MUTOH XpertJet XPJ-1641SR, XpertJet XPJ-1682SR Training Manual

Training Manual

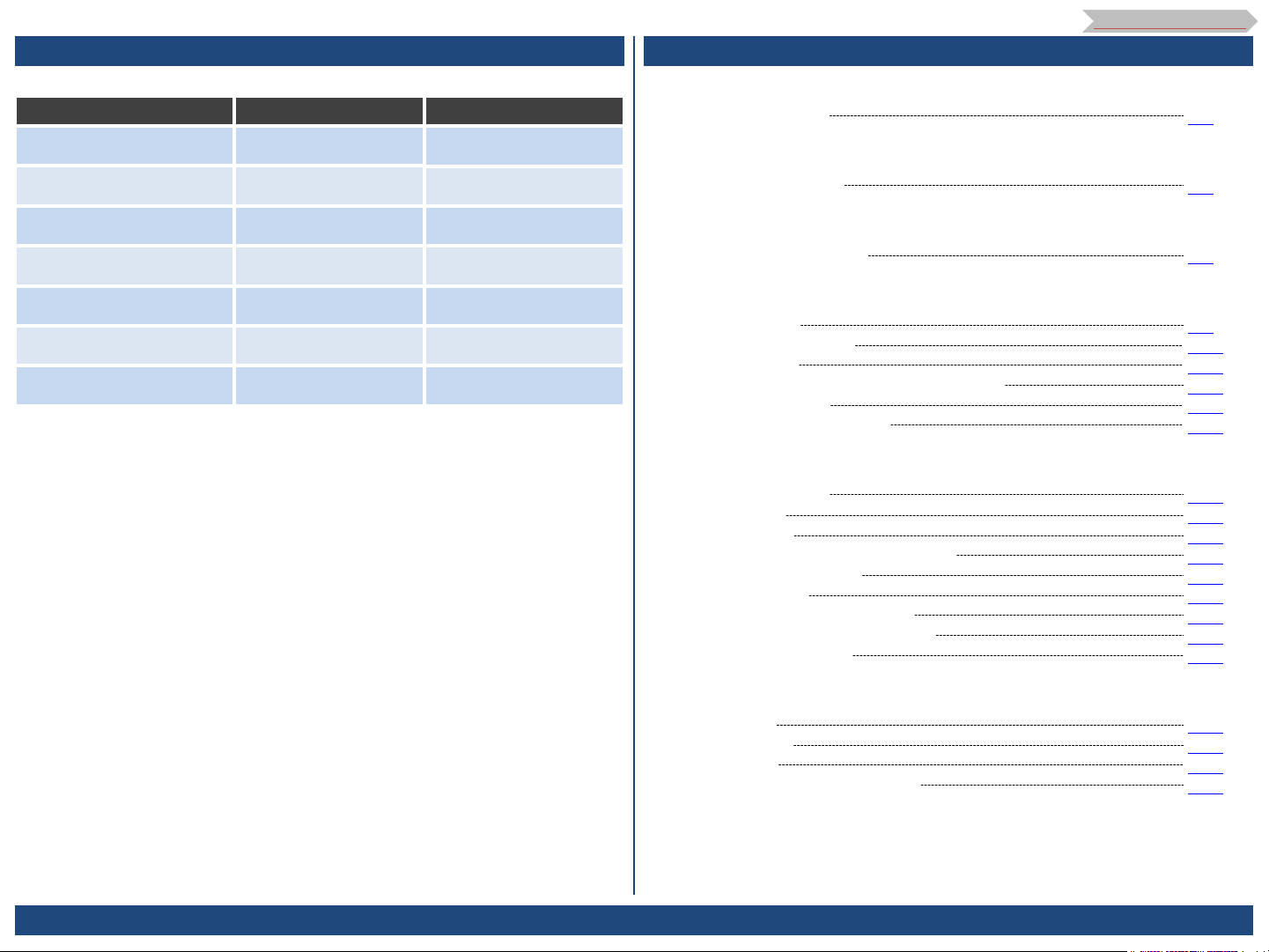

History

Rev.

Date

To Table of Contents

Date

1.00

26.July.2019

◆First version

Rev.1.00

26.July.2019

MUTOH INDUSTRIES LTD

CSTM-XPJ16xxSR(E)_1.00 CONFIDENTIAL Page.

1

Reference

Table of contents (1/2)

To Table of Contents

Reference Material

Item

Operation Manual

Installation Manual

(Startup Guide)

Maintenance Manual

[XPJ-1641SR]

Maintenance Manual

[XPJ-1682SR]

Main Firmware

[XPJ-1641SR]

Main Firmware

[XPJ-1682SR]

H-CONT Firmware

[XPJ-1641SR/XPJ-1682SR]

Number

XPJ16xxSRE-A-01

XPJ16xxSRE-Q-01

XPJ1641SRE-M-00

XPJ1682SRE-M-00

XPJ1641SR_V100.jfl

XPJ1682SR_V100.jfl

new_misc_qj_V600.mfl

Remark

Language: English

Language: English

Language: English

Language: English

ver.1.00

ver.1.01

ver.6.00

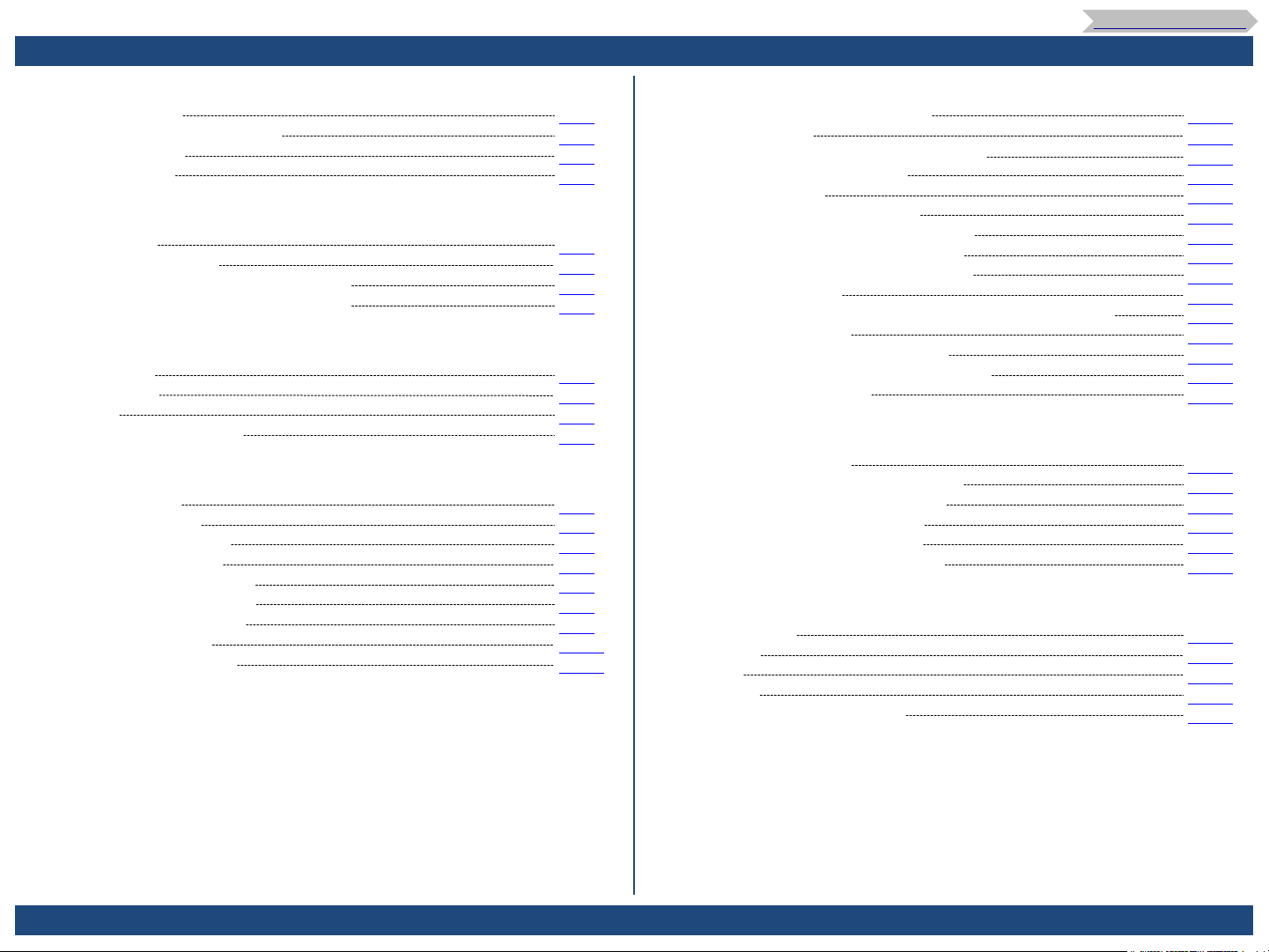

1.Product Feature

1.1.Product Feature P.4

2.Road Map

2.1.VJ&XPJ Road Map P.5

3.Specifications of this product

3.1. List of Specifications P.6

4.Introduction

4.1. Precautions P.9

4.2. Name of each part P.10

4.3. Front Panel P.13

4.4. System Configurations of this product P.15

4.5. Warning Labels P.16

4.6. Instruction Precautions P.18

5.Unpacking and Initial Setup

5.1.Site Preparation P.19

5.2.Unpacking P.20

5.3.Assembling P.23

5.4. Connecting Power and Network P.26

5.5. Printer Initial Setup P.28

5.6. Test Printing P.34

5.7. Nozzle check and cleaning P.39

5.8. Setting the Printing Precision P.40

5.9. Advanced settings P.52

CSTM-XPJ16xxSR(E)_1.00 CONFIDENTIAL Page.

6.Ink

6.1.MS41 ink P.55

6.2.Ink System P.56

6.3.Sub Tank P.58

6.4.Error Message display (Ink) P.59

2

Table of contents (2/2)

13.5. Periodic Maintenance Kit (1/1)

To Table of Contents

7.Carriage

7.1.Carriage Assy P.60

7.2.Changing the Head Height P.61

7.3.Cutting media P.61

7.4.Color Sensor P.63

8.Print Head

8.1.Print Head P.65

8.2.Maintenance Parts P.66

8.3.Replacing print head [XPJ-1641SR] P.68

8.4.Replacing print head [XPJ-1682SR] P.70

9.Printing

9.1.User Type P.72

9.2.Print Mode

9.3.Effect P.79

9.4.Recommended Media P.80

10.Advanced Operations

10.1.Introduction P.81

10.2.Menu 1: Setup P.84

10.3.Menu 2: Test Print P.96

10.4.Menu 3: Cleaning P.97

10.5.Menu 4: Menu Option P.98

10.6.Menu 5: System Info. P.99

10.7.Menu 6: Sleep Mode P.99

10.8.Menu 7: Display P.100

10.9.Menu 8: Job Status P.101

P.76

11.User Maintenance

11.1.Instruction Before Purchase P.102

11.2.Maintenance P.103

11.3.Checking ink and replacing ink bag P.103

11.4.Emptying waste ink tank P.106

11.5.Head cleaning P.107

11.6.Cleaning of cleaning wiper P.108

11.7.Cleaning around the capping unit P.110

11.8.Cleaning around the print head P.111

11.9.Cleaning around the color sensor P.112

11.10.Inside cleaning P.114

11.11.Replacing absorption material for the flushing box P.115

11.12.Replacing cutter P.117

11.13.Replacing the cleaning wiper P.118

11.14.Moving or transporting the printer P.120

11.15.Long-term storage P.121

12.Engineer Maintenance

12.1.Removing Covers P.125

12.2.Electric Wiring Diagram [Board] P.134

12.3.Electric Wiring Diagram [FFC] P.135

12.4.Lifetime replacement parts P.137

12.5.Periodic replacement parts P.137

12.6.Self-Diagnosis Function Mode P.138

13.Maintenance Parts

13.1.Print Head P.145

13.2.Board P.146

12.3.FFC P.148

13.4.Motor P.149

13.5.Periodic Maintenance Kit P.150

CSTM-XPJ16xxSR(E)_1.00 CONFIDENTIAL Page.

3

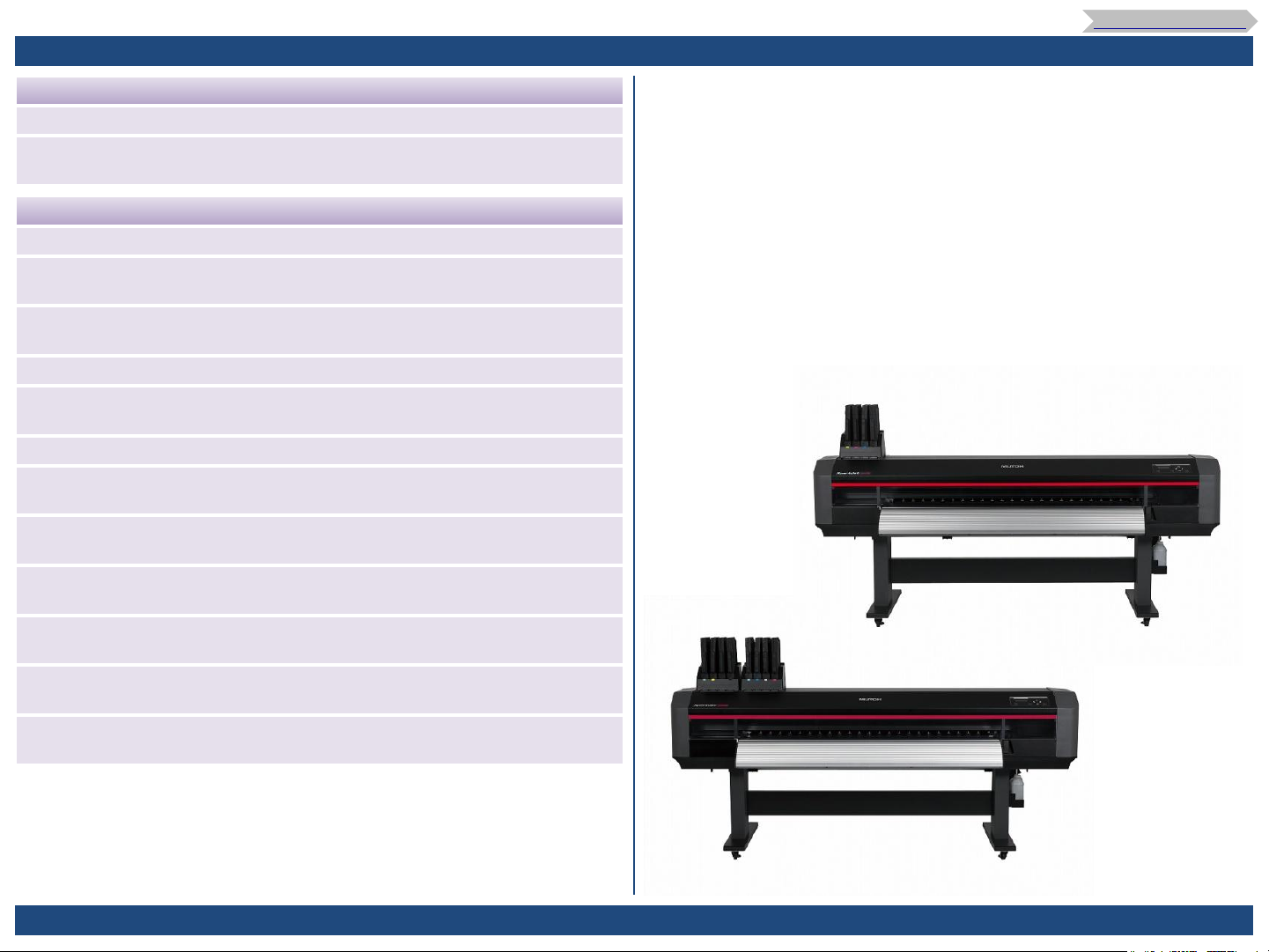

1. Product Feature

1.1. Product Feature

Product Outline

◇ Successor model to VJ-1624X and VJ-1638X.

◇ Adopted a new platform which gives flexibility to develop water-based printer,

UV printer, or printer with new print head.

Product Feature

◆ The new cosmetic refreshes the look of VJ printer series.

◆ The new capacitive touch switch improves visibility and operability to light up

active keys by LED.

◆ The new MS41 eco-solvent ink achieves cost reduction and maintains the

same print quality as conventional ink.

◆ High-capacity ink holder with front access improves usability.

◆ Both operation panel and MSM remote panel support multiple languages (8

languages).

◆ The new spindle less roll media holder allows hassle-free media replacement.

◆ The main board box is located on the rear of the printer to improve

operability and provide easy cable connection without blocking media path.

◆ The built-in color sensor achieves automatic Bi-D adjustment to reduce

calibration time and variation between operators.

To Table of Contents

◆ Offer two lineups; the single head printer for first-time user, the dual head

printer for high productivity.

◆ The individual head cleaning mode is available in the dual head printer to

reduce ink loss.

◆ The print platform LED lighting improves visibility for maintenance and print

inspection during printing.

◆ Two types of ink adapters are available; existing 2000 ml ink bag case and

newly developed 1000 ml ink bag case.

CSTM-XPJ16xxSR(E)_1.00 CONFIDENTIAL Page.

XpertJet

XPJ-1641SR

XpertJet

XPJ-1682SR

4

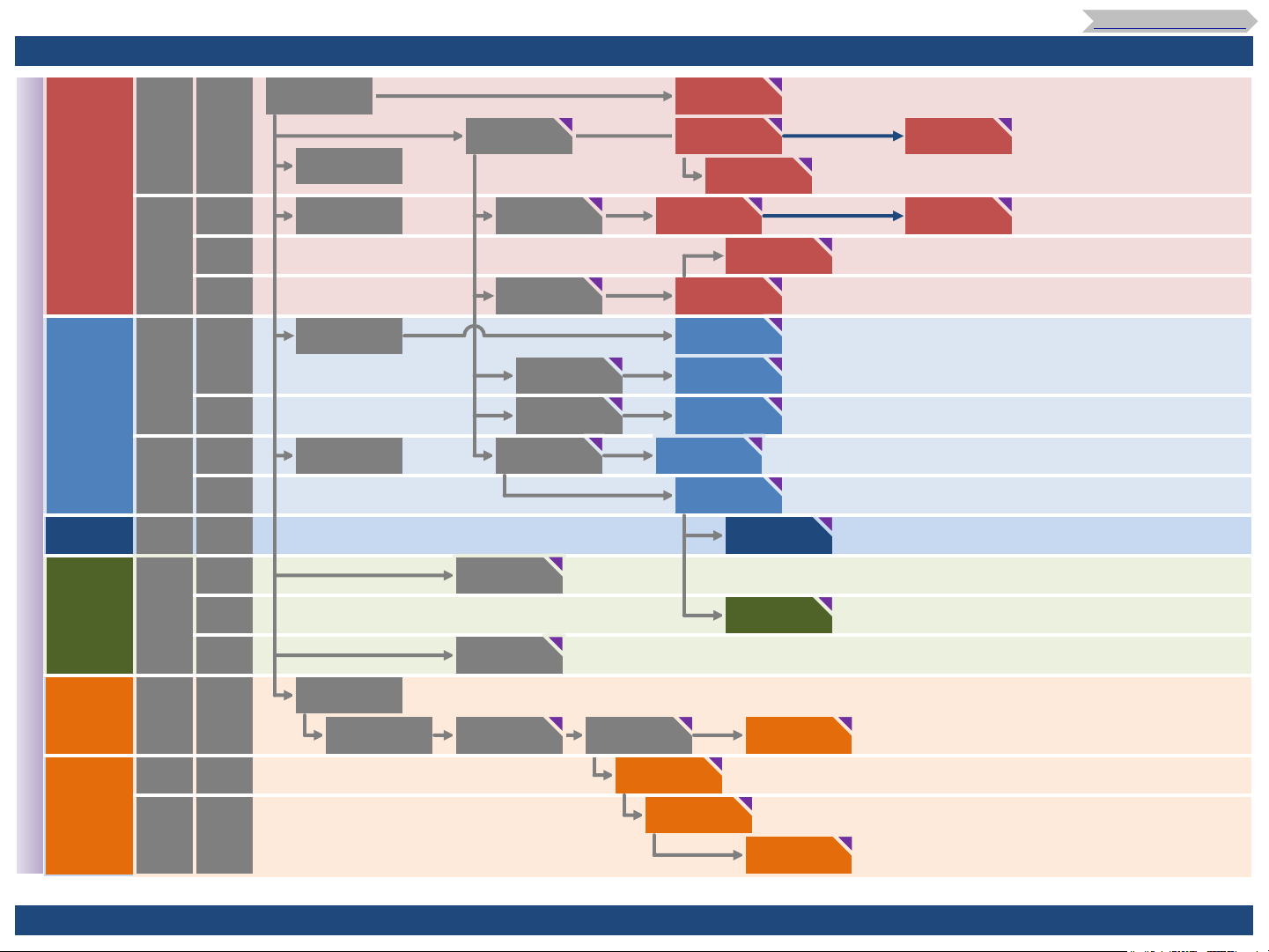

2. Road Map

2.1. VJ&XPJ Road Map

To Table of Contents

Eco

Solvent

Aqueous

Dye-

Sublimation

Textile

VJ&XPJ series 【System more than 1.6m】

MP

UV

Single

head

Double

head

Single

head

Double

head

Four

head

Double

head

Single

head

Single

head

Double

head

1.6m

1.6m

1.9m

2.6m

1.6m

1.9m

1.6m

1.9m

1.9m

1.6m

1.9m

2.6m

1.6m

1.6m

1.6m

VJ-1604

IH-47V [2006]

VJ-1614

IH-47V [2007]

VJ-1618

IA0460 [2007]

VJ-1604W

IH-47V [2007]

VJ-1618W

IA0460 [2007]

VJ-1608

IH-47V [2007]

VJ-1608H

IA0460 [2009]

VJ-1624

IA5540 [2011]

VJ-1638

IA5540 [2011]

VJ-2638

IA5540 [2011]

VJ-1624W

IA5540 [2012]

VJ-1924W

IA5540 [2012]

VJ-1638W

IA5540 [2011]

VJ-1628TD

IA5540 [2010]

VJ-2628TD

IA5540 [2010]

VJ-1608HS

IA0460 [2010]

VJ-1638X

IA5540 [2013]

VJ-1638WX

IA5540 [2013]

VJ-1617H

IA5540 [2012]

VJ-1626UH

IA5540 [2014]

VJ-1638UH

IA5540 [2016]

VJ-1604X

IH-47V [2015]

VJ-1624X

IA5540 [2015]

VJ-1628X

IA5540 [2015]

VJ-1938X

IA5540 [2016]

VJ-2638X

IA5540 [2015]

VJ-1604WX

IH-47V [2015]

VJ-1624WX

IA5540 [2015]

VJ-1924WX

IA5540 [2015]

VJ-1938WX

IA5540 [2015]

VJ-1948WX

IA5540 [2016]

VJ-1938TX

IA5540 [2016]

VJ-1627MH

IA5540 [2017]

VJ-1638UR

IA5540 [2017]

XPJ-1641SR

IA5540 [2019]

XPJ-1682SR

IA5540 [2019]

CSTM-XPJ16xxSR(E)_1.00 CONFIDENTIAL Page.

5

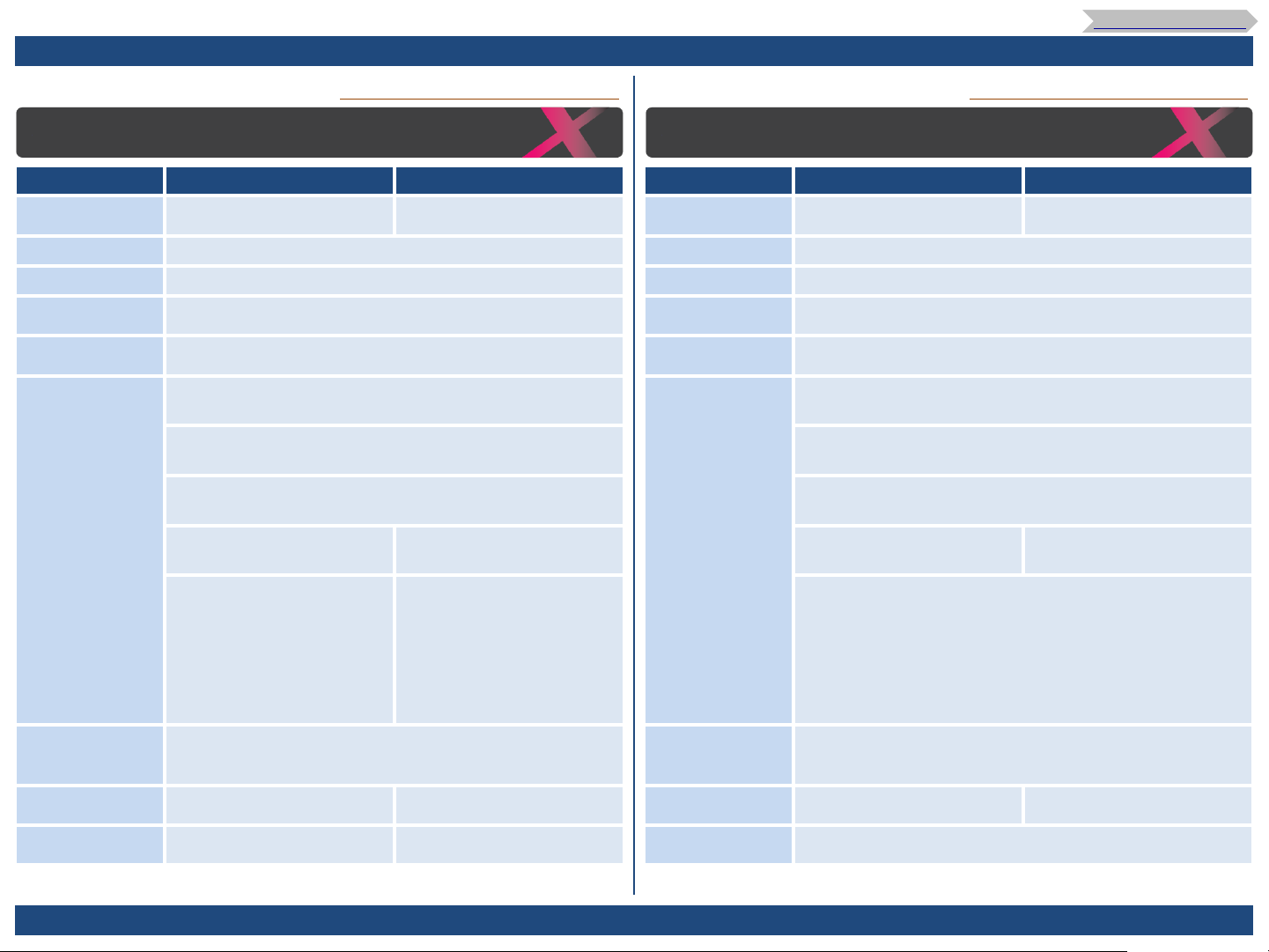

3. Specifications of this product

3.1. List of Specifications (1/3)

To Table of Contents

VJ-1624X vs XPJ-1641SR VJ-1638X vs XPJ-1682SR

Specifications of this product

item ValueJet (VJ-1624X) XpertJet (XPJ-1641SR) ValueJet (VJ-1638X) XpertJet (XPJ-1682SR)

Model Name VJ-1624X

Print method On demand piezo method On demand piezo method

Drive method Firmware servo/DC motor drive Firmware servo/DC motor drive

Media feed

method

Media hold down

system

Conditions of

usable

media

(S/N: HU6U******)

Multipoint pressurizing Grid roller system Multipoint pressurizing Grid roller system

Pressure roller down system by manual lever Pressure roller down system by manual lever

● Media outer diameter

Φ150mm or less

● Media core diameter

2inches or 3inches

● Weight

30kg or less

● Width

900mm ~ 1,625mm

● Maximum thickness

0.3mm(when the head

height is set to Low)

1.3mm(when the head

height is set to High)

cf. Operation Manual(Rev.01-p.161) cf. Operation Manual(Rev.01-p.161)

Specifications of this product

item

VJ-1641SR

(S/N: JF6U******)

●

Width ● Width

500mm ~ 1,625mm

●

Maximum thickness

0.3mm(when the head

height is set to Low)

1.3mm(when the head

height is set to Mid)

2.8mm(when the head

height is set to High)

Model Name

Print method

Drive method

Media feed

method

Media hold down

system

Conditions of

usable

media

VJ-1638X

(S/N: HF6U******)

● Media outer diameter

Φ150mm or less

● Media core diameter

2inches or 3inches

● Weight

30kg or less

900mm ~ 1,625mm

●

Maximum thickness

0.3mm(when the head height is set to Low)

1.3mm(when the head height is set to Mid)

2.8mm(when the head height is set to High)

VJ-1681SR

(S/N: JE6U******)

●

Width

500mm ~ 1,625mm

Maximum

Printable

Width

Maximum print

length

Head height

adjustment

1,615mm Maximum

200m 1,500m Maximum print

Two-level adjustment of Low

and High

Three-level adjustment of Low,

Mid, and High

CSTM-XPJ16xxSR(E)_1.00 CONFIDENTIAL Page.

Printable

Width

length

Head height

adjustment

6

1,615mm

200m 1,500m

Three-level adjustment of Low, Mid, and High

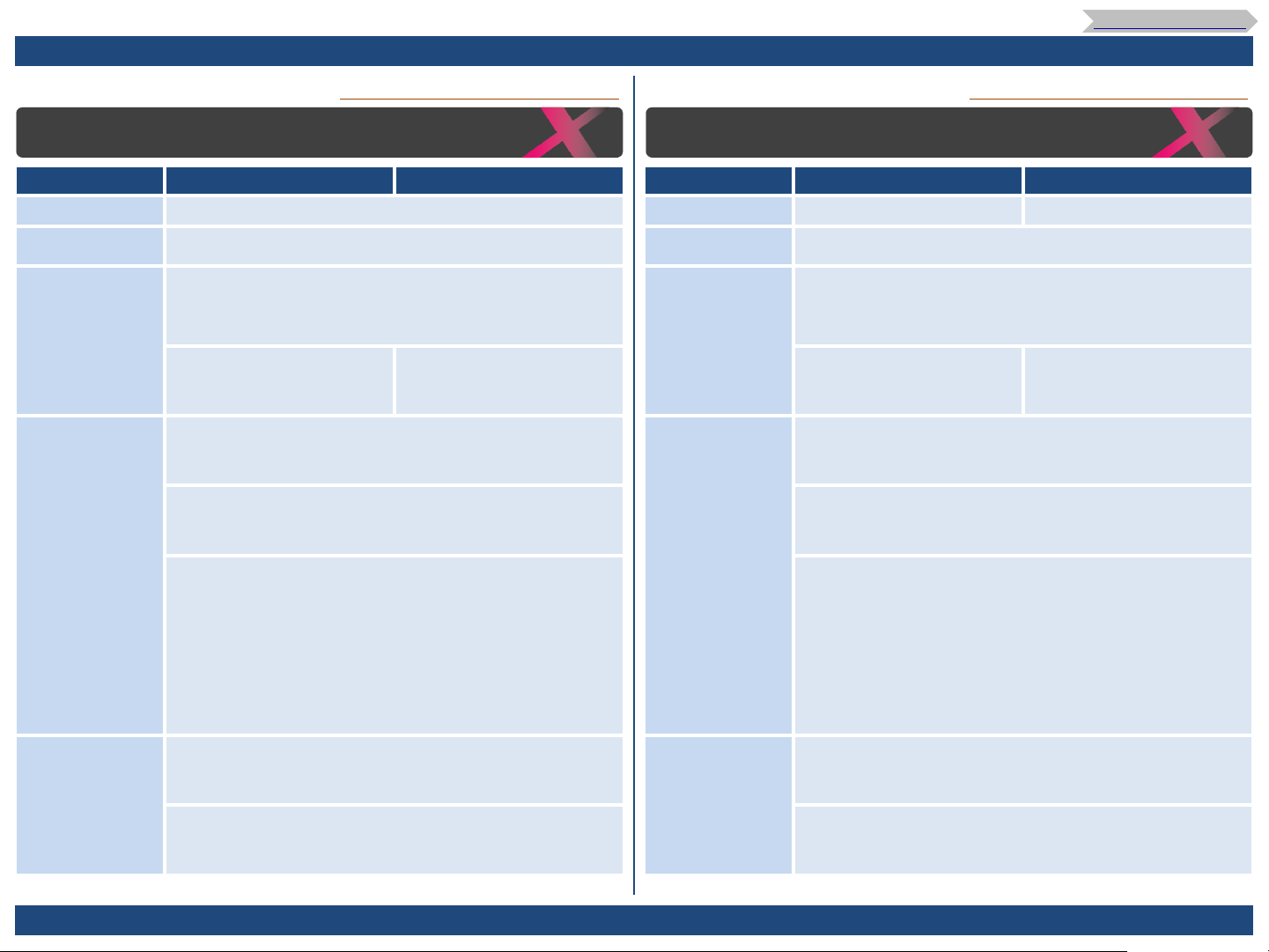

3. Specifications of this product

3.1. List of Specifications (2/3)

To Table of Contents

VJ-1624X vs XPJ-1641SR

cf. Operation Manual(Rev.01-p.161) cf. Operation Manual(Rev.01-p.161)

VJ-1638X vs XPJ-1682SR

Specifications of this product Specifications of this product

item ValueJet (VJ-1624X) XpertJet (XPJ-1641SR) item ValueJet (VJ-1638X) XpertJet (XPJ-1682SR)

Interface Ethernet(10/100BASE-TX) Interface Ethernet(10/100BASE-TX) Gb-Ethernet (1000BASE-T)

Waste ink tank 2,000ml tank is attached to the printer. Empty the tank when

Ink ● Color

Environmental

conditions

Power supply

specifications

needed.

4 colors (Black, Cyan, Magenta, Yellow)

● Type

220ml/440ml ink cartridge

1,000ml ink bag

● Printer Operation Environment

Temperature 20 to 32℃, humidity 40 to 60%

No condensation

● Recommended Printing Environment

Temperature 22 to 30℃, humidity 40 to 60%

No condensation

● Printer Storage Environment

Storage without ink charging: up to 6 months

Temperature -20 to +60℃, humidity 20 to 80%

No condensation

Storage with ink charging: up to 1 week

Temperature -10 to +40℃, humidity 20 to 60%

No condensation

Storage up to 4 days maximum when stored between

※

32℃ to 40℃ .

● MAIN

Voltage: AC 100V to 120V ±10% / AC 200V to 240V ±10%

Frequency: 50/ 60Hz ±1Hz

●

Type ● Type

1,000ml ink bag

(Cleaner is 300ml)

Waste ink tank 2,000ml tank is attached to the printer. Empty the tank when

Ink ● Color

Environmental

conditions

Power supply

specifications

needed.

4 colors (Black, Cyan, Magenta, Yellow)

7 colors (Black, Cyan, Magenta, Yellow, Light Cyan, Light

Magenta, Light Black)

●

Type

220ml/440ml ink cartridge

1,000ml ink bag

● Printer Operation Environment

Temperature 20 to 32℃, humidity 40 to 60%

No condensation

● Recommended Printing Environment

Temperature 22 to 30℃, humidity 40 to 60%

No condensation

● Printer Storage Environment

Storage without ink charging: up to 6 months

Temperature -20 to +60℃, humidity 20 to 80%

No condensation

Storage with ink charging: up to 1 week

Temperature -10 to +40℃, humidity 20 to 60%

No condensation

Storage up to 4 days maximum when stored between

※

32℃ to 40℃ .

● MAIN

Voltage: AC 100V to 120V ±10% / AC 200V to 240V ±10%

Frequency: 50/ 60Hz ±1Hz

1,000ml ink bag

(Cleaner is 300ml)

● HEATER

Voltage: AC 100V to 120V ±10% / AC 200V to 240V ±10%

Frequency: 50/ 60Hz ±1Hz

CSTM-XPJ16xxSR(E)_1.00 CONFIDENTIAL Page.

● HEATER

Voltage: AC 100V to 120V ±10% / AC 200V to 240V ±10%

Frequency: 50/ 60Hz ±1Hz

7

3. Specifications of this product

3.1. List of Specifications (3/3)

To Table of Contents

VJ-1624X vs XPJ-1641SR VJ-1638X vs XPJ-1682SR

cf. Operation Manual(Rev.01-p.162) cf. Operation Manual(Rev.01-p.162)

Specifications of this product Specifications of this product

item ValueJet (VJ-1624X) XpertJet (XPJ-1641SR) item ValueJet (VJ-1638X) XpertJet (XPJ-1682SR)

consumption

Power

consumption

● AC 100V to 120V ● AC 100V to 120V Current

MAIN: 12A or below

HEATER: 12A or below

MAIN: 10A or below

HEATER: 6.5A or below

● Operation

MAIN:

1100W or below

HEATER:

1200W or below

1,261 mm 1,428 mm

2,698mm 2,750 mm

885.5mm 895 mm

MAIN: 9A or below

HEATER: 10A or below

● AC 200V to 240V ● AC 200V to 240V

MAIN: 6A or below

HEATER: 5A or below

● Height ● Height Dimensions

● Width ● Width

● Depth ● Depth

consumption

Power

consumption

MAIN: 12A or below

HEATER: 12A or below

MAIN: 10A or below

HEATER: 6.5A or below

● Operation

MAIN:

1100W or below

HEATER:

1200W or below

1,261 mm 1,428 mm

2,698mm 2,750 mm

885.5mm 895 mm

● AC 100V to 120V ● AC 100V to 120V Current

MAIN: 9A or below

HEATER: 10A or below

● AC 200V to 240V ● AC 200V to 240V

MAIN: 6A or below

HEATER: 5A or below

● Height ● Height Dimensions

● Width ● Width

● Depth ● Depth

● Main body ● Main body Weight

126kg 142kg

● Stand ● Stand

34kg 32kg

CSTM-XPJ16xxSR(E)_1.00 CONFIDENTIAL Page.

● Main body ● Main body Weight

153kg 146kg

● Stand ● Stand

34kg 32kg

8

4. Introduction

4.1. Precautions (1/1)

cf. Operation Manual(Rev.01-p.20)

Introduction

Precautions

Please use this product at least once a week

If the printer is not used for a long time, the print head nozzles can get clogged

・

causing damage to the printer.

Please handle ink bag carefully

Before using an ink bag, make sure to read the Safety Data Sheet (SDS). ・

Do not disassemble Ink bag. ・

Ink may come into contact with your eyes or skin, causing irritation or allergic

reaction.

Wear protective gloves, glasses, and mask when handling ink bags. ・

Avoid contact with your eyes or on your skin. ・

If in your eye or on your skin, immediately wash with water.

It could cause bloodshot eyes or light inflammation.

Should any anomalies occur, immediately seek medical attention.

To Table of Contents

Conduct periodic maintenance

This product requires regular user maintenance.

Run a nozzle check before and after printing. ・

If nozzle missing is found, run a head cleaning.

Clean the cleaning wiper and around the print head once a week. ・

If you are not using the printer for an extended period*, run a head cleaning once

・

a week.

If you may not be able to perform weekly head cleaning, perform [Longstore]

*"Extended period" means one to four weeks.

Clean inside of your printer once a month. ・

Regularly check the waste ink tank and empty the tank as needed. ・

Some parts need to be replaced periodically

In this product, there are some parts required to be replaced after a long-term use.

User replaceable parts: Absorption material for the flushing box, Cutter, Cleaning

・

wiper

Parts required to be replaced by service personnel: Motors, Pumps, Print heads ・

DO NOT drop or hit an ink bag. ・

Ink may leak from the bag.

Be sure to use the ink before it expires. ・

The expired ink should be disposed of as industrial waste.

The empty ink bag should be put in a plastic bag and should be disposed of

according to the local regulations.

MUTOH strongly recommends to use genuine ink. ・

This printer is designed to bring out the best performance when using with the

MUTOH genuine ink.

Non-MUTOH ink may cause print defects or damage to the printer.

CSTM-XPJ16xxSR(E)_1.00 CONFIDENTIAL Page.

9

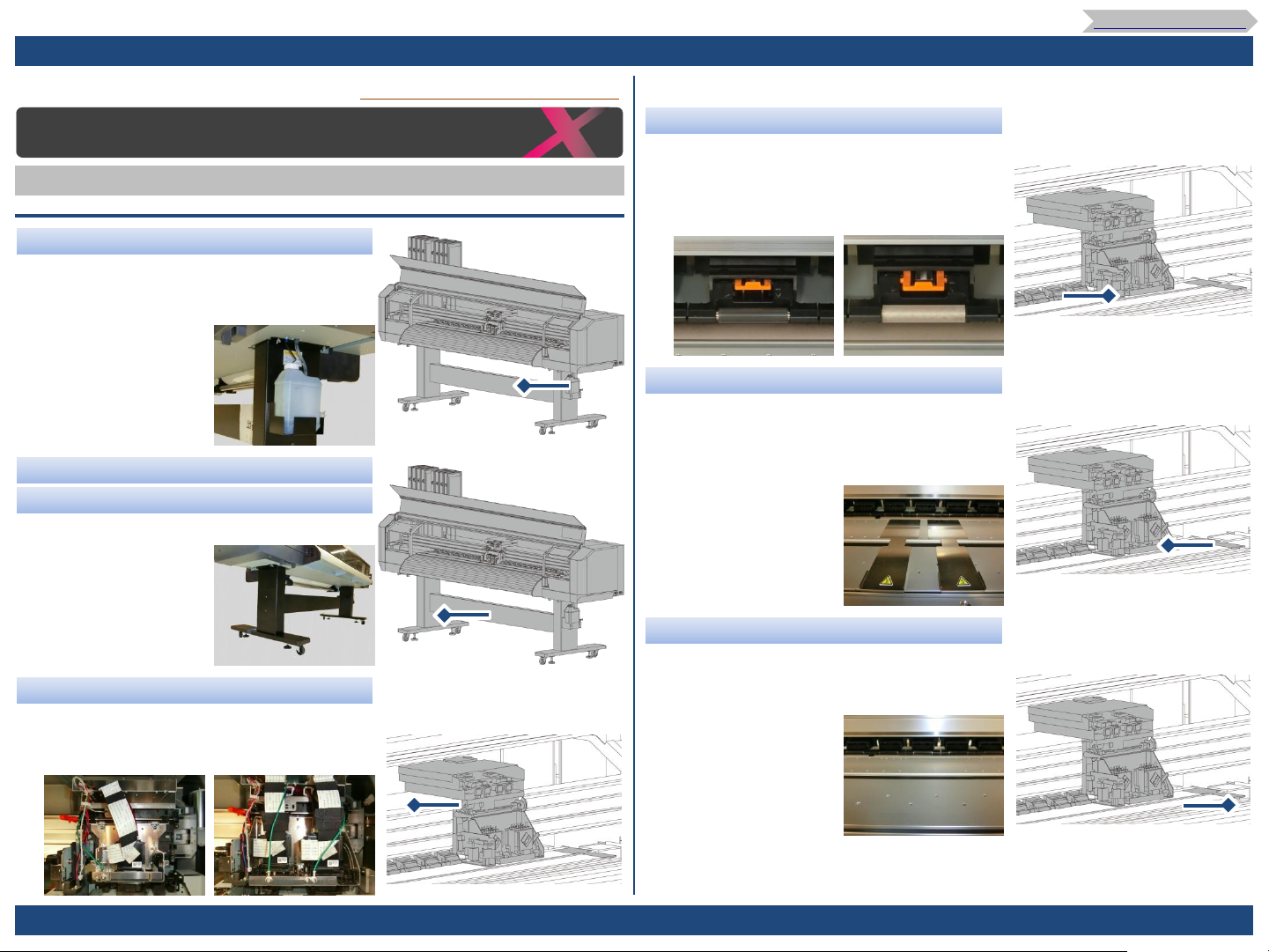

4. Introduction

4.2. Name of each part (1/4)

Introduction

Main components of your printer

Front side ◆

Front cover

Open this cover when loading a roll media or

removing a media jam.

It is normally closed.

Internal LED lights

The lights allows you to inspect inside of the

printer or your print during printing.

To Table of Contents

cf. Operation Manual(Rev.01-p.9)

Maintenance cover R

Open this cover for cleaning or replacing

consumables.

It is normally closed.

Media feed lever

Push the lever to lower the pressure rollers to

keep the media flat while printing.

Pull it to release the media.

The hold down pressure can be changed between

High and Normal using this lever.

Maintenance cover L

Open this cover for cleaning.

It is normally closed.

CSTM-XPJ16xxSR(E)_1.00 CONFIDENTIAL Page.

Media guide

Front media path that the heater is installed inside

to dry the print.

10

4. Introduction

4.2. Name of each part (2/4)

Introduction

Main components of your printer

Front side ◆

Waste ink tank

Collect waste ink produced during printing and

cleaning cycle.

Empty the tank as needed.

Stand

Adjuster

To Table of Contents

cf. Operation Manual(Rev.01-p.9)

Pressure rollers

Keep the media in place to ensure proper feeding.

The hold down pressure can be individually

reduced or canceled by slide lock levers on the

pressure rollers.

◆XPJ-1641SR ◆XPJ-1682SR

Edge holder

Place it on the edge of the media to prevent

media curl while printing.

While not printing, slide them to the left and right

side edges of the platen.

Carriage

The print head is installed on the carriage.

◆XPJ-1641SR ◆XPJ-1682SR

CSTM-XPJ16xxSR(E)_1.00 CONFIDENTIAL Page.

Platen

Media is printed on here.

There is an adsorption fan inside.

11

4. Introduction

4.2. Name of each part (3/4)

Introduction

Main components of your printer

Front side ◆

Cutter

Automatically cut the media after printing.

To Table of Contents

cf. Operation Manual(Rev.01-p.9)

Rear side ◆

Ink slots

Insert an ink bag case into the slot.

(Illustration: XPJ-1682SR)

◆XPJ-1641SR ◆XPJ-1682SR

Media cut groove

Manually cut the media along the groove.

CSTM-XPJ16xxSR(E)_1.00 CONFIDENTIAL Page.

Media feed slot

Insert the front edge of the media into this slot

and pass it to the front side to load it into the

printer.

Media guide

Pass a roll media through the media guide.

12

4. Introduction

4.2. Name of each part (4/4)

To Table of Contents

4.3. Front Panel (1/2)

cf. Operation Manual(Rev.01-p.10)

Introduction

Introduction

Main components of your printer Main components of your printer

Rear side ◆

Media feed lever

Hold down or release the media.

This lever is interlocked with the media feed lever

on the front side.

Roll media holder

Attach the media flanges to both ends of a roll

media and load it onto the roll media holder.

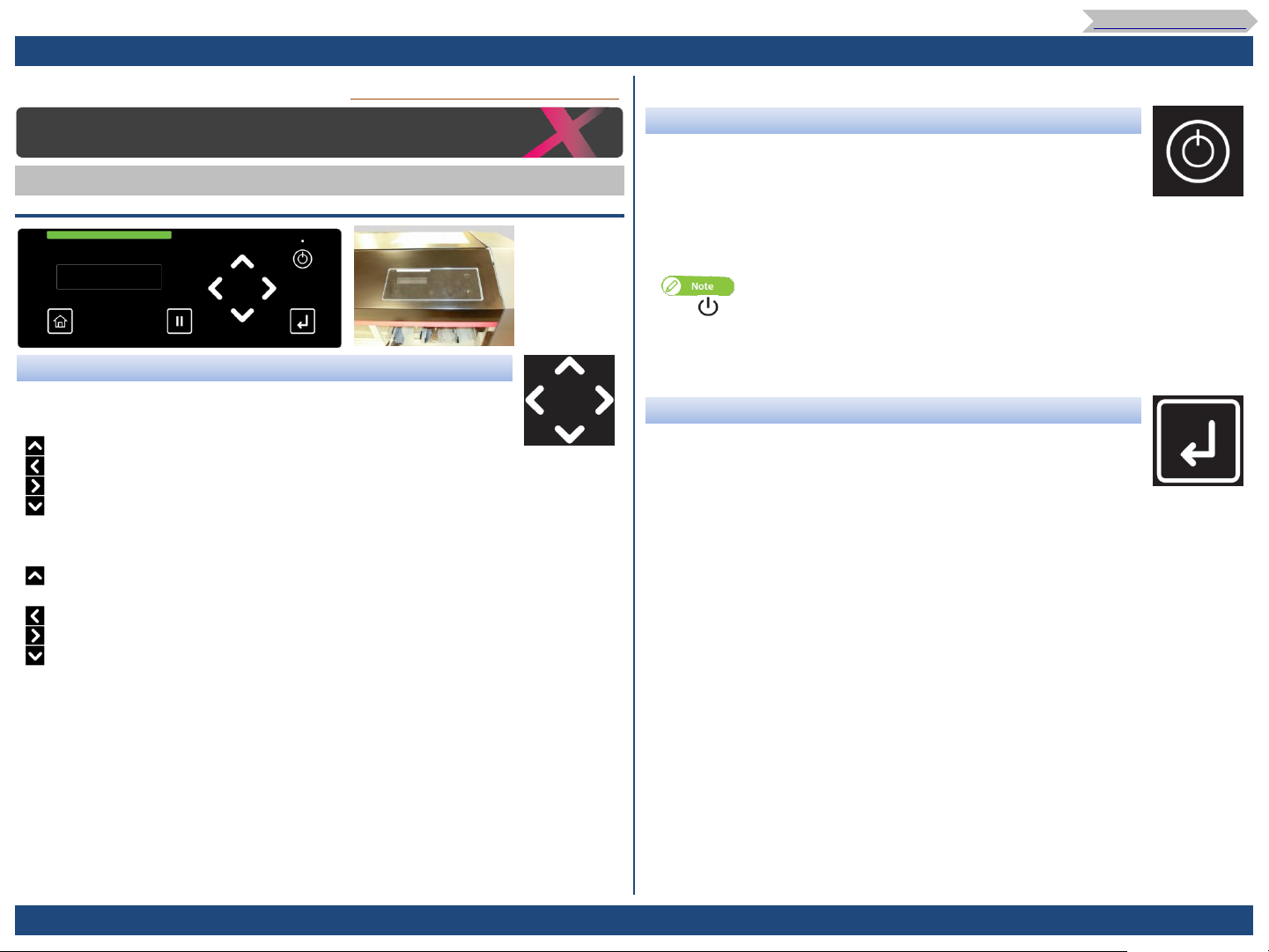

Front Panel ◆

The printer has a touch-screen panel located on the front right of the printer. The active

keys are lit up on the panel for guidance.

Tap: Lightly touch the key with your finger, then immediately release. ・

Long-touch: Keep touching the key. ・

①

②

③

Status Bar ①

Indicates the printer status by LED light.

Working normally: Solid green ・

Error/Alert state: Solid red (error) or flash red (alert) ・

Display ②

Displays the printer status, setting menu, errors and so on.

④

⑤

⑥

⑦

cf. Operation Manual(Rev.01-p.10)

AC inlet

Network interface cable connector

CSTM-XPJ16xxSR(E)_1.00 CONFIDENTIAL Page.

[Home] Key ③

Access to or exit the menu.

[Cancel] key ④

Pause the print job. While pausing, tap the key again to resume

・

printing.

While the printer is not printing, tap the key to cut the media. ・

13

4. Introduction

4.3. Front Panel (2/2)

Introduction

Main components of your printer

Front Panel ◆

①

⑥

cf. Operation Manual(Rev.01-p.11)

[Power] button ⑥

Long press to power on the printer. ・

The Power LED (above the Power button) turns on with a solid

white light.

While the power is on, long press the button to power off the

・

printer.

In the Off state, the Power LED lights off.

To Table of Contents

②

③

Arrow keys: ⑤

When you have entered the setup menu, the arrow keys are used to

select a menu or enter a value.

Go to the previous item.

key:

Return to the upper level menu without saving the change.

key:

Go to the sub menu.

key:

Go to the next item.

key:

While the printer is in standby mode, it is used to feed media, run a

nozzle check, or perform head cleaning.

Feed the media backward.

key:

Long-touch to feed it with high speed.

Tap to run a nozzle check.

key:

Tap to perform cleaning.

key:

Feed the media forward.

key:

Long-touch to feed it with high speed.

④

⑤

⑦

The symbol means “standby”.

Even the Power LED turns off, the device still consumes some power

unless the power cords are disconnected.

This state is referred to as the power being “off” in this Manual.

[Enter] key ⑦

Use the Enter key to select a menu or confirm a value.

While the printer warms up, tap the Enter key to start printing

・

immediately before fully warming up.

CSTM-XPJ16xxSR(E)_1.00 CONFIDENTIAL Page.

14

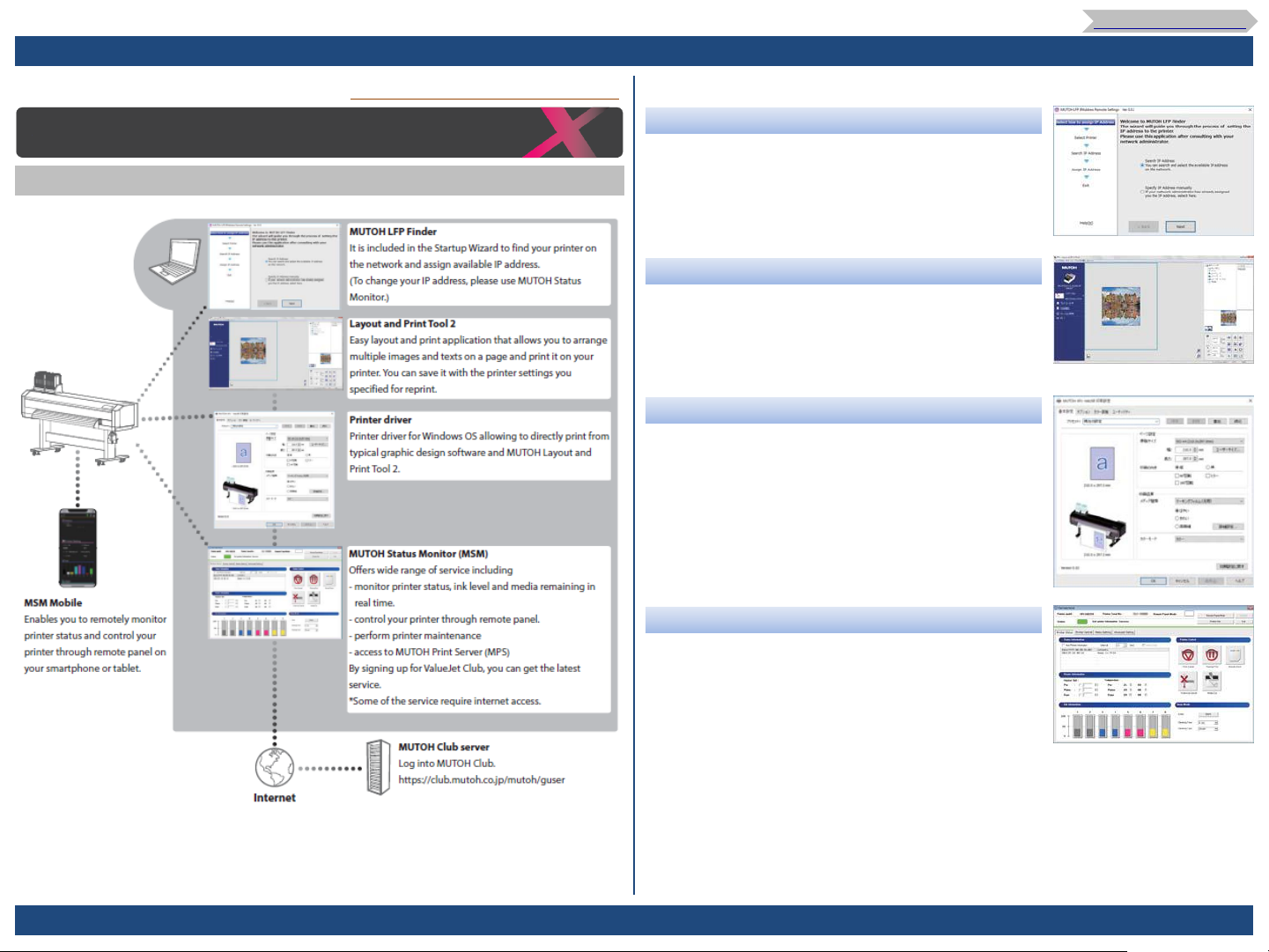

4. Introduction

4.4. System Configurations of this product(1/2)

cf. Operation Manual(Rev.01-p.14)

Introduction

System configurations of this product

To Table of Contents

Mutoh LFP Finder

It is included in the Startup Wizard to find your printer

on the network and assign available IP address.

(To change your IP address, please use MUTOH Status

Monitor.)

Layout and Print Tool 2

Easy layout and print application that allows you to

arrange multiple images and texts on a page and print

it on your printer.

You can save it with the printer settings you specified

for reprint.

Printer driver

Printer driver for Windows OS allowing to directly print

from typical graphic design software and MUTOH Layout

and Print Tool 2.

CSTM-XPJ16xxSR(E)_1.00 CONFIDENTIAL Page.

Mutoh Status Monitor (MSM)

Offers wide range of service including

By signing up for MUTOH Club, you can get the latest

service.

monitor printer status, ink level and media remaining

・

in real time.

control your printer through remote panel. ・

access to MUTOH Print Server (MPS) ・

Some of the service require internet access. ※

15

4. Introduction

4.4. System Configurations of this product(2/2)

To Table of Contents

4.5. Warning Labels (1/3)

cf. Operation Manual(Rev.01-p.14)

Introduction

System configurations of this product

MUTOH Club

By signing up for MUTOH Club, it offers free useful

contents including

download the latest version of application, operation

・

manual

download media profile ・

check printer information ・

(printer information uploaded through MSM can be

viewed)

<Print Support Software>

To get the best out of this product, use the MUTOH Print Server (MPS) function

available from MUTOH

You can download the latest version of MSM from the MUTOH Club Server.

(To use MPS, specify the output port of RIP software to MPS.)

✔ Mutoh LFP Finder

✔ Printer driver

✔ Mutoh Status Monitor (MSM)

(Mutoh Print Server (MPS))

✔ Layout and Print Tool 2

cf. Startup Guide(Rev.01-p.44)

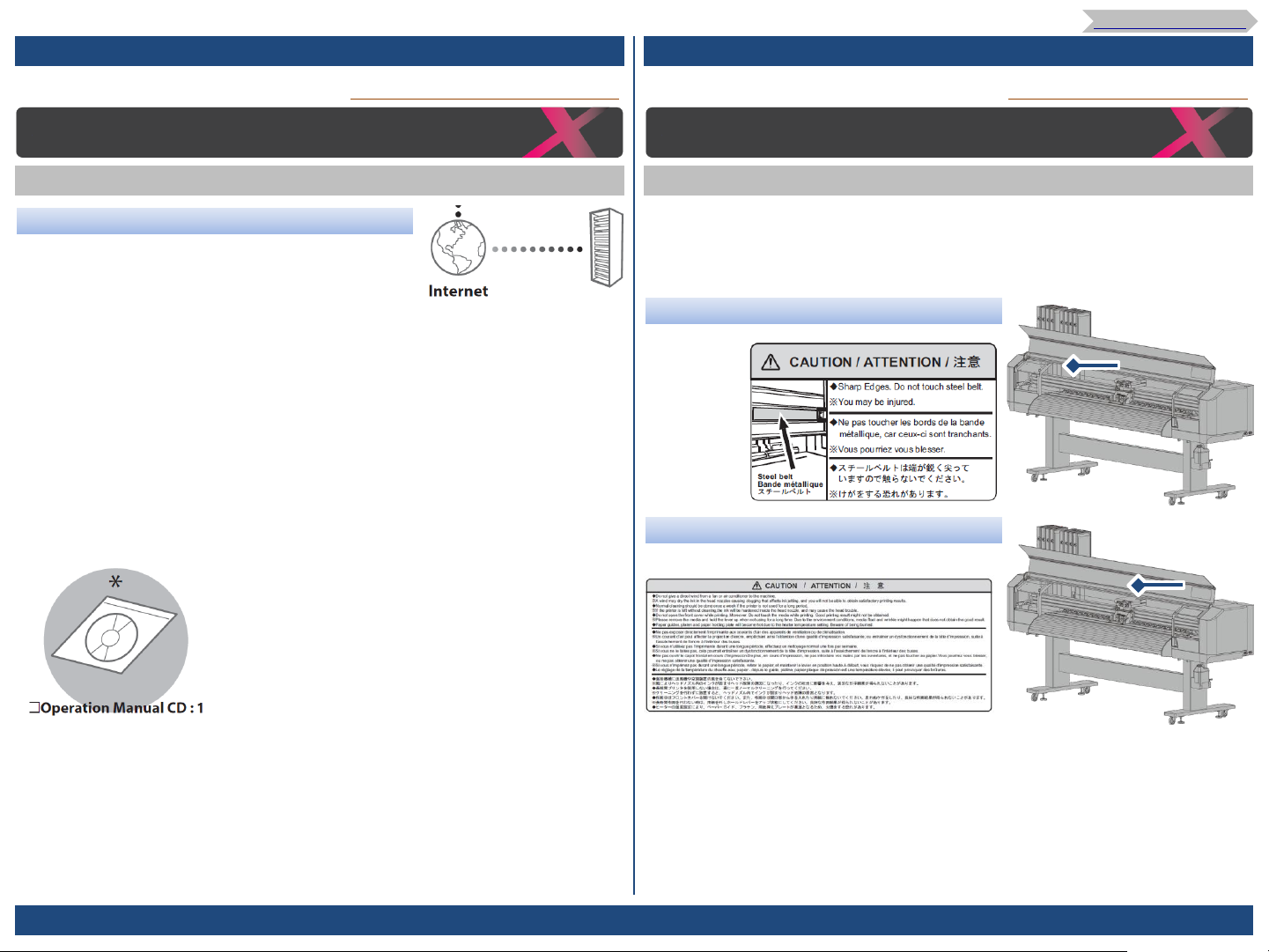

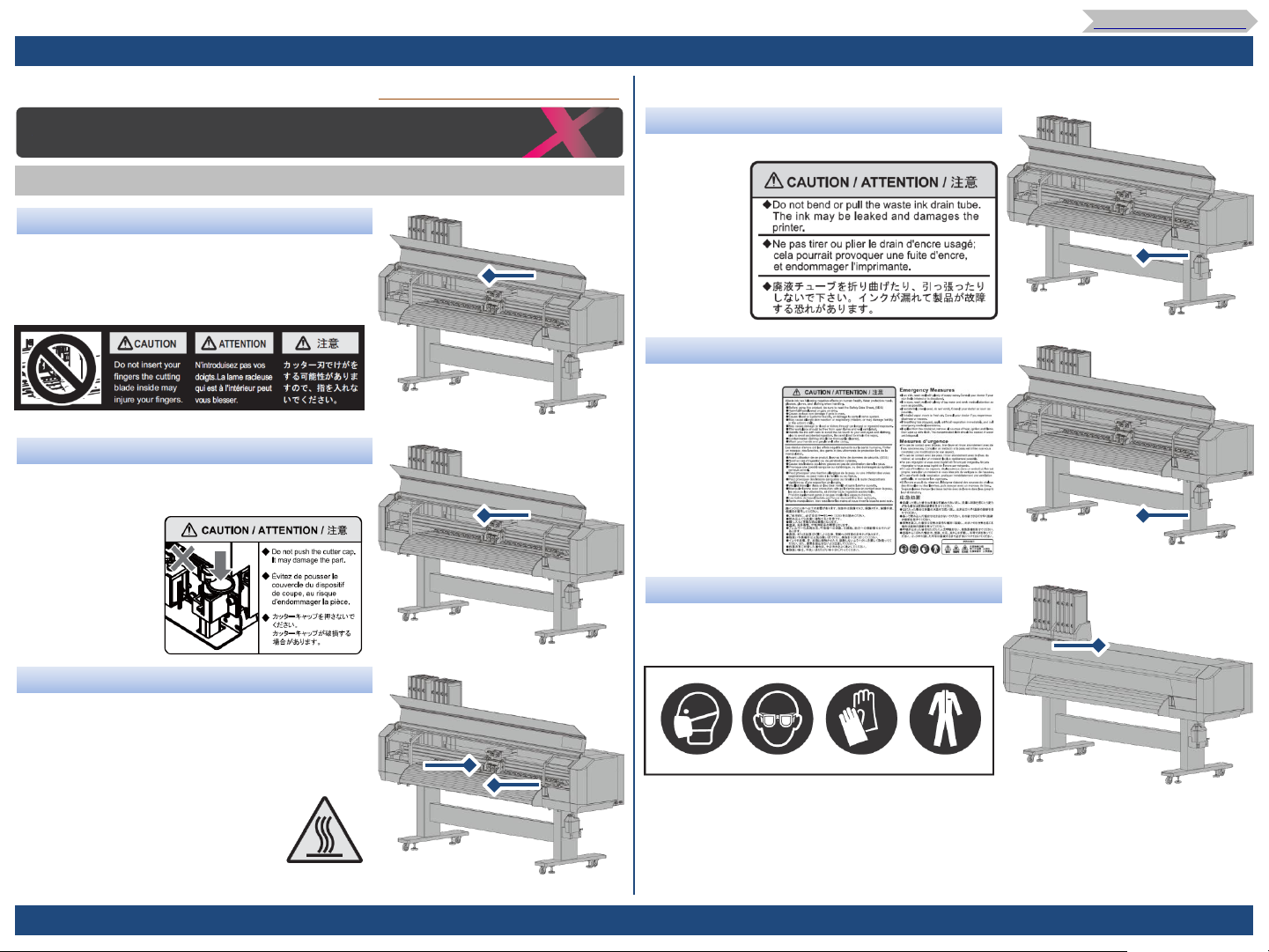

Safety Precautions

Warning Labels

Warning labels are applied onto the product where special attention is required.

Read the messages on the labels and always follows the instructions.

If the labels are peeled off or become dirty, contact your local MUTOH dealer to get new

one.

Cut Hazard Label for Steel Belt

Printer Safe Handling Label

CSTM-XPJ16xxSR(E)_1.00 CONFIDENTIAL Page.

16

4. Introduction

4.5. Warning Labels (2/3)

Safety Precautions

Warning Labels

Cut Hazard Label for Cutter

Cutter Cap Caution Label

When replacing a cutter blade, do not push the

cutter cap.

To Table of Contents

cf. Startup Guide(Rev.01-p.44)

Caution Label for Waste Ink Drain Tube Handling

Waste Fluid Caution Label

Hot Surface Caution Label

The surface may get hot and may cause burn injury.

Do not touch with your hand for at least 30

minutes after turning off the printer.

CSTM-XPJ16xxSR(E)_1.00 CONFIDENTIAL Page.

Protective equipment label

(Mask / Glasses / Gloves / Protective clothing)

Wear protective equipment when handling ink.

17

4. Introduction

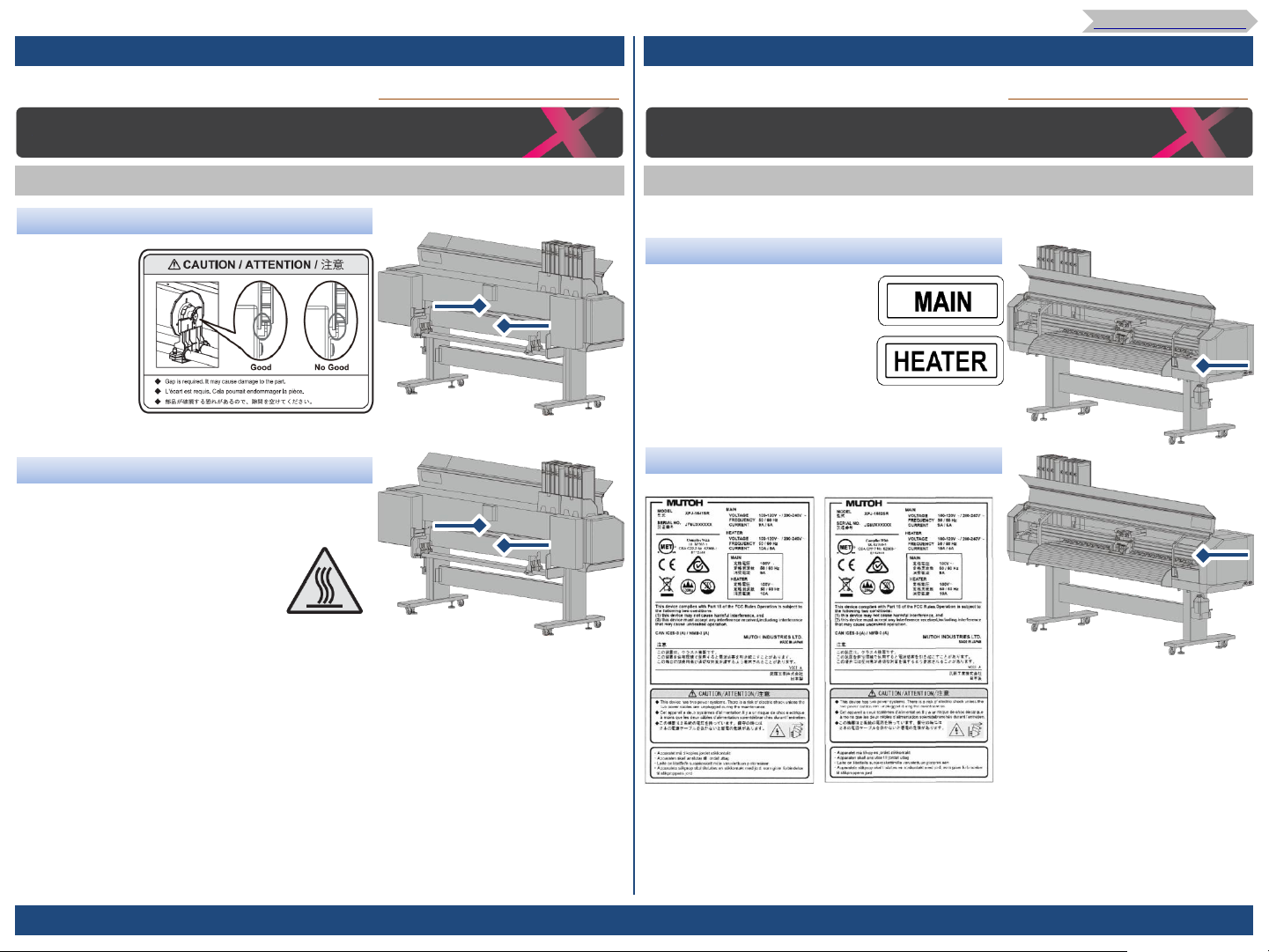

4.5. Warning Labels (3/3)

To Table of Contents

4.6. Instruction Precautions (1/1)

Safety Precautions

Warning Labels

Loading Position Caution Label

Hot Surface Caution Label

The surface may get hot and may cause burn injury.

Do not touch with your hand for at least 30

minutes after turning off the printer.

cf. Startup Guide(Rev.01-p.44)

cf. Startup Guide(Rev.01-p.45)

Safety Precautions

Instruction Labels

The following instructions labels are applied onto the printer to ensure the proper use.

AC Inlet Label

●MAIN

●HEATER

Rated nameplate

◆XPJ-1641SR

◆XPJ-1682SR

CSTM-XPJ16xxSR(E)_1.00 CONFIDENTIAL Page.

◆XPJ-1682SR

18

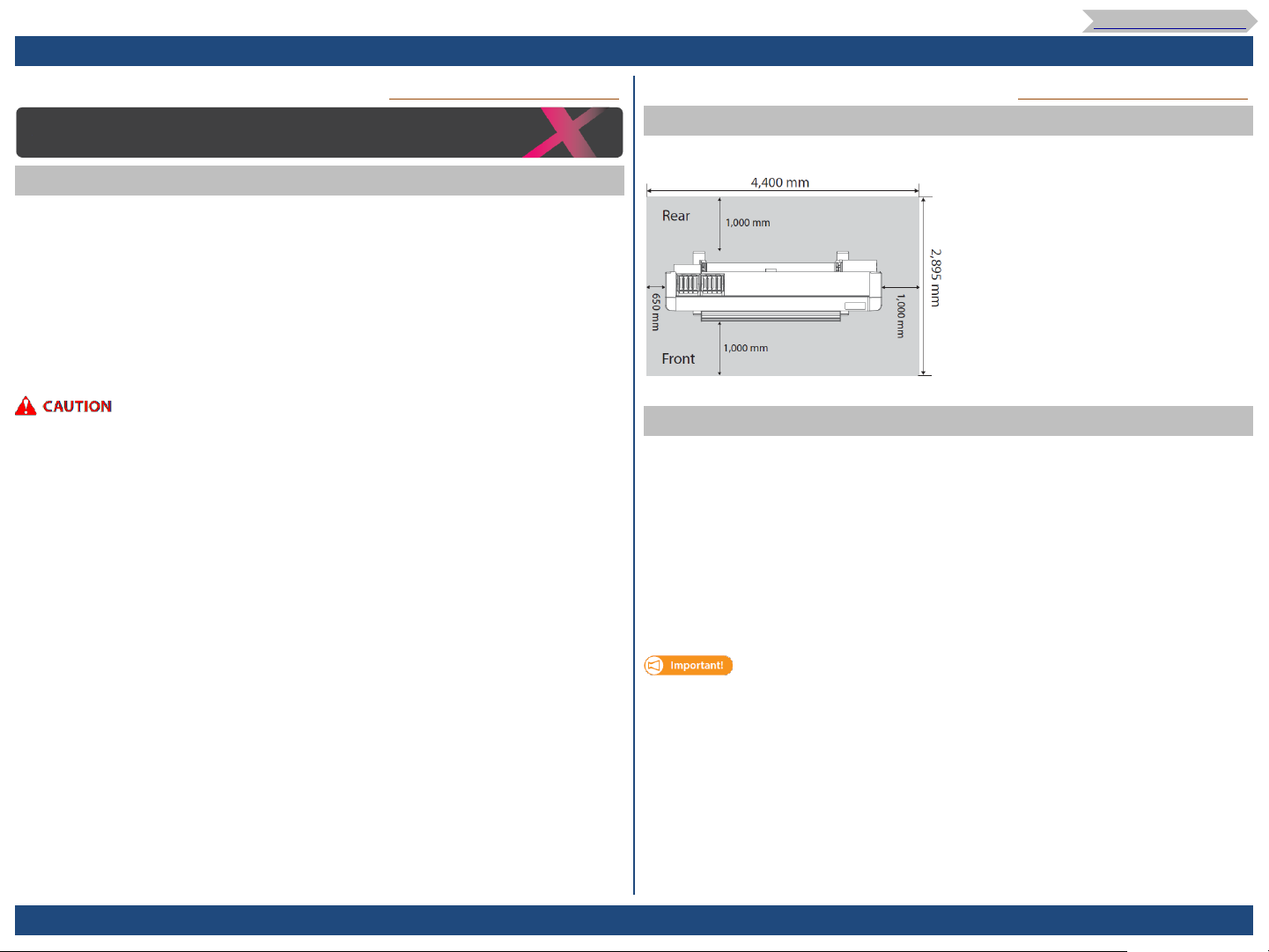

5. Unpacking and Initial Setup

5.1. Site Preparation (1/2)

To Table of Contents

cf. Startup Guide(Rev.01-p.2)

Site Preparation

Installation Location Requirements

Choose the location which satisfies the requirements below.

・ The floor must be level.

・ Avoid vibration from the neighboring devices.

・ Low humidity and free from dust.

・ Less chance of temperature and humidity changes.

・ Avoid direct sunlight.

・ Avoid water.

・ Avoid direct air onto the printer.

・ Low levels of electromagnetic waves.

・ Choose the floor that can safely support the weight of this product.

The total weight of printer and stand is 280 kg.

If the floor does not have sufficient load capacity, it can lead to injury from a fall.

This equipment is not suitable for use in locations where children are likely to

・

be present.

・ Keep the work area well ventilated while operating.

Ink odor may cause health problem such as headache, dizziness, or dull.

If you experience these symptoms, stop printer operation and move to fresh air.

Seek medical attention if vomit persists.

cf. Startup Guide(Rev.01-p.2)

Minimum Space Requirements

The following space is required for installation.

Printer Size

Width x Depth

Height

*1 When installing ink bag cases.

The room height should be at least

1,760mm.

: 2,750mm x 895mm

: 1,611mm *1

Power Specification

The installation site must meet the power specification and environmental

requirements below.

・ Printer:

Input voltage: AC 100V to 120V±10% / AC 200V to 240V±10%

Input frequency: 50 / 60Hz ±1Hz

Input load current: 9 A (AC 100V - 120V), 6 A (AC 200V - 240V)

・ Heater:

Input voltage: AC 100V to 120V±10% / AC 200V to 240V±10%

Input frequency: 50 / 60Hz ±1Hz

Input load current: 10 A (AC 100V - 120V), 5 A (AC 200V - 240V)

CSTM-XPJ16xxSR(E)_1.00 CONFIDENTIAL Page.

This product has two power cords for printer and heater and requires the total

load current as follows:

・ XPJ-1641SR/XPJ-1682SR: 19 A (AC 100V - 120V),11 A (AC 200V - 240V)

If the total current exceeds the maximum capacity of the wall outlet with two or

more jacks, connect one of the two power plugs into another wall outlet.

19

5. Unpacking and Initial Setup

5.1. Site Preparation (2/2)

To Table of Contents

5.2. Unpacking (1/4)

Site Preparation

Environmental Requirements

・ Operating condition:

Temperature :

Humidity

・ Printing Condition:

Temperature :

Humidity

・ Change rate:

Temperature

Humidity

・ Printer Storage Condition:

Without ink filled: Up to 6 months

Temperature

Humidity

With ink filled: Up to 1 week

Temperature

Humidity

20℃ to 32℃

: 40% to 60%, non condensing

22℃ to 30℃

: 40% to 60%, non condensing

: No more than 2℃ per 1 hour

: No more than 5% per 1 hour

: -20℃ to 60℃

: 20% to 80%, non condensing

: -10℃ to 40℃

: 20% to 80%, non condensing

※.

Storage up to 4 days maximum when stored between 32 ℃ to

40℃.

cf. Startup Guide(Rev.01-p.3)

cf. Startup Guide(Rev.01-p.4)

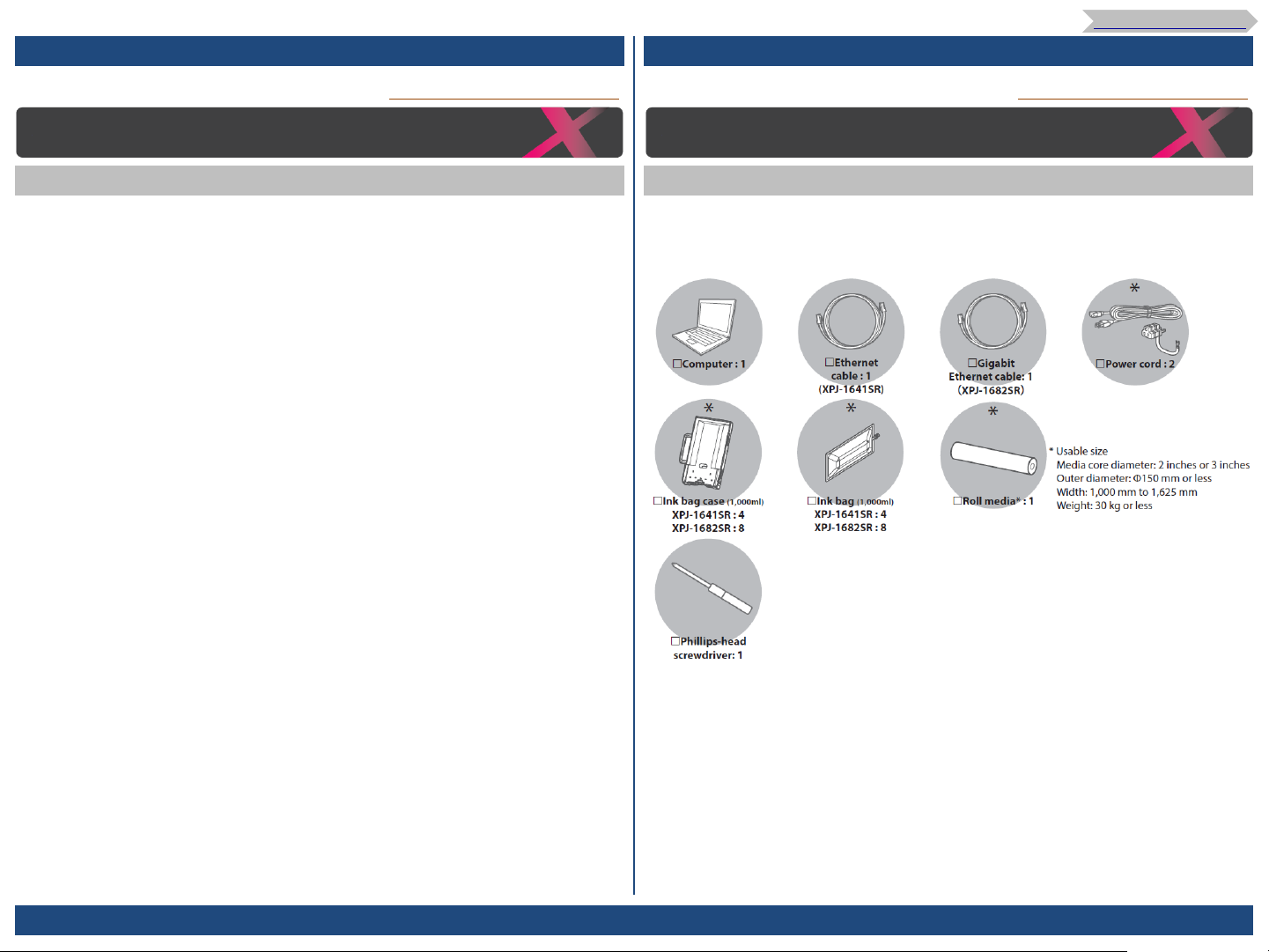

Unpacking

Unpacking Preparation

Before unpacking, read the instructions below and prepare the necessary items.

・ Minimum 4 people are required for unpacking, assembling and installation.

・ The items listed below are required for installation and initial setup.

・ Ink Storage Condition:

Black / Cyan / Magenta / Yellow/ Light Cyan / Light Magenta / Light Black

(1,000ml each)

Temperature

Humidity

Cleaning bag (300ml)

Temperature

Humidity

: -20℃ to 40℃

: 5% to 85%, non condensing

: -5℃ to 40℃

Storage up to 6 months maximum when stored between -5℃ to

※.

5℃ or 30 ℃ to 40℃.

: 80% or less, non condensing

CSTM-XPJ16xxSR(E)_1.00 CONFIDENTIAL Page.

20

5. Unpacking and Initial Setup

5.2. Unpacking (2/4)

To Table of Contents

cf. Startup Guide(Rev.01-p.4)

Unpacking

Use the designated power cords.

Failure to do so may result in electric shock or fire.

Your computer must meet the following minimum requirements:

・ OS: Windows 10 (64bit), Windows 8/8.1 (64bit), Windows 7 (64bit)

・ CPU: Intel (R) Core (TM) i5 / i7

・ Memory: 8GB minimum

・ Network:

XPJ-1641SR: Use a network port that supports Ethernet port, Ethernet cable

(Category 5 or later)

XPJ-1682SR: Use a network port that supports Gigabit Ethernet port, Gigabit

Ethernet cable (Category 6 or later)

Items marked with an asterisk (*) above are accessories or supplies.

cf. Startup Guide(Rev.01-p.5)

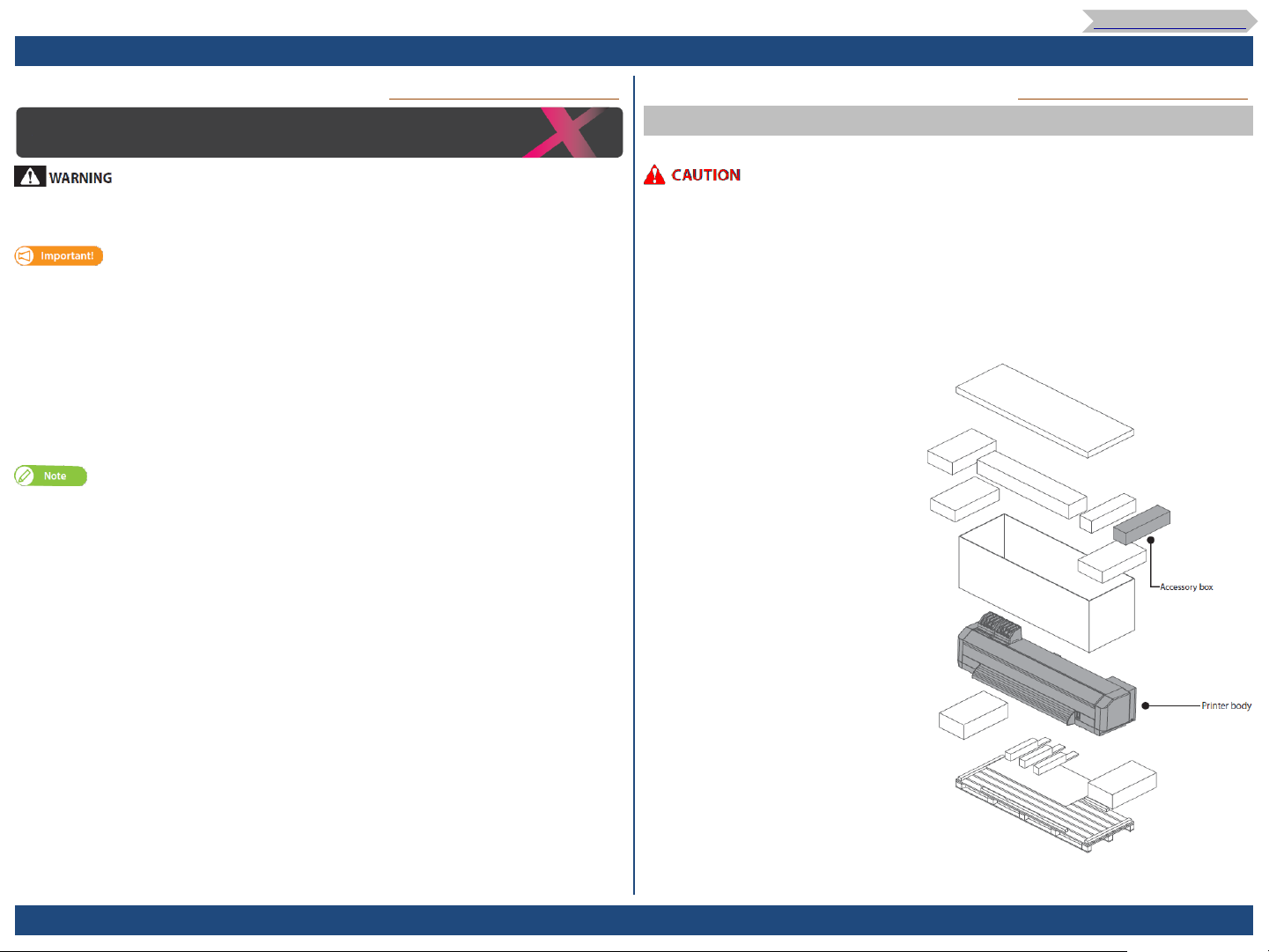

Unpacking the printer

Unpack the product.

・ Minimum four people are required for unpacking and moving this product.

・ When taking out the product from the packing box, remove the plastic sheet

wrapped around the product, then take out the product.

Failure to do so may cause slip and damage to the product.

・ Keep the product level while moving it.

[1] Open the packing box and take out the items listed below.

CSTM-XPJ16xxSR(E)_1.00 CONFIDENTIAL Page.

21

5. Unpacking and Initial Setup

5.2. Unpacking (3/4)

To Table of Contents

Unpacking

Unpacking the printer

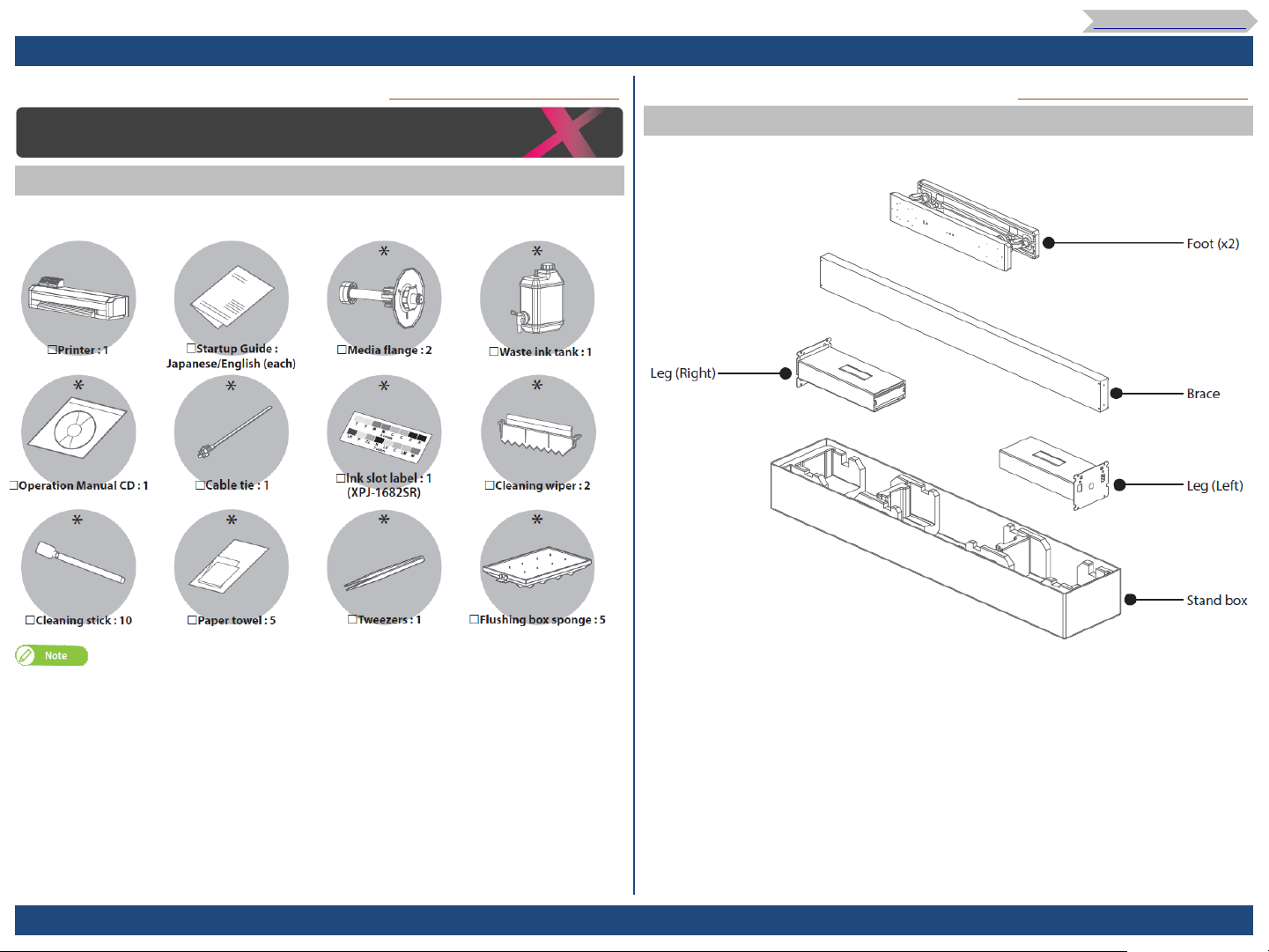

[2] Check that the following items are included.

cf. Startup Guide(Rev.01-p.6)

cf. Startup Guide(Rev.01-p.7)

Unpacking Stand

[1] Open the packing box and take out the items listed below.

Items marked with an asterisk (*) above are in the accessory box.

CSTM-XPJ16xxSR(E)_1.00 CONFIDENTIAL Page.

22

5. Unpacking and Initial Setup

5.2. Unpacking (4/4)

To Table of Contents

5.3. Assembling (1/4)

Unpacking

Unpacking Stand

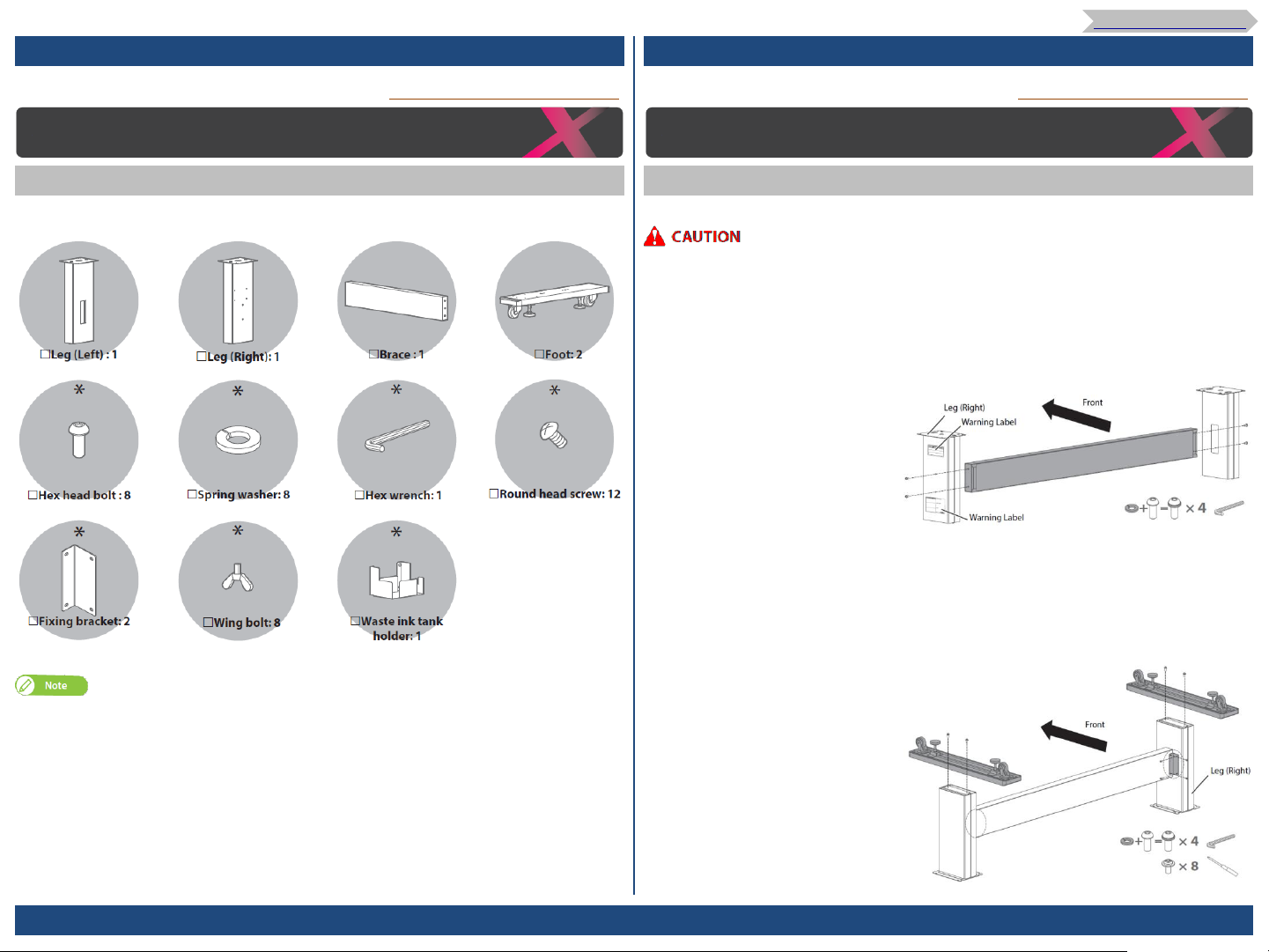

[2] Check that the following items are included.

cf. Startup Guide(Rev.01-p.7)

cf. Startup Guide(Rev.01-p.8)

Assembling

Assembling Stand

Follow the steps below to assemble the stand.

・ Minimum two people are required for assembling the stand.

[1] Attach the left leg and right leg to the brace.

・ Face the groove on the brace toward the rear side of the printer and attach it to

both legs.

・ The leg with two warning labels attached is the right leg.

・ Put the spring washers on the hex head screws (4 each), then tighten the screws.

[2] Attach the foot to the leg.

・ Face the screw holes on the foot toward the front side of the printer and attach it

to the leg.

・ Put the spring washers on the hex head screws (4 each), then tighten the screws.

・ Use the round head screws (×8) to fix the fixing brackets (×2) on the brace and

both legs.

Items marked with an asterisk (*) above are in the accessory box.

CSTM-XPJ16xxSR(E)_1.00 CONFIDENTIAL Page.

23

5. Unpacking and Initial Setup

5.3. Assembling (2/4)

To Table of Contents

cf. Startup Guide(Rev.01-p.9)

Assembling

Assembling Stand

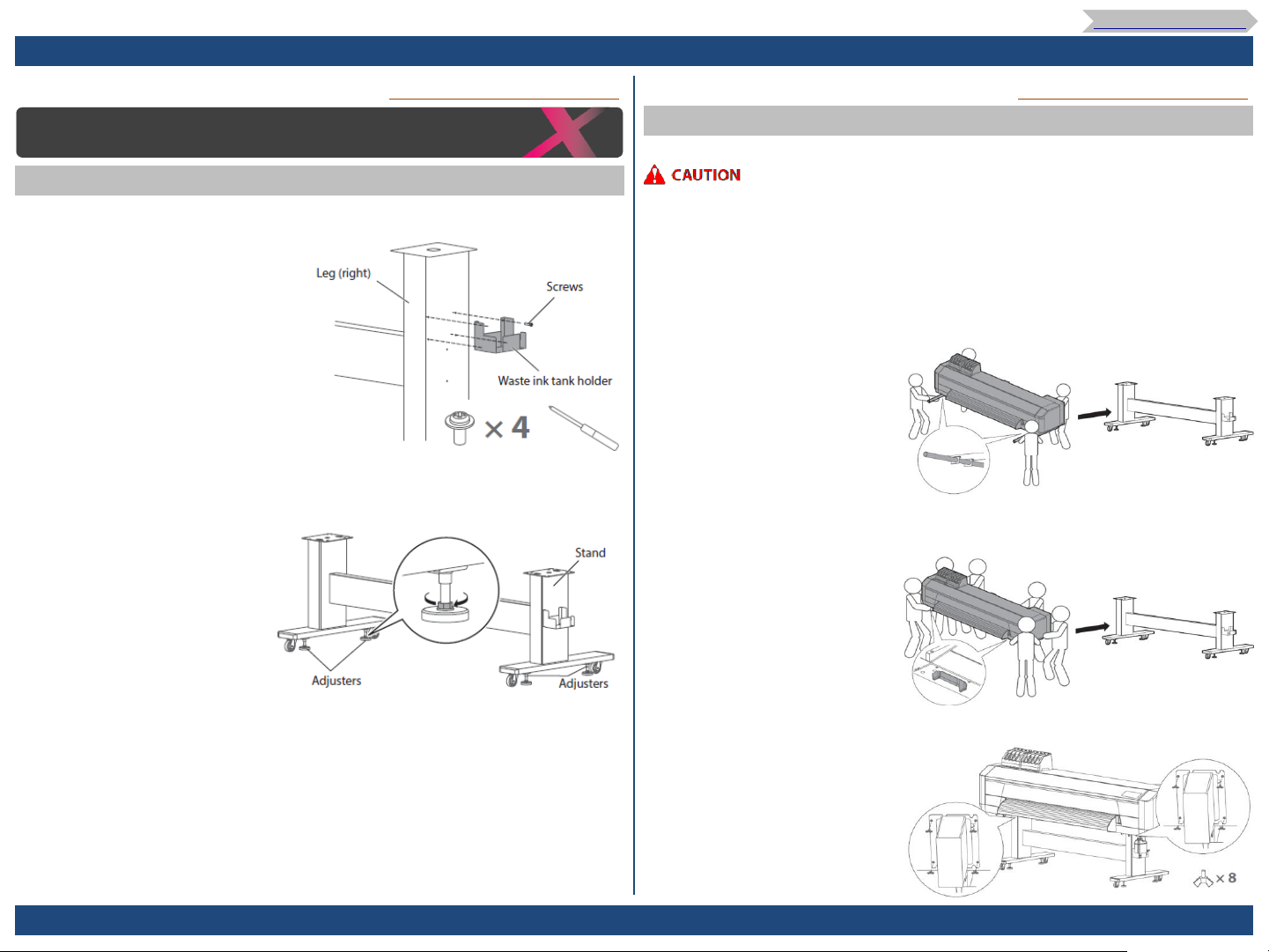

[3] Use the round head screws (×4) to attach the waste ink tank holder to the right leg.

[4] Shake the stand to make sure that each part is firmly attached.

[5] Turn the leveling adjusters (×4) as shown on the left until the stand does not move.

cf. Startup Guide(Rev.01-p.9)

Attaching Printer

Follow the steps below to attach the printer to the stand.

・ Minimum four people are required for this process.

・ When taking out the product from the packing box, remove the plastic sheet

wrapped around the product, then take out the product.

Failure to do so may cause slip and damage to the product.

・ Keep the product level while attaching.

[1] Lift the printer with at least four people and mount it on the stand.

・ Use two lifting bars to insert into the guide holes at the bottom left and right of

the printer, and lift up on the stand.

(If you do not have lifting bars) Lift the printer with at least four people and mount

it on the stand.

・ Use the handholds at the front bottom of the printer.

CSTM-XPJ16xxSR(E)_1.00 CONFIDENTIAL Page.

[2] Use the wing bolts (×8) and attach the printer to the stand.

24

5. Unpacking and Initial Setup

5.3. Assembling (3/4)

To Table of Contents

cf. Startup Guide(Rev.01-p.10)

Assembling

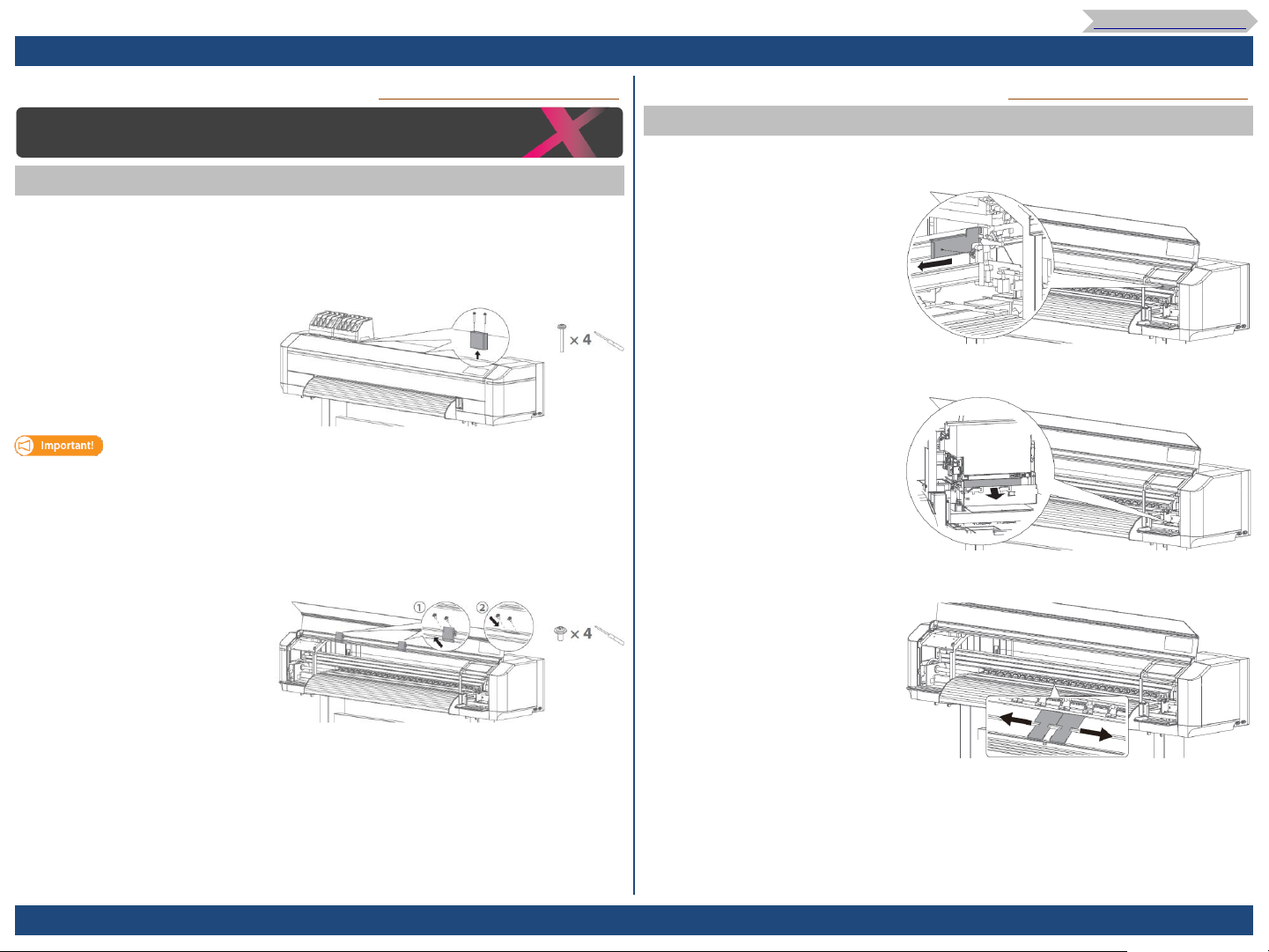

Removing Packing Materials

Remove packing materials from the product.

[1] Remove the packing tapes from all the covers.

[2] (XPJ-1682SR only) Remove two screws each (M3 x 45) to remove two front cover

locks.

Make sure to remove two front cover locks before opening the front cover.

Otherwise it will cause damage to the cover.

[3] (XPJ-1682SR only)

①: Open the front cover and remove two screws each (M4x8) to remove two front

cover lock plates.

②: Use the screws just removed to fasten to the mounting holes on the printer.

cf. Startup Guide(Rev.01-p.11)

Removing Packing Materials

[4] Open the front cover. Remove the wing bolt to remove the shipping bracket from

the carriage.

[5] (XPJ1682SR only)Remove the tape, then remove the packing material from the

bottom of the carriage.

[6] Remove the tape, and move the edge holders to the left and the right edge.

CSTM-XPJ16xxSR(E)_1.00 CONFIDENTIAL Page.

25

5. Unpacking and Initial Setup

5.3. Assembling (4/4)

To Table of Contents

5.4. Connecting Power and Network (1/2)

cf. Startup Guide(Rev.01-p.12)

Assembling

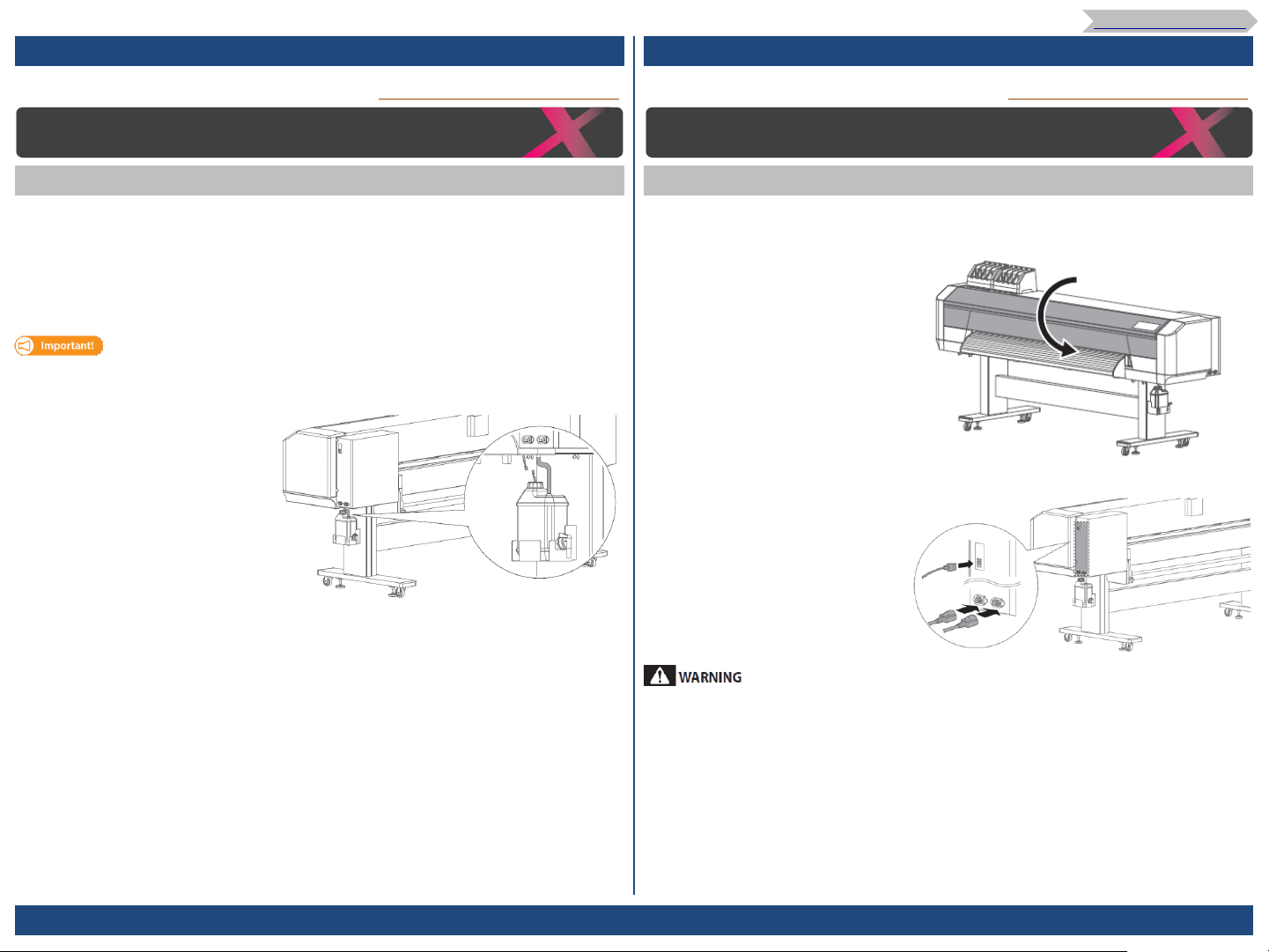

Attaching Waste Ink Tank

Attach the waste ink tank to the printer.

[1] Place the waste ink tank on the waste ink tank holder.

[2] Use the waste ink tank tube to connect the waste ink tank to the printer.

・ Cover up the connector of the tank with the tube.

Connect the waste ink sensor cable to the waste ink sensor connector.

Check that the connector of the tank is fully covered with the tube.

Failure to do so may cause ink spillage.

cf. Startup Guide(Rev.01-p.13)

Connecting Power and Network

Connect Power Cords and Ethernet Cable

Follow the steps below to connect the power cords and Ethernet cable.

[1] Check that the front cover is closed.

[2] Connect two power cords and a Ethernet cable to the printer.

CSTM-XPJ16xxSR(E)_1.00 CONFIDENTIAL Page.

Make sure to plug two power cords into the wall outlets with the same voltage.

Failure to do so may cause damage to the electrical circuit.

26

5. Unpacking and Initial Setup

5.4. Connecting Power and Network (2/2)

To Table of Contents

cf. Startup Guide(Rev.01-p.14)

Connecting Power and Network

Connect Power Cords and Ethernet Cable

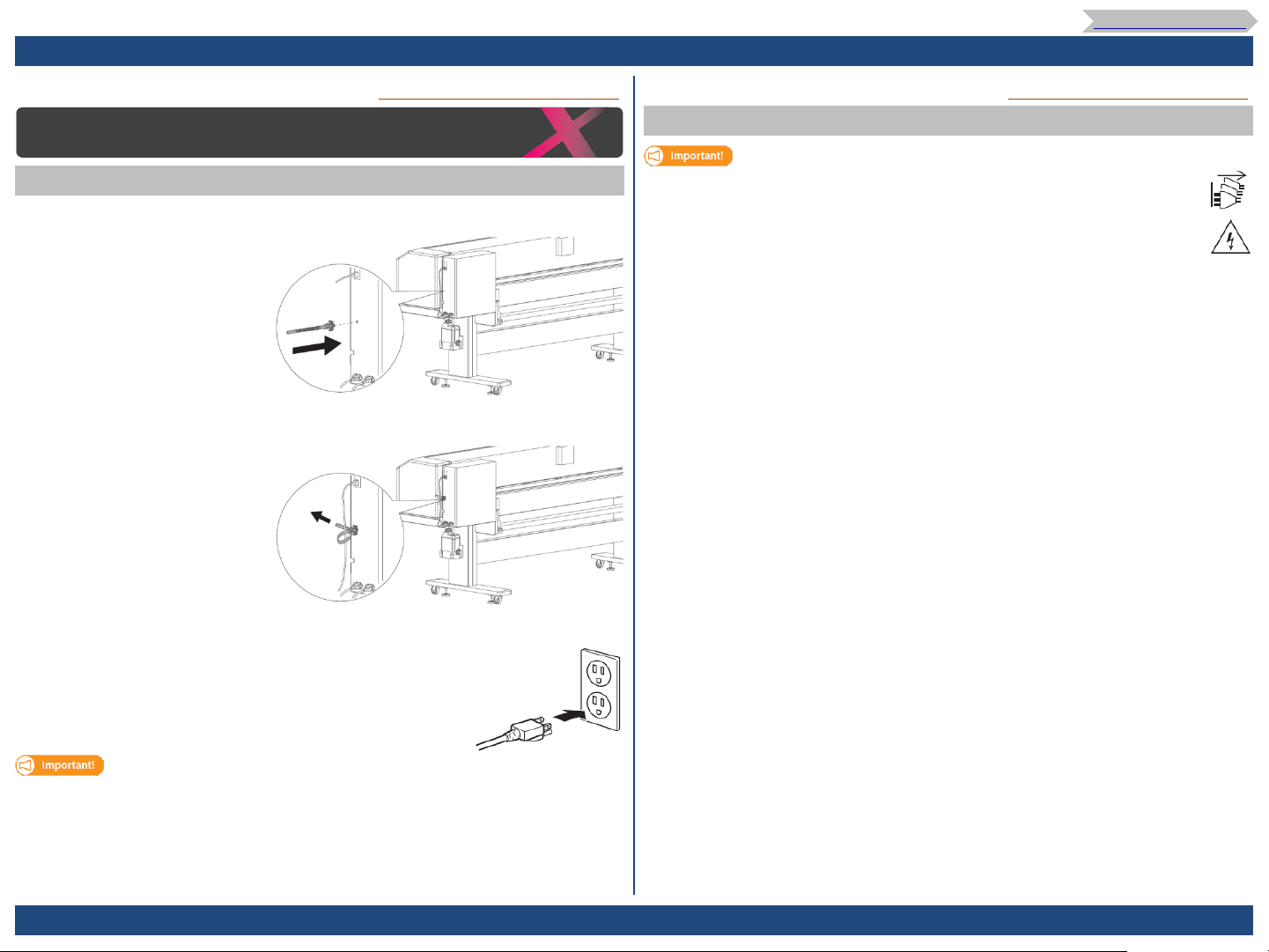

[3] Insert the tip of the cable tie into the hole on the printer to attach it.

[4] Use the cable tie to secure the Ethernet cable to the printer.

cf. Startup Guide(Rev.01-p.14)

Connect Power Cords and Ethernet Cable

Electric shock hazard.

This printer has two power cords.

To unplug from the wall outlet, make sure to unplug both of them.

[3] Plug two power cords into the wall outlets respectively.

To plug into one wall outlet with two or more jacks, check that the total current

does not exceed the maximum capacity of the wall outlet.

If exceeded, connect one of the two power plugs into another wall outlet.

CSTM-XPJ16xxSR(E)_1.00 CONFIDENTIAL Page.

27

5. Unpacking and Initial Setup

5.5. Printer Initial Setup (1/7)

To Table of Contents

cf. Startup Guide(Rev.01-p.15)

Printer Initial Setup

Initial Setup Flow via Startup Wizard

Here is how to get started with your printer.

Use one of the following methods to run the initial setup.

・ Follow the instructions in the Startup Wizard to set up the settings via computer.

・ Follow the instructions in this Guide to set up the settings from operation panel.

cf. Startup Guide(Rev.01-p.16)

Powering on - Installing MSM

To run the initial setup through the Startup Wizard on MSM, install MSM on your

computer.

Then follow the Startup Wizard to run the initial setup.

・ Make sure to install MSM stored in the supplied CD.

[1] Check that the front cover is closed.

[2] Long press the Power button on the front panel.

・ The Power LED (above the Power button) lights up.

・ The printer will start mechanical initialization.

Once the Power LED lights up, release the Power button.

[3] Use the Ethernet cable to connect the printer to your computer

[4] Insert the supplied CD into the CD-ROM drive.

・ The Startup Wizard will start up automatically.

・ If the Startup wizard does not automatically start,

right click the icon of CDROM drive, open the

contents of CD with [Open], and double click

MpTotalInst.exe.

[5] Follow the instructions on the Startup Wizard to setup.

・ When setup is complete, carry out test printing.

CSTM-XPJ16xxSR(E)_1.00 CONFIDENTIAL Page.

・ Please keep the supplied CD at hand. You will need it for reinstallation.

・ If lost, you can download from MUTOH Club (user registration is required).

(MUTOH Club) https://club.mutoh.co.jp/mutoh/guser

28

5. Unpacking and Initial Setup

5.5. Printer Initial Setup (2/7)

To Table of Contents

Printer Initial Setup

Initial Setup Flow via Operation Panel

cf. Startup Guide(Rev.01-p.17)

cf. Startup Guide(Rev.01-p.18)

Step 1 Powering on - Initial settings on the front panel

Power on the printer and configure the initial settings on the front panel.

[1] Check that the front cover is closed.

[2] Long press the Power button on the front panel.

・ The Power LED (above the Power button) lights up.

・ The printer will start mechanical initialization.

Once the Power LED lights up, release the Power button.

[3] Use to select the language.

Tap [Enter].

[4] Tap [Enter].

[5] Tap [Enter].

[6] Sets the IP address of the printer.

key: Increase the number.

key: Decrease the number.

key: Move the cursor to the previous digit.

key: Move the cursor to the next digit.

Tap [Enter] after entering each digit.

CSTM-XPJ16xxSR(E)_1.00 CONFIDENTIAL Page.

[7] Sets the subnet mask of the printer.

key: Increase the number.

key: Decrease the number.

key: Move the cursor to the previous digit.

key: Move the cursor to the next digit.

Tap [Enter] after entering each digit.

29

5. Unpacking and Initial Setup

5.5. Printer Initial Setup (3/7)

To Table of Contents

cf. Startup Guide(Rev.01-p.19)

Printer Initial Setup

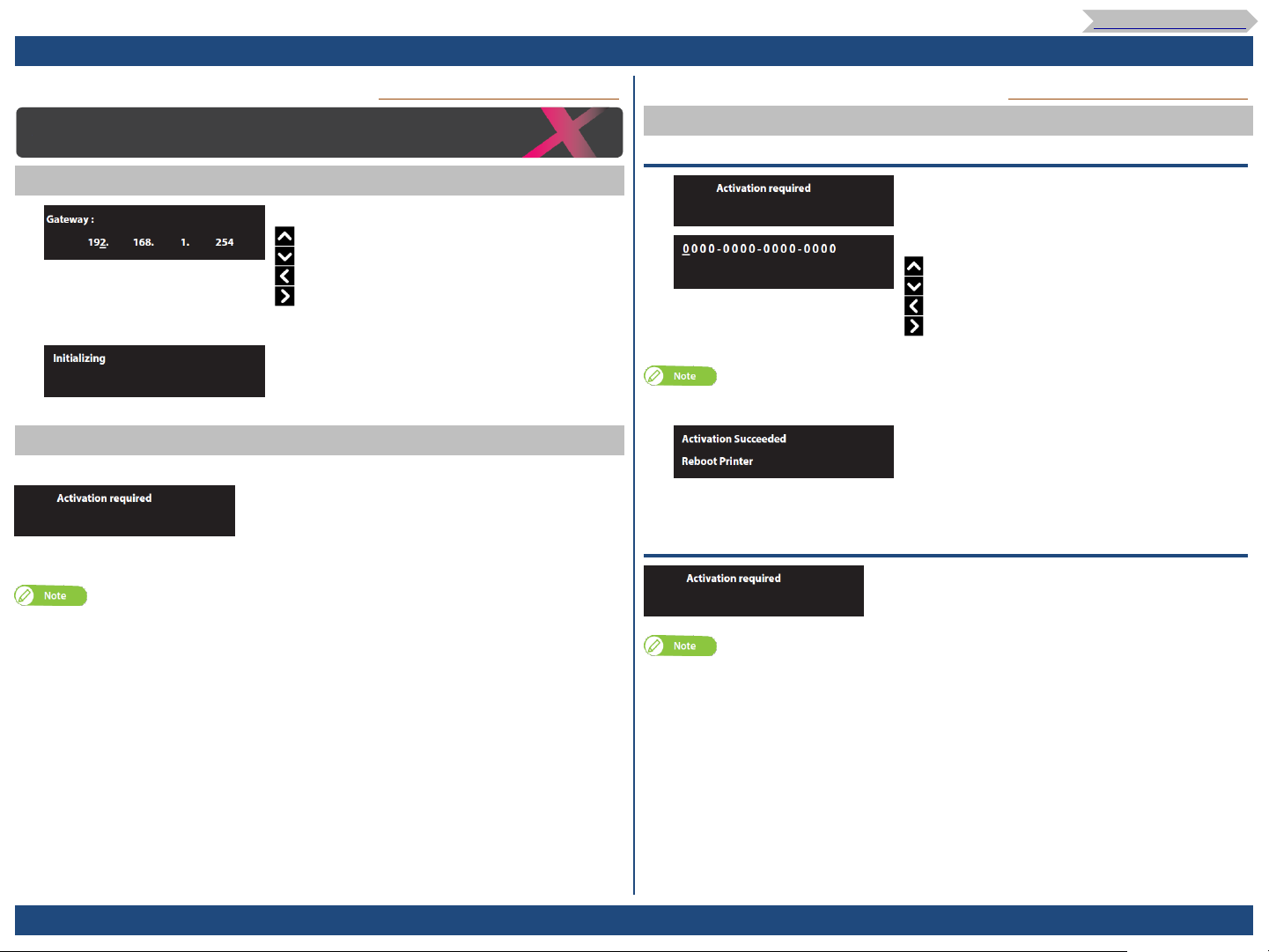

Step 1 Powering on - Initial settings on the front panel

[8] Sets the gateway.

key: Increase the number

key: Decrease the number.

key: Move the cursor to the previous digit.

key: Move the cursor to the next digit.

Tap [Enter] after entering each digit.

[9] The printer will start mechanical initialization.

Step 2 Activation

Follow the steps below to perform activation.

When the message on the left appears, use one of the

following

methods to activate the printer.

"Activation through the front panel" →

"Activation through Internet" →

While “Activation required” is displayed, you can return the initial setting flow (e.g. IP

Address etc.) by tapping [Home] key.

cf. Startup Guide(Rev.01-p.20)

Step 2 Activation

Activation through the front panel

[1] When the message on the left appears, tap

[2] Enter the 16-digit activation code.

To obtain the activation code, please contact your local MUTOH dealer to send it by

email.

[3] When the message on the left appears, long press

Activation through Internet

[Enter].

key: Increase the number.

key: Decrease the number.

key: Move the cursor to the previous digit.

key: Move the cursor to the next digit.

Tap [Enter] after entering each digit.

the Power button to power off the printer.

When the message “Power Off” appears on the

・

panel, release the Power button.

Wait for a few seconds and long press the Power

button to reboot the printer.

When the message on the left appears on the front

panel, follow the instructions on the Printer Activation

Guide to activate the printer.

CSTM-XPJ16xxSR(E)_1.00 CONFIDENTIAL Page.

To obtain the activation code and the Printer Activation Guide, access to MUTOH Club

from the following URL and click “Register” to complete the user registration.

https://club.mutoh.co.jp/mutoh/guser/

30

Loading...

Loading...