MXIC MX26L6420XBI-12, MX26L6420MC-90, MX26L6420TI-12, MX26L6420XAI-12, MX26L6420XAC-90 Datasheet

...

FEATURES

ADVANCED INFORMATION

MX26L6420

64M-BIT [4M x 16] CMOS

MULTIPLE-TIME-PROGRAMMABLE EPROM

• 4,194,304 x 16 byte structure

• Single Power Supply Operation

- 2.7 to 3.6 volt for read, erase, and program

operations

• Low Vcc write inhibit is equal to or less than 2.5V

• Compatible with JEDEC standard

• High Performance

- Fast access time: 90/120ns (typ.)

- Fast program time: 140s/chip (typ.)

- Fast erase time: 150s/chip (typ.)

• Low Power Consumption

- Low active read current: 17mA (typ.) at 5MHz

- Low standby current: 30uA (typ.)

• Minimum 100 erase/program cycle

GENERAL DESCRIPTION

The MX26L6420 is a 64M bit MTP EPROMTM organized

as 4M bytes of 16 bits. MXIC's MTP EPROM

most cost-effective and reliable read/write non-volatile

random access memory. The MX26L6420 is packaged in

44SOP, 48-pin TSOP, 48-ball CSP and 63-ball CSP. It is

designed to be reprogrammed and erased in system or in

standard EPROM programmers.

TM

offer the

• Status Reply

- Data polling & Toggle bits provide detection of

program and erase operation completion

• 12V ACC input pin provides accelerated program

capability

• Output voltages and input voltages on the device is

deterined by the voltage on the VI/O pin.

- VI/O voltage range:1.65V~3.6V

• 10 years data retention

• Package

- 44-Pin SOP

- 48-Pin TSOP

- 48-Ball CSP

- 63-Ball CSP

MXIC's MTP EPROM

memory contents even after 100 erase and program

cycles. The MXIC cell is designed to optimize the erase

and program mechanisms. In addition, the combination of

advanced tunnel oxide processing and low internal

electric fields for erase and programming operations

produces reliable cycling.

TM

technology reliably stores

The standard MX26L6420 offers access time as fast as

90ns, allowing operation of high-speed microprocessors

without wait states. To eliminate bus contention, the

MX26L6420 has separate chip enable (CE) and output

enable OE controls. MXIC's MTP EPROMTM augment

EPROM functionality with in-circuit electrical erasure and

programming. The MX26L6420 uses a command register

to manage this functionality.

P/N:PM0823 REV. 0.5, JAN. 29, 2002

The MX26L6420 uses a 2.7V to 3.6V VCC supply to

perform the High Reliability Erase and auto Program/

Erase algorithms.

The highest degree of latch-up protection is achieved with

MXIC's proprietary non-epiprocess. Latch-up protection

is proved for stresses up to 100 milliamps on address and

data pin from -1V to VCC +1V.

1

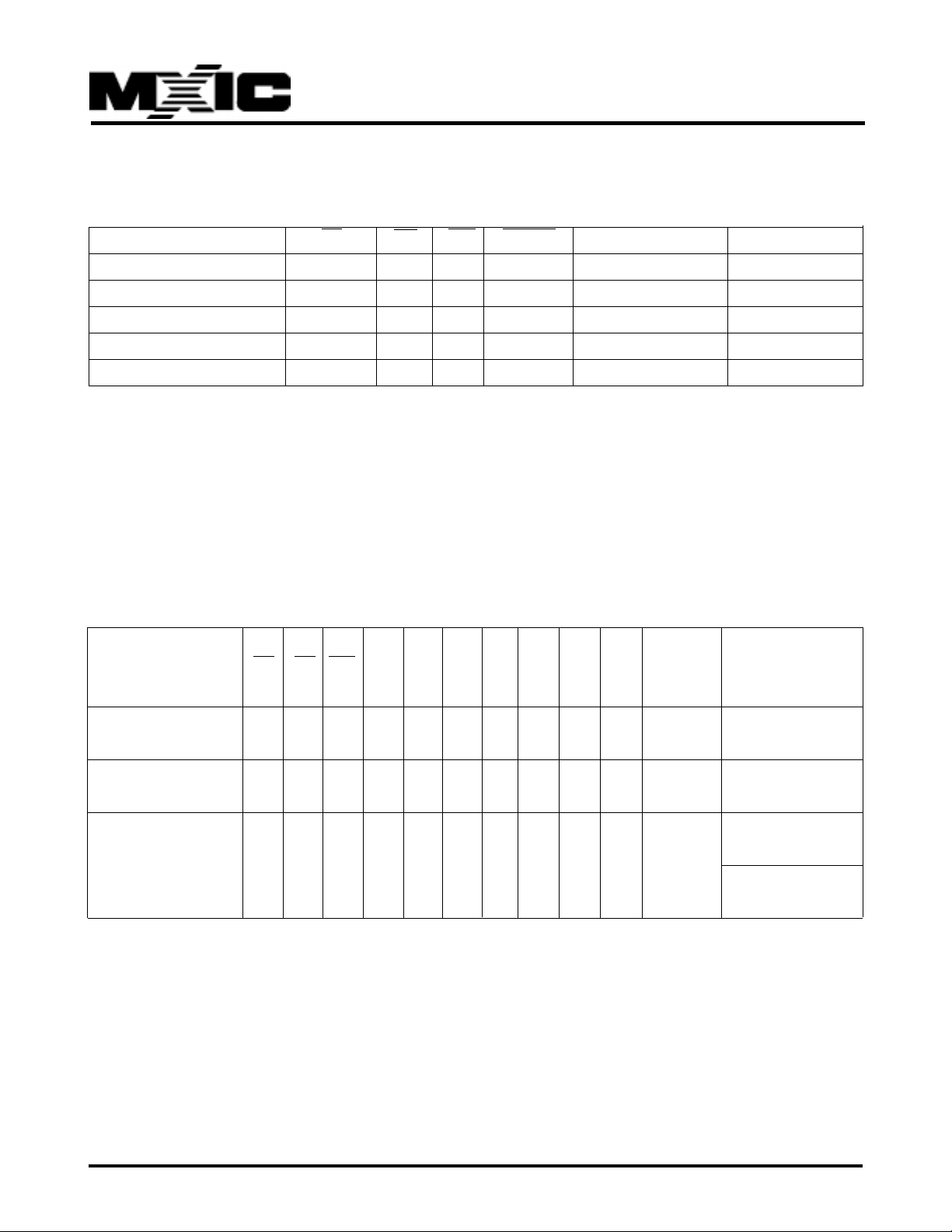

PIN CONFIGURATION

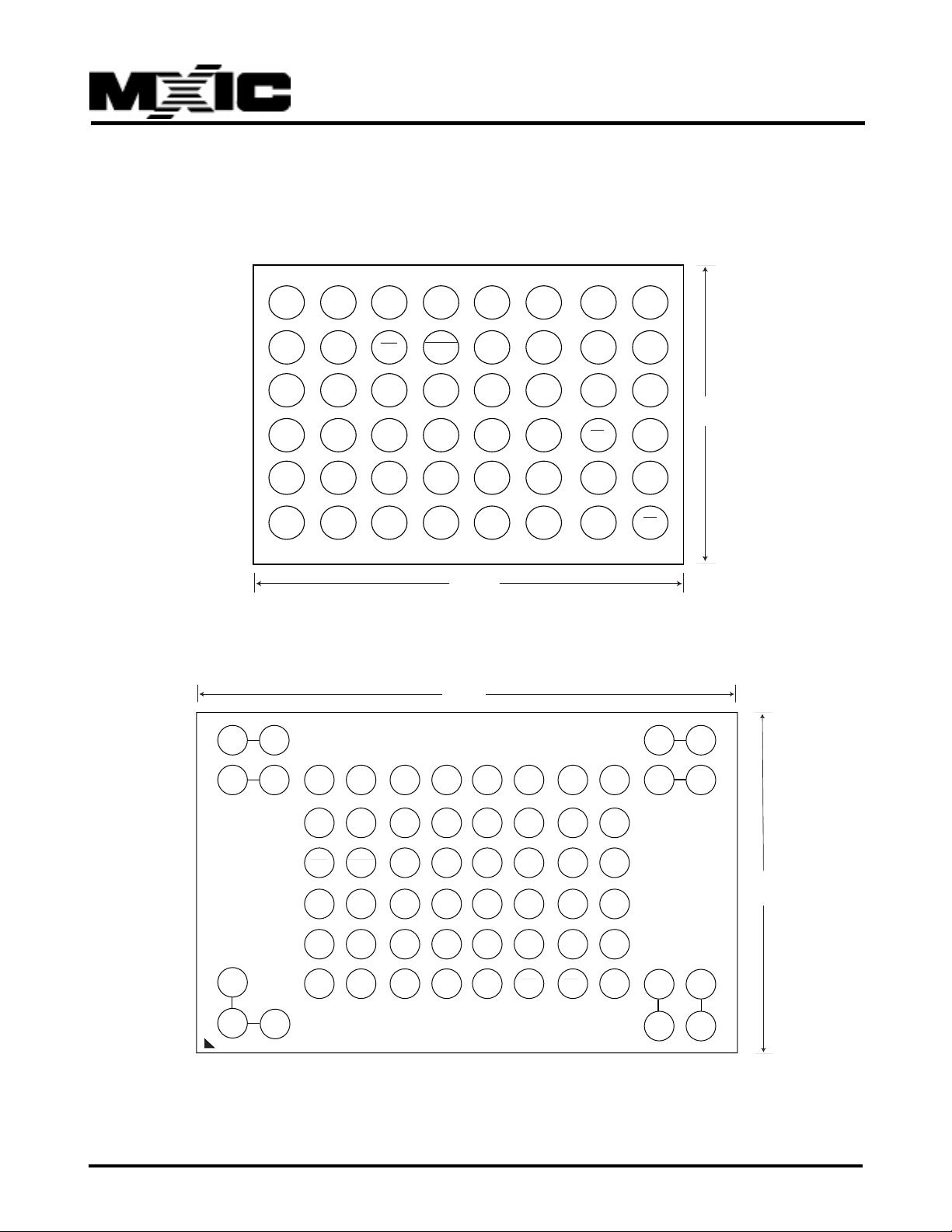

48 CSP Ball pitch=0.75mm for MX26L6420XA (TOP view, Ball down)

12345678

MX26L6420

A

B

C

D

E

F

A13

A14

A15

A16

V I/O

GND

A11

A10

A12

Q14

Q15

Q7

A8

WE

A9

Q5

Q6

Q13

ACC NC

RESET

A21

Q11

Q12

Q4

A18

A20

Q2

Q3

VCC

A19

A17

A6

Q8

Q9

Q10

A7

A5

A3

CE

Q0

Q1

13.0 mm

63 CSP Ball pitch=0.8mm for MX26L6420XB(TOP view, Ball down)

13.0 mm

8

NC

NC

A4

A2

A1

A0

GND

OE

NC*

8.0 mm

NC*

P/N:PM0823

7

6

5

4

3

2

1

* Ball are shorted together via the substrate but not connected to the die.

NC

NC

NC*

NC*

NC*

BCDEFGHJK LM

A

A13

A9

WE

NC

A7

A3

A12

A8

RESET

ACC

A17

A4

A14

A10

A21

A18

A6

A2

A15

A11

A19

A20

A5

A1

A16

VIO

Q7

Q14

Q12

Q5

Q2

Q10

Q0

Q8

A0

CE

Q15

Q13

VCC

Q11

Q9

OE

GND

Q6

Q4

Q3

Q1

GND

NC*

NC*

NC*

NC*

8.0 mm

NC*

NC*

REV. 0.5, JAN. 29, 2002

2

MX26L6420

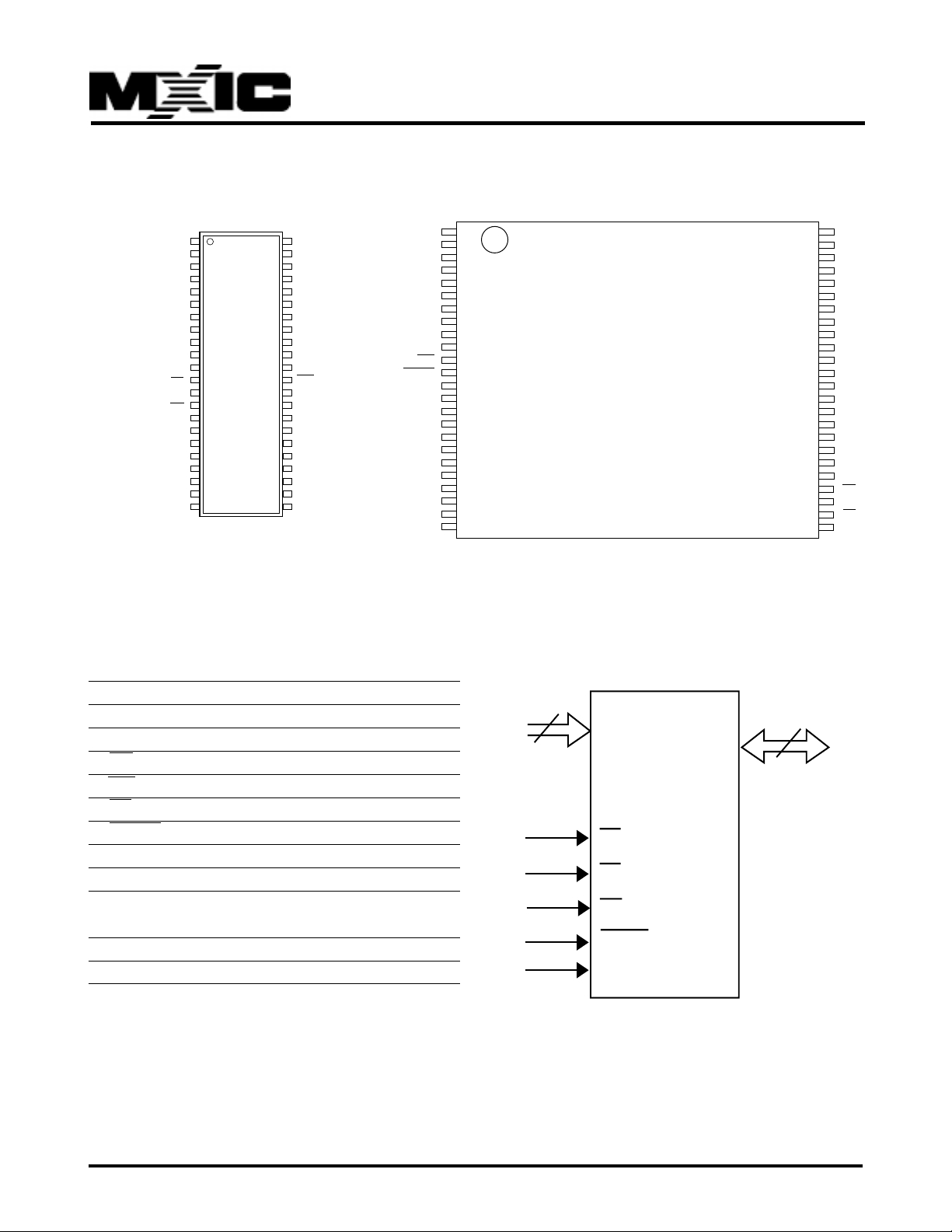

44 SOP

A21

A18

A17

CE

GND

OE

Q0

Q8

Q1

Q9

Q2

Q10

Q3

Q11

48 TSOP

44

A20

43

2

3

4

A7

5

A6

6

A5

7

A4

8

A3

9

A2

10

A1

11

A0

12

13

14

MX26L6420

15

16

17

18

19

20

21

22

A19

42

A8

41

A9

40

A10

39

A11

38

A12

37

A13

36

A14

35

A15

34

A16

33

WE

32

GND

31

Q15

30

Q7

29

Q14

28

Q6

27

Q13

26

Q5

25

Q12

24

Q4

23

VCC

A15

A14

A13

A12

A11

A10

A21

A20

WE

RESET

ACC

VCC

A19

A18

A17

1

2

3

4

5

6

7

A9

8

A8

9

10

11

12

13

14

15

16

17

18

A7

19

A6

20

A5

21

A4

22

A3

23

A2

24

A1

MX26L6420

A16

48

V

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

I/O

GND

Q15

Q7

Q14

Q6

Q13

Q5

Q12

Q4

V

CC

Q11

Q3

Q10

Q2

Q9

Q1

Q8

Q0

OE

GND

CE

A0

PIN DESCRIPTION

SYMBOL PIN NAME

A0~A21 Address Input

Q0~Q15 Data Inputs/Outputs

CE Chip Enable Input

WE Write Enable Input

OE Output Enable Input

RESET Hardware Reset Pin, Active Low

VC C +3.0V single power supply

ACC Hardware Acceleration Pin

V I/O I/O power supply (For 48 TSOP and

63-CSP package only)

GN D Device Ground

N C Pin Not Connected Internally

LOGIC SYMBOL

21

A0-A21

CE

OE

WE

RESET

ACC

16

Q0-Q15

P/N:PM0823

REV. 0.5, JAN. 29, 2002

3

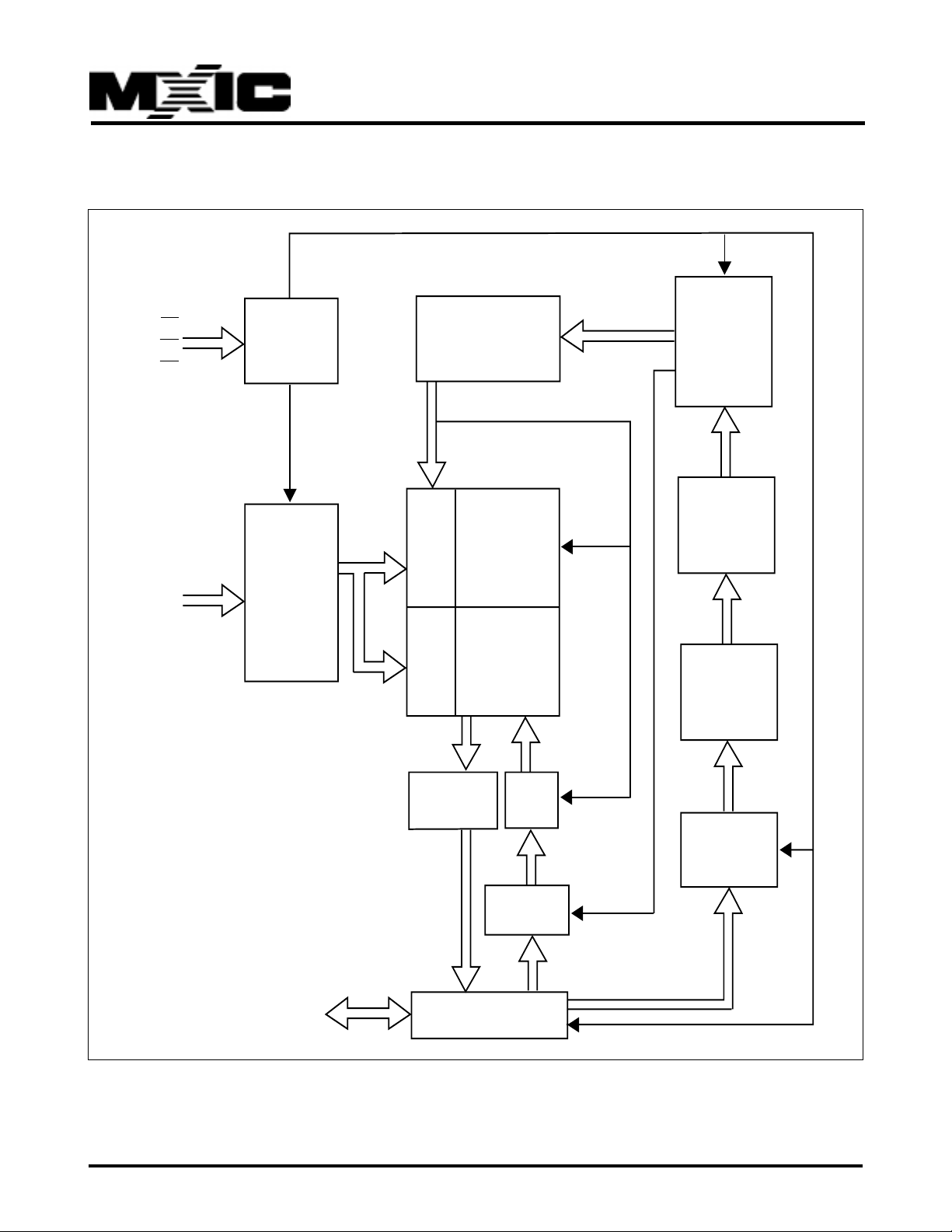

BLOCK DIAGRAM

CE

OE

WE

CONTROL

INPUT

LOGIC

PROGRAM/ERASE

HIGH VOLT A GE

MX26L6420

WRITE

STATE

MACHINE

(WSM)

A0-A21

ADDRESS

LATCH

AND

BUFFER

X-DECODER

MX26L6420

FLASH

ARRA Y

Y-DECODER

Y-PASS GATE

SENSE

AMPLIFIER

DATA LATCH

STATE

REGISTER

ARRAY

SOURCE

HV

COMMAND

DATA

DECODER

PGM

DATA

HV

COMMAND

DATA LATCH

PROGRAM

P/N:PM0823

Q0-Q15

I/O BUFFER

REV. 0.5, JAN. 29, 2002

4

MX26L6420

AUTOMATIC PROGRAMMING

The MX26L6420 is word programmable using the Automatic Programming algorithm. The Automatic Progr amming algorithm makes the external system do not need

to have time out sequence nor to verify the data programmed. The typical chip programming time at room

temperature of the MX26L6420 is less than 150 seconds.

AUTOMATIC PROGRAMMING ALGORITHM

MXIC's Automatic Programming algorithm require the user

to only write program set-up commands (including 2 unlock write cycle and A0H) and a program command (program data and address). The de vice automatically times

the programming pulse width, provides the program verification, and counts the number of sequences. A status

bit similar to DATA polling and a status bit toggling between consecutive read cycles, provide feedback to the

user as to the status of the programming operation.

AUTOMATIC CHIP ERASE

ming and erase operations. All address are latched on

the falling edge of WE or CE, whiche ver happens later.

All data are latched on rising edge of WE or CE, whichever happens first.

MXIC's Flash technology combines years of EPROM

experience to produce the highest levels of quality, reliability, and cost effectiveness. The MX26L6420 electrically erases all bits simultaneously using Fowler-Nordheim tunneling. The bytes are programmed b y using the

EPROM programming mechanism of hot electron injection.

During a program cycle, the state-machine will control

the program sequences and command register will not

respond to any command set. After the state machine

has completed its task, it will allow the command register to respond to its full command set.

The entire chip is bulk erased using 50 ms erase pulses

according to MXIC's Automatic Chip Erase algorithm.

T ypical erasure at room temper ature is accomplished in

less than 90 seconds. The Automatic Erase algorithm

automatically programs the entire array prior to electrical

erase. The timing and verification of electrical erase are

controlled internally within the device.

AUTOMATIC ERASE ALGORITHM

MXIC's Automatic Erase algorithm requires the user to

write commands to the command register using standard microprocessor write timings. The device will automatically pre-program and verify the entire arra y. Then

the device automatically times the erase pulse width,

provides the erase verification, and counts the number

of sequences. A status bit toggling between consecutive read cycles provides feedback to the user as to the

status of the programming operation.

Register contents serve as inputs to an internal statemachine which controls the erase and programming circuitry . During write cycles, the command register internally latches address and data needed for the program-

P/N:PM0823

REV. 0.5, JAN. 29, 2002

5

MX26L6420

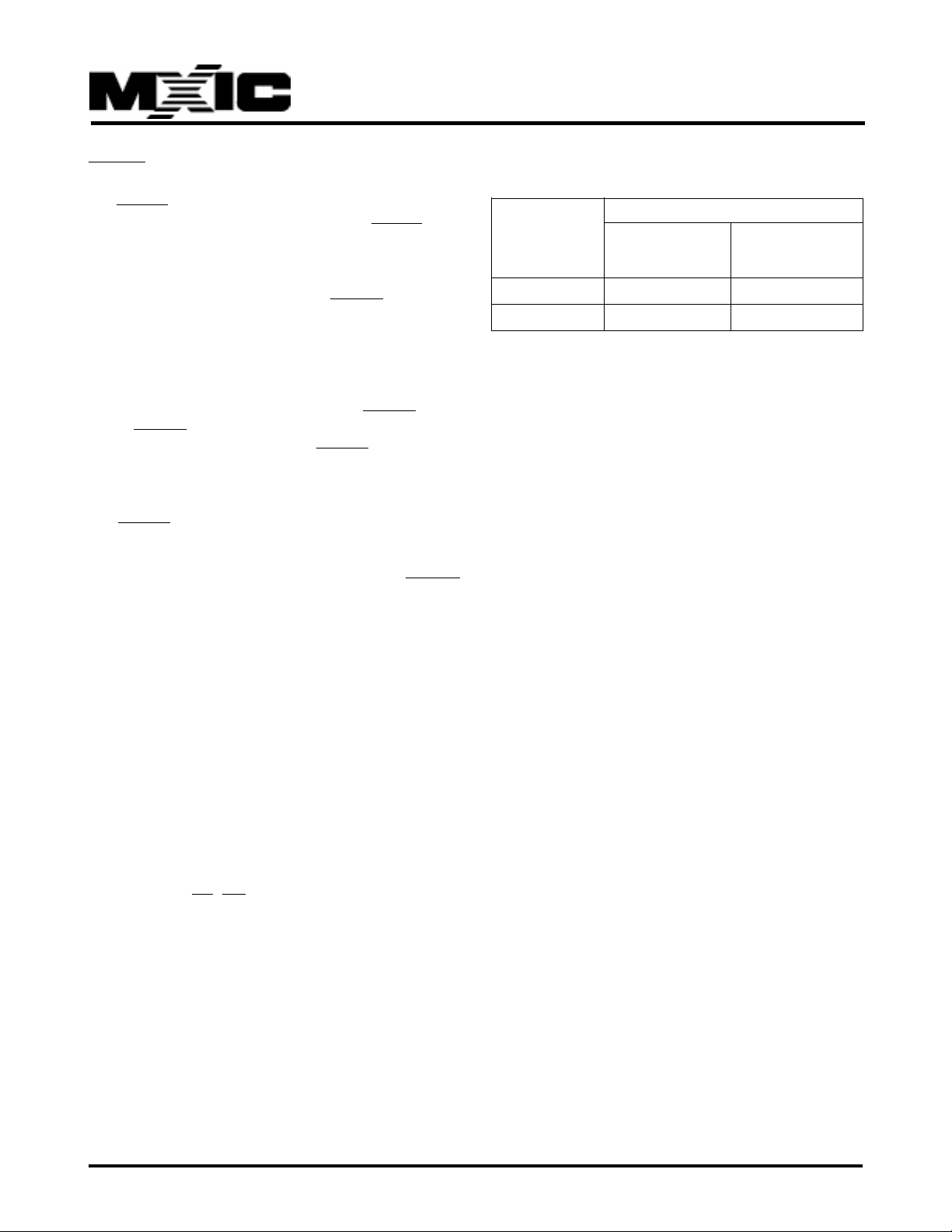

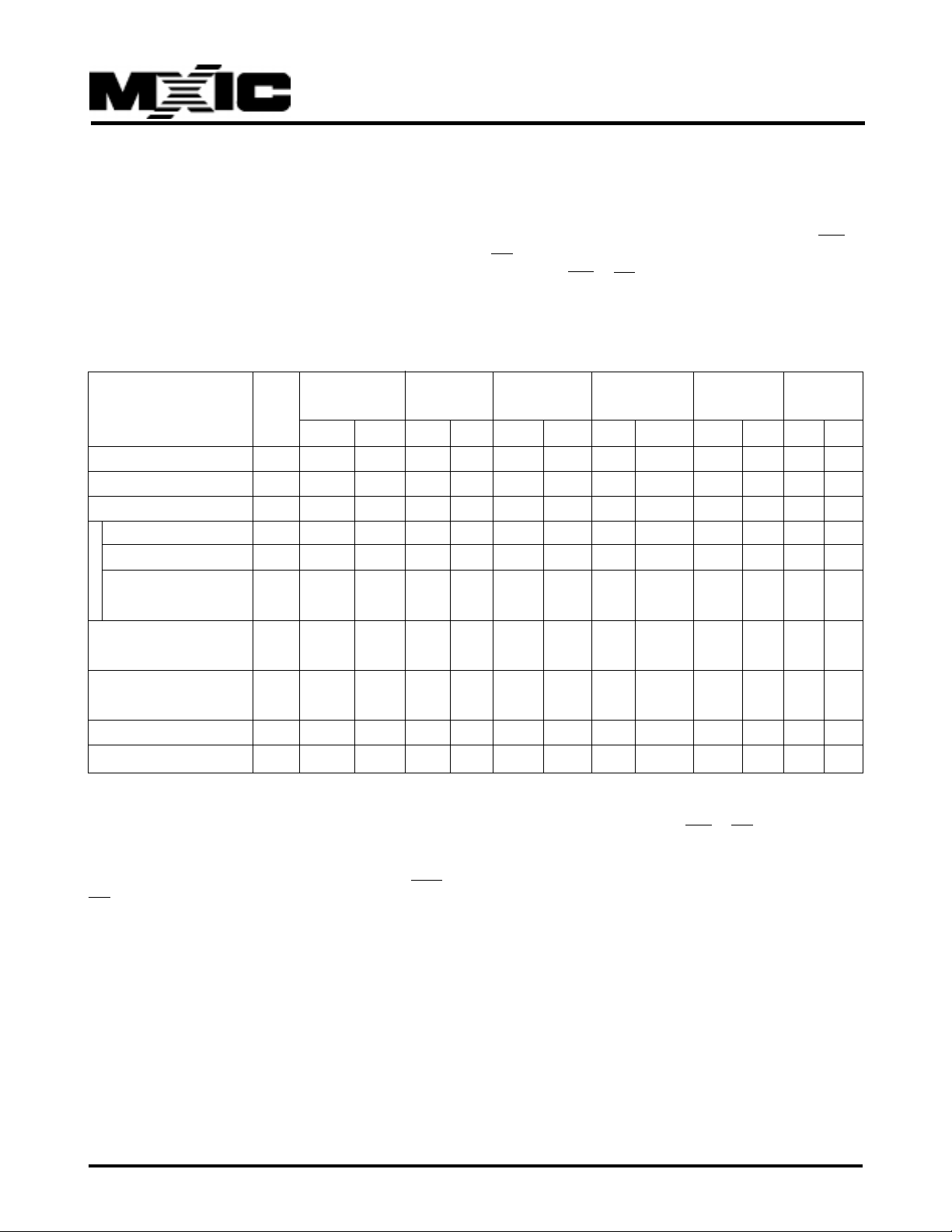

Table 1

BUS OPERATION(1)

Operation CE OE WE RESET Address Q15~Q0

Read L L H H A

Write(Note 1) L H L H A

IN

IN

D

OUT

D

IN

Standby VCC±0.3V X X VCC±0.3V X High-Z

Output Disable L H H H X High-Z

Reset X X X L X High-Z

Legend:

L=Logic LOW=VIL,H=Logic High=VIH,VID=12.0±0.5V,X=Don't Care, AIN=Address IN, DIN=Data IN, D

=Data OUT

OUT

Notes:

1. When the ACC pin is at VHH, the device enters the accelerated program mode. See "Accelerated Prog ram Operations"

for more information.

Table 2. AUTOSELECT CODES (High Voltage Method)

A5 A8 A14

Operation CE OE WE A0 A1 to A6 to A9 to A15~A21 Q15~Q0

A2 A7 A10

Read Silicon ID L L H L L X L X V

X X00 C2 H

ID

Manufactures Code

Read Silicon ID L L H H L X L X V

X X 22FCH

ID

Device Code

Secured Silscon xx88h

Sector Indicator L L H H H X L X V

X X (factory locked)

ID

Bit (Q7) xx08h

(non-factory locked)

P/N:PM0823

REV. 0.5, JAN. 29, 2002

6

MX26L6420

REQUIREMENTS FOR READING ARRAY

DATA

To read array data from the outputs, the system must

drive the CE and OE pins to VIL. CE is the po wer control

and selects the device. OE is the output control and gates

array data to the output pins. WE should remain at VIH.

The internal state machine is set for reading array data

upon device power-up, or after a hardware reset. This

ensures that no spurious alteration of the memory contect

occurs during the power transition. No command is

necessary in this mode to obtain array data. Standard

microprocessor read cycles that assert valid address on

the device address inputs produce valid data on the device

data outputs. The de vice remains enabled for read access

until the command register contents are altered.

WRITE COMMANDS/COMMAND

SEQUENCES

To program data to the device or erase memory , the

system must drive WE and CE to VIL, and OE to VIH.

An erase operation can erase the entire device. The

"Writing specific address and data commands or

sequences into the command register initiates device

operations. Table 1 defines the valid register command

sequences. Writing incorrect address and data values or

writing them in the improper sequence resets the device

to reading array data."section has details on erasing the

entire chip.

After the system writes the autoselect command

sequence, the device enters the autoselect mode. The

system can then read autoselect codes from the internal

reqister (which is separate from the memory array) on

Q15-Q0. Standard read cycle timings apply in this mode.

Refer to the Autoselect Mode and Autoselect Command

Sequence section for more information.

ICC2 in the DC Characteristics table represents the active

current specification for the write mode. The "AC

Characteristics" section contains timing specification

table and timing diagrams for write operations.

STANDBY MODE

MX26L6420 can be set into Standby mode with two different approaches. One is using both CE and RESET

pins and the other one is using RESET pin only .

When using both pins of CE and RESET, a CMOS

Standby mode is achieved with both pins held at Vcc ±

0.3V . Under this condition, the current consumed is less

than 50uA (typ.). If both of the CE and RESET are held

at VIH, b ut not within the range of VCC ± 0.3V , the de vice

will still be in the standby mode, but the standby currect

will be larger. During Auto Algorithm operation, Vcc active current (Icc2) is required even CE = "H" until the

operation is complated. The de vice can be read with standard access time (tCE) from either of these standby

modes.

When using only RESET, a CMOS standby mode is

achieved with RESET input held at Vss ± 0.3V, Under

this condition the current is consumed less than 50uA

(typ.). Once the RESET pin is taken high,the device is

back to active without recovery delay.

In the standby mode the outputs are in the high impedance state, independent of the OE input.

MX26L6420 is capable to provide the Automatic Standby

Mode to restrain power consumption during read-out of

data. This mode can be used eff ectively with an application requested low power consumption such as handy

terminals.

To active this mode, MX26L6420 automatically switch

themselves to low power mode when MX26L6420 addresses remain stable during access time of tACC+30ns.

It is not necessary to control CE, WE, and OE on the

mode. Under the mode, the current consumed is typically 50uA (CMOS level).

OUTPUT DISABLE

With the OE input at a logic high level (VIH), output from

the devices are disabled. This will cause the output pins

to be in a high impedance state.

P/N:PM0823

REV. 0.5, JAN. 29, 2002

7

MX26L6420

RESET OPERATION

The RESET pin provides a hardware method of resetting

the device to reading arra y data. When the RESET pin is

driven low for at least a period of tRP, the device

immediately terminates any operation in progress,

tristates all output pins, and ignores all read/write

commands for the duration of the RESET pluse. The

device also resets the internal state machine to reading

array data. The operation that was interrupted should be

reinitated once the device is ready to accept another

command sequence, to ensure data integrity

Current is reduced for the duration of the RESET pulse.

When RESET is held at VSS±0.3V, the device draws

CMOS standby current (ICC4). If RESET is held at VIL

but not within VSS±0.3V, the standby current will be

greater.

The RESET pin may be tied to system reset circuitry . A

system reset would that also reset the MTP EPROM.

Refer to the AC Characteristics tables for RESET

parameters and to Figure 14 for the timing diagram.

SILICON ID READ OPERATION

Table 3

VCC / VI/O V oltage Range

Part No. VCC=2.7V to 3.6VVCC=2.7V to 3.6V

VI/O=2.7V to 3.6VVI/O=1.65V to 2.6V

MX26L6420-90 90ns 100ns

MX26L6420-12 120ns 130ns

Notes: T ypical v alues measured at VCC=2.7V to 3.6V,

VI/O=2.7V to 3.6V

DATA PROTECTION

The MX26L6420 is designed to offer protection against

accidental erasure or programming caused by spurious

system level signals that may exist during power transition. During power up the device automatically resets

the state machine in the Read mode. In addition, with

its control register architecture, alteration of the memory

contents only occurs after successful completion of specific command sequences. The device also incorporates

several features to prevent inadvertent write cycles resulting from VCC pow er-up and power-down transition or

system noise.

MTP EPROM are intended for use in applications where

the local CPU alters memory contents. As such, manufacturer and device codes must be accessible while the

device resides in the target system. EPROM programmers typically access signature codes by raising A9 to

a high voltage. How ever , multiple xing high voltage onto

address lines is not generally desired system design practice.

MX26L6420 provides hardware method to access the

silicon ID read operation. Which method requires VID on

A9 pin, VIL on CE, OE, A6, and A1 pins. Which apply

VIL on A0 pin, the device will output MXIC's manufacture code of C2H. Which apply VIH on A0 pin, the device

will output MX26L6420 device code of 22FCH.

VI/O PIN OPERATION

MX26L6420 is capable to provide the I/O prower supply

(VI/O) pin to control Input/Output voltage levels of the

device. The data outputs and voltage tolerated at its data

input is determined by the voltage on the VI/O pin. This

device is allows to operate in 1.8V or 3V system as required.

SECURED SILICON SECTOR

The MX26L6420 features a Flash memory region where

the system may access through a command sequence

to create a permant part identification as so called Electronic Serial Number (ESN) in the device. Once this region is programmed, any further modification on the region is impossible. The secured silicon sector is a 512

words in length, and uses a Secured Silicon Sector Indicator Bit (Q7) to indicate whether or not the Secured

Silicon Sector is locked when shipped from the f actory.

This bit is permanently set at the factory and cannot be

changed, which prevent duplication of a factory locked

part. This ensures the security of the ESN once the product is shipped to the field.

The MX26L6420 offers the device with Secured Silicon

Sector either factory locked or custor lockab le. The factory-locked version is always protected when shipped

from the factory , and has the Secured Silicon Sector

Indicator Bit permanently set to a "1". The customerlockable version is shipped with the Secured Silicon

Sector unprotected, allowing customer to utilize that sector in any form they pref er . The customer-loc kable v er-

P/N:PM0823

REV. 0.5, JAN. 29, 2002

8

MX26L6420

sion has the secured sector Indicator Bit permanently

set to a "0". Therefore, the Secured Silicon Sector Indicator Bit permanently set to a "0". Therefore, the Second

Silicon Sector Indicator Bit prevents customer, lockable

device from being used to replace devices that are factory locked.

The system access the Secured Silicon Sector through

a command sequence (refer to "Enter Secured Silicon/

Exit Secured Silicon Sector command Sequence). After

the system has written the Enter Secured Silicon Sector

command sequence, it may read the Secured Silicon

Sector by using the address normally occupied by the

address 000000h-0001FFh. This mode of operation continues until the system issues the Exit Secured Silicon

Sector command sequence, or until power is removed

from the device. On power-up, or following a hardware

reset, the device rever ts to sending command to address 000000h-0001FFFh.

LOW VCC WRITE INHIBIT

When VCC is less than VLKO the device does not accept any write cycles. This protects dataduring VCC

power-up and power-do wn. The command register and

all internal program/erase circuits are disabled, and the

device resets. Subsequent writes are ignored until VCC

is greater thanVLK O. The system must provide the proper

signals to the control pins to prevent unintentional write

when VCC is greater than VLK O.

FACTORY LOCKED:Secured Silicon Sector

Programmed and Protected At the Factory

In device with an ESN, the Secured Silicon Sector is

protected when the device is shipped from the factory.

The Secured Silicon Sector cannot be modified in any

way . A f actory locked device has an 8-word random ESN

at address 000000h-000007h.

CUSTOMER LOCKABLE:Secured Silicon

Sector NOT Programmed or Protected At the

Factory

As an alternative to the factory-locked version, the device

may be ordered such that the customer may program

and protect the 512-word Secured Silicon Sector.

Programming and protecting the Secured Silicon Sector

must be used with caution since, once protected, there

is no procedure available for unprotecting the Secured

Silicon Sector area and none of the bits in the Secured

Silicon Sector memory space can be modified in any

way.

The Secured Silicon Sector area can be protected using

the following procedures:

Write the three-cycle Enter Secured Silicon Sector Region

command sequence. This allows in-system protection

of the Secured Silicon Sector without raising any device

pin to a high voltage. Note that method is only applicable

to the Secured Silicon Sector.

WRITE PULSE "GLITCH" PROTECTION

Noise pulses of less than 5ns(typical) on CE or WE will

not initiate a write cycle.

LOGICAL INHIBIT

Writing is inhibited by holding any one of OE = VIL, CE =

VIH or WE = VIH. To initiate a wr ite cycle CE and WE

must be a logical zero while OE is a logical one.

POWER-UP SEQUENCE

The MX26L6420 powers up in the Read only mode. In

addition, the memory contents may only be altered after

successful completion of the predefined command sequences.

P/N:PM0823

Once the Secured Silicon Sector is programmed, locked

and verified, the system must write the Exit Secured

Silicon Sector Region command sequence to return to

reading and writing the remainder of the array .

REV. 0.5, JAN. 29, 2002

9

SOFTWARE COMMAND DEFINTIONS

MX26L6420

Device operations are selected by writing specific ad-

will reset the device(when applicable).

dress and data sequences into the command register.

Writing incorrect address and data values or writing them

in the improper sequence will reset the device to the

read mode. Table 4 defines the valid register command

All addresses are latched on the falling edge of WE or

CE, whichever happens later . All data are latched on rising edge of WE or CE, whiche ver happens first.

sequences. Either of the two reset command sequences

TABLE4. MX26L6420 COMMAND DEFINITIONS

First Bus Second Bus Third Bus Fourth Bus Fifth Bus Sixth Bus

Command Bus Cycle Cycle Cycle Cycle Cycle Cycle

Cycle Addr Data Addr Data Addr Data Addr Data Addr Data Addr Data

Read(Note 5) 1 RA RD

Reset(Note 6) 1 XXX F0

Autoselect(Note 7)

Manufacturer ID 4 555 AA 2AA 55 555 90 X00 C2

Device ID 4 555 AA 2AA 55 555 90 X01 22FC

Secured Sector 4 55 5 AA 2AA 55 555 90 x0 3 see

Factory Protect Note9

Enter Secured Silicon 3 55 5 AA 2AA 55 5 55 88

Sector

Exit Secured Silicon 4 55 5 AA 2AA 55 5 55 9 0 xxx 00

Sector

Porgram 4 555 AA 2AA 55 5 55 A0 PA PD

Chip Erase 6 55 5 AA 2 AA 5 5 55 5 8 0 55 5 AA 2AA 55 5 55 10

Legend:

X=Don't care

RA=Address of the memory location to be read.

PD=Data to be programmed at location PA. Data is

latched on the rising edge of WE or CE pulse.

RD=Data read from location RA during read operation.

P A=Address of the memory location to be programmed.

Addresses are latched on the falling edge of the WE or

CE pulse.

Notes:

1.See Table 1 for descriptions of bus operations.

2.All values are in hexadecimal.

3.Except when reading array or autoselect data, all bus cycles are write operation.

4.Address bits are don't care for unlock and command cycles, e xcept when PA is required.

5.No unlock or command cycles required when device is in read mode.

6.The Reset command is required to return to the read mode when the device is in the autoselect mode or if Q5 goes

high.

7.The fourth cycle of the autoselect command sequence is a read cycle.

8.In the third and fourth cycles of the command sequence, set A21=0.

8.Command is valid when device is ready to read array data or when device is in autoselect mode.

9.The data is 88h for factory locked and 08h for non-factory locked.

P/N:PM0823

10

REV. 0.5, JAN. 29, 2002

MX26L6420

READING ARRAY DATA

The device is automatically set to reading array data

after device power-up. No commands are required to

retrieve data. The device is also ready to read arra y data

after completing an Automatic Program or Automatic

Erase algorithm.

The system must issue the reset command to re-enable the device for reading array data if Q5 goes high, or

while in the autoselect mode. See the "Reset Command"

section, next.

RESET COMMAND

Writing the reset command to the device resets the

device to reading array data. Address bits are don't care

for this command.

The reset command may be written between the sequence cycles in an erase command sequence before

erasing begins. This resets the device to reading array

data. Once erasure begins, however, the device ignores

reset commands until the operation is complete.

The reset command may be written between the sequence cycles in a program command sequence before

programming begins. This resets the device to reading

array data. Once programming begins ,howe ver , the device

ignores reset commands until the operation is complete.

by writing two unlock cycles, followed by the SILICON

ID READ command. The device then enters the SILICON

ID READ mode, and the system may read at any address

any number of times, without init iating another command

sequence. A read cycle at address XX00h retrieves the

manufacturer code. A read cycle at address XX01h re-

turns the device code.

The system must write the reset command to exit the

autoselect mode and return to reading array data.

WORD PROGRAM COMMAND SEQUENCE

The command sequence requires four bus cycles, and

is initiated by writing two unlock write cycles, followed

by the program set-up command. The program address

and data are written next, which in turn initiate the

Embedded Program algorithm. The system is

to provide further controls or timings. The device

automatically generates the program pulses and verifies

the programmed cell margin. Table 4 shows the address

and data requirements for the byte program command

sequence.

When the Embedded Program algorithm is complete, the

device then returns to reading array data and addresses

are no longer latched. The system can determine the

status of the program operation by using Q7, Q6. See

"Write Operation Status" for information on these status

bits.

not required

The reset command may be written between the sequence cycles in an SILICON ID READ command

sequence. Once in the SILICON ID READ mode, the

reset command

data.

If Q5 goes high during a program or erase operation,

writing the reset command returns the device to reading

array data.

must be written to return to reading array

SILICON ID READ COMMAND SEQUENCE

The SILICON ID READ command sequence allows the

host system to access the manufacturer and devices

codes, and determine whether or not. Table 4 shows the

address and data requirements. This method is an

alternative to that shown in Table 1, which is intended for

EPROM programmers and requires VID on address bit

A9.

The SILICON ID READ command sequence is initiated

P/N:PM0823

Any commands written to the device during the Em-

bedded Program Algorithm are ignored. Note that a

hardware reset immediately terminates the programming

operation. The Word Program command sequence should

be reinitiated once the device has reset to reading array

data, to ensure data integrity.

Programming is allowed in any sequence. A bit cannot

be programmed from a "0" back to a "1". Cause the Data

Polling algorithm to indicate the operation w as successful.

However, a succeeding read will show that the data is

still "0". Only erase operations can convert a "0" to a

"1".

REV. 0.5, JAN. 29, 2002

11

MX26L6420

ACCELERATED PROGRAM OPERATIONS

The device offers accelerated program operations through

the ACC pin. When the system asserts VHH on the ACC

pin, the device automatically bypass the two "Unlock"

write cycle. The device uses the higher voltage on the

ACC pin to accelerate the operation. Note that the ACC

pin must not be at VHH any operation other than accelerated

programming, or device damage may result.

SETUP AUTOMATIC CHIP ERASE

Chip erase is a six-bus cycle operation. There are two

"unlock" write cycles. These are f ollowed b y writing the

"set-up" command 80H. Two more "unlock" write cycles

are then followed by the chip erase command 10H.

The MX26L6420 contains a Silicon-ID-Read operation to

supplement traditional PROM programming methodology.

The operation is initiated by writing the read silicon ID

command sequence into the command register. Follo wing the command write, a read cycle with A6=VIL,

A1=VIL, A0=VIL retrieves the manufacturer code of C2H.

A read cycle with A6=VIL, A1=VIL, A0=VIH returns the

device code of 22FCH for MX26L6420.

AUTOMATIC CHIP ERASE COMMAND

The device does not require the system to preprogram

prior to erase. The A utomatic Erase algorithm automati-

cally preprograms and verifies the entire memory for an

all zero data pattern prior to electrical erase. The system

is not required to provide any controls or timings during

these operations. Table 4 shows the address and data

requirements for the chip erase command sequence.

Any commands written to the chip during the Automatic

Erase algorithm are ignored. Note that a hardware reset

during the chip erase operation immediately terminates

the operation. The Chip Erase command sequence should

be reinitiated once the device has returned to reading

array data, to ensure data integrity.

The system can determine the status of the erase op-

eration by using Q7, Q6. See "Write Operation Status"

for inf ormation on these status bits. When the Automatic

Erase algorithm is complete, the device returns to read-

ing array data and addresses are no longer latched.

Figure 5 illustrates the algorithm for the erase opera-

tion.See the Erase/Program Operations tables in "AC

Characteristics" for parameters, and to Figure 4 for tim-

ing diagrams.

TABLE 5. SILICON ID CODE

Pins A0 A1 A6 Q15 Q7 Q6 Q5 Q4 Q3 Q2 Q1 Q0 Code(Hex)

|

Q8

Manufacture code VIL VIL VIL 00 H 1 1 0 0 001000C2H

Device code for MX26L6420 VIH VIL VIL 22 H 1 1 1 1 111022FCH

P/N:PM0823

12

REV. 0.5, JAN. 29, 2002

Loading...

Loading...