MUTOH VJ-1626UH Installation Manual

Please read this manual

before using

Thank you for purchasing a MUTOH product.

This manual explains the steps for unpacking,

mounting and basic installation before using the

MUTOH Full-color inkjet printer VJ-1626UH.

This manual is intended for owners, installers, and

users of this product.

Understand the contents and instructions in this

manual before installing this product.

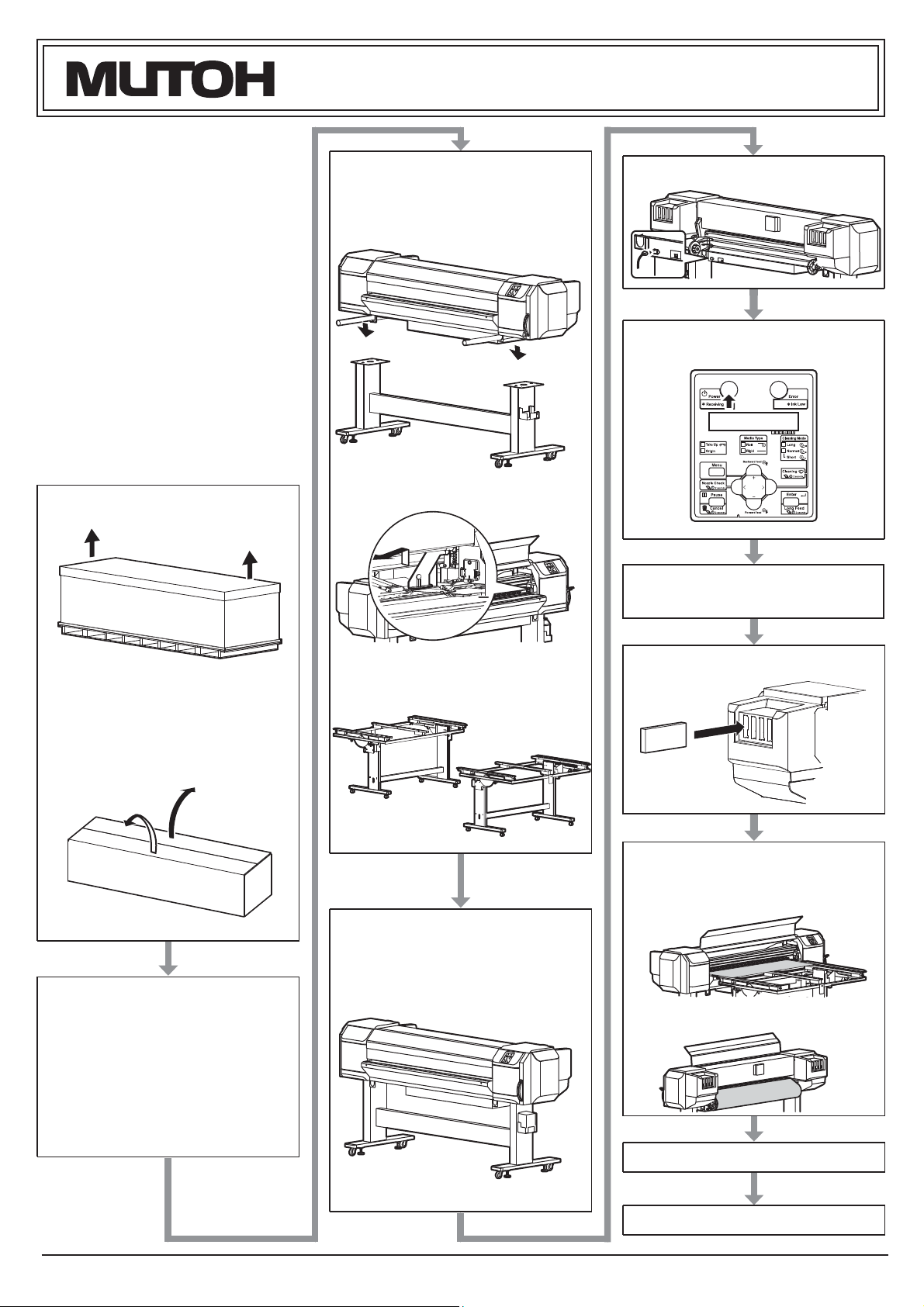

Installation flow chart

The broad steps for installation are shown below.

There are instructions for each section beginning on

the next page.

1 Unpacking boxes

VJ-1626UH INSTALLATION MANUAL

5

3 Assembling

3.1 Assembling the stand

3.2 Attaching the stand

Connecting the power cable

6

T urning the power ON/OFF

1.1 Unpacking the printer box

1.2 Unpacking the stand box and

the Media-feed table F and R

boxes

2

Confirming bundled items

3.3 Detaching fastening materials

3.5

Assembling the Media-feed table

(optional)

4 Installation

4.1 Installation environment

4.2 Installation procedure

7 Product activation

8 Initial ink filling

9

Loading media

9.1 Loading rigid media

2.1 Items in the printer box

2.2 Items in the accessory box

2.3 Items in the stand box

2.4 Items in the Media-feed

table

(optional)

box

9.2 Loading roll media

10

Checking the printing condition

11 Manual composition

1 VJ1626UHE-I-01

VJ-1626UH INSTALLATION MANUAL

1 Unpacking boxes

Procedures for unpacking boxes are explained.

This printer package consists of four boxes: Main

body, Stands, and Media-feed table (two separate

optional boxes).

CAUTION

Make sure to unpack this product with

four persons or more.

While taking out the printer from the box,

make sure to remove the vinyl sheet.

1.1 Unpacking printer box

Unpack the printer box in accordance with the following steps.

1. Carry the box to where you will unpack it.

2. Remove the bands.

3. Open the box and take out the following components.

Printer main body

Accessory box

1

2

3

2

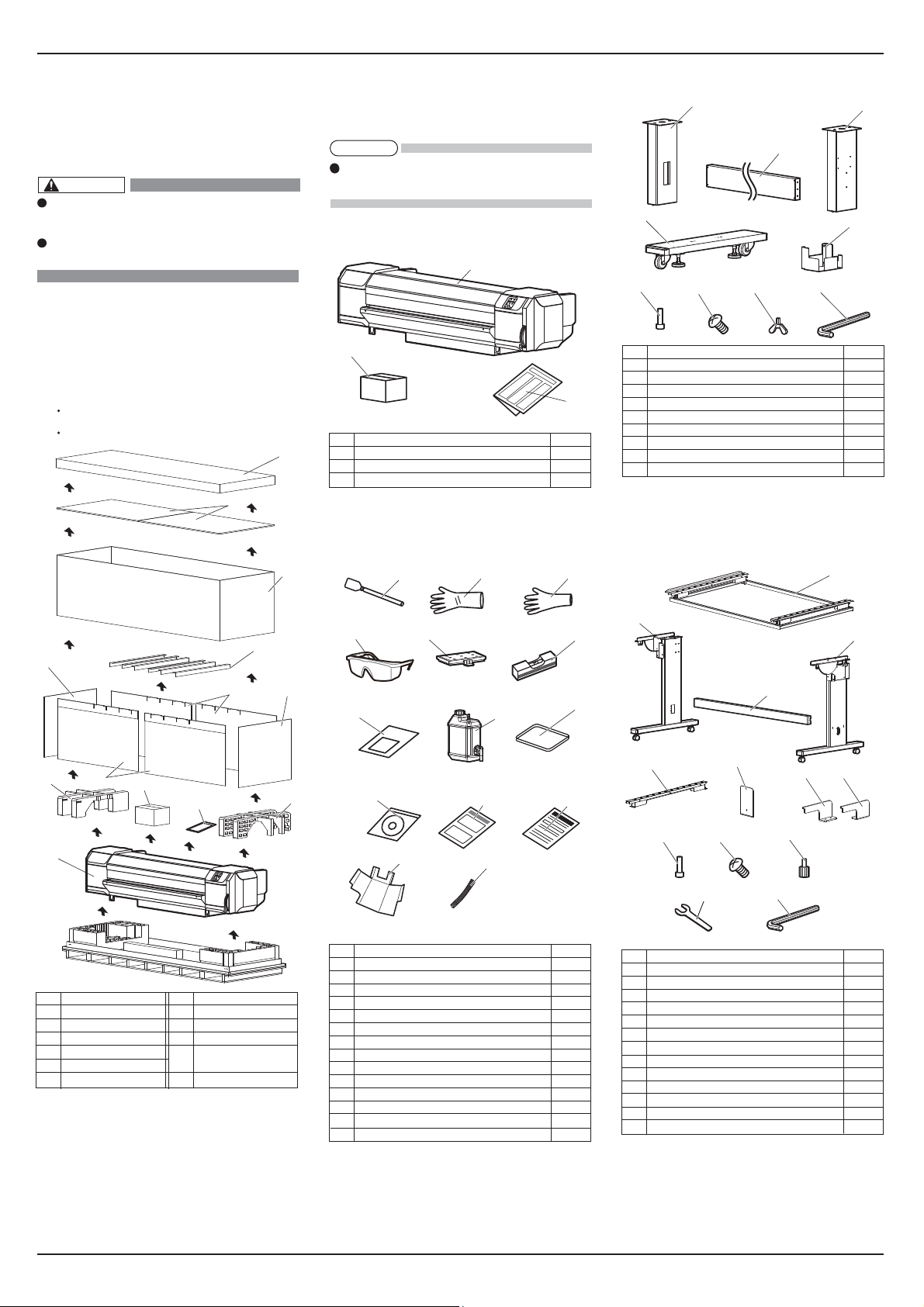

Confirming bundled items

After unpacking, please confirm that the product has

not damaged and no components are missing.

NOTE

If any items are damaged or missing, contact

MUTOH local dealer.

2.1

Items in the printer box

1

2

No. Name Q'ty

1 Printer main body 1 set

2 Accessory box 1

3 Installation Manual (this manual) 1

2.2

Items in the accessory box

12

2.3 Items in the stand box

1

3

4

6

No. Name Q'ty

1 Leg part (Right) 1

2 Leg part (Left) 1

3

3 Connector bar 1

4 Base parts 2

5 Waste fluid tank holder 1

6 Hexagon socket head cap screws 8

7 Waste fluid tank holder fixing screws 4

8 Butterfly screws 8

9 Hexagonal wrench 1

7

89

2

5

2.4 Contents of Media-feed table

(optional) box

3

(half side)

1

4

5

6

7

11

No. Name No. Name

1

2

3

4

5

6

6

Top cover

Top board

Outer board

Center board

Side board A

Side board B

9

10

7

Cushion (Left)

Cushion (Right)

8

Accessory box

9

Installation Manual

10

(this manual)

Printer main body

11

1.2 Unpacking Stand, Media-feed

table

Follow the procedure below to unpack the Stand,

Media-feed table F, and Media-feed table R.

*Media-feed tables F and R are optional.

1. Carry the box to where you will unpack it.

2. Open the box and take out the components.

4

5

7

8

10

No. Name Q'ty

1 Clean stick 10

2 Rubber gloves 100

3 Plastic gloves 100

4 Goggles 1

5 Flushing box sponge 10

6 Spirit level 1

7 Paper towel(Lint-free cloths) 5

8 Waste fluid tank 1

9 Tray 1

10 Operation Manual CD 1

11 Notes for using the dedicated ink 1

12 Notification sheet (Japanese/English) 1

13 Light-shielding cover 1

14 Light-shielding tube 1

5

13

6

8

11

14

9

12

2

3

4

5

9

No. Name Q'ty

1 Frames 1

2 Leg (left) 1

3 Leg (right) 1

4 Reinforcement 1

5 Rails (fixed) 1

6 Stopper 1

7 Installation plate (Left) 2

8 Installation plate (Right) 2

9 Hexagon socket head cap screw 8

10 Screw 8

11 Lug screw 1

12 Hexagonal spanner 2

13 Hexagonal wrench 1

6

10

12 13

7 8

11

VJ1626UHE-I-01 2

VJ-1626UH INSTALLATION MANUAL

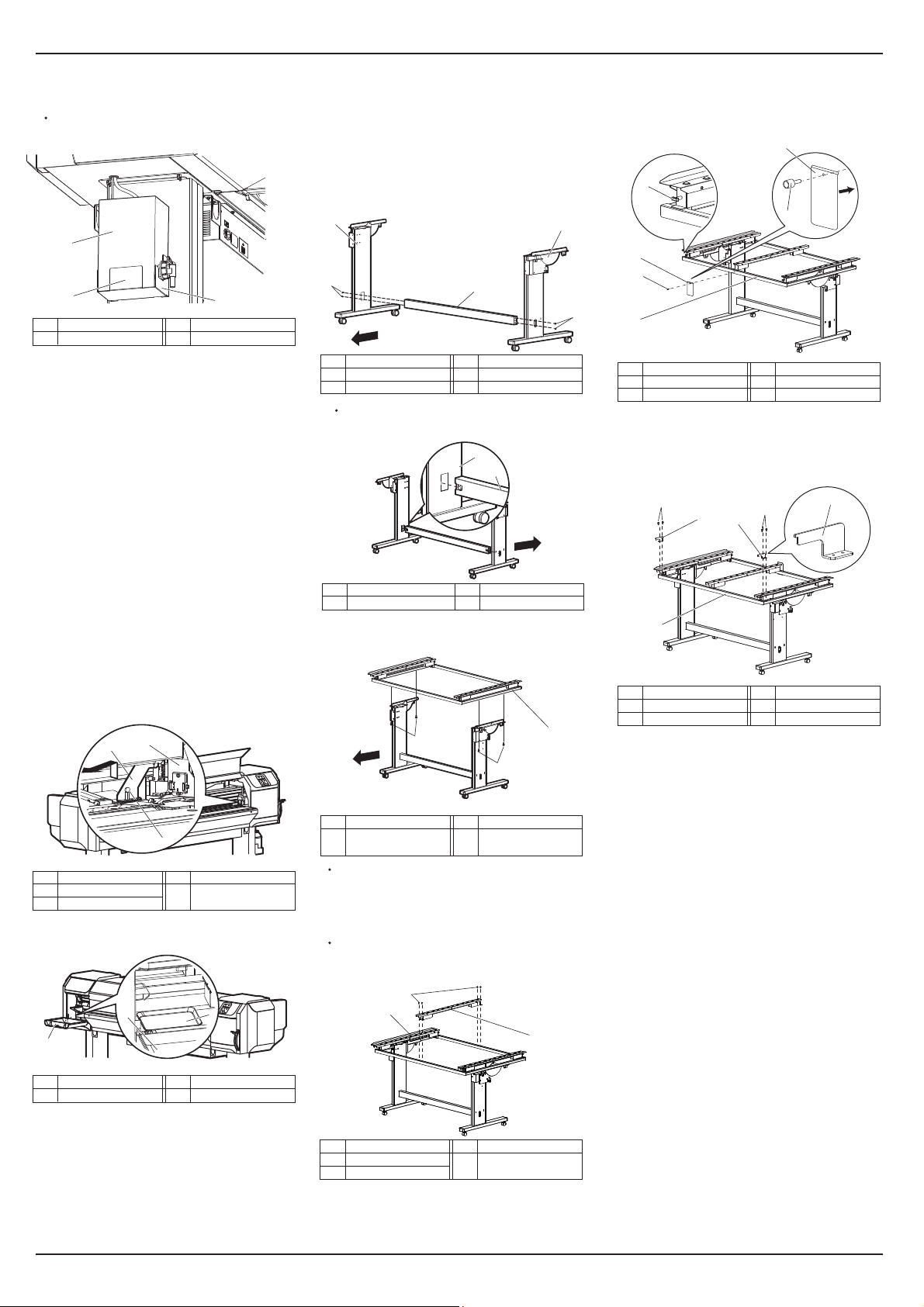

3 Assembling

This section explains how to assemble the printer.

CAUTION

Assemble this printer with 4 persons

or more.

3.1 Assembling the stand

Follow the procedure below to assemble the stand.

1. Follow the procedure below to assemble the right

stand.

a. Attach the right leg part to the right base part so

that four screw holes in the base part are at the front.

b.Tighten two hexagon socket head cap screws using a

hexagonal wrench.

1

Front

4

No. Name No. Name

1 Leg part (Right)

2 Base part

3

Hexagon socket head cap screws

4 Screw holes in base part

2. Assemble the left stand in the same way as in Step 1.

Front

4

2

3

1

2

4. Fasten the connector bar to the left stand in the

same way as in Step 3.

1

Front

3

No. Name No. Name

1 Stand (Left)

2 Connector bar

3 Hexagon socket head

2

cap screws

5. Attach the waste fluid tank holder to the right

stand using four waste fluid tank holder fixing

screws.

1

2

No. Name No. Name

1 Leg part (Right)

2 Waste fluid tank holde

3 Waste fluid tank holder

fixing screws

6. Shake the stand to make sure that each part is

firmly attached.

When the printer is wobbly, loosen the hexagon

socket head cap screws once and then tighten

them again.

3.2 Attaching the stand

Follow the procedure below to attach the stand to the

printer.

1. Turn the four adjusters as shown below to prevent

the stand from moving.

1

3. Remove the two transfer stays and fasten the

printer to the stand using eight butterfly screws.

1

2

3

3

No. Name No. Name

1 Transfer stays 3 Butterfly screws

2 Stand

1

3

2

3

3

2

3

4. Shape the light-shielding cover.

To shape the light-shielding cover, use doublesided adhesive tape (already attached to the

3

light-shielding cover) to glue each tab to the

corresponding side

2

2

1

No. Name No. Name

1 Light-shielding cover 3 Double-sided adhesive

tape (Flip side)

5. Attach the light-shielding tube to the waste fluid

tube.

Fix the light-shielding tube to the rubber bush.

3

2

2

1

1

1

3

No. Name No. Name

1 Leg part (Left)

2 Base part

Hexagon socket head cap screws

3

4 Screw holes in base part

3. Fasten the connector bar to the right stand using

No. Name No. Name

1 Adjusters

2 Stand

2. Insert the two transfer stays into the right and left

transfer brackets, lift the printer with four or more

people and place it on the stand.

two hexagon socket head cap screws.

Attach the connector bar with the groove facing

the rear as shown below.

1

2

Front

3

No. Name No. Name

1 Stand (Right)

2 Connector bar

3 VJ1626UHE-I-01

3

Hexagon socket head cap screws

4 Groove in connector bar

4

1

No. Name No. Name

1 Transfer stays

2 Transfer brackets

2

2

1

3

3 Stand

No. Name No. Name

1 Waste fluid tube 3 Rubber bush

2 Light-shielding tube

4. Follow the procedure below to attach the waste fluid

tank.

a. Place the waste fluid tank in the waste fluid tank

holder.

b. Attach the waste fluid tube to the tank.

c. Insert the waste fluid sensor cable into the

connector on the bottom of the printer.

3

5

4

2

1

No. Name No. Name

1 Waste fluid tank holder

2 Waste fluid tank

3 Waste fluid tube

4 Waste fluid sensor cable

Waste fluid sensor connector

5

VJ-1626UH INSTALLATION MANUAL

2

1

7. Attach the light-shielding cover to the waste fluid

tank.

Insert the light-shielding cover inside the waster

fluid tank holder.

1

2

No. Name No. Name

1 Light-shielding cover 2 Waste fluid tank holder

2

3.3 Detaching fastening materials

This printer has fastening materials in the place shown

below.

1. Remove all tapes from each cover.

3.4 Assembling the Media-feed table

(optional)

Follow the procedure below to assemble the

Media-feed table.

3.4.1

Assembling the Media-feed table

1. Use hexagon socket head cap screws (4 pieces) to

fix the reinforcement between the legs (right and

left).

1

4

3

Front

No. Name No. Name

1

2 Leg (right)

Leg (left)

4

Reinforcement

3

Hexagon socket head cap screws

Place the convex sections of the legs (right and left)

along the notch of the reinforcement to assemble.

2

Front

4. Use the lug screw to fix Stopper on Frame

・Install Stopper on the side of rail retaining screw.

・Install Stopper so that the curved part matches

Frame.

4

2

3

4

1

No. Name No. Name

1 Frame

2 Stopper

3 Lug screw

4 Rail retaining screw

5. Use the screws (2 pieces each) and fix Installation

plates (R and L) on Frame.

・Install Installation plates on the opposite side of rail

fixing screw.

3

1

3

2

2

3

1

2. Open the front cover and remove all protection

materials fixed with tape.

3. Open the right Maintenance cover, and remove all

the packing materials that are fixed with tape.

4. Remove a screw from the head unit fastening

material (metal plate) and remove the material.

1

3

2

No. Name No. Name

1

Head unit

2

Screw

Head unit fastening

3

material (metal plate)

5. Open the left maintenance cover, then place the tray.

1

1

2

No. Name No. Name

1 Leg (left), leg (right) 2 Reinforcement

2. Place the Frame on the legs and fix it with four

hexagon socket head cap screws.

1

Front

No. Name

1 Frame

2

2

No. Name

2 Hexagon socket head

cap screws

Firmly insert the protruding portions of the legs

to the holes of the Frame to fix it.

3. Use the screws (4 pieces) to fix Rails (fixed) on

the center of Frame.

When installing Rails (fixed), make sure that

the left and right rails are facing the same way.

3

2

1

3

No. Name No. Name

1 Installation plates (R)

2 Installation plates (L)

3 Frame

4 Screw

6. Assemble the other side of Media-feed table in the

same way

No. Name No. Name

1 Maintenance cover 2 Tray

1 Rails(fixed)

2 Frame

VJ1626UHE-I-01 4

No. Name No. Name

3 Screw

VJ-1626UH INSTALLATION MANUAL

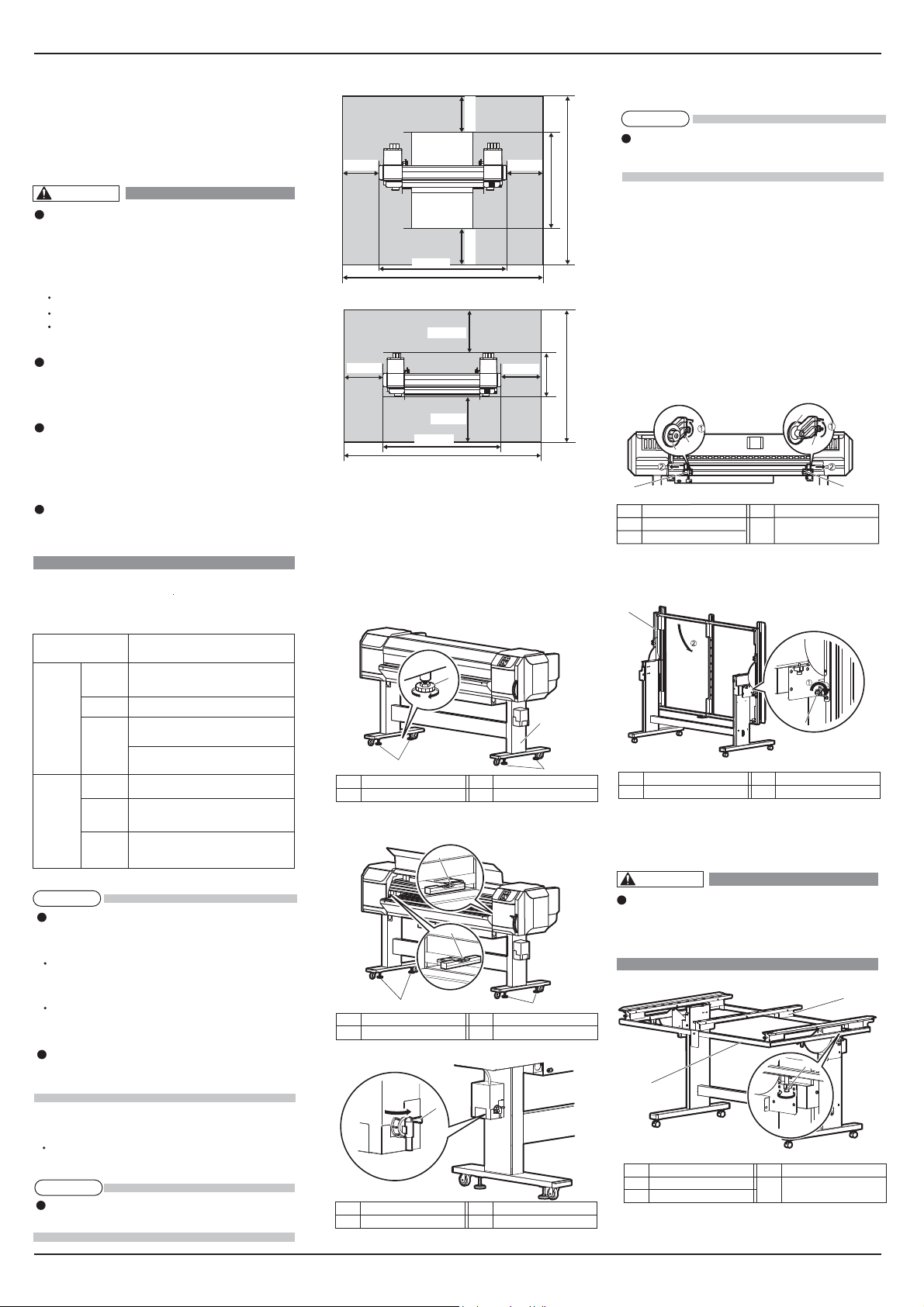

4 Installation

Procedures and environment for installing this product

are explained.

4.1 Installation environment

Install this product to the appropriate place with

reference to the following.

WARNING

Do not install the printer in the

following places where there is a

possibility that the printer may be

damaged or might fall or be fallen by

chance.

On a shaky stand

Slanting location

Places where vibration of other

machines etc. is transmitted.

Do not step on the printer or place

heavy things on top of it.

It may cause an injury if the printer

falls down.

Do not block the vent by covering the

printer with cloths, such as a blanket or

tablecloth. If the vent is blocked, heat

may accumulate inside the printer and

it may cause fire.

Do not install the printer in a location

that has high humidity or is dusty.

It could lead to electric shock and fire.

4.1.1

Installation environmental condition

Select an installation location in accordance with the

table below.

Floor strength of

installation place

Power

Rated

voltage

Specification

Frequency

Range

Power

capacity

Operative

Environm-

condition

ental

conditions

Printing

accuracy

coverage

Change

rate within

warranty

NOTE

For temperature and humidity, avoid locations

such as the following. There is a possibility that

the print quality will be affected.

Places where temperature or humidity may

rapidly change, even though within the required

conditions.

Places that receive direct sunlight, increased

illumination or direct air, for example from an air

conditioner.

To keep the temperature and humidity constant,

install this product in a location where the air

condition is adjustable.

4.1.2 Installation space

Install on a level floor which meets the following condition.

It has enough strength to support the weight of the

printer and the stand.

NOTE

For the weight of the printer and the stand, refer to

the Operation Manual.

More than 2940 Pa (300 kg/m2)

AC100-240V

50/60Hz ± 1Hz

100V-120V: Total of 4.0A

200V-240V: Total of 2.0A

Temperature: 20 °C to 32 °C

Humidity: 40 % to 60 %, No Condensation

Temperature: 22 °C to 30 °C

Humidity: 40 % to 60 %

Without condensation

Temperature: within 2 °C per hour

Humidity: within 5 % per hour

(1) When using the Media-feed table

1,000mm 1,000mm

1,000mm1,000mm

2,698mm

4,698mm

When not using the Media-feed table

(2)

1,000mm

1,000mm

1,000mm

2,698mm

4,698mm

1,000mm

2,730mm

818mm

4.2 Installation procedure

Install this product to the installation place in

accordance with the list shown below.

4.2.1 Installing the printer main unit

1. Carry the printer to the installation place.

2. Turn the following adjusters in the direction as

shown below to prevent the printer from moving.

Stands: adjusters (4)

1

2

1

No. Name No. Name

1 Adjuster 2 Stand

3. Set the level on the right and left platens and

adjust so that the printer stays flat.

1

1

No. Name No. Name

1 Level 2 Adjuster

2

4. Confirm that the waste fluid valve is closed.

1

No. Name No. Name

1 Waste fluid valve

1

2

4.2.2 Installing the Media-feed tables

(optional)

NOTE

When Using the roll media for “10 Checking the

4,730mm

printing condition”, you do not need to install

Media-feed table.

When using rigid media on this printer, use

Media-feed table (optional).

Follow the procedure below to install Media-feed

table.

The following items are required for installing

Media-feed table:

• Spanner: Accessories for Media-feed table

• Level: provided with the printer

2,818mm

(1)Rear side

1. Loosen the fixing levers on the right and left side

of the rear. Set the distance between the roll media

holders wider than the roll media width.

3

1

1

No. Name No. Name

1 Roll media holder(L)

2 Roll media holder(R)

3 Fixing Lever

2. Loosen retaining screws of Media-feed table, and

slowly level the table.

1

No. Name No. Name

1 Media-feed table 2 Leveling screw

3. Tighten the leveling screws of Media-feed table (2

places, both sides), and fix the table.

WARNING

When fixing the leveling screws, hold

the frame while pressuring the rubber

foot, and then turn the

screw until it doesn't turn any further.

3

No. Name No. Name

1 Media-feed table

2 Leveling screw

3 Frame

2

3

2

2

1

2

5 VJ1626UHE-I-01

Loading...

Loading...