Page 1

Diamond Back

quip

OPERATION AND PARTS MANUAL

SP3 “STREET PRO”

PROFESSIONAL SLAB SAW

35 HP WISCONSIN DIESEL ENGINE

MODELS

SP303516, SP303520, SP303526

SP303530

Revision #3 (09/29/06)

To find the latest revision of this

publication, visit our website at:

www.multi

.com

THIS MANUAL MUST

COMPANY THE EQUIPMENT AT ALL TIMES.

Page 2

Page 3

MQ SP-3035 CONCRETE SAW

PROPOSITION 65 WARNING

MQ SP-3035 CONCRETE SAW — OPERATION AND PARTS MANUAL — REV. #3 (09/29/06) — PAGE 1

Page 4

MQ SP-3035 CONCRETE SAW

SILICOSIS /RESPIRATORY HAZARDS

WARNING

WARNING

Grinding/cutting/drilling of masonry,concrete,metaland

other materials with silica in their composition may give

off dust or mists containing crystalline silica. Silica is a

basic component of sand, quartz, brick clay, granite and

numerous other minerals and rocks. Repeated and/or

substantial inhalation of airborne crystalline silica can

cause serious or fatal respiratory diseases, including

silicosis. In addition, California and some other

authorities have listed respirable crystalline silica as a

substance known to cause cancer. When cutting such

materials, always follow the respiratory precautions

mentioned above.

SILICOSIS WARNING RESPIRATORY HAZARDS

Grinding/cutting/drilling of masonry,concrete,metaland

other materials can generate dust, mists and fumes

containing chemicals known to cause serious or fatal

injury or illness, such as respiratory disease, cancer,

birth defects or other reproductive harm. If you are

unfamiliar with the risks associated with the particular

process and/or material being cut or the composition of

the tool being used, review the material safety data

sheet and/or consult your employer, the material

manufacturer/supplier, governmental agencies such as

OSHA and NIOSH and other sources on hazardous

materials. California and some other authorities, for

instance, have published lists of substances known to

cause cancer, reproductive toxicity, or other harmful

effects.

Control dust, mist and fumes at the source where

possible. In this regard use good work practices and

follow the recommendations of the manufacturers or

suppliers, OSHA/NIOSH, and occupational and trade

associations. Water should be used for dust

suppression when wet cutting is feasible. When the

hazards from inhalation of dust, mists and fumes cannot

be eliminated, the operator and any bystanders should

always wear a respirator approved by NIOSH/MSHA for

the materials being used.

MQ SP-3035 CONCRETE SAW — OPERATION AND PARTS MANUAL — REV. #3 (09/29/06) — PAGE 2

Page 5

MQ SP-3035 CONCRETE SAW

Table of Contents

PROPOSITION 65 WARNING .......................................................................................1

SILICOSIS /RESPIRATORY HAZARDS......................................................................2

PARTS ORDERING PROCEDURES........................................................................... 6

SAFETY..............................................................................................................................7

HAZARD SYMBOLS.................................................................................................... 8

GENERAL SAFETY WARNINGS ....................................................................................... 11

BLADE SAFETY......................................................................................................... 13

SAW TRANSPORTATION SAFETY......................................................................... 14

EMERGENCIES .......................................................................................................... 14

MACHINE OPERATION AND SAFETY DECALS................................................... 15

SERIAL TAG................................................................................................................... 16

OPERATION ...................................................................................................................17

BEFORE STARTING......................................................................................................... 17

CONTROL PANEL ........................................................................................................... 18

ENGINE POWER, CUTTING POWER & SHEAVE SIZE........................................................ 19

INSTALLING THE BLADE, BLADE GUARD & BLADE FLANGE ......................................... 20

REMOVING THE BLADE, BLADE GUARD & BLADE FLANGE........................................... 21

STACKING BLADES FOR WIDE CUTS.............................................................................. 22

INSTALLING AND REMOVING THE BLADE GUARD.......................................................... 23

WATER SUPPLY AND CONTROL ..................................................................................... 26

ANDLEBARS................................................................................................................. 27

H

FUELING THE SAW ......................................................................................................... 28

STARTING AND STOPPING THE ENGINE ..........................................................................29

P

OINTER ADJUSTMENT .................................................................................................. 30

RAISE – LOWER CONTROLS ........................................................................................... 31

SETTING THE DEPTH GAUGE & DEPTH STOP ................................................................. 32

DRIVE SYSTEM .............................................................................................................. 33

NIGHT LIGHT ................................................................................................................. 36

TRANSPORTATION TIE-DOWNS AND LIFT POINT ............................................................ 37

PERATION ON A SLOPE OR INCLINE.............................................................................. 38

O

FREEING A STUCK BLADE.............................................................................................. 38

DRAINING THE WATER SYSTEM..................................................................................... 39

MQ SP-3035 CONCRETE SAW — OPERATION AND PARTS MANUAL — REV. #3 (09/29/06) — PAGE 3

Page 6

MQ SP-3035 CONCRETE SAW

MAINTENANCE.............................................................................................................40

REMOVABLE GUARDS AND ACCESS PANELS.................................................................. 40

BELTS AND PULLEYS ..................................................................................................... 41

BLADE FLANGE REMOVAL/INSTALLATION.................................................................... 45

CIRCUIT BREAKERS ....................................................................................................... 50

MAXIMUM CUT DEPTH ADJUSTMENT............................................................................ 50

LUBRICATION ................................................................................................................ 51

ENGINE MAINTENANCE ................................................................................................. 52

RAISE-LOWER SYSTEM.................................................................................................. 53

CONTROL HANDLE ADJUSTMENT .................................................................................. 54

HYDRAULIC SYSTEM ..................................................................................................... 55

POSITRACTION ADJUSTMENT......................................................................................... 60

EXPLANATION OF CODE IN REMARKS COLUMN.............................................61

SUGGESTED SPARE PARTS.......................................................................................62

COMPONENT DRAWINGS..........................................................................................63

NAMEPLATE AND DECALS ASSY.................................................................................... 63

DECK/GAUGE PANEL ASSY. .......................................................................................... 65

CONSOLE/SHEET METAL ASSY...................................................................................... 67

ACCESS PANEL ASSY..................................................................................................... 69

FUEL TANK ASSY. ......................................................................................................... 71

F-N-R CONTROL HANDLE ASSY.................................................................................... 73

JOYSTICK MOUNTING ASSY........................................................................................... 75

LIFT PUMP CIRCUIT ASSY.............................................................................................. 77

WATER SYSTEM ASSY................................................................................................... 79

DEPTH INDICATOR ASSY................................................................................................ 81

ANDLE AND LIGHT ASSY............................................................................................. 83

H

F

RONT/REAR POINTER ASSY. ........................................................................................ 85

GAUGES AND CONTROLS ASSY...................................................................................... 87

FRONT AXLE ASSY. ....................................................................................................... 89

DEPTH STOP ASSY......................................................................................................... 91

PLATFORM ASSY............................................................................................................ 93

DRIVE ASSY................................................................................................................... 95

BLADESHAFT AND MOUNTING ASSY. ............................................................................ 97

POSITRACTION ASSY...................................................................................................... 99

MQ SP-3035 CONCRETE SAW — OPERATION AND PARTS MANUAL — REV. #3 (09/29/06) — PAGE 4

Page 7

MQ SP-3035 CONCRETE SAW

PULLEY AND V-BELT ASSY......................................................................................... 101

BATTERY ASSY............................................................................................................ 103

ENGINE BRACKETS ASSY............................................................................................. 105

ENGINE INSTALLATION ASSY....................................................................................... 107

BLADEGUARD ASSY..................................................................................................... 109

OPTIONAL WATER PUMP KIT ASSY............................................................................. 111

COLLAR PULLER ASSY................................................................................................. 113

SEAL SLEEVE PULLER/SEAL INSTALLATION TOOL ...................................................... 115

BUSHING EXTENSION KITS ..........................................................................................117

ELECTRIC SCHEMATIC...........................................................................................119

SPECIFICATIONS........................................................................................................120

MQ SP-3035 CONCRETE SAW — OPERATION AND PARTS MANUAL — REV. #3 (09/29/06) — PAGE 5

Page 8

y

MQ SP-3035 CONCRETE SAW

PARTS ORDERING PROCEDURES

Order via Internet (Dealers Only):

Best Deal!

Order parts on-line using Multiquip’s SmartEquip website!

Order Parts

Print Specification Information

Ordering parts has never been easier!

Choose from three easy options:

View Parts Diagrams

Go to www. Multiquip .com and click on

to log on and save!

Order Parts

Fax your order in and qualify for a 5% Discount

on Standard orders for all orders which include

complete part numbers.*

If you have an MQ Account, to obtain a

Username and Password, E-mail us at:

parts@multiquip.com.

To obtain an MQ Account, contact your

District Sales Manager for more information.

Note: Discounts Are Subject To Change

Order via Fax (Dealers Only):

All customers are welcome to order parts

via Fax.

Domestic (US) Customers dial:

1-800-6-PARTS-7 (800-672-7877)

Fax your order in and qualify for a 3% Discount

on Standard orders for all orders which include

complete part numbers.*

Note: Discounts Are Subject To Change

Order via Phone:

Domestic (US) Dealers Call:

1-800-427-124

Non-Dealer Customers:

Contact your local Multiquip Dealer

for parts or call 800-427-1244 for help

in locating a dealer near you.

International Customers should contact their local

Multiquip Representatives for Parts Ordering I

information.

When ordering parts, please supply:

Dealer Account Number

Dealer Name and Address

Shipping Address (if different than billing address)

Return Fax Number

Applicable Model Number

Quantit

, Part Number and Description of each Part

www.multiquip.com

NOTE

Unless otherwise indicated by customer, all orders are treated as Standard Ordersand will ship

within 24 hours. We will make every effort to ship Air Shipments the same day the order is received,

if received prior to 2PM PST. Stock Orders must be noted on fax or web order form.

WE ACCEPT ALL MAJOR CREDIT CARDS!

Specify Preferred Method of Shipment:

Fed Ex/UPS

Priority One

Ground

Next Day

Second/Third Day

DHL

Truck

MQ SP-3035 CONCRETE SAW — OPERATION AND PARTS MANUAL — REV. #3 (09/29/06) — PAGE 6

Page 9

MQ SP-3035 CONCRETE SAW

SAFETY

FOR YOUR SAFETY AND THE SAFETY OF OTHERS!

NOTE

Safety precautions should be followed at all times when operating this equipment. Failure to read and

understand the Safety Messages and Operating Instructions could result in injury to yourself and others.

This Owner's Manual has been developed to provide instructions for the

safe and efficient operation of the Multiquip SP-3035 CONCRETE SAW.

For engine maintenance information, please refer to the engine

manufacturers’ instructions for data relative to its safe operation.

Before using this CONCRETE SAW, ensure that the operating individual

has read and understands all instructions in this manual.

SAFETY MESSAGE ALERT SYMBOLS

The three (3) Safety Messages shown below will inform you about potential hazards that could

injure you or others. The Safety Messages specifically address the level of exposure to the

operator, and are preceded by one of three words: DANGER, WARNING, or CAUTION.

DANGER: You WILL be KILLED or SERIOUSLY injured if you

DANGER

DO NOT follow directions.

WARNING: You CAN be KILLED or SERIOUSLY injured if you

WARNING

DO NOT follow directions.

CAUTION: You CAN be injured if you DO NOT follow directions.

CAUTION

Potential hazards associated with SP-3035 Concrete Saw operation will be referenced with "Hazard

Symbols" which appear throughout this manual, and will be referenced in conjunction with Safety

"Message Alert Symbols".

MQ SP-3035 CONCRETE SAW — OPERATION AND PARTS MANUAL — REV. #3 (09/29/06) — PAGE 7

Page 10

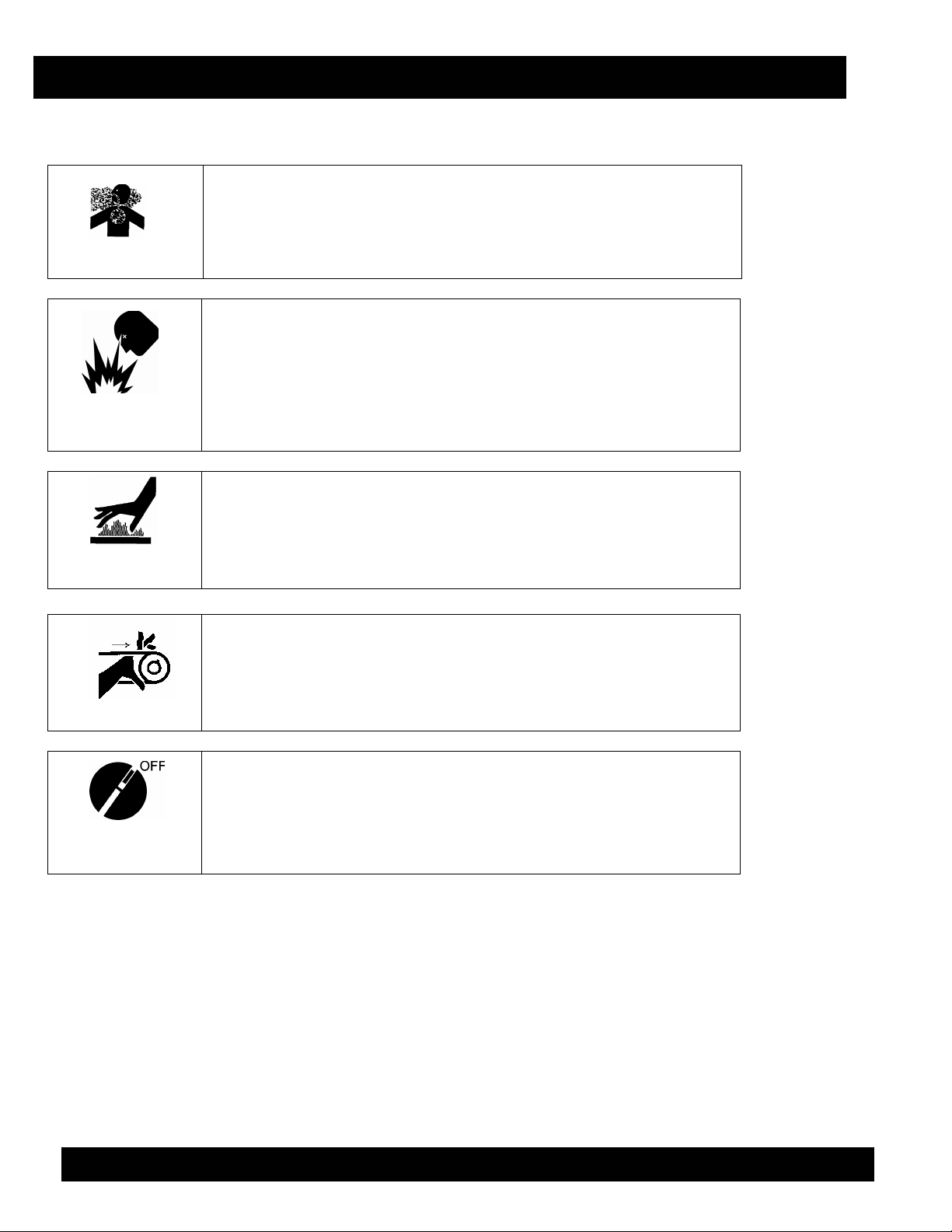

HAZARD SYMBOLS

MQ SP-3035 CONCRETE SAW

Lethal Exhaust

Gases

Explosive Fuel

Burn Hazards

Engine exhaust gases contain poisonous carbon monoxide. This

gas is colorless and odorless, and can cause death if inhaled.

NEVER operate this equipment in a confined area or enclosed

structure that does not provide ample free flow of air.

Gasoline is extremely flammable, and its vapors can cause an

explosion if ignited. DO NOT start the engine near spilled fuel or

combustible fluids. DO NOT fill the fuel tank while the engine is

running or hot. DO NOT overfill the tank, since spilled fuel could

ignite if it comes into contact with hot engine parts or sparks from

the ignition system. Store fuel in approved containers, in wellventilated areas and away from sparks and flames. NEVER use

fuel as a cleaning agent.

Engine components can generate extreme heat. To prevent

burns, DO NOT touch these areas while the engine is running or

immediately after operations. NEVER operate the engine with heat

shields or heat guards removed.

NEVER operate equipment with covers, or guards removed. Keep

fingers, hands, hair and clothing away from all moving parts to

prevent injury.

Rotating Parts

Accidental

Starting

MQ SP-3035 CONCRETE SAW — OPERATION AND PARTS MANUAL — REV. #3 (09/29/06) — PAGE 8

ALWAYS place ON/OFF switch to the OFF position, remove key

and/or disconnect the spark plug leads before servicing the

engine, equipment, or supporting components. Ground the lead to

prevent sparks that could ignite a fire.

Page 11

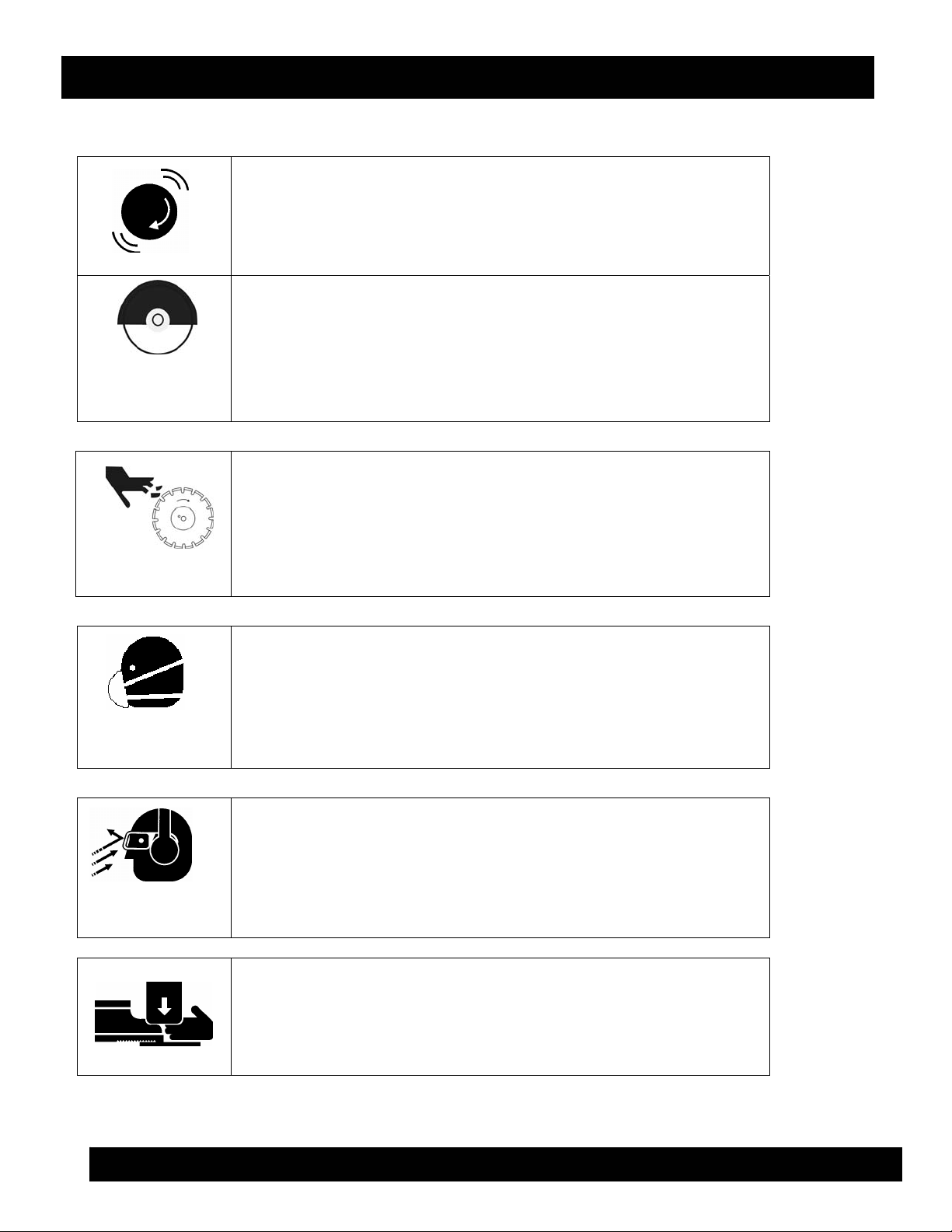

HAZARD SYMBOLS

Over Speed

Guards and

Covers in Place

NEVER tamper with factory settings of engine governor or speed

settings. Ensure the proper Speed Kits are installed to safely

support the prescribed RPM settings for diamond blade

operations.

NEVER operate the saw without blade guards and covers in

place. Adhere to safety guidelines ANSI American National

Standards Institute, OSHA, and/or other applicable local

regulations.

Rotating Blade can cut, tear, and crush. Keep hands and feet

clear.

MQ SP-3035 CONCRETE SAW

Rotating Blade

Respiratory

Hazard

Sight &

Hearing Hazard

Crush Hazard

ALWAYS wear approved respiratory protection.

ALWAYS wear approved eye and hearing protection.

CRUSH AND PINCH HAZARD Keep hands and feet clear.

MQ SP-3035 CONCRETE SAW — OPERATION AND PARTS MANUAL — REV. #3 (09/29/06) — PAGE 9

Page 12

HAZARD SYMBOLS

MQ SP-3035 CONCRETE SAW

Skin Injection

Hazard

NOTE

Other important messages are provided throughout this manual to

help prevent damage to your concrete saw, other property, or the surrounding

environment.

CAUTION

NEVER use your hand to find hydraulic leaks. Use a piece of wood

or cardboard. Hydraulic fluid injected into the skin must be treated

by a knowledgeable physician immediately or severe injury or death

can occur.

Text set off like this presents clarifying information, specific

instructions or commentary designed to help prevent damage to

your saw, other property, or the environment.

Equipment Damage Message

Other important messages are provided throughout this manual

to help prevent damage to your concrete saw, other property, or

the surrounding environment.

NOTE

This concrete saw, other property, or the surrounding environment could be

damaged if you do not follow instructions.

MQ SP-3035 CONCRETE SAW — OPERATION AND PARTS MANUAL — REV. #3 (09/29/06) — PAGE 10

Page 13

MQ SP-3035 CONCRETE SAW

General Safety Warnings

Most accidents involving product operation, maintenance and repair are caused by failure to

observe basic safety rules and precautions. Accidents can often be avoided by recognizing

potentially hazardous situations before an incident occurs.

WARNING

Before operating the saw, make sure all protective guards are securely

in place. All saws are supplied with a blade guard, collar guard and belt

guard.

Whenever necessary, replace operation and safety decals if they

become difficult to read

Verify the engine start switch is set to the OFF position before installing

a blade.

Make sure the operator knows how to turn the engine OFF in case of

an emergency.

Do not go near rotating parts (blades, belts, pulleys or wheels) while

engine is running.

Muffler and exhaust gases are extremely hot. Stay clear of muffler and

exhaust gases. Allow these parts to cool before servicing the saw.

Stay clear of the saw while it is being hoisted.

Anytime the saw is lifted onto its nose, or tilted fully back, for

maintenance access, the high end MUST be blocked up to prevent the

possibility of crush injury!

Allow the engine to cool before adding fuel or performing service and

maintenance functions. Contact with HOT components can cause

serious burns.

Never operate the saw in any enclosed or narrow area where free flow

of air is restricted. If the airflow is restricted it will cause serious

damage to the saw’s engine and may cause injury to people.

Remember the saw’s engine gives off DEADLY carbon monoxide gas.

ALWAYS refuel in a well-ventilated area; away from sparks and open

flame. Avoid “topping off” the filler port as spills can result.

ALWAYS use extreme caution when working with flammable liquids.

When refueling, STOP the engine and allow it to cool.

NEVER smoke around or near the machine. Fire or explosion could

result from fuel vapors, or if fuel is spilled on a HOT engine.

NEVER operate the saw in an explosive atmosphere where fumes are

present or near combustible materials. An explosion or fire could

result causing severe bodily harm or even death.

NEVER use fuel as a cleaning agent.

MQ SP-3035 CONCRETE SAW — OPERATION AND PARTS MANUAL — REV. #3 (09/29/06) — PAGE 11

Page 14

General Safety Warnings

WARNING

ALWAYS read, understand, and follow procedures in the Operator’s

Manual before attempting to operate the equipment.

Be sure the operator is familiar with proper safety precautions and

operating techniques before using the saw.

Make sure the operating area is clear before starting the engine.

Maintain this equipment in a safe operating condition at all times

Keep the saw clean. It will work better and last longer

Use proper blades and follow the blade manufacturer’s

recommendations. Match blade rpm (Spindle rpm) to recommended

blade surface feet per minute (SFPM).

Tighten the 5/8” blade-mounting bolt to 100-125 foot-lbs. torque.

Turn engine OFF prior to fueling the saw!

Start engine with the joystick in NEUTRAL to prevent unexpected saw

movement.

Do not leave saw unattended while engine is running.

Do not start engine on a sloping surface to prevent unexpected loss of

control.

Do not park or leave saw unattended on a slope - the saw can roll when

the engine is OFF. Block the unit when leaving.

If the saw must be parked on a slope, turn it across the angle of the

slope, to prevent accidental downhill movement.

Prior Always store equipment properly when not being used. Equipment

should be stored in a clean, dry location out of the reach of children.

When storing the saw in freezing weather, blow out water lines to

prevent damage to components in the water delivery system.

Prior to service, level the frame surface.

Do not over tighten the Spindle drive belt

Turn on water flow prior to starting the engine, to prevent damage to the

impeller of a belt-driven water pump.

Don’t pollute! Waste oils and other chemicals must be disposed of in a

MQ SP-3035 CONCRETE SAW

manner consistent with local and state environmental protection

regulations.

MQ SP-3035 CONCRETE SAW — OPERATION AND PARTS MANUAL — REV. #3 (09/29/06) — PAGE 12

Page 15

BLADE SAFETY

MQ SP-3035 CONCRETE SAW

WARNING

ALWAYS inspect diamond blades before each use.

The blade should exhibit no cracks, dings, or flaws in

the steel centered core and/or rim. Center (arbor)

hole must be undamaged and true.

Examine blade flanges for damage, excessive wear

and cleanliness before mounting blade. Blade should

fit snugly on the shaft and against the inside/outside

of the saw.

Only cut the material that is specified by the blade.

Read the specifications of the blade to ensure the

proper tool has been matched to the material being

cut.

ALWAYS keep blade guards in place. Exposure of

the blade must not exceed 180 degrees.

Ensure that the blade does not come into contact

with the ground or surface during transportation. DO

NOT drop the blade on the ground or surface.

The engine governor is designed to permit maximum

engine speed in a no-load condition. Speeds that

exceed this limit may cause the blade to exceed the

maximum safe allowable speed.

Ensure that the blade is mounted for proper

operating direction.

MQ SP-3035 CONCRETE SAW — OPERATION AND PARTS MANUAL — REV. #3 (09/29/06) — PAGE 13

Page 16

MQ SP-3035 CONCRETE SAW

SAW TRANSPORTATION SAFETY

WARNING

Use appropriate lifting equipment to ensure the safe

movement of the saw.

DO NOT use the handle bars and/or front pointer as lifting

points.

NEVER attempt to tow the untrailered saw behind a vehicle.

NEVER transport the saw with the blade mounted.

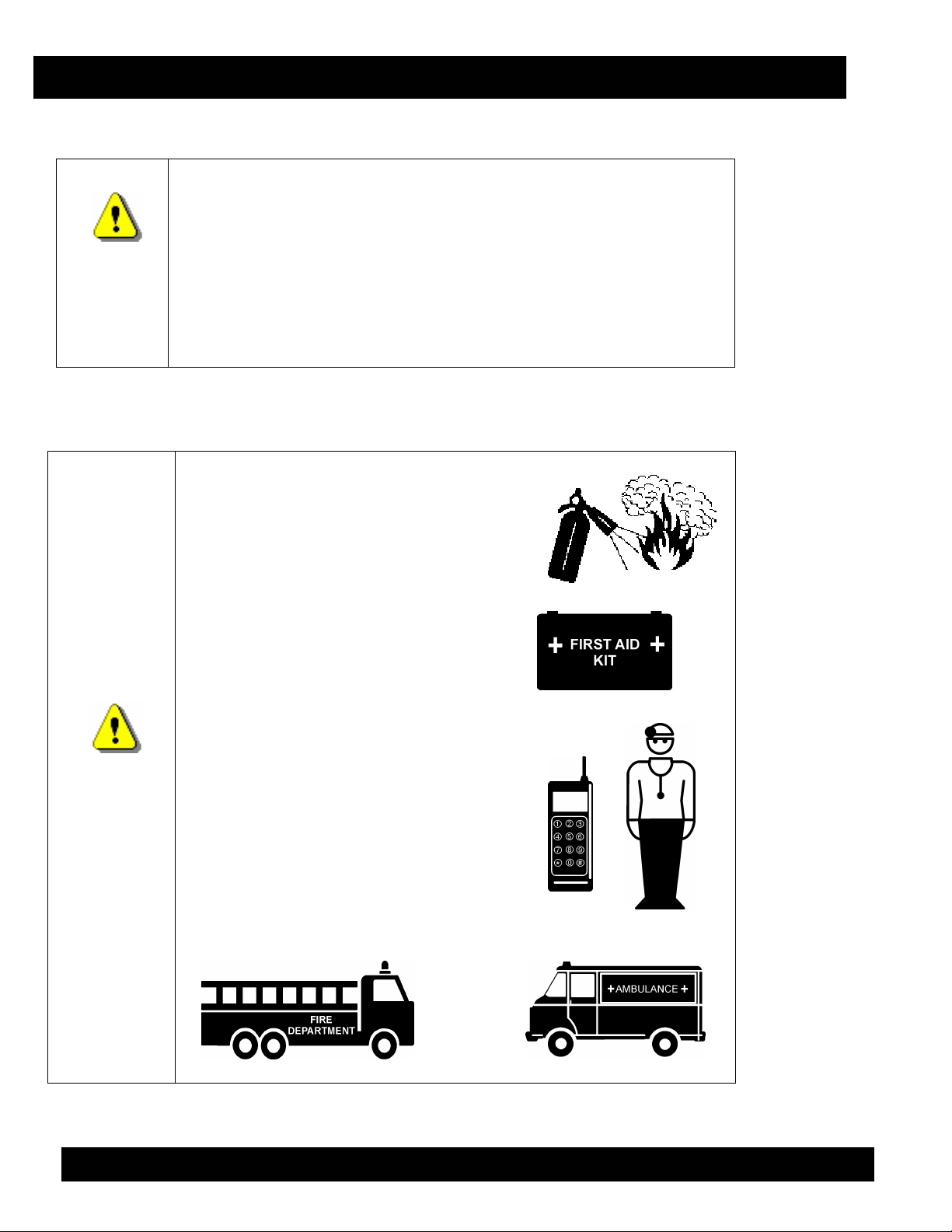

EMERGENCIES

WARNING

ALWAYS know the location of the

nearest fire extinguisher.

ALWAYS know the location of the

nearest first aid kit.

In emergencies always know the

location of the nearest phone or

keep a phone on the job site.

Know the phone numbers of the

nearest ambulance, doctor, and fire

department. Knowing this information

is invaluable in the case of an emergency

and could keep a serious situation from

becoming a tragic one.

MQ SP-3035 CONCRETE SAW — OPERATION AND PARTS MANUAL — REV. #3 (09/29/06) — PAGE 14

Page 17

MQ SP-3035 CONCRETE SAW

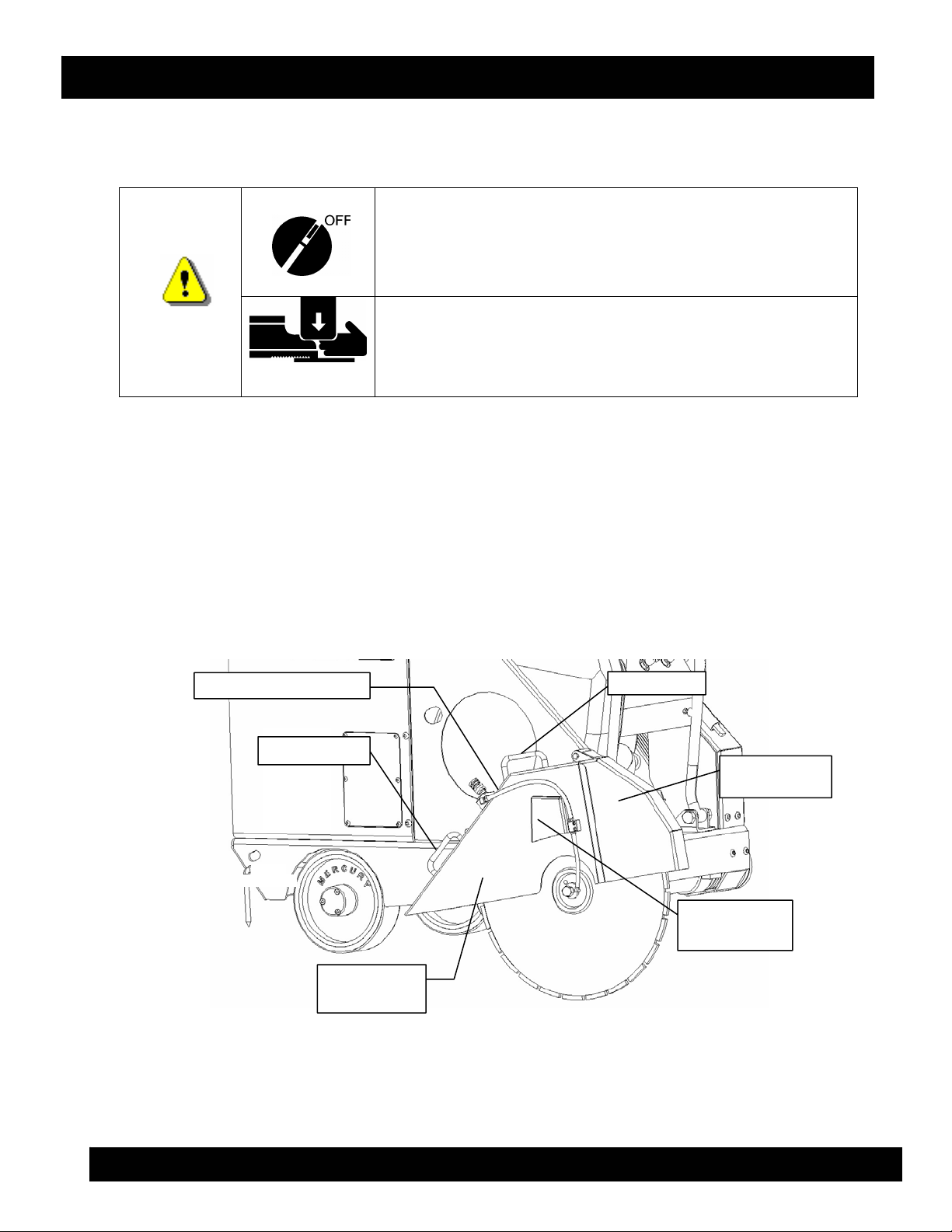

MACHINE OPERATION AND SAFETY DECALS

The Multiquip SP-3035 Saw is equipped with a number of operation and safety decals. Should

any of these decals become unreadable, replacements can be obtained from your dealer.

P/N 604000

P/N 35137

P/N 604001

CAUTION

When Larger Blade and Guard

is Installed, Belt Drive MUST

Be Changed to Proper Size.

See Owners Manual.

FAILURETO COMPLY WITH THE C C AH

JADV EEEAV EEAOIEJGGVCBVVZ

S.M.I. MASONRYAND CONCRETE

SAWMANUFACTURER’S INSTITUTE

P/N 23330-001

P/N 25250-001

WARNING

To avoid injury,

you MUST read

and understand

operator’s manual

before using this

machine.

This machine to

be operated by

qualified

personnel only.

Ask for training

as needed.

WARNING

KEEP FEET

CLEAR

P/N35137

P/N 25249-001

P/N 36099 (ISO Blue)

P/N 20525

WARNING!

KEEP HANDS

CLEAR

P/N 25491

P/N 21571

1-1/2” x 2-1/4”

WARNING

Nasfsaer dfghhte thsfaw wiot

Nesfaer dfgat

the sfarbs in

saccty guizcin

cbccR) 19b4

Nasfsaer dfghhte thsfaw wiot

Nasfsaer dfghhte thsfaw wiot

SMI

Nasfsaer dfghhte thsfaw wiot

Nesfaer df

the sfarbs i

n pbb

Nesfaer dfg

the sfarbs i

Nesfaer dfgate ths

the sfarbs i

Neer dfgate ths

the sfarbs in pbb

Nesfar dfgate ths

tfarbs in pbb

P/N 22122-001

A

T

T

I

O

O

R

N

A

T

T

I

O

O

R

N

P/N 25678

P/N 25483

(small)

CHECK

DECAL SHEET INTL STDS

Fig. 1 — Decals

MQ SP-3035 CONCRETE SAW — OPERATION AND PARTS MANUAL — REV. #3 (09/29/06) — PAGE 15

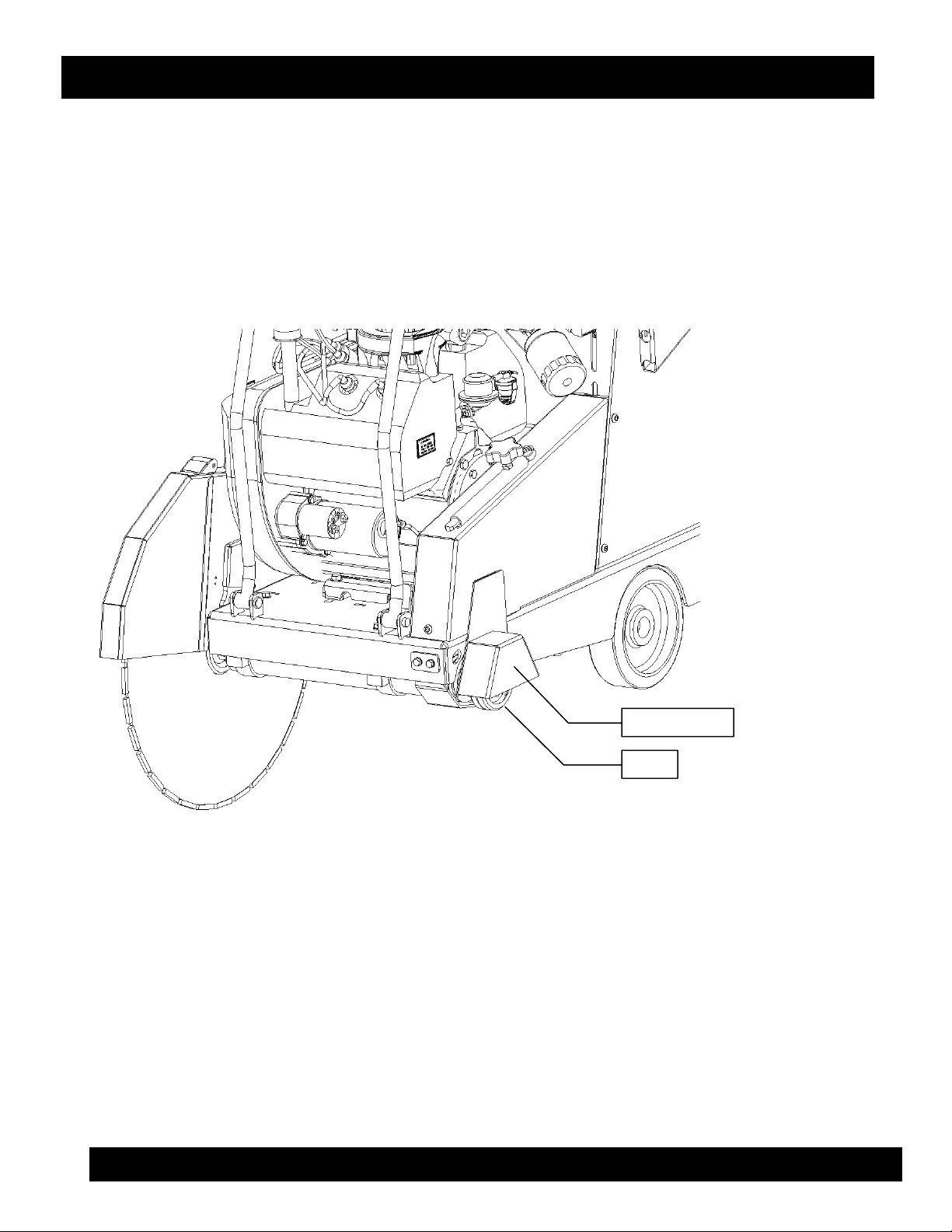

LUBRICATION

P/N 11246

P/N 25782

HOT

BELT DRIVE

D

W

E

R

O

P

C

O

D

E

A

T

P/N 13118

CONTACT MULTIQUIP

SERVICE DEPARTMENT

MODEL

SERIAL NO.

P/N 606004

Page 18

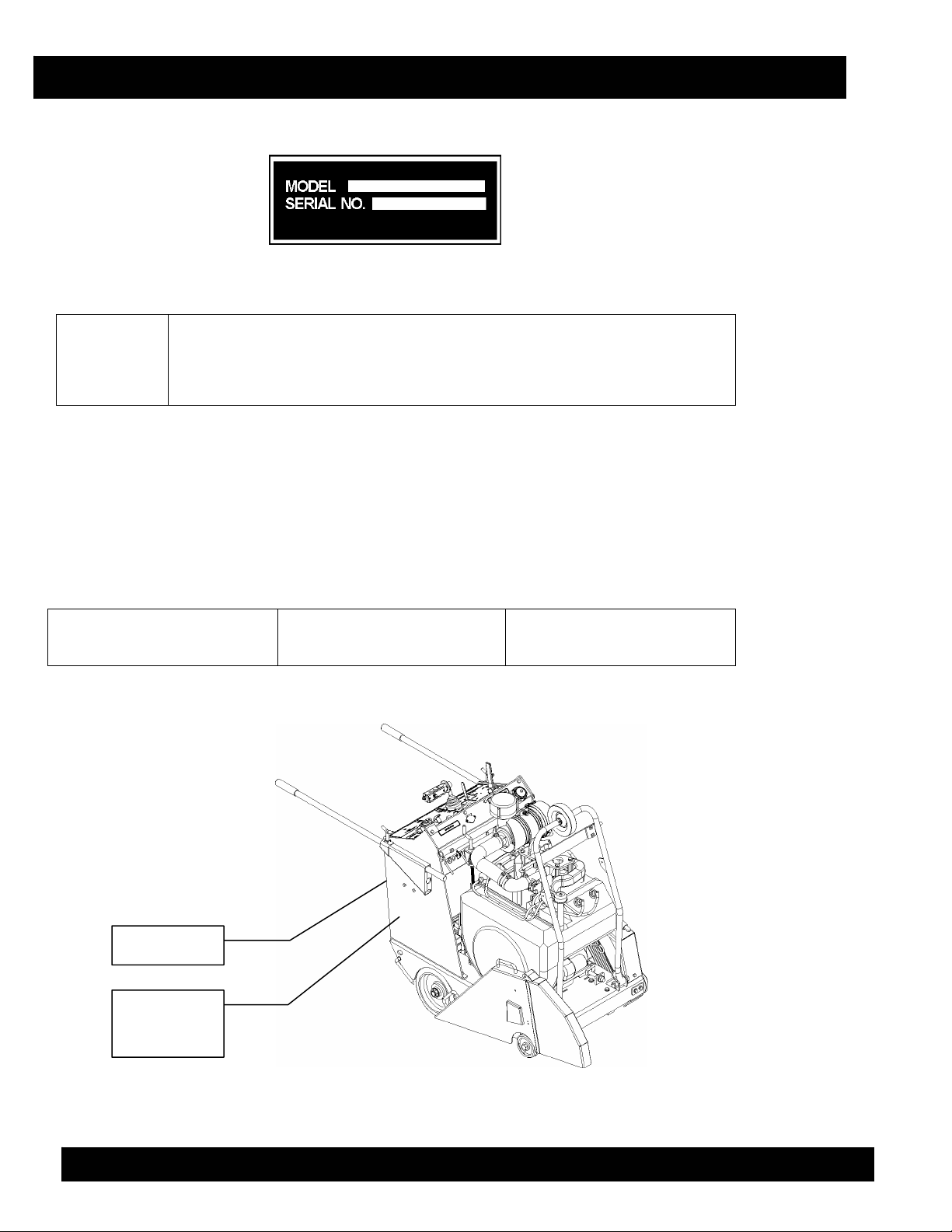

MQ SP-3035 CONCRETE SAW

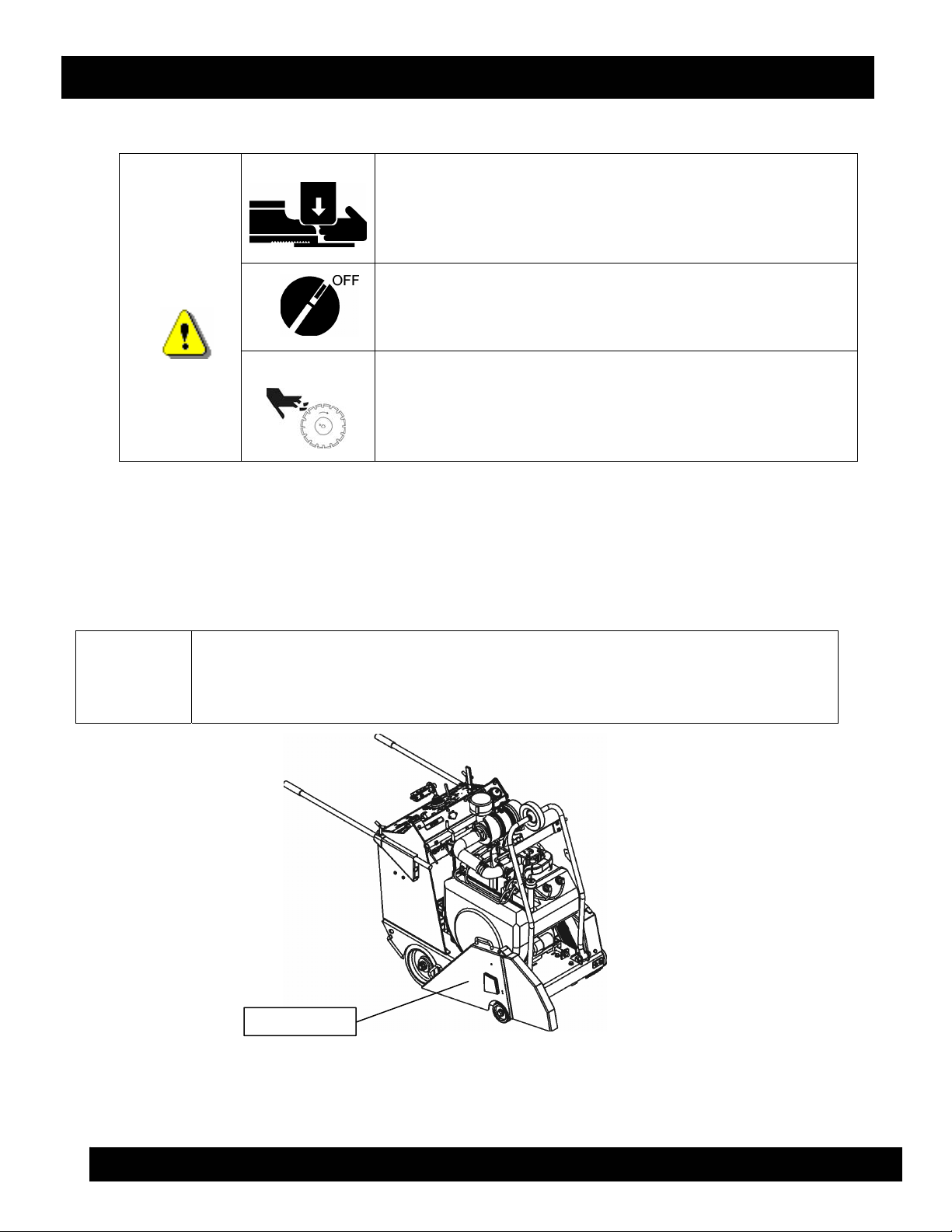

Serial Tag

Fig. 2 — Serial Tag

For future reference, fill in the model number and serial number of

NOTE

The serial tag contains the model number and serial number of the saw. This information details

all parts that were included with the saw when it was shipped from the factory, as well as the date

of manufacture.

your saw in the space above.

Record your ENGINE model number, spec. number and serial number here:

MODEL NO. SPEC. NO. SERIAL NO.

The serial tag is bonded to the inside panel of the console.

Serial Tag

Engine

Serial

Numbers

Fig. 3 — Serial Number Locations

MQ SP-3035 CONCRETE SAW — OPERATION AND PARTS MANUAL — REV. #3 (09/29/06) — PAGE 16

Page 19

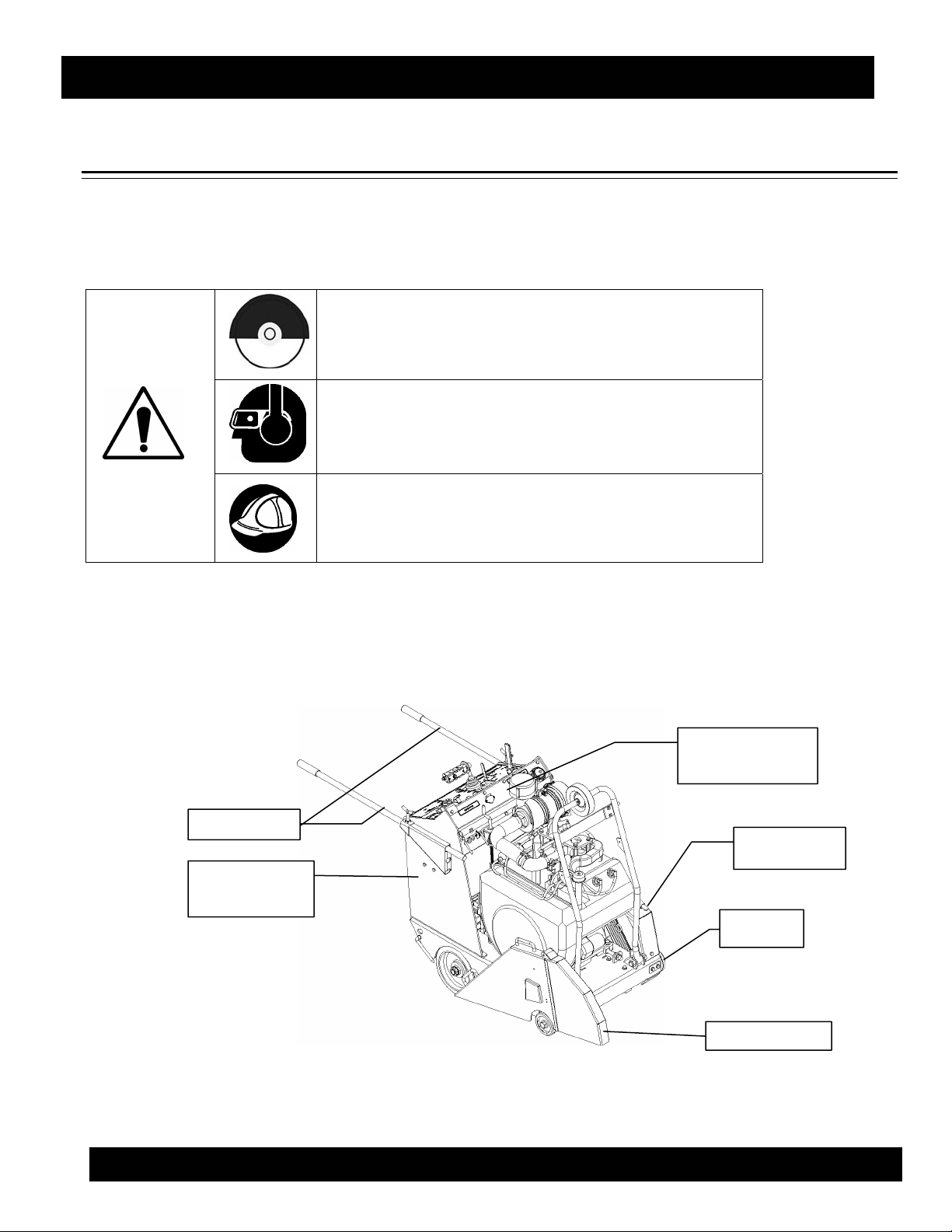

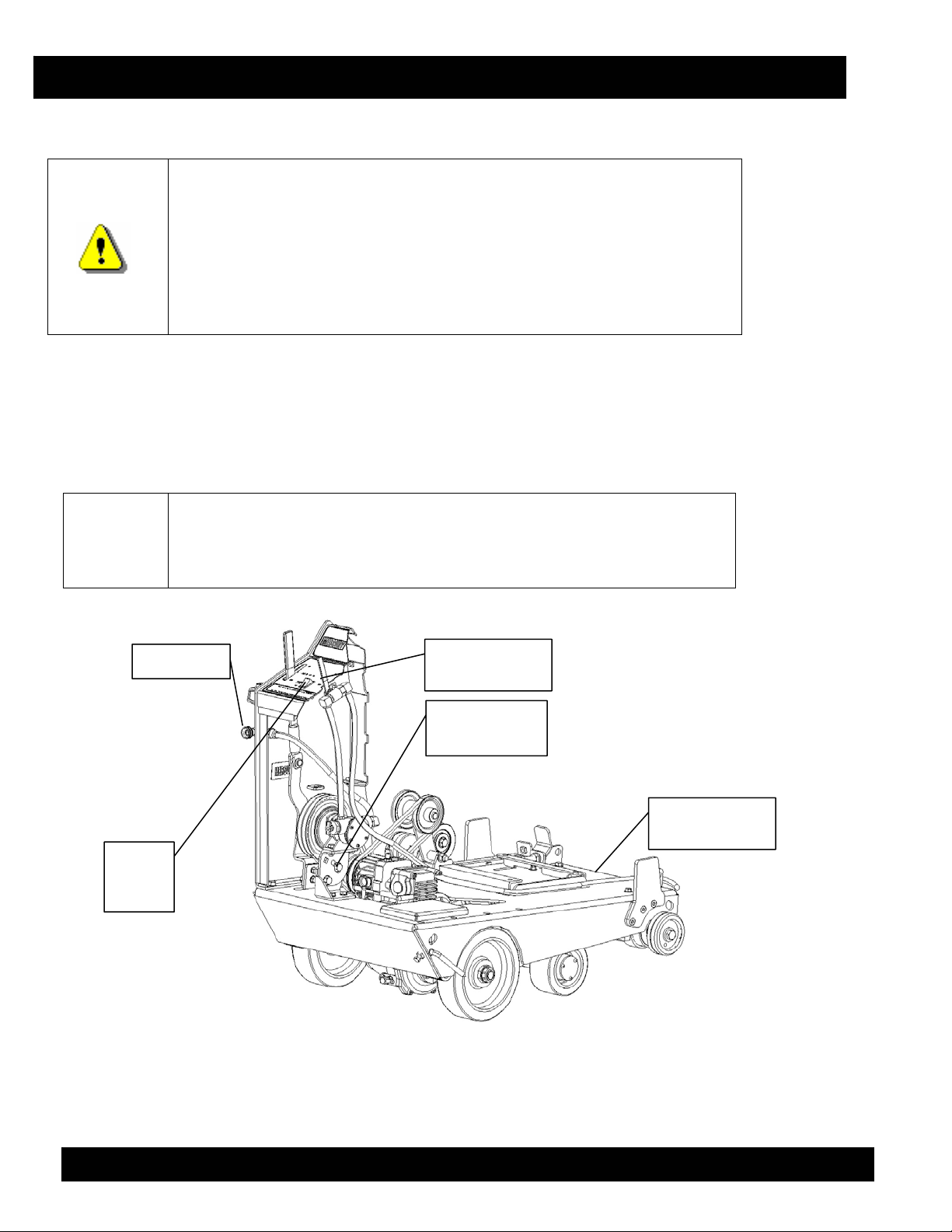

OPERATION

Before Starting

MQ SP-3035 CONCRETE SAW

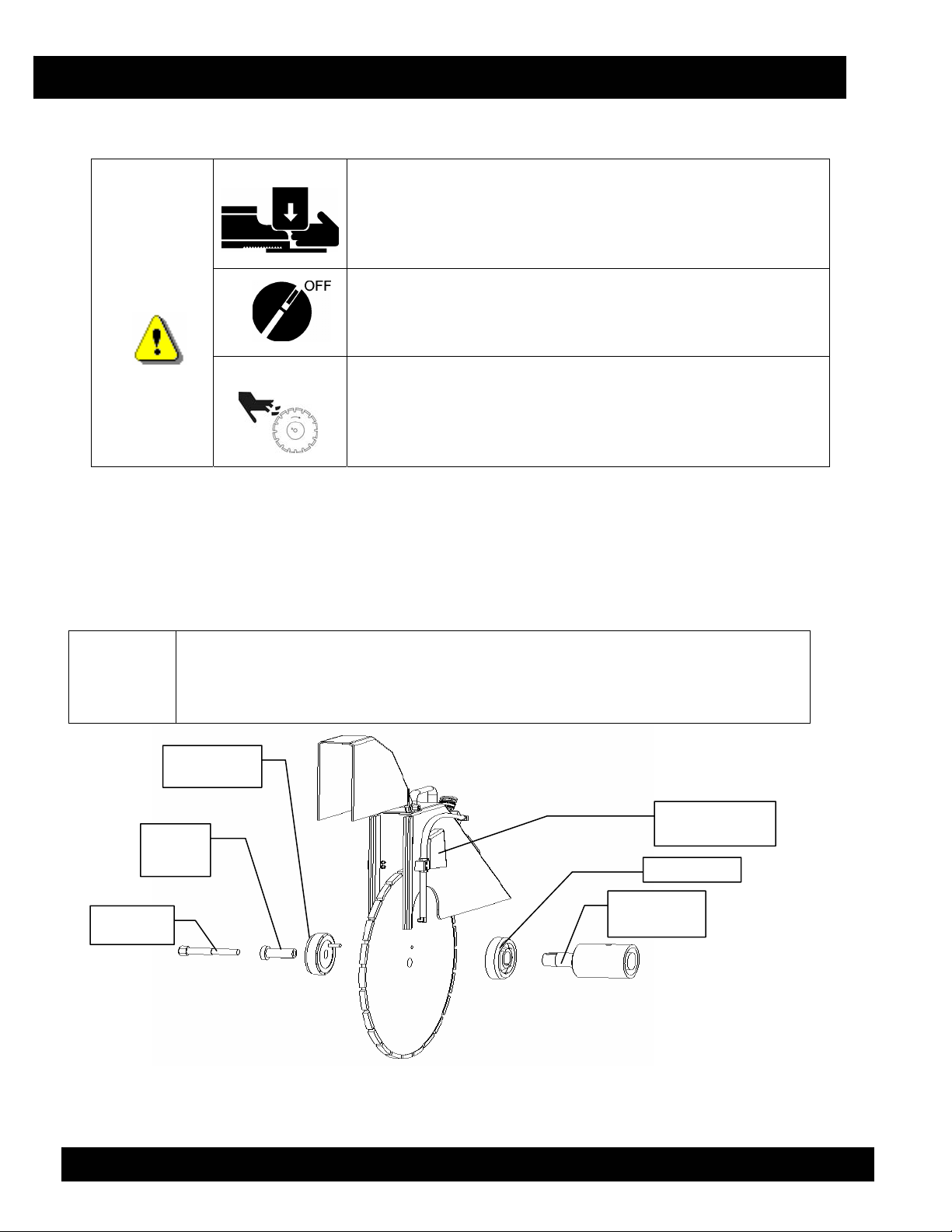

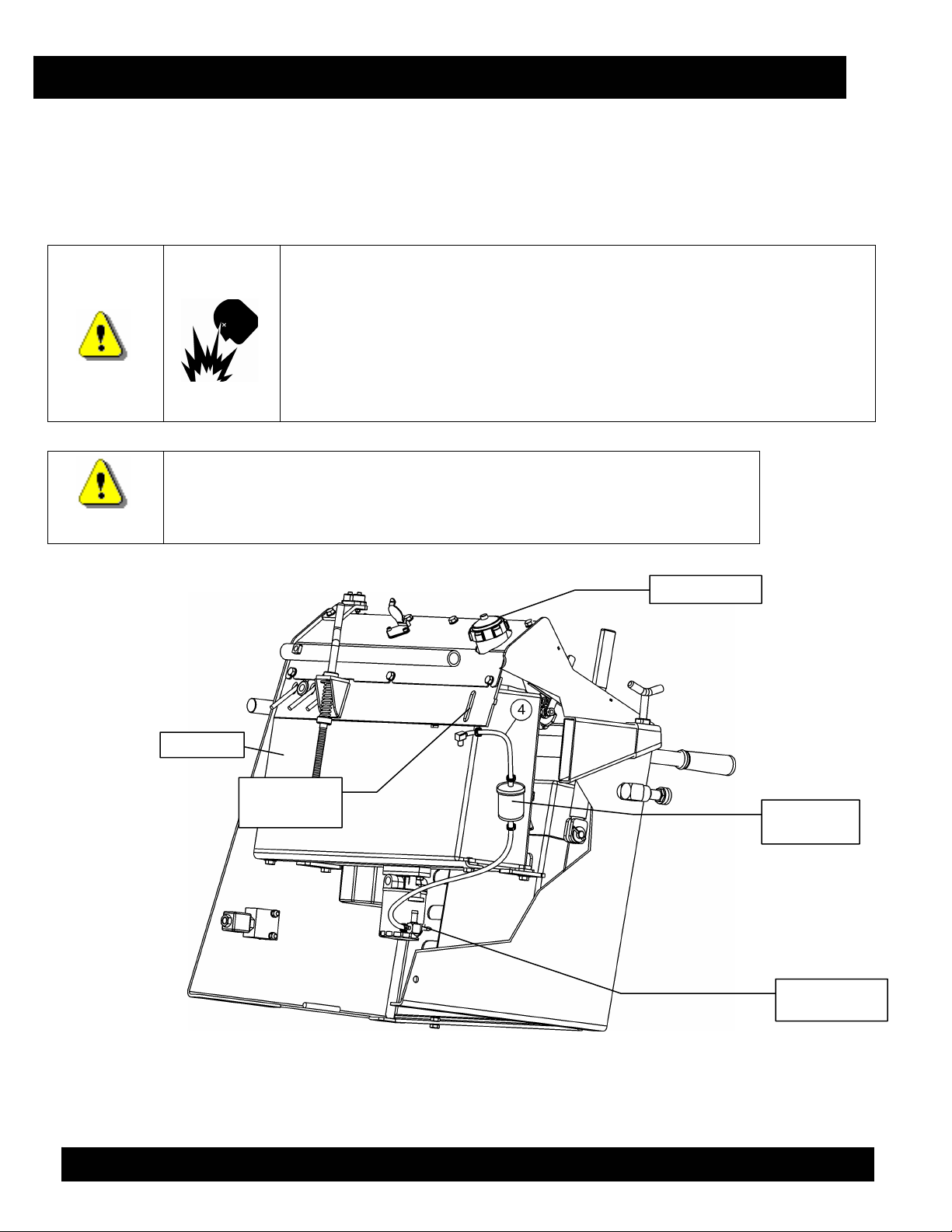

Walk around the saw and ensure that all guards

and panels are properly installed.

Wear eye and hearing protection.

Wear protective clothing.

1. Check engine and hydraulic oil.

2. Verify the proper-sized blade guard is fully installed on the blade guard mounting tab.

3. Adjust handlebars for best operator control.

4. If a belt driven water pump is installed, turn on the water flow before starting the engine.

Console

Access Panel

Handlebars

Belt Guard

Rear Access

Panel

Flange

Blade Guard

Fig. 4 — Guards & Panels

MQ SP-3035 CONCRETE SAW — OPERATION AND PARTS MANUAL — REV. #3 (09/29/06) — PAGE 17

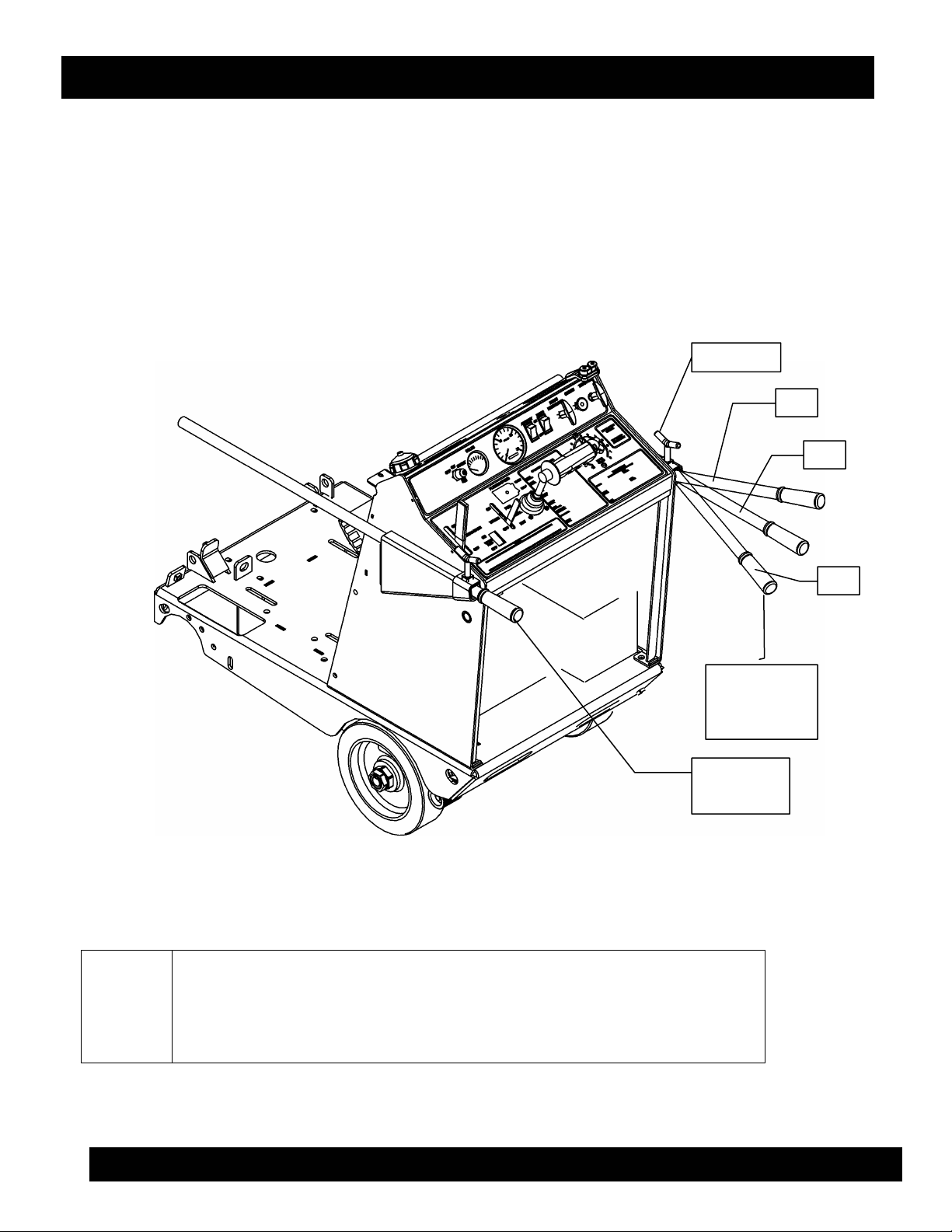

Page 20

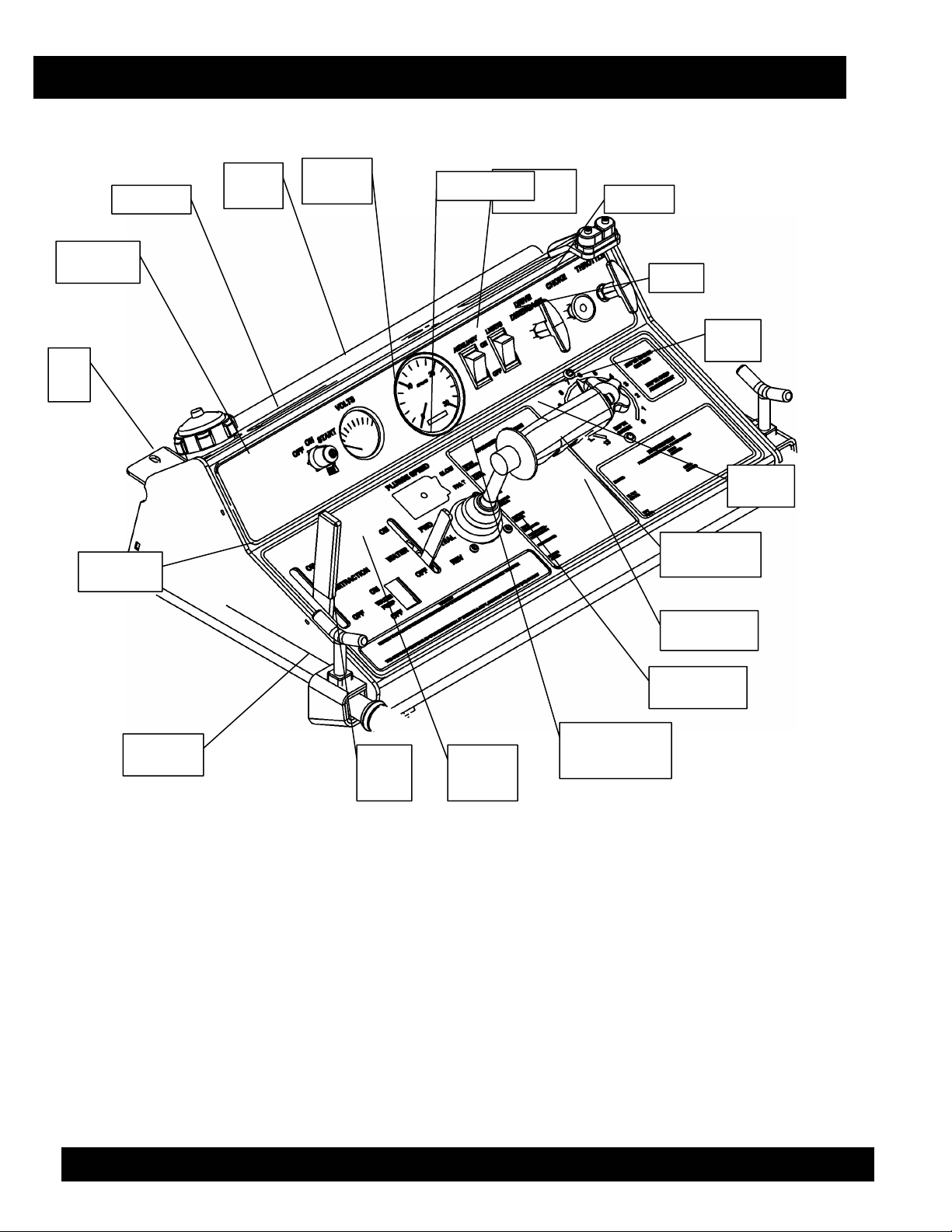

T

f

g

g

Control Panel

MQ SP-3035 CONCRETE SAW

Engine OnOf

-Start

Fuel

Tank

Cap

Positraction

Control

Voltmeter

Engine

Tach

Auxiliary

Switch

Light Switch

Drive

Disengage

hrottle

Choke

Depth Gauge

Zero

Depth

Gau

Plunge

Button

e

Maintenance

Operating

Instructions

Safety

Warnin

s

Water

Pump

Switch

Water

Flow

Control

Speed Control

Joystick

Fig. 5 — The Control Panel

MQ SP-3035 CONCRETE SAW — OPERATION AND PARTS MANUAL — REV. #3 (09/29/06) — PAGE 18

Page 21

MQ SP-3035 CONCRETE SAW

Engine Power, Cutting Power & Sheave Size

NEVER tamper with factory settings of engine governor

WARNING

or speed settings. Ensure the proper Speed Kits are

installed to safely support the prescribed RPM settings

for diamond blade operations.

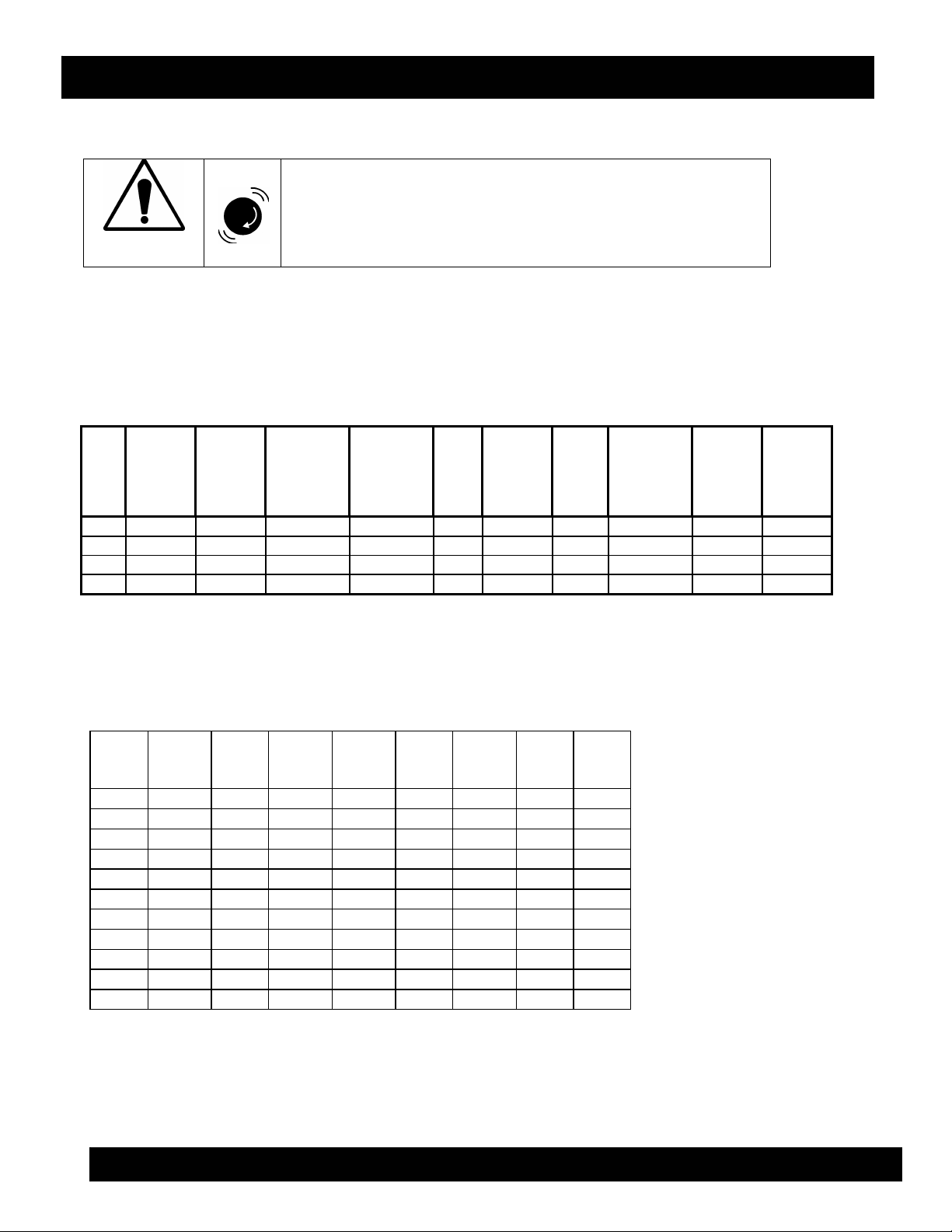

Blade Size & Configuration per Model

The SP-3035 is available in four Blade Speed configurations. The following chart shows the

various configurations for each model.

Blade

Size

16" Q303516 3000 3000 12 25603 540000 3.8" 540006 3.8" 12566

20" Q303520 2520 2800 9 25849 540070 3.6" 540066 4.0" 13195

26" Q303526 2000 2800 7 35103 540012 3.0" 540065 4.2" 13614

30" Q303530 1773 2600 5 35104 540012 3.0" 540049 4.4" 13923

Model Engine

RPM No

Load

Spindle

RPM No

Load

Governor

Setting

(Hole

Number)

Ratio

Kit

Engine

Pulley

Part

Number

Engine

Pulley

Size

When choosing a blade for your cutting conditions, follow the blade manufacturer’s

Spindle

Pulley Part

Number

Spindle

Pulley

Size

Surface

Feet Per

Minute

recommendations. Match blade RPM (Spindle RPM) to the recommended blade Surface Feet Per

Minute (SFPM).

SFPM 12” dia.

RPM

8,000 2546 2183 1910 1698 1528 1273 1175 1019

8,500 2706 2319 2029 1804 1623 1353 1249 1082

9,000 2865 2456 2149 1910 1719 1432 1322 1146

9,500 3024 2592 2268 2016 1814 1512 1396 1210

10,000 3183 2728 2387 2122 1910 1592 1469 1273

10,500 3342 2865 2507 2228 2005 1671 1543 1337

11,000 3501 3001 2626 2334 2101 1751 1616 1401

11,500 3661 3138 2745 2440 2196 1830 1690 1464

12,000 3820 3274 2865 2546 2292 1910 1763 1528

12,500 3979 3410 2984 2653 2387 1989 1836 1592

13,000 4138 3548 3104 2759 2483 2069 1910 1655

14”

dia.

RPM

16” dia.

RPM

18” dia.

RPM

20”

dia.

RPM

24” dia.

RPM

26”

dia.

RPM

30”

dia.

RPM

MQ SP-3035 CONCRETE SAW — OPERATION AND PARTS MANUAL — REV. #3 (09/29/06) — PAGE 19

Page 22

MQ SP-3035 CONCRETE SAW

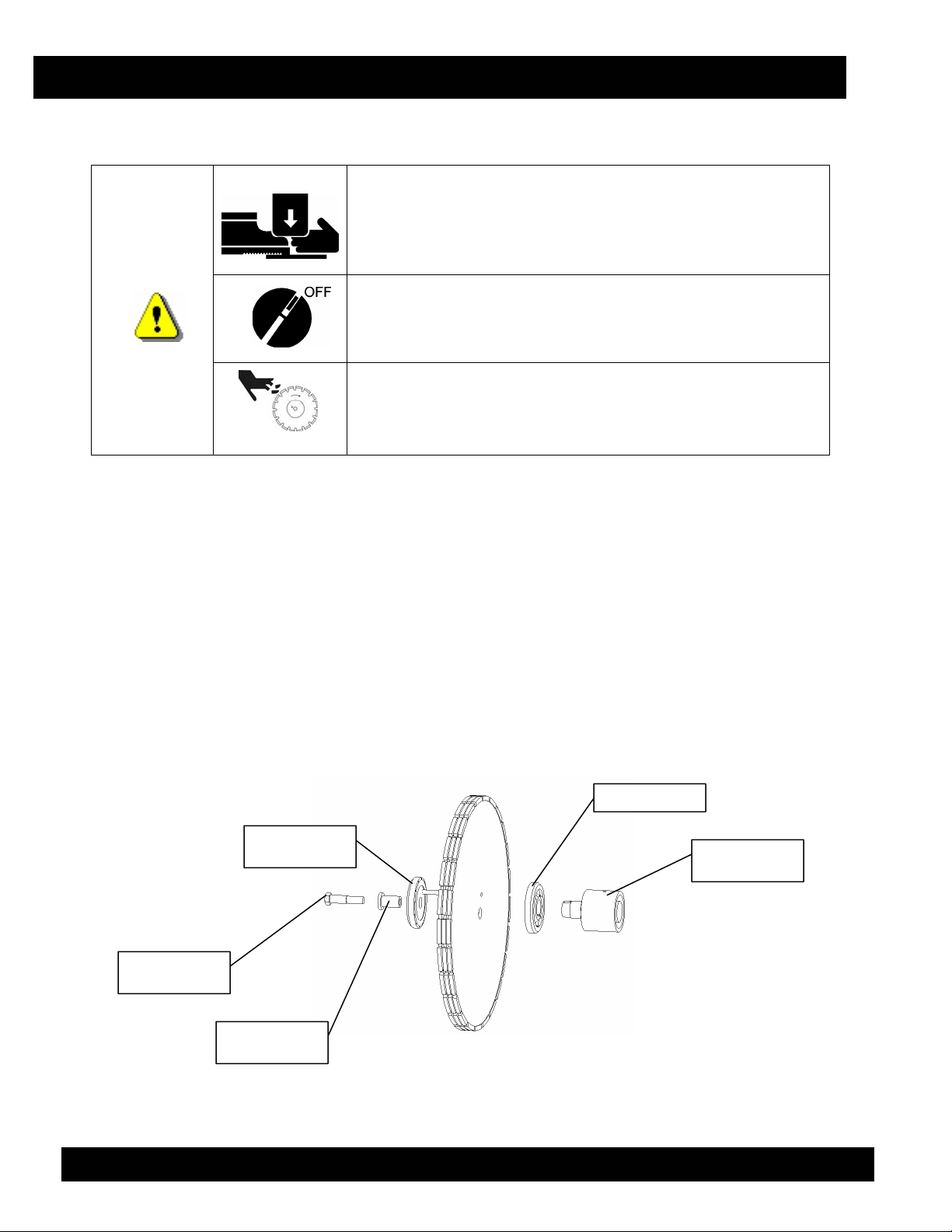

Installing the Blade, Blade Guard & Blade Flange

Remain Clear of all parts of saw while installing blade to

prevent crush injury or death.

Verify the engine start switch is OFF before installing

blade.

Tighten the 5/8” blade-mounting bolt to 100-125 footpounds torque.

WARNING

The blade can be mounted on either side of the saw to accommodate different cutting jobs.

1. Raise the saw so that the blade will clear the ground when installed.

2. Verify that blade flanges are clean and undamaged.

3. Insert the bushing and mounting bolt through the outer flange and blade.

4. Align flange pin through the blade into the inner flange.

5. Tighten the 5/8” mounting bolt to 100-125 foot-pounds of torque.

The blade mounting bolt on the right side of the saw (as viewed from the

NOTE

operator’s position) has a left hand-thread, while the blade-mounting bolt on

the left side of the saw has a right-hand thread.

Mounting

Bolt

MQ SP-3035 CONCRETE SAW — OPERATION AND PARTS MANUAL — REV. #3 (09/29/06) — PAGE 20

Outer Flange

with Pin

Flange

Bushing

Blade Guard

Mounting Clip

Inner Flange

Tapered

Spindle Shaft

Fig. 6 — Blade Components

Page 23

MQ SP-3035 CONCRETE SAW

Removing the Blade, Blade Guard & Blade Flange

WARNING

1. Raise the saw so that the blade will clear the ground.

2. Remove blade guard. See fig. 7

3. Remove the mounting bolt from the outer flange and bushing.

4. Remove blade, outer flange and bushing simultaneously.

Remain Clear of all parts of saw while installing blade to

prevent crush injury or death.

Verify the engine start switch is OFF before installing

blade.

Tighten the 5/8” blade-mounting bolt to 100-125 footpounds torque.

5. Reinstall the flange bushing, outer flange and mounting bolt.

6. Tighten the 5/8” mounting bolt to 75 foot-pounds of torque.

The blade mounting bolt on the right side of the saw (as viewed from the

NOTE

operator’s position) has a left hand-thread, while the blade-mounting bolt on

the left side of the saw has a right-hand thread.

Blade Guard

Figure 7. Blade Guard Removal

MQ SP-3035 CONCRETE SAW — OPERATION AND PARTS MANUAL — REV. #3 (09/29/06) — PAGE 21

Page 24

MQ SP-3035 CONCRETE SAW

Stacking Blades for Wide Cuts

WARNING

Remain Clear of all parts of saw while installing blade to

prevent crush injury or death.

Verify the engine start switch is OFF before installing

blade.

Tighten the 5/8” blade-mounting bolt to 100-125 footpounds torque.

Combining (stacking) blades to make wide cuts requires an optional Bushing Extension Kit.

Kit #18502 allows blade stacking from .375” to .75” thickness.

Kit #18501 allows blade stacking from .75” to 1.125” thickness.

1. Ensure on/off switch is off. See Fig. 5 or Fig. 15

2. Remove the existing blade. See Removing the Blade Fig. 7

3. Replace the standard Flange Bushing, Flange Pin, and Mounting Bolt that came with the saw

with the longer Bolt, Pin and Bushing which comes with the Kit.

4. Insert the Bushing and Mounting Bolt through the Outer Flange and Blades. The longer

bushing and bolt allow blades to be stacked together.

5. Align the Flange Pin through the stack of Blades into the Inner Flange.

6. Tighten the 5/8” Mounting Bolt to 100-125 foot-pounds of torque.

7. Install blade guard.

Inner Collar

Outer Collar

With Pin

Tapered

Blade Shaft

Mounting

Bolt

Collar

Bushing

Fig. 8 — Blade Stacking

MQ SP-3035 CONCRETE SAW — OPERATION AND PARTS MANUAL — REV. #3 (09/29/06) — PAGE 22

Page 25

T

MQ SP-3035 CONCRETE SAW

Installing and Removing the Blade Guard

Blade Guards for the SP-3035 concrete saw can be installed on either side of the saw.

WARNING

Verify the engine start switch is OFF before installing

blade.

Remain clear of all parts of saw while installing blade to

prevent crush injury or death.

Installing the Blade Guard

1. Ensure on/off key is off. See Fig. 5 or Fig. 15

2. Slide the Blade Guard Mounting Clip onto the Guard Mounting Tab on the frame.

3. Connect the water delivery hose to the Blade Guard.

4. Ensure that the water tubes are pointed toward the water distribution grooves in the Blade

Collars. See Fig. 10

5. Make sure the front-hinged section of the Blade Guard is fully closed before use.

Water Delivery Hose

Rear Handle

Blade Guard

rear section

Fig. 9 — The Blade Guard installed

op Handle

Blade Guard

hinged front

Blade Guard

Mounting Clip

MQ SP-3035 CONCRETE SAW — OPERATION AND PARTS MANUAL — REV. #3 (09/29/06) — PAGE 23

Page 26

MQ SP-3035 CONCRETE SAW

Removing the Blade Guard

During use, the Blade Guard can become tight on the tapered mounting tab. To loosen it, wiggle

the Rear Blade Guard Handle up and down, while lifting with the Top Handle.

Blade Guard Water Supply

Verify that the water hose on the saw is connected to the Blade Guard and that the water pipes are

pointed into both Blade Collars.

Make sure that the outlets of the water tubes point toward the lower

NOTE

portion of the blade collars, aimed at the delivery ports, for proper

water delivery to the blade.

Blade Collar

Fig. 10 — Water Tubes and the Blade Collar

Water Tube bracket

Water Tube aimed at

groove in Blade Collar

MQ SP-3035 CONCRETE SAW — OPERATION AND PARTS MANUAL — REV. #3 (09/29/06) — PAGE 24

Page 27

MQ SP-3035 CONCRETE SAW

Installing the Flange Guard

The Flange Guard provides protection from the Blade Flange not in use.

1. Verify that the unused Blade Flange is secured to the Spindle by tightening the mounting bolt.

2. Slide the Flange Guard onto the Guard Mounting Tab on the frame.

Flange Guard

Flange

Fig. 11 — The Flange Guard, Installed

MQ SP-3035 CONCRETE SAW — OPERATION AND PARTS MANUAL — REV. #3 (09/29/06) — PAGE 25

Page 28

Water Supply and Control

MQ SP-3035 CONCRETE SAW

WARNING

To prevent damage to the impeller of a belt driven water pump, do

not run the engine with the water pump switch on, unless the water

supply is connected and water is flowing.

When storing the saw during freezing weather, blow out the water

lines to prevent damage to the water delivery system.

Connect the job water hose to the water inlet fitting on the left side of the saw.

Verify that the water hose on the saw is connected to the Blade Guard and that the water delivery

tubes are pointed into both lower Blade Flanges.

The yellow lever on the control panel regulates water flow volume.

If the saw is equipped with an optional water pump, the ON/OFF switch is on the control panel

next to the water flow control valve.

Because of the water delivery efficiency of the 24-port blade flanges,

NOTE

these saws use less water for blade cooling and flushing than other

saws.

Water Inlet

Pump

ON/OFF

Switch

Flow Control

Lever

Optional

Water Pump

Hose to

Blade Guard

Fig. 12 — The Water Supply System

MQ SP-3035 CONCRETE SAW — OPERATION AND PARTS MANUAL — REV. #3 (09/29/06) — PAGE 26

Page 29

MQ SP-3035 CONCRETE SAW

Handlebars

The handlebars are adjustable to three different angles, for optimum operator control, and can

also be slid fully inward for storage. Once handlebars are adjusted, lock them into position by

tightening the lock knob on each side.

Using the handlebars in position #2 or #3, when employing larger diameter blades reduces the

need to bend over and the effort required by the operator to maneuver the unit.

Lock Knob

P 3

P 2

P 1

Three

operating

positions

Storage

position

NOTE

MQ SP-3035 CONCRETE SAW — OPERATION AND PARTS MANUAL — REV. #3 (09/29/06) — PAGE 27

Fig. 13 — Handlebar Positions

Using the handlebars in position #2 or #3 when employing larger

diameter blades, reduces the need to bend over, and reduces the effort

required by the operator to maneuver the saw.

Page 30

MQ SP-3035 CONCRETE SAW

Fueling the Saw

The 3000 Series saws feature a five-gallon clear molded plastic fuel tank with a sight gauge,

central drain, and shutoff valve. The gas tank cap is located at the front of the saw.

WARNING

CAUTION

To prevent damage to the impeller of a belt driven water pump, do not

run the engine with the water pump switch on, unless the water

supply is connected and water is flowing.

When storing the saw during freezing weather, blow out the water

lines to prevent damage to the water delivery system.

Use 90+ Octane Unleaded Gasoline Only

Gas Tank Cap

Fuel Tank

Fuel Sight

Gauge slots

Inline Fuel

Filter

Fuel Shut-off

Valve

Fig. 14 — Fueling the Saw

MQ SP-3035 CONCRETE SAW — OPERATION AND PARTS MANUAL — REV. #3 (09/29/06) — PAGE 28

Page 31

MQ SP-3035 CONCRETE SAW

Starting and Stopping the Engine

WARNING

CAUTION

1. Check Oil levels in engine and hydraulic system

2. If water pump option is installed, start water supply to blade.

3. Move the speed control joystick to NEUTRAL position.

4. Set the throttle to ½ open

5. Turn on/off switch to “START” position and at the same time pull out choke cable only

sufficient to start the engine. Release choke cable after engine starts. Re-choke if engine tends

to stall. When engine starts, release switch to “RUN” position. Allow engine to warm up

before applying load.

6. Ensure that water lines are attached and water is flowing to the saw.

7. Set the throttle to the recommended engine RPM to match the recommended blade speed of

the attached blade.

8. Lower the blade to the cut depth.

9. Move the joystick FORWARD to advance the cut.

10. When finished cutting, allow the engine to cool down by running at 1000 to 1200 RPM for 3

to 5 minutes depending on how hot the engine has been. This will reduce the chance of

engine damage or vapor lock.

Do not leave the saw unattended while the engine is running.

Do not start, park, or leave the saw unattended on a slope.

If the saw has an optional water pump, do not run the saw dry

with the water pump switch ON — otherwise the pump impellers

will be damaged.

In normal operation, do not stop the engine abruptly when hot!

Reduce the throttle to idle and allow the engine to run one or two

minutes before turning the ignition switch off.

WARNING

Make sure the operator knows how to turn the engine off in case of an

emergency.

Do not go near rotating parts (blade, belts, pulleys, or wheels) while

the saw is running.

To stop the engine, turn the “ON-OFF” switch to the “OFF” position.

ON/OFF

Switch

Fig. 15 — ON/OFF Switch Location

MQ SP-3035 CONCRETE SAW — OPERATION AND PARTS MANUAL — REV. #3 (09/29/06) — PAGE 29

Page 32

oc

ob

MQ SP-3035 CONCRETE SAW

Pointer Adjustment

1. Lower the front pointer assembly: Release the rope from the cam cleat, and rotate the pointer

forward into position.

2. Adjust the pointer rod by loosening the lock knob: Once the pointer rod is set to the cut line,

tighten the lock knob.

3. Adjust the rear pointer to the cut line: Loosen the lock bolt, position the pointer rod, and

tighten the lock bolt.

4. To raise the front pointer assembly, pull back and up on the pointer cable.

5. Secure the pointer assembly in the desired raised position by locking the cable between the

jaws of the cam cleat.

Pointer

Rod

Fig. 16 — Pointer Adjustment

Pointer Rod

k Kn

L

Pointer

Cable

MQ SP-3035 CONCRETE SAW — OPERATION AND PARTS MANUAL — REV. #3 (09/29/06) — PAGE 30

Page 33

MQ SP-3035 CONCRETE SAW

Raise – Lower Controls

This saw uses a 12-volt hydraulic pump and cylinder to raise and lower the blade. Controls are

located on the speed control joystick handle.

Plunge Button

Raise Button

Fig. 17 — Joystick Handle

1. To plunge the blade, depress the button on the outer end of the handle.

2. To raise the blade, depress the button on the forward side of the handle.

See the Maintenance section of this manual for a diagram of the Raise-Lower System components.

MQ SP-3035 CONCRETE SAW — OPERATION AND PARTS MANUAL — REV. #3 (09/29/06) — PAGE 31

Page 34

MQ SP-3035 CONCRETE SAW

Setting the Depth Gauge & Depth Stop

The 3000 Series saws use a cable-controlled Depth Gauge and mechanical Depth Stop to lock the

blade at the desired cut depth. See Fig. 18.

Setting the Depth Gauge

1. Lower the blade until it just touches the cutting surface.

2. Turn the Depth Gauge dial to zero.

The Depth Gauge will show the depth of cut. It should not be necessary to readjust the Depth

Indicator until a different diameter of blade is installed.

Setting the Depth Stop

1. Lower the blade into the cut until the desired cutting depth is achieved.

2. Turn the Depth Stop Crank clockwise to take slack out of the Depth Stop.

To increase cutting depth, turn the Depth Stop Crank counter-clockwise. To reduce cutting depth,

turn the Depth Stop Crank clockwise.

Fig. 18 — Setting the Depth Gauge and Depth Stop

Depth

Stop

Crank

Depth

Gauge

MQ SP-3035 CONCRETE SAW — OPERATION AND PARTS MANUAL — REV. #3 (09/29/06) — PAGE 32

Page 35

MQ SP-3035 CONCRETE SAW

Drive System

The 3000 Series saws have a cable-controlled Hydro-Gear hydrostatic powered transaxle with

fully adjustable F-N-R (Forward-Neutral-Reverse) speed adjustment via a joystick control handle.

The system utilizes a remote oil filter. There are no chains, sprockets or gearboxes requiring daily

service.

The 3000 Series saws can travel at speeds up to 250 feet per minute.

Transaxle Oil

Filter

Positraction

Engagement

Lever

Transaxle

Positraction Bar

Fig. 19 — The Drive System

MQ SP-3035 CONCRETE SAW — OPERATION AND PARTS MANUAL — REV. #3 (09/29/06) — PAGE 33

Page 36

MQ SP-3035 CONCRETE SAW

Drive System Controls

The control handle controls FORWARD-NEUTRAL-REVERSE (F-N-R) speeds and the raising and

lowering of the saw. To increase forward speed, slowly move the joystick FORWARD. Pulling the

joystick backward decreases saw speed, and when the joystick passes NEUTRAL the saw moves

into REVERSE. Reverse speed is also controlled by the position of the joystick.

Although not a true “free wheeling” mode, the Drive Disengage handle, when pulled, allows the

saw to be freely moved when the engine is not running.

DO NOT DISENGAGE WHILE ENGINE IS RUNNING.

Drive

Positraction

Lever

Disengage

WARNING

Speed Control

Joystick in

NEUTRAL position

Fig. 20 — Drive System Controls

Start the engine with the Forward-Neutral-Reverse Control in

NEUTRAL to prevent unexpected saw movement.

MQ SP-3035 CONCRETE SAW — OPERATION AND PARTS MANUAL — REV. #3 (09/29/06) — PAGE 34

Page 37

MQ SP-3035 CONCRETE SAW

Positraction

Positraction, when ON, locks both drive wheels together for straight-line movement. It is

recommended for all cutting and is especially helpful on uneven surfaces, and when loading and

unloading the saw.

1. Move the Positraction lever to “ON” (positraction engaged) to lock both drive wheels.

2. To unlock the drive wheels for easy maneuverability and turning, move the Positraction lever

to OFF.

See the Maintenance Section for instructions on aligning the wheels

NOTE

to correct pulling to the right or left.

Positraction

Engagement

Lever

Positraction Bar

Fig. 21 — The Positraction System

MQ SP-3035 CONCRETE SAW — OPERATION AND PARTS MANUAL — REV. #3 (09/29/06) — PAGE 35

Page 38

MQ SP-3035 CONCRETE SAW

Transaxle

The hydrostatic-powered transaxle has no chains, sprockets or gearboxes to service. There is a

simple cable control for forward-reverse motion, and a single drive belt from the engine to power

the transaxle.

Fig. 22 —Transaxle

Night Light

The optional night light can be used on either side of the saw, and can be extended and rotated for

best illumination of the cutting area. Once the light is aimed, lock it in position by tightening the

lock knob. The light can be removed for storage by loosening the lock knob, disconnecting the

light cord plug and sliding the light bar out of the saw.

Night

Light

Fig. 23 — Night Light

MQ SP-3035 CONCRETE SAW — OPERATION AND PARTS MANUAL — REV. #3 (09/29/06) — PAGE 36

Page 39

MQ SP-3035 CONCRETE SAW

Transportation Tie-downs and Lift Point

Tie-downs

The saw is provided with holes at each corner of the lower frame for easy tie-down during

transportation. The saw MUST be tied down whenever it is being transported.

Tie-down

Fig. 24 —Tie-down Points

Tie-down

Lift Point

The convenient single point for raising the saw with a hoist is located on top of the engine.

Lift Point

Fig. 25 — Lift Point

WARNING

To avoid possible injury, stay clear of the saw while it is

being hoisted.

To avoid possible damage to the saw, use approved rigging

when hoisting the saw.

MQ SP-3035 CONCRETE SAW — OPERATION AND PARTS MANUAL — REV. #3 (09/29/06) — PAGE 37

Page 40

MQ SP-3035 CONCRETE SAW

Operation on a Slope or Incline

Never operate, cut, or face the saw down a slope or incline. The weight of the saw will shift to the

front wheels allowing the rear wheels to skid or come completely off the ground. This allows the saw

to free wheel and possibly cause a runaway condition.

Always remove the blade when transporting or moving the saw outside of the cutting area. Use

the following procedures for loading and unloading the saw.

Using Inclined Ramps to Load and Unload the Saw

Loading UP a Ramp

1. Make sure ramps are of sufficient strength and width to adequately support and load saw.

Ensure the slope of the ramp is gentle enough to load the saw.

2. Remove blade from Spindle if installed.

3. Ensure saw is warmed up to decrease the chance of the engine stalling.

4. Run the engine between ¾ and full throttle.

5. Raise front of saw only enough to get started up ramp. As the rear wheels approach the ramp,

start lowering the front end of the saw. Raise and lower the front end as necessary to keep the

blade flanges off trailer deck.

6. Turn engine off, lower saw fully.

7. Tie the saw down securely for transit.

Unloading DOWN a Ramp

Unload the saw by backing it down the ramp. Never use a ramp with too great a slope as to create

an unsafe loading condition. Use the techniques stated in the steps above to clear the ramp while

keeping the front of the saw as close to the ramp as possible while backing it down. Never unload

with the saw front facing downward on a ramp.

Freeing a Stuck Blade

The only acceptable method for freeing a stuck blade is to remove the saw from the stuck or

pinched blade. DO NOT try to get the blade unstuck using the Raise/Lower system or by lifting

the saw by the lifting bale, etc.

Ensure ignition switch is turned off

Remove blade guard

Remove blade mounting bolt and outer flange

Maneuver saw away from blade

Make a parallel cut next to blade to free blade.

MQ SP-3035 CONCRETE SAW — OPERATION AND PARTS MANUAL — REV. #3 (09/29/06) — PAGE 38

Page 41

MQ SP-3035 CONCRETE SAW

If an attempt is made to start the saw with the blade pinched, the starter will suffer damage. If an

attempt is made to use the lift pump to raise the saw to free the blade, the lift motor and front axle

could be damaged. If an attempt is made to lift the saw and blade out of the cut utilizing

equipment such as a loader or back hoe, the saw frame and axle are likely to be damaged.

CAUTION

If the Water System is not drained when the saw is not in use and

temperatures fall below 32˚F, damage may occur to optional water

pumps and/or oil coolers.

Draining the Water System

When low temperatures fall below 32˚F:

1. If the saw is equipped with an optional Water Pump, open the drain petcock on the pump and

allow the pump to drain.

2. With the engine running, turn the water pump switch on for a few seconds to purge water

remaining inside the pump body.

3. Tilt the saw up and back, to allow water to drain.

4. Tilt the saw forward, to allow water to drain again.

If an air compressor is available, blow out the system by applying compressed air to the Water

Inlet

MQ SP-3035 CONCRETE SAW — OPERATION AND PARTS MANUAL — REV. #3 (09/29/06) — PAGE 39

Page 42

MQ SP-3035 CONCRETE SAW

MAINTENANCE

This saw has many service-saving features, such as fully enclosed oil bath lubricated Spindle

bearings, which require no daily lubrication.

Level the saw frame surface prior to service in order to get accurate

NOTE

Removable Guards and Access Panels

For ease of service access, the following guards and panels are removable:

oil level readings.

Blade guard Flange Guard

Rear access panel Console Access Panel

Belt guard

Replace guards and panels prior to starting the engine.

Rear Access Panel

Console Access Panel

Upper

Belt

Guard

Lower

Belt

Protector

Fig. 26 — Guards and Panels

MQ SP-3035 CONCRETE SAW — OPERATION AND PARTS MANUAL — REV. #3 (09/29/06) — PAGE 40

Blade Guard

Page 43

MQ SP-3035 CONCRETE SAW

Belts and Pulleys

Belt Qty Part Number

Spindle Drive Belt (POWERBAND) 1 520006

Transaxle Drive Belt 1 521005

Engine to Jack shaft Drive Belt 1 521005

Spindle

(Blade Shaft)

Drive Belt

Fig. 27 — Belt Locations

TransAxle Drive Belt

Engine to

Jack Shaft

Drive Belt

V-Belt Tension

The ideal V-Belt tension is the lowest tension at which the belt will not slip under peak load

conditions. Check V-Belt tension frequently during the first 24-48 hours of run-in operation.

CAUTION

Over-tensioning shortens belt and bearing life.

Keep belts clean of foreign material that may cause slippage.

Make V-Belt inspection a periodic procedure.

Never dress belts, as this causes premature failure.

MQ SP-3035 CONCRETE SAW — OPERATION AND PARTS MANUAL — REV. #3 (09/29/06) — PAGE 41

Page 44

MQ SP-3035 CONCRETE SAW

Spindle (Blade Shaft) Drive Belt Tension Adjustment

When loosening drive belts, lower the saw to reduce stress on the

NOTE

WARNING

1. Remove the Upper Belt Guard (see Fig. 26).

2. Loosen the front Engine Mount lock bolts (A, A) only, to allow the engine to slide. DO NOT

loosen the rear bolts (B, B).

3. With the front bolts loose, the rear Engine Mount bolts (B, B) should have a ¼” space, as

shown:

tensioning system, and use gravity to pull the engine forward slightly.

When tightening belts, raise the saw, and gravity will a id the process

also.

NEVER attempt to check or adjust the V-belt

tension with the engine running. Severe injury can

occur. Keep fingers, hands, hair, and clothing

away from all moving parts.

B

A

¼”

Space

A

B

Fig. 28 — Detail of Engine Mount Lock Bolts

MQ SP-3035 CONCRETE SAW — OPERATION AND PARTS MANUAL — REV. #3 (09/29/06) — PAGE 42

Page 45

MQ SP-3035 CONCRETE SAW

4. Loosen the Outer Jam Nut on the Single Point Belt Tension Bolt. Turn the Inner Jam Nut

counter-clockwise.

5. Adjust drive belt to desired tension. Do Not over tighten.

6. Tighten Engine Mount Lock Bolts.

7. Tighten the Jam Nuts to prevent the Single-Point Bolt from turning.

Lower Belt Guard Bolts

Lower Belt Guard

Inner Jam Nut

Outer Jam Nut

Fig. 29 — Spindle Drive Belt Adjustment & Replacement

Engine Mount

Lock Bolt (1 of 2)

Spindle Belt

Upper Belt Guard Bolt

Single-Point

Belt Tension Bolt

Replacing the Spindle Drive Belt

1. Remove the Upper and Lower Belt Guards. See Figs. 26 & 29.

2. Loosen the Engine Mount Lock Bolts.

3. Loosen the Single-Point Belt-Tensioning Bolt to allow the belt to slip off the engine

sheave.

4. Slide the belt off of the engine sheave and pull the belt down around the Spindle

sheave.

5. Slide the belt off the top of the Spindle sheave.

6. Reverse steps 1-5 to install a new belt.

MQ SP-3035 CONCRETE SAW — OPERATION AND PARTS MANUAL — REV. #3 (09/29/06) — PAGE 43

Page 46

y

T

Replacing the Jack Shaft Belt

MQ SP-3035 CONCRETE SAW

WARNING

NEVER attempt to check or adjust the V-belt

tension with the engine running. Severe injury can

occur. Keep fingers, hands, hair, and clothing

away from all moving parts.

1. Remove the Belt Guards (see Figs. 26 & 29).

2. Loosen the Rotary Tensioner.

3. Remove the Spindle Belt (see above).

4. Remove and replace the Jack Shaft Belt.

5. Replace the Spindle Belt (see above).

6. Adjust the Rotary Tensioner.

Rotary Belt Tensioner

The Rotary Belt Tensioner system uses a 3/4”-headed bolt and either a 15/16” or 1” nut to set belt

tension. Adjust Tension Nut to apply tension to the belt. Ridges on the Tensioner Arm gauge the

amount of tension applied.

1. Loosen the Tensioner Lock Bolt Head.

2. Adjust the Tensioner Nut for proper belt tension. (This will be achieved at

approximately 1-1/2 ridges on the gauge.)

3. Tighten the Tensioner Lock Bolt Head.

Jack Shaft Pulle

The Tensioner Nut is

on opposite side

ensioner Pulley

Fig. 30 — Jack Shaft Belt and Rotary Belt Tensioner System

MQ SP-3035 CONCRETE SAW — OPERATION AND PARTS MANUAL — REV. #3 (09/29/06) — PAGE 44

Tensioner Lock Bolt

Head

Tensioner Base

Page 47

MQ SP-3035 CONCRETE SAW

Blade Flange Removal/Installation

Correct removal or installation of the Inner Blade Flange or Flange requires a Flange Puller

(option Part Number 18503) as shown below.

WARNING

Follow instructions closely to prevent injury from flying Blade Flanges!

Because of tapered fit between Blade Flange and Spindle, 5-10 tons

of force is needed to release the inner flange. Parts and tools can

become dangerous projectiles if instructions are not followed properly.

Front Puller Plate

Perimeter Bolt

Puller Bolt

Horseshoe Plate

Perimeter Bolt

Perimeter Bolt

Fig. 31 — Using the Flange Puller

Removing the Inner Blade Flange

With the Outer Blade Flange in place, and the Blade Mounting Bolt loosened approximately ¼”:

1. With the three perimeter bolts holding the two Puller Plates together, slide the Horseshoe Plate

of the Flange Puller behind the (Shaft) side of the Inner Flange as shown above.

2. Tighten the center Puller bolt to remove the Inner Flange from Spindle.

MQ SP-3035 CONCRETE SAW — OPERATION AND PARTS MANUAL — REV. #3 (09/29/06) — PAGE 45

Page 48

MQ SP-3035 CONCRETE SAW

DANGER

If the Inner Flange does not readily come free from the tapered

NOTE

Spindle, lightly tap on the central Puller bolt. This should cause

the flange to break free from the shaft.

Installing the Inner Blade Flange

1. Ensure that the tapered portion of the Spindle, and the Inner Spindle are perfectly clean and

free of burrs or indentations. Clean and repair as necessary.

2. Ensure that the Drive Key is in place.

3. Slide the Inner Flange onto the tapered portion of the Spindle.

Ensure the Outer Flange is in place to prevent the

Puller and Inner Flange from flying off when the taper

breaks loose, and causing injury!

Do Not use any lubricant! Lubricant prevents the tapered

NOTE

4. Install the Outer Blade Flange, Flange Bushing, and Mounting Bolt.

5. Tighten with a ½” impact wrench to seat the tapered surfaces of the Inner Flange and Spindle.

surfaces of the Flange and Shaft from mating properly.

Flange Bushing

Outer Flange

Dowel pin

Inner

Drive Key

Spindle

Fig. 32 — Installing the Inner Spindle

MQ SP-3035 CONCRETE SAW — OPERATION AND PARTS MANUAL — REV. #3 (09/29/06) — PAGE 46

Page 49

MQ SP-3035 CONCRETE SAW

6. Loosen the Mounting Bolt and remove the Outer Flange and Bushing.

7. Inspect the Inner Flange to ensure the proper seating of the tapered fit.

The Inner Flange should be seated between .030” and 0.0” (flush) to the end of the Spindle.

Fig. 33 — Proper seating of the Inner Flange and Spindle

8. Test to ensure that the Inner Flange does not wobble when rotated. Use a dial indicator on the

face of the Flange. Maximum tolerance is .003” run-out on the face of the Flange.

For Spindle Maintenance/hydraulic oil change see page 58.

NOTE

MQ SP-3035 CONCRETE SAW — OPERATION AND PARTS MANUAL — REV. #3 (09/29/06) — PAGE 47

Page 50

Spindle Replacement

MQ SP-3035 CONCRETE SAW

To assure correct Spindle/Wheel alignment it is recommended that

this operation be performed by a Multiquip Authorized Service Center.

DO NOT unbolt the Spindle Mounting Blocks, as they have been

factory installed for correct Spindle/wheel alignment.

NOTE

1. Remove the Spindle Drive Belts (see Replacing the Spindle Belt, above).

2. Tighten the Engine Mount Lock Bolts to prevent engine movement during step #3.

Engine Mount

Lock Bolt

Engine Mount

Lock Bolt

Fig. 34 — Engine Mount Lock Bolts

DANGER

To prevent the possibility of crush injury, always

ensure that the saw is securely supported whenever it

is lifted for maintenance.

3. Block the wheels then lift the saw to the full up position, and block up the front axle to prevent

accidental crush injury.

4. Disconnect the two hoses attached to the Spindle, and plug hoses and Spindle ports to prevent

drips and dirt contamination.

5. Support the Spindle to prevent tipping or shifting of weight.

6. Unbolt the Spindle Saddle Clamps using a 3/8” Allen wrench.

MQ SP-3035 CONCRETE SAW — OPERATION AND PARTS MANUAL — REV. #3 (09/29/06) — PAGE 48

Page 51

MQ SP-3035 CONCRETE SAW

Spindle Mounting

Block

DO NOT REMOVE

Saddle

Clamps

Fig. 35 — Spindle Replacement

7. Remove the Spindle.

DO NOT unbolt the Spindle Mounting Blocks, as they have been factory-installed

for correct Spindle/wheel alignment.

8. Fill the new Spindle with approved hydraulic oil and cap.

9. Perform Steps 1-5 in reverse order.

Spindle Mounting

Block

DO NOT REMOVE

Lower Belt

Protector

Spacing

Spacing

Fig. 36 — Maintain equal spacing when tightening Saddle Clamps

Tighten Saddle Clamp bolts equally, maintaining even spacing as you reattach the

Saddle Clamps. Torque bolts to 35 ft. lbs. Do Not over-torque. Apply medium

strength thread lock, Blue Loctite 242 or equivalent.

MQ SP-3035 CONCRETE SAW — OPERATION AND PARTS MANUAL — REV. #3 (09/29/06) — PAGE 49

Page 52

MQ SP-3035 CONCRETE SAW

Circuit Breakers

Three thermal circuit breakers are located behind the Control Panel access cover.

Remove Dash Panel to

access circuit breakers

Fig. 37 — Circuit Breaker location

Under normal circumstance circuit breakers do not require service; they are automatically re-set

once an overload condition has been corrected. If one or more breakers are cycling on/off, locate

the cause of the electrical overload and repair as required.

Also see the Electrical Schematic on page 61.

Maximum Cut Depth Adjustment

The 3000 Series saws come factory-adjusted for maximum usable cut depth. However, should

you desire to adjust the maximum depth:

1. Park the blade-less saw on a flat and level surface.

2. Fully lower the saw onto the Stop Bolts (see Fig. 38).

3. Measure the distance from the Blade Flanges to the surface.

4. Adjust the Stop Bolts in or out until the Blade Flanges have 1/8” to 3/16” ground clearance.

5. Ensure that both bolts are adjusted to the same setting so that the load is evenly distributed.

MQ SP-3035 CONCRETE SAW — OPERATION AND PARTS MANUAL — REV. #3 (09/29/06) — PAGE 50

Page 53

MQ SP-3035 CONCRETE SAW

Lubrication

This saw has six grease fittings. Locations are shown in Figure 38 on the front axle assembly, and

one, (not shown) on the Jackshaft assembly.

Front axle pivot bearings (2)

Hydraulic lift cylinder end (1)

Depth cylinder pivot bracket (2)

Jackshaft pivot (1)

These fittings are easily accessed by raising the saw half way up, and then lifting the rear of the

saw until the blade flanges rest on the ground.

WARNING

DANGER

To prevent the possibility of crush injury, ensure that

the saw is securely placed on suitable supports before

servicing the lubrication points.

Grease each fitting every 25 hours of operation using premium grade

waterproof E. P. (extreme pressure) grease.

F1

F2

F3

F4

F5

Maximum Cut

Depth Stop Bolt

Maximum Cut

Depth Stop Bolts

Fig. 38 — Grease Fittings and Maximum Cut Depth Stops

MQ SP-3035 CONCRETE SAW — OPERATION AND PARTS MANUAL — REV. #3 (09/29/06) — PAGE 51

Page 54

MQ SP-3035 CONCRETE SAW

Engine Maintenance

The Model SP-3035 uses a 35 HP Wisconsin engine. See the engine manual for service details.

Check air filters daily. Do not clean. Replace as needed. See Caution below.

Check engine oil level daily.

Level the saw frame prior to service to get accurate readings.

Change the engine oil and filter every 50 hours of operation.

Filters

Filter Qty Part Number & Cross Reference

Primary Air Filter 1 300000-1

Safety Air Filter 1 300000-2

Engine Oil Filter 1 306004

Hydraulic System Filter 1 306006

Inline Fuel Filter 1 304000

DANGER

Safety Air Filters are NOT intended to be used for primary air

filtration. When the Primary Filter becomes clogged, replace it

immediately – DO NOT run saw using just the Safety filter.

DO NOT attempt to clean dirty air filters by any means.

Air filter

Engine

Oil filter

Hydraulic Oil

Reservoir

Fuel filter

Transaxle

filter

Fig. 39 — Filters

MQ SP-3035 CONCRETE SAW — OPERATION AND PARTS MANUAL — REV. #3 (09/29/06) — PAGE 52

Page 55

MQ SP-3035 CONCRETE SAW

Raise-Lower System

This saw uses a 12-volt hydraulic pump and cylinder to power the raise-lower system.

Level the frame prior to service to get accurate readings.

Check oil level daily.

Fill the reservoir half full when cold.

Use 5W-30 premium grade engine oil.

Raise-Lower

Pump

Hydraulic

Manifold

Raise-Lower

Cylinder

Raise-Lower

Reservoir

Fig. 40 — Raise-Lower System

MQ SP-3035 CONCRETE SAW — OPERATION AND PARTS MANUAL — REV. #3 (09/29/06) — PAGE 53

Page 56

MQ SP-3035 CONCRETE SAW

Control Handle Adjustment

The Control Handle is adjustable to provide the preferred “feel”.

1. Using a ¼” Allen wrench and 9/16” wrench, loosen both pivot bolts until they can be turned

by hand. Pivot #1 requires only a 9/16” wrench, as the Allen nut side is welded in place.

2. Tighten pivot #1 until the handle is close to the desired “feel”.

3. Tighten pivot #2 until it just starts to increase the force required to move the handle.

Pivot #1

Pivot #2

Fig. 41 — Control Handle Adjustment

MQ SP-3035 CONCRETE SAW — OPERATION AND PARTS MANUAL — REV. #3 (09/29/06) — PAGE 54

Page 57

MQ SP-3035 CONCRETE SAW

Hydraulic System

The hydraulic system consists of:

Spindle Assembly (1) Hydraulic Pump (2)

Transaxle Assembly (9) Hydraulic Manifold (4)

Lift Cylinder (5) Oil Filters (3, 6)

Hydraulic Drive and Spindle Oil Reservoir (7) Lift Cylinder Reservoir (8)

Routine Maintenance

Check oil level daily.

Fill the reservoir to the fill line when cold.

Level frame prior to service to get an accurate reading.

Use 5W-30 premium grade engine oil.

Change transaxle oil and filter every 250 hours of operation or annually.

Change Spindle oil every 250 hours of operation or annually.

1

4

3

2

8

7

6

9

5

Fig. 42 — Hydraulic System Components

MQ SP-3035 CONCRETE SAW — OPERATION AND PARTS MANUAL — REV. #3 (09/29/06) — PAGE 55

Page 58

MQ SP-3035 CONCRETE SAW

Draining & Filling the Hydraulic System

To drain the Transaxle

1. Remove the drain plug from the bottom of the Spindle housing and the bottom of the

Transaxle.

Drain Plug

Fig. 43 — Transaxle Drain Plug

Collect and dispose of the used oil and oil filter in an environmentally

NOTE

2. Remove the old oil filter. See Fig. 43, above.

3. Once drained, reinstall the drain plugs.

4. Pre-fill and install a new oil filter.

5. Refill the Transaxle with hydraulic oil as outlined on page 58

CAUTION

friendly manner. Do not drain onto the ground or pour used oil down

drains.

Pre-fill the oil filter with oil prior to installing to prevent hydraulic

pump damage.

To drain the Spindle

The fully enclosed Spindle eliminates most maintenance. However, if

NOTE

the Spindle ever needs service or repair, contact Multiquip, at the

number listed in the inside of the front cover for details.

MQ SP-3035 CONCRETE SAW — OPERATION AND PARTS MANUAL — REV. #3 (09/29/06) — PAGE 56

Page 59

MQ SP-3035 CONCRETE SAW

Drain

Fig. 44 — Spindle Assembly

1. Raise the saw 2/3 or more up.

2. Remove the drain plug from the bottom of the Spindle housing.

3. Re-install the drain plug and install a new oil filter.

CAUTION

To prevent damage to the hydraulic pump, pre-fill the new oil filter

prior to installation.

To Remote Fill

Reservoir

To refill the hydraulic system

1. Ensure the saw is fully lowered if it had been raised.

2. Add hydraulic oil to the Drive & Spindle System Reservoir.

Oil will need to be added several times.

3. Jack the unit up so the drive wheels are off the ground, then run the engine for a couple

minutes to cycle oil throughout the system.

4. Add more oil as required.

5. Inspect for leaks after service.

Tips

Remove the oil reservoir cap to speed draining.

Before installing a new filter, fill the reservoir and let it drain down to the filter manifold.

Once new oil reaches the manifold, install the new pre-filled filter.

To help speed up the refilling process, raise the saw half-way up and lift the rear of the saw

until the Blade Flanges touch the ground.

After filling the system, jack the saw up so the drive wheels are off the ground. Start the

saw, and move the joystick half way into FORWARD, to purge air out of the system.

MQ SP-3035 CONCRETE SAW — OPERATION AND PARTS MANUAL — REV. #3 (09/29/06) — PAGE 57

Page 60

MQ SP-3035 CONCRETE SAW

Drive Wheel Alignment

Below is the suggested technique for aligning the wheels. Distance X is the same on either side;

the Front Axle and Spindle must be at right angles to the frame edge. Distance A is 3/16” (.187”)

longer on the right side, so that the saw steers slightly left. Users may wish to alter the alignment

to fit a particular application.

Fig. 45 — Drive Wheel Alignment

MQ SP-3035 CONCRETE SAW — OPERATION AND PARTS MANUAL — REV. #3 (09/29/06) — PAGE 58

Page 61

MQ SP-3035 CONCRETE SAW

The drive wheels are aligned by adjusting the entire rear drive assembly.

1. Raise the saw halfway, then lift the rear of the saw until flanges touch the ground. Use suitable

supports to prevent tipping or shifting of weight.

2. Loosen the adjustment-side attachment bolts until washers spin freely.

3. Loosen pivot-side bolts enough to move the adjustment-side wheel in the appropriate

direction to achieve the desired alignment distance.

4. Tighten the Transaxle Attachment Bolts when the appropriate alignment distance is set.

Pivot Side | Adjustment Side

Pivot Side

Attachment Bolts

Adjustment Side

Attachment Bolts

Fig. 46 — Drive Wheel Alignment Bolt Locations

MQ SP-3035 CONCRETE SAW — OPERATION AND PARTS MANUAL — REV. #3 (09/29/06) — PAGE 59

Page 62

Positraction Adjustment

Clamp Position

(Inner Lip of Drive Hub)

Clamp Plate Bolt

MQ SP-3035 CONCRETE SAW

Clamp Position

(Inside Wheel Lip)

Clamp Plate Bolt

Spacer Position

Fig. 47 — Positraction Adjustment Bolt Locations

1. Lift Saw 4” to 6” and tilt forward to place spindle flanges on ground. When flanges are on the

ground, depress Raise Button to raise the rear of the saw to full height. Use suitable stands to

hold rear of saw up.

2. Disengage Positraction Lever fully.

3. Loosen Positraction clamping plate bolts enough to adjust Positraction assembly.

4. Insert 1/8” flat spacer between Positraction drive hub and rear wheel on both sides. Use a

finger-type clamp to compress the drive hub and the rear wheel, insert spacers between

contact points of wheel and hub. Tighten clamp until rear wheel compresses slightly.

5. Tighten Positraction clamping bolts to secure Positraction assembly. Remove clamps and

spacer.

6. Remove supports. Grasp the handlebars securely and depress the “Lower” button until the

rear of the saw has lowered sufficiently to safely lower the rear wheels to the ground.

MQ SP-3035 CONCRETE SAW — OPERATION AND PARTS MANUAL — REV. #3 (09/29/06) — PAGE 60

Page 63

y

EXPLANATION OF CODE IN

REMARKS COLUMN

The following section explains the different symbols

and remarks used in the Parts section of this manual.

Use the help numbers found on the back page of the

manual if there are any questions.

The contents and part numbers listed in the

parts section are subject to change without

notice. Multiquip does not guarantee the

availibilit

Sample Parts List:

NO. PART NO. PART NAME QTY. REMARKS

1 12345 BOLT ....................... 1..... INCLUDES ITEMS W/

2# WASHER, 1/4 IN...... ...... NOT SOLD SEPARATELY

2# 12347 WASHER, 3/8 IN. ..... 1.... MQ-45T ONLY