User’s

Guide

User’s Guide – Ultima cutting plotter

2 AP-75032, Rev 2.2, 20/04/07

User’s Guide – Ultima cutting plotter

3 AP-75032, Rev 2.2, 20/04/07

COPYRIGHT NOTICE

COPYRIGHT © 2007 Mutoh Europe N.V. All rights reserved.

This document may not be reproduced by any means, in whole or in part, without written permission of the

copyright owner.

This document is furnished to support the MUTOH Ultima cutting plotter. In consideration of the furnishing of

the information contained in this document, the party to whom it is given assumes its custody and control and

agrees to the following:

The information herein contained is given in confidence, and any part thereof shall not be copied or

reproduced without written consent of Mutoh Europe N.V.

This document or the contents herein under no circumstances shall be used in the manufacture or

reproduction of the article shown and the delivery of this document shall not constitute any right or license to

do so.

April 2007

Published: Mutoh Europe N.V., Archimedesstraat 13, B-8400 Oostende, BELGIUM

User’s Guide – Ultima cutting plotter

4 AP-75032, Rev 2.2, 20/04/07

User’s Guide – Ultima cutting plotter

5 AP-75032, Rev 2.2, 20/04/07

Dear Customer,

Thank you for choosing a Mutoh Ultima series sign cutting plotter. The Mutoh Ultima drag knife cutting plotter

has been designed to be one of the most user-friendly and versatile cutting plotters in the market.

As a stand-alone cutting plotter, the Ultima can cut and plot designs onto PVC or paper as required.

In combination with an inkjet printer, the Ultima cutting plotter is ready for contour-cutting of preprinted signs

made with any printer capable of printing onto cutting plotter compatible media. Contour-cutting is made

possible via the integrated EPOS (electronic positioning) technology and the in-the-box software.

But even more important, it is easy to use, as the following guide will show you.

User’s Guide – Ultima cutting plotter

6 AP-75032, Rev 2.2, 20/04/07

User’s Guide – Ultima cutting plotter

7 AP-75032, Rev 2.2, 20/04/07

TABLE OF CONTENTS

1. Regulatory and safety information ............................................................................................................ 9

1.1. EMC statement for CE Marking ............................................................................................................. 9

1.2. FCC compliance..................................................................................................................................... 9

1.3. Important notes ...................................................................................................................................... 9

1.4. Safety Labels: Safety Labels, Symboles de sécurité, Sicherheitssymbole......................................... 10

2. Installation Procedures............................................................................................................................. 11

2.1. Preparing the cutting environment ....................................................................................................... 11

2.2. Parts list................................................................................................................................................ 12

2.3. Unpacking and setting up the Ultima Cutter ........................................................................................ 13

2.3.1 Unpacking the body ....................................................................................................................... 13

2.3.2. Mounting cutter body to the stand. ............................................................................................... 14

2.4. Cutter parts & components .................................................................................................................. 15

2.5. Operation panel.................................................................................................................................... 17

2.6. Connecting the cutter to the computer ................................................................................................. 19

2.6.1. Serial Interface.............................................................................................................................. 19

2.6.2. USB interface................................................................................................................................ 19

2.7. How to upgrade your ultima firmware .................................................................................................. 20

2.8. Connecting the power cable................................................................................................................. 23

2.9. Installing a tool ..................................................................................................................................... 24

2.10. Loading media.................................................................................................................................... 25

2.10.1. Loading cut sheet media............................................................................................................. 25

2.10.2. Loading roll media....................................................................................................................... 27

2.11. Straightening the vinyl edge using the auto-sheet-off utility............................................................... 29

3. Cutter Controls .......................................................................................................................................... 31

3.1. Understanding the Operation panel ..................................................................................................... 31

3.2. Direct key access ................................................................................................................................. 35

3.2.1. Force selection.............................................................................................................................. 35

3.2.2. Speed selection ............................................................................................................................ 36

3.2.3. Offset selection ............................................................................................................................. 36

3.2.4. Tool selection................................................................................................................................ 37

3.2.5. Origin selection ............................................................................................................................. 37

3.2.6. Test selection................................................................................................................................ 38

3.2.7. Presets selection........................................................................................................................... 38

3.3. Contour Cutting .................................................................................................................................... 41

3.3.1. Aligning methods .......................................................................................................................... 41

3.3.2. Which Aligning Method should I use?........................................................................................... 45

3.4. Square details ...................................................................................................................................... 46

3.5. special functions for quality .................................................................................................................. 48

3.5.1. EPOS offset fine-tune ................................................................................................................... 48

3.5.2 Print deformation............................................................................................................................ 50

4. CUTTER settings & Special functions..................................................................................................... 51

4.1. General procedure to change settings on the cutter............................................................................ 51

4.2. Overview of General settings ............................................................................................................... 51

4.2.1. Sheet Off Mode............................................................................................................................. 52

4.2.2. Sheet Off Margin........................................................................................................................... 53

4.2.3. Pre-Feed Length ........................................................................................................................... 53

4.2.4. Max Sheet length .......................................................................................................................... 55

4.2.5. Page Mode.................................................................................................................................... 56

4.2.6 Origin.............................................................................................................................................. 57

4.2.7. Laser Speed.................................................................................................................................. 57

User’s Guide – Ultima cutting plotter

8 AP-75032, Rev 2.2, 20/04/07

4.2.8. Tool-up Speed .............................................................................................................................. 58

4.2.9. Cut Quality .................................................................................................................................... 59

4.2.10. Factory Default............................................................................................................................ 60

4.2.11. Copies......................................................................................................................................... 61

4.2.12. Smoothing................................................................................................................................... 62

4.2.13. Bézier selection........................................................................................................................... 63

4.2.14. Language selection..................................................................................................................... 63

4.2.15. Emulation selection..................................................................................................................... 64

4.2.16. Program Step selection............................................................................................................... 64

4.2.17. VS/ZF/AS Settings selection....................................................................................................... 65

4.2.18. Communication selection............................................................................................................ 66

4.3 Special key combinations...................................................................................................................... 67

5. Finetuning your cutter to obtain Mutoh quality...................................................................................... 69

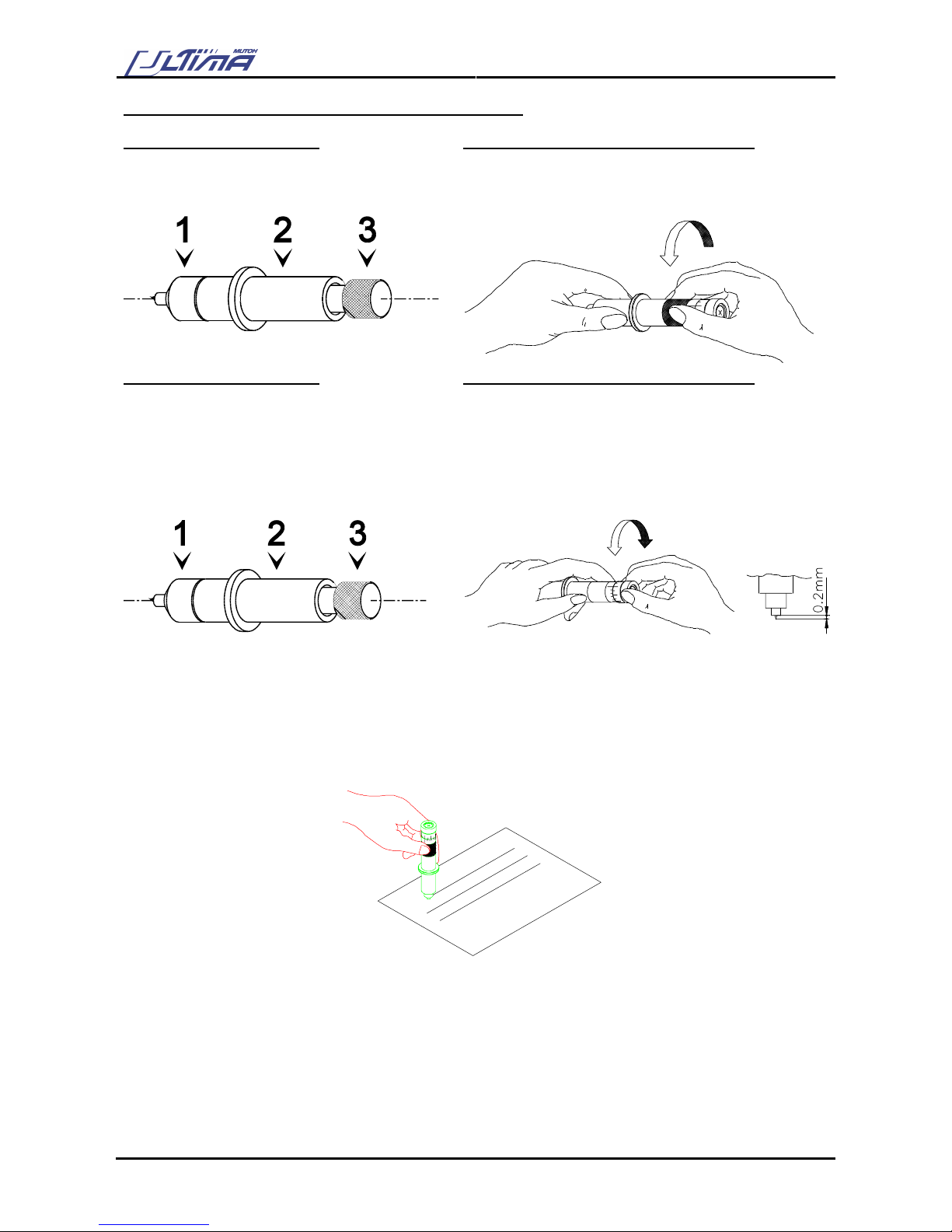

5.1. Adjusting the knife depth ...................................................................................................................... 69

5.2. Setting the cutting pressure / Test squares ......................................................................................... 71

5.3. Offset principle ..................................................................................................................................... 72

5.4. Offset effect .......................................................................................................................................... 72

5.5. Offset adjustment procedure................................................................................................................ 73

5.6. Performing a test cut ............................................................................................................................ 75

5.6.1. Cut Test → SC-850 or SC-1400 ................................................................................................... 75

5.6.2. Quality check ................................................................................................................................ 76

5.6.3. Knife offset → Test ....................................................................................................................... 76

5.6.4. Settings Plot.................................................................................................................................. 77

5.6.5. EPOS Align tune (Manual)............................................................................................................ 78

5.6.6. EPOS Align tune (Automatic) ....................................................................................................... 80

5.6.7. EPOS system → check sensor..................................................................................................... 81

5.6.8. Test sheet verify epos alignment .................................................................................................. 82

6. Plotter maintenance & Troubleshooting ................................................................................................. 83

6.1. Cleaning & Daily maintenance ............................................................................................................. 83

6.1.1. Cleaning the grid rolls ................................................................................................................... 83

6.1.2. Cleaning the cutter blade.............................................................................................................. 84

6.1.3. Cleaning the cutting plotter ........................................................................................................... 84

6.2. Wear & Tear ......................................................................................................................................... 85

6.2.1. Replacing the cutting mat ............................................................................................................. 85

6.2.2. Replacing the knife blade.............................................................................................................. 86

6.2.3. Replacing the auto sheet-off knife ................................................................................................ 87

6.3. Clean sensor and E-pos laser.............................................................................................................. 88

6.3.1. Testing E-pos Laser...................................................................................................................... 88

6.4. Troubleshooting.................................................................................................................................... 89

6.5. Checking the communication settings.................................................................................................. 90

6.6. Error messages .................................................................................................................................... 91

6.6.1. Recoverable system errors........................................................................................................... 91

6.6.2. Unrecoverable system errors........................................................................................................ 92

6.6.3. Communication errors................................................................................................................... 93

6.6.4. Language errors............................................................................................................................ 93

7. Ultima cutting plotters - Media compatibility & Dimensions ............................................................... 95

7.1. Ultima cutting plotters: Media compatibility .......................................................................................... 95

7.2. Physical dimensions Ultima ................................................................................................................. 95

User’s Guide – Ultima cutting plotter

9 AP-75032, Rev 2.2, 20/04/07

1. REGULATORY AND SAFETY

INFORMATION

1.1. EMC STATEMENT FOR CE MARKING

Important

This is a Class A product approved for industrial environments. In a domestic

environment this product may cause radio interference in which case you may be

required to take adequate measures.

1.2. FCC COMPLIANCE

This equipment complies with the requirements for a Class A computing device in the FCC rules, part 15,

subpart J.

Operation of this device in a residential area may interfere with television reception or operation of utilities.

Cutters generate weak radio signals and may interfere with television reception and utilities. If the cutter

does interfere with radio or TV reception, try the following:

¾ Change the direction of your radio and TV reception antenna or feeder.

¾ Change the direction of the cutter.

¾ Move either the cutter or the receiving antenna so that there is more distance between them.

¾ Be sure the cutter and the receiving antenna are on separate power lines.

1.3. IMPORTANT NOTES

Technical problems and maintenance, which require the cutter to be opened, can only be done by qualified

personnel who were trained to repair this type of machine.

Unauthorized removing of covers and/or overruling safety locks can be dangerous and will result in your

guarantee becoming void.

User’s Guide – Ultima cutting plotter

10 AP-75032, Rev 2.2, 20/04/07

1.4. SAFETY LABELS:

SAFETY LABELS, SYMBOLES DE SECURITE,

SICHERHEITSSYMBOLE

Safety Labels are attached to the internal and external area of the cutter to alert you to potentially hazardous

situations or conditions. The following safety labels are used in and on the cutter:

1

2

User’s Guide – Ultima cutting plotter

11 AP-75032, Rev 2.2, 20/04/07

2. INSTALLATION PROCEDURES

2.1. PREPARING THE CUTTING ENVIRONMENT

The location where you set up your equipment is very important. Please see to it that it meets following

conditions:

Power supply of 100 to 120 VAC 50/60 Hz or 200 to 240 VAC 50/60 Hz.

Ambient Conditions

:

Operating environment

- Temperature: 5 °C to 30 °C

- Humidity: 35 % - 75 % non-condensing.

Recommended environment

- Temperature: Room temperature 16 °C to 25 °C

- Humidity: 50 % to 65 %, non-condensing.

Variation rate

- Temperature: 2 °C per hour.

- Humidity: 5 % per hour.

Storage environment

- Temperature: 0 °C to 50 °C

Please protect your cutter from moisture, dust, draughts and direct sunlight. It is best to keep your machine

away from open windows and air-conditioners.

See to it that there is an adequate space around the cutter so that ventilation is not obstructed.

Avoid unnecessary vibrations and set up your cutter on a level surface.

When selecting a place for your cutter, leave at least 90 cm in front and 90 cm at the rear, as shown in the

illustration below.

User’s Guide – Ultima cutting plotter

12 AP-75032, Rev 2.2, 20/04/07

2.2. PARTS LIST

Contents of the plotter box

A

Plotter unit with roll support system, 2

conveyor rolls and small guiding flanges.

J Adapter Cable

B Box with stand and instructions how to install K Mutoh Ultima User’s Guide.

C

One knife holder with pre-mounted cutting

blade

L Application Guide

D

Blade for auto sheet-off. (1 pc – pre-installed

in tool head)

M Quick Start Manual (includes a CD-rom)

E

Set of 2 spare cutting blades and 1 spring for

cutting jobs (45°/ Offset 0.50 mm).

N Ultima Installation CD

F Pressurized ballpoint pen O 5 test sheet verify epos alignment (AP-77010)

G Power Cord. P Quality Cut Sheet

H RS-232 and USB interface cable Q Spare Cutting Mat (1 piece)

I IF-Cable R Starter software kit

(*)

(*)

When ordered as a bundle together with a Mutoh Printer, the in-the-box software may be replaced with one software which handles

cutting, printing and contourcutting.

User’s Guide – Ultima cutting plotter

13 AP-75032, Rev 2.2, 20/04/07

2.3. UNPACKING AND SETTING UP THE ULTIMA CUTTER

2.3.1 Unpacking the body

Notes

• When unpacking the cutter, check whether all parts described in the parts list are included in the box.

Consult your dealer if anything seems to be missing.

• Lifting the machine out of the box should be done by two people. This to avoid back injuries.

• Protect the plotter from firm shocks.

• Do not dismantle the unit

To unpack the cutter, please follow the instructions mentioned below:

Step 1 : Open the box.

Step 2 : Remove the buffer box.

Step 3 : Remove the packaging leg set.

Step 4 : Take out the cutter box.

Step 5 : Lift the cutter unit out of the box and put it on a flat and stable surface.

Step 6 : Remove all plastic wrapping materials.

Step 7 : Remove the pieces of foam, protecting the tool head during transportation.

Step 8 : If you had your cutter delivered with a stand, please refer to the instructions for mounting the

stand.

User’s Guide – Ultima cutting plotter

14 AP-75032, Rev 2.2, 20/04/07

2.3.2. Mounting cutter body to the stand.

Notes

Assemble the stand as described in the procedure enclosed in the stand box.

Step 1 : Position the body above the stand.

There are two positioning points on the stand and one screw hole.

Step 2 : Place the body on the stand and tighten with one screw at both sides.

User’s Guide – Ultima cutting plotter

15 AP-75032, Rev 2.2, 20/04/07

2.4. CUTTER PARTS & COMPONENTS

1 Operation Panel

Removable Panel with LCD-display and control keys.

2 Power Switch

Switches the Ultima cutting plotter ON or OFF.

3 Roll Support System

The roll support system carries the conveyor rolls.

4 Conveyor Rolls

When using roll media for cutting jobs, put the roll of media on top of

the two conveyor rolls.

5 Small guiding Flanges

These flanges on the conveyor rolls will prevent the roll of media from

shifting to the left or to the right when vinyl is pulled off the roll during

the pre-feed cycle.

6 Conveyor Brake

To prevent that the roll media keeps unwinding.

7 Platen & Grid Cover

Supports the cutting media and guides the movement of the media

along the x-axis.

8 Cutting Mat

Provides a reliable cutting surface and minimizes damage to the knife

tip.

9 Firmware Card Socket

Socket to use when using a firmware card.

User’s Guide – Ultima cutting plotter

16 AP-75032, Rev 2.2, 20/04/07

10 USB interface

USB connector to easily connect the cutter for fast and reliable data

transmission.

11 Serial Interface Connector

RS-232 serial interface connector to connect the cutter to the host

computer.

12 Centronics Connector

Centronics Connector to connect the cutter to the host computer.

13 Power Connector

Connector for the power cord, which plugs into the main power

supply of the cutter.

14 Pressure Rollers

Hold the media against the drive rollers during cutting.

15 Drive Rollers

Move the cutting media along the X-axis.

16 Media Basket

Media collecting basket prevents finished cuts to fall on the floor

when they are sheet-off.

17

Cutting head for Cutting

and Sheeting Off

All available tools such as knife holders, drawing pens and painting

pens can be secured into the head using the locking screw. The tool

head moves along the Y-axis to locate the cutting position.

18 Stand

Support the Plotter Body.

19 Hold Lever

Raises and lowers the pressure rollers. Lowering the pressure rollers

will hold the media in place.

User’s Guide – Ultima cutting plotter

17 AP-75032, Rev 2.2, 20/04/07

2.5. OPERATION PANEL

Using the operation panel, you can access different modes and alter several settings, in order to fine-tune

the cutter to match all your needs.

CONTROL-KEY

Key Description

CANCEL

Press the [CANCEL] key to clear all received data.

Press the [CANCEL] key to return to the previous setting (without changes).

EXIT – SHEET OFF

The [EXIT-SHEET OFF] key cancels the changes made in the setting. You will

return to the previous menu.

Press the [EXIT-SHEET OFF] key in normal mode to perform a sheet-off.

ENTER - MENU

Press the [ENTER-MENU] key to select a menu.

Press the [ENTER-MENU] key to confirm the changes made to the setting.

READY / PAUSE

Press the [READY / PAUSE] key to set the cutter READY or PAUSE.

UP

Press the [UP] key to increase the value of the setting or select the next option.

DOWN

Press the [DOWN] key to decrease the value of the setting.

PRESETS

Change the user (there are maximum 32 users); each user has his own set of

settings that are saved when the machine is shut down.

ORIGIN

Press the [ORIGIN] key to change the origin position. (This can change the origin

direction and move the origin point.)

TEST

Press the [TEST] key to choose one of the test plots to plot.

CONTOUR CUTTING

Press the [CONTOUR CUTTING] key to start an auto/manual aligning procedure.

SPEED

Press the [SPEED] key to access the speed menu

User’s Guide – Ultima cutting plotter

18 AP-75032, Rev 2.2, 20/04/07

FORCE

Press the [FORCE] key to access the force menu

OFFSET

Press the [OFFSET] key to access the offset adjustment menu

TOOL

Press the [TOOL] key to change the tool type.

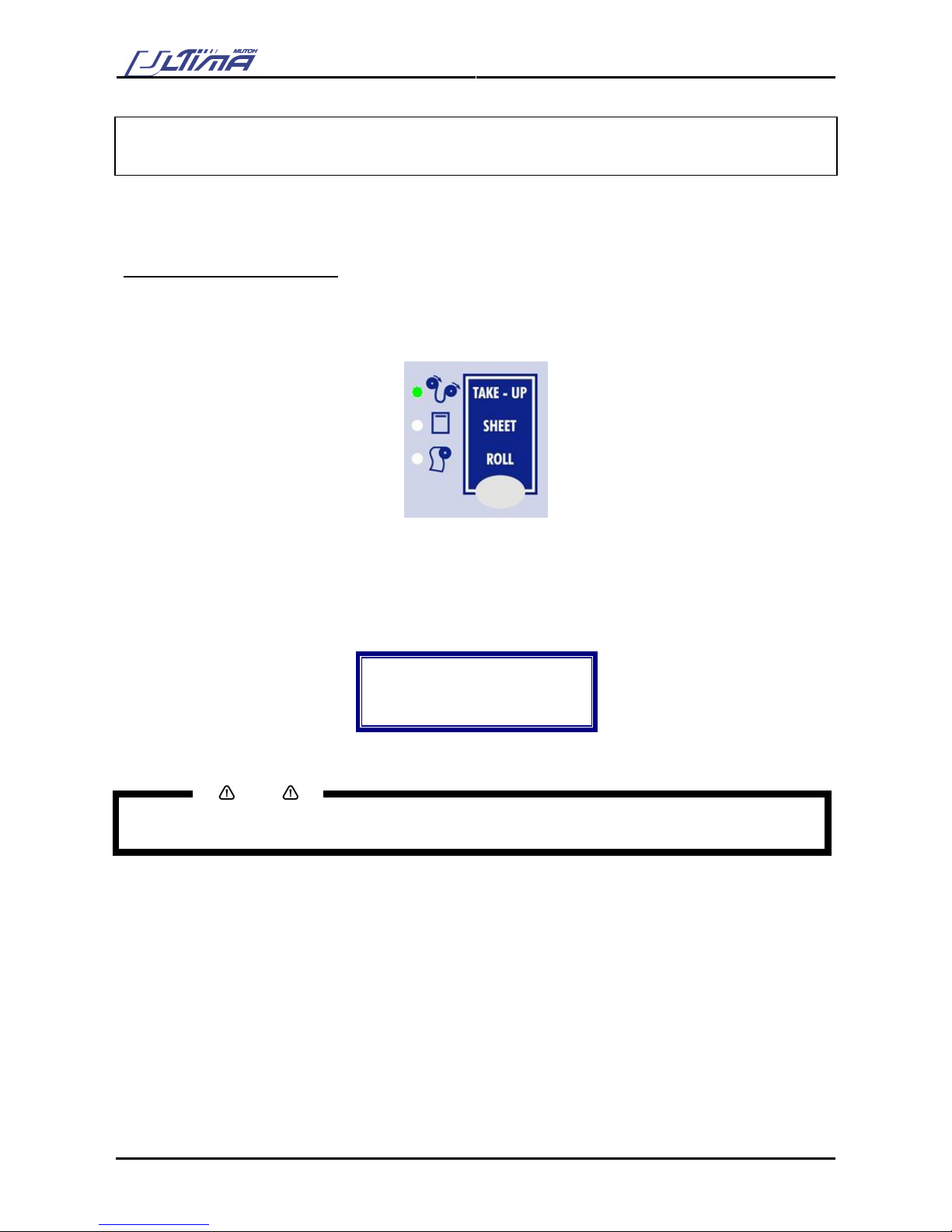

Take-Up / Sheet / Roll

Press the [MEDIA SUPPLY TYPE] key to select how media is loaded.

ARROW-KEY

Press the [ARROW] key for manual movement of the tool head.

LIGHT INDICATORS

LED Description

ORIGIN

Blinks to indicate that you can move the head to replace the origin when you are in

the origin menu.

Lighting indicates that we have a set the origin.

Use the arrow keys to set the origin position by means of the laser led and confirm

with the enter key.

CONTOUR CUTTING

Indicates that an aligning procedure is busy.

TAKE-UP

Indicating that you are working with roll media without front edge detection

SHEET

Indicating that you are working with a sheet of media.

ROLL

Indicating that you are working with roll media using front edge detection

Caution

Please do not use sharp or pointed tools like ballpoints or pencils to press keys. The operation panel is to

be operated with your fingertips.

User’s Guide – Ultima cutting plotter

19 AP-75032, Rev 2.2, 20/04/07

2.6. CONNECTING THE CUTTER TO THE COMPUTER

To make the connection between the cutter and the computer, you are offered two possibilities. The first

possibility is a 2-way RS-232C serial interface. The second possibility is a USB interface.

2.6.1. Serial Interface

The serial RS-232C interface enables the cutter to be connected to and controlled by an RS-232C

compatible host computer system. The cutter is equipped with a standard RS-232C - DB-9P connector on

the rear panel and requires a standard RS-232C DB-9S mating connector.

Step 1 : Make sure both the cutter and the computer are turned off. Connect one end of the serial

interface cable to the serial interface connector at the rear side of the cutting plotter.

Step 2 : Fasten the screws to secure the connector.

Step 3 : Connect the other end of the serial cable to your computer.

Notes

For proper operation of the serial communication, it will be necessary to match the computer settings to the

plotter settings!

9 pin 25 pin 25 pin 9 pin

2.6.2. USB interface

Step 1 : Make sure the USB driver is installed as described in the application guide chapter 1.

Step 2 : Connect one end of the USB cable to the USB connector at the rear side of the cutting plotter.

Step 3 : Connect the other end of the USB cable to your computer or the network.

Notes

Using the serial/USB communication, your cutter will not only be able to receive data from the computer,

but will also be able to send information to the computer (media size, ...).

User’s Guide – Ultima cutting plotter

20 AP-75032, Rev 2.2, 20/04/07

2.7. HOW TO UPGRADE YOUR ULTIMA FIRMWARE

Notes

• Please make sure that the USB driver is installed!

• Please make sure to shut down all programs on your computer before installing new firmware.

Step 1: In case the power is ON, first turn the power of the machine OFF.

Step 2: Connect the Ultima cutting plotter with your PC by means of a USB cable. Remove the RS232

connection.

Step 3: Power ON the Ultima cutting plotter.

Step 4: Go to the “Control Panel – System”.

Step 5: Go to the hardware tab.

Step 6: Press the [Device Manager] button.

User’s Guide – Ultima cutting plotter

21 AP-75032, Rev 2.2, 20/04/07

Step 7: In the “Device Manager” open the list “Ports” (COM & LPT).

Step 8: Check the COM-port number for the USB serial Port (Mutoh Ultima). In the figure above it is

COM3.

Step 9: Start the Ultima update utility on your PC.

Step 10: Select the correct comport (in this case COM3).

Step 11: Press the [Connect] button.

User’s Guide – Ultima cutting plotter

22 AP-75032, Rev 2.2, 20/04/07

Step 12: The status bar starts moving.

Step 13: Press the [Start] button to begin the updating

Step 14: Select the right “.bin” file.

Step 15: The Ultima gives a beep and "Connection with ULTIMA established! Please wait..." is shown in

the update tool.

Step 16: After 13 seconds the message "Sending firmware to ULTIMA!! Please wait...!" appears in the

update tool.

Step 17: The progress bar now starts increasing.

Step 18: The first seconds the progress bar colours red and green. Afterwards the progress bar is black.

Notes

Please note that you passed the critical section of updating when the progress bar is black. When the

machine is shut down in the critical section of the update we refer to the section “When you shut down the

Ultima inside the critical section”.

Step 19: After 1 minute the update finishes with the text "Firmware update successful, restart the

ULTIMA!" on the Ultima update tool.

Step 20: Power OFF the Ultima cutting plotter.

Notes

Please perform a “Code Update” after a firmware upgrade. Without performing a “Code Update”, the panel

keyboard remains in the old firmware version.

Step 21: Restart the Ultima cutting plotter.

User’s Guide – Ultima cutting plotter

23 AP-75032, Rev 2.2, 20/04/07

2.8. CONNECTING THE POWER CABLE

To connect the power cable, please follow the instructions mentioned below.

Step 1 : Make sure the cutter’s power switch is turned OFF.

Step 2 : Plug the plotter-end of the power cable into the connector at the rear of the plotter.

Step 3 : Plug the other end of the power cable into an electrical outlet of the correct voltage and with a

proper grounding.

Notes

The disconnect device is the plug on the power supply cord

User’s Guide – Ultima cutting plotter

24 AP-75032, Rev 2.2, 20/04/07

2.9. INSTALLING A TOOL

At the right-hand side of the cutter head, you will find a pivoting mounting bracket. Opening this bracket will

enable you to install a full range of cutting and drawing tools. To do so, please follow the instructions

mentioned below.

Step 1 : Open the screw (1) to unlock the tool head-mounting bracket.

Step 2 : Hold back the clip (2) of the tool head and slide the tool into position, making sure the tool collar

fits into the groove just beneath the locking screw (3).

Step 3 : Fasten the screw to secure the tool into position.

User’s Guide – Ultima cutting plotter

25 AP-75032, Rev 2.2, 20/04/07

2.10. LOADING MEDIA

When loading media into the cutter, it is necessary to clearly distinguish two situations. The first situation is

when you are using cut-sheet media. The second situation is when you are using roll media.

2.10.1. Loading cut sheet media

Step 1 : Put the pressure rollers (1) in the “up” position using the media hold lever (2) and turn the power

switch ON (3). The cutter will perform its initialization routine and move the tool head (4) to the

rightmost position.

Step 2 : Press the media-select button on the operation panel and select the sheet. After selection the

SHEET-LED will light up.

User’s Guide – Ultima cutting plotter

26 AP-75032, Rev 2.2, 20/04/07

Step 3 : Insert the media into the cutter. It is best to position the media so that half of it hangs in front and

half of it hangs at the back of the cutter.

Step 4 : Adjust the position of the pressure rollers so that they align well with the drive rollers. Doing this

you are helped by the tactile and audible click system for the left pressure roller. The right

pressure roller’s movement is limited so that it can never be malpositioned.

Always make sure that the pressure rollers are completely inside the sheet of the media you want

to load. Especially when you use a cut-sheet of which the corners are not perfectly square, it is

best to put the pressure rollers well inside the vinyl as the width of the sheet may vary.

In case you are using a SC-1400D, you have the opportunity to use either two or three pressure

rollers, depending on the width of the vinyl you are using. When not using the left pressure roller

(i.e. when loading vinyl of a small width), the left pressure roller should be placed at the extreme

left of the cutter (that is, not on top of a grid roller).

Notes

Please note that the middle pressure roller should always be placed on top of a grid roller.

Step 5 : Put the hold lever in the DOWN position.

This action will initialize the media loading sequence, during which the cutter will measure the

loaded sheet. The sheet will be shuffled back and forth, enabling the cutter to determine the

media size and enabling you to verify the media transport.

Step 6 : After finishing the media loading sequence, the tool head will be parked at the origin position and

the cutter will be in ON-LINE mode, ready to receive data from the host computer.

Notes

Do not try to move the pressure rollers when the media hold lever is in the down position as this may cause

damage to the system.

User’s Guide – Ultima cutting plotter

27 AP-75032, Rev 2.2, 20/04/07

2.10.2. Loading roll media

Step 1 : Put the pressure rollers in the “up” position and turn the power switch ON.

The cutter will perform its initialization routine and move the tool head to the rightmost position.

Step 2 : Press the media-select button on the operation panel and select one of the roll loading options.

After selection the ROLL-LED will light up.

Step 3 : Position the roll of media onto the conveyor rolls. Open the protective cover and pull the media

through to be able to choose the best possible position for the pressure rollers.

Notes

Place the media roll on the conveyor rolls as visible on the picture.

To avoid back injuries, the roll of media should be lifted by at least two persons if it’s heavier than 30 kg.

User’s Guide – Ultima cutting plotter

28 AP-75032, Rev 2.2, 20/04/07

Step 4 : Adjust the position of the pressure rollers so that they align well with the drive rollers and that

they can accommodate the roll of vinyl. Doing this, you are helped by the tactile and audible click

system for the left pressure roller. The right pressure roller’s movement is limited so that it can

never be malpositioned. Always make sure that both pressure rollers are at least 5 mm (0.2 inch)

inside the media. It is not recommendable that the rollers run on the very edge of the material.

In case you are using a SC-1400D, you have the opportunity to use either two or three pressure

rollers, depending on the width of the vinyl you are using. When not using the left pressure roller

(i.e. when loading vinyl of a small width), the left pressure roller should be placed at the extreme

left of the cutter (that is, not on top of a grid roller).

Notes

Please note that the middle pressure roller should always be placed on top of a grid roller.

Step 5 : It is best that you hold the front edge of the media in the middle with one hand and with the other

hand, the roll itself.

As you are holding the roll firmly into position, pull the front edge of the media forward so that

there is an even tension across the whole width of the roll.

Step 6 : At this stage, put the hold lever in the DOWN position. Adjust the position of the small conveyor

flanges so that they are just alongside the roll of vinyl. This action will initialize the media loading

sequence, during which the cutter will shuffle a pre-set distance of vinyl. The media will be

shuffled back and forth enabling you to verify the media transport. The page length (pre-feed

length) is factory-set to 1000 mm and can be adjusted by the user.

Step 7 : After finishing the media loading sequence, the tool head will be parked at the origin position and

the cutter will be in ON-LINE mode, ready to receive data from the host computer.

User’s Guide – Ultima cutting plotter

29 AP-75032, Rev 2.2, 20/04/07

2.11. STRAIGHTENING THE VINYL EDGE USING THE AUTOSHEET-OFF UTILITY

The auto-sheet-off mechanism of your cutter can be very easily used to cut the front edge of a new roll of

vinyl straight as well as to cut off a sheet of vinyl from a roll, to be used as a separate sheet.

To do this, proceed as follows:

If you want to sheet-off the vinyl, please follow the instructions below.

Step 1 : Be sure to select take-up with the media supply type key.

Step 2 : Load the media (lever down)

Step 3 : By pressing the Arrow keys, it’s possible to position the media and where to do a sheet off (or

straighten the media)

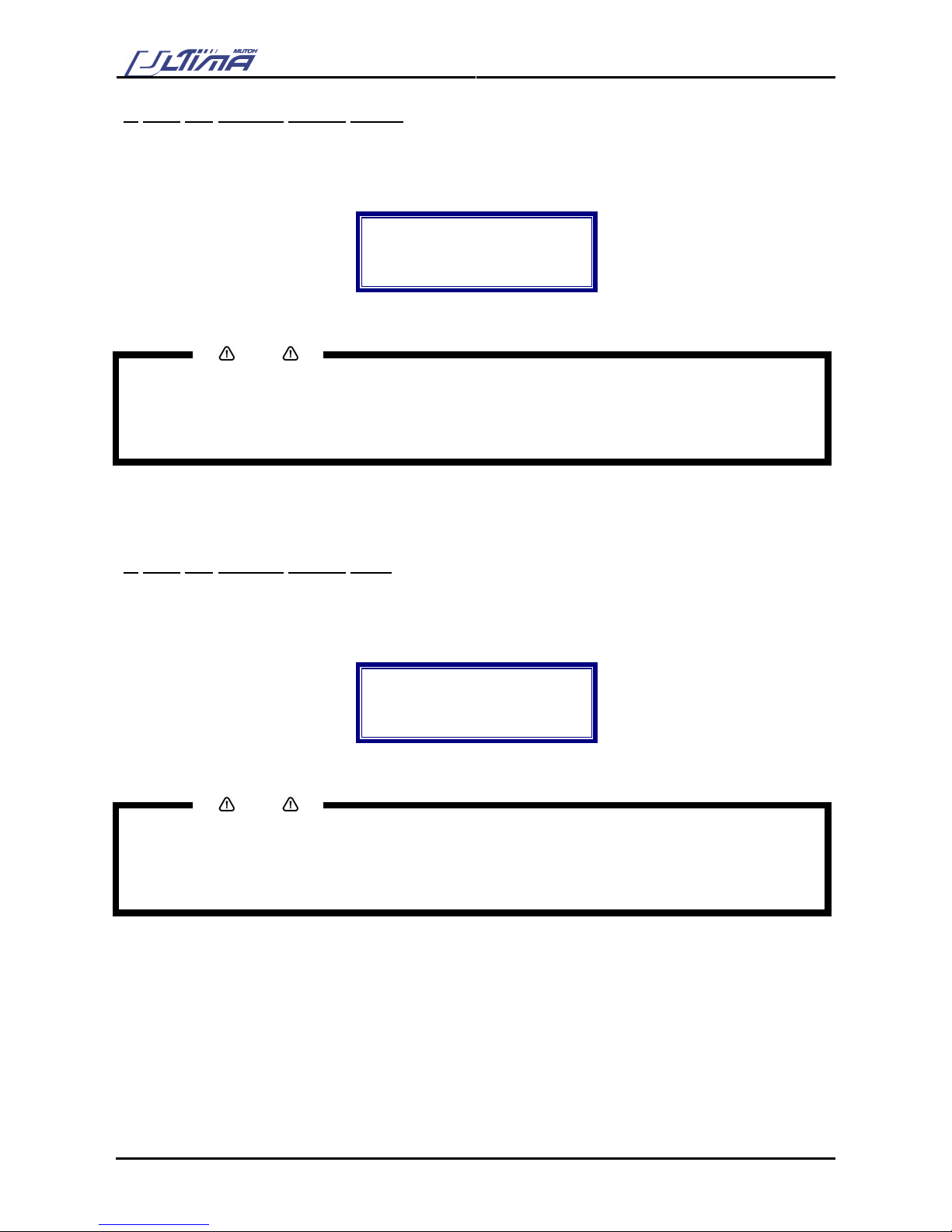

Step 4 : Press the [SHEET OFF] key. The following message will appear on the operation panel.

Do a sheet-off?

Up = No

Down = Yes

Step 5 : Press the [DOWN] key to confirm. A sheet off will be performed.

Notes

Press the [UP] key to not perform a sheet off.

→ Sheet off mode should be enabled first (Menu Option)

User’s Guide – Ultima cutting plotter

30 AP-75032, Rev 2.2, 20/04/07

User’s Guide – Ultima cutting plotter

31 AP-75032, Rev 2.2, 20/04/07

3. CUTTER CONTROLS

3.1. UNDERSTANDING THE OPERATION PANEL

CANCEL-key

The [CANCEL] key can be used for clearing all received data.

Press the [CANCEL] key to return to the previous setting (without changes).

EXIT/SHEET OFF-key

Press the [EXIT/SHEET OFF] key to go to the previous menu setting.

Press the [EXIT/SHEET OFF] key if you do not want to process the changes in

the cutting settings.

Press the [EXIT/SHEET OFF] key in normal mode to perform a sheet-off.

ENTER/MENU-key

Press the [ENTER-MENU] key to enter the menu system.

Press the [ENTER-MENU] key to confirm the changes made to the setting.

PRESETS-key

Pressing the [PRESETS] key you can choose the active user. Each user has its

own settings that are saved. You can make users for different types of cutting

jobs and so pick the desired settings when necessary by selecting the user.

ORIGIN-key

Use the ARROW keys to set the origin position by means of the laser and confirm

with the [ENTER] key.

Diverse Origin Positions can be set in the Origin Menu (Enter Menu)

L Right (default), L Left, Center, U Right, U left

User’s Guide – Ultima cutting plotter

32 AP-75032, Rev 2.2, 20/04/07

TEST-key

By pressing the [TEST] key you can select one of the test plots out of the list to

cut.

CONTOUR CUTTING-key

In this menu you can start a “manual”, “auto no barcode”, “barcode multi” or

“barcode single” aligning procedure by selecting the desired one of the shown

list.

SPEED-key

Press the [SPEED] key to enter the setting menu to change the cutting speed.

Press the [UP] or [DOWN] key to change the speed. Press the [ENTER] key to

confirm the change. If you do not want to change the speed press the

[CANCEL] or [EXIT] key.

FORCE-key

Press the [FORCE] key to enter the setting menu to change the force.

Press the [UP] or [DOWN] key to change the force. Press the [ENTER] key to

confirm the change. If you do not want to change the force press the [CANCEL]

or [EXIT] key.

Press the [FORCE] key again to cut following picture to verify your force cutting

value.

OFFSET-key

By pressing the [OFFSET] key you can change the offset of the knife:

When you enter this menu you can input the offset or the base offset for cutting

the calibration figures.

When you press the [ENTER] key you get a dialog on the cutter that asks if you

want to do a test cutting (select 1 or 2) or not.

When you perform a test cut, 10 reference pictures around the selected base

offset are cut. You can choose the best one by selecting one of the pictures

with the laser pointer and the [UP] and [DOWN] key.

TOOL-key

Press the [TOOL] key to select:

Knife or Pen

READY / PAUSE-key

By pressing this key you can interrupt the cutting job. When you press the

[READY/PAUSE] key again the cutting job is started again. When no media is

loaded you only can be in pause. When media is loaded the status is ready and

can be changed to pause. When in the pause status (media loaded or not) you

still can send a file to the cutter but it will only responds when you go to ready.

User’s Guide – Ultima cutting plotter

33 AP-75032, Rev 2.2, 20/04/07

UP-key

Press the [UP] key to select a desired value when you are in a menu or a

selection dialog.

DOWN-key

Press the [DOWN] key to select a desired value when you are in a menu or a

selection dialog.

TUSR-key

By pressing this key you can select take-up, sheet or roll media loading system.

The selection can only be done when no media is loaded. (= lever up position)

When media is loaded the LED’s only show which type of media is loaded but

cannot be changed.

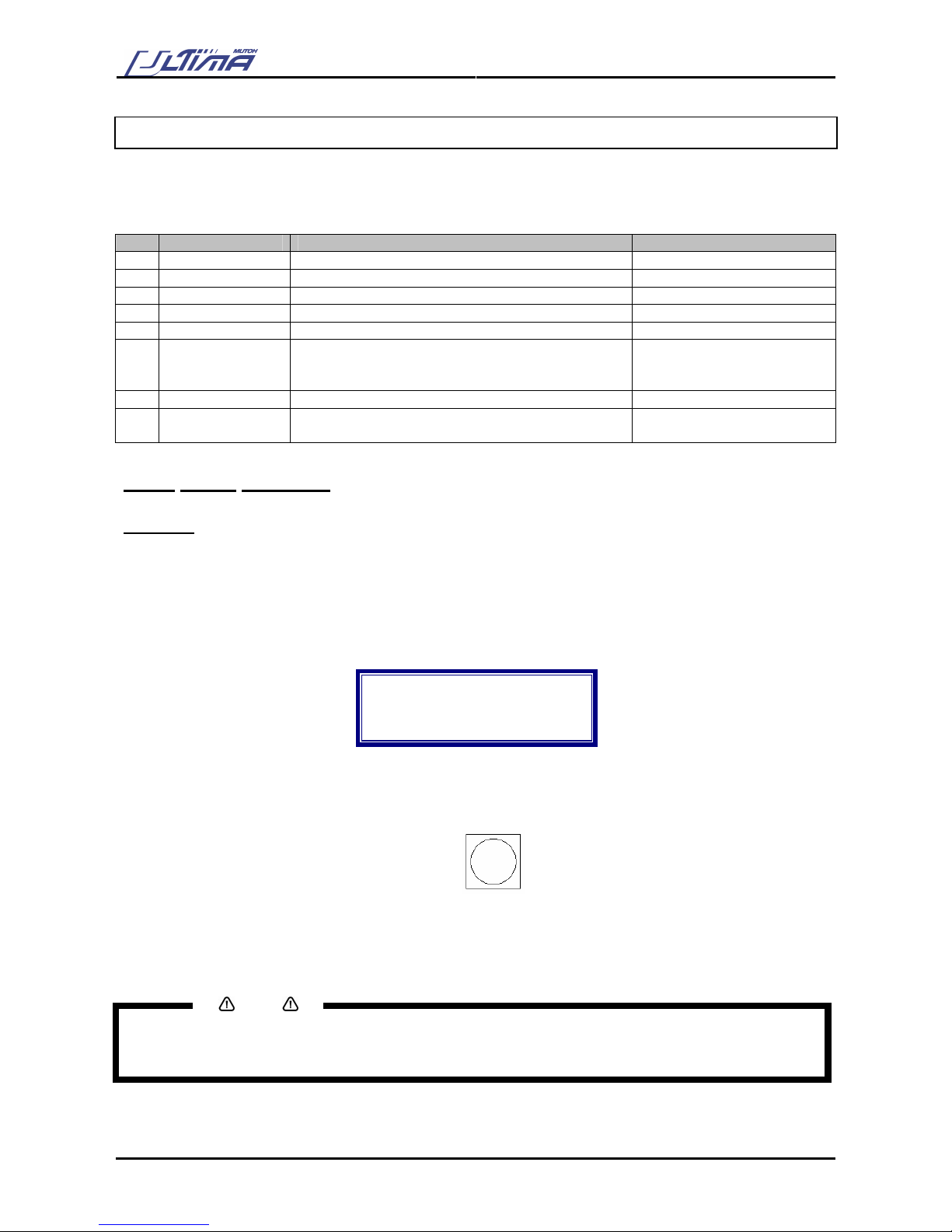

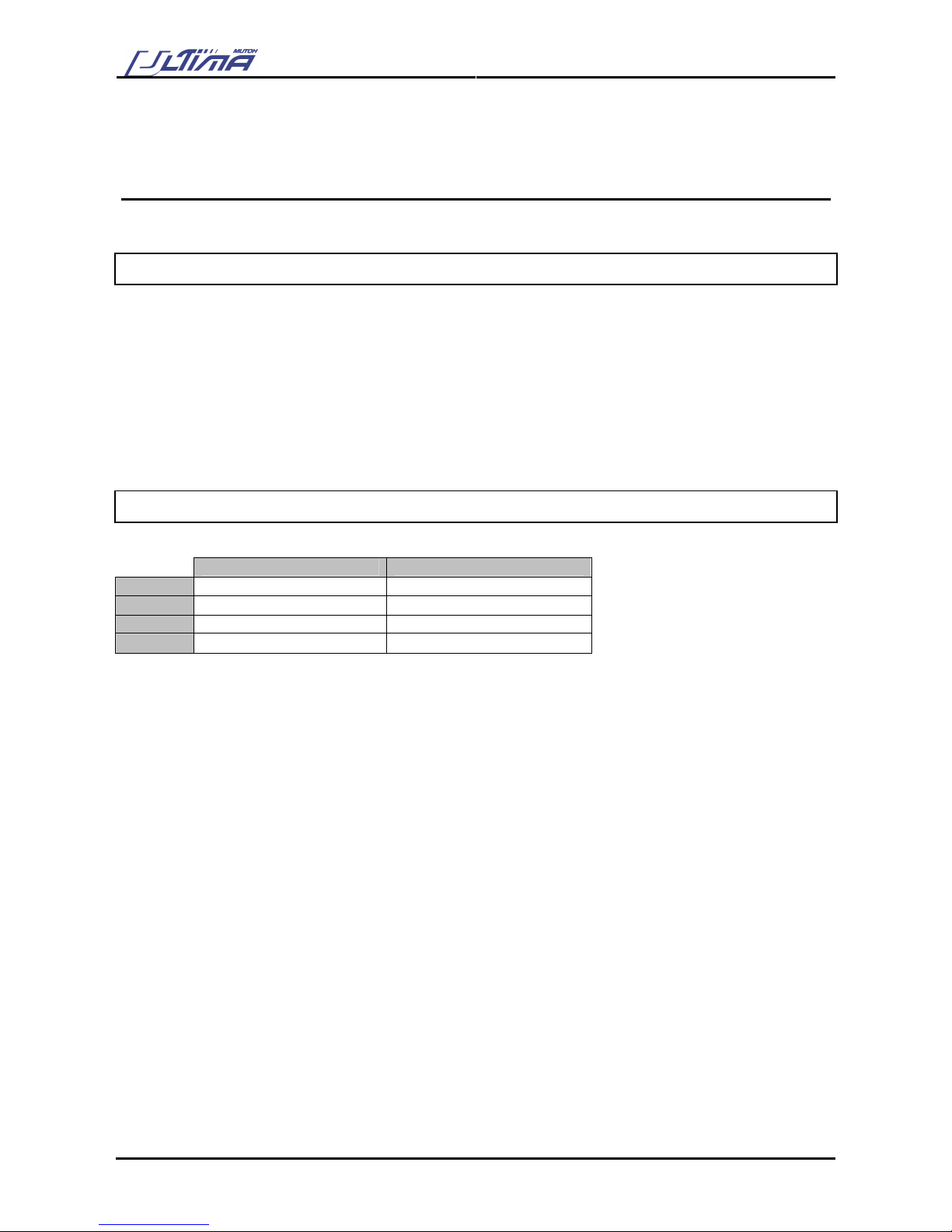

Selection Media Initialization Origin position

Take-Up Right, left + pre-feed At X-loading position

Sheet Right, left + Front + Back Search distance will be the

maximum sheet length.

Origin position at the front

Roll Right, left + Front + Pre-feed At the front

In case the pre-feed value is larger than the sheet length

→ Auto swap from Roll to Sheet

ARROW-key

The [ARROW] keys are always active, the cutter being ONLINE or OFFLINE.

To enable the user to manually move the tool head and the media. This can be

necessary in order to examine specific details of the sign or to set a new origin.

When pressing the [LEFT ARROW] or [RIGHT ARROW] key, the head will move

accordingly. It will move slowly for two seconds and speed up afterwards.

When pressing the [TOP ARROW] or [BOTTOM ARROW] key, the media (if

loaded) will move accordingly. It will move slowly for 2 seconds and speed up

afterwards.

When pressing two [ARROW] keys simultaneously the head will move relative

diagonal to the media.

ORIGIN LED

Lights when alternative origin is selected.

Blinks when changing origin.

CONTOUR CUTTING LED

Blinks when executing alignment procedure.

TAKE-UP LED

This LED will light up if you have selected to load roll media without front edge

detection.

User’s Guide – Ultima cutting plotter

34 AP-75032, Rev 2.2, 20/04/07

SHEET LED

This LED will light up if you selected Sheet Media.

ROLL MEDIA LED

This LED will light up if you selected the Roll Media.

DISPLAY

4 lines / 16 characters

Displays the LCD-display messages, shows settings/values

and allows menu-wise control.

User’s Guide – Ultima cutting plotter

35 AP-75032, Rev 2.2, 20/04/07

3.2. DIRECT KEY ACCESS

On the operation panel are keys to directly change or control some values of the Ultima cutting plotter.

Following items can be changed / controlled directly via the operation panel.

No Function Description Short-key

1 Force Control/change the force of the Ultima. [FORCE] key

2 Speed Control/change the speed of the Ultima. [SPEED] key

3 Offset Control/change the offset of the Ultima. [OFFSET] key

4 Tool Control/change the tool setting of the Ultima. [TOOL] key

5 Origin Control/change the origin of the Ultima [ORIGIN] key

6 Contour Cutting In this menu you can start an “manual”, “auto no

barcode”, “barcode multi” or “barcode single”

alignment procedure.

[CONTOUR CUTTING] key

7 Test Perform one of the test plots onto the Ultima. [TEST] key

8 Presets Select an user previously saved in the Ultima

cutting plotter.

[PRESETS] key

3.2.1. Force selection

Tool force

is the amount of downward pressure that the cutter applies on the tool.

To change or control the tool force, please perform the instructions mentioned below.

Step 1 : Press the [FORCE] key.

Step 2 : The actual FORCE setting for the selected tool will now be shown on the display. Viewing of the

value can be performed in PAUSE as well as in READY mode.

Force

Actual : 30

New : 30

In gram

Step 3 : Press the [UP] or [DOWN] key to change the force setting.

Step 4 : Press the [FORCE] key. The Ultima will cut following picture.

Step 5 : Check the patterns. Especially look for good quality of the corners and easy weeding. If this is

not the case readjust the FORCE selection.

Step 6 : Press the [ENTER] key to confirm the FORCE selection.

Notes

To cancel the changes of the parameter, press the [CANCEL] key. The display will show the previous

value for the parameter.

When you press the [EXIT] key the changed value will be ignored and you go back to the previous menu.

User’s Guide – Ultima cutting plotter

36 AP-75032, Rev 2.2, 20/04/07

3.2.2. Speed selection

To change / control the cutting speed, please perform the instructions mentioned bow.

Step 1 : Press the [SPEED] key.

Step 2 : The actual SPEED setting for the selected tool will now be shown on the display. Viewing of the

value can be performed in PAUSE as well as in READY mode.

Speed

Actual : 10

New : 10

In cm/s

Notes

Changing/viewing of the value can be performed in BUSY mode. Please note that the effect can only be

seen after a few seconds.

Notes

Toolup / laser speed is independent of the cutting speed.

Step 3 : Press the [UP] or [DOWN] key to change the force setting.

Step 4 : Press the [ENTER] key to confirm the SPEED selection.

Notes

To cancel the changes of the parameter, press the [CANCEL] key. The display will show the previous

value for the parameter.

When you press the [EXIT] key the changed value will be ignored and you go back to the previous menu.

3.2.3.

Offset selection

One of the most important factors to obtain good quality, but unfortunately also one of the factors that is

easily forgotten, is the offset.

For more information about the offset, please refer to the chapter ‘Fine-tuning your cutter to obtain Mutoh

quality’.

User’s Guide – Ultima cutting plotter

37 AP-75032, Rev 2.2, 20/04/07

3.2.4. Tool selection

To change / control the tool selection, please perform the instructions mentioned bow.

Step 1 : Press the [TOOL] key.

Step 2 : The actual TOOL setting for the Ultima cutting plotter will be shown on the display. Viewing of

the value can be performed in PAUSE as well as in READY mode.

Tool

Actual : knife

New : knife

Pen or knife

Step 3 : Press the [UP] or [DOWN] key to change the force setting. You can choose between ‘pen’ and

‘knife’.

Notes

Please make sure the tool selected onto the display is the same as the installed tool in the Ultima cutting

plotter.

Step 4 : Press the [ENTER] key to confirm TOOL selection.

Notes

To cancel the changes of the parameter, press the [CANCEL] key. The display will show the previous

value for the parameter.

When you press the [EXIT] key the changed value will be ignored and you go back to the previous menu.

3.2.5. Origin selection

To change / control the origin, please perform the instructions mentioned bow.

Notes

Please make sure media is loaded. If not, the Ultima positioning calculation is based on previously installed

media.

Step 1 : Press the [ORIGIN] key.

Step 2 : The laser LED will be activated automatically. The display will show following message:

Point laser to

Desired origin

Position

Enter = Confirm

Step 3 : Use the arrow keys to move the laser to the desired origin position and press the [ENTER] key.

User’s Guide – Ultima cutting plotter

38 AP-75032, Rev 2.2, 20/04/07

3.2.6. Test selection

In order to enable the user to check if the cutter is fully functional, without needing a computer, MUTOH has

integrated demo test cuts into the Ultima cutters.

For more information about the test cuts, please refer to the chapter ‘Fine-tuning your cutter to obtain Mutoh

quality’.

3.2.7. Presets selection

Using the presets makes it possible to store settings (all settings that can be changed from the panel) for

specific cutting jobs.

In the presets menu following options are available.

¾ Select Preset : Use this function to select a previously saved user setting.

¾ Reset : Change a saved user setting to a default value based on Mutoh’s values.

¾ Add : Add a new user setting.

¾ Remove : Remove a previously saved user setting.

3.2.7.1. ‘Select Presets’

Use this function to select a previously saved user setting. Please follow the instructions mentioned below.

Step 1 : Press the [PRESETS] key.

Step 2 : Following message will appear on the display.

Presets

Select presets

Choose user

Step 3 : Press the [ENTER] key. Following message will appear on the display.

→ User 1

Enter = select

↑ = Up

↓ = Down

Step 4 : Use the [UP] or [DOWN] key to select a user setting.

Step 5 : Press the [ENTER] key to confirm the selected user setting. The Ultima cutting plotter will load

the requested user settings.

Notes

To cancel the changes of the parameter, press the [CANCEL] key. The display will show the previous

value for the parameter.

When you press the [EXIT] key the changed value will be ignored and you go back to the previous menu.

User’s Guide – Ultima cutting plotter

39 AP-75032, Rev 2.2, 20/04/07

3.2.7.2. ‘Reset’

Use this function to change a saved user setting to a default value based on Mutoh’s values. Please follow

the instructions mentioned below.

Step 1 : Press the [PRESETS] key.

Step 2 : Use the [UP] or [DOWN] key to select the following display.

Presets

Reset

Choose user

Step 3 : Press the [ENTER] key. Following message will appear on the display.

→ Monomeric vinyl

Enter = select

↑ = Up

↓ = Down

Step 4 : Use the [UP] or [DOWN] key to select a setting based on Mutoh’s values.

Step 5 : Press the [ENTER] key to confirm the selected user setting. The Ultima cutting plotter will load

the requested settings into the active user setting. The active user setting will now have the

settings based on Mutoh’s values.

Notes

To cancel the changes of the parameter, press the [CANCEL] key. The display will show the previous

value for the parameter.

When you press the [EXIT] key the changed value will be ignored and you go back to the previous menu.

3.2.7.3. ‘Add’

To add a new user setting, please follow the instructions below.

Step 1 : Change all settings for the specific cutting job you will perform.

Step 2 : To store all these settings, press the [PRESETS] key.

Step 3 : Use the [UP] or [DOWN] key to select the following display.

Presets

Add

Choose user

Step 4 : Press the [ENTER] key. The Ultima cutting plotter will store all settings in a new user setting.

Notes

To cancel the changes of the parameter, press the [CANCEL] key. The display will show the previous

value for the parameter.

When you press the [EXIT] key the changed value will be ignored and you go back to the previous menu.

User’s Guide – Ultima cutting plotter

40 AP-75032, Rev 2.2, 20/04/07

3.2.7.4. ‘Remove’

To remove a previously saved user setting, please follow the instructions mentioned below.

Step 1 : Press the [PRESETS] key.

Step 2 : Use the [UP] or [DOWN] key to select the following display.

Presets

Remove

Choose user

Step 3 : Following display will appear.

→ User 1

Enter = select

↑ = Up

↓ = Down

Step 4 : Use the [UP] or [DOWN] key to select the user setting you want to delete.

Step 5 : Press the [ENTER] key to confirm. The Ultima cutting plotter will delete the selected user setting.

Notes

To cancel the changes of the parameter, press the [CANCEL] key. The display will show the previous

value for the parameter.

When you press the [EXIT] key the changed value will be ignored and you go back to the previous menu.

User’s Guide – Ultima cutting plotter

41 AP-75032, Rev 2.2, 20/04/07

3.3. CONTOUR CUTTING

Contour cutting is without doubt the most used feature of the Ultima Cutting Plotter. This feature is made to

cut pre-printed signs on vinyl for sticker production.

Before using this feature, perform the epos alignment as described in chapter 5.6.8.1.

3.3.1. Aligning methods

There are some different approaches to cut your signs which also implicate a different alignment method.

To perform and choose the proper alignment, please follow the instructions mentioned below.

Step 1 : Load the printed media into the cutting plotter.

Step 2 : Install a knife.

Step 3 : Power ON the cutting plotter. The cutting plotter will perform a shuffle sequence.

Step 4 : Press the [CONTOUR CUTTING] key.

Contourcutting :

Methods :

→ BCode Single

Start alignment

Step 5 : By using the [UP] and [DOWN] key you select ‘Manual’, ‘Auto No BCod’, ‘BCode Multi’ or ‘BCode

Single’.

4 methods are possible for aligning:

1) Manual Manual align (MP1)

2) Auto No Bcod Automatic aligning, No Barcode (AL3)

3) Bcode Single Automatic align Barcode Single frame (AL4)

4) Bcode Multi Automatic align Barcode Multi-segment (AL5 or AL6)

Each one of these methods has its own cropmark system (see below)

MP 1 AL 3 AL 4 AL 5

User’s Guide – Ultima cutting plotter

42 AP-75032, Rev 2.2, 20/04/07

Step 6 : Before performing an alignment, ‘X Length’, ‘Y Width’ and ‘Roll Direction’ must be inserted. With

these values the Ultima cutting plotter will calculate the E-pos correction.

Step 7 : Press the [CONTOUR CUTTING] key. On the display following message will appear.

Contourcutting :

X Length (mm) :

→ 500

Start alignment

Step 8 : By using the [UP] and [DOWN] key you select an appropriate value for the X Length.

Notes

Please make sure that the value of the X Length is smaller than the length of the loaded media. Otherwise,

the Ultima cutting plotter cannot complete the alignment – NO VALID EPOS REFERENCE FOUND.

Step 9 : Press the [CONTOUR CUTTING] key to confirm. On the display following message will appear.

Contourcutting :

Y Width (mm) :

→ 500

Start alignment

Step 10 : By using the [UP] and [DOWN] key you select an appropriate value for the Y Width.

Step 11 : Press the [CONTOUR CUTTING] key to confirm. On the display following message will appear.

Contourcutting :

Roll direction

→ Non-reverse

Start alignment

Step 12 : Select the appropriate ‘roll direction’ (non-reverse or reverse) by using the [UP] and [DOWN] key.

Step 13 : Press the [CONTOUR CUTTING] key to check the entered values of the ‘X length’, ‘Y width’ and

‘roll direction’.

Step 14 : To confirm your settings press the [ENTER] key.

Step 15 : The Ultima cutting plotter will start the frame detection. (‘Manual’ or ‘automatic’ as selected in

step 5).

User’s Guide – Ultima cutting plotter

43 AP-75032, Rev 2.2, 20/04/07

In case you selected ‘Auto No BCode’.

Step 15 : The Ultima cutting plotter will automatically measure the four alignments points.

In case you selected ‘Manual’.

Step 15 : After pressing the [ENTER] key following message will appear on the display.

Manual alignment

method

please select

the point

Step 16 : Use the [ARROW] keys to select the first alignment point (P1). Press the [ENTER] key to

perform.

Step 17 : The Ultima cutting plotter will move the head toward the second alignment point. On the display

following message will appear.

Manual alignment

method

please select

the point

Step 18 : Use the [ARROW] keys to select the second alignment point (P2). Press the [ENTER] key to

perform.

Step 19 : The Ultima cutting plotter will move the head toward the third alignment point. On the display

following message will appear.

Manual alignment

method

please select

the point

Step 20 : Use the [ARROW] keys to select the fourth alignment point (P4). Press the [ENTER] key to

perform

Step 21 : The Ultima cutting plotter will move the head toward the fourth alignment point. On the display

following message will appear.

Manual alignment

method

please select

the point

Step 22 : Use the [ARROW] keys to select the third alignment point (P3). Press the [ENTER] key to

perform.

Step 23 : Manual alignment is completed.

Notes

Make sure to keep the order of the alignment points. P1, P2, P4 and then P 3

User’s Guide – Ultima cutting plotter

44 AP-75032, Rev 2.2, 20/04/07

In case you selected ‘BCode Single’

Step 15 : Press the [MENU ▲] key to choose BCode Single.

Step 16 : Press the [CONTOUR CUTTING] button again.

Contourcutting:

→ Repeat Mode

Start Aligning

Step 17 : With the [MENU ▲] key to choose “Single Scan” or “Repeat Mode”.

Notes

> Single Scan: The command will be given to start scanning the bar code of the first / next bounding box

ONLY, from roll or sheet. After finishing this single job, the Ultima returns into the Ready status.

> Repeat Mode: AUTOMATICALLY all succeeding frames will be scanned and contour cut as well, until the

end of roll is reached.

Step 18 : Press the [ENTER] key to start.

In case you selected ‘BCode Multi’

Step 15 : Press the [MENU ▲] key to choose BCode Multi.

Step 16 : Press the [CONTOUR CUTTING] button again.

Contourcutting:

→ Single Scan

Start Aligning

Step 17 : With the [MENU▲] key to choose “Single Scan” or “Repeat Mode”.

Notes

> Single Scan: The command will be given to start scanning the bar code of the first / next bounding box

ONLY, from roll or sheet. After finishing this single job, the Ultima returns into the Ready status.

> Repeat Mode: AUTOMATICALLY all succeeding frames will be scanned and contour cut as well, until the

end of roll is reached.

Step 18 : Press the [ENTER] key to start.

User’s Guide – Ultima cutting plotter

45 AP-75032, Rev 2.2, 20/04/07

3.3.2. Which Aligning Method should I use?

The MP1 (Mutoh Manual Align Method) is the non-automatic method.

Its advantage is that the cropmark system is very small (for small sized jobs), and that this method can be

used in case of vinyl that do not reflect the laser light (meaning, the laser would not be capable of measuring

the cropmarks automatically).

The user has to use the jog keys on the Ultima’s keyboard to measure each cross manually before

contourcutting can start.

The AL3 (Mutoh Auto Align) is the first fully-automated alignment system.

Just place the sign in the cutter, click on PLOT in the cutting software, and the cutter will automatic align the

sign by use of the black bounding box, no user intervention is needed.

This method is ideal for use of single signs, one at the time.

We do not advise to use this method for signs over 2 meter of length, although there is no real limit to the

length that can be used.

The AL4 (Mutoh Auto Align Barcode) is similar to the AL3 method, but there is barcode printed on

the sign.

YOU MUST USE THIS METHOD IN COMBINATION WITH THE CUTSERVER!

This method can be used in case you are creating multiple different contour signs. It allows you to make all

your prints at once (overnight printing for example), and then load the roll with images in the Ultima.

If each sign on the roll has a barcode and if all plot files are in the CutServer, just click on GO in the

CutServer (make sure that the CutServer properties are set to SINGLE FRAME, and REPEAT MODE) and

every sign on the roll will be cut, without the need for user intervention (make sure you’ve enabled autosheet-off in EasySIGN for each contour-sign)

The reason for the two barcodes is to make it possible for the Ultima to auto-detect if the image is loaded

upside-down or correctly.

There is no need for you to search the plot file for each image, the Ultima and the CutServer will do this fullyautomatically, until the complete roll with signs is finished.

We do not recommend this method over 2 m job length, although there is no real limit to the length that can

be used.

The AL5 (Mutoh Auto Align Multiframe) offers all advantages of the AL4 and AL3 method, but it will

split the image in multiple segments of maximum 50cm. (This is to enhance precision over long length).

With AL5, it is possible to make signs of 10m or longer, and the Ultima will measure segment per segment,

and cut segment per segment. This method gives you more accuracy than the AL4 method. We do not

recommend this method for signs smaller than 1,5m

You should use the CutServer for this method, and make sure the CutServer properties are set to MULTIFRAME MODE. (Single scan for 1 AL5 file and Repeat mode for a roll with multiple AL5 files).

Notes

For more details about the Print & Cut workflow and CutServer, please refer to the Application Guide in

the box.

User’s Guide – Ultima cutting plotter

46 AP-75032, Rev 2.2, 20/04/07

3.4. SQUARE DETAILS

Notes

Please note that the creation of an image should be done in a graphics application software (e.g.

CorelDraw, Adobe Illustrator, Adobe Photoshop or Macromedia Freehand) or in origin software with design

functionalities (EasySIGN Power Pack Pro Mutoh Edition or Scanvec Amiable PhotoPRINT DX Mutoh

Edition)

Notes

Do not forget to create the cutting line around your image. The default cutting line is a “magenta hairline” or

“spotcolor” with <CutContour> swatch name (in the CMYK pallet).

→ Thickness line = hairline (or 0.25)

→ Colour = 100% magenta

For more details, please refer to the Application Guide.

To use the automatic alignment procedure, the pre-printed sheet contains a Bounding Box (*) around the

design to be cut. Details can be found below.

VINYL

Bounding Box. This Bounding Box should have a minimum

thickness of 3 mm; default value of this square is 5 mm thick.

Please leave a white edge of 20 mm in front. The sensor firstly

detects the white space.

(*) Please note that the Bounding Box around your design(s) will be printed. Before contour-cutting the Epos technology will search for the Bounding Box and measure the position of the design(s).

The Bounding Box should be at least an A4 format (Portrait). There must be 5 mm white space between the

image and the Bounding Box. Make sure that the Bounding Box is colored black. (→ Contrast) Make sure

that the Bounding Box fits within the margins of the maximum cutting width of your cutting plotter.

Notes

Please note that the position of the design with the Bounding Box compared to the page edges is defined in

the print-software.

User’s Guide – Ultima cutting plotter

47 AP-75032, Rev 2.2, 20/04/07

The square will be detected on the following points.

110 mm or more for a cut-sheet or for the roll end.

Between consecutive boxes: 30 mm – 250 mm

(recommended 65 mm)

5 mm white space

between bounding box

and drawing

Min. side margin of 10

mm.

VINYL

Min. side margin of 10

mm

Black bounding box:

Line thickness of 3

mm-30mm

Default value 5 mm

Minimum size of A4

(Portrait)

Maximum colour

contrast with media.

Min. front margin of 10 mm / max. 250 mm

Notes

When measuring the four points of the box and the cutter establishes a distortion (this means the box is not a

perfect rectangle due to print deformation, or not between the margins), the cutter will beep and shows

following message:

EPOS-warning

********************

Much print

distortion

The cutter will cut a little cross in the lower right corner to remind you and us to its bad print quality in case of

bad contour cutting; however it will continue its workflow after two seconds.

Please refer to next chapter “Print Deformation” for more details.

User’s Guide – Ultima cutting plotter

48 AP-75032, Rev 2.2, 20/04/07

3.5. SPECIAL FUNCTIONS FOR QUALITY

3.5.1. EPOS offset fine-tune

This function is made to fine-tune the EPOS offset.

Please follow the steps below to perform a fine-tune

Step 1 : Install a knife.

Step 2 : Press the [TOOL] key and select ‘knife’.

Step 3 : Load media

Step 4 : Activate the “EPOS offset fine-tune” function by pressing the [TEST] + [CONTOURCUTTING]

button simultaneously. This function is only accurate for 1 job.

EPOS fine-tune

selected for

next job

press any key

Step 5 : Send contour job to the plotter.

Step 6 : The cutter will start cutting 11 lines on the bottom of the box.

Step 7 : When pressing the [UP] or [DOWN] key, the laser goes to the next line. Following message is

displayed

Offset: 0.00

Enter = Select

▲ = Up

▼ = Down

Notes

You can also use the [ARROW] keys

Step 8 : Press the [ENTER] key when laser is above the line which lies on the bottom side of the box.

User’s Guide – Ultima cutting plotter

49 AP-75032, Rev 2.2, 20/04/07

Step 9 : The cutter will start cutting 11 lines on at the right side of the box.

Step 10 : When pressing the [UP] or [DOWN] key, the laser goes to the next line. Following message is

displayed

Offset: 0.00

Enter = Select

▲ = Up

▼ = Down

Notes

You can also use the [ARROW] keys

Step 11 : Press the [ENTER] key when laser is above the line which lies on the right side of the box.

Step 12 : The EPOS offset fine-tune is finished.

User’s Guide – Ultima cutting plotter

50 AP-75032, Rev 2.2, 20/04/07

3.5.2 Print deformation

This function is a warning. Following message could appear when the printed box on the vinyl or other media

is deformed. This means, not a perfect rectangle.

The Ultima can not guarantee a perfect cut workflow when the box is deformed.

When measuring the four points of the box and the cutter establishes a distortion, the cutter will beep and

shows following message:

EPOS-warning

********************

Much print

distortion

The cutter will cut a little cross in the lower right corner and will continue its workflow after two seconds.

User’s Guide – Ultima cutting plotter

51 AP-75032, Rev 2.2, 20/04/07

4. CUTTER SETTINGS & SPECIAL

FUNCTIONS

4.1. GENERAL PROCEDURE TO CHANGE SETTINGS ON THE

CUTTER

Not only there are keys to directly change or control some values of the Ultima cutting plotter, but more

settings are available by following the instructions mentioned below.

Step 1 : Pressing the [ENTER] key, the user enters the setup-menu.

Step 2 : Pressing the [UP] or [DOWN] key, the user can select the parameter he wants to adjust. Confirm

with the [ENTER] key the selection.

Step 3 : The [UP] key will increase the value or select the next parameter. The [DOWN] key will decrease

the value or select the previous parameter. Press the [ENTER] key to confirm the new setting.

After confirmation the display will show the previous menu.

Notes

To cancel the changes of the parameter, press the [CANCEL] key. The display will show the previous

value for the parameter.

When you press the [EXIT] key the changed value will be ignored and you go back to the previous menu.

Step 4 : Press the [EXIT] key to go back to the previous menu and confirm the changed settings.

4.2. OVERVIEW OF GENERAL SETTINGS

The general settings parameter influences the cutter’s reactions to commands given by the computer or

initiated via the control panel. In the general settings menu, several parameters are available:

→

Sheet Off Mode

→

Sheet Off Margin

→

Pre-Feed Length

→

Max Sheet Length

→

Page Mode

→

Laser Speed

→

Tool-Up Speed

→

Cut Quality

→

Factory Default

→

Copies

→

Smoothing

→

Bézier

→

Language

→

Emulation

→

Program Step

→

VS / ZF / AS

→

Communication

User’s Guide – Ultima cutting plotter

52 AP-75032, Rev 2.2, 20/04/07

4.2.1. Sheet Off Mode

With the sheet-off mode, you can select “AUTOMAT”, “MANUAL” or “DISABLE”.

Automatic A sheet-off can be done when pressing the “Exit-Sheet OFF” key.

Manual A sheet-off can be done with a snap-off blade knife; the paper will feed towards the cutgroove.

Disable No sheet-off can be done

The auto-sheet-off mechanism of your cutter can be very easily used to cut the front edge of a new roll of

vinyl straight as well as to cut off a sheet of vinyl from a roll, to be used as a separate sheet. Please refer to

2.11.

To perform sheet off, proceed as follows:

Step 1 : In the general setting select ‘Sheet Off Mode’ by using the [UP] or [DOWN] key.

Step 2 : Press the [ENTER] key to confirm your selection. The actual Sheet Off Mode will now be shown

on the display

Sheet Off

Actual : AUTOMAT

New : AUTOMAT

Sheet Off Mode

Step 3 : By using the [UP] or [DOWN] key select “Automat”, “Manual” or “Disable”.

Step 4 : Press the [ENTER] key to confirm.

Notes

To cancel the changes of the parameter, press the [CANCEL] key. The display will show the previous

value for the parameter.

When you press the [EXIT] key the changed value will be ignored and you go back to the previous menu.

Notes

When pressing the [EXIT-SHEET OFF] key for a while, following message will appear.

Do a sheet off?

▲ = No

▼ = Yes

This message will only appear when Sheet Off Mode is enabled.

User’s Guide – Ultima cutting plotter

53 AP-75032, Rev 2.2, 20/04/07

4.2.2. Sheet Off Margin

With the sheet-off margin, you can select a value from 1 mm to 250 mm. Before performing a sheet-off the

Ultima cutting plotter will forward the media equally to the selected margin.

To do this, proceed as follows:

Step 1 : In the general setting select ‘Sheet Off Margin’ by using the [UP] or [DOWN] key.

Step 2 : Press the [ENTER] key to confirm your selection. The actual Sheet Off Margin will now be shown

on the display

Sheet Off Margin

Actual : 5

New : 5

Margin (mm)

Step 3 : By using the [UP] or [DOWN] key select an appropriate value.

Step 4 : Press the [ENTER] key to confirm.

Notes

To cancel the changes of the parameter, press the [CANCEL] key. The display will show the previous

value for the parameter.

When you press the [EXIT] key the changed value will be ignored and you go back to the previous menu.

4.2.3. Pre-Feed Length

This parameter is directly related to the loading of ROLL media. The Pre-Feed length or SHUFFLE length

has to be set before a roll is loaded.

There are three reasons for using a Pre-Feed Length :

1. The length of media set for the Pre-Feed length parameter will be pulled off the roll, before the

cutting job commences. This will prevent media from being pulled off the roll at high speed and

acceleration. High speed can only be properly used on condition that the media can move freely,

without having to be pulled off the roll during a job.

2. Before actually cutting starts the complete length of the media is shuffled back and forth through the

cutter, ensuring that the pressure rollers have a discrete path while the user has the time to verify if

the vinyl transport goes well.

3. Your Ultima cutter has been equipped with MUTOH’s unique AUTO-SHEET-OFF feature, to

automatically cut off media at the end of a cutting sequence. Following an automatic PAGE

command or a manual PAGE command initiated via the control panel, the cutter will shuffle through

the pre-set Pre-Feed length of media, to ensure that their is enough media left for a possible replot.

If there is not enough media left, the cutter will stop before the end of the assigned media length.

User’s Guide – Ultima cutting plotter

54 AP-75032, Rev 2.2, 20/04/07

To change the value of the Pre-Feed Length, please follow the instructions mentioned below.

Step 1 : In the general setting select ‘Pre-Feed Length’ by using the [UP] or [DOWN] key.

Step 2 : Press the [ENTER] key to confirm your selection. The actual Pre-Feed Length will now be shown

on the display

Pre-Feed Length

Actual : 940

New : 940

Pre-Feed (mm):

Step 3 : By using the [UP] or [DOWN] key select an appropriate value.

Step 4 : Press the [ENTER] key to confirm.

Notes

To cancel the changes of the parameter, press the [CANCEL] key. The display will show the previous

value for the parameter.

When you press the [EXIT] key the changed value will be ignored and you go back to the previous menu.

Notes

Please note that the use of the PRE-FEED LENGTH should not be regarded as a loss of time. If the shuffle

movement is executed without difficulty, the user can be convinced that the sign to be cut will be executed

with very little risk of media tracking problems. As such, it will result in a time-saving operation, preventing

that the user will have to re-cut a very complex design because of bad media alignment.

Notes

Please note that the cutting range is not limited by the Pre-Feed Length which you have set. In case a

design which exceeds the shuffle length is sent to the cutting plotter, the cutter will react as follows:

The first vector, which exceeds the limit, will be cut using reduced speed for the distance exceeding the

limit.

An additional 20 cm (8 inch) of media will be pulled off the roll in order to eliminate any possible snagging at

the roll.

After the additional (20 cm) pre-feed the cutter will continue at the requested speed until the new limit is