Page 1

OPERATION AND PARTS MANUAL

MODEL SFG10E

ELECTRIC SURFACE GRINDER

Revision #2 (05/28/09)

To find the latest revision of this

publication, visit our website at:

www.multiquip.com

THIS MANUAL MUST ACCOMPANY THE EQUIPMENT AT ALL TIMES.

Page 2

SILICOSIS/RESPIRATORY WARNINGS

WARNING

SILICOSIS WARNING RESPIRATORY HAZARDS

Grinding/cutting/drilling of masonry, concrete, metal and

other materials with silica in their composition may give

off dust or mists containing crystalline silica. Silica is a

basic component of sand, quartz, brick clay, granite and

numerous other minerals and rocks. Repeated and/or

substantial inhalation of airborne crystalline silica can

cause serious or fatal respiratory diseases, including

silicosis. In addition, California and some other

authorities have listed respirable crystalline silica as a

substance known to cause cancer. When cutting such

materials, always follow the respiratory precautions

mentioned above.

WARNING

Grinding/cutting/drilling of masonry, concrete, metal and

other materials can generate dust, mists and fumes

containing chemicals known to cause serious or fatal

injury or illness, such as respiratory disease, cancer,

birth defects or other reproductive harm. If you are

unfamiliar with the risks associated with the particular

process and/or material being cut or the composition of

the tool being used, review the material safety data

sheet and/or consult your employer, the material

manufacturer/supplier, governmental agencies such as

OSHA and NIOSH and other sources on hazardous

materials. California and some other authorities, for

instance, have published lists of substances known to

cause cancer, reproductive toxicity, or other harmful

effects.

Control dust, mist and fumes at the source where

possible. In this regard use good work practices and

follow the recommendations of the manufacturers or

suppliers, OSHA/NIOSH, and occupational and trade

associations. Water should be used for dust

suppression when wet cutting is feasible. When the

hazards from inhalation of dust, mists and fumes cannot

be eliminated, the operator and any bystanders should

always wear a respirator approved by NIOSH/MSHA for

the materials being used.

SFG10E ELECTRIC SURFACE GRINDER — OPERATION AND PARTS MANUAL — REV. #2 (05/28/09) — PAGE 2

Page 3

Electric Surface Grinder

TABLE OF CONTENTS

SFG10E

Silicosis/Respiratory Warnings .................................. 2

Table Of Contents ..................................................... 3

Parts Ordering Procedures ....................................... 4

Notice to Operators ................................................ 5-6

Operator Instructional Data Sheet ............................ 7

Safety Precautions ............................................... 8-11

Assembly Instructions/Operations ..................... 12-31

Maintenance/Service ......................................... 32-35

Troubleshooting ...................................................... 36

Storage ................................................................... 37

Specifications .......................................................... 38

Explanation Of Code In Remarks Column .............. 40

Suggested Spare Parts ........................................... 41

Operator Handle Assembly ................................ 42-43

Electric Motor Assembly..................................... 44-45

Wheel Dolly Assembly........................................ 46-47

Frame Assembly ................................................ 48-49

Safety and Dust Shield Assembly ...................... 50-51

Scarifier Assembly ............................................. 52-53

Scrape-R-Tach Assembly .................................. 54-55

Grinding Block Assembly ................................... 56-57

Decals ................................................................ 58-59

As a continuing effort to update our parts

book, contact the MULTIQUIP literature

department for the latest revision of your

"Operation and Parts Manual"

Specification and part number are subject

to change without notice.

Terms and Conditions of Sale ................................. 60

SFG10E ELECTRIC SURFACE GRINDER — OPERATION AND PARTS MANUAL — REV. #2 (05/28/09) — PAGE 3

Page 4

PARTS ORDERING PROCEDURES

Ordering parts has never been easier!

Choose from three easy options:

January 1

Effective:

st

, 2006

Best Deal!

Order via Internet (Dealers Only):

Order parts on-line using Multiquip’s SmartEquip website!

■ View Parts Diagrams

■ Order Parts

■ Print Specifi cation Information

Goto www.multiquip.com and click on

Order Parts

Order via Fax (Dealers Only):

All customers are welcome to order parts via Fax.

Domestic (US) Customers dial:

1-800-6-PARTS-7 (800-672-7877)

Non-Dealer Customers:

Contact your local Multiquip Dealer for

parts or call 800-427-1244 for help in

locating a dealer near you.

to log in and save!

Order via Phone:

If you have an MQ Account, to obtain a Username

and Password, E-mail us at: parts@multiquip.

com.

To obtain an MQ Account, contact your

District Sales Manager for more information.

Use the internet and qualify for a 5% Discount

on Standard orders for all orders which include

complete part numbers.*

Note: Discounts Are Subject To Change

Fax your order in and qualify for a 2% Discount

on Standard orders for all orders which include

complete part numbers.*

Note: Discounts Are Subject To Change

Domestic (US) Dealers Call:

1-800-427-1244

International Customers should contact

their local Multiquip Representatives for

Parts Ordering information.

When ordering parts, please supply:

❒ Dealer Account Number

❒ Dealer Name and Address

❒ Shipping Address (if different than billing address)

❒ Return Fax Number

❒ Applicable Model Number

❒ Quantity, Part Number and Description of Each Part

NOTICE

All orders are treated as Standard Orders and will

ship the same day if received prior to 3PM PST.

❒ Specify Preferred Method of Shipment:

✓ UPS/Fed Ex ✓ DHL

■ Priority One ✓ Truck

■ Ground

■ Next Day

■ Second/Third Day

www.multiquip.com

WE ACCEPT ALL MAJOR CREDIT CARDS!

SFG10E ELECTRIC SURFACE GRINDER — OPERATION AND PARTS MANUAL — REV. #2 (05/28/09) — PAGE 4

Page 5

NOTICE TO OPERATORS

IF YOU CAN NOT READ OR DO NOT FULLY UNDERSTAND THE CONTENTS OF THIS MANUAL,

PLEASE CONTACT THE FACTORY FOR PROPER

ASSISTANCE BEFORE ATTEMPTING TO OPERATE THIS PRODUCT.

SI TU NO PUEDES LE’ER O NO COMPRENDES

EL CONTENIDO DE ESTE MANUAL FAVOR DE

PONERSE EN CONTACTO CON LA. FABRICA

PARA ASSISTENCIA- A PROPIA ANTES DE

INTENTAR PARA OPERAR ESTE PRODUCTO.

SOLLTEN SIE DIESE GEBRAUCHSANWEISUNG

NICHT LESEN KOENNEN ODER ES NICHT

VOLLKOMMEN VERSTEHEN, WENDEN SIE SICH

BITTE AN DEN HERSTELLER FUER RICHTIGE

HILFE EHE SIE VERSUCHEN DIESES PRODUKT

ZU OPERIEREN.

SI VOUS NE LISEZ OU NE COMPRENDRE

ENTIEREMENT LES MATIERES DE CE MANUEL,

S’IL VOUS PLAIT, CONTACTEZ L’USINE POUR

L’ASSISTANCE APPROPRIEE AVANT

D’UTILISER LE PRODUIT.

DANGERDANGER

DANGER

DANGERDANGER

You WILL be

KILLED

or

SERIOUSLY

injured if you DO

NOT follow directions.

CAUTION

CAUTIONCAUTION

CAUTION

CAUTIONCAUTION

You CAN be

INJURED

if you DO NOT follow directions.

These safety alert symbols identify important safety

messages in this manual. When you see these

symbols, be alert to the possibility of personal injury

and carefully read the message that follows.

Do not allow anyone to operate the SURFACE

GRINDER without first reading this Operator Manual

and becoming familiar with its operation. The manufacturer of the SURFACE GRINDER has gone to great

extremes to provide the owner(s) and/or operator(s)

with the finest equipment available for its intended job

function of removing covering materials from concrete

and wood floor surfaces. Yet, the possibility exists that

the SURFACE GRINDER can be utilized in and/or

subjected to job applications not perceived and/or

anticipated by the manufacturer. Such misuse and/or

misapplication of the SURFACE GRINDER can lead

to the possibility of serious damage, injury or even

death. It is the responsibility of the owner(s) and/or

operator(s) to determine that the SURFACE

GRINDER is being utilized and/or operated within the

scope of its intended job function. It is the responsibility of the owner(s) and/or operator(s) to establish,

monitor and constantly upgrade all safety programs

and/or practices utilized in and for the operation of

the SURFACE GRINDER. The purpose of such programs is to provide for owner(s’) and/or operator(s’)

safety. Operators must be instructed to recognize and

avoid unsafe conditions associated with their work

(29 CFR 1926.21 (b)(2)) and/or applicable updated

revisions. It is the responsibility of the owner(s) and/

or operator(s) to determine that no modifications and/

or alterations have been made to the SURFACE

GRINDER. Modifications and/or alterations can lead

to the possibility of serious damage, injury or even

death. It is the responsibility of the owner(s) and/or

operator(s) to make this Operator Manual available

for consultation during all phases of operation. Refer

to OSHA 2207 and/or applicable updated revisions

which contains all OSHA job safety and health rules and

regulations (1926 and 1910) covering construction.

SFG10E ELECTRIC SURFACE GRINDER — OPERATION AND PARTS MANUAL — REV. #2 (05/28/09) — PAGE 5

Page 6

NOTICE TO OPERATORS

The concept of powered SURFACE GRINDER has

been successfully utilized for many years as a

practical solution to many types of surfacve

preparation requirements. The basic concept is

proven and well accepted within the associated

marketplaces. Use of a SURFACE GRINDER

requires strenuous work activity. This type of work

activity can be considered to be greater in

magnitude than that experienced with the use of

many other types of both light construction and

lawn and garden related equipment. This type of

work activity should only be attempted by

operators of adequate physical size and stature,

mental awareness and physical strength and

condition. The body parts most noticeably affected

during any specific process are the arms, hands,

wrists, shoulders, lower back and legs. The

process can also produce excessive stress/strain

directly to the back muscles, spinal vertebrae and

many other body parts. Back related pain can be

a side effect of utilizing a SURFACE GRINDER.

An operator with a chronic back related problem

or a history of back and/or other medically related

problems should not attempt to utilize the

SURFACE GRINDER. Use of the SURFACE

GRINDER may only aggravate this and any other

medically related problem. Because of the diverse

type of prevailing job applications, job site

conditions, operator experience levels and

operator physical characteristics, no warranty,

guarantee, representation and/or liability is made

by the manufacturer as to the absolute

correctness or sufficiency of any operational

procedure, operational position and/or technique.

There is no absolute guarantee that an operator

of any given experience level, physical size and/

or physical condition will be immune to the

possibility of and/or probable physical side effects

of the normal use of the SURFACE GRINDER.

Each potential operator must be made aware of

and assume the operational and physical liability

described and/or associated with the use of the

SURFACE GRINDER. Improper use of the

SURFACE GRINDER can result in property

damage and/or personal injury, including death.

Each potential operator not willing to assume the

operational and physical liability described and/

or associated with the use of the SURFACE

GRINDER, should not operate it. Proper levels of

operator experience, skill and common sense are

essential for maximizing the safe and efficient

operation of the SURFACE GRINDER.

Record the SURFACE GRINDER and electric motor serial numbers in the spaces provided below.

__________________ Model Number

__________________ Serial Number

__________________ Electric Motor Serial Number

__________________ Date of Purchase

Specifications and design are subject to change without

notice or obligation. All specifications are general in nature

and are not intended for specific application purposes.

Multiquip, Inc. reserves the right to make changes in design,

engineering or specifications and to add improvements or

discontinue manufacture at any time without notice or

obligation. Multiquip, Inc. and its agents accept no

responsibility for variations which maybe evident in actual

products, specifications, pictures and descriptions contained

in this publication.

SFG10E ELECTRIC SURFACE GRINDER — OPERATION AND PARTS MANUAL — REV. #2 (05/28/09) — PAGE 6

Page 7

OPERATOR INSTRUCTIONAL DATA SHEET

The following undersigned operators of the SURFACE

GRINDER described and/or pertaining to this Operator

Manual have received formal safety and operational information/instruction from the undersigned owner(s)/

instructor(s) in accordance to OSHA 29 CFR 1926.21 (b)(2)

and/or applicable updated revisions pertaining to, but not

necessarily limited to the:

1) READING, COMPREHENSION AND

ACKNOWLEDGEMENT OF THE MATERIAL COMPRISING THE ENTIRE CONTENTS OF THE

APPLICABLE OPERATOR MANUAL.

2) FORMALIZED OPERATOR SAFETY PROGRAM TO

BE DEVISED BY THE OWNER OF THE SURFACE

GRINDER IN CONJUNCTION WITH THE CONTENTS OF THE APPLICABLE OPERATOR MANUAL

AND THE APPLICABLE MATERIAL INCLUDED IN

THE NATIONAL ELECTRICAL CODE®.

3) OSHA AND NATIONAL ELECTRIC CODE® RULES

AND REGULATIONS RESEARCHED FOR AND/OR

BY THE OWNER OF THE SURFACE GRINDER AND

DEEMED APPLICABLE TO THE SAFE AND

PROPER USE AND/OR OPERATION OF THE SURFACE GRINDER FOR ANY SPECIFIC JOB

APPLICATION.

4) LOCAL LAWS, REGULATIONS AND CUSTOMS

RESEARCHED FOR AND/OR BY THE OWNER OF

THE SURFACE GRINDER AND DEEMED APPLICABLE TO THE SAFE AND PROPER USE AND/OR

OPERATION OF THE SURFACE GRINDER FOR

ANY SPECIFIC JOB APPLICATION.

5) FORMALIZED MAINTENANCE PROGRAM FOR

THE SURFACE GRINDER TO BE DEVISED BY THE

OWNER OF THE SURFACE GRINDER IN ACCORDANCE WITH, BUT NOT NECESSARILY LIMITED

TO, THE SPECIFICATIONS, GUIDELINES AND

OPERATIONAL INFORMATION CONTAINED IN THE

APPLICABLE OPERATOR MANUAL.

6) COMPREHENSIVE OPERATIONAL INSTRUCTIONS FOR THE CORRECT AND PROPER USE OF

THE SURFACE GRINDER AS PER THE CONTENTS

OF THE APPLICABLE OPERATOR’S MANUAL AND

APPLICABLE MATERIAL INCLUDED IN THE NATIONAL ELECTRIC CODE®.

_________________ Operator ____________________ Owner/Instructor _____________ Date

_________________ Operator ____________________ Owner/Instructor _____________ Date

_________________ Operator ____________________ Owner/Instructor _____________ Date

_________________ Operator ____________________ Owner/Instructor _____________ Date

_________________ Operator ____________________ Owner/Instructor _____________ Date

_________________ Operator ____________________ Owner/Instructor _____________ Date

NOTE: INSERT COPIES OF THIS PAGE WITHIN THE OPERATOR’S MANUAL IF SPACE FOR ADDITIONAL

OPERATORS IS REQUIRED.

SFG10E ELECTRIC SURFACE GRINDER — OPERATION AND PARTS MANUAL — REV. #2 (05/28/09) — PAGE 7

Page 8

DANGERDANGER

DANGER

DANGERDANGER

THE FOLLOWING SAFETY PRECAUTIONS PROVIDE

SOME COMMON SENSE GUIDES TO PROMOTE

SAFETY AND EFFICIENCY WITH THE SURFACE

GRINDER. NO WARRANTY, GUARANTEE OR REPRESENTATION IS MADE BY THE MANUFACTURER AS

TO THE ABSOLUTE CORRECTNESS OR SUFFICIENCY OF ANY INFORMATION OR STATEMENT.

THESE SAFETY PRECAUTIONS ARE INTENDED TO

DEAL PRINCIPALLY WITH COMMON PRACTICES

AND CONDITIONS ENCOUNTERED IN THE USE OF

THE SURFACE GRINDER AND ARE NOT INTENDED

TO BE ALL INCLUSIVE. PROPER LEVELS OF OPERATOR EXPERIENCE, SKILL AND COMMON SENSE

ARE ESSENTIAL FOR SAFE AND EFFICIENT OPERATION.

DANGERDANGER

DANGER

DANGERDANGER

INCORRECT USE OF THE SURFACE GRINDER CAN

RESULT IN PROPERTY DAMAGE, PERSONAL

INJURY OR EVEN DEATH. TO REDUCE THIS

POSSIBILITY, GIVE COMPLETE AND UNDIVIDED

ATTENTION TO THE JOB AT HAND AND FOLLOW

THESE SAFETY PRECAUTIONS:

SAFETY PRECAUTIONS

2) Develop a comprehensive program for the safe operation

of the SURFACE GRINDER by its owner(s) and/or

operator(s). Such a program will include, but is not

limited to: instructional requirements for operation,

applicable OSHA requirements, local laws and

regulations, job site safety and a SURFACE GRINDER

maintenance program. Constantly examine and upgrade

this program to guarantee owner(s) and/or operator(s)

safety. Each operator must be fully instructed regarding

the specifics of this safety program.

3) Determine that the SURFACE GRINDER is in its original,

factory configuration and has not been modified in any

manner. Many modifications can result in potentially

dangerous configurations that can lead to property

damage and/or personal injury. If there are any questions

about possible modifications made to the SURFACE

GRINDER, contact the Customer Service Department

for specific information BEFORE utilization. There is

no charge for this service. Do not operate the SURFACE

GRINDER without the use of the original equipment Vbelt guard. Use of the SURFACE GRINDER without an

approved belt guard can lead to property damage and/

or personal injury.

4) Minors should never be allowed to operate the SURFACE

GRINDER. Bystanders, especially children and animals,

should not be allowed in the area where the SURFACE

GRINDER is in use. The grinding process can result in

flying particles being emitted at high velocity and striking

the operator and/or onlookers. This can lead to the

possibility of property damage and/or personal injury.

Keep all body parts, loose clothing, foreign objects and

onlookers clear of the rotating disc, multi-accessory

attachments and flying particles.

PREPARATION

1) This SURFACE GRINDER is specialized type of

powered equipment, designed for a specific job function

and requires adequate and thorough instruction

BEFORE it is operated. The size, power, complexity

and operating characteristics of this type of powered

equipment would dictate that each operator must receive

adequate, professional instruction regarding the proper

operation of this SURFACE GRINDER before being

allowed to utilize it. BEFORE attempting to utilize this

SURFACE GRINDER, read this Operator’s Manual and

the material supplied by the motor manufacturer to

familiarize each operator with its correct operating

procedures. Avoid the urge not to take the necessary

time to read this Operator’s Manual before operating

the SURFACE GRINDER. DO NOT OPERATE THE

SURFACE GRINDER UNTIL EACH OPERATOR

COMPLETELY COMPREHENDS THE CONTENTS OF

THIS MANUAL.

SFG10E ELECTRIC SURFACE GRINDER — OPERATION AND PARTS MANUAL — REV. #2 (05/28/09) — PAGE 8

5) Operators must be in adequate physical condition,

mental health and not under the influence of any

substance (drugs, alcohol, etc.) which might impair

vision, dexterity or judgment. Working with the

SURFACE GRINDER is strenuous. If you have any

condition that might be aggravated by strenuous work,

check with your doctor BEFORE operating the

SURFACE GRINDER. Guide against the possibility of

back related injuries. Always lift the SURFACE

GRINDER with leg muscles and not with the back.

6) Prolonged use of the SURFACE GRINDER (or other,

similar machines) exposes the operator to vibrations

which may produce Whitefinger Disease (Raynaud’s

Phenomenon). This phenomenon reduces the hand’s

ability to feel and regulate temperature, produces

numbness and burning sensations and may cause nerve

and circulation damage and tissue necrosis. Antivibration systems do not guarantee that you will not

sustain Whitefinger Disease. Therefore, continuous and

regular users should closely monitor the condition of

their hands and fingers. After each period of use,

Page 9

SAFETY PRECAUTIONS

exercise to restore normal blood circulation. If any of

the symptoms appear, seek medical advice immediately.

7) Clothing must be sturdy and snug fitting, but allow

complete freedom of movement. Never wear loose fitting

jackets, scarves, neckties, jewelry, flared or cuffed

pants or anything that could become caught on controls

or moving parts. Wear long pants to protect your legs.

Protect your hands with heavy duty, non-slip gloves to

improve your grip. Good footing is most important when

operating the SURFACE GRINDER.

Wear sturdy boots with non-slip soles. Steel-toed safety

shoes are highly recommended. Never wear tennis

shoes or other, similar type shoes which afford little or

no protection. Wear an approved safety hard hat to

protect the operator’(s’) head(s) where there is a danger

of head injuries. Noise, generated by the SURFACE

GRINDER and the actual process itself, can damage

your hearing. Wear approved sound barriers (ear plugs

or ear mufflers) to protect your hearing. Continuous and

regular operators should have their hearing checked

regularly.

8) Visually inspect the SURFACE GRINDER, components,

tools and accessories for damaged or worn parts.

BEFORE each use:

a) Disconnect the power source cable.

b) Clean and remove all accumulated foreign matter

from the wheels and determine that each rotates

freely.

c) Clean and remove all accumulated foreign matter

from inside the mainframe area.

d) Inspect the V-belt drive for proper tension, wear and

general condition. Replace each component as

necessary.

e) Inspect the multi-accessory disc and gimbal head

assembly for excessive wear and structural

integrity. Replace each component as necessary.

The multi-accessory disc rotating at high speed

during the specific process can be subject to high

wear rates if the installed attachment is not properly

maintained and/or replaced at regular service

intervals.

f) Determine that operator controls work freely, all

safety devices are operative and information decals

are readable.

g) Check to see that the SURFACE GRINDER and all

related accessories are in good, mechanical

condition BEFORE utilization.

h) Reconnect the power source cable as applicable.

9) Contact appropriate representatives to determine if/

where electrical cables, gas lines and other hazardous

items are buried under the work surface BEFORE

utilization. The SURFACE GRINDER and related

accessories are not insulated. Contact with buried

electrical cables, gas lines and other hazardous items

can result in electrocution and/or an explosion.

10) Know how the controls operate. Know how to stop the

electric motor quickly in an emergency. Always start

the electric motor according to the instructions as

outlined in this manual to minimize the possibility of

unexpected contact with the work surface. Unexpected

contact with the work surface can cause loss of

machine control, and the possibility of property damage

and/or personal injury.

11) Ground the electrically powered SURFACE GRINDER

motor securely. Determine that any “grounding” wire and/

or device is, in fact, properly grounding the motor. Failure

to properly ground the motor may cause an electrical

shock and/or electrocution, resulting in property

damage and personal, injury including death. Electrical

wiring and all connections should be performed by a

qualified electrician. The electric motor is designed to

operate from a 115 AC power source.

12) When operating the SURFACE GRINDERs on a surface

containing water or other electrically conducting liquid,

special precautions must be taken to minimize the

possibility of operator electrocution. Once such

precaution is to wire and operate the electric motor from

a clean, 20 Ampere, 115 Volt AC power source in

conjunction with a ground fault circuit interrupter (GFCI).

A GFCI is a safety device that disconnects power from

a circuit to a load when a potentially dangerous condition

occurs. The GFCI opens the circuit when the fault

current flow from a power line to a ground exceeds the

safe limit for humans.

The GFCI protects against harmful electrical shock to

a person caused by contact with a defective electrical

product. A GFCI differs from a fuse or circuit breaker. A

fuse or circuit breaker opens the circuit when the total

current flow in the power line exceeds the safe limit of

the power line. They are designed to protect against

fire caused by overheating of the power line. Use of a

GFCI gives on the job protection from electrical shock

hazards caused by ground faults in commercial,

industrial and residential applications. They are simple

and easy to use: plug a portable GFCI into any suitable,

grounded extension cord and plug the SURFACE

GRINDER into the GFCI for automatic protection

against ground faults.

For specific information, consult current National

Electrical Code® publications and OSHA publications

210-22D (or current revision) for construction sites and

555-3 (or current revision) for use around any area

containing water.

13) Never exceed the recommended capacities of the

SURFACE GRINDER. Refer to the Specifications

sections of this manual for more detailed information

SFG10E ELECTRIC SURFACE GRINDER — OPERATION AND PARTS MANUAL — REV. #2 (05/28/09) — PAGE 9

Page 10

SAFETY PRECAUTIONS

OPERATION

1) Give complete and undivided attention to the job at

hand. Do not chew gum, smoke and/or use smokeless

tobacco while utilizing the SURFACE GRINDER. Do

not attempt to eat and/or drink while utilizing the

SURFACE GRINDER. Determine that eyeglasses and/

or hearing aid devices are properly secured.

Use of the SURFACE GRINDER is strenuous and

causes fatigue. Help prevent the cause of an accident.

Plan to take work breaks as required to help maintain

proper mental and physical alertness.

2) This SURFACE GRINDER is not sealed or insulated.

Do not operate the SURFACE GRINDER in an explosive

atmosphere or near combustible materials. Refer to

current OSHA® rules and regulations.

3) The SURFACE GRINDER is designed for use by one

operator. Use of the SURFACE GRINDER by more than

one operator can lead to confusion and loss of control,

resulting in property damage and/or personal injury. If it

is felt that more than one person is required to operate

the SURFACE GRINDER, STOP and contact the

Customer Service Department for specific operational

and service/maintenance information. There is no charge

for this service.

4) Do not operate the SURFACE GRINDER with onlookers

close by. Caution all onlookers to stand clear. The

grinding process can result in flying particles being

emitted at high velocity and striking the operator and/

or onlookers. This can lead to the possibility of property

damage and/or personal injury. Keep all body parts,

loose clothing and foreign objects clear of the rotating

drum and flails.

and fingers. Always make sure the operator handle is

in good condition and free of moisture, pitch, oil or

grease. Wear gloves to improve your grip. Never leave

the SURFACE GRINDER running unattended.

7) Special care must be exercised on slippery conditions

and on difficult, uneven surfaces. Watch for cracks, high

spots and other, surface irregularities. Keep proper

footing and balance at all times. The normal use of this

machine is on level surfaces. Other terrains can be

dangerous and should be avoided. Only properly trained

operators should attempt these techniques.

8) Never start the electric motor with the SURFACE

GRINDER directly over cracked, uneven or irregular

surfaces.

9) Clean and remove all accumulated foreign matter from

inside the mainframe area after each use. This practice

will maximize bearing and V-belt service life.

10) Because this SURFACE GRINDER is classified as a

low cost, hand held, low horsepower, portable type

machine, it is limited in the number of practical and/or

suitable job applications. A particular job site, actual

surface conditions, job specifications and operator skill/

common sense may dictate that a different type of

machine (with characteristics of higher purchase cost,

being mounted to a carrier vehicle, with greater

horsepower and less mobility), method and/or process

be utilized to properly complete the job with the degree

of efficiency and safety required. Contact the Customer

Service Department for specific information regarding

suitable job applications, job sites surface conditions

and operator experience/skill/common sense

recommendations for this SURFACE GRINDER

BEFORE utilization. There is no charge for this service.

5) Start the electric motor according to the instructions

as outlined in this manual to minimize the possibility of

unexpected contact with the work surface. Unexpected

contact with the work surface can cause the loss of

machine control and the possibility of property damage

and/or personal injury.

6) Start and operate the SURFACE GRINDER only in a

well ventilated area. Operate the SURFACE GRINDER

only when/where visibility and light are adequate for

the job at hand. Work carefully. Always hold the operator

handle firmly with both hands. Wrap your fingers around

the handle, keeping it cradled between your thumbs

SFG10E ELECTRIC SURFACE GRINDER — OPERATION AND PARTS MANUAL — REV. #2 (05/28/09) — PAGE 10

Page 11

MAINTENANCE, REPAIR AND STORAGE

1) Use only genuine, approved replacement parts and

accessories for maintenance and repair. Use of parts

and accessories manufactured by others can result

in property damage and/or personal injury.

2) Follow the Service instructions as outlined in the

appropriate section of this manual.

3) Always stop the electric motor and disconnect the

power source cable BEFORE checking or working on

the SURFACE GRINDER.

4) Always properly maintain the SURFACE GRINDER.

Frequently check all fasteners and individual parts.

Built in safety features are effective only if they are

maintained in good working condition. Replace any

questionable part or assembly with a genuine, factory

approved, replacement part. Do not forsake proper

maintenance for the price of a few replacement parts.

Proper maintenance does not cost...it actually pays

dividends. Do not attempt any maintenance repair work

not described in this manual. Have such work

performed at your dealer’s service facility.

SAFETY PRECAUTIONS

5) Do not operate the SURFACE GRINDER without the

use of factory approved V-belt and diamond blade

guards that are maintained in proper structural

condition. Frequently inspect the guards for signs of

wear, cracks and other signs of fatigue. If there is

any question regarding the structural integrity and/or

condition of the belt guard, properly dispose and

replace with a genuine, factory approved, replacement

part only.

6) Maintain all safety and operation decals in proper

condition. If any decal becomes damaged and/or

unreadable, replace with a genuine, factory approved,

replacement part only.

7) The SURFACE GRINDER utilizes many self-locking

type hexagon head nuts to minimize the effects of

vibration. Replace all self-locking hardware with

genuine, factory approved, replacement parts only.

8) Consult the material supplied by the electric motor

manufacturer for specific information relative to proper

operational, lubrication and storage requirements.

SFG10E ELECTRIC SURFACE GRINDER — OPERATION AND PARTS MANUAL — REV. #2 (05/28/09) — PAGE 11

Page 12

ASSEMBLY INSTRUCTIONS/OPERATIONS

Assembly

The SFG10E SURFACE GRINDER is shipped from the

factory secured on a specially designed wooden pallet

and protected from external damage by a corrugated carton

or wood crate. If shipped with a corrugated carton, the

SURFACE GRINDER can be secured to the pallet by wood

laths nailed to the pallet body. Remove the carton or crate

immediately upon receipt using suitable tools to remove

the nails.

REMOVING THE SURFACE GRINDER FROM THE

PALLET

Tools Required:

1 set of pliers.

1 claw hammer or a hammer and an appropriate pry bar.

The SURFACE GRINDER is secured to the pallet with

steel banding. Using the pliers, cut and remove the

banding. The SURFACE GRINDER can then be removed

from the pallet.

DANGERDANGER

DANGER

DANGERDANGER

WEAR SAFETY GLASSES AND OTHER APPROPRIATE SAFETY APPAREL WHEN CUTTING THE STEEL

BANDING AND/OR REMOVING THE CORRUGATED/

WOOD SHIPPING CRATE.

Visually inspect the shipment for freight damage and/or

missing parts. If shipping damage is evident, contact the

delivering carrier immediately to arrange for an inspection

of the damage by their claims representative. Federal law

requires that a claim be filed within a specific time period. If

missing parts are detected, notify your dealer who will assist

you in obtaining them.

The SURFACE GRINDER is shipped from the factory

completely assembled. If ordered with the SURFACE

GRINDER, multi-accessory attachments are normally

shipped separately to minimize the potential for loss during

shipment.

1) To contain loose materials within the platform area of

the SURFACE GRINDER as a direct result of a specific

grinding process. This includes materials removed from

the surface as well as any slurry mixture utilized to

help maximize material removal efficiencies.

2) To provide a method for a vacuum system to help

remove airborne dust related materials from within the

skirt assembly. Dust related materials are usually

created as a result of the grinding process. A specific

job application may require the reduction and/or

minimization of airborne dust related materials from the

atmosphere while the SURFACE GRINDER is being

operated. The kit includes a hose and necessary

hardware to connect the skirt assembly to the 3 inch

diameter vacuum attachment fitting located at the rear

of the machine. Use of the kit along with a suitable

vacuum system will not completely remove all airborne

and loose materials directly from the work surface.

DANGERDANGER

DANGER

DANGERDANGER

THE USE OF THE SFSG121000 SAFETY AND DUST

SHIELD ASSEMBLY KIT ALONG WITH A SUITABLE

VACUUM SYSTEM TO REMOVE HAZARDOUS

CLASSIFIED, AIRBORNE MATERIALS FROM THE

WORK SURFACE WILL NOT ELIMINATE THE

REQUIREMENT FOR PROPER SAFETY RELATED

EQUIPMENT, OPERATING PLAN AND/OR

PROCEDURES.

DANGERDANGER

DANGER

DANGERDANGER

USE OF THE SFSG121000 SAFETY AND DUST SHIELD

ASSEMBLY KIT ALONG WITH A SUITABLE VACUUM

SYSTEM WILL NOT COMPLETELY REMOVE ALL

LOOSE MATERIALS FROM THE WORK SURFACE.

HAZARDOUS CLASSIFIED, LOOSE MATERIALS MUST

BE REMOVED FROM THE WORK SURFACE BY PROCESSES AND/OR PROCEDURES MEETING THE

APPLICABLE OSHA AND/OR EPA REQUIREMENTS.

Check all fasteners for proper security. Consult a fastener

torque chart for the proper torque value if any fastener is

found to require retorquing.

After April 1, 1996 all single head SURFACE GRINDERS

are shipped from the factory with the SFSG121000 Safety

and Dust Shield Assembly Kit. The SFSG121000 Safety

and Dust Shield is designed to perform the following job

functions:

SFG10E ELECTRIC SURFACE GRINDER — OPERATION AND PARTS MANUAL — REV. #2 (05/28/09) — PAGE 12

Page 13

ASSEMBLY INSTRUCTIONS/OPERATIONS

Operation

THEORY OF OPERATION

The SFG10E SURFACE GRINDERS operate on the principle

of various multi-accessory attachments being utilized at

rotational speeds to make direct contact with a work

surface. Various types of multi-accessory attachments are

secured to a recess provided in the rotating, aluminum disc

located on the bottom of the machine. The specific type of

multi-accessory attachment utilized during the grinding

process directly affects the type of material removed, the

material removal rate and the resulting flatness and

smoothness of the surface.

The grinding process is directly controlled by these

conditions:

1) The use of a suitable mechanism (multi-accessory

attachment) of proper design and configuration to grind

the work surface and remove material while delivering

acceptable service life.

2) Sufficient static weight supporting the multi- accessory

attachment to allow it to effectively penetrate the work

surface and remove material.

3) Adequate horsepower capable of propelling the multiaccessory attachment against the work surface to

deliver acceptable productivity rates.

Since no two materials are exactly alike, no two work surface

materials can be penetrated and removed by the exact same

method. The nature of the grinding process, along with

operator experience, skill and common sense, would

suggest that efficient and productive material removal is a

matter of trial and error. Combinations of multi-accessory

attachment type, condition, and feed rate are direct factors

that will also determine the overall success of the job

application.

MULTI-ACCESSORY ATTACHMENTS AND APPLICATIONS

While individual multi-accessory attachment design and

configuration may vary, basic operational characteristics

are identical: impact upon a work surface material and

remove a percentage of the material. This common

operational characteristic has led to the development of

the following popular multi-accessory attachments:

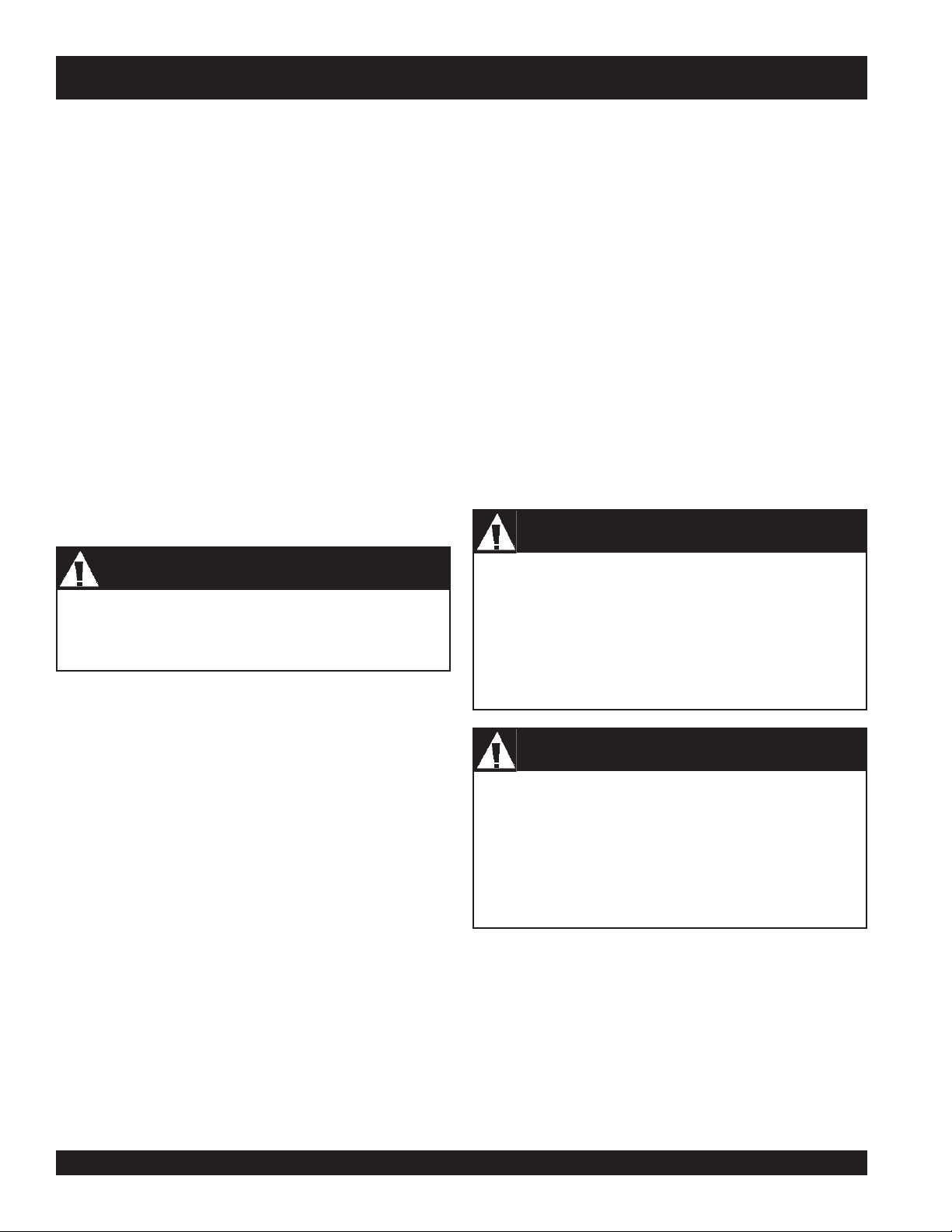

Grinding Stones

Grinding stones are available in a number of grades,

including: C06 extra coarse, C10 coarse, C24 medium, C80

fine and C120 super fine grade. FIGURE 4. All stones

incorporate silicon carbide as the abrasive medium and

employ a clay binder as the matrix material. Vitrified type

stones utilize an oven baking process that produces greater

service life over other manufacturing processes. As the

clay material wears away, it exposes new, sharp, edges of

the imbedded silicon carbide material. All stones have the

identical 2" x 2" X 4" dimensions and are secured to the

machine by the use of a plastic wedge.

FIGURE 4

The designation system for the grinding stones utilizes a

system similarly utilized for most abrasive products: the

larger the number, the finer the grain structure and usually,

the smoother resulting finish.

a) The C06 and C10 coarse grade stones are the most

popular utilized stones and result in maximum material

removal rates. They are utilized for general grinding and the

removal of trowel marks, high spots and rough sections on

concrete surfaces. The average service life is approximately

4 to 10 hours.

b) The C24 medium grade stone will result in lower material

removal rates. It is utilized for finer finish grinding of concrete

and rough grinding on terrazzo and other types of stone

floor configurations. The average service life is approximately

6 to 10 hours.

c) The C80 fine grade stone will result in still lower material

removal rates. It is utilized for polishing concrete and

medium grinding on terrazzo and other types of stone floor

configurations with a water/slurry mixture only. The average

service life is approximately 8 to 20 hours.

d) The C120 super fine grade stone will result in the lowest

material removal rates. It is utilized for final polishing on

terrazzo and other types of stone floor configurations with

a water/slurry mixture only. The average service life is

approximately 40 to 75 hours.

SFG10E ELECTRIC SURFACE GRINDER — OPERATION AND PARTS MANUAL — REV. #2 (05/28/09) — PAGE 13

Page 14

ASSEMBLY INSTRUCTIONS/OPERATIONS

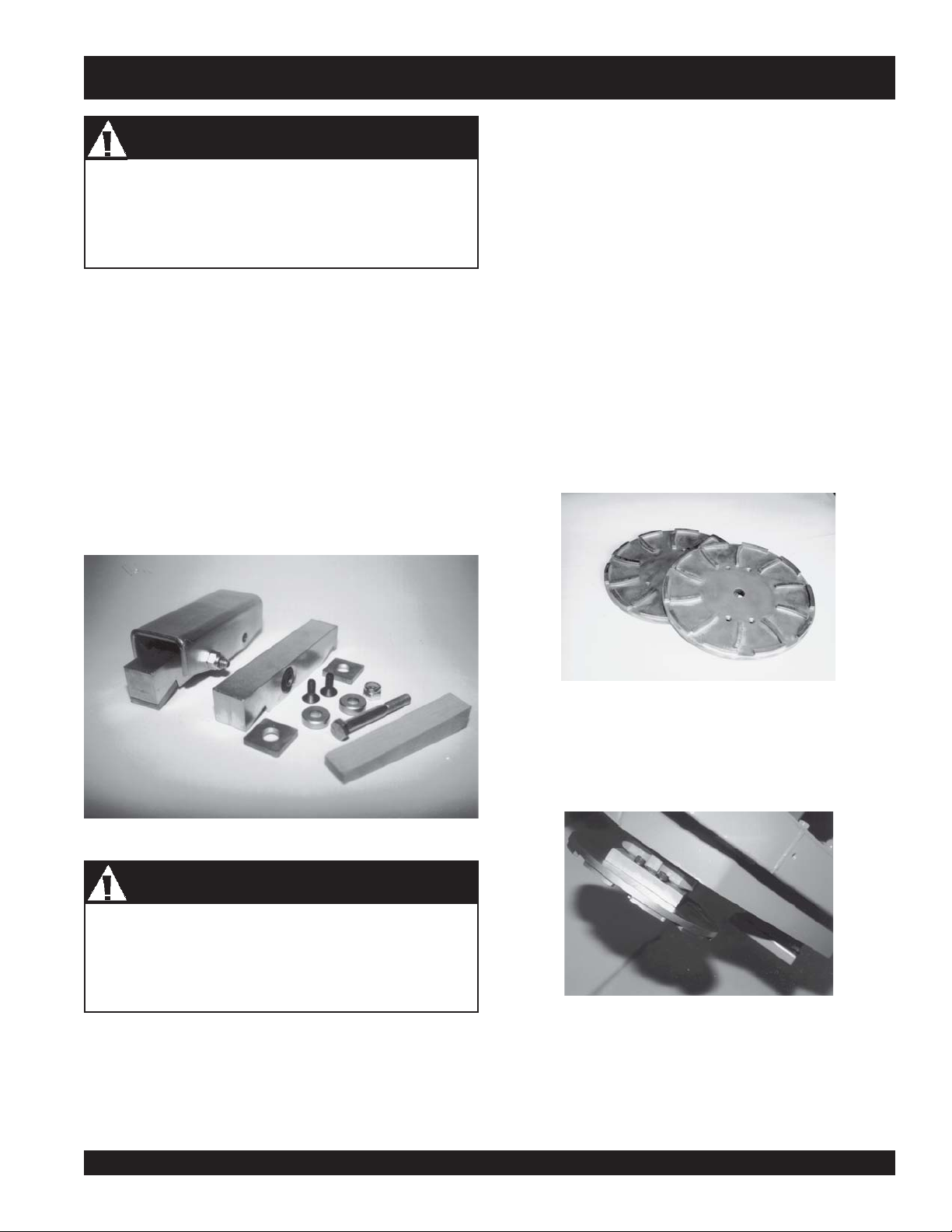

Tungsten Carbide Grinding Block

This multi-accessory attachment is most often utilized on

larger concrete grinding projects where increased production

and service life are required. The block utilizes tungsten

carbide balls approximately 1/16 inch diameter that are

deposited in a molten matrix material during the

manufacturing process at a controlled rate. The end effect

is a multi layer deposit of tungsten carbide balls in the matrix

material. As the softer matrix material wears with use, it

exposes a new layer of fresh tungsten carbide balls to

continue the grinding process. The tungsten carbide grinding

block is considerably more aggressive than the C10 silicon

carbide grinding stone. With the ability to renew itself during

usage, the normal life expectancy for this accessory can

approach several hundred hours. The nominal dimensions for

the tungsten carbide grinding block is 2" x 2" x 4" and is secured

to the machine with a plastic wedge. FIGURE 5.

insert flails. In turn, these costs must be compared to

anticipated service life. All flails will eventually wear to the

point of requiring replacement. The amount of unproductive

time spent to replace worn flails on a job can be substantially

greater than the actual replacement cost of many flails. It

then becomes a balance between purchase cost,

productivity, service life and labor cost.

c) Surface finish and texture. The finest grained surface

finish available from the scarifying process is comparable

to a “swept or broomed” like finish. If a smooth, flat finish is

desired, the scarifying process must be followed with a

grinding or polishing type process. Many job requirements

may call for large amounts of material to be removed, but

followed with additional specifications requiring a finer

surface finish or texture. Many times these jobs dictate the

use of an aggressive flail configuration because of

productivity and cost considerations. Less aggressive flail

configurations can then be utilized for the final finishing

sequence. Generally speaking, the more aggressive the flail

configurations, the more coarse the resulting finish and

texture.

Many flail configurations are available to meet a wide variety

of job applications and surface material specifications. To

give additional perspective to each configuration, a rating

system of 1 to 10 (10 being highest) has been devised.

FIGURE 5

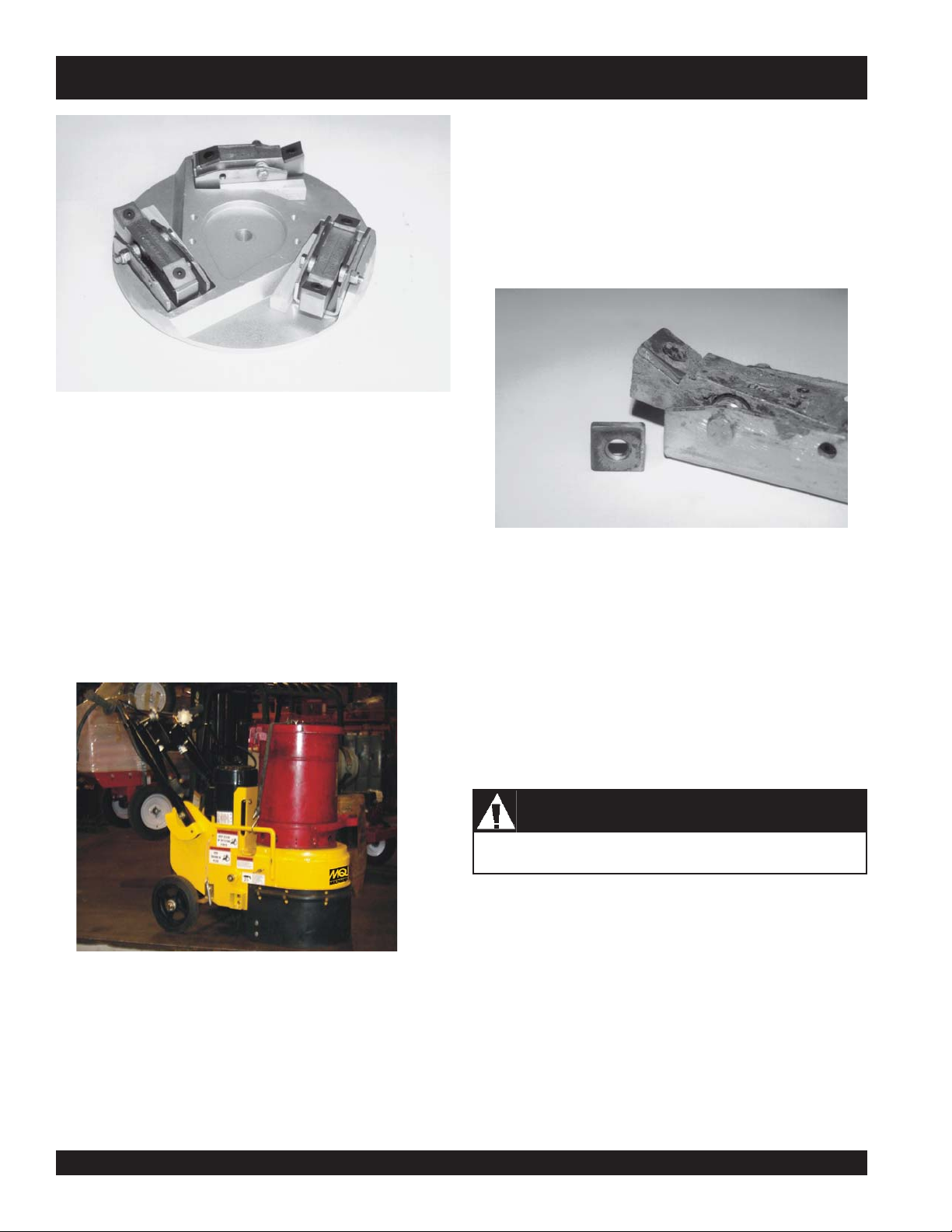

Scarifier Blocks

These multi-accessory attachments are comprised of flails

and spacer washers secured in a rigid steel case. FIGURE

6. Rotation of the multi-accessory disc causes the flails to

impact against the work surface with a variety of results.

Scarifier blocks are secured to the machine with plastic

wedges.

Several factors directly affect the selection of a flail design

for a specific job application:

a) The type and amount of material to be removed from the

work surface. Materials of higher yield and tensile strengths

along with the actual volume of material to be removed will

generally be the first factors under consideration.

b) Purchase cost versus service life. The original purchase

cost of plain, heat-treated steel flails must be compared

against the substantially higher costs of the tungsten carbide

SFG10E ELECTRIC SURFACE GRINDER — OPERATION AND PARTS MANUAL — REV. #2 (05/28/09) — PAGE 14

FIGURE 6

Star Flail

The star flail is manufactured from high carbon steel that is

through hardened for additional service life. It is highly

effective for light cleaning or scarifying and delivers a finer

surface finish texture. FIGURE 7.

Page 15

FIGURE 7

Suggested Applications:

1) Removal of thin coatings and encrusted accumulations.

2) Cleaning concrete and asphaltic surfaces

3) Removing thick material build-ups of greases, paints,

oils, vegetable powders and some resins from floors.

4) Light scarifying prior to the application of coatings,

toppings or sealers.

COST 1

PRODUCTIVITY 3

SERVICE LIFE 1

The star flail should be replaced when the outside diameter

is worn to approximately 1-5/16 inch or the inside diameter

elongates to approximately 3/4 inch.

Beam Flail

The beam type flail is manufactured from high carbon steel

that is through hardened for additional service life. It is highly

effective for scabbling or scarifying and delivers medium to

coarse surface finish texture. FIGURE 8.

FIGURE 8

Suggested Applications:

1) Medium duty asphalt and concrete scarifying.

2) Descaling steel decks.

3) Removing thick material build-ups of greases, paints,

oils, vegetable powders and some resins from floors.

4) Dried, fully cured, carpet and tile adhesive removal.

ASSEMBLY INSTRUCTIONS/OPERATIONS

COST 1

PRODUCTIVITY 5

SERVICE LIFE 2

The beam flail should be replaced when the outside diameter

is worn to approximately 1-5/16 inch or the inside diameter

elongates to approximately 3/4 inch.

Pentagonal Flail

The pentagonal type flail is manufactured from high carbon

steel that is through hardened for additional service life.

Each section of the five sided design features a small,

tungsten carbide insert that is held in position with copper

brazing. It is highly effective for scabbling or scarifying and

delivers medium to coarse finish texture. FIGURE 9.

FIGURE 9

Suggested Applications:

1) Heavy duty asphalt and concrete scarifying.

2) Heavy duty descaling of steel decks.

The pentagonal flail is designed for more aggressive and

rapid removal of a surface in comparison to the beam flail.

The addition of the tungsten carbide inserts contributes to

its long service life and higher production rates. The use of

tungsten carbide is also the main reason for the cost

differential between it and the other flails. The design

configuration yields a rather coarse surface finish and

texture. For many job applications, this finish and texture

will be satisfactory. Some applications may require an

additional smoothing process. If the resulting surface finish

is too coarse to meet specifications, it can be smoothed

with the use of the star or beam flail.

COST 10

PRODUCTIVITY 8

SERVICE LIFE 10

The pentagonal flail should be replaced when two successive

tungsten carbide inserts break off or the inside diameter

elongates to approximately 3/4 inch. In service, the flail

body will wear much faster than the tungsten carbide inserts.

The copper brazing used to weld the inserts into the body

can fail and an insert break off. The flail can still be used in

service. It will just wear a little faster and more uneven in

SFG10E ELECTRIC SURFACE GRINDER — OPERATION AND PARTS MANUAL — REV. #2 (05/28/09) — PAGE 15

Page 16

ASSEMBLY INSTRUCTIONS/OPERATIONS

that particular area. As a general rule, a pentagonal flail

can be utilized until body wear will no longer support the

tungsten carbide inserts.

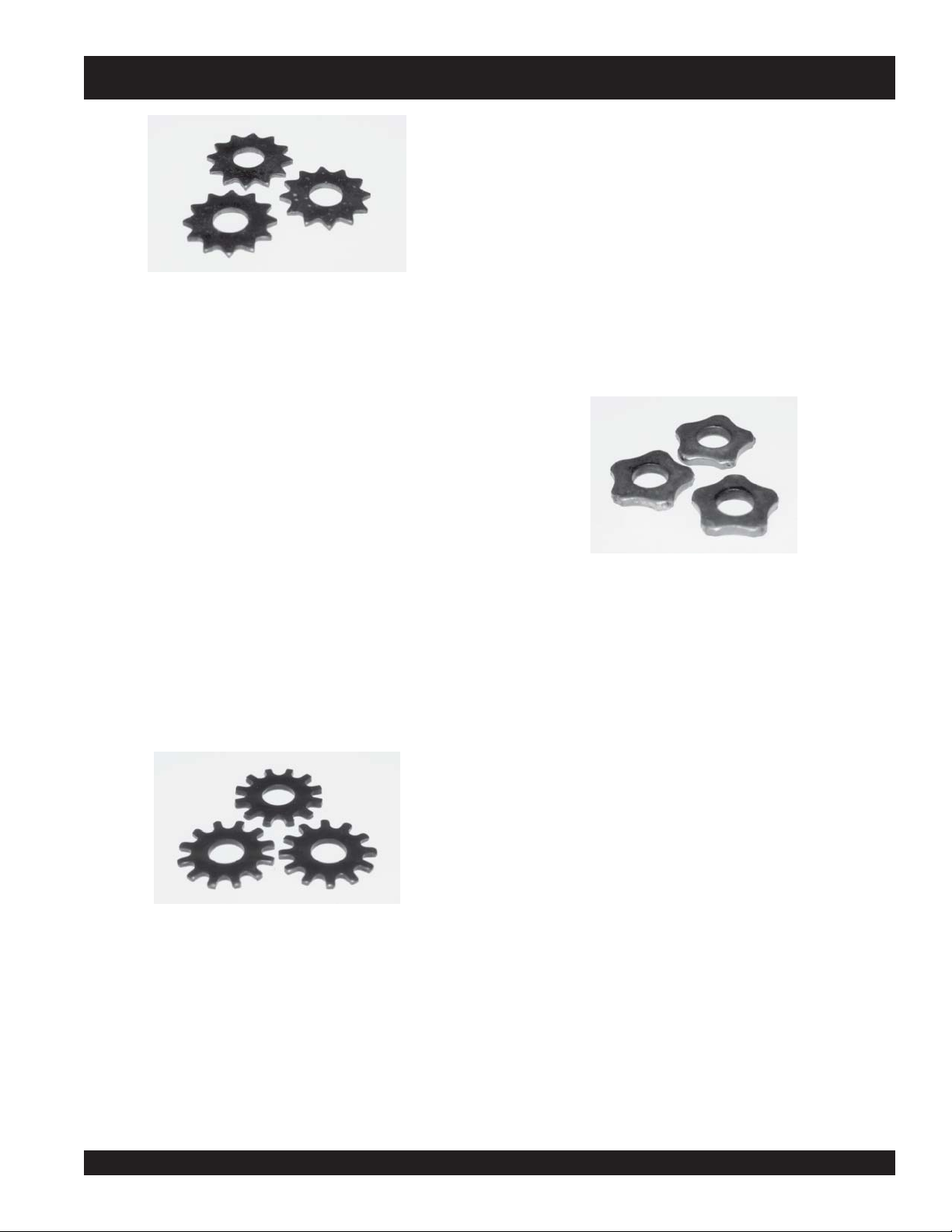

Spacer Washer

Spacer washers are stamped from high carbon steel and

heat-treated for additional service life. FIGURE 10.

Spacer washers serve the following functions:

FIGURE 10

1) Reduces the number of flails required to be mounted

on the scarifier block, thus reducing purchase and

operational costs.

2) Arrange the flails in a sequence or pattern that minimize

“blind” or “open” spots. Normally, at least one spacer

washer is inserted between two consecutive flails. A

scarifier block set up with only star, beam or pentagonal

flails will not penetrate the work surface at satisfactory

rates. This configuration will minimize the hammering

or impact action of the flails.

Variances in material thickness and manufacturing

processes can affect the final thickness of both flails and

spacer washers. Because of this occurrence, trial and error

is important for assembling flails and spacer washer on the

scarifier block. By mixing and matching flails and spacer

washers of specific thicknesses, the required number of

components can be assembled on a block in a minimum

amount of time.

DANGERDANGER

DANGER

DANGERDANGER

USE ONLY FACTORY SUPPLIED SPACER WASHERS

ON THE SCARIFIER BLOCK. OTHER WASHER TYPES

AND/OR CONFIGURATIONS CAN PRODUCE ABNORMAL WEAR AND ELONGATION, RESULTING IN

COMPLETE SEPARATION FROM THE SCARIFIER

BLOCK. INADVERTENT SPACER WASHER SEPARATION CAN LEAD TO PROPERTY DAMAGE AND/OR

PERSONAL INJURY.

Scarifier Block Bushing

Scarifier block bushings are designed to be discarded

whenever the flails are replaced. FIGURE 11. Normal wear

should be uniform about the bushing circumference.

Uneven bushing wear would suggest the following problems:

FIGURE 1 1

1) Inadequate free play exists between the flails/spacer

washers and the scarifier block case. If the flails and

spacer washers do not have complete freedom of

movement, they will not be capable of properly rotating

about the scarifier block bushing. The result is bushing

wear usually confined to two locations that are 180

degrees apart. Variances in flail and spacer washer

thicknesses affect free play when assembled on the

scarifier block.

Because free play is also created during the scarifying

process due to actual flail and spacer washer wear, a

certain amount of “tightness” can sometimes be

tolerated without affecting the service life of the

bushings and flails. The specific amount of “tightness”

can usually be determined through trial and error. If the

flails and spacer washers appear too tight on the

scarifier block, remove an appropriate flail or washer

and reassemble the block. If a short, operational test

indicates normal component wear patterns, the apparent

problem has been solved. A general rule for

consideration: it is better to have the flails and spacer

washers a “little too loose than a little too tight”.

2) Mixing both worn and new flails on the scarifier block.

Proper flail action against the work surface material

requires that the flails be of the same approximate

dimensions. Flails with various inside and outside

dimensions will not impact the work surface material

with the same intensity and deliver the same results.

Flail bushing wear is directly proportional to the amount

of force it must supply against each individual flail. When

a bushing can no longer supply adequate force against

the flails, it will break, allowing the flails to be hurdled

SFG10E ELECTRIC SURFACE GRINDER — OPERATION AND PARTS MANUAL — REV. #2 (05/28/09) — PAGE 16

Page 17

ASSEMBLY INSTRUCTIONS/OPERATIONS

against the inside of the SURFACE GRINDER frame.

The more aggressive flails require greater forces to keep

them contained on the block. These forces, in turn,

create faster and/or uneven bushing wear rates.

Because scarifier bushings are a critical component of

the actual scarifying process, it is important that each

bushing be inspected on a regular basis to determine

proper structural integrity.

Wire brushes

Typical applications include light scarifying and cleaning of

concrete, asphalt, steel and tile surfaces. Wire brushes are

secured to the machine with plastic wedges. FIGURE 12.

Floor Brushes

Eleven inch diameter, silicon carbide impregnated, floor

brushes are available in a number of styles and designs for

general maintenance and cleaning projects. FIGURE 14.

They are especially effective cleaning soiled concrete floors

with the addition of water soluble solvents. These types of

brushes are directly mounted to the multi-accessory disc

with the included 1/2 inch x 2 inch long Grade 5 capscrews.

A kidney shaped drive plate is provided on the back side of

the brush. This drive plate fits into a recess provided in the

multi-accessory disc. FIGURE 15.

FIGURE 14

FIGURE 12

Wire brushes are available in a number of flat wire sizes and

resulting configurations. With continuous use, the flat wire will

take a “set” that can limit effectiveness and overall productivity.

FIGURE 13. For best results, flat wire brushes should be rotated

end for end in the aluminum multi-accessory disc a minimum

of once for every one hour of operation. External weight applied

to the SURFACE GRINDER will not normally increase

productivity rates and only accelerate flat wire wear rates.

FIGURE 13

FIGURE 15

SCRAPE-R-TACH® Industrial Floor Coatings Removal

System

This multi-accessory attachment is designed to remove

many urethanes, epoxies, paints, mastics and other, similar

material accumulations from concrete floor surfaces.

FIGURE 16. Each assembly utilizes two tungsten carbide

inserts set at a precise angle. The rotating inserts “cut and

shave” against the work surface material with a “scraping”

action that removes materials with highly productive results.

To increase the effectiveness of the inserts, the scraper

block design incorporates a Lord® type rubber mount that

helps absorb damaging shocks while allowing the inserts

to more easily follow local variations in the surface contour.

Units are secured to the machine with plastic wedges.

SFG10E ELECTRIC SURFACE GRINDER — OPERATION AND PARTS MANUAL — REV. #2 (05/28/09) — PAGE 17

Page 18

FIGURE 16

The productivity of the product is directly dependent upon the

yield and tensile strength of the material being removed.

Material thickness has also shown to have a direct effect on

overall productivity. For example, the SCRAPE-R-TACH

system is a highly productive method for removing thick paint

accumulations from factory floors. Production rates of up to

several hundred square feet per hour can be realized. However,

many thin film ( ie: 5 mill thickness and thinner) urethane

coatings present a much more difficult removal problem. Since

removal rates are also directly affected by applied down force,

up to 300 lbs of external weight can be applied to the SURFACE

GRINDER to increase productivity. Cement blocks, stacked

bags of cement or weighted drums make excellent weights

and can be secured with “bungy” cords. FIGURE 17.

ASSEMBLY INSTRUCTIONS/OPERATIONS

shear from the concrete floor material. The occurrence is

also aggravated by higher ambient temperatures. This

problem can be significantly reduced with the addition of

various amounts of water or a water saturated, fine sand

combination placed on the floor. The use of the Safety and

Dust Shield Assembly with the SURFACE GRINDER is

highly recommended to contain the water/sand slurry mixture

from damaging surrounding walls and other vertical surfaces.

FIGURE 18

To index the tungsten carbide insert, proceed as follows:

Tools required:

1 each, 5/32 Allen wrench.

1) Clean the SCRAPE-R-TACH unit with a suitable safety

solvent to remove excess material build-up. Remove

as much foreign material from the female hexagon

socket area of the capscrew. This will allow the wrench

to make full contact and maximize the torque transfer

to the cap screw.

FIGURE 17

Each insert provides 8 scraping edges. As an edge become

dull and worn, the insert can be turned and reinstalled to

expose a new, sharp edge. FIGURE 18. When all 4 edges

of one side become worn and dull, the insert can be turned

over to expose an additional 4 edges.

Many materials such as adhesives, rubber deposits and

mastics have the tendency to extrude or smear rather than

SFG10E ELECTRIC SURFACE GRINDER — OPERATION AND PARTS MANUAL — REV. #2 (05/28/09) — PAGE 18

CAUTION

CAUTIONCAUTION

CAUTION

CAUTIONCAUTION

Follow all safety precautions for the safety solvent.

2) Remove the cap screw from the unit. Clean the newly

exposed areas of the insert and SCRAPE-R-TACH unit

with the safety solvent. Clean and inspect the threaded

holes found in older units for excess wear. New style

SCRAPE-R-TACH units feature a through hole design.

3) Index the insert to expose a new edge. Reinstall the

capscrew and apply a torque value that properly seats

the insert firmly against the body of the unit.

Page 19

ASSEMBLY INSTRUCTIONS/OPERATIONS

CAUTION

CAUTIONCAUTION

CAUTION

CAUTIONCAUTION

An insufficient seating torque value will allow the

insert to become loose from the unit body, resulting

in premature component wear and improper

scraping action. An excessive torque value will strip

the threads of the capscrew or unit body.

4) Determine that the unit body is free to rotate about the

5/16 inch diameter capscrew that retains the body to

the unit. A body that does not freely rotate indicates

that a material build-up exists between the rubber mount

and retaining capscrew exits. This build-up must be

removed by disassembling the body from the unit and

cleaning all contact areas with the safety solvent.

FIGURE 20.

The SCRAPE-R-TACH system is designed to be installed

with the edge of the tungsten carbide inserts facing the

direction of rotation. Markings are provided to indicate proper

direction of rotation.

Multi-Segmented, Dry Diamond Disc

Many times increased concrete removal rates can be

achieved with the use of multi-segmented, dry diamond

discs. FIGURE 21. These discs are designed to operate

dry or can also be utilized with water. If the wet option is

chosen, an external source for providing water must be

devised. No provision for water use is provided with the

SURFACE GRINDER. Typical discs are approximately 10

inch diameter and feature up to 20 diamond segments that

are welded or brazed to each assembly.

To install the multi-segmented, dry diamond disc, the

standard, aluminum, multi-accessory disc is first removed

from the SURFACE GRINDER. The diamond disc fastens

directly to the gimbal head with 3/8 inch diameter x 1 inch

long Allen head capscrews. FIGURE 22. The rear wheel

assembly is then placed in the lowest position to

compensate for the thickness variance of the diamond discs.

FIGURE 23.

FIGURE 20

CAUTION

CAUTIONCAUTION

CAUTION

CAUTIONCAUTION

Installing the SCRAPE-R-TACH system with the

tungsten carbide inserts facing opposite the

rotation direction will not deliver satisfactory

material removal rates and result in premature

component wear requiring early replacement.

FIGURE 21

FIGURE 22

SFG10E ELECTRIC SURFACE GRINDER — OPERATION AND PARTS MANUAL — REV. #2 (05/28/09) — PAGE 19

Page 20

FIGURE 23

ASSEMBLY INSTRUCTIONS/OPERATIONS

INSTALLING A MULTI-ACCESSORY ATTACHMENT (not

including multi-segmented, dry diamond discs) IN THE

ROTATING DISC

Tools Required:

1 Small Hammer

Parts Required:

6 each, P/N 29019-017 Plastic Mounting Wedge

DANGERDANGER

DANGER

DANGERDANGER

WHEN INSTALLING A MULTI-ACCESSORY ATTACHMENT ON THE SURFACE GRINDER ALWAYS WEAR

THE APPROPRIATE SAFETY EYEWEAR AND APPAREL TO MINIMIZE THE POTENTIAL FROM FLYING

DEBRIS. FLYING DEBRIS CAN RESULT IN PROPERTY

DAMAGE AND/OR PERSONAL INJURY.

Diamond Segment Block

The diamond insert block is designed to compliment the

multi-segmented diamond disc where a quick changeover

feature to other attachments is desired.

Diamond segments are retained into a steel block assembly

and deliver up to 5 times greater productivity rates than the

silicon carbide stones. FIGURE 24. The design resists

clogging while delivering a conservative service life up to

15 times longer than the stones. Diamond is the ideal choice

for larger concrete removal projects and the removal of

epoxies, paints and many thin film coatings.

The concept is especially useful for removing a thin layer of

concrete in final preparation for a new coating application. Can

be used in both wet and dry job applications. Worn inserts are

easily replaced in a matter of seconds. Service life is dependent

upon many variables, but can approach 35,000 square feet

per set, making it a cost efficient solution for many job

applications.

1) Properly disconnect the extension cord or SURFACE

GRINDER from the power source.

2) Tilt the SURFACE GRINDER back until the operator

handle comes in contact with the surface. Appropriate

wheel chocks are recommended. FIGURE 25.

FIGURE 25

3) Mount the multi-accessory attachment into the slots

provided in the multi-accessory disc. If the attachment

is directional in design, determine that its mounting

position in the disc allows for proper operation.

FIGURE 24

SFG10E ELECTRIC SURFACE GRINDER — OPERATION AND PARTS MANUAL — REV. #2 (05/28/09) — PAGE 20

4) Force a Mounting Wedge P/N 229019-017 into the area

between the multi-accessory attachment and the inside

rib of the aluminum disc by hand. The straight side of

the mounting wedge contacts the multi-accessory

attachment. The angled side of the mounting wedge

contacts the rib of the disc. FIGURE 26. An improper

mounting configuration is depicted in FIGURE 27.

Page 21

FIGURE 26

ASSEMBLY INSTRUCTIONS/OPERATIONS

5) Using a hammer, strike the wider side of the mounting

wedge with controlled, direct blows to firmly seat the

multi-accessory attachment into the aluminum disc.

Usually one or two direct blows will be sufficient to

properly retain the attachment.

CAUTION

CAUTIONCAUTION

CAUTION

CAUTIONCAUTION

Do not apply excessive impact force to the mounting

wedge to cause splitting. Once the multi-accessory

attachment is seated in the aluminum disc, further

impact force on the wedge will not increase the

seating force.

CAUTION

CAUTIONCAUTION

CAUTION

CAUTIONCAUTION

Improper seating force created by an excessive blow

to the mounting wedge will not allow the attachment

to properly release from the aluminum disc if direct

contact with a foreign object is made. Such

occurrence can result in property damage and/or

personal injury. The correct seating force for a

specific job application is that which is sufficient to

retain the attachment, yet still allows it to release

from the aluminum disc when direct contact with a

foreign object is made.

FIGURE 27

DANGERDANGER

DANGER

DANGERDANGER

DO NOT OPERATE THE SURFACE GRINDER WITH THE

229019-017 MOUNTING WEDGES IN AN IMPROPER

MOUNTING CONFIGURATION. MOUNTING A WEDGE

BETWEEN THE MULTI-ACCESSORY ATTACHMENT

AND THE OUTSIDE RIB OF THE ALUMINUM DISC CAN

ALLOW THE WEDGE TO COME IN DIRECT CONTACT

WITH A VERTICAL WALL AND/OR FLOOR OBSTRUCTION. SUCH OCCURRENCE CAN RESULT IN LOSS

OF MACHINE CONTROL, PROPERTY DAMAGE AND/

OR PERSONAL INJURY.

BEFORE OPERATING THE SURFACE GRINDER WITH

ANY MULTI-ACCESSORY ATTACHMENT, DETERMINE

THAT NO PORTION OF THE ATTACHMENT AND/OR

MOUNTING WEDGE EXTENDS BEYOND THE NORMAL

PERIMETER OF THE ALUMINUM DISC.

6) Determine that the multi-accessory attachment is in

full contact with the aluminum disc. If not in proper

contact, refer to REMOVING A MULTI-ACCESSORY

ATTACHMENT (not including multi-segmented, dry

diamond blades) FROM THE ROTATING DISC for proper

removal procedures.

7) Return the SURFACE GRINDER to its normal operating

position.

8) If the machine is to be used immediately, reconnect

the extension cord or SURFACE GRINDER to the power

source. Determine that the ON/OFF switch located on

the operator handle is in the OFF position.

DANGERDANGER

DANGER

DANGERDANGER

UNEXPECTED MACHINE START UP CAN RESULT IN

PROPERTY DAMAGE AND/OR PERSONAL INJURY.

SFG10E ELECTRIC SURFACE GRINDER — OPERATION AND PARTS MANUAL — REV. #2 (05/28/09) — PAGE 21

Page 22

ASSEMBLY INSTRUCTIONS/OPERATIONS

REMOVING A MULTI-ACCESSORY ATTACHMENT (not

including multi-segmented, dry diamond discs) FROM THE

ROTATING DISC

Tools Required:

1 Small Hammer

1 Drift Punch or Small Pry Bar

DANGERDANGER

DANGER

DANGERDANGER

WHEN REMOVING A MULTI-ACCESSORY ATTACHMENT FROM THE SURFACE GRINDER, ALWAYS

WEAR APPROPRIATE SAFETY EYEWEAR AND APPAREL TO MINIMIZE THE POTENTIAL FROM FLYING

DEBRIS. FLYING DEBRIS CAN RESULT IN PROPERTY DAMAGE AND/OR PERSONAL INJURY.

1) Disconnect the extension cord or SURFACE GRINDER

from the power source.

2) Tilt the SURFACE GRINDER back until the operator

handle comes in contact with the surface. Appropriate wheel

chocks are recommended.

3) The multi-accessory attachment can be removed by

both the use of a drift punch or small, pry bar. If utilizing the

drift punch, strike the narrow end of the mounting wedge

with controlled, direct blows until the attachment is released

from the aluminum disc. If utilizing the pry bar, position the

bar between the aluminum disc and the attachment. Use

controlled, direct blows to the bar in order to force the

attachment loose from the aluminum disc. FIGURE 28.

4) Return the SURFACE GRINDER to its normal operating

position.

5) If the machine is to be used immediately, reconnect

the extension cord or SURFACE GRINDER from the

power source. Determine that the ON/OFF switch located

on the operator handle is in the OFF position.

DANGERDANGER

DANGER

DANGERDANGER

UNEXPECTED MACHINE START UP CAN RESULT IN

PROPERTY DAMAGE AND/OR PERSONAL INJURY.

TRANSPORTING THE SURFACE GRINDER

The SURFACE GRINDER has an operational weight that

prohibits one person from loading and/or unloading it alone

by conventional, physical efforts.

DANGERDANGER

DANGER

DANGERDANGER

DO NOT ATTEMPT TO LIFT THE SURFACE GRINDER

UP INTO A TRANSPORTATION VEHICLE WITH THE

USE OF ONE PERSON ALONE. DO NOT ATTEMPT

TO LOWER THE SURFACE GRINDER FROM A TRANSPORTATION VEHICLE WITH THE USE OF ONE

PERSON ALONE. LIFT AND/OR LOWER THE SURFACE GRINDER ONLY BY THE USE OF A POWER

TAILGATE UNIT, A SUITABLE HOIST UNIT OF

PROPER CAPACITY AND/OR CONFIGURATION OR

BY THE USE OF A PROPER QUANTITY OF PERSONNEL IN PROPER PHYSICAL CONDITION.

FIGURE 28

CAUTION

CAUTIONCAUTION

CAUTION

CAUTIONCAUTION

Do not utilize excessive force when removing a multiaccessory attachment with the pry bar. Excessive

force can result in damage to the aluminum disc.

Proper removal techniques by both methods will

result in minimal damage to the aluminum disc.

SFG10E ELECTRIC SURFACE GRINDER — OPERATION AND PARTS MANUAL — REV. #2 (05/28/09) — PAGE 22

1) A lifting bail device can be used to facilitate lifting by a

mechanical device incorporating a chain and suitable

attachment device. The location of the lifting bail may

not always locate the exact position of the center of

gravity for the SURFACE GRINDER. Lifting handles are

also provided on both sides of the transmission case.

These handles can be utilized by personnel whenever

lifting/lowering the SURFACE GRINDER or as

attachment points for a chain sling whenever a suitable

hoisting device is utilized. FIGURE 29.

Page 23

DANGERDANGER

DANGER

DANGERDANGER

EXERCISE EXTREME CAUTION WHEN UTILIZING A

MECHANICAL DEVICE FOR LIFTING THE SURFACE

GRINDER. UTILIZE THE MECHANICAL DEVICE IN

ACCORDANCE TO BOTH ITS STATED STATIC AND

DYNAMIC LOADING ENVELOPES. DO NOT UTILIZE

THE MECHANICAL DEVICE UNTIL THIS INFORMATION IS PROPERLY KNOWN AND UNDERSTOOD BY

ALL APPLICABLE PERSONNEL. FAILURE TO PROPERLY UTILIZE THE MECHANICAL DEVICE CAN

RESULT IN PROPERTY DAMAGE AND/OR PERSONAL INJURY.

2) To minimize the possibility of damage to the

SURFACE GRINDER, always transport in its normal,

upright position. All equipment must be secured in/on

vehicles with suitable strapping or tie-downs. Personnel

should not be transported in the same compartment as

equipment and fuel supplies. Consult applicable OSHA,

AGA, CGA, etc. regulations for the proper transportation

flammable gases.

ASSEMBLY INSTRUCTIONS/OPERATIONS

ADJUSTING THE OPERATOR HANDLE HEIGHT

The SFG10E SURFACE GRINDER incorporates a handle

that can be adjusted to compensate for variances in operator

heights. Correct handle height can increase overall machine

productivity and reduce operator fatigue.

1) Loosen both knobs on the lower handle. FIGURE 30.

2) Pull the top handle until the desired height is reached.

3) Tighten both knobs on the lower handle.

FIGURE 29

FIGURE 30

STARTING THE SFG10E SURFACE GRINDER ON THE

JOBSITE

1) Position the SURFACE GRINDER on a flat and level

surface of firm foundation.

2) Determine that the ON/OFF switch located on the

operator handle is in the OFF position.

DANGERDANGER

DANGER

DANGERDANGER

UNEXPECTED MACHINE START UP CAN RESULT IN

PROPERTY DAMAGE AND/OR PERSONAL INJURY.

3) The motor is designed to operate from a clean, 20

ampere, 115 VAC, 60 Hz nominal power source. A clean

power source refers to the amperage available on the

individual electrical circuit selected. Additional electrical

products already utilizing the same circuit will reduce

the available amperage, resulting in starting and

operational difficulties.

SFG10E ELECTRIC SURFACE GRINDER — OPERATION AND PARTS MANUAL — REV. #2 (05/28/09) — PAGE 23

Page 24

CAUTION

CAUTIONCAUTION

CAUTION

CAUTIONCAUTION

ASSEMBLY INSTRUCTIONS/OPERATIONS

DANGERDANGER

DANGER

DANGERDANGER

Operating the SURFACE GRINDER from a power

source of improper voltage and amperage will result

in un-repairable damage to the electric motor and

related controls.

4) The motor is equipped with automatic thermal protection

device that will stop it before major internal damage

can result. After the motor has cooled to an acceptable

temperature level, the switch must be manually

activated to restart. FIGURE 32.

FIGURE 32

To minimize the voltage drop to the motor, all extension

cords should be copper stranded, 8 AWG or larger. A

NEMA 6-20R twist-lock type receptacle is provided with

the SFG10E SURFACE GRINDER as a standard

accessory. The twist clock feature allows the extension

cord to be pulled by the SURFACE GRINDER without

becoming detached. Wire the NEMA 6-20R receptacle

to the appropriate extension cord that will be coupled

to the NEMA 6-20P plug provided on the SURFACE

GRINDER. FIGURE 33.

PROPERLY INSPECT ALL EXTENSION CORDS AND

WIRING DEVICES FOR STRUCTURAL INTEGRITY. DO

NOT UTILIZE A CORD WITH A WORN OR CUT OUTER

JACKET MATERIAL. DO NOT UTILIZE A CORD WITH

EXPOSED INNER WIRES OR INSULATION MATERIAL. DO NOT UTILIZE A CORD THAT HAS BEEN

REPAIRED WITH ELECTRICAL TAPE. USE OF A AN

EXTENSION CORD OF IMPROPER STRUCTURAL

INTEGRITY CAN RESULT IN PROPERTY DAMAGE

AND/OR PERSONAL INJURY.

DANGERDANGER

DANGER

DANGERDANGER

ALL ELECTRICAL WIRING MUST BE INSTALLED

AND/OR APPROVED IN ACCORDANCE TO LOCAL

ELECTRICAL CODES AND PRACTICES. AN IMPROPER WIRING INSTALLATION CAN RESULT IN

PROPERTY DAMAGE AND/OR PERSONAL INJURY.

5) Determine that the power outlet to be utilized is properly

grounded. This can be accomplished with proper testing

equipment and procedures. If there are any questions

regarding the suitability of a specific power outlet,

contact the Customer Service Department for

assistance BEFORE utilizing the SURFACE GRINDER.

There is no charge for this service. A qualified electrician

can also be consulted. If a 115 VAC power outlet is

selected, it is recommended that a properly tested,

externally mounted, ground fault circuit interrupter

(GFCI) be utilized at all times as an additional safety

precaution. FIGURE 34.

FIGURE 33

SFG10E ELECTRIC SURFACE GRINDER — OPERATION AND PARTS MANUAL — REV. #2 (05/28/09) — PAGE 24

FIGURE 34

Page 25

DANGERDANGER

DANGER

DANGERDANGER

FOR MAXIMUM PROTECTION AGAINST A FAULT,

ALWAYS CONFIGURE THE GROUND FAULT CIRCUIT

INTERRUPTER TO BE PLUGGED INTO THE EXTENSION CORD. A CONFIGURATION WITH THE GROUND

FAULT CIRCUIT INTERRUPTER PLACED BETWEEN

THE POWER SOURCE AND THE EXTENSION CORD

WILL NOT AFFORD MAXIMUM PROTECTION

AGAINST A POTENTIAL FAULT.

6) Couple the NEMA 6-20R receptacle and the NEMA 620P plug together.

7) Grasp the operator handle with firm gripping. When

starting the electric motor, apply a down force directly

to the operator handle to help reduce the amount of

machine weight against the work surface. Turn the ON/

OFF switch to the ON position. Reduce the amount of

applied down force on the operator handle as the electric

motor attains its operational speed.

When operating on 115 VAC, the electric motor will

require additional starting time to help compensate for

the additional starting amperage requirement. This time

is usually within two seconds of activating the ON/OFF

switch.

8) The SFG10E SURFACE GRINDER is not equipped with

a centrifugal clutch assembly. The electric motor is

directly coupled to the multi-accessory disc by a Vbelt/spur gear transmission.

DANGERDANGER

DANGER

DANGERDANGER

AS SOON AS THE ELECTRIC MOTOR HAS STARTED,

THE OPERATOR MUST BE IN A POSITION TO

ASSUME DIRECT AND FULL CONTROL OF THE

SURFACE GRINDER. FAILURE TO ASSUME DIRECT

AND FULL CONTROL CAN RESULT IN PROPERTY

DAMAGE AND/OR PERSONAL INJURY.

ASSEMBLY INSTRUCTIONS/OPERATIONS

OPERATING THE SURFACE GRINDER ON THE