Page 1

OPERATION AND PARTS MANUAL

Reversible Plate

Compactor

Model

MVH-702DRSC

© COPYRIGHT 2003, MULTIQUIP INC.

Revision #1 (12/17/03)

MULTIQUIP INC

18910 WILMINGTON AVE. 800-427-1244

CARSON, CALIFORNIA 90746 FAX: 800-672-7877

310-537-3700

800-421-1244 800-478-1244

FAX: 310-537-3927 FAX: 310-631-5032

E-mail:mq@multiquip.com • www:multiquip.com

Atlanta • Boise • Dallas • Houston • Newark

Montreal, Canada • Manchester, UK

Rio De Janiero, Brazil • Guadalajara, Mexico

..

. PARTS DEPARTMENT:

..

SERVICE DEPARTMENT/TECHNICAL ASSISTANCE:

Page 2

PAGE 2 — MQ-MIKASA MVH-702DRSC COMPACTOR — PARTS & OPERATION MANUAL — REV. #1 (12/17/03)

Page 3

HERE'S HOW TO GET HELP

PLEASE HAVE THE MODEL AND SERIAL

NUMBER

MULTIQUIP’S MAIN PHONE NUMBERS

800-421-1244 FAX: 310-537-3927

310-537-3700

PARTS DEPARTMENT

800-427-1244 FAX: 800-672-7877

310-537-3700 FAX: 310-637-3284

MAYCO PARTS

800-306-2926 FAX: 800-672-7877

310-537-3700 FAX: 310-637-3284

SERVICE DEPARTMENT

800-478-1244 FAX: 310-537-4259

310-537-3700

MQ POWER SERVICE DEPARTMENT

800-835-2551 FAX: 310-638-8046

ON-HAND

WHEN CALLING

310-537-3700

TECHNICAL ASSISTANCE

800-478-1244 FAX: 310-631-5032

WARRANTY DEPARTMENT

800-421-1244, EXT. 279 FAX: 310-537-1173

310-537-3700, EXT. 279

MQ-MIKASA MVH-702DRSC COMPACTOR — PARTS & OPERATION MANUAL — REV. #1 (12/17/03) — PAGE 3

Page 4

TABLE OF CONTENTS

MQ MIKASA MVH-702DRSCREVERSIBLE PLATE

COMPACTOR

Proposition 65 Warning ..............................................2

Here's How To Get Help .............................................3

Table Of Contents ......................................................4

Parts Ordering Procedures ........................................ 5

Safety Message Alert Symbols .............................. 6-7

Rules for Safe Operation ....................................... 8-9

Operation and Safety Decals ............................. 10-11

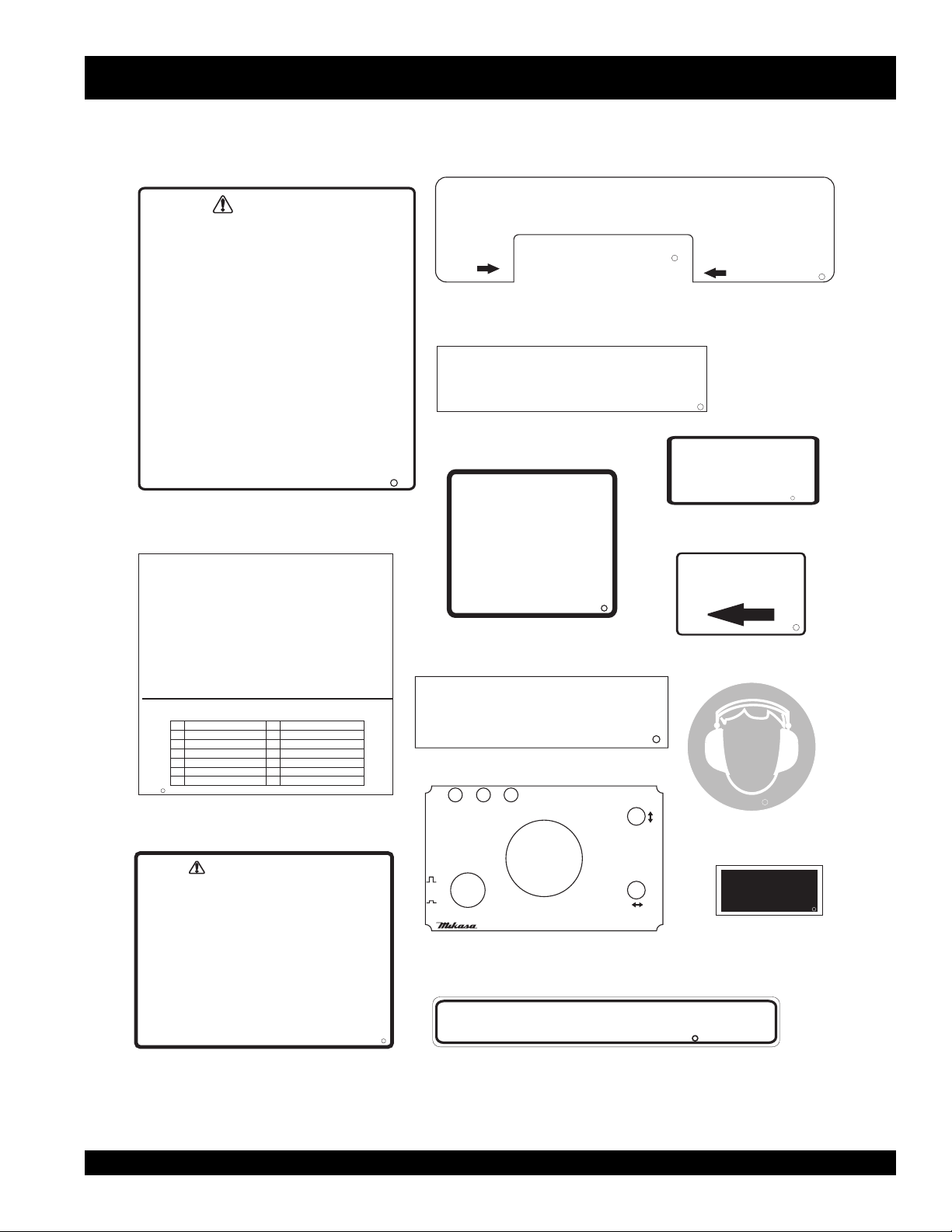

Dimensions and Specifications ................................12

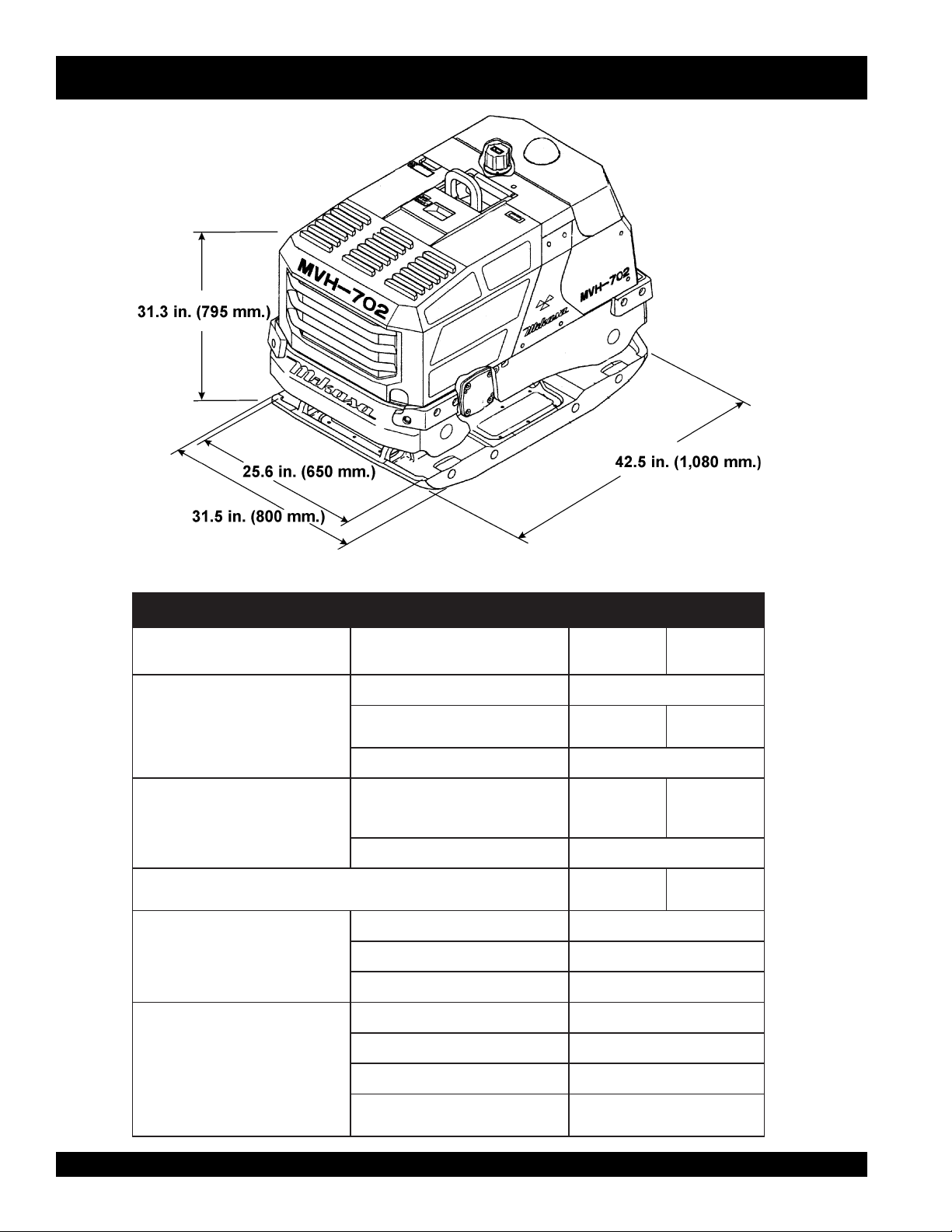

Features ................................................................... 13

Compactor Components .................................... 14-15

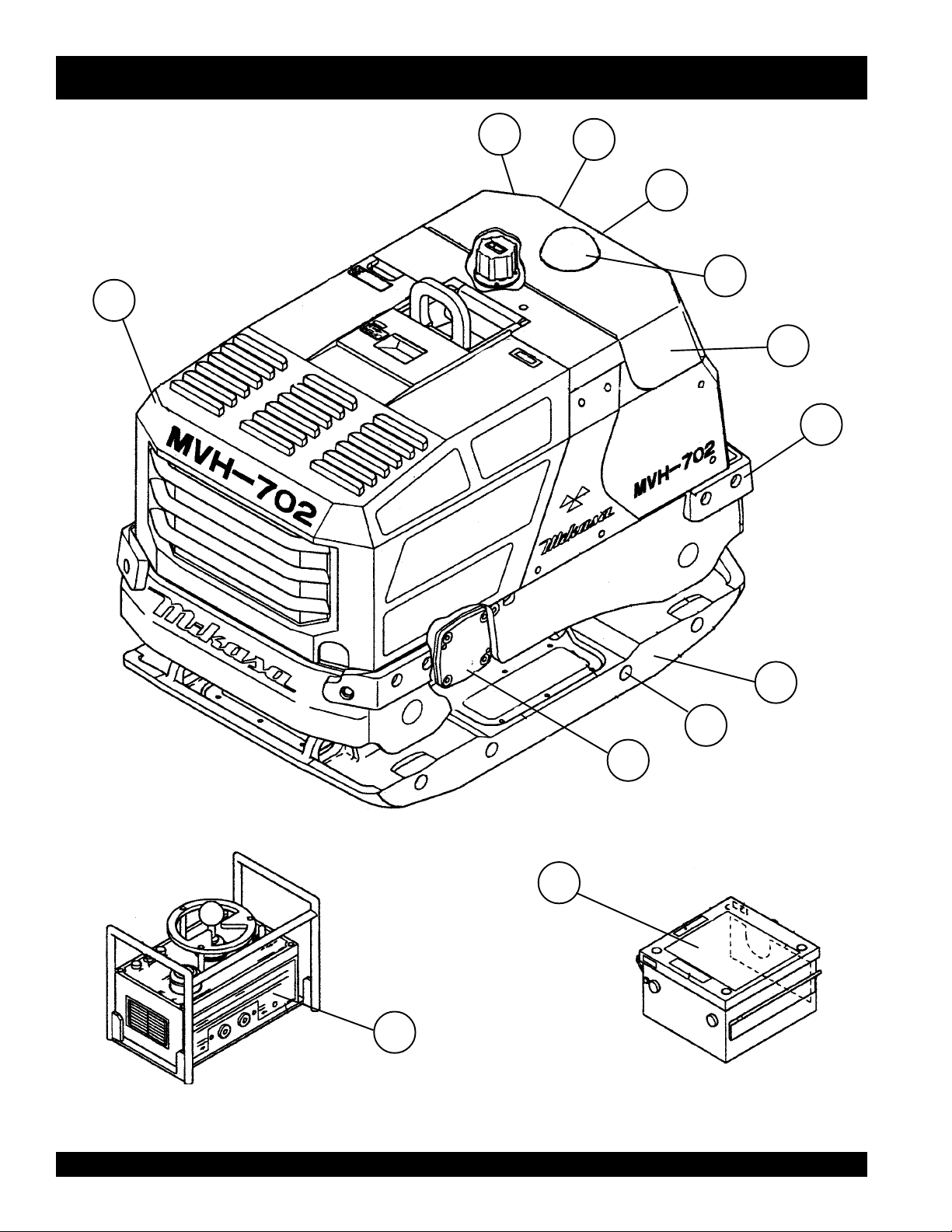

Remote Control Components (Body) ................ 16-17

Remote Control Components (Transmitter) ....... 18-19

Before Start-up ........................................................20

Battery Charging ...................................................... 21

Operation ........................................................... 22-23

Loading and Unloading ............................................24

Maintenance ............................................................ 25

Troubleshooting ................................................. 26-29

Block Diagram ..........................................................30

Reciever Wiring Diagram ......................................... 31

Valve Control Diagram .............................................32

Explanation Of Code In Remarks Column ...............34

Suggested Spare Parts ............................................35

PARTS ILLUSTRATIONS

Nameplate and Decals....................................... 36-37

Vibrating Plate Assembly .................................. 38-39

Vibrator Assembly .............................................. 40-41

Cover Assembly ................................................. 42-45

Engine Assembly ............................................... 46-47

Hydraulic System Assembly ............................... 48-51

Electric Device.................................................... 52-55

Terms and Conditions Of Sale — Parts ...................56

Specification and part

NOTE

number are subject to

change without notice.

PAGE 4 — MQ-MIKASA MVH-702DRSC COMPACTOR — PARTS & OPERATION MANUAL — REV. #1 (12/17/03)

Page 5

PARTS ORDERING PROCEDURES

When ordering parts,

please supply the following information:

❒❒

❒ Dealer account number

❒❒

❒❒

❒ Dealer name and address

❒❒

❒❒

❒ Shipping address (if different than billing address)

❒❒

❒❒

❒ Return fax number

❒❒

❒❒

❒ Applicable model number

❒❒

❒❒

❒ Quantity, part number and description of each part

❒❒

❒❒

❒ Specify preferred method of shipment:

❒❒

✓ FedEx or UPS Ground

✓ FedEx or UPS Second Day or Third Day

✓ FedEx or UPS Next Day

✓ Federal Express Priority One

✓ DHL

✓ Tr u ck

Note: Unless otherwise indicated by customer, all

orders are treated as “Standard Orders”, and will

ship within 24 hours. We will make every effort to

ship “Air Shipments” the same day that the order is

received, if prior to 2PM west coast time. “Stock

Orders” must be so noted on fax or web forms.

Here’s how to get help...

Please have the model and serial number on

hand when calling.

Parts Department

800-427-1244 Fax: 800-672-7877

310-537-3700 Fax: 310-637-3284

Mayco Parts

800-306-2926 Fax: 800-672-7877

310-537-3700 Fax: 310-637-3284

Service Department

800-478-1244 Fax: 310-537-4259

310-537-3700

MQ Power Service Department

800-835-2551 Fax: 310-638-8046

310-537-3700

Technical Assistance

800-478-1244 Fax: 310-631-5032

Warranty Department

800-421-1244, Ext. 279 Fax: 310-537-1173

310-537-3700, Ext. 279

Multiquip’s Main Phone Numbers

800-421-1244 Fax: 310-537-3927

310-537-3700

Place Your Parts Order Via Web or Fax

For Even More Savings!

Extra Discounts!

All parts orders which include complete part numbers

and are received by our automated web parts order

system, or by fax qualify for the following extra

discounts:

Ordered Standard Stock orders

via orders ($750 list and above)

Fax 3% 10%

Web 5% 10%

Special freight allowances

when you order 10 or more

line items via Web or Fax!**

FedEx Ground Service

No other allowances on freight shipped by any other

carrier.

NOTE: DISCOUNTS ARE SUBJECT TO CHANGE

at no charge for freight

MULTIQUIP INC.

18910 WILMINGTON AVENUE

POST OFFICE BOX 6254

CARSON, CALIFORNIA 90749

310-537-3700 • 800-421-1244

FAX: 310-537-3927

E-MAIL: mq@multiquip.com

WWW: multiquip.com

MQ-MIKASA MVH-702DRSC COMPACTOR — PARTS & OPERATION MANUAL — REV. #1 (12/17/03) — PAGE 5

Direct TOLL-FREE access

to our Parts Department:

Toll-free nationwide — 800-427-1244

Page 6

MVH-702DRSC — SAFETY MESSAGE ALERT SYMBOLS

FOR YOUR SAFETY AND THE SAFETY OF OTHERS!

Safety precautions should be followed at all times when

operating this equipment. Failure to read and understand the

Safety Messages and Operating Instructions could result in

injury to yourself and others.

This Owner's Manual has been

developed to provide complete

NOTE

for data relative to its safe operation.

Before using this compactor, ensure that the operating

individual has read and understands all instructions in this

manual.

instructions for the safe and

efficient operation of the Multiquip

Model MVH-702DRSC Reversible

Plate Compactor. Refer to the

engine manufacturer’s instructions

HAZARD SYMBOLS

SAFETY MESSAGE ALERT SYMBOLS

The three (3) Safety Messages shown below will inform you

about potential hazards that could injure you or others. The

Safety Messages specifically address the level of exposure to

the operator, and are preceded by one of three words: DANGER,

WARNING, or CAUTION.

Lethal Exhaust Gases

Engine exhaust gases contain poisonous

carbon monoxide. This gas is colorless and

odorless, and can cause death if inhaled.

NEVER operate this equipment in a confined

area or enclosed structure that does not

provide ample free flow air.

Explosive Fuel

GASOLINE is extremely flammable, and its

vapors can cause an explosion if ignited. DO

NOT start the engine near spilled fuel or

combustible fluids. DO NOT fill the fuel tank

while the engine is running or hot. DO NOT

overfill tank, since spilled fuel could ignite if it

comes into contact with hot engine parts or

sparks from the ignition system. Store fuel in

approved containers, in well-ventilated areas

and away from sparks and flames. NEVER

use fuel as a cleaning agent.

DANGER: You WILL be KILLED or

SERIOUSLY injured if you do not follow

directions.

WARNING: You CAN be KILLED or

SERIOUSLY injured if you do not follow

directions.

CAUTION: You CAN be injured if you

do not follow directions.

Potential hazards associated with this compactor operation will

be referenced with Hazard Symbols which appear throughout

this manual, and will be referenced in conjunction with Safety

Message Alert Symbols.

Burn Hazards

Engine components can generate extreme heat.

To prevent burns, DO NOT touch these areas

while the engine is running or immediately after

operations. Never operate the engine with heat

shields or heat guards removed.

Rotating Parts

NEVER operate equipment with covers, or

guards removed. Keep fingers, hands, hair and

clothing away from all moving parts to prevent

injury.

PAGE 6 — MQ-MIKASA MVH-702DRSC COMPACTOR — PARTS & OPERATION MANUAL — REV. #1 (12/17/03)

Page 7

MVH-702DRSC — SAFETY MESSAGE ALERT SYMBOLS

Accidental Starting

ALWAYS place the engine ON/OFF switch in

the OFF position, when the compactor is not

in use.

Sight and Hearing hazard

ALWAYS wear approved eye and hearing

protection.

Respiratory Hazard

ALWAYS wear approved respiratory

protection.

Equipment Damage Messages

Other important messages are provided throughout this manual

to help prevent damage to your compactor, other property, or

the surrounding environment.

This compactor, other property, or

NOTE

the surrounding environment could

be damaged if you do not follow

instructions.

MQ-MIKASA MVH-702DRSC COMPACTOR — PARTS & OPERATION MANUAL — REV. #1 (12/17/03) — PAGE 7

Page 8

MVH-702DRSC — RULES FOR SAFE OPERATION

CAUTION:

Failure to follow instructions in this manual may

lead to serious injury or even death! This

equipment is to be operated by trained and

qualified personnel only! This equipment is for

industrial use only.

The following safety guidelines should always be used when

operating the MIKASA MVH-702DRSC Reversible Plate

Compactor:

GENERAL SAFETY

■

DO NOT operate or service this equipment before

reading this entire manual.

■

This equipment should not be operated by

persons under 18 years of age.

■

NEVER operate this equipment without proper

protective clothing, shatterproof glasses, steeltoed boots and other protective devices required

by the job. ALWAYS wear slip resistant safety

shoes or boots.

■

NEVER operate this equipment when not feeling

well due to fatigue, illness or taking medicine.

■

NEVER operate this equipment under the

influence or drugs or alcohol.

■

NEVER use accessories or attachments, which are not

recommended by Multiquip for this equipment. Damage to

the equipment and/or injury to user may result.

■

Manufacturer does not assume responsibility for any accident

due to equipment modifications.

■

Whenever necessary, replace nameplate, operation and

safety decals when they become difficult read.

■

ALWAYS wear proper respiratory (mask), hearing and eye

protection equipment when operating the compactor.

■

NEVER touch the hot exhaust manifold,

muffler or cylinder. Allow these parts to

cool before servicing engine or

■

High Temperatures – Allow the engine to cool before adding

fuel or performing service and maintenance functions. Contact

hot

with

■

The engine of this compactor requires an adequate free flow

of cooling air. NEVER operate the compactor in any enclosed

■

ALWAYS refuel in a well-ventilated area, away from sparks

and open flames.

■

ALWAYS use extreme caution when working with flammable

liquids. When refueling, stop the engine and allow it to cool.

DO NOT

could result from fuel vapors, or if fuel is spilled on a hot engine.

■

NEVER operate the compactor in an

explosive atmosphere or near

combustible materials. An explosion or

fire could result causing severe

harm or even death.

■

Topping-off to filler port is dangerous, as it tends to

spill fuel.

■ALWAYS stored the compactor in a clean, dry location out of

the reach of children.

components can cause serious burns.

or narrow area where free

flow of the air is restricted. If

the air flow is restricted it will

cause serious damage to

the compactor or engine

and may cause injury to

people and property.

Remember the

compactor's engine gives off

DEADLY gases.

smoke around or near the machine. Fire or explosion

bodily

■

NEVER Run engine without air cleaner. Severe engine

damage may occur.

■

NEVER leave the compactor unattended, turn off engine.

■

CAUTION must always be observed while servicing this

compactor. Rotating parts can cause injury if contacted.

■

DO NOT leave compactor with engine running. Use chock

blocks if parking

PAGE 8 — MQ-MIKASA MVH-702DRSC COMPACTOR — PARTS & OPERATION MANUAL — REV. #1 (12/17/03)

compactor on a grade.

Page 9

MVH-702DRSC — RULES FOR SAFE OPERATION

■

ALWAYS use extreme care when operating near obstructions,

on slippery surfaces, grades and side slopes.

■

When reversing, particularly on the edges and banks of

ditches, as well as in front of obstacles, the operator must

stay in a standing position at a safe distance from the machine.

■

When operating near any house/building or pipelines, always

check the effect of machine vibration. Stop the work if

necessary.

■

Unauthorized equipment modifications will void all

warranties.

■

Refer to the

questions or information.

■

DO NOT operate the compactor with the front or rear cover

open.

■

Replace any worn or damaged compactor components

immediately.

■

ALWAYS turn the engine

before performing maintenance.

■

ALWAYS make sure compactor is correctly secured to the

trailer. Check all supports attaching the compactor to the trailer

and make sure they are tight.

■

ALWAYS keep the machine away from workers and

obstacles. Also keep the immediate area free of bystanders.

■

ALWAYS check the machine for loosened threads or bolts

before starting.

■

ALWAYS read, understand, and follow procedures in

Operator’s Manual before attempting to operate equipment.

■

ALWAYS be sure the operator is familiar with proper safety

precautions and operations techniques before using

compactor.

■

A copy of this manual shall accompany the compactor at all

times.

■

DO NOT use worn out hoses or couplings; inspect daily.

Engine Owner's Manual

OFF

for engine technical

before performing must be

■

■

Emergencies

■

Maintenance Safety

■

■

■

■

■

■

■

Lifting

■

■

High Temperatures – Always stop engine and allow the

engine to cool before adding fuel, oil or performing service

hot

and maintenance functions. Contact with

cause serious burns.

NEVER disconnect any

These devices are intended for operator safety. Disconnection

of these devices can cause severe injury, bodily harm or even

death! Disconnection of any of these devices will void all

warranties.

ALWAYS know the location of the nearest

and

first aid kit

Also know the phone numbers of the nearest

doctor

and

invaluable in case of an emergency.

NEVER lubricate components or attempt service on a running

machine.

ALWAYS allow the machine a proper amount of time to cool

before servicing.

Keep the machinery in proper running condition.

Fix damage to the machine immediately and always replace

broken parts.

Dispose of hazardous waste properly. Examples of potentially

hazardous waste are used motor oil, fuel and fuel filters.

DO NOT use food or plastic containers to dispose of

hazardous waste.

DO NOT pour waste, oil or fuel directly onto the ground,

down a drain or into any water source.

The compactor has an operating weight of approximately

1600 lbs. (728 Kg). Use lifting equipment capable of lifting

this weight.

Make sure the engine is off before lifting the machine.

. Know the location of the nearest telephone.

fire department

"emergency or safety devices"

. This information will be

components can

.

fire extinguisher

ambulance

,

■

Use reliable cable in lifting the machine.

■

Lift upright with sufficient bearing capacity to prevent machine

from tilting or slipping.

■

When lifting, keep the machine away from workers and

animals.

MQ-MIKASA MVH-702DRSC COMPACTOR — PARTS & OPERATION MANUAL — REV. #1 (12/17/03) — PAGE 9

Page 10

MVH-702DRSC — OPERATION AND SAFETY DECALS

CARSON, CALIF.

FOR EMERGENCY

Pull the knob untill

engine

stops completely

MAIN SWITCH

DANGER

FUEL

WARNING

DUST

WARNING

NOISE

WARNING

DUST

WARNING

NOISE

WARNING

DUST

DANGER

FUEL

DANGER

FUEL

DANGER

FUEL

Operate only in well-

ventilated area

Do not stand next to

machine while lifting

Use caution while

operating

Fire Risk

Wear eye protection

Wear ear protection

Operate only in well-

ventilated area

Do not stand next to

machine while lifting

Use caution while

operating

Shell Tellus Oil

45

P/N: 920109800

P/N: 920109700

P/N: 920108810

P/N: 920209020

P/N: 920100920

P/N: 920108350

P/N: 920101580

P/N: 920109840

P/N: 920109750

P/N: 920109770

P/N: 920109550

Figure 1 displays the operation and safety decals as they appear on the compactor. Should any of these decals become damaged

or unreadable, contact the Multiquip Parts Department for a replacement set.

I.R RECIEVER UNIT

THERMAL SENSOR 1

THERMAL SENSOR 2

FOR EMERGENCY

Pull the knob untill

engine stops completely

CONTROL BOX

HOUR METER

ABNORMAL COMMUNICATIONLAMP

OVERHEATLAMP

ABNORMAL OIL PRESSURE LAMP

REGULATORABNORMALITY LAMP

OPERATION LAMP

LEFT FORWARD SOLENOID

LEFT BACK SOLENOID

RIGHT FORWARD SOLENOID

RIGHT BACK SOLENOID

VIBRATION SOLENOID

OIL PRESSURE SWITCH

MAGNET VALVEOUTPUT

REGULATORABNORMALITY INPUT

STARTEROUTPUT

GND

-

+

BATTERY

H

X

X

X

X

X

LF

LB

RF

RB

VIB

+12V

STARTER

P/N: 920109700

P/N: 920109800

CARSON, CALIF.

HOUR METER

ABNORMAL COMMUNICATIONLAMP

OVERHEATLAMP

ABNORMAL OIL PRESSURE LAMP

REGULATORABNORMALITY LAMP

OPERATION LAMP

LEFT FORWARD SOLENOID

LEFT BACK SOLENOID

RIGHT FORWARD SOLENOID

RIGHT BACK SOLENOID

VIBRATION SOLENOID

MAGNET

VALVE

REGULATOR

GENERATOR

P

OIL PRESSURE

SWITCH

1) Transmitter must be fully charged

before using.

2) Charge Transmitter for initial use

and after prolonged storage.

3) Solar collectors only maintain

battery charge.

4) See Operations Manual for charging

details.

Set Main switch on Control box to

“OFF” position to avoid battery drain

P/N:TBD

CAUTION

STOP

995.133.4

P/N: TBD

J

NPA-951

Shell Tellus Oil

45

NPA-748

P/N: 920108810

CAUTION

ATTENZIONE

ATENÇAÕ

* Read operator’s manual carefully before use.

* Lire le manuel attentivement avant utilisation.

* Bitte lesen Sie vor Inbetriebnahme der Maschine die

Bedienungsanleitung sorgafältig durch.

* Prima dell’ uso leggere attentamente il manuale.

* Lee com atenÇão o manual de instruÇões antes de

usar.

* Leer detenidamente el manual de instrucciones

antes de usar la maquina.

PRECAUCION

P/N: 920108350

NPA-769

J

J

P/N: 920100920

Operate only in well-

ventilated area

Fire Risk

Operate only in well-

ventilated area

P/N: 920109770

PAGE 10 — MQ-MIKASA MVH-702DRSC COMPACTOR — PARTS & OPERATION MANUAL — REV. #1 (12/17/03)

DANGER

FUEL

DANGER

FUEL

DANGER

Do not stand next to

machine while lifting

WARNING

WARNING

DUST

WARNING

Do not stand next to

machine while lifting

P/N: 920209020

FUEL

DUST

DUST

DANGER

FUEL

Use caution while

operating

WARNING

NOISE

WARNING

NOISE

Use caution while

operating

Figure 1a. Operation and Safety Decals

P/N: 920101580

P/N: 920109550

P/N: 920109840

NPA-923

J

MAIN SWITCH

P/N: 920109750

NPA-930

J

Page 11

MVH-702DRSC — OPERATION AND SAFETY DECALS

P/N: 920109710

P/N: 920109780

P/N: 920209250

P/N: 920109730

P/N: 920209080

P/N: 920102710

P/N: 920109720

HYDRAULIC

OIL ONLY

P/N: 920109810

P/N: 920209310

SAE 10W-40

Motor

Oil

P/N: 920209230

P/N: 920203330

P/N: 920109750

Figure 1 displays the operation and safety decals as they appear on the compactor. Should any of these decals become damaged

or unreadable, contact the Multiquip Parts Department for a replacement set.

1. Read owner’s instruction manual before operating or servicing this machine.

CAUTION

2. The machine consists of the engine located in front, and the aluminum hydraulic oil tank in

rear. The operator should stand 7 feet (2m) away from to operate the machine. When

operating the plate while standing in front of the machine please note that the travel controls

will function in the opposite direction.

3. The remote control operation is restricted to a narrower area the further you are from the

machine. The transmitter should be pointed more directly toward the machine.

4. In case for emergency such as the failure of the transmitter, pull Emergency Stop Lever

located on the machine immediately and wait until the engine stops completely.

5.

The remote control operation is not available in the following cases and the vibration stops

automatically in operation.

The case A: Operator stands within approx. 3 feet (1m) distance, to operate machine.

The case B: Operator stands approx. 60 feet (10m) or father from the machine, to operate

[approx. 40 feet (12m) far in the direct rays of the sun]. These distances may vary.

The Case C: Operator stops sending control signals for more than one second.

6. In the case that several machines are operating in the same area, each machine should be

transmitting on a different infra-red channel.

7. A flashing light of the transmitter blinks during normal operation. A voltage drop of the

transmitter battery will cause the flashing light to alternate between on and off.

8. Hang-up the transmitter away from the machine for safety sake.

9. In operation with remote cable, do not pull out the cable strongly or run over it with the

machine.

10. Keep the transmitter away from the machine for safety sake.

11. To avoid excessive dust contamination of air cleaner, water may be used for dust control

in high dust areas.

12. To finish operation, be sure to switch off the main switch on receiver and press the emergency

stop button on transmitter.

13. When storing outside, keep the machine covered from the rain and always keep the

transmitter indoors.

P/N: 920109780

1. Starting engine by electric starter

a. Ensure that the start switch is set at Cell-Start position and move main

switch to “ON” position.

b. Do not run starter longer than 10 seconds to avoid overheating.

c. Warmup the engine without load for 3 to 5 minutes.

2. Manually starting engine

a. Ensure that the start switch is set at Crank-Start position, and move main

switch to “ON” position.

b. Warm up the engine without load for 3 to 5 minutes.

3. Tostop engine

a. Move stop switch to “OFF” position after running at idle for 3 to 5 minutes.

B. If engine does not stop properly, push the throttle lever next to the oil filter

until it comes to a completely stop, which takes approximately 15 seconds.

c. After operation is completed, move both control switches of machine and

controller to the “OFF” position

J

NPA-903

OPERATIONAL CAUTION

No. Contents

MONITOR LAMP LIST

1 LEFT FORWARD

2 LEFT BACK

3 RIGHT FORWARD

4 RIGHT BACK

5START

6 VIBRATION

P/N: 920109710

NPA-919

No. Contents

7STOP

8 RECEPTION

9 CHARGE

10 OIL PRESSURE

11 OVERHEAT

12 SWITCH OFF

1. Operating multiple machines on a jobsite

Each machine has a remote control channel setting, both in the plate and in the transmitter. Toassure proper operation the channel numbers must match

between the machine and the transmitter. When using more than one machine at the same jobsite, each machine and accompanyingtransmitter must be

set a t a different channel number than the other machines but each machine should still match its transmitter.

2. Air Filter service

a. If air cleaner element is clogged, the over-heat lamp will come on.

b. Clean up or replace the cleaner element immediately.Otherwise, machine vibration will stop automatically and will not start its vibration again until the engine

has enough time to cool down.

SIGNAL

CHANNEL

OPERATIONAL CAUTION

P/N: 920109720

MVH-RC

P/N: 920209080

J

DIESEL

FUEL

ONLY

P/N: 920102710

MAIN SWITCH

P/N: 920109750

BATTERYSIGNAL CHARGE

NPA-927

NPA-908

NPA-908

INLET

K

NPA-907

K

BATTERY

CHARGE

K

HYDRAULIC

OIL ONLY

P/N: 920109810

NPA-928

J

OPEN

J

J

NPA-922

P/N: 920209310

J

NPA-904

VIBRATION

SWITCH

ON

OFF

P/N: 920203330

N

J

P

A

3

-

3

3

MQ-MIKASA MVH-702DRSC COMPACTOR — PARTS & OPERATION MANUAL — REV. #1 (12/17/03) — PAGE 11

NR.

(RECIEVING FAILURE LIGHT)

The remote control operation is restricted to a narrower area the further you are from

the machine. If the operative signals do not reach the plate properly, RECEIVING

FAILURE LIGHT is immediately on and will stop the plate vibration automatically (the

engine will continue running)

OP.

(OIL PRESSURE (ENGINE) FAILURE LIGHT)

If the engine oil is low or the hydraulic oil pump is out of order,

OIL PRESSURE FAILURE LIGHT is on and will stop the engine automatically

RE.

(REGULATOR FAILURE LIGHT)

Tif the alternator and regulator in engine are out of order, REGULATOR FAILURE

LIGHT is on, but the machine is operative. Be sure to check them after operation

OH.

(E/G OVERHEAT LIGHT)

If the engine is continuously overloaded or if the air element is plugged due to excessive

dust, the machine E/G OVERHEAT LIGHT will light to notify of an engine overheat. To

correct, run the machine without vibration about 5 minutes or stop the engine for

cleaning air element. If this is not done the machine will stop vibration automatically

and continue to run without vibration for cooling the engine.

The vibrator will not start again until the engine temperature reaches and acceptable

level.

P/N:920109790

CAUTION

MAIN SWITCH

EMERGENCY STOP

ON

OFF

START STOP

MVH-906

ENGINE

SWITCH

P/N: 920109730

NPA-951

J

OH RE OP NR

P/N: 920209250

Figure 1b. Operation and Safety Decals

SAE 10W-40

Motor Oil

P/N: 920209230

NPA-925

J

NPA-748

J

Page 12

MVH-702DRSC — DIMENSIONS AND SPECIFICATIONS

Figure 2. MVH-702DRSC Compactor Dimensions

snoitacificepSrotcapmoCCSRD207-HVM.1elbaT

ralugeRhtiW

etalP

htgneLllarevO)mm080,1(.ni5.24

snoisnemiDydoB

eziSetalP

thgieWgnitarepO

MPV)zH25(mpr021,3

ecnamrofreP

htdiWllarevO

thgieHllarevO)mm597(.ni3.13

htdiW

htgneL)mm001,1(.ni3.34

ecroFlagufirtneC)NK08(wolb/.sbl000,81

deepSlevarT)nim/m820(nim/tf29-0

ledoMF34NNAMYRAF

.ni8.62

mm086(

.ni6.52

)mm056(

.sbl7741

).gk076(

hcni-3htiW

etalPnoisnetxE

.ni5.13

mm008(

.ni5.13

)mm008(

.sbl3451

).gk007(

tuptuOmumixaM)WK4.11(SP5.51

enignE

leuF)sretil5.7(snollag2LESEID

tratS

tratScirtcelE

)ycnegremerofeldnahknarc(

PAGE 12 — MQ-MIKASA MVH-702DRSC COMPACTOR — PARTS & OPERATION MANUAL — REV. #1 (12/17/03)

Page 13

The Mikasa Model MVH-702DRSC is a Reversible Plate

Compactor which operates by infra-red remote control with

forward-reverse motion, steering, and stepless speed control

by single-lever joystick.

Features include:

Machine operation is automatically stopped (vibration

remains on) by releasing the single-lever joystick.

Monitoring lamps for self-diagnosis are installed at the side

of the machine control unit.

Monitoring lights located on top of the machine indicate

any problem or failure.

An hour meter is installed as standard.

The machine control unit wire harness is coated to make

it splash-proof.

The machine has an aluminum oil tank which minimizes

rising of working oil temperature, loss of vibration power

and periodic inferiority of working oil.

Multiple machines can operate in the same area with each

machine transmitting at a different infra-red channel

(channels 0 to 9).

MVH-702DRSC — FEATURES

A safety crank is installed for use in case of battery failure

or problem.

Front cover provides easier access for pre-operational

check and refueling.

The self-cleaning structure of the vibrating plate removes

mud and sand easily from the plate.

MQ-MIKASA MVH-702DRSC COMPACTOR — PARTS & OPERATION MANUAL — REV. #1 (12/17/03) — PAGE 13

Page 14

MVH-702DRSC — COMPACTOR COMPONENTS

11

Figure 3. MVH-702DRSC Compactor Components

9

10

1

7

6

3

14

4

12

5

13

PAGE 14 — MQ-MIKASA MVH-702DRSC COMPACTOR — PARTS & OPERATION MANUAL — REV. #1 (12/17/03)

Page 15

MVH-702DRSC — COMPACTOR COMPONENTS

Figure 3 illustrates the location of the major components for the

MVH-702DRSC Reversible Plate Compactor. The function of

each component is described below:

1. Monitoring Lights – Indicates if there is any failure in the

machine. There are four monitoring lights:

Receiving Failure Light

Oil Pressure (Engine) Failure Light

Regulator Failure Light

E/G Overheat Light

2. Lifting Hook Lever – Used to lift the machine.

3. Rubber Bumper – Protects the machine in case of bumps.

4. Extension Plate – Removable when not needed.

5. Hydraulic Motor – Drives all the operation of the machine

such as speed control, forward-reverse switching motion,

and steering as well as the vibrator unit on the base.

6. Rear Cover - When lifted, allows access to the monitoring

lamps, valve unit, block diagram and owner’s manual.

7. Receiver and Receiving Lamp –Receives infra-red

signals from the transmitter indicated by the flashing light

on the receiving lamp.

8. Fuel Tank/Cap – Fill with diesel fuel. Fuel tank holds

approximately 2 gallons (7.5 liters). DO NOT top off fuel.

Wipe up any spilled fuel immediately.

9. Front Cover - Allows easy pre-operational check and

refueling.

10. Valve Unit – Electromagnetic and hydraulic valve: controls

traveling speed and direction.

11. Oil Tank – Fill with proper grade of diesel engine oil.

12. Vibrator Oil Drain - Allows easy draining of vibrator oil.

13. Reciever - Located inside the compactor. Recieves signals

from portable transmitter durring remote operations.

14. Transmitter - Transmits operational signals to compactor

via the onboard receiver durring remote operations.

MQ-MIKASA MVH-702DRSC COMPACTOR — PARTS & OPERATION MANUAL — REV. #1 (12/17/03) — PAGE 15

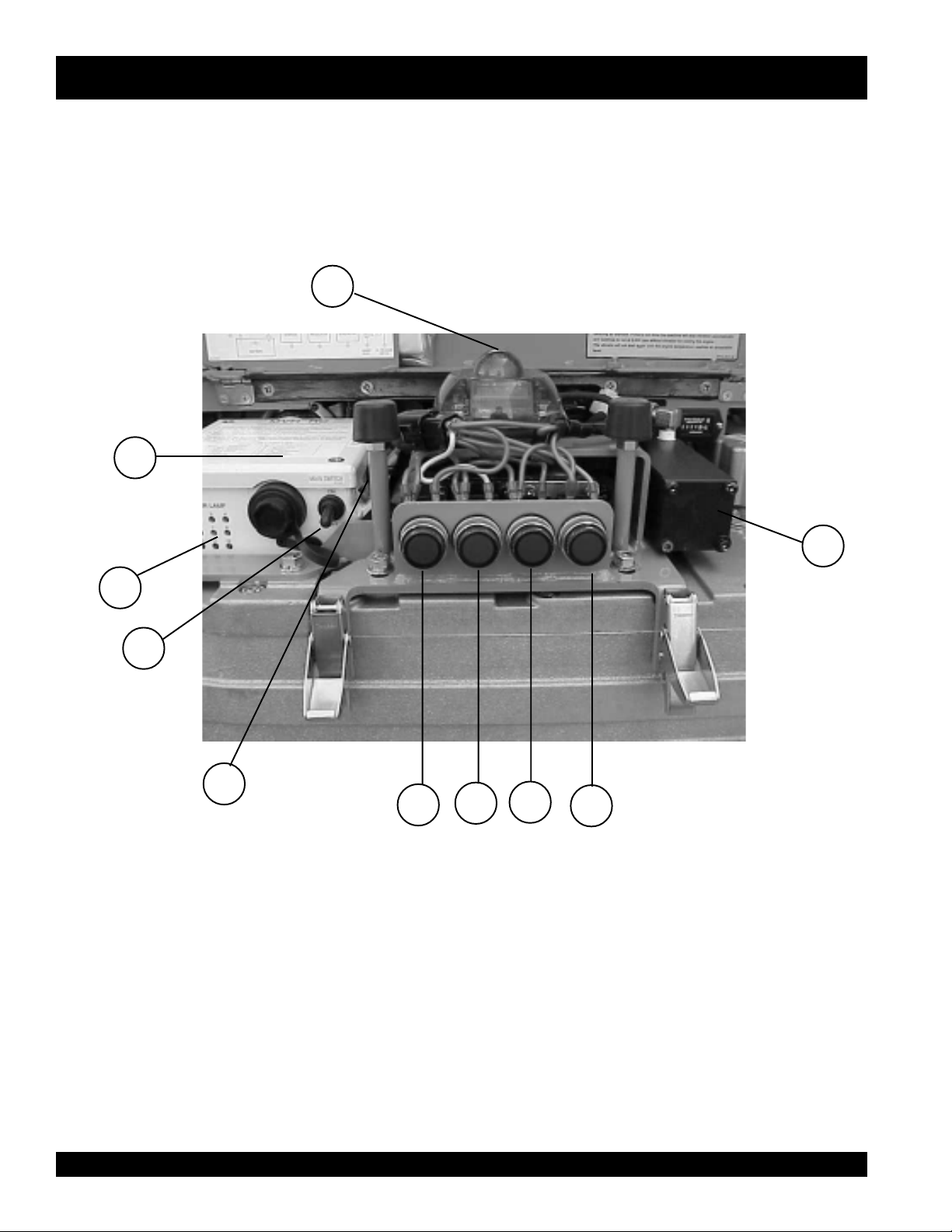

Page 16

1

MVH-702DRSC — REMOTE CONTROL COMPONENTS

2

10

3

5

9

Figure 4. MVH-702DRSC Remote Control Components

8

7

6

4

PAGE 16 — MQ-MIKASA MVH-702DRSC COMPACTOR — PARTS & OPERATION MANUAL — REV. #1 (12/17/03)

Page 17

MVH-702DRSC — REMOTE CONTROL COMPONENTS

CONTROL UNIT (BODY)

Figure 4 illustrates the location of the major components for the

Remote Control on the body of the machine. The function of

each component is described below:

1. Control Unit – Controls engine start/stop and hydraulic

valve unit according to the operation signals from the

transmitter. In addition, it also controls the following

monitoring lights:

Receiving Failure Light

Oil Pressure (Engine) Failure Light

Regulator Failure Light

E/G Overheat Light

2. Receiver and Receiving Lamp – Receives infra-red

signals from the transmitter indicated by the flashing light

on the receiving lamp.

3. Main Switch (Battery Master Switch) –Battery power

switch for control unit on body of machine.

4. Valve Unit – Electromagnetic and hydraulic valve; controls

traveling speed and direction.

5. Cell/Crank Start Switch – Selects electric (cell) start for

normal operation or manual (crank) start for emergencies.

6. Receiving Failure Light - Lights to indicate that the signal

from the transmitter is not received. The remote control

operation is restricted to a narrower area , the farther you

are from the machine. When this light is on, plate vibration

will automatically stop but the engine will continue running.

10. Monitoring Lamp – Depending on which numbered lamps

light up, indicates the status of the machine (Figure 5).

1 is lighted: Main Switch is on.

9, 10, and 12 are lighted: Engine start by cell motor.

9 and 10 are lighted: Engine start by crank handle.

5 and 8 are lighted: Transmitter start switch is turned

on. Shortly after the transmitter start switch is turned

on, all lamps turn off.

6 and 8 are lighted: Transmitter vibration start switch

is on.

7, 8, and 12 are lighted: Transmitter start switch is

turned off.

See Figure 6 for correlation of monitor lamp and joystick lever.

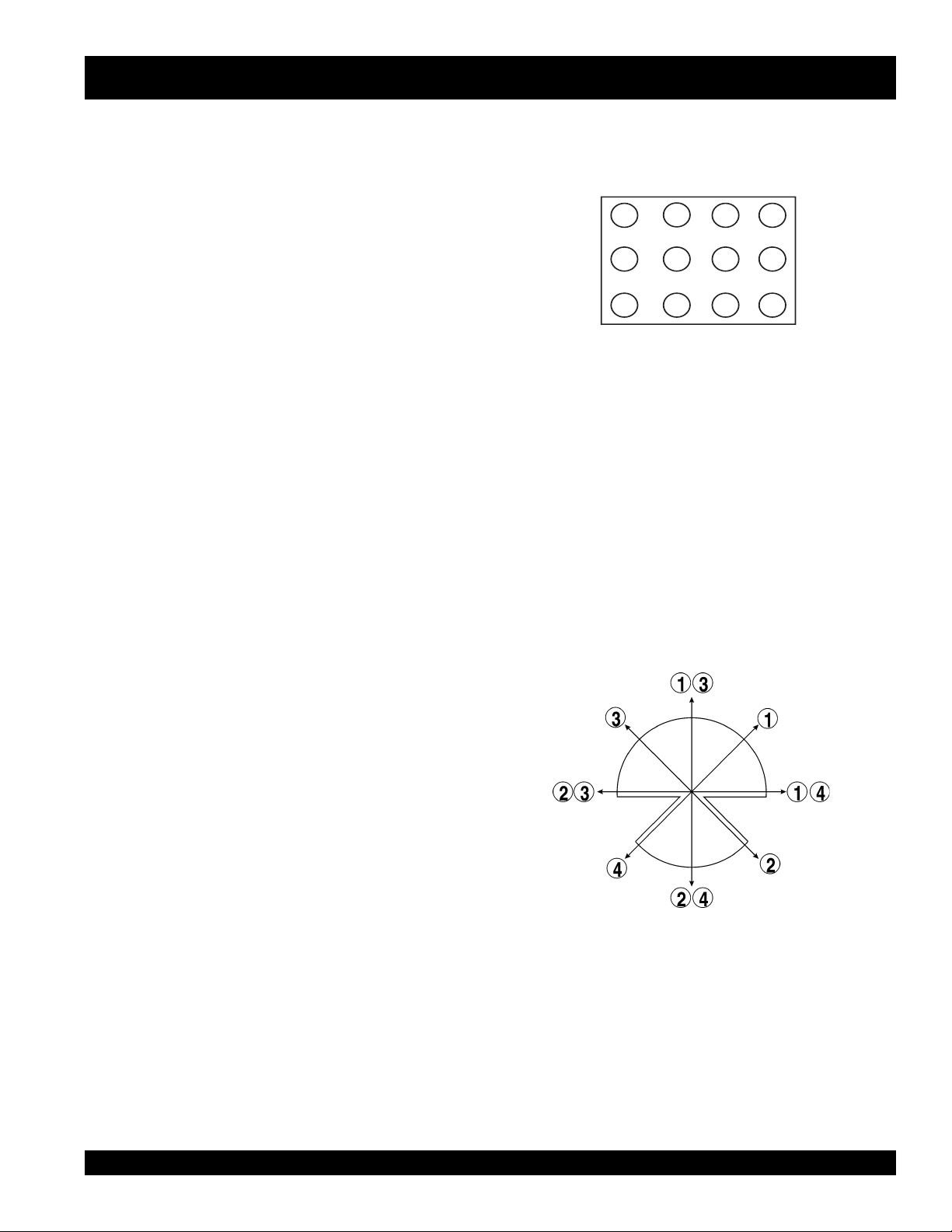

MONITOR LAMP

1

5

9

Figure 5. Monitor Lamp

2

6

10

3

7

4

8

11 12

7. Oil Pressure (Engine) Failure Light –Lights to indicate

that the engine oil is low or the hydraulic oil pump is not

functioning properly. When this light is on, the engine will

automatically stop.

8. Regulator Failure Light – Lights to indicate that the

alternator and regulator are not functioning properly. When

this light is on, the machine is still operating. Check alternator

and regulator after operation.

9. E/G Overheat Light - Lights to indicate engine overheat. If

the engine is continuously overloaded or if the air element

is clogged due to excessive dust, the engine will overheat.

To correct this, run the machine without vibration for about

5 minutes or stop the engine to clean air element. If this is

not done, the machine will automatically stop vibration to

cool the engine, and will not start again until the engine

temperature reaches acceptable level.

MQ-MIKASA MVH-702DRSC COMPACTOR — PARTS & OPERATION MANUAL — REV. #1 (12/17/03) — PAGE 17

Figure 6. Correlation of Monitor Lamp

and Joystick Lever

Page 18

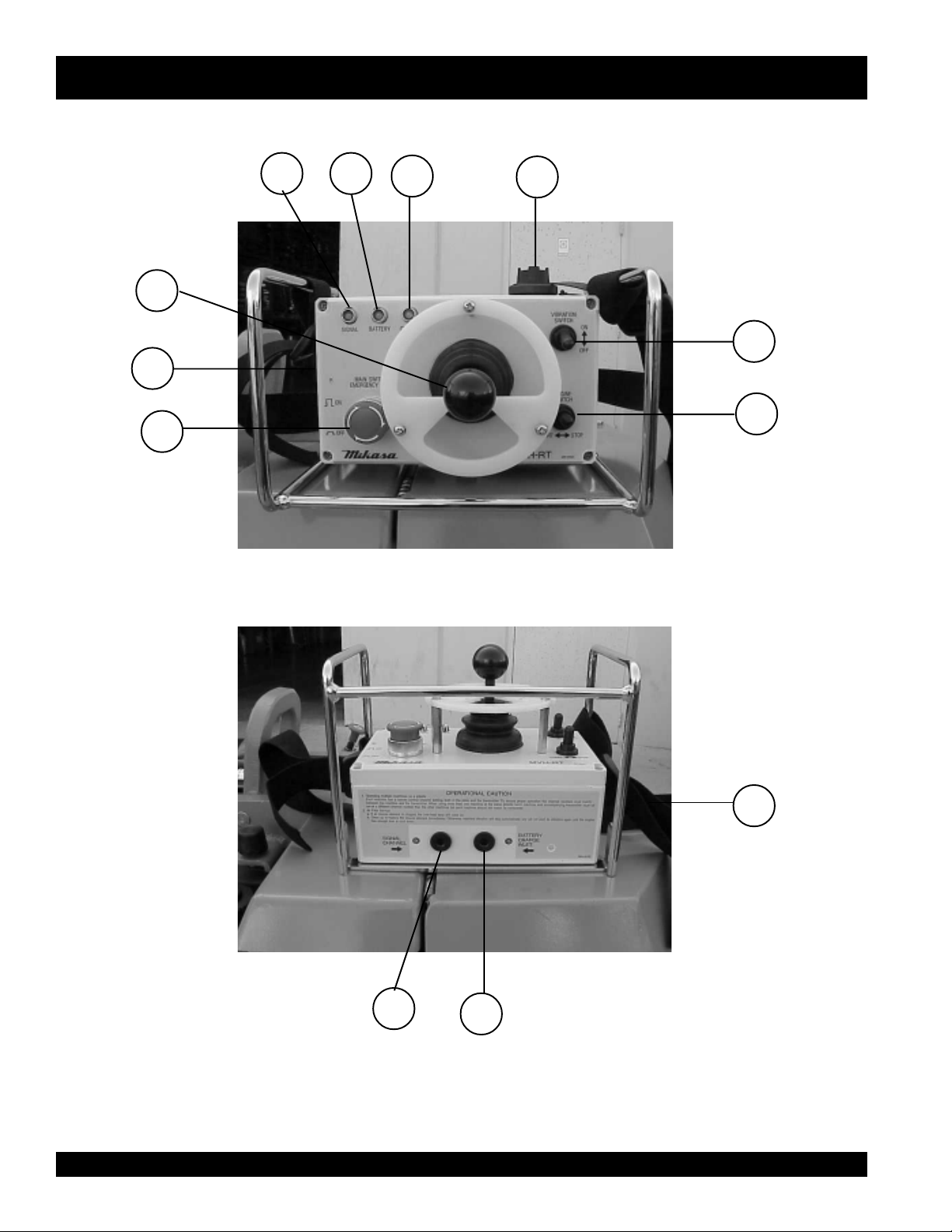

MVH-702DRSC — REMOTE CONTROL COMPONENTS

9

1

2

5 6

7

8

4

3

12

10

Figure 7. MVH-702DRSC Transmitter Components

PAGE 18 — MQ-MIKASA MVH-702DRSC COMPACTOR — PARTS & OPERATION MANUAL — REV. #1 (12/17/03)

11

Page 19

MVH-702DRSC — REMOTE CONTROL COMPONENTS

TRANSMITTER

Figure 7 illustrates the location of the major components of the

transmitter. The function of each component is described below:

1. Joystick Lever – Controls the traveling speed and

direction of the machine.

2. Main Switch/ Emergency Stop – Immediately stops the

machine in an emergency.

3. Engine Switch –Starts and stops the engine.

4. Vibration Switch – Turns vibration on and off.

5. Signal Lamp – Infra-red monitoring lamp.

6. Battery Lamp - Lights to indicate that battery power is low.

7. Charge Lamp –Lights to indicate that the battery is

charging.

8. Cable Connection – Connector for remote control cable.

9.. Solar Cells - Used to charge unit by utilizing the sun’s solar

energy.

10. Signal Channel Control - Sets the operating channel of

the machine.

11. Battery Charging Connector - Connects battery charger

to transmitter.

12. Carrying Belt - Used by operator to carry remote control

transmitter.

MQ-MIKASA MVH-702DRSC COMPACTOR — PARTS & OPERATION MANUAL — REV. #1 (12/17/03) — PAGE 19

Page 20

MVH-702DRSC — BEFORE START-UP

BEFORE START-UP

1. Read this manual carefully and understand all functions of

the machine before start-up.

2. The engine is located on front side of the machine and the

aluminum oil tank is on the rear.

3. The operator should always keep a distance of 2 meters

away from the machine.

SETTING THE OPERATIONAL CHANNEL

In cases where several machines operate in the same area,

each machine should be transmitting in a different infra-red

channel. Ten different channels can be set (0 to 9). See Table 2.

To set the operational channel of a machine, do the following.

1. On the body of the machine, remove the receiver channel

plug. See Figure 9. Using a screwdriver, set the channel

number desired.

4. The operator should always make sure that the machine

will move in the opposite direction (away from him) when

the machine is started.

2. On the transmitter, remove the channel plug. See Figure

9. Using a screwdriver, set the channel number to the

same one as the receiver (set in step 1).

5. In infra-red remote control operation, the farther the machine

moves, the narrower the control area.

6. If the transmitter fails and during emergencies, pull the

emergency stop lever (Figure 8) continuously until the

machine completely stops.

Remove plug

Emergency

Stop Lever

and adjust

Figure 8. Location of Emergency Stop Lever

Remote Control operation is not available in the following cases.

Vibration stops automatically.

Operator stands within approximately 3 feet (1 m) of the

Remove plug

and adjust

machine.

Operator stands approximately 60 feet (18 m) or farther

from the machine (approximately 40 feet (12 m) when far

from the direct rays of the sun). Note that these distances

may vary .

Operator stops sending control signals for more than one

second.

The engine is overloaded. In the engine temperature

increases, the vibration will automatically stop.

The engine stops automatically in the following cases.

Engine oil level is low.

Control unit fails to receive the operational signal for more

than 30 seconds.

During engine or hydraulic oil warm-up, direct the transmitter to

the body receiver to receive the operational signal. Operation

starts only after the main switch of the transmitter is switched on.

MACHINE

TRANSMITTER

Figure 9. Setting Channels

sgnitteSrebmuNlennahC.2elbaT

RETTIMSNARTREVIECER

00

11

22

33

44

55

66

77

88

99

PAGE 20 — MQ-MIKASA MVH-702DRSC COMPACTOR — PARTS & OPERATION MANUAL — REV. #1 (12/17/03)

Page 21

MVH-702DRSC — BATTERY CHARGING

CHARGING THE BATTERY

The battery can be charged in three different ways:

Using the remote cable

Using the AC plug-in battery charger

Solar Energy

Battery Charging Using Remote Cable

1. Make sure that the engine is stopped before charging.

2. If the temperature of the hydraulic tank or its surroundings

is high, wait for it to cool down before charging.

6. Connect one end of remote cable to the receptacle.

7. Make sure that the transmitter main switch is off.

8. Remove the cover of the remote control receptacle in the

transmitter (Figure 11).

9. Connect the other end of the remote cable to the receptacle.

10. Turn the machine main switch on.

11. The charge lamp flashes while the battery is being charged.

12. The charge lamp will automatically go off after the battery

is fully charged.

3. Open the rear cover of the machine.

4. Unpack the remote cable which can be found in a bag on

the side of the machine ( Figure 10).

Location of

Remote

Control

Cable

NOTE

Battery Charging Using AC Plug-In Charger

1. Switch off the transmitter main switch to stop battery

consumption. The battery can be charged though, even

with the main switch on.

If the charge lamp does not light

when the remote cable is connected, the battery does not require

charging.

Figure 10. Location of Remote Control Cable

5. Remove the cover of the remote control receptacle on the

machine (Figure 11).

Remove cover and connect

one end of remote cable

(Machine)

2. Remove the cover of the battery charger receptacle on the

transmitter. See Figure 7, item 11 for location.

3. Connect the AC plug-in charger to the receptacle.

4. The charge lamp lights while the battery is being charged.

5. The charge lamp will automatically go off after the battery

is fully charged.

NOTE

Battery Charging Using Solar Energy

1. Solar Cell Charging can be done whether the transmitter

main switch is on or off.

2. Expose the solar cells of the transmitter to sunlight

frequently for non-operational daily charging.

Remove cover and connect

other end of remote cable

(Transmitter)

Figure 11. Remote Control Cable Connections

Battery Charging Time

Using remote cable - approximately 2 - 3 hours

Using battery charger - approximately 2 hours

Using Solar Energy - supplemental, available anytime

If the charge lamp does not light

when the charger is connected, the

battery does not require charging.

MQ-MIKASA MVH-702DRSC COMPACTOR — PARTS & OPERATION MANUAL — REV. #1 (12/17/03) — PAGE 21

Page 22

BEFORE OPERATION

MVH-702DRSC — OPERATION

1. Familiarize yourself with the operating and control elements

of the machine and the working environment. This includes

obstacles in the working area, bearing capacity of the

ground and the necessary safety provisions.

2. Understand the geographical features and regulations of

the job site.

3. Inspect caution decals and replace missing/worn-out ones.

4. Check nuts and bolts and tighten if necessary. Loose threads

may cause damage to the machine when vibrating.

5. Make sure lifting hook, shock mounts and control parts are

all working properly. Do not start the machine if any failure

is noted.

6. Wipe off any dust from the receiving lamp of the machine.

Checking Engine Oil Level

CAUTION :

DO NOT overfill oil tank. This could cause

oil leaks and sluggish operation. Clean cap

and surrounding area before opening to

prevent dirt from entering tank.

CAUTION :

Checking Engine Oil Level

1. Unscrew the fuel tank cap. See Figure 13 for location.

2. Visually inspect the fuel level and refill if necessary.

DANGER :

Oil Tank

Fuel

Tank

Figure 13. Oil and Fuel Tanks

Lower grade or lower volume of engine oil can

cause engine burns. The built in sensor

continues to run for about 3 minutes after

sensing lack of oil. Make sure that oil level is

sufficient before starting operation

1. Make sure that the machine is situated in a flat surface so

that level measurements will be accurate.

2. Open the front cover of the machine by moving the lever to

the “OPEN” position then slowly lifting the hook on the cover

(Figure 12).

Pull slowly to open

Move to the OPEN

position

CAUTION :

1. Check the oil tank level gauge (Figure 14). Oil level should

be at the upper indication of the gauge.

2. Check the surroundings of the oil tank, hydraulic pump and

motor for oil leakage.

3. After inspection, close the front cover slowly.

DANGER :

Figure 12. Opening the Front Cover

3. Pull out the dipstick from the oil tank (Figure 13). Check the

oil level and refill if necessary. For selection of proper grade

of diesel engine oil, refer to Table 3 in Troubleshooting

section.

Do not refill with fuel in poorly ventilated

environment. When refueling, make sure the

engine is shut down and that there is no

possibility of starting a fire.

.

Wipe off fuel spills immediately when

overfilled.

Checking The Hydraulic System

Always keep hands and fingers away from

pinch points. Do not allow anyone to reach

in on dangerous sections of the machine to

avoid any accidents.

PAGE 22 — MQ-MIKASA MVH-702DRSC COMPACTOR — PARTS & OPERATION MANUAL — REV. #1 (12/17/03)

Page 23

2. To check if restart failure is due to the reasons listed in step

Oil

Level

Gauge

Figure 14. Checking Oil Level Gauge

Refer to Figures 4 and 7 for the location of controls and

components.

STARTING THE ENGINE

1. Move the cell/crank start switch of the machine to the cell

start position.

2. Move the main switch of the machine to the ON position.

2. Start the cell motor by moving the transmitter engine starter

switch to the on position. Do not run starter longer than 10

seconds to avoid overheating.

3. Warm up engine without load for 3 to 5 minutes.

OPERATING THE MACHINE

1. Read all safety information in this manual and understand

the operation of this machine thoroughly before starting

operation.

2. The infra-red remote control system controls the stepless

adjustable speed, forward-reverse, and steering of the

machine by a single joystick lever in the transmitter.

3. Press the joystick lever slightly to the direction you want the

machine to travel.

4. The speed is also controlled by the joystick lever and is

determined by the pressed angle.

5. Switch on the vibration switch of the transmitter to activate

transmission.

3, move the transmitter engine starter switch to the on

position. Check if the signal lamp. If it does not flash then

reasons listed are confirmed.

5. The remote control cable may be used to restart the engine

in this case. See Battery Charging Section on how to install

the remote control cable.

6. Move the machine main switch to the ON position.

7. Move the transmitter engine starter switch to the on position.

8. Move the transmitter engine starter switch to the on position

to restart.

CRANK STARTING THE ENGINE

When the voltage of the main battery drops and the cell motor is

not running, the engine may be manually started with the crank

handle.

1. Move the cell/crank start switch of the machine to the

crankstart position. See Figure 4, item 5 for location.

2. Move the machine main switch to the ON position.

3. Take out the crank handle from the handle holder.

4. Engage the crank handle with crankshaft and turn the

handle clockwise to start (Figure 15).

5. Once the engine starts, follow normal operating procedure.

STOPPING THE ENGINE

1. Run the machine at idle for 3 to 5 minutes before stopping

engine.

2. Move the transmitter engine starter switch to the off position.

3. If the engine does not properly stop, push the throttle lever,

located next to the oil filter, until it comes to a complete stop

(approximately 15 seconds).

4. After operation is completed, move the main switch of the

machine to the off position.

MVH-702DRSC — OPERATION

RESTARTING THE ENGINE

1. If starting fails or engine stops suddenly, allow an interval

of a few seconds to make sure that the crankshaft of the

engine is completely stopped.

2. Move the transmitter engine starter switch to the on position

to restart.

RESTARTING WITH REMOTE CABLE

1. If machine still fails to restart, check for the following:

The operator approached the machine too closely.

The transmitter is too far from the control area.

Low Battery Power.

MQ-MIKASA MVH-702DRSC COMPACTOR — PARTS & OPERATION MANUAL — REV. #1 (12/17/03) — PAGE 23

Figure 15. Crank Handle

Page 24

MVH-702DRSC — LOADING AND UNLOADING GUIDELINES

LIFTING

1. Use a crane or lift to load and unload the machine. A

skilled crane operator is required to perform the job.

2. When lifting the machine, check for any damaged or loose

bolts, lifting hooks, and shock mounts.

3. Check any damaged or loose bolts in the guard frame to

avoid machine sliding off.

4. Make sure that the machine is shut off before machine is

lifted.

5. Use reliable cable for lifting.

6. Always lift the machine vertically and keep the machine

away from workers and animals.

7. Do not lift the machine higher than the required height.

TRANSPORTING

1. Always make sure that the machine is shut off while being

transported.

2. Check that the fuel cap is properly closed and tightened.

3. When traveling long distances or on rugged terrain, drain

the fuel of the machine before transporting.

4. Tie down the machine securely on the transportation so

that it will not move or topple over.

PAGE 24 — MQ-MIKASA MVH-702DRSC COMPACTOR — PARTS & OPERATION MANUAL — REV. #1 (12/17/03)

Page 25

MVH-702DRSC — MAINTENANCE

MACHINE MAINTENANCE

1. At the end of each day’s operation, wipe off any dust from

the transmitter and the receiver on the body of the machine.

2. At the end of each day’s operation, charge the transmitter

battery if necessary.

Refer to Table 4 in the Troubleshooting section for periodic

inspection and maintenance necessary for the machine.

MACHINE BATTERY MAINTENANCE

1. If a battery has not been used for some time, reduce the

charge level initially to protect each plate inside the battery.

2. Check the battery terminals periodically to ensure that they

are in good condition.

3. Use wire brush or sand paper to clean the battery terminals.

4. If the machine will not be in operation for a long period of

time, charge the battery sufficiently, tighten all caps, correctly,

store in cool dry place and check the battery charge level

every month to maintain the performance of the battery.

BATTERY CABLE CONNECTION

1. When removing cable, disconnect the ground side (normally

negative) first (Figure 16).

2. When installing cable connect the ground side (normally

negative) last .

MACHINE BATTERY MAINTENANCE

DANGER :

flush immediately with clean water and get medical advice.

Wear rubber gloves and protective clothes to keep acid off skin.

If acid gets in contact with skin, wash off immediately with clean

water.

Use a flashlight to check battery electrolyte level. Always check

the engine is stopped.

Do not charge battery or jump-start engine when the battery is

frozen. Warm the battery to 15 degrees F or battery may explode.

Replace the battery with the same or similar capacity battery or

battery may explode.

Do not close the exhaust outlet of battery. The gas pressure

building up in the battery may cause explosion.

Before using a battery charger, read and understand the charger

instruction manual thoroughly.

Charge the battery in a non-spark, well-ventilated area. Avoid

fire from cigarette sparks or matches.

CAUTION :

Lead-acid battery contains sulfuric acid, which

may damage eyes or skin on contact.

Always wear a face shield to avoid acid getting

into the eyes. If acid gets in contact with eyes,

1. If a battery has not been used for some time, reduce the

charge level initially to protect each plate inside the battery.

2. Check the battery terminals periodically to ensure that they

are in good condition.

3. Use wire brush or sand paper to clean the battery terminals.

4. If the machine will not be in operation for a long period of

time, charge the battery sufficiently, tighten all caps, correctly,

store in cool dry place and check the battery charge level

every month to maintain the performance of the battery.

Positive

Terminal

Wear safety glasses or face mask , protective

clothes, and rubber gloves when working

with battery.

Negative

Terminal

Figure 16. Battery Location

MQ-MIKASA MVH-702DRSC COMPACTOR — PARTS & OPERATION MANUAL — REV. #1 (12/17/03) — PAGE 25

Page 26

MVH-702DRSC — TROUBLESHOOTING

trahCnoitacilppAliOCSRD207-HVM.3elbaT

METINOITACOL

liOenignEnaPliOenignEedarGDC-IPA

liOrotoMrotarbiVedarGDC-IPA

liOciluardyHknaTciluardyHliOciluardyH

ECIVRES

NOITACIFISSALC

22-31-4-541231405867768

03-52-02-51-01-05 01025203

)C°/F°(ERUTAREPMETTNEIBMA

03-W5/02-W5EAS

03-W01EAS

04-W02EAS

04-W51EAS

04-W01EAS

03-W5EAS

03-W01EAS

23GVOSI

54GVOSI

OSI

86GV

KROW/NOITACOLYADYREVE

leveLleuFkcehC

leveLliOciluardyHkcehC

noitcepsnIrenaelCriA

kcehClanretxElausiV

tuNrotloBesooL

egakaeLleuF,liO

kcehCyrettaB

tnemecalpeRretliFliO

gninaelClanretnI

tnemecalpeRliOrotarbiV

ecnanetniaMdnanoitcepsnIydoBniaMCSRD207-HVM.4elbaT

GNIDAERRETEMRUOH

050010520050001

O

O

O

O

egamaDesoHdnaeiPciluardyH

OOO

OOO

dnatnemecalpeRliOciluardyH

O

OOO

PAGE 26 — MQ-MIKASA MVH-702DRSC COMPACTOR — PARTS & OPERATION MANUAL — REV. #1 (12/17/03)

Page 27

MVH-702DRSC — TROUBLESHOOTING

ecnanetniaMdnanoitcepsnIenignECSRD207-HVM.5elbaT

GNIDAERRETEMRUOH

KROW/NOITACOL

05001051052003053004054

ylraeY

tnemecalpeRliOenignE

tnemecalpeRegdirtraCrenaelCliO

tnemecalpeRegdirtraCretliFleuF

knaTleuFnilavomeRtnemideS

kcehCtleBeniLleuF

tnemecalpeRpmalCdnaeniLleuF

esooLdnadegamaDrofkcehCgniriW

snoitcennoC

OO

OO

O

OO

OO

OOOOOOOO O

O

euqroTtloBCSRD207-HVM.6elbaT

.mc-fgk002,3ebdluohsstnuomkcohsrotinurotarbivrofdesu81MtlobgnittesehT

.mc-fgk002,4ebdluohsetalpnoisnetxeedisrof42MtlobgnittesehT

.mc-fgk006ebdluohsmupciluardyhrof01Mtlobgnitteseht

mm6mm8mm01mm21mm41mm61

)14SS(T4070510030050570011

)C54S(T8-600105200500800310002

)534MCS(T11051004008002100020092

LAIRETAMMUNIMULAROF001053-003007-056

MQ-MIKASA MVH-702DRSC COMPACTOR — PARTS & OPERATION MANUAL — REV. #1 (12/17/03) — PAGE 27

Page 28

MVH-702DRSC — TROUBLESHOOTING

GNITOOHSELBUORTENIGNE.7ELBAT

MOTPMYSMELBORPELBISSOP NOITULOS

siydobenihcamfohctiwsniamehT

siyticirtceleontub,nodehctiws

dna,01,9spmalgnirotinom(elbaliava

)tinulortnocehtnodethgiltonera21

sirettimsnartehtfohctiwsniamehT

tonseodenigneehttub,nodehctiws

seodrettimsnartfopmallangis(trats

).thgilton

sirettimsnartehtfohctiwsniamehT

tonseodenigneehttub,nodehctiws

sthgilrettimsnartfopmallangis(trats

lortnocno8.onpmalgnirotinomtub

).thgiltonseodtinu

sirettimsnartehtfohctiwsniamehT

tonseodenigneehttub,nodehctiws

seodrettimsnartfopmallangis(trats

no8.onpmalgnirotinomdnathgilton

).thgiltonseodtinulortnoc

sirettimsnartehtfohctiwsniameh

nehttubstratsenigneeht,nodehctiws

seodrettimsnartfopmallangis(spots

no8.onpmalgnirotinomdnathgilton

).thgiltonseodtinulortnoc

?yrettabevitcefeD .yrettabecalperroegrahC

?gnikrowtonhctiwsniaM .hctiwsniamecalperroriapeR

?gnikrowtonhctiwstratsknarc/lleC .hctiwsknarc/llececalperroriapeR

?nekorbdraobtiucrictinulortnoC .draobtiucrictinulortnocecalperroriapeR

?yrettabrettimsnartfoegrahcwoL .yrettabegrahC

?hctiwsrettimsnartniamytluaF .hctiwsniamrettimsnartecalperroriapeR

?nekorbdraobtiucricrettimsnarT .draobtiucricrettimsnartecalperroriapeR

?tsudhtiwderevocpmalder-arfnirettimsnaT

?detcennocylreporptonelbaclortnocetomeR

?denrubenignefoyaler/rotomlleC .noitisopNURotrevelelttorhtnoitisopeR

?denrubdraobtiucrictinulortnoC .retlifleufecalpeR

?wolootrewopyrettabniaM yrettabecalperroegrahC

?dionelosleufenignedeliaF .dioneloseufecalperroriapeR

?ssenraheriwdetiucric-trohsrodetcennocsiD

?tratserdeeN .launamsihtfonoitcesenignEgnitratseRotrefeR

paosdlimesu,ytridyrevfI.htolcnaelchtiwpmalepiW

.tridevomerotrenaelcro

.detcennocylreporpsielbaclortnocetomererusekaM

.stiucrictrohselbissopynatcerrocdnakcehC

dnayoreporpdetcennocsissenraheriwerusekaM

.stiucrictrohsynatcerroc

stratsnoitarbivontubstratsenignE

gnirotinomtub,nosihctiwsnoitarbiv(

tonseodtinulortnocfo6.onpmal

).thgil

stratsnoitarbivontubstratsenignE

gnirotinomdnanosihctiwsnoitarbiv(

).sthgiltinulortnocfo6.onpmal

?revelkcitsyojnekorB .revelkcitsyojecalperroriapeR

levarttonseodtubsetarbivenihcaM

forevelkcitsyojdnapmalgnirotinom(

).gnikrowtonerarettimsnart

levarttonseodtubsetarbivenihcaM

forevelkcitsyojdnapmalgnirotinom(

).gnikrowerarettimsnart

?tinurotarbivfoeruliaF .tinurotarbivecalperroriapeR

?draobtiucricrettimsnartfoeruliaF .draobtiucricecalperroriapeR

?draobtiucrictinulortnocfoeruliaF .draobtiucricecalperroriapeR

?draobtiucricrettimsnartfoeruliaF .draobtiucricecalperroriapeR

?draobtiucrictinulortnocfoeruliaF .draobtiucricecalperroriapeR

?krowtonseodrettimsnartnohctiwsnoitarbiV .hctiwsecalperroriapeR

?ssenraheriwdetiucric-trohsrodetcennocsiD

?tinuevlavfodionelosnoitarbivfoeruliaF .dionelosecalperroriapeR

?ssenraheriwdetiucric-trohsrodetcennocsiD

?tinuevlavfodionelosnoitarbivfoeruliaF .dionelosecalperroriapeR

?ssenraheriwdetiucric-trohsrodetcennocsiD

dnayoreporpdetcennocsissenraheriwerusekaM

.stiucrictrohsynatcerroc

dnayoreporpdetcennocsissenraheriwerusekaM

.stiucrictrohsynatcerroc

dnayoreporpdetcennocsissenraheriwerusekaM

.stiucrictrohsynatcerroc

PAGE 28 — MQ-MIKASA MVH-702DRSC COMPACTOR — PARTS & OPERATION MANUAL — REV. #1 (12/17/03)

Page 29

MVH-702DRSC — TROUBLESHOOTING

)deunitnoc(GNITOOHSELBUORTENIGNE.7ELBAT

MOTPMYSMELBORPELBISSOP NOITULOS

krowtonseodthgileruliafgnivieceR

,ylreporpsetarepoenihcamtub

enigneehttubnosithgilerusserpliO

.potstonseod

nosithgileruliafrotalugeR

nosithgiltaehrevoenignE

noisserpmocedrednilycoN

noisserpmocedrednilyctneiciffusnI

rednilycnidetcejniylreporptonsileuF

).wolfwolsrowolfon(

.rednilycnidetcejnitonsileuF

tub,lamronsinoisserpmoceddnaleuF

.tratstonseodenigne

tsuahxeykomsdnataehrevoenignE

.sag

noituloverenigneelbatsnU

?lioytriD.lioegnahC

?ffognimitnoitcejnI .gnimitnoitcejnireporpteS

?elzzondesolC.elzzonnepO

?nekorbthgileruliafgnivieceR .thgileruliafgniviecerecalperroriapeR

?ssenraheriwdetiucric-trohsrodetcennocsiD

?thgilerusserplionekorB .thgilerusserplioecalperroriapeR

?ssenraheriwdetiucric-trohsrodetcennocsiD

?dionelosleufenignedeliaF .dioneloseufecalperroriapeR

?thgileruliafrotalugernekorB .thgileruliafrotalugerecalperroriapeR

?rotanretlaenignefoeruliaF .rotanretlaenigneecalperroriapeR

?ssenraheriwdetiucric-trohsrodetcennocsiD

?detanimatnoctsudsitnemelerenaelcriA .tnemelerenaelcriaecalperronaelC

?enignedetaehrevO .tratsererofebloocenigneteL

?pudehsupevlavtsuahxeroekatnI.evlavtsujdA

?tnemtsujdanoisserpmocedfoeruliaF noisserpmocedtsujdaylreporP

?tcatnocreporpevahtonodsteehsevlaV .steehsevlavtsujdA

?rednilyc/gnirnotsipnroW .rednilyc/gnirnotsipecalpeR

?detcennocylreporptondaehrednilycdnarednilyC .noitcennocreporpfoerusekaM

?teehselzzonesooL .teehselzzonnethgiT

?deggolcelohdetalitnevpacknaT .elohdetalitnevpacknatgolcnU

?deggolcreniarts/retlifleuF reniarts/retlifleufgolcnU

?epipleufnikcutsriA .riaevomerotytpmetonsiknatleuferusekaM

?deggolcpmupleufforegnulprolerraB .regnulprolerrabgolcnU

?deggolcelohelzzoN .elohelzzongolcnU

?kcutseldeenelzzoN .eldeenelzzonkcutsnU

noitarepotratsrooP .enignetratseR

?epipleufnikcutsriA .riaevomerotytpmetonsiknatleuferusekaM

?ecnanetniamnafgniloocrooP .ylreporpnafgniloocniatniaM

?retlifleufnileufhtiwdeximretaW

?troptsuahxerorednilycnideffutsgalsnobraC .galsnobracevomeR

?tesekomsreporpmI .gnittesekomsreporpfoerusekaM

?dedaolrevoenignE .enignededaolrevonurtonoD

?eveelsdnakrofronrevogneewtebtcatnoctcerrocnI .tcatnoctcerroC

?deliafgnirpsronrevoG .ecalperrotcerroC

.deliaf/nrowstrapgnivloverroetalpylF .strapnrowecalperroriapeR

dnayoreporpdetcennocsissenraheriwerusekaM

.stiucrictrohsynatcerroc

dnayoreporpdetcennocsissenraheriwerusekaM

.stiucrictrohsynatcerroc

dnayoreporpdetcennocsissenraheriwerusekaM

.stiucrictrohsynatcerroc

leufotnitegtonseodretawerusekamdnaleufecalpeR

.retlif

MQ-MIKASA MVH-702DRSC COMPACTOR — PARTS & OPERATION MANUAL — REV. #1 (12/17/03) — PAGE 29

Page 30

MVH-702DRSC — BLOCK DIAGRAM

Figure 17. Block Diagram

PAGE 30 — MQ-MIKASA MVH-702DRSC COMPACTOR — PARTS & OPERATION MANUAL — REV. #1 (12/17/03)

Page 31

MVH-702DRSC — RECIEVER WIRING DIAGRAM

Figure 18. Receiver Wiring Diagram

MQ-MIKASA MVH-702DRSC COMPACTOR — PARTS & OPERATION MANUAL — REV. #1 (12/17/03) — PAGE 31

Page 32

MVH-702DRSC — VALVE CONTROL DIAGRAM

Figure 19. Valve Control Diagram

PAGE 32 — MQ-MIKASA MVH-702DRSC COMPACTOR — PARTS & OPERATION MANUAL — REV. #1 (12/17/03)

Page 33

NOTE PAGE

MQ-MIKASA MVH-702DRSC COMPACTOR — PARTS & OPERATION MANUAL — REV. #1 (12/17/03) — PAGE 33

Page 34

MVH-702DRSC — EXPLANATION OF CODE IN REMARKS COLUMN

How to read the marks and remarks used in this parts

book.

Items Found In the “Remarks” Column

Serial Numbers-Where indicated, this indicates a serial

number range (inclusive) where a particular part is used.

Model Number-Where indicated, this shows that the

corresponding part is utilized only with this specific model

number or model number variant.

Items Found In the “Items Number” Column

NOTE

The contents of this catalog are

subject to change without notice

.

NOTE

If more than one of the same

reference number is listed, the

last one listed indicates newest

(or latest) part avaliable.

PAGE 34 — MQ-MIKASA MVH-702DRSC COMPACTOR — PARTS & OPERATION MANUAL — REV. #1 (12/17/03)

Page 35

MVH-702DRSC — SUGGESTED SPARE PARTS

MQ MIKASA MVH-702DRSC REVERSIBLE

PLATE COMPACTOR

1 to 3 Units

Qty. P/N Description

3 .......... 954001910 ........... OIL FILTER, HYDRAULIC

3 .......... 954001920 ........... SUCTION, OIL FILTER HYDRAULIC

1 .......... 954001900 ........... CAP, WITH BREATHER

MQ-MIKASA MVH-702DRSC COMPACTOR — PARTS & OPERATION MANUAL — REV. #1 (12/17/03) — PAGE 35

Page 36

MVH-702DRSC COMPACTOR — NAMEPLATE AND DECALS

NAMEPLATE AND DECALS

PAGE 36 — MQ-MIKASA MVH-702DRSC COMPACTOR — PARTS & OPERATION MANUAL — REV. #1 (12/17/03)

Page 37

MVH-702DRSC COMPACTOR — NAMEPLATE AND DECALS

NAMEPLATE AND DECALS

NO. PART NO. PART NAME QTY. REMARKS

1 920109840 MODEL- MVH- 702 (350) DECAL 1

2 920109550 MODEL- MVH- 702 DECAL 2

3 920209080 CONTROLLER MVH- RC DECAL .................... 1 ..............NPA-908

4 920203330 EAR PROTECTION LABEL ............................. 1 .............. NPA-333

6 920101580 MIKASA MARK 200MM DECAL 1

7 920100920 MIKASA MARK DECAL 2

8 920209250 WARNING LAMP DECAL ................................ 1 .............. NPA-925

20 920209010 DIAGRAM DECAL ........................................... 1 .............. NPA-901

21 920209020 RECEIVER MONITOR LAMP DECAL ............. 1 .............. NPA-901

22 920209030 MONITOR LAMP OPERATION DECAL ........... 1 .............. NPA-903

23 920209040 MAIN SWITCH DECAL ................................... 1 .............. NPA-904

25 920209060 TRANSMITTER CONTROL DECAL ................ 1 .............. NPA-906

26 920209070 TRANSMITTER CAUTION DECAL ................. 1 .............. NPA-907

28 920209190 9-UP WARNING DECAL .................................. 1 .............. NPA-923

29 920209230 CAUTION OPERATION RULES ....................... 1 ..............NPA-919

30 920209310 CAUTION LAMP DECAL ................................. 1 .............. NPA-951

31 920209210 EMERGENGY STOP DECAL.......................... 1 .............. NPA-921

32 920209280 HYDRAULIC OIL DECAL ................................. 1 .............. NPA-922

33 920209300 MAIN SWITCH DECAL ................................... 1 .............. NPA-930

34 920209270 DIESEL FUEL DECAL..................................... 1 .............. NPA-927

35 920108810 SHELL TELLUS OIL 45 DECAL ...................... 1 ..............NPA-748

36 920108350 CAUTION READ MANUAL DECAL ................. 1 ..............NPA-769

37 920209510 CAUTION TRANSMITTER CHARGE .............. 1 ..............NPA-951

41 920209020 MULTIQUIP CARSON, CALIF. DECAL 1

49 920209230 SAE10W-40 DECAL 1

50 920209310 OPEN DECAL ................................................. 1 .............. NPA-922

MQ-MIKASA MVH-702DRSC COMPACTOR — PARTS & OPERATION MANUAL — REV. #1 (12/17/03) — PAGE 37

Page 38

VIBRATING PLATE ASSY.

MVH-702DRSC COMPACTOR — VIBRATING PLATE ASSY.

PAGE 38 — MQ-MIKASA MVH-702DRSC COMPACTOR — PARTS & OPERATION MANUAL — REV. #1 (12/17/03)

Page 39

MVH-702DRSC COMPACTOR — VIBRATING PLATE ASSY.

VIBRATING PLATE ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1 462116380 VIBRATING PLATE 1

2 953405840 DRAIN PLUG M18(H) 1

3 953402930 COPPER PACKING 19 X30 X1 1

4 953400270 PLUG 1/4X14 10L 1

5 953405260 PACKING 1/4 (CU) 1

6 462340050 PLATE (F&R) 2

7 462340060 PLATE (RIGHT) 1

8 462340070 PLATE (LEFT) 1

9 009120407 SUNK HEAD BOLT 10X 20 T 12

10 001221020 BOLT 10 X 20 T 16

11 030210250 WASHER, LOCK M10 16

13 930413001 SHOCK ABSORBER 130- 80H 4

14 020318150 NUT M18 4

15 030218460 WASHER, LOCK M18 8

16 001221835 BOLT 18 X 35 T 4

18 001222452 BOLT 24 X 60 T 8

19 030224590 WASHER, LOCK M24 8

21 462116480 EXTENSION PLATE (75) 2

21 462116490 EXTENSION PLATE (150) ............................... 2 ..............OPTION

MQ-MIKASA MVH-702DRSC COMPACTOR — PARTS & OPERATION MANUAL — REV. #1 (12/17/03) — PAGE 39

Page 40

VIBRATOR ASSY.

MVH-702DRSC COMPACTOR — VIBRATOR ASSY.

PAGE 40 — MQ-MIKASA MVH-702DRSC COMPACTOR — PARTS & OPERATION MANUAL — REV. #1 (12/17/03)

Page 41

MVH-702DRSC COMPACTOR — VIBRATOR ASSY.

VIBRATOR ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1 462116390 VIBRATOR CASE 1

2 001221876 BOLT 18 X 180 T 6

3 001221855 BOLT 18 X 75 4

4 030218460 WASHER, LOCK M18 10

6 047920100 ROLLER BEARING NJ311C4 4

7 462215570 ROTARY DRIVE SHAFT 1

8 462454560 SPLINE MOTOR DRIVE SHAFT 1

9 951406600 KEY 16 X 10 X 46 RR 2

10 462340080 DRIVE GEAR 1

11 080200600 STOP RING S- 60 2

12 462340100 ECCENTRIC DRIVE ROTOR 2

13 462454900 SCT HEAD BOLT 16 X 80 P1.5 2

14 462215580 ROTARY DRIVE SHAFT 1

15 462340110 ECCENTRIC DRIVE ROTOR 2

16 009120307 SCT HEAD BOLT 16 X 35 P1.5 2

17 462340120 CAM RING 180(R) 1

18 462340130 CAM RING 180(L) 1

19 952406460 COLLAR 60 X 70 X 8 2

20 040306012 BEARING 601203 4

21 462340090 DRIVE GEAR /MVH-702 1

22 462454590 SPRING (1) 30- 126L 2

23 462454600 SPRING (2) 24- 126L 2

24 462454610 SPRING (3) 19- 126L 2

25 462454620 SPRING (4) 15- 126L 2

26 462454630 SPRING (5) 11- 126L 2

28 025510075 KNOCK PIN 10 X 75 2

29 455435051 22.4D PISTON 2

30 455010070 PACKING USH- 22.4 X 30 X 5 2

31 462340140 CAM RING PISTON 2

32 462340150 PISTON ROD 2

33 042506000 BEARING 6000ZZSG 8

34 080200100 STOP RING S- 10 4

35 080100260 STOP RING R- 26 4

37 462215590 CYLINDER 2

38 462340160 BEARING COVER 1

39 050101150 O- RING G- 115 3

40 462340170 MOTOR FLANGE 1

41 050101200 O- RING G- 120 1

42 001211030 BOLT 10 X 30 H 16

43 030210250 WASHER, LOCK M10 16

44 031110160 WASHER, FLAT M10 8

46 462454640 SPLINE JOINT /MVH- 702 1

47 025406030 SPRING PIN 6 X 30 1

49 462340290 SAFETY BELT /MVH- 702 2

50 462340180 SPRING HOOK /MVH- 702 2

51 952406470 COLLAR 19 X 33 X 5 4

53 001201216 BOLT 12 X 16 1

54 031112230 WASHER, FLAT M12 1

MQ-MIKASA MVH-702DRSC COMPACTOR — PARTS & OPERATION MANUAL — REV. #1 (12/17/03) — PAGE 41

Page 42

COVER ASSY.

MVH-702DRSC COMPACTOR — COVER ASSY.

PAGE 42 — MQ-MIKASA MVH-702DRSC COMPACTOR — PARTS & OPERATION MANUAL — REV. #1 (12/17/03)

Page 43

MVH-702DRSC COMPACTOR — COVER ASSY.

COVER ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1 462116400 BASE 1

2 953010020 PLUG 4

4 462215600 HOOK FRAME 1

5 001221850 BOLT 18 X 50 T 4

6 030218460 WASHER, LOCK M18 4

7 462340190 HOOK 1

8 462454650 FIXING HOOK SHAFT 1

9 099206020 SOCKET HEAD SCREW 6 X 20 T 2

10 099206010 SOCKET HEAD SCREW 6 X 10 1

11 032118300 CONICAL SPRING WASHER M18 2

12 031118260 WASHER, FLAT M18 1

13 952406640 COLLAR 12.5 X 18 X 7 1

14 462010010 INNER RACE/ FIR121725 1

15 001521245 SOCKET HEAD BOLT 12 X 45 T 1

16 939010170 RUBBER STOPPER 4

17 020308060 NUT M8 4

19 462215610 UPPER CENTER COVER 1

20 001221225 BOLT 12 X 25 T 2

21 030212300 WASHER, LOCK M12 2

22 031112230 WASHER, FLAT M12 2

23 462454660 CABLE STAY 1

24 001220815 BOLT 8 X 15 T 2

25 030208200 WASHER, LOCK M8 2

27 462116460 RIGHT SIDE COVER 1

28 462116470 LEFT SIDE COVER 1

29 001221020 BOLT 10 X 20 T 12

30 030210250 WASHER, LOCK M10 12

31 031110160 WASHER, FLAT M10 12

32 462454720 F. COVER SUPPORT 2

33 001520615 SOCKET HEAD BOLT 6 X15 T 4

35 462340200 COVER 1

36 462455130 RUBBER SPACER 1

37 001220620 BOLT 6 X 20 T 4

38 952406480 WASHER 6 X16 X1.6 4

39 022720607 NYLON NUT M6, H=6.6 4

40 462215640 REAR COVER 1

41 462215620 RUBBER HINGE 1

42 092006015 FLAT HEAD SCREW 6 X15 10

43 462010030 FASTENER (C- 1321) 2

44 001520510 SOCKET HEAD BOLT 5 X 10 T 4

45 091004010 SCREW 4X10 4

46 462010040 HINGE (B- 1224) 2

47 092005012 SCREW 5X 12 8

49 462215650 STAY 1

52 001220820 BOLT 8X20 T 2

53 030208200 WASHER, LOCK M8 2

MQ-MIKASA MVH-702DRSC COMPACTOR — PARTS & OPERATION MANUAL — REV. #1 (12/17/03) — PAGE 43

Page 44

COVER ASSY.

MVH-702DRSC COMPACTOR — COVER ASSY. (CONT.)

PAGE 44 — MQ-MIKASA MVH-702DRSC COMPACTOR — PARTS & OPERATION MANUAL — REV. #1 (12/17/03)

Page 45

MVH-702DRSC COMPACTOR — COVER ASSY. (CONT)

COVER ASSY.

NO. PART NO. PART NAME QTY. REMARKS

54 031108160 WASHER, FLAT M8 2

56 462116410 FRONT COVER 1

57 462010050 HINGE (B- 801- 1) 2

58 001221025 BOLT 10X25 T 12

59 030210250 WASHER, LOCK M10 12

60 462215660 FRONT GRILL 1

61 001220815 BOLT 8 X15 T 4

62 030208200 WASHER, LOCK M8 4

64 462010060 LOCKING DEVICE (C- 873- 2R) 1

65 462454680 SPRING HOOK 1

66 001220630 BOLT 6 X 30 T 3

67 001220635 BOLT 6 X35 T 1

68 030206150 WASHER, LOCK M6 4

69 031106100 WASHER, FLAT M6 4

70 020306050 NUT M6 4

72 462454690 LEVER 1

73 001220825 BOLT 8 X25 T 1

74 032208180 CONICAL SPRING WASHER M8 1

75 020308060 NUT M8 1

76 462454700 TENSION BAR 1

77 001220615 BOLT 6 X15 T 1

78 020306050 NUT M6 1

79 462454710 PIN 1

80 025910060 SNAP PIN /SSP- 6 1

81 462454910 TENSION SPRING 1

83 462010070 DAMPER (KMF120- 20D) 2

84 462455140 DAMPER PPIN 2

85 952406660 COLLAR 9X 12X 11 2

86 025910100 SNAP PIN /SSP- 10 4

88 462340230 BRACKET (C. UNIT) 1

89 001220820 BOLT 8X 20 T 4

90 030208200 WASHER, LOCK M8 4

91 031108160 WASHER, FLAT M8 2

93 462454780 SLING BRACKET 2

94 001221040 BOLT 10X 40 T 4

95 030210250 WASHER, LOCK M10 4

96 031110160 WASHER FLAT M10 4

98 462215680 RUBBER BUMPER (A) 1

99 462215690 RUBBER BUMPER (B) 1

100 462215700 RUBBER BUMPER (C) 1

101 462215710 RUBBER BUMPER (D) 1

102 952406530 COLLAR 11X 17.5X 8 12

103 031112230 WASHER, FLAT M12 12

104 009110018 SCT. HEAD BOLT 10X 20 P1.5 12

MQ-MIKASA MVH-702DRSC COMPACTOR — PARTS & OPERATION MANUAL — REV. #1 (12/17/03) — PAGE 45

Page 46

ENGINE ASSY.

MVH-702DRSC COMPACTOR — ENGINE ASSY.

PAGE 46 — MQ-MIKASA MVH-702DRSC COMPACTOR — PARTS & OPERATION MANUAL — REV. #1 (12/17/03)

Page 47

MVH-702DRSC COMPACTOR — ENGINE ASSY.

ENGINE ASSY.

NO. PART NO. PART NAME QTY. REMARKS

106 918400700 ENGINE AY FARYMANN- 43F 1

107 001221251 BOLT 12X 55 T 2

108 001221252 BOLT 12X 60 T 2

109 030212300 WASHER, LOCK M12 4

110 031112230 WASHER, FLAT M12 4

111 020312100 NUT M12 2

112 462454580 HOSE STAY /MVH- 702 1

113 954494239 CLAMP SA120- 18 1

114 001220620 BOLT 6X 20 T 1

115 030206150 WASHER, LOCK M6 1

116 031106100 WASHER, FLAT M6 1

117 020306050 NUT M6 1

119 462215670 INTAKE BRACKET 1

120 462340210 AIR CLEANER HOSE 1

121 954406570 CLAMP (AH- 705) 2

122 462454730 CYCLONE JOINT 1

123 462010080 CYCLONE CLEANER 1

124 001220615 BOLT 6X 15 T 2