Page 1

OperatiOn Manual

raMMaX viper

MODel rX 1510-C/-i/-Ci

viBratOrY trenCH rOller

(lOMBarDini lDW 1003)

Revision #0 (10/20/10)

To find the latest revision of this

publication, visit our website at:

www.multiquip.com

THIS MANUAL MUST ACCOMPANY THE EQUIPMENT AT ALL TIMES.

Page 2

proposition 65 warning

Diesel engine exhaust and some of

Page 3

RX 1510-C/-I/-CI

Identification:

Product identification:

Manufacturer: Rammax Maschinenbau GmbH

Customer service: Rammax Maschinenbau GmbH

Type: RX 1510

Model: -C/-I/-CI

Series number:

Production date:

Gutenbergstraße 33

72555 Metzingen

Telephone 07123/9223-0

Telefax 07123/9223-50

E-Mail: Service@Rammax.de

Germany

Gutenbergstraße 33

72555 Metzingen

E-Mail: Service@Rammax.de

Germany

Service: Mr. Horst Reusch +49 (0)7123/9223-27

Spare parts: Mr. Joachim Götz +49 (0)7123/9223-34

Fax: +49 (0)7123/9223-55

Document identification:

Title: Operating instructions (Translation of the original

operating instructions)

Document number:

Change index:

– 3 –

Page 4

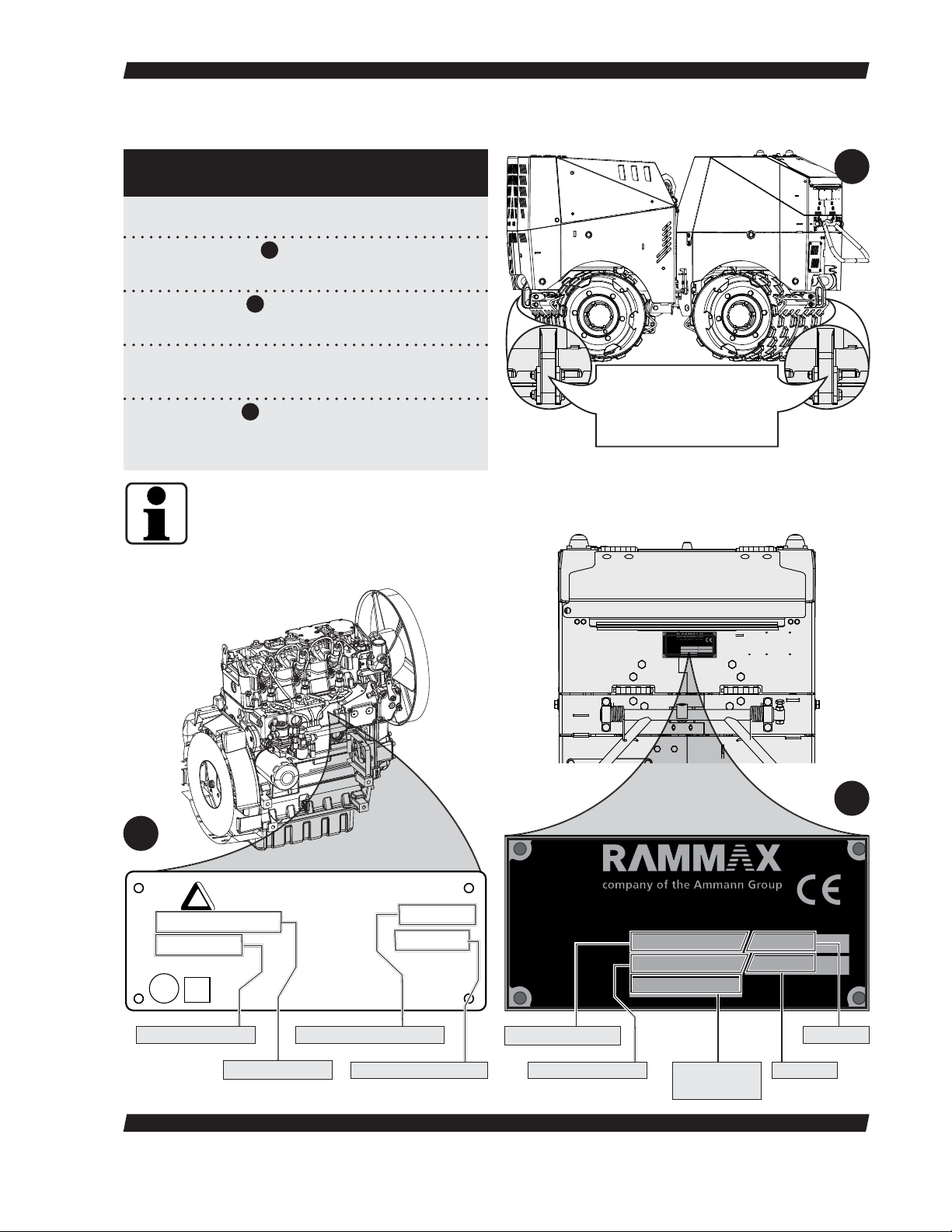

Identification:

Identification of the machine

RX 1510-C/-I/-CI

On transfer of the machine, please

complete:

Type of machine

Series number

Engine type

Motor number

One of our staff or a dealer will instruct you

on use and maintenance of the machine at

delivery. For this purpose, it is absolutely

necessary to observe the safety instructions

and danger warnings.

03

01

02

01

12345

Always indicate the machine series number when

ordering spare parts.

02

Type

LOMBARDINI

LDW 1603/B2

3064770

Series number:

Engine model:

DUBLICATE

LABEL

Adjusted speed:

Customer number:

rpm

2500

K

792006

Typ/Gewicht

Masch.Nr./Leistung

Baujahr

Type of machine:

Series number:

– 4 –

72555 Metzingen

Tel.07123/92230 - Fax07123/922350

Typ/Gewicht

Masch.Nr./Leistung

Baujahr

Made in Germany

72555 Metzingen

Tel.07123/92230 - Fax07123/922350

Made in Germany

Year of

construction:

Output:

03

Weight:

Page 5

RX 1510-C/-I/-CI

General information

The practical development and construction, as well as the experience of many years in manufacturing vibration

trench rollers, guarantee that you have a high-quality and extremely reliable machine. The following operating and

maintenance instruction comprise:

• Safety regulations • Description of the machine

• Operating instructions • Maintenance instructions

• Troubleshooting table

Rammax GmbH accepts no liability for machine function

• In the event of incorrect handling or operation not in compliance with the prescribed mode of operation and

procedures,

• If used for other purposes, which do not comply with the intended use (See Intended Use Subsection 1.1.4)

or to the specified areas of application (Subsection 1.1.3).

No warranty claims may be asserted in the case of:

• Operating errors,

• Lack of maintenance and/or

• Incorrect operating fluids!

General:

For your own safety and in order not to impair the function of the machine only use Rammax spare parts

(Subsection 1.1.7 Changes to the Machine). The spare parts catalogue and the operating instructions are also

available in other languages from your Rammax dealer, with specification of the machine number.

The warranty and liability conditions contained in the General Terms and Conditions of Rammax GmbH are not

extended or replaced by the information contained above or below.

Rammax GmbH Metzingen

Purpose of the operating instructions:

The use of these operating instructions will:

• Simplify the process of familiarisation with your

machine.

• Prevent malfunctions due to operating errors.

Target group:

The operating instructions are addressed to the machine

operators. Detailed specifications on the necessary

training and qualification can be inferred from Chapter

2.4 Organisational/Personal Matters.

Observance of the maintenance instructions will:

• Increase the reliability during use on the building

site,

• Increase the service life of the machine,

• Reduce repair costs and downtimes.

– 5 –

Page 6

General:

Structure of the documentation:

RX 1510-C/-I/-CI

Operating and

Maintenance

Instructions

The machine documentation is divided into 3 individual document groups:

• The operating instructions contain: All information necessary for operating the machine.

• The spare parts list contains: All available spare parts and part sets

• The service and maintenance instructions contain: The information necessary for maintenance and repair and

Spare parts list Service

and maintenance

instructions

Specifications on the maintenance intervals and

accomplishment of the maintenance work

steps

– 6 –

Page 7

RX 1510-C/-I/-CI

The individual chapters of the operating instructions contain the following topics:

Chapter 1:

• Description of the machine

• Technical data

• Features

• Accessories

Chapter 2:

• General safety instructions

• Danger area of the machine

• Safety equipment

• Required qualifications of the operators and of the service staff

• Product specific and additional dangers

• Specifications for an emergency.

Chapter 3:

• Construction and function of the machine.

Chapter 4:

• Display and control elements

• Operation modes of the machine

Chapter 5:

• Start-up of the machine

Important notes on the operating instructions:

Chapter 6:

• Use of the machine

Chapter 7:

• Transport of the machine

Chapter 8:

• Maintenance of the machine

Chapter 9:

• Tightening torques for bolt connections

Chapter 10:

• Troubleshooting table

– 7 –

Page 8

Important notes on the operating instructions:

Used font weights/typeface

Chapter heading: Arial 14Pt Bold

Section heading: Arial 12Pt Bold

Subsection: Arial 10Pt Bold

Main text: Arial 10Pt Regular

Marginal notes and cross references: Arial 10Pt Italic

Passages to be observed: Arial 10Pt Bold

Action steps for which a strict sequence must be observed are marked by numbers:

1)

2)

3)

Subsequent steps of the action steps and results of the actions are marked by arrows:

►

►

►

RX 1510-C/-I/-CI

Enumerations are marked by dots:

•

•

•

Subitems within an enumeration or an action step are marked with an indent:

–

–

–

Pictogram Meaning

User information

– 8 –

Page 9

RX 1510-C/-I/-CI

Safekeeping and completeness of the

operating instructions

These operating instructions are a firm component of

the machine and must be available for the user of the

machine, in order to look up. It must always be kept

within reach. No chapter of these operating instructions

may be removed. Missing instructions or missing pages

- particularly the section "Safety instructions" - must be

replaced immediately, if they are lost.

The operating instructions must be kept for the service

life of the machine and be passed on to each later

owner or operator.

Updating service:

These operating instructions are not subject to the

updating service of Rammax Maschinenbau GmbH. This

documentation can be changed without notification.

Used trademarks

Important notes on the operating instructions:

The trademark POCLAIN HYDRAULICS® is property of the POCLAIN HYDRAULICS SA.

Twin Lock™ is a trademark of the POCLAIN HYDRAULICS SA.

LOMBARDINI® is a registered trademark of LOMBARDINI S.R.L.

Mobil™ is a trademark of the ExxonMobil Central Europe Holding GmbH

Texaco® is a registered trademark of Chevron Products Company, USA

Texaco Rando® is a registered trademark of Chevron Products Company, USA

Copyrights

Reproduction, copying or translating this document, also in part, is only permitted with written permission of the

Rammax GmbH.

©Rammax 2008

Rammax Maschinenbau GmbH

Gutenbergstrasse 33

72555 Metzingen

Telephone 07123/9223-0

Telefax 07123/9223-50

E-Mail: Service@Rammax.de

www.Rammax.de

– 9 –

Page 10

Table of Contents:

Table of Contents

1. Description of the machine 14

1.1 Important notes on the machine 14

1.1.1 Orientation on the machine 14

1.1.2 Description

1.1.3 Areas of application

1.1.4 Intended use

1.1.5 Workplace

1.1.6 Danger areas

1.1.7 Modifications to the machine

1.2 Technical data 17

1.2.1 Main dimensions 17

1.2.2 Turn radius

1.2.3 Operating fluids

1.3 Noise and vibration specifications 21

15

15

15

15

15

15

18

20

RX 1510-C/-I/-CI

1.4 Equipment of the machine

1.4.1 Variations of the machine/machine types 22

1.5 Stowage plan 23

15.1 Position of the hoods and hatches 23

2. Safety instructions 24

2.1 Representation and meaning of the used safety instructions 25

2.1.1 Situation-specific safety instructions 25

2.1.2 Chapter and section-specific safety instructions

2.1.3 Used symbols

2.2 Intended use/Product safety 34

2.2.1 Purpose of use of the machine 34

2.3 Danger areas 34

2.3.1 Workplace 34

2.3.2 Safety equipment

2.3.3 Observing danger warnings on the machine

2.4 Organisational, personal matters 37

27

22

26

34

35

2.5 Product-specific dangers

2.5.1 During operation 37

2.5.2 During maintenance work

37

38

– 10 –

Page 11

RX 1510-C/-I/-CI

2.6 Additional dangers 39

Table of Contents:

2.7 Emergency measures

3. Construction and function 40

3.1 Introduction 40

3.1.1 Basic information on soil compaction 40

3.2 Mechanical construction 40

3.3 Opening and closing of the hoods

3.3.1 Opening the cockpit hatch 41

3.3.2 Turning down the control unit

3.3.3 Opening and closing of the engine hood

3.3.4 Unlocking and opening the radiator cap

3.3.5 Components

3.4 Functional description 43

3.5 Safety and monitoring equipment

3.5.1 Shut down yoke 44

3.5.2 Low distance shutdown (only with infrared control)

3.5.3 Far distance shutdown (only with infrared control)

3.5.4 Inclination indicator

3.5.5 Automatic switch-off generator failure

3.5.6 Automatic switch-off oil pressure

3.5.7 Automatic switch-off cooling water temperature

3.5.8 Automatic speed adjustment

3.5.9 Transport protection

39

41

41

41

42

43

44

44

44

45

45

45

46

46

46

4. Display and operating elements 47

4.1 Introduction 47

4.2 Warning signals

4.3 Display elements

4.4 Operating elements

4.4.1 Manual control device 51

4.4.2 Function codes during operation with cable control

4.4.3 Cockpit display with cable control

4.4.4 Infrared transmitter

4.4.5 Function codes during operation with infrared control

4.4.6 Cockpit display with infrared control

48

49

51

52

53

55

56

57

– 11 –

Page 12

Table of Contents:

5. Start-up 59

5.1 Safety instructions 59

RX 1510-C/-I/-CI

5.2 Examination before start-up

5.2.1 Checking hydraulic oil level 59

5.2.2 Checking engine oil level

5.2.3 Checking cooling water level

5.2.4 Checking the contamination degree of the air filter

5.2.5 Checking fuel level / Tanking fuel

5.2.6 Adjusting address to transmit transmitter signals

5.3 Starting the machine 65

5.3.1 Switching ignition on 65

5.3.2 Stand-by mode

5.3.3 Starting the machine at the ignition lock

5.3.4 Starting the machine with the manual control device

5.3.5 Starting the machine with the infrared control.

5.4 Switching machine off 70

5.4.1 Switching the machine off at the ignition lock 70

5.4.2 Switching the machine off with the manual control device

5.4.3 Switching the machine off with the infrared control device

6. Using the machine 73

6.1 Safety instructions 73

66

59

60

61

62

63

63

66

67

68

71

72

6.1.1 General 73

6.1.2 Before operating the machine

6.1.3 Using the vibration function

6.2 Parking the machine 76

7. Loading and transporting the machine 77

7.1 Safety instructions 77

7.1.1 General 77

7.1.2 Loading the machine with a loading ramp

7.1.3 Loading the machine with hoisting gear

7.2 Using the transport protection 78

7.3. Loading the machine with ramps

7.4 Loading the machine with hoisting gear

7.5 Securing the machine for transport

– 12 –

74

74

77

77

79

79

80

Page 13

RX 1510-C/-I/-CI

8. Maintaining the machine 81

8.1 Safety instructions 81

8.1.1 General 81

8.1.2 Refuelling fuel

8.1.3 Working on the engine

8.1.4 Working on electrical system components

8.1.5 Working on the fuel system

8.1.6 Cleaning work

8.1.7 After completing maintenance work

8.1.8 Repair

8.1.9 Exchanging drums

8.1.10 Working on the hydraulic system

8.2 Maintenance plan 84

82

81

81

81

82

82

82

82

82

Table of Contents:

8.3 Checking engine oil level

8.4 Exchanging engine oil

8.5 Checking the contamination degree of the air filter

8.6 Changing the fuel filter

8.7 Emptying the fuel tank

8.8 Checking hydraulic oil level

8.9 Hydraulic oil change/ Hydraulic filter change

8.10 Checking cooling water level

8.11 Draining /refilling cooling water

8.12 Exchanging drums

95

85

86

88

89

90

91

93

94

88

9.0 Tightening torques: 98

10.0 Troubleshooting table 99

8.13 Adjusting stripper

8.14 Servicing the battery

96

96

– 13 –

Page 14

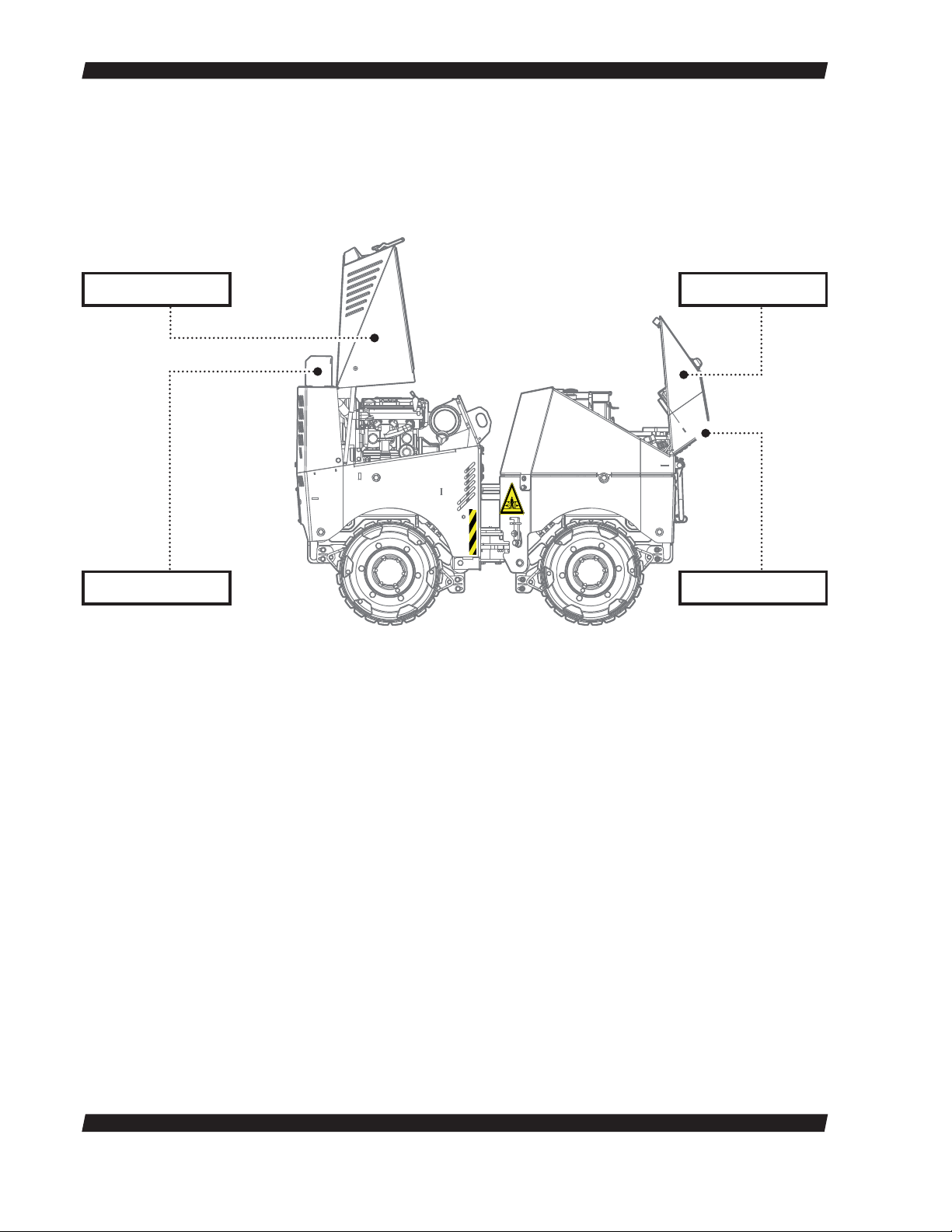

Important notes on the machine

1. Description of the machine

1.1 Important notes on the machine

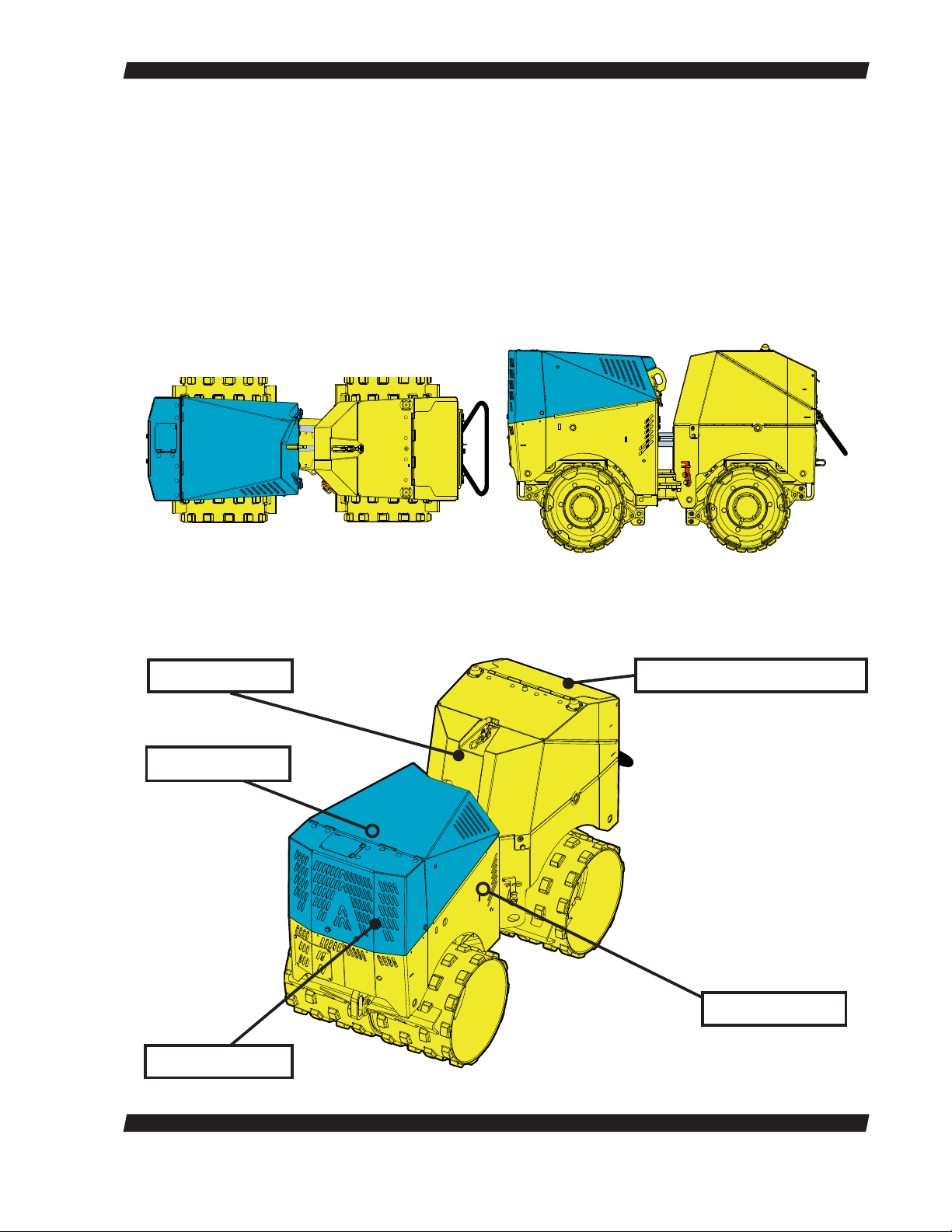

1.1.1 Orientation on the machine

The most important areas of the machine are described here, in order to facilitate

orientation on the machine. Specifications in the text concerning situation and

position are based on the following principle: All specifications on situation or

position are to be seen from the cockpit in driving direction. The descriptions are

therefore characterised as follows:

Right

RX 1510-C/-I/-CI

Above

Front

Left

Names of the most important assembly groups:

Rear end

Drive unit

Rear

Down

Control unit / Cockpit

Vorderwagen

Front car

Articulation

– 14 –

Page 15

RX 1510-C/-I/-CI

Important notes on the machine

1.1.2 Description

Our long experience in the development and construction of vibratory trench

rollers is the basis for the new development of the infrared and/or cable controlled

RX 1510-CI. The enormous degree of operating convenience, which provides

both for cable and infrared control, permits the user to make even more flexible

use of the machine. The hard-wearing, compact design offers a high degree

of security even in the most difficult terrain. The RX 1510-CI is equipped with

hydrostatic steering, vibration, and drive. The machine is extremely maintenance

friendly (with the exception of the diesel engine), no V-belts, drive belts, lubrication

nipples or shiftable clutches are used. Most modern control electronics, as well

as the proven 8 strippers for the drums characterise this machine.

1.1.3 Areas of application

The vibratory trench roller RX 1510-CI is a roller particularly designed for trench

compaction. The complete lack of side walls on the drum enables compaction right

up to the trench wall also in very small and narrow trenches. Wet, clayey soils in

canalisation, pipeline construction, road substructure and construction backfills,

etc., are the ranges of application of this modern trench roller. The infrared control

also permits driving underneath bracings when constructing trenches. During

dangerous construction-site operations, it is possible for the operator to control

the machine from a safe distance and not to expose himself to hazards.

1.1.4 Intended use

The machine is exclusively conceived for the compaction of loose backfill, such

as earth, gravel, or sand, as well as mixtures of these. The machine may not be

used on hard, already compacted or frozen soils.

1.1.5 Workplace

The intended workplace of the machine operator is behind the machine. The

control switches of the control elements only correspond to the direction of

movement of the machine from behind the machine.

1.1.6 Danger areas

There is the risk of crushing in the area of the articulation! Staying in this area

during operation is not permitted. During operation of the vibration function, loose

stones, earth and rubble can be hurdled into air. Persons in this area can be hit

and injured by these flying around objects. A safety distance of at least 2 meters

must be observed around the machine, when the machine is in operation.

1.1.7 Modifications to the machine

For reasons of safety, users are prohibited from making their own modifications

or conversions to the machine. This machine may only be equipped with original

spare parts, which have been constructed for this machine and correspond to the

requirements of the manufacturer. The installation or use of special `equipment

or special parts can impair driving safety.

The manufacturer does not warrant for damages, which result from the use of

non-original parts or optional equipment, each adhesion of the manufacturer is

impossible and all warranty claims become void.

– 15 –

Page 16

g

,

,

Important notes on the machine

Verdichtung

EC-Declaration of Conformity / Déclaration ”CE” de Conformité

gemäß Maschinen-Richtlinie 98/37/EG, Anhang II A und der Outdoor Richtlinie 2000/14/EG

conformément à la directive "CE"' relative aux machines 98/37/CE, Annexe Il A et á la directive outdoor 2000/14/EG

Hersteller (Name und Anschrift): Rammax Maschinenbau GmbH

Manufacturer (name and adress): Gutenbergstr. 33

Fabricant (nom et adresse):

Costruttore (nome ed indirizzo) D-72555 Metzingen

Hiermit erklären wir, daß die Maschine (Typ, Versionsnummer) Vibrationsgrabenwalze

Herewith we declare that the machinery (Type, version number) Vibratory trench roller / Cylindre vibrant pour fossés

Par la présente, nous déclarons que la machine (Type, numèro de version)

Con la presente dichiariamo che il macchinario (Tipo, numero di versione) RX 1510-C/-I/-CI / Lombardini LDW 1003 / 3B65E1

Nutzleistung: 15,8 kW / 2650 U/min

Effective output / puissance utile / capacitá utile:

Seriennummer: 1838728

Serial number / Numéro de série / Numero di serie

Ordnungsnummer: 8.1

Ordinal number / Nombre ordinal / Numero ordinale

folgenden einschlägigen Bestimmungen entspricht: 98/37/EG Anhang 11 A; 89/336/EWG; 2000/14/EG

complies with the following provisions applying to it: 98/37/EC Annex 11 A; 89/336/EC; 2000/14/EC

correspond aux dispositions pertinentes suivantes: 98/37/CE Annexe 11 A, 89/336/CE, 2000/14/CE

risponde a quanto richiesto dalle seguenti direttive in materia:

Angewandte harmonisierte Normen: EN 500-1; EN 500-4

Applied harmonized standards: / Normes harmonisées appliquées: /

Norme armonizzate applicate:

Die gemeldete Stelle nach Anhang IX aus 2000/14/EG TÜV Süddeutschland

The notified body according to Annex IX of 2000/14/EC Niederlassung Stuttgart

L´organisme habilité conformément à l'Annexe IX de 2000/14/CE

L'ufficio responsabile secondo l'Allegato IX di 2000/14/CE D- 70794 Filderstadt

wurde (wird) eingeschaltet zur / was (is) engaged for / intervient pour:

è intervenuto (interverrà) per:

Konformitätsbewertung nach Anhang VI aus 2000/14/EG

valuation of conformity to Annex VI of 2000/14/EC

conformément à l'Annexe VI de 2000/14/CE

Valutazione di conformità secondo l'Allegato VI di 2000/14/CE

An repräsentativem Baumuster gemessener Schallleistungspegel

nach ISO 3744:

L

wA

Measured sound power level L

construction model:

Niveau de puissance de son L

construction représentatif:

Livello di potenza sonora L

rappresentativo secondo ISO 3744:

Gemessener Schallleistungspegel L

Guaranted sound power level: 107 dB(A)

Niveau de puissance de son garanti:

Livello garantito di potenza sonora:

Garantierter Schallleistungspegel L

Guaranted sound power level: 109 dB(A)

Niveau de puissance de son garanti:

Livello garantito di potenza sonora:

Verantwortliche Person zur Aufbewahrung der Unterlagen: Frank Edmaier

Responsible person for safekeeping the documents Ltg. Konstruktion/Entwicklung

Presonne responsable puor garde des documents

Persona responsabile per conservazione dei documenti

as defined by the Machinery Directive 98/37/EC Annex II A and Noise directive 2000/14/EG

in conformità alla Direttiva sui Macchinari 98/37/CE, Allegato II A et ala Direttiva outdoor 2000/14/EG

of ISO 3744 on represented

WA

mesuré à ISO 3744 du modèle de

WA

misurato su un modello

WA

:

WA,m

:

WA,g

EG-Konformitätserklärung

Dichiarazione di conformità CE

RX 1510-C/-I/-CI

Metzingen, 11.4.2008 i. A. Stoll, Vertrieb

ppa. Thomas Remy, Ltg. Vertrieb i.A. Frank Edmaier, Ltg. Konstruktion

Ort, Datum Unterschrift, Angabe der Funktion im Unternehmen

Place, date / Lieu, date Signature, acting in the company / Signature, en qualité de

Luogo, data Firma, funzione all'interno della ditta

Rammax GmbH / Gutenbergstraße 33 / 72555 Metzingen / +49 (0) 7123 92230 / +49 (0) 7123 922350 / Service@Rammax.de

– 16 –

Page 17

RX 1510-C/-I/-CI

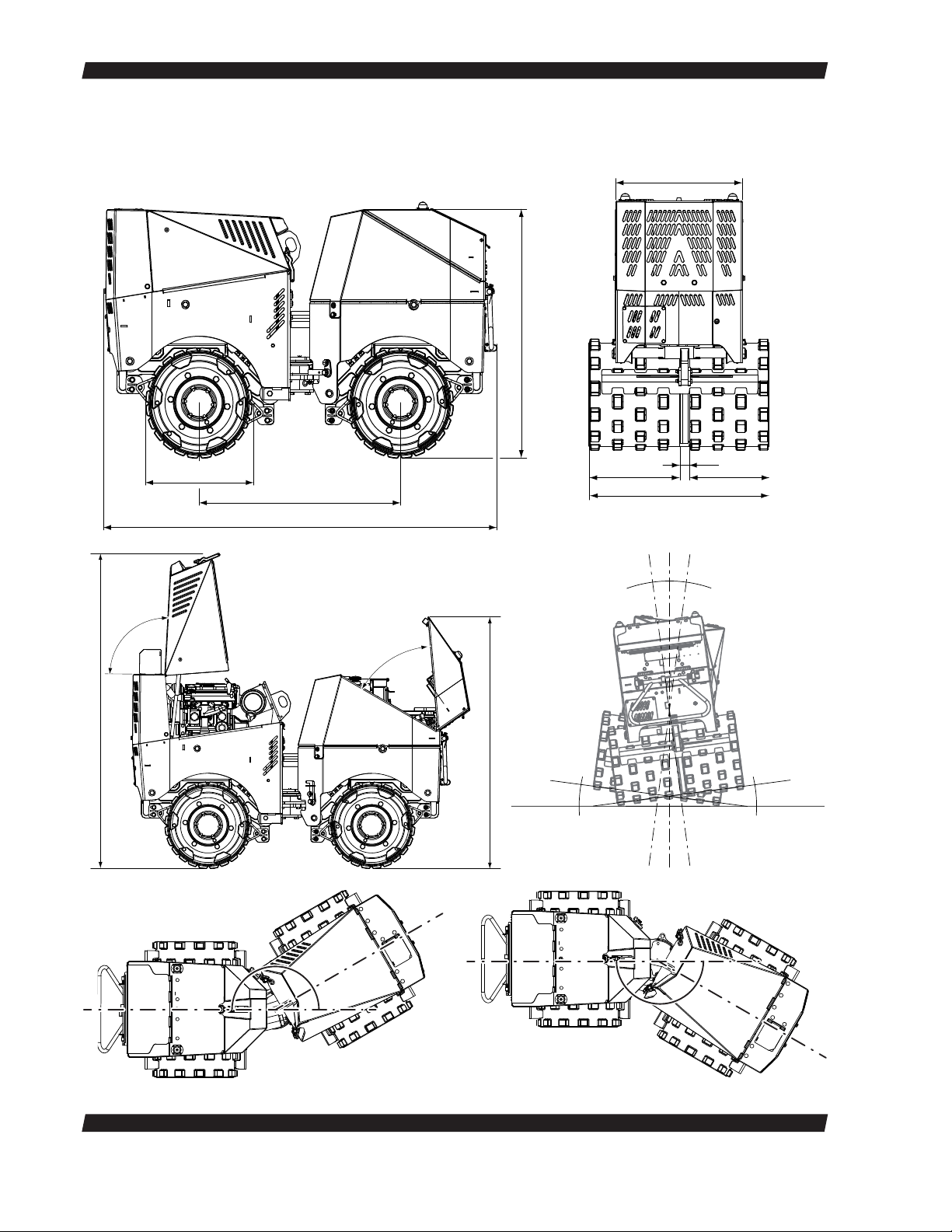

1.2 Technical data

Ø525

1.2.1 Main dimensions

990

1912

1160

428

Specifications:

600

45

377

850

1907

7,5° 7,5°

91°

55°

1524

7,5°7,5°

30°

30°

– 17 –

Page 18

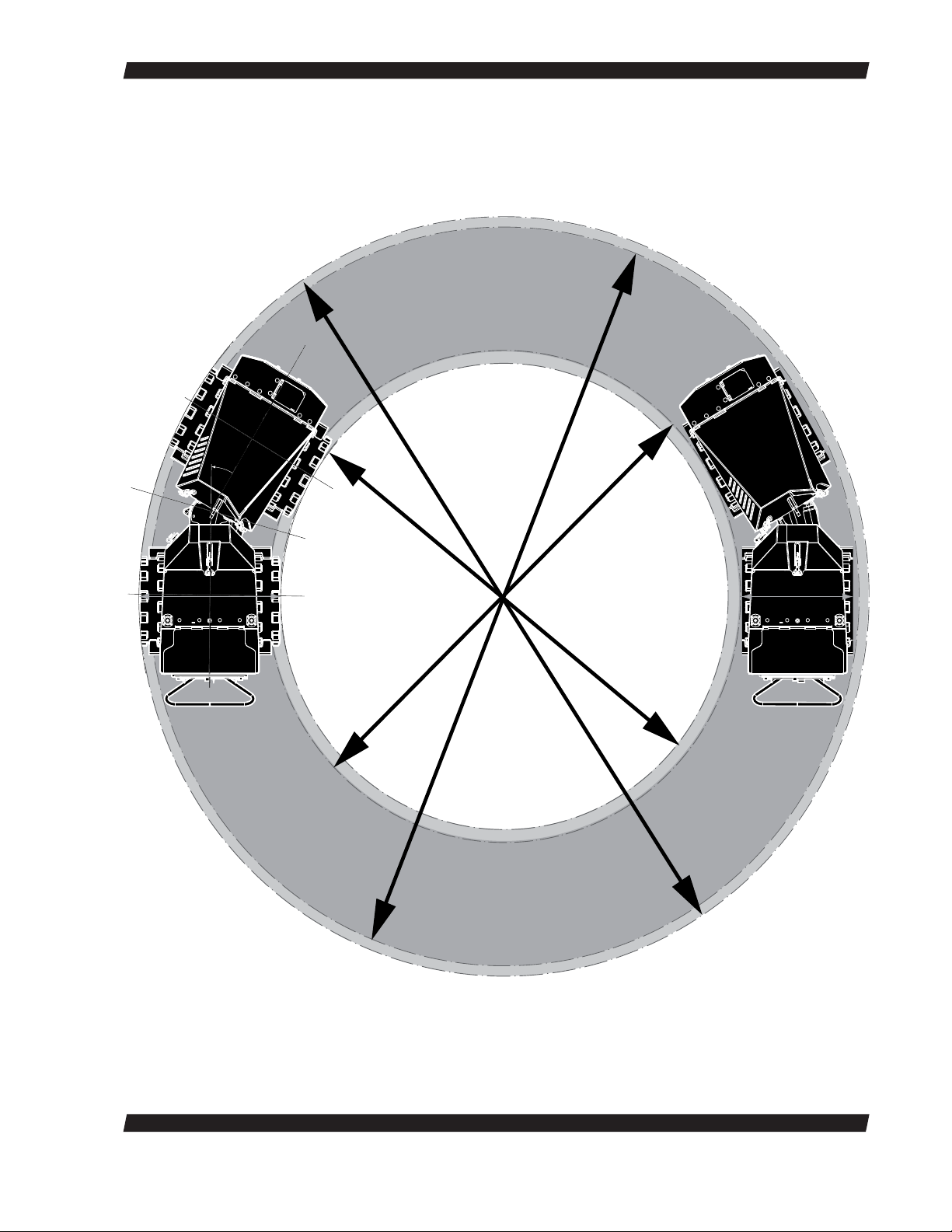

Specifications:

30°

RX 1510-C/-I/-CI

1.2.2 Turn radius

Ø 4,47 m

Ø 2,76 m

85 cm 63 cm

Ø 2,98 m

Ø 4,25 m

– 18 –

Page 19

RX 1510-C/-I/-CI

Specifications:

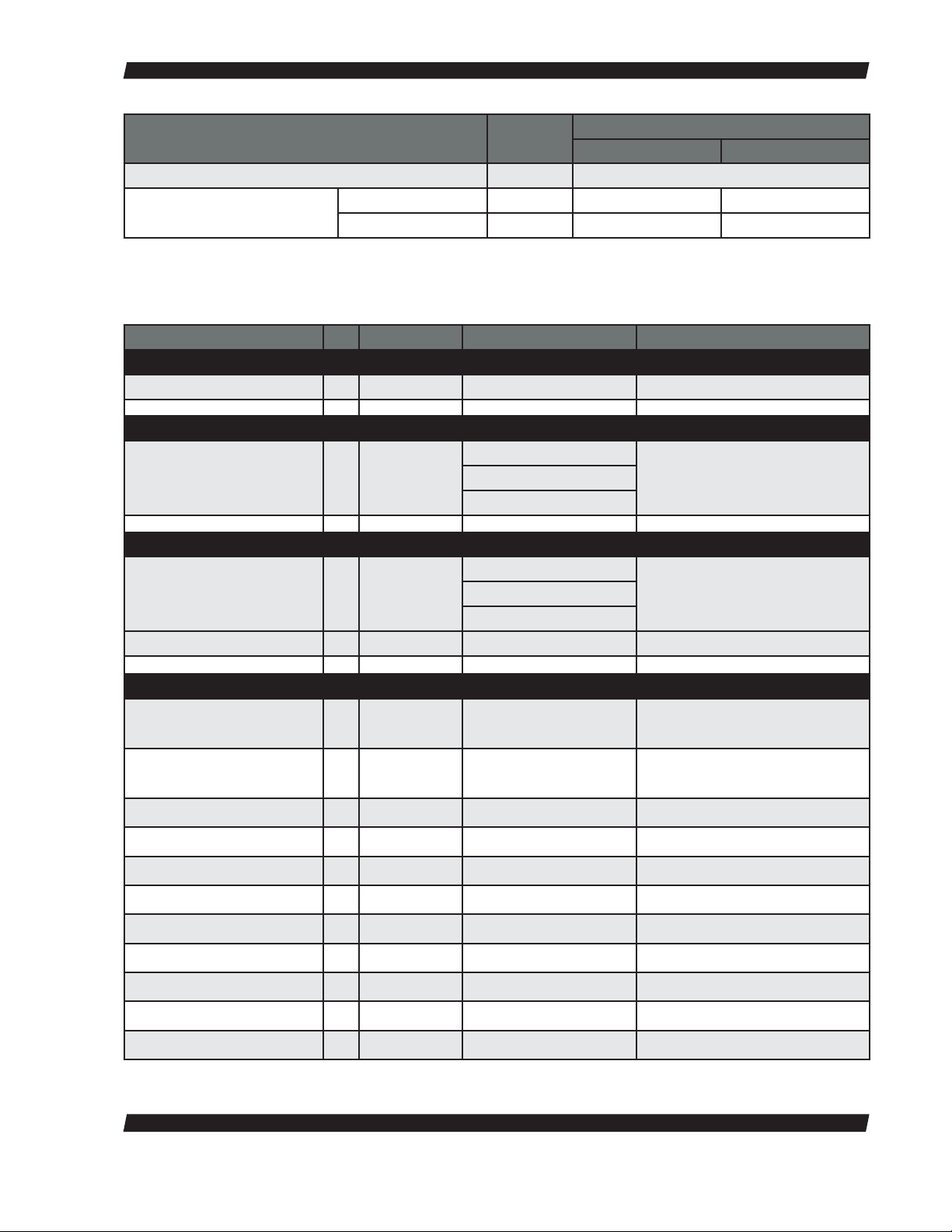

Main dimensions

Dimensions:

Working width: mm 630 850

Overall width:

Overall length: mm 1912

Overall height: mm 1175

Distance between axles: mm 990

Drum diameter: mm 525

Weights:

Operational weight: kg 1470 1530

Axle load front:

Axle load rear: kg 735 765

Static line load: kg/cm 12 9

Dynamic line load: kg/cm 58 46

Drive system:

Engine/Type: Lombardini LDW 1003

mm 630 850

kg 735 765

drum narrow drum wide

RX 1510

Output:

Rotation speed:

No. of cylinders/cooling: 3 / Water cooled

Drive mode: hydrostatic

Vibration system:

Centrifugal

force:

Frequency:

Rotation

speed:

Driving characteristics:

Speed:

Steering: Articulation

Steering angle: +/-° 30

Inclination angle pendulum joint: +/-° 7,5

with large amplitude:

with low amplitude: kN 42

with large amplitude: Hz 41

with low amplitude: Hz 41

with large amplitude: rpm 2460

with low amplitude: rpm 2460

W

High speed: m/min 38

max.: rpm 2850

idling mixture: rpm 1350

orking gear: m/min 16

kW/PS 15,8 / 20,4

kN 73

– 19 –

Page 20

Specifications:

RX 1510-C/-I/-CI

Main dimensions

Gradeability w. / w/o. vibration: % 50/60

urn radius

T

1.2.3 Operating fluids

Fuels:

Diesel fuel: l 23

Hydraulics:

Hydraulic oil: l 43

Lubricants:

Engine oil: l 2,5

Bearing grease per gr approx.100 KHLPF2R Aeronix MoS2

inner: m 2,98 2,76

outer: m 4,25 4,47

Quantity Specification Recommendation

DIN 51524-2 HLP

ISO 6743-6 CKC 46

ACEA

E2/B3/A3

API CG-4/SJ

MIL-L-2104E

drum narrow drum wide

46

RX 1510

Fuchs Renolin B15 VG46ISO 6743-4 HM 46

Fuchs Titan universal

15W40

Cooling system:

Coolant: l 3,75

Freeze protection

capability after ASTM D

W

ater/ethylene

glycol mixture

% 10 -4°C

% 15 -7°C

% 20 -10°C

% 25 -14°C

% 30 -18°C

% 35 -22°C

% 40 -28°C

% 45 -34°C Europe

% 50 -40°C

– 20 –

Fuchs Fricofin S

Page 21

RX 1510-C/-I/-CI

1.3 Noise and vibration specifications

Specifications:

Quantity Specification Recommendation

Use drinkable tap water for making the water/ethylene glycol mixture. Do not

use rainwater or distilled water, since this can create foam. The water/ethylene

glycol mixture should be used all year round in a concentration of at least 35% by

volume.

The noise and vibration specifications listed below in accordance with the EC

Machine Directive in the draft (93/68/EEC) were determined under operating

conditions typical for the machinery in question with vibration over a specified

travel surface (DIN 45635).

In operational application, deviating values may result depending on the prevailing

operating conditions.

Noise emission specification:

The noise emission specification stipulated in accordance with Annex 1, Section

1.7.4.f of the EC Machine Directive is as follows:

- Sound pressure level at the operator station: LpA = 89.9 dB(A)

- Sound power level: LWA = 103 dB(A)

These noise emission values were determined in accordance with ISO 6081 for

the sound pressure level (LpA) and ISO 3744, DIN 45635, for the sound power

level (LWA).

Technical modifications reserved

Rammax RX 1510

– 21 –

Page 22

Equipment:

1.4 Equipment of the machine

RX 1510-C/-I/-CI

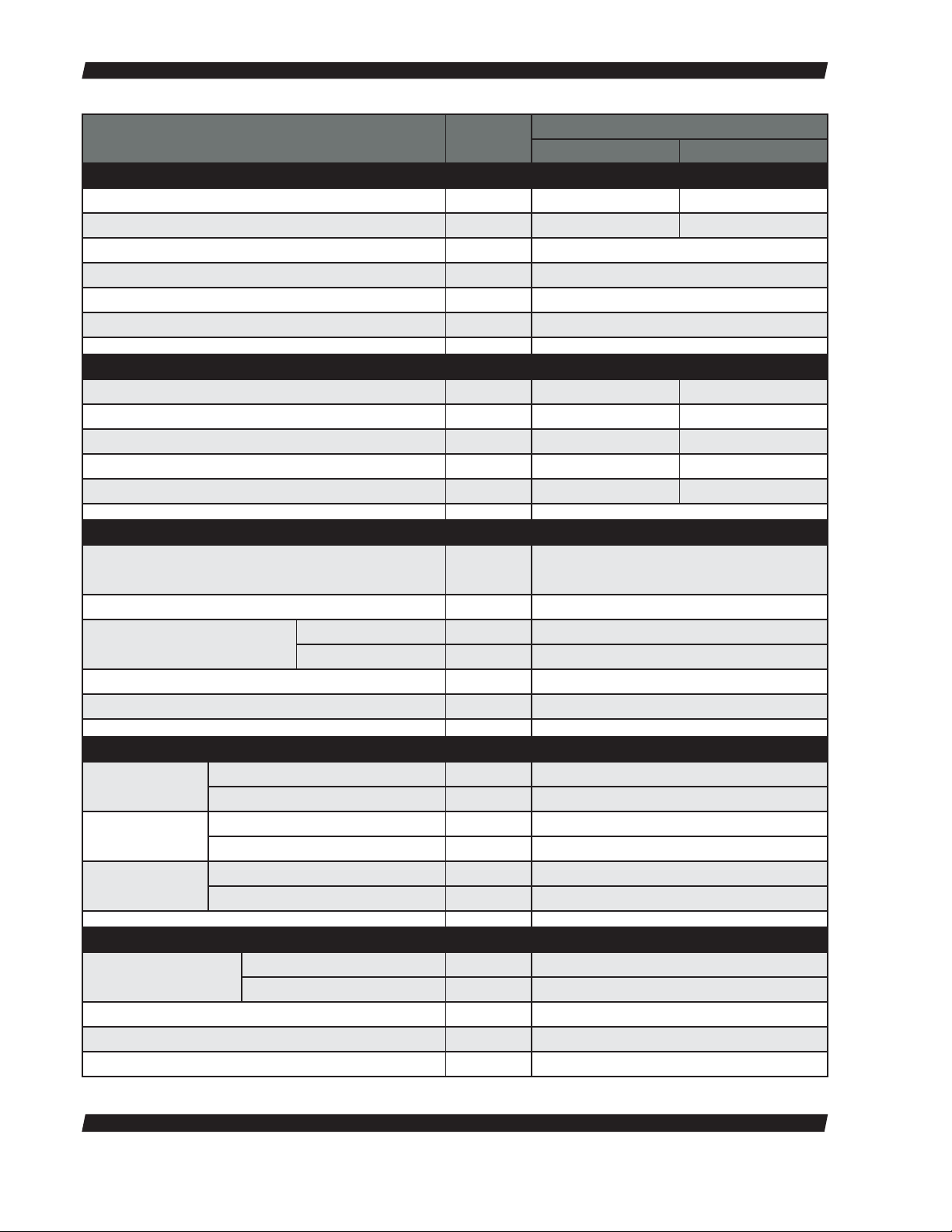

1.4.1 Variations of the machine/machine types

View of the operating unit from the worlplace.

RX 1510-C:

Articulated trench roller with cable control.

Start Stop

RX 1510-I:

Articulated trench roller with infrared control.

RX 1510-CI:

Articulated trench roller with infrared and cable control.

Start Stop

– 22 –

Page 23

RX 1510-C/-I/-CI

1.5 Stowage plan

15.1 Position of the hoods and hatches

The machine is equipped with hoods and hinged components in order to be able

to access all important parts.

Motor hood

Operating panel

Cockpit coverRadiator hatch

– 23 –

Page 24

Safety instructions

2. Safety instructions

RX 1510-C/-I/-CI

– 24 –

Page 25

RX 1510-C/-I/-CI

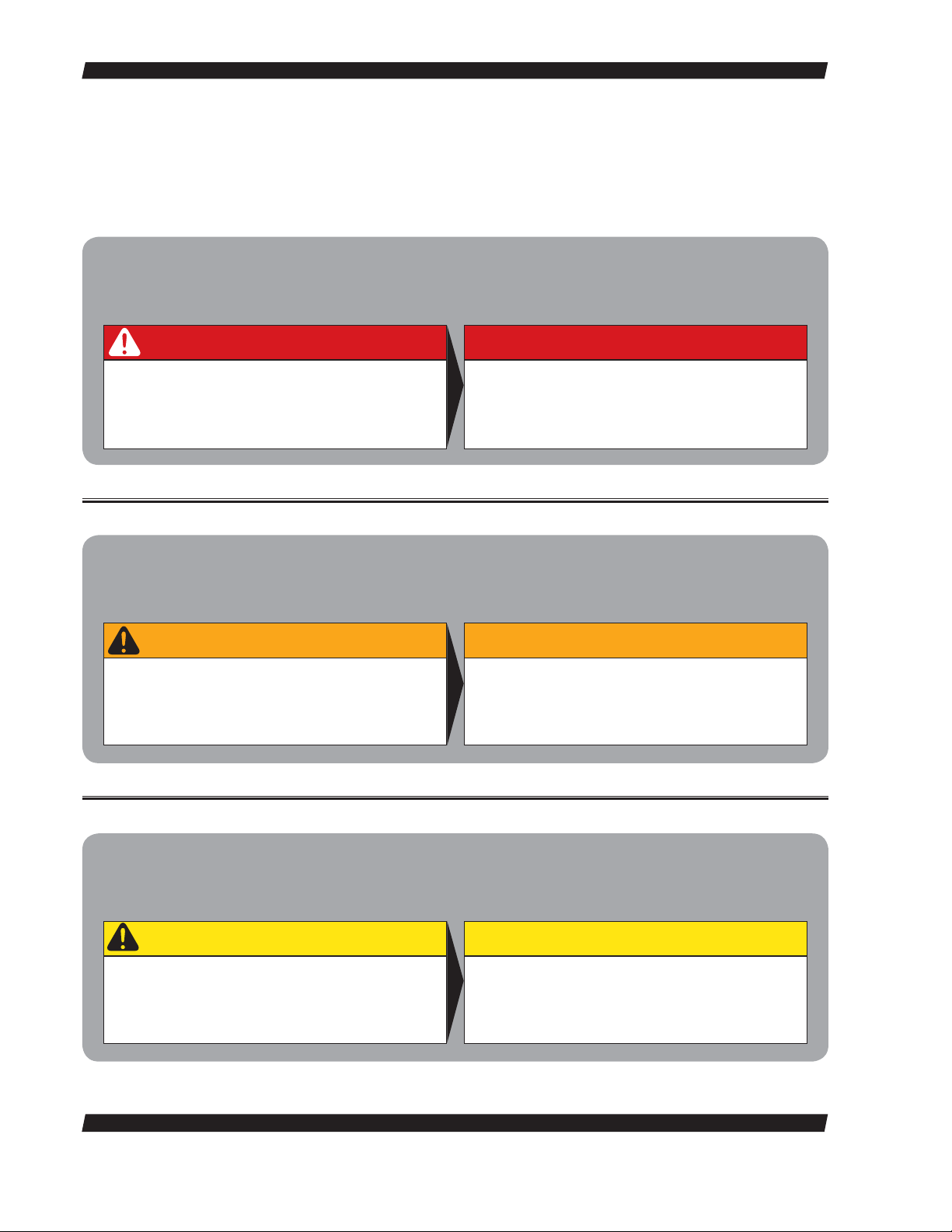

2.1 Representation and meaning of the used safety instructions

2.1.1 Situation-specific safety instructions

Situation-specific safety instructions are safety instructions, which directly refer to

the following activity or situation. They are represented as follows:

DANGER indicates a dangerous situation, which if it is not avoided can result in death or severe injuries.

Safety instructions

Example safety instruction:

DANGER

Dangerous high voltage

Contact causes electric shock

Disconnect power supply before service work.

WARNING indicates a dangerous situation, which if it is not avoided can result in death or severe injuries.

Example safety instruction:

WARNING

Crushing edge

Machine starts automatically.

Keep hands away from draw-in rollers.

Meaning:

RISK LEVEL

Nature and source of the danger

Possible consequences of the danger/reason

for danger

Danger prevention measures

Meaning:

RISK LEVEL

Nature and source of the danger

Possible consequences of the danger/reason

for danger

Danger prevention measures

CAUTION indicates a dangerous situation, which if it is not avoided can result in light or medium severe

injuries.

Example safety instruction:

Danger of burning!

Hot surface.

Do not touch.

CAUTION

Meaning:

RISK LEVEL

Nature and source of the danger

Possible consequences of the danger/reason

for danger

Danger prevention measures

– 25 –

Page 26

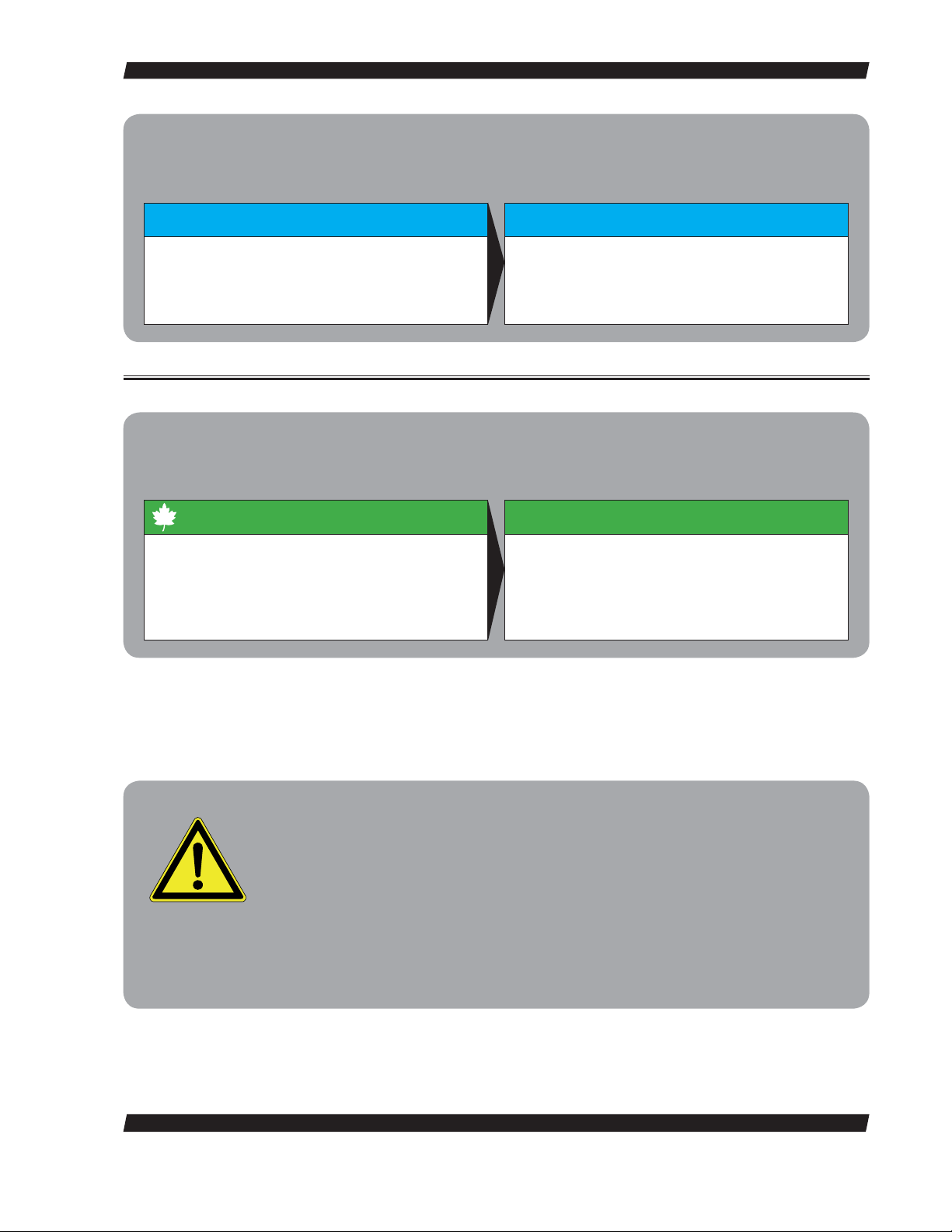

Safety instructions

NOTE refers to situations, which can result in damages to property, describes the consequences, if these

situations cannot be avoided and indicates possibilities to avoid the damages.

RX 1510-C/-I/-CI

Example safety instruction:

Transport protection is still active

Steering movement can damage the transport

protection

Release transport protection before using the

machine

ENVIRONMENT refers to procedures with which the environment can be endangered in the case of

inappropriate activities.

Example note:

ENVIRONMENT

Leaking motor oil!

Lubricants and chemicals pollute the soil

Collect engine oil in suitable containers and

dispose in an environmentally suitable manner

according to the regional regulations.

NOTE

Meaning:

RISK LEVEL

Nature and source of the danger

Possible consequences of the danger/reason

for danger

Danger prevention measures

Meaning:

RISK LEVEL

Nature and source of the danger

Possible consequences of the danger/reason

for danger

Danger prevention measures

2.1.2 Chapter and section-specific safety instructions

At the beginning of each chapter or section, all safety instructions relevant for

the chapter or section are collectively specified. They are highlighted in grey and

marked by a "Caution!" symbol.

– 26 –

Page 27

RX 1510-C/-I/-CI

Safety instructions

2.1.3 Used symbols

Imperative instructions:

Symbol:

Meaning:

Use hearing protection.

– 27 –

Page 28

Safety instructions

RX 1510-C/-I/-CI

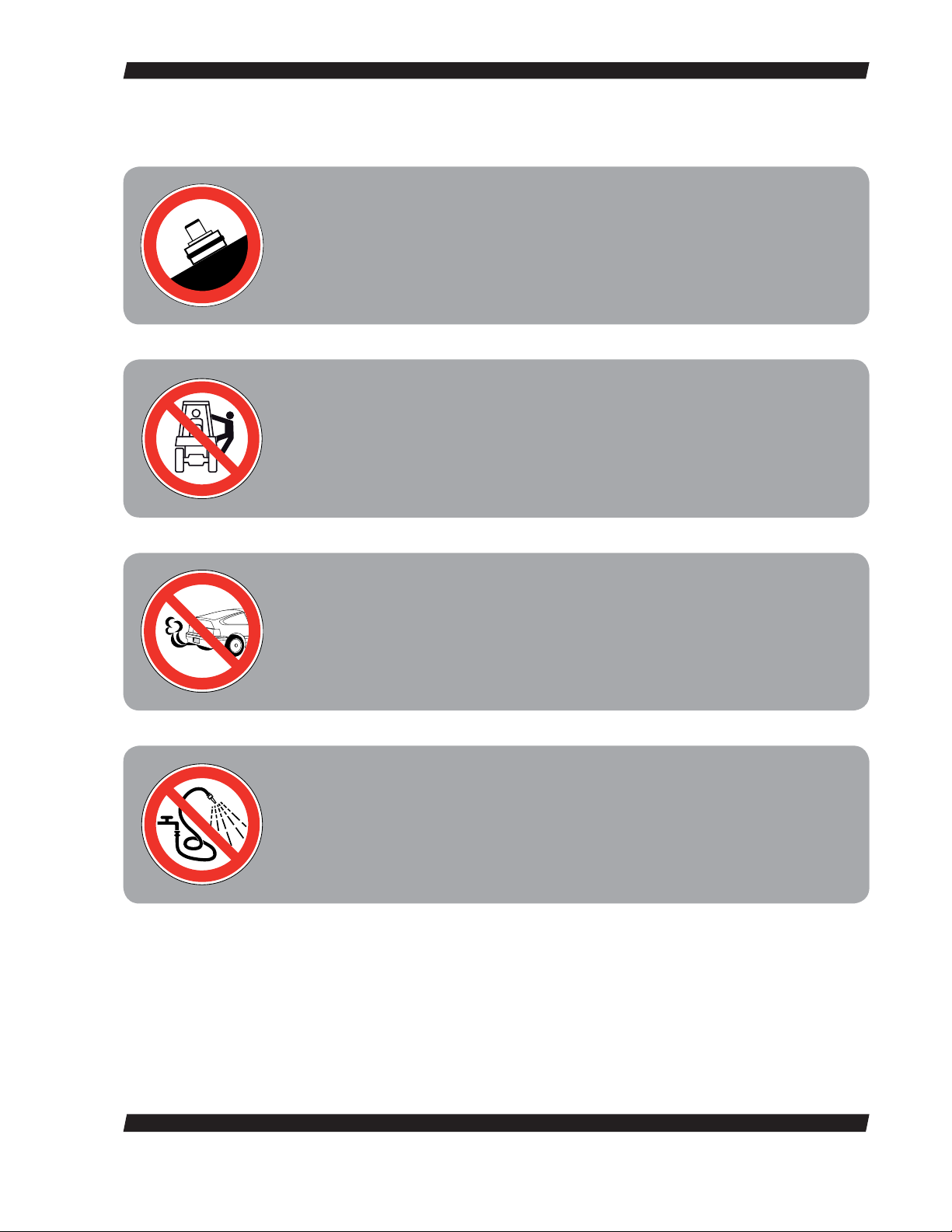

Prohibitions:

Symbol:

Meaning:

Do not drive on slopes diagonally

Do not transport persons

Turn engine off in closed areas

Do not use steam jets

– 28 –

Page 29

RX 1510-C/-I/-CI

Safety instructions

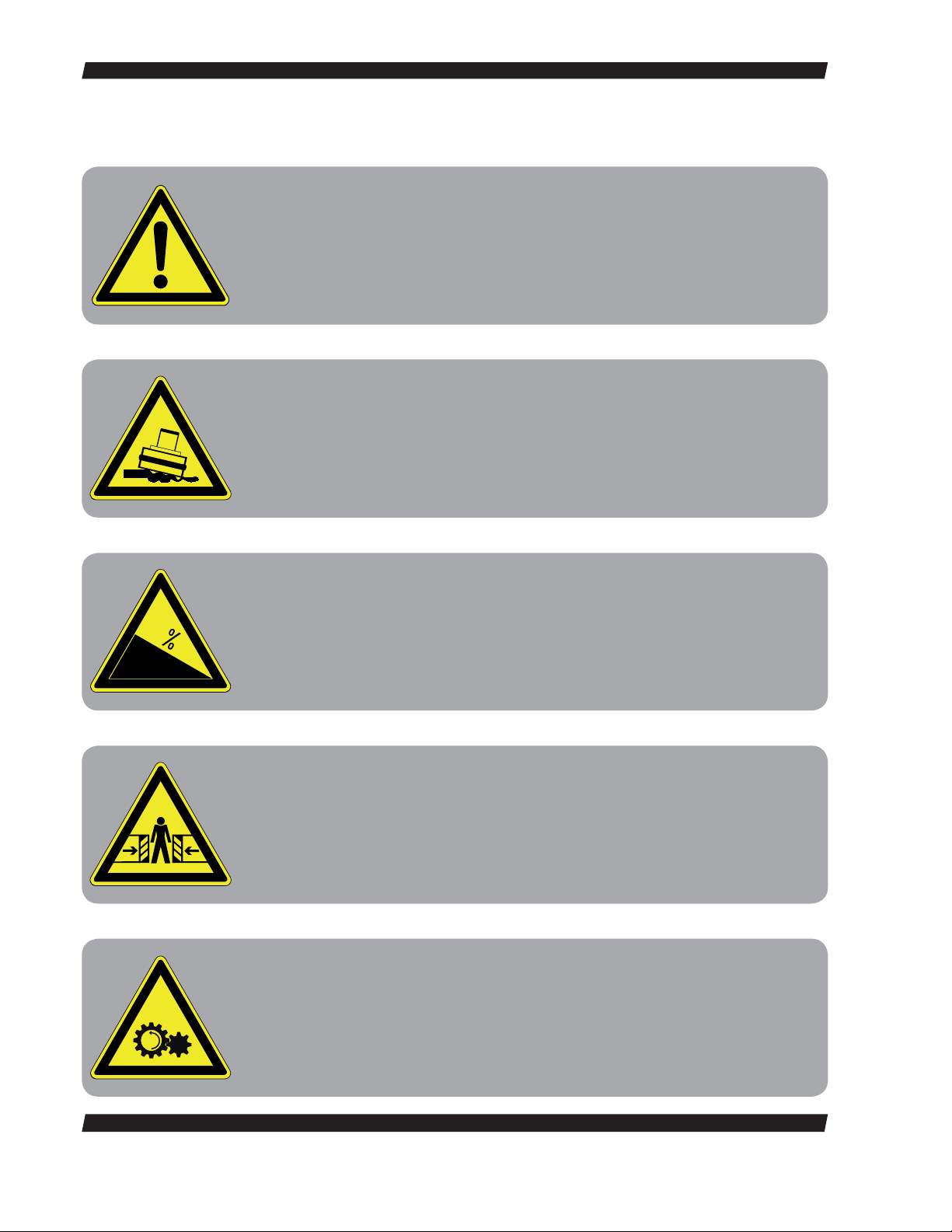

Warning signs:

Symbol: Meaning:

Danger

Special specifications and/or imperative instructions and prohibitions, in order to

prevent injury to persons or substantial damages to property are marked with the

represented pictogram.

The appropriate symbol is placed in front, if the source of danger can be indicated

accurately

Danger of tilting

This sign is placed before activities, in which there is the danger of the machine

tilting or overturning.

Caution downward gradient/upward gradient

This sign is placed before activities or conditions, during which there is the risk of

the machine slipping or overturning.

Risk of crushing

This sign is placed before activities, during which there is the risk of being crushed

or caught.

Rotating parts

This sign is placed before activities, during which there is the risk of limbs being

drawn into mechanically moved parts.

– 29 –

Page 30

Safety instructions

RX 1510-C/-I/-CI

Electricity

This sign is placed before activities, during which there is the risk of a possibly

lethal electric shock.

Risk of chemical burns

This sign is placed before activities, during which there is the risk of chemical

burns by battery acid.

Danger of burning

This sign is placed before activities, during which there is the risk of burning

of the skin by hot surfaces.

Fire danger

This sign is placed before activities, during which there is an increased risk

of fire.

Risk of explosion

This sign is placed before activities, during which there is the risk of an explosion.

The explosion can also be caused by suddenly released pressure.

– 30 –

Page 31

RX 1510-C/-I/-CI

Safety instructions

Risk of being run over

Risk of overturning

Observe distance to articulated joint

Danger caused by pressurised liquids escaping

Risk for limbs by rotating belts

– 31 –

Page 32

Safety instructions

RX 1510-C/-I/-CI

Danger caused by flying around parts

Risk caused by inhalation of toxic gases or vapours

– 32 –

Page 33

RX 1510-C/-I/-CI

Safety instructions

Waste oil disposal/waste oil collecting point

Battery disposal/pollutant collecting point

– 33 –

Page 34

Safety instructions

2.2 Intended use/Product safety

2.2.1 Purpose of use of the machine

RX 1510-C/-I/-CI

The vibration roller RX 1510 is built according to the state-of-the-art and the

recognised safety-related regulations. Nevertheless the use can in danger life and

health of the user or third parties and/or impair the machine and other material

assets:

• It is used in a manner other than its intended use

• It is modified or conversion work is carried out by unqualified persons

• The safety remarks are not observed

• It is not operated or maintained by suitably qualified personnel.

The RX 1510 may only be operated in technically perfect condition as well as

intended, with consideration to safety and the ensuing dangers while observing

the operating instructions! Malfunctions, which in particular could impair safety

must be repaired immediately.

When operating the machine, adherence to the valid accident prevention

regulations and the generally accepted rules of safety, as well as country-specific

regulations is assumed.

The section "Areas of application" (Subsection 1.1.3) identifies the purpose,

for which the RX 1510 is exclusively intended. Any other or further use is not

considered as intended. The manufacturer/supplier is not responsible for such

resulting damages. Only the operator is responsible for this risk.

The machine may not be used on hard, already compacted or frozen soils.

The machine is not a playground.

The machine may not be used as means of transport.

The machine is not intended for transporting persons.

The machine must be transported over larger distances.

2.3 Danger areas

2.3.1 Workplace

The directional and steering switches of the infrared transmitter and cable control

only agree with the direction of movement of the machine when used behind the

machine. The directional and steering switches react in an opposite manner in

front of the machine.

The machine only stops during infrared operation, if the operator approaches

it. The machine does not stop during cable control. The machine does not stop,

if other persons approach it.

2.3.2 Safety equipment

The machine is equipped with various safety equipment. The function of the safety

equipment must be checked before operating the machine. The machine may be

never operated with defective or missing safety equipment. Do not disassemble,

bypass or bridge safety equipment. Defective safety equipment must be replaced

immediately. The machine is equipped with the following safety equipment.

• Shut down yoke

• Low distance shutdown

• Far distance shutdown

Position and working principle of the safety equipment are described in more

detail on page 44 in section "3.4 Safety and monitoring equipment".

– 34 –

Page 35

RX 1510-C/-I/-CI

Safety instructions

2.3.3 Observing danger warnings on the machine

• Ensure that the safety labels and signs are complete and readable.

• Observe the rules and abide by them.

• Immediately renew damaged and illegible safety signs and labels. All signs and

labels can be reordered from the spare parts list. The machine may not be used

from the time, in which the signs are not clearly recognisable and understandable

anymore, until new signs have been attached.

GEFAHR

Verbrühungsgefahr!

DasKühlwasser wird vom Motor sehr stark erhitzt und

derKühler unter Druck gesetzt. Beim Öffnen des Kühlerdeckelsentweicht der Druck plötzlich und das heiße

Kühlwasser verursacht schwere Verbrühungen!

► Den Kühlerdeckel niemals bei laufendem Motor

öffnen!

► Vor dem Öffnen warten, bis der Motor abgekühlt

ist!

Risk of scalding!

Observe sticker when filling the

cooling system.

3-39899

Verbrühungsgefahr!

DasKühlwasserwirdvom Motor sehr stark erhitzt und

derKühlerunter Druck gesetzt. BeimÖffnen desKüh-

lerdeckelsentweichtderDruck plötzlich und das heiße

Kühlwasser verursacht schwere Verbrühungen!

► Den Kühlerdeckel niemals bei laufendem Motor

öffnen!

► Vor dem Öffnen warten, bis der Motor abgekühlt

ist!

GEFAHR

3-39899

Danger zone!

This sign identifies a danger zone.

Staying in this area during operation is

prohibited.

Risk of crushing

Observe distance to articulated

joint! Staying in the area of the

articulated steering of the machine

is prohibited during operation.

– 35 –

Page 36

Safety instructions

RX 1510-C/-I/-CI

Use hearing protection.

– 36 –

Page 37

RX 1510-C/-I/-CI

2.4 Organisational, personal matters

Safety instructions

• Machine operation is only admissible after proper instruction and in observance

of this manual.

• The safety regulations described in these safety regulations must be observed,

likewise the guidelines of the Civil Engineering Professional Association "Safety

regulations for the operation of road rollers and soil compactors" as well as the

relevant accident protection regulations, the recognised safety-related regulations

and country-specific regulations.

• Only qualified and appropriately trained specialised personnel, with a minimum

age of 18 years, may operate or maintenance the machine. Only trained specialists

may carry out maintenance and repair work, which exceeds the scope of these

instructions.

• The operating instructions must have been read and understood before carrying

out any activity on or with the machine.

• Each person, who is assigned with operation, maintenance, or repair of the

machine, must have read and follow the safety regulations. If necessary this must

be verified by the applying enterprise by signature of the assigned person of the

person.

• Persons acting under the influence of drugs, medicines or alcohol may not

operate, maintain or repair the machine.

• Only appropriately trained specialists may carry out work on the electrical system

of the machine.

• Malfunctions or damage to the machine must be reported immediately to the

person responsible on the building site.

• For reasons of safety, users are prohibited from making their own modifications

or conversions to the machine. This machine may only be equipped with original

spare parts, which have been constructed for this machine and correspond to the

requirements of the manufacturer. The installation or use of special `equipment

or special parts can impair driving safety.

2.5 Product-specific dangers

2.5.1 During operation

• There is a permanent risk of crushing during operation in the area of the articulated

joint. Staying in this area during application is therefore not permitted. Generally,

a safety distance of at least 2 meters to the machine must be observed during

operation.

– 37 –

Page 38

Safety instructions

RX 1510-C/-I/-CI

• The vibration function of the machine causes the soil in the area of the drum to

vibrate considerably. Persons should not be exposed to these vibrations.

• When applying the vibration function, loose material, such as stones and clumps

of earth, can be hurled through the air. Persons, who are in the vicinity of the

drum can be hit and injured by these flying around objects. Therefore observe

a sufficient safety distance to the machine, in particular when the vibration

function is active.

• Damp and loose substrates substantially reduce the machine's grip on sloping

surfaces and inclines. When driving on inclines and sloping surfaces adjust the

speed of the machine to the terrain. Soil condition and weather influences impair

the climbing power of the machine. • Never drive up or down slopes steeper than

the maximum climbing ability of the machine. Never drive on slopes diagonally

Risk of tilting! • Always give way to loaded transport vehicles.

2.5.2 During maintenance work

• The hydraulic system is subject to a high pressure during operation.

Depressurise the hydraulic system before working on it. Only loosen or dismantle

parts of the hydraulic system when the diesel engine is turned off.

– 38 –

Page 39

RX 1510-C/-I/-CI

Safety instructions

• Disconnect the battery before working on electrical system components and cover

with insulating materials. • Never insert fuses with a higher amperage or repair

fuses. Fire danger!

• The machine is operated with Diesel fuel. • When carrying out work on the fuel

system, never smoke or expose to a naked flame. Do not carry out welding work

on the fuel tank or in the vicinity of unprotected parts of the fuel system. Never

operate the machine with loose or missing fuel tank cap.

2.6 Additional dangers

Using unexamined, not approved accessories can be dangerous for humans

and machine. Only Rammax accessories and spare parts may be used for the

machine.

Risk of fire and explosion when using solvent based cleaning agents.

2.7 Emergency measures

If the machine touches a power line, never leave the cab until the power has been

turned off.

Emergency equipment

• Always keep a first aid box and a fire extinguisher at hand.

• Keep the emergency telephone numbers for physician, ambulance, hospital, and

fire-brigade near to the telephone.

– 39 –

Page 40

Construction and function

3. Construction and function

3.1 Introduction

3.1.1 Basic information on soil compaction

Subsoil compaction is achieved by the constant effect of vertical impact forces.

These are created by a rotating exciter shaft. The unequal weight distribution of the

exciter shaft cross section displaces the exciter shaft and thus vibrates the drum.

These vibrations affect the compressed material vertically and compress it.

3.2 Mechanical construction

Rear end

RX 1510-C/-I/-CI

Control unit / Cockpit

Drive unit

Front car

Articulated pendulum

joint

– 40 –

Page 41

RX 1510-C/-I/-CI

3.3 Opening and closing of the hoods

Construction and function

3.3.1 Opening the cockpit hatch

The cockpit hatch is kept closed by two fixtures made of rubber and two bolts as

counterparts. In order to open the cockpit hatch, pull it briefly and jerk it upward.

To close it push the cockpit hatch down, until it engages audibly in the fixtures.

Always make sure that the hatch is correctly latched before operation. If the cockpit

hatch is not latched correctly it can be damaged by the occurring vibrations.

3.3.2 Turning down the control unit

A catch is located in the centre of the control unit. Unlock this catch. Pull the

complete operating panel towards you. Make sure that the catch does not get

caught in the locking element.

3.3.3 Opening and closing of the engine hood

The engine hood can only be opened, if the machine is aligned upright. In order to

open the engine hood, unlock the two latches to the left and right of the eyebolt.

Fold the catches upward and release the engine hood. The engine hood is

equipped with a gas-filled shock absorber, which opens the engine hood and

keeps it in an open position.

– 41 –

Page 42

Construction and function

Caution When closing the engine hood and there is the danger of crushing fingers

and hands! In order to close the engine hood push the support bushing of the

gas-filled shock absorber to the cylinder, while pressing the hood downwards.

3.3.4 Unlocking and opening the radiator cap

RX 1510-C/-I/-CI

The cooling system is very hot during operation of the machine. The radiator cap

may only be opened when the engine has cooled down and is not in operation

since there is otherwise the danger of touching parts of the cooling system when

opening. The engine hood must be open, in order to open the radiator cap. The

unlocking screw is to the right above the radiator. Unscrew this. ► The radiator

cap opens. The filler opening of the radiator is located under the radiator cap. To

close the radiator cap push it down and screw in the unlocking screw.

– 42 –

Page 43

RX 1510-C/-I/-CI

Construction and function

3.3.5 Components

Articulation

3.4 Functional description

The drive unit consists of a diesel engine, vibration, and driving pump. It provides

the required hydraulic performance for the driving, steering, and vibration

functions.

The valve block with the integrated control valves guides the output provided by

the driving unit to the connected consumers.

Rear end

Underframe Drive unit

Control unit / CockpitFront car

– 43 –

Page 44

Safety and monitoring equipment

3.5 Safety and monitoring equipment

3.5.1 Shut down yoke

The shutdown yoke is attached to the rear of the machine below the operating unit.

At the rear end below the mounting of the shutdown yoke is a proximity switch. The

shutdown yoke is activated and the proximity switch triggers, if the machine drives

against an obstacle. It thereupon sends a signal to the machine controller and the

machine can only be driven away from the obstacle in a forward direction. An

active vibration function is switched off. The vibration function must be manually

activated again after deactivation of the shutdown yoke. The shutdown yoke must

be fastened with the transport strap during transport (transport position).

RX 1510-C/-I/-CI

3.5.2 Low distance shutdown (only with infrared control)

The low distance shutdown function is accommodated in the machine controller.

The engine continues to run, however all driving functions are deactivated, if the

minimum distance between transmitter and receiver is less than 2 meters. The

driving functions are available again, as soon as the minimum distance has been

attained again.

min. 2 m

Stop

Start

3.5.3 Far distance shutdown (only with infrared control)

The far distance shutdown function is accommodated in the machine controller.

The maximum distance between transmitter and receiver depends on the

weather and is between 20 and 24 meters. The engine continues to run, however

all driving functions are deactivated, if the maximum distance is exceeded. The

driving functions are available again, as soon as the distance is less than the

maximum distance.

– 44 –

Page 45

RX 1510-C/-I/-CI

3.5.4 Inclination indicator

The machine control is equipped with an inclination indicator. This triggers

starting from an inclination angle of 45°. The engine switches itself off in this case

automatically. The machine cannot be started as long as the inclination indicator

is triggered.

Engine oil can penetrate into the combustion chamber, if the machine has tilted

over. The engine could be damaged, if started after straightening up the machine.

► Uprighting the machine. Do not start the engine.

► Inform the service workshop.

Safety and monitoring equipment

max. 20 m

Stop

Start

888888

3.5.5 Automatic switch-off generator failure

The machine is equipped with an automatic switch-off. The warning light for

a generator defect lights up, if no signal is received from the generator. The

machine is shut down after the warning light has lit up for 4 seconds.

888888

3.5.6 Automatic switch-off oil pressure

The machine is equipped with an automatic switch-off. The oil pressure warning

light lights up, if the oil pressure drops under the limit value. The machine is shut

down after the warning light has lit up for 4 seconds.

– 45 –

Page 46

Safety and monitoring equipment

3.5.7 Automatic switch-off cooling water temperature

The machine is equipped with an automatic switch-off. The temperature warning

light lights up, if the cooling water temperature exceeds the limit value. The

machine is shut down after the warning light has lit up for 4 seconds.

RX 1510-C/-I/-CI

888888

888888

3.5.8 Automatic speed adjustment

The machine is equipped with an automatic speed adjustment. The machine

controller automatically puts the diesel engine to idle, if no control signal

is received from the machine for a period longer than 30 seconds. The machine

controller automatically regulates the speed to the maximum speed, if the diesel

engine is idling and the machine receives a control signal. The machine is ready

for operation.

3.5.9 Transport protection

The machine is equipped with a transport protection. The transport protection

must always be used when loading and transporting the machine. It prevents

the front and rear unit coming into contact (danger of crushing). The transport

protection must be removed and stowed away before operating the machine.

– 46 –

Page 47

RX 1510-C/-I/-CI

4. Display and operating elements

4.1 Introduction

The cockpit of the machine is equipped with an electronic display panel. The

display panel informs the operator about operating hours, water temperature, oil

pressure and malfunctions of the machine.

Before initial start-up, Chapter 5 Start-up and 7.Operation must be read.

Display and operating elements:

Warning light generator

Ignition lock Connection for cable manual control

Warning light oil

pressure

(only available for cockpit 3-68562 ► only

RX 1510-C and RX 1510-CI)

Warning light water

temperature

Warning light inclination

indicator

888888

888888

Display for:

• Operating hours

• Function code

• Error code

0

Ignition „Off”

0

Ignition positions:

Ignition „On” /

1

Stand-by

1

– 47 –

2

Starting

2

Page 48

Display and operating elements:

4.2 Warning signals

All warning lights light up when switching the ignition on. Troubleshooting is

necessary, if one of the warning lights does not light up. If the cause is a defective

warning light, this only affects machine safety in as far as a defect will not be

indicated by the machine controller and therefore not immediately recognised by

the operator. The warning lights extinguish after starting the engine, if there is no

malfunction.

• Charging control light:

Lights up, if the alternator does not generate voltage. The stop sequence is activated

after the LED has been illuminated for 4 seconds. The machine is shutdown.

Possible cause: Defective alternator. ► Contact service workshop.

RX 1510-C/-I/-CI

888888

• Oil pressure control light:

Lights up, if the engine oil pressure drops. The stop sequence is activated

after the LED has been illuminated for 4 seconds. The machine is shutdown.

The machine can only be moved again, after the cause of the emergency stop

has been eliminated. Possible cause: Normally, the engine oil fill quantity is

insufficient and engine oil be refilled See page 84 Section 8.3 Checking engine

oil level. Contact the service workshop for other causes than lack of oil.

888888

• Coolant temperature warning lamp:

Lights up, if the coolant temperature of the motor is too high. The stop sequence

is activated after the LED has been illuminated for 4 seconds. The machine is

shutdown. Possible cause: The cooling water level is possibly too low and cooling

water must be refilled ► See page 89, Section 9.13 Checking cooling water level.

Contact the service workshop for other causes than lack of cooling water.

– 48 –

Page 49

RX 1510-C/-I/-CI

Display and operating elements:

888888

• Inclination indicator / Oil deficiency shutdown

The machine control is equipped with an inclination indicator. This triggers

starting from an inclination angle of 45°. The engine switches itself off in this case

automatically. The machine cannot be started as long as the inclination indicator

is triggered.

Engine oil can penetrate into the combustion chamber, if the machine has tilted

over. The engine can be damaged, if it is started.

► Uprighting the machine. Do not start the engine.

► Inform the service workshop.

4.3 Display elements

Display:

123456

▼▼▼▼▼▼

888888

Display Meaning Lights up:

888888

S. --05

888888

The display consists of six numbers. The display elements are tested after

switching the ignition on. The number 888888 lights up thereby. The cockpit

should be exchanged, if a number is not complete.

Function test of the display • When switching the ignition on.

S: Stands for start function

05:

Address set in the

machine controller (The

machine is delivered as

standard with address 05).

• When switching the machine on.

• During the starting procedure.

– 49 –

Page 50

Display and operating elements:

Display Meaning Lights up:

F: Stands for function

F

I: Stands for infrared

I

transmitter.

H: Stands for manual control.

H

E: Stands for error.

E

RX 1510-C/-I/-CI

• If an operator function is carried

out.

• Always in combination with

a numerical value, which represents

the function type. (see page 52

Section 4.4.2 Function codes)

• The operator functions are carried

out with active infrared control

mode.

• Always in combination with the

display F, for function and a numerical

value, which represents the function

type.

The code numbers of this function type

can be found on page 57-58 Section

4.4.6 Cockpit display with infrared

control.

• The operator functions are carried

out with active cable control mode.

• Always in combination with the display

F, for function and a numerical

value, which represents the function

type.

The code numbers of this function type

can be found on page 53-54 Section

4.4.3 Cockpit display with cable

control.

• If a function has an error

• Always in combination with

a numerical value, which

represents the function type.

The error codes can be found on

page 98-99 Section 10.0 Malfunction

table.

• If special errors occur.

0.0

Err: Stands for error

Operating hour meter

– 50 –

The error codes can be found on

page 98-99 Section 10.0 Malfunction

table.

• 1 second after the function test of

the display (888888).

• Flashes alternating with the starting

function S. -- 05, until the engine

has started or the cockpit switches

to stand-by.

Page 51

RX 1510-C/-I/-CI

Display and operating elements:

123456

▼▼▼▼▼▼

888888

4.4 Operating elements

4.4.1 Manual control device

Code numbers are indicated from position 3 to 6.

• Four-digit code numbers are displayed in combination with "F" (function) which

respectively stand for a driving or vibration function. The code numbers for "F"

(function) and their meaning can be found on page 52.

• Four-digit code numbers are displayed in combination with "E" (error/special),

which respectively stand for a function error. The code numbers for "E" (error)

are the same as for the functions.

• 1 or 2-digit code numbers are displayed (position 5 to 6) in combination with "Err"

or "FErr" (error/special), which each stand for an error. The code numbers for

"Err" or "FErr" (error/special) and their meaning can be found on page 98-99.

• 1-, 2-, or 4-digit code numbers are displayed In combination with "S" (Starting

function), dependent on the position of the ignition start switch and/or the

starting programme.

Both infrared control and cable control is available for the machine. According

to the machine version it is equipped with one or both of these control methods.

Retrofitting one of these control methods is possible without problems. Different

operating equipment is required for the control methods.

The manual control is used to operate the machine with cable control.

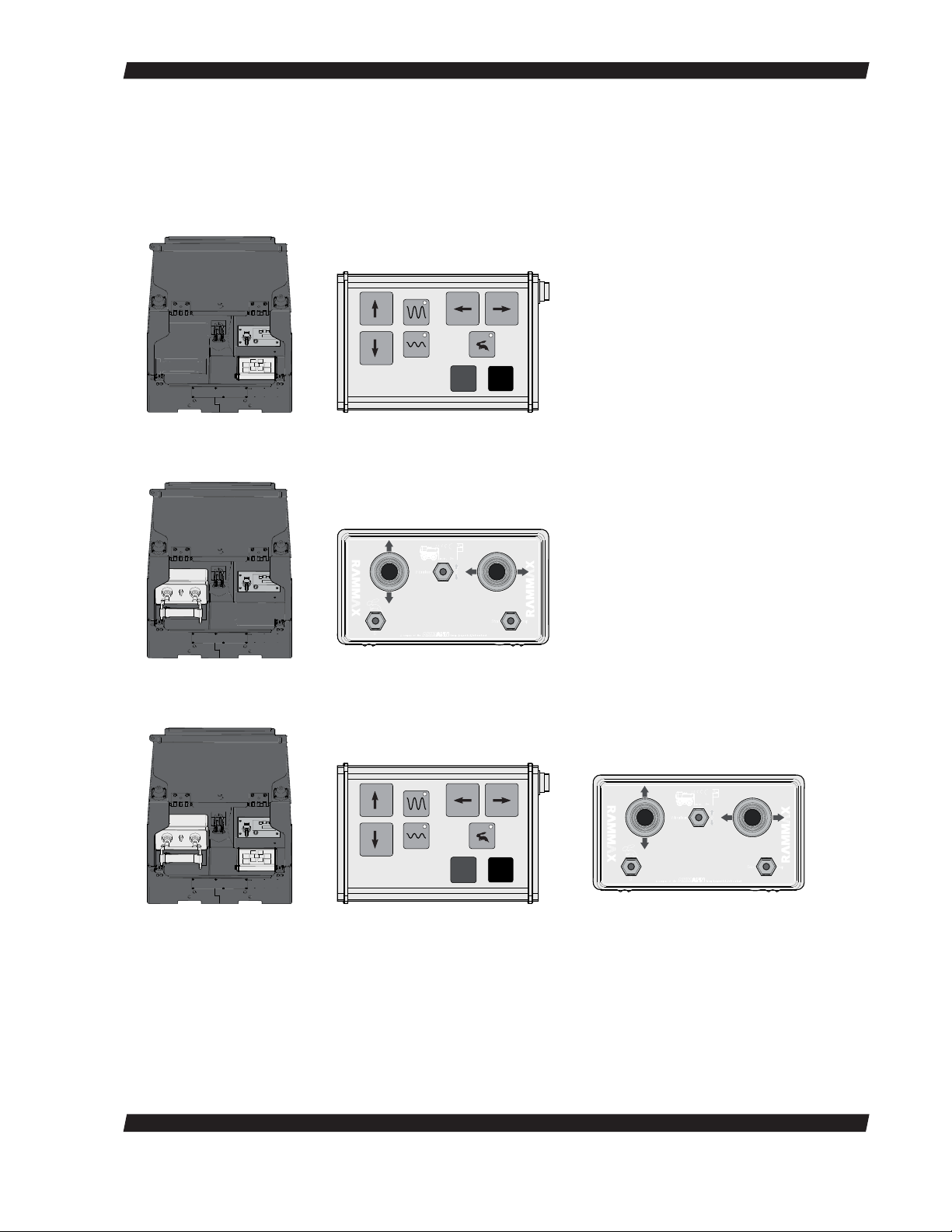

Pos Function

1

2

3

4

5

6

7

8

9

Fast gear on/off

Driving forward

Steering angle left

Vibration forward

Driving backwards

Steering angle right

Vibration reverse

Start

Machine off

2 3

Start Stop

64

9875

1

– 51 –

Page 52

Display and operating elements:

The function keys for vibration with direction of rotation forward, vibration with

direction of rotation backwards and fast gear are equipped with a locking function.

The key functions remain active until they are actuated again. The respective

diode on the key lights up when the function is active.

Function key vibration forward, vibration backwards and fast gear in

active condition

4.4.2 Function codes during operation with cable control

The function codes displays in the cockpit are made up of the code numbers for

the individual function keys. Adding the code numbers results in the indicated

function codes.

RX 1510-C/-I/-CI

Code

number

1

10

100

1000

20

200

2000

4010

4100-

4400

Meaning

Fast gear on/off

Driving forward

Steering angle left

large amplitude

Driving backwards

Steering angle right

low amplitude

Start

Machine off

100 1000

200 4010 20

2000

1

Start Stop

4100 ►

4400

10

– 52 –

Page 53

RX 1510-C/-I/-CI

100 1000

Display and operating elements:

Example display function:

• F H 1100 Driving left forward with vibration forward

Start Stop

4.4.3 Cockpit display with cable control

Start / Stop function

Control mode Code

number:

F H 4010 "Start" key is activated. ► Starting procedure is initiated.

F H 4020 The motor has started. ► Release „Start” key.

F - 4050 This error message appears, if the "Start" key is released during

F H 4100 "Stop" key is activated. ► Stop procedure is initiated. ► The

F H 4200 Stop sequence is continued.

F H 4300 The operating hour meter is secured. K15 is then switched off.

F H 4400 The operating hour meter is saved.

Meaning:

the starting procedure, the engine has not yet started and it is

set to start again immediately after releasing the "Start" key. This

function prevents the starter engaging, while the engine is still in

motion.

machine controller waits, until the generator signal, the speed

signal and the oil pressure signal are not sent anymore.

FH I I00

– 53 –

Page 54

Display and operating elements:

Driving functions

Display Executed functions

F H 0010 Driving Right forward

F H 0011 Driving Right forward High speed

F H 0020 Driving Right backward

F H 0021 Driving Right backward High speed

F H 0100 Driving Left forward

F H 0101 Driving Left forward High speed

F H 0110 Driving Left forward Right forward

F H 0111 Driving Left forward Right forward High speed

F H 0120 Driving Left forward Right backward

F H 0121 Driving Left forward Right backward High speed

F H 0200 Driving Left backward

F H 0201 Driving Left backward High speed

F H 0210 Driving Left backward Right forward

F H 0211 Driving Left backward Right forward High speed

F H 0220 Driving Left backward Right backward

F H 0221 Driving Left backward Right backward High speed

RX 1510-C/-I/-CI

Vibration functions

Display Executed functions

F H 1000 Vibration forward

F H 1010 Vibration forward Driving right forward

F H 1020 Vibration forward Driving right backward

F H 1100 Vibration forward Driving left forward

F H 1110 Vibration forward Driving left forward right forward

F H 1120 Vibration forward Driving left forward right backward

F H 1200 Vibration forward Driving left backward

F H 1210 Vibration forward Driving left backward right forward

F H 1220 Vibration forward Driving left backward right backward

F H 2000 Vibration reverse

F H 2010 Vibration reverse Driving right forward

F H 2020 Vibration reverse Driving right backward

F H 2100 Vibration reverse Driving left forward

F H 2110 Vibration reverse Driving left forward right forward

F H 2120 Vibration reverse Driving left forward right backward

F H 2200 Vibration reverse Driving left backward

F H 2210 Vibration reverse Driving left backward right forward

F H 2220 Vibration reverse Driving left backward right backward

– 54 –

Page 55

RX 1510-C/-I/-CI

4.4.4 Infrared transmitter

The infrared control is used to operate the machine with infrared control. Solar

cells supply the electrical current. Therefore, no batteries are required to operate

the infrared transmitter. The infrared transmitter is equipped with freely selectable

addresses, in order to transmit the transmitter signal. The machine controller

must be set to the same address as the infrared transmitter. The thumb wheel

is located under the square plug

The addresses can be set with a small screwdriver by turning the arrow in the

middle. If several machines are operating within the same work area, then the

machines must be used with differently set addresses. Up to four addresses are

available. Therefore, up to 4 machines can be operated by infrared at the same

time within the same work area. The addresses 6 to 9 are without function.

Display and operating elements:

SI

. This can be screwed off with a screwdriver.

SI

Pos Function

1

2

3

4

5

6

7

8

9

Fast gear on/off

Driving forward

Steering angle left

large amplitude

Driving backwards

Steering angle right

low amplitude

Start

Machine off

1 2 3 64

9875 N

N

Neutral position

– 55 –

Page 56

Display and operating elements:

4.4.5 Function codes during operation with infrared control

The function codes displays in the cockpit are made up of the code numbers for

the individual function keys. Adding the code numbers results in the indicated

function codes.

RX 1510-C/-I/-CI

Code Meaning

1

10

100

1000

20

200

2000

4010

4100-

4400

Fast gear on/off

Drums right forward

Drums left forward

Vibration forward

Drums right

backward

Drums left

backward

Vibration reverse

Start

Machine off /

Transmitter off

N

Neutral position of the toggle switch „Start-Stop”.

This switching position is not indicated in the cockpit.

1

200 4010

Example display function:

2000

100 1000

N

10

20

4100 ►

4400

• F I 1100 Driving left forward with vibration forward

100 1000

F I I I00

– 56 –

Page 57

RX 1510-C/-I/-CI

4.4.6 Cockpit display with infrared control

Start / Stop function

Characteristic Control mode Code

number:

F I 4010 Toggle switch„Start” is activated. ► Starting procedure is

F I 4020 The motor has started. ► Release toggle switch „Start”.

F - 4050 This error message appears, if the toggle switch is released

F I 4100 Toggle switch„Stop” is activated. ► Stop procedure is initiated.

F I 4200 Stop sequence is continued.

F I 4300 The operating hour meter is secured. K15 is then switched off.

F I 4400 The operating hour meter is saved".

Meaning:

initiated.

during the starting procedure, the engine has not yet started

and it is set to start again immediately after releasing the toggle

switch. This function prevents the starter engaging, while the

engine is still in motion.

► The machine controller waits, until the generator signal, the

speed signal and the oil pressure signal are not sent anymore.

Display and operating elements:

Driving functions

Display Executed functions

F I 0010 Driving Right forward

F I 0011 Driving Right forward High speed

F I 0020 Driving Right backward

F I 0021 Driving Right backward High speed

F I 0100 Driving Left forward

F I 0101 Driving Left forward High speed

F I 0110 Driving Left forward Right forward

F I 0111 Driving Left forward Right forward High speed

F I 0120 Driving Left forward Right backward

F I 0121 Driving Left forward Right backward High speed

F I 0200 Driving Left backward

F I 0201 Driving Left backward High speed

F I 0210 Driving Left backward Right forward

F I 0211 Driving Left backward Right forward High speed

F I 0220 Driving Left backward Right backward

F I 0221 Driving Left backward Right backward High speed

– 57 –

Page 58

Display and operating elements:

Vibration functions

Display Executed functions

F I 1000 Vibration forward

F I 1010 Vibration forward Driving right forward

F I 1020 Vibration forward Driving right backward

F I 1100 Vibration forward Driving left forward

F I 1110 Vibration forward Driving left forward right forward

F I 1120 Vibration forward Driving left forward right backward

F I 1200 Vibration forward Driving left backward

F I 1210 Vibration forward Driving left backward right forward

F I 1220 Vibration forward Driving left backward right backward

RX 1510-C/-I/-CI

F I 2000

F I 2010 Vibration reverse Driving right forward

F I 2020 Vibration reverse Driving right backward

F I 2100 Vibration reverse Driving left forward

F I 2110 Vibration reverse Driving left forward right forward

F I 2120 Vibration reverse Driving left forward right backward

F I 2200 Vibration reverse Driving left backward

F I 2210 Vibration reverse Driving left backward right forward

F I 2220 Vibration reverse Driving left backward right backward

Vibration reverse

– 58 –

Page 59

RX 1510-C/-I/-CI

5. Start-up

5.1 Safety instructions

5.2 Examination before start-up

Start-up

Only qualified and appropriately trained specialised personnel, with a minimum

age of 18 years, may operate the machine. Persons acting under the influence of

drugs, medicines or alcohol may not operate the machine.

Before putting the machine into service every day or before a long work period,

the following checks must be performed. The safety regulations must be observed

hereby.

The following must be checked:

• The function of all safety equipment

• Whether the transport protection has been removed

• All bolt connections for firm fit

• Fuel tank and fuel lines for leaktightness

• Machine and engine for damages

• Function of the control elements

• Function of the steering system

• Hydraulic system for leaktightness

5.2.1 Checking hydraulic oil level

The sight glass for the examination of the hydraulic oil level is located under the

operating panel. The fill level should be within the sight glass.

S

– 59 –

Page 60

Start-up

RX 1510-C/-I/-CI

If it is determined during the daily oil level check that hydraulic oil is missing,

immediately examine all aggregates, lines, and hoses for leaktightness and fill up

missing hydraulic oil before beginning work.

Refilling hydraulic oil:

HD

1) Open

2) Fill in hydraulic oil until the fill level is located between the markings.

cap.

NOTE

HD

5.2.2 Checking engine oil level

OS

The dipstick is located on the right side of the engine underneath the cooling

water tank. The engine has been filled in the factory with engine oil, viscosity

class 15W40. If there is the need to change to a different viscosity class (e.g.:

permanent extreme outdoor temperatures), the oil must be changed.

1) Park the machine on flat ground.

OS

– 60 –

Page 61

RX 1510-C/-I/-CI

Start-up

CAUTION

Danger of burning!

The engine and its detachable parts are hot during and immediately after

operation.

Before touching the engine or the detachable parts first allow these to cool

down.

2) Pull the dipstick out.

3) Wipe the dipstick with a dry, fibre-free rag.

4) Insert the dipstick up to the stop in its fixture.

5) Pull the dipstick out again and read the oil level. ► The oil level should be between

the two markings. More engine oil must be filled in, if the oil level is too low (only

use engine oils with the same viscosity).

5.2.3 Checking cooling water level

Work may only be carried out on the cooling system when the diesel engine has

cooled down. The machine must be parked on a level ground. The cooling water

level is examined directly at the radiator. The compensating tank only serves as

a buffer in order to take up water during expansion by the thermal effect and keep

it in the cooling circuit. The engine hood and the radiator hatch must be open, in

order to check the cooling water level.

The radiator must be completely filled. Coolant must be refilled, if the fill level is

too low.

A radiator anti-freezing agent must be used in frost-endangered areas. The

radiator has been filled in the factory with a radiator anti-freezing agent/water

mixture. This mixture is adjusted to a temperature resistance of up to -30°C.

DANGER

Risk of scalding!

The engine extremely heats up the cooling water. The radiator is under

pressure.

When opening the radiator cap the pressure can escape suddenly and the hot

cooling water can cause severe scalding!

► Never open the cap of the radiator when the engine is running!

► Wait until the motor has cooled down before opening.

– 61 –

Page 62

Start-up

RX 1510-C/-I/-CI

1) Open the engine hood.

2) The unlocking screw is to the right above the radiator. Unscrew this. ► The

radiator cap opens. The filler opening of the radiator is located under the radiator

cap.

3) Open the radiator cap.

4) Completely fill the radiator with coolant (Observe mixing ratio antifreeze/water ►

see page 20 Subsection 1.2.3 Operating fluids).

5) Close radiator cap.

6) Close radiator hatch.

5.2.4 Checking the contamination degree of the air filter

The air filter is located at the rear end of the front car of the machine. The engine

hood must be opened, in order to access the air filter. The removable lid of the air

filter is accessible on the left side of the machine.

1) Open the engine hood.

2) Loosen fastening clamps on the air filter cover.

3) Remove air filter and check for the degree of pollution. Clean dirty air filters.

5) Exchange the air filter against a new one in the case of extreme contamination.

Be careful not to damage the air filter by inappropriate cleaning!

Damaged air filters can damage the engine.

Do not clean air filters with compressed air, do not wash, only tap!

NOTE

– 62 –

Page 63

RX 1510-C/-I/-CI

5.2.5 Checking fuel level / Tanking fuel

KA

The sight glass for the examination of the fuel level is located under the

operating panel.

KA

TD

The operating panel must be folded back, in order to refuel.

Fuelling procedure:

TD

1) Open the tank lid

2) Put the tank lid cap with the top downwards on a clean surface. ► This prevents

dirt particles accumulating on the bottom of the tank lid cap and thus getting into

the fuel tank.

.

Start-up

WARNING

Fire danger!

Fuels are extremely flammable.

► Do not smoke during refuelling.

► Keep naked flames and sparks away.

► Never operate the machine with loose or missing fuel tank cap.

3) Refuel the machine with Diesel fuel. ► Use a funnel. It prevents fuel overflowing.

► Use a filter. It prevents dirt particles getting into the fuel tank when refuelling.

4) Close the tank lid after the fuelling procedure.

5.2.6 Adjusting address to transmit transmitter signals

ENVIRONMENT

Leaking fuel pollutes the soil!

► Place an intact container of sufficient size under the tank filler neck before

refuelling.

► Do not spill fuel.

► Collect leaking fuel, do not let it seep into the ground.

– 63 –

Page 64

Start-up

RX 1510-C/-I/-CI

(only for machines with infrared control)

Setting the transmitter address on the machine controller:

1) Fold the operating panel back.

SM

2) Remove the plug

entfernen.

3) Set in the required address by turning the arrow with a screwdriver.

Setting the transmitter address on the infrared control:

Remove the plug „SI“ from the infrared control with a screwdriver entfernen.

• Set the same address as on the machine controller by turning the arrow with

a screwdriver.

The addresses at the transmitter and receiver must correspond.Transmitter and

receiver are factory set to address 5.

SM

from the machine controller with a screwdriver

SI

NOTE

– 64 –

Page 65

RX 1510-C/-I/-CI

5.3 Starting the machine

Start-up

The machine only reacts to the control mode with which your engine was started.

The machine only reacts to control impulses of the manual control, if the engine

has been started with the manual control. The machine only reacts to control

impulses of the infrared control, if the engine has been started with the infrared

control. An exception is starting and shutting down the machine. This is also

always possible with the ignition key. The first used control mode has priority, if

the machine has been started at the cockpit with the ignition key.

5.3.1 Switching ignition on