Napoleon Bipt600rb Owner's Manual

SERIAL #______________________

BUIL T -IN UNIT INSTRUCTION GUIDE

Please use this manual in conjunction with your main manual to properly assemble your built-in grill. Refer to

the main manual for operating, cleaning, and maintenance instructions. This grill is designed for NON-COM-

BUSTIBLE enclosures only, and must be installed and serviced by a qualified installer to local codes.

BUILT IN PROPANE GAS HOOK-UP: The piping up to the gas grill is the responsibility of the installer and piping should be located as

shown in the built-in instructions. A flexible metal connector is included to simplify the installation of the unit. Connect this connector

to the 3/8” flare fitting on the end of the manifold. Connect the other end of the connector to the gas piping. Ensure that the

connector does not pass through a wall, floor, ceiling or partition, and is protected from damage. Do not use hose to connect the

unit. It must be connected with either rigid pipe, copper tube or an approved flexible metal connector. The installation must comply

with CAN B149.1 Natural Gas and Propane installation code in Canada, or to the National Fuel Gas code, ANSI Z223.1 in the United

States. The minimum recommended piping size is NPS 1/2" for rigid pipe, and 1/2" OD for copper tubing (based on a 20 ft run).

Longer runs may require larger sizes to conform with local codes or to conform with CAN B149.1. Propane Gas Installation Code in

Canada or to the National Fuel Gas Code, ANSI Z223.1 in the United States. The gas supply must be connected to the 3/8” flare

elbow fitting located under the right hand side of the control panel. If installing a side burner, a separate line must be branched off to

the side burner unit and enter the side burner opening at the specified location. If the enclosure is to house a propane cylinder, the

tank portion of the enclosure must be ventilated according to local codes, and must not have communication with the cavity used to

enclose the gas grill. A propane tank can not be stored below the gas grill.

BUILT IN NATURAL GAS HOOK-UP: The piping up to the gas grill is the responsibility of the installer and piping should be located as

shown in the built-in instructions. A flexible metal connector is included to simplify the installation of the unit. Connect this connector

to the 3/8” flare fitting on the end of the manifold. Connect the other end of the connector to the gas piping. Ensure that the connector

does not pass through a wall, floor, ceiling or partition, and is protected from damage. Do not use hose to connect the unit. It must

be connected with either rigid pipe, copper tube or an approved flexible metal connector. The installation must comply with CAN

B149.1 Natural Gas and Propane Installation Code in Canada, or to the National Fuel Gas Code, ANSI Z223.1 in the United States.

The minimum recommended piping size is NPS 1/2" for rigid pipe, and 5/8" OD for copper tubing (based on a 20 ft run). Longer

runs may require larger sizes to conform with local codes or to conform with CAN B149.1. Natural Gas Installation Code in Canada

or to the National Fuel Gas Code, ANSI Z223.1 in the United States.

Built in units are supplied with a drip pan which holds only a minimal amount of grease. To prevent grease fires, the pan must

be cleaned after each use.

DANGER: READ ALL INSTRUCTIONS CAREFULLY BEFORE OPERA TING GRILL. FAILURE T O FOLLOW

THESE INSTRUCTIONS EXACTL Y COULD RESUL T IN A FIRE CAUSING SERIOUS INJUR Y OR DEA TH.

THE ENTIRE INST ALLATION MUST BE LEAK TESTED BEFORE OPERA TING THE GRILL.

N415-0175 / MAR 04/08

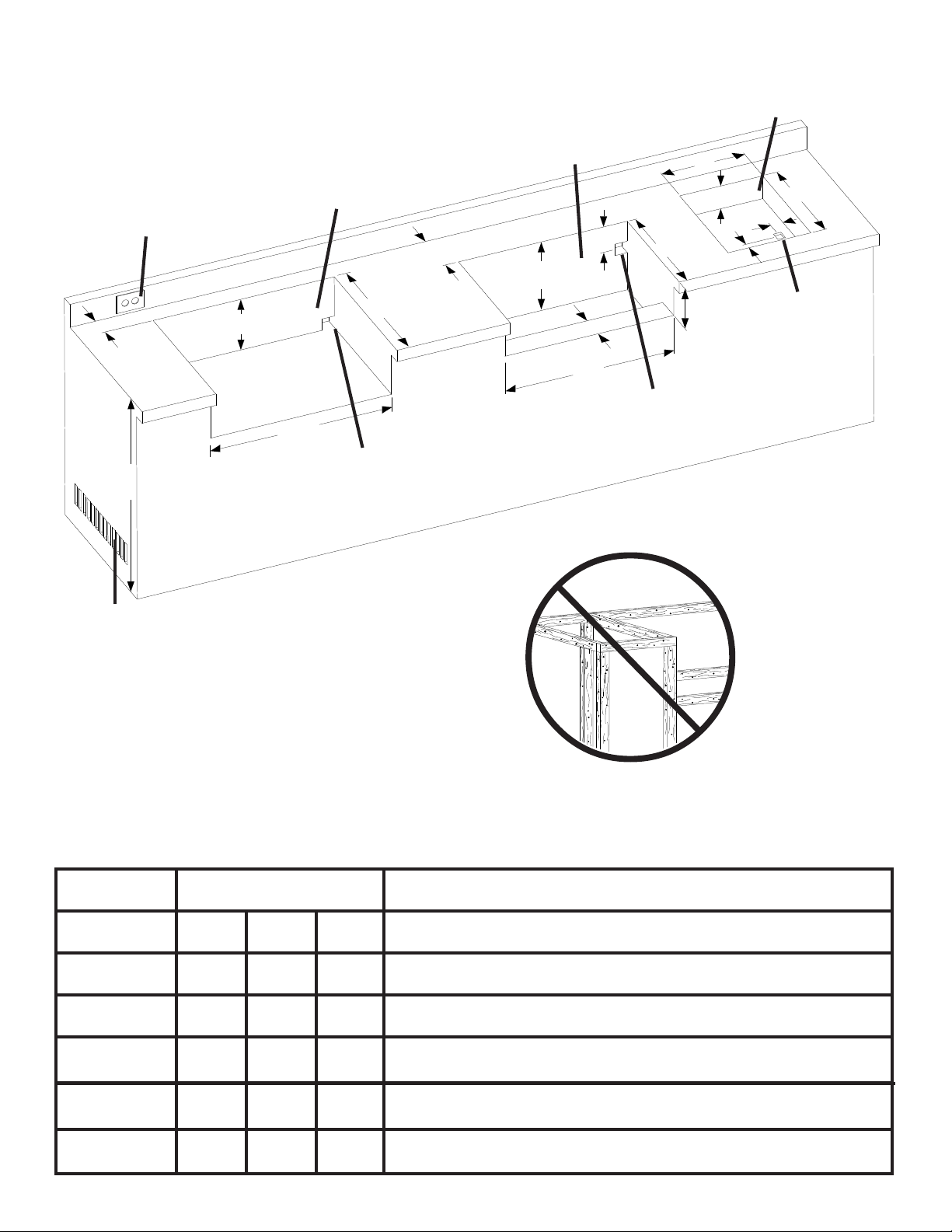

BUIL T -IN UNIT OPENING DIMENSIONS

OUTDOOR GFI ELECTRICAL

OUTLET RECOMMENDED -

LOCA TE ON LEFT SIDE OF

GRILL FOR ROTISSERIE

USE.

BIPT450 / BIPT600 / BIPT750

BUILT-IN GRILL HEADS

3” MIN.

BIU405 BUILT-IN

GRILL HEADS

6”

H

BUILT-IN

SIDEBURNER

W

H

D

1¾”

D

1

¾”

2”

34”

RECOMMENDED

MINIMUM 10 SQ IN OF

VENTILATION REQUIRED

ON EACH END OF CABINET

D

H

W

GAS INLET

OPENING

4”

W

GAS INLET

OPENING

7”

GAS INLET

OPENING

NON-COMBUSTIBLE MATERIAL

MODEL OPENING DIMENSIONS

W D H

BIPT450 29 1/2” 20 5/8” 8 7/8”

BIPT600 37 3/4” 20 5/8” 8 7/8”

BIPT750 49 3/4” 20 5/8” 9 5/8”

BIU405 271/2” 16 3/4” 12”

SIDE BURNER 13 1/2” 17 1/2” 4”

CABINET FRAME AND CABINET MUST BE

MADE FROM NON-COMBUSTIBLE MATERIAL

NOTES

Access must be provided for drip tray removal and cleaning.

Opening of at least 5 sq in must be provided for combustion air for side burner.

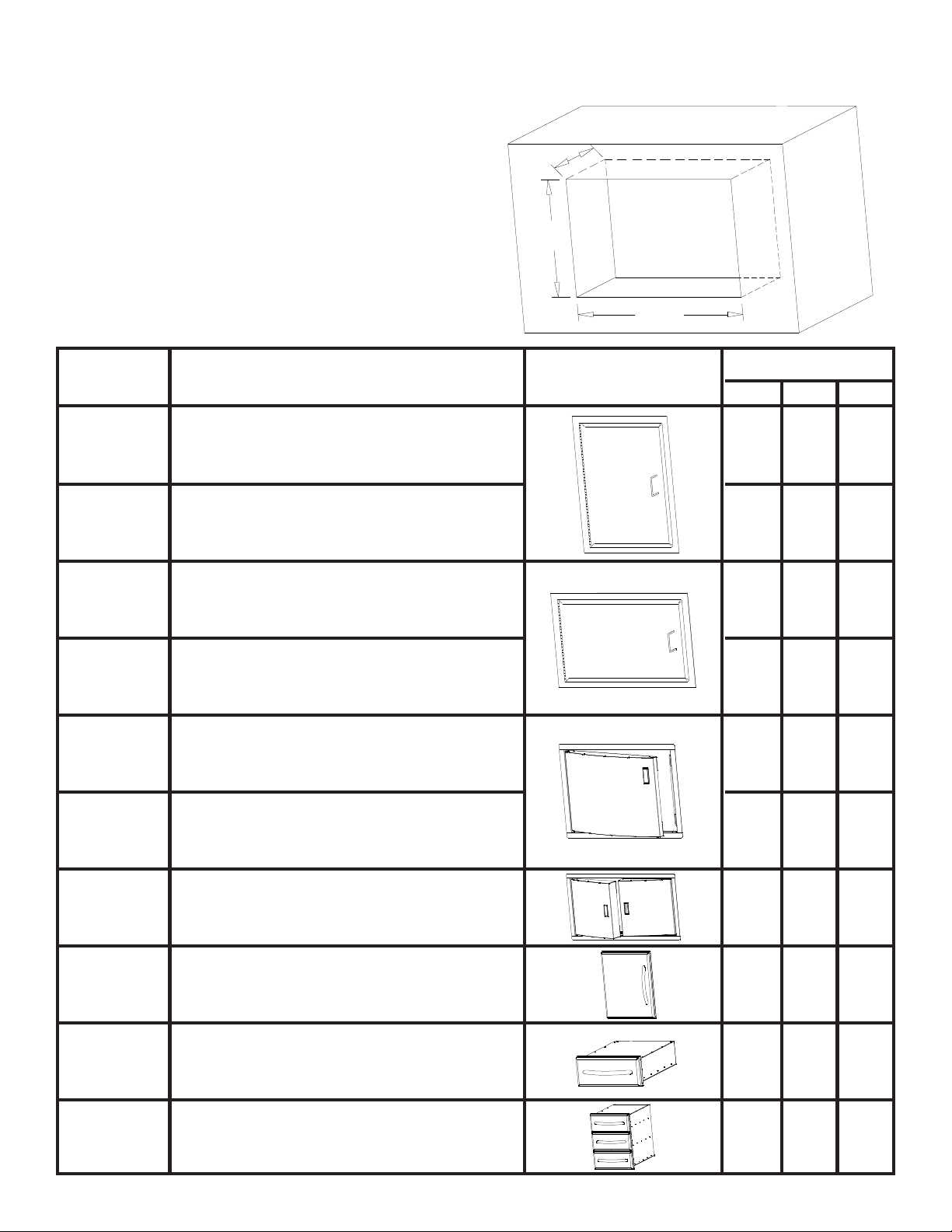

BUIL T -IN ACCESSORY OPENING DIMENSIONS

NOTE: ACCESSORY FRAMES OVERLAP

OPENING BY 1 ½” ON ALL 4 SIDES

D

H

W

Part #

N370-0069 Flat vertical painted door

N370-0071

N370-0070

N370-0072

N370-0356SS Curved stainless steel door - 308 size

Flat vertical stainless steel door

Flat horizontal painted door

Flat horizontal stainless steel door

Description

Picture

OPENING DIMENSION

WH

13 ¼”

18 ¼”

D

13 ¼” 18 ¼”

18 ¼” 13 ¼”

18 ¼” 13 ¼”

22 ½” 19 ¾”

N370-0357SS

N370-0358SS

N370-0361 PF style stainless steel door

N370-0359 PF style stainless steel single drawer

N370-0360 PF style stainless steel triple drawer

Curved stainless steel door - 450 size

Curved stainless steel double door - 600/750 size

27” 19 ¾”

35 ¼” 19”

17”

23 ¼”

17 ¼” 6 ¾”

17 ¼” 22 ¾”

23”

23”

Loading...

Loading...