Page 1

User’s Guide ValueJet 1204

1 AP-75740 – Rev 1.2 – 6/07/2011

User’s

Guide

VJ-1204

Eco-Solvent

Ultra Printer

FOR EUROPE ONLY!

Page 2

User’s Guide ValueJet 1204

2 AP-75740 – Rev 1.2 – 6/07/2011

Page 3

User’s Guide ValueJet 1204

3 AP-75740 – Rev 1.2 – 6/07/2011

COPYRIGHT NOTICE

COPYRIGHT © July 2011 Mutoh Belgium nv. All rights reserved.

This document may not be reproduced by any means, in whole or in part, without written permission of the

copyright owner.

This document is furnished to support the Mutoh ValueJet 1204 printer. In consideration of the furnishing of

the information contained in this document, the party to whom it is given, assumes its custody and control

and agrees to the following:

The information herein contained is given in confidence, and any part thereof shall not be copied or

reproduced without written consent of Mutoh Belgium nv.

This document or the contents herein under no circumstances shall be used in the manufacture or

reproduction of the article shown and the delivery of this document shall not constitute any right or license to

do so.

This guide is intended for the European, African and Middle East (EMEA region) markets only.

July 2011

Published: Mutoh Belgium nv, Archimedesstraat 13, B-8400 Oostende, BELGIUM

www.mutoh.eu

www.mutoh.be

IMPORTANT

NOTICE

For users in Europe

This is a Class A product approved for industrial environments.

In a domestic environment this product may cause radio interference in which case you may be required to

take adequate measures.

Change the direction of the receiving antenna or feeder.

This product is subject to the WEEE regulations.

Environmental information

Disposal of your old product

Your product is designed and manufactured with high quality materials and components, which can be

recycled and reused.

When this crossed-out wheeled bin symbol is attached to a product it means the product is covered by

the European Directive 2002/96/EC.

Please inform yourself about the local separate collection system for electrical and electronic products.

Please act according to your local rules and do not dispose of your old products with your normal household

waste. The correct disposal of your old product will help prevent potential negative consequences for the

environment and human health.

Page 4

User’s Guide ValueJet 1204

4 AP-75740 – Rev 1.2 – 6/07/2011

Trademarks mentioned in this guide

• MUTOH, ValueJet, VJ-1204 are registered trademarks or product names of MUTOH BELGIUM nv.

• Windows95, Windows98, Windows NT4.0, Windows2000, Windows XP, Windows Vista, Windows 7, and

MS-DOS are registered trademarks or product names of Microsoft Corporation.

• Other company and product names may be registered trademarks or product names.

Notes

• The product and the contents of this publication may be changed without prior notification.

• MUTOH Belgium nv has made the best efforts to keep this publication free from errors, but if

you find any uncertainties or misprints, please call us or the reseller from which you bought

this equipment.

• MUTOH Belgium nv shall not be liable for any damages or troubles resulting from the use of

this equipment or this guide.

Page 5

User’s Guide ValueJet 1204

5 AP-75740 – Rev 1.2 – 6/07/2011

ABOUT THIS GUIDE

Purpose and Target Readers

Thank you for purchasing a Mutoh ValueJet 1204 printer!

This guide explains preparations before use and operation procedures for MUTOH’s Full Colour Inkjet printer

VJ-1204.

This guide is prepared for the owners and operators of this product.

Before using the printer, fully understand the contents and directions in this guide.

Guide Configuration

Section Contents

1 Safety instructions

This chapter explains about the printer installation, warning terms which the

operator needs to know, caution items and warning labels stuck on the printer

main unit.

2 Product overview

This chapter explains about the features of the printer along with the names and

functions of each part.

3 Installing the unit This chapter explains how to install the printer.

4 Handling the printer This chapter explains how to handle the printer.

5 Periodical

maintenance

This chapter explains how to perform the maintenance.

6 Troubleshooting

This chapter describes possible troubles during the use of this product and

countermeasures.

7 Appendix Interface specifications & options

Notes

• 1 Safety instructions through 4 Handling the printer must be read before using the printer.

• Read 5 Periodical maintenance through if necessary.

Page 6

User’s Guide ValueJet 1204

6 AP-75740 – Rev 1.2 – 6/07/2011

Page 7

User’s Guide ValueJet 1204

7 AP-75740 – Rev 1.2 – 6/07/2011

TABLE OF CONTENTS

1 SAFETY INSTRUCTIONS ......................................................................................................................... 9

1.1 INTRODUCTION .................................................................................................................................... 10

1.2 WARNINGS, CAUTIONS AND NOTES ....................................................................................................... 10

1.3 IMPORTANT SAFETY INSTRUCTIONS ....................................................................................................... 10

1.4 WARNING LABELS ................................................................................................................................ 13

1.5 OPERATION PROCEDURE LABELS .......................................................................................................... 15

2 PRODUCT OVERVIEW ........................................................................................................................... 17

2.1 FEATURES ........................................................................................................................................... 18

2.2 NAME OF THE PARTS AND FUNCTIONS ................................................................................................... 19

2.3 PRINTER MODE .................................................................................................................................... 24

3 INSTALLING THE UNIT .......................................................................................................................... 25

3.1 INTRODUCTION .................................................................................................................................... 26

3.2 INSTALLATION SPACE ........................................................................................................................... 26

3.3 INSTALLATION PROCEDURE .................................................................................................................. 27

3.4 POWER CABLE CONNECTION ................................................................................................................ 28

3.5 SWITCHING THE POWER ON / OFF ......................................................................................................... 30

3.6 INSTALLING INK CASSETTES FOR THE FIRST TIME ................................................................................... 33

3.7 CONNECTING THE PRINTER TO THE PC ................................................................................................. 39

3.8 TRANSFER AND TRANSPORTATION ........................................................................................................ 41

3.9 STEPS AFTER TRANSFER ...................................................................................................................... 45

4 HANDLING THE PRINTER ..................................................................................................................... 47

4.1 INTRODUCTION .................................................................................................................................... 49

4.2 MAKING THE PRINTER READY-TO-PRINT ................................................................................................ 49

4.3 USING MEDIA ....................................................................................................................................... 50

4.4 HANDLING AND INSTALLING MEDIA ........................................................................................................ 52

4.5 TEST PRINT ......................................................................................................................................... 68

4.6 ADJUST PRINT ..................................................................................................................................... 73

4.7 MENU SETUP ON THE OPERATION PANEL ............................................................................................... 77

4.8 SETUP MENU ....................................................................................................................................... 79

4.9 OPERATING FROM THE OPERATION PANEL ............................................................................................. 93

5 PERIODICAL MAINTENANCE ................................................................................................................ 99

5.1 DONE BY END USER ........................................................................................................................... 100

5.2 DONE BY AUTHORIZED MUTOH TECHNICIAN ........................................................................................ 110

6 TROUBLESHOOTING ........................................................................................................................... 111

6.1 MALFUNCTION AND FAILURE OF THE PRODUCT .................................................................................... 112

6.2 ERROR MESSAGES ............................................................................................................................ 116

6.3 THE MEDIA IS JAMMED ........................................................................................................................ 120

Page 8

User’s Guide ValueJet 1204

8 AP-75740 – Rev 1.2 – 6/07/2011

Page 9

User’s Guide ValueJet 1204

Chapter 2: Product Overview

9 AP-75740 – Rev 1.2 – 6/07/2011

1 SAFETY INSTRUCTIONS

1.1 INTRODUCTION 10

1.2 WARNINGS, CAUTIONS AND NOTES 10

1.3 IMPORTANT SAFETY INSTRUCTIONS 10

1.4 WARNING LABELS 13

1.4.1 Handling the operation procedure labels 13

1.4.2 Locations and types of warning labels 13

1.5 OPERATION PROCEDURE LABELS 15

1.5.1 Handling the operation procedure labels 15

1.5.2 Locations and types of warning labels 15

Page 10

User’s Guide ValueJet 1204

Chapter 2: Product Overview

10 AP-75740 – Rev 1.2 – 6/07/2011

1.1 INTRODUCTION

This chapter explains about the printer installation, warning terms which the operator needs to know, caution

items and warning labels stuck on the printer main unit.

Caution

• When performing installation and operation of the printer, be sure to follow the directions and

warnings mentioned in this document.

1.2 WARNINGS, CAUTIONS AND NOTES

The contents of alarm displays included in this User’s Guide and warning labels stuck on the main body of

the printer are classified into three categories, according to degree of danger.

Understand the meaning of the following warning terms and follow the contents (instructions) in this guide.

Warnings Meaning

Important

If ignored, it would lead to dangerous situations where death or serious

injury may be caused.

Caution

If ignored, it would lead to a dangerous situation, causing slight or middle

class illness, or damage to the product or parts of the product.

Notes

Used for a special caution and information that must be emphasized.

1.3 IMPORTANT SAFETY INSTRUCTIONS

In order to use the printer safely, the general notes which must be followed are explained.

Symbol Meaning

Indicates ‘prohibited’ operations.

Indicates required operations.

Page 11

User’s Guide ValueJet 1204

Chapter 2: Product Overview

11 AP-75740 – Rev 1.2 – 6/07/2011

Important

Do not install the printer places where there is a possibility that the printer may be damaged or might fall

by chance.

• On a shaky stand

• Slanting location

• Places where vibration of other machines etc. is transmitted

Do not stand on the printer or do not place heavy things on top of it. The printer may be damaged or

might fall by chance.

When not in use, cover the printer with a blanket and do not close the vent. If the vent is closed, the

printer could accumulate heat inside and may cause fire.

Do not install the printer in places where the humidity is high and in a dusty environment. It could lead to

electric shock and fire.

Do not use a damaged power cable. It could lead to an electric shock and fire.

Do not take out or insert the power plug with wet hands. This could lead to an electric shock.

Do not connect earth cables in the following areas :

• Gas pipes. Doing so may cause fire or an explosion.

• Earth terminals for telephone lines or lightning rods. Doing so may cause a large flow of voltage if

lightning occurs.

• Water pipes or faucets. If there is a plastic part in the pipe, the grounding will not work correctly.

Do not store combustible materials on the print platform. It could lead to fire when raising the

temperature.

Do not insert or drop metal or objects which are easily combustible through the openings such as fresh

air inlet into the printer. It could lead to an electric shock and fire.

When foreign substances or liquids such as water entered the printer, do not use the printer. It could

lead to an electric shock and fire. Immediately switch off the power, disconnect the power plug from the

electric socket, and contact your local MUTOH dealer.

While installing optional items, be sure to switch OFF the power of the printer and pull out the power

plug. It could lead to an electric shock.

Wire the various codes (cable) as explained in the User’s Guide. Wrong wiring could cause fire.

Be sure to use the power cable supplied with the printer. If other power cables are used, it could cause

an electric shock or fire.

Make sure to use only the specified power supply (AC 100 V - 120 V or AC 220 V - 240 V). If a power

supply other than the specified voltage is used, it could cause an electric shock and fire.

Take power for the printer directly from the power socket (AC 100 V - 120 V or AC 220 V - 240 V). Do

not use complex multiple plugs on the same socket. This could generate heat and might cause fire.

Be sure to use a dedicated power socket with earth wire for the power supply, and connect it to the

earth wire. If the earth wire is not connected, an electric shock or fire may occur.

The waste fluid from the printer should be considered as industrial waste. Proper waste fluid disposal

according to industrial waste disposal laws of your local governments are required. Consign disposal of

waste fluids to specialized processor.

Page 12

User’s Guide ValueJet 1204

Chapter 2: Product Overview

12 AP-75740 – Rev 1.2 – 6/07/2011

Caution

Pay attention to the following points, while handling the power cable.

• Do not place or keep heavy objects on the power cable.

• Do not bend, twist or pull the power cable by force.

• Do not route the power cable near heating appliances.

Pay attention to the following points while handling the power supply plug. Any mishandling of the power cable

could cause a fire.

• Make sure that no foreign substances such as dust etc. are stuck to the power plug.

• Make sure that the power plug is firmly inserted to the edge of the power socket.

While handling the ink cassettes, pay attention so that the ink does not get into your eyes or stick to your skin. If the

ink gets into your eyes or sticks to your skin, immediately wash off with water. It might possibly cause irritation and

light inflammation of your eyes. In cases of any abnormality, consult a physician immediately.

Do not disassemble the ink cassettes. If disassembled, there is a possibility that the ink might come into contact

with your eyes or skin.

Be careful to see that your fingers are not caught in-between opening and closing the media cover.

Do not operate the media set lever during printer initialization. If the carriage portion and the pressurizing roller

portion touch each other, there is a possibility that the printer may break down.

Do not touch the media guide during printing. It is hot and may cause burns.

Do not touch the media feed slot, platen or media guide while heaters are operating. They are hot and may cause

burns.

Do not use volatile solvents such as thinner, benzene, or alcohol on the printer. These could damage the paint.

Be careful that moisture does not enter the printer. There is a possibility that the electric circuits inside the printer

might get short circuited.

Do not open covers attached with screws under any circumstance. This could cause an electric shock or printer

breakdown.

While cleaning with the wiper

• Do not touch the wiper and head cap unit.

Head cleaning may not be executed correctly because of the grease attached.

• Make sure to wipe the print head with a dry poly-knit wiper.

Do not make the main body of the printer slanting or place it in a vertical position or do not keep the printer upside

down. There is a possibility that ink inside the printer may leak. Moreover, normal operation after shifting (to these

positions) cannot be guaranteed.

Opening and moving the printer to the installation place should be done by :

• VJ-1204: 2 or more persons

While taking out the printer from the container box, make sure to remove the vinyl sheet and hold the handles on

the printer side. If the printer is lifted with the vinyl sheet attached, there is a possibility that it might fall and might be

damaged.

Installation of the stand to the printer should be done by :

• VJ-1204: 2 or more persons

While installing the stand, be sure to switch OFF the printer power and to pull out the power plug. It could lead to an

electric shock.

If the printer is not used for a longer period, make sure to pull out the power plug from the power socket for safety

reasons.

Make sure to connect an earth wire to the earth connection which meets the following standards :

• Earth terminal of power socket

• Earth wire with copper plate which is buried at a depth of 650 mm or more.

Set the roll media on an even surface such as a desk etc. If the roll media is set in such a way that the scroller is

standing vertically, there is a possibility that the scroller might get damaged.

Keep the working area well-ventilated.

When printing is finished, the media guide is at high temperature. Wait until the media guide cools off.

Pay attention to the following points when you cut roll media. Mishandling the razor blade may cause an injury on

your finger or hand.

• When you hold media, do not place your finger on the media cut groove.

• Move the razor blade along the media cut groove.

Be sure to switch OFF the power, and disconnect the power plug when cleaning the printer.

Move the printer maintaining it in a horizontal position.

Page 13

User’s Guide ValueJet 1204

Chapter 2: Product Overview

13 AP-75740 – Rev 1.2 – 6/07/2011

1.4 WARNING LABELS

In this section, the handling, location and types of warning labels are explained.

A warning label is used on parts of the printer which especially need caution. Understand the locations and

the descriptions of the danger associated with each label before operating the printer.

1.4.1 Handling the operation procedure labels

When handling the warning labels, be careful about the following points.

1.4.2 Locations and types of warning labels

N° Types of warning label

1

2

Notes

• Check whether all warning labels can be read. If the letters or illustrations on the label are not

clear, remove the dirt from the label.

• Use cloth, water and neutral detergent to remove dirt from a warning label. Avoid using either

organic solvents or gasoline.

• It is necessary to replace the labels if they are damaged, lost or illegible.

If the warning labels have to be replaced, contact your local MUTOH dealer.

Page 14

User’s Guide ValueJet 1204

Chapter 2: Product Overview

14 AP-75740 – Rev 1.2 – 6/07/2011

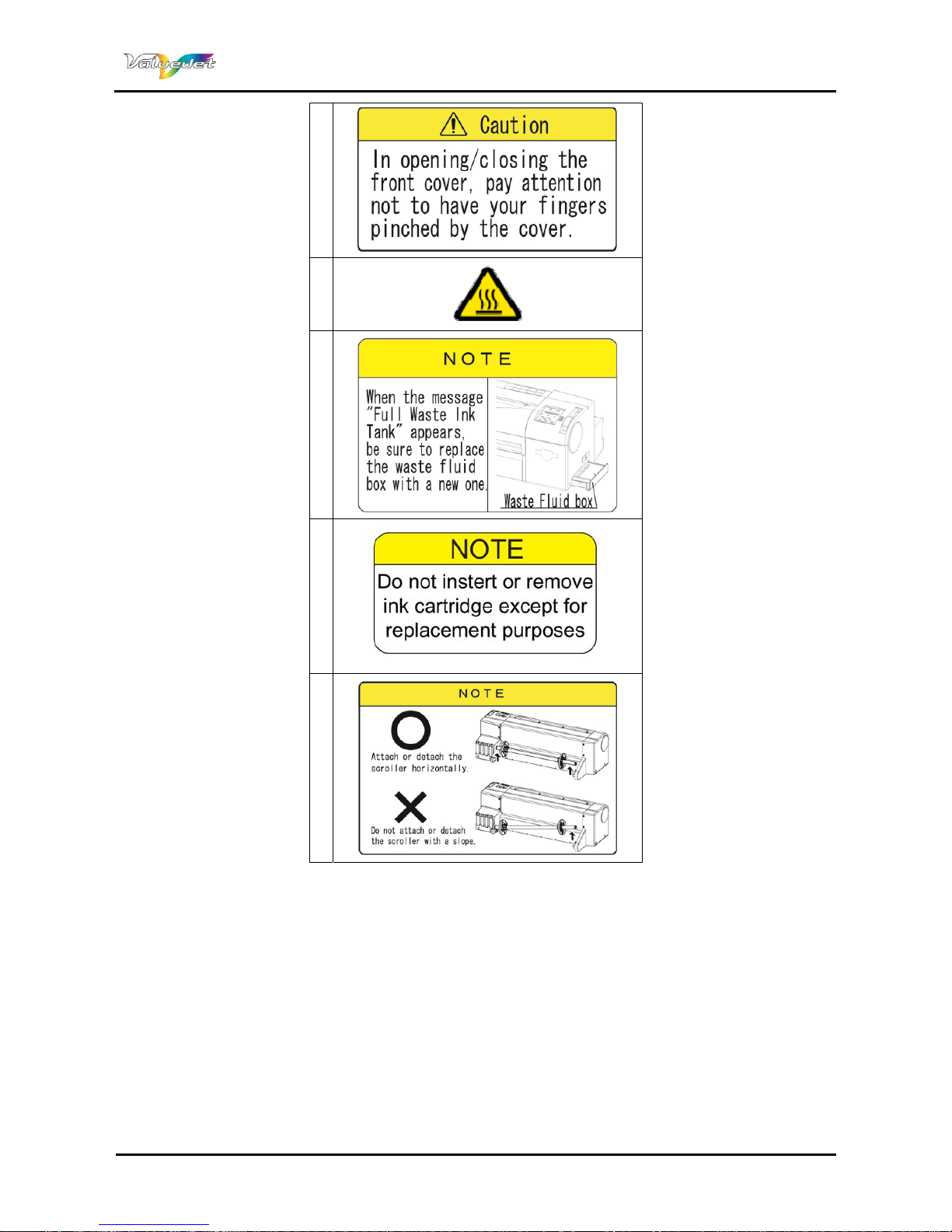

3

4

5

6

Page 15

User’s Guide ValueJet 1204

Chapter 2: Product Overview

15 AP-75740 – Rev 1.2 – 6/07/2011

1.5 OPERATION PROCEDURE LABELS

In this section, the handling, location and types of operation procedure labels are explained. Operation

procedure labels contain items for which the operator should be particularly careful while operating the

printer.

1.5.1 Handling the operation procedure labels

Be careful about the following points, when handling the operation procedure labels.

Notes

• Check whether all operation procedure labels can be read. If the letters or illustrations on the

labels are not clear, remove the dirt from the label.

• Use cloth, water and neutral detergent to remove dirt from an operation procedure label. Avoid

using either organic solvents or gasoline.

• It is necessary to replace the labels if they are damaged, lost or illegible.

If the operation procedure labels have to be replaced, contact your local MUTOH dealer.

1.5.2 Locations and types of warning labels

N° Types of operation procedure labels

1

2

3

Page 16

User’s Guide ValueJet 1204

Chapter 2: Product Overview

16 AP-75740 – Rev 1.2 – 6/07/2011

Page 17

User’s Guide ValueJet 1204

Chapter 2: Product Overview

17 AP-75740 – Rev 1.2 – 6/07/2011

2 PRODUCT OVERVIEW

2.1 FEATURES 18

2.2 NAME OF THE PARTS AND FUNCTIONS 19

2.2.1 Front section 19

2.2.2 Rear section 20

2.2.3 Operation panel 21

2.3 PRINTER MODE 24

2.3.1 Normal mode 24

2.3.2 Menu mode 24

2.3.3 Changing the printer mode 24

Page 18

User’s Guide ValueJet 1204

Chapter 2: Product Overview

18 AP-75740 – Rev 1.2 – 6/07/2011

This chapter explains the features of the printer, and the names and functions of each part.

2.1 FEATURES

In this section, the main features of the printer are explained.

(1) High-speed output

The ValueJet 1204 printer incorporates a new type high speed drop on demand piezo inkjet head.

It offers printing widths up to 1219 mm at one-pass printing and 1200 mm at two-pass printing for VJ-1204.

(2) Wide variety of compatible media

The head is adjustable to two height levels and offers compatibility with maximum media thicknesses of 0.3

mm.

3) Vibrant colour reproduction

ValueJet 1204 utilizes Mutoh’s latest generation Eco-Solvent Ultra inks for indoor and outdoor applications.

This printer uses 220 ml of eco solvent ink cassettes with a dedicated IC chip. The ink level inside of the ink

cassettes is monitored by the printer for maximum productivity

(4) Multi-heater

Heaters are installed at three locations (pre-heater, fixer (platen), dryer) allowing the eco solvent ultra ink to

optimally fix on the media and dry quickly.

(5) Effective use of media

A JOG feature is provided to allow setting of the print starting position as required. Printing can be performed

on media that has already been printed on. This allows effective use of left margins.

Page 19

User’s Guide ValueJet 1204

Chapter 2: Product Overview

19 AP-75740 – Rev 1.2 – 6/07/2011

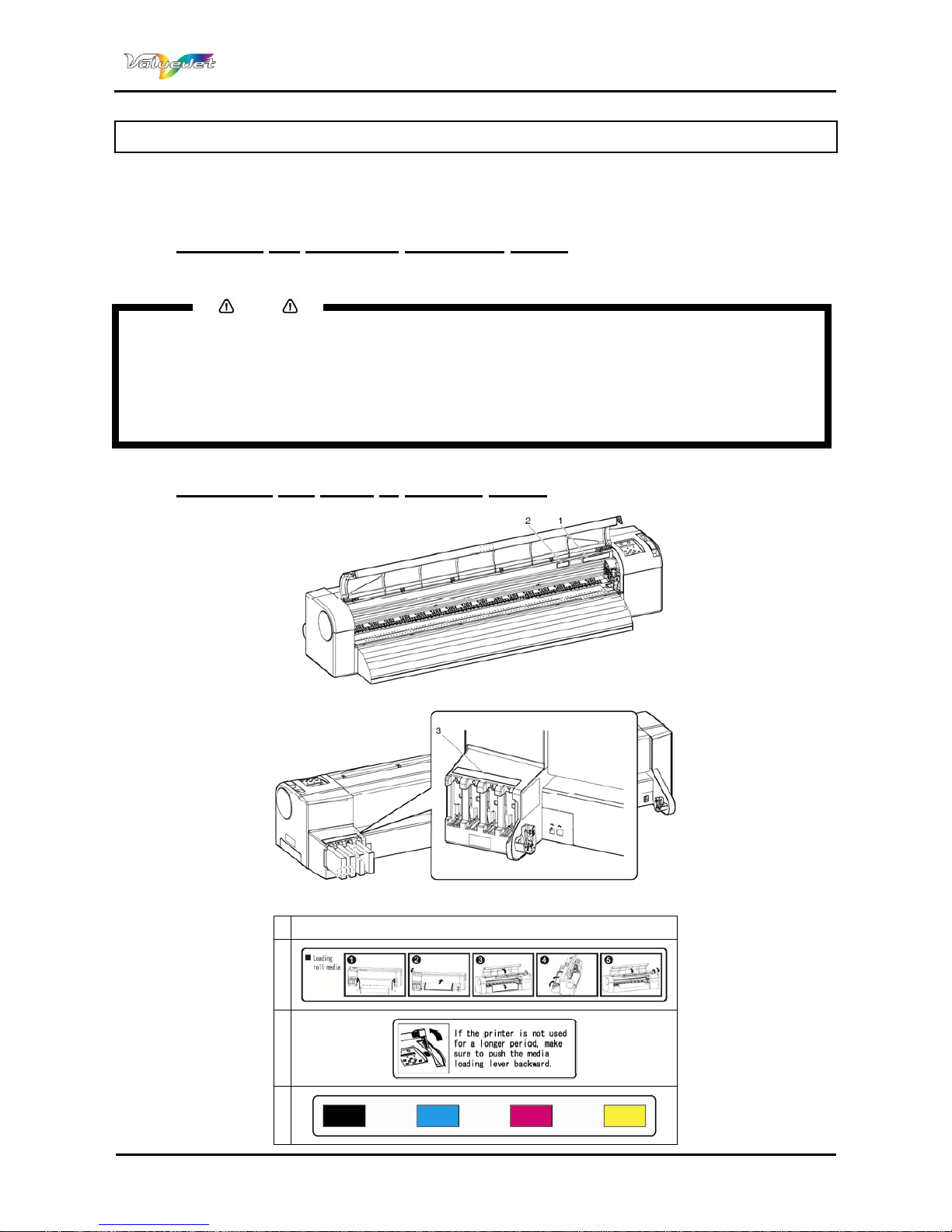

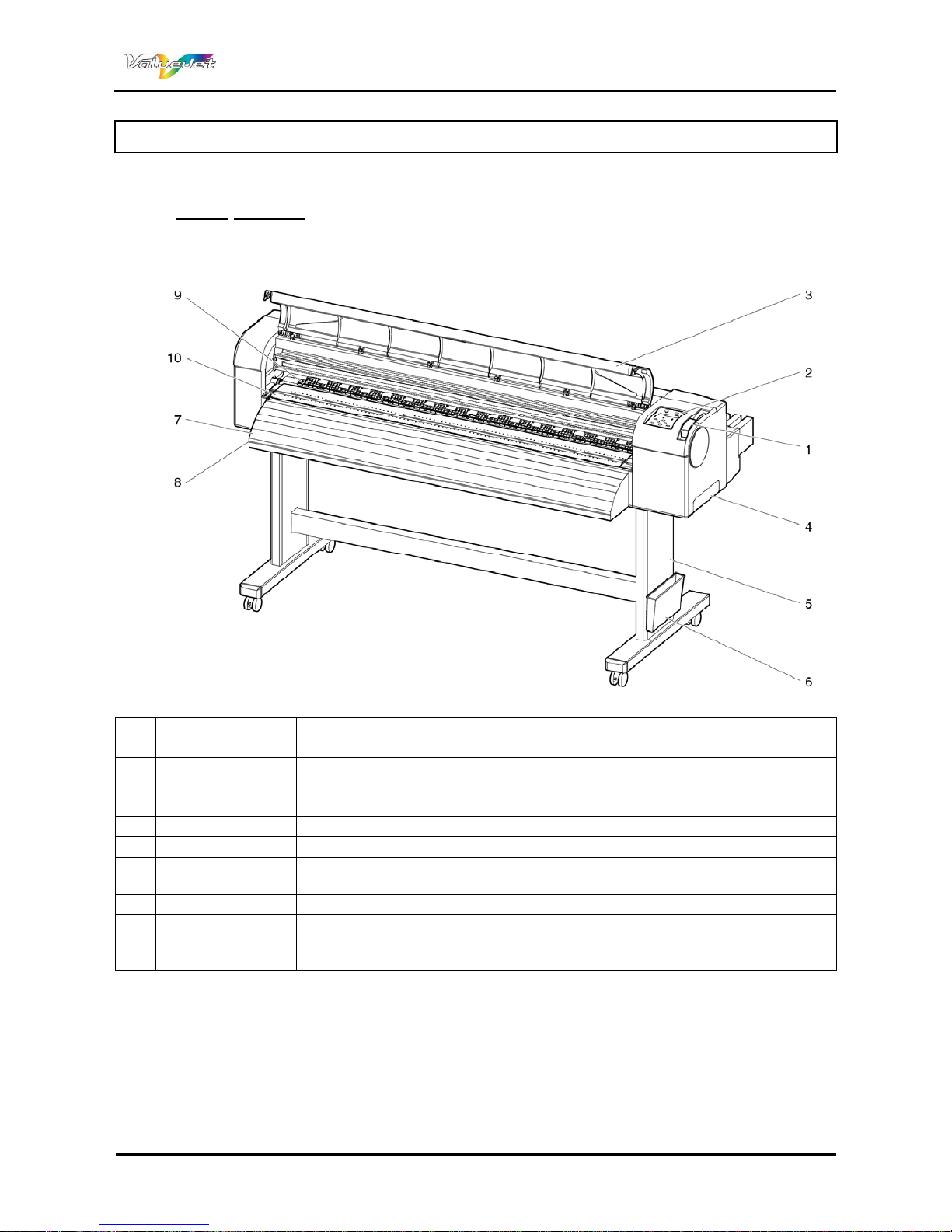

2.2 NAME OF THE PARTS AND FUNCTIONS

In this section, the names and functions of each part are explained.

2.2.1 Front section

N° Name Function

1

Media hold lever To fix and release media.

2

Operation panel To make all printer related settings.

3

Front cover To protect the user from coming in contact with the driving mechanism.

4

Waste fluid tank To collect the printer’s waste fluid.

5

Stand To install the printer on a levelled floor.

6

Book holder To store printer documentation.

7

Media guide

To guide the media smoothly through the printer. The printer also has an

incorporated heater to dry the ink.

8

Media cut groove To guide a knife when cutting off the media.

9

Pressurizing lever

Press and hold the media when printing.

10

Platen

To guide the media smoothly through the printer. The printer also has an

incorporated rest heaters to fix the ink.

Page 20

User’s Guide ValueJet 1204

Chapter 2: Product Overview

20 AP-75740 – Rev 1.2 – 6/07/2011

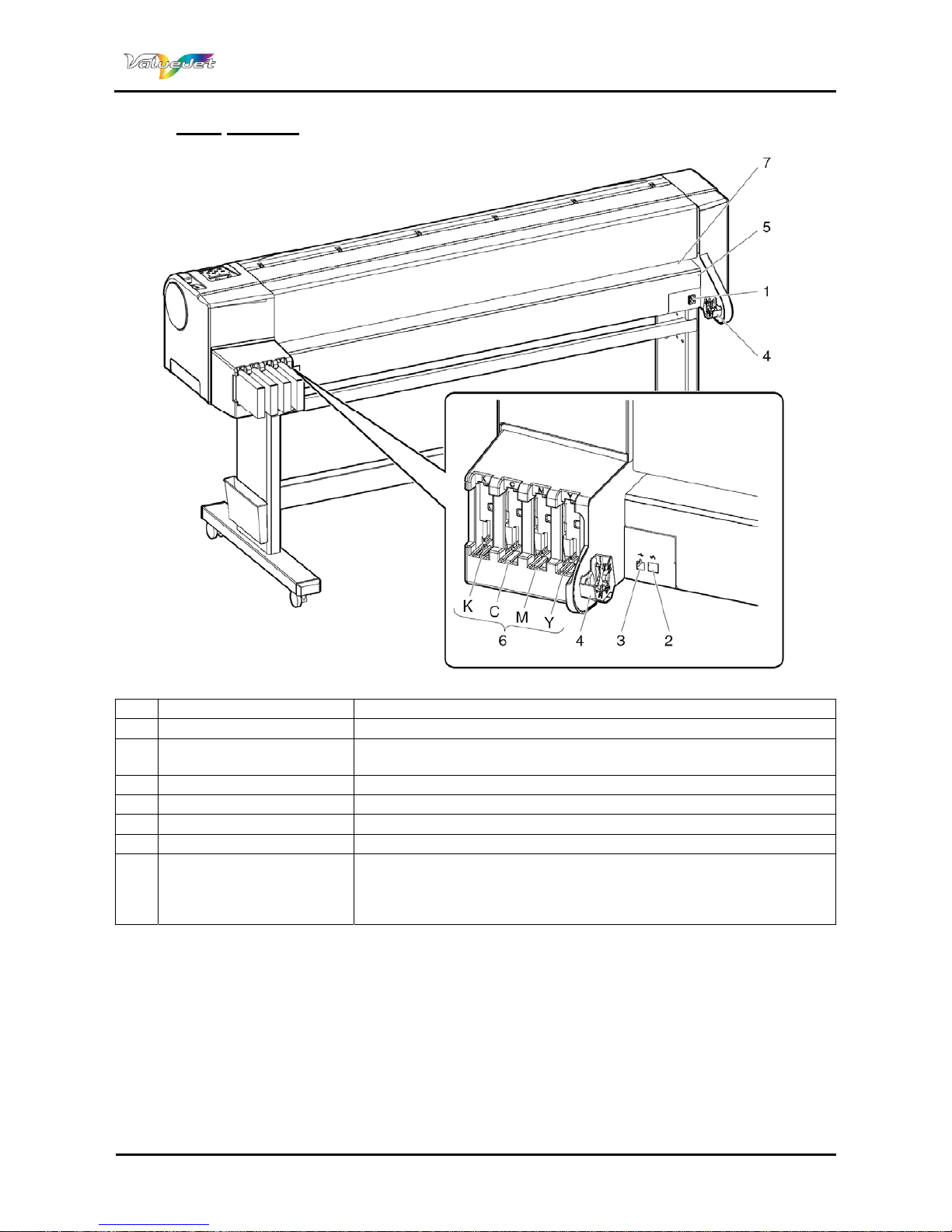

2.2.2 Rear section

N° Name Function

1 AC inlet To connect the power cable.

2

Network interface

connector

To connect the network interface cable.

3 USB connector To connect the USB cable.

4 Scroller receiver To install the scroller with roll media.

5 Media feed slot To insert roll media.

6 Ink cassette slots To install the ink cassettes.

7 Media guide

Used for smoothly feeding through media when the media is set or

printed.

The ValueJet 1204 printer also incorporates a pre-heater element to

warm up the installed media before printing.

Page 21

User’s Guide ValueJet 1204

Chapter 2: Product Overview

21 AP-75740 – Rev 1.2 – 6/07/2011

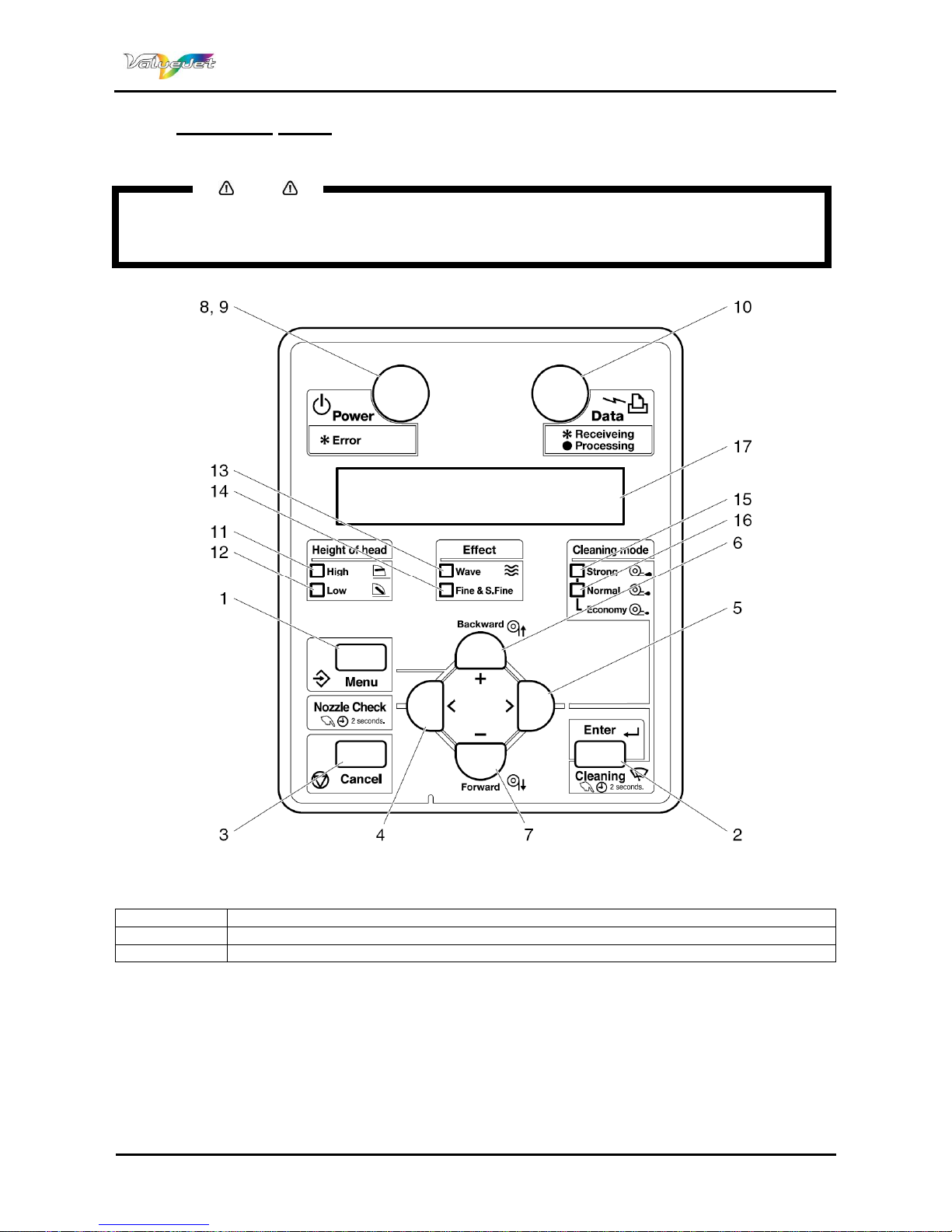

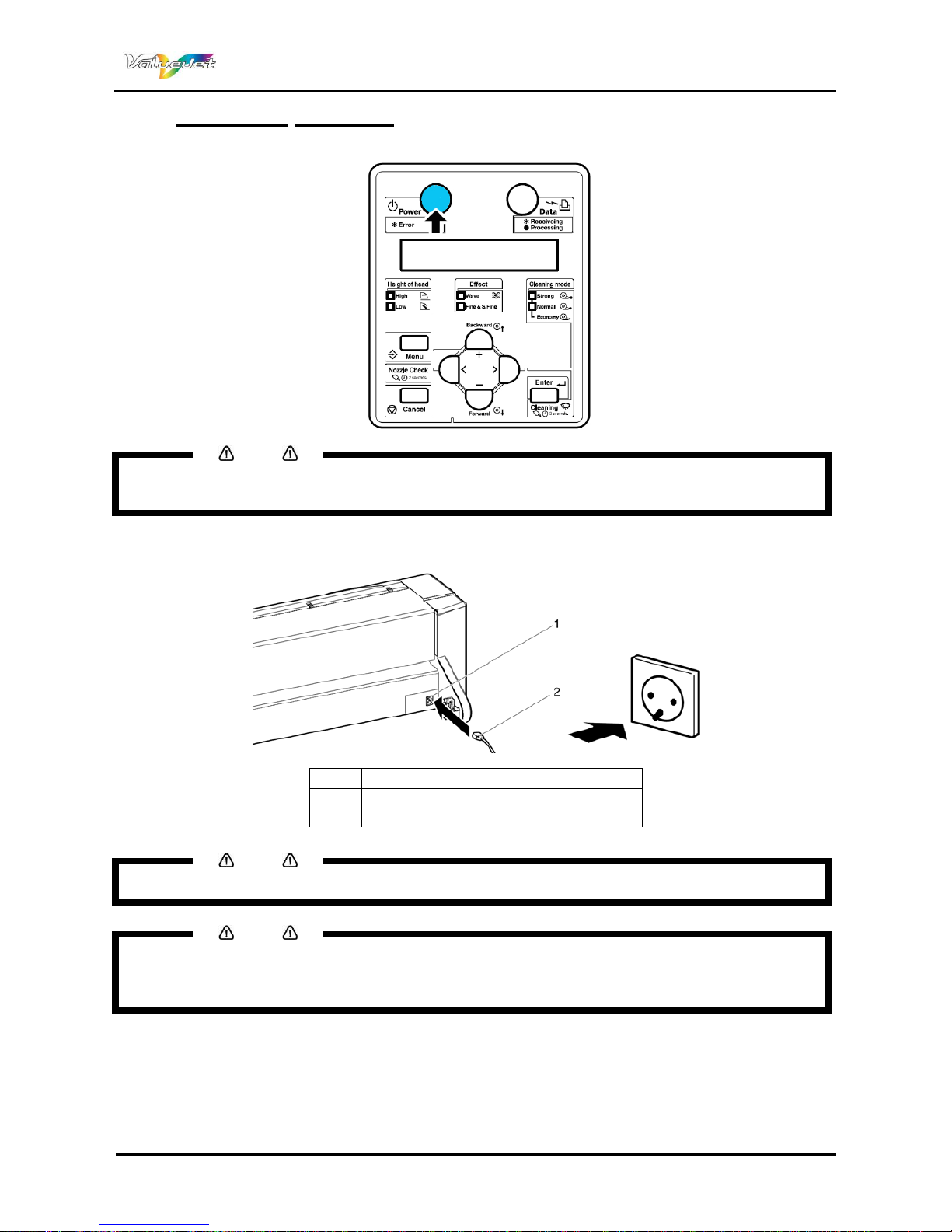

2.2.3 Operation panel

This section explains the name and the function of each operation key and status light.

Notes

Refer to the following for details regarding the operation method of the operation panel.

• When performing menu settings from the operation panel: Menu setup on the operation panel

• When performing various operations on the operation panel: Operating from the operation panel

The operation keys have 2 different functions, depending on the printer mode:

Mode Key functions

Normal mode Various functions for printing can be performed on the operation panel.

Menu mode Various setup items (e.g. IP address, etc…) can be set on the operation panel.

For details on the printer mode, refer to “Printer mode”.

Page 22

User’s Guide ValueJet 1204

Chapter 2: Product Overview

22 AP-75740 – Rev 1.2 – 6/07/2011

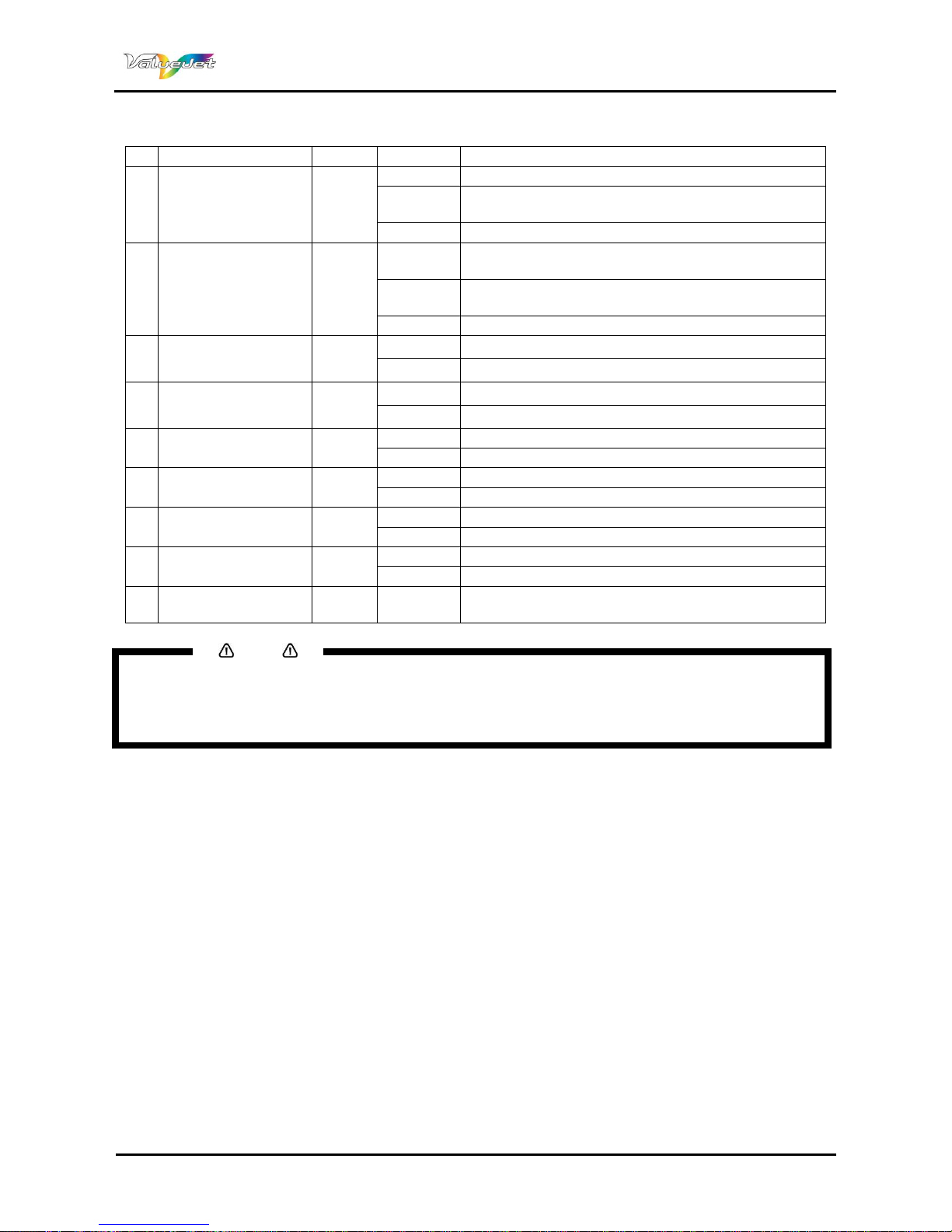

(1) Operation keys in the Normal mode

N° Key Function

1

[Menu] Changes to Menu mode.

2

[Enter] --

[Cleaning] Cleans the printer head when pressed for two seconds or more.

3

[Cancel]

During printing: Printing is terminated and the remaining data is deleted.

During receiving/analysis: All data received and analysed data is already

deleted and the currently received data of the next print file is ignored.

Ink dry timer wait: Ink dry timer wait is cancelled and the media is ejected.

4

[<] -[Nozzle Check] Press and hold this key for two seconds or more to print a nozzle check

5

[>] Sets Cleaning Mode. The indication lights of Cleaning mode light up in green.

6

[Backward feed

↑]

Feeds the media in reverse direction.

[Setting value +] --

7

[Forward feed

↓]

Feeds the media in forward direction.

[Setting value-] --

8

[Power] Switches the printer ON / OFF.

(2) Operation keys in the Menu mode.

N° Key Function

1

[Menu] Shifts from Menu mode to Normal mode.

2

[Enter]

Selects a specific menu or submenu.

The value is entered and saved.

[Cleaning] --

3

[Cancel]

Returns to the previous level in the menus structure. Changes in the setup

value will not be saved.

Shifts from the Menu mode to Normal mode.

4

[Back] Goes to the previous menu.

5

[Next] Goes to the next menu.

6

[Backward feed↑ ] --

[Setting value +] The numerical value is increased.

7

[Forward feed↓ ] --

[Setting value-] The numerical value is decreased.

8

[Power] Switches the printer ON / OFF.

Notes

• For details on how to work with the operation panel, refer to the following topics :

o When working in the Menu mode. Refer to: “Menu setup on the operation panel”.

o When working in the Normal mode. Refer to: “Operating from the operation panel”.

Page 23

User’s Guide ValueJet 1204

Chapter 2: Product Overview

23 AP-75740 – Rev 1.2 – 6/07/2011

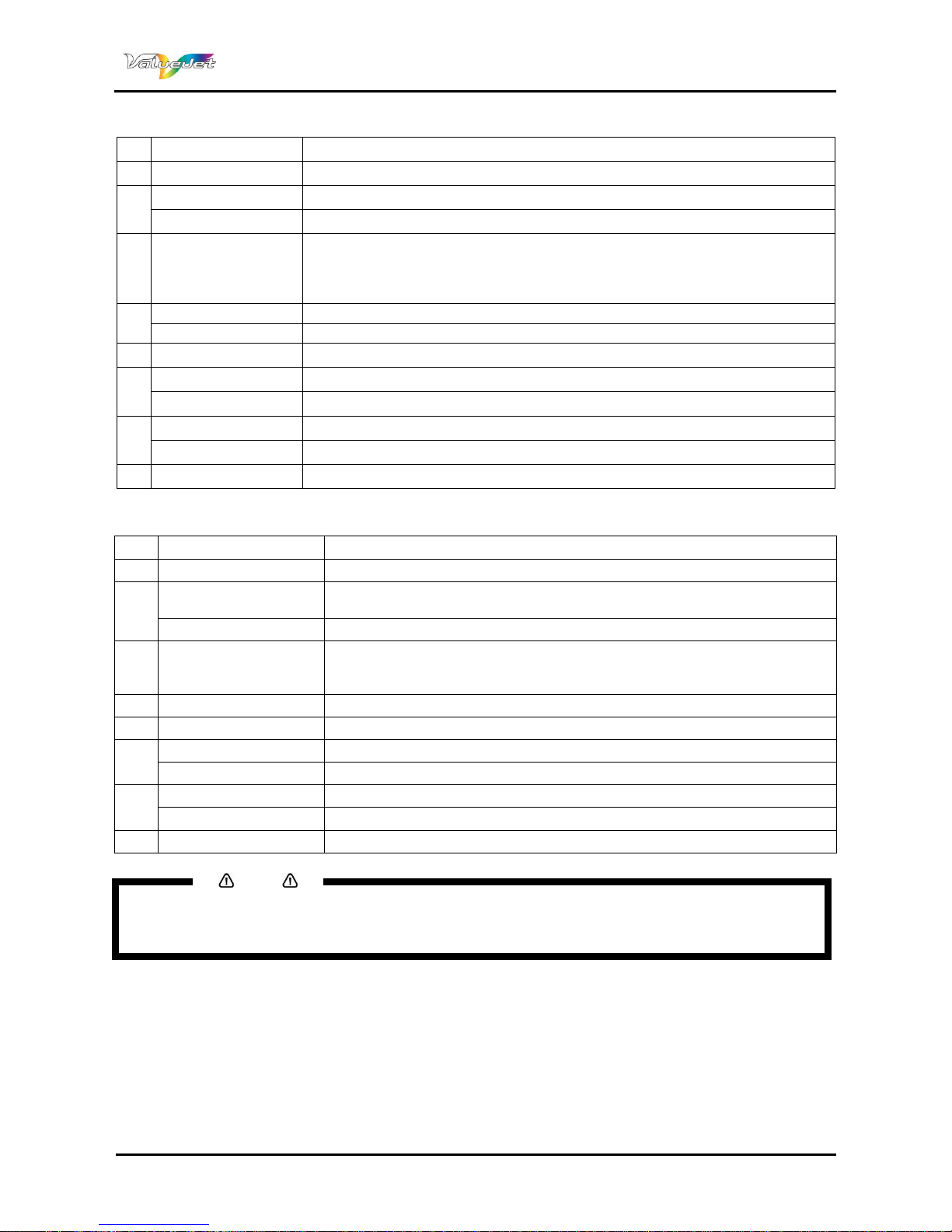

(3) Status lights

N° Light Colour Status Description

9

Power Green

Light ON Power ON.

Light

blinks

An error has occurred. The error message is

displayed on the LCD.

Light OFF Power OFF.

10

Data Orange

Light ON

Analyzing received data.

Printing.

Light

blinks

Receiving data.

Light OFF Data is not received / analyzed.

11

High Green

Light ON Height of head is set to High

Light OFF Height of head is set to Low

12

Low Green

Light ON Height of head is set to Low

Light OFF Height of head is set to High

13

Wave Green

Light ON Printing effect is set to Wave.

Light OFF Printing effect is set to Fine & Super Fine.

14

Fine & Super Fine Green

Light ON Printing effect is set to Fine & Super Fine.

Light OFF Printing effect is set to Wave.

15

Strong Green

Light ON Cleaning mode is set to Strong

Light OFF Cleaning mode is set to Normal

16

Normal Green

Light ON Cleaning mode is set to Normal

Light OFF Cleaning mode is set to Strong

17

LCD display section -- --

Operation status of the printer or error message is

displayed.

Notes

• When an error requiring a restart (fatal malfunction of the printer operation) occurs, all lights

will blink.

• Contact your local MUTOH dealer if the malfunction cannot be solved.

• For more information please refer to: “Error requiring a restart”.

Page 24

User’s Guide ValueJet 1204

Chapter 2: Product Overview

24 AP-75740 – Rev 1.2 – 6/07/2011

2.3 PRINTER MODE

This section explains the printer modes of the printer and how to change them.

2.3.1 Normal mode

The printer is ready to print.

• The media is loaded and the media type is set.

• Various functions for printing can be performed on the operation panel.

• The message ‘Ready to print’ is shown.

2.3.2 Menu mode

In this mode, various setup items (IP address, etc…) can be set on the operation panel.

2.3.3 Changing the printer mode

(1) Changing from Normal mode to Menu mode.

Action: Press the [Menu] key.

Result: The display is in ‘Menu’ mode’, from now on called the ‘Setup Menu display’.

The following message is shown: "Menu 1: Setup>".

(2) Changing from Menu mode to Normal mode

Action: Press the [Cancel] key.

Result: The printer returns to the Normal mode.

Notes

• When the printer is in Menu mode and the keyboard remains untouched for 3 minutes, the

printer automatically returns to Normal mode.

Notes

• For details on Status messages, refer to Status messages.

• For details on the Setup menu, refer to Menu setup on the operation panel.

Notes

• Essential settings for normal printing can be modified / set on the printer driver or the graphics

application software, or via the operation panel.

Page 25

User’s Guide ValueJet 1204

Chapter 3: Installing the Unit

25 AP-75740 – Rev 1.2 – 6/07/2011

3 INSTALLING THE UNIT

3.1 INTRODUCTION 26

3.2 INSTALLATION SPACE 26

3.3 INSTALLATION PROCEDURE 27

3.4 POWER CABLE CONNECTION 28

3.4.1 Important notes and cautions 28

3.4.2 Connection procedure 29

3.5 SWITCHING THE POWER ON / OFF 30

3.5.1 Switching the power ON 30

3.5.2 Switching the power OFF 31

3.6 INSTALLING INK CASSETTES FOR THE FIRST TIME 33

3.6.1 Replacing ink cassettes 36

3.7 CONNECTING THE PRINTER TO THE PC 39

3.7.1 System requirements 39

3.7.2 Selecting cables 39

3.7.3 Connecting network interface cable 39

3.8 TRANSFER AND TRANSPORTATION 41

3.8.1 PACK THE MACHINE 43

3.9 STEPS AFTER TRANSFER 45

3.9.1 Transporting the printer Error! Bookmark not defined.

Page 26

User’s Guide ValueJet 1204

Chapter 3: Installing the Unit

26 AP-75740 – Rev 1.2 – 6/07/2011

3.1 INTRODUCTION

This section explains how to fully install the assembled printer. For further information on how to assemble

your ValueJet printer, please refer to the Installation Guide.

3.2 INSTALLATION SPACE

Install on a level floor which meets the following conditions.

It has enough strength to support the weight of the printer and the stand

Notes

• For the weight of the printer and the stand, refer to the Operation Manual.

A 500 mm E 1440 mm

B 1000 mm F 3000 mm

C 1000 mm G 2660 mm

D 1000 mm

Page 27

User’s Guide ValueJet 1204

Chapter 3: Installing the Unit

27 AP-75740 – Rev 1.2 – 6/07/2011

3.3 INSTALLATION PROCEDURE

Installation procedure when using the network connection

Starting point: ASSEMBLED VALUEJET

↓

Step Action Reference

1

Connect the power cable. Power Cable Connection

2

Install the ink cassettes. Installing ink cassettes for the first time

3

Connect the printer to the PC. Connecting network interface cable

↓

Result: FULLY- INSTALLED VALUEJET

Page 28

User’s Guide ValueJet 1204

Chapter 3: Installing the Unit

28 AP-75740 – Rev 1.2 – 6/07/2011

3.4 POWER CABLE CONNECTION

3.4.1 Important notes and cautions

Important

• Make sure to use the power cable supplied with the printer. Use of a different cable may result

in an electric shock or fire.

• Do not use a damaged power cable. Doing so may result in an electric shock or fire.

• The printer’s disconnect device is the plug on the power cable.

Important

• Do not attempt to plug in electrical plugs with wet hands. Doing so may result in an electric

shock.

• Be sure to use the specified voltage (AC 100V-120V/220V-240V). Otherwise, an electric shock or

fire may occur.

• Use electricity directly from a power outlet (AC 100V-120V/220V-24 0V). Do not put many loads

on one electrical outlet. Otherwise, heat may be generated, causing fire.

• Be sure to use an outlet with an earth terminal, and to use the terminal correctly. Otherwise,

electric shock or fire may occur.

• Do not connect earth cables to :

o Gas pipes. Doing so may cause fire or an explosion.

o Earth terminals for telephone lines or lightning rods. Doing so may cause a large flow of

voltage if lightning occurs.

o Water pipes or faucets. If there is a plastic part in the pipe, the grounding will not work

correctly.

Caution

• Follow the instructions below when handling the power plug. Otherwise, fire may occur.

o Wipe away dust and any other residue before inserting the plug.

o Ensure that the plug is firmly inserted as far as it will go.

• When not using the printer for a long time, disconnect the plug from the power socket.

• Earth wires must be connected to wires or terminals that fulfil the following conditions :

o Power sockets with earth terminals.

o Earth wires with copper, at least 650 mm under the ground.

Caution

• Be careful when handling the power cable :

o Do not make any modifications to the power cable.

o Do not place anything heavy on the power cable.

o Do not bend, twist, or pull the cable.

o Do not wire the cable near equipment that generates heat.

Notes

• When the printer is ON, do not pull out the power cable from the socket. Whenever the plug is

pulled out from the power socket, allow one minute or more before inserting the plug in the

power socket again.

• Contact your local Mutoh technician, when the earth connection cannot be establishe d, or when

the earth connection is not given.

Page 29

User’s Guide ValueJet 1204

Chapter 3: Installing the Unit

29 AP-75740 – Rev 1.2 – 6/07/2011

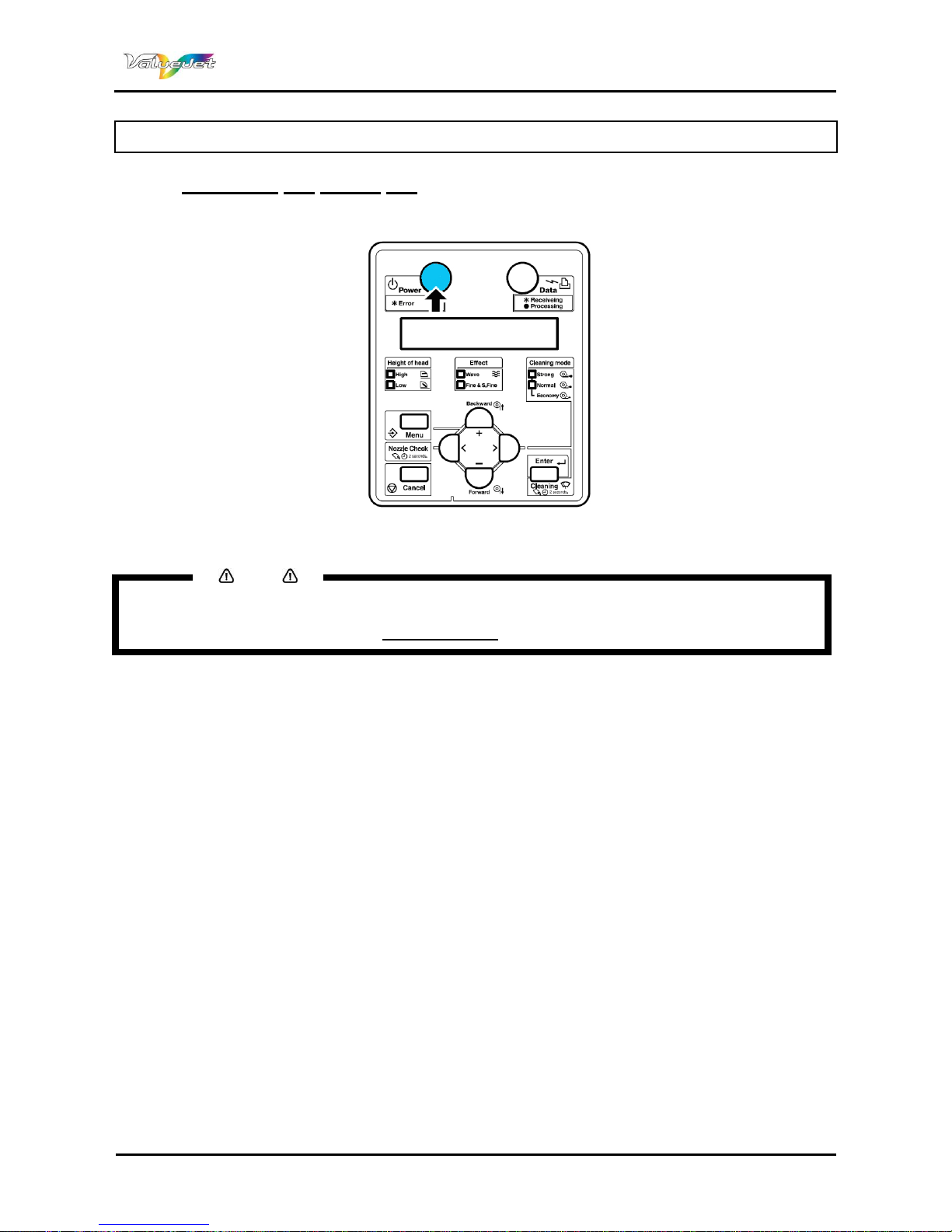

3.4.2 Connection procedure

Step 1 : Make sure that the power key is switched OFF.

Notes

• The power is switched ON when pressing the [Power] key. In that case, press the key once

again to switch OFF the power.

Step 2 : Plug the power cable to the AC inlet at the back of the printer.

N° Name

1 AC inlet

2 Power cable

Notes

• If the power cable is damaged, contact your local MUTOH dealer.

Notes

• If you cannot use earth terminals nor find any of them, contact your local Mutoh distributor.

• Do not unplug the power cable when the printer is on. If the power cable has been unplugged,

leave the printer for at least 1 minute before plugging the cable in again.

Page 30

User’s Guide ValueJet 1204

Chapter 3: Installing the Unit

30 AP-75740 – Rev 1.2 – 6/07/2011

3.5 SWITCHING THE POWER ON / OFF

3.5.1 Switching the power ON

Step 1 : Press the [Power] key to switch ON the printer.

• The Power indication light lights green.

• The printer starts initializing.

• When the initialization is completed, the printer enters its normal status.

Notes

• If there is a problem during initial operation, the printer displays a message and may stop

operating.

In case operation stops, refer to "Troubleshooting

" and deal with the problem.

Page 31

User’s Guide ValueJet 1204

Chapter 3: Installing the Unit

31 AP-75740 – Rev 1.2 – 6/07/2011

3.5.2 Switching the power OFF

Step 1 : Before powering off, be sure that:

• Printing or other operations are stopped or finished.

• The printer (and operation panel) is in normal mode.

• The head height adjustment lever is lowered.

Step 2 : Press the [Power] key to switch OFF the printer.

• The Power indicating switches off.

Notes

• If the operation panel is in the following status, the power is ON. Press the key once again to

switch off the power.

o The [Power] key is pressed in.

o The [Power] indication light lights up in green.

• “Power Off" is displayed.

• The printer automatically switches the power OFF.

Notes

• If the head height adjustment lever is raised, “Change Head Gap Low” is displayed. Lower the

lever.

• All the lamps on the operation panel and the LCD monitor are switched OFF.

• The printer automatically switches the power OFF.

Page 32

User’s Guide ValueJet 1204

Chapter 3: Installing the Unit

32 AP-75740 – Rev 1.2 – 6/07/2011

Notes

• If there is a problem during the Power off sequence, the printer displays a message and may

stop operating.

In case operation stops, refer to “Troubleshooting” and deal with the problem.

• After switching OFF the printer, wait for 10 seconds or longer to switch it ON again.

Step 3 : Raise the media hold lever after the powering OFF cycle. This in order not to damage the media

due to the pressure of the grid rollers.

N° Name

1 Media hold lever

Page 33

User’s Guide ValueJet 1204

Chapter 3: Installing the Unit

33 AP-75740 – Rev 1.2 – 6/07/2011

3.6 INSTALLING INK CASSETTES FOR THE FIRST TIME

Caution

• When handling ink cassettes, be careful not to get ink into your eyes or on your skin. However,

if this happens, flush immediately with water. Otherwise, your eyes may become inflamed

slightly. If you feel discomfort, consult a doctor immediately.

• Do not disassemble ink cassettes. Otherwise, ink may get into your eyes or on your skin.

• Do not shake ink cassettes. Doing so may cause ink leakage.

Notes

• When filling ink in the machine, use Mutoh original Eco-Solvent Ultra inks only.

This printer has been fine tuned for use of genuine ink cassettes. In case of using non original

ink cassettes. Printing might become blurred and the end of ink in the cassette might no longer

be correctly detected.

The problems caused by doing so will not be covered by the warranty and repair expenses will

be paid by the customer.

• Do not shake the ink cassettes strongly to avoid ink leaking out of the cassette.

• Do not disassemble the ink cassette. A disassembled ink cassette cannot be used.

• Make sure to use an original cleaning fluid.

• Before installing the ink cassette, shake it gently. Doing so will preserve printing quality.

• When storing the ink cassettes in a cold room, be sure to take them out of stock at least 3 hours

before using them.

• Insert or remove the ink cassette not more than 10 times.

If inserting or removing the ink cassette 10 times or more, it cannot be used even if there is

some remaining ink inside.

• Each ink cassette has a dedicating smart chip recognising ink types, colour and ink level inside

of the cassette. Taking out a cassette from its cassette slot during printing might result in

damaging the smart chip, causing the cassette to become obsolete.

Step 1 : Switch ON the printer.

• The printer starts initialization.

• The operation panel displays "[KCMY] Discharged".

After the initial operation is complete, "Insert CleaningCart." is displayed.

Page 34

User’s Guide ValueJet 1204

Chapter 3: Installing the Unit

34 AP-75740 – Rev 1.2 – 6/07/2011

Step 2 : Take out the cleaning cassette from the solvent resistant blister.

Step 3 : Install the cleaning cassette into the ink cassette slot.

• Keep the ▲ mark of the cleaning cassette facing up and insert it into the slot of the printer.

• Insert the cleaning cassette to the end of the slot.

N° Name

1 Cleaning cassette

2 Ink cassette slot

• The printer starts filling cleaning fluid.

Step 4 : After cleaning fluid has been filled, take out the cleaning cassette.

• "During washing" is displayed and the printer starts head cleaning

• "Insert Ink cassettes" is displayed after the head cleaning.

Step 5 : Take out the ink cassette from the solvent resistant blister and shake it gently 2-3 times.

• The slots for the ink cassettes are specified depending on the colours of ink cassettes. Match

the colour marked by the side of each slot with the colour of the ink cassette.

• Keep the ▲ mark of the ink cassette facing up and insert it into the slot of the printer.

• Insert the ink cassettes in the printer as follows :

• The ink cassettes must be inserted in a specific slot according to the type and colour used.

• Insert the cassettes with the arrow mark “▲” face-up and pointing to the rear of the printer.

• Insert the cassettes as far as possible.

• Install all four colours.

N° Name

1 Ink cassette

2 Ink cassette slot K

3 Ink cassette slot C

4 Ink cassette slot M

5 Ink cassette slot Y

Page 35

User’s Guide ValueJet 1204

Chapter 3: Installing the Unit

35 AP-75740 – Rev 1.2 – 6/07/2011

Notes

• The ValueJet ink cassettes are developed in such a way that miss-insertion is not possible. For

each colour, a different design is used, i.e., fins are placed at the outside of each cassette, at

different locations, depending on the ink colour used.

Result: The operation panel displays "Ink Refill **%", and the initial ink replenishment starts.

• The ink replenishment takes about five minutes. Initial ink replenishment and pause operation are

repeated during initial filling.

• After the ink replenishment is completed, when “100%” is displayed, the operation panel displays

"Paper End".

Notes

• During ink filling :

o Do NOT switch off the printer.

o Do not pull out the printer power cable.

o Do not open the front cover.

o Do not push the media hold lever to the back side.

Notes

• After an initial ink fill, the following can occur :

o Printed lines become blurred.

o White lines appear in the prints.

• If this is the case, perform two or three head cleanings, and check the results.

• If the quality of the printed image did not improve after performing the head cleanings, leave the

printer idle for more than one hour. After that, perform another head cleaning and check the

printed image. If the quality still did not improve, contact your local MUTOH dealer.

Notes

• Only use Mutoh original ink for ValueJet printers.

This printer is fine tuned for genuine ink cassettes. In case of using non genuine ink cassettes,

notice the following :

o Printing might become blurred and the end of ink in the cassette might no longer be

correctly detected.

o The problems caused by the use of non original ink cassettes will not be covered by the

warranty and repair costs will be at the expense of the customer.

• When ink cassettes are moved from a cold place to a warm place, keep the ink cassettes unused

for three hours or more in the printing environment.

Page 36

User’s Guide ValueJet 1204

Chapter 3: Installing the Unit

36 AP-75740 – Rev 1.2 – 6/07/2011

3.6.1 Replacing ink cassettes

This section describes the replacement time and replacement method for the ink cassettes.

(1) Replacement time

A. When “[****] InkNearEnd” is displayed on the operation panel

• This message is displayed when there is a small amount of ink remaining in the ink cassette.

• When “[****] InkNearEnd” is displayed, the alarm buzzer sounds continuously.

• To stop the buzzer, press the [Enter] key.

• Replace with the new ink cassette.

B. When “[****] InkEnd” is displayed on the operation panel

• This message is displayed when there is no ink remaining in the ink cassette.

• When “[****] InkEnd” is displayed, the alarm buzzer sounds continuously.

• To stop the buzzer, press the [Enter] key.

• Immediately replace it with the new ink cassette.

Notes

• The display indicates which ink colour became low or ran out :

o K: Black

o C: Cyan

o M: Magenta

o Y: Yellow

• Only remove and insert ink cassettes at the time of replacement. Not doing so may result in

incorrect printing behaviour due to failures such as nozzle loss, or air which might come in the

ink tubes.

• If "Ink End" appears, it is not possible to print until you insert the new ink cassette.

• If there is no new ink cassette available, leave the empty ink cassette in the printer. Leaving the

printer without ink cassettes inside the ink cassette slots may result in head clogging.

(2) Cassette Types

Description Model N°

Ink cassette K (Black: 220ml) RJ80U-22-BK

Ink cassette C (Cyan: 220ml) RJ80U-22-CY

Ink cassette M (Magenta: 220ml) RJ80U-22-MA

Ink cassette Y (Yellow: 220ml) RJ80U-22-YE

Notes

• Only use Mutoh original ink.

This printer is developed for use of genuine ink cassettes. In case of using non genuine ink

cassettes, :

o printing might become blurred and the end of ink in the cassette might no longer be

correctly detected.

o the problems caused by doing so will not be covered by the warranty and repair expenses

will have to be paid by the customer.

• When the ink cassette is moved from a cold place to a warm place, keep the ink cassette unused

for three hours or more in the printing environment.

Page 37

User’s Guide ValueJet 1204

Chapter 3: Installing the Unit

37 AP-75740 – Rev 1.2 – 6/07/2011

(3) Replacement steps

Caution

• When handling ink cassettes, be careful not to get ink into your eyes or on your skin. However,

if this happens, flush immediately with water. Otherwise, your eyes may become inflamed

slightly. If you feel discomfort, consult a doctor immediately.

• Do not disassemble ink cassettes. Otherwise, ink may get into your eyes or on your skin.

Notes

• Do not shake ink cassettes. Doing so may cause ink leakage.

• Do not disassemble the ink cassette. A disassembled ink cassette cannot be used.

• When an ink cassette is moved from a cold place to a warm place, keep the ink cassette unused

for three hours or more in the printing environment.

• Do not refill the ink cassettes, doing so may result in incorrect printing.

• Insert or remove the ink cassette at the time of replacement only.

Step 1 : Verify that the printer is ON.

Notes

• Do not replace ink cassettes when the printer is switched OFF. Doing so may result in incorrect

detection of the remaining ink and result in abnormal printing behaviour.

Step 2 : Remove the empty ink cassette(s) from the ink cassette slot (s).

Notes

• A used ink cassette must be put in a vinyl bag or a bag used for this kind of waste. Disposal of

an ink cassette must be done in compliance with the regulations and instructions of the local

authorities.

N° Part Description

1 Ink cassette

2 Ink cassette slot

Page 38

User’s Guide ValueJet 1204

Chapter 3: Installing the Unit

38 AP-75740 – Rev 1.2 – 6/07/2011

Step 3 : Unpack the new ink cassette(s).

Notes

• Open the solvent resistant cassette blister just before inserting the ink cassette into the

cassette slot. Leaving the ink cassette open for a long time may result in an abnormal printing.

• Use the ink cassettes within 2 years from the date printed on the package. Using an ink cassette

after this period may affect the print quality.

• Replace the ink cassette within 6 months after installing it into the printer.

• Insert or remove the ink cassette not more than 10 times. This to prevent that the smart chip or

its reader would be worn out and malfunction in this way. If inserting / removing more than 10

times the ink cassette could malfunction even if there is some ink remaining.

Step 4 : Insert the new ink cassette(s)

Step 5 : Verify that the printer returns to Normal mode

Notes

• The printer resumes printing when replacing ink cassettes.

Page 39

User’s Guide ValueJet 1204

Chapter 3: Installing the Unit

39 AP-75740 – Rev 1.2 – 6/07/2011

3.7 CONNECTING THE PRINTER TO THE PC

3.7.1 System requirements

For details about the system requirements, please refer to the documentation of the RIP software of your

choice.

3.7.2 Selecting cables

The printer is equipped with a network interface and a USB interface to connect it with a PC.

A network interface cable or an USB cable is required to connect the PC with the printer.

Notes

• To connect the printer via a network interface cable, refer to “Connecting network interface

cable”.

• The USB connection is reserved for service technicians only.

3.7.3 Connecting network interface cable

Step 1 : Switch OFF both the printer and the PC.

Step 2 : Plug the network interface cable into the network interface connector located at the back of the

printer.

N° Name

1 Network interface cable

2 Network interface connector

Page 40

User’s Guide ValueJet 1204

Chapter 3: Installing the Unit

40 AP-75740 – Rev 1.2 – 6/07/2011

Step 3 : Secure the network interface cable with the cable clip.

N° Name

1 Network interface cable

2 Cable clip

Step 4 : Plug the other end of the network interface cable into your PC.

Notes

• Refer to the PC documentation for information concerning connection possibilities.

• For network settings on the side of the printer, refer to “Panel setup menu overview”

• The USB connection is reserved for service technicians only.

Page 41

User’s Guide ValueJet 1204

Chapter 3: Installing the Unit

41 AP-75740 – Rev 1.2 – 6/07/2011

3.8 TRANSFER AND TRANSPORTATION

Caution

• Transfer the printer maintaining the horizontal position.

• Do not place the printer on a slope or vertical position, nor keep the printer upside down. This

to avoid ink leaks inside the printer. Moreover, normal operation after shifting to these

positions cannot be guaranteed.

Step 1 Verify that the printer is powered ON.

Step 2 Pull out the waste fluid tank.

N° Description

1

Waste fluid box

Result: the operation panel displays “No Waste fluid box".

Notes

• A used waste fluid tank must be put in a vinyl bag or a bag used for this kind of waste.

• Disposal of a waste fluid tank must be done according to your local laws and regulations.

Step 3 Install a new waste fluid tank.

N° Description

1

Waste fluid box

Step 4 Verify that the operation panel displays "Exchange Tank? No".

Step 5 Select "Exchange Tank? Yes” and press the [Enter] key.

Step 6 Remove all ink cassettes

Step 7 Switch OFF the printer.

• The operation panel displays “Transport Mode”, and the printer starts the ink rejecting operation. This

takes approximately 2 minutes.

Page 42

User’s Guide ValueJet 1204

Chapter 3: Installing the Unit

42 AP-75740 – Rev 1.2 – 6/07/2011

Step 8 Verify that the power light faints when the ink rejection operation is finished.

Step 9 Dispose the waste fluid.

Step 10 Remove the scroller.

Step 11 Remove all cables.

Step 12 Open the front cover and fix the CR belt in the centre section of the printer by fastening the CR

belt clip around.

N° Description

1

CR belt

2

CR belt clip

Step 13 Place the metal plate and fix it with the butterfly screw. The head is now fixed.

N° Description

1

Metal plate

2

Butterfly screw

Page 43

User’s Guide ValueJet 1204

Chapter 3: Installing the Unit

43 AP-75740 – Rev 1.2 – 6/07/2011

3.8.1 PACK THE MACHINE

Step 1 Loosen the butterfly bolts securing the printer to the stand.

N° Description

1

Butterfly bolts

Step 2 Lift the printer main body with the hand grips; be careful not to break off the rubber feet underneath

the printer.

N° Description

1

Hand grips

2

Rubber grips

3

Rubber feet

4

Media guide

Page 44

User’s Guide ValueJet 1204

Chapter 3: Installing the Unit

44 AP-75740 – Rev 1.2 – 6/07/2011

Step 3 Unlock the two casters at the front side of the stand.

Step 4 Remove the book holder at the right side of the stand.

N° Description

1

Leg (right)

2

Book holder

Step 5 Loosen the hexagon head cap screws with the hexagonal wrench and demount the central beam.

N° Description

1

Central beam

2

Left leg

3

Right leg

4

Hexagon head cap screws

Page 45

User’s Guide ValueJet 1204

Chapter 3: Installing the Unit

45 AP-75740 – Rev 1.2 – 6/07/2011

Step 6 Loosen the 2 hexagon head cap screws to detach the right support from the caster section.

N° Description

1

Right support

2

Caster lock

3

Caster section

4

Hexagon head cap screws

Step 7 Detach the left leg from the stand in the same way as the previous step.

Step 8 Now that every component is detached, repack everything in the original packing box before

transporting the machine.

3.9 STEPS AFTER TRANSFER

Step 1 : Choose a suitable place for installation and place the printer.

See “Installation guide”

Step 2 : Verify that the butterfly bolts fixing the stand with the printer are tight.

Step 3 : Connect all cables.

Step 4 : Perform a nozzle check, and verify that there is no clogging in the printer head.

See “Nozzle check”

Step 5 : Perform a head alignment.

See “Adjust print”

Page 46

Page 47

User’s Guide ValueJet 1204

Chapter 4: Handling the printer

47 AP-75740 – Rev 1.2 – 6/07/2011

4 HANDLING THE PRINTER

4.1 INTRODUCTION 49

4.2 MAKING THE PRINTER READY-TO-PRINT 49

4.3 USING MEDIA 50

4.3.1 Media type 50

4.3.2 Cautions on handling media 50

4.3.3 Precaution on storing media 51

4.3.4 The printing area 51

4.3.4.1 Roll media 51

4.3.4.2 Sheet media 51

4.4 HANDLING AND INSTALLING MEDIA 52

4.4.1 Installing roll media 52

4.4.2 Loading roll media 55

4.4.3 Setting media type 58

4.4.4 Head height adjustment 60

4.4.5 Media feed compensation 61

4.4.6 Replacing roll media 65

4.5 TEST PRINT 68

4.5.1 Overview and functions of the test prints 68

4.5.2 Performing a test print 68

4.5.3 Nozzle check 70

4.5.4 Mode Print 70

4.5.5 Setup print 71

4.5.6 Palette print 72

4.6 ADJUST PRINT 73

4.7 MENU SETUP ON THE OPERATION PANEL 77

4.7.1 Menu setup procedure 77

4.7.2 Panel setup menu overview 78

4.8 SETUP MENU 79

4.8.1 MediaType menu 79

4.8.1.1 User media menu 80

4.8.1.2 Print Mode menu 81

4.8.1.3 Dist.Adj menu 81

4.8.1.4 Init.Adj.Print menu 82

4.8.1.5 Init.Adj.Change menu 82

4.8.1.6 Confirm Print menu 82

4.8.1.7 Micro Adj. Print menu 82

4.8.1.8 Micro Adj.Change menu 82

4.8.1.9 Pre Heater menu 83

4.8.1.10 Fixer (platen) menu 83

4.8.1.11 Dryer menu 84

4.8.1.12 StandbyHeating menu 84

4.8.1.13 Vacuum Fan menu 84

4.8.2 Effect menu 85

4.8.3 Flushing menu 85

4.8.3.1 Flushing return count menu 86

4.8.4 Side Margin menu 86

4.8.5 Media Initial menu 86

4.8.6 Media Width / Media Width menu 87

4.8.6.1 Media Width menu 87

4.8.6.2 MediaWidth menu 87

4.8.7 Origin menu 88

4.8.8 Prev. Stick menu 88

4.8.9 CR Movement menu 88

4.8.10 Overwrite Cnt menu 89

4.8.11 Overwrite Wait menu 89

4.8.12 Slant Check menu 89

4.8.13 Auto Cleaning menu 89

4.8.14 Ink Status menu 89

4.8.15 Roll Length menu 90

Page 48

User’s Guide ValueJet 1204

Chapter 4: Handling the printer

48 AP-75740 – Rev 1.2 – 6/07/2011

4.8.15.1 Roll Length menu 90

4.8.16 Head Wash menu 90

4.8.17 CR Maintenance menu 91

4.8.18 Initialization menu 91

4.8.19 Life Times menu 91

4.8.20 IP Address menu 91

4.8.21 Subnet Mask menu 92

4.8.22 Gateway menu 92

4.9 OPERATING FROM THE OPERATION PANEL 93

4.9.1 Feeding media 93

4.9.2 Stop printing 94

4.9.3 Cutting media 95

4.9.4 Changing and confirming settings on the fly 96

4.9.4.1 Procedure for changing and confirming set settings while printing 96

4.9.4.2 settings that can be changed or confirmed while printing 96

Page 49

User’s Guide ValueJet 1204

Chapter 4: Handling the printer

49 AP-75740 – Rev 1.2 – 6/07/2011

4.1 INTRODUCTION

This section describes how to make the fully-installed printer “ready-to-print”. For details on how to obtain a

fully installed printer, see chapter “Installing the unit”

4.2 MAKING THE PRINTER READY-TO-PRINT

Starting point: FULLY- INSTALLED VALUEJET

↓

Step Action Reference

1

Choose the appropriate media.

General info on usable media

2

Install and load the media.

Installing roll media

Loading roll media

3

Set the media type

Setting media type

4

OPTIONAL : Adjust the head height

Head Height Adjustment

5

Set the printing conditions.

Menu setup on the operation panel

6

OPTIONAL: Perform (a) test plot(s)

and perform adjusting, cleaning and

replacing actions when needed.

Test Print

↓

Result: READY-TO-PRINT VALUEJET

Page 50

User’s Guide ValueJet 1204

Chapter 4: Handling the printer

50 AP-75740 – Rev 1.2 – 6/07/2011

4.3 USING MEDIA

4.3.1 Media type

The type and quality of the media affects the result of drawing enormously. Refer to the description below

and use the appropriate media for your purpose.

The following are the recommended media for the printer. Select the appropriate media for your purpose.

Notes

• For more information about the recommended media, contact your local MUTOH dealer.

• Problems that occur due to use of media other than those recommended are not guaranteed.

Notes

• When using recommended media, the setting values for the printing quality is set for each

media type.

• When printing on media other than those specified, information regarding proper should be

found on the instructions for the media. If not contact the supplier of the media.

4.3.2 Cautions on handling media

When you handle media, please pay attention to the following.

Notes

• Use recommended media in an appropriate environment. Following are the appropriate

temperature and humidity ranges for printing.

Temperature Humidity

Recommended working environment 23°C 40% to 70%

Rate of change Within 2°C per hour Within 5% per hour

• Do not use creased, damaged, torn, curled, or wrapped media.

• The size of the recommended sheets can change at a fixed ratio according to the temperature

changes of the working environment. Before using sheet media, place the sheet in the working

environment for at least 30 minutes, to have it match to the temperature of the working area.

• Printing before the media could accommodate to the printing environment may cause media

jams due to slippage or creases. This also adversely affects the quality of printing.

• Media has a printable side and a non-printable side. If you print on a not printable side, blurring

or slight touching may occur.

• Do not touch the printable side of media. Moisture or oil from hands affects the printing quality.

• Do not leave the printer for a long time with media loaded. The media may curl resulting in

misalignment, media jams, or decreased printing quality. In particular, avoid this in winter, dry

seasons, or during final printing.

• Do not lose the box or wrapping bag for storing media.

Page 51

User’s Guide ValueJet 1204

Chapter 4: Handling the printer

51 AP-75740 – Rev 1.2 – 6/07/2011

4.3.3 Precaution on storing media

When storing media, pay attention to the following.

Notes

• Do not store media in high temperature, high humidity, or direct sunlight.

• Store sheet media in the original bag after unpacking.

• Unused roll media must be removed from the scroller, rewound tightly, and stored in the

original wrapping bag and the box.

• Do not wet media.

4.3.4 The printing area

4.3.4.1 Roll media

4.3.4.2 Sheet

media

Page 52

User’s Guide ValueJet 1204

Chapter 4: Handling the printer

52 AP-75740 – Rev 1.2 – 6/07/2011

4.4 HANDLING AND INSTALLING MEDIA

Notes

• Refer to “General info on usable media” for details on media handling.

• It is recommended to use tested and compatible media for this printer.

4.4.1 Installing roll media

Notes

• Only use the scroller supplied with this printer.

• For media with a three inch core, three-inch core adapters must be used.

Notes

• It is possible to load the following roll media on the printer’s scroller :

o two inches diameter media core (outer diameter less than 150 mm, weight 19kg or less)

o three inches diameter media core (outer diameter less than 150 mm, weight 19kg or less)

• For details, refer to: “Product specifications”.

Notes

• Set the roll media on a flat and levelled surface.

• If the roll media and scroller are placed in a vertical position, the scroller might get damaged.

Notes

• If you use an optional Take-Up system, please refer to the user guide of the ValueJet 1204 Take-

Up system.

Step 1 : Remove the movable flange from the scroller.

Step 2 : Install the optional three-inch core adapters :

• If using media on a 2 inch core: Don’t use the three-inch core adapters, go to step 3.

• If using media on a 3 inch core: Click a three-inch core adapter on the fixed flange and the

movable flange.

N° Name

1 Movable flange

2 Fixed flange

3 Three-inch core adapter

Page 53

User’s Guide ValueJet 1204

Chapter 4: Handling the printer

53 AP-75740 – Rev 1.2 – 6/07/2011

Step 3 : Put the roll media on the scroller.

Printable side outside

Step 4 : Push the roll media on the scroller and slide it over the fixed flange.

N° Name

1 Fixed flange

2 Roll media

Page 54

User’s Guide ValueJet 1204

Chapter 4: Handling the printer

54 AP-75740 – Rev 1.2 – 6/07/2011

Step 5 : Move the movable flange over the scroller and firmly press the flange inside the roll media core.

1 Movable flange

2 Roll media

Step 6 : Put the scroller on the printer’s scroller receiver so that the fixed flange is facing the ink cassette

slot side.

N° Name

1 Scroller

2 Fixed flange

3 Ink cassette slot

4 Scroller receiver

Page 55

User’s Guide ValueJet 1204

Chapter 4: Handling the printer

55 AP-75740 – Rev 1.2 – 6/07/2011

4.4.2 Loading roll media

Step 1 : Power ON the printer.

Caution

• Do not use the media hold lever during printer initialization. If the carriage and the pressure

rollers touch each other, the printer might break down.

Step 2 : Push the media hold lever backward.

N° Name

1 Media hold lever

Result: The operation panel displays "Lever Up".

Step 3 : Slide the roll media into the media feed slot.

N° Name

1 Roll media

2 Media feed slot

Page 56

User’s Guide ValueJet 1204

Chapter 4: Handling the printer

56 AP-75740 – Rev 1.2 – 6/07/2011

Notes

• Make sure the roll media is properly wound up on the media core.

• If the front edge of the roll media is not straight, cut it straight on beforehand.

• If the front edge of the roll media is curled, cut it off on beforehand.

• For the cutting method, refer to topic “Cutting media”.

Step 4 : Open the front cover, and pull out the roll media about 0,5 m.

N° Name

1 Front cover

2 Roll media

Step 5 : Wind back the roll media with the scroller while pressing down the media at the front side of the

printer. This will reduce bending and avoid slant of the media.

N° Name

1 Roll media

2 Scroller

Step 6 : Pull the media hold lever forward.

N° Name

1 Media hold lever

Page 57

User’s Guide ValueJet 1204

Chapter 4: Handling the printer

57 AP-75740 – Rev 1.2 – 6/07/2011

Notes

• If the front edge of the roll media is not straight, cut it straight.

Step 7 : Close the front cover.

N° Name

1 Front cover

Result: The operation panel displays the Media setup menu.

Notes

• To change the media type, set the media type as described in “Setting media type”

Page 58

User’s Guide ValueJet 1204

Chapter 4: Handling the printer

58 AP-75740 – Rev 1.2 – 6/07/2011

4.4.3 Setting media type

Introduction:

When loading the media in a ValueJet, you’ll have to set the media type. The Media setup menu is displayed

after the media hold lever is pushed from the backward position to the forward position. (= lever down)

N° Name

1 Media hold lever

Notes

• The printer starts the media initialization without setting the media type when

o The [Cancel] key is pressed.

o No key operations are performed on the operation panel for 10 seconds.

Procedure:

Step 1 : Verify that the printer is switched ON and media is loaded.

Result: After the media is loaded, the display shifts to the Media setup menu.

Notes

• Refer to the following topics for media loading:

o Installing roll media

o Loading roll media

Page 59

User’s Guide ValueJet 1204

Chapter 4: Handling the printer

59 AP-75740 – Rev 1.2 – 6/07/2011

Step 2 : Press the [Setting value +] key or [Setting value-] to select the correct media type.

Step 3 : Press the [Enter] key to confirm your choice.

Result:

• The media type is determined

• The operation panel displays "Paper Initial", and media initialisation starts.

Step 4 : After media initialization, the operation panel displays "Ready to Print".

Step 5 : When using the roll media, wind back the roll media to avoid slackness at the back.

N° Name

1 Roll media

2 Scroller

Page 60

User’s Guide ValueJet 1204

Chapter 4: Handling the printer

60 AP-75740 – Rev 1.2 – 6/07/2011

4.4.4 Head height adjustment

When used?

Use the head height adjustment feature to prevent the print head from touching the media, when printing at

high speeds or when using strongly curved media.

Notes

• If the head height adjustment lever is raised, high print quality will not be guaranteed.

• Do not open the front cover nor change the head height during printing. If the head height is

changed, the head alignment will be changed and high print quality will not be guaranteed.

• To perform a head alignment, refer to “Head height alignment”

Procedure:

Step 1 : Open the front cover.

N° Name

1 Front cover

Step 2 : Move the head height adjustment lever to change the head height.

Head height: Normal Head height: High

N° Name

1 Head height adjustment lever

Result: The High indication light on the operation panel lights up in green

Page 61

User’s Guide ValueJet 1204

Chapter 4: Handling the printer

61 AP-75740 – Rev 1.2 – 6/07/2011

Step 3 : Close the front cover.

N° Name

1 Front cover

4.4.5 Media feed compensation

After every printed swat, the media is fed a certain distance. Depending on the kind of media (weight,

backing) another media feed compensation has to be set. This to avoid the following phenomenon:

• Printed swats overlap.

• White lines between every swat.

In such cases, follow the procedure below and adjust the media feed compensation value.

Step 1 : Display the Media feed compensation menu on the operation panel.

• Press the [Menu] key.

o Shift to the Setup menu display.

o The operation panel displays "Menu 1: Setup>".

• Press the [>] key.

o The operation panel displays "Set1: MediaType".

• Press the [Enter] key.

o The operation panel displays "Media: Type 1".

• Press the [+] or [–] key to select the media type you wish to use.

• Press the [Enter] key.

o The operation panel displays "**>1: Print Mode".

Notes

• The selected media (Type 1-30) is displayed in "**". Please refer to “Media Type menu”

• Press the [+] or [–] key to select "**>2: PF Adjust>".

• Press the [>] key.

o The operation panel displays "PF1: Init.Adj.Print".

Page 62

User’s Guide ValueJet 1204

Chapter 4: Handling the printer

62 AP-75740 – Rev 1.2 – 6/07/2011

Step 2 : Perform the initial adjust print.

• Press the [Enter] key.

o The operation panel displays "Feed Length: 250 mm".

Notes

• The length that media is fed (feeding length) for initial adjustment printing is normally set at 250

mm.

• If you make the feeding length longer, the accuracy of the Media feed compensation improves.

If you want to change the feeding length, press the [+] or [–] key and change the set value.

• Press the [Enter].

o The operation panel displays "Printing".

o Start Initial adjustment printing.

N° Name

1 Feed length

2 Media feeding direction

o When the initial adjustment printing is complete, the printer enters the normal

status

• After the initial adjustment printing, cut the media. Refer to “Cutting media”

Step 3 : Measure the distance between two pluses in the initial adjustment print using a measurement

tool, such as a ruler.

Step 4 : Set up Initial Adjust Change.

• Press the [+] or [–] key to select "PF2: Init.Adj.Change".

• Press the [Enter] key.

o The operation panel displays "Init: 250.0/250mm".

• Press the [+] or [–] key and enter the measured value in step 3.

• Press the [Enter] key.

o The initial adjustment value is saved.

o The operation panel displays "PF2: Init.Adj.Change".

Step 5 : Perform the Confirm Print.

• Press the [+] or [–] key to select "PF3: Confirm Print".

• Press the [Enter] key.

The operation panel displays "Feed Length: 250 mm".

Page 63

User’s Guide ValueJet 1204

Chapter 4: Handling the printer

63 AP-75740 – Rev 1.2 – 6/07/2011

Notes

• The length that media is fed (feeding length) for confirmation printing is set at 250 mm.

• If you make the feeding length longer, the accuracy of the Media feed compensation improves.

If you want to change the feeding length, press the [+] or [–] key and change the set value.

• Press the [Enter].

o The operation panel displays "Printing".

o Start Confirmation adjustment printing.

N° Name

1 Feed length

2 Media feeding direction

After the confirmation adjustment printing, cut the media. Refer to “Cutting media”

Step 6 : Measure the distance between two pluses in the confirmation adjustment print using a ruler.

Then, confirm that the distance matches the feeding length when printing.

• If the distance does not match the feeding length, follow the procedure from 1 to 5 and

readjust.

• If the distance matches the feeding length, proceed to step 7.

Page 64

User’s Guide ValueJet 1204

Chapter 4: Handling the printer

64 AP-75740 – Rev 1.2 – 6/07/2011

Step 7 : Perform Micro adjustment printing.

• Display the Media feed compensation menu as in step 1.

• Press the [+] or [–] key to select "PF4: Micro Adj. Print".

• Press the [Enter] key.

o The operation panel displays "Printing".

o Start Micro adjustment printing.

• After the micro adjustment printing is completed, the operation panel displays "PF4: Micro

Adj. Print".

Step 8 : Check the printing result.

Page 65

User’s Guide ValueJet 1204

Chapter 4: Handling the printer

65 AP-75740 – Rev 1.2 – 6/07/2011

Step 9 : Set up the Micro Adjustment Change.

• Press the [+] or [–] key to select "PF5: Micro Adj.Change".

• Press the [Enter] key.

o The operation panel displays "Micro: 0pulse".

• Press the [+] or [–] key and enter the micro adjustment value according to the printing result

in step 7.

• Press the [Enter] key.

o The micro adjustment value is saved.

o The operation panel displays "PF5: Micro Adj.Change".

o The Media feed compensation is complete.

4.4.6 Replacing roll media

Describes the replacement time and replacement method for roll media.

(1) Replacement time

Replace roll media if...

…the roll media runs out.

• The operation panel displays "End of Roll".

• If the media runs out during printing, the printer stops printing.

…you want to change the media type.

(2) Replacement steps

Caution

• Be careful not to pinch your fingers when opening or closing the front cover.

1. Remove the installed roll media.

Step 1 : Verify that

• the printer is switched ON,

• the printer is in Normal mode, and

• the printer is NOT printing

Step 2 : Push the media hold lever backward (lever up).

N° Name

1 Media loading lever

Page 66

User’s Guide ValueJet 1204

Chapter 4: Handling the printer

66 AP-75740 – Rev 1.2 – 6/07/2011

Step 3 : Lift both ends of the scroller and gently rewind the media.