Napoleon Bipf450 Owner's Manual

SERIAL #

BUILT-IN PF UNIT INSTRUCTION GUIDE

Please use this manual in conjuction with your main manual to properly assemble your built-in grill. Refer to

the main manual for operating, cleaning, and maintenance instructions. The operating instructions are also

located on the bottom of the side burner lid. This grill is designed for NON-COMBUSTIBLE ENCLOSURES

ONLY, and must be installed and serviced by a qualified installer to local codes.

BUILT IN PROPANE GAS HOOK-UP: The piping up to the gas grill is the responsibility of the installer and

piping should be located as shown in the built-in instructions. Do not use hose to connect the unit. It must be

connected with either rigid pipe, copper tube or an approved flexible metal connector. The installation must

comply with CAN B149.1 Natural Gas and Propane Installation Code in Canada, or to the National Fuel Gas

Code, ANSI Z223.1 in the United States. The minimum recommended piping size is NPS 1/2" for rigid pipe,

and 5/8" OD for copper tubing (based on a 20 ft run). Longer runs may require larger sizes to conform with

local codes or to conform with CAN B149.1. Propane Gas Installation Code in Canada or to the National Fuel

Gas Code, ANSI Z223.1 in the United States. If the enclosure is to house a propane cylinder, the tank portion

of the enclosure must be ventilated according to local codes, and must not have communication with the cavity

used to enclose the gas grill. The tank can not be stored below the gas grill.

BUILT IN NATURAL GAS HOOK-UP: The piping up to the gas grill is the responsibility of the installer and

piping should be located as shown in the built-in instructions. Do not use hose to connect the unit. It must be

connected with either rigid pipe, copper tube or an approved flexible metal connector. The installation must

comply with CAN B149.1 Natural Gas and Propane Installation Code in Canada, or to the National Fuel Gas

Code, ANSI Z223.1 in the United States. The minimum recommended piping size is NPS 1/2" for rigid pipe,

and 3/4" OD for copper tubing (based on a 20 ft run). Longer runs may require larger sizes to conform with

local codes or to conform with CAN B149.1. Natural Gas Installation Code in Canada or to the National Fuel

Gas Code, ANSI Z223.1 in the United States.

Built in units are supplied with a drip pan which holds only a minimal amount of grease. To prevent

grease fires, the pan must be cleaned after each use. Access must be provided to the inside of the

enclosure to make gas connections.

DANGER: READ ALL INSTRUCTIONS CAREFULLY BEFORE OPERATING GRILL. FAILURE TO FOLLOW THESE INSTRUCTIONS EXACTLY COULD RESULT IN A FIRE CAUSING SERIOUS INJURY OR

DEATH.

N415-0111 / JUNE 21//07

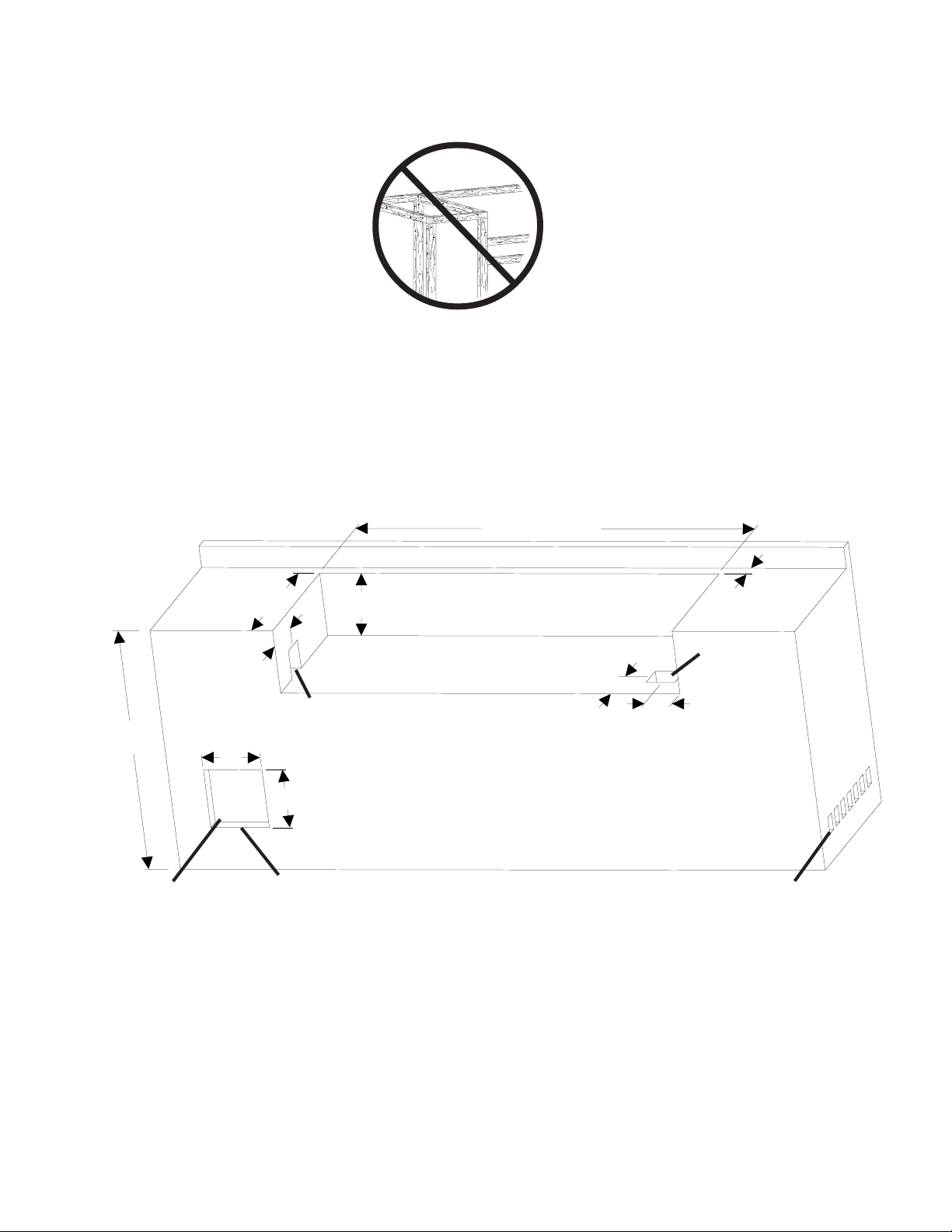

BUILT-IN OPENING DIMENSIONS

DIMENSIONS D’OUVERTURE POUR LES GRILS ENCASTRÉS

CABINET FRAME AND CABINET MUST BE

MADE FROM NON-COMBUSTIBLE MATERIAL

LA CHARPENTE DU CABINET ET LE CABINET

DOIVENT ÊTRE FAITS DE MATÉRIAUX

INCOMBUSTIBLES

34”

RECOMMENDED

ELECTRICAL BOX

OPENING

OUVERTURE DU BOÎTIER

ÉLECTRIQUE

55 ¾” PF600 UNITS

46 ¾” PF450 UNITS

20 5/8”

7”

ELECTRICAL WIRE ACCESS

OPENING (4”x4”)

8 ¼”

OUVERTURE POUR LE

FILAGE ÉLECTRIQUE

8 ¼”

8 7/8”

4”x4”

NON COMBUSTIBLE MATERIAL

MATÉRIAU INCOMBUSTIBLE

CENTER OF ELECTRICAL BOX MUST BE WITHIN 3

FEET OF LEFT EDGE OF GAS GRILL

LE CENTRE DU BOÎTIER ÉLECTRIQUE DOIT ÊTRE

À MOINS DE 3 PIEDS DU CÔTÉ GAUCHE DU GRIL

À GAZ

2” MIN

GAS INLET OPEN-

ING (4”x4”)

6”

4”

MINIMUM 10 SQ IN OF VENTILATION

REQUIRED ON EACH END OF CABINET

MINIMUM DE 10 PO² DE VENTILATION

EST NÉCESSAIRE À CHAQUE

EXTRÉMITÉ DU CABINET

OUVERTURE

POUR LA

CONDUITE DE GAZ

(4” x 4”)

Loading...

Loading...