Nakamichi Soundspace 9, SS-9 Service manual

Service Manual

Service Manual

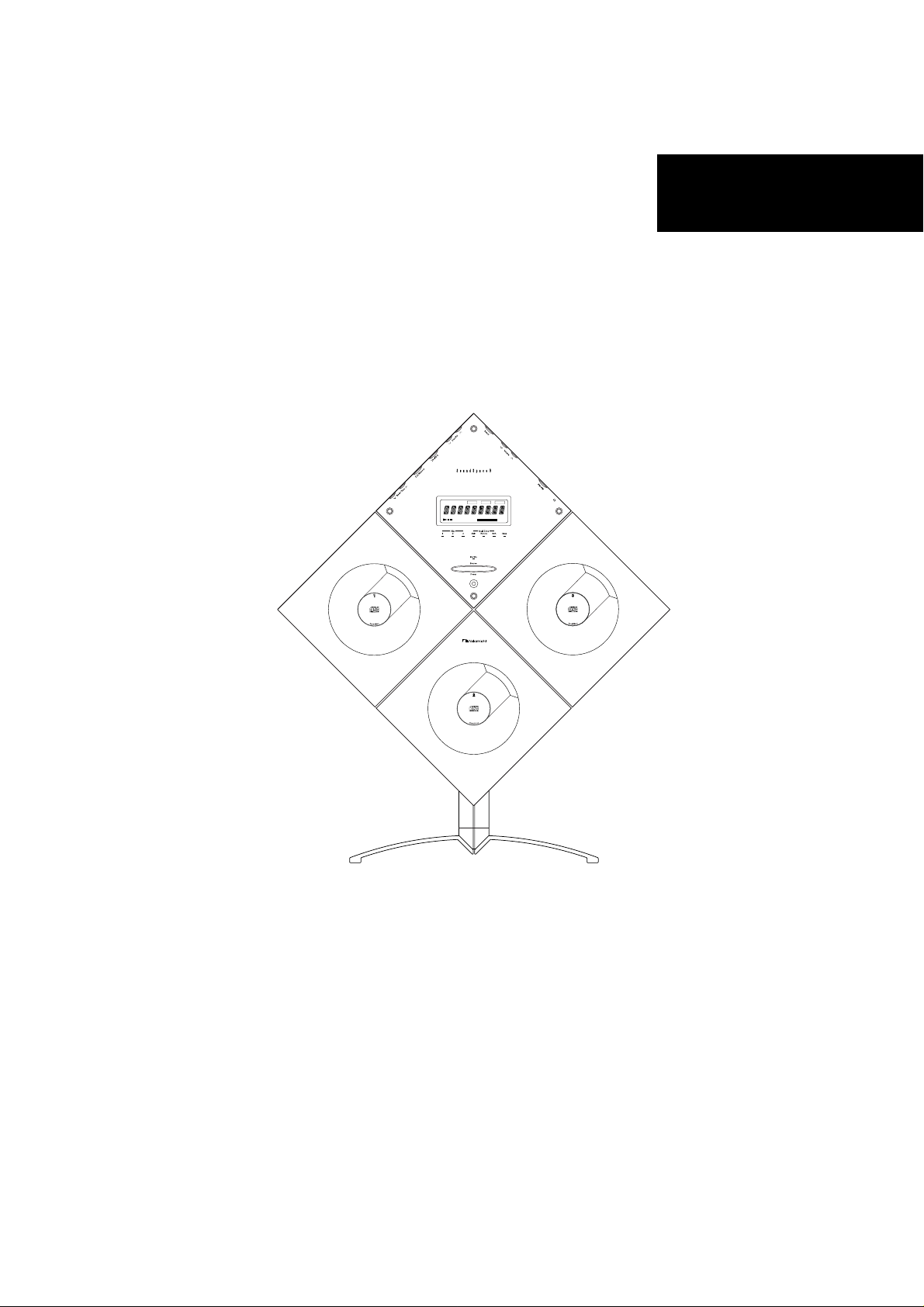

Stereo Music System

SoundSpace 9

SS-9 General

Random

Preset

FMAM

Disc Track RemainingTime

Memory Repeat

ST

Memory No.

Loud.Vol.

i

GENERAL

SS-9 General

1.1. Product Code

D210

Abbreviations for Destinations:

CAN — Canada CH — China

DA — South America

EP — Europe HK — Hong Kong

JPN — Japan KR — Korea

OTR — Other TW — Taiwan

UK — United Kingdom

USA — U.S.A. AUS — Australia

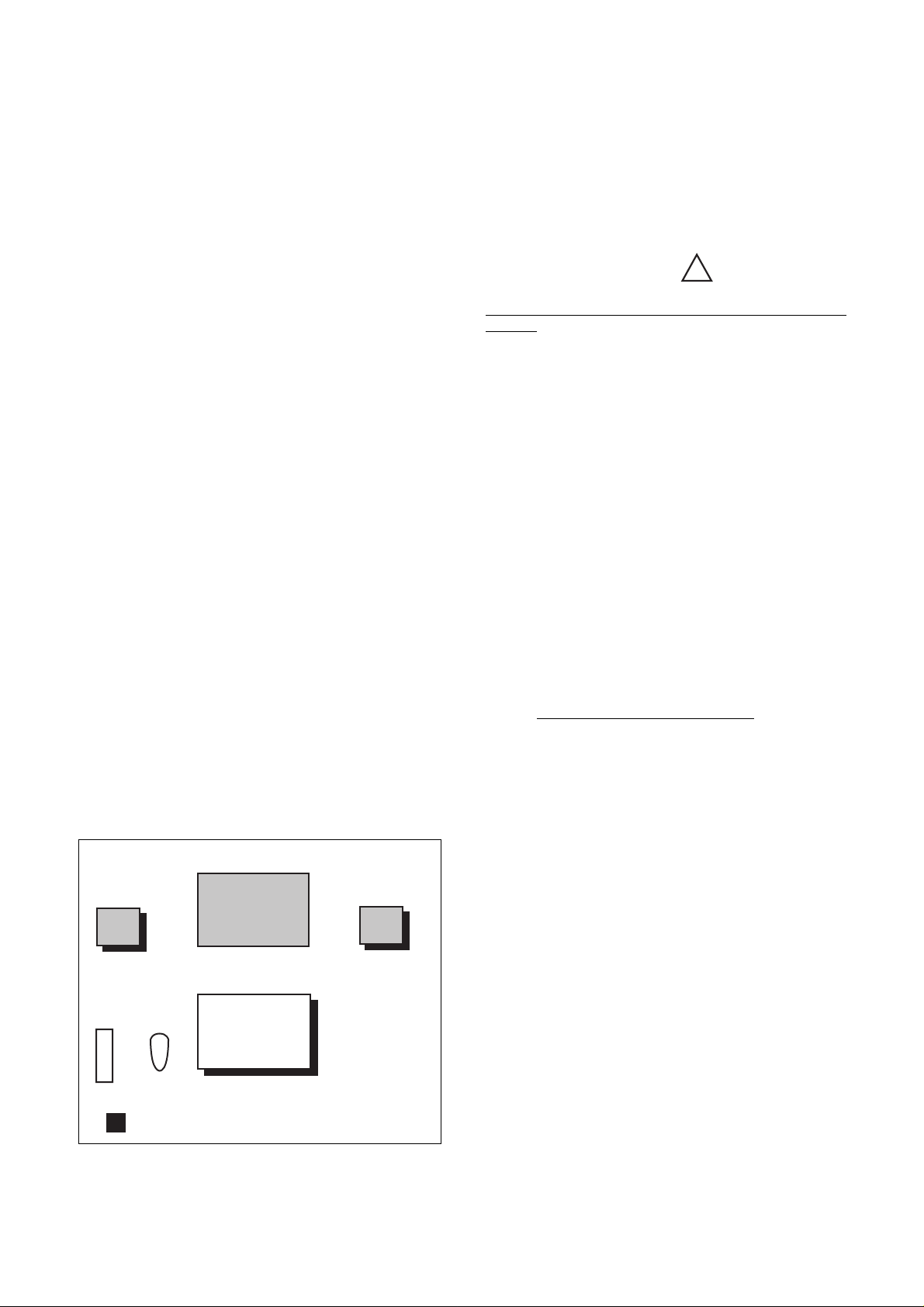

1.2. System Configuration

The SoundSpace consists of the following units.

●Main Unit (See pages 1-1, 1-2, ... in this manual)

Controls entire of the System. Mainly consists of the

following sections:

• Control section (including the system control microprocessor)

• Tuner section

• Operation panel control section

• CD player section (including the mechanism control microprocessor)-- 3 identical CD player sections (Interchangeable with each other except for

the Door Cap Ass'y on which the disc number is

written.)

● Subwoofer

(See pages 2-1, 2-2, ... in this manual)

• Subwoofer

• Power amp. section

• Power supply section

●Floor Stands (Option)

• Floor stand for Main Unit

• Floor stand for Satellite Speakers L/R

1.3. Cautions/Warnings

(1) Product Safety Notice

Parts marked with the symbol in the schematic

diagram have critical characteristics.

Use ONLY replacement parts recommended by the manufacturer. It is recommended that the unit be operated from a

suitable DC supply or batteries during initial check-out procedures.

(2) Leakage Current Check/Resistance Check

Before returning the unit to the customer, make sure you

make either (1) a leakage current check or (2) a line to

chassis resistance check. If the leakage current exceeds

0.5 milliamp, or if the resistance from chassis to either side

of the power cord is less than 240 k ohms, the unit is defective.

WARNING — DO NOT return the unit to the customer

until the problem is located and corrected.

(3) Protection of Eyes from Laser Beam

To protect eyes from invisible laser beam during servicing,

DO NOT LOOK AT THE LASER BEAM

(4) Laser Caution

CAUTION

Adjusting the knobs, switches, and controls, etc. or taking

actions not specified herein may result in a harmful emission of laser beams. This CD Player must be adjusted and

repaired

only by qualified service personnel.

!

on the Changer.

●Satellite Speakers L/R

(See pages 3-1, 3-2, ... in this manual)

●Main Remote Control/Sub Remote Control

Subwoofer

Speaker L

Remote Control

(Main) (Sub)

: Floor Stand (Option)

Fig. 1.1 SS-9 System Configuration

• Power Amp.

• Power Supply

Main Unit

• Tuner

• CD Player x 3

Speaker R

OBSERVERA!

Sådana inställningar av rattarna, omkopplarna eller övriga

kontrollknappar som inte är beskriva i bruksanvisningen

kan resultera i farlig laserutstrålning. Justering eller reparation av denna kompaktskivspelare skall endast utföras av

kvalificerad servicepersonal.

OBS!

Indstilling af knapper, cmskiftere og øvrige kontrolknapper,

som ikke følger den i brugsanvisningen beskrevne måde,

kan resultere i farlig laserudstråling. Justering eller reparation af denno CD-afspiller må kun udføres af kvalificeret

servicepersonale.

OBS!

Justering av ratt, brytere og kontroller andre enn de som er

beskrevet her, kan resultere i farlig laserbestråling. Justering eller reparasjon av denne kompaktdiskspilleren ma

bare utføres av kvalifiserte fagfolk.

HUOMAUTUS

Jos nuppeja, kytkimiä ja säätimiä ym, säädetään tai laitetta

käytetään toisella tavalla kuin on selostettu, tuloksena saattaa olla vaarallista lasersäteiden vuotoa. CD-soittimen

säätö ja korjaus on jätettävä aina asiantuntevan

huoltoteknikon tehtäväksi.

ii

SS-9 General

ADVERSEL: USYNLIG LASERSTRÅLING VED ÅBNING.

UNDGÅ UDSAETTELSE FOR STRÅLING.

VARO!: AVATTAESSA OLET ALTTIINA

NÄKYMÄTTÖMÄLLE LAS-

ERSÄTEILYLLE.

ÄLÄ KATSO SÄTEESEEN.

VARNING —OSYNLIG LASERSTRÅLNING NAR

DENNA DEL ÄR ÖPPNAD. BETRAKTA

EJ STRÅLEN.

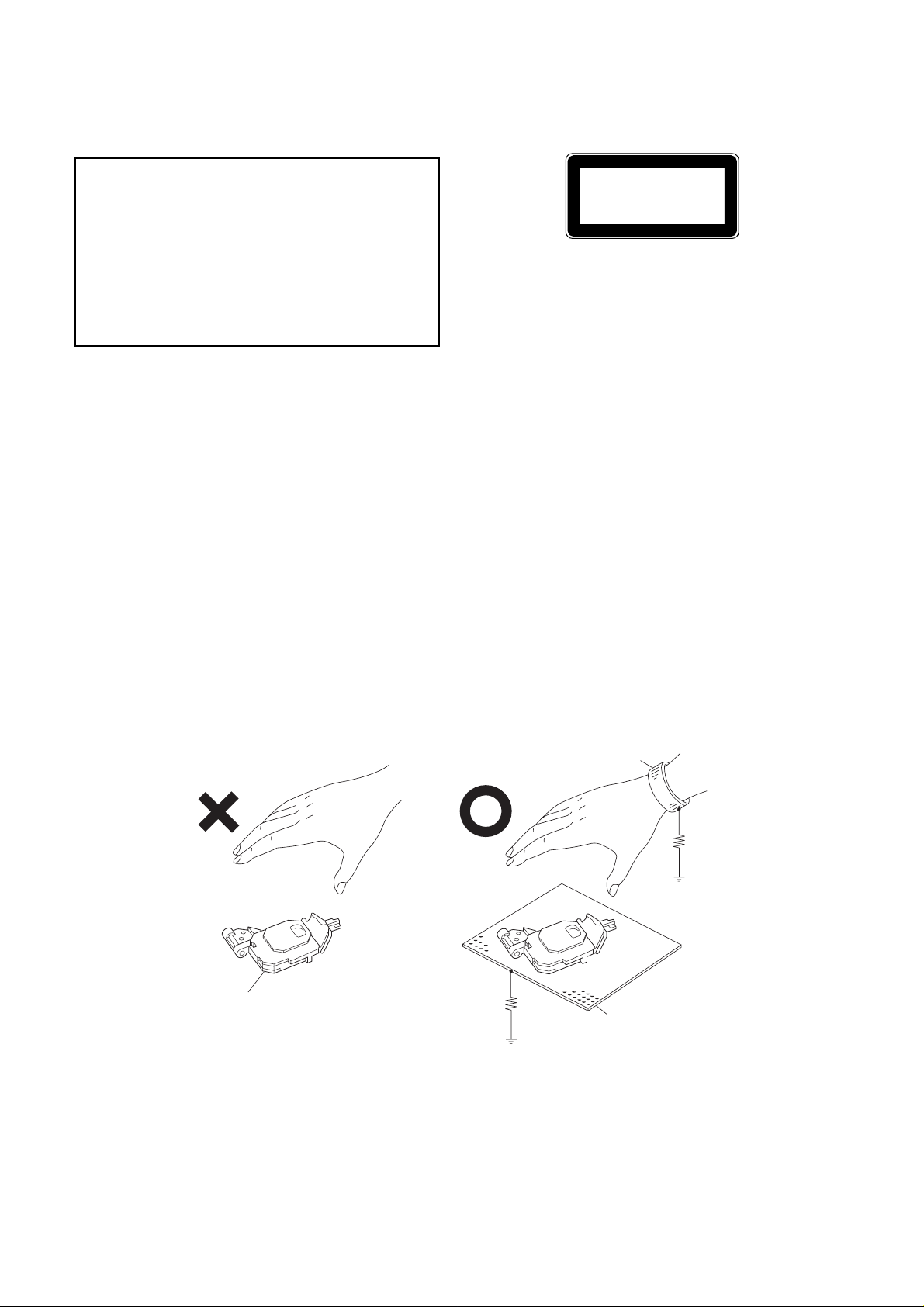

1.4. Handling the Laser Pickup

In case of repair or replacement of the Laser Pickup, pay

attention to the following handling instructions since the laser diode in the Laser Pickup is not resistant to static electricity.

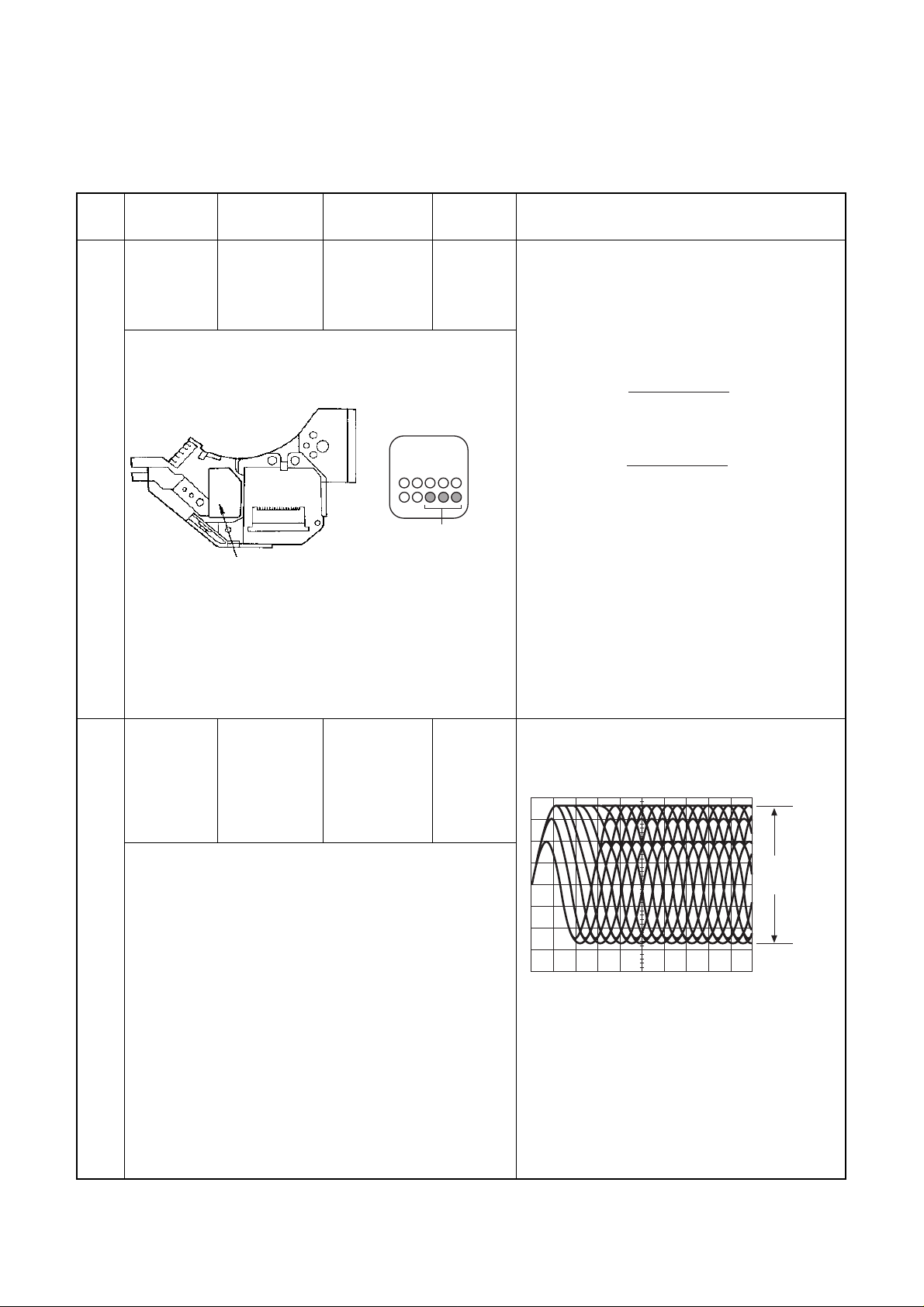

(1) Grounding

When you repair a Laser Pickup, first ground the human body, as well as the measuring instruments and

other tools (with particular caution to soldering iron).

What's more, your workbench and floor should desirably be grounded using conductive sheet or copper

plate. See Fig. 1.2.

NOTE: Be careful so as not to let your clothes touch

the Laser Pickup, as static electricity on the

clothes will not be released even if your body

is grounded.

CLASS 1

LASER PRODUCT

THIS COMPACT DISC PLAYER IS CLASSIFIED

AS A CLASS 1 LASER PRODUCT.

THE CLASS 1 LASER PRODUCT LABEL IS

LOCATED ON THE REAR EXTERIOR.

(2) Discharge of Electricity

Be sure to discharge electricity from objects brought into

contact with the Laser Pickup (i.e., soldering iron, tweezers,

probes, volt-ohm-meter probes, etc.) before starting work

by contacting them with the body chassis. Besides, never

touch the Laser Pickup while power is applied.

(3) Soldering Iron to be Used

The soldering iron for use in repair work should be: (1) a

ceramic soldering iron, (2) a soldering iron with its metal

part grounded, or (3) a soldering iron whose insulation resistance after five minutes of power application is 10 M-ohm

or more at 500 VDC. Soldering should be completed

promptly, at a soldering iron temperature of 320° max (39

W). A soldering iron heated above this temperature can

break down the laser diode.

(NO GOOD)

Laser Pickup

Wrist-strap

for Grounding

(GOOD)

1MΩ

1MΩ

Conductive Sheet or

Copper Plate

Fig. 1.2 Handling the Laser Pickup

iii

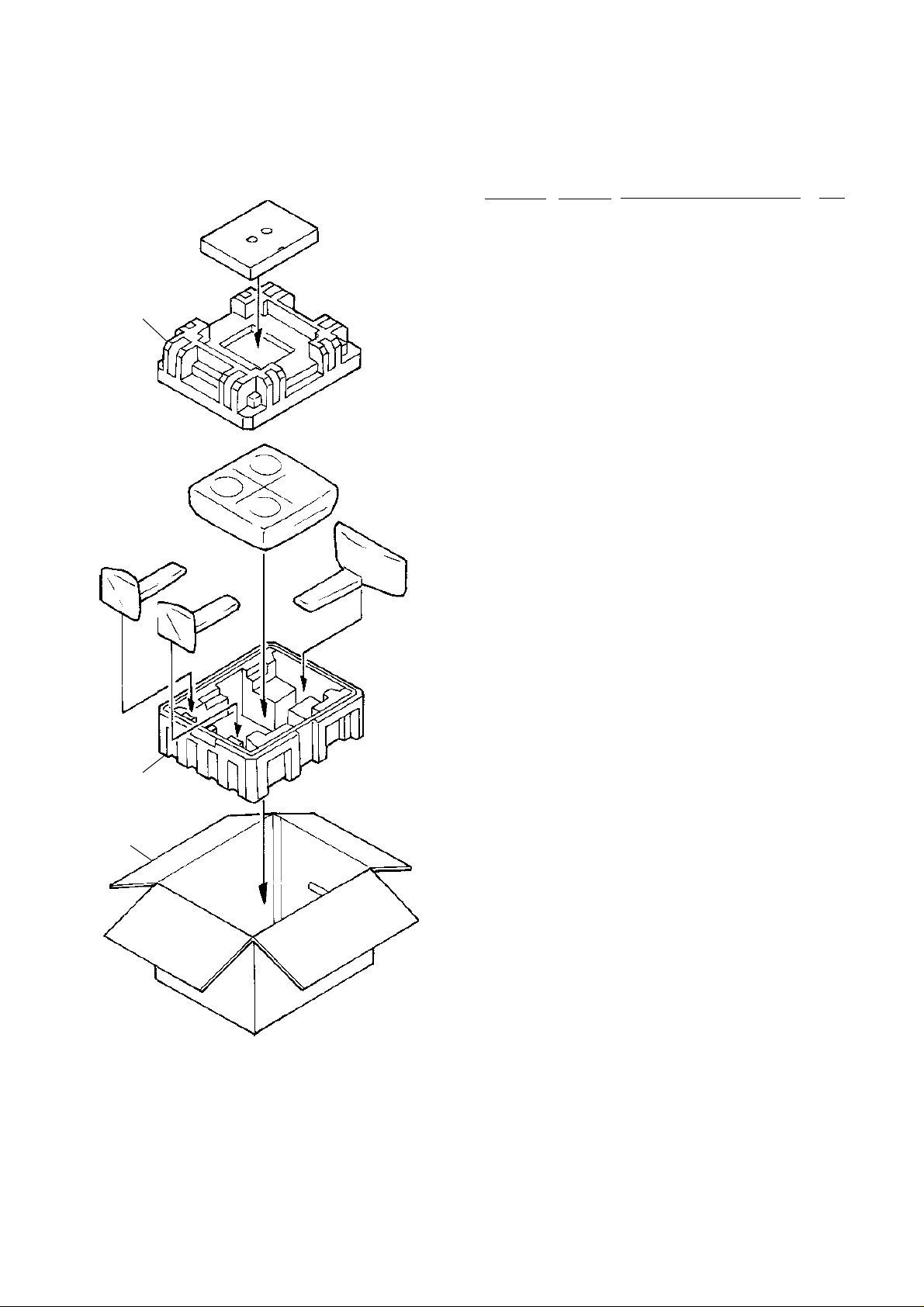

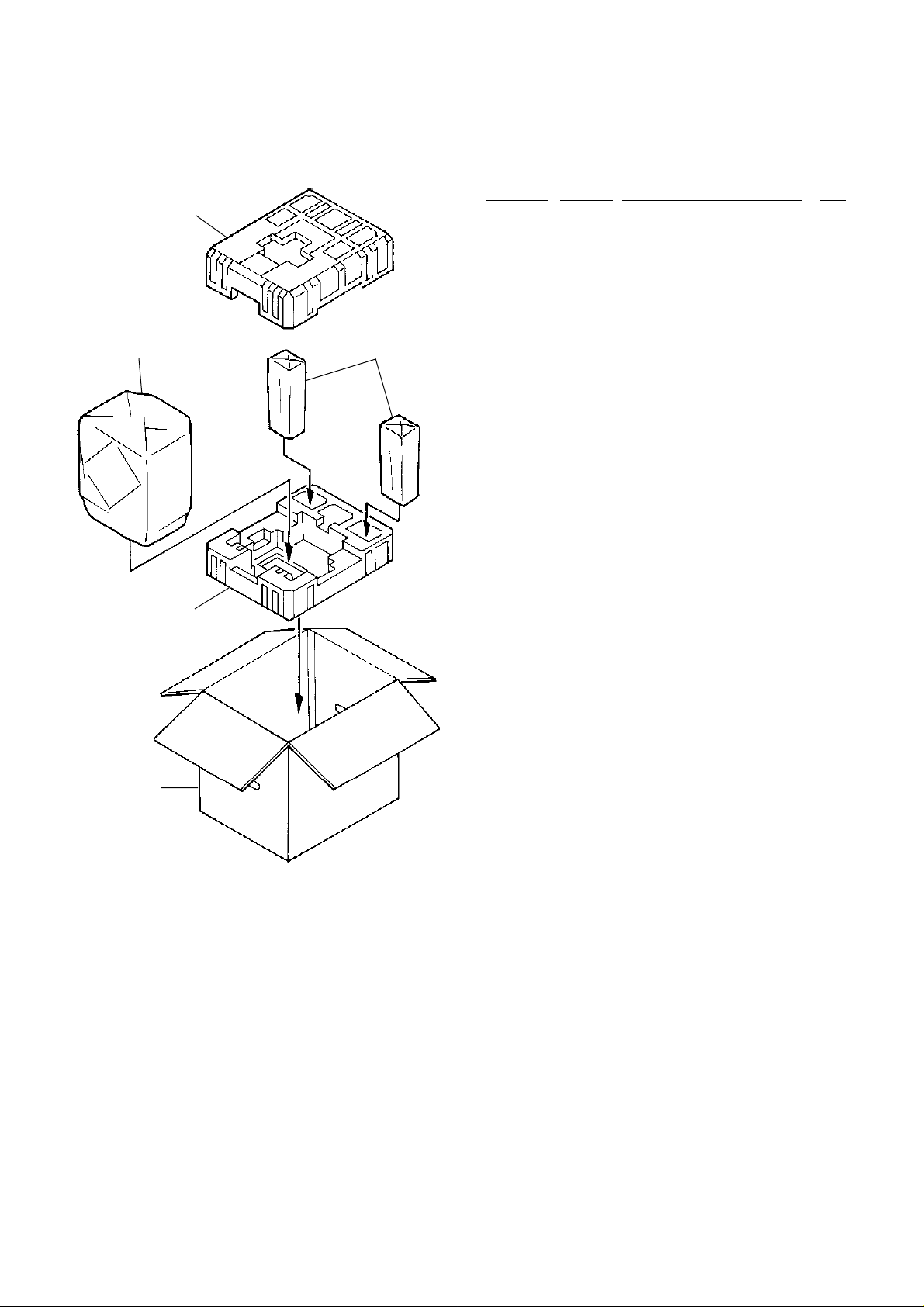

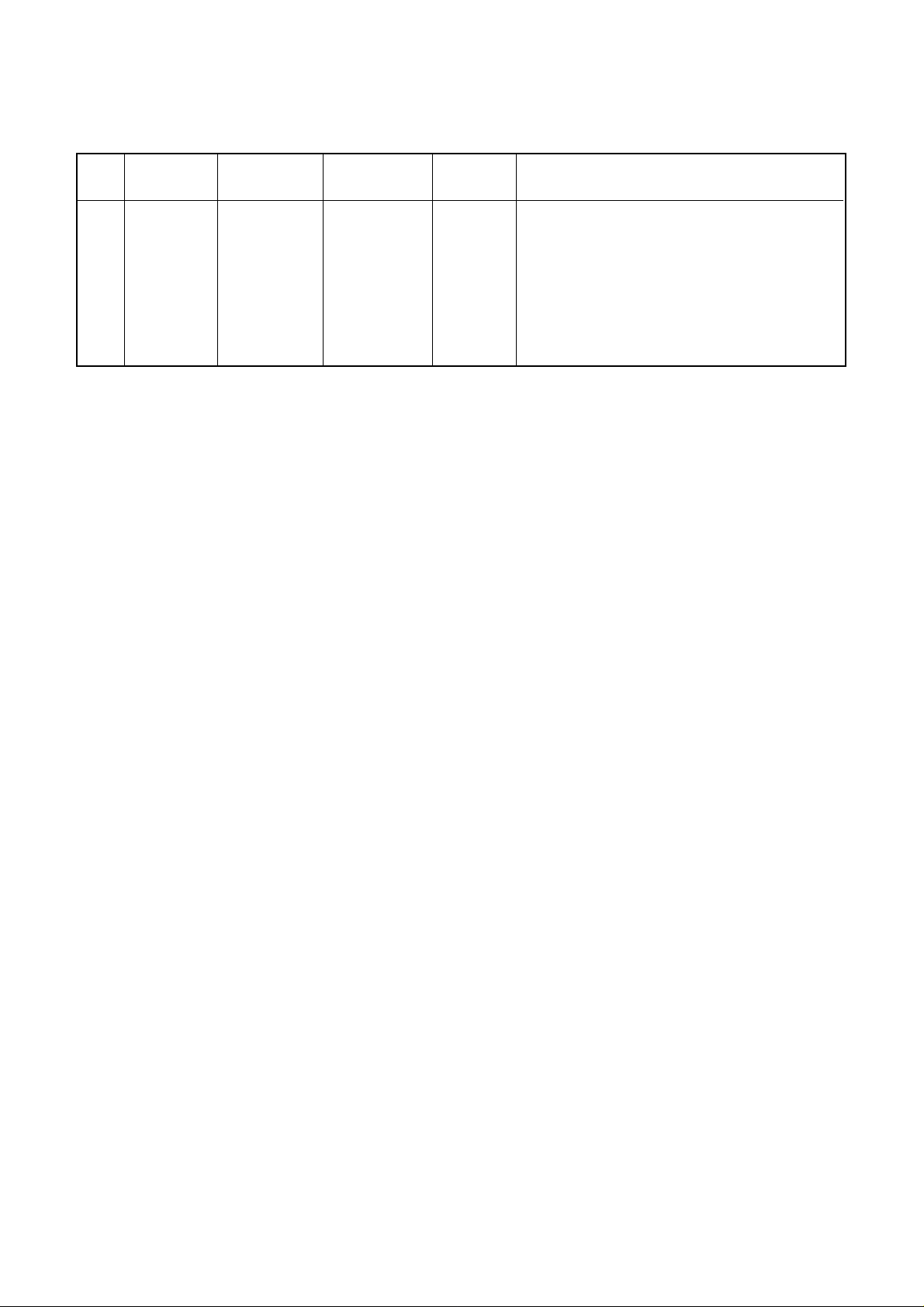

1.5. Package Ass’y and Accessory Ass’y

(1) Main Unit

03

02

01

SS-9 General

Schematic

Ref. No. Part No. Description Q'ty

— Package & Accessory Ass'y

(Main Unit)

01 0F05628A Carton Box 1

02 0F05630A Packing Bottom Center 1

03 0F05629A Packing Top Center 1

— 0F05631A Accessory Box 1

— 0F05689A Soft Sheet D Top A 1

— 0F05690A Soft Sheet D Top B 2

— 0F05692A Soft Bag Center 1

— 0F05693A Soft Bag Stand Top 3

— 0B85619A 13P DIN Cable 5m 1

— 0B85620A 3P RCA Cable 5m 1

— 0B90462A Battery UM4x1 4

— 0B90819A FM Indoor Antenna 1

— 0B90820A Antenna Adaptor 1

(JPN, OTR, USA, CAN, DA, TW)

— 0B91071A Antenna Adapter EP 1

(UK, AUS, EP, CH, HK, KR)

— 0D03092B Poly Bag 1

— 0D07105A Speaker Cable 2

— 0D07238A AC Cord UL (USA, CAN) 1

— 0D07239A AC Cord EP (EP) 1

— 0D07240A AC Cord DA/DU (OTR, DA, TW) 1

— 0D07241A AC Cord DM (JPN) 1

— 0D07242A AC Cord BS/HK (UK, HK) 1

— 0D07243A AC Cord CH (CH) 1

— 0D07244A AC Cord KR (KR) 1

— 0D07245A AC Cord SA (AUS) 1

— 0D07371B Owner’s Manual Japanese 1

— 0D07372B Owner’s Manual English 1

— 0D07375A Template 1

— 0D07376A Owner’s Manual Korean 1

— 0D07450A Owner’s Manual French 1

— 0D07451A Owner’s Manual German 1

— 0D07452B Owner’s Manual Spanish 1

— 0D07453A Owner’s Manual Italian 1

— 0D07454A Template Speaker 1

— 0D07477A AM Loop Antenna 1

— 0F05693A Soft Bag Stand Top 1

— 0H08216A CD Single Adaptor (JPN) 1

— 0H08749A Cable Holder 1

— 0H09008E Stand Holder Cover Center 1

— 0H09012A Stand Pole Cover L67 1

— 0H09013A Stand Pole Cover L82 2

— 0H09031A Base Cover Center DT 1

— 0J08862A Pole Cover Cushion 1

— DA05574A Screw Ass’y D210 1

— DG05310A Remote Control Sub Ass’y SS—5 1

— HA08444A Main Remote Ass’y SS9 1

(Except UK, EP)

— HA08447A Main Remote Ass’y RDS SS9 (UK, EP) 1

Fig. 1.3 Main Unit

iv

(2) Subwoofer and Satellite Speakers

03

04

SS-9 General

Schematic

Ref. No. Part No. Description Q'ty

— Package and Accessory Ass’y

(Subwoofer and Satellite Speakers)

01 0F05694A Carton Box S369 1

02 0F05703A Packing Bottom Subwoofer 1

03 0F05702A Packing Top Subwoofer 1

04 0F05691A Soft Sheet Subwoofer 1

05 0F05541A Soft Bag Satellite 2

— DA05647A Screw Ass’y S369 1

— DA05648A Spacer Ass’y S369 1

05

02

01

Fig. 1.4 Subwoofer and Satellite Speakers

v

Main Unit Section

Memory Repeat

Random

ST

Preset

FMAM

Disc Track RemainingTime

Memory No.

Loud.Vol.

SS-9 Main Unit Section

Main Unit

1-1

SS-9 Main Unit Section

CONTENTS

1. REMOVAL PROCEDURES ................................................................................................................................1-3

1.1. Rear Cover.............................................................................................................................................1-3

1.2. Main P.C.B. Ass'y ..................................................................................................................................1-3

1.3. Mechanism CD Ass'y .............................................................................................................................1-3

1.4. Front P.C.B. Ass'y ..................................................................................................................................1-4

1.5. Mechanism Chassis Block/Door Block of the Mechanism CD Ass'y ....................................................1-4

1.6. Disc Loading Ass'y .................................................................................................................................1-4

1.7. CD P.C.B. Ass'y and Traverse Mecha Ass'y .........................................................................................1-5

1.8. Laser Pickup ..........................................................................................................................................1-6

1.9. Sled Motor ..............................................................................................................................................1-6

2. ELECTRICAL CHECKS ..................................................................................................................................... 1-8

2.1. Measurement Instruments and Jigs ......................................................................................................1-8

2.2. Parts Location for Electrical Check........................................................................................................1-8

2.3. Electrical checks for CD Player .............................................................................................................1-9

3. MECHANISM ASS'Y AND PARTS LIST ...........................................................................................................1-11

3.1. Main Stand Ass'y ......................................................................................................... ..........................1-11

3.2. Synthesis (Main Unit) .............................................................................................................................1-12

3.3. Mechanism CD Ass'y 1/Mechanism CD Ass'y 2 (A01) .........................................................................1-14

3.4. Mechanism Chassis Ass'y (B01) ...........................................................................................................1-16

3.5. Traverse Mecha Ass'y (B02)..................................................................................................................1-17

3.6. Disc Loading Ass'y (B03) ....................................................................................................................... 1-18

4. ELECTRICAL PARTS LIST ...............................................................................................................................1-20

4.1. Main P.C.B. Ass'y......................................................................................................................................1-20

4.2. Front P.C.B. Ass'y .....................................................................................................................................1-20

4.3. CD P.C.B. Ass'y ........................................................................................................................................1-21

4.4. LED P.C.B. Ass'y ......................................................................................................................................1-21

4.5. SEN LD1 P.C.B. Ass'y ..............................................................................................................................1-21

4.6. SEN LD2 P.C.B. Ass'y ..............................................................................................................................1-21

4.7. SEN UD P.C.B. Ass'y ................................................................................................................................1-21

5. IC BLOCK DIAGRAMS .....................................................................................................................................1-22

6. BLOCK DIAGRAM ............................................................................................................................................1-33

SPECIFICATIONS (See the end of this manual.)

SCHEMATIC DIAGRAMS AND MOUNTING DIAGRAMS (See the separate volume.)

1-2

SS-9 Main Unit Section

1. REMOVAL PROCEDURES

NOTE: When parts required lubrication are replaced or reassembled, apply specified lubricant to the parts.

For the parts which require lubrication, refer to 3. "MECHANISM ASS'Y AND PARTS LIST."

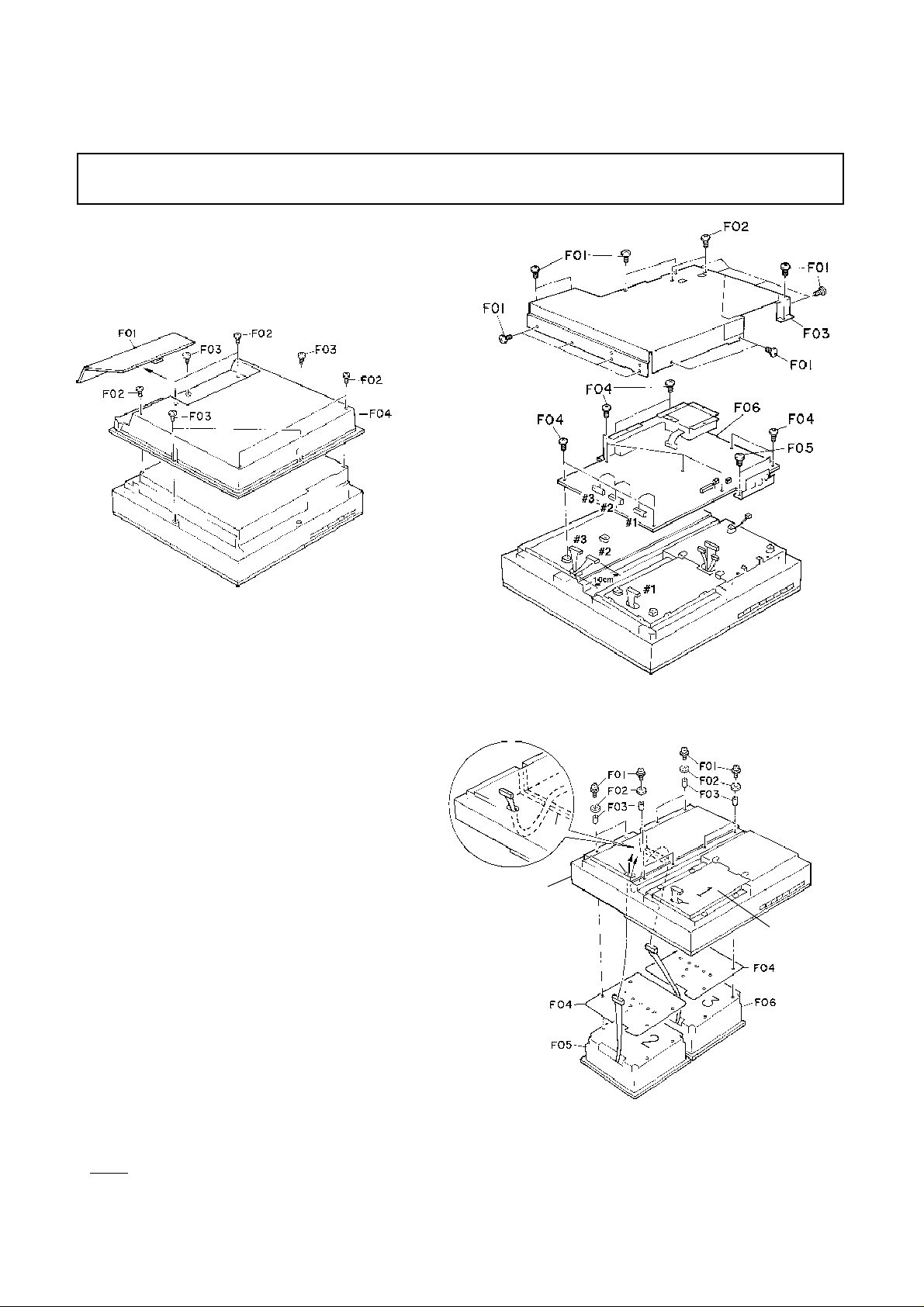

1.1. Rear Cover

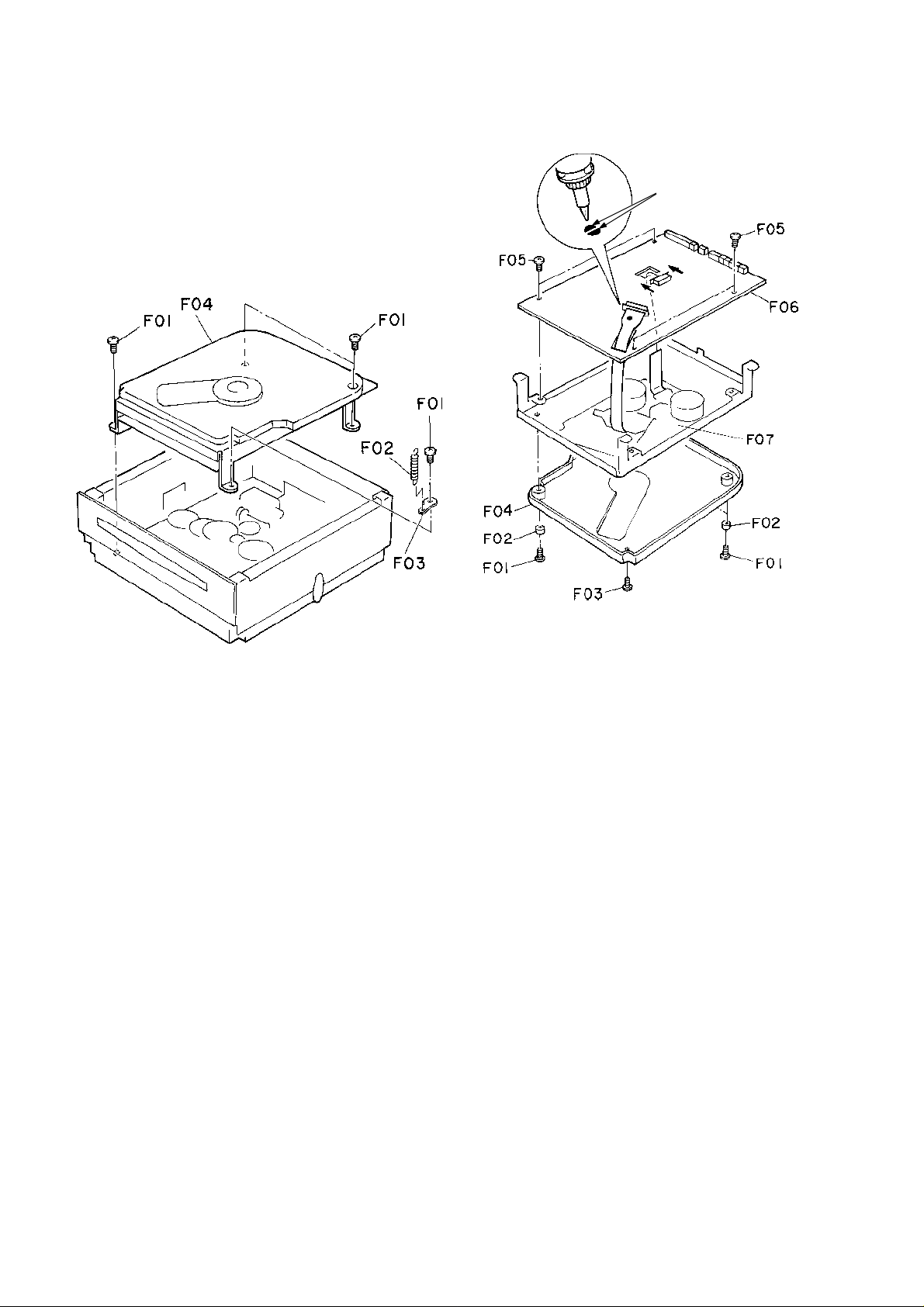

Refer to Fig. 1.1.

(1) Remove F01 (Main Jack Cover) by pulling it out.

(2) Remove screws F02 (ST3x8 + Binding (Black), 5 pcs.)

and F03 (PT3x10 + Trass, 4 pcs.), and detach F04

(Rear Cover) from the main body.

Main P.C.B. Ass'y

Rear Cover

Fig. 1.1

1.2. Main P.C.B. Ass'y

Refer to Fig. 1.2.

(1) Remove the Rear Cover. Refer to item 1.1.

(2) Remove screws F01 (ST3x4 + Binding, 15 pcs.) and

F02 (M2.6x4 + Binding, 2 pcs.), and detach F03.

(3) Remove screws F04 (ST3x5 + Binding, 10 pcs.) and

F05 (ST2.6x4 + Binding, 2 pcs.), and detach F06

(Main P.C.B. Ass'y).

Notes on reassembling:

• Connect the cables #1, #2 and #3 to the connectors #1,

#2 and #3 on the Main P.C.B. Ass'y, respectively.

1.3. Mechanism CD Ass'y

Refer to Fig. 1.3.

(1) Remove the Main P.C.B. Ass'y. Refer to item 1.2.

(2) Remove screws F01 (M3x8 + Binding (2A), 8 pcs.),

F02 (Damper Collar, 8 pcs.) and F03 (Mecha Damper,

8 pcs.).

(3) Lift the Escutcheon and remove F04 (2 pcs.) from F05

(Mechanism CD Ass'y 1-No. 2) and F06 (Mechanism

CD Ass'y 1-No. 3).

Note: The Mechanism CD Ass'y 2-No. 1 can be removed

in the same way.

Notes on reassembling:

• When assembling the Mechanism CD Ass'y 1-No. 3, with

the Mechanism CD Ass'y 1-No. 2 not assembled yet,

pass the cable of the Mechanism CD Ass'y 1-No. 3 over

the frame "A". Otherwise, you cannot assemble the

Mechanism CD Ass'y 1-No. 3.

• Pass the cables of each Mechanism CD Ass'y through

the holes "B" and "C" as shown in Fig. 1.3. For Mechanism CD Ass'y 1-No. 2/No.3, extend their cables approx.

10 cm.

Escutcheon

Mechanism

CD Ass'y 1

-No.2

Fig. 1.2

A

B

C

Mechanism

CD Ass'y 2

-No. 1

Mechanism

CD Ass'y 1

-No. 3

Fig. 1.3

1-3

SS-9 Main Unit Section

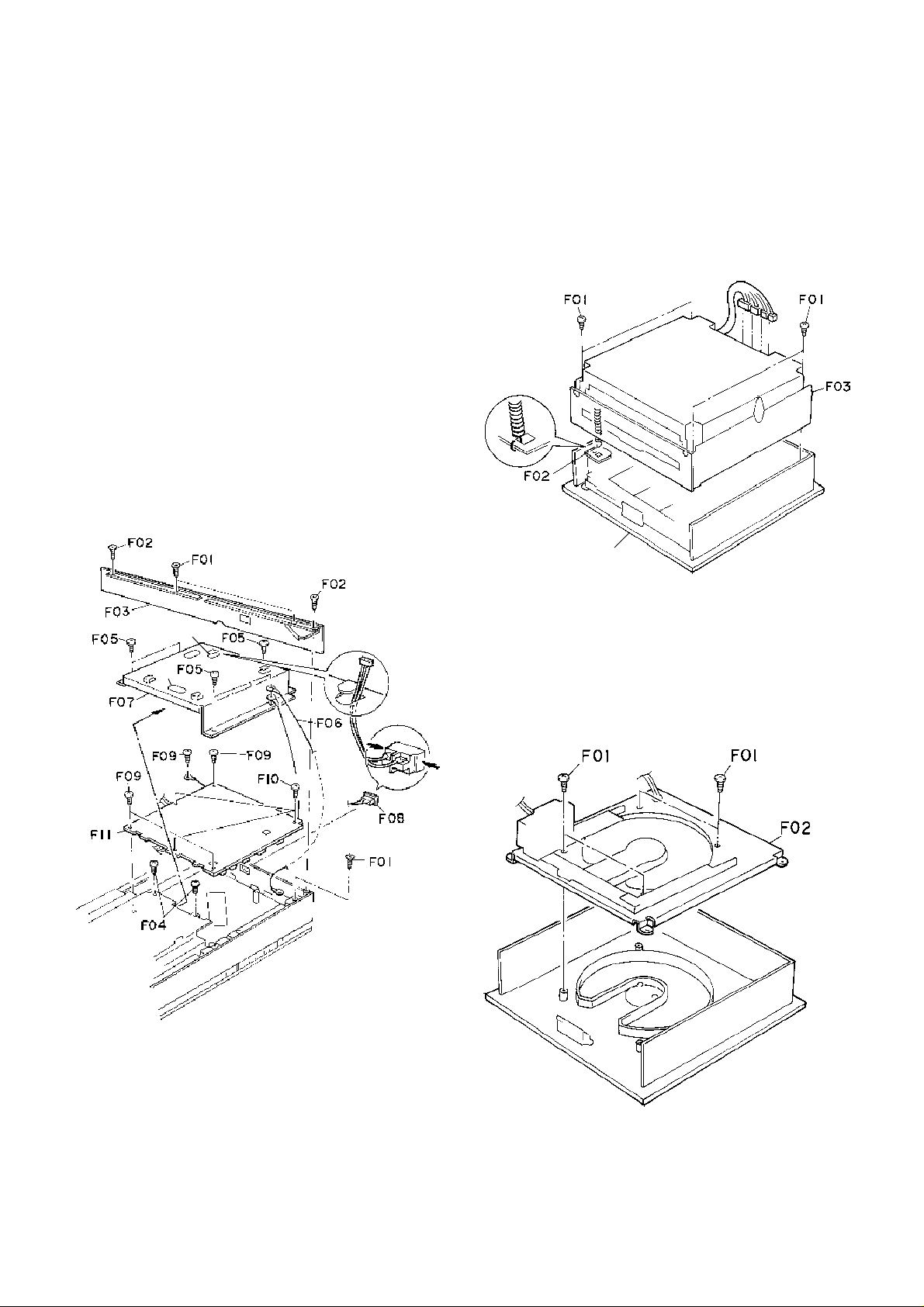

1.4. Front P.C.B. Ass'y

Refer to Fig. 1.4.

(1) Remove the Mechanism CD Ass'y. Refer to item 1.3.

(2) Remove screws F01 (BT2.6x6 + Flat Head, 2 pcs.)

and F02 (PT2.6x8 + Flat Head, 2 pcs.), and detach

F03 (Dress Plate Side C/D).

(3) Remove screws F04 (2 pcs.) and F05 (PT3x8 + Bind-

ing, 5 pcs.), and detach F06 (GND Wire Ass'y).

(4) Remove F07 in the direction shown by the arrow while

passing the power switch cable through the hole "A"

and 3 connectors through the hole "B".

(5) Remove F08 (Power Switch) outward while pinching

its claws inward.

(6) Remove screws F09 (PT3x5 + Binding, 4 pcs.) and

F10 (PT3x8 + Binding, 3 pcs.), and detach F11 (Front

P.C.B. Ass’y).

Notes on reassembling:

• When assembling F08 (Power Switch), be careful so as

not to assemble it upside down.

• When assembling F07, pass the power switch cable

through the hole "A" and 3 cables through the hole "B".

1.5. Mechanism Chassis Block/Door Block of the

Mechanism CD Ass'y

Refer to Fig. 1.5.

(1) Remove the Mechanism CD Ass'y. Refer to item 1.3.

(2) Remove screws F01 (M2.6x5 + Binding, 4 pcs.), un-

hook the spring F02, and detach F03 (Mechanism

Chassis Block) from the Door Block.

Mechanism Chassis

Block

Door Block

Fig. 1.5

Front

P.C.B.

Ass’y

A

1.6. Disc Loading Ass'y

Refer to Fig. 1.6.

B

(1) Remove the Door Block of the Mechanism CD Ass'y.

Refer to item 1.5.

(2) Remove screws F01 (PT2.6x6 + Binding (Black), 4

pcs.), and detach F02 (Disc Loading Ass'y).

Disc Loading Ass'y

Fig. 1.4

1-4

Fig. 1.6

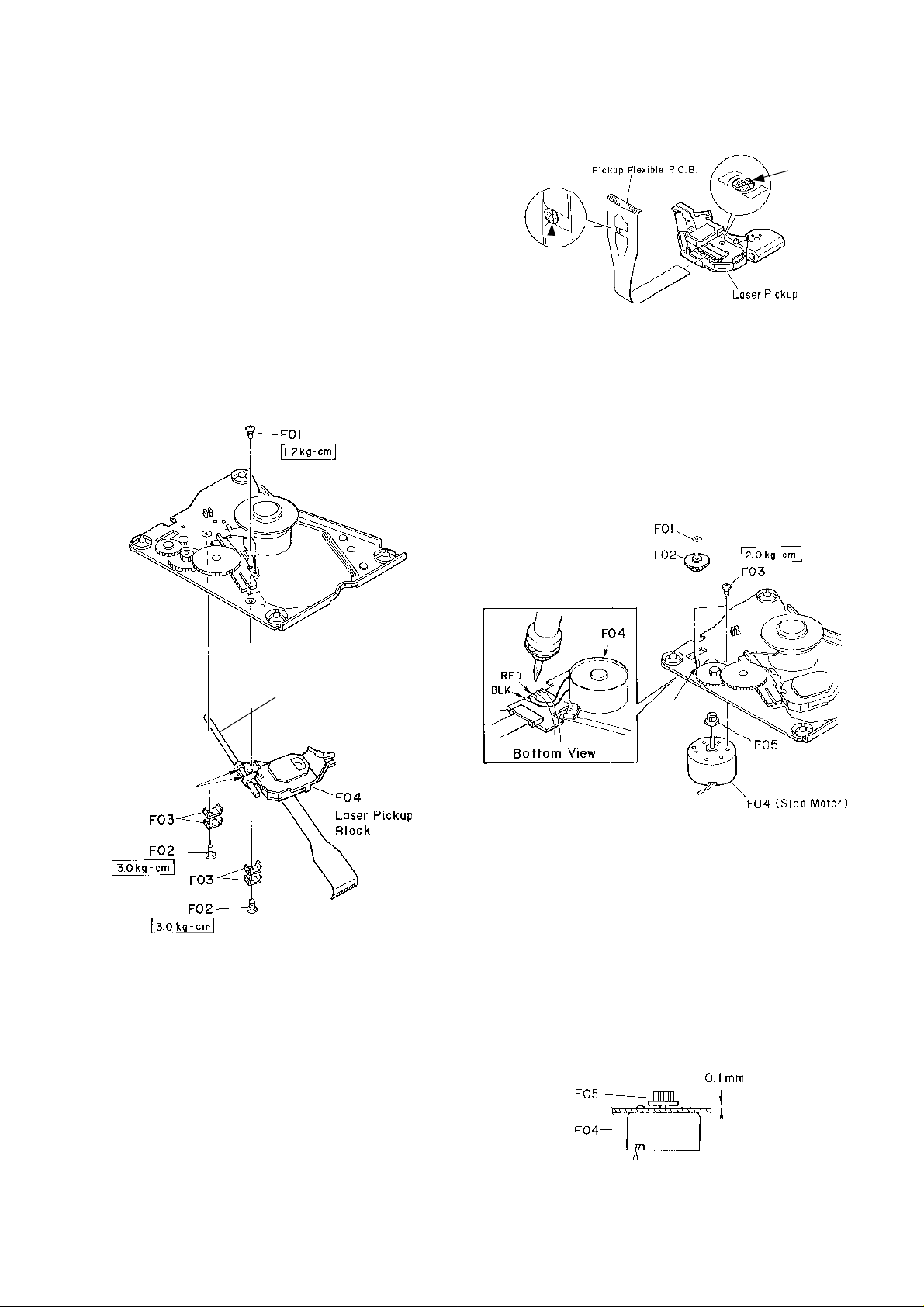

1.7. CD P.C.B. Ass'y and Traverse Mecha Ass'y

Refer to Figs. 1.7.1 and 1.7.2.

(1) Remove the Mechanism Chassis Block. Refer to item

1.5.

(2) Remove screws F01 (M3x5 + Binding (Black), 4 pcs.),

F02 (Stabi SP) and F03, and detach F04 (Traverse

Mechanism Block). Refer to Fig. 1.7.1.

Traverse Mechanism Block

SS-9 Main Unit Section

Laser diode shorting lands

CD P.C.B. Ass’y

Traverse Mecha

Ass’y

Fig. 1.7.1

(3) Remove screws F01 (M2.6x4 + Binding (Black), 3

pcs.), collars F02 (3 pcs.) and one screw F03 (M2.6x4

+ Pan (Black)), and detach F04 (Traverse Cover CD).

Refer to Fig. 1.7.2.

(4) Short the laser diode shorting lands with a soldering

iron.

Note: Use the soldering iron whose metal part is

grounded or a ceramic soldering iron.

CAUTION: Do not disconnect the Flexible Cable from

the CD P.C.B. Ass'y unless the laser shorting lands are shorted.

(5) Remove screws F05 (M3x5 + Binding), 4 pcs.) and de-

tach F06 (CD P.C.B. Ass’y).

(6) Remove three Damper Screw SL and one Damper

Screw SD, and detach F07 (Traverse Mecha Ass'y).

Notes on reassembling:

• Unsolder the laser diode shorting lands after reassembling the CD P.C.B. Ass'y.

Fig. 1.7.2

1-5

SS-9 Main Unit Section

1.8. Laser Pickup

1.8.1. Removing the Laser Pickup

Refer to Fig. 1.8.1.

(1) Remove the Traverse Mecha Ass'y. Refer to item 1.7.

(2) Remove screws F01 (M1.7x4 + Pan, 2 pcs.) and F02

(M2.6x3.5 + Pan, 2 pcs.), and F03 (4 pcs.), and disassemble F04 (Laser Pickup Block).

(3) Pull out the PU Guide Shaft SL from the Laser Pickup

Block.

(4) Before disconnecting the Pickup Flexible P.C.B. from

the Laser Pickup, short the laser diode shorting lands

on the bottom of the Laser Pickup. Refer to Fig. 1.8.2.

NOTE: Use the soldering iron whose metal part is

grounded or a ceramic soldering iron.

(5) Disconnect the Pickup Flexible P.C.B. from the Laser

Pickup.

Short

Already shorted.

(See Fig. 1.7.2)

Fig. 1.8.2

1.9. Sled Motor

1.9.1. Removing the Sled Motor

Refer to Fig. 1.9.1.

(1) Remove the Traverse Mecha Ass'y. Refer to item 1.7.

(2) Remove a cut washer F01 and pull out F02 (Second

Gear).

(3) Remove screws F03 (M1.7x2.5 + Pan #0 Type 3

(Black), 2 pcs.) and detach the Sled Motor Block.

(4) Remove F05 (First Gear) from F04 (Sled Motor).

(5) Unsolder the wires of F04 (Sled Motor) from the Tra-

verse P.C.B. Ass'y.

PU Guide Shaft SL

✪: Apply lubricant

G-4270.

✪

Fig. 1.8.1

1.8.2. Installing a New Laser Pickup

(1) Connect the Pickup Flexible P.C.B. to the new Laser

Pickup. Refer to Fig. 1.8.2.

(2) Open the laser diode shorting lands on the bottom of

the Laser Pickup.

NOTE: Use the soldering iron whose metal part is

grounded or a ceramic soldering iron.

(3) Insert the PU Guide Shaft SL into the Laser Pickup.

(4) Assemble F04 (Laser Pickup Block) with F03 ( 4 pcs.)

by tightening screws F02 (2 pcs.) with a torque of 3.0

kg-cm.

(5) Assemble F04 (Laser Pickup Block) with screws F01

(2 pcs.) with a torque of 1.2 kg-cm. Refer to Fig. 1.8.1.

✪

✪: Apply lubricant

G-4270.

Fig. 1.9.1

1.9.2. Installing a New Sled Motor

(1) Reassemble F04 (Sled Motor) with screws F03 (2

pcs.) with a torque of 2.0 kg-cm.

NOTE: Pay attention to the sled motor installing di-

rection. Install it as shown in Fig. 1.9.1.

(2) Press fit a new F05 (First Gear) so that the gap be-

tween the chassis surface and the bottom of F05 (First

Gear) is 0.1 mm as shown in Fig. 1.9.2.

(3) Solder the wires of F04 (Sled Motor) to the Traverse

P.C.B. Ass'y.

(4) Reassemble other removed parts by reversing the re-

moval procedure.

Fig. 1.9.2

1-6

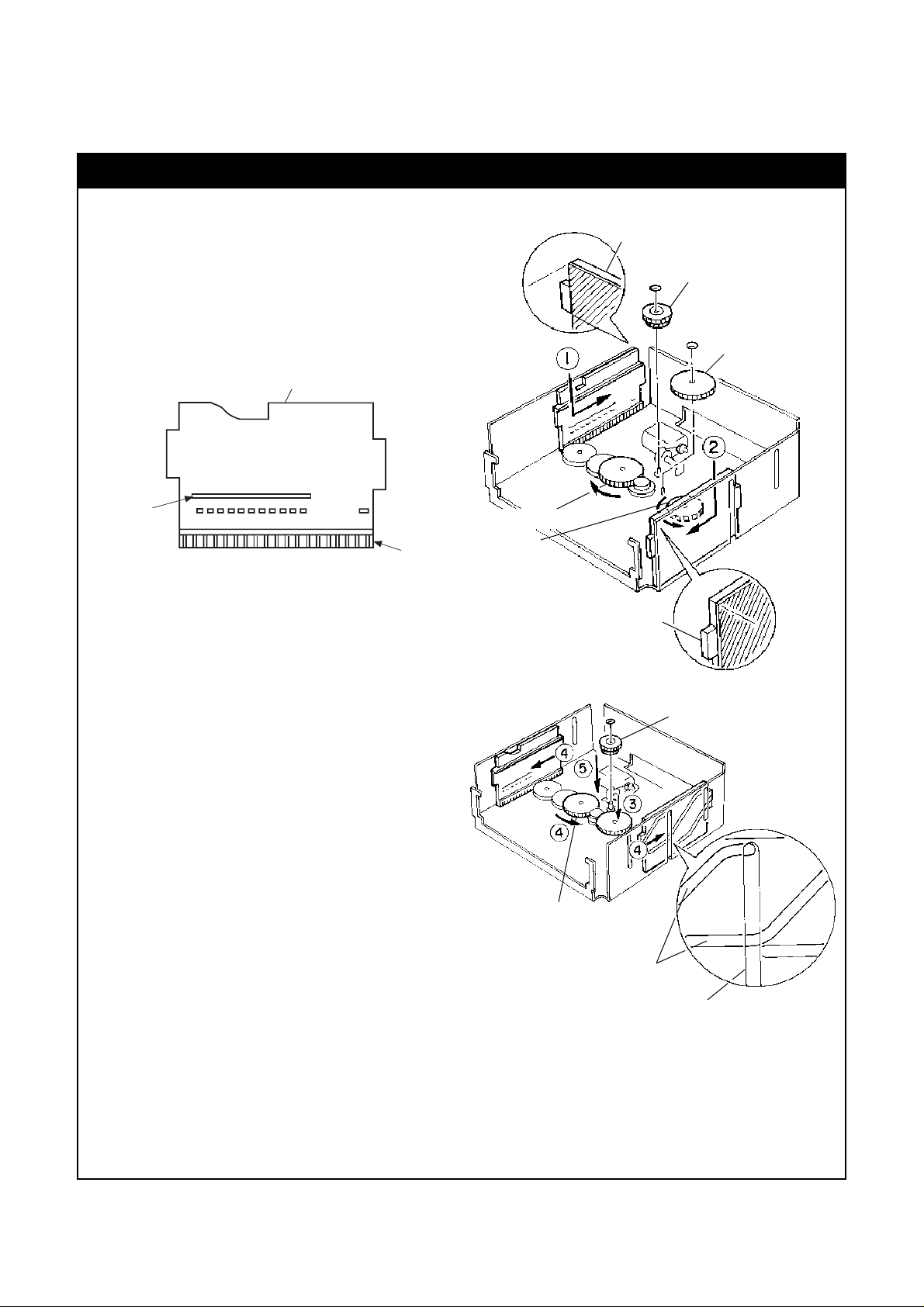

How to reassemble the UD Cam S and UD Cam

How to identify the UD Cam S and UD Cam:

The UD Cam S is used on the left side of the CD Mechanism Ass'y in Fig. A. It has the projections as shown below:

While, the UD Cam is used on the right side of the CD

Mechanism Ass'y in Fig. A, and has not projections.

• Note that they move in the opposite direction each

other. For example, in Fig. A, when the UD Cam S

moves backwards, the UD Cam moves forward.

UD Cam S

SS-9 Main Unit Section

UD Cam S

Cam D WW Guide

Cam D L Gear

Projection

Rack

(1) Remove the cut washer and pull out the Cam D WW

Gear. Refer to Fig. A.

(2) Remove the cut washer and pull out the Cam D L

Gear. (Thus, the link between the UD Cam S and UD

Cam is lost.)

(3) Assemble the UD Cam S on the chassis so that its

rack engages with the gear on the chassis. Then, by

turning the Cam D L Gear on the chassis, align the

edge of the UD Cam S with the edge of the chassis

as shown in Fig. A. (①)

(4) Assemble the UD Cam on the chassis so that its rack

engages with the gear on the chassis. Then, by turning the Cam Drive Gear on the chassis, align the

edge of the UD Cam with the edge of the chassis as

shown in Fig. A. (➁)

(5) Assemble the Cam D L Gear which was removed in

(2) and engage the cut washer. (Then, the UD Cam

S and UD Cam are linked.) (➂) Refer to Fig. B.

(6) By turning the Cam D L Gear, align the grooves on

the UD Cam S and UD Cam with the center slit of the

chassis as shown in Fig. B. (④)

• Fig. B shows the grooves on the UD Cam. Note

that the shape of the UD Cam S's grooves are reversed.

(7) Assemble the Cam D WW Gear which was removed

in (1) and engage the cut washer. (➄)

Note: If the assembled UD Cam S or UD cam is mis-po-

sitioned, the UD Plate S Ass'y (L or R) that engages with its grooves cannot be correctly assembled. In this case, you need to repeat above

steps.

Cam D L Gear

Cam Drive Gear

UD Cam

Fig. A

Cam D WW Guide

Cam D L Gear

Grooves on

the UD Cam

Center Slit of the Chassis

Fig. B

1-7

2. ELECTRICAL CHECKS

Perform the following electrical checks for CD Players.

2.1. Measurement Instruments and Jigs

(1) Oscilloscope (40 MHz or more)

(2) DC Voltmeter (Digital Voltmeter)

(3) ABEX Test Disc TCD-784 (DA09195A)

(4) ABEX Test Disc TCD-726A (DA09204A) or TCD-725A

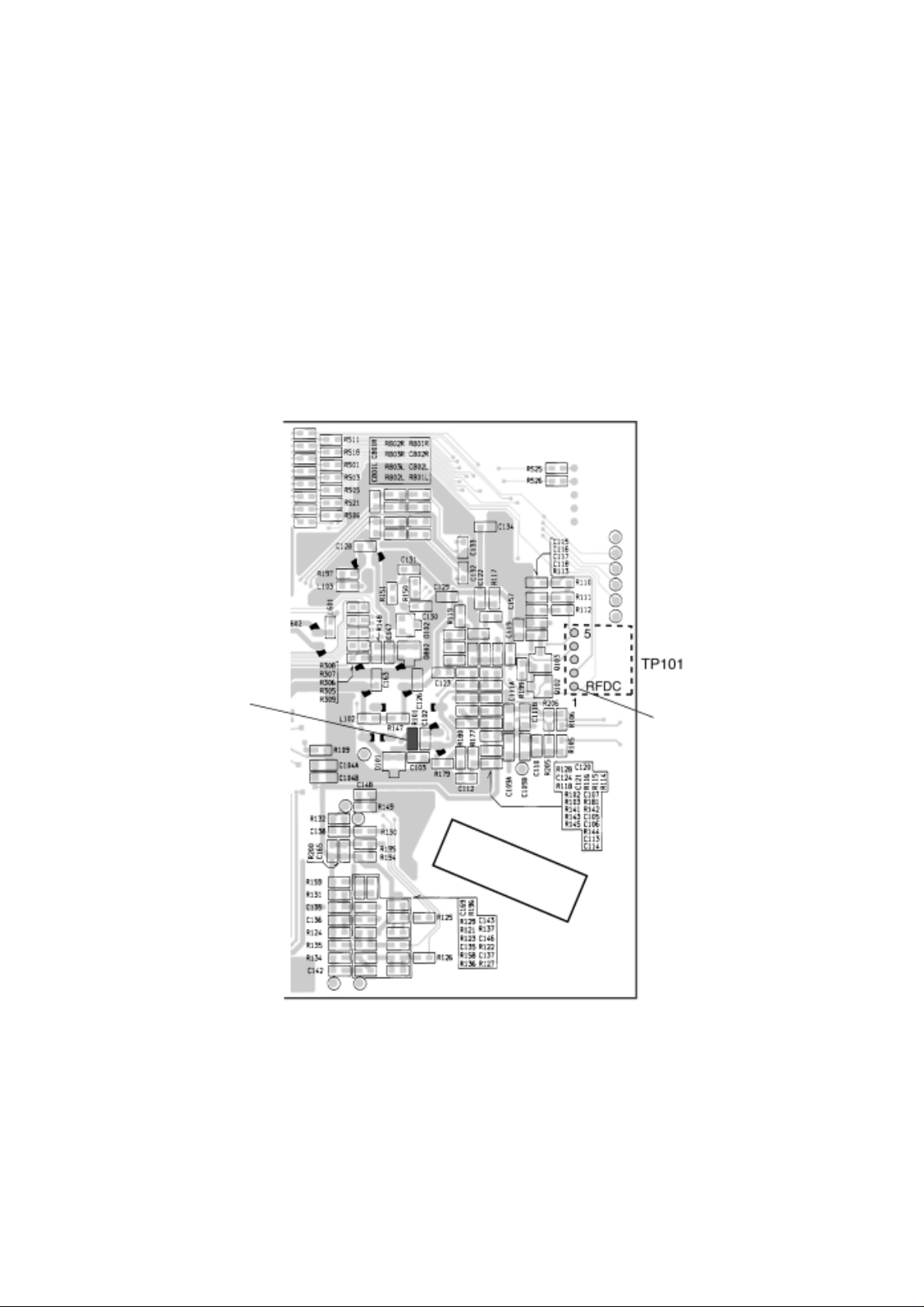

2.2. Parts Location for Electrical Check

● CD P.C.B. Ass'y of the CD Player

(Dip Side View)

SS-9 Main Unit Section

R101

Laser Current Check

Pin 1 of TP101

EFM Signal

Fig. 1.1 Parts Location for Electrical Check -- CD Player

1-8

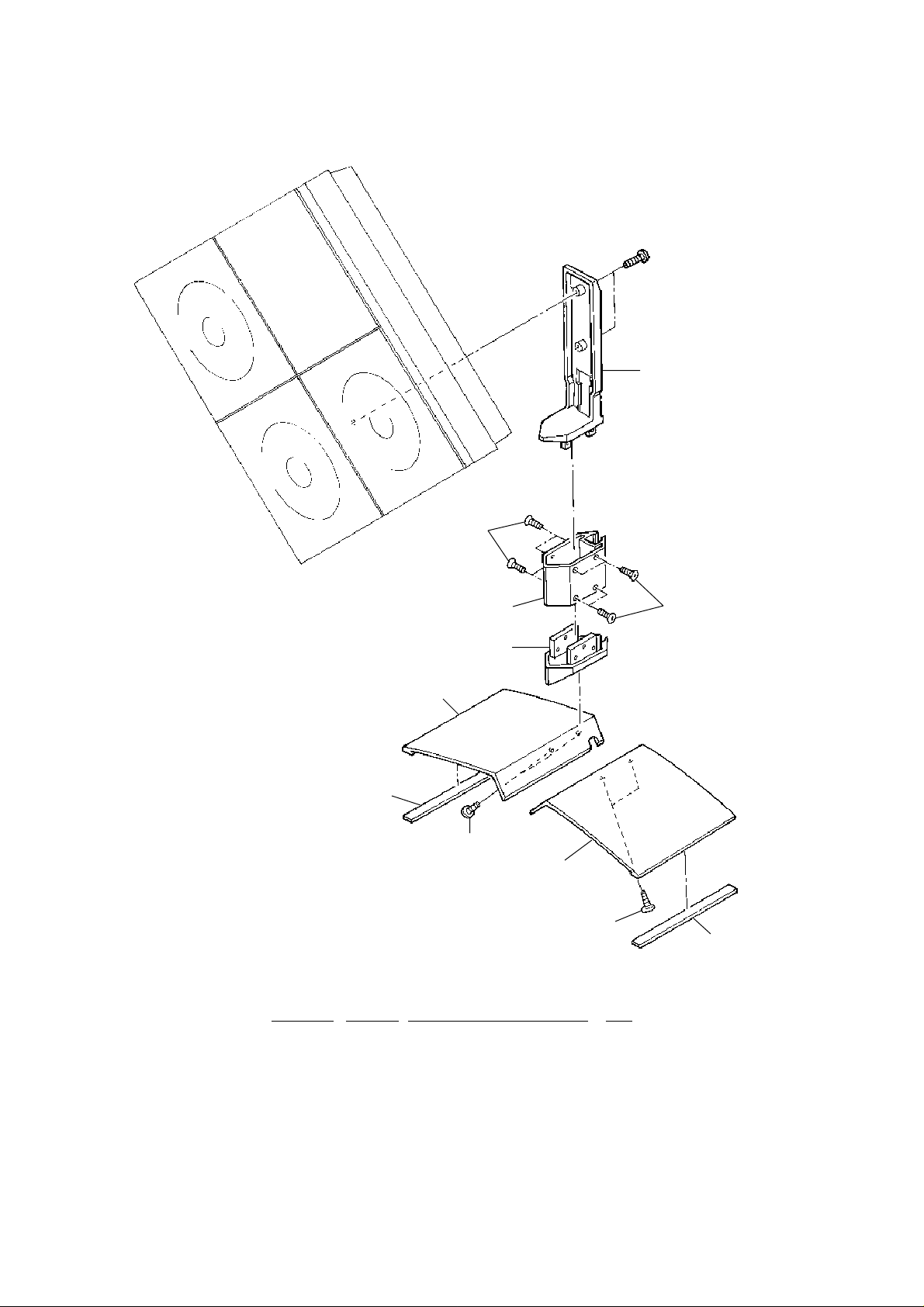

2.3. Electrical checks for CD Player

Note: Do the same check for CD Player Nos. 1 to 3.

SS-9 Main Unit Section

STEP ITEM SIGNAL OUTPUT ADJUST- REMARKS

SOURCE CONNECTION MENT

1 Laser Current ABEX Test Disc DC Voltmeter —

Check TCD-784 across R101

on CD P.C.B.

1. Turn ON the power and load a test disc.

(To load the test disc, press the Open/Close button

of the CD Player.)

2. Play back the test disc and calculate the current

flowing into R101 on the CD P.C.B. Ass'y from the

following formula.

Voltmeter Value

I(Measured) =

R101 (10 Ohms)

Example:

KSS-540A

I(Measured) =

510.3 (mV)

10 (ohms)

3. Check that the I(Measured) obtained in 2 and the

IOP(oo.omA)

Laser Pickup

KSS-540A

rated current value (IOP) shown on the label are

almost the same.

[How to read IOP on the label]

The shaded "OOO" on the label shows the IOP.

If "OOO" is 475, the IOP is 47.5mA.

NOTE: The calculated current (I(Measured))

should be in a range of 30 to 60 mA. If the

value is large, the pickup will be defective.

4. Stop the test disc.

= oo.o mA

= 51.03 mA

2 EFM Signal ABEX Test Disc Oscilloscope —

Adjustment TCD-784 between

pin 1 of TP101

and GND

on CD P.C.B.

1. Play back the first track of the test disc.

2. Be sure that the peak-to-peak value of the EFM

waveform is approx. 1V.

Approx. 1Vp-p

Oscilloscope Setting:

AC Mode, 0.2 V/div, 0.5 µs/div

3. Stop the test disc and eject it.

1-9

STEP ITEM SIGNAL OUTPUT ADJUST- REMARKS

SOURCE CONNECTION MENT

SS-9 Main Unit Section

3 Operation ABEX Test Disc —

Check TCD-726

or TCD-725A

Make sure that no noise nor track-jumping is found in

the following programs on the test disc.

To select the desired program, press Track Search

button on the Main Unit or Remote Control

• Interruption 0.8mm: 4th program

• Black dot Ø0.6mm: 8th program

• Simulated fingerprint Ø65µm: 13th program

1-10

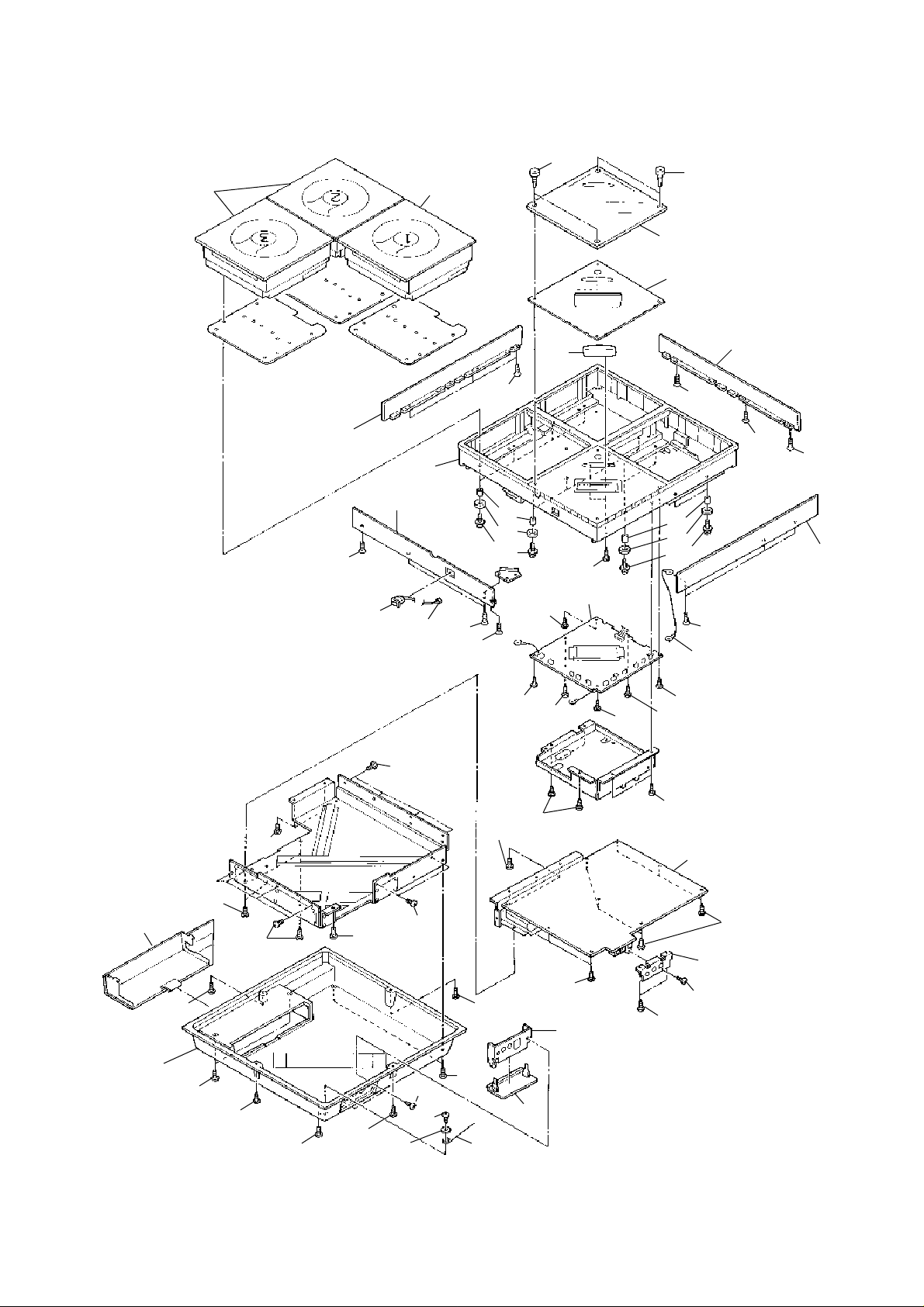

3. MECHANISM ASS'Y AND PARTS LIST

3.1. Main Stand Ass'y

SS-9 Main Unit Section

06

L01

05

04

03

01

L02

02

Fig. 3.1

L02

3.1. Main Stand Ass'y

Schematic

Ref. No. Part No. Description Q'ty

— Main Stand Ass’y (Main Unit) 1

01 0J08792A Base Cushion Center S 2

02 0H08793B Stand Base Center R 1

03 0H08792B Stand Base Center L 1

04 0H08791D Base Joint 1

05 0H08796B Stand Pole 1

06 0H08790C Stand Holder Center 1

L01 0E04323A BT4x10 + Oval Countersunk

L02 0E03972A BT4x12 + Binding

L01

01

1-11

SS-9 Main Unit Section

3.2. Synthesis (Main Unit)

Mechanism CD

Ass'y 1 (A01) 01

L03

06

09

11

Mechanism CD

Ass'y 2 (A01)

02

L02

08

L04

03

L02

L03

12

13

L05

L01

07

L15

14

04

05

12

13

L04

L01

06

L03

L02

L03

06

L02

21

15

16

L08

L09

L16

L08

L07

L07

L09

L07

L08

L07

L11

L07

L13

L10

L08

L09

19

Fig. 3.2

L14

L05

L06

18

L06

L12

17

L06

L05

L06

L06

20

L12

10

L17

L18

1-12

Loading...

Loading...