Page 1

SP-6457 TD

Concrete Saw

Operation Manual

Revision #1 (05/09/03)

Page 2

FOR HELP & INFORMATION

CONTACT MULTIQUIP

Please have the Model and Serial Number on-hand when calling.

MAIN

(M-F 7AM-5PM)

(PACIFIC STANDARD TIME)

PARTS DEPARTMENT

SERVICE DEPARTMENT/

TECHNICAL ASSISTANCE

WARRANTY DEPARTMENT

MULTIQUIP INC.

18910 WILMINGTION AVE.

CARSON, CALIFORNIA 90746

800-421-1244 or 310-537-3700

800-427-1244 or 310-537-3700

FAX: 800-672-7877 or 310-637-3284

800-428-1244 or 310-537-3700

FAX: 310-537-1173

888-661-4279 or 310-661-4279

FAX: 310-537-1173

E-MAIL

WEBSITE

2

Mq@multiquip.com

www.multiquip.com

Page 3

Conventions

WARNING

Throughout this manual, the following conventions are used to indicate

important information.

Text set off like this presents clarifying information, specific

!

NOTE

CAUTION

instructions, commentary, sidelights, or interesting points of

information.

Text set off like this indicates that failure to follow directions could

result in damage to equipment.

Text set off like this indicates that failure to follow directions could

result in bodily harm or loss of life.

!

NOTE

It is extremely important that the operator reads and understands the

safety and message section of this manual.

3

Page 4

WARNING

CALIFORNIA – Proposition 65 Warning

Engine exhaust and some of its constituents, and

some dust created by power sanding, sawing,

grinding, drilling and other construction activities

contain chemicals known to the State of California to

cause cancer, birth defects and other reproductive

harm. Some examples of these chemicals are:

o Lead from lead-based paints.

o Crystalline silica from brick.

o Cement and other masonry products.

o Arsenic and chromium from chemically treated

lumber.

Your risk from these exposures varies, depending on

how often you do this type of work. To reduce your

exposure to these chemicals: ALWAYS work in a

well-ventilated area, and work with approved safety

equipment, such as duct masks that are specially

designed to filter out microscopic particles.

4

Page 5

TABLE OF CONTENTS

CONVENTIONS.................................................................................................................. 3

SAFETY..............................................................................................................................7

OPERATION....................................................................................................................19

BEFORE STARTING......................................................................................................... 19

ENGINE POWER, CUTTING POWER & SHEAVE SIZE........................................................ 20

Blade RPM vs Surface Feet Per Minute (SFPM)...................................................... 22

Stacking Blades for Wide Cuts.................................................................................. 24

WATER SUPPLY AND CONTROL...................................................................................... 28

CONTROL PANEL............................................................................................................ 29

HANDLEBARS................................................................................................................. 30

FUELING THE SAW......................................................................................................... 31

STARTING AND STOPPING THE ENGINE.......................................................................... 32

COLD WEATHER OPERATION......................................................................................... 33

Glow Plugs................................................................................................................ 33

Block Heaters............................................................................................................ 33

Draining the Water System ....................................................................................... 33

POINTER ADJUSTMENT................................................................................................... 34

RAISE — LOWER CONTROLS.......................................................................................... 35

SETTING THE DEPTH GAUGE & DEPTH STOP ................................................................. 36

DRIVE SYSTEM............................................................................................................... 37

Transaxle................................................................................................................... 38

4-Speed BladeShaft................................................................................................... 39

Shifting Gears ........................................................................................................... 40

NIGHT LIGHT.................................................................................................................. 41

TRANSPORTATION TIE -DOWNS AND LIFT POINT............................................................ 41

5

Page 6

MAINTENANCE.............................................................................................................43

REMOVABLE GUARDS AND ACCESS PANELS.................................................................. 43

BELTS AND PULLEYS..................................................................................................... 44

V-Belt Tension........................................................................................................... 44

Adjusting BladeShaft Drive Belt Tension................................................................. 46

Replacing the BladeShaft Belt:................................................................................. 46

Replacing the Jackshaft Belt..................................................................................... 46

BLADESHAFT MAINTENANCE......................................................................................... 48

BladeShaft Replacement ........................................................................................... 48

BLADE COLLAR REMOVAL/INSTALLATION.................................................................... 49

CIRCUIT BREAKERS........................................................................................................ 52

MAXIMUM CUT DEPTH ADJUSTMENT............................................................................ 52

LUBRICATION................................................................................................................. 53

ENGINE........................................................................................................................... 54

Air and Oil Filter Chart............................................................................................ 54

PTO DRIVE MAINTENANCE ........................................................................................... 55

REPLACING THE BATTERY.............................................................................................. 57

RAISE-LOWER SYSTEM .................................................................................................. 58

JOYSTICK TENSION ADJUSTMENT .................................................................................. 59

HYDRAULIC SYSTEM MAINTENANCE............................................................................. 60

Routine Maintenance ............................................................................................... 60

Draining & Filling the Hydraulic System................................................................. 61

Bleeding the Depth Stop Cylinder............................................................................. 63

DRIVE WHEEL ALIGNMENT............................................................................................ 64

SPECIFICATIONS..........................................................................................................66

DIMENSIONS..................................................................................................................67

6457 ELECTRICAL SCHEMATIC ….. ............................................................................... 68

Specifications are subject to change without notice.

!

6

NOTE

Page 7

SAFETY

DANGER:

This Owner's Manual has been developed to provide complete

WARNING:

FOR YOUR SAFETY AND THE SAFETY OF OTHERS!

instructions for the safe and efficient operation of the Multiquip SP-6457

CONCRETE SAW. For engine maintenance information, please refer to

!

NOTE

Safety precautions should be followed at all times when operating this equipment.

Failure to read and understand the Safety Messages and Operating Instructions could

result in injury to you and others.

the engine manufacturers’ instructions for data relative to its safe

operation.

Before using this CONCRETE SAW, ensure that the operating

individual has read and understands all instructions in this

manual.

SAFETY MESSAGE ALERT SYMBOLS

The three (3) Safety Messages shown below will inform you about potential hazards that

could injure you or others. The Safety Messages specifically address the level of

exposure to the operator, and are preceded by one of three words: DANGER,

WARNING, or CAUTION.

You WILL be KILLED or SERIOUSLY injured if you

DO NOT follow directions.

You CAN be KILLED or SERIOUSLY injured if you

DO NOT follow directions.

CAUTION: You CAN be injured if you DO NOT follow directions.

Potential hazards associated with SP-6457 Concrete Saw operation will be referenced

with "Hazard Symbols" which appear throughout this manual, and will be referenced in

conjunction with Safety "Message Alert Symbols".

7

Page 8

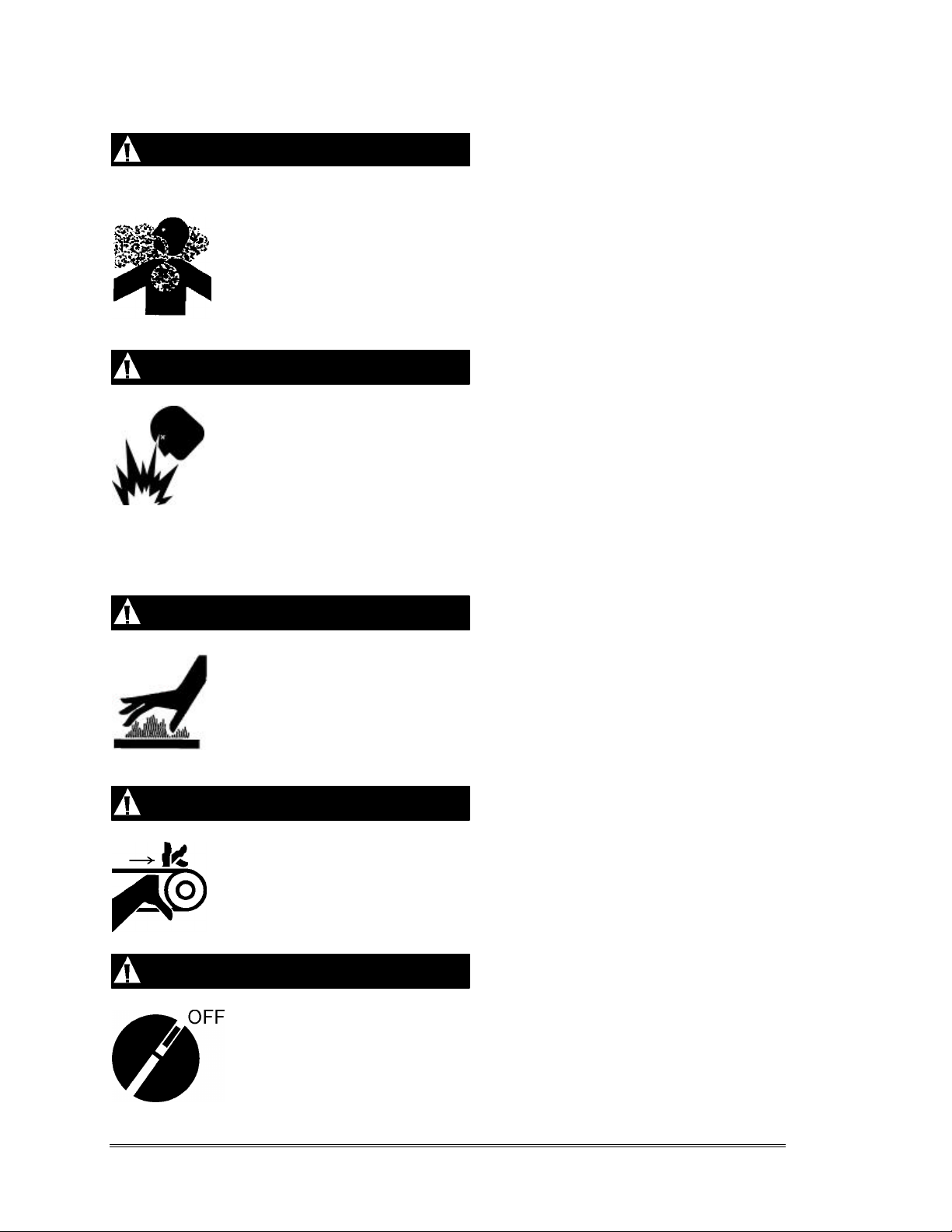

HAZARD SYMBOLS

Lethal Exhaust Gases

Explosive Fuel

Burn Hazards

Rotating Parts

NEVER

operate equipment with covers, or guards removed. Keep

Accidental Starting

ALWAYS

place the engine

ON/OFF

switch in the

OFF

position,

Engine exhaust gases contain poisonous carbon monoxide gas is

colorless and odorless, and can cause death if inhaled. NEVER operate

this equipment in a confined area or structure that does not provide

ample free flow air.

Motor fuels are highly flammable, and can be dangerous if mishandled.

DO NOT start the engine near spilled fuel or combustible fluids. DO

NOT fill the fuel tank while the engine is running or hot. DO NOT overfill

tank, since spilled fuel could ignite if it comes into contact with hot

engine parts or sparks from the ignition system. Store fuel in approved

containers, in well-ventilated areas and away from sparks and flames.

NEVER use fuel as a cleaning agent.

Engine components can generate extreme heat. To prevent burns,

DO NOT touch these areas while the engine is running or immediately

after operations. NEVER operate the engine with heat shields or heat

guards removed.

fingers, hands, hair and clothing away from all moving parts to

prevent injury.

when the saw is not in use.

8

Page 9

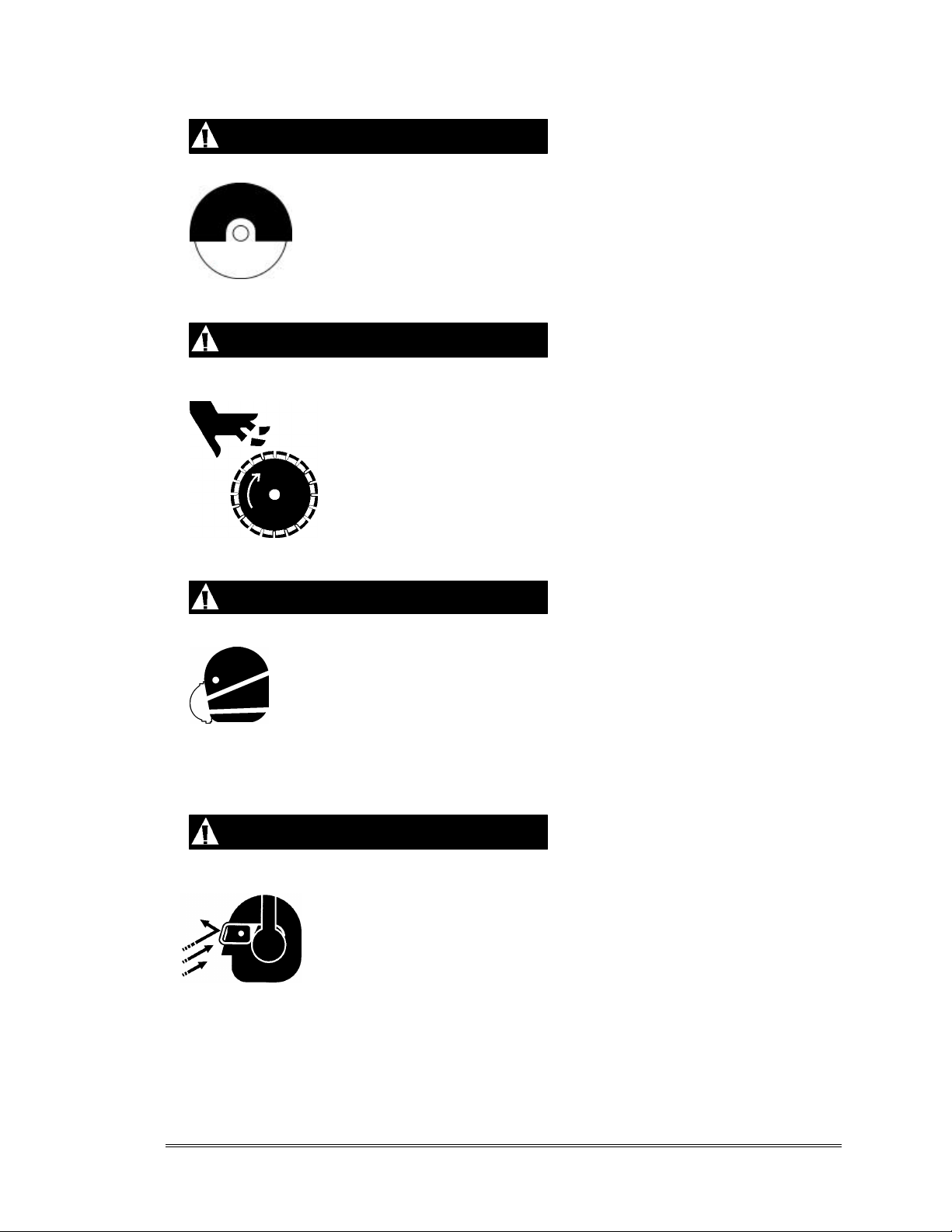

ALWAYS

wear approved respiratory protection.

Guards and Covers

Rotating Blades

Respiratory Hazard

Sight and Hearing Hazard

NEVER

operate the saw without blade guards and covers in place.

Adhere to safety guidelines ANSI American National Standards

Institute, OSHA or other applicable local regulations.

Rotating blade can cut and crush. Keep hands and feet clear.

ALWAYS wear approved eye and hearing protection.

9

Page 10

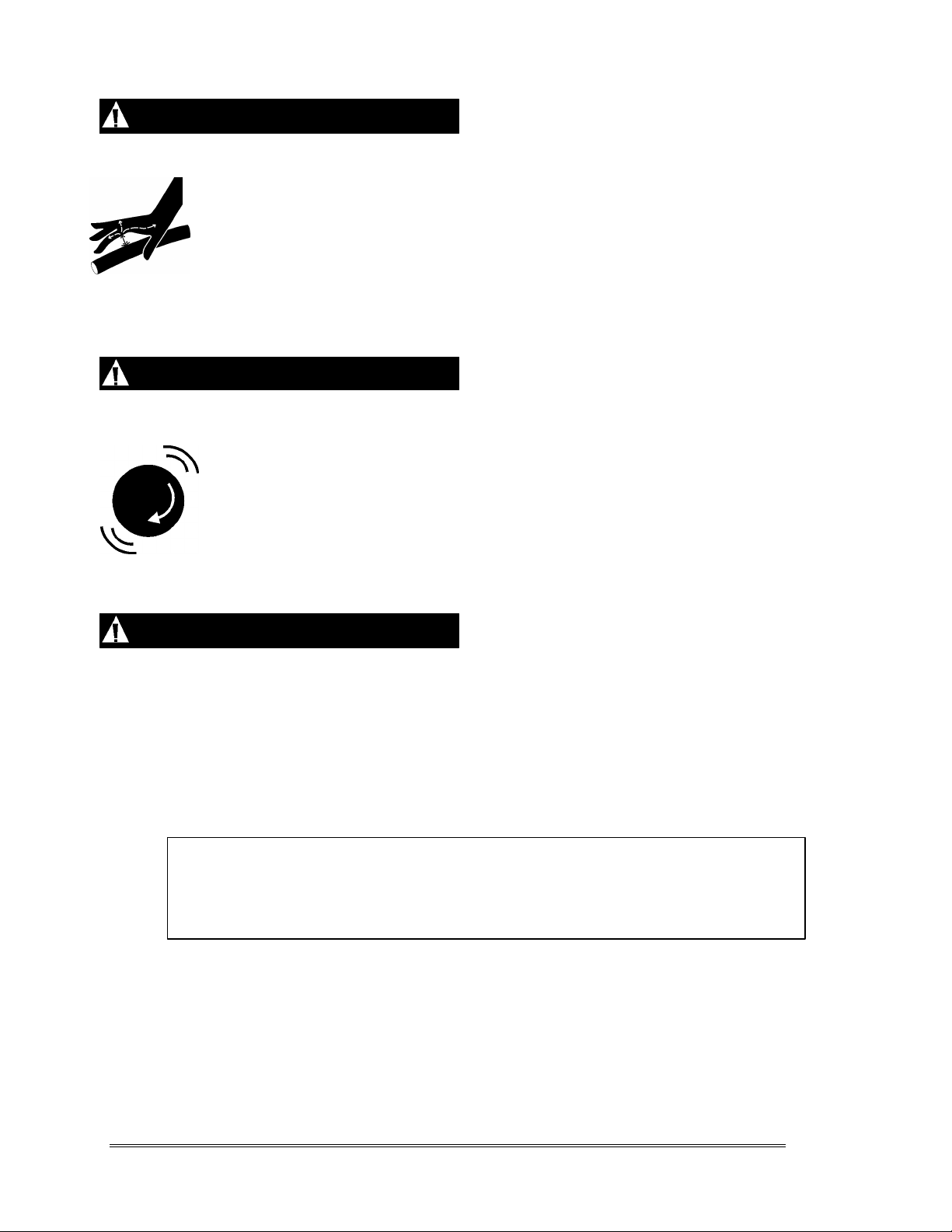

Equipment Damage Messages

Skin Injection Hazard

NEVER

use your hand to find hydraulic leaks. Use a piece of wood

or cardboard. Hydraulic fluid injected into the skin must be treated by

NOTE

Over Speed Conditions

NEVER

tamper with the factory settings of the engine governor or

a knowledgeable physician immediately or severe injury or death can

occur.

engine settings. Personal injury and damage to the engine or

equipment can result if operating in speed ranges above maximum

allowable.

Other important messages are provided throughout this manual to help

prevent damage to your concrete saw, other property, or the surrounding

environment.

This concrete saw, other property, or the surrounding environment could

be damaged if you do not follow instructions.

10

Page 11

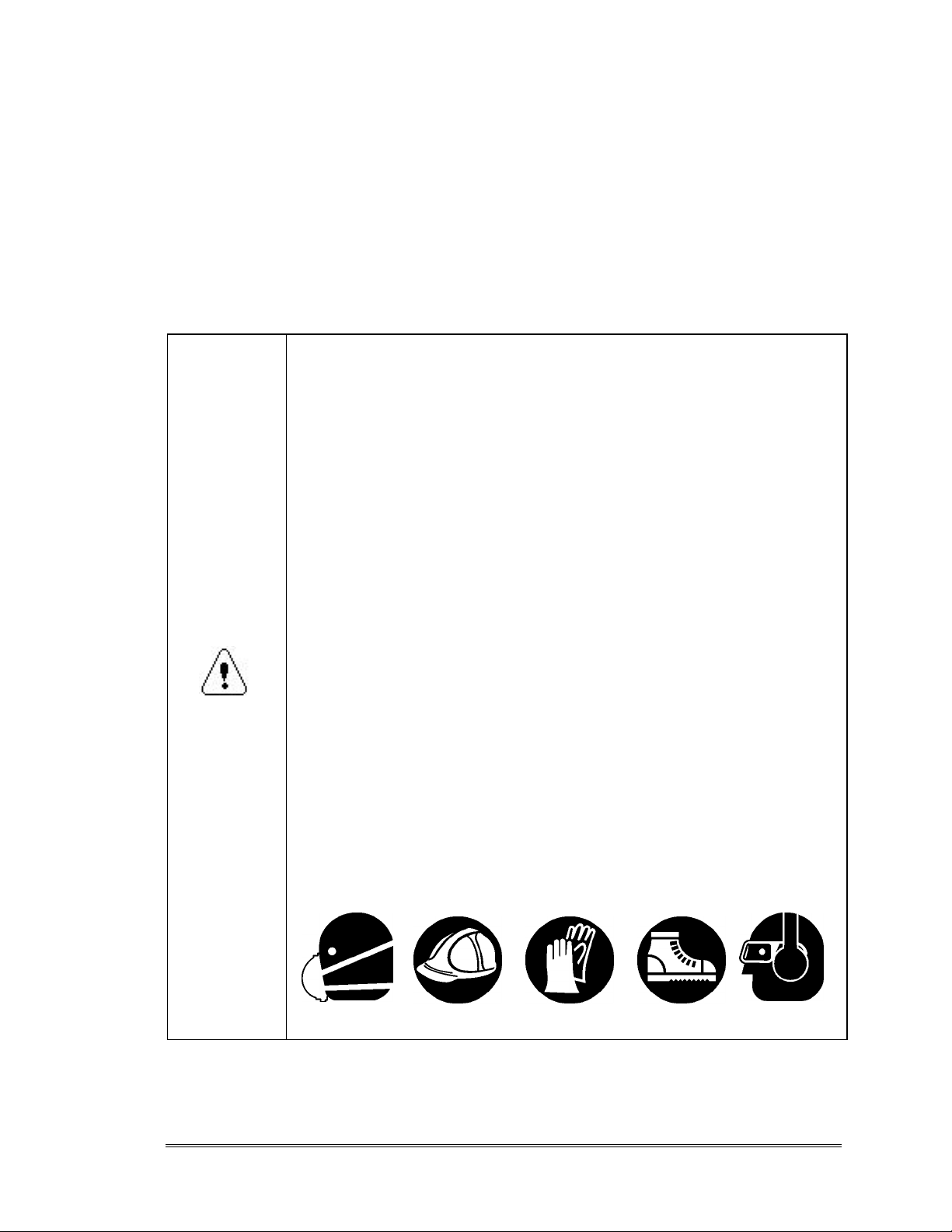

RULES FOR SAFE OPERATION

Most accidents involving product operation, maintenance and repair are caused

by failure to observe basic safety rules and precautions. Accidents can often be

avoided by recognizing potentially hazardous situations before an incident

occurs.

General Safety Warnings

§ DO NOT operate or service this equipment before reading this

entire manual. Failure to follow instructions may lead to serious

injury or death.

§ This equipment is to be operated by trained and qualified

personnel only. This equipment should not be operated by

persons under 18 years of age.

§ This equipment is for industrial use and to be used for its

intended purpose only.

WARNING

§ NEVER operate this equipment when not feeling well due to

fatigue, illness or taking medicine.

§ NEVER operate the saw under the influence of drugs or alcohol.

§ NEVER use accessories or attachments, which are not

recommended by Multiquip for this equipment. Damage to the

equipment and/or injury to user may result. Manufacturer does

not assume responsibility for any accident due to equipment

modifications. Unauthorized equipment modification will void all

warranties.

§ NEVER operate this saw without proper protective clothing;

shatterproof glasses, steel-toed boots, respiration mask, and any

other protective devices required by the job.

11

Page 12

§ Before operating the saw, make sure all protective guards are

securely in place. Multiquip saws are supplied with a blade guard,

collar guard and belt guard.

§ Whenever necessary, replace operation and safety decals if they

become difficult to read.

§ Verify the engine start switch is set to the OFF position before

installing a blade.

§ Make sure the operator knows how to turn the engine OFF in case

of an emergency.

§ Do not go near rotating parts (blades, belts, pulleys or wheels)

while engine is running.

§ Catalytic muffler and exhaust gases are extremely hot. Stay clear

of muffler and exhaust gases. Allow these parts to cool before

servicing the saw.

§ Stay clear of the saw while it is being hoisted.

§ Anytime the saw is lifted onto its nose, or tilted fully back, for

maintenance access, the high end MUST be blocked up to prevent

the possibility of crush injury!

WARNING

§ Allow the engine to cool before adding fuel or performing service

and maintenance functions. Contact with HOT components can

cause serious burns.

§ Never operate the saw in any enclosed or narrow area where free

flow of air is restricted. If the air flow is restricted it will cause

serious damage to the saw’s engine and may cause injury to

people. Remember the saw’s engine gives off DEADLY carbon

monoxide gas.

§ ALWAYS refuel in a well-ventilated area; away from sparks and

open flame. Avoid “topping off” the filler port as spills can result.

§ ALWAYS use extreme caution when working with flammable

liquids. When refueling, STOP the engine and allow it to cool.

§ NEVER smoke around or near the machine. Fire or explosion

could result from fuel vapors, or if fuel is spilled on a HOT engine.

§ NEVER operate the saw in an explosive atmosphere where fumes

are present or near combustible materials. An explosion or fire

could result causing severe bodily harm or even death.

§ NEVER use fuel as a cleaning agent.

12

Page 13

General Safety Precautions

§ ALWAYS read, understand, and follow procedures in the

Operator’s Manual before attempting to operate the equipment.

§ Be sure the operator is familiar with proper safety precautions

and operating techniques before using the saw.

§ Make sure the operating area is clear before starting the engine.

§ Maintain this equipment in a safe operating condition at all times.

§ Keep the saw clean. It will work better and last longer.

§ Use proper blades and follow the blade manufacturer’s

recommendations. Match blade rpm (Blade Shaft rpm) to

recommended blade surface feet per minute (SFPM).

§ Tighten the 5/8” blade-mounting bolt to 100-125 foot-lbs. torque.

§ Turn engine OFF prior to fueling the saw.

§ Start engine with the joystick in NEUTRAL to prevent unexpected

saw movement.

CAUTION

§ Do not leave saw unattended while engine is running.

§ Do not start engine on a sloping surface to prevent unexpected

loss of control.

§ Do not park or leave saw unattended on a slope - the saw can roll

when the engine is OFF. Block the unit when leaving.

§ If the saw must be parked on a slope, turn it across the angle of

the slope, to prevent accidental downhill movement.

§ Always store equipment properly when not being used. Equipment

should be stored in a clean, dry location out of the reach of

children. When storing the saw in freezing weather, blow out

water lines to prevent damage to components in the water

delivery system.

§ Prior to service, level the frame surface.

§ Do not over tighten the Blade Shaft drive belt.

§ Turn on water flow prior to starting the engine, to prevent

damage to the impeller of a belt-driven water pump.

13

§ Don’t pollute! Waste oils and other chemicals must be disposed

of in a manner consistent with local and state environmental

protection regulations.

Page 14

BLADE SAFETY

WARNING

§ ALWAYS inspect diamond blades before each use. The blade

should exhibit no cracks, dings, or flaws in the steel centered core

and/or rim. Center (arbor) hole must be undamaged and true.

§ Examine blade flanges for damage, excessive wear and

cleanliness before mounting blade. Blade should fit snugly on the

shaft and against the inside/outside of the saw.

§ Only cut the material that is specified by the blade. Read the

specifications of the blade to ensure the proper tool has been

matched to the material being cut.

§ ALWAYS keep blade guards in place. Exposure of the blade must

not exceed 180 degrees.

§ Ensure that the blade does not come into contact with the ground

or surface during transportation. DO NOT drop the blade on the

ground or surface.

§ The engine governor is designed to permit maximum engine

speed in a no-load condition. Speeds that exceed this limit may

cause the blade to exceed the maximum safe allowable speed.

§ Ensure that the blade is mounted for proper operating direction.

14

Page 15

SAW TRANSPORTATION SAFETY

CAUTION

§ Use appropriate lifting equipment to ensure the safe movement of

the saw.

§ DO NOT use the handle bars and/or front pointer as lifting points.

§ NEVER attempt to tow the untrailered saw behind a vehicle.

§ NEVER transport the saw with the blade mounted.

EMERGENCIES

§ ALWAYS know the location of the

nearest fire extinguisher .

§ ALWAYS know the location of the

nearest first aid kit.

§ In emergencies always know the

location of the nearest phone or

keep a phone on the job site.

Also know the phone numbers of the

nearest ambulance, doctor, and fire

department. This information will be

invaluable in the case of an emergency.

15

Page 16

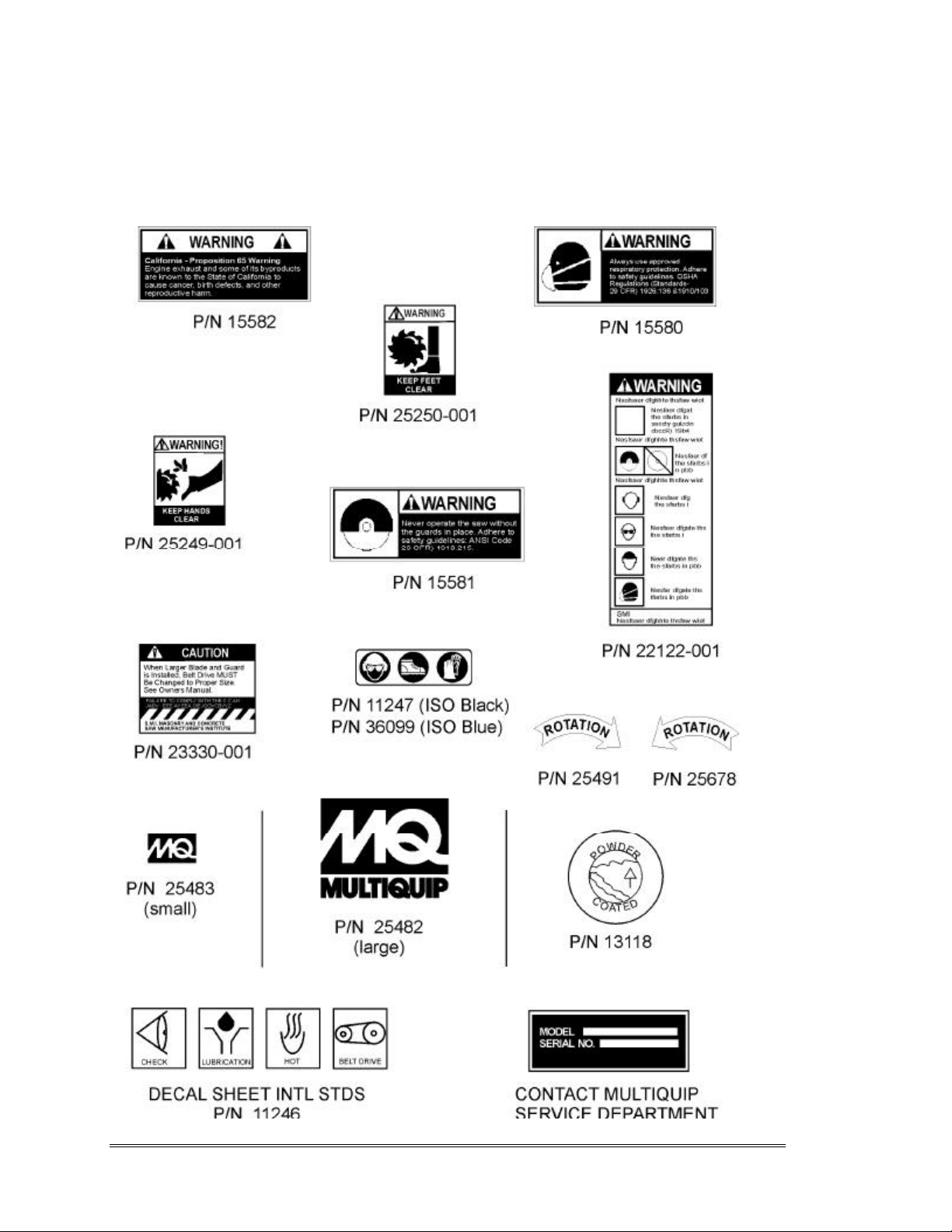

MACHINE OPERATION AND SAFETY DECALS

The Multiquip SP-6457 TD Saw is equipped with a number of operation and

safety decals. Should any of these decals become unreadable, replacements can

be obtained from your dealer.

16

Page 17

Serial Tag

!

NOTE

Fig. 1 — Serial Tag

For future reference, fill in the model number and serial number of

your saw in the spaces on the label above.

The serial tag contains the model number and serial number of the saw. This

information details all parts that were included with the saw when it was

shipped from the factory, as well as the date of manufacture.

Record these numbers, in case you need to contact Multiquip in the future.

Record your ENGINE model, specification number and serial number here:

MODEL NO. SPEC. NO. SERIAL NO.

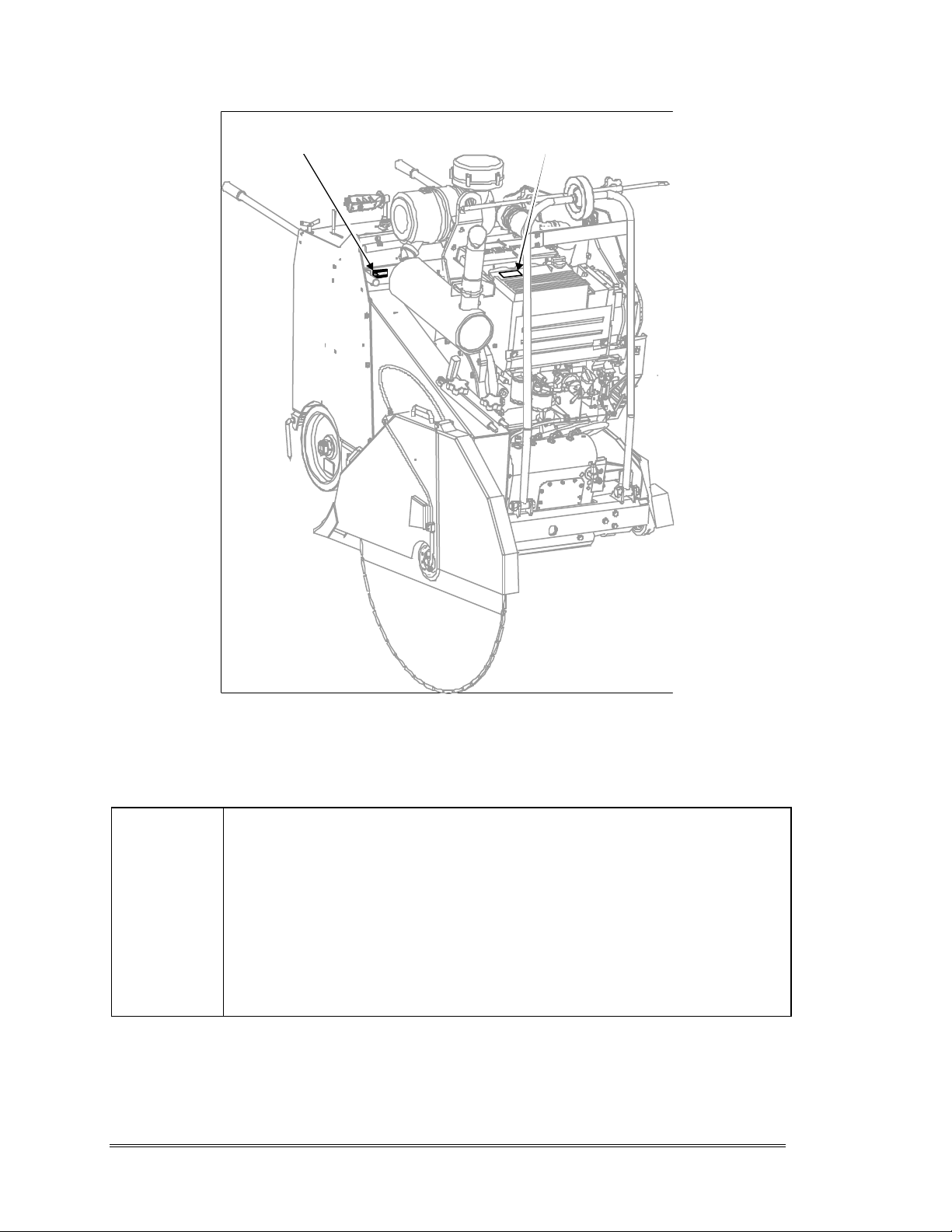

The SERIAL TAG is bonded to the panel forward of the console (between the

console and the engine. (See Figure 2.)

17

Page 18

SERIAL TAG

ENGINE SERIAL

NUMBERS

!

NOTE

18

Fig. 2 — Serial Number Locations

§ The 5/8” blade-mounting bolt on the right side of the saw (as

viewed from the operator’s position) has a left hand thread, while

the blade-mounting bolt on the left side of the saw has a right

hand thread.

§ Most saw hardware is measured in English (inch) units. The

Illustrated Parts List notes any Metric hardware. Be sure to use the

correct hardware and proper tools.

Page 19

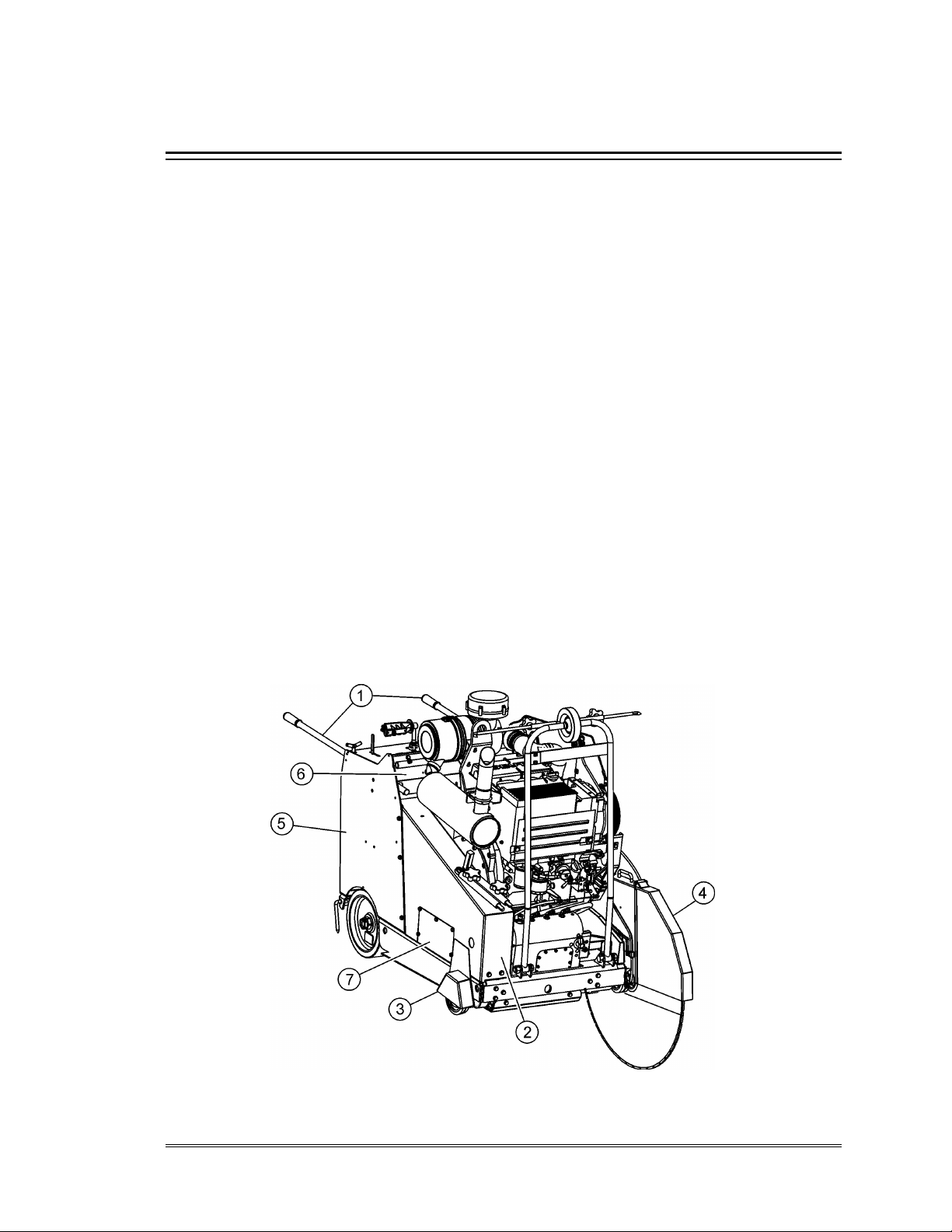

OPERATION

Before Starting

Before starting the saw, carefully follow the checklist below:

r Securely install the Belt Guard (2).

r Fully slide on the Collar Guard (3).

r Verify that proper-sized Blade Guard (4) is fully installed on the Blade

Guard mounting tab.

r Confirm the rear and side access panels (5) (6)& (7) and engine

protector are in place.

r Wear eye and hearing protection and protective clothing.

r Adjust handle bars (1) for best operator control.

r If a belt driven water pump is installed, do not run the engine with the

water pump switch on, unless the water supply is connected and

water is flowing.

19

Fig. 3 — Guards & Panels

Page 20

Engine Power, Cutting Power & Sheave Size

The cutting capability of your saw is a relationship between engine power (as

reflected in the engine RPM) and the speed (RPM) of the Blade Shaft. The diesel

engine of the SP-6457 TD runs at 2800 RPM (full load). If 2800 RPM was a

desirable Blade Shaft speed for the average conditions in which you work, we

would use the same size sheave on the engine shaft and the Blade Shaft; and the

ratio between the two would be 1 : 1.

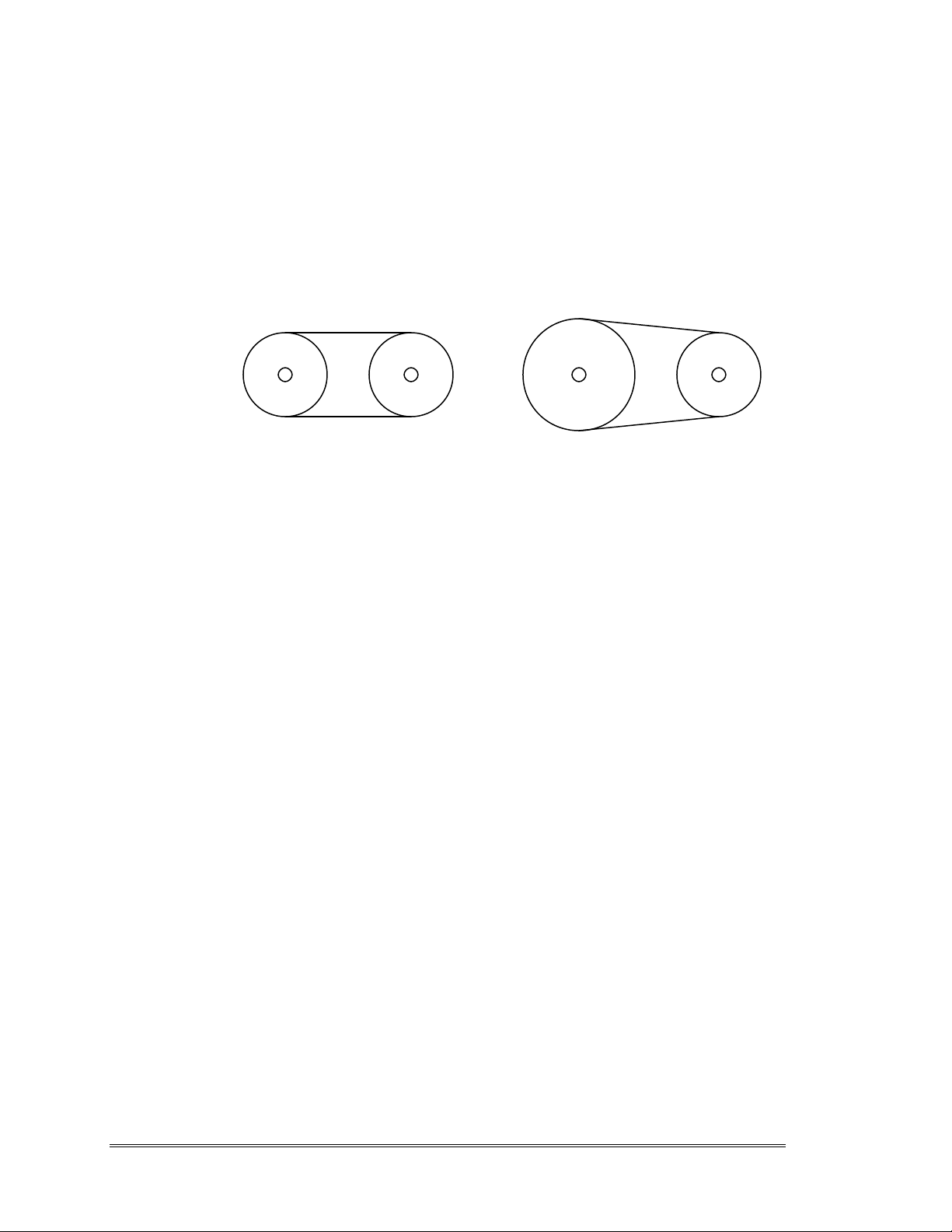

1 : 1 1.4 : 1

Blade Shaft

Fig. 4 — Blade Shaft Ratios

Engine

Blade Shaft

Engine

If, however, for your cutting conditions, you need a Blade Shaft speed slower

than the engine speed (and this is usually the case), then we need to INCREASE

the ratio between the two speeds by putting a larger diameter sheave on the

Blade Shaft. This, in effect, is what occurs when you shift gears on the SP-6457

TD.

If, for example, you know from experience that you need a Blade Shaft speed of

2000 RPM for the size of blade you normally use (see the Blade RPM vs. SFPM

Chart, below):

2800 (engine RPM) ÷ 2000 (desired BS RPM) = 1.4

This is the ratio 1.4 : 1, which means that for every 1.4 revolutions of the engine,

the Blade Shaft only turns once.

Ratios greater than 1 : 1 also have the beneficial effect of increasing the torque of

the Blade Shaft by the same factor (1.4 in our example) . The manufacturer

advertises that the Deutz BF31011 diesel engine develops 123 ft. lbs. of torque.

To find the theoretical torque of our example saw setup:

123 x 1.4 = 172.2 ft. lbs.

Actual torque of the saw will vary somewhat. In general, more torque means

more cutting power.

20

Page 21

Typically, however, the ratios are not used to design a level of torque; they are

used to create a saw with the optimum blade speed (blade Shaft RPM) for you.

The major factors are:

• diameter of blade(s) you commonly use, and

• cutting conditions you work under

The 4 gear ratios we have designed into the SP-6457 TD 4-speed Blade Shaft are:

1st Gear 1.00 : 1

2nd Gear 1.34 : 1

3rd Gear 1.70 : 1

4th Gear 2.02 : 1

In addition to the four” fixed” ratios of the Blade Shaft gears, we can also tailor

the Blade Shaft RPM (blade speed) by adjusting the “primary” ratio between the

engine and the Blade Shaft. By selecting a Blade Shaft sheave and Engine sheave,

a multitude of additional ratios (and Blade Shaft speeds) are possible. The

following Sheave sets are available as standard kits:

Engine

Sheave

5.1 6.0 1.17 : 1

5.4 5.6 1.03 : 1

6.0 5.0 .83 : 1

Blade Shaft

Sheave

Ratio Blade Shaft RPM

2333 in 1st

1741 in 2nd

1372 in 3rd

1154 in 4th

2700 in 1st

2000 in 2nd

1588 in 3rd

1350 in 4th

3373 in 1st

2498 in 2nd

1984 in 3rd

1686 in 4th

Engine

RPM Kit #

2800 18609

2800 18611

2800 18612

21

Page 22

Blade RPM vs. Surface Feet Per Minute (SFPM)

CAUTION

When choosing a blade for your cutting conditions, follow the blade

manufacturer’s recommendations. Match the blade speed (Blade Shaft RPM) to

the recommended blade Surface Feet Per Minute (SFPM).

SFPM 16”

diam.

RPM

8,000 1910 1698 1528 1273 1175 1019 849 728 636

8,500 2029 1804 1623 1353 1249 1082 902 773 676

9,000 2149 1910 1719 1432 1322 1146 955 819 716

9,500 2268 2016 1814 1512 1396 1210 1008 864 756

10,000 2387 2122 1910 1592 1469 1273 1061 910 796

10,500 2507 2228 2005 1671 1543 1337 1114 955 836

11,000 2626 2334 2101 1751 1616 1401 1167 1001 875

11,500 2745 2440 2196 1830 1690 1464 1220 1046 915

12,000 2865 2546 2292 1910 1763 1528 1273 1092 955

12,500 2984 2653 2387 1989 1836 1592 1326 1137 995

13,000 3104 2759 2483 2069 1910 1655 1378 1183 1035

13,500 3229 2866 2581 2149 1985 1719 1433 1228 1074

18”

diam.

RPM

20”

diam.

RPM

24”

diam.

RPM

26”

diam.

RPM

30”

diam.

RPM

36”

diam.

RPM

42”

diam.

RPM

48”

diam.

RPM

14,000 3349 2972 2676 2229 2058 1783 1486 1273 1114

14,500 3468 3078 2772 2308 2132 1847 1532 1319 1153

§ Verify that the engine start switch is OFF before installing blade.

§ Tighten the 5/8” blade-mounting bolt to

125-175 foot-pounds torque.

22

Page 23

Installing the Blade

Blade Guard

Tapered

Outer Collar

Collar

Mounting

The blade can be mounted on either side of the saw to accommodate different

cutting jobs.

1. Raise the saw so that the blade will clear the ground when installed.

2. Verify that blade collars are clean and undamaged.

3. Insert the bushing and mounting bolt through the outer collar and blade.

• Align collar pin through the blade into the inner collar.

4. Tighten the 5/8” mounting bolt to 125-175 foot-pounds of torque.

• The blade-mounting bolt on the right side of the saw (as viewed from the

operator’s position) has a left hand-thread, while the blade-mounting bolt

on the left side of the saw has a right-hand thread.

Mounting Clip

Bolt

with Pin

Inner Collar

Bushing

Blade Shaft

Fig. 5 — Installing the Blade

23

Page 24

Stacking Blades for Wide Cuts

Inner Collar

NEVER attempt to stack blades beyond the capacity of the Kits

described here. NEVER operate the saw without blade guards in

place.

WARNING

Combining (stacking) blades together to make wide cuts requires an optional

Bushing Extension Kit.

• Kit #18501 allows blade stacking from .375” to .75” thickness.

• Kit #18502 allows blade stacking from .75” to 1.125” thickness.

The kits consist of an outer collar with a longer pin, an extended bushing, and

longer bolts.

1. Remove the existing Blade (see Installing the Blade, above).

2. Replace the standard Collar Bushing, Outer Collar, and Mounting Bolt that

came with the saw, with the extended Bolt and Bushing and the new Outer

Collar that came with the Kit.

• The Mounting Bolt for the right side of the saw (as seen from the

operator’s position) has a left hand-thread, while the Mounting Bolt for

the left side of the saw has a right-hand thread.

3. Insert the Bushing and Mounting Bolt through the Outer Collar and stack of

Blades. The longer bushing and bolt allow blades to be stacked together

4. Align the Collar Pin through the stack of Blades into the Inner Collar.

5. Tighten the 5/8” Mounting Bolt to 125-175 foot-pounds of torque.

Outer Collar with extended pin

Extended bushing

Extended bolt

Fig. 6 — Blade Stacking

24

Page 25

Installing and Removing the Blade Guard

Blade Guard

Manifold

Blade Guards are “ambidextrous” – that is, they can be installed on either side of

the saw.

Installing the Blade Guard

1. Slide the Blade Guard Mounting Clip onto the Guard Mounting Tab on the

frame.

2. Connect the water delivery hose to the Blade Guard.

• Ensure that the water pipes are pointed toward the water distribution

grooves in the Blade Collars.

3. Make sure the front-hinged section of the Blade Guard is fully closed before

use.

Top Handle

hinged front

Mounting Clip

Water

Delivery

Hose

Water

Distribution

Rear Handle

Blade Guard

rear section

Fig. 7 — The Blade Guard installed

25

Page 26

Blade Guard Water Supply

Verify that the water hose on the saw is connected to the Blade Guard and that

the water pipes are pointed into both Blade Collars.

Make sure that the 90º outlets of the water tubes point toward the

lower portion of the blade collars, aimed at the delivery ports, for

CAUTION

proper water delivery to the blade.

Water Tube bracket

Water Tube aimed at

groove in Blade Collar

Blade Collar

Fig. 8 — Water Tubes and the Blade Collar

Removing the Blade Guard

During use, the Blade Guard can become tight on the tapered mounting tab. To

loosen it, wiggle the Rear Blade Guard Handle up and down, while lifting with

the Top Handle.

26

Page 27

Installing the Collar Guard

The Collar Guard protects unused Blade Collars.

1. Slide the Collar Guard (1) onto the Guard Mounting Tab on the frame.

2. Verify that the unused Blade Collar (2) is secured to the Blade Shaft, by

tightening the mounting bolt (3).

1 – Collar Guard

3 – Mounting Bolt2 – Blade Collar

Fig. 9 — The Collar Guard, Installed

27

Page 28

Water Supply and Control

4

5

§ To prevent damage to the impeller of a belt driven water pump, do

not run the engine with the water pump switch on, unless the

water supply is connected and water is flowing.

CAUTION

1. Connect the water supply hose to the water inlet (garden hose) fitting (1) on

the left side of the saw.

2. Verify that the water hose on the saw is connected to the Blade Guard (5) and

that the water tubes are pointed into both Blade Collars.

3. The yellow lever (4) on left side of the control panel regulates water flow

volume. The other lever (3) turns the water On and Off.

4. If the saw is equipped with an optional water pump, the ON/OFF switch (2)

is on the control panel next to the water flow control valve.

!

NOTE

2

§ When storing the saw during freezing weather, blow out the water

lines to prevent damage to the water delivery system.

Because of the water delivery efficiency of the 24-port blade collars,

your saw will use less water for blade lubrication than other water

deliver systems.

3

28

1

Fig. 10 — The Water Supply System

Page 29

Control Panel

Engine

Auxiliary

Light

Throttle

Ignition Switch

Upper

Operating

Speed

Water Pump

Maintenance

Water

Depth

Engine Status

Drive

Depth

Water

Pointer Cable

Blade shaft

Lower Plunge

Switch

Cam Cleat

Disengage

Stop

Valve

Switch

ON-OFF

Tachometer

Indicator

Voltmeter

Indicator

Tachometer

Instructions

Plunge

Button

ON/OFF

Control

Valve

Information

29

Flow

Control

Switch

(Option)

Control

Joystick

Button

Raise Button

Fig. 11 — The Control Panel

Page 30

Handlebars

Three

Storage

The handlebars are adjustable to three different angles, for optimum operator

control, and can also be slid fully inward for storage. Once handlebars are

adjusted, lock them into position by tightening the lock knob on each side.

Lock Knob

P3

P2

P1

operating

positions

position

Fig. 12 — Handlebar Positions

Using the handlebars in position #2 or #3 when employing larger diameter

blades, reduces the need to bend over, and reduces the effort required by the

operator to maneuver the saw.

30

Page 31

Fueling the Saw

The saw features a 10-gallon, clear, molded plastic fuel tank with a sight gauge,

central drain, and shutoff valve. The fuel tank cap is located at the front of the

control console.

§ Be sure the engine is turned off prior to fueling the saw.

§ Do not spill diesel fuel on control panel or engine.

§ Do not over-tighten gas cap.

CAUTION

Use

WARNING

Sight Gauge

Shut-off Valve

Fig. 13 — Fuel System

Fuel Tank Cap

31

Page 32

Starting and Stopping The Engine

§ Do not leave the saw unattended while the engine is running.

§ Do not start, park, or leave the saw unattended on a slope.

§ If the saw has an optional water pump, do not run the saw dry

with the water pump switch ON — otherwise the pump impellers

will be damaged.

CAUTION

1. Move the speed control joystick to NEUTRAL position.

2. Set the throttle to IDLE.

3. Ensure that water lines are attached and water is flowing to the saw.

4. Momentarily turn the ignition switch to the START position.

• Allow the engine to warm up for several minutes.

5. Set the throttle to the recommended engine RPM to match the recommended

blade speed of the attached blade.

6. Lower the blade to the cut depth.

7. Move the joystick FORWARD to advance the cut.

8. To stop the engine, turn the ignition switch to the OFF position.

§ Do not stop the engine abruptly when hot! Reduce the throttle to

idle and allow the engine to run one or two minutes before turning

the ignition switch off. This allows the engine to cool down, and

prevents damage to the Turbo unit.

Fig. 14 — ON/OFF Switch Location

§ Make sure the operator knows how to turn the engine off in case

of an emergency.

WARNING

§ Do not go near rotating parts (blade, belts, pulleys, or wheels)

while the saw is running.

Restarting After Running Out of Fuel

The 1011 series Deutz engines do not require bleeding the fuel system if you run

out of fuel. To restart the engine, simply re-fill the fuel tank, and crank the

engine normally (should be only 5-10 seconds) until it re-starts.

32

Page 33

Cold Weather Operation

Glow Plugs

Optional Glow Plugs are installed inside the air intake. In cold weather (low

temperatures below 40°F):

1. Rotate the Ignition Switch PAST the ON position to the GLOW PLUG

position and HOLD there for 20-40 seconds.

2. After 20-40 seconds, continue to rotate the switch to the START position.

3. Once the engine has started, let the switch go-it will return to the ON

position.

In extreme cold weather (below 20°F), 2 or 3 cycles of Glow Plug may be

necessary before the engine will start.

Block Heaters

Optional Block Heaters, (installed directly on the crankcase), are operated by

plugging them into an electrical outlet via an extension cord. The block heater is

NOT thermostatically controlled. Use only just prior to saw use. DO NOT leave

the saw unattended with block heater in operation and DO NOT use when low

temperatures are above 20°F.

§ Do not leave optional Block Heaters plugged in for extended

periods when temperatures may rise above 20°F. The oil could

“cook” inside the crankcase and damage to the engine could

CAUTION

result.

§ If the Water System is not drained when the saw is not in use and

temperatures fall below 32 °F, damage may occur to optional water

pumps and/or oil coolers.

Draining the Water System

When low temperatures fall below 32°F:

1. If the saw is equipped with an optional Water Pump, open the drain petcock

on the pump and allow the pump to drain.

• With the engine running, turn the water pump switch on for a few

seconds to purge water remaining inside the pump body.

2. Tilt the saw up and back, to allow water to drain.

3. Tilt the saw forward, to allow water to drain again.

33

Page 34

4. If an air compressor is available, blow out the system by applying

123

4

compressed air to the Water Inlet (see Fig. 10).

Pointer Adjustment

1. Lower the front pointer assembly.

• Adjust the pointer rod (1) by loosening the lock knob (2).

• Once the pointer rod is set to the cut line, tighten the lock knob.

2. Adjust the rear pointer to the cut line:

• Loosen the lock bolt, position the pointer rod, and tighten the lock bolt.

3. To raise the front pointer assembly, pull back and up on the pointer cable (3).

• Secure the pointer assembly in the desired raised position by locking the

cable between the jaws of the cam cleat (5).

6

5

Fig. 15 — Pointer Adjustment

34

Page 35

Raise — Lower Controls

This saw uses a 12-volt hydraulic pump and cylinder to raise and lower the

blade. The SP-6457 TD saw has a plunge button and a raise button. Controls are

located on the joystick handle.

1

2

Fig. 16 — Joystick Handle Controls

3

1. To slowly lower the blade to the cut, push the top button (1).

2. For a fast plunge to the cut, push the bottom button (2).

3. For a very fast plunge, press both buttons simultaneously.

4. To lift the blade, hold down the Raise button on the side of the handle (3).

See the Maintenance section of this manual for an illustration of the Raise-Lower

System components, and troubleshooting techniques.

35

Page 36

Setting the Depth Indicator

1. Lower the blade until it just touches the cutting surface.

2. Set the Depth Indicator dial to zero. (The Depth Indicator now accurately

indicates how deep the blade is cutting.)

Setting the Depth Stop

This saw uses a hydraulic Depth Stop to position and lock the blade at the

desired cut depth.

1. Depress SLOW LOWERING button until blade has reached desired cutting

depth.

2. While holding the Slow Lowering button, open the Depth Stop Valve.

3. Close the Depth Stop Valve.

4. Release the SLOW LOWERING button.

5. The saw will now repeatedly lower to the set cutting depth, until the Depth

Stop is re-adjusted.

Depth Indicator

Depth Stop Valve

Fig. 17 — Setting the Depth Gauge and Depth Stop

To disable the Depth Stop when it is not needed:

1. Open the Depth Stop Valve.

2. Set the Blade Collars on the ground.

3. Close the Depth Stop Valve.

Slow Lowering

CAUTION

36

Do not cut with the Depth Stop Valve in the OPEN position; this could

cause the blade to rise out of the cut.

Page 37

Drive System

Speed Control

This saw has a cable-controlled Hydro-Gear hydrostatic powered transaxle with

infinite F-N-R speed adjustment via a joystick controller. The saw is designed

with locked axle drive, and can travel at speeds up to 300 feet per minute.

Drive System Controls

The panel-mounted joystick controls FORWARD-NEUTRAL-REVERSE

(F-N-R) and infinitely variable speeds in both directions. To increase forward

speed, slowly move the joystick FORWARD. Pulling the joystick backward

decreases saw speed, and when the joystick passes NEUTRAL the saw moves

into REVERSE. Reverse speed is also controlled by the position of the joystick.

The Drive Disengage handle, when pulled, puts the saw in “free wheeling”

mode. This is not a “true” Neutral, but does provide a by-pass in the

pump/motor group which allows the saw to be readily moved. Some rolling

resistance will be encountered.

Drive Disengage

Fig. 18 — Drive System Controls

Joystick in

NEUTRAL

37

Page 38

Transaxle

The Hydro-Gear hydrostatic-powered transaxle has no chains, sprockets or open

gears to service. There is a simple cable control. The remote filter promotes long

life and easy maintenance.

Drain Plug

Fig. 19 — The Transaxle

38

Page 39

4-Speed Blade Shaft

The exclusive 4-speed Blade Shaft allows optimum performance with a variety of

different blade sizes under a wide range of conditions.

Fig. 20 — The 4-Speed Blade Shaft

The 4-speed design fully encloses the transmission, bearings and Blade Shaft,

and features an oil bath lubrication (no grease fittings). Oil is cooled, filtered and

circulated, and the assembly utilizes a remote, protected fill and vent. Gear

changes are made with rack & pinion shifting. Positive shift lock prevents the

multi-speed Blade Shaft from jumping out of gear. A Blade Shaft tachometer

assists in gear selection.

The 4 gear ratios are:

1st Gear 1.00 : 1

2nd Gear 1.34 : 1

3rd Gear 1.70 : 1

4th Gear 2.02 : 1

The 1: 1 ratio is for the smallest diameter blade. The middle two ratios are for

intermediate sized blades and the 2.02 : 1 ratio is for the largest blade. Blade

range is from 16” to 48”.

See page 21 or visit our web site: www.multiquip.com for additional

discussion of the 4-speed Blade Shaft, gears, and sheave ratios.

To calculate Blade Shaft speed, assuming a 1:1 ratio between engine and blade

rd

gear.

rd

shaft input, divide engine speed by the selected ratio. For example, for the 3

gear Blade Shaft RPM: 2500 Engine RPM ÷ 1.7 = 1470 Blade Shaft RPM in 3

The gear pattern is marked on the casting around the shift lever.

39

Page 40

WARNING

§ Never shift gears with the engine running.

§ Before inserting the Shift Wrench, verify that the ignition is OFF.

§ Disengage the Shift Lock before shifting, and engage the Shift Lock

after shifting.

§ Remove the Shift Wrench before starting engine.

Shifting Gears

1. Verify that the ignition switch is OFF. This prevents accidentally starting the

engine while shifting gears.

2. Insert the Shift Wrench through the marked hole in the belt guard.

3. Pull and rotate the Shift Lock to disengage it.

4. Shift gears by turning the Shift Lever counter-clockwise from 3à1à2à4 or

clockwise from 4à2à1à3.

• Slightly rock the Shift Wrench while turning the Shift Lever to the desired

gear, to make shifting easier.

5. Push and turn the Shift Lock, to lock the selected gear.

6. Slightly rotate the Shift Lever to verify the gear shift lock has popped into

place.

7. Remove the Shift Wrench before starting the engine.

§ DO NOT leave the Shift Wrench in the belt guard when starting the

engine. Injury to the operator or equipment damage is likely to

result.

WARNING

8. Use the Blade Shaft tachometer to verify that recommended blade rpm

matches blade manufacturer’s recommendation.

Shift Instruction Decal

Shift Lever

Insert

Shift Wrench

Here

Shift Lock

Fig. 21 — Gear Shift Components

40

Page 41

Night Light

Lock

Lock

Tie-down

Tie-down

The night light can be used on either side of the saw, and can be extended and

rotated for best illumination of the cutting area. Aim the light, then lock it in

position by tightening the lock knobs. The light can be removed for storage by

loosening the lock knobs, disconnecting the light cord and sliding the light bar

out of the saw.

Knob

Knob

Fig. 22 — Night Light

Transportation Tie-downs and Lift Point

Tie-downs

The saw is provided with holes at each corner of the lower frame for easy tiedown during transportation. The ½” all-thread J-bolts, with which your saw

was attached to its shipping pallet, can be used in a variety of tie-down scenarios.

It is highly recommended that the saw be tied down any time it is being transported.

Fig. 23 —Tie-down Points

41

Page 42

Lift Point

The convenient single point for lifting the saw with a hoist is located just in front

of the console, between it and the engine.

Lift Point

Fig. 24 — Lift Point

WARNING

§ To avoid possible injury, stay clear of the saw while it is being

hoisted.

§ To avoid possible damage to the saw, use approved rigging

(minimum 2000 lb. test) when hoisting the saw.

42

Page 43

MAINTENANCE

This saw has many service-saving features, such as fully enclosed oil bath

lubricated Blade Shaft bearings, which require no daily lubrication.

Level the saw frame surface prior to service to get accurate oil level

!

NOTE

Removable Guards and Access Panels

For ease of service access, the following guards and panels are removable:

• Blade Guard (4) • Belt Guard (2)

• Rear Access Panel (5) • Collar Guard (3)

readings.

• Console Access Panel (6) • Belt Tension Panel (7)

Replace guards and panels prior to starting the engine.

43

Fig. 25 — Guards & Panels

Page 44

Belts and Pulleys

Belt Qty Part Number

Blade Shaft Drive Belt (5) 2 Part # 520009

Jackshaft Belt (3) 1 Part # 521012

Transaxle Drive Belt (2) 1 Part# 521004

Part# 521006

Water Pump Option Belts 1

Part# 521008

JackShaft

3

Belt Tensioner Pulley

2

1

5

4

Fig. 26 — Belt Locations

V-Belt Tension

Ideal V-Belt tension is the lowest tension at which the belt will not slip under

peak load conditions. Check V-Belt tension frequently during the first 24-48

hours of run-in operation.

44

Page 45

CAUTION

§ Over-tensioning shortens belt and bearing life.

Engine Mount

Engine Mount

Access Panel

§ Keep belts clean of foreign material that may cause slippage.

§ Make V-Belt inspection a periodic procedure.

§ Never dress belts, as this can cause premature failure.

Adjusting Blade Shaft Drive Belt Tension

When tightening or loosening drive belts, raise the saw to reduce

!

NOTE

1. Access the Panel on the side of the saw, loosen the Engine Mount Lock

Bolts to allow the engine to rotate forward.

• Requires 15/16” socket, 10”- 12” extension and ratchet or breaker bar.

stress on the tensioning system, and gravity will assist you by pulling

the engine backwards slightly.

45

Lock Bolt

Lock Bolt

Fig. 27 — Engine Mount Lock Bolts

Page 46

Single Point Belt

Tension Bolt

Jam Nut

2. Loosen the jam nut on the Single Point Belt Tension Bolt.

Fig. 28 — Single Point Belt Tension Bolt

3. Adjust drive belt to the desired tension. DO NOT over tighten.

4. Tighten the Engine Mount Lock Bolt.

5. Turn the Single Point Tension Bolt until the head of the bolt no longer

touches the frame. Tighten the jam nut to prevent the bolt from turning.

Replacing the Blade Shaft Belt:

(See Fig. 27 & 28)

1. Remove the lower belt guard from around the Blade Shaft sheave.

2. Loosen the engine mount lock bolts.

3. Loosen the single-point belt-tensioning bolt to allow the engine to roll

forward.

4. Slide the belt off of the engine sheave and pull the belt down around

the Blade Shaft sheave.

5. Slide the belt off the top of the Blade Shaft sheave.

6. Reverse the order to install a new belt.

Replacing the Jackshaft Belt

(See Fig. 29)

1. Remove the Belt Guard.

2. Loosen the Rotary Tensioner Pulley.

3. Replace the Jackshaft Belt.

4. Adjust the Rotary Tensioner.

46

Page 47

Rotary Belt Tensioner

124

5

The Rotary Belt Tensioner system uses a 3/4”-headed bolt and a 15/16” or 1”

nut to set belt tension by positioning an arm between the Tensioner Pulley and

the Tensioner Base. Ridges on the Base mark the amount of tension.

JackShaft Pulley

1. Loosen the Bolt Head.

2. Rotate the Tensioner Nut clockwise until the desired belt tension is

achieved.

3. Tighten the Bolt Head.

4. DO NOT OVER-TIGHTEN.

Engine Sheave

Tensioner Pulley

Tensioner Nut—

Tensioner Bolt Head is

on opposite side

Fig. 29 — The JackShaft Belt and Rotary Belt Tensioner System

3

Tensioner Base

47

Page 48

Blade Shaft Maintenance

The fully enclosed Blade Shaft eliminates most maintenance. However, should

the Blade Shaft need service or repair, contact Multiquip for details.

Fig. 30 — 4-Speed Blade Shaft

Blade Shaft Replacement

To assure correct Blade Shaft/Wheel alignment it is recommended that this

operation be performed by a Multiquip Authorized Service Center.

48

Page 49

Blade Collar Removal/Installation

WARNING

Correct removal or installation of the Inner Blade Collar or Flange requires the

Collar Puller (option Part Number 18503) shown in Figure 31.

Follow instructions closely to prevent injury from flying Blade Collars!

Because of the tapered fit between Blade Collar and Blade Shaft,

5-10 tons of force is needed to release the inner collar. Parts and

tools can become dangerous projectiles if instructions are not

followed properly.

Fig. 31 — Using the Collar Puller

Removing the Inner Blade Collar

With the Outer Blade Collar in place, and the Blade Mounting Bolt loosened

approximately ¼”:

1. While the three perimeter bolts hold the two Puller Plates together, slide

the Horseshoe Plate of the Collar Puller behind the (Shaft) side of the

Inner Collar as shown above.

2. Tighten the center Puller bolt to remove the Inner Collar from the Blade

Shaft.

• Having the Outer Collar in place prevents the Puller and Inner Collar from flying

off when the taper breaks loose, and causing injury!

• If the Inner Collar does not readily come free from the tapered Blade

Shaft, lightly tap on the central Puller bolt. This should cause the collar to

break free from the shaft.

49

Page 50

Installing the Inner Blade Collar

1. Ensure that the tapered portion of the Blade Shaft, and the Inner Blade Collar

are perfectly clean and free of burrs or indentations. Clean and repair as

necessary

2. Ensure that the Drive Key is in place.

3. Slide the Inner Collar onto the tapered portion of the Blade Shaft

• DO NOT use any lubricant! Lubricant prevents the tapered surfaces of the

Collar and Shaft from mating properly.

4. Install the Outer Blade Collar, Collar Bushing, and Mounting Bolt.

• Tighten with a ½” impact wrench to seat the tapered surfaces of the Inner

Collar and Blade Shaft.

Mounting Bolt

Collar Bushing

Outer Collar

Dowel pin

Fig. 32 — Installing the Inner Blade Collar

Inner Collar

Drive Key

Blade Shaft

50

Page 51

5. Loosen the Mounting Bolt and remove the Outer Collar and Bushing.

6. Inspect the Inner Collar to ensure the proper seating of the tapered fit.

• The Inner Collar should be seated between .030” and 0.0” (flush) to the

end of the Blade Shaft.

Inner Collar

Blade Shaft

Fig. 33 — Proper seating of the Inner Collar on the Blade Shaft

7. Test to ensure that the Inner Collar does not wobble when rotated. Use an

indicator dial on the face of the Collar. Maximum tolerance is .003” run out

on the face of the Collar.

51

Page 52

Circuit Breakers

Remove Panel to

Three thermal circuit breakers are located inside the top of the Console.

access circuit

breakers

Fig. 34 — Circuit Breaker location

Under normal circumstances circuit breakers do not require service; they are

automatically re-set when an overload condition is corrected. If a breaker is

cycling on/off, locate the cause of the electrical overload and repair as required.

Maximum Cut Depth Adjustment

This saw comes factory-adjusted for maximum usable cut depth. However,

should you desire to change this setting:

1. Park the blade-less saw on a flat and level surface.

2. Fully lower the saw onto the Stop Bolts (see Fig. 35).

3. Measure the distance from the Blade Collars to the surface.

4. Adjust the Stop Bolts in or out until the Blade Collars have 1/8” to 3/16”

ground clearance.

5. Ensure that both bolts are adjusted to the same settings so the load is evenly

distributed.

52

Page 53

Lubrication

WARNING

CAUTION

Maximum Cut Depth

Maximum Cut Depth

This saw has five grease fittings on the front axle assembly.

• Front axle pivot bearings (F1 & F3)

• Hydraulic lift cylinder ends (F2, and far end of cylinder)

• Depth Stop Pivot Plate (F4)

These fittings are easily accessed by raising the saw half way up, and then lifting

the rear of the saw until the blade collars rest on the ground.

To prevent the possibility of crush injury, ensure that the saw is

securely placed on blocks before servicing the lubrication points.

Grease fittings every 50 hours of operation with a premium grade

waterproof E. P. (extreme pressure) grease.

Stop Bolt

F1

F4

Fig. 35 — Grease Fittings and Maximum Cut Depth Stops (view from back of saw)

F2

Stop Bolt

F3

53

Page 54

Engine

CAUTION

Engine

The Model SP-6457 TD features a Turbocharged 57 HP Deutz diesel engine. See

the engine manual for service details and oil recommendations.

• Check air filters daily, replace as required. Do Not clean air filters.

• Check engine oil level daily.

• Level the frame prior to service to get an accurate reading.

• Do Not over-fill with oil.

• Change engine oil and filter every 125 hours of operation

Safety Air Filters are not intended to be used for primary air

filtration. When the Primary Filter gets clogged, replace it

immediately — do not run saw using just the Safety filter.

Air and Oil Filter Chart

Filter Qty Part Number

Primary Air Filter 1 300004-1 (Donaldson #P827653)

Safety Air Filter 1 300004-2 (Donaldson #P829332)

Engine Oil Filter 1 306012 ( Deutz # 1174416-SP)

Hydraulic System Filter 1 306002 ( HydroGear # 51563)

Fuel Filter 1 304010 ( Donaldson # 1174696)

Oil filter

Fuel filter

Transaxle

filter

Fig. 36 — Remote Filters

54

Page 55

PTO Drive Maintenance

Disassembly of the PTO Drive and replacement of the PTO Drive

Sheave/Bearing Assembly requires the PTO Bearing Puller

(P/N 18610). The Sheave/Bearing Assembly is not serviceable and must be

replaced as a complete unit.

1. Remove the Drive Belt (see Replacing the Blade Shaft Drive Belt).

2. Remove the Drive Plate Assembly from the engine.

• The Assembly is held on by 11 bolts.

• Note the clocking orientation of the plate.

3. On the workbench:

• Remove the Cap Screws and End Cap (Items 1 & 2, Fig. 37).

• Remove the Splined Drive Cap Screws and the Drive Cap (Items 3 & 4,

Fig. 37).

• With a sharp pointed awl or similar tool, remove the flat wound spiral

retaining ring (Item #5, Fig. 37)

• Attach the PTO Bearing Puller in place of the Splined Drive Cap, as shown

in Fig. 37.

• Insert the Puller Alignment Bushing (1).

• Attach the Puller Cap (2) with the Drive Cap Screws (3).

• Thread in the PTO Bearing Puller Bolt (4).

55

Fig. 37 — Attaching the PTO Bearing Puller to the Drive Plate Assembly

• Tighten the Puller Bolt (4), to pull the Sheave/Bearing Assembly off

of the Bearing Support (Fig. 38, #9).

Page 56

Fig. 38 — PTO Drive Sheave/Bearing Assembly

Re-Assembling the PTO Drive

1. Clean and inspect all parts.

2. Use a press to push the new Bearing/Sheave assembly onto the Bearing

Support (9) until the bearings contact the shoulder of the Support.

3. Use a sharp pointed awl or similar tool to install the flat-wound Spiral

Retaining Ring (5) into the top groove of the Bearing Support (9).

4. Install the Splined Drive Shaft (10) in the Splined Drive Shaft Flange (15).

5. Slide the PTO Drive Plate assembly over the Splined Drive Shaft.

6. Bolt the plate to the Engine, making sure to clock the plate to its original

position.

7. Re-install the Splined Drive Cap (4) and bolts (3), with a low-strength

thread-locker (LocTite™ 242 or equivalent).

8. Install the End Cap (2) and screws (1).

9. Replace the Drive Belt.

56

Page 57

Replacing the Battery

Engine Mount

Single Point Belt

This saw uses a Group 75, 12-Volt, 1000 cold cranking amp battery. To replace

the battery:

1. Remove Engine Guard and Upper Belt Guard.

2. Loosen the Rotary Tensioner and remove the Transaxle Belt.

3. Loosen the two Engine Mount Lock Bolts and the Single Point Belt

Tension Bolt.

Jam Nut

Lock Bolt

Access Panel

Fig. 39 — Engine Mount Lock Bolts Single Point Belt Tension Bolt – from Belt Tension

4. Tilt the saw down and roll the engine as far forward as possible, to create

the maximum access opening. See figure 40.

5. Disconnect the battery cables, Positive first, to avoid arcing.

6. Remove the forward battery tie-down clip.

7. Carefully roll the battery up and maneuver it out through the space

between the Control Console and the Engine.

8. To replace the battery, repeat steps 1-5 in reverse order

Fig. 40 — Engine Rotated Forward to Remove the Battery

57

Page 58

Raise-Lower System

3

Hydraulic

This saw uses a 12-volt hydraulic pump and hydraulic cylinder to power the

raise-lower system.

• Level frame prior to service to get an accurate reading.

• Check oil level daily.

• Fill the reservoir half to two-thirds full when cold

• Use 5W-30 premium grade engine oil.

Depth Stop Valve

Lift Pump

Reservoir

Lift

Pump

Depth Stop

Cylinder

Manifold,

Lowering

valves

2

1

4

5

Lift Cylinder

Fig. 41 — Raise-Lower System

Raise/Lower Troubleshooting

If your new saw begins lowering all by itself when you release the Raise button,

the problem may be caused by debris in the hydraulic line which is blocking the

Lower valve in the open position.

58

Page 59

Joystick Tension Adjustment

The speed control joystick uses friction adjustment to provide the preferred

“feel”:

1. Using a ¼” Allen wrench and 9/16” wrench, loosen both pivot bolts until

they can be turned by hand. Pivot #1 only requires a 9/16” wrench, as the

Allen nut side is welded in place.

2. Tighten pivot #1 until the handle is close to the desired “feel”.

3. Tighten pivot #2 until it just starts to increase the force required to move the

handle.

Pivot #2

Pivot #1

Fig. 42 — Joystick Adjustment

59

Page 60

Hydraulic System Maintenance

Lift Cylinder

Hydraulic

Oil Filter

The hydraulic system consists of:

§ Blade Shaft § Hydraulic Pump

§ Transaxle § Hydraulic Manifold

§ Depth Stop Cylinder & Valve § Hydraulic Filter

§ Lift Cylinder § Oil Fill/ System Vent

Routine Maintenance

• Check oil level daily.

• Level the saw frame prior to service to get an accurate reading.

• Fill reservoir to Fill line when cold, with 5W-30 premium grade engine oil.

Fig. 43 — Oil Reservoir Fill Line

• Change oil and filter annually.

Oil Fill/System

Vent

Depth Stop Cylinder

Fuel Filter

Oil Cooler

Assembly

Hydraulic Pump

Transaxle

Manifold

Blade Shaft

Fig. 44 — The Hydraulic System

60

Page 61

Draining & Filling the Hydraulic System

CAUTION

To drain the hydraulic system:

1. Remove the drain plug from the bottom of the Blade Shaft housing and the

bottom of the Transaxle.

Drain Plug

Drain Plug

Fig. 45 — Hydraulic System Drains

2. Collect and dispose of the used oil in an environmentally friendly manner.

3. Remove the used oil filter. See Fig. 44.

4. Once drained, reinstall the drain plugs.

5. Pre-fill and install a new oil filter.

To prevent hydraulic pump damage, pre-fill the filter with oil prior to

installing it.

61

Page 62

To fill the hydraulic system:

90

Collars will be approx. 6”

1. Fully lower the saw.

2. Do not level the saw frame. The 4-Speed Blade Shaft is mounted at a 78° angle

to the saw frame. Adjust the level of the saw so that the face of the Blade Shaft

housing is at right angles to the ground.

Filler Plug

Housing Face

off the ground when

housing is perpendicular to

the ground.

Fig. 45 — Adjusting the level of the Blade Shaft

If the saw is not leveled correctly, the 4-Speed Blade Shaft could be

damaged by operating with too little, or too much, oil.

CAUTION

Sight Glass

Fig. 46 — Filling the Hydraulic System

Ground

Level

3. Add oil to the fill port on top of the 4-Speed Blade Shaft Housing.

4. Start the engine, and run it for a couple minutes to spread the oil throughout

the system

• Add more oil as required.

• Repeat steps 3 & 4 as necessary.

5. When the 4-Speed Blade Shaft is full, and positioned at 90° to the ground, the

oil should show between the center and the top of the sight glass on the front of the

main housing.

6. Inspect for leaks after service.

!

NOTE

62

If the Blade Shaft is drained completely, it will require approximately

1 gallon to refill. If the transaxle is drained as well, it will require

approximately one additional gallon.

Page 63

Bleeding the Depth Stop Cylinder

Depth Stop Block

After changing the hydraulic system oil, or after disturbing the Depth Stop

Cylinder plumbing, air may become trapped in the system and cause the Depth

Stop Cylinder to work improperly. To remedy the situation, the Depth Stop

Cylinder must be bled to remove trapped air. This procedure requires the use of

the Depth Stop Block tool (P/N 584042)..

1. Open the Depth Stop Valve.

2. Fully raise the saw.

3. Place the Depth Stop Block between the Depth Stop Plate and the Front

Axle.

4. Fully lower the saw.

• Verify that the Depth Stop Cylinder has fully collapsed.

5. With the Depth Stop Valve still open, and the engine running:

• At the rear of the cylinder use a 1/8” diameter hose on the bleeder nipple.

Use the length of hose to direct the flow of oil into a suitable receptacle.

• Open the bleeder valve at the rear of the cylinder and allow the oil to flow

until no air is detected in the fluid. Close the bleeder valve.

• Tighten the hose connection.

• Dispose of the waste oil in an environmentally-friendly manner.

6. Remove the Depth Stop Block and test the operation of the Depth Stop.

7. Re-fill the Reservoir Fill bottle at the rear of the Fuel Tank.

63

Depth Stop

Block tool

Fig. 47 — Bleeding the Depth Stop Cylinder

tool in place

Page 64

Drive Wheel Alignment

Distance X

Distance X

Distance A

Distance

= A + .187”

Below is the technique recommended for aligning the wheels. Distance X is the

same on both sides; the Front Wheel and Blade shaft axles must be at right angles

to the frame edge. Distance A is 3/16” (.187”) longer on the right side, so that the

saw steers slightly left. Users may wish to alter the alignment to fit a particular

application.

Fig. 48 — Drive Wheel Alignment

64

Page 65

The drive wheels are aligned by adjusting the entire rear drive assembly:

Adjustment Side

Alignment

1. Loosen the Transaxle Attachment Bolts just enough to move the Transaxle

— do not completely loosen the bolts.

2. Loosen and tighten the Alignment Jackscrew nuts to move the Transaxle

— and thus the wheels — in the appropriate direction to achieve the

desired alignment distance (see Fig.46).

3. Lock down the Transaxle Attachment Bolts when the appropriate

alignment distance is set.

Pivot Side | Adjustment Side

Jackscrew

Pivot Side

Attachment Bolts

Attachment Bolts

Fig. 49 — Drive Wheel Alignment Bolt Locations

65

Page 66

SPECIFICATIONS

Engine

Engine Air Cleaner

Fuel Tank

Blade Shaft Assembly

Blade Collars

Blade Flushing

Blade Range

Max Cut Depth

Blade Guard

Blade Shaft Drive Belt

Blade Control

Blade Depth Stop

Balance

Handlebars

Front Wheels

Rear Wheels

Drive System

Engine Controls

Battery

Front Pointer

Rear Pointer

Hardware

Tools

Dimensions

Weight

Serviceability

57 HP Turbocharged Deutz Diesel, direct injection, air/oil cooling, oil filter and

above-frame remote oil drain.

4-Stage air filtration, pre-cleaner plus cartridge element and safety element.

10 Gallon clear-molded plastic fuel tank with sight gauge, central drain and

shutoff valve.

Fully enclosed transmission, bearings and shaft, oil bath lubrication with cooled

and filtered oil circulation system, 4 protected shaft seals, 2-3/8” diameter blade

shaft, rack & pinion shifting, positive shift lock, oil sight gauge, magnetic drain

plug, easy serviceability, remote protected oil fill and vent, blade usable on either

side of saw, taper lock blade collar attachment, standard blade shaft tachometer,

ratios of 1:1, 1.34:1, 1.7:1, and 2.02:1

Plated quick-disconnect, taper lock attachment, 5.5” diam., 24 water spray ports.

Minimum water usage system, evenly distributed across the blade, panel-

mounted flow control.

14” to 48”.

21”.

Extra heavy design, slip-on type with double lip seal and quick disconnect water

hose, two handles.

Dual 5--Groove premium quality Goodyear HY-T Wedge Torque Team belts.

12-Volt hydraulic raise/lower system, 3 blade plunge speeds, fast and slow blade

plunge speed buttons on joystick, raise button on joystick, one-hand control.

Positive, heavy-duty hydraulically controlled depth stop.

Front steer.

3-Position adjustable angle, storage position, quick locks.

8” x 3”, precision sealed bearings in each wheel with extra end seals and seal

protectors, no grease points.

12” x 3”.

Hydrostatic powered transaxle with infinite speed control, joystick control, remote

oil filter and up to 300 feet per minute travel speed. Locked axle drive.

Twist-lock throttle, backlit tachometer with hour meter, voltmeter, oil pressure

gauge and 3-position ignition switch.

12-Volt, group 75, 1000 cold cranking amps.

Heavy gauge steel, 6” pointer wheel and plastic-coated tether.

Standard, adjustable.

Grade 8 fasteners throughout.

15/16” Blade wrench.

L= 47-1/2” with handlebars stored, W = 32” w/o blade collars, H= 44” with front

pointer up.

1,700 Pounds, with oil but no fuel.

Spin-on oil filters, lubrication points, lube every 50 hours.

66

Page 67

DIMENSIONS

DBC

K

E

G

A

A

71”

Extended, Pointer Bar Up

Max Length, Handle Bar

Max Length, Handle Bar

B

50 3/8”

Removed, Pointer Bar Up

Max Height, Console Top to

C

33 ½”

Surface

E

D

Max Length, Handle Bar

115”

Extended, Pointer Bar Down

Max Height 52 ¾”

F

Wheel Base, Front Wheels 19 ¾”

Wheel Base, Rear Wheels 28”

Max Width, Guards, Covers

G

H

F

H

I

J

Max Width, Guards, Covers

I

J (with Collars & Guards OFF) 32 ½”

OFF

ON

35”

36 ½”

K Wheel Path (per side) 4.0”

Crated Dimensions: 60” x 60” x 61”

Crated Weight - 1 Blade Guard 1800 lbs.

Page 68

Q-6457 Electric Diagram

All Wire 18 Gauge Unless Noted: Ground Wires Are Black

BROWN

GREY/WHT

RED

12 Gauge

12 Gauge

ORANGE

ORN/WHT

RED

VIOLET

RED/GRN

B+ 30

ACC 54

ACC 15

GLOW PLUG 19

START 50a

IGNITION SWITCH

622500- Q-6457 Electrical 08-15-01

IN2 IN4 GEN

IN3IN1 IN5

LOFA

MAG

SIG

KL 15

STOP

LINE

GREEN

OUT

LINE

IN

CB3

WATER

PUMP

SWITCH

WATER

PUMP

KL 31

KL 50

BLUE

AB

WHITE

AIR

FILTER

SWITCH

BLACK

14 Gauge

BLUE/WHT

F-N-R

CONTROL

2-PIN

PACKARD

GREY

PACKARD

EMERGENCY

STOP

4-PIN

VIOLET/ORN

B

YELLOW

RED

A B C D

WHITE/RED

MANIFOLD

CONNECTOR

A BCD

A BD C

1N4007

SLOW

LOWER

SV2

FAST

LOWER

SV1

FSR

BLK/ORANGE

4-PIN

PACKARD

1N4007

TACHVOLTAGE

RED

RED/YL

10-

8-Ground

6-

Oil Pressure

4-Temperature

2-D+

Tachometer-1

BLK/RED

8

34

-- ++

BB

LINE

OUT

LINE

OUT

GREEN/BLK

HYDRAULIC

MANIFOLD

VALVES

Fuel Rack-7

AUX

SWITCH

YL/BLK

BRN/YL

LINE

-9

-5

-3

+

IN

483

TACH

B B

1N4007

-

LIGHT

SWITCH

CB1CB2

FENNER

POWER

UNIT

LINE

LINE

OUT

IN

12 Gauge

ORANGE

RED

VIOLET

RED

1N4007

STARTER

2-PIN

PACKARD

A

B

BATTERY

SOLENOID

/RELAY

-

GLOW

PLUG

S

B

4- PIN

TRAILER

PLUG

1N4007

+

+

8 Gauge

+

SOLENOID

/RELAY

8 Gauge

SPOT

LIGHT

RED

Page 69

MULTIQUIP INC.

Atlanta

• Boise • Dallas • Houston • Newark

POST OFFICE BOX 6254

CARSON, CA 90749

310-537-3700 • 800-421-1244

FAX: 310-537-3927

E-MAIL: mq@multiquip.com

www: multiquip.com

Quebec, Canada • Manchester, UK • Rio De Janiero, BR •

Loading...

Loading...