VJ-1624X/VJ-1624WX

VJ-1924WX

VJ1x24XE-A-00

VJ-1624X/1624WX/1924WX OPERATION MANUAL Important Notice

Important Notice

1. For Users in Europe

The CE marking is a mandatory European marking for certain product groups to

indicate conformity with the essential health and safety requirements set

out in European Directives.

By affixing the CE marking, the manufacturer, his authorized representative, or

the person placing the product on the market or putting it into service ensures that

the item meets all the essential requirements of all applicable EU directives and

that the applicable conformity assessment procedures have been applied.

2. For Users in the United States

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant

to Part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against harmful interference when the

equipment is operated in a commercial environment.

This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference in which case the

user will be required to correct the interference at his own expense.

3. Trademark Mentioned in this Manual

• MUTOH, ValueJet, VJ-1624X, VJ-1624WX, VJ-1924WX, MH-RTL are registered trademarks or

product names of MUTOH INDUSTRIES LTD.

• Windows XP, Windows Vista and Windows 7 are registered trademarks or product names of

Microsoft Corporation.

• Other company and product names may be registered trademarks or product names.

3

Important Notice VJ-1624X/1624WX/1924WX OPERATION MANUAL

NOTE

• No part of this product or publication may be reproduced, copied, or transmitted in any form or by

any means, except for personal use, without the permission of MUTOH INDUSTRIES LTD.

• The product and the contents of this publication may be changed without prior notification.

• MUTOH INDUSTRIES L TD. has made the best efforts to keep this publication free from error , but

if you find any uncertainties or misprints, please call us or the shop where you bought this

equipment.

• MUTOH INDUSTRIES L TD. shall not be liable for any damages or troubles resulting from the use

of this equipment or this manual.

4

VJ-1624X/1624WX/1924WX OPERATION MANUAL Warranty Limitations

Warranty Limitations

1. MUTOH INDUSTRIES LTD. warrants part repair or replacement as a sole measure only if a failure

is found in the system or in the materials and workmanship of the product the seller produced.

However, if the cause of failure is uncertain, decide the action after due mutual consultation.

2. The warranty shall not apply to any direct or indirect loss, or compensation for the loss due to the

product that has been subject to misuse, neglect, or improper alternation.

5

About this Manual VJ-1624X/1624WX/1924WX OPERATION MANUAL

NOTE

About this Manual

1. Contents of the Manual

There are three manuals for this product.

Installation manual

Explains operating procedures along with unpacking, installation and preparation before use.

Operation Manual (this manual)

2. Purpose and Target Readers

This manual explains preparations before use and operation procedures for MUTOH Full Color Ink Jet

Printer

This manual is prepared for the owners and operators of this printer.

Before using this printer, fully understand the contents and directions in this manual.

VJ-1624X/1624WX/1924WX.

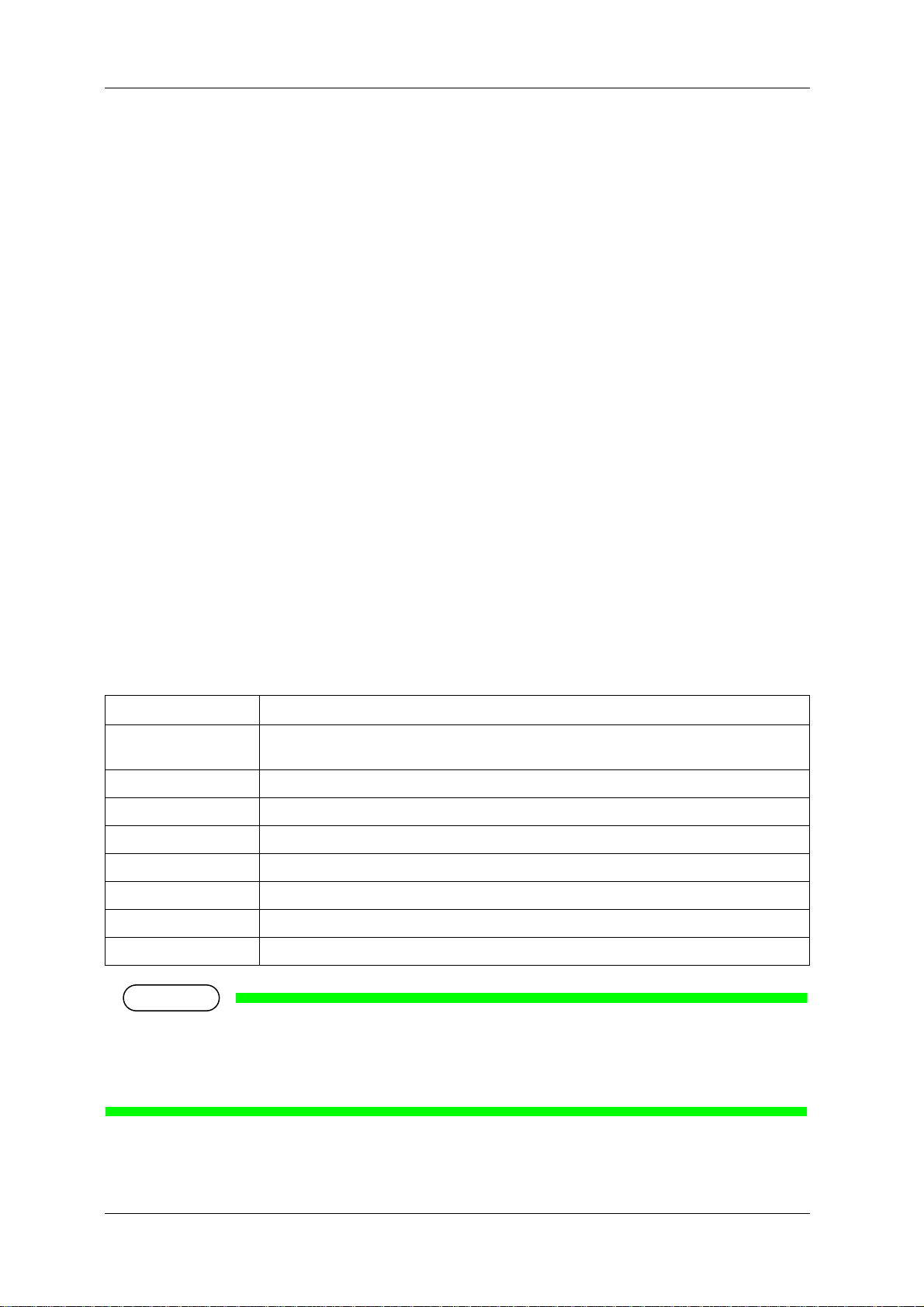

3. Manual Configuration

Section Description

1 Safety instructions This chapter explains the installation of this printer, warning terms that operators need to know,

caution items and warning labels on the printer main unit.

2 Product overview This chapter explains the features of the printer along with the names and functions of each part.

3 Before using This chapter explains necessary steps before using the printer.

4 Handling the printer This chapter explains how to handle the printer.

5 Panel setup menu The section explains the Setup menu of the printer.

6 Maintenance This chapter describes daily maintenance of the product.

7 Troubleshooting This chapter describes possible troubles during the use of this product and countermeasures.

8 Appendix This chapter describes specifications and included components with this printer.

• 1 Safety instructions to 4 Handling the printer must be read before using the printer.

•Read 5 Panel setup menu through "8 Appendix as necessary.

6

VJ-1624X/1624WX/1924WX OPERATION MANUAL About this Manual

WARNING

CAUTION

NOTE

TIP

4. Manual Notation

This section explains general cautions that must be followed in order to use this printer safely.

Warning Meaning

Used for dangerous situations where death or serious injury may be caused.

Used for dangerous situations that may cause slight or medium injury, or when all or parts of

products are damaged.

It is used for special cautions and for information that needs to be emphasized.

Indicates useful tips for operating or understanding the printer.

Indicates "prohibited" operations.

Indicates required operations.

Indicates referrence pages in this manual.

7

About this Manual VJ-1624X/1624WX/1924WX OPERATION MANUAL

8

TABLE OF CONTENTS

1 Safety instructions

1.1 Types and meanings of warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

1.2 Important safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

1.3 Warning labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

1.3.1 Handling the warning labels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

1.3.2 Location and type of warning labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

1.3.2.1 Warning labels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

1.3.2.2 Rear section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2 Product overview

2.1 Names of parts and functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

2.1.1 Front section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

2.1.2 Rear section. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

2.1.3 Operation panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

2.1.4 Ink level indicator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

2.1.4.1 Estimated Ink level graphic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

2.2 Printer status outline. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

2.2.1 Status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

2.2.2 Changing printer status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

3 Before using

3.1 Power cord set connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

3.2 Turning the power ON/OFF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

3.2.1 Turning the power ON . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

3.2.2 Turning the power OFF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

3.3 Filling ink . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

3.3.1 When using 220ml Ink cartridges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

3.3.1.1 For VJ-1624X . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

3.3.1.2 For VJ-1624WX/1924WX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

3.3.2 When using 440ml Ink cartridges (VJ-1624X only) . . . . . . . . . . . . . . . . . . . . . . 60

3.3.3 Changing the angle of Ink cartridge slot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

3.3.3.1 When inserting Ink cartridges vertically. . . . . . . . . . . . . . . . . . . . . . . . . . . 67

3.3.3.2 When inserting Ink cartridges horizontally. . . . . . . . . . . . . . . . . . . . . . . . . 68

3.3.4 Installing the optional High Capacity Ink Pack Adapter (VJ-1624X only) . . . . . 70

3.3.5 When using High-capacity ink pack adapter for the first time on the printer whose

ink is filled.77

3.4 Loading media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

9

Table of Contents VJ-1624X/1624WX/1924WX OPERATION MANUAL

3.4.1 Loading roll media. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

3.4.2 Setting Roll Media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

3.4.3 Setting the User Type Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

3.4.4 Changing the torque of Roll media holder (for VJ-1624X) . . . . . . . . . . . . . . . . 91

3.4.5 Changing the torque of Roll media holder (for VJ-1624WX/1924WX). . . . . . . . 95

3.4.6 Releasing pressure arms individually (VJ-1624WX/1924WX only). . . . . . . . . 100

3.5 Test print. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

3.5.1 Nozzle check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

3.5.2 Mode print . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

3.5.3 Setup print. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

3.5.4 Palette print . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

3.5.5 Color verifier (VJ-1624X only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

3.6 Print quality adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

3.6.1 Standard print quality adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

3.6.1.1 Standard confirmation pattern. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

3.6.1.2 Standard rough adjustment pattern. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

3.6.1.3 Standard micro adjustment pattern. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

3.6.2 Custom Adjustment Pattern. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

3.6.2.1 Custom confirmation pattern. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

3.6.2.2 Custom rough adjustment pattern. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

3.6.2.2.1 Rough Pattern ALL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

3.6.2.2.2 Rough Pattern A to F . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

3.6.2.3 Custom micro adjustment pattern . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

3.6.2.3.1 Fine Pattern ALL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

3.6.2.3.2 Fine Pattern A to F . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

3.7 Connecting the printer to PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

3.7.1 System requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

3.7.2 Preparing cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

3.7.3 Connecting a network interface cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

4 Handling the printer

4.1 Print flow chart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

4.2 Media. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

4.2.1 Media type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

4.2.2 Cautions on handling media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

4.2.3 Precaution on storing media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

4.2.4 Printable area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

4.2.5 Head height adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

4.2.5.1 When setting the head height to Mid (VJ-1624WX/1924WX only) . . . . . 169

4.2.5.2 When setting the head height to High. . . . . . . . . . . . . . . . . . . . . . . . . . . 171

4.2.5.3 When setting the head height to Low . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

4.2.6 Media feed compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

4.2.6.1 Procedure for the media feed compensation value. . . . . . . . . . . . . . . . . 177

4.2.6.2 How to fix the media firmly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

4.2.7 Installing Media holder plates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

4.3 Menu setups on Operation panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

4.3.1 Menu setup procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

10

VJ-1624X/1624WX/1924WX OPERATION MANUAL Table of Contents

4.3.2 Panel setup menu overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

4.4 Operating from Operation panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

4.4.1 Feeding media. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

4.4.2 Stopping printing operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

4.4.3 Cutting media. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

4.4.4 Cutting media manually. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

4.4.5 Changing and confirming settings while printing . . . . . . . . . . . . . . . . . . . . . . . 194

4.4.5.1 Procedure for changing and confirming settings while printing. . . . . . . . 194

4.4.5.2 Settings that can be changed or confirmed while printing. . . . . . . . . . . . 195

4.4.6 Pausing printing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

4.4.7 Starting printing during warming up (VJ-1624X only) . . . . . . . . . . . . . . . . . . . 197

4.4.8 Normal Display while Printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

4.5 Using Spectrophotometer (VJ-1624X only). . . . . . . . . . . . . . . . . . . . . . . 200

5 Panel setup menu

5.1 Setup menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210

5.1.1 User Type menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

5.1.1.1 User Type advanced setup menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

5.1.1.1.1 Print Mode menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

5.1.1.1.2 Adjust Print menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 218

5.1.1.1.3 Media feed compensation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220

5.1.1.1.4 Pre-heater menu (VJ-1624X only) . . . . . . . . . . . . . . . . . . . . . . . . . 222

5.1.1.1.5 Platen Heater menu (VJ-1624X only) . . . . . . . . . . . . . . . . . . . . . . . 223

5.1.1.1.6 Dryer menu (VJ-1624X only). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 224

5.1.1.1.7 Vacuum Fan menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 224

5.1.1.1.8 Media thickness menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

5.1.1.1.9 User Copy menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 226

5.1.2 Spitting menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

5.1.2.1 Spitting Pass Count menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

5.1.3 Side Margin menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

5.1.4 Media Initial menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 231

5.1.5 Media Width menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232

5.1.6 Output Mode menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 234

5.1.6.1 Ink Dry Time menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 234

5.1.6.2 Page Gap menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 235

5.1.7 Method of Cut menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 235

5.1.7.1 Cut Pressure menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 236

5.1.8 Origin menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

5.1.9 Prev. Stick menu (VJ-1624X only). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

5.1.10 Standby Heating menu (VJ-1624X only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

5.1.11 Head Travel menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 240

5.1.12 Multi Strike menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 240

5.1.13 Strike Wait menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 241

5.1.14 Slant Check menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 241

5.1.15 Auto Cleaning menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 242

5.1.15.1 Idle Auto Cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 242

5.1.15.2 Printing Mode Auto Cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 243

5.1.15.3 Pre-printing Mode Auto Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 243

5.1.16 Ink Status menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

11

Table of Contents VJ-1624X/1624WX/1924WX OPERATION MANUAL

5.1.17 Roll Length menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

5.1.17.1 Roll Length menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

5.1.17.2 Print Stop menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 246

5.1.17.3 Near End menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 246

5.1.18 Exhaust Fan menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 247

5.1.19 Longstore menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 248

5.1.20 CR Maintenance menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249

5.1.21 Initialization menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249

5.1.22 Life Times menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 250

5.1.23 IP Address menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 250

5.1.24 Subnet Mask menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 251

5.1.25 Gateway menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 251

5.1.26 Header Dump menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 252

5.1.27 Start Feed Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 253

5.1.28 Heater Control menu (VJ-1628X only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 254

5.2 Test Print Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 255

5.3 Cleaning menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 256

5.4 Menu Option menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 257

5.5 Version menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 260

5.6 Sleep Mode menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 261

5.6.1 Timer Setting menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 262

5.6.2 Sleep Mode Start menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 263

5.7 Display menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 264

5.7.1 Language menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 264

5.7.2 Temperature menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 265

5.7.3 Length menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 265

5.7.4 Remain Ink menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 265

5.8 Job Status Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 266

6 Maintenance

6.1 Replacing consumable components . . . . . . . . . . . . . . . . . . . . . . . . . . . . 268

6.1.1 Replacing Ink cartridges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 268

6.1.2 Replacing Roll Media. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 276

6.1.3 Replacing Flushing box sponges. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 279

6.1.4 Replacing Cutter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 285

6.2 Cleaning the printer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 294

6.2.1 Cleaning the outer case. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 295

6.2.2 Cleaning the inside of the printer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 296

6.2.3 Head cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 300

6.2.4 Cleaning Cleaning wiper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 303

6.2.5 Cleaning the circumference of Print head . . . . . . . . . . . . . . . . . . . . . . . . . . . . 309

6.3 Disposal of waste fluids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 316

6.4 Moving or transporting the printer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 319

6.4.1 Moving the printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 319

12

VJ-1624X/1624WX/1924WX OPERATION MANUAL Table of Contents

6.4.2 Transporting the printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 321

7 Troubleshooting

7.1 Malfunctions and failures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 324

7.1.1 Problems in installation and introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 324

7.1.2 Cannot print at all. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 325

7.1.3 Media-related troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 327

7.1.4 Printing-related troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 330

7.2 Error messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 333

7.2.1 Status messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 333

7.2.2 Message type error display and remedies. . . . . . . . . . . . . . . . . . . . . . . . . . . . 335

7.2.3 Error requiring restart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 338

7.3 The media is jammed. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 339

8 Appendix

8.1 Product specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 344

8.1.1 Printer specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 344

8.2 Interface specification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 346

8.2.1 Network interface specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 346

8.3 Options/Supply list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 347

9 Setup menu diagram

13

Table of Contents VJ-1624X/1624WX/1924WX OPERATION MANUAL

14

VJ-1624X/1624WX/1924WX OPERATION MANUAL 1 Safety instructions

WARNING

1 Safety instructions

This chapter explains the installation of this printer, warning terms that operators need to know , caut ion

items and warning labels on the printer main unit.

• When installing and operating this printer, be sure to follow the directions and

warnings in this manual.

15

1 Safety instructions VJ-1624X/1624WX/1924WX OPERATION MANUAL

WARNING

CAUTION

NOTE

1.1 Types and meanings of warnings

The warnings in the Operation Manual and the warning labels attached to the printer are categorized into

three stages.

Understand the meanings of the following warning terms and follow the contents (instructions) in this

manual.

Warning Meaning

Used for dangerous situations where death or a serious injury may be caused.

Used for dangerous situations that may a cause slight or medium injury , or when all or

parts of the products may be damaged.

Used for special cautions and for information that needs to be emphasized.

16 1.1 Types and me anings of warnings

VJ-1624X/1624WX/1924WX OPERATION MANUAL 1 Safety instructions

WARNING

1.2 Important safety instructions

This section explains general cautions that must be followed in order to use this printer safely.

<Common to V-1624X/1624WX/1924WX>

Do not install this printer in the following places.

It may cause an injury if the printer falls down.

• On a shaky stand

• Slanting location

• Places where vibration of other machines etc. is transmitted

Do not climb on the printer or place heavy things on top of it.

It may cause an injury if the printer falls down.

Do not block the vent when covering the printer with cloths, such as a blanket or tablecloth.

If the vent is blocked, heat may accumulate inside the printer and may cause a fire.

Do not install the printer where it is humid or dusty.

It could lead to an electric shock or fire.

Do not use a damaged power cord set.

It could lead to an electric shock or fire.

Do not pull out or insert the power plug with a wet hand.

This could lead to an electric shock.

Do not connect an earth wire to the following places.

• Gas pipes

There is a possibility of ignition and explosion.

• An earth wire of telephone cables and lightning rods

A heavy current might flow whenever lightning strikes.

• Water pipe and faucet

The earth does not work if part of the metal pipe is plastic.

Do not insert or drop metal or flammable objects into the printer through openings such as a vent.

It could lead to an electric shock or fire.

If foreign substances or liquids such as water entered the printer, do not use the printer as it is.

It could lead to an electric shock or fire.

Immediately turn OFF the power switch, disconnect the power plug from the electric socket, and contact your

local MUTOH dealer.

Wire the various cords as directed in the Operation Manual.

Wrong wiring could cause a fire.

Be sure to use the specified power cord set.

Using a power cord set other than the specified can cause an electric shock or fire.

Make sure to use only the specified power supply (AC 100 V to 120 V or AC 220 V to 240 V).

If a power supply other than the specified voltage is used, it could cause an electric shock or fire.

Ta ke power for the printer directly from the power socket (AC 100 V to 120 V or AC 220 V to 240 V).

Do not use multiple plugs on the same socket.

This could generate heat and might cause a fire.

1.2 Important safety instructions 17

1 Safety instructions VJ-1624X/1624WX/1924WX OPERATION MANUAL

CAUTION

Be sure to use a dedicated power socket with an earth wire for the power supply, and connect it to the earth wire.

If the earth wire is not connected, it may cause an electric shock or fire.

You are obligated to properly dispose of waste fluid from the printer in compliance with Wastes Disposal and

Public Cleansing Act and local ordinances.

Delegate disposal to an industrial waste disposal contractor.

<V-1624X only>

Do not place any combustible materials on Platen while the heater is working.

There may be a risk of fire.

Do not spill flammable liquid on Platen.

It may cause a fire.

<Common to V-1624X/1624WX/1924WX>

Pay attention to the following points when handling the power cord set.

• Do not tamper with the power cord set.

• Do not put heavy objects on the power cord set.

• Do not bend, twist or pull the power cord set by force.

• Do not route the power cord set near heating appliances.

Pay attention to the following points when handling the power plug.

Any mishandling of the power cable could cause a fire.

• Make sure that no foreign substances such as dust are stuck to the power plug.

• Make sure that the power plug is inserted all the way.

When handling Ink cartridges, pay attention so that ink does not come into contact with your eyes or skin.

If ink gets into your eyes or sticks to your skin, immediately wash it off with water.

Failing to do so might cause irritation or light inflammation of eyes.

In case of any abnormality, consult a physician immediately.

Do not disassemble Ink cartridges.

If disassembled, ink might come into contact with your eyes or skin.

Do not operate Media loading lever during initial operation.

Print head may touch Pressurizing roller and cause a malfunction.

Do not use volatile solvents such as thinner, benzene, or alcohol.

These solvents may cause damage to the paint.

Make sure that no moisture enters the printer.

The electric circuit inside the printer may be short-circuited.

Never open covers attached using screws under any circumstances.

This may cause an electric shock or a malfunction.

Do not spill waste fluid when replacing Flushing-box sponges.

If waste fluid comes into contact with Grid roller, it may damage its surface and affect media feeding.

18 1.2 Important safety instructions

VJ-1624X/1624WX/1924WX OPERATION MANUAL 1 Safety instructions

When cleaning Cleaning wiper,

• Do not touch Cleaning wiper and Head cap unit.

Head cleaning may not be performed correctly because of oil from your hands.

• Make sure to use Cleaning stick to wipe Print head.

A wet Cleaning stick may cause Print head to clog.

• Do not reuse Cleaning stick.

The attached dust, etc may damage Print head.

When cleaning around Print head,

• Never touch Print head nozzles.

Doing so may damage Print head.

• Do not touch the tip of Cleaning stick.

Print head may be damaged because of oil from your hands.

• Never put water, etc on the tip of Cleaning stick.

Doing so may damage Print head.

• Do not reuse Cleaning stick.

The attached dust, etc may damage Print head.

Do not slant the printer, prop it against a wall or turn it upside down.

The ink inside the printer may leak.

Moreover, normal operation after shifting (to these positions) cannot be guaranteed.

Unpacking or moving this printer must be done by the following number of people.

• More than 4 people

Installing the dedicated stands on the printer must be done by the following number of people.

• More than 4 people

When taking the printer out of the container box, make sure to remove the vinyl, install Reinforcement for

transportation, and hold Reinforcement.

If lifting up the printer with the vinyl on, there is a possibility the printer can slip and drop, and be damaged.

When you do not use the printer for a long period, make sure to pull out the power plug from the power socket for

safety.

Make sure to connect an earth wire to the earth connection that meets the following standards.

• An earth terminal of power socket

• An earth wire with a copper plate which is buried at 650 mm or more in the ground.

Before operation, make sure to read the Safety Data Sheet (SDS).

Pay attention to the following points when cutting roll media.

Mishandling Razor blade may cause a cut on your finger or hand.

• When you hold media, do not place your finger on Media cut groove.

• Move Razor blade slowly along Media cut groove.

Before cleaning the areas other than Wiper and circumference of Print head, be sure to turn OFF the power and

disconnect the power plug.

When moving the printer, make sure to maintain a horizontal position.

<V -1624X only>

Do not touch Media guide while printing.

Media guide becomes very hot and you could burn yourself.

1.2 Important safety instructions 19

1 Safety instructions VJ-1624X/1624WX/1924WX OPERATION MANUAL

Do not touch Media feed slot, Platen, and Media guide while Heater is working.

Media feed slot, Platen, and Media guide become very hot and you could burn yourself.

Ventilate the workplace.

Not doing so may cause nausea or a fire hazard.

Right after printing, Media guide becomes very hot.

Allow Media guide to cool down before the next operation.

20 1.2 Important safety instructions

VJ-1624X/1624WX/1924WX OPERATION MANUAL 1 Safety instructions

NOTE

1.3 Warning labels

This section explains the handling of warning labels, their pasting locations and types.

Warning labels are attached to parts of the printer that need special caution.

Understand the locations and the descriptions of the danger associated with each label before operating

the printer.

1.3.1 Handling the warning labels

When handling the warning labels, be careful with the following points.

• Check whether all the warning labels can be read.

If the letters or illustrations on the label are not clear, remove the dirt from the label.

• Use cloth, water and mild detergent for removing dirt from the warning labels.

Avoid organic solvents and gasoline.

• Replace the labels if they are damaged, lost or illegible.

If the warning labels have to be replaced, contact your local MUTOH dealer.

1.3 Warning labels 21

1 Safety instructions VJ-1624X/1624WX/1924WX OPERATION MANUAL

3

12

4

4

5

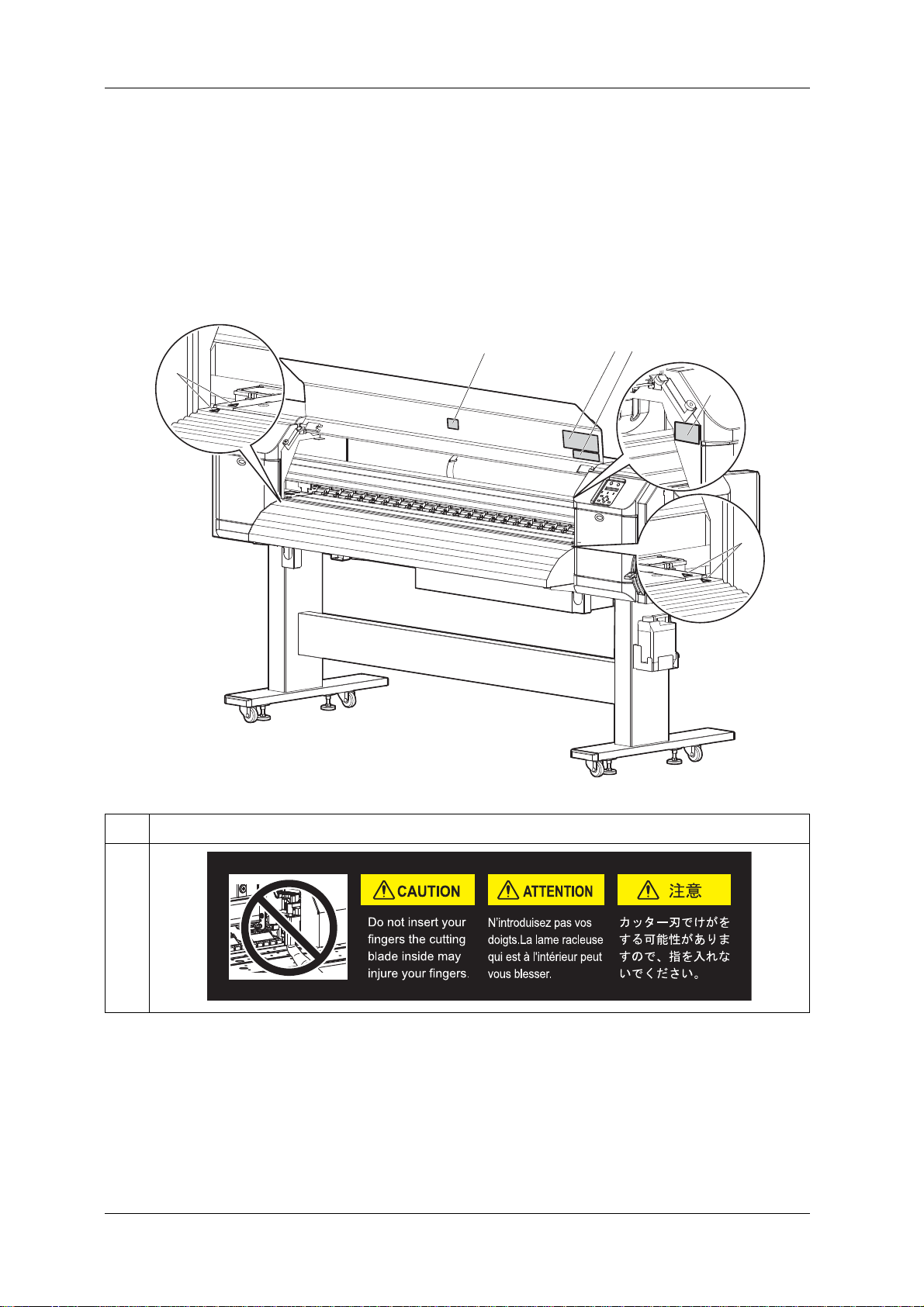

1.3.2 Location and type of warning labels

Pasting locations of the warning labels are shown in the following figure.

1.3.2.1 Warning labels

Front section

No. Types of warning labels

1

22 1.3 Warning labels

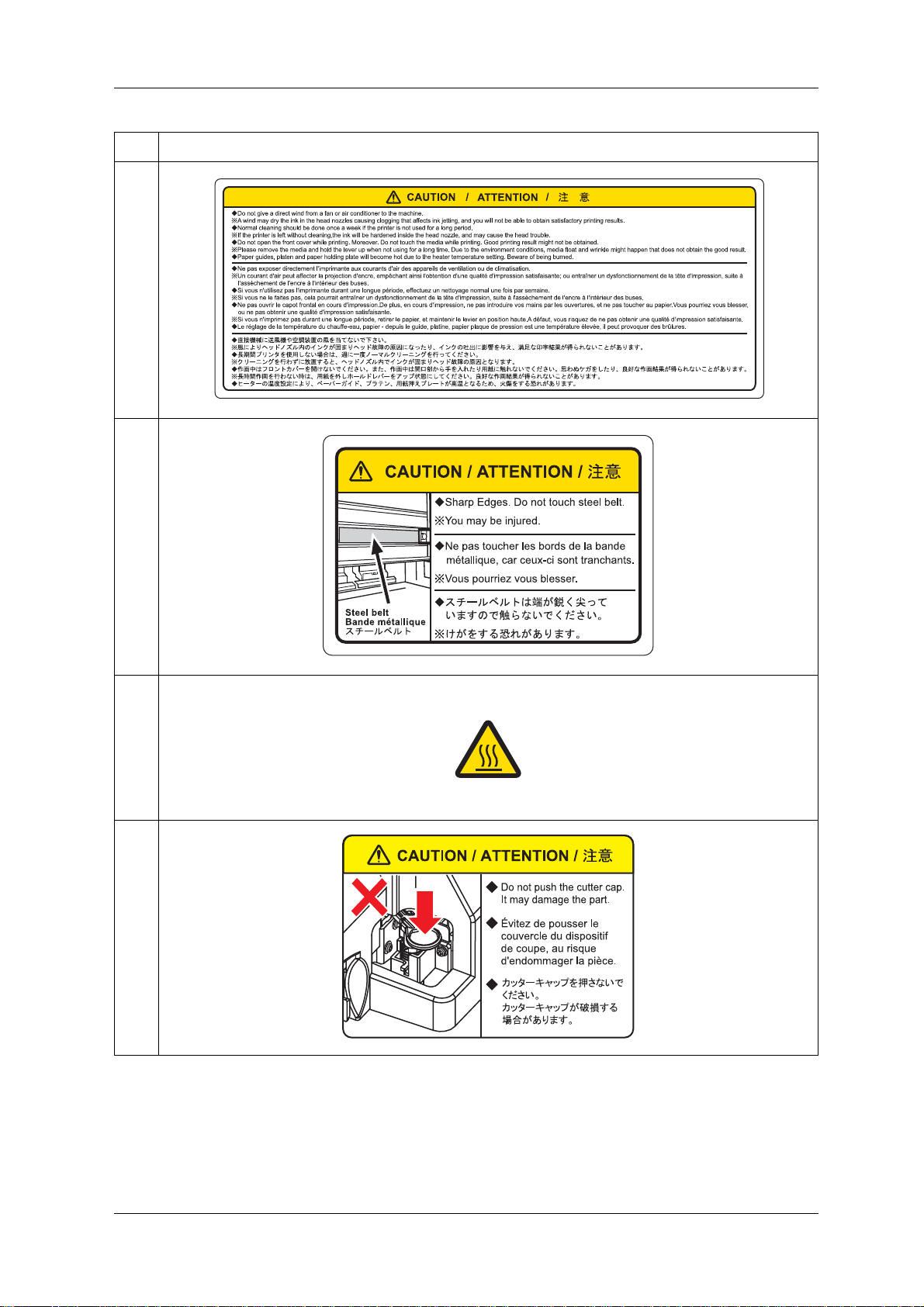

VJ-1624X/1624WX/1924WX OPERATION MANUAL 1 Safety instructions

No. Types of warning labels

2

3

4 VJ-1624X Only

5

1.3 Warning labels 23

1 Safety instructions VJ-1624X/1624WX/1924WX OPERATION MANUAL

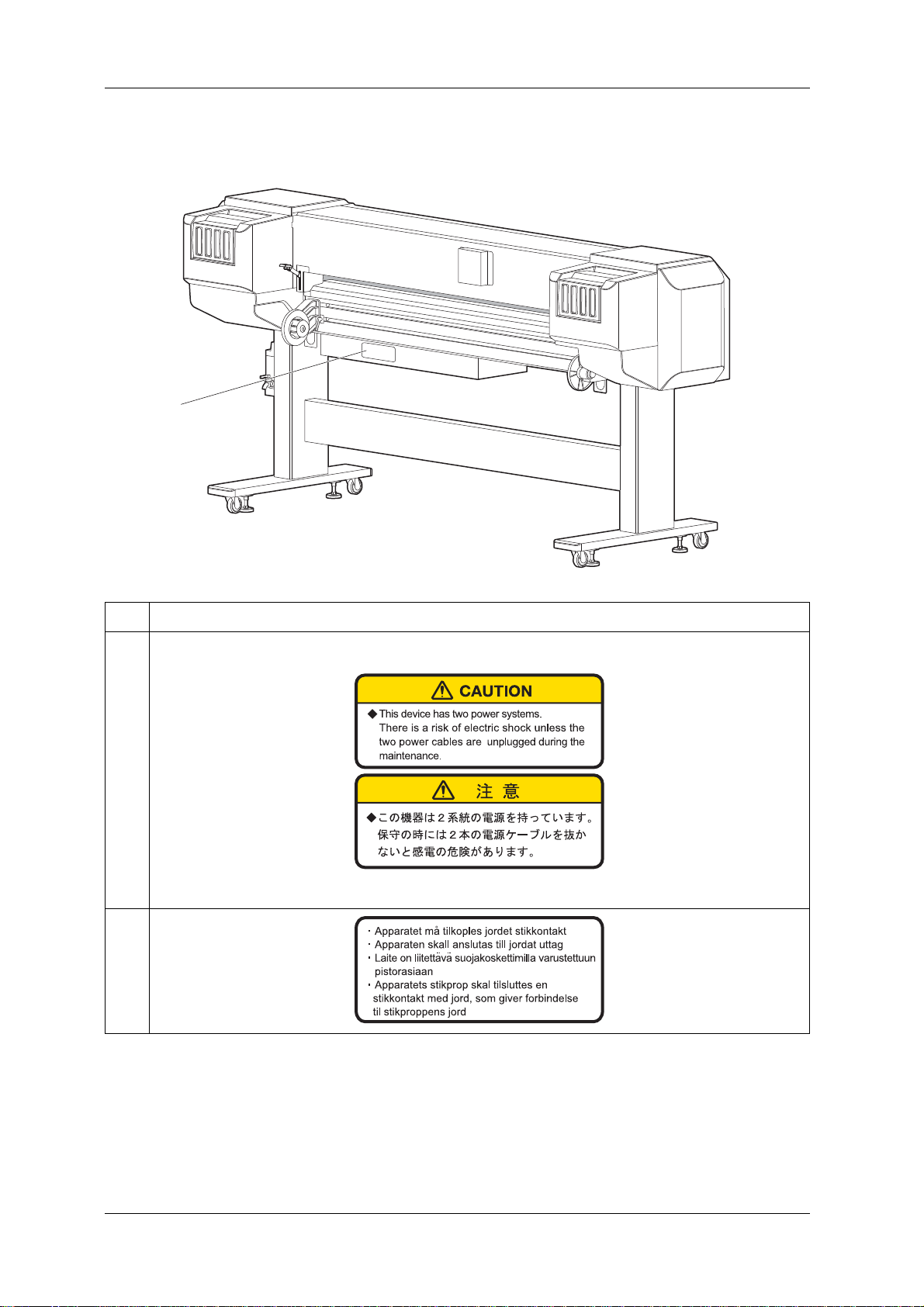

1, 2

1.3.2.2 Rear section

No. Types of warning labels

1 VJ-1624X Only

2

24 1.3 Warning labels

VJ-1624X/1624WX/1924WX OPERATION MANUAL 1 Safety instructions

NOTE

≹᮷ ӵ䘲⭘Ҿ⎧ᤄPԕлൠᆹޘ֯⭘DŽ

㯿᮷

㫉

᮷

༞᮷

Dan hab yungh youq gij digih haijbaz 2000m doxroengz

haenx ancienz sawjyungh.

㔤᮷

≹᮷ Āӵ䘲⭘Ҿ䶎✝ᑖ≄ىᶑԦлᆹޘ֯⭘DŽā

㯿᮷

㫉

᮷

༞᮷

Dan hab yungh youq gij dienheiq diuzgen mbouj dwg diegndat

haenx ancienz sawjyungh.

㔤᮷

The following marks are for China's safety standards.

1.3 Warning labels 25

1 Safety instructions VJ-1624X/1624WX/1924WX OPERATION MANUAL

26 1.3 Warning labels

VJ-1624X/1624WX/1924WX OPERATION MANUAL 2 Product overview

2 Product overview

This chapter explains the features of this printer along with the names and functions of each part.

27

2 Product overview VJ-1624X/1624WX/1924WX OPERATION MANUAL

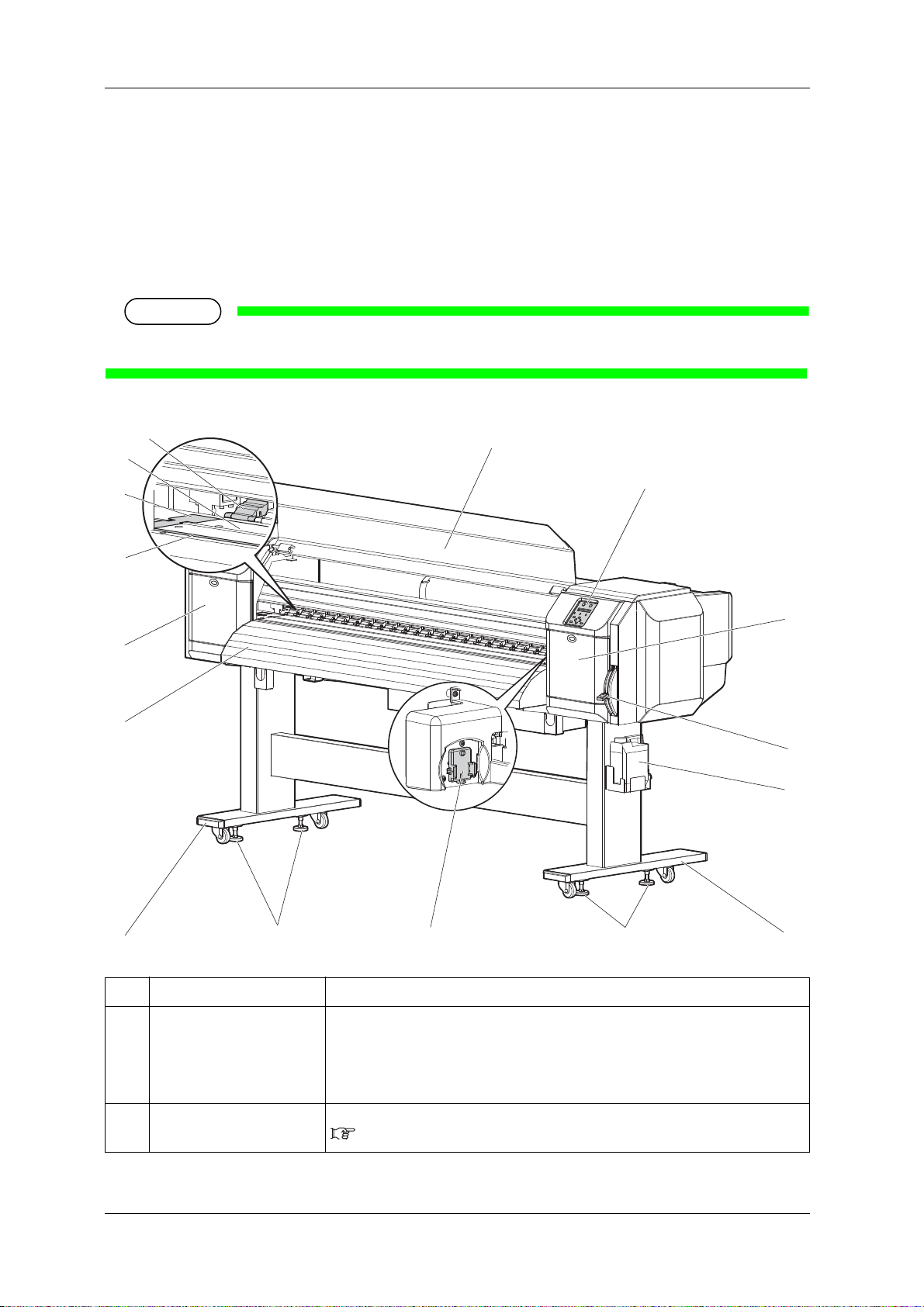

NOTE

11

1

10

2

3

9

4

13

7

8

5

4

12

9

6

10

2.1 Names of parts and functions

This section explains the names and functions of each part.

2.1.1 Front section

The illustrations used in this section are those of VJ-1624X.

No. Name Function

1 Media loading lever Used for fixing or releasing the media.

• Lower Lever to fix the media.

• Lower Lever further to fix the media firmly.

• Raise Lever to release the media.

2 Operation panel Used to set the operation condition, printer display and various functions.

Used to improve the accuracy of media feeding.

2.1.3 Operation pa nel

28 2.1 Names of parts and functions

VJ-1624X/1624WX/1924WX OPERATION MANUAL 2 Product overview

No. Name Function

3 Front cover Used to prevent the user from coming in contact with the driving mechanism during

the printer operation.

Opened and closed when media is loaded or jammed.

It is normally closed.

4 Stand Used when installing the printer on a flat floor.

5 Media guide Used to feed the media smoothly when loading or printing on the media.

• Heater (After heater) to dry ink is installed inside VJ-1624X.

• VJ-1624WX/1924WX is not equipped with Heaters.

6 Platen Installed inside of Front cover.

• Heater (Platen heater) to dry ink is installed inside VJ-1624X.

• VJ-1624WX/1924WX is not equipped with Heaters.

7 Pressurizing rollers Installed inside of Front cover.

Press and hold the whole media when printing.

8 Media cut groove Installed inside of Front cover.

Used to cut media straight.

9 Maintenance cover Used to prevent the user from touching the inner mechanical section.

Open/close in the following cases.

• When cleaning Cleaning wiper

• When cleaning circumference of Print head

• When replacing Cutter

It is normally closed.

10 Adjuster Used to install the printer horizontally.

11 Media holder plate Installed inside of Front cover.

By attaching Media holder plates to both sides of the media, media warpage can be

prevented to a degree.

12 Connector • Used to install Spectrophotometer (SPECTROVUE VM-10) to VJ-1624X.

• VJ-1624WX/1924WX is not equipped with Connector.

13 Waste fluid tank Used for collecting waste ink discharged from the printer.

2.1 Names of parts and functions 29

2 Product overview VJ-1624X/1624WX/1924WX OPERATION MANUAL

2

7

1

1

VJ-1624X

5 6

4

3

VJ-1624WX/1924WX

6

5

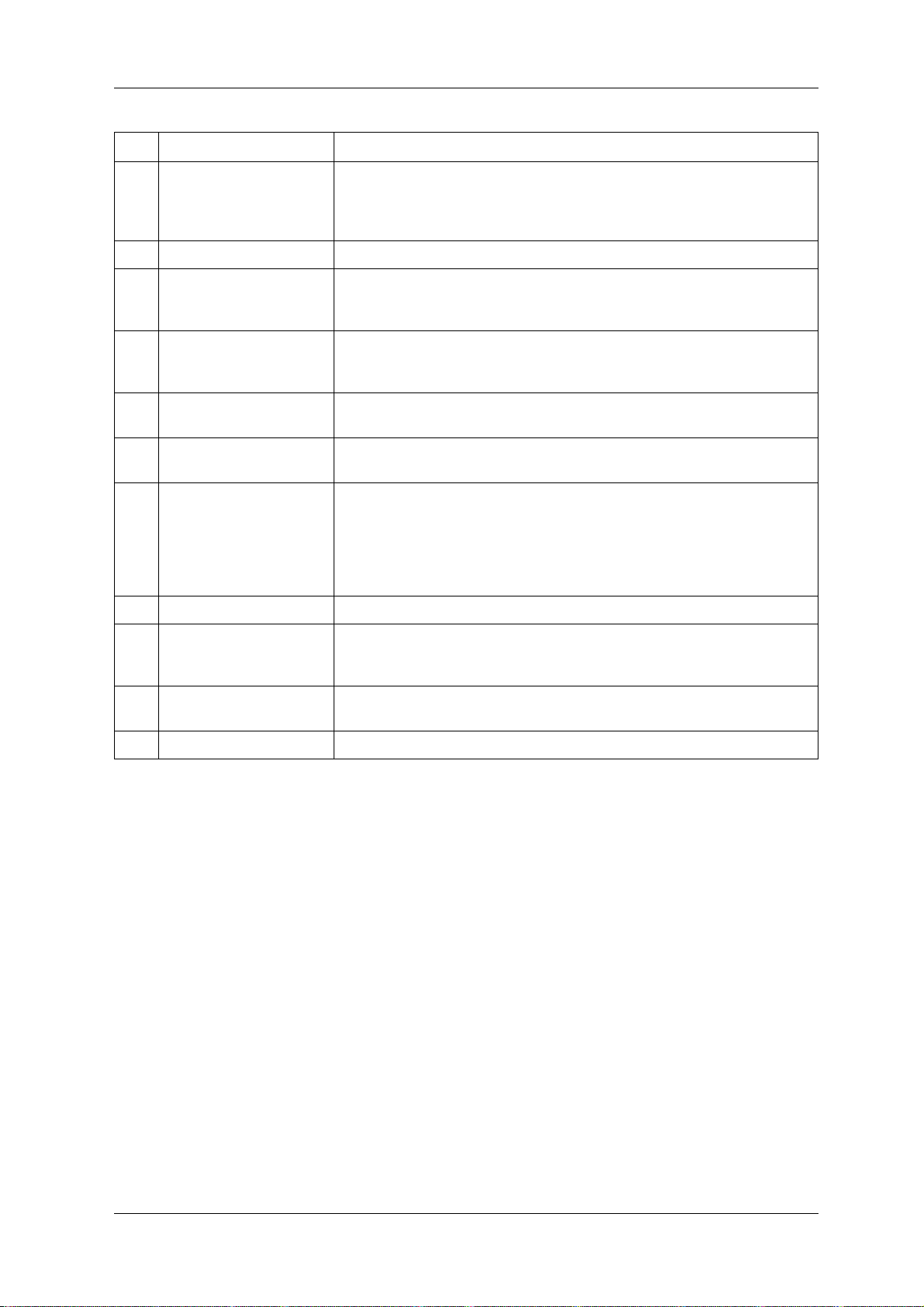

2.1.2 Rear section

No. Name Function

1 Roll media holder Load the roll media.

Equipped with Flanges to attach the roll media and Fixing levers to fix Roll media

holders.

2 Media feed slot Used for feeding media.

3 Ink cartridge slot Insert Ink cartridges.

4 Media guide Used to feed the media smoothly when loading or printing on the media.

5 AC inlet Used for connecting the power cord set.

6 Network interface cable

connector

7 Waste fluid valve Open/close when discharging the waste fluid from Waste fluid tank.

• Heater (Pre-heater) to dry ink is installed inside VJ-1624X.

• VJ-1624WX/1924WX is not equipped with Heaters.

Connects a network interface cable.

It is normally closed.

30 2.1 Names of parts and functions

VJ-1624X/1624WX/1924WX OPERATION MANUAL 2 Product overview

TIP

NOTE

8, 9

3

15

17

16

6

5

11

12

1

13

14

10

27

4

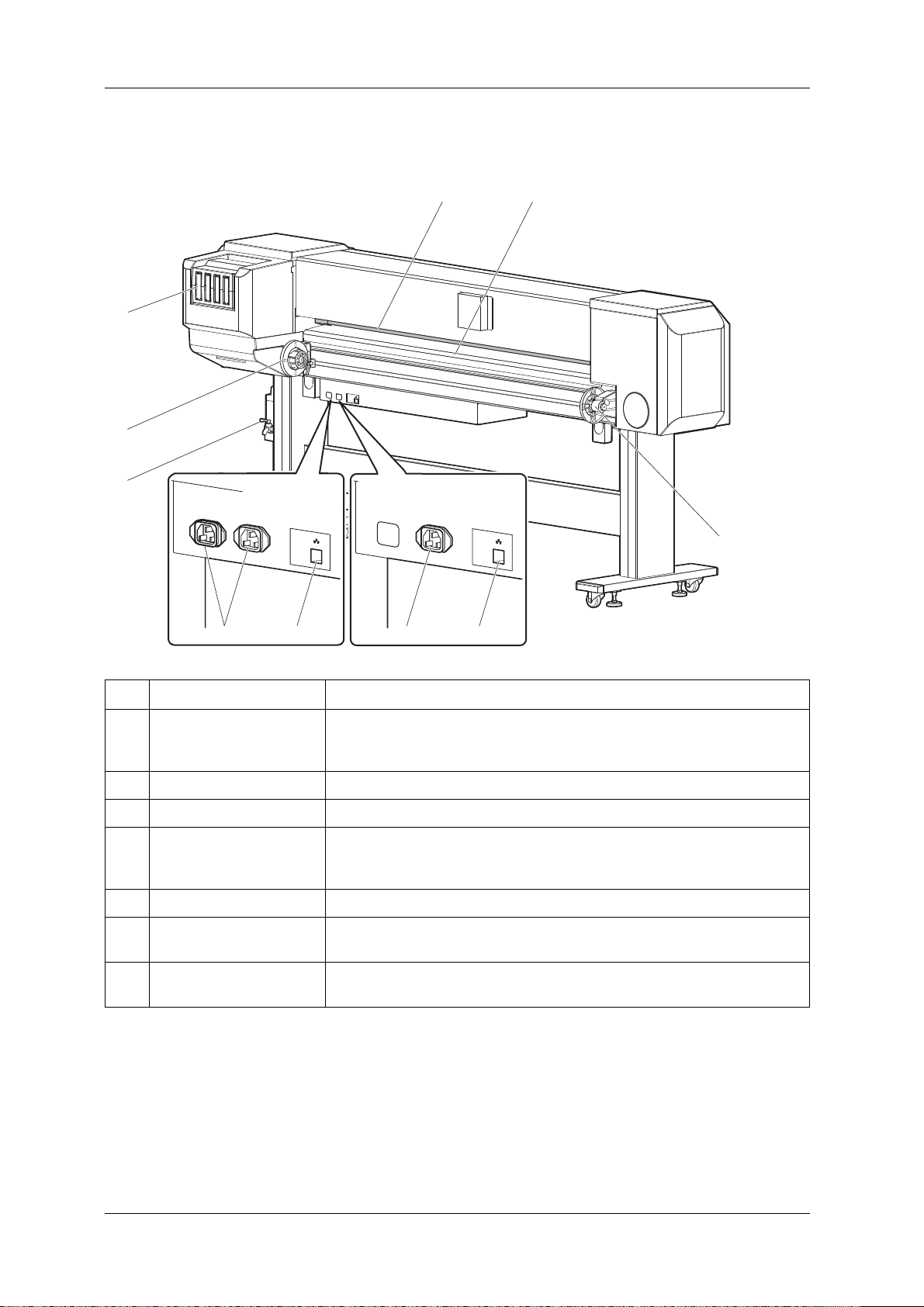

2.1.3 Operation panel

Used to set the operating conditions, to display the status of the printer, and to set various functions.

Explains names of each operation key and status display along with the functions.

•Refer to the following for details regarding the operation method of Operation panel.

•When setting the menu from Operation panel:

•When performing various operations in Operation panel: 4.4 Operating from Operation panel

4.3 Menu setups on Operation panel

(1)Operation keys

• Operation keys are assigned with different functions and names depending on the printer status

(Normal or Setup menu display).

For details about the printer status, refer to "2.2 Printer status outline".

• The symbol means “standby”. Even when the power button is not turned on, the printer

consumes a tiny amount of power so long as the power cable is connected. This state is referred to

as the power being “off” in this Manual.

2.1 Names of parts and functions 31

2 Product overview VJ-1624X/1624WX/1924WX OPERATION MANUAL

No. Name Normal Setup menu display

1 [Menu] key Shifts to the Setup menu. Shifts from Setup menu display to Normal.

2 [Enter] key Restarts printing while printing is being

suspended.

[Cutting] key Cuts the media when pressed for more than

two seconds.

3 [Pause] key Pauses printing. —

[Cancel] key • When printing:

When pressed for more than two seconds,

forcefully terminates printing and deletes

one file of the remaining data.

• When receiving or analyzing data:

When pressed for more than two seconds,

deletes the data already received and

analyzed.

4 [<] key — —

[Nozzle Check] key Press and hold this key for two seconds or

more to perform Nozzle Check printing.

5 [>] key • Sets Cleaning Mode.

• The lamp of Cleaning Mode that you set

lights up in green.

[Cleaning] key When pressed for more than two seconds,

cleaning starts.

• Select the menu to set, and shift to the next

hierarchy.

• The setting is determined and saved.

—

• Returns to the previous menu hierarchy.

Changes made in the setting are discarded.

• Shifts from Setup menu display to Normal.

—

Shifts the menu in the lower hierarchy.

—

6[Backward↑] key The media is fed in the reverse direction. —

[+] key — • Changes the displayed menu to the forward

direction.

• The setting is changed to the reverse

direction.

• The numeric value is increased during

numerical input.

7[Forward↓] key Media is fed in the forward direction. —

[–] key — • Changes the displayed menu to the reverse

direction.

• Changes the setting in the forward

direction.

• The numeric value is decreased during

numerical input.

8 [Power] key Turns the printer ON/OFF. Turns the printer ON/OFF.

32 2.1 Names of parts and functions

VJ-1624X/1624WX/1924WX OPERATION MANUAL 2 Product overview

(2)Display section

No. Name Color Status Description

9 Power lamp Blue Lamp ONPower is ON.

Lamp

blinks

Lamp

OFF

10 Error lamp Orange Lamp ONAn error has occurred.

Lamp

blinks

Lamp

OFF

11 High lamp Green Lamp ONThe head height is set to High.

Lamp

OFF

12 Low lamp Green Lamp ONThe head height is set to Low.

Lamp

OFF

13 Take Up lamp Green Lamp ONMedia ejection mode is set to "Take-up".

• Receiving and analyzing the data.

• Performing media initial operation.

Power is OFF.

The error content is displayed on the LCD.

The remaining amount of ink is low.

There is no error.

When the Low lamp is also turned on, the head height is set to Mid. (VJ1624WX/1924WX only)

The head height is set to Low.

When the High lamp is also turned on, the head height is set to Mid. (VJ1624WX/1924WX only)

The head height is set to High.

Lamp

OFF

14 Auto Cut lamp Green Lamp ONMedia ejection mode is set to "Auto cut".

Lamp

OFF

15 Long lamp Green Lamp ON• Cleaning mode is set to Long.

Lamp

OFF

16 Normal lamp Green Lamp ON• Cleaning Mode is set to Normal.

Lamp

OFF

17 LCD display section — — Displays the operation status of the printer or an error message.

Media ejection mode is set to "Off" or "Auto cut".

Media ejection mode is set to "Off" or "Take-up".

• When the Normal lamp is also on, Cleaning mode is set to Short.

Cleaning Mode is set to Normal.

• When the Long lamp is also on, Cleaning mode is set to Short.

Cleaning mode is set to Long.

2.1 Names of parts and functions 33

2 Product overview VJ-1624X/1624WX/1924WX OPERATION MANUAL

TIP

When an error requiring a restart (fatal malfunction for the printer operation) occurs, al l lam ps blink with an alarm.

7.2.3 Error requiring restart

If the error persists even when the malfunction is fixed, contact your local MUTOH dealer.

34 2.1 Names of parts and functions

VJ-1624X/1624WX/1924WX OPERATION MANUAL 2 Product overview

NOTE

Ink Low

1

3

2

2.1.4 Ink level indicator

When the “Remain Ink menu” on Display menu is set to “On”, the ink level indicator that discribes the

ink or ink cartridge status is displayed on LCD monitor.

5.7 Display menu

5.7.4 Remain Ink menu

• In the normal operation

2.2.1 Status

• During printing

• To display ink or cartridge errors

7.2.2 Message type error display and remedies

The indicator and the corresponding Ink color labels are shown below.

• The ink color labels are attached to the top of the ink cartridge slots.

2.1 Names of parts and functions 35

2 Product overview VJ-1624X/1624WX/1924WX OPERATION MANUAL

2.1.4.1 Estimated Ink level graphic

No. Indicator to display the conditions of ink/cartridges

1 Remaining ink amount :

More than 80%, less than 100%

2 Remaining ink amount :

More than 60%, less than 80%

3 Remaining ink amount :

More than 40%, less than 60%

4 Remaining ink amount :

More than 20%, less than 40%

5 Remaining ink amount :

Less than 20%

6 Ink Low

7 Ink End

8 No cartridge

36 2.1 Names of parts and functions

VJ-1624X/1624WX/1924WX OPERATION MANUAL 2 Product overview

Normal

Setup Menu Display

[Menu] key

[Cancel] key

Leave the printer

as it is for 3 minutes

2.2 Printer status outline

This section explains the printer status.

2.2.1 Status

(1)Normal

Printing is possible when the media is loaded.

The various functions for printing can be performed on Operation panel.

(2)Setup menu display

Various settings regarding printing can be made from Operation panel.

The various functions for printing can be performed on Operation panel.

Display contents in the LCD monitor of Operation panel are as follows.

(3)Panel display contents

2.2 Printer status outline 37

2 Product overview VJ-1624X/1624WX/1924WX OPERATION MANUAL

NOTE

NOTE

2.2.2 Changing printer status

Follow the procedure below and change the printer status.

(1) Normal → Setup menu display

Press the [Menu] key on Operation panel when the printer is set to Normal.

• "Menu 1: Setup>" is displayed on Operation panel and the display shifts to the Setup menu.

For details regarding the Setup menu, refer to 4.3 Menu setups on Operation panel.

(2) Setup menu display → Normal

When the printer is at Setup menu display , perform either of the following operations to shift Operation

panel to the Normal display.

• Press the [Cancel] or [Menu] key on Operation panel.

• In the Setup menu, leave the keys untouched for three minutes.

For details on Status message, refer to 7.2.1 Status messages.

38 2.2 Printer status outline

VJ-1624X/1624WX/1924WX O PERATION MANUAL Before using

3 Before using

This chapter explains necessary steps before using the printer.

39

Before using VJ-1624X/1624WX/1924WX OPERATION MANUAL

WARNING

CAUTION

NOTE

3.1 Power cord set connection

This section explains power cord set connection.

• Be sure to use the specified power cord set.

Using a power cord set other than the specified can cause an electric shock or fire.

• Use the power cord set compliant with the safety standards, po wer-supply volt age,

and plug shape of the country where the printer is used.

• Use a power cord set which is equipped with a protective earth, and securely

connect it to the outlet.

• Do not use a damaged power cord set.

It could lead to an electric shock or fire.

• Pay attention to the following points when handling the power cord set.

• Do not tamper with the power cord set.

• Do not put heavy objects on the power cord set.

• Do not bend, twist or pull the power cord set by force.

• Do not route the power cord set near heating appliances.

Contact your local MUTOH dealer if the power cord set is damaged.

Follow the procedure below to install the power cord set.

1. Make sure that the printer is turned OFF.

40 3.1 Power cord set connection

VJ-1624X/1624WX/1924WX O PERATION MANUAL Before using

NOTE

VJ-1624X

12

VJ-1624WX/1924WX

1

2

The power is ON when the [Power] key of Operation panel is pressed in.

Press the key once again to turn OFF the power.

2. Connect the power cord set to the AC inlets on the right side of the printer (VJ-1624X: 2 places, VJ-

1624WX/1924WX: 1 place).

No. Name

1AC inlet

2 Power cord set

3.1 Power cord set connection 41

Before using VJ-1624X/1624WX/1924WX OPERATION MANUAL

WARNING

CAUTION

3. Insert the plug of the power cord set firmly in the socket.

• Do not pull out or insert the power plug with a wet hand.

This could lead to an electric shock.

• Make sure to use only the specified power supply (AC 100 V to 120 V or AC 220 V to

240 V).

If a power supply other than the specified volt age is used, it could cause an electric

shock or fire.

• Take power for the printer directly from the power socket (AC 100 V to 120 V or AC

220 V to 240 V).

Do not use multiple plugs on the same socket.

This could generate heat and might cause a fire.

• Be sure to use a dedicated power socket with an earth wire for the power supply,

and connect it to the earth wire.

If the earth wire is not connected, it may cause an electric shock or fire.

• Do not connect an earth wire to the following places.

• Gas pipes

There is a possibility of ignition and explosion.

• An earth wire of telephone cables and lightning rods

A heavy current might flow whenever lightning strikes.

• Water pipe and faucet

The earth does not work if part of the metal pipe is plastic.

• Pay attention to the following points when handling the power plug.

Any mishandling of the power cable could cause a fire.

• Make sure that no foreign substances such as dust are stuck to the power plug.

• Make sure that the power plug is inserted all the way.

• When you do not use the printer for a long period, make sure to pull out the power

plug from the power socket for safety.

• Make sure to connect an earth wire to the earth connection that meet s the following

standards.

• An earth terminal of power socket

• An earth wire with a copper plate which is buried at 650 mm or more in the ground.

42 3.1 Power cord set connection

VJ-1624X/1624WX/1924WX O PERATION MANUAL Before using

NOTE

1

• Contact your local MUTOH dealer if the earth connection is not/cannot be established.

• When the printer is ON, do not pull out the power cord set from the power socket.

Whenever the plug is pulled out from the power socket, turn OFF t he power on Operation panel and

allow one minute or more before inserting the plug in the power socket again.

• For VJ-1624X, when connecting two power cord sets, a total capacity of 24A is required.

When you cannot ensure the capacity of 24A, connect two power cord sets to separate outlets.

No. Name

1 Power plug

3.1 Power cord set connection 43

Before using VJ-1624X/1624WX/1924WX OPERATION MANUAL

NOTE

3.2 Turning the power ON/OFF

This section explains how to turn the printer ON/OFF.

3.2.1 T urning the power ON

Follow the procedure below to turn the power ON.

1. Press the [Power] key on Operation panel to turn ON the printer.

• The Power lamp on Operation panel lights up in blue.

• The printer starts the initial operation.

• When the initial operation is complete, the printer enters Normal.

If there is a problem during the initial operation, a message is displayed on Operation panel and the

printer may stop operating.

If operation stops, refer to 7 Troubleshooting and deal with the problem.

44 3.2 Turning the power ON/OFF

VJ-1624X/1624WX/1924WX O PERATION MANUAL Before using

NOTE

NOTE

3.2.2 Turning the power OFF

Follow the procedure below to turn the printer OFF.

1. Verify the following regarding the operational condition of the printer.

• Printing or other operations are not in progress.

• Operation panel display is Normal.

• The Low lamp on Operation panel lights up in green.

• The High lamp on Operation panel is turned off.

If the High lamp on Operation panel lights up in green, the head height is set to High or Mid (only

for VJ-1624WX/1924WX).

Return the head height to Low before turning the power OFF.

4.2.5.3 When setting the head height to Low

2. Press the [Power] key on Operation panel to turn OFF the printer.

• The Power lamp on Operation panel is turned off.

• If Operation panel is in the following status, the power is ON.

• The [Power] key is pressed in.

• The Power lamp lights up in blue.

Press the key once again to turn OFF the power.

• The printer turns the power OFF.

• "Power Off" is displayed on Operation panel.

3.2 Turning the power ON/OFF 45

Before using VJ-1624X/1624WX/1924WX OPERATION MANUAL

NOTE

NOTE

1

If the head height is set to High or Mid (only for VJ-1624WX/1924WX), "Set Height to Low" is

displayed on Operation panel, and the printer stops the procedure to turn the power OFF.

To restart the procedure, return the head height to Low.

4.2.5.3 When setting the head height to Low

• All the lamps on Operation panel and the LCD monitor are turned OFF.

• The printer automatically turns the power OFF.

• If there is a problem during turning OFF operation, a message is displayed on Operation panel and

the printer may stop operating.

If operation stops, refer to 7 Troubleshooting and deal with the problem.

• After turning OFF the printer, wait for ten seconds or longer to turn it ON again.

3. Raise the media loading lever when the printer is not used for a long time.

No. Name

1 Media loading lever

46 3.2 Turning the power ON/OFF

VJ-1624X/1624WX/1924WX O PERATION MANUAL Before using

CAUTION

3.3 Filling ink

This section describes the procedure to install Ink cartridges for the first time.

• Before operation, make sure to read the Safety Data Sheet (SDS).

• When handling Ink cartridges or Ink p acks, p ay attention so that ink do es not come

into contact with your eyes or skin.

If ink gets into your eyes or sticks to your skin, immediately wash it off with water.

Failing to do so might cause irritation or light inflammation of eyes.

In case of any abnormality, consult a physician immediately.

• Do not disassemble Ink cartridges or Ink packs.

If disassembled, ink might come into contact with your eyes or skin.

• Comply strictly with the following during ink filling.

• Do not turn OFF the printer.

• Do not unplug the power cord set.

• Do not open Front cover.

• Do not open Maintenance cover.

• Do not raise Media loading lever.

3.3 Filling ink 47

Before using VJ-1624X/1624WX/1924WX OPERATION MANUAL

NOTE

• Do not use the Ink cartridge(s) you have inserted into Ink cartridge slot(s) for other printers. The

Ink cartridge(s) will not be used again.

• Use genuine Ink cartridges or Ink packs for charging.

This printer is designed to use genuine Ink cartridges and Ink packs.

If you use Ink cartridges which are not produced by the original manufacturer,

• printing might become blurred and the end of the ink might not be detected correctly.

• Any problems caused by using an ink bag other than those recommended above will not be

covered by the warranty, and repair expenses will be paid by the customer.

• For types and details of Ink cartridges, contact your local MUTOH dealer.

• Do not shake Ink cartridges or Ink packs strongly.

Doing so may cause ink leakage.

• Do not disassemble Ink cartridges.

A disassembled Ink cartridge or Ink packs cannot be used.

• Be sure to use the dedicated cleaning fluid.

• (VJ-1624X)product number: VJ-MSINK3-CL220, VJ-MSINK3-CL1000

• (VJ-1624WX/1924WX) Model number: RJ-FGCLS (cleaning fluid for water-color ink), VJ-

DSINK-CL1000g (cleaning fluid for sublimation ink)

• Shake the Ink cartridges or Ink packs lightly before installing.

Doing so may affect the print quality.

• When the Ink cartridge or Ink pack is moved from a cold place to a warm place, leave it for 3 hours

or more in the new printing environment before printing.

• Ink cartridges and Ink packs for this printer have dedicated IC chips on them.

If removing/inserting the ink cartridges and High-capacity ink pack adapter (option) in the

following situations, the information within the IC chips may be damaged and the cartridges cannot

be used.

• During printing

• For ten seconds after inserting all Ink cartrid ges

48 3.3 Filling ink

VJ-1624X/1624WX/1924WX O PERATION MANUAL Before using

NOTE

TIP

3.3.1 When using 220ml Ink cartridges

Follow the procedure below to install the 220ml Ink cartridges.

The procedures differ between VJ-1624X and VJ-1624WX/1924WX. Check your printer model

name and follow the correct procedure.

The 220ml cartridges can be inserted horizontally or vertically.

This section describes the case of horizontal insertion angle only. Refer to "3.3.2 When using 440ml Ink cartridges (VJ1624X only)" for the case of vertical insertion.

3.3.2 When using 440ml Ink cartridges (VJ-1624X only)

3.3.1.1 For VJ-1624X

1. Turn the printer ON.

• The printer starts the initializing operation.

• After the initial operation is compete, "Start Ink Charge->ENTER" is displayed on Operation

panel.

3.3 Filling ink 49

Before using VJ-1624X/1624WX/1924WX OPERATION MANUAL

2

1

2. Press the [Enter] key on Operation panel.

• "Insert CleaningCart." is displayed on Operation panel.

3. Take out Cleaning cartridges (4 pieces) from the bags.

4. Insert Cleaning cartridge into Ink cartridge slot.

• Keep the arrow of Cleaning cartridge facing up and insert it into the printer.

No. Name

1 Cleaning cartridge

2Arrow

50 3.3 Filling ink

VJ-1624X/1624WX/1924WX O PERATION MANUAL Before using

1

2

1

• Insert Cleaning cartridge all the way in Ink cartridge slot.

No. Name

1 Cleaning cartridge

2 Ink cartridge slots

• If the head height is set to High, "Change Head Gap Low" is displayed on Operation panel.

Change the head height to Low.

4.2.5 Head height adjustment

• When all Cleaning cartridges are installed, "Busy-W ashing" is displayed on Operation panel, and

the printer starts charging the cleaning fluid.

• When Cleaning fluid has been charged, "Remove Cartridges" is displayed on Operation panel.

5. Remove all Cleaning cartridges.

No. Name

1 Cleaning cartridge

• "Busy-Washing" is displayed on Operation panel and the printer starts head cleaning.

• When head cleaning is complete, "Wash retry? No" is displayed on Operation panel.

3.3 Filling ink 51

Before using VJ-1624X/1624WX/1924WX OPERATION MANUAL

1

2

4

3

6. Press the [Enter] key on Operation panel.

• "Insert InkCartridges" is displayed on Operation panel.

7. Install Ink cartridges (K, C, M, Y) in Ink cartridge slots on the back of the printer.

• Shake Ink cartridges 2 to 3 times lightly before installing them into Ink cartridge slots.

• Make sure that Ink cartridges are inserted into the correct Slots.

Match the ink color label with the ink color before inserting Ink pack.

• Keep the arrow of Ink cartridge facing up and insert it into the printer.

No. Name

1 Ink cartridge

2Arrow

3 Ink cartridge slots

4 Ink color labels

52 3.3 Filling ink

VJ-1624X/1624WX/1924WX O PERATION MANUAL Before using

CAUTION

1

5

4

3

2

• Insert Ink cartridges all the way in Ink cartridge slots.

No. Name

1 Ink cartridge

2 Ink cartridge slot K

3 Ink cartridge slot C

4 Ink cartridge slot M

5 Ink cartridge slot Y

• When an Ink cartridge is installed, "Ink Refill **%" is displayed on Operation panel and ink

replenishment starts.

• Initial filling takes about 10 minutes.

Ink filling operation and pause operation are repeated during the initial ink replenishment.

• When "100%" is displayed, the initial ink replenishment is complete.

• When the initial ink charge is complete, "SubTank Refill **%" is displayed on the operation

panel, and the printer starts filling the subtank.

• When 100% is displayed, the subtank ink replenishment is complete.

• After the subtank ink replenishment is complete, Media End is displayed on the operation panel.

• Comply strictly with the following during ink filling. If filling is interrupted, ink will

be lost when filling is resumed.

• Do not turn OFF the power of the printer.

• Do not unplug the power cord set of the printer.

• Do not open Front cover.

• Do not open Maintenance cover.

• Do not raise Media loading lever.

3.3 Filling ink 53

Before using VJ-1624X/1624WX/1924WX OPERATION MANUAL

NOTE

• If the printer perform the nozzle check printing immediately after the initial ink replenishment is

complete, the following results may occur.

• Printed lines become blurred.

• The data is partially not printed.

In such cases, follow "5.3 Cleaning menu" and refill a small amount of ink. Then, check the

printing result.

If there is no improvement in the print result even after refilling a small amount of ink, leave the

printer unused for an hour or more. Then, refill a small amount of ink again and check the print

result.

If there is still no improvement, contact your local MUTOH dealer.

3.3.1.2 For VJ-1624WX/1924WX

1. Turn the printer ON.

• The printer starts the initializing operation.

• After the initial operation is compete, "Start Ink Charge->ENTER" is displayed on Operation

panel.

2. Press the [Enter] key on Operation panel.

54 3.3 Filling ink

VJ-1624X/1624WX/1924WX O PERATION MANUAL Before using

NOTE

• When head cleaning is complete, "Wash retry? No" is displayed on Operation panel.

3. Select whether to perform cleaning of the ink path before the initial ink charge.

• Cleaning may be required depending on the ink type to be set.

• To perform head cleaning, make sure to use the cleaning liquid that matches the ink.

a. When cleaning is required, press the [+] key or [-] key to select "Yes".

b. When cleaning is not required, proceed to the step 8.

4. Press the [Enter] key on Operation panel.

• "Insert CleaningCart." is displayed on Operation panel.

5. Take out Cleaning cartridges (4 pieces) from the bags.

3.3 Filling ink 55

Before using VJ-1624X/1624WX/1924WX OPERATION MANUAL

2

1

1

2

6. Insert Cleaning cartridge into Ink cartridge slot.

• Keep the arrow of Cleaning cartridge facing up and insert it into the printer.

No. Name

1 Cleaning cartridge

2Arrow

• Insert Cleaning cartridge all the way in Ink cartridge slot.

No. Name

1 Cleaning cartridge

2 Ink cartridge slots

• If the head height is set to High, "Change Head Gap Low" is displayed on Operation panel.

Change the head height to Low.

4.2.5 Head height adjustment

• When all Cleaning cartridges are installed, "Busy-W ashing" is displayed o n Operation panel, and

the printer starts charging the cleaning fluid.

• When Cleaning fluid has been charged, "Remove Cartridges" is displayed on Operation panel.

56 3.3 Filling ink

VJ-1624X/1624WX/1924WX O PERATION MANUAL Before using

1

7. Remove all Cleaning cartridges.

No. Name

1 Cleaning cartridge

• "Busy-Washing" is displayed on Operation panel and the printer starts head cleaning.

• When head cleaning is complete, "Wash retry? No" is displayed on Operation panel.

8. Press the [Enter] key on Operation panel.

• "Insert InkCartridges" is displayed on Operation panel.

3.3 Filling ink 57

Before using VJ-1624X/1624WX/1924WX OPERATION MANUAL

1

2

4

3

1

5

4

3

2

9. Install Ink cartridges (K, C, M, Y) in Ink cartridge slots on the back of the printer.

• Shake Ink cartridges 2 to 3 times lightly before installing them into Ink cartridge slots.

• Make sure that Ink cartridges are inserted into the correct Slots.

Match the ink color label with the ink color before inserting Ink pack.

• Keep the arrow of Ink cartridge facing up and insert it into the printer.

No. Name

1 Ink cartridge

2Arrow

3 Ink cartridge slots

4 Ink color labels

• Insert Ink cartridges all the way in Ink cartridge slots.

No. Name

1 Ink cartridge

2 Ink cartridge slot K

3 Ink cartridge slot C

58 3.3 Filling ink

4 Ink cartridge slot M

5 Ink cartridge slot Y

VJ-1624X/1624WX/1924WX O PERATION MANUAL Before using

CAUTION

NOTE

• When an Ink cartridge is installed, "Ink Refill **%" is displayed on Operation panel and ink

replenishment starts.

• Initial filling takes about 10 minutes.

Ink filling operation and pause operation are repeated during the initial ink replenishment.

• When "100%" is displayed, the initial ink replenishment is complete.

• When the initial ink charge is complete, "SubTank Refill **%" is displayed on the operation

panel, and the printer starts filling the subtank.

• When 100% is displayed, the subtank ink replenishment is complete.

• After the subtank ink replenishment is complete, Media End is displayed on the operation panel.

• Comply strictly with the following during ink filling. If filling is interrupted, ink will

be lost when filling is resumed.

• Do not turn OFF the power of the printer.

• Do not unplug the power cord set of the printer.

• Do not open Front cover.

• Do not open Maintenance cover.

• Do not raise Media loading lever.

• If the printer perform the nozzle check printing immediately after the initial ink replenishment is

complete, the following results may occur.

• Printed lines become blurred.

• The data is partially not printed.

In such cases, follow 5.3 Cleaning menu and refill a small amount of ink. Then, check the

printing result.

If there is no improvement in the print result even after refilling a small amount of ink, leave the

printer unused for an hour or more. Then, refill a small amount of ink again and check the print

result.

If there is still no improvement, contact your local MUTOH dealer.

3.3 Filling ink 59

Before using VJ-1624X/1624WX/1924WX OPERATION MANUAL

NOTE

NOTE

1

3.3.2 When using 440ml Ink cartridges (VJ-1624X only)

440ml Ink cartridges are not compatible with VJ-1624WX/1924WX.

Follow the procedure below to install Ink cartridges.

1. Check the angle of Ink cartridge slot to see if the insertion angle of Ink cartridge is vertical.

No. Name

1 Ink cartridge slot

• If the insertion angle of Ink cartridge is not vertical, change the angle.

3.3.3 Changing the angle of Ink cartridge slot

Make sure that the insertion angle of the 440ml cartridge is vertical. If the cartridge is inserted

obliquely, the cartridge may fall over.

60 3.3 Filling ink

VJ-1624X/1624WX/1924WX O PERATION MANUAL Before using

2. Turn the printer ON.

• The printer starts the initializing operation.

• After the initial operation is compete, "Start Ink Charge->ENTER" is displayed on Operation

panel.

3. Press the [Enter] key on Operation panel.

• "Insert CleaningCart." is displayed on Operation panel.

4. Take out Cleaning cartridges (4 pieces) from the bags.

3.3 Filling ink 61

Before using VJ-1624X/1624WX/1924WX OPERATION MANUAL

2

1

2

1

5. Insert Cleaning cartridge into Ink cartridge slot.

• Keep the arrow of Cleaning cartridge facing the front side of the printer and insert it into the

printer.

No. Name

1 Cleaning cartridge

2Arrow

• Insert Cleaning cartridge all the way in Ink cartridge slot.

No. Name

1 Cleaning cartridge

2 Ink cartridge slots

• If the head height is set to High, "Change Head Gap Low" is displayed on Operation panel.

Change the head height to Low.

4.2.5 Head height adjustment

• When all Cleaning cartridges are installed, "Busy-W ashing" is displayed o n Operation panel, and

the printer starts charging the cleaning fluid.

• When Cleaning fluid has been charged, "Remove Cartridges" is displayed on Operation panel.

62 3.3 Filling ink

VJ-1624X/1624WX/1924WX O PERATION MANUAL Before using

1

6. Remove all Cleaning cartridges.

No. Name

1 Cleaning cartridge

• "Busy-Washing" is displayed on Operation panel and the printer starts head cleaning.

• When head cleaning is complete, "Wash retry? No" is displayed on Operation panel.

7. Press the [Enter] key on Operation panel.

• "Insert InkCartridges" is displayed on Operation panel.

3.3 Filling ink 63

Before using VJ-1624X/1624WX/1924WX OPERATION MANUAL

2

1

3

1

4

3

8. Install Ink cartridges (K, C, M, Y) in Ink cartridge slots on the back of the printer.

• Shake Ink cartridges 2 to 3 times lightly before installing them into Ink cartridge slots.

• Make sure that Ink cartridges are inserted into the correct Slots.

Match the ink color label with the ink color before inserting Ink pack.

• Keep the arrow of Cleaning cartridge facing the front side of the printer and insert it.

No. Name

1 Ink cartridge

2Arrow

3 Ink cartridge slots

4 Ink color labels

64 3.3 Filling ink

VJ-1624X/1624WX/1924WX O PERATION MANUAL Before using

1

5

4

3

2

• Insert Ink cartridges all the way in Ink cartridge slots.

No. Name

1 Ink cartridge

2 Ink cartridge slot K

3 Ink cartridge slot C

4 Ink cartridge slot M

5 Ink cartridge slot Y

• When an Ink cartridge is installed, "Ink Refill **%" is displayed on Operation panel and ink

replenishment starts.

• Initial filling takes about 8 minutes.

Ink filling operation and pause operation are repeated during the initial ink replenishment.

• When "100%" is displayed, the initial ink replenishment is complete.

• When the initial ink charge is complete, "SubTank Refill **%" is displayed on the operation

panel, and the printer starts filling the subtank.

• When 100% is displayed, the subtank ink replenishment is complete.

• After the subtank ink replenishment is complete, Media End is displayed on the operation panel.

3.3 Filling ink 65

Before using VJ-1624X/1624WX/1924WX OPERATION MANUAL

CAUTION

NOTE

• Comply strictly with the following during ink filling. If filling is interrupted, ink will

be lost when filling is resumed.

• Do not turn OFF the power of the printer.

• Do not unplug the power cord set of the printer.

• Do not open Front cover.

• Do not open Maintenance cover.

• Do not raise Media loading lever.

• If the printer perform the nozzle check printing immediately after the initial ink replenishment is

complete, the following results may occur.

• Printed lines become blurred.

• The data is partially not printed.

In such cases, follow 5.3 Cleaning menu and refill a small amount of ink. Then, check the

printing result.

If there is no improvement in the print result even after refilling a small amount of ink, leave the

printer unused for an hour or more. Then, refill a small amount of ink again and check the print

result.

If there is still no improvement, contact your local MUTOH dealer.

66 3.3 Filling ink

VJ-1624X/1624WX/1924WX O PERATION MANUAL Before using

1

3.3.3 Changing the angle of Ink cartridge slot

The angle of the ink cartridge slot of this printer varies depending on the capacity of ink cartridges (or

ink packs).

Follow the procedure below to change the angle.

3.3.3.1 When inserting Ink cartridges vertically

Before installing the 440ml cartridges, change the angle as follows.

1. Rotale Ink cartridge slot by 90 degrees upward.

No. Name

1 Ink cartridge slot

2. Check if Ink cartridge slot is vertical.

3.3 Filling ink 67

Before using VJ-1624X/1624WX/1924WX OPERATION MANUAL

1

1

3.3.3.2 When inserting Ink cartridges horizontally

Before installing High-capacity ink pack adapters, change the angle as follows.

1. Tilt Ink cartridge slot slightly toward the rear side of the printer.

No. Name

1 Ink cartridge slot

2. To unlock, return Ink cartridge slot to the original position.

No. Name

1 Ink cartridge slot

68 3.3 Filling ink

VJ-1624X/1624WX/1924WX O PERATION MANUAL Before using

1

3. Rotate Ink cartridge slot by 90 degrees downward.

No. Name

1 Ink cartridge slot