Page 1

SERIAL #______________________

BUILT-IN UNIT INSTRUCTION GUIDE

Please use this manual in conjuction with your main manual to properly assemble your built-in grill. Refer to the

main manual for operating, cleaning, and maintenance instructions. This grill is designed for non-combustible

enclosures only , and must be installed and serviced by a qualified installer to local codes.

BUILT IN PROPANE GAS HOOK-UP: The piping up to the gas grill is the responsibility of the installer and piping should be located as

shown in the built-in instructions. Do not use hose to connect the unit. It must be connected with either rigid pipe, copper tube or an

approved flexible metal connector. The installation must comply with CAN B149.1 Natural Gas and Propane installation code in

Canada, or to the National Fuel Gas code, ANSI Z223.1 in the United States. The minimum recommended piping size is NPS 1/2"

for rigid pipe, and 1/2" OD for copper tubing (based on a 20 ft run). Longer runs may require larger sizes to conform with CAN

B149.1. Propane Gas Installation Code in Canada or to the National Fuel Gas Code, ANSI Z223.1 in the United States. The gas

supply must be connected to the 3/8” flare elbow fitting located under the right hand side of the control panel. If installing a side

burner, a separate line must be branched off to the side burner unit and enter the side burner opening at the specified location. If the

enclosure is to house a propane cylinder, the tank portion of the enclosure must be ventilated according to local codes, and must not

have communication with the cavity used to enclose the gas grill. The tank can not be stored below the gas grill.

BUILT IN NATURAL GAS HOOK-UP: The piping up to the gas grill is the responsibility of the installer and piping should be located as

shown in the built-in instructions. Do not use hose to connect the unit. It must be connected with either rigid pipe, copper tube or an

approved flexible metal connector. The installation must comply with CAN B149.1 Natural Gas and Propane Installation Code in

Canada, or to the National Fuel Gas Code, ANSI Z223.1 in the United States. The minimum recommended piping size is NPS 1/2"

for rigid pipe, and 5/8" OD for copper tubing (based on a 20 ft run). Longer runs may require larger sizes to conform with CAN

B149.1. Natural Gas Installation Code in Canada or to the National Fuel Gas Code, ANSI Z223.1 in the United States.

Built in units are supplied with a drip pan which holds only a minimal amount of grease. T oprevent grease fires, the panmust

be cleaned after each use.

N415-0107/APR28/06

Page 2

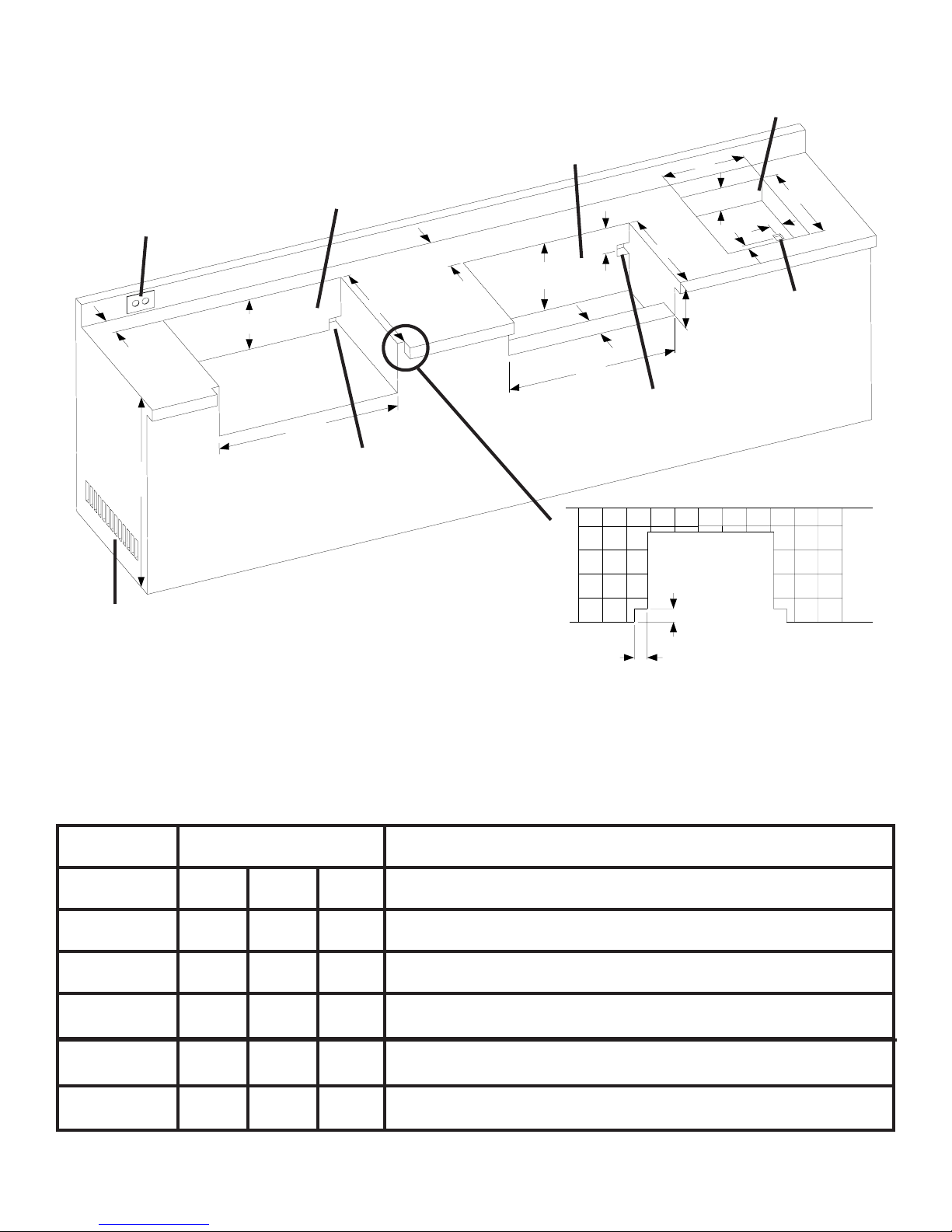

BUILT-IN UNITOPENING DIMENSIONS

OUTDOOR GFIOUTLET

RECOMMENDED -LOCATE

ON LEFT SIDE OF GRILL

FOR ROTISSERIE USE.

BIPT450 / BIPT600 / BIPT750

BUILT-INGRILLHEADS

3”MIN.

BIU405 BUILT-IN

GRILL HEADS

6”

H

BUILT-IN

SIDEBURNER

W

H

D

1¾”

D

1¾”

2”

34”

RECOMMENDED

MINIMUM10SQINOF

VENTILATIONREQUIRED

ON EACH END OF CABINET

D

H

W

GASINLET

OPENING

4”

W

GASINLET

OPENING

WIDE 1 ¼”

OVERHANG NOTCHREQUIREDIF

USING SUPPLIEDTRIMKIT.

7”

DEPTH OF

COUNTERTOP

OVERHANG

GASINLET

OPENING

MODEL OPENINGDIMENSIONS

WDH

BIPT450 29 ½”20e”8f”

BIPT600 37 ¾”20e”8f”

BIPT750 49 ¾”20e”9e”

BIU405 27 ½”16¾” 12”

SIDEBURNER 13 ½”17½”4”

NOTES

Access must be provided for drip tray removal and cleaning.

Opening of at least 5 sq in must be provided for combustion air for side burner.

Page 3

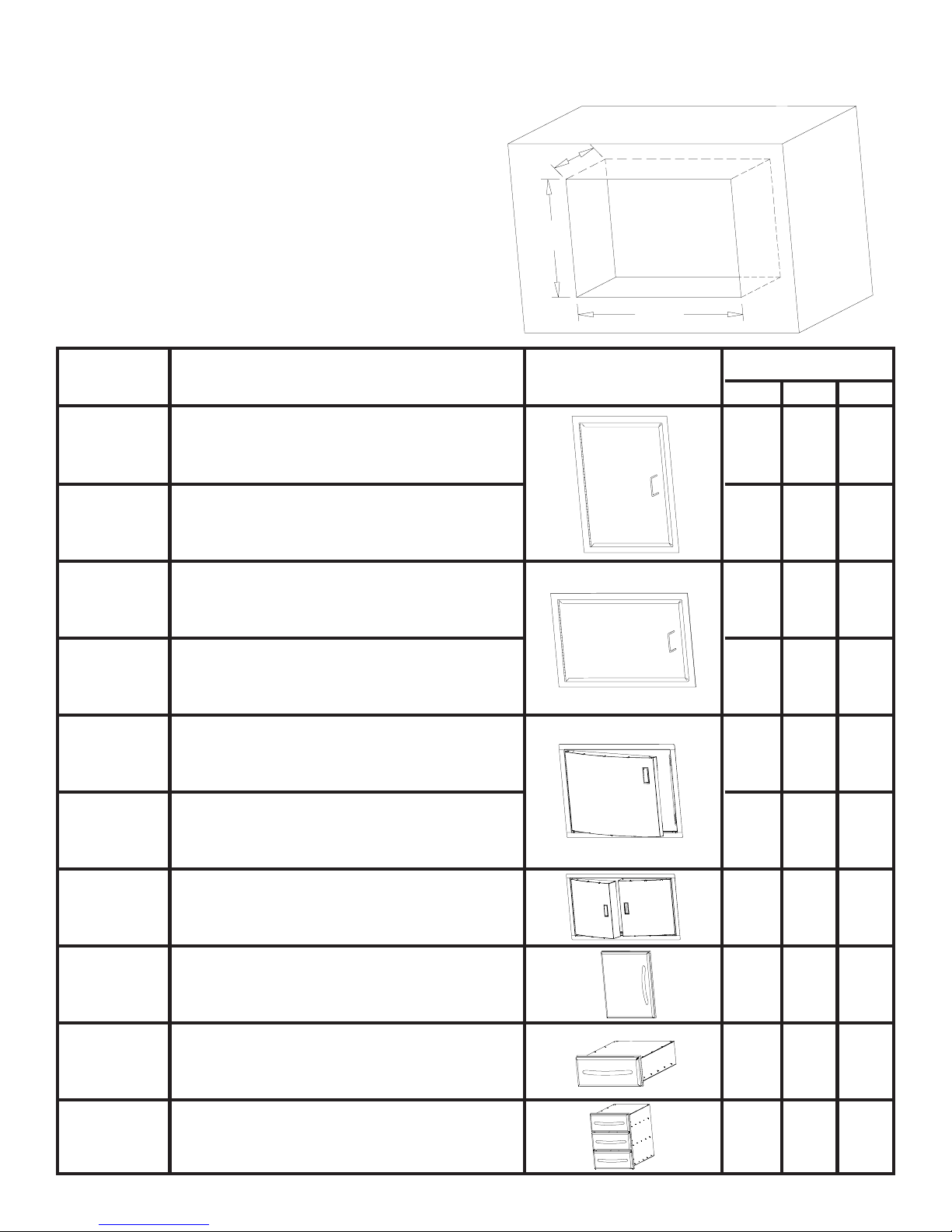

BUILT-INACCESSORYOPENING DIMENSIONS

NOTE:ACCESSORYFRAMES OVERLAP

OPENINGBY 1½” ONALL4SIDES

D

H

W

Part #

N370-0069 Flat vertical painted door

N370-0071

N370-0070

N370-0072

N370-0356SS Curved stainless steel door - 308 size

Flat vertical stainless steel door

Flat horizontal painted door

Flat horizontal stainless steel door

Description

Picture

OPENINGDIMENSION

WH

13¼”

18¼”

D

13¼” 18¼”

18¼” 13 ¼”

18¼” 13 ¼”

22½” 19 ¾”

N370-0357SS

N370-0358SS

N370-0361 PF style stainless steel door

N370-0359 PF style stainless steel single drawer

N370-0360 PF style stainless steel triple drawer

Curved stainless steel door - 450 size

Curved stainless steel double door - 600/750 size

27” 19 ¾”

35¼” 19”

17”

23¼”

17¼” 6 ¾”

17¼” 22 ¾”

23”

23”

Page 4

1. BIPT450 BUILT-IN INSTRUCTIONS

N080-0142

N570-0026

N715-0062

N080-0142

N715-0060

N715-0059

N710-0027

N715-0061

This grill is designed for masonry, non-combustible enclosures only, and must be installed and serviced by a qualified installer to

local codes.

1. Attach side mounting brackets and side trim pieces to each side of the grill using #14 x 1/2" screws (n570-0026).

2. Mount the lower front trim to the bottom front edge of the opening (fasteners not included).

3. Lay the rear trim piece across the back of the opening. To keep it in place, a dab of silicone may be applied to each wing of the

rear trim.

4. Lower the unit in place, and connect the gas supply line to the fitting at the end of the manifold.

5. The unit must be secured in place (fasteners not included). This can be accomplished by mounting the left and right trim pieces

to the sides of the opening, or by another means.

6.The entire installation must be leak tested before operating the unit.

Page 5

2. BIPT600 BUILT-IN INSTRUCTIONS

N080-0066

N715-0059

N380-0009

N051-0001

N715-0072

N080-0142

N710-0044

N570-0026

N715-0060

This grill is designed for masonry, non-combustible enclosures only, and must be installed and serviced by a qualified installer to

local codes.

1. Attach side mounting brackets and side trim pieces to each side of the grill using 1/4-20 x 1/2" screws (n570-0026).

2. Mount the lower front trim to the bottom front edge of the opening (fasteners not included).

3. Lay the rear trim piece across the back of the opening. To keep it in place, a dab of silicone may be applied to each wing of the

rear trim.

4. Lower the unit in place, and connect the gas supply line to the fitting at the end of the manifold.

5. The unit must be secured in place (fasteners not included). This can be accomplished by mounting the left and right trim pieces

to the sides of the opening to the sides of the cabinet.

6.The entire installation must be leak tested before operating the unit.

Page 6

2. BIPT750 BUILT-IN INSTRUCTIONS

N715-0076

N715-0059

N380-0009

N051-0001

N715-0077

N080-0142

N710-0044

N570-0026

N715-0060

This grill is designed for masonry, non-combustible enclosures only, and must be installed and serviced by a qualified installer to

local codes.

1. Attach side mounting brackets and side trim pieces to each side of the grill using 1/4-20 x 1/2" screws (n570-0026).

2. Mount the lower front trim to the bottom front edge of the opening (fasteners not included).

3. Lay the rear trim piece across the back of the opening. To keep it in place, a dab of silicone may be applied to each wing of the

rear trim.

4. Lower the unit in place, and connect the gas supply line to the fitting at the end of the manifold.

5. The unit must be secured in place (fasteners not included). This can be accomplished by mounting the left and right trim pieces

to the sides of the opening to the sides of the cabinet.

6.The entire installation must be leak tested before operating the unit.

Page 7

3. BIU405 BUILT-IN INSTRUCTIONS

N080-0152

N570-0026

N570-0026

N080-0152

N715-0063

N570-0026

23 e c-c

N080-0155

N080-0155

This grill is designed for masonry, non-combustible enclosures only, and must be installed and serviced by a qualified installer to

local codes. Access must be provided in the enclosure for drip tray removal and cleaning.

1. Attach the side mounting brackets and the rear trim to the unit using #14 x 1/2” screws (n570-0026). The wings on the rear trim

should be under the side mounting brackets.

2. Attach the supplied brackets flush with the front of the opening as per the dimensions in the above drawing (fasteners not included).

3. Lower the unit in place ensuring the brackets installed in the previous step engage between the control panel and the base

bracket. Connect the supply line to the fitting at the end of the manifold.

4. The entire installation must be leak tested before operating the unit.

Page 8

4. BUILT-IN SIDE BURNER INSTRUCTIONS

N280-0003P (BLACK)

N280-0004 (STN STL)

1. Fit the side burner frame into the opening. The frame should be attached to the opening to prevent any future movement (fasteners not included).

2. Ensure that there is at least 5 sq in of opening in the bottom of the cut out, for combustion air.

3. Set the side burner into the frame.

4. Connect the gas supply to the side burner valve. Leak test the entire installation before operating the unit.

Page 9

5. BUILT-IN ACCESSORY DRAWER INSTRUCTIONS

1.Unpackthedrawerframeassembly.

2.Remove the drawers from the enclosure by fully extending them and then liftinguptoremovethemfrom the slides.

3. Shim the opening to ensure that the enclosure fits snuggly into the opening. Ensure that the side shims are located at

the same height as the enclosure mounting holes. The bottom of the opening mayneed to be shimmed as well to ensure

that the front of the enclosure is plumb.

4. Once the enclosure islevel and square, fasten into place. (Fasteners not included).

5. Re-install the drawers by tipping the back of the drawer down into the slide. Once the wheels are inserted into the slide,

lower the front of the drawer until it is level, then push in. Note: if the enclosure is installed with shims that are too thick, the

wheel will not engage into the slide. The shim thickness will need to be reduced.

6.Removetheprotectivecoatingfromallremainingsurfaces.

6. BUILT-IN ACCESSORY DOOR INSTRUCTIONS

1. Unpack the door and frame.

a. For the curved stainless steel doors, removethedoor(s) from the frame by lifting the doorwhileholding on to the pivot

rod. This will allow the pivot rodto come out of the hole on the bottom of the frame. Once the pivot is removedfrom the

bottomhole, the entire door can be dropped and removed from theframe.

b. For the PF style stainless steel door, the door needs to be removed by loosening the center philipsscrew on the hinge

furthest away from the door. This will allow the hingeto separate.

2. Center the frame in the opening. Mark the location of the pivot holes,top and bottom. Remember on the PT600 double

doors, there will be a pivot rod on both ends. The PF style doors do not have pivotrods. Once all pivot holes are marked,

remove the frame and using a3/8” drill bit, drill out the clearanceholes for the pivot rod. Theseclearance holes should be

at least 1/2” deep. After the holes are complete, you may once again center the frame in the opening. Starting with the

hinged side, shim between the frame and side wall of the opening. Ensure the shims are close to the hinge on the PF style

doors. When the frame side wall is plumb, fasten it to the cabinet with screws (not provided). Attach the other side of the

frame in the same fashion, ensuring the frameissquare.

3. Other than on the curved stainless steel doubledoor kit, fasteners arenot required on the top and bottom of theframe.

The curved stainless steel double door frame must be fastened in the centerboth at the top and bottom.

4. Once the frame has been securedand checked for squareness, the door canbe re-installed.

5.Remove the protective coating from all remaining surfaces.

Loading...

Loading...