Page 1

Cutting Plotter

VC-600

MANUAL

MAINTENANCE

VC-1300

VC-1800

管理 No.

VCE-MM-02

Page 2

REVISION HISTORY

REV

Date

Sheet No

CONTENTS

00

Mar 26, 2013

All

Release

02

Aug 14, 2013

P9

Added VC-1800

MAINTENANCE MANUAL

01 Apr 30,2013 P.31

P.53-55

P.53-55

P.56

P.57

P31

P32

P33

P34

P36

P37

P38

P39

Changed Main board attachment position

Renamed parts

Added parts photo

Added Service parts(Pinch Roller, X/Y axis belt)

Correction of dimension(Specification list)

Added serial information

Added a notice of Firmware upgrade

Added chapter of “Enter Back up values”

Added chapter of “Initialize all settings”

Added chapter of “Restore the settings”

Changed the Title to “Factory default parameter”

Added a notice of Fuse position

Changed belt tension of VC-1800

VCE-MM-02

2

Page 3

MAINTENANCE MANUAL

Important Safety Information

Safety Instructions

General and Personal Safety Precautions

[PERSONAL SAFETY]

For personal safety, observe the following general precautions:

A second person should be available to disable the system in an emergency.

Wear appropriate protective gear that fits comfortably.

Do not wear loose-fitting clothes. If you are wearing a long-sleeved shirt, fold the cuffs up your

arm.

Never wear gloves close to moving parts.

Necklaces, ties and scarves should be tucked inside shirts.

Long hair should be covered.

[ELECTRICAL TOOL SAFETY]

When using Electrical Tools make sure to:

Use tools that are in good operating order. Any tool that appears electrically or mechanically

faulty must be labeled and sent immediately for repair.

Make sure that you are electrically insulated when using electrical tools. Wear rubber-soled

shoes and stand on a dry surface.

If, during the use of electrical equipment, you feel an electrical discharge (e.g. a tickling

sensation on your skin) immediately stop using that tool. Label it, and send it for repair.

[GENERAL SITE SAFETY REQUIREMENTS]

Fire extinguishers must be in working order and within easy reach.

The main power supply switch must be easily accessible.

The system site must be suitably illuminated from all sides.

Before operation, carefully read the warning labels on your Cutting plotter unit as well as the

cautions and warnings in this manual.

Connect the Cutting plotter to a properly grounded power outlet. Make sure the voltage level of

the Cutting plotter matches that of the power source.

Don't dissemble the unit while system power is on since the power supplies inside contain high

voltage.

Never leave the machine unattended during operation.

Follow the instructions on maintaining and cleaning your system. Not only will this enable you

to utilize your machine efficiently, but it will also ensure that your machine runs safely.

VCE-MM-02

3

Page 4

MAINTENANCE MANUAL

TABL E OF CONTENTS

REVISION HISTORY ...................................................................................... 2

Important Safety Information ........................................................................ 3

Safety Instructions ......................................................................................................................... 3

General and Personal Safety Precautions ........................................................................................... 3

TABLE OF CONTENTS .................................................................................. 4

Introduction and Component ....................................................................... 7

A. Main Unit Assembly ................................................................................................................... 8

B. Electronic and Electrical Assembly ............................................................................................ 9

C. Left End Assembl y .................................................................................................................. 10

D. Right End Assembly ................................................................................................................ 11

E. X Motor Bracket and Belt Assembly ........................................................................................ 12

F . Carriage Assembly................................................................................................................... 13

G. Pinch Roller Assembly ............................................................................................................ 14

H. Main Beam Assembly ............................................................................................................. 15

I. Drum Assembly ........................................................................................................................ 16

System Diagram and Components o f Ma in Board .................................... 17

System Diagram .......................................................................................................................... 18

Wiring Diagram............................................................................................................................ 19

Maintenance ................................................................................................ 20

Components Replacement and Belt Tension Adjustment ............................................................. 20

Removing the Front, Back, End and Top Covers ............................................................................... 20

Replacing the Pinch Roller Sets ......................................................................................................... 21

Replacing the Tool Carriage ............................................................................................................... 23

Replacing the Y -Motor ................................................................................................................. 27

Replacing the VCM PC Board ..................................................................................................... 29

Main board Connection or Replacement...................................................................................... 30

Firmware Upgrade ....................................................................................................................... 32

Enter Back up values................................................................................................................... 33

Initialize all settings ..................................................................................................................... 34

Restore the settings .................................................................................................................... 36

Factory default parameter ........................................................................................................... 37

Replacement of Fuses ................................................................................................................. 38

Adjusting the Tool Carriage Transmission Belt ............................................................................. 39

Adjusting the X Motor Tension Belt .............................................................................................. 40

Adjusting the Y Motor Tension Belt .............................................................................................. 41

Troubleshooting .......................................................................................... 43

VCE-MM-02

4

Page 5

MAINTENANCE MANUAL

Maintenance Diagnostics ............................................................................................................ 43

How to Begin Maintenance Diagnostics ...................................................................................... 43

Diagnostics Function Diagram ..................................................................................................... 44

Diagnostic Test f or SRAM and DRAM.......................................................................................... 45

Diagnostic Test for Lever Sensor ................................................................................................. 45

Diagnostic Test for Media Sensors .............................................................................................. 46

Diagnostic T est for Width Sensor ................................................................................................. 47

Diagnostic Test for Motor Encoder and Tool Holder Encoder ....................................................... 48

X Motor Encoder Test ......................................................................................................................... 48

Y Motor Encoder Test ......................................................................................................................... 48

Holder Encoder Test ........................................................................................................................... 49

Diagnostic Test for Motor Movement ........................................................................................... 50

Drum Movement?................................................................................................................................ 50

Carriage Movement? .......................................................................................................................... 51

Holder Movement? .............................................................................................................................. 51

Diagnostic Test for Interface ........................................................................................................ 52

Check RS-232 9600 ? ......................................................................................................................... 52

Check RS-232 19200 ? ....................................................................................................................... 52

Check Printer Port ............................................................................................................................... 52

Check USB port? ................................................................................................................................ 52

Problems and Solutions ............................................................................................................... 53

The line quality is not good enough at the corner or the end po int. ................................................... 53

The position of pinch roller cannot be detected so that the m edia width cannot be determined correct ly .

............................................................................................................................................................ 53

The function of "Set New O r igi n" does not work................................................................................. 53

Media shifts away when plotting a long drawing. ............................................................................... 53

The lines quality is wavy. .................................................................................................................... 54

Data loses when plotting. .................................................................................................................... 54

Fatal error occurs when loadi ng media. ............................................................................................. 54

Feel electrostatic discharge. ............................................................................................................... 54

Carriage locked, cannot move. ........................................................................................................... 55

The keyboard does not work. ............................................................................................................. 55

The machine makes noise when it is on the standby status. ............................................................. 55

The machine makes abnormal noise from the drum set whe n it is r unning. ...................................... 55

The tool carriage does not per f orm the up/down action. .................................................................... 55

There are some unexpect ed li nes on the final plot. ............................................................................ 56

There appears an unexpected tool force. ........................................................................................... 56

Media drops sometimes. ..................................................................................................................... 56

Appendix ...................................................................................................... 57

VCE-MM-02

5

Page 6

MAINTENANCE MANUAL

Recommend Service Parts List ................................................................................................... 57

Specification ................................................................................................................................ 61

Consumable Item List .................................................................................................................. 62

Optional Item List ........................................................................................................................ 62

VCE-MM-02

6

Page 7

MAINTENANCE MANUAL

Introduction and Component

This Maintenance Guide provides step-by-step instructions for replacing and maintaining the

components of the ValueCut Cutting plotter. It also includes a troubleshooting chapter with some

handy hints when problems arise or if the plotter does not operate properly. This Maintenance Guide

provides system diagrams, wiring diagrams and numerous flow charts detailing the maintenance

diagnostics built into the ValueCut Cutting plotter. Finally there is a parts list and spare parts order

form for convenience of ordering replacement parts.

For further Tech Support enquiries and assistance please contact the following Email address:

cs_service@mutoh.co.jp

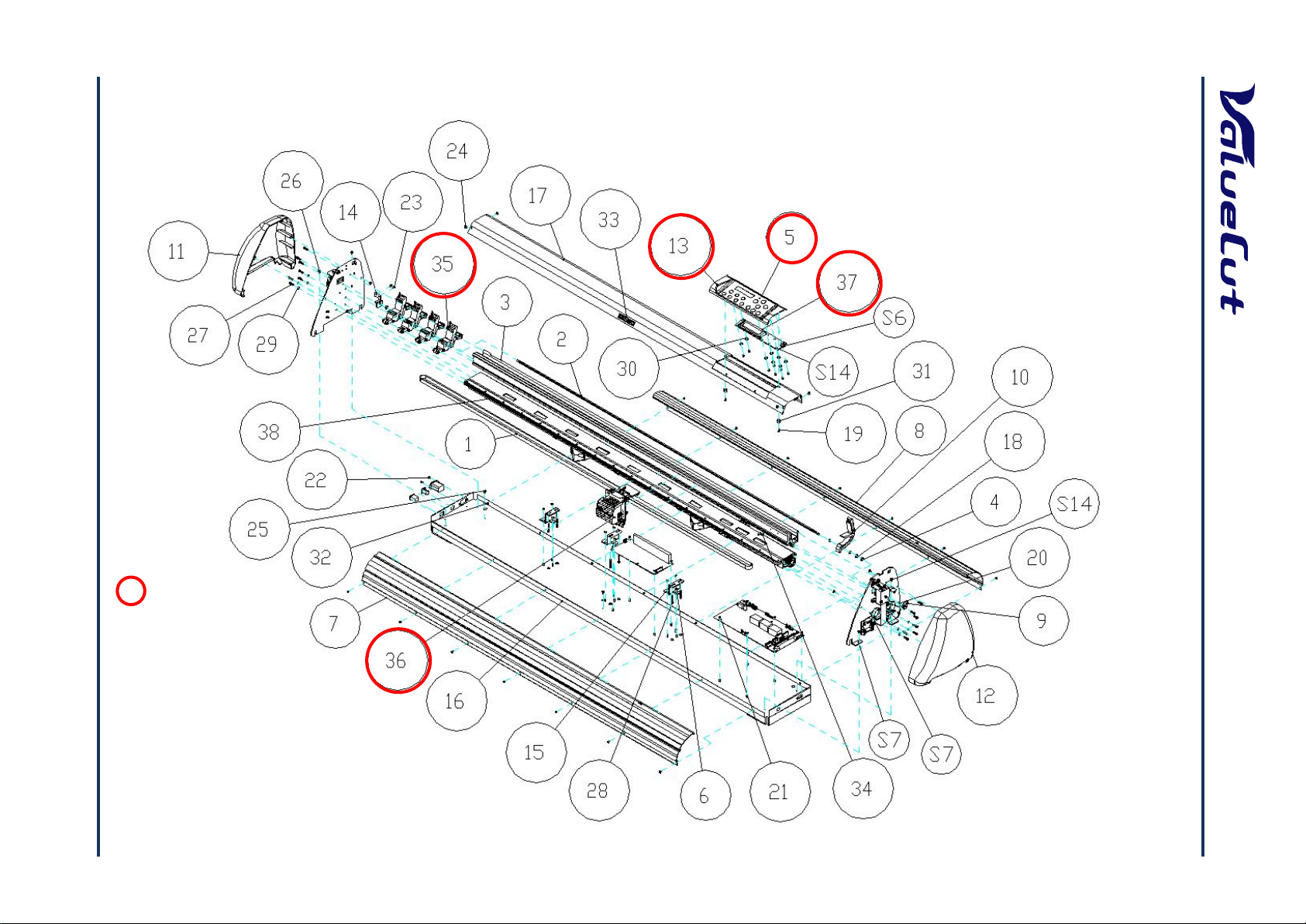

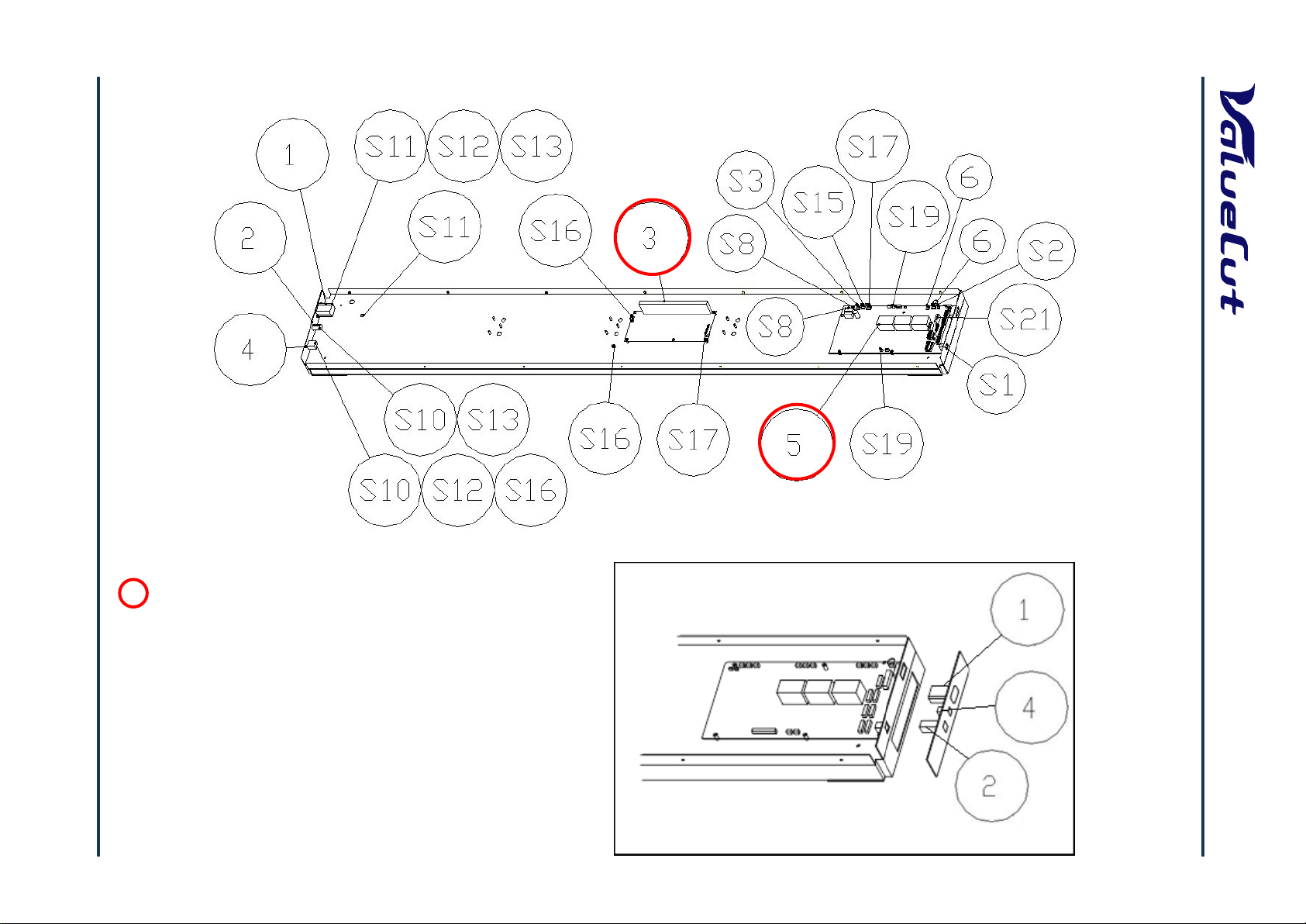

The following diagrams represent all of the maintainable mechanical and electronic components of

the ValueCut Plotter with corresponding parts lists for convenient identification.

VCE-MM-02

7

Page 8

VCE-MM-02

8

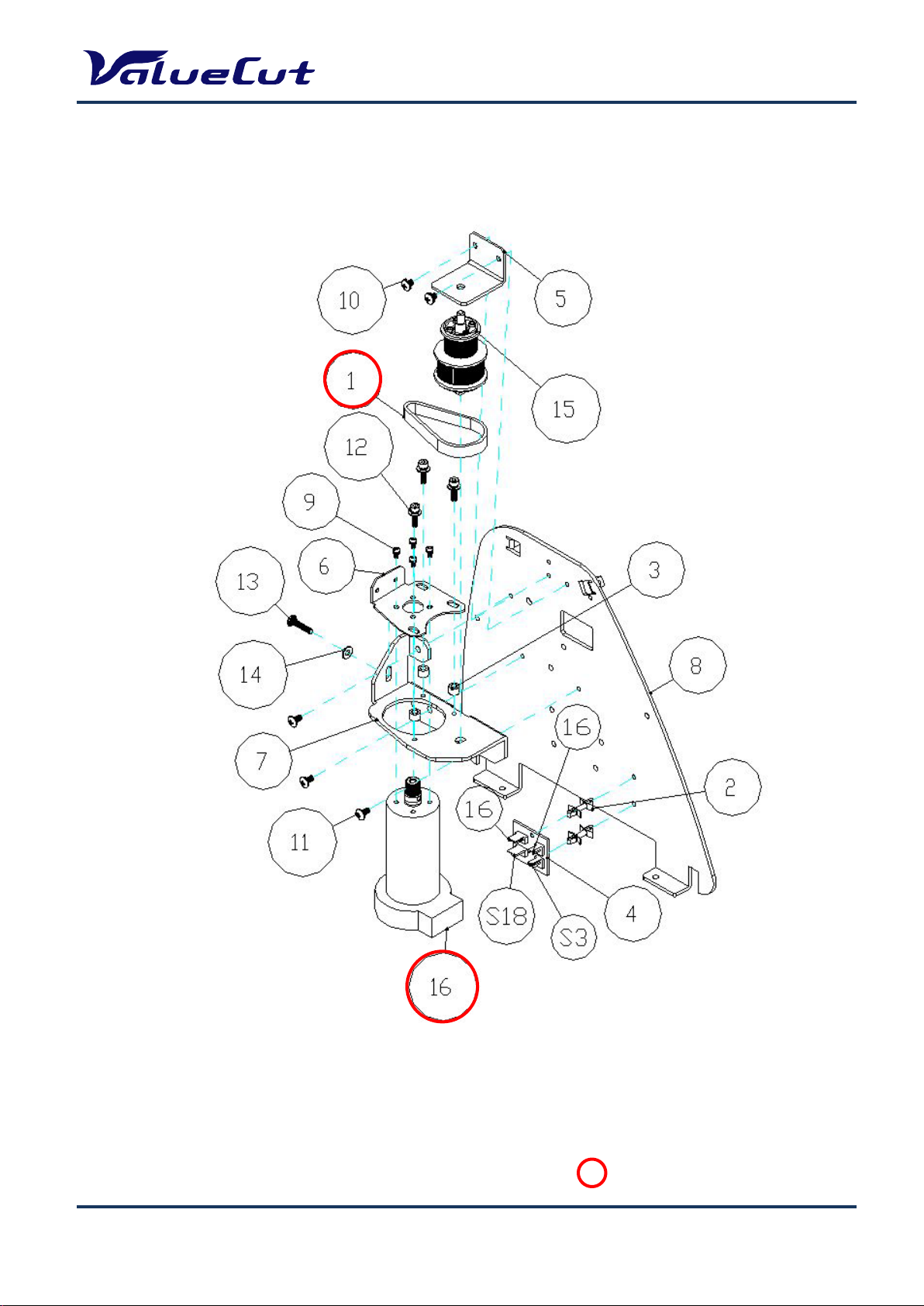

A. Main Unit Assembly

: Recommend Service Parts

MAINTENANCE MANUAL

Page 9

VCE-MM-02

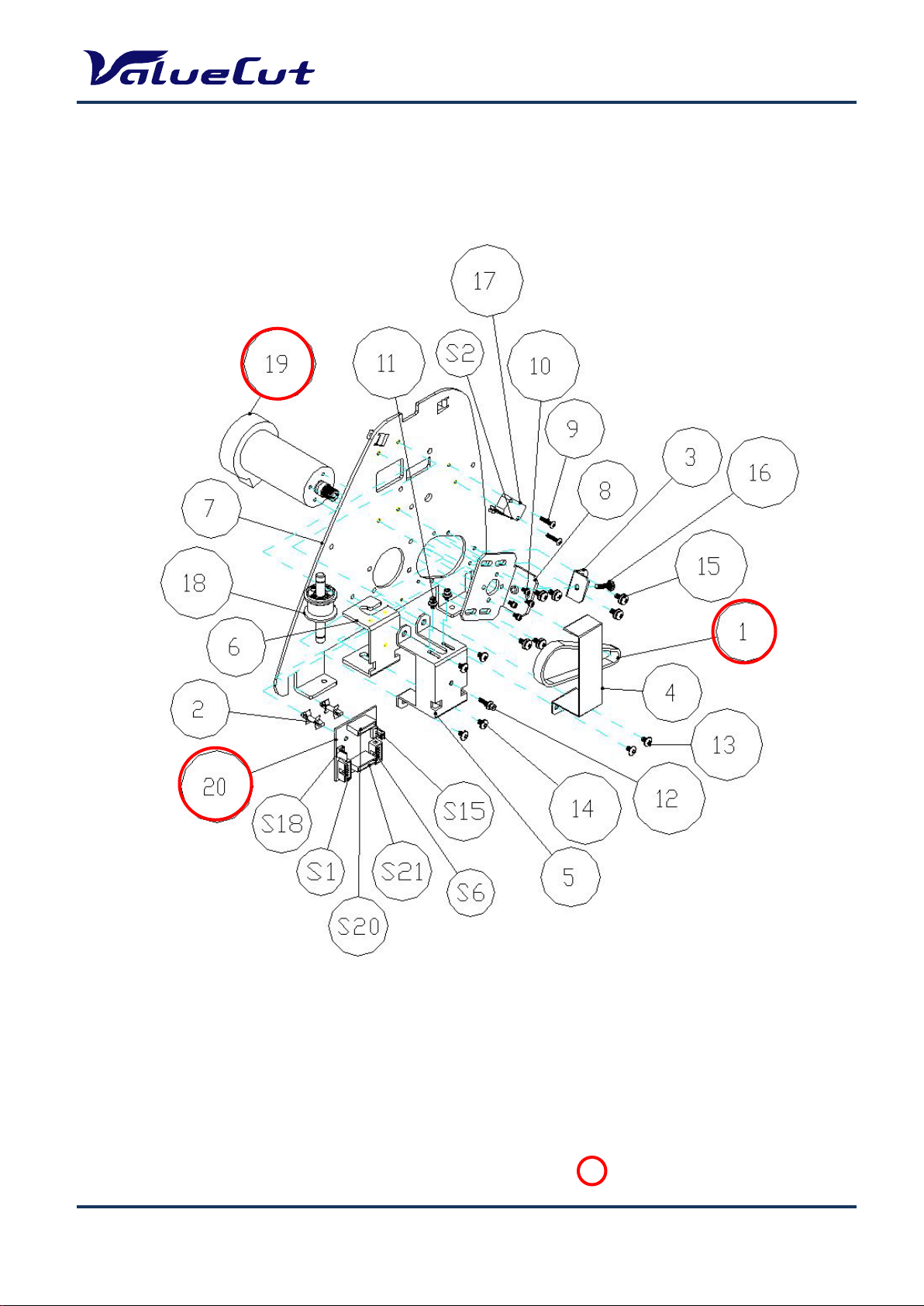

: Recommend Service Parts

VC-1800

VC-600/1300

9

B. Electronic and Electrical Assembly

MAINTENANCE MANUAL

Page 10

C. Left End A ssembly

: Recommend Service Parts

MAINTENANCE MANUAL

VCE-MM-02

10

Page 11

D. Right End A ssembly

MAINTENANCE MANUAL

VCE-MM-02

: Recommend Service Parts

11

Page 12

VCE-MM-02

: Recommend Service Parts

12

E. X Motor Bracket and Belt Assembly

MAINTENANCE MANUAL

Page 13

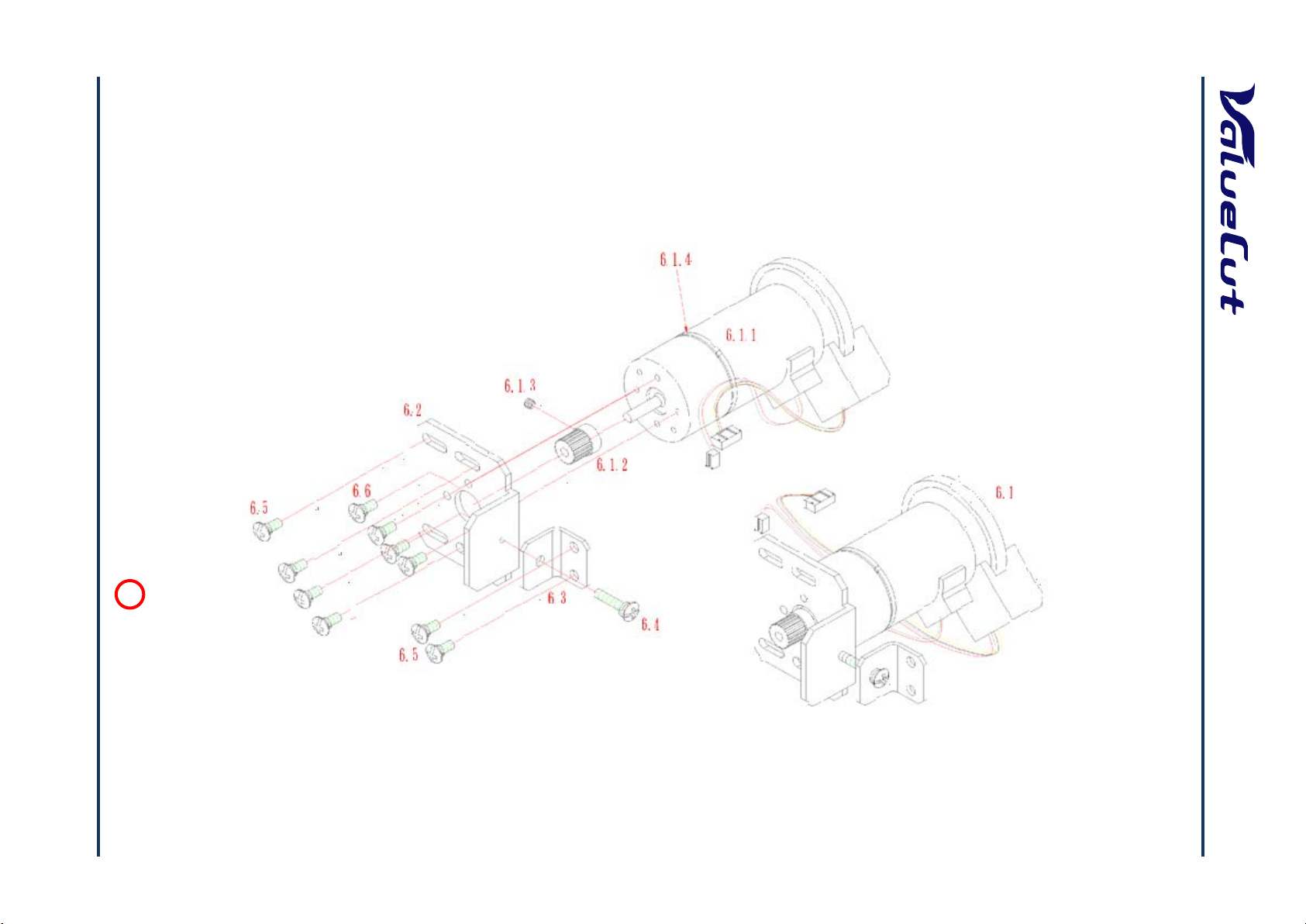

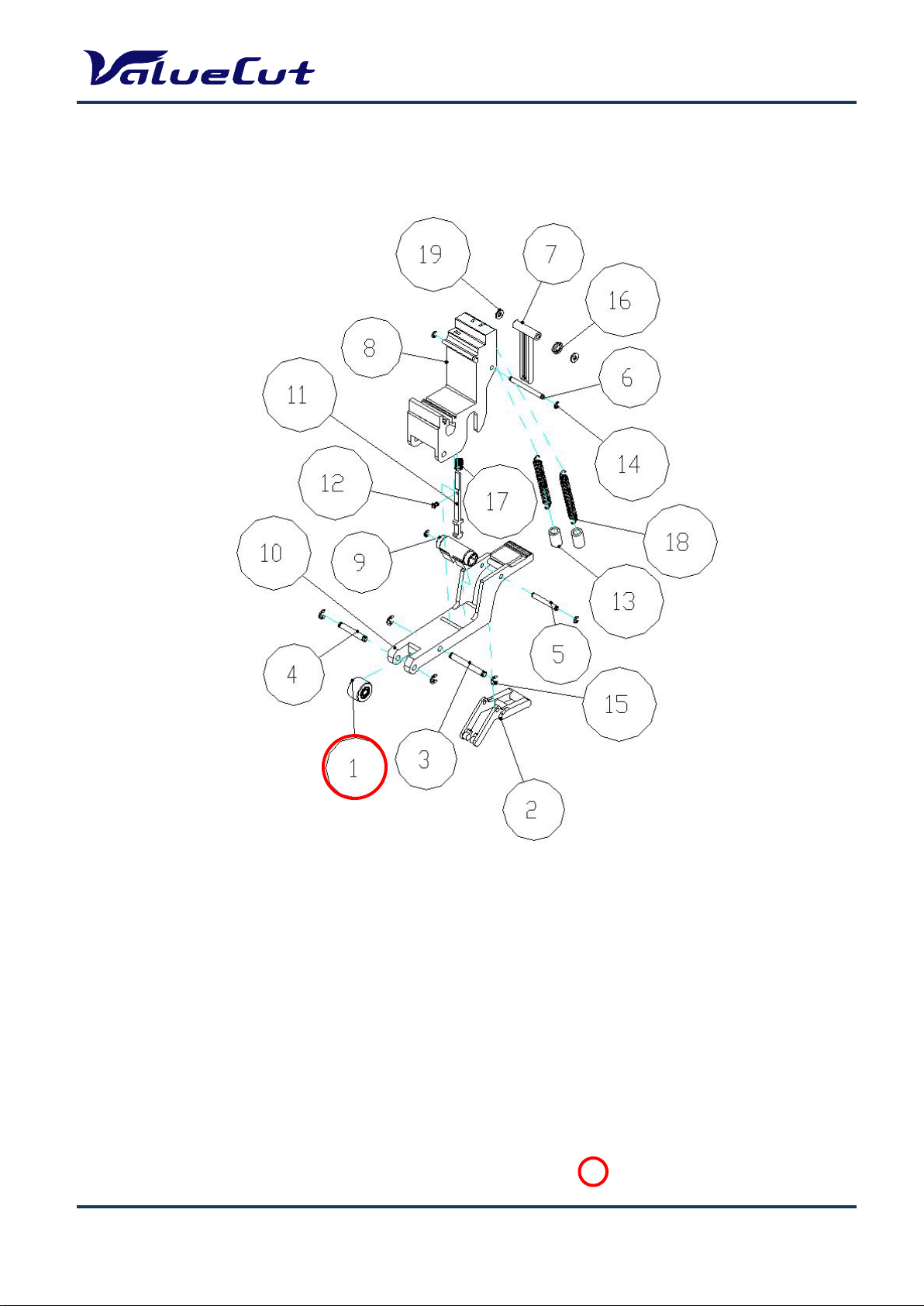

F. Carriage A ssembly

: Recommend Service Parts

MAINTENANCE MANUAL

VCE-MM-02

13

Page 14

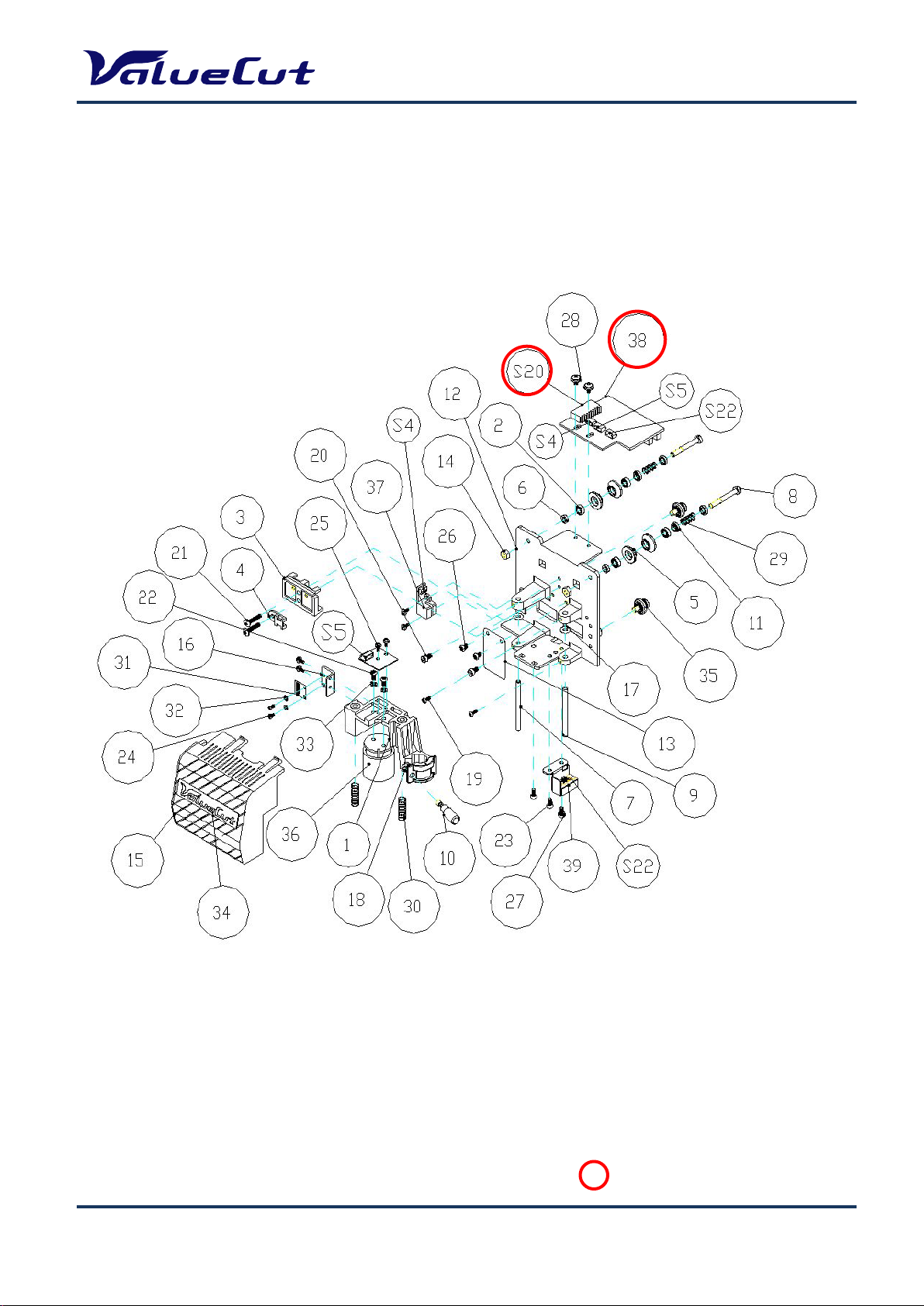

G. Pinch Roller A ssembly

: Recommend Service Parts

MAINTENANCE MANUAL

VCE-MM-02

14

Page 15

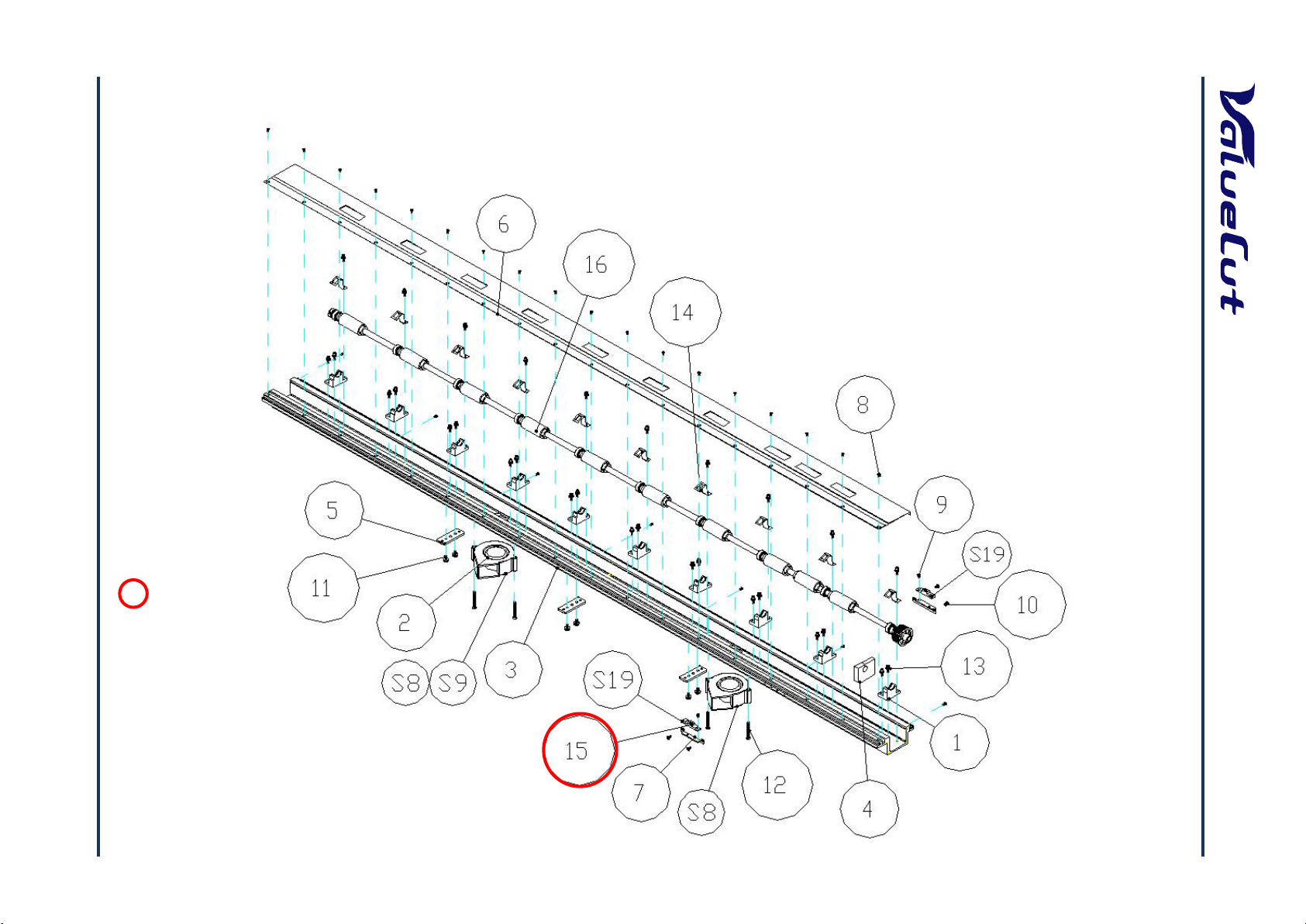

VCE-MM-02

: Recommend Service Parts

15

H. Main Beam Assembly

MAINTENANCE MANUAL

Page 16

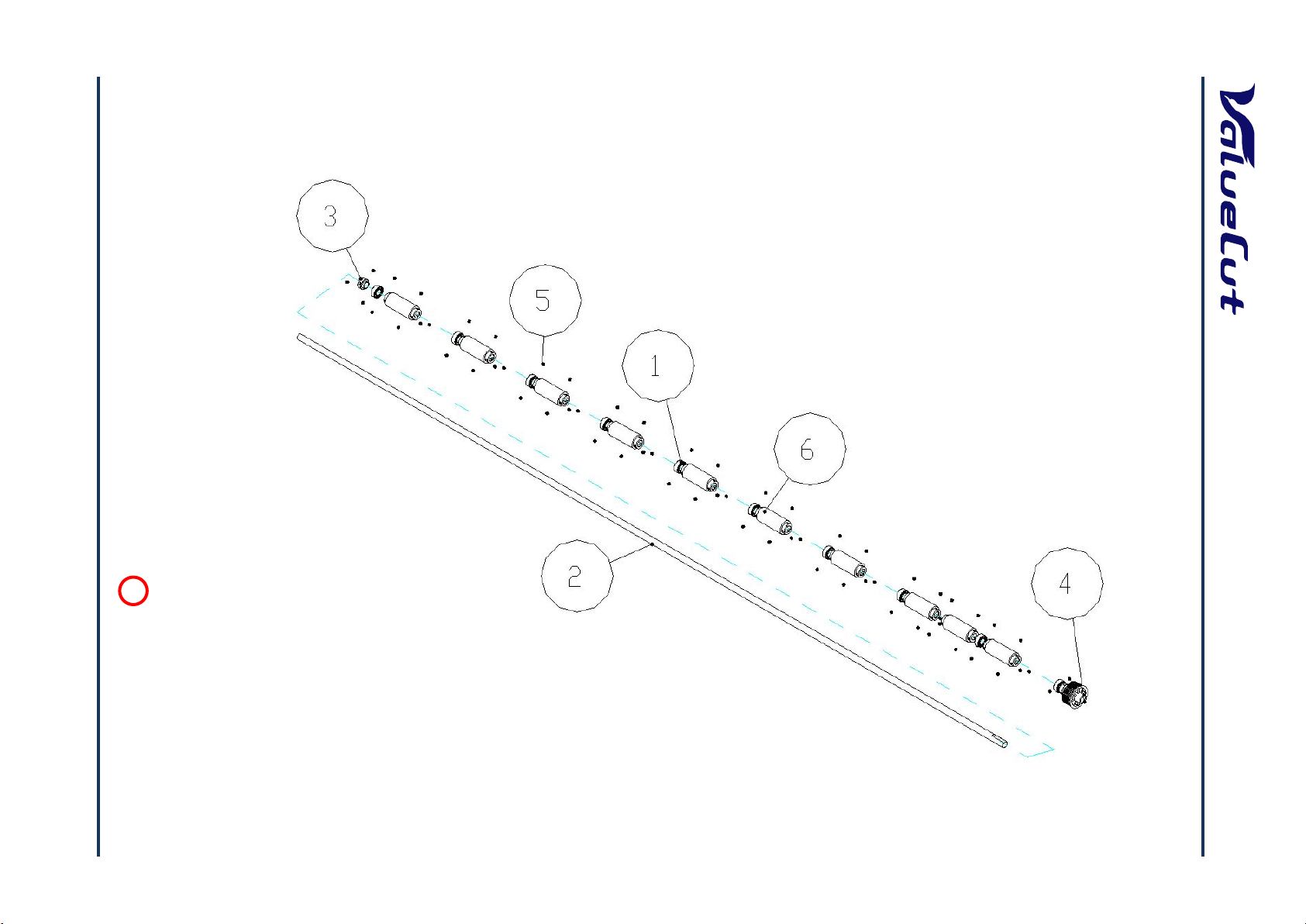

VCE-MM-02

: Recommend Service Parts

16

I. Drum Assembly

MAINTENANCE MANUAL

Page 17

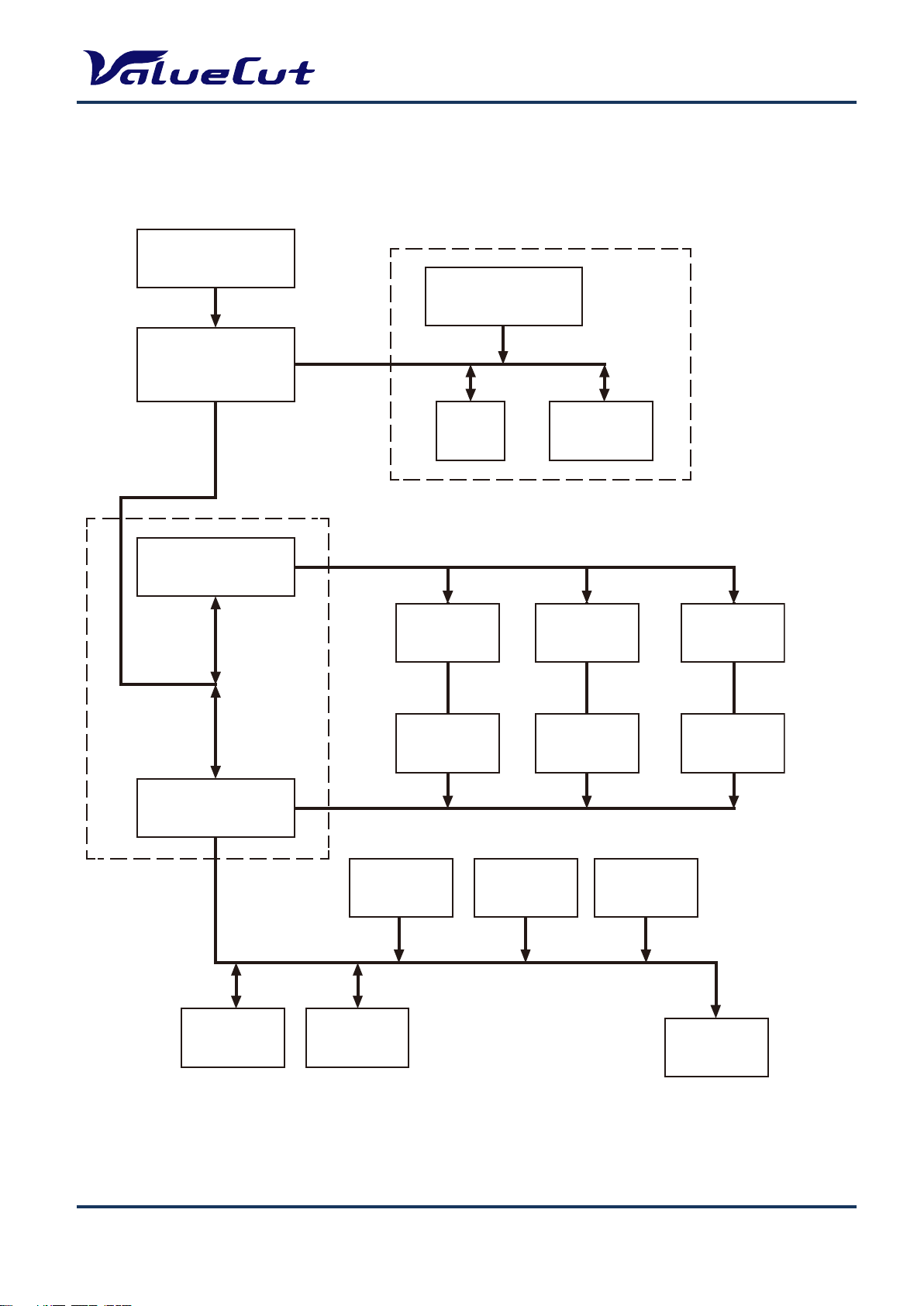

MAINTENANCE MANUAL

System Diagram and Components of Main Board

VCE-MM-02

17

Page 18

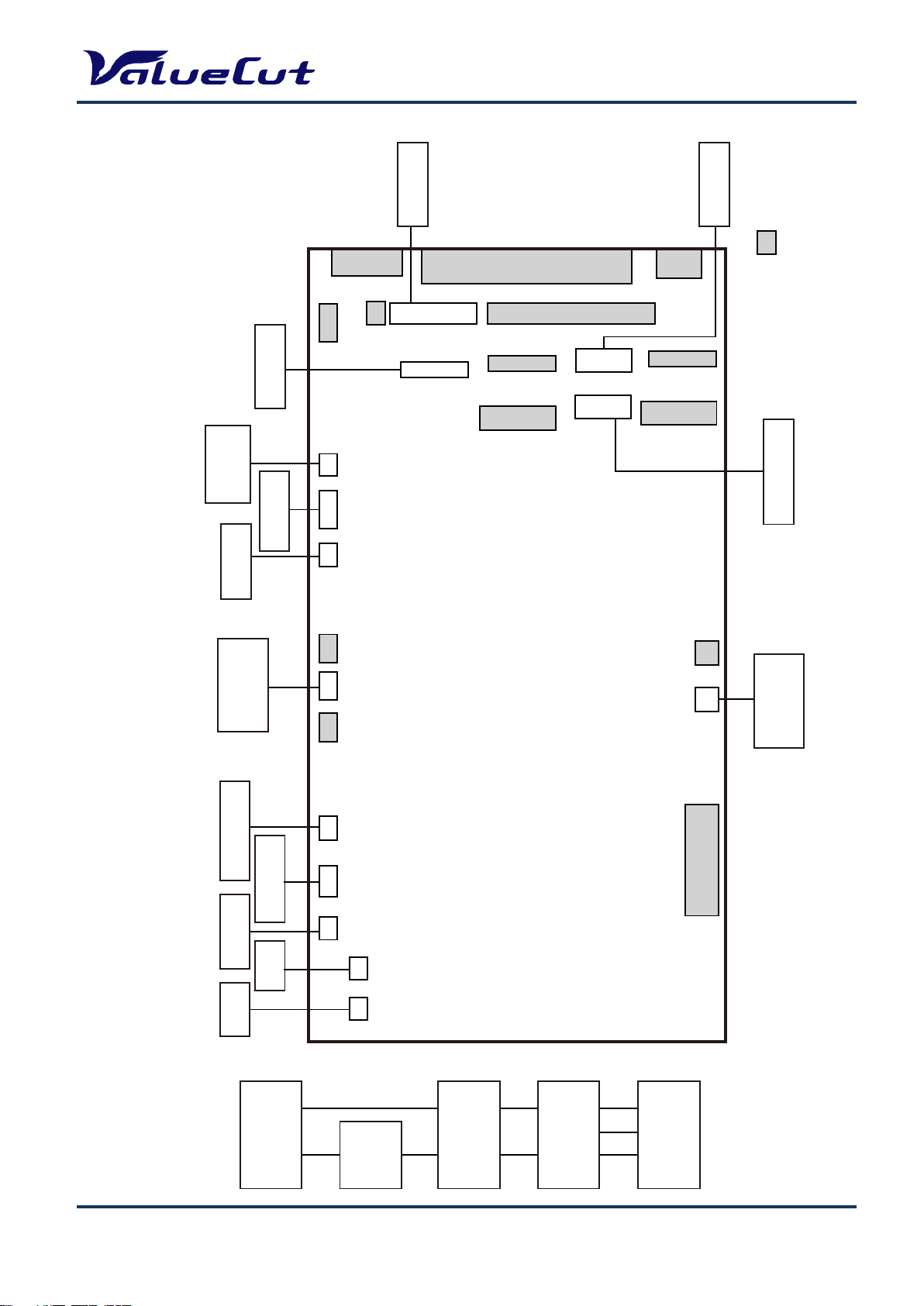

System Diagram

OSC 54MHz

OSC 54MHz

CPU

54MHz

MCF5206EAB54

FLASH

512KBx2 or 512KBx3

DRAM

1MB or 4MB

SRAM

64KB

TIMER & PWM

Generator

TIMER & PWM

Generator

X Motor

Driver

Y Motor

Driver

VCM

Driver

X Motor

Encoder

Y Motor

Encoder

VCM

Encoder

LCM

Display

USB

Port

Serial

Port

Media

Sensor (x2)

Carriage

Sensor

Lever

Sensor

Memory

FPGA

MAINTENANCE MANUAL

VCE-MM-02

18

Page 19

Wiring Diagram

FAN

FAN

Y Motor

Y Encoder

X Motor

X Encoder

JP10 JP11

JP15 JP18 JP25 JP6 JP5 JP22 JP21 JP23 JP7 JP16

Paper Rear

Sensor

Lever

Sensor

Serial Port

USB Port

JP1

JP3 JP4

JP30

JP27

JP33

JP8

JP31

JP28

JP20

JP10A

JP32

JP13

JP12

JP2

JP19

CR Board

Paper Front

Sensor

Control Panel

Power Board

FRONT SIDE

REAR SIDE

: N/C

MAIN BOARD

AC input

100v-240v

3A FUSE

On/Off

Switch

Power

Board

DC 40V/5V

Output

MAINTENANCE MANUAL

VCE-MM-02

19

Page 20

MAINTENANCE MANUAL

1. Remove the end cover screws.

2. Put equal pressure on both sides of the

End Cover and pull to remove.

1. Unscrew the 7 Front Cover and 7 Back Cover screws

Maintenance

This chapter deals with component replacement and maintenance of the ValueCut Cutting Plotter. It

gives detailed step-by-step instruction on how to replace or adjust the components of this machine.

Components Replacement and Belt Tension Adjustment

Removing the Front, Back, End and Top Covers

The following steps are those involved in removal of the front, back, end and top covers.

To Remove the End Covers:

To Remove the Front and Back Covers:

VCE-MM-02

20

Page 21

1. Unscrew the two screws at each end of the

2. Unplug the Control Panel Cable before

1. Pull down the Square Bar Lever to unlatch

To Remove the Top Cover:

MAINTENANCE MANUAL

Top Cover.

removing the top cover completely.

Replacing the Pinch Roller Sets

The following steps are those involved in replacing pinch roller sets.

To Unlatch the Pinch Roller Lever:

VCE-MM-02

the Pinch Rollers

21

Page 22

To Remove the Square Bar Holding Bracket:

1. Unscrew the 2 bracket screws.

2. Remove the bracket and washer.

1. Slide the pinch roller to the notch at the

2. Remove the pinch roller set through the

To Remove the Pinch Roller Sets:

MAINTENANCE MANUAL

right end of the Square Bar.

notch.

VCE-MM-02

22

Page 23

MAINTENANCE MANUAL

1. Unscrew the 2 retaining screws, but don’t remove them. Then turn the Adjustment

Adjustment Screw

Retaining Screws

Note: When re-installing the Pinch Roller Set, the Cam Roller must be aligned squarely to the

Square Bar.

Note: When aligning the Cam Roller please remember to keep the release grip locked down.

Note: Pinch-roller is color-coded by pressure force. When replacing the pinch-roller, make sure to

replace all the pinch-rollers with the same color.

Cam Roller

Release Grip

Replacing the Tool Carriage

The following are those you must follow to successfully replace the Tool Carriage.

To Loosen the Carriage Belt:

VCE-MM-02

Screw anti-clockwise to loosen the carriage belt.

23

Page 24

1. Depress the two locking clips at the top of the Tool Carriage Cover and pull the Cover

1. Pop up the plastic locking pins using a

2. Disconnect the Flat Sensor Cable.

To Remove the Tool Carriage cover:

MAINTENANCE MANUAL

To Prepare the Tool Carriage for Removal:

away.

flathead screwdriver.

VCE-MM-02

24

Page 25

MAINTENANCE MANUAL

3. Unbolt and remove nut A and B, and then unscrew both Bolt A

Belt B

Belt A

Separate the Sprung Washer/Rollers as seen in the figure

To Remove the Tool Carriage:

1.

and Bolt B until they are flush with the bracket.

VCE-MM-02

above.

25

Page 26

MAINTENANCE MANUAL

2. Swing the Tool Carriage down and out while keeping the

Sprung Washer/Rollers apart.

Note1: To install a new Tool Carriage or replace the original Tool Carriage simply reverse the steps

for Tool Carriage removal.

Note2: Remember to separate the Sprung Washer/Rollers, and then place them on the Carriage track

before you swing the Tool Carriage back into place

VCE-MM-02

26

Page 27

Replacing the Y-Motor

1. Loosen the all 3 tension-bracket retaining screws as well as the tension adjustment screw, but do

2. Depress the jumper clips, and pull to

3. Lift the belt off of the Y-motor,then unscrew

The following steps are those involved in the replacement of the Y-motor:

MAINTENANCE MANUAL

not remove them.

unplug the 2 Y-motor Jumpers.

VCE-MM-02

27

and remove the 4 Y-motor screws.

Page 28

MAINTENANCE MANUAL

Note1: To install or replace the Y-motor, simply reverse the steps to remove it.

Note2: After the Y-motor is in place, you must adjust the Y- motor belt tension as described in the

Y-motor belt tension adjustment section of this chapter.

Note3: Make the Y-motor jumper reconnection the last step after the Y-motor tension belt adjustment

when you have finished installing or replacing the Y-motor.

VCE-MM-02

28

Page 29

Replacing the VCM PC Board

The following is what is involved in replacement of the VCM PC board.

2. Unplug the two sensor connectors, and then unscrew the

two PC board screws to remove the board.

MAINTENANCE MANUAL

Note1: If the Pinch Roller Sensor is still not effective after replacement the Tool Carriage or the Flat

Cable may need replacement.

VCE-MM-02

29

Page 30

MAINTENANCE MANUAL

Fan

X motor encoder

X motor power

Level Switch Jumper

X motor power

1. Unplug all of the jumpers and connectors attached to all off board components.

Main board Connection or Replacement

Main board connection or replacement must follow the following steps to be sure that no damage

comes to either service personnel or the components:

Note1: To ensure absolute safety for service personnel and components, please follow the safety

instruction at the beginning of this manual, before installing or replacing any current

carrying components

T Parallel Port Connector o unplug the jumpers and connectors from the main board

Power Board jumper

Rear paper sensor

Com port extend jumper

Flat cable to carriage

X motor encoder

Note: Please refer to the Wiring Diagram for more detail on jumper and connector attachment

VCE-MM-02

Front paper sensor

30

Control Panel

USB Extend jumper

Page 31

MAINTENANCE MANUAL

1. Unscrew and remove the 5 restraining screws, and the pop out support to completely

remove the main board.

Note: To install or replace the main board simply reverse the steps to remove it.

Note: Main board attachment position changed as below (refer to the below image) from the “Serial

Interface connector (RS-232C) 9pin type machines.(Serial see below)

Remove the X motor before replacing the Main board.

VC-600 EVC2U0070~

VC-1300 EVC5U0068~

VC-1800 EVC7U0112~

VCE-MM-02

31

Page 32

MAINTENANCE MANUAL

1. Press indicated buttons by different port transmission

2. Select a desired firmware and port on "ValueCut File

3. When update of the firmware is completed, machines

Firmware Upgrade

When you change the Main board, it is necessary to upgrade firmware to latest version. This is done

as follows:

Note1: A main board is required to be pre-programmed with a loader in order to become flash able for

firmware uploading.

Note2: Normally, before a new spare main board is ready to ship, a loader or even a firmware

(smallest size of ordered model series) will be uploaded first on it. In case of functionality

problem happening due to incorrect firmware version, please verify if the existing firmware

on this main board is the desired one. A new program called (Firmware Upgrade) is a tool for

users to easily upgrade firmware, followed by the steps listed below.

Port to use USB port Serial port

Operation [Down] key + Power on [CUT TEST] key + Power on

listed on the table and open a "ValueCut File Uploade".

Uploader" dialogue box, then press START for uploading.

reboot with a normal mode automatically.

Note: After firmware installation, please perform initialize the setup information and re-enter the

setup information.

Note: Write down all the setting values before performing initialization. Re-enter the values again

from the panel after initialization is done. (“AAS Offset X/Y” and “Scale Length/Width” values

will be backed-up, so resetting will not be required.)

VCE-MM-02

32

Page 33

MAINTENANCE MANUAL

x2

Enter Back up values

Requires restore when updating the firmware and restore will initialize all the settings. Only "AAS

Offset X/Y", "Scale Length/Width" values can be backed-up even performing restore.

Press "TOOL SELECT" key and enter to tool setting menu.

Offline For

System Setup

1S 72 F 80 O0.250M

Press "

Press "CUT TEST" key and "ON/OFF LINE" key at the same time.

" key twice and display the restore menu.

}

Select:{} Ok:ENTER

Restore default ?

Select:{} Ok:ENTER

Press "ENTER" key.

VCE-MM-02

BackUp Setting

N:ONLINE Ok:ENTER

Sure to Backup

N:ONLINE Ok:ENTER

33

Page 34

Press "ENTER" key.

x2

MAINTENANCE MANUAL

Note: Only "AAS Offset X/Y", "Scale Length/Width" can be backed-up.

Note: If you want to Initialize the backup value, please go to Initialize all settings

Offline For

System Setup

Initialize all settings

Completely initialize all the settings including backed-up "AAS Offset X/Y", "Scale length/Width"

values.

Press "TOOL SELECT" key and enter to tool setting menu.

Press "

" key twice and display the restore menu.

}

Offline For

System Setup

1S 72 F 80 O0.250M

Select:{} Ok:ENTER

Restore default ?

Select:{} Ok:ENTER

VCE-MM-02

34

Page 35

Press "CUT TEST" key and "ON/OFF LINE" key at the same time.

MAINTENANCE MANUAL

Press "ENTER" key.

Press "DATA CLEAR" key.

BackUp Setting

N:ONLINE Ok:ENTER

Sure to Backup

N:ONLINE Ok:ENTER

Restore default ?

Select:{} Ok:ENTER

Press "ENTER" key then all the setting values will be initialized.

Turn off the power after initialization.

Re-Power On Please

VCE-MM-02

35

Page 36

Restore the settings

Return to the default value except backed-up values.

Press "TOOL SELECT" key and enter to tool setting menu.

MAINTENANCE MANUAL

Press "

Press "ENTER" key.

" key twice and display the restore menu.

}

Offline For

System Setup

1S 72 F 80 O0.250M

Select:{} Ok:ENTER

セッテイ ショキカ

Select:{} Ok:ENTER

Turn off the power after performing restore.

Re-Power On Please

VCE-MM-02

36

Page 37

MAINTENANCE MANUAL

Factory default parameter

Factory default parameter information is attached under the machine.

Below are the items for setup. Numbers shown in each parenthesis below are the example numbers

of this machine (serial# L75354).

AAS Offset (X= -0.6, Y= -0.5)

Scale Length (Length: 500 / 496.4 mm)

Width Length (Width: 500 / 500.2 mm)

AAS Offset setup steps

Press the [MICS] key by "OFF LINE" mode to enter the Setup Menu, then select [AAS Offset] and

input each X, Y value.

Scale setup steps

Press the [MICS] key by "OFF LINE" mode to enter the Setup Menu, then select [Scale Length] and

change the left number to [500]. Next change the right number to the value shown on the "Parameter

record card".

VCE-MM-02

37

Page 38

Replacement of Fuses

With your fingers apply equal pressure to both of the holding clips on the Fuse housing,

The Fuse pops out for easy replacement as follows:

MAINTENANCE MANUAL

Note: Position of the fuse (inlet switch) depends on the model.

1.

and push it out.

VC-600/1300:Leftside VC-1800:Right side

Handling clip

VCE-MM-02

38

Page 39

MAINTENANCE MANUAL

1. Move the tool carriage to the far left

5. To tighten the tension, turn the belt tension

screw clockwise. To loosen the tension turn

the belt tension screw anticlockwise, until

the desired adjustment tension is reached.

2. Loosen the 2 retaining screws on top of

3. Use a tension gauge to measure

the belt's tension by placing

the gauge's push arm to the

center of the belt, as seen in

4. To change belt tension adjust the belt

tension screw on the side of the

Adjusting the Tool Carriage Transmission Belt

When you replace the tool carriage or belt itself, the belt tension needs to be adjusted. This is done as

follows:

end of the guide beam after the tool

carriage or belt being replaced.

the figure above.

carriage belt roller housing.

the carriage belt roller housing.

The desirable tension is as follows.

VC-600 650g~850g

VC-1300 220g~320g

VC-1800 180g~200g

Note: Fasten the retaining screws on the top of the carriage belt roller housing once the adjustment

is made.

VCE-MM-02

39

Page 40

Adjusting the X Motor Tension Belt

2. Place the push-pull tension

the motor toward yourself

3. Tighten the 4 retaining screws

MAINTENANCE MANUAL

to lock the bracket in place.

4. Fix the tension retaining screw.

1. Loosen the 4 retaining screws

locking the X-motor bracket in

place.

gauge's hook-arm at the hole

of X motor bracket and pull

along the direction parallel to

the racket edge, and keep it at

the 4kg tension position.

Note: The belt connecting the drum and X motor needs to be tightened to a tension of 4 kg.

VCE-MM-02

40

Page 41

Adjusting the Y Motor Tension Belt

1. Loosen the 3 retaining screws

pull tension

the motor toward yourself

the line that passes through

3. Once the desired tension is

found tighten the 3 retaining

screws to lock the tension

MAINTENANCE MANUAL

locking the tension bracket in

place but do not remove them.

2. Place the push-

gauge's hook-arm at the hole

of Y motor bracket and pull

along the direction parallel to

the motor shaft and the drive

pulley shaft.

VCE-MM-02

bracket in place.

41

Page 42

MAINTENANCE MANUAL

3.

Tighten the tension screw to retain the tension.

Note: The belt connecting the drive pulley and Y motor needs to be tightened up with a tension of 4

kg.

VCE-MM-02

42

Page 43

MAINTENANCE MANUAL

Troubleshooting

Maintenance Diagnostics

This section provides maintenance diagnostics as troubleshooting aids. This diagnostic feature is to

check hardware to find out which components are good or defective. Using this diagnostic test facility

enables the diagnosing of the hardware components.

How to Begin Maintenance Diagnostics

To start the Maintenance Diagnostics facility hold down the On/Off Line button and CUT TEST

button while turning on the cutter. The following sub-sections will explain the function of each

maintenance diagnostic sequence.

VCE-MM-02

43

Page 44

Diagnostics Function Diagram

Holder Down ?

Carriage Movement ?

Check RS-232 ?

Check Printer Port ?

Check Width Sensor?

Check Media Sensors?

X Motor Encoder?

Y Motor Encoder?

Check USB Port ?

System cannot go on testing,

LCM display current message

Initial State

XMb DRAM OK

SRAM OK

<key

>key

<key

>key

<key

>key

<key

>key

Check Lever Sensor?

>key

Holder Encoder?

Down Movement ?

Exit Diagnostic Test

<key

MAINTENANCE MANUAL

more than 3 seconds.

<key >key

<key >key

Cancel key

>key

Please Reset Machine

<key >key

<key >key

VCE-MM-02

<key >key

<key >key

44

Page 45

MAINTENANCE MANUAL

or

Lever sensor

Diagnostic Test for SRAM and DRAM

This test provides the ability to diagnose the SRAM and DRAM. If these two components are bad,

replace them. Otherwise the cutting plotter will not work properly.

Diagnostic Test for Lever Sensor

This feature diagnoses the lever sensor. If the sensor is faulty, the cutting plotter cannot sense that

the pinch rollers have been lowered or not. If the lever sensor is down, you will see a lift the lever

message on the LCM. If the lever is up, you will see a lower the lever message on the LCM. You can

use the ON/OFF LINE KEY to abort your test when you have finished the lever sensor test.

Check Lever Sensor ?

Select:{} Ok:ENTER

Lever is Up now

ON/OFF

Lever is Down now

ON/OFF

[ENTER] Key [ON/OFF LINE] Key

VCE-MM-02

45

Page 46

MAINTENANCE MANUAL

or

Diagnostic Test for Media Sensors

This test is to diagnose the media sensors. If they are faulty, the cutting plotter cannot detect the

media length correctly. You can see the current front and rear sensor condition, you can turn it on or

off to see if sensors are out of order or not.

Check Media Sensor ?

Select:{} Ok:ENTER

[ENTER] Key [ON/OFF LINE] Key

Now Front is OPEN

Rear is OPEN ON/OFF

Now Front is CLOSE

Rear is CLOSE ON/OFF

VCE-MM-02

Paper sensor

46

Page 47

MAINTENANCE MANUAL

or

Diagnostic Test for Width Sensor

If the sensor is faulty, the cutter cannot sense the media width correctly. Refer to the maintenance

chapter to replace it. You must first move the tool carriage to the rightmost position; the lever must

be down to do this. Once this is done please move the tool carriage to left. Be careful when moving

the tool carriage close to the pinch roller, since the message changes quickly when sensor is between

on and off.

Check Width Sensor ?

Select:{} Ok:ENTER

Now Sensor is off

Move Carriage Slowly

Now Sensor is on

Move Carriage Slowly

[ENTER] Key [ON/OFF LINE] Key

VCE-MM-02

Width sensor

47

Page 48

MAINTENANCE MANUAL

[ON/OFF LINE] Key

Seconds later

[ENTER] Key

[ON/OFF LINE] Key

Seconds later

Diagnostic Test for Motor Encoder and Tool Holder Encoder

This feature provides the ability to diagnose the X and Y motor encoder and tool holder encoder. If

the encoder is defective, the cutting plotter cannot work properly. To check if the encoder is bad or

good, you can apply a slight force to the tested part (such as a drum, the tool carriage or the tool

holder) then examine the readings. If the encoder reading changes dramatically, the encoder is bad.

Refer to the maintenance chapter to replace the motor or tool carriage.

X Motor Encoder Test

X Motor Encoder ?

Select:{} Ok:ENTER

Y Motor Encoder Test

[ENTER] Key

Move Drum By Hand

Wait for 3 seconds

X Encoder Reading

1234 ON/OFF

Y Motor Encoder ?

Select:{} Ok:ENTER

Move Carriage By Han

d Wait for 3 seconds

VCE-MM-02

Y Encoder Reading

1234 ON/OFF

48

Page 49

Holder Encoder Test

[ENTER] Key

[ON/OFF LINE] Key

Seconds later

MAINTENANCE MANUAL

Holder Encoder ?

Select:{} Ok:ENTER

Move Holder Up/Down

Wait for 3 seconds

Holder Encoder Value

1234 ON/OFF

VCE-MM-02

49

Page 50

MAINTENANCE MANUAL

[ENTER] Key

[ON/OFF LINE] Key

[Forward] Key

Diagnostic Test for Motor Movement

This feature is to diagnose the X and Y motors and drivers. If you encounter a motor movement

problem, try to change the main board first. If the problem still remains after replacing the main

board, try replacing the motor.

Drum Movement?

Drum Movement ?

Select:{} Ok:ENTER

X Motor Moving Now

ON/OFF

X Motor Moving Now

Forward ON/OFF

[Backward] Key

X Motor Moving Now

Backward ON/OFF

VCE-MM-02

50

Page 51

Carriage Movement?

[ON/OFF LINE] Key

[Right] Key

[ENTER] Key

[ENTER] Key

[ON/OFF LINE] Key

[Left] Key

MAINTENANCE MANUAL

Carriage Movement ?

Select:{} Ok:ENTER

[ENTER] Key

Y Motor Moving Now

ON/OFF

Y Motor Moving Now

Right ON/OFF

Y Motor Moving Now

Left ON/OFF

Holder Movement?

[ON/OFF LINE] Key

Holder Down ?

Select:{} Ok:ENTER

Holder Moving Now

ON/OFF

Holder Moving Now

Down ON/OFF

Holder Moving Now

Up ON/OFF

VCE-MM-02

51

Page 52

Diagnostic Test for Interface

[ENTER] Key

[ENTER] Key

[ENTER] Key

[ENTER] Key

[ON/OFF LINE] Key

[ON/OFF LINE] Key

[ON/OFF LINE] Key

[ON/OFF LINE] Key

This is a function that is not normally used in maintenance work.

Check RS-232 9600 ?

Check RS-232 19200 ?

Check RS-232 9600?

Select:{} Ok:ENTER

Receive file from PC

1048576 Byte ON/OFF

MAINTENANCE MANUAL

Check Printer Port

Check USB port?

Check RS-232 19200?

Select:{} Ok:ENTER

Receive file from PC

1048576 Byte ON/OFF

Check Printer Port?

Select:{} Ok:ENTER

Receive file from PC

1048576 Byte ON/OFF

Check USB Port?

Select:{} Ok:ENTER

VCE-MM-02

Receive file from PC

1048576 Byte ON/OFF

52

Page 53

MAINTENANCE MANUAL

Problems and Solutions

This section discusses typical problems you may encounter while operating the cutting plotter and

offers you possible solutions.

The line quality is not good enough at the corner or the end point.

[Causation and recovery:]

Forgetting to fasten the tool (Fasten it.)

The blade is worn. (Change it.)

The offset value is wrong. (Correct the offset value.)

Media is not flat enough. (Reload the media.)

Media is wet. (Change it.)

The quality of media is not good enough. (Change the media.)

Drum or pinch roller is worn. (Change the drum set or pinch roller.)

The position of pinch roller cannot be detected so that the media width cannot be determined correctly.

[Causation and recovery:]

Forgetting to lower the pinch roller. (Enable the pinch roller and push the lever forward to lower

down the pinch roller)

The orientation of the width sensor on the carriage PCB is not correct. (Adjust the orientation of

the carriage PCB)

The position of the width sensor on the carriage PCB is too high to sense the block bar on the

pinch roller. (Lower the carriage PCB)

Flat cable is broken. (Change it.)

Width sensor is damaged. (Change it.)

Carriage PCB set is damaged. (Change carriage set.)

The function of "Set New Origin" does not work.

[Causation and recovery:]

The origin point will be set by pressing the ENTER button when the ValueCut is in an OFFLINE

state, only then will the LCD display the distance between the new and old origin.

Media shifts away when plotting a long drawing.

[Causation and recovery:]

The media is not accurately aligned. (Reload the media.)

VCE-MM-02

53

Page 54

MAINTENANCE MANUAL

Pre-run the media back and forth using the arrow key will help. (Reload the media and pre-run.)

The edge of the media is not straight. (Change the media.)

Media is too thin. (Change it.)

Drum is coated with paper chips or dust. (Clean the surface of drum.)

Drum or pinch roller is worn. (Change the drum set or pinch roller.)

The lines quality is wavy.

[Causation and recovery:]

Forget to fasten the tool fastening screw. (Fasten it.)

The blade is worn. (Change it.)

The acceleration is too high. (Set the acceleration to a lower value; please refer to the default

value.)

The carriage belt tension is incorrect. (Adjust the belt tension.)

X or Y motor belt tension is incorrect. (Adjust the belt tension.)

The spring loading bearing of carriage is damaged. (Change the carriage set.)

The length of the media is too short in X direction. (Change the media.)

Media is too thin. (Change it.)

Drum or pinch roller is worn. (Change the drum set or pinch roller.)

X or Y motor is damaged. (Change it.)

Data loses when plotting.

[Causation and recovery:]

Memory chip is bad. (Change it.) Main board set is bad. (Change it.)

Fatal error occurs when loading media.

[Causation and recovery:]

Forget to pull out some media from the media roll. (Pull out some media from the roll before you

start to load media.)

X motor belt is too tight. (Adjust the belt tension.)

Feel electrostatic discharge.

[Causation and recovery:]

Power out let does not have ground connection. (Improve it.)

VCE-MM-02

54

Page 55

MAINTENANCE MANUAL

Carriage locked, cannot move.

[Causation and recovery:]

The spring loading bearing of carriage is damaged. (Change the carriage set.)

The carriage belt is too tight. (Adjust the belt tension.)

Some fasten screws are loose so that the shaft bearing of carriage belt drops. (Fasten the

screws.)

The keyboard does not work.

[Causation and recovery:]

The connection between keyboard and main board is broken. (Re-plug the connector or change

the keyboard set.)

Dust or moist surface makes a bad keyboard contact. (Change the keyboard set.)

The machine makes noise when it is on the standby status.

[Causation and recovery:]

The screws of tool carriage cover are loose. (Fasten the screws.)

X or Y motor belt is loose. (Adjust the belt tension.)

The carriage belt is loose (Adjust the carriage belt tension)

The driver board set is damaged. (Change it.)

The machine makes abnormal noise from the drum set when it is running.

[Causation and recovery:]

X or Y motor belt is loose. (Adjust the belt tension.)

The driver board set is damaged. (Change it.)

The gear at the left of drum set is not tightly mounted on the shaft. (Change it.)

The screws that fasten the drum to the shaft are loose. (Fasten the screws.)

X or Y motor is damaged. (Change it.)

The tool carriage does not perform the up/down action.

[Causation and recovery:]

The blade holder is not installed properly. (Re-install it, please refer to user’s guide.)

The flat cable is broken. (Change it.)

The carriage PCB is damaged. (Change it.)

VCM is damaged. (Change the Carriage set.)

The encoder of the VCM is damaged. (Change the Carriage set.)

VCE-MM-02

55

Page 56

MAINTENANCE MANUAL

The driver board set is damaged. (Change it.)

The linear bearing shaft of VCM is rusty. (Change the Carriage set.)

The two small bearings clamp the linear bearing shaft too tight. (Adjust them).

There are some unexpected lines on the final plot.

[Causation and recovery:]

The blade holder is not installed properly. (Re-install it; please refer to user’s guide.)

The media is not flat enough. Maybe there are some bubbles on the surface. (Re-load the media)

The fan cannot make enough airflow to suck the media. (Change the fan or driver board)

The carriage does not perform the up action. (Please refer to the previous paragraph)

The command of output file of cutting software package is not compatible with HPGL or HPGL/2.

(Ask your cutting software package agent for help.)

There are some communication errors. (Check the communication protocol.)

There appears an unexpected tool force.

[Causation and recovery:]

The setting of tool force is wrong. (Reset the tool force.)

The blade length out of the blade holder is too short. (Re-load the blade.)

The initial force setting is wrong. (Reset the initial force. please contacts the manufacturer.)

VCM is damaged. (Change the carriage set.)

VCM encoder is damaged. (Change the carriage set.)

Media drops sometimes.

[Causation and to recovery:]

Media is loaded askew. (Re-load the media.)

The position of pinch roller is not on the top of drum. (Move the pinch roller to a right position.)

The edge of media is broken. (Change the media.)

The front of media is not even. (Cut the front edge of the media evenly and reload the media.)

Drum is coated with paper chips or dust. (Clean the surface of drum.) Drum or pinch roller is

worn. (Change the drum set or pinch roller.)

VCE-MM-02

56

Page 57

Appendix

Recommend Service Parts List

Part no. Part name VC-600 VC-1300 VC-1800 Location

Control panel assembly(MUT)

MAINTENANCE MANUAL

ME-G290072900G-00

ME-G29005258G-00

ME-G234000330G-00

V V V A-13

Control Panel Board assembly

V V V A-37

Control Panel Sticker.(MUT)

V V V A-5

Watch dog-Interface converter board

Assembly

ME-G29005256G-00

Motor Assembly

ME-G29001804G-00

VCE-MM-02

V V V D-20

V V V C-16, D-19

57

Page 58

MAINTENANCE MANUAL

Part no. Part name VC-600 VC-1300 VC-1800 Location

Flat cable Assembly VC6 (L=120cm)

ME-G290071460G-00

ME-G290071420G-00

ME-G290071450G-00

Flat cable assembly VC13 (L=195cm)

Flat cable assembly VC18 (L=250cm)

Pinch roller Assembly

V

V

V

F-S20

F-S20

F-S20

ME-G29002348G-00

ME-G29004369G-00

ME-G29004854G-00

AASII carriage board assembly

Paper Sensor Assembly VC6/VC13

V V V A-35

V V V F-38

V V

H-15

VCE-MM-02

58

Page 59

MAINTENANCE MANUAL

Part no. Part name VC-600 VC-1300 VC-1800 Location

Paper Sensor Assembly VC18

ME-G29004856G-00

ME-G29004680G-00

ME-G29005316G-00

Carriage assembly VC6/VC13

Carriage assembly VC18

2 in 1 Cutter main board

V V

V

V

H-15

A-36

A-36

ME-G29005378G-00

250W Isolated Dual Output with PFC

Function(PID-250C)

ME-G24500083G-00

V V V B-5

V V V B-3

VCE-MM-02

59

Page 60

MAINTENANCE MANUAL

Part no. Part name VC-600 VC-1300 VC-1800 Location

Pinch Roller

ME-G20200003G-00

ME-G20600009G-00

ME-G20600007G-00

V V V G-01

X - axis Belt (2GT-L210-W10)

V V V D-01

Y – axis Belt (2GT-L172-W10)

V V V C-01

VCE-MM-02

60

Page 61

Specification

Model Number

VC-600

VC-1300

VC-1800

Operation Method

Paper Moving Type

Max. Cutting Width

610mm(24in)

1320mm(52in)

1830mm(72in)

Max. Media Loading Width

770mm(30.3in)

1594mm(62.7in)

1900mm(74.8in)

Min. Media Loading Width

50mm(1.97in)

300mm(11.8in)

Number of Pinch Rollers

3 4 6

Drive Motor

DC Servo Control

Cutting Force

5~600 g

Max. Cutting Speed

1530 mm/sec (60ips / Diagonal)

Blade Offset

0~1.0 mm (0.025mm/step)

Memory Buffer

4 MB

Interface

USB 2.0 (Full Speed) and Serial (RS-232C)

Software Resolution

0.025 mm

Distance Accuracy

±0.254 mm or ±0.1% of move, whichever is greater

Curve & Arc Smoothing

Yes

Configurable Origin

Yes

Test Cut capability

Yes

Repeat

Yes

Copy

Yes

Pouncing

Yes

Control Panel

LCD (20 digits x 2lines), 14keys, 1 Power LED

Power Supply

AC 100-240V, 50~60 Hz (Auto switching)

Power Consumption

110 watts - 251.8 watts

Net Weight

18 kg

50 kg

64 kg

Stand

Optional

Standard

Media Basket

Optional

Standard

Environment

Humidity

25% - 75%

Max. Cutting Length 50m(164ft)

Acceptable Material Thickness 0.8mm(0.03in)

Acceleration 4.2 G (Gravity)

MAINTENANCE MANUAL

Type of Command HP-GL, HP-GL/2

Mechanical Resolution

Repeatability ±0.1mm

Tangential Yes

Automatic-Aligning System Completely Automatic Contour Cutting System for print to cut solution

Dimension (HxWxD) mm 412 * 950 * 486 1113 * 1774 * 651 1127 * 2170 * 756

0.006mm

Operation

The specification and data sheet may vary with different materials used. In order to obtain the

best output quality, please maintain the machine regularly and properly.

MUTOH reserves the right to change the specifications at any time without notice.

The above listed specification values are effective only when operated with media certified by

MUOTH.

VCE-MM-02

Temperature 15 ゚ C – 30 ゚ C, 60 ゚ F – 86 ゚ F

61

Page 62

Consumable Item List

VC-CHD

Cutting Blade Holder

Cutting Blade Green Cap (60゚0.5) (1pcs/box)

VC-CBBU1

Cutting Blade Blue Cap (60゚0.25) (1pcs/box)

VC-CMAT

Cutting Pad (6mmx10m)

VC-SB

Safe Blade

Item Number Item Name

MAINTENANCE MANUAL

VC-CBRE5

VC-CBGR1

VC-CBBK1

VC-CBYE5

PSGB-BK Pressurized Ballpoint Pen

VC-PT Pouncing Tool assembly (Diameter:1.5mm)

VC-PMAT Pouncing Pad (1.5m/Roll)

VC-TW Tweezers (L=11cm, W=0.85cm)

Optional Item List

Cutting Blade Red Cap (45 ゚ 0.25) (5pcs/box)

Cutting Blade Black Cap (42 ゚ 0.175) (1pcs/box)

Cutting Blade Yellow Cap (25 ゚ 0.25) (5pcs/box)

Item Number Item Name

VC-STD600 Stand for VC-600

VC-TBL Add-on flat table for VC-600

VC-RS RS-232 Cable (25pin)

VC-USB USB Cable

VCE-MM-02

62

Page 63

MUTOH INDUSTRIESLTD.

http://www.mutoh.co.jp/en/

MUTOH AMERICA INC.

http://www.mutoh.com

MUTOH BELGIUM nv

http://www.mutoh.be

MUTOH DEUTSHLAND GmbH

http://www.mutoh.de/

MUTOH North Europ e S.A.

http://www.segroup.lu/

MUTOH HONGK O NG LT D.

MUTOH SINGAPORE PTE. LTD.

MUTOH AUSTRALIA PTY . LTD.

http://mutoh-au.com/

Tel:81-(0)3-6758-7030

Fax:81-(0)3-6758-7021

E-mail:cs_service@mutoh.co.jp

Tel:352-445-906

Fax:352-447-093

E-mail:info@segroup.lu

Tel:+1-480-968-7772

Fax:+1-480-968-7990

E-mail:sales@mutoh.com

Tel:852-2377-3411

Fax:852-2377-3422

http://www.mutoh.co.jp/en/

Tel:32-(0)59-561400

Fax:32-(0)59-807117

E-mail:mutoh@mutoh.be

Tel:65-6325-3150

Fax:65-6220-4342

http://www.mutoh.co.jp/en/

Tel:49-(0)211-385474-0

Fax:49-(0)211-385474-74

E-mail:vertrieb@mutoh-gmbh.de

Tel:61-2-9437-1366

Fax-61-2-9436-2871

E-mail:sales@mutoh-au.com

Loading...

Loading...