Page 1

PP3000

POS PRINTER

MANUAL

Rev.B

TM

Page 2

TM

WARRANTY AND EXCEPTIONS

Federal Communications Commission Radio Frequency Interference

Statement

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant

to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment. This equipment generates,

uses, and can radiate radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications. Operation of this equipment

in a residential area is likely to cause harmful interference in which case the user will be required to

correct the interference at his own expense.

For compliance with Federal Noise Interference Standard, this equipment requires a shielded cable.

This statement will be applied only for the printers marketed in U.S.A.

CE manufacturer Declaration of Conformity

(EC Council Directive 89/336/EEC of 3 May 1989)

This product has been designed and manufactured in accordance with the International Standards

EN50081-1/01.92 and EN50082-1/01.92 following the provisions of the Electro Magnetic Compatibility

Directive of the European Communities as of May 1989

Warranty Limits

Warranty will terminate automatically when the machine is opened by any person other than the

authorized technicians. The user should consult his/her dealer for the problem happened. Warranty voids

if the user does not follow the instructions in application of this merchandise. The manufacturer is by no

means responsible for any damage or hazard caused by improper application.

About This Manual

This manual is aimed to assist the user to utilize the PP3000 series which is a series of POS

printers delicately designed to work with either serial or parallel interface connection. This manual covers

both operational and technical aspects. This manual is revised to cover also the Epson emulation

commands and some frequently asked questions.

The manufacturer of the PP3000 series heartily apologizes to the user for reserving the right to

change or to modify this manual without notice due to the rapid and constant progress and improvement

on science and technology. The user may always obtain the most up to date information through our web

site:

© Copyright Mustek Corp. 1997

All rights are strictly reserved. No part of this documentation may be reproduced, stored in a

retrieval system, or transmitted in any form or by any means, electronic, mechanical, photocopying, or

otherwise, without the prior written consent of Mustek Corp. the publisher of this documentation.

The following terms used in this publication are trademarks or service marks of Mustek Corp.

the publisher of this documentation: POSiFLEX; Mustek; PP3000 POS printer; POSiFLEX PST system.

Other company, product and service names may be trademarks or service marks of others.

Page 3

TM

CHAP. 1

GENER…

CHAP. 2

INSTA…

CHAP. 3

OPERA…

CHAP. 4

TECHN…

CHAP. 5

MAIN …

CHAP. 6

MAINT…

CHAP. 7

CONTR…

APP. A

STAR …

APP. B

FONT …

APP. C

Q & A …

Page 4

Page 5

TM

Table of Contents

GENERAL DESCRIPTION · · · · · · · · · · · · · · · · · · ·1 - 1

OVERVIEW · · · · · · · · · · · · · · · · · · · · · · · · · · · ·1 - 1

MODEL NUMBERS · · · · · · · · · · · · · · · · · · · · · · · ·1 - 1

FEATURES · · · · · · · · · · · · · · · · · · · · · · · · · · · · 1 - 2

INSTALLATION · · · · · · · · · · · · · · · · · · · · · · · · · · 2 - 1

UNPACKING CONTENTS · · · · · · · · · · · · · · · · · · · · 2 - 1

BASIC MOUNTING · · · · · · · · · · · · · · · · · · · · · · · · 2 - 1

FOR POSiFLEX PST POS SYSTEM · · · · · · · · · · · · · 2 - 1

FOR OTHER SYSTEM · · · · · · · · · · · · · · · · · · · 2 - 3

CABLE CONNECTIONS · · · · · · · · · · · · · · · · · · 2 - 3

LOADING RIBBON CARTRIDGE · · · · · · · · · · · · · · · · 2 - 4

LOADING PAPER · · · · · · · · · · · · · · · · · · · · · · · · 2 - 6

REMOVING THE ROLL PAPER · · · · · · · · · · · · · · 2 - 8

OPERATION GUIDE · · · · · · · · · · · · · · · · · · · · · · · 3 - 1

FRONT PANEL · · · · · · · · · · · · · · · · · · · · · · · · · · 3 - 1

SELF PRINT TEST · · · · · · · · · · · · · · · · · · · · · · · · 3 - 2

HEXADECIMAL DUMP MODE · · · · · · · · · · · · · · · · · 3 - 4

CLEAR PRINT BUFFER · · · · · · · · · · · · · · · · · · · · · 3 - 4

MICRO FEED · · · · · · · · · · · · · · · · · · · · · · · · · · ·3 - 4

VALIDATION PRINTING · · · · · · · · · · · · · · · · · · · · 3 - 4

i

Page 6

OPERATION METHOD · · · · · · · · · · · · · · · · · · · 3 - 5

PRINTING FORMAT · · · · · · · · · · · · · · · · · · · · 3 - 6

DATA FORMAT · · · · · · · · · · · · · · · · · · · · · · 3 - 6

PAPER FORMAT · · · · · · · · · · · · · · · · · · · · · · 3 - 6

THER CONSIDERATIONS · · · · · · · · · · · · · · · · · 3 - 6

PERIPHERAL UNIT DRIVE CIRCUIT · · · · · · · · · · · · · · 3 - 7

TECHNICAL BACKGROUND · · · · · · · · · · · · · · · · 4 - 1

BLOCK DIAGRAM · · · · · · · · · · · · · · · · · · · · · · · · 4 - 1

CIRCUITRY LAYOUT & CONNECTORS · · · · · · · · · · · · 4 - 2

JUMPERS & SWITCHES · · · · · · · · · · · · · · · · · · · · · 4 - 4

JUMPER SETTING · · · · · · · · · · · · · · · · · · · · · 4 - 4

SERIAL INTERFACE SWITCH · · · · · · · · · · · · · · · 4 - 4

PARALLEL INTERFACE SWITCH · · · · · · · · · · · · · 4 - 7

DATA STRUCTURE IN SERIAL INTERFACE · · · · · · · · · ·4 - 9

DTR MODE · · · · · · · · · · · · · · · · · · · · · · · · ·4 - 9

STATUS · · · · · · · · · · · · · · · · · · · · · · · 4 - 9

PAPER OUT · · · · · · · · · · · · · · · · · · · · · 4 - 9

MECHANICAL ERROR · · · · · · · · · · · · · · · · 4 - 10

FRAMING ERROR · · · · · · · · · · · · · · · · · · 4 - 10

CASH DRAWER OPEN DETECTION SWITCH · · · · · 4 - 10

X-ON/X-OFF MODE · · · · · · · · · · · · · · · · · · · · 4 - 10

STATUS · · · · · · · · · · · · · · · · · · · · · · · 4 - 11

PAPER OUT · · · · · · · · · · · · · · · · · · · · · 4 - 11

MECHANICAL ERROR · · · · · · · · · · · · · · · · 4 - 11

FRAMING ERROR · · · · · · · · · · · · · · · · · · 4 - 12

CASH DRAWER OPEN DETECTION SWITCH · · · · · 4 - 12

STX-ETX MODE · · · · · · · · · · · · · · · · · · · · · · 4 -12

TM

ii

Page 7

TM

MAIN SPECIFICATION · · · · · · · · · · · · · · · · · · · · · 5 - 1

INTERFACE · · · · · · · · · · · · · · · · · · · · · · · · · · · 5 - 1

PARALLEL INTERFACE · · · · · · · · · · · · · · · · · · 5 - 1

SERIAL INTERFACE · · · · · · · · · · · · · · · · · · · · 5 - 3

PERIPHERAL UNIT DRIVE · · · · · · · · · · · · · · · · 5 - 3

POWER SUPPLY · · · · · · · · · · · · · · · · · · · · · · · · · 5 - 4

OPTION LIST · · · · · · · · · · · · · · · · · · · · · · · · · · ·5 - 4

FONT MATRICES · · · · · · · · · · · · · · · · · · · · · · · · 5 - 4

COMMANDS · · · · · · · · · · · · · · · · · · · · · · · · · · · 5 - 6

FRICTION TYPE · · · · · · · · · · · · · · · · · · · · · · 5 - 6

SPROCKET TYPE · · · · · · · · · · · · · · · · · · · · · 5 - 6

EXTERNAL DIMENSIONS · · · · · · · · · · · · · · · · · · · · 5 - 6

FRICTION TYPE · · · · · · · · · · · · · · · · · · · · · · 5 - 6

SPROCKET TYPE · · · · · · · · · · · · · · · · · · · · · 5 - 6

WEIGHT · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 5 - 6

FRICTION TYPE · · · · · · · · · · · · · · · · · · · · · · 5 - 6

OPERATING ENVIRONMENT · · · · · · · · · · · · · · · · · · 5 - 6

TEMPERATURE · · · · · · · · · · · · · · · · · · · · · · 5 - 6

HUMIDITY · · · · · · · · · · · · · · · · · · · · · · · · · 5 - 6

STORAGE ENVIRONMENT · · · · · · · · · · · · · · · · · · · 5 - 6

TEMPERATURE · · · · · · · · · · · · · · · · · · · · · · 5 - 6

HUMIDITY · · · · · · · · · · · · · · · · · · · · · · · · · 5 - 6

iii

Page 8

MAINTENANCE · · · · · · · · · · · · · · · · · · · · · · · · · · 6 - 1

CLEANING · · · · · · · · · · · · · · · · · · · · · · · · · · · · 6 - 1

PAPER JAM · · · · · · · · · · · · · · · · · · · · · · · · · · · 6 - 1

TROUBLE SHOOTING · · · · · · · · · · · · · · · · · · · · · · 6 - 2

CONTROL CODES · · · · · · · · · · · · · · · · · · · · · · · · 7 - 1

STAR COMPATIBLE MODE · · · · · · · · · · · · · · · · · · · 7 - 1

CONTROL CODES FOR CHARACTER SETTING · · · · · · 7 - 1

CONTROL CODES FOR LINE SPACING · · · · · · · · · · 7 - 2

CONTROL CODES FOR PAGE LAYOUT · · · · · · · · · · 7 - 2

CONTROL CODES FOR GRAPHICS PRINTING · · · · · · · 7 - 3

CONTROL CODES FOR DOWNLOAD CHARACTERS · · · 7 - 3

CONTROL CODES FOR PERIPHERAL UNITS · · · · · · · 7 - 4

OTHER CONTROL CODES · · · · · · · · · · · · · · · · · 7 - 4

EPSON EMULATION MODE · · · · · · · · · · · · · · · · · · · 7 - 4

BASIC REFERENCE · · · · · · · · · · · · · · · · · · · · 7 - 4

HARDWARE MODIFICATION REQUIRED · · · · · · · · · 7 - 4

REFERENCE EPSON MODELS EMULATED · · · · · · · · 7 - 5

CHARACTER SIZE/FONT MATRICES · · · · · · · · · · · 7 - 5

UNSUPPORTED CONTROL CODES · · · · · · · · · · · · 7 - 5

SUPPORTED CONTROL CODES · · · · · · · · · · · · · · 7 - 5

TM

iv

Page 9

TM

APPENDIX A

STAR COMPATIBLE MODE COMMAND DETAIL · · A - 1

APPENDIX B

FONT TABLES · · · · · · · · · · · · · · · · · · · · · · · · · · B - 1

U.S.A. & EUROPE · · · · · · · · · · · · · · · · · · · · · · · · ·B - 1

IBM CHARACTER SET #1 · · · · · · · · · · · · · · · · · · · · B - 3

IBM CHARACTER SET #2 · · · · · · · · · · · · · · · · · · · · B - 5

JAPAN · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · B - 7

INTERNATIONAL CHARACTER SET · · · · · · · · · · · · · · B - 9

APPENDIX C

Q & A · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · C - 1

v

Page 10

Page 11

GENERAL DESCRIPTION

OVERVIEW

The PP3000 series POS printer is a stream-lined low profile 40 column 9

pin dot matrix printer designed to fit the PST system perfectly well and also for

other POS printing applications. This printer utilizes a mechanism supplied from

Star Micronics Co., LTD., and is compatible to the SP312 printers of Star

Micronics in every aspects (with validation print). An optional version of this

printer to simulate the EPSON command set is also available.

MODEL NUMBERS

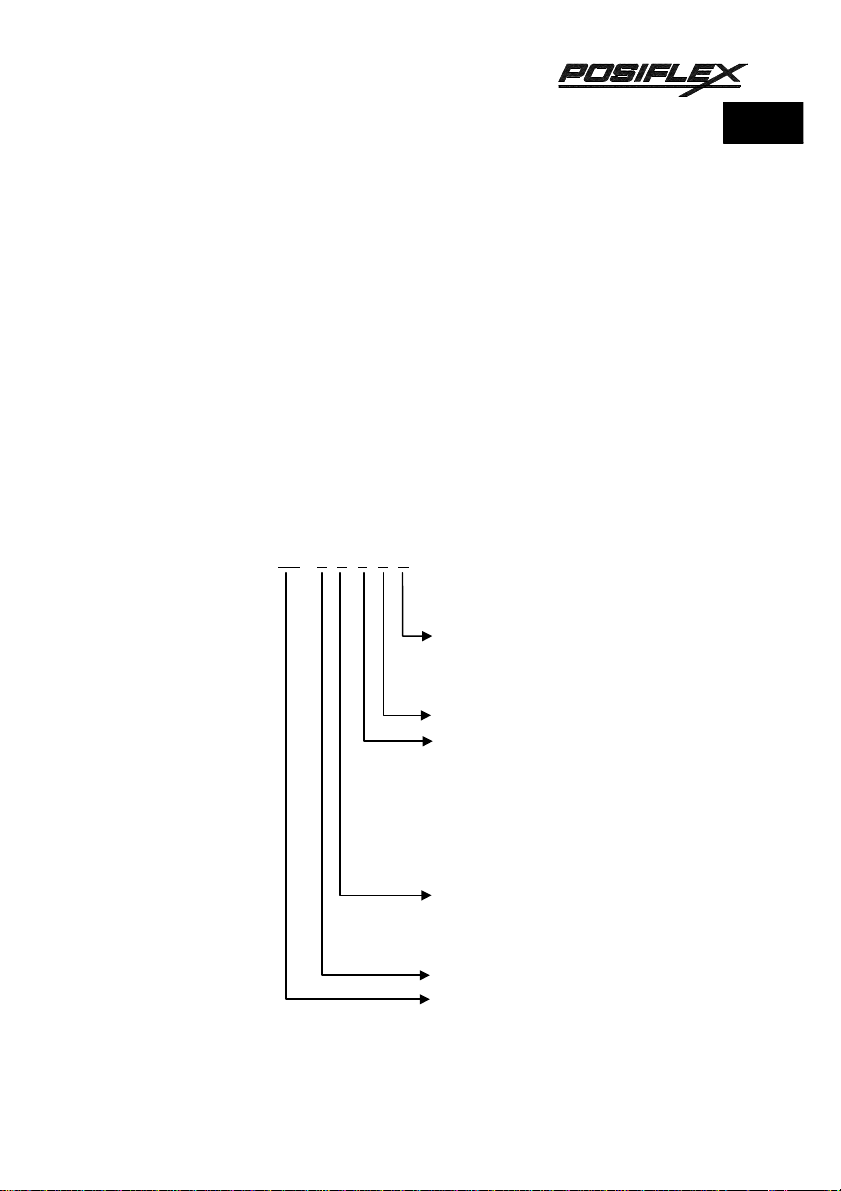

EXAMPLE: PP - 3 0 0 0 S

Interface:

C: parallel

S: serial

Reserved

Language / Expanded character set:

0: English (standard)

1: GB-code Chinese

2: BIG-5 code Chinese

3: Korean

4: Thai

Paper feed:

0: friction type

1: sprocket type

Product series

POS printer

TM

CHAP. 1

GENER…

1 - 1

Page 12

CHAP. 1

GENER…

TM

FEATURES

• Dot matrix 9 pin printer head

• Bi-directional printing

• Friction type paper feed with optional sprocket paper feed

• 40 columns for 15.4cpi

• Accepts paper width 2.25/3/3.25 inches with adjustable paper guide (3.5

inches paper width for sprocket option)

• Print on ordinary paper or up to 3-fold carbonless copy paper

• DC 24V powered

• Selectable parallel or serial (RS232C) interface

∗ Change from serial to parallel: change jumper settings; interface cable.

∗ Change from parallel to serial: modification by manufacturer required.

• Optional serial interface of RS422

• 4 character sets supported: USA & Europe, IBM character set #1, IBM

character set #2, Japan

• Versatile print function as inverted character printing and underlining set by

software print commands

• About 4KB max. input buffer available enabling simultaneous printing and

data receiving

• Peripheral unit drive circuit enables control with short circuit protection of

external devices such as Cash Drawer

• Hardware/software hand shaking in serial interface through DIP switch

selection

• Manual paper cut mechanism

• Validation printing function

• Dimension: friction type: 273mm(l) x 125mm(w) x 174mm(h)

sprocket type: 400mm(l) x 155mm(w) x 180mm(h)

• Epson command emulation model also available

1 - 2

Page 13

INSTALLATION

UNPACKING CONTENTS

• The printer

• Test ribbon cartridge

• Roll paper shaft

• Spacer for 3” paper roll (2 ea.)

• Spacer for 2.25” paper roll (2 ea.)

• E -ring (2 ea.)

• Test paper roll

• Springy hook plate (mounted)

• Rear hook

• Screws to hold springy hook plate (mounted) and rear hook

• Manual

• Power adapter with power cord (option)

TM

CHAP. 2

INSTA…

BASIC MOUNTING

For POSiFLEX PST POS System

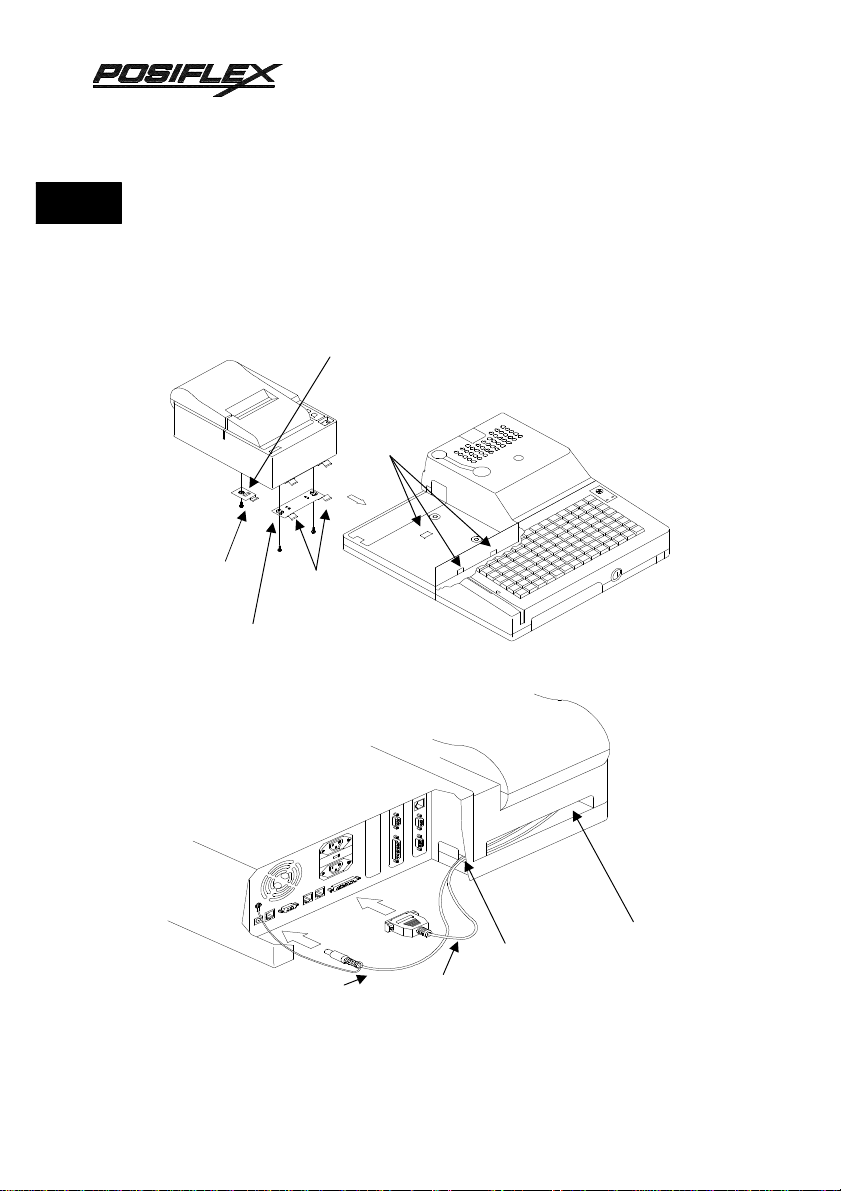

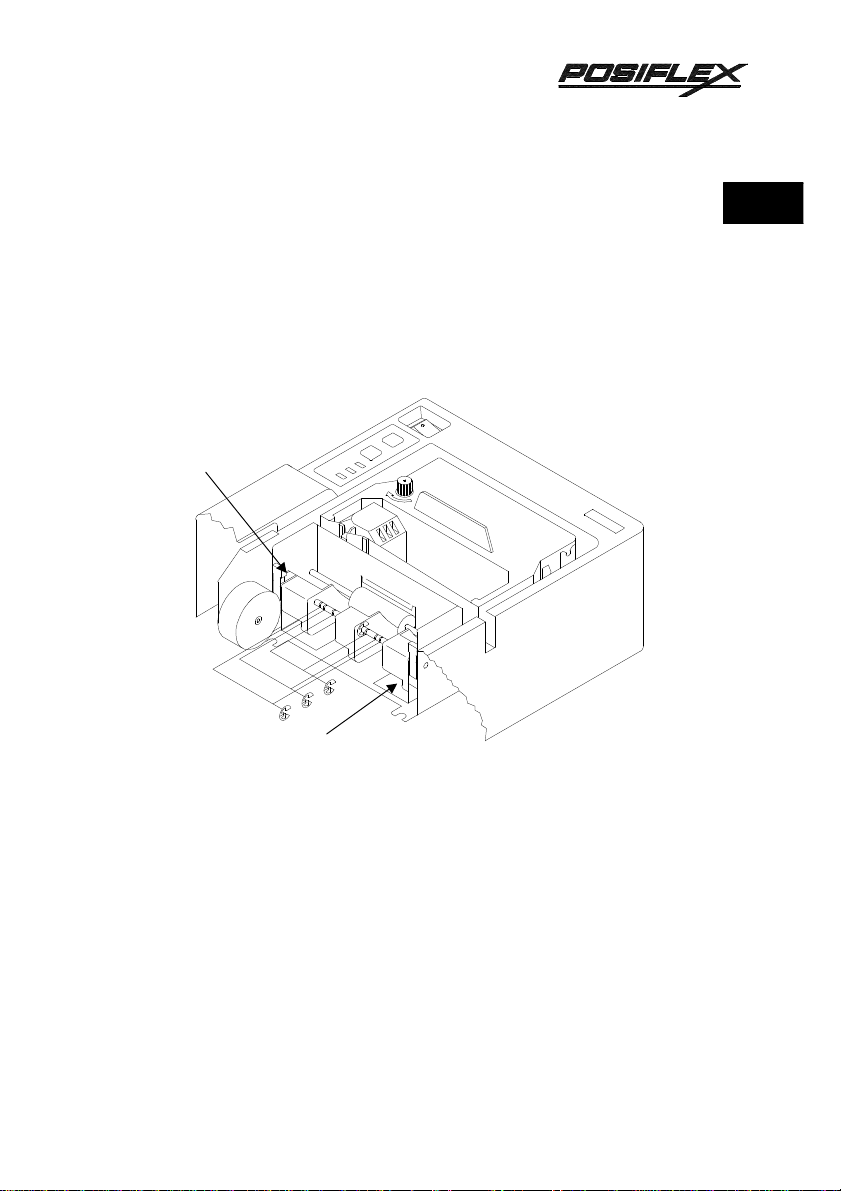

First install the springy hook plate and rear hook onto the metal bottom

plate of the POS printer. Unscrew and re-install the springy hook plate in the

way that the two springy hooks come out of the front edge of the metal bottom

plate (they were pointing inward when shipped). Install the rear hook with its

middle hook lock into the metal bottom plate first and screw the rear hook to the

metal bottom plate (ref. Fig. 1). Connect the power cable and the printer cable

(CCBLA-191 for serial interfaced printer or CCBLA-192 for parallel interfaced

printer) in the way illustrated in the section of “CABLE CONNECTIONS”. Push

open the battery cover of PST system and pass the cables through the opening

beside the battery cover on the PST POS system and close the battery cover

2 - 1

Page 14

TM

Power cable

Springy hook plate

Rear hook

CHAP. 2

INSTA…

again. (ref. Fig. 2, the example uses parallel interface) Aim the rear hook to the

rectangular opening on the printer platform and push the printer down and

forward till the two springy hooks click into the openings between the

programmable keyboard and the printer platform in PST system. Consolidate the

cables and connect them to the appropriate ports inside the back cover of PST

system.

Hook lock on

rear hook

Openings for

hooks

L3L4

L2

L1

L0

LP

Springy hooks

Fig. 1 Mounting printer to PST

2 - 2

Routing cables

Printer cable

through this opening

(serial or parallel)

Fig. 2 Cable routing in PST application

Battery over

Page 15

TM

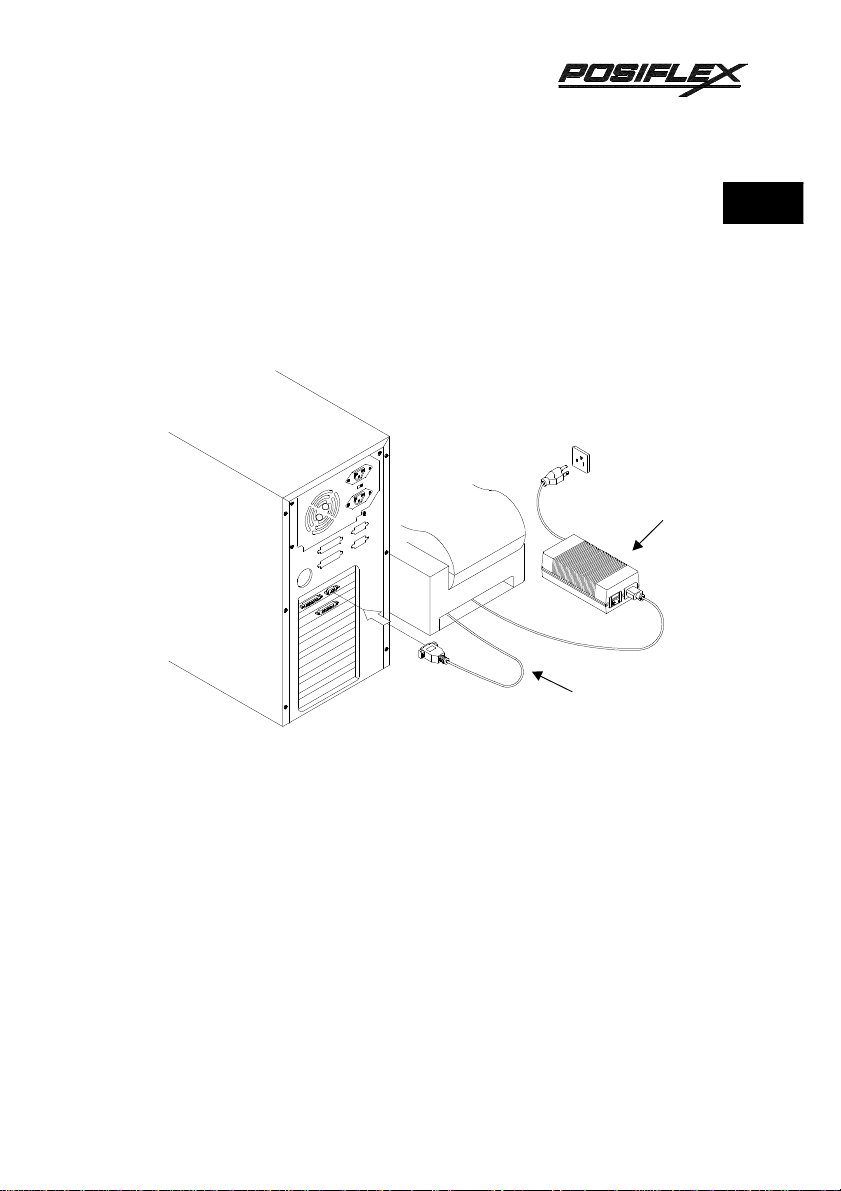

For Other System

Install the printer on a stand or table which has a flat, even surface.

Connect the power cord supplied for the power adapter (ref. Fig. 3) which varies

according to destination region to a power outlet which is not used for any other

electrical noise generating devices such as an electrical motor, etc.. Connect the

printer cable as required.

Power

adapter

Printer cable

(serial or parallel)

Fig. 3 Installation to other system

CHAP. 2

INSTA…

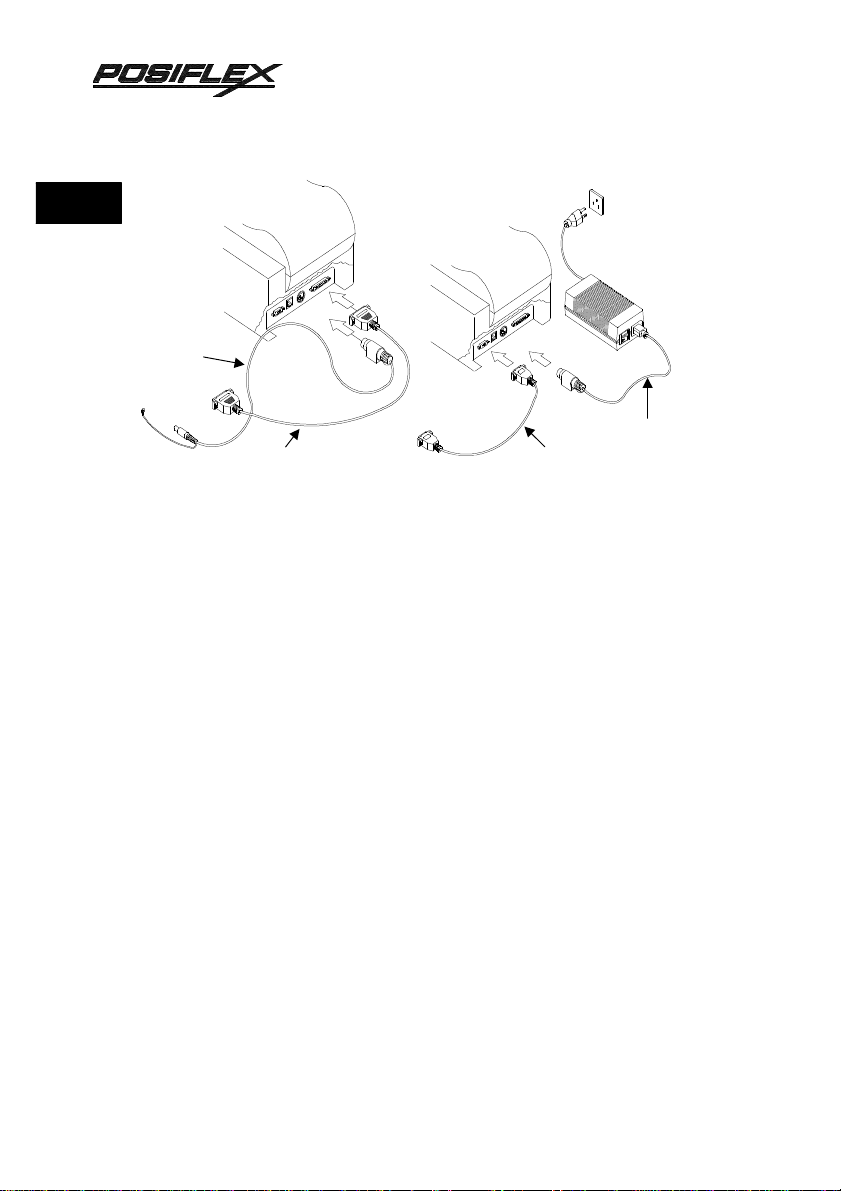

Cable Connections

The PP3000 can either be powered by the PST system or by a separate

power adapter. The serial interface and parallel interface apply different interface

cables. The following drawings demonstrate two examples of the cable

connections to the POS printer PP3000 series.

2 - 3

Page 16

CHAP. 2

Parallel interface cable

9PM

9PF

25PF

25PM

INSTA…

TM

Power cable

from PST system

Power cable

Serial interface

cable

from adapter

Fig. 4 Cable connection examples

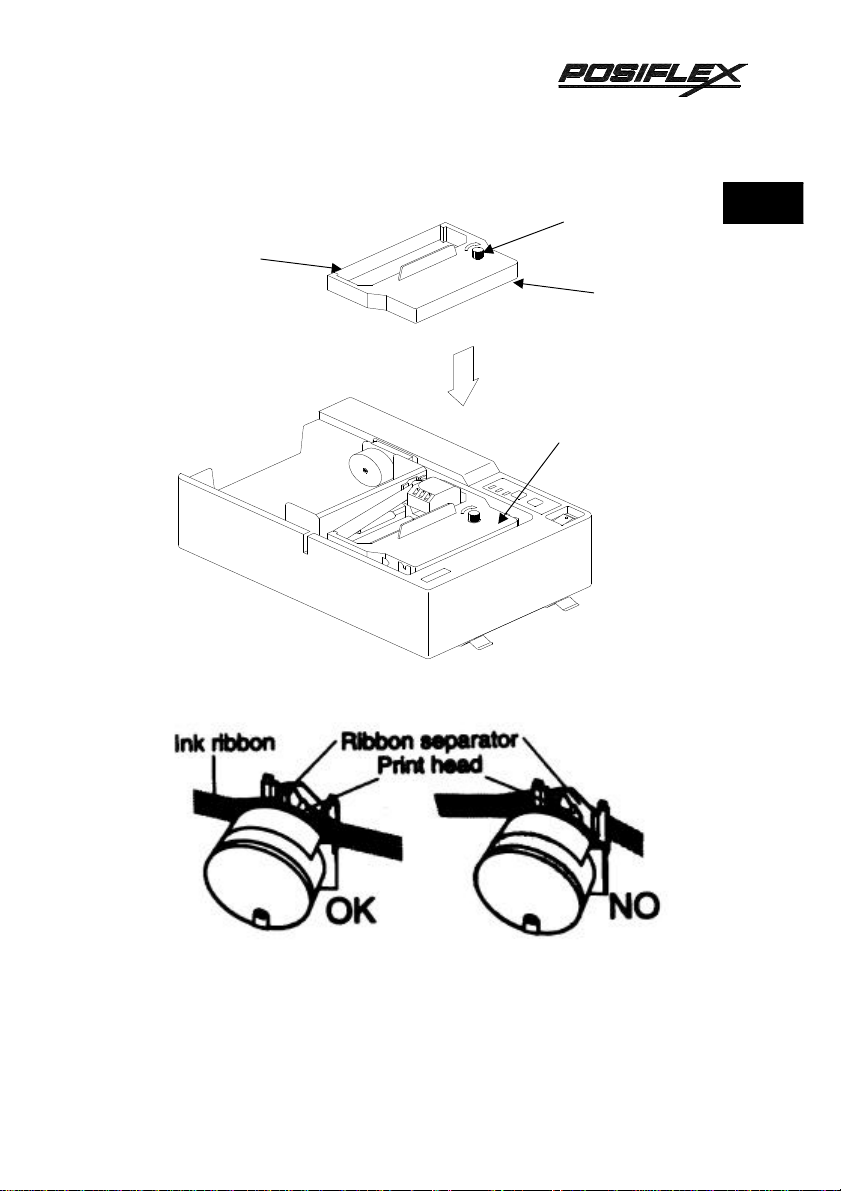

LOADING RIBBON CARTRIDGE

• Turn the power for the printer off.

• Squeeze the two side walls of the top cover inward at the rear portion and

raise and pull it back to remove it.

Note: Do not touch the print head immediately after printing as it gets very

hot.

• Turn the ribbon feed knob of the ribbon cartridge in the direction of the arrow

to remove slack in the ribbon.

• Align the ribbon cartridge guide with the notched part of the frame. Insert the

ribbon cartridge from that position till you hear a locking sound (ref. Fig. 5).

Insert the ink ribbon between the print head and ribbon separator (ref. Fig. 6).

At this time, make sure that the ink ribbon is not protruding beyond the

ribbon separator.

• Turn the ribbon feed knob of the ribbon cartridge in the direction of the arrow

to remove slack in the ribbon.

• Mount the front cover by reversing the procedure outlined in previous steps.

2 - 4

Page 17

Ink ribbon

Ribbon

feed knob

Ribbon

cartridge

Ribbon cartridge

inserted in place

TM

CHAP. 2

INSTA…

Fig. 5 Loading ribbon cartridge

Fig. 6 Detail of ink ribbon at print head

2 - 5

Page 18

CHAP. 2

INSTA…

TM

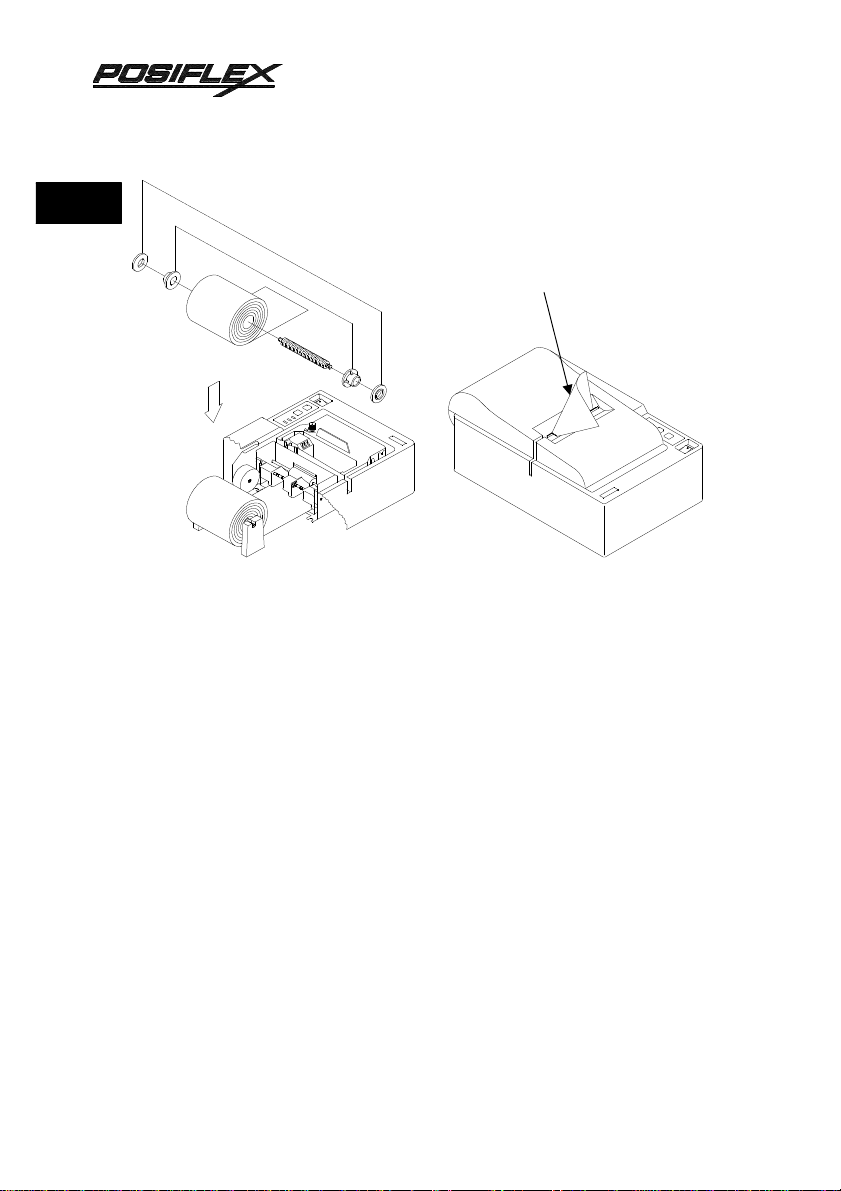

LOADING PAPER

• Be sure to turn off the power for the printer.

• Press the two sides of the top cover near the rear part a little bit inward and

lift the top cover up from the rear end and remove it.

• Set DIP switch 2-5 to match the width of the paper to use (refer to Fig. 17 on

board layout for DIP switch setting).

DIP switch ON OFF

2-5

(All the switches in the DIP switch array are factory preset to ON)

• Release the lock levers of both the left and right paper guides and push the

paper guides outward to show the three sets of grooves on the paper guide

shaft. Insert the E - rings into the grooves corresponding to the paper width

(ref. Fig. 7 ). Push the paper guides inward to touch the E - rings and fix the

lock levers leaving a 0.5mm gap between each paper guide and each edge of

the paper to feed.

• Now, turn the power back on.

• Cut off the front edge of the roll paper perpendicularly. In case of roll paper

with its front edge stuck with a label or so, cut off the part containing the

label and then cut edge straight. If the label’s adhesive is allowed to remain

on the paper roll, it may stick onto the printer’s rollers, causing paper

misfeed.

• Hold the roll paper as shown in the illustration, then insert the top end of the

paper beneath the paper guide as far as it will go and press the FEED switch

on the control panel to feed the paper.

• When the front edge of the paper feeds out of the printer, release the FEED

switch. Next, insert the roll paper shaft into the center hole of the paper roll,

when the paper width is 2.25 or 3 inches, add the two spacers from each end

3.25 inches

3.0 inches

2.25 inches

2 - 6

Page 19

TM

(the thinner spacer for 3” and the thicker for 2.25” both with the flat side

facing inward) and put the whole assembly onto the roll paper shaft holder

(ref. Fig. 8).

• Insert the top edge of the paper into the paper cut slot, then mount the top

cover by reversing the procedure for removing the top cover in previous

steps (ref. Fig. 9).

Lock lever (right)

2.25"

3.0"

3.25"

Paper guide (left)

Fig. 7 Grooves on paper guide shaft

CHAP. 2

INSTA…

2 - 7

Page 20

CHAP. 2

INSTA…

TM

(3.0" SPACER)

(2.25" SPACER)

Insert paper through

the paper cut slot

behind the tear bar

Fig. 8 Putting spacer to roll paper shaft Fig. 9 Finish paper loading

Removing The Roll Paper

Remove the top cover then cut off the paper near the rear of the paper

guide and press the FEED switch to feed out the paper remaining in the unit.

When the paper runs out, a buzzer will sound 4 times per cycle for 2 cycles.

Note 1. Remove the paper remaining in the printer by pressing the FEED switch

(If you remove the paper by hand, the paper could be wrinkled or slip

and cause a paper jam).

2. When the paper end mark appears on the paper, replace the roll paper

before it runs out.

2 - 8

Page 21

OPERATION GUIDE

TM

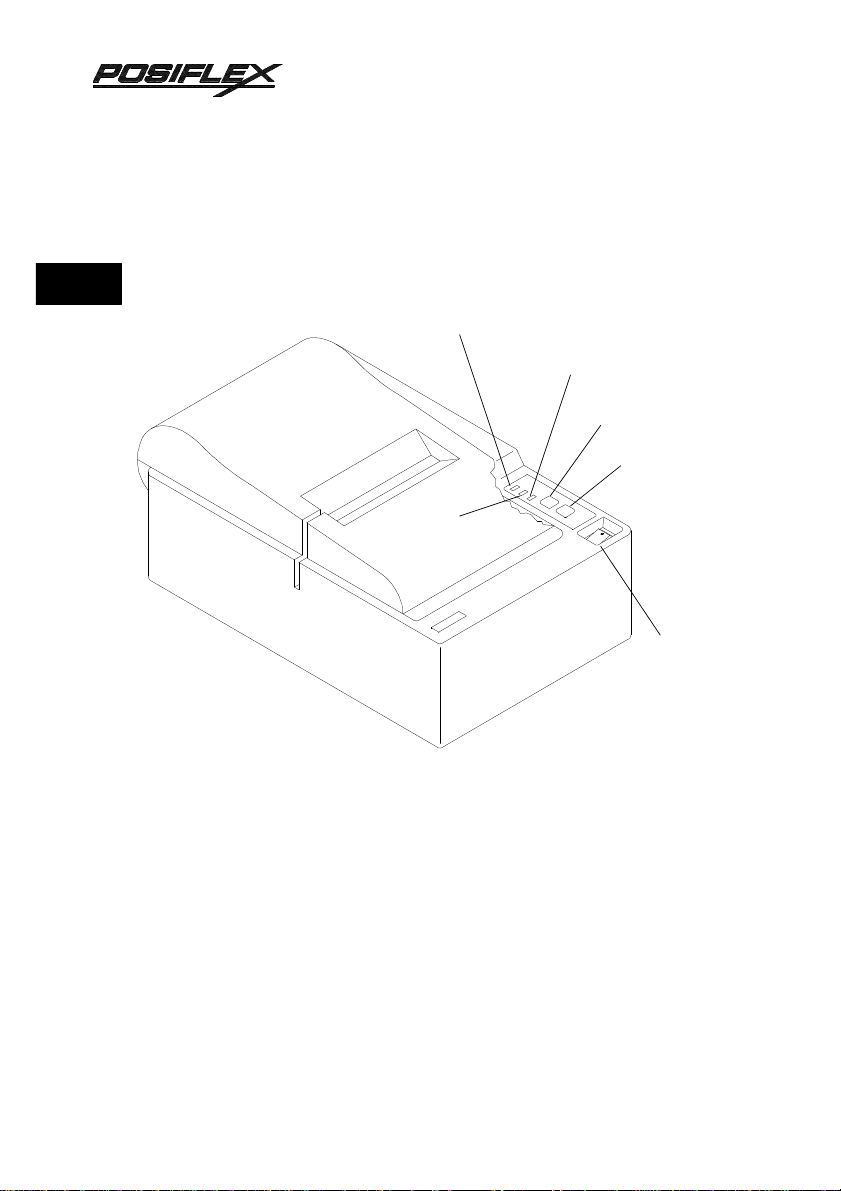

FRONT PANEL

The positions of the below mentioned switches and LED’s are indicated

in Fig. 10.

“ON LINE” switch

Switches the printer between “ON LINE” and “OFF LINE” status.

Whenever the printer switches between “ON LINE” and “OFF LINE”, the

buzzer gives one short beep (“ON LINE” and “OFF LINE” switching is possible

only when paper is loaded in the printer).

“FEED” switch

When this switch is pressed and then released within 0.5 sec., the paper

feeds one line. When this switch is held depressed for more than 0.5 sec., the

paper feeds continuously (The above paper feed operation is possible for both

“ON LINE” and “OFF LINE” modes).

“POWER” LED (green)

Lights when the power for the printer is on.

“ALARM” LED (red)

Lights when the paper is out. (If the paper is out, load a new roll and

press the “ON LINE” switch.)

Flashes when a mechanical error (motor lock etc.) occurs. The buzzer will

give one short beep followed by a long beep. Mount the top cover properly and

press the “ON LINE” switch. If the buzzer still sounds and the “ALARM” LED

flashes, this signifies that a mechanical error has occurred. Locate the cause of

the error and turn the power of the printer off and back on again to reset the

printer (In case of a mechanical error, this restart does not definitely clear up the

data buffer).

CHAP. 3

OPERA…

“ON LINE” LED (green)

LED lit: Printer is ON LINE

LED off: Printer is OFF LINE

LED flashes: Validation printing mode is set.

3 - 1

Page 22

CHAP. 3

OPERA…

TM

When all LEDs light up simultaneously and the buzzer sounds

continuously, a CPU error has occurred. In case of a CPU error, turn off the

power then turn it on again. When turning off the power, the data will be

cleared.

Power LED

(Green)

On-line LED

(Green)

On-line

switch

Feed

switch

Alarm LED

(Red)

Power

On-off

switch

Fig. 10 Locations of switches and LED’s

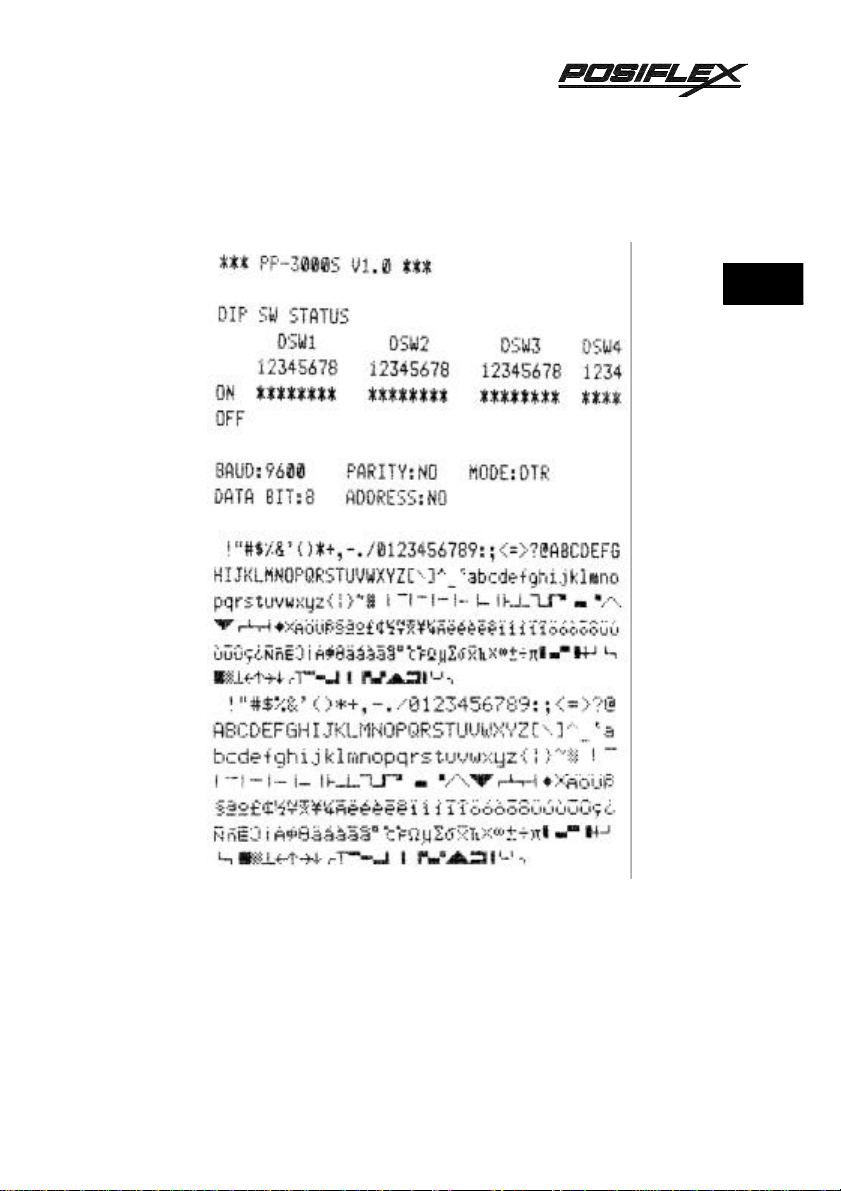

SELF PRINT TEST

“FEED” + “POWER ON” (Turn the power on while holding the “FEED” switch

depressed)

Self-printing will be performed according to the version no., DIP switch

settings, mode settings and the character order. When the “FEED” switch is held

3 - 2

Page 23

continuously during self printing, only the characters will be printed out

repeatedly.

A sample of the output of self print is given in Fig. 11.

TM

CHAP. 3

OPERA…

Fig. 11 Self print sample

3 - 3

Page 24

TM

HEXADECIMAL DUMP MODE

CHAP. 3

OPERA…

“ON LINE” + “POWER ON” (Turn the power on while holding the “ON LINE”

switch depressed)

Each of the signals sent from the computer to the printer will be printed

out in hexadecimal code. This function allows you to check if a control code

sent to the printer by the program being used is correct or not. The buzzer will

sound once to indicate the printer is in hexadecimal dump mode. After the

program has been run, the last line buffer should be flushed by pressing the “ON

LINE” switch. To turn off the mode, it is necessary to turn off the printer

completely.

CLEAR PRINT BUFFER

“FEED” + “ON LINE” + “POWER ON” (Turn the power on while holding both

the “FEED” and “ON LINE” switches depressed)

This operation clears the printer buffer (The buzzer gives two short

beeps). When the printer power is shut off, the data content could degenerate

and become unusable. For this reason, when the printer power is turned off and

there are some left-over in the data buffer or if there is any scramble up in data

receiving, perform the above operation to clear the data in the data buffer. Note

that the data in the buffer can also be cleared by control code <CAN>.

MICRO FEED

“ON LINE” + “FEED” (Press the “FEED” switch while holding the “ON LINE”

switch depressed when the printer is “OFF LINE”)

As a result of this mode, the paper will feed in very small increments.

VALIDATION PRINTING

This printer can print one line of validation printing as described below.

3 - 4

Page 25

Operation Method

TM

1. Open the top cover, pull the adjust lever one notch from standard position

toward the operation panel side. When you cannot find standard position,

push the lever as far as possible toward the rear, then pull it by 2 notches

after having pressed it down. The lever is now in standard position.

2. Mount the top cover.

3. Set the printer for the validation print mode through control codes to the

printer. In this instance, the buzzer gives two short beeps.

4. Make sure that the “ON LINE” LED is flashing.

5. Align the right edge of paper with the right end of the tear bar then insert the

paper from the top in front of the tear bar.

6. The printer starts printing about 1 second after the paper is loaded.

7. When printing is completed, pull the paper upward and remove it from the

printer.

Note: When printing a roll paper, it is recommended to adjust the lever at

the same position as for validation printing.

CHAP. 3

OPERA…

Fig. 12 Validation printing

3 - 5

Page 26

TM

Printing Format

CHAP. 3

OPERA…

Prints one line in 7 x 9 font normal printing.

32 columns (from the 5th to the 36th column)

Even if the setting for paper width is changed by the DIP switch, the 32-column

format will not change.

Data Format

<GS> data <LF>

Paper Format

Fig. 13 Dimensional limits of Validation print

Other Considerations

• The FEED and ON LINE switches will not operate normally during

validation printing.

• When the printer receives an immediate execution command for peripheral

units during validation printing, it executes the command when the validation

print mode is canceled.

• Modes in effect before the validation printing (such as emphasized printing,

inverted printing, expanded printing and underlining) are invalid during

validation printing. But these become valid again after validation printing.

3 - 6

Page 27

• Data received before a <GS> code is printed out when the printer receives the

DC source

<GS> code.

TM

PERIPHERAL UNIT DRIVE CIRCUIT

A drive circuit for driving peripheral units (such as cash drawers) is

featured in this printer. There is a modular connector of 6 pin telephone jack at

the bottom back for this connection. The user shall prepare a cable with a

modular 6 pin telephone plug referring to the circuitry given below.

Fig. 14 Telephone jack and plug for peripheral unit drive

Printer side

Peripheral

unit

Cash drawer open

detection switch

CHAP. 3

OPERA…

Fig. 15 Circuit diagram for peripheral unit drive

Notes:

1. Peripheral units 1 and 2 shall not be driven simultaneously (When the

printer has been driven continuously, set the drive duty to maximum 20%).

3 - 7

Page 28

CHAP. 3

OPERA…

TM

2. The status of the cash drawer open detection switch is interpreted as bit 7 of

the printer status data (Refer to Data Structure in Serial Interface).

3. Recommended resistance values of coils L1 and L2 are minimum 10Ω.

4. The pin assignment of this connector is compatible to Star SP-312 and SP-

320 series.

5. The cable CCBLA-180 is used for this connector to connect to POSiFLEX

cash drawer CR3100 or CR3200.

3 - 8

Page 29

TECHNICAL BACKGROUND

Serial

Control

Paper

24 VDC

5 VDC

Parallel

BLOCK DIAGRAM

Data

(from host computer)

TM

CHAP. 4

TECHN…

Peripheral unit

panel

board

out

detector

interface

EPROM

32KB

RAM 8KB

interface

Gate array

CPU

Fig. 16 Circuit block diagram

Driver

Driver

Control board

Print head

Carriage motor

Detectors

Paper feed

motor

Printer

mechanism

4 - 1

Page 30

CHAP. 4

TECHN…

TM

CIRCUITRY LAYOUT & CONNECTORS

CN2

U1

JP4JP3

1

3

CN5

CN8

CN11

BZ1

CN1 : Reserved

SW1

SW2

SW3

SW4

CN1

U5

TMP90C041AF

EDG

8

7

6

5

4

3

2

1

ON

3

EDG

8

1

7

6

5

4

3

2

1

ON

EDG

8

7

6

5

U11

4

3

2

1

ON

1

3

EDG

4

3

2

ON

1

U16

PST-PRT001A-TJ

U2

U6

2

1

6

5

JP5

U8

JP12

JP8

JP10

JP6

JP9

JP11

JP13

JP7

B303 6DAHG

JP14

Fig. 17 Board layout

M27C512

JP2

JP1

1

3

SP232ACP

U3

BAT1

JP15

CN3

CN4

CN6

CN7

CN9

CN10

CN2 : Control panel connector

This CN2 connector connects the control panel board through cable CCBLA-

189.

CN3 : Power switch connector

This CN3 is connected to cable CCBLA-188 to connect to the printer power

switch.

CN4 : Serial interface connector

This connector is used to connect the host computer by RS-232C or RS-422A.

The MAX232A has to be installed in U3 to use RS-232 interface and MC3451

4 - 2

Page 31

has to be installed in U2 to use RS-422A interface. The details are described in

the table below.

U3 U2

RS-232C

RS-422A

Install MAX232A NOT installed

NOT installed Install MC3451

The cable used in RS-232C application is CCBLA-191 (a DB 9 male to DB 9

female cable).

CN5 : Reserved

CN6 : Peripheral drive connector

This connector uses cable CCBLA-180 to drive peripheral unit such as cash

drawer.

CN7 : Paper detector connector

This connector uses cable CCBLA-190 to detect whether paper is set or

out .When the paper is out, the buzzer will sound and the alarm LED will be

flashing to remind the user.

CN8 : Printer control connector

This connector is connected to printer mechanism through a nineteen pin flexcable, to drive the carriage motor.

TM

CHAP. 4

TECHN…

CN9 : Printer power input connector

This is the power input connector, and the input voltage is 24V DC.

CN10 : Parallel interface connector

This connector uses cable CCBLA-077-2 (DB 25 male to DB 25 female cable)

to connect to the host computer by parallel interface or CCBLA-192 to connect

to parallel port (LPT 1) of POSiFLEX PST system.

CN11 : Print head drive connector

This connector connects to printer mechanism through a fourteen pin flex-cable

to drive the mechanism printer head.

BZ1 : Printer buzzer

The printer buzzer will sound when printers error occurs.

4 - 3

Page 32

CHAP. 4

TECHN…

TM

U6&U8 : Font and BIOS socket

This socket is used to install BIOS and character font. Each type of printer

requires different BIOS and character font. For example, the BIOS for friction

type mechanism and the BIOS for sprocket type mechanism are different.

JUMPERS & SWITCHES

Jumper Setting (Interface Select)

INTERFACE JP3 JP4 JP6-JP13 JP14 JP15

SERIAL PORT

PARALLEL PORT

When using either interface, the connector of the other interface must be

disconnected. DIP SW3 and DIP SW4 have to be turned off when parallel

interface is used.

OPEN 1-2 SHORT 1-2 SHORT SHORT

2-3 SHORT 2-3 SHORT 2-3 SHORT OPEN

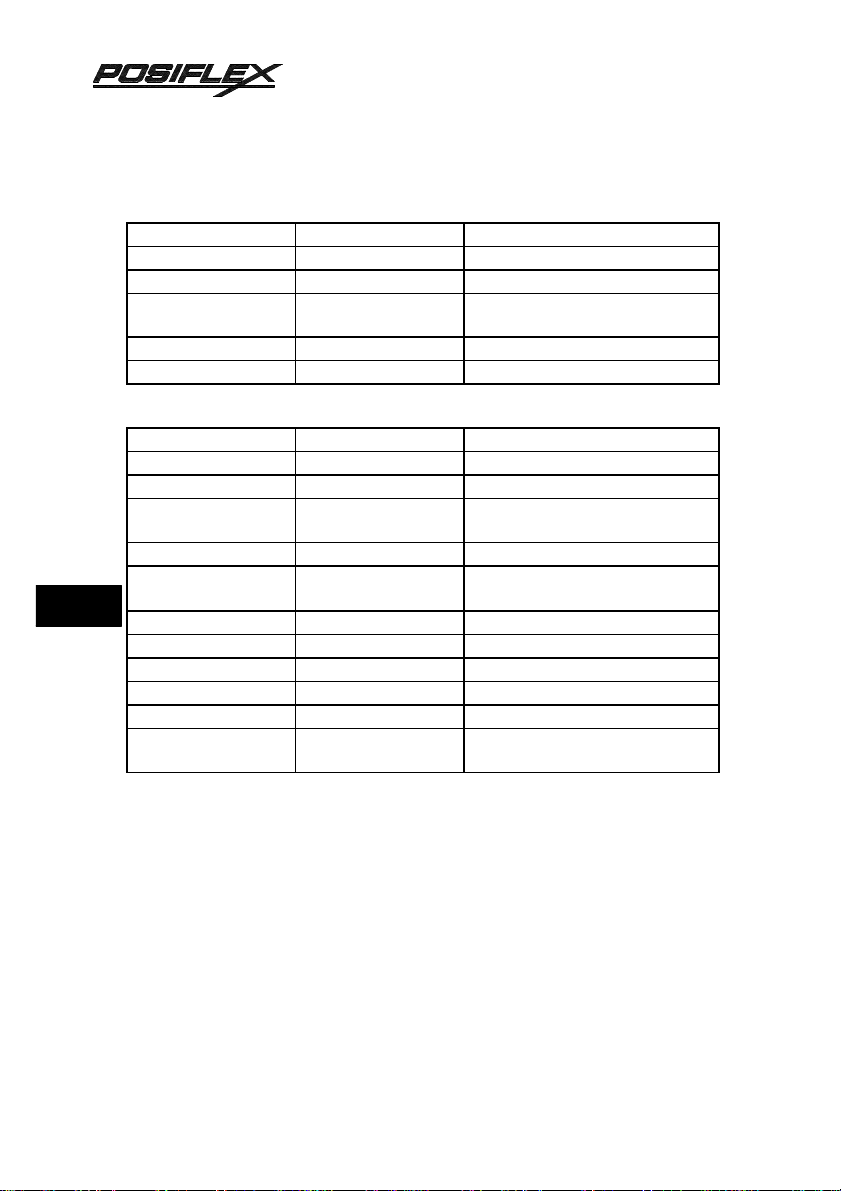

Serial Interface Switch

DIP - SW1

Switch Function ON OFF

1-1 Data transmission

1-2 Rate (baud rate ) See next table

1-3

1-4 Not used

1-5 Hand shake DTR mode X-ON/X-OFF mode

1-6 Data bit 8-bit data 7-bit data

1-7 Parity check No parity check Parity check

1-8 Parity selection Odd parity Even parity

4 - 4

Page 33

Data transmission rate ( baud rate )

bps 1-1 1-2 1-3

150

300

600

1200

2400

4800

9600

OFF OFF OFF

OFF OFF

OFF ON OFF

OFF ON ON

ON OFF OFF

ON OFF ON

ON ON ON/ OFF

DIP-SW 2

Switch Function ON OFF

2-1

2-2 International character set See table below

2-3

2-4

2-5 Paper width for friction

3.0 inch or 3.25 inch 2.25 inch

type

2-6 Not used

2-7 Character code table See table below

2-8

TM

CHAP. 4

TECHN…

International character set

Switch USA France Germany England Denmark Sweden Italy Spain

2-1

2-2

2-3

2-4

ON ON ON ON OFF OFF OFF OFF

ON ON OFF OFF ON ON OFF OFF

ON OFF ON OFF ON OFF ON OFF

ON ON ON ON ON ON ON ON

Switch Japan Norway DenmarkII Croatian N.A. N.A. N.A. N.A.

2-1

2-2

2-3

2-4

ON ON ON ON OFF OFF OFF OFF

ON ON OFF OFF ON ON OFF OFF

ON OFF ON OFF ON OFF ON OFF

OFF OFF OFF OFF OFF OFF OFF OFF

4 - 5

Page 34

CHAP. 4

TECHN…

TM

Character code table

Switch U.S.A. & Europe IBM #1 IBM #2 Japan

2-7

2-8

ON ON OFF OFF

ON OFF ON OFF

DIP-SW3

Switch Function ON OFF

3-1

3-2 Not used

3-3 Control code CR Invalid Valid

3-4 When turning DC1,DC3 Select Deselect

the power on. mode

Addressable Deselect Select

mode

3-5 Setting the paper feed length 1/6 - inch 1/8 - inch

3-6 Setting the buffer size 4 K-bytes 256 bytes

3-7 Not used

3-8 Paper out detection function Valid Invalid

DIP-SW 4

MODE

DIP SW

4 - 1

4 - 2

4 - 3

4 - 4

DC1, DC3

invalid

Addressable mode

ON Refer to OFF

ON next table for OFF

ON switch setting and OFF

ON address selection OFF

DC1, DC3

valid

Address selection for addressable mode:

SW #1 #2 #3 #4 #5 #6 #7 #8 #9 #10 #11 #12 #13 #14

4 - 1

OFF ON OFF ON OFF ON OFF ON OFF ON OFF ON OFF ON

4 - 2

ON OFF OFF ON ON OFF OFF ON ON OFF OFF ON ON OFF

4 - 3

ON ON ON OFF OFF OFF OFF ON ON ON ON OFF OFF OFF

4 - 4

ON ON ON ON ON ON ON OFF OFF OFF OFF OFF OFF OFF

Note: The addressable mode is valid only when an optional RS-422A serial

interface is mounted.

4 - 6

Page 35

a) When DIP SW4-1 through 4-4 are all ON (DC1/DC3 invalid mode)

DC1 and DC3 codes are invalid.

b) When DIP SW4-1 through 4-4 are OFF (DC1/DC3 valid mode)

DC1: Select

DC3: Deselect

When the printer receives the DC3 code, it throws away data until it

receives the DC1 code. (all the data between the DC3 and DC1 code)

DTR is always ready.

c) Other settings (addressable mode)

DC1 n: selects n (address)

DC3: Deselect

When the printer receives the DC3 code, it throws away data until it

receives the DC1 n code (with the n matching the printer’s own address).

DTR is always ready.

Note : DIP sw1-4 select the select/deselect state for the printer when the power

is first switched on.

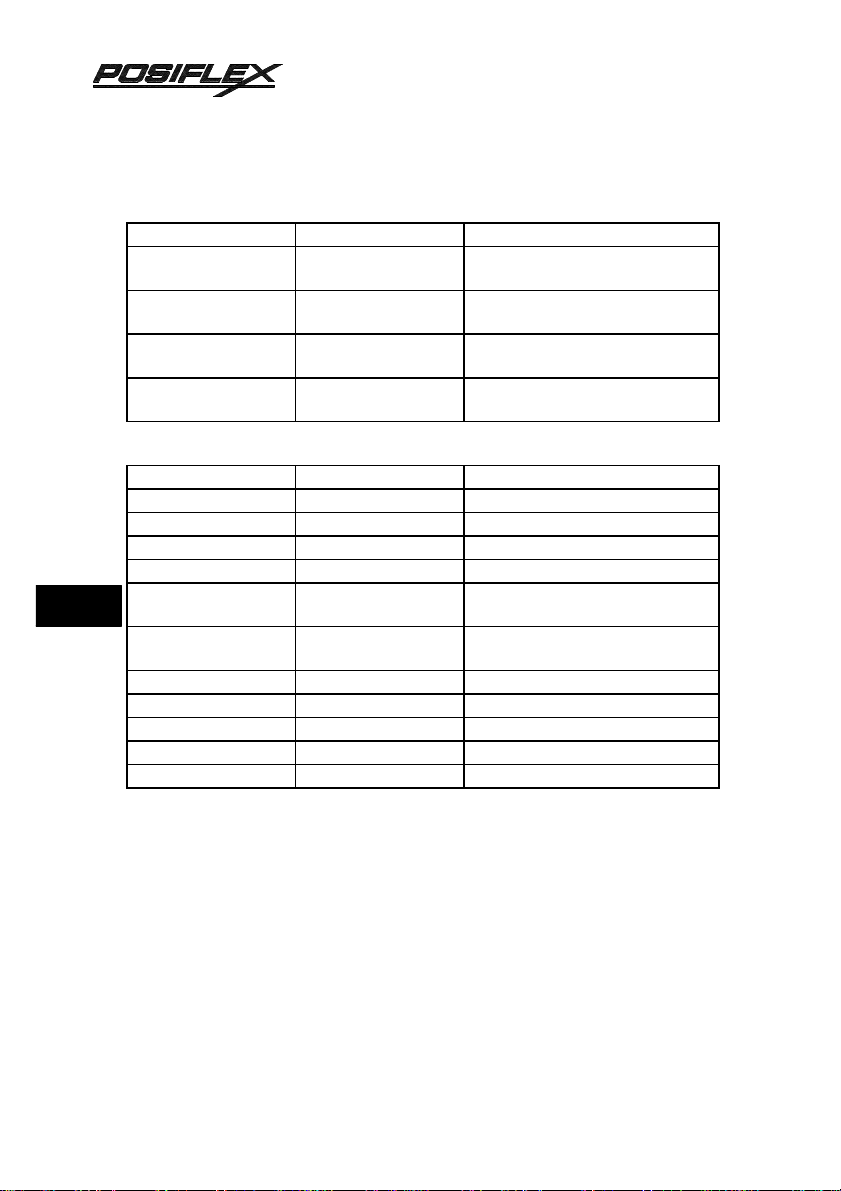

Parallel Interface Switch

DIP-SW1

Switch Function ON OFF

1-1

1-2 Not used

1-3 Control code CR Invalid Valid

1-4 Not used

1-5 Setting the paper feed length 1/6 - inch 1/8 - inch

1-6 Setting the buffer size 4 K-bytes 256 bytes

1-7 Not used

1-8 Paper out detection function Valid Invalid

TM

CHAP. 4

TECHN…

4 - 7

Page 36

CHAP. 4

TECHN…

TM

DIP-SW 2

Switch Function ON OFF

2-1

2-2 International character set See table below

2-3

2-4

2-5 Not used

2-6

2-7 Character code table See table below

2-8

International character set

Switch USA France Germany England Denmark Sweden Italy Spain

2-1

ON ON ON ON OFF OFF OFF OFF

2-2

ON ON OFF OFF ON ON OFF OFF

2-3

ON OFF ON OFF ON OFF ON OFF

2-4

ON ON ON ON ON ON ON ON

Switch Japan Norway DenmarkII Croatian N.A. N.A. N.A. N.A.

2-1

ON ON ON ON OFF OFF OFF OFF

2-2

ON ON OFF OFF ON ON OFF OFF

2-3

ON OFF ON OFF ON OFF ON OFF

2-4

OFF OFF OFF OFF OFF OFF OFF OFF

Character code table

Switch U.S.A. & Europe IBM #1 IBM #2 Japan

2-7

2-8

ON ON OFF OFF

ON OFF ON OFF

4 - 8

Page 37

DATA STRUCTURE IN SERIAL INTERFACE

DTR Mode

This mode is accessed when the DIP switch 1-5 is ON. Signals are

controlled using the DTR line as BUSY flag. If a printer errors do not occur after

the power is turned on, the DTR signal line changes to “SPACE”. When the host

computer confirms that the DTR signal line is set to “SPACE”, the host

computer sends the data text via the RXD signal line to the printer. Also, the

printer will set the DTR signal line to “MARK” when the empty space in the

data buffer is below 256 bytes. After the host computer detects that the DTR

signal line is at “MARK”, transmission of the data text is stopped. In this

instance, data can still be received up until the data buffer becomes completely

full. When the empty space in the data buffer is increased following printing

(when the data in the data buffer is reduced to 256 bytes or less), the printer sets

the DTR signal line to “SPACE”.

Status

Bit position Definition Level

b0 Vertical parity error 1:error

b1 Framing error 1:error

b2 Mechanical error 1:error

b3 Paper empty 1:empty

b4 Constantly set at “0” 0

b5 Buffer empty 1:empty

b6 Buffer overflow 1:overflow

b7

Cash drawer open detection

switch high level

switch is set to ON

TM

CHAP. 4

TECHN…

Paper out

When the “paper out” detector senses the end of the paper, the printer

stops printing after printing a maximum of two lines or on feeding the paper.

Immediately after a “paper out” condition is detected, the printer sets to “OFF

LINE” and the DTR changes to “MARK”. To reset the printer after a “paper

4 - 9

Page 38

CHAP. 4

TECHN…

TM

out”, load paper into the printer and press the “ON LINE” switch to set the

printer to “ON LINE”.

Mechanical error

Mechanical errors are detected when the motor locks or else and the unit

will not print. Immediately after a mechanical error occurs, the printer sets the

DTR to “MARK” and then sets the printer to “OFF LINE”. To cancel a

mechanical error, close the front cover properly and press the “ON LINE”

switch. If the buzzer sounds and the “ALARM” LED flashes at this time, then

locate the cause of the error and turn the power for the printer off and back on

again to reset the printer.

Framing error

A framing error occurs when “SPACE” is detected at the stop bit. When a

framing error or a vertical parity error occurs for the data which is received, the

printer prints out a “?” mark to indicate that the error occurred.

Cash drawer open detection switch

When pin 6 of the peripheral unit drive circuit connector is set “HIGH”,

status bit 7 becomes “1”.

X-ON/X-OFF Mode

This mode is accessed when the DIP switch 1-5 is OFF. If printer errors

do not occur after the power is turned on, the printer outputs an X-ON (DC1 by

control code; 11H by hexadecimal data) signal on the TXD signal line of the

printer which sends it to the host computer. When the host computer receives the

X-ON signal, the host computer transmits the data to the RXD signal line of the

printer. If data text is not sent from the host computer (even after transmitting

the X-ON signal to the host computer), the printer outputs an X-ON signal at 3

second intervals until the printer receives data. The printer starts outputting an

X-OFF (DC3, 13H) signal when the empty space in the buffer reduces below

256 bytes. When the host computer receives the X-OFF signal, it halts output of

data (however, the printer can continue receiving data until the buffer becomes

4 - 10

Page 39

completely full). Output of the X-ON signal is resumed when the data in the

buffer is printed out and drops to below 256 bytes.

Status

Bit position Definition Level

b0 Vertical parity error 1:error

b1 Framing error 1:error

b2 Mechanical error 1:error

b3 Paper empty 1:empty

b4 Constantly set at “0” 0

b5 Buffer empty 1:empty

b6 Buffer overflow 1:overflow

b7

Cash drawer open detection

switch high level

switch is set to ON

Paper out

When the “paper out” detector senses the end of the paper, the printer

stops printing after printing a maximum of two more lines or on feeding the

paper. The printer will set the DTR to “MARK” and set the printer to OFF LINE

five seconds after a “paper out” condition is detected. To reset the printer after a

“paper out”, load a new roll of paper into the printer and press the ON LINE

switch to set the printer ON LINE.

TM

CHAP. 4

TECHN…

Mechanical error

Mechanical error occurs when the motor locks or else and printing stops.

After the error occurs, the printer outputs an X-OFF signal and stops printing.

The printer sets the DTR signal to “MARK” and sets to “OFF LINE” five

seconds after a mechanical error occurs. To reset the printer after a mechanical

error occurs, close the top cover properly and press the “ON LINE” switch. If a

buzzer sounds and the “ALARM” LED flashes at this point, locate the cause of

the error and turn the power off and then back on to reset the printer.

4 - 11

Page 40

CHAP. 4

TECHN…

TM

Framing error

A framing error occurs when “SPACE” is detected at the stop bit. When a

framing error or a vertical parity error occurs for the data which is received, the

printer prints out a “?” mark to indicate that the error occurred.

Cash drawer open detection switch

When pin 6 of the peripheral unit drive circuit connector is set at

“HIGH”, status bit 7 becomes “1”.

STX-ETX Mode

This mode is accessed from whichever DTR mode or X-ON/X-OFF

mode. To set this mode, the data buffer must be empty. The host computer sends

an “ENQ” code to the printer and acknowledges the printer status. Then, the host

computer checks if the printer buffer is empty. After the host computer detects

that the buffer is empty, a STX code and data are transmitted. After 1 block of

data is transmitted, the host computer sends an ENQ code to the printer and then

receives the printer status and check byte (horizontal parity for the printer). At

this point, the host computer performs a status and horizontal parity check.

When the host computer determines that there was no error, it transmits an ETX

code which serves as end text code. After the printer receives the ETX code, data

in the data buffer is printed out. If an error occurs, a CAN code is transmitted by

the host computer (In this instance, the data which was previously sent to the

buffer is cleared, thus, the host computer must retransmit the same data to the

printer). A flowchart of this operation is illustrated as the following on next

page.

4 - 12

Page 41

Sends ENQ

byte

YES

NO

YES

YES

YES

YESNONONONO

signal

byte

signal

NO

YES

Starts the STX-

ETX mode

ETX mode

Receives status

Is the

data buffer

empty ?

Sends STX signal

Sends an ENQ

Receives status

Receives a check

Is the

status an

error?

Horizontal

parity check

TM

CHAP. 4

TECHN…

Is it

odd parity

check?

Set test byte FFH

Set test byte 00H

Acquires the exclusive OR of the

content of the test byte and the

data to send, then it is used as the

content of the test byte

Transmits the data to

the printer

Is this

the last data in

a block ?

Check byte

= test byte?

Sends CAN

Sends ETX

Ends the STX -

Is there a

data block in the STX-

ETX mode?

RET

4 - 13

Page 42

CHAP. 4

TECHN…

TM

4 - 14

Page 43

MAIN SPECIFICATION

INTERFACE

Parallel Interface

25 pin Female D-sub connector

Pin

Signal Name I/O Function

#

Signals when data is ready to be read. Signal goes

1 STROBE I

DATA 0

2

3 DATA 1 I

DATA 2

4

DATA 3

5

DATA 4

6

DATA 5

7

8 DATA 6 I

from HIGH to LOW (for at least 0.5 microsec.) when

data is available.

This signal provides the information of the first bit

(LSB) of parallel data. The signal is at HIGH level

I

for a logical 1 and at a LOW level for a logical 0.

This signal provides the information of d1 the

second bit of parallel data. The signal is at HIGH

level for a logical 1 and at a LOW level for a logical

0.

This signal provides the information of d2 the third

bit of parallel data. The signal is at HIGH level for a

I

logical 1 and at a LOW level for a logical 0.

This signal provides the information of d3 the fourth

bit of parallel data. The signal is at HIGH level for a

I

logical 1 and at a LOW level for a logical 0.

This signal provides the information of d4 the fifth

bit of parallel data. The signal is at HIGH level for a

I

logical 1 and at a LOW level for a logical 0.

This signal provides the information of d5 the sixth

bit of parallel data. The signal is at HIGH level for a

I

logical 1 and at a LOW level for a logical 0.

This signal provides the information of d6 the

seventh bits of parallel data. The signal is at HIGH

level for a logical 1 and at a LOW level for a logical

0.

TM

CHAP. 5

MAIN …

5 - 1

Page 44

CHAP. 5

MAIN …

TM

This signal provides the information of d7 the eighth

9 DATA 7 I

bit (MSB) of parallel data. The signal is at HIGH

level for a logical 1 and at a LOW level for a logical

0.

10 ACK

A 9 microsecond LOW pulse to acknowledge receipt

O

of data.

When this signal goes LOW, the printer is ready to

accept data. When the printer is in one of the

11 BUSY O

conditions below, HIGH is set:

1. Data being entered

2. Off line

3. Error condition

12 PAPER END O

This signal is normally LOW. It will go HIGH if the

printer runs out of paper.

13 SELECTED O This signal is HIGH when the printer is on-line.

14 N/C

This signal is normally HIGH. This signal goes LOW

15 ERROR O

to signal that the printer cannot print due to an error

condition

16 N/C

17 SLCTIN I

When this signal goes LOW, the printer is selected to

work.

18 GND Ground

19 GND Ground

20 GND Ground

21 GND Ground

22 GND Ground

23 GND Ground

24 GND Ground

25 GND Ground

5 - 2

Page 45

Serial Interface

9 pin Female D-sub connector

Pin

Signal Name I/O Function

#

1 DCD O Data carrier detect

2 TXD O Transmit data

3 RXD I Receive data

4 N.C.

5 GND Ground

6 RTS O

Request to send. This is always “SPACE” when the

printer is turned on.

7 N.C.

8 DTR O

Data terminal ready. This signal changes to

PACE” when the printer is ready to receive data.

9 N.C.

Peripheral Unit Drive

6 pin telephone jack

Pin

Signal Name I/O Function

#

1 Chassis GND

2 L1 Drive O

3 SW Sense I

4 +24 V DC O Connected to +24VDC supplied by the printer.

5 L2 Drive O

6 GND O

To connect the shield of cable between printer and

the peripheral device

Supplies a low trigger pulse to drive the circuitry L1

with a diode protection. This shall not be driven

together with L2 at the time.

To connect through diode and resistor to +24VDC

to detect the status of cash drawer open detection

switch.

Supplies a low trigger pulse to drive the circuitry L1

with a diode protection. This shall not be driven

together with L2 at the time.

TM

CHAP. 5

MAIN …

5 - 3

Page 46

TM

POWER SUPPLY

PIN ASSIGNMENT OF 3 PIN JACK:

CHAP. 5

MAIN …

PIN DEFINITION

1 +24 V

2

CASE

2 GND

3 N.C.

CASE CHASSIS GND

1

3

Fig. 18 Pin layout of power plug

HIMPORTANT: To unplug this connector, one should pull the outer sleeve of

the power plug instead of pulling the power cable itself. This connector is

equipped with a lock mechanism, pulling the cable itself without unlocking by

pulling the sleeve will cause certain damage to the connector.

OPTION LIST

•

Inked ribbon cartridge

• Paper roll

FONT MATRICES

The printed format of the fonts used is determined by the character size

which is defaulted as 15 CPI yet can be changed to 12 CPI or 8 CPI through

command received by the printer. The font format and dimension definition of

each character size is given in Fig.19 and Fig. 20.

E

D

F

A

E

C

B

D

F

A

C

B

Fig. 19 Font format for 15 CPI Fig. 20 Font format for 12 CPI and 8 CPI

5 - 4

Page 47

The specifications for each character size are listed in the following table:

Character size 15 CPI 12 CPI 8 CPI

Font type 7 x 9 half dot 5 x 9 full dot 5 x 9 pulse 3 full dot

For 3.25” and 3.0” paper:

Max # of columns 40 33 22

Total # of dots / row 200 198 132

Print area (horizontally) 65.7 mm 65.0 mm 64.8 mm

For 2.25” paper:

Max # of columns 28 23 15

Total # of dots / row 140 138 90

Print area (horizontally) 45.9 mm 45.2 mm 44.1 mm

A – dot diameter 0.30 mm 0.30 mm 0.30 mm

B – dot spacing (H) 0.330 mm 0.330 mm 0.495 mm

TM

CHAP. 5

MAIN …

C – dot spacing (V) 0.353 mm 0.353 mm 0.353 mm

D – character size (H) 1.29 mm 1.62 mm 2.28 mm

E – character size (V) 2.42 mm 2.42 mm 2.42 mm

F – column spacing 1.65 mm 1.98 mm 2.97 mm

5 - 5

Page 48

TM

COMMANDS

Friction type: 100% compatible to STAR SP312FV

EPSON compatible model is option.

Sprocket type: 100% compatible to STAR SP322S

EXTERNAL DIMENSIONS

CHAP. 5

MAIN …

Friction type: 125 mm (H) x 273 mm (D) x 174 mm (W)

(4.9” x 10.7” x 6.9”)

Sprocket type: 155 mm (H) x 400 mm (L) x 180 mm (W)

(6.1” x 15.7” x 7.1”)

WEIGHT

Friction type: 2.4 kg (net weight of printer alone).

OPERATING ENVIRONMENT

Temperature: 0° C to +50° C

Humidity : 10% to 90% RH (without condensation)

STORAGE ENVIRONMENT

Temperature: -20° C to +70° C

Humidity : 5% to 90% RH (without condensation)

5 - 6

Page 49

MAINTENANCE

CAUTION:

Do not open the top cover and touch the print head immediately after

printing, because the print head may be very hot.

CLEANING

• To clean the dust, paper particles, or dirt on and in the printer:

Use a vacuum cleaner to clean thoroughly.

Remove any pieces of paper from the paper path.

• To wipe off stains:

Use a clean soft dry cloth to wipe off stains.

If the stains can not be wiped off using the dry cloth, use a neutral

detergent.

CAUTION:

To avoid damaging the printer, do not use benzene, benzine, alcohol, thinner,

trichloroethylene, or ketone-based solvents on the printer’s plastic and

rubber components.

TM

CHAP. 6

MAINT…

PAPER JAM

• Turn off the printer.

• Open the top cover after the print head cools down.

• Cut the paper roll from the paper guide with a pair of scissors.

• Turn the printer power back to on.

• Press the FEED switch to forward the paper out of the paper guide. Engage

mechanical help like tweezers or manual pull if necessary.

6 - 1

Page 50

TM

CAUTION:

Remove the remaining paper in a forward direction. Do not pull it

backwards.

• Clean the paper path when necessary.

• Reload the paper as instructed in “INSTALLATION”.

• Press the on-line switch to get the printer ready.

TROUBLE SHOOTING

If any of the following errors is detected while the printer is operating, the

printer halts and ERROR signal turns to “LOW” level.

CHAP. 6

MAINT…

1. Mechanical errors

• Motor lock

• Defective of timing detector (signal not issued)

• Abnormal home position check

To reset the emergency suspension, rectify the cause of trouble & adopt

one of the following 2 methods.

• Turn the printer power off and on again.

• Push “ON LINE” switch.

The RAM is not cleared immediately when power is turned OFF. Printing

resumes from the line being printed when the mechanism stopped if the

error is corrected immediately.

2. CPU error

If CPU goes erratic due to external noise, the printer halts, treating it as

CPU error. Normal operation can be resumed by turning ON the power supply

again, but the data contained in RAM gets cleared.

3. RAM Check Function

Before self printing and when clearing the buffer, a RAM check is

performed.

6 - 2

Page 51

CONTROL CODES

STAR COMPATIBLE MODE

Control Codes for Character Setting

Control Codes Hex Codes Function

ESC R “n” <1B> <52> “n”

ESC 6 <1B> <36> Select IBM character set #2

ESC 7 <1B> <37> Select IBM character set #1

ESC M <1B> <4D> Select 15 CPI character size

ESC P <1B> <50> Select 12 CPI character size

ESC : <1B> <3A> Select 8 CPI character size

SO

ESC W 1

ESC W <1>

DC4

ESC W 0

ESC W <0>

ESC E <1B> <45> Select emphasized print mode

ESC F <1B> <46> Cancel emphasized print mode

ESC - 1

ESC - <1>

ESC - 0

ESC - <0>

ESC _ 1

ESC _ <1>

ESC _ 0

ESC _ <0>

ESC 4 <1B> <34> Select highlighted print mode

ESC 5 <1B> <35> Cancel highlighted print mode

SI <0F> Select inverted print mode

DC2 <12> Cancel inverted print mode

<0E>

<1B> <57> <31>

<1B> <57> <01>

<14>

<1B> <57> <30>

<1B> <57> <00>

<1B> <2D> <31>

<1B> <2D> <01>

<1B> <2D> <30>

<1B> <2D> <00>

<1B> <5F> <31>

<1B> <5F> <01>

<1B> <5F> <30>

<1B> <5F> <00>

Select international character set

Select expanded character mode

Cancel expanded character mode

Select underline mode

Cancel underline mode

Select overline mode

Cancel overline mode

TM

CHAP. 7

CONTR…

7 - 1

Page 52

CHAP. 7

CONTR…

TM

Control Codes for Line Spacing

Control Codes Hex Codes Function

LF <0A> Line feed

CR <0D> Line feed (same as LF)

ESC z 1

ESC z <1>

<1B> <7A> <31>

<1B> <7A> <01>

Set 1/6 inch line feed

ESC 0 <1B> <30> Set 1/8 inch line feed

ESC a “n” <1B> <61> “n”

Feed paper n lines

Control Codes for Page Layout

Control Codes Hex Codes Function

FF <0C> Page feed (form feed)

ESC C “n” <1B> <43> “n”

ESC C <0> “n”

<1B> <43> <00>

“n”

VT <0B> Execute vertical tab

ESC B “n1…nk”

<0>

<1B> <42>

“n1…nk” <00>

ESC N “n” <1B> <4E> “n”

ESC O <1B> <4F> Cancel bottom margin

ESC I “n” <1B> <6C> “n”

ESC Q “n” <1B> <51> “n”

HT <09> Execute horizontal tab

ESC D “n1” “n2”

<1B> <44> “n1”

“n2”

Set page length at n lines

Set page length at n inches

Set vertical tab positions

Set bottom margin

Set left margin

Set right margin

Set horizontal tab positions

7 - 2

Page 53

Control Codes for Graphics Printing

Control Codes Hex Codes Function

ESC 1 <1B> <31> Set 7/72 inch line feed

ESC A “n” <1B> <41> “n”

ESC 2 <1B> <32> Set n/72 inch line feed

ESC J “n” <1B> <4A> “n”

ESC z 0

ESC z <0>

<1B> <7A> <30>

<1B> <7A> <00>

ESC y “n” <1B> <79> “n”

ESC 3 “n” <1B> <33> “n”

ESC K “n1” <0>

ESC L “n1” “n2”

ESC h 1

ESC h <1>

ESC h 0

ESC h <0>

<1B> <4B> “n1”

<00>

<1B> <4C> “n1”

“n2”

<1B> <68> <31>

<1B> <68> <01>

<1B> <68> <30>

<1B> <68> <00>

Define n/72 inch line feed

One time line feed of n/72 inch

Set 1/12 inch line feed

Set n/144 inch line feed

Set n/216 inch line feed

simulation

8 dot single density bit image

8 dot double density bit image

Select vertical expanded

character mode

Cancel vertical expanded

character mode

TM

CHAP. 7

CONTR…

Control Codes for Download Characters

Control Codes Hex Codes Function

ESC & <0> “n1”

“n2”

ESC % 1

ESC % <1>

ESC % 0

ESC % <0>

<1B> <26> <00>

“n1” “n2”

<1B> <25> <31>

<1B> <25> <01>

<1B> <25> <30>

<1B> <25> <00>

Definition of down load

characters

Enable download character set

Disable download character set

7 - 3

Page 54

CHAP. 7

CONTR…

TM

Control Codes for Peripheral Units

Control Codes Hex Codes Function

ESC BEL “n1” “n2” <1B> <07> “n1”

“n2”

BEL <07>

FS <1C>

EM

SUB

<19>

<1A>

Adjust drive pulse width for

peripheral unit 1

Deferred drive command for

peripheral unit 1

Immediate drive command for

peripheral unit 1

Immediate drive command for

peripheral unit 2

Other Control Codes

Control Codes Hex Codes Function

RS <1E> Sound buzzer

CAN <18> Cancel print data in buffer

DC3 <13> Select deselect mode

DC1 <11> Set select mode

ESC U 1

ESC U <1>

ESC U 0

ESC U <0>

ESC @ <1B> <40> Initialize printer

GS “data” LF <1D> “data” <0A>

ENQ <05> Enquiry

STX <02> Enter STX-ETX mode

ETX <03> Terminate STX-ETX mode

<1B> <55> <31>

<1B> <55> <01>

<1B> <55> <30>

<1B> <55> <00>

Select uni-directional print mode

Select bi-directional print mode

Select validation printing of data

EPSON Emulation Mode

Basic Reference

PP-3000 Series Mini Printer User’s Guide.

Hardware Modification Required

Refer to page 4 - 2 Fig. 17, the BIOS at U8 should be changed.

7 - 4

Page 55

Reference Epson Models Emulated

EPSON TM-300 series.

Character Size/Font Matrices

Refer to page 5 - 4, the 8 CPI character size (5 x 9 pulse 3 full dot mode)

is not applicable for EPSON emulation.

Unsupported Control Codes:

Following EPSON control codes are not supported in PP-300E series due

to hardware difference:

Control Codes Function

ESC < Return home

ESC c 3 Select paper sensor(s) for “paper-out” output signal

ESC c 4 Select paper sensor(s) to stop printing

ESC i Partial cut (leave 1 point)

ESC m Partial cut (leave 3 points)

ESC r Select print color

Supported Control Codes:

NOTES:

• Default character spacing for 7 x 9 font is 3 dots, for 5 x 9 is 2 dots. These

values are the minimum settings. In 5 x 9 font, no odd number spacing is

allowed, or it will be automatically decreased.

‚ Font select: 1⇒ 7 x 9; 0⇒ 5 x 9.

ƒ 7 x 9 font is recommended in defining user-define characters. When original 9

x 9 characters are downloaded under 5 x 9 font printing mode, the characters

will be automatically transferred to 5 x 9 by removing the half-dot bits.

„ Internatioal character n in hex code:

<00>⇒USA, <01>⇒France, <02>⇒Germany,

<03>⇒England, <04>⇒Denmark, <05>⇒Sweden,

<06>⇒Italy, <07>⇒Spain, <08>⇒Japan,

<09>⇒Norway, <0A>⇒Denmark II, <0B>⇒Croatia.

… Character table n in hex code:

<00>⇒USA&Europe, <01>⇒IBM 1, <02>⇒IBM 2,

<03>⇒JAPAN.

TM

CHAP. 7

CONTR…

7 - 5

Page 56

CHAP. 7

CONTR…

TM

†These control codes are applicable in serial interface only.

Control Codes Hex Codes Function

HT <09> Horizontal tab

LF <0A> Print and line feed

CR <0D> Print and carriage return

ESC SP •

ESC ! ‚

ESC %

ESC & ƒ

ESC *

<1B> <20> “n”

<1B> <21> “n”

<1B> <25> “n”

<1B> <26> “y” “c1”

“c2” [<x> <d1> …

<d(yxx)>]c2-c1+1

<1B> <2A> “m” “nL”

“nH” [<d>]k

Set right side character spacing

Set printer mode (Font select)

Set/cancel the user-defined

character set

Define user-defined character set

(max. 10 characters)

Select bit image mode

ESC 2 <1B> <32> Set 1/6 inch line space

ESC 3

<1B> <33> “n”

Set line spacing

ESC @ <1B> <40> Initialize printer

ESC D

ESC J

ESC R „ <1B> <52>

ESC U

ESC c 5

ESC d

ESC p

<1B> <44> [<n>]k

<00>

<1B> <4A> “n”

Set horizontal tab positions

Print and feed paper

Select an international character

set

<1B> <55> “n”

<1B> <63> <35> “n”

Turn uni-directional printing

mode on/off

Enable/disable panel button

<1B> <64> “n” Print and feed n lines

<1B> <70> “m” “t1”

“t2”

Generate pulse (peripheral

device)

ESC t … <1B> <74> Select character code table

ESC { <1B> <7B>

Turn upside-down printing mode

on/off

ESC u † <1B> <73> Transmit peripheral device status

ESC v † <1B> <76> Transmit paper sensor status

ESC = †

<1B> <3D> “n”

Select peripheral device

7 - 6

Page 57

APPENDIX A

STAR COMPATIBLE MODE COMMAND DETAIL

(All commands are listed in hexadecimal code sequence)

CODES (HEX/CONTROL) : 02 / <STX>

FUNCTION : Enter STX-ETX mode

APPLICATION LIMIT : This code is valid when using serial interface

printer. When IBM character set #2 is selected by character code, the code

<ETX> does not exist (In this instance, select another code).

DETAIL DESCRIPTION : STX-ETX mode is set.

CODES (HEX/CONTROL) : 03 / <ETX>

FUNCTION : Terminate STX-ETX mode

APPLICATION LIMIT : This code is valid when using serial interface

printer. When IBM character set #2 is selected by character code, the code

<ETX> does not exist (In this instance, select another code).

DETAIL DESCRIPTION : Terminates the STX-ETX mode and prints

out the text data.

TM

APP. A

STAR …

CODES (HEX/CONTROL) : 05 / <ENQ>

FUNCTION : Enquiry

APPLICATION LIMIT : This code is valid when using serial interface

printer. When IBM character set #2 is selected by character code, the code

<ENQ> does not exist (In this instance, select another code).

DETAIL DESCRIPTION : Causes printer to transmit status byte (not in

STX-ETX mode). When this code is received after receiving text data in the

STX-ETX mode, the printer transmits the status and check byte.

A - 1

Page 58

TM

CODES (HEX/CONTROL) : 07 / <BEL>

FUNCTION : Deferred drive command for peripheral unit 1

DETAIL DESCRIPTION : Execute drive pulse for peripheral unit 1

when this code is processed (deferred).

CODES (HEX/CONTROL) : 09 / <HT>

FUNCTION : Execute horizontal tab.

APPLICATION LIMIT : When no horizontal tab position is set, this

code is ignored.

DETAIL DESCRIPTION : The print position skips to the next

horizontal tab position in same line. However, underline and overline do not

take place in the spaces between characters set with the horizontal tab function.

CODES (HEX/CONTROL) : 0A / <LF>

FUNCTION : Line feed

DETAIL DESCRIPTION : Data in the line buffer is printed out and one

line is fed. If data does not exist before this code is received, the printer only

feeds one line.

APP. A

STAR …

CODES (HEX/CONTROL) : 0B / <VT>

FUNCTION : Execute vertical tab.

APPLICATION LIMIT : When no vertical tab is set, line feed is not

performed.

DETAIL DESCRIPTION : Prints data before this command as <LF>

does and feeds the paper to the next vertical tab set position. If the current line is

at or below the last vertical tab set position, the paper feeds to the top of the next

page.

A - 2

Page 59

CODES (HEX/CONTROL) : 0C / <FF>

FUNCTION : Page feed (form feed)

DETAIL DESCRIPTION : After data in the line buffer is printed out,

feeds the paper to the top of the next page.

CODES (HEX/CONTROL) : 0D / <CR>

FUNCTION : Line feed (Same as LF)

APPLICATION LIMIT : When DIP SW 1-3 of parallel interfaced

printer or DIP SW 3 - 3 of serial interfaced printer is set to ON, this code

becomes invalid (which is the default).

DETAIL DESCRIPTION : Functions the same as an LF code.

CODES (HEX/CONTROL) : 0E / <SO>

FUNCTION : Select expanded character mode

DETAIL DESCRIPTION : Data following this code is printed in

double-width characters.

TM

CODES (HEX/CONTROL) : 0F / <SI>

FUNCTION : Select inverted print mode

APPLICATION LIMIT : This code is valid only when input at the

beginning of a line, thus, normal and inverted characters cannot be mixed in the

same line.

DETAIL DESCRIPTION : Data following this code is printed out in

inverted characters (up side down and right to left).

A - 3

APP. A

STAR …

Page 60

TM

CODES (HEX/CONTROL) : 11 / <DC1> or 11 n / <DC1> n

FUNCTION : Set select mode

DETAIL DESCRIPTION :

1. When using serial interface printer

This function differs depending on the setting of DIP switch 4.

a) When the DC1, DC3 invalid mode is set DIP switches 4-1 to 4-4 are all set

to ON), the printer ignores this code.

b) In the DC1, DC3 valid mode (with DIP switches 4-1 to 4-4 set to OFF),

when the printer receives a <DC1> code, the deselect mode is canceled and

data following this code is input to buffer.

c) If the printer receives a <DC1> n code (n is the DIP switch controlled

address) during the addressable mode (with DIP switches 4-1 to 4-4 set to

other settings than a) and b) above), the deselect mode is canceled and data

following this code is input to the buffer.

Note that addressable mode is valid only when optional RS-422A interface

is installed.

2. When using parallel interface printer

When the printer receives a <DC1> code, the deselect mode is canceled and

data following this code is input to the buffer.

APP. A

STAR …

CODES (HEX/CONTROL) : 12 / <DC2>

FUNCTION : Cancel inverted print mode

APPLICATION LIMIT : This code is valid only when input at the

beginning of a line.

DETAIL DESCRIPTION : Cancel the inverted character mode.

A - 4

Page 61

CODES (HEX/CONTROL) : 13 / <DC3>

FUNCTION : Set deselect mode

DETAIL DESCRIPTION :

1. When using serial interface printer

This function differs depending on the setting of DIP switch 4.

a) When the DC1, DC3 invalid mode is set (DIP switches 4-1 to 4-4 are all

set to ON), the printer ignores this code.

b) In the DC1, DC3 valid mode (with DIP switches 4-1 to 4-4 set to OFF),

data following this code is ignored when the printer receives a<DC3>

code.

The deselect mode is canceled by <DC1> code.

c) If the printer receives a <DC3> code during an addressable mode (with

DIP switches 4-1 to 4-4 set to settings other than a) and b) above), the data

following this code is ignored.

Deselect mode can be canceled by a <DC1> n code.

Note that addressable mode is valid only when the RS-422A interface

option is installed.

2. When using parallel interface printer

Data following this code is ignored when the printer receives a <DC3> code.

The deselect mode is canceled by <DC1> code.

TM

CODES (HEX/CONTROL) : 14 / <DC4>

FUNCTION : Cancel expanded character mode

DETAIL DESCRIPTION : Cancel expanded character mode set by

<SO> code (Data following this code is printed out in normal size characters).

CODES (HEX/CONTROL) : 18 / <CAN>

FUNCTION : Cancel print data in buffer

DETAIL DESCRIPTION :

1. When using serial interface printer

Clears the data buffer and the line buffer

Clears the data buffer in the STX-ETX mode, and terminates the STX-ETX

mode.

2. When using parallel interface printer

Clears the data buffer and the line buffer

A - 5

APP. A

STAR …

Page 62

APP. A

STAR …

TM

CODES (HEX/CONTROL) : 19 / <EM>

FUNCTION : Immediate drive command for peripheral unit 2

APPLICATION LIMIT : Peripheral units 1 and 2 cannot be driven

simultaneously.

DETAIL DESCRIPTION : Drives peripheral unit 2. Pulse width is fixed

at 200ms with a fixed delay time of 200ms. Same as <SUB>.

CODES (HEX/CONTROL) : 1A / <SUB>

FUNCTION : Immediate drive command for peripheral unit 2

APPLICATION LIMIT : Peripheral units 1 and 2 cannot be driven

simultaneously.

DETAIL DESCRIPTION : Drives peripheral unit 2. Pulse width is fixed

at 200ms with a fixed delay time of 200ms.

CODES (HEX/CONTROL) : 1B 07 n1 n2 / <ESC> <BEL> n1 n2

FUNCTION : Adjust drive pulse width for peripheral unit 1

DEFINITION RANGE : 1

≤

n1 ≤ 127, 1 ≤ n2 ≤ 127

APPLICATION LIMIT : Adjustment is not necessary for standard cash

drawers in the U.S.A. market.

DETAIL DESCRIPTION : Adjusts drive pulse width for peripheral

device #1 requiring other than standard 200 ms pulse time and recovery time.

Energizing time = 10 x n1 ms

Recovery time = 10 x n2 ms

Executed by <BEL> or <FS> code.

Printing and paper feed are prohibited throughout the energizing and recovery

time.

CODES (HEX/CONTROL) : 1B 25 00 / <ESC> “%” <0>

FUNCTION : Disable download character set

DETAIL DESCRIPTION : Disable the selected download character set

and selects the built-in character set. When the power for the printer is initially

turned on, the built-in character set is selected.

A - 6

Page 63

CODES (HEX/CONTROL) : 1B 25 01 / <ESC> “%” <1>

FUNCTION : Enable download character set

DETAIL DESCRIPTION : Enable the download character set.

Download characters defined by the <ESC> “&” <0> code cannot be printed

until enabled by this command.

CODES (HEX/CONTROL) : 1B 25 30 / <ESC> “%” “0”

FUNCTION : Disable download character set

DETAIL DESCRIPTION : Disable the selected download character set

and selects the built-in character set. When the power for the printer is initially

turned on, the built-in character set is selected.

CODES (HEX/CONTROL) : 1B 25 31 / <ESC> “%” “1”

FUNCTION : Enable download character set

DETAIL DESCRIPTION : Enable the download character set.

Download characters defined by the <ESC> “&” <0> code cannot be printed

until enabled by this command.

TM

A - 7

APP. A

STAR …

Page 64

APP. A

STAR …

TM

CODES (HEX/CONTROL) : 1B 26 00 n1 n2 / <ESC> “&” <0> n1 n2

When 15 CPI character size is set (default setting), the detail of the code is :

1B 26 00 n1 n2 [m0 m1 m2 m3 m4 m5 m6 m7]

[m0 m1 m2 m3 m4 m5 m6 m7]

(n2-n1+1)

/ <ESC> “&” <0> n1 n2

(n2-n1+1)

When 8 CPI or 12 CPI character size is set, the detail of the code is :

1B 26 00 n1 n2 [m0 m1 m2 m3 m4 m5]

m2 m3 m4 m5]

(n2-n1+1)

/ <ESC> “&” <0> n1 n2 [m0 m1

(n2-n1+1)

FUNCTION : Definition of download characters

DEFINITION RANGE : 21H

≤

n1 ≤ n2 ≤ 7FH, m0 = 00H or 80H

APPLICATION LIMIT : When the 15 CPI character size is set (the

default setting), printing of adjacent horizontal dots is not allowed.

DETAIL DESCRIPTION : Defines download characters from host

computer. Up to 10 download characters can be defined and the defined

character patterns can be stored in the printer’s memory. Definitions of the

variables in the command code are as follows:

n1 and n2 represent the starting address and the ending address of the range

of download characters respectively. When defining only one character, n1 =

n2.

Each set of m0 to m7 (for 7 x 9 fonts) or m0 to m5 (for 5 x 9 fonts) defines

one download character. However, only either top 8 or bottom 8 print pins

out of total 9 print pins of the print head can be used. m0 defines which set of

pins to be used.

m1 to m7 or m1 to m5 indicates each column of the download character

pattern consecutively. Each bit in m1 to m7 or m1 to m5 defines a dot within

that column to be printed (in vertical position). The relationship of each bit

with each print pin combined with m0 can be illustrated in the following

table, where the print pin # starts count at 1 from top of the print head:

bit # of m1 to m7 or m1 to m5 8 (MSB) 7 6 5 4 3 2 1 (LSB)

engage print pin # (when m0 = 00h) 2 3 4 5 6 7 8 9

engage print pin # (when m0 = 80h) 1 2 3 4 5 6 7 8

For example, the following hexadecimal codes received under 12 CPI will define

the characters at addresses A0h, A1h and A2h to be like the graphs below when

selected:

1B 26 00 A0 A2 80 F8 A8 FF A8 F8 80 46 49 51 61 43 00 31 06 F8 06 31

A0: A1: A2:

A - 8

Page 65

CODES (HEX/CONTROL) : 1B 2D 00 / <ESC> “-” <0>

FUNCTION : Cancel underline mode

DETAIL DESCRIPTION : The previously selected underline mode is

canceled for data following this code to print.

CODES (HEX/CONTROL) : 1B 2D 01 / <ESC> “-” <1>

FUNCTION : Select underline mode

DETAIL DESCRIPTION : Data following this code is printed out

underlined (However, the space generated by horizontal tab are not underlined).

CODES (HEX/CONTROL) : 1B 2D 30 / <ESC> “-” “0”

FUNCTION : Cancel underline mode

DETAIL DESCRIPTION : The previously selected underline mode is

canceled for data following this code to print.

CODES (HEX/CONTROL) : 1B 2D 31 / <ESC> “-” “1”

FUNCTION : Select underline mode

DETAIL DESCRIPTION : Data following this code is printed out

underlined (However, the space generated by horizontal tab are not underlined).

TM

APP. A

STAR …

CODES (HEX/CONTROL) : 1B 30 / <ESC> “0”

FUNCTION : Set 1/8 inch line feed

DETAIL DESCRIPTION : Line feed is set at 1/8 inch after this code is

received, and is effective since first <LF> received after this command.

CODES (HEX/CONTROL) : 1B 31 / <ESC> “1”

FUNCTION : Set 7/72 inch line feed

DETAIL DESCRIPTION : Line feed is set at 7/72 inch after this code is

received, and is effective since first <LF> received after this command.

A - 9

Page 66

APP. A

STAR …

TM

CODES (HEX/CONTROL) : 1B 32 / <ESC> “2”

FUNCTION : Set n/72 inch line feed

DETAIL DESCRIPTION : This code sets the line feed at a defined

value with the last <ESC> “A” previously described or the default value 12, and

is effective since first <LF> received after this command.

CODES (HEX/CONTROL) : 1B 33 n / <ESC> “3” n

FUNCTION : Set n/216 inch line feed simulation

DEFINITION RANGE : 1