Page 1

OPERATION AND PARTS MANUAL

MODEL QP3Ti

TRASH PUMP

(HONDA iGX270UT2QZMD

GASOLINE ENGINE)

Revision #1 (05/07/18)

To find the latest revision of this

publication, visit our website at:

www.multiquip.com

THIS MANUAL MUST ACCOMPANY THE EQUIPMENT AT ALL TIMES.

Page 2

PROPOSITION 65 WARNING

PAGE 2 — QP3Ti TRASH PUMP • OPERATION AND PARTS MANUAL — REV. #1 (05/07/18)

Page 3

NOTES

QP3Ti TRASH PUMP • OPERATION AND PARTS MANUAL —REV. #1 (05/07/18) — PAGE 3

Page 4

TABLE OF CONTENTS

QP3Ti Centrifugal Pump

Proposition 65 Warning ........................................... 2

Parts Ordering Procedures ...................................... 5

Safety Information .............................................. 6-10

Specifications (Pump) ............................................ 11

Specifications (Engine) .......................................... 12

General Information ............................................... 13

Pump Components ........................................... 14-15

Basic Engine .......................................................... 16

Control Panel .................................................... 17-18

Inspection (Engine) ................................................ 19

Setup ..................................................................... 20

Operation .......................................................... 21-23

Maintenance (Pump) ........................................ 24-25

Maintenance (Engine) ...................................... 26-28

Storage .................................................................. 29

Troubleshooting (Engine) .................................. 30-31

Troubleshooting (Pump) ........................................ 32

Wiring Diagram — Control Panel........................... 34

Wiring Locator — Control Panel ........................... 35

Explanation Of Code In Remarks Column............. 36

Suggested Spare Parts ......................................... 37

Component Drawings

Nameplate and Decals Assembly ..................... 38-39

Pump Assembly ................................................ 40-43

Control Panel Assembly ...................................44-45

Float Switches and Utility Box Assembly .......... 46-47

Frame and Battery Assembly ........................... 48-49

Engine Service Parts ........................................ 50-51

Terms And Conditions Of Sale — Parts ................ 52

NOTICE

Specifications and part numbers are subject to change

without notice.

PAGE 4 — QP3Ti TRASH PUMP • OPERATION AND PARTS MANUAL — REV. #1 (05/07/18)

Page 5

PARTS ORDERING PROCEDURES

www.multiquip.com

Ordering parts has never been easier!

If you have an MQ Account, to obtain a Username

parts@multiquip.

To obtain an MQ Account, contact your

Effective:

, 2006

Choose from three easy options:

January 1

st

Best Deal!

Order via Internet (Dealers Only):

Order parts on-line using Multiquip’s SmartEquip website!

■ View Parts Diagrams

■ Order Parts

■ Print Specification Information

Goto www.multiquip.com and click on

Order Parts

to log in and save!

Order via Fax (Dealers Only):

All customers are welcome to order parts via Fax.

Domestic (US) Customers dial:

1-800-6-PARTS-7 (800-672-7877)

Order via Phone:

Non-Dealer Customers:

Contact your local Multiquip Dealer for

parts or call 800-427-1244 for help in

locating a dealer near you.

and Password, E-mail us at:

com.

District Sales Manager for more information.

Use the internet and qualify for a 5% Discount

on Standard orders for all orders which include

complete part numbers.*

Fax your order in and qualify for a 2% Discount

on Standard orders for all orders which include

complete part numbers.*

Domestic (US) Dealers Call:

1-800-427-1244

International Customers should contact

their local Multiquip Representatives for

Parts Ordering information.

Note: Discounts Are Subject To Change

Note: Discounts Are Subject To Change

When ordering parts, please supply:

❒ Dealer Account Number

❒ Dealer Name and Address

❒ Shipping Address (if different than billing address)

❒ Return Fax Number

❒ Applicable Model Number

❒ Quantity, Part Number and Description of Each Part

NOTICE

All orders are treated as Standard Orders and will

ship the same day if received prior to 3PM PST.

WE ACCEPT ALL MAJOR CREDIT CARDS!

QP3Ti TRASH PUMP • OPERATION AND PARTS MANUAL —REV. #1 (05/07/18) — PAGE 5

❒ Specify Preferred Method of Shipment:

✓ UPS/Fed Ex ✓ DHL

■ Priority One ✓ Tr uc k

■ Ground

■ Next Day

■ Second/Third Day

Page 6

SAFETY INFORMATION

Do not operate or service the equipment before reading

the entire manual. Safety precautions should be followed

at all times when operating this equipment.

Failure to read and understand the safety

messages and operating instructions could

result in injury to yourself and others.

SAFETY MESSAGES

The four safety messages shown below will inform you

about potential hazards that could injure you or others. The

safety messages specifi cally address the level of exposure

to the operator and are preceded by one of four words:

DANGER, WARNING, CAUTION

SAFETY SYMBOLS

Potential hazards associated with the operation of this

equipment will be referenced with hazard symbols which

may appear throughout this manual in conjunction with

safety messages.

DANGER

Indicates a hazardous situation which, if not avoided,

WILL result in DEATH or SERIOUS INJURY.

WARNING

Indicates a hazardous situation which, if not avoided,

COULD result in DEATH or SERIOUS INJURY.

CAUTION

Indicates a hazardous situation which, if not avoided,

COULD result in MINOR or MODERATE INJURY.

or NOTICE.

NOTICE

Addresses practices not related to personal injury.

PAGE 6 — QP3Ti TRASH PUMP • OPERATION AND PARTS MANUAL — REV. #1 (05/07/18)

Page 7

SAFETY INFORMATION

GENERAL SAFETY

PUMP SAFETY

pump volatile, explosive, fl ammable or low fl ash

The engine fuel exhaust gases contain poisonous carbon

monoxide. This gas is colorless and odorless, and can

The engine of this equipment requires an adequate free

operate this equipment in any

pump corrosive chemicals or water containing

toxic substances. These fl uids could create serious

health and environmental hazards. Contact local

emergency or safety devices.

These devices are intended for operator safety.

Disconnection of these devices can cause severe injury,

bodily harm or even death. Disconnection of any of these

CAUTION

NEVER operate this equipment without proper protective

clothing, shatterproof glasses, respiratory protection,

hearing protection, steel-toed boots and other protective

devices required by the job or city and state regulations.

NEVER operate this equipment when not

feeling well due to fatigue, illness or when

under medication.

NEVER operate this equipment under the infl uence of

drugs or alcohol.

NOTICE

This equipment should only be operated by trained and

qualifi ed personnel 18 years of age and older.

DANGER

NEVER

point fl uids. These fl uids could ignite or explode.

cause death if inhaled.

fl ow of cooling air. NEVER

enclosed or narrow area

where free fl ow of the air is

restricted. If the air fl ow is

restricted it will cause injury

to people and property and

serious damage to the

equipment or engine.

NEVER operate the equipment in an explosive

atmosphere or near combustible materials. An

explosion or fi re could result causing severe

bodily harm or even death.

WARNING

DANGEROUS

GAS FUMES

Whenever necessary, replace nameplate, operation and

safety decals when they become diffi cult read.

Manufacturer does not assume responsibility for any

accident due to equipment modifi cations. Unauthorized

equipment modifi cation will void all warranties.

NEVER use accessories or attachments that are not

recommended by Multiquip for this equipment. Damage

to the equipment and/or injury to user may result.

ALWAYS know the location of the nearest

fi re extinguisher.

ALWAYS know the location of the nearest

fi rst aid kit.

ALWAYS know the location of the nearest phone or keep

a phone on the job site. Also, know the phone numbers

of the nearest ambulance, doctor and fi re department.

This information will be invaluable in the case of an

emergency.

NEVER

authorities for assistance.

NEVER open the priming plug when pump

is hot. Hot water inside could be pressurized

much like the radiator of an automobile.

Allow pump to cool to the touch before

loosening plug. The possibility exists of

scalding, resulting in severe bodily harm.

NEVER disconnect any

devices will void all warranties.

QP3Ti TRASH PUMP • OPERATION AND PARTS MANUAL —REV. #1 (05/07/18) — PAGE 7

Page 8

SAFETY INFORMATION

ENGINE SAFETY

run engine without an air fi lter or with a dirty air

fi lter. Severe engine damage may occur. Service air fi lter

add fuel to equipment if it is placed inside truck

bed with plastic liner. Possibility exists of explosion or

start the engine near spilled fuel or combustible

fl uids. Fuel is extremely fl ammable and its vapors can

refuel in a well-ventilated area, away from

use extreme caution when working with

CAUTION

NEVER lubricate components or attempt service on a

running machine.

NEVER block or restrict flow from discharge hose.

Remove kinks from discharge line before starting pump.

Operation with a blocked discharge line can cause water

inside pump to overheat.

DO NOT touch control panel with wet hands.

NOTICE

ALWAYS fi ll the pump casing with water before starting

the engine. Failure to maintain water inside the pump

housing will cause severe damage to the pump and

mechanical seal.

In winter drain water from pump housing to prevent

freezing.

NEVER start the pump with the clean-out cover removed.

The rotating impeller inside the pump can cut or sever

objects caught in it. Before starting the pump, check that

the clean-out cover is securely fastened.

CAUTION

NEVER touch the hot exhaust manifold,

muffl er or cylinder. Allow these parts to cool

before servicing equipment.

NOTICE

NEVER

frequently to prevent engine malfunction.

NEVER tamper with the factory settings

of the engine or engine governor. Damage

to the engine or equipment can result

if operating in speed ranges above the

maximum allowable.

FUEL SAFETY

DANGER

DO NOT

fi re due to static electricity.

ALWAYS keep the machine in proper running condition.

ALWAYS ensure pump is on level ground before use.

DO NOT swing or whirl around fl oat switches.

ALWAYS retract handle before operation.

Fix damage to machine and replace any broken parts

immediately.

ALWAYS store equipment properly when it is not being

used. Equipment should be stored in a clean, dry location

out of the reach of children and unauthorized personnel.

WARNING

NEVER operate the engine with heat shields or

guards removed.

DO NOT remove the engine oil drain plug

while the engine is hot. Hot oil will gush

out of the oil tank and severely scald any

persons in the general area of the pump.

FUEL

FUEL

DO NOT

cause an explosion if ignited.

ALWAYS

sparks and open fl ames.

ALWAYS

fl ammable liquids.

PAGE 8 — QP3Ti TRASH PUMP • OPERATION AND PARTS MANUAL — REV. #1 (05/07/18)

Page 9

SAFETY INFORMATION

DO NOT fi ll the fuel tank while the engine is running

BATTERY SAFETY (ELECTRIC START ONLY)

If the battery liquid (dilute sulfuric acid) comes into

, rinse eyes immediately with plenty

of water and contact the nearest doctor or hospital to

NEGATIVE battery terminal

keep battery cables in good working condition.

check and make sure that there is no water

allow any person or animal to stand underneath

tow unit. The wheels are for manual transport

drop the unit from a height as it may cause

damage to the unit even if the wheels are puncture-proof.

Before lifting, make sure that the equipment parts (hook

and vibration insulator) are not damaged and screws are

Always make sure crane or lifting device has been

properly secured to the lifting bail (hook) of the

Tighten fuel tank cap securely and close fuel cock to

Use adequate lifting cable (wire or rope) of suffi cient

or hot.

DO NOT overfi ll tank, since spilled fuel could ignite if it

comes into contact with hot engine parts or sparks from

the ignition system.

Store fuel in appropriate containers, in well-ventilated

areas and away from sparks and fl ames.

NEVER use fuel as a cleaning agent.

DO NOT smoke around or near the

equipment. Fire or explosion could result

from fuel vapors or if fuel is spilled on a

hot engine.

DANGER

DO NOT drop the battery. There is a possibility that the

battery will explode.

DO NOT expose the battery to open fl ames,

sparks, cigarettes, etc. The battery contains

combustible gases and liquids. If these

gases and liquids come into contact with a

fl ame or spark, an explosion could occur.

contact with eyes

seek medical attention.

CAUTION

ALWAYS disconnect the

before performing service on the equipment.

ALWAYS

Repair or replace all worn cables.

ALWAYS

residue inside the battery box before each operation.

TRANSPORTING SAFETY

CAUTION

NEVER

the equipment while lifting.

DO NOT

only.

NOTICE

DO NOT

WARNING

ALWAYS wear safety glasses when

handling the battery to avoid eye irritation.

The battery contains acids that can cause

injury to the eyes and skin.

Use well-insulated gloves when picking up

the battery.

ALWAYS keep the battery charged. If the battery is not

charged, combustible gas will build up.

DO NOT charge battery if frozen. Battery can explode.

When frozen, warm the battery to at least 61°F (16°C).

ALWAYS recharge the battery in a well-ventilated

environment to avoid the risk of a dangerous concentration

of combustible gases.

If the battery liquid (dilute sulfuric acid)

comes into contact with clothing or skin,

rinse skin or clothing immediately with

plenty of water.

not loose or missing.

equipment.

ALWAYS shutdown engine before transporting.

NEVER lift the equipment while the engine is running.

prevent fuel from spilling.

strength.

QP3Ti TRASH PUMP • OPERATION AND PARTS MANUAL —REV. #1 (05/07/18) — PAGE 9

Page 10

Use one point suspension hook and lift straight upwards.

ENVIRONMENTAL SAFETY/

Decommissioning is a controlled process used to safely

retire a piece of equipment that is no longer serviceable.

If the equipment poses an unacceptable and unrepairable

safety risk due to wear or damage or is no longer cost

effective to maintain (beyond life-cycle reliability) and is to

be decommissioned (demolition and dismantlement),be

sure to follow rules below.

LIFTING

BALE

When the life cycle of this equipment is over, remove

battery and bring to appropriate facility for lead

reclamation. Use safety precautions when handling

When the life cycle of this equipment is over, it is

recommended that the trowel frame and all other metal

Metal recycling involves the collection of metal from

discarded products and its transformation into raw

materials to use in manufacturing a new product.

Recyclers and manufacturers alike promote the process

of recycling metal. Using a metal recycling center

The gasoline engine used in this equipment has been

designed to reduce harmful levels of carbon monoxide

(CO), hydrocarbons (HC) and nitrogen oxides (NOx)

This engine has been certifi ed to meet US EPA Evaporative

Attempting to modify or make adjustments to the engine

emmission system by unauthorized personnel without

proper training could damage the equipment or create an

Additionally, modifying the fuel system may adversely affect

evaporative emissions, resulting in fi nes or other penalties.

The emission control label is an integral part of the emission

If a replacement emission label is needed, please contact

SAFETY INFORMATION

batteries that contain sulfuric acid.

parts be sent to a recycling center.

DO NOT lift machine to unnecessary heights.

ALWAYS tie down equipment during transport by

securing the equipment with rope.

DECOMMISSIONING

NOTICE

DO NOT pour waste or oil directly onto the ground, down

a drain or into any water source.

Contact your country's Department of

Public Works or recycling agency in your

area and arrange for proper disposal of

any electrical components, waste or oil

associated with this equipment.

promotes energy cost savings.

EMISSIONS INFORMATION

NOTICE

contained in gasoline exhaust emissions.

emissions requirements in the installed confi guration.

unsafe condition.

Emission Control Label

system and is strictly controlled by regulation(s).

The label must remain with the engine for its entire life.

PAGE 10 — QP3Ti TRASH PUMP • OPERATION AND PARTS MANUAL — REV. #1 (05/07/18)

your authorized engine distributor.

Page 11

SPECIFICATIONS (PUMP)

Table 1. Specifications (Pump)

Model QP3Ti

Type Trash Pump

Suction 3.0 in. (76 mm.)

Discharge Size 3.0 in. (76 mm.)

Pump

Dry Net Weight

Maximum Pumping Capacity

396 gallons/minute

(1,500 liters/minute)

Max. Solids Diameter 1.50 in. (38 mm)

Maximum Lift 25 ft. (7.6 m)

Max. Head 95 ft. (29.0 m)

Max. Pressure 41 psi (283 kPa)

200 lbs. (91 Kg.)

G

F

E

A

B

C

D

Figure 1. QP3Ti Dimensions

NOTE: shown with optional

utility box.

H

I

Table 2. Dimensions

A

B

C

D

E

39.7 in. (1010 mm)

51.1 in (1300 mm)

51.6 in. (1312.7mm)

40.2 in. (1022.7 mm)

30.3 in. (770 mm)

F

G

H

I

19.6 in. (500 mm)

20.6 in. (525 mm)

26.9 in. (685 mm)

28.8 in. (732 mm)

QP3Ti TRASH PUMP • OPERATION AND PARTS MANUAL —REV. #1 (05/07/18) — PAGE 11

Page 12

SPECIFICATIONS (ENGINE)

METERS

500

10

Table 3. Specifications (Engines)

Model

Type

Bore x Stroke

Displacement 270 cc (16.5 cu-in)

Engine

Net Power

(in accordance with SAE J1349)

Fuel Tank Capacity

Fuel Unleaded Automobile Gasoline

Lube Oil Capacity 1.16 quarts (1.10 liters)

Speed Control Method STR Governor (self tuning regulator)

Starting Method

Dimension

(L x W x H)

Dry Net Weight

Engine power ratings are calculated by the individual engine manufacturer and the rating method may vary among engine manufacturers. Multiquip Inc. and its subsidiary companies

*

makes no claim, representation or warranty as to the power rating of the engine on this equipment and disclaims any responsibility or liability of any kind whatsoever with respect to the

accuracy of the engine power rating. Users are advised to consult the engine manufacturer’s owners manual and its website for specific information regarding the engine power rating.

TOTAL HEAD

100

30

FT.

Suction Line : 3 inch Discharge Line : 3 inch

HONDA

GX270UT2QZMD

Air-cooled 4 stroke, Single

Cylinder, OHV,

Horizontal Shaft Gasoline

Engine

3.03 in. x 2.30 in.

(77 mm x 58 mm)

8.6 H.P./3600 R.P.M.

Approx.1.4 U.S. Gallons

(5.3 Liters)

Electric Starter

(switch on control panel)

14.1 x 18.2 x 16.6 in.

(358 x 462 x 422 mm)

66.8 lbs (30.3 Kg.)

25

20

15

U.SGALLONS

PER MINUTE

LITERS

PER MINUTE

90

80

70

60

50

40

30

20

5

10

0

0 50 100 150 200 250 300 350 400

0

23.3 FT

16.7 FT

10 FT

1000

3.3 FT

Figure 2. QP3Ti Performance Curve

PAGE 12 — QP3Ti TRASH PUMP • OPERATION AND PARTS MANUAL — REV. #1 (05/07/18)

1500

Page 13

GENERAL INFORMATION

APPLICATION

The Multiquip QP3Ti Trash Pump is designed to be used

for dewatering applications. Both the suction and discharge

ports on the QP3Ti trash pump use a 3-inch diameter

opening,which allows the pump to pump at a rate of

approximately 396 gallons/minute (gpm) or 1,500 liters/

minute (lpm).

This Wet Primed pump requires that the pump casing

is first filled with water to assist with initial self-priming

operations. Once a partial vacuum is created within the

unit, the reduced atmospheric pressure allows water to

flow through the suction line and the centrifugal force of

the impeller/volute assembly permits water to be expelled

from the discharge ports.

TRASH PUMP

Trash pumps derive their name from their ability to handle

a greater amount of debris and solids than standard

centrifugal pumps. These pumps generally handle solids

up to 1/2 the size of the discharge opening making them

less likely to clog. Also trash pumps are capable of handling

water with 25% solids by weight.

The advantage of using a trash pump is that it can be

quickly and easily disassembled in the field "without tools"

and easily cleaned when clogged.

POWER PLANT

This trash pump is powered by a 8.6 horsepower air cooled

4-stroke, single cylinder HONDA iGX270 gasoline engine

that incorporates a low “Oil Alert Feature.”

OIL ALERT FEATURE

In the event of low oil or no oil, the HONDA iGX270 engine

has a built-in oil alarm engine shut-down feature. In the

event the oil level is low the engine will automatically

shutdown.

SUCTION LIFT

This pump is intended to be used for dewatering applications

and is capable of suction lifts up to 25 feet at sea level. For

optimal suction lift performance keep the suction hose or

line as short as possible. In general always place the pump

as close to the water as possible.

PUMP SUPPORT

NEVER place the pump on soft soil. The suction hose or

pipe connection should always be checked for tightness

and leaks. A small suction leak in the hose or fittings could

prevent the pump from priming.

Elevation

Higher elevations will effect the performance of the pump.

Due to less atmospheric pressure at higher altitudes,

pumps DO NOT have the priming ability that they have at

sea level. This is due to the “thinner air” or lack of oxygen

at higher altitudes.

A general rule of thumb is that for every 1,000 feet of

elevation above sea level a pump will lose one foot of

priming ability.

For example, in Flagstaff, Arizona where the elevation is

approximately 7,000 feet, the pump would have a suction

lift of only 18 feet rather than the 25 feet at sea level.

Table 4 shows suction lift at various elevations.

Table 4. Suction Lift at Various Elevations

Altitude

Feet

(Meters)

Sea Level 10.0 (3.048) 15.0 (4.572) 20.0 (6.096) 25.0 (7.620)

2,000 (610) 8.80 (2.680) 13.2 (4.023) 17.6 (5.364) 22.0 (6.705)

4,000 (1,219) 7.80 (2.377) 11.7 (3.566) 15.6 (4.754) 19.5 (5.943)

6,000 (1,829) 6.90 (2.103) 10.4 (3.169) 13.8 (4.206) 17.3 (5.273)

8,000 (2,438) 6.20 (1.889) 9.30 (2.834) 12.4 (3.779) 15.5 (4.724)

10,000 (3,048) 5.70 (1.737) 8.60 (2.621) 11.4 (3.474) 14.3 (4.358)

Table 5 shows percentage drops in performance as

elevation increases.

Table 5. Performance Loss at Various Elevations

Altitude

Feet (Meters)

Sea Level 100% 100%

2,000 (610) 97% 95%

4,000 (1,219) 95% 91%

6,000 (1,829) 93% 87%

8,000 (2,438) 91% 83%

10,000 (3,048) 88% 78%

Suction Lift in Feet (Meters)

Discharge Flow Discharge Head

The pump should always be placed on solid stationary

ground in a level position.

QP3Ti TRASH PUMP • OPERATION AND PARTS MANUAL —REV. #1 (05/07/18) — PAGE 13

Page 14

PUMP COMPONENTS

5

4

6

3

2

1

12

7

8

9

NOTE:

CONTACT YOUR NEAREST

MULTIQUIP DEALER FOR

QUICK DISCONNECT HOSES

AND FITTINGS.

11

4

10

PAGE 14 — QP3Ti TRASH PUMP • OPERATION AND PARTS MANUAL — REV. #1 (05/07/18)

Figure 3. QP3Ti Key Components

Page 15

PUMP COMPONENTS

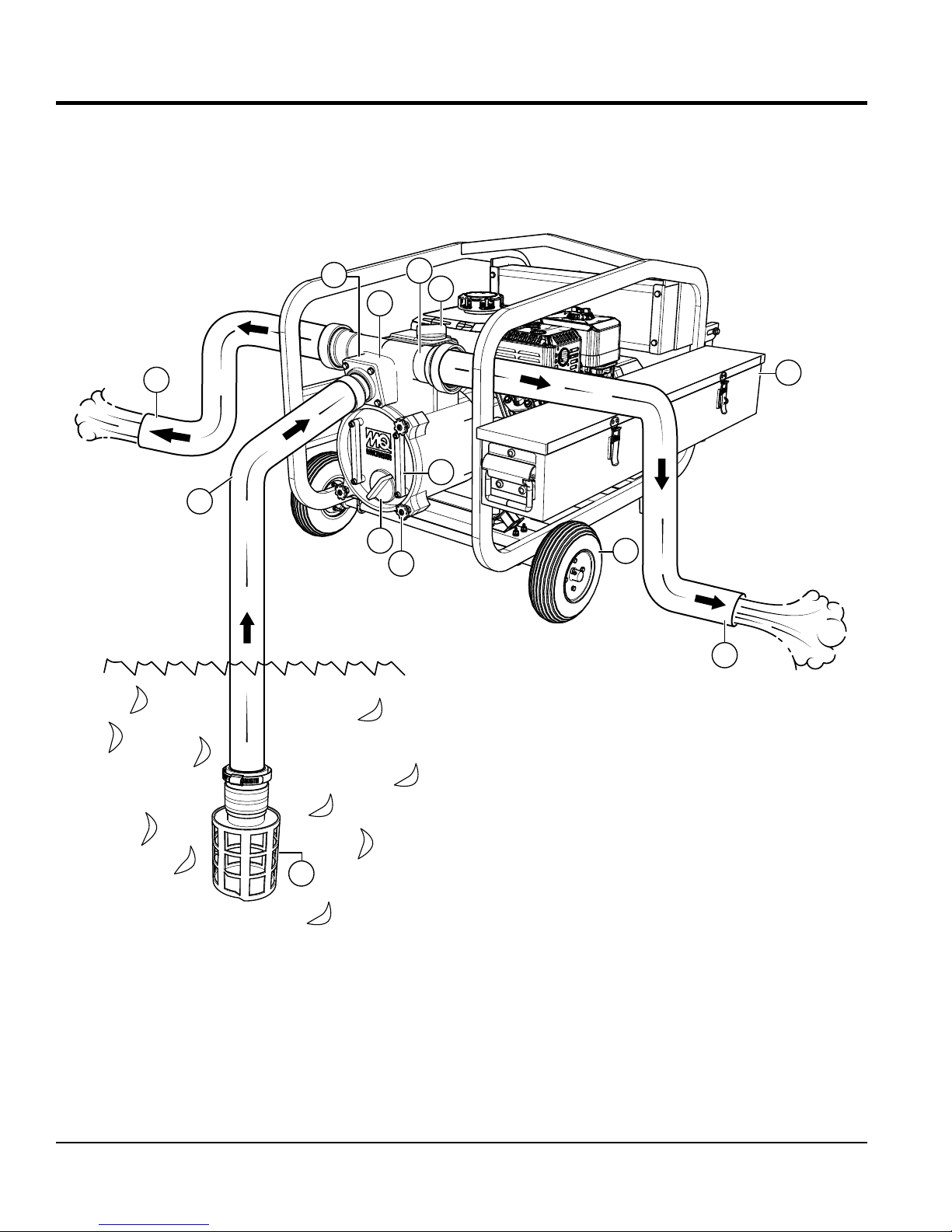

Figure 3 shows key component areas of the QP3Ti.

1. Pump — The QP3Ti offers a revolutionary choice for a

compact trash pumping system. It is the first gasolinepowered, compact, pipe-framed, centrifugal pump to

provide unattended operations, automatic no prime

shutdown, and easy manual dial water flow control.

Supported by the industry recognized QPT3 pump

end, this truly unique pump supports the watering/

dewatering jobs associated with: excavations, flood

waters, manholes, sewage bypass, barge cleaning,

foundations, and water transfer.

2. Fill Cap — Prior to operation, the pump casing MUST

BE filled with water. Remove this cap to add water to

the pump. After the initial prime, a sufficient amount of

water will be retained in the casing so that the operator

will not need to re-prime later.

3. Discharge Ports — The pump is equipped with left

and right side discharge ports. These ports are 3” male

NPT thread and can accommodate discharge hose or

pipe. Quick disconnect (Cam & Groove lock) hoses

can be fitted onto the discharge ports with an optional

coupler (A300A).

4. Discharge Hose — This pump is fitted with 3” male

NPT thread discharge ports and can accommodate

either threaded discharge hose or pipe. Quick

disconnect (Cam & Groove lock) hoses can be fitted

onto the discharge ports with an optional coupler

(A300A). Make sure hoses lay flat and are not kinked.

Contact MQ Sales Department for ordering information.

5. Suction Port — This pump is fitted with a 3” male

NPT thread suction port and can accommodate either

a threaded or quick disconnect (Cam & Groove lock)

hose. For quick disconnect connections, an optional

coupler (A300A) is necessary. Contact MQ Parts

Department for ordering assistance.

6. Suction Hose — Use only recommended suction

hoses. This pump is fitted with a 3” male NPT thread

suction port and can accommodate threaded or quick

disconnect (Cam & Groove lock) suction hose. Cam

& Groove lock hose can be fitted onto the suction

port with an optional coupler (A300A). Make sure

the suction hose is not kinked. Contact MQ Sales

Department for ordering information.

7. Clean-out Cover — When the pump is subjected to

applications where large quantity of debris is present,

it may be necessary to clean out the casing cavity of

large rocks and such that have not passed through the

pump. To open and gain access to the pump’s cleanout cavity, loosen the four locking knobs (item 9). Grip

the cover handles and twist counterclockwise. Once

the cover is clear of the four knob fasteners, pull the

cover out towards you.

8. Drain Plug — After usage, and for storage, remove

this plug and drain all water from the pump casing.

9. Locking Knobs — Turn both knobs counterclockwise

to release cover. Turn clockwise to secure clean-out

cover.

10. Strainer — Always attach a strainer to bottom side of

the suction hose to prevent large objects and debris

from entering the pump. Strainer should be positioned

so that it will remain completely under water. Running

the pump with the strainer above water for long periods

can damage pump.

11. Wheel Kit — The QP3Ti comes with a wheel kit that

includes all necessary components and hardware. The

tires are 8” diameter, rugged terrain foam filled type.

12. Utility Box — Used to store float switches and can

also store tools necessary for pump use, setup, and

maintenance (optional).

QP3Ti TRASH PUMP • OPERATION AND PARTS MANUAL —REV. #1 (05/07/18) — PAGE 15

Page 16

BASIC ENGINE

5

4

3

2

Figure 4. Engine Controls and Components

INITIAL SERVICING

The engine (See Figure 4) must be checked for proper

lubrication and filled with fuel prior to operation. Refer to the

manufacturers engine manual for instructions and details

of operation and servicing. The engine shown above is a

HONDA engine, operation for other types of engines may

vary somewhat.

1. Fuel Filler Cap — Remove this cap to add unleaded

gasoline to the fuel tank. Make sure cap is tightened

securely. DO NOT over fill.

DANGER

Adding fuel to the tank should be done

only when the engine is stopped and has

had an opportunity to cool down. In the

event of a fuel spill, DO NOT attempt to

start the engine until the fuel residue has

been completely wiped up, and the area

surrounding the engine is dry.

2. Fuel Valve Lever — OPEN to let fuel flow, CLOSE to

stop the flow of fuel.

6

3. Air Cleaner — Prevents dirt and other debris from

entering the fuel system. Remove wing-nut on top of

air filter cannister to gain access to filter element.

NOTICE

Operating the engine without an air filter, with a

damaged air filter, or a filter in need of replacement

will allow dirt to enter the engine, causing rapid engine

wear.

4. Spark Plug — Provides spark to the ignition system.

Set spark plug gap to 0.6 - 0.7 mm (0.028 - 0.031 inch).

Clean spark plug once a week.

5. Muffler — Used to reduce noise and emissions.

6. Fuel Tank — Holds unleaded gasoline. For additional

information refer to engine owner's manual.

NOTICE

The iGX engine design does not require a choke lever.

1

PAGE 16 — QP3Ti TRASH PUMP • OPERATION AND PARTS MANUAL — REV. #1 (05/07/18)

Page 17

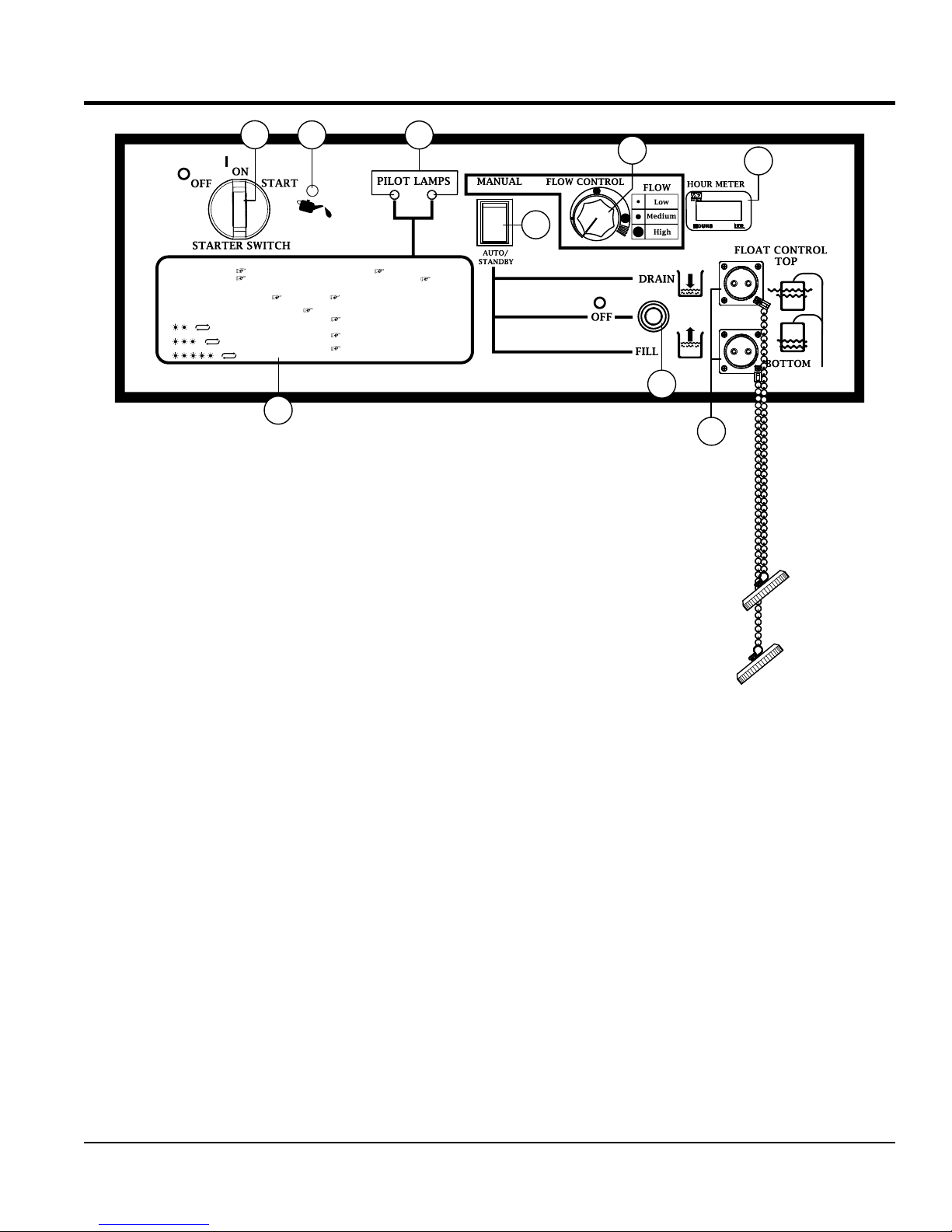

CONTROL PANEL

1

PILOT LAMPS INDICATOR

I ) No Green or Red lights

II ) Green and Red lights on Battery power supply is on.

PILOT LAMPS ALERTS

I ) Red light Flashing in 1 second intervals

III) Red light Flashing 2 times, turns OFF for 3 seconds and repeats Low fuel.

IV ) Red light Flashing 3 times, turns OFF for 3 seconds and repeats

V ) Red light Flashing 5 times, turns OFF for 3 seconds and repeats ECU error. Contact Multiquip for service.

No Battery power.

2

III ) Green light stays on

IV ) Green light Flashing in 1 second internals

Priming Failure. Inspect hose for kinds, leaks, missing gaskets,

clogged strainer or lack of water.

Check float connections.II ) Green and Red lights on Flashing in 0.5 sec interval

Check electrical connections.

Engine running.

3

Auto/Standby.

7

Figure 5. QP3Ti Control Panel

5

6

4

8

9

1. Starter Switch — Used to engage the battery, start

and turn off the engine.

2. Oil Alert — Lights up where the oil is low or if there

is no oil.

3. Pilot Lamp — Indicates operating status. Refer

to Table 6 for the different lamp indicators and

corresponding status.

4. Auto/Manual Switch — Used to select either Auto or

Manual mode of operation.

5. Flow Control Switch — Used to adjust flow volume

(this switch only works in Manual mode).

QP3Ti TRASH PUMP • OPERATION AND PARTS MANUAL —REV. #1 (05/07/18) — PAGE 17

6. Hourmeter — Indicates total operating hours.

7. Pilot Lamp Decal — Lists the different lamp indicators

and alerts.

8. Drain/Fill Switch — Used to select Auto Drain

Operation or Auto Fill Operation.

9. Float Control Terminals — Provide connection to top

and bottom float switches.

Page 18

CONTROL PANEL

Table 6. Pilot Lamps Indicators

Light/Flash Pattern Operation Status Red and Green Lamps State

Green and Red Lamps

OFF

Green and Red Lamps

ON

Green Lamp ON

Red Lamp OFF

Green Lamp FLASHING

(in 1 sec intervals)

Red Lamp OFF

Red Lamp FLASHING

(in 1 sec intervals)

Green Lamp OFF

Green and Red Lamps

FLASHING in 0.5 sec

intervals

No battery power

(Starter Switch — OFF).

Battery power supply is

On and Standby Mode

(Starter Switch — ON).

Engine running

Pump priming

Manual Mode.

Auto/Standby Mode.

Priming Failure

(No water for priming).

Wrong float connection

(suh as upsidedown

connection of top/bottom).

Red Lamp FLASHING

2 times, OFF for 3 sec

then repeats

Green Lamp OFF

Red Lamp FLASHING

3 times, OFF for 3 sec

then repeats

Green Lamp OFF

Red Lamp FLASHING

5 times, OFF for 3 sec

then repeats

Green Lamp OFF

PAGE 18 — QP3Ti TRASH PUMP • OPERATION AND PARTS MANUAL — REV. #1 (05/07/18)

Abnormal Engine RPM

(low fuel or starting

failure).

Failure of electrical

connections from engine

to control box.

Circuit or ECU error in

control box.

Page 19

INSPECTION (ENGINE)

UPPER LIMIT

LOWER LIMIT

CAUTION

DO NOT attempt to operate the pump

untilthe Safety Information, General

Information and Inspection sections

of this manual have been read and

thoroughly understood.

BEFORE STARTING

1. Read safety instructions at the beginning of manual.

2. Clean the pump, removing dirt and dust, particularly

the engine cooling air inlet, carburetor and air cleaner.

3. Check the air filter for dirt and dust. If air filter is dirty,

replace air filter with a new one as required.

4. Check carburetor for external dirt and dust. Clean with

dry compressed air.

5. Check fastening nuts and bolts for tightness.

Engine Oil Check

1. To check the engine oil level, place the pump on secure

level ground with the engine stopped.

2. Remove the filler dipstick from the engine oil filler hole

(See Figure 6) and wipe clean.

3. Insert and remove the dipstick without screwing it into

the filler neck. Check the oil level shown on the dipstick.

4. If the oil level is low (See Figure 7), fill to the edge

of the oil filler hole with the recommended oil type

(Table 7). Maximum oil capacity is 1.16 quarts

(1.1 liters).

Figure 7. Engine Oil DipStick (Oil Level

Table 7. Oil Type

Season Temperature Oil Type

Summer 25°C or Higher SAE 10W-30

Spring/Fall 25°C~10°C SAE 10W-30/20

Winter 0°C or Lower SAE 10W-10

DANGER

Motor fuels are highly flammable and can

be dangerous if mishandled. DO NOT

smoke while refueling. DO NOT attempt

to refuel the pump if the engine is hot!

or running.

Fuel Check

1. Remove the gasoline cap located on top of fuel tank.

Figure 6. Engine Oil Dipstick (Removal

QP3Ti TRASH PUMP • OPERATION AND PARTS MANUAL —REV. #1 (05/07/18) — PAGE 19

2. Visually inspect to see if the fuel level is low. If fuel is

low, replenish with unleaded fuel

3. When refueling, be sure to use a strainer for filtration.

DO NOT top-off fuel. Wipe up any spilled fuel

immediately!

.

Page 20

SETUP

1. It is advantageous to place the pump as close as

possible to the water source (Figure 7) on a solid,

level operating surface. The most critical factor for

successful pump operations is not to exceed 25’ Total

Suction Lift (at sea level).

2. Ensure that the pump has the proper level of fuel and

engine oil.

3. Initially prime the pump by removing the fill cap (see

Figure 3) and filling the casing with water. If the pump

casing is not filled with water prior to operations, it will

not be able to start the pumping process and you risk

overheating the mechanical seal assembly.

4. Attach the proper suction and discharge hoses to the

pump ports. Ensure that the hose O-rings are in place,

and that hose do not show any cracks, gouges, or

holes. The hoses should not be kinked, and must be

secured tightly to their respective ports.

5. A proper suction hose is commonly reinforced with rigid

PVC helix and is specifically designed to safeguard

against collapsing during pumping operations. It is

essential that the pump utilize a suction hose with the

same diameter as the suction port.

6. Ensure that the strainer is placed on the end of the

suction hose, and that the hose is placed in the water

source in such a manner as not to bury the strainer

into sand or silt.

CAUTION

The strainer should be positioned so it will remain

completely under water. Running the pump with the

strainer above water for long periods can damage the

pump.

7. The discharge side may utilize proper discharge hoses,

PVC pipe, or concrete pipe.

8. Check that discharge hoses lay flat and as straight as

possible. Remove any sharp bends or kinks from the

hose so the water flow cannot be blocked.

9. Once the engine is started; and depending on the

application set-up, the priming process will take a few

moments before water begins to flow.

10. The performance of the pump (Flow, Head, Water

Velocity, and Pressure) is dependent on the many

factors that surround the application. These factors

include, but are not limited to: operating altitude, suction

lift, discharge and suction hose diameter and length,

overall friction loss coefficients, the specify gravity of

the fluid to be pumped, the fluid temperature, and total

discharge head.

Figure 8. Pump Placement

PAGE 20 — QP3Ti TRASH PUMP • OPERATION AND PARTS MANUAL — REV. #1 (05/07/18)

Page 21

OPERATION

CAUTION

DO NOT attempt to start the engine unless the pump

has previously been primed with water. Severe pump

damage will occur if pump has not been primed.

1. Place the engine fuel valve lever (See Figure 9) to the

ON position.

Figure 9. Engine Fuel Valve Lever (ON)

2. Select the mode of operation that you require by setting

the Auto/Manual switch to either AUTO/STANDBY or

MANUAL mode (Figure 10).

MANUAL MODE

If manual mode is selected, the pump flow can be controlled.

1. Make sure that the engine fuel valve lever is in the ON

position (Figure 9).

2. Turn the starter switch to the START position

(Figure 11).

STARTER SWITCH

(START POSITION)

PILOT LAMPS INDICATOR

I ) No Green or Red lights

II ) Green and Red lights on Battery power supply is on.

PILOT LAMPS ALERTS

Figure 11. Starter Switch (START)

NOTICE

No Battery power.

III ) Green light stays on

IV ) Green light Flashing in 1 second internals

Engine running.

Auto/Standby.

AUTO/MANUAL

SWITCH

Figure 10. Operation Mode Selection

Recoil Starter is not available. Engine can only be

started with the Starter Switch on the control panel.

3. After the engine has started, turn the flow control switch

to the desired flow volume (Figure 12).

FLOW CONTROL

SWITCH

Figure 12. Flow Control Switch

QP3Ti TRASH PUMP • OPERATION AND PARTS MANUAL —REV. #1 (05/07/18) — PAGE 21

Page 22

OPERATION

AUTO/STANDBY MODE

In the automatic mode:

Engine senses and adjusts RPMs automatically to match

the application's load and speed requirements.

Engine keeps running at higher RPM right after start

which makes speedy pump priming. It then goes back

automatically to normal RPM, in 15 seconds after start

for smooth flow discharging.

Engine turns off automatically one minute after water is

fully pumped, even if unattended, which prevents NoLoad running and useless fuel consumption.

1. Turn the DRAIN/FILL switch to the OFF position

(Figure 13).

DRAIN/FILL

SWITCH

1. Prepare and connect suction hose and discharge hose

to the suction port/discharge port of pump (Figure 3).

Make sure suction hose is placed deep into the water

source and discharge hose is not kinked and lays flat.

2. Connect the terminal plugs of float switches to the float

control ports on the control panel (Figure 14)

FLOAT CONTROL

PORTS

Figure 14. Float Control Ports

NOTICE

Figure 13. DRAIN/FILL Switch

2. Make sure that the engine fuel valve lever is in the ON

position (Figure 9).

3. Turn the starter switch to the START position

(Figure 11).

4. Engine will run at the most suitable RPM as it senses

the job-load.

NOTICE

If automatic mode is selected, the pump flow cannot

be controlled by the flow control switch.

AUTO/DRAIN OPERATION

Pump starts draining water automatically at the set high

level, utilizing float switches, then turns off at the set low

level. When the water reaches the set high level again,

pump starts draining again.

Note that there are two ports for the float control

connection. One is for the high level (TOP) and the

other for low level (BOTTOM).

3. Set the top (drain) and bottom (stop) water levels you

expect to control with the float switches (Figure 15).

NOTICE

at least 100mm

distance to be kept

Figure 15. Float Switches

top (upper) level

range to

control

bottom (low) level

PAGE 22 — QP3Ti TRASH PUMP • OPERATION AND PARTS MANUAL — REV. #1 (05/07/18)

Page 23

OPERATION

4. Turn the AUTO/MANUAL switch on control panel to the

AUTO/STANDBY position (Figure 10).

5. Turn the DRAIN/FILL switch to the DRAIN position

(Figure 13).

6. Turn the starter switch to the START position

(Figure 11).

7. The engine starts and pump starts draining the water

Green pilot lamp starts flashing in 1 second intervals

AUTO/FILL OPERATION

Pump starts filling with water automatically at the set low

level, utilizing float switches, then turns off at the set high

level. When the water reaches the set low level again, pump

starts filling again.

1. Prepare and connect suction hose and discharge hose

to the suction port/discharge port of pump (Figure 3).

Make sure suction hose is placed deep into the water

source and discharge hose is not kinked and lays flat.

2. Connect the terminal plugs of float switches to the float

control ports on the control panel.

NOTICE

Note that there are two ports for the float control

connection. One is for the high level (TOP) and the

other for low level (BOTTOM).

4. Turn the AUTO/MANUAL switch on control panel to the

AUTO/STANDBY position (Figure 10).

5. Turn the DRAIN/FILL switch to the FILL position

(Figure 13).

6. Turn the starter switch to the START position

(Figure 11).

7. The engine starts and pump starts filling water. Green

pilot lamp starts flashing in 1 second intervals.

STOPPING THE ENGINE

8. Turn the starter switch to the OFF position (Figure 16).

STARTER SWITCH

(OFF POSITION)

PILOT LAMPS INDICATOR

I ) No Green or Red lights

II ) Green and Red lights on Battery power supply is on.

PILOT LAMPS ALERTS

Figure 16. Starter Switch (OFF)

No Battery power.

III ) Green light stays on

IV ) Green light Flashing in 1 second internals

Engine running.

Auto/Standby.

3. Set the top (drain) and bottom (stop) water levels you

expect to control with the float switches (Figure 15).

QP3Ti TRASH PUMP • OPERATION AND PARTS MANUAL —REV. #1 (05/07/18) — PAGE 23

Page 24

MAINTENANCE (PUMP)

PUMP VACUUM TEST

CAUTION

DO NOT attempt to start the engine unless the pump

has previously been primed with water. Severe pump

damage will occur if pump has not been primed.

To perform the pump vacuum test do the following:

1. Remove the pump fill cap (See Figure 3), and fill the

pump with water.

2. Start the engine as outlined in the initial start-up

section, and wait for the pump to begin pumping.

3. As shown in Figure 17, place a water hose inside

the discharge opening of the pump, and turn on the

water. This flow of water into the discharge opening

will prevent the pump from running dry.

4. Place the Pump Vacuum Tester (P/N 7000030) over the

pump suction (inlet) opening (See Figure 17) with the

vacuum gauge facing upwards. It may be necessary

to apply a small amount of water around the rubber

seal of the vacuum tester to make a good suction fit.

ADJUSTING IMPELLER CLEARANCE

1. If it is necessary to replace impeller or volute, be sure

clearance between impeller and volute is adjusted

2. The impeller should be as close to the volute as

possible without rubbing against it. Clearance is

adjusted by adding or removing shims from behind

the impeller.

3. Check clearance between impeller and insert by slowly

pulling starter rope to turn impeller.

NOTICE

It is important not to remove too many shims or the

clearance between the impeller and volute will become

too wide and pump performance will be reduced.

Remember as the impeller wear down, additional shims

may be required to maintain the clearance between the

impeller and insert.

4. Check the impeller every six months for wear, and for

clearance between the impeller face and the volute.

Also check the shaft seal for wear, as well as the shaft

sleeve.

5. Check and make sure that there are no air leaks

between the vacuum tester and the inlet port on the

pump. If air leaks are present reseat vacuum tester.

6. Run the pump for a few minutes while monitoring

the vacuum gauge. If the gauge indicates a reading

between -25 and -20 in. Hg. (inches of mercury) then

it can be assumed that the pump is working correctly.

NOTICE

25 in. Hg (inches of mercury) translates into 25 feet of

lift at sea level.

7. If the vacuum tester gauge indicates a reading below

-20 in. Hg, it can then be assumed that the pump is

not functioning correctly, and corrective action needs

to be taken.

8. To test the flapper valve, shutdown the engine. The

vacuum tester should remain attached to the pump

suction inlet port by vacuum. This indicates the pump's

flapper valve is seating properly to hold water in the

suction hose when the engine is stopped. This prevents

backflow and allows for faster priming when the engine

is restarted.

PUMP CLEANING

After pumping water containing large amounts of dirt and

debris, perform the following:

1. Remove the drain plug from the pump housing

(Figure 3) and drain any water left in the pump.

2. See Components section, Clean-out Cover, for pump

cleaning procedure.

3. Clean and remove dirt, debris from pump casing.

Inspect impeller and volute for wear. Replace any

damaged or worn parts.

CAUTION

The impeller may develop sharp edges. Use extreme

care when cleaning around the impeller to prevent

being cut..

PAGE 24 — QP3Ti TRASH PUMP • OPERATION AND PARTS MANUAL — REV. #1 (05/07/18)

Page 25

PLACE VACUUM

TESTER OVER

PUMP SUCTION

PORT

MAINTENANCE (PUMP)

CAUTION

DO NOT RUN PUMP

WITHOUT WATER.

DISCHARGE

PORT

WATER HOSE

ACCEPTABLE READING

SHOULD BE BETWEEN

-25 AND -20 IN. HG.

PUMP VACUUM

TESTER

-25

-20

-30

-60

-80

-100

-15

-40

kPa

in. Hg

WIKA

WATER

SOURCE

DIRECTION

OF WATER

FLOW

-1

0

25 IN. HG. TRANSLATES

-20

R

-5

INTO 25 FEET OF LIFT

AT SEA LEVEL.

QP3Ti TRASH PUMP • OPERATION AND PARTS MANUAL —REV. #1 (05/07/18) — PAGE 25

Figure 17. Pump Vacuum Tester

Page 26

MAINTENANCE (ENGINE)

ENGINE MAINTENANCE

Perform engine maintenance procedures as referenced by Table 8 below:

Table 8. Engine Maintenance Schedule

First

Description (3) Operation Before

Engine Oil

Air Cleaner

All Nuts and

Bolts

Spark Plug

Cooling Fins CHECK X

Spark Arrester CLEAN X

Fuel Tank CLEAN X

Fuel Filter CHECK X

Idle Speed CHECK-ADJUST X (2)

Valve Clearance CHECK-ADJUST X (2)

Fuel lines CHECK Every 2 years (replace if necessary) (2)

CHECK X

CHANGE X

CHECK X

CHANGE X (1)

Re-tighten If

Necessary

CHECK-CLEAN X

REPLACE X

X

Month or

10 hrs

Every 3

Months or

25 hrs

Every 6

Months or

50 hrs

Every

Year or

100 hrs

Every 2

Years or

200 hrs

1. Service more frequently when used in DUSTY areas.

2. These items should be serviced by your service dealer, unless you have the proper tools and are mechanically

proficient. Refer to the HONDA shop Manual for service procedures.

3. For commercial use, log hours of operation to determine proper maintenance intervals.

NOTICE

Refer to manufacturer engine manual for specific

servicing instructions.

PAGE 26 — QP3Ti TRASH PUMP • OPERATION AND PARTS MANUAL — REV. #1 (05/07/18)

Page 27

MAINTENANCE (ENGINE)

DAILY

1. Thoroughly remove dirt and oil from the engine and

control area. Clean or replace the air cleaner elements

as necessary. Check and retighten all fasteners as

necessary. Check the spring box and bellows for oil

leaks. Repair or replace as needed.

WEEKLY

1. Remove the fuel filter cap and clean the inside of the

fuel tank.

2. Remove or clean the filter at the bottom of the tank.

3. Remove and clean the spark plug (See Figure

18), then adjust the spark gap to 0.028~0.031 inch

(0.6~0.7 mm). This unit has electronic ignition, which

requires no adjustments.

DANGER

DO NOT use gasoline as a cleaning

solvent, because that would create a risk

of fire or explosion.

ENGINE AIR CLEANER

1. Remove the air cleaner cover and foam filter element

as shown in Figure 20.

2. Tap the paper filter element (See Figure 20)

several times on a hard surface to remove dirt, or

blow compressed air [not exceeding 30 psi (207 kPa,

2.1 kgf/cm

cleaner case side. NEVER brush off dirt. Brushing

will force dirt into the fibers. Replace the paper filter

element if it is excessively dirty.

3. Clean foam element in warm, soapy water or

non-flammable solvent. Rinse and dry thoroughly. Dip

the element in clean engine oil and completely squeeze

out the excess oil from the element before installing.

2

)] through the filter element from the air

Figure 18. Spark Plug Gap

ENGINE OIL

1. Drain the engine oil when the oil is warm as shown

in Figure 19.

2. Remove the oil drain bolt and sealing washer and allow

the oil to drain into a suitable container.

3. Replace engine oil with recommended type oil as listed

in Table 5. Engine oil capacity is 1.16 quarts (1.1 liters).

DO NOT over fill.

4. Install drain bolt with sealing washer and tighten

securely.

Figure 19. Engine Oil (Draining)

QP3Ti TRASH PUMP • OPERATION AND PARTS MANUAL —REV. #1 (05/07/18) — PAGE 27

Figure 20. Engine Air Cleaner

Page 28

MAINTENANCE (ENGINE)

SPARK ARRESTER CLEANING

Clean the spark arrester every 6 months or 100 hours.

1. Remove the 4 mm screw (3) from the exhaust deflector,

then remove the deflector. See Figure 21.

2. Remove the 5 mm screw (4) from the muffler protector,

then remove the muffler protector.

3. Remove the 4 mm screw from the spark arrester, then

remove the spark arrester

4. Carefully remove carbon deposits from the spark

arrester screen (Figure 22) with a wire brush.

Figure 22. Cleaning The Spark Arrester

5. If the spark arrester is damaged and has breaks or

holes, replace with a new one.

6. Reinstall the spark arrester and muffler protector in

reverse order of disassembly.

Figure 21. Spark Arrester Removal

PAGE 28 — QP3Ti TRASH PUMP • OPERATION AND PARTS MANUAL — REV. #1 (05/07/18)

Page 29

PUMP STORAGE

For storage of the pump for over 30 days, the following is

required:

Drain the fuel tank completely.

Run the engine until the fuel is completely consumed.

Completely drain used oil from the engine crankcase

and fill with fresh clean oil, then follow the procedures

described in the engine manual for engine storage.

Remove the drain plug from the pump and drain out any

water from left in the housing.

Remove the pump cover and clean inside of pump

housing. Coat inside of pump housing with a light film

of oil to reduce corrosion. A spray can of oil works well

for this application.

Cover suction and discharge ports with duct tape to

prevent any foreign matter from falling into pump.

STORAGE

Cover pump and engine with plastic covering or

equivalent and store in a clean, dry place.

To protect the water cooled-seals, place one-half pint

of lubricating oil (new or used) through the discharge

opening on the pump and crank the engine several times.

This will prevent excessive corrosion and also keep the

mechanical seal lubricated.

QP3Ti TRASH PUMP • OPERATION AND PARTS MANUAL —REV. #1 (05/07/18) — PAGE 29

Page 30

TROUBLESHOOTING (ENGINE)

Troubleshooting (Engine)

Symptom Pilot Lamp Status Possible Problem Solution

Difficult to start, fuel is

available but spark plug will

not ignite. (Power available

at high tension cable).

Difficult to start, fuel is

available but spark plug

will not ignite. (Power NOT

available at high tension

cable).

Difficult to start, fuel is

available, spark plug ignites

(compression is normal).

Difficult to start, fuel is

available, spark plug ignites.

(compression is low).

Engine does not start.

Red lamp flashes 2 times,

turns OFF for 3 sec and

repeats.

Red lamp flashes 2 times,

turns OFF for 3 sec and

repeats.

Red lamp flashes 2 times,

turns OFF for 3 sec and

repeats.

Red light flashes 2 times,

turns OFF for 3 sec and

repeats.

Red light flashes 2 times,

turns OFF for 3 sec and

repeats.

Oil Alert Lamp On and Red

light flashes 2 times and

repeats.

Green and red lamps OFF.

Red light flashes 5 times

and repeats.

Red light flashes 2 times,

turns OFF for 3 sec and

repeats

Ignition plug bridging? Check gap, insulation or replace spark plug.

Carbon deposit at ignition? Clean or replace ignition.

Short circuit due to defective insulators? Replace insulators.

Improper spark plug gap? Set to proper gap.

Short circuit at stop switch?

Ignition coil defective? Replace ignition coil.

Muffler clogged with carbon deposits? Clean or replace muffler.

Mixed fuel quality is inadequate? Check fuel-to-oil mixture.

Fuel in use inadequate (water, dust)?

Air cleaner clogged? Clean or replace air cleaner.

Defective cylinder head gasket?

Cylinder worn? Replace cylinder.

Spark plug loose? Tighten spark plug.

Low fuel or No fuel? Add fuel.

Low oil or No oil? Add oil.

No battery power?

Insufficient battery power? Charge or Replace battery.

Wrong battery? Replace with suitable size of battery.

ECU error? Contact Multiquip.

Harness disconnected? Repair harness connection.

Check switch wiring, replace switch if

defective.

Flush fuel system and replace with fresh

fuel.

Tighten cylinder head bolts or replace head

gasket.

Check battery or battery terminal

connection.

PAGE 30 — QP3Ti TRASH PUMP • OPERATION AND PARTS MANUAL — REV. #1 (05/07/18)

Page 31

TROUBLESHOOTING (ENGINE)

Troubleshooting (Engine) - continued

Symptom Pilot Lamp Status Possible Problem Solution

Air cleaner clogged? Clean or replace air cleaner.

Weak in power,

compression is proper and

does not misfire.

Weak in power,

compression is proper but

misfires.

Engine overheats. Green lamp stays on.

Rotational speed

fluctuates.

Engine running and then

stopped suddenly

Operation not satisfactory

under DRAIN mode

operation

Operation Not satisfactory

under FILL mode

operation

Green lamp stays on.

Green lamp stays on.

Green lamp stays on.

Red lamp flashes 2 times Low fuel or No fuel? Add fuel.

Oil Alert lamp On and red

lamp flashes 2 times and

repeats.

Red lamp flashes 3 times

and repeats.

Green lamp stays on. Float switch connection failure?

Green and red lamps flash

in 0.5 sec interval.

Green lamp stays on. Float switch cable disconnected/broken? Replace float switch cable.

Green lamp stays on. Float switch connection failure?

Green and red lamps flash

in 0.5 sec interval.

Green lamp stays on. Float switch cable disconnected/broken? Replace float switch cable.

Air in fuel line? Bleed (remove air) from fuel line.

Fuel level in carburetor float chamber

improper?

Carbon deposits in cylinder? Clean or replace cylinder.

Ignition coil defective?

Ignition plug often shorts? Replace ignition wires, clean ignition.

Fuel in use inadequate (water, dust)?

Excessive carbon deposition in

combustion chamber?

Exhaust or muffler clogged with carbon? Clean or replace muffler.

Spark plug heat value incorrect?

Fuel flow erratic? Check fuel line.

Air taken in through suction line? Check suction line.

Low oil or No oil? Add oil.

Harness disconnected? Repair harness connection.

Float switch connection failure

(upside down installation of upper/bottom

float switches)?

Float switch connection failure

(upside down installation of upper/bottom

float switches)?

Adjust carburetor float.

Flush fuel system and replace with

fresh fuel.

Flush fuel system and replace with

fresh fuel.

Clean or replace crankcase.

Replace spark plug with correct type

spark plug.

Check for proper connection of float

switch.

Correct connection of float switches.

Check for proper connection of float

switch.

Correct connection of float switches.

QP3Ti TRASH PUMP • OPERATION AND PARTS MANUAL —REV. #1 (05/07/18) — PAGE 31

Page 32

Symptom Pilot Lamp Status Possible Problem Solution

Pump does not take on water

(MANUAL mode).

Troubleshooting (Trash Pump)

Green lamp stays on, when

engine starts and red lamp

starts flashing, when pump

does not take on water in 5

minutes.

TROUBLESHOOTING (PUMP)

Not enough priming water in the

housing?

Engine speed too low? Increase throttle.

Strainer plugged? Clean strainer.

Suction hose damaged? Replace or repair hose, and clamps.

Air leak at suction port?

Pump is located too high above water

line?

Debris collecting in pump housing? Clean pump housing.

Too much distance between impeller and

volute?

Water leaking out weep hole between

pump and engine?

Not enough priming water in the

housing?

Strainer plugged? Clean strainer.

Add water.

Check that fittings are tight and properly

sealed.

Move pump closer to water.

Adjust clearance by adding shims or

replace impeller. Min. .006 inch - Max.

.020 inch

Check condition of mechanical seal and

gaskets, between pump end and engine

housing.

Add water.

Green lamp stays on, when

Pump does not take on water

(AUTO mode).

Pump takes in water, little or

no discharge.

Suction hose leaks at inlet. Green lamp stays on.

Discharge does not stay on

coupling.

Impeller does not turn, pump

is hard to start.

engine starts and red lamp

starts flashing, when pump

does not take on water in 5

minutes.

Green lamp stays on.

Green lamp stays on.

Green and red lamps OFF.

Suction hose damaged? Replace or repair hose, and clamps.

Air leak at suction port?

Pump is located too high above water

line?

Debris collecting in pump housing? Clean pump housing.

Too much distance between impeller and

volute.

Water leaking out weep hole between

pump and engine?

Engine speed too low

(MANUAL mode)?

Suction strainer partially plugged? Clean strainer.

Impeller/Volute worn?

Fittings/clamps are not sealed properly?

Hose diameter is too large?

Pressure too high? Check pressure, add additional clamp.

Hose kinked or end blocked? Check hose.

Impeller jammed or blocked?

Impeller and volute binding?

Defective engine? See Engine Owner's Manual.

Check that fittings are tight and properly

sealed.

Move pump closer to water.

Adjust clearance by adding shims or

replace impeller. Min. .006" - Max. .020".

Check condition of mechanical seal and

gaskets, between pump end and engine

housing.

Increase throttle speed

(MANUAL mode).

Adjust clearance by adding shims or

replace impeller/volute.

Tighten, replace or add clamp. (Keep

extra seals on pump).

Use smaller diameter hose or replace

hose.

Open pump cover and clean dirt and

debris from inside housing.

Adjust clearance by removing shim from

behind impeller.

PAGE 32 — QP3Ti TRASH PUMP • OPERATION AND PARTS MANUAL — REV. #1 (05/07/18)

Page 33

NOTES

QP3Ti TRASH PUMP • OPERATION AND PARTS MANUAL —REV. #1 (05/07/18) — PAGE 33

Page 34

WIRING DIAGRAM — CONTROL PANEL

COM_12V

COM_TX

COM_RX

S_GND

OUTPUT

SW1

SW2

PWR1

PWR2

ECU

(SW VERSION)

FLOW CONTROL KNOB

INTERFACE

(B/W)

B/R

L/R

L/Y

LG

P

W

B (B) (W)

POWER

A

(LG)

(L/Y)

(L/R)

COIL

GR GR

CHARGE COIL

CONTROL PANEL

AUTO/STANDBY SW

B

AN

CONTROL BOX

RXD

COM_12V 5V

(GR)

(GR)

(P)

(GR) (GR)

L

Y

LED

OIL_ALT

IGN COILSPARK PLUG

A_GND

TXD

B

R

EXT (-)

SW1

S_GND

EXT (+)

SW2

SW3

GND

OIL

LEVEL SW

C

DRAIN/FILL/OFF SW

RED PILOT LAMP

D

GREEN PILOT LAMP

RL_OUT

LAMP_OUT

ST_SIG

ST

(Y)

BATTERY

12V

FLOAT CONTROL SW (UPPER)

FLOAT CONTROL

LO

EXT (+)

EXT (-)

STARTER SW

F

SW (LOWER)

E

H

RECTIFIER

HOUR METER OIL LAMP

I

J

LIGHT INDICTOR

G

(W)

W

MAIN

FUSE

K

30A

(W)

W

FUSE

L

7.5A

(B)(B)

R(R)

(W)

(B/W)

B/W

(G/W)

(B/W)

(R)

(R)

(B/Y)

B

R

W

W

B/W

G/W

B/Y

STARTER SW

M

ENGINE

SW CONNECTION TABLE

EXT (+) FS (+) FS (-)EXT (-) LO BAT ST

OFF

ON

ST

PAGE 34 — QP3Ti TRASH PUMP • OPERATION AND PARTS MANUAL — REV. #1 (05/07/18)

B BLACK BROWN

BR

BLUE

RED

ORANGEO

SKY BLUESB

LIGHT GREEN

LG

P

GR

BE

PINK

GRAY

BEIGE

YELLOW

Y

L

GREEN

G

R

WHITE

W

VIOLET

V

COLOR COMBO : GROUND/MARKING

Page 35

WIRING LOCATOR — CONTROL PANEL

ENGINE

CONTROL

UNIT

I

(ECU)

L

M

PILOT LAMPS INDICATOR

I ) No Green or Red lights

II ) Green and Red lights on Battery power supply is on.

PILOT LAMPS ALERTS

I ) Red light Flashing in 1 second intervals

III) Red light Flashing 2 times, turns OFF for 3 seconds and repeats Low fuel.

IV ) Red light Flashing 3 times, turns OFF for 3 seconds and repeats

V ) Red light Flashing 5 times, turns OFF for 3 seconds and repeats ECU error. Contact Multiquip for service.

No Battery power.

J

III ) Green light stays on

IV ) Green light Flashing in 1 second internals

Priming Failure. Inspect hose for kinds, leaks, missing gaskets,

clogged strainer or lack of water.

Check float connections.II ) Green and Red lights on Flashing in 0.5 sec interval

Check electrical connections.

Engine running.

DE

Auto/Standby.

K

A

B

H

F

C

G

QP3Ti TRASH PUMP • OPERATION AND PARTS MANUAL —REV. #1 (05/07/18) — PAGE 35

Page 36

EXPLANATION OF CODE IN REMARKS COLUMN

The following section explains the different symbols and

remarks used in the Parts section of this manual. Use the

help numbers found on the back page of the manual if there

are any questions.

SAMPLE PARTS LIST

NO.

1 12345 BOLT

2% WASHER, 1/4 IN.

2% 12347 WASHER, 3/8 IN.

3 12348 HOSE

4 12349 BEARING

NO. Column

PART NO. Column

QTY. Column

— Item quantity can be indicated by a

A/R (As Required) is generally used for hoses or other

A blank entry generally indicates that the item is not sold

separately. Other entries will be clarifi ed in the “Remarks”

Some of the most common notes found in the “Remarks”

Column are listed below. Other additional notes needed

— All items on the parts list with the

same unique symbol will be included when this item is

— Used to list an effective serial

— Indicates that the part

is used only with the specifi c model number or model

number variant listed. It can also be used to show a

part is NOT used on a specifi c model or model number

— Indicates that the part can

be purchased at any hardware shop or made out of

available items. Examples include battery cables, shims,

— Indicates that an item cannot

be purchased as a separate item and is either part of an

assembly/kit that can be purchased, or is not available

Numbers Used

number, a blank entry, or A/R.

NOTICE

The contents and part numbers listed in the parts

section are subject to change without notice. Multiquip

does not guarantee the availability of the parts listed.

PART NO. PART NAME QTY. REMARKS

.....................1 .....INCLUDES ITEMS W/%

..........NOT SOLD SEPARATELY

..1 .....MQ-45T ONLY

..................A/R ...MAKE LOCALLY

..............1 .....S/N 2345B AND ABOVE

Unique Symbols — All items with same unique symbol

(@, #, +, %, or >) in the number column belong to the

same assembly or kit, which is indicated by a note in the

“Remarks” column.

Duplicate Item Numbers — Duplicate numbers indicate

multiple part numbers, which are in effect for the same

general item, such as different size saw blade guards in

use or a part that has been updated on newer versions

of the same machine.

parts that are sold in bulk and cut to length.

Column.

REMARKS Column

to describe the item can also be shown.

Assembly/Kit

purchased.

Indicated by:

“INCLUDES ITEMS W/(unique symbol)”

Serial Number Break

number range where a particular part is used.

Indicated by:

“S/N XXXXX AND BELOW”

“S/N XXXX AND ABOVE”

“S/N XXXX TO S/N XXX”

NOTICE

When ordering a part that has more than one item

number listed, check the remarks column for help in

determining the proper part to order.

Numbers Used — Part numbers can be indicated by a

number, a blank entry, or TBD.

TBD (To Be Determined) is generally used to show a

part that has not been assigned a formal part number

at the time of publication.

A blank entry generally indicates that the item is not sold

separately or is not sold by Multiquip. Other entries will

be clarifi ed in the “Remarks” Column.

Specifi c Model Number Use

variant.

Indicated by:

“XXXXX ONLY”

“NOT USED ON XXXX”

“Make/Obtain Locally”

and certain washers and nuts.

“Not Sold Separately”

for sale through Multiquip.

PAGE 36 — QP3Ti TRASH PUMP • OPERATION AND PARTS MANUAL — REV. #1 (05/07/18)

Page 37

SUGGESTED SPARE PARTS

QP3TI TRASH PUMP

1 TO 3 UNITS

Qty. P/N Description

1............KIT3TE .................MECHANICAL SEAL KIT

1............1992040033ASSY IMPELLER KIT

1............43342012400011 ..IMPELLER WASHER

1............0480570850 ..........O-RING, VOLUTE CASING

2............0631211159 ..........CAP, FLOOD/DRAIN W/O-RING

2............1992108050 ..........CAP

HONDA iGX270UT2QZMD GASOLINE ENGINE

1 TO 3 UNITS

Qty. P/N Description

3............17210Z5KW00 ......ELEMENT COMP. A/C

1............17218ZE2505 ....... FILTER, OUTER A/C

3............9807955846 ..........SPARK PLUG

1............17620Z4H900 ....... CAP COMP. FUEL TANK

1............9820040750 ..........FUSE, MINI 7.5A

1............9820043000 ..........FUSE, MINI 30A

NOTICE

Part numbers on this Suggested Spare Parts list may

supersede/replace the part numbers shown in the

following parts lists.

QP3Ti TRASH PUMP • OPERATION AND PARTS MANUAL —REV. #1 (05/07/18) — PAGE 37

Page 38

NAMEPLATE AND DECALS ASSEMBLY

1

This pump designed for pumping non-hazardous liquids only.

2

3

ATTENTION

CAUTION

Stop Engine

at fueling.

No Smoking

while Refueling.

No Smoking

while Refueling.

Do not run engine

in enclosed area.

CAUTION

HOT MUFFLER CAN

BURN YOU.

Stay away if engine

has been running.

WARNING

Gasoline is highly flammable and explosive.

Turn engine off and let cool before refueling.

The engine emits toxic carbon monoxide.

Do not run in an enclosed area.

Read Owner’s Manual before operation.

Thai Honda Mfg. Co., Ltd. MADE IN THAILAND

DO NOT RUN DRY

4

5

PAGE 38 — QP3Ti TRASH PUMP • OPERATION AND PARTS MANUAL — REV. #1 (05/07/18)

Operation of this equipment may create sparks that can start fires around dry

vegetation. A spark arrestor may be required. The operator should contact local

fire agencies for laws or regulations relating to fire prevention requirements.

7

Pumps manufactured exclusivel for Multiquip by: Matsusaka Engineering Co., Ltd. Japan

WARNING

6

Decal No. 0011

Page 39

NAMEPLATE AND DECALS ASSEMBLY

NO. PART NO. PART NAME QTY. REMARKS

1 TBD DECAL, CAUTION, NO SMOKING 1

2 TBD DECAL, CAUTION, HOT MUFFLER 1

3 TBD DECAL, DO NOT RUN PUMP DRY 1

4 SERIAL PLATE ......................................................1............CONTACT MQ PARTS DEPT.

5 TBD DECAL, WARNING, FLAMMABLE 1

6 TBD DECAL, WARNING, START FIRES 1

7 TBD DECAL, MQ LOGO/STRIPE 1

QP3Ti TRASH PUMP • OPERATION AND PARTS MANUAL —REV. #1 (05/07/18) — PAGE 39

Page 40

PUMP ASSEMBLY

54

7

28

16

38

23

KIT

MECHANICAL

58

2

SEAL & O-RINGS

18

25

21

6

27

41

44

12

26

27-1

36

37

11

21

42

8

10

13

20

1

34

29

49

43

56

13

55

57

32

40

14

17

31

3

39

4

9

50

24

30

5

PAGE 40 — QP3Ti TRASH PUMP • OPERATION AND PARTS MANUAL — REV. #1 (05/07/18)

Page 41

PUMP ASSEMBLY

NO. PART NO. PART NAME QTY. REMARKS

1 1992100011 CASING 1

2 1992100020 CASING COVER 1

3 13910001600014 SUCTION COVER 1

4 1992100173 DRAIN COVER 1

5 19920002200014 DRAIN COVER HANDLE 4

6 1992040033ASSY IMPELLER ASSY. ..................................................1............REPLACES P/N 1992040033

............................................................................................. INCLUDES ITEMS W/#

7 1992000110 VOLUTE CASING 1

8 1992100742 SUCTION PLATE 1

9 12471002500002 DRAIN COVER SET HANDLE ...............................2............REPLACES P/N 1247100250

10 1992330410 SUCTION PLATE PACKING 1

11 1992250700 WEAR PLATE 1

12 2008020 BOLT, CASING COVER .........................................4............REPLACES P/N 0105090820

13 07904330300014 NIPPLE, NPS 3X3 NPT 2

14 1378350350 CHECK VALVE 1

16 43130006000014 CASING COVER SET PLATE 1

17@ 0483602250 O-RING, DRAIN COVER 1

18 0489403400 O-RING, CASING 1

19 0105091020 BOLT 2

20 0481310800 O-RING, NIPPLE 2

21#@ 0482200240 O-RING 2

23 0631211159 FLOODING CAP 1

24 0631211159 DRAIN CAP 1

25@ 0803442930 MECHANICAL SEAL 1

26@ 0811885446 MECHANICAL SEAL SLEEVE 1

27@ 0852834525 ADJUST LINER 1

27-1@ 0852854525 ADJUST LINER 1

28 0191170625 BOLT, CASING COVER SET PLATE 4

29 0131190823 CAP SCREW, VOLUTE CASING 4

30 0141090825 SCREW, DRAIN COVER SET HANDLE 4

31 0131191290 CAP SCREW, CASING 1

32 0131191235 CAP SCREW, CASING 4

34 0459220120 SEAL WASHER, CASING 1

36# 0458220100 SEAL WASHER, IMPELLER 1

37# 0191190750 BOLT, IMPELLER 1

NOTICE

Item 21, O-ring, is included in Impeller Kit, Item 6.

When ordered as part of the kit, quantity of -ring is

one. Replacement Impeller requires two O-rings, so it

is necessary to order one additional O-ring.

QP3Ti TRASH PUMP • OPERATION AND PARTS MANUAL —REV. #1 (05/07/18) — PAGE 41

Page 42

PUMP ASSEMBLY (CONTINUED)

54

7

28

16

38

23

KIT

MECHANICAL

58

2

SEAL & O-RINGS

18

25

21

6

27

41

44

12

26

27-1

36

37

11

21

42

8

10

13

20

1

34

29

49

43

56

13

55

57

32

40

14

17

3

31

39

5

4

24

9

50

30

PAGE 42 — QP3Ti TRASH PUMP • OPERATION AND PARTS MANUAL — REV. #1 (05/07/18)

Page 43

PUMP ASSEMBLY (CONTINUED)