NAPCO StarLink SLE-LTE Commercial, SLE-LTEV-CB, SLE-LTEV-CFB, SLE-LTEV-CB-TF, SLE-LTEV-CFB-PS Installation Instructions Manual

Page 1

333 Bayview Avenue

Amityville, New York 11701

For Sales and Repairs, (800) 645-9445

For Technical Service, (800) 645-9440 or visit us at

(Note: Technical Service is for security professionals only)

http://tech.napcosecurity.com/

Publicly traded on NASDAQ Symbol: NSSC

© NAPCO 2018

StarLink™ SLE-LTE Commercial Series

Alarm Communicators

INSTALLATION INSTRUCTIONS

WI2226ALF 8/18

INTRODUCTION

The StarLink™ Commercial / Residential Fire and Burglary

alarm capture radio communicators are fully supervised,

wireless digital two-way subscriber units supported by an

extensive nationwide wireless network. All models are

compatible with most 12VDC alarm control panels (always

adhere to the documentation provided by the control panel

manufacturer). Model SLE-LTEV-CFB is compatible with

most 12 or 24VDC control panels. All can function as a

backup to existing telephone lines, or as sole path primary

communicators. In backup mode, all units will automatically switch the communication channel from the telephone

line to the network when telephone line trouble is detected.

See WI2140 for programming information.

The SLE-LTE Series radios use data-capture technology

that captures the alarm report from the control panel and

transmits the alarm signals to the SLE Control Center; the

alarm signals are then forwarded to ANY central station via

Contact ID or Sur-Gard System II or Sur-Gard System V

central station receivers via TCP/IP using standard line

security. The SLE Control Center reports a trouble signal

in the event that the network does not receive the expected

supervision signal from the wireless communicator.

For Commercial Burglary installations, under the

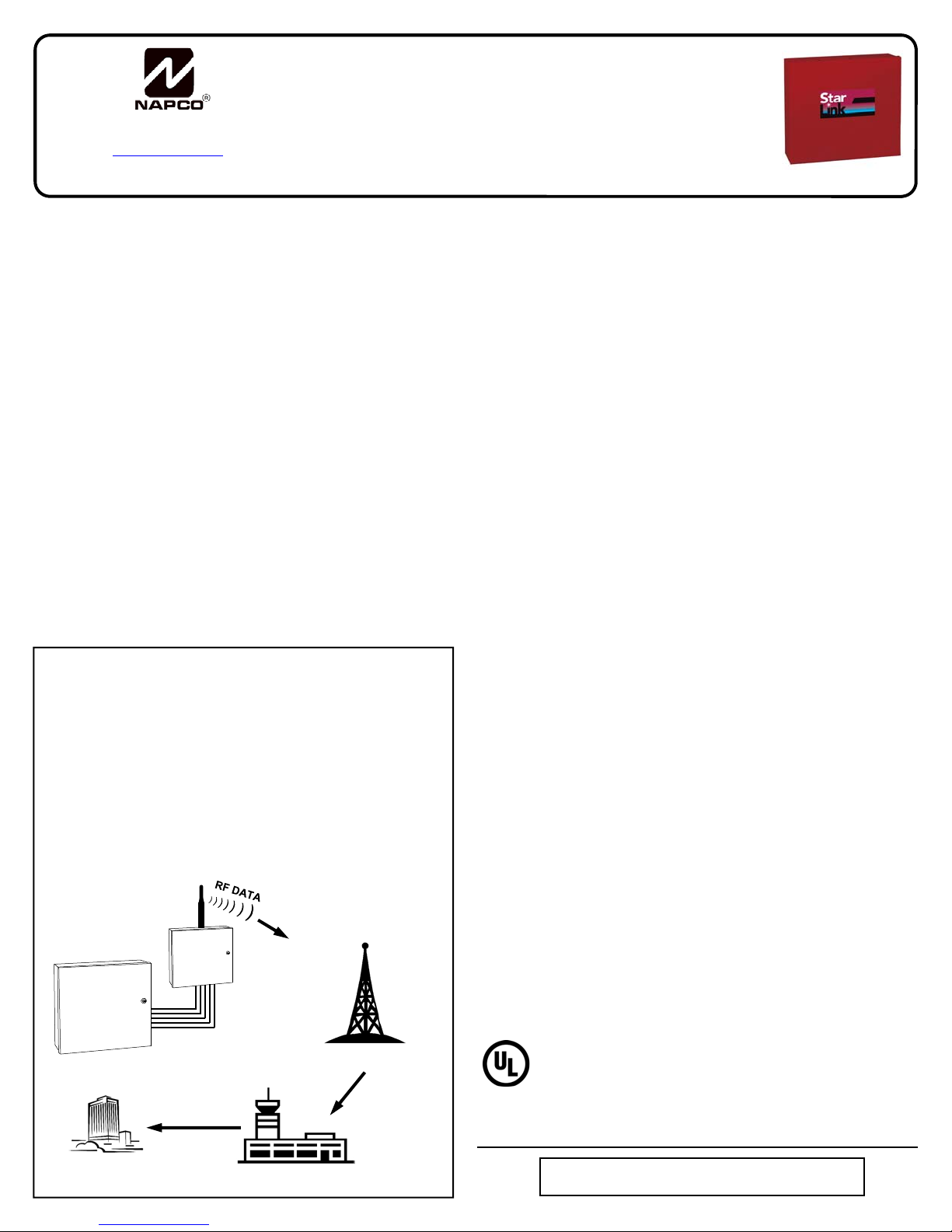

STARLINK RADIO REPORTING PATH

The diagram below shows the transmission path of a

signal from the StarLink radio to the central station.

1. Signal from a Control Panel.

2. StarLink radio receives the signal transmission

(from the TIP an RING wires); sends RF signal

through the network operator.

3. Network Operator, part of the vendor system, a

section of the cellular spectrum.

4. SLE Control Center, receiv es and routes data.

5. Central Station.

( ( ( ( ( ( ( ( ( ( ) ) ) ) ) ) ) ) ) )

StarLink

Radio

armed condition, any loss of communication must be

treated as a Burglary Alarm at the Central Station.

The following models are available:

SLE-LTEV-CFB-PS: Commercial / Residential Fire and

Burglary Radio in red metal housing with SLE-ULPS-R

power supply and 16.5V / 20VA transformer mounted

inside housing

SLE-LTEV-CB-TF: Commercial / Residential Burglary

and Residential Fire Radio in white metal housing with

SLE-ULPS-R power supply and TRF12/T123 plug-in

16.5V / 20VA transformer

SLE-LTEV-CFB: Commercial / Residential Fire and Bur-

glary in red metal housing. Powered directly from control

panel (no power supply, no transformer, rated 12/24VDC

input)

SLE-LTEV-CB: Commercial / Residential Burglary and

Residential Fire Radio in white metal housing. Powered

directly from control panel (no power supply, no transformer)

The following features are included with models that include

a SLE-ULPS-R power supply:

Power limited output to the StarLink radio PC board 12V

input terminals

Battery connection red and black flying leads

Monitored battery charging and Active battery test circuits

StarLink radio trouble input (from StarLink radio PC board

PGM1 terminal to de tect StarLink radio trouble)

Requires a sealed lead acid min 4AH / max 7AH battery

for minimum 24-hour standby time (max charge current

200mA).

Trouble relay output (C, N/O and N/C termi nals) to w i re

to a panel zone dedicated to "LTE Trouble" (dry contacts). Remove jumper "J2" to isolate common from

ground

Green AC ON LED visible from the exterior housing

Yellow TROUBLE LED on PC board. Flashes signify:

One flash: AC fail / brownout (2 hour delay)

Two flashes: Low battery

Three flashes: Charging circuit trouble

Four flashes: StarLink radio trouble

The housing-mounted transformer (when provided) is mount-

(2)

Control

Panel

CENTRAL

STATION

StarLink

™

SLE-LTE Commercial Series Alarm Communicators -- Installation Instructions 1

(1)

(5)

UL Classified StarLink Network

Operations Center

(3)

Network

Operator

(4)

AGENCY LISTINGS

UL 864 Standard For Control Units and Accessories For

Fire Alarm Systems, 10th Editio n

UL 1610 Standard For Central-Station Burglar-Ala rm Units

UL 985 Standard For Household Fi re Wa rning Sy stem Unit s

UL 1023 Standard For Household Burglar-Alarm System

Units

LTEV models are Verizon® Network Certified

Page 2

ed inside its own housing compartment with a replaceable

UL Listed .5A fast blow primary fuse. 120VAC connections

are to be made by a licensed electrician using suitable connectors, in accordance with N.E.C. and local code requirements.

ADDITIONAL COMPONENTS

In addition to the models listed above, the following sub-

assemblies are available:

SLE-ULPS-R - Power Supply. Required for installations

where the control panel cannot provide the 71mA of

Auxiliary power required to operate the StarLink radio.

Uses a standard 4AH / 12V minimum (7AH maximum)

rechargeable battery to provide radio standby power.

Requires connection to either the model NAPCO

TRF12/T123 (16.5V / 20VA) external plug-in transformer

or the chassis-mounted 16.5VAC / 20VA transformer

affixed inside the housing (see wiring diagrams further in

this manual). Note: For models without the SLE-ULPSR, connect the radio terminals 1 and 2 to the control

panel Aux Power terminals (observing polarity).

SLE-DLCBL - Download Cable, 6 feet

SLE-ANTEXT30 - Extended antenna with 30 feet of cable

SLE-ANTEXT50 - Extended antenna with 50 feet of cable

SLE-ANTEXT75 - Extended antenna with 75 feet of cable

(Any suitable external cellular antenna is permitted by

UL). Always follow the manufacturer's installation instructions. Note: Antennas are not Listed by UL. For

LTE radios where an External Antenna needs to be installed outside of the room in which the radio is installed

(maximum 30 meters (98 feet) in Residential applications), please use RF Transmitter Board

9SLELTEEXAPSLD available from our Customer Service Department, if not provided. The

9SLELTEEXAPSLD is identified by "two red dots" located on the lower right corner of the board. See WI2239

included with the 9SLELTEEXAPSLD for the simple installation procedure.

GEM-Tamperkit - Tamper switches and screws to protect

metal housing (see page 18).

SPECIFICATIONS

The following specifications apply to all StarLink radio mod-

els unless otherwise stated:

Electrical Ratings for 120VAC, 60Hz

For Models with Power Supply

Input Voltage: 120VAC nominal

Input Current: 150mA maximum

Maximum Charging Current: 200mA

Electrical Ratings for +12V

For Models without Power Supply*

Input Voltage: 10-15VDC (power-limited output from

Listed control panel). Note: Model SLE-LTEV-CFB is

rated 10-25VDC input.

Input Current for SLE-LTEV-CB: 10V = 90mA , 12V =

71mA, 15V = 63mA, with peak RF transmission current

of 200mA.

Input Current for SLE-LTEV-CFB: 10V = 90m A , 12V =

71mA, 25V = 68mA, with peak RF transmission current

of 200mA.

Electrical Ratings for the IN 1 Burg/Fire Input:

Input Voltage: 9-15VDC. Note: Model SLE-LTEV-CFB

is rated 9-25VDC input.

Maximum Input Current: Up to 2mA from FACP NAC

circuit

Electrical Ratings for IN 2 and IN 3:

Maximum Loop Voltage: 15VDC. Note: Model SLE-

LTEV-CFB is rated max 25VDC input.

Maximum Loop Current: 1.2mA

End of Line Resistor (EOLR) Value: 10K (2 req'd)

Electrical Ratings for 3 PGM Outputs:

Open Collector Outputs: Maximum Voltage 3V when

active; 15V maximum when not active. Note: Model

SLE-LTEV-CFB is rated max 25VDC output.

Maximum PGM Sink Current: 50mA (up to 15VDC),

25mA (15.1VDC - 25VDC)

Physical (W x H x D)

Metal Housing: 11½ x 9½ x 3½" (29.2 x 24.1 x 8.9cm)

Mounting: Metal housing includes two keyhole slots for

wall mounting (see measurements on page 7)

Environmental

Operating Temperature: 0°C - 49°C (32°F - 120°F)

Humidity: Maximum 93% Non-Condensing

Indoor / dry location use only

NOTICE TO AUTHORITIES HAVING JURISDICTION, USERS, INSTALLERS,

DEALERS, AND OTHER AFFECTED PARTIES

FIRE PROGRAMMING OPTION

Unattended Remote Downloading No Enable / Disable

IN2 and IN3 Unsupervised Yes Supervised / Unsupervised

7 Day Supervision, Radio to NOC No

*For Commercial Fire installations, a UL Listed Fire Alarm regulated power supply or FACP regulated auxiliary output is required.

2 StarLink

PERMITTED IN

UL864? (Y/N)

AVAILABLE SETTINGS REQUIRED UL 864 SETTINGS

Disabled (Jumper 1 installed). Also required for Commercial / Burgla-

ry installations. Note: See page 7 "Configuration Download / Firm-

ware Updates" for jumper instructions.

Unsupervised using conduit within 20 feet of FACP (default). If not

using conduit, install Jumpers 4 and 5 and EOL Resistors (see pages

3 and 4).

200 seconds, 5 minutes,

60 minutes, 7 days

™

SLE-LTE Commercial Series Alarm Communicators -- Installation Instructions

200 seconds, 5 minutes, 60 minutes

Page 3

TERMINAL DESCRIPTIONS

Configure all inputs and outputs using the Management Center screen (located at www.napconoc.com).

Located at the bottom of the StarLink radio PC board, the

17 terminals are described as follows:

TB1: PWR (+12V) Note: Model SLE-LTEV-CFB is rat-

ed 12/24VDC input.

(Refer to section "STEP 4: APPLY POWER")

TB2: PWR GND (–)

(Refer to section "STEP 4: APPLY POWER")

TB3: PGM1 (–): Open collector output. PGM1 is nor-

mally on (active low). When it is triggered (for ex-

ample, a trouble is detected) it becomes open col-

lector/high. To have a zone dedicated to an Star-

Link radio trouble, insert one side of the end of line

resistor into this PGM1 terminal, and wire the other

side of the resistor to the positive terminal of the

zone.

TB4: PGM2 (–): Open collector output. This output is

defaulted as "Fail to Communicate", and is normally

open collector/high. When a report fails to com-

municate anywhere in the communications path, the

output is active low.

TB5: PGM3 (–): Open collector output. This output is

defaulted as "Telephone Line Cut". When the tele-

phone line voltage is correct, the output is open col-

lector/high; when the telephone line voltage is too

low, the output is active low.

TB6: IN 1: Active high input for wiring to the panel

bell output. When this input detects a pulsing tem-

poral 3 high, it sends a Fire alarm; a pulsing tem-

poral 4 (CO Alarm), a CO alarm is sent. When

used, these conductors must be run in conduit (max

20 feet for Commercial Fire, and 3 feet for Residen-

tial Fire). Do not use for Burglary applications.

TB7: IN 2: See TB9, below.

TB8: GND: Common ground terminal.

TB9: IN 3: Both terminals IN 2 and IN 3 by default are

supervised end-of-line resistor inputs that can be

triggered with N/O or N/C relay contacts. Wire the

common ground terminal GND (terminal TB8) to the

relay common. In Burglary applications, when used

as arm/disarm status input, a low indicates "armed"

and a high indicates "disarmed". For these inputs to

report to a central station, the radio must be configured with the central station telephone number and

correct reporting formats and codes. See table on

page 17 for more information.

TB10: TIP: See TB11, below.

TB11: RING: Terminals TIP and RING: Wh en used f o r

backup reporting, the house Tip and Ring telephone

wires must be routed from the outside to these terminals. Under normal back up conditions, these

terminals are internally wired to the PANEL TIP and

PANEL RING terminals, allowing all transmissions

to the central station to be monitored. These wires

are monitored for voltage such that if voltage falls

below 1.5V, a Telco Line Fault trouble is detected,

and the StarLink radio applies telephone line voltage to the control panel Tip and Ring DACT interconnect to the radio allowing it to receive and transmit any alarms sent by the panel.

TB12: PANEL RING: See wiring diagrams.

TB13: PANEL TIP: See wiring diagrams.

Note: TB14-TB17 no connections permitted by UL.

TB14: RTS (R): See TB17 below.

TB15: PANEL TX (B): See TB17 below.

TB16: PANEL RX (G): See TB17 below.

TB17: CTS (Y): No connections permitted.

LED DESCRIPTIONS

The PC board contains several LED's, as follows:

GREEN RF SIGNAL STRENGTH LED

Labeled "D3", this LED is located at the lower right corner

of the PC board.

Every 30 seconds, the StarLink radio receiver section

turns on and listens to the cell tower. Depending on the

Supervised Fire / Burg Input

8 7 9

Radio GND

(TB8)

(Radio)

(Alarm Panel)

10K

10K

C C N/O

TBL*

The EOLR must be installed and located within the control panel housing.

*Reverse polarity / energized state.

StarLink

™

SLE-LTE Commercial Series Alarm Communicators -- Installation Instructions 3

Alarm

-or-

To StarLink

Terminals

IN2 (TB7)

-or-

IN3 (TB9)

N/O

N/C

Supervised Arm / Disarm Input

To StarLink

-or-

8 7 9

Radio GND

(TB8)

(Radio)

(Alarm Panel)

10K

10K

C

Open = Disarmed

Closed = Armed

The EOLR must be installed and located within the control panel housing.

Terminals

IN2 (TB7)

-or-

IN3 (TB9)

Page 4

RED DIAGNOSTIC LED (Labeled "D7")

YELLOW OPERATIONAL STATUS LED (Labeled "D4")

GREEN RF SIGNAL STRENGTH LED (Labeled "D3")

RED TROUBLE LED (Labeled "D5")

D4 D3 D5

LED LOCATIONS

signal strength detected, it will blink the Signal Strength

LED from 1 to 8 times, providing a signal strength indicator that is updated constantly and is always displayed.

Refer to Coverage Table below.

Green LED Operation

Signal strength (as received by the radio) is displayed by

this LED blinking 1 to 8 times at a constant rate (with a

short delay between blink cycles). Acceptable power

level is greater than or equal to -91dBm (minimum 4

blinks at the mounting location).

LED Blinks 8 7 6 5 4 3 2 1

GREEN RF SIGNAL STRENGTH LED

RADIO RECEIVER COVERAGE TABLE

Power

(dBm)

-55 -65 -75 -85 -91 -95 -99 -105

YELLOW OPERATIONAL STATUS LED

Labeled "D4", this LED is located at the bottom right of

the PC board. Operation is as follows:

Normal Standby Condition:

Blinks on momentarily every 10 seconds: Unit is in

standby waiting for an alarm to report.

Processing Alarm Conditions:

When processing an alarm, this LED will blink variably

during each part of the process (dialing, handshaking,

data transmission, etc.).

RED TROUBLE LED

Labeled "D5", this LED is located at the bottom right of

the PC board. Operation is as follows:

1 Blink: Low Aux Power input voltage

2 Blinks: Battery trouble

3 Blinks: Alarm report Failed to Communicate

4 Blinks: RF trouble (antenna connection or cellu-

lar registration)

5 Blinks: Network trouble (signal unable to reach

the SLE Control Center)

6 Blinks: Unit disabled (r eporting or control panel

downloading not allowed)

7 Blinks: Unit was shutdown and has no function-

ality; requires a restart (full power down and full power

up sequence) to restore operation

8 Blinks: Telco Line Cut (this is not the DACT inter-

connect to the radio)

RED DIAGNOSTIC LED

Labeled "D7", this LED is located in the middle of the PC

board. One blink indicates a weak or non-existent signal

from the network (green LED is off). If this red LED is

blinking in any other manner, please contact technical

support.

SUPPLYING POWER

Control panels can provide power through their Auxiliary

Power terminals if the available standby current is reduced by

71mA. When there is insufficient standby current due to the

application (such as when 24-hour standby time is required

for Fire or CO), the SLE-ULPS-R Charger Module accessory

must be used to charge an additional battery and to supply

the power for the StarLink radio. See WI2131.

JUMPER DESCRIPTIONS

Jumper block labeled "X5"; from top to bottom, as detailed in

the following table. Note: Contact ID is always available in

response to a Contact ID handshake.

Tech on site must temporarily

remove to download

4/2 with Checksum Pulse Format 2 4/2 Pulse Format

Supervised inputs. EOLR(s) re-

quired, see page 3

The StarLink SLE-LTE Series radios are compatible with

any Listed alarm control unit DACT communicating contact

ID or any 4+2 pulse format (4/2 Pulse Dialing formats such

as Ademco Slow, Radionics Slow, Silent Knight Fast, Radionics Fast and Universal High Speed, with 10pps, 20pps,

and 40pps with and without checksum, either 1400Hz or

2300Hz handshake / kissoff).

The StarLink SLE-LTE Series radios and NOC are compati-

ble with the Listed Ademco model 685 with model 685-8 line

card DACR or any Listed compatible DACR with any 4+2

pulse or contact ID format which is specified in the Installation Instructions for the interconnected DACT / Alarm Control Unit.

Refer to WI2140 (available on the NOC) for selecting the

required handshake / kissoff frequency in the NOC

(www.NapcoNOC.com) setup screens (as required by the

control panel).

Jumper Block "X5" Options

Jumper block labeled "X5" contains 5 jumper terminals; from top

(labeled "1") to bottom (labeled "5") as follows:

Jumper ON

Backup Mode 3 Primary Mode

Jumper

Number

1

4 and 5

Jumper OFF

Not permitted by UL 864 and

UL 1610

Not permitted by UL 864 and

UL 1610 (UL 864 permits use of

conduit within 20 feet of FACP in

lieu of Supervision)

PRIMARY AND BACK-UP REPORTING

The StarLink radio can function as a primary wireless com-

municator, in cases where there are no telephone lines present, when connected directly to the control panel Telco

4 StarLink

™

SLE-LTE Commercial Series Alarm Communicators -- Installation Instructions

Page 5

terminals. For primary reporting, do NOT install jumper 3

in terminal block "X5". The StarLink radio can also function as a backup to the existing telephone lines (install

jumper 3 in terminal block "X5"). When used as a back up

communicator and when it senses telephone line trouble,

the StarLink radio automatically switches the communication channel from the telephone line to the network.

NETWORK COVERAGE

The StarLink radio constantly supervises the network cov-

erage. When the StarLink radio is configured for primary

reporting, and the StarLink radio detects a loss in network

coverage, the StarLink radio must be configured to prompt

the control panel to announce a Telco Line Cut failure trouble using the Management Center screen (located at

www.NapcoNoc.com). Note: This Telco Line Cut failure

trouble will NOT activate when the StarLink radio is configured for backup reporting.

INSTALLATION STEPS

STEP 1: ACCOUNT REGISTRATION

Create a new account and register specific StarLink radio

modules at www.NapcoComNet.com. Accounts and modules registered via the Internet are enabled for activation

within 24 hours.

STEP 2: SELECT A MOUNTING LOCATION

The mounting location should be indoors within the protected area and selected based on RF performance. It is

HIGHLY recommended that the installer carefully adhere to

the following recommendations BEFORE any wires are installed.

Generally, high locations are best. DO NOT mount radio

in basements or below grade as unpredictable performance may result.

DO NOT mount the radio in non-climate controlled envi-

ronments (i.e. attics may become extremely hot in summer, garages may become extremely cold in winter).

Avoid mounting locations within 3 feet of AC power lines,

fluorescent light fixtures, or large metal objects (air conditioners, metal garage doors, etc.) as these locations

have been shown to have a detrimental effect on signal

strength.

A fair amount of care may be required to mount the Star-

Link radio so as to achieve an optimal RF path. The

installer should spend as much time as needed to obtain

the highest signal level possible.

For Commercial Burglary installations, install in accord-

ance with UL 681, Standard for Installation and Classification of Burglary and Holdup Alarm Systems. Installation shall also be in accordance with UL 827, Standard

for Central-Station Alarm Services, and UL 1641, Standard for Installation and Classification of Residential Burglar Alarm Systems

a. Before applying power, be sure to connect the

antennas. Temporarily connect power to the StarLink radio from a fully charged 12V (4AH minimum)

battery. DO NOT mount the radio at this time. Press

Tamper switch to send a signal.

b. Position the unit in the desired mounting location, with

antenna oriented vertically. The signal strength is

displayed by the Green "Signal Strength LED" labeled

StarLink

™

SLE-LTE Commercial Series Alarm Communicators -- Installation Instructions 5

"D3" (located at the lower right corner of the PC

board). The radio tower signal strength may fluctuate

from day to day, therefore it is best to try to find a

mounting location where the LED provides a mini-

mum of 4 blinks.

c. Once a location has been selected based on signal

coverage, permanently secure the unit using #8

screws (not supplied) in the two mounting holes.

WARNING: To ensure user safety and to satisfy FCC

RF exposure requirements, this unit must be installed so

that a minimum separation distance of 60cm (24") is always maintained between the antenna of the transmitting

device and nearby persons.

STEP 3: WIRING (PRIMARY AND BACKUP MODES)

22-gauge wire may be used if mounted up to 50 feet from

the control panel, and 18-gauge wire should be used for up

to 100 feet. Reference the wiring diagrams further in this

manual. See the section CONTROL PANEL PROGRAM-

MING further in this manual.

For Primary Mode:

Remove jumper #3 in jumper block labeled "X5". The wiring between the control panel and the StarLink radio is over

five (5) wires, as follows:

TB1: PWR (+12V) Note: Model SLE-LTEV-CFB is

rated 12/24VDC input.

TB2: PWR GND (–)

TB13: PANEL TIP

TB12: PANEL RING

TB3: PGM1 (–). Normally low output wired to the

(+) of a zone dedicated to monitoring the radio status.

See page 12 for GEMC-F8ZCPIM wiring. Should be

programmed on Napco control panels as Day Zone, but

be programmed to sound locally and NOT activate the

bell. Note : See steps "a" and "b", below.

For Backup Mode:

Install jumper #3 in jumper block labeled "X5". The wiring

between the control panel and the StarLink radio is over

seven (7) wires, as follows:

TB1: PWR (+12 or 12/24V)

TB2: PWR GND (–)

TB10: TIP

TB11: RING

TB13: PANEL TIP

TB12: PANEL RING

TB3: PGM1 (–). Normally low output wired to the

(+) of a zone dedicated to monitoring the radio status

(see page 12 for GEMC-F8ZCPIM wiring). Should be

programmed on Napco panels as Day Zone, but be

programmed to sound locally and NOT activate the bell.

a. Without applying power (voltage), connect to screw

terminals TB1 (+12 or 12/24V) and TB2 (–). If t h e

control panel Aux. Output cannot supply the necessary current, then you must use the SLE-ULPS-R

Power Supply accessory with additional battery (see

WI2131). For wir i ng con n ec ti ons , se e t he wi r ing d iagrams further in this manual.

b. Referencing the correct wiring diagram for the ap-

propriate control panel (wiring diagrams are located

further in this manual), connect the "TELCO" control

Page 6

panel terminals TIP and RING (DACT interconnect

wiring to the radio). Do NOT connect the StarLink

radio terminals TB10-13 to house telephone lines

(RJ31X modular plug wires, etc.).

Wiring Methods

Strip wire carefully to avoid exposed conductors after

installation, etc.

Use UL Listed wire, ensuring that all conductors are to be

insulated for the maximum voltage of any conductor in

the enclosure

All wiring methods must be performed in accordance with

NFPA 70, Articles 725, and 800

STEP 4: APPLY POWER

Attach primary (top left) antenna before applying

power !

The StarLink radio requires +12 or 12/24VDC. It draws

less than 71mA during standby, and almost 200mA dur-

ing transmissions (for less than 1 second).

STEP 5: SIGNAL VERIFICATION

Verify Online: To veri fy t hat the signals have been

received by the StarLink radio LTE Network online, go to

www.napconoc.com, log in with your Username and

Password, enter your Company ID number and the Star-

Link LTE Radio Number, then click Signal Log.

IMPORTANT: Verify that the signals transmitted by the

StarLink radio have been properly received by your central

station before leaving the premises.

NAPCO CONTROL PANEL PROGRAMMING

To program the central station receiver reporting format,

use PCD-Windows Quickloader download software. Open

the Digital Communications screen, Central Station Receiv-

ers tab, as shown in the following image. A "Point

ID" (also called "Contact ID") receiver format programming

example is shown:

The radio can transmit to any central station capable of re-

ceiving SIA Contact ID via DACR technology or the DSC

Sur-Gard System II or Sur-Gard System V central station

receivers via TCP/IP.

STARLINK RADIO RELATED EVENT

REPORT CODES

EVENT AREA

IN 1 Fire

IN 2 Panic

IN 3 Trouble

Low Battery/Voltage

Tamper Trouble

Line Cut

Reboot

IN 1 CO (Carbon Monoxide)

Panic Alarm*

Holdup Alarm*

Medical Alarm*

24 hour Aux. Alarm*

24 hour Aux. Restore*

Burg Perimeter Alarm*

Burg Interior Alarm*

Keypad Holdup Alarm (ambush)*

Keypad Panic Alarm*

Keypad Emergency Alarm*

Opening*

Closing*

A.C. Trouble*

Tel 1 Fail*

*Not generated by the StarLink radio.

Note: A receiver reporting format must be entered for

each telephone number used, but each telephone number

may be assigned a different format.

CAUTION: The installer should always be certain an

area code is programmed into the control panel.

Optional: If you wish the StarLink radio to report a code

and zone number (Contact ID by default) to the central station in response to a triggered input event, see the table on

(Contact ID by default)

CONTACT ID

CODE ZONE #

0 E110 990 1A

0 E120 992 22

0 E300 993 F3

0 E302 994 F4

0 E341 995 F5

0 E352 996 F6

0 E625 997 F7

0 E162 998 18

E123

E122

E100

E150

R150

E131

E132

E121

E123

E140

E401

R401

E301

E351

PULSE

4/2

SIGNALS ORIGINATED AT THE NOC

NOC Originated

Alarms

Supervisory Fail E356 A00 Zn000

Press to Send

Test Signal

Press to Send

Radio Test

6 StarLink

Contact ID

Event Data

Sent

E601 A00 Zn000

Not Applicable

Nothing sent to

CS receiver

Automatically by NOC if fail to receive any signal

from StarLink radio within Supervisory Timeout

duration.

Manually by dealer from the Management Center

Signal Log screen (located at

www.napconoc.com). Sends test into CS receiv-

er.

Manually by dealer from the Management Center

Checkins screen (located at

www.napconoc.com). Sends a command to the

StarLink radio to force a check-in to the NOC.

Initiated By Comments

For Auto Enroll, uses captured telephone number,

Sub ID and format. For Dealer Programmed, uses

entered telephone number, Sub ID and format.

Same comment as above.

----

™

SLE-LTE Commercial Series Alarm Communicators -- Installation Instructions

Page 7

the previous page.

Note: These event codes and zone numbers can be

changed from the Management Center screen (located at

www.napconoc.com).

Upon alarm, the NOC can optionally send an SMS message to a third party that includes the appropriate Contact

ID alarm code, including the zone or user number, if applicable. The "STARLINK RADIO RELATED EVENT RE-

PORT CODES" table also includes the most common Contact ID alarm codes.

Programming StarLink Radio Troubles

It is required that if a StarLink radio or control panel trou-

ble is detected, that it is reported to the central station.

When the StarLink radio detects and sends a trouble to

the control panel, the control panel must be programmed

to annunciate this trouble. The radio can detect multiple

troubles as indicated by the "Red Trouble LED" ("D5").

For these troubles to be annunciated at the panel, there

are several methods, some of them are configurable at the

Management Center screen (www.napconoc.com):

Wire the radio PGM1 output to a dedicated control panel

zone (input) to annunciate the trouble (activate a trouble

sounder) when an open is detected. The radio must

also report this trouble to the central station. With Napco control panels, program a dedicated zone for Day

Zone, Mini-sounder on Alarm and No bell on Alarm.

Wire the zone as indicated in the wiring diagrams further

in this manual.

For models with the SLE-ULPS-R Power Supply, wire

this Power Supply trouble output relay to the two terminals of the control panel zone dedicated to the trouble.

With the GEMC Commercial Fire control panels, use the

dry contacts of the Power Supply relay by removing the

jumper and using the contacts of the Power Supply relay

(Common and N/O) in series with a 2.2k EOLR.

For radio models without the SLE-ULPS-R Power Sup-

ply (powered by the control panel Aux Power terminals),

wire the radio directly to the PGM1 output of the control

panel (program the radio to report all troubles on

PGM1). Alternatively, you can use the GEMC-F8ZCPIM

module to detect a trouble on the zone by use of a PGM

output of the radio. See special wiring instructions for

use of the GEMC-F8ZCPIM zones.

You can also wire to the positive terminal of the dedicat-

ed zone on a GEMC-EZM8. Thus when a radio trouble

is detected, the radio PGM activates the control panel

zone, and the panel generates a trouble that is sent to

the central station.

All installations also require wiring an output from the

control panel, as follows: With Gemini C-Series

(GEMC) control panels, we recommend using the Fire

Aux Relay. Program the Fire Aux Relay to activate as a

trouble relay. Wire this relay to the StarLink module IN2

terminal.

Note: We recommend using the text " LTE Trouble"

as the Zone Description.

StarLink Radio Supervision

If the two Telco wires (DACT interconnect wiring to the

radio) between the StarLink radio and the control panel

are cut or otherwise disconnected, the control panel must

detect and generate a local trouble indication. The control

panel must trigger an output to activate the StarLink radio

to report this line cut fault to the central station. Program

the control panel for telephone supervision. Program the

StarLink radio using the Management Center "Advanced

Features" screen (at www.napconoc.com) to enable the

Line Cut feature on all troubles (therefore a dedicated zone

is not required). Note: Some control panels may require a

different duration than the default time of 3 minutes.

Supervision Time Schedule Considerations

If a status change (alarm trouble, etc.) is transmitted, the

radio supervision timer is restarted.

For example, if a status change is sent, the next regular

supervision transmission will occur at the interval determined by your rate plan.

Configuration Download / Firmware Updates

Technician on site required.

For Commercial Installations a technician is required to be

on site during any reprogramming of the radio or control

panel and must perform / re-perform acceptance testing.

To perform a download or update the radio firmware,

jumper 1 must be removed. UL requires that the jumper

be replaced after the download is complete. Failure to

replace the jumper would allow downloads to the radio

without a technician on-site.

For Residential installations jumper 1 may be removed to

permit uploading and downloading without a technician on

site, however, the dealer is responsible for ensuring the

system is operating correctly after any downloads or

changes to the system.

Cover Tamper

The SLE-LTE series radios in the metal housings may op-

tionally have front and rear tamper switches installed

(GEM-Tamperkit) and wired to the control panel (see page

18). Note: The tamper switch on the radio PC board is

not used in this housing (but continues to function if

pressed).

11-1/2"

10-1/8"

9-1/2"

9-21/64"

Red and White Metal Housing Dimensions (inches)

StarLink

™

SLE-LTE Commercial Series Alarm Communicators -- Installation Instructions 7

Page 8

(Commercial Fire and Commercial Burglary)

SLELTEV-CFB-PS

Wiring Diagram

(To

control

panel*)

BLK

.5A

Fuse

SLELTEV-CFB-PS

PC Board

All connections are power limited except AC

Mains, Telco and battery terminals

Terminals 14-17: No connections permitted .

PANEL

(–)

PGM1 PGM2 PGM3 IN3 RING TIP

+V

IN1

6 7 8 15 14 13 12 11 9 10 2* 3 4 5 1*

IN2*

GND

RING

Note: Connect IN2 to a

panel output used for

identifying Telco line cut (this

is the DACT interconnect

wiring to the radio).

PANEL

RTS

PANEL

PANEL

TIP

(R)

RX (G)

TX (B)

16.5VAC

Class 2

CTS

17 16

Yellow

Trouble

LED

Green AC

ON LED

Power Supply

(SLE-ULPS-R)

Relay contacts rated

max 30VDC,

0.5A

12VDC

output is

Y

power limited

AC IN

+ 12V –

N/O

COM

8 9 10

N/C

IN1

J2

+ BAT –

RED BLK

6 7 2 3 4 5 1

Red (+)

Black (‒)

Battery

Remove shunt J2 to isolate relay

EOLR*

Note: Maintain

minimum 1/4"

separation of

battery leads from

all other wiring.

common from ground (i.e. jump-

er on = wet; off = dry contact)

(Earth Ground)

Chassis Mounted 16.5VAC / 20VA Transformer

*Notes:

Connect the StarLink radio to the control panel output for Telco Trouble (this is the DACT interconnect wiring to the

radio). Remember to program the StarLink communicator module to report this IN2 Telco Trouble and for line cut

(EOLR) to the central station (options 1 or 4 on page 17). In addition, always add an EOLR at the control panel Telco

Trouble Output (Fire Aux Relay for the GEMC control panels).

Use EOLR value as specified by the control panel installation instructions.

IN1 not supervised. IN2 and IN3 are supervised.

Licensed electrician required to wire the 120VAC connections to the transformer in accordance with N.E.C. and local

code requirements.

Route 1 20VAC only through the transformer compartment knockouts.

Keep all non-power limited wiring separate from all power-limited wiring inside the housing by 1/4". In addition, maintain

a minimum 1/4" separation of all primary wiring in the transformer compartment from the yellow secondary wires of the

transformer.

Remove shunt J2 to isolate relay common from ground (i.e. jumper on = wet (circuit common); off = dry contact). When

wet, configuration is used; the power should be derived from the alarm control panel.

StarLink module must be configured to trigger PGM1 on any trouble.

PGM1 of the StarLink module must be wired to the trouble input (terminal 5) of the power supply.

The Power Supply Trouble Output must be wired to a control panel zone dedicated to a LTE trouble; see control panel

programming instructions and program to Report Alarm / Alarm Restore / Trouble / Trouble Restore.

8 StarLink

Note: Maintain minimum 1/4" separation

of all wiring in this compartment from the

yellow wires of the transformer.

™

SLE-LTE Commercial Series Alarm Communicators -- Installation Instructions

Page 9

(Commercial Burglary)

SLE-LTEV-CB-TF

Wiring Diagram

(To

control

panel*)

TRF12/T123

SLE-LTEV-CB-TF

PC Board

Yellow

Trouble

LED

Green AC

ON LED

All connections are power limited except

AC Mains, Telco and battery terminals

Power Supply

(SLE-ULPS-R)

Terminals 14-17: No connections permitted.

Note: Connect IN2 to a

panel output used for

identifying Telco line cut (this

is the DACT interconnect

wiring to the radio).

PANEL

PANEL

RTS

PANEL

(–)

PGM1 PGM2 PGM3 IN3 RING TIP

+V

IN1

IN2*

GND

RING

PANEL

TIP

(R)

TX (B)

6 7 8 15 14 13 12 11 9 10 2* 3 4 5 1*

Transformer

16.5V / 20VA

16.5VAC

Class 2

RX (G)

CTS

17 16

Y

Relay contacts rated

max 30VDC,

0.5A

12VDC

output is

power limited

AC IN

+ 12V –

N/O

COM

8 9 10

IN1

N/C

J2

+ BAT –

RED BLK

6 7 2 3 4 5 1

Red (+)

Black (‒)

Battery

Remove shunt J2 to isolate relay

common from ground (i.e. jump-

EOLR*

Note: Maintain

minimum 1/4"

separation of

battery leads from

all other wiring.

er on = wet; off = dry contact)

*Notes:

Connect the StarLink radio t o the control panel output for Telco Trouble (this is the DACT interconnect wiring to

the radio). Remember to program the StarLink communicator module to report this IN2 Telco Trouble and for line

cut (EOLR) to the central station (options 1 or 4 on page 17). In addition, always add an EOLR at the control

panel Telco Trouble Output (Fire Aux Relay for the GEMC control panels).

Use EOLR value as specified by the control panel installation instructions.

IN1 not supervised. IN2 and IN3 are supervised.

Keep all non-power limited wiring separate from all power-limited wiring inside the housing by 1/4".

Remove shunt J2 to isolate relay common f rom ground (i.e. jumper on = wet (circuit common); off = dry contact).

When wet, configuration is used; the power should be derived from the alarm control panel.

StarLink module must be configured to trigger PGM1 on any trouble.

PGM1 of the StarLink module must be wired to the trouble input (terminal 5) of the power supply.

The Po wer Supply Trouble Output must be wired to a control panel zone dedicated to a LTE trou ble; see control

panel programming instructions and program to Report Alarm / Alarm Restore / Trouble / Trouble Restore.

StarLink

™

SLE-LTE Commercial Series Alarm Communicators -- Installation Instructions 9

Page 10

Transformer

Wiring Diagram for PRIMARY Reporting Configuration

Generic Control Panels

(Use when telephone line is NOT available)

(CONTROL PANEL HOUSING)

CONTROL PANEL PC BOARD

12VDC

TBL INPUT

GND

AUX POWER

Optional: When Power

Supply SLE-ULPS-R is not

used, connect Panel Aux

Power to StarLink terminals

1 and 2 (observing polarity)

(–) (+)

(–) (+)

(RING)

(TIP)

Wire to dedicated zone on the control

panel for Supervision when the Power

Supply board (SLE-ULPS-R) is n ot used.

6 7 8 15 14 13 12 11 9 10 2* 3 4 5 1*

+V

PGM1 PGM2 PGM3 IN1 IN2 GND IN3 RING TIP

(–)

PANEL

RING (+)

StarLink Radio Terminals

SLE-LTEV-CB-TF PC Board: All connections

are power limited except AC Mains, Telco and

battery terminals. Terminals 14-17: No connec-

(STARLINK RADIO HOUSING)

tions permitted.

*Refer to section "SUPPLYING POWER".

10 StarLink

N/O

Note: Connect IN2 to a

panel output used for

identifying Telco line cut (this

is the DACT interconnect

wiring to the radio).

COM

8 9 10

N/C

J2

17 16

PANEL

TIP (–)

PANEL

TX (B)

PANEL

RX (G)

CTS

Y

Power Supply (SLE-ULPS-R)

RTS

(R)

(optional)

Either the TRF12/T123 (16.5V /

20VA) transformer or the chas-

sis-mounted 16.5VAC / 20VA

transformer

™

SLE-LTE Commercial Series Alarm Communicators -- Installation Instructions

are not power limited

(+)

(–)

RED

BLACK

StarLink

BATTERY

Note: Battery leads

Page 11

Wiring Diagram for BACKUP Reporting Configuration

Generic Control Panels

Transformer

TO TELCO

RING TIP

RJ31X

HOME

PHONES

(CONTROL PANEL HOUSING)

CONTROL PANEL PC BOARD

TELCO

TBL

OUTPUT

10K

Telco TBL

Output

Relay

10K

GND

Optional: When Power Supply

SLE-ULPS-R is not used,

connect Panel Aux Power to

StarLink terminals 1 and 2

12VDC

AUX POWER

(observing polarity)

(–) (+)

(TELCO) (PHONE)

(RING)

(TIP)

(TIP)

YELLOW (–)

BLACK (+)

(RING)

ZONE (+)

DEDICATED

TO

SUPERVISION

*For StarLink terminals 1 and 2: May

be wired directly to

Aux Power of the

control panel when

71mA standby

current is available

+V

Note: Connect IN2 to a

panel output used for

identifying Telco line cut

(this is the DACT

interconnect wiring to the

radio).

PGM1 PGM2 PGM3 IN1 IN2 GND IN3 RING TIP

(–)

(STARLINK RADIO HOUSING)

GRN

RED

BRN

GRAY

Wire to dedicated

zone on the

control panel for

Supervision when

the Power Supply

board (SLE-

ULPS-R) is not

used.

GRN

6 7 8 15 14 13 12 11 9 10 2* 3 4 5 1*

StarLink Radio Terminals

SLE-LTEV-CB-TF PC Board: All connec-

tions are power limited except AC Mains,

Telco and battery terminals. Terminals 14-

17: No connections permitted.

RED

PANEL

RING (+)

BLACK

YELLOW

PANEL

TIP (–)

RTS

(R)

PANEL

TX (B)

17 16

PANEL

CTS

RX (G)

Y

Either the TRF12/T123

(16.5V / 20VA) transformer

or the chassis-mounted

16.5VAC / 20VA transformer

TELCO QUAD WIRE

N/O

COM

8 9 10

N/C

J2

Power Supply (SLE-ULPS-R)

(optional)

EOLR

(+)

(–)

RED

BLACK

StarLink

BATTERY

Note: Battery leads

are not power limited

*Refer to section "SUPPLYING POWER".

StarLink

™

SLE-LTE Commercial Series Alarm Communicators -- Installation Instructions 11

Page 12

Wiring Diagram for PRIMARY Reporting Configuration

GEMC-32, GEMC-96, GEMC-128 and GEMC-255 Control Panels

(Use when telephone line is NOT available)

(CONTROL PANEL HOUSING)

RJ31X

GEMC Control

Panel PC Board

RING TIP

RJ31X

RING TIP

SEE WIRING

DIAGRAM

AND WI FOR

ADDITIONAL

INFORMATION

10K

10K

MONITOR

COM

ZONE (+)

DEDICATED TO

SUPERVISION

TELCO TROUBLE OUTPUT

Special Wiring Instructions for the

GEMC-F8ZCPIM as a Monitor Zone Only

When PGM1 is wired to a GEMC-F8ZCPIM

zone, replace the 2.2k ohm EOL resistor wit h

a 560ohm 1/2 watt min EOL resistor. Connect

PGM1 to the negative terminal of the zone.

When PGM2 and/or PGM3 are wired to a

GEMC-F8ZCPIM zone, replace the 2.2k ohm

+V

EOL resistor with two 1K ohm 1/4 watt min

EOL resistors. Connect the PGM wire to the

common wire of the two resistors in series.

GEMC-F8ZCPIM

ZONE

(+)

(‒)

EOLR 560Ω

(min 1/2W)

Radio PGM1 terminal

GEMC-F8ZCPIM

ZONE

EOLR

EOLR

1K

1K

Ω

Ω

Radio PGM2 or PGM3

terminal

Note: Connect IN2 to a

panel output used for

identifying Telco line cut (this

is the DACT interconnect

wiring to the radio).

(STARLINK RADIO HOUSING)

*Refer to section "SUPPLYING POWER".

12 StarLink

2.2K

6 7 8 15 14 13 12 11 9 10 2* 3 4 5 1*

PGM1 PGM2 PGM3 IN1 IN2 GND IN3 RING TIP

(–)

StarLink Radio Terminals

SLE-LTEV-CB-TF PC Board: All connections are power limited except AC Mains,

Telco and battery terminals. Terminals

14-17: No connections permitted.

™

SLE-LTE Commercial Series Alarm Communicators -- Installation Instructions

PANEL

RING (+)

PANEL

TIP (–)

RTS

(R)

PANEL

TX (B)

PANEL

RX (G)

17 16

CTS

Y

Page 13

Wiring Diagram for PRIMARY Reporting Configuration

GEMC-32, GEMC-96, GEMC-128 and GEMC-255 Control Panels

(Use when telephone line is NOT available)

(CONTROL PANEL HOUSING)

RJ31X

GEMC Control

Panel PC Board

RING TIP

RJ31X

RING TIP

SEE WIRING

DIAGRAM

AND WI FOR

ADDITIONAL

INFORMATION

10K

10K

COM

ZONE (+)

DEDICATED

TO SUPER-

TELCO TROUBLE OUTPUT

VISION

Note: Connect IN2

to a panel output used

for identifying Telco

line cut (this is the

DACT interconnect

wiring to the radio).

2.2K

6 7 8 15 14 13 12 11 9 10 2* 3 4 5 1*

+V

PGM1 PGM2 PGM3 IN1 IN2 GND IN3 RING TIP

(–)

StarLink Radio Terminals

Wire to dedicated zone

on the control panel for

Supervision when the

Power Supply board

(SLE-ULPS-R) is not

used.

(STARLINK RADIO HOUSING)

*Refer to section "SUPPLYING POWER".

StarLink

™

SLE-LTE Commercial Series Alarm Communicators -- Installation Instructions 13

SLE-LTEV-CB-TF PC Board: All connections are power limited except AC

Mains, Telco and battery terminals. Ter-

minals 14-17: No connections permitted.

PANEL

RING (+)

PANEL

TIP (–)

RTS

(R)

PANEL

TX (B)

PANEL

RX (G)

17 16

CTS

Y

Either the

TRF12/T123

(16.5V / 20VA)

transformer

or the chassis-

mounted

16.5VAC /

20VA

transformer

N/O

COM

8 9 10

N/C

J2

Power Supply (SLE-ULPS-R)

(optional)

2.2K

(+)

(–)

RED

BLACK

StarLink

BATTERY

Page 14

Wiring Diagram for BACKUP Reporting Configuration

GEM-X255 / GEM-P9600 / GEM-P3200 Control Panels

(CONTROL PANEL HOUSING)

16VAC

Transformer

RING TIP

HOME

PHONES

TO TELCO

RJ31X

GRN

RED

Control Panel PC Board

1

16VAC

2

3

4

5

(Cut Jumper A)

AUX RELAY

COM

10K

6

N/C

7

N/O

8

Summary of connections:

RJ31X RED to StarLink module 10

RJ31X GREEN to StarLink module 11

RJ31X BROWN to Panel 32

RJ31X GRAY to Panel 33

Panel 30 to StarLink module 13

Panel 31 to StarLink module 12

9

10K

10

11

REMOTE

AUX PWR

PWR (─)

(+) (–)

13 14 15 16 17 18 19 20 21 22 26 27 28 29 23 24 25 33 30 31 32

TEL LINE PHONE

TIP RING TIP RING

12

GRAY

BRN

BLACK

YELLOW

Optional: When Power Supply

COM

TELCO TBL

BRN

GRAY

SLE-ULPS-R is not used,

connect Panel Aux Power to

StarLink terminals 1 and 2

(observing polarity)

GRN

RED

*For StarLink module

terminals 1 and 2:

May be wired directly

to Aux Power of the

control panel when

71mA standby current is available.

Note: Connect

IN2 to a panel

output used for

identifying Telco

line cut (this is the

DACT interconnect

wiring to the radio).

GRN

RED

6 7 8 15 14 13 12 11 9 10 2* 3 4 5 1*

+V

Wire to dedicated zone on

Power Supply board (SLE-

(STARLINK RADIO HOUSING)

PGM1 PGM2 PGM3 IN1 IN2 GND IN3 RING TIP

(–)

StarLink Radio Terminals

the control panel for

Supervision when the

ULPS-R) is not used.

SLE-LTEV-CB-TF PC Board: All connections are pow-

er limited except AC Mains, Telco and battery termi-

nals. Terminals 14-17: No connections permitted.

*Refer to section "SUPPLYING POWER".

PANEL

RING (+)

14 StarLink

BLACK

ZONE (+)

RED

GRN

TELCO QUAD WIRE

YELLOW

Either the

TRF12/T123

17 16

PANEL

TIP (–)

PANEL

RTS

(R)

™

PANEL

TX (B)

RX (G)

SLE-LTE Commercial Series Alarm Communicators -- Installation Instructions

CTS

Y

(16.5V / 20VA)

transformer

or the chassis-

mounted

16.5VAC /

20VA

transformer

Power Supply (SLE-ULPS-R)

(optional)

DEDICATED

SUPERVISION

N/O

COM

8 9 10

N/C

J2

TO

2.2K

(+)

(–)

RED

BLACK

StarLink

BATTERY

Page 15

Wiring Diagram for PRIMARY Reporting Configuration

GEM-816 / GEM-P1632 / GEM-P1664 Control Panels

(Use when telephone line is NOT available)

(CONTROL PANEL HOUSING)

*Refer to section

"SUPPLYING

POWER".

+V

AUX POWER

Control Panel PC Board

(+) (–)

5

6

TELCO PHONE

TIP RING TIP RING

13 14 15 16 17 18 19 20 21 22 26 27 28 29 23 24 25

~ ~

(un-polarized)

ZONE (+)

DEDICATED TO

SUPERVISION

2.2K

6 7 8 15 14 13 12 11 9 10 2* 3 4 5 1*

PGM1 PGM2 PGM3 IN1 IN2 GND IN3 RING

(–)

StarLink Radio Terminals

TIP

PANEL

RING

(un-polarized)

Note: Connect IN2 to a

panel output used for

identifying Telco line cut (this

is the DACT interconnect

wiring to the radio).

(un-polarized)

~ ~

PANEL

TIP

RTS

(R)

PANEL

TX (B)

PANEL

RX (G)

SLE-LTEV-CB-TF PC

Board: All connections are power lim-

17 16

CTS

Y

ited except AC

Mains, Telco and

battery terminals.

Terminals 14-17: No

connections permit-

ted.

(CONTROL PANEL HOUSING)

*Refer to section

"SUPPLYING

POWER".

Wiring Diagram for PRIMARY Reporting Configuration

GEM-X255 / GEM-P9600 / GEM-P3200 Control Panels

(Use when telephone line is NOT available)

Control Panel PC Board

(Cut Jumper A)

AUX RELAY

COM

10K

10K

6

7

8

9

10

N/C

N/O

AUX POWER

(+) (–)

TEL LINE PHONE

TIP RING TIP RING

13 14 15 16 17 18 19 20 21 22 26 27 28 29 23 24 25 33 30 31 32

~

~

(un-polarized)

(un-polarized)

Note: Connect

IN2 to a panel

output used for

ZONE (+)

identifying Telco

SUPERVISION

DEDICATED TO

line cut (this is the

DACT interconnect

wiring to the radio).

2.2K

~ ~

6 7 8 15 14 13 12 11 9 10 2* 3 4 5 1*

PANEL

+V

PGM1 PGM2 PGM3 IN1 IN2 GND IN3 RING

(–)

StarLink Radio Terminals

TIP

PANEL

RING

TIP

(un-polarized)

RTS

(R)

PANEL

TX (B)

PANEL

RX (G)

SLE-LTEV-CB-TF

PC Board: All connections are power

limited except AC

Mains, Telco and

17 16

CTS

battery terminals.

Terminals 14-17:

Y

No connections

permitted.

StarLink

™

SLE-LTE Commercial Series Alarm Communicators -- Installation Instructions 15

Page 16

Wiring Diagram for BACKUP Reporting Configuration

GEM-816 / GEM-P1632 / GEM-P1664, Freedom F-64 Control Panels

16VAC

Transformer

TO TELCO

RING TIP

RJ31X

HOME

PHONES

(CONTROL PANEL HOUSING)

1

2

3

4

Optional: When Power

Supply SLE-ULPS-R is not

used, connect Panel Aux

Power to StarLink terminals

1 and 2 (observing polarity)

5

6

7

8

9

10

11

12

GRN

RED

BRN

GRAY

Control Panel PC Board

VAC

16

Summary of connections:

AUX POWER

(+)

(–)

13 14 15 16 17 18 19 20 21 22 26 27 28 29 23 24 25

RJ31X RED to StarLink module 10

RJ31X GREEN to StarLink module 11

RJ31X BROWN to Panel 28

RJ31X GRAY to Panel 29

Panel 27 to StarLink module 12

Panel 26 to StarLink module 13

TELCO PHONE

TIP RING TIP RING

GRAY

BRN

BLACK

YELLOW

ZONE (+)

DEDICATED

TO

SUPERVISION

BRN

GRAY

*For StarLink module terminals 1 and

RED

GRN

2: May be wired

directly to Aux

Power of the control panel when

71mA standby

current is available.

Wire to dedicated zone on the

control panel for Supervision

when the Power Supply board

(SLE-ULPS-R) is not used.

GRN

RED

6 7 8 15 14 13 12 11 9 10 2* 3 4 5 1*

+V

Note: Connect IN2 to

a panel output used for

identifying Telco line

cut (this is the DACT

interconnect wiring to

the radio).

(STARLINK RADIO HOUSING)

PGM1 PGM2 PGM3 IN1 IN2 GND IN3 RING TIP

(–)

StarLink Radio Terminals

SLE-LTEV-CB-TF PC Board: All connections are pow-

er limited except AC Mains, Telco and battery termi-

nals. Terminals 14-17: No connections permitted.

*Refer to section "SUPPLYING POWER".

PANEL

RING (+)

16 StarLink

BLACK

YELLOW

PANEL

TIP (–)

BRN

GRAY

YELLOW

BLACK

TELCO QUAD WIRE

2.2K

N/O

COM

8 9 10

N/C

J2

Either the

TRF12/T123

17 16

PANEL

RTS

(R)

PANEL

RX (G)

CTS

Y

TX (B)

™

SLE-LTE Commercial Series Alarm Communicators -- Installation Instructions

(16.5V /

20VA)

transformer

or the chassis-mounted

16.5VAC /

20VA

transformer

Power Supply (SLE-ULPS-R)

(optional)

(+)

RED

StarLink

BATTERY

(–)

BLACK

Page 17

Option

Application

FACP with DACT

Use IN2 or IN3 only for

trouble. Panel reports via

1

dialer capture, but Linecut

for DACT interconnection

wiring to the radio reports via

an input on radio.

FACP with DACT

Use IN1 (not supervised)

either for trouble or alarm.

2

Panel has trouble (or alarm)

relay that closes on the

condition.

FACP without DACT

Use IN2 or IN3 for both

3

Alarm and Trouble on one

input. Panel has alarm and

trouble relay outputs.

BURG with DACT

Use IN2 or IN3 for only

trouble reporting. Panel

4

reports via dialer capture but

Linecut for DACT intercon-

nection wiring to the radio

reports via an input on radio.

BURG without DACT

Use IN2 or IN3 for both

Alarm and Trouble. Panel

has alarm and Trouble

5

Relay/PGM outputs. Two

EOLRs are needed since for

UL Burg it is required to

detect both wire breaks and

6

vise for both wire breaks and

shorts.

BURG without DACT:

Armed Status

Use IN2 or IN3 for Armed

Status input. Two EOLRs

are needed since for UL

Burg it's required to super-

shorts.

Input Configuration Options

Armed Disarmed

Cut

Wire*

TBL TBL TBL - - - Yes

TBL TBL ALARM - - - Yes

ALARM ALARM ALARM TBL TBL TBL No

ALARM TBL ALARM TBL TBL TBL No

TAMPER

ALARM

Open Short

-- -- -- - - - Yes

-

TBL

(or

ALARM)

N/A ALARM TBL N/A TBL No

Cut

Open Short

Wire*

- - - - Yes

Resend

TBL every

24 Hrs.

NOC Inputs

"Function"

Selection

Supervised Fire

Trouble (Linecut)

User Defined

Unsupervised Fire

Trouble (Linecut)

Un-Supervised Fire

Trouble (use 'User

Defined' selection

for Alarms)

Supervised Fire

Alarm/Trouble

Supervised Burg-

Linecut

Supervised Burg

Alarm/Trouble

Supervised Arm/

Disarm Status

Comments

Requires two EOLRs. Radio reports in CID

(use jumpers 4/5)

Non-supervised (use conduit max 20 feet

Commercial Fire or 3 feet Residential Fire)

(remove jumpers 4/5).

Non-supervised (use conduit activation

requires +12V or 12/24V)

Requires two EOLRs. The Trouble relay

N.O. contact (de-energized opens) is put in

series with one EOLR. Alarm relay put

across both EOLR and trouble relay.

Requires two EOLRs. Program panel to

report Open/Close (radio remembers last

state of panel for Napco panels when used

with local download cable).

Requires two 10K EOLRs. Three off nor-

mal conditions can be detected, namely,

cut wire, shorted loop and one of the

EOLR's having a closed contact in series.

The Trouble relay N.O. contact (de-

energized opens) is put in series with one

EOLR. The Alarm relay N.O. contact is put

across both EOLRs and trouble relay. The

panel Armed or Disarmed state is deter-

mined by a separate input (see Option 6 in

this table below for armed status opera-

tion). (Note: The Alarm relay should NOT

activate on 24hr zones.)

Requires two 10K EOLRs. A relay or PGM

for Arm/Disarm status goes in series with

one EOLR where open is disarmed and

closed is armed. The other EOLR is across

the series combination (relay for Arm/

Disarm and first EOLR) to provide the loop

supervision.

REN = 0. The Ringer Equivalence Number (REN) indicates the maximum number

of devices allowed to be connected to a telephone interface. The termination of an

interface may consist of any combination of devices subject only to the requirement that

the sum of the RENs of all the devices not exceed five (5).

*Note: On line cut, PGM1 will activate.

StarLink

™

SLE-LTE Commercial Series Alarm Communicators -- Installation Instructions 17

Page 18

Tamper Switch Mounting Instructions

WIRING THE TAMPER SWITCHES

(REQUIRED FOR UL COMMERCIAL BURGLARY)

Before installation and wiring, the tamper switches (part GEMTamperkit) are normally open devices; when placed into

the circuit and into operation, they are normally closed devices.

Tamper switches protect against the opening of the radio cabinet door or the removal of the radio enclosure from the wall or

other mounting surface.

There are two places in the cabinet to mount tamper switches:

(1) To prevent cabinet removal from the wall, located on the

left side of the cabinet there is one knockout for the switch

plunger and three mounting holes (in the enclosure sheet metal). (2) To protect the cabinet door, mount a tamper switch in

the three mounting holes (in the enclosure sheet metal).

When mounted, the switch button contacts the inside surface

of the door. Note: Be sure to alert the user that opening the

enclosure door will cause a tamper alarm.

Wiring a normally closed sensor loop for tamper supervision,

wire to a zone on the control panel.

Back Tamper

2

1

VIEW OF TAMPER SWITCHES:

(1) = ENCLOSURE BASE;

(2-BACK) = TAMPER SWITCH TO PREVENT REMOVAL FROM WALL;

(3-DOOR) = TAMPER SWITCH TO PROTECT THE ENCLOSURE

DOOR

Door Tamper

3

GEM-Tamperkit

consists of

SC206LF

SW105 Tamper Switch 2

Description QTY

Slotted Pan Head 6-32 x 3/4

Machine Screw

NYCFD Conditions of Acceptability

1. Only radios Listed for UL 864 Commercial Fire are NYCFD approved.

2. All installations must be dual path (DACT and Radio) and DACT shall be primary.

3. Each path must be supervised not exceeding 24 hours.

4. Failure of either path shall be annunciated at the protected premises.

5. Failure of either path shall cause a trouble to be sent to the central station within 5 minutes on the other

communications path.

6. When a remote antenna is used, the antenna transmission line shall be installed in rigid metal, intermediate metal,

or electrical metallic tubing in accordance with NFPA70, NEC.

7. Interconnections between elements of transmitting equipment, including any antennas, shall be supervised either to

cause an indication of failure at the protected premises or to transmit a trouble signal to the supervising station.

8. All UL requirements must be complied with.

6

18 StarLink

™

SLE-LTE Commercial Series Alarm Communicators -- Installation Instructions

Page 19

Optional Alternate Methods for Commercial Fire

Branch Circuit Power Connections to the SLE Charger Board

COVER

EXAMPLE OF CONDUIT LOCATION

Min. 4 inch with flush

mount receptacle

EXAMPLE

OF

CONDUIT

LOCATION

8 IN.

FRONT VIEW

8 IN.

Minimum Pull

Box

Dimensions

4 to 6 IN.

SIDE VIEW

and min. 6 inch with

surface mount

receptacle

UL LISTED ELECTRICAL PULL BOX WITH LISTED OUTLET BOX AND NON-SWITCHED RECEPTACLE

ON DEDICATED FIRE ALARM SYSTEM BRANCH CIRCUIT

CONDUIT TRANSFORMER OUTPUT WIRING

UL LISTED PULL BOX

WALL

CONDUIT

120V

TRANSFORMER SECONDARY WIRING CONDUIT LIMITED TO 20 FEET MAXIMUM LENGTH

UL LISTED NAPCO TRF12/T123 TRANSFORMER FOR

CONNECTION TO SLE CHARGER BOARD

UL LISTED SURFACE OR FLUSH MOUNT OUTLET BOX

AND NON-SWITCHED RECEPTACLE

Maintain a minimum of 1/4 inch separation of

circuits (transformer secondary wiring from

120V branch circuit).

StarLink

™

SLE-LTE Commercial Series Alarm Communicators -- Installation Instructions 19

Page 20

NAPCO LIMITED WARRANTY

NAPCO SECURITY SYSTEMS, INC. (NAPCO) warrants its products to be

free from manufacturing defects in materials and workmanship for 36

months following the date of manufacture. NAPCO will, within said period,

at its option, repair or replace any product failing to operate correctly

without charge to the original purchaser or user.

This warranty shall not apply to any equipment, or any part thereof, which

has been repaired by others, improperly installed, improperly used, abused,

altered, damaged, subjected to acts of God, or on which any serial numbers

have been altered, defaced or removed. Seller will not be responsible for

any dismantling or reinstallation charges.

THERE ARE NO WARRANTIES, EXPRESS OR IMPLIED, WHICH

EXTEND BEYOND THE DESCRIPTION ON THE FACE HEREOF. THERE

IS NO EXPRESS OR IMPLIED WARRANTY OF MERCHANTABILITY OR

A WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

ADDITIONALLY, THIS WARRANTY IS IN LIEU OF ALL OTHER

OBLIGATIONS OR LIABILITIES ON THE PART OF NAPCO.

Any action for breach of warranty, including but not limited to any implied

warranty of merchantability, must be brought within the six months following

the end of the warranty period. IN NO CASE SHALL NAPCO BE LIABLE

TO ANYONE FOR ANY CONSEQUENTIAL OR INCIDEN TAL DAMAGES

FOR BREACH OF THIS OR ANY OTHER WARRANTY, EXPRESS OR

IMPLIED, EVEN IF THE LOSS OR DAMAGE IS CAUSED BY THE

SELLER'S OWN NEGLIGENCE OR FAULT.

In case of defect, contact the security professional who installed and

maintains your security system. In order to exercise the warranty, the

product must be returned by the security professional, shipping costs

prepaid and insured to NAPCO. After repair or replacement, NAPCO

assumes the cost of returning products under warranty. NAPCO shall have

no obligation under this warranty, or otherwise, if the product has been

repaired by others, improperly installed, improperly used, abused, altered,

damaged, subjected to accident, nuisance, flood, fire or acts of God, or on

which any serial numbers have been altered, defaced or removed. NAPCO

will not be responsible for any dismantling, reassembly or reinstallation

charges.

This warranty contains the entire warranty. It is the sole warranty and any

prior agreements or representations, whether oral or written, are either

merged herein or are expressly cancelled. NAPCO neither assumes, nor

authorizes any other person purporting to act on its behalf to modify, to

change, or to assume for it, any other warranty or liability concerning its

products.

In no event shall NAPCO be liable for an amount in excess of NAPCO's

original selling price of the product, for any loss or damage, whether direct,

indirect, incidental, consequential, or otherwise arising out of any failure of

the product. Seller's warranty, as hereinabove set forth, shall not be

enlarged, diminished or affected by and no obligation or liability shall arise

or grow out of Seller's rendering of technical advice or service in connection

with Buyer's order of the goods furnished hereunder.

NAPCO RECOMMENDS THAT THE ENTIRE SYSTEM BE COMPLETELY

TESTED WEEKLY.

Warning: Despite frequent testing, and due to, but not limited to, any or all

of the following; criminal tampering, electrical or communications disruption,

it is possible for the system to fail to perform as expected. NAPCO does not

represent that the product/system may not be compromised or

circumvented; or that the product or system will prevent any personal injury

or property loss by burglary, robbery, fire or otherwise; nor that the product

or system will in all cases provide adequate warning or protection. A

properly installed and maintained alarm may only reduce risk of burglary,

robbery, fire or otherwise but it is not insurance or a guarantee that these

events will not occur. CONSEQUENTLY, SELLER SHALL HAVE NO

LIABILITY FOR ANY PERSONAL INJURY, PROPERTY DAMAGE, OR

OTHER LOSS BASED ON A CLAIM THE PRODUCT FAILED TO GIVE

WARNING. Therefore, the installer should in turn advise the consumer to

take any and all precautions for his or her safety including, but not limited

to, fleeing the premises and calling police or fire department, in order to

mitigate the possibilities of harm and/or damage.

NAPCO is not an insurer of either the property or safety of the user's family

or employees, and limits its liability for any loss or damage including

incidental or consequential damages to NAPCO's original selling price of

the product regardless of the cause of such loss or damage.

Some states do not allow limitations on how long an implied warranty lasts

or do not allow the exclusion or limitation of incidental or consequential

damages, or differentiate in their treatment of limitations of liability for

ordinary or gross negligence, so the above limitations or exclusions may

not apply to you. This Warranty gives you specific legal rights and you may

also have other rights which vary from state to state.

NOTE: This equipment has been tested and found to comply with the limits for a C l ass B Unintentional Radiator, pursuant to Part

15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a residential installation.

This equipment generates, uses, an d can radiate radio frequency energy and, if not installed a nd used in accordance with the Instruction

Manual, may cause harmful interference to radio communications. However, there is no guarantee that interference will not occur in a

particular installation. If this equipment does cause harmful interference to radio or television reception, which can be determined by turning

the equipment off and on, the user is encouraged to try to correct the interference by one of more of the following measures: 1. Reorient or

relocate the receiving antenna; 2. Increase the separation between the equipment and receiver; 3. Connect the equipment into an outlet on

a circuit different from that to which the receiver is connected; 4. Consult the dealer or an experienced radio/TV technician for help.

IMPORTANT WIRING METHODS

For single-conductor terminal

blocks (l ik e th e t yp e sh ow n at

left), to terminate more than one

conductor to a terminal, use the

In

wiring methods shown at right:

For "barrier" type terminal

blocks (like the type sho wn at

left), to terminate two conductors

to a terminal, use the wiring methods shown at right:

To terminate more than two conductors or

conductors of different wire sizes to a terminal,

use the "pigtail" type wiring method as shown at

right. Use insulated wire for the pigtail, and firmly

secure the conductors to the pigtail using an appropriate wire nut or crimp connector for the number and gauge of conductors used.

20 StarLink

Incorrect

Incorrect

Incorrect

Out

™

SLE-LTE Commercial Series Alarm Communicators -- Installation Instructions

In

Correct -- Single incoming and/or pigtail with wire nut / crimp connectors

Correct -- Separate incoming and outgoing conductors

PIGTAIL

Correct -- Use pigtail and wire nut / crimp connector

PIGTAIL

WIRE NUT OR

CRIMP

CONNECTOR

WIRE NUT OR

CONNECTOR

In Out

CRIMP

PIGTAIL

Loading...

Loading...