Page 1

INSTALLER: PLEASE FAMILIARIZE YOURSELF WITH VENTING/DRAINING SECTIONS OF

THIS MANUAL BEFORE PROCEEDING WITH THE INSTALLATION. LEAVE

THIS MANUAL WITH THE APPLIANCE FOR FUTURE REFERENCE.

CONSUMER: RETAIN THIS MANUAL FOR FUTURE REFERENCE.

INSTALLATION AND

OPERATING INSTRUCTIONS

CERTIFIED TO ANSI Z21.47b / CSA 2.3b-2008

1

9700 SERIES

TWO STAGE HIGH EFFICIENCY

(CONDENSING) FORCED AIR GAS FURNACE

SAFETY INFORMATION

!

WARNING

ELECTRICAL SHOCK, FIRE OR

EXPLOSION HAZARD

Failure to follow safety warnings exactly

could result in serious injury, death or

property damage.

Improper servicing could result in

dangerous operation, serious injury, death

or property damage.

- Installation and service must be performed by a

qualifi ed installer, service agency or the gas supplier.

- Before servicing, disconnect all electrical power to

furnace.

- When servicing controls, label all wires prior to

disconnecting. Reconnect wires correctly.

- Verify proper operation after servicing.

- Do not store or use gasoline or other fl ammable

vapors and liquids in the vicinity of this or any other

appliance.

- WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use

any phone in your building.

• Leave the building immediately.

• Immediately call your gas supplier from a

neighbour’s phone. Follow the gas supplier’s

instructions.

• If you cannot reach your gas supplier, call the fi re

department.

!

MANUFACTURER RESERVES THE RIGHT TO DISCONTINUE, OR CHANGE

AT ANY TIME, SPECIFICATIONS OR DESIGNS WITHOUT NOTICE AND

Annual Fuel Utilization Efficiency (AFUE)

Gas- or Propane-fired forced-air furnace

with a high efficiency motor

90%

WITHOUT INCURRING OBLIGATIONS.

Patent Pending

97.0

98%

Wolf Steel Ltd., 24 Napoleon Rd., Barrie, ON, L4M 0G8 Canada /

103 Miller Drive, Crittenden, Kentucky, USA, 41030

Phone (705)721-1212 • Fax (705)722-6031 • www.napoleonheatingandcooling.com • ask@napoleonproducts.com

$10.00

W415-1064 / 11.11.11

Page 2

2

TABLE OF CONTENTS

1.0 INTRODUCTION 3

2.0 SAFETY SYMBOLS AND WARNINGS 4

2.1 SAFETY RULES 5

2.2 CODES 5

2.3 INSTALLATION REQUIREMENTS SPECIFIC TO THE STATE OF MASSACHUSETTS FOR DIRECT VENT,

MECHANICAL VENT, AND DOMESTIC HOT WATER APPLIANCES. 8

3.0 FURNACE SIZING 10

4.0 LOCATION OF UNIT 11

4.1 GENERAL GUIDELINES 11

4.2 OTHER CONSIDERATIONS 11

4.3 INSTALLATION IN UPFLOW POSITION 12

4.4 AIR CONDITIONING 12

5.0 COMBUSTIBLE CLEARANCES 13

6.0 DUCTWORK 14

6.1 DUCTWORK STEPS 15

7.0 VENTING AND COMBUSTION PIPING 16

7.1 ACCEPTABLE MATERIALS IN CANADA 16

7.2 ACCEPTABLE MATERIALS IN UNITED STATES 16

8.0 NON-DIRECT VENT FURNACE INSTALLATIONS USING INDOOR COMBUSTION AIR (ONE PIPE

SYSTEM) 17

8.1 DETERMINING COMBUSTION AIR 18

8.1.1 CASE 1: FURNACE LOCATED IN A UNCONFINED SPACE 18

8.1.2 CASE 2: FURNACE LOCATED IN A CONFINED SPACE 18

8.1.3 CASE 3: FURNACE LOCATED IN A CONFINED SPACE, OUTDOOR AIR FROM ATTIC OR CRAWL SPACE 19

8.1.4 CASE 4: FURNACE LOCATED IN A CONFINED SPACE, OUTDOOR AIR DUCTED HORIZONTALLY 20

8.1.5 CONNECTION TO FURNACE NON-DIRECT VENT 20

9.0 VENTING GUIDELINES 21

9.1 VENT TERMINATION 22

9.2 IN CANADA 23

9.3 IN UNITED STATES 23

9.4 FURNACE VENTING INSTALLATIONS 24

9.4.1 NON-DIRECT VENT INSTALLATION USING INDOOR COMBUSTION AIR (ONE PIPE SYSTEM) 24

9.4.2 DIRECT VENT INSTALLATION USING OUTDOOR COMBUSTION AIR (TWO PIPE SYSTEM) 24

9.4.3 COMBUSTION AIR 24

10.0 TERMINATIONS 25

10.1 COMBUSTION AIR 25

10.2 EXHAUST 25

10.3 CONCENTRIC VENTING KIT 25

10.4 CONCENTRIC VENT TERMINATION INSTALLATION INSTRUCTIONS 25

10.5 LOCATION 26

10.6 MULTIPLE VENTING 26

10.7 IN CANADA 27

10.8 IN UNITED STATES 27

10.9 FURNACE CONNECTION 27

10.9.1 ROUTING OPTIONS 30

10.9.2 EXHAUSTER ROTATION INSTRUCTIONS & PRESSURE SWITCH MOUNTING 30

10.9.3 PREPARATIONS FOR VENT AND DRAINING OPTION 31

11.0 CONDENSATE DRAINS 33

11 .1 DRAIN HOSE INSTALLATION 33

11.1.1 DRAIN PIPING 33

11.1.2 ALTERNATE CONDENSATE DRAIN PIPING INSTALLATION USING PVC OR CPVC 34

11.2 CONDENSATE NEUTRALIZERS 35

12.0 GAS SUPPLY AND PIPING 36

12.1 GAS SUPPLY 36

12.2 GAS PIPING 36

12.3 GAS INLET PRESSURE 37

12.4 LEAK TESTING 37

12.5 PURGING GAS LINES 37

13.0 CONVERSIONS 38

13.1 CHECKING THE INLET GAS PRESSURE 38

13.2 SETTING THE MANIFOLD GAS PRESSURE 39

13.3 CHECKING FURNACE INPUT 40

14.0 ELECTRICAL SPECIFICATIONS 41

14.1 ELECTRICAL WIRING AND CONNECTIONS 41

14.2 FURNACE CONNECTION 42

W415-1064 / 11.11.11

Page 3

3

15.0 LOW VOLTAGE WIRING 43

15.1 SINGLE STAGE THERMOSTAT 43

15.2 TWO STAGE THERMOSTAT 43

15.3 THERMOSTAT LOCATION 43

16.0 OPTIONAL ACCESSORIES (FIELD SUPPLIED/INSTALLED) 44

16.1 ELECTRIC AIR CLEANER 44

16.2 POWER HUMIDIFIER 44

16.3 EMERGENCY HEAT MODE 44

17.0 STARTUP PROCEDURES 45

17.1 TO START THE FURNACE 45

17.2 TO SHUT DOWN THE FURNACE 45

17.3 SEQUENCE OF OPERATION 46

17.4 PROGRAMMABLE THERMOSTAT (OPTION) 46

18.0 AIR FLOW 47

18.1 TEMPERATURE RISE CHECK 47

18.2 CALCULATING AIR FLOW 48

18.3 ADJUSTING BLOWER SPEEDS ON ECM 2.3 BLOWER MOTORS 48

18.4 DEHUMIDIFICATION - ECM 2.3 49

18.5 SETTING BLOWER “ON” AND “OFF” TIMINGS - ECM 2.3 MODELS ONLY 49

18.6 CONTINUOUS FAN OPERATION 49

18.7 UV LAMP REPLACEMENT 49

19.0 MAINTENANCE AND TROUBLESHOOTING 51

19.1 AIR FILTER 51

19.2 LUBRICATION 52

19.3 TERMINATIONS 52

19.4 INTAKE AIR/EXHAUST PIPING 52

19.5 OPERATING TIPS 52

19.6 ANNUAL INSPECTION/SERVICE 53

19.7 TROUBLESHOOTING FLOWCHART 54

19.8 DIAGNOSTIC CODES FOR STATUS LED 55

19.9 FAULT CODE HISTORY 55

19.10 INTERNAL LIGHTING SYSTEM 55

20.0 WIRE DIAGRAM FOR TWO STAGE FURNACE WITH ECM 2.3 56

21.0 WARRANTY 57

22.0 REPLACEMENT PARTS LIST 58

23.0 SERVICE HISTORY 59

24.0 NOTES 60

NOTE: Changes, other than editorial, are denoted by a vertical line in the margin.

ATTENTION:

UPFLOW VENTING RIGHT, MUST DRAIN ON

LEFT SIDE.

1.0 INTRODUCTION

This high effi cient gas fi red two stage condensing furnace is an upfl ow warm air furnace suitable for residential

and light commercial heating applications with inputs from 60,000 to 120,000 Btu/hr.

This high effi cient furnace series is CSA certifi ed as a Category IV indirect or direct vent central forced air

furnace. When installed as a direct vent furnace, all combustion air is supplied to the furnace burners through the

air intake system. (See Section 7, “Ventilation and Combustion Piping.”)

The furnace is shipped completely assembled except for the condensate drain trap assembly. Please inspect

for damage when the furnace is unpacked.

IMPORTANT:

PLEASE READ THIS MANUAL CAREFULLY

AND KEEP IN A SAFE PLACE FOR FUTURE

REFERENCE BY A SERVICE TECHNICIAN.

W415-1064 / 11.11.11

Page 4

4

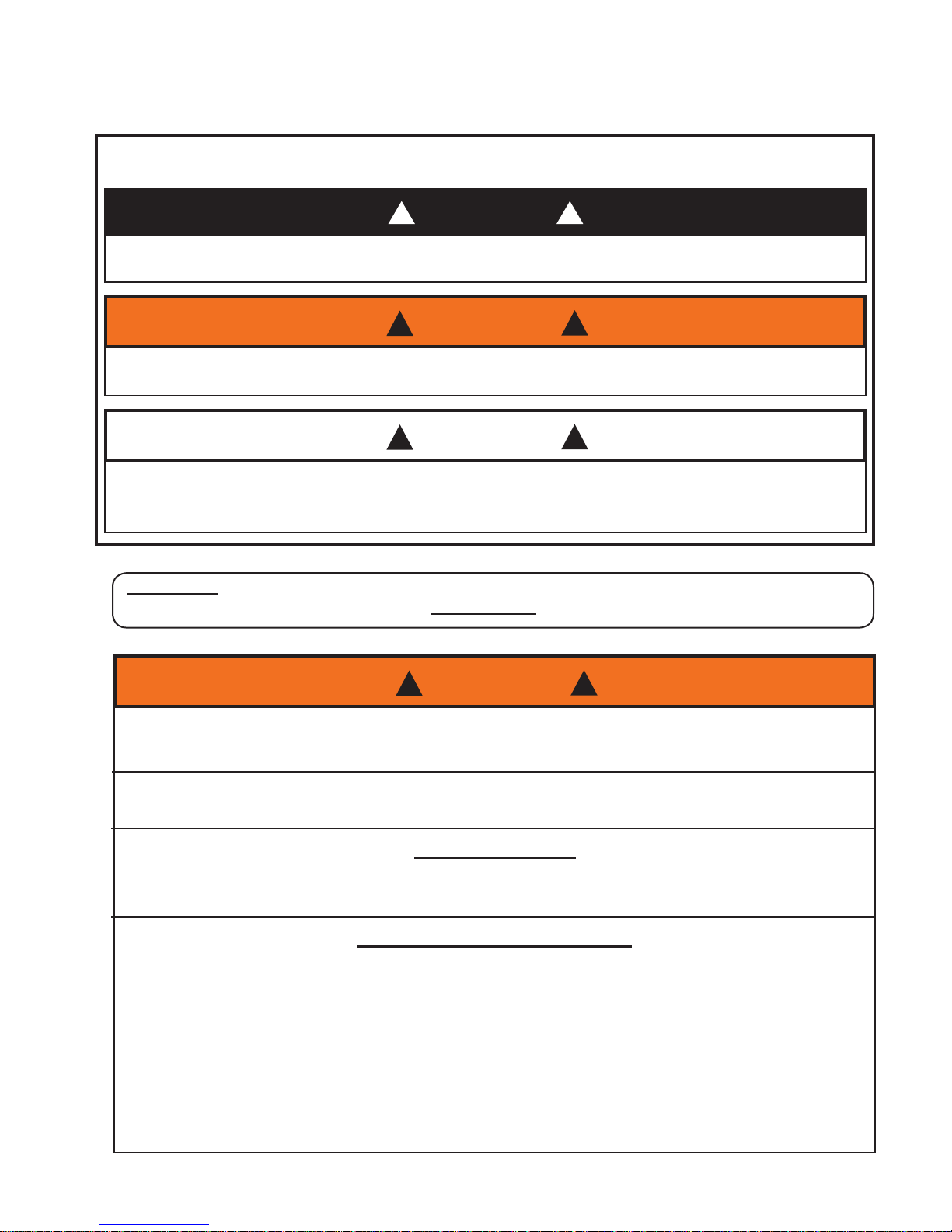

2.0 SAFETY SYMBOLS AND WARNINGS

Understand and pay particular attention to the words DANGER, WARNING, and CAUTION and the following

defi ned symbols are used throughout this manual to notify the reader of potential hazards of varying risk levels.

! !

DANGER

INDICATES AN IMMINENTLY HAZARDOUS SITUATION WHICH, IF NOT AVOIDED, WILL

RESULT IN DEATH OR SERIOUS INJURY.

!

WARNING

INDICATES A POTENTIALLY HAZARDOUS SITUATION WHICH, IF NOT AVOIDED, COULD

RESULT IN DEATH OR SERIOUS INJURY.

!

CAUTION

INDICATES A POTENTIAL HAZARDOUS SITUATION WHICH, IF NOT AVOIDED, MAY

RESULT IN MINOR OR MODERATE INJURY. IT MAY ALSO BE USED TO ALERT AGAINST

UNSAFE PRACTICES.

IMPORTANT:

READ THE FOLLOWING INSTRUCTIONS COMPLETELY BEFORE INSTALLING!

!

WARNING

IF THE INFORMATION IN THESE INSTRUCTIONS IS NOT FOLLOWED EXACTLY, A FIRE

OR EXPLOSION MAY RESULT, CAUSING PROPERTY DAMAGE, PERSONAL INJURY OR

LOSS OF LIFE.

!

!

!

THIS PRODUCT MUST BE INSTALLED BY A LICENSED PLUMBER OR GAS FITTER

WHEN INSTALLED WITHIN THE COMMONWEALTH OF MASSACHUSETTS.

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS AND LIQUIDS, OR

OTHER COMBUSTIBLE MATERIALS IN THE VICINITY OF THIS OR ANY OTHER APPLIANCE.

• DO NOT TRY TO LIGHT ANY APPLIANCE.

• DO NOT TOUCH ANY ELECTRICAL SWITCH; DO NOT USE ANY PHONE IN YOUR

BUILDING.

• IMMEDIATELY CALL YOUR GAS SUPPLIER FROM A NEIGHBOR’S PHONE, OR A CELLULAR PHONE FROM A LOCATION WELL AWAY FROM THE BUILDING. FOLLOW THE

GAS SUPPLIER’S INSTRUCTIONS.

• IF YOU CANNOT REACH YOUR GAS SUPPLIER, CALL THE FIRE DEPARTMENT.

• DO NOT RE-ENTER THE BUILDING UNTIL AUTHORIZED TO DO SO BY THE GAS

SUPPLIER OR THE FIRE DEPARTMENT.

W415-1064 / 11.11.11

FOR YOUR SAFETY

WHAT TO DO IF YOU SMELL GAS

Page 5

5

IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION, SERVICE OR MAINTENANCE

CAN CAUSE INJURY, PROPERTY DAMAGE OR LOSS OF LIFE. REFER TO THIS MANUAL.

INSTALLATION AND SERVICE MUST BE PERFORMED BY A QUALIFIED INSTALLER,

THESE INSTRUCTIONS ARE INTENDED AS AN AID TO QUALIFIED SERVICE

PERSONNEL FOR PROPER INSTALLATION, ADJUSTMENT AND OPERATION OF

THIS FURNACE. READ THESE INSTRUCTIONS THOROUGHLY BEFORE ATTEMPTING

INSTALLATION OR OPERATION. FAILURE TO FOLLOW THESE INSTRUCTIONS MAY

RESULT IN IMPROPER INSTALLATION, ADJUSTMENT, SERVICE OR MAINTENANCE,

POSSIBLY RESULTING IN FIRE, ELECTRICAL SHOCK, CARBON MONOXIDE

POISONING, EXPLOSION, PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

2.1 SAFETY RULES

1. Use this furnace only with type of gas approved for this furnace. Refer to the furnace rating plate.

2. Install this furnace only in dry indoor locations (protected from weather).

3. Provide adequate combustion and ventilation air to the furnace space as specifi ed in Section 7 of this

manual, “Ventilation and Combustion Piping.”

4. Combustion products must be discharged outdoors. Connect this furnace to an approved vent system

only, as specifi ed in Section 7 of this manual, “Venting and Combustion Piping.”

5. Never test for gas leaks with an open fl ame. Use a commercially available soap solution made

specifi cally for the detection of leaks to check all connections as specifi ed in Section 12 of this manual,

“Gas Supply and Piping.”

6. Always install furnace to operate within the furnace’s intended temperature-rise range with a duct

system, which has an external static pressure within the allowable range, listed on the furnace rating

plate, and as specifi ed in Sections 3, 6, and 18 of this manual, “Furnace Sizing,” “Ductwork,” and

“Airfl ow.”

7. When a furnace is installed so that the supply ducts carry air circulated by the furnace to areas outside

the space containing the furnace, the return air shall also be handled by duct(s) sealed to the furnace

casing and terminating outside the space containing the furnace. (Furnace for heating the home located

in the attached garage, for example).

!

WARNING

!

SERVICE AGENCY OR THE GAS SUPPLIER.

8. A gas-fi red furnace for installation in a residential garage must be installed so that the burners and ignitor

are no less than 18” above the fl oor. The furnace must be located, or protected to avoid physical damage

by vehicles. (See safety warning).

9. This furnace must not be used for temporary heating of buildings under construction.

2.2 CODES

1. This furnace must be installed:

a. In accordance with all local codes, by-laws and regulations by those authorities having jurisdiction.

b. In Canada, this furnace must be installed in accordance with the current CAN/CGA -B149.1 and .2

Natural Gas and Propane, and the National Electric Code (NEC) NFPA 70.

c. In the United States, this furnace must be installed in accordance with the current ANSI Z223.1 (NFPA

54) National Fuel Gas Code.

W415-1064 / 11.11.11

Page 6

6

2. Electrical connections must be made in accordance with:

a. Any applicable local codes, by-laws and regulations.

b. Canada: current edition of CAN/CSA C22.1, Canadian Electrical Code (Part 1).

c. United States: current edition of ANSI/NFPA 70, National Electrical Code.

Codes and additional information may be obtained from:

Canadian Standards Association American Gas Association

5060 Spectrum Way 400 North Capitol Street, NW, Suite 450

Mississauga, Ontario, L4W 5N6 Washington DC, 20001

Phone: (416) 747-4000 Phone: (202) 824-7000

website: www.csa.ca website: www.aga.org

National Fire Protection Association

1 Batterymarch Park

Quincy, MA, 02169-7471

Phone: (617) 770-3000

website: www.nfpa.org

!

WARNING

!

DO NOT INSTALL THIS FURNACE IN A MOBILE HOME! THIS FURNACE IS NOT

APPROVED FOR INSTALLATION IN A MOBILE HOME. DOING SO COULD CAUSE FIRE,

PROPERTY DAMAGE, PERSONAL INJURY OR LOSS OF LIFE.

THE FURNACE CONTAINS FOIL COVERED FIBERGLASS INSULATION. INHALATION OF

FIBERGLASS PARTICLES IS ASSOCIATED WITH RESPIRATORY DISEASE INCLUDING

CANCER.

NATURAL GAS AND PROPANE ARE NORMALLY ODORIZED BY THE FUEL SUPPLIER. IN

SOME CASES, THE ODORANT MAY NOT BE PERCEIVABLE. INSTALLATION OF UL AND

ULC RECOGNIZED FUEL GAS DETECTORS INSTALLED IN ACCORDANCE WITH THEIR

MANUFACTURER’S INSTRUCTIONS IS RECOMMENDED AS AN ADDITIONAL MARGIN OF

SAFETY.

THE EXHAUST GASES FROM THIS FURNACE CONTAIN CHEMICALS WHICH ON

SOME OCCASIONS MAY INCLUDE CARBON MONOXIDE. CARBON MONOXIDE IS AN

ODORLESS, TASTELESS, CLEAR COLORLESS GAS WHICH IS HIGHLY TOXIC. EVEN

LOW CONCENTRATIONS ARE SUSPECTED OF CAUSING BIRTH DEFECTS AND OTHER

REPRODUCTIVE HARM.

UL AND ULC RECOGNIZED CO DETECTORS ARE RECOMMENDED FOR ALL BUILDINGS

EQUIPPED WITH FOSSIL FUEL BURNING APPLIANCES. ALL CO DETECTORS SHOULD

BE INSTALLED IN ACCORDANCE WITH THEIR MANUFACTURER’S INSTRUCTIONS AND

APPLICABLE LOCAL BUILDING CODES.

FIRE, EXPLOSION OR CARBON MONOXIDE POISONING HAZARD!

FAILURE TO REPLACE WITH PROPER CONTROL COULD RESULT IN FIRE, EXPLOSION

REPLACE GAS VALVE ONLY WITH THE SAME MODEL NUMBER OR AS SPECIFIED BY THE

W415-1064 / 11.11.11

OR CARBON MONOXIDE POISONING.

MANUFACTURER.

Page 7

!

WARNING

WHEN THIS FURNACE IS INSTALLED IN A RESIDENTIAL GARAGE, IT MUST BE

INSTALLED SO THE BURNERS AND IGNITION SOURCE ARE LOCATED NO LESS THAN

18” ABOVE THE FLOOR TO PREVENT THE RISK OF IGNITING FLAMMABLE VAPORS

WHICH MAY BE PRESENT IN THE GARAGE.

THE FURNACE MUST BE LOCATED OR PROTECTED TO AVOID PHYSICAL DAMAGE BY

VEHICLES.

FAILURE TO HEED THESE WARNINGS CAN CAUSE A FIRE OR EXPLOSION, RESULTING

IN PROPERTY DAMAGE, PERSONAL INJURY OR LOSS OF LIFE.

FIGURE 1 - FURNACE DIMENSIONS AND CLEARANCE TO COMBUSTIBLES

%

!

7

$/7(51$7(

&20%867,21

$,5

+9(17

)

$

TOP

*

$/7(51$7(

)/8(

/2&$7,21

&

$/7*$6/,1(

6&+

$/7)/8(/2&$7,21

$/7&20%867,21

$,5/2&$7,21

'

$/7(51$7(

5(7851$,5

(

LEFT SIDE

$/7(51$7(&21'( 16$7(

75$3/2&$7,21

$/7(51$7(&21'( 16$7(

75$3/2&$7,21

$/7(51$7(

(/(&75,&$/& 211(&7

TABLE A - FURNACE DIMENSIONS (INCHES)

INPUT

OUTPUT

HIGH

INPUT

LOW

OUTPUT

LOW Width Depth Height Supply Air Return Air

K/Btu/hr K/Btu/hr K/Btu/hr K/Btu/hr A B C (F x G) (D x E)

60 58 27 26 17½ 31 32 7/8 16 x 19½ 14 x 22

80 78 48 47 17½ 31 32 7/8 16 x 19½ 14 x 22

100 97 60 58 22½ 31 32 7/8 21½ x 19½ 14 x 22

120 116 72 70 22½ 31 32 7/8 21½ x 19½ 14 x 22

$/7*$6/,1(6&+

$/7&20%867,21

$,5/2&$7,21

$/7)/8(/2&$7,21

5(7851$,5

'

(

RIGHT SIDE

TABLE B - MINIMUM CLEARANCES TO COMBUSTIBLE

MATERIALS (INCHES)

TOP 0

PLENUM TOP 1/2

FRONT 0*

BACK 0

SIDES 0

BOTTOM 0***

FLUE PIPE 0

ENCLOSURE CLOSET

*24” REQUIRED FOR SERVICE

*** CERTIFIED FOR CLOSET INSTALATION ON COMBUSTIBLE FLOORING.

UPFLOW

0

Top

NOTES:

S - Service clearance 24 inches or more.

C - Combustible oor (but not carpet or non-ceramic tile).

All models approved for closet installation.

W415-1064 / 11.11.11

Page 8

8

2.3 INSTALLATION REQUIREMENTS SPECIFIC TO THE STATE OF

MASSACHUSETTS FOR DIRECT VENT, MECHANICAL VENT, AND

DOMESTIC HOT WATER APPLIANCES.

For all side wall horizontally vented gas fueled equipment installed in every dwelling, building or structure used

in whole or in part for residential purposes, including those owned or operated by the commonwealth and

where the side wall exhaust vent termination is less than seven feet above fi nished grade in the area of the

venting, including but not limited to decks and porches, the following requirements shall be satisfi ed:

1. INSTALLATION OF CARBON MONOXIDE DETECTORS:

At the time of installation of the side wall horizontal vented gas fueled equipment, the installing plumber

or gasfi tter shall observe that a hard wired carbon monoxide detector with an alarm and battery back-up

is installed on the fl oor level where the gas equipment is to be installed. In addition, the installing plumber

or gasfi tter shall observe that a battery operated or hard wired carbon monoxide detector with an alarm is

installed on each additional level of the dwelling, building or structure served by the side wall horizontal

vented gas fueled equipment. It shall be the responsibility of the property owner to secure the services of

qualifi ed licensed professionals for the installation of hard wired carbon monoxide detectors.

a. In the event that the side wall horizontally vented gas fueled equipment is installed in a crawl

space or an attic, the hard wired carbon monoxide detector with alarm and battery back-up may be

installed on the next adjacent fl oor level.

b. In the event that the requirements of this subdivision can not be met at the time of completion of

installation, the owner shall have a period of thirty (30) days to comply with the above requirements;

provided, however that during said thirty (30) day period, a battery operated carbon monoxide

detector with an alarm shall be installed.

2. APPROVED CARBON MONOXIDE DETECTORS:

Each carbon monoxide detector as required in accordance with the above provisions shall comply with

NFPA 720 and be ANS/UL 2034 listed and IAS certifi ed.

3. SIGNAGE:

A metal or plastic identifi cation plate shall be permanently mounted to the exterior of the building at

a minimum height of eight (8) feet above grade directly in line with the exhaust vent terminal for the

horizontally vented gas fueled heating appliance or equipment. The sign shall read, in print size no less

than one-half) 1/2 inch in size,

“GAS VENT DIRECTLY BELOW. KEEP CLEAR OF ALL OBSTRUCTIONS”.

4. INSPECTION:

The state or local gas inspector of the side wall horizontally vented gas fueled equipment shall not approve

the installation unless, upon inspection, the inspector observes carbon monoxide detectors and signage

installed in accordance with the provisions of 248 CMR 5.0(2)(a)1. through 4.:

5. EXEMPTIONS:

The following equipment is exempt from 248 CMR 5.08(2)(a)1. through 4.:

1. The equipment listed in Chapter 10 entitled “Equipment Not Required To Be Vented” in the most

current edition of NFPA54 as adopted by the Board; and

2. Product Approved side wall horizontally vented gas fueled equipment installed in a room or structure

separate from the dwelling, building or structure used in whole or in part for residential purposes.

6. (A) MANUFACTURER REQUIREMENTS - GAS EQUIPMENT VENTING SYSTEM PROVIDED. When the

manufacturer of Product Approved side wall horizontally vented gas equipment provides a venting system

design or venting system components with the equipment, the instructions provided by the manufacturer

for installation of the equipment and the venting system shall include:

1. Detailed instructions for the installation of the venting system design or the venting system

components; and

2. A complete parts list for the venting system design or venting system.

W415-1064 / 11.11.11

Page 9

7. INSTALLATION INSTRUCTIONS:

A copy of all installation instructions, and any instructions relating to venting shall remain with the furnace

at the completion of the installation.

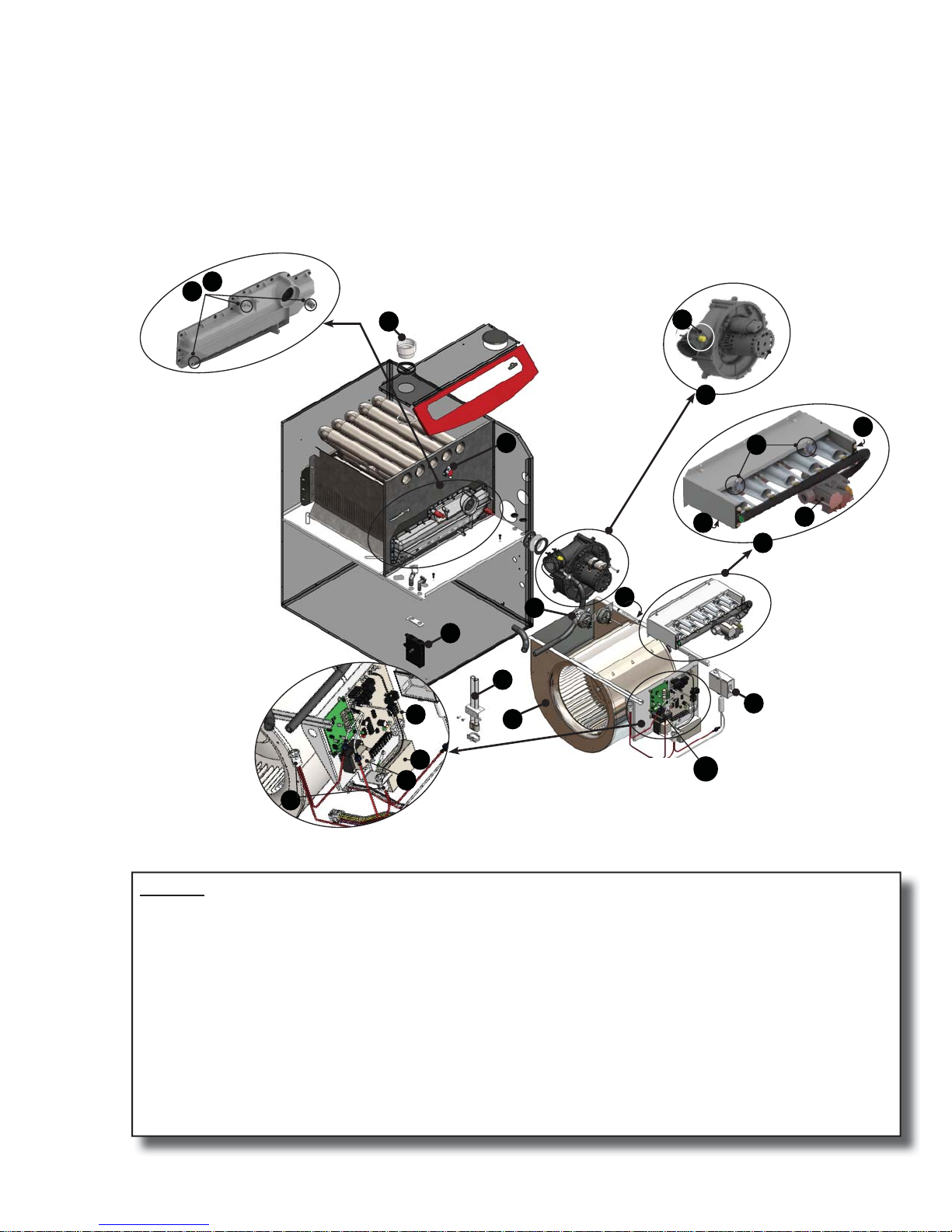

FIGURE 2 - FURNACE COMPONENTS

15

7

9

22

1

5

18

10

9

20

14

8

21

19

6

13

12

2

3

17

*16

4

11

LEGEND

1. Combustion Air Intake Fitting 13. Two Speed Exhauster

2. Flame Roll-Out Switch (2) 14. Pressure Switch Assembly

3. Flame Sensor - located underneath 15. Front Manifold Cover Pressure Tap (3)

4. Two Stage Gas Valve *16. PFC “Choke Coil” (used on ¾ and 1 Hp units only)

5. Air High Temperature Limit - supply air 17. Door Switch and Junction Box

6. Vent and Drain (Assembly) Coupling 18. Blower Motor (not shown, located on right side of

7. Drain for Recovery Coil (3) blower)

8. Condensate Trap 19. Circulating Air Blower

9. Two Stage Integrated Furnace Control (IFC) 20. UV Light Ballast

10. Transformer for 24 VAC / 40 VA 21. UV Light Bulb

11. Burner Assembly 22. LED Trouble Light (2)

12. Hot Surface Igniter (HSI)(located underneath)

W415-1064 / 11.11.11

Page 10

10

3.0 FURNACE SIZING

The maximum hourly heat loss for each heated space shall be calculated in accordance with the procedures

described in the manuals of the Heating, Refrigeration and Air Conditioning Institute of Canada (HRAI), or

by any other method which is suitable for local conditions, provided the results obtained are in substantial

agreement with, and not less than those obtained using the procedure described in their manuals.

In the United States, “Manual J - Load Calculation,” published by the Air Conditioning Contractors of America,

describes a suitable procedure for calculating the maximum hourly heat loss.

If the installation is a retrofi t application, do not rely on the capacity of the existing heating equipment as a

method to size the new furnace. Many of the heat transfer multiples listed in earlier versions of load calculation

manuals were much higher than those listed in more recent editions. It is possible that energy saving

measures have been completed since the installation of the existing furnace. This might include additional

insulation in the attic or walls, the application of sprayed foam insulation, the addition of storm windows and

doors, weather-stripping, caulking, etc.

Many of the older furnaces were equipped with large belt drive blower systems, operating at low RPM’s. If

replacing an existing furnace, be sure that the existing ductwork can handle the amount of airfl ow necessary

for a reasonable temperature rise. Most older gas furnaces operated with a system temperature rise of 70 100°F. This furnace is designed to be operated with a system temperature rise (∆T) of High Fire 35 - 65°F, Low

Fire 20 - 50°F. If the furnace selected has an identical output

capacity as the original furnace, a substantial increase in

system air fl ow will be necessary. See Table 1 and the airfl ow

characteristics in Section 18 of this manual, “Airfl ow”.

Existing ductwork should be assessed for its air handling

capabilities.

The “Equal Friction Chart,” as published by ASHRAE and HRAI, is the basis for the various air duct calculators

available through heating supply companies. Following the air velocity guide lines, according to the “Equal

Friction Chart,” or a slide rule air duct calculator, a typical 6” round duct has a capacity of approximately 100

cfm.

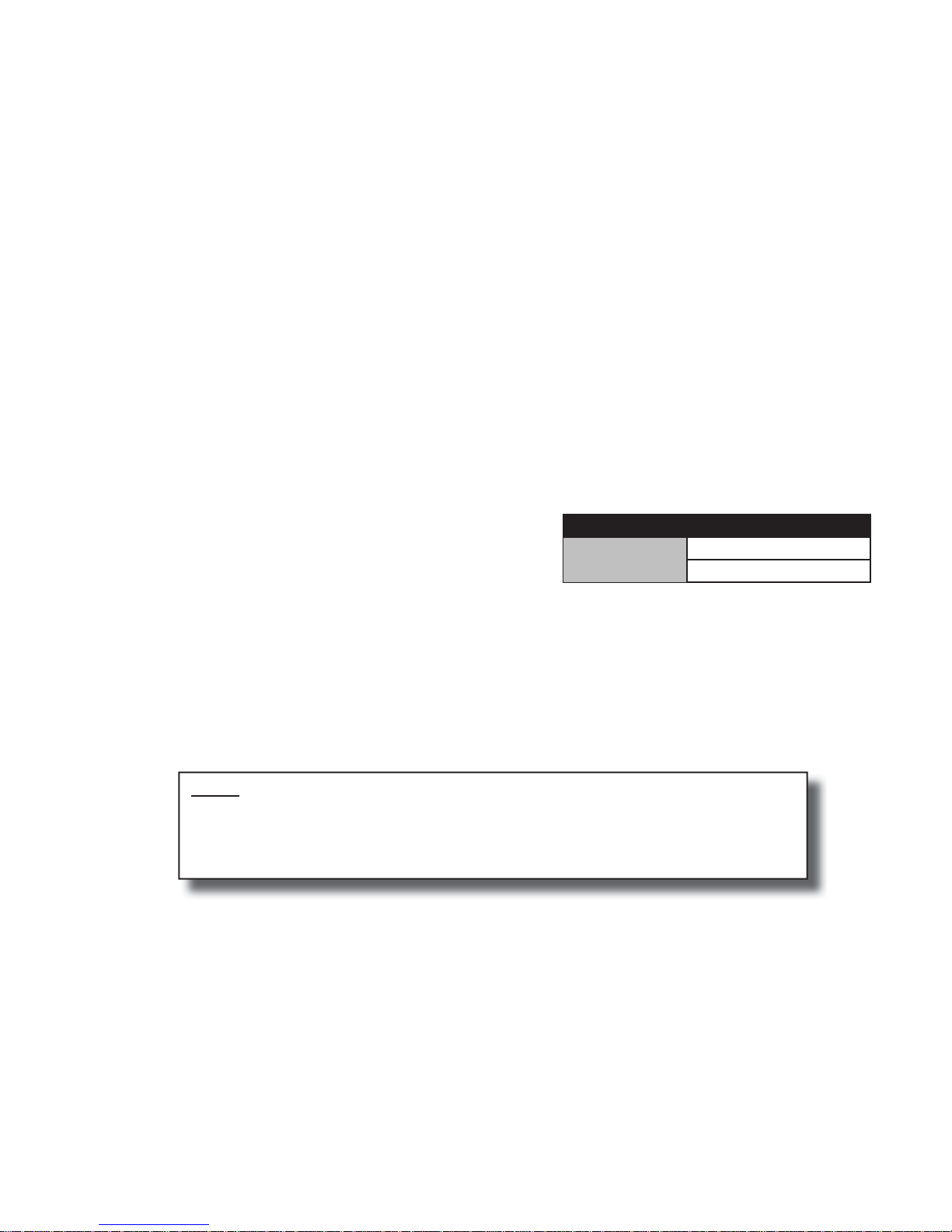

TABLE 1 - RANGE OF TEMPERATURE RISE

Furnace Models Temperature Rise

ALL

High Fire (HF) 35 - 65°F

Low Fire (LF) 20 - 50°F

NOTE:

The return air system is equally as important as the supply air system. An under-sized

return air system will prevent suffi cient quantities of air from reaching the supply air

system and will consequently reduce the service life of the furnace and its components.

W415-1064 / 11.11.11

Page 11

4.0 LOCATION OF UNIT

4.1 GENERAL GUIDELINES

1. Select a location where the exhaust and combustion air piping can be routed between the furnace and

their terminations with a minimum of lengths and fi ttings. Be sure to check that the proposed termination

location will meet code requirements with respect to location and minimum clearances. (See venting

section for minimum and maximum limits.)

2. Select a location as near as possible to the existing or proposed duct system.

3. The furnace location must have provisions for condensate drainage. If a suitable drain is unavailable near

the furnace, a condensate pump must be used. The condensate pump drain tubing must not terminate

outdoors; similar to some air conditioning condensate installations. Be sure to select a condensate pump

that has been approved for furnace condensate applications.

4. The furnace location must permit access for servicing and be within the clearance to combustibles

guidelines as marked on the appliance rating plate.

5. The furnace must be installed on a level surface. It is recommended that the rear of the furnace be

elevated 1/4” higher than the front to facilitate proper condensate drainage.

6. If the furnace is being installed so that the return air will enter through the bottom, the perimeter of the

furnace must be properly supported.

7. In right venting confi guration, furnace must drain on the left side.

11

4.2 OTHER CONSIDERATIONS

1. If the furnace is to be located in an area where the combustion air is laden with chemical compounds such

as bromine, chlorine or fl uorine, as may be found in swimming pool chemicals, laundry detergents, etc.,

use outdoor air for combustion. These compounds when exposed to fl ame, form acids which attack the

heat exchanger and other components.

Exposure to the following substances in the combustion air supply (but not limited to the following) will also

require OUTDOOR AIR for combustion:

• Aerosols, particularly CFC based or propelled aerosols

• Air fresheners

• “Airplane Glue” and similar adhesives and cements

• Ammonia, as commonly found in permanent wave solutions used in hair dressing salons

• Anti-static fabric softeners used in clothes dryers

• Carbon tetrachloride

• Chlorinated cleaners and waxes

• Chlorine and bromine based swimming pool chemicals

• De-icing salts or chemicals (rock salt, etc.)

• Dry cleaning fl uids such as perchloroethylene

• Fumes from curing polyurethane and similar substances

• Halogen based refrigerants including R-12 and R-22

• Hydrochloric acid, muriatic acid and other acid based masonry washing and curing materials

• Printer’s inks, paint removers, varnishes, varsol, toluene, etc.

• Water softener salt and chemicals

2. If this furnace is to be installed in an area over a fi nished ceiling or living area, install a fi eld fabricated

auxiliary drain pan under the furnace to protect that area from accidental condensate spills. The auxiliary

pan should be large enough to collect accidentally spilled condensate from the air conditioning evaporator

coil assembly if applicable.

3. If the furnace is installed in an area where freezing may occur, a garage, an attic, a crawl space or any

unconditioned space, steps must be taken to protect the condensate trap and drain line from freezing.

One possible measure could be to use a self-regulating 5 or 6 watt per foot heat tape covered with a jacket

of insulation. Heat tapes are available in plumbing supply houses.

W415-1064 / 11.11.11

Page 12

12

4.3 INSTALLATION IN UPFLOW POSITION

UPFLOW INSTALLATION: Vent positioning, pressure switch location and drain locations shall be performed in

accordance with instructions in the appropriate sections of this manual.

NON-SUSPENDED INSTALLATION: Maintain clearances to combustibles as outlined in Figure 1, Table B. The

furnace must be supported in such a way as to not allow twisting or sagging of the cabinet.

IMPORTANT:

• THE FURNACE MUST BE INSTALLED ON A LEVEL SURFACE. IT IS RECOMMENDED

THAT THE REAR OF THE FURNACE BE ELEVATED 1/4” HIGHER THAN THE FRONT

TO FACILITATE PROPER CONDENSATE DRAINAGE.

• IF THE FURNACE AND AIR CONDITIONER IS LOCATED ABOVE A FINISHED SPACE,

INSTALL A DRAIN PAN UNDERNEATH THE UNIT.

NOTE

THIS FURNACE IS CERTIFIED FOR UPFLOW INSTALLATION ONLY.

This furnace is approved for installation in attics, alcoves, utility rooms, closets and crawl spaces. If this

furnace is to be installed in a utility room, be sure that it is located in such a way as to allow access for

servicing or the removal of other appliances installed in the room (hot water heater, for example). It is not

permissible to use a rear return on this appliance. Use only side and bottom returns.

4.4 AIR CONDITIONING

This furnace may be used as part of an air conditioning system. The furnace wiring and control system is “air

conditioning ready.” There are the following factors to consider:

The air conditioning evaporator coil must be downstream of the heat exchanger. The cooled air passing

over the warmer heat exchanger tubes can cause condensation inside the tubes, resulting in corrosion and

premature failure.

A parallel duct system can be installed to direct the air from the furnace through the evaporator coil only. Use

dampers or other means to bypass the heat exchanger. If (summer/winter) dampers are used, they should be

interlocked to prevent system operation unless the dampers are in the full open or full closed position.

NOTE

If installing a two stage air conditioning system, clip the JW38 jumper wire between Y and Y2 on the furnace

control board.

W415-1064 / 11.11.11

Page 13

5.0 COMBUSTIBLE CLEARANCES

Figure 1, Table B provides the certifi ed clearances to combustibles and dimensional information. Also see

the appliance rating plate affi xed to the furnace for specifi c model number, serial number and clearance to

combustibles information.

IMPORTANT:

THIS FURNACE REQUIRES A MINIMUM OF 24” OF FRONT CLEARANCE FOR SERVICE

PURPOSES. FOR THIS PURPOSE, SERVICE CLEARANCE TAKES PRECEDENCE OVER

CLEARANCE TO COMBUSTIBLES.

13

WARNING

THIS FURNACE IS CERTIFIED FOR INSTALLATION ON COMBUSTIBLE FLOORS. THIS

SHALL BE INTERPRETED AS A WOOD FLOOR ONLY.

THE FURNACE MUST NOT BE INSTALLED DIRECTLY ON CARPETING, OR OTHER

COMBUSTIBLE MATERIAL EXCEPT WOOD.

INSTALLATION ON COMBUSTIBLE MATERIAL CAN RESULT IN FIRE, CAUSING PROPERTY

DAMAGE, PERSONAL INJURY OR DEATH.

THE AREA AROUND THE FURNACE MUST BE KEPT CLEAR AND FREE OF ALL

COMBUSTIBLE MATERIALS INCLUDING GASOLINE AND OTHER FLAMMABLE VAPORS

AND LIQUIDS.

THE HOMEOWNER SHOULD BE CAUTIONED THAT THE FURNACE AREA MUST NOT BE

USED AS A CLOSET OR FOR ANY OTHER STORAGE PURPOSE.

! !

W415-1064 / 11.11.11

Page 14

14

6.0 DUCTWORK

Proper airfl ow is required for the correct operation of this furnace. Insuffi cient airfl ow may cause erratic

operation, could cause the furnace to cycle on the high temperature limit, and may damage the heat

exchanger. Excessive airfl ow may result in an excessively noisy duct system and may result in undesirable

consequences such as creating uncomfortable drafts.

If air conditioning is to be used with the furnace, the duct system must be capable of delivering the correct

amount of airfl ow for each system.

The ductwork should be sized and constructed in accordance with accepted industry standards. Duct sizing

and construction information may be obtained from:

• A.C.C.A. (Air Conditioning Contractors of America)

• A.S.H.R.A.E. (American Society of Heating, Refrigeration and Air Conditioning Engineers

• H.R.A.I. (Heating, Refrigerating and Air Conditioning Institute (Canada)

• S.M.A.C.N.A. (Sheet Metal and Air Conditioning Contractors’ National Association (United States)

All of the above professional organizations have duct sizing manuals available.

The total static pressure drop of the air distribution system (including fi lters) should not exceed 1.0” w.c.

!

WARNING

DO NOT ALLOW GAS PIPING TO BE ROUTED THROUGH JOIST SPACES THAT ARE

USED FOR RETURN AIR PURPOSES. DO NOT USE JOIST SPACES FOR RETURN AIR

PURPOSES IF THE JOIST SPACE ALREADY CONTAINS PLUMBING STACKS, CHIMNEY

COMPONENTS, ETC. UNLESS THE PORTION USED FOR RETURN AIR PURPOSES CAN

BE COMPLETELY ISOLATED FROM PORTIONS WITH OTHER USAGES.

NEVER ALLOW THE PRODUCTS OF COMBUSTION FROM THE FLUE TO ENTER THE

RETURN AIR OR SUPPLY AIR DUCTWORK.

ALL RETURN AIR DUCTWORK MUST BE ADEQUATELY SEALED AND SECURED TO

THE FURNACE WITH SHEET METAL SCREWS. TAPE THE SHEET METAL SEAMS IN THE

VICINITY OF THE FURNACE WITH DUCT TAPE OR SIMILAR MATERIAL.

WHEN THE FURNACE IS MOUNTED ON A PLATFORM WITH RETURN AIR THROUGH THE

BOTTOM, IT MUST BE SEALED AIR TIGHT BETWEEN THE FURNACE AND THE RETURN

AIR PLENUM. THE FLOOR OR PLATFORM MUST PROVIDE SOUND PHYSICAL SUPPORT

OF THE FURNACE WITHOUT SAGGING, CRACKS OR GAPS AROUND THE BASE,

PROVIDING A SEAL BETWEEN THE SUPPORT AND THE BASE.

FAILURE TO PREVENT PRODUCTS OF COMBUSTION FROM BEING CIRCULATED INTO

THE LIVING SPACE CAN CREATE POTENTIALLY HAZARDOUS CONDITIONS, INCLUDING

CARBON MONOXIDE POISONING THAT COULD RESULT IN PERSONAL INJURY OR

DEATH.

!

DO NOT, UNDER ANY CIRCUMSTANCES, CONNECT RETURN OR SUPPLY AIR

DUCTWORK TO OR FROM ANY OTHER HEAT PRODUCING DEVICE SUCH AS A

FIREPLACE INSERT, STOVE, ETC. DOING SO MAY RESULT IN FIRE, CARBON MONOXIDE

POISONING, EXPLOSION, PERSONAL INJURY, LOSS OF LIFE, OR PROPERTY DAMAGE.

W415-1064 / 11.11.11

Page 15

6.1 DUCTWORK STEPS

1. Position the furnace to minimize ductwork length and fi ttings.

2. Cut open a return air inlet. The choices are furnace bottom, either side, or any combination thereof (i.e.,

two sides or a side and the bottom).In all cases, cut the return air opening the full width of the return air

markers on the side panel.

15

!

WARNING

!

DO NOT USE THE REAR PANEL AS A RETURN AIR INLET. THERE IS INSUFFICIENT

ROOM TO PERMIT ADEQUATE AIRFLOW.

3. Connect the return air duct or fi lter fi tting to the furnace. The connection should be sealed air tight to prevent

entraining combustion gases from an adjacent fuel burning appliance, or entraining combustion air for this

furnace or adjacent fuel burning appliances.

4. Ensure that there is adequate space and accessibility for air fi lter removal.

NOTE: If two return air inlets are used, both must be equipped with fi lters.

5. If an air conditioning evaporator coil is required, position it on the supply air side of the furnace. Ensure

that no air can bypass the evaporator coil.

6. Connect the supply air plenum to the supply air outlet.

FLEXIBLE DUCT CONNECTORS are an effective device to prevent the telegraphing of mechanical noise from

the furnace to other parts of the home via the ductwork. If using fl exible connectors, ensure that the adjoining

duct is independently supported.

W415-1064 / 11.11.11

Page 16

16

7.0 VENTING AND COMBUSTION PIPING

!

WARNING

READ, UNDERSTAND AND FOLLOW ALL INSTRUCTIONS IN THIS SECTION. FAILURE TO

PROPERLY VENT OR SUPPLY COMBUSTION AIR TO THIS FURNACE CAN CAUSE CAR-

BON MONOXIDE POISONING, OR AN EXPLOSION OR FIRE, RESULTING IN PROPERTY

DAMAGE, PERSONAL INJURY OR LOSS OF LIFE.

7.1 ACCEPTABLE MATERIALS IN CANADA

Effective August 1, 2007, all vent piping materials and fi ttings for fl ue gas venting must be ULC S636 listed

and identifi ed as such on the material. The fi rst 3ft. (900mm) of venting must be readily available for visual

inspection. Specifi ed primers and glues of the certifi ed vent system must be from a single system manufacture,

and not intermixed with other system manufacture’s vent system parts. The components of the certifi ed vent

system must not be interchanged with other vent systems, or unlisted pipe, and or fi ttings. Follow the venting

manufacturers instructions on installation, cutting, de-burring, cementing, curing and supporting of the venting

system.

This furnace must be vented with ULC S636 certifi ed PVC (Poly Vinyl Chloride) or PPE (Polypropolene)

material with a minimum rating of 149°F (65º C) or more.

The combustion air piping does not have fl ue gases traveling through it and may be installed with common

ABS, PVC or CPVC piping or fi ttings. This piping, fi ttings, primer and cement will need to be installed as per

the manufacturers instructions including cementing, cutting, curing and supporting the piping.

!

7.2 ACCEPTABLE MATERIALS IN UNITED STATES

For United States installations, the combustion air and vent piping and fi ttings may be comprised of:

• Schedule 40 PVC, ASTM D1785 or CSA B137.3

• PVC-DWV, ASTM D2665 or CSA B181.2

• Schedule 40 CPVC, ASTM F441 or CSA B137.6

• PVC PRIMER AND SOLVENT CEMENT: ASTM D2564

Follow piping manufacturers instructions on proper installation of piping and fi ttings including cutting, deburring,

priming, cementing, curing and supporting.

W415-1064 / 11.11.11

Page 17

8.0 NON-DIRECT VENT FURNACE INSTALLATIONS

USING INDOOR COMBUSTION AIR (ONE PIPE

SYSTEM)

The furnace, although designed as a direct vent type appliance, may be installed with the intake vent inside the

structure.

17

!

WARNING

THIS FURNACE AND ANY OTHER FUEL BURNING APPLIANCE MUST BE PROVIDED

WITH ENOUGH FRESH AIR FOR PROPER COMBUSTION AND VENTILATION OF THE

FLUE GASES. MOST HOMES WILL REQUIRE THAT OUTSIDE AIR BE BROUGHT TO

THE FURNACE AREA. FAILURE TO DO SO CAN CAUSE PERSONAL INJURY, OR DEATH

FROM CARBON MONOXIDE POISONING.

Adequate provisions for combustion and ventilation air must be in accordance with CAN/CGA-B149 in Canada,

and ANSI Z223.1 - 1992, section 5.3, “Air for Combustion and Ventilation,” in the United States. Check with

local authorities for any additional building codes bylaws or regulations.

!

CAUTION

AIR FOR COMBUSTION AND VENTILATION PURPOSES MUST NOT ORIGINATE FROM A COR-

ROSIVE ATMOSPHERE. ANY FURNACE FAILURE CAUSED BY CORROSIVE ELEMENTS IS

EXCLUDED FROM WARRANTY COVERAGE.

The following types of installation sites (but not limited to the following) will REQUIRE OUTDOOR AIR for

combustion because of chemical exposures:

• Commercial buildings

• Buildings with indoor swimming pools

• Furnaces installed in laundry rooms

• Furnaces in hobby or craft rooms

• Furnaces installed near chemical storage areas

• Exposure to the following substances in the combustion air supply (but not limited to the following) will

also require OUTDOOR AIR for combustion:

• Aerosols, particularly CFC based or propelled aerosols

• Air fresheners

• “Airplane Glue” and similar adhesives and cements

• Ammonia, as commonly found in permanent wave solutions used in hair dressing salons

• Anti-static fabric softeners used in clothes dryers

• Carbon tetrachloride

• Chlorinated cleaners and waxes

• Chlorine and bromine based swimming pool chemicals

• De-icing salts or chemicals (rock salt, etc.)

• Dry cleaning fl uids such as perchloroethylene

• Fumes from curing polyurethane and similar substances

• Halogen based refrigerants including R-12 and R-22

• Hydrochloric acid, muriatic acid and other acid based masonry washing and curing materials

• Printer’s inks, paint removers, varnishes, varsol, toluene, etc.

• Water softener salt and chemicals

!

!

W415-1064 / 11.11.11

Page 18

18

Combustion air must be free of acid forming chemicals such as sulphur, fl uorine and chlorine. These elements

are found in aerosol sprays, detergents, bleaches, cleaning solvents, air fresheners, paint and varnish

removers, refrigerants, and many other commercial and household products. When burned in a gas fl ame,

vapors from these products form acid compounds. Acid compounds increase the dew point temperature of the

fl ue products and are highly corrosive after they condense.

8.1 DETERMINING COMBUSTION AIR

8.1.1 CASE 1: FURNACE LOCATED IN A UNCONFINED SPACE

Unconfi ned space does not necessarily mean that ventilation will not have to be introduced from the outdoors,

particularly in airtight homes. The minimum requirement for unconfi ned space is a volume of 50 cubic feet for

each 1000 Btu/hr for all fuel burning appliances located within the unconfi ned area.

If the amount of combustion and ventilation air is insuffi cient to properly operate the furnace and other fuel

burning appliances within the unconfi ned area, it will be necessary to supply it from the outdoors based on the

criteria used when calculating the air supply for a confi ned space.

NOTE

If planning to use the inside air in an unconfi ned space, remember to test for proper furnace operation (as well

as other fuel burning appliances located within the unconfi ned space) with respect to adequate combustion and

ventilation air with fi replace dampers open, clothes dryer running, bathroom exhaust fans on, kitchen range hood

on, etc.

8.1.2 CASE 2: FURNACE LOCATED IN A CONFINED SPACE

A confi ned space, (any space smaller than the minimums discussed in Case 1), must have two air openings;

one within 12” of the ceiling and the other within 12” of the fl oor. The air openings must be sized based on

whether the combustion and ventilation air is being taken from indoors or outdoors, the method outdoor air (if

used) is introduced, and taking into account any other fuel burning appliances in the confi ned space.

If suffi cient indoor combustion and ventilation air is available for the furnace and all other fuel burning

appliances, size each opening on the basis of one square inch of free area per 1000 Btu/hr. (Figure 4)

NOTE

Be sure to consider all clothes dryers, bathroom fans, range hoods, etc., when making this calculation.

The minimum requirement for these openings is 100

square inches, even for the furnace models under

100,000 Btu/hr.

NOTE

If using grills to cover the two

openings, factor in the free

area of the grill. Typically, a

sidewall grill will have a free area

approximately 50% of its nominal

size. Consequently, if the required

opening is 10 x 10, it will have to

be doubled if using a sidewall grill

with 50% free area.

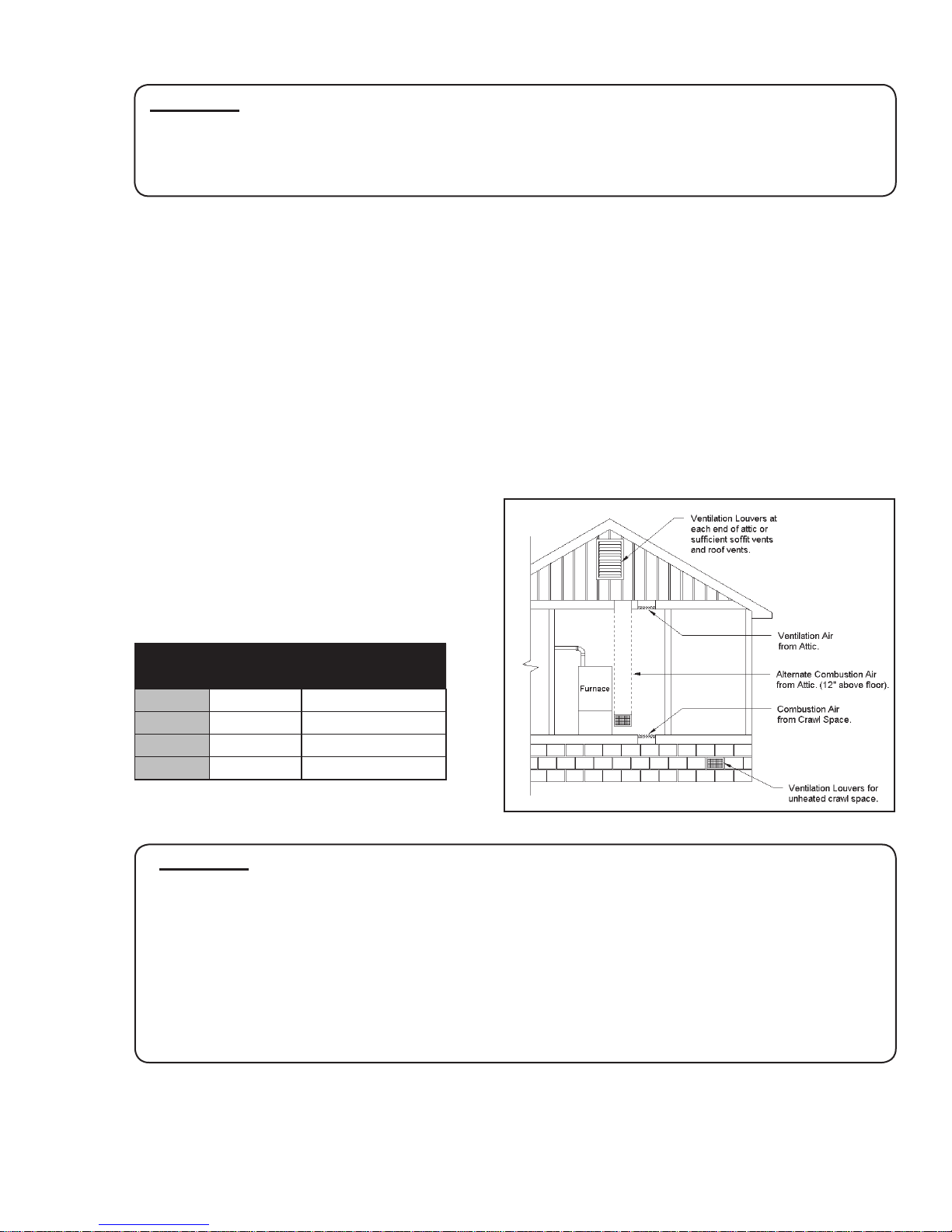

FIGURE 4 - COMBUSTION/DILUTION AIR FROM

HEATED INSIDE SOURCES (CASE 2)

W415-1064 / 11.11.11

Page 19

19

IMPORTANT:

IF AN EXHAUST FAN, FIREPLACE, CLOTHES DRYER OR ANY SIMILAR DEVICE IS PRESENT IN THE

INDOOR AREA FROM WHICH THE COMBUSTION AND VENTILATION AIR WILL BE DRAWN, NEGATIVE

PRESSURE COULD BE A PROBLEM IF NATURAL INFILTRATION FROM THE OUTDOORS DOES NOT

MATCH THE RATE AT WHICH AIR IS EXHAUSTED.

8.1.3 CASE 3: FURNACE LOCATED IN A CONFINED SPACE,

OUTDOOR AIR FROM ATTIC OR CRAWL SPACE

In this circumstance, the free area of each of the two combustion and ventilation air openings is based on

a minimum of 1 square inch per 4000 Btu/hr. In this confi guration, one opening can originate from the fl oor

drawing combustion and ventilation air from the ventilated crawl space.

The other opening may communicate freely with a ventilated the attic. If using the attic air, ensure that the

opening is ducted from the ceiling high enough to be above the insulation. The attic must be adequately

vented with soffi t vents or gable vents (Figure 5).

As an alternative to creating an opening in the fl oor to draw air from a crawl space, a duct may be dropped from

the attic terminating 12” above the fl oor.

The following table shows minimum free areas

and round pipe sizes when drawing combustion air

vertically from the attic or crawl space for the furnace

only. If other fuel burning appliances are present,

their combustion air and ventilation air requirements

must be added to those of the furnace.

FIGURE 5 - OUTSIDE AIR FOR COMBUSTION, ATTIC OR

CRAWL SPACE (CASE 3)

TABLE 2 - VERTICAL AIR SUPPLY (CASE 3)

Input Free Area

K/Btu/hr Ea. Opening

60 15 in. ² 5 in.

80 20 in. ² 6 in.

100 25 in. ² 6 in.

120 30 in. ² 7 in.

IMPORTANT:

Round Pipe Size

IF THE ATTIC HAS AN EXHAUST FAN (POWER VENT), IT MAY CREATE A NEGATIVE

PRESSURE SUFFICIENTLY LARGE ENOUGH TO PREVENT THE ATTIC FROM BEING

AN EFFECTIVE SOURCE OF COMBUSTION AND VENTILATION AIR. POWERED ATTIC

FANS DO NOT CUSTOMARILY RUN DURING THE HEATING SEASON; HOWEVER,

SOME ARE CONTROLLED BY A HUMIDISTAT AS WELL AS A THERMOSTAT, WHICH MAY

ALLOW SOME OPERATION DURING THE HEATING SEASON. THE CHOICES ARE (A)

USE THE DIRECT VENT OPTION; (B) OBTAIN OUTDOOR AIR FROM ELSEWHERE; OR

(C) INTERLOCK THE ATTIC EXHAUST FAN WITH THE FURNACE SUCH THAT THE TWO

CANNOT OPERATE SIMULTANEOUSLY.

W415-1064 / 11.11.11

Page 20

20

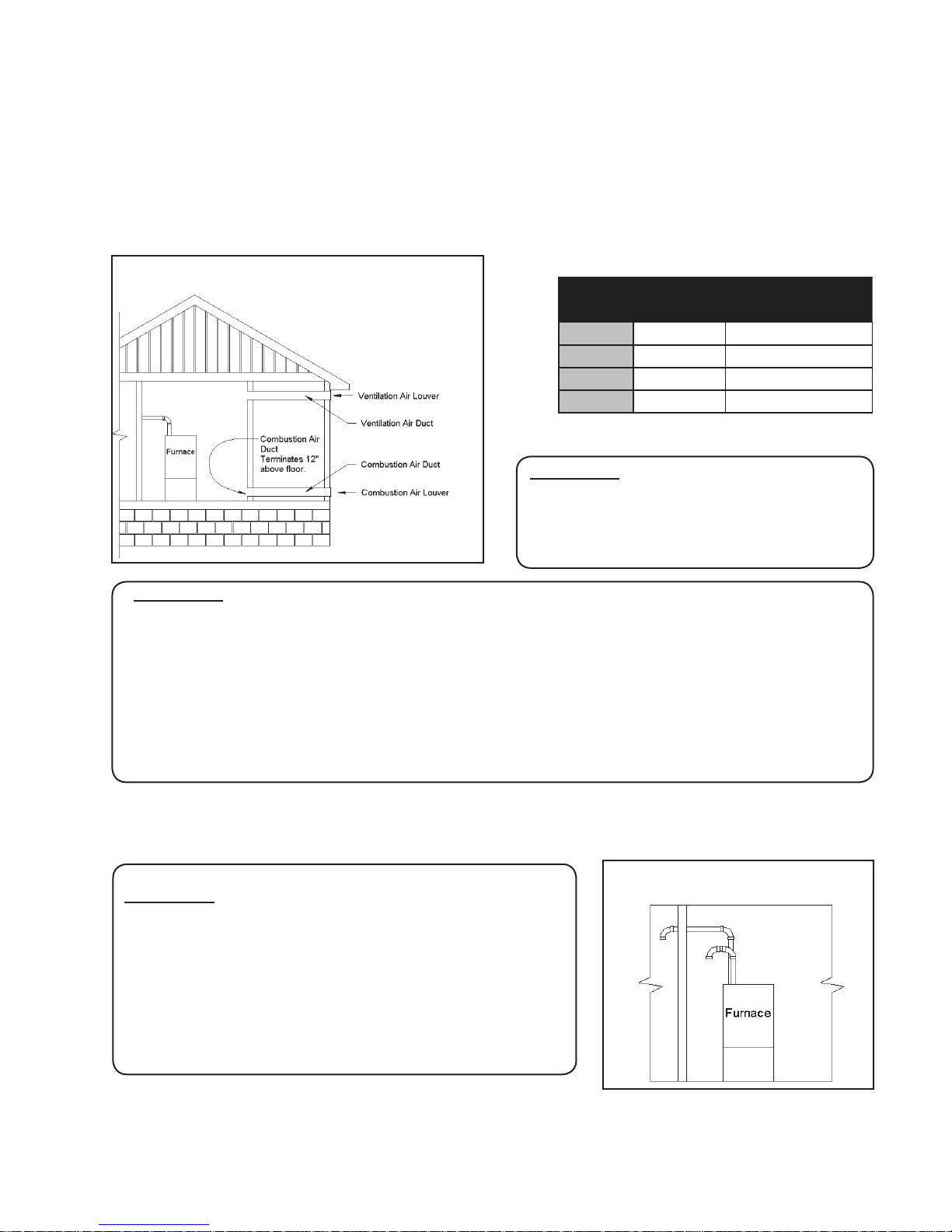

8.1.4 CASE 4: FURNACE LOCATED IN A CONFINED SPACE,

OUTDOOR AIR DUCTED HORIZONTALLY

Similar to Case 3, outdoor air for combustion and ventilation may be drawn through horizontal ducting. The

free area for each opening is calculated on the basis of a minimum of 1 square inch per 2000 Btu/hr input.

The following table shows minimum free areas and round pipe sizes when drawing combustion air horizontally

from the outdoors for the furnace only. If other fuel burning appliances are present, their combustion air and

ventilation air requirements must be added to those of the furnace.

FIGURE 6 - OUTDOOR AIR FOR COMBUSTION,

HORIZONTAL (CASE 4)

TABLE 3 - HORIZONTAL AIR SUPPLY (CASE 4)

Input Free Area

K/Btu/hr Ea. Opening

60 30 in. ² 7 in.

80 40 in. ² 8 in.

100 50 in. ² 8 in.

120 60 in. ² 9 in.

IMPORTANT:

Round Pipe Size

THE OUTDOOR GRILLS MUST BE

INSTALLED IN A LOCATION WHERE

THE

Y WILL NOT BE OBSTRUCTED IN

ANY MANNER.

IMPORTANT:

IF GRILLS ARE USED ON THE OUTSIDE WALL, THEY MUST BE SIZED PROPERLY.

MOST SIDEWALL GRILLS HAVE ONLY 50% FREE AREA. IN THE CASE OF A UNIT

WITH 100,000 BTU/HR INPUT, WHICH REQUIRES A PAIR OF 8” ROUND PIPES TO

OBTAIN SUFFICIENT COMBUSTION AND VENTILATION AIR, THE DUCT COULD BE AN

EQUIVALENT RECTANGULAR DUCT; 8” X 7” FOR EXAMPLE. BASED ON 50% FREE AREA

FOR THE INLET GRILLS, THE ACTUAL GRILL SIZE WOULD HAVE TO BE 14” X 8” OR ITS

EQUIVALENT. A TRANSITION MAY BE USED TO REDUCE TO THE SMALLER DUCT SIZE

IF NECESSARY.

8.1.5 CONNECTION TO FURNACE NON-DIRECT VENT

IMPORTANT:

WHEN USING INDOOR AIR OR THE NON-DIRECT VENT

CONFIGURATION, THE COMBUSTION AIR INLET TO THE

FURNACE MUST BE PROTECTED FROM BLOCKAGE.

USE A DOUBLE ELBOW ARRANGEMENT IF SUPPLYING

COMBUSTION AIR THROUGH THE TOP, OR A DOWNWARD

POINTING SINGLE ELBOW IF SUPPLYING COMBUSTION

AIR THROUGH THE SIDE. (FIGURE 7)

W415-1064 / 11.11.11

FIGURE 7 - NON-DIRECT

COMBUSTION AIR INLET

Page 21

9.0 VENTING GUIDELINES

21

!

CAUTION

FAILURE TO FOLLOW ALL VENTING GUIDELINES MAY RESULT IN ERRATIC FURNACE

OPERATION, FREEZE-UP OF THE EXHAUST AIR PIPING, OR SOOTING OF THE FURNACE.

!

WARNING

READ AND FOLLOW ALL INSTRUCTIONS IN THIS SECTION. FAILURE TO PROPERLY VENT THIS

FURNACE CAN CAUSE CARBON MONOXIDE POISONING OR AN EXPLOSION OR FIRE RESULTING

IN PROPERTY DAMAGE, PERSONAL INJURY OR LOSS OF LIFE.

NOTE

• Combustion air intake and exhaust termination should be inspected periodically to ensure they are clear of

obstructions. i.e. vegetation, debris, snow, etc.

• Accumulation of snow around the combustion air intake and exhaust termination may have negative effects

on appliance operation and/or performance. Snow accumulation should be considered when locating

combustion air intake and exhaust terminations.

• Venting may be vertical or horizontal.

• Minimum vent length - 15 total equivalent feet. (See Venting Table)

• Horizontal piping must slope back towards the furnace at a minimum rate of ¼” to the foot, so that condensate

drains towards the furnace.

• Horizontal runs must be supported at least every 3 feet. Horizontal sections must not dip or sag.

• All vent runs through unconditioned space where freezing might occur should be insulated with 1” thick, medium

density, foil-faced Fiberglass insulation. An equivalent “arm-a-fl ex” or “rub-a-tex” may also be used as long as there

is no heat tape applied to the vent pipe. For horizontal runs where water may collect, wrap the vent pipe with self

regulating 3 or 5 watt heat tape. The heat tape must be CSA, UL, or ULC listed and installed per the manufacturer’s

instructions.

• DO NOT COMMON VENT WITH ANY OTHER APPLIANCE.

• If venting vertically, do not vent up a chimney serving another appliance or install in a chase with a metal or

high temperature plastic pipe from another gas or fuel burning appliance unless the required clearances to

combustibles can be maintained between the furnace venting system and other pipes.

All exhaust piping must be installed in accordance with CAN/CGA-B149.in Canada; the latest edition of

National Fuel Gas Code, NFPA 54 / ANSI Z223.1 in the United States, as well as in accordance with local

codes.

Size the combustion air and exhaust piping in accordance with Table 4. When calculating allowable vent

lengths, be sure to count all termination fi ttings in addition to counting the concentric vent as a straight pipe.

Take the building orientation and the presence of other buildings or other nearby structures into consideration

when planning the venting system location. Certain external structures could create air turbulence around the

vent termination leading to downdrafts and similar venting problems. In windy and hill locations, roof venting

may improve operations. Maximum venting length is based on 30 mph winds, areas where higher gusts are

dominant it is suggest to shorten the horizontal vent length.

The vent and combustion air intake shall be installed so that both are located in the same wind pressure zone.

!

!

W415-1064 / 11.11.11

Page 22

22

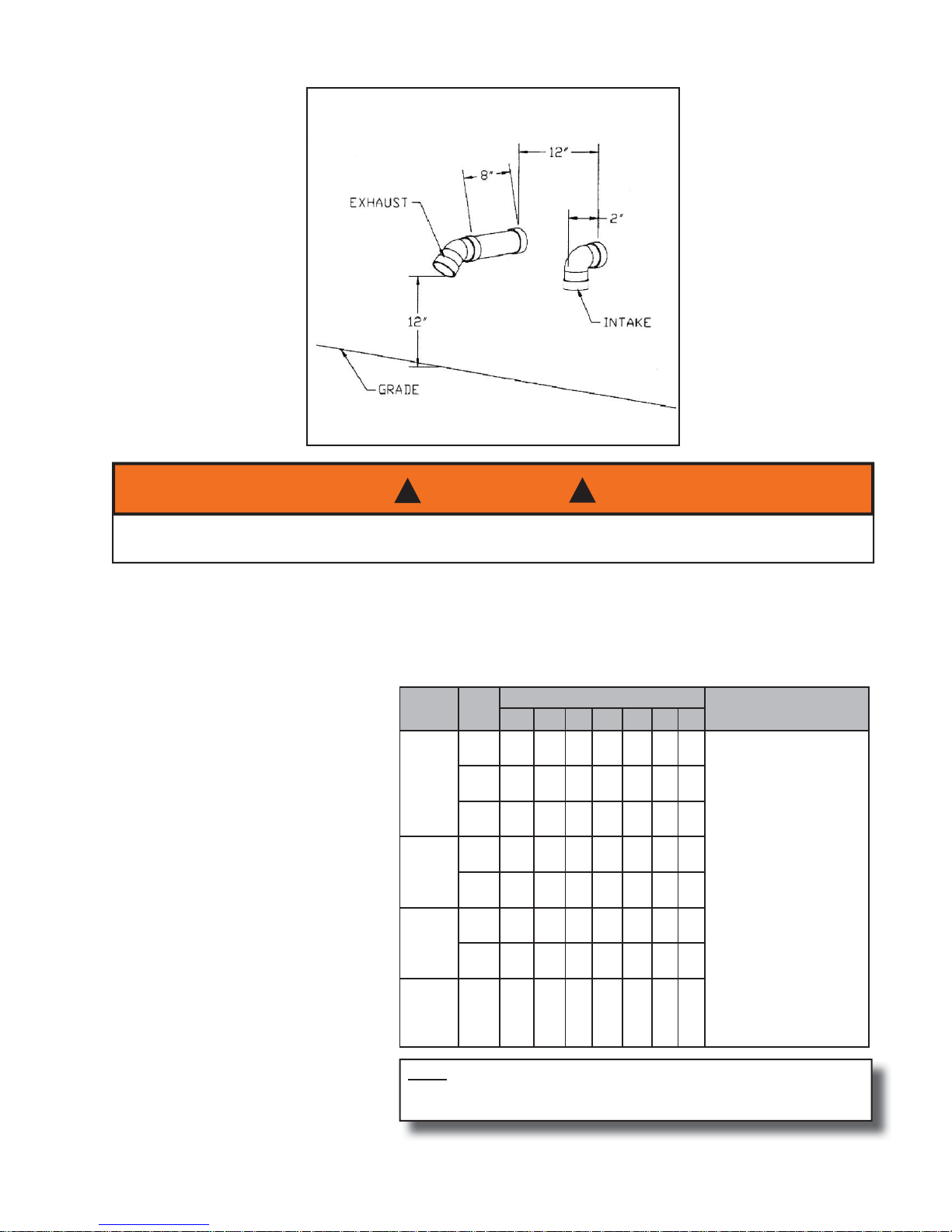

FIGURE 8 - STANDARD (STRAIGHT) HORIZONTAL

VENT DETAIL

RECOMMENDED

*

*18” MIN. FOR COLD CLIMATES (SUSTAINED 0°F (-17°C) FOR 24 OR MORE

CONSECUTIVE HOURS

DO NOT CONNECT FURNACE TO A CHIMNEY OR FLUE SERVING OTHER APPLIANCES OR A

9.1 VENT TERMINATION

Horizontal vents should pass through

the exterior wall. Figure 8 shows

a standard horizontal vent detail.

Terminate the vent approximately 8” or

more from the wall.

Exterior vent pipe greater than 24”

should be insulated with ½” insulation

to prevent moisture from freezing within

the pipe and accumulating.

Size the exhaust pipe as specifi ed in

Table 4 - Direct and Non-Direct Vent

Lengths. This table lists the maximum

allowable length of pipe with respect to

the number of 90° elbows used. For the

purposes of this calculation, one 90°

elbow is equivalent to two 45° elbows.

Avoid locating the terminal in locations

where dripping condensate may cause

problems such as sidewalks, patios,

above planters, near windows where

exhaust gases may cause fogging, etc.

Avoid locating the termination too close

to shrubs and other vegetation. The

condensate may stunt or kill them.

!

WARNING

!

SOLID FUEL BURNING APPLIANCE.

TABLE 4 - DIRECT AND NON-DIRECT VENT LENGTHS

Maximum Allowable Length Of Exhaust Or Intake. Minimum Vent Length 15 ft.

or equivalent.

INPUT

K/Btu/hr

100

120 3 100 95 90 85 80 75 70

NOTE

When 1½” or 3” pipe is used, exit the cabinet with 2” pipe. Reduce or

increase immediately after exiting the cabinet on both intake and exhaust.

60

80

PIPE

SIZE

1½ 60 55 50 45 40 35 30

275706560555045

3 100 95 90 85 80 75 70

250454035302520

3 100 95 90 85 80 75 70

250454035302520

3 100 95 90 85 80 75 70

NUMBER OF 90° ELBOWS

0123456

NOTES

1. Count concentric vent

fi tting as straight pipe.

2. Use medium or long

sweep elbows where

possible.

3. One 90° elbow is

equivalent to two 45°

elbows.

4. For direct vent, the

listed lengths are

allowed for each vent

(intake and exhaust).

5. For non-direct vent,

the listed lengths are allowed for exhaust. The

intake should have a

1½” or 2” snorkel intake

fi tting. (Figure 7)

W415-1064 / 11.11.11

Page 23

23

FIGURE 9 - PERISCOPED VENT DETAIL

RECOMMENDED

*

*18” MIN. FOR COLD CLIMATES

(SUSTAINED 0°F (-17°C) FOR

24 OR MORE CONSECUTIVE

MOISTURE IN THE FLUE GASES CONDENSES AS IT LEAVES THE TERMINAL. THIS MOISTURE

CAN FREEZE ON EXTERIOR WALLS, ON SOFFITS, AND OTHER NEARBY OBJECTS. SOME

DISCOLORATION IS TO BE EXPECTED; HOWEVER, IMPROPER LOCATION OR INSTALLATION CAN

CAUSE STRUCTURAL OR EXTERIOR FINISH DAMAGE TO THE BUILDING.

Caulk all cracks, seams or joints within a 6 foot radius of the termination.

Do not terminate under a deck unless there is adequate clearance to prevent damage from the fl ue gases.

A termination may be located at the end of a patio deck. Piping running beneath the deck must be suitably

insulated and suspended in a manner to prevent condensate from collecting and freezing.

Do not locate the terminal on the side of the building facing the prevailing winter winds.

HOURS

!

CAUTION

FIGURE 10 - VERTICAL VENTING

!

9.2 IN CANADA

In addition to the general guidelines, in Canada, the non-direct vent exhaust shall not terminate:

• Directly above a paved sidewalk or paved driveway which is located between two single-family dwellings and

serves both dwellings;

• Less than 7 feet above a paved sidewalk or paved driveway located on public property;

• Within 6 feet of a mechanical air supply inlet to any building;

• Above a meter/regulator assembly within 3 feet horizontally of the center line of the regulator;

• Within 6 feet of any service regulator vent outlet;

• Less than 12” above grade level or anticipated snow level;

• Within 12” of any door, window, or non-mechanical air supply inlet to any building;

• Within 12” of the combustion air inlet of any other appliance;

• Underneath a veranda, porch or deck, unless (a) the veranda, porch or deck is fully open on a minimum of

two sides beneath the fl oor, and (b) the distance between the top of the vent termination and the underside

of the veranda, porch or deck is greater than 12”.

9.3 IN UNITED STATES

In addition to the general guidelines, in the United States, the non-direct vent exhaust shall be installed in

accordance with the following:

• The clearance from the bottom of the terminal to grade shall be 12”.

• The vent shall not terminate over public walkways or over an area where condensate or vapor could

create a nuisance or hazard.

• The vent terminal shall be installed 4 feet below, 4 feet horizontally from, or 1 foot above any door, window,

soffi t, under eave vent or gravity air inlet to the building.

• The vent terminal shall have a minimum horizontal clearance of 4 feet from electric meters, gas meters,

regulators and relief equipment.

W415-1064 / 11.11.11

Page 24

24

• Locate the vent terminal 3 feet above any forced air inlet located within 10 feet. Any fresh air or make-up

air inlet, such as for a dryer or furnace area is considered a forced air inlet.

The vent terminal should be located no fewer than 6 feet from an inside corner formed by two exterior walls; a

10 foot distance is recommended.

Recommended clearance from overhangs is a minimum of 1 foot vertically for each foot horizontally up to 6 ft.

9.4 FURNACE VENTING INSTALLATIONS

!

WARNING

!

READ AND FOLLOW ALL INSTRUCTIONS IN THIS SECTION. FAILURE TO PROPERLY

VENT THIS FURNACE CAN CAUSE CARBON MONOXIDE POISONING OR AN EXPLOSION

OR FIRE RESULTING IN PROPERTY DAMAGE, PERSONAL INJURY OR LOSS OF LIFE.

9.4.1 NON-DIRECT VENT INSTALLATION USING INDOOR

COMBUSTION AIR (ONE PIPE SYSTEM)

Non-direct vent installations require only a vent pipe. This may be desirable when using outdoor combustion

air is not practical.

• Provisions are not made for routing of combustion air;

• The outdoor environment may contain contaminants undesirable for combustion.

• Install a short piece of intake air pipe with a 90° elbow to prevent objects from entering burner

area, and or objects from blocking combustion air intake.

9.4.2 DIRECT VENT INSTALLATION USING OUTDOOR COMBUSTION

AIR (TWO PIPE SYSTEM)

The direct vent confi guration is the preferred installation method. The primary advantages are:

• No special kit or modifi cations are required for direct vent installations

• Dedicated combustion air and vent piping eliminates the need to use already heated air for combustion

purposes;

• The probability of corrosive contaminants being present in the combustion air is greatly reduced;

• The direct vent confi guration is unaffected by any other appliances, exhaust fans, or other devices that

tend to create negative pressure conditions while operating.

• No vents for combustion and ventilation air are required in confi ned spaces.

9.4.3 COMBUSTION AIR

This furnace is certifi ed as a Category IV Type FSP Non-Direct and Direct Vent Furnace. When installed

as a direct vent furnace, all combustion air is supplied from the outdoors via the plastic piping system. All

components are fi eld supplied, except for the 2” PVC connector used to connect the piping to the furnace.

The combustion air piping, like the exhaust piping, must be air tight throughout the system. The adapter joining

the combustion air to the furnace is supplied with one gasket.

IMPORTANT:

• IF PLANNING TO USE ABS PIPE, USE AN ALL-PURPOSE CLEANER AND ABS

TO PVC TRANSITION CEMENT. IF PLANNING TO USE CPVC PIPE, USE AN ALLPURPOSE CLEANER, A CLEAR OR PURPLE PRIMER AND ALL-PURPOSE CEMENT

APPROVED FOR THE PURPOSE.

• ADDITIONAL INFORMATION ABOUT CLEANERS, PRIMERS, SOLVENTS AND

CEMENTS MAY BE OBTAINED FROM THEIR MANUFACTURERS.

• IF THE FURNACE IS TO BE INSTALLED IN THE VICINITY OF OTHER FUEL BURNING

APPLIANCES, ADEQUATE COMBUSTION AIR MUST BE AVAILABLE FOR THE NON-

DIRECT VENT APPLIANCES. SEE SECTION 8.1, “DETERMINING COMBUSTION AIR”.

W415-1064 / 11.11.11

Page 25

10.0 TERMINATIONS

10.1 COMBUSTION AIR

25

HORIZONTAL - The combustion air termination is made up of a

medium or long sweep 90° elbow pointing downward to prevent

rain from readily entering the combustion air intake piping. An

intake screening is optional; however, unless there is a compelling

reason to use one, the screen may actually encourage the

formation of rime ice, which could cause the intake to become

blocked in certain weather conditions.

If the required clearance to grade cannot be obtained with the

“straight through” confi guration, the combustion air intake pipe may

be “periscoped” up to 24” to gain extra height (Figure 9)

VERTICAL - The combustion air termination is made up of a pair

of medium or long sweep 90° elbow pointing downward to prevent

rain from entering the combustion air intake piping. The termination

inlet must be positioned within 3” of the companion exhaust piping.

The combustion air inlet must be located a minimum of 12” above grade, and 12” below the exhaust outlet.

(Figure 11)

10.2 EXHAUST

HORIZONTAL - The exhaust termination is normally a 45° elbow or a medium or long sweep 90° elbow

pointing within 45° of the downward position, away from the combustion air intake terminal.

If the required clearance to grade cannot be obtained with the “straight through” confi guration, the exhaust

pipe may be “periscoped” up to 24” to gain extra height. (Figure 9) In this case, the fl ue gases may be expelled

horizontally. Use the same size pipe as the interior run and count the fi ttings and length as part of the total vent length.

FIGURE 11 - STANDARD VERTICAL

VENTING DETAIL

If winter prevailing wind conditions are variable and likely to occasionally blow fl ue gases back in on the

combustion air intake, the exhaust termination may be raised 18-24” above the combustion air intake terminal

to take advantage of the natural buoyancy of the fl ue gases to help prevent re-circulation of the exhaust.

(Figure 9)

VERTICAL - No termination fi tting is required if venting vertically through a roof. The end of the exhaust pipe

must be 12” higher than the entrance of the combustion air intake terminal. (Figure 11)

The exhaust pipe extending through the roof must extend a minimum of 18” above any obstruction within an

18” horizontal distance.

10.3 CONCENTRIC VENTING KIT

Concentric venting terminal kits may be used for this series furnace. They provide a means of obtaining

combustion air and exhausting products of combustion utilizing a single penetration through the exterior wall.

This can be useful when there is limited wall space available. Kits are available in 2” and 3” sizes. If venting

the 60K Btu/hr model with 1½” vent material, and a concentric vent kit is necessary, a increase coupling may

be used to connect to the 2” concentric venting kit. Read the instructions supplied with the kit for additional

installation instructions and details.

10.4 CONCENTRIC VENT TERMINATION INSTALLATION INSTRUCTIONS

Follow the concentric vent termination manufacturer instructions for installation of the concentric vent

termination kit. These instructions can be found by contacting the furnace manufacture. Furnace

manufacturer contact information is found on the front cover of this installation manual and operating

instructions.

W415-1064 / 11.11.11

Page 26

26

10.5 LOCATION

Avoid locating the terminals where the fl ue gas could become stagnant and allow recirculation into the

combustion air intake.

Avoid locating the terminal in locations where dripping condensate may cause problems such as sidewalks,

patios, above planters, near windows where exhaust gases may cause fogging, etc.

Avoid locating the termination too close to shrubs and other vegetation. The condensate may stunt or kill them.

Caulk all cracks, seams or joints within a 6 foot radius of the termination.

Do not terminate under a deck unless there is adequate clearance to prevent damage from the fl ue gases.

A termination may be located at the end of a patio deck. Piping running beneath the deck must be suitably

insulated and suspended in a manner to prevent condensate from collecting and freezing.

Do not locate the terminal on the side of the building facing the prevailing winter winds.

IMPROPER LOCATION OR INSTALLATION CAN RESULT IN STRUCTURAL DAMAGE TO

THE BUILDING, DAMAGE TO THE EXTERIOR FINISH OF THE BUILDING, OR MAY ALLOW

RECIRCULATION OR FREEZING OF THE FLUE GASES ONTO OR INTO THE COMBUSTION

MOISTURE IN THE FLUE GASES CONDENSES AS IT LEAVES THE TERMINALS. THIS

MOISTURE CAN FREEZE ON EXTERIOR WALLS, SOFFITS, AND OTHER NEARBY

OBJECTS. SOME DISCOLORATION IS TO BE EXPECTED.

The vent terminal should be located no fewer than 6 feet from an inside corner formed by two exterior walls. A

10 foot distance is recommended.

Recommended clearance for overhangs is a minimum of 1 foot vertically for each foot horizontally up to 6 feet.

Any adjacent painted surfaces should be in good condition; no cracks, peeling paint, etc. If wooden surfaces that

may be periodically exposed to fl ue gases are present, consider treating with a sealer.

10.6 MULTIPLE VENTING

IMPORTANT:

WHEN INSTALLING MULTIPLE FURNACES IN CLOSE PROXIMITY, EACH REQUIRES

DEDICATED COMBUSTION AIR AND EXHAUST VENTING.

COMMON VENTING IS PROHIBITED!!

If two of these furnaces are to be installed in close proximity, the combustion air intake and exhaust

terminations may be installed as shown in Figures 12 and 13.

FIGURE 12 - MULTIPLE VENTING (STANDARD

HORIZONTAL)

!

CAUTION

AIR INTAKE.

!

FIGURE 13 - MULTIPLE VENTING (STANDARD

VERTICAL)

W415-1064 / 11.11.11

Page 27

If more than two furnaces are being installed in close proximity, each additional combustion air intake and

exhaust termination set shall not terminate less than 12 in (300 mm) apart. Note: Canadian installations of

120000 Btu/hr require 3 ft (900 mm).

27

RECIRCULATION OF FLUE GASES MAY OCCUR CAUSING THE INTAKE PIPE TO

FREEZE SHUT DURING COLD WEATHER OPERATION IF THE VENTING SYSTEM IS NOT

INSTALLED PER THESE GUIDELINES.

10.7 IN CANADA

Refer to Section 9.0 “Venting Guidelines”, 9.2 “In Canada”.

10.8 IN UNITED STATES

Refer to Section 9.0 “Venting Guidelines”, 9.3 “In United States”.

10.9 FURNACE CONNECTION

IMPORTANT:

• CLEAN AND DE-BURR ALL PIPE CUTS. THE SHAVINGS MUST NOT BE ALLOWED TO

BLOCK THE EXHAUST, COMBUSTION AIR INLET OR CONDENSATE DRAIN LINES.

• IF THE PIPE AND FITTINGS ARE TO BE OTHER THAN PVC, USE THE PROPER CLEANER,

PRIMER AND CEMENT FOR THE DISSIMILAR MATERIALS.

!

WARNING

!

!

WARNING

THERE MUST NOT BE ANY OPENINGS BETWEEN THE BLOWER DIVISION PANEL AND

THE COMBUSTION COMPARTMENT. THE BLOWER COMPARTMENT IS UNDER GREATER

SUCTION TH

AIR FROM THE BURNERS AND CAUSE INCOMPLETE COMBUSTION AND ERRATIC

THE EXHAUST VENT MUST BE SUPPORTED APPROPRIATELY PRIOR TO IT BEING

FITTED TO THE EXHAUSTER. UNDER NO CIRCUMSTANCES SHALL THE EXHAUSTER

AN THE COMBUSTION COMPARTMENT AND CAN PULL COMBUSTION

FURNACE OPERATION.

BEAR ANY WEIGHT OF THE VENTING SYSTEM.

!

W415-1064 / 11.11.11

Page 28

28

FIGURE 14A - DIRECT VENT TERMINAL CLEARANCES

W415-1064 / 11.11.11

Page 29

FIGURE 14B - NON-DIRECT VENT TERMINAL CLEARANCES

29

W415-1064 / 11.11.11

Page 30

30

10.9.1 ROUTING OPTIONS

This furnace must be installed in the upfl ow position only. Figure 22 on the following page shows the three vent

installation positions. The installer must consider the following services: gas pipe, electrical power, drain trap,

intake and exhaust vents. Also consider the air conditioning connections and drain, access to

fi lter(s) and access to furnace and a/c for repair. Drains and traps of furnaces installed in spaces

subjected to freezing temperature must also be protected against freezing.

The combustion air inlet fi tting is a 2” PVC Socket to Pipe Thread adapter. Choose the intake

location and remove the appropriate plastic cap. Install the adapter to the exterior panel using the

gasket (on the outside of the panel and the locknut on the inside of the panel).

10.9.2 EXHAUSTER ROTATION INSTRUCTIONS & PRESSURE SWITCH

MOUNTING

1. Disconnect exhauster wire connection.

2. Remove the 3 exhauster screws.

3. Remove pressure switch assembly (switches) and front manifold cover pressure sensing hose.

4. Remove exhauster.

5. Reverse the bands on the rubber drain coupling so the screws are accessible if necessary. (Do not

reverse the drain coupling.) Confi rm that directional arrow on drain coupling points away from exhauster.

6. Remove the appropriate plastic cap on the side panel. Install cap on vent opening not in use.

7. Reinstall the exhauster and the pressure switch assembly in the correct orientation with the (3) exhauster

screws removed in step 2. Reinstall the pressure switches so that they are above the heat exchanger

drain, to eliminate the chance of condensate draining into the pressure switch sensing hose causing

erratic furnace operation. See Figure 22 for reference.

8. Rotate the drain coupling so the drain holes are angled downward 15° and tighten coupling band to

exhauster.

9. Complete the venting as installation requires.

Always secure or support the vent and intake to the fl oor joists or rafters to avoid sagging and possible fatigue

of venting materials. This ensures proper drainage and prevents spilling the products of combustion into the

building.

The blower compartment should be completely isolated from the burner compartment, and in tight rooms

with other combustion devices, be completely isolated from the room (unless indirect vent). Ensure that the

combustion door gasket is in good condition.

IMPORTANT:

KEEP PRESSURE SWITCH HOSES ABOVE HEAT

EXCHANGER DRAIN, AND CUT TO APPROPRIATE

LENGTH TO PREVENT ANY SAGS OR TRAPS

FORMING IN THE HOSES.

TABLE 5

ORIENTATION

FURNACE FLUE

Up Left Y

Up Right Y

Up Vertical N

W415-1064 / 11.11.11

ROTATE

EXHAUSTER

SEE FIGURE 22

FOR

RECOMMENDED

MOUNTING

Page 31

31

Affi x the condensate trap assembly to the interior of the side panel in the blower compartment.

Three plastic drain hose clamps are provided in the parts bag. The large one (black) is used for securing the

drain hose to the front manifold cover drain outlet. The medium one (white) is used for securing the drain hose

to the 5/8” barbed fi tting on the condensate trap assembly. The small one (black) is used to secure the drain

hose to the ½” barbed fi tting on the condensate trap assembly.

NOTE: It is recommended that pliers be used to fi rmly clamp the plastic hose clamps.

10.9.3 PREPARATIONS FOR VENT AND DRAINING OPTION

1. Determine the most suitable vent and drain options for installation. See Figure 22 for reference, and refer

to Exhauster Rotation Instructions section if necessary.

2. Remove the 3½” plastic vent cap (if required), and cover vent hole not in use. Install rubber grommet (in

parts bag) for 2” vent pipe. Connect vent pipe (field supplied). If using 1½” or 3” vent, make transition as

close as possible to the unit and on a vertical section.

3. Remove the plastic air inlet cap and connect the 2” PVC air intake connector with the rubber gasket on the

outside of the unit using the 2” lock nut (in parts bag). If using 1½” or 3” air intake pipe, make transition as

close as possible to the unit and on a vertical section.

4. Connect 2” air intake pipe (field supplied). The exhaust vent must be supported appropriately prior to

it being fitted to the exhauster. Under no circumstances shall the exhauster bear any weight of the

venting system.

5. Install appropriate gaskets on condensate trap, and remove the two plastic caps attached to the blower

division, and the one attached to the side panel if applicable.

6. Affix the condensate trap assembly to the interior of the side panel in the blower compartment using the

two screws provided (in parts bag).

NOTE

• Condensate drain tubing must be cut to appropriate length and slopping towards condensate

trap, ensuring that drain hoses do not create traps prior to the condensate trap assembly.

• Condensate trap must be primed with water prior to initial furnace start up.

• Any increase in venting diameter must be done on the vertical sections NOT horizontal sections.

UPFLOW:

Requires the top sealing gasket .

A

IMPORTANT:

CONNECT ½” TEE FITTING (FIELD

SUPPLIED) TO THE OUTLET OF THE

NOTE

Barbed fi ttings must

be fully inserted

into condensate

trap, seated to barb

fl ange.

CONDENSATE TRAP.

W415-1064 / 11.11.11

Page 32

32

FIGURE 22 - UPFLOW VENT AND DRAINING OPTION

LEFT VENT INSTALLATION TOP VENT INSTALLATION

RIGHT VENT INSTALLATION

GASKET

“A”

ONLY

IMPORTANT:

• PRIME CONDENSATE TRAP WITH

WATER AND CUT DRAIN HOSES TO

PROPER LENGTH.

• CUT PRESSURE SWITCH TUBING

TO PROPER LENGTH.

NOTE

Upfl ow Vent Right - condensate

trap must be installed on left side.

W415-1064 / 11.11.11

Page 33

11.0 CONDENSATE DRAINS

The furnace may condense as much as a 4½ pounds of water per hour (approximately 2 imperial quarts, 2½ U.S.

quarts or 2¼ liters). It is necessary to make provisions for draining the condensate away. The furnace is supplied

with a drain trap assembly. See Figure 22 for possible locations of the drain trap.

In the left and right vent installation, the drain coupling on the exhauster will work better if the drain holes are

pointed down about 15 degrees. The drain hose supplied with the furnace is long enough to reach either side

panel; however, it must be cut to fi t each application. This is to prevent kinking in the drain lines.

33

THE TWO INLETS TO THE DRAIN TRAP ARE FOR VENT PIPE AND CONDENSATE

COLLECTION. THE VENT PIPE INLET IS SMALLER THAN THE CONDENSATE

COLLECTION INLET. ENSURE THAT THE DRAIN HOSES ARE PROPERLY CUT TO THE

REQUIRED LENGTH

11 .1 DRAIN HOSE INSTALLATION

1. Connect one end of the 5/8” tubing (in parts bag) to the most direct drain outlet on the front manifold cover,

and the other end to the larger elbow on the condensate trap assembly. Cut excess tubing if necessary

and hold in place with the supplied plastic hose clamps (in parts bag).

2. Connect one end of the 1/2” tubing, using the reducing coupling (in parts bag), to the lower drain outlet

on the exhauster coupling, and the other end to the smaller elbow on the condensate trap assembly. Cut

excess tubing if necessary.

NOTE

All condensate drain tubing must slope towards the condensate trap, ensuring that the drain

hoses do not create traps prior to the condensate trap assembly.

!

CAUTION

, CONNECTED AND SECURED.

!

11.1.1 DRAIN PIPING

Condensate from the outlet of the drain trap assembly must be conveyed to a fl oor drain, sump pit, or, if these

are unavailable, to a condensate pump. If using a condensate pump, be sure that it is approved for furnace

condensate.

DO NOT DRAIN THE CONDENSATE OUTDOORS. DO NOT RUN THE CONDENSATE LINE

THROUGH AREAS WHERE FREEZING MIGHT OCCUR. FREEZING OF CONDENSATE CAN

RESULT IN ERRATIC FURNACE OPERATION AND IN PROPERTY DAMAGE.

!

CAUTION

!

W415-1064 / 11.11.11

Page 34

34

IMPORTANT:

THE CONDENSATE DRAIN TRAP ASSEMBLY SHOULD BE FULL OF WATER (PRIMED)

BEFORE STARTING THE FURNACE. TO FILL THE CONDENSATE DRAIN TRAP ASSEMBLY,

TEMPORARILY REMOVE THE VENT DRAIN HOSE FROM THE EXHAUSTER ASSEMBLY

ELBOW/DRAIN FITTING, AND POUR APPROXIMATELY ONE CUP OF WATER DOWN THE

HOSE. WATER WILL BEGIN RUNNING OUT THE CONDENSATE DRAIN TRAP OUTLET

WHEN IT IS FULL. REFASTEN THE VENT DRAIN HOSE TO THE EXHAUSTER ASSEMBLY

ELBOW/DRAIN FITTING.

THE CONDENSATE DRAINAGE CONFIGURATION REQUIRES A VENT. IT TAKES LESS

THAN A ONE INCH RISE ANYWHERE ALONG THE HORIZONTAL ROUTE OF THE DRAIN

TUBE TO CREATE A VAPOR LOCK, WHICH WILL PREVENT CONDENSATE FROM

DRAINING AWAY FREELY, AND RESULT IN ERRATIC FURNACE OPERATION.