Page 1

F-114 / F-114P

DIGITAL LASER MFP

SERVICE MANUAL

Contents

1. Precautions

2. Product Specifications & Features

3. Disassembly and Reassembly

4. Alignment & Troubleshooting

5. Exploded Views and Parts Lists

6. System Diagram

7. Reference Information

Page 2

Page 3

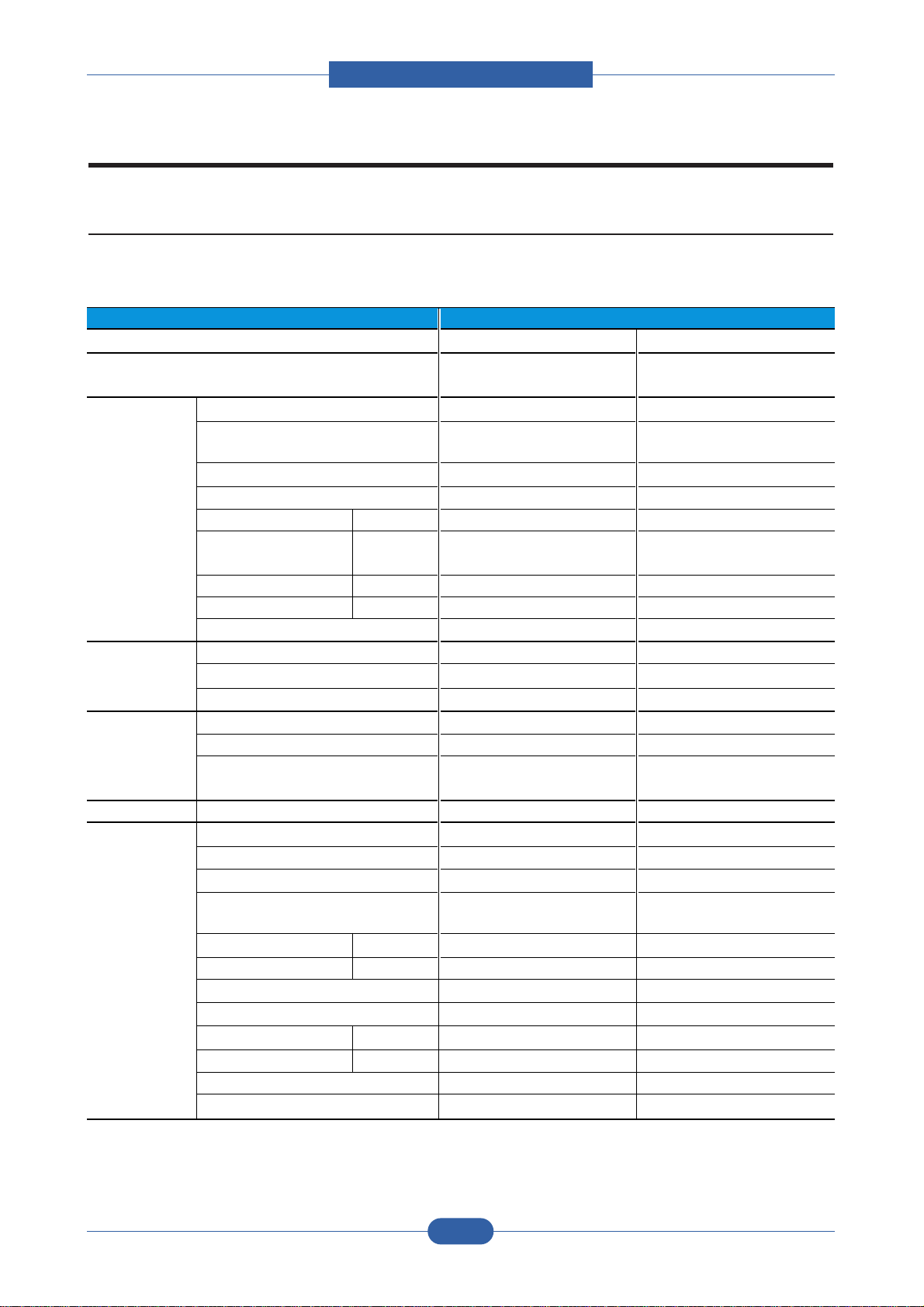

Contents

1. Precautions

1.1 Safety Warning 1-1

1.2 Caution for safety

1.3 ESD Precautions

2. Product Specifications and Features

2.1 Product Specifications 2-1

2.2 Summary of Product

2.2.1 Printer Components

2.2.2 Overview of System

2.2.3 System Layout

2.2.4 Main PBA(SPL Model)

2.2.5 SMPS & HVPS

2.2.6 Engine F/W

2.2.7 OPE PBA

1-2

1-5

2-5

2-5

2-9

2-11

2-15

2-18

2-22

2-23

3. Disassembly and Reassembly

3

.1 General Precautions on Disassembly 3-1

3.2 White Roller Ass,y

3.3 Rear Cover

3.4 Side Cover L

3.5 Side Cover R

3.6 OPE Unit

3.7 ADF Rubber Pad

3.8 CIS

3.9 Exit Roller

3.10 Front Cover Ass'y

3.11 Scan Ass'y

3-2

3-2

3-3

3-3

3-4

3-6

3-7

3-7

3-8

3-9

Page 4

Continued

3.12 Scan Motor Ass'y 3-10

3.13 ADF Roller

3.14 Sub Hook PBA

3.15 Drive Ass'y

3.16 DC-Fan

3.17 Exit Cover Ass'y

3.18 LSU-Unit

3.19 Engine Shield Ass'y

3.20 Main PBA

3.21 SMPS

3.22 Fuser Ass'y

3.23 Transfer Ass'y

3.24 Feed Ass'y

3.25 Pick up Ass'y

3.26 Solenoid

3-11

3-12

3-13

3-13

3-14

3-15

3-15

3-16

3-17

3-18

3-20

3-21

3-23

3-23

4. Alignment & Troubleshooting

4.1 Alignment and Adjustments 4-1

4.1.1 Paper path 4-1

4.1.2 Clearing Paper Jams

4.1.3 User Mode(F-114P) 4

4.1.4 Tech Mode

4.1.5 Engine Test Mode

4.1.6 Identify Sale Date

4.1.7 Consumables and Replacement Parts

4.1.8 Abnormal Image Printing and Defective Roller

4.1.9 Error Messages

4.2 Troubleshooting

4.2.1 Procedure of Checkig the Symptoms

4.2.2 The cause and solution of image quality

4.2.2 Fax & Phone Problems

4-4

-12

4-13

4-18

4-19

4-20

4-21

4-22

4-25

4-25

4-26

4-42

Page 5

Continued

4.2.3 Copy Problems 4-51

4.2.4 Paper Feed problems – Causes and Solutions

4.2.5 Printer Faults – Causes and Solutions

4.2.6 Toner Cartridge Service

4.2.7 Software Problems – Causes and Solutions

5. Exploded Views & Parts Lists

5.1 Main Exploded View 5-2

5.2 Top Cover Exploded View

5.3 OPE Ass’y Exploded View

5.4 Scan Upper Ass’y Exploded View

5.5 Main Frame Exploded View

5.6 Fuser Unit Exploded View

5.7 Exit Cover Exploded View

5.8 Cassette Unit Exploded View

4-55

4-63

4-73

4-78

5-5

5-7

5-9

5-11

5-14

5-16

5-18

6. System Diagram

6.1 Block Diagram 6-1

6.1 Connection Dia ram

7. Reference Information

7.1 Troubleshooting Tools 7-1

7.2 Acronyms and Abbreviations

7.3 Selecting printer locations

7.4 LAN (Optional Function)

7.5 Sample Tests Patterns

6-2

7-2

7-4

7-4

7-5

Page 6

Page 7

Service Manual

Precautions

1. Precautions

In order to prevent accidents and to prevent damage to the equipment please read the precautions listed

below carefully before servicing the printer and follow them closely.

CAUTION - INVISIBLE LASER RADIATION

WHEN THIS COVER OPEN.

DO NOT OPEN THIS COVER.

VORSICHT - UNSICHTBARE LASERSTRAHLUNG,

WENN ABDECKUNG GEÖFFNET.

NICHT DEM STRAHL AUSSETZEN.

ATTENTION - RAYONNEMENT LASER INVISIBLE EN CAS

D’OUVERTURE. EXPOSITION DANGEREUSE

AU FAISCEAU.

ATTENZIONE - RADIAZIONE LASER INVISIBILE IN CASO DI

APERTURA. EVITARE L’ESPOSIZIONE AL

FASCIO.

PRECAUCION - RADIACION LASER IVISIBLE CUANDO SE ABRE.

EVITAR EXPONERSE AL RAYO.

ADVARSEL. - USYNLIG LASERSTRÅLNING VED ÅBNING, NÅR

SIKKERHEDSBRYDERE ER UDE AF FUNKTION.

UNDGÅ UDSAETTELSE FOR STRÅLNING.

ADVARSEL. - USYNLIG LASERSTRÅLNING NÅR DEKSEL

ÅPNES. STIRR IKKE INN I STRÅLEN.

UNNGÅ EKSPONERING FOR STRÅLEN.

VARNING - OSYNLIG LASERSTRÅLNING NÄR DENNA DEL

ÄR ÖPPNAD OCH SPÄRREN ÄR URKOPPLAD.

BETRAKTA EJ STRÅLEN. STRÅLEN ÄR FARLIG.

VARO! - AVATTAESSA JA SUOJALUKITUS OHITETTAESSA

OLET ALTTIINA NÄKYMÄTTÖMÄLLE LASER-

SÄTEILYLLE ÄLÄ KATSO SÄTEESEEN.

1.1 Safety Warning

(1) Only to be serviced by appropriately qualified service engineers.

High voltages and lasers inside this product are dangerous. This printer should only be serviced by a suitably

trained and qualified service engineer.

(2) Use only authorized replacement parts

There are no user serviceable parts inside the printer. Do not make any unauthorized changes or

additions to the printer, these could cause the printer to malfunction and create electric shock or fire haz-ards.

(3) Laser Safety Statement

The Printer is certified in the U.S. to conform to the requirements of DHHS 21 CFR, chapter 1 Subchapter J for

Class 1(1) laser products, and elsewhere, it is certified as a Class I laser product

con-forming to the requirements of IEC 825. Class I laser products are not considered to be hazardous. The

laser system and printer are designed so there is never any human access to laser radiation above a Class I

level during normal operation, user maintenance, or prescribed service condition.

Warning >> Never operate or service the printer with the protective cover removed from Laser/Scanner assembly. The

reflected beam, although invisible, can damage your eyes. When using this product, these basic safety

pre-cautions should always be followed to reduce risk of fire, electric shock, and injury to persons.

1-1

Page 8

Service Manual

Precautions

1.2 Caution for safety

1.2.1 Toxic material

This product contains toxic materials that could cause illness if ingested.

(1) If the LCD control panel is damaged it is possible for the liquid inside to leak. This liquid is toxic. Contact with the skin

should be avoided, wash any splashes from eyes or skin immediately and contact your doctor. If the liquid gets into

the mouth or is swallowed see a doctor immediately.

(2) Please keep toner cartridges away from children. The toner powder contained in the toner cartridge may be harmful

and if swallowed you should contact a doctor.

1.2.2 Electric Shock and Fire Safety Precautions

Failure to follow the following instructions could cause electric shock or potentially cause a fire.

(1) Use only the correct voltage, failure to do so could damage the printer and potentially cause a fire cause an

electric shock.

(2) Use only the power cable supplied with the printer. Use of an incorrectly specified cable could cause the cable

to overheat and potentially cause a fire.

(3) Do not overload the power socket, this could lead to overheating of the cables inside the wall and could lead to

a fire.

(4) Do not allow water or other liquids to spill into the printer, this can cause electric shock. Do not allow paper

clips, pins or other foreign objects to fall into the printer these could cause a short circuit leading to an electric

shock or fire hazard..

(5) Never touch the plugs on either end of the power cable with wet hands, this can cause electric shock. When

servicing the printer remove the power plug from the wall socket.

(6) Use caution when inserting or taking off the power plug. The power plug has to be inserted completely. If not,

a fire will be caused due to poor contact. When taking off the power plug, grip the plug and remove it.

(7) Take care of the power cable. Do not allow it to become twisted, bent sharply round corners or other wise

damaged. Do not place objects on top of the power cable. If the power cable is damaged it could overheat and

cause a fire or exposed cables could cause an electric shock. Replace a damaged power cable immediately,

do not reuse or repair the damaged cable. Some chemicals can attack the coating on the power cable,

weakening the cover or exposing cables causing fire and shock risks.

(8) Ensure that the power sockets and plugs are not cracked or broken in any way. Any such defects should be

repaired immediately. Take care not to cut or damage the power cable or plugs when moving the machine.

(9) Use caution during thunder or lightening storms. It is recommend that this machine be disconnected from

the power source when such weather conditions are expected. Do not touch the machine or the power cord if it

is still connected to the wall socket in these weather conditions.

(10) Avoid damp or dusty areas, install the printer in a clean well ventilated location. Do not position the machine

near a humidifier. Damp and dust build up inside the machine can lead to overheating and cause a fire.

(11) Do not position the printer in direct sunlight. This will cause the temperature inside the printer to rise possibly

leading to the printer failing to work properly and in extreme conditions could lead to a fire.

(12) Do not insert any metal objects into the machine through the ventilator fan or other part of the casing, it could

make contact with a high voltage conductor inside the machine and cause an electric shock.

1-2

Page 9

Service Manual

Precautions

1.2.3 Handling Precautions

The following instructions are for your own personal safety, to avoid injury and so as not to damage the printer

(1) Ensure the printer is installed on a level surface, capable of supporting its weight. Failure to do so could cause

the printer to tip or fall.

(2) printer contains many rollers, gears and fans. Take great care to ensure that you do not catch your fingers, hair

or clothing in any of these rotating devices.

(3) Do not place any small metal objects, containers of water, chemicals or other liquids close to the printer which if

spilled could get into the machine and cause damage or a shock or fire hazard.

(4) Do not install the machine in areas with high dust or moisture levels, beside on open window or close to a

humidifier or heater. Damage could be cause to the printer in such areas.

(5) Do not place candles, burning cigarettes, etc on the printer, These could cause a fire.

1.2.4 Assembly / Disassembly Precautions

Replace parts carefully, always use authorized parts. Take care to note the exact location of parts and also

cable routing before dismantling any part of the machine. Ensure all parts and cables are replaced correctly.

Please carry out the following procedures before dismantling the printer or replacing any parts.

(1) Check the contents of the machine memory and make a note of any user settings. These will be erased if the

mainboard or network card is replaced.

(2) Ensure that power is disconnected before servicing or replacing any electrical parts.

(3) Disconnect printer interface cables and power cables.

(4) Only use approved spare parts. Ensure that part number, product name, any voltage, current or temperature

rating are correct.

(5) When removing or re-fitting any parts do not use excessive force, especially when fitting screws into plastic.

(6) Take care not to drop any small parts into the machine.

(7) Handling of the Toner Cartridge

- The OPC Drum can be irreparably damaged if it exposed to light.

Take care not to expose the OPC Drum either to direct sunlight or to fluorescent or incandescent room

lighting. Exposure for as little as 5 mins can damage the surface’s photoconductive properties and will result

in print quality degradation. Take extra care when servicing the printer. Remove the OPC Drum and store it in

a black bag or other lightproof container. Take care when working with the covers(especially the top cover)

open as light is admitted to the OPC area and can damage the OPC Drum.

- Take care not to scratch the green surface of OPC Drum Unit.

If the green surface of the Drum Cartridge is scratched or touched the print quality will be compromised.

1-3

Page 10

Service Manual

Precautions

1.2.5 Disregarding this warning may cause bodily injury

(1) Be careful with the high temperature part.

The fuser unit works at a high temperature. Use caution when working on the printer. Wait for the fuser to cool

down before disassembly.

(2) Do not put finger or hair into the rotating parts.

Take care when using a printer. It contains many rotating parts. Ensure that fingers, hair, clothing etc. do not

become caught in the mechanism as this could cause injury.

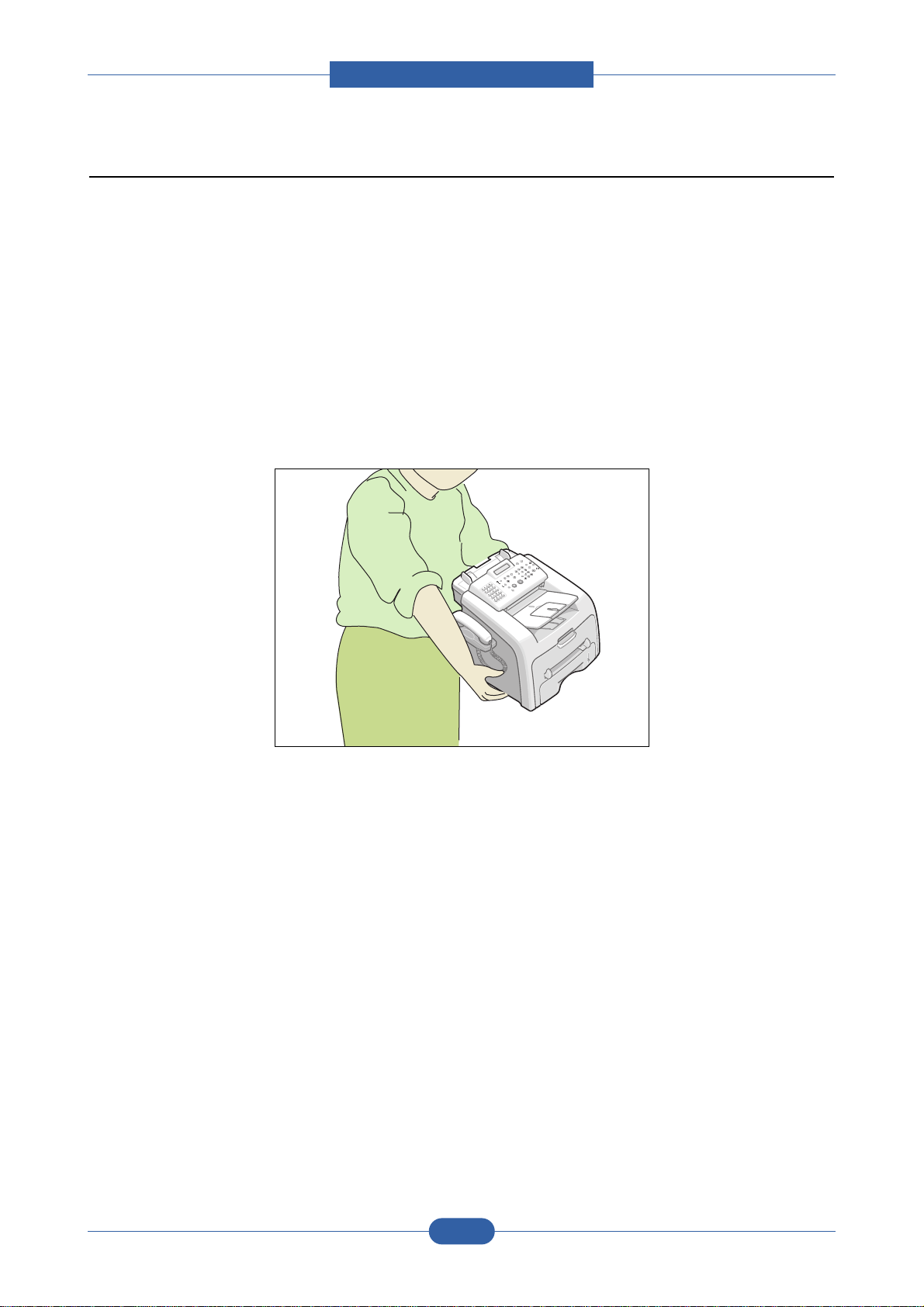

(3) When you move the printer.

This printer weighs 10kg including toner cartridge and cassette. Use safe lifting and handling techniques. Use

the lifting handles located on each side of the machine. Back injury could be caused if you do not lift carefully.

(4) Ensure the printer is installed safely.

The printer weighs 10Kg, ensure the printer is installed on a level surface, capable of supporting its weight.

Failure to do so could cause the printer to tip or fall possibly causing personal injury or damaging the printer.

(5) Do not install the printer on a sloping or unstable surface. After installation, double check that the printer is

stable.

1-4

Page 11

Service Manual

Precautions

1.3 ESD Precautions

Certain semiconductor devices can be easily damaged by static electricity. Such components are commonly called

“Electrostatically Sensitive (ES) Devices”, or ESDs. Examples of typical ESDs are: integrated circuits, some field

effect transistors, and semiconductor “chip” components.

The techniques outlined below should be followed to help reduce the incidence of component damage caused by

static electricity.

Caution >>Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

1. Immediately before handling a semiconductor component or semiconductor-equipped assembly, drain off any

electrostatic charge on your body by touching a known earth ground. Alternatively, employ a commercially available wrist strap device, which should be removed for your personal safety reasons prior to applying power to the

unit under test.

2. After removing an electrical assembly equipped with ESDs, place the assembly on a conductive surface, such as

aluminum or copper foil, or conductive foam, to prevent electrostatic charge buildup in the vicinity of the assembly.

3. Use only a grounded tip soldering iron to solder or desolder ESDs.

4. Use only an “anti-static” solder removal device. Some solder removal devices not classified as “anti-static” can

generate electrical charges sufficient to damage ESDs.

5. Do not use Freon-propelled chemicals. When sprayed, these can generate electrical charges sufficient to damage ESDs.

6. Do not remove a replacement ESD from its protective packaging until immediately before installing it. Most

replacement ESDs are packaged with all leads shorted together by conductive foam, aluminum foil, or a comparable conductive material.

7. Immediately before removing the protective shorting material from the leads of a replacement ESD, touch the protective material to the chassis or circuit assembly into which the device will be installed.

8. Maintain continuous electrical contact between the ESD and the assembly into which it will be installed, until completely plugged or soldered into the circuit.

9. Minimize bodily motions when handling unpackaged replacement ESDs. Normal motions, such as the brushing

together of clothing fabric and lifting one’s foot from a carpeted floor, can generate static electricity sufficient to

damage an ESD.

1-5

Page 12

Page 13

Service Manual

Product spec and feature

2. Product specification and feature

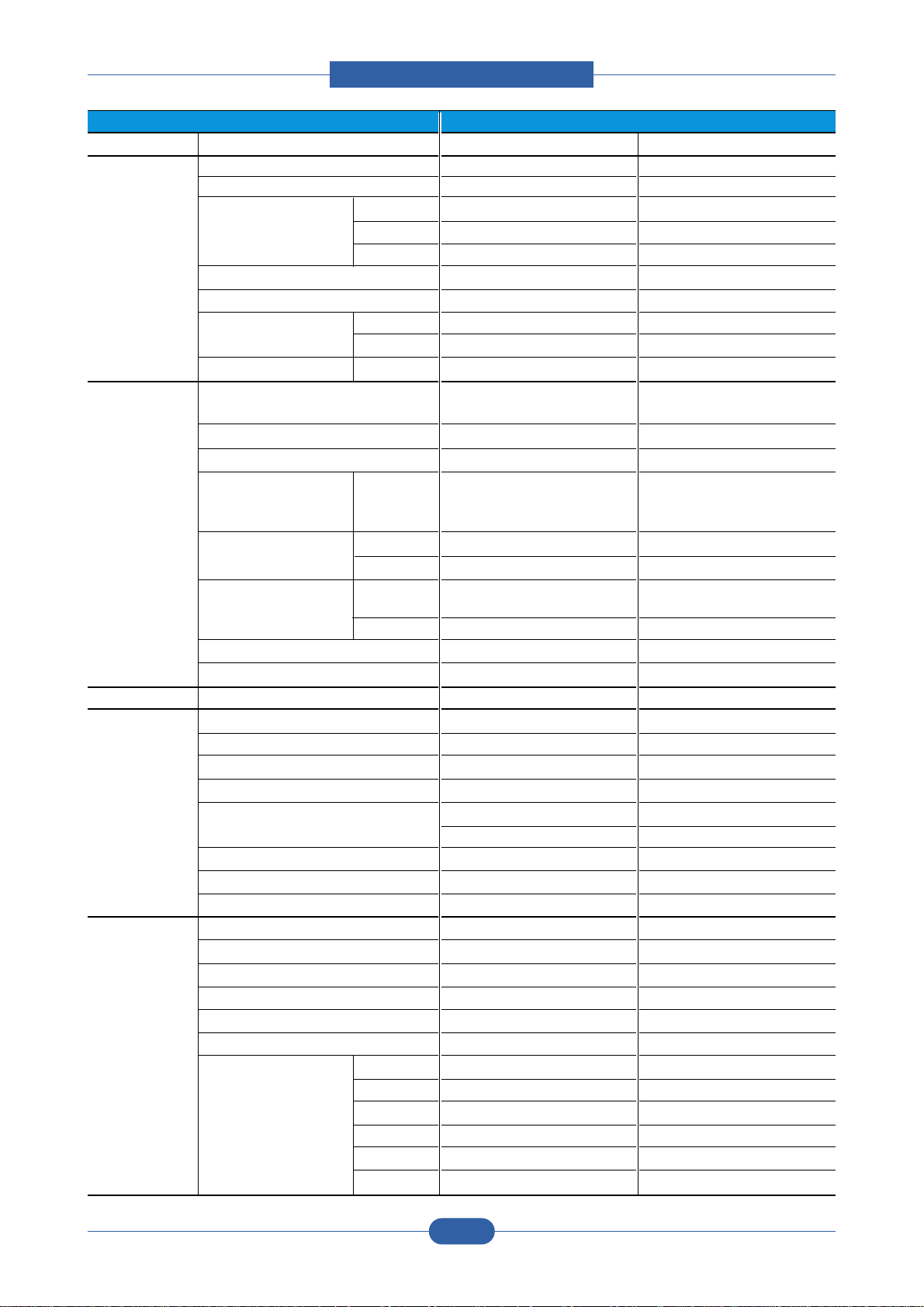

2.1 Product Specifications

Specfications are correct at the time of printing. Product specifications are subject to change without notice.

See below for product specifications.

Model Name F-114P F-114

Functions Fax,Copier,Printer,Scanner Fax,Copier

General Size (W*D*H) w/o Hand Set 363.0 * 398.0 * 308.3(mm) 363.0 * 398.0 * 308.3(mm)

Power Power Switch Yes Yes

Consumption Input Voltage

**Noise Operating(ADF) Less than 52 dBA Less than 52 dBA

EMI Approval EMI Approval Class B Class B

PC Print Power Save Mode Yes (5/10/15/30/45min.off) Yes (5/10/15/30/45min.off)

Items F-114 Series

Weight Without Toner Cartridge 10kg 10kg

With Toner Cartridge 11.5kg 11.5kg

LCD 16*2 16*2

Interface USB 1.1 USB 1.1 : f/w Down Load

AMV(Average Month Volume)

Duty cycle, Monthly Printing Up to 10,000 pages Up to 10,000 pages

Engine Life Up to 120,000 Pages Up to 120,000 Pages

Power Sleep Mode Energy Star Compliant Energy Star Compliant

Standby Less than 39 dBA Less than 39 dBA

Printing Less than 509 dBA Less than 50 dBA

Print Method Laser Laser

N/W I/f No No

* Speed (Engine) Up to 16 PPM in A4 size, -

Resolution Normal

Print Language GDI Toner Save Yes Yes(Text Mode)

Fpot Stand by Approx. 12 seconds -

Printable Area 208 x 273 mm (Letter) Duplex Print

Printing 500 Scan to Copy

or Scan to Fax

ADF SCAN Up to 2,000 pages Up to 2,000 pages

RET No -

Power Save Less than 42 seconds -

500 500

AC110V~127V, 220V ~ 240V AC110V~127V, 220V ~ 240V

(Fax Rec., Memory Copy)

Up to 17 PPM in Letter size

Up to 600 x 600 DPI effective output

Manual (driver support provided)

-

-

* Speed will be affected by Operating System used, computing performance, application software, connect-

ing method, media type, media size and job complexity.

** Sound Pressure Level, ISO 7779

2-1

Page 14

Service Manual

Product spec and feature

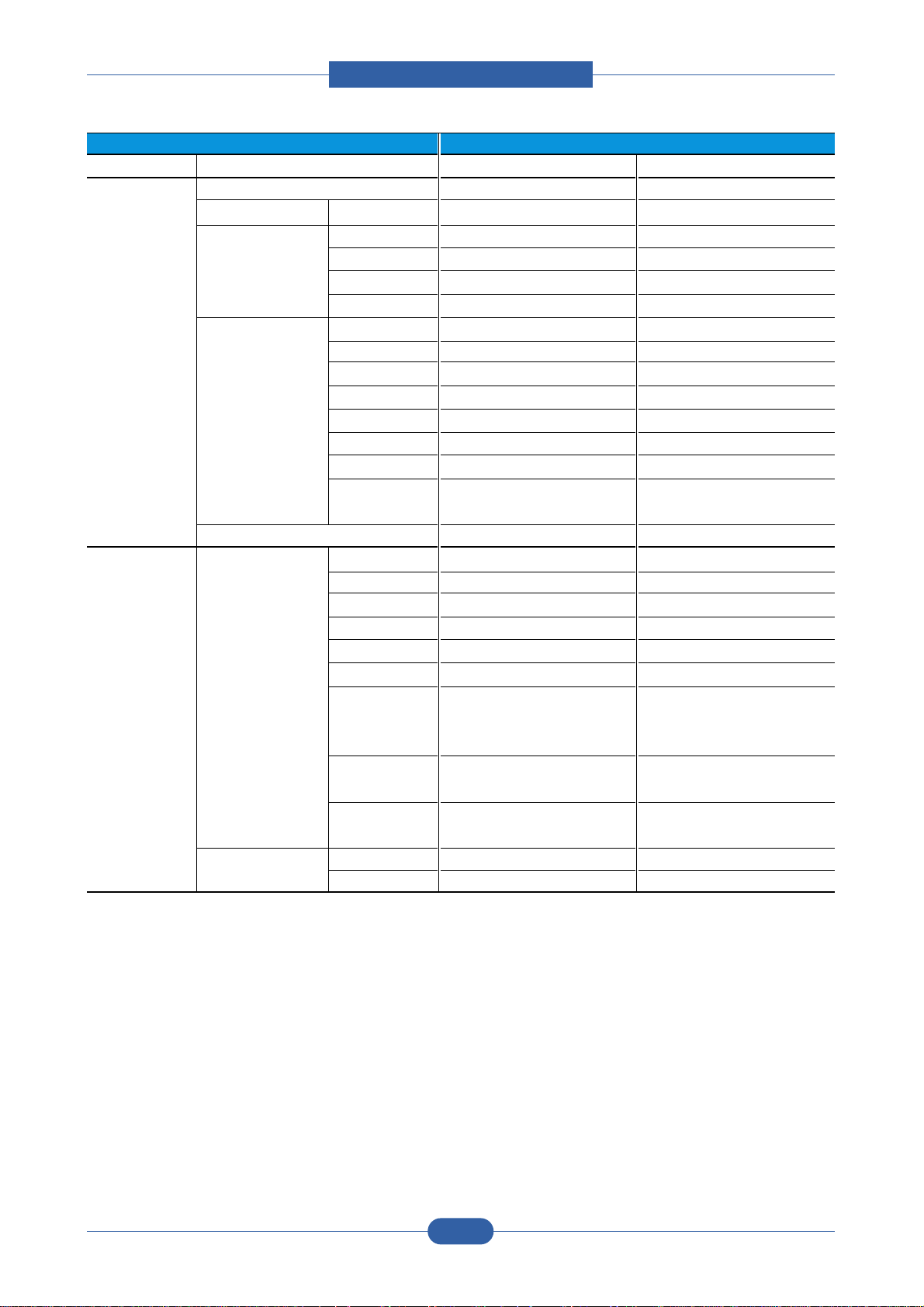

Items F-114 Series

Model Name F-114P F-114

Scan Halftone 256level 256level

Scan Method "CIS, Mono" "CIS, Mono"

*Scan Speed Gray Up to 72 sec (Second /scan) Color - -

Black&White Up to 25 sec -

Resolution(Optical)

Up to 200 x 200 DPI effective output Up to 200 x 200 DPI effective output

Halftone 256level Scan Width Max 216mm -

Effective 208mm -

Scan Length Max 400mm -

Copy Speed Up to 16 PPM in A4 size, Up to 16 PPM in A4 size,

Up to 17 PPM in Letter size Up to 17 PPM in Letter size

Resolution

Up to 300 x 300 DPI effective output Up to 300 x 300 DPI effective output

Halftone 256level 256level

Copy Quality Selection Text 16sec/Letter 16sec/Letter

or Original Image type Photo 16sec/letter 16sec/letter

selection Mode

FCOT Power Save Yes Yes

Stand by approx : 30sec approx : 30sec

*Copy Speed SDMC Up to 16 PPM in A4 size, Up to 16 PPM in A4 size,

Up to 17 PPM in Letter size Up to 17 PPM in Letter size

MDMC 3cpm 3cpm

Zoom Range 50-150% 50-150%

Multi Copy 1~99 1~99

Telephone Handset Yes Yes

1-Touch Dial 20 20

Speed Dial 80 80

TAD No No

TAD I/F Yes Yes

Tone/Pulse Tone (DTMF) Tone (DTMF)

Pulse : setting in tech mode Pulse : setting in tech mode

Earth/Recall No No

SMS No No

External Phone Interface Yes Yes

Fax Compatibility ITU-T G3 ITU-T G3

Communication System PSTN/PABX PSTN/PABX

Modem Speed 33.6Kbps 33.6Kbps

TX Speed approx. 3 sec approx. 3 sec

Compression MH/MR/MMR MH/MR/MMR

ECM Yes Yes

Resolution Std

Fine

S.Fine

Up to 203 x 98 DPI effective output Up to 203 x 98 DPI effective output

Up to 203 x 196 DPI effective output Up to 203 x 196 DPI effective output

Up to 203 x 392 DPI effective output Up to 203 x 392 DPI effective output

Std Up to 6 sec Up to 6 sec

Fine Up to 12 sec Up to 12 sec

S.Fine Up to 24 sec Up to 24 sec

2-2

Page 15

Service Manual

Product spec and feature

* Copy or Scan speed will be affected by Operating System used, computing performance, application software,

connecting method, media type, media size and job complexity.

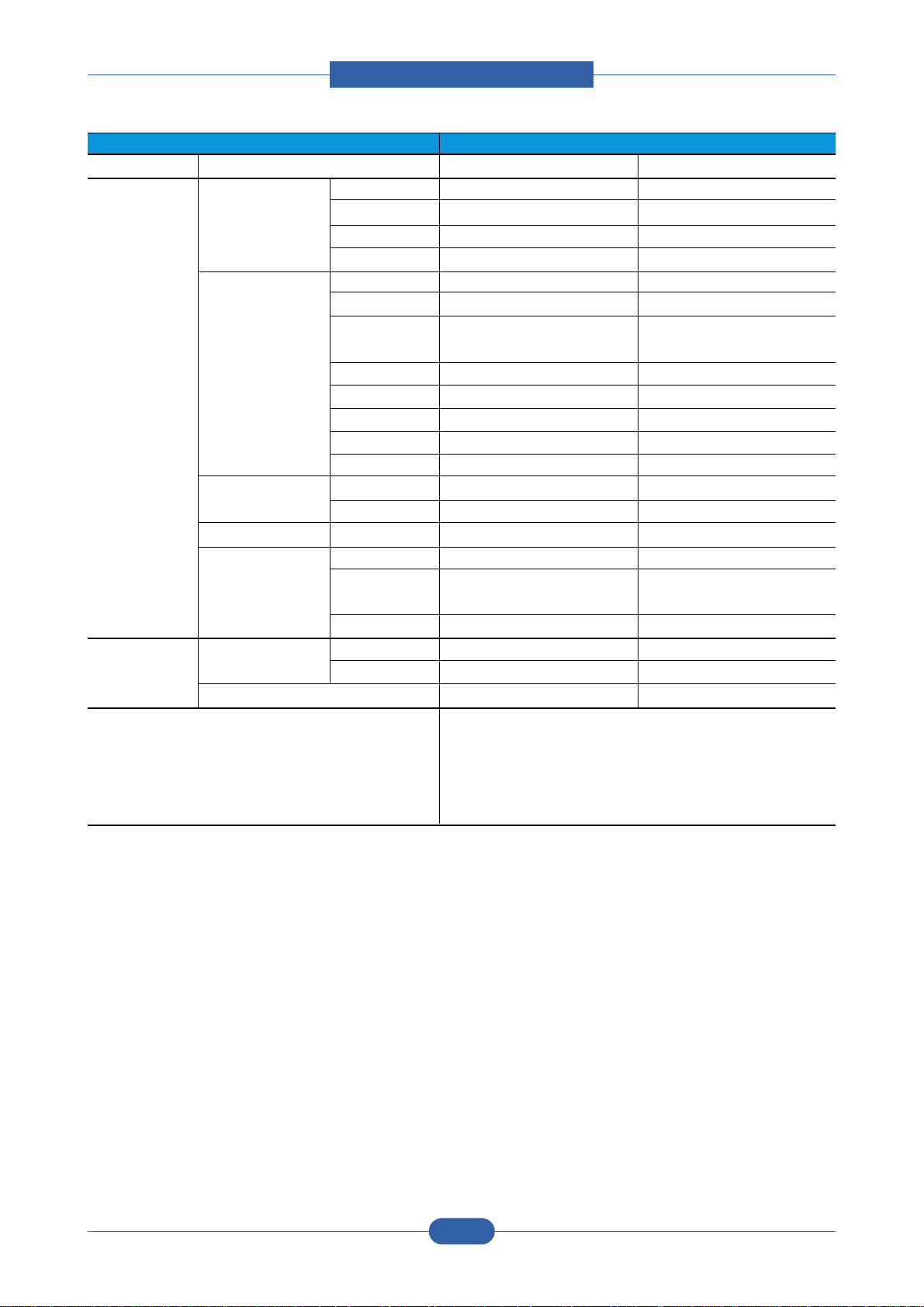

Items F-114 Series

Model Name F-114P F-114

Fax Halftone 256level 256level

(Continued) Memory Capacity

Optional Memory

Total memory: 8MB( Fax: 2MB) Total memory: 8MB(Fax: 2MB)

No No

Broadcasting Yes Yes

Delay TX Yes Yes

Memory RX Yes Yes

Functions Voice Request No No

TTI Yes Yes

RTI Yes Yes

Polling Rx Polling Rx Polling

Security Receive Yes Yes

Flash No No

Auto Reduction Yes Yes

"F/W Upgrade Yes Yes

from Remote"

Memory B/U Yes(96 Hour) Yes(96 Hour)

Paper Handling

Casstte Type Cassette Cassette

Input Capacity 250Sheets/20lb 250Sheets/20lb

Optional Cassette

Output Capacity

No No

Max. 150 sheets/20lb Max 150 sheets/20lb

Output Control Face down Face down

Bypass 1sh 1sh

Media Size for For Fax and Copy: A4,Letter, For Fax and Copy: A4,Letter,

Main Tray Legal For PC Print : A4,Letter, Legal For PC Print : A4,Letter,

Legal. Folio, Executive, B5 Legal. Folio, Executive, B5"

Media Size for Envelope6 3/4, 7 3/4,#9, Envelope6 3/4, 7 3/4,#9,

Bypass #10,DL,C5,B5 #10,DL,C5,B5

Media Weight Auto : 16 ~ 28 Ib Auto : 16 ~ 28 Ib

Bypass: 16 ~ 43 Ib Bypass: 16 ~ 43 Ib

ADF Input Capacity Min. 20 Sheets Min. 20 Sheets

Media Weight 12.5lb ~ 28lb, 32lb(1 sheet) 12.5lb ~ 28lb, 32lb(1 sheet)

2-3

Page 16

Service Manual

Product spec and feature

Items F-114 Series

Model Name F-114P F-114

Software Windows Win 2000 Yes No

Compatiblity Win 2003 Yes No

(Scan/Print) Win XP Yes No

Win Vista Yes No

Driver GDI Printer SPL No

TWAIN Yes No

FaxRCP Yes No

(Windows ONLY)

Mac Printer Yes No

Mac Scanner No No

Linux Printer Yes No

Linux Scanner Yes No

PC-FAX No No

M/S Certification WHQL Yes (Win 2000/2003/XP) -

WIA No No

Bundle S/W SmarThru 3 Media CD-ROM Yes -

Manual Standalone Fax: Book Standalone Fax: Book

MFP: CD

Diskette No No

Consumables Life Initial 1,000 Pages 1,000 Pages

Running 3,000 Pages 3,000 Pages

Toner Sensor (Software) Yes(Dot Counter) Yes(Dot Counter)

Periodic Replacing Parts Pick Up Roller : Up to 60,000 sheets

Transfer Roller : Up to 60,000 sheets

Fuser Assembly : Up to 60,000 sheets

ADF Roller : Up to 60,000 sheets

ADF Rubber : Up to 10,000 sheets

2-4

Page 17

Product spec and feature

2.2 Summary of Product

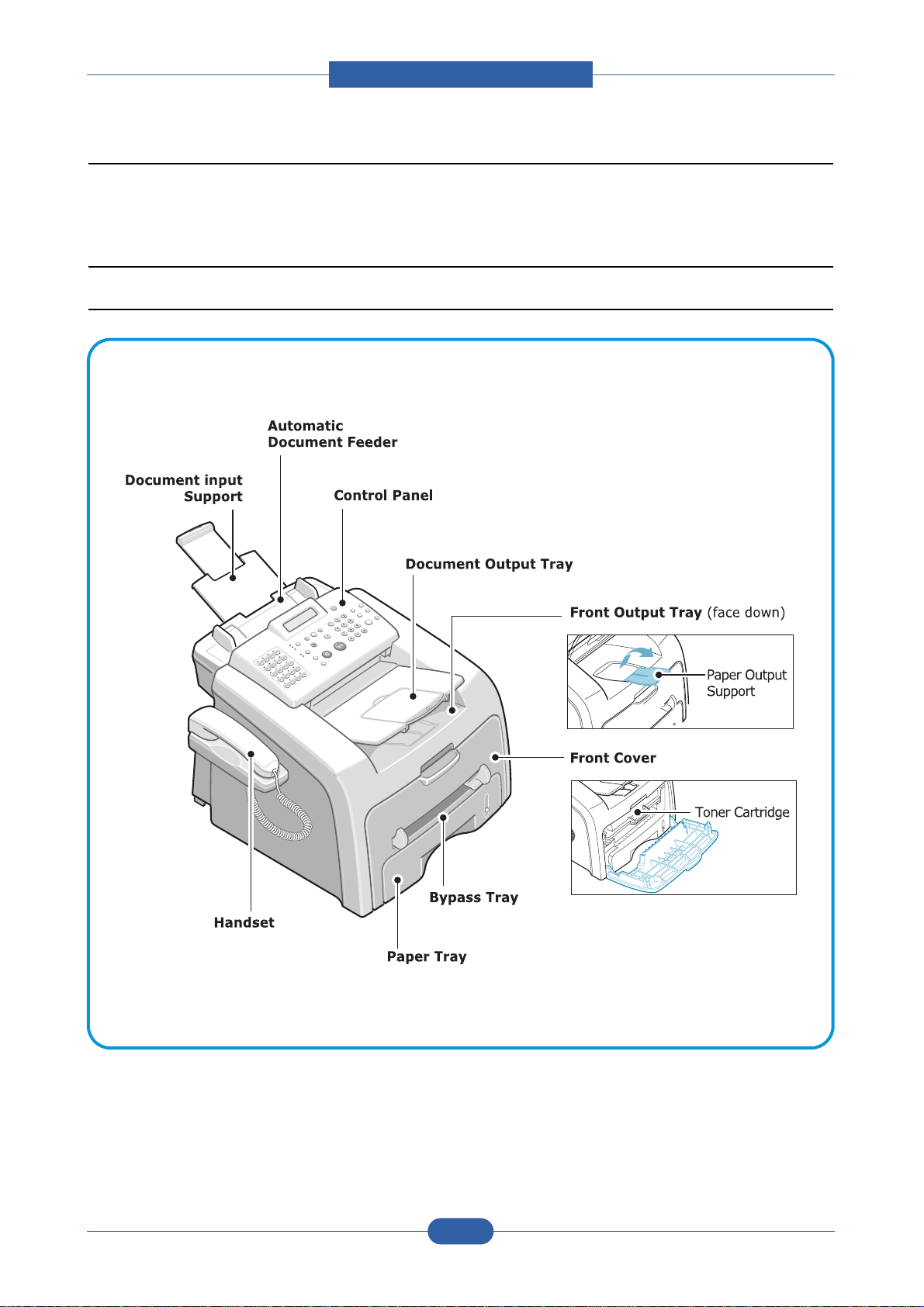

This chapter describes the functions and operating principals of the main components.

2.2.1 Printer Components

2.2.1.1 Front View

Summary of Product

Service Manual

2-5

Page 18

Service Manual

Product spec and feature

Items F-114 Series

Model Name F-114P F-114

Software Windows Win 2000 Yes No

Compatiblity Win 2003 Yes No

(Scan/Print) Win XP Yes No

Win Vista Yes No

Driver GDI Printer SPL No

TWAIN Yes No

FaxRCP Yes No

(Windows ONLY)

Mac Printer Yes No

Mac Scanner No No

Linux Printer Yes No

Linux Scanner Yes No

PC-FAX No No

M/S Certification WHQL Yes (Win 2000/2003/XP) -

WIA No No

Bundle S/W SmarThru 3 Media CD-ROM Yes -

Manual Standalone Fax: Book Standalone Fax: Book

MFP: CD

Diskette No No

Consumables Life Initial 1,000 Pages 1,000 Pages

Running 3,000 Pages 3,000 Pages

Toner Sensor (Software) Yes(Dot Counter) Yes(Dot Counter)

Periodic Replacing Parts Pick Up Roller : Up to 60,000 sheets

Transfer Roller : Up to 60,000 sheets

Fuser Assembly : Up to 60,000 sheets

ADF Roller : Up to 60,000 sheets

ADF Rubber : Up to 10,000 sheets

2-4

Page 19

Service Manual

Product spec and feature

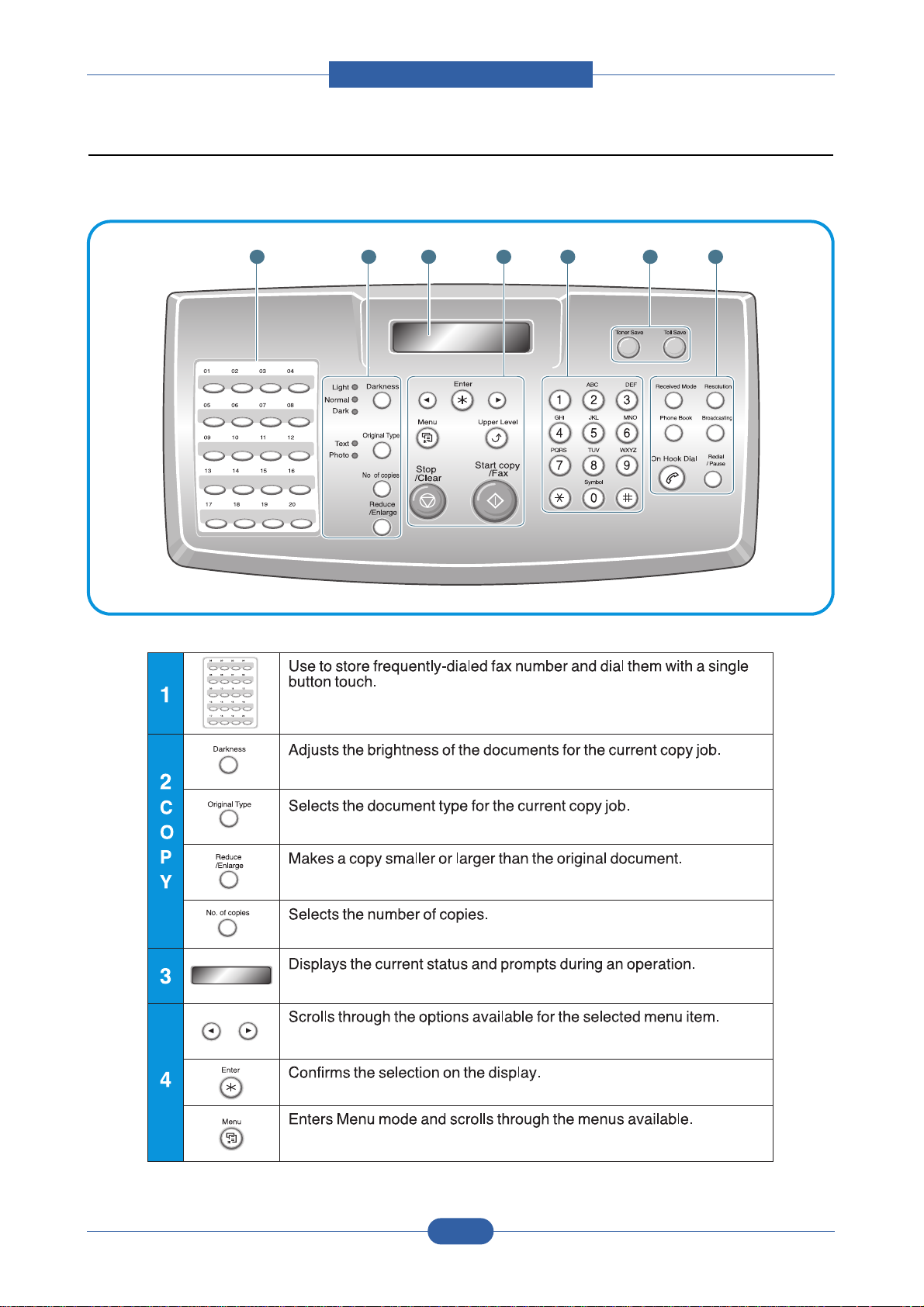

1 2 43 5 6 7

2.2.1.3 Control Panel

< F-114 / F-114P >

2-7

Page 20

Service Manual

Product spec and feature

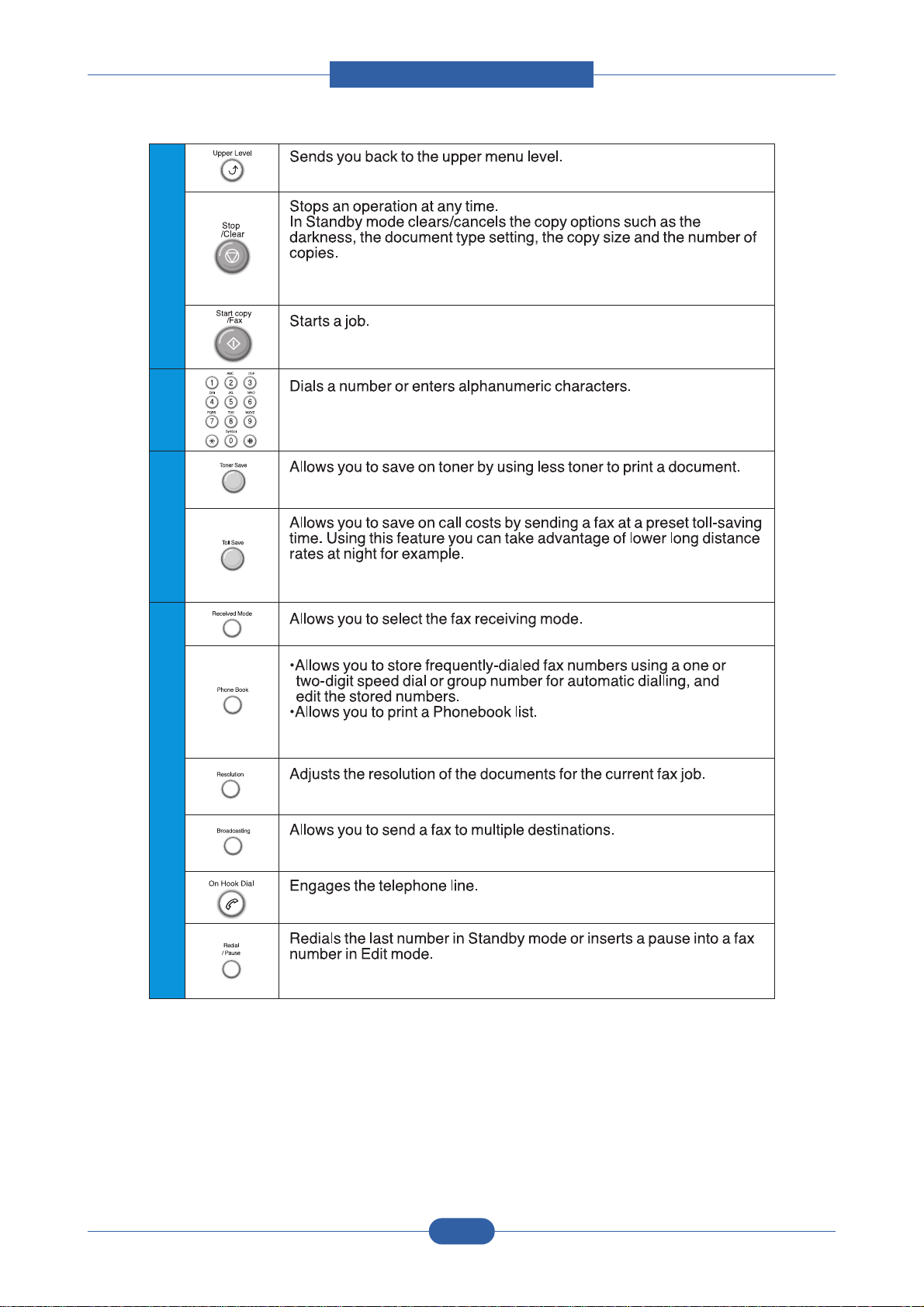

4

5

6

S

A

V

E

7

F

A

X

2-8

Page 21

Service Manual

Product spec and feature

2.2.2.2 Line Interface.

This part connects the set with the PSTN. The main functions of this section are Line Interface, Line Monitoring,

and connection to an external phone or TAD using the built in EXT connector..

2.2.2.3 Print Engine.

The Print Engine consists of the following sections: Frame, Paper Feed, Image Transfer, Imaging Unit, Toner

Cartridge, Fuser, High Voltage Supply and Scanner. The set uses an Electro Photographic process using the LSU

to develop a latent image on the OPC drum. The Toner process is a single part diamagnetic process. Copy and

Transfer processes use a CIS Module.

2.2.2.5 Summary of Main Unit

- Main Board

This is an integral unit having the Engine and Video control on a single PBA. It controls the Electrophotographic

Process to take the image from the PC Interface and generate the Video Data for the LSU. It also manages the

transfer of that image onto paper and the fusing of the image. The main PBA unit consists of the following circuits:

Motor (Paper Feed and Exit) Driver, the Clutch driver, Pre-transfer Lamp Driver, the Fuser Driver and the Fan

Driver. The signals from the Paper Feed Sensor, the Paper Empty Sensor, MP sensor and Exit Sensor are input to

the Main Board from the SMPS/HVPS PBA.

2.2.2 Overview of System

The F-114 / F-114P can be divided into the following main constituent parts: Main Controller, Operator’s Panel,

PC Interface, Scanner, Line Interface and Power Supply. The Main Controller uses an SPGPm processor. The

Operator’s panel; (OPE) has its own MICOM which communicates serially with a UART built into the SPGPm

processor. The Scanner uses an Image Processor chip (CIP4) to control the CIS. The Line Interface an FM336

integrated with the Main Board and communicates with the LIU at speeds up to 33.6Kbps. The Power Supply has

both the SMPS and HVPS integrated on one PBA.

2.2.2.1 Main Controller.

The Main Controller of the F-114 / F-114P consists of two ASICs (CPU, Image Processor), Scanner, Fax Modem

and Print sections. Bus Control, I/O Handling, Scanner, all motor drivers and the PC Interface function is controlled

by the CPU.

It uses the chorus2. These control the peripherals and the Image Processing.

2.2.2.4 Scanner.

The scanner is designed around a 200dpi CIS module. The CIS scanning width is maximum 216mm,

effective width is 208mm. The F-114 operates at 200lpi, the F-114P operates at 300 lpi.

2-9

Page 22

Product spec and feature

- SMPS Board & HVPS Board

These are integrated into a singe PBA. The Power Supply uses the 110VAC/220VAC supply voltage to

generate the DC Voltages used by the system. The SMPS has 3 output channels (+5V, +12V, +24V, +24VS) and

supplies the Main Board and the OPE Board.

The HVPS creates the high voltages (THV/MHV/Supply/Dev) used for the electrophotographic process. The high

voltage is created from the 24VS line from the SMPS. High Voltage output is supplied to the Toner, the OPC

Cartridge and the Transfer Roller.

- OPE Board

The Operation Panel is driven by its own internal program using the OPE MICOM chip separate from the Main

Board processor. Data is transferred using the UART Port in the Main Controller serially. This unit

consists of the MICOM, the Key Pad Matrix and the LCD.

- Toner Cartridge

The Toner Cartridge consists of integrated Exposure and Developer units. The Exposure Unit consists of the OPC

Drum and the Charge Roller, and the Developer Unit consists of the toner particles and its tank, the Supply Roller

and the Developer Roller.

- LSU (Laser Scanner Unit)

This is the core of the laser printer. It converts the video data received from the computer into an electrostatic

latent image on the surface of the OPC drum. This is achieved by controlling the laser beam and exposing the surface of the OPC drum to the laser light. A rotating polygon mirror reflects the laser light onto the OPC and each

side of the mirror is one scan line. The OPC drum turns as the paper feeds to scan the image down the page.

The /HSYNC signal is created when the laser beam from LSU reaches the end of the polygon mirror and this signal is sent to the controller. The controller detects the /HSYNC signal to adjust the vertical line of the image on

paper. In other words after the /HSYNC signal is detected the image data is sent to the LSU to adjust the left margin on the paper.

- Toner Transfer

Toner is transferred from the OPC drum onto the paper using a PTL (Pre-transfer Lamp) and a transfer roller. The

PTL shines light onto the OPC, this reduces the electrical charge on the surface of the OPC

surface and improves the efficiency of the transfer.

The transfer roller transfers toner from the OPC drum to the paper.

Life span: Print over 100,000 sheets (at 15~30ºC)

- Fuser

This consists of a heat lamp, heat roller, pressure roller, thermistor and thermostat. By use of heat and pressure

toner is caused to melt and adhere to the paper surface in order to complete the printing process.

Service Manual

2-10

Page 23

Service Manual

Product spec and feature

2.2.3 System Layout

2.2.3.1 Feeding section

There is a universal cassette which automatically loads paper and the manual feed which supplies paper

single sheet at a time. The cassette has a friction pad which separates paper to ensure single sheet

feeding, and it has a sensor, which checks when the paper tray is empty.

- Feeding Method: Universal Cassette Type

- Feeding Standard: Center Loading

- Feeding Capacity: Cassette-250 sheets (75g/m

2

, 20lb paper standard)

Manual 1 sheet (Paper, OHP, Envelop, etc.)

- Paper detecting sensor: Photo sensor

- Paper size sensor: None

2.2.3.2 Transfer Ass’y

This consists of the PTL (pre-transfer lamp) and the Transfer Roller. The PTL shines a light onto the OPC

drum. This lowers the charge on the drum’s surface and improves transfer efficiency.

The transfer roller transfers toner from the OPC drum surface to the paper.

- Life expectancy: Over 60,000 sheets (at 15~30°C)

2.2.3.3 Driver Ass’y

- Gear driven power unit. The motor supplies power to the paper feed unit, the fuser unit, and the toner

cartridge.

2.2.3.4 Fixing Part(Fuser)

- The fuser consists of the Heat Lamp, Heat Roller, Pressure Roller, Thermistor, and Thermostat. It fixes

toner to the paper using pressure and heat to complete the printing job.

2.2.3.4(a) Temperature-Intercepting Device (Thermostat)

The thermostat is a temperature sensing device, which cuts off the power to the heat lamp to prevent

overheating fire when the heat lamp or heat roller overheats.

2.2.3.4(b) Temperature Detecting Sensor (Thermistor)

The Thermistor detects the surface temperature of the heat roller, this information is sent to the main

processor which uses this information to regulate the temperature of the heat roller.

2.2.3.4(c) Heat Roller

The surface of the Heat Roller is heated by the Heat Lamp. As the paper passes between the Heat and

Pressure rollers the toner is melted and fixed permanently to the paper. The surface of the roller is coated

with Teflon. This ensures that toner does not adhere to the roller surface.

2.2.3.4(d) Pressure roller

The Pressure Roller mounted under the heat roller, it is made of a silicon resin, and the surface of the roller

is coated with Teflon. This ensures that toner does not adhere to the roller surface.

2-11

Page 24

Product spec and feature

2.2.3.4(e) Safety Features

• To prevent overheating

- 1st protection device: Hardware cuts off when overheated

- 2nd protection device: Software cuts off when overheated

- 3rd protection device: Thermostat cuts off mains power to the lamp.

• Safety device

- Fuser power is cut off when the front cover is opened

- LSU power is cut off when the front cover is opened

- The temperature of the fuser cover's surface is maintained at less than 80ºC to protect the user and a

caution label is attached where the customer can see it easily when the rear cover is opened.

2.2.3.5 Scanner

• Scan Image Controller

1.Minimum Scan Line Time : 1.23ms

2.Scan Resolution : Color (Max 600 DPI)

3.Scan Width : 208mm

4.Function

- White Shading Correction

- Gamma Correction

- CIS Interface

- 256 Gray Scale

• CIS Driver Circuit

- CIS Max Frequency : 0.5MHz

- CIS Line Time : 5ms

- White Data Output Voltage : Max 1.2V

• Tx Driver Circuit

- Tx Motor Speed : Max 2200pps

- Motor Driver : STA471A

- Voltage : 24V DC

Service Manual

2-12

Page 25

Service Manual

Product spec and feature

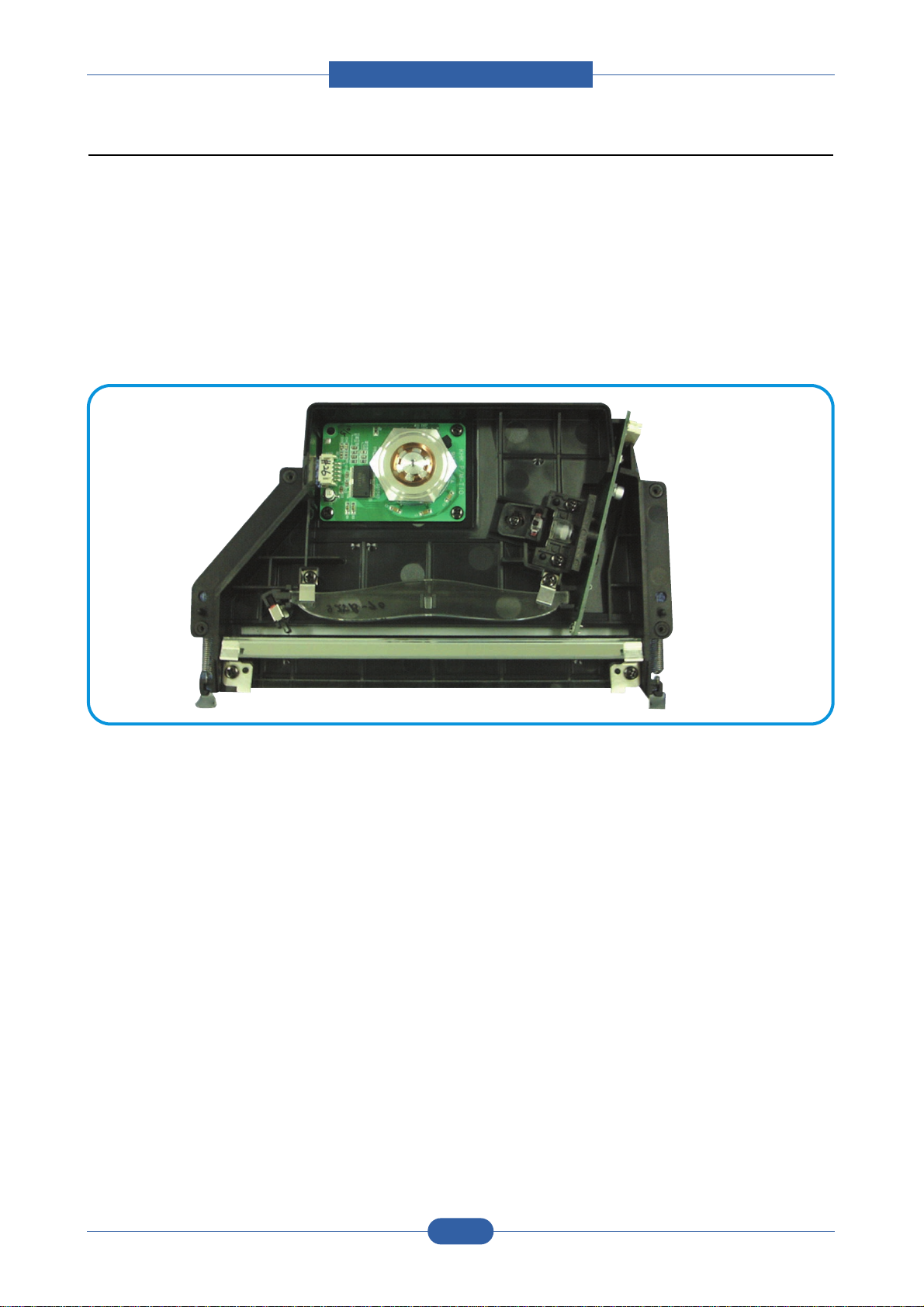

2.2.3.6 LSU (Laser Scanner Unit)

This is the core of the laser printer. It converts the video data received from the computer into an electrostatic latent image on the surface of the OPC drum. This is achieved by controlling the laser beam and exposing the surface of the OPC drum to the laser light. A rotating polygon mirror reflects the laser light onto the

OPC and each side of the mirror is one scan line. The OPC drum turns as the paper feeds to scan the

image down the page.

The /HSYNC signal is created when the laser beam from LSU reaches the end of the polygon mirror and

this signal is sent to the controller. The controller detects the /HSYNC signal to adjust the vertical line of the

image on paper. In other words after the /HSYNC signal is detected the image data is sent to the LSU to

adjust the left margin on the paper.

2-13

Page 26

Service Manual

Product spec and feature

2.2.3.7 Toner Cartridge

The toner cartridge is an integral unit containing the OPC unit and toner unit. The OPC unit consists of the

OPC drum and charging roller, and the toner cartridge unit consists of the toner, supply roller, developing

roller, and blade (Doctor blade)

- Developing Method: Non magnetic 1 element contacting method

- Toner: Non magnetic 1 element shatter type toner

- The life span of toner: 3,000 sheets (IDC Pattern/A4 standard)

- Toner remaining amount detecting sensor: Yes

- OPC Cleaning: Electrostatic process

- Management of waste toner: Collect the toner using a Cleaning Blade

- OPC Drum protecting Shutter: Yes

- Classifying device for toner cartridge: ID is classified by interruption of the frame channel

2-14

Page 27

Service Manual

Product spec and feature

FLASH

MEMORY

MODEM

EXPANSION I/O

(HCT273)

Battery

SDRAM

STA471

(SCAN MOTOR DRIVE I/C)

SUPER1284

BUFFER(INVERTER)

74HCTO 4M

MODEM CLOCK

MOTOR DIRVE IC

(A3 977 SLP)

ASIC

74LVX161284

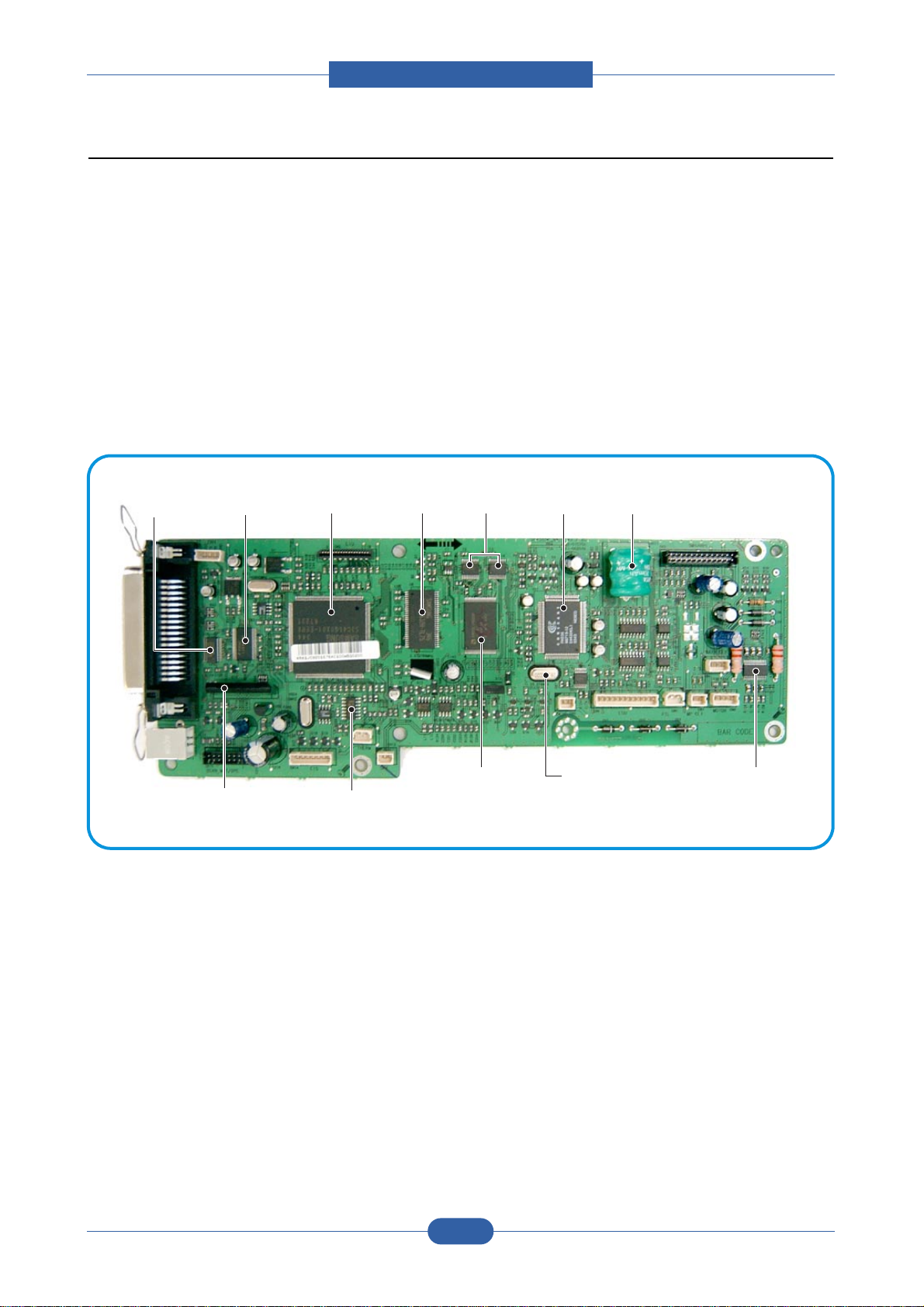

2.2.4 Main PBA(SPL Model)

The Engine Board and Controller Board have been integrated into a single PBA. This consists of the CPU,

printer scanner and line control functions. The CPU functions as the bus controller, I/O handler, motor driver

and PC inter-face. The main board sends the Current Image Video data to the LSU and manages the

Electrophotographic printing process. Circuits on the PBA drive include the main motor (paper feed,

cartridge, fuser), clutch driver, pre-transfer lamp driver, heat-lamp driver, CIS driver, scan motor driver,

modem and fan driver.

The signals from the paper feed jam sensor and paper empty sensor are inputted to the main board from

the power supply PBA.

Line interface circuit, it is a circuit for interfacing a telephone line with a modem and DAA. The circuit consists of

a matching circuit to conform to the impedance of the receiving telephone line and a circuit to conform to the impedance

of a modem.

Also, there is a ring detect circuit to detect a ring signal from the switchboard and a surge absorber to protect against

lighting strike surges on the incoming line.

2-15

Page 28

Service Manual

Product spec and feature

2.2.4.2 Flash Memory

This stores the system program. Firmware upgrade is achieved by downloading from the new image using the PC

Interface.

• Capacity : 0.5 M Byte

• Access Time : 70 nsec

2.2.4.3 SDRAM

This is used as a buffer, system working memory area, etc. while printing and scanning. This memory is also used to

store faxes waiting to be sent or waiting to be printed.

• Access Time : 60 nsec

2.2.4.1 ASIC (Chorus2)

The unt's S3C46Q0X 16/32-bit RISC micro controller is designed to provide a cost-effective, low power,

small die size and high performance micro-controller solution for MFP.

The S3C46Q0X is developed using ARM7TDMI core, 0.18(m CMOS standard cell, and memory cell.

•Main function block

• 1.8V internal, 3.3V external (I/O boundary) microprocessor with 4KByte Cache

• Image Processor

• On-chip clock generator with PLL

• Memory & External Bank Control

• DMA Control (5-channel)

• Interrupt Control

• 2-port USB Host /1- port USB Device (ver 1.1) Interface Control

• UART (2 Channel)

• Synchronous Serial Interface Control

• Timer (4 Channel)

• Watch Dog Timer

• Power control: Normal, Slow, Idle, Stop and SL_IDLE mode

• A/D Converter (10-bit, 2 Channel)

• General I/O Port Control

• Print Head Control

• Carrier Motor Control

• Paper Motor Control

• Tone Generator

• RTC with calendar function

• S/W Assistant function( Rotator )

2-16

Page 29

Service Manual

Product spec and feature

2.2.4.4 Sensor input circuit

1) Paper Empty Sensor

The Paper Empty sensor (Photo Interrupter) on the SMPS/HVPS PBA is monitored by the CPU on

signal(nP_EMPTY, CN3-Pin 1). When the cassette is empty the printer displays a message on the LCD

panel.

2) MP Sensing

Presence of paper in the MP tray is detected by operation of the MP Sensor (Photo Interrupter) on the

SMPS/HVPS PBA. The CPU monitors signal(MP_EMPTY, CN3-Pin 13) to recognize paper in the MP,

and paper is fed from MP if there is paper present.

3) Paper Feed Sensor, (Toner Cartridge Sensor)

When paper passes the actuator on the feed sensor, it is detected by the Photo interrupter.

signal(nP_FEED, CN3-Pin 2) monitored by the CPU and this signal starts the process of creating the

image after certain delay time If the feed sensor is not detected within 1 sec. after paper is fed, a paper

Jam0 occurs. (Displayed on the LCD panel).

When a toner cartridge is inserted it also operates the Paper Feed sensor. A message is displayed on the

LCD if no cartridge is detected.

4) Paper Exit Sensor

This detects that paper exits cleanly from the Machine using an exit sensor on the engine board and

actuator on the frame. The monitors signal(P_EXIT, CN3-Pin 26) and detects the on/off time of the exit

sensor and if jam status is detected then JAM2 is displayed the on the LCD panel.

5) Cover Open Senser

The Cover open sensor actuator is located on the front cover and the senor is in the main frame. When the

front cover is opened the +24VS to the DC fan, solenoid, main motor, polygon motor part of LSU, HVPS that

are cut off. The CPU monitors

signal(COVER_OPEN)

to recognize when the cover is opened.

6) DC FAN / SOLENOID Driving

It is driven by a transistor and controlled by signal(FAN, CN3-Pin 24) bit of the CPU.

When it is high the fan is activated by turning on the TR, and it is off when the sleep mode is selected.

There are two solenoids and these are driven by the Paper Pick-up and MP signals. The drive time is

300ms. The diode protects the driving TR from the Back-EMF pulse which is generated when the

solenoid is de-energized.

7) Motor Driving

The motor driving circuit is activated when the Driver IC is enabled. An A3977 (Motor driver IC) is used in

this case. The resistance Rs value of sensing and the voltage value of the V reference can be changed

by the motor driving voltage value.

2-17

Page 30

Service Manual

Product spec and feature

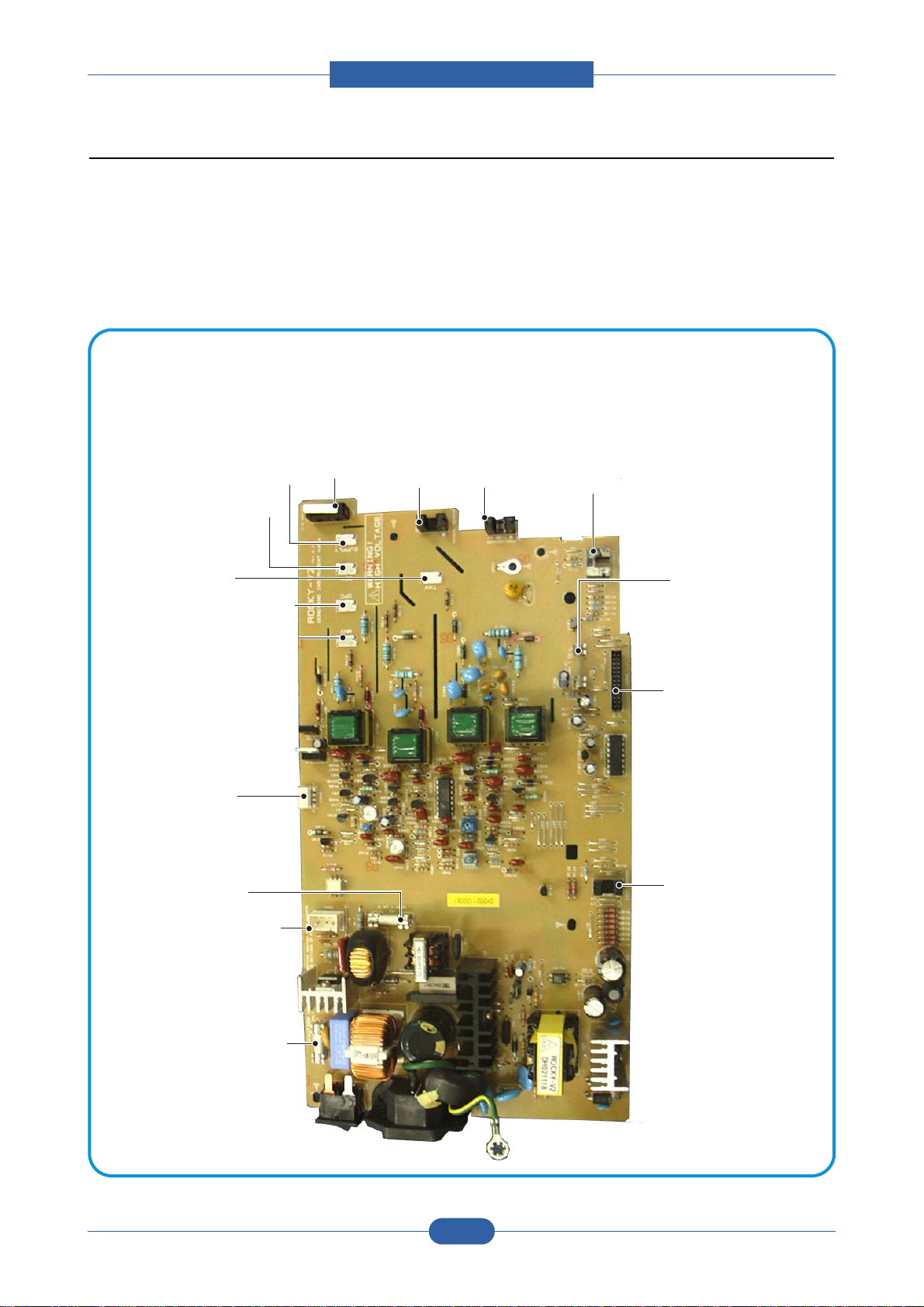

2.2.5 SMPS & HVPS

The SMPS and HVPS are on one integrated board.

The SMPS supplies the DC power to the system. It takes either 110V or 220V and outputs the +5V,

-5V/0.5A, 12V and 24V supplies to the main and ADF PBAs.

The HVPS creates the high voltage of THV/MHV/Supply/Dev and supplies it to the toner cartridge. The CPU is

used to modify some of these voltage settings to provide the ideal voltages to create the image.

The HVPS part uses the 24V and outputs the high voltage for THV/MHV/BIAS and the outputted high voltage is

supplied to the toner, OPC cartridge and transfer roller.

MAIN PBA CON.

CN3

(FAN CON.)

CN1

(H/L CON.)

F101

250V L2A

EXIT SENSOR

MHV

OPC

DEV

SUPPLY

THV

COVER OPEN SWITCH

MANUAL SENSOR

FEED SENSOR

PAPER-EMPTY SENSOR

F1

110V : 125V/8A

220V : 250V T 5A H

F2

110V : 125V/3A

220V : 250V 2A H

2-18

Page 31

Service Manual

Product spec and feature

2.2.5.1 HVPS(High Voltage Power Supply)

1) Transfer High Voltage (THV+)

- Function : It is this voltage that transfers toner from the OPC Drum to the paper.

- Output voltage : +1300V DC±20V

- Error : IF THV (+) is not present, low density printing occurs due to toner on the OPC Drum not being

transferred to the paper. It is possible that waste toner over-flow can occur if this condition persists.

Ghost images may appear which repeat at 76mm intervals.

2) Charge Voltage (MHV)

- Function : It is this voltage that charges the surface of the OPC to -900V ~ -1000V.

- Output voltage : -1550V DC ± 50V

- Error : IF MHV is not present toner then since the OPC drum surface has no charge toner is attracted to

the whole OPC surface. A black page is printed out when this happens.

3)Cleaning Voltage (THV-)

- Function : It removes toner contamination from the rear side of the paper by sending (-) polarity to the

transfer roller forcing toner to transfer back to the to OPC drum.

- Output Voltage : +300V/-150V

- Error : Smudges and toner contamination on the reverse side of the printed page.

4) Developing Voltage (DEV)

- Function: It is this voltage that develops toner with on to the section of the OPC drum surface exposed

by the LSU

(Laser Scanning Unit).

* When printing the exposed voltage on the OPC is -180V, unexposed is -900~-1000V, and the exposing

voltage on the DEV is -430V. Therefore toner with (-) polarity is developed onto an exposed

section of the OPC.

- Output voltage: -430V DC ± 20V

- Error: a) If DEV is GND, print density gets extremely low.

b) When DEV is floating due to poor connection between the frame and cartridge contacts etc.,

print density gets extremely high.

5) Supply Voltage (SUP)

- Function: It is this voltage that supplies toner to the developing roller.

- Output voltage: : -630V DC ± 50V (Use ZENER, DEV Gear)

- Error: a) When SUP is GND print density gets extremely low.

b) If SUP is floating due to poor connection between the frame and cartridge contacts etc. density

gets extremely low such that it is hard to see toner with the eyes

6) OPC Ground ZENER Voltage

- Function: It is this voltage that prevents image contamination under low temperature and low humidity

environment conditions.

- When a set prints without an output voltage, -130V DC ± 15V is maintained on OPC ground. (-103V

ZENER diode is connected to OPC ground)

- Error type:

a) When the ZENER diode is - 0V there is no serious image problem in general environment,

but in low temperature and low humidity environments it is possible that contamination

can occur on the entire image

b) When the ZENER diode is disconnected a blank page is printed out. (It is the same when

a ZENER diode is disconnected from OPC ground.)

2-19

Page 32

Service Manual

Product spec and feature

2.2.5.2 SMPS (Switching Mode Power Supply)

ItThis is the power source for the whole system. It is an independent module so that it is possible to use it for

common use. It is mounted at the bottom of the set.

It consists of the SMPS section, which supplies the DC power to drive the system, and the AC heater control

part, which supplies the power to the fuser. The SMPS has four output channels ((+5V, -5V, +12V, +12Vand

+24Vs).

There are three kinds of power, 120V exclusive (America), 220V exclusive (Europe), and 220V for China

(nations with unstable power supply).

1) AC Input

- Inputting rated voltage : AC 220V ~ 240V AC 100~127V

- Inputting voltage fluctuating range : AC 198V ~ 264V AC 90V ~ 135V

- Rated frequency : 50/60 Hz

- Frequency fluctuating range : 47 ~ 63 Hz

- Inputting Current : Under 4.0Arms/2.0Arms

2) Rated Power Output

3) Consumption Power

4) Length of Power Cord :

1830 ± 50mm

5) Power Switch :

Fitted

NO Item CH1 CH2 CH3 CH4

1 Channel name +5V -5V +24.0V +24.0VS

2 CONNECTOR PIN CON 2 CON2 CON2 CON2

3.3V PIN: 3, 4 -5V PIN : 7 24V PIN: 11, 12 24V PIN: 13, 16

GND PIN: 5, 6 GND PIN: 8 GND : 9, 10 GND : 18

3 Rated outputting voltage +5V ± 5% -5V ± 5% +24V ± 10% +24V ± 10%

(4.75 ~ 5.25V) (-4.75~-5.25V) (21.6 ~ 26.4V) (21.6 ~ 26.4V)

4 Rated outputting current 1.5 A 0.5A 1.5 A 1.0 A

5 Ripple noise voltage 150mVp-p 150mVp-p 500mVp-p 500mVp-p

6 Maximum output 7.5W 0.6W 36.0W 24.0W

NO Item CH1 CH2 CH3 CH4 System

(+5V) (+12V) (+24V) (+24VS)

1 Stand-By 1.0 A 0.05A 1.0 A 0.5 A AVG : 60 Wh : 220V

AVG : 75 Wh : 110V

2 Operating 1.5 A 0.5A 1.5 A 1.0 A AVG : 320 Wh

3 Sleep-Mode 0.3A 0.0A 0.0A 0.06A AVG : 15 Wh

2-20

Page 33

Product spec and feature

6) Feature

- Insulating resistance : over 50MΩ (at DC500V)

- Insulating revisiting pressure : Must be no problem within 1min. (at 1500Vzc, 10mA)

- Leaking current : under 3.5mA

- Running current : under 40A peak (at 25°c, Cold start) Under 60A peak (in other conditions)

- Rising Time : Within 2Sec

- Falling Time : Over 20ms

- Surge : Ring Wave 6KV-500A (Normal, Common)

7) Environment Condition

- Operating temperature range : 0°c ~ 40°c

- Storage temperature range : -25°c ~ 85°c

- Storage humidity range : 30% ~ 90% RH

- Operating atmospheric pressure range : 1

8) EMI Requirement :

CISPR ,FCC, CE, MIC, C-Tick,

9) Safty Requrement

- IEC950, C-UL, TUV,Semko,iK,CB, CCC, EPA,

2.2.5.3 Fuser AC Power Control

The Fuser (HEAT LAMP) is heated using AC power. The AC power is controlled by a Triac (THY1), a

semiconductor switch. 'On/Off control' is achieved when the gate of the Triac is turned on/off by a Photo

triac (PC1), this is an insulting part.

In the other words the AC control part is a passive circuit. It turns the heat lamp on/off by taking a signal

from the engine control section. When the 'HEATER ON' signal is activated by the engine the LED of PC1

(Photo Triac) flashes. The flashing light causes the Triac (PC1) to switch and a voltage is supplied to the

gate of Triac THY1.

As a result AC current flows in the heat lamp, and heat is produced.

On the other hand, when the signal is off, PC1 is off, the voltage is cut off at the gate of Triac THY1, this

Triac is therefore off, and thus the heat lamp is turned off.

1) Triac (THY1) feature

- 12A,600V SWITCHING

2) Phototriac Coupler (PC3)

- Turn On If Current : 15mA ~ 50mA(Design: 16mA)

- High Repetive Peak Off State Voltage : Min 600V

Service Manual

2-21

Page 34

Service Manual

Product spec and feature

2.2.6 Engine F/W

2.2.6.1 Feeding

If feeding from the cassette the drive of the pickup roller is controlled by controlling the pick-up solenoid.

The on/off of the solenoid is controlled by controlling the general output port or the external output port. If

feeding from the manual feeder the set decides to feed the paper according to the operation of the manual

sensor, and by driving the main motor, insert the paper in front of the feed sensor. When paper moves the

occurrence of a paper jam is judged as below.

2.2.6.1(a) Jam 0 – Jam in Feed area

• After a page was picked up, paper did not enter the unit due to a paper misfeed.

• After a page was picked up, paper entered but it did not reach the feed sensor in certain time due to slip, etc.

• After a page was picked up, if the feed sensor is not on try to pick up again. After retrying if the feed

sensor is still not on after certain time, it is Jam 0.

- this indicates that the leading edge of the paper doesn't pass the feed sensor within a certain time.

• Even though the paper reaches the feed sensor, the feed sensor does not turn on.

- this indicates that the leading edge of the paper already passed the feed sensor or that the sensor is

fauty.

2.2.6.1(b) Jam 1 – Jam inside the print engine

• After the leading edge of the paper passes the feed sensor, the trailing edge of the paper does not pass

the feed sensor within certain time. (During this time the feed sensor cannot be Off)

• After the leading edge of the paper passes the feed sensor, the paper does not reach the exit sensor within certain time. (The exit sensor cannot be On during this time)

- There is already paper between the feed sensor and the exit sensor.

2.2.6.1(c) Jam 2 – Jam in the Exit area

• After the trailing edge of the paper passes the feed sensor the trailing edge of the paper does not pass

the exit sensor within certain time.

2.2.6.2 Drive

The main motor drives the paper feed, developing unit and the Fuser It is driven by software which controls

the acceleration, constant speed and deceleration profiles. The Motor is managed with an A3977 driver IC

and controlled by step and enable signals from the CPU.

2.2.6.3 Transfer

The charging voltage, developing voltage and the transfer voltage are controlled by PWM (Pulse Width

Modulation). Each output voltage is changeable according to the PWM duty cycle. The transfer voltage

used when the paper passes the transfer roller is decided by environment recognition. The resistance value

of the transfer roller changes due to the surrounding environment in the room or within the set, this change

in resistance in turn changes the value of the voltage due to loading. This voltage is fed back into the set

through the A/D converter. Based on this fed back value the PWM cycle is changed to maintain the

required transfer voltage

2-22

Page 35

Service Manual

Product spec and feature

2.2.6.4 Fusing

The temperature of the heat roller's surface is detected according to the resistance value of the thermistor.

The thermistor resistance is measured using the A/D converter and thus the CPU can determine the

temperature of the heat roller. The AC power is controlled by comparing the target temperature to the value

from the thermistor. If the value from the thermistor is out of the controlling range while controlling the fusing

process, the error stated in the table occurs. (For the domestic model, the Q-PID method has been applied.)

Error Type

2.2.6.5 LSU

The LSU consists of the LD (Laser Diode) and the polygon motor control. When the printing signal occurs,

the LD is turned on and the polygon motor is enabled. When the light sensor detects the beam, Hsync occurs.

When the polygon motor speed becomes a normal, LReady occurs. If these two conditions are satisfied, the

status bit of the LSU controller register becomes 1 ant the LSU is judged to be ready. If the two conditions

are not satisfied, the error shown in the table below occurs.

Error Description

Open heat error When warming up, it has been lower than 68 °C over 25 sec

Lower heat error • Standby:

It has been lower than 100°C over 25 sec

• Printing:

- 2 consecutive pages: it has been lower than 145°C over 5 sec

- 3 consecutive page; it has been 40°C lower than the fixed fusing temperature over 4 seconds.

Over heat error It have been higher than 220°C over 3 seconds

Error Description

Polygon motor error When the polygon motor’s speed doesn’t become a normal

Hsync error The polygon motor’s speed is normal, but the Hsync signal is not created.

2.2.7 OPE PBA

The OPE board consists of various function keys and an LCD to display set status and operator messages.

A MICOM (HOLTEC HT48R50) and drives the LEDs and LCD. Communication between the OPE and the

CPU on the main board is serial (related signals are /Reset, TXD, and RXD).

2-23

Page 36

Page 37

Service Manual

Disassembly and Reassembly

3. Disassembly and Reassembly

3.1 General Precautions on Disassembly

When you disassemble and reassemble components, you must use extreme caution. The close

proximity of cables to moving parts makes proper

routing a must.

If components are removed, any cables disturbed

by the procedure must be restored as close as

possible to their original positions. Before removing any component from the machine, note the

cable routing that will be affected.

Whenever servicing the machine, you

must perform as follows:

1. Check to verify that documents are not stored

in memory.

2. Be sure to remove the toner cartridge before

you disassemble parts.

3. Unplug the power cord.

4. Use a flat and clean surface.

5. Replace only with authorized components.

6. Do not force plastic-material components.

7. Make sure all components are in their proper

position.

Releasing Plastic Latches

Many of the parts are held in place with plastic

latches. The latches break easily; release them

carefully.

To remove such parts, press the hook end of the

latch away from the part to which it is latched.

3-1

Page 38

Service Manual

Disassembly and Reassembly

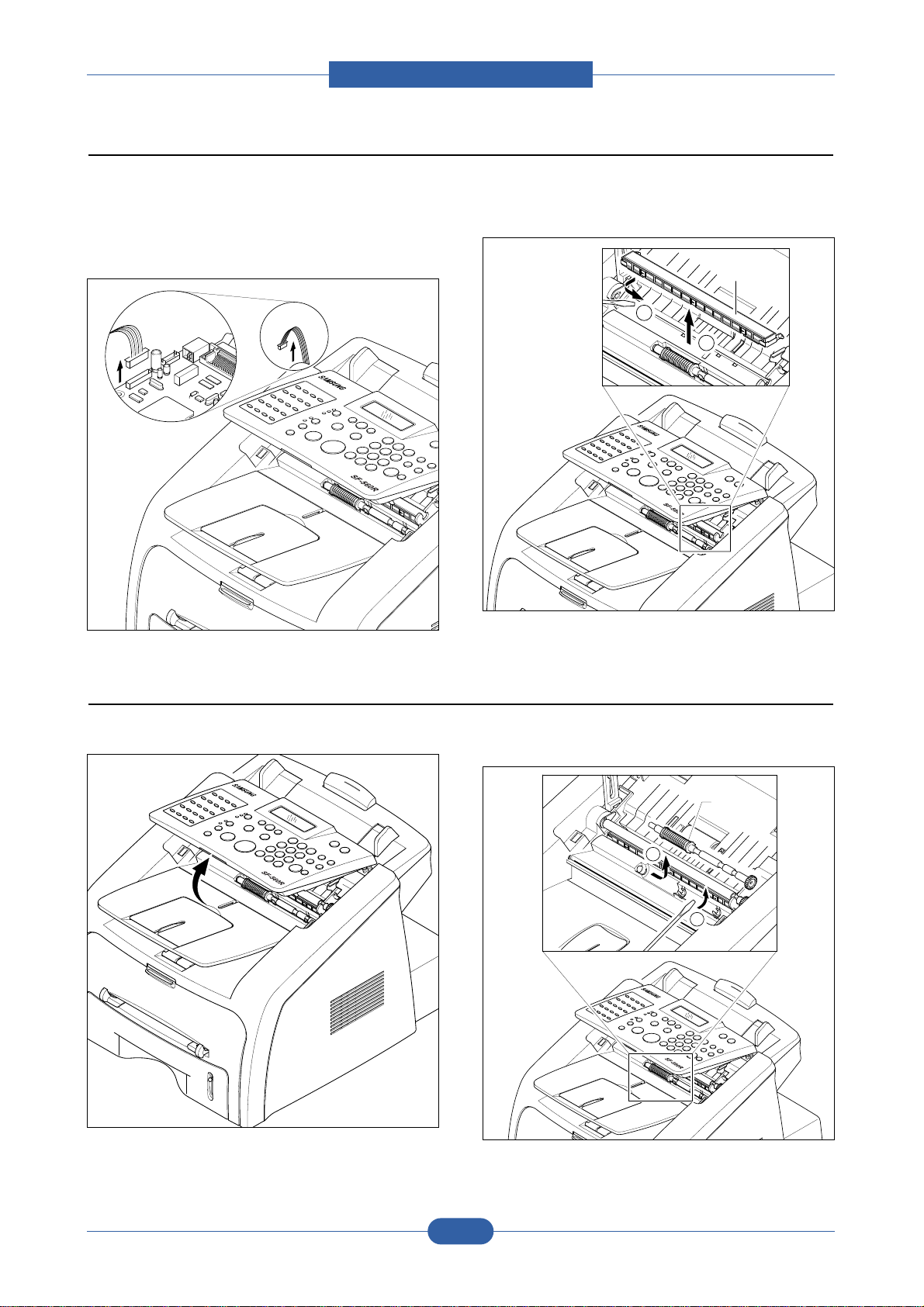

3.2 White Roller Ass,y

1. Open the OPE Unit. 2. Push the Bushing on RH end of the roller slightly inward,

then rotate it until it reaches the slot as shown below.

Then lift the roller out.

Note: Check the roller for any dirt. Clean with a soft cloth

dampened with water.

If the roller is heavily worn replace it with a new one.

3.3 Rear Cover

1. Remove the four screws securing the Rear Cover and

remove it, as shown below.

2. Unlatch the Face up Cover Securing the Rear Cover,

as shown below. Then lift the Face up Cover out.

Cover-Face up

2

White Roller

Bush

1

Rear Cover

3-2

Page 39

Service Manual

Disassembly and Reassembly

3.4 Side Cover L

1. Before you remove the Side Cover L, you should

remove:

- Remove handset and cradle.

2. Release the latches from Frame Ass,y in the direction

of the arrow, as shown below. Take care to disconnect

speaker harness.

3. If necessary, remove the two screws securing the

Speaker and remove it.

Speaker

Bracket

3.5 Side Cover R

1. Before you remove the Side Cover R, you should

remove:

- Rear Cover (see section 3.3)

2. Release the latches from Frame Ass'y in the direction

of the arrow, as shown below.

Side Cover R

Side Cover L

3-3

Page 40

Service Manual

Disassembly and Reassembly

3.6 OPE Unit

1. Before you remove the OPE Unit, you should remove:

- Rear Cover (see section 3.3)

2. Unplug the OPE connector from the Main PBA and

Scan Motor Harness, as shown below.

Then remove the two screws securing the Ground

Cable and remove it. Note the position of the bronze

earth plate.

3. Open the OPE and release the latch from Holder, as

shown below.

4. Carefully release the latches from Top Cover in the

direction of the arrow, as shown below.

5. Remove the two screws securing the Scan Upper

Ass'y and remove it.

Speaker

1

OPE Unit

2

OPE

Scan

Upper Ass'y

3-4

Page 41

Disassembly and Reassembly

6. Remove the seven screws securing the OPE PBA

and remove it.

OPE PBA

8. Remove the Key Pad from the OPE Cover.

Key Pad

7. Remove the Contact Rubber from the OPE Cover.

Contact Rubber

Service Manual

3-5

Page 42

Service Manual

Disassembly and Reassembly

3-6

Samsung Electronics

1. Before you remove the ADF Rubber Pad, you should

remove:

- Rear Cover (see section 3.3)

- OPE Unit (see section 3.6)

2. Insert a flat-blade screwdriver into the slot as shown

below, and release the latches.

Take out the Rubber Holder and the Rubber Pad.

Note:

• When you reassemble the Rubber Pad, be sure that

the Rubber Pad and Holder fit into the Guide Boss

and the Holder latches fit into the corresponding holes.

Then push firmly until it clicks.

• Clean the surface of the Rubber Pad with ethyl alcohol.

After wiping it, be sure to dry it. Check the rubber for

wear. If the wear reaches 1/2 it's original thickness,

replace it with a new one.

3.7 ADF Rubber Pad

Rubber Pad

Rubber Holder

Page 43

Service Manual

Disassembly and Reassembly

3-7

Samsung Electronics

1. Before you remove the CIS, you should remove:

- White Roller Ass'y (see section 3.2)

- Rear Cover (see section 3.3)

2. Unplug the CIS connector from the Main PBA. (CN14)

3. Unlatch the CIS using a flat-blade screwdriver and

release it, as shown below. Disconnect harness from

CIS unit.

3.8 CIS

CIS

CIS

1. Open the OPE Unit. 2. Pull up the Exit Roller using a flat-blade screwdriver

and remove it, as shown below.

3.9 Exit Roller

CIS

1

2

Exit Roller

2

1

Page 44

Service Manual

Disassembly and Reassembly

3-8

Samsung Electronics

1. Take out the Cassette.

2. Open the Front Cover.

3. Unlatch the Front Cover from the Frame Ass'y. Then

remove the Front Cover, as shown below.

3.10 Front Cover Ass'y

Cassette

Front Cover

Page 45

Disassembly and Reassembly

3.11 Scan Ass'y

1. Before you remove the Scan Ass'y, you should

remove:

- Rear Cover (see section 3.3)

- Side Cover L (see section 3.4)

- Side Cover R (see section 3.5)

- Front Cover (see section 3.10)

2. Unplug the three connectors (OPE, CIS, scan motor)

from the Main PBA. Then remove the two Ground

Cables, as shown below.

OPE

CIS

CIS

OPE

3. Remove the four screws securing the Top Cover and

remove the Scan Ass'y, as shown below.

Scan Ass'y

Service Manual

3-9

Page 46

Disassembly and Reassembly

3.12 Scan Motor Ass'y

1. Before you remove the Scan Motor Ass'y, you should

remove:

- Rear Cover (see section 3.3)

- Side Cover L (see section 3.4)

- Side Cover R (see section 3.5)

- OPE Unit (see section 3.6)

- Front Cover (see section 3.10)

- Scan Ass'y (see section 3.11)

2. Open the OPE Unit.

3. Remove the three silver screws securing the Scan

Motor Ass'y and remove it.

Scan Motor Ass'y

4. If necessary, remove the one screw securing the Scan

Motor and release the latches from Motor Bracket in

the direction of the arrow, as shown below.

1

2

Scan Motor

Service Manual

3-10

Page 47

Disassembly and Reassembly

3.13 ADF Roller

1. Before you remove the ADF Roller, you should

remove:

- Rear Cover (see section 3.3)

- Side Cover L (see section 3.4)

- Side Cover R (see section 3.5)

- Front Cover (see section 3.10)

- Scan Ass'y (see section 3.11)

- Scan Motor Ass'y (see chapter 3.12)

2. Carefully release the ADF Gear from the ADF Roller,

as shown below.

1

3. Carefully release the ADF Roller from Top Cover in

the direction of the arrow, as shown below.

2

1

ADF Roller

2

ADF Gear

Service Manual

3-11

Page 48

Disassembly and Reassembly

3.14 Sub Hook PBA

1. Before you remove the Sub Hook PBA, you should

remove:

- Rear Cover (see section 3.3)

- Side Cover L (see section 3.4)

2. Unplug the one connector from the Sub Hook PBA,

as shown below.

3. Remove the one screws securing the Sub Hook PBA

and remove it.

Sub Hook PBA

Service Manual

3-12

Page 49

Disassembly and Reassembly

3.15 Drive Ass'y

1. Before you remove the Drive Ass'y, you should

remove:

- Rear Cover (see section 3.3)

- Side Cover L (see section 3.4)

2. Remove the six screws securing the Drive Ass'y and

remove it. Then unplug the one connector from the

Drive Motor, as shown below.

Note : When re-fitting the Drive Ass’y tighten the screws

in the order that they are numbered on the base

plate.

3.16 DC-Fan

1. Before you remove the Fan, you should remove:

- Rear Cover (see section 3.3)

- Side Cover R (see section 3.5)

Drive Ass'y

2. Unplug the one connector from the SMPS, as shown

below. Then take out the Fan.

Service Manual

3-13

DC Fan

Page 50

Disassembly and Reassembly

3.17 Exit Cover Ass'y

1. Before you remove the Exit Cover Ass'y, you should

remove:

- Scan Ass'y (see section 3.11)

- Sub High PBA (see section 3.14)

2. Remove the four screws securing the Exit Cover Ass'y

and remove it, as shown below.

Exit Cover Ass'y

3. Remove the Exit Gear and Bearing using a flat-blade

screwdriver, as shown below.

Then take out the Exit Roller.

Exit Gear

Bearing

2

Exit Roller

1

Service Manual

3-14

Page 51

Disassembly and Reassembly

3.18 LSU-Unit

1. Before you remove the LSU, you should remove:

- Scan Ass'y (see section 3.11)

2. Unplug the two connectors from the LSU, as shown

below.

3. Remove the four screws securing the LSU and

remove it.

LSU

3.19 Engine Shield Ass'y

1. Before you remove the Engine Shield Ass'y, you

should remove:

- Rear Cover (see section 3.3)

- Side Cover L (see section 3.4)

- Side Cover R (see section 3.5)

2. Remove the twelve screws securing the Engine Shield

Ass'y and remove it. Then unplug the all connectors

from the SMPS and Main PBA, Main High PBA.

Engine Shield

Ass'y

Service Manual

3-15

Page 52

Disassembly and Reassembly

3.20 Main PBA

1. Before you remove the Main PBA, you should

remove:

- Engine Shield Ass,y (see section 3.19)

2. Remove the three screws securing the Main PBA and

remove it. Then carefully release the latches from

Supporter, as shown below.

Main PBA

2

Supporter

1

Service Manual

3-16

Page 53

Disassembly and Reassembly

3.21 SMPS

1. Before you remove the SMPS, you should remove:

- Engine Shield Ass,y (see section 3.19)

2. Remove the three screws securing the Inlet Bracket

and remove it.

Inlet Bracket

4. Remove the four screws securing the SMPS and

remove it. Then Lift the SMPS out, as shown below.

SMPS

3. Unplug one connector.

Service Manual

3-17

Page 54

Disassembly and Reassembly

3.22 Fuser Ass'y

1. Before you remove the Fuser Ass'y, you should

remove:

- Engine Shield Ass,y (see section 3.19)

2. Unplug the two connectors from the Main PBA and

SMPS, as shown below. Then remove the four

screws securing the Fuser Ass'y and remove it.

4. Remove the two screws securing the Halogen Lamp.

Then take out the Halogen Lamp from the Heat

Roller, as shown below.

Heat Roller

Fuser Ass'y

Halogen Lamp

3. Remove the two screws securing the Thermostat.

Then lift the Thermostat out.

Thermostat

5. Remove one screw securing the Idle Gear and

remove it.

Idle Gear

Service Manual

3-18

Page 55

Disassembly and Reassembly

6. Remove the four screws securing the Fuser Cover

and remove it, as shown below.

Claw

Fuser Cover

7. Unwrap the Thermister Harness, as shown below.

8. Remove the one screw securing the Thermister and

remove it, as shown below.

Thermister

Thermister Harness

Service Manual

3-19

Page 56

Service Manual

Disassembly and Reassembly

3-20

Samsung Electronics

1. Before you remove the Transfer Ass'y, you should

remove:

- LSU (see section 3.18)

2. Remove the three screws securing the Transfer Earth

and remove it.

3. Unplug the PTL Holder connector, then remove the

PTL Holder and PTL Lens, as shown below.

4. Release the frame latch at the R side of the Transfer

roller and lift the roller out. Release the latch on each

bush and lift them out.

3.23 Transfer Ass'y

Transfer

Earth

PTL

Holder

PTL

Lens

Transfer

Roller

Bush

Page 57

Service Manual

Disassembly and Reassembly

3-21

Samsung Electronics

1. Before you remove the Feed Ass'y, you should

remove:

- Scan Ass'y (see section 3.11)

- Drive Ass'y (see section 3.15)

- LSU (see section 3.18)

2. Remove the two screws securing the Paper Guide

and remove it.

3. Pull up the Feed Idle Bush and Feed Idle Shaft, as

shown below.

4. Remove the three screws securing the Feed Bracket

and remove it.

5. Remove the Idle Gear and Feed Gear2.

3.24 Feed Ass'y

Paper Guide

Feed Bracket

Bush

Feed Idle

Shaft

Feed Gear2

Idle Gear

Page 58

Service Manual

Disassembly and Reassembly

3-22

Samsung Electronics

6. Remove the Feed Gear1 Ass'y. 7. Pull up the Feed Roller and Feed Roller1.

Feed Gear1

Ass'y

Feed Roller

Feed Roller1

Page 59

Service Manual

Disassembly and Reassembly

3-23

Samsung Electronics

1. Before you remove the Pick up Ass'y, you should

remove:

- Scan Ass'y (see section 3.11)

- Drive Ass'y (see section 3.15)

- LSU (see section 3.18)

- Engine Shield Ass,y (see section 3.19)

2. Remove the Pick up Gear Ass,y.

3. Take out the Pick up Ass'y, as shown below.

3.25 Pick up Ass'y

Pick up Ass'y

1

2

Bush

1. Before you remove the Solenoid, you should remove:

- Scan Ass'y (see section 3.11)

- Feed Ass'y (see section 3.25)

- Pick up Ass'y (see section 3.26)

2. Remove the two screws securing the Manual

Solenoid and Pick up Solenoid.

Then remove Manual Solenoid and Pick up Solenoid.

3.26 Solenoid

(Pick up)

Solenoid

(Manual)

Solenoid

Pick up Gear

Ass'y

Page 60

Page 61

Service Manual

Alignment & Troubleshooting

4. Adjustment and Troubleshooting

4.1 Alignment and Adjustments

4.1.1 Paper path

ADF Part

PTL

P

I

C

K

/

R

PR

CR

DR

SR

TR FR

OPC

L S U

Fuser

Toner Cartridge

1

2

3

4

5

6

8

7

Engine Part

ADF R

10

9

ER

WR

4-1

Page 62

Service Manual

Alignment & Troubleshooting

4.1.1.1 Copy & Scan Document Path

ADF Part

ADF R

10

9

ER

WR

4-2

Page 63

Service Manual

Alignment & Troubleshooting

4.1.1.2 Printer Paper Path

1) After receiving print job the printer feeds printing paper from the cassette or manual feeder.

2) The fed paper passes the paper feeding sensor. (Jam 0 occurs if the sensor is not operated within a certain time)

3) After passing the feed sensor the paper passes through the print process to the paper exit sensor.

(Jam 1 occurs if the sensor is not operated by the paper’s leading edge within a certain time)

4) After passing the exit sensor paper exits from the set. (Jam 2 occurs if the trailing edge of the paper

does not pass the exit sensor within a certain time)

Engine Part

1

2

3

4

Paper Input (Cassette)

Paper Input (Manual Feed)

Paper Out (Face Down)

5

6

7

Paper Empty Sensor (Cassette)

Paper Feed Sensor

Paper Exit Sensor

Paper Empty Sensor (Manual)

PTL

P

I

C

K

/

R

PR

CR

DR

SR

TR FR

OPC

L S U

Fuser

Toner Cartridge

1

2

3

4

5

6

7

4-3

Page 64

Service Manual

Alignment & Troubleshooting

4.1.2 Clearing Paper Jams

Occasionally paper can become jammed during a print job. Some of the causes include:

• The tray is loaded improperly or overfilled.

• The tray has been pulled out during a print job.

• The front cover has been opened during a print job.

• Paper was used that does not meet paper specifications.

• Paper that is outside of the supported size range was used.

If a paper jam occurs the On Line/Error LED on the control panel lights red. Find and remove the jammed

paper. If you don't see the paper, open the covers.

Do not use a tweezers, pincers or other metal tools when removing a jam.

This could damage the internal mechanism causing print quality problems or possibly electrical shock..

Paper Jam0

PTL

P

I

C

K

/

R

PR

CR

DR

SR

TR FR

Empty Sensor

OPC

L S U

Fuser

Toner Cartridge

EXIT

Sensor

Feed

Sensor

MP Sensor

Paper Jam1

PTL

P

I

C

K

/

R

PR

CR

DR

SR

TR FR

Empty Sensor

OPC

L S U

Fuser

Toner Cartridge

EXIT

Sensor

Feed

Sensor

MP Sensor

Paper Jam2

PTL

P

I

C

K

/

R

PR

CR

DR

SR

TR FR

Empty Sensor

OPC

L S U

Fuser

Toner Cartridge

EXIT

Sensor

Feed

Sensor

MP Sensor

Bypass Jam

L S U

Fuser

EXIT

PR

Sensor

Empty Sensor

CR

DR

OPC

SR

PTL

TR FR

Toner Cartridge

MP Sensor

Feed

Sensor

R

/

K

C

I

P

4-4

Page 65

Service Manual

Alignment & Troubleshooting

4.1.2.1 Clearing Document Jams

When a document jams while passing through the ADF (Automatic Document Feeder) "Document Jam" appears on the

display.

4.1.2.1(a) Input Misfeed

1) Remove the remaining documents from the ADF.

2) Pull the jammed document gently out of the ADF.

3) Load the documents back into the ADF.

NOTE :To prevent document jams do not use thick, thin or mixed documents.

4-5

Page 66

Alignment & Troubleshooting

4.1.2.1(b) Exit Misfeed

1) Remove the remaining documents from the ADF.

2) Open the control panel by gripping its lower front edge and lifting gently.

3) Pull the document gently out of the ADF.

4) Close the control panel, then load the documents back into the ADF.

Service Manual

4-6

Page 67

Service Manual

Alignment & Troubleshooting

4.1.2.2 Clearing Paper Jams

When a paper jam occurs, "Paper Jam" appears on the display. Refer to the table below to locate and clear the paper jam.

To avoid tearing the paper pull the jammed paper out gently and slowly. Follow the steps on the next pages to clear the jam.

4.1.2.2.1 In the Paper Tray

1) Open and close the front cover. The jammed paper is automatically ejected from the machine. If the paper is not ejected

continue to step 2.

2) Pull the paper tray open.

Message Location of Jam

Paper Jam 0 In the paper tray.

Paper Jam 1 In the fuser area or around the toner

cartridge.

Paper Jam 2 In the paper exit area

Bypass Jam In the manual feeder

4-7

Page 68

Alignment & Troubleshooting

3) Remove the jammed paper by gently pulling it straight out.

If there is any resistance and the paper does not move when you pull or if you cannot see the paper in this area, skip to

the fuser area around the toner cartridge.

4) Insert the paper tray into the machine until it snaps into place.

5) Open and close the front cover to resume printing.

Service Manual

4-8

Page 69

Service Manual

Alignment & Troubleshooting

4.1.2.3 In the Paper Exit Area

1) Open and close the front cover. The jammed paper is automatically ejected from the machine. If the paper is not

ejected continue to step 2.

2) Gently pull the paper out of the front output tray. Skip to step 6.

If there is any resistance and the paper does not move when you pull or if you cannot see the paper in the front output tray continue to step 3.

3) Open the rear cover.

4) Remove the jammed paper by gently pulling it straight out.

5) Close the rear cover.

6) Open and close the front cover to resume printing.

4-9

Page 70

Service Manual

Alignment & Troubleshooting

4.1.2.4 In the Fuser Area or Around the Toner Cartridge

NOTE :The fuser area is hot. Take care when removing paper from the machine.

1) Open the front cover and lightly push down on the cartridge then pull to take it out.

2) Remove the jammed paper by gently pulling it straight out.

3) Replace the toner cartridge and close the front cover.

Printing automatically resumes.

4-10

Page 71

Service Manual

Alignment & Troubleshooting

4.1.2.5 In the Bypass Tray

"Bypass Jam" appears on the display when you try to print using the manual feeder and the machine does not detect

paper due to no paper or improper paper loading.

The error message may also occur when the paper is not properly fed into the machine through the manual feeder.

In this case pull the paper out of the machine.

4.1.2.6 Tips for Avoiding Paper Jams

By selecting the correct paper types most paper jams can be avoided. When a paper jam occurs follow the steps outlined in page 6-10

• Follow the procedures on page 6-10 when you load paper. Ensure that the adjustable guides are positioned correctly.

• Do not overload the paper tray. Ensure that the paper is below the paper capacity mark on the inside wall of the paper tray.

• Do not remove the paper from the tray while your machine is printing.

• Flex, fan and straighten the paper before loading.

• Do not use creased, damp or highly curled paper.

• Do not mix paper types in the paper tray.

• Use only recommended print materials. See "Paper Specifications" in the user manual.

• Ensure that the print side of print materials is facing down in the paper tray and facing up in the Bypass tray.

4-11