Page 1

Service manual

ValueJet 1304

Page 2

Page 3

ValueJet 1304 Service manual

1 AP-74109 Rev 1.1

Important Notice

1. For Users in Europe

2. For Users in the United States

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant

to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment.

This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference in which case the

user will be required to correct the interference at his own expense.

3. Trademark Mentioned in this Manual

• MUTOH, ValueJet, VJ-1304 are registered trademarks or product names of MUTOH INDUSTRIES

LTD.

• Centronics and BiCentronics are registered trademarks or product names of Centronics Data Computer

Corporation.

• Windows95, Windows98, Windows98SE, Windows NT4.0, Windows2000, Windows XP, and MS-

DOS are registered trademarks or product names of Microsoft Corporation.

• Intel and Pentium are trademarks or registered trademarks of Intel Corporation.

• Other company and product names may be registered trademarks or product names.

This is a Class A product approved for industrial environments. In a domestic environment this product may cause

radio interference in which case you may be required to take

adequate measures.

Important:

• No part of this product or publication may be reproduced, copied, or

transmitted in any form or by any means, except for personal use,

without the permission of MUTOH INDUSTRIES LTD.

• The product and the contents of this publication may be changed

without prior notification.

• MUTOH INDUSTRIES LTD. has made the best efforts to keep this

publication free from error, but if you find any uncertainties or

misprints, please call us or the shop where you bought this equipment.

• MUTOH INDUSTRIES LTD. shall not be liable for any damages or

troubles resulting from the use of this equipment or this manual.

Page 4

ValueJet 1304 Service manual

AP-74109 Rev 1.1 2

Warranty Limitations

1. MUTOH INDUSTRIES LTD. warrants part repair or replacement as a sole measure only if a failure is

found in the system or in the materials and workmanship of the product the seller produced.

However, if the cause of failure is uncertain, decide the action after due mutual consultation.

2. The warranty shall not apply to any direct or indirect loss, or compensation for the loss due to the product

that has been subject to misuse, neglect, or improper alternation.

3.

The warranty period is described in the warranty certificate.

Page 5

ValueJet 1304 Service manual

3 AP-74109 Rev 1.1

About this Manual

1. Purpose and Target Readers

This manual explains preparations needed before maintaining and checking operations for MUTOH Full

Color Ink Jet Printer (VJ-1304).

This manual is prepared for the maintenance personnel of this printer.

Before using this printer, fully understand the contents and directions in this manual.

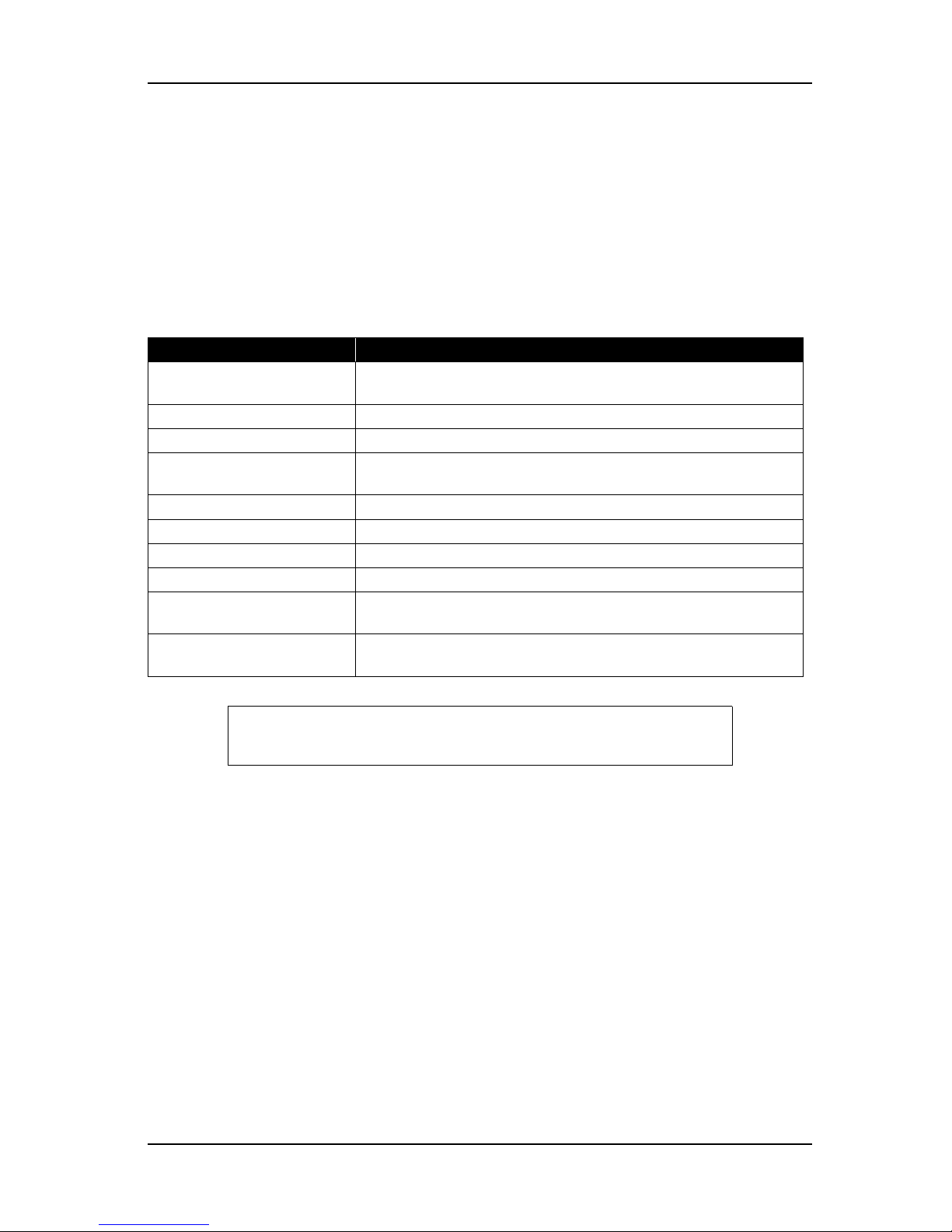

2. Manual Configuration

Section Contents

1 Safety Instructions Explains types of warnings, cautions and warnings labeled on the printer

for the both operators of the printer and maintenance personnel.

2 Product Overview Explains the features, part names, and functions of the printer.

3 Specifications Explains the specifications of the printer.

4 Parts Replacement Explains the procedures of replacement and removal of the service parts

of the printer.

5 Self-Diagnostic Mode Explains the self-diagnostic functions of the printer.

6 Maintenance Mode Explains the maintenance mode of the printer.

7 Adjustment Explains the adjusting procedures of the printer parts.

8 Maintenance Explains daily maintenance of the printer.

9 Troubleshooting Explains troubles that may occur when using the printer and how to

solve them.

10 Appendix Explains the maintenance information and the exploded views for this

printer.

Use the built-in self-diagnostic program to locate a defective part and adjust/

check during maintenance.

Page 6

ValueJet 1304 Service manual

AP-74109 Rev 1.1 4

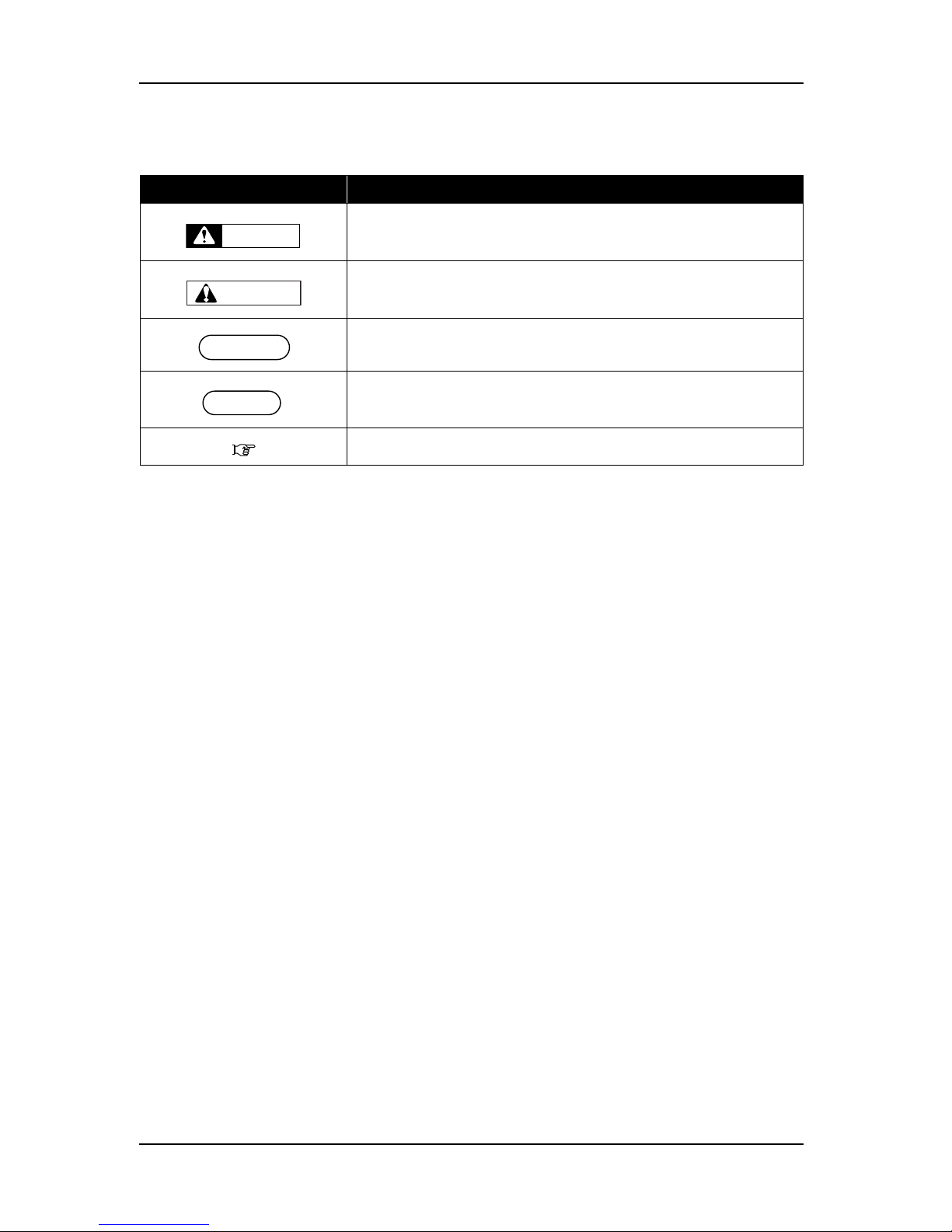

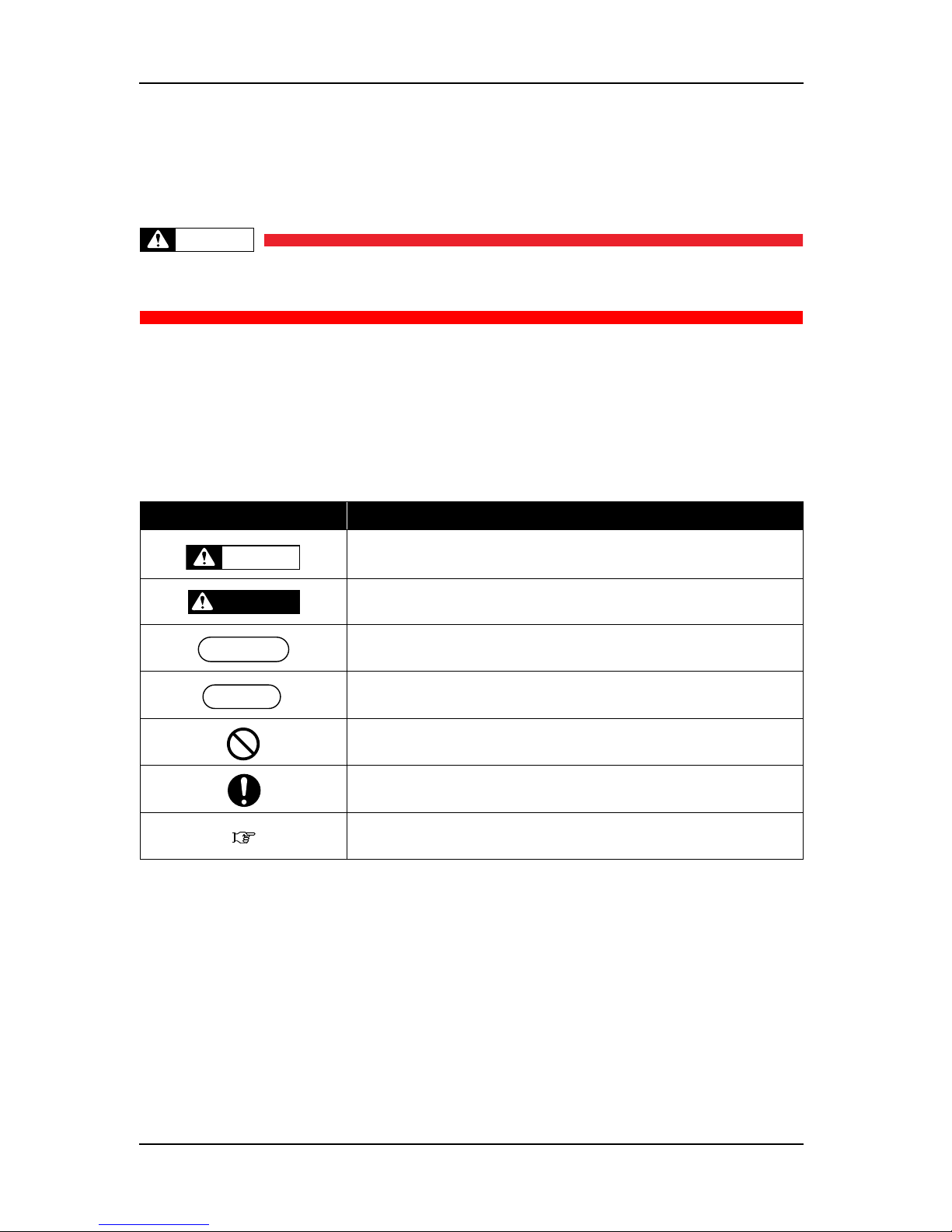

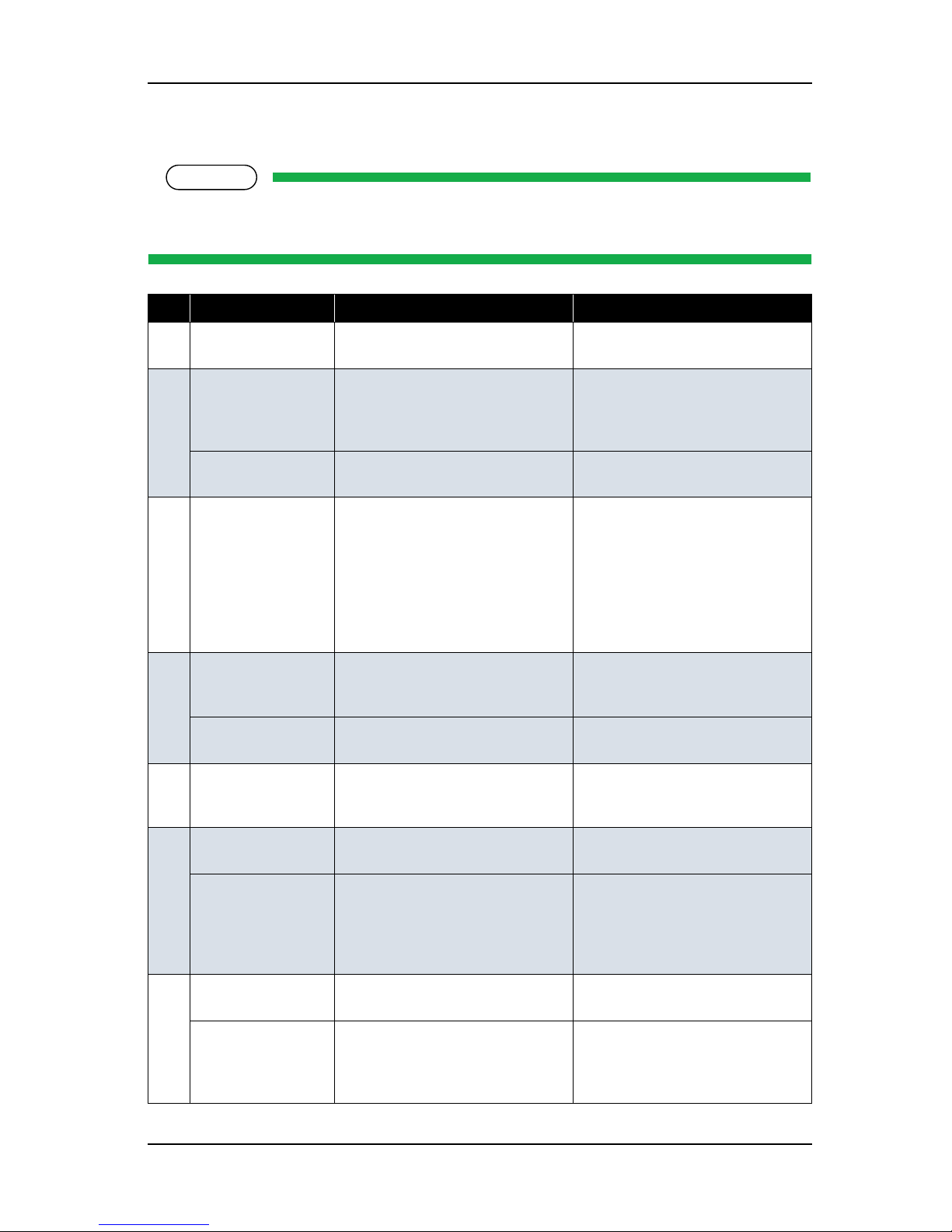

3. Manual Notation

The following symbols are used in this manual for easier understanding of the information.

4. Establishment Date of This Document

This document was established on September 18, 2007.

5. Firmware version covered by this document

Firmware version: Ver.1.00

Symbol Meaning

Must be followed carefully to avoid death or serious bodily injury

Must be observed to avoid slight or moderate bodily injury or damage to

your equipment

Contains important information and useful tips on the operation of the

product

Indicates useful tips for operating or understanding the equipment

Indicates reference pages in this manual

WARNING

CAUTION

NOTE

TIP

Page 7

ValueJet 1304 Service manual

2-3 AP-74109 Rev 1.1

General Table of Contents

1 Safety Instructions

1.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.2 Warnings, Cautions and Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.3 Important Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.4 Warning Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

1.4.1 Handling the Warning Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

1.4.2 Locations and Types of Warning Labels . . . . . . . . . . . . . . . . . . . . . . . . 1-9

1.5 Operation Labels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

1.5.1 Handling the Operation Labels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

1.5.2 Locations and Types of Operation Labels . . . . . . . . . . . . . . . . . . . . . . 1-12

2 Product Overview

2.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.2 Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.3 Part Names and Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.3.1 Front Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.3.2 Rear Section. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2.3.3 Winding unit (Optional). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2.3.4 Operation Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

2.4 Printer Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

2.4.1 Normal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

2.4.2 Setup Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

2.4.3 Self-Diagnosis Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

2.4.4 Maintenance Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

2.4.5 Selecting Panel Language and Panel Temperature. . . . . . . . . . . . . . . 2-12

Page 8

ValueJet 1304 Service manual

AP-74109 Rev 1.1 2-4

3 Specifications

3.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.2 Product Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.3 Interface Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3.3.1 Network Interface Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3.4 Choosing a Place for the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

4 Parts Replacement

4.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

4.2 Removal of Covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

4.2.1 Removing R Side Cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

4.2.2 Removing Operation Panel Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

4.2.3 Removing L Side Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

4.2.4 Removing Ink Holder (I/H) Cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

4.2.5 Removing Front Cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

4.2.6 Removing Top Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

4.2.7 Removing Media Guide F . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

4.2.8 Removing Media Guide R2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-17

4.2.9 Removing Scroller Receiver (L, R). . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

4.2.10 Assembling of Scroller Receiver L and R. . . . . . . . . . . . . . . . . . . . . . . 4-20

4.3 Replacement of Board Base Section Components. . . . . . . . . . . . . . . . . 4-23

4.3.1 Removing Connector Panel and Cooling Fan . . . . . . . . . . . . . . . . . . . 4-23

4.3.2 Removing Main Board Bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-24

4.3.3 Replacing Main Board Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-29

4.3.4 Replacing HEATER CONT board assembly . . . . . . . . . . . . . . . . . . . . 4-30

4.3.5 Replacing HEATER RELAY board assembly . . . . . . . . . . . . . . . . . . . 4-32

4.3.6 Replacing Power Board Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-35

4.3.7 Replacing Fuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-38

4.3.8 Replacing Inlet Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-41

4.4 Replacement of PF Driving Section Components. . . . . . . . . . . . . . . . . . 4-44

4.4.1 Replacing PF Motor Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-44

4.4.2 Replacing PF_ENC Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-47

4.4.3 Replacing PF_ENC Scale . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-48

4.4.4 Replacing Heater and Thermistor Assembly . . . . . . . . . . . . . . . . . . . . 4-49

Page 9

ValueJet 1304 Service manual

2-5 AP-74109 Rev 1.1

4.5 Replacement of CR Driving Section Components. . . . . . . . . . . . . . . . . . 4-51

4.5.1 CR Motor Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-51

4.5.2 Replacing CR Origin Point Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-52

4.5.3 Replacing Lever Sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-54

4.5.4 Replacing T Fence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-55

4.5.5 Replacing CR Driven Pulley . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-58

4.5.6 Replacing Pressure Arm Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . 4-460

4.6 Replacement of Head Section Components . . . . . . . . . . . . . . . . . . . . . . 4-61

4.6.1 Replacing Print Head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-61

4.6.2 Replacing Cutter Holder Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-66

4.7 Replacement of Maintenance Section Components . . . . . . . . . . . . . . . . 4-71

4.7.1 Removing Maintenance Base Assembly . . . . . . . . . . . . . . . . . . . . . . . 4-71

4.7.2 Replacing Maintenance Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-76

4.7.3 Replacing Cleaner Head (Cleaning Wiper) . . . . . . . . . . . . . . . . . . . . . 4-77

4.8 Replacement of Ink Supply Section Components. . . . . . . . . . . . . . . . . . 4-79

4.8.1 Replacing Ink Holder (I/H) Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . 4-79

4.8.2 Replacing Ink Sensor Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-82

4.8.3 Replacing Cover Sensor Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-85

4.8.4 Replacing Heater Junction Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-87

4.9 Replacement of Frame Section Components . . . . . . . . . . . . . . . . . . . . . 4-89

4.9.1 Replacing Suction Fan Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-89

4.9.2 Replacing P_REAR Sensor Assembly . . . . . . . . . . . . . . . . . . . . . . . . . 4-90

4.10 Replacement of Cable Guide Section Components . . . . . . . . . . . . . . . . 4-91

4.10.1 Replacing CR Board Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-91

4.10.2 Replacing Ink Tube . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-93

4.10.3 Replacing CR Tape Wire . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-97

4.11 Replacing accessory unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-88

4.11.1 Replacing level switch (waste fluid) . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-89

4.12 Replacing Take up unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-102

4.12.1 Removing Tension arm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-103

4.12.2 Removing take up unit fixing plate . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-104

4.12.3 Removing take up unit cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-105

4.12.4 Replacing scroller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-108

4.12.5 Replacing VJ take up unit CNT board assembly . . . . . . . . . . . . . . . . 4-109

4.12.6 Replacing CR_HP sensor, lever sensor. . . . . . . . . . . . . . . . . . . . . . . 4-117

4.12.7 Replacing peripheral devices of VJ take up unit motor assembly . . . 4-120

Page 10

ValueJet 1304 Service manual

AP-74109 Rev 1.1 2-6

5 Self-Diagnosis Mode

5.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

5.2 Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

5.2.1 Preparations on Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

5.2.2 Starting Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

5.3 Operations in Self-Diagnosis Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

5.3.1 Operating Self-Diagnosis Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

5.3.2 Diagnosis Items in Self-Diagnosis Menu . . . . . . . . . . . . . . . . . . . . . . . . 5-8

5.4 Platen Adjustment Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

5.5 Inspection Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

5.5.1 Memory Size Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

5.5.2 Version Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

5.5.3 Operation Panel Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-14

5.5.4 Sensor Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

5.5.5 Encoder Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-17

5.5.6 Fan Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-17

5.5.7 History Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

5.5.8 Head Waveform Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-21

5.6 Ink Charging Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-22

5.7 Adjustment Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-23

5.7.1 CR return position adjustment menu . . . . . . . . . . . . . . . . . . . . . . . . . . 5-25

5.7.2 Head Nozzle Check Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-26

5.7.3 Skew Check Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-28

5.7.4 Head Slant Check Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-29

5.7.5 Voltage Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-33

5.7.6 Uni-D / Bi-D Low and High Adjustment . . . . . . . . . . . . . . . . . . . . . . . . 5-36

5.7.7 Side Margin Adjustment Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-42

5.7.8 Test Printing Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-43

5.7.9 HeadWash Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-44

5.7.10 Software Counter Initialization Menu . . . . . . . . . . . . . . . . . . . . . . . . . . 5-45

5.7.11 Feed Pitch Check Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-46

5.7.12 Solid Print Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-47

5.8 Cleaning Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-48

Page 11

ValueJet 1304 Service manual

2-7 AP-74109 Rev 1.1

5.9 Sample Printing Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-49

5.9.1 Adjustment pattern ALL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-50

5.9.2 Parameter ALL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-50

5.9.3 Error history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-50

5.9.4 Dot pattern . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-51

5.10 Time Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-52

5.11 Parameter Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-52

5.11.1 Parameter Initialization Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-53

5.11.2 Parameter Update Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-56

5.12 Servo Setting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-64

5.13 Endurance Running Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-67

5.13.1 CR Motor Endurance Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-68

5.13.2 PF Motor Endurance Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-69

5.13.3 Pump Endurance Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-70

5.13.4 Print Head Endurance (Nozzle Print) Menu . . . . . . . . . . . . . . . . . . . . . 5-71

5.13.5 General Endurance Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-72

5.13.6 Endurance Running Check Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-73

5.14 Media Feed Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-73

5.15 ExControl Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-74

5.15.1 Version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-74

5.15.2 Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-75

5.15.3 Heater. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-76

5.15.4 History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-76

5.16 PaperInitial Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-77

6 Maintenance Mode 2

6.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

6.2 Operations in Maintenance Mode 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

6.2.1 Starting Up the Maintenance Mode 2. . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

6.2.2 Operating Maintenance Mode 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

6.3 Maintenance Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

6.3.1 Counter Display Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

6.3.2 Counter Initialization Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

6.3.3 Counter Print Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

6.3.4 Media Feed Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

Page 12

ValueJet 1304 Service manual

AP-74109 Rev 1.1 2-8

7 Adjustment

7.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

7.2 Adjustment Item . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

7.3 Working with Mutoh Maintenance Engineer Assistant. . . . . . . . . . . . . . . 7-8

7.3.1 Parameter Backup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-12

7.3.2 Jigs and Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-12

7.3.3 Required Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-12

7.3.4 Receiving Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-19

7.3.5 Firmware Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-21

7.3.6 Sending Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-28

7.3.7 Sub Controller Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-29

7.3.8 Date & Time Setting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-31

7.4 PF Speed Reduction Belt Tension Adjustment . . . . . . . . . . . . . . . . . . . . 7-32

7.4.1 Jigs and Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-32

7.4.2 Adjustment Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-32

7.5 PF Encoder Assembly Position Adjustment . . . . . . . . . . . . . . . . . . . . . . 7-33

7.5.1 Adjustment Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-33

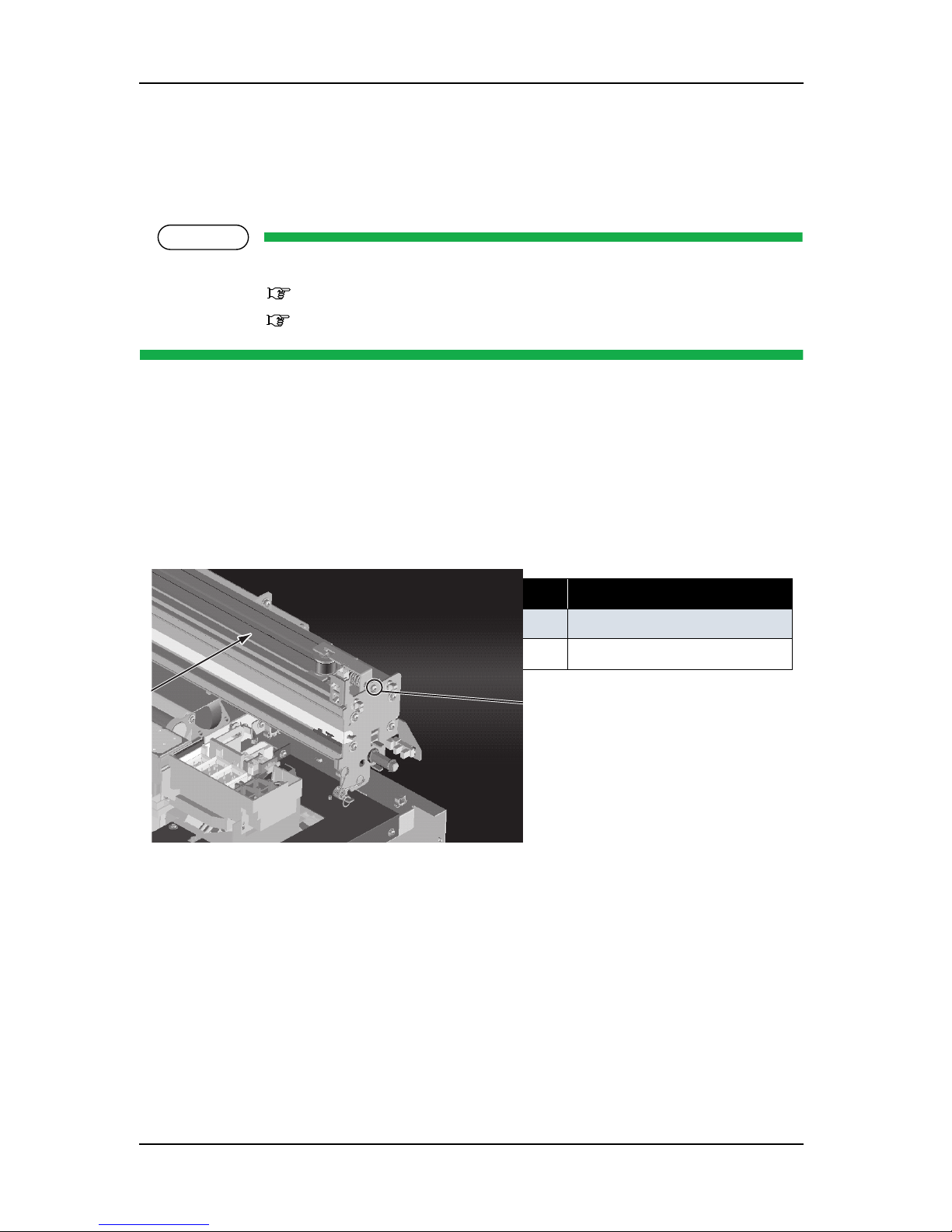

7.6 CR Belt Tension Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-35

7.7 Head Alignment (Horizontal Height) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-36

7.8 Head Alignment (Vertical Slant) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-38

7.9 Cutter Holder Height Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-40

7.9.1 Jigs and Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-40

7.9.2 Adjustment Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-40

7.10 PG Height Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-43

7.10.1 Jigs and Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-43

7.10.2 Adjustment Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-43

7.11 Media Sensor Sensitivity Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-45

7.11.1 P_EDGE Sensor Sensitivity Adjustment . . . . . . . . . . . . . . . . . . . . . . . 7-45

7.11.2 P_REAR Sensor Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-48

Page 13

ValueJet 1304 Service manual

2-9 AP-74109 Rev 1.1

8 Maintenance

8.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

8.2 Periodical Services. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

8.2.1 Periodical Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

8.2.2 Parts need to be checked or replaced . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

8.3 Part Life Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

8.4 Lubrication/Bonding. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-7

8.5 Transportation of Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-8

9 Troubleshooting

9.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

9.2 Troubleshooting with Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

9.2.1 Operation Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-3

9.2.2 Errors with Message. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-5

9.2.3 Errors Requiring Reboot. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-9

9.2.4 Error Messages During File Transmission . . . . . . . . . . . . . . . . . . . . . . 9-25

9.3 Troubleshooting Without Error Messages . . . . . . . . . . . . . . . . . . . . . . . . 9-30

9.3.1 Initial Operation Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-30

9.3.2 Media Feed Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-39

9.3.3 Printing Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-41

9.3.4 Noise Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-59

9.3.5 Online Function Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-62

9.3.6 Other Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-65

9.3.7 Troubleshooting for a dedicated network software. . . . . . . . . . . . . . . . 9-67

10 Appendix

10.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-2

10.2 Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-2

10.3 Jigs and Tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-3

10.3.1 Required Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-3

10.4 Operation Panel Messages (Bilingual List) . . . . . . . . . . . . . . . . . . . . . . . 10-4

10.5 Exploded View. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-9

Page 14

ValueJet 1304 Service manual

AP-74109 Rev 1.1 2-10

Page 15

ValueJet 1304 Service manual

1-1 AP-74109 Rev 1.1

1 Safety Instructions

1.1 Introduction............................................................................................. 1- 2

1.2 Warnings, Cautions and Notes.............................................................. 1- 2

1.3 Important Safety Instructions ................................................................ 1- 3

1.4 Warning Labels ....................................................................................... 1- 9

1.4.1 Handling the Warning Labels......................................................... 1-9

1.4.2 Locations and Types of Warning Labels........................................ 1-9

1.5 Operation Labels................................................................................... 1- 11

1.5.1 Handling the Operation Labels .................................................... 1-11

1.5.2 Locations and Types of Operation Labels ................................... 1-12

Page 16

ValueJet 1304 Service manual

AP-74109 Rev 1.1 1-2

1.1 Introduction

This chapter explains the meaning of safety terms for personnel who installs, operates, or maintains this

equipment, important safety instructions, and the warning labels attached to the equipment.

WARNING

Make sure to follow all instructions and warnings on this manual when installing, operating,

or maintaining the equipment.

1.2 Warnings, Cautions and Notes

Safety terms in this manual and the contents of warning labels attached to the printer are categorized into the

following three types depending on the degree of risk (or the scale of accident).

Read the following explanations carefully, and follow the instructions in this manual.

Table 1-1 Safety Terms Descriptions

Safety terms Details

Must be followed carefully to avoid death or serious bodily injury

Must be observed to avoid slight or moderate bodily injury or damage to

whole or part of the product

Contains important information and useful tips on the operation of the

product

Indicates useful tips for operating or understanding the printer

Indicates "prohibited" operations

Indicates required operations

Indicates reference page in this manual

WARNING

DANGER

NOTE

TIP

Page 17

ValueJet 1304 Service manual

1-3 AP-74109 Rev 1.1

1.3 Important Safety Instructions

General safety instructions that must be observed to use the equipment safely are explained below.

WARNING

Do not place the printer in the following areas. Doing so may result in the printer

tipping or falling over and causing injury.

• Unstable surfaces

• Angled place

• Areas subject to vibration by other equipment

Do not stand on or place heavy objects on your printer. Doing so may result in the

printer tipping or falling over and causing injury.

Do not cover the ventilation hole of your printer with cloth, such as a blanket or table

cloth. Doing so could obstruct ventilation and cause fire.

Do not place the printer in humid and dusty areas. Doing so may result in electrical

shock or fire.

Do not use damaged power cable. It could lead to an electric shock and fire.

Do not take out or insert power plug with a wet hand. This could lead to an electric

shock.

Make sure that the following is performed before parts replacement.

• Turn off the power of the printer.

• Remove the power cable from the power outlet.

Not doing so may cause electric shock or damage to the electric circuit.

• Unplug the cables connected to the printer.

Failure to do so could result in damage to the printer.

Do not connect an earth wire to the following places.

• Gas pipe

There is a possibility of ignition and explosion.

• Earth wire of telephone cables and lightning rods

Heavy current might flow whenever a lightning strikes.

• Water pipe and faucet

The earth might not work if a plastic pipe is connected in the middle of the metal

pipe.

Do not store combustible materials on Platen while performing the heater operation.

It could lead to fire.

Do not spill flammable liquid over platen. This could lead to fire.

Page 18

ValueJet 1304 Service manual

AP-74109 Rev 1.1 1-4

Do not insert or drop metal or flammable objects into the printer through openings

such as a fresh air inlet. It could lead to an electric shock and fire.

When foreign substances or liquids such as water entered the printer, do not use

the printer as it is. It could lead to an electric shock and fire. Immediately turn OFF

the power switch, disconnect the power plug from the electric socket.

Be sure to use the power cable supplied with the printer. If other power cables are

used, it would cause an electric shock or fire.

Make sure to use only the specified power supply (AC 100 V - 120 V or AC 220 V 240 V). If the power supply other than the specified voltage is used, it could cause

an electric shock and fire.

Take power for the printer directly from the power socket (AC 100 V - 120 V or AC

220 V - 240 V). Do not use complex multiple plugs on the same socket. This could

generate heat and might cause fire.

Be sure to use a dedicated power socket with earth wire for the power supply, and

connect it to the earth wire. If the earth wire is not connected, an electric shock or

fire may occur.

The waste fluid from the printer is a waste oil (waste ink) of industrial waste. Proper

waste fluid disposal according to industrial waste disposal laws and ordinances of

your local governments are required. Consign disposal of waste fluids to specialized

processor.

Page 19

ValueJet 1304 Service manual

1-5 AP-74109 Rev 1.1

CAUTION

Assembling and disassembling of the printer are possible only for the parts that

disassembling procedures are shown in this manual. Do not disassemble any frame

parts or parts that disassembling procedures are not shown in this manual.

Doing so may cause trouble that cannot be restored, as the printer is originally

assembled in the factory with a high accuracy of 1/100 mm.

Do not touch the elements on the circuit board with bare hands.

Doing so may cause static electricity and break the elements.

Do not press the transparent film on the damper assembly with your hands. Doing

so may discharge the ink filled inside the damper assembly.

Be careful not to damage the transparent film on the damper assembly.

Do not touch the nozzles of the print head. Make sure that the nozzles do not get

any dust.

There are some remaining ink in the tubes. Be careful that the ink is not spilled from

the tube outlet onto the printer or items close to the printer.

If you need to operate the printer with the cover removed for maintenance, be

careful not to get hurt by the driving parts.

Never lube the printer mechanism with lube other than that designated by MUTOH.

Doing so may damage the parts or shorten the lifetime.

If the power board assembly needs to be removed, remove the power cable and

wait for 5 minutes or more before taking it out; this will discharge the residual

electrical charge of the electrolytic capacitor.

Touching the board before the capacitor discharges may cause electric shock.

When connecting or removing an FFC type cable on a main board assembly

connector, make sure to connect or remove the cable perpendicular to the

connector.

Connecting or removing at a slant angle may damage, break or short-circuit the

inner terminal of the connector. That may damage the elements on the board.

When connecting or removing an FFC type cable on the CR board assembly

connector, make sure to connect or remove the cable perpendicular to the

connector.

Connecting or removing at a slant angle may damage, break or short-circuit the

inner terminal of the connector. That may damage the elements on the board.

Make sure there is sufficient space around the printer when performing

maintenance work.

Maintenance must be done by more than two persons for the following work.

• When disassembling or reassembling the product and the optional stand

• When packing the printer for transportation

Page 20

ValueJet 1304 Service manual

AP-74109 Rev 1.1 1-6

Pay attention to the following points, while handling power cable.

• Do not do anything forcefully on the power cable.

• Do not keep heavy objects on the power cable.

• Do not bend, twist or pull the power cable by force.

• Do not route the power cable near heating appliances.

Pay attention to the following points while handling power supply plug. Any

mishandling of the power cable could cause a fire.

• Make sure that no foreign substances such as dust etc. are stuck to the power

plug.

• The power plug is firmly inserted to the edge of the power socket.

Be careful not to pinch your fingers when opening/closing the front cover or

maintenance cover.

While handling ink cartridge, pay attention so that the ink does not get into eyes or

stick to the skin. If the ink gets into the eyes or sticks to the skin, immediately wash

it off with water. It might possibly cause irritation and light inflammation of eyes. In

case of any abnormality, consult a physician immediately.

Do not disassemble ink cartridges. If disassembled, there is a possibility that the ink

might come into contact with eyes or skin.

Do not operate the media loading lever during initial operation. The carriage portion

may touch the pressurizing roller portion causing a malfunction.

Do not touch the media guide during printing. It is hot and may cause a burn.

Be careful that your fingers are not caught in the driven section of the winding unit.

Pay attention to the following points when you cut roll media. Mishandling the razor

blade may cause a cut on your finger or hand.

• When you hold media, do not place your finger on the media cut groove.

• Move the razor blade along the media cut groove.

Do not apply Jetwash, thinner, benzine, or alcohol to the printer parts, excluding

listed below. Such use may result in printer malfunction

• Inside the maintenance cover

• Surface of the print head

Be careful that moisture does not enter the printer. There is a possibility that electric

circuit inside the printer is short circuited.

Page 21

ValueJet 1304 Service manual

1-7 AP-74109 Rev 1.1

While cleaning with the cleaning wiper

• Do not touch the cleaning wiper and head cap unit.

Head cleaning may not be operated correctly because of the grease attached.

• Make sure to wipe the print head with a dry poly-knit wiper.

A wet poly-knit wiper may cause the print head to clog.

• Do not use clean sticks.

Attached dust may damage the print head.

Be careful the followings when cleaning the outer of the print head:

• Do not touch the print head nozzle part.

Such operation may damage the print head.

• Do not touch the tip of the clean stick.

Fat sticks to the clean stick may damage the print head.

• Do not sink the clean stick into water.

Such operation may damage the print head.

• Do not re-use any used clean stick.

Attached dust may damage the print head.

Do not slant the printer body, prop it against a wall or turn it upside down. There is

a possibility that ink inside the printer may leak. Moreover, normal operation after

shifting (to these positions) cannot be guaranteed.

Unpack or move the printer by more than two person.

When taking this printer out of the package box, make sure to remove the vinyl

sheet and hold the handles on the side of the printer. If the printer is lifted with the

vinyl sheet attached, there is a possibility that the printer falls slipping from hands

and gets damaged.

When you do not use the printer for a long period, make sure to pull out the power

plug from the power socket for safety.

Make sure to connect an earth wire to the earth connection which meets the following

standards.

• Earth terminal of power socket

• Earth wire with copper plate which is buried at 650 mm or more, deep in the ground.

• Earth terminal which grounded properly (earth resistance: 100

Ω or less).

Keep the work area well-ventilated. This prevents fire and operators from feeling

sick from bad air.

Execute the following operation by more than two persons:

• Setting the winding unit.

When printing is finished, the media guide and the platen are at high temperature. Wait

until the media guide and the platen cool off.

Page 22

ValueJet 1304 Service manual

AP-74109 Rev 1.1 1-8

When cleaning the printer, be sure to turn OFF the power and disconnect the power

plug.

Move the printer maintaining a horizontal position.

Be sure to operate the following before attaching option units.

• Turn the printer power off.

• Unplug the power cable.

• Unplug the cables connected to the printer.

Otherwise, the printer or computer may be damaged.

• Remove the static electricity by touching the metal part of the printer from your

cloth or body.

Electric part such as RAM may be damaged.

Do not touch the board elements when attaching option units. The elements become

high temperature and may cause the burn.

Page 23

ValueJet 1304 Service manual

1-9 AP-74109 Rev 1.1

1.4 Warning Labels

The handling, attachment locations, and types of warning labels are explained below.

Warning labels are attached to areas where care should be taken. Read and understand the positions and

contents thoroughly before maintenance operation.

1.4.1 Handling the Warning Labels

Make sure to note the following when handling the warning labels.

NOTE

• Make sure that all warning labels can be recognized. If text or illustrations cannot be seen clearly,

clean or replace the label.

• When cleaning warning labels, use a cloth with water or neutral detergent. Do not use a solvent or

gasoline.

• If a warning label is damaged, lost, or cannot be recognized, replace the label.

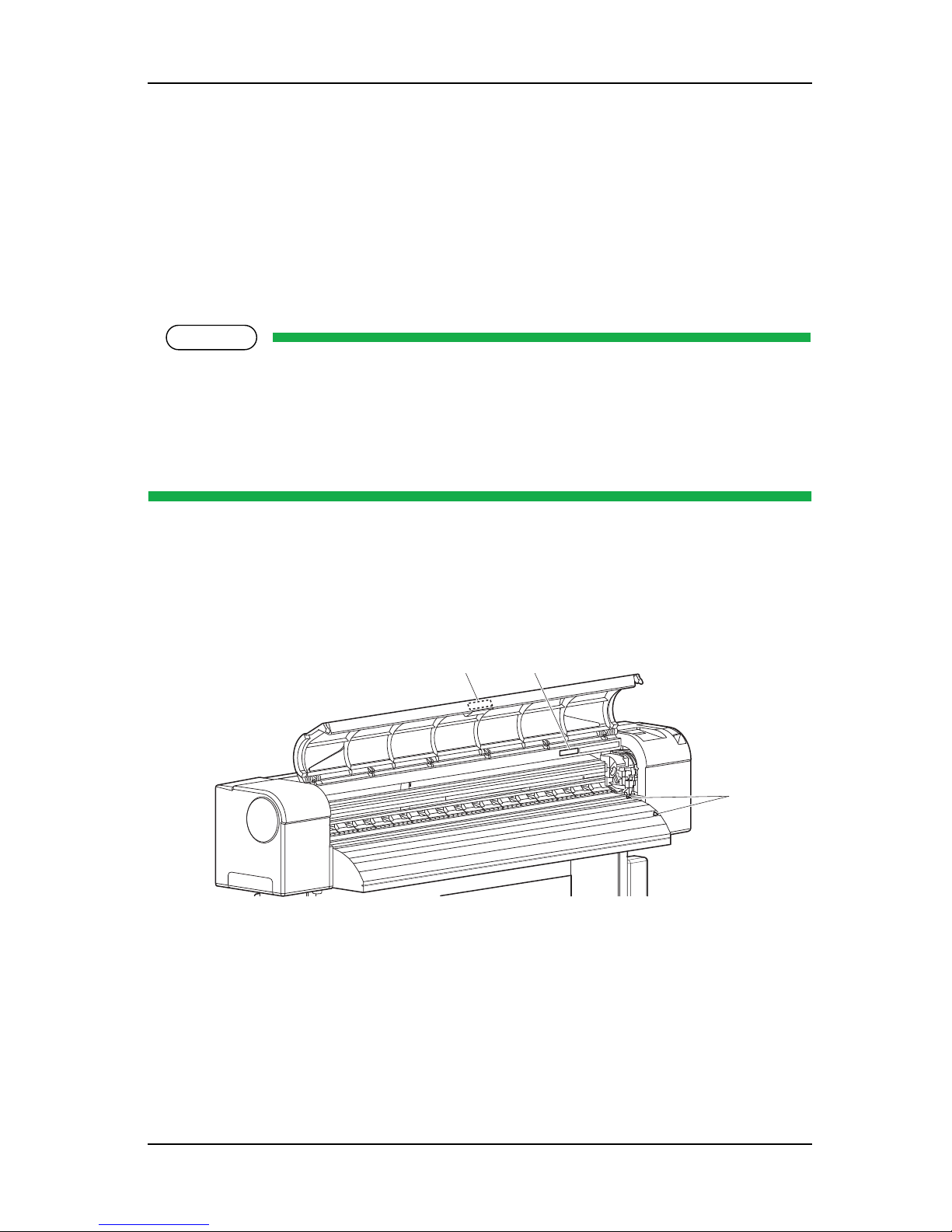

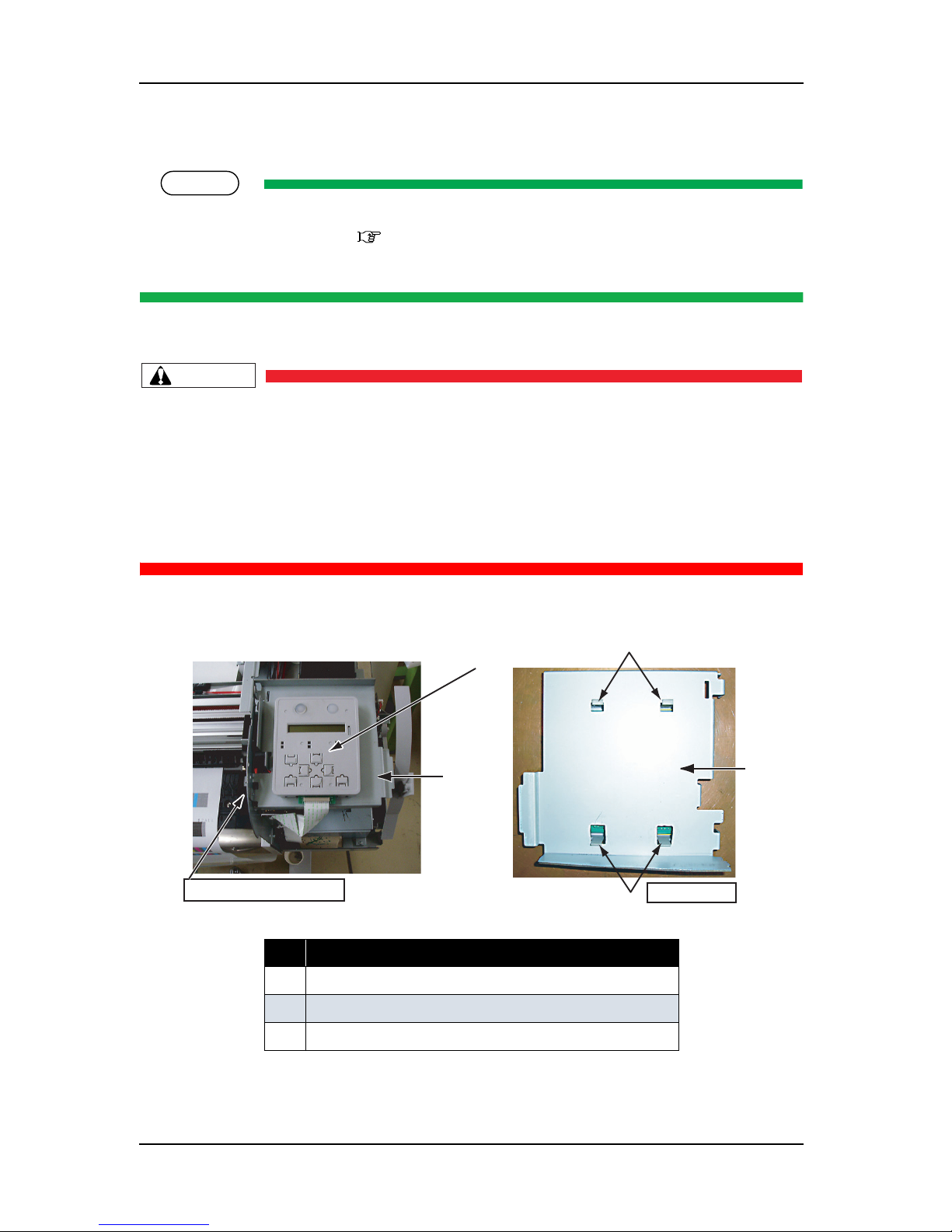

1.4.2 Locations and Types of Warning Labels

The locations of warning labels are shown below.

(1) Main Body

21

3

Page 24

ValueJet 1304 Service manual

AP-74109 Rev 1.1 1-10

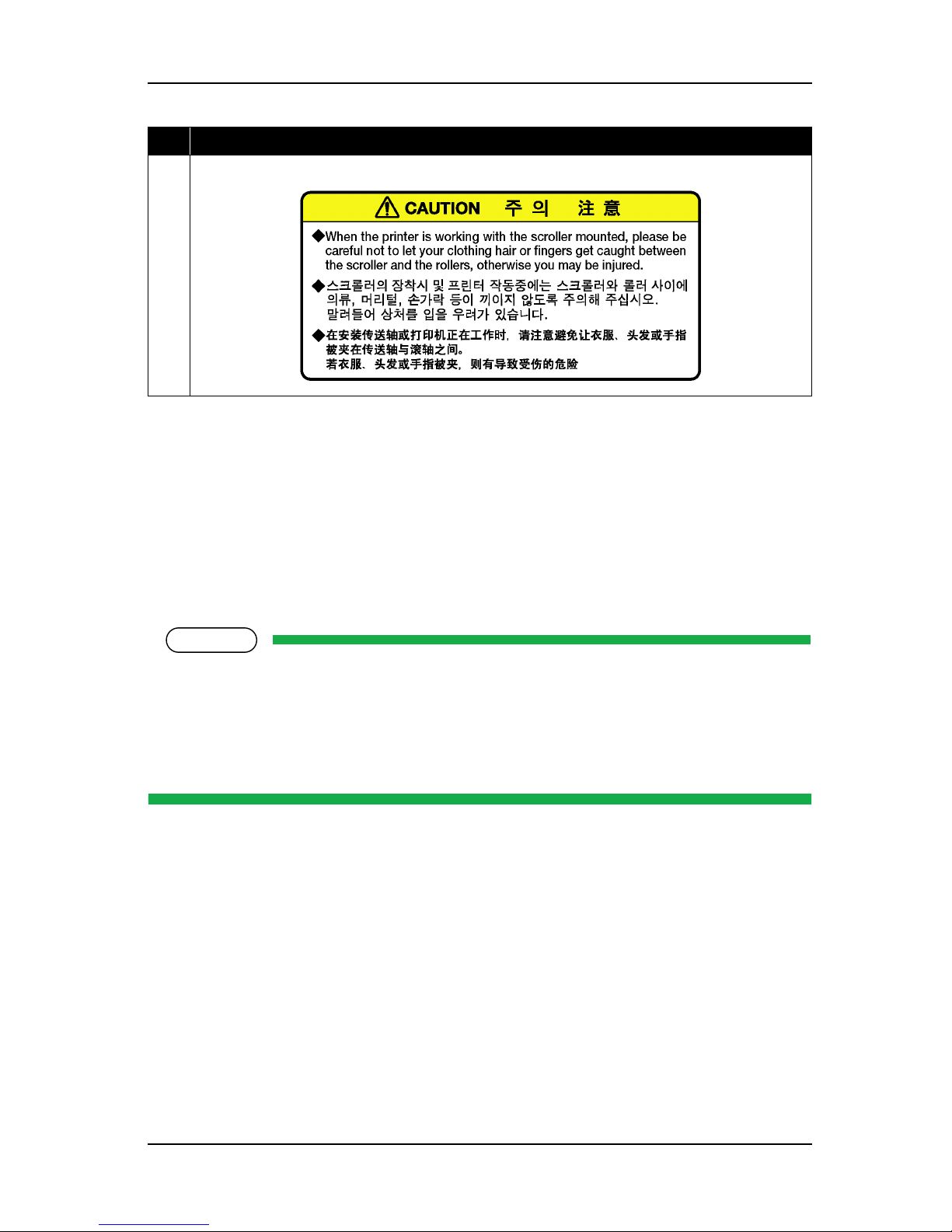

(2) Winding unit

The locations of warning labels on the winding unit are shown below.

Table 1-2 List of Warning Labels

No. Warning label type

1

(T fence handling caution)

2

(Front cover open/close caution)

3

(High temperature caution)

1

Page 25

ValueJet 1304 Service manual

1-11 AP-74109 Rev 1.1

1.5 Operation Labels

This chapter describes the operation labels including their types and attaching positions.

The operation labels are attached on the product to provide the brief instructions for the particularly important

operations. Learn the instructions and the attaching positions before operation.

1.5.1 Handling the Operation Labels

Make sure to note the following when handling the operation labels.

NOTE

• Make sure that all operation labels can be recognized. If text or illustrations cannot be seen clearly,

clean or replace the label.

• When cleaning operation labels, use a cloth with water or neutral detergent. Do not use a solvent

or gasoline.

• If an operation label is damaged, lost, or cannot be recognized, replace the label.

No. Warning label type

1

(Catching caution)

Page 26

ValueJet 1304 Service manual

AP-74109 Rev 1.1 1-12

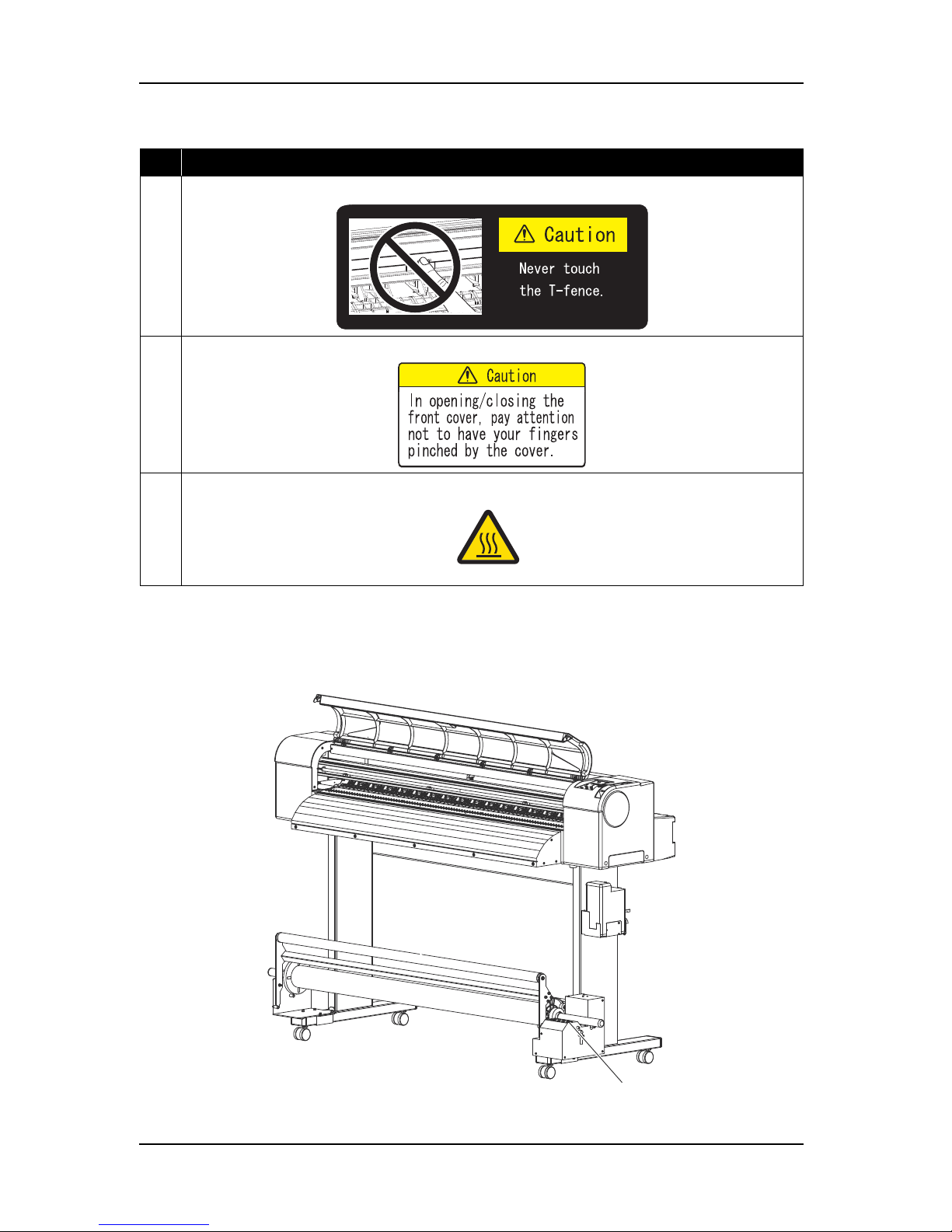

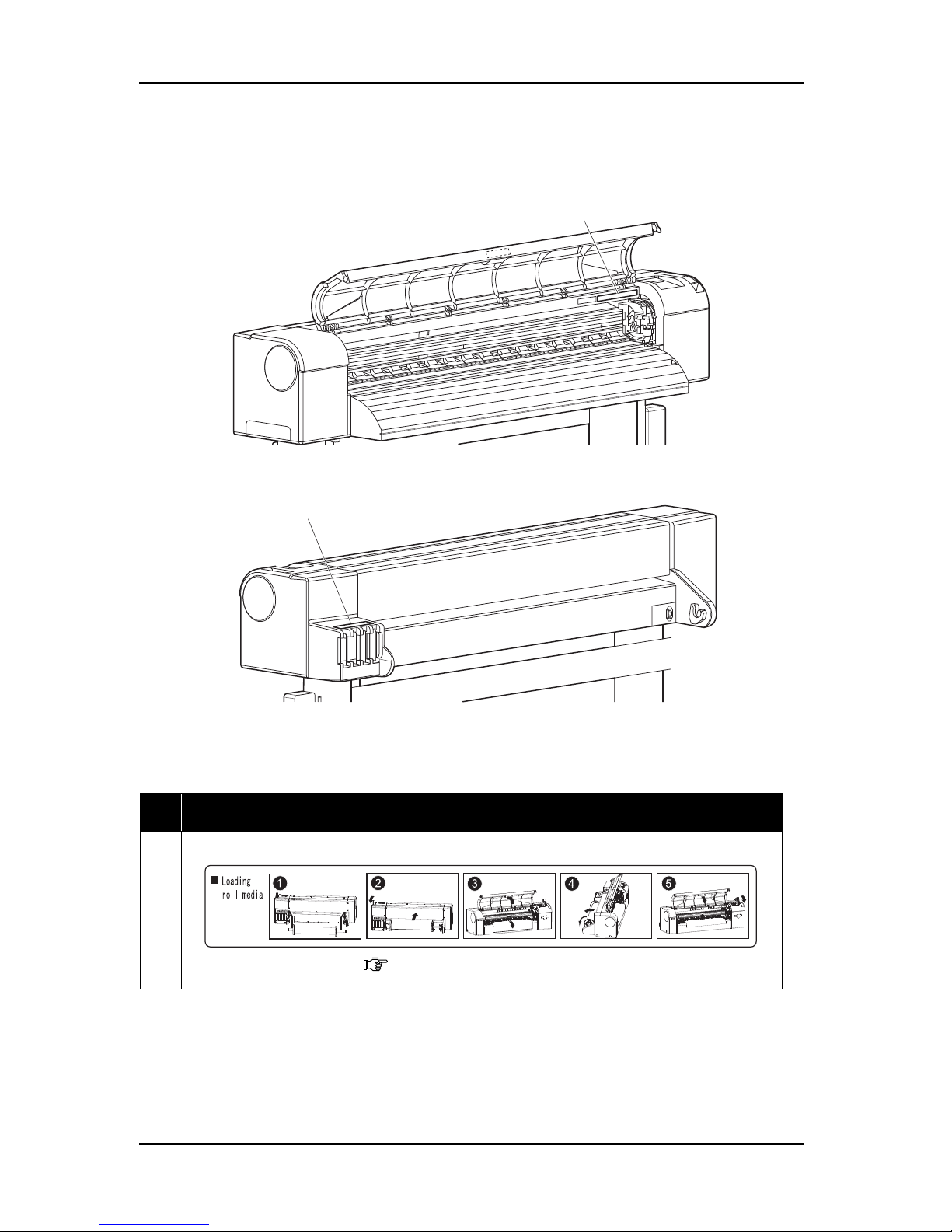

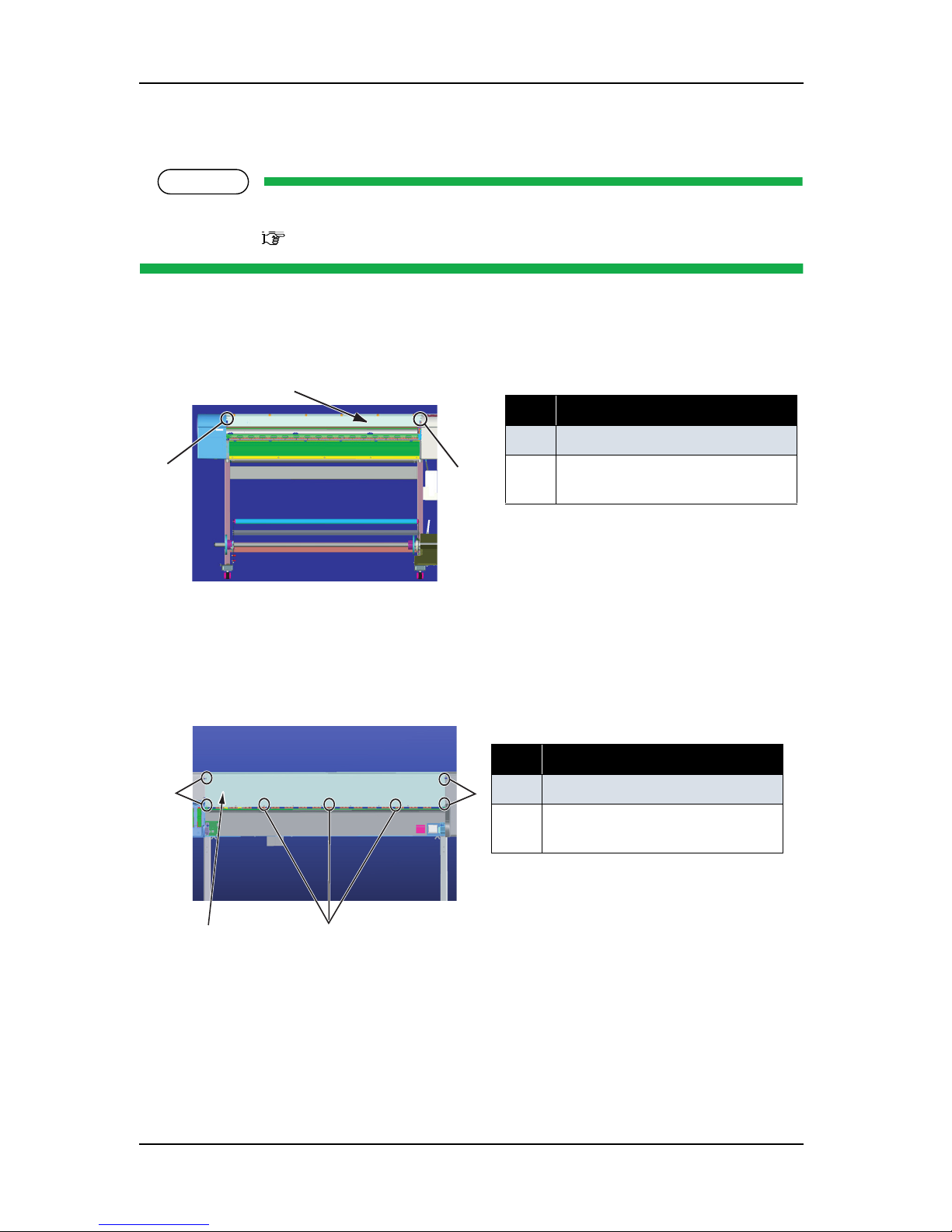

1.5.2 Locations and Types of Operation Labels

The locations of operation labels are shown below.

Table 1-3 List of Operation Labels

No. Operation label type

1

(Roll media setting)

"Operation manual" Setting Roll Media

1

2

Page 27

ValueJet 1304 Service manual

1-13 AP-74109 Rev 1.1

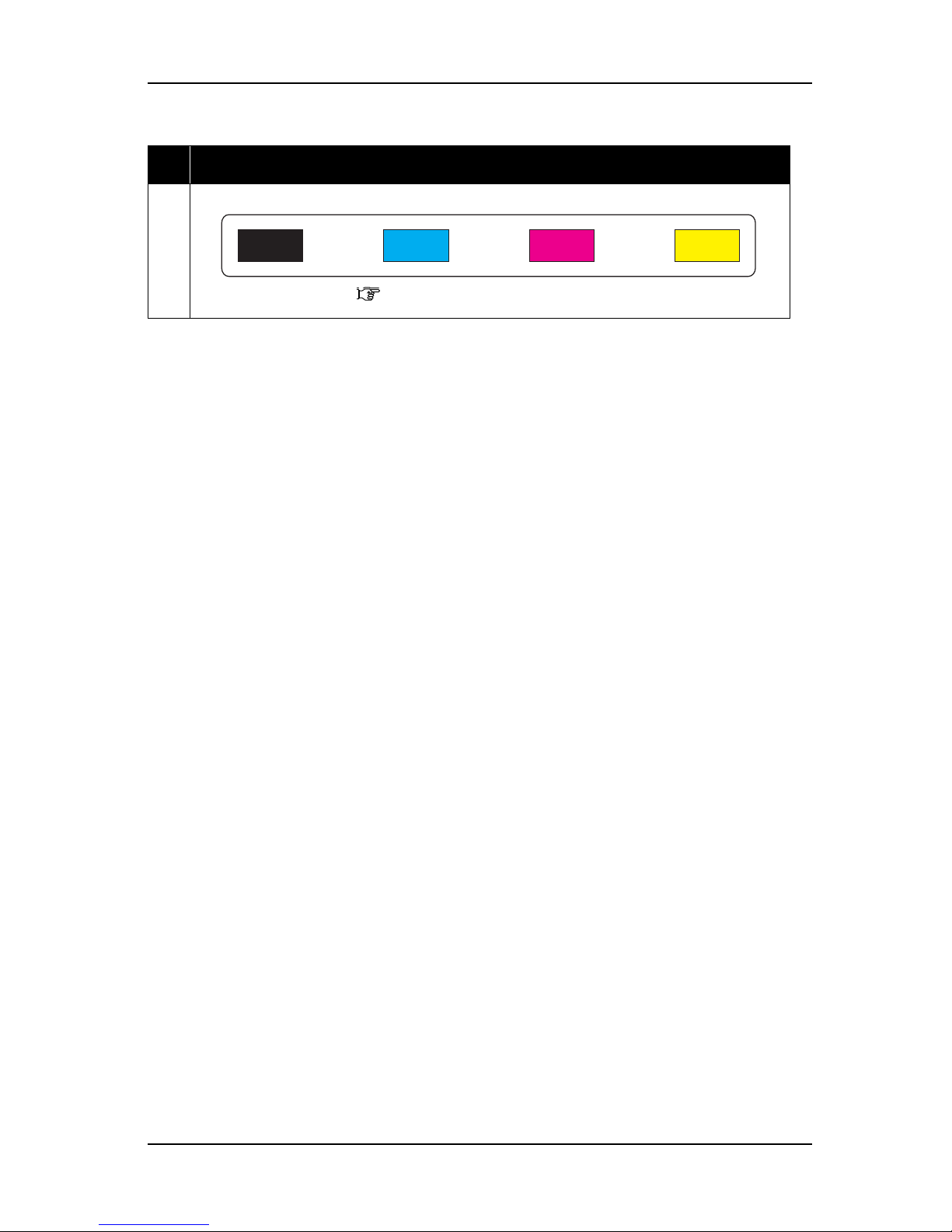

2

(Ink arrangement)

"Operation manual" Replacing Ink Cartridges

Table 1-3 List of Operation Labels (Continued)

No. Operation label type

Page 28

ValueJet 1304 Service manual

AP-74109 Rev 1.1 1-14

Page 29

ValueJet 1304 Service manual

2-1 AP-74109 Rev 1.1

2 Product Overview

2.1 Introduction............................................................................................. 2- 2

2.2 Features................................................................................................... 2- 2

2.3 Part Names and Functions..................................................................... 2- 3

2.3.1 Front Section ................................................................................. 2-4

2.3.2 Rear Section.................................................................................. 2-5

2.3.3 Winding unit (Optional) .................................................................. 2-6

2.3.4 Operation Panel............................................................................. 2-8

2.4 Printer Status ........................................................................................ 2- 11

2.4.1 Normal ......................................................................................... 2-11

2.4.2 Setup Menu ................................................................................. 2-11

2.4.3 Self-Diagnosis Function............................................................... 2-11

2.4.4 Maintenance Mode ...................................................................... 2-11

2.4.5 Selecting Panel Language and Panel Temperature .................... 2-12

Page 30

ValueJet 1304 Service manual

AP-74109 Rev 1.1 2-2

2.1 Introduction

This chapter explains the features, part names, and functions of the printer.

2.2 Features

The features of the printer are explained below.

(1) Fast Print

The new print head adopted on this printer performs fast to print images.

Also, this printer prints up to 1355.5mm (when uni-directional print mode) or 1336.5mm (when bi-directional

print mode) in width.

(2) Variety of Print Media

The height of the print head position can be set high/low, so that this model can print on the media of which

thickness is between 0.08 and 1.00 mm.

(3) Vivid Color Reproduction

For vivid color reproduction, this model has high-capacity (220 ml) 4 color ink cartridges with exclusive

smart IC chip on it. With the IC chip, you can manage the ink level of the cartridges and can get better

productivity.

Also, with the variable dot method, richer color expression can be enhanced.

(4) Multi-Heater System

The media-heating system which have been equipped to PJ series is changed to match the solvent ink. There

are 3 heaters on Pre / Platen / After positions and improved the ink flexibility and drying property.

(5) Effective Utilization of Media

The JOG function is featured, which allows to set random print start positions. Printed media can be reprinted

and blank areas on the media can be put to effective use.

Page 31

ValueJet 1304 Service manual

2-3 AP-74109 Rev 1.1

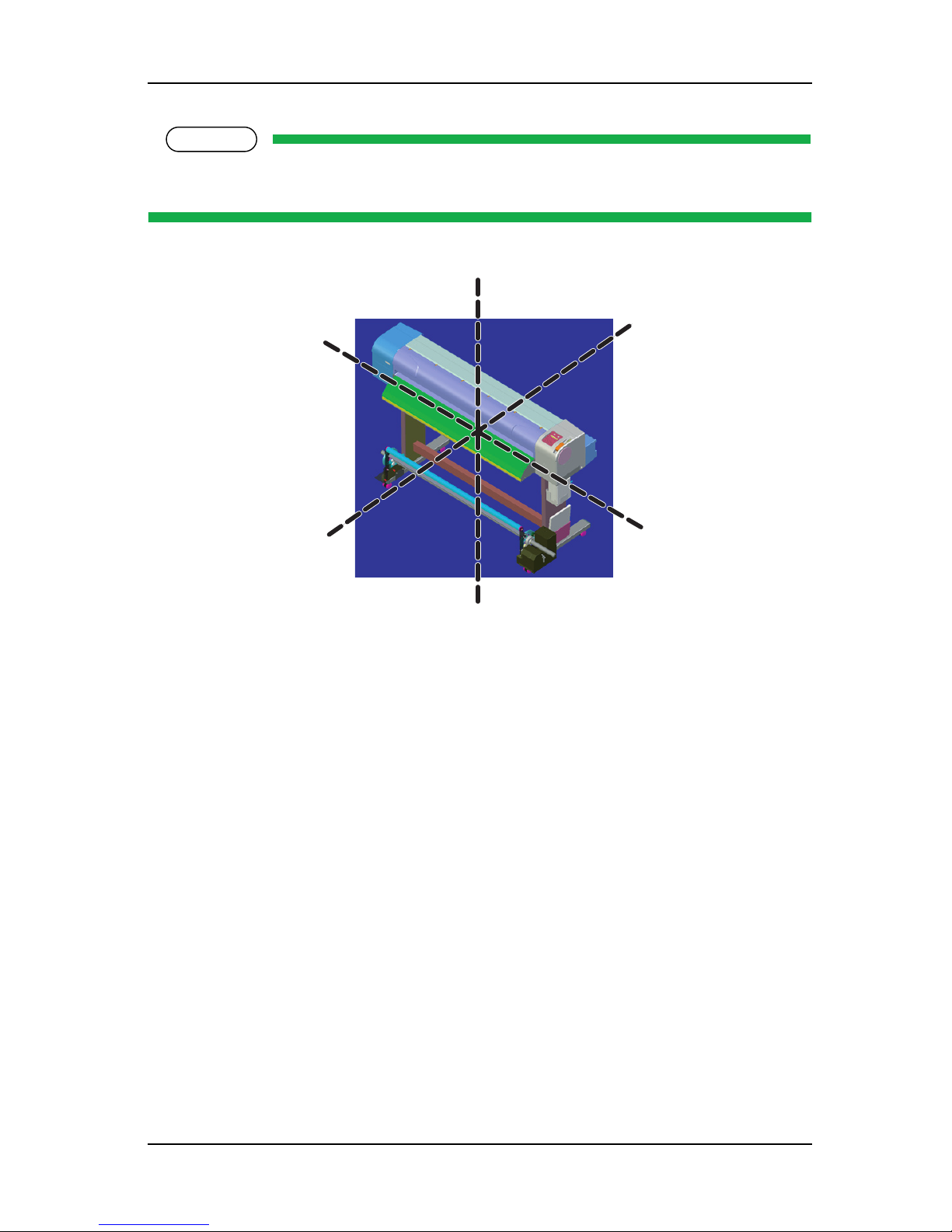

2.3 Part Names and Functions

Part names and functions are explained below.

NOTE

For the directions described in this document, refer to the following figure.

Rear

Upper

Lower

Right

Front

Left

Page 32

ValueJet 1304 Service manual

AP-74109 Rev 1.1 2-4

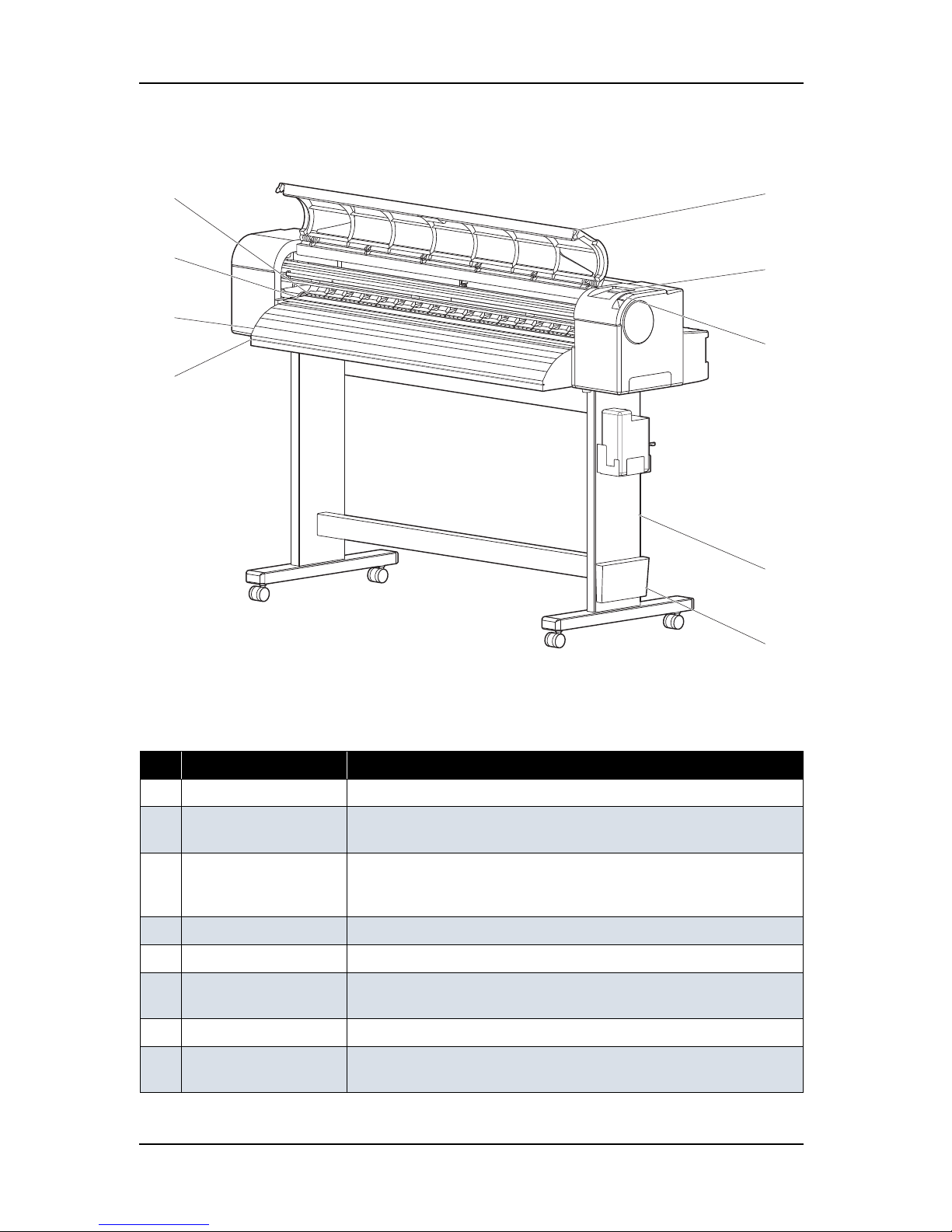

2.3.1 Front Section

Table 2-1 Part Names and Functions of Front Section

No. Name Function

1 Media set lever This lever is used to fix or release the media.

2 Operation panel This panel is used to set operational conditions, the status of the printer,

and other functions.

3 Front cover This cover keeps the operator safe from the drive parts of the printer while

it is operating.This is opened/closed when replacing the cutter or paper is

jammed.This should be closed during normal use.

4 Stand This stand is used to set the printer on the level surface of the floor.

5 Book holder This holder is used to store printed guide such as Quick Reference Guide.

6 Media Guide This guide is used to feed media smoothly when setting media and

printing.

7 Media cut guide This guide groove is used to cut printed media straight.

8 Pressure roller This is inside the front cover.

Presses and supports the media in the width when printing.

Page 33

ValueJet 1304 Service manual

2-5 AP-74109 Rev 1.1

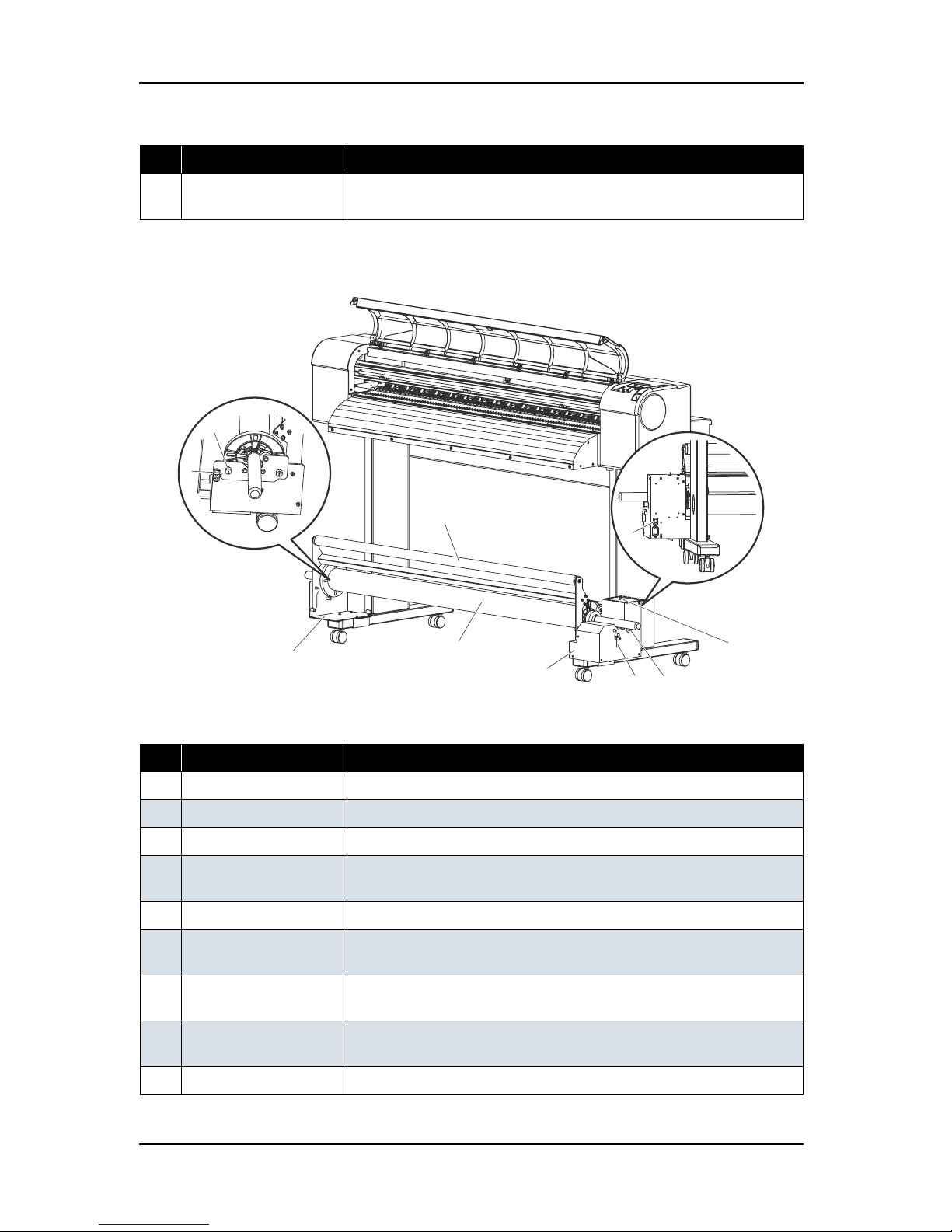

2.3.2 Rear Section

9 Platen This is inside the front cover.

There are heaters (platen heater) inside to dry ink.

Table 2-2 Part Names and Functions of Rear Section

No. Name Function

1 AC inlet For inserting the power cable plug.

2 Network interface

connector

Connector to connect a network interface cable.

3

USB connector This printer does not support the connector.

4 Scroller receiver The scroller is set here when using roll media.

5 Media feed slot Insert media from here when feeding media.

6 Ink cartridge slot This holds the ink cartridge.

7 Media guide Supports the media to be feed smoothly when media setting and printing.

There are pre heaters inside to warm the media.

8 Waste fluid tank This is a tank that contains the waste ink.

Table 2-1 Part Names and Functions of Front Section (Continued)

No. Name Function

1

4

23

K

C

6

M

Y

5

7

4

8

9

Page 34

ValueJet 1304 Service manual

AP-74109 Rev 1.1 2-6

2.3.3 Winding unit

9 Waste fluid valve Open this valve to discharge the waste fluid from the waste fluid tank.

In other case, close the valve.

Table 2-3 Part Names and Functions of Winding Unit

No. Name Function

1 Winding unit Winds the printed media.

2 Cushioning roller Loads the printed media to the winding unit.

3 Scroller receiver Used when setting the scroller of the winding unit.

4 Scroller release lever Releases the scroller from the winding unit, allowing you to turn the

scroller with your hand.

5 Scroller Used when winding the printed media.

6 Scroller height fixing

screw

Fix the height of the scroller receiver.

7 Scroller height

adjustment screw

Adjust the height of the scroller receiver.

8 Horizontal adjustment

screw

Adjust the side position of the scroller.

9 Power switch Used when turning the power ON and OFF.

Table 2-2 Part Names and Functions of Rear Section (Continued)

No. Name Function

48

5

3

2

10

1

7

9

6

Page 35

ValueJet 1304 Service manual

2-7 AP-74109 Rev 1.1

10 Operation panel Used for setting operation conditions, display of unit status.

"Winding unit for VJ-1304"

Table 2-3 Part Names and Functions of Winding Unit

No. Name Function

Page 36

ValueJet 1304 Service manual

AP-74109 Rev 1.1 2-8

2.3.4 Operation Panel

The operation panel is used to set operational conditions, display the status of the printer, and set other

functions.

The names and functions of the operation keys and status lamps are explained below.

TIP

Operation manual

8, 9

3

15

17

16

6

5

11

12

1

13

14

10

27

4

Page 37

ValueJet 1304 Service manual

2-9 AP-74109 Rev 1.1

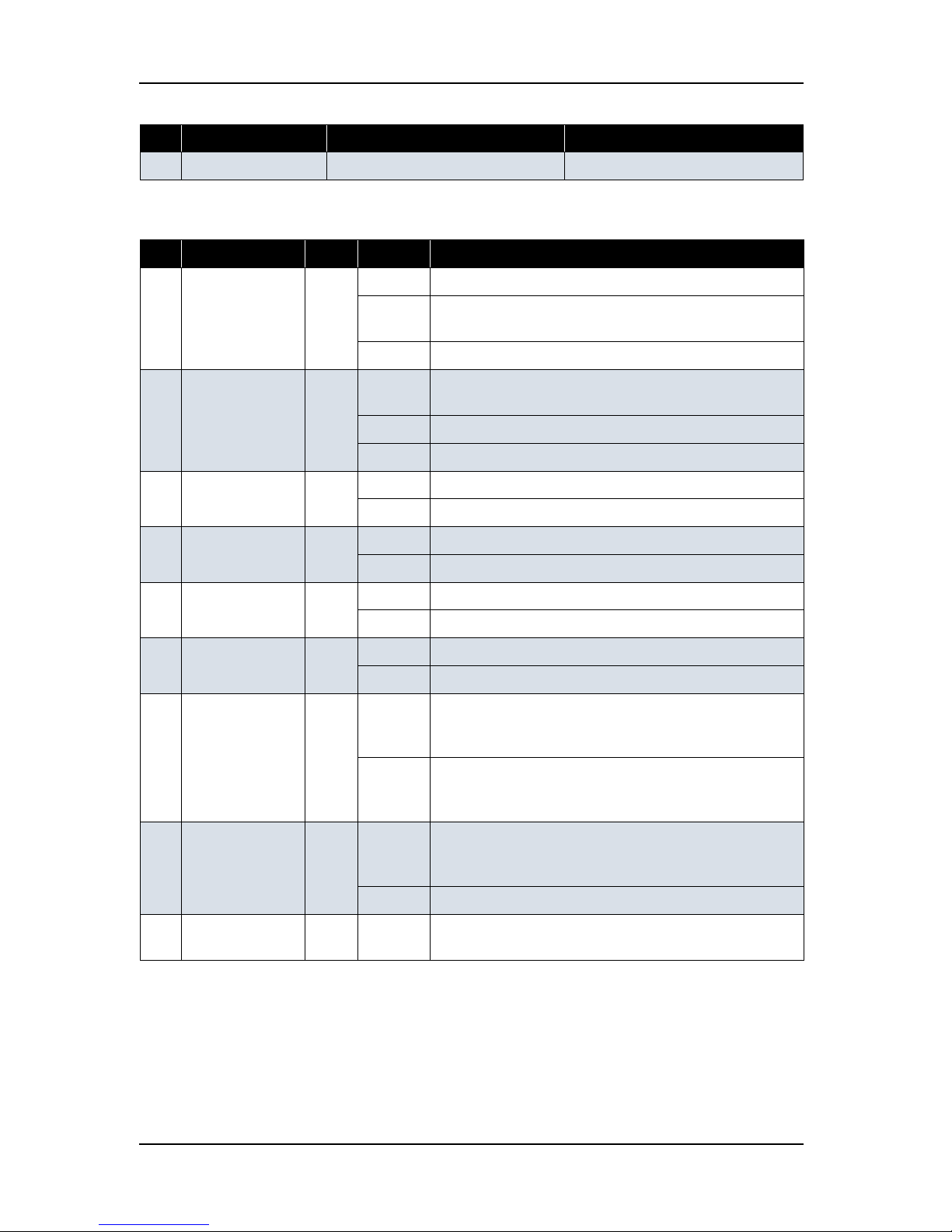

(1) Operation Keys

NOTE

Some keys have multiple functions and names depending on the printer status (normal or setup menu

display). See "2.4 Printer Status" p.2-11 for more details.

No. Name Normal Setup menu display

1

[Menu] key

Changes the LCD monitor display to

setup menu status.

Changes the setup menu display

status to normal status.

2 [Enter] key - - Selects the menu to be set and shifts

to the next hierarchy.

- Determines and saves the parameter

value.

[Cleaning] key If held down for 2 seconds or more,

starts cleaning the printer head.

-

3 [Cancel] key - During plotting: Terminates printing

forcibly and deletes 1 file of

remaining data.

- During reception/analysis: Deletes

the data that has been already

received/analyzed and ignores 1 file

of data received after that.

-

- Returns to the previous menu

hierarchy. Changed parameter values

are disabled.

- Changes the setup menu display

status to normal status.

4 [<] key Sets the media type.

• - The lamp for the cleaning mode

lights on (green).

-Changes the setting value in the

following menu:

• Origin setting menu

[Nozzle Check] key If held down for 2 seconds or more,

starts checking the printer nozzle.

-

5 [>] key Sets the cleaning mode.

- The lamp for the media type lights

on (green).

Displays lower rank menu items.

6 [Backward ↑ ] key Feeds the media in the reverse

direction.

-

[ + ] key - -Changes the menu in forward order.

-Changes the setting value in forward

order.

-Increases the value when inputting

setting value.

7[Forward

↓ ] key Feeds the media in the forward

direction.

-

[ - ] key - - Changes the menu in the reverse

direction.

- Decreases the value when inputting

values.

Page 38

ValueJet 1304 Service manual

AP-74109 Rev 1.1 2-10

(2) LCD Monitor and Status Lamps

8 [Power] key Turns the printer on and off. Turns the printer on and off.

No. Name Color Status Function

9 Power lamp Green On The printer is switched on.

Blinking An error has occurred. The contents will be displayed on the

LCD monitor.

Off The printer is switched off.

10 Data lamp Red On - The printer is analyzing received data.

- The printer is printing data.

Blinking The printer is receiving data.

Off The printer is not receiving, analyzing or printing data.

11 High lamp Green On The print head height is set to High position.

Off The print head height is set to Low position.

12 Low lamp Green On The print head height is set to Low position.

Off The print head height is set to High position.

13 Wave lamp Red On The effect menu is set to Wave.

Off The effect menu is set to either Fine or SuperFine.

14 Fine & S.Fine

lamp

Red On The effect menu is set to either Fine or SuperFine.

Off The effect menu is set to Wave.

15 Strong lamp Green On - The cleaning mode is set to Strong.

- When the Normal lamp is also on, the cleaning mode is set

to Economy.

Off - The effect menu is set to Wave.

- When the Strong lamp is also on, the cleaning mode is set

to Economy quality.

16 Normal lamp Green On - The cleaning mode is set to Normal.

- When the Strong lamp is also on, the cleaning mode is set

to Economy quality.

Off The cleaning mode is set to Strong.

17 LCD monitor - - This monitor displays the operation status and error

messages of the printer.

No. Name Normal Setup menu display

Page 39

ValueJet 1304 Service manual

2-11 AP-74109 Rev 1.1

2.4 Printer Status

The status of the printer is explained below.

2.4.1 Normal

Indicates that the printer can print when media is loaded.

Each setup concerning printing can be operated by using operation panel.

TIP

Operation manual

2.4.2 Setup Menu

Each setup concerning printing can be operated by using operation panel.

The settings required for normal printing are usually made on the printer driver or application, but can also

be made using the operation panel.

TIP

Operation manual

2.4.3 Self-Diagnosis Function

Indicates that each settings concerning printing using the operation panel. Names and functions of the

operation panel keys are the same as those of setup menu display.

TIP

"5 Self-Diagnosis Mode" p.5-1

2.4.4 Maintenance Mode

Indicates that each setup concerning to the life counter on this printer can be operated by using the operation

panel. Names and functions of the operation panel keys are the same as those of setup menu display.

TIP

"6 Maintenance Mode 2" p.6-1

Page 40

ValueJet 1304 Service manual

AP-74109 Rev 1.1 2-12

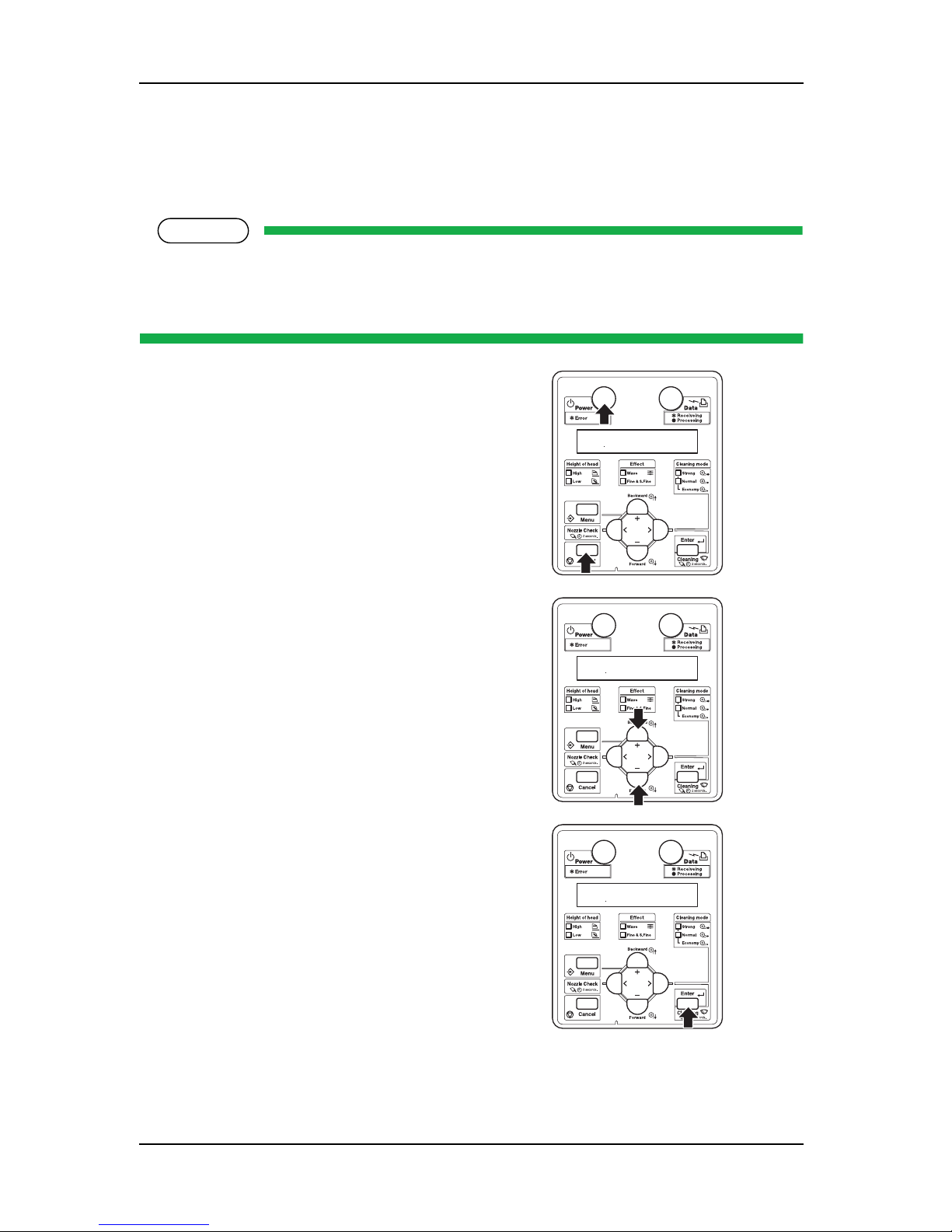

2.4.5 Selecting Panel Language and Panel Temperature

This section describes how to select the language displayed in the operation panel.

Follow the steps below to select the language.

NOTE

You can choose panel language and panel temperature as follows.

Language:Japanese or English

Temperature:Celsius or Fahrenheit

1. Press [Power] key in the operation panel while

pressing [Cancel] key.

2. Press [Setting/value +] key or [Setting/value -]

key in the operation panel to modify the value.

3. To save the modified value, press [Enter] key in

the operation panel.

* panel temperature appears after panel

language. Operation is same as before.

Page 41

ValueJet 1304 Service manual

3-1 AP-74109 Rev 1.1

3 Specifications

3.1 Introduction............................................................................................. 3- 2

3.2 Product Specifications........................................................................... 3- 2

3.3 Interface Specifications.......................................................................... 3- 4

3.3.1 Network Interface Specifications.................................................... 3-4

3.4 Choosing a Place for the Printer .......................................................... 3- 5

Page 42

ValueJet 1304 Service manual

AP-74109 Rev 1.1 3-2

3.1 Introduction

This chapter explains the specifications of the product, optional parts, and supplies. Installation environment

requirements are also explained.

3.2 Product Specifications

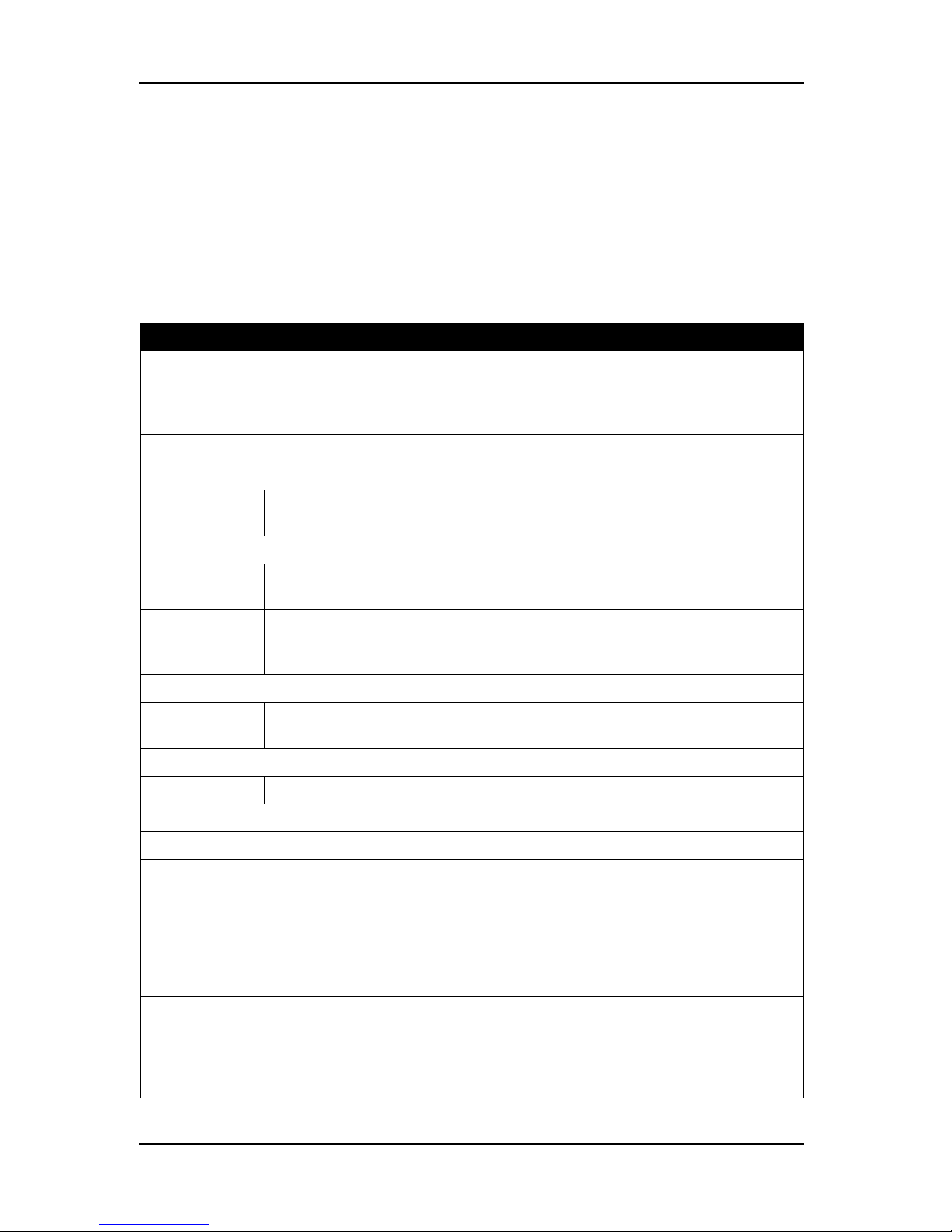

(1) Main Unit Specifications

Item Specifications

Model name

VJ-1304

Plotting method

On-demand piezo drive

Motor driving method

Firmware servo/DC motor drive

Media feeding method

Multi-point pressure grid roller method

Media fixing method

Pressurizing roller manual-down method

Media supply and

ejection

Roll media

Front feeding/front paper ejection

Media type

Tracing Paper

Roll media outer

diameter

2-inch

150 mm or less

Maximum

loadable media

weight

Roll media

19 kg (41.9 lb) or less

Maximum media width

1371.5 mm (54 in.)

Maximum media

length:

Roll media

50 m (160 ft.)

Maximum plot length

1355 mm (53.3 in.)

Plotting margins Roll media

Top: 3mm, Bottom: 3mm, Left: 3mm, Right: 3mm

Media cutting method

Manual cutting across the media

Head height adjustment

2 levels: Normal and High

Distance accuracy The larger value either ± 0.25 mm or ± 0.1% of moving distance

•Used media: Roll MF-3G

• Plot length: 1355.5 mm (4.45 ft.)

• Operating temperature: 22 to 30ºC (71.6 to 86F)

• Operating humidity: 40 to 60%

•PG: Low

• Plot mode: Graphics1

Right angle accuracy ±0.1mm or less against the moving distance (500.0mm)

•Used media: Roll MF-3G

• Operating temperature: 22 to 30ºC (71.6 to 86F)

• Operating humidity: 40 to 60%

• Plot mode: Graphics1

Page 43

ValueJet 1304 Service manual

3-3 AP-74109 Rev 1.1

CPU

64Bit RISC CPU

Memory

128MB

Command

MH-RTL (RTL-PASS)

Interface

Network Interface (IEEE802.3)

After-heater

OFF / 30 to 50°C (86 to 122F)

Platen heater

OFF / 30 to 50°C (86 to 122F)

Pre-heater

OFF / 30 to 50°C (86 to 122F)

Ink Supply method

Tube supply from separate four separated cartridges

Cartridge

Black, cyan, magenta, yellow: 220ml ± 5ml for each color

Head life expectancy

60 billion dots per nozzle (in case of sequence discharging under the condition

of the temperature of 25

ºC (77F) with no dust)

Environmental conditions

Operation environment

Temperature: 20ºC (68F) to 32ºC (90F)

Humidity: 40% to 60%, with no condensation

Plotting accuracy warranty range

Temperature: 22ºC (71.6F) to 30ºC (86F)

Humidity: 40% to 60%, with no condensation

Rate of change

Temperature: 2ºC/hour or less

Humidity: 5%/hour or less

Storage

environment

Without ink

Temperature: -20ºC (-4F) to 60ºC (140F)

Humidity: 20% to 80%, with no condensation

Storage period: 6 months

With ink

Temperature: -10ºC (14F) to 40ºC (104F)

Humidity: 20% to 80%, with no condensation

Storage period: 6 months

Power source Voltage

AC 90 - 132V ± 10%

Frequency

50Hz/60Hz ± 1Hz

Power

consumption

During Plotting 1260W or less (when heater is ON)

During standby 40W or less (when standby heater is OFF)

Outer dimensions Height

1218mm (48 in.) * including stand

Width

1875 mm (73.8 in.)

Depth

685 mm (27 in.)

Weight Main body

58.0 kg (127.8 lb.)

Stand

21.3 kg (46.9 lb)

Item Specifications

Page 44

ValueJet 1304 Service manual

AP-74109 Rev 1.1 3-4

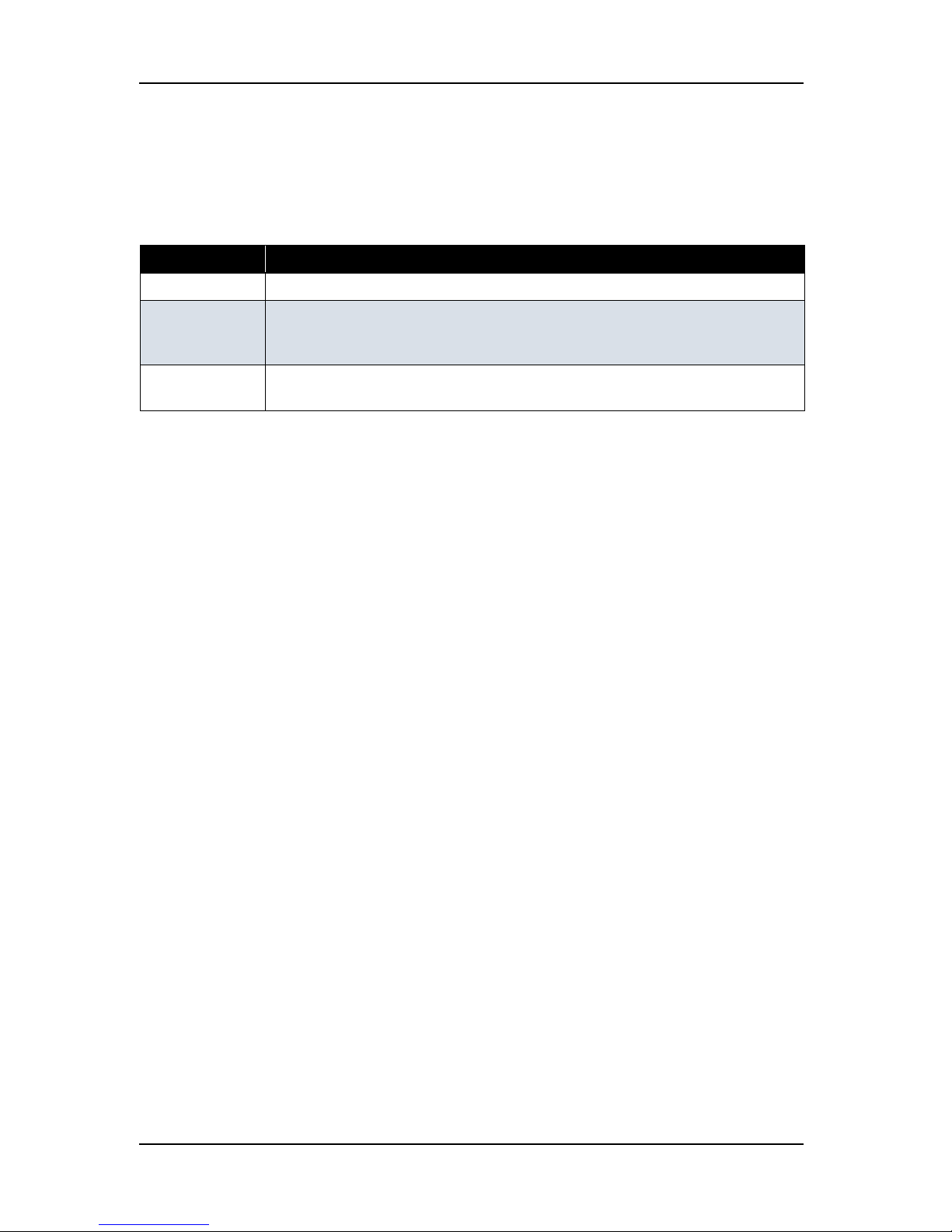

3.3 Interface Specifications

This section explains the specification of the interfaces Supported for this printer.

3.3.1 Network Interface Specifications

Item Specifications

Network type Ethernet IEEE802.3

Network I/F 10BASE-T / 100BASE-TX Auto-switching

(RJ-45 connector twist pair cable)

MDI / MDI-X Auto-switching

Corresponding

protcol

TCP/IP

Page 45

ValueJet 1304 Service manual

3-5 AP-74109 Rev 1.1

3.4 Choosing a Place for the Printer

WARNING

• Do not place the printer in a location under the following conditions. Doing so may cause

the product to fall, become damaged, or cause injury.

• Unstable surfaces

• Slanted areas

• Locations that are subject to vibration from other product

• Do not stand on the printer or place any heavy objects on it.

Doing so may cause it to fall over, become damaged, or cause injury.

• Do not cover the ventilation hole of the printer with cloth, such as a blanket or table cloth.

Doing so could prevent the printer from ventilating and cause fire.

• Keep the printer away from humid and dusty areas. Failure to do so may result in

electrical shock or fire.

(1) Installation Environment Requirements

Choose a place for printer installation following the requirements of the table below.

Table 3-1 Installation Environment Requirements List

Floor loading capability 2940Pa (300kgf/m2) or over

Electrical

specifications

Voltage AC 90 V - 120 V ± 10%

Frequency 50/60Hz ± 1Hz

Capacity 10A or more

Environmental conditions Temperature Humidity

Operation

environment

20º C (68F) to 32ºC (86F) 40% to 60%, with no condensation

Plotting accuracy

warranty range

22ºC (71.6F) to 30ºC (86F) 40% to 60%, with no condensation

Rate of change 2ºC/hour or less 5%/hour or less

Page 46

ValueJet 1304 Service manual

AP-74109 Rev 1.1 3-6

NOTE

• Avoid the following temperature and humidity conditions. Otherwise, Plotted images may appear

differently from what you expect.

• Places where sudden changes in temperature and humidity are expected, even though the

condition is within the range specified

• Places where direct sunlight or excessive lighting are expected

• Places where air conditioners blow directly

• MUTOH recommends that the printer should be installed where air conditioning can be adjusted

easily.

(2) Required Space

Install the printer on a flat surface that fulfills the following conditions.

• The place to install printer with the optional stand should have enough loading capacity.

NOTE

• For the printer and the optional stand, refer to"3.2 Product Specifications" p.3-2.

• When maintaining the printer, 1000 mm of space is required on the left side of the printer in

addition to the spaces shown below.

* Do not use VJ-1304 without stand.

g

e

a

d

b

c

f

a=500mm

b=1000mm

c=1000mm

d=1000mm

e=1440mm

f=3000mm

g=2660mm

Page 47

ValueJet 1304 Service manual

4-1 AP-74109 Rev 1.1

4 Parts Replacement

4.1 Introduction............................................................................................. 4- 4

4.2 Removal of Covers ................................................................................. 4- 5

4.2.1 Removing R Side Cover ................................................................ 4-6

4.2.2 Removing Operation Panel Unit .................................................... 4-9

4.2.3 Removing L Side Cover............................................................... 4-10

4.2.4 Removing Ink Holder (I/H) Cover................................................. 4-12

4.2.5 Removing Front Cover................................................................. 4-14

4.2.6 Removing Top Cover................................................................... 4-15

4.2.7 Removing Media Guide F............................................................ 4-16

4.2.8 Removing Media Guide R2.......................................................... 4-17

4.2.9 Removing Scroller Receiver (L, R) .............................................. 4-18

4.2.10 Assembling of Scroller Receiver L and R .................................... 4-20

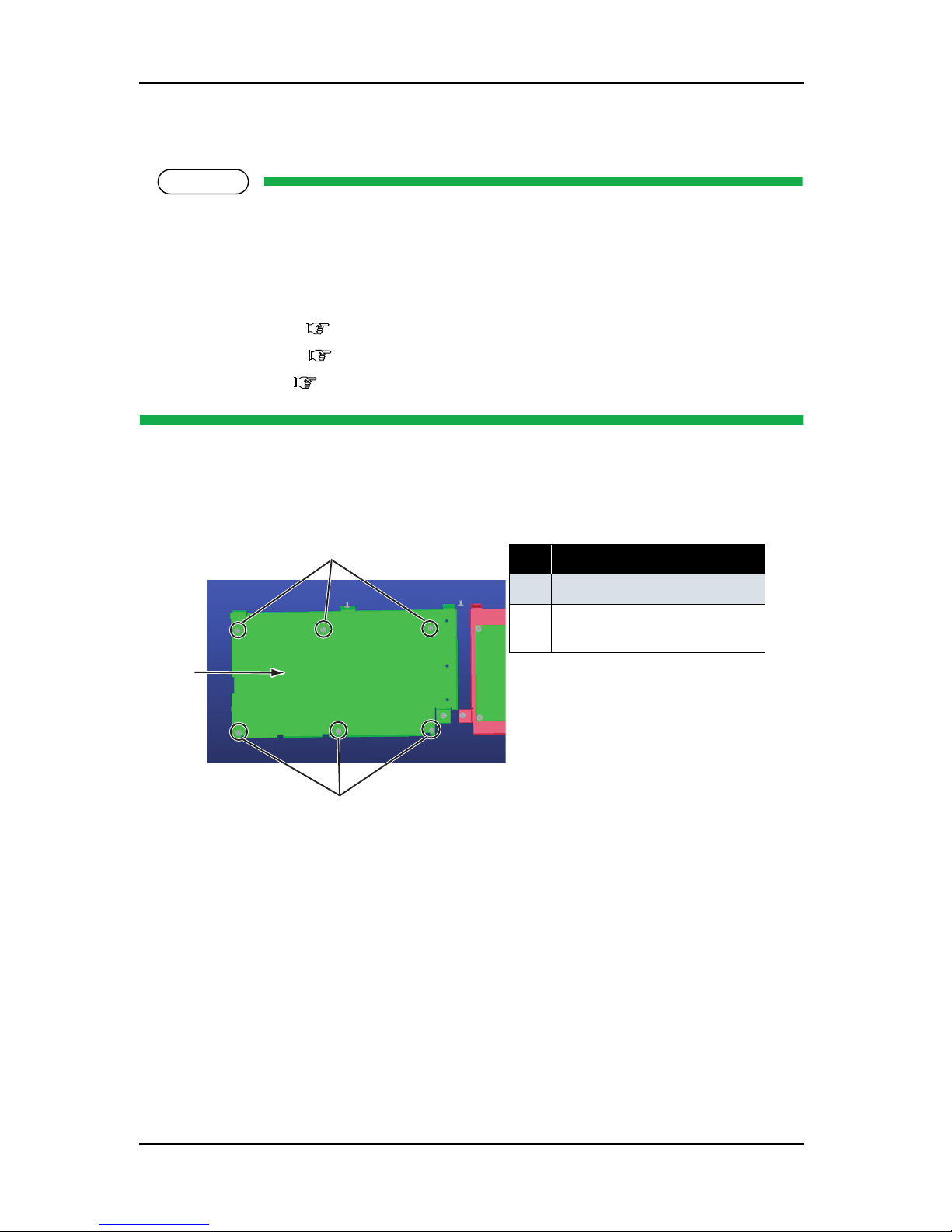

4.3 Replacement of Board Base Section Components ........................... 4- 23

4.3.1 Removing Connector Panel and Cooling Fan.............................. 4-23

4.3.2 Removing Main Board Bracket.................................................... 4-24

4.3.3 Replacing Main Board Assembly................................................. 4-29

4.3.4 Replacing HEATER CONT board assembly................................ 4-30

4.3.5 Replacing HEATER RELAY board assembly .............................. 4-32

4.3.6 Replacing Power Board Assembly............................................... 4-35

4.3.7 Replacing Fuse............................................................................ 4-38

4.3.8 Replacing Inlet Assembly............................................................. 4-41

4.4 Replacement of PF Driving Section Components ............................. 4- 44

4.4.1 Replacing PF Motor Assembly..................................................... 4-44

Page 48

ValueJet 1304 Service manual

AP-74109 Rev 1.1 4-2

4.4.2 Replacing PF_ENC Assembly...................................................... 4-47

4.4.3 Replacing PF_ENC Scale ............................................................ 4-48

4.4.4 Replacing Heater and Thermistor Assembly................................ 4-49

4.5 Replacement of CR Driving Section Components .............................4- 51

4.5.1 CR Motor Assembly...................................................................... 4-51

4.5.2 Replacing CR Origin Point Sensor ............................................... 4-52

4.5.3 Replacing Lever Sensor ............................................................... 4-54

4.5.4 Replacing T Fence ....................................................................... 4-55

4.5.5 Replacing CR Driven Pulley and CR belt ..................................... 4-58

4.5.6 Replacing Pressure Arm Assembly.............................................. 4-60

4.6 Replacement of Head Section Components .......................................4- 61

4.6.1 Replacing Print Head.................................................................... 4-61

4.6.2 Replacing Cutter Holder Assembly............................................... 4-66

4.7 Replacement of Maintenance Section Components ..........................4- 71

4.7.1 Removing Maintenance Base Assembly...................................... 4-71

4.7.2 Replacing Maintenance Assembly ............................................... 4-76

4.7.3 Replacing Cleaner Head (Cleaning Wiper) .................................. 4-77

4.8 Replacement of Ink Supply Section Components..............................4- 79

4.8.1 Replacing Ink Holder (I/H) Assembly............................................ 4-79

4.8.2 Replacing Ink Sensor Assembly................................................... 4-82

4.8.3 Replacing Cover Sensor Assembly.............................................. 4-85

4.8.4 Replacing Heater Junction Board................................................. 4-87

4.9 Replacement of Frame Section Components .....................................4- 89

4.9.1 Replacing Suction Fan Assembly................................................. 4-89

Page 49

ValueJet 1304 Service manual

4-3 AP-74109 Rev 1.1

4.9.2 Replacing P_REAR Sensor Assembly......................................... 4-90

4.10 Replacement of Cable Guide Section Components .......................... 4- 91

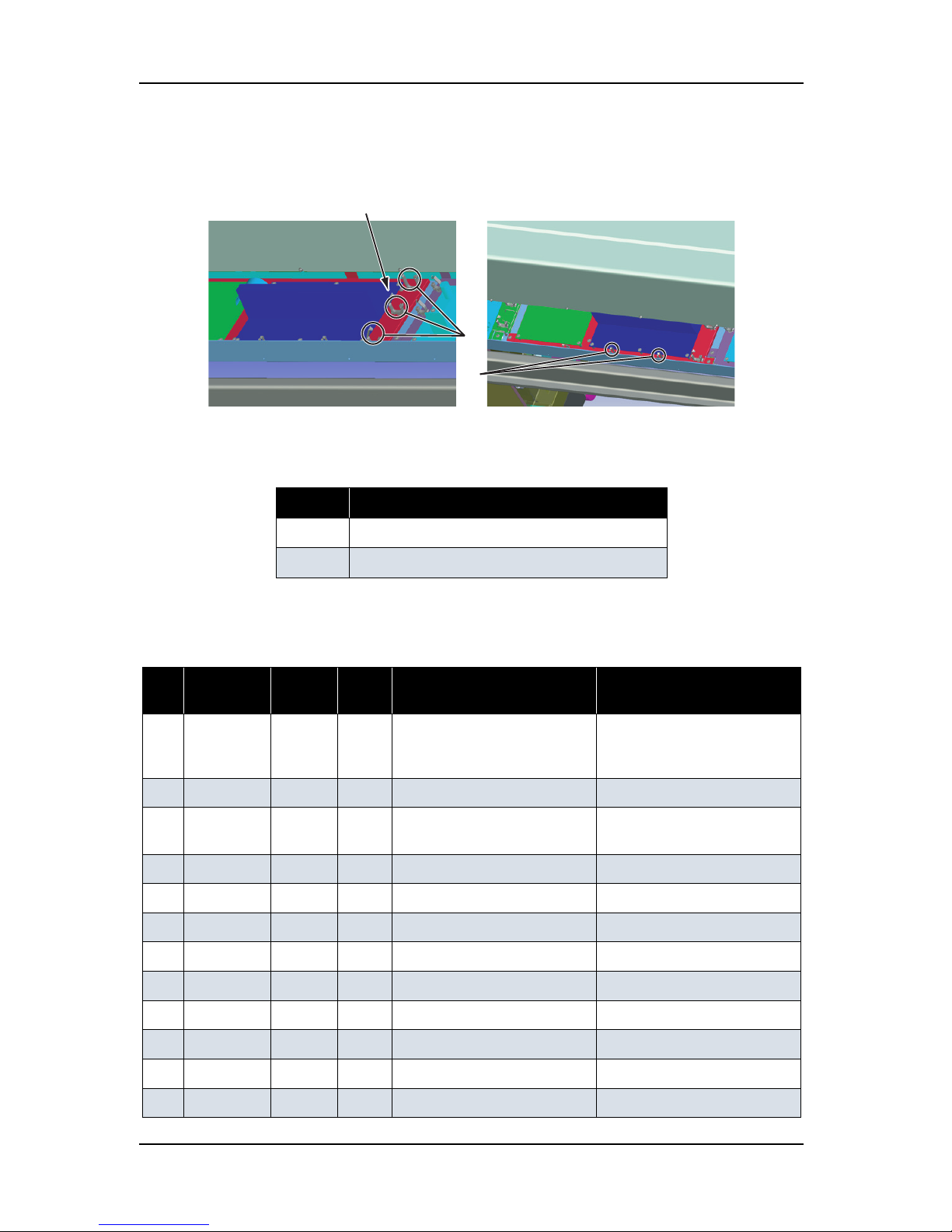

4.10.1 Replacing CR Board Assembly.................................................... 4-91

4.10.2 Replacing Ink Tube...................................................................... 4-93

4.10.3 Replacing CR Tape Wire ............................................................. 4-97

4.11 Replacing Accessory Unit.................................................................. 4- 101

4.11.1 Replacing Level Switch (Waste Fluid) ....................................... 4-101

4.12 Replacing Take Up Unit...................................................................... 4- 102

4.12.1 Removing Tension Arm ............................................................. 4-103

4.12.2 Removing Take Up Unit Fixing Plate......................................... 4-104

4.12.3 Removing Take Up Unit Cover .................................................. 4-105

4.12.4 Replacing Scroller...................................................................... 4-108

4.12.5 Replacing VJ Take Up Unit CNT Board Assembly .................... 4-109

4.12.6 Replacing CR_HP Sensor, Lever Sensor.................................. 4-117

4.12.7 Replacing Peripheral Devices of VJ Take Up Unit Motor assy.. 4-120

Page 50

ValueJet 1304 Service manual

AP-74109 Rev 1.1 4-4

4.1 Introduction

This chapter provides information on removal and replacement of service parts.

WARNING

Before starting part replacement, always perform the following operations.

• Turn OFF the machine power.

• Remove the power plug from the outlet.

Otherwise, you may suffer electric shock or the system circuit may be damaged.

• Remove any cables connected to the machine.

Otherwise, the machine may be damaged.

CAUTION

The components in the machine can be disassembled only if so instructed in this manual.

Do not disassemble the frame components and other components that are not instructed to

disassemble in the manual.

The machine has been assembled in the MUTOH factory with extremely high precision up

to 1/100mm. If disassembled inappropriately, it may not restore its normal functionality.

Page 51

ValueJet 1304 Service manual

4-5 AP-74109 Rev 1.1

NOTE

After replacing any service parts, perform necessary lubrication and bonding following the

instructions in section "8.4 Lubrication/Bonding" p.8-7.

Rear

Upper

Lower

Right

Front

Left

Page 52

ValueJet 1304 Service manual

AP-74109 Rev 1.1 4-6

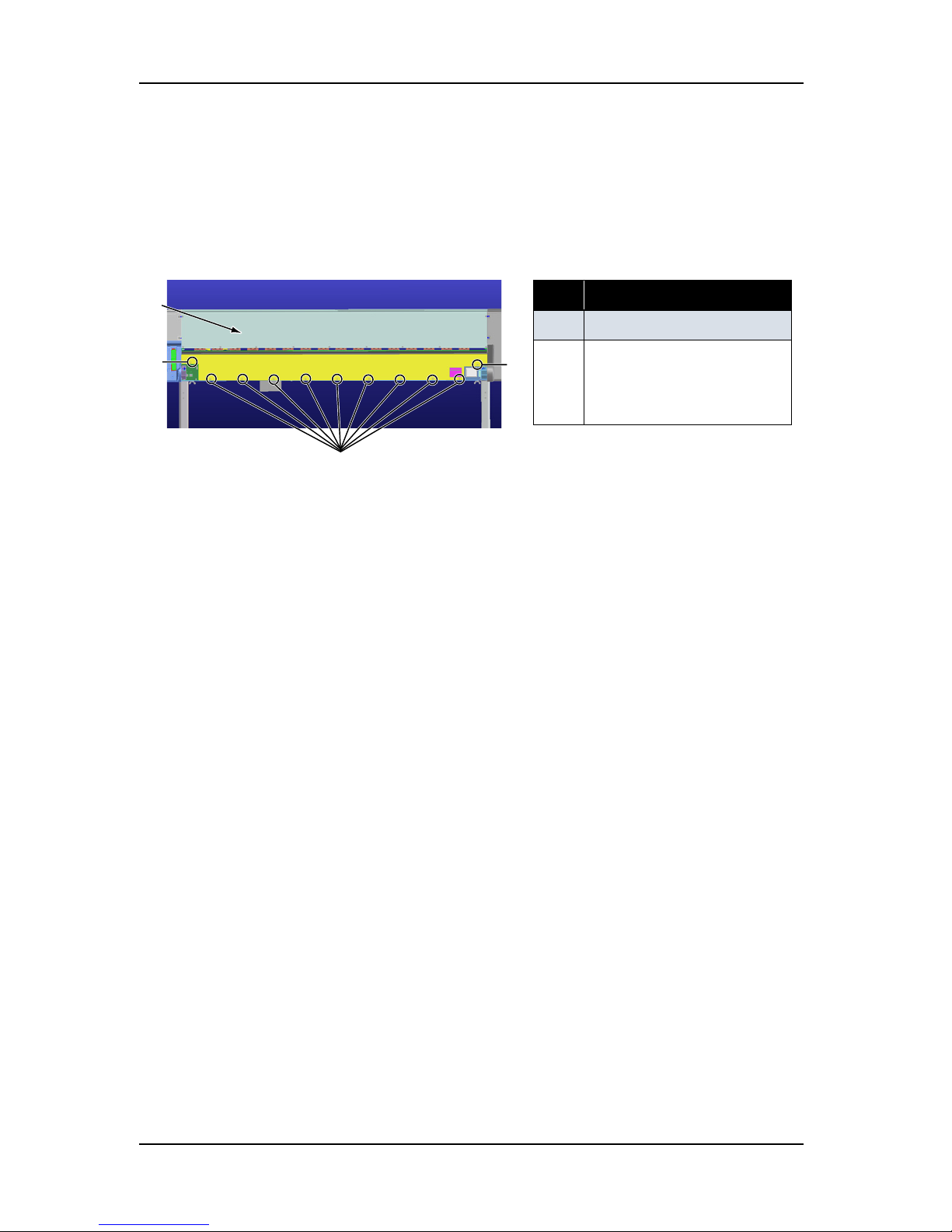

4.2 Removal of Covers

Before replacing any service parts in the machine, you must remove some external covers.

This section describes the procedure to remove covers.

Table 4-1 Cover Component List

No. Part name

1

L side cover

2

Front cover

3

Media guide F

4

R side cover

5

Waste fluid bottle

6

I/H cover

7

Operation panel unit assembly

8

Media guide R2 (rear side)

9

Top cover

1

3

2

4

5

6

7

9

8

(Rear side)

Page 53

ValueJet 1304 Service manual

4-7 AP-74109 Rev 1.1

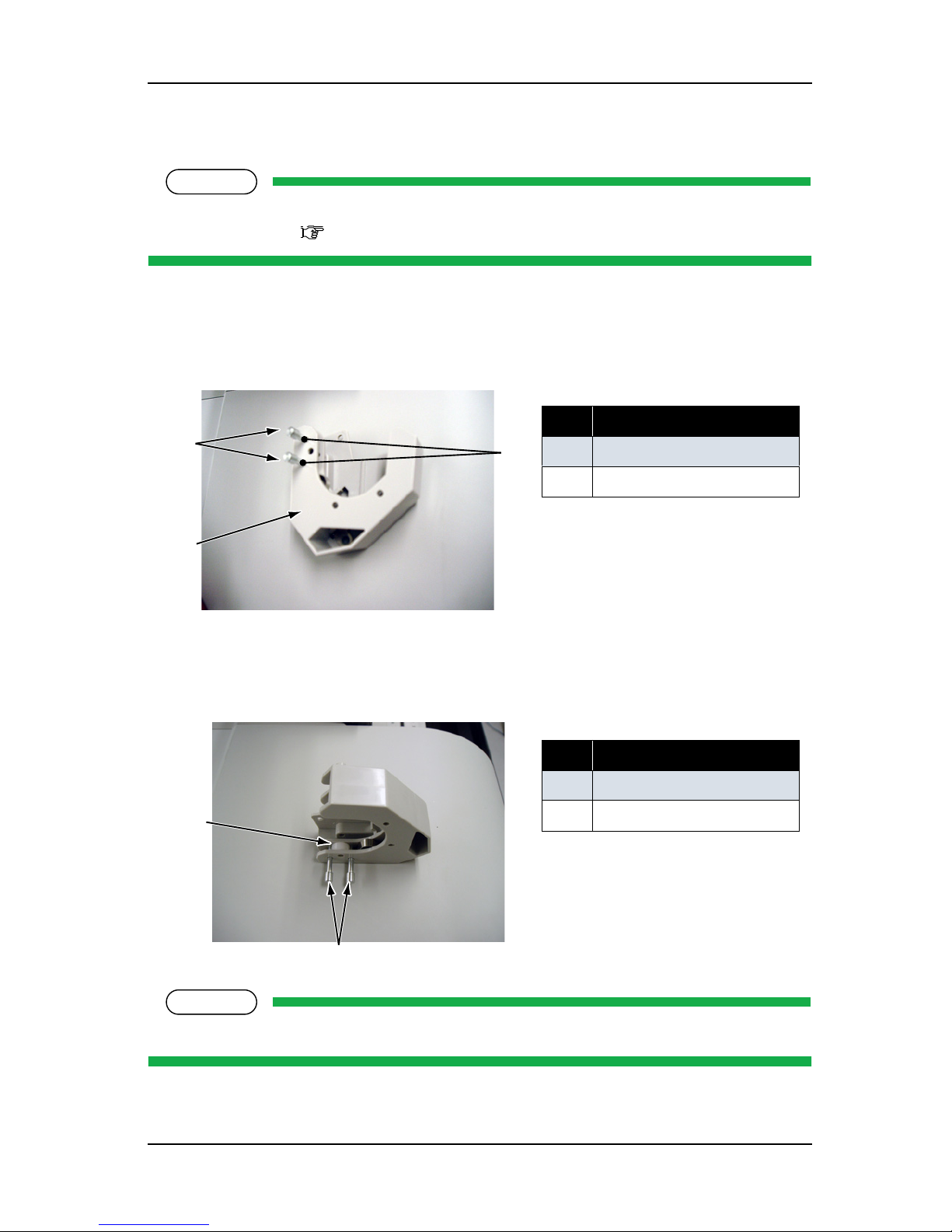

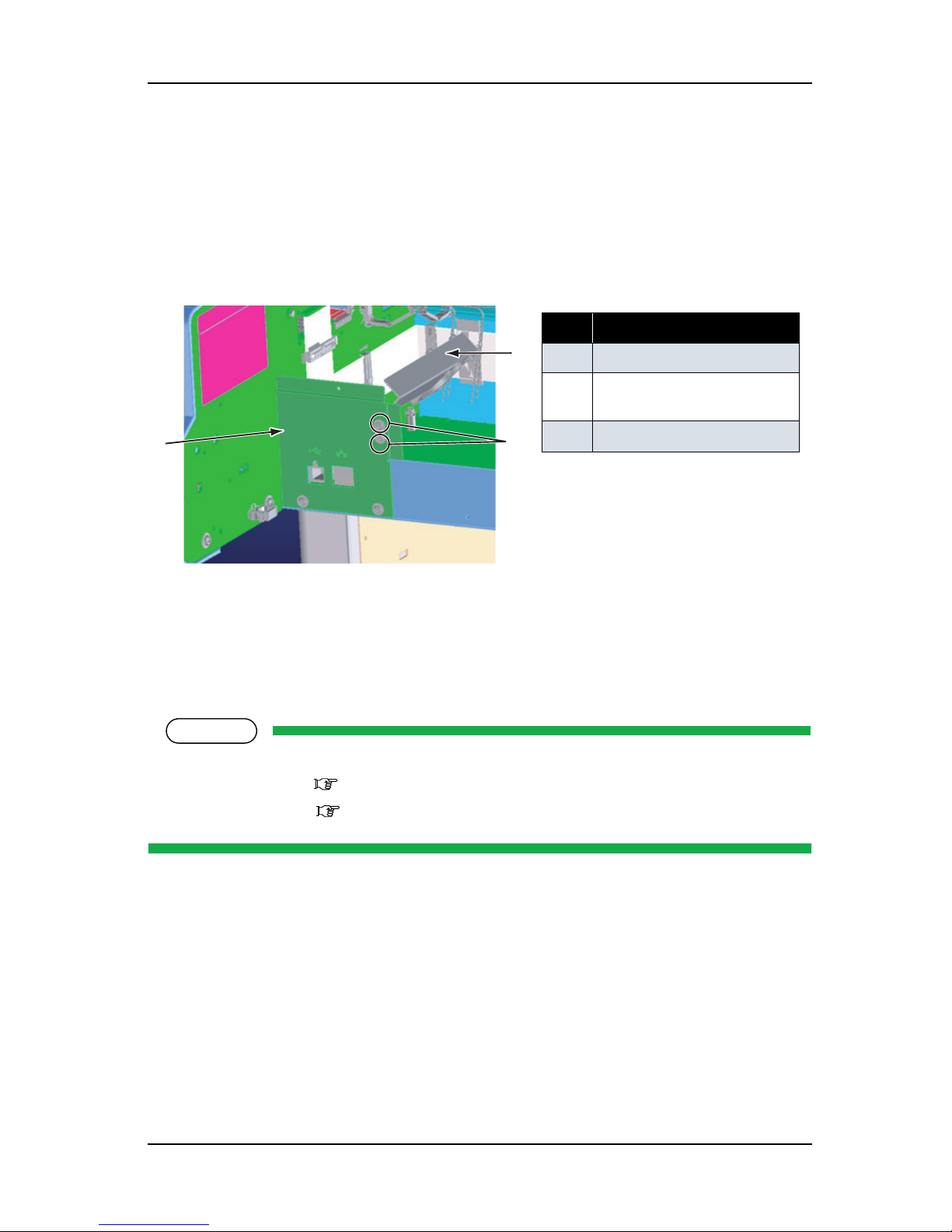

4.2.1 Removing R Side Cover

1. Move down the pressure lever backward.

2. Remove the pressure lever cap-retaining screw (M4 × 10, P tight binding: 1).

3. Remove the R side cover outer screw (Tapping screw M4

× 8, S tight cup: 2).

表 4-2

No. Part name

1 Pressure lever cap

2 Pressure lever cap screw

(M4

× 10, P tight binding)

表 4-3

No. Part name

1 R side cover

2 Waste fluid unit cover

3 R side cover outer screw

(M4

× 8, P tight cup)

1

2

1

2

3

Page 54

ValueJet 1304 Service manual

AP-74109 Rev 1.1 4-8

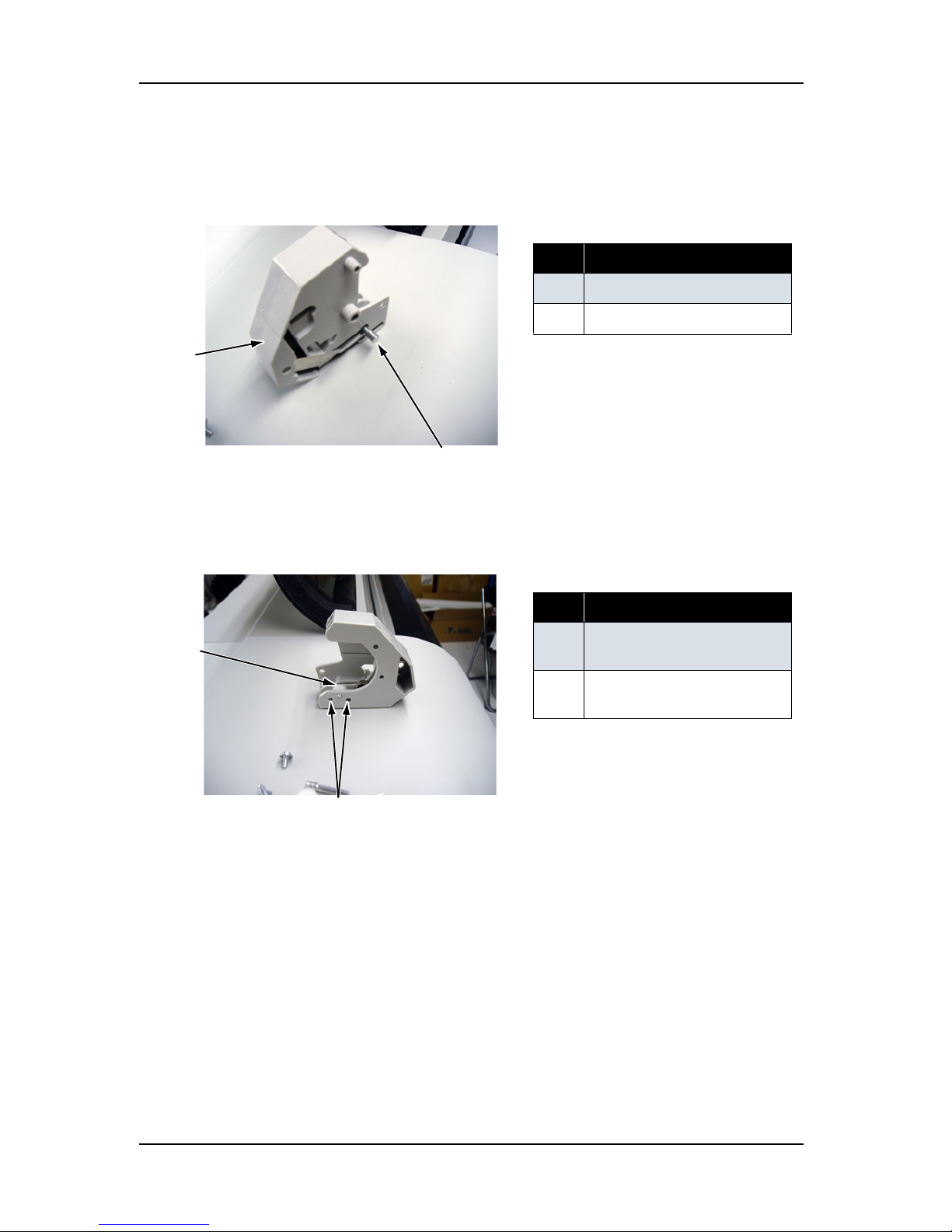

4. Remove the waste fluid unit cover-retaining screw (tapping screw M3 × 6, S tight cup: 2)

5. Remove the waste fluid unit cover.

6. Open the front cover.

7. Remove the R side cover inner screw (tapping screw M4

× 12, P tight binding black: 2).

表 4-4

No. Part name

1 Waste fluid cover

2 waste fluid unit cover-retaining

screw (Tapping screw M3

× 6, S

tight cup: 2)

表 4-5

No. Part name

1 R side cover

2 R side cover inner screw

(tapping screw M4

× 12, P tight

binding black)

1

2

2

1

Page 55

ValueJet 1304 Service manual

4-9 AP-74109 Rev 1.1

8. Remove the R side cover rear screw (tapping screw M4 × 12, S tight cup: 2).

9. Return the pressure lever forward and remove the R side cover to the upper right direction.

10. Replace the parts inside the product.

11. To reassemble the unit, reverse the removal procedure.

表 4-6

No. Part name

1 R side cover

2 R side cover rear screw

(tapping screw M4

× 12, S tight

cup)

1

2

Page 56

ValueJet 1304 Service manual

AP-74109 Rev 1.1 4-10

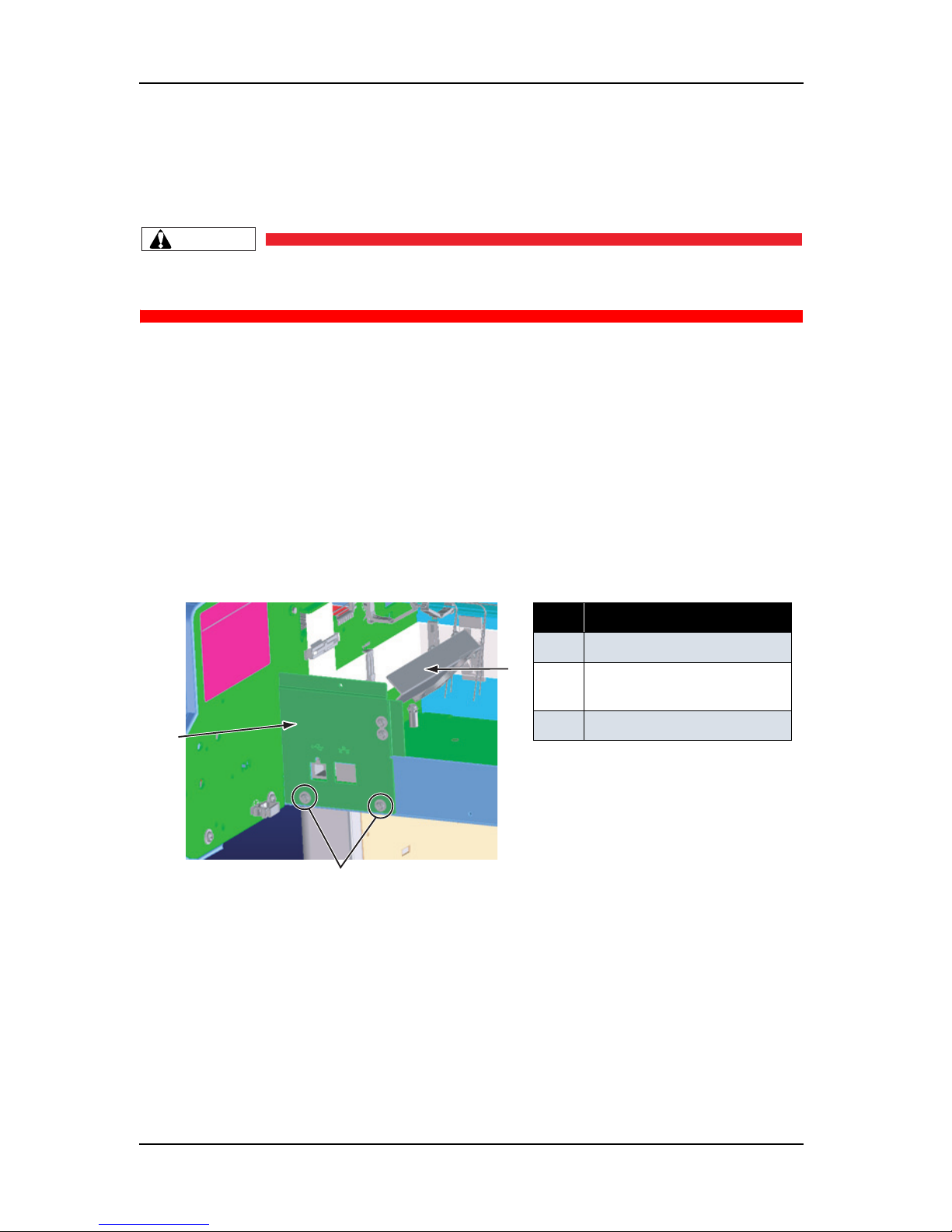

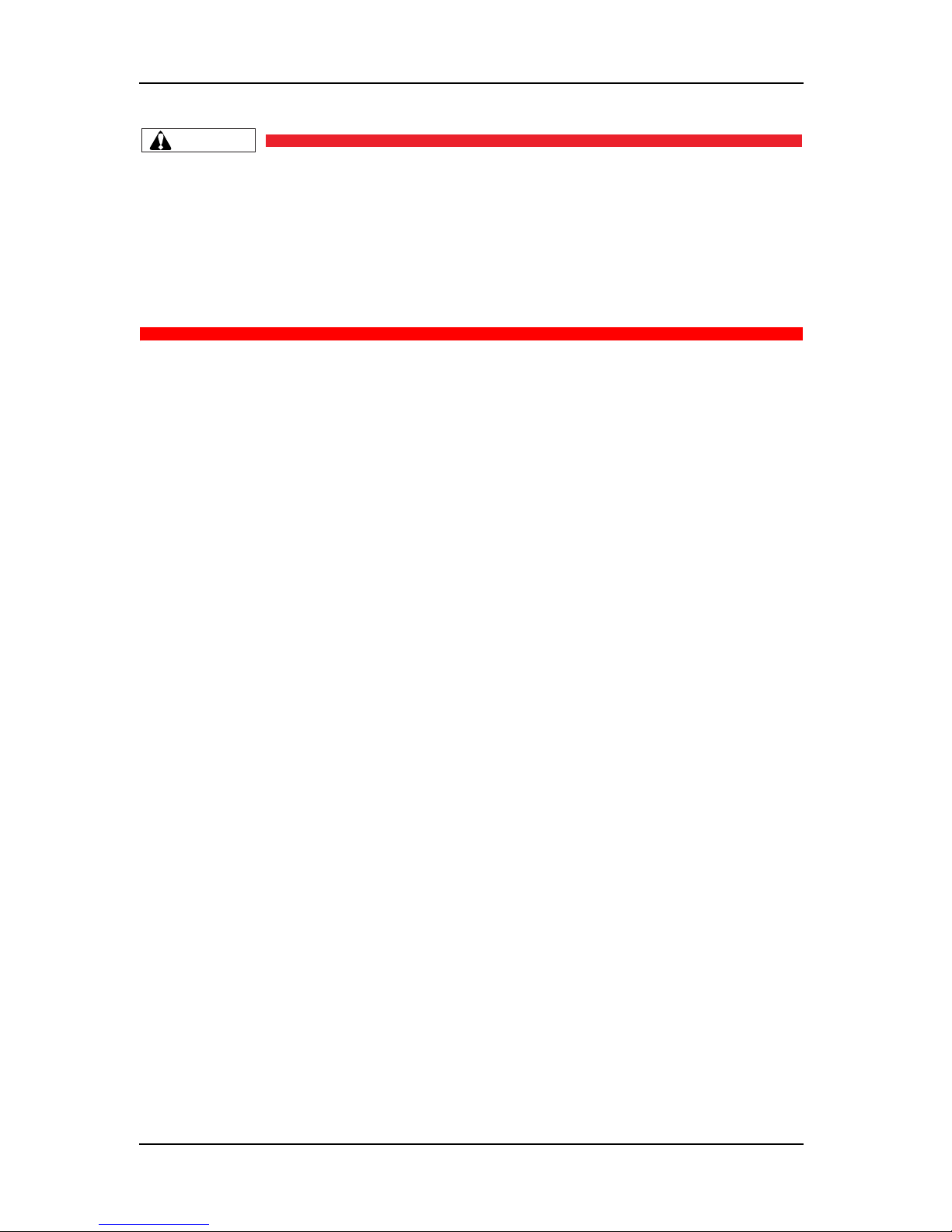

4.2.2 Removing Operation Panel Unit

TIP

Before removing the operation panel unit, perform the following work.

• Removing the R side cover: "4.2.1 Removing R Side Cover" p.4-6

• Unlocking and moving the carriage.

1. Remove the operation panel unit tape wire (FFC).

CAUTION

• Before replacing board or connecting/removing tape wire (FFC), unplug the power cable

and leave the printer for a while. Or board may be damaged by overcurrent.

• When connecting or removing the tape wire (FFC) to the operation panel unit connector,

always pull or push the wire perpendicularly to the connector. Pulling or pushing the wire

slantwise may damage/short/break the terminals in the connectors, resulting in a

breakdown of the on-board devices.

• You can connect/remove the tape wire up to five times.

2. Release the tab on the rear side of the operation panel unit from the panel stay.

3. Remove the operation panel unit.

4. To reassemble the unit, reverse the removal procedure.

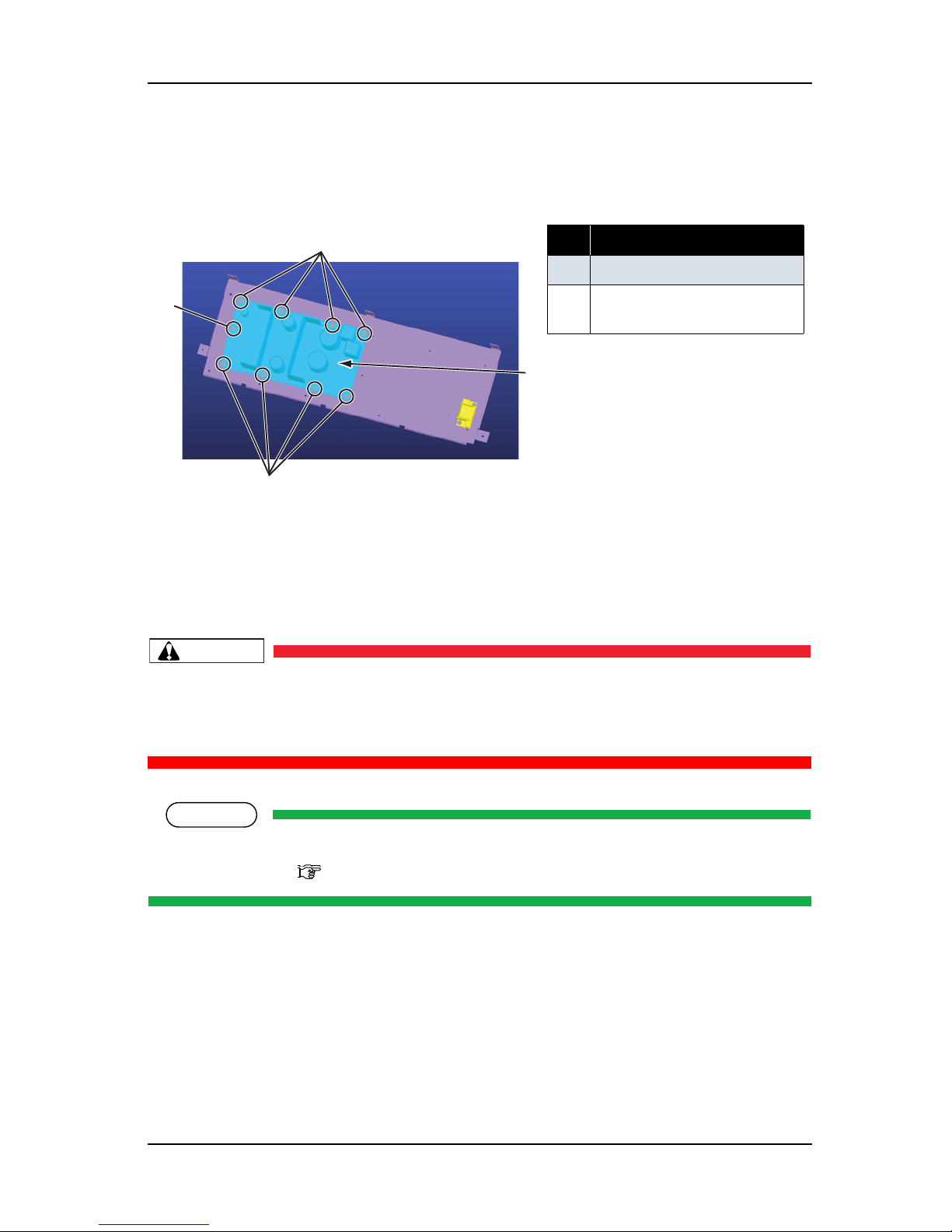

No. Part name

1 Operation panel unit

2 Panel stay

3 Operation panel unit-retaining tab

1

2

3

3

Insert a hand from here.

bottom view

2

Page 57

ValueJet 1304 Service manual

4-11 AP-74109 Rev 1.1