Page 1

PARTS MANUAL

MODEL SP2S20H

SELF-PROPELLED

PROFESSIONAL PAVEMENT SAW

(HONDA GX630RTXF2 GASOLINE ENGINE)

Revision #0 (02/17/2012)

To find the latest revision of this

publication, visit our website at:

www.multiquip.com

THIS MANUAL MUST ACCOMPANY THE EQUIPMENT AT ALL TIMES.

PN: 35524

Page 2

PROPOSITION 65 WARNING

Engine exhaust and some of

its constituents, and some dust created

by power sanding, sawing, grinding,

drillingandotherconstructionactivities

contains chemicals known to the State

of California to cause cancer, birth

defects and other reproductive harm.

Some examples of these chemicals are:

Leadfromlead-basedpaints.

Crystallinesilicafrombricks.

Cementandothermasonryproducts.

Arsenicandchromiumfrom chemically

treatedlumber.

Your risk from these exposures varies,

dependingonhowoftenyoudothistype

of work. To reduce your exposure to

these chemicals: work in aALWAYS

well ventilated area, and work with

approved safety equipment, such as

dust masks that are specially designed

to filter out microscopic particles.

PAGE 2 — SP2S20H PAVEMENT SAW • OPERATION AND PARTS MANUAL — REV. #0 (02/17/12)

Page 3

SILICOSIS/RESPIRATORY WARNINGS

WARNING

SILICOSIS WARNING RESPIRATORY HAZARDS

Grinding/cutting/drilling of masonry, concrete, metal and

other materials with silica in their composition may give

off dust or mists containing crystalline silica. Silica is a

basic component of sand, quartz, brick clay, granite and

numerous other minerals and rocks. Repeated and/or

substantial inhalation of airborne crystalline silica can

cause serious or fatal respiratory diseases, including

silicosis. In addition, California and some other

authorities have listed respirable crystalline silica as a

substance known to cause cancer. When cutting such

materials, always follow the respiratory precautions

mentioned above.

WARNING

Grinding/cutting/drilling of masonry, concrete, metal and

other materials can generate dust, mists and fumes

containing chemicals known to cause serious or fatal

injury or illness, such as respiratory disease, cancer,

birth defects or other reproductive harm. If you are

unfamiliar with the risks associated with the particular

process and/or material being cut or the composition of

the tool being used, review the material safety data

sheet and/or consult your employer, the material

manufacturer/supplier, governmental agencies such as

OSHA and NIOSH and other sources on hazardous

materials. California and some other authorities, for

instance, have published lists of substances known to

cause cancer, reproductive toxicity, or other harmful

effects.

Control dust, mist and fumes at the source where

possible. In this regard use good work practices and

follow the recommendations of the manufacturers or

suppliers, OSHA/NIOSH, and occupational and trade

associations. Water should be used for dust

suppression when wet cutting is feasible. When the

hazards from inhalation of dust, mists and fumes cannot

be eliminated, the operator and any bystanders should

always wear a respirator approved by NIOSH/MSHA for

the materials being used.

SP2S20H PAVEMENT SAW • OPERATION AND PARTS MANUAL — REV. #0 (02/17/12) — PAGE 3

Page 4

SP2S20H Pavement Saw

Proposition 65 Warning ........................................... 2

Silicosis/Respiratory Warnings ................................ 3

Table Of Contents .................................................... 4

Parts Ordering Procedures ...................................... 5

Explanation Of Code In Remarks Column............... 6

Suggested Spare Parts ........................................... 7

Component Drawings

Nameplate and Decals Assembly .........................8-9

Under Carriage Assembly ................................10-11

Blade Shaft Assembly ......................................12-13

Lifting Bale Assembly. ....................................... 14-15

Console Assembly ............................................ 16-17

Engine Mount Assembly ................................... 18-19

Engine Assembly .............................................. 20-21

Pointers and Covers Assembly. ........................ 22-23

Water System Assembly ................................... 24-25

Blade Guard Assembly ..................................... 26-27

Manual Raise and Lower Assy. (20-in.) ............ 28-29

Battery Assembly.............................................. 30-31

Transmission Engage Lever Assembly ............ 32-33

Hydrostatic Transmission Assembly ................34-35

Hydrostatic Drive Assembly .............................. 36-37

TABLE OF CONTENTS

Terms and Conditions Of Sale — Parts ................. 38

NOTICE

Specifications are subject to change without notice.

PAGE 4 — SP2S20H PAVEMENT SAW • OPERATION AND PARTS MANUAL — REV. #0 (02/17/12)

Page 5

PARTS ORDERING PROCEDURES

Ordering parts has never been easier!

If you have an MQ Account, to obtain a Username

Effective:

Choose from three easy options:

January 1st, 2006

Best Deal!

Order via Internet (Dealers Only):

Order parts on-line using Multiquip’s SmartEquip website!

■ View Parts Diagrams

■ Order Parts

■ Print Specifi cation Information

Goto www.multiquip.com and click on

Order Parts

to log in and save!

Order via Fax (Dealers Only):

All customers are welcome to order parts via Fax.

Domestic (US) Customers dial:

1-800-6-PARTS-7 (800-672-7877)

Order via Phone:

Non-Dealer Customers:

Contact your local Multiquip Dealer for

parts or call 800-427-1244 for help in

locating a dealer near you.

and Password, E-mail us at: parts@multiquip.

com.

To ob ta in an MQ Account , contac t yo ur

District Sales Manager for more information.

Use the internet and qualify for a 5% Discount

on Standard orders for all orders which include

complete part numbers.*

Fax your order in and qualify for a 2% Discount

on Standard orders for all orders which include

complete part numbers.*

Domestic (US) Dealers Call:

1-800-427-1244

International Customers should contact

their local Multiquip Representatives for

Parts Ordering information.

Note: Discounts Are Subject To Change

Note: Discounts Are Subject To Change

When ordering parts, please supply:

❒ Dealer Account Number

❒ Dealer Name and Address

❒ Shipping Address (if different than billing address)

❒ Return Fax Number

❒ Applicable Model Number

❒ Quantity, Part Number and Description of Each Part

NOTICE

All orders are treated as Standard Orders and will

ship the same day if received prior to 3PM PST.

❒ Specify Preferred Method of Shipment:

✓ UPS/Fed Ex ✓ DHL

■ Priority One ✓ Truck

■ Ground

■ Next Day

■ Second/Third Day

www.multiquip.com

WE ACCEPT ALL MAJOR CREDIT CARDS!

SP2S20H PAVEMENT SAW • OPERATION AND PARTS MANUAL — REV. #0 (02/17/12) — PAGE 5

Page 6

EXPLANATION OF CODE IN REMARKS COLUMN

The following section explains the different symbols and

QTY. Column

— Item quantity can be indicated by a

A/R (As Required) is generally used for hoses or other

A blank entry generally indicates that the item is not sold

separately. Other entries will be clarified in the “Remarks”

Some of the most common notes found in the “Remarks”

Column are listed below. Other additional notes needed

same unique symbol will be included when this item is

— Used to list an effective serial

— Indicates that the part

part is NOT used on a specific model or model number

available items. Examples include battery cables, shims,

— Indicates that an item cannot

be purchased as a separate item and is either part of an

assembly/kit that can be purchased, or is not available

remarks used in the Parts section of this manual. Use the

help numbers found on the back page of the manual if there

are any questions.

Numbers Used

number, a blank entry, or A/R.

NOTICE

The contents and part numbers listed in the parts

section are subject to change without notice. Multiquip

does not guarantee the availability of the parts listed.

SAMPLE PARTS LIST

NO. PART NO. PART NAME QTY. REMARKS

1 12345 BOLT ......................1 .....INCLUDES ITEMS W/%

2% WASHER, 1/4 IN. ...........NOT SOLD SEPARATELY

2% 12347 WASHER, 3/8 IN. ...1 .....MQ-45T ONLY

3 12348 HOSE ..................A/R ...MAKE LOCALLY

4 12349 BEARING ..............1 .....S/N 2345B AND ABOVE

NO. Column

Unique Symbols — All items with same unique

symbol

(@, #, +, %, or >) in the number column belong to the

same assembly or kit, which is indicated by a note in the

“Remarks” column.

Duplicate Item Numbers — Duplicate numbers indicate

multiple part numbers, which are in effect for the same

general item, such as different size saw blade guards in

use or a part that has been updated on newer versions

of the same machine.

NOTICE

When ordering a part that has more than one item

number listed, check the remarks column for help in

determining the proper part to order.

PART NO. Column

Numbers Used — Part numbers can be indicated by a

number, a blank entry, or TBD.

TBD (To Be Determined) is generally used to show a

part that has not been assigned a formal part number

at the time of publication.

A blank entry generally indicates that the item is not sold

separately or is not sold by Multiquip. Other entries will

be clarified in the “Remarks” Column.

parts that are sold in bulk and cut to length.

Column.

REMARKS Column

to describe the item can also be shown.

Assembly/Kit — All items on the parts list with the

purchased.

Indicated by:

“INCLUDES ITEMS W/(unique symbol)”

Serial Number Break

number range where a particular part is used.

Indicated by:

“S/N XXXXX AND BELOW”

“S/N XXXX AND ABOVE”

“S/N XXXX TO S/N XXX”

Specific Model Number Use

is used only with the specific model number or model

number variant listed. It can also be used to show a

variant.

Indicated by:

“XXXXX ONLY”

“NOT USED ON XXXX”

“Make/Obtain Locally” — Indicates that the part can

be purchased at any hardware shop or made out of

and certain washers and nuts.

“Not Sold Separately”

for sale through Multiquip.

PAGE 6 — SP2S20H PAVEMENT SAW • OPERATION AND PARTS MANUAL — REV. #0 (02/17/12)

Page 7

SUGGESTED SPARE PARTS

SP2 S20H SAW WITH HO NDA GX630RTXF2

GASOLINE ENGINE

1 to 3 units

Qty. P/N Description

3............15897 ...................................V-BELTS, DRIVE

1............07055-050 ...........................V-BELTS, TRANSMISSION

1............29013-001 ...........................WRENCH, BOX END 1-1/2 IN.

1............60087 ...................................ROPE, FRONT POINTER 1/4 IN.

2............15081 ...................................GRIPS, HANDLE BAR 1 IN.

1............06922-003 ...........................BLADE SHAFT NUT, RIGHT

1............07038-016 ...........................BLADE SHAFT NUT, LEFT

1............26928-004 ...........................OUTER BLADE FLANGE

3............17210Z6LP821575 ..............ELEMENT, AIR CLEANER

3............15400PLMA01PE ................OIL FILTER

3............9807955876 .........................SPARK PLUG

1............15229 ...................................CAP, W/GUAGE

1............35480Z6L003 ......................SWITCH, ASSY., OIL LEVEL

1............16910Z6L003 ......................STRAINER, FUEL

1............9820043000 .........................FUSE, MINI, 30A

1............35110ZV5V50 ......................KEY, IGNITION

NOTICE

Part number on this Suggested Spare Parts list may

supersede/replace the P/N shown in the text pages of

this book..

SP2S20H PAVEMENT SAW • OPERATION AND PARTS MANUAL — REV. #0 (02/17/12) — PAGE 7

Page 8

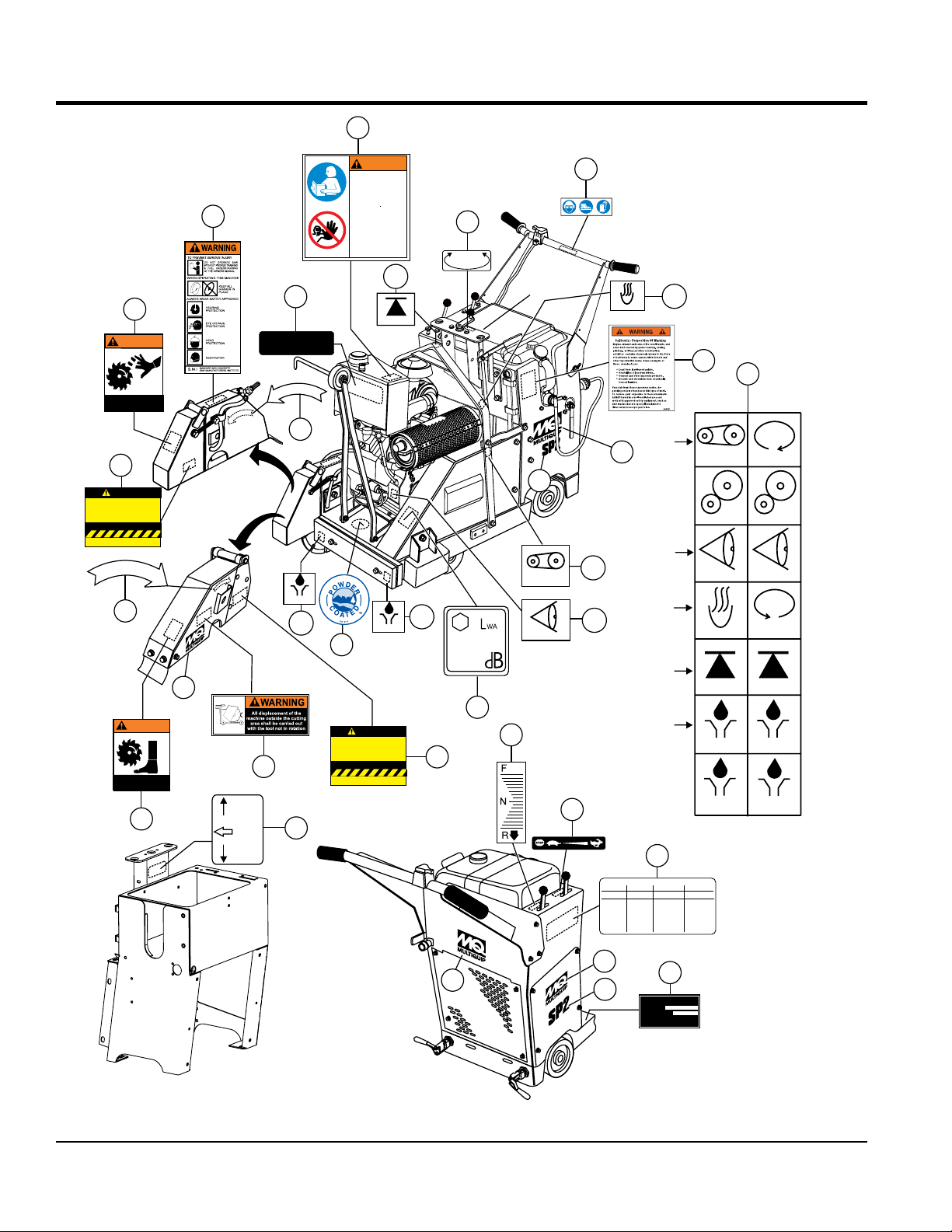

NAMEPLATE AND DECALS

8

3

5

114

LUBRICATION

LUBRICATION

KEEP FEET

CLEAR

WARNING

CHECK

GEAR DRIVE

GEAR DRIVE

CHECK

HOT

BELT DRIVE

CLOCKWISE

COUNTER

CLOCKWISE

LUBRICATION

LUBRICATION

LIFTING POINTLIFTING POINT

LUBRICATION

LUBRICATION

DECAL SHEET

INTL STDS ISO

P/N 11246

C

E

B

D

A

BLADE

LOWER

RAISE

35136

LIFTING POINT

UNLEADED GASOLINE

ONLY

MAX 10% ETHANOL

9

CAUTION

When Larger Blade and Guard

is Installed, Belt Drive MUST

Be Changed to Proper Size.

See Owners Manual.

S.M.I. MASONRYAND CONCRETE

SAW MANUFACTURER’S INSTITUTE

FAILURETO COMPLY COULD RESULT

IN SERIOUS BODILYINJURY.

CAUTION

When Larger Blade and Guard

is Installed, Belt Drive MUST

Be Changed to Proper Size.

See Owners Manual.

S.M.I. MASONRYAND CONCRETE

SAW MANUFACTURER’S INSTITUTE

FAILURETO COMPLY COULD RESULT

IN SERIOUS BODILYINJURY.

13

12

1

15

1

4

To avoid injury,

you MUST read

and understand

operator’s manual

before using this

machine.

Ask for training

as needed.

This machine to

be operated by

qualified

personnel only.

P/N 35137

WARNING

6

2

8

22

14

16

22E

22E

22A

22D

22C

P/N

360

99

ENGAGE

DRIVE

LEVER

DISENGAGE

P/N 35135

MODEL

SERIAL NO.

8

RECOMMENDED MAINTENANCE

CHECK

LUBRICATE CLEAN

DAILY:

OCCASIONALLY:

ENGINE OIL

SPINDLE BEARINGS

AIR CLEANER

(WHEN CUTTING DRY)

BELTTENSION

HYDROSTATIC

TRANSMISSION OIL

HYDRAULIC LIFT

SYSTEM RESERVOIR

(IF SO EQUIPPED)

ALLBEARINGS

SUBFRAME PIVOT

REARAXLE

JACK SHAFT

HANDWHEEL

(IF SO EQUIPPED)

CLEVIS PINS

ROLLER CHAINS

FRONTWHEEL BEARINGS

LIFTMECHANISM

SCREW

(IF SO EQUIPPED)

FUELSTRAINERS

FILTERS

AIR CLEANER

WATER PUMP

INLETSTRAINER

COMPLETE MACHINE

23596-001

19

8

17

18

9

20

7

21

11

22B

CHECK

O

R

WARNING

KEEP HANDS

CLEAR

A

T

T

I

O

N

A

T

O

R

T

I

HOT

O

N

10

BELT DRIVE

PAGE 8 — SP2S20H PAVEMENT SAW • OPERATION AND PARTS MANUAL — REV. #0 (02/17/12)

Page 9

NAMEPLATE AND DECALS

NO. PART NO. PART NAME QTY. REMARKS

1 23330-001 DECAL, CAUTION, BELT GUARD 2

2 25249-001 DECAL, WARNING, KEEP HANDS CLEAR 1

3 22122-001 DECAL, WARNING, SERIOUS INJURY 1

4 23587 DECAL, UNLEADED GASOLINE ONLY 1

5 35137 DECAL, WARNING, READ MANUAL 1

6 35136 DECAL, BLADE RAISE/ LOWER 1

7 36099 DECAL, PROTECTIVE CLOTHING 1

8 20525 DECAL, PROP. 65, 3.25" X 4.25" 1

9 38213 DECAL, MQ MULTIQUIP 5

10 38224 DECAL, SP2, BLACK 5" X 3" 2

11 35308 DECAL, GUARANTEED SOUND PWR. 114 DB. 1

12 13118 DECAL, POWDER COATED 1

13 25678 DECAL, CCW BLADE ROTATION 1

14 25491 DECAL, CW BLADE ROTATION 1

15 25867 DECAL, ROTATION DISPLACEMENT 1

16 25260-001 DECAL, WARNING, KEEP FEET CLEAR 1

17 28853-001 DECAL, FORWARD/REVERSE LEVER 1

18 29736 DECAL, THROTTLE 1

19 23596-001 DECAL, RECOMMENDED MAINTENANCE 1

20 NAMEPLATE ......................................................1................CONTACT MQ PARTS DEPT.

21 35135 DRIVE LEVER 1

22A 11246 DECAL, BELT DRIVE 1

22B 11246 DECAL, CHECK OIL LEVEL 1

22C 11246 DECAL, HOT 1

22D 11246 DECAL, LIFTING POINT 1

22E 11246 DECAL, LUBRICATION 2

SP2S20H PAVEMENT SAW • OPERATION AND PARTS MANUAL — REV. #0 (02/17/12) — PAGE 9

Page 10

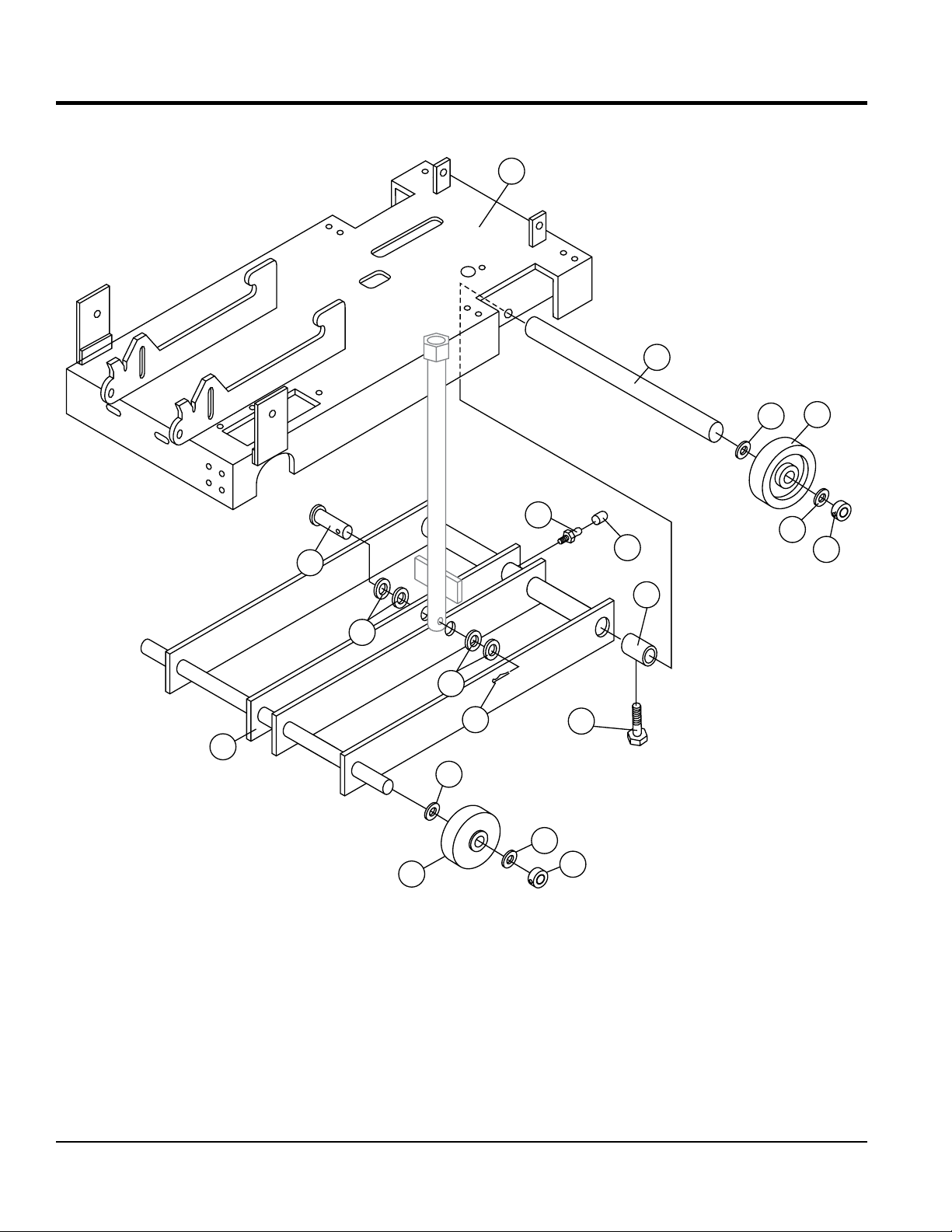

UNDER CARRIAGE ASSY.

1

2

4

6

13

9

10

10

11

3

6

5

12

6

8

14

7

6

8

PAGE 10 — SP2S20H PAVEMENT SAW • OPERATION AND PARTS MANUAL — REV. #0 (02/17/12)

Page 11

UNDER CARRIAGE ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1 28777-352 FRAME ASSY. 16”/18”/20” 1

2 28781-002 AXLE, REAR 1

3 28782-351 FRAME, UNDERCARRIAGEE ASSY. 1

4 28086-001 WHEEL, 8 X 2 .75 ROLLER BEARING REAR 2

5 28085-001 WHEEL, 5 X 2 .75 ROLLER BEARING FRONT 2

6 8151 WASHER, FLAT SAE 3/4 8

7 10065-090 BEARING PLAIN 2

8 25181-001 COLLAR, SET 0.75 X 1.50 X .50, SPLIT 4

9 8081 PIN, CLEVIS 1/2 X 2-3/4 1

10 0447 WASHER, FLAT SAE 1/2 4

11 2219 PIN, COTTER 1/8D X 1 1

12 25490 SCREW, SHS 5/16-18 X 3/8 2

13 2621 ZERK, GREASE STR. 1/4-28 1

14 1162 A CAP, ZERK FITTING 1

SP2S20H PAVEMENT SAW • OPERATION AND PARTS MANUAL — REV. #0 (02/17/12) — PAGE 11

Page 12

BLADE SHAFT ASSY.

8

9

7

20

5

16

LUBRICATION

4

15

POINT

3

ENGINE PULLEY

2

1

6

15

12

2

11

13

17

18

16

LUBRICATION

POINT

14

PAGE 12 — SP2S20H PAVEMENT SAW • OPERATION AND PARTS MANUAL — REV. #0 (02/17/12)

19

Page 13

BLADE SHAFT ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1 28807-002 SPINDLE, BLADE 1

2 28081-001 BEARING, PILLOW BLK 1.25ID AS206-20 2

3 28811-002 FLANGE, BLADE INSIDE 4.0OD X 1.0ID 1

4 26928-004 FLANGE, BLADE OUTSIDE 1.0ID X4.0OD X 56 1

5 0125 KEY, WOODRUFF #15 1

6 6059 B KEY, 1/4”SQ. X 2”, 1018 STOCK 1

7 06922-003 NUT, HEX JAM LH 1-14 PLATED 1

8 06502-012 SCREW, HHC 7/16-14 X 1-1/2 4

9 2955 WASHER, LOCK 7/16 ZINC 4

10 0448 WASHER, FLAT SAE 7/16 4

11 35447 PULLEY, BLADE SHAFT, 4F3V412X1.25 .........1................4 GROOVE

12 1528 SCREW, SHS 2

13 28841-001 BUSHING, SPLIT TYPE 1

14 0424 SCREW, 1/4-20 X 1-1/4 3

15 2621 ZERK FITTING 2

16 1162 A CAP,GREASE ZERK, #2 RED 2

17 15897 V-BELT, 3V x 355 4

18 23250-002 SPACER, SPINDLE 1

19 07038-016 NUT, HEX JAM 1”-14 PLATED 1

20 24894-024 PIN, DOWEL 3/8 x 1-1/4 LG 1

SP2S20H PAVEMENT SAW • OPERATION AND PARTS MANUAL — REV. #0 (02/17/12) — PAGE 13

Page 14

1

LIFTING BALE ASSY.

5

5

2

6

6

4

3

PAGE 14 — SP2S20H PAVEMENT SAW • OPERATION AND PARTS MANUAL — REV. #0 (02/17/12)

Page 15

LIFTING BALE ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1 28890-351 LIFT BALE 1

2 28893-002 BRACE, LIFT BAIL 1

3 22106 SCREW, HHFS 3/8-16 X 1-1/4 2

4 10133 NUT, NYLOC 3/8-16 2

5 49071 NUT, FLANGED SERRATED PLTD 5/16-18 2

6 9091 SCREW, HHFS 5/16-18 X 1 GR5 2

SP2S20H PAVEMENT SAW • OPERATION AND PARTS MANUAL — REV. #0 (02/17/12) — PAGE 15

Page 16

CONSOLE ASSY.

12

15

16

5

7

4

3

1

13

2

3

9

14

12

3

9

8

PAGE 16 — SP2S20H PAVEMENT SAW • OPERATION AND PARTS MANUAL — REV. #0 (02/17/12)

Page 17

CONSOLE ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1 28796-351 HANDLE ASSY. 1

2 15081 GRIP, 1” ID 2

3 38274 SCREW, HHC 3/8-16 X .75 4

4 1475 CONNECTOR SPLICE TAP 1

5 35127 SWITCH, KILL MAGURA 1

6 28091-401 SHIFT CONTROL ASSY. 1

7 35299 SCREW, PHP M4-0.7X25MM 2

8 28834-001 COVER, REAR 1

9 19266 NUT, BLIND 1/4-20X.27-165 8

12 49048 SCREW, HHFS 1/4-20 X 3/4 GRD 5 4

13 35155 HARNESS, FCG KILL SWITCH 1

14 28791-351 HOUSING ASSY. 1

15 28805-001 COVER, CONSOLE SIDE 1

16 29013-001 WRENCH, BOX END 1 1/2 1

SP2S20H PAVEMENT SAW • OPERATION AND PARTS MANUAL — REV. #0 (02/17/12) — PAGE 17

Page 18

3

ENGINE MOUNT ASSY.

6

7

4

2

9

5

2

2

1

7

8

2

5

PAGE 18 — SP2S20H PAVEMENT SAW • OPERATION AND PARTS MANUAL — REV. #0 (02/17/12)

Page 19

ENGINE MOUNT ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1 15868-032 SCREW, SQHS 1/2-13 X 4, CUP PLAIN 1

2 0447 WASHER, FLAT SAE 1/2 9

3 968011 NUT, HEX FINISH 1/2-13 1

4 10176 NUT, NYLOC 1/2-13 4

5 3214 SCREW, HHC 1/2-13 X 1-1/4 4

6 9154 SCREW, HHC 3/8-16 X 1- 3/4 4

7 10136 WASHER, FLAT SAE 3/8 8

8 10133 NUT, NYLOC 3/8-16 4

9 35507 ENGINE BASE ASSY. 1

SP2S20H PAVEMENT SAW • OPERATION AND PARTS MANUAL — REV. #0 (02/17/12) — PAGE 19

Page 20

11

ENGINE ASSY.

31

17

15

32

27

29

26

22

13

23

24

25

12

21

14

35

20

34

18

19

TO FUEL

PUMP

33

7

6

8

9

5

6

4

3

7

2

10

16

1

28

30

36

38

37

39

3

44

5

4

46

2

NOTES:

1

2

3

4

5

6

7

SEE BLADE SHAFT

ASSY., ITEM 11

SEE BLADE SHAFT

ASSY., ITEM 17

SEE HYDROSTATIC DRIVE

ASSY., ITEM 14

SEE

HYDROSTATIC DRIVE

ASSY., ITEM 15

SEE

HYDROSTATIC DRIVE

ASSY., ITEM 25

ITEM 5, FWD/REV CONTROL

LEVER INCLUDES CABLE

ITEM 3, SPEED CONTROL

LEVER INCLUDES 50 IN.

(1270 MM.) CABLE

40

41

42

43

45

1

PAGE 20 — SP2S20H PAVEMENT SAW • OPERATION AND PARTS MANUAL — REV. #0 (02/17/12)

Page 21

ENGINE ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1 12277 CLAMP, HOSE WORM #36, 1-13/16 X 2-3/4 2

2 35110ZV5V50 KEY, IGNITION 2

3 15168 HANDLE, CONTROL, W/KNOB AND CABLE ............1 ....SPEED CONTROL

4 10024 NUT, NYLOC 1/4-20 4

5 28091-401 HANDLE, CONTROL, W/KNOB AND CABLE ............1 ....FWD./REV.

6 0948 WASHER, FLAT SAE 1/4 4

7 0131 A SCREW, HHC 1/4-20 X 3/4 4

8 35280 CABLE, CHOKE CONTROL 35 IN. 1

9 9820043000 FUSE, MINI, 30 AMP 1

10 35100Z6L003 SWITCH ASSY., COMBINATION 1

11 60004 HOSE,FUEL .187 D 50PSI LOW PERM 1

12 23508 VALVE, ROLL OVER, STD CP 1

13 23507 GROMMET, ROLL OVER VALVE 1

14 35503 FUEL TANK W\A, 20 HON SP2 1

15 2712 CAP, W/GAUGE 7.5", "UNLEADED", EPA 1

16 23505 CANISTER, CARBON, 390CC 1

17 60028 HOSE,FUEL .312 D 50PSI LOW PERM. 1

18 950024100008 CLAMP, TUBE (D10) 2

19 16850Z6L000 TUBE COMP. A. FUEL 1

20 16910Z6L003 FILTER, FUEL 1

21 60013 HOSE,FUEL .250 D 50PSI LOW PERM. 1

22 22082 FITTING, BRASS 90 4BARB -1/4MP 1

23 12464 SCREW, HHC M6-1.0 X 16 MM 4

24 9501858320 BAND AIR CLEANER CONNECTING TUBE 2

25 17251Z6L810 TUBE, AIR CLEANER CONNECTING 1

26 17320Z6LH001377 RAIN CAP 1

27 9501858320 BAND A/C CONNECTING TUBE 2

28 17300Z6LP522958 VACUATOR VALVE 1

29 17210Z6LP821575 AIR FILTER ELEMENT 1

30 957010601600 BOLT, FLANGE, 6X16 2

31 35480Z6L003 SWITCH, ASSY., OIL LEVEL 1

32 91309Z6L000 O-RING 37.9 X 2.4 1

33 2299 SCREW, HHC M8-1.25 X 16MM 2

34 35522 MUFFLER KIT, GX630 HI LEFT, HONDA VHLM 1

35 35517 MOUNT, FUEL TANK W/A, SP2 20 HONDA 1

36 19266 NUT, BLIND 1/4-20 X .027-.165 2

37 35518 ENGINE, HONDA 20HP GX630RTXF2 1

38 49048 SCREW, HHFS 1/4-20 x 3/4 GR5 2

39 17300Z6LP522840 PIPE PLUG 1

39 31200Z6L003 MOTOR ASSY., STARTER 1

41 6059 B KEY 1/4" SQ. X 2, 1018 STOCK 1

42 35513 BRACKET, IDLER SPRING 1

43 0161 C WASHER, LOCK 5/16 MED 2

44 16105 SCREW, HHC 5/16-24 x 3/4 PLATED 2

45 15400PLMA01PE FILTER, OIL 2

46 35446 PULLEY, ENG. 43V26/A30 X 1-1/8" 5 GROOVE 1

SP2S20H PAVEMENT SAW • OPERATION AND PARTS MANUAL — REV. #0 (02/17/12) — PAGE 21

Page 22

11

POINTERS AND COVERS ASSY.

9

4

11

7A

7

8

15

1

9

9

20

12

9

6

22

21

22

20

23

9

24

13

9

5

12

3

2

10

19

9

PAGE 22 — SP2S20H PAVEMENT SAW • OPERATION AND PARTS MANUAL — REV. #0 (02/17/12)

16

13

14

Page 23

POINTERS AND COVERS ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1 28646-351 BLADE GUIDE WELDMENT 1

2 28649-001 SPANNER BUSHING CSI 1

3 28648-001 WHEEL, 3.00 X 1.25 .50 ID POLY CSI 1

4 28647-001 POINTER 1

5 1456 NUT, HEX FINISH 3/8-16 2

6 10133 NUT, NYLOC 3/8-16 2

7 15830 SASH, ASSY. .....................................................2................INCLUDES ITEMS W/%

7A% 15114 SLEEVE, SASH 2

8% 60087 ROPE, 1/4” NYLON, BRAIDED, WHITE 8' ........1................8 FT. REQUIRED

9 36720 SCREW, HHFS 5/16-18 X 3/4 GR5 9

10 49071 NUT, FLANGED 5/16-16 X 1-1/4" GR. 5 1

11 35358 PALNUT, U, 5/16-18 X .05/.20 PANEL 3

12 10136 WASHER, FLAT SAE 3/8 4

13 0166 A WASHER, LOCK 3/8 MED. 2

14 0205 SCREW, HHC 3/8-16 X 1.0 3

15 35511 BELT GUARD, SP2 20 HONDA 1

16 28835-001 GUARD, PULLEY 1

19 29745-554 SPINDLE GUARD ASSY. - RED 1

20 1023 SCREW, HHC 3/8-16 X 1-1/4 GR5 7

21 35509 GUARD, BELT 1

22 49048 SCREW HHFS 1/4-20X3/4 GR.5 3

23 11534 NUT, "U" TYPE, 1/4-20 2

24 49070 NUT, FLANGED 1/4-20 SERRATED PLTD 1

SP2S20H PAVEMENT SAW • OPERATION AND PARTS MANUAL — REV. #0 (02/17/12) — PAGE 23

Page 24

11

TER SOURCE

WATER SYSTEM ASSY.

13

A

16

1

10

12

17

15

14

8

7A

6

9

1

A

7

CONNECT

WA

HERE

2

5

2

4

1

3

NOTES:

INCLUDED WITH

1

ITEM 4

INCLUDED WITH

2

ITEM 6

PAGE 24 — SP2S20H PAVEMENT SAW • OPERATION AND PARTS MANUAL — REV. #0 (02/17/12)

Page 25

WATER SYSTEM ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1 12694-008 HOSE CLAMP, SPRING TYPE 7/8 O.D HOSE 4

2 60088 HOSE, PVC BRAIDED .5 I.D. X .75 O.D. 1

3 23566-001 FITTING, PLASTIC 90 1/2MP X 1/2BARB 1

4 23259-001 VALVE, BALL 1/2 MPT BRASS NIBCO T585-70 1

5 23254-001 FITTING, NIPPLE 1/2MP X 2 GALV. 1

6 2399 U-BOLT 1" I.D. PLTD. W/NUTS 1

7 15544 FITTING, BRASS 1/2FP-3/4F GRDN., STR 1

7A 13336-001 WASHER, GARDEN HOSE 1

8 24778-001 FITTING, BRASS 1/2 BARB X 3/4 GRDN 1

9 1662 TIE, CABLE TY-RAP BLACK 2

10 28861-501 TRIM, WATER TANK RUBBER 1

11 28089-001 TANK, WATER ASSY., 5 GAL. .....................................1 ........... INCLUDES ITEM W/ *

12 60002 HOSE, PVC CLEAR, .375 X .5 X 1.58" 2

13 28862-001 CORD, TANK RETAINER 1

14 28860-001 KNOB 1

15 1579 HHCS 1/4-20 x 1/2 1

16* 28089-002 VALVE, WATER TANK (SPIGOT ONLY) 1

17 0181 B WASHER, LOCL 1/4" MEDIUM 1

SP2S20H PAVEMENT SAW • OPERATION AND PARTS MANUAL — REV. #0 (02/17/12) — PAGE 25

Page 26

BLADE GUARD ASSY.

8

19

16

11

17

18

3

10

15

4

6

3

7

14

13

12

9

17

15

18

2

15

5

1

PAGE 26 — SP2S20H PAVEMENT SAW • OPERATION AND PARTS MANUAL — REV. #0 (02/17/12)

Page 27

BLADE GUARD ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1 29406-354 BLADE GUARD ASSY., SP20" .....................................1 ........... SAFETY ITEM

2 28729-002 GUARD, SPLASH BLADE 1

3 60021 HOSE, 3/8ID X 5/8 OD BRAIDED PVC “PAC” ..............3 ........... 1 PIECE = 1FT.

4 49048 SCREW, HHFS 1/4-20 X 3/4 GR5 2

5 10024 NUT, NYLOC 1/4-20 2

6 14233-004 FITTING, PLASTIC Y 6 BARB USP 64016 1

7 12694-006 HOSE CLAMP, SPRING TYPE 3/4 O.D. HOSE 2

8 24778-001 FITTING, BRASS 1/2BARB X 3/4F GRDN 1

9 18626-001 SPRING TENSION, GUARD BLADE 2

10 22129-001 PIPE STRAP 3/8 2

11 21168 SCREW, HHC 3/8-16 X 4.75 1

12 0424 SCREW, HHC 1/4-20 X 1 1/4 4

13 0949 NUT, HEX FINISH 1/4-20 PLATED 4

14 0181 B WASHER, LOCK 1/4 MED. 4

15 0948 WASHER, FLAT SAE 1/4 6

16 38274 SCREW, HHFS 3/8-16 X .75 ZINC 1

17 0166 A WASHER, LOCK 3/8 MED. 2

18 10136 WASHER, FLAT SAE 3/8 2

19 28876-001 FITTING, BRASS 3/8BARBx 3/4M GRDN 1

SP2S20H PAVEMENT SAW • OPERATION AND PARTS MANUAL — REV. #0 (02/17/12) — PAGE 27

Page 28

7

8

MANUAL RAISE AND LOWER ASSY. (20 IN.)

6

16

11

15

9

17

B

5

14

9

4

13

3

LUBRICATION

POINT

1

2

12

PAGE 28 — SP2S20H PAVEMENT SAW • OPERATION AND PARTS MANUAL — REV. #0 (02/17/12)

Page 29

MANUAL RAISE AND LOWER ASSY. (20 IN.)

NO. PART NO. PART NAME QTY. REMARKS

1 28793-352 JACKPOST ASSY. 1

2 2621 ZERK, GREASE STR. 1/4-28 1

3 28806-001 JACKSCREW 1

4 28083-001 BEARING, FLANGE 1

5 28809-001 SPACER, JACKSCREW 1

6 4568 PIN, ROLL 3/16 X 1 1

7 28877-351 SCREW COVER ASSY., RED 1

8 49048 SCREW, HHFS 1/4-20 X 3/4 GR5 3

9 0948 WASHER, FLAT SAE 1/4 4

11 0424 SCREW, HHC 1/4-20 X 1 2

12 1162 A CAP,GREASE ZERK, #2 1

13 10024 NUT, NYLOC 1/4-20 2

14 1121 SCREW, HHC 3/8-16 X 2 3/4 1

15 1876 NUT, HEX JAM 3/8-16 CLASS 2B 1

16 4403 KNOB, SHIFT 1

17 28808-002 ARM-CRANK 1

SP2S20H PAVEMENT SAW • OPERATION AND PARTS MANUAL — REV. #0 (02/17/12) — PAGE 29

Page 30

BATTERY ASSY.

9

5

8

1

3

2

4

10

6

1

NOTES:

INCLUDED WITH

1

ITEM 3

PAGE 30 — SP2S20H PAVEMENT SAW • OPERATION AND PARTS MANUAL — REV. #0 (02/17/12)

Page 31

BATTERY ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1 4671 BATTERY, WET GR.U1, GT-X GOLD LA 1

2 28096-001 BRACKET BATTERY 1

3 28095-401 BATTERY HOLD DOWN KIT 425-405 1

4 28093-001 CABLE, BATTERY POS 6GA X 42” RING TONGUE 1

5 28094-001 STRAP, GROUND 1

6 49048 SCREW, HHFS 1/4-20 X 3/4 GR5 2

7 49070 NUT, BATTERY DISCONNECT 1

8 0949 NUT, FLANGED SERRATED PLTD. 1/4-20 X 3/4 2

9 36720 SCREW, HHFS 5/16-18 X 3/4 GR5 3

10 49071 NUT, FLANGED SERRATED PLTD. 5/16-18 3

SP2S20H PAVEMENT SAW • OPERATION AND PARTS MANUAL — REV. #0 (02/17/12) — PAGE 31

Page 32

TRANSMISSION ENGAGE LEVER ASSY.

2

1

6

10

7

5

8

5

6

9

3

4

13

14

7

11

12

6

PAGE 32 — SP2S20H PAVEMENT SAW • OPERATION AND PARTS MANUAL — REV. #0 (02/17/12)

Page 33

TRANSMISSION ENGAGE LEVER ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1 28825-351 LEVER ASSY. TRANS. ENGAGE 1

2 3360 GRIP, 1/4 X 1 BLACK 1

3 36720 MOUNT ASSY., LEVER RED 1

4 0655 SCREW, HHFS 5/16-18 X 3/4 GR5 4

5 10136 WASHER, FLAT SAE 3/8 6

6 6014 B PIN, COTTER 3/32D X 1.0 1

7 5291 PIN, CLEVIS 3/8 2

8 0300 B WASHER, FLAT SAE 5/16 2

9 49071 NUT, FLANGED SERRATED PLTD 5/16-18 8

10 08326-019 PIN, CLEVIS 3/8 X 2” USEABLE LENGHT 1

11 2199 NUT, HEX JAM 3/8-24 2

12 08327-012 YOKE END, 3/8-24 X 2.50 2

13 28830-001 ROD, TRANS. ENGINE 1

14 28819-351 TRANS. BRACKET ASSY. 1

SP2S20H PAVEMENT SAW • OPERATION AND PARTS MANUAL — REV. #0 (02/17/12) — PAGE 33

Page 34

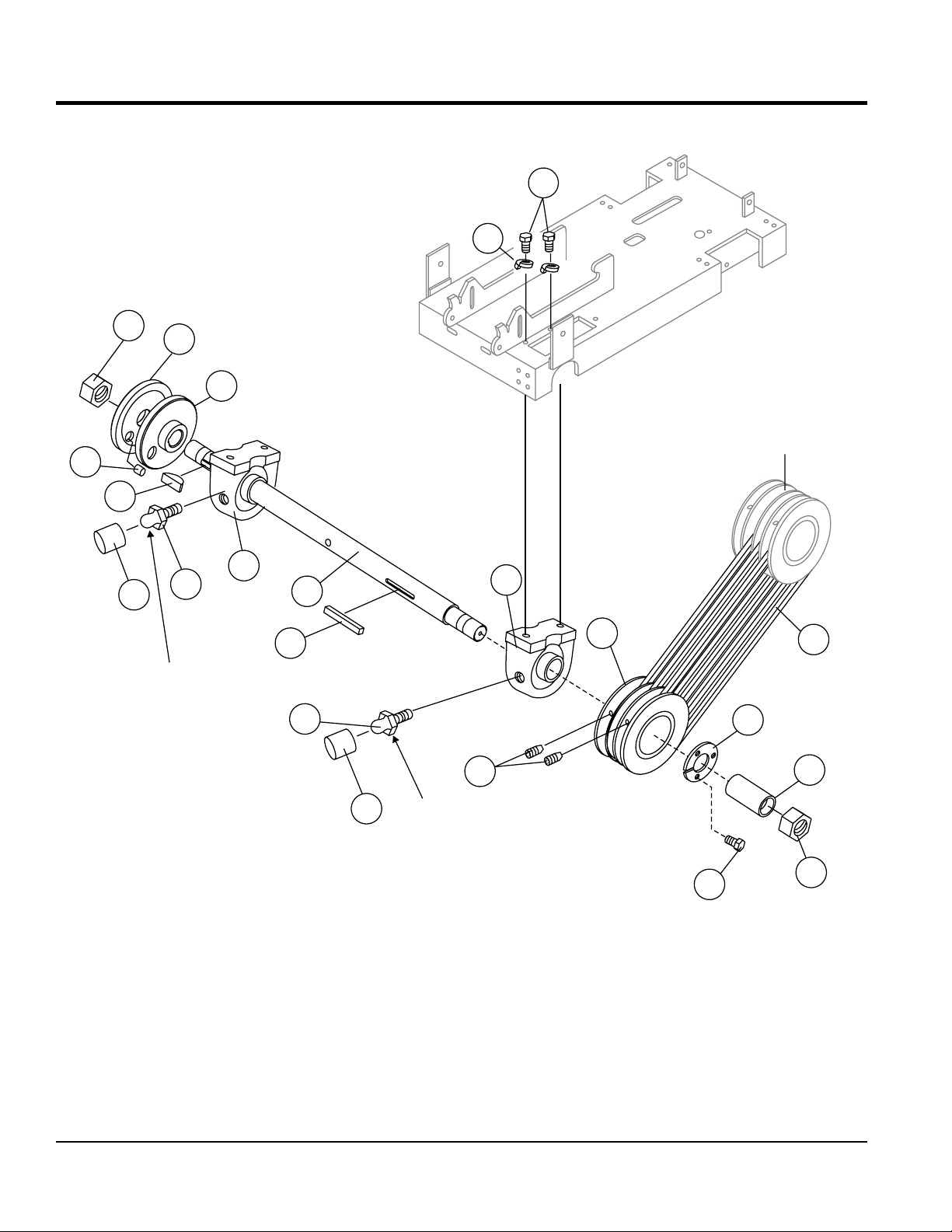

HYDROSTATIC TRANSMISSION ASSY.

1

3

2

15

17

2

4

5

16

18

5

6

1

14

19

8

8

7

13

11

9

8

12

4

5

4

NOTES:

FORWARD/REVERSE CABLE ASSY.

1

INCLUDED WITH SHIFT CONTROL

LEVER ITEM 5, ENGINE ASSY.

PAGE 34 — SP2S20H PAVEMENT SAW • OPERATION AND PARTS MANUAL — REV. #0 (02/17/12)

Page 35

HYDROSTATIC TRANSMISSION ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1 20559-001 SPRING, EXT. 3.38FL X 71OD X .105 1

2 1493 SCREW, HHC 3/8-18 X 3.25 4

3 28836-001 LINK, RETURN SPRING 1

4 10133 NUT, NYLOC 3/8-16 6

5 10136 WASHER, FLAT SAE 3/8 7

6 1023 SCREW, HHC 3/8-16 X 1 1/4 GR 5 2

7 15354 TRANSMISSION, HYD EATON 1

8 1578 KEY, WOODRUFF #3 2

9 4001 WASHER, FLAT USS 3/8 PLD 4

10 1456 NUT, HEX FINISH 3/8-16 4

11 28828-351 SHIFT ARM ASSY. 1

12 28829-001 PIN, PIVOT 2

13 10450 SCREW, SHS 10-32 X 1/4 1

14 103530-000 CAP, TRANSMISSION 1

15 923199 SCREW, SHC 8-32 X 1-1/4 2

16 15173 WASHER, FLAT, #8 2

17 13287 NUT, NYLOC 8-32 2

18 2584 SWITCH, PUSH BUTTON 1

19 35525 HARNESS, NEUTRAL SWITCH, SP2S20H 1

SP2S20H PAVEMENT SAW • OPERATION AND PARTS MANUAL — REV. #0 (02/17/12) — PAGE 35

Page 36

27

12

1

LOCTITE #242

HYDROSTATIC DRIVE ASSY.

1

3

4

26

BLUE

2

1

26

1

7

13

6

18

8

7

5

9

BLUE

LOCTITE #242

27

10

12

18

20

11

25

26

1

28

14

18

15

17

16

19

23

22

21

NOTES:

APPLY BLUE LOCTITE #242

1

P/N 60091

PAGE 36 — SP2S20H PAVEMENT SAW • OPERATION AND PARTS MANUAL — REV. #0 (02/17/12)

Page 37

HYDROSTATIC DRIVE ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1 23227-001 SPROCKET, TRANSMISSION 12 TOOTH MACH 1

2 25039 SCREW, SHS 10-24 X 1/4 2

3 19371-023 CHAIN, ROLLER ANSI STANDARD 1

4 10504-035 LINK, CHAIN 1

5 49071 NUT, FLANGED SERRATED PLTD, 5/16-18 2

6 28084-001 SPROCKET, 3548 X 3/4 1

7 0126 KEY, WOODRUFF #9 3

8 28832-001 JACKSHAFT 1

9 23284-001 BEARING, FLANGE .34SQ x 3/4ID 2

10 25354 SCREW, SHS 1/4-20 X 1/2 HOLOKROME 1

11 9091 SCREW, HHFS 5/16-18 X 1 GR5 2

12 28831-001 GEAR, DRIVE 2

13 1578 KEY, WOODRUFF #3 3

14 28087-001 PULLEY, MA60 X 17MM 1

15 25682-001 IDLER PULLEY 1

16 1665 SCREW, HHC 3/8-16 X 2 1

17 10136 WASHER, FLAT SAE 3/8 1

18 10133 NUT, NYLOC 3/8-16 3

19 23303-001 IDLER ARM 1

20 23230-001 SPRING EXT. IDLE 1

21 1284 SCREW, HHC 3/8-16 X 1 1/2 1

22 18574-004 WASHER, BELLEVILLE 3/8 1

23 28864-001 WASHER, FIBRE 1

25 07055-051 V-BELT, TRANSMISSION 4L510 1

26 0130 A SCREW, SHS 1/4 X 20 X 1/4 4

27 60091 LOCTITE, BLUE #242 1

28 1456 NUT, HEX FINISH 3/8-1 1

SP2S20H PAVEMENT SAW • OPERATION AND PARTS MANUAL — REV. #0 (02/17/12) — PAGE 37

Page 38

PAYMENT TERMS

5. Par ts must be in new and resalable

Multiquip reserves the right to quote and

who use our products as integral parts of their

LIMITATIONS OF SELLER’S LIABILITY

liable for loss of profi t or good will or for any

connection with the sale of its products. Apart

statutory, which extend beyond the description

TERMS AND CONDITIONS OF SALE — PARTS

Terms of payment for parts are net 30 days.

FREIGHT POLICY

All parts orders will be shipped collect or

prepaid with the charges added to the invoice.

All shipments are F.O.B. point of origin.

Multiquip’s responsibility ceases when a

signed manifest has been obtained from the

carrier, and any claim for shortage or damage

must be settled between the consignee and

the carrier.

MINIMUM ORDER

The minimum charge for orders from Multiquip

is $15.00 net. Customers will be asked for

instructions regarding handling of orders not

meeting this requirement.

RETURNED GOODS POLICY

Return shipments will be accepted and

credit will be allowed, subject to the following

provisions:

1. A Retu rned Mat er ia l Auth or iz atio n

must be approved by Multiquip prior to

shipment.

2. To obtain a Return Material Authorization,

a list must be provided to Multiquip

Parts Sales that defi nes item numbers,

quantities, and descriptions of the items

to be returned.

a. The parts numbers and descriptions

b. The list must be typed or computer

c. The list must state the reason(s)

d. The list must reference the sales

e. The list must include the name

3. A copy of the Return Material Authorization

must accompany the return shipment.

4. Freight is at the sender’s expense. All

parts must be returned freight prepaid to

Multiquip’s designated receiving point.

must match the current parts price

list.

generated.

for the return.

ord er(s) or in vo i ce (s) u nder

which the items were originally

purchased.

and phone number of the person

requesting the RMA.

co nd it io n, in the original Mul ti quip

package (if any), and with Multiquip part

numbers clearly marked.

6. The following items are not returnable:

a. Obsolete parts. (If an item is in the

price book and shows as being

replace d by ano ther item, it is

obsolete.)

b. Any parts with a limited shelf life

(such as gaskets, seals, “O” rings,

and other rubber parts) that were

purchased more than six months

prior to the return date.

c. Any line item with an extended

deale r n et pr ice of less th an

$5.00.

d. Special order items.

e. Electrical components.

f. Paint, chemicals, and lubricants.

g. Decals and paper products.

h. Items purchased in kits.

7. The sender will be notifi ed of any material

received that is not acceptable.

8. Such material wil l be held for five

working days from notifi cation, pending

instructions. If a reply is not received

within five days, the material will be

returned to the sender at his expense.

9. Credit on returned parts will be issued

at dealer net price at time of the original

purch ase , l ess a 15 % restoc k in g

charge.

10. In cases where an item is accepted, for

which the original purchase document

can not be determined, the price will be

based on the list price that was effective

twelve months prior to the RMA date.

11. Credit issued will be applied to future

purchases only.

PRICING AND REBATES

Prices are subject to change without prior

notice. Price changes are effective on a

specifi c date and all orders received on or

after that date will be billed at the revised price.

Rebates for price declines and added charges

for price increases will not be made for stock

on hand at the time of any price change.

sell direct to Government agencies, and to

Original Equipment Manufacturer accounts

own products.

SPECIAL EXPEDITING SERVICE

A $ 35.00 surcharge will be added to the

invoice for special handling including bus

shipments, insured parcel post or in cases

where Multiquip must personally deliver the

parts to the carrier.

Multiquip shall not be liable hereunder for

damages in excess of the purchase price of

the item with respect to which damages are

claimed, and in no event shall Multiquip be

other special, consequential or incidental

damages.

LIMITATION OF WARRANTIES

No warr an ties, express or implied, are

made in connection with the sale of parts or

trade accessories nor as to any engine not

manufactured by Multiquip. Such warranties

made in connection with the sale of new,

complete units are made exclusively by a

statement of warranty packaged with such

units, and Multiquip neither assumes nor

authorizes any per son to ass ume for it

any other obligation or liability whatever in

from such written statement of warranty,

there are no warranties, express, implied or

of the products on the face hereof.

Effective: February 22, 2006

PAGE 38 — SP2S20H PAVEMENT SAW • OPERATION AND PARTS MANUAL — REV. #0 (02/17/12)

Page 39

NOTES

SP2S20H PAVEMENT SAW • OPERATION AND PARTS MANUAL — REV. #0 (02/17/12) — PAGE 39

Page 40

PARTS MANUAL

HERE’S HOW TO GET HELP

© COPYRIGHT 2012, MULTIQUIP INC.

Multiquip Inc

trademarks are the property of their respective owners and used with permission.

This manual

The information and specifications included in this publication were in effect at the time of approval for printing. Illustrations, descriptions, references and technical data contained in

this manual are for guidance only and may not be considered as binding. Multiquip Inc. reserves the right to discontinue or change specifications, design or the information published

in this publication at any time without notice and without incurring any obligations.

PLEASE HAVE THE MODEL AND SERIAL

NUMBER ON-HAND WHEN CALLING

United StateS

Multiquip Corporate Office MQ Parts Department

18910 Wilmington Ave.

Carson, CA 90746

Contact: mq@multiquip.com

Service Department Warranty Department

800-421-1244

310-537-3700

Technical Assistance

800-478-1244 Fax: 310-943-2238

Tel. (800) 421-1244

Fax (800) 537-3927

Fax: 310-537-4259 800-421-1244

800-427-1244

310-537-3700

310-537-3700

Fax: 800-672-7877

Fax: 310-637-3284

Fax: 310-943-2249

mexico United Kingdom

MQ Cipsa Multiquip (UK) Limited Head Office

Carr. Fed. Mexico-Puebla KM 126.5

Momoxpan, Cholula, Puebla 72760 Mexico

Contact: pmastretta@cipsa.com.mx

Tel: (52) 222-225-9900

Fax: (52) 222-285-0420

Unit 2, Northpoint Industrial Estate,

Globe Lane,

Dukinfield, Cheshire SK16 4UJ

Contact: sales@multiquip.co.uk

Canada

Multiquip

4110 Industriel Boul.

Laval, Quebec, Canada H7L 6V3

Contact: jmartin@multiquip.com

Tel: (450) 625-2244

Tel: (877) 963-4411

Fax: (450) 625-8664

Tel: 0161 339 2223

Fax: 0161 339 3226

, the MQ logo and the Whiteman logo are registered trademarks of Multiquip Inc. and may not be used, reproduced, or altered without written permission. All other

MUST accompany the equipment at all times. This manual is considered a permanent part of the equipment and should remain with the unit if resold.

Your Local Dealer is:

PN: 35524

Loading...

Loading...