NAiS EBL512 Operating Instructions Manual

Operating Instructions

MEW00442

Revision -

Fire Alarm System EBL512

Author: Jan Pettersson Date: 2003-09-09 Rev. date:

Checked by: Mikael Östergren S-class: Public Rev. by:

Approved by: Rutger Pålsson Number of pages: 111

L:\Product Documentation\Manuals\Doc\MEW00442.doc

V1.44.x

This page has deliberately been left blank.

Matsushita Electric Works Fire & Security Technology AB

MEW00442 Rev: - Operating Instructions EBL512, V1.44.x

Table of contents

1 Introduction________________________________ 5

2 Definitions / Explanations ____________________ 6

2.1 MFSTech_________________________________________ 6

2.2 Alarm points ______________________________________ 6

2.2.1 Smoke detector _______________________________ 6

2.2.2 Sensor ______________________________________ 6

2.2.3 Analog detector _______________________________ 6

2.2.4 (Analog) Sensor Base (ASB)_____________________ 6

2.2.5 Conventional detector __________________________ 6

2.2.6 Conventional Detector Base (CDB) _______________ 6

2.2.7 Addressable Detector Base (ADB) ________________ 6

2.2.8 Addressable __________________________________ 7

2.2.9 Old detector __________________________________ 7

2.2.10 External line / Conventional zone line _____________ 7

2.2.11 ADB input / Addressable zone interface ____________ 7

2.3 Output unit _______________________________________ 7

2.4 Output / Control output ______________________________ 7

2.5 Short circuit isolator ________________________________ 7

2.6 Display unit _______________________________________ 7

2.7 COM loop ________________________________________ 7

2.8 BS4 loop _________________________________________ 7

2.9 Control Unit (C.U.) / C.I.E.___________________________ 8

2.10 Fire Brigade Panel (FBP) ____________________________ 8

2.11 Control panel (CP) _________________________________ 8

2.12 System___________________________________________ 8

2.13 Network / TLON® / LonWorks® / Echelon / Node / TLON

Conn. board / Gateway / Channel / Router / Repeater ____________ 8

2.14 LED_____________________________________________ 9

2.15 External Indicator (LED) ____________________________ 9

2.16 Display / LCD _____________________________________ 9

2.17 Door open / Key switch______________________________ 9

2.18 SSD / Site Specific Data _____________________________ 9

2.19 SW / Software / System program ______________________ 9

3 Overview _________________________________ 10

3.1 The EBL512 system _______________________________ 10

3.1.1 Expansion boards ____________________________ 10

3.1.2 Printer _____________________________________ 10

3.2 SW versions _____________________________________ 10

3.3 Documents_______________________________________ 11

3.4 Applications _____________________________________ 11

3.5 PC SW__________________________________________ 11

4 Control Unit ______________________________ 12

1

Matsushita Electric Works Fire & Security Technology AB

MEW00442 Rev: - Operating Instructions EBL512, V1.44.x

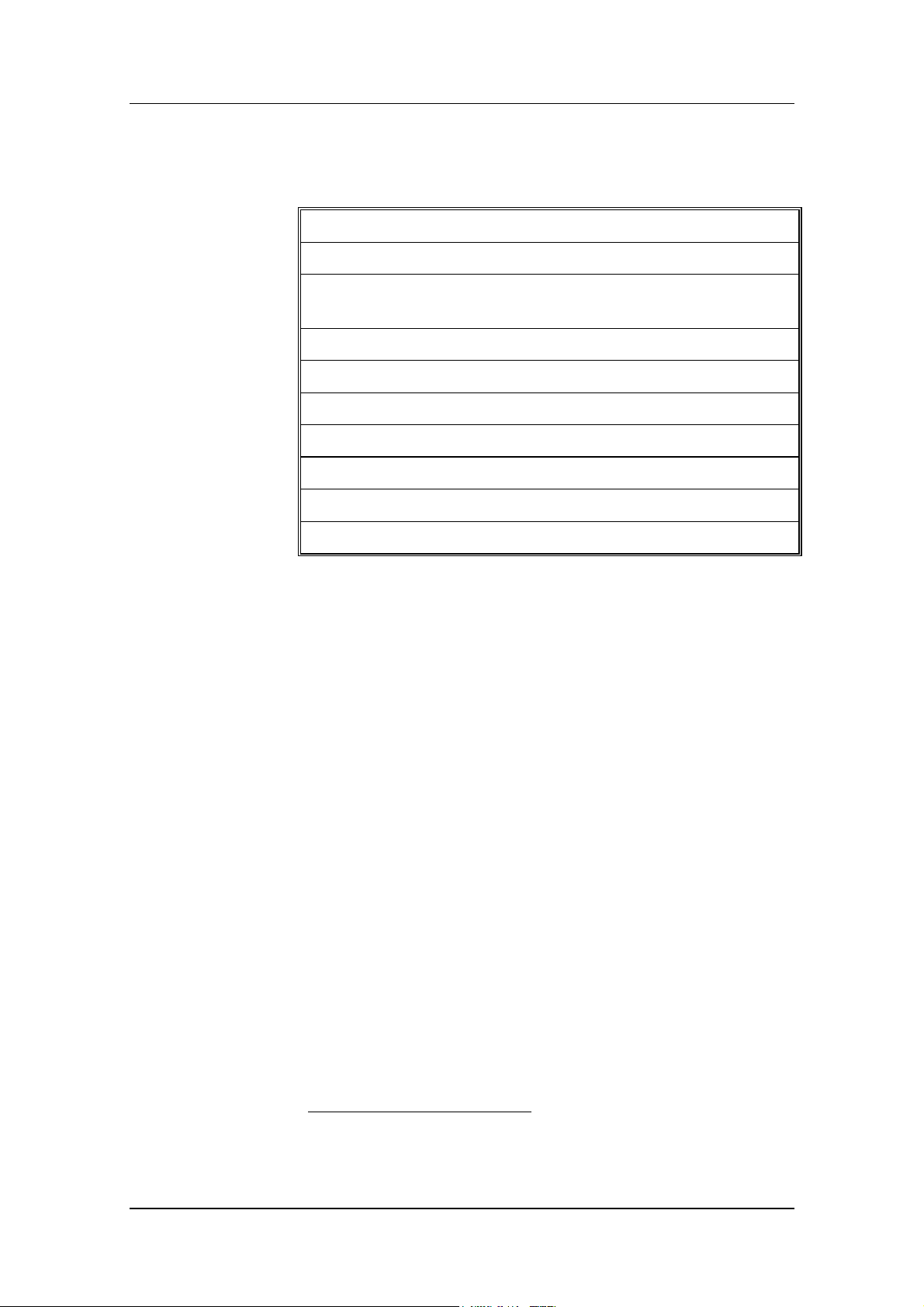

5 LED indicators and push buttons _____________ 14

6 Access levels_______________________________ 17

6.1 Access level 1 ____________________________________ 17

6.2 Access level 2 ____________________________________ 18

6.3 Access level 3 ____________________________________ 19

6.4 Access level 4 ____________________________________ 20

6.5 Access level 5 ____________________________________ 20

7 Normal operation __________________________ 21

8 Push button "Silence" ______________________ 22

8.1 Silence before a fire alarm __________________________ 22

8.2 Silence during a fire alarm __________________________ 22

9 Alarm device on / Alarm device off____________ 23

10 Controls ON / Controls OFF _________________ 24

11 Door open (Key switch) _____________________ 25

11.1 LED "Key switch"_________________________________ 25

11.2 Disable outputs for routing equipment (Fire brigade tx and

Fault tx) _______________________________________________ 25

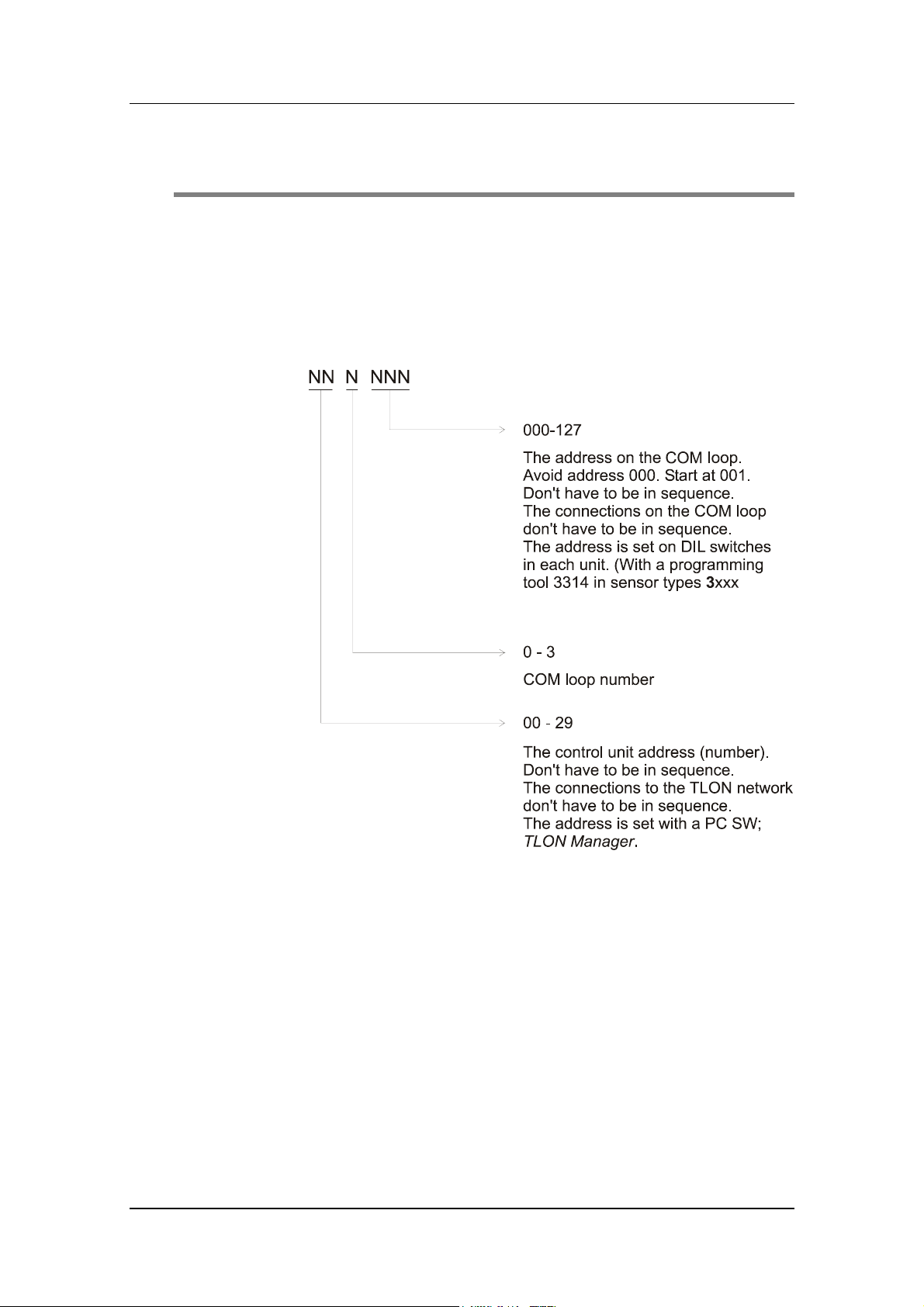

12 Technical number / Presentation number ______ 26

12.1 Technical number for COM loop units _________________ 26

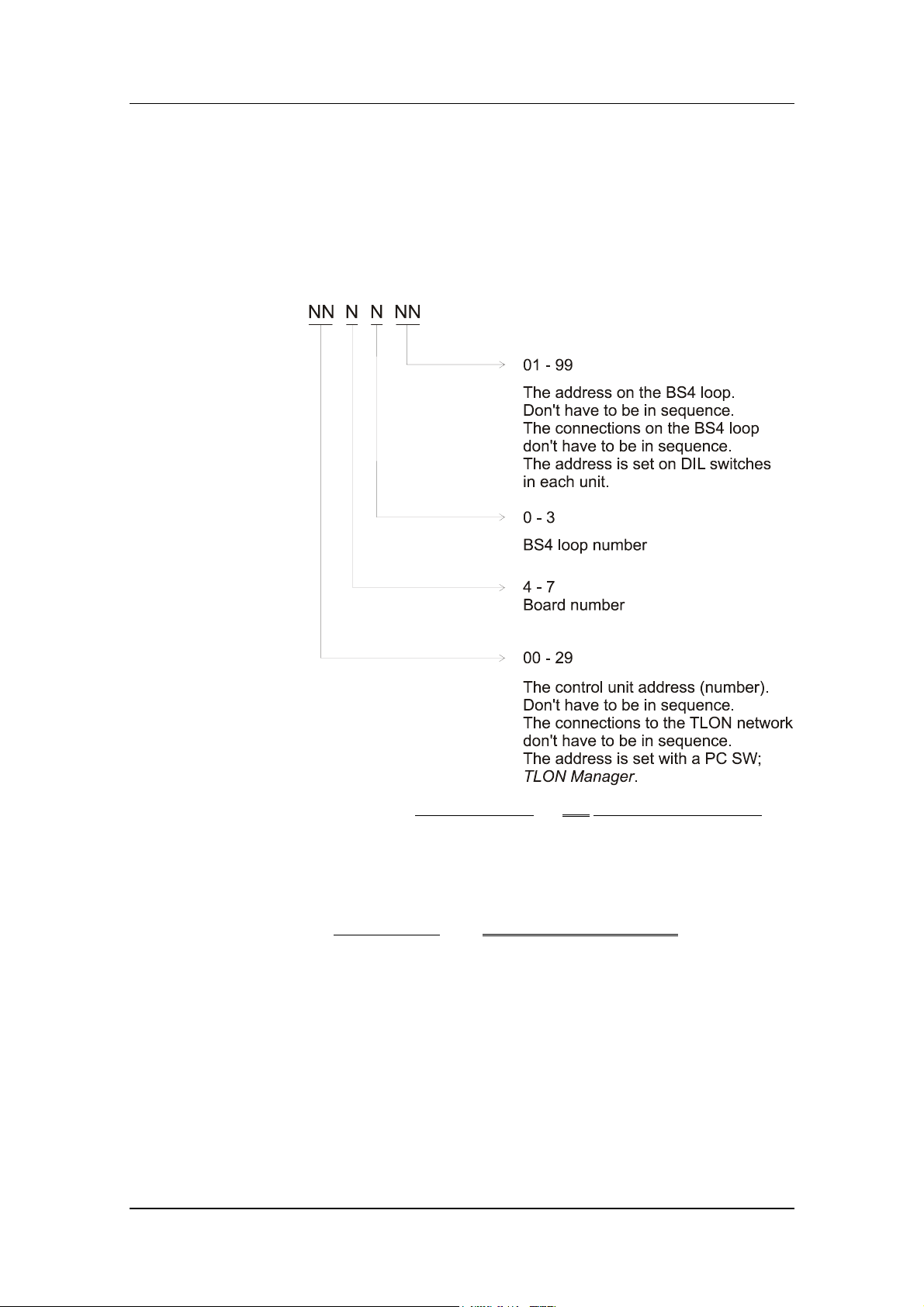

12.2 Technical number for BS4 loop units __________________ 27

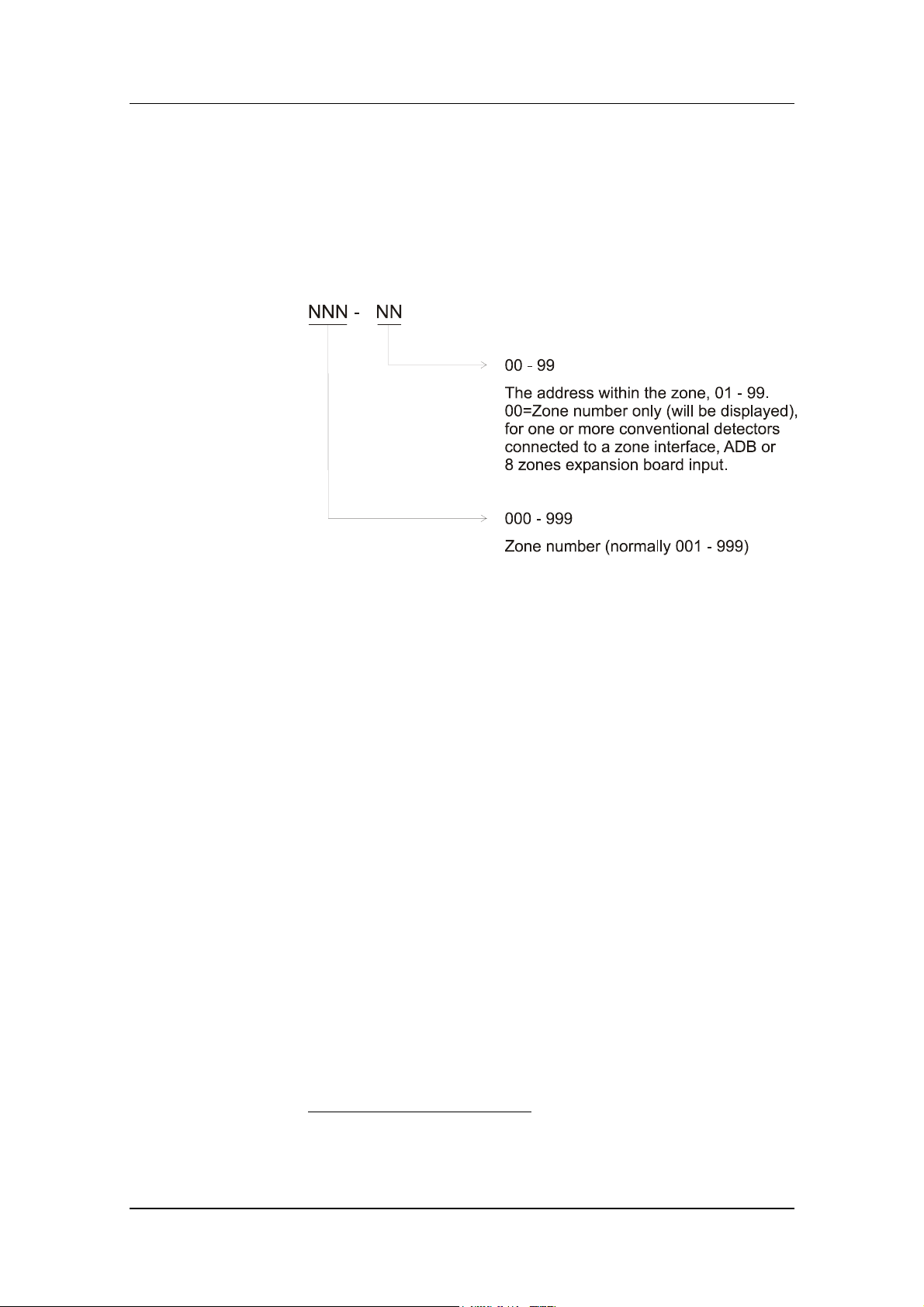

12.3 Presentation number _______________________________ 28

13 Alarm types _______________________________ 29

13.1 Pre-alarm________________________________________ 29

13.2 Fire alarm _______________________________________ 30

13.2.1 Alert annunciation ____________________________ 31

13.2.2 2-zone / address dependence ____________________ 31

13.3 Heavy smoke alarm________________________________ 31

14 Key cabinet _______________________________ 32

14.1 Key cabinet alarm _________________________________ 32

14.2 Key cabinet opened in conjunction with a fire alarm ______ 32

14.2.1 Restoring the key after a fire alarm _______________ 32

15 Alarm reset _______________________________ 33

15.1 Pre-alarm reset ___________________________________ 33

15.2 Fire alarm reset ___________________________________ 33

15.3 Heavy smoke alarm reset ___________________________ 33

15.4 Key cabinet alarm reset_____________________________ 34

15.5 Zone/Detector not reset _____________________________ 34

16 Fault _____________________________________ 35

16.1 Fault messages ___________________________________ 35

16.2 Fault acknowledge ________________________________ 47

17 Commissioning an installation _______________ 48

17.1 Single Control Unit ________________________________ 48

2

Matsushita Electric Works Fire & Security Technology AB

MEW00442 Rev: - Operating Instructions EBL512, V1.44.x

17.2 Control Units in a TLON network ____________________ 48

17.2.1 TLON network programming (configuration) ______ 49

18 Programming (SSD download) _______________ 50

18.1 Single Control Unit ________________________________ 50

18.2 Control Units in a TLON network ____________________ 50

18.3 User definable text messages download ________________ 51

18.3.1 Download in Control unit ______________________ 51

18.3.2 Download in Display unit ______________________ 51

19 New system program (SW) version download ___ 52

19.1 Control Units in a TLON network ____________________ 52

20 EBL512 settings download___________________ 53

20.1 Control Units in a TLON network ____________________ 54

21 Reset / Restart _____________________________ 55

22 Access ____________________________________ 57

23 Perform monthly test (H1)___________________ 58

24 Disable or re-enable (H2) ____________________ 60

24.1 Disable zone (H2/B1) ______________________________ 61

24.2 Disable zone / address (H2/B2)_______________________ 62

24.3 Disable control output (H2/B3)_______________________ 63

24.4 Re-enable zone (H2/B4) ____________________________ 64

24.5 Re-enable zone / address (H2/B5)_____________________ 65

24.6 Re-enable control output (H2/B6)_____________________ 66

24.7 Re-enable non-reset zone / address (H2/B7)_____________ 67

24.8 Control on / Control off (H2/B8) _____________________ 68

24.9 Alarm device on / Alarm device off (H2/B9) ____________ 69

25 Set calendar and clock (H3) __________________ 70

26 Present system status on display and printer (H4) 71

26.1 Disablement (H4/U1) ______________________________ 71

26.2 Disablement by time channel (H4/U2) _________________ 72

26.3 Show open doors (H4/U3) __________________________ 73

26.4 Activated 2-zone/address dependent (H4/U4) ___________ 74

26.5 Show sensors week average values (H4/U5) ____________ 75

26.5.1 Reset of a sensor week average value _____________ 75

26.6 Show sensors momentary values (H4/U6) ______________ 76

26.7 Sensors activating SERVICE signal (H4/U7)____________ 77

26.8 Show event log (H4/U8) ____________________________ 78

26.9 Show configuration (H4/U9)_________________________ 79

27 Programming (H5) _________________________ 80

27.1 Access code for programming (H5) ___________________ 81

27.2 Calibration of monitored outputs (H5/A1) ______________ 82

27.3 Sensitive fault detection mode (H5/A2) ________________ 83

27.4 Direction for communication on COM-loop (H5/A3) _____ 84

27.5 Show information about site specific data (H5/A4) _______ 85

3

Matsushita Electric Works Fire & Security Technology AB

MEW00442 Rev: - Operating Instructions EBL512, V1.44.x

27.6 Display current consumption in unit (H5/A5)____________ 86

27.7 Display current consumption COM-/BS4-loop (H5/A6) ___ 87

27.8 Display statistics for COM-loop (H5/A7)_______________ 88

27.9 Select unit on COM-loop to use for triggering (H5/A8)____ 89

27.10 Change access code for PC-communication (H5/A9) ___ 90

27.11 Change access code for programming (H5/A10)_______ 91

28 Acknowledge FAULTS (H6) _________________ 92

29 Perform ZONE TEST (test mode) (H7) ________ 93

30 Maintenance (H8) __________________________ 95

30.1 Access code for maintenance ________________________ 95

30.2 Disable or re-enable outputs for routing equipment (H8/S1) 96

30.3 Disconnect COM-loop (H8/S2) ______________________ 97

30.4 Re-connect Loop (H8/S3) ___________________________ 98

30.5 Acknowledge SERVICE signal (H8/S4)________________ 99

30.6 Safe shut down of control unit (H8/S5) _______________ 100

30.7 Activate address in alarm mode (H8/S6) ______________ 101

30.8 Synchronize the control units (H8/S7) ________________ 102

30.9 Change access code for maintenance (H8/S8) __________ 103

31 Change access code for daily duties (H9) ______ 104

32 Annual control ___________________________ 105

33 Changing paper in the printer_______________ 106

34 Battery maintenance_______________________ 107

35 How to avoid unnecessary (nuisance) fire alarms 108

36 Information regarding radioactive radiation source110

37 Revision history___________________________ 111

4

Matsushita Electric Works Fire & Security Technology AB

MEW00442 Rev: - Operating Instructions EBL512, V1.44.x

1 Introduction

EBL512 Operating Instructions, is a document intended to be used by

the end user and the fire brigade personnel as well as service /

commissioning engineer.

Due to continual development and improvement, different SW

versions are to be found. This document is valid for SW version

1.44.x.

Since the EBL512 control unit (c.i.e.) is produced for many countries

the look, the texts, the functions, etc. may vary.

Products

Consists of one or more parts (HW) according to a Product Parts

List. A product has:

• a type number (e.g. 1548)

• an article number, often = the type no. and sometimes is a

country code added (e.g. 1548SE)

• a product name (e.g. EBL512 control unit, 128 addresses,

without printer)

HW

A HW (e.g. a printed circuit board) has:

• a type number (e.g. 1556)

• an article number, often = the type no. and sometimes is a

country code added (e.g. 1556SE)

• a product name (e.g. Main Board 128 addr.)

• a p.c.b. number (e.g. 9261-3A) and could have a configuration

(e.g. CFG: 1), a revision (e.g. REV: 2)

• sometimes a SW

SW

A SW has:

• a version number (e.g. V1.44.1)

• sometimes additional information

functions / facilities), Language, Number of addresses, etc.

, such as Convention (different

5

Matsushita Electric Works Fire & Security Technology AB

MEW00442 Rev: - Operating Instructions EBL512, V1.44.x

2 Definitions / Explanations

Definitions / explanations / abbreviations / etc. frequently used or not

explained elsewhere in the document.

2.1 MFSTech

Matsushita Electric Works Fire & Security Technology AB

2.2 Alarm points

Units, which can generate fire alarm (in the control unit), i.e. a sensor,

a conventional detector, a manual call point, etc.

2.2.1 Smoke detector

Two types of analog and conventional smoke detectors are available:

photo electric (optical) and ionization.

2.2.2 Sensor

Sensor = Analog detector

2.2.3 Analog detector

Contains an A/D-converter. The Control Unit pick up the digital

values ("sensor values") for each detector individually. All

evaluations and "decisions" are then made in the C.U. Analog

detectors are addressable – an address setting tool is used for detector

types 3xxx and a DIL-switch in the ASB (see below)for detectors

2xxx. An analog detector has to be plugged in an ASB.

2.2.4 (Analog) Sensor Base (ASB)

A sensor is plugged in an ASB, which is connected to a COM loop

(see below). Sensor Base types 2xxx have a DIL-switch for COM

loop address setting.

2.2.5 Conventional detector

Detector with two states, normal or fire alarm. The detector contains a

closing contact and a series alarm resistor. Some types are plugged in

an ADB (see below) or a CDB (see below). Some types are also

available as addressable, to be connected to a COM loop (see below).

(Normally plugged in a CDB (see below), connected to a conventional

zone line with end-of-line resistor.)

2.2.6 Conventional Detector Base (CDB)

A conventional detector is plugged in a CDB, connected to an external

line, an addressable zone interface, conventional zone line, etc.

2.2.7 Addressable Detector Base (ADB)

A conventional detector is plugged in an ADB, connected to a COM

loop (see below).

6

Matsushita Electric Works Fire & Security Technology AB

MEW00442 Rev: - Operating Instructions EBL512, V1.44.x

2.2.8 Addressable

A unit with a built-in address device, i.e. each unit is individually

identified, handled and indicated in the control unit.

(The unit can consequently be an addressable zone interface, to which

one or more conventional "alarm points" can be connected.).

2.2.9 Old detector

Conventional detector with a closing contact (short circuit; no alarm

resistor), or detector with two breaking contacts.

2.2.10 External line / Conventional zone line

Input (to an ADB / an addressable zone interface or expansion board),

intended for one or more conventional alarm points. End-of-line

resistor in the last alarm point.

2.2.11 ADB input / Addressable zone interface

Unit with an input (ext. line / conventional zone line) intended for one

or more conventional alarm points. End-of-line resistor in the last

alarm point.

2.3 Output unit

Addressable unit with programmable control outputs. To be

connected to a COM loop (see below).

2.4 Output / Control output

Defined or programmable function. Relay or (supervised / monitored)

voltage output, in the C.U. or an output unit.

2.5 Short circuit isolator

Addressable unit for automatic disconnection of a part of a COM loop

(see below) in case of a short circuit on the loop.

2.6 Display unit

Addressable unit for fire alarm presentation (incl. user definable text

messages, if programmed). Connected to a COM loop (see below).

2.7 COM loop

Loop = a cable, with two wires, to which all the addressable MFSTech

units can be connected. It starts in the C.U. and it returns back to the

C.U.

2.8 BS4 loop

Loop = a cable, with two wires, to which all the addressable Autronica

(BS100) units can be connected. It starts in the C.U. (EBL512) and it

returns back to the C.U.

7

Matsushita Electric Works Fire & Security Technology AB

MEW00442 Rev: - Operating Instructions EBL512, V1.44.x

2.9 Control Unit (C.U.) / C.I.E.

Control Unit = C.U. = Control and Indicating Equipment = Unit to

which the alarm points are connected, e.g. EBL512. Indicates fire

alarm, fault condition, etc. Fire Brigade Panel & Control Panel (see

below) included or not included. Printer included or not included.

2.10 Fire Brigade Panel (FBP)

Unit intended for fire alarm presentation, etc. for the fire brigade

personnel. Can be a part of the control unit (front adhesive) or a

separate unit; an external FBP.

In the ext. FBP. a printer can be included or not included.

2.11 Control panel (CP)

A part of the control unit (front adhesive), intended for the building

occupier, service personnel, etc., to "communicate" with the control

unit / system.

2.12 System

Several control units connected via a TLON network (co-operating

control units).

2.13 Network / TLON® / LonWorks® / Echelon /

Node / TLON Conn. board / Gateway /

Channel / Router / Repeater

Brief explanations to the words/expressions to be found in connection

with a "network". See also separate TLON Technical description.

®

TLON

network

The protocol is LonTalk and the transmission works with doublyterminated bus topology (Echelon FTT-10). To connect a control unit

to the network, a TLON connection board

unit. (Some old types of control units, not prepared for network

connection, have to be connected via a serial interface and a

Gateway

A network can be one

connected via routers

= TeleLarm Local Operating Network = a LonWorks®- based

1

for communication between several control units (nodes).

is plugged in the control

).

channel (FTT-10) or several channels,

or repeaters.

Repeaters

C.U. in a network.

1

LonWorks® = A "summing-up-name" for the market of Echelon

Corporation Inc. technology.

are used to increase the maximum cable length, C.U. to

8

Matsushita Electric Works Fire & Security Technology AB

MEW00442 Rev: - Operating Instructions EBL512, V1.44.x

Router or Repeater is the same type of unit (different configuration).

All network programming (configuration) are made with the PC

program "TLON Manager".

2.14 LED

LED (Light Emitting Diode) = Yellow, green or red optical indicator

("lamp").

2.15 External Indicator (LED)

A unit with an LED. Connected to an ASB, ADB, CDB or a detector

with a built-in LED. Lit when the built-in LED is lit.

2.16 Display / LCD

LCD (Liquid Crystal Display) = Display for presentation of fire

alarms, fault messages, etc. Normally alphanumeric characters and

backlight.

2.17 Door open / Key switch

In most EBL512 configurations there is a door switch which is

activated when the control unit door is opened. In some

configurations does a key switch replace this door switch.

The LED "Key switch" is indicating "door open" / key switch in

position "access".

2.18 SSD / Site Specific Data

This data is unique for each installation. All alarm points,

presentation numbers, user definable text messages, programmable

outputs, etc. are programmed (configured) in the PC program Win512

and has to be downloaded in EBL512.

2.19 SW / Software / System program

The SW makes the control unit (the microprocessor) work. It is

factory downloaded but a new version can be downloaded in EBL512

on site.

9

Matsushita Electric Works Fire & Security Technology AB

MEW00442 Rev: - Operating Instructions EBL512, V1.44.x

3 Overview

3.1 The EBL512 system

EBL512 is a microprocessor controlled intelligent fire alarm system,

intended for analog addressable smoke detectors, as well as

conventional detectors and manual call points. Programmable control

outputs and output units are available. Up to 512 addresses can be

connected to each control unit (c.i.e.).

Regarding alarm points, outputs, display units, etc. see chapter

"Definitions / Explanations", page 6.

EBL512 is available in several types, versions and configurations. It

can be connected to a TLON network, a "system", with up to 30

independent control units. Each control unit has total access to all

information.

EBL512 is designed according to the European standards EN 54, part

2 and 4.

3.1.1 Expansion boards

In the control unit (c.i.e.) it is possible to mount up to six expansion

boards. The following types are available:

1580 8 zones expansion board

1581 8 relays expansion board

1582 External FBP interface board

1583 German FBP interface board

1584 Autronica interface board (four BS4 loops)

Regarding the expansion boards, see the EBL512 Planning

Instructions.

3.1.2 Printer

In control unit 1548 it is possible to mount a 1558 Printer.

3.2 SW versions

Due to continual development and improvement, different SW

versions could be found. When installing a new control unit in a

system with "older" control units, you may have to update the SW in

the old control units.

2

3

4

2

Max. two 1582 boards per C.U.

3

Max. one 1583 board per C.U. 1583 board is not possible to use in

Swedish convention.

4

Max. four 1584 boards per C.U.

10

Matsushita Electric Works Fire & Security Technology AB

MEW00442 Rev: - Operating Instructions EBL512, V1.44.x

3.3 Documents

The following documents are available:

• Planning instructions (incl. drawings)

• Operating instructions

Normally information that is found in one document is not to be found

in another document, i.e. the documents complements each other.

3.4 Applications

The EBL512 system is intended for small, medium and large

installations. The intelligent control units offer the system designer

and end user a technically sophisticated range of facilities and

functions. Programming (PC SW Win512) and commissioning of the

control unit / system is very easy. Start with one control unit and then,

when required, add more units. The TLON network makes it possible

to install the control units in one building or in many buildings.

3.5 PC SW

Win512 is used for programming and commissioning of one or more

control units:

• download / backup of site specific data

• download of SW / settings / configurations / C.U. & system data

• create and download the user definable text messages shown in

the alphanumeric display in the C.U. / ext. FBP and in the Display

units.

TLON Manager is used for programming of network data / addresses

/ etc.

NEWTEXT (DOS based "older" program) could be used to create /

download the user definable text messages shown in the Display units

connected to the COM loops.

11

Matsushita Electric Works Fire & Security Technology AB

MEW00442 Rev: - Operating Instructions EBL512, V1.44.x

4 Control Unit

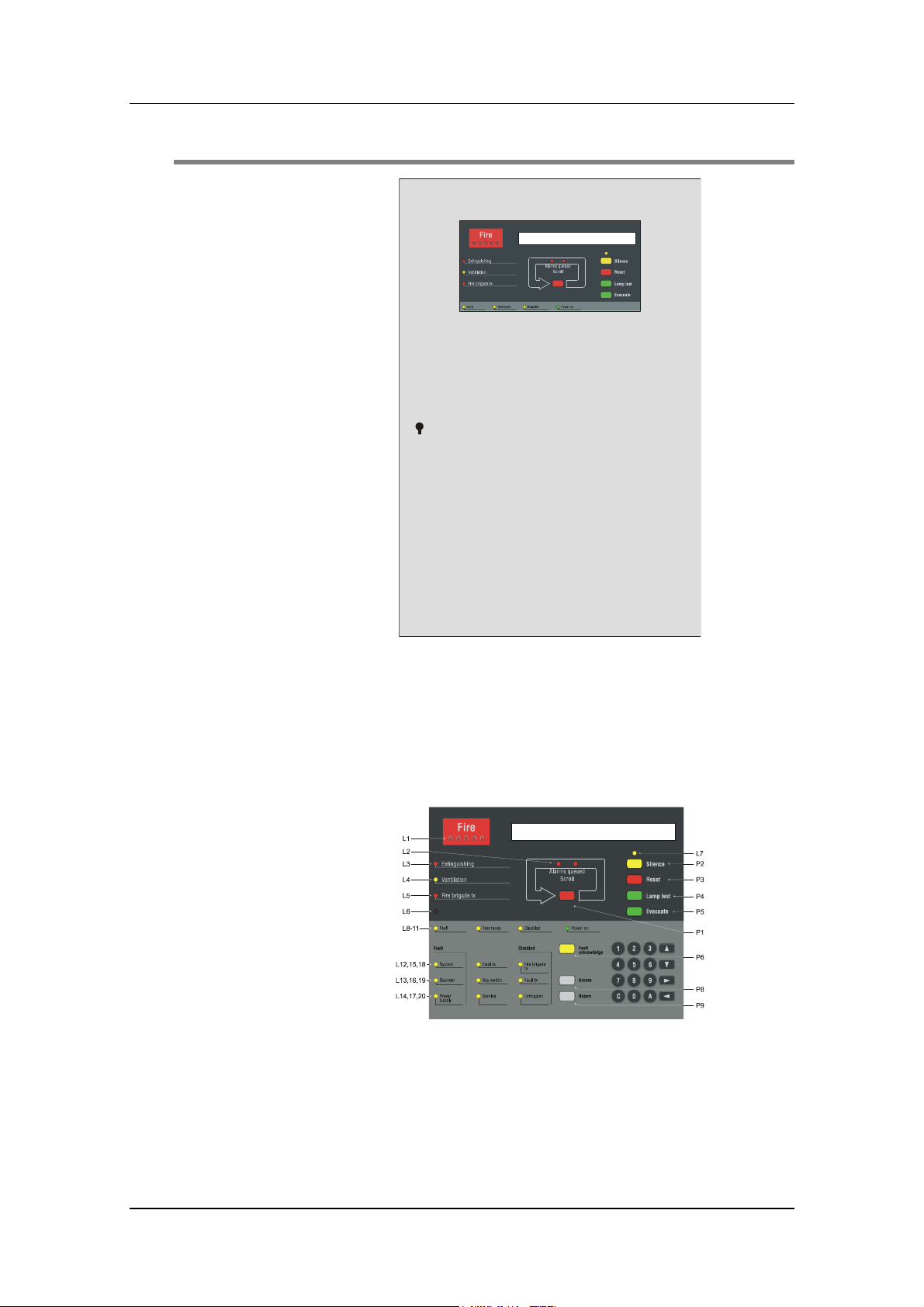

Figure 1. EBL512 Control Unit (1548 / 1549). The look may

vary according to configuration, country, etc.

The control unit (c.i.e.) is housed in a grey metal cabinet. The door

has a Plexiglas ahead of the FBP part, see Figure 1. When the door is

open, you fully see the front adhesive (the Fire Brigade Panel, FBP,

and Control Panel, CP), see Figure 2.

Figure 2. Front adhesive; FBP (upper black part) and CP (lower

grey part) in EBL512. The look may vary according to

configuration. (English config. in figure).

The fire brigade personnel use the FBP to see which alarm point(s)

having generated fire alarm. In the display (LCD, 2x40 alphanumeric

characters), is on the first row displayed the zone number and the

12

Matsushita Electric Works Fire & Security Technology AB

MEW00442 Rev: - Operating Instructions EBL512, V1.44.x

address within the zone. On the second row is shown a user definable

text message, if programmed.

Required fire brigade personnel manoeuvres can be performed from

the FBP.

The CP is used to "communicate" with the system, e.g. for

commissioning, monthly tests or maintenance. The CP has several

system status LEDs. A keypad is used to get access to the system (a

menu tree with main and sub menus) and for different manoeuvres.

Access codes for different access levels are required.

13

Matsushita Electric Works Fire & Security Technology AB

MEW00442 Rev: - Operating Instructions EBL512, V1.44.x

5 LED indicators and push buttons

LEDs and push buttons vary according to type and configuration

(convention / country / language).

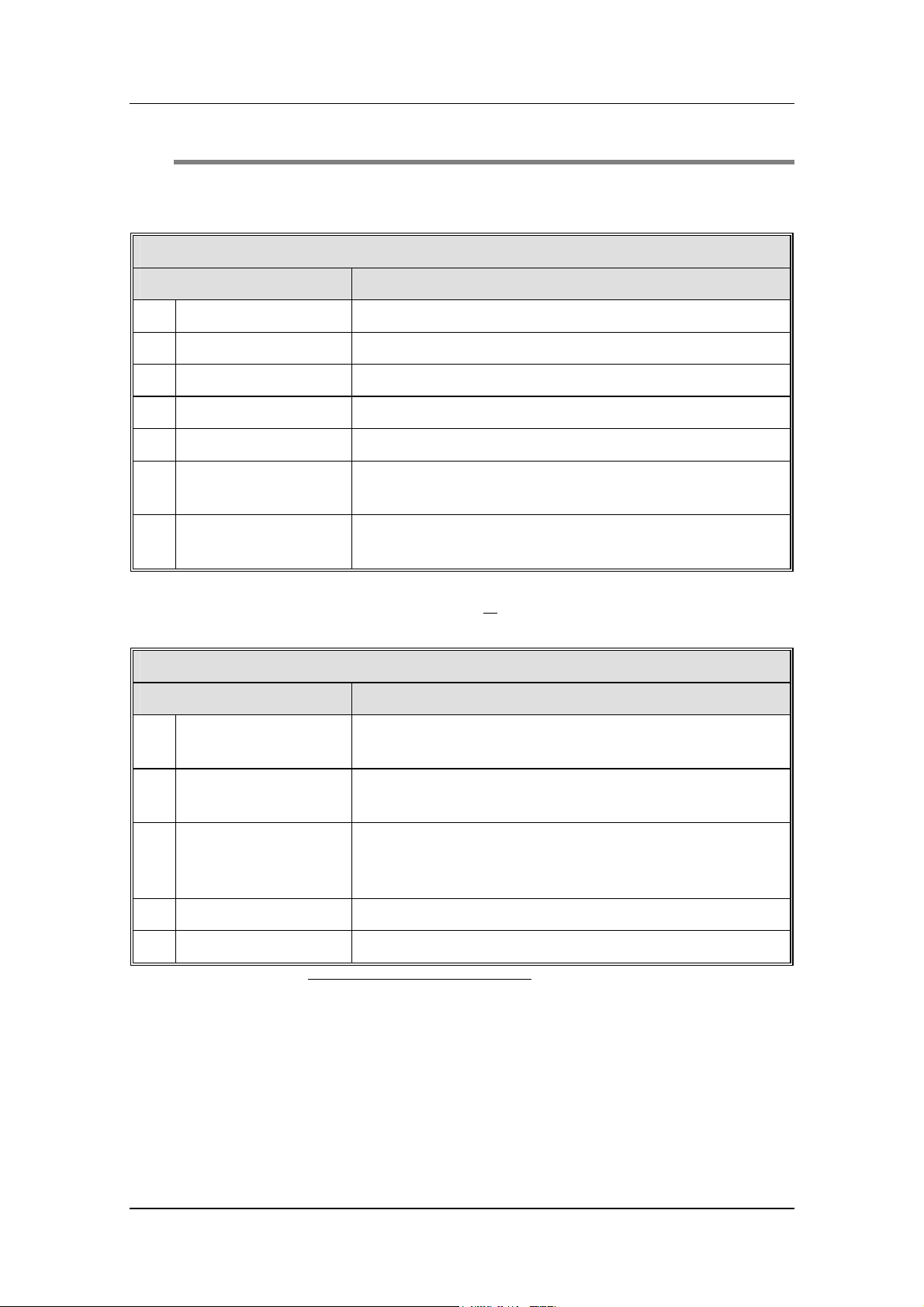

LED indicators on the Fire Brigade Panel (FBP)

LED indicator Indicating

L1 Fire (5 red) Fire alarm generated.

L2 Alarms queued (2 red) More than one alarm point/zone have generated fire alarm.

L3 Extinguishing (red) Output(s) for extinguishing equipment activated.

L4 Ventilation (yellow) Output(s) for fire/smoke ventilation equipment activated.

L5 Fire brigade tx (red) Output(s) for fire brigade tx (routing equipment) activated

L6 (Zone/Detector not

5

reset)

(An alarm point has been reset while still in alarm status, i.e.

it is non-reset ("isolated") and has to be re-enabled.)

L7 Silence (yellow) The sounders (alarm devices) are silenced by the push button

"Silence".

L3-L5 can be individually programmed to indicate when it's normal

trigger condition is met or

when a programmable input is activated

(e.g. L5 will be turned on when an input is activated by a TX output.

Push buttons on the Fire Brigade Panel (FBP)

Push button Operation/function

P1 Scroll (red) Used, when LEDs "Alarms queued" are lit, to scroll/browse

through the queued alarms.

P2 Silence (yellow) 6 Used to silence the sounders (i.e. to "reset" resp. outputs).

LED "Silence" indicates silenced sounders.

P3 Reset (red) Resets the fire alarm displayed in the LCD. When more than

one fire alarm is generated (LEDs "Alarms queued" are lit).

Each fire alarm has to be individually reset.

P4 Lamp test (green) 7 To test all the LEDs on the FBP and the CP.

P5 Evacuate (green) 8 Manual activation of sounders (alt. Paper feed).

5

Normally only used in Swedish configuration / convention.

6

Has a special function in some configurations / conventions.

7

Not used in all configurations / conventions. If not used, it's black and has

no function.

8

Normally only used in Brittish Standard convention. In B.S. (Marine

application) convention it has the function "Paper feed". Otherwise it's black

and has no function (or the function "Paper feed").

14

Matsushita Electric Works Fire & Security Technology AB

MEW00442 Rev: - Operating Instructions EBL512, V1.44.x

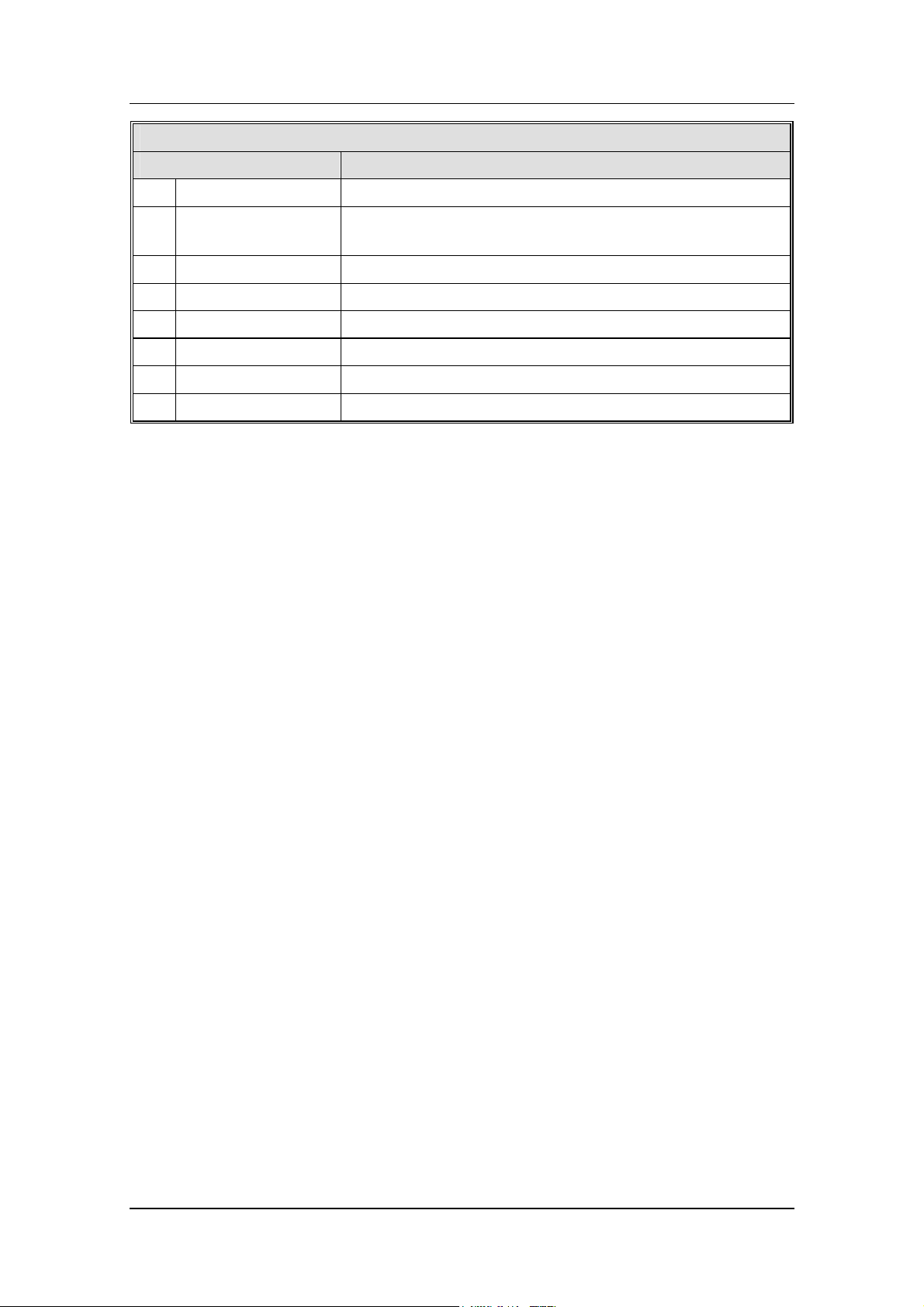

LED indicators on the Control Panel (CP)

LED indicator Indicating

L8 Fault (yellow) Acknowledged fault(s) and/or acknowledged but not

corrected fault(s).

L9 Test mode (yellow) One or more zones are in "test mode".

L10 Disabled (yellow) Something in the system is disabled.

L11 Power on (green) Power on, i.e. the power supply (rectifier and/or

battery are connected and working properly.

L12 Fault System (yellow) System program (SW) is not running correct (e.g.

CPU/memory fault).

L13 Fault Sounder (yellow) One or more supervised outputs (type 3=alarm

device) have generated fault.

L14 Fault Power supply (yellow) Power supply fault(s), described in chapter "Fault

messages", page 35.

L15 Fault tx (yellow) 1. One or more faults (not acknowledged) are

generated in the system.

2. Output(s) for fault tx (routing equipment) is(are)

activated.

L16 Key switch 9 (yellow)

(see chapter "Door open

(Key switch)", see page 25.

The control unit door is open. When a TLON

network is used, one or more doors in the system are

10

open.

L17 Service (yellow) One or more sensors have reached the service level.

L18 Disabled Fire brigade tx

(yellow)

Output(s) for fire brigade tx (routing equipment)

is(are) disabled via menu (H8/S1) or open door.

11

L19 Disabled Fault tx (yellow) Output(s) for fault tx (routing equipment) is(are)

disabled via menu (H8/S1) or open door.

11

L20 Disabled Extinguish Output(s) for extinguishing equipment is(are)

disabled via time channel or menu (H2/B3 or B8).

9

In Brittish Standard (Marine application) convention: "Door open".

10

It is programmable if also the ext. FBP open door(s) should be indicated

and if it should indicate for each control unit individually or the whole

system.

11

It is programmable if open door should disable the output(s).

15

Matsushita Electric Works Fire & Security Technology AB

MEW00442 Rev: - Operating Instructions EBL512, V1.44.x

Keypad/push buttons on the Control Panel (CP)

Key/push button Operation/function

0 - 9 Numeric keys for the figures 0-9.

← →

↑ ↓

Left / right keys to move the cursor in a menu.

Up / down keys to scroll between the menus.

C Clear /deletes just written data.

A Accept a menu and accept input of data.

P6 Fault acknowledge Fault acknowledge (menu H6).

P7 - -

P8 Access To get access to the menu tree (via access code).

P9 Return To leave a menu ("one step up") and to stop input of data.

16

Matsushita Electric Works Fire & Security Technology AB

MEW00442 Rev: - Operating Instructions EBL512, V1.44.x

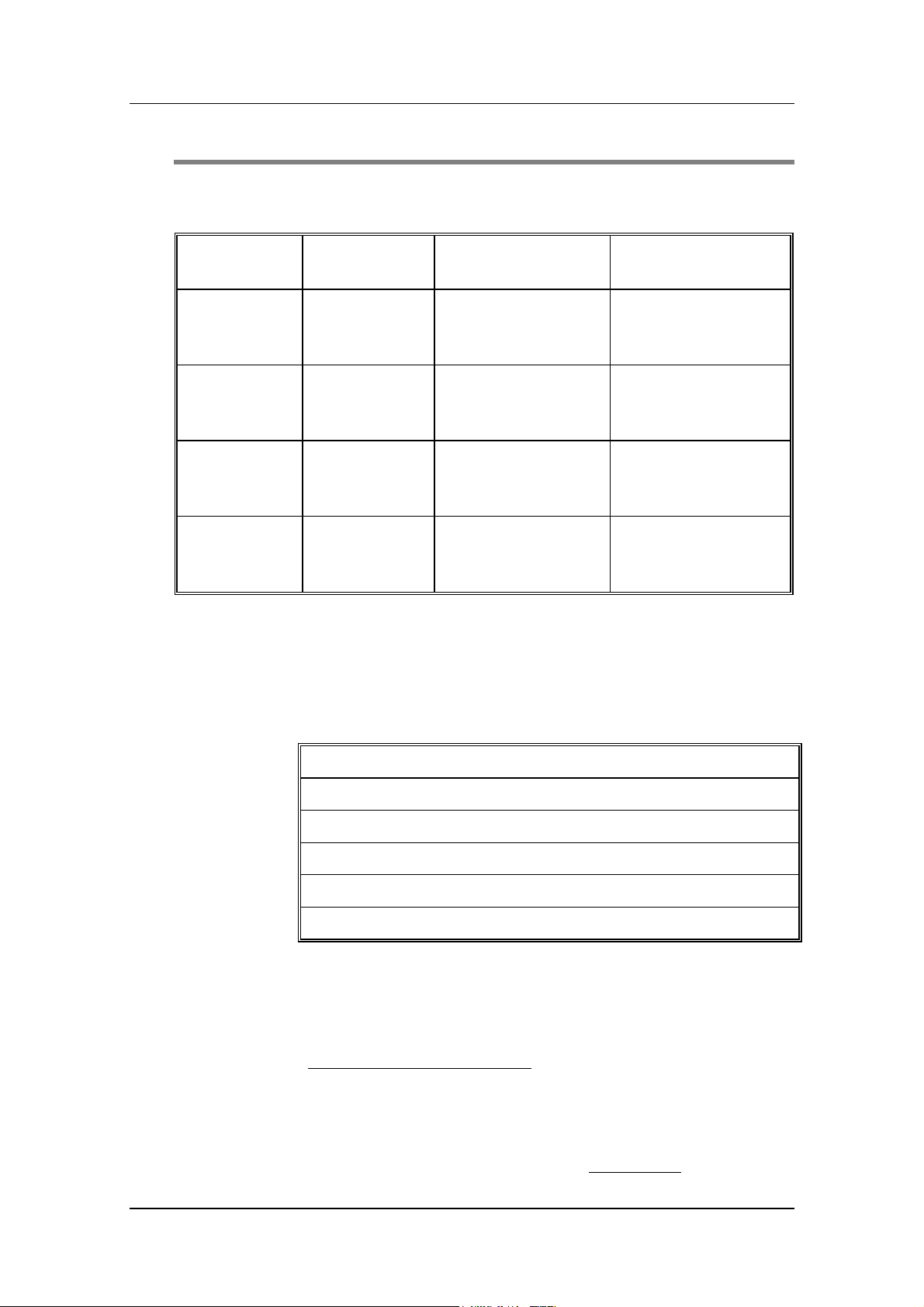

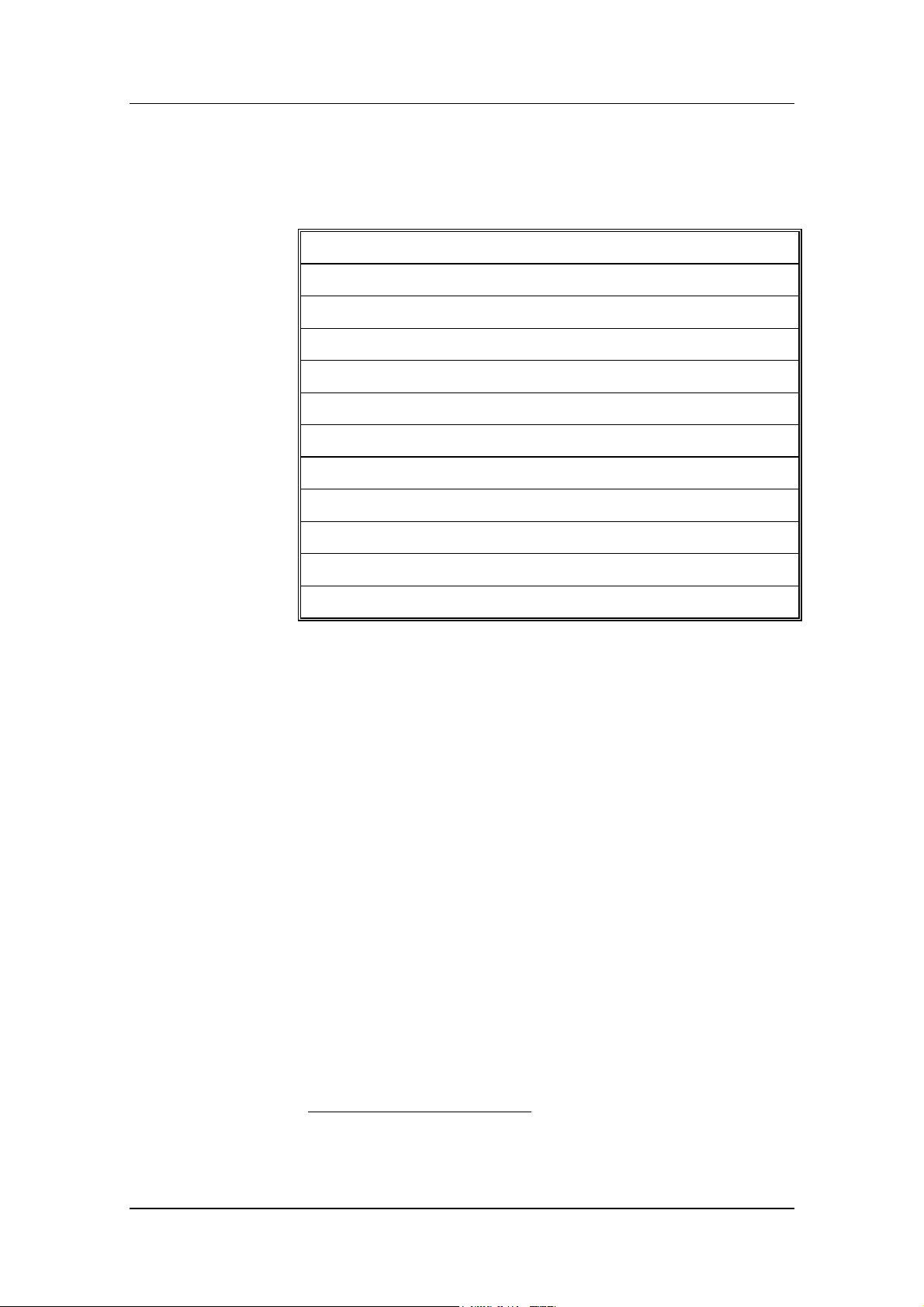

6 Access levels

The control unit has five access levels which are adapted to different

kind of users.

Access level 1 Open door

Fire brigade personnel Fire alarm handling

(key is needed)

Access level 2 Access code for

Building occupier Installation handling,

level 2 (or 3 or 4)

is required

Access level 3 Access code for

Service personnel Service, maintenance

level 3 (or 4) is

required

Access level 4 Access code for

level 4 is

required

Access level 5 Access code for

level 5 is

required

Service /

commissioning

engineer

Service /

commissioning

engineer

The access codes can be changed. To change a code you have to

know the valid code or use a code for a higher access level.

6.1 Access level 1

After the door has been opened (LED "Key switch" is lit), the user /

fire brigade personnel will be able to use the push buttons / keypad to:

monthly tests, etc.

Service, commissioning

the system, etc.

Code to connect a PC,

i.e. for Win512.

Scroll / browse through the queued alarms.

Silence the sounders (alarm devices).

Reset fire alarm(s).

Perform lamp (LED) test.12

Start the sounders.13

Get access (after login) to certain menus / functions in the system.14

12

Not in all configurations / conventions.

13

Normally only used in English configuration / convention.

14

Normally, the fire brigade personnel have no access code.

17

Matsushita Electric Works Fire & Security Technology AB

MEW00442 Rev: - Operating Instructions EBL512, V1.44.x

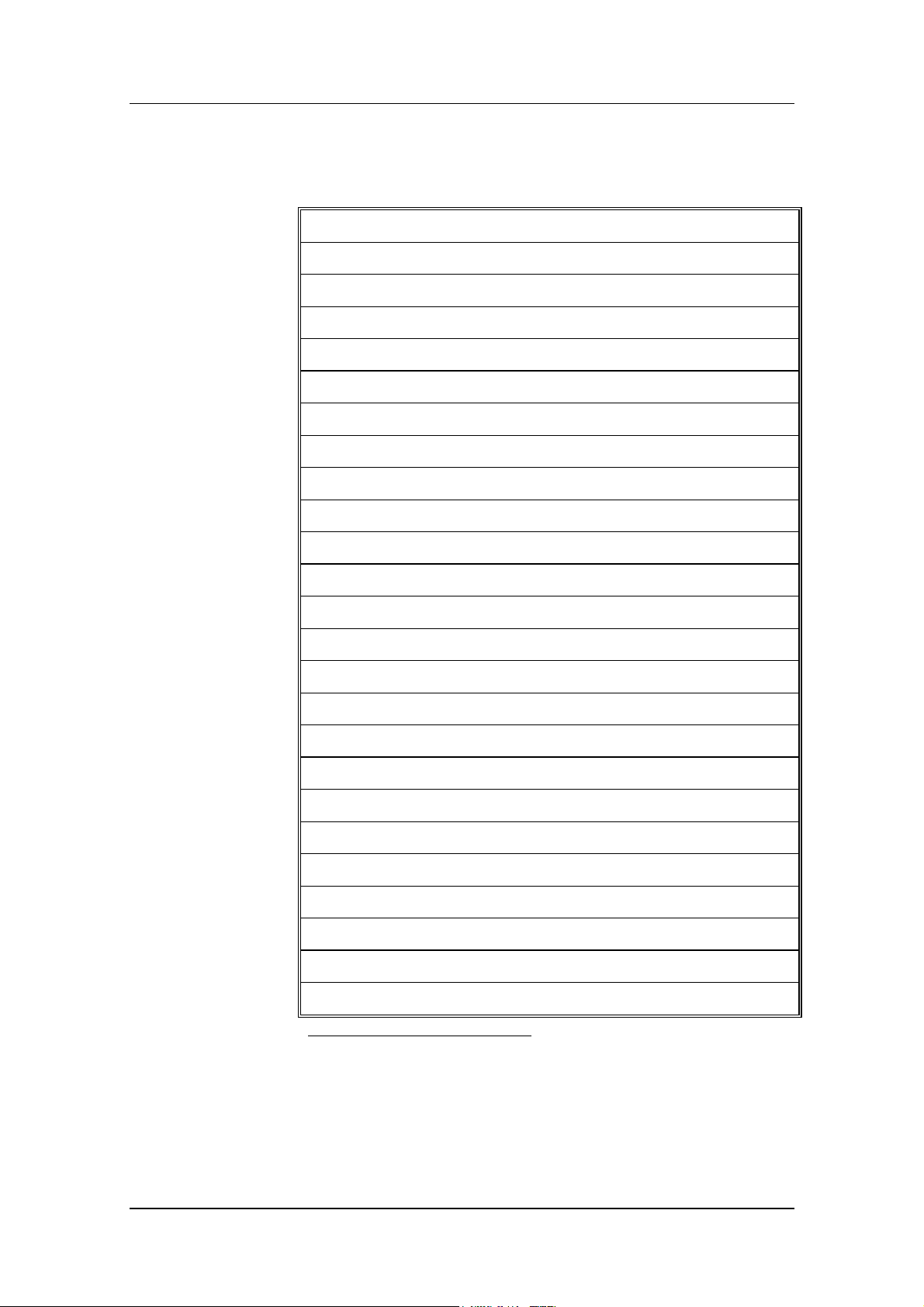

6.2 Access level 2

From access level 1, the user can login to access level 2, which gives

access to the following menus:

H1 Perform monthly test.

H2 Disable or re-enable.

B1 Disable zone

B2 Disable zone / address

B3 Disable control output

B4 Re-enable zone

B5 Re-enable zone / address

B6 Re-enable control output

B7 Re-enable non-reset zone / address15

B8 Control on / Control off

B9 Alarm device on / Alarm device off

H3 Set calendar and clock.

H4 Present system status on display and printer.

U1 Disablement

U2 Disablement by time channel.

U3 Show open doors.16

U4 Activated 2-zone / address dependent zone / address.

U5 Show sensors week average values.

U6 Show sensors momentary values.

U7 Sensors activating service signal

U8 Show event log

U9 Show configuration

H6 Acknowledge faults.

H7 Perform zone test (Test mode).

H9 Change access code for daily duties (access level 2).

15

Normally only in Swedish configuration / convention.

16

When a TLON network is used, one or more doors in the system could be

open. It is programmable if also ext. FBP open door(s) should be indicated

and if it should indicate for each control unit individually or the whole

system. See also chapter Door open (Key switch), page 25.

18

Matsushita Electric Works Fire & Security Technology AB

MEW00442 Rev: - Operating Instructions EBL512, V1.44.x

6.3 Access level 3

From access level 217, the user can login to access level 3, which gives

access to the following menus, normally used by service personnel:

Same menus as in access level 2 plus the following:

H8 Maintenance

S1 Disable or re-enable outputs for routing equipment (Fire

brigade tx & Fault tx)

S2 Disconnect COM loop.

S3 Re-connect Loop.

S4 Acknowledge service signal.

S5 Safe shut down of control unit.

S6 Activate address in alarm mode.

S7 Synchronize the control units.

S8 Change access code for maintenance (access level 3).

17

If code for access level 3 or 4 has been used to login to access level 2, new

login to access level 3 is not required.

19

Matsushita Electric Works Fire & Security Technology AB

MEW00442 Rev: - Operating Instructions EBL512, V1.44.x

6.4 Access level 4

From access level 218, the user can login to access level 4, which gives

access to the following menus, normally used by a Service /

Commissioning Engineer:

Same menus as in access level 2 and 3 plus the following:

H5 Programming

A1 Calibration of monitored outputs

A2 Sensitive fault detection mode

A3 Direction for communication on COM loop (and BS4 loop)

A4 Show information about site specific data.

A5 Display current consumption in unit

A6 Display current consumption on COM-/BS4-loop

A7 Display statistics for COM-loop

A8 Select unit on COM-loop (and BS4 loop) to use for triggering

A9 Change access code for PC-communication (access level 5).

A10 Change access code for programming (access level 4).

6.5 Access level 5

Used by Service / Commissioning Engineer when a PC is to be

connected to the control unit, i.e. when Win512 is to be used for

backup, downloading site specific data, downloading SW / settings /

configurations / C.U. and system data, on-line status checking, etc.

18

If code for access level 4 has been used to login to access level 2, new

login to access level 4 is not required.

20

Matsushita Electric Works Fire & Security Technology AB

MEW00442 Rev: - Operating Instructions EBL512, V1.44.x

7 Normal operation

When the control unit / system is in normal operation, i.e. no fire

alarm, no fault, no disablement, no service signal, not in test mode and

no open doors, etc., only the LED "Power on" (L11) is to be lit.

21

Matsushita Electric Works Fire & Security Technology AB

MEW00442 Rev: - Operating Instructions EBL512, V1.44.x

8 Push button "Silence"

In the control unit (on the FBP) there is a push button (P2) "Silence"

and an LED (L7) "Silence". In some configurations / conventions,

this button could have special function(s).

8.1 Silence before a fire alarm

19

If the push button "Silence" is pushed before a fire alarm / fault,

the following will happen:

• LEDs "Silence" and "Disabled" (L10) will light up (steady

ON)

• the buzzer in the control unit will be disabled

• outputs programmed for sounders (type 3 = alarm devices)

will be disabled

If case of a fire alarm, the buzzer and the sounders will remain turned

OFF (not sound).

In case of a fault, the buzzer will remain turned OFF (not sound).

To reset this function, push "Silence" once more. The LEDs will be

turned OFF, indicating a normal state.

8.2 Silence during a fire alarm

If the push button "Silence" is pushed during a fire alarm, the

following will happen:

• LEDs "Fire" and "Alarms queued"

blinking to steady ON

• the buzzer in the control unit will be turned OFF

• activated outputs, programmed for sounders (type 3 = alarm

devices), will be turned OFF

In case of a new fire alarm

again, the buzzer and the sounders (i.e. the outputs), will automatically

be turned ON and LEDs "Fire" and "Alarms queued" starts blinking.

If the push button "Silence" is pushed during a fault condition, the

following will happen:

• the buzzer in the control unit will be turned OFF

It will be turned OFF until the push button "Silence" is pushed again

(or a fire alarm is activated).

, or if the push button "Silence" is pushed

20

(L2) changes from

19

In some configurations / conventions, e.g. Swedish (RUS), Brittish

Standard and B.S. (Marine application) is this function not valid.

20

When more than one fire alarm is activated.

22

Matsushita Electric Works Fire & Security Technology AB

MEW00442 Rev: - Operating Instructions EBL512, V1.44.x

9 Alarm device on / Alarm device off

Via menu H2/B9, all outputs, programmed for sounders (type 3 =

alarm devices), can be turned OFF (disabled).

In case of a fire, the sounders will remain turned OFF (not sound).

They will be turned OFF (disabled) until they are turned ON (reenabled) again, via menu H2/B9.

Alarm device OFF is indicated by LED "Disabled" (L10).

23

Matsushita Electric Works Fire & Security Technology AB

MEW00442 Rev: - Operating Instructions EBL512, V1.44.x

10 Controls ON / Controls OFF

Via menu H2/B8, all control output types:

0 = control (general)

1 = fire ventilation

21

2 = extinguishing system

can be collective turned OFF (disabled).

They will be turned OFF (disabled) until they are turned ON (reenabled) again, via menu H2/B8.

Controls OFF is indicated by LED "Disabled" (L10).

21

Also the "Extinguish equipment output" on the German FBP interface

board 1583.

24

Matsushita Electric Works Fire & Security Technology AB

MEW00442 Rev: - Operating Instructions EBL512, V1.44.x

11 Door open (Key switch)

A key is used to open the control unit door to get access to the system,

see chapter "Access levels", page 17.

Door open is indicated by LED "Key switch" (L16), see below.

Door open can disable output(s) for fire alarm and fault routing

equipment respectively. LEDs "Fire brigade tx Disabled" and "Fault

tx Disabled" indicate this respectively. See below.

11.1 LED "Key switch"

In Win512, the following can be programmed:

Door in any control unit in the system

LED "Key switch" is indicating door open in one or more control

units in the system.

or

Door in control unit

LED "Key switch" is indicating door open in the same control unit as

the LED is situated.

Indication open door external FBP

In both cases above could be chosen, if an open door in one or more

external FBPs should be indicated by the LED "Key switch", or not.

11.2 Disable outputs for routing equipment (Fire

brigade tx and Fault tx)

In Win512, the following can be programmed:

No disabling

Output(s) for routing equipment (Fire brigade tx and Fault tx), are not

disabled by an open door.

or

Disable if any door in the system is open

Output(s) for routing equipment (Fire brigade tx and Fault tx), are

disabled when a door in a control unit is open

22

.

Disabled outputs for routing equipment are indicated by the LED

"Disabled", "Fire brigade tx Disabled" (L18) and "Fault tx Disabled"

(L19).

22

No choice between control unit and any control unit in the system. Only

valid for control unit doors, not ext. FBP doors.

25

Matsushita Electric Works Fire & Security Technology AB

MEW00442 Rev: - Operating Instructions EBL512, V1.44.x

12 Technical number / Presentation

number

12.1 Technical number for COM loop units

The technical number, NNNNNN, is used when programming all

units connected to the COM loops.

Technical number is also used to identify which unit has generated a

fault.

Regarding DIL-switch address setting, see dwg 512-71.

26

Matsushita Electric Works Fire & Security Technology AB

MEW00442 Rev: - Operating Instructions EBL512, V1.44.x

12.2 Technical number for BS4 loop units

Autronica interface board 1584 (four BS4 loops) is required in the

control unit.

The technical number, NNNNNN, is used when programming all

units connected to the BS4 loops.

Technical number is also used to identify which unit has generated a

fault.

NOTE! In the technical number

board number 4 = Autronica interface board 0, the board number 5 =

Autronica interface board 1, the board number 6 = Autronica interface

board 2 and the board number 7 = Autronica interface board 3 in the

control unit.

In fault messages

information is shown: Control unit (00-29), BS4 board (0-3) and if

required BS4 loop (0-3)

for Autronica interface boards, the following

for unit connected to a BS4 loop, the

27

Matsushita Electric Works Fire & Security Technology AB

MEW00442 Rev: - Operating Instructions EBL512, V1.44.x

12.3 Presentation number

For each fire alarm point / input, a presentation number, NNN-NN,

has to be programmed. This number is shown in the FBP display(s)

23

to identify the point / zone generating fire alarm. It is also used to

disable / re-enable fire alarm points / zones and in control conditions

(expressions) to activate the programmable outputs.

Together with the zone number and the address, a user definable, 40

character, text message can be displayed (if programmed).

,

23

Presentation number is also shown in the display units connected to the

COM loops.

28

Loading...

Loading...