Page 1

MUTOH Belgium nv

Archimedesstraat 13

8400 Oostende - Belgium

www.mutoh.eu

Tel +32(0)59 56 14 00

Fax +32(0)59 80 71 17

BTWBE 0441.745.423

RPR Oostende

AP-76942_Rev 1.0 Page 1/19

Dear customer,

Each ink has its own specific drying speed and drying characteristics, which has a n influ en ce on

its periodical maintenance cycle.

To maximise the life-time of all parts which are exposed to ink, it is crucial to carry out some easy

but important maintenance.

The most important maintenance act ion s ar e:

Wash away ink remainders from parts which are not (easily) accessible, avoiding that the ink

dries out, possibly causing blockage.

Regularly remove ink remainders from accessible parts.

Hereafter, tailored to each ink type, you will find simple guidelines explaining how you can

maintain excellent print quality and avoid that parts wear untimely.

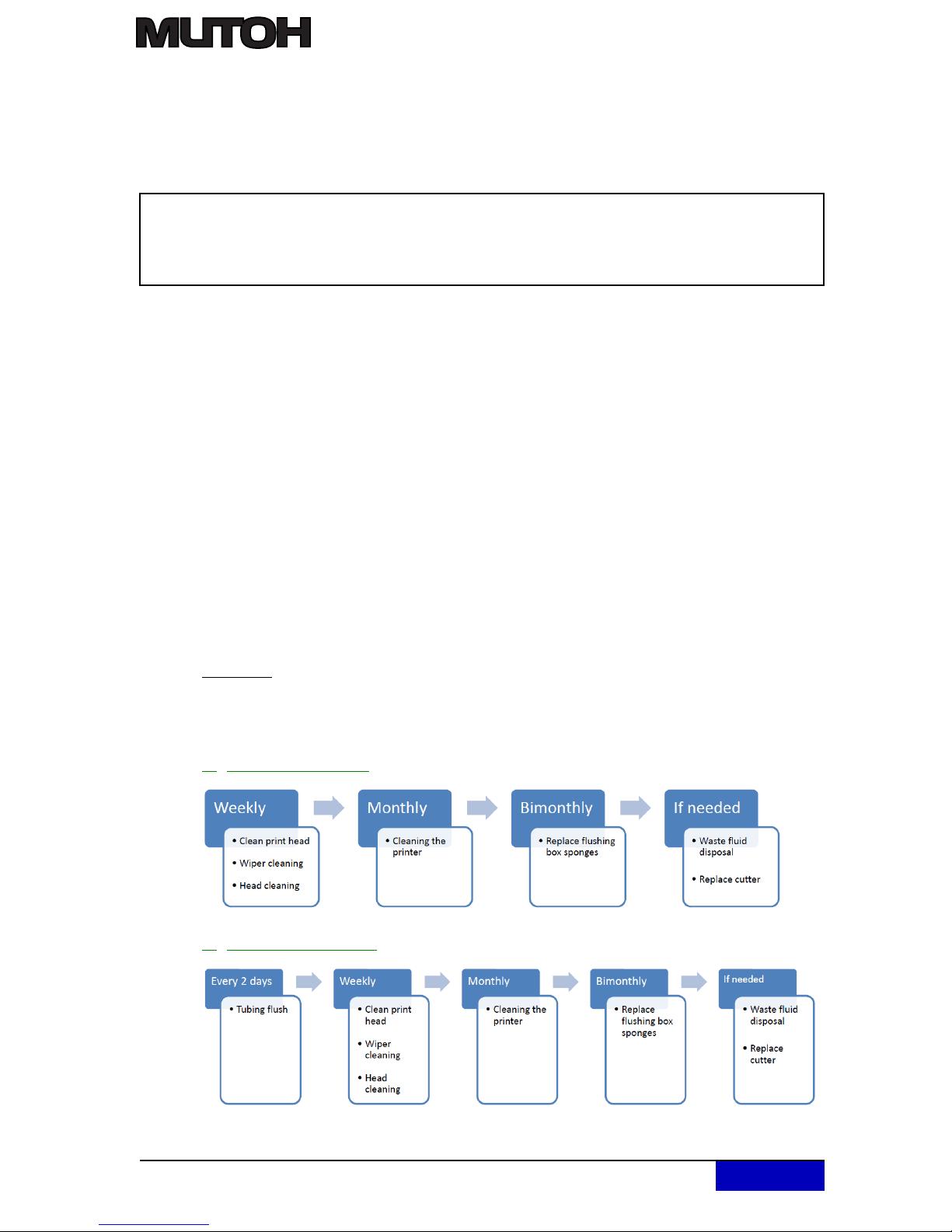

Overview

When using the VJ-1614 it is important to perform periodic maintenance. This will help you

maintaining excellent output quality and avoid parts to wear untimely. Depending on your current

ink setup, follow the required periodical maintenance scheme.

1) When using Eco ink

2) When using UMS ink

ValueJet 1614

Regular maintenance using Mutoh UMS or Eco-Ultra ink

Page 2

Page 2/19 AP-76942_Rev 1.0

Items needed

Important

Please be aware that next to this periodical maintenance, a certified Mutoh

Technician needs to perform yearly maintenance as well. Please contact your

Authorised Mutoh Reseller for more information.

Important

Please keep in mind to use the correct cleaning fluid

Eco Ultra cleaning

Used to start up new printers.

Used to perform periodical main te na n ce when printer is loaded with Eco ink

UMS cleaning

Used to perform periodical main te na n ce when printer is loaded with UMS ink

Part number Description Quantity

PJ-GLOV Glove 100

PP-10001 Cleaning s

tick 50

PP-10030 Kit Pipette 10 ml 6

DG-40317 Flushing absorbent 5

VJ-CB Cutter 1

KY-14044 Poly-knit wiper 30

CL-90250 Eco Ultra cleaning liquid 250 ml

RJ80UMS-100-CLN UMS cleaning liquid 1 litre

Page 3

AP-76942_Rev 1.0 Page 3/19

1 Performing a tubing flush

(1) Cleaning frequency

Once every two days

(2) Cleaning procedures

Use UMS cleaning liquid to perform a tubing flush when working with UMS ink.

Step 1: If the printer is powered ON, make sure that printing or other operations are not in

progress.

Step 2: Display the CR Maintenance menu

Press the [Menu] key

“Menu1: Setup>” is displayed.

The operation panel shifts to the Setup menu display.

Press [>].

“Set1: User Type” is displayed.

Press [+] or [–] to select “Set20: CR Maintenance”.

Press [Enter]

“CR Mainte.: Start” is displayed.

The display enters the CR Maintenance menu.

Step 3: Press the [Enter] key

Maintenance starts.

The print head moves to the left.

“CR Maintenance: End” is displayed.

Step 4: Press the [▼] key

The pumps start pumping.

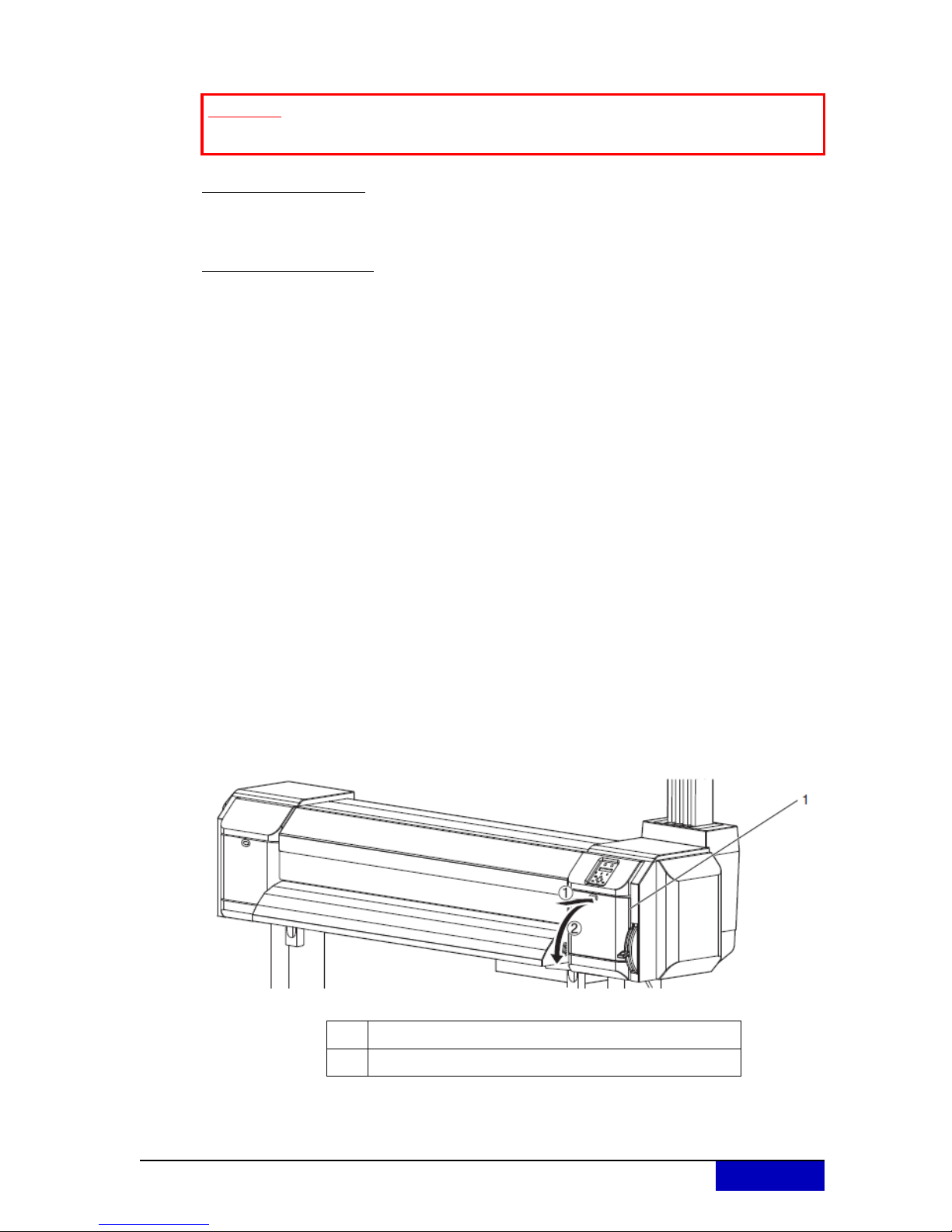

Step 5: Open the maintenance cover at the right side of th e pr int er.

Important

Only needed when working with UMS ink!

No. Name

1 Maintenance cover

Page 4

Page 4/19 AP-76942_Rev 1.0

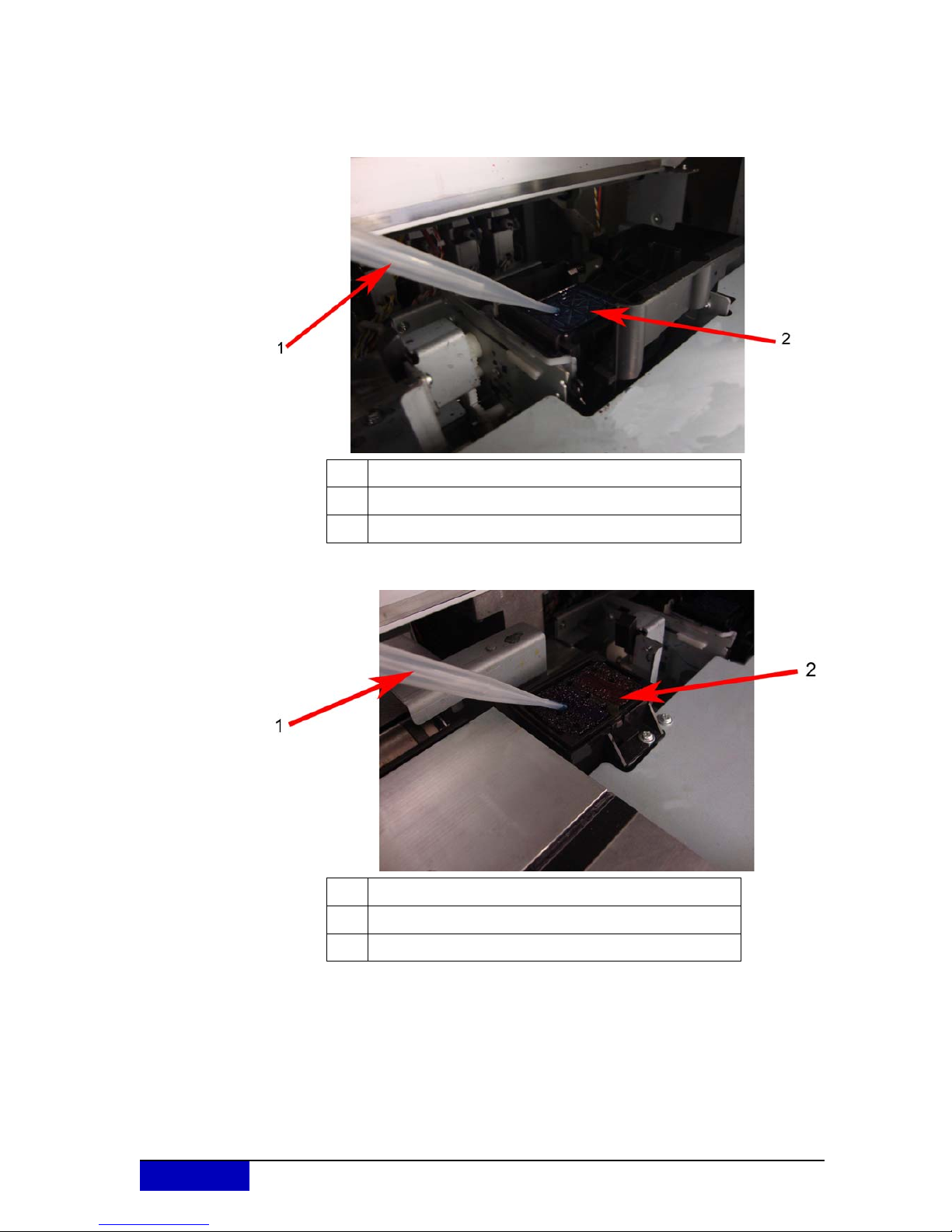

Step 6: Using a pipette filled with UMS cleaning liquid, drip about 5 ml of cleaning liquid onto

the head cap unit as shown in the illustration. The cleaning liquid will be sucked into the

capping unit and the connected tubing. It will remove ink remainders and prevent

blocking of the tubing. Also drip some cleaning liquid onto the right flushing-box

sponge.

Also drip some cleaning liquid onto the flushing box sponge.

Step 7: Press the [▼] key once again to stop the pumps.

If you do not press [▼], pumping stops automatically after 60 seconds.

Step 8: Press the [ENTER] key

The print head returns to the capping position.

“CR Mainte.: Start” is displayed.

Step 9: Press the [Menu] key.

The tube flush procedure is completed.

No. Name

1 Pipette

2 Head cap unit

No. Name

1 Pipette

2 Flushing-box sponge

Page 5

AP-76942_Rev 1.0 Page 5/19

2 Cleaning around the print head

(1) Cleaning frequency

On a weekly basis, check if foreign substances (ink clots that can cause missing dots or ink

leakage) are attached around the print head. If it is the case, remove them as described.

(2) Cleaning procedures

Step 1: If the printer is powered ON, make sure that printing or other operations are not in

progress.

Step 2: Display the CR Maintenance menu

Press the [Menu] key

“Menu1: Setup>” is displayed.

The operation panel shifts to the Setup menu display.

Press [>].

“Set1: UserType” is displayed

Press [+] or [–] to select “Set20: CR Maintenance”.

Press [Enter].

“CR Mainte.: Start” is displayed.

The display enters the CR Maintenance menu.

Step 3: Press the [Enter] key

Maintenance starts.

The print head moves to the left.

“CR Maintenance: End” is displayed

Step 4: Open the left maintenance cover.

Note

Before cleaning around the print head, read this procedure thoroughly to fully

understand it, and clean promptly and correctly.

While cleaning around the print head, the print head cap is removed, therefore

cleaning must be done before the print head dries.

Leaving the print head at the replacement position for a long time, may result in

clogging of the print head. Please limit to 15 minutes

Use the cleaning stick to clean around the print head.

Page 6

Page 6/19 AP-76942_Rev 1.0

Step 5: Move the print head manually so that you have a clear view on the print head.

Step 6: Use a

penlight, etc. to check if any foreign substances, such as dust or ink are attached

to the following places.

No. Name

1 Print head section

2 Circumference of the print head

No. Name

1 Around the print head

2 Head guide

3 Nozzle plate

4 Dust, ink clots, etc.

Caution

When cleaning around the print head,

Do not touch the nozzle plate. Doing so may damage the print head.

Do not touch the tip of the cleaning stick. The print head may be damaged because of

skin oil.

Never put water, etc. on the tip of the cleaning stick. Doing so may damage the print

head.

Do not reuse the cleaning stick. The attached dust, etc may damage the print head.

Page 7

AP-76942_Rev 1.0 Page 7/19

Step 7: When some foreign substance such as dust or ink clot is attached, use the cleaning

stick to remove it. To facilitate this action you can moisten the cleaning stick with

suitable cleaning liquid.

Step 8: Close the left

maintenance cover firmly to make sure it is locked.

Step 9: Press the [Enter] key

The print head returns to its original position.

“CR Mainte.: Start” is displayed.

Step 10: Press the [Cancel] key

Cleaning around the print head is complete.

No. Name

1 Around the print head

2

H

ead guide

3 Nozzle plate

4 Cleaning stick

Page 8

Page 8/19 AP-76942_Rev 1.0

3 Cleaning the cleaning wiper

(1) Cleaning frequency

Once a week, or when blurs or lacking parts appear on printed media after head cleaning.

(2) Cleaning procedures

Use the cleaning stick moistened with suitable cleaning liquid to clean the cleaning wiper.

Step 1: If the printer is powered ON, make sure that printing or other operations are not in

progress.

Step 2: Display the CR Maintenance menu

Press the [Menu] key

“Menu1: Setup>” is displayed.

The operation panel shifts to the Setup menu display.

Press [>].

“Set1: User Type” is displayed.

Press [+] or [–] to select “Set20: CR Maintenance”.

Press [Enter].

“CR Mainte.: Start” is displayed.

The display enters the CR Maintenance menu.

Important

Please make sure the wiper is in optimal condition. If you do not clean the wiper

regularly, ink residue will stick to the wiper (as shown below), which will lead to

bad printing quality.

Page 9

AP-76942_Rev 1.0 Page 9/19

Step 3: Press the [Enter] key

Maintenance starts.

The print head moves to the left.

The cleaning wiper shifts towards the front.

“CR Maintenance: End” is displayed

Step 4: Open the maintenance cover at the right side of th e pr int er.

No. Name

1 Maintenance cover

Caution

When cleaning the cleaning wiper

Do not touch the cleaning wiper and head cap unit with your hands.

Head cleaning may not be performed correctly because of skin oil.

Make sure to wipe the print head using the cleaning stick.

A cleaning stick moistened with water may cause the print head to clog. When

moistening, always use the cleaning liquid matching your ink type.

Do not reuse the cleaning s tick.

The attached dust, etc may damage the print head.

Page 10

Page 10/19 AP-76942_Rev 1.0

Step 5: Use a cleaning stick moistened with a suitable cleaning liquid to remove the ink and

dust on the cleaning wiper.

Front side of the cleaning wiper:

Remove the ink and dust in the horizontal direction.

k

Cleaning wiper back side:

Remove the ink and dust in the upper direction.

Step 6: Close the ri

ght maintenance cover.

Close the cover firmly until it is locked.

Step 7: Press the [Enter] key

The print head returns to its original position.

The cleaning wiper returns to the original posit ion .

“CR Mainte.: Start” is displayed.

Step 8: Press the [Menu] key

Cleaning the cleaning wiper is complete.

No. Name

1 Cleaning wiper

2

Clean

ing stick

3 Head cap unit

No. Name

1 Cleaning wiper

2

Clean

ing stick

3 Head cap unit

Page 11

AP-76942_Rev 1.0 Page 11/19

4 Head cleaning

If printed data is blurred or lacks part of it, perform a cleaning sequence as described below.

When not using the printer for a long period (2 weeks or more), perform head cleaning.

If not performing head cleaning, the print head is clogged. Doing a head cleaning will

preserve print quality.

Remove media when cleaning.

Cleaning with media loaded may lead to contact between the print head and media.

Step 1: Check that the media loading lever is lowered.

Step 2: Press the [>] key on the operation panel to select the cleaning mode.

Step 3: Press the [Cleaning] key on the operation panel for at least two seconds.

Start Head cleaning.

“Cleaning **%” is displayed

If blurs or lacking parts on printed media do not disappear with one time of head

cleaning, perform strong cleaning.

If blurs or lacking parts in printed media do not disappea r with several times of head

cleaning, refer to the chapter “Troubleshooting” in the Users Guide, and take

appropriate measures.

Important

Please be aware that in case your printe r is loade d with UMS ink, it is nec essar y to

perform a tubing flush after a head cleaning.

Page 12

Page 12/19 AP-76942_Rev 1.0

5 Cleaning the printer

Periodic (every month) cleaning is necessary to keep the printer in good condition.

Cleaning the outer case

Wipe out dust and dirt attached to the outer case by using a soft cloth.

Cleaning the inside of the printer

Step 1: Open the front cover.

Step 2: Remove paper powder and dust attached to the pressure rollers using a soft brush.

Do not blow paper powder inside the printer using tools such as an air duster.

It may cause an abnormal noise from the inside of the printer.

Important

Do not insert or drop metal or flammable object s into the print er through openings

such as a vent.

It could lead to an electric shock or fire.

If foreign substances or liquids such as water entered the printer, do not use the

printer as it is.

It could lead to an electric shock or fire.

Immediately turn OFF the power switch, disconnect the power plug from the

electric socket, and contact your local MUTOH dealer.

When cleaning the printer, be sure to turn OFF the power and disconnect the

power plug.

Do not use volatile solvents such as thinner, benzene, or alcohol.

These solvents could damage the paint.

Be careful that no moisture enters the printer.

There is a possibility that the el ec tric circuit inside the printer is short circuited.

Do not open covers attached using screws under any circumstances.

This may cause an electric shock or a malfunction.

No. Name

1 Pressure rollers

Page 13

AP-76942_Rev 1.0 Page 13/19

Step 3: Apply a damp and tightly squeezed soft cloth to wipe out paper powder and ink

attached to the platen and media guide.

Step 4: Appl

y a damp and tightly squeezed soft cloth to wipe of f the di rt of the unp ainted (silver

colour) area in the centre of the grid roller.

No. Name

1Platen

2 M

edia guide

No. Name

1 Grid roller

Page 14

Page 14/19 AP-76942_Rev 1.0

6 Replacing the flushing box sponges

(1) Replacement time

Replace the flushing-box sponges in the following situations:

When the flushing-box sponge is deformed or saturated

When ink is spattered on the media.

When more than two months have passed since the last replacement.

(2) Replacing steps

You need to inspect 2 flushing-box sponges, 1 on the left side and 1 on the right side of the

printer. Please be aware the flushing-box sponge on the left side is less frequently used. Due to

this you do not need to replace the 2 flushing-box sponges at the same time.

(2-a) Replacement procedure

Step 1: If the printer is powered ON, make sure that printing or other operations are not in

progress.

Step 2: Display the CR Maintenance Menu.

Press the [Menu] key.

“Menu1: Setup>” is displayed.

The operation panel shifts to the Setup menu display.

Press the [>] key.

“Set 1: User Type” is displayed.

Press the [+] key or [–] key to select “Set20: CR Maintenance”.

Press the [Enter] key.

“CR Mainte.: Start” is displayed.

The display enters the CR Maintenance menu.

Step 3: Press the [Enter] key.

Maintenance process starts.

The print head moves to the left.

“CR Maintenance: End” is displayed.

Step 4: Open the front cover.

Replace the flushing-box sponge in a short time.

Leaving the print head at the replacement position for a long time, may result in

clogging of the print head. Please limit to 15 minutes (Refer to topic 2 (2).

No. Name

1 Flushing-box sponge on the right

2

F

lushing-box sponge on the left

Page 15

AP-76942_Rev 1.0 Page 15/19

Step 5: Use tweezers to remove the flushing-box sponge.

Step 6: Install the ne

w flushing-box sponge.

Step 7: Close the front cover.

Step 8: Press the [Enter] key.

The print head returns to its original position.

“CR Mainte.: Start” is displayed.

Step 9: Press the [Menu] key.

Flushing-box sponge replacement is complete.

N° Name

1 Flushing boxes

2 Flush

ing-box sponges

Caution

Do not drop waste fluid when replacing the flushing-box sponges.

If waste fluid comes into contact with the grid roller, the surface of the grid roller

will be damaged, and the media feed function may be affected.

Page 16

Page 16/19 AP-76942_Rev 1.0

7 Disposal of waste fluids

(1) Disposal timing

Dispose of waste fluids in the following cases:

When the waste fluid tank is more than half full.

When “Waste Ink Tank Full” is displayed

(2) Disposal method

Step 1: Please have an empty container such as a supply waste fluid bottle, to contain the

waste fluid.

Step 2: Put some protective material on the floor under the waste fluid tank.

Step 3: Open the waste fluid tap, and transfer the waste fluid to the container.

When transferring the waste fluid to the empty container, the waste fluid may

spatter.

Make sure to put the container close to the waste fluid tap.

Step 4: Af

ter p

ouring the waste fluid to the empty container, close the waste fluid tap securely.

Step 5: Wipe the opening of the waste fluid tap with a cloth, etc.

Step 6: Dispose of the waste fluid as an industrial waste product.

Disposal of waste fluids is completed.

Important

Please dispose according to local rules and regulations. For details, please

verify the corresponding safety data sheet MSDS on the Mutoh website.

Disposal can be found in section 13 of the SDS.

No. Name

1 Waste fluid tap

2 E

mpty container

Page 17

AP-76942_Rev 1.0 Page 17/19

8 Replacing the cutter

(1) Replacement time

Replace the cutter when the following situatio n occurs:

When the media is not cut smoothly

When the cut surface is feathered, etc.

(2) Replacing steps

Step 1: If the printer is powered ON, make sure that printing or other operations are not in

progress.

Step 2: Display the CR Maintenance menu

Press the [Menu] key

“Menu1: Setup>” is displayed.

The operation panel shifts to the Setup menu display.

Press [>].

“Set1: User Type” is displayed

Press [+] or [–] to select “Set20: CR Maintenance”.

Press [Enter].

“CR Mainte.: Start” is displayed

The display enters the CR Maintenance menu.

Step 3: Press [Enter].

Maintenance starts.

The print head moves to the left of the printer (cutter replacement position).

“CR Maintenance: End” is displayed

Step 4: Open the maintenance cover at the left side of the printer.

Note

Replace the cutter in a short time.

Leaving the print head at the cutter replacement position for a long time may

result in clogging of the print head. Please limit to 15 minutes.

Page 18

Page 18/19 AP-76942_Rev 1.0

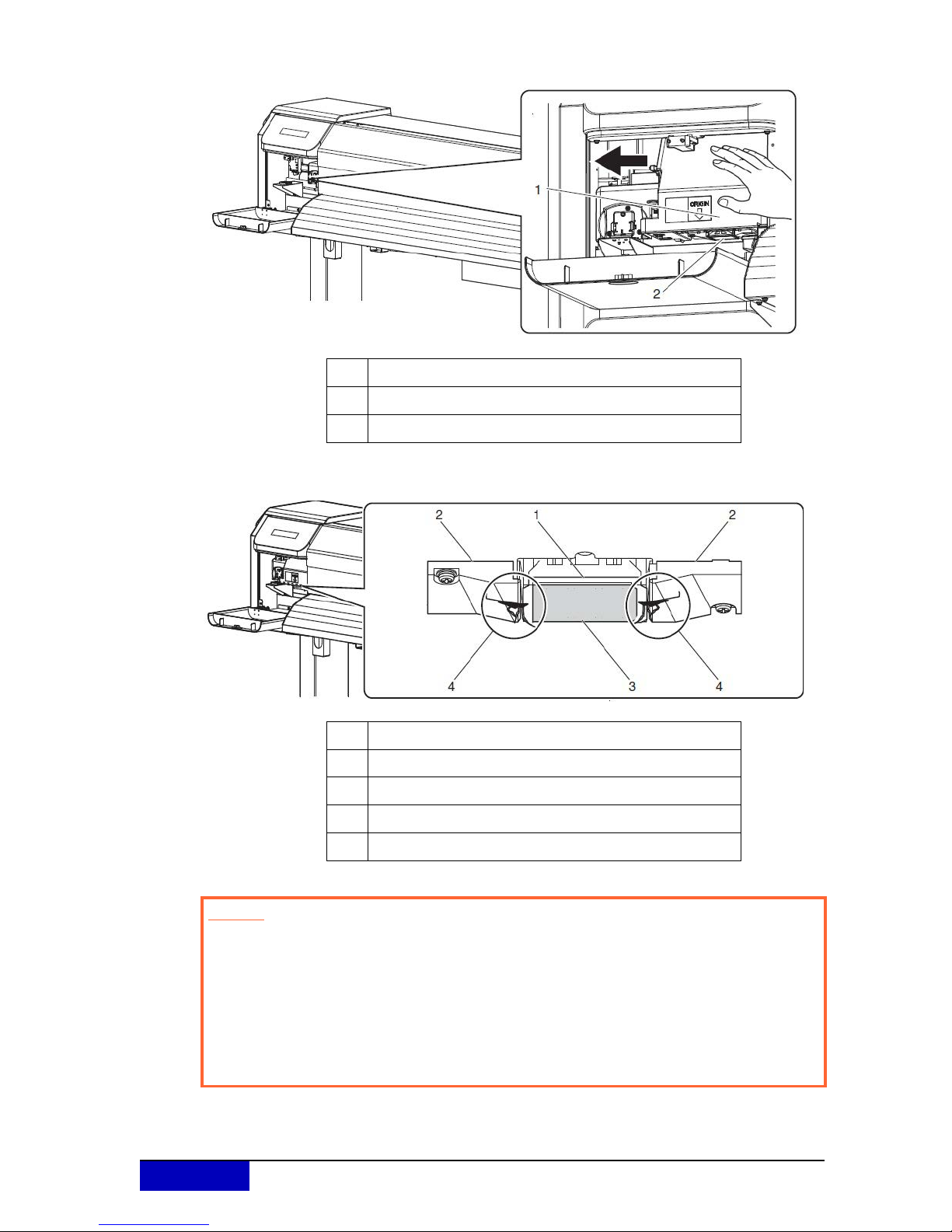

Step 5: Press the tab of the cutter gently, turn the cutter holder in the direction as illustrated

below.

Do not press the tab of the cutter strongly or suddenly let it go.

There is a spring in the cutter holder and it may pop out.

Do not push the cutter all the way in.

The cutter blade may damage the inside of the printer.

Step 6: Remove the cutter.

Used cutter should be put in a plastic bag, etc, and dispo se d of in complia nc e

with local ordinance and instructions of local authorities.

No. Name

1 Cutter holder

2 Cutter holder lever

Caution

Do not touch the blade edge. It may cause an injury.

Do not touch the cutter blade edge with a hard substance or drop the cutter.

The cutter blade may be damaged or chipped.

No. Name

1 Cutting blade

Page 19

AP-76942_Rev 1.0 Page 19/19

Step 7: Install a new cutter.

Make sure that the spring in the cutter holder does not fly out while installing.

Step 8: Pres

s the tab of the cutter gently, return the cutter holder to its initial position.

Do not press the tab of the cutter strongly or suddenly let it go.

There is a spring in the cutter holder and it may pop out.

Do not push the cutter all the way in.

The cutter blade may damage the inside of the printer.

Refer to the illustrations below and install the cutter holder correctly.

If it is not installed correctly, it may cause an error.

If an error occurs, check if the cutter holder is installed correctly.

Step 9: Close the ma

intena

nce cover.

Step 10: Press the [Enter] key

The print head returns to its original position.

“CR Mainte.: Start” is displayed

Step 11: Press the [Menu] key

Cutter replacement is complete.

No. Name

1 Cutting blade

No. Name

1 Cutter holder

2

C

utter holder lever

Copyright Mutoh Belgium. All rights reserved. Unauthorised copying or distribution prohibited.

Written approval required from Mutoh Belgium.

Loading...

Loading...