Page 1

User’s Guide

Spitfire 100 Extreme

For Maintenance Kits, Spares,

Service and Support

Call: +44 (0) 1628 588755

E-mail: support@colourgen.com

Downloaded From ManualsPrinter.com Manuals

Page 2

Spitfire 100 Extreme series printers Users Guide

2 AP-75194 - Rev. 2.2

Downloaded From ManualsPrinter.com Manuals

Page 3

Spitfire 100 Extreme series printers Users Guide

3 AP-75194 - Rev. 2.2

COPYRIGHT NOTICE

COPYRIGHT © 2011 Mutoh Belgium nv. All rights reserved.

Mutoh reserves the right to modify the information contained in this manual at any time without prior notice.

This document may not be reproduced by any means, in whole or in part, without written permission of the

copyright owner.

This document is furnished to support the Mutoh Spitfire 100 Extreme series printers. In consideration of the

furnishing of the information contained in this document, the party to whom it is given, assumes its custody

and control and agrees to the following:

The information herein contained is given in confidence, and any part thereof shall not be copied or

reproduced without written consent of Mutoh Belgium nv.

This document or the contents herein under no circumstances shall be used in the manufacture or

reproduction of the article shown and the delivery of this document shall not constitute any right or license to

do so.

24 February 2011

Published: Mutoh Belgium nv, Archimedesstraat 13, B-8400 Oostende, BELGIUM

Downloaded From ManualsPrinter.com Manuals

Page 4

Spitfire 100 Extreme series printers Users Guide

4 AP-75194 - Rev. 2.2

Downloaded From ManualsPrinter.com Manuals

Page 5

Spitfire 100 Extreme series printers Users Guide

5 AP-75194 - Rev. 2.2

TABLE OF CONTENTS

1 Regularisation and safety information .................................................................................................7

1.1 Regulations ......................................................................................................................................8

1.2 MANAGING VOCs..........................................................................................................................9

1.3 HANDLING INKS + waste .............................................................................................................9

1.4 Warnings, Cautions and Notes ...................................................................................................10

1.5 SAFETY INSTRUCTIONS...........................................................................................................10

1.6 Warning labels...............................................................................................................................12

2 Product Overview..................................................................................................................................17

2.1 Part names and functions............................................................................................................18

2.2 Installation requirements..............................................................................................................24

3 Basics .....................................................................................................................................................27

3.1 Powering on ...................................................................................................................................29

3.2 Powering OFF ...............................................................................................................................30

3.3 Switch ON-OFF the winding system. .........................................................................................31

3.4 Media handling ..............................................................................................................................32

3.5 Ink cassettes..................................................................................................................................41

3.6 Replacing the cutting blade .........................................................................................................43

3.7 Replacing the waste bottle ..........................................................................................................44

3.8 Working with Mutohs SmartChip management System ........................................................45

3.9 Switch between ink configurations. ............................................................................................49

3.10 Unattended printing or leave printer idle during night .............................................................50

3.11 LongStore.......................................................................................................................................52

3.12 Transferring the printer.................................................................................................................56

4 Periodical maintenance........................................................................................................................59

4.1 P eriodicalS ervicesdone by end user..............................................................................................60

4.2 Cleaning .........................................................................................................................................61

4.3 Cleaning the wipers ......................................................................................................................61

4.4 Flushing the caps ..........................................................................................................................62

4.5 Cleaning the edges of the caps ..................................................................................................64

4.6 Clean around bottom of the head...............................................................................................65

4.7 Replace the spitting box sponge ................................................................................................66

4.8 Replacing the wipers ....................................................................................................................67

Downloaded From ManualsPrinter.com Manuals

Page 6

Spitfire 100 Extreme series printers Users Guide

6 AP-75194 - Rev. 2.2

4.9 Replacing the pump tubings........................................................................................................68

4.10 Replacing the absorbent behind the maintenance station. ....................................................69

4.11 Changing the absorbent under the waste bottle ......................................................................70

4.12 Changing the absorbent in the manual cleaning station.........................................................71

4.13 Head cleaning................................................................................................................................72

4.14 Service done by authorised Mutoh technician .........................................................................74

5 Prepartions before printing ..................................................................................................................75

5.1 Using media ...................................................................................................................................76

5.2 Testprinting ....................................................................................................................................79

5.3 Set the correct distance adjust (step) ........................................................................................85

5.4 Printing flow ...................................................................................................................................89

6 Printer menu ..........................................................................................................................................91

6.1 How to work in the menu .............................................................................................................95

6.2 Operation panel IN standby mode .............................................................................................97

6.3 Operating panel during printing ................................................................................................102

6.4 Operations after printing ............................................................................................................106

6.5 Menu overview (1/7 7/7).......................................................................................................108

7 Troubleshooting ..................................................................................................................................165

7.1 Introduction ..................................................................................................................................166

7.2 Failures and malfunctions of the printer ..................................................................................166

7.3 Error messages ...........................................................................................................................171

7.4 When media jams occur ............................................................................................................175

7.5 Emergency capping procedure.................................................................................................176

Downloaded From ManualsPrinter.com Manuals

Page 7

Spitfire 100 Extreme series printers Users Guide

7 AP-75194 - Rev. 2.2

1 REGULARISATION AND SAFETY

INFORMATION

1.1 Regulations ......................................................................................................................................8

1.2 MANAGING VOCs..........................................................................................................................9

1.3 HANDLING INKS + waste .............................................................................................................9

1.4 Warnings, Cautions and Notes ...................................................................................................10

1.5 SAFETY INSTRUCTIONS...........................................................................................................10

1.6 Warning labels...............................................................................................................................12

1.6.1 Handling the warning labels ................................................................................................12

1.6.2 Position of the warning labels .............................................................................................12

1.6.2.1 Front of the machine. ...................................................................................................12

1.6.2.2 Rear of the machine. ....................................................................................................13

1.6.2.3 Types of warning labels on the winding system.......................................................14

1.6.3 Labels in function of transportation ....................................................................................15

1.6.4 Ink related labels...................................................................................................................16

Downloaded From ManualsPrinter.com Manuals

Page 8

Spitfire 100 Extreme series printers Users Guide

8 AP-75194 - Rev. 2.2

1.1 REGULATIONS

The CE marking is a mandatory European marking for certain product groups to

indicate conformity with the essential health and safety requirements set out in

European Directives.

By affixing the CE marking, the manufacturer, his authorized representative, or the

person placing the product on the market or putting it into service ensures that the item

meets all the essential requirements of all applicable EU directives and that the

applicable conformity assessment procedures have been applied.

This product is tested and approved by the Canadian Standards Association (CSA), this

to provide increased assurance of quality and safety.

The product is tested according to IEC60950.

This standard tries to cover all safety aspects.

Mechanical, electrical

Choice of components

Choice of materials: flammability!

Connectors, cables

Fire enclosure

This means the product is safe for users, service personnel and production personnel.

CSA International certification is not a legal commitment but it assures the quality and

safety of the machine.

Your product is designed and manufactured with high-quality materials and

components, which can be recycled and reused.

When this crossed-out wheeled bin symbol is attached to a product, it means the

product is covered by the European Directive 2002/96/EC WEEE regulation.

Please inform yourself about the local separate collection system for electrical and

electronic products.

Please act according to local rules and do not dispose of your old products with your

normal household waste. The correct disposal of your old product will help prevent

potential negative consequences for the environment and human health.

FCC

This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with the instruction

manual, may cause harmful interference to radio communications. Operation of this

equipment in a residential area is likely to cause harmful interference in which case the

user will be required to correct the interference at his own expense.

ICES

This Class A digital apparatus complies with Canadian ICES-003.

Downloaded From ManualsPrinter.com Manuals

Page 9

Spitfire 100 Extreme series printers Users Guide

9 AP-75194 - Rev. 2.2

1.2 MANAGING VOCS

When Mutoh printers with (low)-Solvent inks are used, volatile organic compounds (VOCs) will be

released.

In order to protect human health and the environment, VOCs must be managed. This means VOCs

need to be controlled and compliance with all local, state and federal environmental, occupational

health and safety regulations on VOCs in the atmosphere and in the workplace is needed.

The amount of released VOCs depends on multiple factors: room volume, unforced ventilation, print

mode, number of printers in the room, heaters settings, kind of media, use of extra dryers, print

production

Because of differences in local regulations and working conditions, it is recommended to consult a

local consultancy agency to determine the regulations involved. An acknowledged laboratory can

determine the total amount of released VOCs in the atmosphere and in the workplace. Consequently

they can determine if forced ventilation for occupational health and air pollution control devices are

needed. An engineering firm could be consulted on the installation of the ventilation system where

prints are produced, handled and stored.

1.3 HANDLING INKS + WASTE

Before handling inks / cleaning fluids and their waste, please read the Material Safety Data Sheets

(MSDS) and the labels for important health, safety and environmental information carefully. All safety

data sheets are periodically updated. These sheets and their translations can be found on

www.mutoh.eu/Products/Downloads/extra/msds .

Only use original manufacturers ink and appropriate cleaning liquid. Before installing an ink holder,

shake it gently. Doing so will preserve print quality.

When ink is moved from a cold place to a warm place, keep the ink for three hours or more in the new

printing environment before printing.

Do not disassemble ink holder. Otherwise, ink may get in your eyes or on your skin. A disassembled

ink holder cannot be used either.

When refilling ink, use original manufacturers ink. Our Mutoh printers are designed to use original ink. If

you use ink which are not produced by the original manufacturer :

± printing might become blurred and the end of the ink in the holder might not be detected

correctly

± Any problems caused by using an ink holder other than those recommended above will not be

covered by the warranty, and repair expenses will be paid by the customer.

For handling waste : see section 13 on the MSDS-sheet

Inks / Waste

± General advice: wear safety glasses and gloves especially when handling the

waste ink.

± After spill: remove contaminated clothing.

± After inhalation: if difficulties occur after vapour/aerosol has been inhaled,

remove to fresh air and seek medical attention.

± After skin contact: wash thoroughly with soap and water.

± After eye contact: wash affected eyes for at least 15 minutes under running water

while the eyelids are held open.

± After swallowing: rinse mouth and drink plenty of water. Never induce vomiting.

Downloaded From ManualsPrinter.com Manuals

Page 10

Spitfire 100 Extreme series printers Users Guide

10 AP-75194 - Rev. 2.2

1.4 WARNINGS, CAUTIONS AND NOTES

Safety terms in this manual and the contents of warning labels attached to the printer are categorized into

the following three types, depending on the degree of risk (or the scale of accident).

Read the following explanations carefully and follow the instructions in this manual.

S afety term s Details

Important Must be followed carefully to avoid death or serious bodily injury.

Caution Must be observed to avoid bodily injury (moderate or light) or damage to your equipment.

Notes

Contains important information and useful tips on the operation of your printer.

1.5 SAFETY INSTRUCTIONS

Machines must be installed according to Mutohs Installation Guide also after moving machines to

another location; maintenance needs to be done according to the service manual.

To prevent fire or electrical shock, never use a power supply source other than the one rated for the

product in the country where you purchased the product.

Use only the provided power cable. To prevent fire or electrical shock, follow the instructions below

when handling the power cable:

± Do not cut or modify the cable.

± Do not put heavy objects on the cable.

± Do not bend, twist, knot or pull the cable.

± Do not wire the cable near equipment that generates heat.

± Do not use the cable with any other electrical device

± Do not handle the cable with wet hands

Be aware of all caution and warning labels to avoid potentially hazardous situations.

To prevent fire or electrical shock, machines must be connected to a properly grounded electrical power

outlet. Do not connect the power cable to a power strip or a power source shared by other electrical

devices.

± Make sure that no foreign substances such as dust etc. are stuck to the power plug.

± Make sure that the power plug is firmly inserted to the edge of the power socket.

Do not disable any safety precautions systems.

Do not operate the unit unless all parts are mounted.

Do not place the machine in the following areas. Doing so may result in the machine tipping or falling

over and causing injury.

± Unstable surfaces

± Sloping floors

± Areas subject to vibration by other equipment

Do not stand on or place heavy objects on your machine. Doing so may result in the machine tipping or

falling over and causing injury.

Do not place the machine in humid and dusty areas or in areas exposed to flammables. Doing so may

result in electrical shock or fire.

Do not cover the ventilation hole of your machine with cloth, such as a blanket or table cloth. Doing so

could obstruct ventilation and cause fire.

Downloaded From ManualsPrinter.com Manuals

Page 11

Spitfire 100 Extreme series printers Users Guide

11 AP-75194 - Rev. 2.2

Do not insert or drop metal or inflammable objects into openings, such as ventilation outlets. Doing so

may result in electrical shock and fire.

Do not touch the media guide during printing. It is hot and may cause a burn.

Do not touch the media feed slot, platen or media guide while heaters are operating. They are

hot and may cause a burn.

Stop using your machine if a liquid has been spilled into it. This may cause electrical shock or fire.

Switch the machine off as soon as possible, unplug the power cord, and contact your local MUTOH

dealer.

Be sure to power OFF the machine and unplug the power cable from the outlet before cleaning the

machine. Use a damp cloth to clean the machine. Do not use thinner, benzene, alcohol or other active

agents. Doing so may result in damage or paint peeling from the casing.

Do not bend or pull the waste fluid tube. Doing so may cause waste fluid to leak out and malfunction of

the product.

Do not tilt the machine, place it against a wall or turn it upside down. Doing so may cause ink to leak

inside the machine. Movement after transport is also not covered by the warranty.

When cutting roll media, be careful of the following. Incorrect handling can result in injury to the hands

and fingers from the razor blade.

± When holding the media, do not place fingers over the media cut groove.

± Move the razor blade slowly along the media cutting groove.

To prevent back pains and other injuries, always work with at least 4 people to unpack or move the

machine. Keep the machine horizontally during transportation.

Do NOT transport the machine to another room without contacting your local Authorized Mutoh Dealer.

Downloaded From ManualsPrinter.com Manuals

Page 12

Spitfire 100 Extreme series printers Users Guide

12 AP-75194 - Rev. 2.2

1.6 WARNING LABELS

Warning labels are attached on areas which require attention. Read and understand the positions and

contents thoroughly before performing your work.

1.6.1 Handling the warning labels

Be sure to note the following when handling the labels.

Notes

Make sure that all labels can be recognized. If text or illustrations cannot be seen clearly, either

clean or replace the label.

When cleaning labels, use a cloth with water or neutral detergent. Do not use a solvent or

gasoline.

If a warning label is damaged, lost or cannot be recognized, replace the label. When replacing

warning labels, contact your local MUTOH dealer.

1.6.2 Position of the warning labels

1.6.2.1 Front of the machine.

Downloaded From ManualsPrinter.com Manuals

Page 13

Spitfire 100 Extreme series printers Users Guide

13 AP-75194 - Rev. 2.2

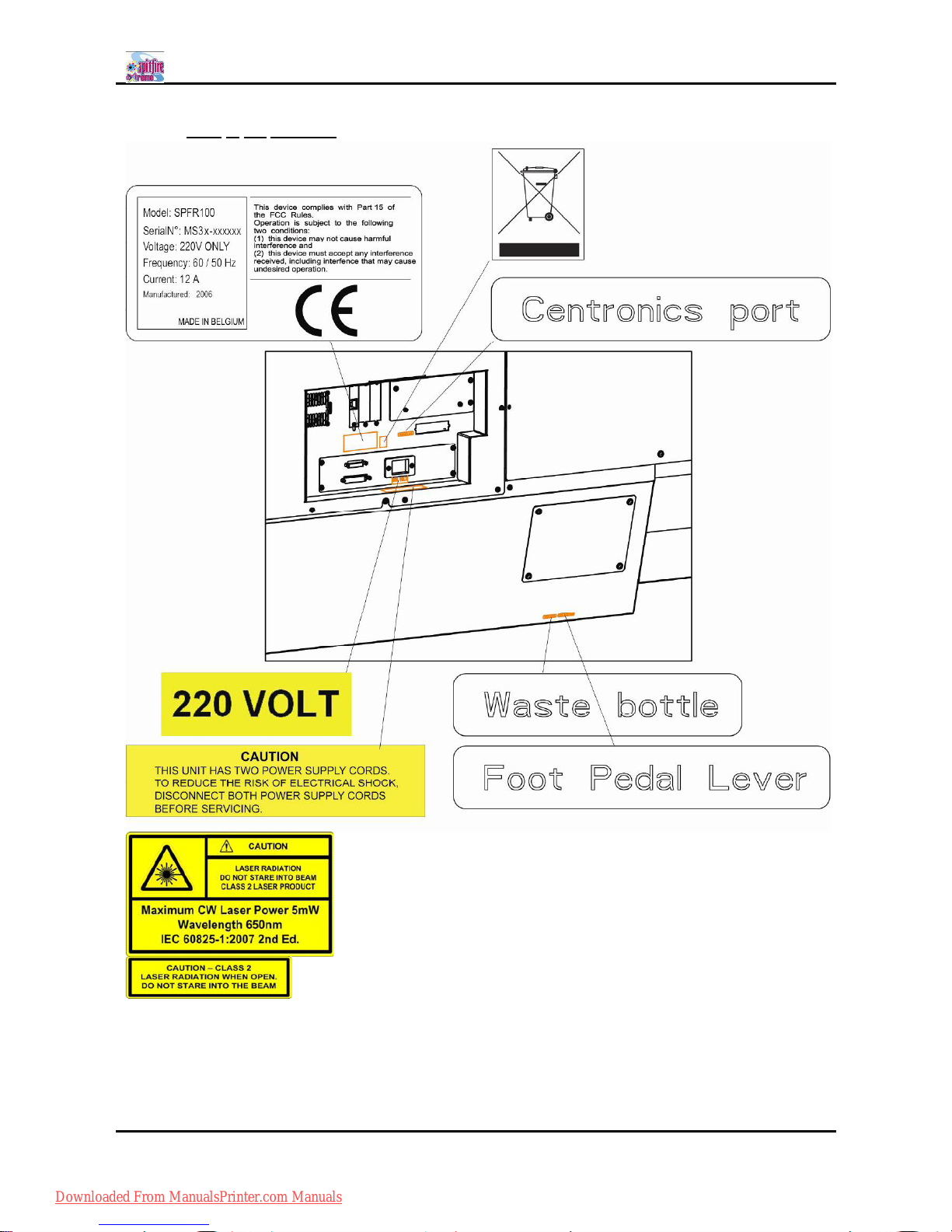

1.6.2.2 Rear of the machine.

Downloaded From ManualsPrinter.com Manuals

Page 14

Spitfire 100 Extreme series printers Users Guide

14 AP-75194 - Rev. 2.2

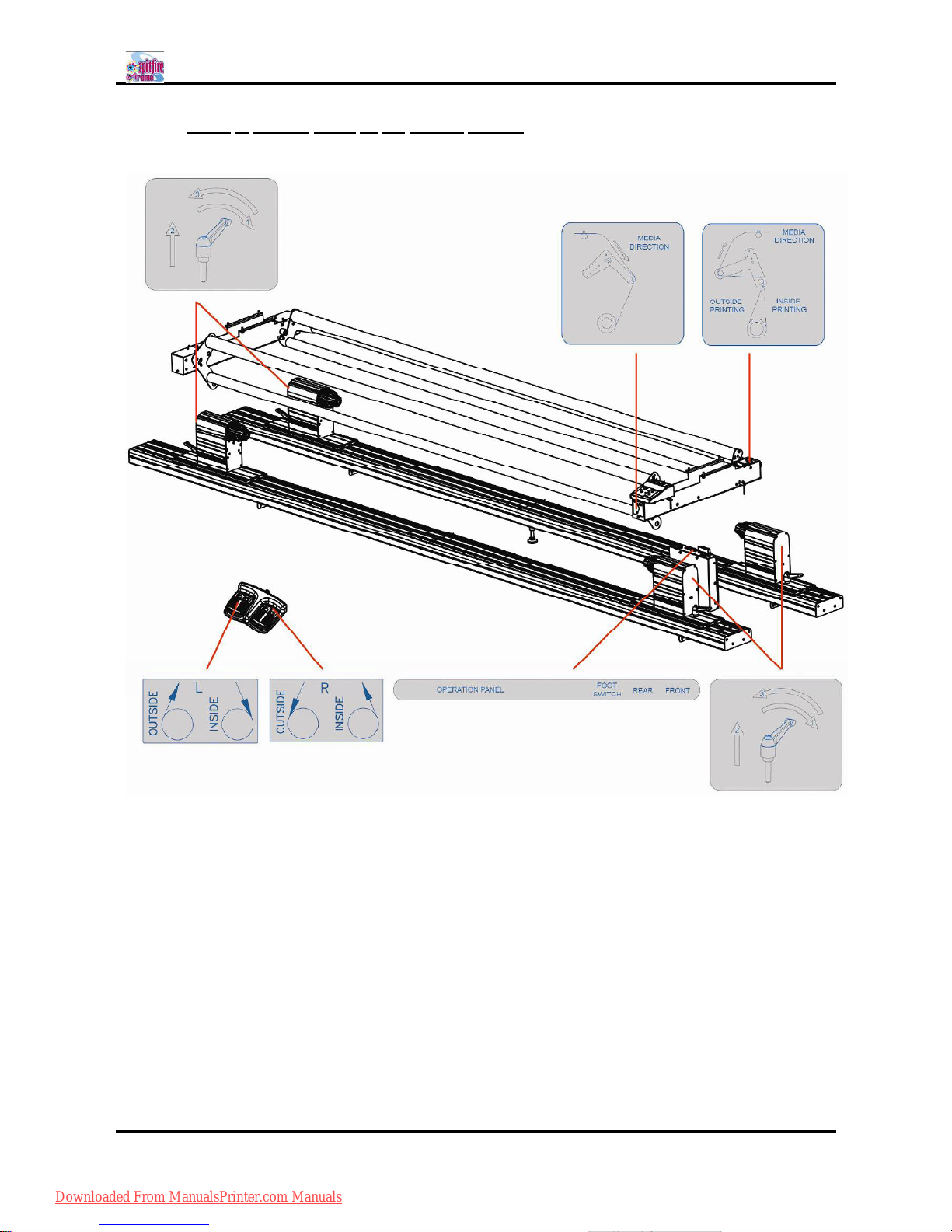

1.6.2.3 Types of warning labels on the winding system.

Downloaded From ManualsPrinter.com Manuals

Page 15

Spitfire 100 Extreme series printers Users Guide

15 AP-75194 - Rev. 2.2

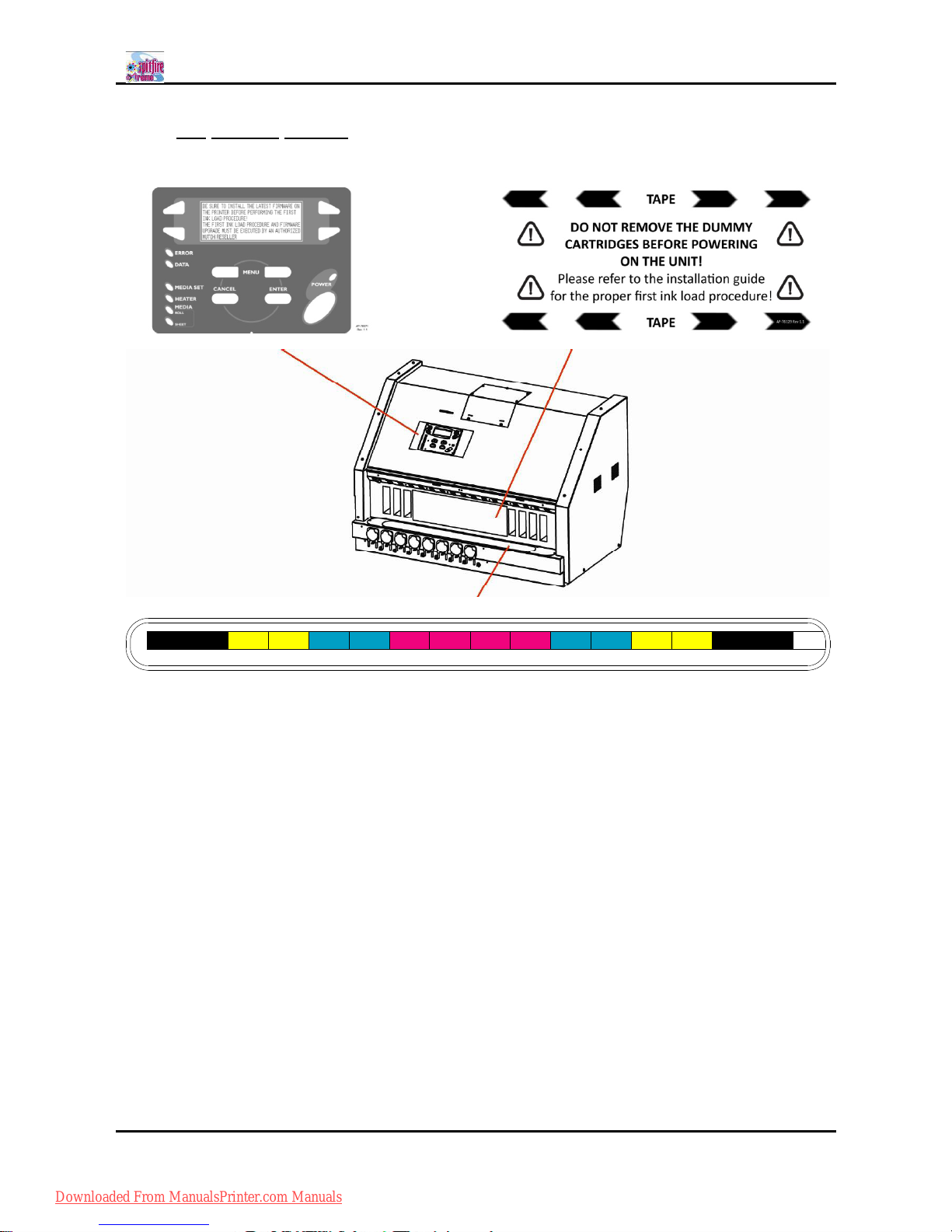

1.6.3 Labels in function of transportation

Downloaded From ManualsPrinter.com Manuals

Page 16

Spitfire 100 Extreme series printers Users Guide

16 AP-75194 - Rev. 2.2

1.6.4 Ink related labels.

1

2

P1 P2 P3

3 4

P4

5

P5

6

P6

7

P7

8

P8

9

10

11

12

13 14 15

16

HEAD 1

HEAD 2 HEAD 3

HEAD 4 HEAD 5 HEAD 6

HEAD 7

HEAD 8

4x4 colours

Downloaded From ManualsPrinter.com Manuals

Page 17

Spitfire 100 Extreme series printers Users Guide

17 AP-75194 - Rev. 2.2

2 PRODUCT OVERVIEW

2.1 Part names and functions....................................................................................................................18

2.1.1 Front ........................................................................................................................................18

2.1.2 Rear ........................................................................................................................................19

2.1.3 Heater system .......................................................................................................................20

2.1.4 Operation panel.....................................................................................................................21

2.1.4.1 Printer .............................................................................................................................21

2.1.4.2 Winding System ............................................................................................................23

2.2 Installation requirements..............................................................................................................24

2.2.1 Environment...........................................................................................................................24

2.2.2 Working space.......................................................................................................................25

Downloaded From ManualsPrinter.com Manuals

Page 18

Spitfire 100 Extreme series printers Users Guide

18 AP-75194 - Rev. 2.2

2.1 PART NAMES AND FUNCTIONS

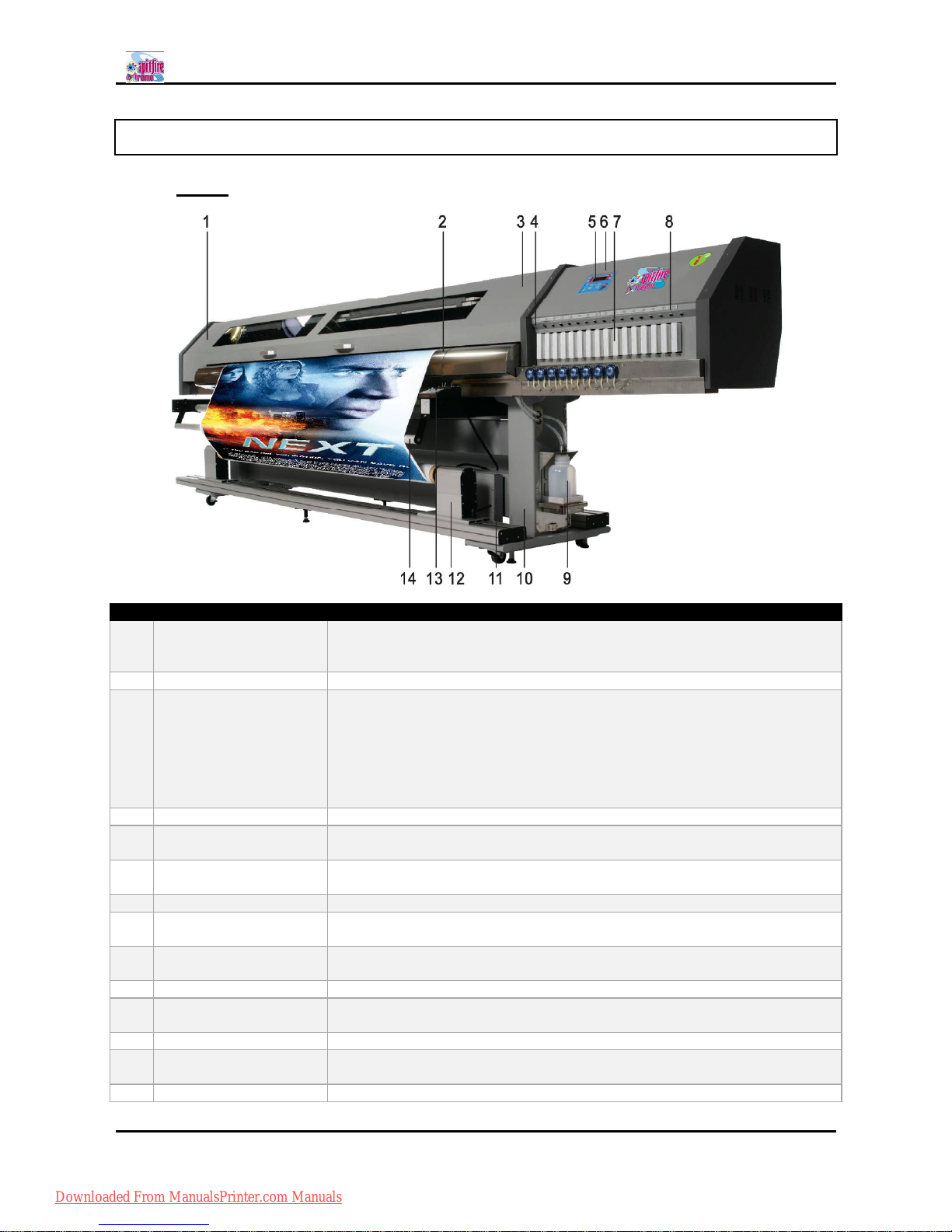

2.1.1 Front

N° Name Function

1 Maintenance Area

To perform a part of the daily and weekly maintenance. For example

cleaning around the heads.

A mirror has been installed to optimize sight.

2 Paper Guide Support the media during printing.

3 Front cover

This cover keeps the operator safe from the drive parts of the printer while it

is operating. Only open and or close the cover to perform following

operations.

Media set and replacement

Cutter blade replacement

Cleaning the wipers and other maintenance

In case of media jams

4 TL light switch To light up the TL lights (blue and white)

5 Operation panel

This panel is used to set operational conditions, the status of the printer and

other functions.

6

SmartChip

Management System

To control the ink volume on your printer

7 Ink compartment Sixteen slots available to install ink cassettes.

8 LED indicators

Indicates if there is a cassette in the slot below the LED and if it is empty or

not.

9 Waste bottle

To collect the waste fluid. Should be emptied according to the procedure

described in this manual.

10 Stand This stand is used to install the printer on a flat surface floor.

11

Unwinder/Winder PCB

Box

This box contains all electronics to control the unwinder winder 100 system.

12 Winder system Motorized roll-up system.

13

Unwinder/Winder

control panel

To control the complete unwinder/winder 100 system.

14 Front swingbar To adjust the tension of the media and to optimize the winding of the media.

Downloaded From ManualsPrinter.com Manuals

Page 19

Spitfire 100 Extreme series printers Users Guide

19 AP-75194 - Rev. 2.2

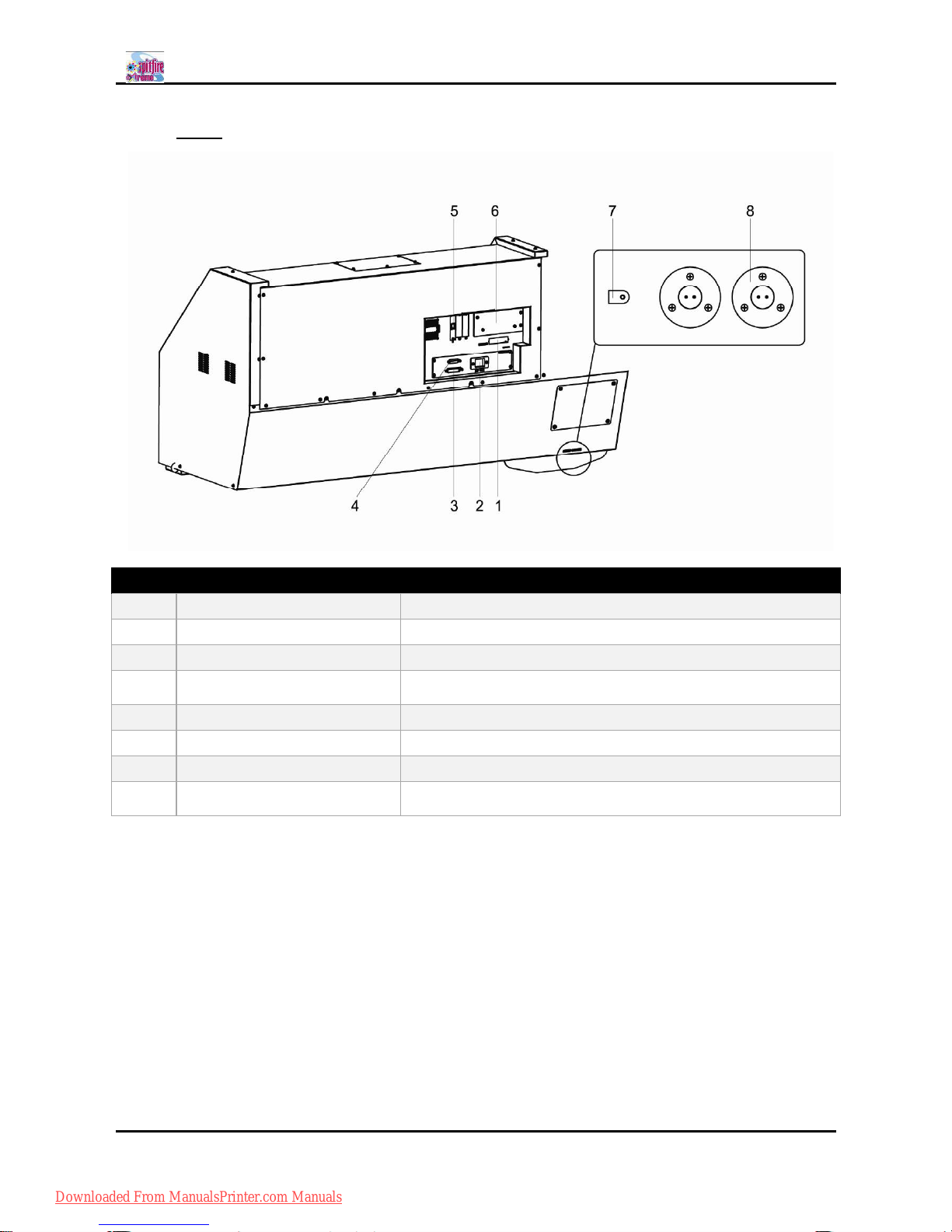

2.1.2 Rear

N° Name Function

1 Interface connector This is the connector to which the interface cable is connected

2 AC inlet This is the inlet interface to which the power plug is connected

3 BIS - CLIB To connect the optional Bulk Ink System

4 BIS - Sensors

To connect the sensor cable of the optional Bulk Ink System with

the printer

5 Insertion slot Network card installed. To connect the network cable

6 Hard disk slot For the hard disk

7 Waste bottle connector To connect the waste bottle sensor cable

8 Foot switch connectors

To connect the footswitches to lower or higher the pressure

rollers

Downloaded From ManualsPrinter.com Manuals

Page 20

Spitfire 100 Extreme series printers Users Guide

20 AP-75194 - Rev. 2.2

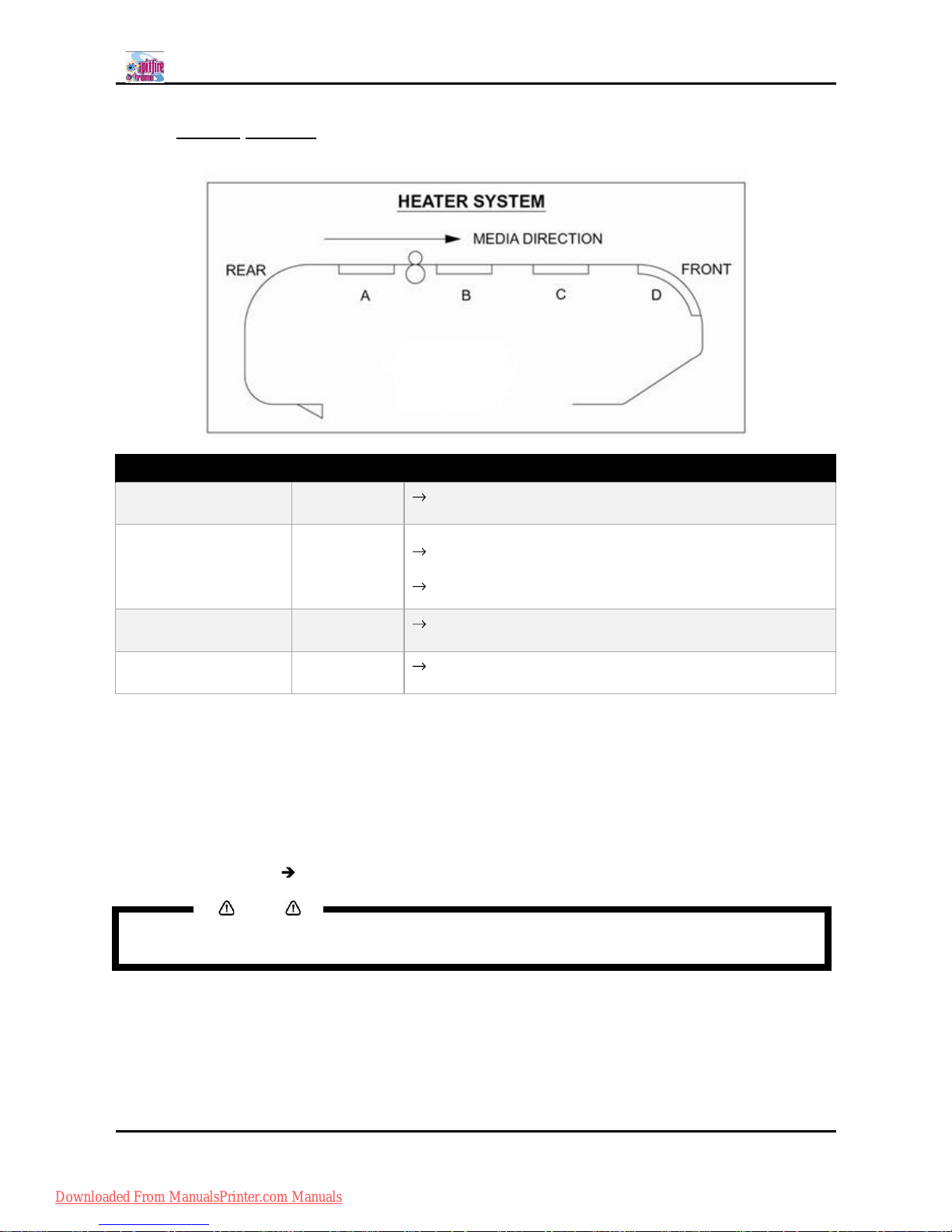

2.1.3 Heater system

Heater Element Temperature Function

Pre-heater (Heater A) 20 50°C

Open the pores to make the media more receptive for Spitfire

Mild Solvent series Ink.

Fixer (Heater B)

20 40°C

(for MS - MS

Plus)

20-70°C

(for Eco)

To establish optimum fixation onto the media (coated and

uncoated).

Optimizes the dot gain control.

Post-Fixer (Heater C) 20 70°C

The post-fixer finalizes the fixation process and helps to

make the prints touch-dry.

Dryer (Heater D) 20 50°C

The dryer completes the drying for compatibility with the

take-up in combination with higher output speeds.

There have been a number of requests from the field, asking the heaters to be on by default for a few user

settings. This has now been implemented as follows:

For user 1 and user 8 default settings are as follows:

a. Pre heater A: 50°C

b. Fixer B: 40°C

c. Post Fixer C: 50°C

d. Dryer D: 50°C

For users 2 7, by default the heaters are still OFF.

Notes

Please note some RIP software do not allow selection of the user from software side. In some

cases, however, they do automatically activate user 8

Downloaded From ManualsPrinter.com Manuals

Page 21

Spitfire 100 Extreme series printers Users Guide

21 AP-75194 - Rev. 2.2

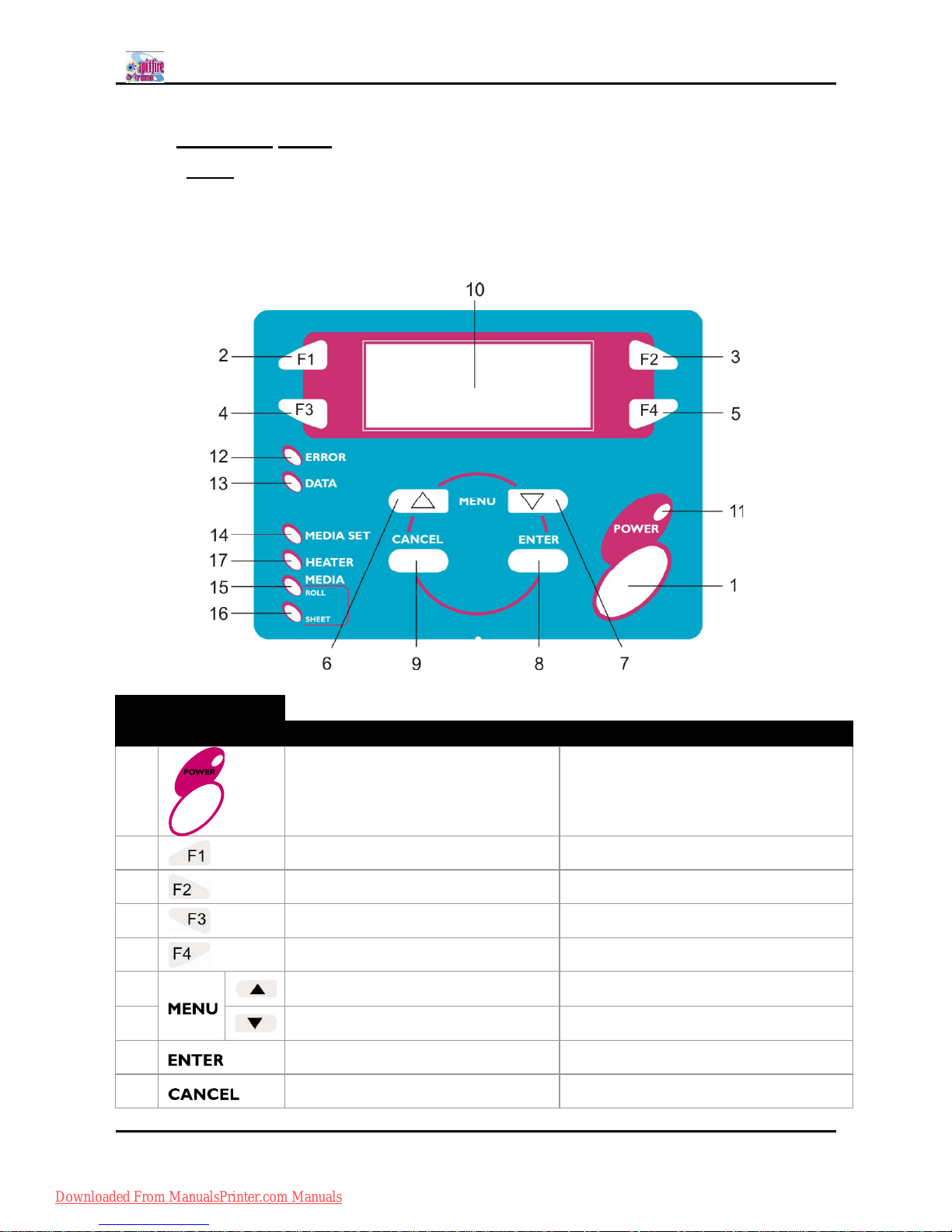

2.1.4 Operation panel

2.1.4.1 Printer

The operation panel is used to set operational conditions, display the status of the printer, and set other

functions.

The names and functions of the operation keys and status lamps are explained below.

KEYS

N° Name In the Main Screen In the Setup Menu

1 Switch the printer ON and OFF Switch the printer ON and OFF

2 Executes the function assigned to F1. Executes the function assigned to F1.

3 Executes the function assigned to F2. Executes the function assigned to F2.

4 Executes the function assigned to F3. Executes the function assigned to F3.

5 Executes the function assigned to F4. Executes the function assigned to F4.

6

Changes the LCD monitor display to

the setup menu status.

Changes the menu in reverse order.

7

Changes the LCD monitor display to

setup menu status.

Changes the menu in forward order.

8 Displays the print mode currently set. Confirm a new value, feature change.

9 - Declines a new value, feature change.

Downloaded From ManualsPrinter.com Manuals

Page 22

Spitfire 100 Extreme series printers Users Guide

22 AP-75194 - Rev. 2.2

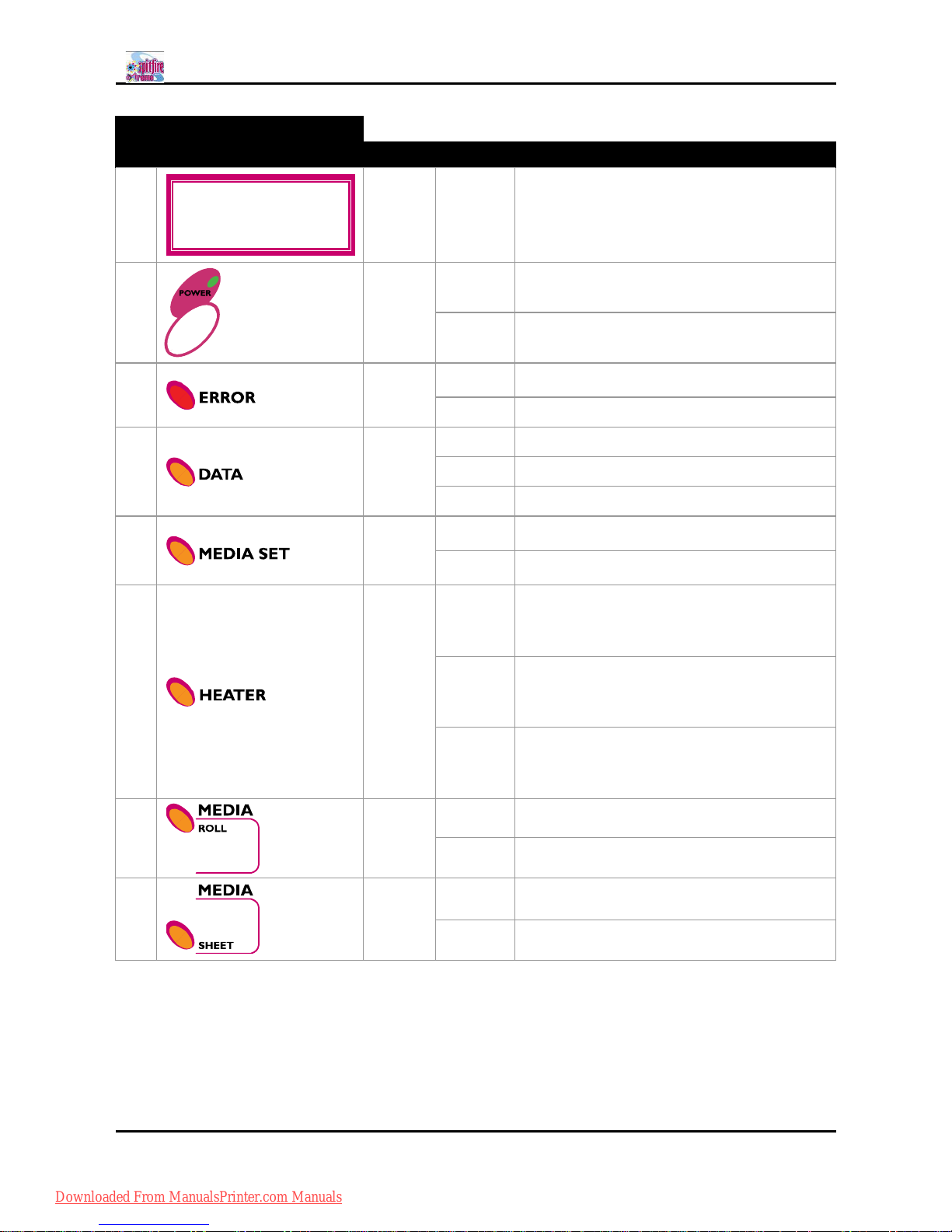

LCD and LEDS

N° Name Colour Status Function

10 Green -

The monitor displays the operation status and

error messages of the printer.

11 Green

ON The printer is on.

OFF The printer is off.

12 Red

Flashing

An error has occurred. The contents will be

displayed on the LCD monitor.

OFF Either there is no error or the power is off.

13 Orange

ON The printer is receiving print data.

Flashing The printer is analyzing received data.

OFF The printer is waiting to receive print data.

14 Orange

ON

The pressure roller is in the release position.

Media has not been loaded.

OFF

The pressure roller is in the secured position.

The media has not been loaded.

15 Orange

ON

The temperature of the heating elements is at

the requested temperature.

The real temperature is the same as the

requested temperature.

Flashing

The heating elements are warming up.

The real temperature is different from the

requested temperature.

OFF The heating elements are powered OFF.

16 Orange

ON The media type is set to roll media.

OFF The media type is set to sheet media.

17 Orange

ON The media type is set to sheet media.

OFF The media type is set to roll media.

Downloaded From ManualsPrinter.com Manuals

Page 23

Spitfire 100 Extreme series printers Users Guide

23 AP-75194 - Rev. 2.2

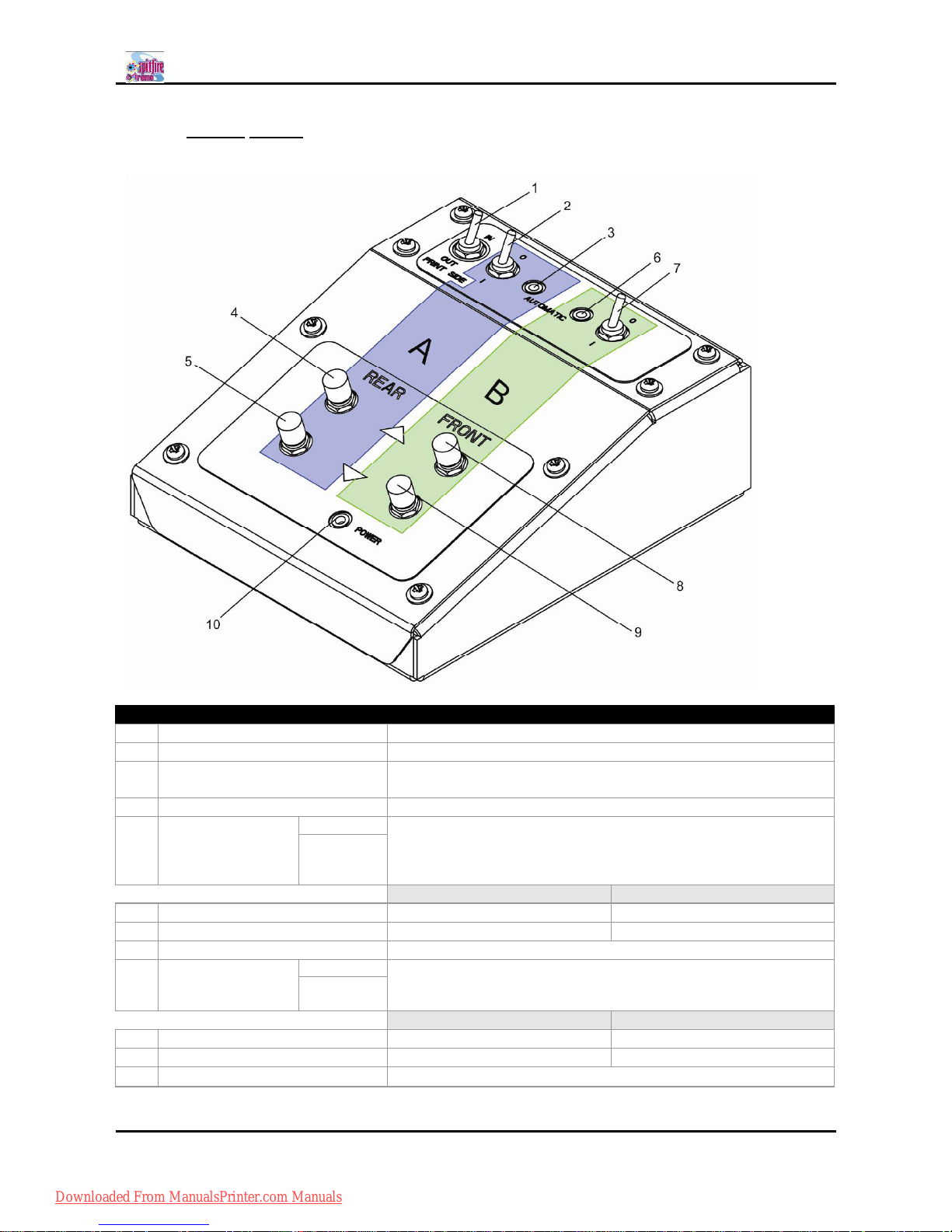

2.1.4.2 Winding System

The operation panel is used to set operational conditions.

N° Name Function

A / Part of the operation panel controlling the unwinder 100.

B / Part of the operation panel controlling the winder 100.

1 Print Side Selector

In case you loaded media with printed side on the outside select

OUT, otherwise select IN.

2 Unwinder 100 switch Toggle between Manual (0) and Automatic (I) mode.

3 Unwinder 100 LED

Manual LED lights up when pushing one of the buttons

Motor turns: LED flashes.

Motor is off: LED is out.

Motor accelerates: LED burns continuously.

Automatic

Outside printing Inside printing

4 Backwards button Roll-off unwinder Roll-up unwinder

5 Forwards button Roll-up unwinder Roll-off unwinder

6 Winder 100 switch Toggle between Manual (0) and Automatic (I) mode.

7 Winder 100 LED

Manual LED lights up when pushing one of the buttons

Motor turns: LED flashes

Motor is off: LED is out.

Automatic

Outside printing Inside printing

8 Backwards button Roll-off winder Roll-off winder

9 Forwards button Roll-up winder Roll-up winder

10 Power LED Lightens up if the system is powered ON.

Downloaded From ManualsPrinter.com Manuals

Page 24

Spitfire 100 Extreme series printers Users Guide

24 AP-75194 - Rev. 2.2

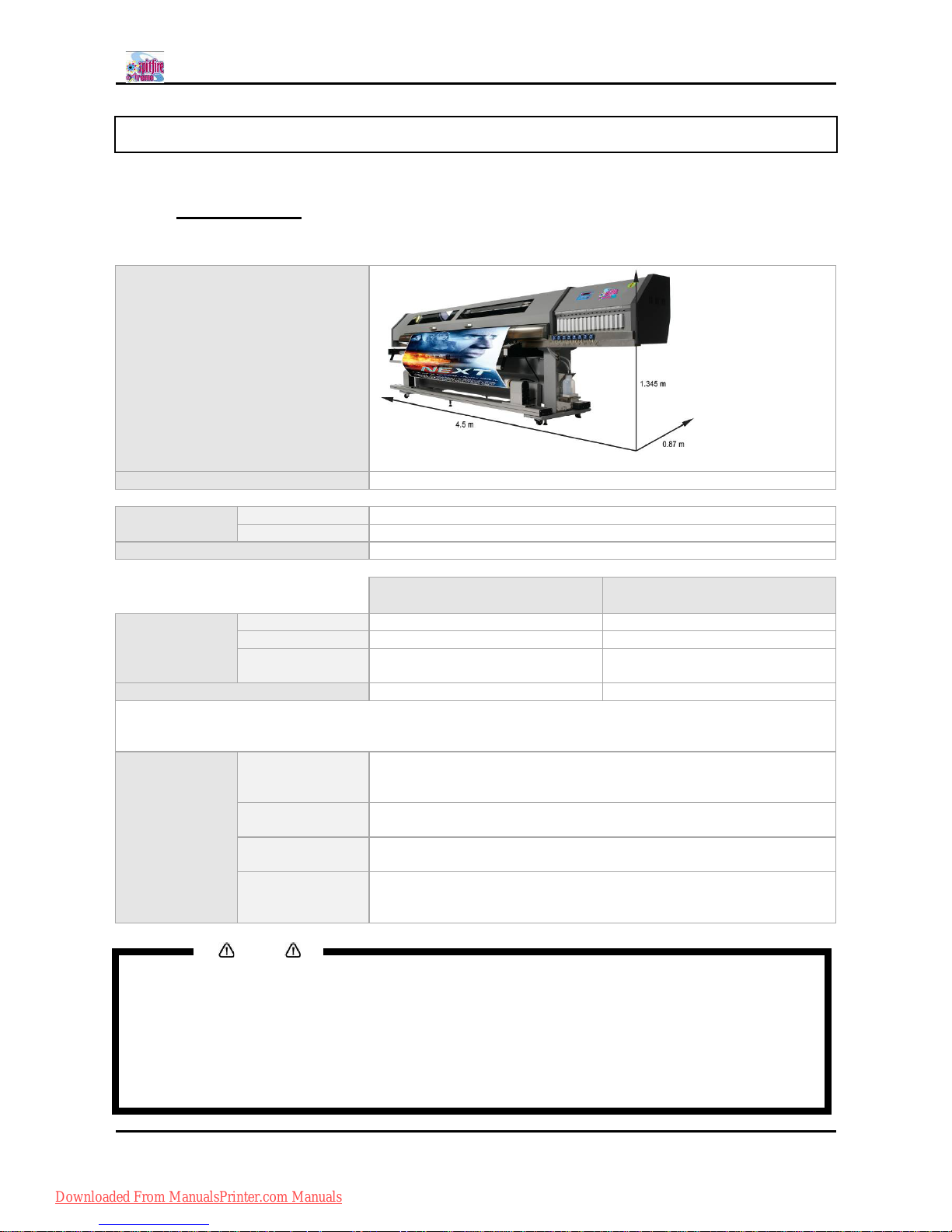

2.2 INSTALLATION REQUIREMENTS

It is very important that the installation environment fulfils following conditions to obtain a good print quality.

2.2.1 Environment

Choose a place for printer installation following the requirements in the table below.

Dimension machine

Area (printer only) 3,915 m² (42 ft²)

Total weight

machine

Without media ± 500 kg (1100 Lb)

With media ± 600 kg (1430 Lb)

Maximum load on one wheel 200 kg (440 Lb)

Printer Winding System

Electrical Voltage

AC 220-240V AC 100-120V / AC 220-240V

Frequency 50Hz±1Hz 60Hz, 50Hz±1Hz

Capacity AC220V-240V : 12A AC100V-120V : 0.3 A

AC220V-240V : 0.13 A

Maximum capacity 2500 Watt

In order to protect the printer for over currents, short circuits and earth faults, the building

installation should be equipped with an automatic breaker double pole of 20 A and an earth leakage

switch of 300 mA.

Environmental Recommended

working

environment

Temperature: 23°C

Humidity: 55%, without condensation

Operational

conditions

Temperature: 20°C - 30°C

Humidity: 40% to 65%, without condensation

Rate of change Temperature: No more than 2°C per hour

Humidity: No more than 5% per hour

Storage

environment

Temperature: 4°C to 50°C

Humidity: 40 to 80%, without condensation (When ink has been

discharged.)

Notes

Avoid the following temperature and humidity conditions. Otherwise, printed images may

appear differently from what you expect:

± Places where sudden changes in temperature and humidity are expected, even though the

condition is within the range written above.

± Places where direct sunlight or excessive lighting are expected.

± Places where air conditioners blow directly.

MUTOH recommends that the printer should be installed where air conditioning can be

adjusted easily.

Downloaded From ManualsPrinter.com Manuals

Page 25

Spitfire 100 Extreme series printers Users Guide

25 AP-75194 - Rev. 2.2

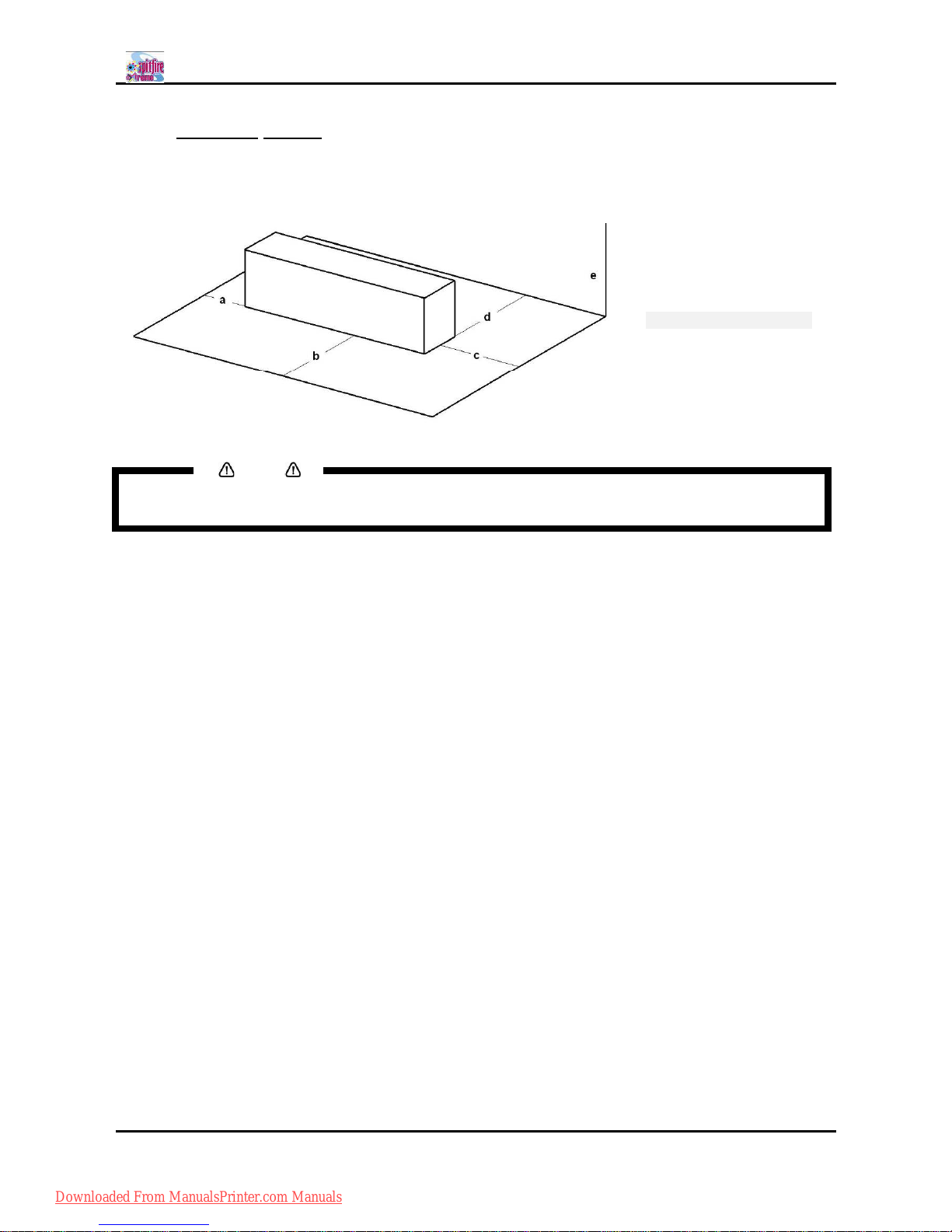

2.2.2 Working space

Install the product on a flat surface that fulfils following conditions:

Recommended space

A = 1 meter

B = 2 meter

C = 2.5 meter

D = 2 meter

E = 3 meter

Notes

These are recommended values. When loading media with a trolley or manually, different

values should be used.

Downloaded From ManualsPrinter.com Manuals

Page 26

Spitfire 100 Extreme series printers Users Guide

26 AP-75194 - Rev. 2.2

Downloaded From ManualsPrinter.com Manuals

Page 27

Spitfire 100 Extreme series printers Users Guide

27 AP-75194 - Rev. 2.2

3 BASICS

3.1 Powering on ...................................................................................................................................29

3.2 Powering OFF ...............................................................................................................................30

3.3 Switch ON-OFF the winding system. .........................................................................................31

3.4 Media handling ..............................................................................................................................32

3.4.1 Setting media type in detail .................................................................................................32

3.4.2 Loading Roll media ...............................................................................................................33

3.4.3 Loading sheet media ............................................................................................................38

3.4.4 Using media retainers. .........................................................................................................39

3.4.5 Using the media core braces. .............................................................................................40

3.5 Ink cassettes..................................................................................................................................41

3.5.1 Ink cassette behaviour .........................................................................................................41

3.5.2 Types ......................................................................................................................................42

3.5.3 Replacement procedure.......................................................................................................42

3.6 Replacing the cutting blade .........................................................................................................43

3.6.1 Replacement time .................................................................................................................43

3.6.2 Replacement procedure.......................................................................................................43

3.7 Replacing the waste bottle ..........................................................................................................44

3.7.1 Replacement Time................................................................................................................44

3.7.2 Replacement Procedures ....................................................................................................44

3.8 Working with Mutohs SmartChip management System ........................................................45

3.8.1 Introduction ............................................................................................................................45

3.8.2 Selecting the correct modes................................................................................................46

3.8.3 Transferring ink volume .......................................................................................................47

3.8.3.1 Via the smart chip reader slot .....................................................................................47

3.8.3.2 Via the Cassette slots of the printer. ..........................................................................48

3.9 Switch between ink configurations. ............................................................................................49

3.10 Unattended printing or leave printer idle during night .............................................................50

3.10.1 Unattended Printing..............................................................................................................50

3.10.2 Leave your printer IDLE during night. ................................................................................51

3.11 LongStore.......................................................................................................................................52

3.11.1 Procedure to LongStore.......................................................................................................53

Downloaded From ManualsPrinter.com Manuals

Page 28

Spitfire 100 Extreme series printers Users Guide

28 AP-75194 - Rev. 2.2

3.11.2 Starting up after a LongStore..............................................................................................54

3.12 Transferring the printer.................................................................................................................56

3.12.1 Hints, tips and warnings.......................................................................................................56

3.12.2 Transferring the printer.........................................................................................................57

Downloaded From ManualsPrinter.com Manuals

Page 29

Spitfire 100 Extreme series printers Users Guide

29 AP-75194 - Rev. 2.2

3.1 POWERING ON

Caution

Before powering ON the printer, make sure that the waste bottle is installed and that the waste

tubes are connected to the waste bottle.

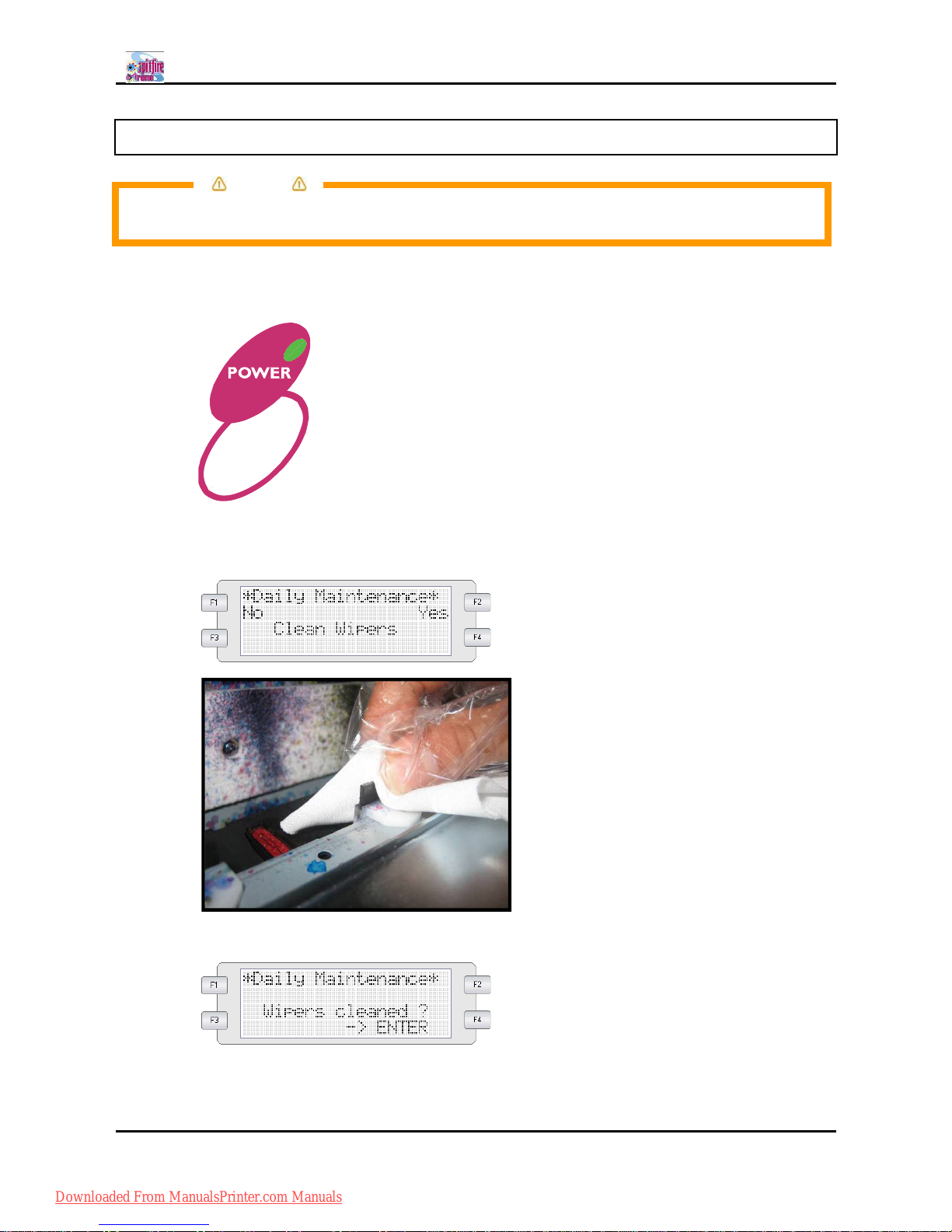

Step 1 : Press the [POWER] key of the operation panel.

The POWER lamp of the operation panel will light (green).

Step 2 : The printer will ask if you want to clean the wipers. When it is the first start up in a few hours, it is

highly recommended to press [YES] [F2] and to clean the wipers with Mutoh Mild cleaning in

order to remove all ink and to make the wipers more elastic.

Step 3 : Press the ENTER key when you have done. The carriage will cap in again.

Step 4 : After finishing the daily maintenance, the print will automatically perform a normal cleaning.

Step 5 : After finishing the cleaning cycle, the media measurement screen will be displayed (in case there

is media loaded)

Downloaded From ManualsPrinter.com Manuals

Page 30

Spitfire 100 Extreme series printers Users Guide

30 AP-75194 - Rev. 2.2

Step 6 : Make the correct settings and press the [F4]-key to start the media initialization.

Step 7 : If everything is done correctly, the following screen should appear.

Notes

If there are any problems during the initial start-up operation, the printer will display a message, and

the operation may stop. If the operation stops, refer to "Troubleshooting", and take the appropriate

actions.

Step 8 : Before start printing, be sure to perform a nozzle check to ensure all nozzles are present. If not,

perform the necessary cleaning cycles.

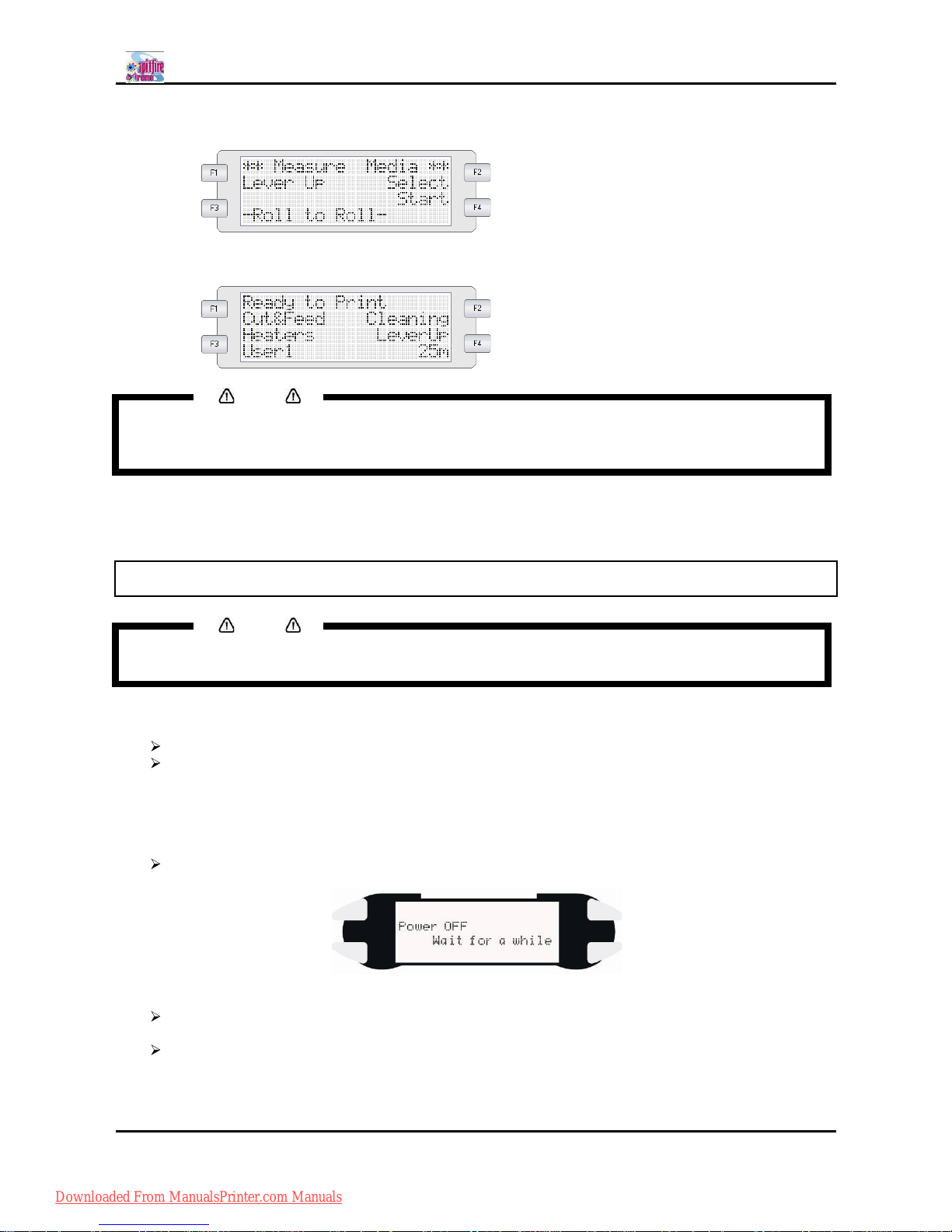

3.2 POWERING OFF

Notes

Please be sure to perform the necessary maintenance before powering OFF the machine. All details

can be found in chapter 4.

Step 1 : Verify the following regarding the operational condition of the printer:

There is no printing operation being performed.

The operation panel is in the main screen.

Step 2 : Press the [POWER] key of the operation panel to switch OFF the printer.

Step 3 : [Power OFF] will be displayed for a few seconds

Following message is displayed.

All lamps and the LCD of the operation panel will switch OFF.

The printer will automatically perform a Tubing Flush and power OFF.

Downloaded From ManualsPrinter.com Manuals

Page 31

Spitfire 100 Extreme series printers Users Guide

31 AP-75194 - Rev. 2.2

3.3 SWITCH ON-OFF THE WINDING SYSTEM.

There is a switch located on the power supply box of the winding system.

Its status is marked with O and I.

I Switched ON Power LED on control panel of winding system will light up

O Switched OFF Power LED on control panel of winding system will not be lid.

Downloaded From ManualsPrinter.com Manuals

Page 32

Spitfire 100 Extreme series printers Users Guide

32 AP-75194 - Rev. 2.2

3.4 MEDIA HANDLING

Loading, installing and setting media are very important handlings when you want to obtain a perfect print

quality. When the media is not loaded centrally, not installed properly head crashes, banding can occur.

Also the complete winding system should be installed and aligned properly by an Authorized Mutoh

Technician.

3.4.1 Setting media type in detail

After lowering the pressure rollers, you will be asked each time to set the media type. Even if it is a sheet of

roll, different profiles are possible to select.

[F1]-key Lever UP

[F2]-key Browse through the media profiles

(lower left corner)

[F4]-key Start media measurement using the

Selected profile in the lower left corner.

Please find below the different profiles and decide which one to use.

OFF Roll LeftRight

(**)

Roll LeftRightTop

(**)

Roll to Roll Sheet

Measurement None

(*)

Left

Right

Left

Right

Top

Left

Right

Left

Right

Top

Bottom

Take Up Not used Not used Not used Used Not used

SlantCheck No Yes Yes Yes No

Cutting media

possible?

Yes Yes Yes

Yes

(no auto cut)

Yes

Cut Test No No Yes No Yes

Feeder speed Low Low Low Low High

(*)

Load the media at the right side of the printer. Position the media next to the media setting position (line of little holes in the

media guide platform). The maximum distance between the guideline and media is 5 mm. Set the width of the media in the

Utility menu in SetupMenu 4/7.

(**)

Use Roll LeftRight for flexible media and Roll LeftRightTop for rigid media. In the second option, a media cut test will be

performed which means scrolling back and forward of the media (backwards feeding). When loading flexible media, it could

get stuck into the media groove and can cause head strikes.

Downloaded From ManualsPrinter.com Manuals

Page 33

Spitfire 100 Extreme series printers Users Guide

33 AP-75194 - Rev. 2.2

3.4.2 Loading Roll media

Please follow the procedure below to install and load roll media.

Step 1 : Make sure the printer and Unwinder/Winder 100 are switched ON.

Step 2 : Press the [F4] key in the main menu to raise the pressure rollers or use the foot pedal of the

printer.

Step 3 : Open the front cover carefully using both handles.

Step 4 : Make sure both unwinder (REAR) and winder (FRONT) unit are set to MANUAL mode.

Step 5 : Consider the specifications of the printer before loading media:

Metrical Imperial

Maximum loading capacity 100 kg 220 lb

Maximum width 2604 mm 102.5 in

Inner core diameter 50.8 mm or 76.2 mm 2 in or 3 in

Step 6 : Remove the packaging of the media roll.

Step 7 : Check whether the media is inside or outside printable. This affects the installation method on

the unwinder at the rear of the machine.

Step 8 : Install a media core brace in case the media is wider than 2 meter. This to prevent the media to

bend.

Downloaded From ManualsPrinter.com Manuals

Page 34

Spitfire 100 Extreme series printers Users Guide

34 AP-75194 - Rev. 2.2

Step 9 : Install the media between the two roll units at the back of the machine. Loosen the handles to

move the roll units left and right.

Step 10 : Be sure that the media is loaded centrally. This to be sure that the media is wound up straight.

This can be easily checked by the yellow labels on the winding rails. Be sure to mount the left

and right roll unit on the same distance from the 0I0 label.

Step 11 : Install an empty core between the front roll units.

A. Make sure the core is longer than the media width.

B. Load it centrally as described in previous step

C. Install a media core brace in case the media is wider than 2 meter. This to prevent the media to

bend. Please refer to Using the media core braces-chapter.

Step 12 : Use the foot-switch to release some media on the rear.

Downloaded From ManualsPrinter.com Manuals

Page 35

Spitfire 100 Extreme series printers Users Guide

35 AP-75194 - Rev. 2.2

Step 13 : Load media through the rear swingbar, over the print platform, under the pressure rollers as

pictured below.

Outside printable Inside Printable

1 Roll unit

2 Media roll

3 Rear swingbar

4 Print platform and pressure rollers

Step 14 : Take the media on the front of the printer and pull until the rear tensioning system gently hits the

back of the machine. This to become an equal tension.

Step 15 : Lower the pressure rollers by pressing the F4 key or using the foot pedal.

Step 16 : Set the unwinder (REAR) unit to AUTOMATIC.

The rear tensioning system will go to its initial position.

Notes

Be sure to make the correct settings on the control panel of the winding system.

Downloaded From ManualsPrinter.com Manuals

Page 36

Spitfire 100 Extreme series printers Users Guide

36 AP-75194 - Rev. 2.2

Step 17 : Decide which kind of media measurement should be done. The following profiles are available.

Profiles

Settings

OFF Roll LeftRight

(**)

Roll LeftRightTop

(**)

Roll to Roll

Measurement None

(*)

Left

Right

Left

Right

Top

Left

Right

Take Up

Not used Not used Not used Used

SlantCheck No Yes Yes Yes

Cutting media

possible?

Yes Yes Yes

Yes

(no auto cut)

Cut Test No No Yes No

Feeder speed

Low Low Low Low

(*)

Align media to media guide dots on the print platform. Set width in Utility menu.

(**)

Use Roll LeftRight for flexible media and Roll LeftRightTop for rigid media. In the second option, a

media cut test will be performed which means scrolling back and forward of the media (backwards

feeding). When loading flexible media, it could get stuck into the media groove and can cause head

strikes.

Go to step 20 when you have chosen for OFF - Roll LeftRight or Roll LeftRightTop. When you have chosen

for Roll to Roll, go to step 18

Step 18 : Forward the media until you can stick it to the core installed between the front roll units.

Make sure to have an equal tension on both sides of the media.

1 Roll unit

2 Empty core

3 Front swingbar

Downloaded From ManualsPrinter.com Manuals

Page 37

Spitfire 100 Extreme series printers Users Guide

37 AP-75194 - Rev. 2.2

HINT

To ease the winding up of the media on the front core, it is permitted to cut the media in a Vshape.

Step 19 : Tighten the media straight to the core with tape.

Step 20 : After closing the front cover, the media initialize will start.

[F1]-key Lever UP

[F2]-key Browse through the different profiles for

media measurement

[F4]-key Start media measurement using the

selected profile in the lower left corner

Step 21 : Set the winder (FRONT) unit to ACTIVE. The front tensioning system will be activated.

Step 22 : Install the media retainers if necessary as explained in one of the next chapters.

Step 23 : Installation of the media is completed.

Notes

With a small intervention it is possible to reverse your winding direction. Mount the twist cable

between the control box and the front motorized unit cable.

1 Normal winding direction

2 Twisted motor cable attached

Downloaded From ManualsPrinter.com Manuals

Page 38

Spitfire 100 Extreme series printers Users Guide

38 AP-75194 - Rev. 2.2

3.4.3 Loading sheet media

Please follow the procedure below to load sheet media.

Step 1 : Make sure the printer is switched ON.

Step 2 : Press the [F4] key in the main menu to raise the pressure rollers or use the foot pedal of the

printer.

Step 3 : Open the front cover carefully using both handles.

Step 4 : Consider the specifications of the printer before loading a sheet:

Metrical Imperial

Maximum media width 2604 mm 102.5 in

Maximum printing width 2594 mm 102.13 in

Step 5 : Slide a sheet over the print platform, under the pressure rollers.

Step 6 : Pay attention that the sheet is loaded straight to avoid slant errors.

Step 7 : Lower the pressure rollers by pressing the F4 key or using the foot pedal.

Step 8 : Decide which kind of media measurement should be done. The following profiles are available.

Profiles

Settings

OFF Sheet

Measurement None

(*)

Left Right Top - Bottom

Take Up

Not used Not used

SlantCheck

No No

Cutting media possible? Yes Yes

Cut Test No Yes

Feeder speed Low High

(*)

Align media to media guide dots on the print platform. Set width in Utility menu.

Step 9 : After closing the front cover, the media initialize will start.

[F1]-key Lever UP

[F2]-key Browse through the different profiles for

media measurement

[F4]-key Start media measurement using the

selected profile in the lower left corner

Step 10 : Install media retainers if necessary as explained in next chapter.

Step 11 : Installation of a sheet is finished. You can start printing.

Downloaded From ManualsPrinter.com Manuals

Page 39

Spitfire 100 Extreme series printers Users Guide

39 AP-75194 - Rev. 2.2

3.4.4 Using media retainers.

Some media are fragile to cockling. When installing the media retainers at the edge of the media, the media

is kept down and the risk of head crashes and bad print quality is smaller.

Caution

Never use the media retainers when working in CutSheet mode or with a sheet.

Step 1 : Mount as well the left as right media retainer in the grooves. Always insert them from the left side

of the machine. Be sure the pins are correctly installed in the grooves.

Step 2 : Move the right media retainer to the far right side and the left media retainer to the most left side.

Step 3 : Install the roll media as explained in previous chapters.

Step 4 : After the initializing of the paper, shove the media retainers over the media edges.

Caution

Do not push the media retainers as far as possible over the media, otherwise the printed file

will go under the media retainer and will leave a mark.

The media retainer should not come further over the media as the minimum margin. This is 5

mm.

Step 5 : You are ready to print.

³¿®¹·² ±º ë ³³

Downloaded From ManualsPrinter.com Manuals

Page 40

Spitfire 100 Extreme series printers Users Guide

40 AP-75194 - Rev. 2.2

3.4.5 Using the media core braces.

Media core braces are developed to prevent the media cores to bend while printing. This could cause bad

print quality or paper slant.

From the moment the core is larger than 2050 mm, we recommend installing the brace. Do NOT install the

brace when the core is smaller than 2050 mm.

In the packaging box of the machine you will find two cores and two media core braces. There are already 3

spacers installed per brace with an outer diameter of 74 mm. In box 3/4 there are 6 spacers of 76 mm.

Please follow the instructions below to install and use the braces correctly.

Step 1 : First check which spacer fits the best in the used core. If this one is not installed yet, remove the

installed one with a Hexagon Wrench 2 mm (in box 2/4) and install the correct one as shown

below. There is already a hole in the core in which the locking screw fits.

Step 2 : Push the brace in the core. (Picture 1).

Be sure that the distance X is the same as Y (picture 2) and at least 75 mm.

N° Description

1 Roll Unit

2 Positioning Cone

3 Media Core Brace of 1900 mm

4 Spacer

5 Core of minimum 2050 mm

Downloaded From ManualsPrinter.com Manuals

Page 41

Spitfire 100 Extreme series printers Users Guide

41 AP-75194 - Rev. 2.2

3.5 INK CASSETTES

3.5.1 Ink cassette behaviour

Please read this chapter thoroughly to know the behaviour of a Mutoh ink cassette used with the Spitfire 100

Extreme.

An ink cassette contains 220 or 440 ml of ink. The amount of ink left in the cassette is monitored by the

smart chip installed on the cassette. During printing, two ink related messages can be displayed:

Ink Near End message

This message will be displayed when there is only 6 % of ink left in the ink cassette. The numbers

correspond the near empty ink cassettes.

You can print until the [Ink End]-message is displayed. Be sure to have a new cassette at hand.

Ink End message

This message will be displayed when the flag (2) in the cassette comes out. The cassette has to be changed

as soon as possible. The printer will stop all actions. No further action can be taken until you have done the

replacement. The numbers correspond the near empty ink cassettes.

1

2

Downloaded From ManualsPrinter.com Manuals

Page 42

Spitfire 100 Extreme series printers Users Guide

42 AP-75194 - Rev. 2.2

3.5.2 Types

Important

In case of working with another type of Mutoh ink than described in this manual, refer to the

dedicated instruction sheet added to the ink kit.

This printer is designed to use Mutoh Ink cassettes.

If using other ink cassettes

Warranty will be void.

Prints may not reach the expected quality level.

Heads can be damaged.

Printer will not recognize these cassettes when inserting (smart chip)

Please refer to the latest price list to know the available ink and cleaning cassettes for the Spitfire 100

Extreme and for the latest price and part numbers.

3.5.3 Replacement procedure

Step 1 : Remove the empty ink cassette(s) when shown on the display or when the empty lamp on the

LED bar is lit.

Step 2 : Dispose the used ink cassette by putting it in a plastic bag in accordance with local regulations or

laws.

Step 3 : Remove the new ink cassette out of its package.

Step 4 : Insert the cassette in the appropriate slot according to the ink colour configuration label.

Be sure to insert the cassette correctly, with the SmartChip-side (1) first and flag (2) pointing right.

Step 5 : The printer will continue printing.

1

2

Downloaded From ManualsPrinter.com Manuals

Page 43

Spitfire 100 Extreme series printers Users Guide

43 AP-75194 - Rev. 2.2

3.6 REPLACING THE CUTTING BLADE

3.6.1 Replacement time

Replace the cutting blade under the following conditions.

a. Media cannot be cut clearly

b. When the cut edge has scuffing

3.6.2 Replacement procedure

Follow the steps below to replace the cutting blade.

Step 1 : If the printer is powered ON, verify following items:

Printing or other operations are not performed.

Make sure that the display shows the normal status.

The MEDIA SET light goes off.

Step 2 : Go to the H. Unlock menu (SetupMenu 5/7) and unlock the head.

Step 3 : Open the front cover.

Step 4 : While pressing the cutting blade holder tab, rotate the cutting blade holder lever in the direction

shown on the picture (2).

Step 5 : Take out the cutting blade (3) and insert the new cutter into the media cutting blade holder (4).

Step 6 : While slightly pressing the cutting blade holder tab, return the cutting blade lever to its original

position.

Step 7 : Close the front cover.

Step 8 : Press the [ENTER] key.

Step 9 : The carriage returns to its original position and returns to menu 6/7.

Step 10 : Cutting blade replacement has been finished.

Downloaded From ManualsPrinter.com Manuals

Page 44

Spitfire 100 Extreme series printers Users Guide

44 AP-75194 - Rev. 2.2

3.7 REPLACING THE WASTE BOTTLE

3.7.1 Replacement Time

Replace the waste bottle when the waste bottle is full. This is determined firmware wise.

3.7.2 Replacement Procedures

Follow the steps below to replace the waste bottle.

Step 1 : Check the following if the power of the printer is ON.

Printer is not printing.

Operation panel is in normal status.

Media setting light is off.

Step 2 : Lower the waste ink tank tray till it touches the sensor at the bottom.

Step 3 : Remove the waste ink bottle.

Step 4 : Replace the full one with an empty one (in-the-box) and empty the full one.

Notes

Put the used waste bottle in a solvent resistant container and follow the local regulations when

disposing.

The counter of the waste bottle will be reset from the moment the tray releases the sensor. So

be sure to empty the waste tank, otherwise it will overflow.

Step 5 : Replace the waste ink bottle and guide the waste ink tank tray back to its home position.

Step 6 : Following message will be displayed after replacement

Downloaded From ManualsPrinter.com Manuals

Page 45

Spitfire 100 Extreme series printers Users Guide

45 AP-75194 - Rev. 2.2

3.8 WORKING WITH MUTOHS SMARTCHIP MANAGEMENT

SYSTEM

3.8.1 Introduction

On each ink cassette, a SmartChip is attached. On this SmartChip, ink volume is stored. When printing, the

ink volume will be reduced from the SmartChip.

When working with Mutoh's Bulk Ink System, no SmartChips are attached to the cartridges. Therefore, each

bulk ink bottle includes a SmartChip with the necessary ink volume.

The SmartChip management system makes it possible to load this ink volume via the SmartChip slot

installed at the back of the printer.

With this feature it is also possible to:

review the remaining ink volume

scan the ink cassette slots for ink volume

Important

Do not pull any SmartChip cards from ink cassettes to use them in the reader. The ink volume

on the SmartChip cards of the cassettes can be transferred to the SmartChip management

system by scanning them one by one. Please find in the next coming chapters more info.

Downloaded From ManualsPrinter.com Manuals

Page 46

Spitfire 100 Extreme series printers Users Guide

46 AP-75194 - Rev. 2.2

3.8.2 Selecting the correct modes

Depending on printing with ink cassettes or with a bulk ink system, the ink volume has to be transferred in a

different way. You can choose between printer and cassette mode in the ChipManager menu:

Please follow the steps to switch between the two modes:

Step 1 : Power ON the printer.

Step 2 : Go to InkManager ChipMgr and choose printer to enable the SM system.

Step 3 :

Parameters Description

Cassette Use the smart chips on the ink cassettes

Printer Use the smart chip management system. Recommended when working with a

Spitfire Bulk Ink System.

Step 4 : When you have selected cassette mode, you are ready to print, no further settings should be

made.

Step 5 : When you have selected printer mode, the colour mode should be set.

Go to SetupMenu 5/7 InkManager ColorMode

Extreme1C1H (*)

K K Y Y C C M M M M C C Y Y K K

2x4_Symm

K Y C M M C Y K Cl Cl Cl Cl Cl Cl Cl Cl

6LcLm

K Lm C Lc Cl M Cl Y Y Cl M Cl Lc C Lm K

4x4_Symm

K Y C M M C Y K K Y C M M C Y K

4x4_1C1H For future use only

K Black

C Cyan

Lc Light Cyan

M Magenta

Lm Light Magenta

Y Yellow

Cl Cleaning

(*) HIGHLY RECOMMENDED BY MUTOH

Downloaded From ManualsPrinter.com Manuals

Page 47

Spitfire 100 Extreme series printers Users Guide

47 AP-75194 - Rev. 2.2

3.8.3 Transferring ink volume

3.8.3.1 Via the smart chip reader slot

Please follow the instructions below to transfer the ink volume on the SmartChips to the SmartChip

Management System.

Step 1 : Browse to the ChipStatus menu and press the F1 key.

Notes

Be sure to be in printer mode, otherwise ChipStatus will be replaced by InkStatus.

Step 2 : Insert the SmartChip in the reader slot and press the ENTER key.

Step 3 : The system will scan the reader slot.

Step 4 : Perform the correct action based on the displayed message.

IF THEN

a cleaning card is detected

Remove the SmartChip card and

press ENTER

a valid card is found

Press ENTER to transfer the ink volume

Press CANCEL to quit the operation

no valid card is found

Remove the SmartChip card. You will be asked if you

want to scan the cartridge slots for ink volume.

Please refer to the next chapter for all the details.

the total printer chip value exceeds 40 000 ml

The transfer has been cancelled automatically.

Downloaded From ManualsPrinter.com Manuals

Page 48

Spitfire 100 Extreme series printers Users Guide

48 AP-75194 - Rev. 2.2

Step 5 : Remove the SmartChip card when the transfer is finished and press the ENTER key afterwards.

Step 6 : The printer returns to the ChipStatus menu.

3.8.3.2 Via the Cassette slots of the printer.

When there is no smart chip inserted, or if inserting an invalid SmartChip card, the management system will

ask to scan all the cassette slots and transfer the rest ink volume from the SmartChip on the cassette to the

management system.

Step 1 : Press the ENTER key to scan all slots.

Step 2 : If ink value is detected on one of the SmartChips, the following message will be displayed. Press

the ENTER key to transfer or the CANCEL key to abort.

Step 3 : The management system will scan until it finds a SmartChip with ink volume, repeat this

procedure until no ink volume is left.

Downloaded From ManualsPrinter.com Manuals

Page 49

Spitfire 100 Extreme series printers Users Guide

49 AP-75194 - Rev. 2.2

3.9 SWITCH BETWEEN INK CONFIGURATIONS.

It is possible to switch from between ink configurations. Please follow the procedure below:

Important

In case of working with another type of Mutoh ink than described in this manual, refer to the

dedicated instruction sheet added to the ink kit.

Step 1 : Remove all cassettes.

Step 2 : Discharge ALL heads for 15 seconds.

Step 3 : Insert Spitfire Cleaning Cassettes.

Step 4 : Charge ALL heads for 3 minutes.

Step 5 : Pull out all cassette

Step 6 : Discharge ALL heads for 15 seconds.

Step 7 : Put back the Spitfire cleaning cassettes.

Step 8 : Charge ALL heads for 3 minutes.

Step 9 : Remove all cassettes.

Step 10 : Discharge ALL heads for 15 seconds.

Step 11 : Use the arrow keys to change the ColorMode to 2x6 or 4x4 depending on the switch.

SetupMenu 5/7 InkManager ColorMode

Step 12 : Insert Spitfire Mild Solvent ink Cassettes, and Stabilizer liquid in case of 2x6, according to the ink

configuration label

Step 13 : Charge ALL heads for 2 minutes.

Step 14 : An Authorized Mutoh Technician has to shift or unshift head block 5 to 8.

Shifted heads are needed when printing in 4x4 mode.

Unshifted heads (in 1 line) are needed when printing in 2x6 mode.

Step 15 : Perform a nozzle check and clean if necessary until all nozzles are present.

Notes

Please refer to Charge/Discharge-chapter for more details about these functions.

Downloaded From ManualsPrinter.com Manuals

Page 50

Spitfire 100 Extreme series printers Users Guide

50 AP-75194 - Rev. 2.2

3.10 UNATTENDED PRINTING OR LEAVE PRINTER IDLE

DURING NIGHT

3.10.1 Unattended Printing.

It is not recommended to leave the printer unattended. Some things should be checked frequently:

Is the media still going straight through the printer?

Arent there any head crashes or other media problems?

What if the printer stops printing for electronic, mechanic or firmware reasons?

To prevent production loss, it is recommended to control the above on frequent base. In some cases, a head

crash can occur, which means that the printer stops printing and that the head will be uncapped. This could

damage the printer irrevocably.

We advise installing a webcam when sending a print from another place from where the printer stands and to

set the following features:

Step 1 : Before you send your last job to the printer be sure to

a. Perform a tubing flush with cleaning (Please refer to Daily Maintenance)

Clean the wipers with polyknit wipers and Solvent cleaning liquid.

b. Set your CapCycle to 1 hour.

Step 2 : When you arrive in the morning follow this procedure

a. Perform a tubing flush with cleaning (Please refer to Daily Maintenance)

b. Perform a nozzle check

c. Depending on the amount of lost nozzles, perform a normal or powerful cleaning until all

nozzles are back.

d. Switch OFF the CapCycle feature.

Downloaded From ManualsPrinter.com Manuals

Page 51

Spitfire 100 Extreme series printers Users Guide

51 AP-75194 - Rev. 2.2

3.10.2 Leave your printer IDLE during night.

In case you want to leave your printer IDLE during the night for some reason, a special procedure should be

followed.

Step 1 : Before leaving the office:

a. Set your AutoClean on 6 hours and powerful. This will perform a powerful cleaning every 6

hours.

b. Set your CapCycle to 7 hours. An hour after the cleaning, a tubing flush will be performed.

Step 2 : When arriving in the office, be sure to:

a. Perform a tubing flush with cleaning (Please refer to Daily Maintenance)

b. Perform a nozzle check

c. Depending on the amount of lost nozzles, perform a normal or powerful cleaning until all

nozzles are back.

d. Switch off the CapCycle and AutoClean feature.

Downloaded From ManualsPrinter.com Manuals

Page 52

Spitfire 100 Extreme series printers Users Guide

52 AP-75194 - Rev. 2.2

3.11 LONGSTORE

Important

In case of working with another type of Mutoh ink than described in this manual, refer to the

dedicated instruction sheet added to the ink kit.

When transporting your printer or leaving your printer unattended for five days or more, for example on

holidays, it is highly recommended to LongStore the printer in order not to damage the heads and/or the

complete ink system.

Please note that there are LongStore kits available:

For Mutoh Mild Solvent ink configurations KY-80240

N° Description Quantity

1 Mutoh Mild Solvent Cleaning Liquid 16

2

Mutoh Mild Solvent ink

Black

Cyan

Magenta

Yellow

4

4

4

4

For Mutoh Mild Solvent Plus ink configurations KY-81740

N° Description Quantity

1 Mutoh Mild Solvent Cleaning Liquid 16

2

Mutoh Mild Solvent Plus ink

Black

Cyan

Magenta

Yellow

4

4

4

4

Downloaded From ManualsPrinter.com Manuals

Page 53

Spitfire 100 Extreme series printers Users Guide

53 AP-75194 - Rev. 2.2

3.11.1 Procedure to LongStore

Be sure to

• perform the weekly maintenance

• perform the daily maintenance

• moisten the caps

before starting the LongStore procedure

Step 1 : Remove all Spitfire Mild Solvent cassettes.

Step 2 : Manually start a discharge cycle for 15 seconds.

Go to the Ink Manager Menu > Charge/Discharge > set the following parameters in this order.

Handle following order

Select ALL with [F2] key

Press F1 to select ALL heads

Select Discharge with [F3] key

Press the F4 key to go to next menu

Set 15 seconds with [F2]-[F4] and press

ENTER

Step 3 : Insert 16 Spitfire Mild Solvent cleaning cassettes and manually start a charge of 2 minutes on all

heads.

Step 4 : Please perform a nozzle check to be sure all tubings are filled with cleaning liquid before

shipping.

Notes

Ink rests in the nozzle check could be caused by an ink cycle which is not completely airtight.

This could be easily solved by moistening the sides of the caps with Mutoh Solvent Cleaning.

Moistening the caps can be done by unlocking the head with the TubingFlush menu.

After moistening the caps charge again for 2 minutes.

After charging, perform a NozzleCheck to verify whether all tubings have been filled with

cleaning liquid.

Please refer to Handling the printer Menu 5/7 Charge/Discharge Menu for more

details on how to charge and discharge.

Downloaded From ManualsPrinter.com Manuals

Page 54

Spitfire 100 Extreme series printers Users Guide

54 AP-75194 - Rev. 2.2

3.11.2 Starting up after a LongStore.

Step 1 : Go to menu 6/7 and choose TubingFlush.

Step 2 : Moist the edge of the caps with Solvent Cleaning Liquid to guarantee that the ink cycle is airtight.

Step 3 : Press the ENTER key when finished.

Step 4 : Remove the Spitfire Mild Solvent Cleaning Liquid cassettes and manually start a discharge cycle

for 15 seconds.

Go to the Ink Manager Menu > Charge/Discharge > set the following parameters in this order.

Handle following order

Select ALL with [F2] key

Press F1 to select ALL heads

Select Discharge with [F3] key

Press the F4 key to go to next menu

Set 15 seconds with [F2] [F4] and press

ENTER

Step 5 : A timer will start on the display.

When finished, the printer will go to its status screen automatically.

Downloaded From ManualsPrinter.com Manuals

Page 55

Spitfire 100 Extreme series printers Users Guide

55 AP-75194 - Rev. 2.2

Step 6 : Insert Spitfire Mild Solvent (Plus) ink Cassettes, and Stabilizer liquid in case of 2x6, according to

the ink configuration label and charge for 3 minutes

Go to the Ink Manager Menu > Charge/Discharge, set the following parameters in this order.

Handle following order

Select ALL with [F2] key

Press F1 to select ALL heads

Select Charge with [F3] key

Press the F4 key to START cycle

Set 180 seconds with [F2] [F4] and press

ENTER

Step 7 : A timer will start on the display.

When finished, the printer will go to its status screen automatically.

Step 8 : Perform a NozzleCheck to be sure all nozzles are present.

Downloaded From ManualsPrinter.com Manuals

Page 56

Spitfire 100 Extreme series printers Users Guide

56 AP-75194 - Rev. 2.2

3.12 TRANSFERRING THE PRINTER

3.12.1 Hints, tips and warnings

When transporting the printer to its final location pay attention to the following:

Only use the strengthening arms (1) to move the printer.

Do NOT use a forklift or other lifting tools to avoid distortion of the machine.

Do NOT pull the swingbars to move the printer. These are very fragile and adjusted.

Lock the swingbars with the positioning pen (1)

Downloaded From ManualsPrinter.com Manuals

Page 57

Spitfire 100 Extreme series printers Users Guide

57 AP-75194 - Rev. 2.2

3.12.2 Transferring the printer

(1) Before the transfer

Follow the steps below to transfer the printer.

Step 1 : Make sure the printer and winding system are switched OFF.

Step 2 : Make sure the head is in the right edge position (capping position).

Step 3 : Disconnect the power cables and all other cables.

Step 4 : Higher all levelling feet.

Step 5 : Install the 2 transportation arms.

Step 6 : Transfer the printer.

Notes

The caster attached to the stand has been designed for transferring the printer during short

distances.

(2) After the transfer

Step 1 : Follow the steps below to prepare the printer to be used after the transfer.

Step 2 : Make sure that you place the printer on an adequate place

Step 3 : Connect the power cable and other cables.

Step 4 : Perform a nozzle check to check if the printer head has clogged.

Step 5 : Perform a fine adjustment of image quality.

Step 6 : Check if the winding system is still well aligned.

Caution

Before transporting the printer, contact your local Authorized Mutoh Dealer.