Page 1

OPERATION MANUAL

DRY PRIME PUMP

MP150SDLTE (6-inch, High Flow, Deutz F3L914, Electric Brakes)

MP150SDLTS (6-inch, High Flow, Deutz F3L914, Surge Brakes)

MP150SDLSM (6-inch, High Flow, Deutz F3L914, Skid Mount)

MP200DLTE (8-inch, High Flow, Deutz F3L914, Electric Brakes)

MP200DLTS (8-inch, High Flow, Deutz F3L914, Surge Brakes)

MP200DLSM (8-inch, High Flow, Deutz F3L914, Skid Mount)

MP200SDLTE (8-inch, High Flow, Deutz F4L914, Electric Brakes)

MP200DLST (8-inch, High Flow, Deutz F4L914, Surge Brakes)

MP200SDLSM (8-inch, High Flow, Deutz F4L914, Skid Mount)

Revision #3 (10/06/08)

To find the latest revision of this

publication, visit our website at:

www.multiquip.com

THIS MANUAL MUST ACCOMPANY THE EQUIPMENT AT ALL TIMES.

P/N 17567

Page 2

PROPOSITION 65 WARNING

Diesel engine exhaust and some of

PAGE 2 —DRY PRIME PUMP — OPERATION MANUAL — REV. #3 (10/06/08)

Page 3

REPORTING SAFETY DEFECTS

REPORTING SAFETY DEFECTS

If you believe that your vehicle has a defect that could cause a crash or could cause injury or

death, you should immediately inform the National Highway Traffic Safety Administration

(NHTSA) in addition to notifying Multiquip at 1-800-421-1244.

If NHTSA receives similar complaints, it may open an investigation, and if it finds that a safety

defect exists in a group of vehicles, it may order a recall and remedy campaign. However,

NHTSA cannot become involved in individual problems between you, your dealer, or

Multiquip.

To contact NHTSA, you may either call the Vehicle Safety Hotline toll-free at 1-888-327-4236

(TTY: 1-800-424-9153), go to http://www.nhtsa.dot.gov; or write to:

Administrator

NHTSA

1200 New Jersey Avenue S.E.

Washington, DC 20590

You can also obtain information about motor vehicle safety from http://www.safecar.gov.

DRY PRIME PUMP — OPERATION AND PARTS MANUAL — REV. #3 (10/06/08) — PAGE 3

Page 4

TRAINING CHECKLIST

TRAINING CHECKLIST

This checklist will lists some of the minimum requirements for machine maintenance and operation. Please feel free to detach it and

make copies. Use this checklist whenever a new operator is to be trained or it can be used as a review for more experienced

operator’s.

TSILKCEHCGNINIART

.ON NOITPIRCSED ?KO ETAD

1 .yletelpmoclaunaMs’rotarepOdaeR

2

3 .erudecorpgnileufer,metsysleuF

4 .erudecorpgnimirppmuP

5 .serudecorppotsycnegremE

6 .erudecorppu-tratsenignE

7 )liabgnitfil(enihcamfognitfiL

8 ).ctesesu,tfil(snoitacilppapmuP

9 .tnemecalpreniartsnoitcuS

01 .snoitcennocesoH

11 .tnemecalppmuP

21 .senilediugytefasreliarT

liodnaenignefognikcehc,stnenopmocfonoitacol,tuoyalenihcaM

.slevel

31 .senilediuggnihtolcevitcetorP

41 .erudecorptsetmuucaV

51 .egarotsdnatropsnartenihcaM

61 .erudecorpytivacpmuptuonaelC

Operator _________________________________________ Trainee __________________________________________

COMMENTS:

PAGE 4 —DRY PRIME PUMP — OPERATION MANUAL — REV. #3 (10/06/08)

Page 5

DAILY PRE-OPERATION CHECKLIST

1 .levellioenignekcehC

2 .)leufnaelcrofdna(levelleufkcehC

3 .wolfriagniloocdnasnifgniloockcehC

4 .renaelcriaenignekcehC

5 .snoitcennocelbacdnayrettabenignekcehC

6 .)etulovdnarellepmi(roiretnipmupkcehC

7 .liolaespmupmuucavkcehC

8 .liognisuohgniraebkcehC

9 .laespmupkcehC

DAILY PRE-OPERATION CHECKLIST

SILKCEHCNOITAREPO-ERPYLIAD T

COMMENTS:

01 .skcarcrofgnisacpmupkcehC

11 .ssenthgitrofstungulleehwreliartkcehC

21 .sgniraebleehwreliartkcehC

31 .llabdnahctihreliartkcehC

41 .)dnatskcaj(erawdrahdnasgnirpsreliartkcehC

51 .erusserperitreliartkcehC

61 .sthgilreliartkcehC

DRY PRIME PUMP — OPERATION AND PARTS MANUAL — REV. #3 (10/06/08) — PAGE 5

Page 6

Multiquip Dry Prime

Diesel Powered Trash Pump

California Proposition 65 Warning ............................. 2

Reporting Safety Defects .......................................... 3

Training Checklist ...................................................... 4

Daily Pre-Operation Checklist ................................... 5

Table Of Contents ..................................................... 6

Safety Message Alert Symbols .............................. 8-9

Rules For Safe Operation .................................. 10-12

Pump Dimensions ................................................... 13

Trailer Dimensions .................................................. 14

Pump Specifications ................................................ 15

Engine Specifications .............................................. 16

General Information ................................................ 17

Pump Components ............................................ 18-19

Engine Components ............................................... 20

Engine Control Box Components............................ 21

Pumping Application ............................................... 22

Towing Application .................................................. 23

Setup ....................................................................... 24

Setup ....................................................................... 25

Operation ........................................................... 26-27

Maintenance (Pump) .............................................. 28

Maintenance (Engine)........................................ 29-30

Maintenance (Trailer) ......................................... 31-34

Trailer Safety Guidelines .................................... 35-44

Tire Safety .......................................................... 45-50

Trailer Lights Wiring Diagram .................................. 51

Nameplate and Decals............................................ 52

Troubleshooting (Pump) .......................................... 53

Troubleshooting (Engine) ................................... 54-55

Trailer Brakes (Hydraulic) ....................................... 56

Trailer Brakes (Electric) ........................................... 56

TABLE OF CONTENTS

Terms and Conditions Of Sale — Parts .................. 57

NOTE

Specification and part number

are subject to change without

notice.

PAGE 6 —DRY PRIME PUMP — OPERATION MANUAL — REV. #3 (10/06/08)

Page 7

NOTES

DRY PRIME PUMP — OPERATION AND PARTS MANUAL — REV. #3 (10/06/08) — PAGE 7

Page 8

SAFETY MESSAGE ALERT SYMBOLS

FOR YOUR SAFETY AND THE SAFETY OF OTHERS!

Safety precautions should be followed at all times when

operating this equipment. Failure to read and understand the

Safety Messages and Operating Instructions could result in

injury to yourself and others.

NOTE

This Owner's Manual has been developed to provide

complete instructions for the safe and efficient operation

of the Multiquip Model

engine manufacturer's instructions for data relative to its

safe operation.

Before using this trash pump, ensure that the

operating individual has read and understood all

instructions in this manual.

SAFETY MESSAGE ALERT SYMBOLS

The three (3) Safety Messages shown below will inform you

about potential hazards that could injure you or others. The

Safety Messages specifically address the level of exposure to

the operator, and are preceded by one of three words: DANGER,

WARNING, or CAUTION.

Dry Prime Pump

. Refer to the

HAZARD SYMBOLS

Lethal Exhaust Gases

Engine exhaust gases contain poisonous

carbon monoxide. This gas is colorless and

odorless, and can cause death if inhaled.

NEVER operate this equipment in a confined

area or enclosed structure that does not

provide ample free flow air.

Explosive Fuel

DIESEL fuel is extremely flammable, and its

vapors can cause an explosion if ignited. DO

NOT start the engine near spilled fuel or

combustible fluids. DO NOT fill the fuel tank

while the engine is running or hot. DO NOT

overfill tank, since spilled fuel could ignite if it

comes into contact with hot engine parts or

sparks from the ignition system. Store fuel in

approved containers, in well-ventilated areas

and away from sparks and flames. NEVER

use fuel as a cleaning agent.

DANGERDANGER

DANGER

DANGERDANGER

You WILL be

NOT follow directions.

WARNINGWARNING

WARNING

WARNINGWARNING

You CAN be

NOT follow directions.

CAUTION

CAUTIONCAUTION

CAUTION

CAUTIONCAUTION

You CAN be

Potential hazards associated with the

operation will be referenced with Hazard Symbols which appear

throughout this manual, and will be referenced in conjunction

with Safety Message Alert Symbols.

KILLED

KILLED

INJURED

or

or

if you DO NOT follow directions.

SERIOUSLY

SERIOUSLY

Dry Prime Trash Pump

injured if you DO

injured if you DO

Burn Hazards

Engine components can generate extreme heat.

To prevent burns, DO NOT touch these areas

while the engine is running or immediately after

operations. Never operate the engine with heat

shields or heat guards removed.

Rotating Parts

NEVER operate equipment with covers, or

guards removed. Keep fingers, hands, hair and

clothing away from all moving parts to prevent

injury.

PAGE 8 —DRY PRIME PUMP — OPERATION MANUAL — REV. #3 (10/06/08)

Page 9

SAFETY MESSAGE ALERT SYMBOLS

Accidental Starting

ALWAYS place the engine ON/OFF switch in

the OFF position. Close the vandal cover door

on the engine control box. Lock the door by

placing a pad lock on the door hasp when the

machine is not in use.

Sight and Hearing Hazard

ALWAYS wear approved eye and hearing

protection.

Respiratory Hazard

ALWAYS wear approved respiratory

protection.

Equipment Damage Messages

Other important messages are provided throughout this manual

to help prevent damage to your pump, other property, or the

surrounding environment.

This pump, other property, or the

NOTE

surrounding environment could be

damaged if you do not follow

instructions.

DRY PRIME PUMP — OPERATION AND PARTS MANUAL — REV. #3 (10/06/08) — PAGE 9

Page 10

RULES FOR SAFE OPERATION

■

DANGERDANGER

DANGER

DANGERDANGER

Failure to follow instructions in this manual may lead to

serious injury or even death! This equipment is to be

operated by trained and qualified personnel only! This

equipment is for industrial use only.

The following safety guidelines should always be used when

operating the

GENERAL SAFETY

■

DO NOT operate or service this

equipment before reading this entire

manual.

■

This equipment should not be operated by persons under

18 years of age.

■

NEVER operate this equipment without proper protective

clothing, shatterproof glasses, steel-toed boots and other

protective devices required by the job.

Dry Prime Pump

Read this manual!

:

NEVER touch the hot exhaust

manifold, muffler or cylinder. Allow

these parts to cool before servicing

engine or pump.

■

High Temperatures – Allow the

engine to cool before adding fuel or

performing service and maintenance

functions. Contact with

burns.

■

The air-cooled diesel engine

of this pump requires an

adequate free flow of cooling

air.

NEVER

pump in any enclosed or

narrow area where free flow

of the air is restricted. If the

air flow is restricted it will

cause serious damage to the pump or engine and may

cause injury to people. Remember the engine gives off

DEADLY

hot!

components can cause serious

operate the

carbon monoxide gas.

■

ALWAYS refuel in a well-ventilated area, away from

sparks and open flames.

■

NEVER operate this equipment when not

feeling well due to fatigue, illness or taking

medicine.

■

NEVER operate this equipment under the influence of

drugs

or

alcohol

■

ALWAYS wear proper respiratory (mask),

hearing and eye protection equipment when

operating the pump.

■

Whenever necessary, replace nameplate, operation and

safety decals when they become difficult read.

■

Manufacture does not assume responsibility for any

accident due to equipment modifications.

.

■

ALWAYS use extreme caution when

working with flammable liquids. When

refueling, stop the engine and allow it to

cool. DO NOT

machine. Fire or explosion could result

from fuel vapors, or if fuel is spilled on a

hot engine.

■

NEVER operate the pump in an

explosive atmosphere or near

combustible materials. An explosion or

fire could result causing severe

harm or even death.

■

Topping-off to filler port is dangerous, as it tends to spill

fuel.

■

Stop the engine when leaving the pump unattended.

■

Block the unit when leaving or when using on a slope.

smoke

around or near the

bodily

■

NEVER use accessories or attachments, which are not

recommended by Multiquip for this equipment. Damage

to the equipment and/or injury to user may result.

PAGE 10 —DRY PRIME PUMP — OPERATION MANUAL — REV. #3 (10/06/08)

Page 11

RULES FOR SAFE OPERATION

■

NEVER pump volatile, flammable or low flash point fluids.

These fluids could ignite or explode.

■

NEVER pump corrosive chemicals or water containing toxic

substances. These fluids could create serious health and

environmental hazards. Contact local authorities for

assistance.

■

NEVER open the volute cover during operation or start the

pump with the cover off. The rotating impeller inside the pump

can cut or sever objects caught in it.

■

NEVER block or restrict flow from discharge hose. Remove

kinks from discharge line before starting pump. Operation

with a blocked discharge line can cause water inside pump to

overheat.

■

NEVER run engine without air cleaner. Severe engine damage

may occur.

■

ALWAYS read, understand, and follow procedures in

Operator’s Manual before attempting to operate equipment.

■

ALWAYS be sure the operator is familiar with proper safety

precautions and operations techniques before using pump.

■

ALWAYS store equipment properly when it is not being used.

Equipment should be stored in a clean, dry location out of the

reach of children.

■

Refer to the

questions or information.

■

In winter, drain water from pump housing to prevent freezing.

Engine Owner's Manual

for engine technical

Maintenance Safety

■

■

■

■

■

■

■

Lifting

■

NEVER lubricate components or attempt service on a running

machine.

ALWAYS allow the machine a proper amount of time to cool

before servicing.

Keep the machinery in proper running condition.

Fix damage to the machine immediately and always replace

broken parts.

Dispose of hazardous waste properly. Examples of potentially

hazardous waste are used motor oil, fuel and fuel filters.

DO NOT use food or plastic containers to dispose of

hazardous waste.

DO NOT pour waste, oil or fuel directly onto the ground,

down a drain or into any water source.

The pump has an operating weight of 3180 lbs. (1,442 kg) or

more . Use lifting equipment with a rated capacity of at least

14,000 lbs. (6,350 kg). Remove suction & discharge hoses/

pipes before lifting.

Add 1000 lbs. (454 kg.) to the

NOTE

operating weight for a full tank of

fuel, 140 gallons (530 liters).

■

ALWAYS make sure pump is correctly secured to the trailer.

Check all supports attaching the pump to the trailer and make

sure they are tight.

■

ALWAYS make sure that the pump's trailer is placed on solid

level ground so that it cannot slide or shift around, endangering

workers. Deploy jack stands for stabilization. Place blocks

under the trailer's bumper to make it level (prevents tipping),

and use a chocked block underneath the wheels to prevent

rolling. Also keep the immediate area free of bystanders.

■

High Temperatures – Allow the engine to cool before adding

fuel or performing service and maintenance functions. Contact

hot

with

components can cause serious burns.

EMERGENCIES

■

■

ALWAYS know the location of the nearest

extinguisher

In emergencies

nearest phone or

and first aid kit.

always

know the location of the

keep a phone on the job site

fire

.

Also know the phone numbers of the nearest

ambulance, doctor

and

fire department

. This

information will be invaluable in the case of an

emergency.

DRY PRIME PUMP — OPERATION AND PARTS MANUAL — REV. #3 (10/06/08) — PAGE 11

Page 12

RULES FOR SAFE OPERATION

Battery

The battery contains acids that can cause injury to the eyes and

skin. To avoid eye irritation,

shielding. Use well-insulated gloves when picking up the battery.

Use the following guidelines when handling the battery.

■

DO NOT drop the battery. Any impact to the battery may

cause it to explode.

■

DO NOT expose the battery to open flames,

sparks, lit cigarettes etc. The battery

contains combustible gases and liquids. If

these gases and liquids come in contact

with a flame or spark an explosion can occur.

■

ALWAYS keep the battery charged. If the

battery is not charged, a buildup of

combustible gas will occur.

■

ALWAYS keep battery cables in good working condition.

Repair or replace all worn cables.

■

ALWAYS disconnect the

performing service on the equipment.

always

wear safety glasses or face

negative battery terminal

before

■

Inadequate battery connections may cause poor starting

of the trowel, and create other malfunctions.

■

ALWAYS recharge the battery in a vented air environment

to avoid risk of a dangerous concentration of combustible

gases.

■

DO NOT charge battery if frozen. Battery can explode. When

frozen, warm battery to at least 61°F (16°C).

■

If the battery liquid (dilute sulfuric acid) comes in contact with

clothing or skin

plenty of water.

■

If the battery liquid (dilute sulfuric acid) comes in contact with

eyes

your

contact the nearest doctor or hospital and seek medical

attention.

, rinse eyes immediately with plenty of water, then

, rinse skin or clothing immediately with

PAGE 12 —DRY PRIME PUMP — OPERATION MANUAL — REV. #3 (10/06/08)

Page 13

B

PUMP DIMENSIONS

A

C

Figure 1. Pump Dimensions

ECNEREFER

RETTEL

ATHGIEH

BHTDIW

CHTPED

SNOISNEMIDPMUP.3ELBAT

NOITPIRCSED

I5.84

SNOISNEMID

)MM(SEHCNI

SEHCNI74

)MM8.3911(

SEHCN

)MM79.1321(

SEHCNI6.54

)MM41.8511(

DRY PRIME PUMP — OPERATION AND PARTS MANUAL — REV. #3 (10/06/08) — PAGE 13

Page 14

TRAILER DIMENSIONS

Figure 2. Trailer Dimensions

SNOISNEMIDRELIART.2ELBAT

ECNEREFER

RETTEL

ATHGIEH

BHTD

C

DHTGNELGNIPPIHS

ETHGIEHNOITCUSDBT

FTHGIEHEGRAHCSIDDBT

GEGNARDNATHGIEHHCTIHDBT

IW

NOITPIRCSED

HTGNEL

)dednetxEeugnoT(

(

SNOISNEMID

)MM(SEHCNI

SEHCNI35.58

)MM43.2712(

SEHCNI37.27

)MM43.7481(

SEHCNI65.141

)MM66.5953(

SEHCNI49

)MM6.7832

PAGE 14 —DRY PRIME PUMP — OPERATION MANUAL — REV. #3 (10/06/08)

Page 15

SPECIFICATIONS

SNOITACIFICEPSPMUP.1ELBAT

ledoMMSLDS051PMETLDS051PMSTLDS051PMMSLD002PMETLD002PMSTLD002PMMSLDS002PMETLDS002PMSTLDS002PM

ytic

apaC

PH

MPRmpr0081mpr0081mpr0081mpr0081mpr0081mpr0081mpr0081mpr

C-riA

gnipmuPmumixaM

tfiLnoitcuSmumixaM

daeHlatoTmumixaM

sdiloSmumixaM

erusserPdnuoSABd47ABd47ABd47ABd47ABd47ABd47ABd67ABd67ABd67

emiTnuRsruoh65sruoh65sruoh65sruoh65sruoh65sruoh6

)detnuoMdikS(thgieW

enignEdeloo

yticapaCleuF

MPG0052

3

m4.9(

).nim/

.tf03

)sretem1.9(

.tf221

)sretem73(

.ni2.3

)mm2.18(

PH34

)Wk23(

.sbl0573

).gk0071(

ztueD

419L3F

lag521

)sretil574(

MPG0052

3

m4.9(

).nim/

.tf03

)sretem1.9(

.t

f221

)sretem73(

.ni2.3

)mm2.18(

PH34

)Wk23(

.sbl0093

).gk9671(

ztueD

419L3F

lag521

)sretil574(

MPG0052

3

m4.9(

).nim/

.tf03

)sretem1.9(

.tf221

)sretem73(

.ni2.3

)mm2.18(

PH34

)Wk23(

.sbl0093

).gk9671(

ztueD

419L3F

lag521

)sretil574(

MPG0072

3

m2.01(

).nim/

.tf52

)sretem8.7(

.tf221

)sretem73(

.ni2.3

)mm2.18(

PH34

)W

k23(

.sbl0083

).gk

3271(

ztueD

419L3F

lag521

)sretil574(

MPG0072

3

m2.01(

).nim/

.tf52

)sretem8

.7(

.tf221

)sretem73(

.ni2.3

)

mm2.18(

PH34

)Wk23(

.sbl0593

).gk1971(

ztueD

419L3F

lag521

)sretil574(

MPG0072

3

m2.01(

).nim/

.tf52

)sretem8.7(

.tf221

)sretem73(

.ni2.3

)mm2.18(

PH34

)Wk23(

5sruoh14sruoh14sruoh14

.sbl0593

).gk1971(

ztueD

419L3F

l

ag521

)sretil574(

MPG0053

3

m2.31(

).nim/

.tf52

)sretem8.7(

.tf531

)sretem14(

.ni6.3

)mm4.19(

PH06

)Wk84(

.sbl0693

).gk6971(

ztueD

419L4F

lag521

)sretil574(

3

m2.31(

0081mpr0081

MPG0053

).nim/

.tf52

)sretem8.7(

.tf531

)

sretem14(

.ni6.3

)mm4.19(

PH06

)Wk84(

.sbl0114

).gk3681(

ztueD

419L4F

lag521

)sretil574(

MPG0053

3

m2.31(

).nim/

.tf52

)sretem8.7(

.tf531

)sretem14(

.ni6.3

)mm4.19(

PH06

)Wk84(

.sbl0114

).gk3681(

ztueD

419

L4F

lag521

)sretil574(

SOUND MEASUREMENTS

The required sound specifications, per Appendix 1, paragraph 1.7.4.f of the EC-Machine

Regulations, are defined as follows:

The sound pressure level at the operator's location (L) = 87 dB (A)

The sound power level (L) = 97 dB (A)

These sound values are determined according to ISO 3744 for the sound power level (L)

and ISO 6081 for the sound pressure level (L) at the operator's location.

The sound measurements were obtained with the unit operation on pavement at nominal

speed.

DRY PRIME PUMP — OPERATION AND PARTS MANUAL — REV. #3 (10/06/08) — PAGE 15

Page 16

SPECIFICATIONS (ENGINE)

SNOITACIFICEPSENIGNE.4ELBAT

ekaMenignEztueDztueD

ledoMenignE419L3F419L4F

epyTenignEdelooCriAdelooCriA

fOrebmuN34

/eroBekortS

tnemecalpsiD

Heni)Wk8.92(PH04)Wk8.83(PH25

gnEP

srednilyC

ni2.5/4

mm231/201

ni-uc5.791

)cc6323(

yticapaCliO)sretil6.9(lag35.2)sretil0.31(lag34.3

epyTleuFleseiDleseiD

TleuF

1

yticapaCkna

)detnuoMdikS(thgieW

dohteMgnitratStr

)gk692(

atScirtcelEtratScirtcelE

)sretil235(lag041)sretil235(lag041

.sbl75.256

.reliartfotrapsiknatleuF)1

ni2.5/4

mm231/201

ni-uc3.362

)cc4134(

.sbl82.008

)gk363(

PAGE 16 —DRY PRIME PUMP — OPERATION MANUAL — REV. #3 (10/06/08)

Page 17

GENERAL INFORMATION

The Multiquip Dry Prime pump is a prime dry and primeassist pump that can handle dewatering, sewer bypass, and

wellpoint applications.

The Dry Prime pump uses a vacuum pump to remove the

air. This becomes important in certain applications such as

long suction hose runs or multiple suction points (such as

wellpoints). In these cases, high volumes of air enters into

the pump. Dry Prime uses direct-drive vacuum pump to

efficiently remove very large volumes of air quickly to obtain

the priming necessary for these special applications. Dry

Prime is very useful when you have to move a lot of water

fast.

Impeller

The Dry Prime impeller has a patented design to eliminate

cavitation. It is a 2-blade spiral, smooth flow, open, non-clog

impeller, designed to handle up to 3.2-inch solids. The impeller

pulls water directly into the pump from the priming tank,

reducing friction losses, and then pushes it out the volute

discharge. This design does not cause turbulence normally

found in centrifugal pumps.

Wear Plate

In conjunction with the impeller, the wear plate gives a perfect

match for great pump performance and durability. The wear

plate can be fully adjusted up to .6 inch (15mm) for wear.

Priming System

The vacuum system is innovative, simple, yet rugged and

dependable. I uses direct drive which means no belt failure

and with only one moving part, means no maintenance. It

uses liquid-ring design with a closed water system. Separate

oil bath lubrication for the seal and bearings with oil reservoir,

can run dry without damage. It operates quietly with no

pollution or unwanted discharge noise.

Float and Backflush (Priming Tank)

The priming tank float is a one-piece welded construction,

rubber valve seat, self-aligning rubber hinge. This design

increases reliability. The backflush valve allows for cleaning

of the suction strainer or wellpoint headswhile the engine is

running.

Fuel Tank

Run time is up to 72 hours with the Dry Prime’s fuel tank,

good for continuous running for those long-term jobs. There

are two corner fuel drains to check condition of fuel. The

TrackBar system allows for the easy addition of jack stands,

fenders, axle, lifting bail, and other options. This allows for

fast and easy positioning of the jack stands on the job site

to fit the application, or to add subtract jack stands as

required. The removable, retractable towing tongue minimizes

storage requirements.

Volute

The pump volute has an external inspection cover to inspect

or clear the impeller. The pump shaft bearings and

mechanical seal are run in independent oil baths for low

maintenance.

LOFA Engine Control Panel

Vandal protected panel that provides engine status and shutdowns in the event of low oil pressure, high engine heat,

and alternator belt breakage. Optional auto-start module with

floats can be added for automatic start-stop of pump engine

and pumping operation.

Frame and Trackbar System

DRY PRIME PUMP — OPERATION AND PARTS MANUAL — REV. #3 (10/06/08) — PAGE 17

Page 18

PUMP COMPONENTS

13

6

4

10

12

15

5

1

2

3

1

4

Figure 3-A shows the location of the components of the Dry

Prime pump. The function of each component or control is

described below:

1. Rear Fuel Tank Drain Plugs – Remove either plug to

drain fuel.

2. Primary Tank Drain Valve – Open valve to drain water

from priming tank. In freezing weather conditions water

inside priming pump should always be drained.

3. License Plate Light – ALWAYS make sure light is

working correctly before towing at night.

4. Rear Tail Lights – Before towing make sure both tail-

lights are working correctly and are properly connected

to the towing vehicle brake light system.

5. Inlet Port – Attach suction hose to this port. ALWAYS

make sure suction hose is securely attached.

6. Priming System Tank Fill Reservoir – Used to fill

inner priming tank and vacuum system.

7. Priming System Drain Valve – Open valve to drain in

water priming tank.

9

8

7

14

9. Bearing/Seal Sight Glasses – Use these sight glasses

to determine if oil is present. Oil must be

at the slight glasses.

10. Pump Driveshaft Access Panel – Remove this panel

to gain access to the pump driveshaft (gear) or second

vacuum pump.

11. Tires – This pump uses XX-inch X-ply tires. Replace with

only recommended type tires. Replace defective or worn

tires immediately.

12. Fuel Cap – Remove to visually inspect fuell level and

to refill fuel tank. Refuel using only recommended types

of diesel fuel (see Deutz Manual). DO NOT top off fuel

and wipe up any spilled fuel immediately.

13. Jackstand – Use jack stands to level and stabilize

pump. ALWAYS make sure jack stands are deployed

before operating pump.

14. Tie Downs –When transporting of the pump is required,

use these tie-downs (4) to secure the pump.

15. Front Fuel Tank Drain Plug –Remove either plugs to

drain fuel.

8. Impeller/Volute – The impeller is a two-blade sprial

open impeller connected to a drive shaft, when rotated

creates a partial vacuum, drawing fluid through the pump

creating suction. The volute houses the impeller.

11

13

14

Figure 3-A. Pump

Components

visible

midway

PAGE 18 —DRY PRIME PUMP — OPERATION MANUAL — REV. #3 (10/06/08)

Page 19

PUMP COMPONENTS

23

24

26

27

28

29

30

31

25

Figure 3-B shows the location of the more components of

the Dry Prime pump, The function of each component or

control is described below:

16. Safety Chain – ALWAYS attach safety chain to the

towing vehicle. NEVER tow the pump with the safety

chain unattached! See towing section of this manual.

17. Towing Coupler/Ring – Attach this coupler to the towing

vehicle. Use only the specified ball diameter as indicated

on your coupler (2-5/16). Use of any other ball diameter

will create an extremely dangerous condition which can

result in separation of the coupler and ball or ball failure. A

3-inch tow ring is also available as an option.

18. Ajustable Tow Tongue – Tow tongue is adjustable by

removing locking pin to adjust tongue length then

reinserting pin to lock tongue in place.

19. Battery – Unit uses a +12VDC wet battery Group 31.

20. Engine – These pumps are equipped with either a

Deutz F3L914 or F4L914 three or four cylinder aircooled diesel engine.

21. Skid Lifting Bail –When lifting of the pump skid is required,

attach a strap or chain of adequate lifting capacity to lift the

skid.

22. Engine Control Box – Vandal proof (lockable) engine

control box displaying engine guages, tachometer,

tempertature, battery voltage, hour meter, oil pressure

and ignition switch.

23. Document Box – Contains all documentation relating

to the pump or engine.

21

22

33

32

24. Vacuum Pump Mechanical Seal Oil Reservoir – Oil

level should always be maintained to the FULL level

marked on the bottle.

25. Backflush Valve – Open valve to backflush wellpoints

or to clean suction strainer.

26. Priming Tank Lifting Bail – When removing of the

priming tank is required, attach a strap or chain of adequate

lifting capacity to lift vacuum pump.

27. Pump Discharge – Attach discharge hose to this port.

ALWAYS make sure discharge hose is securely

attached.

28. Float Valve – Regulates and controls vacuum level

during pump operation. Consist of self-aligning

reinforced rubber hinge that doubles as a seal and a

one piece welded float assembly.

29. Priming Tank – Vacuum system that creates a vacuum

in the outer priming tank, drawing water in. Water drawn

into the outer priming tank then flows into the volute,

priming the pump.

30. Vacuum Gauge – Vacuum gauge for priming system.

Monitors air discharge. Required when troubleshooting.

31. Fuel Tank – Holds 140 gallons (530 liters) of diesel

fuel

32. Volute Inspection Cover – Remove this cover to

inspect or clear the impeller.

33. Vacuum Pump – This unit uses a direct-drive 60 CFM

vacuum pump to remove large volumes of air to obtain

priming for the pump.

20

17

19

18

16

Figure 3-B. Pump

Components

DRY PRIME PUMP — OPERATION AND PARTS MANUAL — REV. #3 (10/06/08) — PAGE 19

Page 20

3

ENGINE COMPONENTS

4

7

6

5

9

13

2

1

Figure 4. Basic Engine Components

Figure 4 illustrates the location of the basic components for the

Deutz Model F3L914 and F4L914 Engines. The function of each

component is described below:

1. Starter Motor/Solenoid – NEVER

foreign debris to come in contact with the starter motor/

solenoid.

2. Alternator – (not shown) Provides power to the electrical

system. Replace with only manufactures recommended

type alternator.

3. Muffler/Guard – DO NOT

is running. The muffler can become extremely hot, causing

severe burns. NEVER run the pump with the muffler guard

removed.

4. Engine – Air-cooled, 4-stroke, 3 or 4 cylinder diesel

engine. See Table 2 for detailed specifications.

5. Engine Throttle Lever – Controls the speed of the

engine. For load conditions (pumping water) ALWAYS

run the engine at

6. Fuel Filter – Replace or clean the fuel pump or fuel filter as

specified in the maintenance section of this manual.

full speed

touch the muffler when engine

allow concrete or any

.

7. Air Cleaner – Prevents dirt and other debris from entering

the fuel system. Remove wing-nut on top of air filter

cannister to gain access to filter element. Replace with only

manufactures recommended type air cleaner.

8. V-Belts – ALWAYS make sure that V-belts are properly

tensioned. Loose or defective V-belts can adversely affect

the performance of the pump.

9. Cooling Fan Blades – Make sure that the blades of the

cooling fan are not

can cause the engine to run hot and overheat.

10. Oil Filler Port Cap – Remove this cap to add engine oil to

the crankcase. Fill with recommended type oil as specified

in the maintenance section of this manual.

11. Crankcase Drain Plug – Remove this plug to drain engine

oil from the crankcase. Replace with recommended engine

oil as specified in the maintenance section of this manual.

12. Dipstick – Remove this dipstick to determine if engine oil

is low. Maintain oil level at the "H "marking on the dipstick.

NEVER

12. Oil Filter – Replace oil filter as recommended in the

maintenance section of this manual.

12

11

10

bent or broken

run engine with low oil.

8

. A damaged fan blade

PAGE 20 —DRY PRIME PUMP — OPERATION MANUAL — REV. #3 (10/06/08)

Page 21

ENGINE CONTROL BOX COMPONENTS

1

0

1

2

8

1

4

1

6

VDO

P

S

I

2

0

4

0

6

0

0

2

3

QUARTZ

1

4

0

8

0

bar

0

5

0

025

H

O

V

D

O

AUX

AUX

U

1

2

R

S

8

5

AUTOSTART

(WHENEQUIPPE

2

0

10

RPM

3

0

0

x100

4

0

VDO

F

2

0

0

2

6

0

1

2

0

3

1

2

0

0

9

0

0

5

0

C

1

5

0

VDO

O

F

F

D)

0

R

U

N

P

I

II

I

I

I

START

10

12

8

14

16

V

D

1

7

O

PSI

20

40

60

0

2

3

1

4

0

b

ar

V

D

O

QUARTZ

80

00

5

HOURS

025

5

20

10

R

P

M

30

0

x

1

0

0

40

V

D

O

F

2

0

0

2

6

0

1

2

0

3

1

2

0

0

9

0

0

5

0

C

1

5

0

VDO

2

3

4

5

AUX

AUX

Figure 5. Control Box

Figure 5 shows the location of the components for the engine

control box. The function of each component is described

below:

1. Voltmeter Gauge – Indicates the battery charge.

2. Engine Tachometer – Monitors engine RPM's.

3. Temperature Meter - Indicates engine coolant

temperature.

4. Engine Hour Meter – Displays the number of hours

6. Engine ON/OFF Switch – Turn the knob here to start

the engine. Turn the knob clockwise to the RUN position,

then continue turning clockwise to the START position

and release. To stop the engine turn the knob fully

counterclockwise to the OFF position.

7. Oil Pressure Meter - Monitors engine oil pressure.

8. Vandal Cover - Close cover and lock to prevent

unauthorized personnel from starting engine.

the engine has been in use.

5. LED Panel– contains LED fault indicators that light up

to indicate battery discharge, low oil pressure, high

temperature, alternator failure and V-belt failure. LED

will remain lit indicating fault until reset.

O

F

A

U

T

O

S

(

W

H

E

N

E

Q

1

2

F

T

A

R

T

U

I

P

P

E

D

)

0

RUN

P

I

III

START

6

DRY PRIME PUMP — OPERATION AND PARTS MANUAL — REV. #3 (10/06/08) — PAGE 21

Page 22

DISCHARGE HOSE

JACK

STAND

PUMPING APPLICATION

DISCHARGE HEAD

JACK

STAND

JACK

STAND

(PREVENT ROLLING)

SUCTION HOSE

STRAINER

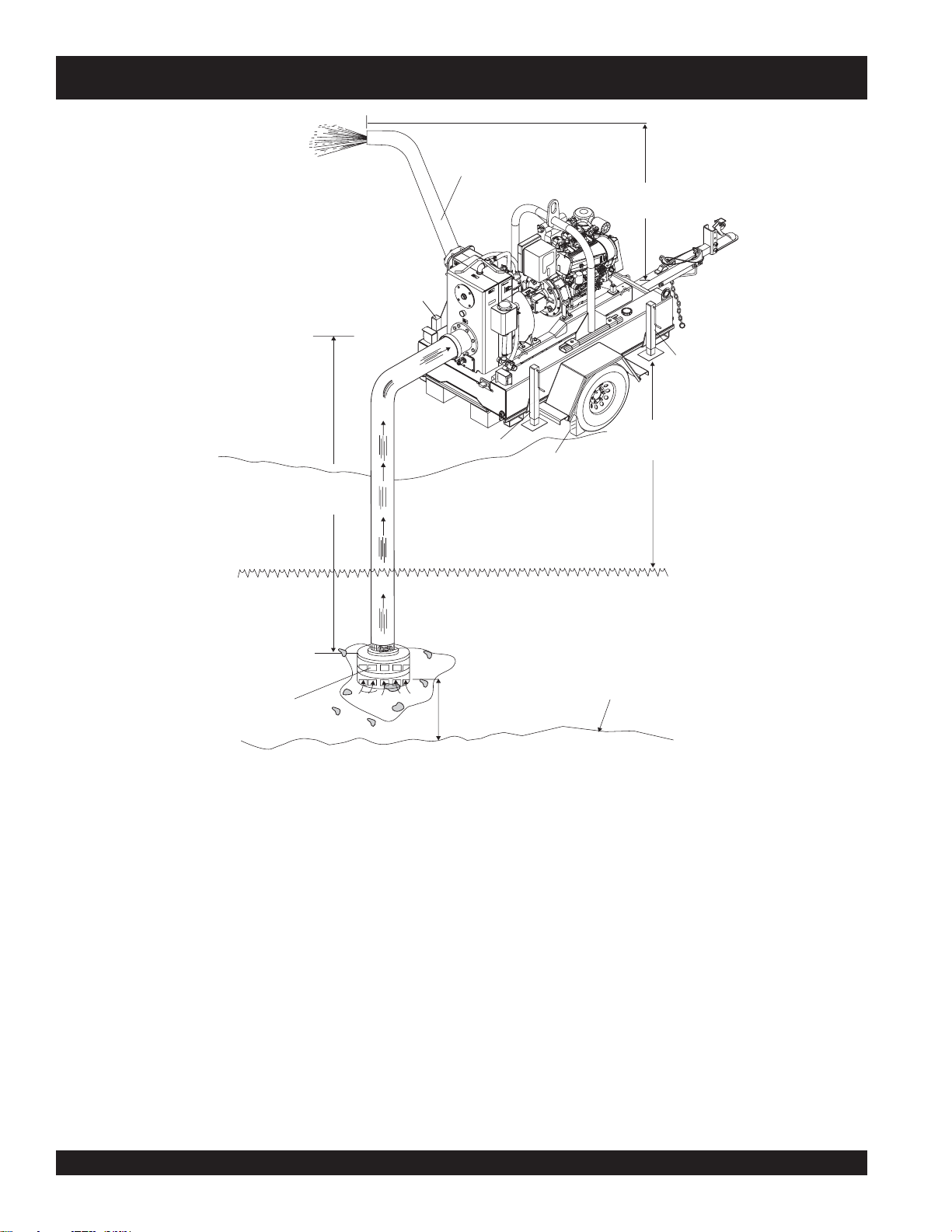

Figure 6 shows a typical application using the Dry Prime

diesel-powered prime-assist pump. Please note that this

pump is intended for the removal of clean water and water

containing some debris and solids. Maximum size of solids

should not exceed 3.2 inches (81.2 mm) in diameter. DO

NOT set strainer on bottom of water bed.

Placing the strainer above the water bed will prevent the

pump from drawing in excessive amounts of sand and foreign

debris.

The following terms are usually used when referring to

head

:

DO NOT LAY

STRAINER ON

BOTTOM SURFACE

lift

or

3. Dynamic Suction Head – The static

suction lift plus the friction in the suction

line. Also referred to as

head

4. Dynamic Discharge Head – The static

discharge head plus the friction in the

discharge line. Also referred to as

discharge head

5. Total Dynamic Head – The Dynamic Head

Suction Head plus the Dynamic Discharge

Head. Also referred to as

CHOCKED

BLOCKS

.

BOTTOM

SURFACE

.

STATIC

SUCTION

LIFT

Figure 6. Pump Application

total suction

total

total head

.

1. Static Suction Lift – The vertical distance from the

water line to the center of the impeller.

2. Static Discharge Head – The vertical distance from

the discharge outlet to the point of discharge or liquid

level when discharging into the bottom of a water tank.

PAGE 22 —DRY PRIME PUMP — OPERATION MANUAL — REV. #3 (10/06/08)

Page 23

NOTE

TOWING APPLICATION

See "Trailer Safety Guidelines"

section in this manual for a complete understanding on towing

techniques.

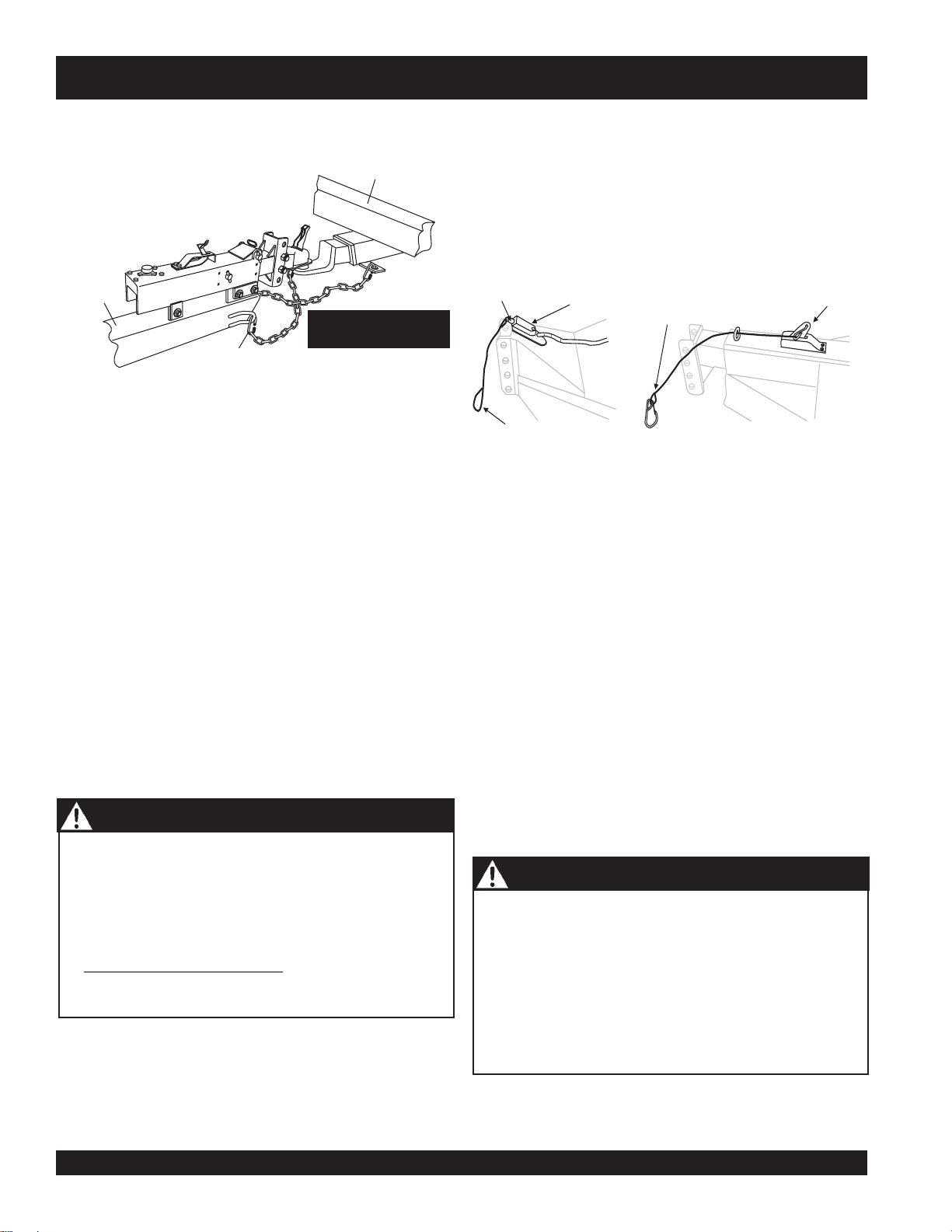

Figure 7. Typical Coupler and

Safety Chain Connection

TRAILER

TONGUE

BREAK-AWAY

SAFTEY CABLE

SAFETY CHAIN

MASTER LINK

COUPLER

LOCK

LATCH

2-5/16 INCH

TRAILER

COUPLER

2-5/16”

BALL HITCH

SAFETY CHAIN

HOOK

IMPORTANT!

CROSS BOTH

SAFETY CHAINS

DRY PRIME PUMP — OPERATION AND PARTS MANUAL — REV. #3 (10/06/08) — PAGE 23

Page 24

SETUP

Before Starting

1. Read safety instructions at the beginning of manual.

2. Place pump as near to water as possible. Level the pump with

jack stands. Rear jack stand on suction end of the pump must

be used as the weight of the suction hose filled with liquid

could cause the pump to tip. The jack stands can be moved

from side to side and optional extra jack stands can be added.

3. Fill the vacuum system with water. Water level should be up

to the middle of the hose below the priming system tank fill

reservoir. Fill with clean water, free of solids or foreign

material. Do not use salt water, water with abrasives, or acidic

water as this will cause damage to the system. Non-polluting,

environmentally-safe antifreeze should be used in freezing

conditions.

Pump will not be able to begin

NOTE

4. Check for

between the pump and bearing housing, the seal inside the

pump may be worn or damaged. Continued operation of the

pump is not recommended. Further usage of the pump under

these conditions may cause severe water damage to bearing

housing assembly.

Suction and Discharge Hoses

1. Check that the suction hose is

pump. Make certain suction hose (Figure 3) does not have

any air leakage. Tighten hose clamps and couplings as

required.

2. Shorter suction lift and suction hose length will produce

better performance.

3. Make sure the

securely attached to the water end of the suction hose. The

strainer is designed to protect the pump by preventing large

objects from being pulled into the pump. Failure to use a

strainer could cause damage to the pump, impeller, pump

shaft, pump bearings, or wear plate.

4. If a strainer becomes clogged with debris, the strainer can be

cleared while the pump is running by opening the backflush

valve.

leaks

between pump and engine. If water is leaking

suction strainer

pumping unless the water level is up

to the middle of the hose below the

fill port tank

.

securely

(Figure 6) is clean and

attached to the

DANGER - High Pressure

PVC discharge hoses and thin-walled

rubber hoses can easily fail at the end of

the hose fittings. Leaks from the hoses

can cause high-pressure liquid to be

discharged, causing dangerous

conditions. Make sure pressure rating of

hoses exceeds the pump maximum pressure to prevent hose

failure.

CAUTION - Strainer Placement

The strainer should be positioned so it will remain completely

under water

water for long periods can damage the pump.

5. Multiple suction lines may be used but valves need to be

installed in all lines to adjust for different flows and suction lift.

Suction lines of lengths of 1000 feet or more will lower

performance of the pump.

Check that the

6.

tached and not restricted. Place hose so that it lays as straight

as it is possible on the ground. Remove any twists or sharp

bends from hose which may block the flow of water.

7. Light discharge hose should be anchored to avoid movement with high flow or high pressure.

NOTE

DANGER - Flammable Fluids

DO NOT pump flammable fluids, corrosive chemicals or fluids

containing toxic substances. These fluids can create potentially

dangerous health and environmental hazards. Contact local

authorities for assistance.

8. Always use a suction hose or pipe that matches the size of

the pump inlet to insure optimum performance and reduce

the risk of damage to the pump.

9. It is recommended that the discharge hose or pipe match

the size of the pump outlet to reduce friction as much as

possible. Using a discharge line that is larger than the pump

outlet will reduce friction and improve water flow. Similarly, a

smaller line will reduce water flow by increasing friction.

. Running the pump with the strainer above

discharge

hose (Figure 6) is securely at-

Suction and discharge hoses are

available from Multiquip. Contact your

nearest dealer for more information.

PAGE 24 —DRY PRIME PUMP — OPERATION MANUAL — REV. #3 (10/06/08)

Page 25

INSPECTION

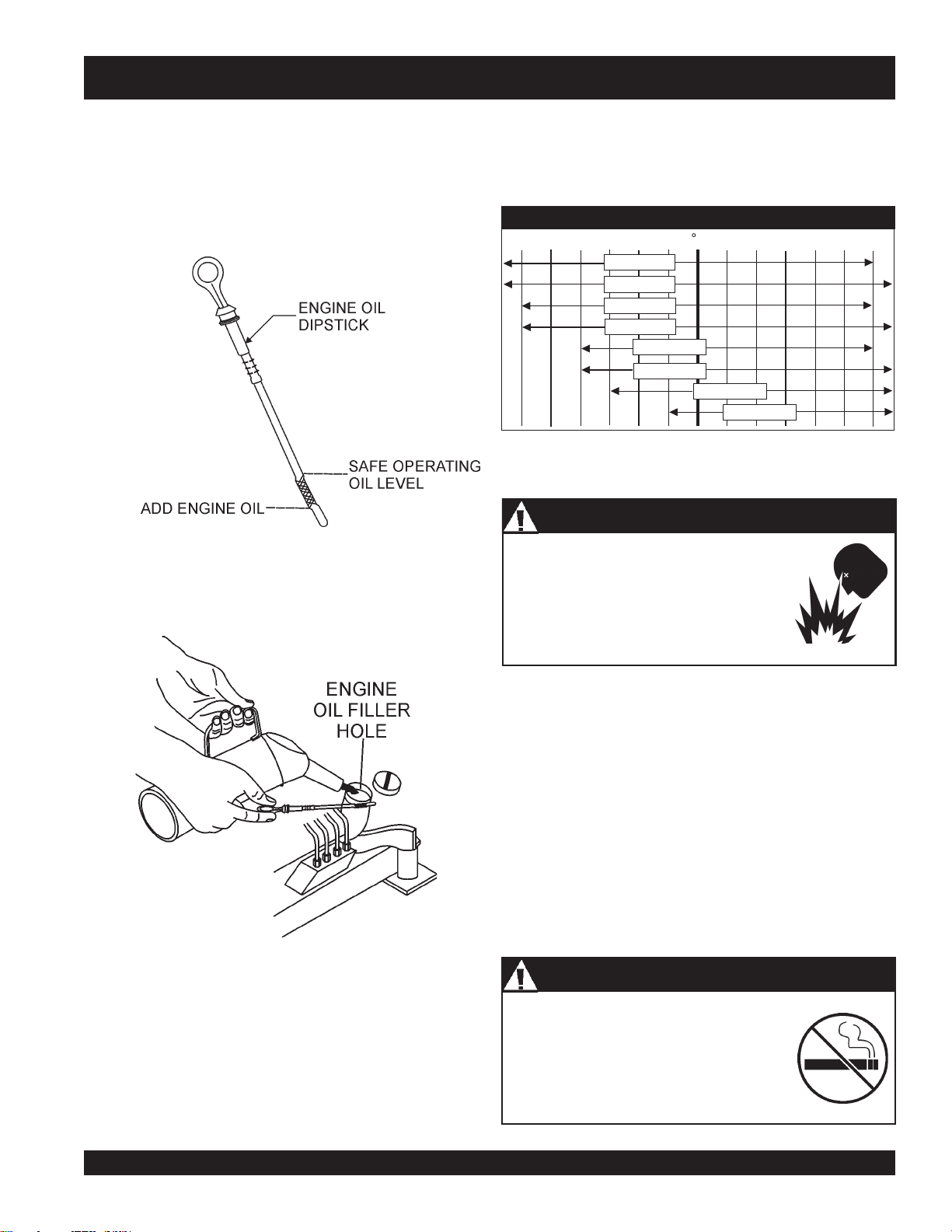

Engine Oil

1. Make sure pump/engine is on level ground.

2. Pull the engine oil dipstick from its holder.

3. Verify that oil level (Figure 8) is maintained between the

two notches on the dipstick.

Figure 8. Engine Oil Dipstick

4. If engine oil is low, fill engine crankcase with lubricating

oil through filler hole (Figure 9), but DO NOT overfill.

5. The oil listed in Table 5 is recommended to ensure better

engine performance. Use class CD or higher grade motor

oil.

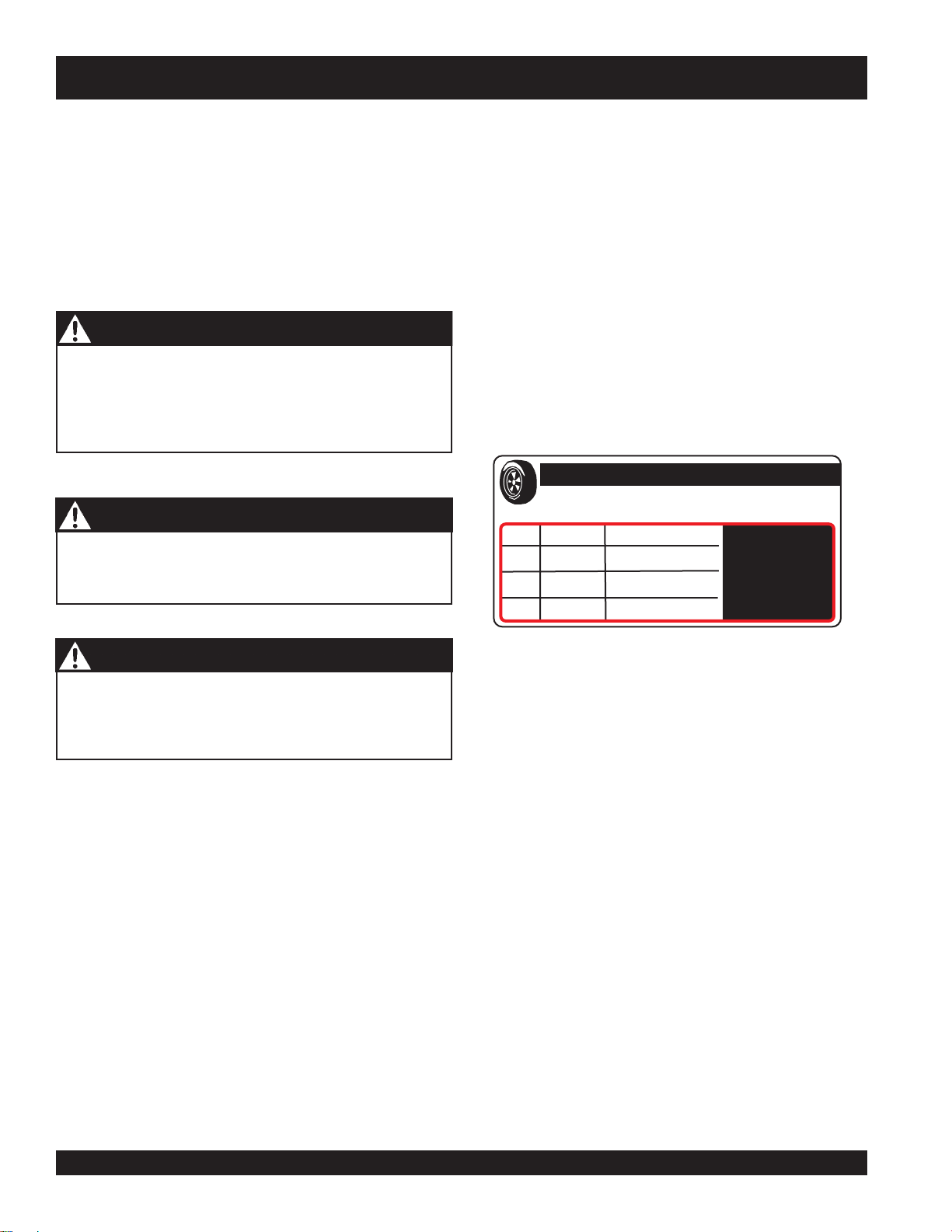

TABLE 5. OIL CHART

-30 -25

-20 -15

-10 -5

SAE 0W - 30

SAE 0W - 40

SAE 5W - 30

SAE 5W - 40

SAE 10W - 30

SAE 10W - 40

0C

51015

SAE 15W - 40

SAE 20W - 50

20

25 30

Fuel

DANGER - Fire/Explosion

NEVER fill the fuel tank while the engine

is running or in the dark. Fuel spillage on a

hot engine can cause a fire or explosion.

If fuel spillage occurs, wipe up the spilled

fuel completely to prevent fire hazards.

Figure 9. Engine Oil Filler Hole

1. Remove the fuel cap from the trailer frame and visually

inspect if the engine fuel level is low. If low, fill with

recommended type diesel fuel. DO NOT fill the tank

beyond capacity.

2. Handle fuel in a safety container. If the container does

not have a spout use a funnel.

3. Pay attention to the fuel tank capacity when replenishing

fuel. Refer to the fuel tank capacity listed in Engine

Specification Table 1.

4. Tighten fuel tank cap securely after filling.

DANGER - No Smoking

DO NOT smoke while refueling, motor

fuels are highly flammable and can be

dangerous if mishandled.

DRY PRIME PUMP — OPERATION AND PARTS MANUAL — REV. #3 (10/06/08) — PAGE 25

Page 26

OPERATION

Engine Startup

Speed Control Lever

1. Set the

Speed Control Lever

half way between start and stop.

Figure 10. Speed Control Lever

Engine Control Box

1

0

1

2

8

1

4

1

6

V

D

O

PSI

20

40

60

0

2

3

Q

1

0

U

4

A

R

T

Z

80

b

a

r

00

5

025

5

HOURS

V

D

O

AUTOSTART

(

W

H

E

N

E

Q

U

I

P

P

E

D

A

U

X

1

A

U

X

2

Figure 11. Ignition Switch

4. Release engine start stop switch as soon as engine

star ts, and verify that ignition switch automatically

(Figure 10) to a position

returns back to the RUN position.

5. Verify that the battery charge and status LED indicator

lamps are OFF.

6. If battery charge indicator lamp remains lit, increase

engine speed until light goes off. When the charge

indicator light goes off, it can then be assumed that the

charging system is working correctly.

7. If the charge light remains on while the engine is running,

refer to Engine Troubleshooting or the Deutz Engine

Repair Manual.

8. If the AUX 1 status LED lamp is ON, stop engine and

check for broken or defective V-belt.

9. Move

speed control lever

to full speed position for

maximum engine speed.

If engine does not start, place

engine start/stop switch in OFF

NOTE

20

10

R

P

M

30

0

x

1

0

0

40

V

D

O

F

2

0

0

2

6

0

1

2

0

3

1

2

0

0

9

0

0

5

0

C

1

5

0

V

D

O

position to reset. Wait 10 seconds

before restarting. Use hand fuel

pump to remove air from fuel return

line.

Operation

O

F

F

)

0

RUN

P

I

S

I

T

A

I

R

T

III

ENGINE

1. The Dry Prime pump should begin pumping water within

a minute depending on the length of suction hose and

height the pump is above water.

ON/OFF

SWITCH

Longer suction hoses will require

NOTE

more time for the pump to begin

pumping water.

1. Turn engine start switch (see Figure 11) to the RUN

position, and verify that voltmeter gauge indicates 12

2. If pump does not begin to pump water after a few

VDC.

2. Verify that the battery and status LED indicator lamps

are ON.

3. Continue turning the ignition key from the RUN position

to the START position.

PAGE 26 —DRY PRIME PUMP — OPERATION MANUAL — REV. #3 (10/06/08)

minutes, check for loose connections or air leaks in

suction hose. Make sure there is water in the vacuum

system and strainer is not clogged with debris, reference

Pump Troubleshooting Flowchart.

Page 27

OPERATION

Engine Shut-Down

1. Place

speed control lever

in the idle position and place

the engine start/stop switch in the OFF position.

2. Close vandal cover on engine control box, and lock.

Store pad lock key in a safe place, out of the reach of

unauthorized persons.

CAUTION - Locking Engine Control Box

Pump Storage

For storage of the pump for over 30 days, the following is

required:

z

Drain the fuel tank completely.

z

Run the engine until the fuel in the injection system is

completely consumed.

z

Completely drain used oil from the engine crankcase

and fill with fresh clean oil, then follow the procedures

described in the engine manual for engine storage.

When the pump is not in use,

on the engine control box and

cover

the engine control box will prevent unauthorized

personnel from starting the pump. Store key in a

safe place.

close the vandal

lock

. Locking

z

Remove the drain plug from the pump and drain out any

water from left in the housing.

z

Remove the pump cover and clean inside of pump

housing. Coat inside of pump housing with a light film of

oil to reduce corrosion. A spray can of oil works well for

CAUTION - Disconnecting Discharge Hose

If pumping in a positive head (pumping up hill), be sure to

open discharge check valve drain and release pressure

before uncoupling hose.

this application.

z

Cover suction and discharge ports with duct tape to

prevent any foreign matter from falling into pump.

z

Cover pump and engine with plastic covering or

equivalent and store in a clean, dry place.

Pump Inspection After Use

It is recommended that the pump be inspected after use for

damage or wear.

1. Drain and flush pump volute and priming system. Usually

from suction end.

2. Inspect impeller for wear or damage and measure

impeller clearance if it appears worn. Inspect interval

should be about every 1000 hours. This inspection should

be done when the pump is scheduled for maintenance

inspection.

3. Inspect discharge check valve for wear or damage.

Replace if necessary.

4. Inspect fuel tank and check for water by removing

0.5-inch drain plugs. Do not overtighten when replacing.

5. Check oil reservoirs for contamination or water.

6. Do dry vacuum test to check seal and check valve seal.

This check should be done when the pump is scheduled

for maintenance inspection.

DRY PRIME PUMP — OPERATION AND PARTS MANUAL — REV. #3 (10/06/08) — PAGE 27

Page 28

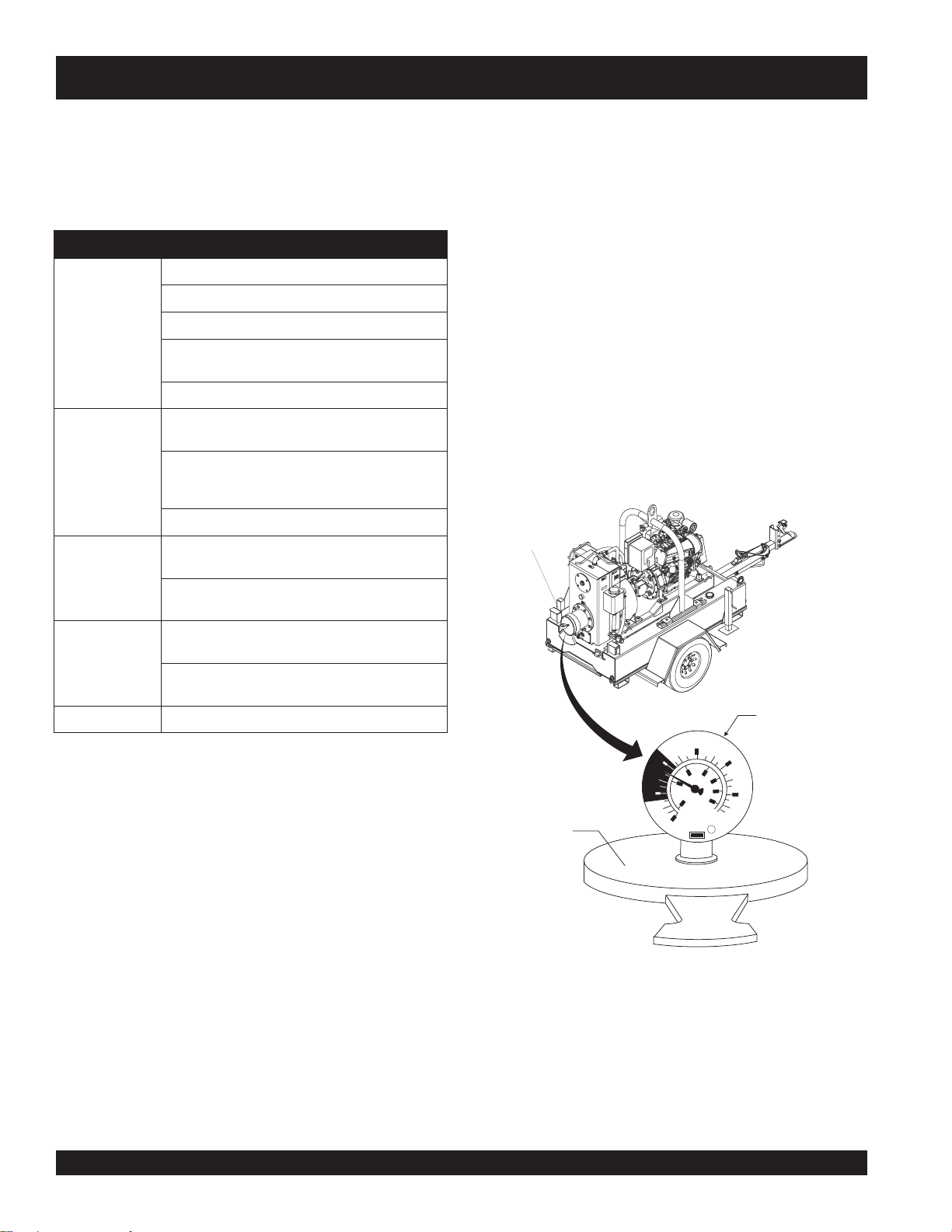

MAINTENANCE (PUMP)

Engine Maintenance

To ensure longer pump life and service, please follow the

pump maintenance guidelines as listed in Table 6 and on

preceeding pages.

ecnanetniaMpmuP.6elbaT

.gnisuohgniraebkcehC

riovreserliolaespmupkcehC

yliaD

.metsysmuucavnisnoitidnoc

sruoH052yrevE

.yrassecenfiecalper

sruoH005yrevE

.dedeensaecnaraelc

.riovreserliolaespmupmuucavkcehC

ezeerf-itnadnametsysmuucavnilevelretawkcehC

.snoitidnocrehtaewrofnoitartnecnoc

.esohegrahcsidnisknikdnaskaelrofkcehC

rofthgirsiezeerf-itnadnanaelcsiretawfikcehC

dnalaespmup,sgniraebrofsriovreserliokcehC

dnaniard,noitanimatnocroflaespmupmuucav

.ssenthgitroftlobrellepmikcehC

naelchtiwllifdnaknatretawmetsysmuucavhsulF

.yrassecenfiezeerfitnaddA.retaw

tsujdA.ecnaraelcdnanoitidnocrellepmikcehC

Dry Pump Vacuum Test

To perform the pump vacuum test do the following:

1. Perform all start-up steps without installing the hoses.

2. Block the suction with a plug or heavy rubber flap as

shown in Figure 12. An accurate vacuum gauge should

be installed in the plug or flap to check vacuum system

performance and pump vacuum gauge.

2. Start the engine and run at 1,800 RPM. Note the

maximum vacuum reading.

3. Shut off the engine and check the vacuum reading. The

vacuum reading should be .75 to .9 Bar or 25 to 27

inches. Vacuum reading should hold for about 3 to 10

minutes before dropping to zero. If vacuum reading drops

fast, check for leaks and repair if necessary. Listen for

leaks. If area is quiet, small air leaks should be easy to

hear.

PUMP VACUUM

TESTER

sruoH0001yrevE

sruoH0002yrevE .sgniraebpmupmuucavesaerG

.sriovreserlaespmupmuucavdna

.yrassecen

,gnisuohgniraebpmup,laespmupnilioegnahC

fiecalpeR.raewrofevlavkcehcegrahcsidtcepsnI

ACCEPTABLE READING

SHOULD BE BETWEEN

-27 AND -25 IN. HG.

-10

25 IN. HG TRANSLATES

-5

INTO 25 FEET OF LIFT

AT SEA LEVEL.

(In. Hg = INCHES

OF MERCURY)

PLACE VACUUM TESTER

OVER PUMP INLET.

-15

-20

-40

-60

-80

-20

-100

-25

kPa

in. Hg

-30

R

WIKA

PUMP VACUUM TESTER

Figure 12. Dry Pump Vacuum Test

PAGE 28 —DRY PRIME PUMP — OPERATION MANUAL — REV. #3 (10/06/08)

Page 29

Engine Maintenance

The following engine maintenance guidelines are intended

to assist the operator in preventative maintenance. For a

more detailed maintenance schedule refer to the

Engine Instruction Manual

Changing Engine Oil

Change engine oil after first 20 hours of operation. Drain and

refill engine crankcase with the correct type and amount oil

(reference Table 5) after 250 hours of operation hours or once

a week thereafter.

When draining engine crankcase oil, place oil into a suitable

container while engine is still warm. Replace the drain plug

tightly. Add oil through the filler hole.

supplied with the pump.

Deutz

NOTE

MAINTENANCE (ENGINE)

Figure 14. In-Line Fuel Filter

When reinstalling fuel filters,

please note the arrows indicating

direction of fuel flow

the

.

Changing Oil Filter

Change the Deutz engine oil filter (Figure 13) after 250 hours

of operation.

Figure 13. Oil Filter Element

Fuel Filter System

The Deutz engine fuel system incorporates four different

types of fuel filters, in-line, easy change, IMSA, and a fuel

water separator.

In-line Fuel Filter

Replace the in-line fuel filter (Figure 14) every 500 hours. If

the purity of the fuel being used is of lesser quality replace

the in-line fuel filter more often as needed.

Easy-Change Fuel Filter

Replace the easy change fuel filter (Figure 15) every 500

hours.

Cleaning the IMSA Fuel Filter

1. Close the fuel shut-off valve and loosen the retaining on

the IMSA fuel filter (Figure 16).

2. Remove the cover and the fuel strainer.

3. Clean the fuel strainer with diesel fuel. Replace fuel

strainer if necessary.

4. Reassemble IMSA fuel filter.

5. Bleed fuel system and check for fuel leaks.

Figure 15. Easy-Change Fuel Filter

DRY PRIME PUMP — OPERATION AND PARTS MANUAL — REV. #3 (10/06/08) — PAGE 29

Page 30

MAINTENANCE (ENGINE)

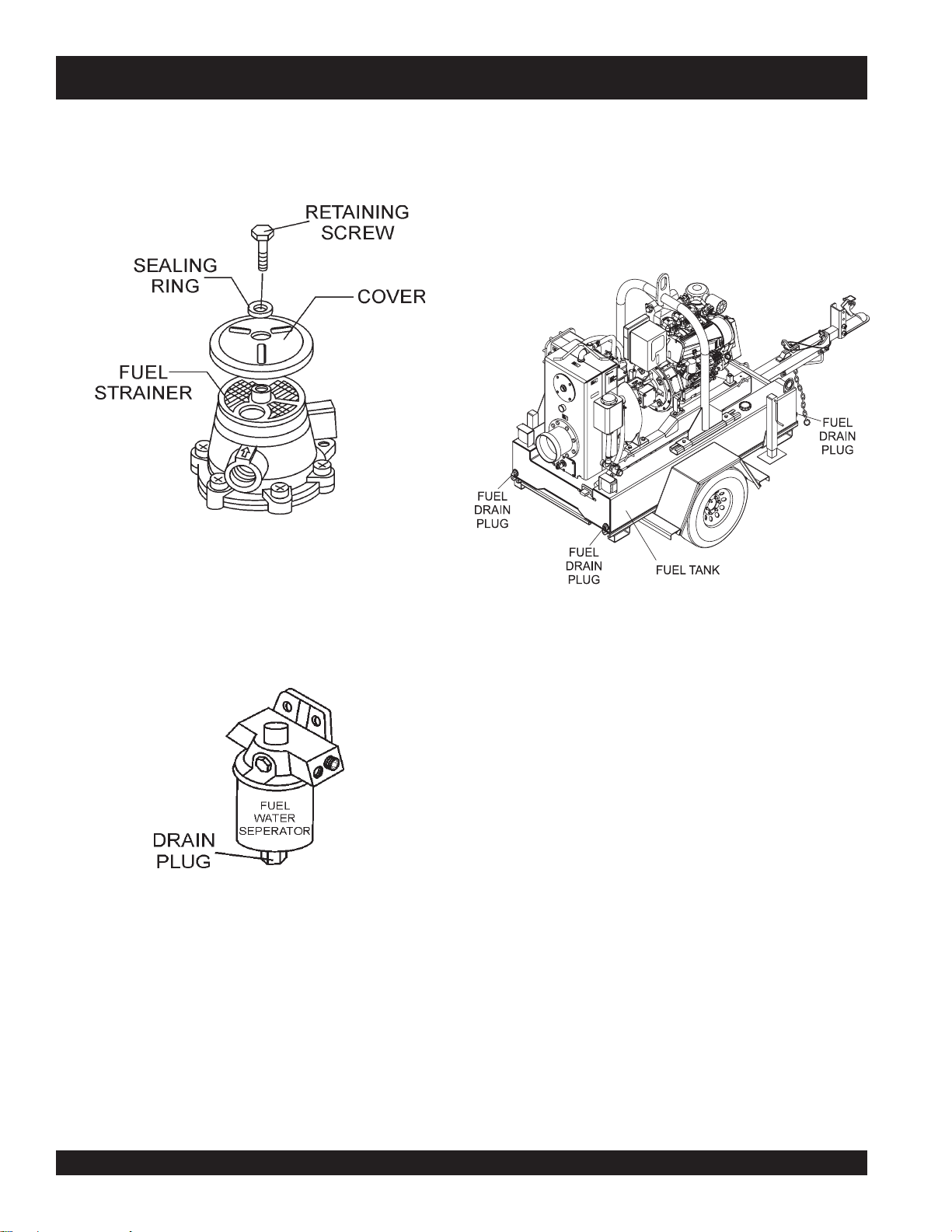

IMSA Fuel Filter

Inspect and clean (replace if necessary) the IMSA fuel filter

(Figure 16) every 500 hours. This filter is part of the fuel

pump.

Figure 16. IMSA Fuel Filter

Fuel Tank

Unscrew the fuel drain plug on the fuel tank (Figure 18) to

remove water and sediment every 500 hours. If the purity of

the fuel being used is of lesser quality drain the fuel tank

more frequently.

Fuel Water Separator Filter

1. Inspect the fuel water separator (Figure 17) every 40

hours. If the fuel water separator requires maintenance

follow steps 2 and 3 below:

Figure 17. Fuel Water separator Filter

2. Open the drain plug on the fuel water separator (Figure

18) to remove any sediment or water that may have

accumulated in the fuel water separator reservoir.

3. After water and sediment and foreign debris has been

drained from the fuel water separator, reinstall the drain

plug on fuel water separator.

Figure 18. Fuel Tank/Drain Plug

PAGE 30 —DRY PRIME PUMP — OPERATION MANUAL — REV. #3 (10/06/08)

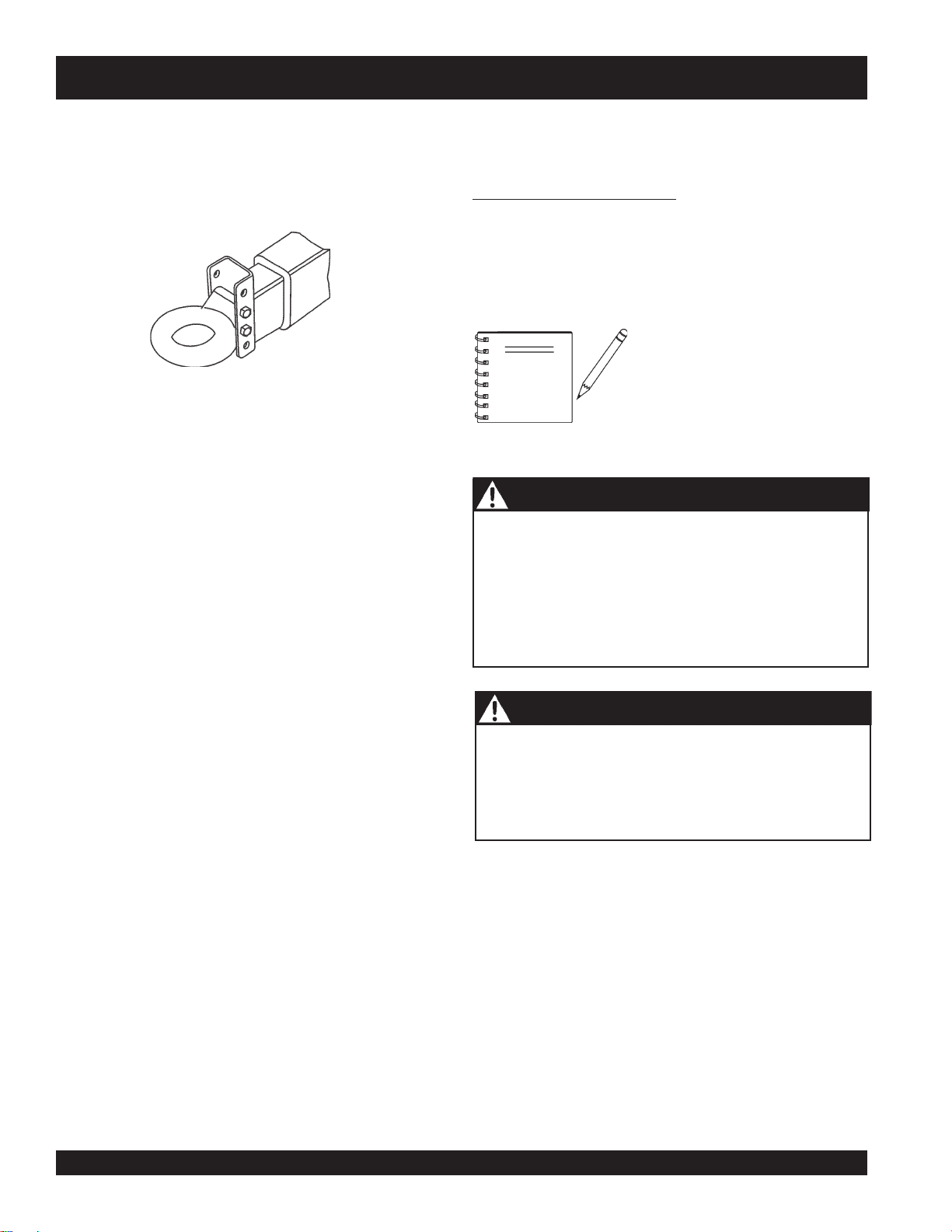

Page 31

MAINTENANCE (TRAILER)

The following trailer maintenance guidelines are intended to

assist the operator in preventative maintenance.

Trailer Brakes

Properly functioning brake shoes and drums are essential to

ensure safety. The brakes should be inspected the first 200

miles of operation. This will allow the brake shoes and drums

to seat properly. After the first 200 mile interval, inspect the

brakes every 3,000 miles. If driving over rough terrain, inspect the brakes more frequently.

Surge Brakes

If your trailer has surge-operated brakes, they

function the same way the surge brakes do on your tow

vehicle. The surge braking system must be inspected at

least as often as the brakes on the tow vehicle, but no less

than once per year. This inspection includes an

assessment of the condition and proper operation of the wheel

cylinders, brake shoes, brake drums and hubs.

Manually Adjusting the Brakes

Most axles are fitted with a brake mechanism that will

adjust the brakes during a hard stop. However, some

braking systems are not automatically adjusted by hard

stopping. These brakes require manual adjustment. The

following steps apply to adjust most manually adjustable

brakes.

1. Jack up the trailer and secure it on adequate capacity

jack stands.

2. Be sure the wheel and brake drum rotate freely.

3. Remove the adjusting-hole cover from the adjusting slot

on the bottom of the brake backing plate.

4. With a screwdriver or standard adjusting tool, rotate the

starwheel of the adjuster assembly to expand the brake

shoes. Adjust the brake shoes out until the pressure of

the linings against the drum makes the wheel very

difficult to turn. Note: Your trailer maybe equipped with

drop spindle axles. See axle manual for your axle type.

You will need a modified adjusting tool for adjusting the

brakes in these axles. With drop spindle axles, a

modified adjusting tool with about an 80 degree angle

should be used.

5. Rotate the starwheel in the opposite direction until the

wheel turns freely with a slight drag.

6. Replace the adjusting-hole cover.

7. Repeat the above procedure on all brakes.

8. Lower the trailer to the ground.

You must check the fluid level in the master cylinder

reservoir at least every three months. If you tow your trailer

an average of 1,000 miles per month in a hot and dry

environment, you must check the brake fluid level once a

month. The brake fluid reservoir is located on the tongue of

the trailer. Always fill with clean, uncontaminated DOT 4

brake fluid.

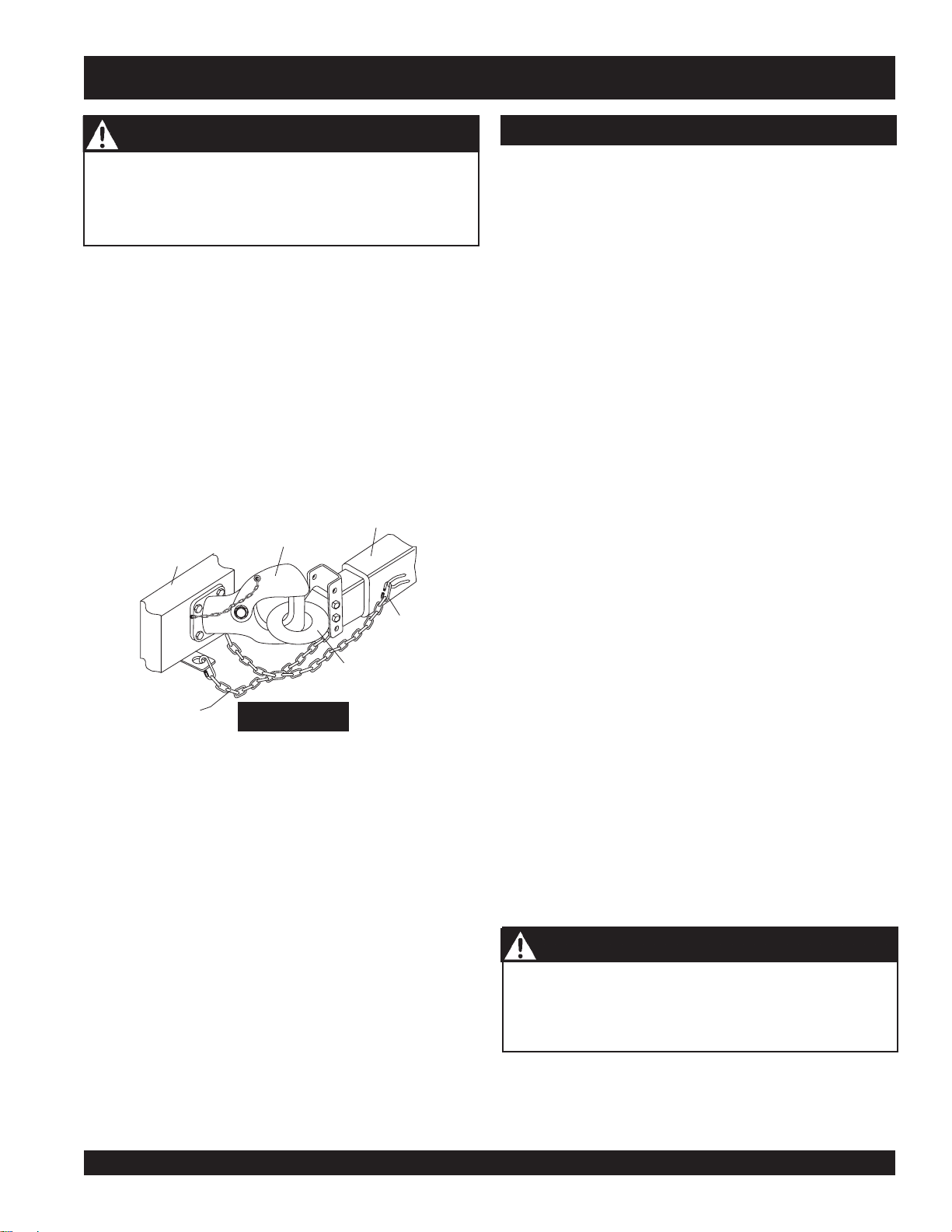

Figure 19 below displays the major air/surge brake components that will require inspection and maintenance. Please

inspect these components as required using steps 1 through

6 as referenced in the “Manually Adjusting The Brakes” section on this page. See Table 11 Surge Brake Troubleshooting.

Electric Brakes

Electrically actuated brakes (Figure 20) are similar to

surge brakes. The basic difference is that surge brakes are

actuated by an electromagnet. Listed below are some of

the advantages that electric brakes have over

surge brakes:

Brake system can be manually adjusted to provide the

corrected braking capability for varying road and load

conditions.

Brake system can be modulated to provide more or

less braking force, thus easing the brake load on the

towing vehicle.

Brake system has very little lag time between the time

the vehicle’s brakes are actuated and the trailer’s brakes

are actuated.

Brake system can provide an independent emergency

brake system.

Figure 19. Surge Brake Components

DRY PRIME PUMP — OPERATION AND PARTS MANUAL — REV. #3 (10/06/08) — PAGE 31

Page 32

MAINTENANCE (TRAILER)

Remember in order to properly synchronize the tow vehicle’s

WARNING - Breakaway Brake System

braking to the trailer’s braking, can only be accomplished by

road testing. Brake lockup, grabbiness or harshness is due

to lack of synchronization between the tow vehicle and the

trailer being towed or under-adjusted brakes.

If electric breakaway brakes do not operate when trailer is uncoupled

from the tow vehicle, death or serious injury can occur.

Check emergency breakaway brake system BEFORE each tow.

Before any brake synchronizations adjustments can be

made, the trailer brakes should be burnished-in by applying

the brakes 20-30 times with approximately a 20 m.p.h. decrease in speed, e.g. 40 m.p.h. to 20 m.p.h. Allow ample

time for brakes to cool between application. This allows the

brake shoes to slightly be seated into the brake drum sur-

NOTE

face.

Figure 20 displays the major electric brake components that

will require inspection and maintenance. Please inspect

these components as required. See Table 12 Electric Brake

Troubleshooting.

and follow the axle/brake and the brake controller

manufacturers’ instructions. To make certain an electricallyoperatedbraking system will function properly, you must have

your dealer inspect the magnets at least once a year, or

each 12,000 miles. See the brake manual for wear and current inspection instructions.

The electric brakes that operate in

conjunction with the tow vehicle

brakes must be

“synchronized”

so that braking is properly distributed to the tow vehicle brakes and

the trailer brakes. For proper operation and synchronization, read

Hydraulic Brack Actuator

The the surge brake actuator (Figure 21) is the mechanism

that activates the trailer’s brake system. This actuator

changes fluid power into mechanical power. Therefore, the

fluid level must be checked frequently to assure that the

brakes function properly.

Figure 20. Electrical Brake Components

Breakaway Battery

This battery supplies the power to operate the trailer brakes

if the trailer uncouples from the tow vehicle. Be sure to

check, maintain and replace the battery according to the

battery manufacturer’ instructions.

Breakaway Switch

This switch causes the breakaway battery to operate the

electric brakes if the trailer uncouples from the tow vehicle.

The pull cable for the pull pin is connected to the tow

vehicle, and the switch is connected to the trailer. To check

for proper functioning of the switch, battery and brakes, you

WARNING - Actuator Fluid Level

must pull the pin from the switch and confirm that the brakes

apply to each wheel. You can do this by trying to pull the

trailer with the tow vehicle, after pulling the pin. The trailer

Failure to maintain proper fluid level in the actuator may

result in loss of braking action which could cause severe

property damage, injury or death.

brakes may not lock, but you will notice that a greater force

is needed to pull the trailer.

HYDRAULIC

BRAKE FLUID

RESERVOIR

Figure 21. Trailer Actuator

PAGE 32 —DRY PRIME PUMP — OPERATION MANUAL — REV. #3 (10/06/08)

Page 33

MAINTENANCE (TRAILER)

Periodically check the actuator mounting fasteners for

damage or loosening. Inspect the actuator for worn or damaged parts. As you are towing your trailer, be aware of any

changes in braking quality. This could be an early warning of

brake or actuator malfunction and requires immediate

attention. Consult a certified brake specialist to make

DANGER - Wheel Bearings

If trailer wheels are under water for a long period of time,

wheel bearings may fail. If this is the case, service wheel

bearings immediately.

The possibility exists of the wheels falling off, causing

equipment damage and severe bodily harm even death!

necessary adjustment or repairs.

Replace bearings that have flat spots on rollers, broken

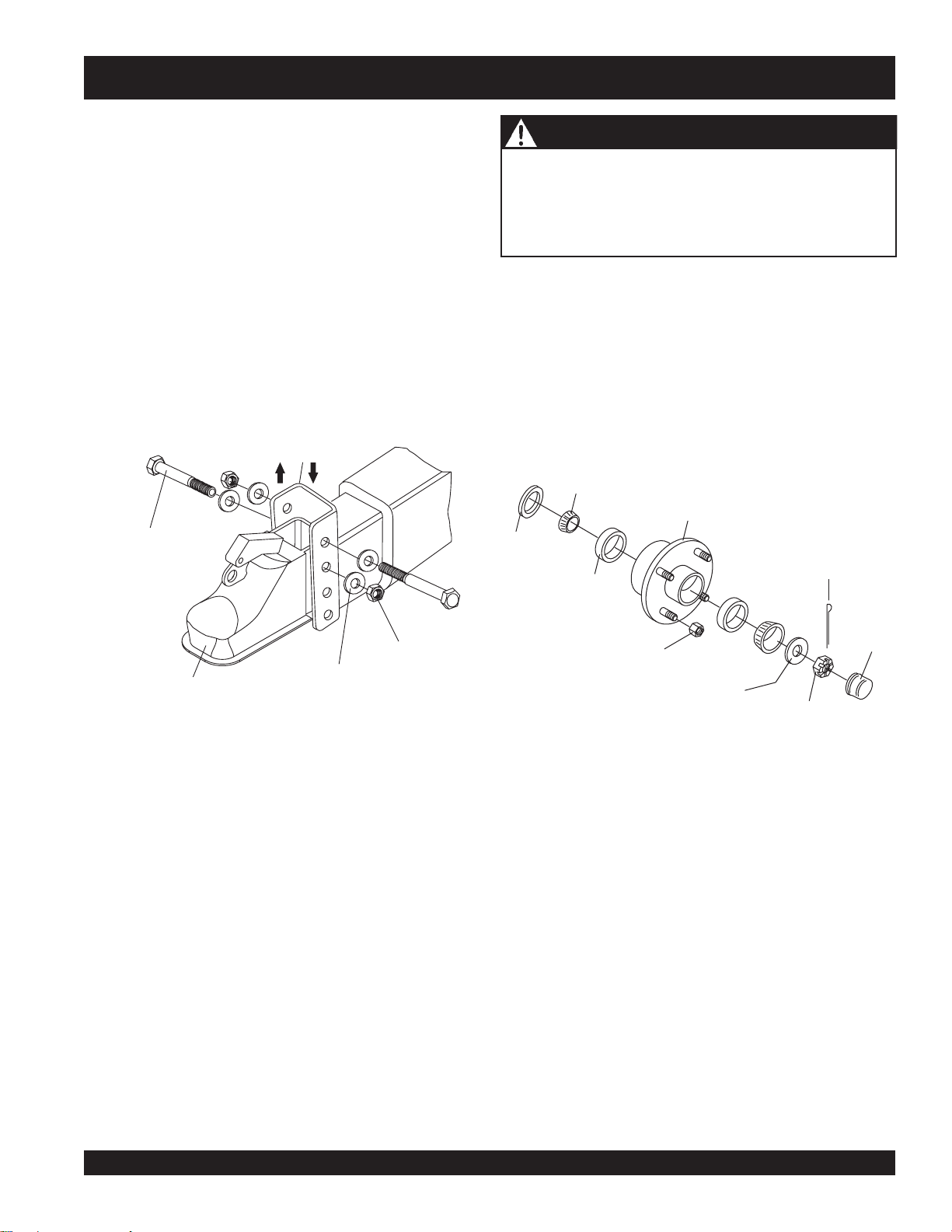

Adjustable Channel

Your trailer may be equipped with an adjustable channel (Figure 22) that allows the coupler to be raise or lowered to a

desired height. Periodically check the channel bolts for dam-

roller cages, rust or pitting. Always replace bearings

and cups in sets. The inner and outer bearings are to be

replaced at the same time.

Replace seals that have nicks, tears or wear.

age or loosening.

Lubricate the bearings with a high quality EP-2

ADJUSTABLE

CHANNEL

5/8”X11”X5”

BOLT

automotive wheel bearing grease.

BEARING

OIL

SEAL

CONE

BEARING

CUP

WHEEL

HUB

COTTER

PIN

5/8”

5/8” FLAT

2-5/16” BALL

COUPLER

WASHER

Figure 22. Adjustable Channel

With Pintle Eye Coupler

Wheel Bearings (Hubs)

Wheeel bearings (Figure 23) must beinspected and lubricated once a year or 12,000 miles toinsure safe operation of

your trailer.

If a trailer wheel bearing is immersed in water, it must be

NYLOC

NUT

Figure 23. Wheel Hub Components

Wheel Hub Adjustment

Every time the wheel hub is removed and the bearings are

reassembled, follow the steps below to check the wheel

bearings for free running and adjust.

Turn the hub slowly, by hand, while tightening the spindle

nut, until you can no longer turn the hub by hand.

replaced.

If the pump/trailer has not been used for an extended amount

of time, have the bearings inspected and packed more

Loosen the spindle nut just until you are able to turn it

(the spindle nut) by hand. Do not turn the hub while the

spindle nut is loose.

frequently, at least every six months and prior to use.

Follow the steps below to disassemble and service the

wheel bearings.

After removing the dust cap, cotter pin, spindle nut

and spindle washer, remove the hub and drum to

Install a new cotter pin through the spindle nut and axle.

Check the adjustments. Both the hub and the spindle

nut should be able to move freely (the spindle nut

motion will be limited by the cotter pin).

inspect the bearings for wear and damage.

LUG

NUT

SPINDLE

WASHER

DUST

CAP

CASTLE

NUT

DRY PRIME PUMP — OPERATION AND PARTS MANUAL — REV. #3 (10/06/08) — PAGE 33

Page 34

TRAILER MAINTENANCE

Danger - Raising the Trailer

NEVER! crawl under the trailer unless it is on firm and

level ground and resting on properly placed and secured

jack stands.

The possibility exists of the trailer falling thus causing

equipment damage and severe bodily harm even death!

DANGER - Trailer Inspection

When performing trailer inspection and maintenance activities, you must jack up the trailer using jacks and jack

stands.

When jacking and using jack stands, place them so as

to clear wiring, brake lines, and suspension parts

(i.e.,springs,torsion bars). Place jacks and jack stands

inside of the perimeter strip on the supporting structure

to which the axles are attached.

Torsion Suspension

The mounting bracket (Figure 24) of the torsion suspension

assembly is bolted directly to the trailer frame. Except for

periodic inspection of the bracket’s fasteners to the trailer

frame, no other suspension maintenance is required on the

axles.

5/8”-18 X 2”

MOUNTING

BOLT

MOUNTING

BRACKET

SPINDLE

TORSION

ARM

TORSION

BAR

5/8”-18

NYLOC NUT

GRADE C

Figure 24. Torsion Suspension

AXLE

TUBE

WARNING - Trailer Impact

If the trailer is involved in an accident have it inspected

immediately by qualified personnel. In addition, the trailer

should be inspected annually for signs of wear or

deformations.

WARNING - Cracked or Broken Welds

Improper weld repair will lead to early failure of the trailer

structure and can cause serious injury or death.

DO NOT repair cracked or broken welds unless you have

a

certified welder

welds repaired by your dealer.

perform the repair. If not, have the

Danger - Trailer Welds

Broken or damaged welds can cause injury or severe

damage to your trailer and contents. Inspect all of the

welds for cracks or failure at least twice a year.

Danger - Worn or Defective Suspension

Worn or broken suspension parts can cause loss of

control, damage to equipment and severe bodily injury

even

death!

Check suspension regularly.

PAGE 34 —DRY PRIME PUMP — OPERATION MANUAL — REV. #3 (10/06/08)

Page 35

TRAILER SAFETY GUIDELINES

■

TRAILER SAFETY INFORMATION

Safety precautions should be followed at all times when

operating this equipment. Failure to read, understand and

follow the Operating Instructions could result in injury to

yourself and others. Loss of control of the trailer or tow vehicle can result in death or serious injury.

Common Causes for Loss of Trailer

■

Driving too fast for the conditions (maximum speed

when towing a trailer is 60 m.p.h.).

■

Overloading the trailer or loading the trailer unevenly

■

Trailer improperly coupled to the hitch

■

No braking on trailer

■

Not maintaining proper tire pressure

■

Not keeping lug nuts tight

■

Not properly maintaining the trailer structure.

Trailer Towing Guidelines

■

Recheck the load tiedowns to make sure the load will

not shift during towing.

■

Before towing, check coupling, safety chain, safety

brake, tires, wheels and lights.

■

Check the lug nuts or bolts for tightness.

■

Check coupler tightness after towing 50 miles.

■

Adjust the brake controller to engage the trailer brakes

before the tow vehicle brakes. Your dealer can assist

you by making this adjustment.

■

Use your mirrors to verify that you have room to change

lanes or pull into traffic.

■

Use your turn signals well in advance. Allow plenty of

stopping space for your trailer and tow vehicle.

■

Allow plenty of stopping space for your trailer and tow

vehicle.

ALWAYS use lower gears for climbing and descending

grades.

■

DO NOT ride the brakes while descending grades, they

may get so hot that they stop working. Then you will

potentially have a runaway tow vehicle and trailer.

■

To conserve fuel, don’t use full throttle to climb a hill.

instead, build speed on the approach.

■

Slow down for bumps in the road. Take your foot off the

brake when crossing the bump.

■

DO NOT brake while in a curve unless absolutely necessary.

Instead, slow down before you enter the curve

and power through the curve. This way, the towing vehicle

remains in charge.

■

DO NOT apply the brakes to correct extreme trailer swaying.

Continued pulling of the trailer, and even slight

acceleration, will provide a stabilizing force.

■

Anticipate the trailer “swaying.” Swaying is the trailer

reaction to the air pressure wave caused by passing

trucks and busses. Continued pulling of the trailer

provides a stabilizing force to correct swaying. DO NOT

apply the brakes to correct trailer swaying.

■

Use lower gear when driving down steep or long grades.

Use the engine and transmission as a brake. Do not

ride the brakes, as they can overheat and become

ineffective.

■

Be aware of your trailer height, especially when

approaching roofed areas and around trees.

■

Make regular stops, about once each hour. Confirm that:

A. Coupler is secure to the hitch and is locked.

B. Electrical connectors are made.

C. There is appropriate slack in the safety chains.

D. There is appropriate slack in the breakaway

E. Tires are not visibly low on pressure

switch pullpin cable.

■

DO NOT drive so fast that the trailer begins to sway due

to speed.

■

Allow plenty of room for passing. A rule of thumb is that

the passing distance with a trailer is 4 times the passing

distance without the trailer.

■

Shift your automatic transmission into a lower gear for

city driving.

DRY PRIME PUMP — OPERATION AND PARTS MANUAL — REV. #3 (10/06/08) — PAGE 35

WARNING - Drive Safely

Driving too fast for severe road conditions can

result in loss of control and cause death or serious

injury.

Decrease your speed as road, weather and lighting

conditions deteriorate.

ALWAYS check for local trailer-tow speed limits in

your area.

Page 36

TRAILER SAFETY GUIDELINES

CAUTION - Lcal Towing Regulations

Check with your county or state safety towing

pump

regulations department before towing your

.