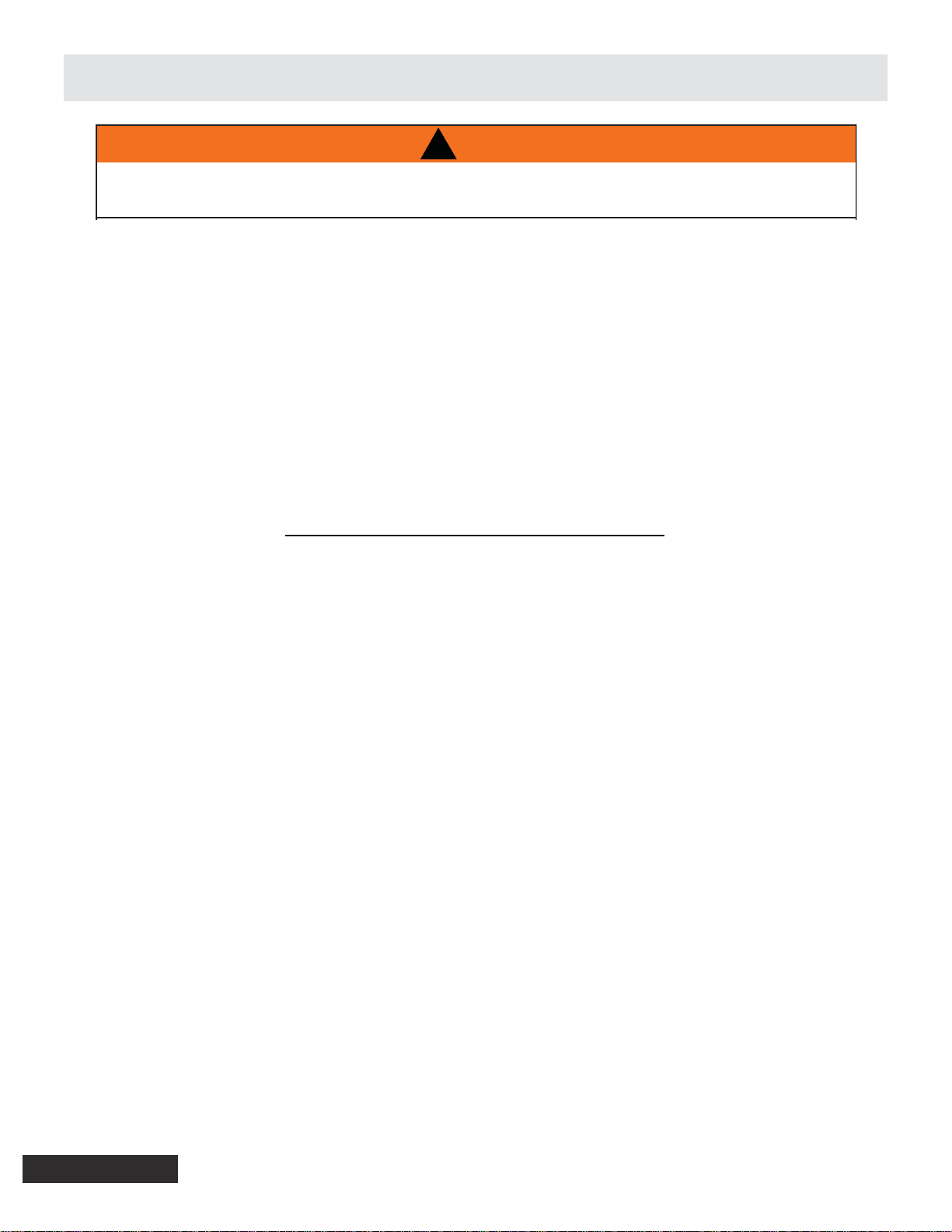

2.0 REPLACEMENT PARTS

!

WARNING

FAILURE TO POSITION THE PARTS IN ACCORDANCE WITH THIS MANUAL OR FAILURE TO USE

ONLY PARTS SPECIFICALLY APPROVED WITH THIS APPLIANCE MAY RESULT IN PROPERTY

DAMAGE OR PERSONAL INJURY.

Contact your dealer for questions concerning prices and policies on replacement parts. Normally, all parts

can be ordered through your Authorized dealer / distributor.

FOR WARRANTY REPLACEMENT PARTS, A PHOTOCOPY OF THE ORIGINAL INVOICE WILL BE

REQUIRED TO HONOUR THE CLAIM.

When ordering replacement parts always give the following information:

• Model & Serial Number of appliance

• Installation date of appliance

• Part number

• Description of part

• Finish

PARTS, PART NUMBERS AND AVAILABILITY ARE SUBJECT TO CHANGE WITHOUT NOTICE.

PARTS IDENTIFIED AS STOCKED WILL BE DELIVERED WITHIN 2 TO 5 BUSINESS DAYS FOR MOST

DELIVERY DESTINATIONS.

PARTS NOT IDENTIFIED AS STOCKED WILL BE DELIVERED WITHIN A 2 TO 4 WEEK PERIOD, FOR

MOST CASES.

PARTS IDENTIFIED AS ‘SO’ ARE SPECIAL ORDER AND CAN TAKE UP TO 90 DAYS FOR DELIVERY.

41.1C

For after sales service, please call 1-888-721-8324

EN

W415-1698 / 12.20.16

4

Page 5

1

2

3

4

5

6

7

9

8 10 12

11

13

14 15

NEFL32FH / NEFL42FH / NEFL50FH / NEFL60FH / NEFL72FH / NEFL100FH

REF. NEFL32FH NEFL42FH NEFL50FH NEFL60FH NEFL72FH NEFL100FH DESCRIPTION

1 W300-0226 W300-0224 W300-0227 W300-0228 W300-0229 W300-0230 FRONT GLASS

2 W475-1192 W475-1185 W475-1193 W475-1194 W475-1195 W475-1196 ACRYLIC PLASTIC PANEL

3 W405-0033 W405-0033 W405-0033 W405-0037 W405-0037 W405-0037 LED LIGHT

4 W497-0014 W497-0013 W497-0015 W497-0016 W497-0017 W497-0018 PLASTIC STRIP

5 W080-1616 W080-1616 W080-1616 W080-1616 W080-1616 W080-1621 WALL MOUNTING BRACKET

6 W200-0571 W200-0572 W200-0572 W200-0572 W200-0572 W200-0572 CORD COVER

7 W527-0009 W527-0008 W527-0010 W527-0011 W527-0012 W527-0013 REFLECTOR SPINDLE

8 W435-0077 W435-0077 W435-0077 W435-0077 W435-0077 W435-0077 SYNCHRONUS MOTOR

9 W010-3728 W010-3728 W010-3728 W010-3728 W010-3728 W010-3728 BLOWER AND HEATER ASSEMBLY

10 W190-0095 W190-0095 W190-0095 W190-0095 W190-0095 W190-0095 REMOTE CONTROL

11 W190-0096 W190-0096 W190-0096 W190-0101 W190-0101 W190-0101 CIRCUIT BOARD

12 W497-0019 W497-0020 W497-0021 W497-0022 W497-0023 W497-0024 CRYSTAL

13 W370-0050 W370-0050 W370-0050 W370-0055 W370-0055 W370-0057 HARDWARE KIT

14 W475-1184 W475-1184 W475-1184 W475-1184 W475-1184 W475-1184 CONTROL PANEL (WITH REMOTE RECEIVER)

15 W750-0370 W750-0371 W750-0372 W750-0373 W750-0374 W750-0375 WIRE HARNESS

16 W690-0021 W690-0021 W690-0021 W690-0021 W690-0021 W690-0021 THERMOSTAT

16

NEFL42FH-MT / NEFL50FH-MT / NEFL60FH-MT

REF. NEFL42FH-MT NEFL50FH-MT NEFL60FH-MT DESCRIPTION

1 W300-0224 W300-0227 W300-0228 FRONT GLASS

2 W475-1185 W475-1193 W475-1194 ACRYLIC PLASTIC PANEL

3 W405-0033 W405-0033 W405-0037 LED LIGHT

4 W497-0013 W497-0015 W497-0016 PLASTIC STRIP

5 W080-1616 W080-1616 W080-1616 WALL MOUNTING BRACKET

6 W200-0572 W200-0572 W200-0572 CORD COVER

7 W527-0008 W527-0010 W527-0011 REFLECTOR SPINDLE

8 W435-0077 W435-0077 W435-0077 SYNCHRONUS MOTOR

9 W010-3728

10 W190-0095 W190-0095 W190-0095 REMOTE CONTROL

11 W190-0096 W190-0096 W190-0101 CIRCUIT BOARD

12 W497-0020 W497-0021 W497-0022 CRYSTAL

13 W370-0050 W370-0050 W370-0055 HARDWARE KIT

14 W475-1184 W475-1184 W475-1184 CONTROL PANEL (WITH REMOTE RECEIVER)

15 W750-0371 W750-0372 W750-0373 WIRE HARNESS

16 W690-0021 W690-0021 W690-0021 THERMOSTAT

W010-3728 W010-3728 BLOWER AND HEATER ASSEMBLY

NOTE: Care must be taken when removing and disposing of any broken glass or damaged

components. Ensure to vacuum up any broken glass from inside the appliance before operation.

5

EN

W415-1698 / 12.20.16

Page 6

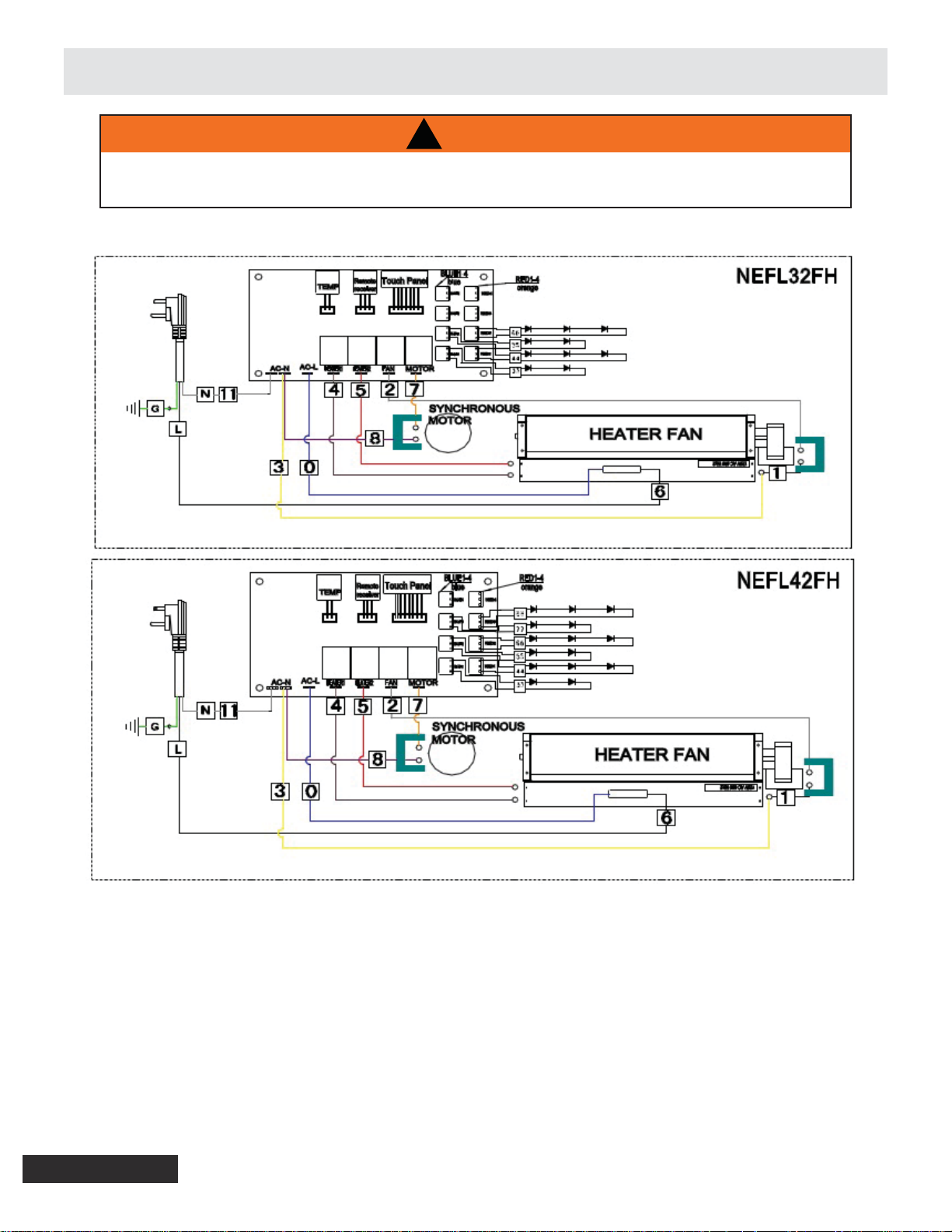

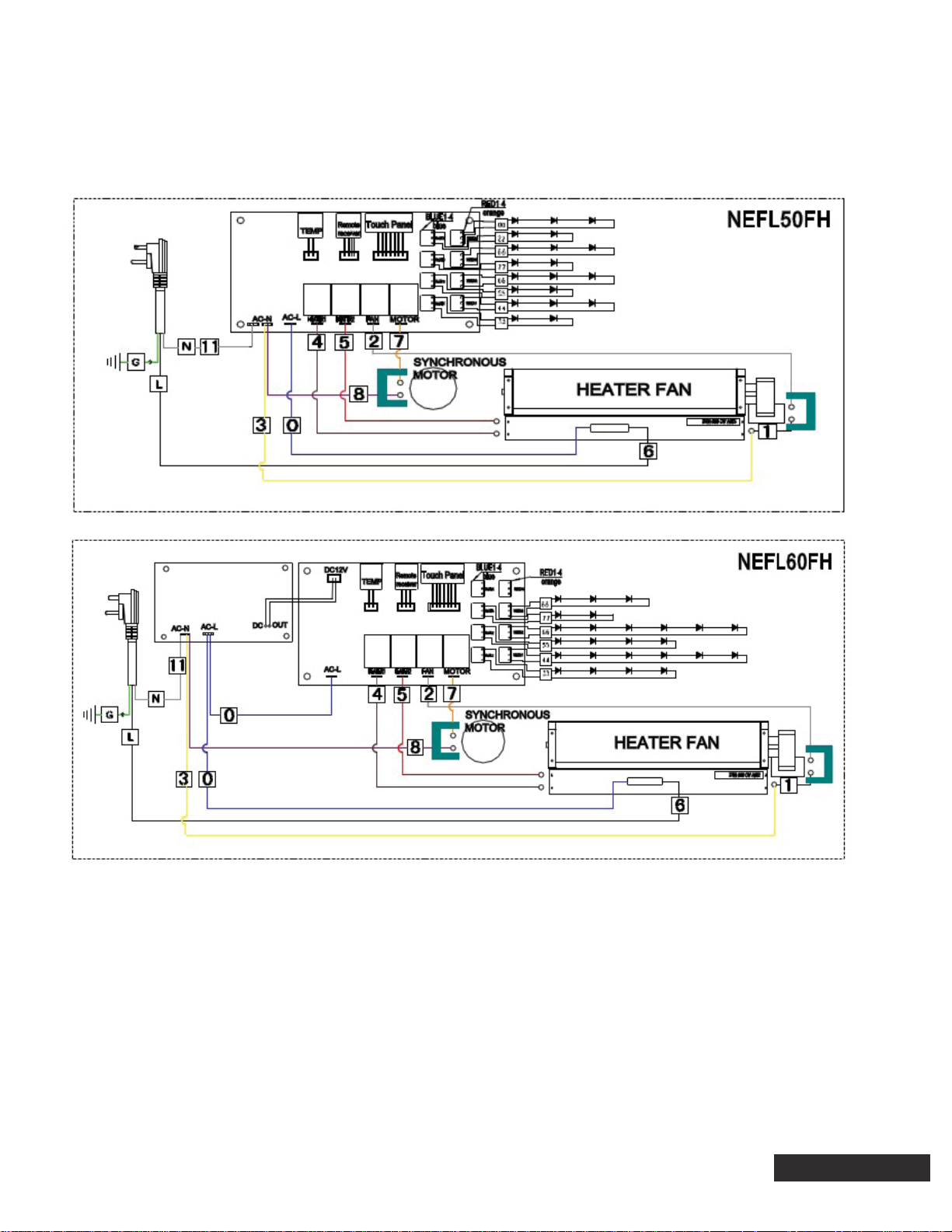

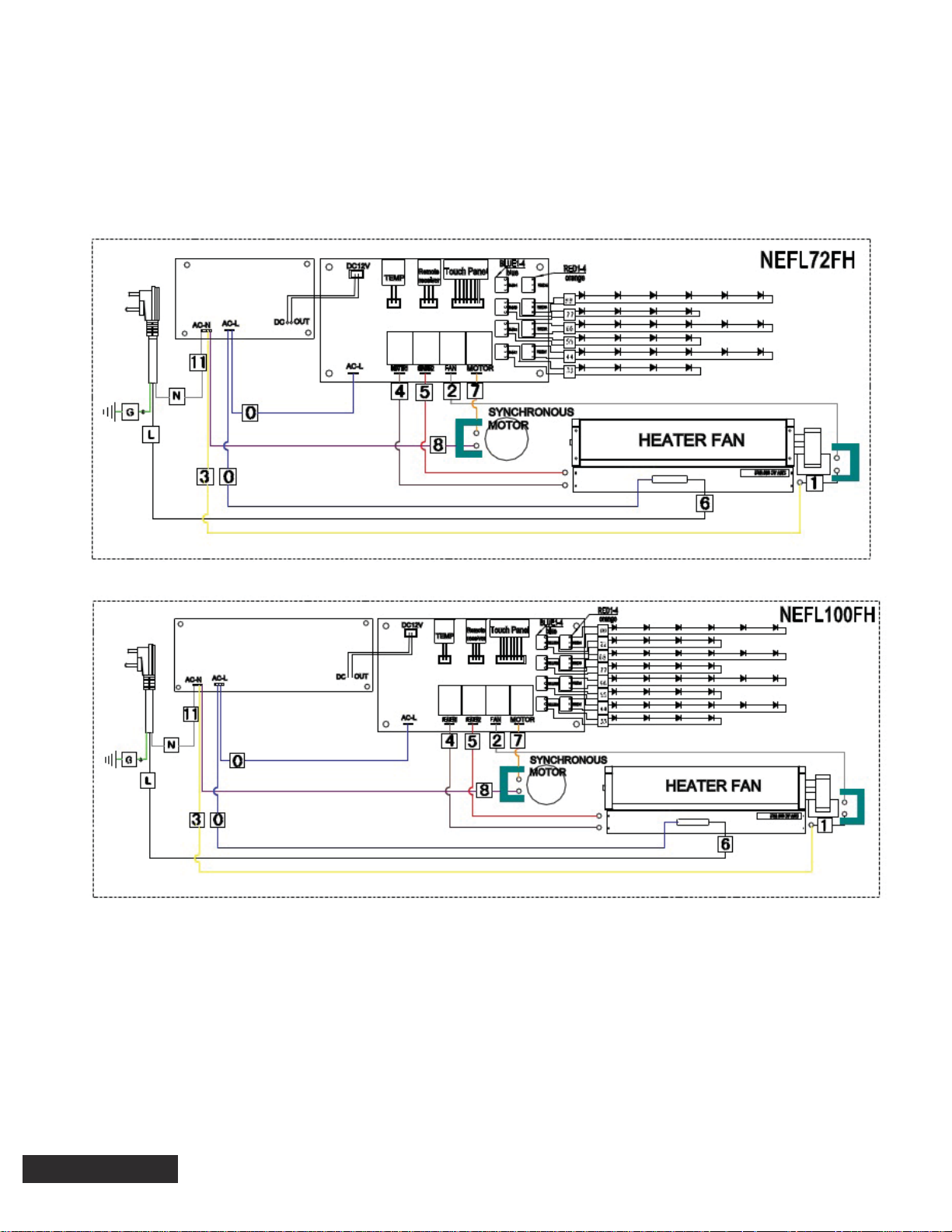

3.0 WIRING DIAGRAM

!

WARNING

TURN OFF THE APPLIANCE COMPLETELY AND LET COOL BEFORE SERVICING. ONLY A QUALIFIED

SERVICE PERSON SHOULD SERVICE AND REPAIR THIS ELECTRIC APPLIANCE.

EN

W415-1698 / 12.20.16

6

Page 7

EN

7

W415-1698 / 12.20.16

Page 8

EN

W415-1698 / 12.20.16

8

Page 9

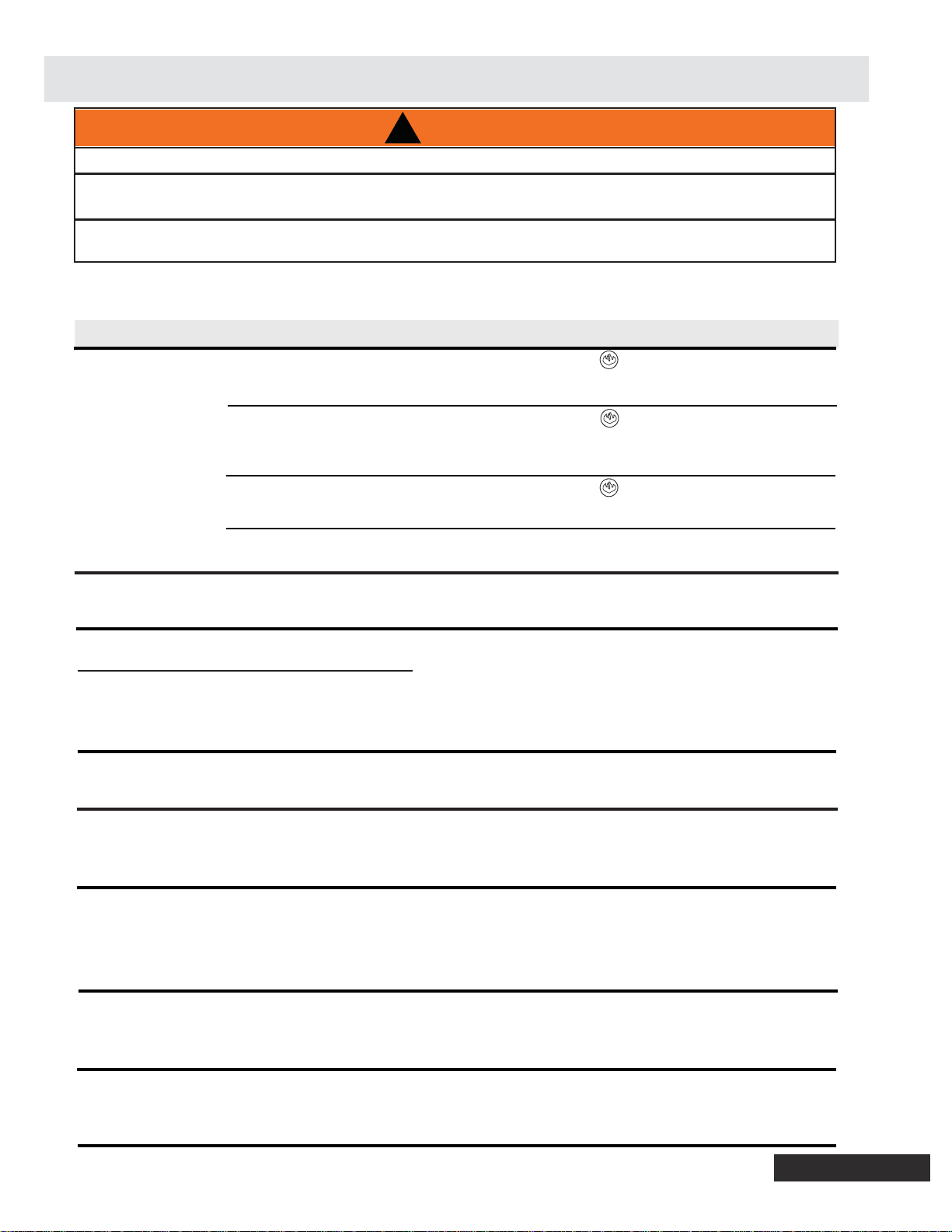

4.0 TROUBLESHOOTING

!

WARNING

TURN OFF THE APPLIANCE COMPLETELY AND LET THE APPLIANCE COOL DOWN BEFORE SERVICING.

IF YOU ARE EXPERIENCING ANY OF THESE ISSUES, UNPLUG APPLIANCE FROM THE POWER OR TURN OFF

CIRCUIT BREAKER FOR 30 SECONDS TO FACTORY RESET THE APPLIANCE.

FOR ALL HARDWIRED APPLIANCES, DO A VOLTAGE TEST TO ENSURE THAT THERE IS NO POWER RUNNING

THROUGH THE UNIT.

TO ACCESS COMPONENTS OF THE APPLIANCE, REFER TO SECTION 5.0 SERVICE PREPARATION

SYMPTOM PROBLEM TEST SOLUTION

Dim or no fl ame Dim Flame

No moving fl ame (LED light on)

No LED light

Missing a fl ame colour 1. Press corresponding button to turn on colour

1. Press the fl ame buttons on the control panel to cycle through

brightness levels in order check if the light will get brighter.

2. If light is still dim, refer to section 4.1

1. Press the fl ame buttons on the control panel to cycle through

the fl ame settings (from F1, F2, F3, to F0) as this could restart the

refl ector spindle to animate the fl ame.

2. If fl ame is still not moving, refer to section 4.1

1. Press the fl ame buttons on the control panel to cycle through

the brightness levels

2. If the LED light is still off, refer to section 4.1

2. If the desired colour is still not functioning, refer to section 4.1

No warm air is coming

out of the appliance

Appliance fl ashes on

and off

Heater shuts off and

LED fl ashes after 30

seconds

Heater is on but little

to no heat is produced

E1 Error Code

E2 Error Code

Appliance is tripping

circuit breaker

Room temperature is higher than

the set temperature setting

Appliance has overheated

Blower malfunction

One or more heating elements

has malfunctioned

Thermostat failure

Thermostat or PCB is shorting

Current is overloading the

circuit or a short created by an

internal component

1. Set temperature to a higher setting with remote control.

2. If heater does not turn on, proceed with "LED indicator light is

fl ashing" test solution.

1. Unplug the appliance and wait 15-20 minutes for the appliance

to cool down

2. Ensure nothing is blocking the air fl ow from the exhaust of the

appliance

3. Plug in the appliance. If problem persists, refer to section 4.2

1. Refer to section 4.2

1. Ensure wire connections are fi rmly connected at the thermostat

and PCB.

2. If appliance is still showing error code E1, replace thermostat.

Refer to section 6.5

1. Ensure wire connections are fi rmly connected at the thermostat and

PCB.

2. If unit is still showing error code E2, replace thermostat.

Refer to section 6.5

3. If unit is still showing error code E2, replace the PCB.

Refer to section 6.2

1. Inspect connected electrical load (appliance must be connected to

15A, grounded, and a dedicated circuit).

2. Inspect all internal components. Refer to section 4.1 - 4.3

Appliance beeps when

plugged in but will not

turn on

Control panel issue

1. Remove front glass and ensure yellow protective cover is removed

from the control panel buttons

2. If unit still does not work, inspect control panel. If it needs to be

replaced, refer to section 6.3

EN

9

W415-1698 / 12.20.16

Page 10

4.1 FLAME LED TESTING

START HERE

Perform LED testing

(Section 4.1.1)

YES

Is the refl ector spindle

turning?

NO

Perform motor and LED testing

(Section 4.1.1 - 4.1.2)

4.1.1 LED TESTING

Unplug the appliance

(if hardwired, turn off circuit breaker)

Ensure the wires from the fl ame LED

are not pinched, frayed, and are fi rmly

connected on the PCB and fl ame LED

(Figure 1)

Ensure refl ector spindle is free

of any obstructions

Plug in the appliance and press

power button on the control panel

(if hardwired, turn on circuit breaker)

Cycle through the brightness

settings by pushing the fl ame

button on the control panel

NO

Are the LEDs on?

START HERE

Unplug the appliance

(If hardwired, turn off circuit breaker)

Appliance is functioning accordingly.

YES

Is the refl ector spindle

turning?

NO

Perform motor testing

(Section 4.1.2)

YES

Set multimeter to read

DC voltage

Plug the appliance

(If hardwired, turn on circuit breaker)

Ensure to set the brightest

LED setting

Unclip the wire harness from the

corresponding terminal for the LED

strip that you are testing (Figure 2)

Place positive probe on the corresponding

LED on the PCB (Figure 3)

Place negative probe on the corresponding

LED on the PCB (Figure 3)

Is the voltage reading

12V DC?

NO

Replace the wire harness

Refer to section 6.7 (Wire

Harness Replacement)

YES

Replace the fl ame LED strip.

Refer to section 6.4

(LED Replacement)

EN

W415-1698 / 12.20.16

10

Page 11

FIGURES

-

+

Fig. 1

Fig. 2

Fig. 3

FLAME LED TERMINALS

11

EN

W415-1698 / 12.20.16

Page 12

4.1.2 MOTOR TESTING

START HERE

Replace the PCB

Refer to section 6.2 (Control

Board Replacement)

Unplug the appliance

(If hardwired, turn off circuit breaker)

Set multimeter to read

AC voltage

Disconnect the wire on the

MOTOR terminal on the PCB

Plug in the appliance and press power

button on the control panel

(If hardwired, turn on circuit breaker)

Place positive probe on the MOTOR

terminal of the PCB (Figure 4)

Place negative probe on the AC-N / AC-N1

terminal of the PCB (Figure 5)

Is there a voltage reading

NO

approximately 120V AC?

YES

Unplug the appliance

(If hardwired, turn off circuit breaker)

Replace the wire harness

Refer to section 6.7 (Wire

Harness Replacement)

Reconnect the wire into the

MOTOR terminal on the PCB

Follow the wire from the motor until

you reach the plastic connectors and

disconnect them (Figure 6)

Using the female wire connector coming from

the PCB, place positive probe into the terminal

with the orange wire and the negative probe

into the terminal with the purple wire (Figure 7)

Plug in the appliance and press

power button on the control panel

(If hardwired, turn on circuit breaker)

NO

Is the voltage reading

approximately 120V AC?

YES

Replace the motor

Refer to section 6.1

(Motor Replacement)

EN

W415-1698 / 12.20.16

12

Page 13

FIGURES

MOTOR

TERMINAL

+

Fig. 4

Fig. 5

-

AC-N1

Fig. 6

Fig. 7

+

-

13

EN

W415-1698 / 12.20.16

Page 14

4.2 HEATER/BLOWER TESTING

START HERE

Perform heater testing

(Section 4.3.2)

YES

Is the blower on?

NO

Perform blower and heater testing

(Section 4.3.1 - 4.3.2)

4.2.1 BLOWER TESTING

START HERE

Unplug the appliance

(if hardwired, turn off circuit breaker)

Perform a visual check for burns,

sparks, damages, etc. Replace any

damaged parts

Ensure the wires from FAN, HEATER1,

and HEATER 2 terminals are not

pinched, frayed, and are fi rmly

connected on both sides (Figure 8)

Plug in the appliance

(if hardwired, turn on circuit breaker)

Turn on heater by pressing the heater

button on the control panel

YES

Is the heater on?

NO

Appliance is functioning

accordingly.

YES

Is the blower on?

NO

Perform blower testing

(Section 4.3.1)

Unplug the appliance

(if hardwired, turn off circuit breaker)

Does the fan spin with little

or no resistance?

Set multimeter to

read AC voltage

Disconnect the grey wire connector

on the FAN terminal on the PCB

(Figure 9)

Plug the appliance

(if hardwired, turn on circuit breaker)

Place the positive probe on the

FAN terminal of the PCB

(Figure 10)

Place the negative probe on the

AC-N / AC-N1 terminal of the PCB

(Figure 11)

Turn on heater by pressing the heater

button on the control panel

Is the voltage reading

approximately 120V AC?

YES

Unplug the appliance

(if hardwired, turn off circuit breaker)

Follow the wire from the fan

until you reach the plastic

connectors and disconnect it

Identify which side of the

disconnected wire is coming from

the PCB (female connector)

Replace the wire harness

Refer to section 6.7 (Wire

Harness Replacement)

NO

Replace the PCB

Refer to section 6.2 (Control

Board Replacement)

Plug in the appliance and press

power button on the control panel

(if hardwired, turn on circuit breaker)

Place the positive probe into the terminal

with the grey wire (Figure 12)

Place the negative probe into the

terminal with the white wire (Figure 12)

Turn on heater by pressing the heater

button on the control panel

Is the voltage reading

NO

approximately 120V AC?

EN

W415-1698 / 12.20.16

YES

Defective blower

Refer to section 6.6 (Heater, Blower,

and High Limit Switch Replacement)

14

Page 15

FIGURES

FAN

TERMINAL

Fig. 8

Fig. 9

+

Fig. 10 Fig. 11

-

AC-N1

Fig. 12

+

-

15

EN

W415-1698 / 12.20.16

Page 16

4.2.2 HEATER TESTING

START HERE

Turn appliance on

Set heater setting on H2

Set a clamp multimeter to read

amperage and clamp around L1,

wire #0 (Figure 13)

Is the amperage reading

less than 1A?

YES

Set multimeter to

read AC voltage

Check power supply for

120V AC (Figure 18)

NO

!

WARNING

RISK OF ELECTRICAL SHOCK.

Is the amperage reading

approximately 5-6A?

YES

Cycle through the heat settings

Set heater setting on H2

Using a clamp multimeter,

clamp around wire #4 then

wire #5 (Figure 19 & 20)

Did both wires read

approximately 5-6A?

YES

Appliance is functioning

accordingly

NO

Appliance is functioning accordingly

YES

Is the amperage reading

NO

approximately 10-12A?

NO

Unplug the appliance

(if hardwired, turn off circuit breaker)

Ensure wire connections are fi rmly

connected at the heater/blower

assembly and at the PCB.

Refer to the wiring diagram

Set multimeter to

read AC voltage

Place negative probe on

the AC-N / AC-N1 terminal

of the PCB (Figure 14)

Place positive probe on the AC-L

terminal of the PCB (Figure 15)

Is the voltage reading

approximately 120V AC?

Are the connections to

the junction box, heater,

and thermal cutoff fi rmly

secured?

Reconnect any loose

wires

Replace PCB

Refer to section 6.2

(Control Board

Replacement)

(if hardwired, turn off circuit breaker)

Replace wire harness

Refer to section 6.7 (Wire

Harness Replacement)

EN

W415-1698 / 12.20.16

Contact a certifi ed

NO

YES

YES

NO

NO

Did both terminals

read approximately

120V AC?

Unplug the appliance

Check continuity of the heater

wire #4 and #5 to neutral

(Figures 21, 22, and 23)

Is there continuity?

NO

electrician to inspect

YES

16

house wiring

YES

NO

Check power

supply for 120V AC

(Figure 18)

Plug in the appliance and press

power button on the control panel (if

hardwired, turn on circuit breaker)

Place positive probe on the HEATER1

and then HEATER2 terminals of the PCB

Measure the ohm value of HEATER1 and

HEATER2 by placing the probes on each

side of HEATER1 and HEATER2 terminals

on the heating element (Figures 24 & 25)

*Keep the negative probe on AC-N / AC-N1

Is the nominal voltage

reading approximately

120V AC?

YES

Unplug the appliance

(if hardwired, turn off

circuit breaker)

Unplug the wires from

HEATER1 and HEATER2

terminals on the PCB

Set heater setting on H2

(Figures 16 &17)

Did both heating

elements read 19-20 Ω?

NO

Defective heater

Refer to section 6.6

(Heater, Blower, and

High Limit Switch

Replacement)

Page 17

FIGURES

Fig. 13

-

Fig. 14

+

Fig. 15

+

-

Fig. 19

Fig. 21

+

Fig. 18

+

Fig. 20

Fig. 22

+

+

Fig. 16

Fig. 17

+

+

-

Fig. 23

-

Fig. 24

Fig. 25

-

17

EN

W415-1698 / 12.20.16

Page 18

4.3 HIGH LIMIT SWITCH TESTING

START HERE

Unplug the appliance

(if hardwired, turn off circuit breaker)

Leave appliance turned off for 15-20 minutes

for the appliance to cool down

Inspect wires to and from the high limit

switch to ensure there are no damaged

or disconnected wires

If the appliance is shutting off constantly 8-10 sec

after heater button is pushed, the high limit

switch and/or circuit is open

Inspect wires # 2, 4, 5, 6, and 11.

Refer to the wiring diagram

Ensure there are no frayed

or damaged wires

Are there any broken

connectors or wires?

YES

Replace wire harness

Refer to section 6.7 (Wire

Harness Replacement)

NO

NOTE: THIS ENSURES THE HIGH

LIMIT SWITCH HAS COOLED

DOWN AND RESET

Set the multimeter to read AC voltage

Place negative probe on AC-N / AC-N1

terminal of the PCB (Figure 26)

Place the positive probe on the left terminal

of the high limit switch (Figure 27)

Is the voltage reading

approximately 120V AC?

YES

Keep the negative probe on AC-N / AC-

N1 terminal of the PCB and place the

positive probe on the right terminal of the

high limit switch (Figure 28)

Is the voltage reading

approximately 120V AC?

YES

NO

NO

Check power supply

for 120V

Defective high limit

switch. Refer to

section 5.12

(High Limit Switch,

Heater, and Blower

Replacement)

EN

W415-1698 / 12.20.16

Replace wire harness

Refer to section 6.7 (Wire

Harness Replacement)

18

Page 19

FIGURES

-

Fig. 26

Fig. 27

+

+

Fig. 28

19

EN

W415-1698 / 12.20.16

Page 20

5.0 SERVICE PREPARATION

!

WARNING

ALWAYS DISCONNECT THE POWER AND ALLOW THE ELECTRIC APPLIANCE TO COOL BEFORE

PERFORMING ANY CLEANING, MAINTENANCE, OR RELOCATION OF THIS ELECTRIC APPLIANCE.

TURN CONTROLS TO OFF AND REMOVE PLUG FROM OUTLET OR TURN OFF THE HOUSE

CIRCUIT BREAKER TO ELECTRIC APPLIANCE RECEPTACLE.

FRONT REMOVAL

1. Unscrew the top 2 screws that are securing the front bracket.

2. Lift the front glass up to unhook the front brackets from the hooking tabs and pull the front glass

away from the appliance.

1

EN

W415-1698 / 12.20.16

2

20

Page 21

MEDIA TRAY REMOVAL

1. Remove the acrylic crystals from the media tray.

2. Unscrew the media tray. Depending on the model, screws vary in numbers.

3. Remove the media tray from the appliance.

PLASTIC PANEL REMOVAL

1. Unscrew and remove the top plastic panel bracket.

2. unscrew the side plastic panel brackets. Depending on the model, screws will vary in numbers.

3. Pull the plastic panel using the sides on the upper half of the panel.

4. Carefully lift the plastic panel out of the appliance.

1

2

3

21

EN

W415-1698 / 12.20.16

Page 22

CONTROL BOARD COVER REMOVAL

1. Remove the 4 screws on the control board cover plate.

METAL FLAME CUTOUT REMOVAL

1. Remove the screws on the side and bottom tray of the metal cutout. Depeneding on the model, the

number of screws will vary.

EN

W415-1698 / 12.20.16

22

Page 23

CONTROL PANEL PLATE REMOVAL

1. Remove the screws on the control panel plate. Depending on the model, the number of screws will vary.

BLOWER / HEATER TRIM REMOVAL

1. Unscrew and remove middle blower/heater trim.

2. Unscrew and remove the side blower/heater trims to access the heater, blower, and high limit switch

assembly.

1

2

23

EN

W415-1698 / 12.20.16

Page 24

6.0 REPLACING COMPONENTS

!

WARNING

PREPARATION FOR MAINTENANCE

ALWAYS DISCONNECT THE POWER AND ALLOW THE ELECTRIC APPLIANCE TO COOL BEFORE

PERFORMING ANY CLEANING, MAINTENANCE, OR RELOCATION OF THIS ELECTRIC APPLIANCE.

TURN CONTROLS TO OFF AND REMOVE PLUG FROM OUTLET OR TURN OFF THE HOUSE

CIRCUIT BREAKER TO ELECTRIC APPLIANCE RECEPTACLE.

TO ACCESS THE FOLLOWING COMPONENTS, REFER TO THE SERVICE PREPARATION SECTION.

6.1 MOTOR AND REFLECTOR SPINDLE REPLACEMENT

1. Remove 2 screws that hold the motor and disconnect the wire connector.

2. Unplug the quick connect motor wire from the wire harness.

3. Pull the motor out of the unit. For ease of removal, turn the motor

slightly to remove it.

4. To remove the refl ector spindle, pull the refl ector away from the motor for it

to release.

5. Remove the rubber adapter from the motor.

6. Remove two screws holding the motor and take the motor out of the appliance.

7. Install new motor with the refl ector spindle and the rubber adapter.

8. Screw the new motor back into the motor bracket.

REFLECTOR SPINDLE

6.2 CONTROL BOARD REPLACEMENT

1. Unplug all the wires connected to the control board. For ease of wire disconnection, use a pair of

needle-nose pliers.

2. Remove control board from appliance. NOTE: To prevent stripping of the plastic plugs on the back

of the control board, hold the plugs with a pair of needle-noise pliers while removing each of the

screws.

3. Install the new control board into the appliance.

4. Connect all of the wires to the board.

MOTOR

EN

W415-1698 / 12.20.16

24

Page 25

6.3 CONTROL PANEL REPLACEMENT

1. Disconnect the quick connector from the control panel (Figure 1).

2. Push in the holding tabs of the control panel and gently push the control panel out of the plate (Figure 2).

3. Install the new control panel into the plate. Ensure to push the new control panel gently until you hear a

click to confi rm that the holding tabs are secure.

4. Plug the quick connector to the new control panel.

FIG. 1 FIG. 2

6.4 LED REPLACEMENT

1. Find the connector on the PCB for the LED strip you want to replace and follow it to the LED strip.

2. Cut the cable tie and release the wire harness from the LED.

3. Use a pair of needle-nose pliers to pinch the plastic connectors to release the LED.

4. Install the new LED strip and plug in the necessary wire connectors to the new LED strip.

25

EN

W415-1698 / 12.20.16

Page 26

6.5 REMOTE RECEIVER / THERMOSTAT REPLACEMENT

1. Find the connector of the component you need to replace and unplug it on the PCB.

2. Cut the cable ties.

3. Unscrew the component from the appliance.

4. Screw the new compnent and connect the wires to the appropriate connectors.

5. Using a cable tie, secure the wires.

RECEIVER

THERMOSTAT

EN

W415-1698 / 12.20.16

26

Page 27

6.6 HEATER, BLOWER, AND HIGH LIMIT SWITCH ASSEMBLY REPLACEMENT

1. Remove the screws from the holding brackets on each side of the blower.

2. Remove heater, blower, and high limit switch assembly from the appliance.

3. Unplug the wire connectors connected to the assembly.

4. Install the new heater, blower, and high limit switch assembly and secure by fastening the assembly to

the holding brackets.

HOLDING BRACKETS

HEATER, BLOWER, AND HIGH LIMIT SWITCH ASSEMBLY

27

EN

W415-1698 / 12.20.16

Page 28

6.7 WIRE HARNESS REPLACEMENT

1. Remove wire connections from the PCB and heater/blower/high limit switch assembly.

2. Replace wire harness assembly. Refer to wiring diagram.

PCB WITH WIRE CONNECTORS PCB WITHOUT WIRE CONNECTORS

6.8 REMOTE BATTERY INSTALLATION

NOTE: The remote control has a removable plastic tab to prolong the battery life while shipping,

remove the tab for the remote control to function.

1. To replace the existing battery remove the

battery holder.

2. To remove the battery holder turn remote onto

rear side and press the left side leaver towards

the center while pulling the battery holder out

using the slot provided.

3. Replace existing battery, type CR 2025, with a

new battery and reinstall the battery holder into

the remote by sliding it into position, as shown.

BATTERY (CR 2025)

BATTERY HOLDER

NOTE: The remote control must remain within 5 meters or 17 feet of the appliance to be effective, this

range may be reduced when battery power is depleted.

REMOTE

(REAR SIDE)

EN

W415-1698 / 12.20.16

28

Page 29

7.0 NOTES

44.1

29

EN

W415-1698 / 12.20.16

Page 30

Products

®

Other Napoleon

'JSFQMBDF*OTFSUTt$IBSDPBM(SJMMT t(BT'JSFQMBDFTt8BUFSGBMMTt8PPE4UPWFT

)FBUJOH$PPMJOHt&MFDUSJD'JSFQMBDFTt0VUEPPS'JSFQMBDFTt(BT(SJMMT

/BQPMFPO3PBE#BSSJF0OUBSJP$BOBEB-.(

#BZWJFX%SJWF#BSSJF0OUBSJP$BOBEB-/:

.JMMFS%SJWF$SJUUFOEFO,FOUVDLZ64"

5SBOT$BOBEB)JHIXBZ.POUSFBM2VFCFD$BOBEB)5"

'JSFQMBDFT)FBUJOH$PPMJOHDBMMt(SJMMTDBMM

napoleonproducts.com

Loading...

Loading...