Page 1

OPERATION MANUAL

MODELS

RX1575

RX157533

TRENCH ROLLER

(YANMAR 3TNV76 DIESEL ENGINE)

Revision #0 (04/28/15)

To find the latest revision of this

publication, visit our website at:

www.multiquip.com

THIS MANUAL MUST ACCOMPANY THE EQUIPMENT AT ALL TIMES.

Page 2

RX1575 Trench Roller

Declaration Of Conformity (CE) ............................... 3

General ................................................................. 4-7

Product Description ............................................ 8-12

Safety Information ............................................ 13-20

Structure And Function ..................................... 21-23

Operating And Display Elements ...................... 24-31

Commissioning ...................................................... 32

Operation ......................................................... 33-38

Options .................................................................. 39

Maintenance ..................................................... 40-69

Repair ............................................................... 70-82

Storage .................................................................. 83

Transport ..........................................................84-87

Disposal ............................................................ 88-89

Appendix ........................................................... 90-94

TABLE OF CONTENTS

NOTICE

Specifications are subject to change without notice.

PAGE 2 — RX1575 SERIES TRENCH ROLLER • OPERATION MANUAL — REV. #0 (04/28/15)

Page 3

DECLARATION OF CONFORMITY (CE)

Declaration of Conformity

This is to certify that the machine | group of machines indicated below conform(s) to the relevant basic safety

and health requirements of the relevant EC directives in terms of their conception and design and in the form

marketed by us.

This declaration shall cease to be valid in the event of any change made to the machine/group of machines

after handover to the trader/user if such changes are not agreed with us.

Name of machine or group of machines:

Model | Type:

Mode of functioning:

Serial number:

Relevant EC directives:

Applicable harmonized standards:

Issuing testing office for

noise tests:

Machine type as per appendix I from

2000/14/EC:

Conformity evaluation as per 2000/14/EC:

Noise emissions:

Manufacturer:

Address:

Signatures:

Trench rollers

Rammax 1575

Ground compaction

See identification plate

- Machinery Directive 2006/42/EC

- Directive on Electromagnetic Compatibility 2004/108/EC

- Noise Directive 2000/14/EC

EN 500-1, EN 500-4,

TÜV Austria

Testing office number: 0408

No.: 8

According to appendix VI

Recorded sound power level: 100dB(A)

Guaranteed sound power level: 103dB(A)

Ammann Schweiz AG

Eisenbahnstrasse 25

CH-4901 Langenthal

Name:

Mode of functioning:

Authorized representative:

Place, Date:

H. Queder

Plant manager

The technical documents are stored in the care of the abovementioned persons

Langenthal, December 2012

Ch. Anliker

Technology Manager

RX1575 SERIES TRENCH ROLLER • OPERATION MANUAL — REV. #0 (04/28/15) — PAGE 3

Page 4

1230047 | 21.06.2013

1.1 About this manual

This manual is part of the customer documentation for the Rammax 1575 trench roller. It is customer documentation of the Ammann Schweiz AG and its representatives

in other countries.

1.1.1 Target audience

The target audience for this manual is the owner/operator of the Rammax 1575

trench roller along with his employees who have been authorized for repair, operation and maintenance by the owner/operator.

1.1.2 Purpose

The purpose of this manual is to ensure the optimal use and safe application of the

roller for the following processes.

● Commissioning

● Operation

● Maintenance

● Repair

GENERAL

1.1.3 Overview of customer documentation

Please check that the delivery is complete and inform us within 14 days after

purchase if the delivery is not complete. Please always indicate the serial number.

The customer documentation for the trench roller and its components includes,

among others, the following customer documents.

● Roller manual

● Spare parts catalog for roller

● Yanmar engine manual in English

● Yanmar engine manufacturer’s declaration

Tab. 1-1 Documentation for the Rammax 1575

Language Manual

German 1230045

English 1230047

French 1230046

1.1.4 Validity of the manual

This manual is valid for the following roller:

Rammax 1575

PAGE 4 — RX1575 SERIES TRENCH ROLLER • OPERATION MANUAL — REV. #0 (04/28/15)

Page 5

An assortment of optional equipment is available for the roller, which we can install

as you wish. For this reason, some of the figures or descriptions in this manual could

deviate from your roller.

1.1.5 Storage of the manual

Ammann Schweiz AG delivers every trench roller with this manual. The manual is a

permanent component of the roller. Store it so that it is always available for viewing

by the users.

Ensure that the manual is complete and legible. If the manual should become lost,

damaged or illegible, replace it promptly.

The obligation to properly store the manual for the roller covers the roller's entire service life. If you loan the roller, ensure that the manual is taken along on board the

roller. If the roller is sold, hand the manual over to the new owner.

1.1.6 Technical changes

In the interest of technical developments, Ammann Schweiz AG reserves the right to

make changes to this customer document at any time without separate notice.

GENERAL

1.1.7 Copyrights

The publisher of this EC compliant customer document is Ammann Schweiz AG.

We reserve all rights for this document and the roller described therein. Reproduction, disclosure to third parties or utilization of its content is forbidden without our

express permission. © 2011 Ammann Schweiz AG

1.1.8 Spare parts

In this manual, we describe selected maintenance work. We refer you to your authorized dealer for the remaining maintenance work in accordance with the maintenance

plan.

When performing scheduled and unscheduled repairs, you may need to replace

components of the roller.

Only use spare parts which meet the requirements specified by the Amman Schweiz

AG. These requirement are fulfilled if only original Ammann spare parts are used.

For the ordering of spare parts, we provide you with a spare parts catalog.

1.2 Structure of the manual

The following explanations are designed to familiarize you with the roller and to provide support for handling and maintenance.

RX1575 SERIES TRENCH ROLLER • OPERATION MANUAL — REV. #0 (04/28/15) — PAGE 5

Page 6

It is essential that you read chapter 3 Safety information carefully before

Rear

!

!

commissioning and carrying out maintenance work.

Observing the "safety instructions" in particular increases the reliability of the roller in

operation and its service life. This reduces repair costs and down time.

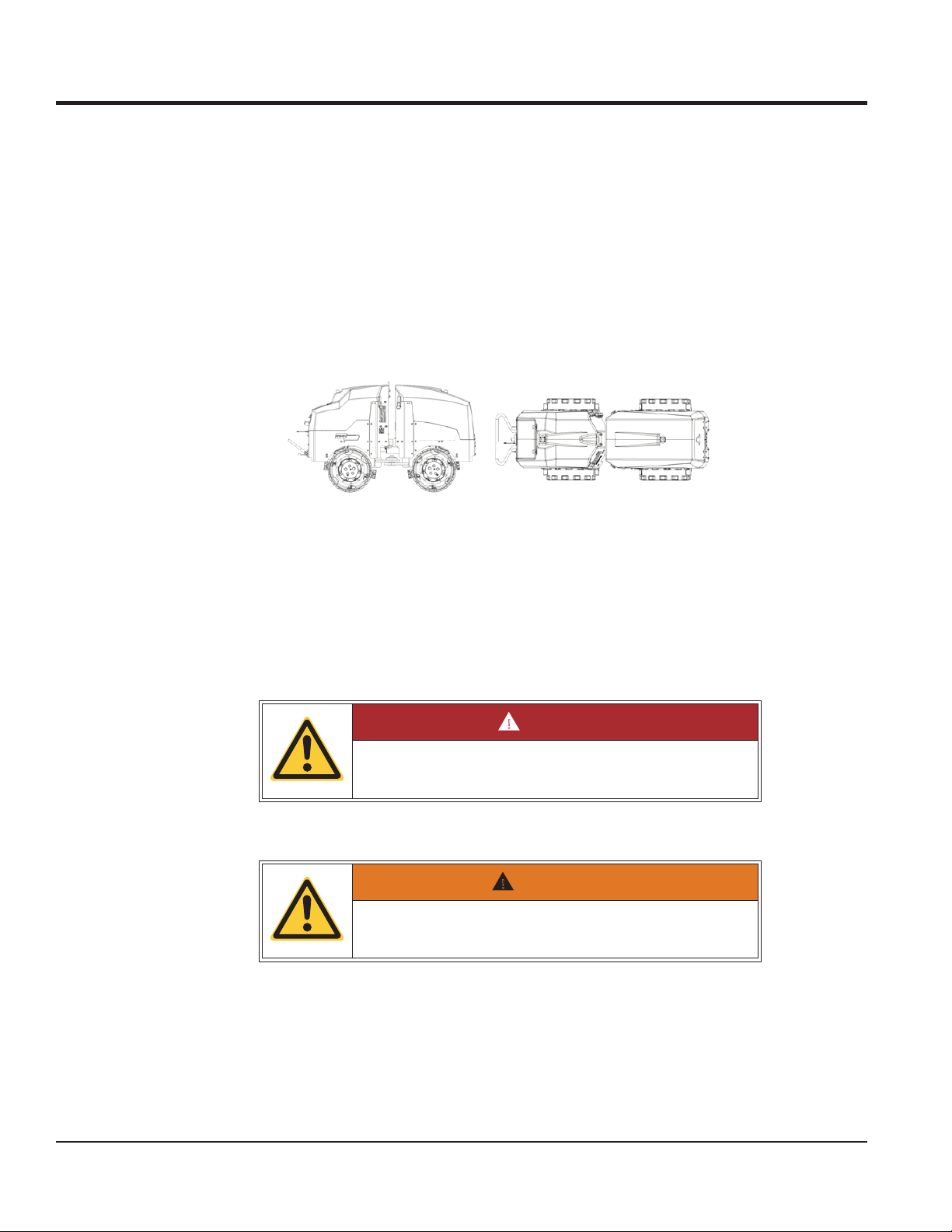

1.2.1 Orientation on the roller

When describing the components of the roller, we inform you of their position on the

roller. We adhere to the orientation below when doing so.

GENERAL

Fig. 1-1 Rammax 1575 orientation

We view the roller from the position of the driver standing behind the roller looking in

the direction of travel.

1.2.2 Warnings

Please observe the meaning of the following warnings:

Top

Bottom

Left

Front

Right

DANGER

● DANGER represents an immediate hazard leading to severe bodily injury or

death.

WARNING

● WARNING represents a possibly hazardous situation which could lead to se-

vere bodily injury or to death.

PAGE 6 — RX1575 SERIES TRENCH ROLLER • OPERATION MANUAL — REV. #0 (04/28/15)

Page 7

GENERAL

!

CAUTION

● CAUTION represents a possibly hazardous situation which could lead to

slight bodily injury.

● Caution also represents a hazard of environmental pollution causing local or

global environmental damage.

NOTE The battery poles and terminals must be clean. If they are coated with a (whi-

tish or greenish) sulfur crust they must be cleaned.

NOTE Risk of cable fire or short circuit

● NOTE represents first of all: damage which could be caused to the roller or parts

of it.

● NOTE represents secondly: Application tips and other particularly useful informa-

tion.

● NOTE is not a signal word for a hazardous or damaging situation.

RX1575 SERIES TRENCH ROLLER • OPERATION MANUAL — REV. #0 (04/28/15) — PAGE 7

Page 8

2.1 Identification of the roller

2.1.1 Machine types

The data given below serve to identify the models. The machine models differ only

in terms of weight and the width of the roller drum.

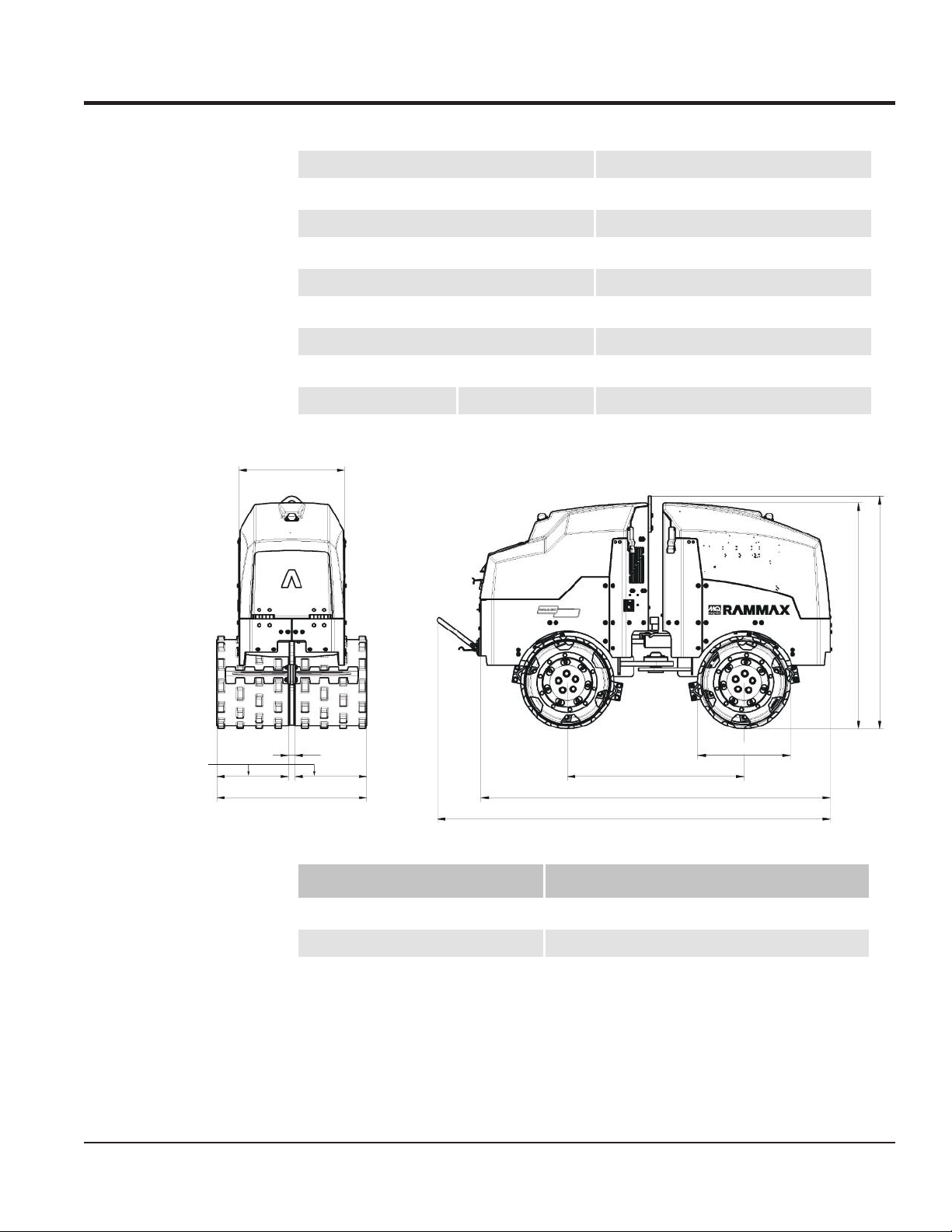

Tab. 2-1 Rammax 1575

Model Roller Drum Width Weight

5751 xammaR

with 24" drums

with drum rings 33 in (850 mm)

Rammax 157533

24 in (640 mm)

33 in (850 mm)

PRODUCT DESCRIPTION

3,087 lbs (1400 kg)

3,197 lbs (1450 kg)

3,197 lbs (1450 kg)

2.2 Product data

2.2.1 Dimensions

Fig. 2-1 1575 dimensions

2.2.2 Specifications

Tab. 2-2 Rammax 1575 performance data

Roller drum width in (mm) 24 (640) 33 (850)

Service weight according to CECE lbs (kg)

Static linear load lbs/in (kg/ cm)

Inside turning radius in (mm) 61 (1541) 57 (1436)

Outside Turning Radius-in (mm) 86.25 (2,191) 90 (2,286)

Rammax 1575

3,087 (1400)

10.1 (11.6) 7.7 (8.9)

3,197 (1450)

PAGE 8 — RX1575 SERIES TRENCH ROLLER • OPERATION MANUAL — REV. #0 (04/28/15)

Page 9

11.89 in (302 mm)/

16.02 in (407 mm)

PRODUCT DESCRIPTION

Low/ High amplitude in (mm) .024 (0.6)/.043 (1.1)

05/04noitarbiv tuohtiw/htiw % ni tneidarG

Drive YANMAR 3TNV76/EPA 4

Wk0.516403 OSI ot gnidrocca ecnamrofreP

/20.4HP

Operating speed 2400 1/min

Low Travel Speed ft/min (m/min)

High Travel Speed ft/min (m/min)

Vibration frequency

23.66 in (601 mm)

1.42 in

(36 mm)

25.20 in (640 mm)/

33.46 in (850 mm)

vpm (Hz)

2,460 (41)

39.37 in (1000 mm)

77.95 in (1980 mm)

87.68 in (2227 mm)

82 (25)

148 (45)

/+/-7°

°03-/+gnitovip/elgna gnireetS

20.67 in

(525 mm)

50.47 in (1282 mm)

51.85 in (1317 mm)

Filling capacities

Tab. 2-3 Rammax 1575 filling capacities

Container Contents

Hydraulic Oil Tank gal (liter)

Diesel Fuel Tank gal (liter)

4.2 (16)

7.4 (28)

RX1575 SERIES TRENCH ROLLER • OPERATION MANUAL — REV. #0 (04/28/15) — PAGE 9

Page 10

2.3 Roller designation

2.3.1 Identification plate

An identification plate is affixed to the roller for identification. The identification plate

is attached to the rear part of the chassis below the steering column.

Fig. 2-2 Data on the identification plate

NOTE When ordering spare parts you must indicate the serial number (S/N) of the rol-

ler.

1 Roller designation

2 Homologation number

3 Name and address of the manufacturer

4 Vehicle Identification Number (VIN)

5 Roller model

6 Year of manufacture

7 Serial number

8 Fuel engine output at

9 Speed of fuel motor (rpm )

10 CECE total weight

11 Axle load, front

12 Axle load, rear

13 Number stamped in chassis

1

2

5

6

7

8

11

4

9

3

12

10

13

PRODUCT DESCRIPTION

PAGE 10 — RX1575 SERIES TRENCH ROLLER • OPERATION MANUAL — REV. #0 (04/28/15)

Page 11

PRODUCT DESCRIPTION

2.4 Intended use

2.4.1 Intended purpose of the Rammax 1575

The Rammax 1575 trench roller is a roller specially designed for trench compacting.

The unlimited side clearance of the roller drums allows compacting in very narrow,

tight trenches right up to the trench walls. The wet, clayey soils found in sewer construction, pipeline construction, road foundations and construction backfilling, etc., are

the areas of application for this modern trench roller. The infrared remote control also

makes it possible to drive underneath trench shoring in trenches. In hazardous construction site applications, it is possible for the operator to control the machine from a

safe distance with no personal risk.

Normal modes of

operation

Special operating

modes

Use the Rammax 1575 roller exclusively for driving on and compacting:

● Unbonded layers (earth, gravel, crushed stone).

● Transport of the roller from A to B (crane and low loader).

● Cleaning the roller.

● Maintenance of roller according to maintenance plan or in the event of defects.

● Rectification of machine faults by trained personnel based on error messages.

● Towing the roller.

● Proper disposal by the operator in accordance with national regulations.

2.4.2 Requirements for the roller driver

Only trained, suitable and reliable specialists may operate the rollers.

2.4.3 Application limits

Tab. 2-4 Limits for application in consideration of environmental conditions

Operation Storage

Temperature limit -10°C to +48°C -25°C to +48°C

Humidity All-year operation/outdoor storage

Terrain Graded Graded

Upslope 40% with -/50% without vibration max. 15%

Downslope 40 % with -

/50% without vibration max. 15%

RX1575 SERIES TRENCH ROLLER • OPERATION MANUAL — REV. #0 (04/28/15) — PAGE 11

Page 12

1230047 | 21.06.2013

2.5 Inappropriate use

Inappropriate use includes any use not listed under intended use. Note the following

in particular:

● The roller is not a playground.

● The roller must not be used as a traction vehicle.

● The roller is not a passenger transporter.

● In the case of movements greater than 3km, the roller must be loaded on a trans-

porter.

● The roller is not a rock crusher, breaking chisel or similar.

2.5.1 Disclaimer

Ammann Schweiz AG accepts no liability for the continued reliable functioning of the

roller if it is not used appropriately.

Unauthorized conversions and changes to the roller are prohibited for safety reasons

and void any and every Ammann guarantee as well as, possibly, the CE directive.

Replaced spare or wear parts must meet the technical requirements specified by

Ammann. These requirements are fulfilled if only original Ammann spare parts are

used.

PRODUCT DESCRIPTION

The instructions given in the various sections must be adhered to. The safety instructions must be observed at all times. Failure to adhere to working instructions, their

correct order, safety instructions or safety labeling requirements causes liability

claims to become void.

PAGE 12 — RX1575 SERIES TRENCH ROLLER • OPERATION MANUAL — REV. #0 (04/28/15)

Page 13

1230047 | 21.06.2013

3.1 General working safety

!

● The roller may only be used for driving on and compacting loose top layers (gra-

vel, earth). Other uses are prohibited.

● Rollers may only be operated with all safety devices operating. Manipulation or

disregard of safety devices and regulations invalidates the CE conformity.

● Before starting every shift, check the effectiveness of the operation and safety de-

vices and that the protection devices are in place.

● Check the steering and brakes when you start work. If defects are apparent, roller

operation is not permitted.

● If you identify any defects on the safety system or defects that impair safe opera-

tion of the equipment, inform your supervisor immediately. The roller may no longer be operated.

● If you identify any defects which endanger safe operation, cease operation imme-

diately.

● Only perform work on and clean the roller if it is stationary and secured from

rolling away.

● Switch off the engine when filling the fuel tank. Do not fill up fuel in enclosed spa-

ces. No open flames.

● Do not vibrate on slopes or inclines where there is a hazard of slipping or overtur-

ning.

● Do not drive on slopes that are steeper than the maximum climbing capacity of

the equipment. Always drive the roller carefully perpendicular to the slope dip.

● Do not vibrate inside buildings and on unstable ground.

● The driving and working field of view must not be obstructed in any way.

● Switch off the engine before leaving the roller. Secure the roller against unautho-

rized start-up and rolling away.

● Take suitable visible measures to secure parked rollers that pose an obstruction.

● Never work under the influence of drugs, alcohol or medicines that impair consci-

ousness.

● Only operate the roller in good general light conditions and good workspace illu-

mination.

● The workplace of the operator is located at a safe distance of at least 2m.

SAFETY INFORMATION

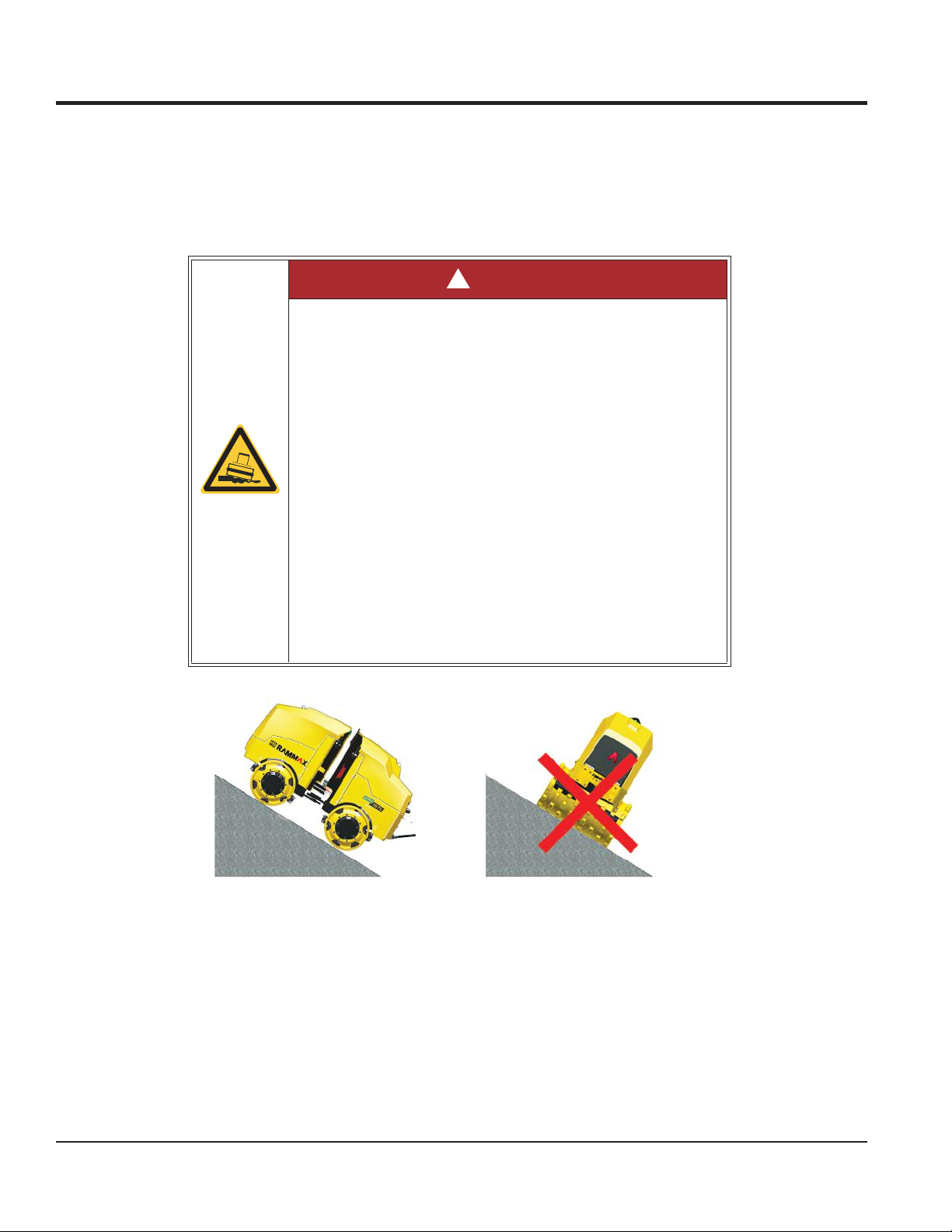

3.2 Roller operation

DANGER

Rollover hazard when driving the roller!

• Only start the roller using the handheld transmitter.

• Personnel may not stand in front of or behind the roller while it

is in operation.

• Persons necessary for operations at the sides of the equipment

must remain at a safe distance of at least 2 m.

RX1575 SERIES TRENCH ROLLER • OPERATION MANUAL — REV. #0 (04/28/15) — PAGE 13

Page 14

3.2.1 Shear points

A

● When closing the hood ensure that no objects are situated between the hood and

the chassis.

● Take care that nothing is jammed in the joint plates when rotating the roller drums.

● Do not put hands between the roller drum and support during operation.

SAFETY INFORMATION

DANGER

Danger to life through tipping or slipping of the roller! The edges of filled areas may give way!

• Only travel directly up or down slopes.

• Do not drive across slopes.

• Keep your distance to embankments and edges!

• Do not drive at an angle into or out of the trench.

• Park the roller on slopes only in such a way that it cannot overturn.

• Use the roller on slopes only in such a way that it cannot overturn.

• The roller drums have very poor adhesion on snow and ice. Driving or working on a slope in snow or ice is prohibited.

• Damp a

upward and downward grades considerably. Adapt the speed

of the machine to the terrain when driving on grades.

• The nature of the ground and weather conditions can negatively affect the climbing ability of the machine.

Never drive on slopes that are steeper than the maximum climbing ability of the machine.

nd loose surfaces reduce the traction of the machine on

Fig. 3-1 Tipping hazard

Construction site conditions can have a negative effect on stability and the tipping

angle.

PAGE 14 — RX1575 SERIES TRENCH ROLLER • OPERATION MANUAL — REV. #0 (04/28/15)

Page 15

1230047 | 21.06.2013

!

!

!

!

SAFETY INFORMATION

DANGER

Crushing hazard in the area of the articulated joint

• During operation, there is always a crushing hazard in the area

of the articulated joint. Therefore, it is not permitted for persons

to be in this area during operation. In general, a safety distance

of at least 2 meters to the machine must be maintained during

operation.

DANGER

Crushing of toes through careless handling of the roller!

• Wear safety shoes when working with the roller in order to help

avoid crushed toes.

DANGER

3.3 Noise levels

The following noise level measurements were carried out by an accredited testing

and monitoring body in accordance with machine directive 2000/14/EEC of the

European parliament and council.

Danger of accident through improper operation of the roller!

• Read the operating instructions before operating the roller.

• Adhere to the safety regulations at all costs.

• In case of lack of clarity, contact your authorized dealer.

WARNING

Hearing damage due to continuous noise level!

Depending on the use of equipment it is possible that the allowed noise level of 85dB (A) will be exceeded.

• Wear ear protectors in accordance with national accident prevention regulations when working at higher noise levels.

Inspecting and monitoring organization: TÜV Österreich (Austrian technical inspectorate) Testing body no. 0408

RX1575 SERIES TRENCH ROLLER • OPERATION MANUAL — REV. #0 (04/28/15) — PAGE 15

Page 16

SAFETY INFORMATION

Tab. 3-1 Sound power level

Model Value

Measured sound power level 100dB (A)

NOTE The obligation to wear ear protection is standardized nationally. In Switzerland

and Germany, this is as of a measured level of 85dB (A) (sound pressure).

3.4 Safety markings on the machine

● Observe and adhere to the rules.

● Keep the safety stickers and signs complete and legible.

● Replace any damaged or illegible stickers and signs immediately.

● You can order new stickers from Ammann Schweiz AG.

From the moment the signs are no longer recognizable and understandable at first

glance, the machine must be shut down until new signs are installed.

3.4.1 Warning stickers

Tab. 3-2 Warning stickers on board

Warning stickers Meaning

Location on roller:

Air intake opening

Danger:

Damage to electrical controls!

Explanation:

Never spray a water jet into electrical or electronic components.

Never spray into the engine combustion air intake.

Location on roller: Outer cowling cover.

Danger: Danger of injury due to incompetent operation:

Explanation: Read the operating instructions before ope-

rating the roller. Adhere to the safety regulations at all

costs. Contact your authorized dealer if anything is unclear.

/Inside of cowling

PAGE 16 — RX1575 SERIES TRENCH ROLLER • OPERATION MANUAL — REV. #0 (04/28/15)

Page 17

1230047 | 21.06.2013

Warning stickers Meaning

Location on roller: Between the front and rear parts of

the roller.

Danger: Crushing hazard!

Explanation: Only stand in this area when necessary and

only with extreme caution!

Location on roller: In the middle of the front and back.

Danger:Rollover hazard

Explanation: Only stand in this area when necessary and

only with extreme caution!

SAFETY INFORMATION

Location on roller: Radiator, both sides.

Danger: Warnings for cooling water radiator

Explanation: Do not put hands in the radiator fan when

the machine is running.

RX1575 SERIES TRENCH ROLLER • OPERATION MANUAL — REV. #0 (04/28/15) — PAGE 17

Page 18

SAFETY INFORMATION

Warning stickers Meaning

Location on roller: Inner cowling cover.

Designation: If the roller has overturned, do not start the machine.

Explanation: Avoid oil shock.

Location on roller: Outer cowling cover.

Requirement: Wear ear protectors!

Explanation: Wear ear protectors in accordance with nati-

onal accident prevention regulations when working at higher noise levels.

3.4.2 Notice stickers

Tab. 3-3 Notice stickers on board

Notice stickers Meaning

Location on roller: Chassis rear

Designation: Guaranteed sound power level.

Explanation: Indicates the overall noise level produced by

the roller.

Location on roller: On the hydraulic oil tank

Designation: Hydraulic oil

Explanation: Please only use hydraulic oil indicated

PAGE 18 — RX1575 SERIES TRENCH ROLLER • OPERATION MANUAL — REV. #0 (04/28/15)

Page 19

1230047 | 21.06.2013

Notice stickers Meaning

Location on roller: Chassis rear.

Designation: Hydraulic oil drain.

Explanation: Drain hole for the hydraulic oil

Location on roller: Chassis, front right.

Designation: Motor oil drain.

Explanation: Drain hole for the motor oil

Location on roller: Chassis rear.

Designation: Fuel.

Explanation: Filler neck for diesel fuel.

Location on roller: On the middle of the front and rear

chassis.

Designation: Tie-down point.

Explanation: Points on the roller at which lashing means

for securing the roller on the transport vehicle can be attached.

SAFETY INFORMATION

Location on roller: Roll bar, rear.

Designation: Suspension hooks.

Explanation: Points on the roller at which hoisting tackle

for lifting the roller can be attached.

Location on roller: Rear chassis, front upper left.

Designation: Lifting and tie-down points.

Explanation: Illustrates how the machine is to be loaded

and transported.

RX1575 SERIES TRENCH ROLLER • OPERATION MANUAL — REV. #0 (04/28/15) — PAGE 19

Page 20

Notice stickers Meaning

Location on roller: Rear chassis, front upper left.

Designation: Spare parts information

Explanation: Information about the filters of the machine.

Location on roller: Inner cowling cover.

Designation: Close the cover.

Explanation: Attention: When driving using remote cont-

rol and when parking the machine, the cover must be closed.

Location on roller: Inner cowling cover.

Designation: Ignition

Explanation: Attention: Current is present when the igni-

tion is on.

SAFETY INFORMATION

3.5 Radiation compliance

This machine complies with the emission requirements for radio interference due to

radiation, European Norm EN 13309, for construction machinery.

PAGE 20 — RX1575 SERIES TRENCH ROLLER • OPERATION MANUAL — REV. #0 (04/28/15)

Page 21

4.1 Component overview

Fig. 4-1 View from the right

1 1-point lifting eye

2 Identification plate

3 Roller drum scraper

4 Rear hood latch (cowling)

5 Front hood latch (engine hood)

6 Front infrared sensor

STRUCTURE AND FUNCTION

Fig. 4-2 View from left

1 Articulated joint protection

2 Shutdown bar (optional)

3 Cockpit cover

4 Rear infrared sensor

RX1575 SERIES TRENCH ROLLER • OPERATION MANUAL — REV. #0 (04/28/15) — PAGE 21

Page 22

STRUCTURE AND FUNCTION

Fig. 4-3 Cockpit overview

1 Infrared transmitter

2 Storage area for spiral cable

3 Display unit

4 Ignition switch

5 Fuses

6 Connector for spiral cable to infrared sensor (back area)

2

Fig. 4-4 Overview of interior of rear chassis

1 Oil cooler

2 Fuel tank

3 Hydraulic tank

4 Battery

5 Controller (machine controller)

1

3

4

5

PAGE 22 — RX1575 SERIES TRENCH ROLLER • OPERATION MANUAL — REV. #0 (04/28/15)

Page 23

1230047 | 21.06.2013

Fig. 4-5 Front bottom view

1 Engine oil drain plug

STRUCTURE AND FUNCTION

RX1575 SERIES TRENCH ROLLER • OPERATION MANUAL — REV. #0 (04/28/15) — PAGE 23

Page 24

1230047 | 21.06.2013

5.1 Display unit

5.1.1 Control lamps

OPERATING AND DISPLAY ELEMENTS

1 Display/operating hours counter

2 Control lamp f

3 Error control lamp

4 Control lamp for engine oil pressure

5 Control lamp for cooling water temperature

6 Control lamp for shutdown bar

7 Control lamp for pre-heating

The control lamps for engine oil pressure and charging light up when the ignition is

switched on. They extinguish once the engine is running.

or battery charge level (charge control)

5.1.2 Control lamp functions

Error The Error control lamp lights as soon as the controller recognizes an error. Error

codes are shown on the LED display.

1 Check whether the desired function is working. (This also applies when the tilt

sensor is triggered.)

If the battery charging lamp is still lit after carryin

g out these checks, call a specialist.

PAGE 24 — RX1575 SERIES TRENCH ROLLER • OPERATION MANUAL — REV. #0 (04/28/15)

Page 25

!

OPERATING AND DISPLAY ELEMENTS

Battery If the battery charge level control lamp lights up during operation or does not go

off after starting, carry out the following check immediately.

1 Stop the engine.

2 Check the engine for defective or loose V-belt.

If the battery charging lamp is still lit after carrying out these checks, call a specialist.

Engine oil pressu-reIf the engine oil pressure control lamp lights up during operation or does not go off

after starting, stop the roller and turn off the engine immediately!

1 Check the engine for oil loss and correct oil level.

1.1 The oil level in the engine is correct: Call a specialist to remedy the pro-

blem.

NOTE The machine is equipped with an automatic shutdown system. If the oil pres-

sure falls below the limit value, the oil pressure warning lamp lights up. After

the warning lamp has been lit for 4 seconds, the machine is shut down.

Coolant temperature

WARNING

Danger of scalding! The cooling circuit is pressurized.

NOTE Danger of engine overheating. Stop immediately!

If the coolant temperature control lamp lights up during operation of the machine,

switch off the engine immediately and top up coolant!

1 Allow the engine to cool down.

2 Remove the radiator cap.

3 In order to avoid scalding, first unscrew the radiator cap one turn and allow the

pressure to drop.

4 As soon as the pressure has dropped, remove the cap and top up the liquid.

5 Check the cooling system for leaks and the radiator/expansion vessel for cor-

rect coolant level.

5.1 You are unable to find an error: Call a specialist to remedy the problem.

NOTE The machine is equipped with an automatic shutdown system. If the cooling

water temperature exceeds the limit value, the temperature warning lamp

lights up. After the warning lamp has been lit for 4 seconds, the machine is

shut down.

RX1575 SERIES TRENCH ROLLER • OPERATION MANUAL — REV. #0 (04/28/15) — PAGE 25

Page 26

1230047 | 21.06.2013

Pre-heating The pre-heating time lasts about 6 s. The pre-heating indicator lamp extinguishes

when the engine is started.

Shutdown bar

The shutdown bar indicator lamp remains lit as long as the shutdown bar is actuated.

1 Check whether the shutdown bar has been released.

2 Release the shutdown bar.

5.1.3 LED error display on the display unit

Error display

Tab. 5-1 Error display (tilt switch)

NOTE For safety reasons, as soon as the roller tips over, the ignition is also shut off.

The machine controller is equipped with an inclination sensor. It triggers as of

an angle of 45°. In this case, the engine shuts itself off automatically. The machine cannot be started as long as the inclination sensor remains triggered.

If the machine has tipped over, it is possible for engine oil to enter the combustion area. If the machine is started after it has been righted, engine damage is

possible.

• Set the machine upright. Do not start the engine un

der any circumstances.

• Inform the service workshop.

Tab. 5-2 Error and shutdown bar display

NOTE Bear in mind the priority of the displays: First is the tilt switch, then “Wait” and

last, the status error transistor.

Display Cause Remedy

Error lights up The tilt switch has been triggered.

The roller is at an angle of more

than about 45° or has tipped over.

Set the machine upright.

Display Cause Remedy

Error lights up A switching transistor signals

a status error. This means

that, for example, a short circuit or a cable break has

been detected.

Check the cable for a short circuit or cable break.

Error and shutdown

bar light up in unison

The machine controller is

waiting for both the inputs “Oil

pressure” and “Lima” to be at

the rest position.

Check the oil pressure and lima

outputs.

(OPTIONAL)

OPERATING AND DISPLAY ELEMENTS

PAGE 26 — RX1575 SERIES TRENCH ROLLER • OPERATION MANUAL — REV. #0 (04/28/15)

Page 27

OPERATING AND DISPLAY ELEMENTS

Display

Tab. 5-3 Shutdown bar display

Shutdown bar

Display Cause Remedy

Shutdown bar lights up Switch on shutdown bar has

Shutdown bar is blinking

Shutdown bar is flashing

triggered.

Close proximity shutdown

has been detected.

Close proximity has been

detected.

Move the shutdown bar to its original position.

Move more than 2m away from

the roller.

If the roller is controlled by

means of the cable, the user

must be present in the close

proximity area (between 2 and

4m)

NOTE Bear in mind the priority of the displays: First the bar switch, then the close

proximity shutdown and last, the close proximity area.

5.2 Infrared transmitter

5.2.1 Design

Fig. 5-1 Infrared transmitter

1 Work gear/transport gear

2 Forward travel/backward travel

3 Large/small amplitude vibration

4 Steering angle left/ right

RX1575 SERIES TRENCH ROLLER • OPERATION MANUAL — REV. #0 (04/28/15) — PAGE 27

Page 28

1230047 | 21.06.2013

OPERATING AND DISPLAY ELEMENTS

5 Start/ Stop

6 LED (error and charging display from IR transmitter)

7 Cable

5.2.2 LED error display on the IR transmitter

There are two LEDs on the cover: a green one and a red one.

Fig. 5-2 LED error display, green/red

Standard

Battery charge

monitoring

Tab. 5-4 Standard display

Display Cause

The green LED is blinking slowly. The roller is being controlled via the cable.

The green LED is flashing. The roller is being controlled via infrared.

The red LED blinks either faster or slower depending on the battery charge level. The lower

the charge state, the longer the on-phase of the LED.

Tab. 5-5 Battery charge monitoring display while performing a function

Display Cause Remedy

The red LED flashes briefly The battery is slowly

The red LED always lights when a

control is operated.

The red LED flashes. The battery is being

The red LED is lit. The battery is fully

becoming drained

When the battery is

drained, it is no longer

sent.

charged.

charged.

Connect the charging

cable for at least 1h.

Connect the charging

cable for at least 1h.

NOTE It is still possible to control via the cable once the battery is empty.

Battery warnings and errors are only displayed during active control (i.e., when

a control element is actuated).

As soon as and as long as the infrared transmitter is attached to the machine

controller via the cable and the ignition is turned to I, the red LED must flash

or be lighted.

PAGE 28 — RX1575 SERIES TRENCH ROLLER • OPERATION MANUAL — REV. #0 (04/28/15)

Page 29

OPERATING AND DISPLAY ELEMENTS

Automatic pairing

NOTE This procedure normally only takes a maximum of about 3seconds. If this blin-

Special cases

Tab. 5-6 Automatic pairing display

Display Cause

The green and red LEDs are blinking in unison quickly.

king lasts longer or should even become permanent, there is a problem with

pairing:

• A cable break in one of the signal lines

• A short circuit in one of the signal lines

As long as this blinking pattern remains, no control signals will be sent to the

machine controller.

Automatic pairing occurs at the moment the cable is unplugged, or, if the cable

is plugged in, when the infrared transmitter is switched on.

● When the infrared transmitter is switched on, both LEDs are switched on briefly.

This feature helps to determine that the LEDs are still functioning.

● As soon as the cable is unplugged from the handheld transmitter or from the rol-

ler, the red LED lights up for about 1 second.

The infrared transmitter is coupled with the

machine controller.

5.2.3 Cable connection

Fig. 5-3 Spiral cable connector

1 Spiral cable connector/protective cover fastener

2 Solar cells/Transmission elements

RX1575 SERIES TRENCH ROLLER • OPERATION MANUAL — REV. #0 (04/28/15) — PAGE 29

Page 30

1230047 | 21.06.2013

5.2.4 Handling

!

Sticker

The infrared transmitter is located in the black lower part of the housing. It contains

the following transmission elements:

● The solar cells

● The infrared diodes for data transmission and measuring the safety distance.

● Before startup, clean the transmission elements.

● Before startup, be sure that the solar cells in the lower part of the housing are not

covered over.

● Keep the solar cells clean during operation.

OPERATING AND DISPLAY ELEMENTS

CAUTION

Accident hazard due to covered over lower part of the

housing!

• Before and during operation with the infrared transmitter, make

sure that the entire lower part of the housing remains completely uncovered for the entire time of operation.

• In particular, the operator’s hand must not cover the lower part

of the housing even partially.

Wear the infrared transmitter correctly

1 Pay attention to correct positioning.

1.1 The cable connector must face forwards or be oriented according to the

sticker on the transmitter. The infrared transmitter may rest on the stomach of the operator.

1.2 Adjust the strap for the correct length to ensure optimal wearing comfort.

2 Pay attention to correct operation.

2.1 Only hold the housing by the upper part; see the warning information.

PAGE 30 — RX1575 SERIES TRENCH ROLLER • OPERATION MANUAL — REV. #0 (04/28/15)

Page 31

OPERATING AND DISPLAY ELEMENTS

RX1575 SERIES TRENCH ROLLER • OPERATION MANUAL — REV. #0 (04/28/15) — PAGE 31

Page 32

1230047 | 21.06.2013

6.1 Commissioning

NOTE Familiarize yourself with the manual before commissioning.

6.1.1 Inspection before commissioning

In order to begin operating the roller (driving), the following conditions must be fulfilled:

The following must be checked:

● The function of all safety devices

● Whether the transport restraint has been removed

● Whether the shutdown bar has been released

● All screw connections for tightness

● Fuel tank and pipes for leaks

● Machine and engine for damage

● Function of the controls

● Function of the steering

● Hydraulic system for leaks

● IR transmitter battery status (LED must be lit).

● Pair infrared transmitter with the machine controller (see below).

● Electronic ballast interference (an external influence from fluorescent tubes)

COMMISSIONING

NOTE The infrared transmitter does not work and no LEDs are lit.

• Connect the transmitter to the machine via the spiral cable. The battery will

be charged!

6.1.2 Automatic pairing of infrared transmitter and machine controller

In order to operate the machine using the infrared transmitter, they must first perform

a mutual address assignment. This is only necessary if a new infrared transmitter

must be registered on the machine.

1 Connect the cable to the transmitter.

2 Turn the ignition key to position I.

3 After approx. 3 seconds, the cable can be removed.

The cable is not required for infrared operation.

NOTE Pairing is required in order to operate the machine with a new infrared trans-

mitter. Pairing ensures that only one machine can be operated with one transmitter.

The green LED and the red LED blink during pairing

PAGE 32 — RX1575 SERIES TRENCH ROLLER • OPERATION MANUAL — REV. #0 (04/28/15)

Page 33

1230047 | 21.06.2013

7.1 Protection against vandalism

Always fold the vandalism protection cover upward before start-up of the roller.

The vandalism protection cover protects the display unit and the infrared sensor

from:

● the effects of weathering

● vandalism

● alterations by third parties

If you wish to secure the display unit and the infrared sensor from unauthorized

access by third parties, you can install a padlock on the loop provided for this purpose.

Commercially available padlocks can be obtained in any building supplies store.

OPERATION

Fig. 7-1 Vandalism protection cover opened/closed

7.2 Start the engine

7.2.1 Starting the engine using the ignition switch

0 Off

All electrical loads are off.

I Ignition on

All electrical consumers can be switched on.

II Pre-heating

III Start

7.2.2 Starting the engine using the infrared transmitter

1 Turn the ignition key clockwise to position I.

2 Hold the switch on the infrared sensor in the start position.

2.1 Preglow for a max. of 6sec.

3 Release the switch.

RX1575 SERIES TRENCH ROLLER • OPERATION MANUAL — REV. #0 (04/28/15) — PAGE 33

Page 34

OPERATION

Fig. 7-2 Start the engine/Infrared sensor

NOTE The control lamps for engine oil pressure and charging light up when the igni-

tion is switched on. They extinguish once the engine is running.

Pre-heating If the outside temperature is below 0°C:

1 Turn the ignition key to position II.

1.1 Hold it in this position for max. 6 sec.

2 Turn the ignition key further to position III.

NOTE The engine is always to be started at idling speed.

NOTE If the ignition key remains at position I and the machine has not yet been star-

ted or has just been shut off, then:

• The machine goes into standby mode automatically after 10minutes.

Standby

NOTE If the ignition key remains at position I and the machine has not yet been star-

OFF

It is possible at any time to start the machine via the transmitter, using the cable operation mode or via the ignition switch.

ted or has just been shut off, and no function is activated within 4hours, then:

• The machine controller shuts itself off completely.

To be able to start the machine, the ignition key must first be moved to position 0 briefly.

PAGE 34 — RX1575 SERIES TRENCH ROLLER • OPERATION MANUAL — REV. #0 (04/28/15)

Page 35

1230047 | 21.06.2013

7.3 Driving and braking

7.3.1 Position of the operator

Distance to roller:

< 6.5 ft (2m) Operation is not possible.

> 13 ft (4m) Cable is too short, operation is not possible (do not overstretch the cable).

OPERATION

156 in

Fig. 7-3 Position of the operator/Distance to roller

Overview of functions

Operation with the cable Operation with the infrared sensor

Automatic pairing

Steering functions

Vibration functions

max. range = 13 ft (4 m) max. range = 65 ft (20 m)

Close proximity shutdown, 6.5 ft (2 m)

RX1575 SERIES TRENCH ROLLER • OPERATION MANUAL — REV. #0 (04/28/15) — PAGE 35

Page 36

OPERATION

Controller

opening angle

0°

10°

20°

30°

40°

50°

60°

70°

2 4 6 8 10 12 14 16 18 20 m

Fig. 7-4 Controller opening angle

NOTE After a function has been executed, the engine speed is automatically increa-

sed to the working speed. If no function is executed for 15 seconds, the engine

speed is automatically reduced to idling speed.

7.3.2 Driving forwards/backwards

1 Move the switch:

2a Toward the front: The roller moves forward.

2b Toward the rear: The roller moves backward.

7.3.3 Steering left/right

1 Move the switch:

2a Toward the left: The roller moves left.

2b Toward the right: The roller moves right.

7.3.4 Work gear /Transport gear

The roller is equipped with two gears.

1 Move the switch:

2a Toward the top (rabbit): the hydraulic system switches to the "transport gear"

drive level.

The roller drives at a high speed.

2b Toward the bottom (0): the hydraulic system switches to the “working gear"

drive level. The roller drives at a low speed.

PAGE 36 — RX1575 SERIES TRENCH ROLLER • OPERATION MANUAL — REV. #0 (04/28/15)

Page 37

1230047 | 21.06.2013

NOTE Please also bear the following in mind:

!

• When large/small vibration is switched on, it is only possible to drive in the

working gear.

• When the machine is cold, the difference between high speed and low

speed is minimal.

7.3.5 Large/small amplitude vibration

1 Move the switch:

2a Toward the top: The roller vibrates with a large amplitude.

2b To the center: The roller does not vibrate.

2c Toward the bottom: The roller vibrates with a small amplitude.

Danger to life through slipping or caving in of the roller!

• Do not use vibration on steep embankments or at steep angles!

• Do not vibrate inside buildings and on unstable ground!

OPERATION

WARNING

NOTE Damage to material due to harsh vibration movement.

• Never use vibration while at a standstill! If the large/ small vibration function

is activated for more than 15seconds while at a standstill, the machine controller shuts it off automatically.

• When first started, it is only possible to use the small amplitude vibration

function for the first 2minutes.

7.4 Safety and monitoring equipment

7.4.1 Brake

The machine is equipped with an hydraulic service brake. It is switched on automatically when no function is being executed.

NOTE When a function is once again performed, there may be a jerking movement.

This has no effect on the stability of the machine.

7.4.2 Close proximity and distant shutdown

The close proximity and distant shutdown function is an electronic safety feature

designed to prevent the operator from loosing visual contact with the machine and to

keep it from coming to close.

RX1575 SERIES TRENCH ROLLER • OPERATION MANUAL — REV. #0 (04/28/15) — PAGE 37

Page 38

!

OPERATION

All of the distance values indicated are measured between the front or back infrared

sensor and the infrared transmitter.

The table below shows the approximate distance values for this feature.

Tab. 7-1 Distance values for close proximity and distant shutdown

Cable operation IR operation

Close proximity shutdown approx. 6.5 ft (2 m) approx. 6.5 ft (2 m)

Distant shutdown approx. 13 ft (4 m) approx. 65 ft (20 m)

NOTE The distance values can vary in dependence on weather conditions. If the ma-

ximum range is exceeded in infrared operation/cable operation, the diesel engine continues to idle, but the functions are interrupted. Reduce the distance

to the machine in order to resume control of it.

7.5 Turning off the engine

1 Move the switch on the infrared transmitter to “STOP”.

2 Turn the ignition key to the “0” position.

CAUTION

As long as the “Start-Stop” rocker switch is placed in the

“neutral” position, the transmitter remains operational.

• Always switch off the transmitter during work breaks and after

completing work by moving the rocker switch to the “Stop” position.

PAGE 38 — RX1575 SERIES TRENCH ROLLER • OPERATION MANUAL — REV. #0 (04/28/15)

Page 39

1230047 | 21.06.2013

8.1 Shutdown bar (OPTIONAL)

The shutdown bar is located on the rear of the machine under the operating unit. A

proximity switch is located on the rear section of the machine above the attachment

point of the shutdown bar. If the machine moves against an obstacle with the shutdown bar, the shutdown bar is actuated and triggers the proximity switch. This sends

a signal to the machine controller and the machine can now only be moved forward

away from the obstacle. If the vibration function is

vibration function must be restarted manually after the

tivated. The shutdown bar must be secured with the transport strap for transportation

(transport position).

OPTIONS

running, it will be shut down. The

shutdown bar has been deac-

Fig. 8-1 Shutdown bar

1 Shutdown bar

2 Securing point for strapping down the shutdown bar

3 Proximity switch

RX1575 SERIES TRENCH ROLLER • OPERATION MANUAL — REV. #0 (04/28/15) — PAGE 39

Page 40

1230047 | 21.06.2013

9.1 General safety information

!!!

Maintenance may only be carried out by trained personnel!

● Only perform maintenance and repair work on the roller if it is static and secured

from rolling away.

● Secure the roller with the joint protection.

● Relieve pressure before working on the hydraulic pipes.

● Disconnect the battery before commencing work on the roller's electrical systems.

○ Cover the battery with isolating material or remove it completely. This does not

apply to work requiring an electric current.

○ In the event of injuries caused by acid, rinse immediately with clean water and

consult a doctor.

● Replace all protection devices properly after performing maintenance and repair

work.

Danger to life through an unsafe work area!

• Always use an accident-proof support when working on a raised roller.

• Never work below a roller which is only supported by a crane or

other electrical/hydraulic lifting device.

• Only stand under a raised roller if it has been mechanically secured.

• Only use stable loading ramps suitable for the weight of the roller for loading.

• On transport vehicles, correctly secure the roller against rolling,

slipping and overturning.

MAINTENANCE

DANGER

DANGER

Gas poisoning through letting engine run in enclosed spaces!

• Do not leave the engine running in closed areas.

• If use of the roller in a confined space cannot be avoided, the

exhaust fumes must be extracted directly from the exhaust pipe.

DANGER

Danger of scalding from hot water / steam!

• Never remove the expansion cap or radiator cap while the engine is running or hot!

• First loosen the cap to the first stop to release the pressure.

Only then remove the cap.

PAGE 40 — RX1575 SERIES TRENCH ROLLER • OPERATION MANUAL — REV. #0 (04/28/15)

Page 41

!

!

!

MAINTENANCE

DANGER

Danger of severe injury through loose clothing being caught

and drawn in!

• Only open the engine hood when the engine is switched off.

• If trouble shooting makes working on moving parts (engine or

roller) unavoidable, never wear: necklaces, bracelets, rings,

scarves, ties or other loose items of clothing.

If any of these get caught in moving parts there is a danger of

serious injury!

WARNING

Danger of scalding from hot water / steam!

• Only work on a cool engine.

• Keep enough distance to the exhaust.

CAUTION

Environmental hazard through operating materials!

• Do not allow any liquids to enter drains, the soil or the environment.

NOTE Damage to electrical controls through contact with water!

• Never spray a water jet into electrical or electronic components.

• Never spray into the engine combustion air intake.

NOTE Damage to hydraulic controls through use of wrong oil!

Hydraulic tubes decompose.

• It is forbidden to change used rollers for use with biodegradable hydraulic

oils!

• If hydraulic hoses on a roller running on synthetic ester HE need replacing,

only those declared by the supplier as being compatible with synthetic esters may be used.

RX1575 SERIES TRENCH ROLLER • OPERATION MANUAL — REV. #0 (04/28/15) — PAGE 41

Page 42

1230047 | 21.06.2013

9.1.1 Battery safety instructions

!

!

Risk of serious injury through leaking battery acid!

The sulfuric acid in the battery is poisonous and so strong it

can burn holes in clothes and dissolve skin. If it gets into eyes

it can lead to blindness.

• Protect the battery from fire, flames and sparks.

• Protect the battery from mechanical damage

Risk of explosion when charging battery!

• Never check the battery charge level with a metal object. Use

a voltmeter or the battery's charge indicator.

• When disconnecting the battery always disconnect the negative terminal first (-).

• Connect the positive terminal (+) first when reconnecting.

MAINTENANCE

DANGER

.

DANGER

NOTE Doing welding work on the roller when the battery in installed can damage the

electrical controls!

• Always remove the battery completely before performing welding wo

the roller.

NOTE Always replace the battery with a service-free battery. If you are using a battery

that requires maintenance, always observe the safety instructions in the battery manual.

rk on

9.2 General information about maintenance

NOTE Not all maintenance tasks are listed in these operating and maintenance inst-

ructions. We would also like to point out the separate manual for the Yanmar

engine.

●

When carrying out maintenance work always observe the applicable safety

regu-lations in the 3 Safety information section.

● Maintenance work and inspections must be performed according to the following

maintenance tables in order to guarantee reliable roller operation.

● Remove all dirt before taking off any covers, plugs, measuring rods, etc. to inspect

or top up engine oil, hydraulic oil, diesel or other liquids.

● Any parts that do not pass the following inspections must be replaced immedia-

tely.

The protective devices must be correctly refitted after every service.

PAGE 42 — RX1575 SERIES TRENCH ROLLER • OPERATION MANUAL — REV. #0 (04/28/15)

Page 43

9.3 Rammax 1575 maintenance

Maintenance intervals in operating hours [h] and in calendar peri-

ods [daily, weekly, monthly, quarterly, semi annually, annually]

9.3.1 Maintenance plan

MAINTENANCE

Chapter / D = information

from dealer

Exchange, replace

Lubricate, treat

Clean, drain

Check, inspect, test, correct, set up

-

-

9.10

9.8

/Expansion tank

Object, condition

Coolant

Fuel system leakage

Hydraulic oil cooler

Engine oil level

• • •

• • • • • • • • •

9.11.2

Air-intake filter

9.7

9.9

Fuel level

Hydraulic oil level

9.8.4

9.11.1

/engine oil filter

Roller drum scraper

Engine oil

• • •

9.13

Brake test

-

9.12

Steering cylinder bearing

Hydraulic system leaks

•

9.9.5

9.9.6

Hydraulic oil tank ventilation filter

Hydraulic oil/hydraulic oil filter

ded

as nee-

1000

500

250

100

50

10

1 year

6 months

3 months

1 month

1 week

1 day

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

(•) 2nd

(•) 1st

•

•

•

•

•

•

•

•

•

(•) 1st

(•) 1st

•

RX1575 SERIES TRENCH ROLLER • OPERATION MANUAL — REV. #0 (04/28/15) — PAGE 43

Page 44

1230047 | 21.06.2013

MAINTENANCE

Object, condition

ded

as nee-

9.7.5

Fuel filter element

9.7.6

Water separator filter element

D

D

9.11.2

D

Air filter cartridge

Check 1-point lifting eye for cracks

and deformation

Check web plate tension sleeve for cracks

and deformation

Drive motor seal

9.7.4

Clean the fuel

D

Roller drum rubber elements

-

Fuel hoses

D

Hydraulic hoses

10.3

Gas strut for hood, front and rear

10.1

Battery

9.10

Cooling water radiator

10.2

Relays and fuses

D

Preparation for welding work

D

D

Roller drum bearings/roller drum maintenance

Hood hinges, front and rear

• • • • ••• • ••

• •

• •

• • • • • • • •

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

1000

500

250

100

50

10

1 year

6 months

3 months

1 month

1 week

1 day

•

•

•

•

•

•

•

NOTE Please also observe the Yanmar engine operating manual and the detailed in-

structions given there.

PAGE 44 — RX1575 SERIES TRENCH ROLLER • OPERATION MANUAL — REV. #0 (04/28/15)

Page 45

9.4 Maintenance check sheet

Roller, serial no.________________

MAINTENANCE

Date

Operating

hours

Comments /

Activity

Signature

RX1575 SERIES TRENCH ROLLER • OPERATION MANUAL — REV. #0 (04/28/15) — PAGE 45

Page 46

1230047 | 21.06.2013

9.5 Opening the hood, front and rear

!

!

DANGER

Danger of severe injury through loose clothing being caught

and drawn in!

•Only open the engine hood when the engine is switched off.

• If trouble shooting makes working on moving parts (engine or

roller) unavoidable, never wear: Necklaces, bracelets, rings,

scarves, ties or other loose items of clothing.

If any of these get caught in moving parts there is a danger of

serious injury!

WARNING

Danger of scalding from hot water / steam!

• Only work on a cool engine.

• Keep enough distance to the exhaust.

MAINTENANCE

There is one locking device each on the front and back as well as the left and right

of the roller.

1 Open both catches, on the right and the left.

2 Open the hood.

2.1 Lift the hood with slight pressure toward the center of the roller.

2.2* If the hood is defective, replace it immediately.

Fig. 9-1 Locking device

NOTE Two gas struts reduce the force required to open the hood and give it its final

position. If you need more force to open the hood, replace the gas

absorbers. See When replacing fuses, do not mix them up.

PAGE 46 — RX1575 SERIES TRENCH ROLLER • OPERATION MANUAL — REV. #0 (04/28/15)

Page 47

9.6 Engine compartment overview

6

9.6.1 Left side of the engine

MAINTENANCE

7

Fig. 9-2 Left side of the engine

1 Air-intake filter

2 Engine oil filter

3 Oil dipstick

4 Coolant drain

5 Engine oil filler neck

6 Coolant filler neck

7 Fuel filter

2

1

3

4

5

RX1575 SERIES TRENCH ROLLER • OPERATION MANUAL — REV. #0 (04/28/15) — PAGE 47

Page 48

1230047 | 21.06.2013

9.6.2 Right side of the engine

a

MAINTENANCE

Fig. 9-3 Right side of the engine

1 Engine oil filler neck

2 Alternator

3 Fuel pump

4 Coolant level display

5 Flow divider

6 Nozzle block

7 Water separator

Risk of burning and injury when handling parts in the engine

compartment!

• Switch the diesel engine off when performing any inspection

work. The locking brake is active when the diesel engine is

switched off.

WARNING

PAGE 48 — RX1575 SERIES TRENCH ROLLER • OPERATION MANUAL — REV. #0 (04/28/15)

Page 49

9.7 Fuel (diesel)

9.7.1 Checking fuel level

1 Open the hood.

2 Check the level in the plastic tank.

9.7.2 Refueling

1 Fill the fuel tank with diesel fuel up to the lower edge of the filler neck.

1a Every day before beginning work

The tank holds 28liters of diesel fuel.

MAINTENANCE

Fig. 9-4 Diesel fuel filler neck

Diesel

Specifications

NOTE Poor quality diesel can:

NOTE For more detailed information, please see the Yanmar engine manual.

Tab. 9-1 Excerpt from the Yanmar engine manual about diesel specifications

Diesel specifications Application

No. 2-D, No.1-D, ASTM D975-94 USA

EN 590:96 Europe

lanoitanretnIXMD 7128 OSI

BS 2869-A1 or A2 Great Britain

JIS K2204 grade no. 2 Japan

KSM-2610 Korea

anihC252BG

• Reduce the performance of the engine

• Damage the engine

RX1575 SERIES TRENCH ROLLER • OPERATION MANUAL — REV. #0 (04/28/15) — PAGE 49

Page 50

1230047 | 21.06.2013

9.7.3 Draining fuel

!

1 Unscrew the cover screw (1) under the roller (AF size27 wrench).

2 Place a container under the drain tap.

3 Drain off the diesel.

4 Install the screw plug (1).

4.1 Tighten the screw connection hand tight.

1

MAINTENANCE

CAUTION

Environmental hazard through operating materials!

• Do not allow any liquids to enter drains, the soil or the environment.

Fig. 9-5 Diesel drain, rear left on chassis

9.7.4 Cleaning the fuel tank

Over time, condensation water gathers in the fuel tank. It must be drained once a

year.

1 Unscrew the cover screw (1) under the roller (AF size27 wrench).

2 Place a container under the drain tap.

3 Allow about 1/2 liter of fluid to drain.

First, the water which has collected on the bottom of the tank will run out.

4 Install the screw plug (1).

4.1 Tighten the screw connection hand tight.

PAGE 50 — RX1575 SERIES TRENCH ROLLER • OPERATION MANUAL — REV. #0 (04/28/15)

Page 51

9.7.5 Fuel filter element

3

1

Fig. 9-6 Fuel filter

Replace fuel filter element (1) according to the maintenance plan.

1 Close stop cock (3).

1.1 Move to OFF.

2 Unscrew the filter housing (2).

3 Remove the old filter element (1).

MAINTENANCE

2

4 Insert new filter element (1).

5 Screw the filter housing (2) on.

6 Open stop cock (3).

6.1 Move to ON.

9.7.6 Water separator filter element

3

2

Fig. 9-7 Water separator

Drain filter

housing

If there is water in the filter housing, the housing must be drained at once.

1 Close stop cock (3).

1

1.1 Move to OFF.

2 Unscrew filter housing and empty.

RX1575 SERIES TRENCH ROLLER • OPERATION MANUAL — REV. #0 (04/28/15) — PAGE 51

Page 52

1230047 | 21.06.2013

3 Screw the filter housing on.

4 Open stop cock (3).

4.1 Move to ON.

MAINTENANCE

Filter element

clean

Clean water separator element (1) according to the maintenance plan.

1 Close stop cock (3).

1.1 Move to OFF.

2 Unscrew the filter housing (2).

3 Clean filter element (1).

4 Screw the filter housing (2) on.

5 Open stop cock (3).

5.1 Move to ON.

9.8 Engine oil

9.8.1 Checking the engine oil level

Oil dipstick

1 Check engine oil level daily using the dipstick. The dipstick (1) is located on

the left of the engine.

1.1 Check oil level while the roller is standing on a level surface and the

engine is cold.

1.2 You can see the engine oil level on the dipstick.

The oil level must be between the top (x) and bottom (y) marks.

2* Top up engine oil as required.

1

x

y

Fig. 9-8 Location of dipstick

PAGE 52 — RX1575 SERIES TRENCH ROLLER • OPERATION MANUAL — REV. #0 (04/28/15)

Page 53

9.8.2 Topping up the engine oil

!

1 Top up the engine oil at one of the two oil filler necks.

1a Filler neck on the left-hand side of the engine.

1b Filler neck on the engine.

b

MAINTENANCE

a

Fig. 9-9 Filler neck to the left and filler neck on top.

NOTE In order to guarantee operating safety of the engine for the long term, you must

not put any additives in the engine oil.

9.8.3 Draining engine oil

The engine oil drain (1) is located under the chassis at the front left.

1

Fig. 9-10 Roller turned fully /Engine oil drain

CAUTION

Environmental hazard through operating materials!

• Do not allow any liquids to enter drains, the soil or the environment.

RX1575 SERIES TRENCH ROLLER • OPERATION MANUAL — REV. #0 (04/28/15) — PAGE 53

Page 54

1230047 | 21.06.2013

1 Place a container under the drain.

2 Open the union by turning it anti-clockwise (size 27wrench).

The oil starts to flow out immediately.

9.8.4 Replace the engine oil filter

1

Fig. 9-11 Engine oil filter

1 Loosen the filter (1) by hand or using a filter wrench.

MAINTENANCE

2

1.1 The oil starts to flow out immediately. It’s best to place a rag under it

beforehand.

2 Replace oil filter (2).

3 Screw the complete filter back in place.

9.9 Hydraulic oil

9.9.1 Checking the hydraulic oil level

Inspection window

Always check the hydraulic oil level at operating temperature with the engine running.

1 Place the roller on level ground.

2 Let the roller continue to idle.

3 Check the oil level in the inspection window.

4* If the oil level is at the middle of the inspection glass, add 1 liter of hydraulic oil

via the filler neck.

9.9.2 Topping up hydraulic oil

1 Remove the screw lid (1) on the filler neck.

2 Add 1 liter of hydraulic oil.

PAGE 54 — RX1575 SERIES TRENCH ROLLER • OPERATION MANUAL — REV. #0 (04/28/15)

Page 55

3 Reinstall the screw lid (1).

3.1 Important: Always grease the O-ring before screwing it in place.

1

Fig. 9-12 Hydraulic oil filler neck

NOTE Observe the table of lubricants in chapter 9.14.

9.9.3 Draining the hydraulic oil

MAINTENANCE

NOTE Only drain the hydraulic oil at operating temperature.

• The oil flows better.

• Residues in the tank will be flushed out with the oil.

1 Place a container (with at least a 30 liter capacity) under the hydraulic oil drain.

2 Remove the hydraulic oil tank lid.

3 Unscrew the cover screw (1) under the roller (AF size27 wrench).

4 Allow the oil to drain into the container.

5 Install the screw plug (1).

5.1 Tighten the screw connection hand tight.

1

Fig. 9-13 Hydraulic oil drain

NOTE When you drain the hydraulic oil, please also replace the hydraulic oil filter.

See chapter 9.9.5.

RX1575 SERIES TRENCH ROLLER • OPERATION MANUAL — REV. #0 (04/28/15) — PAGE 55

Page 56

1230047 | 21.06.2013

NOTE Tighten the screw connections in the hydraulic tank hand tight.

9.9.4 Cleaning the hydraulic oil cooler

1 Check the cooling ribs of the hydraulic oil cooler for dirt and clogging.

2 Clean the ribs with water or blow them out with compressed air.

NOTE Never clean the cooler with high pressure (e.g. powerful water jet).

1

MAINTENANCE

Fig. 9-14 Hydraulic oil cooler grill

9.9.5 Replacing the hydraulic oil filter

1 Remove the filter lid.

2 Unlock the filter element.

3 Lift the filter element out of the filter housing.

3.1 Dispose of the filter element in an ecologically appropriate manner.

21

Fig. 9-15 Replacing the hydraulic oil filter, steps 1 to 3

4 Place the new filter element in the proper position.

3

PAGE 56 — RX1575 SERIES TRENCH ROLLER • OPERATION MANUAL — REV. #0 (04/28/15)

Page 57

4.1 Observe the position of the locking cam.

5 Turn the filter element fully clockwise to the stop.

MAINTENANCE

4

Fig. 9-16 Replacing the hydraulic oil filter, steps 4 to 6

6 Lightly oil the sealing ring on the filter lid.

7 Put the filter lid in place.

7.1 Tighten the lid with a torque wrench (max. torque, 20Nm).

87

Fig. 9-17 Replacing the hydraulic oil filter, steps 7 to 8

4.1 5

9.9.6 Replacing the ventilation filter

1

Fig. 9-18 Ventilation filter

RX1575 SERIES TRENCH ROLLER • OPERATION MANUAL — REV. #0 (04/28/15) — PAGE 57

Page 58

1230047 | 21.06.2013

Replace the ventilation filter (1) according to the maintenance plan.

!

9.10 Coolant

A coolant antifreeze mixture for up to -25° is provided upon delivery from the factory.

For temperatures colder than -25°, the fluid must be replaced by a suitable coolant

antifreeze mixture.

9.10.1 Checking coolant level

1 Check coolant level every day.

1.1 Check oil level while the roller is standing on a level surface and the

engine is cold.

1.2 You can read off the level of coolant on the expansion tank display.

The water level must be between the top (FULL) and bottom (LOW)

marks.

2* Top up coolant as required.

MAINTENANCE

Fig. 9-19 Expansion tank

9.10.2 Topping up coolant

Danger of scalding from hot water / steam!

• Only open the tank once the engine and the coolant have cooled down.

1 Unscrew the tank lid of the radiator.

2 Add coolant with antifreeze until the tank is full.

FULL

LOW

CAUTION

PAGE 58 — RX1575 SERIES TRENCH ROLLER • OPERATION MANUAL — REV. #0 (04/28/15)

Page 59

Fig. 9-20 Coolant filler neck

9.10.3 Cleaning the radiator

1 Check the cooling ribs of the water tank for dirt and clogging.

2 Clean the ribs with water or blow them out with compressed air.

MAINTENANCE

NOTE Never clean the cooler with high pressure (e.g. powerful water jet).

Fig. 9-21 Radiator grill

RX1575 SERIES TRENCH ROLLER • OPERATION MANUAL — REV. #0 (04/28/15) — PAGE 59

Page 60

1230047 | 21.06.2013

MAINTENANCE

9.11 Functional check

9.11.1 Scrapers

640 and 850 1 Before driving, adjust the roller drum scraper so that there is a clearance of

about 5mm between the roller drum and the scraper.

Fig. 9-22 Roller drum scraper

9.11.2 Air-intake filter

Soiling indicator 1 If a red ring appears on the soiling display (1) during operation of the roller, you

must:

2a clean the air filter cartridge,

3a or replace it.

1

Fig. 9-23 Soiling indicator

Air filter cartridge The air filter is located on the left side of the engine.

1 Remove the wing nut (1) with the cover.

2 Remove the wing nut (2) from the air filter cartridge.

3 Remove the air filter cartridge (3).

4 Check the air filter cartridge for:

PAGE 60 — RX1575 SERIES TRENCH ROLLER • OPERATION MANUAL — REV. #0 (04/28/15)

Page 61

5a Damage: replace the cartridge.

6a Soiling: clean the cartridge.

MAINTENANCE

1

2

Fig. 9-24 Air filter cartridge

NOTE If the machine is used on very dusty surfaces, the air filter must be checked for

clogging once per week.

• When cleaning/replacing the cartridge, take care that no dirt enters the intake hose.

Air intake 1 Check the air intake for:

1a Soiling: clean the intake opening.

3

Fig. 9-25 Air intake

9.11.3 Pendulum support

Check the pendulum support once a year for excessive play.

1 Attach the roller to a crane (central lifting point).

The play can be checked by alternately applying and releasing upward pressure to

the roller (visual inspection).

RX1575 SERIES TRENCH ROLLER • OPERATION MANUAL — REV. #0 (04/28/15) — PAGE 61

Page 62

1230047 | 21.06.2013

Fig. 9-26 Pendulum support

9.11.4 Articulated joint

Check the articulated joint once a year for excessive play.

1 Attach the roller to a crane (central lifting point).

The play can be checked by alternately applying and releasing upward pressure to

the roller (visual inspection).

MAINTENANCE

Fig. 9-27 Articulated joint

9.12 Lubricating steering cylinder, bearing

1 Rotate the roller's steering fully to the stop in order to grease the cylinder.

2 Steer the roller briefly to the right and the left. This causes the bearing to be

unloaded.

3 Clean the grease nipple (1) before greasing.

4 Connect the

5 Press grease into the bearing until it visibly begins to ooze out.

6 Put the protective cover back on.

grease gun to the grease nipple

PAGE 62 — RX1575 SERIES TRENCH ROLLER • OPERATION MANUAL — REV. #0 (04/28/15)

.

Page 63

MAINTENANCE

1

Fig. 9-28 Location of grease nipples on steering cylinder

NOTE Damager to property due to increased wear!

• Regrease the bearing after every cleaning/ steam cleaning of the roller.

1

RX1575 SERIES TRENCH ROLLER • OPERATION MANUAL — REV. #0 (04/28/15) — PAGE 63

Page 64

1230047 | 21.06.2013

9.13 Brake test

The function of the brakes must be checked periodically.

9.13.1 Cable/ connector Y9

The cable/connector Y9, which must be disconnected for the brake test, is located

at the front under the hood.

MAINTENANCE

Fig. 9-29 Cable/ connector Y9 under the hood

9.13.2 Brake test

Fig. 9-30 Cable/ connector Y9 under the hood

1 Put the machine into the work gear.

2 Disconnect connector Y9 (1) from the connector housing at the magnet.

3 Perform the forwards and backwards driving functions using the infrared sen-

sor.

4 Check all four roller drum

1

s for rotation (slipping).

If a brake is defective,

NOTE If a brake is defective, the roller is no longer safe for operation. Contact your

authorized dealer and have the roller repaired professionally.

the corresponding roller drum will rotate.

PAGE 64 — RX1575 SERIES TRENCH ROLLER • OPERATION MANUAL — REV. #0 (04/28/15)

Page 65

9.14 Lubricant table

Tab. 9-2 Lubricant table

Brand Hydraulic oil

Synthetic hydraulic

oil based on HE

esters

MAINTENANCE

Grease

Standard

Application

AGIP Amica 46

BLASER Blasol 148 Foodgrease SPM00

BP Bartran HV 46

CASTROL Hyspin AWH 46

ESSO Univis HP 46

MOBIL Mobil DTE15

Motorex Corex HV 46 MOLY 218

PANOLIN HLP Universal 46 HLP Synth 46

SHELL Tellus T 46

TOTAL Equivis ZS 46

ISO VG 46 HVLP

DIN 51524 T3

Drive and

vibration hydraulics

ISO 15380 HEES

Drive and

vibration hydraulics

ISO 2137

DIN 51502

(Rammax vibro bea-

ring)

(steering cylinder)

NOTE Using the wrong oil can cause damage to the hydraulic controls! Hydraulic tu-

bes decompose.

• It is forbidden to change used rollers for use with biodegradable hydraulic

oils!

• If hydraulic hoses on a roller running on synthetic ester HE need replacing,

only those declared by the supplier as being compatible with synthetic esters may be used.

RX1575 SERIES TRENCH ROLLER • OPERATION MANUAL — REV. #0 (04/28/15) — PAGE 65

Page 66

1230047 | 21.06.2013

9.15 Consumables

Tab. 9-3 Consumables

Designation Brand Quantity Art.no.

Engine oil Motorex Focus CF SAE 10W/40 1l 1242375

Grease Motorex Moly 218 400g 1111368

Grease Motorex 174 0.85kg 1144019

Grease Blaser Foodgrease SPM00 0.38kg 1094392

Blue adhesive Ergo 4052 50ml 1-907977

Red adhesive Ergo 4100 50ml 1-907978

Paint spray RAL dark gray 400ml 1202234

Paint spray RAL 1016 Sulfur yellow 400 ml 1-922700

Paint spray RAL 6033 Mint turquoise 400ml 1-922701

Sealant Ergo 4207 250g 1-923054

NOTE The screws can loosen due to the vibration of the roller!

MAINTENANCE

• Unless otherwise specified, secure all screws with blue thread-lock.

9.16 Tightening torques

The values below apply:

● Unless otherwise specified in the operating manual or in the workshop manual

● To female steel threads

9.16.1 Screws

Tab. 9-4 Tightening torque: Hex screws/bolts (including tapping screws) and hexagon-socket-head

screws

AF

size

hex

10 5 M6 8.8 10

AF

size

Allen

7 3 M4 8.8 3

8 4 M5 8.8 6

Screw

diameter

Steel quality

Tightening torque in

Nm

13 6 M8 8.8 25

13 6 M8 10.9 36

15 M10x1.25 10.9 90

PAGE 66 — RX1575 SERIES TRENCH ROLLER • OPERATION MANUAL — REV. #0 (04/28/15)

Page 67

MAINTENANCE

AF

size

hex

17 8 M10 8.8 48

19 10 M12 8.8 84

19 10 M12 10.9 123

24 - M16 8.8 206