Rev No. V5a 2015 Jan

USER MANUAL

Sign Cutting Plotter

Read This Manual Before Using The Plotter.

VC-600

VC-1300

VC-1800

Trademark Mentioned in this Manual

MUTOH, ValueCut, VC-600, VC-1300, VC-1800, ValueJet are registered trademarks or

product names of MUTOH INDUSTRIES LTD.

Other company and product names may be registered trademarks or product names.

Caution

No part of this product or publication may be reproduced, copied, or transmitted in any

form or by any means, except for personal use, without the permission of MUTOH

INDUSTRIES LTD.

The product and the contents of this publication may be changed without prior notification.

MUTOH INDUSTRIES LTD. has made the best efforts to keep this publication free from

error, but if you find any uncertainties or misprints, please call us or the shop where you

bought this equipment.

MUTOH INDUSTRIES LTD. shall not be liable for any damages or troubles resulting from

the use of this equipment or this manual.

ValueCut USER MANUAL Important Information

Important Information

Thank you for purchasing the ValueCut Cutting Plotter.

Before you use the cutting plotter, please make sure that you have read

the safety precautions and instructions below.

Caution

!

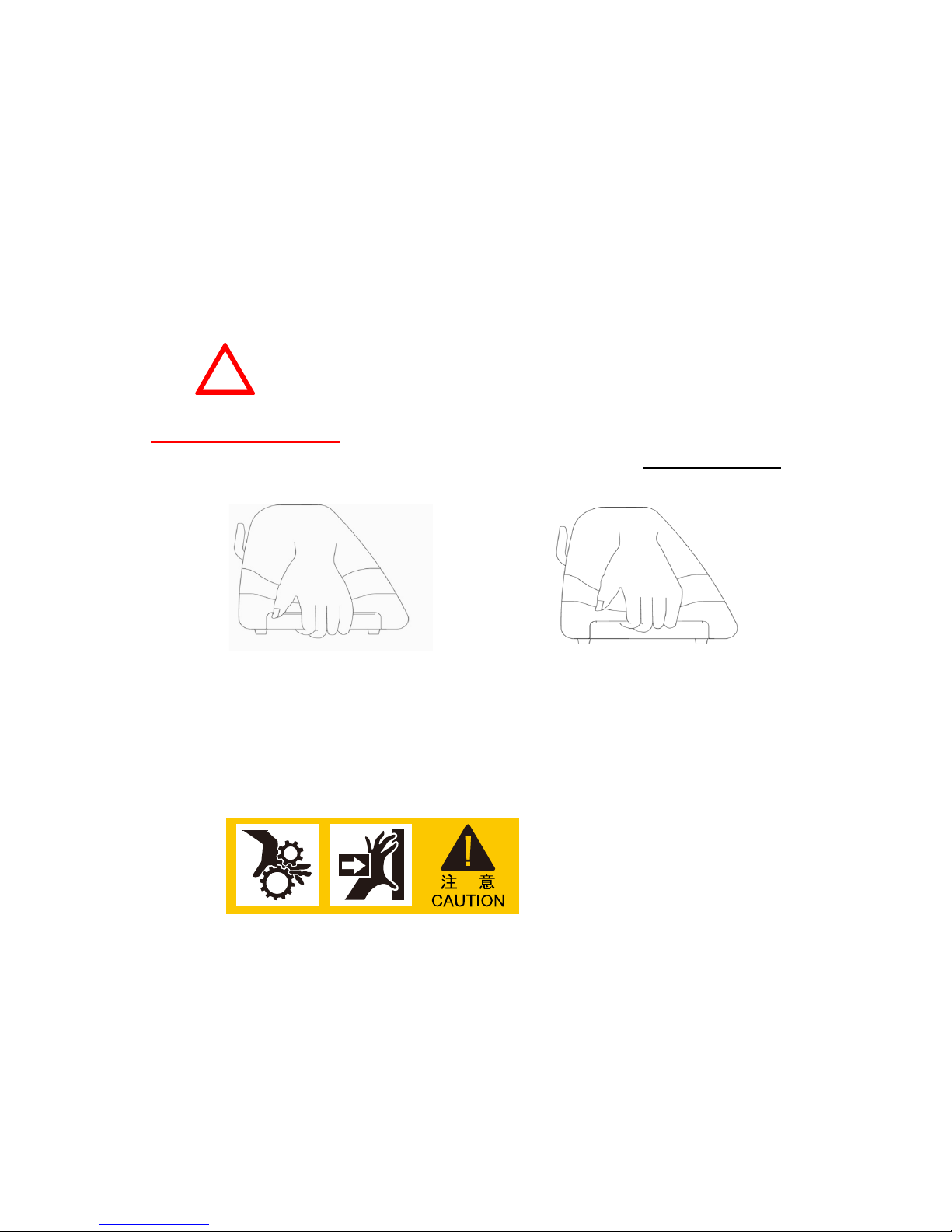

SAFETY PRECAUTION

For safety concern, please always hold the cutter firmly from the bottom while

moving it. Do not move the cutter by clasping the depression area on both sides.

Do not place your hand close to the tool carriage to prevent your fingers from

being clamped during the operation of the cutting plotter.

O (Correct) X (Incorrect)

3

V5a 2015 Jan

Important Information ValueCut USER MANUAL

Hazardous moving parts keep fingers and other body parts away!

Do not shake or drop the blade holder, a blade tip can fly out.

During an operation, do not touch any of the moving parts of this machine (such

as the carriage). Also be careful to make sure that clothing and hair do not get

caught.

Always connect the power cable to a grounded outlet.

Always use the accessory power cable which is provided. Do not wire the power

cable so that it becomes bent or caught between objects.

Do not connect the power cable to branching outlet to which other machines are

also connected, or use an extension cable. There is danger of overheating an d of

mis-operation of the machine.

Keep the tools away from children where they can reach.

4

V5a 2015 Jan

ValueCut USER MANUAL Important Information

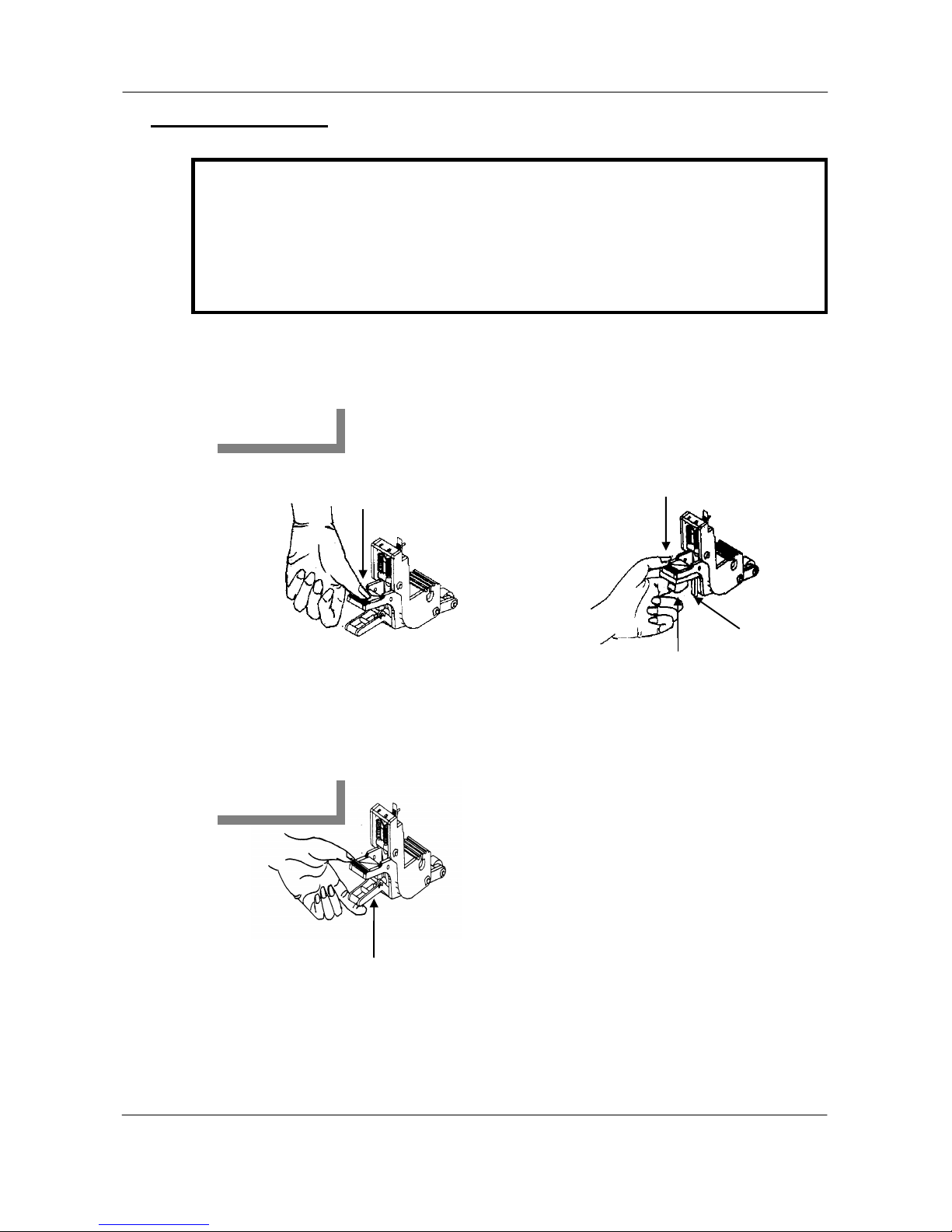

Operation precaution

Always put the pinch rollers within the white marks.

Note: Never press the top release grip (the release grip is fully pressed when a

clip sound is heard) and pull the bottom release grip at the same time as the

pictures shown below. This will prevent you from disabling the pinch roller as

the stop bar will not reach the correct position and therefore will not be

functioning.

Pull up bottom to release grip

Disable

Press down

O (Correct)

Stop bar

Push

X (Incorrect)

Enable

Press down

5

V5a 2015 Jan

Table of Contents ValueCut USER MANUAL

Table of Contents

1 General Information ............................................ 9

1.1 Introduction ............................................................................................................... 9

1.2 Package Items ........................................................................................................... 9

1.3 Production Features ............................................................................................... 11

1.4 Appearance of ValueCut ......................................................................................... 12

1.4.1 The Front View ....................................................................................................................... 12

1.4.2 The Back Vuew ...................................................................................................................... 13

1.4.3 The Whole View of ValueCut .................................................................................................. 13

1.4.4 The Left Side View ................................................................................................................. 14

1.4.5 The Right Side View ............................................................................................................... 14

2 Installatopn ........................................................ 15

2.1 Precaution ............................................................................................................... 15

2.2 Stand & Flexible Media Support System (VC-1300/1800) .................................... 16

2.3 Desktop Flexible Media Support System (VC-600) .............................................. 22

2.4 Instruction of Damper Roller ................................................................................. 24

2.5 Installation of Media Basket System ..................................................................... 25

2.6 Cutting Pad Installation .......................................................................................... 28

2.7 Blade Installation .................................................................................................... 30

2.8 Automatic Blade Length Detection ....................................................................... 32

2.9 Cable Connection ................................................................................................... 34

3 The Control Panel ............................................. 35

3.1 The LCD Panel ........................................................................................................ 35

3.2 Menu in On-line mode ............................................................................................ 36

3.3 Menu in Off-line Mode ............................................................................................ 37

3.4 Menu Items .............................................................................................................. 39

4 Operation ........................................................... 43

4.1 Media Loading ......................................................................................................... 43

4.1.1 Loading the Sheet Media ....................................................................................................... 43

6

V5a 2015 Jan

ValueCut USER MANUAL Table of Contents

4.1.2 Loading the Roll Media ........................................................................................................... 45

4.2 Tracking Performance ............................................................................................ 48

4.3 Cutting Force and Offset Adjustment ................................................................... 49

4.4 How to Cut 3mm Letters ........................................................................................ 50

4.5 How to Make A Long Plot ....................................................................................... 50

4.6 When Completing the Cutting Job ........................................................................ 51

5 Automatic Aligning System II .......................... 52

5.1 Introduction ............................................................................................................. 52

5.2 AAS Calibrating the System .................................................................................. 53

5.2.1 Media Calibration ................................................................................................................... 53

5.2.2 AAS Calibration ...................................................................................................................... 53

5.2.3 AAS II on ValueCut ................................................................................................................. 54

5.3 Printer Test .............................................................................................................. 56

5.4 Registration Mark Offset Range ............................................................................ 58

5.5 Contour Cutting ...................................................................................................... 58

5.6 Tips for AAS ............................................................................................................ 60

6 Maintenance ...................................................... 61

6.1 Cleaning the Cutting Plotter .................................................................................. 61

6.2 Cleaning the Grid Drum ......................................................................................... 62

6.3 Cleaning the Pinch Rollers .................................................................................... 62

7 Trouble Shooting .............................................. 63

7.1 Non-operation Problems ........................................................................................ 63

7.2 Operational Problems ............................................................................................ 64

7.2.1 LCM Error Messages ............................................................................................................. 64

7.2.2 Other operational problems .................................................................................................... 65

7.3 Cutting Plotter/Computer Communication Problems .......................................... 67

7.4 Software Problems ................................................................................................. 68

7.5 Cutting Quality Problems ....................................................................................... 69

8 FlexiSTARTER Quick Start Guide .................... 70

8.1 Introduction ............................................................................................................. 70

8.2 Install of the FlexiSTARTER ................................................................................... 70

8.3 Start up of the FlexiSTARTER ................................................................................ 71

8.4 Add Device by Using the Production Manager .................................................... 72

8.5 Initial Settings of the Production Manager ........................................................... 73

8.5.1 Change to the setting of leaving job that finishes runnin g ...................................................... 73

7

V5a 2015 Jan

Table of Contents ValueCut USER MANUAL

8.5.2 Change unit of measures used in the Production Manager .................................................... 74

8.6 Basic Settings ......................................................................................................... 75

8.6.1 Overview of the FlexiSTARTER screen .................................................................................. 75

8.6.2 Standard T oolbar .................................................................................................................... 76

8.6.3 Main T oolbar ........................................................................................................................... 77

8.7 Create the Character .............................................................................................. 78

8.7.1 Cut/Plot Window ..................................................................................................................... 79

8.8 Cut the Character .................................................................................................... 80

8.9 Create Date of the Contour Cut Line ..................................................................... 82

8.9.1 Procedure of the cut contour .................................................................................................. 82

8.9.2 Read in the data of the Adobe Illustrator ................................................................................ 82

8.9.3 Create data of the contour cut line ......................................................................................... 83

8.9.4 Cut contour mark .................................................................................................................... 84

8.9.5 Create a cut contour mark ...................................................................................................... 85

8.10 Cut Contour ........................................................................................................... 86

8.10.1 Image Print ........................................................................................................................... 86

8.10.2 Cut contour window .............................................................................................................. 86

8.10.3 Cut Contour .......................................................................................................................... 87

8.11 Feature List ............................................................................................................ 88

8.12 Troubleshooting .................................................................................................... 90

8.12.1 Can not send the data from FlexiSTARTER ......................................................................... 90

8.12.2 How to change the pen up speed ......................................................................................... 90

9 Appendix ........................................................... 91

9.1 ValueCut Specification ........................................................................................... 91

9.2 Blade Specification ................................................................................................. 92

9.3 About the T ool ......................................................................................................... 93

9.4 Consumable and Optional Item List ...................................................................... 94

8

V5a 2015 Jan

ValueCut USER MANUAL General Information

1 General Information

1.1 Introduction

ValueCut series c utt i ng plotters have been designed to produce computer-generated images or perform

contour cutting on sheets or rolls of vinyl media.

This manual covers the following models of ValueCut series cutting plotters:

‧VC-600 for media width: 50mm(1.97”) ~ 770mm(30.3”)

‧VC-1300 for media width: 50mm(1.97”) ~ 1594mm(62.7”)

‧VC-1800 for media width: 300mm(11.8”) ~ 1900mm(74.8”)

1.2 Package Items

The package of the ValueCut model contents the items listed below, please check carefully.

If you find any item missing, please consult your local dealer for further ass ist anc e.

SSttaannddaarrdd IItteemm

QQuuaannttiittyy

1. Cutting Plotter Main unit 1

2. Stand Set ( for VC-1300/1800 only )(Optional for VC-600)

2 piece of T-shape stand

1 piece of stand beam

18 pieces of M6 screws

1 piece of M5 L-shape hexagon screw driver

1 piece of Installation Guide for Stand Set

1

9

V5a 2015 Jan

General Information ValueCut USER MANUAL

3. Flexible Media Support System Package

Items VC-1300/1800 Only VC-600

1 set of Roll Media Flange (2 pieces) V V

1 set of Roll Holder (2 pieces) V V

1 set of Roll Holder Guide Bushes (4 pieces)

V V

1 set of Roll Holder Support (2 pieces) V V

1 piece of M6 L-shape hexagon screw driver V V

1 piece of Installation Guide for Roll Holder V

1 piece of M5 L-shape hexagon screw driver

V

1 set of Desktop Support Brackets (2 pieces) V

4 pieces of Plastic Foot V

4 pieces of M4 screws V

12 pieces of M6 screws V

1 piece of M4 L-shape hexagon screw driver

V

1

4.Media Basket (VC-1300/1800 only) (VC-600 : opt.)

2 pieces of Basket Arm

2 pieces of Basket Rod

1 piece of Basket

4 pieces of Basket Screw

2 pieces of Fixtures (for Basket Arms)

8 pieces of M3 screws

1 piece of 2mm L-shape hexagon screw driver

1

5. Accessories

1 piece of User’s Compact Disk

1 piece of data cable (RS-232C 3m)

1 piece of data cable (USB cable 3m)

1 set of Blade Holder Assembly (Installed in tool carriage of the cutting plotter)

1 piece of Blade (45° with Red Cap/ Installed in Blade Holde r)

1 piece of Safe Blade

1 piece of Cutting Pad for Vinyl cutting

1 piece of Tweezers

1 Oily ball-point pen

1

10

V5a 2015 Jan

ValueCut USER MANUAL General Information

1.3 Production Features

The following are the main features of the ValueCut series cutting plotters:

‧ Tri-port connectivity provides you with greater flexibility

‧ Up to 600-gram cutting f orce

‧ Up to 60-inch/per second cutting speed

‧ Guaranty 10-meter trac king

‧ User friendly, multi-language control panel

‧ Ingenious media basket (optional item)

‧ Enhanced Automatic Aligning System for automatic contour cutting

11

V5a 2015 Jan

General Information ValueCut USER MANUAL

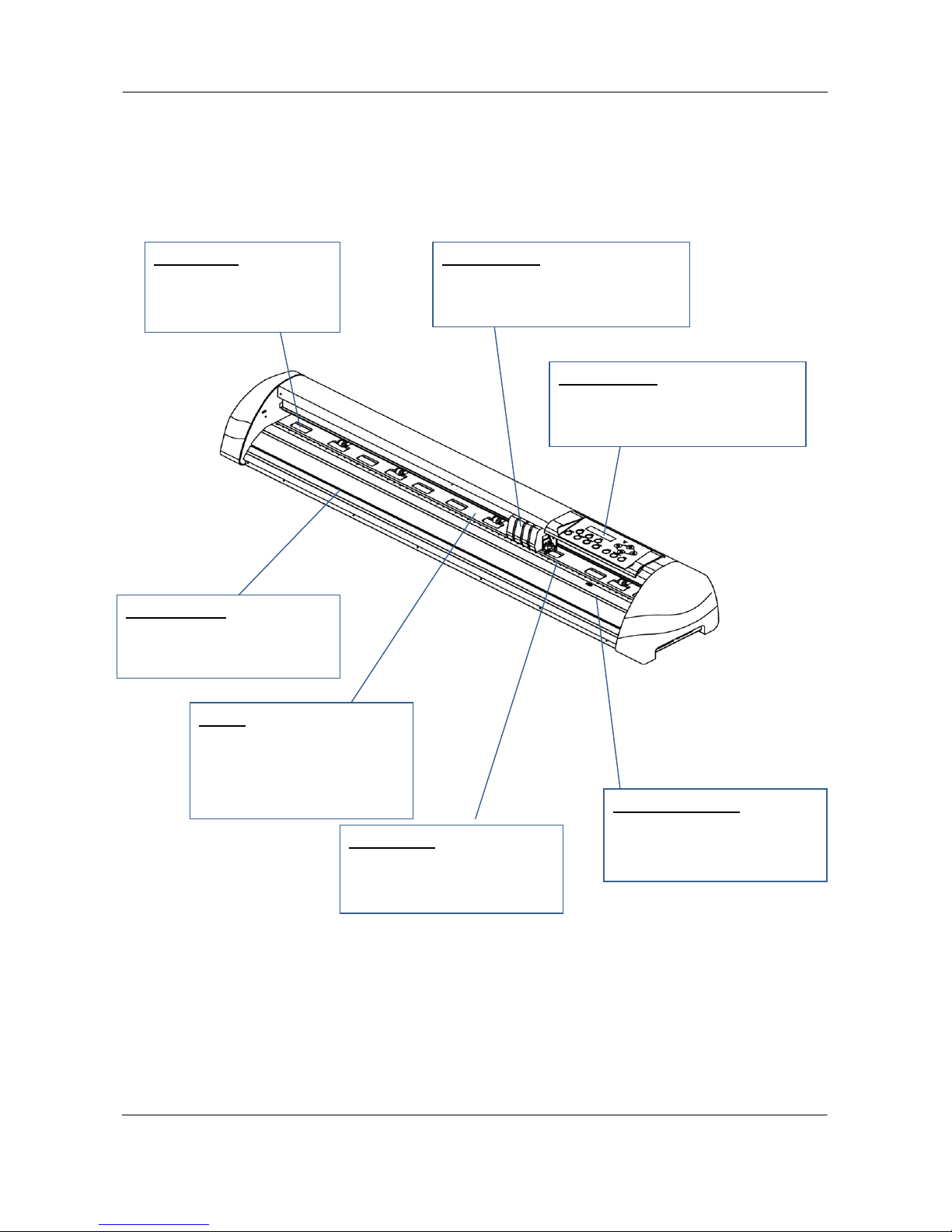

1.4 Appearance of ValueCut

1.4.1 The Front View

Figure 1-1

Grid Drums – move the

media back and forth

during operation.

Tool Carriage – performs the

cutting with the installed blade and

pen with AAS module.

Slicer Groove – slice off the

extra media easily along this

groove.

Platen – provides the surface

for holding and supporting

media while performing cutting.

Alignment Rulers – media

can be aligned with the clear

guide line marks.

Cutting Pad – provides the

protection of blade when the

blade is cutting.

Control panel – consists of 14

control keys and 1 LED and 1 LCM

showing messages and menus.

12

V5a 2015 Jan

ValueCut USER MANUAL General Information

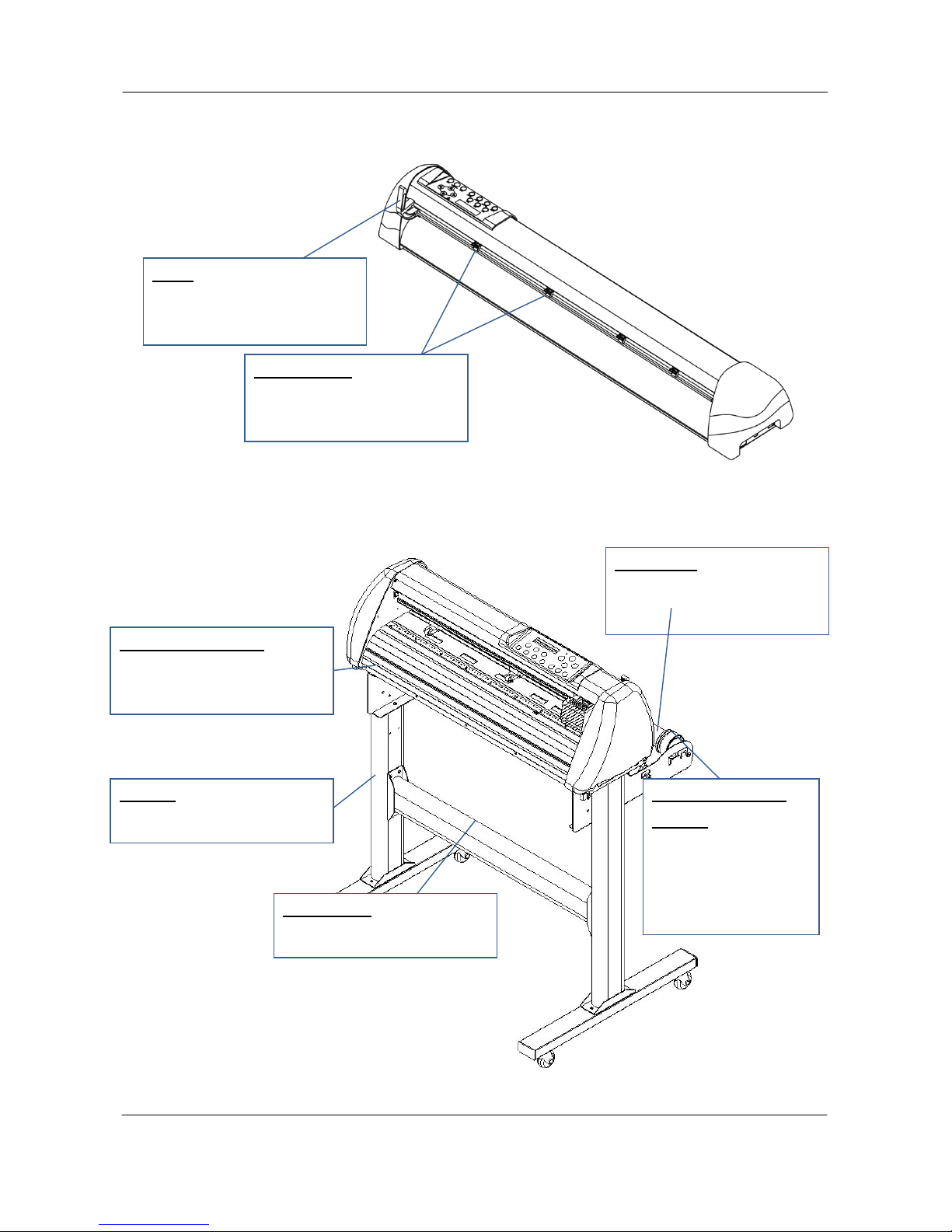

1.4.2 The Back Vuew

1.4.3 The Whole View of ValueCut

Figure 1-2

Figure 1-3

Pinch Rollers –

hold the media during cutting.

Lever –

raises or lowers the pinch

rollers.

Roll Holder – holds and

supplies the roll media for

cutting.

Roll Holder Guide

Bushes – serve to keep

the roll media in place

when media is pulled

from the roll.

T-Stand –supports the cutti ng

plotter body.

Roll Holder Support –

supports roll holders.

Stand Beam – stabilizes the

body.

13

V5a 2015 Jan

General Information ValueCut USER MANUAL

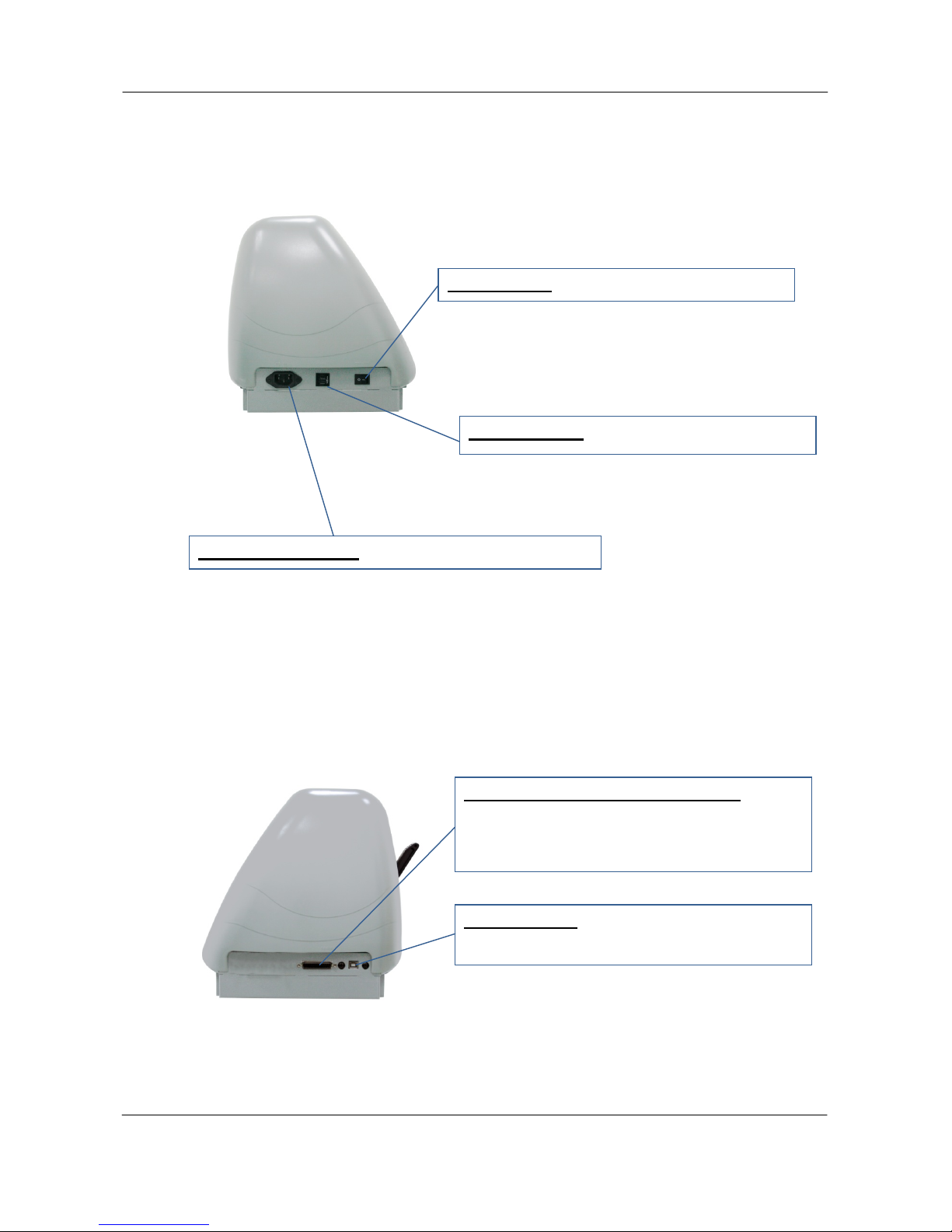

1.4.4 The Left Side View

1.4.5 The Right Side View

Figure 1-4

Figure 1-5

Power Switch – On when switches to [I]; Off to

Circuit Breaker – 3 Amp.

AC Power Connector – used to insert the AC power

Serial Interface Connector (RS232C) – used

to connect the cutting plotter to a computer

through a serial interface cable.

USB Connector – used to connect the cutting

plotter to a computer through a USB cable.

14

V5a 2015 Jan

ValueCut USER MANUAL Installation

2 Installatopn

2.1 Precaution

Please read the following information carefully before you start installation.

Note:

1.

Make sure the power switch is off before installing the cutting plotter.

Carefully handle the cutter to prevent any injuries.

2. Choosing a proper place before setting up the cutting plotter

Before installing your cutting plotter, select a suitable location,

which meets the

following conditions.

The machine can be approached easily from any direction.

Keep enough space for the machine, accessories and supplies.

Keep the working area stable, avoiding sever vibration.

Keep the temperature between 15 and 30

℃

(60-86oF) in the workshop.

The relative humidity of the working environment should be between 25% to 75%.

Protecting the machine from dust and strong air current.

Preventing the machine from direct sunlight or extremely bright lighting.

3. Connecting the Power Supply

Check the plug of the power cord to see if it matches with the wall outlet. If not, please

contact your dealer.

Insert the plug (male) into a grounded power outlet.

Insert the other end (female) of power cord into the AC connector of cutting plotter.

15

V5a 2015 Jan

Installation ValueCut USER MANUAL

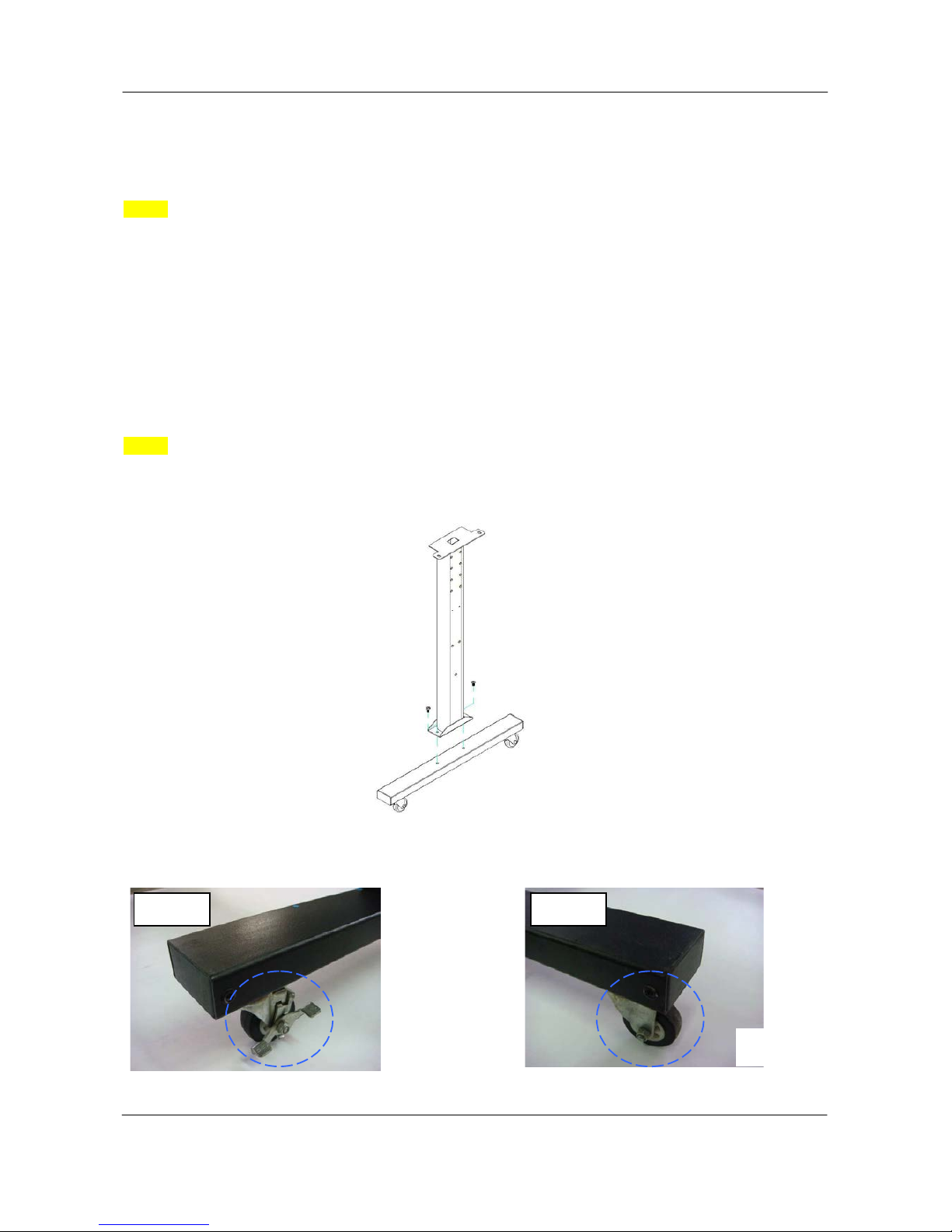

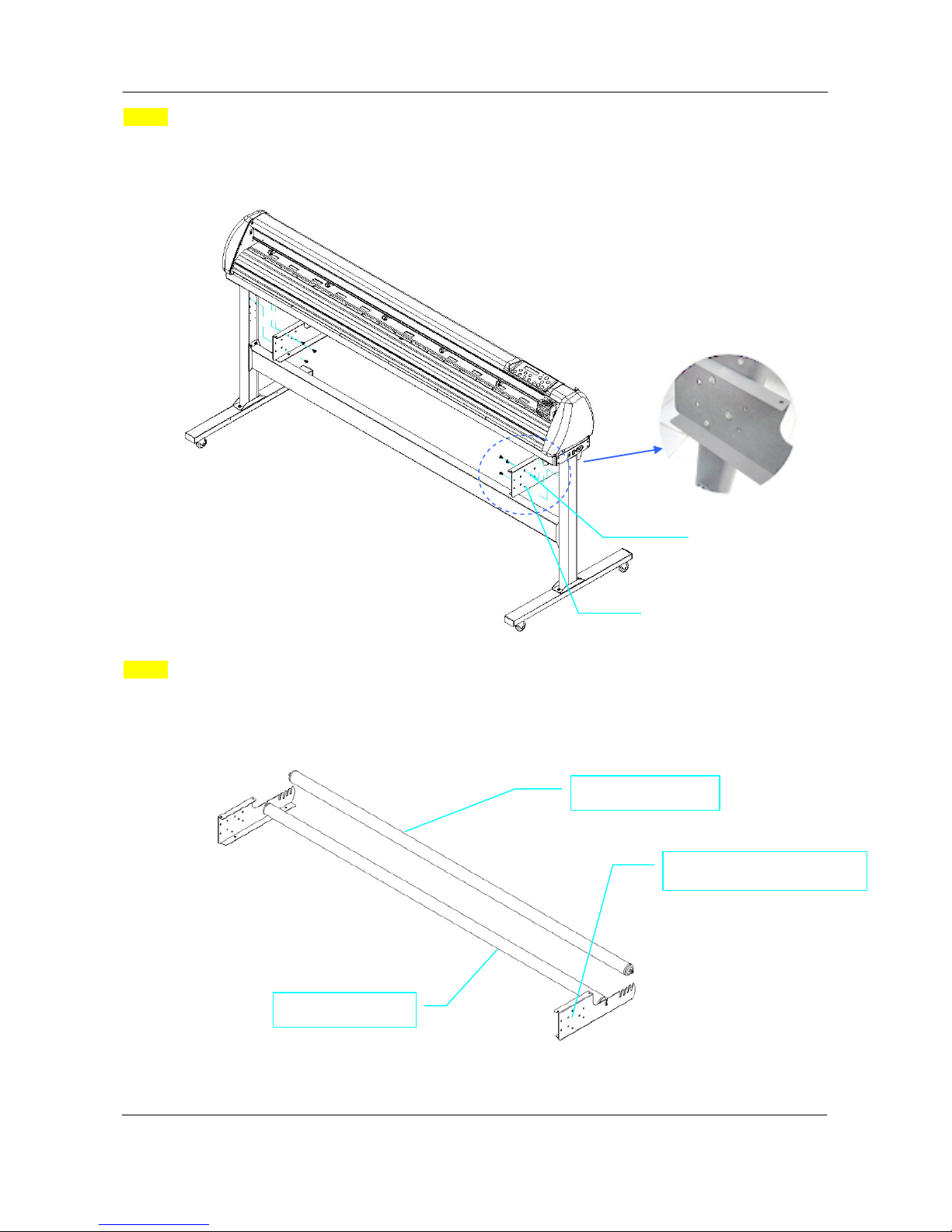

2.2 Stand & Flexible Media Support System (VC-1300/1800)

Step 1

Please examine supplied items in the accessory box of stand carton:

2 pieces of base beams

2 pieces of side beams

1 piece of stand beam

20 pieces of M6 screws

1 piece of M5 L-shape hexagon screw driver

1 piece of Installation Guide for Stand Set

Step 2

Remove the plotter body and the accessories from the s hipped carton.

Assemble the base beam to the side beam with 2 screws to f orm a T-shape stand.

Please pay attention to the direction of the base beam (t he wheel on the front end of the beam comes

with a break while the rear one is on its own).

Figure 2-1

Figure 2-2

Figure 2-3

Front

Rear

16

V5a 2015 Jan

ValueCut USER MANUAL Installation

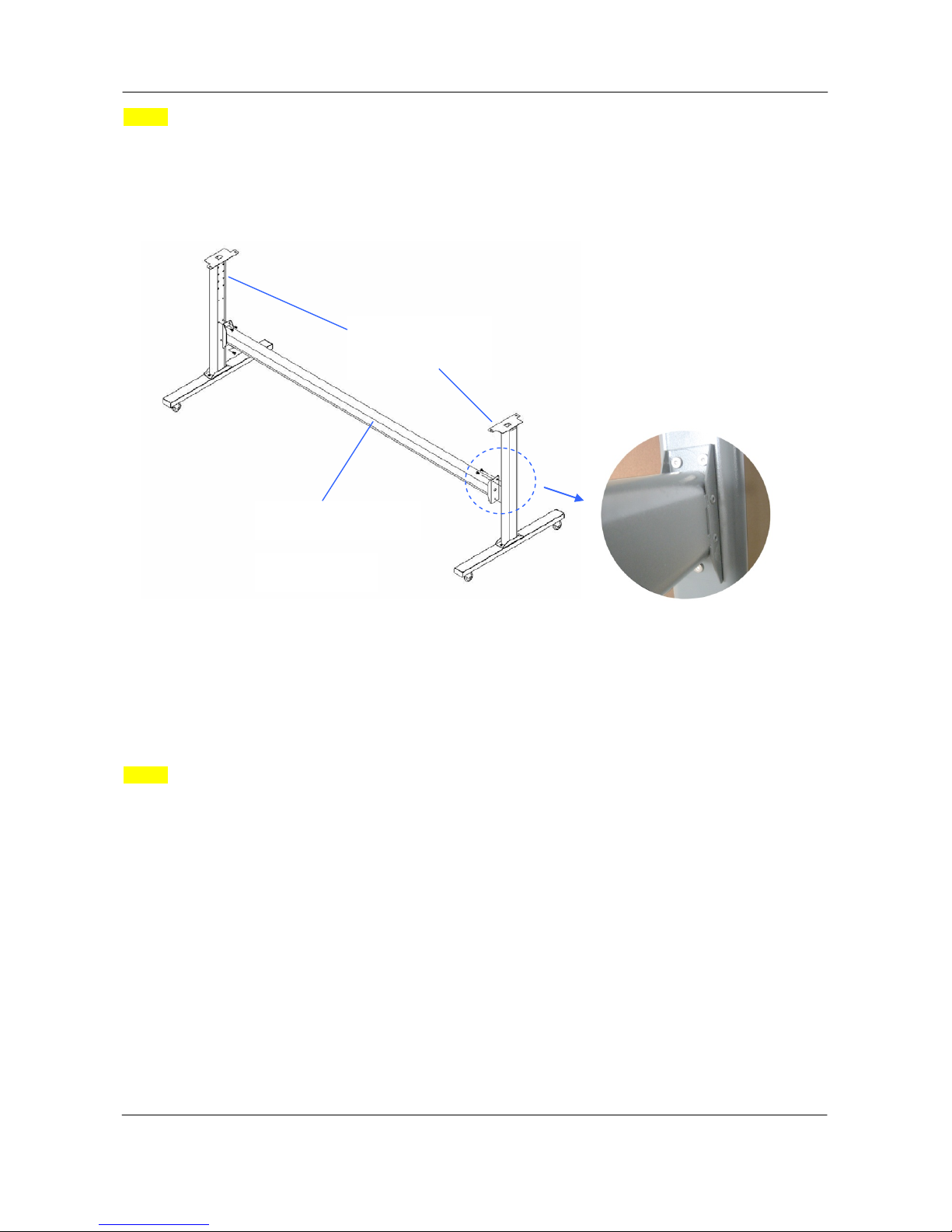

Step 3

Place the stand beam upright on the T-stand and follow number (1) (2)to assemble. (See Figure

2-4 & 2-5)

Step 4

Position the stand beam perpendicularly to part (1)and put the screws into the holes and tighten them as

Figure 2-5. Then the complete picture of stand will be like Figure 2-4.

(1) T-Stand

(2) Stand beam

Figure 2-4

Figure 2-5

17

V5a 2015 Jan

Installation ValueCut USER MANUAL

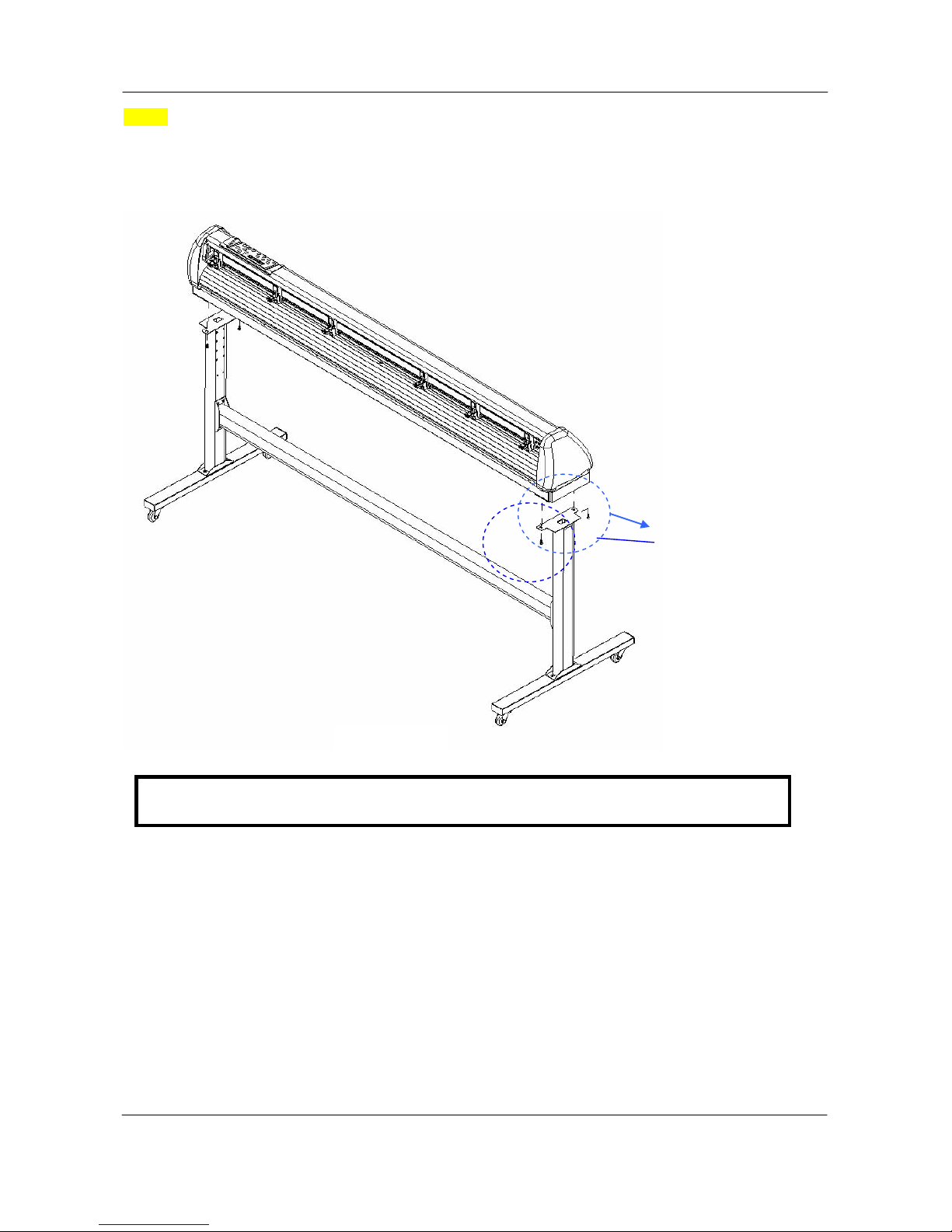

Step 5

Remove the cutting plotter from the carton. Position your stand under the plot ter, and then insert the

screws into the holes on plotter’s bottom and tighten them up as shown in Figure 2-6.

を

Screw(M6)

Figure 2-6

Note: The cutting plotter needs to be assembled by at least two people.

18

V5a 2015 Jan

ValueCut USER MANUAL Installation

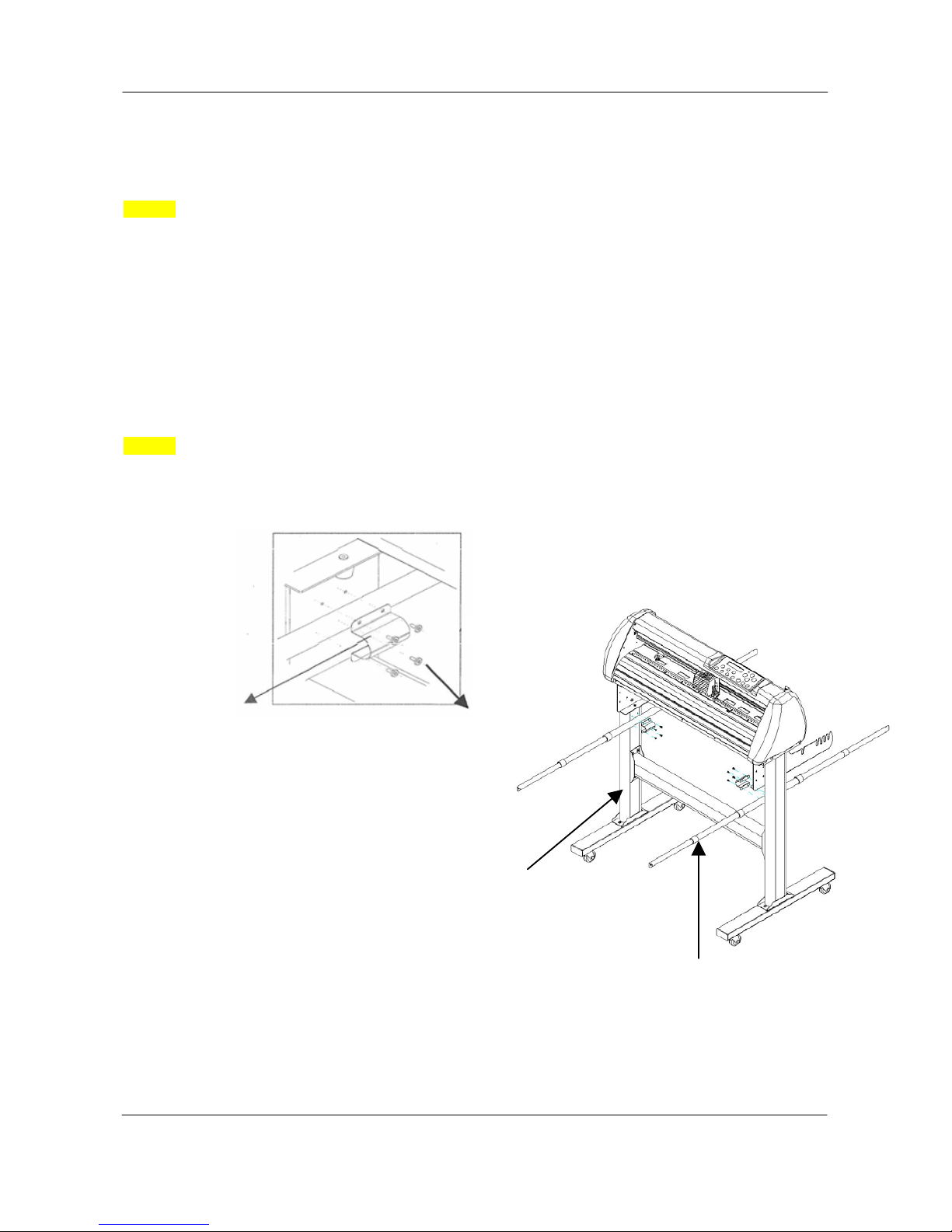

Step 6

Insert the roll holder support with the screws into the holes of the stand, and then tighten them up as

shown in Figure 2-7. You could decide roll holder support’s position by insert i ng into different holes.

Step 7

Place roll holder 1 into the holes in the roll holder support. (Figure 2-8)

Roll holder support

Roll holder 1

Figure

2-8

Roll holder support

3 screws

Roll holder 2

Figure 2-7

19

V5a 2015 Jan

Installation ValueCut USER MANUAL

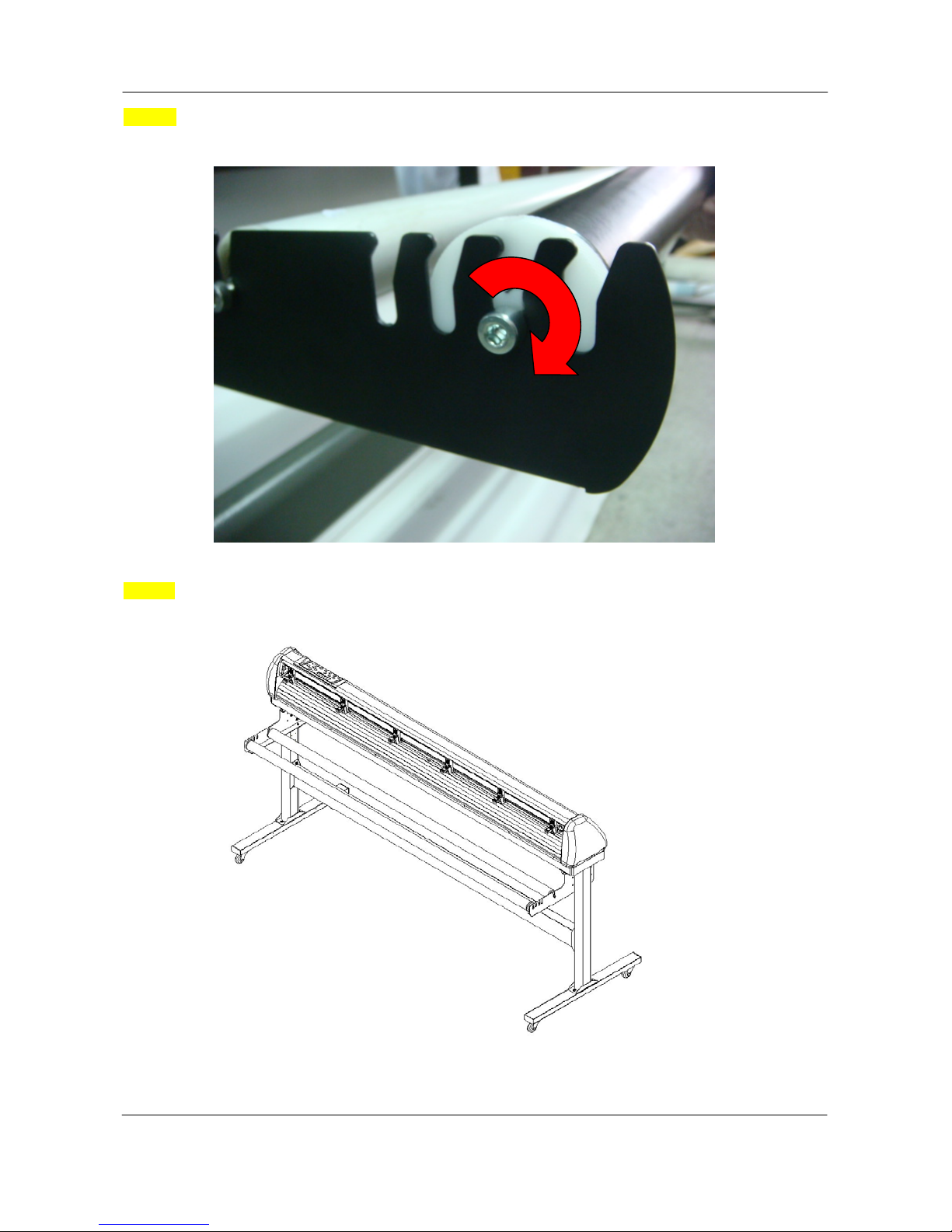

Step 8

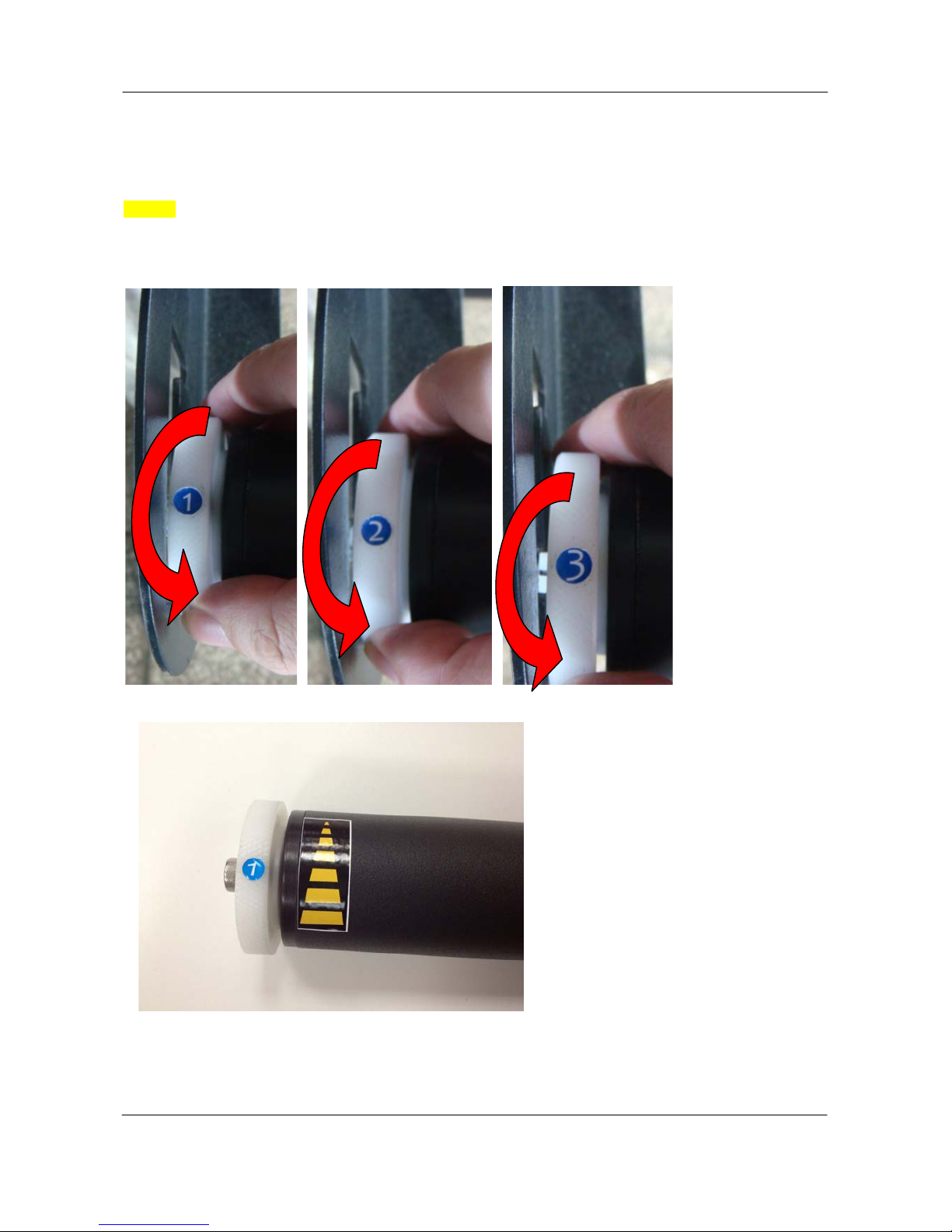

Turn the screw counter-clockwisely for around three times after unpacking roll holder 2 (Figure 2-9).

Step 9

Insert the end of the roll holder without the damper into the left roll holder support and then insert the end

of the roll holder with the damper into the right roll holder support. Ensure the white protrusion is wedged

in the groove (Figure 2-10).

Figure 2-9

Figure 2-10

20

V5a 2015 Jan

ValueCut USER MANUAL Installation

Step 10

Tighten the screw on the damper until it is securely attached to the right roll holder support (Figure 2-11).

Step 11

Lastly, the complete picture will be shown like below (Figure 2-12).

Figure

2-12

Figure 2-11

21

V5a 2015 Jan

Installation ValueCut USER MANUAL

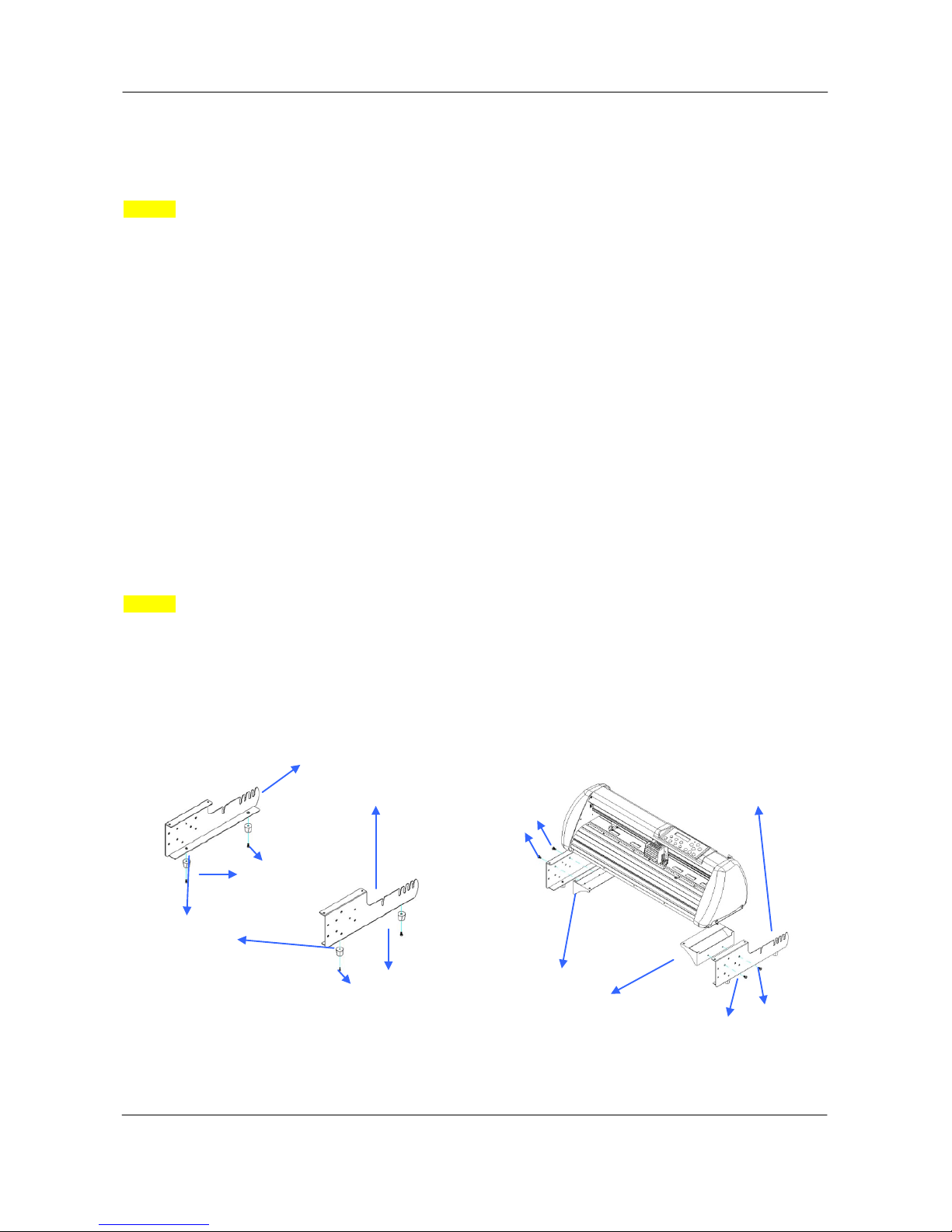

2.3 Desktop Flexible Media Support System (VC-600)

Step 1

Please examine the following items in stand carton’s accessory box:

1 set of Roll Media F l ange (2 pieces)

1 set of Roll Holder ( 2 pieces)

1 set of Roll Holder Guide Bushes (4 pieces)

1 set of Roll Holder Support (2 pieces)

1 set of Desktop Support Bracket (2 pieces)

4 pieces of Plas tic Foot

4 pieces of M4 screws

12 pieces of M6 screws

1 piece of M4 L-shape h exagon screw driver

1 piece of M5 L-shape h exagon screw driver

1 piece of M6 L-shape h exagon screw driver (for adjusting the screws of Roll Hol ders)

1 piece of Installation Guide for Roll Holder

Step 2

Put the 4 Plastic Foot under the Roll Holder Support and insert the M4 screw into the hole of Plastic Foot

and tighten them with the M4 L-shape screw driver. (Figure 2-13

)

M6 screws

Figure 2-14

M6 screws

Figure 2-13

M4 screws

Plastic

M4 screws

Roll Holder Support Roll Holder

Support

Desktop Support Brackets

22

V5a 2015 Jan

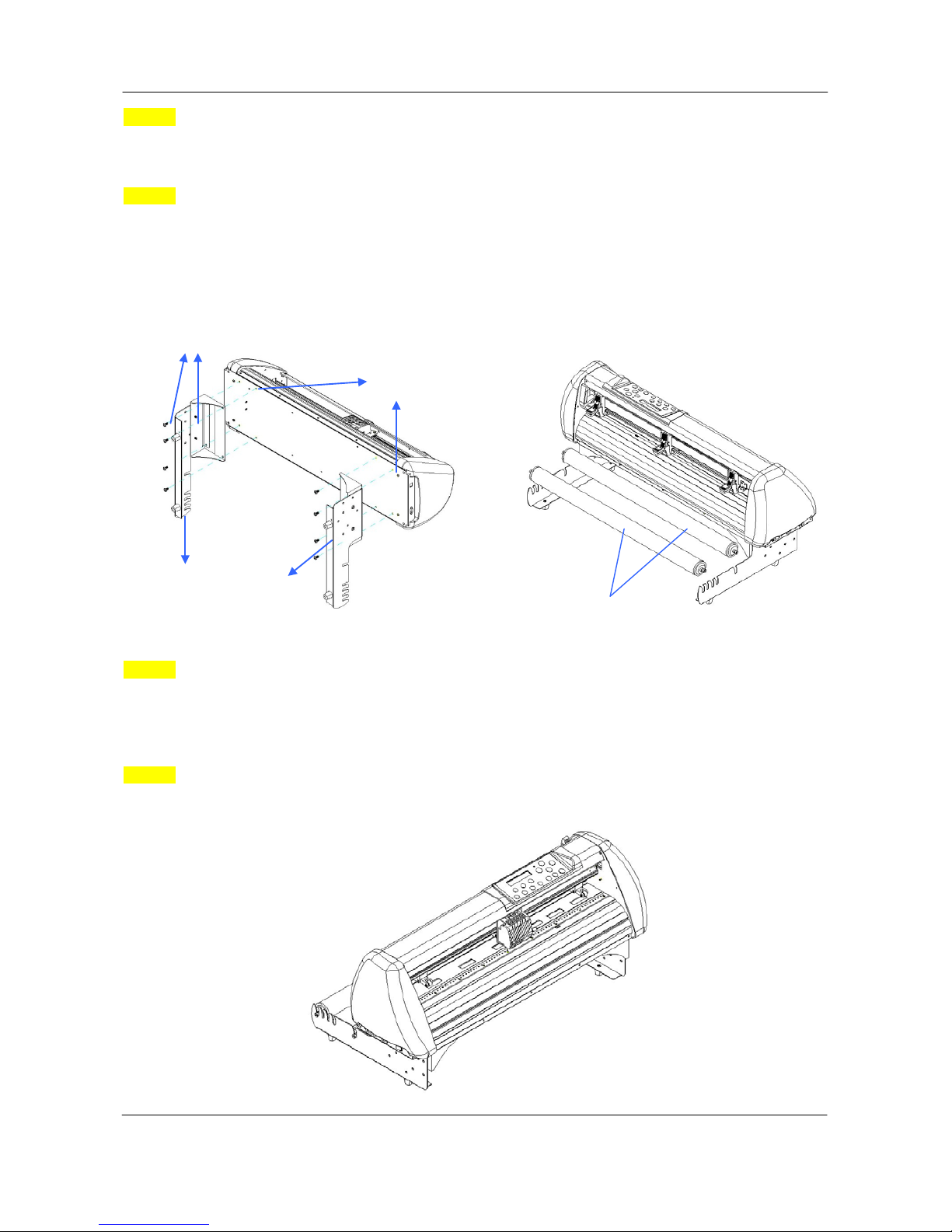

ValueCut USER MANUAL Installation

Step 3 Position the Desktop Support Brackets beside the Roll Holder Support and insert M6 screws

into the Roll Holder Support and tighten them with M6 L-shape screw driver. (Refer to Figure 2-14 at the

left).

Step 4

Put the bottom of machine in lateral, and position the Roll Hol der Assembly beside the bottom of the

machine. Then, insert the M6 screws into the holes of Roll Holder support assembly and tighten them

with M6 L-shape screwdriver. Like Figure 2-15.

Step 5

Place the two roll holders into the holes of Roll Holder Support (Figure 2-16). T o install the roll holder with

damper, please refer to chapter 2.2, step 8 to step 10.

Step 6

The complete Desktop Media Support System will be shown as in Figure 2-17.

Figure 2-17

Figure 2-16

Roll Holder Shaft

Figure 2-15

Screw holes

M6 screws

Roll Holder Assembly

23

V5a 2015 Jan

Installation ValueCut USER MANUAL

2.4 Instruction of Damper Roller

Step 1

Turn the wheel as instructed below to adjust damping. The bigger the number is, the stronger the

damping. The volume symbol sticker indicates the damping level (Figure 2-18, 2-19).

Figure 2-18

Figure 2-19

24

V5a 2015 Jan

ValueCut USER MANUAL Installation

2.5 Installation of Media Basket System

Step 1

Please examine the supplied items in the accessory box

2 pieces of basket arms

2 pieces of basket rods

1 piece of basket

2 pieces of fixtures (for basket arms)

8 pieces of M3 screws

1 piece of 2mm L-shape hexagon screw driver

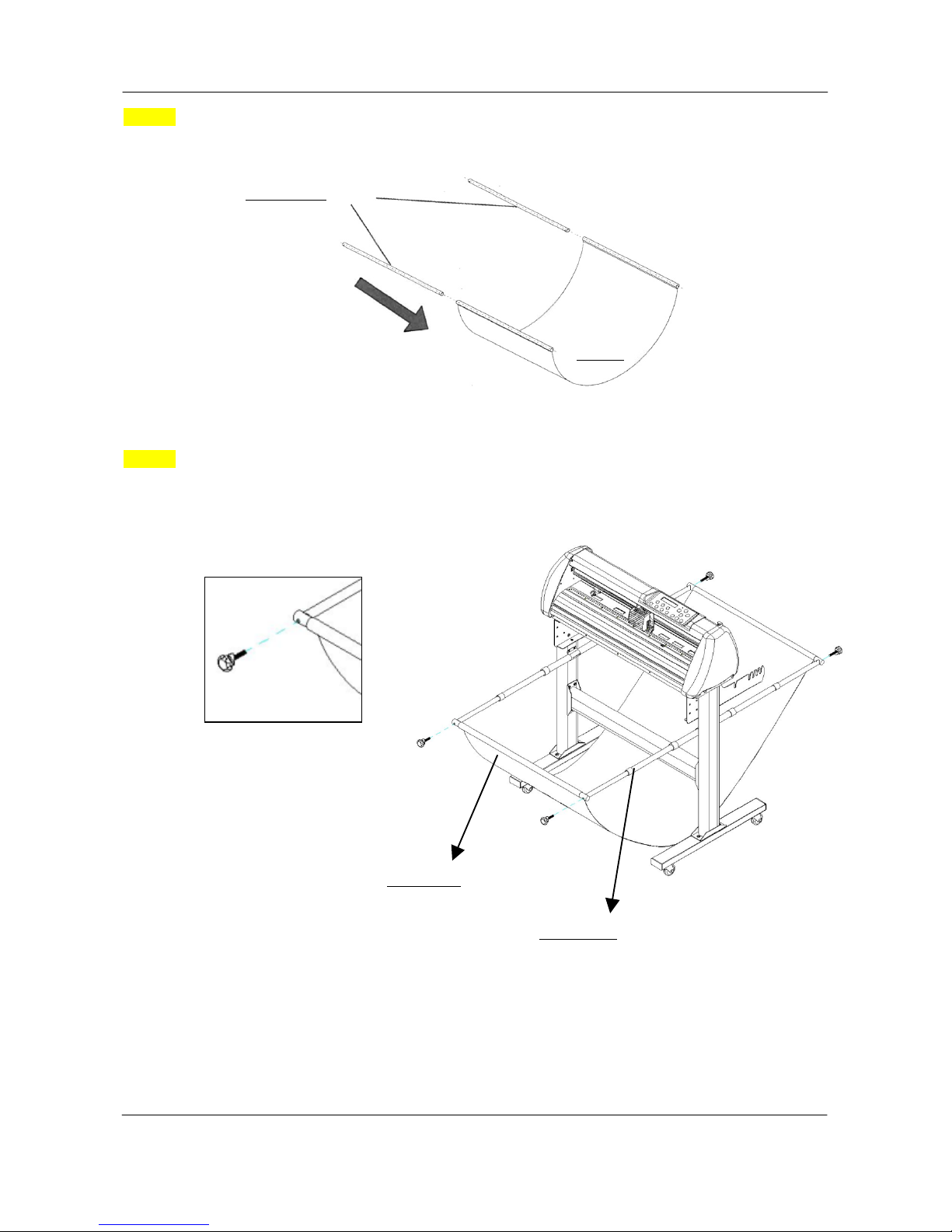

Step 2

First, place the basket arms beside the stand and fix them with fixtures. Then insert the M3 screws and

tighten them with the 2mm L-shape screw driver. (See Figure2-20)

Stand

M3 screws

Fixtures

Figure 2-20

Basket arm

25

V5a 2015 Jan

Installation ValueCut USER MANUAL

Step 3

Insert the basket rods to the basket holes (See Figure 2-21)

Step 4

Loosen the basket screws from the basket arms. Posit i on the basket rod in front of the basket arms and

insert the basket screws into the holes on the basket rod and tighten them. (Figure 2-22)

Basket rods

Basket

Basket rod

Basket arm

Figure 2-21

Figure 2-22

26

V5a 2015 Jan

ValueCut USER MANUAL Installation

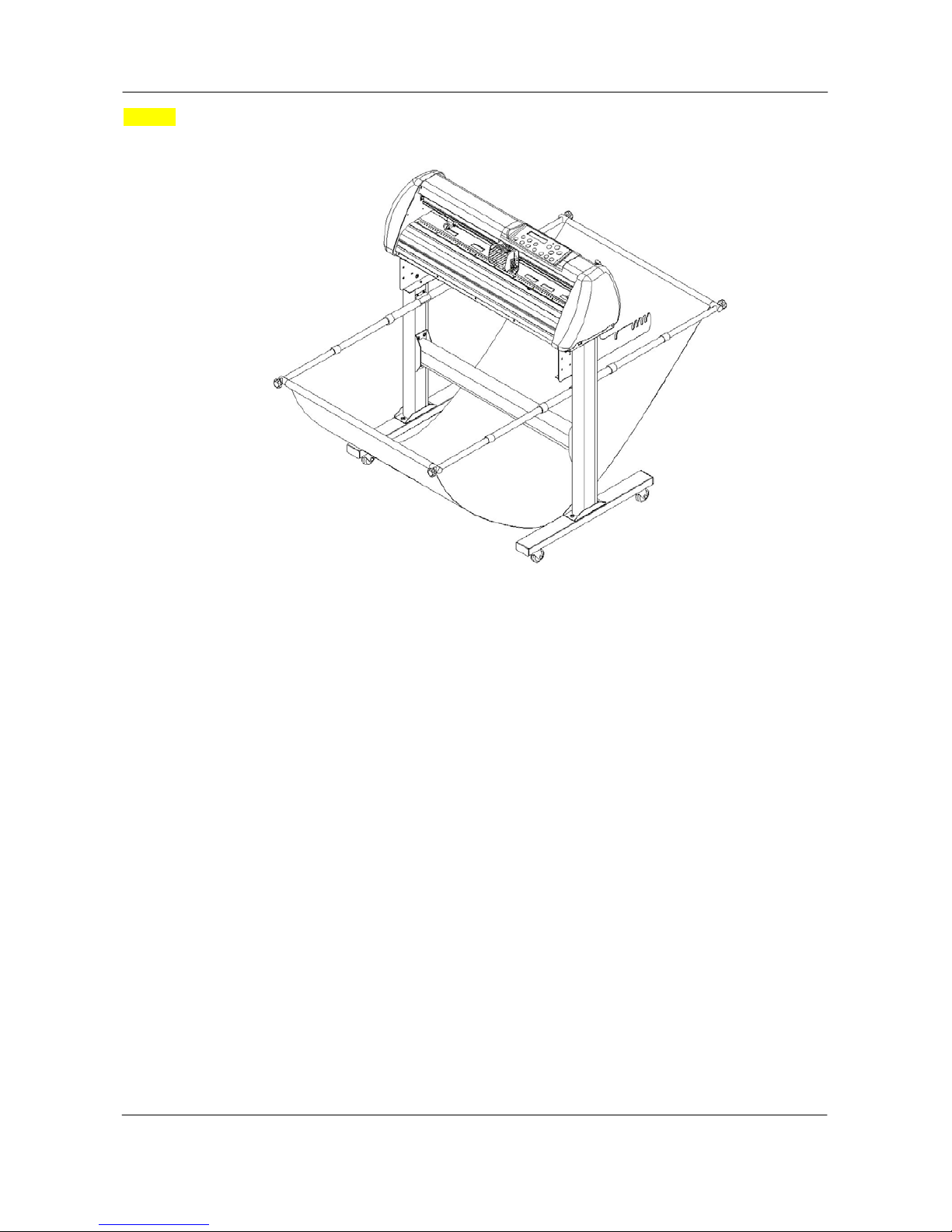

Step 5

The complete Media Basket System will be like Figure 2-23.

Figure 2-23

27

V5a 2015 Jan

Installation ValueCut USER MANUAL

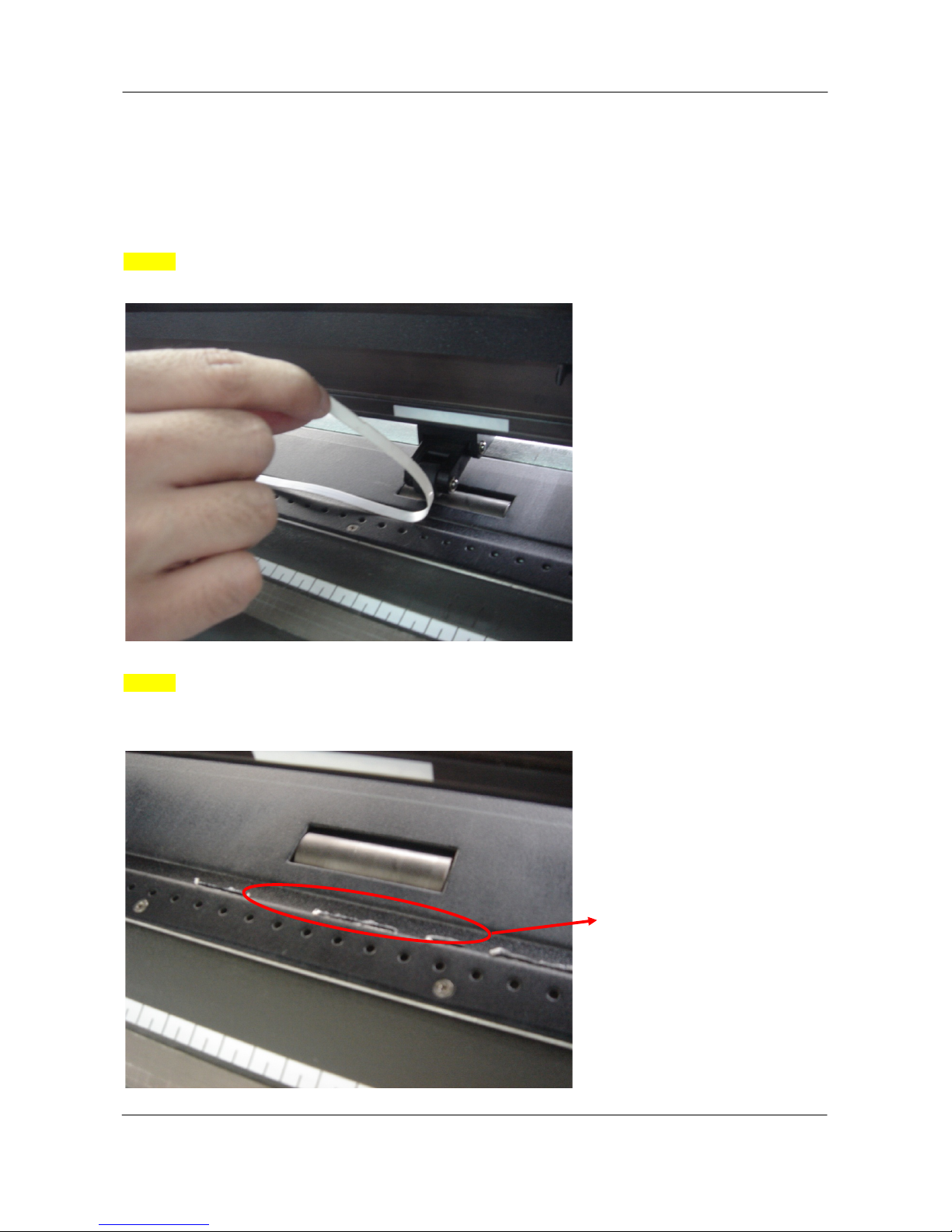

2.6 Cutting Pad Installation

1 piece of cutting pad is included in the accessory pack. F ol low the instruction below to install

a new cutting pad when the existing pad is worn out.

Step 1

Carefully remove the cutting pad from the unit.

Step 2

Remove the remaining adhesive on the groove with alcohol or cleaning naphtha.

Remaining adhesive

Remaining adhesive

Figure 2-24

Figure 2-25

28

V5a 2015 Jan

ValueCut USER MANUAL Installation

Step 3

Attach the new cutting pad to the groove after unrolling i t and removing the backing sheet and

the installation process is completed.

Figure 2-26

Figure 2-27

29

V5a 2015 Jan

Installation ValueCut USER MANUAL

2.7 Blade Installation

Figure 2-28 is the ill ustrator of the blade hold er. Insert a blade into the bottom of the blade holder and

remove the blade by pushing the pin. Make sure that your fingers are awa y from the blade tip.

Step 1

Install blade (Figure 2-29).

Step 2

Push the blade to the bottom of the blade holder. (Figure 2-30).

Step 3

Adjust the blade tip to suitable length by screwing

“Blade tip adjustment screw” clockwise orcount-clockwise. (Figure 2-31).

Figure 2-31

Figure 2-30

Tips:

“The proper length” means the blade’s length

is adjusted 0.1mm more than film’s thickness.

That is, if the thickness of film is 0.5mm, then

blade’s length is properly adjusted 0.6mm and

it can completely cut through the film layer yet

avoid penetrating the backing.

Figure 2-28

Outward ring

Adjustment depth knob

Figure 2-29

Pin

30

V5a 2015 Jan

ValueCut USER MANUAL Installation

Step 4

Insert the blade holder into tool carriage. Please note the outward ring of the holder must put into the

grooves of carriage firmly (see Figure 2-32), then fasten the case (Figure2-33).

Step 5

Use the reversing steps to remove the blade holder.

Step 6

Eject the blade. Push “Blade eject pin” to eject blade when the blade needs to be replaced.

Note:

The blade will lose its sharpness after a period of us age, the cutting quality might be affected.

By increasing the cutting force, it mi ght do the trick. However, once the blade is worn out and no

longer provides a reliable cutting, you should repla ce a new one. The bl ade is cons umable and must

be replaced as often as necessary to maintain the cutting quali ty. The quality of the blade deeply

affects cutting quality. So be sure to use a high quality blade to ensure good cutting results.

Figure 2-32 Figure 2-33

31

V5a 2015 Jan

Installation ValueCut USER MANUAL

Figure 2-34

Figure 2-35

2.8 Automatic Blade Length Detection

Figure 2-34 is the new blade holder with a scale and the carriage with a mark . T his blade holder det e ct s

blade length automatically and shows how the knob needs to be turned on the LCM.

There are 10 units on the scale; each unit equals t o 0.05 mm, allowing you to adjust the blade length for

0.00mm-5.00mm (Figure 2-35).

Follow the steps below to adjust the length of the blade:

1. Keep the blade tip within the blade holder before you s tart adjusting.

2. Align one of the scales on the blade holder to the mark on the carriage

3. Select “Blade Length Adjust” under “CUT TEST” on the LCM, enter the blade length wished in “Set

Length”; test the blade holder first and then test the blade length by pressing ENTER.

Mark

Scale

1 unit

Note:

Keep the blade holder at the same position when you perform blade holder and blade length tests.

32

V5a 2015 Jan

ValueCut USER MANUAL Installation

Figure 2-37 Figure 2-36

4. When blade holder and blade length tests are finished, t he screen will show you to what degree (the

unit of the value following “CW” or “CCW” is “circle”) and in which directi on [CW (clockwise) or CCW

(counterclockwise)] you should turn the adjustm ent knob.

EG, Turn CW 5 is telling you that you should turn t he knob for 5 units clock-wisely (Figure 2-36,

Figure 2-37).

5. The screen will show "Adjustment completes " when the value on the screen is 0, the blade length is

perfect and no more adjustment needs to be made. Press "Enter" now to complete the process and

you may start cutting at this point.

33

V5a 2015 Jan

Installation ValueCut USER MANUAL

2.9 Cable Connection

The cutting plotter communicates with a computer through a USB (Universal Serial Bus) or a

Serial port (RS-232C). This chapter shows you how to connect the cutting plotter to a host

computer and how to set up the computer/cutting plotter interconnection.

Figure 2-38

Serial port

Note:

When USB connection is enabled, both parallel port and serial port will be disabled automatically

USB port

34

V5a 2015 Jan

ValueCut USER MANUAL Control Panel

3 The Control Panel

This chapter describes the button operations with the LCM menu flowcharts of ValueCut.

When the cutting plotter is ready for use as des cribed in Chapter 1 & 2, all functions are

under default parameters.

3.1 The LCD Panel

SPEED FORCE OFFSET

MISC TOOL SELECT DATA CLEAR CUT TEST

ON/OFF

LINE

PAUSE / RESUME ENTER

POWER

< LCD Control Panel on ValueCut series >

Key Function

LCD Screen To display functions and error messages.

Power LED To indicate the power status ( light up: power on; light off: power off )

4 Arrow Keys To move position, select function, or change setting.

ENTER To set item or register the immediately preceding input value.

PAUSE/RESUME To temporarily halt cutting process or to continue

ON/OFF LINE To switch modes, stop cutting job, or abort changes of setti ngs.

OFFSET To adjust the value of blade’s offset.

FORCE To adjust the value of cutting force.

SPEED To adjust the value of cutting speed and quality.

CUT TEST To perform cutting tests in different ways.

DATA CLEAE To clear up buffer memory.

TOOL To select tools.

MISC To set up functions.

Please see details "3.4 Menu Items"

35

V5a 2015 Jan

Control Panel ValueCut USER MANUAL

3.2 Menu in On-line mode

Power On ValueCut in processing

Sending data

[

PAUSE

]

[ FORCE]

[ SPEED ]

[ OFFSET ]

[ DATA CLEAR ]

[TOOL SELECT ]

Top menu

Speed--- Force----- Offset---- Length---- Width----Tool set----Metric

MUTOH

LCM Version 1.3

Firmware V3.01

VC-1300

Place Media And Then

Lower Up The Lever

Roll Edge Single

~ Key | Key } Key

Sizing Media Width

Lever Down To Abort

Sizing Media Length

Lever Down To Abort

Pause

Setup RESUME

Force: 80 gf ~

Ok:ENTER|

Speed: 72 cm/s~

Select:{} Ok:ENTER|

UP Speed: 72 cm/s~

Select:{} Ok:ENTER|

Quality: Normal~

Select:{} Ok:ENTER|

Offset: 0.250 mm ~

Ok:ENTER|

Clear data memory

N:ONLINE Ok:ENTER

1S 72 F 80 O0.250M

Select:{} Ok:ENTER|

Set Smoothing Cut

Select:{} Ok:ENTER

OverCut: 0.00 mm ~

Select:{} Ok:ENTER|

Set Tangential Mode

Select:{} Ok:ENTER

Pouncing: 0 mm ~

Select:{} Ok:ENTER|

S 72 F 80 O 0.250

L: 150000W: 914 T1M

36

V5a 2015 Jan

ValueCut USER MANUAL Control Panel

Ratio: 100% - 400%

Pattern: Cross, Arrow

3.3 Menu in Off-line Mode

Press [ON/OFF LINE] to switch to the offline mode

Draft, Fair, Normal, Fine, Small Letter

[CUT TEST ]

Offline For

System Setup

Force: 80 gf ~

Ok:ENTER|

Offset: 0.250 mm ~

Ok:ENTER|

Clear data memory

N:ONLINE Ok:ENTER

Speed: 72 cm/s~

Select:{} Ok:ENTER|

UP Speed: 72 cm/s~

Select:{} Ok:ENTER|

Quality: Normal~

Select:{} Ok:ENTER|

~|{} move origin

X: Y:

Square Cut

Select:{} Ok:ENTER

Repeat AAS Job

Select:{} Ok:ENTER

Redo Jobs in Memory

Select:{} Ok:ENTER

Pattern Setting

Select:{} Ok:ENTER

Pattern: Arrow

Change:~| Ok:ENTER

Ratio Setting

Select:{} Ok:ENTER

Ratio: 100 %

Change:~| Ok:ENTER

Blade Length Adjust

Select:{} Ok:ENTER

Set Length 0.00 mm

Change:~| Ok:ENTER

Test Blade Holder

Ok:ENTER

Test Blade Length

Ok:ENTER

Turn CW 1 Turn

N:ONLINE Ok:ENTER

[ FORCE]

5~600 with an increment of 5(gram force)

[ OFFSET ]

[ DATA CLEAR ]

Speed:3~153 with an increment of 3(cm/s)

[ SPEED ]

0.000~1.000 with an increment of 0.025(mm)

UP Speed:3~153 with an increment of 3(cm/s)

[ Arrow Key ]

37

V5a 2015 Jan

Control Panel ValueCut USER MANUAL

Offline For

System Setup

[TOOL SELECT ]

[ MISC ]

use~|to select from 1S to 4S; [ENTER] to adjust the

parameters

1S 72 F 80 O0.250M

Select:{} Ok:ENTER|

Pouncing: 0 mm ~

Select:{} Ok:ENTER|

Panel Setup

Select:{} Ok:ENTER

OverCut: 0.00 mm ~

Select:{} Ok:ENTER|

Set Tangential Mode

Select:{} Ok:ENTER

Set Smoothing Cut

Select:{} Ok:ENTER

Restore default ?

Select:{} Ok:ENTER

Pouncing:0-200mm with an

increment of 1mm

OverCut:0.00-3.00mm with an

increment of 0.05mm

Image Scale Width

Select:{} Ok:ENTER

Image Scale Length

Select:{} Ok:ENTER

Select Units

Select:{} Ok:ENTER

Select Language

Select:{} Ok:ENTER

Set Communication

Select:{} Ok:ENTER

Paper Saving Mode

Select:{} Ok:ENTER

AAS Offset

Select:{} Ok:ENTER

First Back To Origin

Select:{} Ok:ENTER

Vcuum

Select:{} Ok:ENTER

Auto Unrolled Media

Select:{} Ok:ENTER

Metric (cm/gf) or English

English

Both Expanded Mode、Length Expanded Mode

、

Width Expanded Mode、Both Unexpanded Mode

Select Language

Select:{} Ok:ENTER

38

V5a 2015 Jan

ValueCut USER MANUAL Control Panel

3.4 Menu Items

Below describes the functions of menu items

Menu or Key Function Setting Default

--- Media sizing ---

Place Media

And Then

Lower Down

The Lever

To instruct the user to lower the lever after the materi al is

loaded.

When the medium is loaded, the user will be requested t o

lower the lever; once the lever is lowered, users can proceed

to the three sizing modes (Roll/Edge/Single).

Roll

To measure media width.

Maximum Tracking

150 meters

Edge

To measure media width and pull the media back till the front

paper sensor open.

Maximum Tracking

150 meters

Single

To measure media width and length.

Maximum Tracking

10 meters

--- POWER ---

To indicate the power status.

[ Arrow Keys ]

1. To move the tool carriage position on X or Y axis.

2. To select functions or change values of settings.

[ ENTER ]

1. The displayed parameters will be saved automatically.

2. To set a new origin at the present tool carriage posit i on.

In “offline” mode, moving the tool carriage to desired

position by [Arrow Keys], then press [ENTER] key to set a

new origin. While moving with the parameters of XY-axes

displayed, press [MISC] key will enable fine-tune

movement; press [MISC] key again to disable the function.

[ PAUSE/RESUME ]

To temporarily halt the cutting process.

To resume the process by press [Pause/Resume] key again.

[ ONLINE/OFFLINE ]

1. To switch between online mode and offline mode.

2. To stop the cutting job or abort the change of setting.

Once press this key, the cutting job will be terminated

immediately and cannot be resumed.

[ OFFSET ]

To set or modify the distance between the blade tip and the

center axis.

Please refer to section 4.3 or Chapter A-2 for more

information.

0.000~1.000mm

0.250mm

[ FORCE ]

To set or modify the value of tool force.

When the cutting force exceeds 450g, the maximum c ut ting

speed would be 15cm/sec and the cutting quality would be

Small Letter Mode (0.2g) and while the cutting force is

5~600gram;

5 gram/ step

80 gram

39

V5a 2015 Jan

Control Panel ValueCut USER MANUAL

300g-449g, the maximum cutting speed would be 30 cm/sec

and the cutting quality would be Fine Mode (0.5g)

[ SPEED ]

Speed

To set or modify tool down speed at horizontal moving.

3~153cm/sec;

3cm/sec per step

72cm/sec

Up Speed

To set or modify tool up speed at horizontal moving.

3~153cm/sec;

3cm/sec per step

72cm/sec

Cutting Quality

To set or modify cutting quality.

While cutting small letter, set as “Small letter”.

While cutting in high speed, set as “Draft”.

For normal operation, set as “Normal”.

Draft(4.2G),

Fair(2.8G),

Normal(1.4G),

Fine(0.7G),Small

Letter(0.2G)

Normal

[ CUT TEST ]

Square Cut

To perform a cutting test at present blade position.

For more information, please refer to “4.3 Adjusting the

Cutting Force and Offset” to adjust blade force and cutting

speed.

Repeat AAS

Job

To repeat AAS jobs automatically without having to operate

on the computer side.

Please be noted that this feature is mainly applied to the

Single paper mode; please ensure a new piece of material

you wish to apply this feature on is loaded and the origin

repositioned to the first registration mark before starting.

When the first AAS job repeat completes, the user will be

offered the choice of “Repeat AAS Job Again”, please

press ”Online/Offline” to return to the main menu.

Repeat Last

Plot

Recut:

To repeat the last job without re-sending the data

.

1~99;

1 per step

Copy:

To copy the last job without re-sending the data.

* 1mm gap will be auto-generated between 2 copies).

* If the media length is not enough to continue, it will show

below message on LCM:

* If both functions are enabled at the same time, t he cutter

will

perform the last setting only.

1~99;

1 per step

Pattern Setting

To provide two patterns for cut test

Note: It is recommended to select “Cross” if you are working

on thick pieces of materials.

“Arrow” and

“Cross” patterns

“Arrow”

Ratio Setting

To adjust the size of the pattern

100%, 200%,

300%, 400%

100%

Blade Length

Adjust

Please see 2.5 Automatic Blade Length Adjustment for further

details.

0.00mm-5.00mm

0.00mm

[ DATA CLEAR ]

To clear up buffer memory.

Out Of Space; #

of Copies finished

40

V5a 2015 Jan

ValueCut USER MANUAL Control Panel

[ TOOL SELECT ]

Set Smoothing

Cut

To enable smooth-cutting function.

This function aims to make connections smoother a nd is

suggested to be disabled when cutting small-sized images or

characters

Enable

Over Cut

To generate an overcut to facilitate weeding.

This function mainly applies to thick materials, aiming to

sharpen corners and ensure perfect connections.

0.00mm-3.00mm

0.05mm/per step

0.00mm

Set Tangential

Mode

To enable the emulated tangential-cutting mode for thicker

media types and small letter cuts.

Note: while the Offset value setting at 0.000 mm, “Set

Tangential Mode” will automatically be disabled.

Enable

Pouncing

To make perforated patterns.

* In order to use this function, Pouncing tool must be installe d.

* Before start pouncing, place pouncing strip on top of the

cutting pad to protect the cutting pad.

* Set the value as 0 mm to disable the pouncing mode.

* Pouncing tool is an optional item.

0~200mm

0mm

Panel Setup

Accept setup command:

To accept commands of the Force, Speed, Cutting Qual i t y,

and Offset only via software.

Control panel only:

To accept commands of the Force, Speed, Cutting Qual i t y,

and Offset only via control panel of the cutter.

Restore Default

To turn all parameters of the menu items to factory-default

settings.

[ MISC ]

Auto Unrolled

Media

To avoid paper jam and motor crash by automatically unroll

media (50cm and up) before cutting while enabled. .

* Auto-unroll only affects on roll/edge media.

* Using Single mode to size media will disable this function

automatically.

* If the length of the rolled media is less than 2 meters or t he

weight is light, it is recommended to set this mode disabled.

Enable

Vacuum

To help improve tracking and cutting accuracy by tur ning on

the fans. If you turn off the vacuum system, the fans

will remain inactive during cutting or plotting.

Enable

First Back to

Origin

To enable the carriage back to the previous origin; w hen

“Enable” is selected and the button Online/Offline has been

pressed, the carriage will go back to the previous origin

while

the selection of “Disable” will not allow the carriage to do so.

Enable

Disable

Enable

AAS Offset

To set or modify AAS offset value.

You can refer to “5.3 Printer Test” for more details.

Paper Saving

Mode

To save media by four different modes:

1. Length expanded mode 2. Width expanded mode

3. Both expanded mode 4. Both unexpanded mode

Length

expanded

mode

Set

Communication

To build up the communication between host computer and

cutter.

Baud Rate is to determine the speed of data transmiss i on.

Data Bits refers to the size of one block of data.

Parity is used to check if data was revived correctly or not.

9600, n, 7, 1, p 9600pbs, 7 Bits with NO Parity

9600,N,8,1

,p

41

V5a 2015 Jan

Control Panel ValueCut USER MANUAL

9600, o, 7, 1, p 9600pbs, 7 Bits with ODD Parity

9600, e, 7, 1, p 9600pbs, 7 Bits with EVEN Parity

9600, n, 8, 1, p 9600pbs, 8 Bits with NO Parity

9600, o, 8, 1, p 9600pbs, 8 Bits with ODD Parity

9600, e, 8, 1, p 9600pbs, 8 Bits with EVEN Parity

19200, n, 7, 1, p 19200pbs, 7 Bits with NO Parity

19200, o, 7, 1, p 19200pbs, 7 Bits with ODD Parity

19200, e, 7, 1, p 19200pbs, 7 Bits with EVEN Parity

19200, n, 8, 1, p 19200pbs, 8 Bits with NO Parity

19200, o, 8, 1, p 19200pbs, 8 Bits with ODD Parity

19200, e, 8, 1, p 19200pbs, 8 Bits with EVEN Parity

Firmware

Version

To display the version number of Firmware and FPGA code.

Select

Language

To select displayed languages on LCM panel in English,

Spanish, Italian, Deutsch, Japanese, Portugue se, P ol ish,

Turkish or French.

English

Select Units

Provide two-unit systems for users convenient.

Metric(cm/g)

Unit(inch/g)

Unit(cm/oz)

English(inch/oz)

Metric

Image Scale

Length

To adjust the scale of media length and width that may cause

by the thickness of the media.

The Denominator is the actual length, and the Numerator is

the ideal length measured from the resultant.

For example, cutting a line with 500.0 mm length. The

procedure as follows:

1. Press the [LEFT ARROW] to choose the Numerator and

select 500.0 mm,

2. Cut the length by sending a graph file,

3. Measure the length then use the [RIGHT ARROW] key to

choose the Denominator, then

4. Press [UP ARROW /DOWN ARROW] to

change the values

of the actual length.

250mm/250mm

500mm/500mm

750mm/750mm

250mm/25

0mm

Image Scale

Width

42

V5a 2015 Jan

ValueCut USER MANUAL Operation

4 Operation

4.1 Media Loading

4.1.1 Loading the Sheet Media

To load the media properly, please follow the procedures listed below:

Step 1

Use the lever on the upper right side of the cutting plotter to raise or lower down pinch rollers. P ull the

lever forward until it makes a clicking sound then the pinc h rollers are raised (

Figure 4-1).

Step 2

Load your media on the platen and slide it under the pinch rollers from either the front side or the

backside. The alignment rulers on the platen extension will help you to adjust the m edia precisely.

Note:

Be sure that the media must cover

the paper sensors on the platen when

loading the media. At least one of the

two paper sensors (Figure 4-2)

should be covered. Once the media

covers the sensor, the cutting plotter

will size the media width and length

automatically.

Paper sensors

Figure 4-2

Lever

Figure 4-1

43

V5a 2015 Jan

Operation ValueCut USER MANUAL

Step 3

Then move the pinch rollers manually to the proper position. Be sure the pinch rollers must be positioned

above the grid drum. The white marks on the top trail will remind you where the gri d drums are (Figure

4-3).

Step 4

Push the lever backward to lower down the pinch rollers.

Step 5

Turn on the power, the tool carriage will meas ure the size of the media automatically. And the plotting

cutter begins to work.

t

Figure 4-4

(X) Incorrect

Note:

1. Always adj ust the position with the pinch roller raised.

2. Move the pinch roller by applying force at the rear portion of the pinch roller support.

3. Do not move it by holding its front rubber roller (Figure 4-4).

White marks

Figure 4-3

44

V5a 2015 Jan

ValueCut USER MANUAL Operation

4.1.2 Loading the Roll Media

Step 1

Put the roll media guide bushes on two roll holders (Figure 4-6).

Pull up bottom to release grip

Figure 4-5

Note:

Please pull up the bottom of all pinch rollers (Figure 4-5) before the lever is pushed backwards to

ensure accurate media width detection.

Enable

Roll media guide bushes

Figure 4-6

45

V5a 2015 Jan

Operation ValueCut USER MANUAL

Step 2

-- Option A (Recommended)

Insert the two roll holders into the roll media support set then place the roll media directly between the

two roll holders (

Figure 4-7).

-- Option B (Use the media flanges )

Insert a roll media flange at the end of each roll

media and tighten the thumbscrew until the roll

media is firmly gripped(see Figure 4-8).

Then put the roll media on the roll holders. Adjust the

position of the roll media ensure that media flanges are

able to run in the grooves of media guide bushes.

(Figure 4-9)

Step 3

Load the media on the platen. Please refer to “4.1.1 Loading the sheet media”. After loading the roll

media, flatten the media on the platen and hold the front edge of the roll media firmly (Figure 4-10).

Figure 4-8

Figure 4-9

Figure 4-7

46

V5a 2015 Jan

ValueCut USER MANUAL Operation

Step 4

Turn the roll downward to make an equal tension across the media (Figure 4-11)

Step 5

Move the pinch rollers to the appraise location and

note that the pinch rollers must be positioned above

the grid drums.

Step 6

Push the lever backward to lower down the pinch rollers.

Step 7

Fix roll media guide bushes on the roll holder to secure the rol l media.

Step 8

Turn on the power switch, the tool carriage will sizing the media automatically.

Then the cutting plotter is ready to work.

Step 9

Use the reverse steps to remove the media.

Note:

Make sure that the media tension is equally distributed from left to right. If the media were not

tightened enough against the platen, it would cause tracking problems!

図

4-11

図

4-10

47

V5a 2015 Jan

Operation ValueCut USER MANUAL

4.2 Tracking Performance

In order to achieve the best tracking performance for a long plot, we recommend some significant media

loading procedures described as follows:

If the media length is less than 4 meters, leave the margin of 0.5mm—25mm in the left and right ed ges

of the media (Figure 4-12).

If the media length is greater than 4 meters, leave at least 25mm margi n on the left and right edges of

the media (Figure 4-13).

Please refer to the paragraph “4.5 How to Make A Long Plot” for more details.

Figure 4-12

Pinch roller

Pinch roller

0.5mm - 25mm

0.5mm - 25mm

Figure 4-13

> or = 25mm

> or = 25mm

48

V5a 2015 Jan

ValueCut USER MANUAL Operation

4.3 Cutting Force and Offset Adjustment

Before sending your designs for cutting, you may perf orm a “cut test” to generate satisfactory cutting

results. The “Cut Test” should be repeated until the appropriate cutti ng conditions for the media are

discovered.

After sizing the media, press [CUT TEST] button to select the “square cut”, and press [ENTER KEY] to

confirm.

The default cutting force and offset value of the cutting test are 80gf and 0.275mm respectively. Press

[ARROW KEY] to move the tool carriage to the position where you like. Then, press the [ENTER KEY] to

perform Cut T est.

Note: At the same time, the new origin is also set at the cutting test position.

When the cutting test is completed, a pattern appears. Peel off the pattern to see if it can be easily

separated from the media base. If yes, the setup tool forc e is appropriate. If not or cut through the back

paper, press [FORCE KEY] to adjust the tool force until an optimum force is obtained (Figure 4-14).

If the pattern appears to be BB or CC layout,

press [OFFSET KEY] to adjust the offset

value until AA pattern discovered. Increase

the offset value when BB occurs and

decrease the value when CC appears.

S q u a r e C u t

Press ENTER_KEY

AA CCBB

Press ENTER_KEY

E n t e r:O KS e l e c t :

M o v e t t ec u

X Y: :

M

s t

S q u a r e C u t

Press SPEED_KEY,

FORCE_KEY,

OFFSET_KEY to setup

or

Press arrow keys to

desired position for next

square cut

E n t e r:O K

C o n t

/N : O O F FN

Machine

3mm

80 mm

3mm

80 mm

Press ENTER_KEY

80 mm

Finish square cut

Press

ENTER_KEY

Press ON/OFF

line_KEY

i n o u s

L NI E

Figure 4-14

49

V5a 2015 Jan

Operation ValueCut USER MANUAL

4.4 How to Cut 3mm Letters

To obtain good quality output, narrow media is recommended. However, if wide media is used, you

should:

1. Position two pinch rollers as close as possible to both edges of the cutting area.

2. Make sure the loaded media is held flat with equal tension across the platen.

3. Suggest ed operation settings:

Force: 55 gf. (or depending on the material)

Speed: 45-50 cm/sec

Up speed: 45-60 cm/sec

Set smoothing cut: Disable

Cutting quality: Small Letter

4.5 How to Make A Long Plot

When you are making a long plot with a roll of heavy and wide vi nyl, paper you need to use the “AUTO

UNROLL MEDIA“ function. The following parameter settings are to help users get the best cutting quality .

The actual output quality may vary when using different kind of materials

1. If the length of graphic is between 3m and 5m, the cutting speed is

better slower than 72cm/sec and the cutting quality is set as Norm al.

2. If the length is longer than 5m or if the material type is difficult to cut, it is

better to further slow down the cutting speed.

3. After loading the roll media all pinch rollers are raised at this st age,

flatten the media on the platen and hold the front edge of the roll m edia

firmly (Figure 4-15).

Figure 4-15

50

V5a 2015 Jan

ValueCut USER MANUAL Operation

Then turn the roll downward to make an equal tension across the media (See Figure 4-16)

4. Engage pinch rollers.

5. Fixes roll media guide bushes on the roll holder to secure the roll media.

6. The protrusion length of the blade should be longer than the thickness of the vinyl.

(Please check the “Blade Spec ification: About the Tool” in Appendix.) After you notice all

the above, you’ll enjoy your gigantic signs production!

4.6 When Completing the Cutting Job

After completing the cutting job, raise the sheet-loading lever, and then remove the material. You can

also cut off the finished job by the Safe Blade (a standard accessory) along the knife guide. (Figure 4-17)

Make sure that the media tension is

equally distributed from left to right. If the

media is not tight enough against the

platen, it will cause tracking problems.

Figure 4-16

Figure 4-17

51

V5a 2015 Jan

Automatic Aligning System ValueCut USER MANUAL

5 Automatic Aligning System II

5.1 Introduction

The ValueCut series cutting plotters feature a standard Automatic Aligning System (AAS II) to guarantee

precise contour cutting quality by detecting the regi stration marks printed around the graphic.

Notice

Avoid any kind of light source horizontally illuminating the AAS module.

- PROHIBITED - ACCEPTABLE

DO NOT take off the cover of AAS module while in operati on.

- PROHIBITED

52

V5a 2015 Jan

ValueCut USER MANUAL Automatic Aligning System

5.2 AAS Calibrating the System

The AAS system has one calibration procedures t o ensure maximum accuracy of AAS operation. To

operate the AAS you need to learn about the method of media feeding firstly. (Refer to 4.1 Media

Loading.)

5.2.1 Media Calibration

Media Calibration is to ensure the sensor being able t o recognize the registration marks.

The factory default works on a wide range of materials. Howeve r, certain types of materials may

not work properly. Performing a media calibration may become necessary while working with

such materials to change the sensitivity of AAS for greater reliability.

Media calibration adjusts the media feeding according to media type for better accuracy during

cutting.

When to use

We suggest white media for best cutting result. It is not necessary to perform media cal ibrat i on every

time unless the registration marks on the printed media become undetectable in AAS sensing process.

5.2.2 AAS Calibration

The first registration mark is designed to be different in order to i dentify the origin for AAS

auto-detection. The following precaution must be aware for registration marks to be read

automatically.

Type of media

Registration mark pattern

Reading range required for detection the registration marks

Position for registration marks and medium

The registration marks have to be:

Created by cutting software like CorelDRAW plug-in

In black color (printing quality of registration marks is essential; incorrect, misaligned colors,

blurry or smeared printout might leading to inaccurate cutting result)

Length: The length of marks

Range: 5mm~50mm

Optimized Setting: 25mm

Thickness: The line thickness of marks

Range: 1mm~2mm

Optimized Setting: 1mm

53

V5a 2015 Jan

Automatic Aligning System ValueCut USER MANUAL

Margin: The distance between marks and images

Range: 0mm~50mm

Optimized Setting: 5mm

The cutter can not detect the marks while:

Cutter carria ge is not located near the outside area of first mark before detecting (See the

picture in page 5-7 for auto-detecting area of first mark.)

Medium thickness is more than 0.8mm

Transparent medium is used

Non-monochrome drawing. The marks can’t be read if is printed on colored medium

Dirty or creas ed medium surface

5.2.3 AAS II on ValueCut

There are three types of AAS II mark patterns: 4-Point Positioning, Segmental Positioning, and Multiple

Copies. Note that before print out your designs by ink jet pri nters, the registration marks have to be

created on your graphic designs by cutting software. Hand-made marks or drawings won’t be

reorganized by Mutoh cutting plotters.

1. 4-Point Positioning

This is the basic mark pattern that AAS II will auto detect four registration marks and contour cut

images inside those marks.

Command: Esc.D1;(XDist);(YDist):

Layout: 4 L-shaped marks at the 4 corners around the design

2. Segmental Positioning

In addition to 4 original points, the intermediate registration marks are added on both X axis and Y

axis to help contour cut accurately, especially for cutting large images.

Command: Esc.D2;(XDist);(YDist);(XStep);(YStep):

Layout:

In-between distance on X: 200~600mm, default 300mm

In-between distance on Y: 200-600mm, default 300mm

54

V5a 2015 Jan

ValueCut USER MANUAL Automatic Aligning System

High Precis i on Long Picture Cutting

ValueCut performs segm ental cutting to enhance output qualities.

The object will be output following the Data Block pattern based on the Segmental

Positioning parameters.

Cutting sequ ence: Date Block1-> Date Block2-> Date Block3- >Date Block4

3. Multiple Copies

The function is used to duplicate images to l et you c ut quantities of images at a time.The AAS II

sensor will automatically scan registrat i on marks for each individual image to ensure the cont our

cutting precision.

Command: Esc.D3;(XCopies);(YCopies);(Space):

Layout:

Condition 1 (Default) Condition 2

55

V5a 2015 Jan

Automatic Aligning System ValueCut USER MANUAL

4. Automatic Distinction of the Plot Direction

For the convenience of users, ValueCut automatically detects the feeding direction of the material

when performing contour cutting. Figure 5-1 shows the Registration Mark detection sequence when

the material is fed in the standard way (1->2->3->4) while Fi gure 5-2 is how ValueCut detects

registration marks (3->4->1->2) when the material i s reversely fed. ValueCut is able to detect

registration marks and performs contour cutting howe ver users feed the media.

Direction detection steps:

a. Detects the position of the 3rd Registration Mark

b. Proceeds to the 4th Registration Mark to detect the direction

(The existing detection procedure will be performed, followed by the detect i on of new line

segments)

c. The information is reflected in the driver and recalculated bef ore output

d. The registration mark detection and object output process is implem ented

(Registration Mark detection sequence: 3->4->1->2)

Figure 5-1 Figure 5-2

5.3 Printer Test

Before performing AAS contour cutting, it’s recommended to print out a test file that you can find in the

enclosed Installation CD to make sure the AAS II cutting accuracy of ValueCut.

There are two testing files for AASII:

56

V5a 2015 Jan

ValueCut USER MANUAL Automatic Aligning System

AAS offset Calibration.pdf (Print data)

AAS offset Calibration.plt (Cutting data)

1. Print out the Print data by 100%. ( Please use high precis ion printer)

2. Load the graphic to ValueCut and sent the Cutting data to test the cutting job

You can output the cutting data from Production Manager of FlexiSTARTER.

3. If there are any adjustments to be made, you can change the offset value by foll owi ng the steps:

Measure the offset values from the printed line and the actual cutting line.

Enter the AAS Offset under MISC function for the values you just measured, then

press Enter

Test the cutting again

AAS II offset X and Y value is defined as following:

Horizontal line is defined as X and vertical is def ined as Y (when facing the cutting

plotter)

When the actual cutting line and the printed line need to be changed towards the

direction of origin mark, then simply add the negative value of the offset. If the

direction is from the opposite of the origin mark , then enter positive values for the

offset (see the following figures). This method applies to both X and Y axes.

57

V5a 2015 Jan

Automatic Aligning System ValueCut USER MANUAL

5.4 Registration Mark Offset Range

Please correctly load your media (refer to the alignment ruler on the platen) to make sure the registration

marks are successfully detected. Deviation exceeds the range below will lead to detection failure.

5.5 Contour Cutting

For accurate contour cutting with AAS function, please proceed the following steps:

Step 1

Creating Graphics

Create the graphic that you want to print and cut in your software.

Create a contour for cutting around the graphic.

Note:

Before adjus ting the AAS II settings, please proceed scaling for width and length.

The blade offset value isn’t set for this test graphic, please set it according to the blade you

use.

If you have any question, please contact us or your local distributor for assi st ance.

58

V5a 2015 Jan

ValueCut USER MANUAL Automatic Aligning System

TIPS1: Leave some space between the graphic and contour line.

TIPS2: Create the contour in a separate layer and assign a different color for i t.

Add registration marks around the graphic.

Step 2

Placing the Registration Marks

The AAS Layout Instruction:

* Auto-detection function on the 1st mark covers the grey area

Suggested 3 0mm margin on both left and right sides of media sheet.

Suggested 50-70 m m margin on top and bottom edge of the media sheet to prevent

sheets dropping or any error occurred while media sizing.

Note:

The Multiple Copies function is also available. It automatically copy the graphic and registration

marks.

59

V5a 2015 Jan

Automatic Aligning System ValueCut USER MANUAL

Step 3

Print the Graphics

Print the graphic and the marks with your printer

(Scaling = 100%).

When printing on a roll media, make sure the orientation as following:

Step 4

The Origin Mark is is different from the rest registration marks. Please make sure the media

is fed with correct direction.

Step 5

Cut the Contour

Send out the command from software to perform the contour cutting job.

5.6 T ips for AAS

For getting better results of contour cutting, there are some tips below for your reference.

Keep light sources simple and avoid illuminating from the si des of c utter.

Before operating AAS, change the maximum paper size in ValueCut driver property.

STEP 1 Find the ValueCut model in the “Printer & Fax” folder of your PC.

STEP 2 Open the Properties window and select the “Paper” tab.

STEP 3 Change the maximum Paper Size of X to 1200mm.

Adjust the cut ting speed to between 300~600mm/sec.

Avoid the registration marks locating on the tracks of pinch rollers.

60

V5a 2015 Jan

ValueCut USER MANUAL Maintenance

6 Maintenance

This chapter explains the basic maintenance (i.e. cleaning the cut ting plotter) required for

the cutting plotter. Except for the procedures mentioned below, all other maintenance must

be performed by a qualified service technician.

6.1 Cleaning the Cutting Plotter

Cleaning the machine properly and regularly will ensure optimal performance out of your machine.

Cleaning Precaution !

Recommended Methods:

Gently wipe the cutting plotter surface with a lint-free cloth. If necessary, with a damp cloth

immersed in water or alcohol. Dry and wipe any remaining residue off a soft, lint-free cloth.

Wipe all dust and dirt from the tool carriage rails.

Use a vacuum cleaner to empt y any accumulated dirt and media residue bene ath the pinch roller

housing.

Clean the platen, paper s ensors and pinch rollers wi th a damp cloth immersed i n water or alcohol ,

and dry with a soft, lint-free cloth.

Wipe dust and dirt from the stand.

Unplug the cutting plotter before cleaning it in

order to prevent electrical shock.

Never use solvents, abrasive cleaners or strong

detergents for cleaning. They may damage the

surface of the cutting plotter and the moving parts.

61

V5a 2015 Jan

Maintenance ValueCut USER MANUAL

6.2 Cleaning the Grid Drum

1. Turn off the cutting plotter, and move the tool carriage away from the area needed to be cleaned.

2. Raise the pinch rollers and move them away from the grid drum for cleaning.

3. Use a bristle brush (a toothbrush is accept able) to remove dust from the drum surface. Rotate the

drum manually while cleaning. Refer to

Figure 6-1.

6.3 Cleaning the Pinch Rollers

1. If the pinch rollers require a thorough cleaning, use a lint-free cloth or cotton swab to wipe away the

accumulated dust from the rubber portion of the pinch rollers. To prevent the pinch rollers from

rotating while cleaning, use your finger to hol d the pinch rollers to prevent them from rotation

2. To remove the deeply-embedded or persistent dust, use the lint-free cloth or cotton swab moistened

with rubbing alcohol.

Figure 6-1

Note:

The daily maintenance of your cutting plotter is very important. Be sure to clean up the grid drum and

pinch rollers regularly for better cutting accuracy and output quality.

62

V5a 2015 Jan

ValueCut USER MANUAL Trouble Shooting

7 Trouble Shooting

This chapter is to help you correct some common problems you may come across. Prior to

getting into the details of this chapter, please be sure that your application environment is

compatible with the cutting plotter.

Possible Causes:

7.1 Non-operation Problems

Check the following first:

Does the AC power cord plug in properly?

Does the AC power cord connected to the power connector pr operly?

Does the power LED still illuminate?

Solutions:

If the LCM is able to display the message, the cutting plotter should be in a normal

condition. Switch off the cutting plotter and turn it on again to see if the problem still

existing.

If the LCM is not able to display any message, contact the technician from your dealer.

Why is the cutting plotter not functioning?

Note:

Before having your cutting plotter serviced, pl ease make sure that the malfunction is in your cutti ng

plotter, not the result of an interface problem or a malfunction in your computer or a software problem.

63

V5a 2015 Jan

Trouble Shooting ValueCut USER MANUAL

7.2 Operational Problems

Some mechanical problems or failure during operation will cause some problems. If the

problem still exists after the recommended actions have been taken, have your cutting

plotter serviced.

7.2.1 LCM Error Messages

The error messages shown on the LCM present the problem first, and followed by recommended

actions.

This message indicates that there might be a

problem on the X axis (the media feeding

direction). Check if the drum is working well and if

the media is well loaded. Correct the problem and

re-power on to reboot system.

This message indicates that there might be an

obstruction to carriage relating to a problem on the Y

axis (the carriage moving direction). Correct the

problem and re-power on to reboot system

.

This message indicates that the blade up/down

sensor malfunction. Re-power on to re-boot system.

If the problem still exists, find a serviceman.

This message indicates that the cutting exceeds the

cutting limit. Reload larger media or re-scale t he plot

to a smaller size; then press the key followed by the

display of LCM to continue.

Error;Check Carriag

Sensor Or VC Motor

Graph Was Clipped

Data In Buffer

Error; Check Media

Or Drum Or X Motor

Error; Check Media

Or Y Motor

64

V5a 2015 Jan

ValueCut USER MANUAL Trouble Shooting

7.2.2 Other operational problems

1. Pinch rollers

O (CORRECT) X (INCORRECT)

Press down

Stop bar

Pull up bottom to release grip

PRESS

Note: Never press the top release grip (the release grip is fully pressed when a clip sound is heard)

and pull the bottom release grip at the same time as the pictures shown below. This will prevent

you from disabling the pinch roller as the stop bar will not reach the correct position and therefore

will not be functioning.

Enable

65

V5a 2015 Jan

Trouble Shooting ValueCut USER MANUAL

2. Media is rolled up during the cutting process

Step 1 Turn off the cutting plotter

Step 2 Move the pinch rollers to the side

Step 3 Pull the lever up

Step 4 Trim off the rolled up part of the media

Step 5 Reload the material

3 The media runs diagonally

Step 1 Stop the operation

Step 2 Move the pinch rollers to the side

Step 3 Pull the lever up

Step 4 Reload the media and make sure the media is correctl y l oaded (refer to the alignment ruler).

4. The media lifts

Step 1 Stop the operation

Step 2 Move the pinch rollers to the side

Step 3 Pull the lever up

Step 4 Reload the sheet and ensure there are two pinch roll ers on the very two sides of the sheet.

Step 5 Ensure the vacuum is on (check the control panel) and increase the number of pinch rollers.

5. The start and end points of the object are shifted

Step 1 Move the pinch rollers to the side

Step 2 Pull the lever up

Step 3 Reload the media and increase the number of pinch rollers.

Step 4 Activate “Over Cut” in “Tool Select” on the control panel if the above does not work

66

V5a 2015 Jan

ValueCut USER MANUAL Trouble Shooting

7.3 Cutting Plotter/Computer Communication Problems

The messages showed below present problems i n rel ation to cutting plotter/computer communication.

Communication Error

Setup: MISC. key

Is the connection cable connected to

the cutting plotter and computer

properly?

Yes No

Has the interface setting been

done correctly?

Refer to Chapter 2 Connecting your cutting

plotter.

Yes No

Try the communication between

your cutting plotter and computer.

If it still does not work, have your

cutting plotter serviced.

Refer to the “MISC” key in Chapter

3 - Description of Operation for the

port setup.

If your cutting plotter can not

recognize the

HP-GL/2 or HP-GL commands, please check the

HP-GL/2 or HP-GL commands applied to your

cutting plotter are used properly.

Note:

The computer also needs to set up compatible communication parameters to the

cutting plotter set up.

HP-GL/2 Cmd. Error

67

V5a 2015 Jan

Trouble Shooting ValueCut USER MANUAL

7.4 Software Problems

Check the following first:

Does your software package indicate that it will work with your

computer and cutting plotter?

Does your software support HP-GL and HP-GL/2 drivers?

(* check the configuration settings of your software.)

Yes

No

Does the cutting plotter interface

match the requirements of your

software?

Does your

software

recommend using

a different cable?

Does the software

vendor provide a

sample file?

Most well known cutting softwares in

the world have drivers for our cutting

plotters. If not, use software that has

HP-GL and HP-

GL/2 emulation

supports and you can chose the

following three drivers:

A3 size: HP7475A

A1 size: HP7580A

A0 size: HP Draf Pro Exl or HP

Draf Master

Yes

No

Refer to Chapter 2 Connecting your

cutting plotter.

Yes

No

Try using the

recommended

cable.

Yes No

Re-power on the cutting

plotter and try to send

the file again.

Do something about the error

message display on LCM, or

consult your software vendor.

68

V5a 2015 Jan

ValueCut USER MANUAL Trouble Shooting

7.5 Cutting Quality Problems

Is the blade installed correctly and the blade holder

fastened securely?

Yes

No

Is the blade dull or

chipped?

Yes No

Replace

with a new

blade

Is tool force set up

properly? (The default for

tool force is 80 gf)

Yes

No