Page 1

OPERATION AND PARTS MANUAL

MODEL SG1400C3-55748

3-POSITION SWITCH/PARALLELING

1400 AMP STUDIO GENERATOR

(CUMMINS QSB7-G5 DIESEL ENGINE)

Revision #1 (02/15/12)

To find the latest revision of this

publication, visit our website at:

www.mqpower.com

THIS MANUAL MUST ACCOMPANY THE EQUIPMENT AT ALL TIMES.

EE55916

Page 2

PROPOSITION 65 WARNING

Diesel engine exhaust and some of

PAGE 2 — SG1400C3 STUDIO GENERATOR • OPERATION AND PARTS MANUAL — REV. #1 (02/15/12)

Page 3

REPORTING SAFETY DEFECTS

If you believe that your vehicle has a defect that could cause a crash or could cause

injury or death, you should immediately inform the National Highway Traffic Safety

Administration (NHTSA) in addition to notifying Multiquip at 1-800-421-1244.

If NHTSA receives similar complaints, it may open an investigation, and if it finds

that a safety defect exists in a group of vehicles, it may order a recall and remedy

campaign. However, NHTSA cannot become involved in individual problems

between you, your dealer, or Multiquip.

To contact NHTSA, you may either call the Vehicle Safety Hotline toll-free at 1-888327-4236 (TTY: 1-800-424-9153), go to http://www.nhtsa.dot.gov; or write to:

Administrator

NHTSA

1200 New Jersey Avenue S.E.

Washington, DC 20590

You can also obtain information about motor vehicle safety from

http://www.safecar.gov.

SG1400C3 STUDIO GENERATOR • OPERATION AND PARTS MANUAL — REV. #1 (02/15/12) — PAGE 3

Page 4

TABLE OF CONTENTS

SG1400C3 Studio Generator

Proposition 65 Warning ........................................... 2

Reporting Safety Defects ......................................... 3

Table Of Contents .................................................... 4

Parts Ordering Procedures ...................................... 5

Safety Information ..............................................6-11

Specifications ........................................................ 12

Dimensions ............................................................ 13

Installation ........................................................14-15

General Information .......................................... 16-18

Generator Major Components .......................... 20-21

Basic Engine Components .................................... 22

Basic Trailer Components ...................................... 23

Control Panel ......................................................... 24

Camlok/Voltage Output Panel ................................ 25

Circuit Breaker Panel ............................................. 26

Digital Controller ................................................... 27

Load Application/Generator Output ....................... 28

Generator Outputs ................................................. 29

Inspection/Setup ............................................... 30-33

Startup .............................................................. 34-36

Protective Devices ................................................. 37

Maintenance ..................................................... 38-43

Troubleshooting (Generator) .................................. 44

Troubleshooting (Engine) ....................................... 45

Troubleshooting (Controller) .................................. 46

Trailer Guidelines .............................................. 47-61

Hydraulic Hoses Schematic ................................... 62

Maintenance Parts Locator .................................... 63

Generator Wiring Diagram ................................ 64-65

Explanation Of Codes In Remarks Column ........... 66

Suggested Spare Parts ......................................... 67

Component Drawings

Housing (Base) Assy.........................................68-69

Housing (Interior) Assy. ....................................70-71

Camlok Assy. .................................................... 72-73

Control Box Assy. (Panel) ................................. 74-75

Control Box Assy. (Interior) ............................... 76-77

Engine/Generator Mounting Assy. .................... 78-79

Radiator/Muffler Support ..................................80-81

Radiator/Fan Assy. ............................................ 82-83

Radiator Piping ................................................. 84-85

Air Filter Hosing/Piping ..................................... 86-87

Exhaust Assy. ................................................... 88-89

Saddle Box Assy. .............................................. 90-91

Engine Starter, Relay And Battery Assy. .......... 92-93

Fuel System Assy. ............................................ 94-97

Hyd. Vent Actuator Hosing Assy. ....................... 98-99

Engine Component Assy...............................100-101

Hyd. Manifold, Valve And Hose Assy. ........... 102-103

Hyd. Tank, Filter And Hose Assy. .................. 104-107

Hyd. Pump, Cooler, Fan Motor And Hose Assy. 108-109

Crankcase Ventilation Assy. .......................... 110-111

Trailer Assy. ................................................... 112-113

Terms And Conditions Of Sale — Parts .............. 114

NOTICE

Specifications are subject to change without notice.

PAGE 4 — SG1400C3 STUDIO GENERATOR • OPERATION AND PARTS MANUAL — REV. #1 (02/15/12)

Page 5

Ordering parts has never been easier!

If you have an MQ Account, to obtain a Username

Effective:

PARTS ORDERING PROCEDURES

Choose from three easy options:

January 1st, 2006

Best Deal!

Order via Internet (Dealers Only):

Order parts on-line using Multiquip’s SmartEquip website!

■ View Parts Diagrams

■ Order Parts

■ Print Specification Information

Goto www.multiquip.com and click on

Order Parts

to log in and save!

Order via Fax (Dealers Only):

All customers are welcome to order parts via Fax.

Domestic (US) Customers dial:

1-800-6-PARTS-7 (800-672-7877)

Order via Phone:

Non-Dealer Customers:

Contact your local Multiquip Dealer for

parts or call 800-427-1244 for help in

locating a dealer near you.

and Password, E-mail us at: parts@multiquip.

com.

To ob tai n an MQ Acc o un t , cont a ct yo u r

District Sales Manager for more information.

Use the internet and qualify for a 5% Discount

on Standard orders for all orders which include

complete part numbers.*

Fax your order in and qualify for a 2% Discount

on Standard orders for all orders which include

complete part numbers.*

Domestic (US) Dealers Call:

1-800-427-1244

International Customers should contact

their local Multiquip Representatives for

Parts Ordering information.

Note: Discounts Are Subject To Change

Note: Discounts Are Subject To Change

When ordering parts, please supply:

❒ Dealer Account Number

❒ Dealer Name and Address

❒ Shipping Address (if different than billing address)

❒ Return Fax Number

❒ Applicable Model Number

❒ Quantity, Part Number and Description of Each Part

NOTICE

All orders are treated as Standard Orders and will

ship the same day if received prior to 3PM PST.

❒ Specify Preferred Method of Shipment:

✓ UPS/Fed Ex ✓ DHL

■ Priority One ✓ Truck

■ Ground

■ Next Day

■ Second/Third Day

www.multiquip.com

WE ACCEPT ALL MAJOR CREDIT CARDS!

SG1400C3 STUDIO GENERATOR • OPERATION AND PARTS MANUAL — REV. #1 (02/15/12) — PAGE 5

Page 6

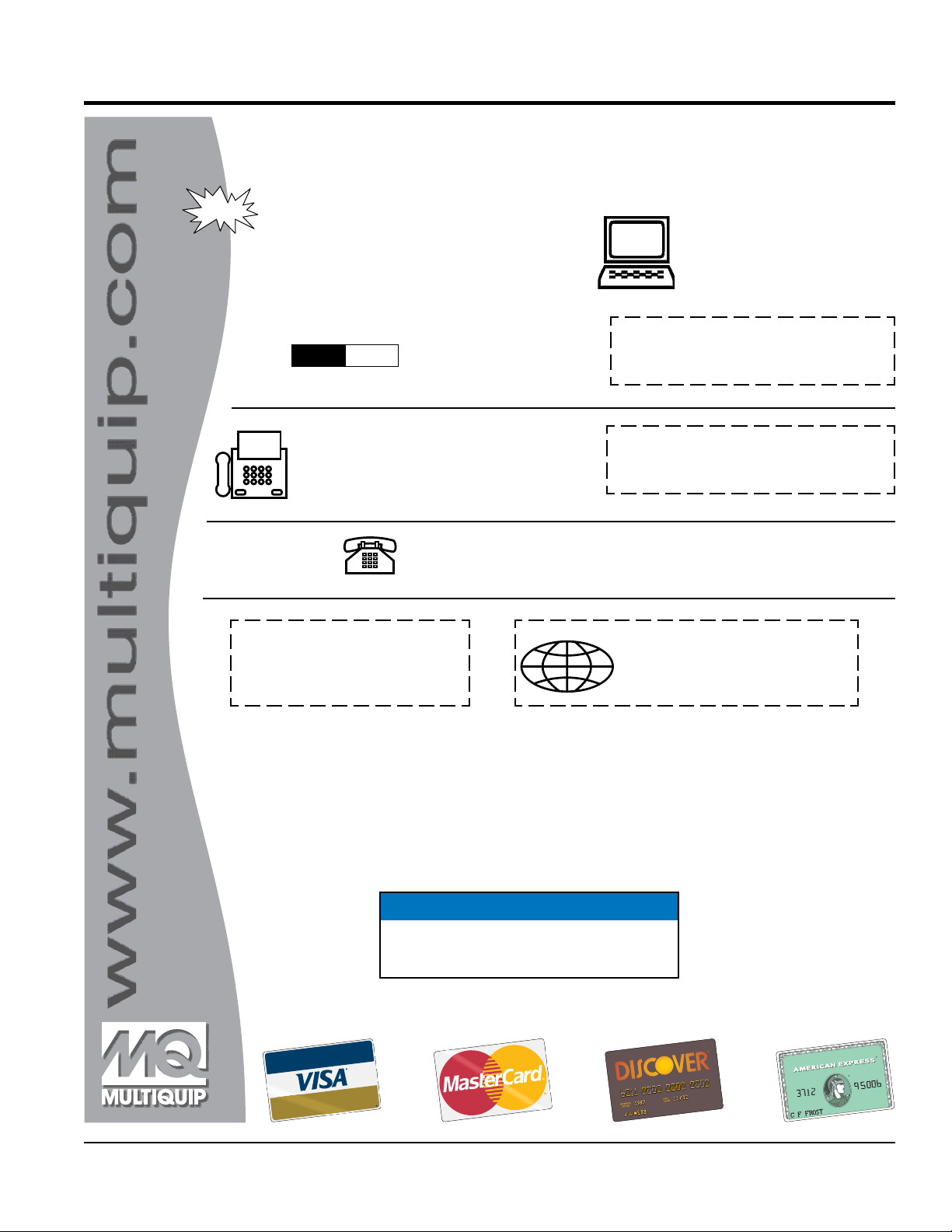

SAFETY INFORMATION

Do not operate or service the equipment before reading the

Potential hazards associated with the operation of this

entire manual. Safety precautions should be followed at all

times when operating this equipment. Failure to read and

understand the safety messages and operating instructions

could result in injury to yourself and others.

SAFETY MESSAGES

The four safety messages shown below will inform you

about potential hazards that could injure you or others. The

safety messages specifi cally address the level of exposure

to the operator and are preceded by one of four words:

DANGER, WARNING, CAUTION or NOTICE.

SAFETY SYMBOLS

DANGER

Indicates a hazardous situation which, if not avoided,

WILL result in DEATH or SERIOUS INJURY.

WARNING

equipment will be referenced with hazard symbols which

may appear throughout this manual in conjunction with

safety messages.

Indicates a hazardous situation which, if not avoided,

COULD result in DEATH or SERIOUS INJURY.

CAUTION

Indicates a hazardous situation which, if not avoided,

COULD result in MINOR or MODERATE INJURY.

NOTICE

Addresses practices not related to personal injury.

PAGE 6 — SG1400C3 STUDIO GENERATOR • OPERATION AND PARTS MANUAL — REV. #1 (02/15/12)

Page 7

SAFETY INFORMATION

GENERAL SAFETY

NEVER use accessories or attachments that are not

recommended by MQ Power for this equipment. Damage

Also, know the

and

This information will be invaluable in

emergency or safety devices.

Disconnection of these devices can cause severe injury,

bodily harm or even death. Disconnection of any of these

ensure generator is on level ground before use.

keep the machine in proper running condition.

store equipment properly when it is not being

used. Equipment should be stored in a clean, dry location

out of the reach of children and unauthorized personnel

CAUTION

NEVER operate this equipment without proper protective

clothing, shatterproof glasses, respiratory protection,

hearing protection, steel-toed boots and other protective

devices required by the job or city and state regulations.

NEVER operate this equipment when not

feeling well due to fatigue, illness or when

under medication.

NEVER operate this equipment under the infl uence of

drugs or alcohol.

ALWAYS check the equipment for loosened threads or

bolts before starting.

DO NOT use the equipment for any purpose other than

its intended purposes or applications.

to the equipment and/or injury to user may result.

ALWAYS know the location of the nearest

fi re extinguisher.

ALWAYS know the location of the nearest

fi rst aid kit.

ALWAYS know the location of the nearest

phone or keep a phone on the job site.

phone numbers of the nearest ambulance, doctor

fi re department.

the case of an emergency.

GENERATOR SAFETY

DANGER

NEVER operate the equipment in an explosive

atmosphere or near combustible materials. An

explosion or fi re could result causing severe

bodily harm or even death.

WARNING

NOTICE

This equipment should only be operated by trained and

qualifi ed personnel 18 years of age and older.

Whenever necessary, replace nameplate, operation and

safety decals when they become diffi cult read.

Manufacturer does not assume responsibility for any

accident due to equipment modifi cations. Unauthorized

equipment modifi cation will void all warranties.

NEVER disconnect any

These devices are intended for operator safety.

devices will void all warranties.

CAUTION

NEVER lubricate components or attempt service on a

running machine.

NOTICE

ALWAYS

ALWAYS

Fix damage to machine and replace any broken parts

immediately.

ALWAYS

SG1400C3 STUDIO GENERATOR • OPERATION AND PARTS MANUAL — REV. #1 (02/15/12) — PAGE 7

Page 8

ENGINE SAFETY

NOTICE

run engine without an air fi lter or with a dirty air

fi lter. Severe engine damage may occur. Service air fi lter

Wet stacking is a common problem with diesel engines

no load applied. When a diesel engine operates without

suffi cient load (less than 40% of the rated output), it will

not operate at its optimum temperature. This will allow

In order for a diesel engine to operate at peak effi ciency,

it must be able to provide fuel and air in the proper ratio

and at a high enough engine temperature for the engine

applied to relieve the condition. It can reduce the system

Codes specify that in certain locations, spark arresters

must be used on internal combustion engines that use

hydrocarbon fuels. A spark arrester is a device designed

from the engine exhaust. Spark arresters are qualifi ed

SAFETY INFORMATION

DANGER

The engine fuel exhaust gases contain poisonous carbon

monoxide. This gas is colorless and odorless, and can

cause death if inhaled.

The engine of this equipment

requires an adequate free

fl ow of cooling air. NEVER

operate this equipment in

any enclosed or narrow area

where free fl ow of the air is

restricted. If the air fl ow is

restricted it will cause injury to people and property and

serious damage to the equipment or engine.

WARNING

DO NOT pla c e hand s or f i n g e rs in s ide en gine

compartment when engine is running.

NEVER operate the engine with heat shields or

guards removed.

Keep fi ngers, hands hair and clothing away

from all moving parts to prevent injury.

DO NOT remove the radiator cap while the

engine is hot. High pressure boiling water

will gush out of the radiator and severely

scald any persons in the general area of

the generator.

DO NOT remove the coolant drain plug while the engine

is hot. Hot coolant will gush out of the coolant tank and

severely scald any persons in the general area of the

generator.

NEVER

frequently to prevent engine malfunction.

NEVER tamper with the factory settings

of the engine or engine governor. Damage

to the engine or equipment can result

if operating in speed ranges above the

maximum allowable.

which are operated for extended periods with light or

unburned fuel to accumulate in the exhaust system,

which can foul the fuel injectors, engine valves and

exhaust system, including turbochargers, and reduce

the operating performance.

to completely burn all of the fuel.

Wet stacking does not usually cause any permanent

damage and can be alleviated if additional load is

performance and increase maintenance. Applying an

increasing load over a period of time until the excess

fuel is burned off and the system capacity is reached

usually can repair the condition. This can take several

hours to burn off the accumulated unburned fuel.

State Health Safety Codes and Public Resources

DO NOT remove the engine oil drain plug while the

engine is hot. Hot oil will gush out of the oil tank and

severely scald any persons in the general area of the

generator.

CAUTION

NEVER touch the hot exhaust manifold,

muffl er or cylinder. Allow these parts to cool

before servicing equipment.

PAGE 8 — SG1400C3 STUDIO GENERATOR • OPERATION AND PARTS MANUAL — REV. #1 (02/15/12)

to prevent accidental discharge of sparks or fl ames

and rated by the United States Forest Service for this

purpose. In order to comply with local laws regarding

spark arresters, consult the engine distributor or the

local Health and Safety Administrator.

Page 9

FUEL SAFETY

DANGER

Make sure the hitch and coupling of the towing vehicle

NEVER

tow a trailer with defective hitches, couplings, chains, etc.

Trailer tires should be infl ated to 50 psi cold.

safety

attach trailer’s safety chains to towing

make sure the vehicle and trailer directional,

unless

posted otherwise. Recommended off-road towing is not to

Avoid sudden stops and starts. This can cause skidding,

Trailer should be adjusted to a level position at all times

rolling

underneath the trailer’s bumper

Use the trailer’s swivel jack to adjust the trailer height to

SAFETY INFORMATION

are rated equal to, or greater than the trailer “gross

vehicle weight rating.”

DO NOT start the engine near spilled fuel or combustible

fl uids. Diesel fuel is extremely fl ammable and its vapors

can cause an explosion if ignited.

ALWAYS refuel in a well-ventilated area, away from

sparks and open fl ames.

ALWAYS use extreme caution when working with

fl ammable liquids.

DO NOT fi ll the fuel tank while the engine is running

or hot.

DO NOT overfi ll tank, since spilled fuel could ignite if it

comes into contact with hot engine parts or sparks from

the ignition system.

Store fuel in appropriate containers, in well-ventilated

areas and away from sparks and fl ames.

NEVER use fuel as a cleaning agent.

DO NOT sm o ke around or near the

equipment. Fire or explosion could result

from fuel vapors or if fuel is spilled on a

hot engine.

TOWING SAFETY

Check with your local county or state safety

towing regulations, in addition to meeting

Depar tment of Transportation (DOT)

Safety Towing Regulations, before towing

your generator.

Refer to MQ Power trailer manual for additional safety

information.

In order to reduce the possibility of an accident while

transporting the generator on public roads, ALWAYS

make sure the trailer that supports the generator and

the towing vehicle are mechanically sound and in good

operating condition.

ALWAYS shutdown engine before transporting

CAUTION

ALWAYS inspect the hitch and coupling for wear.

Check the tire air pressure on both towing vehicle and

trailer.

Also check the tire tread wear on both vehicles.

ALWAYS make sure the trailer is equipped with a

chain.

ALWAYS properly

vehicle.

ALWAYS

backup, brake and trailer lights are connected and

working properly.

DOT Requirements include the following:

• Connect and test electric brake operation.

• Secure portable power cables in cable tray with tie

wraps.

The maximum speed for highway towing is 55 MPH

exceed 15 MPH or less depending on type of terrain.

or jack-knifi ng. Smooth, gradual starts and stops will

improve towing.

Avoid sharp turns to prevent rolling.

when towing.

Raise and lock trailer wheel stand in up position when

towing.

Place chock blocks underneath wheel to prevent

while parked.

Place support blocks

to prevent tipping while parked.

a level position while parked.

SG1400C3 STUDIO GENERATOR • OPERATION AND PARTS MANUAL — REV. #1 (02/15/12) — PAGE 9

Page 10

ELECTRICAL SAFETY

DANGER

Make sure power cables are securely connected to the

make certain that proper power or extension

cord has been selected for the job. See Cable Selection

make sure that electrical circuits are properly

Severe injury or death by

can result from operating an ungrounded

DO NOT touch output terminals during

operation. Contact with output terminals

during operation can cause electrocution,

electrical shock or burn.

SAFETY INFORMATION

generator’s output receptacles. Incorrect connections

may cause electrical sho ck and dam age to the

generator.

NOTICE

ALWAYS

The electrical voltage required to

operate the generator can cause severe

injury or even death through physical contact with live

circuits. Turn generator and all circuit breakers OFF

before performing maintenance on the generator or

making contact with output terminals.

NEVER insert any objects into the output

receptacles dur ing operation. This is

extremely dangerous. The possibility exists

of electrical shock, electrocution or

death.

Backfeed to a utility system can cause

electrocution and/or property damage.

NEVER connect the generator to a

building’s electrical system without

a transfer switch or other approved

device. All installations should be

performed by a licensed electrician in accordance with

all applicable laws and electrical codes. Failure to do so

could result in electrical shock or burn, causing serious

injury or even death.

Chart in this manual.

Grounding Safety

DANGER

ALWAYS

grounded to a suitable earth ground (ground rod) per

the National Electrical Code (NEC) and local codes

before operating generator.

electrocution

generator.

NEVER use gas piping as an electrical ground.

Power Cord/Cable Safety

DANGER

NEVER let power cords or cables lay in water.

NEVER stand in water while AC power from the

generator is being transferred to a load.

NEVER use damaged or worn cables or cords when

connecting equipment to generator. Inspect for cuts in

the insulation.

NEVER grab or touch a live power

cord or cable with wet hands. The

possibility exists of electrical shock,

electrocution or death.

PAGE 10 — SG1400C3 STUDIO GENERATOR • OPERATION AND PARTS MANUAL — REV. #1 (02/15/12)

Page 11

SAFETY INFORMATION

BATTERY SAFETY

ENVIRONMENTAL SAFETY

pour waste, oil or fuel directly onto the ground,

DANGER

DO NOT drop the battery. There is a possibility that the

battery will explode.

DO NOT expose the battery to open fl ames,

sparks, cigarettes, etc. The battery contains

combustible gases and liquids. If these

gases and liquids come into contact with a

fl ame or spark, an explosion could occur.

WARNING

ALWAYS wear safety glasses when handling

the battery to avoid eye irritation. The battery

contains acids that can cause injury to the

eyes and skin.

Use well-insulated gloves when picking up the battery.

ALWAYS keep the battery charged. If the battery is not

charged, combustible gas will build up.

ALWAYS recharge the battery in a well-ventilated

environment to avoid the risk of a dangerous concentration

of combustible gasses.

NOTICE

Dispose of hazardous waste properly.

Examples of potentially hazardous waste

are used motor oil, fuel and fuel fi lters.

DO NOT use food or plastic containers to

dispose of hazardous waste.

DO NOT

down a drain or into any water source.

If the battery liquid (dilute sulfuric acid) comes into

contact with clothing or skin, rinse skin or clothing

immediately with plenty of water.

If the battery liquid (dilute sulfuric acid) comes into

contact with eyes, rinse eyes immediately with plenty

of water and contact the nearest doctor or hospital to

seek medical attention.

CAUTION

ALWAYS disconnect the NEGATIVE battery terminal

before performing service on the generator.

ALWAYS keep battery cables in good working condition.

Repair or replace all worn cables.

SG1400C3 STUDIO GENERATOR • OPERATION AND PARTS MANUAL — REV. #1 (02/15/12) — PAGE 11

Page 12

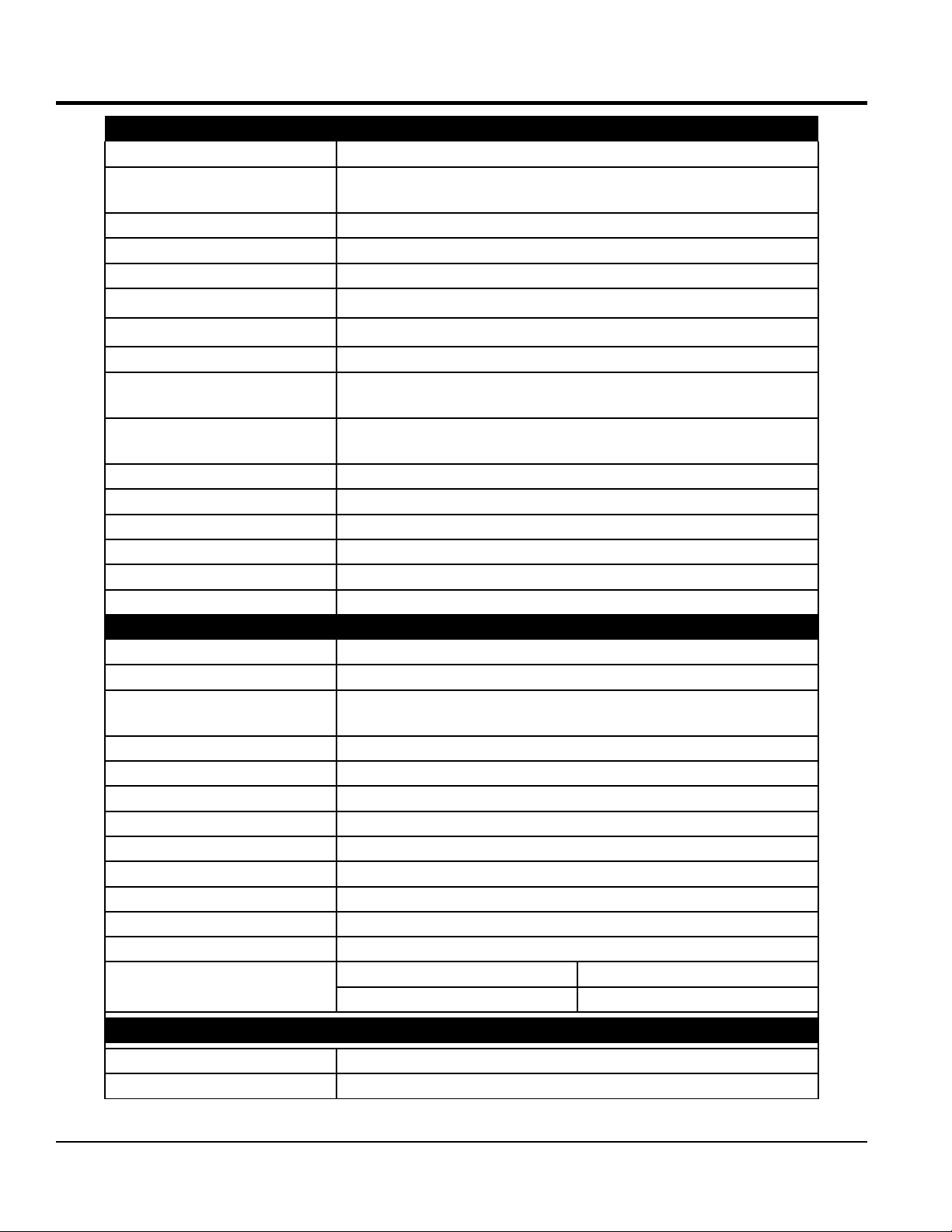

Model

Type

Armature Connection

No of Poles

Prime Output

SPECIFICATIONS

Table 1. Generator Specifications

SG1400C3

Revolving field, self ventilated,

open protected type synchronous generator

12-Lead WYE

4

200 kVA

1Ø Voltage

3Ø Voltages

Frequency

Voltage Regulation

(no load to full load)

Frequency Regulation

(steady state load)

Speed

Power Factor

Aux. AC Voltage

Weight (Generator Only)

Weight (Trailer Only)

Dimensions (LxWxH)

Model

Emissions

Type

No. of Cylinders

Bore x Stroke in (mm)

Displacement

Rated Output

Starting

Coolant Capacity

Lube Oil Capacity

Fuel Type

Fuel Tank Capacity

Fuel Consumption

120/240 V

120/208 V and 277/480 V

60 Hz

±1%

±0.25%

1800 rpm

0.8

120/240V, 60 Hz

5,900 lbs. (2,994 kg)

2,640 lbs. (1,170 kg)

100 x 48 x 110 in (254 x 122 x 279 cm)

Table 2. Engine Specifications

Cummins QSB7-G5

Tier 3

4 cycle, direct injection, turbocharged,

charge air cooled

6 cylinders

4.21 x 4.88 (107 x 124)

408 cu. in. (6,690 cc)

279 HP/1800 RPM

Electric

7.8 gal. (29 liters)

5.0 gal. (19.0 liters)

#2 Diesel Fuel

150 gal. (567 liters)

13.3 gal. (64 L)/hr at full load 10.6 gal. (40 L)/hr at 3/4 load

7.8 gal. (30 L)/hr at 1/2 load 4.0 gal. (15 L)/hr at 1/4 load

Table 3. Battery Specifications

Battery (Top Post)

Dimensions HxWxL in. (cm)

PAGE 12 — SG1400C3 STUDIO GENERATOR • OPERATION AND PARTS MANUAL — REV. #1 (02/15/12)

12V 750 CCA x 2 (24 VDC System ) Group 27

8 x 12 x 6.6 (20.3 x 30.5 x 16.8)

Page 13

TOP VIEW

DIMENSIONS

A

B

Figure 1. Dimensions

SIDE VIEW

L

FRONT VIEW

C

D

E

F

G

H

J

I

K

Table 4. Dimensions

Reference

M

AC VOLTS

AC AMPERES

AC AMPERES

AC AMPERES HERTZ

Letter

A 90 (2,286) H 130 (3,302)

B 115 (2,921) I 22.5 (571)

C 96 (2,438) J

D 27 (686)

E 24 (610)

Dimensions

in. (mm)

Reference

Letter

J

K

Dimensions

in. (mm)

23 (584)

Chrome Wheels

24 (610)

Aluminum Wheels

180 (4,572)

F 24 (610)

G 79 (2,007) M 47 (1,194)

L

24.5 (622)

SG1400C3 STUDIO GENERATOR • OPERATION AND PARTS MANUAL — REV. #1 (02/15/12) — PAGE 13

Page 14

INSTALLATION

GROUND LUG

NOTE: GROUND LUG MUST

BE INSTALLED BY USER.

GENERATOR

GROUND CABLE

8 FT. MINIMUM

REFERENCE

NEC 250-52(C)

GROUND ROD

FOR EARTH

GROUND

CONNECT TO

BUILDING

GROUND

Figure 2. Typical Generator Grounding Application

PAGE 14 — SG1400C3 STUDIO GENERATOR • OPERATION AND PARTS MANUAL — REV. #1 (02/15/12)

Page 15

INSTALLATION

OUTDOOR INSTALLATION

Install the generator in a area that is free of debris,

bystanders, and overhead obstructions. Make sure the

generator is on secure level ground so that it cannot slide

or shift around. Also install the generator in a manner so

that the exhaust will not be discharged in the direction of

nearby homes.

The installation site must be relatively free from moisture

and dust. All electrical equipment should be protected from

excessive moisture. Failure to do will result in deterioration

of the insulation and will result in shor t circuits and

grounding.

Foreign materials such as dust, sand, lint and abrasive

materials have a tendency to cause excessive wear to

engine and alternator parts.

CAUTION

Pay close attention to ventilation when operating the

generator inside tunnels and caves. The engine exhaust

contains noxious elements. Engine exhaust must be

routed to a ventilated area.

GENERATOR GROUNDING

To guard against electrical shock and possible damage to

the equipment, it is important to provide a good EARTH

ground.

Article 250 (Grounding) of the National Electrical Code

(NEC) provides guidelines for proper grounding and

specifies that the cable ground shall be connected to the

grounding system of the building as close to the point of

cable entry as practical.

NEC articles 250-64(b) and 250-66 set the following

grounding requirements:

1. Use one of the following wire types to connect the

generator to earth ground.

a. Copper - 10 AWG (5.3 mm2)

b. Aluminum - 8 AWG (8.4 mm2)

2. When grounding the generator (Figure 2) connect the

ground cable between the lock washer and the nut on

the generator and tighten the nut fully. Connect the

other end of the ground cable to earth ground.

INDOOR INSTALLATION

Exhaust gases from diesel engines are extremely

poisonous. Whenever an engine is installed indoors the

exhaust fumes must be vented to the outside. The engine

should be installed at least two feet from any outside wall.

Using an exhaust pipe which is too long or too small can

cause excessive back pressure which will cause the engine

to heat excessively and possibly burn the valves.

3. NEC article 250-52(c) specifies that the earth ground rod

should be buried a minimum of 8 ft. into the ground.

NOTICE

When connecting the generator to any buildings

electrical system ALWAYS consult with a licensed

electrician.

NOTICE

If connection of the ground rod is not feasible, please

check city, local or state electrical requirements on

generator grounding requirements.

SG1400C3 STUDIO GENERATOR • OPERATION AND PARTS MANUAL — REV. #1 (02/15/12) — PAGE 15

Page 16

GENERAL INFORMATION

Generator

The MQ Power Model SG1400C3 is a 200kVA studio

generator that is designed as a high quality power source

for entertainment and studio applications.

In keeping with Multiquip's policy of constantly improving

its products, the specifications quoted herein are subject

to change without prior notice.

Permanent Magnet Generator Excitation System

The SG1400C3 generator is equipped with a PMG

(Permanent Magnet Generator) generator end. The

excitation system provides a minimum short circuit support

current of 300% of the standby rating for 10 seconds at 60

Hz, and approximately 275% at 50 Hz.

Both the PMG and the exciter are mounted outboard of the

bearing for ease of maintenance. The rotating brushless

exciter features hermetically sealed diodes for three-phase

full-wave rectification. The three-phase bridge is protected

against abnormal transient conditions by a multiplate

selenium surge protector.

Engine

shaft continues to rotate, the main rotor (field) induces a

voltage into the generator's main stator (armature). At rated

speed, the main stator's voltage produced by the residual

magnetism of the exciter allows the automatic voltage

regulator to function.

The regulator provides voltage to the exciter resulting in

a build-up of generator terminal voltage. This system of

using residual magnetism eliminates the need for a special

field flashing circuit in the regulator. After the generator

has established the initial residual voltage, the regulator

provides a controlled DC field voltage to the exciter stator

resulting in a controlled generator terminal voltage.

Voltage Regulation

In the standard configuration (shunt excited), the automatic

voltage regulator receives both its input power and voltage

sensing from the generator's output terminals. The regulator

automatically monitors the generator's output voltage

against an internal reference set point and provides the

necessary DC output voltage to the exciter field required

to maintain constant generator terminal voltage. The

generator's terminal voltage is changed by adjusting the

regulator's reference set point.

This generator is powered by a six-cylinder, 4-cycle direct

injection, turbocharged, air-cooled Cummins QSB7-G5

diesel engine. Engine speed is set at the factory at 1800

RPM. This engine is designed to meet every performance

requirement for the generator. Refer to Table 2 for engine

specifications.

Principle Of Operation

This generator is a brushless, self-excited, externally

voltage regulated, synchronous AC generator. The

generator is made up of six major components: main stator

(armature), main rotor (field), exciter stator (field), exciter

rotor (armature), rectifier assembly, and voltage regulator.

The generator's exciter consists of a stationary field and

a rotating armature. The stationary field (exciter stator)

is designed to be the primary source of the generator's

residual magnetism. This residual magnetism allows the

exciter rotor (armature) to produce AC voltage even when

the exciter stator (field) is not powered. This AC voltage

is rectified to DC by the rotating rectifier assembly and

fed directly to the main rotor (field). As the generator

Electronic Governor System

The electronic governor system controls the RPMs of the

engine. When the engine demand increases or decreases,

the governor system regulates the frequency variation to

± 0.25%.

Battery

The battery system is located in the engine compartment

on the sub-base. The battery’s primary purpose is to

provide starting power for the diesel engine starter motor.

The battery system is comprised of two 12 VDC, sealed

lead acid batteries wired in series to provide 24 VDC to

the starting motor. The battery is charged by the charging

alternator while the engine is engaged.

Exhaust System

The exhaust system is located above the diesel engine. The

exhaust system is comprised of rigid and flexible tubing, a

silencer, and a roof-mounted exhaust riser with a rain cap.

PAGE 16 — SG1400C3 STUDIO GENERATOR • OPERATION AND PARTS MANUAL — REV. #1 (02/15/12)

Page 17

GENERAL INFORMATION

Fuel Tank

This generator can be equipped with a 150 gallon (567

liters) fuel tank located beneath the trailer deck. The tank

is made of steel (baffled). The tank can be filled from an

external fill port located on the side of the trailer. The fill

port has a 2-inch (51 mm) fill neck with vented cap.

When refueling, it is recommended to use ASTM-D975/No.

2 diesel fuel. A drain port is provided on the end of the tank.

Fuel Priming Pump

The generator set is equipped with an electric (24 VDC)

fuel priming pump to assist in priming the system for

maintenance purposes. The priming pump, bypass valves,

and priming switch are located on the side of the diesel

engine in the engine compartment.

Fuel Water Separator

A 30-micron Racor 900 fuel water separator is part of the

fuel system assembly and is located on the side of the

engine in within the enclosure compartment.

The supply line between the engine fuel pump and tank

passes through an in-line fuel/water separator filter. The

filter element is rated to filter elements down to 10 microns.

Intake Ventilation Door

Interior Lighting

The interior lighting system is distributed throughout the

interior. There are three separate lighting fixtures. Two

lights are in the engine compartment, and one light is in

the generator compartment.The lighting system operates

from the 24 VDC battery system.

The light fixtures are sealed incandescent bulbs which are

activated by a 0-15 minute timer switch located on the side

control panel box. The DC lighting system can be used to

perform off-line maintenance or assist in setup prior to AC

power connection.

Trailer (Optional)

If equipped, the generator set can be mounted on a tandem

axle trailer. Standard trailer is available with 8-lug chrome

wheels and electric or hydraulic brakes. Options may

include electric jack stands, adjustable hitch, ground rod

holder and rear stabilizing jacks.

OPTIONS

Battery Charger — 24 VDC/3 AMP, 120 V Input

Battery Disconnect Switch — 400 Amps

Optima Red Top Batteries — Replaces standard

batteries

The intake air ventilation door is located on the roof of the

generator set enclosure near the control panel. The door is

hydraulically actuated. Upon startup of the diesel engine,

pressure fills the cylinder and opens the door. Intake air

passes through the opening, and across the engine’s

radiator to cool the engine.

During rainy conditions the roof ventilation door will close

when the front ventilation door is opened.

Block Heater —120 V, 1500 Watt

CSA Package — Includes 400 Amp and 200 Amp Circuit

Breakers

Exterior Lights

Fire Extinguisher and Box — Mounted on Door

Forklift Base

GPS and Remote Monitoring Module

Lift-off Doors

Low Oil Murphy Swichgage®

Oil Level Sight Glass

30-Micron Racor 1000 Fuel/Water Separator —

Replaces Racor 900

SG1400C3 STUDIO GENERATOR • OPERATION AND PARTS MANUAL — REV. #1 (02/15/12) — PAGE 17

Page 18

GENERAL INFORMATION

InteliVision 5 ™ Digital Controller

The InteliVision 5 Digital Controller provides monitoring

and fault detection capability of all engine and generator

operating parameters. A list of operating parameters is

shown below:

AC Metering Display

• Voltage/Amperage / Frequency

• Generator Phase Voltage / Current

• Generator Frequency

Engine Information Display

• Engine Temperature / Oil Pressure (psi)

• Battery Voltage (DC) / Tachometer

• Hourmeter

Minor Fault Warning Display

• Switch Not In Auto

• Low Fuel Level

• Low Oil Pressure Alarm

• Low Engine Temperature

• High Engine Temperature Alarm

• Low Battery Voltage

• High Battery Voltage

• Weak Battery Condition

• Battery Charger Input Fail

• Undervoltage

• Over / Underfrequency

• Overcurrent

Major Fault Shutdown Display

• Overvoltage

• Emergency Stop

• Loss Of Speed

• Overcrank

• Overspeed

• Low Oil Pressure

• High Engine Temperature

• Low Coolant Level

• Spare Programmable Digital Faults

Switches And Operating Controls

• Run / Off / Auto / Load Test Buttons

• Decrement / Increment / Previous

(Exit) /Next (Enter) Program Buttons

• Emergency Stop Button

• Audible Alarm Horn

• Alarm Horn Silence Button

• Lamp Test Button

• Fault Reset Function

• RS-485 Remote Communications,

External Expansion Module Ports

Timer Countdown Display

• Engine Start Delay

• Oil Bypass

• Overcrank

• Cycle Crank

• Starter Re-engage Delay

• Bypass Delay

Control LED Indicators

• Switch Position (Run, Off, Auto, Test)

• Common Alarm (Minor Fault)

• Common Shutdown (Major Fault)

• Generator Ready (When in Auto)

• Speed Signal

• Emergency Stop

Diagnostic LED Indicators:

• Run Output Energized

• Crank Output Energized

• Remote Start Signal Initiated

• Common Fail Output Energized

• Watchdog - CPU Running

• Programmable Output Contacts

PAGE 18 — SG1400C3 STUDIO GENERATOR • OPERATION AND PARTS MANUAL — REV. #1 (02/15/12)

Page 19

NOTES

SG1400C3 STUDIO GENERATOR • OPERATION AND PARTS MANUAL — REV. #1 (02/15/12) — PAGE 19

Page 20

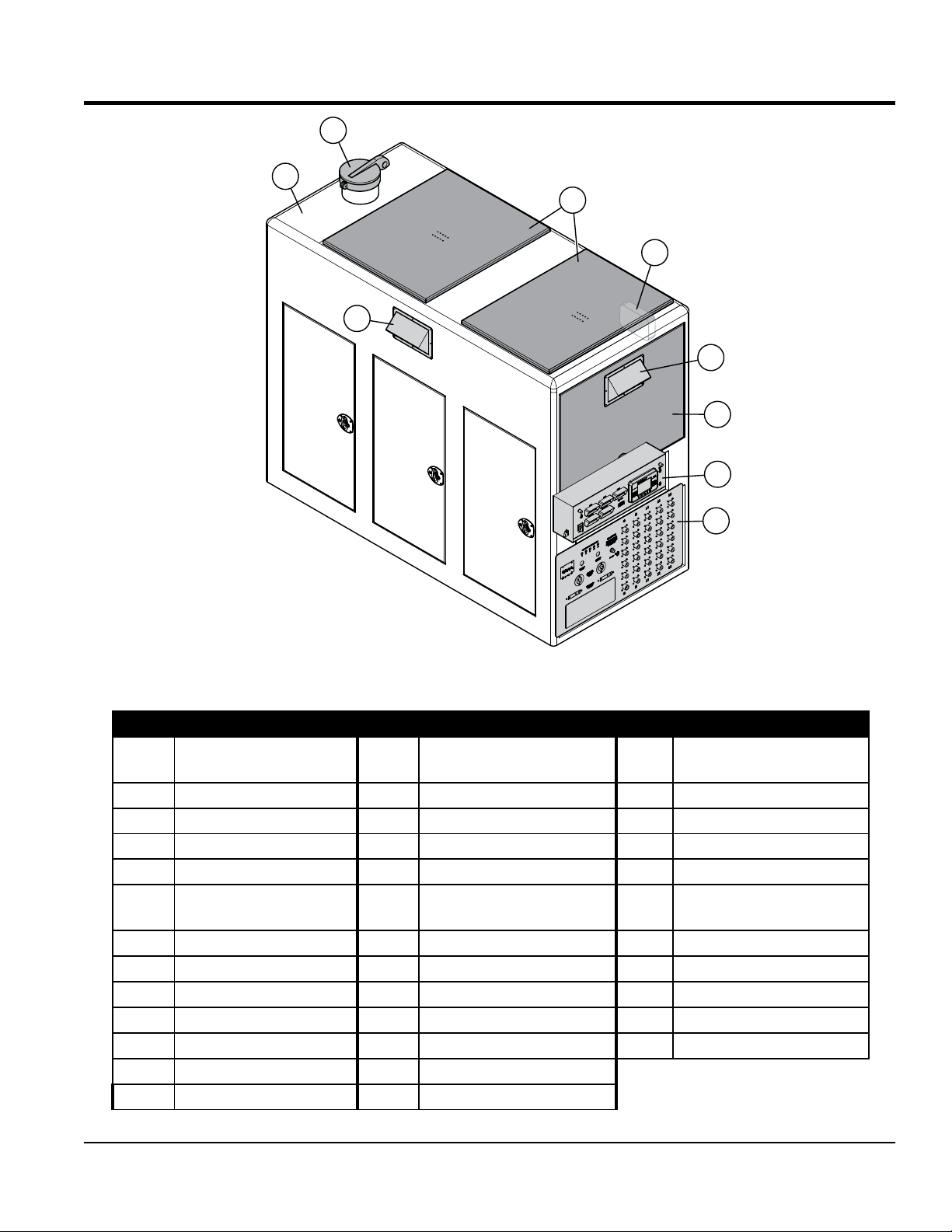

GENERATOR MAJOR COMPONENTS

3

1

4

2

14

13

30

15

31

16

32

33

17

11

6

5

7

12

9

10

8

Figure 3. Major Components

18

19

20

21

22

PAGE 20 — SG1400C3 STUDIO GENERATOR • OPERATION AND PARTS MANUAL — REV. #1 (02/15/12)

Page 21

29

28

24

GENERATOR MAJOR COMPONENTS

23

Inside

34

Housing

24

25

26

27

Figure 3. Major Components

Table 5. Generator Major Components

ITEM

NO.

DESCRIPTION

ITEM

NO.

DESCRIPTION

ITEM

NO.

DESCRIPTION

1 Muffler 13 Hydraulic Oil Sight Gauge 25 Rain Door Intake Vent

2 Air Filter 14 Fuel Priming Pump Switch 26 Control Box

3 Hydraulic Cylinders 15 Fuel-Water Separator 27 Camlok Panel

4 Coolant Overflow Bottle 16 Hydraulic Actuator Manifold 28 Rain Cap

Charge Oil Cooler

5

(Hydraulic)

17 Radiator 29 Housing Assembly

6 Charge Air Cooler 18 Interior Lights 30 Water Drain

7 Saddlebox 19 Circuit Breaker Panel 31 Oil Drain

8 3 kVA Transformer 20 Fuel Pump 32 Fuel In

9 Generator 21 Hydraulic Oil Tank 33 Fuel Out

10 Fuel Gauge 22 Batteries 34 GPS Module (Option)

11 Fuel Cap, Vented 23 Roof Intake/Exhaust Vents

12 Hydraulic Oil Filter 24 Exterior Lights (Option)

SG1400C3 STUDIO GENERATOR • OPERATION AND PARTS MANUAL — REV. #1 (02/15/12) — PAGE 21

Page 22

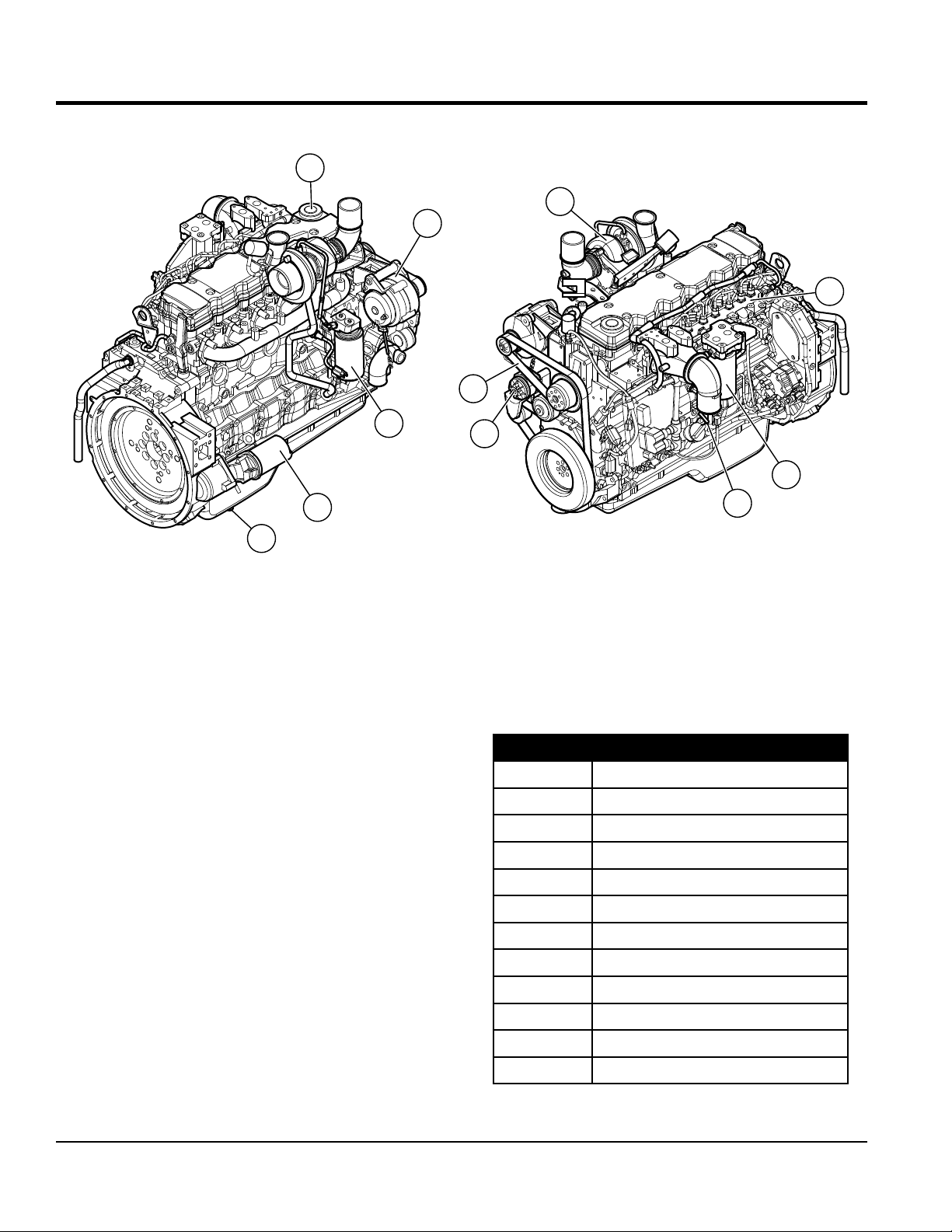

BASIC ENGINE COMPONENTS

1

11

2

10

6

3

4

5

Figure 4. Basic Engine Components

7

9

8

Table 6. Basic Engine Components

ITEM NO. DESCRIPTION

1 Oil Filler Cap

2 Alternator

3 Oil Filter

4 Starter

5 Oil Drain Plug

6 Belt

7 Water Pump

8 Oil Dipstick

9 Fuel Filter

10 Fuel Rail

11 Turbocharger

PAGE 22 — SG1400C3 STUDIO GENERATOR • OPERATION AND PARTS MANUAL — REV. #1 (02/15/12)

Page 23

BASIC TRAILER COMPONENTS

1

2

4

3

5

14

13

19

18

17

Figure 5. Basic Trailer Components

The definitions below describe the controls and functions

of the Trailer (Figure 6).

1. Pintle Eye Coupler — Adjustable 3-inch eye coupler

rated at 20,000 lbs. (9,072 kg).

12

9

6

7

16

8

15

10

11

10. License Plate Lights — Illuminates license plate.

11. Axle — Tandemum axle, Gross Axle Weight Rating

(GAWR) 6,000 lbs. (2,722 kg) Gross Vehicle Weight

Rating is 10,000 lbs. (4,536 kg).

2. Hydraulic Brake Actuator — Replaceable bolt-on

actuator, assists in the stopping of the trailer. Rated at

12,000 lbs. (5,443 kg)

3. Spare Tire — Tongue mounted spare tire with anti-theft

wheel lock and locking mount.

4. Jackstand — Tongue mounted swivel jack with flat

disc foot, rated 5000 lbs. (2,268 kg) lift.

5. Reflectors — Side mounted reflectors are mounted on

both sides of the trailer to provide high visibility when

towing in dark areas.

6. Tires — Recommended tire size is LT235/85R16 LR E.

Tire load rating is 3,500 lbs/tire.

7. Reflective Tape — Provides high visibility when towing

in dark areas.

8. Brake/Turn Lights — DOT approved tail, stop, and

turn signal lamps.

9. Bumper Guard — Protects trailer frame when coming

in contact with stationary objects.

12. Rear Bumper Reflectors — Provides high visibility

when towing in dark areas.

13. Safety Chains — Connect to towing vehicle. Reference

towing section in this manual.

14. Tool Box — Tongue mounted tool box, lift spare tire

to gain access to this compartment

15. Fuel Tank — Holds 150 gallons (568 liters) of No. 2

diesel fuel.

16. Fuel Tank Filler Port — Fuel filler port, 2-inch (51 mm)

neck.

17. Side Running Lamps — Provides high visibility when

towing in dark areas.

18. Tool Box Locking Latch — Release this latch to gain

access to tool box. Pull spare tire upward and back.

19. Plug Holder — Holds trailer harness (lights) cable plug.

SG1400C3 STUDIO GENERATOR • OPERATION AND PARTS MANUAL — REV. #1 (02/15/12) — PAGE 23

Page 24

CONTROL PANEL

2

1

8

7

16

17

3

6

Figure 6. Control Panel

4

5

The definitions below describe the controls and functions

of the Control Panel (Figure 6).

1. Voltage Adjust Switch — To increase the output

voltage, pull upward and hold the switch until the

desired voltage is achieved by monitoring the AC

voltage display (item 8). To decrease the voltage, pull

downward.

2. Line 1 AC Amps Display — Indicates the amount of

current the load is drawing from line 1 of the generator.

3. Line 2 AC Amps Display — Indicates the amount of

current the load is drawing from line 2 of the generator.

4. Line 3 AC Amps Display — Indicates the amount of

current the load is drawing from line 3 of the generator.

5. Voltage Status LEDs — During operation these status

LED's will indicate the phase/voltage of the generator,

3Ø-277/480, 3Ø-120/208 or 1Ø-120/240.

6. Frequency Display — Indicates the frequency of the

generator in Hertz.

7. AC Voltmeter Display — Indicates the output voltage

present at the camlok terminals. This display is used in

conjunction with the voltmeter select switch (item 8).

13

12

11

14

15

9

10

10. Controller Power Switch — Provides power to engine

controller.

11. Light Switch — In the up position, turns on exterior

lights. In the down position, turns on panel lighting. In

the center position, turns off all lights.

12. Panel Lights — Located on each side of the digital

control panel is a panel light. Lights are activated by

light switch.

13. Light Timer Control — The interior lights are controlled

by an electronic turn dial timer that allows the operator

to turn on the lights inside the generator for up to 15

minutes. The lights will automatically shut off when the

timer reaches zero.

14. AC Output Connector — Provides AC power to

various electronic assemblies.

15. DC Output Connector — Provides DC power to

engine interface.

16. Fan Control Module — Provides necessary control

electronics to operate fan.

17. Engine Com Connector — 9-pin connector for

communication to engine via a PC with engine software.

8. Voltmeter Selector Switch — Place switch in desired

position to read line-line or line-neutral voltage. Switch

is used in conjunction with AC voltmeter display (item 7).

9. Digital Controller — Starts and stops the generator

and monitors various engine operating parameters.

PAGE 24 — SG1400C3 STUDIO GENERATOR • OPERATION AND PARTS MANUAL — REV. #1 (02/15/12)

Page 25

1 2

CAMLOK/VOLTAGE OUTPUT PANEL

3

4

7 7

5

6

88

Figure 7. Camlok/Voltage Output Panel

The definitions below describe the controls and functions

of the Camlok/Voltage Output Panel (Figure 7).

1. CB4/CB5 Circuit Breakers — These circuit breakers

protect the 120 VAC auxiliary output receptacles from

overload.

2. CB6/CB7 Circuit Breakers — These circuit breakers

protect the bates output receptacles from overload.

3. Generator Voltage Test Points — To determine if

the generator's output voltage is present and correct,

connect a test meter to these test points during

troubleshooting and maintenance.

4. Paralleling Cable In — This Ethernet input connection

point is used when multiple generators are going to be

connected.

5. Paralleling Cable Out — This Ethernet output

connection point is used when multiple generators are

going to be connected.

GREEN WHITE RED BLUE BLACK

9

7. 120 VAC Output Receptacles — These 15-amp

receptacles provide 120 VAC output. The maximum

allowable combined amps (both receptacles) is 25 amps

when the voltage selector switch in the 3Ø 277/480 VAC

position.

8. Bates 120VAC Output Receptacles — These

receptacles provide AC voltage output. Each receptacle

is protect by a 100 amp breaker. These receptacles

cannot be used when the voltage selector switch is in

the 3Ø 277/480 VAC position.

9. Camlok Receptacles — These output voltage

connection points (6 pairs) are used for load connection.

ALWAYS pay close attention when connecting and

disconnecting power cables from these camlok

receptacles. The possibility exists of electrocution,

shock or even death if cables are connected or

unplugged when the bus hot indicator lamp is lit.

6. BUS Hot Indicator Lamp — When lit, this indicator

lamp informs that the voltage bus is active (high

voltage). NEVER connect or disconnect cables from

the camlok or auxiliary receptacles when this indicator

is ON. The possibility exists of electrocution, shock or

even death if cables are connected or unplugged when

this indicator is lamp lit.

SG1400C3 STUDIO GENERATOR • OPERATION AND PARTS MANUAL — REV. #1 (02/15/12) — PAGE 25

Page 26

CIRCUIT BREAKER PANEL

2

3

Electronic Trip Unit

450 AMP

LONG — INST.

Push to Trip

Instantaneous Trip Setting - Amps

E

D

F

C

G

BAH

A — 500

B — 600

C — 800

D — 1000

E — 1250

F — 1500

G — 2000

H — 2500

Test

Status

1

4

Figure 8. Main Breaker Panel

The definitions below describe the controls and functions

of the Main Breaker Panel (Figure 8).

1. CB2 Circuit Breaker — This breaker monitors, senses

the generator voltage bus. If breaker trips, signal is

sent to controller.

2. CB3 Circuit Breaker — This breaker monitors,

senses the voltage bus. If breaker trips, signal is sent

to controller.

Electronic Trip Unit

450 AMP

LONG — INST.

NOTICE

When setting the trip point on the electric trip unit, be

careful not to set the trip point too high. Setting the

trip point too high may cause the main breaker not

to trip. This condition could cause serious damage to

the equipment, and serious bodily harm even death to

operating personnel.

Push to Trip

Instantaneous Trip Setting - Amps

E

F

G

A — 500

B — 600

C — 800

D — 1000

D

C

BAH

E — 1250

F — 1500

G — 2000

H — 2500

Test

Status

3. Main Circuit Breaker — This 600 amp breaker

protects the camlok receptacles (load) from overload.

4. Electronic Trip Unit — This unit protects the generator

from in-rush current (load spikes).

Always be conservative when setting the trip point. The

trip setting for this generator is position B 600 amps.

DO NOT adjust the trip point setting when the

equipment is in operation.

PAGE 26 — SG1400C3 STUDIO GENERATOR • OPERATION AND PARTS MANUAL — REV. #1 (02/15/12)

Page 27

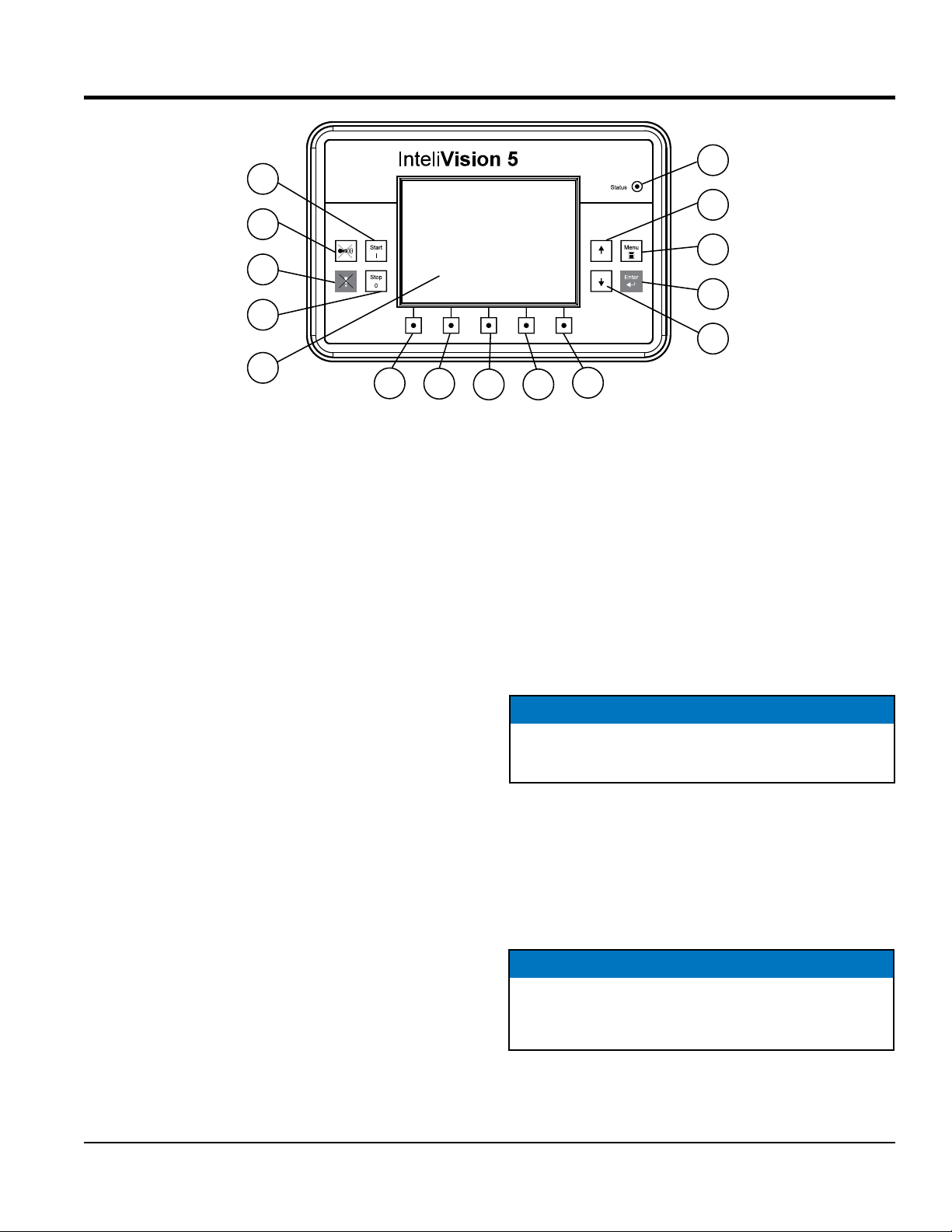

11

14

13

12

DIGITAL CONTROLLER

1

2

4

5

3

15

10

Figure 9. Digital Controller

Refer to Figure 9 for location of controls and indicators.

1. STATUS LED — Indicates status of the controller.

Lights green when the controller is running.

9

NAVIGATIONS BUTTONS

2. ARROW UP Button — Press button to scroll up

through the status menus or programming prompts.

3. ARROW DOWN Button — Press button to scroll down

through the status menus or programming prompts.

4. MENU Button — Press button to jump to menu/sub-

menu page or escape from any dialog window.

5. ENTER Button — Press button to confirm a value or

open a value adjustment within setting dialogs.

CONTEXT BUTTONS

8

7

6

CONTROL BUTTONS

11. START Button — Press button to go idle mode (about

an hour) then generator starts. A second press will

bypass idle mode and generator goes to full speed

immediately.

12. STOP Button — Press button to cool the generator

for about 5 minutes then the generator will stop. A

second press will bypass cool down and will stop the

generator immediately.

NOTICE

START and STOP buttons work in MAN (manual) or

SEM (semi-manual) mode only.

13. FAULT RESET Button — Press button to acknowledge

faults and alarms (active only in Alarm screen).

6. MODE Button — Press button to jump to the controller

mode window.

7. HISTORY Button — Press button to jump to history

screen.

8. ALARM Button — Press button to jump to alarm list

9. GCB (Generator Circ uit Breake r) CON TROL

Button — Press button to close/open GCB.

10. MCB CONTROL Button — Not functional in this

application.

SG1400C3 STUDIO GENERATOR • OPERATION AND PARTS MANUAL — REV. #1 (02/15/12) — PAGE 27

14. HORN RESET Button — Press button to deactivate

the horn (audible alarm).

15. DISPLAY — Shows menu, measurements, setpoints,

alarm list, history, and help/others screens.

NOTICE

For more detailed operating and programming

information on the digital controller, refer to the

InteliVision 5™ Controller User's Guide.

Page 28

LOAD APPLICATION/GENERATOR OUTPUT

SINGLE PHASE LOAD

Always be sure to check the nameplate on the generator

and equipment to insure the wattage, amperage, frequency,

and voltage requirements are satisfactorily supplied by the

generator for operating the equipment.

Generally, the wattage listed on the nameplate of the

equipment is its rated output. Equipment may require

130—150% more wattage than the rating on the nameplate,

as the wattage is influenced by the efficiency, power factor

and starting system of the equipment.

.

NOTICE

If wattage is not given on the equipment’s name plate,

approximate wattage may be determined by multiplying

nameplate voltage by the nameplate amperage.

WATTS = VOLTAGE x AMPERAGE

The power factor of this generator is 1.0. See Table 7 below

when connecting loads.

Table 7. Power Factor By Load

Type of Load Power Factor

THREE PHASE LOAD

When calculating the power requirements for 3-phase

power use the following equation.

NOTICE

If 3Ø load (kVA) is not given on the equipment

nameplate, approximate 3Ø load may be determined

by multiplying voltage by amperage by 1.732.

NOTICE

Motors and motor-driven equipment draw much greater

current for starting than during operation.

An inadequate size connecting cable which cannot carry

the required load can cause a voltage drop which can burn

out the appliance or tool and overheat the cable. Refer to

Table 8 to select the correct cable size.

When connecting a resistance loa d such as an

incandescent lamp or electric heater, a capacity of up to

the generator’s rated output (kW) can be used.

Single-phase induction motors 0.4-0.75

Electric heaters, incandescent lamps 1.0

Fluorescent lamps, mercury lamps 0.4-0.9

Electronic devices, communication

equipment

1.0

Common power tools 0.8

Table 8. Cable Selection (60 Hz, Single Phase Operation)

Current

in

Amperes

2.5 300 600 1000 ft. 600 ft. 375 ft. 250 ft.

5 600 1200 500 ft. 300 ft. 200 ft. 125 ft.

7.5 900 1800 350 ft. 200 ft. 125 ft. 100 ft.

10 1200 2400 250 ft. 150 ft. 100 ft.

15 1800 3600 150 ft. 100 ft. 65 ft.

20 2400 4800 125 ft. 75 ft. 50 ft.

Load in Watts Maximum Allowable Cable Length

At 100

Volts

CAUTION: Equipment damage can result from low voltage

At 200

Volts

#10 Wire #12 Wire #14 Wire #16 Wire

When connecting a fluorescent or mercury lamp, a

capacity of up to the generator's rated output (kW)

multiplied by 0.6 can be used.

When connecting an electric drill or other power tools,

pay close attention to the required starting current

capacity.

When connecting ordinary power tools, a capacity of up to

the generator’s rated output (kW) multiplied by 0.8 can be

used.

DANGER

Before connecting this generator to any building’s

electrical system, a licensed electrician must install

a transfer switch. Serious damage to the building’s

electrical system may occur without this transfer switch.

PAGE 28 — SG1400C3 STUDIO GENERATOR • OPERATION AND PARTS MANUAL — REV. #1 (02/15/12)

Page 29

GENERATOR OUTPUTS

120/208

277/480 120/240

3

1

3

GENERATOR OUTPUT VOLTAGES

A wide range of voltages are available to supply voltage for

many different applications. Voltages are selected by using

the voltage selector switch (Figure 10). To obtain some

of the voltages as listed in Table 9 (see below) will require

a fine adjustment using the voltage adjust toggle switch

located on the digital control panel.

Voltage Selector Switch

The voltage selector switch (Figure 10) is located on the

back side of the Saddle Box Assembly. It has been provided

for ease of voltage selection.

Generator Amperage

Table 10 shows the maximum amps the generator can

provide. DO NOT exceed the maximum amps as listed.

Table 10. Generator Maximum Amps

Rated Voltage Line Amps Total Amps

1Ø 240 Volt 538 amps 1076 amps

3Ø 208 Volt 466 amps 1400 amps

3Ø 480 Volt 202 amps 606 amps

Figure 10. Voltage Selector Switch

.

CAUTION

NEVER change the position of the voltage selector

switch while the engine is running. ALWAYS place

main circuit breaker in the OFF position before selecting

voltage and activate voltage change mode switch.

L1 L2 L3 Output

Terminal Lugs

Line-Line

3Ø

1Ø Line-Neutral 120V 127V 139V 240V 254V 277V

1Ø Line-Neutral/

Line-Line

NOTICE

Controller has over/under-voltage protection based on

208 V nominal/480 V nominal/240 V nominal voltage.

Table 9. Voltages Available

Voltage Selector Switch

3-Phase 120/208V Position

208V 220V 240V 416V 440V 480V

Voltage Selector Switch Single-Phase 240/120V Position

120V

Line-Neutral

N/A N/A

Voltage Selector Switch

3-Phase 480/277V Position

240V

Line-Line

N/A N/A

SG1400C3 STUDIO GENERATOR • OPERATION AND PARTS MANUAL — REV. #1 (02/15/12) — PAGE 29

Page 30

INSPECTION/SETUP

MAIN CIRCUIT BREAKER

The generator is equipped with a 3-pole, 600-amp circuit

breaker to protect the camlok receptacles from overload.

Make sure that the main circuit breaker is in the OFF

position prior to starting the engine.

LUBRICATION OIL

Fill the engine crankcase with lubricating oil through the

filler hole, but DO NOT overfill. Make sure the generator

is level and verify that the oil level is maintained between

the two notches (Figure 11) on the dipstick. See Table 11

for proper selection of engine oil.

Figure 11. Engine Oil Dipstick

When checking the engine oil, be sure to check if the oil is

clean. If the oil is not clean, drain the oil by removing the

oil drain plug, and refill with the specified amount of oil as

outlined in the Cummins Engine Owner’s Manual. Oil

should be warm before draining.

Other types of motor oils may be substituted if they meet

the following requirements:

API Service Classification CC/SC

API Service Classification CC/SD

API Service Classification CC/SE

API Service Classification CC/SF

Table 11. Recommended Motor Oil

FUEL CHECK

DANGER

Fuel spillage on a hot engine can cause

a fire or explosion. If fuel spillage occurs,

wipe up the spilled fuel completely to

prevent fire hazards. NEVER smoke

around or near the generator.

Refilling the Fuel System

CAUTION

ONLY properly trained personnel who have read

and understood this section should refill the fuel tank

system.

This generator has a fuel tank located in the sub base

assembly frame. ALWAYS fill the fuel tank with clean fresh

#2 diesel fuel. DO NOT fill the fuel tank beyond its capacity.

Pay attention to the fuel tank capacity when replenishing

fuel. The fuel tank cap must be closed tightly after filling.

Handle fuel in a safe container. If the container does

not have a spout, use a funnel. Wipe up any spilled fuel

immediately.

Refueling Procedure:

WARNING

Diesel fuel and its vapors are dangerous

to your healt h and the surro unding

environment. Avoid skin contact and/or

inhaling fumes.

CAUTION

ALWAYS make sure generator is on firm level ground

before refueling to prevent spilling and maximize the

amount of fuel that can be pumped into the tank.

PAGE 30 — SG1400C3 STUDIO GENERATOR • OPERATION AND PARTS MANUAL — REV. #1 (02/15/12)

Page 31

1. Place the generator level with the ground. Failure to do

DO NOT fill on

so will cause fuel to spill from the tank before reaching

full capacity (Figure 12).

70

unlevel ground

!

!

INSPECTION/SETUP

1/2

E F

=

Unlevel Ground

Level Ground

Figure 12. Only Fill on Level Ground

NOTICE

ONLY use #2 diesel fuel when refueling.

2. Remove fuel cap and fill tank (Figure 13).

Unlevel Ground

Level Ground

DIESEL

FUEL

Figure 14. Full Fuel Tank

CAUTION

DO NOT OVERFILL fuel system. Leave room for fuel

expansion. Fuel expands when heated (Figure 15).

Heat Source

Fuel EXPANDS

when heated

1/2

!

!

E F

Figure 13. Fueling the Generator

3. Monitor the fuel gauge while filling fuel tank. Stop filling

when the fuel gauge indicates full (Figure 14). DO NOT

wait for fuel to rise in filler neck.

Figure 15. Fuel Expansion

SG1400C3 STUDIO GENERATOR • OPERATION AND PARTS MANUAL — REV. #1 (02/15/12) — PAGE 31

Page 32

INSPECTION/SETUP

COOLANT (ANTIFREEZE/SUMMER COOLANT)

Cummins recommends antifreeze/summer coolant, for use

in their engines, which can be purchased in concentrate (and

mixed with 50% demineralized water) or pre-diluted. See the

Cummins Engine Owner’s Manual for further details.

WARNING

If adding coolant/antifreeze mix to the

radiator, do not remove the radiator cap

until the unit has completely cooled. The

possibility of hot coolant exists which can

cause severe burns.

Day-to-day addition of coolant is done from the recovery

tank. When adding coolant to the radiator, DO NOT remove

the radiator cap until the unit has completely cooled. See

Table 12 for engine, radiator, and recovery tank coolant

capacities. Make sure the coolant level in the recovery tank

is always between the “H” and the “L” markings.

Table 12. Coolant Capacity

Engine and Radiator 7.8 gal (29.5 liters)

Reserve Tank 6 quarts (6.6 liters)

CLEANING THE RADIATOR

The engine may overheat if the radiator fins become

overloaded with dust or debris. Periodically clean the

radiator fins with compressed air. Cleaning inside the

machine is dangerous, so clean only with the engine turned

off and the negative battery terminal disconnected.

AIR CLEANER

Periodic cleaning/replacement is necessary. Inspect it in

accordance with the Cummins Engine Owner’s Manual.

FAN BELT TENSION

A slack drive belt may contribute to overheating, or to

insufficient charging of the battery, adjust drive belt in

accordance with the Cummins Engine Owner’s Manual.

DRIVE BELT INSPECTION

Inspect the drive belt for damage and wear. Horizontal

(across the belt) cracks are acceptable. See Figure 16

below. Vertical (direction of belt ribs) cracks that intersect

with horizontal cracks are not acceptable.

If the drive belt is frayed, punctured, or material is missing

do not use drive belt.

OPERATION IN FREEZING WEATHER

When operating in freezing weather, be certain the proper

amount of antifreeze (Table 13) has been added.

Table 13. Anti-Freeze Operating Temperatures

Vol %

Anti-

Freeze

50 -37 -34 108 226

NOTICE

When the antifreeze is mixed with water, the antifreeze

mixing ratio must be less than 50%.

Freezing Point Boiling Point

°C °F °C °F

NO

NO

Figure 16. Drive Belt Inspection

CAUTION

NEVER place hands near the belts or fan

while the generator is running.

PAGE 32 — SG1400C3 STUDIO GENERATOR • OPERATION AND PARTS MANUAL — REV. #1 (02/15/12)

Page 33

INSPECTION/SETUP

BATTERY

This unit is of negative ground. DO NOT connect in reverse.

Always maintain battery fluid level between the specified

marks. DO NOT over fill. Battery life will be shortened if

the fluid level is not properly maintained. Add only distilled

water when replenishment is necessary.

Check to see whether the battery cables are loose. Poor

contact may result in poor starting or malfunction. Always

keep the terminals firmly tightened. Coat the terminals with

an approved battery terminal treatment compound. Replace

battery with only recommended type battery.

The battery is sufficiently charged if the specific gravity

of the battery fluid is 1.28 (at 68° F). If the specific gravity

should fall to 1.245 or lower, the battery is dead and needs

to be recharged or replaced.

Before charging the battery with an external electric source,

be sure to disconnect the battery cables.

Battery Cable Installation

ALWAYS make sure that the battery cables (Figure 17) are

properly connected to the battery terminals as shown below.

CAUTION

When connecting the battery do the following:

1. Place a small amount of battery terminal treatment

compound around both battery terminals. This will

ensure a good connection and will help prevent

corrosion around the battery terminals.

2. Connect the red cable to the positive terminal of the

battery and the black cable to the negative terminal

of the battery.

.

NOTICE

If the battery cable is connected incorrectly, electrical

damage to the generator will occur. Pay close attention

to the polarity when connecting the battery.

CAUTION

Inadequate battery connections may cause poor

starting of the generator, and create other malfunctions.

ALTERNATOR

The polarity of the alternator is negative grounding type.

When an inverted circuit connection takes place, the circuit

will short instantaneously resulting in alternator failure.

ALWAYS disconnect the negative terminal FIRST and

reconnect negative terminal LAST.

Figure 17. Battery Connections

DO NOT put water directly on the alternator. Water in the

alternator can cause corrosion and damage.

WIRING

Inspect the generator for bad, worn electrical wiring or

connections. If any wiring or connections are exposed

(insulation missing), replace wiring immediately.

PIPING AND HOSE CONNECTION

Inspect all piping, oil hose, and fuel hose connections for

fatigue, wear and tightness. Tighten all hose clamps and

check hoses for leaks.

If any hose (fuel or oil) lines are defective, replace them

immediately.

SG1400C3 STUDIO GENERATOR • OPERATION AND PARTS MANUAL — REV. #1 (02/15/12) — PAGE 33

Page 34

STARTUP

BEFORE STARTING

CAUTION

The engine’s exhaust contains harmful emissions.

ALWAYS have adequate ventilation when operating.

1. Place the Control Power switch (Figure 18) on the

digital control panel in the up position (ON).

ON (UP)

Figure 18. Control Power Switch (ON)

2. Place the voltage selector switch (Figure 19) in the

desired voltage setting position. The corresponding

Voltage Status LED on the control panel will light to

indicate the selected voltage (Figure 20).

120/208

3

277/480 120/240

3

1

FUEL VALVES IN

PRIME MODE

Figure 21. Fuel Valves (Prime Mode)

ON (UP)

Figure 22. Fuel Priming Switch (ON)

4. After priming is complete, release the fuel priming

switch. Place the fuel valves in the run mode (Figure

23).

FUEL VALVES IN

RUN MODE

Figure 19. Voltage Selector Switch

120/208 3Ø Position

Figure 23. Fuel Valves (Run Mode)

5. Verify that all three circuit breakers (Figure 24)are in

the ON position prior to starting the engine.

LIGHTS IF

SELECTED

450 AMP

LONG — INST.

Electronic Trip Unit

ON

Instantaneous Trip Setting - Amps

E

Push to Trip

A — 500

D

F

B — 600

C

G

C — 800

BAH

D — 1000

Figure 20. Voltage Status LEDs

3. If it is necessary to prime engine before starting (such

as after changing fuel filter or running out of fuel), place

VERIFY CIRCUIT

BREAKERS ARE ON

the fuel valves in the prime position (Figure 21). Place

the fuel priming switch (Figure 22) in the up position.

Figure 24. Circuit Breakers (ON)

PAGE 34 — SG1400C3 STUDIO GENERATOR • OPERATION AND PARTS MANUAL — REV. #1 (02/15/12)

Test

E — 1250

F — 1500

G — 2000

Status

H — 2500

Page 35

STARTUP

6. If unit is to be used in parallel with another unit,

interconnect the units. Interconnect the output buses

with suitable power cables to carry full load capacity.

Special male-to-male Camlok cables will be needed.

For 480 V mode, it is recommended that one 4/0 cable

per phase, neutral and ground be used. For 208V

mode, use two 4/0 cables per phase and neutral and

one 4/0 cable for ground. Also connect the parallel

communication cables.

7. Connect the load to the receptacles on the Camlok/

Voltage Output Panel. When the camloks are inserted

into the outlet connector, rotate clockwise until they are

locked in place. Make sure the camloks are connected

securely.

8. Press the MODE button (Figure 25) on the Digital

Controller Display and select manual mode (MAN)

with the arrow keys. Press Enter key when MAN is

highlighted on the screen.

4. To bypass idle mode, press the START button again.

The generator should go to full speed.

NOTICE

If START button is not pressed again, the engine will

remain in idle mode for about an hour then will go to

full speed.

5. Verify that the no-load frequency reading on the

control panel frequency display is approximately 60

Hz (1800 rpm).

6. Verify that the voltage reading on the control panel AC

voltmeter display matches the voltage selector switch

position that was selected prior to startup.

7. Press the GCB control button on the controller

(Figure 27) to close circuit breaker.

MAN

PRESS MODE BUTTON

Figure 25. Mode Button (Manual)

STARTING (MANUAL)

1. Press the START button (Figure 26) on the controller

to start the engine.

Figure 26. START Button

2. The engine will go to idle mode.

3. Listen for any abnormal noises. If any abnormalities

exist, shut down the engine and correct the problem.

Close GCB

PRESS GCB CONTROL BUTTON

Figure 27. Generator Circuit Breaker (Closed)

8. Verify that the BUS HOT light on the Camlok/Voltage

Output Panel is on. Voltage is now available at the

receptacles.

BUS HOT

LIGHT

Figure 28. Bus Hot Light

SG1400C3 STUDIO GENERATOR • OPERATION AND PARTS MANUAL — REV. #1 (02/15/12) — PAGE 35

Page 36

STARTUP

9. If paralleling to another unit and the bus was already

energized from another unit (BUS HOT light already

on), pressing to close GCB button once would initiate

a synchronizing mode. The light above the button will

begin flashing, bring the generator into phase and

automatically close the breaker. Once the breaker

closes, the light above the button would then become

solid and the generators would now be in parallel. As

load is applied, units will share the load proportionally.

CLOSING THE ENCLOSURE DOORS

1. Close the enclosure doors once the generator has

started (Figure 29). Top vents stay open for proper

ventilation.

RAIN DOOR

INTAKE VENT

1. Press the GCB control button on the controller

(Figure 30) to open circuit breaker.

Open GCB

PRESS BUTTON

Figure 30. Generator Circuit Breaker (Open)

2. Let the engine cool by running it at full speed for 3-5

minutes with no load applied.

3. Press the STOP button (Figure 31) on the controller.

The engine will go to idle mode.

Close

Doors

Figure 29. Engine Enclosure Doors

2. If access to the controls or other components is

necessary while the engine is running, make sure the

doors are not left open for an extended period of time.

3. To protect the unit from rain, the top intake vent can

be closed by opening the upper front vent door on the

generator enclosure. The front vent will automatically

close the upper roof intake vent. The upper exhaust

vent will remain open.

NORMAL SHUTDOWN PROCEDURE

To shutdown the generator, use the following procedure:

WARNING

NEVER stop the engine suddenly except in an

emergency.

Figure 31. STOP Button

4. Press the STOP button again to shut down the engine.

NOTICE

If STOP button is not pressed again, the engine will

remain in idle mode for about an hour then will shut

down.

5. Place the Control Power switch (Figure 32) on the

control panel to the OFF position.

OFF (DOWN)

Figure 32. Control Power Switch (OFF)

EMERGENCY SHUTDOWN PROCEDURE

1. Press the STOP button twice (Figure 31) on the

controller to shut down the engine.

2. Place the main circuit breaker (Figure 30) in the OFF

position.

PAGE 36 — SG1400C3 STUDIO GENERATOR • OPERATION AND PARTS MANUAL — REV. #1 (02/15/12)

Page 37

PROTECTIVE DEVICES

PROTECTIVE DEVICES

Protection devices and emergency stop devices are

designed as standard components for protection of the

generator against trouble during operation. The LCD on

the Digital Controller will inform the user when a fault has

occurred.

When a major fault is detected, such as low oil pressure,

high water temperature, and overspeed, the engine

automatically shuts down. Check the display for the fault

and correct the problem.

For minor faults, the engine will continue working. Stop the

engine and remedy the cause of the problem. The Digital

Controller will display the cause of the fault.

Before inspecting or troubleshooting the generator, press

the OFF button on the Digital Controller. Place the main

circuit breaker in the OFF position and allow sufficient time

for adequate cooling.

After automatic shutdown, always inspect the generator

and eliminate any problems that might have caused the

shutdown before attempting to restart the generator.

When ready to restart, check and make sure that no

alarms are shown in the Alarm List on the Digital Controller.

Restart the generator as outlined in the Startup section of

this manual.

Refer to the InteliVision 5™ Controller User's Guide for

detailed information of faults and display information.

CAUTION

To prevent damage to the equipment and severe bodily

harm, even death, please follow all lock-out safety

procedures when performing maintenance.

SG1400C3 STUDIO GENERATOR • OPERATION AND PARTS MANUAL — REV. #1 (02/15/12) — PAGE 37

Page 38

MAINTENANCE

Use Table 14 as a general maintenance guideline when servicing your engine. For more detail engine maintenance

information, refer to the engine owner’s manual supplied with your engine.

Table 14. Engine Maintenance Schedule

INTERVAL

DESCRIPTION OPERATION

DAILY

250 HOURS

3

3 MONTHS

OR

500 HOURS

3

6 MONTHS

OR

1,2,3

1000 HOURS

OR

1 YEAR

3

2000 HOURS

OR

2 YEARS

2,3

5000 HOURS

4 YEARS

OR

Air Intake Piping Check X

Engine Lubricating Oil Level Check X

Air Tank and Reservoirs Drain X

Crankcase and Breather Tube Inspect X

Engine Coolant Level Check X

Fuel -Water Separator Drain X

Air Cleaner Restriction Check X