User’s Guide

ValueJet 1608 HS

Downloaded From ManualsPrinter.com Manuals

Downloaded From ManualsPrinter.com Manuals

User’s Guide ValueJet 1608 HS

Copyright notice

COPYRIGHT © 7/4/11 Mutoh Belgium nv All rights reserved.

Mutoh Belgium nv reserves the right to modify the information contained in this manual at any

time without prior notice.

This document may not be reproduced by any means, in whole or in part, without written

permission of the copyright owner.

This document is furnished to support the Mutoh ValueJet 1608 HS series printers. In

consideration of the furnishing of the information contained in this document, the party to

whom it is given, assumes its custody and control and agrees to the following:

The information herein contained is given in confidence, and any part thereof shall not be

copied or reproduced without written consent of Mutoh Belgium nv

This document or the contents herein under no circumstances shall be used in the

manufacture or reproduction of the article shown and the delivery of this document shall not

constitute any right or license to do so.

7 April 2011

Published: Mutoh Belgium nv, Archimedesstraat 13, B-8400 Oostende, BELGIUM

www.Mutoh.eu

IMPORTANT NOTICE

For users in Europe

This is a Class A product approved for industrial environments.

In a domestic environment this product may cause radio interference in which case you may

be required to take adequate measures.

Change the direction of the receiving antenna or feeder.

AP-75810 - Revision 2.0 3

Downloaded From ManualsPrinter.com Manuals

User’s Guide ValueJet 1608 HS

Trademarks mentioned in this guide

Mutoh, ValueJet 1608 HS, Spitfire, VJ-1608 are registered trademarks or product names

of Mutoh Belgium nv

Other company and product names may be registered trademarks or product names.

Note

The product and the contents of this publication may be changed without prior

notification.

Mutoh Belgium nv has made the best efforts to keep this publication free from

errors, but if you find any uncertainties or misprints, please call us or the

reseller from which you bought this equipment.

Mutoh Belgium nv shall not be liable for any damages or troubles resulting

from the use of this equipment or this guide.

4 AP-75810 - Revision 2.0

Downloaded From ManualsPrinter.com Manuals

User’s Guide ValueJet 1608 HS

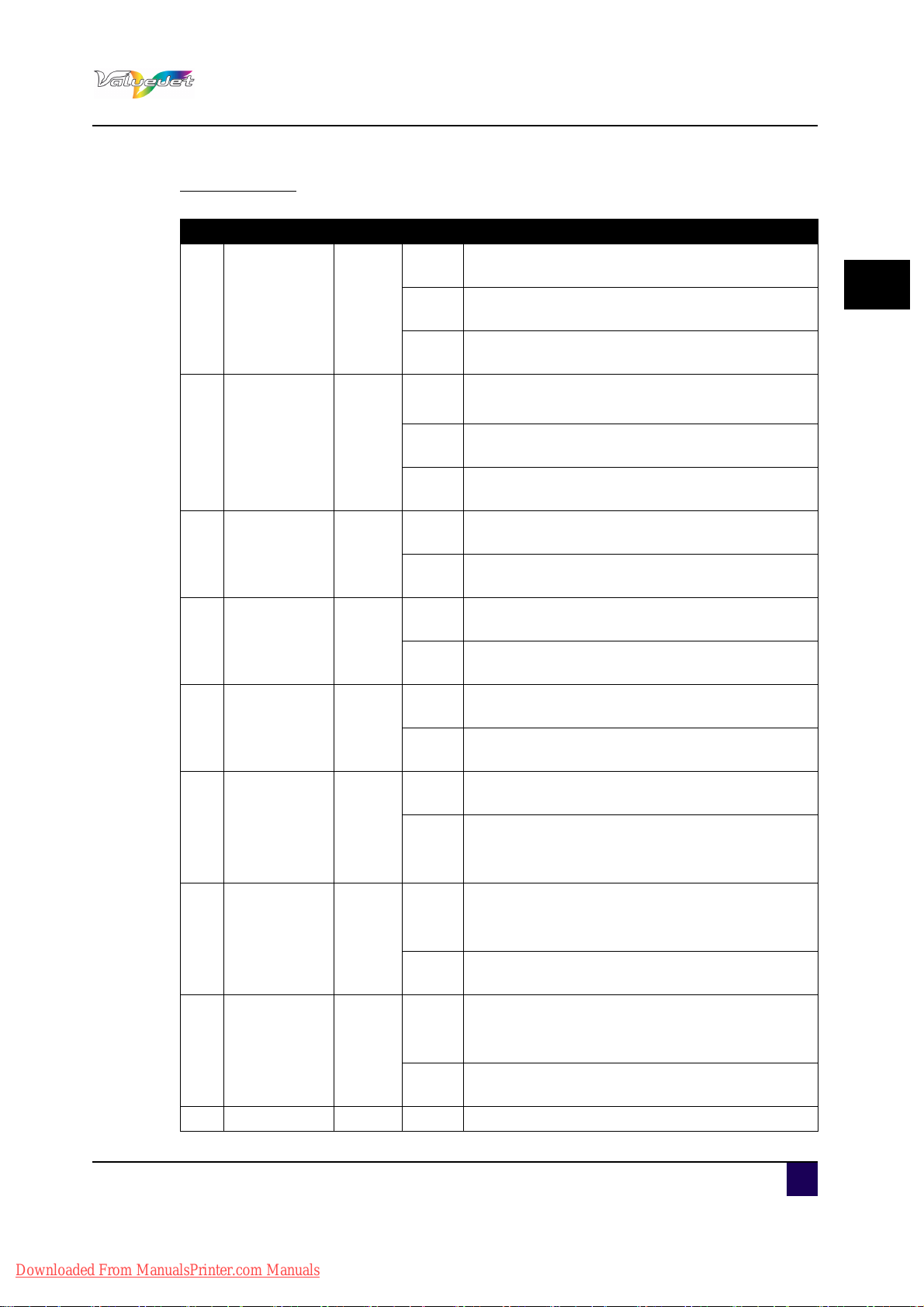

Table of contents

Chapter 1 Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.1 Compliance with the following regulations . . . . . . . . . . . . . . . 9

1.2 Managing VOCs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.3 Handling inks / cleaning or waste fluids (cleaning & ink). . . 11

1.4 Warnings, cautions and notes. . . . . . . . . . . . . . . . . . . . . . . . . 12

1.5 Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.6 Warning labels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Handling the operation procedure labels. . . . . . . . . . . . . . . . . . . . . 15

Location and type of warning labels. . . . . . . . . . . . . . . . . . . . . . . . . 16

Chapter 2 Product overview . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.1 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

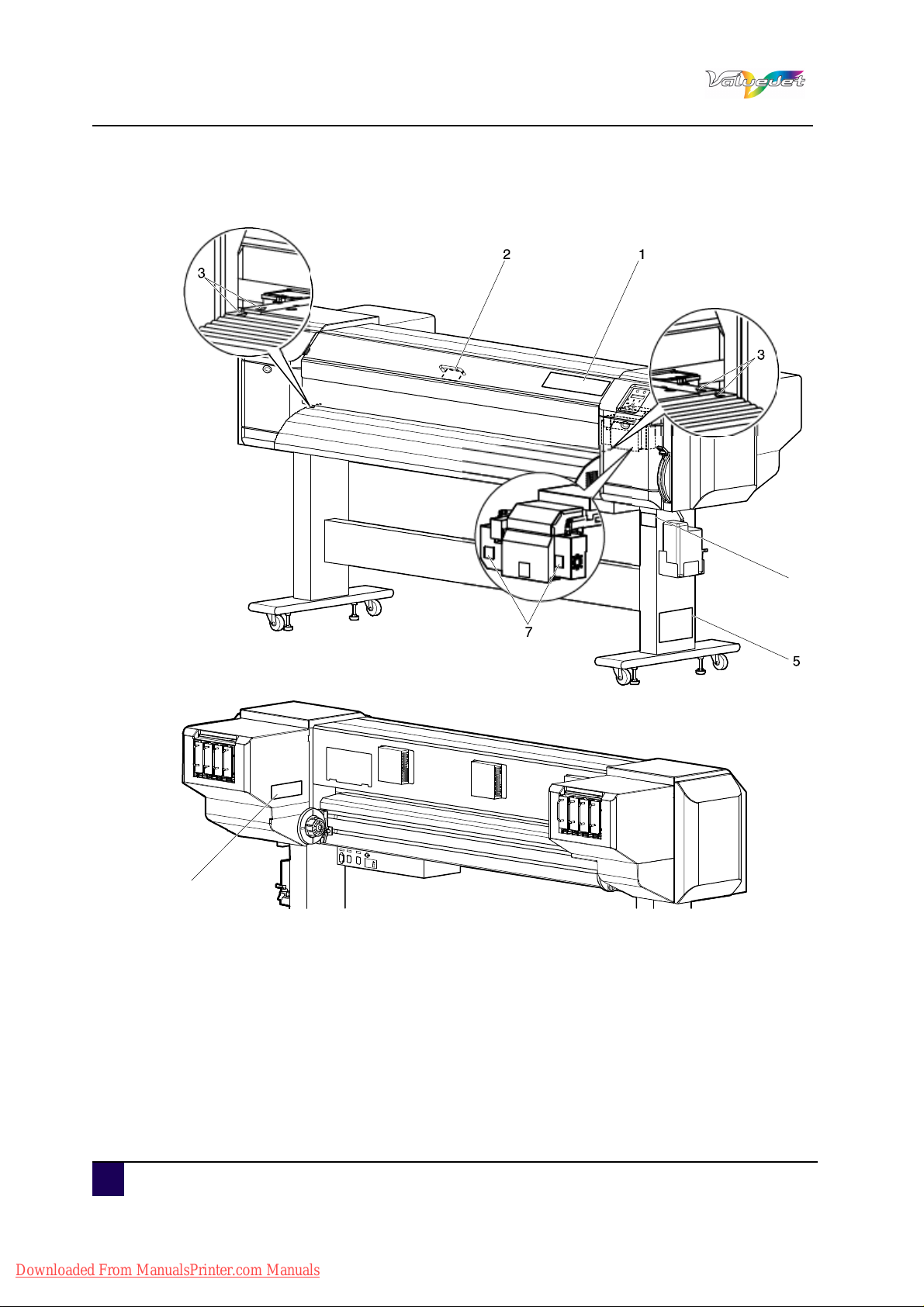

2.2 Names of parts and functions . . . . . . . . . . . . . . . . . . . . . . . . . 21

Front section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Rear section. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Operation panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Chapter 3 Basics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.1 Switching the power ON/OFF. . . . . . . . . . . . . . . . . . . . . . . . . . 29

Switching the power ON. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Switching the power OFF. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

3.2 Loading media. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

loading rigid media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Loading roll media. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Setting media type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

AP-75810 - Revision 2.0 - 7/4/11 5

Downloaded From ManualsPrinter.com Manuals

User’s Guide ValueJet 1608 HS

3.3 Perfect media handling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Unwinder / Winder 100 / T-winder 30. . . . . . . . . . . . . . . . . . . . . . . . 42

Rigid printing tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Media retainers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Head height adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Adjusting the pressure on the media . . . . . . . . . . . . . . . . . . . . . . . . 48

Heater settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

3.4 Using the air heater. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Filter connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Setting the Air nozzle pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

3.5 Replacing the ink bags. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

3.6 Emptying the waste bottle . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

3.7 Transfer and transportation. . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Transferring the printer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Transporting the printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

3.8 Longstore. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Longstore procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Chapter 4 Preparations before printing . . . . . . . . . . . . . . . . . . 71

4.1 General info on usable media . . . . . . . . . . . . . . . . . . . . . . . . . 72

Media compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

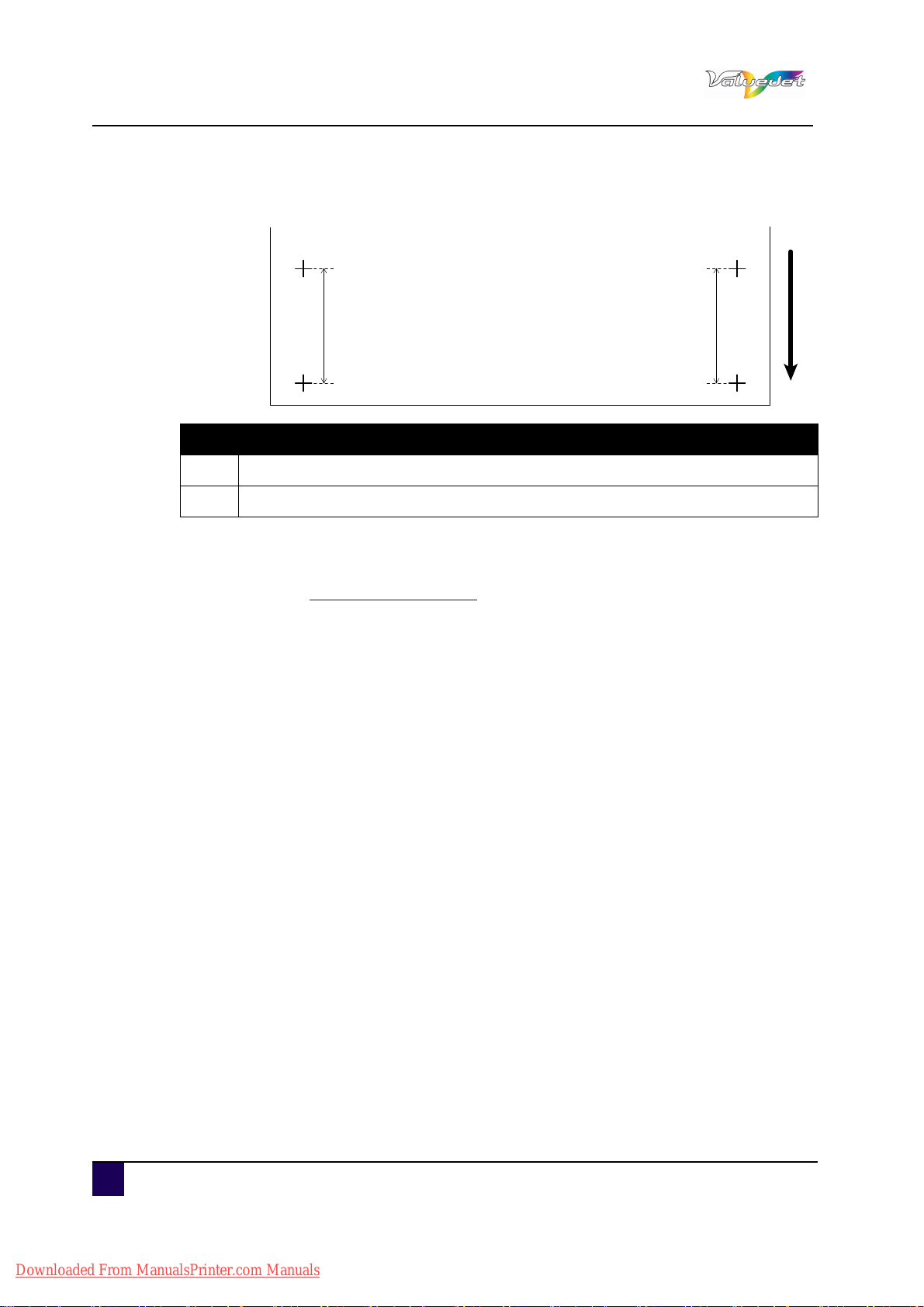

Printing area. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Notes on handling media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Notes on storing media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

4.2 Test print . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Overview and functions of the test prints. . . . . . . . . . . . . . . . . . . . . 75

Performing a Test print. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Nozzle Check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Mode Print . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Setup print . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Palette print . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

AP-75810 - Revision 2.0 - 7/4/11 6

Downloaded From ManualsPrinter.com Manuals

User’s Guide ValueJet 1608 HS

4.3 Set the correct distance adjust (Step). . . . . . . . . . . . . . . . . . . 81

Basics about the step . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

4.4 Adjust print . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Chapter 5 Printer menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

5.1 How to work in the menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Normal mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Setup menu display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Changing the printer status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

5.2 Operating from the operation panel . . . . . . . . . . . . . . . . . . . . 93

Feeding media. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Stop printing operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Cutting media. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Changing and confirming settings while printing . . . . . . . . . . . . . . 96

Pause printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

5.3 Menu setup on the operation panel. . . . . . . . . . . . . . . . . . . . . 99

Panel setup menu overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Menu setup procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Menu overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

5.4 Panel Setup Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Menu 1: Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Menu 2 - 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Menu 7: Version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Menu 8: Sleep mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Chapter 6 Periodical maintenance . . . . . . . . . . . . . . . . . . . . . 135

6.1 Done by end user . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Keeping optimum printing conditions . . . . . . . . . . . . . . . . . . . . . . . 137

Cleaning the printer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Cleaning the outer case . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Cleaning the inside of the printer . . . . . . . . . . . . . . . . . . . . . . . . . . 138

AP-75810 - Revision 2.0 - 7/4/11 7

Downloaded From ManualsPrinter.com Manuals

User’s Guide ValueJet 1608 HS

Head cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Cleaning the cleaning wiper and around the print head . . . . . . . 143

Draining condensated water . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

Replacing the spitting box sponges . . . . . . . . . . . . . . . . . . . . . . . . 152

Cleaning the timing fence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

Cleaning the P-rear sensor surface . . . . . . . . . . . . . . . . . . . . . . . . 157

6.2 Done by Authorized Mutoh Technician. . . . . . . . . . . . . . . . . 158

Chapter 7 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

7.1 Malfunctions and failures. . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

Problems in installation and introduction . . . . . . . . . . . . . . . . . . . . 161

Cannot print at all . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

Media-related troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

Printing-related troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

Air pressure related troubleshooting . . . . . . . . . . . . . . . . . . . . . . . 170

7.2 Error messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

Status messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

Error message display and remedies. . . . . . . . . . . . . . . . . . . . . . . 174

Data error display and solutions . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

Command error display and remedies. . . . . . . . . . . . . . . . . . . . . . 176

Error requiring restart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

7.3 The media is jammed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

Removing Thick Media. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

Removing Roll Media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

8 AP-75810 - Revision 2.0 - 7/4/11

Downloaded From ManualsPrinter.com Manuals

User’s Guide ValueJet 1608 HS

Safety instructions

Chapter 1 Safety instructions

This chapter explains the safety of the printer, warning terms that operators need to know,

caution items and warning labels on the printer main unit.

Important

When operating this printer, be sure to follow the directions and warnings in

this guide.

1.1 Compliance with the following regulations

The CE marking is a mandatory European marking for certain

product groups to indicate conformity with the essential health and

safety requirements set out in European Directives.

1

By affixing the CE marking, the manufacturer, his authorized

representative, or the person placing the product on the market or

putting it into service ensures that the item meets all the essential

requirements of all applicable EU directives and that the applicable

conformity assessment procedures have been applied.

Your product is designed and manufactured with high-quality

materials and components, which can be recycled and reused.

When this crossed-out wheeled bin submenu is attached to a

product, it means the product is covered by the European Directive

2002/96/EC - WEEE regulation.

Please inform yourself about the local separate collection system for

electrical and electronic products.

Please act according to local rules and do not dispose of your old

products with your normal household waste. The correct disposal of

your old product will help prevent potential negative consequences

for the environment and human health.

AP-75810 - Revision 2.0 9

Downloaded From ManualsPrinter.com Manuals

User’s Guide ValueJet 1608 HS

Safety instructions

1.2 Managing VOCs

Using Mutoh printers with Bio Solvent Inks, volatile organic compounds will be

released. (VOCs)

In order to protect human health and the environment, VOCs must be managed. This

means VOCS need to be controlled and complying with all local, state and federal

environmental, occupational health, and safety regulations on VOCs in the atmosphere

and in the workplace is needed.

The amount of released VOCs depends on multiple factors: room volume, unforced

ventilation, print mode, number of printers in the room, heaters settings, kind of media,

use of extra dryers, print production…

Because of differences in local regulations and working conditions, it's recommended

to consult a local consultancy agency to determine the regulations involved. An

acknowledge laboratory can determine the total amount of released VOCs in the

atmosphere and in the workplace. Consequently they can determine if forced

ventilation for occupational health and air pollution control devices are needed. An

engineering firm could be consulted on the installation of the ventilation system where

prints are produced, handled and stored.

10 AP-75810 - Revision 2.0

Downloaded From ManualsPrinter.com Manuals

User’s Guide ValueJet 1608 HS

Safety instructions

1.3 Handling inks / cleaning or waste fluids (cleaning & ink)

Before handling inks/ cleaning and their waste, do carefully read the MSDS-sheet and

the container labels for important health, safety and environmental information.

Only use original manufacturer's ink and appropriate cleaning liquid.

Before installing the ink pack, shake it gently. Doing so will preserve print quality.

To avoid ink separation, please remove and shake all ink packs gently once a week. To

gently shake the ink packs, rotate them side to side at least 2 or 3 times. Then, turn the ink

pack upside down and rotate side to side another 2 or 3 times.

When moving ink from a cold place to warm place, keep the ink for three hours or more in

the new printing environment before printing.

Inks

General advice: wear safety glasses and gloves especially when handling the waste

ink.

After spill: remove contaminated clothing.

After inhalation: if difficulties occur after vapour/aerosol has been inhaled, remove to

fresh air and seek medical attention.

After skin contact: wash thoroughly with soap and water.

After eye contact: wash affected eyes for at least 15 minutes under running water while

eyelids held open.

After swallowing: rinse mouth and drink plenty of water. Never induce vomiting.

Do not disassemble ink container. Otherwise, ink may get in your eyes or on your skin.

Also a disassembled ink container can not be used.

When refilling ink, use original manufacturer's ink. This printer is designed to use genuine

ink. When using non-original manufacturer’s ink,

printing might become blurred and the end of the ink in the container might not be

detected correctly

any problems caused by using ink other than those recommended above will not be

covered by the warranty, and repair expenses will be paid by the customer.

For handling waste: see section 13 on the MSDS-sheet

1

AP-75810 - Revision 2.0 11

Downloaded From ManualsPrinter.com Manuals

User’s Guide ValueJet 1608 HS

Safety instructions

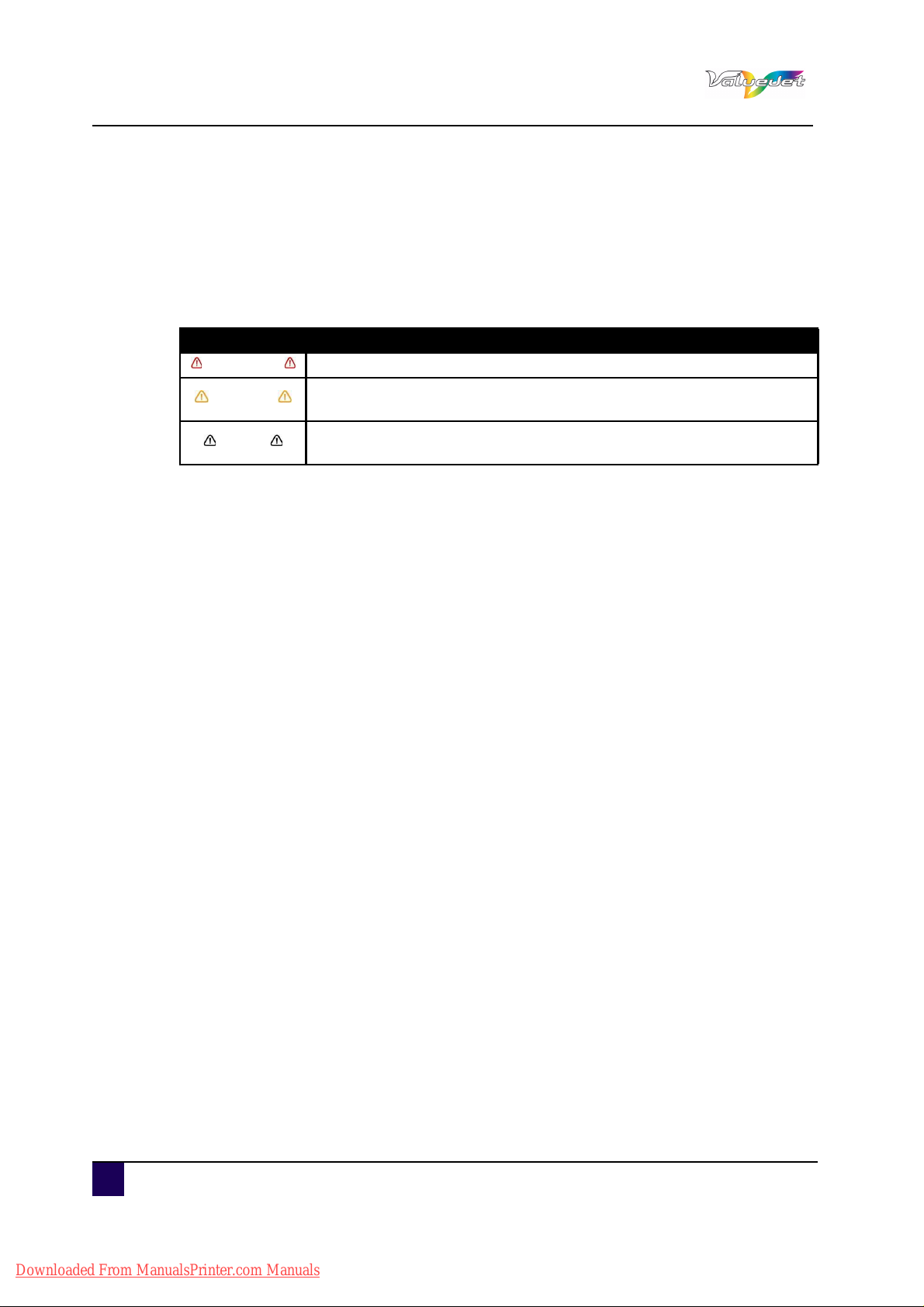

1.4 Warnings, cautions and notes

Safety terms in this manual and the contents of warning labels attached to the printer are

categorized into the following three types, depending on the degree of risc (or the scale of

accident).

Read the following explanations carefully and follow the instructions in this manual.

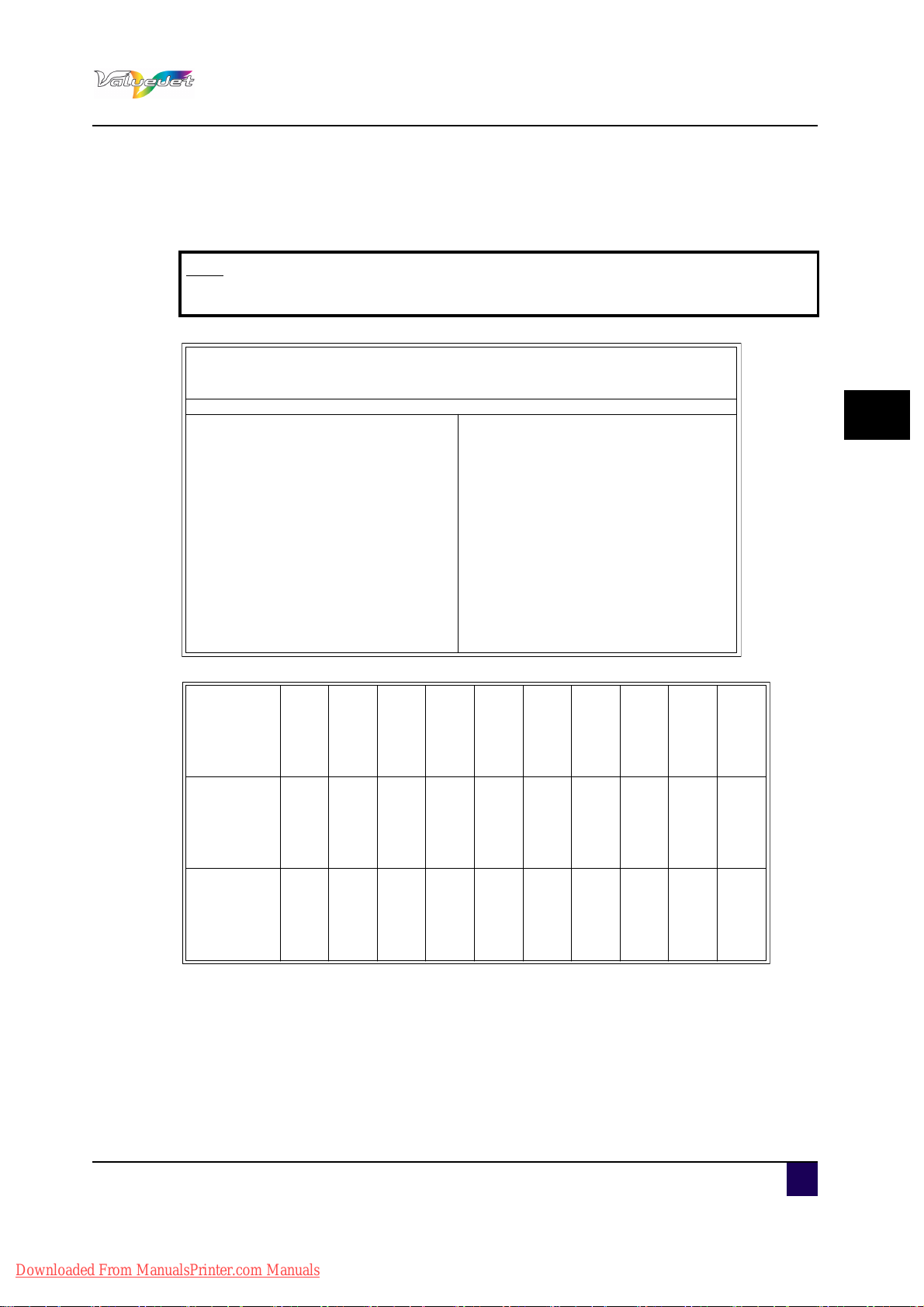

Safety terms Details

Important Must be followed carefully to avoid death or serious bodily injury.

Caution

Notes

Must be observed to avoid bodily injury (moderate or light) or damage to

your equipment.

Contains important information and useful tips on the operation of your

printer.

12 AP-75810 - Revision 2.0

Downloaded From ManualsPrinter.com Manuals

1.5 Safety instructions

Machines must be installed according to Mutoh’s Installation Guide also after moving

machines to another location; maintenance needs to be done according to the

maintenance manual.

To prevent fire or electrical shock, never use a power supply source other than the one

rated for the product in the country where you purchased the product.

To prevent fire or electrical shock, machines must be connected to a properly grounded

electrical power outlet. Do not connect the power cable to a power strip or a power source

shared by other electrical devices.

Make sure that no foreign substances such as dust etc. are stuck to the power plug.

Make sure that the power plug is firmly inserted to the edge of the power socket.

Use only the provided power cable. To prevent fire or electrical shock, follow the

instructions below when handling the power cable:

Do not cut or modify the cable.

Do not put heavy objects on the cable.

Do not bend, twist, knot or pull the cable.

Do not wire the cable near equipment that generates heat.

Do not use the cable with any other electrical device.

Do not handle the cable with wet hands.

Be aware of all caution and warning labels to avoid potentially hazardous situations.

Do not disable any safety precautions systems.

Do not operate the unit unless all parts are mounted.

Do not stand on or place heavy objects on your machine. Doing so may result in the

machine tipping or falling over and causing injury.

Do not place the machine in humid and dusty areas or in areas exposed to flammables.

Doing so may result in electrical shock or fire.

Do not place the machine in the following areas. Doing so may result in the machine

tipping or falling over and causing injury.

Unstable surfaces

Sloping floors

Areas subject to vibration by other equipment.

Do not cover the ventilation hole of your machine with cloth, such as a blanket or table

cloth. Doing so could obstruct ventilation and cause fire.

Do not insert or drop metal or inflammable objects into openings, such as ventilation

outlets. Doing so may result in electrical shock and fire.

Do not touch the media guide during printing. It is hot and may cause a burn.

Do not touch the media feed slot, platen or media guide while heaters are operating. They

are hot and may cause a burn.

Keep the machine horizontally during transportation.

User’s Guide ValueJet 1608 HS

Safety instructions

1

AP-75810 - Revision 2.0 13

Downloaded From ManualsPrinter.com Manuals

User’s Guide ValueJet 1608 HS

Safety instructions

To prevent back pains and other injuries, always work with at least 4 people to unpack or

move the machine.

Stop using your machine if a liquid has been spilled into it. This may cause electrical shock

or fire. Switch the machine off as soon as possible, unplug the power cord, and contact

your local Mutoh dealer.

Be sure to power OFF the machine and unplug the power cable from the outlet before

cleaning the machine. Use a damp cloth to clean the machine. Do not use thinner,

benzene, alcohol or other active agents. Doing so may result in damage or paint peeling

from the casing.

Do not bend or pull the waste fluid tube. Doing so may cause waste fluid to leak out and

malfunction of the product.

Do not tilt the machine, place it against a wall or turn it upside down. Doing so may cause

ink to leak inside the machine. Movement after transport is also not covered by the

warranty.

When cutting roll media, be careful of the following. Incorrect handling can result in injury

to the hands and fingers from the razor blade.

When holding the media, do not place fingers over the media cut groove.

Move the razor blade slowly along the media cutting groove.

Do NOT transport the machine to another room without contacting your local Authorized

Mutoh Dealer.

14 AP-75810 - Revision 2.0

Downloaded From ManualsPrinter.com Manuals

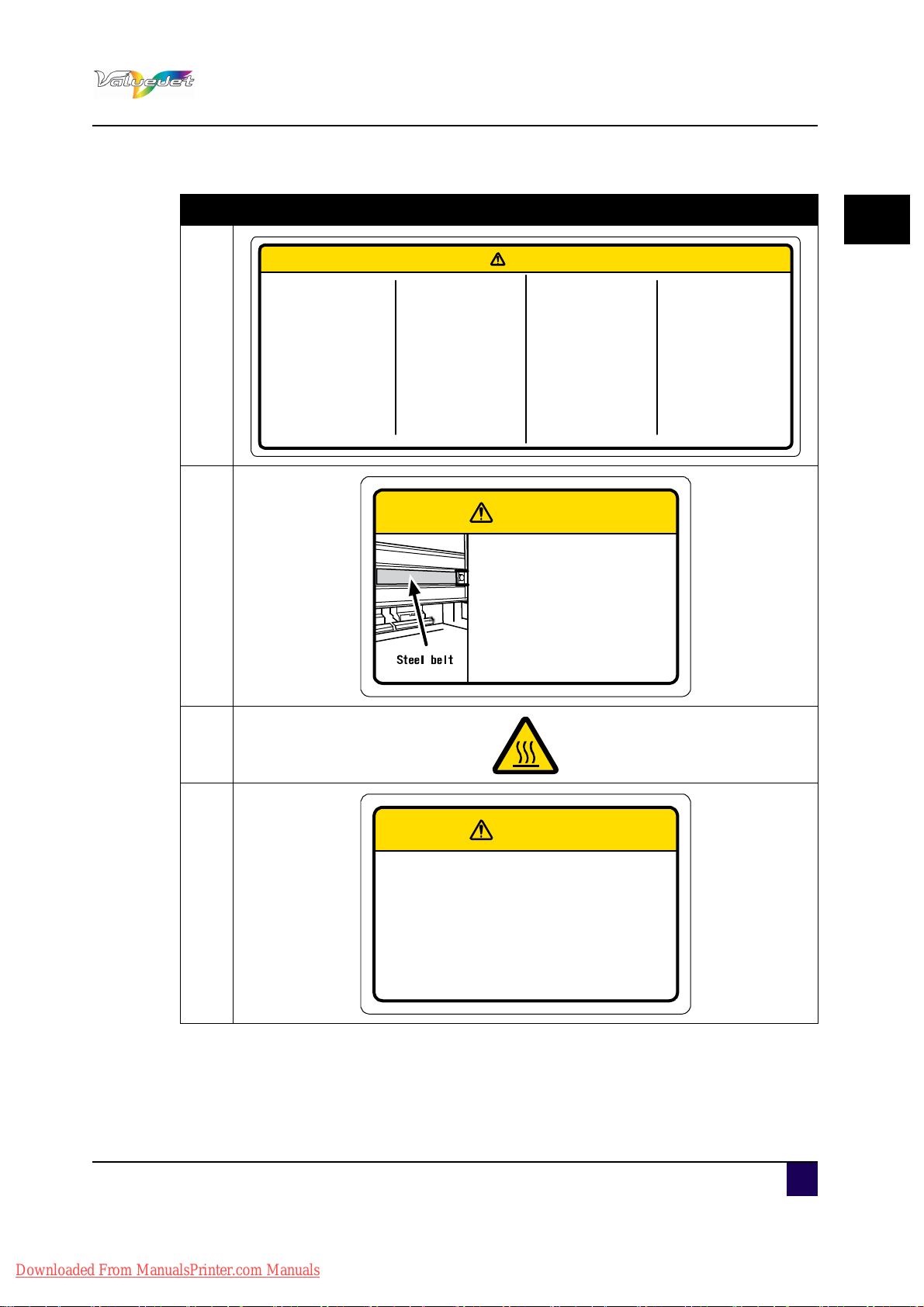

1.6 Warning labels

Be sure to read and understand the safety warnings before handling the printer.

A warning label is used on parts of the printer which especially need your attention.

Understand the locations and the descriptions of the danger associated with each label

before operating the printer.

1.6.1 Handling the operation procedure labels

Note

Check whether all the warning labels can be read. If the letters or illustrations

on the label are not clear, remove the dirt from the label.

Use cloth, water and mild detergent to remove the dirt from the label. avoid

either organic solvents or gasoline.

if warning labels need to be replaced, contact your local Mutoh dealer.

User’s Guide ValueJet 1608 HS

Safety instructions

1

AP-75810 - Revision 2.0 15

Downloaded From ManualsPrinter.com Manuals

User’s Guide ValueJet 1608 HS

4

6

Safety instructions

1.6.2 Location and type of warning labels

16 AP-75810 - Revision 2.0

Downloaded From ManualsPrinter.com Manuals

User’s Guide ValueJet 1608 HS

◆Do not open thefront cover while

printing.

Moreover. Do not touch the media while

printing.

Good printing result might not be

obtained.

※Pleaseremovethemediaandholdthe

lever upwhen not usingfor a longtime.

Due to the environment conditions,

media floatand wrinkle mighthappen

that does notobtain the goodresult.

注 意

◆作画中はフロントカバーを開けないで

ください。

また、作画中は開口部から手を入れた

り用紙に触れないでください。

思わぬケガをしたり、良好な作画結果

が得られないことがあります。

※長時間作画を行わない時は、用紙を外

しホールドレバーをアップ状態にして

ください。

良好な作画結果が得られないことがあ

ります。

◆Paper guides,platenand paper holding

plate willbecome hot dueto the heater

temperature setting.

Beware ofbeing burned.

◆ヒーターの温度設定により、ペーパ-

ガイド、プラテン、用紙押えプレート

が高温となるため、火傷をする恐れが

あります。

◆Normal cleaning should be done once

a week if the printer is notu sedfor a

long period.

※If the printer is left without cleaning,the

ink willb ehardened inside the head

nozzl e,and may cause the he ad

trouble.

◆長期間プリンタを使用しない場合は、

週に一度ノーマルクリーニングを行って

ください。

※クリーニングを行わずに放置すると、

ヘッドノズル内でインクが固まりヘッド

故障の原因となります。

◆Do not give adirect wind from a fan or

air conditioner to the machine.

※A wind may dry theink in the head

no zzles causi ng clog ging t hat affe cts

ink jetting,and yo uw illno t be able to

obtain satisfactory printing results.

◆直接機械に送風機や空調装置の風を当て

ないで下さい。

※風によりヘッドノズル内のインクが固ま

りヘッド故障の原因になったり、インク

の吐出に影響を与え、満足な印字結果が

得られないことがあります。

CAUTION

◆Sharp Edges

Do not touch steel belt.

※You may be injured.

スチールベルト

◆スチールベルトは端が鋭く尖って

いますので触らないでください。

※けがをする恐れがあります。

注 意

CAUTION

◆Do not bend or pull the waste ink drain tube.

The ink may be leaked and damages the

printer.

◆廃液チューブを折り曲げたり、引っ張ったり

しないで下さい。インクが漏れて製品が故障

する恐れがあります。

注 意

CAUTION

Safety instructions

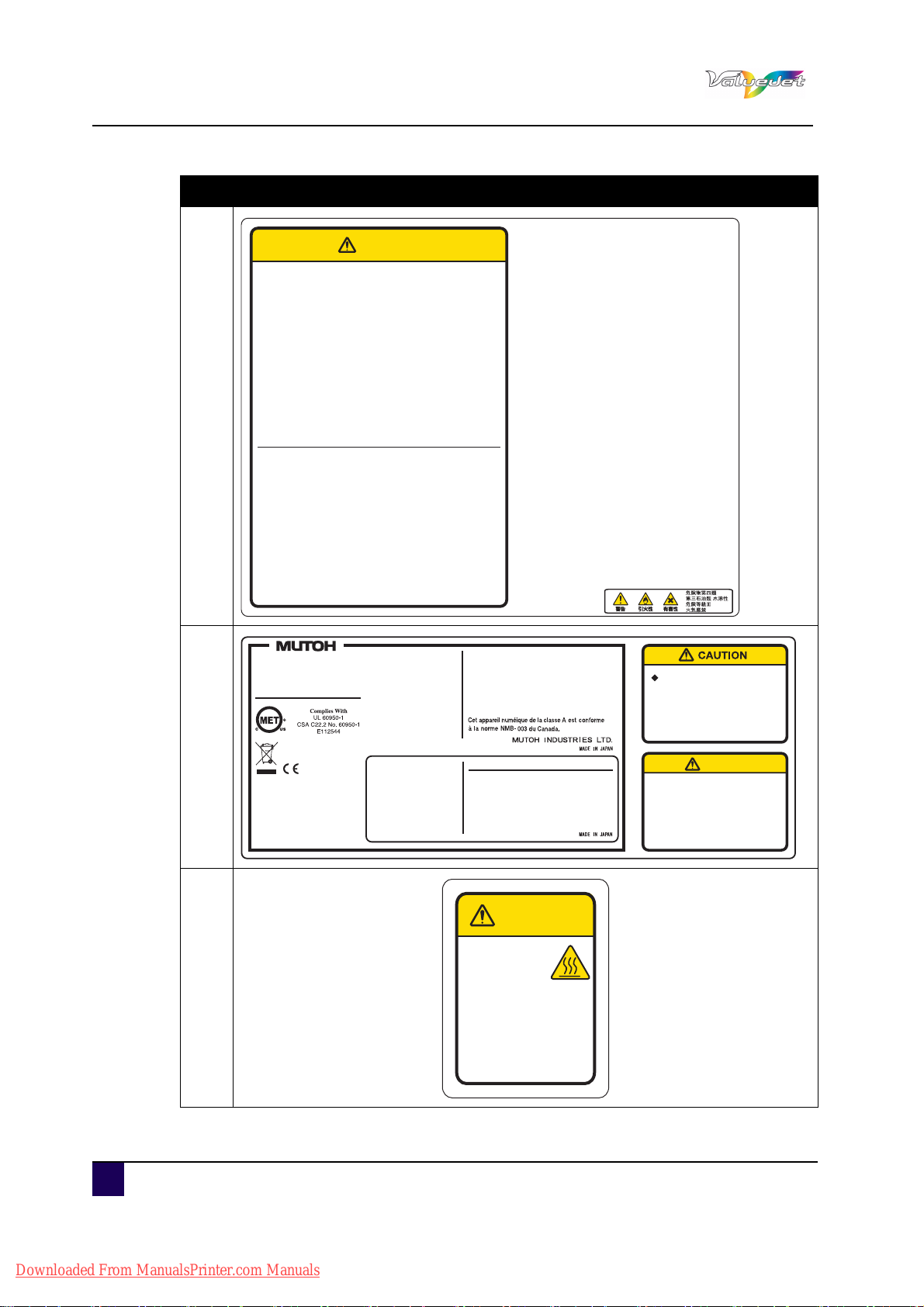

N° Description

1

2

1

3

4

AP-75810 - Revision 2.0 17

Downloaded From ManualsPrinter.com Manuals

User’s Guide ValueJet 1608 HS

This device has three power

systems. There is a risk of electric

shock unless the three power

cables are unplugged during the

maintenance.

MODEL

SERIAL NO.

VJ-1608HS

GN6X XXXXXX

MAIN

VOLTAGE

FREQUENCY

AC 100-240V

50 / 60 Hz

CURRENT 9A - 5A

HEATER 1 / HEATER 2

VOLTAGE

FREQUENCY

AC 100-240V

50 / 60 Hz

CURRENT 10A - 5A

型式

製造番号

This Class A digital apparatus complies with Canadian

ICES-003.

This device complies with Part 15 of the FCC Rules.

Operation is subject to the following two conditions:

(1) this device may not cause harmful interference, and

(2) this device must accept any interference received,

including interference that may cause undesired

operation.

MAIN

定格電圧

定格周波数

AC 100V

50 / 60 Hz

消費電流 9A

HEATER 1 / HEATER 2

定格電圧

定格周波数

AC 100V

50 / 60 Hz

消費電流 10A

注意

この装置は、クラスA情報技術装置です。

この装置を家庭環境で使用すると電波妨害を

引き起こすことがあります。

この場合には使用者が適切な対策を講ずるよう

要求されることがあります。 VCCI-A

武藤工業株式会社

◆この機器は3系統の電源を持っ

ています。

保守の時には3本の電源ケーブ

ルを抜かないと感電の危険があ

ります。

注 意

◆Hot surface,be

careful not to

burn your fingers!

◆この面は大変熱くなっ

ています。

火傷をしないよう注意

してください。

注 意

CAUTION

Safety instructions

N° Description

CAUTION

注 意

●Before using this product,please be sure to read the Material

Safety Data Sheet (MSDS).

●The workplace should be free from open flame and well

ventilated.

●Please handle the ink with care to avoid the ink touch to your

skin,eyes and clothing,also to avoid accidental ingestion.

Be careful not to inhale the steam.

●Please wear a protective mask,eyewear,gloves, long sleeves

and long trousers to avoid contact with the ink during the

operation.

●Work clothes that soiled with the ink should be thoroughly

cleaned.

●Please wash your hands and gargle well after using.

5

●Do not bring food near.

●Please store out of reach of children.

●Do not use for anything other than VJ.

●ご使用前に、必ず製品安全データシート (MSDS) をお読みくだ

さい。

●取扱い作業場所は火気の無い所で行い、換気を十分に行ってく

ださい。

●インクを皮膚、目、衣服に接触させたり、誤飲しないよう十分

に注意して取扱ってください。

また、蒸気を吸込まないよう注意してください。

●取扱中はなるべくインクとの接触を避けるため、保護マスク、

保護メガネ、保護手袋、長袖、長ズボン等を着用してください。

●作業衣等に付着した場合は、その汚れをよく落としてください。

●取扱い後は、手洗い及びうがいを十分に行ってください。

●食品に近づけないでください。

●子供の手の届かないところへ保管してください。

●VJ以外には使用しないでください。

Emergency Measures

●If it sticks to your skin,wash well with plenty of soapy

water.

Consult your doctor if your skin feels imitated or is

discolored.

●If it gets in your eyes,wash well with plenty of tap water

and see your doctor as soon as possible.

●If accidentally swallowed,do not vomit.

Consult your doctor as soon as possible.

●If you inhaled the steam,move to clean air and consult

your doctor if you feel giddy or nauseous.

●If breathing has stopped,apply artificial respiration

immediately, and get anemergency medication.

●If spilled from the container,remove heat sources,

sparks and flame first,then wipe up with cloth.

Used cloths containing ink should be soaked in

water until disposal.

応急処置

●皮膚に付着した場合は多量の石鹸水で洗い流し、皮膚に

刺激を感じたり変化がある場合は医師の診断を受けてく

ださい。

●目に入った場合は多量の水道水で洗い流し、出来るだけ

早く医師の診断を受けてください。

●誤って飲み込んだ場合は吐き出さないでください。

その後できるだけ早く医師の診断を受けてください。

●蒸気を吸入した場合は空気の清浄な場所に移動し、めま

いや吐き気を感じる場合は医師の診断を受けてください。

●呼吸が止まった場合はただちに人工呼吸を行い、救急医

療を受けてください。

●容器からこぼれた場合は、熱源、火花、炎からまず離し、

布等で拭き取ってください。インクが付着した布等は廃

棄するまで必ず水につけておいてください。

6

7

Downloaded From ManualsPrinter.com Manuals

18 AP-75810 - Revision 2.0

User’s Guide ValueJet 1608 HS

Product overview

Chapter 2 Product overview

Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Names of parts and functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Front section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Rear section. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Operation panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Operation keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Display section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2

AP-75810 - Revision 2.0 19

Downloaded From ManualsPrinter.com Manuals

User’s Guide ValueJet 1608 HS

Product overview

2.1 Features

This section explains the main features of the printer.

High-speed output

The new type print head achieves high-speed output.

Wide variety of compatible media

The thickness of the media is automatically detected. This printer supports media with a

minimum thickness of 0.08 mm and a maximum of 10.0 mm.

It is compatible with media widths up to 1615 mm.

Vibrant colour reproduction

Four colours of ink are used for printing in order to reproduce sharp and vivid colours.

This printer uses 880 ml of large capacity ink bags with a dedicated S/C card.

Use of variable dots can also improve colour reproduction.

Multi-heater

Heaters are installed at three locations (Pre Heater, Platen Heater, Drier) allowing the ink to

fix better on media and dry quickly.

The built-in air heater improves fixing and drying of the ink on thick media.

Effective use of media

A JOG feature is provided to allow setting the print starting position as required.

Printing can be performed on media that has already been printed on. This allows effective

use of left margins.

20 AP-75810 - Revision 2.0

Downloaded From ManualsPrinter.com Manuals

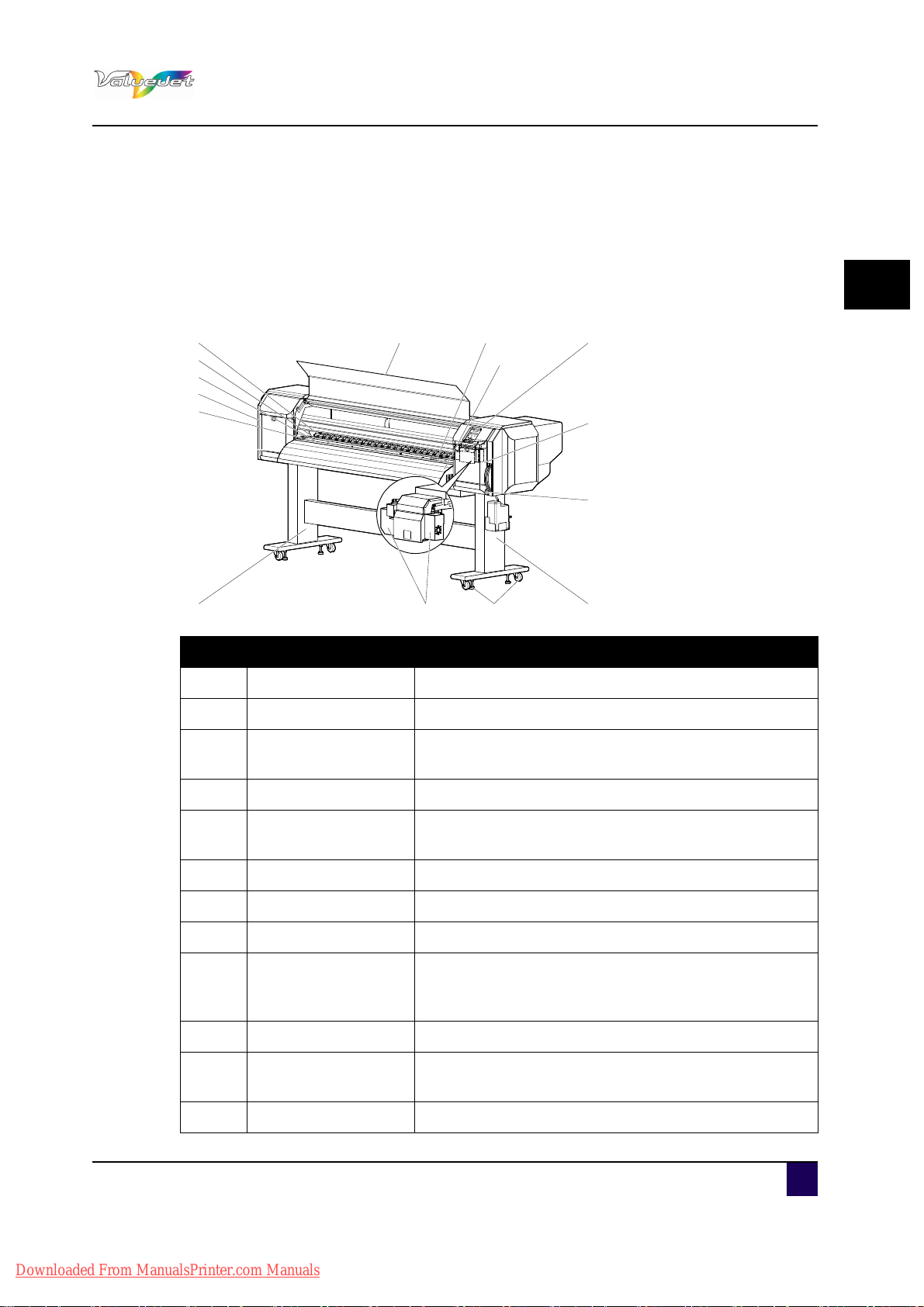

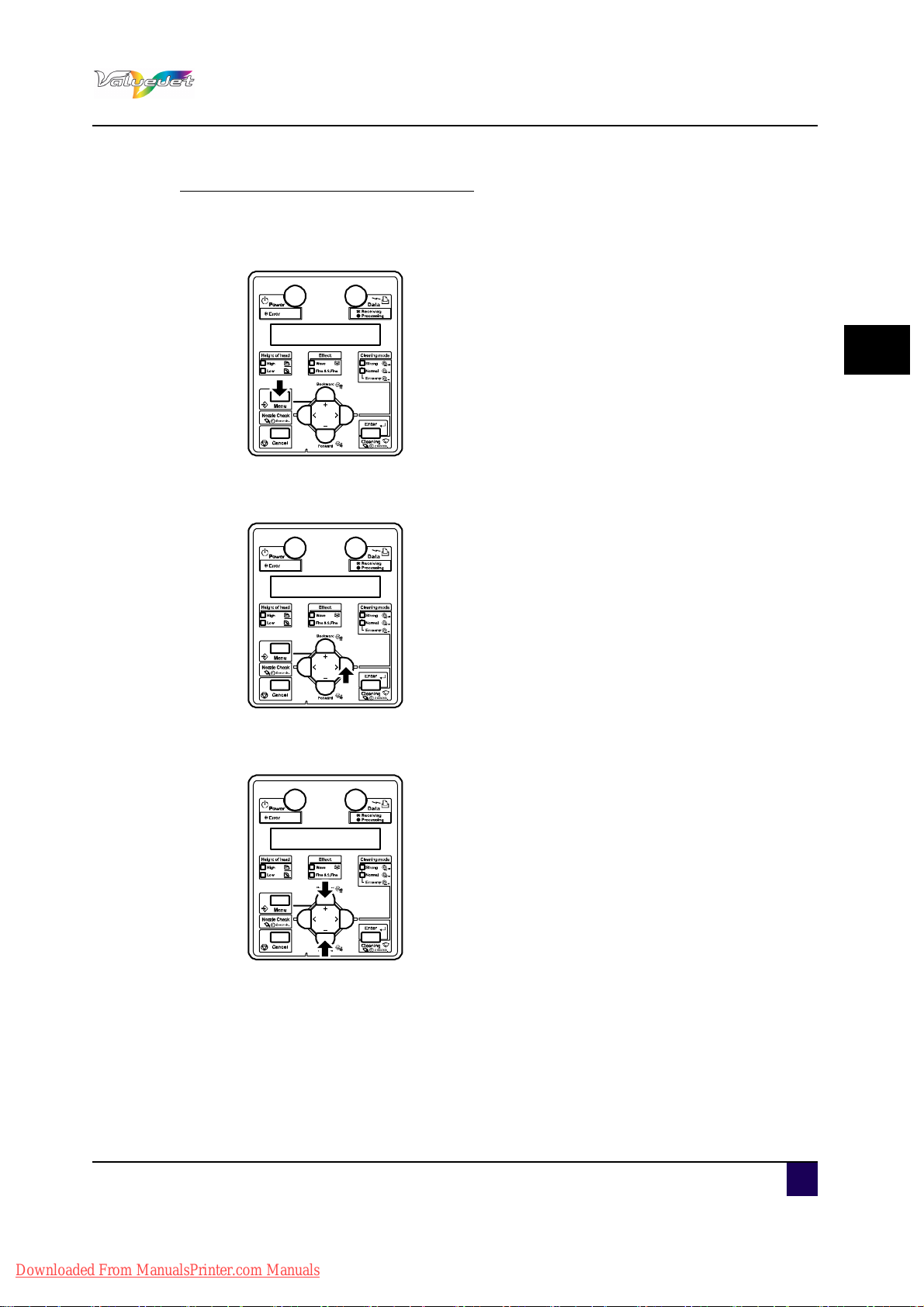

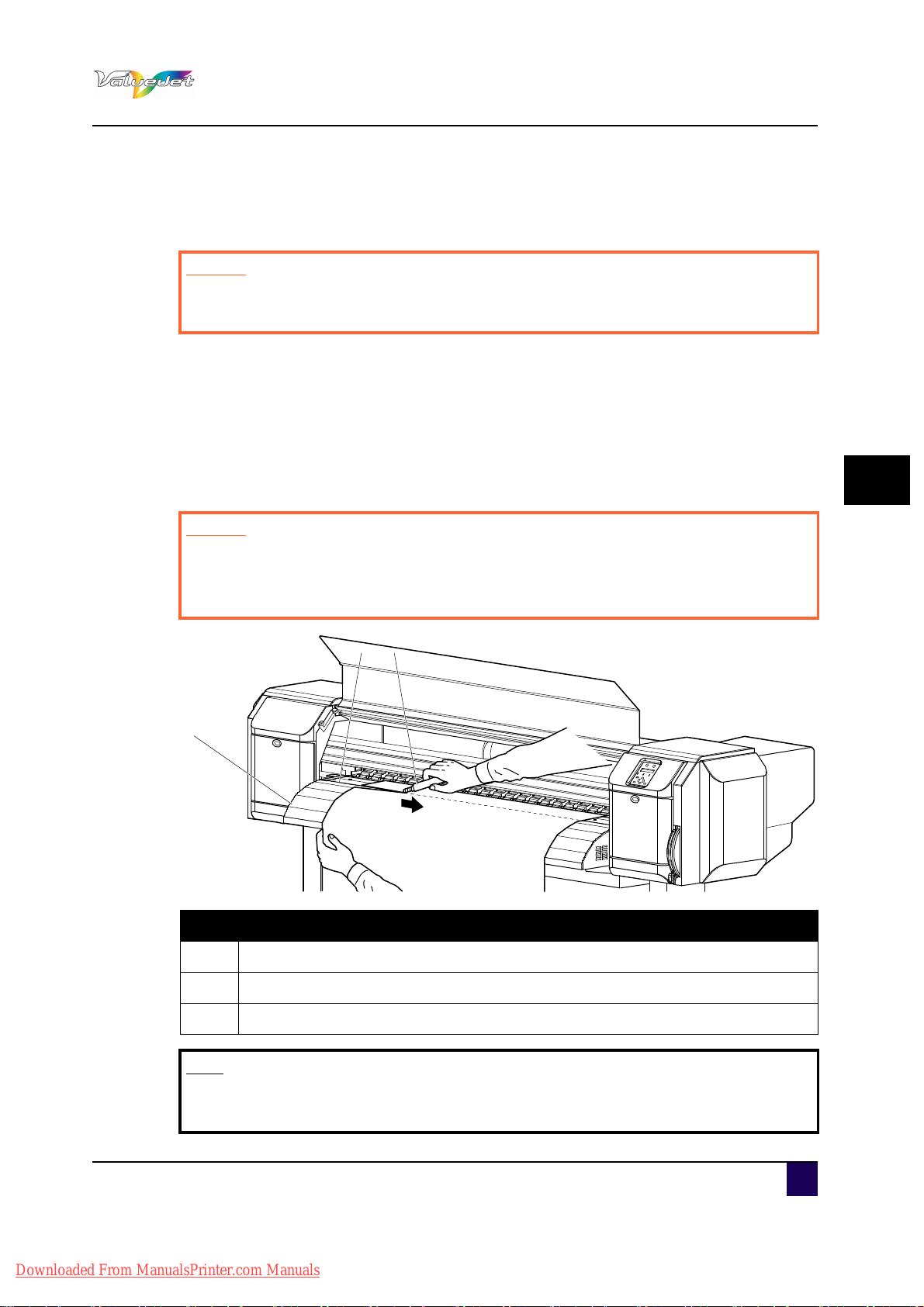

2.2 Names of parts and functions

11

1

10

2

113

9

4

7

8

12

4

9

6

5

This section explains the names and functions of each part.

User’s Guide ValueJet 1608 HS

Product overview

2.2.1 Front section

N° Description Function

1 Media loading lever Used to release or fix the media

2 Operation panel Various functions are performed via the panel.

2

3 Front cover

Used to prevent that a user comes in contact with the

driving mechanism.

4 Stand To install the printer on a level floor.

5 Media guide

Used to feed media smoothly through the printer. The

media guide incorporates the heaters to dry ink.

6 Platen The heater is installed inside of the front cover.

7 Pressure rollers Used to hold the media down while printing.

8 Media cut groove Use this groove to manually cut the media.

Only open and close when cleaning the cleaning wiper

9 Maintenance cover

unit or when cleaning around the print head.

In all other cases, leave this cover closed.

10 Adjuster Used to install the printer horizontally

11 Media retainers

12 Air heater Blows hot air to accelerate the drying of the ink.

AP-75810 - Revision 2.0 21

Attach media retainers to both sides of the media to

prevent warpage.

Downloaded From ManualsPrinter.com Manuals

User’s Guide ValueJet 1608 HS

5

4

1

10

8

9

6 7

1

3

2

43

Product overview

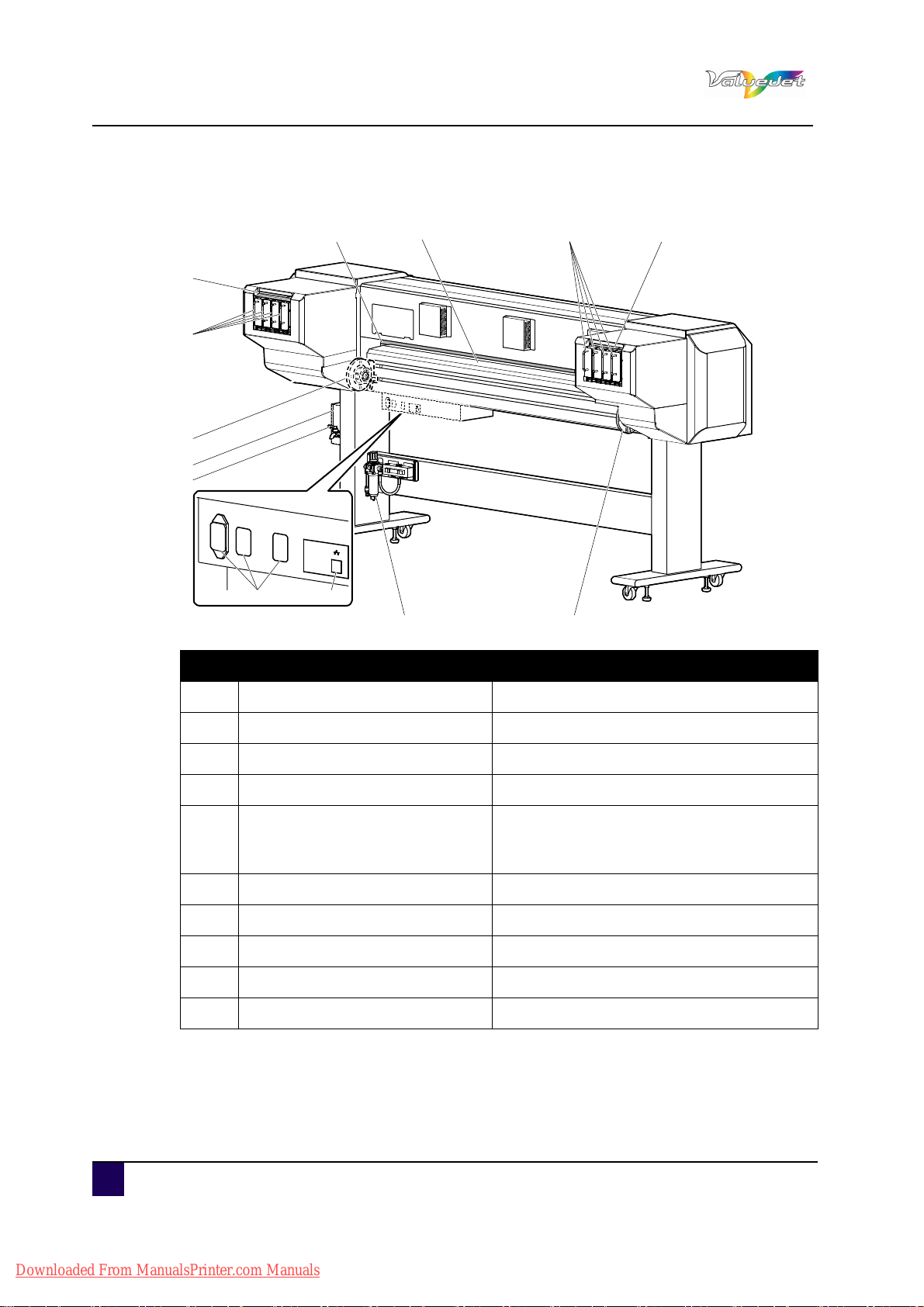

2.2.2 Rear section

N° Description Function

1 Roll media holders Used to load the roll media.

2 Media feed slot Used to feed media

3 Ink bag slot Slot that holds the ink bag

4 S/C card slot Slot that holds the S/C card

Used to feed the media smoothly through.

5 Media guide

The media guide incorporates the heater

system.

6 AC inlet Used to connect the power cables

7 Network interface connector Connects a network interface cable

8 Waste fluid tank To collect the discharged waste ink.

9 Waste fluid valve Open and close when discharging waste fluid.

10 Solenoid valve unit Controls the flow to the air heater.

22 AP-75810 - Revision 2.0

Downloaded From ManualsPrinter.com Manuals

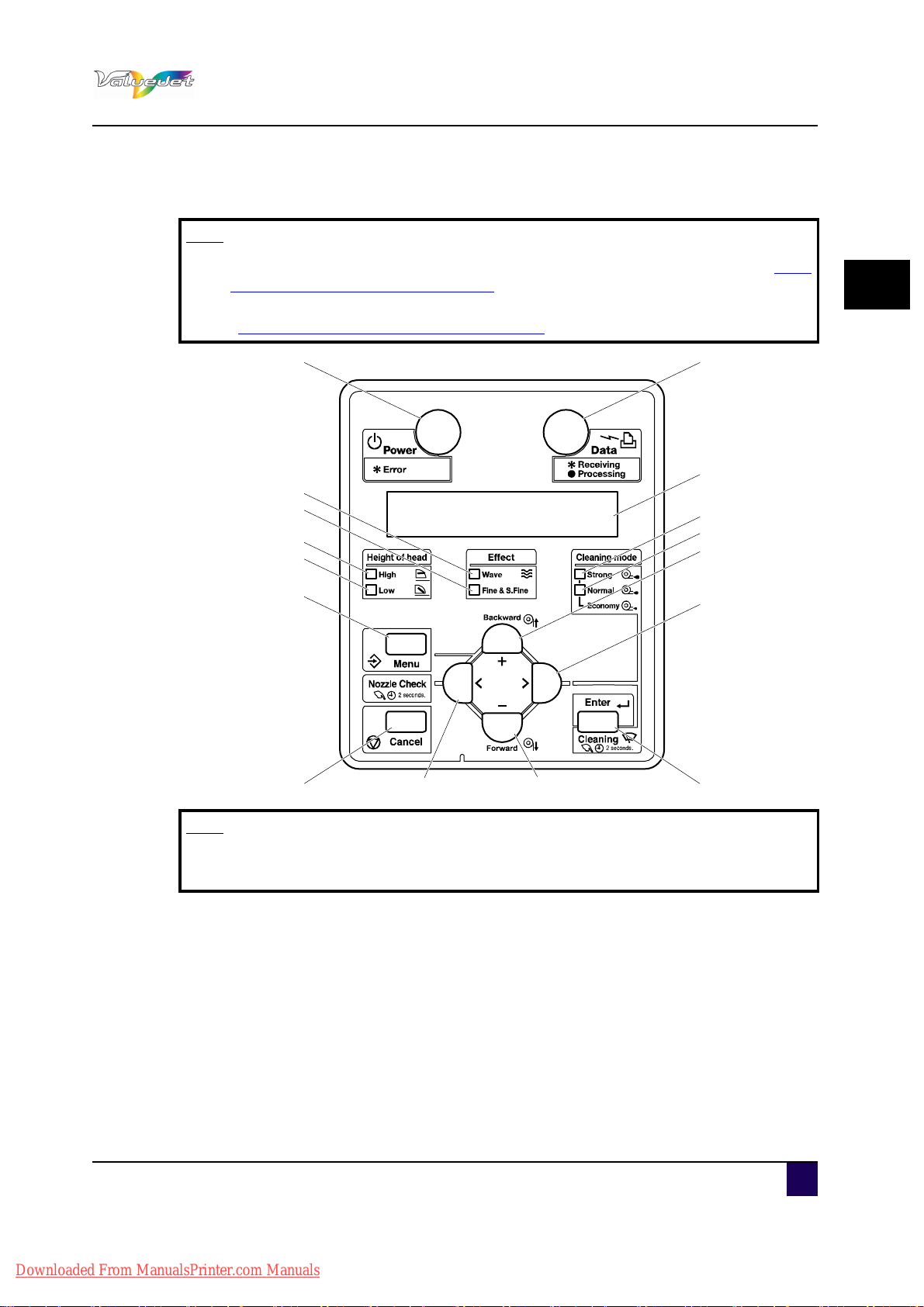

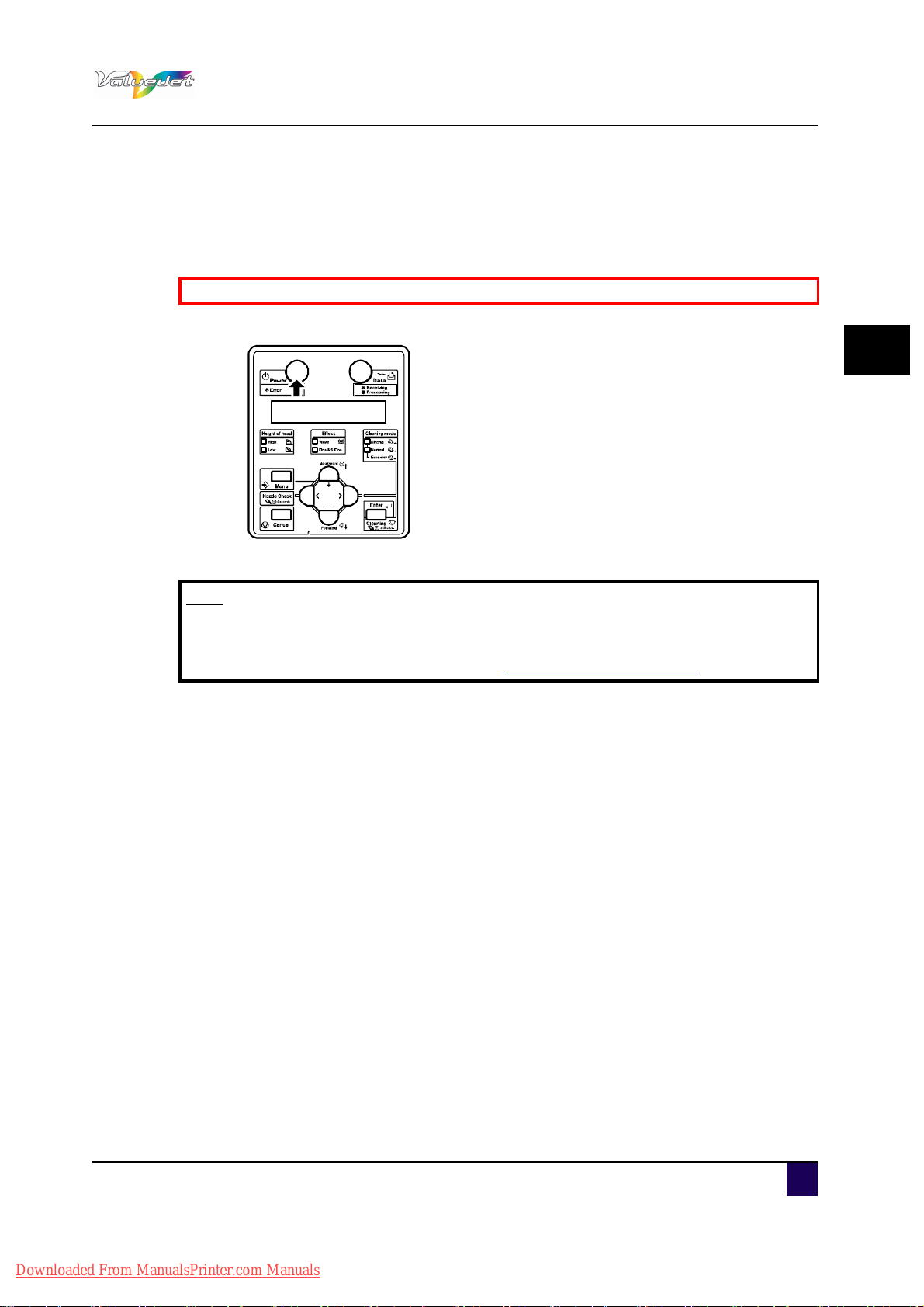

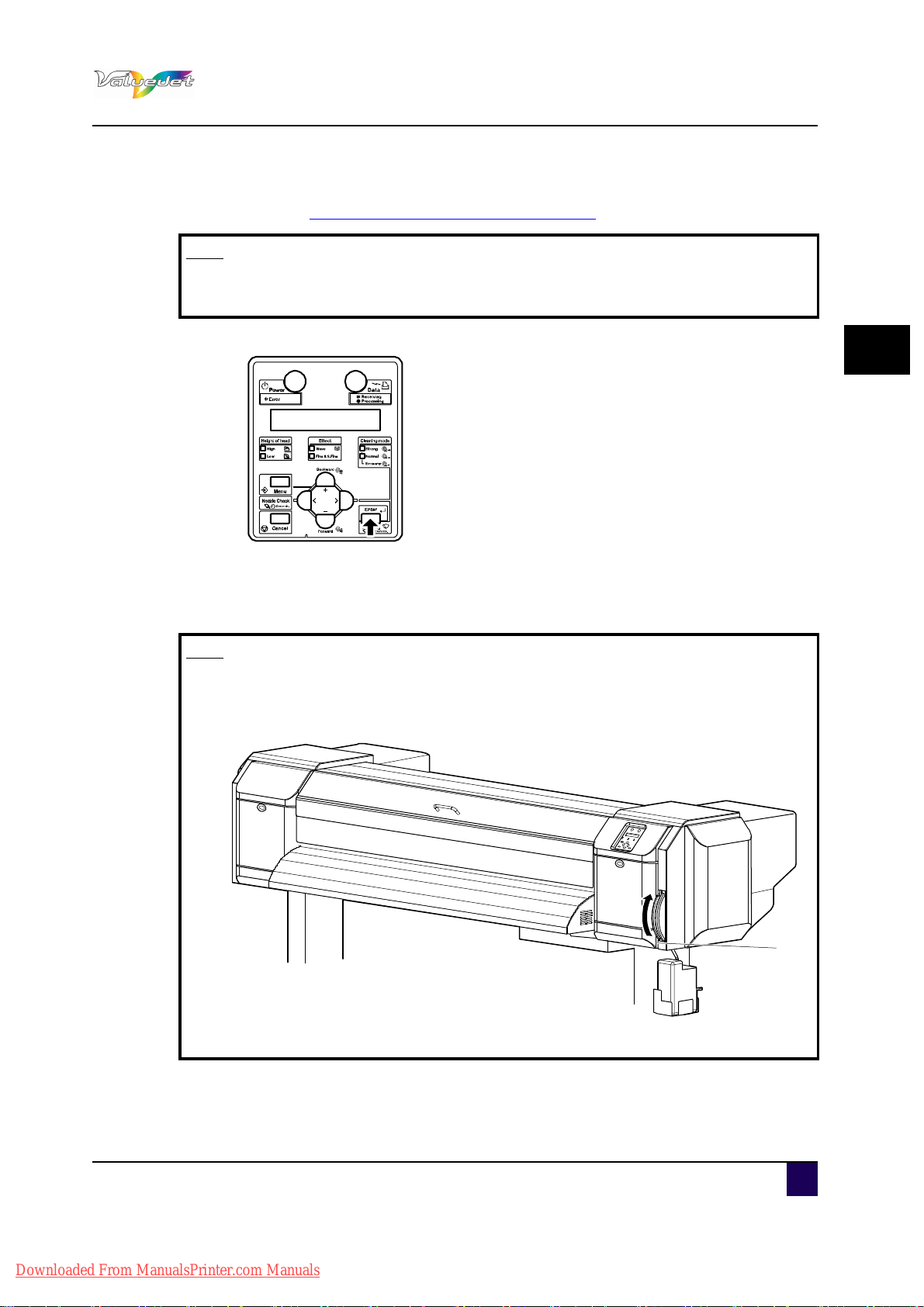

2.2.3 Operation panel

8, 9

3

15

17

16

6

5

11

12

1

13

14

10

27

4

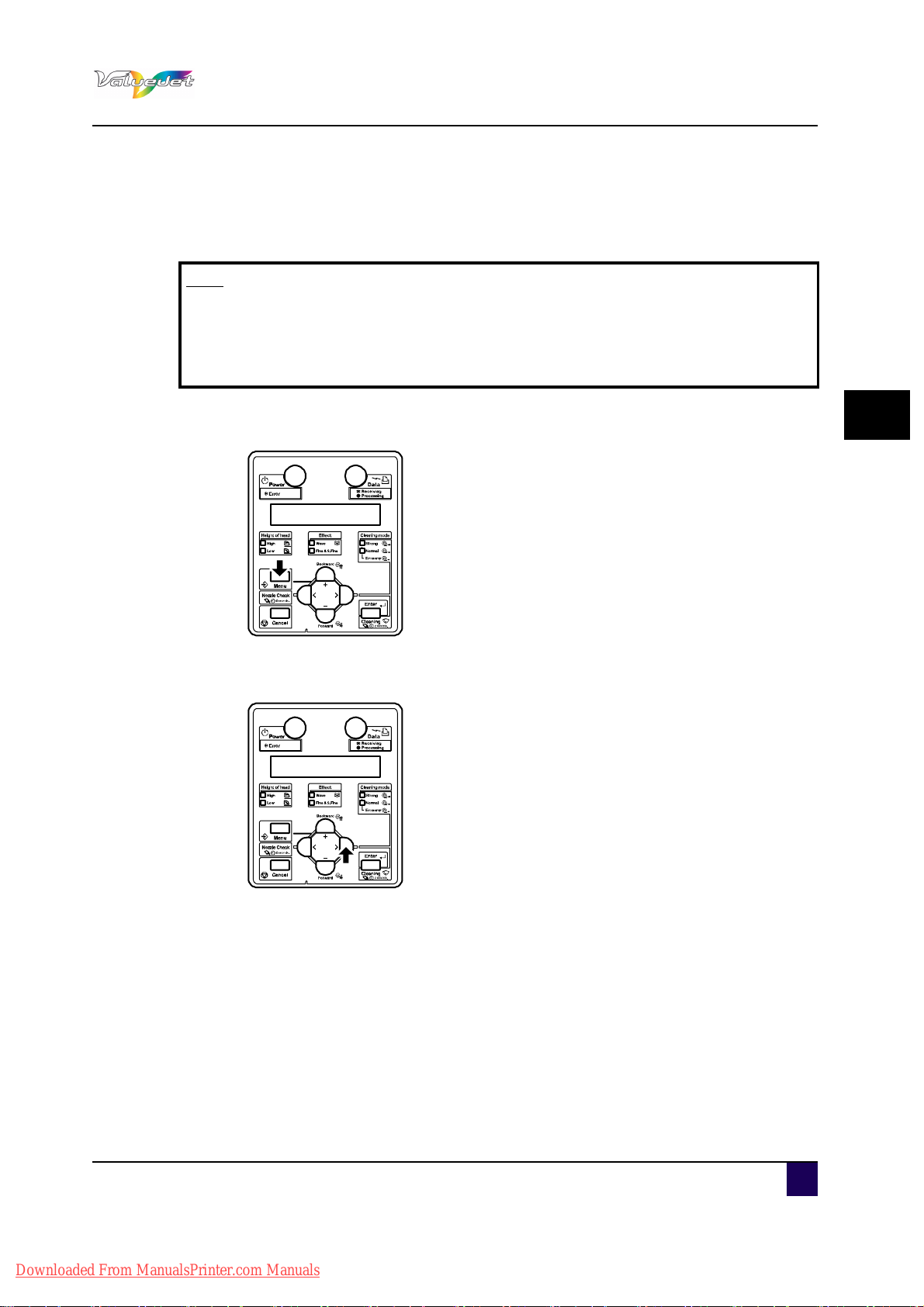

Note

When performing menu settings from the operation panel, please refer to Menu

setup on the operation panel on page99.

When performing various operations in the operation panel, please refer to

“Operating from the operation panel on page93

User’s Guide ValueJet 1608 HS

Product overview

2

”.

Note

The operation keys are assigned with different functions and names depending

AP-75810 - Revision 2.0 23

Downloaded From ManualsPrinter.com Manuals

on the printer status (Normal or Setup menu display)

User’s Guide ValueJet 1608 HS

Product overview

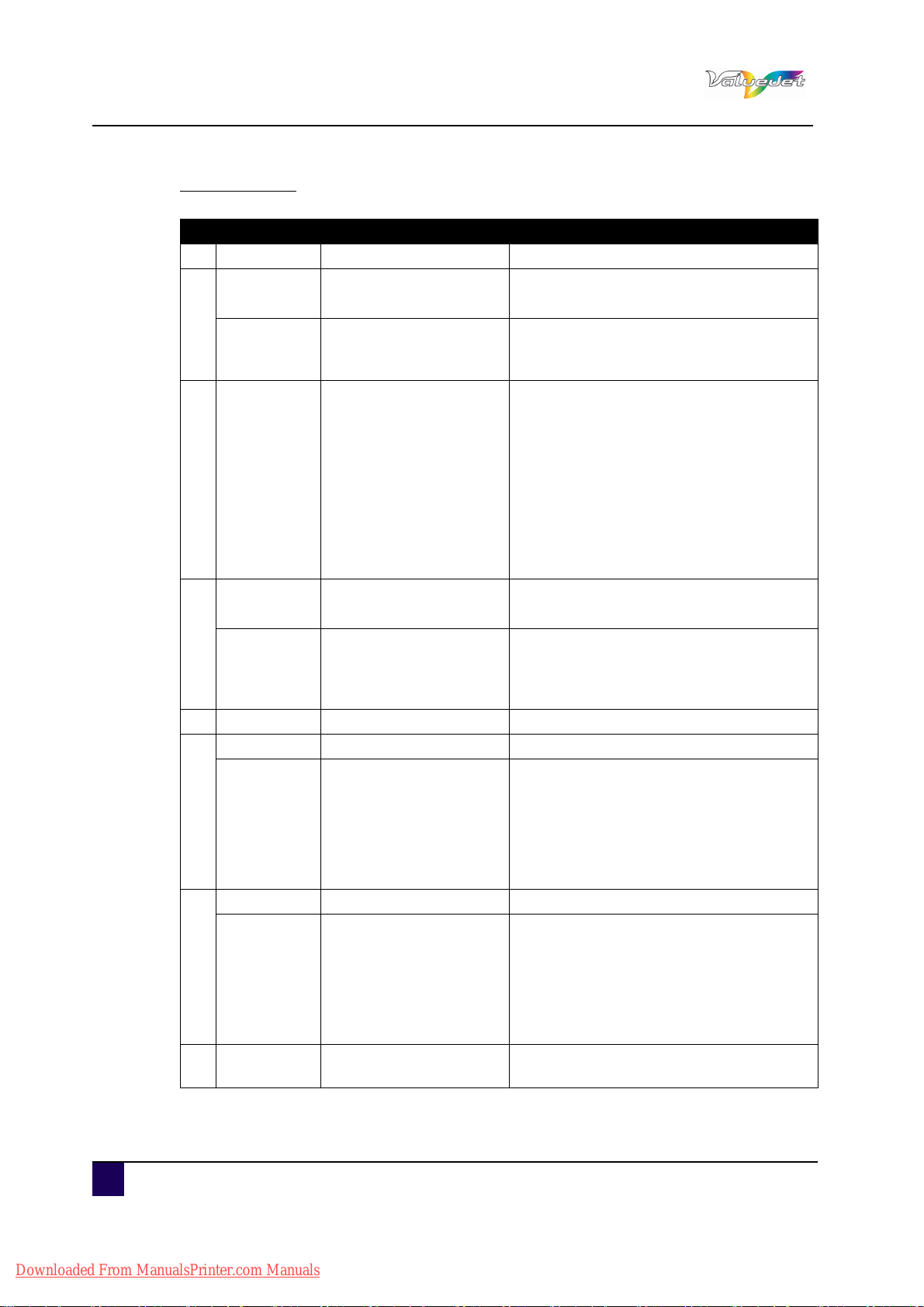

Operation keys

N° Key Normal Setup menu display

1 Menu Shifts to the Setup menu. Shifts from Setup menu display to Normal.

Enter

2

Cleaning

3 Cancel

< —

4

Nozzle Check

5 > Sets Cleaning Mode. Down the menu level in the directory tree.

Backward Media is fed backwards. —

6

+ —

Forward Media is fed forwards —

7

–

8 Power

Restarts printing during

printing.

Press and hold for two

seconds to clean the print

head.

When printing:

Terminates printing

and deletes one file of

the remaining data.

When receiving or

analysing:

Deletes data that are

already received and

analysed, and delete

the next data.

Press and hold two

seconds or more to

perform Nozzle Check

printing.

Pauses the print during

printing.

Powers the printer ON

and OFF.

Shifts to the selected menu

The setting is determined and saved.

—

Returns to the previous menu hierarchy.

Changes made in the setting are

discarded.

Shifts from Setup menu display to

Normal.

The following menu changes the set value.

Origin menu

—

Changes to the previous item in the

displayed menu.

The setting is changed to the forward

direction.

The numeric value is increased during

numerical input.

Changes to the previous item in the

menu.

The setting is changed to the reverse

direction.

The numeric value is decreased during

numerical input.

Switches the printer ON and OFF.

24 AP-75810 - Revision 2.0

Downloaded From ManualsPrinter.com Manuals

User’s Guide ValueJet 1608 HS

Display section

N° Name Colour Status Description

Lamp

ON

9 Power lamp Green

Lamp

blinks

Lamp

OFF

Lamp

ON

10 Data lamp Orange

Lamp

blinks

Lamp

OFF

Lamp

ON

11 High lamp Green

Lamp

OFF

Lamp

12 Low lamp Green

ON

Lamp

OFF

Lamp

13 Wave lamp Green

ON

Lamp

OFF

Lamp

ON

Fine &S.Fine

14

lamp

Green

Lamp

OFF

Lamp

15 Strong lamp Green

ON

Lamp

OFF

Lamp

16 Normal lamp Green

ON

Lamp

OFF

17 LCD display — — Displays the status of the printer.

Power ON.

An error has occurred.

The operation panel displays the error content.

Power OFF.

Analysing received data.

Under printing.

Receiving data.

Not receiving or analysing data.

The head height is set to High.

The head height is set to Low.

The head height is set to Low.

The head height is set to High.

The Effect menu is set to Wave or Fuzz.

The Effect menu is set to None.

The Effect menu is set to Fine or Super Fine.

The Effect menu is set to Wave or Fuzz.

When the Wave lamp is OFF, the Effect menu

is set to None.

Cleaning Mode is set to Strong.

When the Normal lamp is on, Cleaning Mode

is set to Economy.

Cleaning Mode is set to Normal.

Cleaning Mode is set to Normal.

When the Strong lamp is also on, Cleaning

Mode is set to Economy.

Cleaning Mode is set to Strong.

Product overview

2

AP-75810 - Revision 2.0 25

Downloaded From ManualsPrinter.com Manuals

User’s Guide ValueJet 1608 HS

Product overview

26 AP-75810 - Revision 2.0

Downloaded From ManualsPrinter.com Manuals

Chapter 3 Basics

Switching the power ON/OFF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Switching the power ON . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

User’s Guide ValueJet 1608 HS

Basics

Switching the power OFF. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Loading media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

loading rigid media. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Loading roll media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Setting media type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Perfect media handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Unwinder / Winder 100 / T-winder 30 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Rigid printing tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Media retainers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

How to work with the media retainers. . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Head height adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Adjusting the pressure on the media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Heater settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Pre-heater temperature setting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Platen Heater temperature setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Drier temperature setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

3

Air Heater temperature setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Using the air heater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Filter connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Setting the Air nozzle pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Adjusting the air pressure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Replacing the ink bags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Emptying the waste bottle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Transfer and transportation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Transferring the printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

AP-75810 - Revision 2.0 27

Downloaded From ManualsPrinter.com Manuals

User’s Guide ValueJet 1608 HS

Basics

Preparation before moving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Reinstalling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Transporting the printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Longstore . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Longstore procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

28 AP-75810 - Revision 2.0

Downloaded From ManualsPrinter.com Manuals

3.1 Switching the power ON/OFF

3.1.1 Switching the power ON

Be sure to read and understand the safety warnings before handling the printer.

Step 1: Press Power to switch ON the printer.

User’s Guide ValueJet 1608 HS

Basics

3

When the initial operation is complete, the printer enters Normal.

Note

If there is a problem during the initial operation, the operation panel displays a

message and the printer may stop operating.

In case the operation stops, refer to “Troubleshooting on page159

”

AP-75810 - Revision 2.0 29

Downloaded From ManualsPrinter.com Manuals

User’s Guide ValueJet 1608 HS

Basics

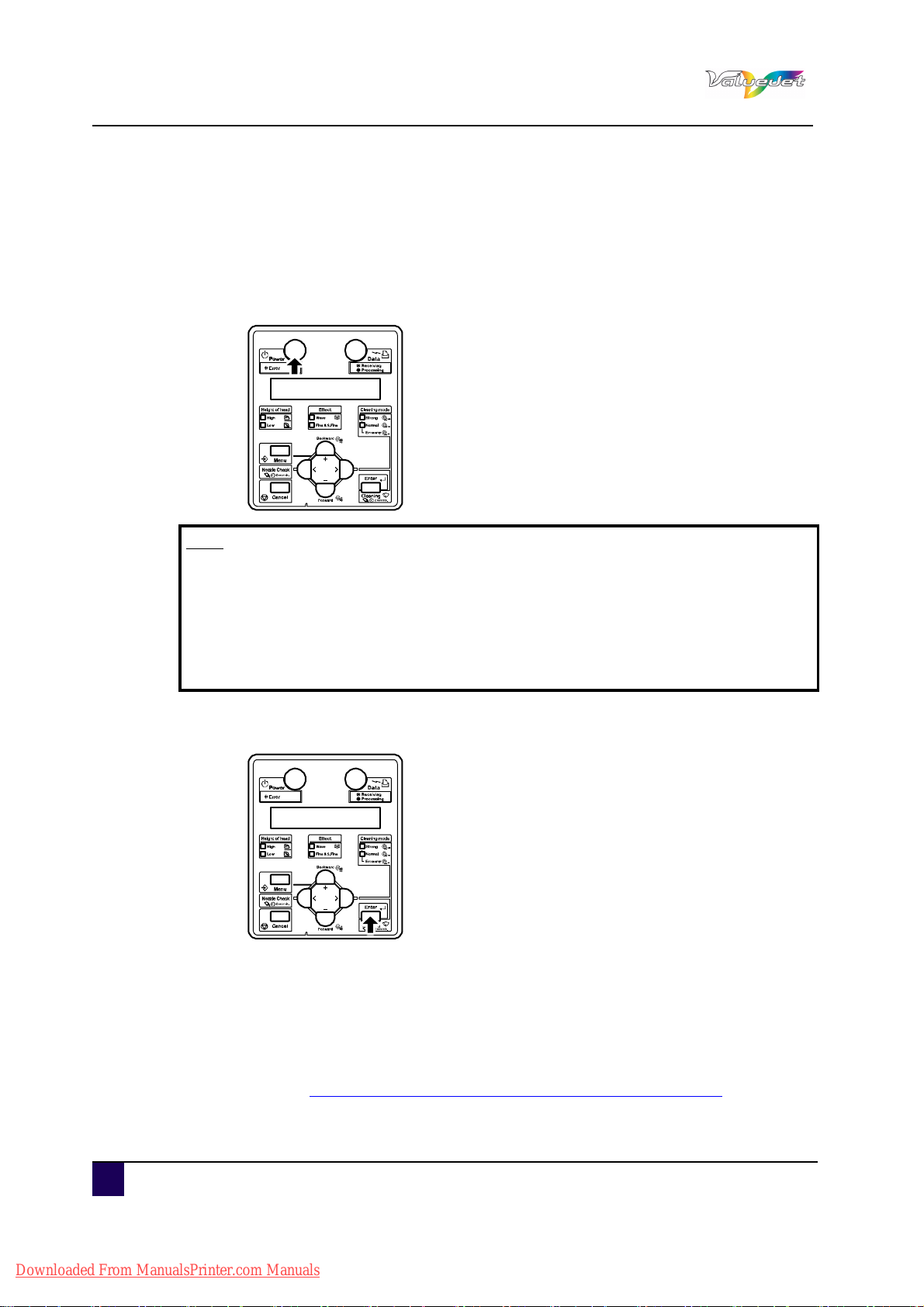

3.1.2 Switching the power OFF

Step 1: Verify that.

Printing or other operations are not in progress.

The operation panel display is Normal.

Step 2: Press Power to switch OFF the printer.

Note

If pressing the POWER, or the power indication light lights up green, the power

is ON.

Press the key once again to switch OFF the printer.

In case the head temperature is higher than 41°C, the Head cooling down

procedure starts automatically. This sequence continues until the head

temperature is back at 37°C.

The operation panel displays “CR Mainte.: Start”.

Step 3: Press ENTER.

Maintenance starts.

The print head moves to the left.

The cleaning wiper raises.

The operation panel displays “CR Maintenance: End”.

Step 4: Clean the cleaning wiper unit.

Refer to Cleaning the cleaning wiper unit and head cap unit on page144

30 AP-75810 - Revision 2.0

Downloaded From ManualsPrinter.com Manuals

User’s Guide ValueJet 1608 HS

1

Step 5: Clean around the print head.

Refer to Cleaning around the print head on page147

Note

If you wish to bypass the maintenance, press CANCEL. Be aware that proper

maintenance is necessary to obtain perfect printing quality.

Step 6: After cleaning is complete, press ENTER.

Basics

3

The cleaning wiper returns to its original position.

The print head returns to its original position.

The printer powers OFF.

Note

When powering OFF the printer, wait for 10 seconds or more before powering

ON again.

If you do not use the printer for a long period, raise the media loading lever.

1 = Lever

AP-75810 - Revision 2.0 31

Downloaded From ManualsPrinter.com Manuals

User’s Guide ValueJet 1608 HS

Basics

3.2 Loading media

3.2.1 loading rigid media

This section explains how to load rigid media.

Caution

When printing on resin board, aluminium sheets (including composite sheets),

steel sheets, glass or other rigids, do not place them directly on the rigid

printing table.

Doing so may cause erroneous printing.

The grid roller will become worn and media will not be fed correctly.

Note

The following media can be loaded on the rigid printing tables

Weight max 5 kg

Length max 1200 mm

Width 1600 mm

Thickness max 10 mm.

Note

We recommend working with the rigid printing tables when printing on rigid

materials.

Please refer to the Installation Guide of the rigid printing tables for more

information.

Note

Use mild detergent to wipe off dirt or dust before using thick media.

When printing on thick media, use both air and platen heater.

When printing using only one of the heaters, the heated surface of the thick

media expands, which warps the media, causing head friction.

The set temperatures for the air heater and platen heater vary depending on the

material and width of the thick media you are using.

Try printing on the thick media you are using once to set the temperature.

Refer to Heater settings on page50

After changing the media type, reset the media feed compensation.

32 AP-75810 - Revision 2.0

Downloaded From ManualsPrinter.com Manuals

User’s Guide ValueJet 1608 HS

1

Step 1: Power ON the printer.

Refer to Switching the power ON on page29

Caution

Do not operate the media loading lever during initial operation and printing.

The printhead may touch the pressure rollers and cause malfunction.

The operation panel displays “Media end”.

Step 2: Raise the media loading lever.

Basics

3

N° Description

1 Media loading lever

The operation panel displays “Lever Up”.

AP-75810 - Revision 2.0 33

Downloaded From ManualsPrinter.com Manuals

User’s Guide ValueJet 1608 HS

Dowel

1

2

1

2

1

2

Basics

Step 3: Open the front cover.

Step 4: Put the dowels in place.

Step 5: Load the media on the rear table making use of the media guidance system.

Step 6: Manually feed the media through.

Note

When loading rigid media, make sure that the outer pressure rollers are at least

34 AP-75810 - Revision 2.0

half covered.

If the outer pressure rollers are not half covered, reposition the dowels so that

the outer pressure rollers are fully covered.

Downloaded From ManualsPrinter.com Manuals

Step 7: Lever down.

1

N° Description

User’s Guide ValueJet 1608 HS

Basics

3

1 Media loading lever

Step 8: Remove the dowels.

Step 9: Close the front cover.

Step 10: The operation panel displays media type setup menu.

Step 11: Press + or - to select the type of media.

AP-75810 - Revision 2.0 35

Downloaded From ManualsPrinter.com Manuals

User’s Guide ValueJet 1608 HS

Basics

Step 12: Press ENTER.

The media type is set.

The operation panel displays “Head Height Initial”.

Head height initial operation starts.

The media's thickness is detected and the optimum distance of the printhead

from the platen is automatically adjusted. The operation panel displays

“Change:*.* =>”.

Note

Before starting the printing operation, make sure to remove the dowels. This to

ensure unstraight media follows the correct feeding path.

Step 13: To change the setting value for the head height, press + or - and change the setting.

36 AP-75810 - Revision 2.0

Downloaded From ManualsPrinter.com Manuals

3.2.2 Loading roll media

This section explains how to load roll media.

Note

The following media can be attached to the scroller supplied with this unit.

Outer diameter 150 mm or less

Tube diameter: 3 inch

Weight: maximum 30 kg

Length: maximum 50 m

Width maximum 1.625 mm

Thickness maximum 0.3 mm

Step 1: Loosen the fixing levers on the right and left side. Set the distance between the roll

media holders wider than the roll media width.

User’s Guide ValueJet 1608 HS

Basics

3

N° Description

1 Left roll media holder

2 Right roll media holder

3 Roll media

4 Fixing lever

AP-75810 - Revision 2.0 37

Downloaded From ManualsPrinter.com Manuals

User’s Guide ValueJet 1608 HS

1

1

2

1 2

Basics

Step 2: Fix the left roll media holder.

N° Description

1 Left roll media holder

2 Fixing lever

Step 3: Set the roll media to the left roll media holder.

N° Description

1 Left roll media holder

2 Roll media

38 AP-75810 - Revision 2.0

Downloaded From ManualsPrinter.com Manuals

User’s Guide ValueJet 1608 HS

1

3

2

2

3

31 2

1

3

4 4

Step 4: Set the roll media to the right roll media holder and fix the fixing lever.

N° Description

1 Right roll media holder

Basics

3

2 Roll media

3 Fixing lever

Step 5: Loosen both the right and left fixing levers of the media holders, move the roll media

to the centre and tighten the levers.

Note

Press the holders to the printer to fix the roll media holders.

N° Description

1 Left roll media holder

2 Right roll media holder

3 Roll media

4 Fixing lever

AP-75810 - Revision 2.0 39

Downloaded From ManualsPrinter.com Manuals

User’s Guide ValueJet 1608 HS

Basics

3.2.3 Setting media type

This section explains how to set the media type.

Note

After changing the media type, reset the media feed compensation.

Step 1: Power ON the printer.

Step 2: Load media.

Step 3: Press + or - to select the type of media.

Step 4: Press ENTER.

Note

If not touching any keys for 10 seconds, or pressing CANCEL when in the media

type setup menu, the printer starts media initial operation with the media type

displayed on the panel.

40 AP-75810 - Revision 2.0

Downloaded From ManualsPrinter.com Manuals

User’s Guide ValueJet 1608 HS

The media type is set.

The operation panel displays “Head Height Initial”.

Head-height initial operation starts.

The media's thickness is detected and the optimum distance (setting value of

the head height) of the print head from the platen is automatically adjusted.

The operation panel displays “Change: *.* mm –>”.

Caution

When setting the Media Initial menu to “Off “, “TopWidth”, or “Width”, the head

height initial operation will not be conducted.

When the operation panel displays “Warning! *.* mm ->”, check if the value

matches the thickness of the loaded media. If the value is wrong, enter the

correct setting value.

If a wrong value is set, the head and media can collide and may damage the

head.

Step 5: To change the value of the head height, press + or -.

Basics

3

Note

If the printing side of the rigid media is soft, the head height setting value

displayed and the actual thickness of the media may differ.

In this case, follow the steps below to input the correct value to align the head

height with the actual thickness of the media.

Remove the media from the printer.

Measure the media's thickness with a calliper.

Set the thick media again.

Input the difference of the setting value and the actual thickness as the

adjustment value.

Step 6: Press ENTER.

The operation panel displays “Media Initial”.

After media initial operation is complete, the operation panel displays “Ready to

Print” and the display shifts to Normal.

The procedure for setting media type is complete.

AP-75810 - Revision 2.0 41

Downloaded From ManualsPrinter.com Manuals

User’s Guide ValueJet 1608 HS

Basics

3.3 Perfect media handling

3.3.1 Unwinder / Winder 100 / T-winder 30

The Winder systems always provide an equal tension on the media when printing.

It is important that the Winder system is perfectly lined out to prevent cockling. To line out the

Winder system, please refer to the corresponding User’s Guide.

3.3.2 Rigid printing tables

When printing on Rigid materials, we recommend to install the rigid printing tables. These

tables will smoothly guide your media through the printer.

For more information, please refer to the installation guide of the rigid printing tables.

3.3.3 Media retainers

Some media tends to curl and cockle, which could lead to head crashes. Media retainers

keep the media edges pushed down.

Note

When using roll media, we recommend you to always use the media retainers.

Note

When using sheet media, media retainers are not necessary used. If used,

make sure the media is loaded straight. Otherwise, media can slant and the

media retainers could tear the media.

42 AP-75810 - Revision 2.0

Downloaded From ManualsPrinter.com Manuals

User’s Guide ValueJet 1608 HS

How to work with the media retainers

Step 1: Display the Side margin menu on the operation panel.

Step 2: Press Menu.

The operation panel displays “Menu 1: Setup>”.

Step 3: Press >.

Basics

3

The operation panel displays “Set1: MediaType” i

Step 4: Press the + or – to select “Set4: Side Margin”.

AP-75810 - Revision 2.0 43

Downloaded From ManualsPrinter.com Manuals

User’s Guide ValueJet 1608 HS

Basics

Step 5: Press Enter.

The operation panel displays “Side Margin: ** mm”.

Step 6: Set up the margins (side margins) to 10 mm while printing.

Step 7: Press + or – to select “Side Margin: 10 mm”.

Step 8: Press Enter.

After saving the setting, the operation panel displays “Set4: Side Margin”.

Step 9: Press Cancel several times.

The operation panel returns to Normal.

44 AP-75810 - Revision 2.0

Downloaded From ManualsPrinter.com Manuals

User’s Guide ValueJet 1608 HS

1

1

4

3

2

1

4

2

3

1

1

2

1

2

Step 10: Slide the media holder plates from both sides of the platen to set them.

Note

Do not use the media retainers when the media thickness is larger then 0.5mm.

Basics

3

Caution

If media is jammed when using media retainers, stop using the printer and do

not remove the jammed media by force. This could deform the media retainers.

Using the printer with deformed media retainers could damage the grid roller or

print head.

If the media retainers are deformed, contact your local Mutoh dealer.

Step 11: If the media retainers are not used, return them to their initial position.

AP-75810 - Revision 2.0 45

Downloaded From ManualsPrinter.com Manuals

User’s Guide ValueJet 1608 HS

Basics

3.3.4 Head height adjustment

Printing with high printing rate or using strongly-curved media can cause head crashes.

Adjusting the distance from the print head surface to the media (head height) allows you to

prevent head crashes.

Follow the procedure below to adjust the head height

Note

If raising the head height, high print quality is not guaranteed.

Step 1: Press Menu.

The operation panel displays “Menu 1: Setup>.

The operation panel shifts to the Setup menu display.

Step 2: Press the >.

The operation panel displays “Set1: MediaType”.

Step 3: Press Enter.

The operation panel displays “Media: Type 1".

46 AP-75810 - Revision 2.0

Downloaded From ManualsPrinter.com Manuals

Step 4: Press the + or – to select the media type to use.

Step 5: Press Enter.

The operation panel displays “**>1: Print Mode”.

Step 6: Press the + or - to change the setting value.

Note

User’s Guide ValueJet 1608 HS

Basics

3

The valid range is as follows:

Upper limit: 11.0 mm

Lower limit: 0.0 mm

Step 7: Press Enter.

The value set is saved.

The operation panel displays “**>9: Thickness Ajst.”.

Step 8: Press Cancel several times.

The operation panel returns to Normal.

Head height adjustment is complete.

AP-75810 - Revision 2.0 47

Downloaded From ManualsPrinter.com Manuals

User’s Guide ValueJet 1608 HS

2

1

3

Basics

3.3.5 Adjusting the pressure on the media

This section explains how to adjust the pressure on the media.

Step 1: Check that the media loading lever is raised.

Step 2: Measure the thickness of the media you are loading with callipers.

Step 3: Open the left maintenance cover.

Step 4: Turn the pressure adjustment handle and adjust it so that it comes to the level

measured in previous step.

N° Description

1 Pressure adjustment handle

2 White line

3 Media thickness gradation

48 AP-75810 - Revision 2.0

Downloaded From ManualsPrinter.com Manuals

Step 5: Close the maintenance cover.

1

User’s Guide ValueJet 1608 HS

Basics

3

N° Description

1 Maintenance cover

Note

Depending on the media type, even when measured media thickness is set,

feeding accuracy may not be stabilized. In such cases, turn the pressure

adjustment handle to shift the white line towards MAX. But make sure to avoid

that the pressure roller leave marks on the media.

AP-75810 - Revision 2.0 49

Downloaded From ManualsPrinter.com Manuals

User’s Guide ValueJet 1608 HS

Basics

3.3.6 Heater settings

The pre-heater, platen heater, drier, and air heater are built into this printer.

Pre-heater: Set up, to pre-heat the media before printing. For roll media, set the

temperature higher than that of the platen heater.

Platen heater: Warms up the media to increase adhesion property of ink and printing

quality.

Drier: Dries the ink after printing

Air-heater: Blows hot air on the media surface while printing on thick media to accelerate

drying of the ink.

Set appropriate heater temperatures depending on the media.

The following is a guide for temperature settings.

For marking films

Pre-heater: 45°C

Platen heater: 40°C

Drier: 50°C

Air-heater: 130°C

For 5 mm plastic cardboard

Pre-heater: Off

Platen heater: Off

Drier: Off

Air-heater: 160°C

Note

When printing on thick media, use both air heater and platen heater.

If printing using only one of the heaters, the heated surface of the thick media

expands, which warps the media, causing head friction.

50 AP-75810 - Revision 2.0

Downloaded From ManualsPrinter.com Manuals

Pre-heater temperature setting

Set the pre-heater temperature following the procedure below.

Step 1: Press Menu.

The operation panel displays “Menu 1: Setup>”.

Step 2: Press >.

User’s Guide ValueJet 1608 HS

Basics

3

The operation panel displays “Set1: MediaType”.

Step 3: Press Enter.

The operation panel displays “Media: Type 1".

Step 4: Press the + or – to select the media type for using.

AP-75810 - Revision 2.0 51

Downloaded From ManualsPrinter.com Manuals

User’s Guide ValueJet 1608 HS

Basics

Step 5: Press Enter.

The operation panel displays “**>1: Print Mode”.

Note

The selected media (Type 1 to 30) is displayed in “**”.

Refer to

Set 1: MediaType menu on page106

Step 6: Press + or – to select “**3: Pre-heater”.

Step 7: Press Enter.

The operation panel displays “Pre-heater: Off”.

Step 8: Press + or – to set the pre-heater temperature.

Step 9: Press Enter.

The temperature of pre-heater is set.

52 AP-75810 - Revision 2.0

Downloaded From ManualsPrinter.com Manuals

User’s Guide ValueJet 1608 HS

Platen Heater temperature setting

Follow the procedure below to set the platen heater temperature.

Step 1: Press Menu.

The operation panel displays “Menu 1: Setup>”.

Step 2: Press >.

Basics

3

The operation panel displays “Set1: MediaType”.

Step 3: Press Enter.

The operation panel displays “Media: Type 1".

AP-75810 - Revision 2.0 53

Downloaded From ManualsPrinter.com Manuals

User’s Guide ValueJet 1608 HS

Basics

Step 4: Press + or – to select the media type.

Step 5: Press Enter.

The operation panel displays “**>1: Print Mode”.

Note

The selected media (Type 1 to 30) is displayed in “**”.

Refer to

Set 1: MediaType menu on page106

Step 6: Press the + or – to select “**4: Platen heater”.

Step 7: Press Enter.

The operation panel displays “Platen heater: 42° C”.

Step 8: Press + or – to set the platen heater temperature.

Step 9: Press Enter.

The temperature of platen heater is set.

54 AP-75810 - Revision 2.0

Downloaded From ManualsPrinter.com Manuals

Drier temperature setting

Follow the procedure below to set the drier temperature.

Step 1: Press Menu.

The operation panel displays “Menu 1: Setup>”.

Step 2: Press >.

User’s Guide ValueJet 1608 HS

Basics

3

The operation panel displays “Set1: MediaType”.

Step 3: Press Enter.

The operation panel displays “Media: Type 1".

AP-75810 - Revision 2.0 55

Downloaded From ManualsPrinter.com Manuals

User’s Guide ValueJet 1608 HS

Basics

Step 4: Press + or – to select the media type for using.

Step 5: Press Enter.

The operation panel displays “**>1: Print Mode”.

Note

The selected media (Type 1 to 30) is displayed in “**”.

Refer to

Set 1: MediaType menu on page106

Step 6: Press + or – to select “**5: After heater”.

Step 7: Press Enter.

The operation panel displays “After heater: Off”.

Step 8: Press + or – to set the drier temperature.

Step 9: Press Enter.

The temperature of drier is set.

56 AP-75810 - Revision 2.0

Downloaded From ManualsPrinter.com Manuals

Air Heater temperature setting

Refer to Using the air heater on page59 for more information.

Follow the procedure below to set the air heater temperature.

Step 1: Press Menu

The operation panel displays “Menu 1: Setup>”.

Step 2: Press >.

User’s Guide ValueJet 1608 HS

Basics

3

The operation panel displays “Set1: MediaType”.

Step 3: Press Enter.

The operation panel displays “Media: Type 1".

AP-75810 - Revision 2.0 57

Downloaded From ManualsPrinter.com Manuals

User’s Guide ValueJet 1608 HS

Basics

Step 4: Press + or – to select the media type for using.

Step 5: Press Enter.

The operation panel displays “**>1: Print Mode”.

Note

The selected media (Type 1 to 30) is displayed in “**”.

Refer to

Set 1: MediaType menu on page106

Step 6: Press + or – to select “**7: Air heater”.

Step 7: Press Enter.

The operation panel displays “Air heater:190° C”.

Step 8: Press + or – to set the air heater temperature.

Step 9: Press Enter.

The temperature of air heater is set.

58 AP-75810 - Revision 2.0

Downloaded From ManualsPrinter.com Manuals

3.4 Using the air heater

This section explains how to use the air heater.

The air heater blows hot air on the media surface during printing, which dries ink faster.

Follow the procedure below to use the air heater.

Caution

User’s Guide ValueJet 1608 HS

Basics

The supplied air must comply to ISO 8573-1 1.1.2 - 1.6.2:2001.

If using air that does not satisfy the quality grade, it may not only cause

inappropriate printing results but may also cause parts deterioration/

damage, or a fire.

When following the example below, the above mentioned quality grade

will be guaranteed.

3.4.1 Filter connection

When following the example below, the above

Connection, joints and tubes are also required.

For details, contact the air compressor manufacturer or dealer.

Step 1: Make sure the printer is OFF.

Step 2: Power the air compressor ON.

Step 3: Power ON the printer.

Step 4: Set the temperature of air heater.

3

Refer to

When printing starts, the air heater automatically operates.

Caution

Do not touch the air heater before a cooling down period of 30 minutes.

It is hot and may cause a burn.

AP-75810 - Revision 2.0 59

Downloaded From ManualsPrinter.com Manuals

Air Heater temperature setting on page57

User’s Guide ValueJet 1608 HS

Air pressure valve knob

Basics

3.4.2 Setting the Air nozzle pressure

The heated air nozzle system must be calibrated to the proper pressure to ensure consistent

print quality. Please use the following guidelines to set up and operate your ValueJet 1608

HS.

Adjusting the air pressure

Note

For more information concerning the air quality, refer to Using the air heater on

page59.

The regulator valve on the back of the printer has a gauge that reads from 0 - 1 MPa. The

specifications for the air flow through the heated air nozzles is 0.06 - 0.2 MPa. The needle on

the gauge must be at or just below the first thick mark on the gauge.

Step 1: To adjust the pressure, pull straight up on the knob.

Turn counter clockwise to decrease the pressure.

Turn clockwise to increase the pressure.

Note

As a general rule, the air pressure must be set high enough to activate the flow

switch circuit, and yet allow the heat elements to fully come up to the set

temperature.

Note

If problems occur, refer to Air pressure related troubleshooting on page170

60 AP-75810 - Revision 2.0

Downloaded From ManualsPrinter.com Manuals

3.5 Replacing the ink bags

Important

In case of working with another type of Mutoh ink than described in this

manual, refer to the dedicated instruction sheet added to the ink kit.

Replacement time

Caution

Before using the ink and cleaning cassettes, be sure to read and understand

the msds-sheets which come together with the ink and cleaning cassettes.

When the operation panel displays “[*******] InkNearEnd”

There is a small amount of ink remaining in the ink bag.

The alarm buzzer sounds. To stop the buzzer, press Enter.

Replace with new ink bags and ink S/C cards.

User’s Guide ValueJet 1608 HS

Basics

3

When the operation panel displays “[*******] ink end”

There is no ink remaining in the ink bag.

Printing operation stops.

The alarm buzzer sounds. To stop the buzzer, press Enter.

Replace with new ink bags and ink S/C cards immediately.

Note

If displaying “Ink End”, printing operation is suspended even during printing.

If displaying “Ink End”, you cannot print until inserting the new ink bag.

If there is no ink bag for replacement at hand, leave the empty ink bag inserted

in the printer.

Leaving the printer with the ink bag removed may cause the print head to clog

Note

This printer is designed to use genuine ink bags.

If you use a non genuine ink bag,

Printing might become blurred, or the end of the ink in the bag might not be

correctly detected.

Any problems caused by using non genuine ink will not be covered by the

warranty. All repair expenses will be paid by the customer.

AP-75810 - Revision 2.0 61

Downloaded From ManualsPrinter.com Manuals

User’s Guide ValueJet 1608 HS

1

2

Basics

Replacing steps

Caution

When handling ink bags, make sure that ink does not get into your eyes or

stick to your skin.

If ink gets into your eyes or sticks to your skin, immediately wash it off with

water.

Failing to do so might cause irritation or light inflammation of eyes.

In case of any abnormality, consult a physician immediately.

Do not disassemble the ink bags.

If disassembled, there is a possibility that ink might come into contact with

eyes or skin.

Note

Do not shake the ink bags strongly. Doing so may cause ink leakage.

Do not disassemble the ink bags. A disassembled ink bags cannot be used.

When moving an ink bag from a cold place to warm place, keep the ink bag for

three hours or more in the new printing environment before printing.

Do not refill an ink bag with ink. It may result in abnormal printing.

Step 1:

Power ON the printer.

Note

Do not replace the ink bags when the printer is OFF.

The remaining ink may not be detected correctly, causing abnormal printing.

Step 2: Remove the ink S/C card

N° Description

1

S/C card

2 S/C card slot

62 AP-75810 - Revision 2.0

Downloaded From ManualsPrinter.com Manuals

Step 3: Pull out the ink bag you want to replace.

1

2

N° Description

Ink bag

1

2 Ink slot

User’s Guide ValueJet 1608 HS

Basics

3

Note

Used ink bags should be disposed of in compliance with local regulations.

Step 4: Take out the new ink S/C card and the ink bag from the plastic bag.

Note

Open the bag just before placing the ink bag in the bag slot. Leaving the ink

bag open for a long time may result in abnormal printing.

Use the ink bag within the expiration date. Using an ink with an expired shelf

life may affect print quality.

If not using the ink bags while installed in the printer, replace the ink three

months after installing it into the printer.

AP-75810 - Revision 2.0 63

Downloaded From ManualsPrinter.com Manuals

User’s Guide ValueJet 1608 HS

1 2

&

1

Basics

Step 5: Install the new ink S/C card and ink bag.

Insert the ink S/C card into the S/C card slot.

Ink S/C cards are specified depending on the colours of the ink bag. Match

the mark on each slot with the colour of the ink bag.

Insert the S/C card all the way to the end of the slot.

N° Description

1

S/C card

2 S/C card slot

Shake the new ink bag two or three times gently side ways and front to back.

then turn it over and shake again before inserting it into the ink bag slot.

64 AP-75810 - Revision 2.0

Downloaded From ManualsPrinter.com Manuals

User’s Guide ValueJet 1608 HS

1

2

Insert the new ink bag into the ink bag slot and push the slot all the way to the

end of the slot.

N° Description

1

Ink bag

2 Ink bag slot

Basics

3

Step 6: Confirm that the operation panel returns to Normal.

AP-75810 - Revision 2.0 65

Downloaded From ManualsPrinter.com Manuals

User’s Guide ValueJet 1608 HS

1

2

Basics

3.6 Emptying the waste bottle

The timing and method for the disposal of waste fluid are described below.

Disposal timing

Dispose the waste fluids in the following cases:

When the waste fluid tank is more than half full.

When the operation panel displays “Waste Ink Tank Full”.

Disposal method

Follow the procedure below to dispose of waste fluid.

Important

Waste fluid is considered industrial waste. Proper waste fluid disposal

according to industrial waste disposal laws and ordinances of your local

government is required.

Step 1: Prepare an empty container to contain the waste fluid.

Step 2: Lay a protective material on the floor under the waste fluid tank.

Step 3: Open the waste fluid valve, and transfer the waste fluid to the container.

Note

When pouring the waste fluid to the empty container, the waste fluid may

splash, therefore put the container close to the waste fluid valve.

N° Description

1

Waste fluid valve

2 Empty container

Step 4: After pouring the waste fluid into the empty container, close the waste fluid valve.

Step 5: Wipe the opening of the waste fluid valve with a cloth.

66 AP-75810 - Revision 2.0

Downloaded From ManualsPrinter.com Manuals

3.7 Transfer and transportation

11

1

3.7.1 Transferring the printer

Caution

User’s Guide ValueJet 1608 HS

Basics

Move the printer while maintaining a horizontal position.

Do not slant the printer, prop it against a wall or turn it upside down. There is a

possibility that the ink inside the printer may leak.

Preparation before moving

Step 1: Make sure the printer is OFF.

Step 2: When the air compressor is connected, remove the tube from the solenoid valve

unit.

Step 3: Dispose the waste fluid.

Step 4: Remove all cables such as power cables.

Step 5: Loosen the 4 adjusters of the stand.

3

N° Description

1

Adjusters

AP-75810 - Revision 2.0 67

Downloaded From ManualsPrinter.com Manuals

User’s Guide ValueJet 1608 HS

Basics

Step 6: Move the printer.

Note

The casters supplied with the dedicated stand are manufactured for little

movement in flat indoor areas, not for transporting equipment.

Reinstalling

After moving the printer, follow the procedure below to set it ready for use.

Step 1: Select a suitable place for installation.

Refer to the installation guide for more information.

Step 2:

Step 3: Attach all cables such as the power cables

Step 4: Perform a nozzle check and confirm that there is no clogging in the print head.

Move and install the printer to the location.

3.7.2 Transporting the printer

When transporting the printer, it is necessary to pack in the same condition as purchased

using protective and packing materials to protect the printer from vibrations and shocks.

Note

When transporting the printer, consult your local Mutoh Technician.

68 AP-75810 - Revision 2.0

Downloaded From ManualsPrinter.com Manuals

3.8 Longstore

Caution

In case of working with other inks than described in this manual, refer to the

instruction sheet enclosed with the ink to know if a longstore procedure is

necessary and how to perform the procedure correct.

User’s Guide ValueJet 1608 HS

Basics

When transporting your printer or leaving it unattended for five days or more, for example on

holidays, it is highly recommended to longstore your printer in order not to damage the print

head and / or the complete ink system. This means that the complete ink channel system will

be filled with cleaning liquid.

3.8.1 Longstore procedure

Be sure to perform the daily and weekly maintenance before starting the longstore procedure.

Action Panel message

Step 1:

Step 2: Press the menu key

Step 3: Press the > key

Step 4: Press the + or - key to select

Step 5: Press Enter

Step 6: Press Enter